Page 1

Hardware Reference, Installation, and Troubleshooting Manual D2-3340-1

GV3000 AC Power Modules

Version 5.0

Page 2

Important User Information

IMPORTANT

Solid-state equipment has operational characteristics differing from those of electromechanical equipment. Safety

Guidelines for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

your local Rockwell Automation sales office or online at http://www.rockwellautomation.com/literature/

important differences between solid-state equipment and hard-wired electromechanical devices. Because of this difference,

and also because of the wide variety of uses for solid-state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the

use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation,

Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

available from

) describes some

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

Identifies information that is critical for successful application and understanding of the product.

Allen-Bradley, Rockwell Software, Rockwell Automation, and TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

Document Update

Document Update

Electronic Motor Overload

Protection

This product does not offer speed-sensitive overload protection, thermal memory

retention or provisions to act upon motor over-temperature sensing in motors. If

such protection is needed in the end-use product, it needs to be provided by

additional means.

1

Page 4

Document Update

Notes:

2

Page 5

Summary of Changes

The information below summarizes the changes made to this manual since

its last release (December 1995).

Description of Changes Page

Added Document Update. After manual

front cover

Deleted the following statement: ‘The Motor Overload Enable parameter (P.040) can

be used in place of the electronic thermal overload relays in single motor

applications’.

6-1

Page 6

soc-ii Summary of Changes

Notes:

Page 7

Manufacturer's Declaration

Manufacturer:

Reliance Electric Industrial Co.

24701 Euclid Avenue

Cleveland, Ohio 44117 - USA

declares that the product:

GV3000, AĆC Speed Controller for Electric Motors

Ć is intended to be incorporated into machinery or to be assembled with other machinery to

constitute machinery covered by Directive 89/392/EEC, as amended;

and that

Ć the following harmonized standards have been applied:

EN 60204Ć1: Electrical equipment of industrial machines - Part 1: General Requirements

and furthermore declares that the product covered by this Declaration must not be put into service

until the machinery into which it is to be incorporated or of which it is a component has been found

and declared to be in conformity with the provisions of Directive 89/392/EEC and with national

implementing legislation, i.e., as a whole, including the product referred to in this Declaration.

Authorized Representative of the Company:

Place: Reliance Electric Industrial Co., Cleveland, Ohio 44117, USA

Date:

Signature:

Name: Charles Janki

Position: Product Development Safety Engineer

December 1, 1995

Page 8

Page 9

Table of Contents

1.0 Becoming Familiar with the Manual 1Ć1.

1.1 Finding Information 1Ć1.

1.2 Assumptions About the Audience 1Ć2.

1.3 Taking Safety Precautions 1Ć2.

1.4 Understanding Terms Used in this Manual 1Ć2.

1.5 If You Want to Know More 1Ć2.

1.6 Getting Assistance from Reliance Electric 1Ć2.

2.0 About the Drive 2Ć1.

2.1 Identifying the Drive by Model Number 2Ć1.

2.2 NEMA Enclosures 2Ć2.

2.3 1Ć25 HP GV3000 Drive Components and Locations 2Ć3.

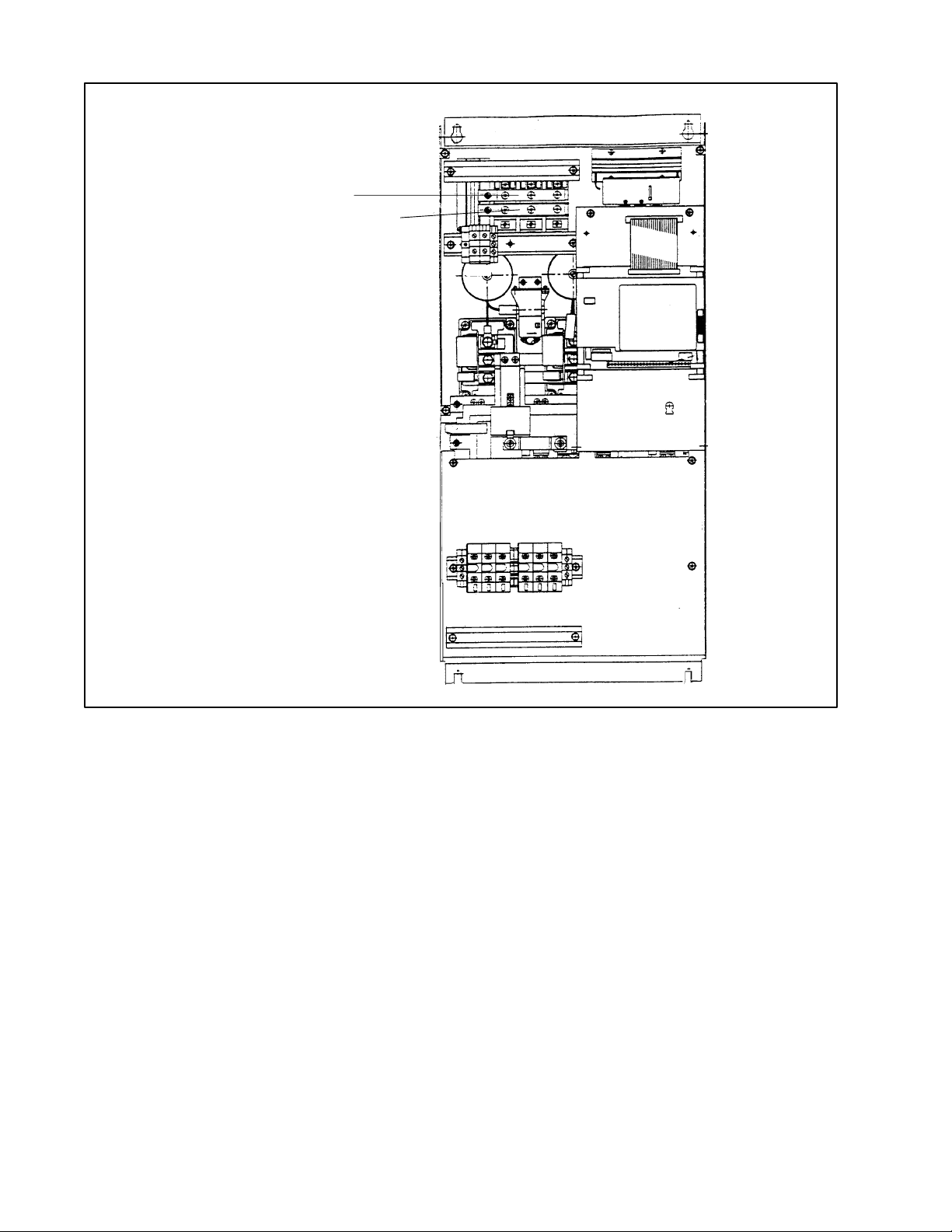

2.4 25Ć60 HP GV3000 Drive Components and Locations 2Ć6.

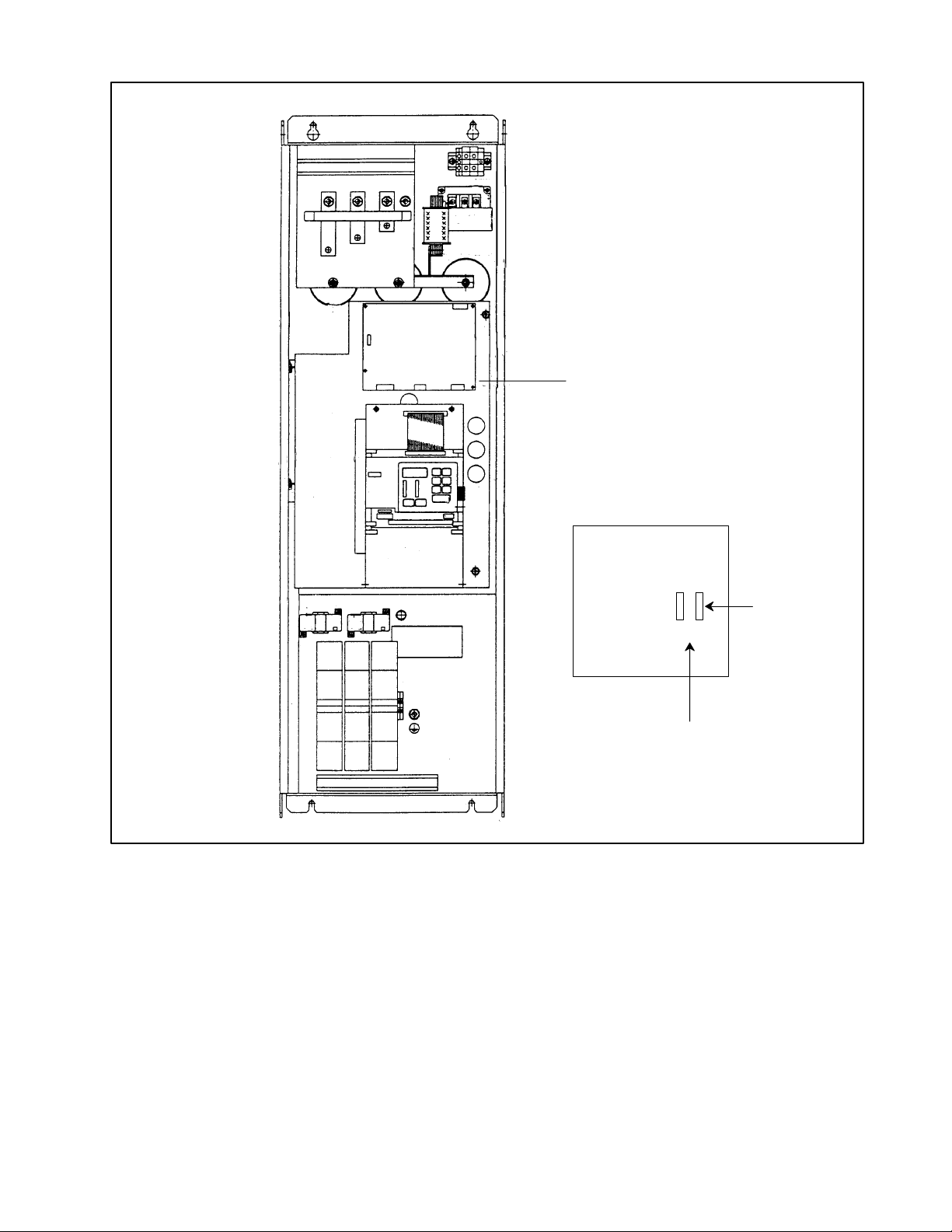

2.5 60Ć100 HP GV3000 Drive Components and Locations 2Ć7.

2.6 100Ć150 HP GV3000 Drive Components and Locations 2Ć8.

2.7 Regulator Board Description 2Ć9.

2.7.1 Jumper Locations and Settings 2Ć12.

2.7.1.1 Analog Input Speed Reference Jumper 2Ć12.

2.7.1.2 Analog Output Jumper 2Ć13.

2.7.2 Wiring the Terminal Strip 2Ć14.

2.7.3 RSĆ232 Communication Port 2Ć15.

2.7.4 Option Board Connector 2Ć15.

2.7.5 Operator Interface Module Connector 2Ć15.

2.7.6 Keypad/Display 2Ć15

2.8 Drive Kit Options 2Ć16.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.0 Planning Before Installing 3Ć1.

3.1 Requirements for the Installation Site 3Ć1.

3.1.1 Making Sure Environmental Conditions are Met 3Ć1.

3.1.2 Determining Total Area Required Based on Drive Dimensions 3Ć2.

3.1.3 Verifying the Site Provides for Recommended Air Flow Clearances 3Ć4.

3.1.4 Verifying Power Module Input Ratings Match Supplied Power 3Ć5.

3.2 Wiring Requirements for the Drive 3Ć5.

3.2.1 Meeting Terminal Strip Input and Output Specifications 3Ć5.

3.2.2 Determining Wire Size Requirements 3Ć5.

3.2.2.1 Conduit Entry Opening Sizes 3Ć5.

3.2.2.2 Recommended Power Wire Sizes 3Ć5.

3.2.2.3 Recommended Control and Signal Wire Sizes 3Ć6.

3.2.2.4 Recommended Motor Lead Lengths 3Ć6.

3.2.2.5 Recommended Serial Communication Cable Lengths 3Ć7.

3.2.3 Selecting Input Line Branch Circuit Fuses 3Ć7.

3.2.4 Meeting Pulse Tachometer Specifications (Vector Regulation Only) 3Ć8.

3.2.5 Verifying Power Module Output Current Rating is Greater Than Motor Full

Load Amps 3Ć8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

I

Page 10

4.0 Mounting the Drive, Grounding, and Finding Wire Routing Locations 4Ć1.

. . . . . . . . . . . . . . . . . .

4.1 Mounting the Drive 4Ć1.

4.1.1 Verifying the Drive's Watts Loss Rating 4Ć1.

4.2 Routing Input, Motor Output, Ground, and Control Wiring for the Drive 4Ć1.

4.3 Grounding the Drive 4Ć8.

5.0 Installing Input Power Wiring 5Ć1.

5.1 Installing Transformers and Reactors (Optional) 5Ć1.

5.2 Installing Fuses for Branch Circuit Protection 5Ć1.

5.3 Installing a Required External/Separate Input Disconnect 5Ć4.

5.4 Installing Power Wiring from the AĆC Input Line to the Drive's Power Terminals 5Ć4.

5.5 Installing Power Wiring from an External DĆC Bus to the Drive's Internal DĆC Bus

Terminals 5Ć5.

6.0 Installing Output Power Wiring 6Ć1.

6.1 Installing Output Contactors (Optional) 6Ć1.

6.2 Installing Mechanical Motor Overload Protection (Optional) 6Ć1.

6.3 Installing Output Wiring from the Drive Output Terminals to the Motor 6Ć1.

7.0 Wiring the Regulator Board Terminal Strip 7Ć1.

7.1 Stopping the Drive 7Ć5.

7.1.1 Compliance with EN 60204Ć1: 1992 7Ć5.

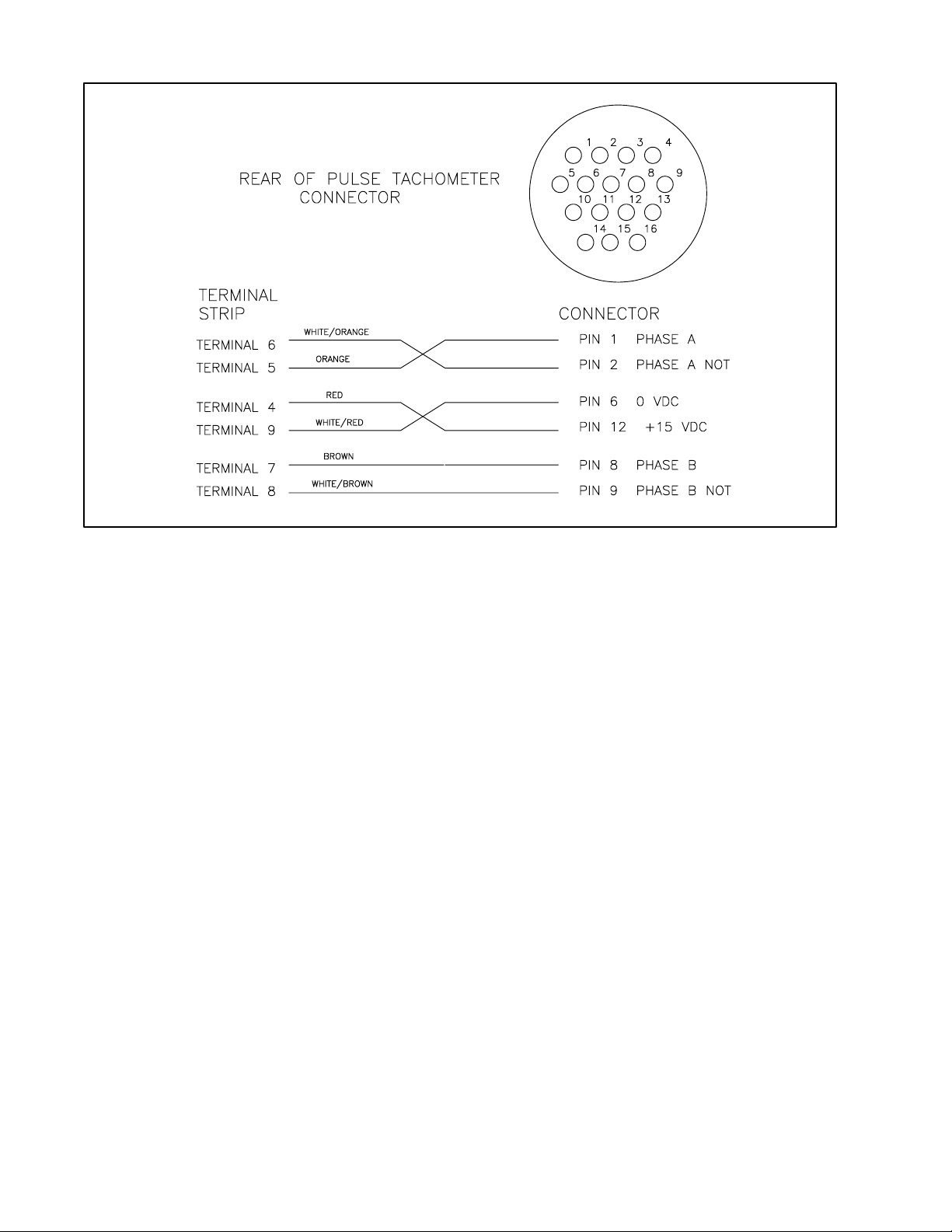

7.2 Wiring the Speed Feedback Device (Vector Regulation Only) 7Ć5.

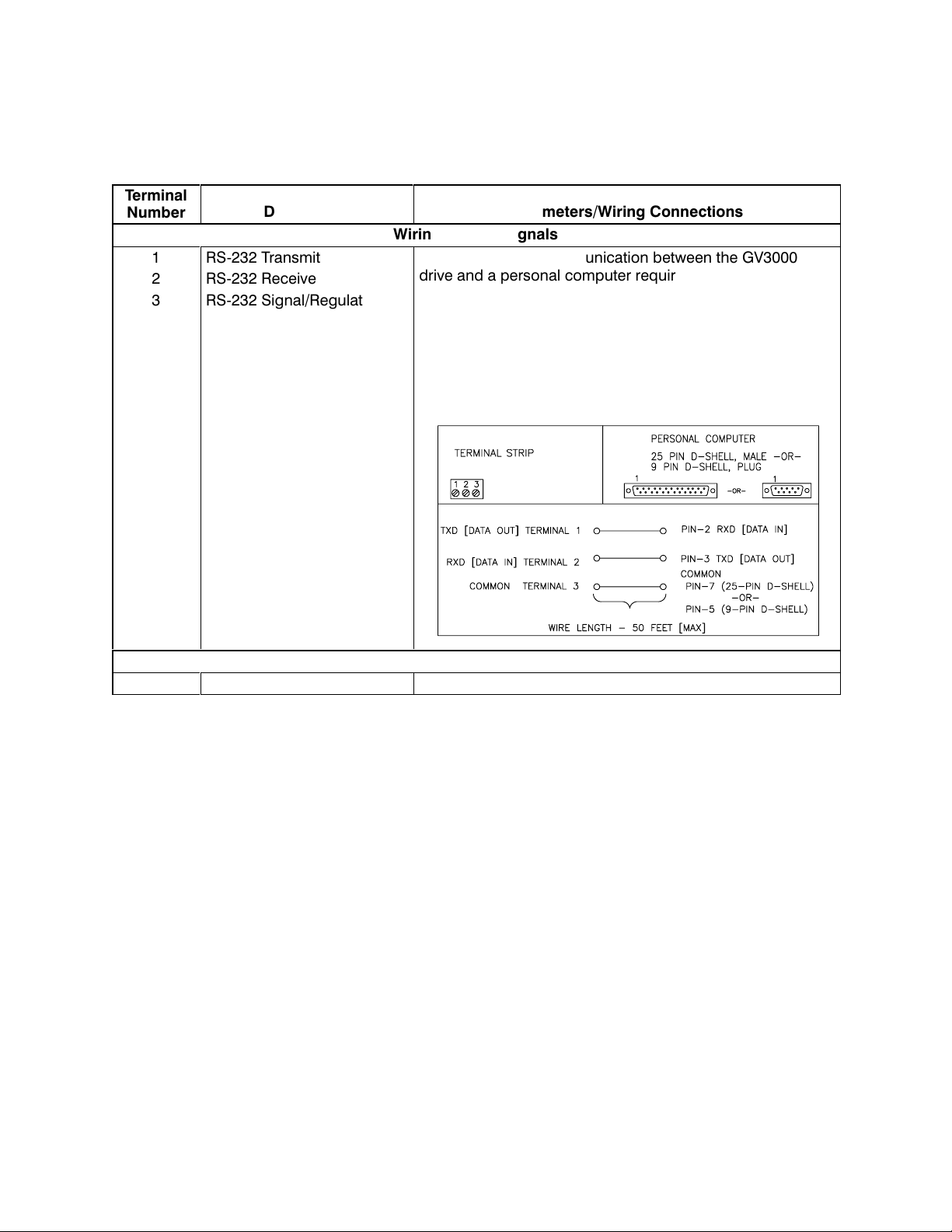

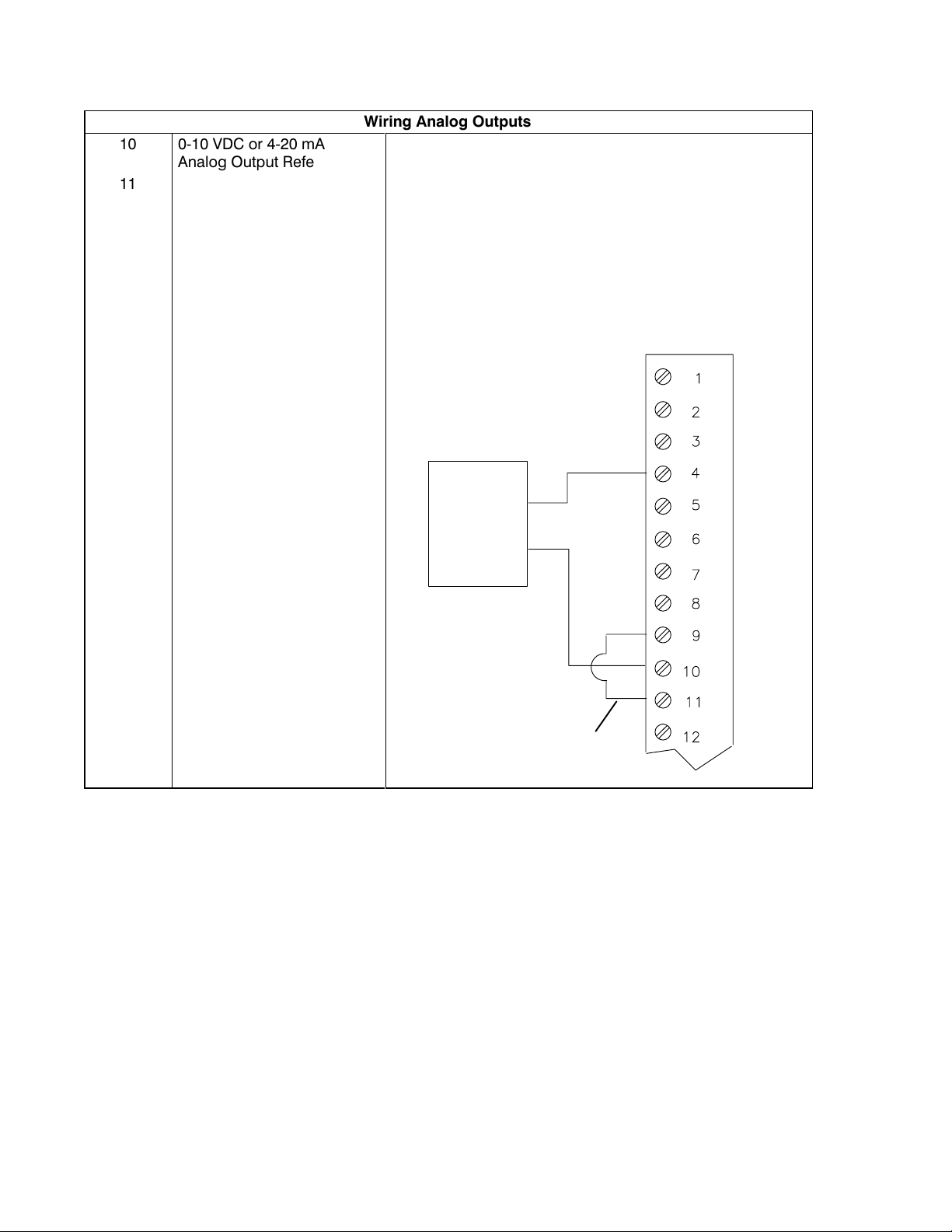

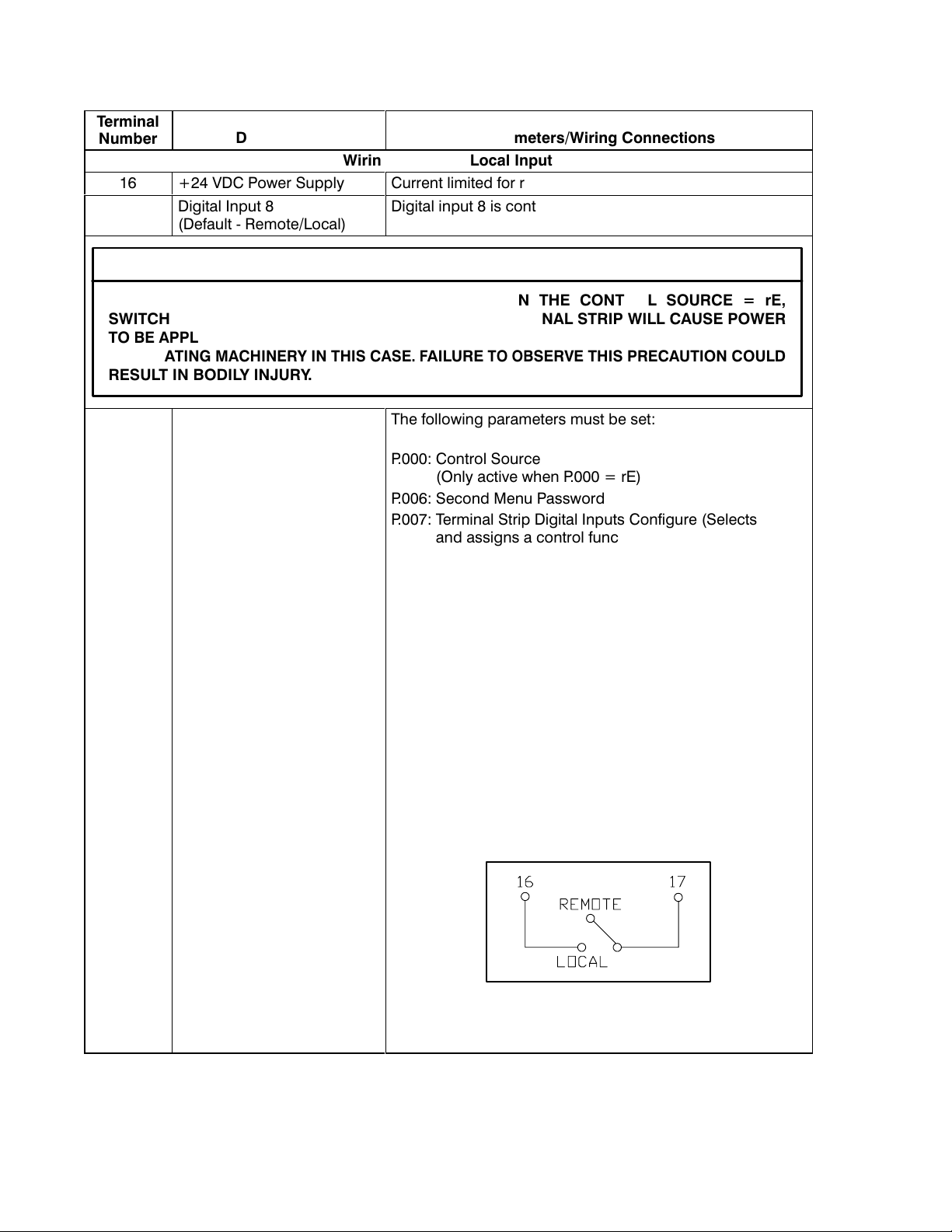

7.3 Wiring the Signal and Control I/O 7Ć7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . . . . . . .

8.0 Completing the Installation 8Ć1.

8.1 Checking the Installation 8Ć1.

8.2 Installing the Cover for NEMA 4X/12 Drives 8Ć2.

8.3 Powering Up After Installation is Complete 8Ć2.

9.0 Troubleshooting the Drive 9Ć1.

9.1 Test Equipment Needed to Troubleshoot 9Ć1.

9.2 Drive Alarms and Faults 9Ć1.

9.3 Verifying That DĆC Bus Capacitors are Discharged 9Ć1.

9.4 Checking Out the Power Modules with Input Power Off 9Ć6.

9.5 Replacement Parts 9Ć8.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II

Page 11

Appendix A

Technical Specifications AĆ1.

Appendix B

Drive Regulation Overview BĆ1.

Appendix C

Compliance with EN 60204Ć1: 1992 CĆ1.

Appendices

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Index IndexĆ1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

III

Page 12

List of Figures

Figure 2.1 Ć Identifying the Drive Model Number 2Ć1.

Figure 2.2 Ć 1Ć5 HP Drive Components and Locations 2Ć3.

Figure 2.3 Ć 7.5Ć10 HP Drive Components and Locations 2Ć4.

Figure 2.4 Ć 15Ć25 HP Drive Components and Locations 2Ć5.

Figure 2.5 Ć 25Ć60 HP Drive Components and Locations 2Ć6.

Figure 2.6 Ć 60Ć100 HP Drive Components and Locations 2Ć7.

Figure 2.7 Ć 100Ć150 HP Drive Components and Locations 2Ć8.

Figure 2.8 Ć 1Ć60 HP Regulator Board Components and Locations 2Ć10.

Figure 2.9 Ć 60Ć150 HP Regulator Board Components and Locations 2Ć11.

Figure 2.10 Ć Jumper J4 Settings for Analog Input Speed Reference 2Ć12.

Figure 2.11 Ć Jumper J17 Settings for Analog Outputs 2Ć13.

Figure 2.12 Ć Typical Terminal Strip Connections 2Ć14.

Figure 2.13 Ć Keypad/Display 2Ć15.

Figure 3.1 Ć Drive Dimensions 3Ć3.

Figure 3.2 Ć Recommended Air Flow Clearances 3Ć4.

Figure 3.3 Ć Single and Multiple Motor Lead Lengths 3Ć7.

Figure 4.1 Ć Wire Routing Locations for 1Ć5 HP Drives 4Ć2.

Figure 4.2 Ć Wire Routing Locations for 7.5Ć10 HP Drives 4Ć3.

Figure 4.3 Ć Wire Routing Locations for 15Ć25 HP Drives 4Ć4.

Figure 4.4 Ć Wire Routing Locations for 25Ć60 HP Drives 4Ć5.

Figure 4.5 Ć Wire Routing Locations for 60Ć100 HP Drives 4Ć6.

Figure 4.6 Ć Wire Routing Locations for 100Ć150 HP Drives 4Ć7.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Figure 5.1 Ć Typical AĆC Input Electrical Connections 5Ć2.

Figure 5.2 Ć Typical DĆC Bus Electrical Connections 5Ć3.

Figure 7.1 Ć TwoĆWire Start/Stop Sample Control Wiring 7Ć3.

Figure 7.2 Ć ThreeĆWire Start/Stop Sample Control Wiring 7Ć4.

Figure 7.3 Ć Wiring Connections for the Speed Feedback Device 7Ć6.

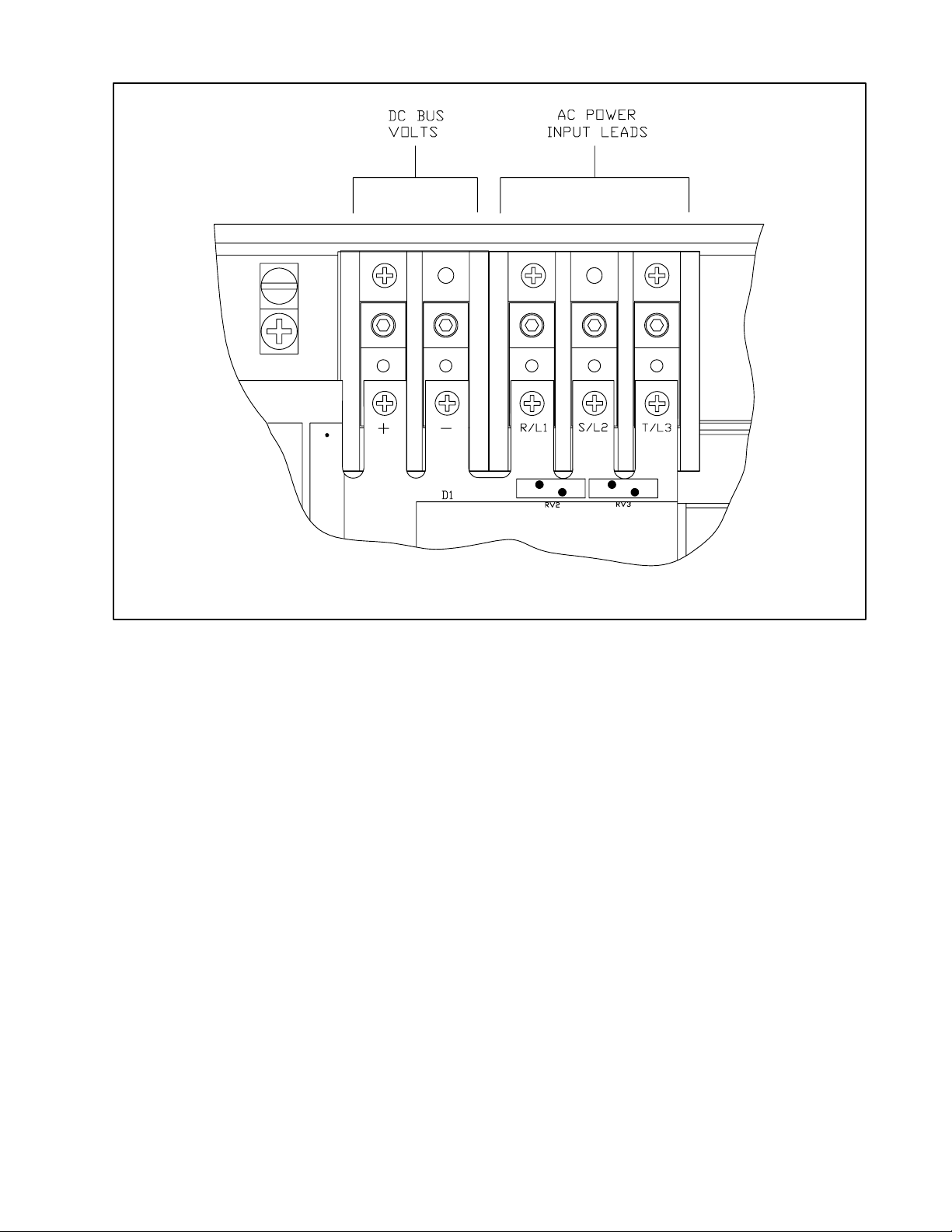

Figure 9.1 Ć DĆC Bus Voltage Terminals (1Ć25 HP Drives) 9Ć2.

Figure 9.2 Ć DĆC Bus Voltage Terminals (25Ć60 HP Drives) 9Ć3.

Figure 9.3 Ć DĆC Bus Voltage Terminals (60Ć100 HP Drives) 9Ć4.

Figure 9.4 Ć DĆC Bus Voltage Terminals (100Ć150 HP Drives) 9Ć5.

Figure B.1 Ć Volts/Hertz Regulation Block Diagram BĆ2.

Figure B.2 Ć Vector Regulation Block Diagram BĆ3.

IV

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 13

List of Tables

Table 2.1 Ć Power and NEMA Enclosure Ratings 2Ć2.

Table 2.2 Ć Available Kits and Options 2Ć16.

Table 3.1 Ć Ambient Conditions 3Ć1.

Table 3.2 Ć Drive Dimensions and Weights 3Ć2.

Table 3.3 Ć Recommended Power Wire Sizes for 1Ć10 HP Drives 3Ć5.

Table 3.4 Ć Recommended Power Wire Sizes for 15Ć25 HP Drives 3Ć5.

Table 3.5 Ć Recommended Power Wire Sizes for 25Ć60 HP Drives 3Ć6.

Table 3.6 Ć Recommended Power Wire Sizes for 60Ć100 HP Drives 3Ć6.

Table 3.7 Ć Recommended Power Wire Sizes for 100Ć150 HP Drives 3Ć6.

Table 3.8 Ć Recommended Terminal Strip Wire Sizes 3Ć6.

Table 3.9 Ć AĆC Input Line Fuse Selection Values 3Ć8.

Table 5.1 Ć Terminal Tightening Torques 5Ć4.

Table 7.1 Ć Wiring Signal and Control I/O to the Terminal Strip 7Ć7.

Table 9.1 Ć Resistance Checks 9Ć6.

Table 9.2 Ć 1Ć5 HP Drive Replacement Parts 9Ć8.

Table 9.3 Ć 7.5Ć10 HP Drive Replacement Parts 9Ć8.

Table 9.4 Ć 15Ć25 HP Drive Replacement Parts 9Ć9.

Table 9.5 Ć 25Ć60 HP Drive Replacement Parts 9Ć10.

Table 9.6 Ć 60Ć100 HP Drive Replacement Parts 9Ć11.

Table 9.7 Ć 100Ć150 HP Drive Replacement Parts 9Ć12.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table A.1 Ć Service Conditions AĆ1.

Table A.2 Ć Ambient Conditions AĆ1.

Table A.3 Ć Terminal Strip Input Specifications AĆ2.

Table A.4 Ć Terminal Strip Output Specifications AĆ2.

Table A.5 Ć RSĆ232 Specifications AĆ2.

Table A.6 Ć Speed Feedback Device Specifications (Vector Regulation Only) AĆ2.

Table A.7 Ć Input Signal Response Times (Worst Case) AĆ3.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

V

Page 14

Page 15

1.0 BECOMING FAMILIAR WITH THE MANUAL

This

chapter provides help in finding information in the manual and describes the intended audience.

Also included are references to other related publications and instructions on receiving assistance

from Reliance Electric.

1.1 Finding Information

This

instruction manual describes the GV3000 drive's Power Module and regulator hardware. It does

not cover the GV3000 software. F

Purpose (V/Hz) and V

As an aid in finding information in this manual, each chapter is briefly described below:

D

Chapter 1

Chapter 2ĆAbout the Drive

D

D

Chapter 3 ĆPlanning Before Installing

D

Chapter 4ĆMounting the Drive, Grounding, and Finding W

ector Duty Drive Software Start

Ć Becoming Familiar with the Manual

Provides information on how the manual is organized and where to find additional

information.

Identifies drive components and shows their locations.

Presents information that must be considered when planning a drive installation.

Describes how to mount the drive and properly ground it.

or additional software information, refer to the GV3000 AĆC General

ĆUp and Reference Manual (D2Ć3339).

ire Routing Locations

D

Chapter 5ĆInstalling Input P

Describes incoming AĆC and D

them.

Chapter 6ĆInstalling AĆC Output P

D

Describes output AĆC line components and how to properly connect them to the

motor.

Chapter 7

D

Chapter 8ĆCompleting the Installation

D

Chapter 9

D

D Appendix A Ć T

D Appendix B Ć

ĆW

iring the Regulator Board T

Provides information on the I/O wiring that connects to the terminal strip on the

Regulator board.

Provides instructions on how to perform a final check of the installation before

power is applied.

ĆT

roubleshooting the Drive

Describes the equipment that is needed to troubleshoot the drive and how to

measure D

echnical Specifications

Lists drive specifications in table form.

Drive Regulation Overview

Briefly describes volts/hertz and vector regulation.

ower W

ĆC bus voltage. Replacement part lists are also provided.

iring

ower W

ĆC line components and how to properly connect

iring

erminal Strip

D Appendix C Ć Compliance with EN 60204Ć1: 1992

Lists the sections of standard EN 60204Ć1: 1992 that the GV3000 drive complies

with.

1Ć1

Page 16

1.2 Assumptions About the Audience

This

manual is intended for qualified electrical personnel. It is task

according to a logical progression of steps to be followed to install and troubleshoot the drive.

1.3 Taking Safety Precautions

Ćoriented and is organized

Dangers,

three types of precautions are enclosed in a box to call attention to them.

A DANGER ALERTS A PERSON OF A CONDITION WHICH COULD RESULT IN SEVERE BODILY

INJURY OR LOS

W

ARNING ALERTS A PERSON OF A CONDITION WHICH COULD RESUL

A

INJURY IF PROCEDURES ARE NOT FOLLOWED.

CAUTION:

equipment.

warnings, and cautions are used in this manual to point out potential problem areas. All

DANGER

S OF LIFE

A caution alerts a person of a condition which could result in damage to, or destruction of the

.

WARNING

T IN POTENTIAL B

1.4 Understanding Terms Used in this Manual

The

following terms are defined according to the way they are used in this manual:

D

GV3000 drives will typically be referenced by horsepower

model numbers will also be included.

. If additional clarity is required, drive

ODILY

D P

arameters will be referenced either as parameter (P

.030) or Elapsed T

1.5 If You Want to Know More

Refer

to the following related publications as necessary for more information:

D D2Ć3339 GV3000 AĆC General Purpose (V/Hz) and V

Reference Manual

D D2Ć3291

D D2Ć3305

D D2Ć3308

D D2Ć3348

D D2Ć3341

D D2Ć3342

Snubber Resistor Braking Kit

Motor Encoder Cable Kit

AutoMax Network Communication Board

Control and Configuration Software (C

Remote Meter Interface

Operator Interface Module

ector Duty Drive Software Start

S3000)

1.6 Getting Assistance from Reliance Electric

If

you have any questions or problems with the products described in this instruction manual, contact

your local Reliance Electric sales office. F

or technical assistance, call 1Ć800ĆRELIANCE

ime Meter Reset (P

ĆUp and

.

.030).

1Ć2

Page 17

2.0 ABOUT THE DRIVE

This

chapter describes how to identify the drive using the model number matrix and illustrates the

differences between the NEMA enclosures. Major components of each drive group are also shown.

The GV3000 AĆC drive is a P

WM drive that provides vector and general purpose (volts/hertz or V/Hz)

regulation for a wide range of applications.

Using vector regulation, the drive can provide high dynamic response, maintain full rated motor

torque to zero speed, and precisely control motor speed in both directions using pulse tachometer

feedback.

Using general purpose (volts/hertz) regulation, the drive is suited for a broad range of applications

requiring adjustable speed control of motors.

2.1 Identifying the Drive by Model Number

Each GV3000 AĆC drive can be identified by its model number

on the shipping label and on the drive's nameplate. The drive's model number includes the P

Module and the regulator

Horsepower Ratings

GV3000

. Drive power ratings are provided in table 2.1.

NNN A N N NN

V = v 50 HP

R = u 50 HP

G = V/Hz Only

. See figure 2.1. This number appears

ower

Voltage

2 = 200*230V

4 = 380

*460V

Enclosure

1 = NEMA 1

2 = NEMA 12 Only

4 = NEMA 4X (Indoor Only) or NEMA 12

Regulator Version

5.0 = Vector and V/Hz Regulator

Figure

2.1 Ć Identifying the Drive Model Number

2Ć1

Page 18

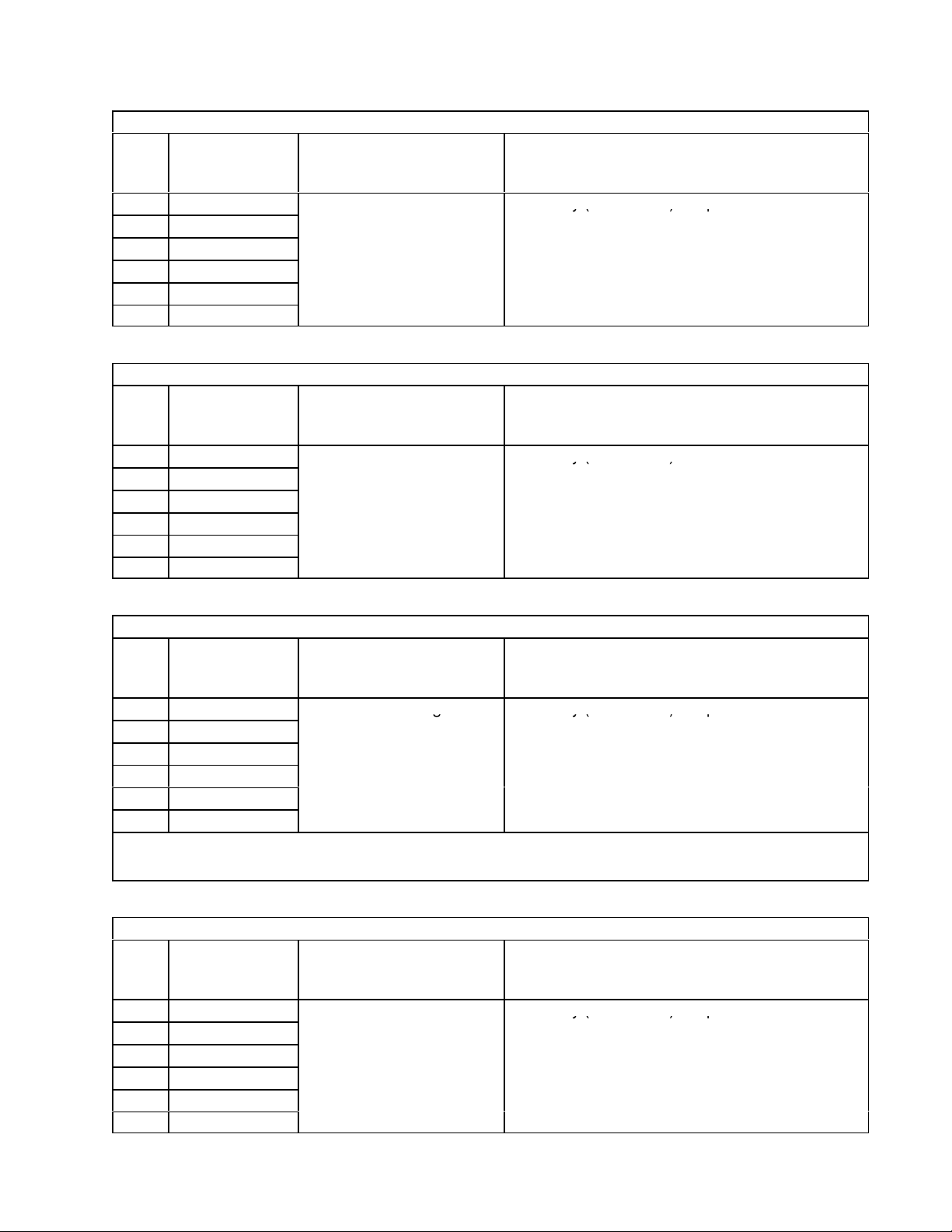

Table 2.1 Ć P

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

ower and NEMA Enclosure Ratings

ÁÁÁ

Model

Number

ÁÁÁ

1V4150

1V4450

2V4150

ÁÁÁ

2V4450

3V4150

3V4450

5V4150

ÁÁÁ

5V4450

7V4150

ÁÁÁ

7V4250

10V4150

10V4250

15V4150

ÁÁÁ

15V4250

20V4150

20V4250

ÁÁÁ

25G4150

25G4250

25V4150

ÁÁÁ

25V4250

30V4150

30V4250

ÁÁÁ

40V4150

40V4250

50V4150

ÁÁÁ

50V4250

50R4150

ÁÁÁ

60G4150

60G4250

75R4150

ÁÁÁ

125R4150

ÁÁÁ

Selected

БББББББ

Regulation* and

Horsepower Rating

БББББББ

V/Hz

or V

ector

(1 HP)

V/Hz or Vector

БББББББ

(2 HP)

V/Hz or Vector

(3 HP)

V/Hz or Vector

БББББББ

(5 HP)

V/Hz or Vector

БББББББ

(7.5 HP)

V/Hz or Vector

(10 HP)

V/Hz or Vector

БББББББ

(15 HP)

V/Hz or Vector

БББББББ

(20 HP)

V/Hz

(25 HP)

V/Hz or Vector

БББББББ

(25 HP)

V/Hz or Vector

БББББББ

(30 HP)

V/Hz or Vector

(40 HP)

V/Hz or Vector

БББББББ

БББББББ

(50 HP)

V

ector (50 HP)

V/Hz (75 HP)

V/Hz

(60 HP)

Vector (60-75 HP)

БББББББ

V/Hz (100 HP)

Vector (100-125 HP)

V/Hz (125-150 HP)

БББББББ

Input

ÁÁÁÁ

Voltage

(+/- 10%)

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

ÁÁÁÁ

380-460 VAC

380-460 VAC

ÁÁÁÁ

380-460 VAC

ÁÁÁÁ

ÁÁ

NEMA

Rating

ÁÁ

1

4X/12

1

ÁÁ

4X/12

1

4X/12

1

ÁÁ

4X/12

1

ÁÁ

12

1

12

1

ÁÁ

12

1

12

ÁÁ

1

12

1

ÁÁ

12

1

12

ÁÁ

1

12

1

ÁÁ

12

1

ÁÁ

1

12

1

ÁÁ

1

ÁÁ

Á

Input

KVA

Á

2.0

3.3

Á

5.1

7.9

Á

10.7

Á

13.4

20.2

Á

26.1

Á

29.5

30.2

Á

35.0

Á

46.2

57.3

Á

65.0

81.0

Á

71.7

80.0

Á

100

127

170

Á

Á

Input

Amps

Á

2.5

4.2

Á

6.4

9.9

Á

13.4

Á

16.8

25.4

Á

32.7

Á

37.0

38.0

Á

44.0

Á

58.0

72.0

Á

81.0

102

Á

90.0

101

Á

126

159

213

Á

Output

ÁÁÁ

Amps

at 8 kHz

ÁÁÁ

2.1

3.4

ÁÁÁ

5.3

8.2

ÁÁÁ

11.1

ÁÁÁ

14.2

21.0

ÁÁÁ

27.0

ÁÁÁ

30.4

34.5

ÁÁÁ

39.0

ÁÁÁ

54.0

67.0

ÁÁÁ

70.0**

90.0**

ÁÁÁ

78.0

89.0**

ÁÁÁ

116**

152**

210**

ÁÁÁ

Power

ÁÁÁ

Loss W

(F

ull Load)

ÁÁÁ

60

100

ÁÁÁ

140

180

ÁÁÁ

210

ÁÁÁ

250

375

ÁÁÁ

600

ÁÁÁ

600

750

ÁÁÁ

800

ÁÁÁ

960

1200

ÁÁÁ

1420

ÁÁÁ

1200

1400

ÁÁÁ

1780

2410

3200

ÁÁÁ

ă*With V/Hz regulation, 110% continuous output current capability. With vector regulation, 150% output current capability for one

minute.

**At 2 kHz. For 4 kHz operation, derate by 20%. For 8 kHz operation, derate by 40%.

atts

2.2 NEMA Enclosures

Each of the GV3000 P

D

NEMA 1:Vented. Contains a communication access door that allows access to the

communication port without removing the cover

applications.

D NEMA 4X/12:

D

NEMA 12: Intended for use in indoor environments that require a dust

See table 2.1 for a listing of the P

2Ć2

ower Modules have one of following NEMA ratings:

. Intended for generalĆpurpose indoor

Not vented. Supplied with base and keypad gaskets. Intended for use in indoor

environments that require a water

Ćtight/dust

Ćtight enclosure. An enclosure with this

NEMA rating encompasses both ratings (4X and 12).

Ćtight/dripĆtight enclosure.

ower Modules and their individual NEMA ratings.

Page 19

2.3 1Ć25 HP GV3000 Drive Components and Locations

The

1Ć25 HP GV3000 drives have the following main components. The identification numbers

provided correspond to the numbers used in figures 2.2 to 2.4. Replacement parts are listed in

chapter 9.

ă1. Fan/Fan Assembly

Membrane Switch (K

ă2.

ă3.

Regulator Printed Circuit Board (PCB)

ă4.

Capacitor PCB/Input Capacitors

ă5.

Current F

ă6. Power PCB (15Ć25 HP drives only)

eedback PCB

eypad/Bracket)

ă7. Power Supply PCB (15Ć25 HP drives only)

Gate Driver PCB (15Ć25 HP drives only)

ă8.

ă9.

Internal F

IGBT Module

10.

11. Diode Bridge

12. Fan W

an Assembly

ire Harness

M/N M/N

1V4150 3V4150

1V4450 3V4450

2V4150 5V4150

2V4450 5V4450

Figure 2.2 Ć 1Ć5 HP Drive Components and Locations

2Ć3

Page 20

M/N

7V4150

7V4250

10V4150

10V4250

Figure 2.3 Ć 7.5Ć10 HP Drive Components and Locations

2Ć4

Page 21

M/N

15V4150

15V4250

20V4150

20V4250

M/N

25G4150

25G4250

Figure 2.4 Ć 15Ć25 HP Drive Components and Locations

2Ć5

Page 22

2.4 25Ć60 HP GV3000 Drive Components and Locations

The

25Ć60 HP drives have the following main components. The identification numbers provided

correspond to the numbers used in figure 2.5. Replacement parts are listed in chapter 9.

1. Fan

2.

Membrane Switch (K

3. Regulator Board

4.

Bus Capacitors

5.

Not Used

6. P

ower Board

eypad/Bracket)

7. Power Supply Board

8.

Gate Driver Board

9.

Internal F

10.

IGBT Module

11. Diode Bridge

12. W

an Assembly

ire Harness

2Ć6

M/N

25V4150

25V4250

30V4150

30V4250

M/N

40V4150

40V4250

50V4150

50V4250

M/N

60G4150

60G4250

Figure 2.5 Ć 25Ć60 HP Drive Components and Locations

Page 23

2.5 60Ć100 HP GV3000 Drive Components and Locations

The

60Ć100 HP drives have the following main components. The identification numbers provided

correspond to the numbers used in figure 2.6. Replacement parts are listed in chapter 9.

1.

Regulator Printed Circuit Board (PCB)

2. P

ower Module Interface PCB

3.

Gate Driver PCB

4. Bus Clamp PCB Ć Right

Bus Clamp PCB Ć Left

5.

6.

Intelligent P

ower Module PCB

7. Diode Bridge

8. DĆC Bus Fuse

9.

Precharge Contactor

10.

11.

12.

13.

14.

15. 24 VDC Fan

16. Keypad

14

7

Current T

Ground F

ransformer

ault T

ransformer

Output Reactor

Precharge Resistor

Bus Discharge Resistor

14

11

M/N

50R4150

75R4150

16

1

2

12

10

9

3

13

10

6

5

10

4

8

15

Figure 2.6 Ć 60Ć100 HP Drive Components and Locations

2Ć7

Page 24

2.6 100Ć150 HP GV3000 Drive Components and Locations

The

100Ć150 HP drive has the following main components. The identification numbers provided

correspond to the numbers used in figure 2.7. Replacement parts are listed in chapter 9.

1.

Regulator Printed Circuit Board (PCB)

2. P

ower Module Interface PCB

3.

Gate Driver PCB

4. Bus Clamp PCB Ć Right

5.

Bus Clamp PCB Ć Left

6.

Intelligent P

7.

Thyristor Precharge Module

ower Module PCB

8. DĆC Bus Fuse

9.

Not Used

11

10.

Current T

Ground F

11.

Output Reactor

12.

13.

Not Used

14.

Bus Discharge Resistor

ransformer

ault T

15. 24 VDC Fan

16. Keypad

Thyristor Firing P

17.

14

7

ransformer

ulse PCB

12

10

3

17

2

16

15

6

5

3

5

8

1

2

2Ć8

M/N

125R4150

Figure 2.7 Ć 100Ć150 HP Drive Components and Locations

Page 25

2.7 Regulator Board Description

GV3000

and 2.9. Drive operation is adjusted by the parameters entered through the keypad. The Regulator

board accepts power circuit feedback signals, an external speed reference signal, and internal heat

sensor feedback, as well as data from a pulse tachometer that is attached to the motor when set up

for vector regulation. The Regulator board provides:

D P

D F

D

D An analog output

drive regulation is performed by a microprocessor on the Regulator board. See figures 2.8

WM gating signals to the IGBT power devices

Based on the output of the control loop, the regulator sends P

Current F

Insulated Gate BiĆpolar T

that corresponds to the speed (vector regulation) or frequency (volts/hertz regulation) reference.

The IGBT

orm A and B contacts for drive status indicators

The F

or B transition can indicate drive status. The contacts are rated for 5 Amps resistive load at 250

VAC/ 30 VDC and are made available through the terminal strip.

Display data for a four

The four

codes. The fourteen single LEDs indicate drive status and mode, as well as identifying drive

outputs whose values are displayed on the four

The analog output is a scaled voltage (0Ć10 VDC) or current (4Ć20 mA) signal proportional to

either motor speed (RPM) or motor torque or current (%TORQUE). The current selection (via

jumper J17) requires a power supply for operation. The power can be sourced from the pulse

tachometer terminals (4 and 9) or from an external 15V power supply

and 11, for more information. The analog output signal is available through the terminal strip.

eedback board to isolated drivers on the Gate Driver board. These drivers switch the

ransistors (IGBT

s can be switched at either a 2, 4 or 8 kHz carrier frequency

orm A and B contacts are under control of the user via programmable parameters. A F

Ćcharacter display and fourteen indicator LEDs

Ćcharacter display is used to indicate drive parameters, parameter values, and fault

s), producing a P

Ćcharacter display

WM gating signals through the

ulse W

idth Modulated (P

.

.

. See table 7.1, terminals 10

WM) waveform

orm A

D

A snubber resistor braking signal

The 1Ć60 HP regulator provides a signal for use by an optional snubber resistor braking kit. The

signal goes through an isolating driver

Two Regulator boards are used on the GV3000 drives: 1Ć60 HP Regulator boards are used with

1Ć60 HP drives; 60Ć150 HP Regulator boards are used with 60Ć150 HP drives. As shown in figures 2.8

and 2.9, the Regulator boards are similar but have different P

, made available through the terminal strip.

ower Module interface connectors.

2Ć9

Page 26

J3

USER DISPLAY

J5

26-Pin Ribbon Cable

34-Pin Ribbon Cable

J7

J8

J17

J3 Ć Option Board Connector

J4 Ć Analog Input Jumper

J5 Ć Power Module Feedback Cable

J7 Ć OIM (Optional) Connector

J4

J8 Ć RS232C Port

J9 Ć Keypad/Display Connector

J17 Ć Analog Output Jumper

USER I/O TERMINAL STRIP

Figure 2.8 Ć 1Ć60 HP Regulator Board Components and Locations

J9

2Ć10

Page 27

J3

J16

60ĆPin Ribbon Cable

USER DISPLAY

J9

34ĆPin Ribbon Cable

J7

J17

J4

J8

USER I/O TERMINAL STRIP

J3 Ć Option Board Connector

J4 Ć Analog Input Jumper

J7 Ć OIM (Optional) Connector

J8 Ć RS232C Port

J9 Ć Keypad/Display Connector

J16 Ć Power Module Feedback Cable

J17 Ć Analog Output Jumper

Figure 2.9 Ć 60Ć150 HP Regulator Board Components and Locations

2Ć11

Page 28

2.7.1 Jumper Locations and Settings

Jumpers

J4 and J17 on the Regulator board are factory

Ćset for voltage in and voltage out signals.

Refer to figures 2.8 and 2.9 for their locations on the Regulator boards. If you need to change the

jumpers' settings, use the following procedures.

CAUTION:

this

precaution could result in damage to or destruction of the equipment.

2.7.1.1 Analog

Do not alter the setting of any jumper not described in this

instruction manual. F

ailure to observe

Input Speed Reference Jumper

Jumper

+/- 10 VDC or 0Ć20 mA input. P

jumper

J4 is the analog speed/torque (U

arameters P

.000) reference jumper

.009, P.010, and P

.011 are used in conjunction with the

. This jumper selects either

. Note that if the position of jumper J4 is changed after the parameters are programmed, the

software will not recognize that the input reference or polarity has been changed. Be sure to verify

that parameters P

.009, P.010, and P

.011 are correct before starting the drive. Refer to instruction

manual D2Ć3339 for more information.

Use the following procedure to set jumper J4:

DANGER

DĆC BUS CAPACITORS RETAIN HAZARDOUS VOLTAGES AFTER INPUT POWER HAS BEEN

DISCONNECTED.

TER DISCONNECTING INPUT POWER

, W

AIT FIVE (5) MINUTES FOR THE D

AF

BUS CAPACITORS TO DISCHARGE AND THEN CHECK THE VOLTAGE WITH A VOLTMETER TO

ENSURE THE DĆC BUS CAPACITORS ARE DISCHARGED BEFORE TOUCHING ANY INTERNAL

COMPONENTS. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY

INJURY OR LOS

S OF LIFE

.

ĆC

Step 1. T

Step 2.

Step 3. V

Step 4.

Step 5.

Step 6.

urn off input power to the drive and wait five minutes.

Remove the cover from the drive by unscrewing the four attaching screws.

erify that the D

ĆC bus voltage is zero by following the procedure in section 9.3.

Locate jumper J4 on the Regulator board. Refer to figures 2.8 and 2.9.

Locate pin 1 on jumper J4. Move the jumper to the desired setting as shown in figure 2.10.

ReĆattach the cover

.

Step 7. ReĆapply input power.

Step 8. V

erify that T

(P.010), and T

erminal Strip Analog Input Offset (P

erminal Strip Analog Input Invert (P

manual D2Ć3339 for more information.

Voltage

Input Option

Pins 2Ć3 Pins 1Ć2

+10 VDC

.009), T

erminal Strip Analog Input Gain

.011) are correctly set. Refer to instruction

Current Input Option

0Ć20 mA

2Ć12

J4 J4

(default)

Figure 2.10 Ć Jumper J4 Settings for Analog Input Speed Reference

Page 29

2.7.1.2 Analog Output Jumper

Jumper

signal output that is programmable for either speed or torque, parameter P

J17 is the analog output jumper

. This jumper selects either a 0Ć10 VDC or 4Ć20 mA scaled

.012. The jumper only

selects a 0Ć10 VDC source voltage or 4Ć20 mA sink current to represent speed or torque. Note that

the 4Ć20 mA current selection requires a power supply for operation as shown in table 7.1, terminals

10 and 11.

Use the following procedure to set jumper J17:

DANGER

DĆC BUS CAPACITORS RETAIN HAZARDOUS VOLTAGES AFTER INPUT POWER HAS BEEN

DISCONNECTED.

TER DISCONNECTING INPUT POWER

, W

AIT FIVE (5) MINUTES FOR THE D

ĆC

AF

BUS CAPACITORS TO DISCHARGE AND THEN CHECK THE VOLTAGE WITH A VOLTMETER TO

ENSURE THE DĆC BUS CAPACITORS ARE DISCHARGED BEFORE TOUCHING ANY INTERNAL

COMPONENTS. FAILURE TO OBSERVE THIS PRECAUTION COULD RESULT IN SEVERE BODILY

INJURY OR LOS

Step 1. T

Step 2.

Step 3. V

Step 4.

Step 5.

Step 6.

S OF LIFE

.

urn off input power to the drive and wait five minutes.

Remove the cover from the drive by unscrewing the four attaching screws.

erify that the D

ĆC bus voltage is zero by following the procedure in section 9.3.

Locate jumper J17 on the Regulator board. Refer to figures 2.8 and 2.9.

Locate pin 1 on jumper J17. Move the jumper to the desired setting as shown in figure 2.11.

ReĆattach the cover

.

Step 7. ReĆapply input power.

Step 8. V

erify that parameter P

Voltage

Output Option

Pins 2Ć3

+10 VDC

J17 J17

(default)

Figure

2.11 Ć Jumper J17 Settings for Analog Outputs

.012 is set correctly for either speed or current.

Current Output Option

Pins 1Ć2

0Ć20 mA

2Ć13

Page 30

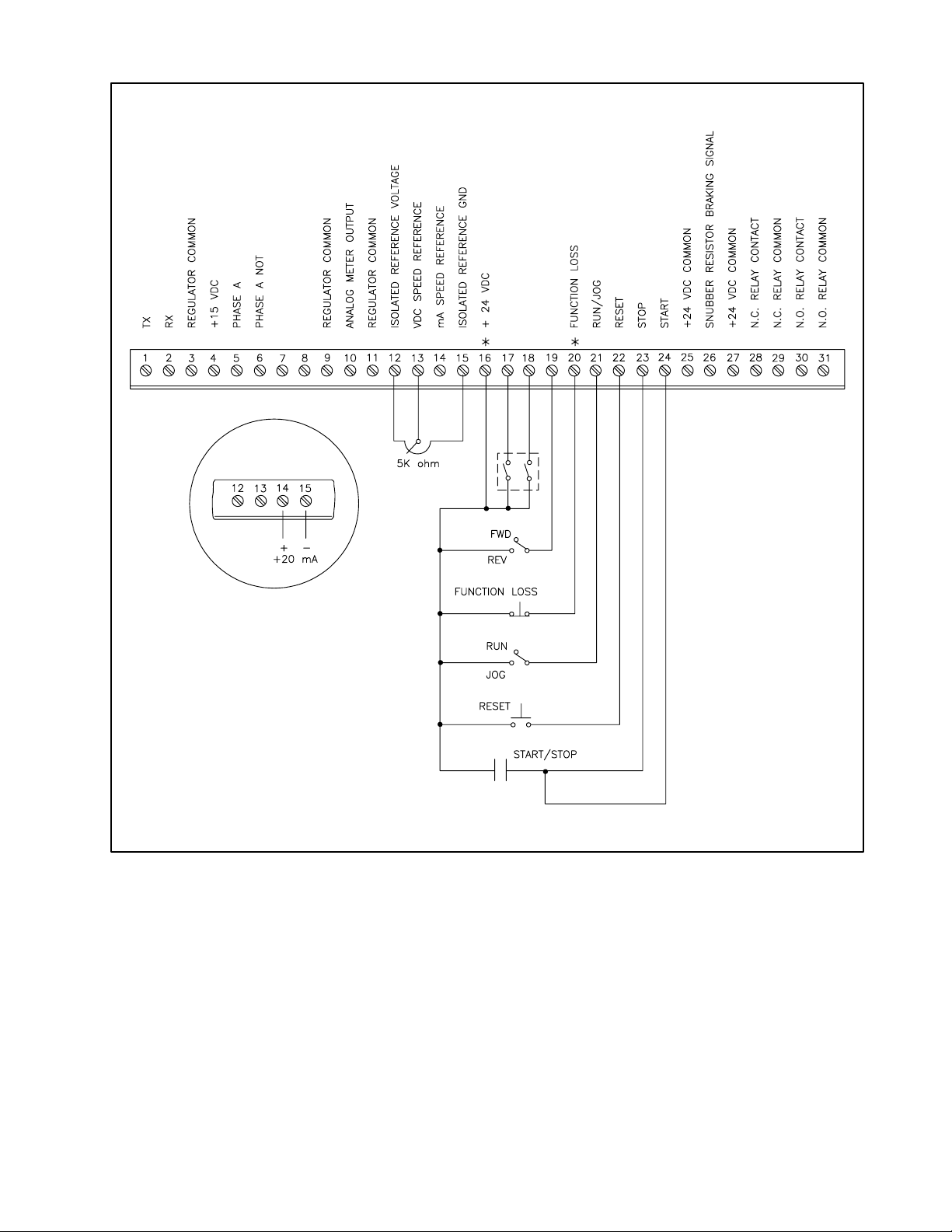

2.7.2 Wiring the Terminal Strip

The

terminal strip on the Regulator board provides terminals for connecting customer I/O devices.

See figures 2.8, 2.9, and 2.12. The following terminals are provided:

D Terminals 1Ć3: RS

D T

erminals 4Ć9: pulse tachometer connections

D T

erminals 10Ć11: analog output connections

D T

erminals 12Ć15: analog speed/torque reference connections

D Terminals 16Ć25: 24V D

D T

erminals 26Ć27: snubber resistor braking control connections (1Ć60 HP Regulator boards only)

D T

erminals 28Ć31: status relay connections

Ć232 connections

ĆC digital input connections (1Ć60 HP Regulator boards only)

DIGITAL INPUT 8 (REMOTE/LOCAL)

DIGITAL INPUT 7 (RAMP1/RAMP2)

PHASE B NOT

DIGITAL INPUT 6 (FORWARD/REVERSE)

PULSE TACHOMETER

CONNECTIONS

FACTORY

INSTALLED

WIRES BETWEEN TERMINALS 16+16A AND

20 + 20A ARE NECESSARY FOR PROPER

OPERATION OF THE FUNCTION LOSS

INPUT. THEY SHOULD NOT BE REMOVED.

2Ć14

Figure 2.12 Ć Typical T

erminal Strip Connections

Page 31

2.7.3 RSĆ232 Communication Port

The Regulator board contains a 9Ćpin DĆshell RS

RS

Ć232 communication between the GV3000 drive and a personal computer running the Control and

Configuration (C

S3000) software. See figures 2.8 and 2.9. Refer to instruction manual D2Ć3348, for

more information.

2.7.4 Option Board Connector

The

flat

Ćribbon cable connector (J3) on the left side of the Regulator board is a parallel bus

connection port that provides a means of attaching optional boards such as the DeviceNet board, the

RMI board, or the AutoMax Network Communication board to the GV3000 drive. See figures 2.8

and 2.9. The option board is mounted below the Regulator board inside the drive. Refer to the

appropriate board instruction manual for more information. Refer to section 2.7 of this manual for

more information on optional drive kits.

2.7.5 Operator Interface Module Connector

FlatĆribbon

(OIM). The OIM is available for use as a remote keypad for the GV3000.

connector J7 provides a means of attaching the optional Operator Interface module

2.7.6 Keypad/Display

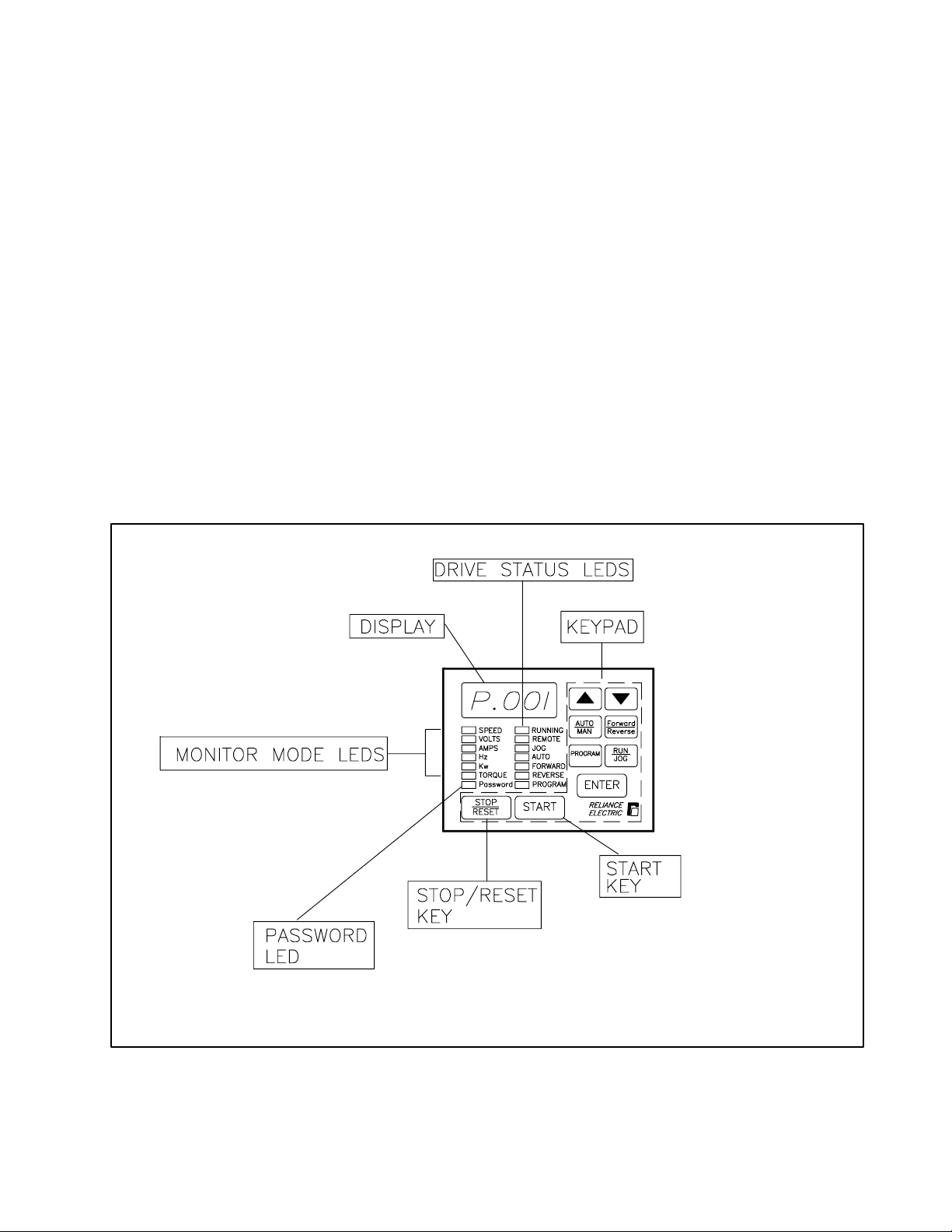

The front panel keypad/display is used to program and operate the GV3000 drive. See figure 2.13.

Refer to instruction manual D2Ć3339 for more information.

Ć232 communication port (J8). This port provides

1. Stops the drive.

2. Resets faults.

1. When this LED is on, parameters cannot be modified

from the keypad without entering the correct password

into P.051 (Programming Disable).

Figure 2.13 Ć Keypad/Display

1. Applies power to the motor if the

keypad is selected as the control source.

2Ć15

Page 32

2.8 Drive Kit Options

Table 2.2 provides a listing of the available GV3000 kit options.

Table 2.2 Ć Available Kits and Options

Kit Description

Snubber

Resistor Braking

Low Energy Snubber Braking

Resistor

Snubber T

Line Regeneration Unit

(1)(2)

ransistor Only

(1)(2)(3)

(1)(2)(3)

Option Kit Model Number Instruction Manual

2SR40400

2SR40600

2SR41200

2SR41800

(1)

(2)

(2)

(3)

2DB4010

2DB4020

2ST40027 D2Ć3291

1RG42008

1RG42015

1RG42045

2TC3025

2TC3075

Motor Encoder Cable

(1)(2)(3)(4)

2TC4025

2TC4075

2TC4100

2TC4300

AutoMax Network Communication

Board w/10 F

eet of Cable

(1)(2)(3)(4)

Remote Meter Interface (RMI)

DeviceNet Board

Operator Interface Module (OIM)

Control and Configuration Software

(CS3000)

(1) 1Ć5 HP GV3000 Drives

(2) 7.5Ć10 HP GV3000 Drives

(3) 15Ć60 HP GV3000 Drives

(4) 60Ć150 HP GV3000 Drives

(5) For use with Reliance NEMA Vector Inverter Duty Motors (tachometer connector and exposed wire pairs).

(6) For use with Reliance NEMA Vector Inverter Duty Motors (exposed wire pairs on both ends).

2AX3000 D2Ć3308

2SI3000 D2Ć3341

2DV3000 HEĆHGV3DN

2RK3000 D2Ć3342

2CS3000 D2Ć3348

(5)

(5)

(5)

(5)

(6)

(6)

D2Ć3291

D2Ć3179

N/A

D2Ć3305

2Ć16

Page 33

3.0 PLANNING BEFORE INSTALLING

This

chapter provides information that must be considered when planning a GV3000 drive

installation. Installation site requirements, drive requirements, and wiring requirements are presented.

DANGER

ONLY QUALIFIED ELECTRICAL PERSONNEL FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THIS EQUIPMENT AND THE HAZARDS INVOLVED SHOULD INSTALL, ADJUST,

OPERATE,

APPLICABLE

PRECAUTION COULD RESULT IN SEVERE BODIL

OR SERVICE THIS EQUIPMENT

MANU

ALS IN THEIR ENTIRETY BEFORE PROCEEDING. F

. READ AND UNDERST

Y INJURY OR LOSS OF LIFE

DANGER

AND THIS MANU

AIL

URE TO OB

.

AL AND

SERVE THIS

OTHER

USER IS RESPONSIBLE FOR CONFORMING WITH ALL APPLICABLE L

THE

INTERNATIONAL CODES. WIRING PRACTICES, GROUNDING, DISCONNECTS, AND

OVERCURRENT PROTECTION ARE OF PARTICULAR IMPORTANCE. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN SEVERE BODIL

CAUTION: Use of p

motor,

n

uisanc

proceeding. Failur

e t

ripping

e t

owe

o o

r c

orrectio

, a

nd/o

bserv

n c

apacitor

r p

ermanen

e t

his precautio

t d

s o

amag

n c

Y INJURY OR LOSS OF LIFE

n the o

utpu

t o

f the d

riv

e can r

e t

o the d

rive

. R

emov

e p

ould resul

t i

n damag

e t

o o

owe

OCAL

esul

t i

n e

r c

orrectio

r destructio

.

rrati

n o

, NA

c o

n c

apacitor

f the e

TIONAL,

peratio

n o

s b

quipment.

3.1 Requirements for the Installation Site

It

is important to properly plan before installing a GV3000 drive to ensure that the drive's environment

and operating conditions are satisfactory

This area must be kept clear of all control and power wiring. Read the following recommendations

before continuing with drive installation.

3.1.1 Making Sure Environmental Conditions are Met

Before

deciding on an installation site, consider the following guidelines:

D V

erify that NEMA 1 drives can be kept clean, cool, and dry

The area chosen should allow the space required for proper air flow as defined in section 3.1.2.

D

D

Be sure that NEMA 1 drives are away from oil, coolants, or other airborne contaminants.

. Note that no devices are to be mounted behind the drive.

.

AND

f t

he

efore

D

Do not install the drive above 1000 meters (3300 feet) without derating output power

91.4 meters (300 feet) above 3300 feet, derate the output current 1%.

D V

erify that the drive location will meet the environmental conditions specified in table 3.1.

T

able 3.1 Ć Ambient Conditions

Condition Specification

Operating T

Storage T

Humidity

emperature (Ambient)

emperature (Ambient)

0r to +40r C (32r to 104rF)

-40rāto +65rC (-40r to +149rF)

5 to 95% (nonĆcondensing)

. F

or every

3Ć1

Page 34

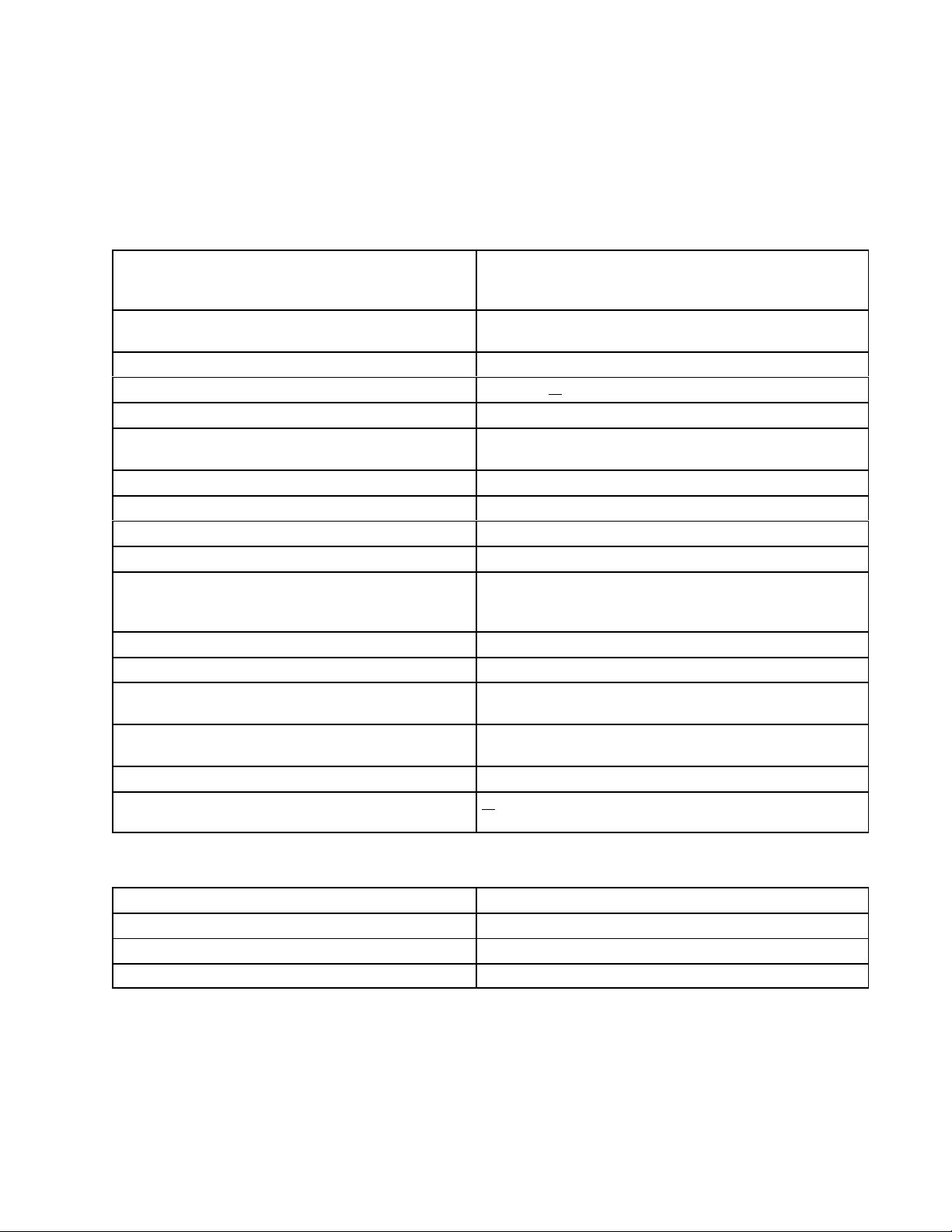

3.1.2 Determining Total Area Required Based on Drive Dimensions

2V4450

7V4250

11.05

13.32

9.76

12.17

7.87

20 lbs

20V4150

Drive

dimensions and weights are listed in table 3.2. Overall drive dimensions are illustrated in

figure 3.1 as an aid in calculating the total area required by the GV3000 drives.

T

able 3.2 Ć Drive Dimensions and W

eights

GV3000 Drive

1V4150

1V4450

2V4150

2V4450

3V4150

3V4450

5V4150

5V4450

7V4150

7V4250

10V4150

10V4250

15V4150

15V4250

20V4150

20V4250

25G4150

25G4250

25V4150

25V4250

30V4150

30V4250

40V4150

40V4250

50V4150

50V4250

60G4150

60G4250

50R4150

75R4150

125R4150 465.0 mm

Dim. A Dim. B Dim. C Dim D. Dim. E Weight

222.3 mm

8.75"

280.6 mm

11.05"

288.0 mm

11.34"

376.0 mm

14.80"

376.0 mm

14.80"

421.0 mm

16.60"

18.30"

280.7 mm

11.05"

338.4 mm

13.32"

463.0 mm

18.23"

605.0 mm

23.82"

605.0 mm

23.82"

880.0 mm

34.65"

1457 mm

57.36"

198.1 mm

7.80"

248.0 mm

9.76"

223.0 mm

8.78"

308.0 mm

12.13"

308.0 mm

12.13"

360.0 mm

14.17"

330.0 mm

12.99"

254.3 mm

10.01"

309.1 mm

12.17"

442.0 mm

17.40"

565.2 mm

22.25"

565.2 mm

22.25"

850.0 mm

33.46"

1414 mm

55.66"

200.0 mm

7.87"

200.0 mm

7.87"

238.1 mm

9.37"

350.0 mm

13.78"

350.0 mm

13.78"

322.0 mm

12.68"

355.0 mm

13.97"

6.3 kg

14 lbs

9 kg

20 lbs

15.75 kg

35 lbs

23.6 kg

52 lbs

25.8 kg

57 lbs

70 kg

154 lbs

96 kg

211 lbs

3Ć2

Page 35

1-60 HP

60-150 HP

Figure 3.1 Ć Drive Dimensions

3Ć3

Page 36

3.1.3 Verifying the Site Provides for Recommended Air Flow Clearances

Be

sure there is adequate clearance for air ventilation around the drive. F

not mount GV3000 drives directly above each other

. Note that no devices are to be mounted behind

the drive. This area must be kept clear of all control and power wiring. Refer to figure 3.2 for

recommended air flow clearances.

1-60 HP

or best air movement, do

60-150 HP

*If adjacent to other drives.

3Ć4

Figure 3.2 Ć Recommended Air Flow Clearances

Page 37

3.1.4 Verifying Power Module Input Ratings Match Supplied Power

12 A

WG, 3 (mm

)

6 AWG, 13 (mm )

It

is important to verify that plant power will meet the input power requirements of the GV3000 drive's

P

ower Module circuitry

the drive corresponds to the drive nameplate voltage and frequency

. Refer to table 2.1 for input power rating specifications. Be sure input power to

.

3.2 Wiring Requirements for the Drive

Certain

sizes, branch circuit protection, speed feedback (for vector regulation), and EĆstop wiring (see

chapter 7), are all areas that need to be evaluated.

drive requirements should be checked before continuing with the drive installation. W

3.2.1 Meeting Terminal Strip Input and Output Specifications

The

terminal strip on the Regulator board provides terminals for 24 VDC power for the eight remote

control inputs. Refer to tables A

.3 and A

.4 for control input and output specifications.

3.2.2 Determining Wire Size Requirements

Wire

size should be determined based on the size of conduit openings, NEC/CEC regulations, and

applicable local codes.

DANGER

USER IS RESPONSIBLE FOR CONFORMING WITH ALL APPLICABLE L

THE

INTERNATIONAL CODES. WIRING PRACTICES, GROUNDING, DISCONNECTS, AND

OVERCURRENT PROTECTION ARE OF PARTICULAR IMPORTANCE. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN SEVERE BODIL

3.2.2.1 Conduit Entry Opening Sizes

It

is important to accurately determine the size of the conduit openings so that the wire planned for a

specific entry point will fit through the opening. Conduit opening sizes are shown in figures 4.1

through 4.6.

Y INJURY OR LOSS OF LIFE

OCAL

.

, NA

TIONAL,

ire

AND

3.2.2.2 Recommended Power W

Input

power wiring should be sized according to applicable codes to handle the drive's

continuousĆrated input current. Output wiring should be sized according to applicable codes to

handle the drive's continuousĆrated output current. See tables 3.3 through 3.7 for recommended

power wire sizes.

Table 3.3 Ć Recommended P

Type of Wiring Terminals

AĆC

Input P

Output P

D

ĆC Input P

Type of Wiring Terminals

AĆC

Input P

Output P

D

ĆC Input P

ower R/L1, S/L2, T/L3

ower U/T1, V/T2, W/T3

ower +, -

Table 3.4 Ć Recommended P

ower R/L1, S/L2, T/L3

ower U/T1, V/T2, W/T3

ower +, -

ire Sizes

ower W

ower W

ire Sizes for 1Ć10 HP Drives

Size of W

12 A

ire Sizes for 15Ć25 HP Drives

Size of W

6 AWG, 13 (mm2)

ire (Maximum)

WG, 3 (mm2)

ire (Maximum)

3Ć5

Page 38

Table 3.5 Ć Recommended P

R/L1, S/L2, TL3

/(),()

AĆC I

1L1, 1L2, 1L3

)

4/0 AWG, 95 (mm )

AĆC I

1L1, 1L2, IL3

)

2/0 AWG (2X), 185 (mm )

ower W

ire Sizes for 25Ć60 HP Drives

Type of Wiring Terminals

AĆC Input P

Output P

D

ĆC Input P

ower

ower U/T1, V/T2, W/T3

ower +, -

Table 3.6 Ć Recommended P

ower W

Type of Wiring Terminals

nput Power

Output P

AĆC Ground

D

ĆC Input P

D

ĆC Ground

ower U, V

ower 45, 47 4/0 AWG, 95 (mm2)

Table 3.7 Ć Recommended P

1L1, 1L2, 1L3

2L1, 2L2

, W

PE 2 AWG, 35 (mm2)

ower W

Type of Wiring Terminals

nput Power

Output P

AĆC Ground

D

ĆC Input P

ower U, V

ower 45, 47 2 AWG, 35 (mm2)

1L1, 1L2, IL3

2L1, 2L2

, W

PE 4/0 AWG, 95 (mm2)

Size of W

2/0 AWG (2X), 185 (mm2)

ire Sizes for 60Ć100 HP Drives

Size of W

4/0 AWG, 95 (mm

6 AWG, 16 (mm2)

ire Sizes for 100Ć150 HP Drives

Size of W

2/0 AWG (2X), 185 (mm

ire (Maximum)

ire (Maximum)

2

ire (Maximum)

2

D

ĆC Ground

3.2.2.3 Recommended

The

recommended wire sizes to connect I/O signals to the terminal strip on the Regulator board are

shown in table 3.8. Recommend terminal tightening torque is 0.5 NewtonĆmeters (4.5 inĆlbs).

Terminals Wire

3.2.2.4 Recommended

The

following motor lead lengths are recommended to reduce line disturbances and noise. See

figure 3.3.

D F

or applications using one motor, motor lead length should not exceed 76 meters (250 feet).

D F

or applications with multiple motors, total motor lead length should not exceed 76 meters

(250 feet).

When total lead length exceeds 76 meters (250 feet), nuisance trips can occur

caused by capacitive current flow to ground. Note that these capacitively

taken into consideration when working in areas where drives are running. If the motor lead length

must exceed these limits, output line reactors or other steps must be taken to correct the problem.

Note that drives set up for vector regulation can only be connected to one motor at a time.

Control and Signal Wire Sizes

Table 3.8 Ć Recommended T

erminal Strip W

ire Sizes

1 to 31 20 to 14 A

Motor Lead Lengths

6 AWG, 16 (mm2)

Size

WG, 2 to 0.5 (mm2)

. These trips are

Ćcoupled currents should be

3Ć6

Page 39

GV3000

Drive

GV3000

Drive

GV3000

Drive

38

m (125')

Motor

Motor

38 m (125')

15 m (50')

Motor

GV3000

Drive

Motor

60 m (200')

Motor

76 m (250')

60 m (200')

8 m (25') 8 m (25')

Motor Motor

Figure 3.3 Ć Single and Multiple Motor Lead Lengths

3.2.2.5 Recommended

Connector J8 on the Regulator boards is an RS

Serial Communication Cable Lengths

Ć232 serial communication port. This connector

allows the GV3000 drive to communicate with external devices such as a personal computer using

RSĆ232 protocol. See table A

.5. T

wo RSĆ232 cables are available from Reliance: a 3.5 meter (12 feet)

DĆshell 9Ćpin to 9Ćpin cable (M/N 615184Ć1A) and a 0.3 meter (1 foot) DĆshell 9Ćpin to 25Ćpin adaptor

cable (M/N 615184Ć2A). User

Ćconstructed cables can be up to 15 meters (50 feet) in length. Note that

for communication between a GV3000 drive and a personal computer

software must also be used. Refer to instruction manual D2Ć3348 for more information.

The Regulator boards have one set of RS

only one

device at a time: connector J8, the RS

Ć232 transmit/receive lines. These lines can be accessed by

Ć232 terminals (1Ć3) on the terminal strip, or an

Operator Interface module (OIM).

3.2.3 Selecting Input Line Branch Circuit Fuses

CAUTION:

er

wiring. Install the fuses recommended in table

precaution

The NEC/CEC requires

that upstream branch circuit protection be provided to protect input pow

3.9. Do not exceed the fuse ratings. F

could result in damage to or destruction of the equipment.

Input line branch circuit protection fuses must be used to protect the input power lines. See figures

5.1 and 5.2. Recommended fuse values are shown in table 3.9. The input fuse ratings listed in table

3.9 are applicable for one drive per branch circuit. No other load may be applied to that fused circuit.

, the Control and Configuration

Ć

ailure to observe this

3Ć7

Page 40

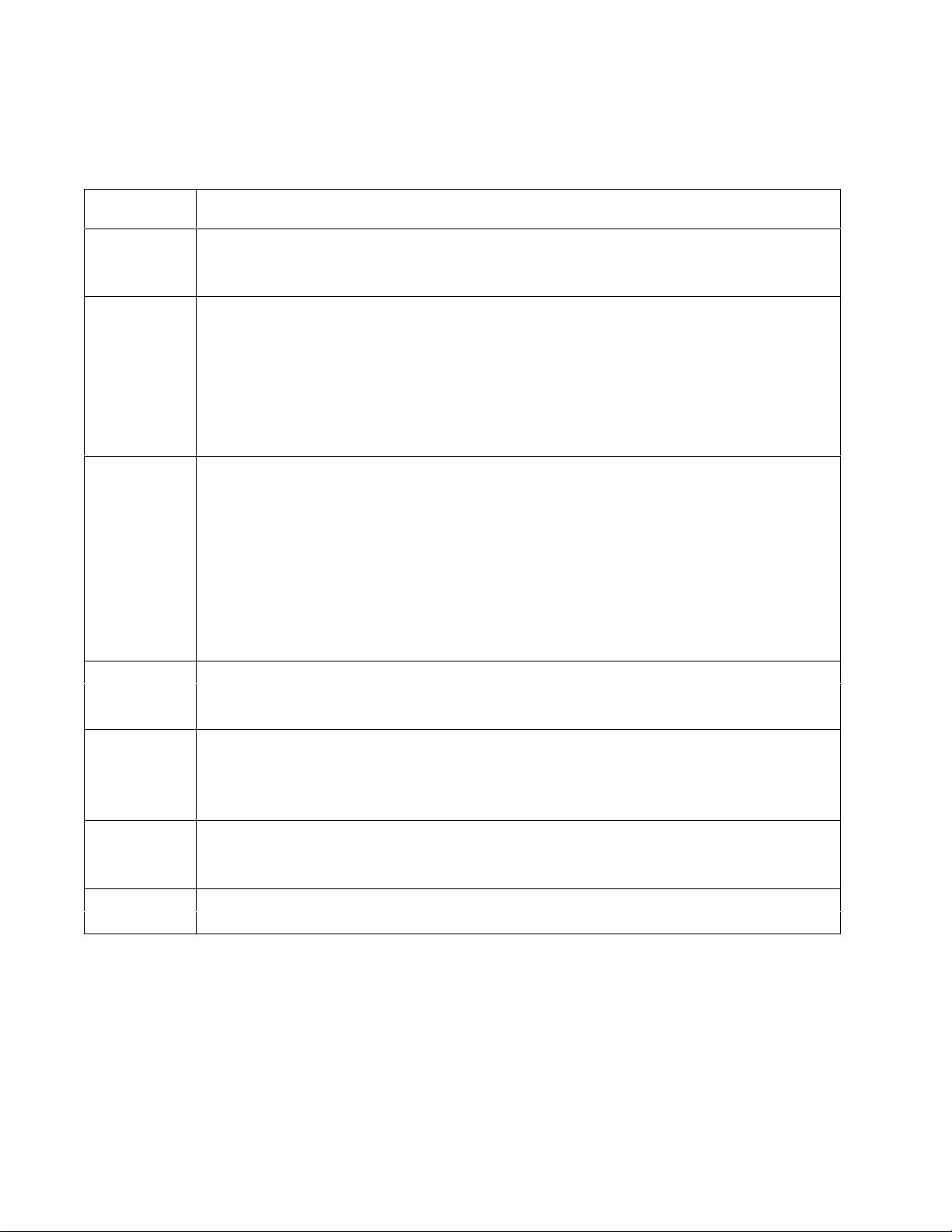

Table 3.9 Ć AĆC Input Line F

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Model

Number

1V4150

БББББББ

1V4450

2V4150

БББББББ

2V4450

3V4150

Horsepower Rating

1

БББББББ

2

БББББББ

3

3V4450

БББББББ

5V4150

5V4450

7V4150

БББББББ

7V4250

10V4150

БББББББ

10V4250

15V4150

БББББББ

БББББББ

БББББББ

5

7.5

10

15

15V4250

БББББББ

20V4150

20V4250

25G4150

БББББББ

25G4250

25V4150

БББББББ

25V4250

30V4150

БББББББ

30V4250

40V4150

БББББББ

БББББББ

БББББББ

БББББББ

20

25

25

30

40

40V4250

БББББББ

50V4150

50V4250

50R4150

БББББББ

60G4150

БББББББ

60G4250

75R4150

БББББББ

БББББББ

БББББББ

50

V

ector 50

V/Hz 75

60

Vector 60Ć75

V/Hz 100

БББББББ

125R4150

*Recommended fuse type: UL Class J, 600V, time delay, or equivalent.

Vector 100Ć125

БББББББ

V/Hz 125Ć150

use Selection V

alues

Input Voltage

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

БББББББ

380Ć460 VAC

380Ć460 VAC

БББББББ

Fuse Rating*

6A

БББББББ

8A

БББББББ

12A

БББББББ

20A

25A

БББББББ

35A

БББББББ

45A

БББББББ

60A

70A

БББББББ

70A

БББББББ

100A

БББББББ

100A

БББББББ

125A

125A

БББББББ

150A

БББББББ

125A

150A

БББББББ

250A

3.2.4 Meeting Pulse Tachometer Specifications (Vector Regulation Only)

GV3000

P

not require a pulse tachometer for feedback because they operate in the open loop mode.

drives set up for vector regulation require a pulse tachometer for closed loop operation.

ulse tachometer specifications are provided in table A

.6. Drives set up for volts/hertz regulation do

3.2.5 Verifying Power Module Output Current Rating is Greater Than Motor Full Load

Amps

Verify

that the GV3000 output current rating is greater than the motor's full load current (amps).

T

able 2.1 lists the output current values.

3Ć8

Page 41

4.0 MOUNTING THE DRIVE, GROUNDING, AND

FINDING WIRE ROUTING LOCATIONS

This

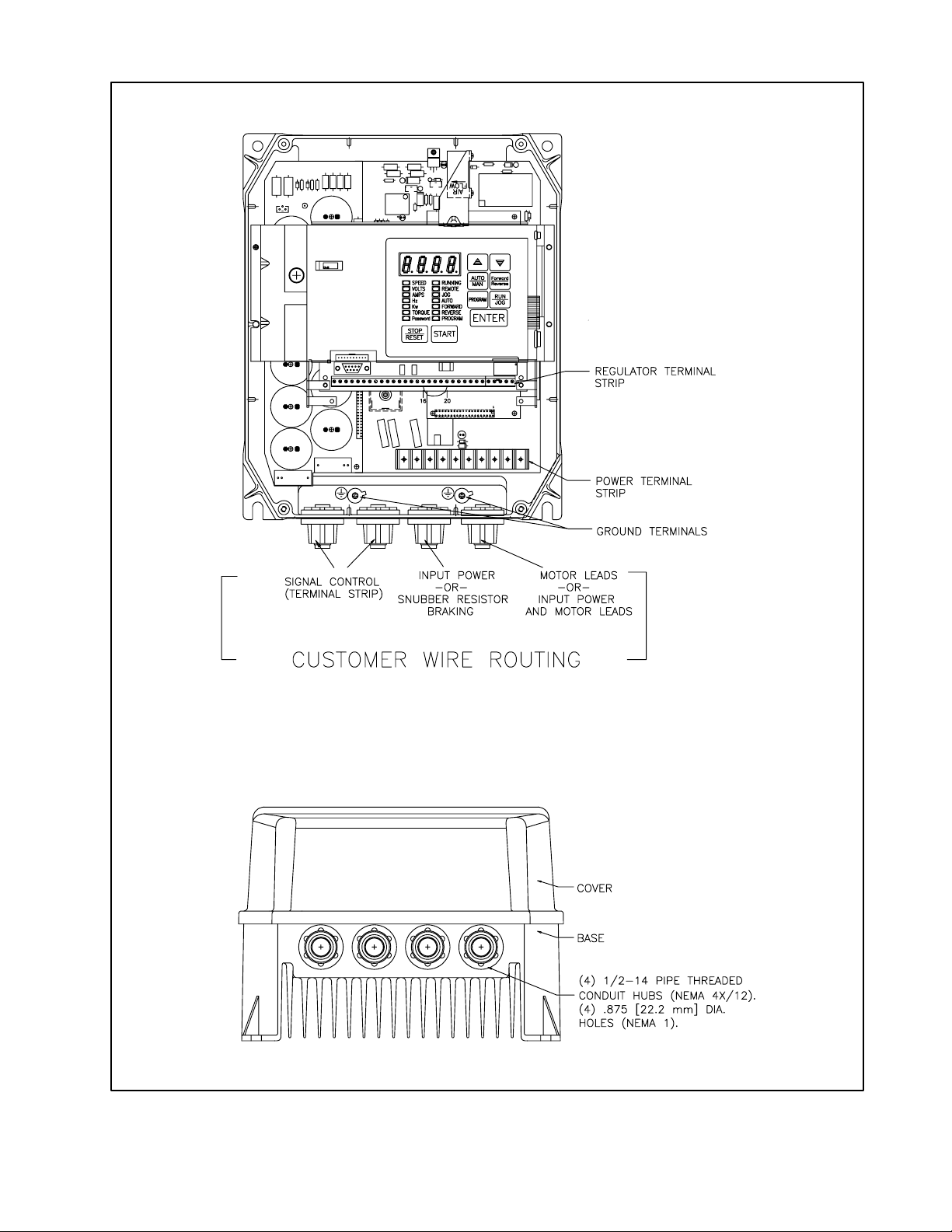

chapter shows how to mount the drive and properly ground it. Also shown are the conduit entry

areas where wiring is to be routed in and out of the drive.

4.1 Mounting the Drive

Attach

the drive to the vertical surface selected using the four (4) mounting holes provided. In order

to maintain a flat mounting surface and to ensure that bolt tightness is maintained, use washers

under the bolt heads. Refer to figure 3.2 and table 3.2 for drive mounting dimensions. Use the

following user

D 1Ć5HP drives: M6 (1/4"Ć20 )

D 7.5Ć10HP drives: M8 (5/16"Ć18 )

D 15Ć60HP drives: M8 or M10 (3/8"Ć16 )

D 60Ć150HP drives: M8 (3/8" Ć16)

4.1.1 Verifying the Drive's Watts Loss Rating

When

mounting the drive inside of another enclosure, you should examine the watts loss rating of the

drive as shown in table 2.1. This table lists the typical full load power loss watts value under all

operating carrier frequencies. Ensure adequate ventilation is provided based on the drive's watts loss

rating.

Ćsupplied mounting bolts and washers:

4.2 Routing Input, Motor Output, Ground, and Control Wiring for the

Drive

All

wiring should be installed in conformance with the NEC/CEC and applicable local codes. Signal

wiring, control wiring, and power wiring must be routed in separate conduits to prevent interference

with drive operation. Note that no wires are to be routed behind the drive. Use grommets, when hubs

are not provided, to guard against wire chaffing. Figures 4.1 through 4.6 show the wire routing,

grounding terminal, and power terminal strips of the GV3000 drives.

CAUTION: Do not route signal and control wiring with power wiring in the same conduit. This can cause

interference

of

the equipment.

with drive operation. F

Note that in applications using GV3000 drives (75 HP and above), induced electrical noise may result

when the motor output leads from two or more drives are run together in the same conduit. It is

recommended that separate conduit be run from each drive to the motor it is operating.

ailure to observe this precaution could result in damage to or destruction

4Ć1

Page 42

B V

4Ć2

Figure 4.1 Ć W

ire Routing Locations for 1Ć5 HP Drives

Page 43

B V

Figure 4.2 Ć W

ire Routing Locations for 7.5Ć10 HP Drives

4Ć3

Page 44

B V

4Ć4

Figure 4.3 Ć W

ire Routing Locations for 15Ć25 HP Drives

Page 45

B V

Figure 4.4 Ć W

ire Routing Locations for 25Ć60 HP Drives

4Ć5

Page 46

AĆC

Input

1Ć3/4"

Motor

Leads

View From Bottom

Signals

DĆC Input

Terminals

and Ground

45 47

GND

(PE1)

GND

4Ć6

Figure 4.5 Ć W

IL1 IL2 IL3

AĆC Input Terminals

and Ground

UVW

AĆC Output Terminals

and Ground

ire Routing Locations for 60Ć100 HP Drives

Page 47

DĆC Input

Terminals

and Ground

AĆC Input

Terminals

and Ground

AĆC Input

IL1 IL2 IL3

45 47

1Ć1/2"

View From Top

AĆC

Inputs

Ground

View From Bottom

AĆC Output

Terminals

and Ground

VUW

Figure 4.6 Ć W

1Ć1/2"

Output

Terminals

Ground Signals

ire Routing Locations for 100Ć150 HP Drives

7/8"

4Ć7

Page 48

4.3 Grounding the Drive

DANGER

USER IS RESPONSIBLE FOR CONFORMING WITH ALL APPLICABLE L

THE

INTERNATIONAL CODES. WIRING PRACTICES, GROUNDING, DISCONNECTS, AND

OVERCURRENT PROTECTION ARE OF PARTICULAR IMPORTANCE. FAILURE TO OBSERVE THIS

PRECAUTION COULD RESULT IN SEVERE BODIL

the following steps to ground the drive:

Use

Step 1.

Step 2.

Step 3.

Step 4.

Remove the drive's cover

Run a suitable equipment grounding conductor unbroken from the drive's ground terminal

to the motor's ground terminal and then to earth ground. See figures 4.1 to 4.6, 5.1, and

5.2.

Connect a suitable grounding conductor to the motor frame, the remote control station (if

used), and the transformer. Run each conductor

Note that to conform with C

conductor wire to a single chassis ground, twist the conductors together

ReĆattach the drive's cover

.

SA requirements, when adding more than one grounding

.

Y INJURY OR LOSS OF LIFE

unbroken

OCAL

, NA

.

to earth ground.

.

TIONAL,

AND

4Ć8

Page 49

5.0 INSTALLING INPUT POWER WIRING

This

chapter describes incoming line components and how to install them.

5.1 Installing Transformers and Reactors (Optional)

Input

isolation transformers might be needed to help eliminate the following:

D

Damaging line voltage transients from reaching the drive.

D

Line noise from the drive back to the incoming power source.

D

Damaging currents that could develop if a point inside the drive becomes grounded.