sauter PI 43 User Manual

2003-10-28

PI 43 e

Disk-type tool turret

without tool drive

series 0.5.440.xxx

with tool drive Series

0.5.433./436.xxx

0.5.435.xxx

10/2003

Re: Documents on control PI 44 e

Contents

Disk-type tool turret series 0.5.440.xxx without tool drive

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 Admissible loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 Precision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 Fluid rotary feed-through. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Turret series 0.5.433.xxx/0.5.436.xxx with axial tool drive

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11 Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 Alternate configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Turret series 0.5.435.xxx with radial tool drive

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16 Motor arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17 Performance data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18 Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Type key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Ordering details . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

NOTE:

The information contained in this Product Information is in conformity with the knowledge at the point of printing. Subject to modifications which occur within the framework of continuous further development.

PI 43 e |

3 |

Turret series 0.5.440.xxx

Description

Disk-type tool turret series 0.5.440.xxx

These turrets are suitable for use on turning machines for forward as well as reverse machining. They are equipped with all of the features and functions of modern highperformance and high-capacity tool turrets. Their robust design and short switching times means they are also suitable for heavy-duty use in series manufacture.

Turret series |

without tool drive |

– 0.5.440.xxx |

|

with axial tool drive |

– 0.5.433.xxx |

|

|

– 0.5.436.xxx |

|

with radial tool drive |

– 0.5.435.xxx |

Features:

}Drive with controllable electric motor for very fast bidirectional positioning

}Optimum utilization of

•standard servo-motors

•or a Sauter drive unit with motor and converter

}Use of absolute encoders is possible – no reference point travel is required!

}High degree of stability due to high locking forces

}Hydraulically activated locking with triple generating crown gear (pat.) – hydraulic or pneumatic

}Not affected by collisions due to the low kinetic energy of the drive and fastening snap ring groove for the tool disk

}Directly controllable with machine controller

}Connection with centralised lubricating system to ensure extremely high service and usage life

}Can be installed in any position

}Mechanically largely connection-compatible with Sauter disk-type tool turrets of series 0.5.480.5xxx and 0.5.680.1xx

}Options:

•Block-shaped housing or with flange fitting form for especially high degree of rigidity

•Central rotary feedthrough fur fluid-actuated tools and for a high-pressure cooling lubricant device

•Installation of transfer elements for switching buttons in the tool disk

•Attachment of sensors for cutting force monitoring

•Turret with y-axis slide feed unit

•u.a.m.

4 |

PI 43 e |

Turret series 0.5.440.xxx

Description

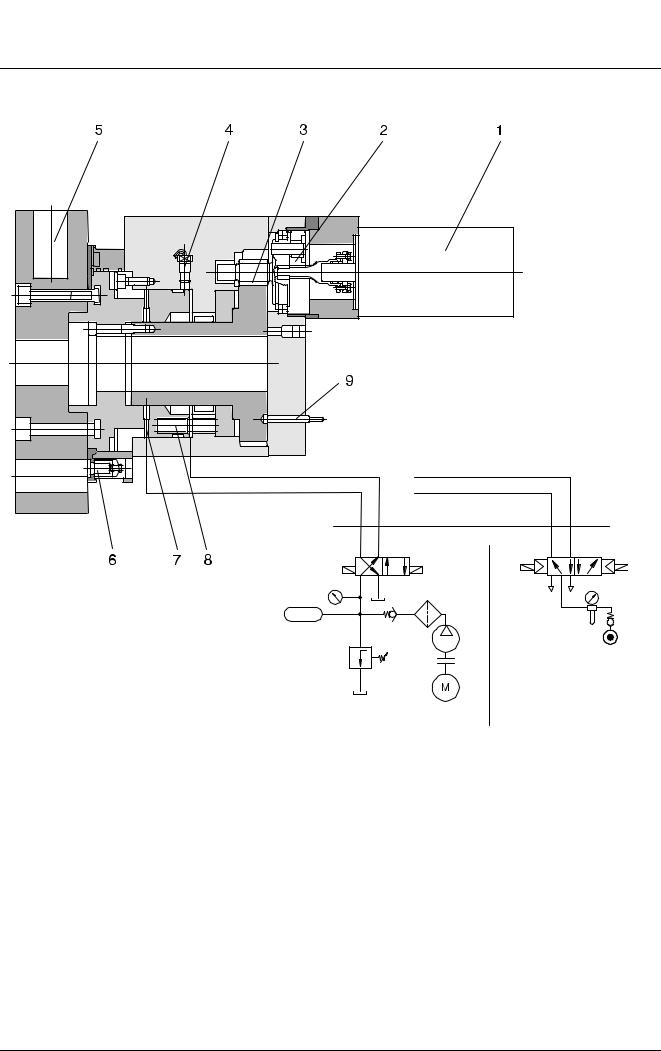

Hydraulics |

Pneumatics |

1Drive motor

2Planetary gearbox

3Spur gear

4electrical locking control

5Tool disk

6Cooling lubricant valve

7Hirth-type gearing

8Spring

9Reference switch – optional –

PI 43 e |

5 |

Turret series 0.5.440.xxx

Technical Data

Series

Disk-type tool turret 0.5.440.xxx

Number of switching positions |

|

|

||

|

|

|

||

Admissible tangential load (turret locked) 5.) |

|

kNm |

||

Adm. mass moment of inertia of tools 1.) |

Standard load stage |

kgm2 |

||

|

|

(tool disk and holder) |

High load load stage |

kgm2 |

Adm. out-of-balance (load moment) |

Standard load stage |

Nm |

||

due to tooling |

|

High load load stage |

Nm |

|

|

|

|

|

|

Indexing times 2.) |

|

|

|

|

Rotate tool disk |

|

|

|

|

• incl. acceleration and braking |

Standard load stage |

s |

||

|

per partial step 30° |

High load load stage |

|

|

|

|

|

||

• without acceleration and braking |

Standard load stage |

s |

||

|

per additional partial step |

High load load stage |

|

|

Turret unlock/lock |

|

|

|

|

• |

hydraulic |

|

|

s |

• |

pneumatic |

|

|

s |

|

|

|||

Adm. indexing frequency 2.) (median switching angle ϕm=90°) |

min-1 |

|||

Gearbox ratio drive motor turret shaft 3.) |

|

|

||

|

|

|

||

Operating pressure |

|

|

||

|

|

|

|

|

Hydraulics |

± 10 % |

|

bar |

|

Pneumatics |

± 15 % |

|

bar |

|

|

|

|

|

|

Cooling lubricant |

|

|

|

|

• with medium pressure valve |

|

bar |

||

• with central high-pressure cooling lubricant device |

bar |

|||

|

|

|

||

Fluid absorption volume |

|

cm3 |

||

|

Turret unlock/lock |

|

||

Mass |

|

|

|

|

|

Revolver (incl. drive motor) |

|

kg |

|

|

Tool disk and tooling (max.) |

|

kg |

|

|

|

|

||

Adm. ambient temperature |

|

°C |

||

|

|

|

|

|

1.) Indexing times available

2.) Conditions: • Fluid supply sufficiently large

•Turret up to operating temperature

•Drive motor 1FK7043 7AH71 – made by Siemens

•without controller-related non-productive time

3.) Values in parentheses are subject to change with drive motors featuring higher mass moments of inertia; switching times may change as well.

4.) Comply with the fineness of the filter required for the utilised tools, e.g. spindle heads with internal cooling lubricant supply.

6 |

PI 43 e |

Turret series 0.5.440.xxx

Technical Data

Size

|

12 |

|

|

|

16 |

|

|

|

20 |

|

|

|

|

25 |

|

|

|

32 |

|

|

|

|

40 |

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

81.) |

|

12 |

|

161.) |

81.) |

|

12 |

|

161.) |

81.) |

|

12 |

|

161.) |

81.) |

|

12 |

|

161.) |

8 |

12 |

|

16 |

8 |

|

12 |

16 |

|

|

0.7 [0.8] |

|

|

1.3 [1.8] |

|

|

3.2 [3.6] |

|

|

|

6.3 [7.2] |

|

|

|

|

|

|

|

|

|

||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

0.8 |

|

|

|

1.8 |

|

|

|

3.2 |

|

|

|

|

8 |

|

|

|

|

|

|

|

|

|

|

||||

|

1.2 |

|

|

|

2.5 |

|

|

|

5.0 |

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

12 |

|

|

|

25 |

|

|

|

40 |

|

|

|

|

80 |

|

|

|

|

|

|

|

|

|

|

||||

|

16 |

|

|

|

32 |

|

|

|

63 |

|

|

|

|

125 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.10 |

|

|

|

|

0.12 |

|

|

|

|

0.15 |

|

|

|

|

|

0.19 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

|

0.11 |

|

|

|

|

0.13 |

|

|

|

|

0.17 |

|

|

|

|

|

0.22 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.06 |

|

|

|

|

0.07 |

|

|

|

|

0.09 |

|

|

|

|

|

0.12 |

|

|

|

|

|

|

|

|

|

|

|

|

0.06 |

|

|

|

|

0.07 |

|

|

|

|

0.09 |

|

|

|

|

|

0.12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

in preparation |

|

|

|||

|

0.10/0.10 |

|

0.10/0.10 |

|

0.12/0.12 |

|

|

0.14/0.14 |

|

|

|

|

||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||||||||||||

|

0.10/0.04 |

|

0.12/0.05 |

|

0.14/0.06 |

|

|

0.18/0.08 |

|

|

|

|

|

|

|

|

||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

25 |

|

|

|

20 |

|

|

|

16 |

|

|

|

|

12.5 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

45 |

|

|

|

54 |

|

|

|

72 |

|

|

|

|

90 |

|

|

|

|

|

|

|

|

|

|

||||

|

(25) |

|

|

|

(30) |

|

|

|

(50) |

|

|

|

|

(50) |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

50 |

|

|

|

50 |

|

|

|

50 |

|

|

|

|

50 |

|

|

|

|

|

|

|

|

|

|

||||

|

7 |

|

|

|

7 |

|

|

|

7 |

|

|

|

|

7 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

5 .. 25 |

|

|

Filtering 100 µm 4) |

|

|

|

|

|

|

|

|

|||||||

|

|

|

|

|

|

|

|

|

|

100 |

|

|

|

Filtering 25 µm 4) |

|

|

|

|

|

|

|

|

||||||

|

15 |

|

|

|

30 |

|

|

|

45 |

|

|

|

|

65 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||

|

38 |

|

|

|

50 |

|

|

|

70 |

|

|

|

|

110 |

|

|

|

|

|

|

|

|

|

|

||||

|

40 |

|

|

|

80 |

|

|

|

160 |

|

|

|

|

250 |

|

|

|

|

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

10 ... 40 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

5.) Values in square brackets apply to hydraulic locking

PI 43 e |

7 |

Loading...

Loading...