Scania DC16, DC13, DC09 Service Manual

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

01:04 Issue 10 en-GB 1

Exhaust system

Industrial engines

DC09, DC13, DC16

333 380

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

01:04 Issue 10 en-GB 2

Sound reduction.......................................................................................................3

Exhaust noise....................................................................................................... 3

Exhaust system design ........................................................................................ 5

Connection of exhaust system to engine ................................................................9

V-clamp............................................................................................................... 9

Stage III B/Tier 4i and less restrictive emission laws ....................................... 10

Stage IV/Tier 4f................................................................................................. 16

Exhaust back pressure .......................................................................................... 18

Exhaust back pressure for all engine types ....................................................... 18

Exhaust back pressure Stage III B/Tier 4i......................................................... 19

Exhaust back pressure for Stage IV/Tier 4f ...................................................... 20

Measuring exhaust back pressure...................................................................... 21

Insulating the exhaust system...............................................................................24

Insulation of SCR components.......................................................................... 25

Insulation of Stage IV/Tier 4f engines .............................................................. 25

Protection against water ingress ..........................................................................27

Multi-engine installation.......................................................................................28

Dimensioning the exhaust system ........................................................................30

Calculation example.......................................................................................... 31

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 3

Sound reduction

Assess the need for sound reduction in new installations from case to case, based on

the applicable conditions in relation to noise requirements, length and type of exhaust

system, location of the exhaust system outlet etc.

Some form of sound reduction is required in most installations.

The thermal insulation of the exhaust system affects the sound level. A thermally insulated system can result in a higher noise level than an uninsulated system.

This document contains information on SCR components. More detailed information

on the SCR system can be found in the SCR system installation manual.

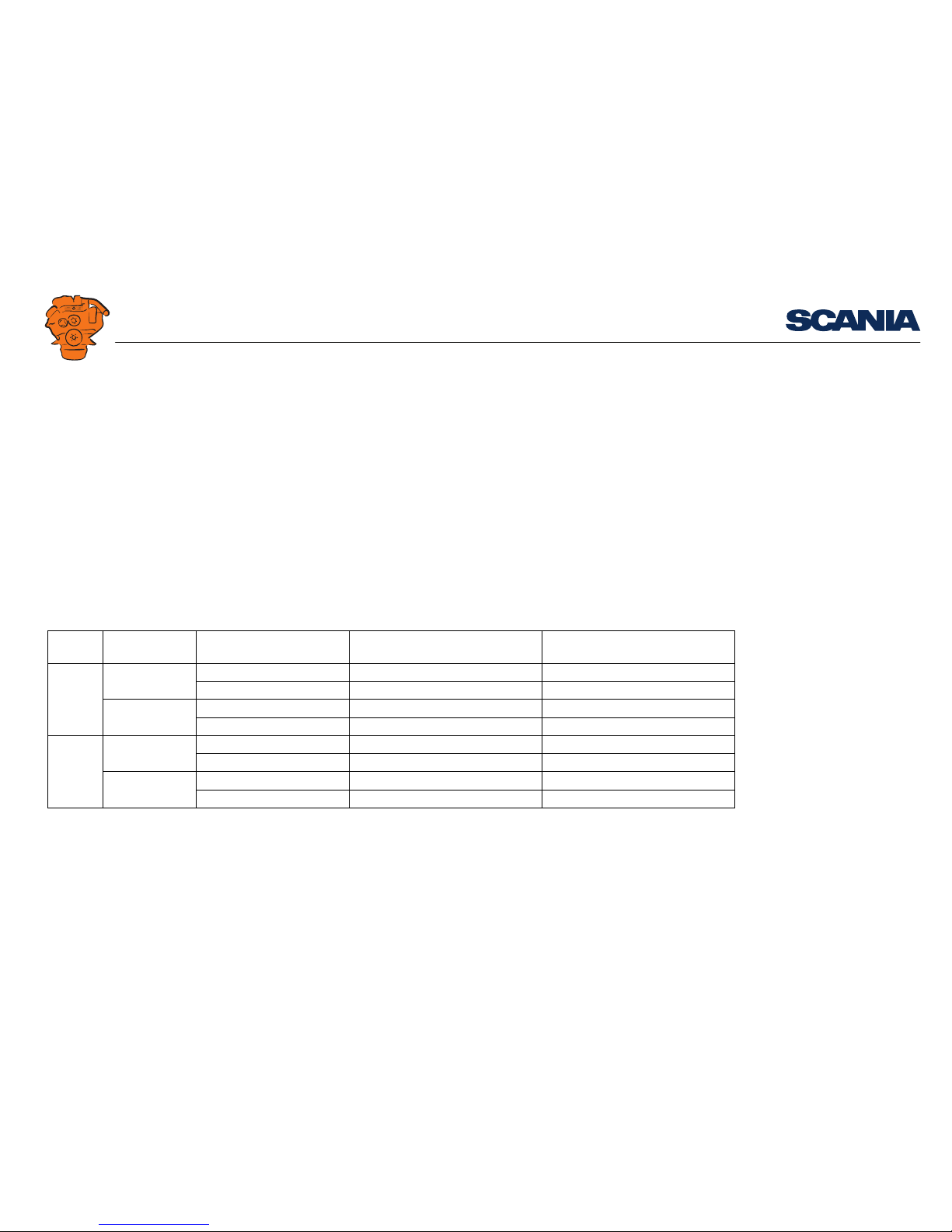

Exhaust noise

The table shows undamped exhaust noise measured 1 metre after the turbocharger at

full power output.

Engine Power (kW) Engine speed (rpm) Sound level (dBA) Most important one-third octave

bands (Hz)

DC09 202-243 1,500 115 63 and 125

1,800 and 2,100 117 80 and 160

257-294 1,500 117 63 and 125

1,800 and 2,100 119 80 and 160

DC13 257-316 1,500 115 80 and 160

1,800 and 2,100 117 100 and 200

331-405 1,500 118 80 and 160

1,800 and 2,100 120 100 and 200

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 4

The most important frequency range for exhaust noise is between 50 and 500 Hz. The

exhaust flow in the system can generate hissing sounds, e.g. at sharp bends and edges. This phenomenon occurs higher up in the frequency range and is effectively

dampened with an absorption silencer (e.g. glass fibre).

Vibrations in the silencer casing can also generate noise. For this reason, avoid silencers with flat surfaces.

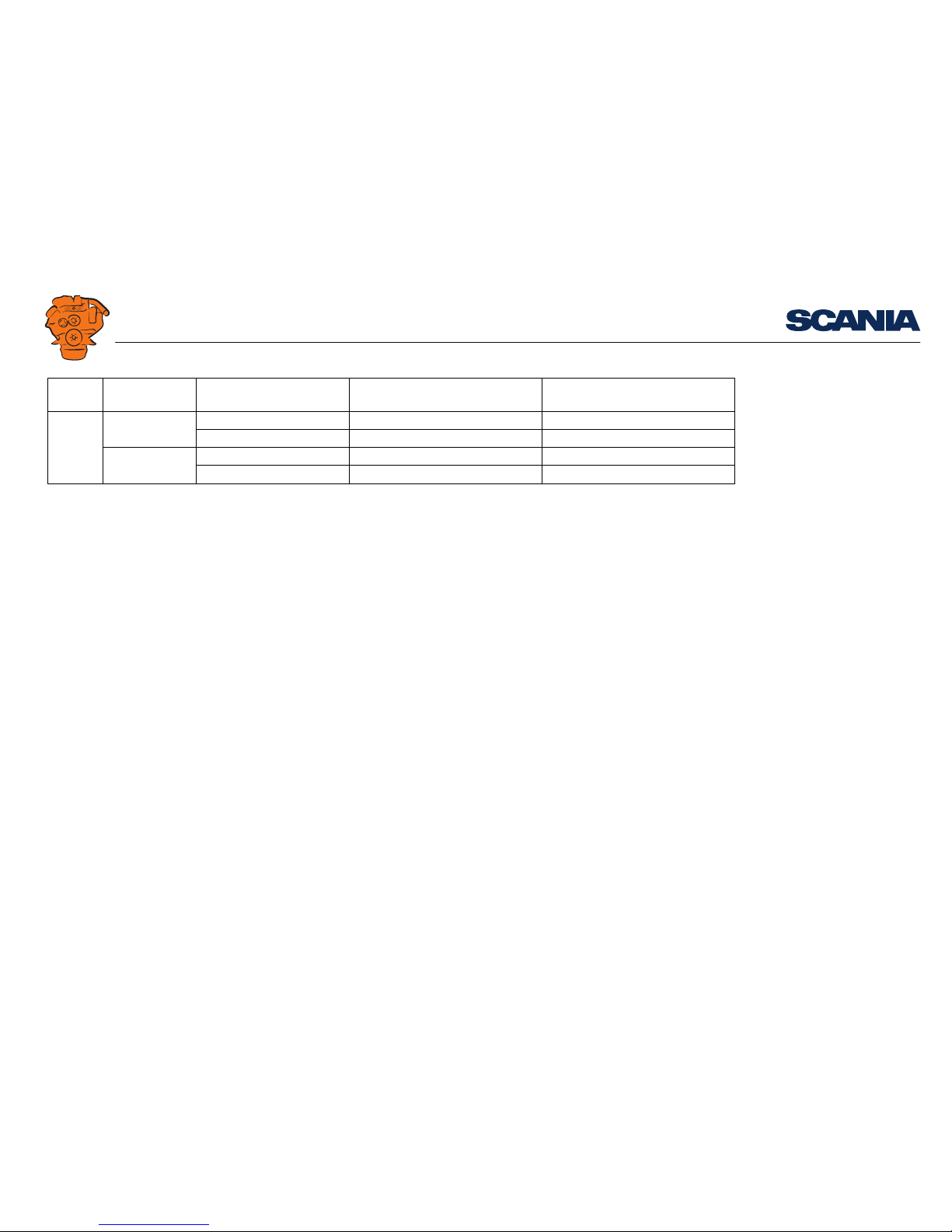

DC16 405 1,500 116 100 and 200

1,800 and 2,100 119 125 and 250

478-515 1,500 118 100 and 200

1,800 and 2,100 121 125 and 250

Engine Power (kW) Engine speed (rpm) Sound level (dBA) Most important one-third octave

bands (Hz)

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 5

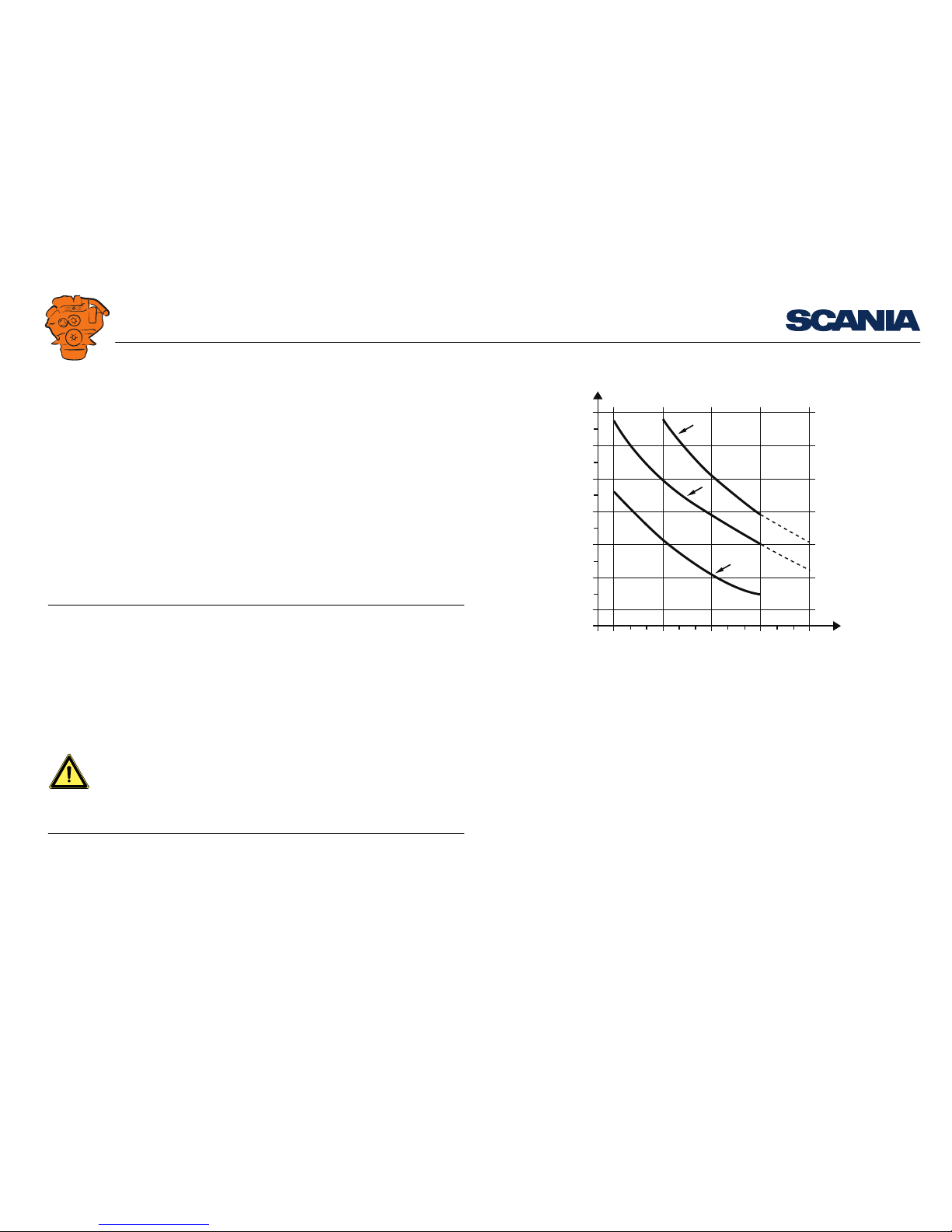

Exhaust system design

Position the silencer as close to the end of the exhaust system as possible. In order to

obtain the best noise reduction, there should only be a short tailpipe after the silencer

(0.8-1.5 m) as shown in the chart.

• For all-speed engines, read the specified maximum speed for the engine.

• For single-speed engines, read the operating speed of the engine.

If the silencer cannot be positioned close to the exhaust system outlet because of a

lack of space, it should be placed as close to the engine as possible. This location is,

however, unfavourable in silencing terms if the pipes beyond it are long. It may be

advisable to install another silencer near to the outlet.

Note:

Sharp exhaust pipe bends close to the outlet increase the risk of hissing sounds.

Exhaust outlet

Design the exhaust system so that the exhaust gases are not reflected against vertical

walls, since this results in increased noise level.

Position the exhaust outlet so that no exhaust gases can be drawn into the engine intake. If exhaust gases are drawn into the intake, intake air temperature increases rapidly. The exhaust gases contain soot particles so there is also a risk of the air filter

becoming blocked.

WARNING!

Position the exhaust outlet so that exhaust gases cannot penetrate areas occupied by

people, e.g. residential buildings.

1

2

3

1200

2.0

L(m)

rpm

1.8

1.6

1.4

1.2

1.0

0.8

1500 1800 2100 2400

337 694

Graph for determining the longest length of tailpipe.

1. DCI9.

2. DC13.

3. DC16.

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 6

Example

If 2 silencers are used in the system, they should be positioned in series at a distance

of 2/3 of the length of the tailpipe and with the silencer used to dampen high-frequency noise furthest away from the engine.

Since the pipes which form part of an exhaust system also operate as silencers, it is

important that they are dimensioned correctly.

Note:

The exhaust back pressure increases with the number of pipe bends and with increased pipe length. This leads to higher fuel consumption and loss of power.

IMPORTANT!

The installer is responsible for ensuring that the exhaust system is well sealed during

installation. He is also responsible for ensuring that the pipe and silencer suspension

is designed in such a way that system leaks cannot arise during operation.

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 7

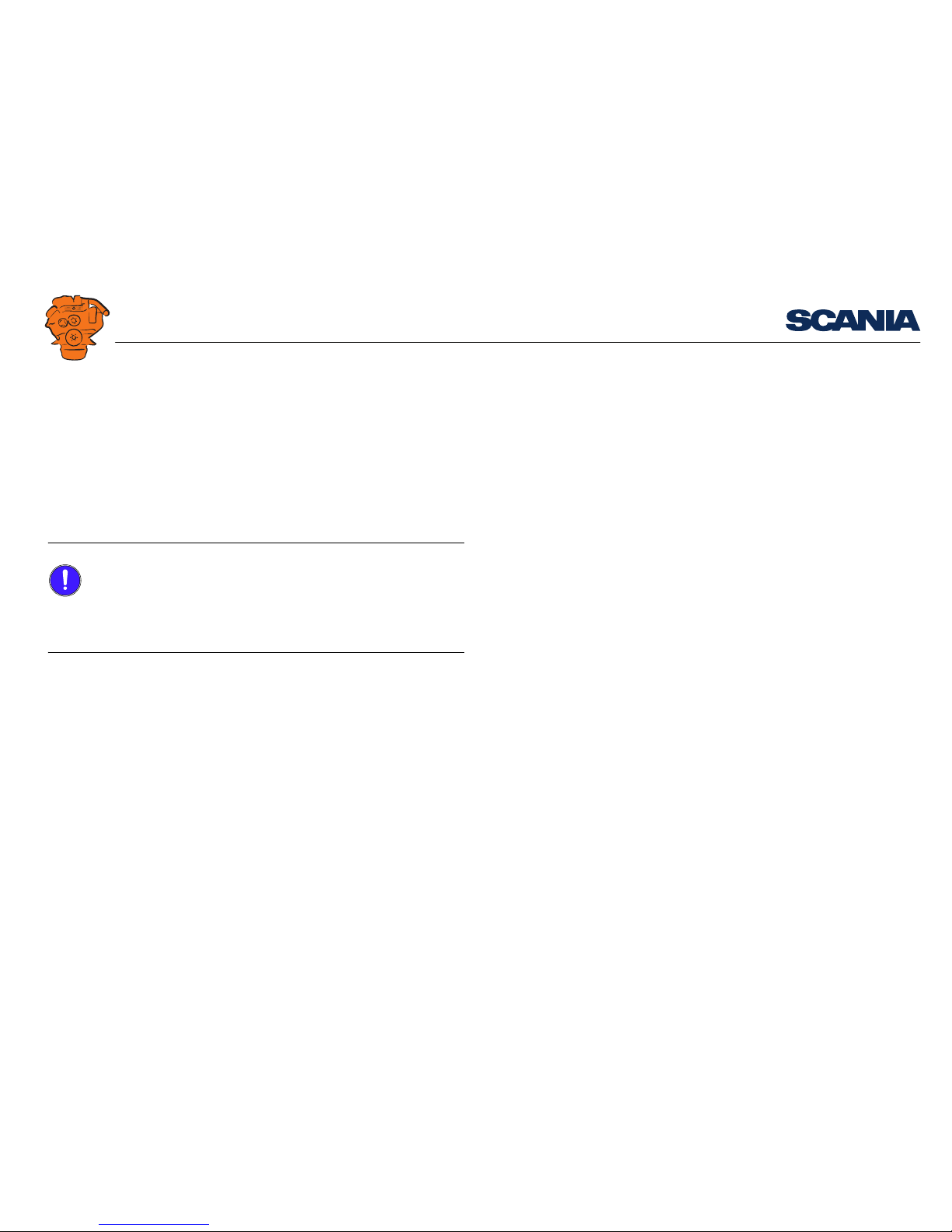

Examples of long exhaust systems (i.e. longer than 5 metres) with designs which aid

sound reduction.

Examples of short exhaust systems with designs which aid sound reduction.

L = Length of tailpipe, determined from graph.

a = 2/3 of L. Length a is less significant in exhaust systems with only one silencer.

338 555

338 554

aL

338 556

L

a

338 557

L

a

a

L

338 558

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Sound reduction

01:04 Issue 10 en-GB 8

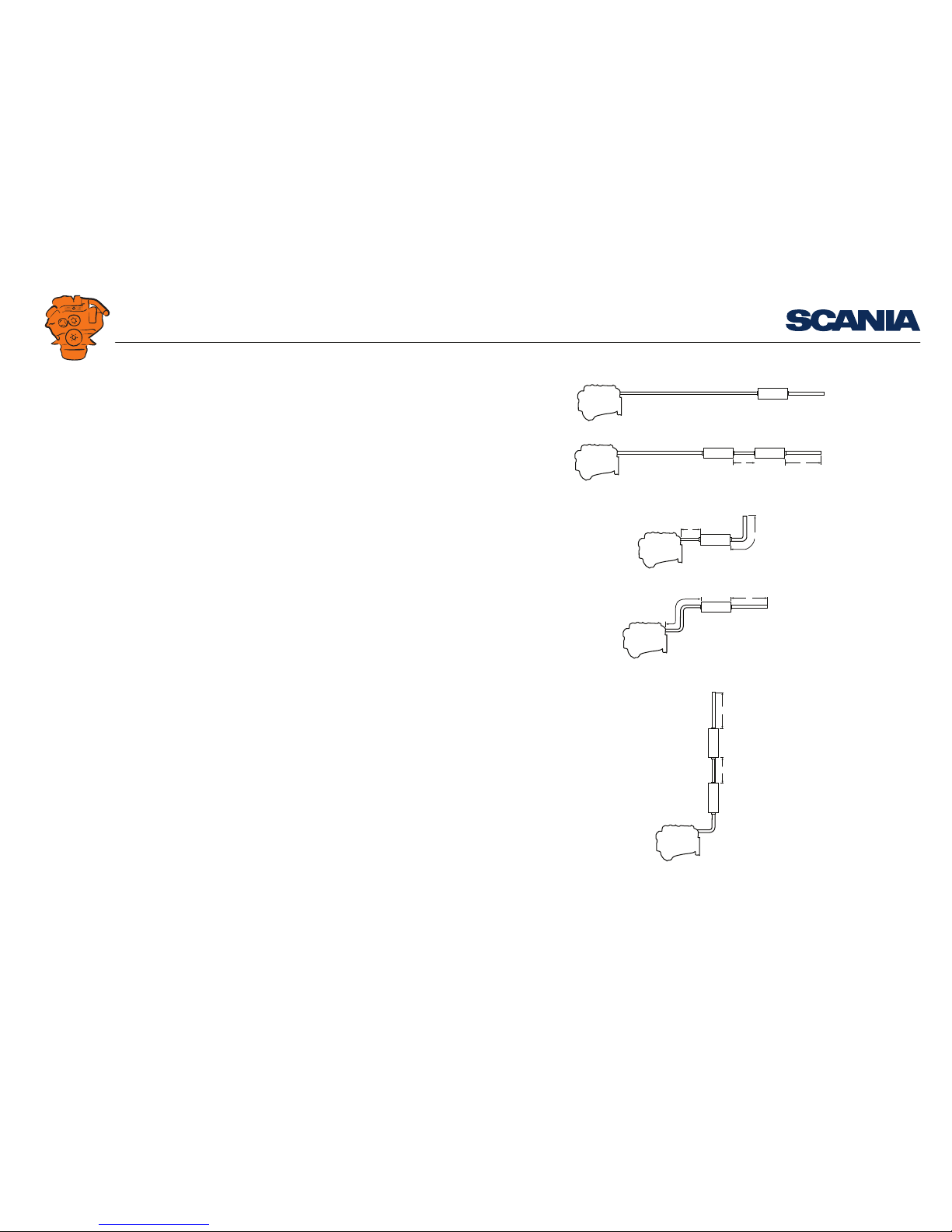

SCR system

For engines with an SCR system, in most cases the exhaust system needs to be supplemented by a silencer.

More information on the positioning of SCR components can be found in the SCR

system installation manual.

Oxidation catalytic converter

The oxidation catalytic converter provides a sound reduction of approximately

1.5 dB from 500 Hz and higher frequencies. At lower frequencies, the oxidation catalytic converter has no sound reducing effect.

aL

2

1

3 4

337 506

1. Oxidation catalytic converter.

2. Evaporator or hydrolysis catalytic converter.

3. SCR catalytic converter.

4. Silencer.

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Connection of exhaust system to engine

01:04 Issue 10 en-GB 9

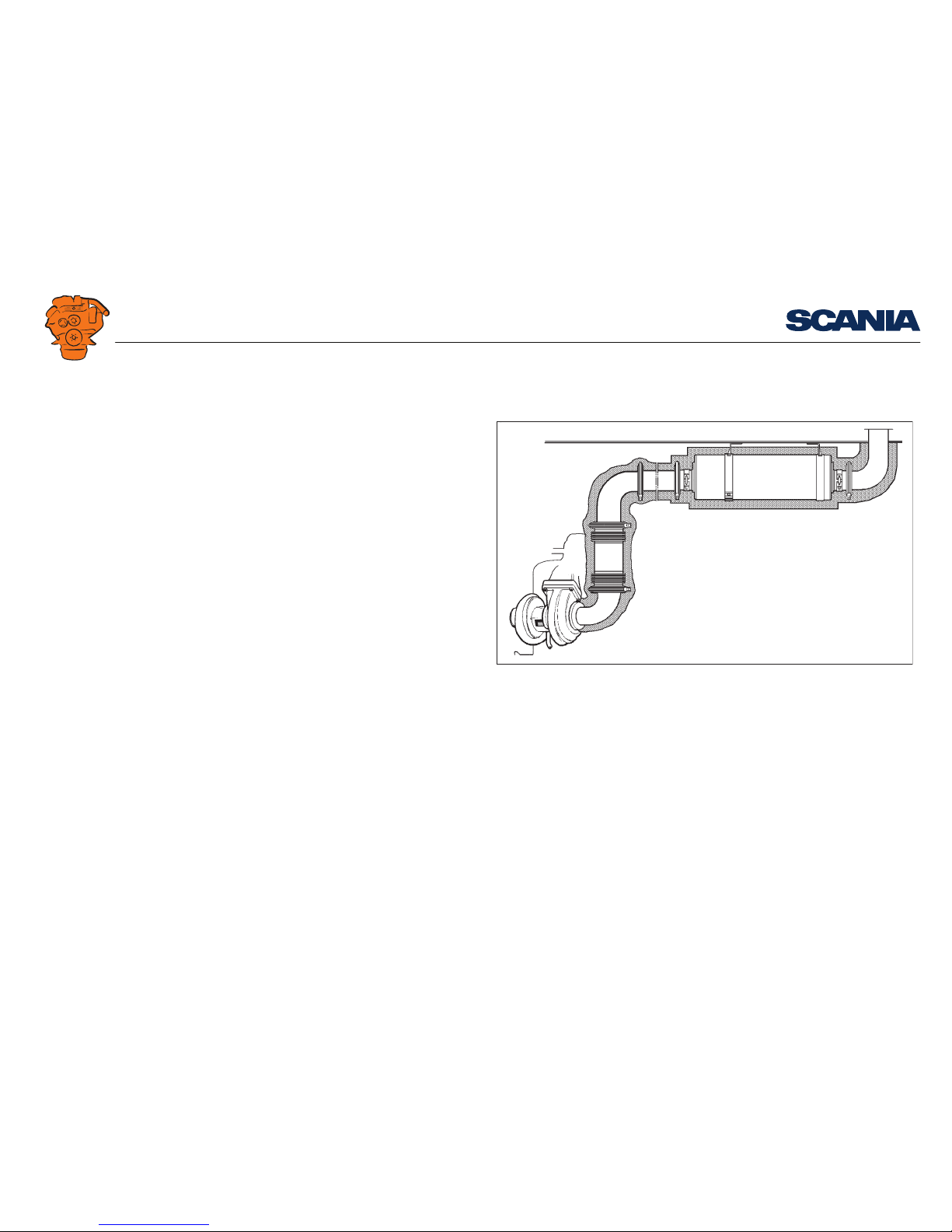

Connection of exhaust system to engine

There should always be a flexible connection between the exhaust system and the engine which absorbs the movement of the engine and changes in length in the exhaust

system due to temperature changes. A flexible connection can consist of the Scania

exhaust bellows. Position the flexible connection as close to the turbocharger connection as possible.

IMPORTANT!

The weight of the exhaust system must not load the exhaust bellows or turbocharger.

Therefore, place a suspension point immediately after the flexible connection.

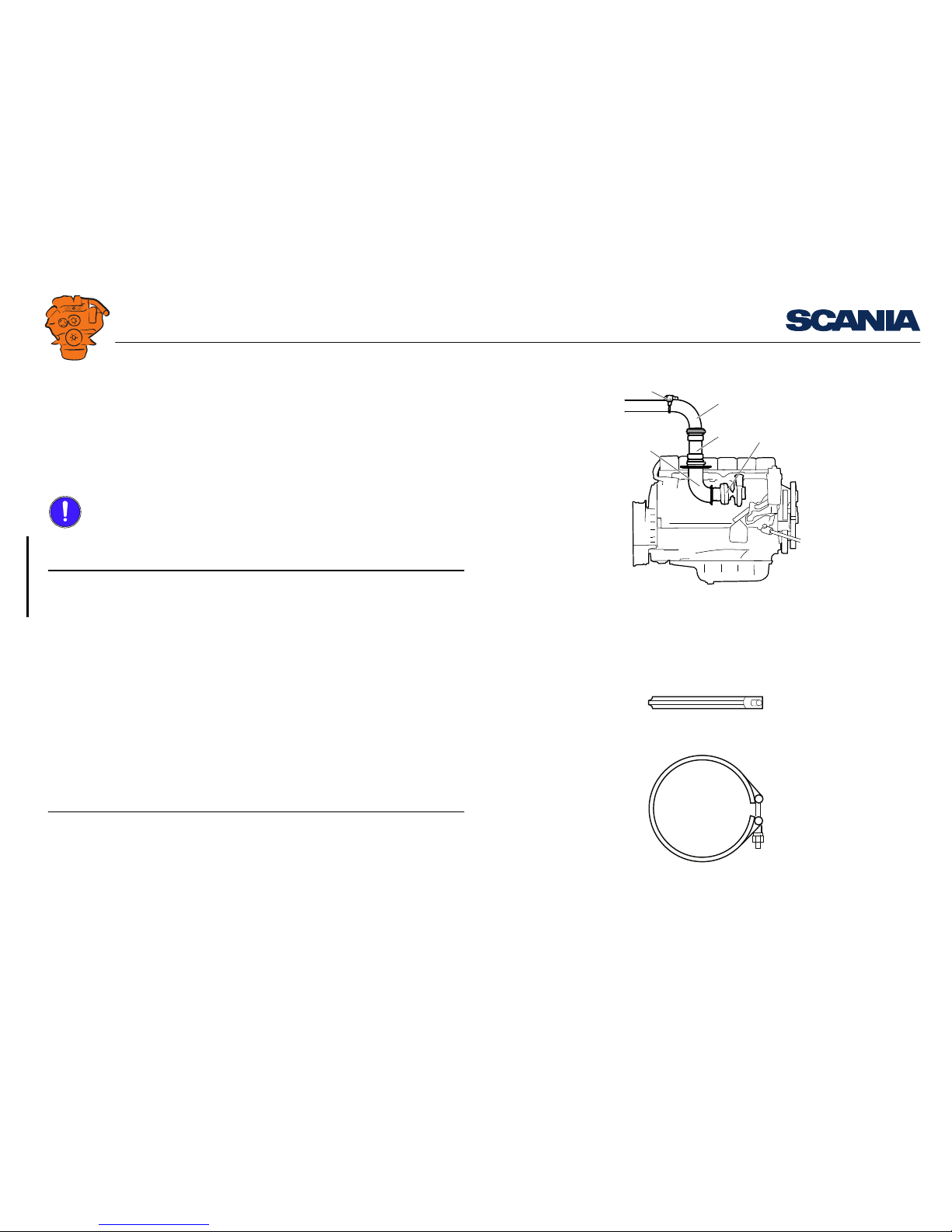

The illustration to the right shows the recommended installation of the exhaust system.

If the exhaust pipes are very long or if the exhaust system has a relatively long horizontal part between 2 vertical parts, several flexible connections may be required in

the system. There must then be a fixed anchorage point on one side of the vertical

exhaust bellows and a suspension which allows axial movement on the other side.

V-clamp

Scania pipe sections have flanges secured with V-clamps.

Note:

The V-clamp must not be used to force together joints, but only to fix the flanges.

1

3

4

5

2

369 3

11

Recommended installation of exhaust system.

1. Turbocharger.

2. Exhaust pipe bend.

3. Exhaust bellows.

4. Exhaust pipe.

5. Bracket.

338 567

INSTALLATION

MANUAL

©

Scania CV AB 2016, Sweden

Connection of exhaust system to engine

01:04 Issue 10 en-GB 10

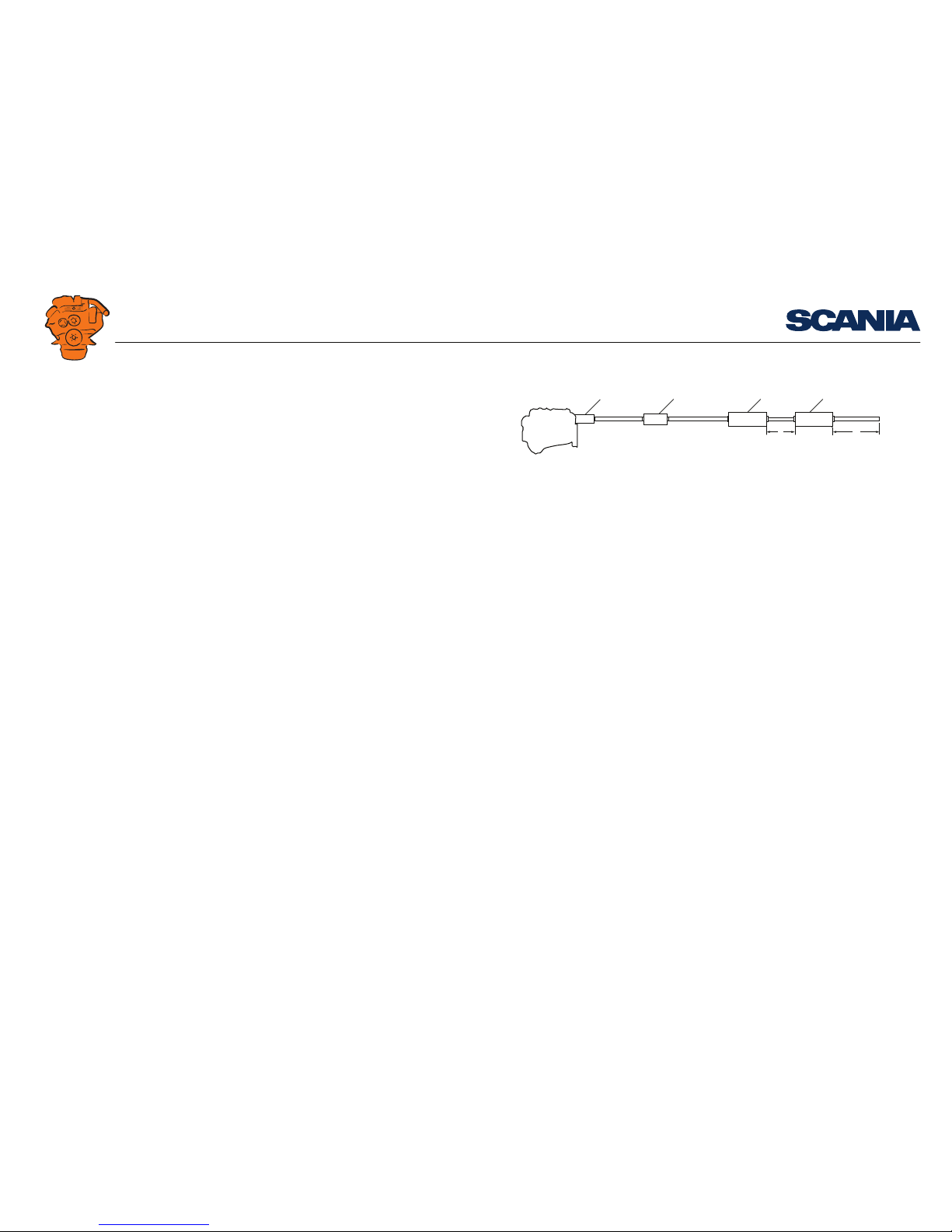

Stage III B/Tier 4i and less restrictive emission laws

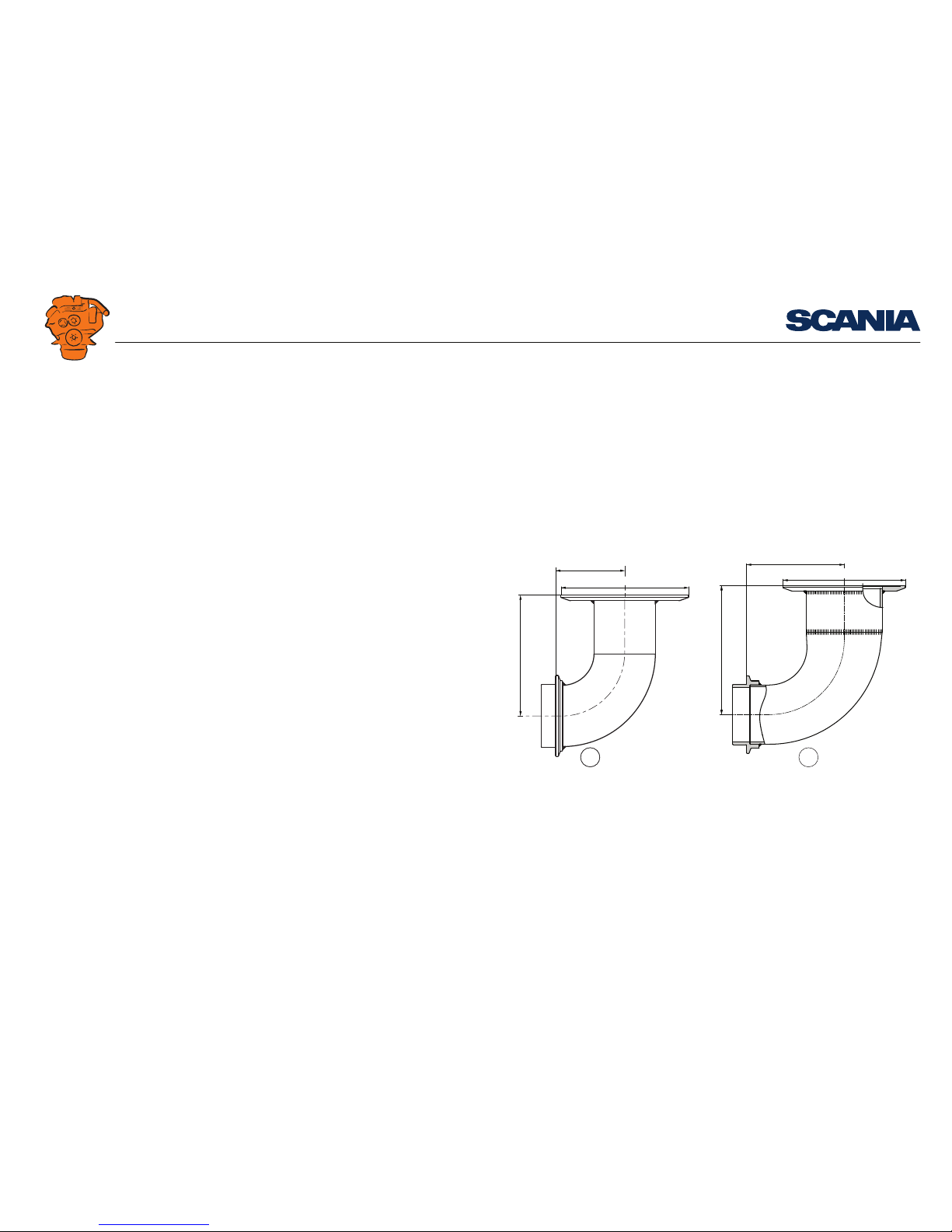

Exhaust pipe bends

The engines can be equipped with a 90° exhaust pipe bend on the turbocharger exhaust outlet. The exhaust pipe bend can be fitted at different angles and rotated 360°

around the connection with the turbocharger.

The exhaust pipe bend is connected to the turbocharger with a V-clamp.

The exhaust pipe bend outlet has a flange that is connected with a V-clamp. It is usually connected directly to the Scania exhaust bellows.

Exhaust pipe bends for DC09 and DC13

1. DC09 071A.

2. Other DC09 engines and DC13 072/073A.

148

195

Ø185.3

195

175

100

Ø185.3

12

335 011

Loading...

Loading...