Samsung NX60T8311SG, NX60T8511SG, NX60T8111SG Installation Manual

Gas Slide-in Range

Installation manual

NX60*8*****

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 1 2020-03-26 6:41:17

WARNING: If the information in this manual is not followed exactly,

a re or explosion may result causing property damage, personal

injury or death.

ANTITIP DEVICE

WARNING

• DO NOT store or use gasoline or other ammable vapors and

liquids in the vicinity of this or any other appliance.

• WHAT TO DO IF YOU SMELL GAS:

- DO NOT try to light any appliance.

- DO NOT touch any electrical switch.

- DO NOT use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call the re

department.

• Installation and service must be performed by a qualied installer,

service agency, or the gas supplier.

ALL RANGES CAN TIP, RESULTING IN PERSONAL INJURY.

TIPPING RANGES CAN CAUSE BURNS FROM SPILLS,

PERSONAL INJURY, AND/OR DEATH.

INSTALL AND CHECK THE ANTI-TIP BRACKET FOLLOWING

THE INSTRUCTIONS AND TEMPLATE SUPPLIED WITH THE

BRACKET.

• To prevent accidental tipping of the range, attach an approved

anti-tip device to the oor. (See Installing the Anti-Tip Device in the

Installation Instructions.) Check for proper installation by carefully

tipping the range forward. The anti-tip device should engage and

prevent the range from tipping over.

• If the range is pulled out away from the wall for any reason, make

sure the anti-tip device is reengaged after the range has been

pushed back into place.

• Follow the installation instructions found in the Installation Manual.

Failure to follow these instructions can result in death, serious

personal injury, and / or property damage.

• DO NOT step / sit / lean on the door or drawer to prevent accidental

tipping of the range.

2 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 2 2020-03-26 6:41:17

Contents

Before you begin

Before you begin 3

Important safety information 4

Gas range components 11

What’s in the box 11

Installation requirements 13

Location requirements 13

To avoid breakage 15

Gas requirements 16

Special gas requirements (gas models sold in massachusetts) 17

Electrical requirements 17

Installation instructions 19

Installing your gas range 19

Step 1. Unpack the range 19

Step 2. Connect the range to gas supply 19

Step 3. Convert to lp gas (optional) 20

Step 4. Install the anti-tip device 21

Step 5. Plug in and place 21

Step 6. Level the range 22

Step 7. Assemble the surface burners 22

Step 8. Check the ignition of surface burners 23

Step 9. Final installation checklist 24

Adjusting the oven burner air adjustment shutters 24

About this manual

READ THESE INSTRUCTIONS COMPLETELY AND CAREFULLY.

Important note to the installer

• Read all instructions contained in these installation instructions before installing

the range.

• Remove all packing materials from the oven compartments before connecting the

electric and gas supply to the range.

• Observe all governing codes and ordinances.

• Be sure to leave these instructions with the consumer.

• Installation of this appliance requires basic mechanical skills.

• Proper installation is the responsibility of the installer.

• Product failure due to improper installation is not covered under the Warranty.

Important note to the consumer

Keep these instructions with your user manual for future reference.

• As when using any appliance generating heat, there are certain safety

precautions you should follow.

• Be sure your range is installed and grounded properly by a qualied installer or

service technician.

• Make sure the wall coverings around the range can withstand the heat generated

by the range.

• Cabinet storage space above the surface burners should be a minimum of 30 in

(76.2 cm).

Important note to the servicer

The electrical diagram is in an envelope attached to the back of the range.

Before you begin

English 3

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 3 2020-03-26 6:41:17

Important safety information

Important safety information

Important safety information

READ ALL INSTRUCTIONS BEFORE USING THIS APPLIANCE

• All electrical and gas equipment with moving parts can be dangerous. Please

read the important safety instructions for this appliance in this manual. The

instructions must be followed to minimize the risk of injury, death, or property

damage.

• Save this manual. Please Do Not Discard.

Symbols used in this manual

WARNING

Hazards or unsafe practices that may result in severe personal injury or death.

CAUTION

Hazards or unsafe practices that may result in electric shock, personal injury, or

property damage.

NOTE

Useful tips and instructions.

These warning icons and symbols are here to prevent injury to you and others.

Please follow them explicitly. After reading this section, keep it in a safe place for

future reference.

California Proposition 65 Warning

WARNING

Cancer and Reproductive Harm - www.P65Warnings.ca.gov

Commonwealth of Massachusetts

• This product must be installed by a licensed plumber or gas tter qualied or

licensed by the State of Massachusetts. When using ball-type gas shut-off valves,

you must use the T-handle type. Multiple exible gas lines must not be connected

in series.

General safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Do not touch any part of the range, including

but not limited to, oven burners, surface burners,

or interior surfaces during or immediately after

cooking.

• Know the location of the gas shut-off valve and

how to shut it off.

• Make sure the anti-tip device is properly installed on the range. See the

installation instructions for more information.

• Do not let children near, in, or on the range. Do not let children play with the

range or any part(s) of the range. Do not leave children unattended in an area

where the range is in use. For children’s safety, we recommend utilizing the

control/door lockout feature.

• Remove all packaging materials from the range before operating to prevent

ignition of these materials. Keep all packaging materials out of children’s reach.

Properly dispose the packaging materials after the range is unpacked.

• Do not store any object of interest to children on the cooktop or backguard of the

range. Children climbing on the range to reach items could be killed or seriously

injured.

4 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 4 2020-03-26 6:41:18

• Do not operate the range if the range or any part of the range is damaged,

malfunctioning, or missing parts.

• Do not use the range as a space heater. This range is to be used for cooking

purposes only.

• Do not use oven cleaners or oven liners in or around any part of the oven.

• Use only dry pot holders.

• Do not use the range to heat unopened food containers.

• Do not strike the oven glass.

• When disposing of the range, cut off the power cord and remove the door.

• Unplug or disconnect power before servicing.

• Make sure all meat and poultry is cooked thoroughly. Meat should always be

cooked to an internal temperature of 160 °F (71 °C). Poultry should always be

cooked to an internal temperature of 180 °F (82 °C).

Fire safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Do not store, place, or use ammable or

combustible materials such as paper, plastic,

pot holders, linens, curtains, gasoline or other

ammable vapors or liquids near the range.

• Do not wear loose tting or hanging garments

while using the range.

• To avoid grease buildup, regularly clean the vents.

• Do not let pot holders or other ammable materials touch a heating element. Do

not use a towel or other bulky cloths in place of a pot holder.

• Do not use water on a grease re. To put out a grease re, turn off the heat

source and smother the re with a tight-tting lid or use a multipurpose dry

chemical or foam-type re extinguisher.

• If a grease re should occur in the oven, turn off the oven by pressing the OFF/

CLEAR button. Keep the oven door closed until the re goes out. If necessary, use

a multipurpose dry chemical or foam-type re extinguisher.

• Do not heat unopened food containers - buildup of pressure may cause container

to burst and result in injury.

Important safety information

English 5

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 5 2020-03-26 6:41:18

Important safety information

Important safety information

Gas safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

If you smell gas:

• Close the valve and do not use the range.

• Do not light a match, candle, or cigarette.

• Do not turn on any gas or electric appliances.

• Do not touch any electrical switches or plug a

power cord into an outlet.

• Do not use any phone in your building.

• Evacuate the room, building, or area of all

occupants.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call the

re department.

Checking for gas leaks

• Leak testing of the appliance shall be conducted according to the manufacturer’s

instructions. Do not use a ame to check for gas leaks. Use a brush to spread a

soapy water mixture around the area you are checking. If there is a gas leak, you

will see small bubbles in the soapy water mixture at the leak point.

Electrical and grounding safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Plug into a grounded 3-prong outlet.

• Do not remove the ground prong.

• Do not use an adapter or an extension cord.

• Do not use a damaged power plug, power cord,

or loose power outlet.

• Do not modify the power plug, power cord, or

power outlet in any way.

• Do not put a fuse in a neutral or ground circuit.

• Use a dedicated 120-volt, 60-Hz, 20-amp, AC, fused electrical circuit for this

range. A time-delay fuse or circuit breaker is recommended. Do not plug more

than one appliance into this circuit.

• Do not connect the ground wire to plastic plumbing lines, gas lines, or hot water

pipes.

• This range must be Earth grounded. In the event of a malfunction or breakdown,

grounding will reduce the risk of electrical shock by providing a path for the

electric current. This range is equipped with a cord having a grounding plug.

The plug must be rmly plugged into an outlet that is properly installed and

grounded in accordance with the local codes and ordinances. If you are unsure

whether your electrical outlet is properly grounded, have it checked by a licensed

electrician.

• The range is supplied with a 3-pronged grounded plug. This cord must be

plugged into a mating, grounded 3-prong outlet that meets all local codes and

ordinances. If codes permit the use of a separate ground wire, we recommend

that a qualied electrician determine the proper path for this ground wire.

• Electrical service to the range must conform to local codes. Barring local codes,

it should meet the latest ANSI/NFPA No. 70 – Latest Revision (for the U.S.) or the

Canadian Electrical Code CSA C22.1 – Latest Revisions.

• It is the personal responsibility of the range owner to provide the correct

electrical service for this range.

6 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 6 2020-03-26 6:41:18

Installation safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Have your range installed and properly

grounded by a qualied installer, in accordance

with the installation instructions. Any

adjustment and service should be performed

only by qualied gas range installers or service

technicians.

• Do not attempt to service, modify, or replace your range or any part of your

range unless it is specically recommended in this manual. All other service

should be referred to a qualied technician.

• Always use new exible connectors when installing a gas appliance. Do not use

old exible connectors.

• Make sure the anti-tip device is properly installed on the range. See the

installation instructions for more information.

• Due to the size and weight of the range, have two or more people move the

range.

• Remove all tape and packaging materials.

• Remove all accessories from the cooktop, oven, and/or lower drawer. Grates and

griddles are heavy. Use caution when handling them.

• Make sure no parts came loose during shipping.

• Make sure your range is correctly installed and adjusted by a qualied service

technician or installer for the type of gas (natural or LP) you will use. For your

range to utilize LP gas, the installer must replace the 5 surface burner orices

and 2 oven orices with the provided LP orice set, and reverse the GPR adapter.

These adjustments must be made by a qualied service technician in accordance

with the manufacturer’s instructions and all codes and requirements of the

authority having jurisdiction. The qualied agency performing this work assumes

the gas conversion responsibility.

• Installation of this range must conform with local codes or, in the absence of local

codes, with the National Fuel Gas Code, ANSI Z223.1/NFPA.54, latest edition. In

Canada, installation must conform with the current Natural Gas Installation Code,

CAN/CGA-B149.1, or the current Propane Installation Code, CAN/CGA-B149.2, and

with local codes where applicable. This range has been design-certied by ETL

according to ANSI Z21.1, latest edition, and Canadian Gas Association according

to CAN/CGA-1.1, latest edition.

Important safety information

English 7

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 7 2020-03-26 6:41:18

Important safety information

Important safety information

Location safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• This range is for indoor, household use only.

Do not install the range in areas exposed to the

weather and/or water.

• Do not install the range in a place which is

exposed to a strong draft.

• Select a level, well-constructed oor that can support the range’s weight.

Synthetic ooring, such as linoleum, must withstand 180 °F (82 °C) temperatures

without shrinking, warping, or discoloring. Do not install the range directly over

interior kitchen carpeting unless a sheet of ¼ inch plywood or a similar insulator

is placed between the range and carpeting.

• Select a location where a grounded, 3- prong outlet is easily accessible.

• If the range is located near a window, do not hang long curtains or paper blinds

on that window.

• For the range to ventilate properly, make sure the range’s vents are not blocked

or covered, and that there is enough clearance at the top, back, sides, and

underneath the range. The vents allow the necessary exhaust for the range to

operate properly with correct combustion and get the good cooking result.

• Make sure the wall coverings around the range can withstand heat up to 194 °F

(90 °C) generated by the range.

• Cabinet storage above the surface of the range should be avoided. If cabinet

storage above the range is necessary: allow a minimum clearance of 30 inches

(76.2 cm) between the cooking surface and the bottom of cabinets; or install a

range hood that projects horizontally a minimum of 5 inches (12.7 cm) beyond

the bottom of the cabinets.

Cooktop safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Make sure all burners are off when not in use.

• Do not use aluminium foil to line the grates or

any part of the cooktop.

• Do not leave burners unattended on medium or

high heat settings.

• Before igniting, make sure all burner caps are

properly in place and all burners are level.

• Always use the LITE position when igniting the burners and make sure the

burners have ignited. If ignition fails, turn the knob to OFF and wait until the gas

has dissipated.

• When you set a burner to simmer, do not turn the knob quickly. Make sure the

ame stays on.

• Do not place any objects other than cookware on the cooktop.

• This cooktop is designed to cook with a wok or wok ring attachment. If foods are

amed, they should only be amed under a ventilation hood that is on.

• Before removing or changing cookware, turn off the burners.

• Remove food and cookware immediately after cooking.

• Before removing any parts of the burner for cleaning, make sure the range is off

and completely cool.

• After cleaning the burner spreader, make sure it is completely dry before re-

assembling.

• Make sure the spark mark on the dual burner spreader is placed beside the

electrode when it is assembled.

• To avoid carbon monoxide poisoning, do not pour water into the cooktop well

while cleaning.

• Select cookware that is designed for top-range cooking. Use cookware that is

large enough to cover the burner grates. Adjust the burner ames so that the

ames do not extend beyond the bottom of the cookware.

• To avoid cookware discoloration, deformity, and/or carbon monoxide poisoning,

do not use cookware that is exceedingly larger than the grate.

8 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 8 2020-03-26 6:41:19

• Make sure cookware handles are turned to the side or rear of the cooktop, but

not over other surface burners.

• Stand away from the range while frying.

• Always heat frying oils slowly, and watch as they heat. If you are frying foods at

high heat, carefully watch during the cooking process. If a combination of fats or

oils is to be used during frying, mix them together before heating.

• Use a deep-fryer thermometer whenever possible. This prevents overheating the

fryer beyond the smoking point.

• Use a minimum amount of oil when shallow pan-frying or deep-frying. Avoid

cooking unthawed food or food with excessive amounts of ice.

• Before moving cookware full of fats or oils, make sure it has completely cooled.

• To prevent delayed eruptive boiling, always allow heated liquids to stand at least

20 seconds after you have turned off the burner so that the temperature in the

liquid can stabilize. In the event of scalding, follow these rst aid instructions:

1. Immerse the scaled area in cool or lukewarm water for at least 10 minutes.

2. Do not apply any creams, oils, or lotions.

3. Cover with a clean, dry cloth.

Oven safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Do not use the oven for non-cooking purposes

such as drying clothes or storage. Use the oven

for cooking purposes only.

• Make sure the inner portion of the split oven-rack is in the proper position within

the outer rack.

• Make sure the oven racks are placed on the same level on each side.

• Do not damage, move, or clean the door gasket.

• Do not spray water on the oven glass while the oven is on or just after you have

turned it off.

• Do not use aluminium foil or foil liners anywhere in the oven. Do not use

aluminium foil or like material to cover any holes or passages in the oven bottom

or to cover an oven rack.

• Stand away from the oven when opening the oven door.

• Keep the oven free from grease buildup.

• When repositioning the oven racks, make sure the oven is completely cool.

• Only use cookware that is recommended for use in gas ovens.

• To avoid damaging the burner control knobs, always bake and/or broil with the

oven door closed.

• Do not broil meat too close to the burner ame. Trim excess fat from meat before

cooking.

• When using cooking or roasting bags in the oven, follow the manufacturer’s

directions.

Important safety information

English 9

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 9 2020-03-26 6:41:19

Important safety information

Important safety information

Storage drawer safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• Do not use the drawer for non-cooking purposes

such as drying clothes or storage. Use the

drawer for cooking purposes only.

• Do not touch the interior drawer surface or heating element.

• To avoid steam burns, use caution when opening the drawer.

• Do not use aluminium foil to line the drawer.

• Do not use the drawer in the oven. Do not put the drawer in the oven during a

self-cleaning cycle.

• Do not leave containers of fat drippings in or near the drawer.

Self-cleaning oven safety

WARNING

To reduce the risk of re, electric shock, personal injuries, and/or death, obey the

following precautions.

• The self-cleaning feature operates the oven at

temperatures high enough to burn away food

soils in the oven. The range is extremely hot

during a self-cleaning cycle. Do not touch any

surfaces of the range during a self-cleaning

cycle.

• Keep children away from the oven during a self-cleaning cycle.

• Before starting a self-cleaning cycle, remove all racks, cookware, and utensils

from the oven. Only porcelain-coated oven racks may be left in the oven.

• Before starting a self-cleaning cycle, wipe grease and food soils from the oven.

• Do not put the lower drawer into the oven cavity when you run a self-cleaning

cycle.

• When opening the door after a self-cleaning cycle, stand away from the oven.

• If the self-cleaning cycle malfunctions, turn off the oven, disconnect the power

supply, and contact a qualied service technicia.

10 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 10 2020-03-26 6:41:19

Gas range components

What’s in the box

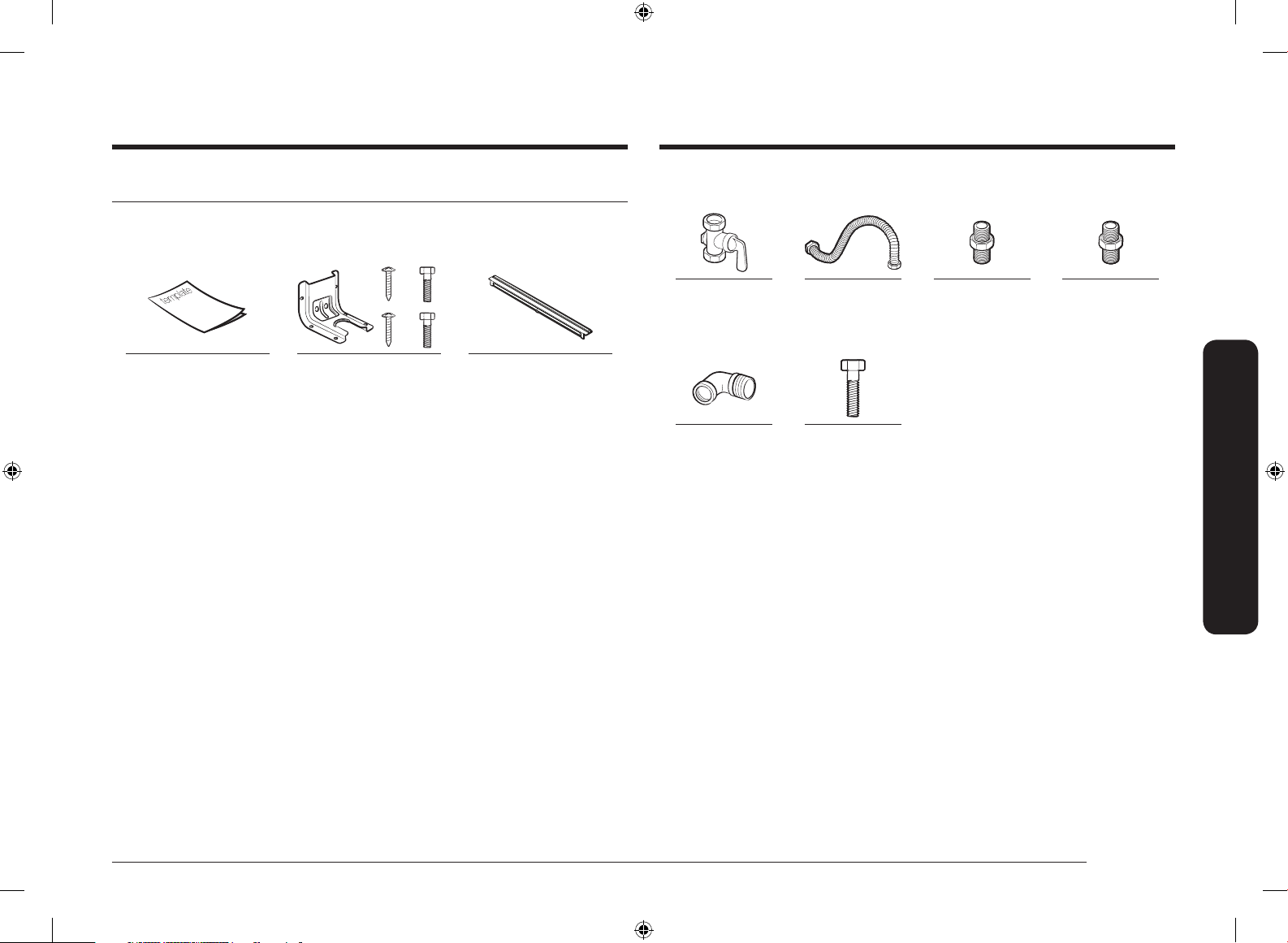

Parts supplied

Template Anti Tip Bracket (1) /

Screws (4)

• Make sure you have received all of the supplied parts shown above.

• If your range was damaged during shipping or you do not have all of the

supplied parts, contact your local retailer.

Filler Kit (1) & Screws (2)

Parts needed

Gas line shut-off

valve

135-degree elbow

(optional)

Flexible metal

appliance connector

½ in (ID) x 5 ft

Lag bolt or ½-in

(OD) sleeve anchor

Flare union adapter

¾ in or ½ in (NPT) x

½ in (ID)

Flare union adapter

½ in (NPT) x ½ in

(ID)

Gas range components

English 11

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 11 2020-03-26 6:41:20

Gas range components

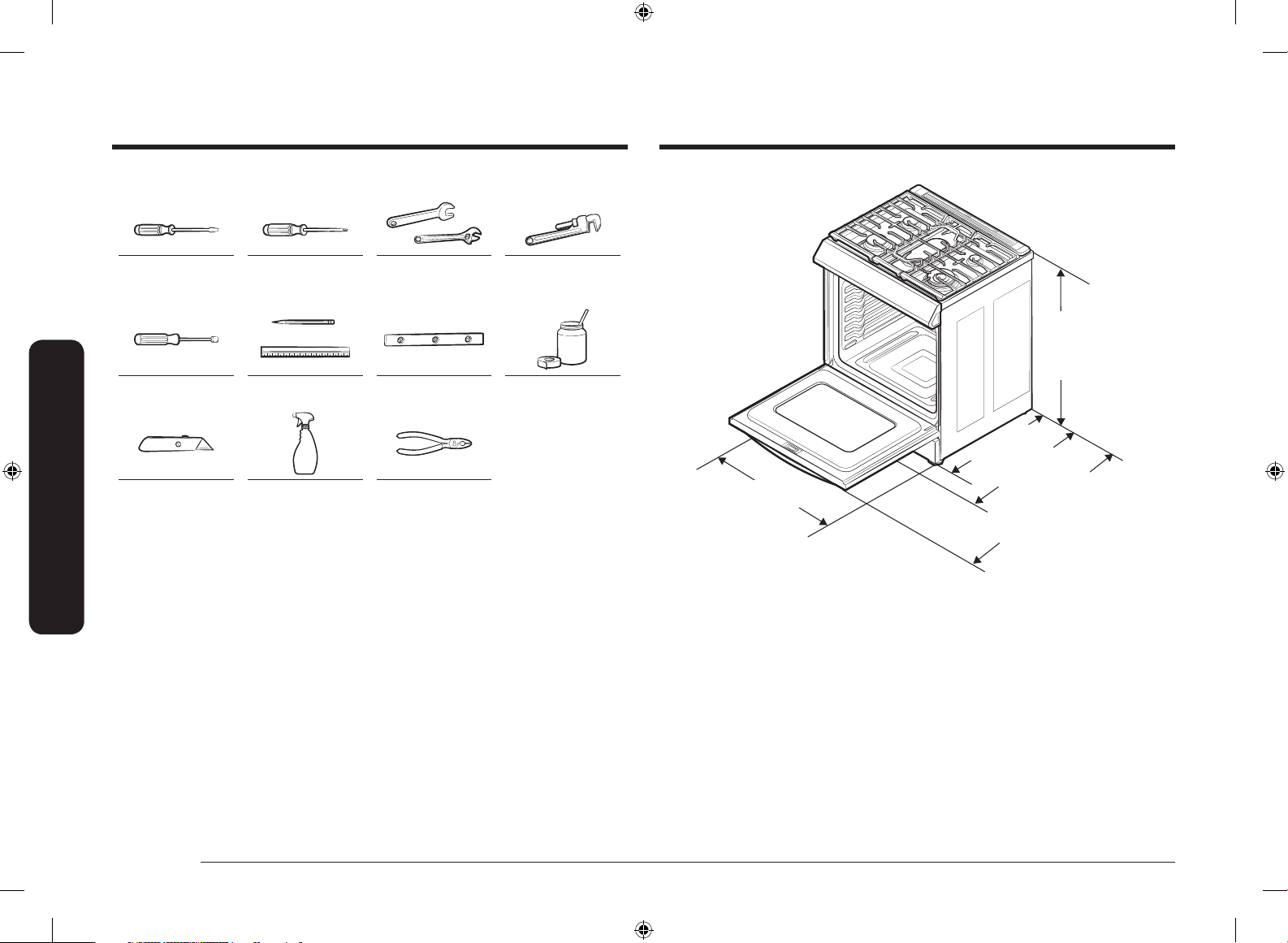

Tools needed

Flat-blade

screwdriver

¼" Nut driver Pencil and ruler Level

Phillips screwdriver Open-end or

adjustable wrench

Pipe wrench (2)

Pipe joint compound

361/4 in

(921.2 mm) Min.

37 in

(939.8mm) Max.

Gas range components

in

16

7

Utility knife Soapy water

solution

Pliers

2915/16 in

(761.0 mm)

/

26

(671.7 mm)

in

16

/

11

28

(728.6 mm)

With handle

in (1250.3 mm)

4

1

/

49

Door fully open

12 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 12 2020-03-26 6:41:21

Installation requirements

Location requirements

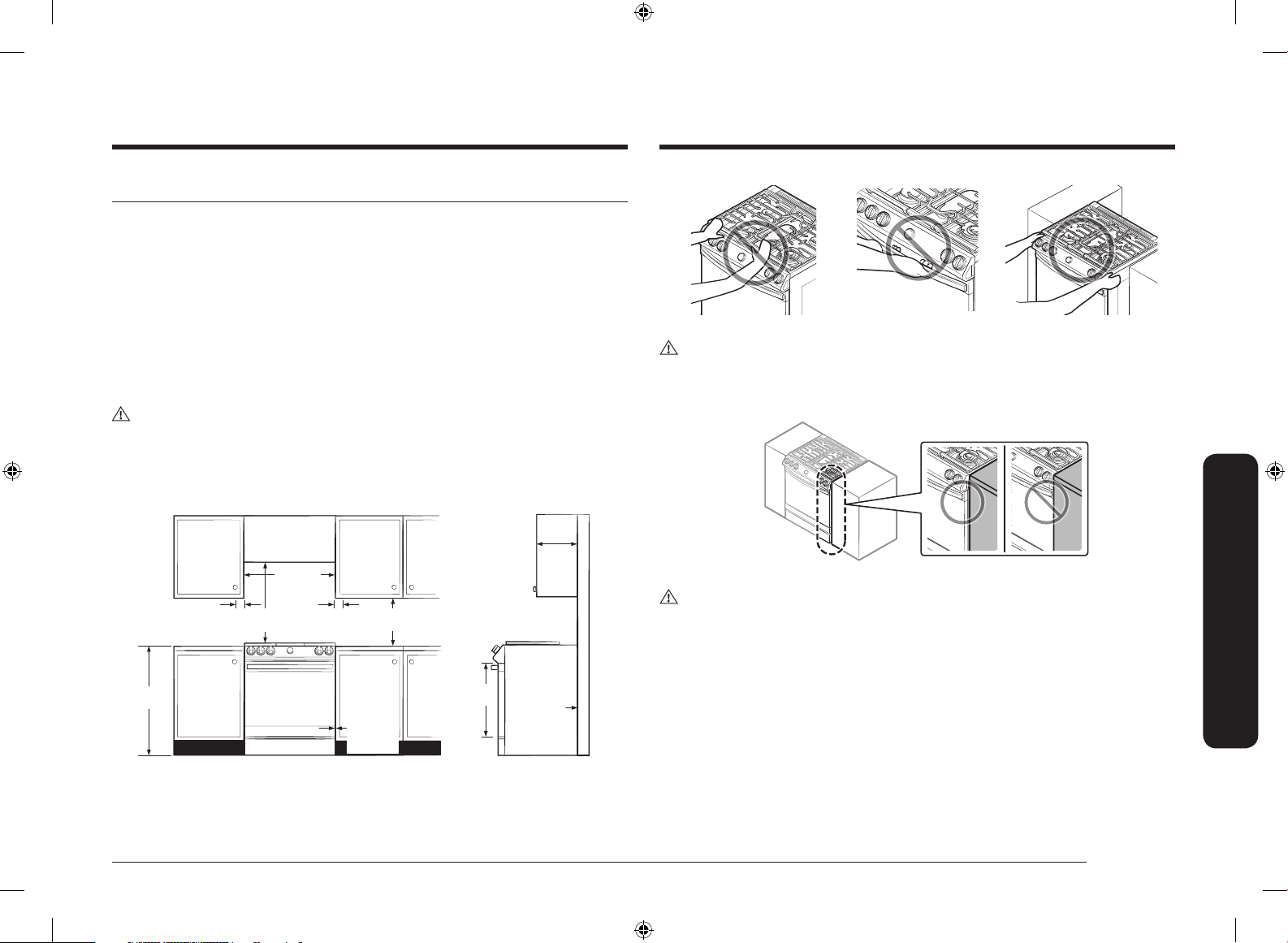

Clearances and dimensions

BEFORE YOU BEGIN to install this appliance, refer to the following information,

dimensions, and clearances. Do not locate the range where it may be subject

to strong drafts. Provide adequate clearances between the range and adjacent

combustible surfaces. These dimensions must be met for safe use of the range.

The location of the electrical outlet and gas piping may be adjusted to meet the

following dimensions and clearances.

For installation in Canada, a free-standing range is not to be installed closer than

4.7 in (12 cm) from any adjacent surface.

CAUTION

This range has been designed to comply with the maximum allowable wood

cabinet temperature of 194 °F (90 °C). Make sure the wall covering, countertops,

and cabinets around the range can withstand the heat (up to 194 °F [90 °C])

generated by the range. If not, discoloration, delamination, or melting may occur.

Side

Clearance

Above

Cooking

Surface to

Wall

4 in

(10.2 cm)

Minimum from

top of cooktop to

cabinets

30 in

(76.2 cm)

30 in

(76.2 cm)

6 in

(15.2 cm)

18 in

(45.7 cm)

13 in (33 cm)

Overhead

Cabinet Depth

CAUTION

Do not grasp the knob, handle and push when you install.

Installation requirements

CAUTION

DO NOT install the oven so that the door is ush with the cabinet.

For OTR over Gas Stove, please follow local GAS CODE.

0 in (0 cm)

Clearance

Below

Cooking Top

and at Rear

and Sides of

Range

24.2 in

(61.5 cm)

0 in

(0 cm)

36 in

(91.4 cm)

24 in

(61 cm)

Lower

Cabinet

Depth

English 13

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 13 2020-03-26 6:41:22

Installation requirements

Minimum dimensions

Installation guide

WARNING

24"

3"

24"

3"

6"

B

If overhead cabinets are provided, a range hood should also be provided that

projects horizontally a minimum of 5 in (12.7 cm) beyond the front of the cabinets.

This will dissipate any heat buildup in the overhead cabinets to prevent death,

personal injury, and/or re hazard. The ventilating hood must be constructed of

sheet metal not less than 0.0122” thick. Install above the cooktop with a clearance

of not less than 1/4” between the hood and the underside of the combustible

293⁄4"

25"

357⁄8"

material or metal cabinet. The hood must be at least as wide as the appliance

and centered over the appliance. Clearance between the cooking surface and the

ventilation hood surface must never be less than 24 inches.

Exception 1 : Installation of a listed microwave oven or cooking appliance over the

cooktop shall conform to the installations packed with that appliance.

• 30-in (76.2-cm) minimum clearance between the top of the cooking surface and

361/4"-37"

2915⁄16"

2811⁄16"

267⁄16"

491⁄4"

A

the bottom of an unprotected wood or metal cabinet; or If no 30-in (76.2- cm)

minimum clearance, 24-in (61-cm) minimum when the bottom of the wood or

Installation requirements

metal cabinet is protected by not less than 0.25-in (0.64-cm) ame-retardant

millboard covered with not less than no. 28 MSG sheet steel, 0.015-in (0.038-cm)

stainless steel, 0.024-in (0.061-cm) aluminum, or 0.020-in (0.051-cm) copper.

• 18-in (45.7-cm) minimum between the countertop and the adjacent cabinet

bottom.

A: Cabinet opening 30” (76.2)

IMPORTANT: If your cabinet have height over 37”, this range cannot be installed

without supporting unit like hard block.

Exception 2 : For island installation, maintain 2-1/2” minimum from cutout to back

edge of countertop and 4” minimum from cutout to side edges of countertop.

IMPORTANT:

To eliminate the risk of burns or re caused by reaching over heated surface

units, avoid having cabinet storage space located above the surface units. If you

have cabinet storage space over the heating elements, you can reduce the risk by

installing a range hood that projects horizontally a minimum of 5 inches beyond

the bottom of the cabinets.

14 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 14 2020-03-26 6:41:22

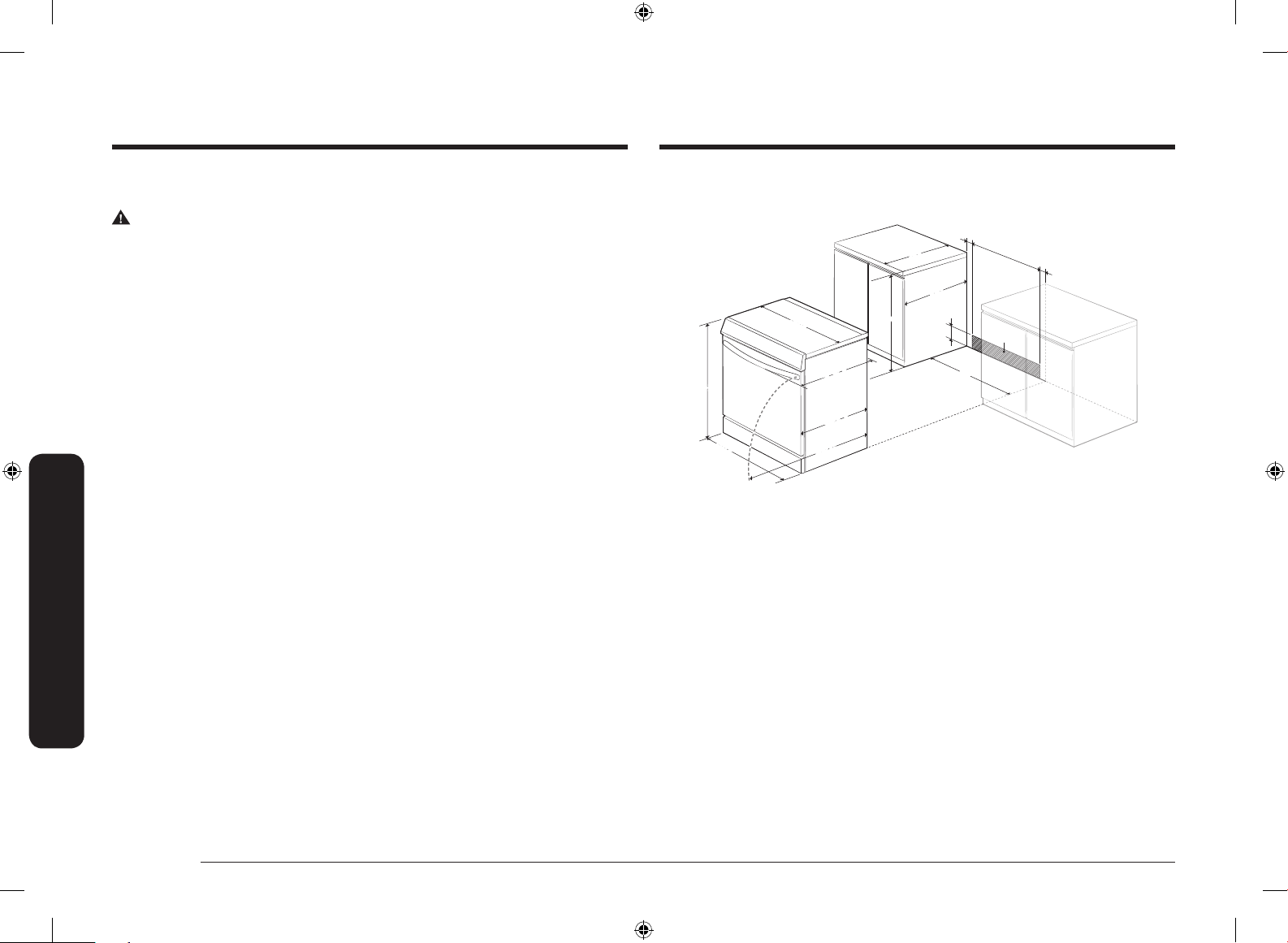

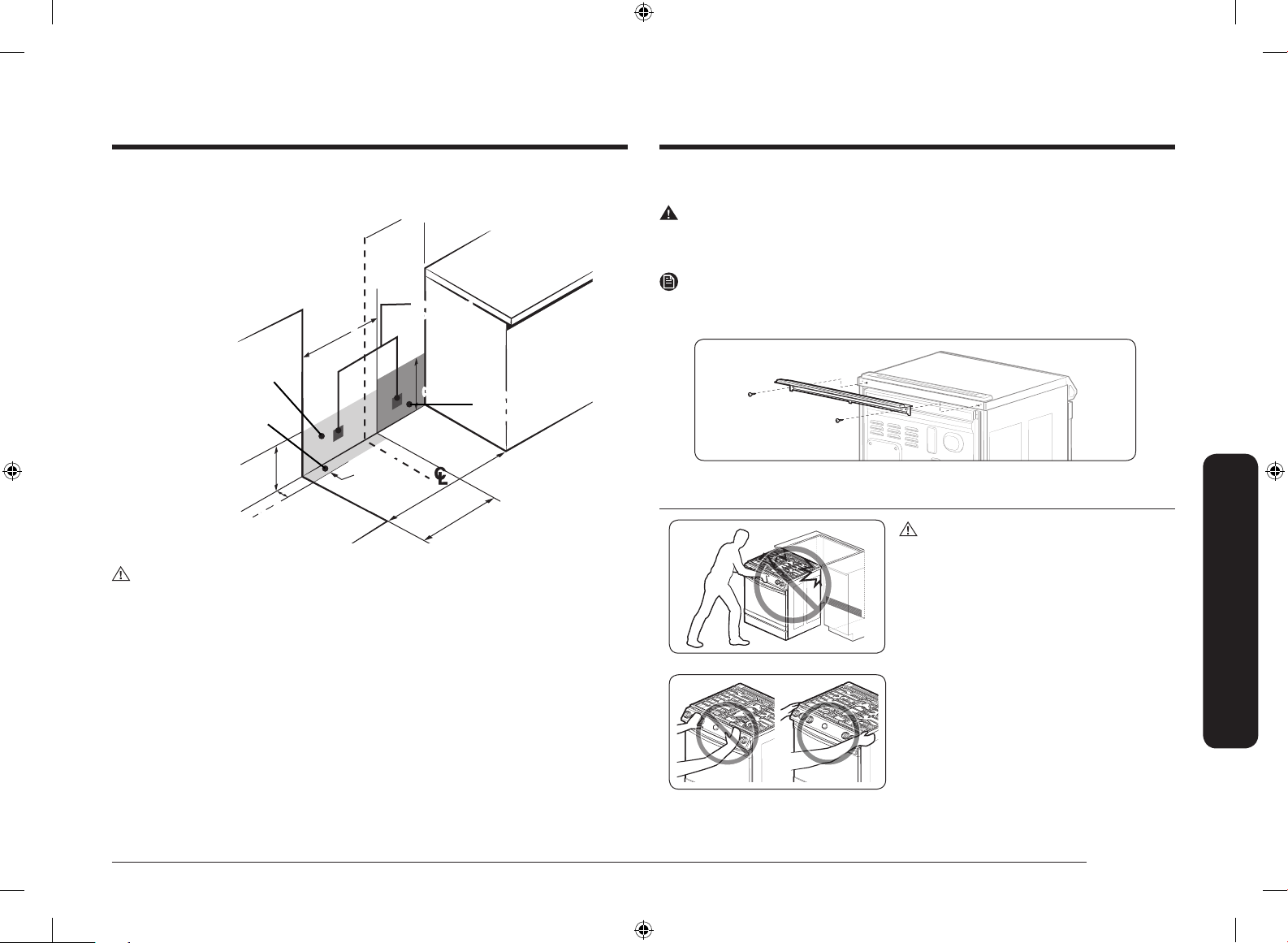

Recommended locations for gas piping and electrical outlets

(For model NX60*8*****)

Recommended

17 in

(43.2 cm)

position

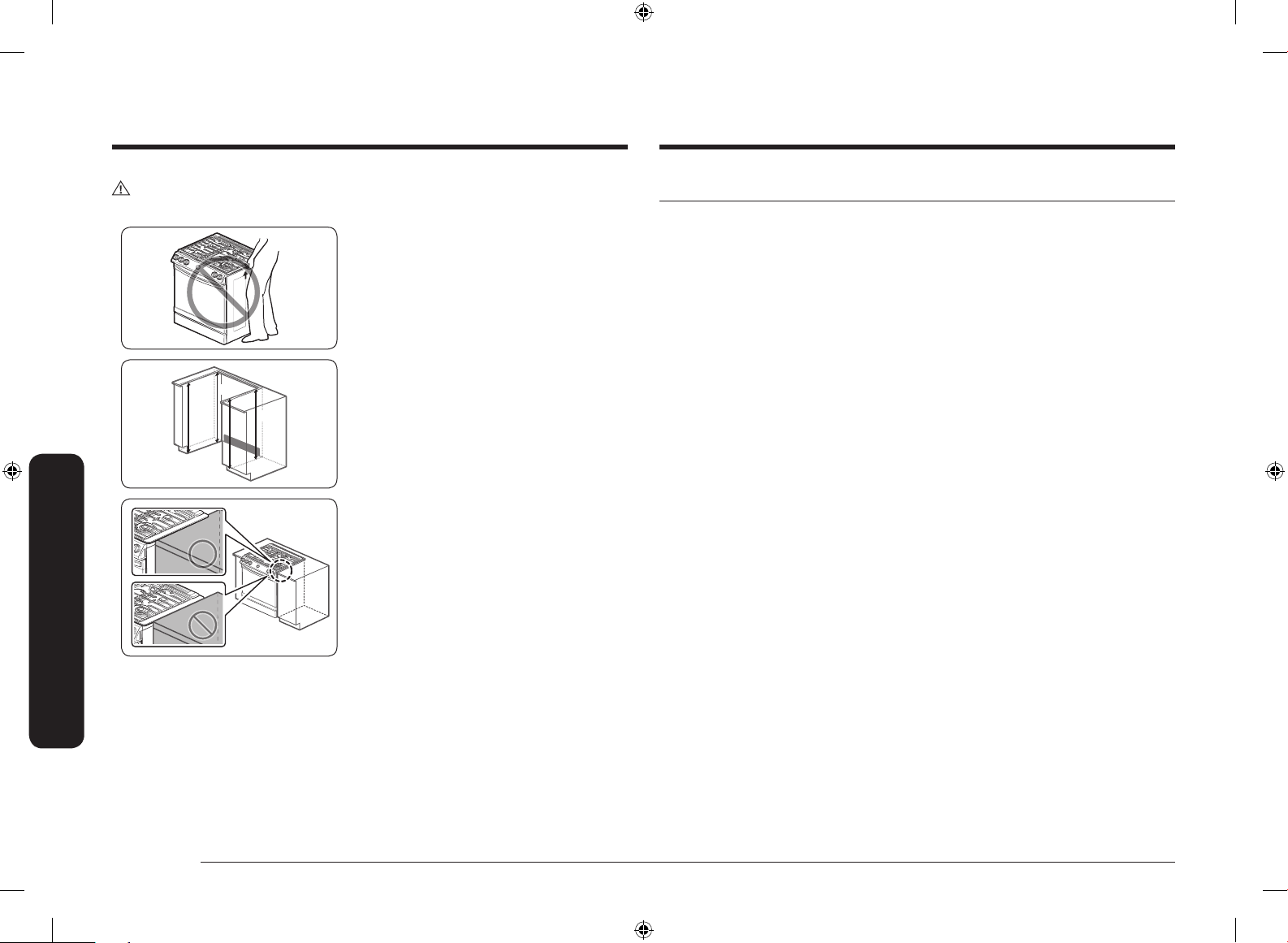

Optional rear ller kit

WARNING

Used to ll gap between the range back and wall. Adds a ller strip to the rear of

the range. This kit can only be used when the opening in the countertop is 25” deep.

NOTE

If the countertop depth is greater than 25”, there will be a gap between the ller

kit and the back wall.

Gas Wall Area

Recommended area for

through-the-wall and through-

the-oor connection of gas

pipe stub and shut-off valve.

9 in

(22.9 cm)

2 in

(5.1 cm)

Gas Floor Area

12 in

(30.5 cm)

30 in (76.2 cm)

Cabinet Opening

17 in (43.2 cm)

Recommended area for

120V electrical outlet

on rear wall

CAUTION

You must use the rear ller kit to install the range in a freestanding cutout cabinet.

For more information, see “Optional rear ller kit” as shown below.

To avoid breakage

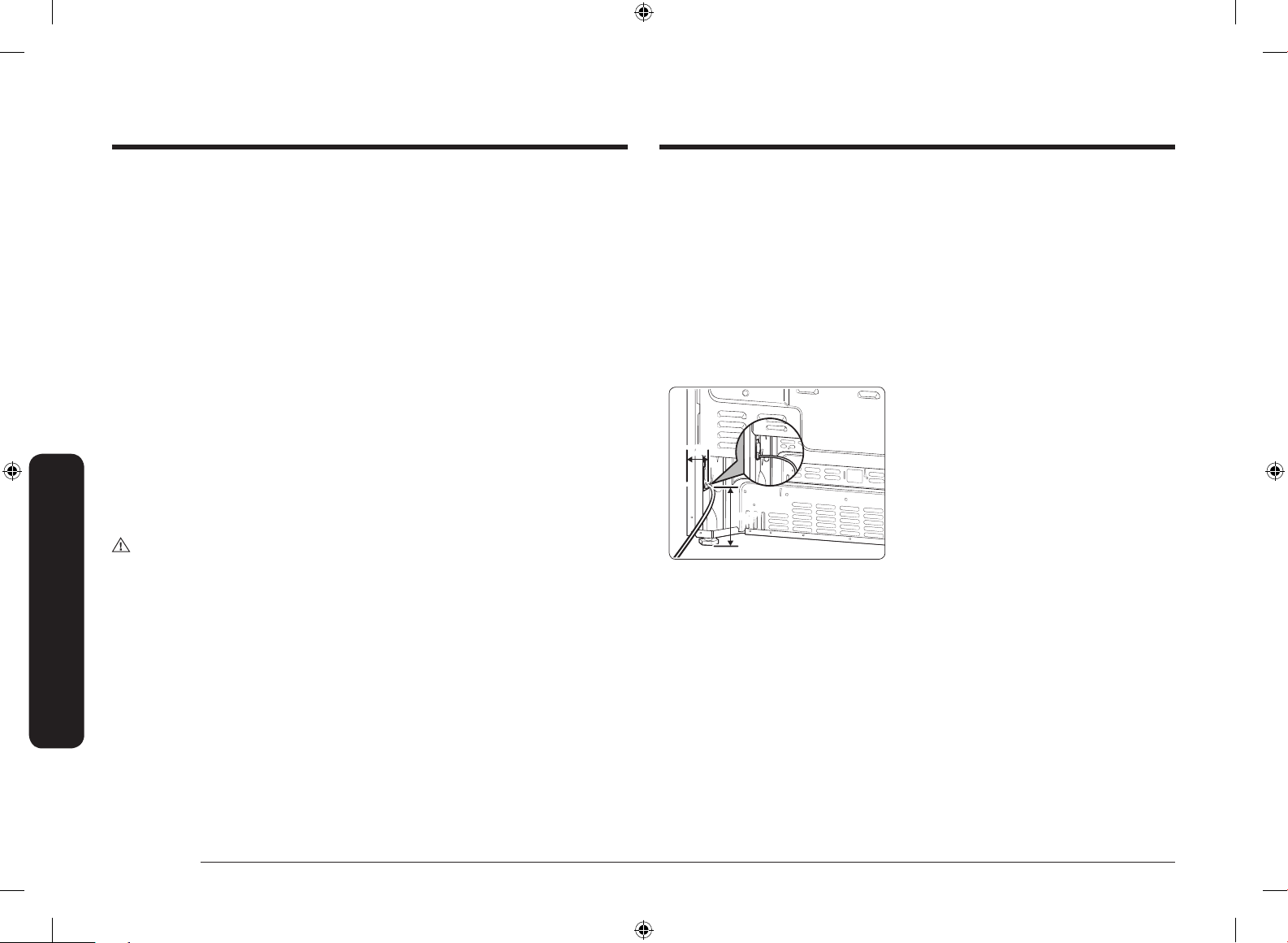

Installation requirements

CAUTION

Please DO NOT push the unit strongly when

you install. These actions can cause the

damage to the unit.

Please DO NOT push the burner knobs when

installing the range.

(Grasp the L/R door area to push the unit.)

English 15

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 15 2020-03-26 6:41:23

Installation requirements

CAUTION

Gas requirements

Do NOT lift or handle the unit by the cooktop frame.

1. The counter top around the cut-out

should be at and leveled (See hatched

area on Fig. 1).

2. Before installing the unit, measure the

heights of the two cabinet sides (C1~C4),

front and back (See Fig. 1) from the oor

to the top of the counter.

3. Level the range using the four leveling

C2

C1

C4

C3

legs so that the height from the oor

to the underside of the cooktop frame

is greater than the tallest cabinet

measurement by at least

1

/16”.

4. Slide the unit into the cabinet (DO NOT

Fig. 1

Installation requirements

PUSH THE UNIT HARD). Make sure the

center of the unit aligns with the center

of the cabinet cut-out.

5. The metal ange under each side of the

cooktop MUST be placed over the cabinet

countertop for proper unit support. The

cooktop should NOT rest directly on the

countertop or else it could cause damage

to the cooktop voiding the warranty.

Level the unit if needed.

Provide adequate gas supply

This range is designed to operate at a pressure of 5 in (13 cm) of water column on

natural gas or 10 in (25 cm) of water column on LP gas (propane or butane).

Make sure you are supplying your range with the type of gas for which it is

designed. Do not attempt to convert the appliance from the gas specied in this

manual to a different gas without consulting the gas supplier.

This range is convertible for use on natural or propane gas. If you decide to use

this range on LP gas, conversion must be made by a qualied LP installer before

attempting to operate the range.

For proper operation, the pressure of natural gas supplied to the regulator must be

between 5 in and 13 in (13 cm and 33 cm) of water column.

For LP gas, the pressure supplied must be between 10 in and 13 in (25 cm and

33 cm) of water column.

When checking for proper operation of the regulator, the inlet pressure must be at

least 1 in (2.5 cm) greater than the operating (manifold) pressure as given.

The pressure regulator located at the inlet of the range manifold must remain in

the supply line regardless of whether natural or LP gas is being used.

A exible-metal appliance connector used to connect the range to the gas supply

line should have an I.D. of 0.5 in (1.3 cm) and be 5 ft (152 cm) in length for ease of

installation. In Canada, exible connectors must be single-wall metal connectors no

longer than 6 ft (183 cm) in length.

Do not kink or damage the exible metal tubing when moving the range.

16 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 16 2020-03-26 6:41:23

Special gas requirements (gas models sold in massachusetts)

Electrical requirements

COMMONWEALTH OF MASSACHUSETTS REQUIREMENTS:

WARNING

Gas leaks may occur in your system, creating a dangerous situation.

– Gas leaks may not be detected by smell alone.

– Gas suppliers recommend you purchase and install a UL-approved gas detector.

Gas detector should be installed in accordance with the manufacturers

instructions.

• Range must be installed by a qualied plumber or gas tter by the State of

Massachusetts.

• A T-handle manual gas valve MUST be installed in the gas supply line to your

range.

• If a exible gas connector is used to install your range, multiple exible gas lines

must not be connected in series.

WARNING

To reduce the risk of re, electric shock, or personal injury:

All ranges

• Do not use an extension cord or adapter plug with this range.

• This range must be properly grounded.

• Check with a qualied electrician if you are in doubt as to whether your range is

properly grounded.

• Do not modify the plug provided with your range—if it doesn’t t the outlet, have

a proper outlet installed by a qualied electrician.

• All wiring and grounding must be done in accordance with local codes or, in the

absence of local codes, with the National Electrical Code, ANSI/NFPA No. 70 –

Latest Revision (for the U.S.) or the Canadian Electrical Code CSA C22.1 – Latest

Revisions and local codes and ordinances.

• Wiring diagram is located on the back of the range. (Inside of the cover back wire)

• This range is equipped with an electronic ignition system that will not operate if

plugged into an outlet that is not properly polarized.

Gas models

• All gas models are equipped with a power cord with an equipment-grounding

conductor and a grounding plug.

• A 120-Volt, 60-Hz, AC, approved electrical service with 20-amp circuit breaker or

time-delay fuse is required for all U.S. and Canadian models.

• Check for ¾-in (1.9-cm) UL-listed strain relief where the power cord comes out of

the range cabinet.

• Do not reuse a power supply cord from an old range or other appliance.

• The power cord electric supply wiring must be retained at the range cabinet with

a suitable UL-listed strain relief.

• A time-delay fuse or circuit breaker is also recommended.

Installation requirements

English 17

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 17 2020-03-26 6:41:23

Installation requirements

Grounding

• All ranges must be grounded for personal safety.

• All gas models have a power cord with an equipment-grounding conductor and a

grounding plug.

• The plug must be rmly plugged into a three-prong outlet that is properly

installed and grounded in accordance with all local codes and ordinances. In

the event of a malfunction or breakdown, grounding will decrease the risk of

electrical shock by providing a path for the electric current.

• Do not use a damaged power plug or loose wall outlet.

• Do not use an extension cord or adapter with this appliance.

• Do not, under any circumstances, cut, modify, remove, or otherwise defeat the

grounding (third) prong from the power cord. If the plug and the outlet do not

match or you have any doubt, have a qualied electrician install the proper

outlet.

The customer should have the wall receptacle and circuit checked by a qualied

electrician to make sure the receptacle is properly grounded.

Ground Fault Circuit Interrupters (GFCIs) are not required or recommended for

gas range receptacles.

Installation requirements

• NEVER connect ground wire to plastic plumbing lines, gas lines, or water pipes.

CAUTION

Failure to follow these instructions can result in death, re, or electrical shock.

Usage situations where appliance power cord will be disconnected frequently

Do not use an adapter plug in these situations because disconnecting of the

power cord places undue strain on the adapter and leads to eventual failure

of the adapter ground terminal. Where a standard two-prong wall receptacle

is encountered, it is the personal responsibility and obligation of the customer

to have it replaced with a three-prong (grounding) receptacle by a qualied

electrician before using the appliance.

Additional installation requirements for mobile homes

The installation of appliances designed for mobile home installation must conform

with the Manufactured Home Construction and Safety Standard, Title 24 CFR, Part

3280 (formerly the Federal Standard for Mobile Home Construction and Safety,

Title 24, HUD, Part 280) or, when such standard is not applicable, the Standard

for Manufactured Home Installations, latest edition (Manufactured Home Sites,

Communities and Set-Ups), ANSI A225.1, latest edition, or with local codes. In

Canada, mobile home installation must be in accordance with the current CAN/CSA

Z240/MH Mobile Home Installation Code.

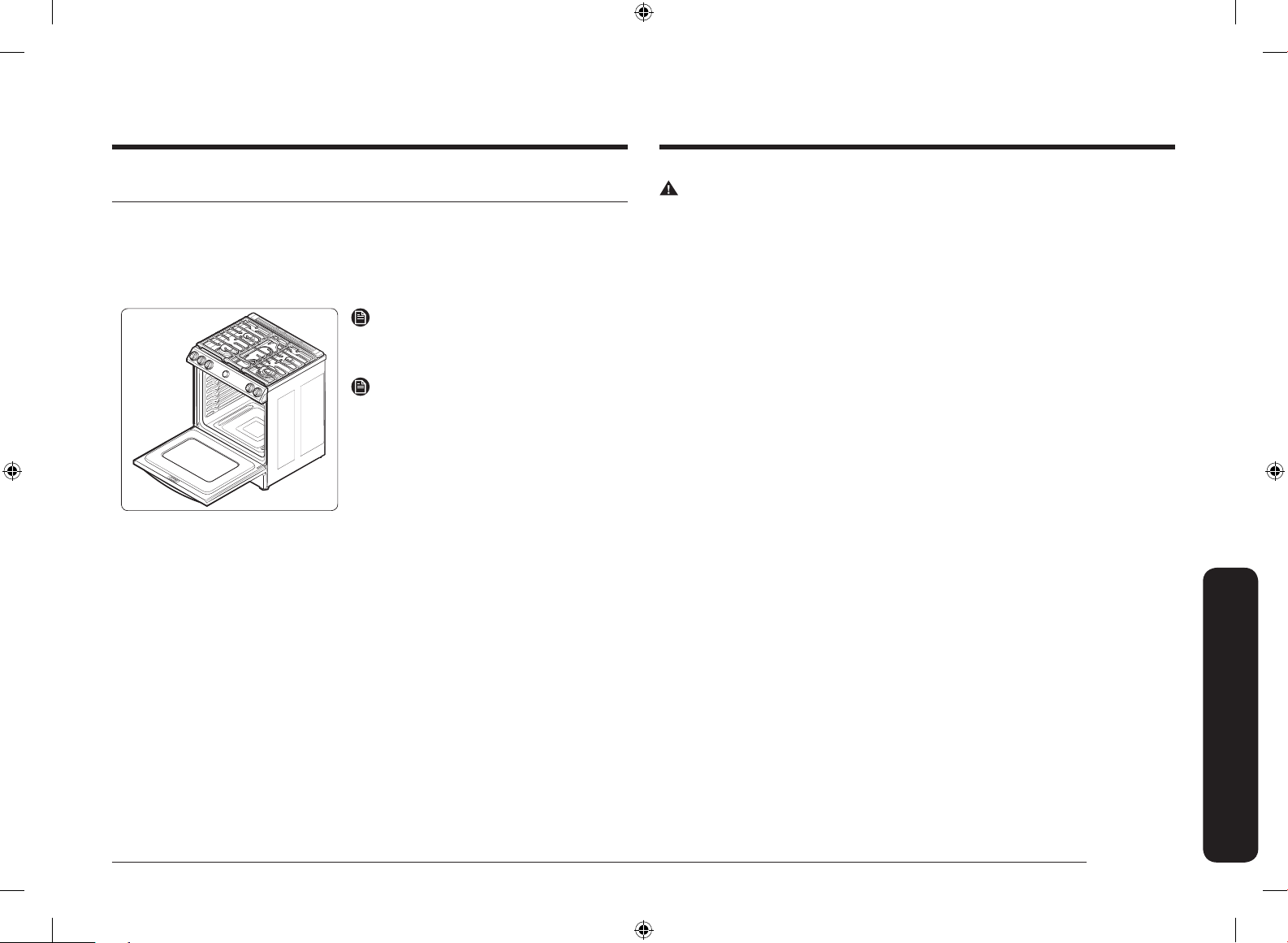

Power cord location

The power cord for this appliance is located

on the back of the range, near the bottom

right hand corner. The 53-in (135-cm)

2”

71/8”

Power cord location

power cord will come installed on the range

and taped to the back for shipping.

18 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 18 2020-03-26 6:41:24

Installation instructions

Installing your gas range

IMPORTANT:

Please read the following instructions, as well as the Important Safety Instructions

section at the front of this manual, completely and carefully BEFORE installing

and/or operating the gas range. Improper installation, adjustment, service, or

maintenance can cause personal injury or property damage.

NOTE

To order parts or accessories, contact your

local retailer or refer to the last page.

NOTE

To ensure proper installation, we strongly

recommend that you hire a professional

installer.

Step 1. Unpack the range

Remove all packaging materials. Failure to remove packaging materials could

result in damage to the appliance.

Inventory all loose parts against the Parts supplied components listed on page 11.

Check for shipping damage and/or missing parts. Any damage and/or missing

parts should be reported to your local retailer.

Step 2. Connect the range to gas supply

Shut off the main gas supply valve before disconnecting the old range and leave

it off until the new hookup has been completed. Don’t forget to relight the pilot on

other gas appliances when you turn the gas back on.

Because hard piping restricts movement of the range, the use of a CSA

International-certied exible metal appliance connector is recommended unless

local codes require a hard-piped connection.

WARNING

If the information in this manual is not followed exactly, a re or explosion may

result, causing death, personal injury, or property damage.

– Do not store or use gasoline or other ammable vapors and liquids in the

vicinity of this or any other appliance.

– WHAT TO DO IF YOU SMELL GAS:

• DO NOT light a match, candle, or cigarette.

• DO NOT try to light any appliance.

• DO NOT touch any electrical switch.

• DO NOT use any phone in your building.

• Clear the room, building, or area of all occupants.

• Immediately call your gas supplier from a neighbor’s phone. Follow the gas

supplier’s instructions.

• If you cannot reach your gas supplier, call the re department.

– Installation and service must be performed by a qualied installer, service

agency, or gas supplier.

Never use an old connector when installing a new range. If the hard-piping method

is used, you must carefully align the pipe; the range cannot be moved after the

connection is made.

To prevent gas leaks, apply pipe-joint compound or wrap pipe-thread tape with

Teon on all male (external) pipe threads.

1. Install a manual gas line shut-off valve in the gas line in an easily accessed

location outside of the range.

Make sure everyone operating the range knows where and how to shut off the

gas supply to the range.

2. Install male 0.5-in (1.3-mm) are union adapter to the 0.5-in (1.3-mm) NPT

internal thread at the regulator inlet. Use a backup wrench on the regulator

tting to avoid damage.

When installing the range from the front, remove the 90° elbow for easier

installation.

3. Install male 0.5-in (1.3-mm) or 0.75-in (1.9-mm) are union adapter to the NPT

internal thread of the manual shut-off valve, taking care to back up the shut-off

valve to keep it from turning.

Installation instructions

English 19

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 19 2020-03-26 6:41:24

Installation instructions

Installation instructions

4. Connect exible metal appliance connector to the adapter on the range. Position

range to permit connection at the shut-off valve.

5. When all connections have been made, make sure all range controls are in the

off position and turn on the main gas supply valve. Use a liquid leak detector at

all joints and connections to check for leaks in the system.

WARNING

To prevent death, personal injury, explosion, and/or re hazard, DO NOT use a

ame to check for gas leaks.

When using test pressures greater than ½ psig to pressure-test the gas supply

system of the residence, disconnect the range and individual shut-off valve from

the gas supply piping. When using test pressures of ½ psig or less to test the gas

supply system, simply isolate the range from the gas supply system by closing the

individual shut-off valve.

WARNING

Do not exceed 25 ft-lbs of torque when making gas line connections.

Overtightening may crack the pressure regulator resulting in a gas leak.

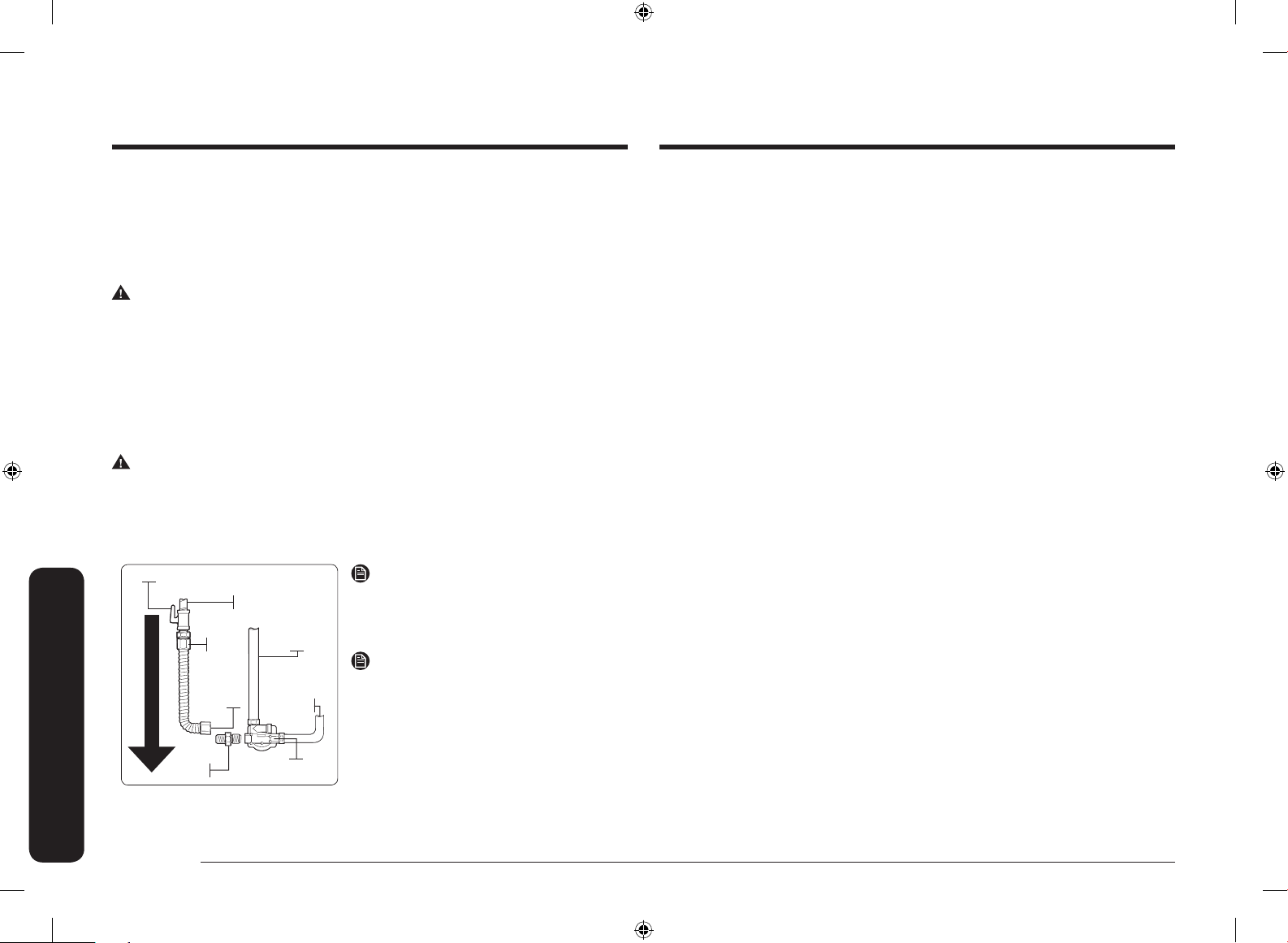

Flexible connector hookup

Installer: Inform the consumer of the location of the gas shut-off valve.

Gas Shut-Off Valve

Adapter

Flex

Connector

(6-ft max.)

Gas Flow into Range

Adapter

0.5-in or 0.75-in

Gas Pipe

Tubing Line to

Oven Burner

Control Valve

Tubing Line

to Cooktop

Control

Manifold

Pressure

Regulator

NOTE

If your area requires a rigid pipe hookup,

contact a qualied installer, service agency,

or gas supplier.

NOTE

The gas shut-off valve should be installed

in an accessible location in the gas piping,

external to the appliance, for the purpose

of turning on or shutting off the gas to the

appliance.

Step 3. Convert to lp gas (optional)

All new gas ranges are shipped from the factory set up to use natural gas. Any

Samsung gas range can be converted to use LP gas. Refer to page 55 in the User

Manual to contact a qualied service technician.

The conversion process should only be performed by a qualied LP gas installer.

Conversion instructions and LP orices will be supplied with the LP conversion kit.

The conversion to LP requires all burner orices to be changed (5 surface burners

and 2 oven burners).

In addition, the nozzle on the gas pressure regulator needs to be reversed. All

replaced orices must be left with the consumer, including the instructions and

retrot sizes and orice indication.

Checking the ame quality all burner after converting to lp gas.

20 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 20 2020-03-26 6:41:24

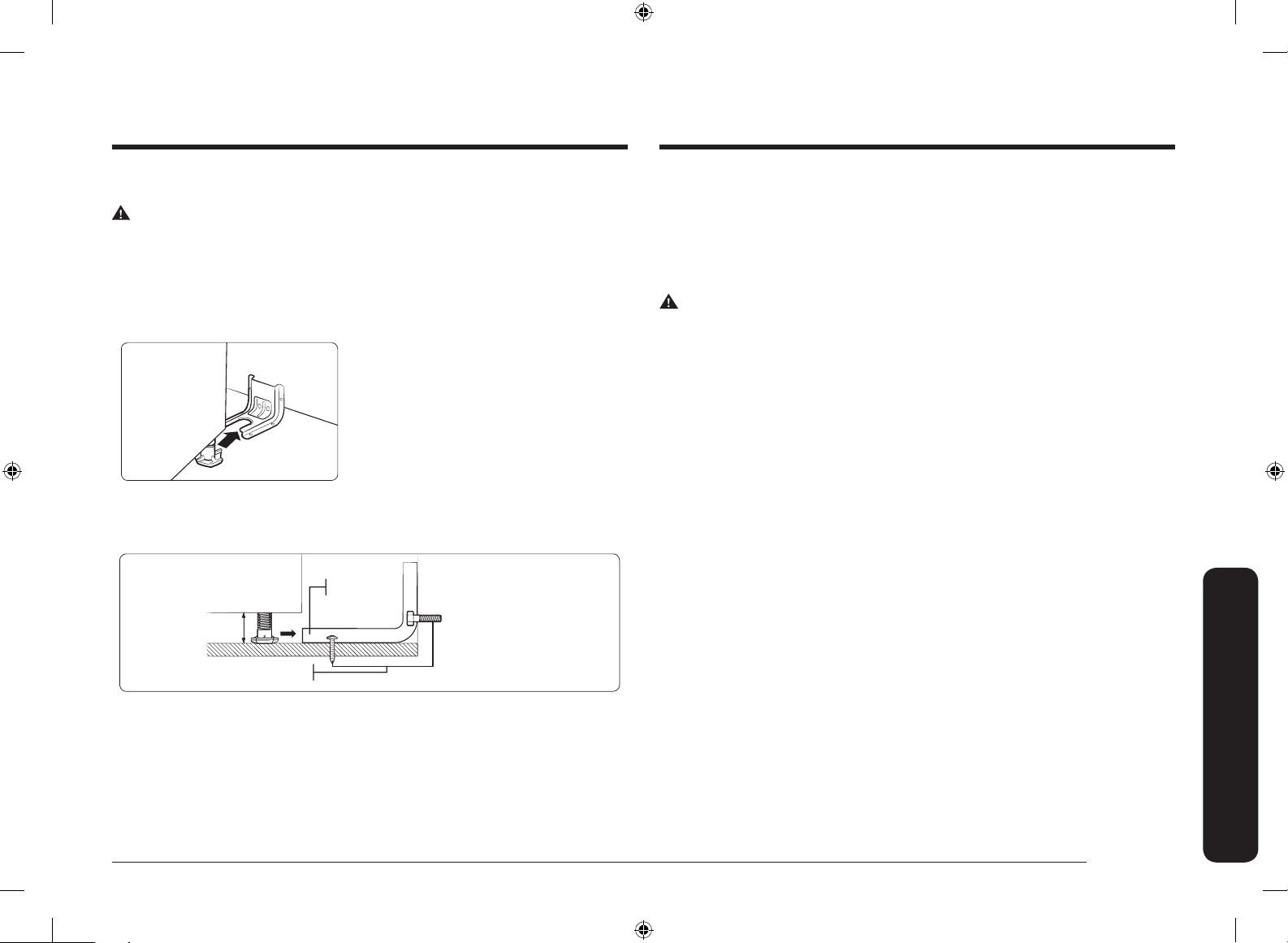

Step 4. Install the anti-tip device

WARNING

To reduce the risk of tipping, the appliance must be secured by properly installing

the anti-tip device packed with the appliance.

• All ranges can tip, resulting in personal injury.

• Tipping ranges can cause burns from spills, personal injury, and/or death.

• To prevent accidental tipping, install and check the anti-tip bracket following the

instructions and template supplied with the bracket.

An anti-tip bracket and screws, installation

instructions, and template are shipped

with every range (PN DG94-00870B). The

instructions include information necessary

to complete the installation of the anti-tip

bracket. Read and follow the instructions on

the sheet and use the template for anti-tip

bracket installation. If not properly installed,

the range could be tipped by you or a child

standing, sitting, or leaning on an open oven

door.

*approximately

21

/32” (16.5 mm)

Anti-Tip

bracket

Screw must enter

wood or concrete

*NOTE: To install the Anti-Tip

bracket, release the leveling

leg. A minimum clearance of

21

/32” (16.5 mm) is required

between the range bottom

and the kitchen oor.

To check if the bracket is installed and engaged properly, remove storage drawer

and look underneath the range to see that the leveling leg is engaged in the

bracket. Carefully tip the range forward. The bracket should stop the range within

4 inches (10.2 cm) of tipping. If it does not, the bracket must be reinstalled.

If the range is pulled from the wall for any reason, always repeat this procedure

to verify the range is properly secured by the anti-tip bracket. Never completely

remove the leveling legs or the range will not be secured to the anti-tip device

properly.

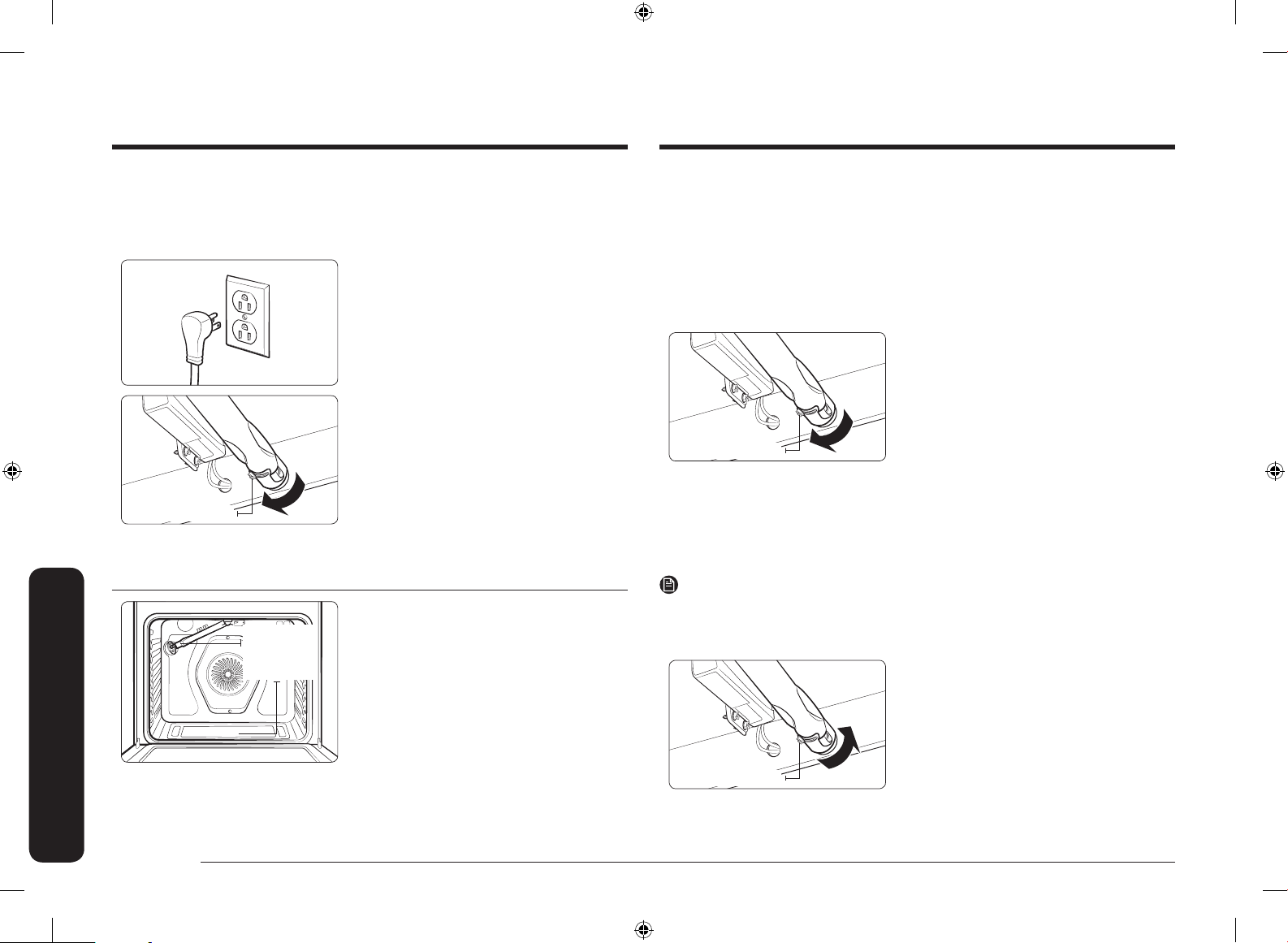

Step 5. Plug in and place

WARNING

BEFORE OPERATING OR TESTING, follow the grounding requirements on pages 17

18 in this manual. Improper connection of the grounding plug can result in a risk

~

of electric shock.

• All gas ranges come with a power cord. The power cord is connected to the rear

of the range. Please review “Electrical requirements” on pages 17 ~ 18.

• The electrical system, including the power cord, is preinstalled and prewired at

the factory. Altering any part of this system may result in a short or overload.

1. Plug in the power cord. Make sure the outlet meets local or national electrical

codes as referenced on pages 17 ~ 18.

2. Slide the range into place.

3. Check the gas supply line to make sure it did not get damaged and it stayed

connected during positioning.

4. Check to make sure the back leg of the range has slid into the anti-tip bracket.

Carefully tip the range forward to ensure that the anti-tip bracket engages the

back brace and prevents tip-over.

Installation instructions

English 21

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 21 2020-03-26 6:41:24

Installation instructions

Installation instructions

Step 6. Level the range

Leveling leg

1. Make sure the range is positioned where

you want it.

2. Using a wrench, level the range by

turning the front leveling legs in or out

as necessary. Counterclockwise shortens

the leg and lowers the range. Clockwise

lengthens the leg and raises the range.

NOTES

• Adjusting the two front legs is usually

sufcient, but adjust all four legs if

necessary.

• Adjust the leveling legs only as far as

necessary to level the range. Extending

the leveling legs more than necessary or

removing legs can cause the range to be

unstable.

3. If range is next to or between cabinets,

make sure the cooktop (without the

surface burner grates) is level with the

countertops.

4. Position an oven rack in the center rack

position.

5. Check the level of the range with a

carpenter level using the two positions

shown at right.

6. After the range becomes level, slide the

range away from the wall so that the

anti-tip bracket can be installed.

Step 7. Assemble the surface burners

Precise Simmer Burner (RR)

Flat surface Concave line

CAUTION

Do not operate the surface burners without

all burner parts in place.

1. Position surface burner heads on top of

the surface burner manifolds as shown at

right. The electrodes will t into the slot

in the bottom of the heads. Make sure the

surface burner heads are at and parallel

with the cooktop.

2. Place the matching size caps on top of

each surface burner head.

NOTE

The caps on Precise simmer burner

(RR) and inside Dual Burner (RF) can be

interchangeably used.

3. Place the left, center, and right surface

burner grates on the cooktop. The edges

of the grates should match up with the

edges of the cooktop.

22 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 22 2020-03-26 6:41:25

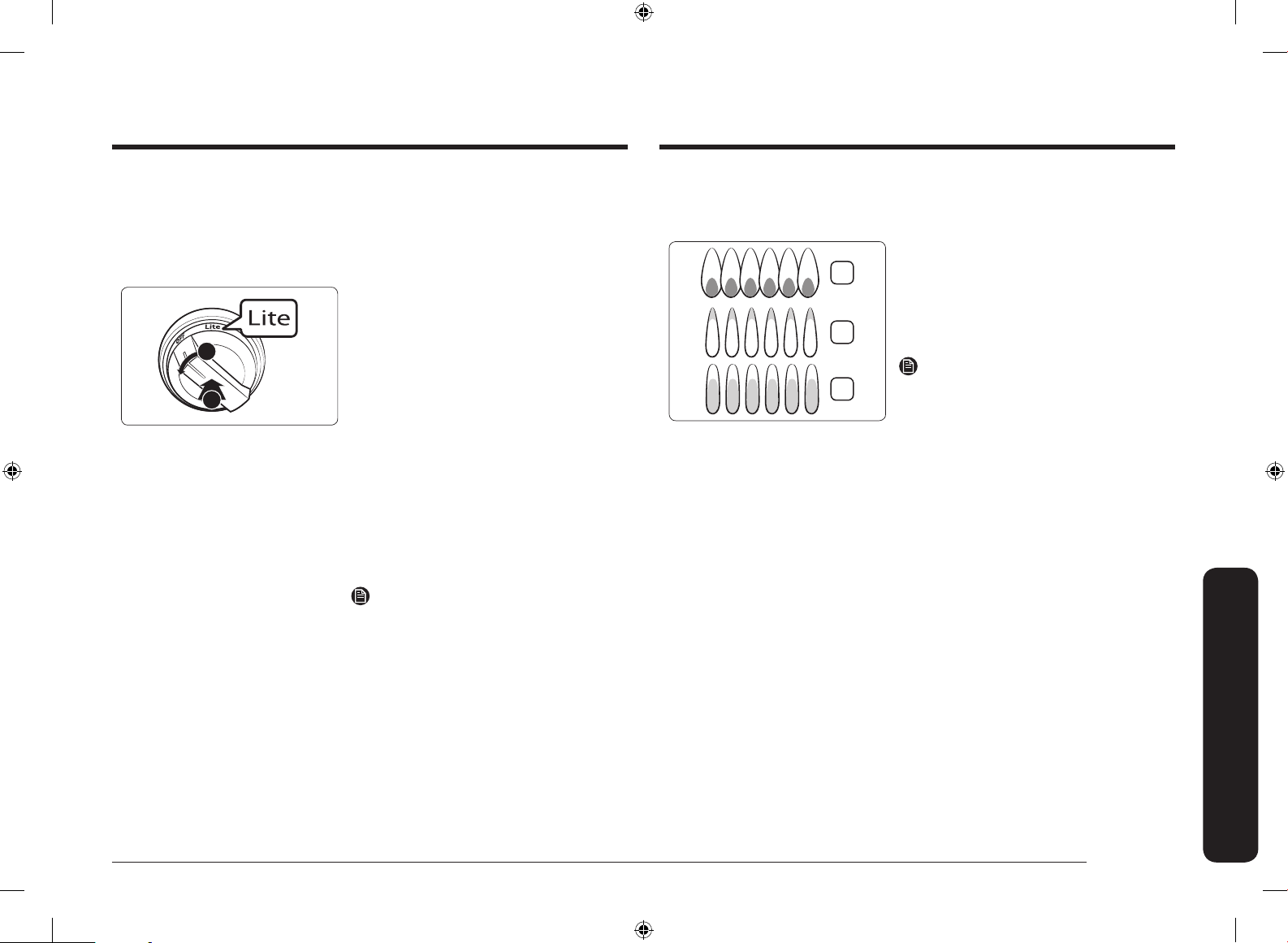

Step 8. Check the ignition of surface burners

2

1

2

3

1

Check the operation of all cooktop and oven burners after the range has been

installed and assembled, gas supply lines have been carefully checked for leaks,

and electrical power cord has been plugged in.

All surface and oven burners have electronic ignition.

To turn on a surface burner:

1. Push in and turn the control knob for that

surface burner to the Lite position. The

“clicking” sound indicates the electronic

ignition system is operating properly. The

burner will light in about 4 seconds, after

the air has been purged from the supply

line.

2. After the burner lights, turn the control

knob to the desired setting. The “clicking”

sound will stop and the ame height will

change from Max. to Min. during turning

the control knob.

3. Repeat steps 1 and 2 to check the

operation of each surface burner in

succession.

NOTE

Place food in the oven after preheating

if the recipe calls for it. Preheating is

important for good baking results. After

the oven has reached the desired cooking

temperature, it will beep 6 times.

Checking the ame quality:

All combustion ames need to be visually checked to determine their ame

quality.

1. Soft blue ames—Normal for natural gas

operation.

2. Yellow tips on outer cones—Normal for LP

gas operation.

3. Yellow ames—Abnormal for any gas

operation; call for service.

NOTE

If burner ame looks like 3, the range

should not be used until it is serviced. Call

for service. Normal burner ames shall look

like 1 or 2, depending on the gas type you

use.

Installation instructions

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 23 2020-03-26 6:41:26

English 23

Installation instructions

Installation instructions

Step 9. Final installation checklist

You have just completed installing your range. Make sure all controls are in the off

position and the ow of ventilation air to the range is unobstructed. The following

is a checklist to conrm your range is safely installed and ready for operation.

– Gas line has been properly connected to

the range. The gas has been turned on. All

connections have been checked for leaks.

– Range is plugged into the properly

grounded electrical receptacle.

Gas Range Plug

Locking screw

– Approved anti-tip bracket is properly

installed and engaged with the range.

– Range is leveled and is rmly sitting on a

solid, level oor.

– Gas surface burners have been properly

assembled.

– All burners have been tested for proper

operation.

– FOR INSTALLER ONLY—Check and/or

adjust the broil and oven burner ames as

described on pages 22-23 in this manual.

Adjusting the oven burner air adjustment shutters

All oven burners have an air adjustment

Air

adjustment

shutter

shutter. The purpose of the shutter is to

regulate the ow of air to the ames.

Properly adjusted ames should burn

steadily with approximately 1-in of blue

cone. The ames should never extend

past the edge of the burner bafes. Even

though these are preset at the factory, they

should be checked and, if needed, adjusted

periodically to ensure efcient operation.

To check and adjust the oven burner air adjustment shutters:

1. Open the oven door.

2. Remove the oven racks.

3. Remove the oven oor.

4. Press the Bake pad, then the START/SET pad.

5. After the oven has lit, visually check the ames coming out of the upper and

lower burners. If adjustment is needed, carefully adjust the air adjustment

shutters.

The shutters are located at the base of the

burner manifolds near the back oven wall.

To adjust the shutter, loosen the locking

screw and rotate the shutter towards the

open or closed position as needed. If ames

Locking screw

NOTE

If the range is set up for natural gas, the ames should burn with no yellow

tipping. If the range is set up for LP gas, small yellow tips at the end of the cones

are normal.

Locking screw

are lifting off the burner ports, gradually

reduce the air shutter opening until the

ames are stabilized.

If ames are too yellow and/or too large,

gradually increase the air shutter opening

until the ames have approximately a 1-in

blue cone.

After the ames are adjusted properly, shut

off the oven, retighten the locking screws,

replace the oven bottom and racks, and

close the oven door.

24 English

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 24 2020-03-26 6:41:26

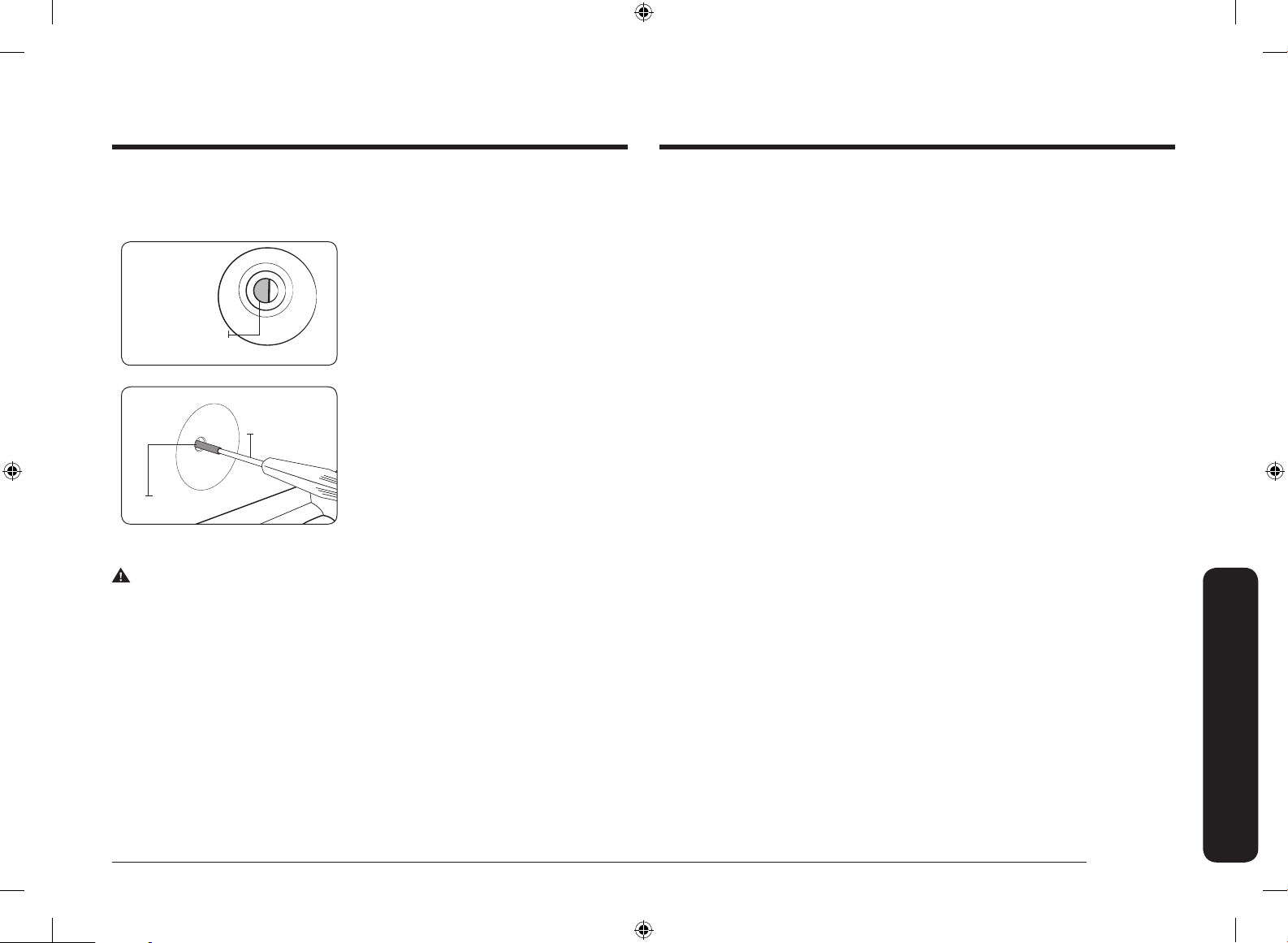

To adjust ame low setting

Identify which burner is exhibiting too high or too low of simmer rate via manifold

panel graphics.

1. Rotate a knob to LO position and remove

the knob from the valve stem while the

ame is lit.

Simmer Set

Screw

Memo

Small

Screwdriver

Valve Stem

WARNING

1. Do not completely remove the valve set screw from the valve stem. The valve

set screw is an integral part of the gas valve assembly. Removing the valve set

screw will cause gas to leak.

2. After adjusting the valve set screw, inspect the assembly for gas leaks.

2. Carefully push the screw driver into the

stem of the valve, until it hits the simmer

set screw. Make sure the screwdriver

athead is seated into the set screw

groove.

3. Rotate valve set screw clockwise to

decrease LO setting ame output, or

rotate set screw counter clockwise to

increase LO setting ame output.

Installation instructions

English 25

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 25 2020-03-26 6:41:26

Memo

Install_NX60T9700_BEST_BETTER_AA_DG68-01243A-00_EN.indd 26 2020-03-26 6:41:26

Loading...

Loading...