Page 1

CS-200M Mechanical Chair Scale

Installation & Operation Instructions

The CS-200M Mechanical Chair Sale is designed for the mobile challenged who have a difficult time

standing on a conventional scale. It is ideal for use in clinics and nursing facilities. The scale is durable,

having a sturdy enameled steel body, a durable molded plastic seat, heavy-duty footrest, and heavy-duty

caster wheels for easy portability.

Figure 1. Mecha n i cal Chair Scale

August 2011 Version 1.0

Page 2

Installation Instructions

m

r

You will receive your Mechanical Chair Scale partially assembled. Those items that need additional

assembly are:

• Pillar and beam assembly to scale base

• Steelyard rod connection

• Transport handle onto scale base

• Seat and footrest installation

• Arm rest installation

Remove all components from the shipping crate and lay out in a convenient place.

Pillar and Beam Installation

The pillar and beam comes separate from the scale base and must be attached prior to use.

Bea

Pilla

Figure 2. Pillar and Beam Components

Use the following steps to attach the pillar and beam to the scale base.

1. Have the scale sitting on the floor in an area that allows you to work freely.

2. Lock casters on the frame to eliminate the unit from rolling while assembling the scale.

Push down on latching assembly

to lock wheels and prevent scale

from rolling.

Figure 3. Lock Casters to Keep From Rolling

2

Page 3

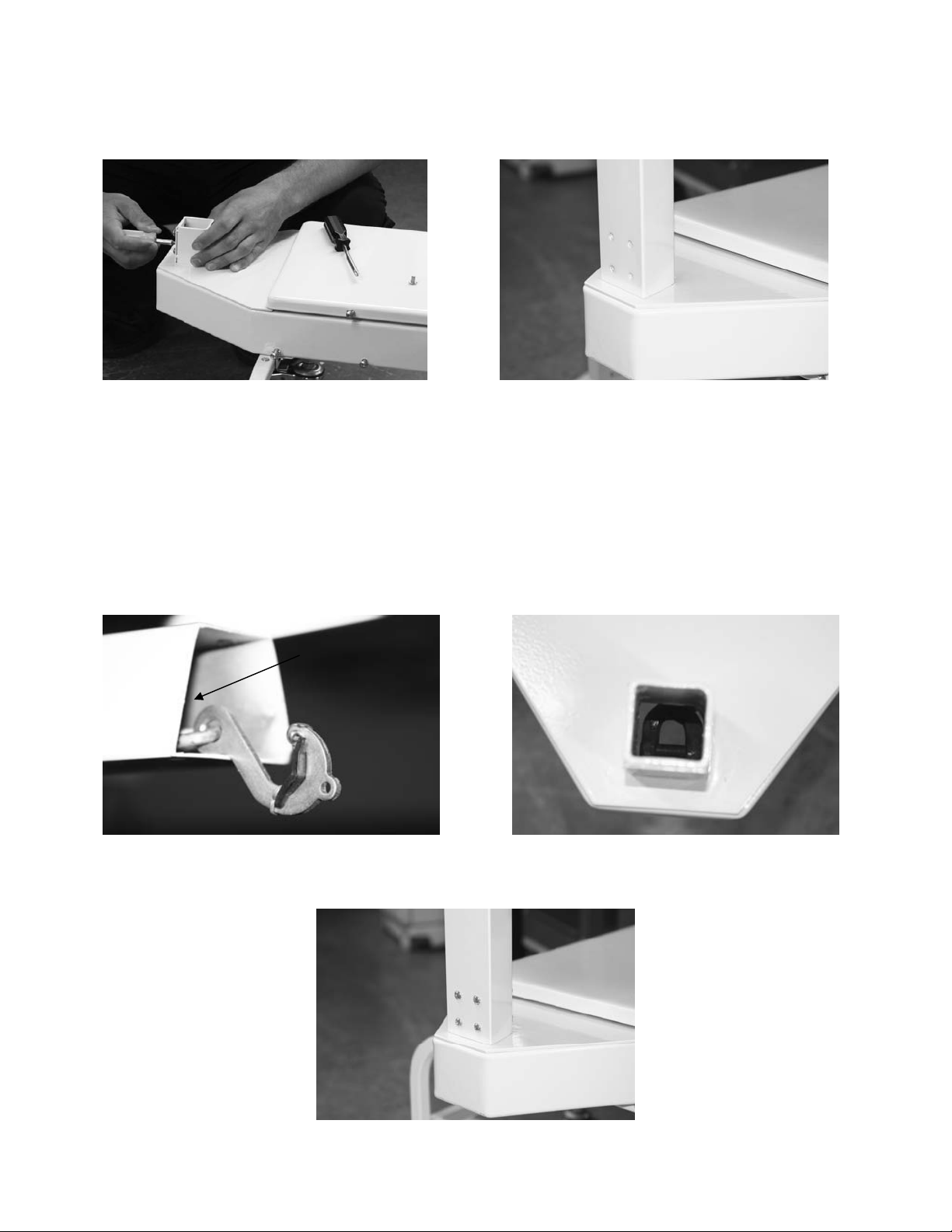

3. Remove the eight screws from the scale base using a phillips head screwdriver (as shown in the left

oo

hand photo) and set screws aside in a safe place.

Figure 4. Remove Screws From Scale Base and Insert Pillar and Beam into Scale Base Assembly

Insert, but don’t fasten the pillar and beam into the scale base assembly as shown in Figure 4 (right

hand side photo).

Steelyard Rod Connection

The steelyard rod is located inside the pillar. Remove the wire tie(s) holding the steelyard rod

during shipment

steelyard rod must be attached to the bottom of the scale. The two photos below show the hook of the

steelyard rod and an inside photo of the ring in the scale bottom. Latch the hook onto the D-shaped ring

shown in the right hand side picture.

. Insert the pillar into the base. Once the pillar is inserted to the scale base, the

Steelyard rod (not

shown)

Steelyard rod

h

k

Figure 5. Attach The Steelyard Rod To the Scale Base D-Ring

Fasten the eight screws once the pillar and beam is connected to the scale base and the steelyard rod is

hooked.

Figure 6. Insert and Tighten The Eight Screws

3

Page 4

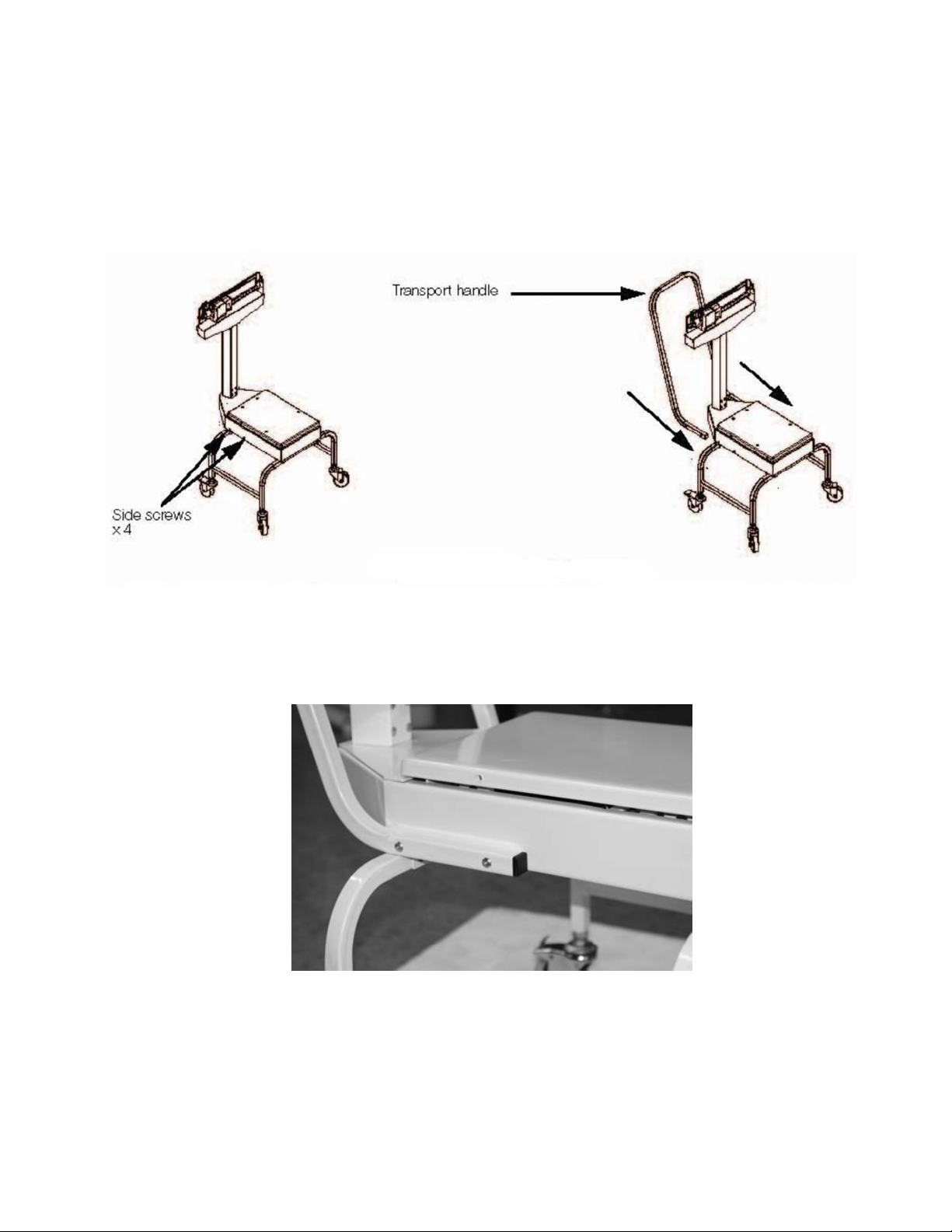

Installing Transport Handle

Once the pillar and beam are attached to the scale support frame and secured, it’s time to attach the

transport handle to the scale support frame (transport handle is illustrated in Figure 8).

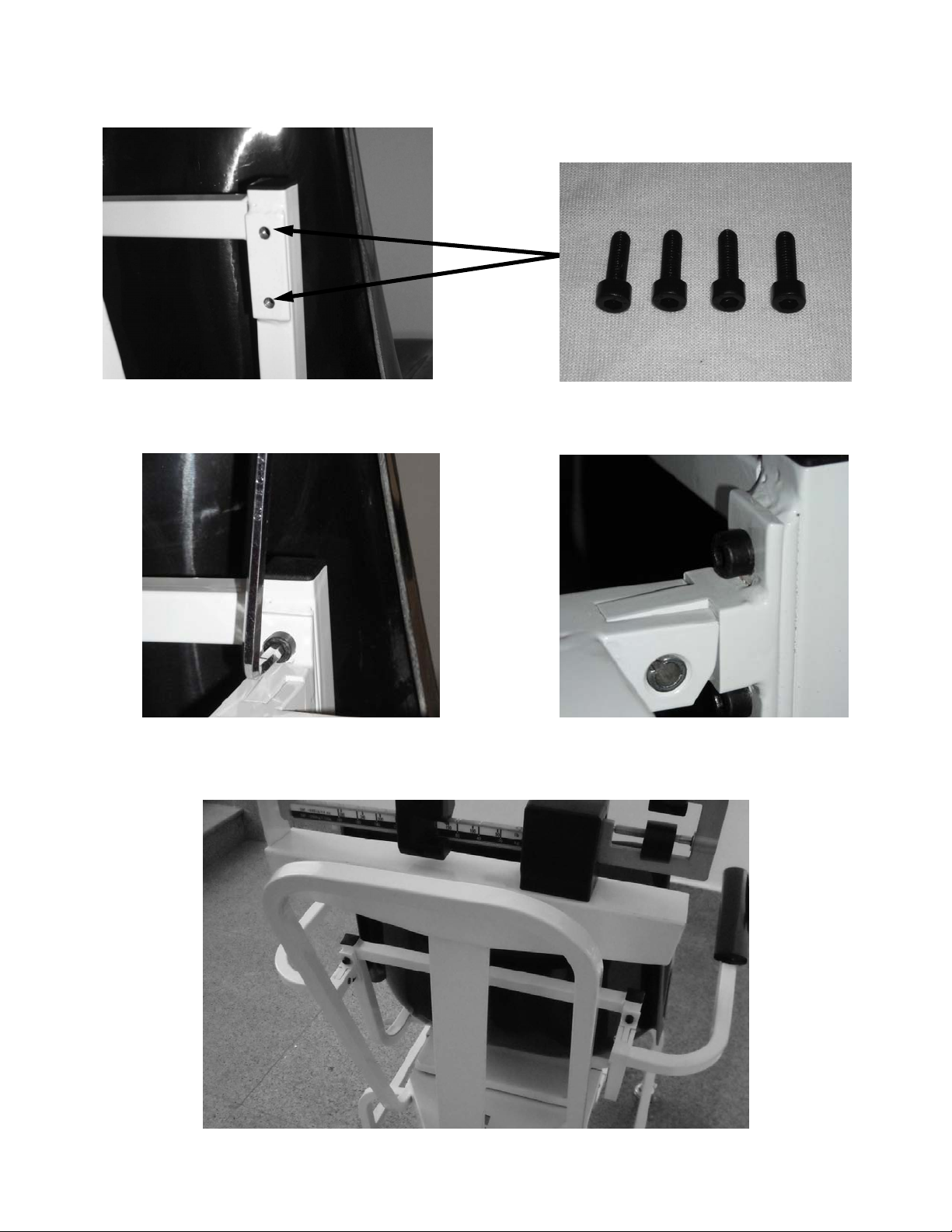

1. Remove the four side screws (two on each side as shown in left hand side of Figure 7) from the

scale support frame and set aside. The transport handle will attach to the scale support frame using

those screws.

Figure 7. Transport Handle Installation

2. Insert the transport handle into the two sides of the scale support frame as shown in right side of

Figure 7.

3. Insert and tighten the four screws using a phillips screwdriver as shown in Figure 8.

Figure 8. Insert and Tighten Four Screws for Securing the Transport Handle to the Scale Support Frame

The transport handle should fit snuggly against the scale support frame.

4

Page 5

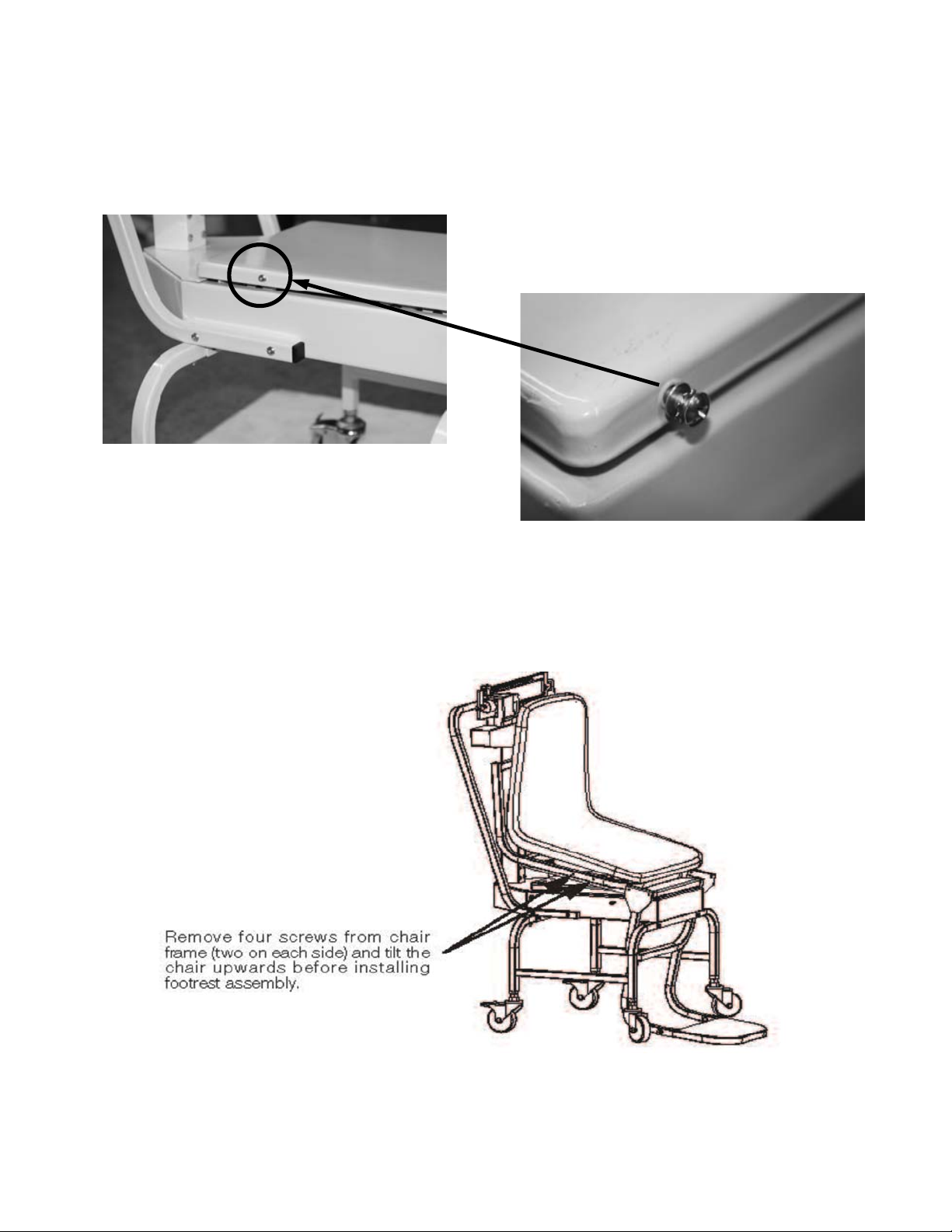

Seat and Footrest Installation

Once the transport handle is attached the next step is to install the molded seat to the scale support

frame.

1. Remove the four screws from the movable scale support frame platform and set aside.

Four screws on scale support

Frame – only one screw shown

Figure 9. Removable Screws on The Movable Scale Support Frame

2. Set the chair onto the scale support frame platform but do not fasten the screws as the footrest

assembly will also have to be put into place prior to tightening all screws.

3. Remove screws from the chair frame (shown in Figure 10) and set aside.

4. Tilt the chair upwards as shown in Figure 10. This will allow the installer to get the footrest assembly in

place prior to securing the chair to the platform

Figure 10. Tilt the Chair Upward Before Installing the Footrest Assembly

5. Slide the footrest assembly onto the chair scale base as shown in Figure 10.

Note that the footrest assembly for the footrest is hanging on the metal chair channel and lined up

with the screw holes on the channel of the chair scale frame as shown in Figure 11.

5

Page 6

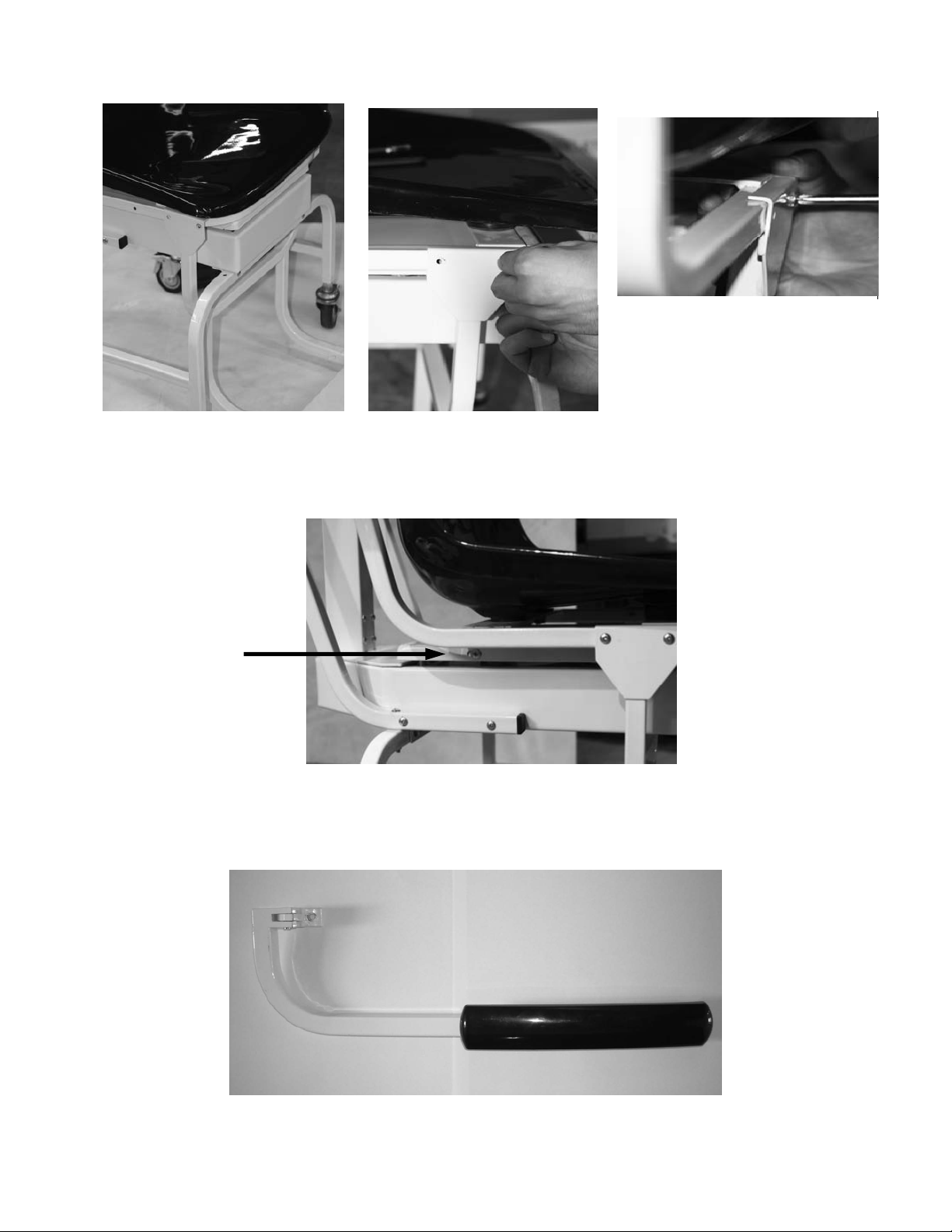

Push footrest assembly back

so that the holes line up.

Figure 11. Slide the Footrest Assembly So That Holes Line Up

Once the footrest is secured and the screws tightened for it, secure the molded seat onto the chair

scale frame.

6. Secure the four screws (shown below).

Secure screws (only

one shown)

Figure 12. These Screws Hold The Molded Chair to the Scale Base

Arm Rest Installation

The last item to be installed on the mechanical chair scale are the two arm r ests.

Figure 13. Detachable Arm Rest for the Mechanical Chair Scale

Use the following steps to attach the two arm rests to the mechanical chair scale molded seat.

6

Page 7

1. Locate the bolt hole (x 4) location on the back of the molded chair.

two bolts for each arm rest

Figure 14. Hole Location and Four Bolts Used for Securin g Arm Re st to Ch air

2. Secure the arm rests to the molded chair using the four bolts (provided and shown in Figure 14), using

the 5mm allen wrench that’s been provided in this packaging.

Figure 15. Secure Arm Rests to the Molded Chair

3. The arm rests are now in position and can be moved up and down.

Figure 16. Arm Rests Are Secured to the Molded Chair Seat

7

Page 8

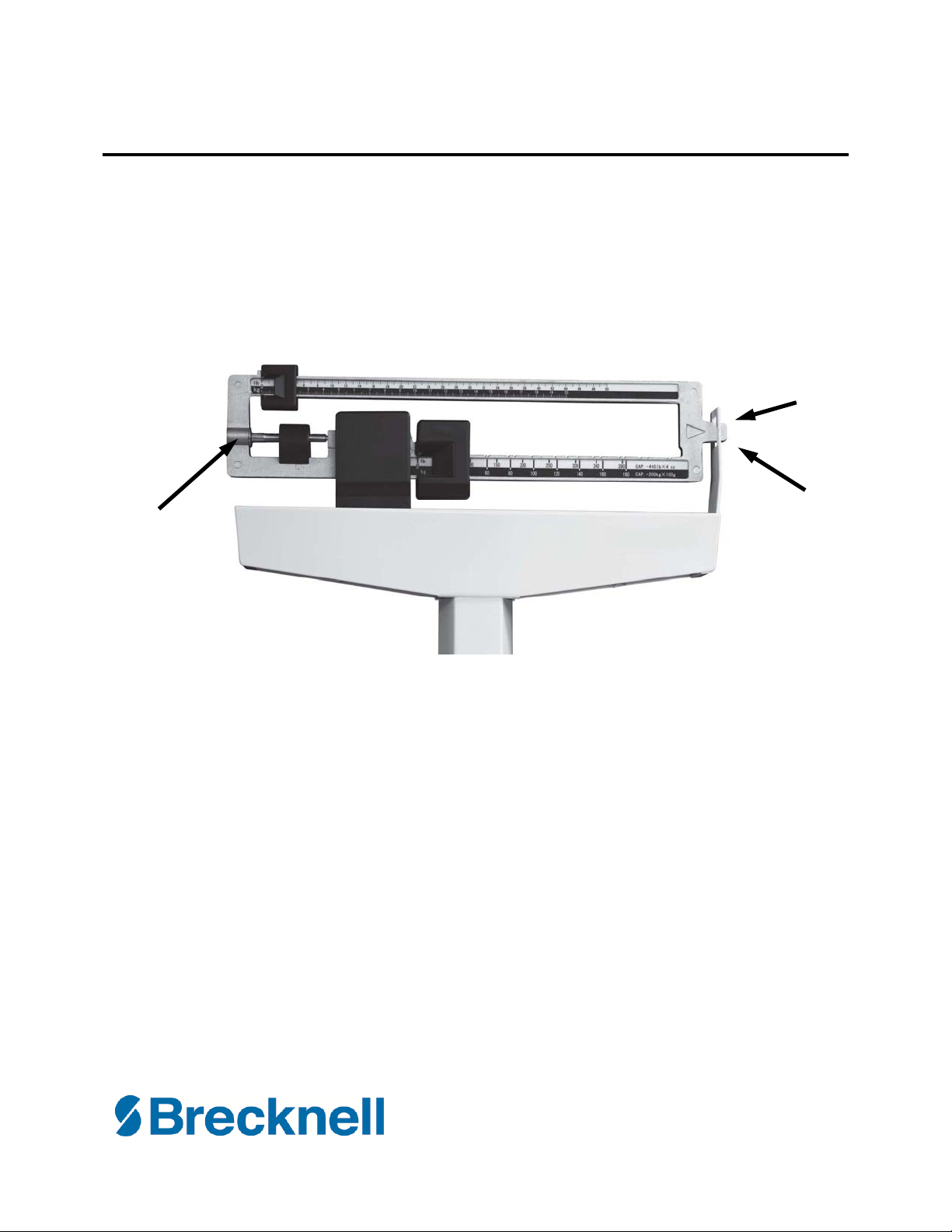

Zero Adjustment

p

To ensure accurate weighments, a zero adjustment should be done to the scale upon arrival and setup.

To perform a zero adjustment, perform the following steps.

1. Ensure the scale is sitting on a level surface.

2. Check the eye loop area of the scale to ensure that the scale pointer is equally balanced between the

eye loop area.

Scale

ointer

Zero

Eye Loop Area

Adjusting

Screw

Figure 17. Eye Loop Area and Zero Adjusting Screw Location

3. If the scale is not balancing properly, then the small zero balance weight must be adjusted. Turn the

zero adjusting screw (shown in Figure 17) using a flat head screwdriver. By adjusting the screw, the

zero balance weight will move accordingly.

4. The scale is now ready to weigh patients.

5. Have the patient sit down on the molded seat. The patient should be completely seated in the

chair, not leaning forward, and having feet firmly positioned on the footrest assembly.

USA

Brecknell

1000 Armstrong Drive

Fairmont MN 56031

Toll Free: 800-637-0529

Tel: 507-238-8702

Email:sales@brecknellscales.com

Fax: 507-238-8271

www. brecknellscales.com

8

Web site: www. brecknellscales.co.uk

Tel: +44 (0) 845 246 6717

Email: sales@brecknellscales.co.uk

UK and Europe

Brecknell

Foundry Lane

Smethwick

West Midlands, B66 2LP.

Fax: +44 (0) 845 246 6718

Loading...

Loading...