Page 1

02:07 Issue 1.0 en-GB

© Scania CV AB 2016, Sweden

Installation manual

SCR system

Marine engines

DI13, DI16

377 168

Page 2

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

02:07 Issue 1.0 en-GB 2

SCR and reductant..................................................................................................3

System overview ......................................................................................................4

Exhaust pipe............................................................................................................. 6

Pipe lengths ......................................................................................................... 6

Exhaust pipe bends.............................................................................................. 7

Pipe material........................................................................................................ 8

Other requirements.............................................................................................. 8

Branch pipe ......................................................................................................... 8

Main tank for reductant and reductant pipes ...................................................... 9

Example of installation........................................................................................ 9

Materials for pipes and main tank ..................................................................... 10

Main tank........................................................................................................... 10

Main tank to buffer tank.................................................................................... 10

Buffer tank to the evaporator ............................................................................ 11

Reductant tank (buffer tank) ...............................................................................12

Position.............................................................................................................. 12

Mounting ........................................................................................................... 13

Connecting the reductant tank........................................................................... 14

Exhaust routing valve ........................................................................................... 15

Position.............................................................................................................. 15

Mounting ........................................................................................................... 16

Connection of coolant ....................................................................................... 17

Evaporator ............................................................................................................. 19

Position.............................................................................................................. 19

Mounting ........................................................................................................... 19

Connection of reductant doser........................................................................... 20

SCR catalytic converter........................................................................................ 21

Position ............................................................................................................. 21

Mounting........................................................................................................... 21

NOx sensor............................................................................................................. 22

Fitting................................................................................................................ 22

Exhaust gas temperature sensor.......................................................................... 23

Fitting................................................................................................................ 24

Page 3

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

SCR and reductant

02:07 Issue 1.0 en-GB 3

SCR and reductant

SCR (Selective Catalytic Reduction) is a system in which reductant is added to the

exhaust gases in order to reduce the nitrogen oxide (NOx) content. This document

describes SCR system components and how they should be connected.

Reductant is a solution consisting of urea and water, and is usually called AdBlue®,

DEF, ARLA 32 eller AUS 32, depending on the market. If the engine is equipped

with an SCR system, the reductant is added to the exhaust gases upstream of the catalytic converter. This reduces nitrogen oxide emissions.

Reductant in accordance with ISO 2241 contains 32.5% by weight of urea and freezes at approximately -11°C (12°F). When the solution freezes, ice and urea always

maintain the same concentration. Always store reductant at a temperature between 11°C and 30°C (12-86°F).

REQUIREMENT!

In order for the emission control to meet the emission requirements set by the public

authorities, the reductant should be specified in accordance with ISO 22241.

IMPORTANT!

Cleanliness is very important when working on the reductant circuit. Clean thoroughly around all parts to prevent dirt from entering the system.

When working on the SCR system, the reductant connections may only be lubricated

with soapy water or with distilled water with a 3% urea mixture. Any other types of

lubricants may block and damage the components in the SCR system.

Rec. % by weight of urea Limit values according to ISO 22241

32.5% 31.8-33.2%

Reductant is highly corrosive. For this reason, only pipes and couplings resistant to

urea may be used in the SCR system. Always rinse away reductant spillage on connections and other parts with lukewarm water to prevent corrosion. If reductant seeps

into electrical connections or electrical cables, these must be renewed.

Page 4

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

02:07 Issue 1.0 en-GB 4

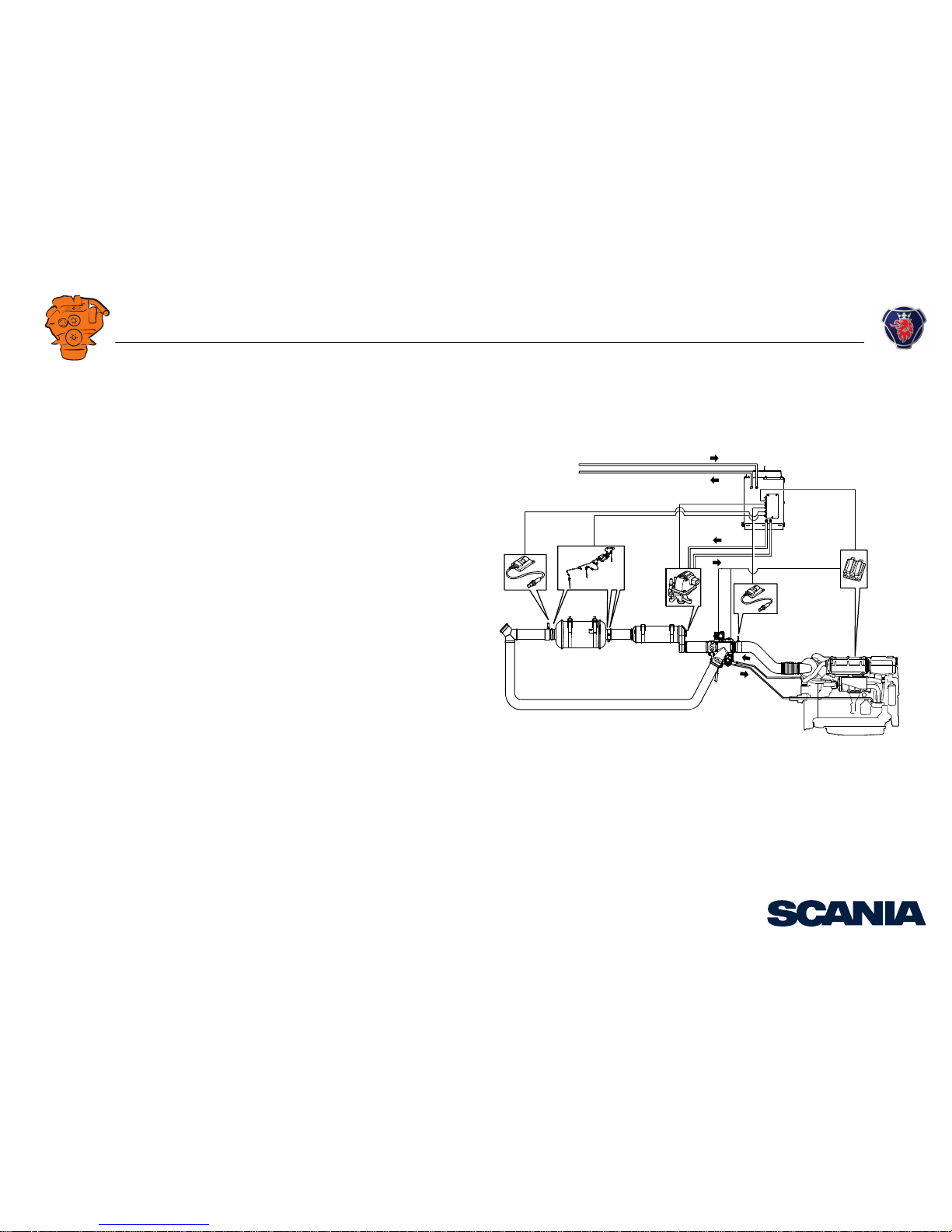

System overview

AB

368 025

1

2

4

3

5

6

7

8

10

9

11

12

13

14

1515

16

16

17

17

17

18

7

7

18

20

20

19

A: DI16.

B: DI13.

Page 5

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

System overview

02:07 Issue 1.0 en-GB 5

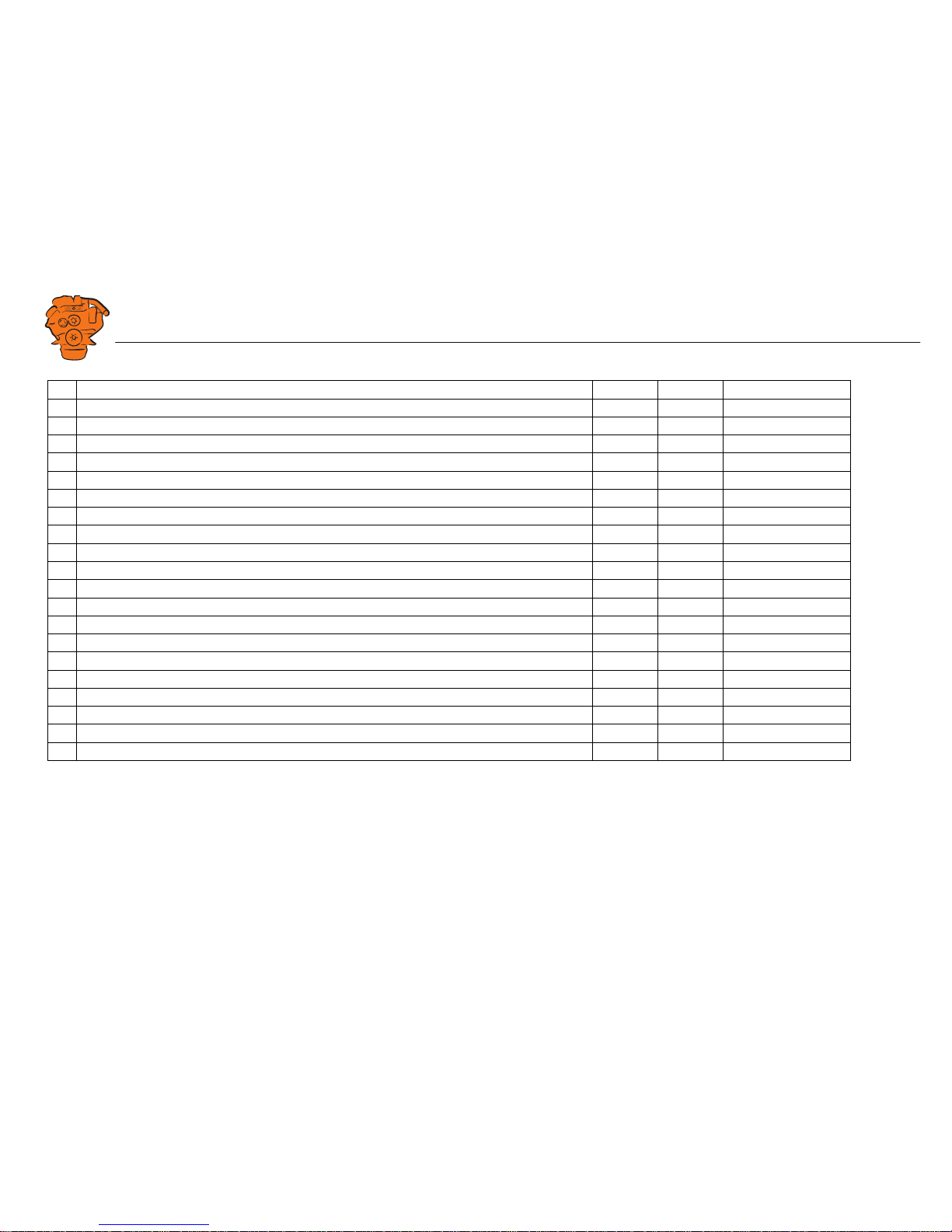

Component Standard Option Fitted by fitter

1. Pressure pipe for reductant from the main tank - - x

2. Return pipe for reductant to the main tank - - x

3. Reductant tank (buffer tank) x - x

4. Pressure pipe for reductant from the buffer tank - - x

5. Return pipe for reductant to buffer tank - - x

6. Engine control unit x- -

7. NOx sensor (x 2) x- x

8. Exhaust bellows -xx

9. Coolant line from the engine to the exhaust control valve actuator - - x

10. Coolant return --x

11. Pipe section with outlet for NOx sensor T131 x - x

12. Exhaust routing valve with 2 actuators x - x

13. Handle to bypass the SCR system x - -

14. Reductant doser x- -

15. Evaporator x- x

16. Exhaust temperature sensor (x 3) x - x

17. SCR catalytic converter with outlets for 2 exhaust gas temperature sensors x - x

18. Pipe section with outlet for NOx sensor T115 and 1 exhaust gas temperature sensor x - x

19. Bypass pipe --x

20. Branch pipe (DI16 only) x - x

Page 6

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust pipe

02:07 Issue 1.0 en-GB 6

Exhaust pipe

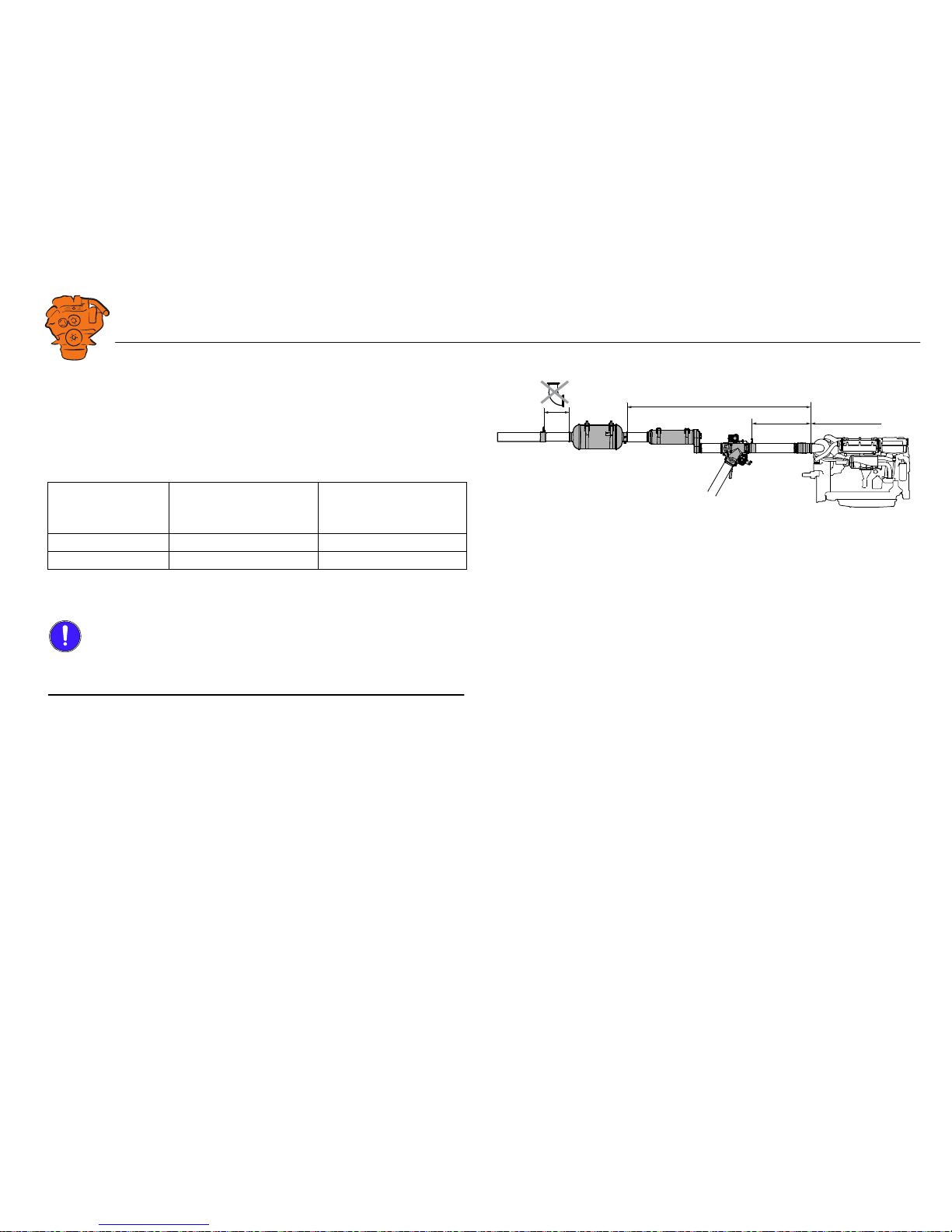

Pipe lengths

From To Max/min pipe length (mm)

A Turbocharger Pipe section for NOx sensor Max 1,500

B Turbocharger Evaporator intake Max 2,000

C Exhaust routing valve outlet Evaporator intake Max 500

D

1

1. DI16 only.

Evaporator outlet Branch pipe Min 300

E Evaporator outlet SCR catalytic converter inlet Max 1,500

F SCR catalytic converter outlet Pipe section for NOx sensor and exhaust temperature sensor Max 400

G Pipe section for NOx sensor and exhaust temperature sensor Exhaust outlet Min 500

12

A

B

C

E

F

DG G

E

F

368 800

1. DI16.

2. DI13.

Page 7

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust pipe

02:07 Issue 1.0 en-GB 7

Exhaust pipe bends

The sum of the exhaust pipe bends between the turbocharger outlet and NOx sensor

upstream of the exhaust routing valve must not exceed 270°.

The sum of the exhaust pipe bends between the turbocharger outlet and SCR catalytic

converter inlet must not exceed 540°. Example:

The radius of the exhaust pipe bends must be at least 1.5 x pipe diameter, based on a

pipe diameter of 127 mm (5 inches).

IMPORTANT!

No exhaust pipe bends may be installed between the SCR catalytic converter outlet

and the NOx sensor downstream of the SCR catalytic converter.

Max. angle before

Number of 90° exhaust

pipe bends

Number of 45° exhaust

pipe bends

SCR catalytic converter

540° 4 off 4 off

540° 6 off 0 off

379 171

Max 540°

Max 270°

Max. number of exhaust pipe bends in the SCR system.

Page 8

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust pipe

02:07 Issue 1.0 en-GB 8

Pipe material

The exhaust pipe between the evaporator and the SCR catalytic converter must be

made from stainless metal type 1.4301 or 1.4509, US grade 316L or equivalent. Scania also recommends that this material is used for other exhaust pipes downstream of

the SCR catalytic converter. Other instructions on exhaust system shape and fitting

are available in 02:04 Exhaust system.

Other requirements

IMPORTANT!

There should always be a flexible connection between the exhaust system and the engine which absorbs the movement of the engine and changes in length in the exhaust

system due to temperature changes. Also see 02:04 Exhaust system.

The brackets for exhaust routing valve, bypass pipe, evaporator and SCR catalytic

converter must be able to bear the weight of the component. The weight of the components must not load the exhaust bellows or turbocharger.

Tighten the V-clamps in the SCR system after the engine has warmed up to working

temperature for the first time. Carry out the retightening when the engine has cooled

down again. Tightening torque 20 Nm.

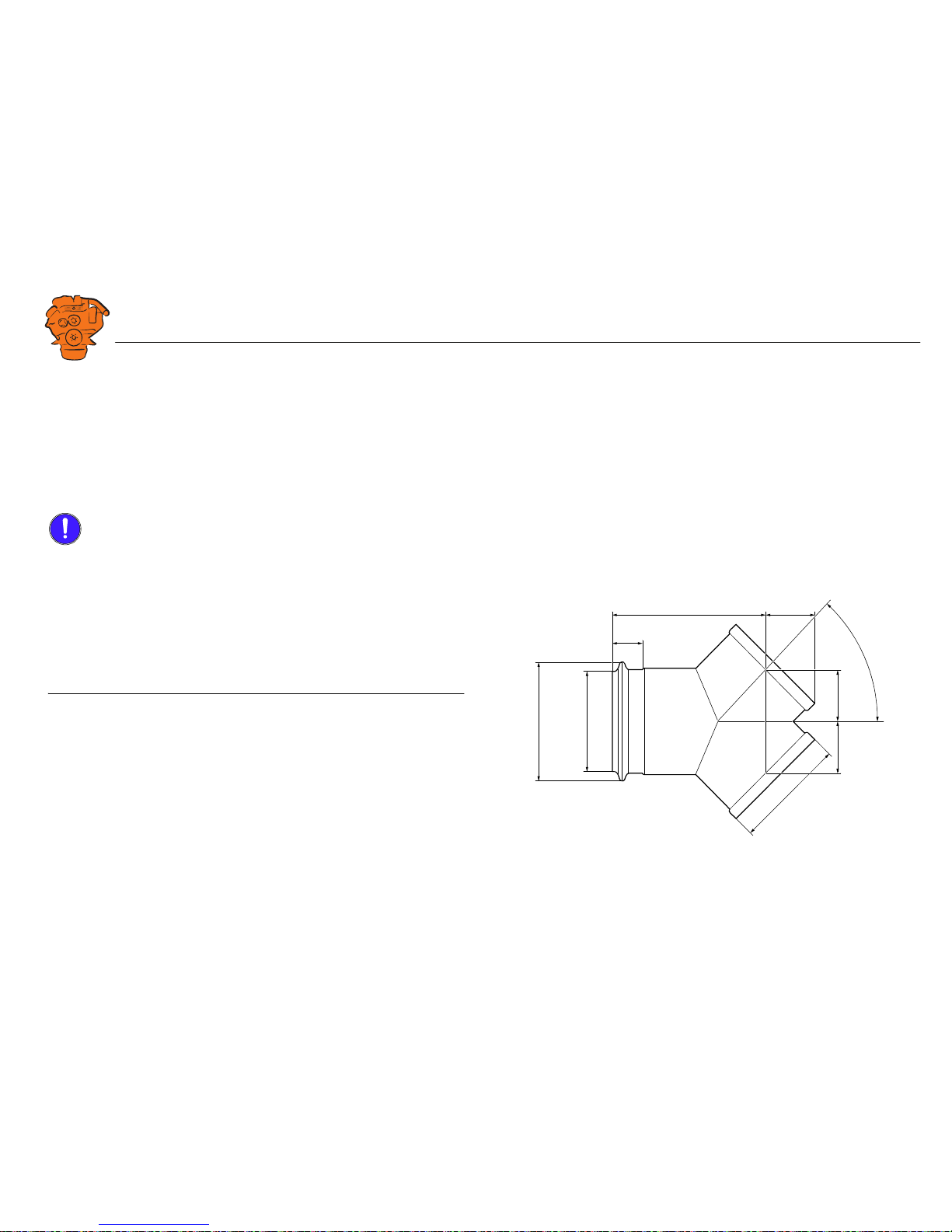

Branch pipe

The image shows the dimensions of the branch pipe used to connect the SCR catalytic converters to DI16.

366 031

2 x

2 x

45°

63,5

40

194

55

Ø122Ø144

Ø131 x 2

Page 9

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Main tank for reductant and reductant pipes

02:07 Issue 1.0 en-GB 9

Main tank for reductant and reductant

pipes

Example of installation

1. Evaporator.

2. Reductant doser.

3. Pressure pipe for reductant from the buffer tank.

4. Return pipe for reductant to buffer tank.

5. Buffer tank.

6. Pressure pipe for reductant from the main tank.

7. Return pipe for reductant to main tank.

8. Feed pump.

9. Prefilter.

10. Main tank for reductant.

11. Filling.

12. Overfill protection.

13. Level gauge.

14. Inspection hatch.

15. Ventilating valve.

16. Draining tap.

17. Baffle plate.

A = Max. height 2 metres from the pressure pipe connection on the buffer tank to the

reductant doser, max. length 16 metres.

1

5

10

16

2

15

6

98

7

14

17

11

13

12

3

4

380 406

A

Example of installation of the main tank for reductant and reductant pipes

Page 10

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Main tank for reductant and reductant pipes

02:07 Issue 1.0 en-GB 10

Materials for pipes and main tank

The main reductant tank, the reductant pipes and all couplings must be made of urearesistant material, such as stainless steel X5CrNi 18-10 in accordance with SS-EN

10088-2 or similar. Follow classification society requirements. If the material is

welded, its anti-corrosive qualities must be retained.

Dimension the reductant pipes according to the dimensions of the connections on the

buffer tank, as indicated in the Connecting the reductant tank

section.

Main tank

• Dimension the main tank so that there is sufficient reductant for the specific use

and area. Reductant consumption is approx. 9% of fuel consumption.

• The tank must be fitted with internal baffle plate to prevent the reductant from being thrown about at sea.

• The tank must have a drain tap.

• There must be ventilation or bleed line from the upper part of the tank to the outside of the hull. It should be designed so that water cannot enter and so that reductant cannot run out when the ship is leaning heavily.

• The tank must be fitted with inspection hatches so that it can be inspected and

cleaned inside.

• The pipe fitting should be at a sufficient distance from the bottom of the tank, so

as not to suck up deposits gathered at the bottom.

Main tank to buffer tank

• The pipes to the buffer tank should be as short as possible and should be mounted

in such a way that they cannot be exposed to mechanical damage.

• There must be a return pipe from the buffer tank to the main tank so that any surplus fluid runs back to the main tank.

Page 11

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Main tank for reductant and reductant pipes

02:07 Issue 1.0 en-GB 11

• There must be a prefilter with a filtration rating of 30-50 micrometres.

• There must be a fuel pump with a flow capacity of between 0.4 and 5 litres/minute.

Buffer tank to the evaporator

• The maximum length of the pipes between the buffer tank and evaporator reductant doser is 16 metres.

• The reductant doser should be installed level with or higher than the top of the

buffer tank. Otherwise there is a risk of a siphoning effect when the system is

switched off, leading to components breaking.

• The reductant doser can be installed a maximum of 2 metres above the pressure

pipe connection on the buffer tank.

Page 12

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Reductant tank (buffer tank)

02:07 Issue 1.0 en-GB 12

Reductant tank (buffer tank)

In the reductant tank, the reductant pump and SCR control unit are in front of an inspection hatch on the right-hand side of the tank.

Empty, the reductant tank weighs approx. 25 kg.

• Total volume: 30 litres.

• Filling volume: 16 litres.

Position

Do not position the reductant tank in a twisted or non-vertical position. Place the reductant tank so that the return pipe connection (1) is above the main tank, so that the

reductant can run back into the main tank. It does not matter how the reductant tank

is fitted in relation to the level of the engine.

Position the reductant tank so that the reductant cannot freeze. If the reductant freezes, the tank must be drained and cleaned. See the Workshop Manual.

Do not position the reductant tank near exhaust systems or heat sources. The reductant must not be heated to more than 55°C.

366 027

465,5

248

66

102,5

70

80,2

60

40

26

36

54

277

75

25,2

17

30

249

40

170,2

25

24,5

1

366 266

Page 13

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Reductant tank (buffer tank)

02:07 Issue 1.0 en-GB 13

Clearances

When the reductant tank is installed, the clearances below should be observed so that

the reductant tank can be maintained and repaired in a simple way.

Mounting

The reductant tank should be fitted with 3 brackets with 5 x 14 mm holes in each

bracket. The bottom brackets are shown in the picture to the right. The upper rear

bracket has the same dimensions and is shown under the heading Reductant tank

(buffer tank).

Use at least 2 of the brackets and 2 of the holes in each bracket when mounting. In

order to be able to remove the reductant tank for maintenance and repair, the brackets

must not be welded.

mm Purpose

A 235 To access the drain plug.

B 555 To lift out the reductant pick-up unit.

C 560 To open the inspection hatch to renew the reductant filter

and access the reductant pump and SCR control unit.

D 220 To undo the reductant pump screws.

E 225 To connect the reductant pipes and connectors.

366 029

B

C D

E

A

366 028

358

4 x

97,25

Ø 14

Page 14

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Reductant tank (buffer tank)

02:07 Issue 1.0 en-GB 14

Connecting the reductant tank

Description Connection

1. Pressure pipe for reductant from the

main tank

Nipple, Ø 8 mm, 24° internal conical thread in accordance with

DIN 3861

2. Return pipe for reductant to the main

tank

Nipple, Ø 22 mm, 24° internal conical thread in accordance with

DIN 3861

3. Voltage supply from engine. CAN connection

C7

4. Reductant doser C316

5. NOx sensor upstream of the exhaust

routing valve

C4051

6. NOx sensor downstream of the SCR

catalytic converter

C4011

7. Exhaust gas temperature sensor C4092

8. Reductant pressure pipe Pipe with ferrule,

to reductant doser Ø 8 mm

9. Reductant return pipe Pipe with ferrule,

to reductant pump Ø 10 mm

10 Drain plug 3/4" BSP

377 167

10

2

3

4

1

5

98

7

6

Page 15

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust routing valve

02:07 Issue 1.0 en-GB 15

Exhaust routing valve

Position

The exhaust routing valve may be installed horizontally or vertically. However, it

must not be mounted on the engine.

As the exhaust routing valve actuator may be damaged if the temperature is too high,

the space around the exhaust routing valve must be well-ventilated, and the accompanying insulation must be used. In addition, the actuators must be cooled by connecting a coolant circuit. See Connection of coolant

.

The exhaust routing valve weighs approximately 24 kg.

366 267

202

60°

234

115

85

405

146

39

244

179

30

26

24

Page 16

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust routing valve

02:07 Issue 1.0 en-GB 16

Mounting

The exhaust routing valve should be fitted with a bracket with 11 M10 holes. Use at

least 4 of the holes when mounting. The bracket must not be welded because the two

actuators may get damaged. In addition, it must be possible to remove the exhaust

routing valve in order to carry out repairs to it.

366 030

135

162

26

62

15

82

74

22

31

20

95

95

120

30

95

12

25

160

25

33

40

20

30 40

140

°

Exhaust routing valve bracket.

Page 17

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust routing valve

02:07 Issue 1.0 en-GB 17

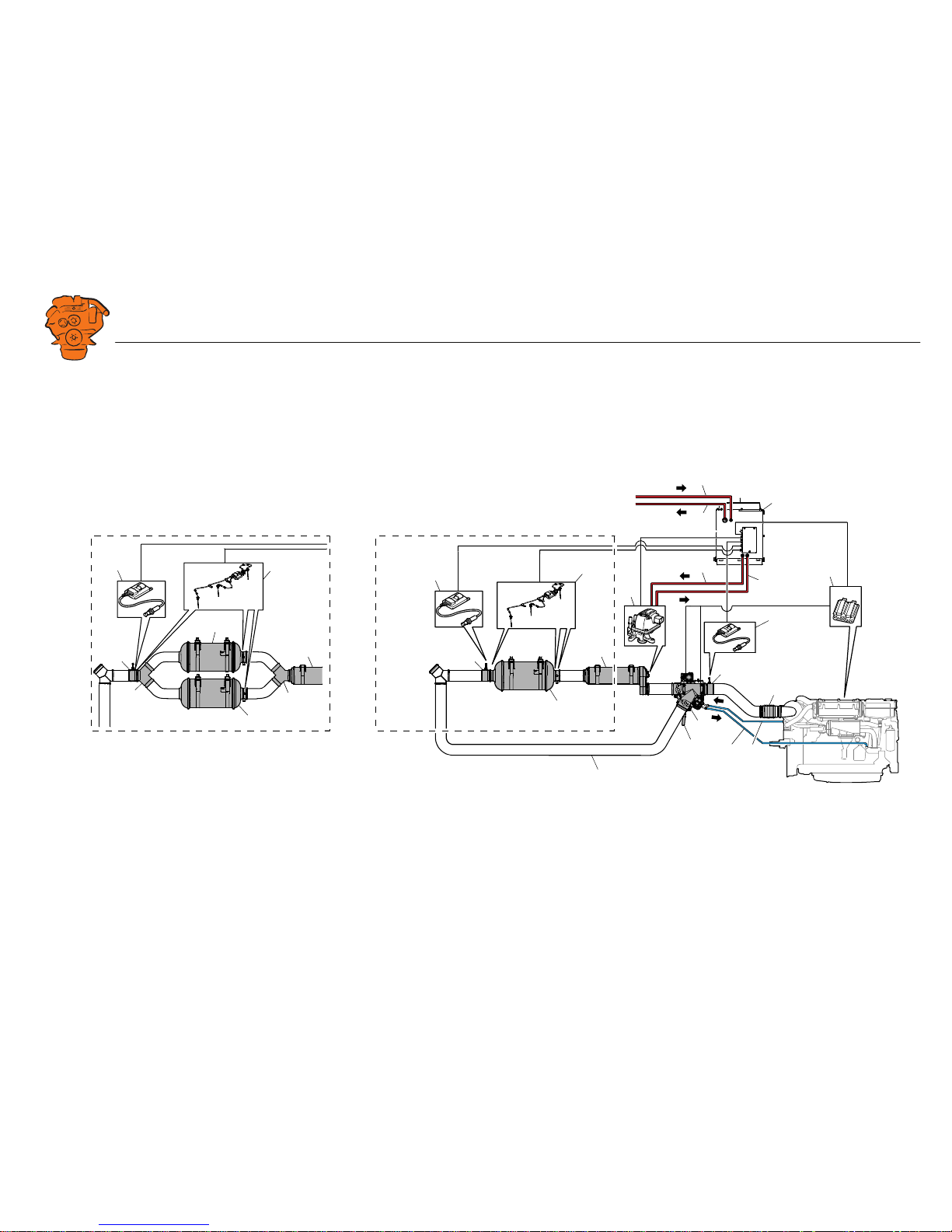

Connection of coolant

This section shows how to connect a circulating coolant circuit between the engine

and the exhaust routing valve. However, it is also possible to connect an external

coolant circuit.

Note:

Do not use sea water to cool the exhaust routing valve.

Scania recommends using pipes, but it is also possible to use hose.

It does not matter which of the connections of the exhaust routing valve (3) are used

for coolant intake or coolant return.

The images show the coolant connections on DI13 and DI16:

1. Coolant out of the engine. M22x1.5.

2. Coolant return to the engine. DI13: M22x1.5. DI16: M26x1.5.

3. Coolant connection to exhaust routing valve. M22x1.5.

2

3

1

377 169

DI13.

2

1

1

377 170

DI16.

Page 18

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust routing valve

02:07 Issue 1.0 en-GB 18

Connecting the coolant pipe

If pipes are used for coolant connection, there must be at least one hose connection

on each pipe to and from the engine, which will absorb vibrations from the engine.

The pipe material must be refrigerant-resistant.

If pipe is to be used, the pre-assembled nipples on the exhaust routing valve must be

removed.

Hose connection

Use hose with an internal diameter of 16 mm to connect to the pre-assembled nipples

on the exhaust routing valve. The material must be EPDM-type or similar, and must

be able to withstand a working pressure of 2.4 bar. The material must be refrigerantresistant.

Note:

To ensure sufficient flow, hoses must not have any sharp bends and there must be no

spots where they are at risk of being pinched.

377 171

1

6

43

Nipples to connect the coolant hose to the exhaust routing valve.

Page 19

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Evaporator

02:07 Issue 1.0 en-GB 19

Evaporator

Position

The evaporator must be fitted in the direction of the exhaust gases as illustrated. It

may be installed horizontally or with the outlet pointing downwards. The intake can

be rotated 360°.

The space around the evaporator must be well-ventilated. The maximum permissible

ambient temperature is 115°C. The accompanying insulation must be used. The

evaporator weighs approx. 17 kg.

Mounting

The evaporator is supplied with two retaining straps with brackets. Attach the brackets with flange screw M12 or a common screw of a suitable length. Use an M12

flange nut if necessary.

Tightening torques

Flange bolt M12: 77 Nm. Regular screw M12: 70 Nm.

Retaining strap: 40 Nm.

377 172

203

80

343

210 300 174 112

400

37

22,5

Ø 13

122

122

Page 20

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Evaporator

02:07 Issue 1.0 en-GB 20

Connection of reductant doser

The evaporator is supplied with two hoses which are connected to the reductant doser. The hoses must be used as they absorb vibrations from the pipes to and from the

reductant tank. The maximum bend radius for the hoses is 50 mm.

Connection Note

1. Electrical cable to reductant tank. V117

2. Reductant return pipe. Ø 10 mm

3. Reductant pressure pipe. Ø 8 mm

1

3

2

377 173

Page 21

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

SCR catalytic converter

02:07 Issue 1.0 en-GB 21

SCR catalytic converter

Position

The SCR catalytic converter must be fitted in the direction of the exhaust gases as

illustrated. It may be installed horizontally or with the outlet pointing upwards.

For DI16, two SCR catalytic converters are used. They may be longitudinally displaced. Longitudinal displacement is limited by the length of the electrical cables of

the exhaust gas temperature sensors. See the Exhaust gas temperature sensor

section.

The SCR catalytic converter weighs approx. 30 kg. It can be ordered with or without

insulation.

Mounting

The SCR catalytic converter is supplied with two retaining straps with brackets. Attach the brackets with M10 flange screws.

Tightening torques

M10 42 Nm

Retaining strap 39 Nm

366 032

Ø 10

270 300 285

369

36

130

Page 22

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

NOx sensor

02:07 Issue 1.0 en-GB 22

NOx sensor

The SCR system comes with two NOx sensors, which have their own control unit.

The sensor control units are connected to the SCR control unit in the reductant tank.

See Connecting the reductant tank

. The control unit should be shielded from radiated

heat and knocks. The electrical cables between the sensors and the control units must

not be spliced.

Fitting

Fit NOx sensor T131 to one of the accompanying pipe sections, which should be positioned upstream of the exhaust routing valve. The pipe section has only one outlet

for this NOx sensor.

The other pipe section must be fitted on the outlet side of the SCR catalytic converter.

The pipe section has an outlet for NOx sensor T115 and also an outlet for an exhaust

gas temperature sensor. See the following section.

Electrical cable length

(mm)

Tightening torque (Nm)

910 50 ±10

368 023

148

108

65

3

A

9

7

NOx sensor (x 2).

T131: A = 42 mm.

T115: A = 38 mm.

21

366 033

100100

1. Outlet for NOx sensor T131 in pipe section upstream of exhaust routing valve.

2. Outlet for NOx sensor T115 in pipe section downstream of SCR catalytic convert-

er.

Page 23

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust gas temperature sensor

02:07 Issue 1.0 en-GB 23

IMPORTANT!

The NOx sensors and control units must not be painted. The NOx sensors must be

fitted so that there is no risk of them coming into contact with water. The maximum

installation angle is 90°.

Exhaust gas temperature sensor

The SCR system comes with three exhaust gas temperature sensors, which share a

control unit. The sensor control unit is connected to the SCR control unit in the reductant tank. See Connecting the reductant tank

. The control units should be shielded

from radiated heat and knocks. The electrical cables between the sensors and the control unit must not be spliced. The connection between the sensor and the electrical

cables must not be insulated, as it may be damaged if it is exposed to temperatures

above 200°C.

Colour

code

Electrical cable

length (mm)

Max. rotation (°)

1

1. Max. rotation means how much the electrical cable can be twisted around its own axis.

Tightening torque

(Nm)

1 Blue 980 180

35-402 Yellow 1,570 270

3 White 1,220 270

max 90

o

max 90

o

0

o

352 613

Maximum installation angle for NOx sensors.

368 024

1

2

3

90

109

52,5

81

28

6

Exhaust gas temperature sensor.

Page 24

INSTALLATION

MANUAL

© Scania CV AB 2016, Sweden

Exhaust gas temperature sensor

02:07 Issue 1.0 en-GB 24

Fitting

The two shorter exhaust temperature sensors (blue and white in colour) should be fitted to the outlets of the inlet side of the SCR catalytic converter (1). On DI16, one

temperature sensor should be fitted to each SCR catalytic converter and the other outlet plugged.

The longer exhaust temperature sensor (yellow in colour) should be fitted to the pipe

section on the outlet side of the SCR catalytic converter (1).

1

368 022

1. Outlet for exhaust temperature sensor (blue and white) on the inlet side of the

SCR catalytic converter.

380 185

1

100

1. Outlet for exhaust temperature sensor (yellow) in the pipe section downstream of

the SCR catalytic converter.

Loading...

Loading...