Page 1

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

01:02 Issue 6 en-GB 1

Intake system and ventilation

Industrial engines

DC09, DC13, DC16

Page 2

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

01:02 Issue 6 en-GB 2

Intake air ..................................................................................................................3

Intake air taken from outside engine compartment............................................. 4

Intake air taken from engine compartment ......................................................... 7

Air cleaners ..............................................................................................................8

Air cleaners with precleaner................................................................................ 9

Air cleaners without precleaner......................................................................... 10

Crankcase ventilation............................................................................................11

Open crankcase ventilation ............................................................................... 11

Closed crankcase ventilation............................................................................. 12

Connection to turbocharger .................................................................................13

Cleanliness requirement .................................................................................... 13

Charge air pipe .................................................................................................. 13

Stage IV/Tier 4f engines ................................................................................... 14

Page 3

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Intake air

01:02 Issue 6 en-GB 3

Intake air

If the intake line is located close to exhaust pipes or other hot parts, radiation protection should be used to limit unnecessary heating of the intake air.

REQUIREMENT!

The temperature of the intake air must not exceed the ambient temperature by more

than 5°C.

If the intake air temperature upstream of the turbocharger continuously exceeds

30°C, then engine power may drop. If the engine is enclosed in some manner, make

sure that there is an adequate flow of intake air.

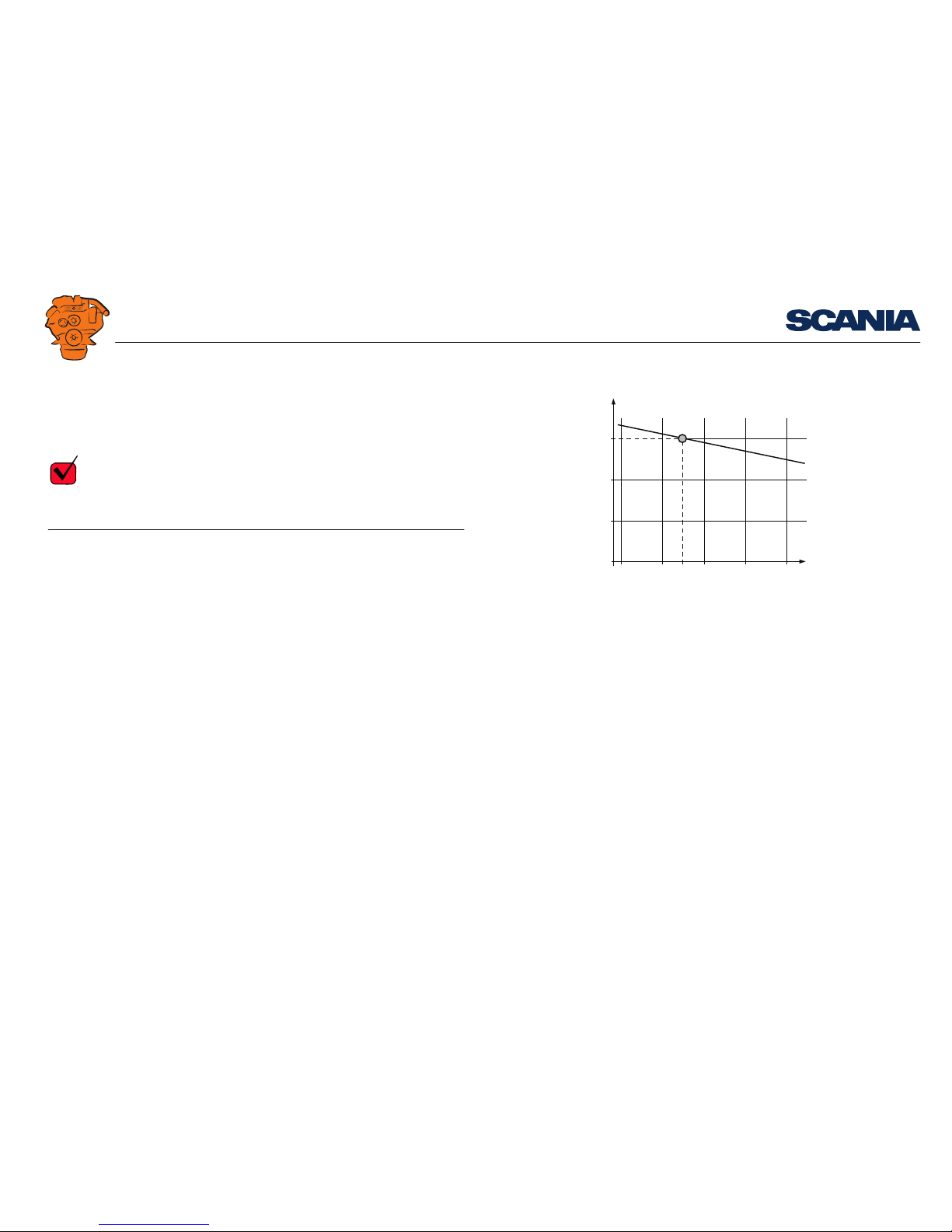

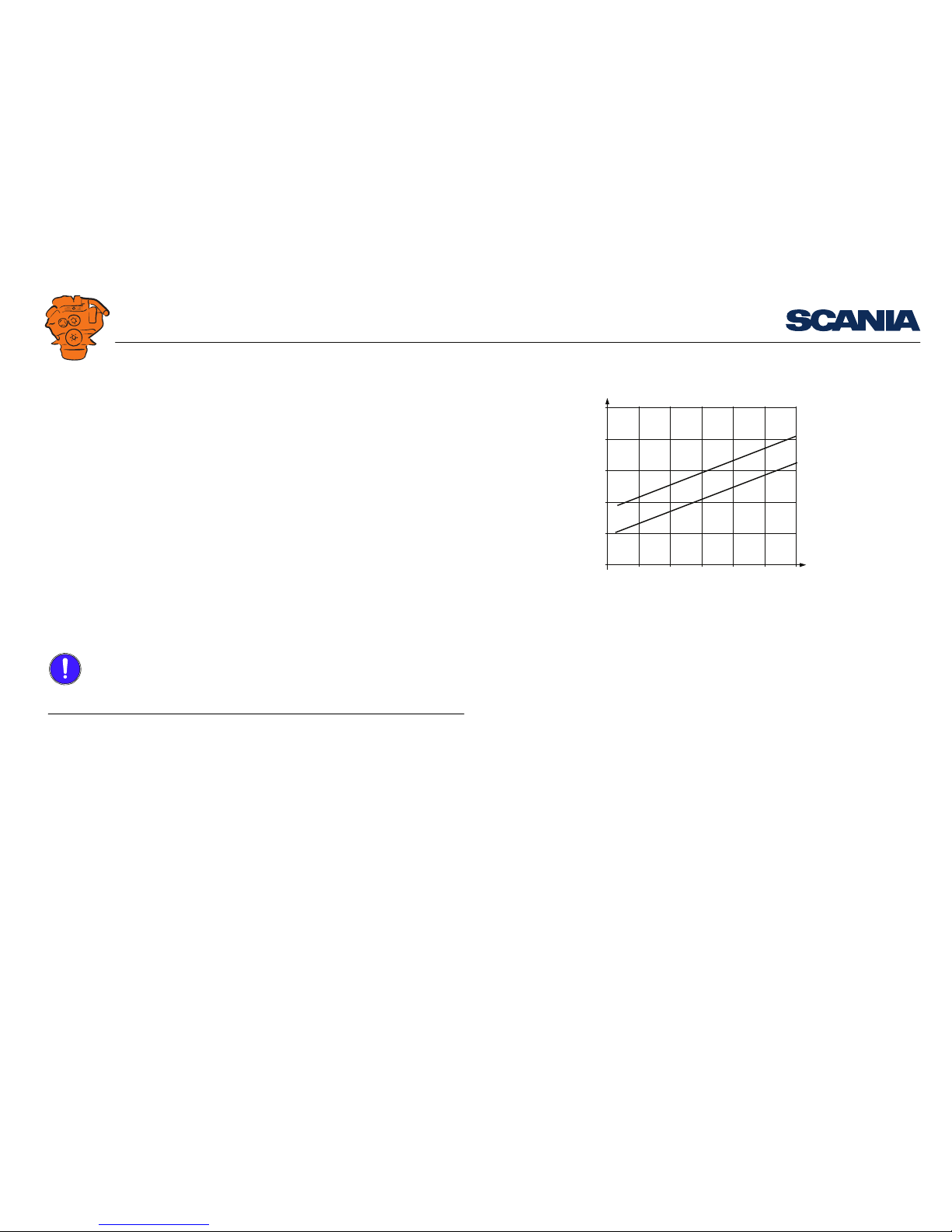

The dependence of the engine power on intake air temperature is shown in the chart

on the right. 100% engine power is shown under actual test conditions at the factory.

The engine air consumption in kg/min at full power and at different engine speeds is

indicated in the tables showing the air consumption and radiated heat for the relevant

engine type under Technical data in the Installation manual.

100

95

90

%

A

B

10 20 302540 50

°C

340 422

Engine power dependence on intake air temperature. 100% at 25°C, 1,000 mbar, engine power setting not corrected

A = Engine power

B = Intake air temperature

Page 4

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Intake air

01:02 Issue 6 en-GB 4

Intake air taken from outside engine compartment

In engine systems where the engine intake air comes from outside the engine compartment and is led via a fresh air line to the engine, the pressure drop for the intake

system should be measured.

The air intake should be located so that the intake air is as clean as possible and so

that neither the engine exhaust gases nor heated air from the engine compartment can

mix with the intake air.

The intake air must not contain chemical pollutants, such as CFCs.

The air intake should be designed to exclude water, snow and contamination.

Maximum permissible pressure drop is 30 mbar. This value includes the pressure

drop in the new air filter, connected coarse filter and in the fresh air line.

Page 5

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Intake air

01:02 Issue 6 en-GB 5

The following applies to the fresh air line:

• The fresh air line must not be routed with any sharp bends.

• The inside of the fresh air line must be flat and even.

• If a hose is used as a fresh air line, it must be hard so that it does not collapse onto

itself.

It is not necessary to check the pressure drop in the following cases:

• The intake system comprises air hoses and air pipes from Scania's standard range.

• If the fresh air line is maximum 5 m and has an inside diameter of at least 160 mm

for DC09 or 210 mm for DC13 and DC16, respectively.

If the planned fresh air line is longer than 5 m, the required diameter must be calculated as illustrated. The vacuum upstream of the turbocharger must then be measured.

The pressure drop measurement is normally made at the vacuum indicator. If the line

between the filter and turbocharger is not a Scania standard line, the pressure drop

should be measured on a straight section as close to the turbocharger as possible.

IMPORTANT!

The total pressure drop with a blocked air filter must not exceed 65 mbar.

Engine damage will not occur up to 100 mbar, but fuel consumption and smoke will

increase. Above 100 mbar there is a risk that the air volume to the engine will be inadequate, resulting in breakdowns.

100

200

300

400

25m

5m

10 20 30 40 50

A (mm)

(m /min)

3

B

340 421

Calculation of minimum diameter of the intake line

A = Intake line diameter

B = Air consumption

Page 6

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Intake air

01:02 Issue 6 en-GB 6

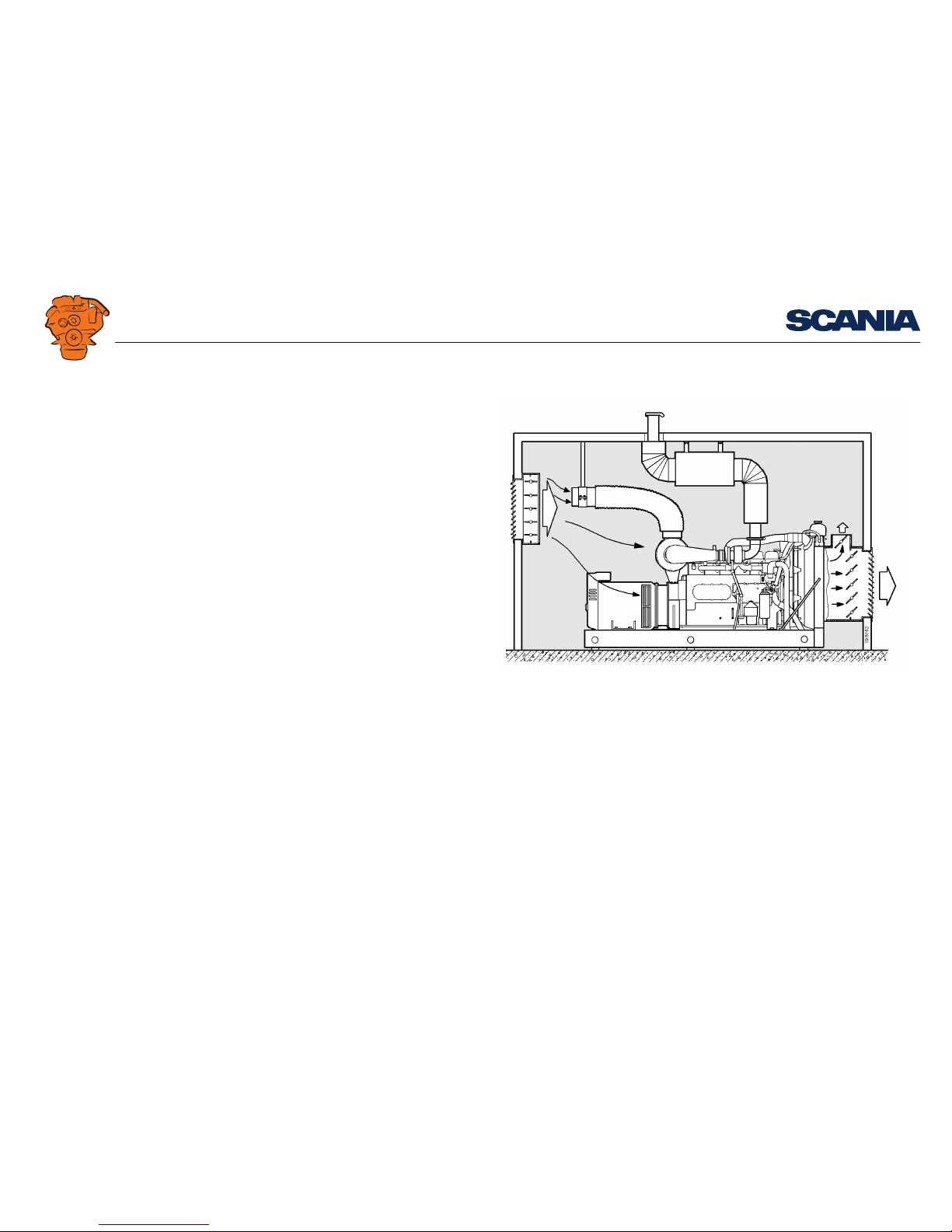

Ventilation of the engine compartment with fresh air line to the

engine

When the intake air to the engine is taken from outside the engine compartment, it is

important to check that the temperature in the engine compartment does not exceed

90°C. If the temperature exceeds this value, there is a risk that the engine's electric

components and control unit will malfunction.

If there is a risk that the temperature will exceed 90°C, the engine compartment must

be ventilated.

When dimensioning the engine compartment ventilation, other air consumers in the

engine compartment must also be considered.

The amount of radiated heat emitted by various engines is indicated under Technical

data in the Installation manual.

The exhaust pipes should be insulated to reduce the radiated heat in the engine compartment. See Exhaust system in the Installation manual.

Page 7

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Intake air

01:02 Issue 6 en-GB 7

Intake air taken from engine compartment

When the engine intake air is taken from the engine compartment, the air intake must

be located in the engine compartment. The opening area should be large enough to

ensure that no vacuum arises in the engine compartment. The air intake should also

be designed and positioned so that it cannot be closed or accidentally blocked by water, snow or contaminants.

The air intake should be located so that the intake air is as clean as possible and so

that neither the engine exhaust gases nor heated air from the engine compartment can

mix with the intake air to the engine.

In the chart on the right-hand side, the recommended minimum area for the air intake

can be read from the engine air consumption.

If several engines or other air consumers are located in the same engine compartment, the diameter should be increased correspondingly.

Measure the pressure difference during operation, when the engine or engines have

been running for about 5 minutes at full load. The pressure difference must not exceed 1 mbar. For engines without a fan, a vacuum of 2 mbar is permissible.

For installations where the engine draws the intake air directly from the engine compartment, the engine compartment must normally be equipped with a ventilation system. This system should extract the air heated by radiation etc. in order for the

requirement of a low intake air temperature to be met.

If there is a refrigerator compressor in the engine compartment, it is important that

any leakage of refrigerant does not contaminate the intake air.

The radiated heat from the engine exhaust pipe downstream of the engine must also

be taken into account. The heat radiation depends on how much of the line is inside

the engine compartment and how much of it is insulated.

There is also additional heat due to efficiency losses in driven units located in the engine compartment.

10

0,1 0,2 0,3 0,4

20

30

40

50

60

kg/min

m

2

25

o

C

340 420

Calculation of minimum air intake area

Page 8

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Air cleaners

01:02 Issue 6 en-GB 8

The amount of radiated heat emitted by the engine is indicated in the tables showing

the radiated heat for the relevant engine type under Technical data in the Installation

manual.

Air cleaners

The engines are delivered with air cleaners with paper filter. The air cleaner is available with or without integrated self-cleaning precleaner.

If the air cleaner has a precleaner, it always has a safety cartridge. This protects the

engine from contamination, for example, if the main filter is damaged or when renewing the main filter element. An air cleaner without precleaner is not available

with safety cartridge.

Bear in mind the following when installing an air cleaner:

• The air cleaner must be fitted so that it is easily accessible for cleaning and filter

renewal.

• The vacuum indicator must be positioned so that it can be read easily.

• In order to be able to remove the filter element clearance in the air cleaner extension is required.

• The intake line between the air cleaner and the turbocharger must be sealed so that

no unfiltered air can be drawn into the engine. The intake line must be designed

in such a way that it cannot collapse onto itself as a result of a large pressure drop.

The intake line should be able to withstand a vacuum of 200 mbar before it collapses onto itself.

• The material and composition of the intake line between the air filter and turbocharger must be such that it cannot release rust or objects that could damage the

engine.

An effective self-cleaning prefilter is recommended for particularly dusty environments. Even engine systems exposed to driving snow can require a special type of

prefilter.

Page 9

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Air cleaners

01:02 Issue 6 en-GB 9

For such equipment, Scania refers to filter system specialists who can give recommendations about the system which is most suitable for a particular type of engine

installation.

It is also important to make sure that any insulation in the engine compartment and

around the exhaust pipes cannot come loose and be drawn into the intake line.

If a non-Scania air filter is used, engine air consumption and filter element pore size

must be considered.

Air cleaners with precleaner

Air filters with precleaner are available in 3 different sizes: 13 inch, 15 inch and 18

inch.

IMPORTANT!

The air cleaners must be fitted horizontally with the drain pipe pointing downwards.

165

900

340 419

152

340 418

Page 10

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Air cleaners

01:02 Issue 6 en-GB 10

Air cleaners without precleaner

Air filters without precleaner are available in 2 different sizes: 13 inch and 15 inch.

IMPORTANT!

The air cleaner must be fitted horizontally with the air intake (1) pointing downwards. The air cleaner may also be fitted vertically, but only if it is fitted indoors or

in such a way that water cannot get into the air filter.

165

900

1

340 417

152

340 416

Page 11

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Crankcase ventilation

01:02 Issue 6 en-GB 11

Crankcase ventilation

Open crankcase ventilation

If the engine is located in an enclosed space, crankcase gases should be led out of the

engine compartment.

This is especially important when the engine is equipped with a driving fan since the

crankcase gases will otherwise settle on the radiator, binding dirt and dust, which reduces the cooling effect.

The crankcase ventilation pipe (1) has a diameter of 32 mm.

The following points are important for external ventilation of crankcase gases:

• The crankcase gases must not be led to outlet ducts for engine compartment ventilation or exhaust gases.

• The crankcase ventilation lines from multiple engines must not be joined to form

a single pipe.

• The crankcase ventilation line should be made from pipe or oil-resistant hose,

connected to the ventilation pipe on the engine.

• When the crankcase ventilation line is extended in cold environments, it must be

designed to ensure that condensation cannot freeze in the hose. The extension of

a crankcase ventilation line may need to be insulated.

• When the crankcase ventilation line is extended, the extension must be designed

to ensure that no pockets are formed. It must also have a continuous downward

slope so that it can neither freeze nor can oil accumulations form resulting in too

high a pressure in the crankcase.

• Any crankcase ventilation pipe with its outlet outside the engine compartment

must be protected so that no water or contaminants can get into the crankcase.

• If pipe is used, there should be a flexible, oil-resistant line between the engine and

pipe to absorb the engine movements.

• If hose is used, it must be clamped so that no sharp kinks are formed.

A

B

1

1

335 751

Open crankcase ventilation

A. DC09

B. DC13

1

335 753

Open crankcase ventilation, DC16

Page 12

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Crankcase ventilation

01:02 Issue 6 en-GB 12

• The crankcase ventilation pipe outlet must not be positioned where there is a risk

of it becoming blocked.

Closed crankcase ventilation

For certain engine systems, external ventilation of crankcase gases could be extensive and expensive. This applies, for example, to generator sets in large buildings

where very long evacuation pipes are required.

When there are special requirements for closed crankcase ventilation, e.g. for environmental reasons, it is permissible to allow the crankcase gases to be led to the intake line between the air filter and the turbocharger.

It is not permissible to lead the crankcase gases to the intake upstream of the engine

air filter.

A

B

335 754

Closed crankcase ventilation

A. DC09, DC13

B. DC16

Page 13

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Connection to turbocharger

01:02 Issue 6 en-GB 13

Connection to turbocharger

Cleanliness requirement

IMPORTANT!

Observe the utmost cleanliness when installing all parts from the air filter up to the

turbocharger. If foreign particles enter the turbocharger, this could quickly lead to

impaired performance and breakdown.

Do not remove the protection from the turbocharger inlet pipes and charge air pipe

before they are connected.

Charge air pipe

The installation of the charge air pipe recommended by Scania is shown in the illustration.

IMPORTANT!

Position a flexible hose as close to the turbocharger connection as possible to reduce

forces and torques.

The weight of the charge air pipe must not put any load on the turbocharger. Therefore, support the charge air pipe downstream of the turbocharger connection with a

sturdy bracket.

2

1

3

42

337 360

Recommended installation of charge air pipe

1. Turbocharger

2. Flexible hose

3. Charge air pipe

4. Bracket

Page 14

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Connection to turbocharger

01:02 Issue 6 en-GB 14

Stage IV/Tier 4f engines

Inlet pipe for connection to turbocharger

The Scania inlet pipes for connection to the turbocharger must be used on all engines

certified according to Stage IV/Tier 4f. The inlet pipes are available in 2 different

versions for DC09 and DC13, and in 1 version for DC16.

Combined sensor T4000 for measuring ambient pressure and temperature is positioned in each version of the inlet pipe.

Tightening torque for the clamp joint connected to the turbocharger: 20 Nm. Applies

only to DC09 and DC13.

336 772

Inlet pipes for DC09 and DC13

340 413

Inlet pipe for DC16

Page 15

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Connection to turbocharger

01:02 Issue 6 en-GB 15

Mass flow sensor pipe

All engines certified according to Stage IV/Tier 4f are supplied with an inlet pipe

with a mass flow sensor T126. The mass flow sensor pipes are available in 2 different

versions for DC09 and DC13, and in 1 version for DC16.

The dimensions and air direction for the mass flow sensor pipes are shown in the illustrations below.

Mass flow sensor pipes for DC09 and DC13

389

Ø 126

80

40

Ø 150

4x M10

336 769

271

Ø 126

60

190

40

Ø 150

2x M8

336 770

Page 16

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Connection to turbocharger

01:02 Issue 6 en-GB 16

In order to get the best possible measured value when measuring the mass flow, the

following recommendations for the installation of all types of mass flow sensor pipes

apply:

• Install the mass flow sensor pipe as near to the turbocharger as possible.

• Use pipes between the turbocharger and the mass flow sensor pipe as far as possible.

• Make pieces of hose as short as possible.

• Maximum distance between the inlet pipe and mass flow sensor pipe is 800 mm.

This applies to all combinations of inlet pipes and mass flow sensor pipes.

• Use hose which is sturdy enough so that it does not collapse onto itself.

Tightening torque for hose clamps: 5 Nm.

4xM8

M8

340 412

Ø 150

60

Ø 140

220

414

Mass flow sensor pipe for DC16

Max. 800 mm

336 774

Maximum distance between the inlet pipe and mass flow sensor pipe

Page 17

INSTALLATION

MANUAL

©

Scania CV AB 2014, Sweden

Connection to turbocharger

01:02 Issue 6 en-GB 17

• The switch of the mass flow sensor must not be on the underside of the mass flow

sensor pipe where it may come into contact with condensation and dirt. See the

illustration.

• If a pipe bend is installed upstream of the mass flow sensor pipe, the outer radius

of the pipe bend must be on the same side as the measuring body of the mass flow

sensor ±90°. The airflow must hit the measuring body of the mass flow sensor (1).

1

1

336 873

The relationship between the pipe bend and mass flow sensor pipe if a pipe bend is

installed upstream of the mass flow sensor pipe

Loading...

Loading...