Page 1

1689 Rover 214 & 414 Updated Version 09/97

Rover 214 & 414

Service and Repair Manual

Mark Coombs and Christopher Rogers

Models covered

Rover 214 and 414 models fitted with eight or sixteen-valve 1397 cc ‘K-series’ engine

Covers major mechanical features of Cabriolet

Does not cover Diesel engine models

(1689-288-9AA3)

© Haynes Publishing 1997

A book in the Haynes Service and Repair Manual Series

All rights reserved. No part of this book may be reproduced or transmitted

in any form or by any means, electronic or mechanical, including

photocopying, recording or by any information storage or retrieval system,

without permission in writing from the copyright holder.

ISBN 1 85960 458 7

British Library Cataloguing in Publication Data

A catalogue record for this book is available from the British Library.

Printed by J H Haynes & Co. Ltd, Sparkford, Nr Yeovil,

Somerset BA22 7JJ

Haynes Publishing

Sparkford, Nr Yeovil, Somerset BA22 7JJ, England

Haynes North America, Inc

861 Lawrence Drive, Newbury Park, California 91320, USA

Editions Haynes S.A.

147/149, rue Saint Honoré, 75001 PARIS, France

Haynes Publishing Nordiska AB

Fyrisborgsgatan 5, 754 50 Uppsala, Sverige

Page 2

1689 Rover 214 & 414 Updated Version 09/97

LIVING WITH YOUR ROVER 214 & 414

Introduction Page 0•4

Safety First! Page 0•5

Roadside Repairs

Introduction Page 0•6

If your car won’t start Page 0•6

Jump starting Page 0•7

Wheel changing Page 0•8

Identifying leaks Page 0•9

Towing Page 0•9

Weekly Checks

Introduction Page 0•10

Underbonnet check points Page 0•10

Engine oil level Page 0•11

Coolant level Page 0•11

Brake fluid level Page 0•12

Screen washer fluid level Page 0•12

Power steering fluid level Page 0•13

Wiper blades Page 0•13

Tyre condition and pressure Page 0•14

Electrical systems Page 0•15

Battery Page 0•15

Lubricants, Fluids, Capacities and Tyre Pressures Page 0•16

MAINTENANCE

Routine Maintenance and Servicing Page 1•1

Maintenance schedule Page 1•3

Maintenance procedures Page 1•6

Contents

Page 3

1689 Rover 214 & 414 Updated Version 09/97

REPAIRS AND OVERHAUL

Engine and Associated Systems

Engine in-car repair procedures Page 2A•1

Engine removal and general overhaul procedures Page 2B•1

Cooling, heating and ventilation systems Page 3•1

Fuel and exhaust systems - carburettor engines Page 4A•1

Fuel and exhaust systems - single-point fuel injected engines Page 4B•1

Fuel and exhaust systems - multi-point fuel injected engines Page 4C•1

Emission control systems Page 4D•1

Ignition system - carburettor engines Page 5A•1

Ignition system - fuel injected engines Page 5B•1

Starting and charging systems Page 5C•1

Transmission

Clutch Page 6•1

Gearbox Page 7•1

Driveshafts Page 8•1

Brakes and Suspension

Braking system Page 9•1

Suspension and steering Page 10•1

Body Equipment

Bodywork and fittings Page 11•1

Body electrical systems Page 12•1

Wiring Diagrams Page 12•20

REFERENCE

Dimensions and Weights Page REF•1

Conversion Factors Page REF•2

Buying Spare Parts and Vehicle Identification Page REF•3

General Repair Procedures Page REF•4

Jacking and Vehicle Support Page REF•5

Radio/cassette Anti-theft System - precaution Page REF•5

Tools and Working Facilities Page REF•6

MOT Test Checks Page REF•8

Fault Finding Page REF•12

Glossary of Technical Terms Page REF•19

Index Page REF•24

Contents

Page 4

1689 Rover 214 & 414 Updated Version 09/97

0•4

The Rover 214 Hatchback and 414 Saloon

models covered in this Manual are a muchdeveloped version of the original 213 and 216

models first launched in 1984. The 214 five-door

model was the first to be introduced in October

1989 and was closely followed by the

414 model introduced in March 1990. The 214

model range was further updated in September

1990 when a three-door variant was introduced.

All models are fitted with the new 1.4 litre

‘K’ series engine. The 214 S model (first

introduced in September 1990) has an eightvalve single overhead camshaft version of the

engine which is fed by an SU KIF carburettor.

All other 214 and 414 models are equipped

with a sixteen-valve double overhead

camshaft version of the engine which is

controlled by a Rover/Motorola Modular

Engine Management System (MEMS) with

either single-point fuel injection (SPi) or multipoint fuel injection (MPi). All versions of the

engine are able to accept a full range of

emission control systems, up to and including

a three-way regulated catalytic converter.

The five-speed transmission, which is a

joint development by Rover and Peugeot

engineers, is of Peugeot design and produced

by Rover. The transmission is fitted to the left-

hand end of the engine. The complete

engine/transmission unit is mounted

transversely across the front of the car and

drives the front wheels through unequallength driveshafts.

The front suspension incorporates

MacPherson struts and the rear is of the

double wishbone type.

Braking is by discs at the front and drums

at the rear, with a dual-circuit hydraulic

system. On all models in the range, an Antilock Braking System (ABS) was offered as an

optional extra. If ABS is fitted, then braking is

by discs both at the front and rear.

Rover 114GTa Rover Metro 1.1S

Introduction

Acknowledgements

The aim of this manual is to help you get

the best value from your vehicle. It can do so

in several ways. It can help you decide what

work must be done (even should you choose

to get it done by a garage), provide

information on routine maintenance and

servicing, and give a logical course of action

and diagnosis when random faults occur.

However, it is hoped that you will use the

manual by tackling the work yourself. On

simpler jobs it may even be quicker than

booking the car into a garage and going there

twice, to leave and collect it. Perhaps most

important, a lot of money can be saved by

avoiding the costs a garage must charge to

cover its labour and overheads.

The manual has drawings and descriptions

to show the function of the various components

so that their layout can be understood. Then

the tasks are described and photographed in a

clear step-by-step sequence.

Your Rover 214 & 414 Manual

Thanks are due to Champion Spark Plug

who supplied the illustrations showing spark

plug conditions, and to Duckhams Oils who

provided lubrication data. Thanks are also

due to Sykes-Pickavant Limited, who

supplied some of the workshop tools, and to

all those people at Sparkford who helped in

the production of this Manual.

We take great pride in the accuracy of

information given in this manual, but

vehicle manufacturers make alterations

and design changes during the production

run of a particular vehicle of which they

do not inform us. No liability can be

accepted by the authors or publishers for

loss, damage or injury caused by any

errors in, or omissions from the

information given.

Page 5

1689 Rover 214 & 414 Updated Version 09/97

0•5

Safety First!

Working on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

Scalding

• Don’t remove the radiator or expansion

tank cap while the engine is hot.

• Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Burning

• Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

Crushing

• When working under or near

a raised vehicle,

always

supplement the

jack with axle

stands, or use

drive-on

ramps.

Never

venture

under a car which

is only supported by a jack.

• Take care if loosening or tightening hightorque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

Fire

• Fuel is highly flammable; fuel vapour is

explosive.

• Don’t let fuel spill onto a hot engine.

• Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

• Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

• Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

• Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

Electric shock

• Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.

• Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Fume or gas intoxication

• Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

• Fuel vapour is also

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

Poisonous or irritant substances

• Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

• Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oilsoaked clothes and do not keep oily rags in

your pocket.

• Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Asbestos

• Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Special hazards

Hydrofluoric acid

• This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 4000C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

• When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

• Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

• The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

• Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

• Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potentially fatal

results.

Remember...

DO

• Do use eye protection when using power

tools, and when working under the vehicle.

• Do wear gloves or use barrier cream to

protect your hands when necessary.

• Do get someone to check periodically

that all is well when working alone on the

vehicle.

• Do keep loose clothing and long hair well

out of the way of moving mechanical parts.

• Do remove rings, wristwatch etc, before

working on the vehicle – especially the

electrical system.

• Do ensure that any lifting or jacking

equipment has a safe working load rating

adequate for the job.

A few tips

DON’T

• Don’t attempt to lift a heavy component

which may be beyond your capability – get

assistance.

• Don’t rush to finish a job, or take

unverified short cuts.

• Don’t use ill-fitting tools which may slip

and cause injury.

• Don’t leave tools or parts lying around

where someone can trip over them. Mop

up oil and fuel spills at once.

• Don’t allow children or pets to play in or

near a vehicle being worked on.

Page 6

1689 Rover 214 & 414 Updated Version 09/97

0•6

Roadside repairs

The following pages are intended to help in dealing with

common roadside emergencies and breakdowns. You will find

more detailed fault finding information at the back of the

manual, and repair information in the main chapters.

If your car won’t start

and the starter motor

doesn’t turn

M If it’s a model with automatic transmission, make sure the

selector is in ‘P’ or ‘N’.

M Open the bonnet and make sure that the battery terminals

are clean and tight.

M Switch on the headlights and try to start the engine. If the

headlights go very dim when you’re trying to start, the

battery is probably flat. Get out of trouble by jump starting

(see next page) using a friend’s car.

If your car won’t start

even though the starter

motor turns as normal

M Is there fuel in the tank?

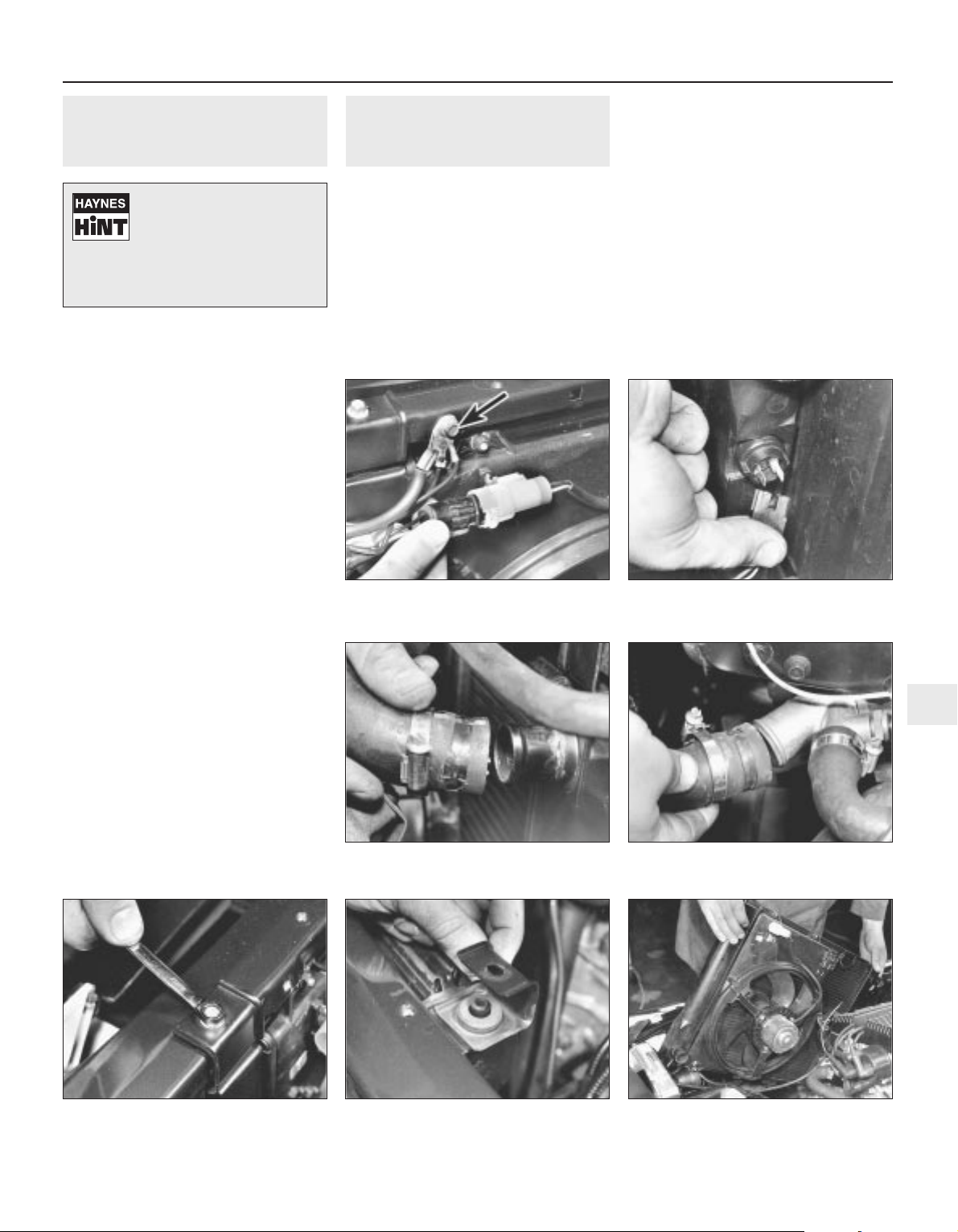

M Is there moisture on electrical components under the

bonnet? Switch off the ignition, then wipe off any obvious

dampness with a dry cloth. Spray a water-repellent aerosol

product (WD-40 or equivalent) on ignition and fuel system

electrical connectors like those shown in the photos.

Pay special attention to the ignition coil wiring connector

and HT leads. (Note that Diesel engines don’t normally

suffer from damp.)

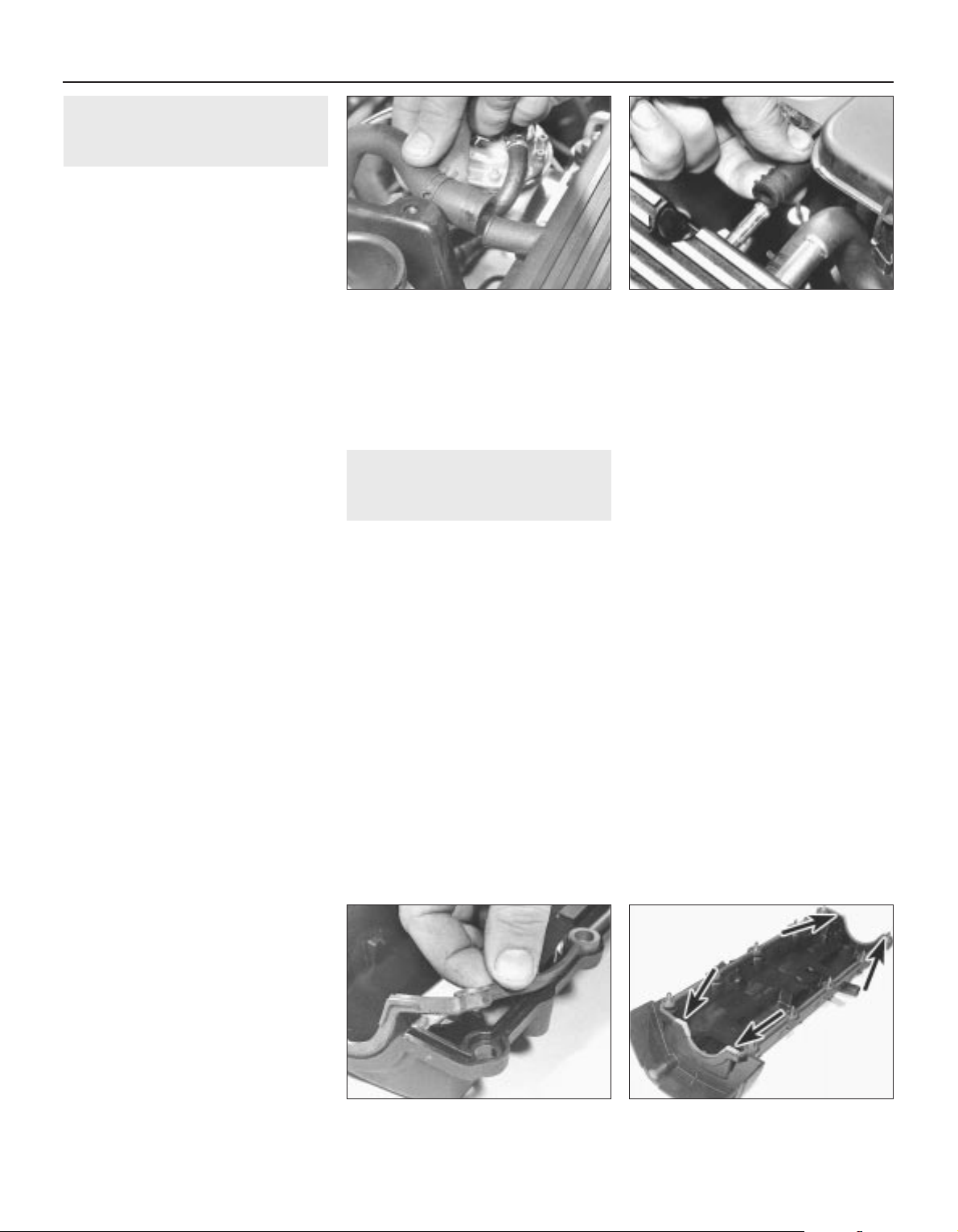

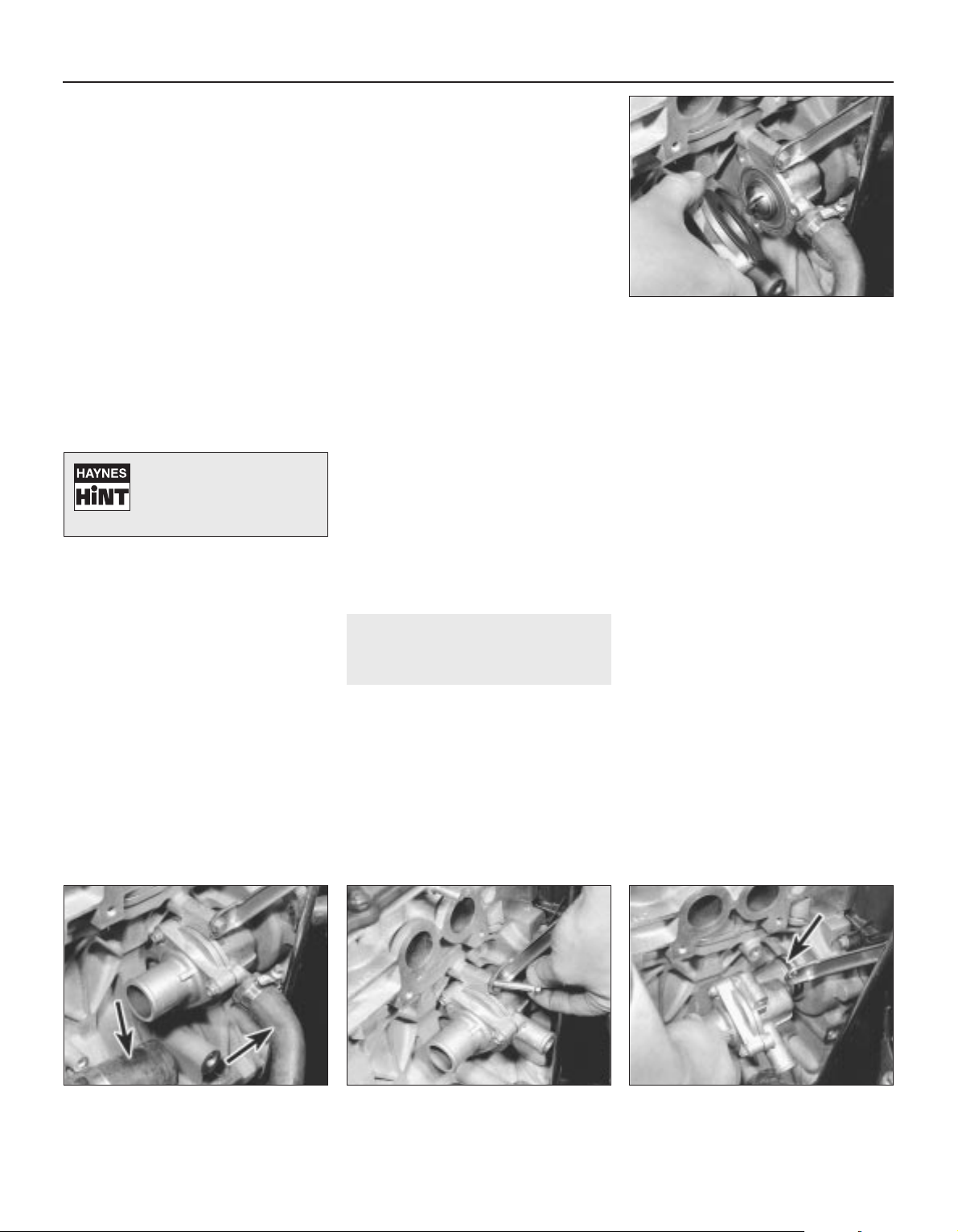

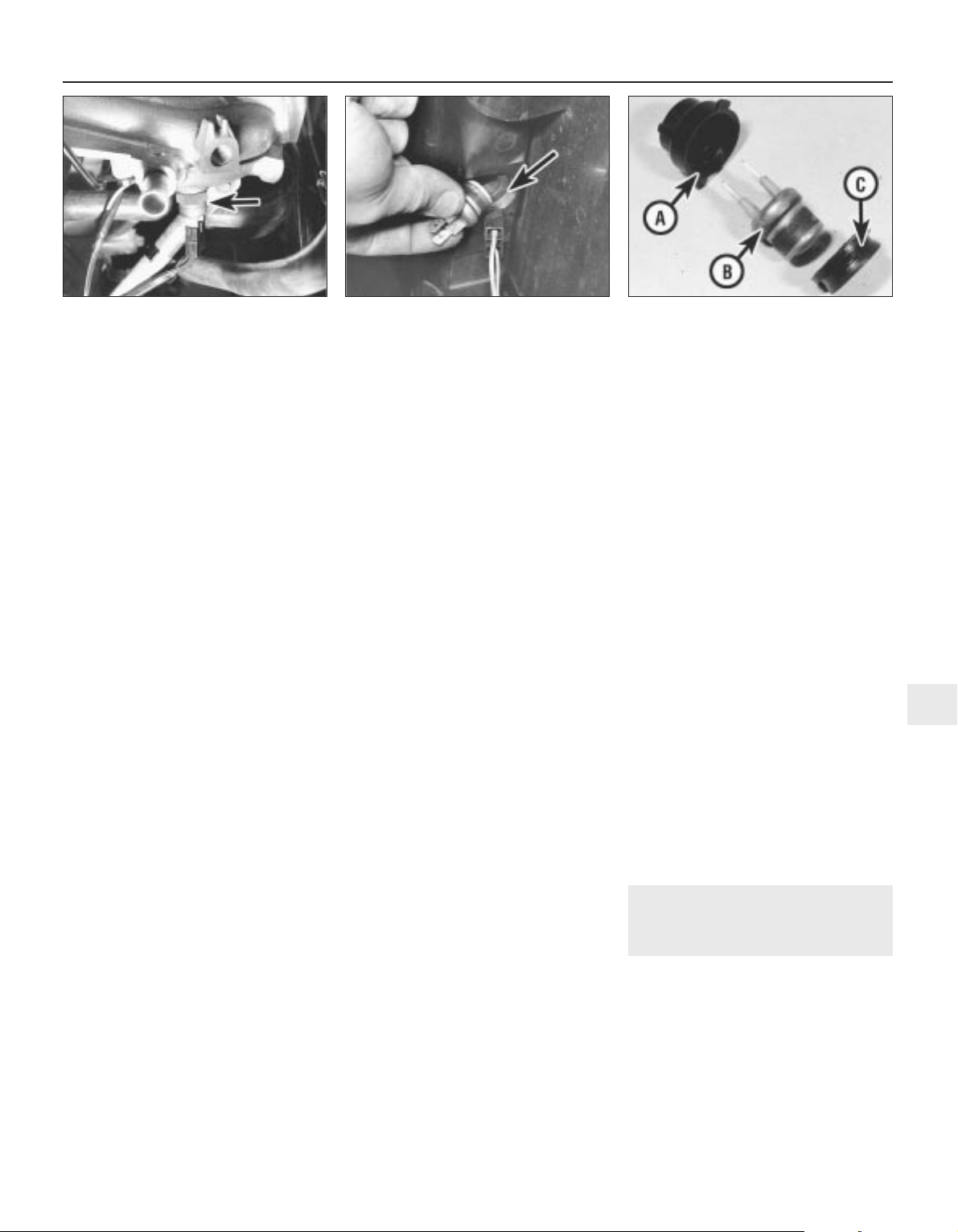

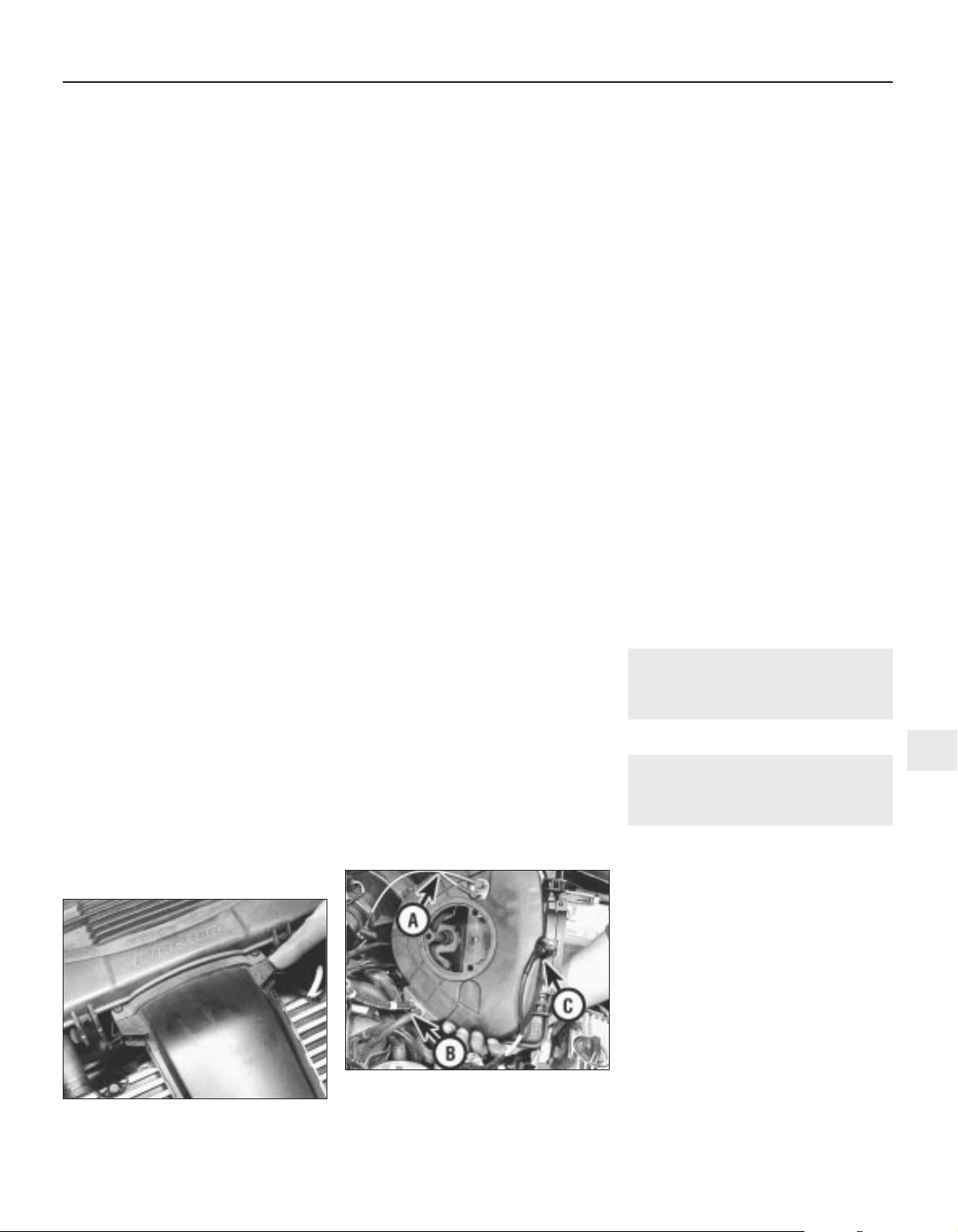

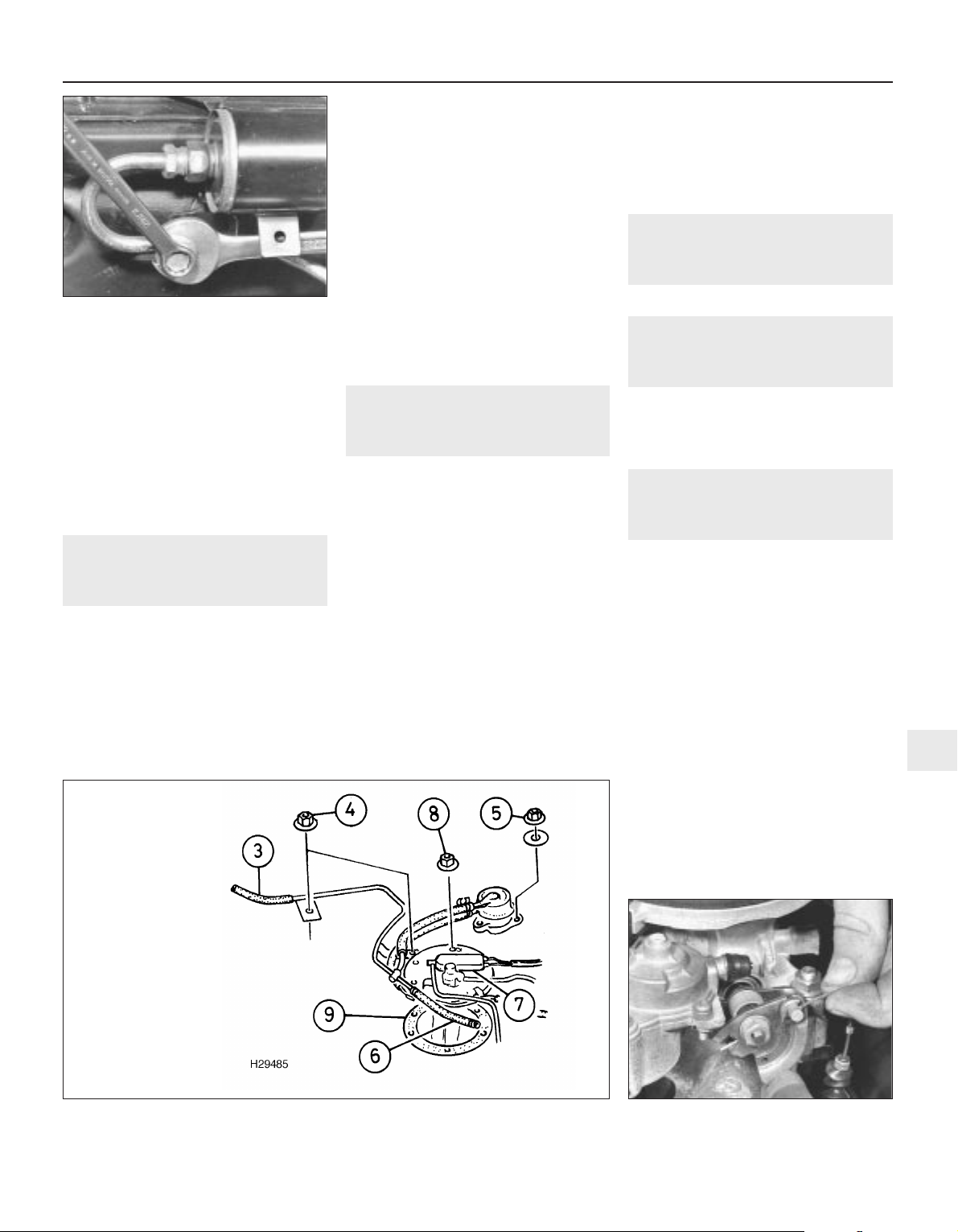

Check that the distributor HT lead

connections are clean and secure

A

Check that the spark plug HT lead

connections are clean and secure cover removed

B

Check that the ignition coil HT and LT

lead connections are clean and secure

C

Check the security and condition of the

battery connections

D

The ECU wiring plugs may cause

problems if dirty or not properly

connected

E

Check that electrical connections are secure (with the ignition off) and spray them with a waterdispersing spray like WD40 if you suspect a problem due to damp

Page 7

0•7

1689 Rover 214 & 414 Updated Version 09/97

Roadside repairs

When jump-starting a car using a

booster battery, observe the following

precautions:

4 Before connecting the booster

battery, make sure that the ignition

is switched off.

4 Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

4 Take note of any special precautions

printed on the battery case.

4 Make sure that the booster battery

is the same voltage as the

discharged one in the vehicle.

4 If the battery is being jump-started

from the battery in another vehicle,

the two vehicles MUST NOT TOUCH

each other.

4 Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting will get you

out of trouble, but you must

correct whatever made the

battery go flat in the first

place. There are three possibilities:

1) The battery has been drained by

repeated attempts to start, or by

leaving the lights on.

2) The charging system is not working

properly (alternator drivebelt slack or

broken, alternator wiring fault or

alternator itself faulty).

3) The battery itself is at fault (electrolyte

low, or battery worn out).

Connect one end of the red jump lead

to the positive (+) terminal of the flat

battery

Connect the other end of the red lead

to the positive (+) terminal of the

booster battery

Connect one end of the black jump lead

to the negative (-) terminal of the

booster battery

Connect the other end of the black

jump lead to a bolt or bracket on the

engine block, well away from the

battery, on the vehicle to be started

1 2 3

4

Make sure that the jump leads will not

come into contact with the fan,

drivebelts or other moving parts of the

engine

5

Start the engine using the booster

battery, then with the engine running at

idle speed, disconnect the jump leads

in the reverse order of connection

6

Jump starting

Page 8

1689 Rover 214 & 414 Updated Version 09/97

0•8

Roadside repairs

Location of spare wheel and tools in boot

Wheel changing

Some of the details shown here will vary

according to model. For instance, the location

of the spare wheel and jack is not the same

on all cars. However, the basic principles

apply to all vehicles.

Warning: Do not change a wheel in a situation where you risk being hit by

other traffic. On busy roads, try to stop in a lay-by or a gateway. Be wary of

passing traffic while changing the wheel – it is easy to become distracted by

the job in hand.

Finally...

M Remove the wheel chocks.

M Stow the jack and tools in the correct

locations in the car.

M

Check the tyre pressure on the wheel just

fitted. If it is low, or if you don’t have a

pressure gauge with you, drive slowly to

the nearest garage and inflate the tyre to

the right pressure.

M Have the damaged tyre or wheel repaired

as soon as possible.

Use the wheel brace to slightly loosen the

wheelnuts

Locate the jack head in the correct

jacking point

Raise the jack until the wheel is clear of

the ground

Remove the trim to expose the wheelnutsUnscrew the spare wheel retaining cap

1

2

3

4

5

Remove the wheelnuts and lift off the

wheel

7

Fit the replacement wheel and tighten the

nuts

8

6

Preparation

M When a puncture occurs, stop as soon as

it is safe to do so.

M Park on firm level ground, if possible,

and well out of the way of other traffic.

M Use hazard warning lights if necessary.

M If you have one, use a warning triangle to

alert other drivers of your presence.

M Apply the handbrake and engage first or

reverse gear (or Park on models with

automatic transmission).

M Chock the wheel diagonally opposite the

one being removed – a couple of large

stones will do for this.

M If the ground is soft, use a flat piece of

wood to spread the load under the jack.

Changing the wheel

Page 9

1689 Rover 214 & 414 Updated Version 09/97

0•9

Roadside repairs

Towing

Puddles on the garage floor or drive, or

obvious wetness under the bonnet or

underneath the car, suggest a leak that needs

investigating. It can sometimes be difficult to

decide where the leak is coming from,

especially if the engine bay is very dirty

already. Leaking oil or fluid can also be blown

rearwards by the passage of air under the car,

giving a false impression of where the

problem lies.

Warning: Most automotive oils

and fluids are poisonous. Wash

them off skin, and change out of

contaminated clothing, without

delay.

Identifying leaks

The smell of a fluid leaking

from the car may provide a

clue to what’s leaking. Some

fluids are distinctively

coloured. It may help to clean the car

carefully and to park it over some clean

paper overnight as an aid to locating the

source of the leak.

Remember that some leaks may only

occur while the engine is running.

When all else fails, you may find yourself

having to get a tow home – or of course you

may be helping somebody else. Long-distance

recovery should only be done by a garage or

breakdown service. For shorter distances, DIY

towing using another car is easy enough, but

observe the following points:

M Use a proper tow-rope – they are not

expensive. The vehicle being towed must

display an ‘ON TOW’ sign in its rear window.

M Always turn the ignition key to the ‘on’

position when the vehicle is being towed, so

that the steering lock is released, and that the

direction indicator and brake lights will work.

M Only attach the tow-rope to the towing

eyes provided.

M Before being towed, release the handbrake

and select neutral on the transmission.

M Note that greater-than-usual pedal

pressure will be required to operate the

brakes, since the vacuum servo unit is only

operational with the engine running.

M On models with power steering, greaterthan-usual steering effort will also be required.

M The driver of the car being towed must

keep the tow-rope taut at all times to avoid

snatching.

M Make sure that both drivers know the route

before setting off.

M Only drive at moderate speeds and keep

the distance towed to a minimum. Drive

smoothly and allow plenty of time for slowing

down at junctions.

M On models with automatic transmission,

special precautions apply. If in doubt, do not

tow, or transmission damage may result.

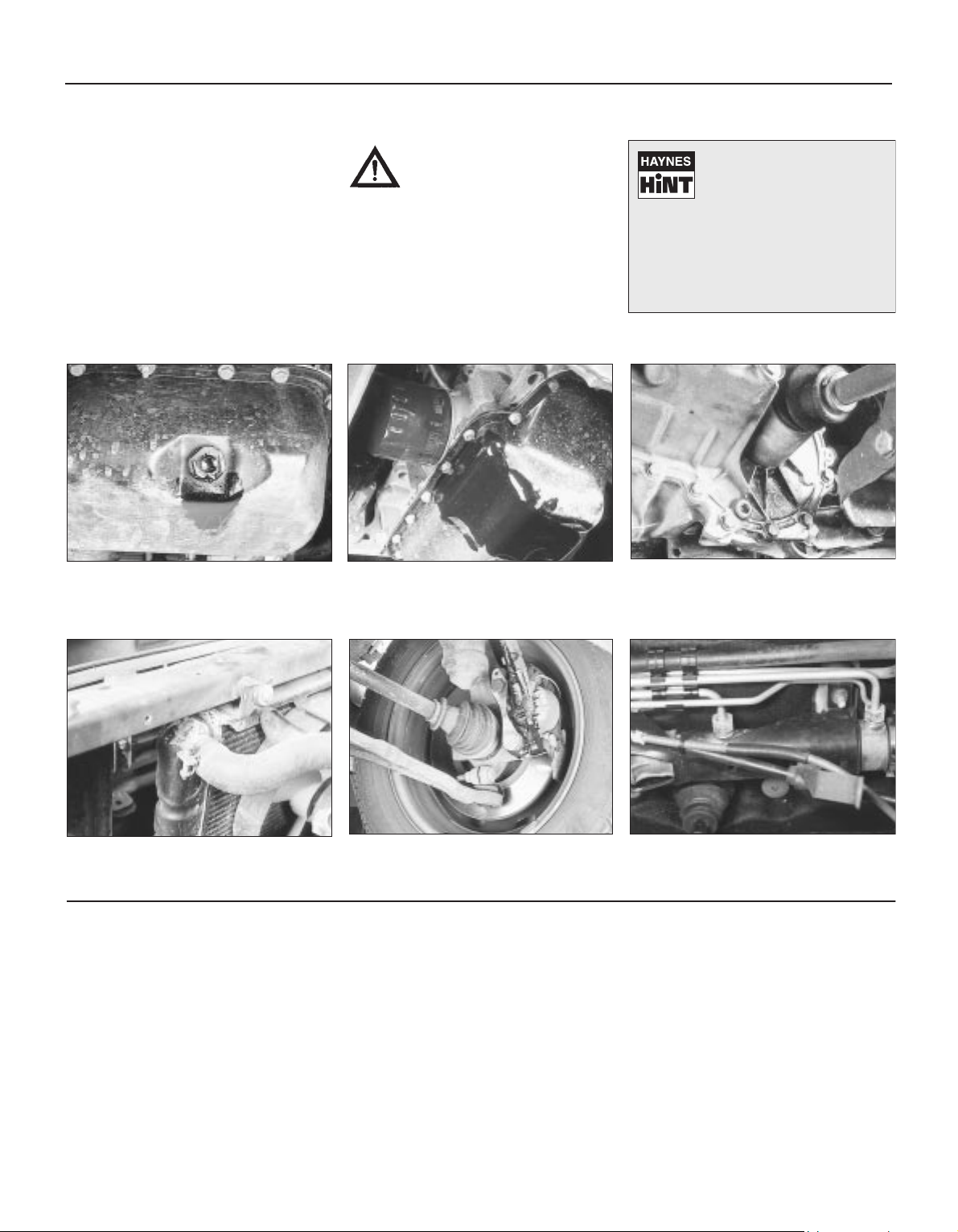

Sump oil Gearbox oil

Brake fluid Power steering fluid

Oil from filter

Antifreeze

Engine oil may leak from the drain plug... ...or from the base of the oil filter.

Leaking antifreeze often leaves a crystalline

deposit like this.

Gearbox oil can leak from the seals at the

inboard ends of the driveshafts.

A leak occurring at a wheel is almost

certainly brake fluid.

Power steering fluid may leak from the pipe

connectors on the steering rack.

Page 10

1689 Rover 214 & 414 Updated Version 09/97

0•10

There are some very simple checks which

need only take a few minutes to carry out, but

which could save you a lot on inconvenience

and expense.

These “Weekly Checks” require no great skill

or special tools, and the small amount of time

they take to perform could well prove to be

very well spent, for example:

mm Keeping an eye on tyre condition and

pressures, will not only help to stop them

wearing out prematurely but could also save

your life.

mm Many breakdowns are caused by electrical

problems. Battery-related faults are particularly

common and a quick check on a regular basis

will often prevent the majority of these.

mm If your car develops a brake fluid leak, the

first time you might know about it is when

your brakes don’t work properly. Checking

the level regularly will give advance warning of

this kind of problem.

mm If the oil or coolant levels run low, the cost

of repairing any engine damage will be far

greater than fixing the leak.

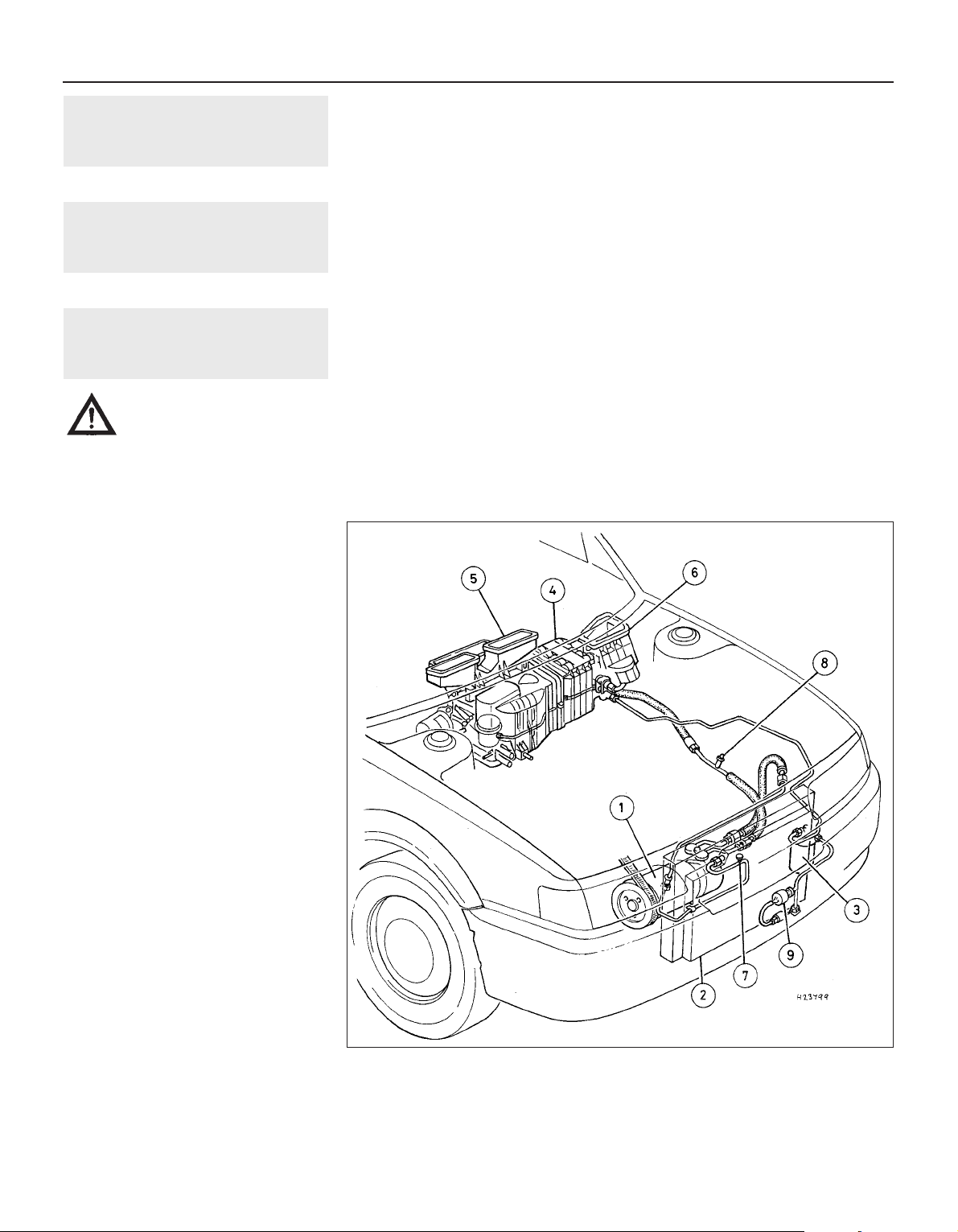

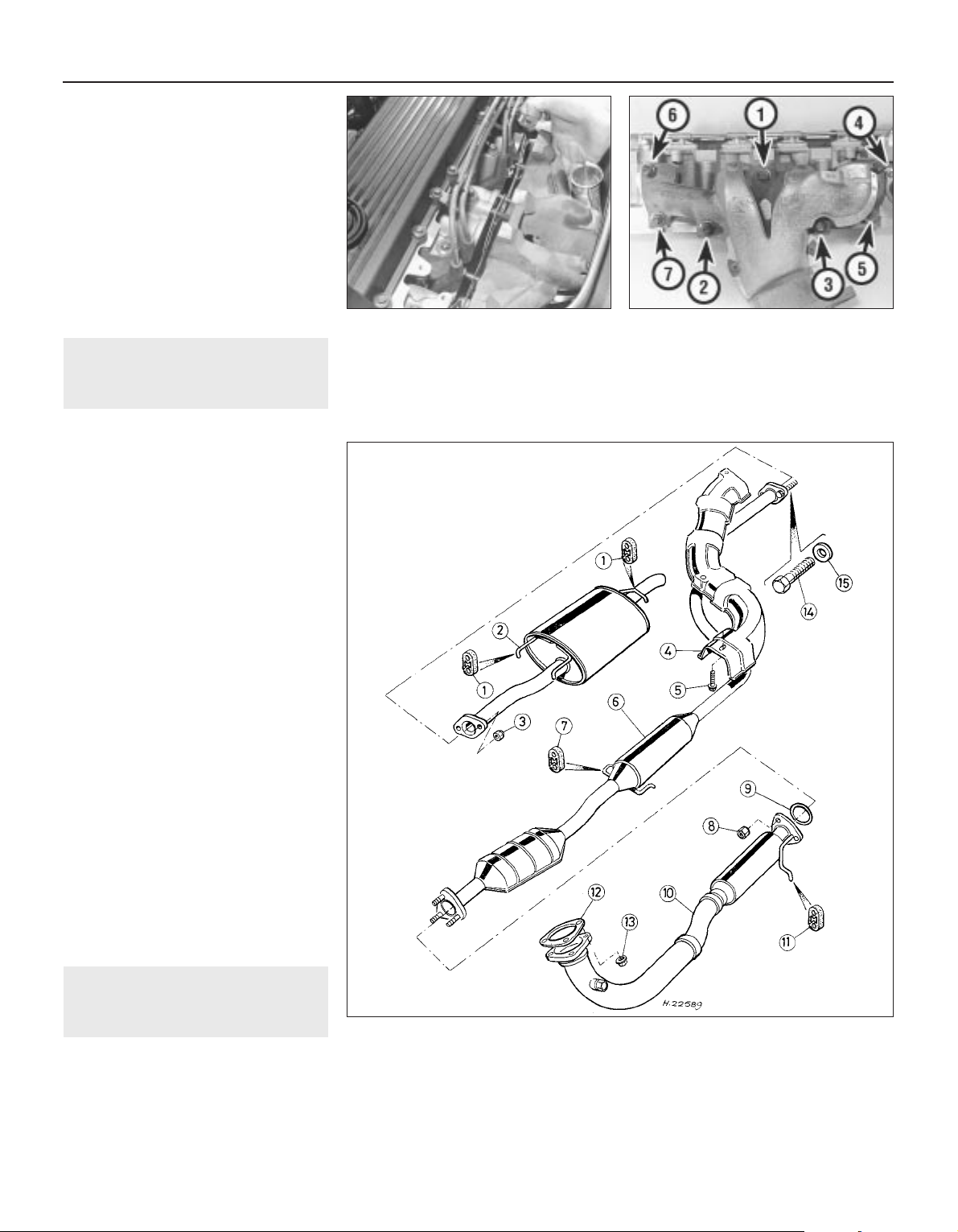

Underbonnet Check Points

K16 MPi engine with plastic inlet manifold

Introduction

Weekly checks

A

Engine oil level dipstick

B

Engine oil filler cap

C

Coolant expansion tank

D

Brake fluid reservoir

E

Power steering fluid reservoir

F

Screen washer fluid reservoir

G

Battery

Page 11

1689 Rover 214 & 414 Updated Version 09/97

0•11

Weekly checks

Engine oil level

Before you start

4 Make sure that your car is on level ground.

4 Check the oil level before the car is driven,

or at least 5 minutes after the engine has been

switched off.

The correct oil

Modern engines place great demands on their

oil. It is very important that the correct oil for

your car is used (see “Lubricants and Fluids”

on page 0•16).

Car Care

l If you have to add oil frequently, you should

check whether you have any oil leaks. Place

some clean paper under the car overnight,

and check for stains in the morning. If there

are no leaks, then engine may be burning oil

(see “Fault Finding”).

l Always maintain the level between the

upper and lower dipstick marks. If the level is

too low, severe engine damage may occur. Oil

seal failure may result if the engine is overfilled

by adding too much oil.

Using a clean rag or paper towel, wipe all

the oil from the dipstick. Insert the clean

dipstick into the tube as far as it will go, then

withdraw it again.

Note the oil level on the end of the

dipstick, which should be between the

upper HI mark and the lower LO mark.

Approximately 1.0 litre of oil will raise the level

from the lower mark to the upper mark.

Oil is added through the filler cap. Rotate

the cap through a quarter-turn anticlockwise and withdraw it. Top-up the level. A

funnel may help to reduce spillage. Add the oil

slowly, checking the level on the dipstick

often. Do not overfill.

The dipstick is located at the rear right-hand

end of the engine (see “Underbonnet Check

Points” on page 0•10 for exact location).

Withdraw the dipstick.

1 2

3 4

If the oil is checked

immediately after driving the

vehicle, some of the oil will

remain in the upper engine

components, resulting in an inaccurate

reading on the dipstick.

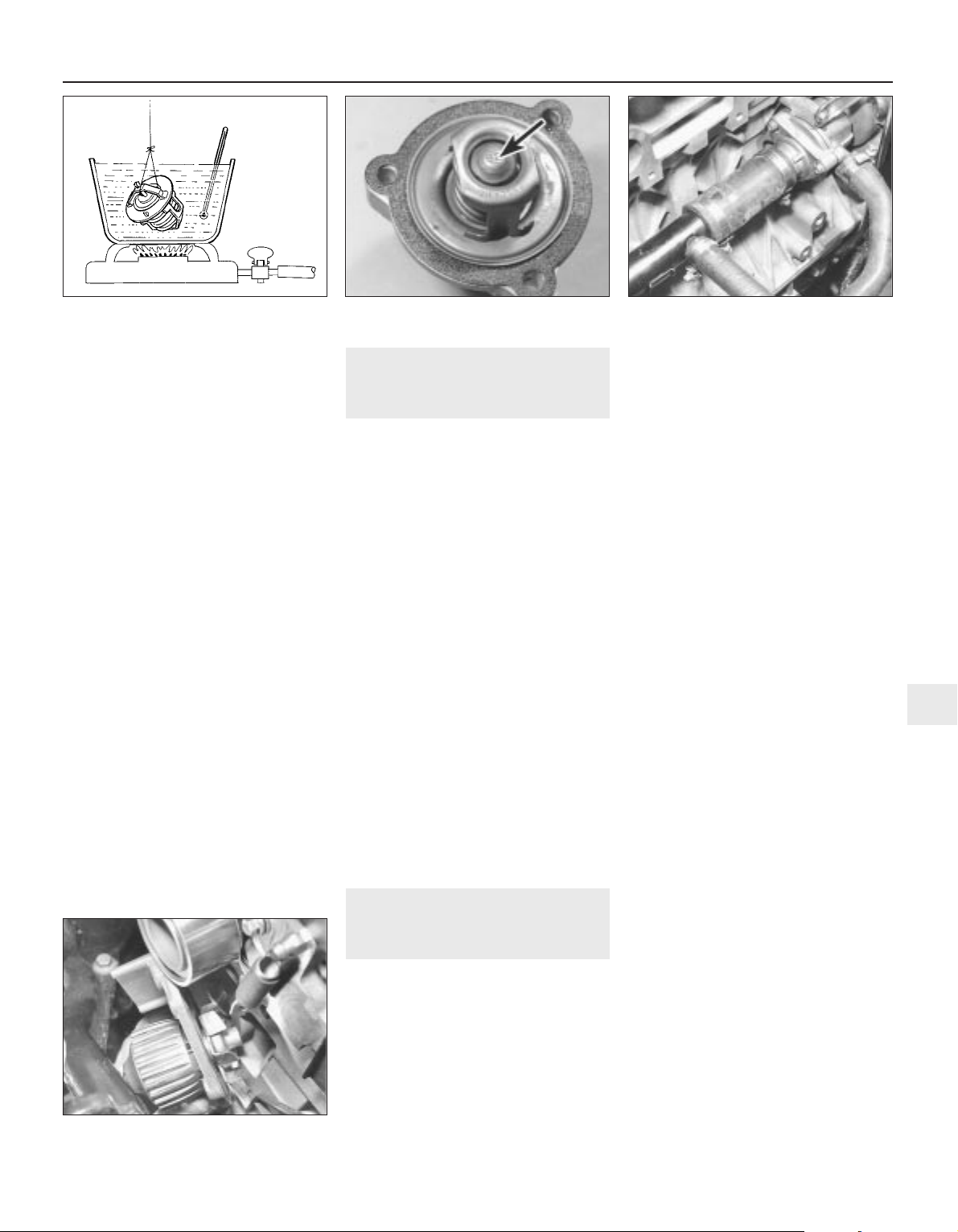

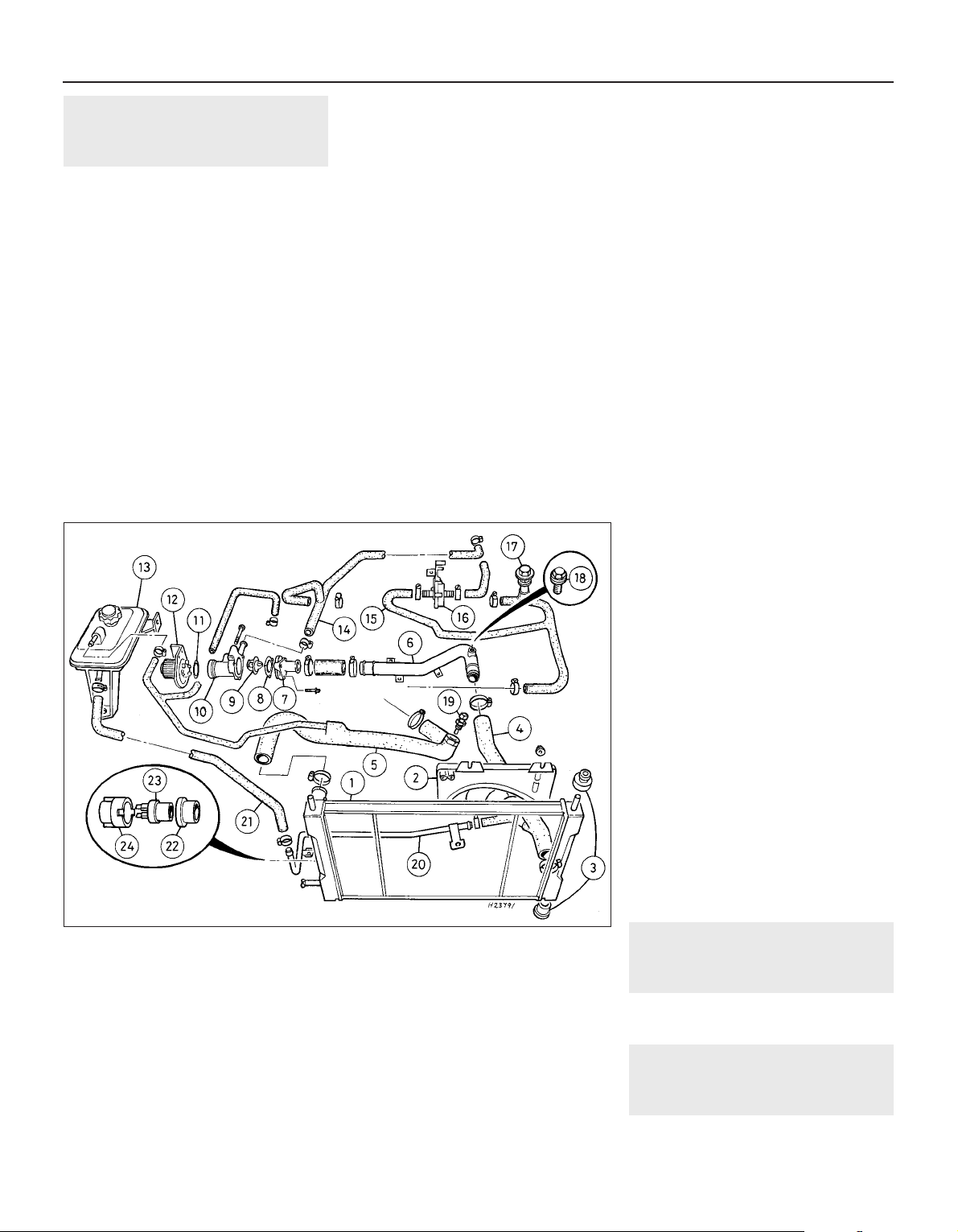

Coolant level

Add a mixture of water and antifreeze

through the expansion tank filler neck,

until the coolant is up to the upper level. Refit

the cap, turning it clockwise as far as it will go

until it is secure.

If topping-up, wait until the engine is

cold, then cover the filler cap with a layer

of rag and start unscrewing the cap. Wait until

any hissing ceases, indicating that all

pressure is released, then slowly unscrew the

cap until it can be removed. At all times keep

well away from the filler opening.

When the engine is cold, the coolant level

should be between the expansion tank

ridge/seam and the level indicated above

COOLANT LEVEL on the side of the

expansion tank, which is located in the front

right-hand corner of the engine compartment.

1 2 3

Warning: Do not attempt to

remove the expansion tank

pressure cap when the engine is

hot, as there is a very great risk

of scalding. Do not leave open containers

of coolant about, as it is poisonous.

Car Care

l With a sealed-type cooling system, adding

coolant should not be necessary on a regular

basis. If frequent topping-up is required, it is

likely there is a leak. Check the radiator, all

hoses and joint faces for signs of staining or

wetness, and rectify as necessary.

l It is important that antifreeze is used in the

cooling system all year round, not just during

the winter months. Don’t top up with water

alone, as the antifreeze will become diluted.

Page 12

1689 Rover 214 & 414 Updated Version 09/97

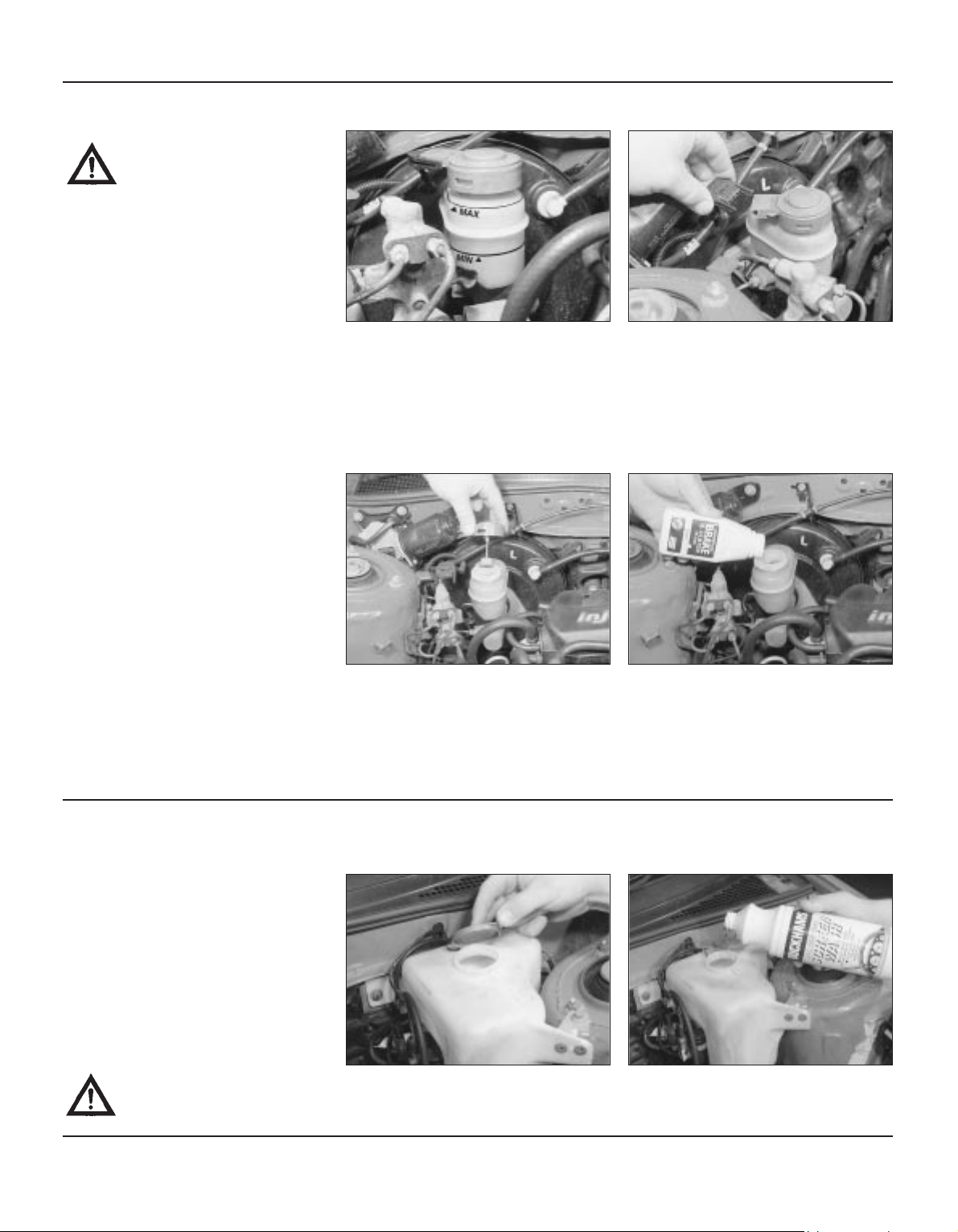

Warning: Brake fluid can harm

your eyes and damage painted

surfaces, so use extreme

caution when handling and

pouring it. Do not use fluid which has

been standing open for some time, as it

absorbs moisture from the air, which can

cause a dangerous loss of braking

effectiveness.

Before you start

4 Make sure that the car is on level ground.

4 Cleanliness is of great importance when

dealing with the braking system, so take

care to clean around the reservoir cap

before topping-up. Use only clean brake fluid

from a container which has stood for at least

24 hours (to allow air bubbles to separate

out).

Safety first

l If the reservoir requires repeated toppingup, this is an indication of a fluid leak

somewhere in the system, which should be

investigated immediately.

l If a leak is suspected, the car should not be

driven until the braking system has been

checked. Never take any risks where brakes

are concerned.

Brake fluid level

Carefully add fluid avoiding spilling it on

surrounding paintwork. Use only the

specified fluid; mixing different types can

cause damage to the system. After filling to

the correct level, refit the cap securely, to

prevent leaks and the entry of foreign matter.

Ensure that the fluid level switch plunger is

free to move. Wipe off any spilt fluid.

Before adding fluid, it’s a good idea to

inspect the reservoir. The system should

be drained and refilled if dirt is seen in the

fluid (see Chapter 9 for details).

The brake master cylinder and fluid

reservoir is mounted on the vacuum

servo unit in the engine compartment. The

MAX and MIN level marks are indicated on the

side of the reservoir and the fluid level should

be maintained between these marks at all

times.

1

If topping-up is necessary, unplug the

electrical connector and wipe the area

around the filler cap with a clean rag before

removing the cap. When adding fluid, pour it

carefully into the reservoir to avoid spilling it

on surrounding painted surfaces. Be sure to

use only the specified brake hydraulic fluid

since mixing different types of fluid can cause

damage to the system.

2

3 4

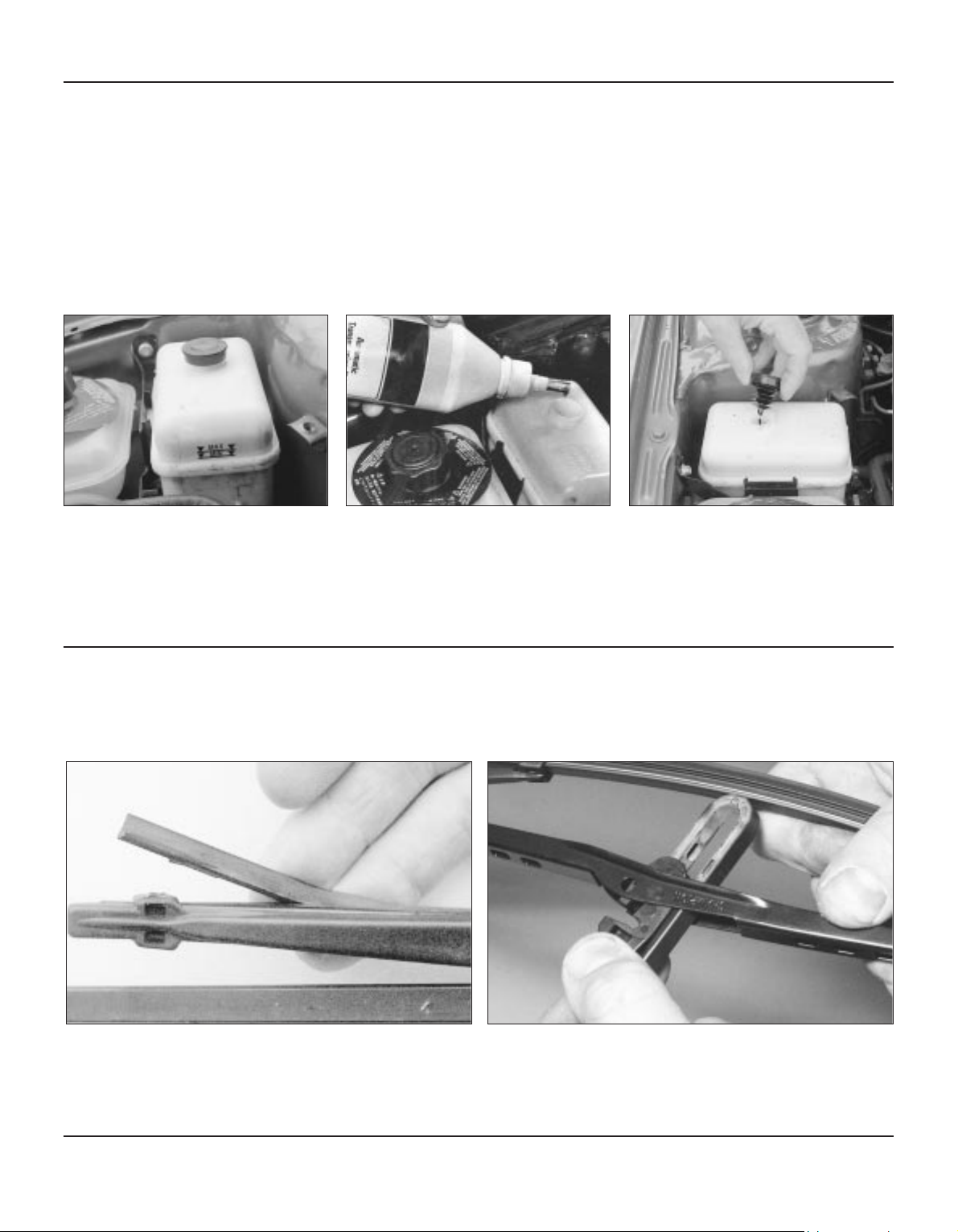

Screen washer fluid level

The reservoir for the windscreen and rear

window (where fitted) washer systems is

located on the left-hand side of the engine

compartment.

When topping-up the reservoir(s) a

screenwash additive should be added in

the quantities recommended on the bottle.

Car care

l Screenwash additives not only keep the

windscreen clean during bad weather, they

also prevent the washer system freezing in

cold weather - which is when you are likely to

need it most. Don’t top up using plain water,

as the screenwash will become diluted and

will freeze in cold weather.

l Check the operation of the windscreen and

rear window washers. Adjust the nozzles

using a pin if necessary, aiming the spray to a

point slightly above the centre of the swept

area.

Warning: On no account use

engine coolant antifreeze in the

screen washer system - this will

damage the paintwork.

1 2

0•12

Weekly checks

Page 13

1689 Rover 214 & 414 Updated Version 09/97

0•13

Weekly checks

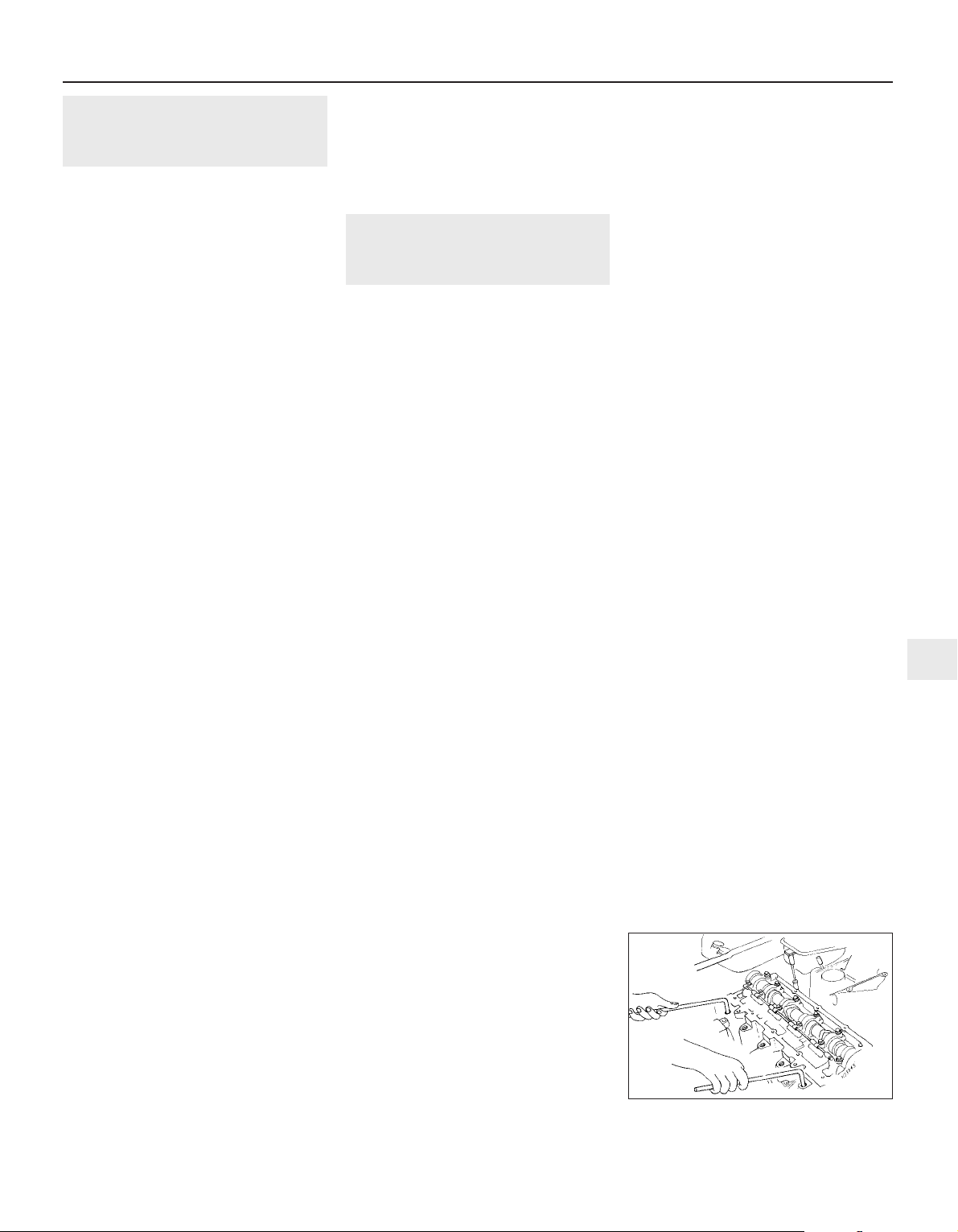

To remove a wiper blade, pull the arm fully away from the glass

until it locks. Swivel the blade through 90º, press the locking tab

with a finger nail and slide the blade out of the arm’s hooked end. On

refitting, ensure that the blade locks securely into the arm.

Check the condition of the wiper blades. If they are cracked or

show any signs of deterioration, or if the glass swept area is

smeared, renew them. For maximum clarity of vision, wiper blades

should be renewed annually, as a matter of course.

2

After filling the reservoir to the proper

level, make sure that the cap is refitted

securely to avoid leaks and the entry of

foreign matter into the reservoir.

3

If topping-up is necessary, first wipe the

area around the filler cap with a clean rag

before removing the cap. When adding fluid,

pour it carefully into the reservoir to avoid

spillage. Be sure to use only the specified

fluid.

2

The power steering fluid reservoir is

located on the right-hand side of the

engine compartment, just behind the cooling

system expansion tank. MAX and MIN level

marks are indicated on the side of the

reservoir and the fluid level should be

maintained between these marks at all times.

1

1

Wiper blades

Power steering fluid level

Before you start

4 Make sure that the car is on level ground.

4 Set the front roadwheels in the straight-

ahead position.

4 The engine should be stopped.

4 Do not operate the steering once the

engine is stopped.

Safety first

l If the reservoir requires repeated toppingup, there is a fluid leak somewhere in the

system which should be investigated

immediately.

l If a leak is suspected, the car should not be

driven until the power steering system has

been checked.

Page 14

1689 Rover 214 & 414 Updated Version 09/97

0•14

Weekly checks

It is very important that tyres are in good

condition, and at the correct pressure - having

a tyre failure at any speed is highly dangerous.

Tyre wear is influenced by driving style - harsh

braking and acceleration, or fast cornering,

will all produce more rapid tyre wear. As a

general rule, the front tyres wear out faster

than the rears. Interchanging the tyres from

front to rear (“rotating” the tyres) may result in

more even wear. However, if this is

completely effective, you may have the

expense of replacing all four tyres at once!

Remove any nails or stones embedded in the

tread before they penetrate the tyre to cause

deflation. If removal of a nail does reveal that

the tyre has been punctured, refit the nail so

that its point of penetration is marked. Then

immediately change the wheel, and have the

tyre repaired by a tyre dealer.

Regularly check the tyres for damage in the

form of cuts or bulges, especially in the

sidewalls. Periodically remove the wheels,

and clean any dirt or mud from the inside and

outside surfaces. Examine the wheel rims for

signs of rusting, corrosion or other damage.

Light alloy wheels are easily damaged by

“kerbing” whilst parking; steel wheels may

also become dented or buckled. A new wheel

is very often the only way to overcome severe

damage.

New tyres should be balanced when they are

fitted, but it may become necessary to rebalance them as they wear, or if the balance

weights fitted to the wheel rim should fall off.

Unbalanced tyres will wear more quickly, as

will the steering and suspension components.

Wheel imbalance is normally signified by

vibration, particularly at a certain speed

(typically around 50 mph). If this vibration is

felt only through the steering, then it is likely

that just the front wheels need balancing. If,

however, the vibration is felt through the

whole car, the rear wheels could be out of

balance. Wheel balancing should be carried

out by a tyre dealer or garage.

Tyre Pressure Check

Check the tyre pressures regularly with

the tyres cold. Do not adjust the tyre

pressures immediately after the vehicle has

been used, or an inaccurate setting will result.

Tyre pressures are shown on page 0•16

Tread Depth - manual check

Alternatively tread wear can be

monitored with a simple, inexpensive

device known as a tread depth indicator

gauge.

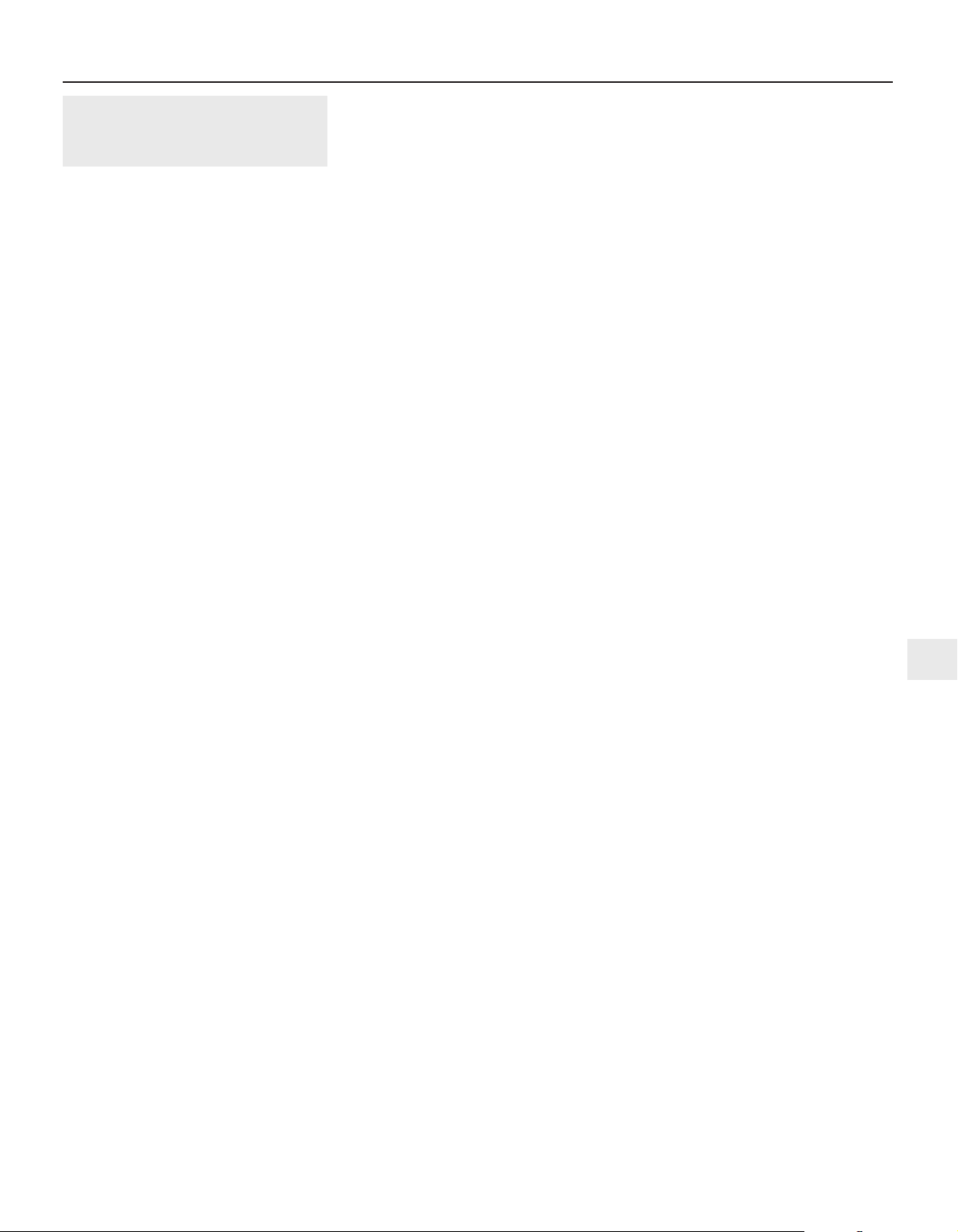

Tread Depth - visual check

The original tyres have tread wear safety

bands (B), which will appear when the

tread depth reaches approximately 1.6 mm.

The band positions are indicated by a

triangular mark on the tyre sidewall (A).

1 2 3

Tyre condition and pressure

Tyre tread wear patterns

Shoulder Wear

Underinflation (wear on both sides)

Under-inflation will cause overheating of the

tyre, because the tyre will flex too much, and

the tread will not sit correctly on the road

surface. This will cause a loss of grip and

excessive wear, not to mention the danger of

sudden tyre failure due to heat build-up.

Check and adjust pressures

Incorrect wheel camber (wear on one side)

Repair or renew suspension parts

Hard cornering

Reduce speed!

Centre Wear

Overinflation

Over-inflation will cause rapid wear of the

centre part of the tyre tread, coupled with

reduced grip, harsher ride, and the danger of

shock damage occurring in the tyre casing.

Check and adjust pressures

If you sometimes have to inflate your car’s

tyres to the higher pressures specified for

maximum load or sustained high speed, don’t

forget to reduce the pressures to normal

afterwards.

Uneven Wear

Front tyres may wear unevenly as a result of

wheel misalignment. Most tyre dealers and

garages can check and adjust the wheel

alignment (or "tracking") for a modest charge.

Incorrect camber or castor

Repair or renew suspension parts

Malfunctioning suspension

Repair or renew suspension parts

Unbalanced wheel

Balance tyres

Incorrect toe setting

Adjust front wheel alignment

Note: The feathered edge of the tread which

typifies toe wear is best checked by feel.

4

Page 15

1689 Rover 214 & 414 Updated Version 09/97

0•15

Weekly checks

Electrical system

If more than one indicator light or

headlight has failed, it is likely that either

a fuse has blown or that there is a fault in the

circuit (see Chapter 12).

If a single indicator light, brake light or

headlight has failed, it is likely that a bulb

has blown and will need to be replaced. Refer

to Chapter 12 for details. If both brake lights

have failed, it is possible that the brake light

switch operated by the brake pedal is faulty.

Refer to Chapter 9 for details.

1

If you need to check your

brake lights and indicators

unaided, back up to a wall or

garage door and operate the

lights. The reflected light should show if

they are working properly.

4 Check all external lights and the horn. Refer

to the appropriate Sections of Chapter 12 for

details if any of the circuits are found to be

inoperative, and replace the fuse if necessary.

Most fuses are located behind the cover in the

right-hand lower facia panel. Other fuses are

located in the fusebox on the left-hand side of

the engine compartment. To replace a blown

fuse, pull it from position, using the plastic

tool provided. Fit a new fuse of the same

rating. If a second fuse blows, it is important

that you find the reason - do not use a fuse

with a higher rating.

4 Visually check all accessible wiring

connectors, harnesses and retaining clips for

security, and for signs of chafing or damage.

2

Battery

Caution: Before carrying out any work on

the vehicle battery, read the precautions

given in “Safety first” at the start of this

manual.

4 Make sure that the battery tray is in good

condition, and that the clamp is tight.

Corrosion on the tray, retaining clamp and the

battery itself can be removed with a solution

of water and baking soda. Thoroughly rinse all

cleaned areas with water. Any metal parts

damaged by corrosion should be covered

with a zinc-based primer, then painted.

4 Periodically (approximately every three

months), check the charge condition of the

battery as described in Chapter 5A.

4 If the battery is flat, and you need to jump

start your vehicle, see “Jump starting”.

The battery is located on the left-hand

side of the engine compartment. The

exterior of the battery should be inspected

periodically for damage such as a cracked

case or cover.

Check the tightness of battery clamps to

ensure good electrical connections. You

should not be able to move them. Also check

each cable for cracks and frayed conductors.

If corrosion (white, fluffy deposits) is

evident, remove the cables from the

battery terminals, clean them with a small wire

brush, then refit them. Accessory stores sell a

useful tool for cleaning the battery post ...

1 2

3

... as well as the battery cable clamps

4

Battery corrosion can be kept to a

minimum by applying a layer of

petroleum jelly to the clamps and

terminals after they are reconnected.

Page 16

1689 Rover 214 & 414 Updated Version 09/97

0•16

Lubricants, fluids, capacities and tyre pressures

Lubricants and fluids

Capacities

Tyre Pressures (tyres cold)

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multigrade engine oil, viscosity SAE 10W/40 to spec.

API-SG or SG/CD, CCMC G4, or RES.22.OL.G4

(Duckhams QS, QXR, Hypergrade Plus, Hypergrade, or

10W/40 Motor Oil)

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Antifreeze to spec. BS 6580 and BS 5117. Ethylene-

glycol based with non-phosphate corrosion inhibitors,

containing no methanol. Mixture 50% by volume

(Duckhams Antifreeze and Summer Coolant)

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Special gearbox oil. Refer to your Rover dealer

(Duckhams Hypoid PT 75W/80 may be used for toppingup only)

Braking system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Hydraulic fluid to spec. SAE J 1703 or DOT 4

(Duckhams Universal Brake and Clutch Fluid)

Power steering system . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic transmission fluid (ATF) to Dexron II D

specification (Duckhams Uni-Matic)

General greasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Multi-purpose lithium-based grease to NLGI consistency

No. 2 (Duckhams LB10)

Engine oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4.5 litres - including filter

Cooling system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.8 litres

Gearbox . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 litres

Power steering reservoir . . . . . . . . . . . . . . . . . . . . . . . . 1.2 litres

Fuel tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55 litres

Washer system reservoir . . . . . . . . . . . . . . . . . . . . . . . 3.1 litres

Front Rear

155 SR 13 tyres

Normal driving conditions . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) 2.1 bar (30 psi)

Loads in excess of four persons . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) 2.3 bar (34 psi)

Speeds in excess of 100 mph - all loads . . . . . . . . . . . . . 2.2 bar (32 psi) 2.2 bar (32 psi)

175/65 TR 14 tyres

All loads - up to 100 mph . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) 2.1 bar (30 psi)

All loads - over 100 mph . . . . . . . . . . . . . . . . . . . . . . . . . 2.2 bar (32 psi) 2.2 bar (32 psi)

185/60 HR 14 tyres

All loads - up to 100 mph . . . . . . . . . . . . . . . . . . . . . . . . . 2.1 bar (30 psi) 2.1 bar (30 psi)

All loads - over 100 mph . . . . . . . . . . . . . . . . . . . . . . . . . 2.5 bar (36 psi) 2.5 bar (36 psi)

Note: Pressures apply only to original equipment tyres and may vary if any other make or type is fitted. Check with

the tyre manufacturer or supplier for correct pressures if necessary

Page 17

2A

1689 Rover 214 & 414 Updated Version 09/97

Chapter 2 Part A

Engine in-car repair procedures

Camshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Camshafts and hydraulic tappets - removal, inspection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Compression test - description and interpretation . . . . . . . . . . . . . . 3

Crankshaft oil seals - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Crankshaft pulley - removal and refitting . . . . . . . . . . . . . . . . . . . . . 6

Cylinder head - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . 13

Cylinder head cover - removal and refitting . . . . . . . . . . . . . . . . . . . 5

Engine oil and filter - renewal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Engine/gearbox mountings - inspection and renewal . . . . . . . . . . . . 19

Flywheel - removal, inspection and refitting . . . . . . . . . . . . . . . . . . . 18

General information and precautions . . . . . . . . . . . . . . . . . . . . . . . . 1

Oil pump - dismantling, inspection and reassembly . . . . . . . . . . . . . 16

Oil pump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Sump - removal and refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Timing belt - removal, inspection, refitting and adjustment . . . . . . . 8

Timing belt covers - removal and refitting . . . . . . . . . . . . . . . . . . . . . 7

Timing belt tensioner and sprockets - removal, inspection and

refitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Top Dead Centre (TDC) for number one piston - locating . . . . . . . . 4

Valve clearances - general information . . . . . . . . . . . . . . . . . . . . . . . 12

2A•1

Contents

Specifications

General

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Four-cylinder in-line, four-stroke, liquid-cooled

Designation:

1.4 8-valve sohc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K8

1.4 16-valve dohc . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . K16

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.00 mm

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79.00 mm

Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1396 cc

Firing order . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-4-2 (No 1 cylinder at timing belt end)

Direction of crankshaft rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Clockwise (seen from right-hand side of vehicle)

Compression ratio:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.75 : 1

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.50 : 1

Minimum compression pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10.3 bar

Maximum compression pressure difference between cylinders . . . . . . 1.4 bar

Maximum power (EEC):

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76 ps (56 kW) @ 5700 rpm

K8 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 ps (55 kW) @ 5500 rpm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95 ps (70 kW) @ 6250 rpm

K16 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90 ps (66 kW) @ 6250 rpm

Maximum torque (EEC):

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117 Nm (86 lbf ft) @ 3500 rpm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 Nm (91 lbf ft) @ 4000 rpm

K16 (with catalytic converter) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120 Nm (89 lbf ft) @ 4000 rpm

Cylinder block/crankcase

Note: Service liners are Grade B

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminium alloy

Cylinder liner bore diameter - 60 mm from top of bore:

Standard - grade A (Red) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.975 to 74.985 mm

Standard - grade B (Blue) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.986 to 74.995 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75.045 mm

Easy, suitable for

novice with little

experience

Fairly easy, suitable

for beginner with

some experience

Fairly difficult,

suitable for competent

DIY mechanic

Difficult, suitable for

experienced DIY

mechanic

Very difficult,

suitable for expert DIY

or professional

Degrees of difficulty

5

4

3

2

1

Page 18

Crankshaft

Number of main bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Main bearing journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.979 to 48.000 mm

Main bearing journal size grades:

Grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.993 to 48.000 mm

Grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.986 to 47.993 mm

Grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47.979 to 47.986 mm

Crankpin journal diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.986 to 43.007 mm

Crankpin journal size grades:

Grade A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43.000 to 43.007 mm

Grade B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.993 to 43.000 mm

Grade C . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42.986 to 42.993 mm

Main bearing and crankpin journal maximum ovality . . . . . . . . . . . . . . . 0.010 mm

Main bearing and big-end bearing running clearance . . . . . . . . . . . . . . 0.021 to 0.049 mm

Crankshaft endfloat:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.10 to 0.30 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.50 mm

Thrustwasher thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.61 to 2.65 mm

Gudgeon pins

Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18.0 mm

Fit in connecting rod . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Interference

Pistons and piston rings

Note: Service pistons are Grade B

Piston diameter: Grade A Grade B

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.940 to 74.955 mm 74.956 to 74.970 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74.945 to 74.960 mm 74.960 to 74.975 mm

Piston-to-bore clearance:

K8 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.015 to 0.045 mm

K16 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.010 to 0.040 mm

Service limit - all . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.080 mm

Piston ring end gaps (fitted 20 mm from top of bore):

Top compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.45 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.50 mm

Second compression ring - all models . . . . . . . . . . . . . . . . . . . . . . . . 0.30 to 0.50 mm

Oil control ring:

K8 - standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 1.00 mm

K16:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 to 0.50 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.60 mm

Piston ring-to-groove clearance:

Top compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.09 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.07 mm

Second compression ring:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.08 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 to 0.07 mm

Oil control ring - all models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.06 mm

Cylinder head

Material . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Aluminium alloy

Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118.95 to 119.05 mm

Reface limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 mm

Maximum acceptable gasket face distortion . . . . . . . . . . . . . . . . . . . . . 0.05 mm

Valve seat angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Valve seat width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.5 mm

Seat cutter correction angle:

Upper . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30°

Lower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60°

Valve stem installed height:

K8:

new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.95 to 40.81 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41.06 mm

K16:

new . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38.93 to 39.84 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40.10 mm

2A•2 Engine in-car repair procedures

1689 Rover 214 & 414 Updated Version 09/97

Page 19

Valves

Seat angle:

Inlet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45°

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44° 30’

Head diameter:

Inlet:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28.0 mm

Exhaust:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24.0 mm

Stem outside diameter:

Inlet:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.967 to 6.975 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.952 to 5.967 mm

Exhaust:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.952 to 6.967 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5.947 to 5.962 mm

Guide inside diameter:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.000 to 7.025 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.000 to 6.025 mm

Stem-to-guide clearance:

Inlet:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.03 to 0.04 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 mm

Exhaust:

standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.07 to 0.08 mm

service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.11 mm

Valve timing:

K8:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13° BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47° ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53° BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7° ATDC

K16:

Inlet opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15° BTDC

Inlet closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45° ABDC

Exhaust opens . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55° BBDC

Exhaust closes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5° ATDC

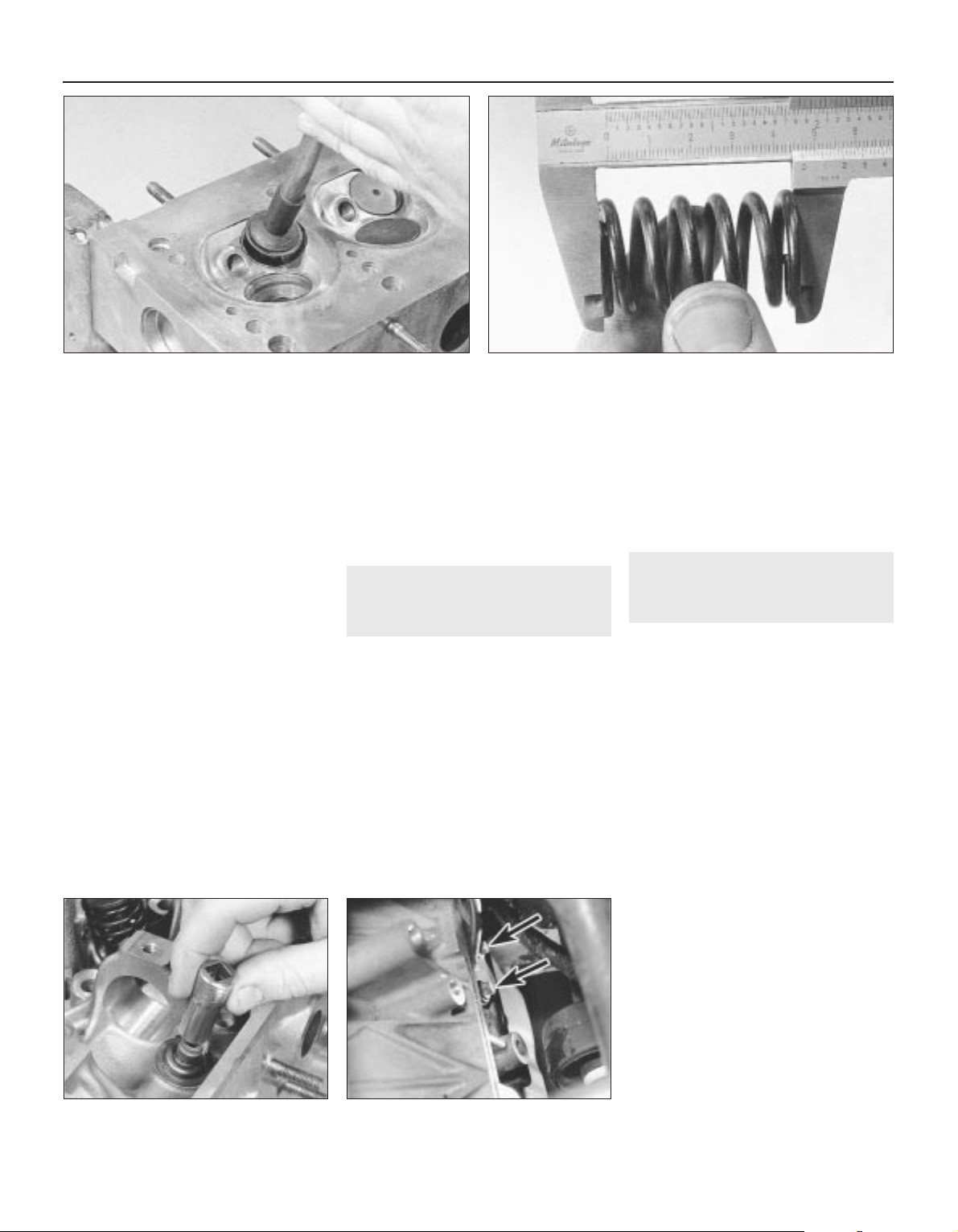

Valve spring free length:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46.2 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50.0 mm

Valve guide fitted height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.0 mm

Camshaft

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Toothed belt

Number of bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Bearing journal running clearance:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 to 0.094 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.150 mm

Camshaft endfloat:

Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.060 to 0.190 mm

Service limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.500 mm

Valve lift:

K8 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9.0 mm

K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.2 mm

Hydraulic tappet outside diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32.959 to 32.975 mm

Lubrication system

System pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.0 bar @ idle speed

Oil pump type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Trochoidal, eccentric-rotor

Oil pump clearances:

Rotor endfloat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 to 0.06 mm

Outer rotor-to-body clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.28 to 0.36 mm

Rotor lobe clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 to 0.13 mm

Pressure relief valve operating pressure . . . . . . . . . . . . . . . . . . . . . . . . 4.1 bar

Oil pressure warning lamp lights at . . . . . . . . . . . . . . . . . . . . . . . . . . . . Below 0.3 to 0.5 bar

Engine in-car repair procedures 2A•3

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 20

Torque wrench settings Nm lbf ft

Spark plug (HT) lead clip screws - K8 . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Air intake duct support bracket-to-cylinder head screws . . . . . . . . . . . 4 3

Spark plug cover screws - K16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 1.5

Cylinder head cover bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Camshaft bearing cap/carrier-to-cylinder head bolts . . . . . . . . . . . . . . 9 7

Cylinder head bolts:

1st stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

2nd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through 180°

3rd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through (a further) 180°

Timing belt cover fasteners:

Upper right-hand (outer) cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 3

Lower and upper left-hand (inner) covers . . . . . . . . . . . . . . . . . . . . . . 9 7

Timing belt tensioner backplate clamp bolt . . . . . . . . . . . . . . . . . . . . . . 25 19

Timing belt tensioner pulley Allen screw . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Camshaft sprocket bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33 24

Crankshaft pulley bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160 118

Oil pump-to-cylinder block/crankcase bolt and screws . . . . . . . . . . . . . 9 7

Alternator mounting bracket-to-cylinder block/crankcase bolts . . . . . . 45 33

Dipstick tube-to-cylinder block/crankcase bolts . . . . . . . . . . . . . . . . . . 9 7

Flywheel bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Transmission-to-engine bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Flywheel cover plate screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Flywheel rear cover plate bolt and nut . . . . . . . . . . . . . . . . . . . . . . . . . . 38 28

Big-end bearing cap bolts:

1st stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 15

2nd stage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tighten through 45°

Main bearing ladder-to-cylinder block/crankcase bolts . . . . . . . . . . . . . 10 7

Oil rail-to-main bearing ladder nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Oil pump pick-up/strainer pipe bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 7

Sump bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10 7

Engine oil drain plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42 31

Engine/transmission right-hand mounting:

Bracket-to-cylinder block/crankcase bolts . . . . . . . . . . . . . . . . . . . . . 45 33

Mounting-to-bracket nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 74

Mounting-to-body through-bolt and nut . . . . . . . . . . . . . . . . . . . . . . . 85 63

Engine/transmission left-hand mounting:

Mounting-to-body bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 33

Mounting-to-transmission bracket bolts . . . . . . . . . . . . . . . . . . . . . . 60 44

Transmission bracket bolts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 100 74

Engine/transmission rear mounting:

Mounting bracket-to-transmission bolt . . . . . . . . . . . . . . . . . . . . . . . 85 63

Connecting link-to- transmission bracket bolt . . . . . . . . . . . . . . . . . . 60 44

Connecting link-to-body bolt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85 63

Anti-beaming bracket-to-support bracket bolt . . . . . . . . . . . . . . . . . . . 45 33

2A•4 Engine in-car repair procedures

1689 Rover 214 & 414 Updated Version 09/97

1 General information and

precautions

How to use this Chapter

This Part of the Chapter describes those

repair procedures that can reasonably be

carried out on the engine whilst it remains in

the vehicle. If the engine has been removed

from the vehicle and is being dismantled as

described in Part B of this Chapter, any

preliminary dismantling procedures can be

ignored.

Note that whilst it may be possible

physically to overhaul items such as the

piston/connecting rod assemblies with the

engine in the vehicle, such tasks are not

usually carried out as separate operations

and usually require the execution of several

additional procedures (not to mention the

cleaning of components and of oilways). For

this reason, all such tasks are classed as

major overhaul procedures and are described

in Part B of this Chapter.

Engine information

The engine is of four-cylinder, in-line type,

mounted transversely at the front of the

vehicle with the clutch and transmission on its

left-hand end. The engine is available in two

forms - the K8 engine, which is the eight-valve

single overhead camshaft engine fitted to the

carburettor-equipped 214 S model, and the

K16 engine, which is a sixteen-valve double

overhead camshaft engine which is fitted to all

fuel-injected models. Apart from the different

cylinder head designs, both engines are of

identical construction.

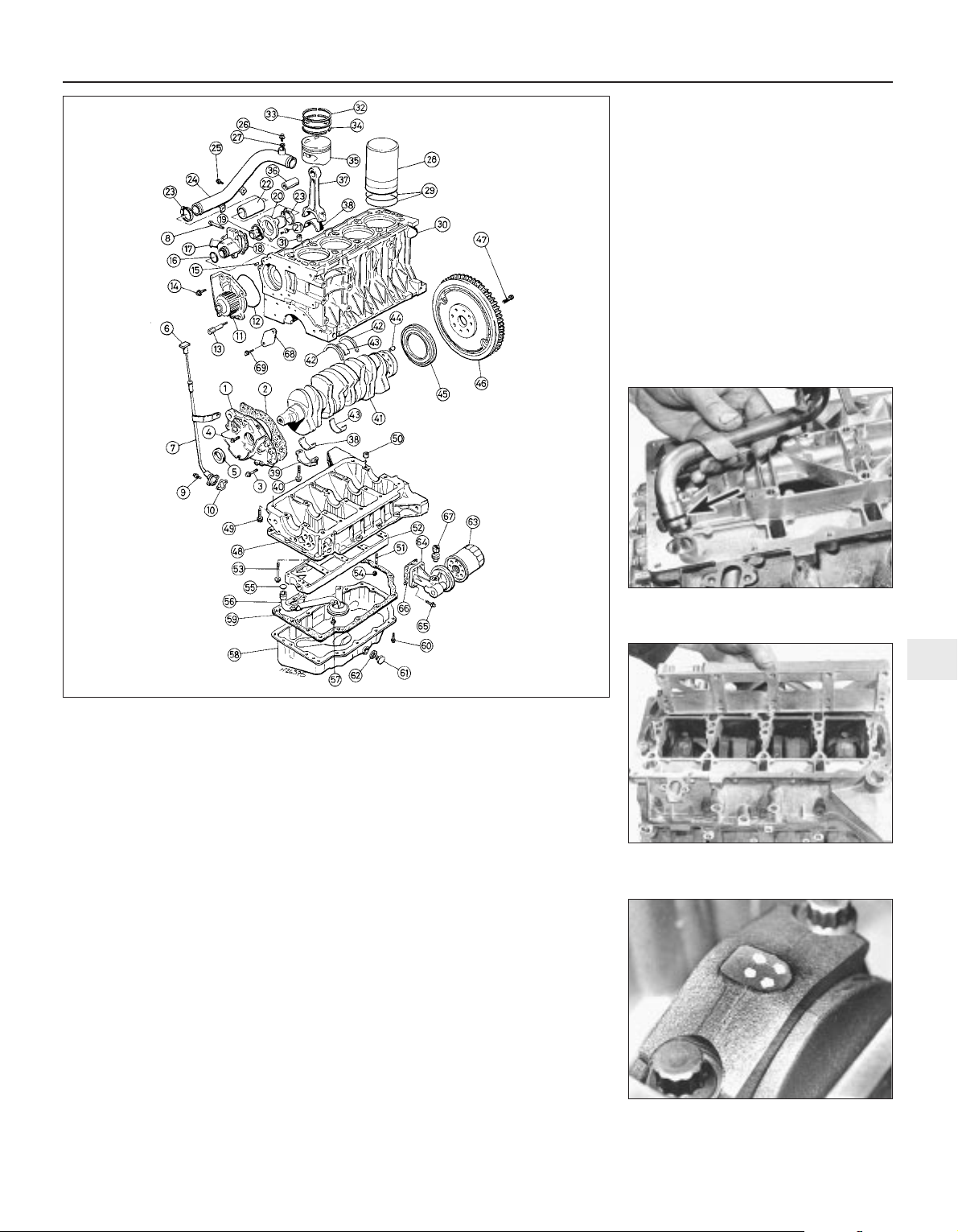

Apart from the pressed steel sump, the

plastic timing belt covers and the aluminium

alloy cylinder head cover, the engine consists

of three major castings which are the cylinder

head, the cylinder block/crankcase and the

crankshaft main bearing ladder. There is also

an oil rail underneath the main bearing ladder

and the camshaft carrier/bearing caps.

All major castings are of aluminium alloy

and are clamped together by ten long

through-bolts which perform the dual role of

cylinder head bolts and crankshaft main

bearing fasteners. Since these bolts pass

through the cylinder block/crankcase and the

main bearing ladder, the oil rail is secured also

to the main bearing ladder (by two nuts) and

the main bearing ladder is secured also to the

cylinder block/crankcase (by ten smaller bolts)

so that the cylinder head can be removed

without disturbing the rest of the engine. The

passages provided for the bolts in the major

castings are used as breather passages or as

returns for the oil to the sump.

Page 21

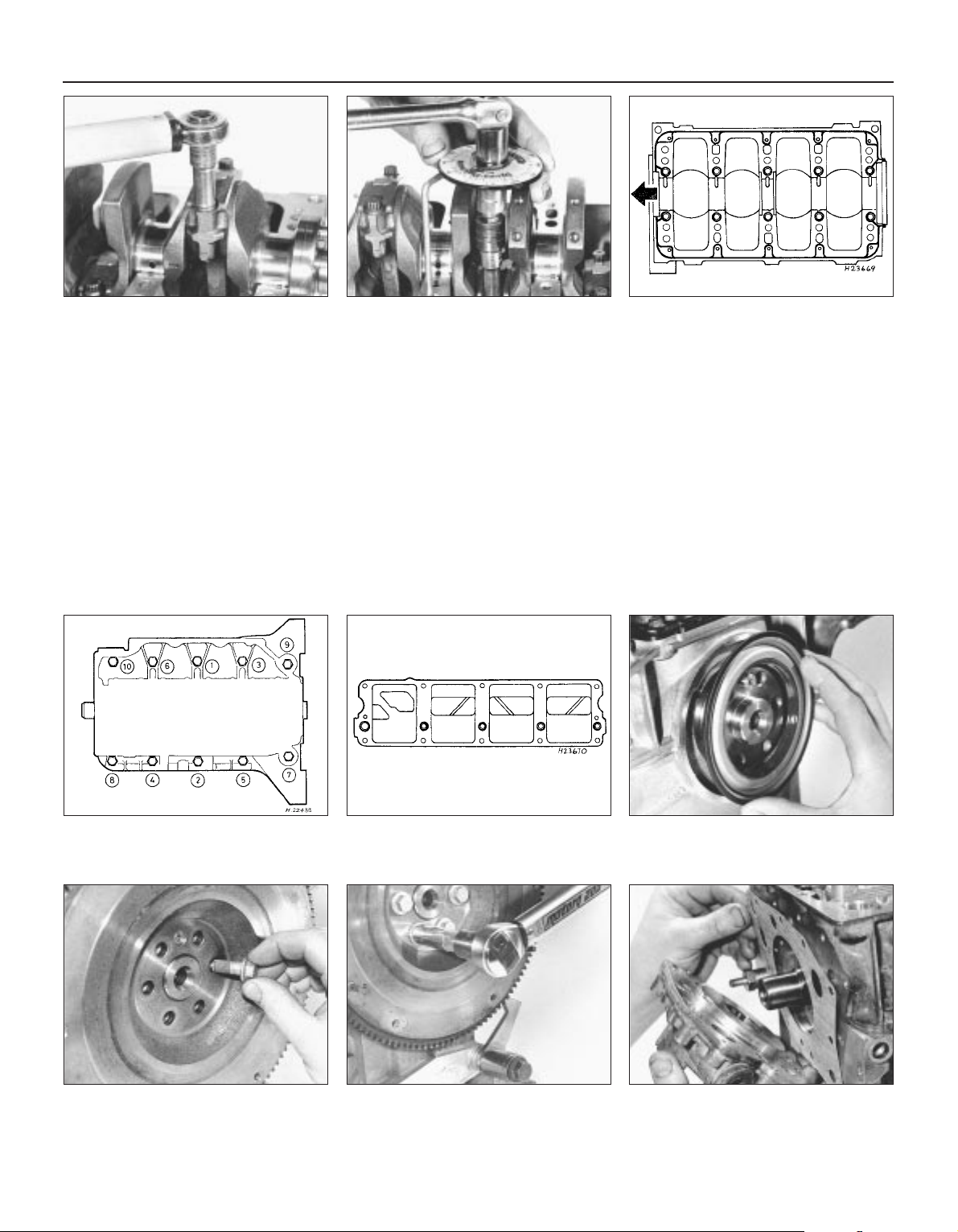

The crankshaft runs in five main bearings.

Thrustwashers are fitted to the centre main

bearing (upper half) to control crankshaft

endfloat.

The connecting rods rotate on horizontallysplit bearing shells at their big-ends. The

pistons are attached to the connecting rods

by gudgeon pins which are an interference fit

in the connecting rod small-end eyes. The

aluminium alloy pistons are fitted with three

piston rings, comprising two compression

rings and an oil control ring.

The cylinder bores are formed by

replaceable wet liners which are located from

their top ends. Two sealing rings are fitted at

the base of each liner to prevent the escape of

coolant into the sump.

The inlet and exhaust valves are each

closed by coil springs and operate in guides

pressed into the cylinder head. The valve seat

inserts are pressed into the cylinder head and

can be renewed separately if worn.

On the K8 engine, the camshaft is driven by

a toothed timing belt and operates the eight

valves via self-adjusting hydraulic tappets,

thus eliminating the need for routine checking

and adjustment of the valve clearances. The

camshaft rotates in six bearings that are linebored direct in the cylinder head and the

(bolted-on) bearing caps. This means that the

bearing caps are not available separately from

the cylinder head and must not be

interchanged with others from another engine.

The distributor is driven from the left-hand

end of the camshaft and the mechanical fuel

pump is operated by an eccentric on the

camshaft.

Apart from the fact that it has two

camshafts, one inlet and one exhaust, each

controlling eight valves and both retained by a

single camshaft carrier, the same applies to

the K16 engine. On the K16 engine, the

distributor is driven from the left-hand end of

the inlet camshaft. The fuel pump is

electrically-operated.

On both engine types, the coolant pump is

driven by the timing belt.

Lubrication is by means of an eccentricrotor trochoidal pump mounted on the

crankshaft right-hand end. It draws oil

through a strainer located in the sump and

then forces it through an externally-mounted

full-flow cartridge-type filter into galleries in

the oil rail and cylinder block/crankcase, from

where it is distributed to the crankshaft

(main bearings) and camshaft(s). The big-end

bearings are supplied with oil via internal

drillings in the crankshaft, while the camshaft

bearings and the hydraulic tappets receive a

pressurised supply. The camshaft lobes and

valves are lubricated by splash, as are all

other engine components.

Repair operations possible with

the engine in the car

The following work can be carried out with the

engine in the vehicle:

a) Compression pressure - testing.

b) Cylinder head cover - removal and

refitting.

c) Crankshaft pulley - removal and refitting.

d) Timing belt covers - removal and refitting.

e) Timing belt - removal, refitting and

adjustment.

f) Timing belt tensioner and sprockets -

removal and refitting.

g) Camshaft oil seal(s) - renewal.

h) Camshaft(s) and hydraulic tappets -

removal, inspection and refitting.

i) Cylinder head - removal and refitting.

j) Cylinder head and pistons -

decarbonising.

k) Sump - removal and refitting.

l) Oil pump - removal, overhaul and refitting.

m) Crankshaft oil seals - renewal.

n) Engine/transmission mountings -

inspection and renewal.

o) Flywheel - removal, inspection and

refitting.

Precautions

Note that a side-effect of the above

described engine design is that the crankshaft

cannot be rotated once the cylinder head and

block through-bolts have been slackened.

During any servicing or overhaul work the

crankshaft always must be rotated to the

desired position before the bolts are

disturbed.

2 Engine oil and filter - renewal

1 Details of checking the engine oil levels and

renewing both the oil and filter are contained

in “Weekly Checks” and Chapter 1.

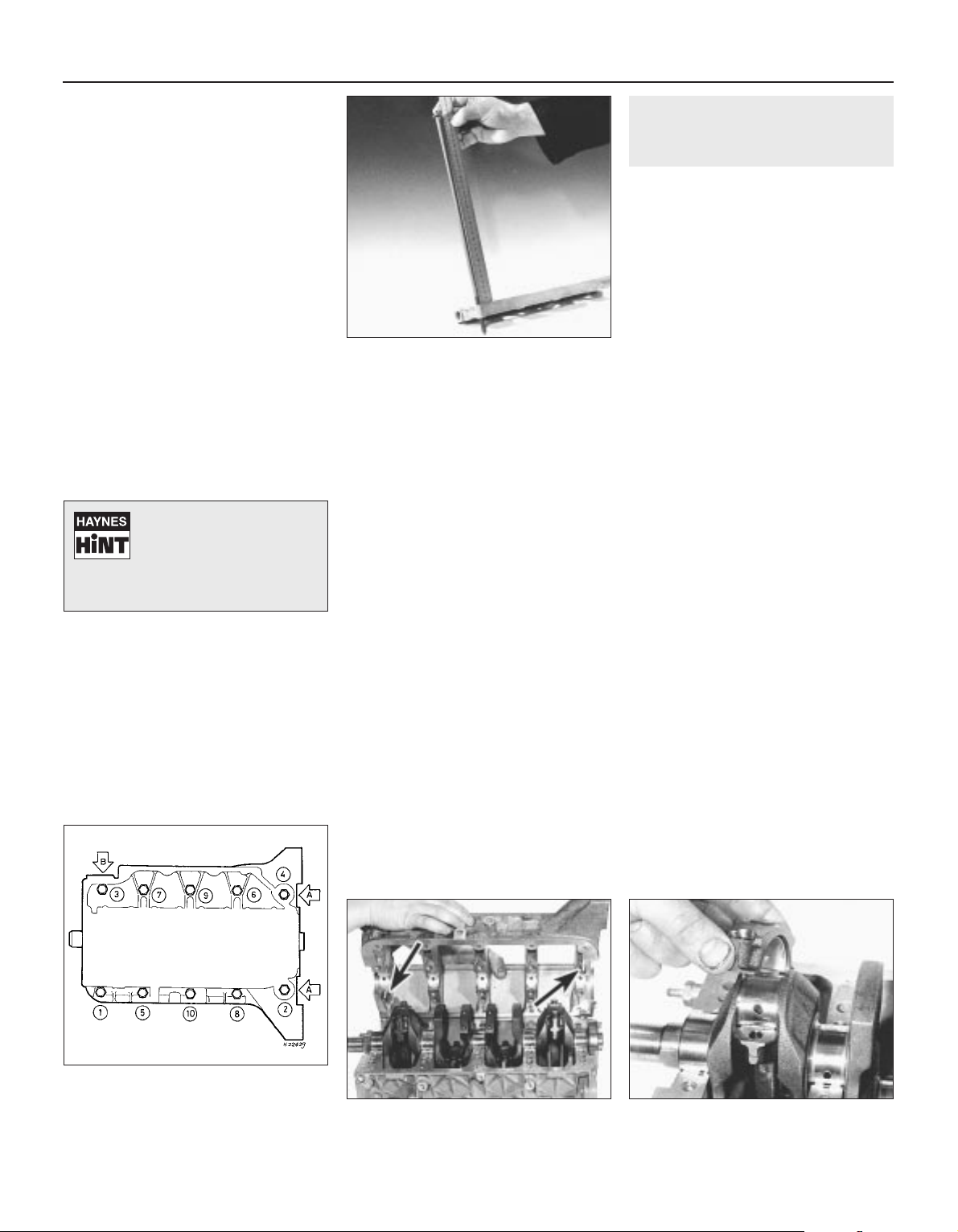

3 Compression test -

description and interpretation

2

1 When engine performance is down, or if

misfiring occurs which cannot be attributed to

the ignition or fuel systems, a compression

test can provide diagnostic clues as to the

engine’s condition. If the test is performed

regularly it can give warning of trouble before

any other symptoms become apparent.

2 The engine must be fully warmed up to

normal operating temperature, the battery

must be fully charged and the spark plugs

must be removed. The aid of an assistant will

be required.

3 Disable the ignition system by

disconnecting the ignition HT coil lead from

the distributor cap and earthing it on the

cylinder block. Use a jumper lead or similar

wire to make a good connection.

4 Fit a compression tester to the No 1

cylinder spark plug hole. The type of tester

which screws into the plug thread is preferred

(see illustration).

5 Have the assistant hold the throttle wide

open and crank the engine on the starter

motor. After one or two revolutions, the

compression pressure should build up to a

maximum figure and then stabilise. Record

the highest reading obtained.

6 Repeat the test on the remaining cylinders,

recording the pressure in each.

7 All cylinders should produce very similar

pressures. Any difference greater than that

specified indicates the existence of a fault.

Note that the compression should build up

quickly in a healthy engine. Low compression

on the first stroke, followed by gradually

increasing pressure on successive strokes,

indicates worn piston rings. A low

compression reading on the first stroke, which

does not build up during successive strokes,

indicates leaking valves or a blown head

gasket (a cracked head could also be the

cause). Deposits on the undersides of

the valve heads can also cause low

compression.

8 If the pressure in any cylinder is reduced to

the specified minimum or less, carry out the

following test to isolate the cause. Introduce a

teaspoonful of clean oil into that cylinder

through its spark plug hole and repeat the

test.

9 If the addition of oil temporarily improves

the compression pressure, this indicates that

bore or piston wear is responsible for the

pressure loss. No improvement suggests that

leaking or burnt valves, or a blown head

gasket, may be to blame.

10 A low reading from two adjacent cylinders

is almost certainly due to the head gasket

having blown between them and the presence

of coolant in the engine oil will confirm this.

11 If one cylinder is about 20 percent lower

than the others and the engine has a slightly

rough idle, a worn camshaft lobe could be the

cause.

12 If the compression reading is unusually

high, the combustion chambers are probably

coated with carbon deposits. If this is the

case, the cylinder head should be removed

and decarbonised.

13 On completion of the test, refit the spark

plugs and reconnect the ignition system.

Engine in-car repair procedures 2A•5

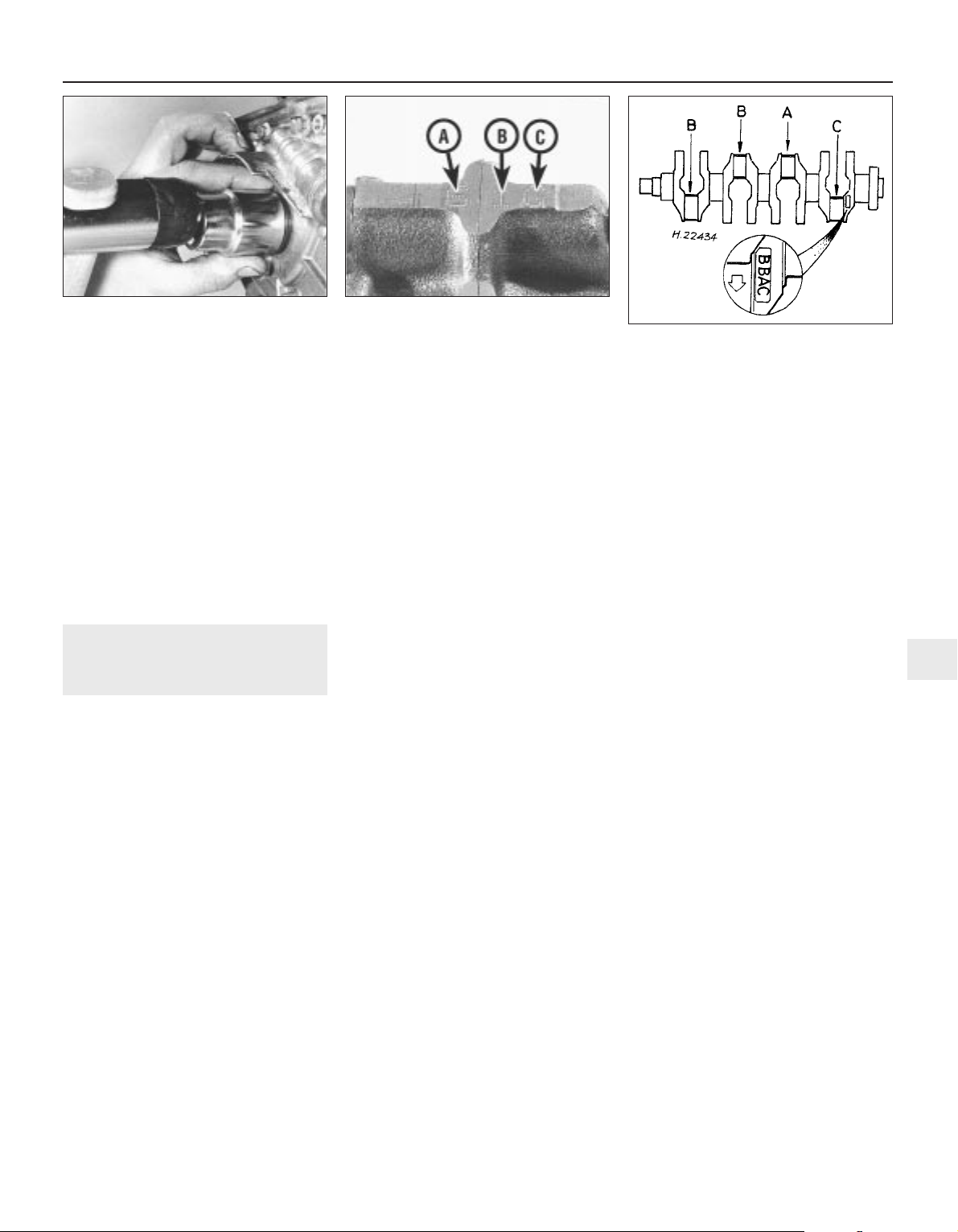

3.4 Measuring compression pressure

2A

1689 Rover 214 & 414 Updated Version 09/97

Page 22

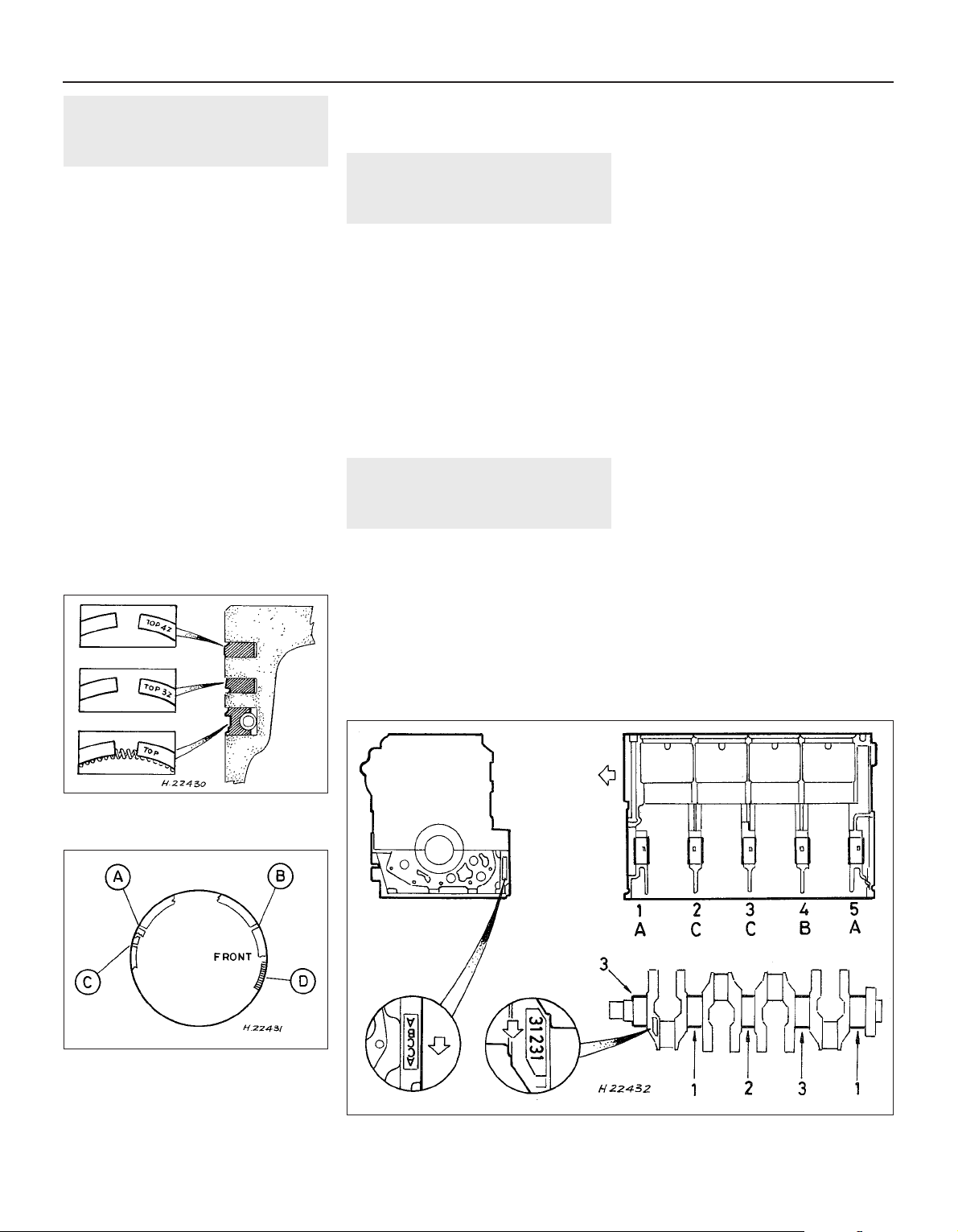

4 Top Dead Centre (TDC) for

number one piston - locating

2

General

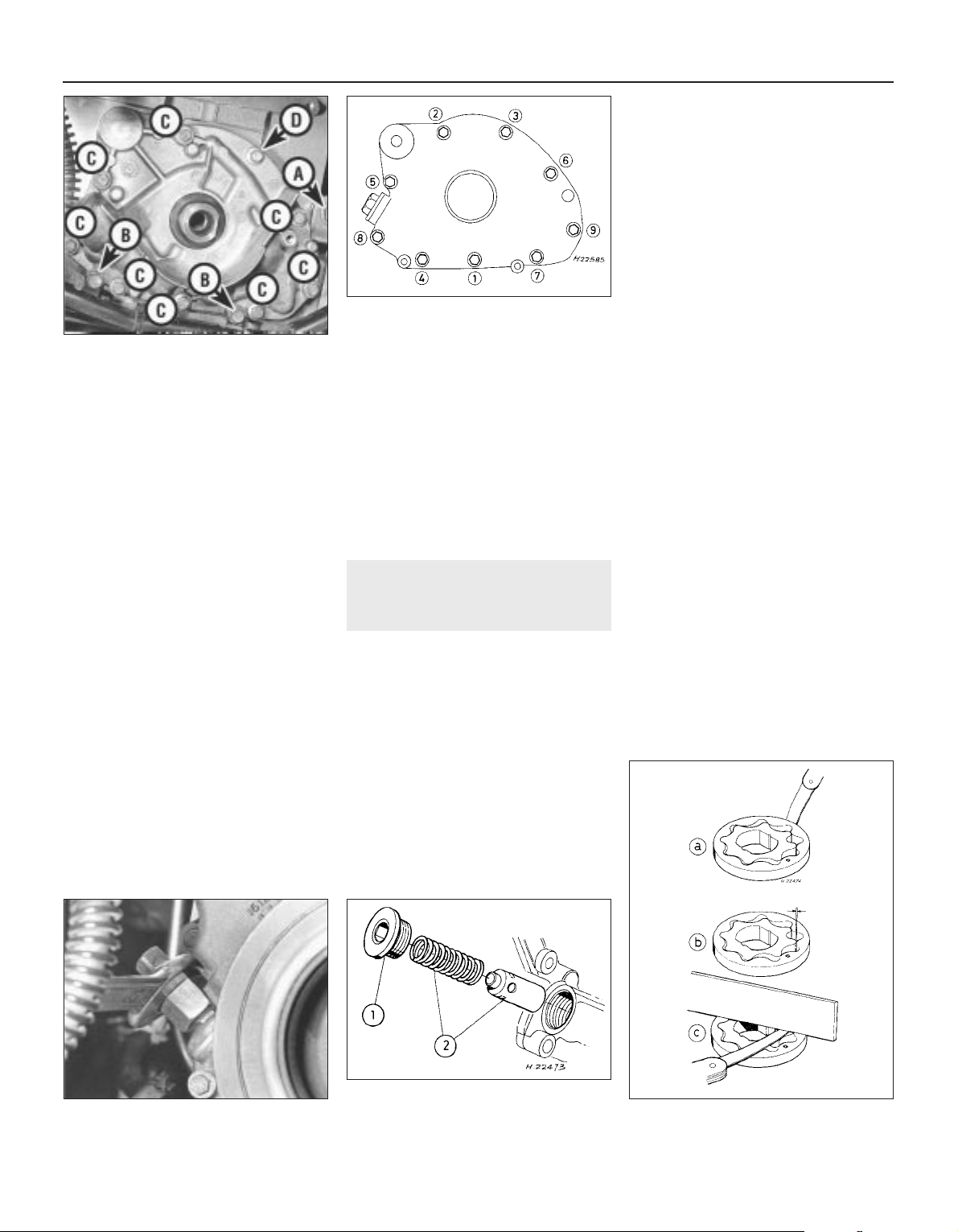

1 The crankshaft pulley, crankshaft and

camshaft sprockets are provided by the

factory with clear marks which align only at

90° BTDC. This positions the pistons half-way

up the bores so that there is no risk of

damage as the engine is reassembled. These

marks do not indicate TDC. Use only the

ignition timing marks, as described in this

Section, to find TDC.

2 Top dead centre (TDC) is the highest point

in its travel up-and-down the cylinder bore

that each piston reaches as the crankshaft