INDUCTION HOB

BASIC : NZ63K7777BK

MODEL : NZ64K5747BK

MODEL CODE : NZ64K5747BK/EF

Manual

SERVICE

NZ64K5747BK/EU

NZ64K5747BK/EO

NZ64K5747BK/EE

NZ64K5747BK/WT

NZ64K5747BK/ET

INDUCTION HOB CONTENTS

INDUCTION HOB

1. Precaution

2. Product Specication

3. Disassembly and Reassembly

4. Troubleshooting

5. PCB Diagrams

6. Wiring Diagrams

NZ64K5747BK

Contents

Contents

1. General Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2. Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-1 Induction Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-2 Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

2-3 Table of Specication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2-4 Accessory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2-5 Installing the hob . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3. Disassembly and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3-1 Tools for Removal and Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3-2 Replacement of the Assy Top Plate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3-3 Replacement of the Assy Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3-4 Replacement of the Working Coil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3-5 Replacement of the PBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

3-6 Replacement of the POWER CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4. Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-1 Part Checking method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4-2 DEMO mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

4-3 Failure Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

4-4 Electrical Malfunction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

4-5 Auto Function Check Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

5. P.C.B Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5-1 P.C.B Diagrams : Touch (Control) PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

5-2 P.C.B Diagrams : SMPS PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

5-3 P.C.B Diagrams : Inverter PCB . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6. Wiring Diagrams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

This document can not be used without Samsung’s authorization.

1. General Safety Precautions

1. Information contained in this manual is intended for

use by a qualied service technician. The technician

is required to be familiar with proper and safe procedures to be followed when repairing appliance.

All tests and repairs are to be performed using

proper tools and measuring devices. All component

replacements should be made using only factory

approved replacement parts.

2. Electrical shock and injury can result if service or

repairs are attempted by an unqualied individual.

Improper disassembly, assembly or adjustments

can create hazardous conditions.

3. Even for a skilled technician, a risk of injury or

electrical shock exists while performing service or

repairs. Electrical injury can be serious or fatal.

Extreme caution must taken when performing

voltage checks on individual components of an

appliance.

NOTE

Except as necessary to perform a particular

step in servicing a product, the electrical power

supply should always be disconnected when

servicing a product.

4. To avoid possible injury, the appliance must be

properly grounded. Never plug in or direct wire an

appliance unless it is properly grounded. See the

installation instructions that originally accompanied the product for proper grounding procedures.

5.The ventilation gap between the worktop and front of

the unit underneath it must not be covered.

8. The hob is to be connected to the mains using a

device that allows the appliance to be disconnected

from the mains at all poles with a contact opening

width of at least 3 mm, eg. automatic line protecting

cut - out, earth leakage trips or fuse.

9. Pay attention (conformity) to phase and neutral

allocation of house connection and appliance

(connection schemes); otherwise, components can

be damaged.

Warranty does not cover damage resulting from

improper installation.

If the supply cord is damaged, it must be replaced

by a special cord or assembly available from the

manufacturer or its service agent.

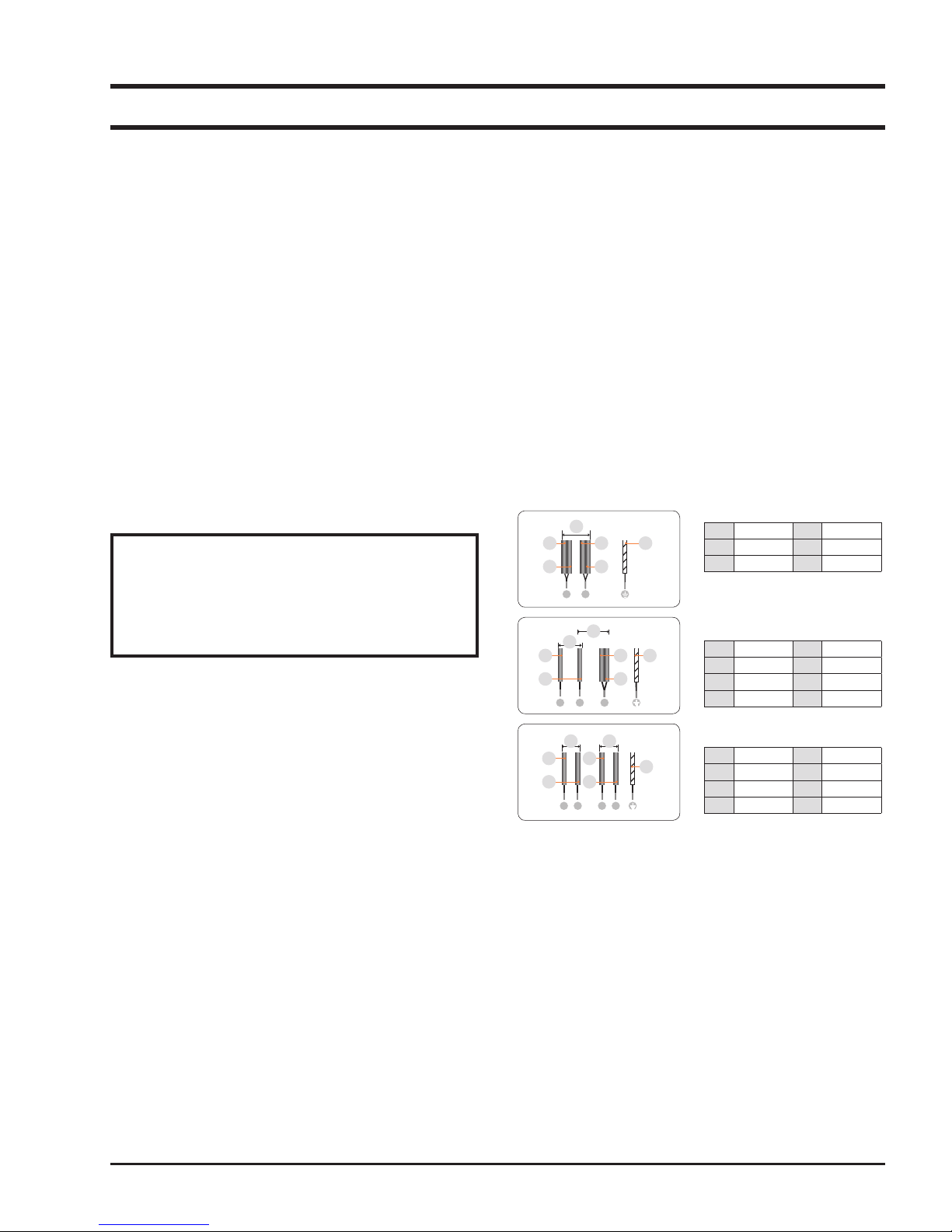

1N~ (32A)

220-240 V ~

01

Brown

02

Black

03

2N~ (16A): Separate the 2-phase wires

(L1 and L2) before connection.

220-240 V ~

01

380-415 V ~

02

Brown

03

Black

04

2 x 1N~ (16A): Separate the wires before

01

02

03

04

connection.

220-240 V ~

Brown

Blue

220-240 V ~

04

05

06

05

06

07

05

06

07

Blue

Gray

Green/Yellow

Blue

Gray

Green/Yellow

Black

Gray

Green/Yellow

02

03

L N

02

03

04

L1 L2 N

01 04

02

03

L1 N1 L1 N2

01

01

05

06

04 06

05

05

06

07

07

6. Before connecting, check that the nominal voltage

of the appliance, that is, the voltage stated on the

rating plate, corresponds to the available supply

voltage. The rating plate is located on the lower

casing of the hob.

7. The heating element voltage is AC230V~. The

appliance also works perfectly on networks with

AC220V~ or AC240V~.

- 1 -

This document can not be used without Samsung’s authorization.

2. Specications

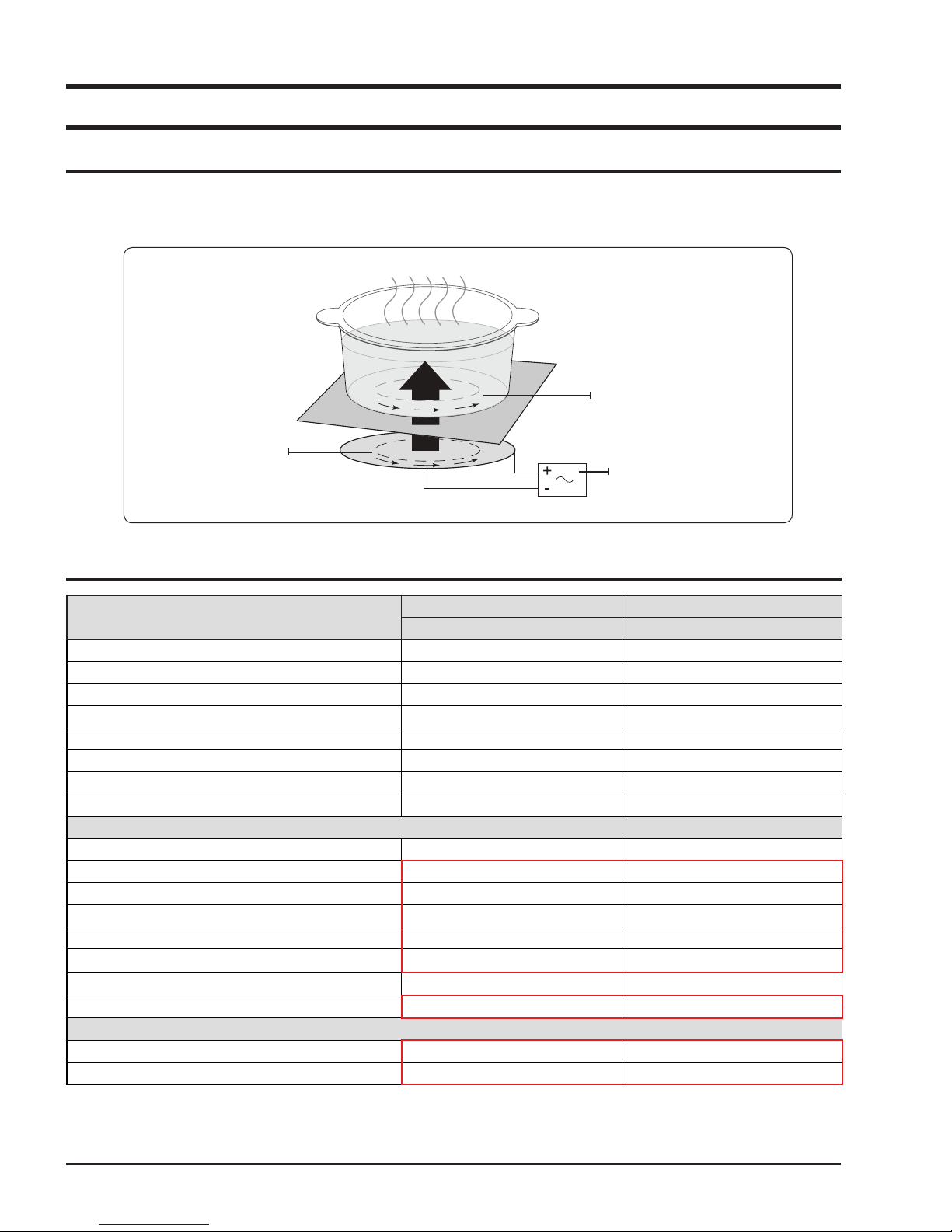

2-1 Induction Heating

• The Principle of Induction Heating: When you place your cookware on a cooking zone and you turn it on, the electronic

circuits in your induction hob produce “induced currents” in the bottom of the cookware which instantly raise cookware’s

temperature.

Induced currents

Induction coil

Electronic circuits

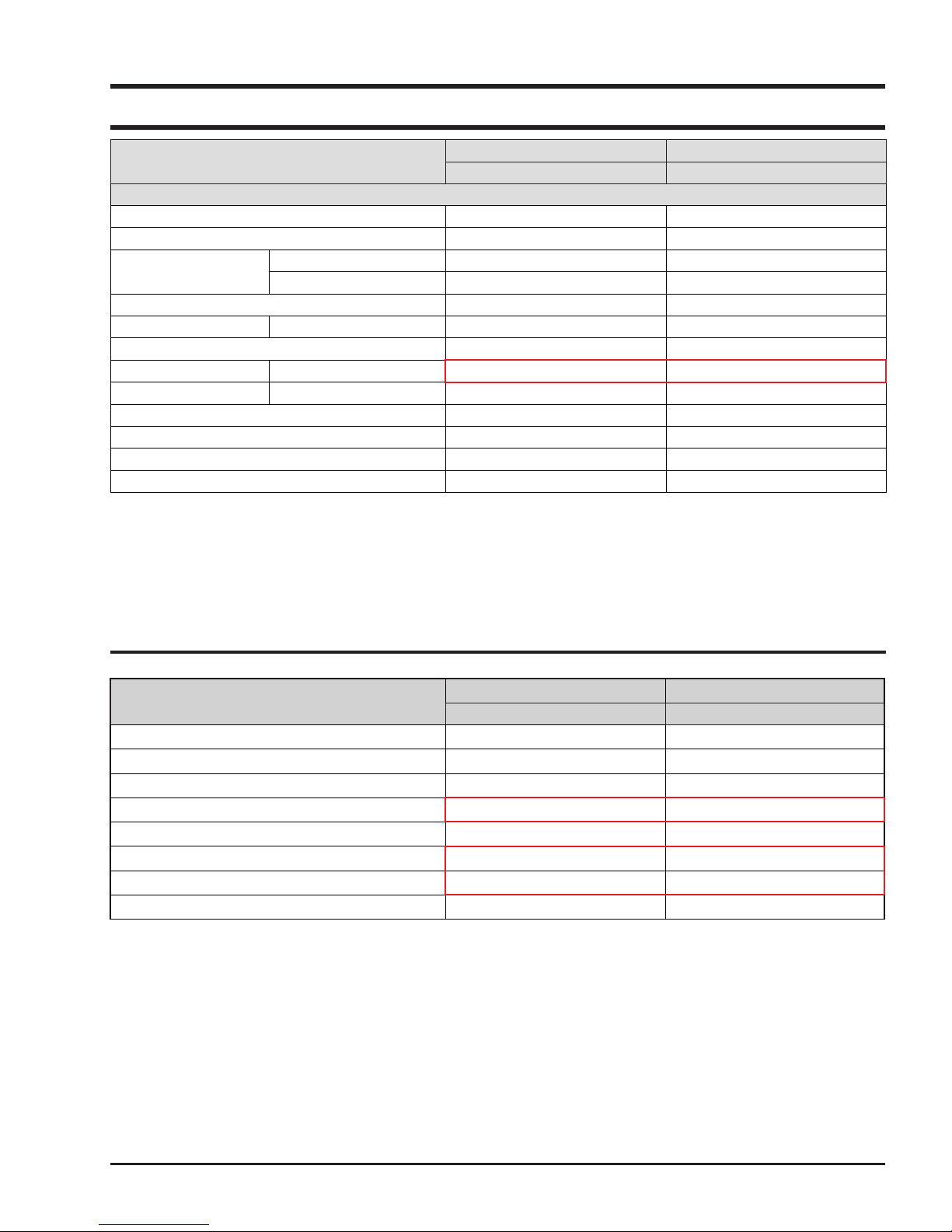

2-2 Features

Model Name

Product Type Induction Hob Induction Hob

Glass Ceramic Glass Ceramic Glass

Control Method Touch Sensor Touch Sensor

Residual Heat Indicator Yes Yes

Safety Shutoff Yes Yes

Pan Detection Yes Yes

Install Type Built-In Built-In

Design 1Bevel 1Bevel

Electric Features

Burner Power

Front Left 1,800W/Boost 2,600W

Rear Left 1,800W/Boost 2,600W

Flex Front 1,800W/Boost 2,600W

Flex Rear 1,800W/Boost 2,600W

Rear Right - 1,400W/Boost 2,000W

Front Right 2,200W/Boost 3,200W 2,200W/Boost 3,200W

Flex zone 3,300W/Boost 3,600W 3,300W/Boost 3,600W

Burner Size

Rear Right - 145mm

Front Right 200mm 210mm

Basic Model New Model

NZ63J9770EK NZ64K5747BK

- 2 -

2. Specications

This document can not be used without Samsung’s authorization.

Model Name

Control Features

Sound on/off Headen Lock Yes Yes

Power Level 1~15 level 1~15 level

Timer

Power Control 15+Booster 15+Booster

Direct Access +/-1 Yes Yes

Power On/Off Yes Yes

Ready Pan Flex Zone Yes No

Keep Warm +/-1 Yes Yes

Pause Yes Yes

Quick Start Yes Yes

Quick Stop Yes Yes

Demo Mode Yes Yes

Kichen Timer Yes Yes

Alarm Yes Yes

Basic Model New Model

NZ63J9770EK NZ64K5747BK

2-3 Table of Specication

Model Name

Electrical Connection 220~240V, 50/60Hz 220~240V, 50/60Hz

Rated voltage 2N : 380~415V, 50/60Hz 2N : 380~415V, 50/60Hz

Mains-connection 1N : 220~240V, 50/60Hz 1N : 220~240V, 50/60Hz

Output Power Max 6,800W Max 7,200W

"Outside Dimensions (WxLxH)" 600 x 520x 56 mm 600 x 520x 56 mm

Net Weight 13.5kg 12.7kg

Gross Weight 16.5kg 15.5kg

Export Zone EU EU

Basic Model New Model

NZ63J9770EK NZ64K5747BK

- 3 -

2-4 Accessory

This document can not be used without Samsung’s authorization.

Bracket Spring

- 4 -

This document can not be used without Samsung’s authorization.

01

02

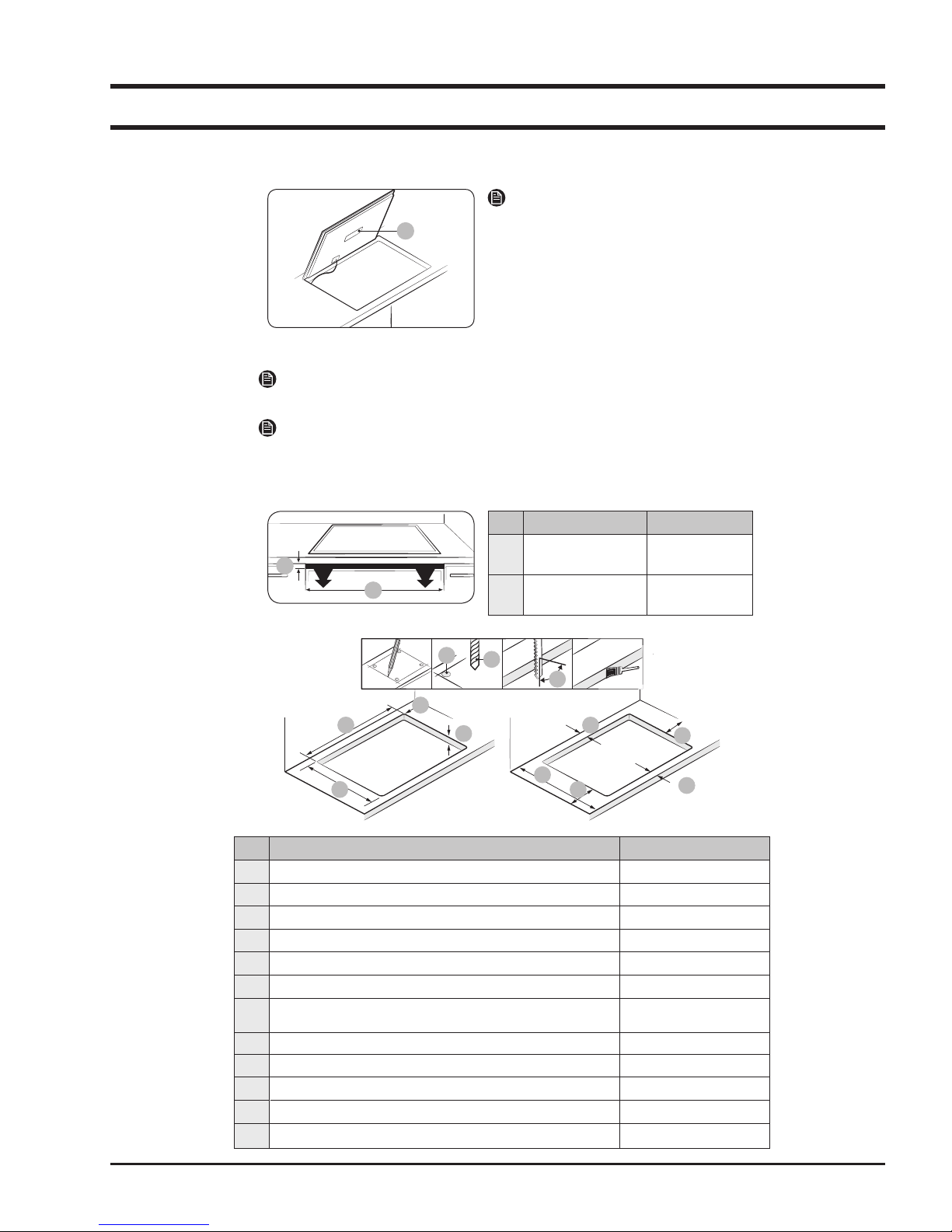

2-5 Installing the hob

2-5-1 Installing into the countertop

A

A. Serial number

NOTE

Pay special attention to the minimum space and clearance requirements.

NOTE

The bottom of the hob is equipped with a fan. If there is a drawer under the hob

it should not be used to store small objects or paper, since they could damage the

fan or interfere with the cooling if they are sucked into it.

NOTE

Make a note of the serial number on the

appliance rating label prior to installation.

This number will be required in the case

of requests for service and is no longer

accessible after installation, as it is on the

original rating plate on the underside of the

appliance.

No. Explanation Size

01 Height of

ventilation hole

02 Width of

ventilation hole

Min 2 mm

560 mm

01

02

03

06

10

08

11

12

Max 50 mm,

Min 20 mm

04

05

No. Explanation Size

01 Check 4 Point

02 Drill diameter Ø 6

03 Right angle of cutting point 90 °

04 Width Size 560±1 mm

05 Height Size 490±1 mm

06 Curve Size R3

07 Size of table thickness

08 Distance between end of table and cutting point (Top-side) Min 60 mm

09 Height of table Min 600 mm

10 Distance between end of table and cutting point (Left-side) Min 60 mm

11

Distance between end of table and cutting point (Right-side) Min 60 mm

12 Distance between end of table and cutting point (Bottom-side) Min 50 mm

07

09

- 5 -

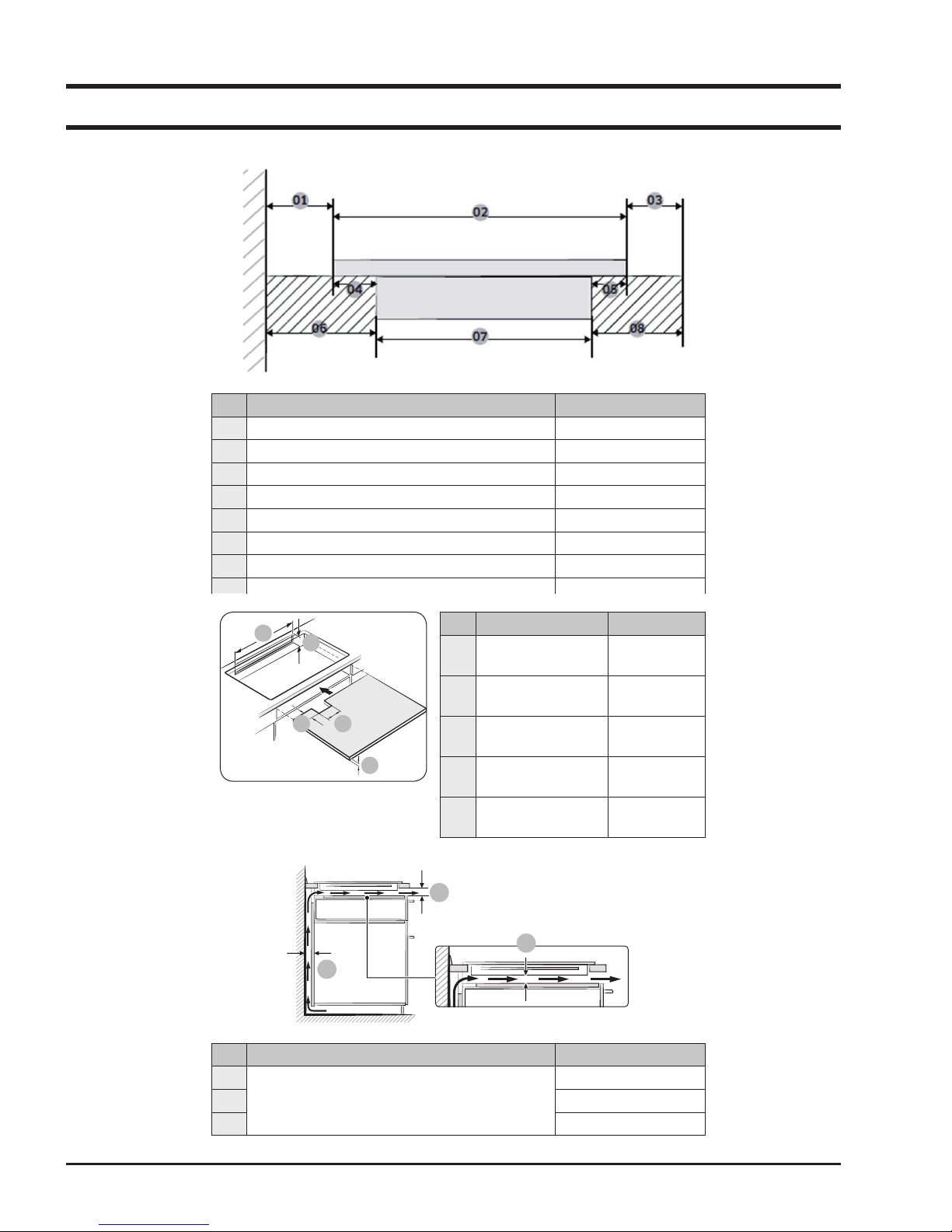

2-5 Installing the hob

06

07

08

04

02

05

01

03

05

02

01

03

04

No. Explanation Size

01 Distance between wall and Induction Min 40 mm

02 Size of depth of Induction 520 mm

03 Distance between Induction and end of table Min 40 mm

04 Distance between glass and case burner 25 mm

05 Distance between glass and case burner 15 mm

06 Distance between wall and case burner. Min 60 mm

07 Size of depth of case burner 480 mm

This document can not be used without Samsung’s authorization.

No. Explanation Size

01 Width of rear

ventailation

02 Height of rear

ventaliation

03 Depth of power

cord path

04 Width of power

cord path

05 Height of block

board

Min 550 mm

Min 35 mm

Min 65 mm

Min 100 mm

Min 5 mm

02

01

No. Explanation Size

01

02 Min 2 mm

03 Min 20 mm

Size of Ventaliation

03

Min 20 mm

- 6 -

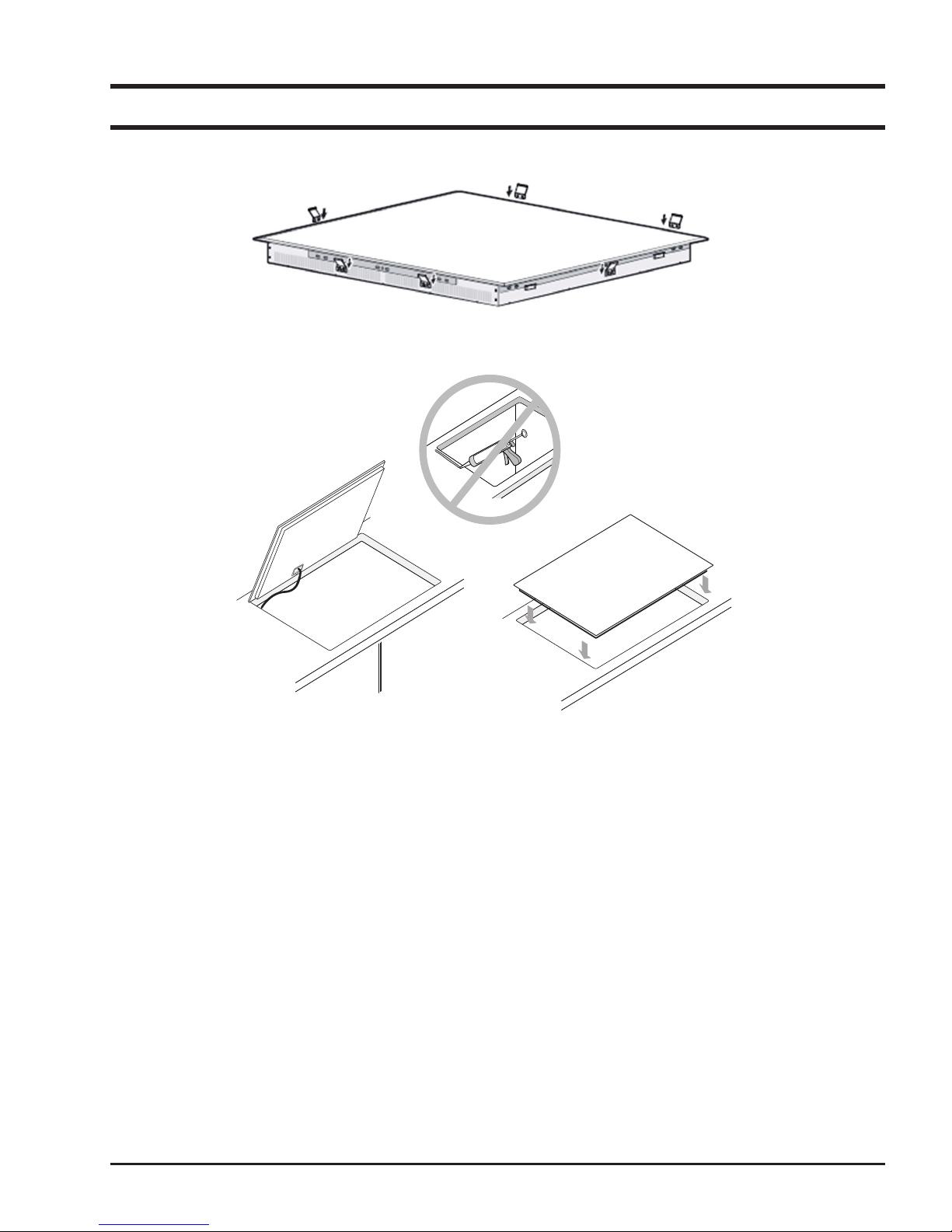

2-5 Installing the hob

This document can not be used without Samsung’s authorization.

- 7 -

This document can not be used without Samsung’s authorization.

3. Disassembly and Reassembly

3-1 Tools for Removal and Reassembly

Tool

1. Tool : Longnose

2. Remarks : PBA hook

1. Tool : Driver

2. Type : ( + )

3. Remarks : SCREW

- 8 -

This document can not be used without Samsung’s authorization.

3-2 Replacement of the Assy Top Plate

Attention

The Ceramic Glass may break if you use force especially on the edge.

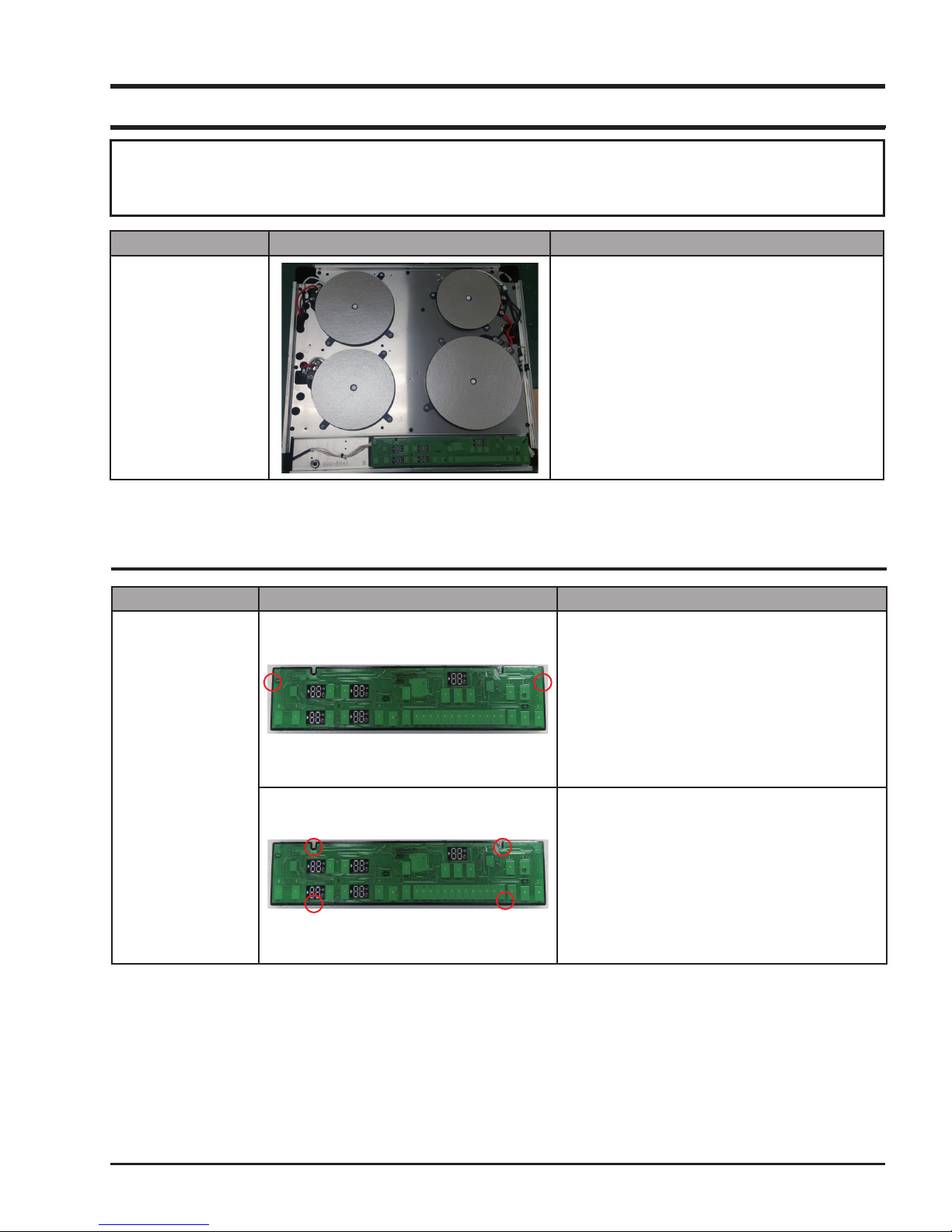

Parts Explanation Photo Explanation

Assy Top Plate

(Ceramic Glass)

1. Disconnect power.

2. Remove 4 - side direction 16 Screws

securing the Assy Top Plate to the Assy

Case Burner.

3. Raise the Assy Top Plate.

4. After replacement of the Assy Top Plate,

Screw the Assy Top Plate to the Assy Case

Burner.

3-3 Replacement of the Assy Control Panel

Parts

Assy Control Panel

Explanation Photo

Explanation

1. Lift up the Control Panel Assy.

2. Disconnect all connectors.

3. Control PBA is xed by double-faced tape.

Separate Control PBA from Support PCB.

- 9 -

This document can not be used without Samsung’s authorization.

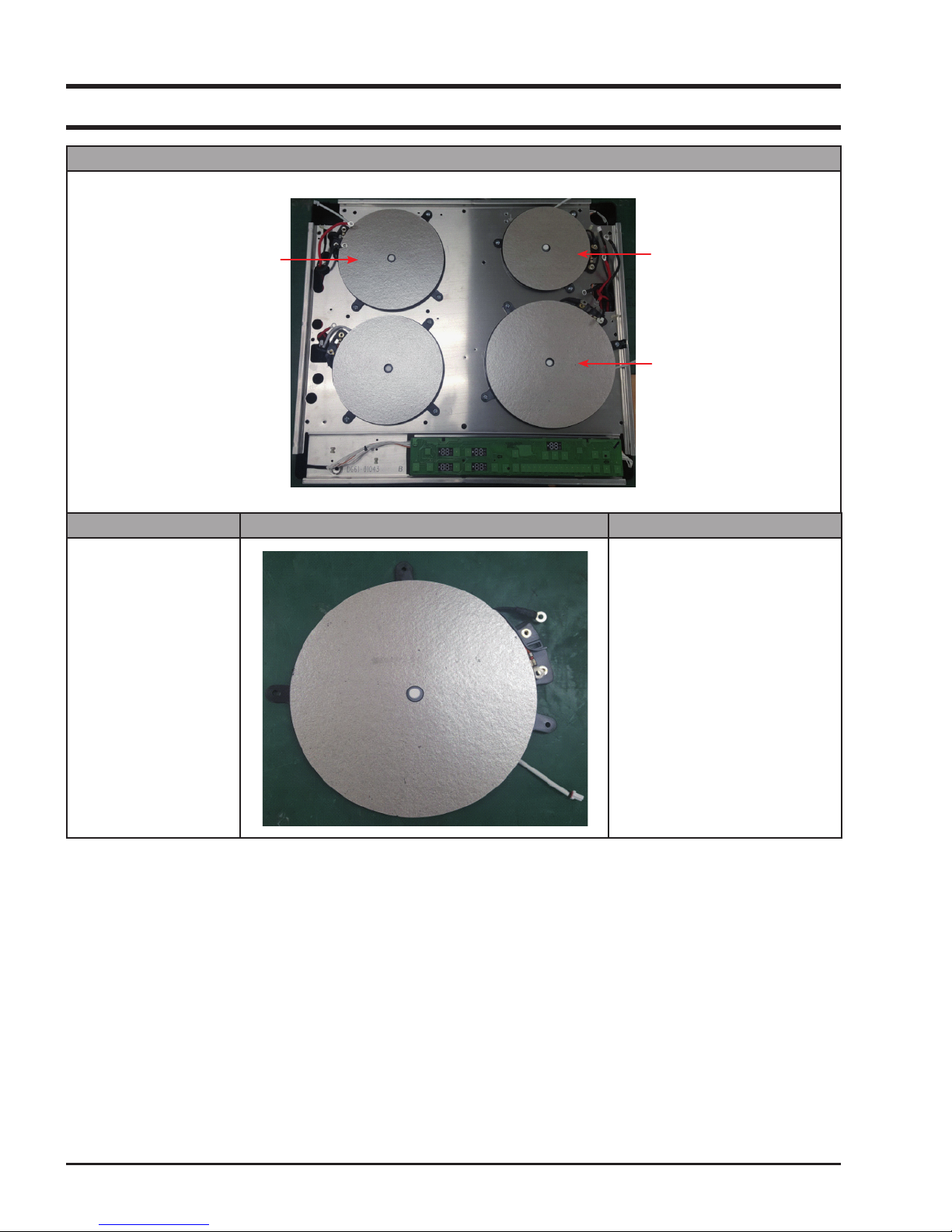

3-4 Replacement of the Working Coil

Explanation Photo

COIL WORKING FLEX

Parts Explanation Photo Explanation

Working Coil

COIL WORKING 145

COIL WORKING 210

1. Bend the Cover-Coil a little.

- 10 -

This document can not be used without Samsung’s authorization.

3-4 Replacement of the Working Coil

Parts Explanation Photo Explanation

2. Remove Screws securing the

Working-Coil

3. Disconnect all lead wires from the

Assy-Working Coil.

Working Coil

pull & rotate

4. For the replacement of Sensor-Top,

pull the Sensor-Top toward bottom

side.

5. Rotate the Sensor-Wire by

90degree until the Sensor-Top can

be remove from the Coil-Working.

- 11 -

This document can not be used without Samsung’s authorization.

3-5 Replacement of the PBA

Parts Explanation Photo Explanation

1. Remove all screws securing the

CASE-INDUCTION.

2. Disconnect all wires from the

WORKING-COIL.

PBA

3. Remove the CASE-INDUCTION.

4. Disconnect all wires from the

PBA.

- 12 -

This document can not be used without Samsung’s authorization.

3-5 Replacement of the PBA

Parts Explanation Photo Explanation

PBA

5. Remove all screws securing the

PBA.

6. The PBA is xed in place by a

series of hooks.

Remove these using a tool

Then remove the PBA.

- 13 -

This document can not be used without Samsung’s authorization.

01

02

03

04 06

05

L N

1N~ (32A)

01

220-240 V ~

04

Blue

02

Brown

05

Gray

03

Black

06

Green/Yellow

01

02

03

04

05

07

06

L1 L2 N

2N~ (16A): Separate the 2-phase wires

(L1 and L2) before connection.

01

220-240 V ~

05

Blue

02

380-415 V ~

06

Gray

03

Brown

07

Green/Yellow

04

Black

01 04

02

03

05

06

07

L1 N1 L1 N2

2 x 1N~ (16A): Separate the wires before

connection.

01

220-240 V ~

05

Black

02

Brown

06

Gray

03

Blue

07

Green/Yellow

04

220-240 V ~

3-6 Replacement of the POWER CABLE

Parts Explanation Photo Explanation

1. Remove screws securing the GND

WIRE and HOLDER-CABLE.

2. Remove locking holder.

Power Cable

3. Pull the POWER CABLE outwards

to remove it from the socket.

4. After nishing service, connect the

power cable properly to main power

supply.

- 14 -

This document can not be used without Samsung’s authorization.

4. Troubleshooting

4-1 Part Checking method

Parts Photo Good No Good

SENSOR TEMP

(DG32-00015A)

20˚C : 292.9kΩ

40˚C : 118.7kΩ

60˚C : 52.76kΩ

80˚C : 25.38kΩ

The others

IGBT Sensor

(DE95-00001A)

Coil-Working

20˚C : 57.9KΩ ~ 65.5KΩ

25˚C : 46.4KΩ ~ 52.2KΩ

30˚C : 37.5KΩ ~ 41.9KΩ

0.01~1Ω 100MΩ exceed

The others

- 15 -

This document can not be used without Samsung’s authorization.

4-2 DEMO mode

This mode is for Shop display.

At this mode, user can only operate touch key button without burner power on.

1. Touch Lock key for 3 seconds.

2. Touch Timer key for 3 seconds. An acoustic signal will sound.

3. Touch Pause key for 3 seconds within 10 seconds. An acoustic signal will sound.

4. Demo mode will be activated.

5. To exit the Demo mode, repeat No.1 ~ 3 procedure.

- 16 -

This document can not be used without Samsung’s authorization.

4-3 Failure Codes

4-3-1 Temp Sensor Information

Information

Code

Top Sensor Open Information (Sensor-Top)

It occurs due to a defective sensor, misplaced wires, a defective PCB and

when A/D value that MICOM senses rises over 252.

Also, it may occur when the ambient temperature falls under -10˚C.

Top Sensor Short Information (Sensor-Top)

It occurs due to a defective sensor, misplaced wires, a defective PCB and

when A/D value that MICOM senses falls under 10.

IGBT Sensor Open Information (Assy-Inverter Module)

It occurs due to a defective sensor, misplaced wires, a defective PCB and

when A/D value that MICOM senses rises over 239.

Also, it may occur when the ambient temperature falls under -10˚C.

IGBT Sensor Short Information (Assy-Inverter Module)

It occurs due to a defective sensor, misplaced wires, a defective PCB and

when A/D value that MICOM senses falls under 10.

Solution Page

18 Page

19 Page

20 Page

21 Page

4-3-2 Safety Information

Information Code Gerneral Function Solution Page

Touch Button Short

Information

Touch key data

Information

Over Temperature

Information

Pan Detection

Information

DC Motor Locking

Information

It occurs when the control panel’s sensor eld is shorted

for more than 8 seconds.

ex: No.1 Place a damp cloth on the control panel.

No.2 Liquid boils over and lands on the control panel.

No.3 More than one key is pressed for more than

8 seconds.

No.4 Defective Assy-Touch PCB

It occurs when the Touch key data at Display PCB is interrupted, due to some noise, defects of Display PCB.

It occurs when the temperature of the Top Sensor rises

very highly.

(Estimated temperature of ceramic glass’s surface is

more than 250˚C.)

ex: Place a empty cookware on the burner and operate the

hob.

It occurs when the cookware is unsuitable or too small or

no cookware has been placed on the cooking zone.

If the suitable cookware is placed again, the hob will operate normally.

It occurs when the DC Motor cannot operate due to defects

of PCB, wiring or some disturbance on motor blade.

Page

Page

Page

Page

Page

22

23

24

25

26

Communications

between main

It occurs when the Main PCB and sub PCB not

communication.

- 17 -

27

Page

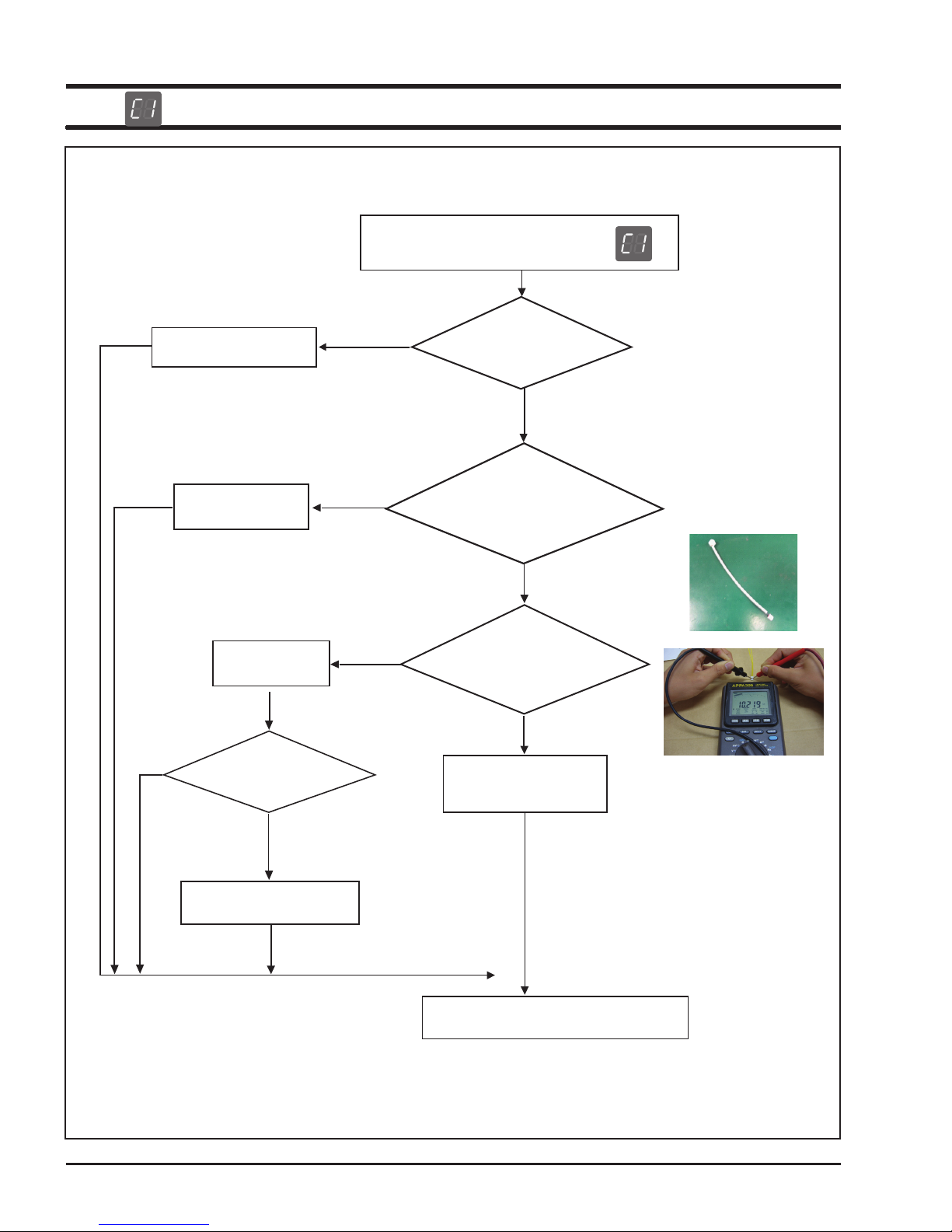

4-3-3

This document can not be used without Samsung’s authorization.

Connect the sensor.

Replace the wire.

Connect the wire

properly.

S/W Information

NO

After Power -> On, does

the symptom continue?

Top Sensor Open Information ( )

NO

NO

NO

Is the sensor connected?

Is the sensor wire

connected properly

by burner position?

Is the sensor's real

resistance a opened

The sensor has defect.

Replace the sensor.

circuit?

YES

: check if the sensor wire is damaged,

if the sensor housing is inserted into

the connector of the PCB.

YES

YES

YES

Replace the Assy Touch PCB.

Perform the operation again and check

if it is working properly.

- 18 -

4-3-4

This document can not be used without Samsung’s authorization.

Remove any foreign substance

from the shorted part.

S/W Information

NO

After Power -> On, does

the symptom continue?

YES

Top Sensor Short Information ( )

YES

NO

Is the sensor terminal part

of the PCB shorted?

real resistance a

The sensor has defect.

Replace the sensor.

No

Is the sensor's

shorted circuit?

YES

: check if the sensor is slightly shorted.

Replace the Assy Touch PCB.

Perform the operation again and check

if it is working properly.

- 19 -

4-3-5

connector of the PCB.

This document can not be used without Samsung’s authorization.

IGBT Sensor Open Information( )

Connect the sub wire.

Replace the sub wire.

S/W Information

NO

After Power -> On, does

the symptom continue?

NO

(from Assy-Inverter Module to

NO

NO

Is the sub wire connected?

Assy Touch PCB)

YES

Is the sub wire sequence matched

with PCB schematic?

YES

Is the sensor's real resistance a

opened circuit?

YES

The sensor has defect.

Replace the Assy-Inverter Module PCB.

: check if the sub wire is damaged

if the housing is inserted into the

YES

Replace the

Assy-Inverter Module PCB.

Perform the operation again and check

if it is working properly.

- 20 -

4-3-6

connector of the PCB.

This document can not be used without Samsung’s authorization.

IGBT Sensor Short Information ( )

Connect the sub wire.

Replace the sub wire.

S/W Information

NO

After Power -> On, does

the symptom continue?

NO

NO

NO

Is the sub wire connected?

(from Assy-Inverter Module to

Assy Touch PCB)

YES

Is the sub wire sequence matched

with PCB schematic?

YES

Is the sensor's real resistance a

shorted circuit?

YES

The sensor has defect.

Replace the Assy-Inverter Module PCB.

: check if the sub wire is damaged

if the housing is inserted into the

YES

Replace the

Assy-Inverter Module PCB.

Perform the operation again and check

if it is working properly.

- 21 -

4-3-7

This document can not be used without Samsung’s authorization.

Key Short Information ( )

Assy Touch PCB is

defective

Replace the

Assy Touch PCB

YES

YES

YES

Is the key not recognized

Is the key not recognized

after cleaning the control panel?

NO

does the symptom continue?

at all?

Is the key recognized

intermittently?

S/W Information

After Power > On,

NO

NO

NO

YES

Replace the sub wire

or Assy Touch PCB.

Perform the operation again and check if it

is working properly.

- 22 -

4-3-8

This document can not be used without Samsung’s authorization.

Touch key data Information ( )

After connect plug,

does the symptom continue?

YES

Replace the Touch PCB.

Perform the operation again and check

NO

Touch PCB is interrupted

due to some electrical noise.

if it is working properly.

- 23 -

4-3-9

This document can not be used without Samsung’s authorization.

Over Temperature Information ( )

Make the hob be cool

(Ceramic glass's surface)

Connect the wire

properly.

S/W Information

NO

After Power -> On, does

the symptom continue?

NO

YES

NO

Is the hob operated with

empty cookware?

NO

Is the Top sensor wire

connected properly by burner position?

YES

Is the Top sensor's real

resistance a

opened circuit?

YES

The Top sensor has defect.

Replace the sensor.

YES

Replace the Assy Touch PCB.

Perform the operation again and check

if it is working properly.

- 24 -

4-3-10

This document can not be used without Samsung’s authorization.

Pan Detection Information ( )

Place the cookware

Place the suitable

cookware

YES

YES

NO

Is the hob operated with

no cookware?

NO

Is the hob operated with

un-suitable cookware?

(small size, aluminium, etc)

NO

S/W Information

After Power -> On, does

the symptom continue?

YES

Replace the Assy-Inverter Module

or Assy Touch PCB,or Check the PCB Wiring.

Perform the operation again and check

if it is working properly.

- 25 -

4-3-11

This document can not be used without Samsung’s authorization.

DC Motor Locking Information ( )

Connect the Motor wire.

Remove the

interference at Motor.

YES

NO

Is the Motor wire connected?

YES

Is there some interference at rotor

or blade of Motor?

NO

S/W Information

NO

After Power -> On, does

the symptom continue?

YES

Replace the Inverter PCB,

Touch PCB or DC Motor.

Perform the operation again and check

if it is working properly.

- 26 -

4-3-12

This document can not be used without Samsung’s authorization.

Commnunication information ( )

Is the wire connected properly?

YES

Is the Main PCB or Sub PCB

S/W check properly?

YES

Replace the Main PCB and Sub PCB

YES

Perform the operation again and check

NO

NO

if it is working properly.

Connect wire propely

Update to S/W

YES

- 27 -

4-4 Electrical Malfunction

Troubleshooting (Power)

Check terminal block voltage.

(220V~240V, 50/60Hz)

YES

YES

YES

NO

No Power

Check the wiring.

NO

Check the votage of PCB, SMPS

-input : 220V~240V

-output : 12V, 5V

Replace the defected PCB.

Check the terminal block connections

Check the circuit breaker.

Replace or Repair the wiring

Troubleshooting (Heating)

Check the relay terminal voltage

(220V~240V)

NO

YES

YES

NO

Heating Failure

Check the wiring.

NO

Check the all IGBT terminal resistance

(G-E, G-C, E-C)

Is there any shorted circuit?

Perform the 'PCB failure' process

Repair the relay or missing circuit

component.

Replace or Repair the wiring

Check Fuse at Filter PCB.

Normally, If IGBT is damaged

and shorted, Fuse will blow and

power off.

YES

1. Replace the Fuse at Filter PCB.

If not change Fuse, Repaired Inverter

PCB will damage again.

2. Replace the Inverter PCB.

This document can not be used without Samsung’s authorization.

- 28 -

This document can not be used without Samsung’s authorization.

4-4 Electrical Malfunction

Troubleshooting (PCB failure)

PCB Failure

- Check the input voltage of

PCB SMPS (input checkpoint : 220V~240V )

YES

- Check the output voltage of

PCB SMPS (Output checkpoint : 5V/12V )

YES

Do all relays operate?

YES

Check the Assy-Inverter Module & Assy Touch PCB’s

input voltage(5V,12V,GND)

NO

NO

- Check Terminal block

voltage(220V~240V).

Reset the circuit braker or

check main power.

NO

Repair the relay or replace

NO

Replace PCB

PCB.

NO

YES

Replace or Repair the wiring

Repair Faulty wiring

or PCB check

YES

Replace PCB

- 29 -

This document can not be used without Samsung’s authorization.

4-5 Auto Function Check Test

Induction Hob can do self check test.

If product have some problem, test program will be stopped and display the corresponding information code.

Auto Function Check

Touch the LOCK

key for 3 seconds

If have some problem,

test will be stopped and

display the information code

Touch the KEEP WARM

key for 3 seconds

Touch the PAUSE key

for 3 seconds

Auto check start

Refer to 18 page

Failure Codes

* Information cause is wiring mistake or PCB defects.

- 30 -

- 31 -

This document can not be used without Samsung’s authorization.

5. P.C.B Diagrams

5-1 P.C.B Diagrams : Touch (Control) PCB

( This Document can not be used without Samsung’s authorization )

No Parts Number Part Name Function and Role

1

CN1 Inverter PBA wire connector Communication with Inverter PBA

2 CN2 VF PBA wire connector Communication with VF PBA

3 BZ Buzzer Beep sound

4 IC1 Touch MICOM MICOM for Touch Key operation

5 CN3 Touch MICOM burning connector Touch MICOM burning port. Not conntected

6 IC2 Main MICOM Main MICOM

7 CN4 Main MICOM burning connector Main MICOM burning port. Not conntected

8 IC3 Touch MICOM MICOM for Touch Key operation

9 CN5 Inverter PBA wire connector Communication with Inverter PBA

10 CN6 Relay PBA wire connector Communication with Relay PBA

11 CN7 Touch MICOM burning connector Touch MICOM burning port. Not conntected

2

1

3

4

5

6

7

8

9

10

11

- 32 -

This document can not be used without Samsung’s authorization.

5. P.C.B Diagrams

5-2 P.C.B Diagrams : SMPS PCB

( This Document can not be used without Samsung’s authorization )

No. Parts Number Part Name Function and Role

1 CON01 AC Input connector AC Voltage input of SMPS PCB

2 CON02 DC Output connector DC 12V, 5V supply to other PCB

1

2

- 33 -

This document can not be used without Samsung’s authorization.

5. P.C.B Diagrams

5-3 P.C.B Diagrams : Inverter PCB

( This Document can not be used without Samsung’s authorization )

No Parts Number Part Name Function and Role

1

BD1 Bridge Diode IC Bridge Diode IC

2 Q1 IGBT IC High freguency switching IC

3 CN1 Inverter MICOM burning connector Inverter MICOM burning port. Not conntected

4 CN2 Top-sensor wire connector Connect Top-sensor wire

5 CN3 Control PBA wire connector Communication with Control PBA

4

4

2 2

3

5

1

- 35 -

This document can not be used without Samsung’s authorization.

6. Wiring Diagrams

( This Document can not be used without Samsung’s authorization )

GSPN (GLOBAL SERVICE PARTNER NETWORK)

Area Web Site

Europe, CIS, Mideast & Africa gspn1.samsungcsportal.com

Asia gspn2.samsungcsportal.com

North & Latin America gspn3.samsungcsportal.com

China china.samsungportal.com

This Service Manual is a property of Samsung Electronics Co.,Ltd.

Any unauthorized use of Manual can be punished under applicable

International and/or domestic law.

© Samsung Electronics Co., Ltd. March.

2016 Printed in Korea

Loading...

Loading...