Page 1

DI13

Marine engine

en-GB 2 453 210

Issue 4.0

Operator's manual

PDE

Important information

Serious risk of injury

When working on the engine, for example when adjusting drive belts and the clutch, or when changing the

oil, it is important not to start the engine. The engine could be damaged, but more importantly there is a

serious risk of injury.

For this reason, always secure the starting device or disconnect a battery cable before working on the engine.

This is especially important if the engine has a remote starter or automatic starting.

WARNING!

This warning symbol and text can be found next to those maintenance items where it is particularly important to bear in mind the risk of injury.

Start-up Report – Warranty

The warranty starts when the start-up report has been filled in and sent to Scania. The normal warranty period is 1 year, but other conditions can apply.

Fill in the particulars from the start-up report below as well. This can make things easier if you need to contact a workshop, for example.

Engine type and variant are indicated on the engine data plate.

Engine serial number

Date of entry into service

User's name and address

Signature

Engine type

Variant

Page 2

OPM 250 en-GB 2

©

Scania CV AB 2016, Sweden

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Power classes . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Environment and safety . . . . . . . . . . . . . . . . . . 5

Environmental responsibility . . . . . . . . . . . . . 5

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Warnings and advisories . . . . . . . . . . . . . . . . . 6

Certification . . . . . . . . . . . . . . . . . . . . . . . . . 12

Engine data plate . . . . . . . . . . . . . . . . . . . . . . . 13

Component identification . . . . . . . . . . . . . . . . 14

Starting and running . . . . . . . . . . . . . . . . . . . . 15

Checks before first start . . . . . . . . . . . . . . . . 15

Checks before running . . . . . . . . . . . . . . . . . 15

Starting the engine . . . . . . . . . . . . . . . . . . . . 15

Running. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Engine shutdown. . . . . . . . . . . . . . . . . . . . . . 18

Checks after running . . . . . . . . . . . . . . . . . . . 18

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Maintenance intervals . . . . . . . . . . . . . . . . . . 20

Lubrication system . . . . . . . . . . . . . . . . . . . . . 21

Oil grade . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Oil analysis . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Checking oil level . . . . . . . . . . . . . . . . . . . . . 22

Changing the oil . . . . . . . . . . . . . . . . . . . . . . 23

Oil grade labels . . . . . . . . . . . . . . . . . . . . . . . 24

Cleaning the centrifugal oil cleaner . . . . . . . 25

Operational testing . . . . . . . . . . . . . . . . . . . . 29

Renewing the oil filter. . . . . . . . . . . . . . . . . . 30

Renewing the double, commutative oil filter 30

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . 32

Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Checking coolant level . . . . . . . . . . . . . . . . . 35

Checking coolant antifreeze and corrosion pro-

tection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Checking sacrificial anodes . . . . . . . . . . . . . 37

Checking the sea water pump impeller . . . . . 37

Changing the coolant and cleaning the cooling

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Reading the air cleaner vacuum indicator. . . 48

Renewing the air cleaner filter element . . . . 48

Renewing the air cleaner safety cartridge . . . 49

Renewing an air filter with a non-renewable ele-

ment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Fuel system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Checking fuel level . . . . . . . . . . . . . . . . . . . . 50

Renewing the fuel filter. . . . . . . . . . . . . . . . . 51

Renewing and bleeding double, commutative

fuel filters . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Renewing the water separating fuel filter . . . 53

Bleeding the fuel system using a hand pump 54

Bleeding the fuel system using a suction tool 55

Miscellaneous . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Checking the drive belt . . . . . . . . . . . . . . . . . 56

Checking for leaks . . . . . . . . . . . . . . . . . . . . .57

Checking and adjusting the valve clearance .58

Diesel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Composition of the fuel . . . . . . . . . . . . . . . . .64

Sulphur content of fuel. . . . . . . . . . . . . . . . . .64

Using DMX and DMA fuels in marine engines.

64

Temperature dependency of the fuel . . . . . . .65

Biodiesel (FAME) . . . . . . . . . . . . . . . . . . . . .65

Preparing the engine for storage . . . . . . . . . . .66

Handling the engine . . . . . . . . . . . . . . . . . . . .66

Preservative coolant . . . . . . . . . . . . . . . . . . . .66

Preservative fuel. . . . . . . . . . . . . . . . . . . . . . .66

Preservative oil. . . . . . . . . . . . . . . . . . . . . . . .66

Preparations for storage . . . . . . . . . . . . . . . . .67

EC declaration of conformity . . . . . . . . . . . . .69

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . .70

General data . . . . . . . . . . . . . . . . . . . . . . . . . .70

Lubrication system . . . . . . . . . . . . . . . . . . . . .71

Injection system . . . . . . . . . . . . . . . . . . . . . . .71

Cooling system. . . . . . . . . . . . . . . . . . . . . . . .72

Intake system . . . . . . . . . . . . . . . . . . . . . . . . .72

Electrical system . . . . . . . . . . . . . . . . . . . . . .72

Material content . . . . . . . . . . . . . . . . . . . . . . .73

Scania Assistance . . . . . . . . . . . . . . . . . . . . . . .74

Page 3

OPM 250 en-GB 3

©

Scania CV AB 2016, Sweden

Introduction

Introduction

This Operator's manual describes the operation

and maintenance of Scania marine engines.

The engines are direct-injection, liquid-cooled,

four-stroke turbocharged diesel engines.

The engines are available with different output

and speed settings. The engine power of the engine ordered is indicated on the engine data

plate.

Note:

Only standard components are described in the

operator's manual. Information about special

equipment is contained in instructions from the

various manufacturers.

To ensure the maximum performance and the

longest service life for the engine remember the

following:

• Read through the Operator's Manual before

starting to use the engine. Even regular users

of Scania engines will get new information

from the Operator's manual.

• Always follow the maintenance instructions.

• Read the section on safety carefully.

• Get to know your engine so that you know

what it can do and how it works.

• Always contact an authorised Scania workshop for maintenance and repairs.

The information in this Operator's manual was

correct at the time of going to press. Scania reserves the right to make alterations without prior

notice.

Note:

Always use Scania spare parts for maintenance

and repair.

Page 4

OPM 250 en-GB 4

©

Scania CV AB 2016, Sweden

Power classes

Power classes

Scania supplies engines in 4 different power classes:

ICFN – continuous operation: Intended for unlimited number of operational hours per year at a total load

factor of 100%.

IFN – periodic operation: Intended for periodic operation, where full power is available 1 h/3 h. The accumulated load factor must not exceed 80% of the calculated load. Unlimited number of hours per year.

Patrol Craft Long: Intended for periodic operation, where full power is available 1 h/6 h. In between periods of operation at full load, the engine speed must be reduced by at least 10% of the maximum engine

speed attained. The maximum accumulated operating time must be 2,000 hours per year.

Patrol Craft Short: Intended for periodic operation where the calculated power is available 1h/12h. In between periods of operation at full load, the engine speed must be reduced by at least 10% of the maximum

engine speed attained. The maximum accumulated operating time must be 1,200 hours per year.

The engine serial numbers and power classes for the engines that are used in this installation should be listed

below:

Indicate below the type of operation, and enter it on page 1.

Engine serial number:

Engine type:

Engine power: kW at rpm

ICFN – continuous operation

IFN – periodic operation

Patrol Craft Long

Patrol Craft Short

Page 5

OPM 250 en-GB 5

©

Scania CV AB 2016, Sweden

Environment and safety

Environment and safety

Environmental responsibility

Scania develops and produces engines that are as

environmentally-friendly as possible. Scania has

made major investments in the reduction of

harmful exhaust emissions in order to fulfil the

environmental requirements in force in almost

every market.

At the same time, we have been able to maintain

a high level of performance and operating economy for Scania marine engines. To maintain

these throughout the entire service life of the engine, it is important for the user to follow the instructions on running, maintenance and fuel and

lubricating oil as outlined in the Operator's manual.

Other green initiatives taken include ensuring

that, following maintenance and repair, waste

that is harmful to the environment (for example

oil, fuel, coolant, filters and batteries) is disposed

of accordance with the applicable environmental

requirements.

Safety

The following pages contain a summary of the

safety precautions to be complied with when operating and maintaining Scania engines. The

equivalent text can also be found under the relevant maintenance item.

To prevent damage to the engine and to ensure

that it runs optimally, follow the instructions in

the warnings and advisories.

If the instructions are not followed, the warranty

can cease to apply.

Different types of advisory

Warning!

All advisories preceded by Warning! are very

important. They warn of serious faults and incorrect operation that could lead to personal injury.

Example:

WARNING!

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

Important!

Advisories preceded by Important! warn of

faults and incorrect operation that could lead to

equipment being damaged. Example:

IMPORTANT!

An excessively high coolant temperature can

damage the engine.

Page 6

OPM 250 en-GB 6

©

Scania CV AB 2016, Sweden

Environment and safety

Note:

Advisories preceded by Note: refer to information important to ensure the best possible operation and functionality. Example:

Note:

Leave the engine off for at least 1 minute before

you check the oil level.

Environment

This Operator’s Manual contains specially highlighted text with instructions to help protect the

environment during maintenance. Example:

Environment

Use a suitable container. Used fuel must be disposed of as specified in national and international laws and regulations.

Warnings and advisories

Smoking

WARNING!

Smoking is prohibited

• in the vicinity of flammable or explosive material, e.g. fuel, oils, batteries, chemicals

• when refuelling and in the vicinity of the filling station

• when working on the fuel system

Safety precautions for running the

engine

Daily maintenance

Always carry out a visual inspection of the engine and engine compartment before starting the

engine or when the engine has been switched off

after operation.

This inspection should be done to detect fuel, oil

or coolant leaks, or anything else that may require corrective action.

Fuel

WARNING!

The wrong fuel grade can cause breakdowns or

stoppages by causing the injection system to

malfunction. This can cause damage to the engine and, possibly, personal injury.

IMPORTANT!

The operator is responsible for using the correct

type of fuel to ensure that local laws and regulations are complied with.

For further information on fuel, see the section

Composition of the fuel

.

Page 7

OPM 250 en-GB 7

©

Scania CV AB 2016, Sweden

Environment and safety

Refuelling

WARNING!

During refuelling there is a risk of fire and explosion. The engine must be switched off and smoking is prohibited.

Never overfill the tank as the fuel needs space to

expand. Make sure that the filler cap is fully

closed.

Hazardous gases

WARNING!

Only start the engine in a well ventilated area.

The exhaust gases contain carbon monoxide and

nitrogen oxides, which are toxic.

If it is run in an enclosed space, there should be

an effective device to extract exhaust gases and

crankcase gases.

Starter lock

IMPORTANT!

If the instrument panel is not fitted with a starter

lock, the engine compartment should be locked

to prevent unauthorised personnel from starting

the engine. Alternatively, a lockable master

switch or battery master switch can be used.

Starter gas

WARNING!

Never use starter gas or similar agents to help

start the engine. This can cause an explosion in

the intake manifold and possible injury.

Page 8

OPM 250 en-GB 8

©

Scania CV AB 2016, Sweden

Environment and safety

Running

WARNING!

The engine must not be run in environments

where there is a risk of explosion, as all of the

electrical or mechanical components can generate sparks.

Approaching a running engine always poses a

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts such as the

fan and cause injury. For personal safety all rotating parts and hot surfaces must be fitted with

guards.

Safety precautions for handling materials

Fuel and lubricating oil

WARNING!

All fuels and lubricants as well as many chemicals are flammable. Always follow the instructions on the relevant packaging.

The work must be carried out on a cold engine.

Fuel leaks and spillage on hot surfaces can cause

fire.

Store used rags and other flammable materials

safely so as to avoid spontaneous combustion.

Batteries

WARNING!

The batteries contain and form oxyhydrogen gas,

particularly during charging. Oxyhydrogen gas

is flammable and highly explosive.

There must be no smoking, naked flames or

sparks near the batteries or the battery compartment. Incorrect connection of a battery cable or

jump lead can cause a spark, which can cause the

battery to explode.

Chemicals

WARNING!

Most chemicals such as glycol, anti-corrosive

agents, preservative oils and degreasing agents,

are hazardous to health.

Some chemicals, such as preservative oil, are

also flammable.

Always follow the safety precautions on the relevant packaging.

Store chemicals and other materials which are

hazardous to health in approved and clearly

marked containers, where they are inaccessible

to unauthorised persons.

Environment

Always hand in leftover and used chemicals to

an authorised waste disposal contractor.

Page 9

OPM 250 en-GB 9

©

Scania CV AB 2016, Sweden

Environment and safety

Safety precautions for maintenance

and repair

Switch off the engine

WARNING!

Working with a running engine always poses a

safety risk. Parts of the body, clothes or dropped

tools can get caught in rotating parts and cause

injury.

Always switch off the engine before carrying out

maintenance and repairs, unless otherwise indicated.

Make it impossible to start the engine: Remove

any starter key, or cut the power using the main

power switch or battery master switch and lock

them.

Fix a warning plate somewhere appropriate,

showing that work is being carried out on the engine.

Hot surfaces and fluids

WARNING!

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are engine

manifolds, turbochargers, oil sumps, hot coolant

and oil in pipes and hoses.

Lifting the engine

WARNING!

Never work underneath a suspended engine!

Always use the engine lifting eyes. Always

check that lifting accessories are in good condition and are designed to lift the weight.

Optional equipment on the engine can change

the centre of gravity. This means that it may be

necessary to use additional lifting devices to balance the engine correctly and lift it safely.

Batteries

WARNING!

The batteries contain highly corrosive sulphuric

acid. Take care to protect your eyes, skin and

clothes when charging or handling batteries.

Wear protective gloves and goggles.

If sulphuric acid comes in contact with the skin:

Wash with soap and plenty of water. If it gets in

your eyes: Rinse immediately with plenty of water and seek medical attention.

Environment

Always hand in used batteries to an authorised

waste disposal contractor.

Page 10

OPM 250 en-GB 10

©

Scania CV AB 2016, Sweden

Environment and safety

Electrical system

IMPORTANT!

Always use Scania spare parts for the fuel and

electrical systems. Scania spare parts are designed to minimise the risk of fire and explosion.

The engine must be switched off and the power

disconnected using the master switch or battery

master switch before working on the electrical

system. External power supplies to extra equipment on the engine must also be disconnected.

Electric welding

IMPORTANT!

When carrying out welding work on and near the

engine, disconnect the battery and alternator

leads. Pull out the multi-pin connector for the engine control unit as well.

Connect the welding clamp close to the component to be welded. The welding clamp must not

be connected to the engine, or so that the current

can cross a bearing.

When welding is finished:

1. Connect the alternator and engine control

unit cables first.

2. Then connect the batteries.

Lubrication system

WARNING!

Hot oil can cause burns and skin irritation. Wear

protective gloves and goggles when changing

hot oil.

Make sure that there is no pressure in the lubrication system before starting work on it.

The oil filler cap must always be in place when

starting and running the engine to prevent oil being ejected.

Environment

Use a suitable container. Used oil must be disposed of as specified in national and international laws and regulations.

Page 11

OPM 250 en-GB 11

©

Scania CV AB 2016, Sweden

Environment and safety

Cooling system

WARNING!

Never open the coolant filler cap when the engine is hot. Hot coolant and steam may spray out

and cause burns.

If the cap has to be opened do it slowly and carefully to release the pressure before removing the

cap. Wear gloves as the coolant is still very hot.

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and international laws and regulations.

Fuel system

WARNING!

Maintenance and repairs of injection equipment

are to be carried out by an authorised Scania

workshop.

Always use Scania spare parts for the fuel and

electrical systems. Scania spare parts are designed to minimise the risk of fire and explosion.

Environment

Use a suitable container. Used fuel must be disposed of as specified in national and international laws and regulations.

Before starting

WARNING!

Never start the engine without the air filter being

in place. If you do, this could cause injury and severe engine damage.

Ensure that all guards are in place before starting

the engine. Ensure that no tools or other objects

have been left on the engine.

Page 12

OPM 250 en-GB 12

©

Scania CV AB 2016, Sweden

Environment and safety

Certification

IMPORTANT!

For Scania to guarantee that the engine corresponds to its certified configuration, and take responsibility for any damage and injuries that

occur, maintenance must be carried out in accordance with the instructions in this Operator's

manual.

An emissions certified engine fulfils the emissions requirements for a particular range of application.

On each emissions certified engine there is a label which shows which requirements the engine

fulfils. Scania guarantees that each such engine

fulfils the emissions requirements for the range

of application for which it is certified.

The following are required for the certified engine to fulfil the emissions requirements once it

has been taken into service:

• Maintenance is to be carried out in accordance with the instructions in this Operator's

manual.

• Maintenance and repairs of injection equipment are to be carried out by an authorised

Scania workshop.

• The engine may only be modified with equipment that has been approved by Scania.

• Seals may be broken and setting data edited

only once approval has been granted by Scania. Modifications may be made by authorised personnel only.

• Modifications affecting the exhaust and intake systems must be approved by Scania.

Otherwise, the instructions in the Operator's

manual for the running and maintenance of the

engine shall apply. Follow the safety precautions

on the previous pages.

Page 13

OPM 250 en-GB 13

©

Scania CV AB 2016, Sweden

Engine data plate

Engine data plate

The engine data plate indicates, in the form of a code, the engine type, its size and applications. It also indicates the engine power and operating speed. The engine EU type approval for exhaust emissions is indicated under Output.

The engine serial number is stamped onto the top of the cylinder block at the front right.

Example: DI13 070M

DI Supercharged diesel engine with water-cooled charge air cooler.

13 Displacement in whole dm

3

.

070 Performance and certification code. The code indicates, together

with the application code, the normal gross engine output.

M Code for application. M means for marine use.

Made b

y

T

ype

Engine No

Output.

kW

r

pm.

DI13 070M

6950106

405

1800

348 329

Example of an engine data plate

Page 14

OPM 250 en-GB 14

©

Scania CV AB 2016, Sweden

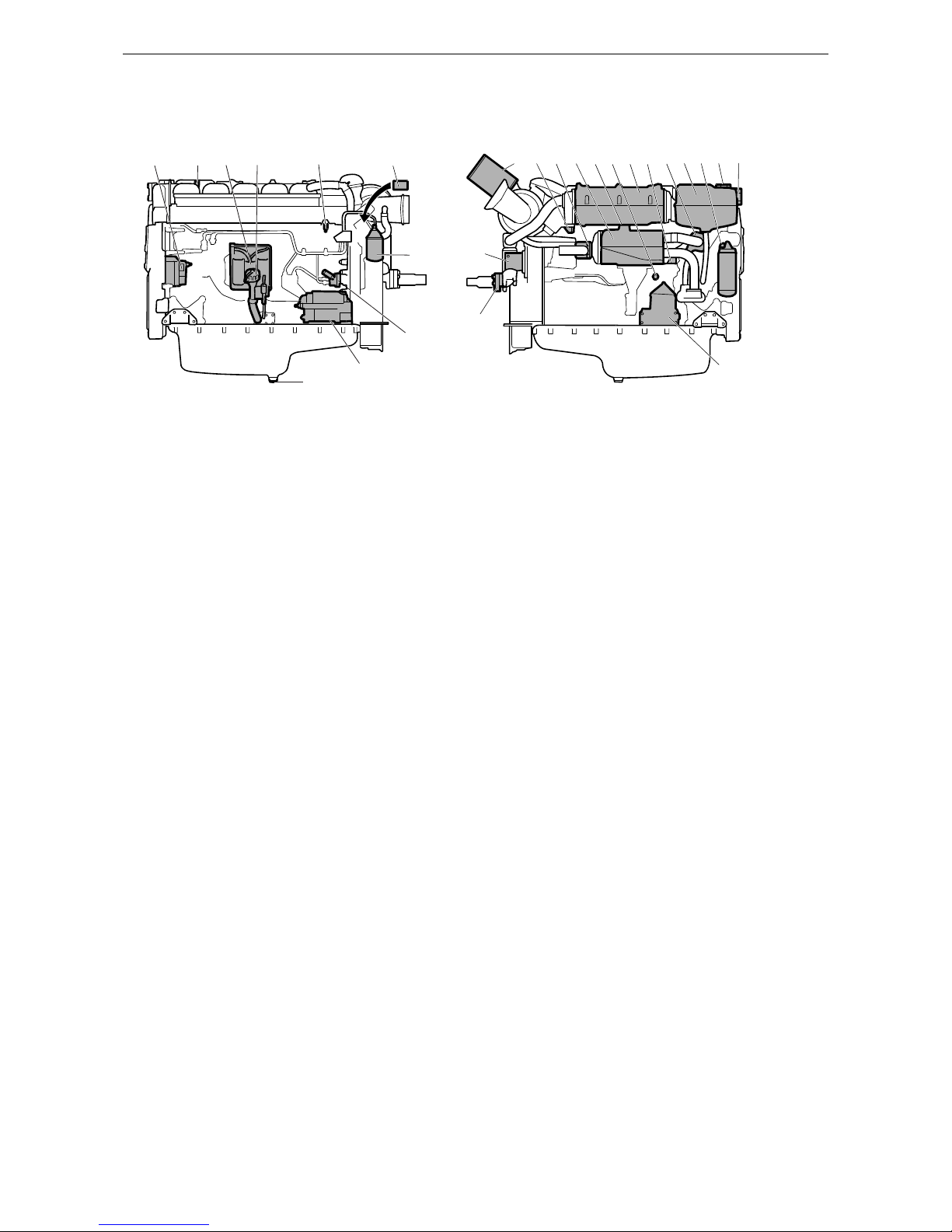

Component identification

Component identification

1. Alternator

2. Oil filler cap

3. Engine control unit

4. Oil dipstick

5. Fuel manifold bleed nipple

6. Engine data plate

7. Fuel filter

8. Fuel pump with hand pump

9. Starter motor

10. Oil plug

11. Air filter

12. Sacrificial anodes (2)

13. Sea water outlet

14. Heat exchanger

15. Holes for draining condensation in charge air cooler

16. Valve for draining coolant

17. Charge air cooler

18. Thermostat

19. Expansion tank

20. Oil filter

21. Filling coolant

22. Level glass for checking coolant level

23. Centrifugal oil cleaner

24. Sea water intake

25. Sea water pump

1

5

6

12

11

7

8

10

9

2

13

14

25

24

23

15 161712

18

19 20

21

22

3

4

343 190

The illustration shows a normal version of a DI13 engine with heat exchanger. The engine ordered may have

different equipment.

Page 15

OPM 250 en-GB 15

©

Scania CV AB 2016, Sweden

Starting and running

Starting and running

Checks before first start

Before the engine is started for the first time, carry out the maintenance items listed under First

start in the maintenance schedule. The following

must be checked:

• Oil level

• Coolant

•Fuel level

• Fluid level in batteries

• State of battery charge

• Condition of the drive belt

See also Maintenance intervals

.

Checks before running

Carry out daily maintenance as described in the

maintenance schedule prior to operation. See

Maintenance intervals

.

Starting the engine

WARNING!

Never use starter gas or similar agents to help

start the engine. This can cause an explosion in

the intake manifold and possible injury.

Only start the engine in a well ventilated area.

When the engine is run in an enclosed space,

there must be effective devices to extract exhaust

gases and crankcase gases.

IMPORTANT!

The starter motor must only be cranked twice for

30 seconds at a time. After that, it must rest for at

least 5 minutes before the next attempt to start it.

For environmental reasons the Scania engine has

been developed to be started with a low fuel feed.

Using unnecessarily large amounts of fuel when

starting the engine always results in emissions of

unburnt fuel.

1. Open the fuel cock if fitted.

2. Disengage the engine.

3. If the engine has a battery master switch:

Switch on the power by means of the battery

master switch.

4. Start the engine.

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

system. See section Bleeding the fuel system us-

ing a hand pumpor Bleeding the fuel system using a suction tool.

Page 16

OPM 250 en-GB 16

©

Scania CV AB 2016, Sweden

Starting and running

Starting at low temperatures

Take the local environmental requirements into

account. Use a fuel heater and engine heater to

avoid starting problems and white smoke.

Scania recommends that an engine heater should

be used if the engine will be used at temperatures

below -10°C.

A low engine speed and a moderate load on a

cold engine limits white smoke, gives better

combustion and warms up the engine more

quickly than warming it up with no load.

Avoid running it longer than necessary at idling

speed.

Running

Check instruments and warning lamps at regular

intervals.

Engine speed range

The engine operating speed range is between low

idling and the nominal engine speed. The nominal engine speed is indicated on the engine data

plate. Low idling can be set between 500 and

1,050 rpm.

Limp home mode

If there is a fault in the normal throttle opening or

if CAN communication is interrupted, the following emergency operation option is provided:

A CAN fault or throttle opening fault in an allspeed engine (both signal and idling switch):

• The throttle opening value is 0% and the engine is running at normal idling speed.

• The throttle opening value is 0% and the engine is running at raised idling speed (750

rpm) if this function is activated.

Throttle opening fault, but the idling switch is

working:

• The throttle opening value can be increased

slowly between 0 and 50% by using the idling

switch.

CAN fault:

• The engine is switched off if the shutdown

function is activated.

Driving at high altitude

When driving at high altitudes engine power is

reduced automatically due to the lower oxygen

content in the air. It is then not possible to run the

engine at maximum power.

• ICFN and PRP engines may be used at an altitude of up to 2,000 metres.

• IFN, Patrol Craft Long and Patrol Craft Short

engines must not be used at an altitude of

more than 1,000 metres.

• Contact Scania if the operating conditions deviate from these.

Page 17

OPM 250 en-GB 17

©

Scania CV AB 2016, Sweden

Starting and running

Coolant temperature

IMPORTANT!

An excessively high coolant temperature can

damage the engine.

Normal coolant temperature during operation is

approximately 94°C/200°F.

The alarm levels are set in the engine control

unit. The default setting for the lowest and highest limit values for high coolant temperature are

95°C/203°F and 105°C/221°F respectively.

The high coolant temperature alarm has the following functions:

• Alarm only.

• Alarm and torque reduction at the lowest limit value.

• Alarm at the lowest limit value and engine

shutdown at the highest limit value.

• Alarm, torque reduction at the lowest limit

value and engine shutdown at the highest limit value.

• Alarm at the lowest limit value and engine

shutdown at the highest limit value with the

possibility of engine shutdown override control.

• Alarm, torque reduction at the lowest limit

value and engine shutdown at the highest limit value, with the possibility of engine shutdown override control.

If run for extended periods under an extremely

light load, the engine may have difficulty in

maintaining the coolant temperature. At an increased load the coolant temperature rises to the

normal value.

Oil pressure

Information about the normal oil pressure and

lowest permitted oil pressure is contained in the

Lubrication system

section in the Technical Data

chapter.

The engine management system has the following alarm levels:

• At an engine speed below 1,000 rpm and an

oil pressure below 0.7 bar/10.2 psi.

• At an engine speed above 1,000 rpm and an

oil pressure below 2.5 bar/36.3 psi for longer

than 3 seconds.

The incorrect oil pressure alarm has the following functions:

• Alarm only.

• Alarm and torque reduction by 30%.

• Alarm and engine shutdown.

• Alarm and engine shutdown override control.

Note:

High oil pressure (above 6 bar/87 psi) is normal

when starting a cold engine.

Charging indicator lamp

If the lamp comes on during operation:

• Check and adjust the drive belt according to

the section Checking the drive belt

.

If the charging indicator lamp is still on, this

could be due to an alternator fault or a fault in the

electrical system.

Belt transmission

When the belt transmission is new, it may make

a squeaking noise when running. The noise is

normal and disappears after 50-100 hours of operation. The noise does not affect the service life

of the belt transmission.

Page 18

OPM 250 en-GB 18

©

Scania CV AB 2016, Sweden

Starting and running

Engine shutdown

IMPORTANT!

There is risk of post boiling and of damage to the

turbocharger if the engine is switched off without cooling. The power must not be switched off

before the engine has stopped.

Note:

The battery voltage must remain on for a few

seconds after the 15 voltage is switched off so

that the control units can store the values and

switch to standby mode.

10 prohibited engine shutdowns will cause a

torque reduction (70% of fuel quantity). Reset

the engine by switching it off correctly once.

1. Run the engine without a load for a few min-

utes if it has been run continuously with a

heavy load.

2. Switch off the engine.

Checks after running

WARNING!

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are turbochargers, oil sumps, hot coolant and oil in pipes

and hoses.

IMPORTANT!

Check the coolant level following the first start.

Top up with coolant as necessary.

1. Check that the power supply has been cut.

2. Fill the fuel tank. Make sure that the filler

cap and the area round the filler opening are

clean to avoid contamination of the fuel.

3. If there is a risk of freezing, the cooling sys-

tem must contain enough glycol. See the section Coolant resistance to cold

.

4. If the temperature is below 0°C/32°F: Pre-

pare for the next start by connecting the engine heater (if fitted).

Page 19

OPM 250 en-GB 19

©

Scania CV AB 2016, Sweden

Maintenance

Maintenance

The maintenance programme covers a number of

points that are divided into the following sections:

• Lubrication system

• Cooling system

• Air cleaner

• Fuel system

• Miscellaneous

WARNING!

Block the starting device when working on the

engine. If the engine starts unexpectedly, there is

a serious risk of injury.

There is always a risk of sustaining burns when

an engine is hot. Particularly hot parts are turbochargers, oil sumps, hot coolant and oil in pipes

and hoses.

The maintenance programme includes the following:

• S maintenance: Minimum basic maintenance.

• M maintenance: More extensive maintenance.

• L maintenance: Includes nearly all maintenance items.

• XL maintenance: Includes all maintenance

items.

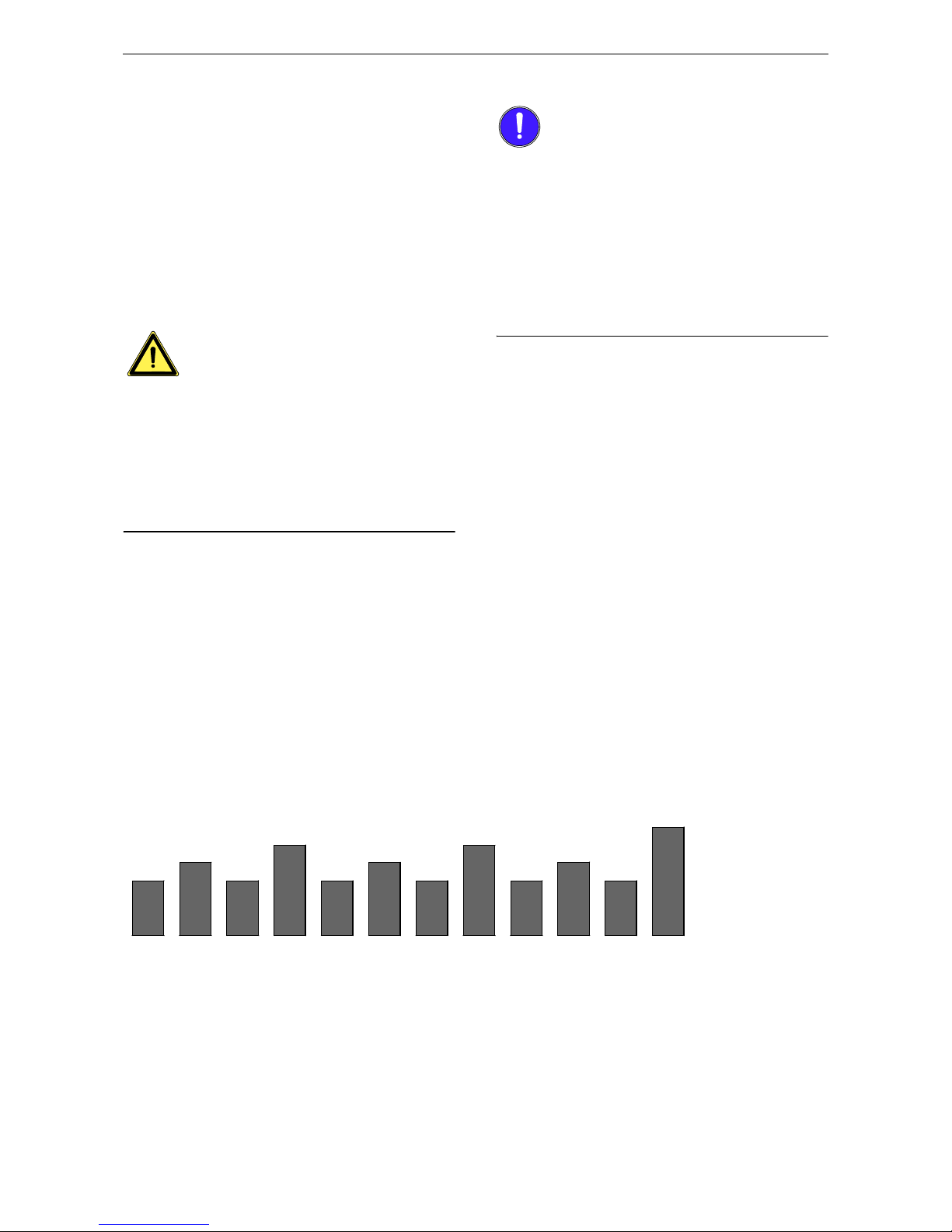

During a period, the sequence is S-M-S-L-S-MS-L-S-M-S-XL.

XL

6000

S

5500

M

5000

S

4500

L

4000

S

3500

M

3000

S

2500

L

2000

S

1500

M

1000

S

500

313 153

IMPORTANT!

On delivery a Scania engine is optimised for its

application. However, regular maintenance is

necessary to

• prevent unplanned stops

• extend the service life of the engine

• maximise the long-term emission performance of the engine

• give the best possible operating economy.

Page 20

OPM 250 en-GB 20

©

Scania CV AB 2016, Sweden

Maintenance

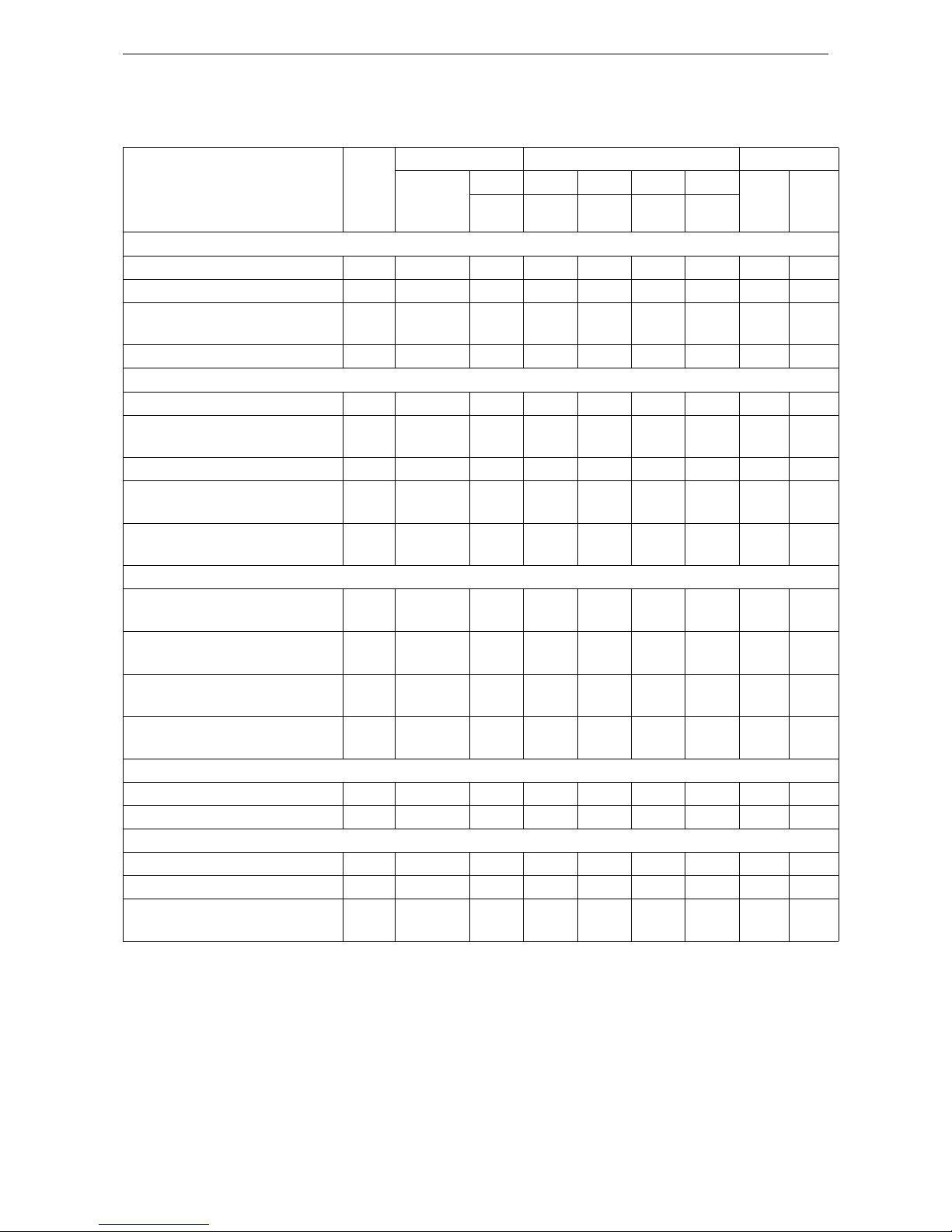

Maintenance intervals

Daily First time at Interval (hours) At least

first start 500 500 1,000 2,000 6,000 annu-

ally

every

5

years

RSMLXL

Lubrication system

Checking oil level XX

Changing the oil XXXXXX

Cleaning the centrifugal oil

cleaner

XXXXXX

Renewing the oil filter XXXXXX

Cooling system

Checking coolant level X X XXXXX

Checking coolant antifreeze and

corrosion protection

XXXX

Checking sacrificial anodes XXXXXX

Checking the sea water pump

impeller

XXXXX

Changing the coolant and cleaning the cooling system

XX

Air cleaner

Reading the air cleaner vacuum

indicator

X XXXXX

Renewing the air cleaner filter

element

XX X

Renewing the air cleaner safety

cartridge

XX X

Renewing an air filter with a

non-renewable element

XX X

Fuel system

Checking fuel level XX

Renewing the fuel filters XXX X

Miscellaneous

Checking the drive belt XXXXX

Checking for leaks XXXXX

Checking and adjusting the valve

clearance

XXX

Page 21

OPM 250 en-GB 21

©

Scania CV AB 2016, Sweden

Lubrication system

Lubrication system

Oil grade

Scania LDF stands for the Scania Long Drain

Field test standard. Scania LDF oils have been

carefully selected after extensive testing. The approval is only granted to the highest quality engine oils available on the market.

The engine oil must fulfil the following quality

requirements:

• ACEA E5/API CI-4.

• ACEA E7/API CI-4 +.

• For engines not run on low-sulphur fuel, the

TBN (Total Base Number) should be at least

12 (ASTM D2896).

• Oils with a low ash content (ACEA E9/API

CJ4) are not recommended.

Check with your oil supplier that the oil meets

these requirements.

If the engine is used in areas of the world where

lubricating oil with ACEA or API classification

is not available, the oil grade must be measured

in actual operation. In this case contact the nearest Scania workshop.

For operation at extremely low outdoor temperatures: Consult your nearest Scania representative

on how to avoid starting difficulties.

Recommended oil

Scania Oil LDF-3

Scania Oil LDF-2

Scania Oil LDF

Scania Oil E7

Viscosity class Outdoor temperature

SAE 20W-30 -15°C (5°F) - +30°C (86°F)

SAE 30 -10°C (14°F) - +30°C (86°F)

SAE 40 -5°C (23°F) - > +45°C (113°F)

SAE 50 0°C (32°F) - > +45°C (113°F)

SAE 5W-30 < -40°C (-40°F) - +30°C (86°F)

SAE 10W-30 -25°C (-13°F) - +30°C (86°F)

SAE 15W-40 -20°C (-4°F) - > +45°C (113°F)

Page 22

OPM 250 en-GB 22

©

Scania CV AB 2016, Sweden

Lubrication system

Oil analysis

To be able to extend the oil change intervals using an oil analysis, Scania LDF-2 and LDF-3 oils

must be used. Oil companies can offer analysis

of the engine oil.

The following conditions must remain fulfilled

when the oil is changed:

• Viscosity at 100°C (212°F): max ±20% of

original value of the fresh oil.

• TBN (in accordance with ASTM D4739): >

3.5.

• TBN (in accordance with ASTM D4739): >

TAN (in accordance with ASTM D664).

• Soot (in accordance with DIN 51452): < 3%.

Such analysis measures the oil's TBN (Total

Base Number), TAN (Total Acid Number), fuel

dilution, water content, viscosity and the quantity of particles and soot in the oil. The result of a

series of analyses is used as the basis for establishing a suitable oil change interval.

If the conditions are changed, a new oil analysis

programme must be carried out to establish new

oil change intervals.

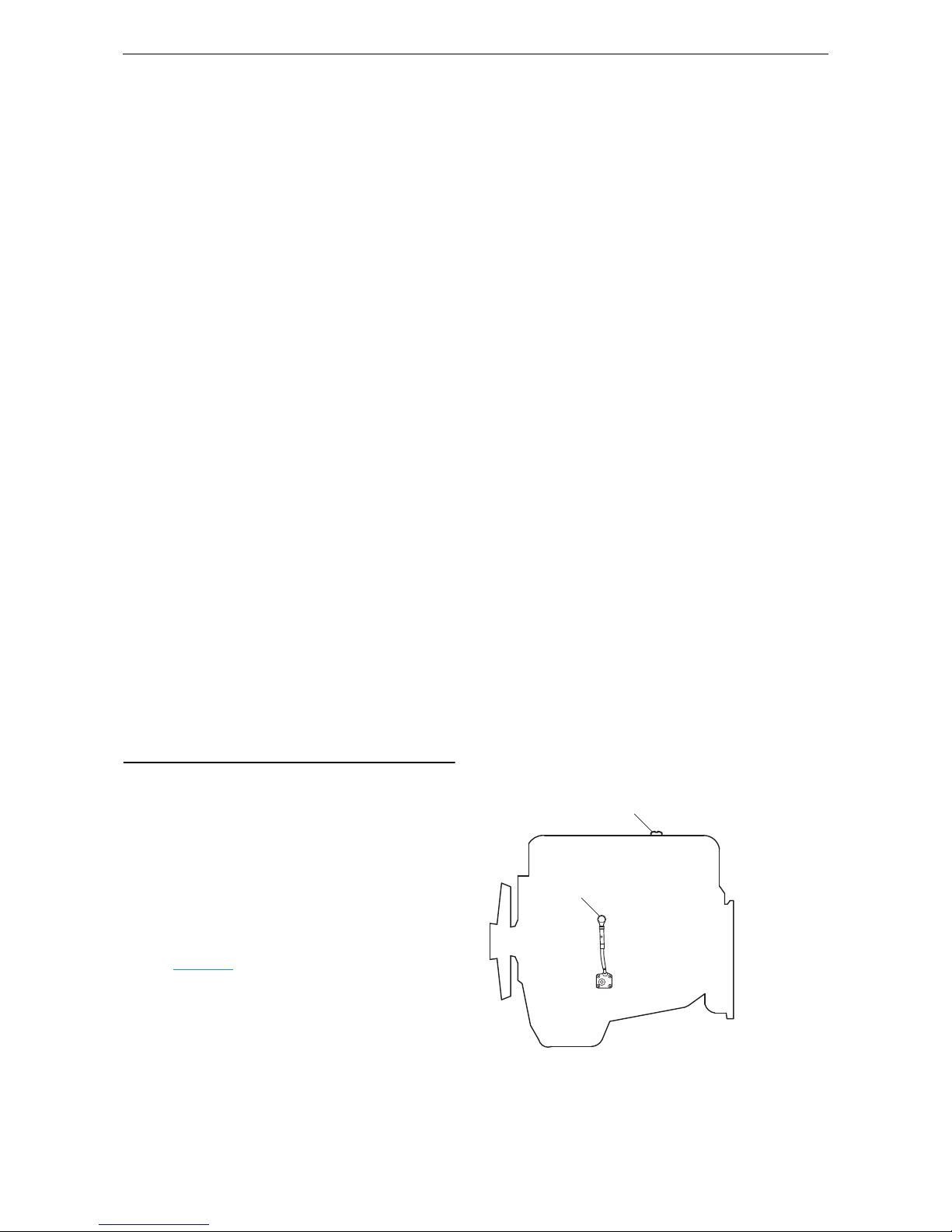

Checking oil level

Checking the oil level with the engine

switched off

Note:

Leave the engine off for at least 1 minute before

you check the oil level.

1. Remove the oil dipstick (1) and check the oil

level. The correct level is between the minimum and maximum marks on the oil dipstick.

2. Top up with more oil via the oil filler (2)

when the oil level is at or below the minimum mark.

For information on the correct oil type, see the

section Oil grade

.

312 506

2

1

Page 23

OPM 250 en-GB 23

©

Scania CV AB 2016, Sweden

Lubrication system

Changing the oil

WARNING!

Hot oil can cause burns and skin irritation. Wear

protective gloves and goggles when changing

hot oil. Make sure that there is no pressure in the

lubrication system before starting work on it.

The oil filler cap must always be in place when

starting and running the engine to prevent oil being ejected.

Note:

Renew the oil filter and clean the centrifugal oil

cleaner when changing oil.

Change oil more often if the engine is subjected

to particularly demanding operation, such as a

dusty environment, or if deposits in the centrifugal oil cleaner are thicker than 28 mm (1.1 in).

Environment

Use a suitable container. Used oil must be disposed of as specified in national and international laws and regulations.

1. Unscrew the oil plug and drain the oil when

the engine is hot. In certain engines the oil is

pumped out by means of a bilge pump.

When draining with the valve, the oil should

be hot. Alternatively, use a pump. This so

that draining occurs more quickly.

2. Clean the magnet on the oil plug.

3. Refit the oil plug.

4. Top up with oil.

5. Check the level on the oil dipstick.

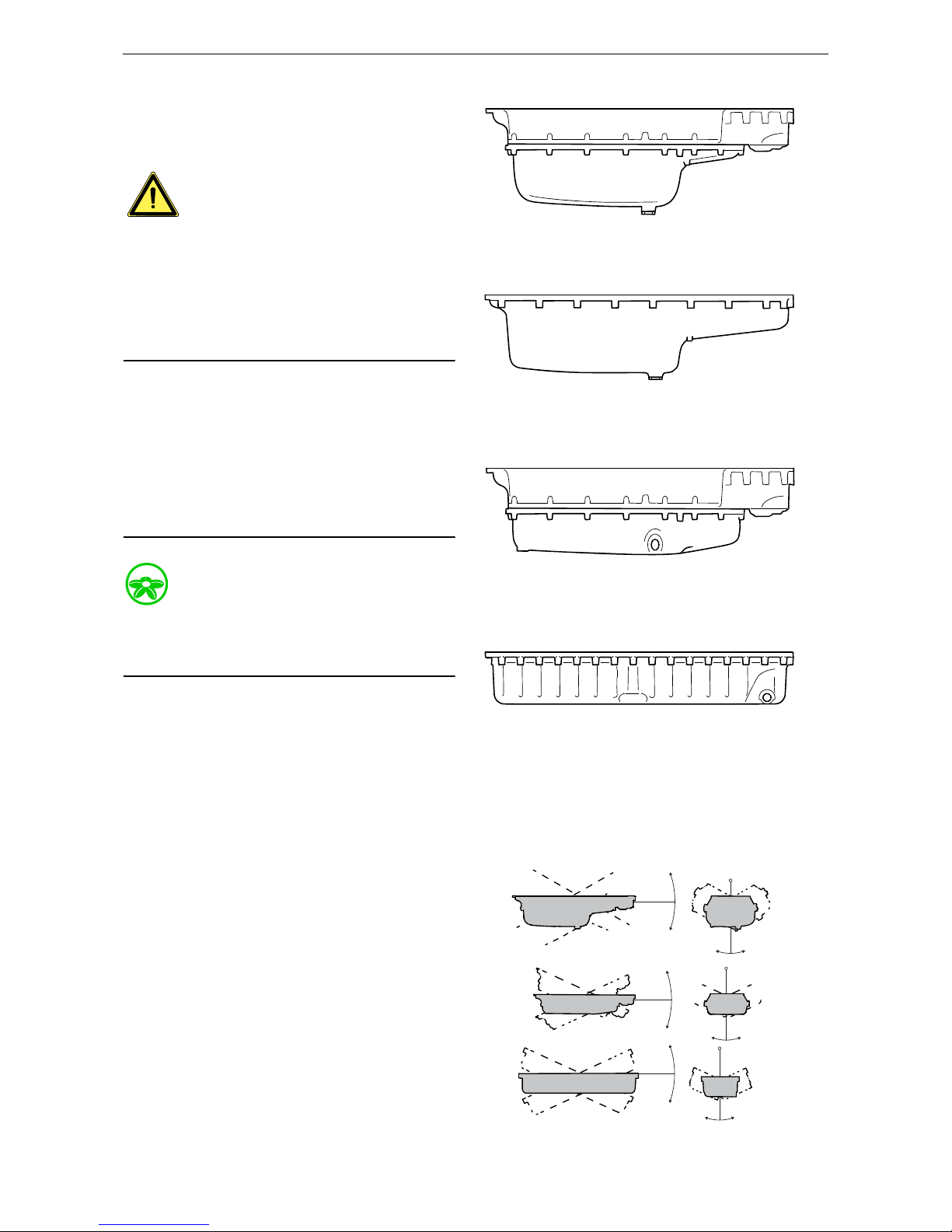

Maximum angles of inclination during operation

Maximum permissible angles during operation

vary, depending on the type of oil sump. See illustration.

362 865

Max. 45 litres (11.9 US gallons).

Min. 39 litres (10.3 US gallons).

362 866

Max. 36 litres (9.5 US gallons).

Min. 30 litres (7.9 US gallons).

362 867

Max. 34 litres (9.0 US gallons).

Min. 28 litres (7.4 US gallons).

362 868

Max. 30 litres (7.9 US gallons).

Min. 25 litres (6.6 US gallons).

30°

30°

30° 30°

30°

25°

25°

30°

30°

25°

25°

30°

343 842

Page 24

OPM 250 en-GB 24

©

Scania CV AB 2016, Sweden

Lubrication system

Oil grade labels

When changing oil it is important to use the correct engine oil grade.

The oil filler cap must therefore be clearly

marked with a label for the oil grade that is required. If the label is missing or if the engine oil

grade is changed, a new label must be fitted.

Parts

Oil grade Colour Part No. Part No.

Label for cylinder block Label for rocker cover

Scania LDF-2 Blue 2 132 424 2 296 064

Scania LDF-3 Red 2 132 426 2 296 066

Scania LDF Grey 2 269 345 2 296 071

ACEA E7 White 2 132 425 2 296 065

Scania Low Ash Green 2 132 427 2 296 067

Scania Bioethanol Black 2 132 428 2 296 068

Scania BEO-2 Orange 2 258 841 2 296 070

ACEA E9 - 2 132 429 2 296 069

336 492

Filling label in the cylinder block.

353 114

Filling label in the rocker cover.

Page 25

OPM 250 en-GB 25

©

Scania CV AB 2016, Sweden

Lubrication system

Cleaning the centrifugal oil

cleaner

WARNING!

The oil may be hot. Carefully remove the cover

from the centrifugal oil cleaner.

Note:

Always use genuine Scania parts during maintenance of the centrifugal oil cleaner. This will ensure that the centrifugal oil cleaner continues to

function.

Tools

When the centrifugal oil cleaner is cleaned, there

should be some dirt deposits in the rotor cover.

This indicates that the rotor is working. If the rotor cover is clean, in other words the rotor is not

working, the cause must be established immediately.

If the dirt deposit exceeds 28 mm at the recommended maintenance intervals, the rotor cover

should be cleaned more often.

1. Clean the cover. Unscrew the nut securing

the outer cover.

2. Let the oil run out from the rotor.

3. Lift out the rotor. Wipe off the outside. Undo

the rotor nut and unscrew it about 1.5 turns to

protect the bearing.

Designation Illustration

Torque wrench

Ratchet head

364 731

364 729

x 1.5

133 315

Page 26

OPM 250 en-GB 26

©

Scania CV AB 2016, Sweden

Lubrication system

4.

If the rotor nut is difficult to get loose, turn

the rotor upside down and fasten the rotor nut

in a vice. Turn the rotor anti-clockwise

1.5 turns by hand or use an M20 nut, see illustration.

IMPORTANT!

The rotor must not be put in a vice. Never strike

the rotor cover. This may cause damage resulting

in imbalance.

5. Remove the rotor cover by holding the rotor

in both hands and tapping the rotor nut

against the table. Never strike the rotor directly as this may damage its bearings.

6. Remove the strainer from the rotor cover. If

the strainer is stuck, insert a screwdriver between the rotor cover and strainer and carefully prise them apart.

x 1.5

M20

Page 27

OPM 250 en-GB 27

©

Scania CV AB 2016, Sweden

Lubrication system

7.

Remove the paper insert and scrape away

any remaining dirt deposits inside the rotor

cover. If the deposits are thicker than 28 mm,

the centrifugal oil cleaner must be cleaned

more often.

8. Wash the parts.

9. Inspect the 2 nozzles on the rotor. Ensure that

they are not blocked or damaged. Renew any

damaged nozzles.

10. Check that the bearings are undamaged. Re-

new damaged bearings.

11. Fit a new paper insert inside the rotor cover.

333 044

333 037

Page 28

OPM 250 en-GB 28

©

Scania CV AB 2016, Sweden

Lubrication system

12.

Fit the strainer onto the rotor.

13. Fit a new O-ring by sliding it over the strain-

er.

14. Refit the rotor cover. Ensure that the O-ring

is not outside the edges.

15. Tighten the rotor nut by hand.

16. Check that the rotor shaft is not damaged or

loose.

17. Refit the rotor and rotate it by hand to check

that it rotates easily.

127 882

Page 29

OPM 250 en-GB 29

©

Scania CV AB 2016, Sweden

Lubrication system

18.

Fit a new O-ring in the cover. Refit the cover

and tighten the lock nut.

IMPORTANT!

To reduce the risk of oil leakage it is important to

tighten the cover to the correct tightening torque.

From engine serial number 6 841 928:

Tightening torque 20 Nm.

Older engine serial number:

Tightening torque 15 Nm.

Operational testing

Operational testing need only be carried out if it

is suspected that the centrifugal oil cleaner is

malfunctioning. For example, if the dirt deposit

is abnormally small given the distance driven.

The rotor rotates very fast and should continue to

turn when the engine has stopped.

1. Run the engine until it reaches normal oper-

ating temperature.

2. Turn off the engine and listen for the sound

from the rotor. Use your hand to feel if the

filter housing is vibrating.

3. If the filter housing is not vibrating, disman-

tle and check the centrifugal oil cleaner.

333 043

333 039

Page 30

OPM 250 en-GB 30

©

Scania CV AB 2016, Sweden

Lubrication system

Renewing the oil filter

Tools

IMPORTANT!

Clean the centrifugal oil cleaner at the same time

as you change the oil filter. Otherwise, the oil filter will be blocked and resistance in the filter will

increase. If this happens, an overflow valve in

the filter retainer opens and lets the oil pass without being filtered.

1. Remove the old filter.

2. Oil the rubber gasket on the new filter.

3. Tighten the filter by hand. Never use tools

because the filter could sustain damage, obstructing circulation.

4. Start the engine and check for leaks.

Renewing the double, commutative oil filter

During operation, the rotary control (1) should

point 90° towards the filter being used.

1. Turn the rotary control 90° to the right so that

it points towards filter B. The oil then flows

through the filter.

2. Clean filter A with a cloth.

3. Unscrew filter A.

4. Apply oil to the gasket on the new filter.

5. Fill the filter with engine oil.

6. Screw filter A into place by hand until it

makes contact.

7. Turn screw a further half turn by hand.

8. Turn the rotary control 90° to the left so that

the rotary control points towards filter A. Fil-

Designation Illustration

Hexagon socket, drive

1/2", 36 mm

118 268

325 164

1

A

B

346 953

Page 31

OPM 250 en-GB 31

©

Scania CV AB 2016, Sweden

Lubrication system

ter B can then be renewed in the same way as

filter A.

Page 32

OPM 250 en-GB 32

©

Scania CV AB 2016, Sweden

Cooling system

Cooling system

Coolant

WARNING!

Ethylene glycol can be fatal if ingested and can

cause skin irritation and eye damage.

Note:

The coolant should be changed when the cooling

system is cleaned: every 6,000 hours or at least

every 5 years. See Changing the coolant and

cleaning the cooling system.

The coolant has several characteristics which are

important for the operation of the cooling system:

• Corrosion protection

• Antifreeze

• Increases the boiling point

Scania recommends that the coolant used is a

mixture of water with antifreeze and corrosion

inhibitor (ethylene glycol). The coolant should

always contain 35-55% by volume of antifreeze

and corrosion inhibitor so that the coolant has the

correct properties for the cooling system to work.

Coolant resistance to cold

The following example shows coolant properties

with 30 percent by volume of antifreeze and corrosion inhibitor:

• Ice slush starts to form at -16°C (3°F).

• At -30°C (-22°F), there is a risk of cooling

system malfunction.

• There is no risk of damage by freezing with a

minimum antifreeze and corrosion inhibitor

content of 35 percent by volume.

The chart depicts coolant properties at different

percents of antifreeze and corrosion inhibitor

concentration by volume.

Curve A: Ice formation starts (ice slush)

Curve B: Damage by freezing occurs

Area 1: Safe area

Area 2: Malfunctions may occur (ice

slush)

Area 3: Risk of damage by freezing

312 505

2

1

3

°C BA

-50

-40

-30

-20

-16

-10

0

100 20304050%

Page 33

OPM 250 en-GB 33

©

Scania CV AB 2016, Sweden

Cooling system

Antifreeze and corrosion inhibitor concentration table

35% by volume of Scania antifreeze provides

sufficient protection against corrosion.

Example:

• The total volume of the cooling system is 40

litres.

• The measured concentration of ethylene glycol is 35% by volume (freezing point -21°C).

According to the table there are 14 litres of

ethylene glycol in the cooling system.

• The required concentration of ethylene glycol

is 45% by volume (freezing point -30°C). According to the table, 18 litres of ethylene glycol are required in the cooling system.

• Since there are already 14 litres in the cooling

system, 4 litres of ethylene glycol must be

added to the cooling system (18 - 14 = 4 litres).

For calculation Adequate protection against corrosion

Volume of ethylene glycol

(%) 202530 3540455060

Cooling system

volume (litres)

Ice slush forms (°C) -6 -9 -12 -21 -24 -30 -38 -50

Volume of ethylene glycol (litres)

5 6 8 1112141518 30

6 8 10 14 16 18 20 24 40

8 1013 1820232530 50

9 1215 2124273036 60

11 14 18 25 28 32 35 42 70

12 16 20 28 32 36 40 48 80

14 18 23 32 36 41 45 54 90

15 20 25 35 40 45 50 60 100

17 22 28 39 44 50 55 66 110

18 24 30 42 48 54 60 72 120

20 26 33 46 52 59 65 78 130

21 28 35 49 56 63 70 84 140

23 30 38 53 60 68 75 90 150

24 32 40 56 64 72 80 96 160

26 34 43 60 68 77 85 102 170

27 36 45 63 72 81 90 108 180

29 38 48 67 76 86 95 114 190

30 40 50 70 80 90 100 120 200

Page 34

OPM 250 en-GB 34

©

Scania CV AB 2016, Sweden

Cooling system

Antifreeze and corrosion inhibitor concentration table

35% by volume of Scania antifreeze provides

sufficient protection against corrosion.

Example:

• The total volume of the cooling system is

10.6 US gallons.

• The measured concentration of ethylene glycol is 35% by volume (freezing point -6°F).

According to the table there are 3.7 US gallons of ethylene glycol in the cooling system.

• The required concentration of ethylene glycol

is 45% by volume (freezing point -22°F). According to the table, 4.8 US gallons of ethylene glycol are required in the cooling system.

• Since the cooling system already contains

3.7 US gallons, fill another 1.1 US gallons of

ethylene glycol in the cooling system (4.8 -

3.7=1.1USgallons).

For calculation Adequate protection against corrosion

Volume of ethylene glycol

(%) 202530 3540455060

Cooling system

volume (US gallons)

Ice slush forms (°F) 21 16 10 -6 -11 -22 -36 -58

Volume of ethylene glycol

(US gallons)

1.3 1.6 2.1 2.9 3.2 3.7 4 4.8 7.9

1.6 2.1 2.6 3.7 4.2 4.8 5.3 6.3 10.6

2.1 2.6 3.4 4.8 5.3 6.1 6.6 7.9 13.2

2.4 3.2 4 5.5 6.3 7.1 7.9 9.5 15.9

2.9 3.7 4.8 6.6 7.4 8.5 9.2 11.1 18.5

3.2 4.2 5.3 7.4 8.5 9.5 10.6 12.7 21.1

3.7 4.8 6.1 8.5 9.5 10.8 11.9 14.3 23.8

4 5.3 6.6 9.2 10.6 11.9 13.2 15.9 26.4

4.5 5.8 7.4 10.3 11.6 13.2 14.5 17.4 29.1

4.8 6.3 7.9 11.1 12.7 14.3 15.9 19 31.7

5.3 6.9 8.7 12.2 13.7 15.6 17.2 20.6 34.3

5.5 7.4 9.2 12.9 14.8 16.6 18.5 22.2 37

6.1 7.9 10 14 15.9 18 19.8 23.8 39.6

6.3 8.5 10.6 14.8 16.9 19 21.1 25.4 42.3

6.9 9 11.4 15.9 18 20.3 22.5 26.9 44.9

7.1 9.5 11.9 16.6 19 21.4 23.8 28.5 47.6

7.7 10 12.7 17.7 20.1 22.7 25.1 30.1 50.2

7.9 10.6 13.2 18.5 21.1 23.8 26.4 31.7 52.8

Page 35

OPM 250 en-GB 35

©

Scania CV AB 2016, Sweden

Cooling system

Antifreeze and corrosion protection

products

Only Scania coolant or other products that Scania has tested to provide proper antifreeze and corrosion protection, may be used in Scania

engines. Products that do not satisfy the requirements for use in a Scania engine can result in

faults in and damage to the cooling system. This

can lead to the invalidation of Scania's warranty

for faults and damage caused by the use of inappropriate coolant.

The antifreeze and corrosion protection products

used in Scania engines should be of the ethylene

glycol type.

Below is a list of Scania antifreeze and corrosion

protection products.

Scania concentrate

Coolant with antifreeze and corrosion inhibitor

in the form of a concentrate.

Scania Ready Mix

Coolant with antifreeze and corrosion inhibitor

Ready Mix 50/50.

Part No. Volume Volume

litres US gallons

1 894 323 5 1.3

1 894 324 20 5.3

1 894 325 210 55

1 894 326 1,000 264

Part No. Volume Volume

litres US gallons

1 921 955 5 1.3

1 921 956 20 5.3

1 921 957 210 55

1 896 695 1,000 264

Checking coolant level

WARNING!

Do not open the coolant filler cap in the expansion tank if the engine is hot. Hot coolant and

steam may spray out and cause burns.

If the cap has to be opened do it slowly and carefully to release the pressure before removing the

cap. Wear gloves as the coolant is still very hot.

IMPORTANT!

It is not permissible to top up large amounts of

coolant via the expansion tank. Filling via the expansion tank leads to air locks in the cooling system which can lead to e.g. damage to the coolant

pump shaft seal. If a large amount of coolant

must be added, follow the instructions in the section Filling coolant

.

Never fill a large amount of cold coolant in a hot

engine. There is great risk of cracks forming in

the cylinder block and cylinder heads.

Only pour pre-mixed coolant into the cooling

system.

The following instructions apply to Scania expansion tanks. For other types of expansion

tanks, follow the manufacturer's instructions.

1. Check the coolant level through the sight

glass on the expansion tank.

2. Top up with coolant as necessary.

Page 36

OPM 250 en-GB 36

©

Scania CV AB 2016, Sweden

Cooling system

Checking coolant antifreeze

and corrosion protection

Note:

Use only pure fresh water that is free from particles, sludge and other impurities.

Tools

1. Pour a small amount of coolant into a con-

tainer and check that the coolant is pure and

clear.

2. Change the coolant if it is contaminated or

cloudy.

3. Measure the antifreeze content with a refrac-

tometer.

The following rules apply to ethylene glycolbased coolant:

• The antifreeze and corrosion inhibitor content

must be minimum 35 percent by volume for

corrosion protection to be sufficient.

• An antifreeze and corrosion inhibitor content

greater than 55 percent by volume impairs the

ability to protect against frost.

• If ice forms in the coolant, there are disruptions initially, but there is no immediate risk

of damage. The engine should not be subjected to heavy loads when ice starts to form.

Designation Illustration

Refractometer

305 523

138008

Page 37

OPM 250 en-GB 37

©

Scania CV AB 2016, Sweden

Cooling system

Checking sacrificial anodes

1. Drain the sea water circuit as described in

Draining the sea water circuit

.

2. Check the sacrificial anodes and scrape off

all loose material from them.

3. Renew the sacrificial anode if less than half

of it is left. A new sacrificial anode is 60 mm

long with a diameter of 17 mm.

4. Renew the gasket when fitting.

If the sacrificial anodes are very corroded, the inspection intervals must be reduced.

Checking the sea water pump

impeller

1. Drain the sea water circuit as described in

Draining the sea water circuit

.

2. Check that the vanes of the impeller are not

heavily splintered or damaged.

325 163

Position of sacrificial anodes.

330 593

Sea water pump cover.

Page 38

OPM 250 en-GB 38

©

Scania CV AB 2016, Sweden

Cooling system

Renewing the sea water pump impeller

Note:

If the impeller must be renewed frequently, the

cleaning of the sea water needs to be improved.

There should be a spare impeller on board.

The impeller can be deformed during extended

periods of inactivity. Renew the impeller before

starting or remove the impeller before longer periods of stoppage. See also the section Prepara-

tions for storage.

Special tools

1. Pull out the impeller using the puller.

Note:

Note the direction of rotation of the impeller

vanes.

2. Fit a new impeller and then the cover for the

sea water pump. Check that the cap seal is

not hard or damaged.

Note:

When fitting the new impeller, bend the vanes in

the same direction as on the old one.

Number Designation Illustration

98 482 Puller

326 942

325 165

Page 39

OPM 250 en-GB 39

©

Scania CV AB 2016, Sweden

Cooling system

Changing the coolant and

cleaning the cooling system

Draining coolant

WARNING!

Use protective gloves as coolant can cause irritation if it comes in contact with the skin. Hot coolant can also cause scalding.

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and international laws and regulations.

Special tools

1. Connect the coolant pump to the lowest drain

valve in the cooling system. The location of

the lowest drain valve for the engine may differ depending on engine application.

2. Place the other hose from the pump into an

empty container.

3. Connect the pump's 2 cable terminals to the

battery's negative and positive terminal.

Make sure that the drainage starts. If the

drainage does not start: Change the position

of the cable terminals.

Number Designation Illustration

2 443 679 Coolant pump

360 625

326 710

Example of a drain valve.

Page 40

OPM 250 en-GB 40

©

Scania CV AB 2016, Sweden

Cooling system

Draining the sea water circuit

1. Close the bottom valve on the sea water inlet

and remove the connection pipe on the outlet

from the heat exchanger.

2. Remove the cover from the sea water pump

to empty the pump completely.

3. The lowest point in the sea water circuit may

be at different points, but it is usually in the

sea water pump intake.

IMPORTANT!

Plug the connections to prevent dirt ingress into

the engine.

Removing the charge air cooler

When the cooler core of the charge air cooler

needs cleaning, the charge air cooler must be removed if there is no space behind it to take out

the cooler core.

Before starting work: Make sure that the cooling

system is empty as described earlier.

1. Remove the protective plate on the charge air

cooler.

2. Remove the charge air pipe between the

charge air cooler and the turbocharger. Twist

the pipe to facilitate removal.

If the turbocharger has a wastegate valve and

the charge air pipe must be removed, the pipe

bracket must be removed and the pipe must

be turned 90° upwards before the hose and

the pipe are removed.

3. Remove the charge air pipe between the

charge air cooler and the inlet pipe.

4. Remove the sea water pipe between the sea

water pump and charge air cooler.

5. Release the hose clamp and remove the sea

water hose between the charge air cooler and

the heat exchanger.

6. Remove the charge air cooler.

330 586

123

1

2

3

362 794

4

6

5

362 795

Page 41

OPM 250 en-GB 41

©

Scania CV AB 2016, Sweden

Cooling system

Cleaning the charge air cooler

The charge air cooler must be removed if there is

no space behind it to take out the cooler core. See

previous section.

1. Remove the cover (1) of the charge air cool-

er.

2. Press in the cooler core (3) slightly on one

side and pull it out from the other side.

3. Clean the cooler core on the outside with par-

affin-based engine detergent. Remove any

internal deposits using a round rod. Renew

the cooler core if it is damaged.

IMPORTANT!

Do not use caustic soda as this could damage the

aluminium.

4. Renew damaged or hard O-rings (2).

5. Assemble the charge air cooler. Tighten the

M8 screws on the covers to 15 Nm.

2

5

2

4

2

3

2

1

1

362 798

1. Cover.

2. O-rings.

3. Cooler core.

4. Charge air cooler housing.

5. Spacer.

Page 42

OPM 250 en-GB 42

©

Scania CV AB 2016, Sweden

Cooling system

Removing the heat exchanger

When the cooler core of the heat exchanger

needs cleaning, the heat exchanger must be removed.

Before starting work: Make sure that the cooling

system is empty as described earlier.

1. Undo the V-clamp for the hose between the

heat exchanger and the water-cooled exhaust

pipe bend, if the engine has one. Bend the

hose to one side.

2. Remove the inlet and outlet coolant pipes

and the sea water pipe from the heat exchanger.

3. Release the hose clamp and remove the sea

water hose between the charge air cooler and

the heat exchanger.

4. Remove the screws holding the heat ex-

changer in the two brackets.

5. Slacken the screws holding the heat ex-

changer bracket in the cylinder block sufficiently to allow the heat exchanger to be

removed.

1

4

2

3

2

5

362 796

Page 43

OPM 250 en-GB 43

©

Scania CV AB 2016, Sweden

Cooling system

Cleaning the heat exchanger

1. Remove the cover (1) of the heat exchanger.

2. Press in the cooler core (5) slightly on one

side and pull it out from the other side.

3. Clean the cooler core on the outside with par-

affin-based engine detergent. Remove any

internal deposits using a round rod. Renew

the cooler core if it is damaged.

IMPORTANT!

Do not use caustic soda as this could damage the

aluminium.

4. Renew damaged or hard O-rings (2).

5. Assemble the heat exchanger. Tighten the

M8 screws on the covers to 15 Nm.

1

3

2

1

2

2

2

5

4

364 555

1. Cover.

2. O-rings.

3. Spacer.

4. Heat exchanger housing.

5. Cooler core.

Page 44

OPM 250 en-GB 44

©

Scania CV AB 2016, Sweden

Cooling system

Fitting the heat exchanger

IMPORTANT!

There is a risk that the joint will crack if these installation instructions are not followed.

1. Fit the heat exchanger (4) in place against the

brackets.

2. Fit the sea water hose (3) between the heat

exchanger and charge air cooler (use vaseline if necessary) and tighten the hose clamp.

IMPORTANT!

To prevent leakage, a hose clamp with a safety

ring can be used.

3. Fit the screws (5 off) securing the heat ex-

changer without tightening them.

4. Tighten the screws securing the heat ex-

changer bracket (5) in the cylinder block.

5. First tighten the screw on the charge air cool-

er bracket and then the 4 screws on the heat

exchanger bracket.

6. Fit the inlet and outlet coolant pipes and the

sea water pipe from the heat exchanger (2).

7. Fit the hose (1) between the heat exchanger

and the water-cooled exhaust pipe bend, if

the engine has one and tighten the V-clamp.

Tightening torques

M6 10 Nm

M8 26 Nm

M10 50 Nm

1

4

2

3

2

5

362 796

Page 45

OPM 250 en-GB 45

©

Scania CV AB 2016, Sweden

Cooling system

Fitting the charge air cooler

1. Fit the charge air cooler (6) in place against

the brackets.

2. Fit the sea water hose (5) between the charge

air cooler and heat exchanger (use vaseline if

necessary) and tighten the hose clamp.

3. Fit the screws for the charge air cooler brack-

ets and tighten them.

4. Fit the sea water pipe (4) between the sea wa-

ter pump and the charge air cooler.

5. Fit the charge air pipe (3) between the intake

manifold and charge air cooler. To facilitate

fitting, lubricate the O-ring and the inside of

the connection in the charge air cooler with

vaseline. Press the charge air pipe straight towards the charge air cooler while carefully

twisting the pipe to the right and left. Check

that the charge air pipe is properly fitted.

6. Fit the charge air pipe (2) between the charge

air cooler and turbocharger. To facilitate fitting, lubricate the O-ring and the inside of the

connection in the charge air cooler with

vaseline. Press the charge air pipe straight towards the charge air cooler while carefully

twisting the pipe to the right and left. Check

that the charge air pipe is properly fitted.

7. Fit the protective plate (1) on the charge air

cooler.

Tightening torques

M6 10 Nm

M8 26 Nm

M10 50 Nm

4

6

5

362 795

1

2

3

362 794

Page 46

OPM 250 en-GB 46

©

Scania CV AB 2016, Sweden

Cooling system

Internal: Removing oil and grease

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and international laws and regulations.

1. Run the engine until it has reached operating

temperature and then drain the cooling system. See the section Draining coolant

.

2. Remove the thermostats.

3. Fill the cooling system with clean, hot water

mixed with liquid dishwasher detergent for

household machines. Concentration 1% (0.1/

10 litres).

4. Run the engine until it has reached operating

temperature for approximately 20-30 minutes. Remember to switch on the cab heating

system, if one is installed.

5. Drain the cooling system.

6. Fill the cooling system with clean, hot water

and run the engine for about 20-30 minutes.

7. Drain the water from the cooling system.

8. Refit the thermostats.

9. Fill the cooling system with new coolant as

described in the section Filling coolant

.

Internal: Removing deposits

Environment

Use a suitable container. Used coolant must be

disposed of as specified in national and international laws and regulations.

1. Run the engine until it has reached operating

temperature and then drain the cooling system. See the section Draining coolant

.

2. Remove the thermostats.

3. Fill the cooling system with clean, hot water

mixed with radiator detergent which is based

on sulphamic acid and contains dispersing

agents. Follow the manufacturer's instructions for the concentration and cleaning period.

4. Run the engine for the specified time. Re-

member to switch on the cab heating system,

if one is installed.

5. Drain the cooling system.

6. Fill the cooling system with clean, hot water

and run the engine for about 20-30 minutes.

7. Drain the water from the cooling system.

8. Refit the thermostats.

9. Fill the cooling system with new coolant as

described in the section Filling coolant

.

Page 47

OPM 250 en-GB 47

©

Scania CV AB 2016, Sweden

Cooling system

Filling coolant

This procedure applies when the cooling system

has been drained and needs to be filled with a

large amount of coolant.

IMPORTANT!

It is not permissible to fill large amounts of coolant via the expansion tank. Filling via the expansion tank leads to air locks in the cooling system

which can lead to damage to the coolant pump

shaft seal for example.

Never fill a large amount of cold coolant in a hot

engine. There is great risk of cracks forming in

the cylinder block and cylinder heads.

Fill the cooling system only with ready-mixed

coolant.

Do not start the engine until the correct coolant

level has been obtained. If the engine is started

with a coolant level that is too low, the coolant

pump shaft seal may be damaged, which can result in leaks.

Special tools

1. Connect the coolant pump to the lowest drain

valve in the cooling system. The location of

the lowest drain valve for the engine may differ depending on engine application.

2. Connect the pump's 2 cable terminals to the

battery's negative and positive terminal.

Make sure that the filling starts. If the filling

does not start: Change the position of the cable terminals.

Number Designation Illustration

2 443 679 Coolant pump

360 625

Finishing work

1. Open the bottom valve on the sea water inlet.

2. Start the engine and check that no leakage

occurs.

3. Check the coolant level and top up the cool-

ant via the expansion tank if necessary.

Page 48

OPM 250 en-GB 48

©

Scania CV AB 2016, Sweden

Air cleaner

Air cleaner

Reading the air cleaner vacuum indicator

If the indicator's red plunger is fully visible, renew the air cleaner filter element following the

instructions below.

Renewing the air cleaner filter

element

This procedure applies if the engine is fitted with

a Scania air cleaner.

WARNING!

Never start the engine without the air filter being

in place. If you do, this could cause injury and severe engine damage.

Note:

Renew the filter element earlier than the maintenance interval if the indicator shows red.

There is always a risk that the filter element will

be damaged when it is cleaned.

The filter element must not be cleaned in water

or be blown clean with compressed air.

1. Remove the cover from the air cleaner.

2. Renew the filter element.

3. Insert a torch into the element and check

from the outside that there are no holes or

cracks in the filter paper.

4. Assemble the air cleaner.

5. Reset the vacuum indicator by pressing the

button.

A B

336 100

A Vacuum indicator.

B Filter element.

326 671

Resetting the vacuum indicator.

Page 49

OPM 250 en-GB 49

©

Scania CV AB 2016, Sweden

Air cleaner

Renewing the air cleaner

safety cartridge

This procedure applies if the engine has an air

cleaner with a safety cartridge from Scania.

WARNING!

Never start the engine without the air filter being

in place. If you do, this could cause injury and severe engine damage.

IMPORTANT!

When you renew the safety cartridge, take great

care to ensure that no dirt or other impurities get

into the engine. Do not remove the safety cartridge unnecessarily.

1. Remove the cover from the air cleaner.

2. Remove the filter element.

3. Remove the safety cartridge.

4. Fit a new safety cartridge from Scania.

5. Renew or clean the filter element.

6. Check the condition of the O-ring. Renew

the O-ring if it is damaged or hard.

7. Assemble the air cleaner. Ensure that the O-

ring is not outside the edges.

Renewing an air filter with a

non-renewable element

Note:

If the engine has an air filter with a non-renewable Scania element, it should be renewed instead

of cleaned.

4

2

3

1

361 380

Air cleaner

1. Cover.

2. Filter element.

3. Safety cartridge.

4. O-ring.

325 166

Air filter with a non-renewable element.

Page 50

OPM 250 en-GB 50

©

Scania CV AB 2016, Sweden

Fuel system

Fuel system

IMPORTANT!

The whole fuel system is very sensitive to dirt

and even very small particles. Foreign particles

in the system can cause serious malfunctions. It

is therefore very important that everything is as

clean as possible when work is carried out on the

fuel system. Before starting work on the fuel system, the engine must be washed. If possible, a

hot water wash should be used.

It is strictly forbidden to carry out any machining

work or work with compressed air near an open

fuel system.

Be extra careful and always use clean, lint-free

and dust-free clothes and gloves when working

on the fuel system. Scania recommends using

Tegera 848 gloves.

Clean tools before they are used and do not use

any worn or chrome-plated tools. Material and

flakes of chrome may come off.

Clean connections and the surrounding area before removal. When cleaning, cloths or paper

which shed fibres must not be used. Use clean

and lint free cloths, part number 588 879.

Plug or cover the connections during removal.

Also clean the connections before the components are fitted. Place removed components on a

thoroughly cleaned, dust-free surface. Scania

recommends using a stainless steel bench top,

part number 2 403 296. Cover the components

with a lint-free cloth.

Checking fuel level

Check the fuel level and top up with fuel as necessary.

Note:

If the fuel tank has been run dry or if the engine

has not been used for a long time, bleed the fuel

system. See section Bleeding the fuel system us-

ing a hand pumpor Preparations for storage.

Page 51

OPM 250 en-GB 51

©

Scania CV AB 2016, Sweden

Fuel system

Renewing the fuel filter

Environment

Use a suitable container. Used fuel must be disposed of as specified in national and international laws and regulations.

1. Clean the exterior of the filter with a damp

cloth.

2. Unscrew the filter.

3. Apply oil to the gasket on the new filter.

4. Screw the filter into place by hand until it