Page 1

GV3000/SE 230 VAC 30-100 HP

General Purpose (Volts/Hertz)

and Vector Duty Drive

Software Start-Up and Reference Manual

Version 6.04

Instruction Manual D2-3416-1

Page 2

The information in this manual is subject to change without notice.

Throughout this manual, the following notes are used to alert you to safety considerations:

ATTENTION: Identifies information about practices or circumstances that can lead to personal

injury or death, property damage, or economic loss.

!

Important: Identifies information that is critical for successful application and understanding of the product.

ATTENTION: Only qualified electrical personnel familiar with the construction and operation of

this equipment and the hazards involved should install, adjust, operate, or service this equipment.

!

Read and understand this manual and other applicable manuals in their entirety before

proceeding. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: DC bus capacitors retain hazardous voltages after input power has been

disconnected. After disconnecting input power, wait five (5) minutes for the DC bus capacitors

to discharge and then check the voltage with a voltmeter to ensure the DC bus capacitors are

discharged before touching any internal components. Failure to observe this precaution could

result in severe bodily injury or loss of life.

ATTENTION: The drive can operate at and maintain zero speed. The user is responsible for

assuring safe conditions for operating personnel by providing suitable guards, audible or visual

alarms, or other devices to indicate that the drive is operating or may operate at or near zero

speed. Failure to observe this precaution could result in severe bodily injury or loss of life.

ATTENTION: Do not install modification kits with power applied to the drive. Disconnect and

lock out incoming power before attempting such installation or removal. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION: The user must provide an external, hardwired emergency stop circuit outside of

the drive circuitry. This circuit must disable the system in case of improper operation.

Uncontrolled machine operation may result if this procedure is not followed. Failure to observe

this precaution could result in bodily injury.

ATTENTION: The user is responsible for conforming with all applicable local, national, and

international codes. Failure to observe this precaution could result in damage to, or destruction

of, the equipment.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

ControlNet is a trademark of ControlNet International, Ltd.

PROFIBUS is a trademark of PROFIBUS International.

GV3000/SE, AutoMax, ControlNet, and Reliance are trademarks of Rockwell International.

© 1999 Rockwell International Corporation.

Page 3

CONTENTS

Preface .............................................................................................................................. VII

Chapter 1 Starting Up the Drive for Volts/Hertz Regulation

1.1 Preparing for Start Up (Volts/Hertz)......................................................... 1-2

1.2 Start-Up Procedure (Volts/Hertz)............................................................. 1-3

Chapter 2 Starting Up the Drive for Vector Regulation

2.1 Preparing for Start Up (Vector)................................................................ 2-2

2.2 Start-Up Procedure (Vector).................................................................... 2-3

Chapter 3 Using the Keypad/Display to Program, Monitor, and Control the Drive

3.1 Monitor Mode ........................................................................................... 3-2

3.1.1 Displaying the Selected Reference .............................................. 3-2

3.1.2 Entering the Manual Speed Reference ........................................ 3-3

3.2 Program Mode ......................................................................................... 3-3

3.3 Drive Control ............................................................................................ 3-4

3.4 The Display .............................................................................................. 3-4

3.4.1 Display Range .............................................................................. 3-4

3.4.2 Scaling the Manual Reference, Speed Display, and

Reference Display Using P.028 ................................................... 3-5

3.5 The Keypad.............................................................................................. 3-6

3.6 Drive Status LEDs ................................................................................... 3-8

Chapter 4 Programming Reference

4.1 Parameter Menus .................................................................................... 4-1

4.2 Parameter Types ..................................................................................... 4-2

4.3 Displaying or Changing Parameter Values ............................................. 4-3

4.4 Ensuring Program Security...................................................................... 4-5

4.5 First Menu Parameters ............................................................................ 4-6

4.5.1 First Menu General Parameter Descriptions (P.000 to P.006) .... 4-6

4.6 Second Menu Parameters ....................................................................... 4-11

4.6.1 Entering the Second Menu Password .......................................... 4-11

4.6.2 Second Menu General Parameter Descriptions (P.007

to P.099) ..................................................................................... 4-14

4.6.3 Second Menu V/Hz Parameter Descriptions (H.000 to

H.022) ..................................................................................... 4-57

4.6.4 Second Menu Vector Parameter Descriptions (U.000 to

U.048) ..................................................................................... 4-70

Chaoter 5 Troubleshooting the Drive Using Error Codes

5.1 Identifying Alarm Codes and Recovering ................................................ 5-2

5.2 Identifying Fault Codes and Recovering ................................................. 5-3

5.3 Accessing, Reading, and Clearing the Faults in the Error Log ............... 5-6

5.4 Identifying Fatal Fault Codes and Recovering ........................................ 5-9

Table of Contents

I

Page 4

Appendix A Alphabetical Listing of Parameters................................................................... A-1

Appendix B Record of User Parameter Settings .................................................................. B-1

Appendix C Power Module-Dependent Parameter Default Values

(230 V Series)....................................................................................................... C-1

Appendix D European and Japanese Default Parameter Settings ..................................... D-1

Appendix E Configuring the Digital Inputs When the RMI Board is

Installed in the Drive........................................................................................... E-1

Appendix F Using the Terminal Strip Analog Input ............................................................. F-1

Appendix G Drive Regulation Overview ................................................................................ G-1

II

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 5

List of Figures

Figure 3.1 – Keypad/Display ........................................................................... 3-1

Figure 3.2 – Example of a Monitor Mode Display ........................................... 3-2

Figure 3.3 – Example of a Program Mode Display ......................................... 3-4

Figure 4.1 – Parameter Menu Structure.......................................................... 4-2

Figure 4.2 – Analog Output Selection and Setting.......................................... 4-21

Figure 4.3 – Trim Reference Source Selection ............................................... 4-22

Figure 4.4 – Draw and Trim Gain .................................................................... 4-23

Figure 4.5 – S-Curves ..................................................................................... 4-25

Figure 4.6 – Typical Preset Operation ............................................................ 4-34

Figure 4.7 – Drive Start, Stop, and Running Status when Configured for

Edge Control vs. Level Control ................................................... 4-44

Figure 4.8 – Sample Alarm Circuit for 30-100 HP Drives Using the Level

Sense Enable Feature ................................................................ 4-45

Figure 4.9 – Signal Selection for Network Output Registers .......................... 4-54

Figure 4.10 – Volts/Hertz Ratio ......................................................................... 4-57

Figure 4.11 – Torque Boost Voltage ................................................................. 4-59

Figure 4.12 – Avoidance Frequency Band........................................................ 4-63

Figure 4.13 – Volts/Hertz Curve Selection ........................................................ 4-67

Figure 4.14 – Motor Equivalent Circuit Diagram for Calculating Rotor Time

Constant...................................................................................... 4-82

Figure 4.15 – Outer Control Loop Proportional Trim......................................... 4-92

Figure F.1 – Terminal Strip Analog Input ........................................................ F-1

Figure F.2 – Analog Input Conversion Scaling (Speed and Trim Reference) . F-3

Figure G.1 – Volts/Hertz Regulator Block Diagram ......................................... G-3

Figure G.2 – Flux Vector Control Block Diagram ............................................ G-4

Figure G.3 – Sensorless Vector Control Block Diagram.................................. G-4

Figure G.4 – Vector Regulator: Reference Detail ............................................ G-5

Figure G.5 – Vector Regulator: Speed Loop Detail ......................................... G-6

Figure G.6 – Vector Speed PI and Iq Reference Limit Selection .................... G-7

Figure G.7 – Outer Control Loop Block Diagram ............................................. G-8

Table of Contents

III

Page 6

List of Tables

Table 3.1 – Display Range Examples ............................................................ 3-5

Table 3.2 – Drive Status LEDs....................................................................... 3-8

Table 3.3 – Monitor Mode LEDs .................................................................... 3-9

Table 4.1 – Speed Reference Source Based on P.000 and AUTO/MAN

Key Status................................................................................... 4-7

Table 4.2 – Function Selection for Digital Inputs 6, 7, and 8 ......................... 4-14

Table 4.3 – Acceptable P.007 and P.008 Selection Combinations ............... 4-18

Table 4.4 – Preset Speed Digital Inputs ........................................................ 4-33

Table 4.5 – Faults That Can Be Auto Reset .................................................. 4-37

Table 4.6 – AUTO/MAN Key Status Based on P.000 and P.052 .................. 4-41

Table 4.7 – STOP/RESET Key Status Based on P.000 and P.055 .............. 4-46

Table 5.1 – List of Alarm Codes..................................................................... 5-2

Table 5.2 – List of Fault Codes ...................................................................... 5-3

Table 5.3 – Fatal Fault Codes That Can Be Reset........................................ 5-9

Table F.1 – Analog Input Conversion Scaling for Speed or Trim Reference. F-2

Table F.2 – Analog Input Conversion Scaling for Torque Reference ............ F-4

Table of Contents

V

Page 7

PREFACE

This manual is a start-up and programming reference guide for the version 6.04

GV3000/SE (Sensorless Enhanced) drive. The drive can be set up for either volts

per hertz (V/Hz) or vector regulation. This manual provides a start-up procedure for

both.

The start-up procedures are followed by reference information. This information

includes a complete list of all parameters and a description of the keypad/display.

• You will need to know to use the keypad to perform the start-up procedures

described in chapters 1 and 2. If you do not, refer to chapter 3 first.

• For drives that will be set up for V/Hz regulation, go to chapter 1 for the start-up

procedure.

• For drives that will be set up for vector regulation, go to chapter 2 for the start-up

procedure.

• For a description of all the parameters, go to chapter 4.

• For troubleshooting guidelines, go to chapter 5.

• For a description of the drive hardware, refer to the GV3000/SE 230 VAC Drive

Hardware Reference, Installation, and Troubleshooting instruction manual

(D2-3417-1).

New Features in Version 6.04

The GV3000/SE version 6.04 software includes support for the following features:

• Optional outer control loop without requiring an option board (vector control

only). See U.040 through U.048.

• Enhanced analog input configuration. See P.011 (Analog Input Configure).

• Enhanced output relay configuration. See P.013 (Output Relay Configuration).

Getting Assistance from Reliance Electric

If you have any questions or problems with the products described in this instruction

manual, contact your local Reliance sales office. For technical assistance, call

1-800-726-8112.

Preface

VII

Page 8

CHAPTER 1

Starting Up the Drive

for Volts/Hertz Regulation

This chapter describes the basic start-up procedure for drives which utilize open-loop

V/Hz regulation. V/Hz regulation is the default method of regulation. You do not

need to select it.

If you are starting up a drive which will perform vector regulation, refer to the vector

start-up procedure in chapter 2.0 instead. Do not perform the start-up procedure in

this chapter.

The start-up procedure below provides step-by-step instructions for:

• powering up

• checking monitor mode displays

• accessing program mode

• configuring General parameters (designated with a "P")

• configuring specific V/Hz parameters (designated with an "H")

• checking motor rotation direction

• running the drive

This start-up procedure describes how to program the minimum set of parameters

that usually need to be programmed for applications using V/Hz regulation. Once

you program these parameters, their values are retained even if power is lost. You

only need to re-program them if you want to change how the drive operates.

Your application may require programming other parameters in addition to the ones

described in this start-up procedure. Refer to chapter 4 for a description of all the

parameters to verify whether you need to program any additional parameters as

well. Appendix A provides a list of parameters listed alphabetically.

Throughout this manual, you will see references to parameter names and the

numbers that identify them for the drive. This manual uses the same format that will

be shown on the keypad/display to refer to parameters:

P.nnn

U.nnn

H.nnn

r.nnn

where: nnn is a number

P designates General parameters

U designates Vector parameters

H designates Volts/Hertz parameters

r designates optional RMI parameters

Starting Up the Drive for Volts/Hertz Regulation

1-1

Page 9

1.1 Preparing for Start Up (Volts/Hertz)

Read through the following sections to prepare for the start-up procedure.

What You Need To Know:

• You must be qualified to perform the procedure and be familiar with V/Hz

regulation.

• You should be familiar with the keypad/display. If you are not familiar with the

keypad/display, refer to chapter 3, which describes it.

What You Need To Do:

• Complete all hardware installation as described in the hardware reference

manual. This includes connecting input power, input transformers (if required),

disconnects, fuses, and the terminal strip on the drive.

• Record the following motor data from each motor nameplate for use during the

procedure. Space is provided for recording information from three motors:

Motor rated amps:

Motor rated volts:

Motor base frequency:

Motor rated amps:

Motor rated volts:

Motor base frequency:

Motor rated amps:

Motor rated volts:

Motor base frequency:

• Connect the drive to the motor.

• Check that you have not been prevented from programming the drive. If the

PASSWORD LED on the keypad is on, programming has been prevented in

parameter P.051, Programming Disable. Refer to section 4.4 in this manual for

the procedure to enable programming.

If You Have a Problem:

To Exit:

During most of the start-up procedure, you will be in program mode, which is used

to program parameters. If you want to stop programming parameters, you can exit

program mode. You can do this by pressing the PROGRAM key until the

PROGRAM LED turns off. This will place the keypad/display in monitor mode, the

default. You can read more about these modes in chapter 3.

1-2

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 10

To Restore a Default Parameter Value after Writing over It:

If you enter the wrong value while programming parameters, you can restore the

default if you have not yet pressed the ENTER key. To do so:

1. Press the PROGRAM key.

2. Press the ENTER key. The default value of the parameter will be displayed

again. You can select it with ENTER or enter a new one and press ENTER.

To Restore All the Default Values to General (P) Parameters:

If you need to restore all the default values for General (P) parameters after

programming them, you can do so using the Restore Defaults parameter (P.050).

1.2 Start-Up Procedure (Volts/Hertz)

This section describes the start-up procedure for drives set up for V/Hz regulation.

Before using this procedure, you should have read section 1.1 for information you

need to know before working with the drive.

Step 1. Power Up the Drive

This step verifies that the drive powers up and passes the power-up diagnostics.

After the drive passes the diagnostics, the keypad/display automatically enters

monitor mode, with speed displayed.

Turn power on.

STOP

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

RESET

AUTO

MAN

PROGRAM

ENTER

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Forward

Reverse

RUN

JOG

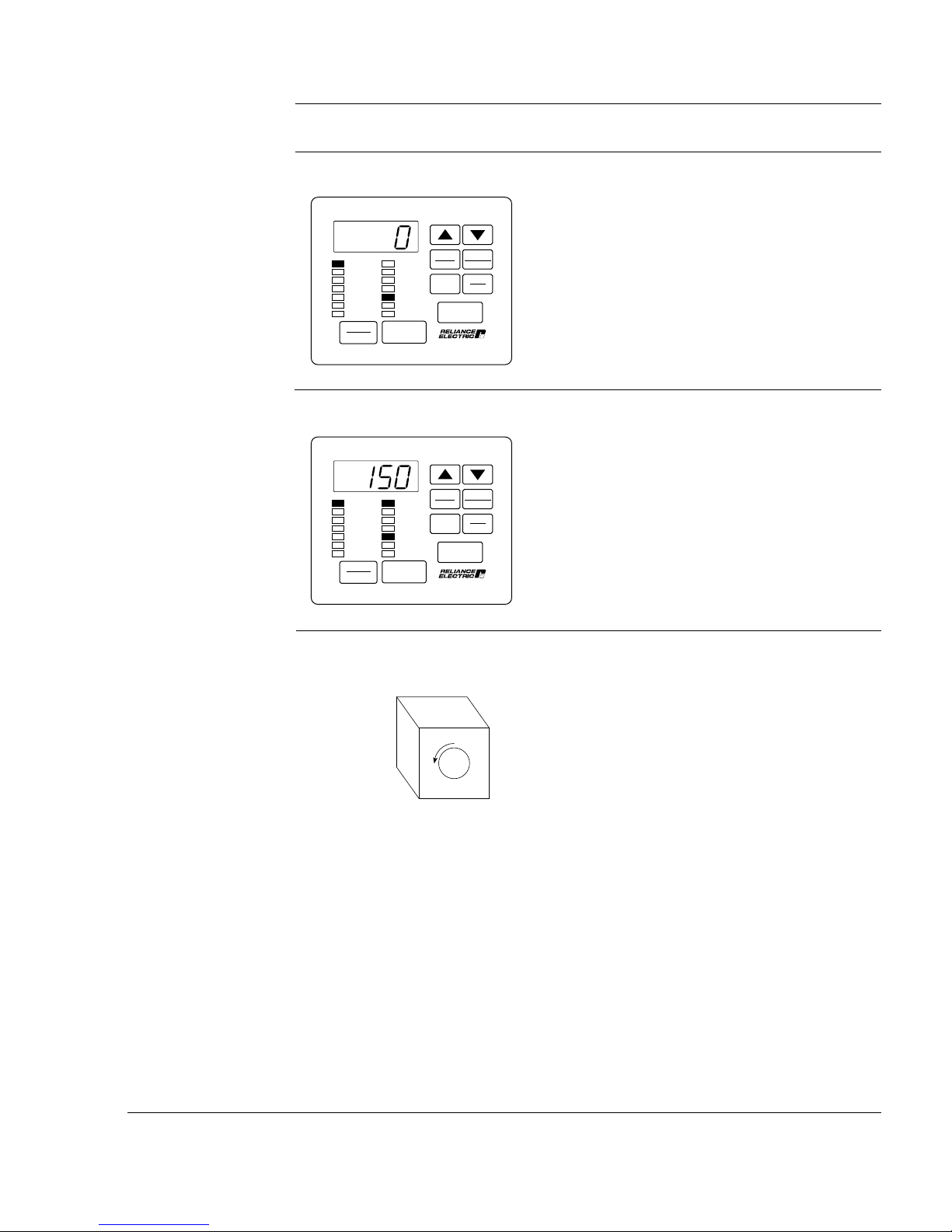

The initial display shows SELF, with all

monitor mode and status LEDs on, indicating

the drive is performing power-up

diagnostics.

After diagnostics are complete (5-6

seconds), the SPEED LED is on and the

keypad/display is in monitor mode. The

displayed value is zero. You can move

through the five items accessible in monitor

mode - Speed, Volts, Amps, Hz, and Kw - by

pressing the ENTER key.

Starting Up the Drive for Volts/Hertz Regulation

1-3

Page 11

Step 2. Select Program Mode

In this step, you will select program mode, which will give you access to the First

Menu General (P) parameters.

Press the PROGRAM key.

The PROGRAM LED is on and the First

Menu General (P) parameters can be

accessed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3. Program First Menu General Parameters P.000 - P.005

This step describes how to change First Menu General (P) parameters P.000

through P.005. P.000 selects where the drive is controlled from. This procedure

assumes local control from the keypad (P.000 = LOCL), which is the default setting

for the parameter.

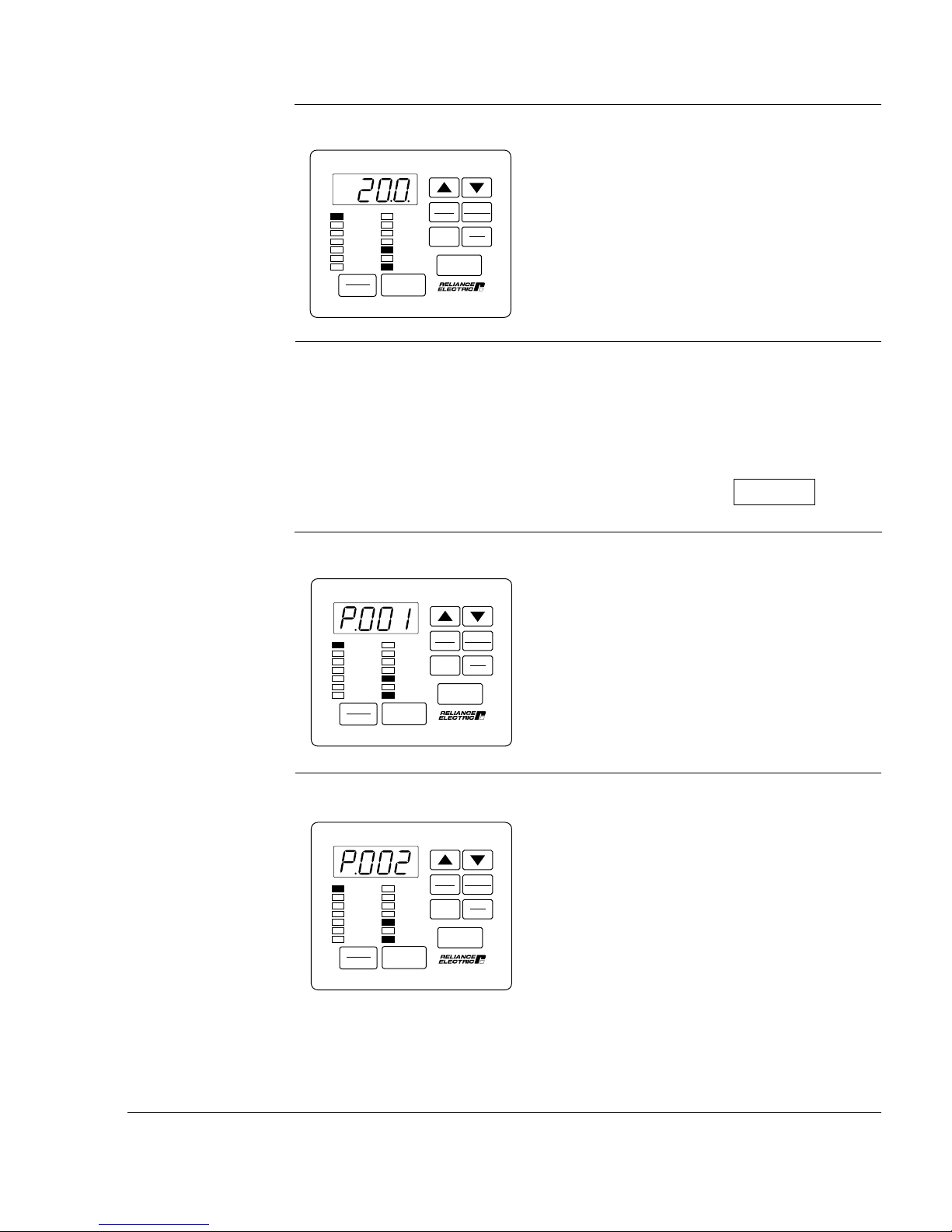

Step 3.1 Press the ENTER key to display the first parameter, P.000, Control Source.

The default setting for P.000 is LOCL, or

local control.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.2 Press the £ key to display P.001, Accel Time 1 (RAMP 1).

This parameter sets the acceleration time in

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

seconds.

1-4

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 12

Step 3.3 Press the ENTER key to display the default setting of P.001.

This displays the default setting for

acceleration time (20.0 seconds).

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.4 Press the £ key to increase acceleration time, or the ¥ key to decrease

acceleration time.

The adjustment range is:

1.0 to 999.9 seconds.

VALUE ENTERED:

Step 3.5 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

number is displayed. You can now go to the

next parameter.

Step 3.6 Press the £ key to display P.002, Decel Time 1 (RAMP 1).

This parameter sets the deceleration time in

seconds. The default stop method is

coast-to-stop, set in P.025.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Starting Up the Drive for Volts/Hertz Regulation

1-5

Page 13

Step 3.7 Press the ENTER key to display the default setting of P.002.

This displays the default setting for

deceleration time (20.0 seconds).

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.8 Press the £ key to increase deceleration time, or the ¥ key to decrease

deceleration time.

The adjustment range is:

1.0 to 999.9 seconds.

VALUE ENTERED:

Step 3.9 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

number is displayed. You can now go to the

next parameter.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

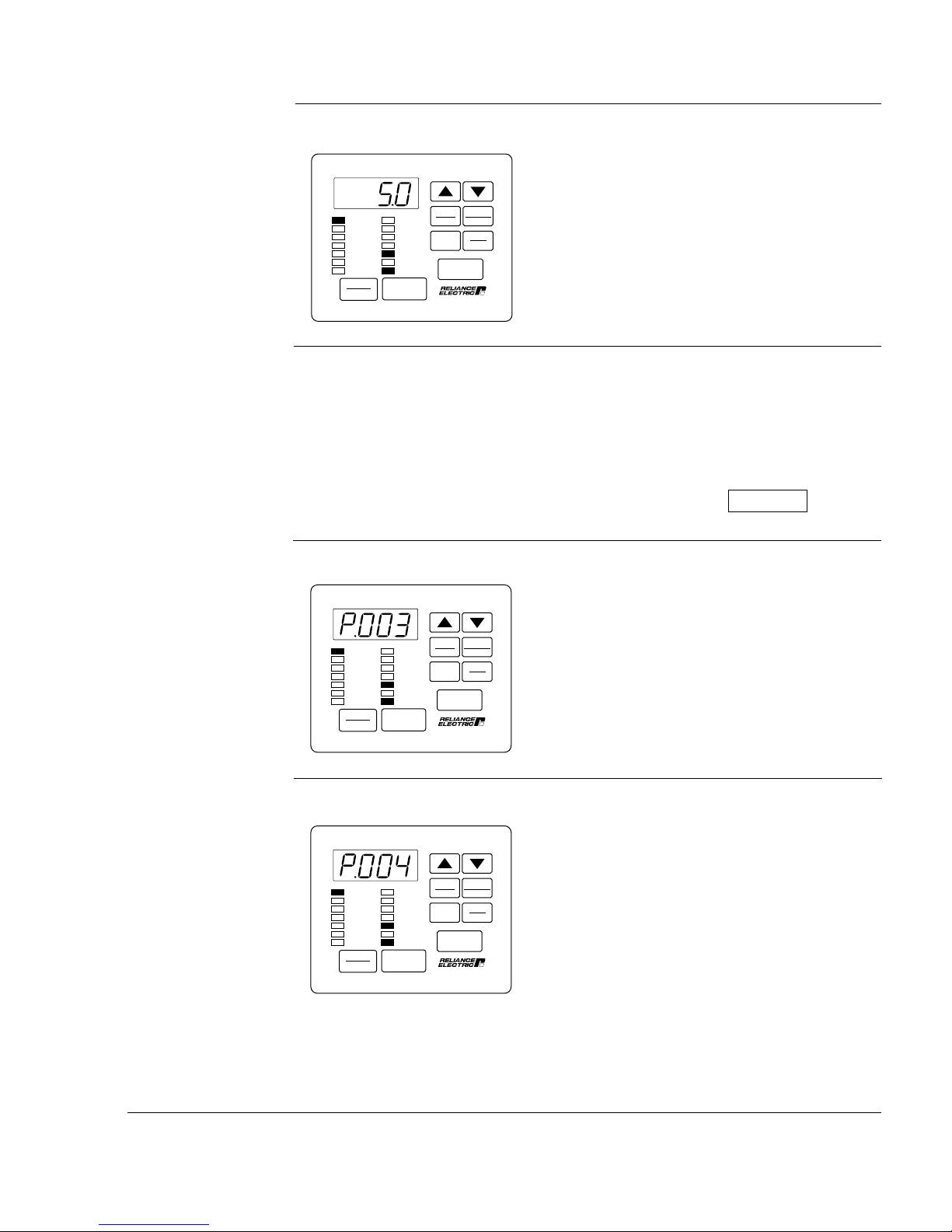

Step 3.10 Press the “ key to display P.003, Minimum Speed.

This parameter sets the minimum speed in

Hz.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

1-6

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 14

Step 3.11 Press the ENTER key to display the default setting of P.003.

This shows that the default setting for

Minimum Speed is 5.0 Hz.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.12 Press the £ key to increase minimum speed or the ¥ key to decrease

minimum speed.

The adjustment range is:

0.5 Hz to the value set for P.004 (Maximum

Speed).

VALUE ENTERED:

Step 3.13 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

number is displayed. You can now go to the

next parameter.

Step 3.14 Press the £ key to display P.004, Maximum Speed.

This parameter sets the maximum speed in

Hz.

In addition, the drive has overfrequency

protection by means of H.022. Refer to the

description of this parameter and be sure to

set it appropriate to your application.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Starting Up the Drive for Volts/Hertz Regulation

1-7

Page 15

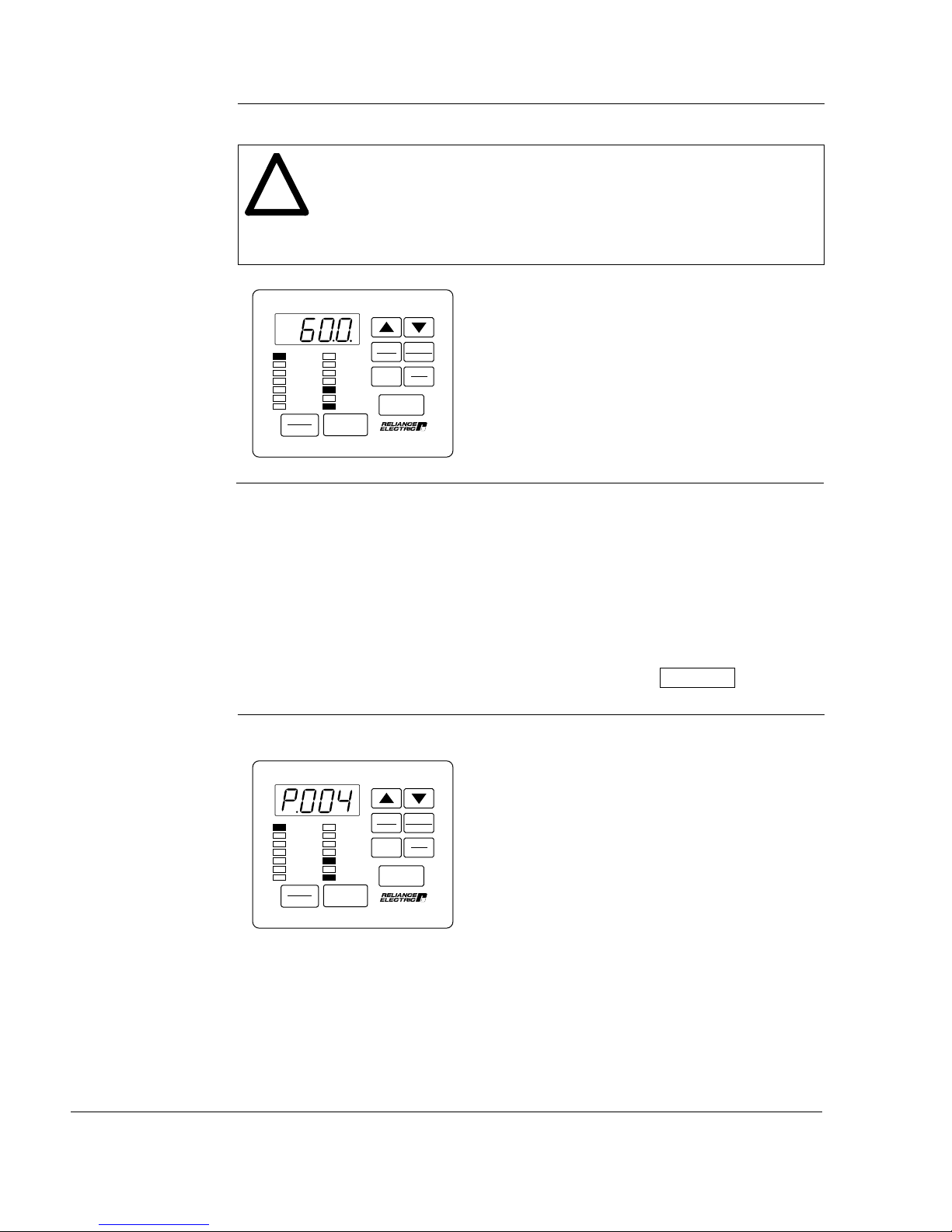

Step 3.15 Press the ENTER key to display the default setting of P.004.

ATTENTION: The user is responsible for ensuring that driven machinery,

all drive-train mechanisms, and application material are capable of

!

safe operation at the maximum operating speed of the drive. In V/Hz

regulation, overfrequency protection in the drive is provided by means

of H.022. Failure to observe this precaution could result in bodily

injury.

This shows that the default setting for

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Maximum Speed is 60.0 Hz.

Step 3.16 Press the £ key to increase maximum speed or the ¥ key to decrease

maximum speed.

The adjustment range is:

15.0 Hz to the value set for H.022

(Overfrequency Limit).

The maximum value is 210 Hz.

VALUE ENTERED:

Step 3.17 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

number is displayed. You can now go to the

next parameter.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

1-8

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 16

Step 3.18 Press the £ key to display P.005, Current Limit.

This parameter sets Current Limit, which

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

corresponds to the value in parameter

P.095, Power Module Output Amps.

Step 3.19 Press the ENTER key to display the default setting of P.005.

This shows that the default setting for

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Current Limit is 100.

Step 3.20 Press the ¥ key to decrease current limit. Decrease current limit only

if the motor nominal current rating is less than the drive nominal current

rating.

Use the following equation to calculate

current limit:

x 100

Motor Rated Amps

Rated Drive Output Amps

(1)

From motor nameplate

(2)

See the hardware reference manual for

(1)

(2)

ratings.

Adjustment Range: 50 to 110

VALUE ENTERED:

Starting Up the Drive for Volts/Hertz Regulation

1-9

Page 17

Step 3.21 Press the ENTER key to save the entered value.

After pressing ENTER, the same parameter

number is displayed. You can now move to

the next parameter.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 4. Enter the Second Menu Password

This step is required in order to access the Second Menu General (P) parameters

and the Volts/Hertz (H) parameters.

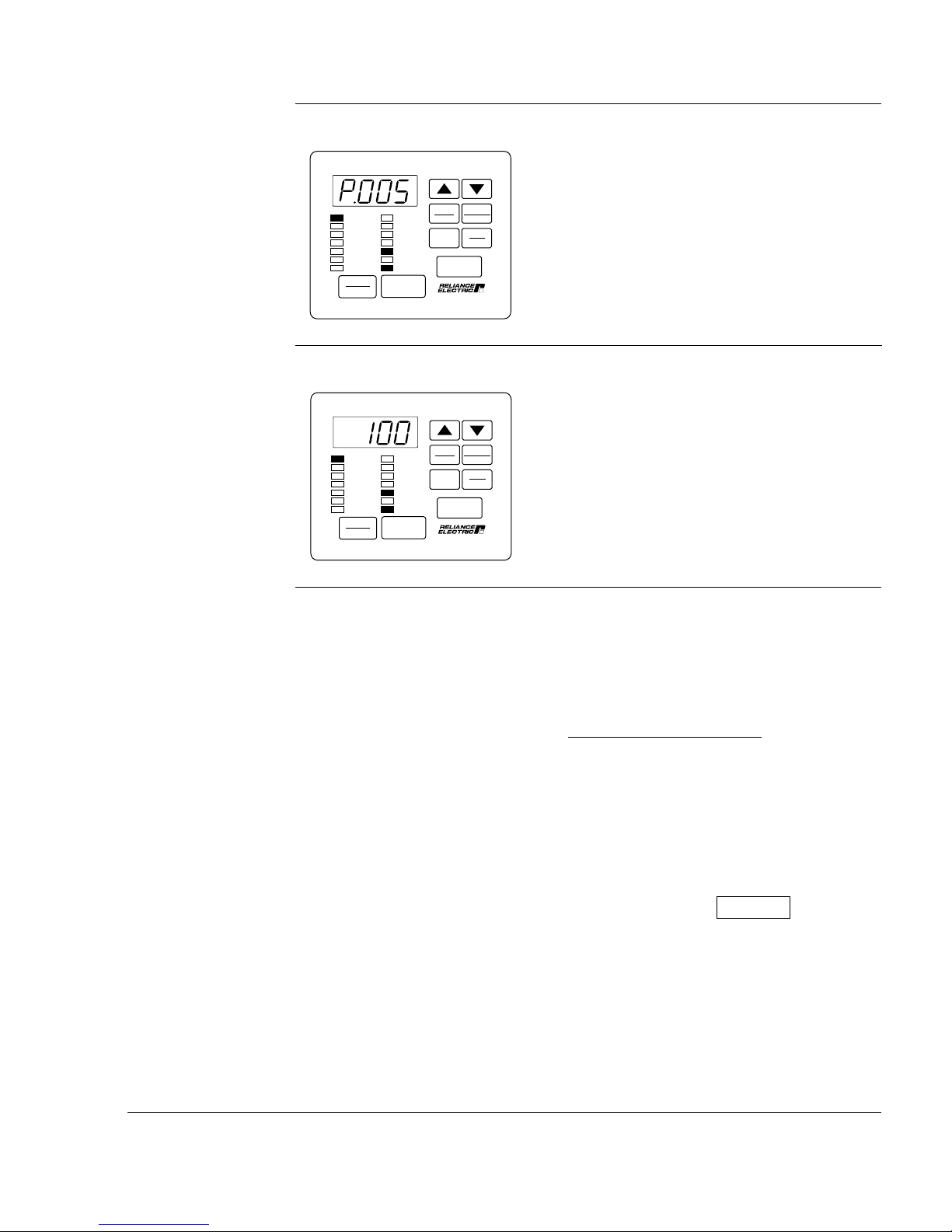

Step 4.1 Press the £ key to display parameter P.006, Second Menu Password.

This parameter allows you to enter the

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

factory preset password that allows access

to the Second Menu.

The Second Menu provides access to all

parameters and the error log.

1-10

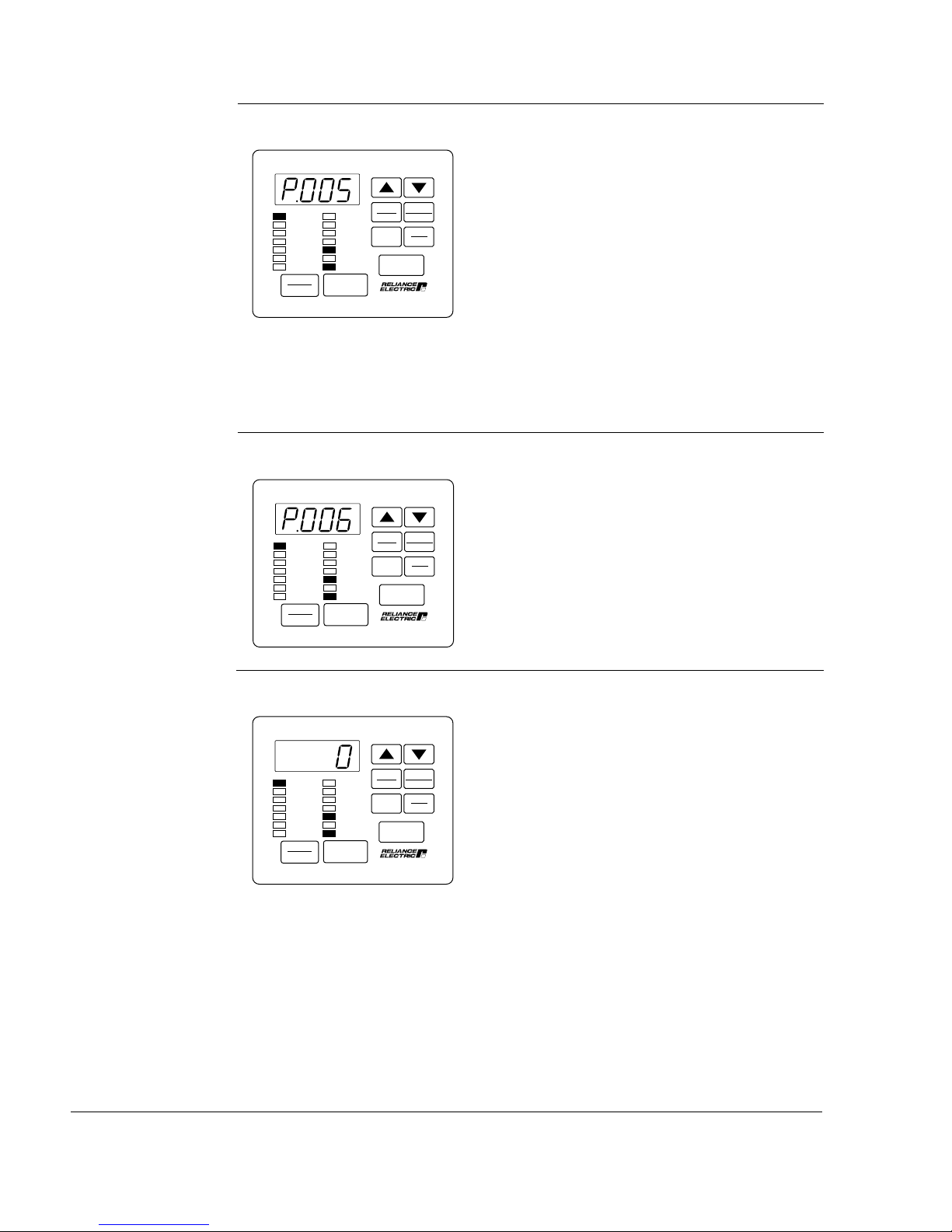

Step 4.2 Press the ENTER key.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Zero is displayed.

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 18

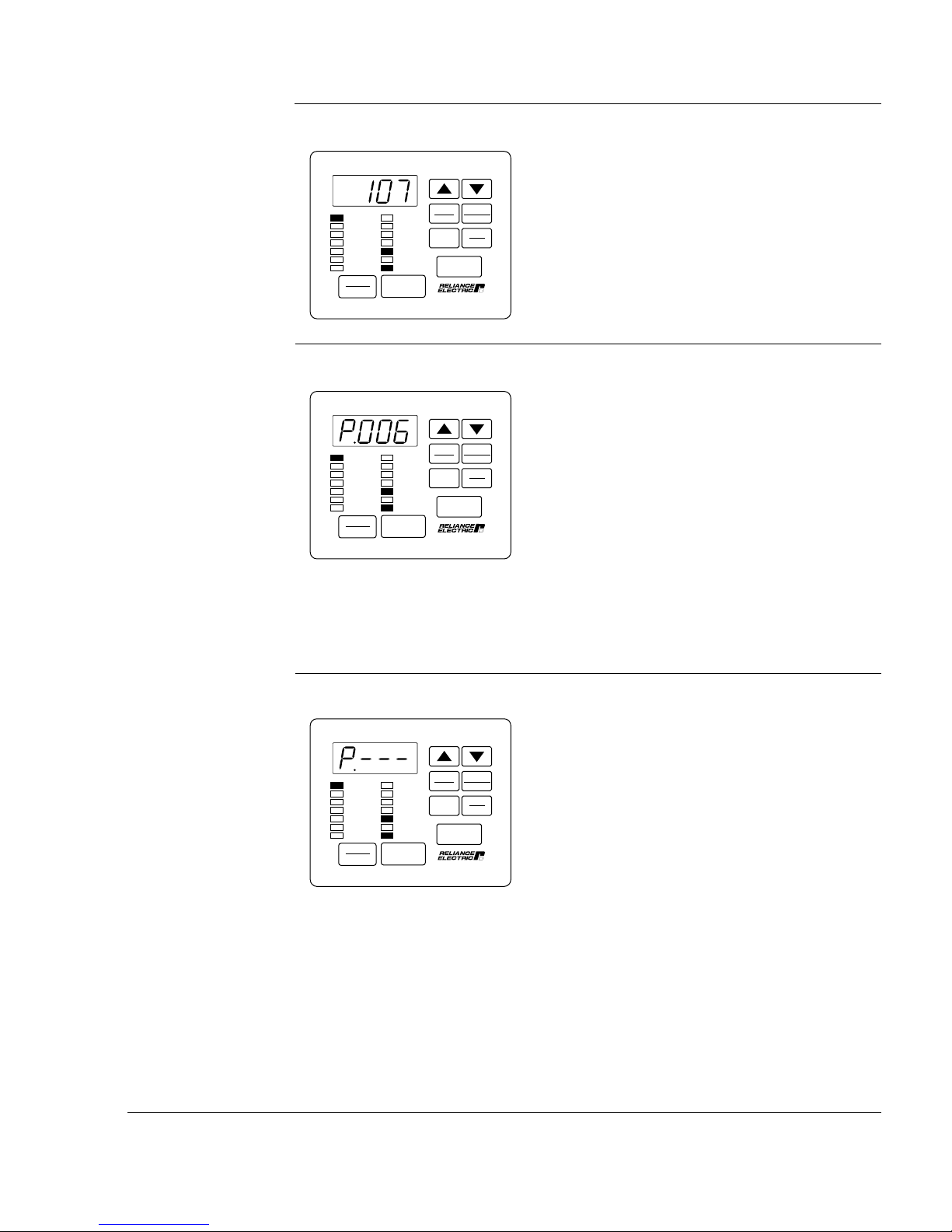

Step 4.3 Press the £ key until the password number "107" is displayed.

Note that the password, and access to the

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Second Menu, will be retained if the drive

loses and regains power.

Step 4.4 Press the ENTER key to save the password number.

After pressing ENTER, P.006 is displayed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

You now have access to all parameters and

the error log.

After the password is entered, the parameter

value is reset to 0.

Step 5. Program the Second Menu Volts/Hertz (H) Parameters

This step describes how to program the parameters that apply to V/Hz regulation

only.

Step 5.1 Press the PROGRAM key to return to the First Menu.

The display returns to the General (P)

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

parameters in the First Menu.

Starting Up the Drive for Volts/Hertz Regulation

1-11

Page 19

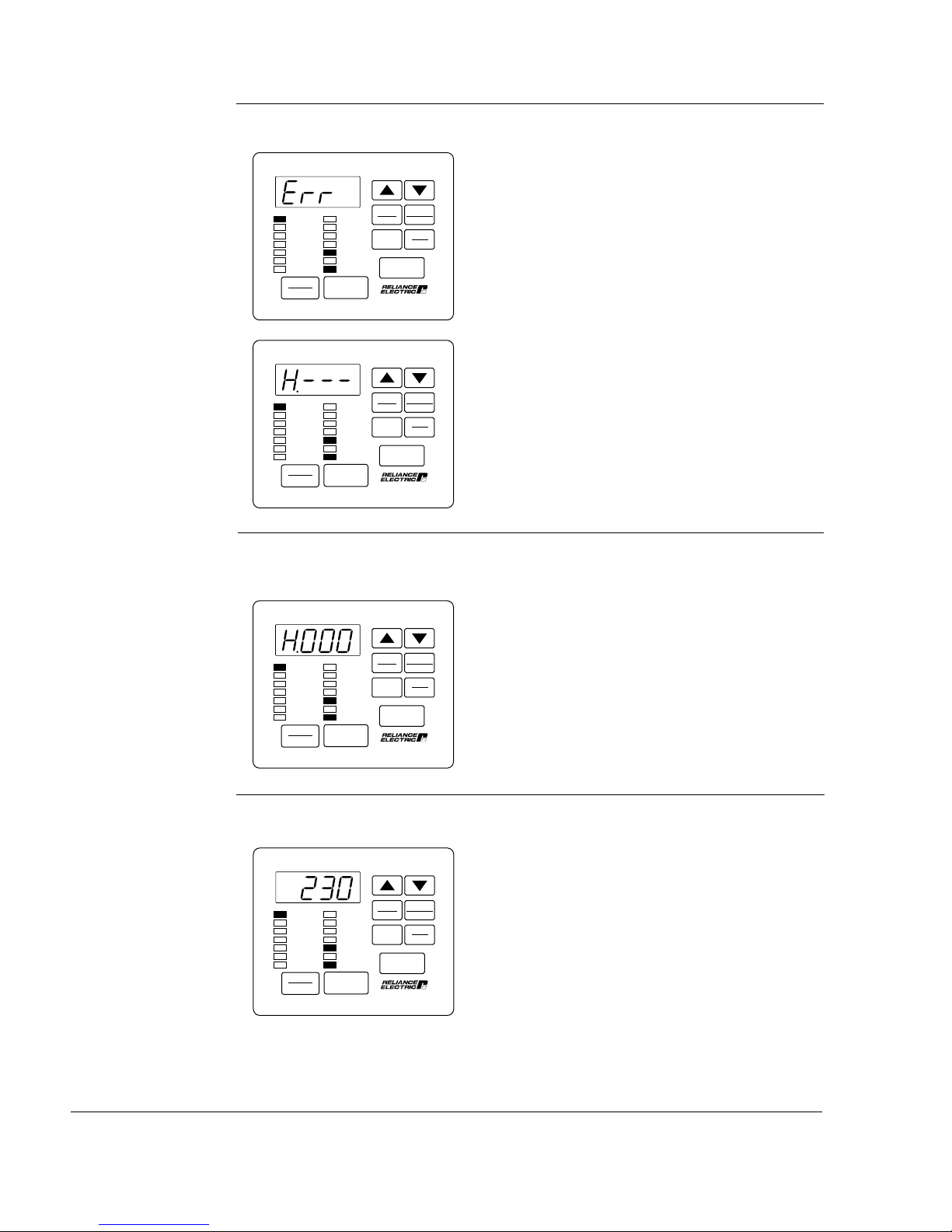

Step 5.2 Press the £ key twice.

The error log (Err) is bypassed, then ......

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

.... the Volts/Hertz (H)

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

parameter main menu is

displayed.

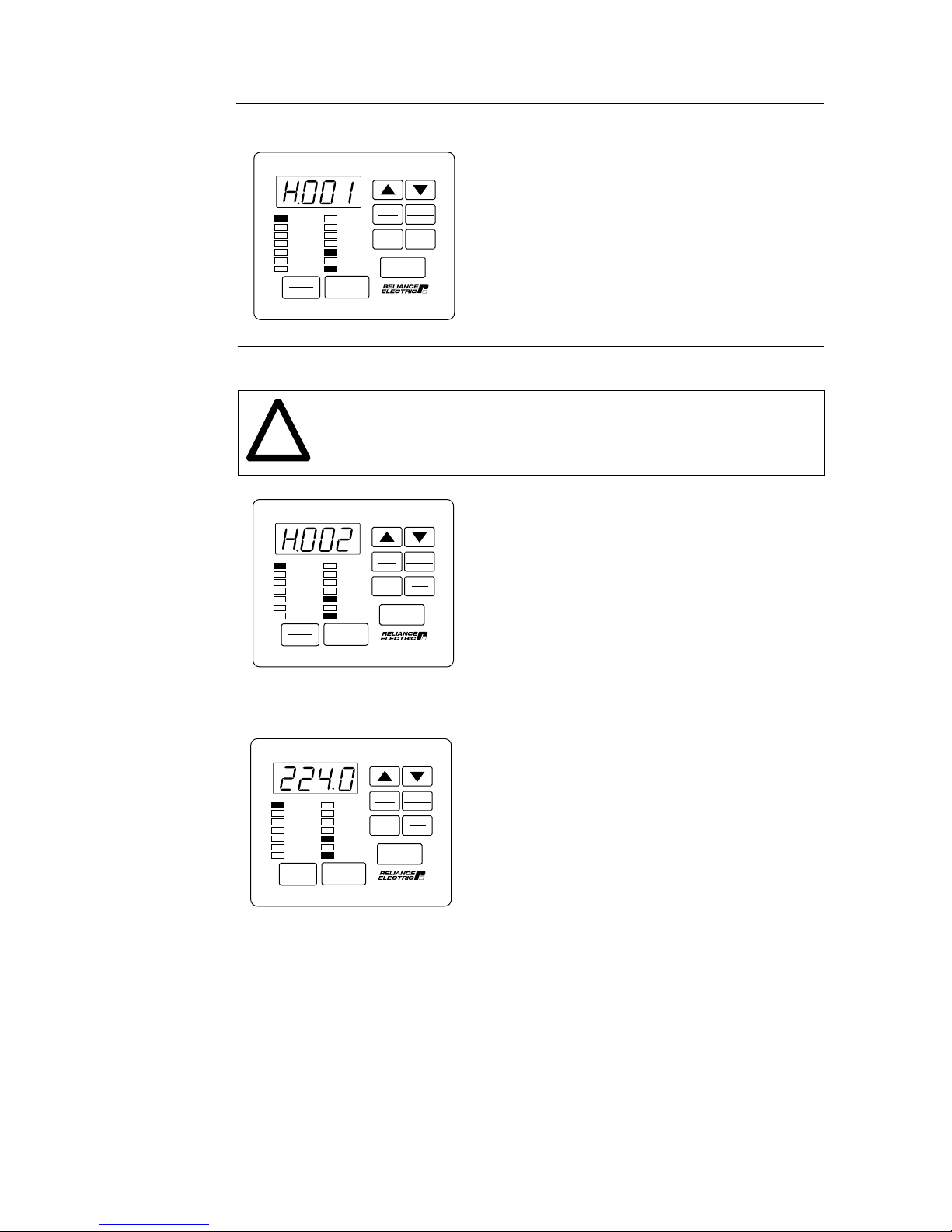

Step 5.3 Press the ENTER key to access the first Volts/Hertz parameter: H.000,

Motor Nameplate Volts.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.4 Press the ENTER key.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Default value varies.

This parameter sets the Motor Nameplate

Volts and is taken directly from the motor

nameplate.

The default setting for H.000 is displayed.

The default setting is 230.

1-12

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 20

Step 5.5 If no change was made, press the ENTER key to return to the parameter. If

you changed the value, press ENTER to accept the change and return to

the parameter.

After pressing ENTER, the same parameter

is displayed. You can now move to the next

parameter.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

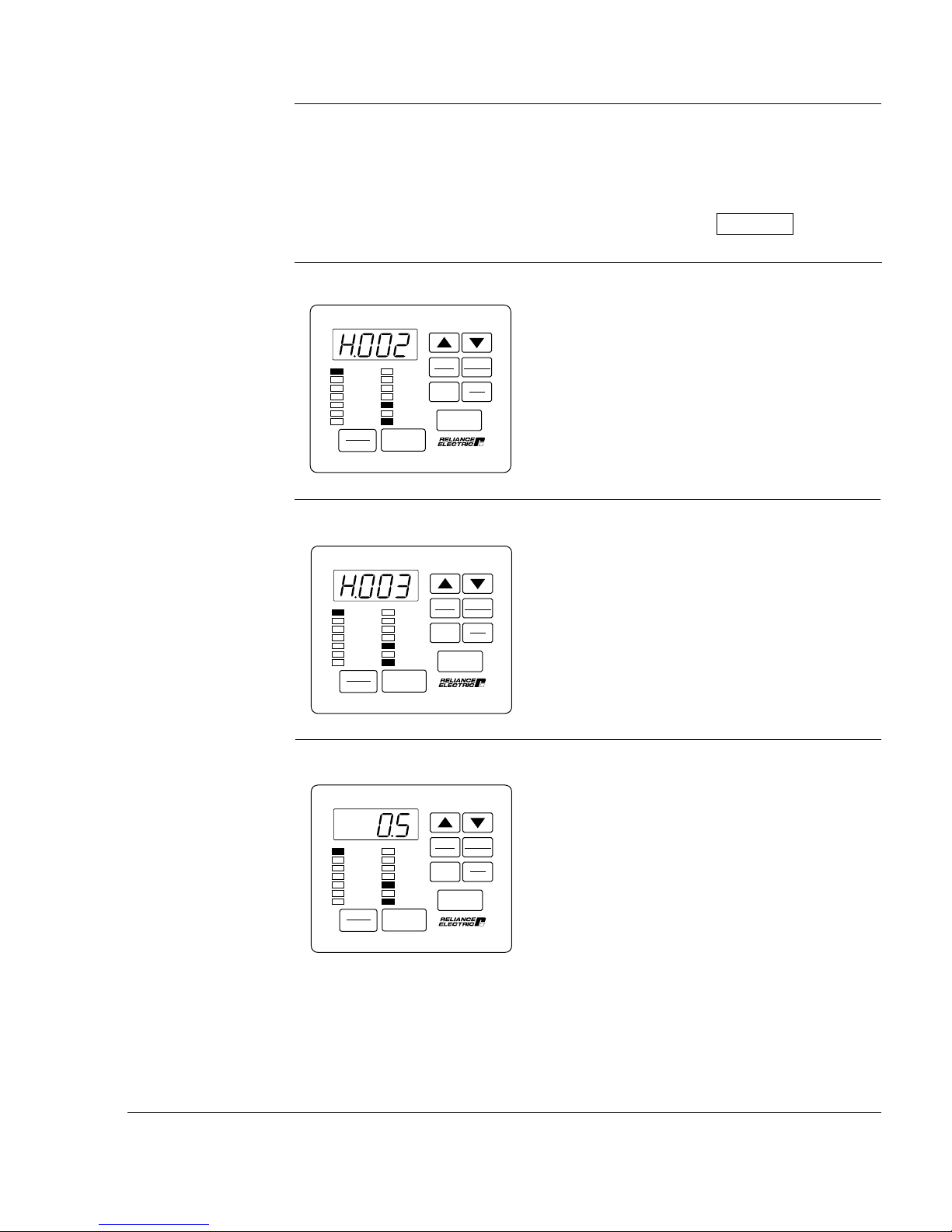

Step 5.6 Press the £ key to display H.001, Motor Nameplate Base Frequency.

Note that if Motor Nameplate Base Frequency is not set correctly, the

monitor mode SPEED display will also not be scaled correctly.

This parameter adjusts the volts/hertz ratio.

Base frequency is the set frequency at which

the output voltage reaches the Motor

Nameplate Voltage.

See figure 4.10 for more information.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.7 Press the ENTER key.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

Step 5.8 Press the ¥ key to decrease base frequency, if necessary.

Starting Up the Drive for Volts/Hertz Regulation

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

The default setting of 60.0 Hz is displayed.

This value will typically not need to be

changed from 60 Hz.

1-13

Page 21

Step 5.9 Press the ENTER key.

After pressing ENTER, the same parameter

is displayed. You can now move to the next

parameter.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

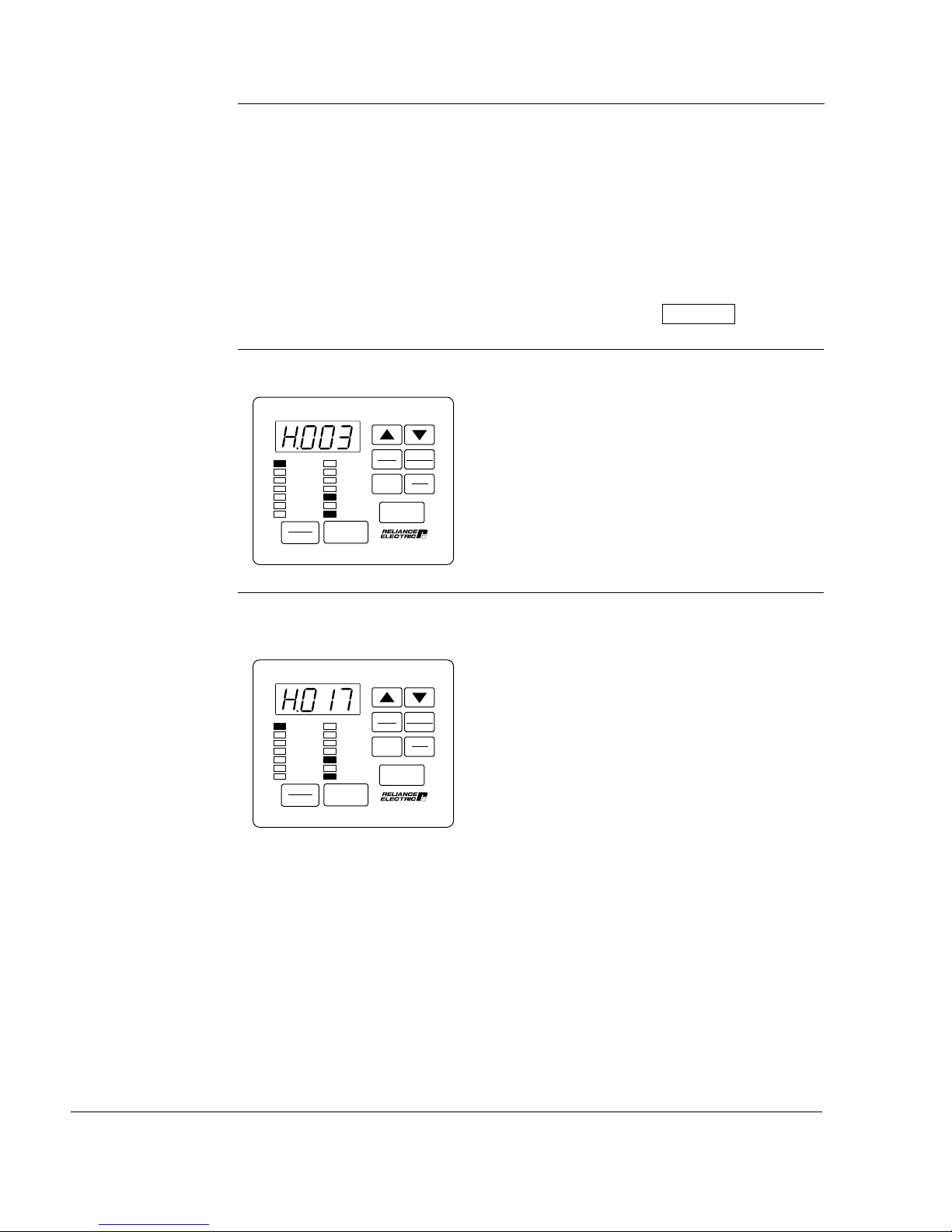

Step 5.10 Press the £ key to display H.002, Motor Nameplate Amps.

ATTENTION: This parameter setting must not exceed the rated amps

found on the nameplate. Overcurrent or excess heating of the motor

!

could result if this is not the case. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

This parameter specifies the Motor

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Nameplate Amps and is taken directly from

the motor nameplate.

1-14

Step 5.11 Press the ENTER key.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

The default setting depends on the drive

rating. The display shown here is only an

example.

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 22

Step 5.12 Press the £ key to increase the motor nameplate amps, or the ¥ key

to decrease motor nameplate amps.

The adjustment range depends on the drive

rating. See Appendix C.

VALUE ENTERED:

Step 5.13 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

is displayed. You can now move to the next

parameter.

Step 5.14 Press the £ key to display H.003, Torque Boost Voltage.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.15 Press the ENTER key.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

This parameter is required to offset the

voltage drop of the motor at low speeds and

produce constant torque. For example, high

friction loads may require high starting

torque.

Refer to figure 4.11 for more information.

The default setting is 0.5.

Starting Up the Drive for Volts/Hertz Regulation

1-15

Page 23

Step 5.16 Press the £ key to increase the torque boost voltage, or the ¥ key to

decrease torque boost voltage.

Important: If you set H.003 = 0, you must perform the identification test, controlled by

H.020, prior to running. Refer to the H.020 parameter description for

more information.

The adjustment range is:

0.0% to 20.0%

VALUE ENTERED:

Step 5.17 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

is displayed. You can now move to the next

parameter.

Step 5.18 Press the £ key until H.017, Input Power/Snubber Configuration, is

displayed.

This parameter selects the input power

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

supply type/snubber resistor kit

configuration. See chapter 4 for more

information.

1-16

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 24

Step 5.19 Press the ENTER key.

The default setting is 0.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.20 Press the £ key to increase the selection value, or leave it at 0.

If you do not have AC input or you are using a snubber resistor, see the

H.017 parameter description for more information.

The adjustment range is:

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

0 = AC input; snubber resistor not used;

ride-through enabled.

1 = AC input; snubber resistor used;

ride-through enabled.

2 = DC input; snubber resistor not used;

ride-through disabled.

3 = DC input; snubber resistor used;

ride-through disabled.

4 = DC input, snubber resistor not used;

ride-through enabled.

5 = DC input; snubber resistor used;

ride-through enabled.

Step 5.21 Press the ENTER key to save the changed value.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

Starting Up the Drive for Volts/Hertz Regulation

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

VALUE ENTERED:

After pressing ENTER, the same parameter

is displayed. You can now move to the next

parameter.

1-17

Page 25

Step 5.22 Press the £ key until H.018, Volts/Hertz Curve Type, is displayed.

This parameter selects the type of curve for

volt/hertz regulation. See chapter 4 and step

5.24 for more information.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.23 Press the ENTER key.

The default setting is 0 for linear curve.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.24 Press the £ key to increase the selection value to 1 or 2, or leave it at 0.

The adjustment range is:

0 =Linear curve

1 =Optimized curve for Reliance Electric

RPM AC motors

2 = For centrifugal pump and fan motor

applications

VALUE ENTERED:

Step 5.25 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

is displayed. You can now move to the next

parameter.

1-18

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 26

Step 6. Return to Monitor Mode

This step describes how to exit program mode and return to monitor mode.

Step 6.1 The display should now show the last parameter adjusted in Step 5,

H.018.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 6.2 Press the PROGRAM key twice to exit program mode.

The display returns to monitor mode with

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

speed displayed. The SPEED LED is on

and the PROGRAM LED is off.

Starting Up the Drive for Volts/Hertz Regulation

1-19

Page 27

ATTENTION: The subsequent steps require rotating parts and/or

electrical circuits to be exposed. Stay clear if unit must be running, or

!

disconnect and lock out or tag power source if contact must be made.

Failure to observe this precaution could result in severe bodily injury or

loss of life.

Important: The stop input on the terminal strip is not active when the Control

Source parameter (P.000) is set to LOCL, as it is during this start-up

procedure. Use the STOP/RESET key if you need to stop the drive.

Step 7. Check Motor Rotation Direction

This step involves verifying the speed reference is set to minimum speed, starting

the drive, and checking that the motor rotates in the correct direction. It is

performed with the motor disconnected from the load.

Step 7.1 Press the PROGRAM key until the PROGRAM LED turns off.

The keypad/display will enter monitor mode.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 7.2 Verify that the AUTO LED is off (press the AUTO/MAN key until the

AUTO LED turns off).

This selects the local keypad as the speed

reference source.

Step 7.3 Press the £ key or the ¥ key once.

The monitor mode LEDs will all turn off and

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

the manual speed reference value will be

displayed. The speed reference value is in

the units defined in P.028. The display

shown here is only an example.

Step 7.4 If the speed reference is at minimum speed, then proceed to Step 7.6.

If the speed reference is not at minimum speed, proceed to Step 7.5.

1-20

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 28

Step 7.5 Press the ¥ key to decrease the speed reference value.

Step 7.6 Press the ENTER key to return to monitor mode.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

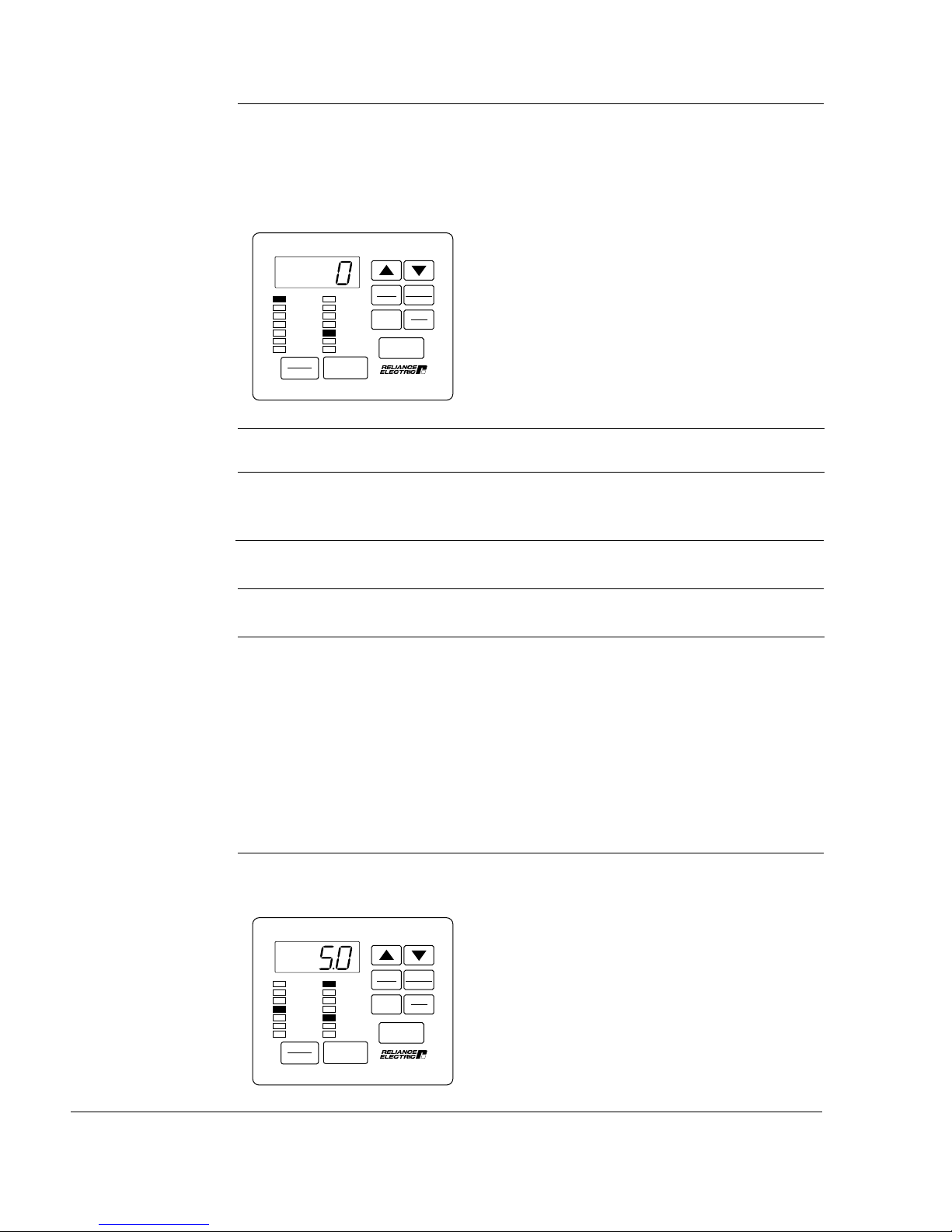

Step 7.7 Verify that you have selected RUN and FORWARD. Press the START key.

The drive is now running. The keypad/

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

display is in monitor mode and the SPEED,

RUNNING, and FORWARD LEDs are on.

The drive should be running at minimum

speed. The sample display shows 150

RPM.

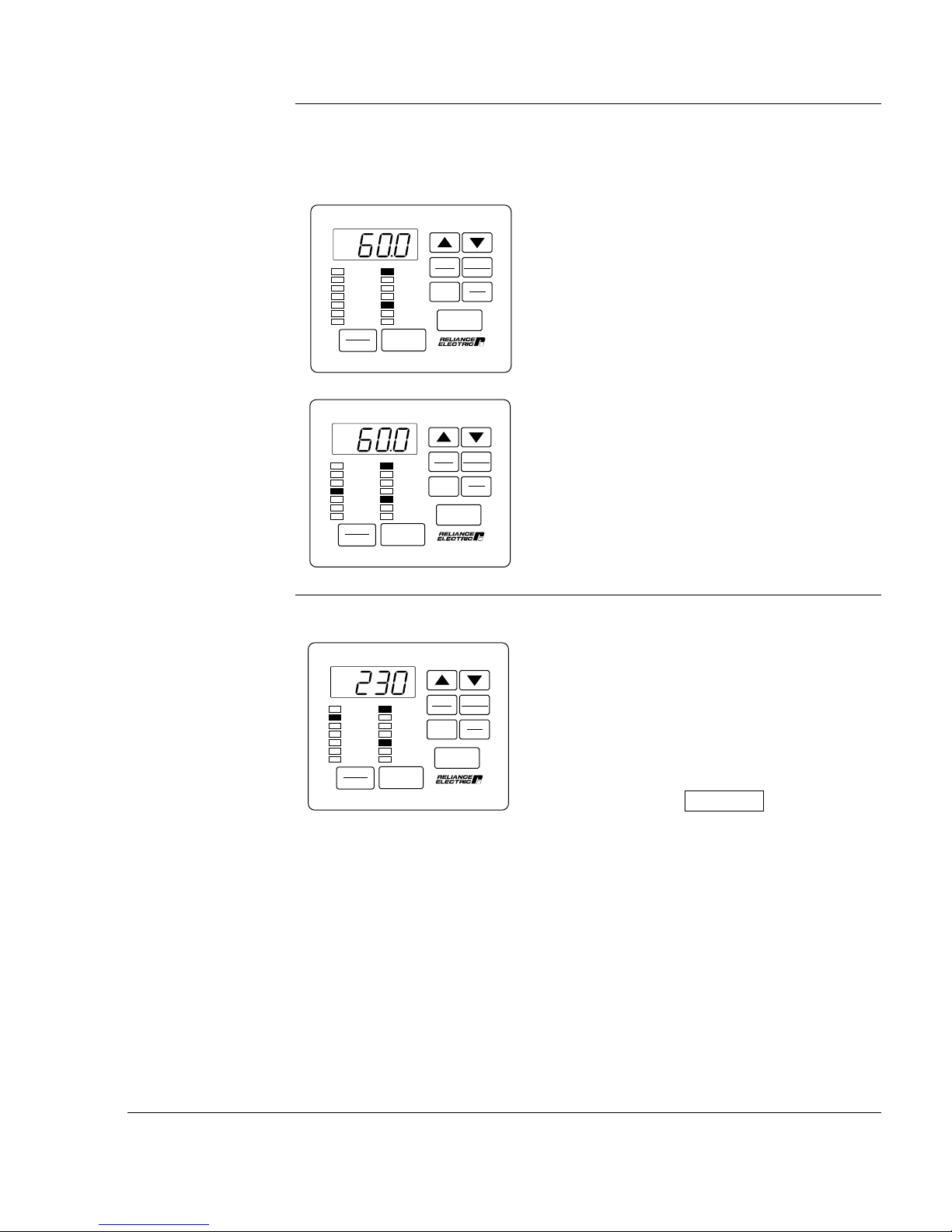

Step 7.8 Visually check that the motor rotates counter-clockwise (CCW) when

viewed from the driven motor shaft end.

CCW

Starting Up the Drive for Volts/Hertz Regulation

1-21

Page 29

Step 7.9

• If the rotation direction is NOT correct, press the STOP/RESET key and

continue with Step 7.10.

• If the rotation direction is correct, continue with Step 7.14.

When the STOP/RESET key is pressed, the

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

RUNNING LED turns out.

Step 7.10 Turn off and lock out or tag power to the drive.

Step 7.11 Verify that the DC bus capacitors are discharged. Refer to the

hardware reference manual for this procedure.

Step 7.12 Switch any two of the motor leads (U, V, or W).

Step 7.13 Turn power on, and press the START key. Repeat Step 7.8.

Step 7.14 To make sure that the drive is not inadvertently started, turn off and

lock out or tag power to the drive. Verify that the motor direction is

appropriate for the required machine direction, and then connect the

motor to the load.

Step 8. Run the Drive

This step describes how to adjust the speed reference from the keypad and run the

motor up to maximum speed in Hz. At maximum Hz, you must check values in

monitor mode. This step assumes you have connected motor to the load.

Step 8.1 Press the ENTER key until the Hz LED turns on. (If the drive is not

running, press the START key.)

This example shows the minimum hertz

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

setting of parameter P.003.

1-22

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 30

Step 8.2 Press the £ or ¥ key once. All of the monitor mode LEDs turn off.

Increase the speed reference to the maximum value by using the £ key.

Wait five seconds or press the ENTER key to return to monitor mode.

This increases the drive speed reference

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

and the motor will rotate up to maximum

speed.

The monitor mode LEDs turn off when the

reference is changed.

The display now shows the drive speed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Your speed display may be different.

Step 8.3 Press the ENTER key to move to the VOLTS display.

This example shows the output volts at

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Maximum Speed (P.004). Your actual

reading may be different.

VALUE READ:

Starting Up the Drive for Volts/Hertz Regulation

1-23

Page 31

Step 8.4 Press the ENTER key to move to the AMPS display.

This example shows the output amps at

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Maximum Speed (P.004). Your actual

reading may be different.

VALUE READ:

Step 8.5 Press the ENTER key to move to the Hz display.

This example shows the Hz value

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

corresponding to the value set in parameter

P.004, Maximum Speed. Your actual

reading may be different.

VALUE READ:

Step 8.6 Press the STOP/RESET key. The driven motor should stop as

programmed in P.025, Stop Type.

End of V/Hz Start-Up Procedure

This is the end of the basic V/Hz start-up procedure. When the start-up values are

final, Appendix B can be used to record final settings.

To configure remaining parameters according to the specific application, refer to

Chapter 4, Programming Reference. If you have purchased the Control and

Configuration Software (CS3000), save your configuration to a personal computer.

Refer to the CS3000 software instruction manual (D2-3348) for this procedure.

Recall that the Control Source parameter (P.000) was set to LOCL in this start-up

procedure. If you need to operate the drive from a different control source, you will

need to change the setting in parameter P.000.

1-24

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 32

CHAPTER 2

Starting Up the Drive

for Vector Regulation

This chapter describes the basic start-up procedure for drives which utilize flux

vector control (FVC) or sensorless vector control (SVC). Part of this procedure

describes how to select vector regulation.

If you are starting up a drive which will perform V/Hz regulation, refer to the V/Hz

start-up procedure in chapter 1.0 instead. Do not perform the start-up procedure in

this chapter.

The start-up procedure below provides step-by-step instructions for:

• powering up

• checking monitor mode displays

• accessing program mode

• configuring General parameters (designated with a "P")

• configuring specific vector parameters (designated with a "U")

• checking motor rotation direction

• running the drive

This start-up procedure describes how to program the minimum set of parameters

that usually need to be programmed for applications using vector regulation. Once

you program these parameters, their values are retained even if power is lost. You

only need to re-program them if you want to change how the drive operates.

Your application may require programming other parameters in addition to the ones

described in this start-up procedure. Refer to chapter 4 for a description of all

parameters to verify whether you need to program any additional parameters as

well. Appendix A provides a list of parameters listed alphabetically.

Throughout this manual, you will see references to parameter names and the

numbers that identify them for the drive. This manual uses the same format that will

be shown on the keypad/display to refer to parameters:

P.nnn

U.nnn

H.nnn

r.nnn

where: nnn is a number

P designates General parameters

U designates Vector parameters

H designates Volts/Hertz parameters

r designates optional RMI parameters

Starting Up the Drive for Vector Regulation

2-1

Page 33

2.1 Preparing for Start Up (Vector)

Read through the following sections to prepare for the start-up procedure.

What You Need To Know:

• You must be qualified to perform the procedure and be familiar with vector

regulation.

• You should be familiar with the keypad/display. If you are not familiar with the

keypad/display, refer to chapter 3, which describes it.

What You Need To Do:

• Complete all hardware installation as described in the hardware reference

manual. This includes connecting input power, input transformers (if required),

disconnects, fuses, the encoder (if used), and the terminal strip on the drive.

• Record the following motor data from motor nameplate for use during the

procedure:

Motor rated horsepower:

Motor rated amps:

Motor rated volts:

Motor base frequency:

Number of motor poles* :

* RPM AC motors are 4-pole regardless of base RPM. Standard NEMA motors are

as follows:

Consult your motor supplier if you are unsure of the motor design you are using.

3600 RPM = 2 poles

1800 RPM = 4 poles

1200 RPM = 6 poles

900 RPM = 8 poles

• If an encoder is used, record the following encoder data. Make sure the

encoder is mounted to the motor and connected to the drive.

Encoder PPR:

• Connect the drive to the motor and disconnect the motor from the load.

• Check that you have not been prevented from programming the drive. If the

PASSWORD LED on the keypad is on, programming has been prevented in

parameter P.051, Programming Disable. Refer to section 4.4 in this manual for

the procedure to enable programming.

If You Have a Problem:

To Exit:

During most of the start-up procedure, you will be in program mode, which is used

to program parameters. If you want to stop programming parameters, you can exit

program mode. You can do this by pressing the PROGRAM key until the

PROGRAM LED has turned off. This will place the keypad/display in monitor mode,

the default. You can read more about these modes in chapter 3.

2-2

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 34

To Restore a Default Parameter Value after Writing over It:

If you enter the wrong value while programming parameters, you can restore the

default if you have not yet pressed the ENTER key. To do so:

1. Press the PROGRAM key.

2. Press the ENTER key. The default value of the parameter will be displayed

again. You can select it with ENTER or enter a new one and press ENTER.

To Restore All the Default Values to General (P) Parameters:

If you need to restore all the default values for General (P) parameters after

programming them, you can do so using the Restore Defaults parameter (P.050).

2.2 Start-Up Procedure (Vector)

This section describes the start-up procedure for drives set up for vector regulation.

Before using this procedure, you should have read section 2.1 for information you

need to know before working with the drive.

Step 1. Power Up the Drive

This step verifies that the drive powers up and passes the power-up diagnostics.

After the drive passes the diagnostics, the keypad/display automatically enters

monitor mode with speed displayed.

Turn power on.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Forward

Reverse

RUN

JOG

The initial display will show SELF, with all

monitor mode and status LEDs on, indicating

the drive is performing power-up diagnostics.

After diagnostics are complete (5-6

seconds), the SPEED LED is on and the

keypad/display is in monitor mode. The

displayed value is zero. You can move

through the six items that can be accessed

in monitor mode – Speed, Volts, Amps, Hz,

Kw, and Torque – by pressing the ENTER

key.

Starting Up the Drive for Vector Regulation

2-3

Page 35

Step 2. Select Program Mode

In this step, you will select program mode, which gives you access to the First Menu

General (P) parameters.

Step 2.1 Press the PROGRAM key.

The PROGRAM LED is on and the First

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Menu General (P) parameters can be

accessed.

Step 2.2 Press the ENTER key.

The first General (P) parameter in the First

Menu, P.000, is displayed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

2-4

Step 3. Enter the Second Menu Password

This step is required to access the Second Menu General (P) parameters and

Vector (U) parameters.

Step 3.1 Press the £ key until P.006, Second Menu Password, is displayed.

This parameter allows you to enter the

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

password that allows access to the Second

Menu.

The Second Menu provides access to all the

parameters and the error log.

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 36

Step 3.2 Press the ENTER key.

Zero is displayed.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.3 Press the £ key until the password 107 is displayed.

Note that the password, and access to the

Second Menu, will be retained if the drive

loses and then regains power.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 3.4 Press the ENTER key to save the password number.

After pressing ENTER, P.006 is displayed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

You now have access to all parameters and

the error log.

Starting Up the Drive for Vector Regulation

2-5

Page 37

Step 4. Program the Drive for Vector Regulation

This step describes how to change parameter P.048 (Volts/Hertz or Vector

Regulation) to vector.

Within vector regulation, you can program the drive for flux vector control (FVC) or

sensorless vector control (SVC). FVC operation requires an encoder. SVC

operation does not require an encoder. Both options require U.048 to be set to

UEC. In a later step, you will select either the FVC option or the SVC option.

When you enter the value for vector regulation (P.048 = UEC), the drive will

perform a diagnostic check. After the diagnostics, the drive enters monitor mode

with speed displayed.

Step 4.1 Press the £ key until P.048, Volts/Hertz or Vector Regulation, is displayed.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 4.2 Press the ENTER key.

The default setting for P.048 is V/Hz

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

regulation.

Step 4.3 Press the £ key to display UEC, vector regulation.

AUTO

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

2-6

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 38

Step 4.4 Press the ENTER key to save the setting.

After pressing ENTER, the same parameter

number is displayed. You can now go to the

next step.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 4.5 Note the display.

After the regulation selection is changed, the

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

drive will perform diagnostics and displays

SELF, with all monitor mode and status

LEDs on.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

When the diagnostics are complete, the

keypad/display will enter monitor mode with

speed displayed.

Starting Up the Drive for Vector Regulation

2-7

Page 39

Step 5. Program First Menu General Parameter P.000 - P.005

This step describes how to change First Menu General (P) parameters P.000

through P.005. P.000 selects where the drive is controlled from. This procedure

assumes local control from the keypad (P.000 = LOCL), which is the default setting

for the parameter.

Step 5.1 Press the PROGRAM key.

You are now in program mode. The

PROGRAM LED is on and the First Menu

General (P) parameters can be accessed.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.2 Press the ENTER key to display the first parameter, P.000, Control Source.

The default setting for P.000 is LOCL, or

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

local control.

2-8

Step 5.3 Press the £ key to display P.001, Accel Time 1 (RAMP 1).

This parameter sets the acceleration time in

seconds.

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Page 40

Step 5.4 Press the ENTER key to display the default setting of P.001.

This displays the default setting for

acceleration time (20.0 seconds).

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.5 Press the £ key to increase acceleration time, or the ¥ key to decrease

acceleration time.

The adjustment range is:

0.1 to 999.9 seconds.

VALUE ENTERED:

Step 5.6 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

number is displayed. You can now go to the

next parameter.

Step 5.7 Press the ¥ key to display P.002, Decel Time 1 (RAMP1).

This parameter sets the deceleration time in

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

seconds. The default stop method is

coast-to-stop, set in P.025.

Starting Up the Drive for Vector Regulation

2-9

Page 41

Step 5.8 Press the ENTER key to display the default setting of the P.002.

This displays the default setting for

deceleration time (20.0 seconds).

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Step 5.9 Press the £ key to increase deceleration time, or the ¥ key to decrease

deceleration time.

The adjustment range is:

0.1 to 999.9 seconds.

VALUE ENTERED:

Step 5.10 Press the ENTER key to save the changed value.

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

After pressing ENTER, the same parameter

number is displayed. You can now go to the

next parameter.

2-10

GV3000/SE 230 VAC Drive, Software Reference Version 6.04

Page 42

Step 5.11 Press the £ key to display P.003, Minimum Speed.

ATTENTION: The drive can operate at and maintain zero speed. The

user is responsible for ensuring safe conditions for operating personnel by

!

providing suitable guards, audible or visual alarms, or other devices to

indicate that the drive is operating or may operate at or near zero

speed. Failure to observe this precaution could result in severe bodily

injury or loss of life.

This parameter sets the minimum speed in

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

RPM.

Step 5.12 Press the ENTER key to display the default setting of P.003.

This displays the default setting for Minimum

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

Speed, 150 RPM.

Step 5.13 Press the £ key to increase minimum speed or the ¥ key to decrease

minimum speed.

The adjustment range is:

0 to the value set for P.004 (Maximum

Speed).

VALUE ENTERED:

Starting Up the Drive for Vector Regulation

2-11

Page 43

Step 5.14 Press the ENTER key to save the changed value.

After pressing ENTER, the same parameter

SPEED

VOLTS

AMPS

Hz

Kw

TORQUE

Password

STOP

RESET

RUNNING

REMOTE

JOG

AUTO

FORWARD

REVERSE

PROGRAM

START

AUTO

MAN

PROGRAM

ENTER

Forward

Reverse

RUN

JOG

number is displayed. You can now go to the

next parameter.

Step 5.15 Press the £ key to display P.004, Maximum Speed.

ATTENTION: The user is responsible for ensuring that driven machinery,

all drive-train mechanisms, and application material are capable of

!