Page 1

Guardmaster Guard Locking

Switch

Catalog Numbers 440G-MZS20SNRJ, 440G-MZS20UNRJ,

440G-MZS20SNLJ, 440GMZS20UNLJ

User Manual

Original Instructions

Page 2

Guardmaster Guard Locking Switch User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may

lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or

economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc

Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements

for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 3

Table of Contents

Preface

Who Should Use This Manual? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Terminology. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 1

Product Overview Guardmaster 440G-MZ Safety Switch Overview. . . . . . . . . . . . . . . . . . . . . 7

Guard Locking on Power to Release Versions. . . . . . . . . . . . . . . . . . . . 8

Guard Locking on Power to Lock Versions . . . . . . . . . . . . . . . . . . . . . . 8

Assembly Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Product Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Package Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Chapter 2

Safety Concept Safety Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Safety Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Chapter 3

Installation General Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Correct Use. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Switch Orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Actuator Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Pair Proximity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Environmental Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Mount the Switch and Actuator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Typical Applications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Auxiliary Release. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Padlock Accessory. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Functional Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OSSD Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

GuardLink Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Chapter 4

Wiring and System Integration Pin Assignment and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

OSSD Mode Safety Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GuardLink Mode Safety Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

GuardLink System Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Add Device to a Studio 5000 Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Upload Method. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Manual Method . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Lock Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

OSSD Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

GuardLink Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 3

Page 4

Table of Contents

Chapter 5

Commission the Safety Switch Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

First-time Learn . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Learn Additional Replacement Actuators . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Lock the Actuator Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Error Codes during the Commissioning Process . . . . . . . . . . . . . . . . . . . 26

Chapter 6

Device Status and

Troubleshooting

Status Indicators during Power-up Routine . . . . . . . . . . . . . . . . . . . . . . . 27

Status Indicators During Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Diagnostic/Fault Codes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Diagnostic Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Mounting Holes of the Switch Body Cracked or Broken . . . . . . . . . 30

Chapter 7

Application Examples Wire to GLP Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Circuit Status as Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Safely-limited Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Wire to GLT Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Wire to DI and EMD Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Circuit Status as Shown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Stopping. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Wire to DG Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Wire to CR30 Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Wire to POINT Guard I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Wire to ArmorBlock Guard I/O Module . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Wire to MSR55P Back EMF Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Appendix A

Specifications Safety Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Outputs (Guard Door Closed and Locked) . . . . . . . . . . . . . . . . . . . . . . . . . 52

Environmental . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Compliance to European Union Directives . . . . . . . . . . . . . . . . . . . . . . . . 53

Approximate Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

4 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 5

Preface

Who Should Use This Manual?

Purpose of This Manual

Summary of Changes

Use this manual to design, install, program, or troubleshoot systems that use

the Guardmaster® 440G-MZ Guard Locking Safety Switches.

You are required to have a basic understanding of electrical circuitry and

familiarity with safety-related control systems. If you do not, obtain the proper

training before using this product.

This manual is a reference guide for the Guardmaster 440G-MZ safety switch.

It describes the procedures that you use to install, wire, and troubleshoot your

switch. This manual accomplishes the following:

• Explains how to install and wire your 440G-MZ safety switch

• Provides an overview of the Guardmaster 440G-MZ safety switch

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

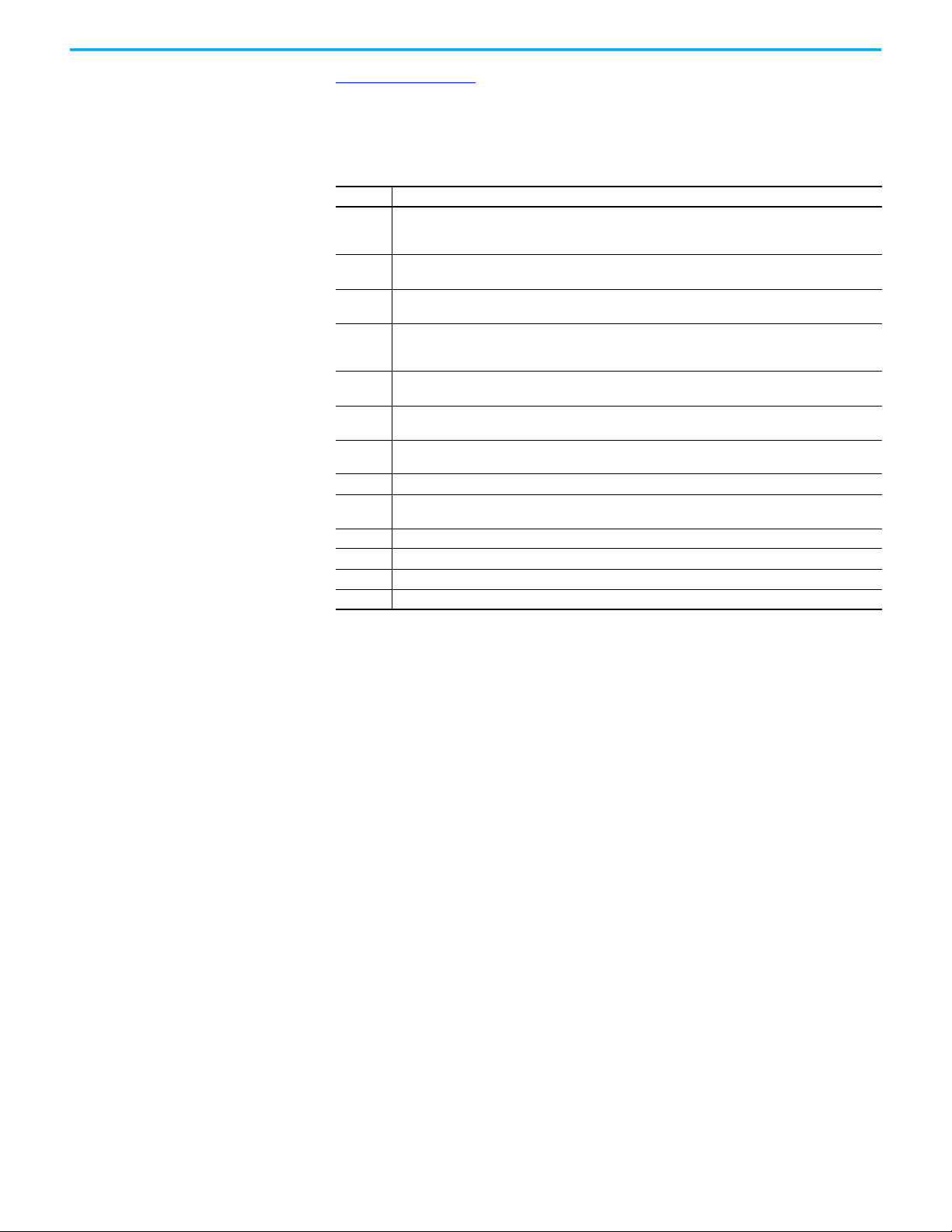

Top ic Page

Added FCC and IC certification information 53

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 5

Page 6

Preface

Ter mi no logy

The Industrial Automation Glossary (publication AG-QR071) contains terms

and abbreviations that are used by Rockwell Automation to describe industrial

automation systems. Table 1

lists specific terms and abbreviations that are

used in this manual.

Table 1 - Terms and Abbreviations

Term Definition

CLU (Command, Lock,

and Unlock)

HI Logic state of being ON or a voltage level to be above the turn-on threshold.

LO Logic state of being OFF or a voltage level to be below the turn-off threshold.

NC No connection

Operational state

OSSD (Output Signal

Switching Device)

PLC A programmable logic controller or a programmable automation controller.

Reaction time Describes the time between the true state of the input to the ON state of the output.

Response time

RFID Radio frequency identification

Safe state

Standard coding Same as Low coding as defined in ISO 14119

Tap

Unique coding Same as High coding as defined in ISO 14119

This signal is either static or dynamic. When static, this signal is LO when the system is

operational and HI when a demand is placed on the safety system. The signal is

dynamic when an unlock or lock command is issued to a GuardLink-enabled guard

locking device, such as a 440G-MZ safety switch.

The switch is in operational state when there is no demand on its safety function (that

is, the switch is closed and locked).

Typically a pair of solid-state signals pulled up to the DC source supply. The signals are

tested for short circuits to the DC power supply, short circuits to the DC common, and

short circuits between the two signals.

Describes the time between the trigger of the input to the OFF state of the output.

Throughout this manual, the safety outputs may be described as turning off

immediately, which means that the safety outputs turn off within the response time.

The switch is in safe state when there is a demand on its safety function (that is, the

switch is unlocked).

A connection in a GuardLink® circuit that associates a safety device to the GuardLink

circuit.

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

440G-MZ Guard Locking Switch Installation Instructions,

publication 440G-IN018

Guardmaster EtherNet/IP Network Interface User Manual,

publication 440R-UM009

Guardmaster DG Safety Relay and GuardLink System User Manual,

publication 440R-UM015

EtherNet/IP Network Devices User Manual, publication ENET-UM006

Ethernet Reference Manual, publication ENET-RM002 Describes basic Ethernet concepts, infrastructure components, and infrastructure features.

System Security Design Guidelines Reference Manual,

publication SECURE-RM001

Industrial Components Preventive Maintenance, Enclosures, and Contact

Ratings Specifications, publication IC-TD002

Safety Guidelines for the Application, Installation, and Maintenance of

Solid-State Control, publication SGI-1.1

Industrial Automation Wiring and Grounding Guidelines, publication 1770-4.1 Provides general guidelines for installing a Rockwell Automation industrial system.

Product Certifications website, rok.auto/certifications

. Provides declarations of conformity, certificates, and other certification details.

Provides general guidelines for installing a Rockwell Automation® guard locking switch.

Provides a detailed description of module functionality, configuration, installation

procedure, and information on how to use the Guardmaster EtherNet/IP Network Interface

(440R-ENETR).

Provides general guidelines for configuring a Rockwell Automation Guardlink safety system.

Describes how to configure and use EtherNet/IP devices to communicate on the

EtherNet/IP™ network.

Provides guidance on how to conduct security assessments, implement Rockwell

Automation products in a secure system, harden the control system, manage user access,

and dispose of equipment.

Provides a quick reference tool for Allen-Bradley industrial automation controls and

assemblies.

Designed to harmonize with NEMA Standards Publication No. ICS 1.1-1987 and provides

general guidelines for the application, installation, and maintenance of solid-state control in

the form of individual devices or packaged assemblies incorporating solid-state

components.

You can view or download publications at rok.auto/literature

6 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

.

Page 7

Product Overview

Chapter 1

Guardmaster 440G-MZ Safety Switch Overview

This 440G-MZ Guardmaster® safety switch locks a guard door in the closed

position and does not release it until the hazardous machine functions that are

covered by the guard are in a safe condition. The safety control system allows

the hazardous machine functions to operate only when the guard is closed and

locked.

The locking bolt drive mechanism and logic confirm that the locking bolt is

allowed to extend only when the corresponding actuator is detected within

range.

RFID technology enables high precision operation while meeting the

requirements to prohibit actuator substitution as described in ISO 14119. The

440G-MZ safety switches are classified as Type 4 interlocking devices with

guard locking and the unique coded actuators are classified as having a high

level of coding according to ISO 14119.

The 440G-MZ safety switch features two OSSD outputs or a single-wire safety

output when connected in a GuardLink® system. These safety outputs are

enabled only when the locking bolt is sensed in its extended position. This

action only happens when the guard is both closed and locked.

The locking bolt drive mechanism uses a bi-stable solenoid. As a result, the

switch consumes little electrical power, with peak currents occurring (only

briefly) on startup and after each movement of the locking bolt.

Because of its bi-stable drive, not only does the device consume minimal

power, but it also does not produce heat while it is locked or unlocked.

Although the locking bolt drive uses a bi-stable solenoid, the device logic and

functionality are configured to replicate the functionality of a Power to Release

or Power to Lock solenoid-operated switch (depending on type).

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 7

Page 8

Chapter 1 Product Overview

Actua tor

LINK and DEVICE

status indicators

Guard Locking on Power to Release Versions

With a Power to Release switch, the locking bolt extends when the guard is

closed with the actuator inserted in the switch and a lock command is issued to

the switch:

Table 2 - Lock Command

Mode Description

OSSD The lock signal (pin 5) is connected to 0V DC

GuardLink® A lock command is issued to the switch on the CLU signal from a GuardLink safety master.

IMPORTANT If power is removed from a Power to Release switch in the locked position, the

locking bolt remains in its extended position (switch locked). Use the auxiliary

release to unlock the switch.

ATTENTION: Under normal operating conditions, the locking bolt does not extend in

the absence of the actuator. The only exception is when power is removed from a

switch in the first 4 seconds of the start-up sequence. In this case, the bolt does

extend. If the guard door is closed when the start-up sequence is interrupted, the

guard door is locked. Use the auxiliary release to unlock the switch.

Guard Locking on Power to Lock Versions

With a Power to Lock switch, the locking bolt extends when the guard is closed

with the actuator inserted in the switch and a lock command is issued to the

switch:

Table 3 - Lock Command

Mode Description

OSSD The lock signal (pin 5) is connected to 24V DC

GuardLink A lock command is issued to the switch on the CLU signal from a GuardLink safety master.

IMPORTANT If power is removed from a Power to Lock switch or a fault occurs while in the

locked position, the bolt retracts and the switch unlocks.

ATTENTION: Under normal operating conditions, the locking bolt does not extend in

the absence of the actuator. The only exception is when power is removed from a

switch in the first 4 seconds of the start-up sequence. In this case, the bolt does

extend. If the guard door is closed when the start-up sequence is interrupted, the

guard door is locked. Use the auxiliary release to unlock the switch.

Assembly Overview

8 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 9

Chapter 1 Product Overview

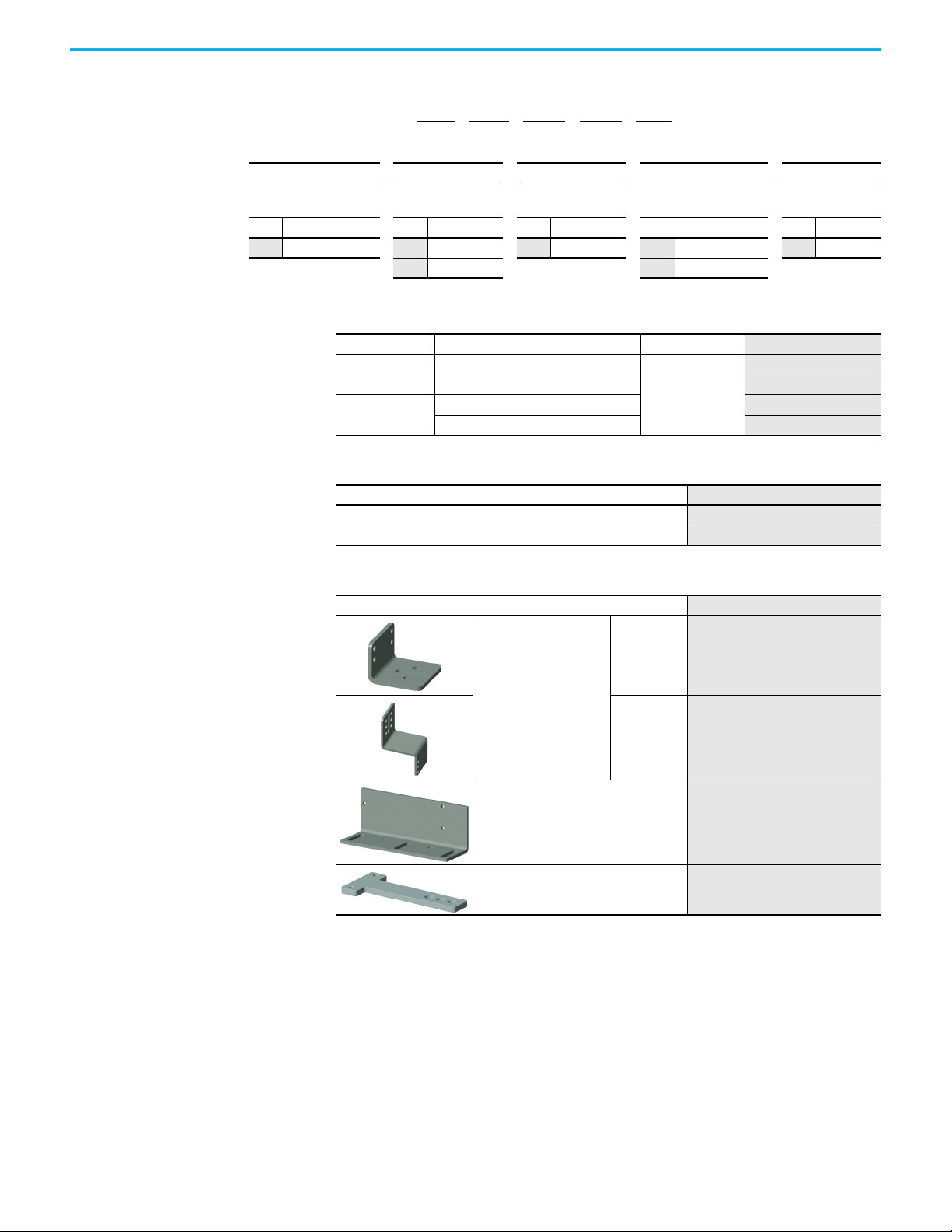

Product Selection

Table 4 - Catalog Number Explanation

440G-MZS 20 S N R J

abc de

abcde

Outputs (Safety/

Auxiliary)

Code Description Code Description Code Description Code Description Code Description

20 Two safety/no aux SStandard code N No auxiliary R Power to Release J M12 5-pin

Actuator Code Auxiliary Type Lock Type Connection Type

U Unique code L Power to Lock

Table 5 - Complete Switches, including Switch Body and Actuator

Type Actuator Coding Escape Release Cat No.

Power to Release

Power to Lock

Standard (Low level to ISO 14119)

Unique (High level to ISO 14119)

Standard (Low level to ISO 14119) 440G-MZS20SNLJ

Unique (High level to ISO 14119)

No

440G-MZS20SNRJ

440G-MZS20UNRJ

440G-MZS20UNLJ

Table 6 - Spare Actuators

Description Cat. No.

Standard code actuator (Low level to ISO 14119)

Unique code actuator (High level to ISO 14119) 440G-MZAU

440G-MZAS

Table 7 - Accessories

Description Cat. No.

L-shaped

Actuator mounting bracket

Z-shaped

Switch mounting bracket 440G-MZAM3

Padlock accessory

440G-MZAM1

440G-MZAM2

440G-MZAL

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 9

Page 10

Chapter 1 Product Overview

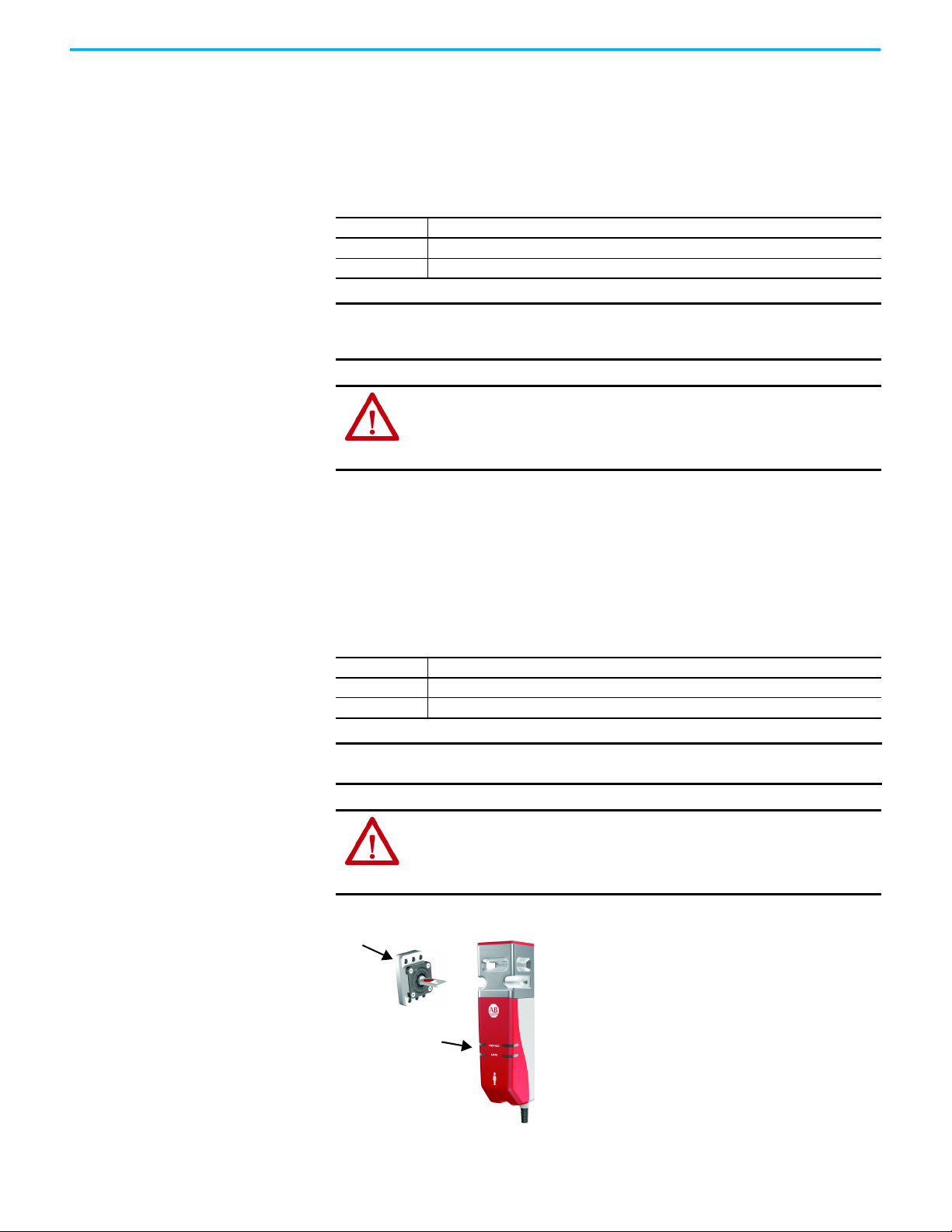

Package Contents

The box includes the following components:

Description Photo

Switch Body

Actuator

Installation Instructions:

publication 440G-IN018

10 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 11

Safety Concept

Chapter 2

Safety Standards

Safety Certification

The Guardmaster® 440G-MZ safety switch satisfies applicable requirements in

the following standards that are related to functional safety and machinery

assembly:

• IEC 60947-5-3

•IEC 61508

•IEC 62061

•EN ISO 13849-1

• ISO 14119

•UL 508

The 440G-MZ safety switch is certified for use in safety applications up to and

including SIL 3 according to IEC 61508 and IEC 62061 with a proof test interval

of 20 years, and Performance Level e (PLe) Category 4 in compliance with ISO

13849-1.

Safety requirements are based on the standards applicable at the time of

certification.

The TÜV Rheinland group has approved the 440G-MZ safety switch for use in

safety-related applications where PLe is required for the door position

monitoring and guard locking functions.

The 440G-MZ safety switch must be installed in accordance with the applicable

regulation and standards.

While the 440G-MZ safety switch can be used for SIL 3, PLe, and Category 4

applications, the installation must comply with guard requirements (for

example, ISO 13854 and ISO 13857), and in some cases minimum (safe)

distance requirements (for example, ISO 13855).

The installed system, including the safety control system and the means by

which the machine stops, must achieve the needed safety performance. The

440G-MZ safety switch is one element in the safety system.

Additional guidance on guards, guard locking and guard interlock can be

found in:

• EN ISO 12100

•EN ISO 13854

•EN ISO 13855

•EN ISO 13857

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 11

• EN ISO 14119

• EN ISO TR 24119

• EN ISO 14120

• Application-specific C-level standards

Page 12

Chapter 2 Safety Concept

Notes:

12 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 13

Installation

Chapter 3

General Considerations

Correct Use

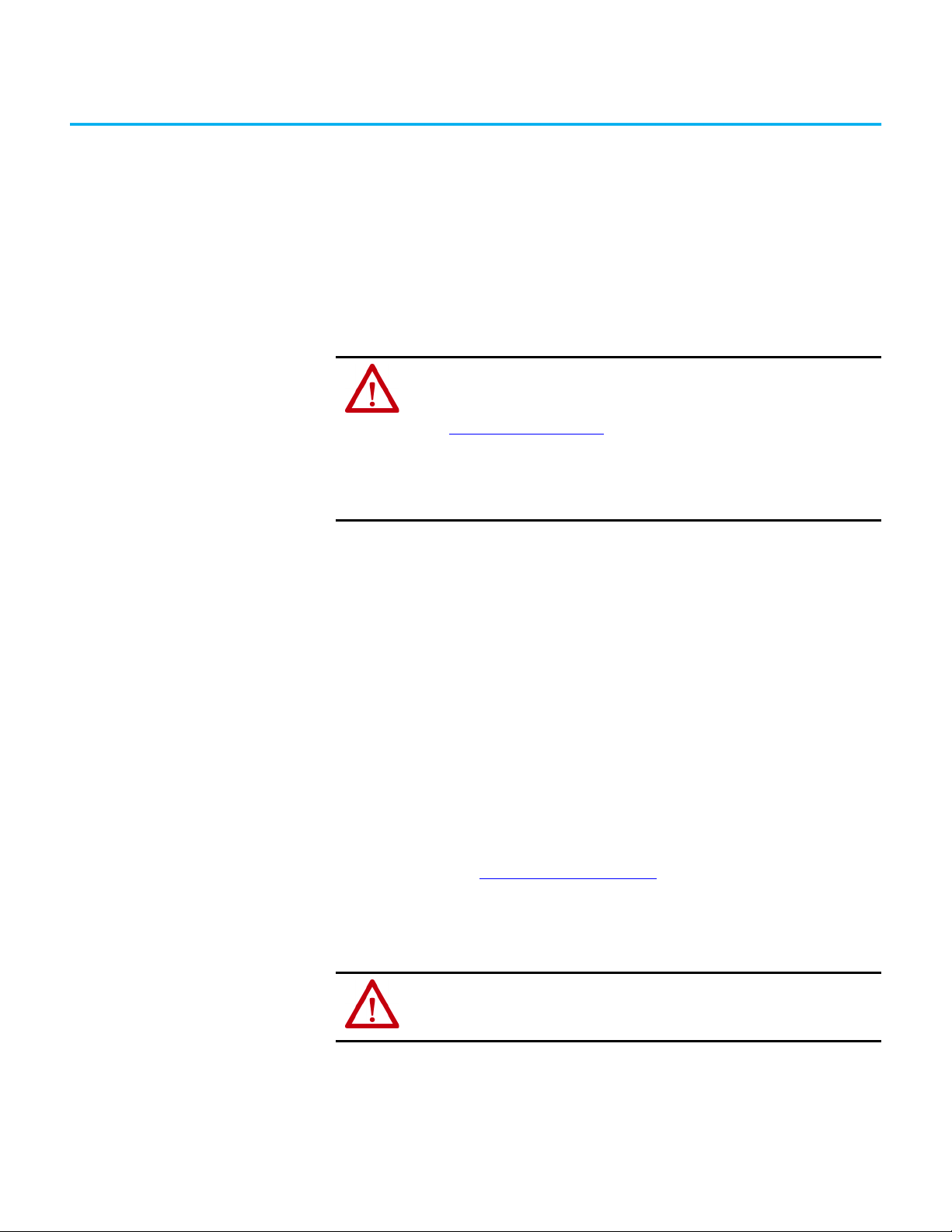

Installation must be in accordance with the present manual and implemented

by qualified personnel exclusively. The 440G-MZ safety switch is intended to be

part of the safety-related control system of a machine.

ATTENTION: Before installation, a thorough risk assessment must be performed to

determine whether the specifications of this device are suitable for all foreseeable

operational and environmental characteristics of the application.

A functional test of the system is necessary to validate that it works as expected

(see Functional Testing on page 17

Guard locking switches that use the Power to Lock principle (Cat. No.

440G-MZS20*NLJ*) must only be used after a risk assessment has shown that the

use of a Power to Release principle (Cat. No. 440G-MZS20*NRJ*) is inappropriate.

This assessment is necessary since the guard can be immediately opened after a

loss of power supply or upon deactivation of the unlocking signal.

Review the following requirements and guidelines for proper use of the safety

switch to achieve optimal performance.

• The 440G-MZ safety switch is designed for use on medium- and fullsized guards including guards where whole-body access to the

safeguarded area is possible.

• The switch is not to be used as a mechanical stop. Check that a separate

door stop is used.

• A separately mounted latch (for example, magnetic or mechanical) is

recommended to maintain proper alignment of the actuator. The

locking bolt must be free to enter and withdraw from the actuator

without binding.

• Use appropriate screws, bolts, or nuts that are fitted by tools to mount

the switch and actuator to avoid tampering.

• Do not over torque the mounting hardware.

• A minimum distance of 100 mm (3.94in.) must separate adjacent

switches, see Pair Proximity on page 14

• The 440G-MZ safety switch is designed for use in a NEC Class 2 circuit.

Connect the 440G-MZ safety switch to a dedicated Class 2 power supply

or use electronic circuit protection (for example, 1692-ZRCLSS) to

achieve NEC Class 2 compliance.

).

.

ATTENTION: For the switch, actuator, and actuator mounting bracket:

• Only use the designated mounting holes.

• Never drill or use to support other structures such as a conduit, cable ways, or other

hardware.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 13

Page 14

Chapter 3 Installation

1

2

3

100 (3.94)

Switch Orientation

Actuator Orientation

Can be used in all mounting orientations.

The actuator can approach the switch from three directions (Figure 1).

Figure 1 - Three Directions of Approach

Pair Proximity

The flexible actuator can move in multiple axes to accommodate guard door

misalignment (Figure 2

). For optimal performance, verify that the locking bolt

can enter and withdraw from the tongue actuator without binding. A

separately mounted door latch is recommended to avoid door misalignment.

Figure 2 - Actuator Function

If a pair of 440G-MZ safety switches are mounted too close to one another, the

two electromagnetic fields interact causing crosstalk, which can result in

nuisance faults and false operation.

A minimum of 100 mm (3.94 in.) must separate a pair of switches to help

achieve correct operation (Figure 3 on page 14

Figure 3 - Minimum Distance between Switches [mm (in.)]

).

IMPORTANT If the minimum separation distance is not observed, the electromagnetic fields

14 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

interact causing crosstalk. Crosstalk can result in nuisance faults and false

operation.

Page 15

Chapter 3 Installation

3 x M5

2 x M5

Environmental Considerations

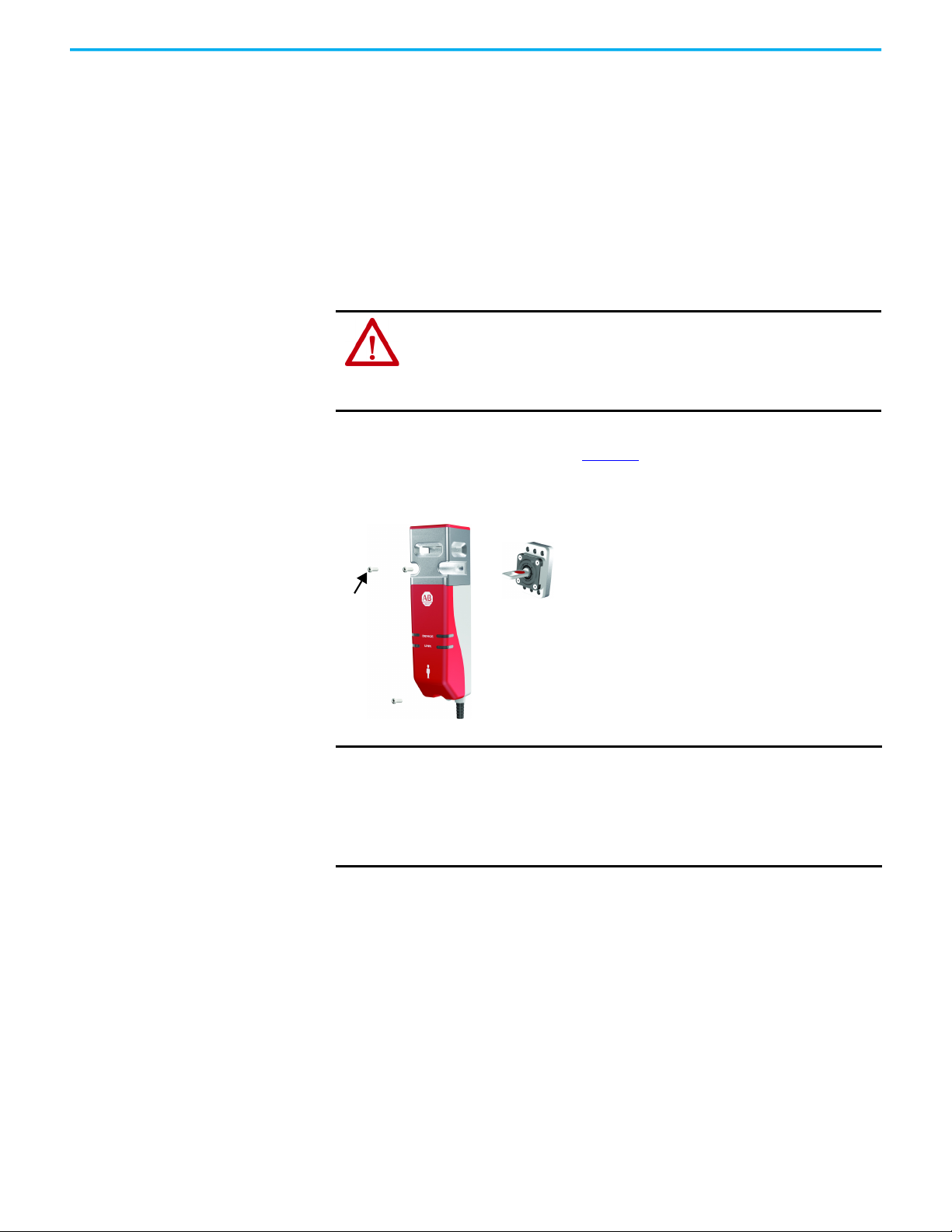

Mount the Switch and Actuator

The 440G-MZ safety switch is rated for IP69K in accordance with ISO 20653

and IP69 per IEC 60529. This rating involves a short-term test that is made

with high-pressure water jets at 80 °C (176 °F). The test is passed if no water

enters the enclosure of the switch that contains the electrical components and

the switch function is not impaired.

This rating does not promise protection from any liquids other than water and

does not promise the mechanical longevity from continuous or frequent

exposure.

ATTENTION: Do not defeat, tamper, remove, or bypass this unit. Severe injury to

personnel could result.

The presence of spare actuators can compromise the integrity of the safety

systems. Personal injury or death, property damage, or economic loss can result.

Appropriate management controls, working procedures, and alternative protective

measures should be introduced to control their use and availability.

Three M5 fasteners (not provided) are required for proper mounting of the

switch to a rigid guard door frame (Figure 4

). Two M5 fasteners (not provided)

are required to mount the actuator.

Figure 4 - Required Mounting Hardware for Switch and Actuator

IMPORTANT Do not use a washer with the screw at the base of the switch body. Using a

washer causes the plastic to crack.

Loctite 242 thread-locking adhesive is known to cause stress cracks in the

plastic housing of the 440G-MZ safety switch and should not be used. Lab tests

have determined that Loctite 425, a cyanoacrylate adhesive, does not cause

cracking and can be considered if the faster cure time is acceptable in the

application.

Check the manufacturer specifications of any thread-locking compound used

to secure the screws. It is recommended to use a cyanoacrylate-type

compound. Other compounds can cause stress cracks in the plastic feet of the

switch.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 15

Page 16

Chapter 3 Installation

Switch

mounting

bracket

Switch

mounting

bracket

Actuator

Actuator

Z-shaped Actuator

Mounting Bracket

Z-shaped Actuator

Mounting Bracket

L-shaped Actuator

Mounting Bracket

L-shaped Actuator

Mounting Bracket

Actuator

Typical Applications

The 440G-MZ safety switch can be mounted on the inside or outside of a

hinged or sliding guard door. The following shows three examples of the

switch and actuator mounted to a hinged or sliding guard door.

• Mount the switch on the inside of a hinged door

• Mount the switch on outside of a hinged door

• Mount the switch on a sliding door

16 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 17

Chapter 3 Installation

5 (0.2)

Top View

Up to three nominal

6.35 mm (0.25 in.) locks

Auxiliary Release

Padlock Accessory

Operation of the auxiliary release causes a fault condition.

To reset the switch, cycle the power or issue a RESET command over the link in

a GuardLink® safety system.

Figure 5 - Auxiliary Release Operation [mm (in.)]

The padlock accessory (Figure 6) can be inserted through the actuator opening

of the 440G-MZ safety switch to help prevent the locking of the guard door and

restarting of the machine while an operator is inside the safeguarded area. The

padlock accessory can accommodate up to three nominal 6.35 mm (0.25 in.)

locks.

Figure 6 - Padlock Accessory (Cat. No. 440G-MZAL)

Functional Testing

A manual functional test must be made:

•After installation

• After any maintenance or change of component

• If the guard is used infrequently

- Less than once a month for SIL 3, cat. 3 or cat. 4, PLe

- Less than once a year for SIL 2, cat. 3, PLd

ATTENTION: During the functional test, verify that there are no persons in the

danger area and that the machine startup does not cause a hazard.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 17

Page 18

Chapter 3 Installation

OSSD Mode

1. Confirm that the guard door is open.

2. Connect the 24V DC power to pin 1 and ground (0V) to pin 3. The switch

conducts a self-testing routine at the end of which the device status

indicator is steady red (if lock signal is set to UNLOCK) or flashing

amber (if lock signal is set to LOCK).

3. Test to confirm that the machine cannot start.

4. Confirm the lock signal at pin 5 is set to LOCK (0V for PTR and 24V for

PTL types).

5. Test again to confirm that the machine cannot start.

6. Close the guard door and then confirm that the guard is mechanically

locked and the device status indicator is steady green.

7. Test to confirm that the machine can start.

8. Change the lock signal at pin 5 to UNLOCK (24V for PTR and 0V for PTL

types).

9. Confirm the machine stops, the guard door is mechanically unlocked,

and the machine cannot restart.

GuardLink Mode

1. To begin a functional test of the 440G-MZ safety switch when

connected in a GuardLink system, all other devices on the link must be

in the operational state.

2. Confirm that the guard door is open.

3. Test to confirm that the machine cannot start.

4. Send a lock command to the 440G-MZ safety switch over the link.

5. Test again to confirm that the machine cannot start.

6. Close the guard door.

7. Send a lock command to the switch over the link.

8. Confirm that the switch is mechanically locked and the Device status

indicator is steady green.

A flashing green status indicator on the device indicates that another device on the link

is tripped. To proceed, verify that all other devices on the link are in operational state.

9. Test to confirm that the machine can start.

10. Send an unlock command to this 440G-MZ safety switch only over the

link.

11. Confirm that the machine stops, the guard door is mechanically

unlocked, and the machine cannot restart.

18 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 19

Wiring and System Integration

5

4

3

1

2

Chapter 4

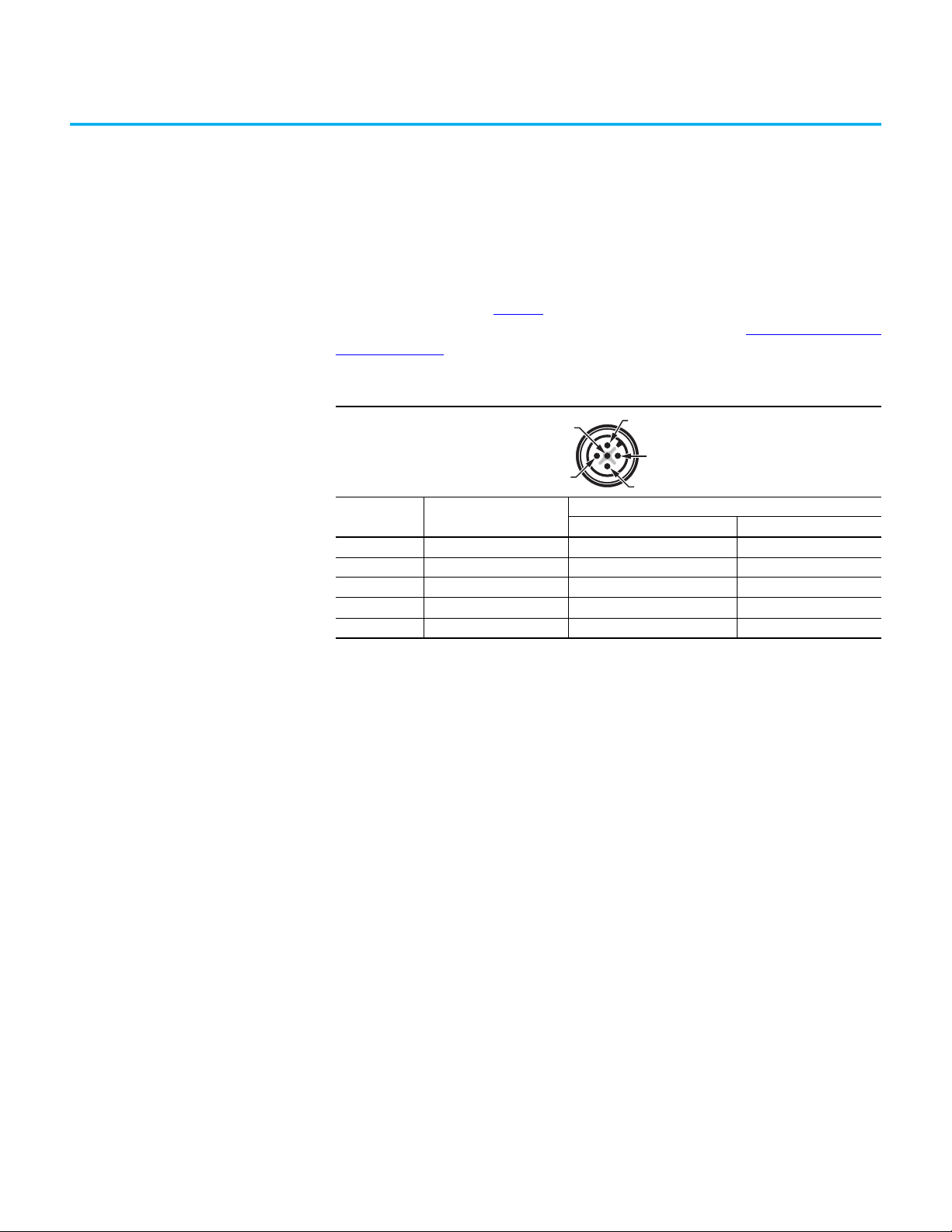

Pin Assignment and Function

The 440G-MZ safety switch is available with a 5-pin DC Micro M12 quickdisconnect connector. Table 8

shows the pin assignments and their functions

and typical mating cordsets. Other cordsets are available at DC Micro Cordsets

and Patchcords.

Table 8 - 5-pin Micro (M12)

Pin Color

1 Brown +24V +24V

2 White Safety A Safety In

3Blue 0V 0V

4 Black Safety B Safety Out

5 Gray Lock Command CLU

(1) The recommended cordset is catalog number 889D-F5AC-2 (2 m [6.5ft]). For additional lengths, replace the 2 with 5 [5 m

(16.4 ft)] or 10 [10 m (32.8 ft)] for standard cable lengths.

The recommended patchcord for use with GuardLink® and ArmorBlock® Guard Safety I/O is the 2 m (6.5 ft) catalog number

889D-F5ACDM-2. Replace the 2 with 0M3 [0M3 (0.98 ft)], 1 [1 m (3.28 ft)], 5 [5 m (16.4 ft)], or 10 [10 m (32.8 ft)] for standard

cable lengths.

(1)

Function

OSSD Mode GuardLink® Mode

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 19

Page 20

Chapter 4 Wiring and System Integration

OSSD Mode Safety Signals

In OSSD mode, safety outputs Safety A and Safety B are OFF (0V) when the

switch is in safe state (that is, the switch is unlocked). When the switch is in

operational state (that is, closed and locked), safety outputs Safety A and Safety

B are ON (24V) and contain test pulses. The test pulses are used to detect short

circuits to 24V, to 0V and cross faults (from Safety A to Safety B). This

description of the test pulses is provided for informational purposes; you

cannot modify them.

IMPORTANT To prohibit nuisance tripping, mask the OSSD input channels of the safety

system with an On to Off delay of at least 1 ms.

Figure 7 - Output Test Pulses

OSSD test pulses into a 10K resistive load.

Safety OSSD A

Safety OSSD B

5V/Div

580 μs

26 ms

2ms/Div

GuardLink Mode Safety Signals

GuardLink System Integration

Safety OSSD A

Safety OSSD B

5V/Div

189 ms

20ms/Div

When the 440G-MZ safety switch is connected in a GuardLink system, the

safety signals are Safety In and Safety Out. These signals are dynamic signals

in operational state and two-way communication signals in the safe state.

ATTENTION: For information on a known anomaly, see Knowledgebase Article

Unlocked 440G-MZ switch on GuardLink doesn't respond to lock command on power up

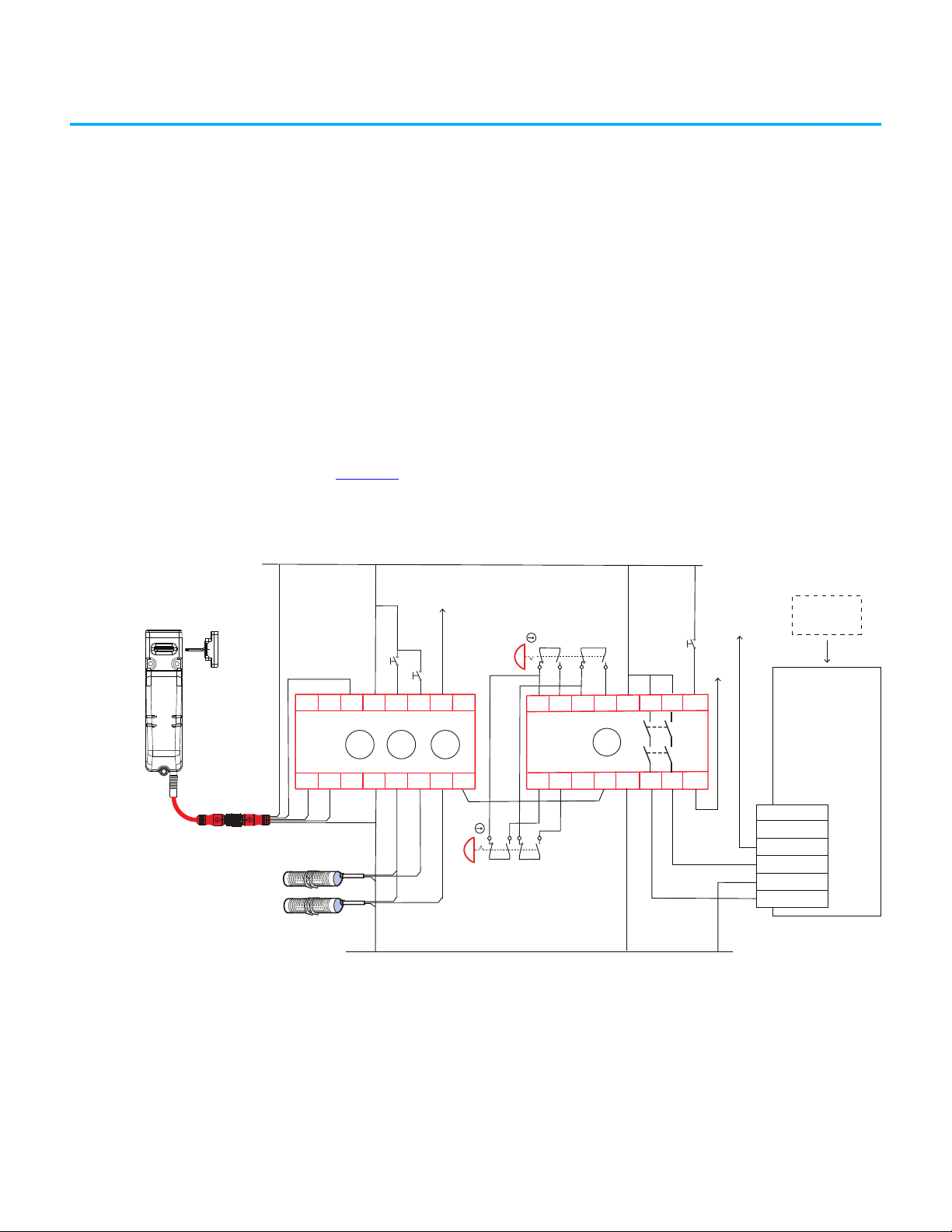

Figure 8 on page 21 shows the basic components of a GuardLink system with a

DG safety relay master. The 440G-MZ safety switch, with embedded

GuardLink technology, connects to the link with a passive tap (as shown in

Figure 8 on page 21

) or a passive power tap (catalog number 440S-PF5D4).

.

20 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 21

Chapter 4 Wiring and System Integration

INPUT

NS

LNK2

LNK1

MS

4

3

2

1

0

5

6

7

8

9

A2A1

LNK2

LNK1

IP: 192. 168. 1. ABC

4

3

2

1

0

5

6

7

8

9

4

3

2

1

0

5

6

7

8

9

A

B

C

S12 S22 S32 S42

A1 A2 S11 S21

X1 X2 X3 X4

13 14 23 24

OUT

IN 1

IN X

Reset

FB

Cong/Set

Sel./Save

DG

Reset

Time

OUT X

IN 2

PWR/Fault

0

.

2

.

4

.

6

.

8

.

1

0

.

1

2

.

1

4

.

INPUTINPUT INPUT

1

7

4

3

8

6

4 6

5 5

5

2

1

1

1

440G-MZ 440G-MZ

Different types and versions of GuardLink enabled and passive taps can be

connected in any order and can be mixed on the same link. For more

information about the configuration a GuardLink safety system, see

publication 440R-UM015

Both the Power to Release and Power to Lock versions of the 440G-MZ safety switch can

be connected to a GuardLink safety system.

Figure 8 - GuardLink System Components

.

Add Device to a Studio 5000 Project

Item Description Cat. No.

1

5-pin device patchcord

(1)

2Cordset

889D-F5NCDM-x

889D-F4NE-y

(2) (3)

(4)

3 Terminator 898D-418U-DM2

4 GuardLink passive tap

5 4-pin link patchcords

6 GuardLink enabled tap

440S-PF5D

889D-F4NEDM-x

440S-SF5D

(5) (6)

(3) (7)

(6)

7 EtherNet/IP™ Network Interface 440R-ENETR

8DG Safety Relay

(1) Optional: Device can be connected directly to the passive tap.

(2) 10 m (32.8 ft) length, max.

(3) Replace x with 0M3 (300 mm [0.98 ft]), 0M6 (600 mm [1.97 ft]), 1 (1 m [3.3 ft]), 2 (2 m [6.6 ft]), 5 (5 m [16.4 ft]), or 10 (10 m

[32.8 ft]) for standard cable lengths.

(4) Replace y in order number with 2 (2 m [6.6 ft]), 5 (5 m [16.4 ft]), 10 (10 m [32.8 ft]), 15 (15 m [49.2 ft]), 20 (20 m [65.6 ft]), or

30 (30 m [98.4 ft]) for standard cable lengths.

(5) A passive power tap (Cat. No. 440S-PF5D4) can also be used.

(6) Mounting brackets sold separately. Cat. No. 440S-GLTAPBRK1 (pack of 1) or Cat. No. 440S-GLTAPBRK5 (pack of 5).

(7) 30 m (98.4 ft) length, max

440R-DG2R2T

Information about how to add a 440G-MZ safety switch to a GuardLink system

in a Studio 5000® project can be found in the user manual for the GuardLink

safety master. See publication 440R-UM009

for information about using the

upload method or manual method to add a 440G-MZ safety switch in a

GuardLink circuit controlled by a Guardmaster® DG safety relay.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 21

Page 22

Chapter 4 Wiring and System Integration

1

2

Upload Method

After the upload is complete, the position and type of connected 440G-MZ

safety switches is shown in the Module Definition tab as shown in Figure 9

Figure 9 - Upload Method

.

Manual Method

With the manual method, a 440G-MZ safety switch can be added to a

GuardLink circuit in steps as shown in Figure 10

Figure 10 - Manual Method

1. Right-click the GuardLink and select Add Device.

2. Select the correct catalog number from the device list

.

22 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 23

Chapter 4 Wiring and System Integration

Lock Command

OSSD Mode

Table 9 shows the lock command function. The lock command is a 24V logic

signal with a current of less than 2 mA. The function of the logic signal is

dependent on the catalog number.

Table 9 - Lock Command Function

Cat. No. Function Value

440G-MZS20*MR* Power to Release

440G-MZS20*ML*Power to Lock

Catalog codes for both types are explained in Table 4 on page 9

24V = Unlock

0V = Lock

24V = Lock

0V = Unlock

.

GuardLink Mode

In a GuardLink system, the GuardLink safety master (for example a DG safety

relay) issues lock and unlock commands to the 440G-MZ safety switch via the

GuardLink Control, Lock, and Unlock (CLU) signal. This signal is either static

or dynamic. When static, this signal is LO when the system is operational and

HI when a demand is placed on the safety system. The signal is dynamic when

an unlock or lock command is issued to the 440G-MZ safety switch.

When multiple guard locking devices are installed in a GuardLink system, the

GuardLink safety master inserts a short delay between commands to each

successive device to minimize the momentary inrush current to the solenoids.

The device closest to the master receives the command first. The device

furthest away from the master receives the command last.

See publication 440R-UM015

for more information.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 23

Page 24

Chapter 4 Wiring and System Integration

Notes:

24 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 25

Chapter 5

Commission the Safety Switch

The 440G-MZ safety switch is available with standard coded actuators or

unique coded actuators.

• Switches with standard coded actuators are ready for use and do not

require commissioning.

• Switches with unique coded actuators must be commissioned before

use. The actuator teach process is not performed at the factory and

must be performed when the switch is first put into use. After the firsttime learn, this process can be repeated up to seven more times with

unique coded replacement actuators.

IMPORTANT When the switch learns a new actuator, it no longer recognizes previously

learned actuators.

Setup

The 440G-MZ safety switch can be set up in OSSD mode or GuardLink® mode.

IMPORTANT If the 440G-MZ safety switch is connected in a GuardLink system, verify that the

GuardLink is powered ON and the switch is unlocked to insert the actuator and

initiate the teach process.

During commissioning, connect the switch as shown in Figure 11

Figure 11 - Wiring

DEVICE

LINK

Brown

White

Black

Gray

Blue

889D-F5NC-x

or

889D-F5BC-x

+24V DC

NC

NC

NC

Gnd 0V

.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 25

Page 26

Chapter 5 Commission the Safety Switch

First-time Learn

Apply power to the switch without the actuator present. After the switch

completes the power-sequence (approximately 8 seconds), the status indicator

flashes green eight times, indicating the total number of times a new actuator

can be learned. This status indicator sequence repeats until an actuator is

inserted in the switch (in the guard closed position).

Table 10 - Commissioning Process for Unique Coded Switches

Step State Approximate Duration Status Indicators

1 Actuator Present 15 s

2 Verifying Actuator 15 s Flashing red/green, slow

3 Programming Switch 15 s Flashing red/green, fast

4 Program Finalization 15 s

5

(1) Out of box condition only.

(2) When teaching an actuator, the switch must be unlocked to insert the actuator. At the end of the finalization step, the switch

remains unlocked and in the safe state.

IMPORTANT After teaching a new actuator, a power cycle is required to complete the

Run Mode

(2)

process.

—Steady red

Flashing 8x green, repeating

Steady red (learning a replacement actuator)

Flashing green (number of times a new

actuator can be learned)

(1)

Perform a functional test of the switch to validate that it works as expected (see

Functional Testing on page 17

).

Learn Additional Replacement Actuators

Lock the Actuator Code

Error Codes during the Commissioning Process

The switch automatically starts a new teach process when a unique coded

replacement actuator is inserted in the switch (in the guard closed position).

IMPORTANT When the switch learns a new actuator, it no longer recognizes previously

learned actuators.

If the actuator is removed from the switch and then reinserted into the switch

during the 15-second Program Finalization stage (see Step 4 in Table 10

), this

action triggers the switch to LOCK the actuator code. This action can be

performed during any of the eight unique coded actuator learn cycles.

IMPORTANT After a unique coded actuator is locked using this method, the switch cannot

learn additional replacement actuators for the remaining life of the switch. If

the actuator is lost or damaged, the switch must be replaced.

The following indicator patterns repeat until a Power Off/On cycle is

completed.

Status/Diagnostic Indicator Error Code

Flashing green OSSD inputs not valid

Red-red-red-green Cannot learn a standard actuator

Red-red-red-green-green Actuator already learned

Red-red-red-green-green-green Bad RFID; actuator moved out of range

Red-red-red-green-green-green-green Exceeded learning eight actuators

Red-red-red-green-green-green-green-green Unit locked: cannot learn another actuator

26 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 27

Device Status and Troubleshooting

Chapter 6

Status Indicators during Power-up Routine

Status Indicators During Run Mode

When power is applied to the switch, the DEVICE status indicator is steady red

for 2.5 seconds, then the DEVICE and LINK status indicators flash red/green

for 1 second, and then the DEVICE status indicator is steady red for 3 seconds.

At the conclusion of the start-up sequence, the state of the status indicators is

determined by whether there is a demand on the safety function and the status

of the lock signal. See Table 11

.

Table 11 shows the status of the 440G-MZ safety switch during run mode.

Table 11 - Switch Status Indication During Run Mode

Indicator State Description

Steady green

Flashing green @ 1 Hz

Device

(2)

Link

(1) This state occurs when connected to a GuardLink system only

(2) The Link status indicator is only used when the 440G-MZ safety switch is connected in a GuardLink system. It is OFF when the

440G-MZ safety switch is connected directly to an I/O device or safety relay (OSSD mode).

Flashing amber @ 1 Hz

Steady red

Flashing red @ 1 Hz The switch is in the fault state.

Off

Steady green

Steady red

Flashing red @ 1 Hz The link is faulted.

The switch is in the operational state with no demand on the safety

function (that is, closed and locked).

The switch is in the operational state with no demand on the safety

(1)

function, but the link is in the safe state due to a demand on

another device in the link.

The switch is ready to be locked, or attempting to lock. The lock

command is set to LOCK but the door is in the open position or

slightly ajar. Check that the door is closed.

The switch is in the safe state due to a demand on the safety

function (that is, unlocked).

Indicates no communication to the DG safety relay over the link.

The switch is wired directly to I/O and is not part of a GuardLink®

system.

The link is in the operational state. This switch and all other devices

on the link are in the operational state.

The link is in the safe state due to a demand or fault on this switch

or another device in the link.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 27

Page 28

Chapter 6 Device Status and Troubleshooting

Diagnostic/Fault Codes

When connected in a GuardLink system, the 440G-MZ safety switch

communicates information about its current state with diagnostic and fault

codes.

Diagnostic codes (Table 12

) warn that a condition exists which prevents the

switch from transitioning to the operational state (for example, the switch is a

unique coded switch that must be commissioned), or causes the switch to fault

(for example, the input voltage is approaching the minimum value) if not

addressed.

Fault codes (Table 13 on page 29

) provide information about why the switch is

in the faulted state (as indicated by the DEVICE status indicator flashing red.)

When a fault is present, perform the recommended action, if stated. Issue a

RESET command to the 440G-MZ safety switch over the link to clear the fault.

IMPORTANT When a Power to Lock switch faults in the locked position, the bolt retracts

and the switch unlocks.

Diagnostic Codes

Table 12 - Diagnostic Codes

Decimal

(Hex)

00 (00) No diagnostic No action required.

04 (04)

31 (1F) Ready to lock

32 (20) Device is attempting to lock

33 (21)

38 (26) Actuator not paired

40 (28) Guard door open

Description Recommended Action

Input voltage is approaching

minimum (20.4V DC)

Device is attempting to

unlock

Evaluate input voltage. Input voltage must be 20.4…26.4V under all

electrical load conditions.

A lock command has been sent to the device but the guard door is open

or ajar. Check the actuator alignment or close the guard door.

Check actuator alignment. Check the wiring for the lock feedback

input.

Check for load on actuator or bolt. Check the wiring for the lock

feedback input.

Unique coded switch has not been paired with an actuator yet. Insert a

unique coded actuator (Cat. No. 440G-MZAU) to start the

commissioning process.

The actuator is not detected (RFID is not present). Close the guard door

to lock.

28 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 29

Fault Codes

Table 13 - Fault Codes

Chapter 6 Device Status and Troubleshooting

Decimal

(Hex)

00 (00) No fault. No action required.

05 (05) Power error

07 (07)

08 (08) Internal memory (ROM) fault Internal memory fault. Reset the device. If error persists, replace it.

09 (09) Runtime memory (RAM) fault Internal memory fault. Reset the device. If error persists, replace it.

10 (0A) Internal memory (CPU) fault Internal memory fault. Reset the device. If error persists, replace it.

15 (0F) No response on GuardLink Check GuardLink wiring and connections.

31 (1F) GuardLink application fault GuardLink system fault. Reset the device. If error persists, replace it.

32 (20) Product application fault Product Application fault. Reset the device. If error persists, replace it.

40 (28)

41 (29) Invalid actuator detected Cannot teach a standard actuator to a unique coded switch.

42 (2A) No learns left

43 (2B) Actuator relearn Switch cannot learn a previously learned actuator. Use a new actuator.

44 (2C) Actuator teach fault

56 (38) Bolt detection fault

57 (39) Failure to lock

58 (3A) Failure to unlock

59 (3B) Actuator detection fault

255 (FF) Internal fault

Description Recommended Action

Evaluate input voltage. Input voltage must be 20.4…26.4V under all

electrical load conditions.

Failure to detect device type

(OSSD or GuardLink)

Unique code actuator is

locked

Check wiring and cycle power to the switch. If error persists, replace

the switch.

A new actuator cannot be learned because the current actuator is

locked.

Teaching is not possible. The switch has learned 8 actuators and

cannot learn any more actuators.

Actuator moved out of range during teach process or the switch has

detected an invalid RFID tag.

Keep actuator within sensing range during learn process.

During operational state, the device failed to detect the bolt. On escape

release models, this fault can be caused by engaging the escape

release. It can also occur if the auxiliary release was actuated.

Inspect the bolt. Disengage the escape release mechanism (if

applicable). Reset the device if the fault is not cleared.

Device attempted to lock for specified lock attempt length, but lock

status input did not indicate that the device locked.

Check guard door and actuator alignment.

Device attempted to unlock for specified unlock attempt length, but

lock status input did not indicate that the device unlocked.

Check the device. Verify that door is not applying a side load on the

locking bolt.

During operational state, the device failed to detect the RFID tag in the

actuator. Inspect the actuator and RFID tag for signs of damage. Fault

reset the device. If the error persists, replace the actuator.

An internal device fault has occurred. Reset the device. If error

persists, replace it.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 29

Page 30

Chapter 6 Device Status and Troubleshooting

Troubleshooting

Mounting Holes of the Switch Body Cracked or Broken

The mounting hole of the switch body can crack when washers are used to

mount the switch or when an incompatible thread locking compound is used

to secure the mounting hardware. Three M5 fasteners are required to mount

the switch body properly. Do not over torque the screws.

IMPORTANT Do not use a washer with the screw at the base of the switch body. Using a

washer causes the plastic to crack.

Loctite 242 thread-locking adhesive is known to cause stress cracks in the

plastic housing of the 440G-MZ safety switch and should not be used. Lab tests

have determined that Loctite 425, a cyanoacrylate adhesive, does not cause

cracking and can be considered if the faster cure time is acceptable in the

application.

Check the manufacturer specifications of any thread-locking compound used

to secure the screws. It is recommended to use a cyanoacrylate-type

compound. Other compounds can cause stress cracks in the plastic feet of the

switch.

30 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 31

Chapter 7

800FM-MT44

GLP

A2 11L22S21S

L12

L61

51

P12 P22

A1

45S44S

42X41X

AP

Y32

S11

S12 S21 S22

S32 S42 L11 L12

S34

A1 13

A2 142324 Y32

DI

440R-D22R2

LOGIC

4

LOGIC SL1 SL2

3

5

8

440R-GL2S2P

SLS

Request

to PAC

Reset

& Lock

Request

Unlock

Request

800FM-MT44

872C-D8NP18-E5

Blue

Blue

Brown Brown

Black

Black

+24V DC

COM

Status

Safety Input 1

Safety CO M

Safety Input 2

1

2

3

4

5

6

Kinetix® 300 Drive

Safe Torque-o

(STO)

Connector with

Wiring H eader

Safety

Status

to PAC

K300

Status

to PAC

Stop/Start/SLS

from PAC

Brown

White

Black

Blue

Gry

+24V DC, Class 2, PELV

24V DC COM

440G-MZS20*NR*

889D-F5NC-X

Reset

Application Examples

The following application and wiring examples are intended to show how the

440G-MZ safety switch products can be applied. If you are the user or the

designer, you may require variations to these examples to meet your specific

requirements.

Wire to GLP Safety Relay

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 31

The GLP safety relay is designed to operate with Power to Release (PTR)

switches. To use a Power to Lock (PTL) switch, you must use an interposing

relay on the lock command at GLP terminal 51. In the example shown in

Figure 12

, the GLP safety relay allows the gate to be unlocked when the motor is

running at a Safely-limited Speed.

Figure 12 - GLP and 440G-MZ Safety Switch Schematic

Page 32

Chapter 7 Application Examples

Circuit Status as Shown

The gate is open and unlocked. The motor is off. The GLP safety relay is ready

for reset. The GLP safety relay has a Logic setting of 3: (Safely-limited Speed

with Logic IN OFF), a Safely-limited Speed (SLS1) setting of 5 (5 Hz) and a

maximum (SLS2) speed setting of 8 (2000 Hz). The safety outputs (X14 & X24),

the single wire safety output (L11), and the auxiliary output (Y32) are OFF.

IMPORTANT Start the GLP logic configuration from “0” to configure X14 and X24 for use as

safety outputs.

Starting

Close the gate and press Reset to lock the gate and turn on the GLP safety

outputs. Press Start to turn the motor ON.

Safely-limited Speed

A normal production stop is performed by pressing Stop. Access through the

safety gate is initiated by pressing Gate Unlock Request. The Y32 output of the

GLP safety relay turns ON, which makes an SLS request to the PAC. The PAC

commands the Kinetix® drive to bring the motor to a safe slow speed. When

the proximity sensors detect the speed has dropped below the Safely-limited

Speed (5 Hz), the gate becomes unlocked. The operator can enter the machine

cell, as the motor continues to run at the safe slow speed. After you leave the

cell and close the gate, press Reset to lock the gate and return the machine to

production speeds.

The circuit meets the safety requirements up to Category 3, Performance

Leveld in accordance with ISO 13849-1 and SIL CL 2 in accordance with

IEC 62061.

32 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 33

Chapter 7 Application Examples

Blue (Gnd)

Brown (+24)

24V DC Com

M

Gate

Unlock

Request

Reset and

Gate Lock

Request

GLT

440R-GL2S2T

A2S12 S22B2L61

51

L12

A145S

44S21S11S

L11

Y32

LOGIC

TIME

RANGE

Gate control

power supply

Gate control

circuit

S1

S2

1 Stop

PowerFlex

525

2 Start

4 Gnd

11 +24V DC

440G-MZS20*NR*

Power to Release

No aux

14 24

Gray - Lock Cmd

White - OSSD 1

Black - OSSD 2

889D-F5NC-X

Safety Gate

440G-MZ

UVW

L1 L2 L3

+24V DC, Class 2, PELV

3 4

8

RS T

Wire to GLT Safety Relay

The GLT safety relay is designed to operate with PTR switches. To use a PTL

switch, you must use an interposing relay on the lock command at terminal 51

of the GLT safety relay.

In this example shown in Figure 13

, the GLT safety relay sends an immediate

command to the drive to turn OFF. After 8 seconds, the GLT safety relay turns

off its safety outputs and unlocks the gate. The risk assessment must

determine adequate time delay for the machine to achieve a safe state before

unlocking the gate.

Figure 13 - GLT and 440G-MZ Safety Switch Schematic

Circuit status as shown: The gate is open and unlocked. The motor is off. The

GLT safety relay is ready for reset. The GLT safety relay has a Logic setting of

3: (Category 1 Stop), a Range setting of 4 (10 seconds) and a Time setting of 8

(80%). The Y32 output turns OFF immediately; 8 seconds later, the safety

outputs turn OFF.

The safety outputs (14 and 24) and the single wire safety output (L11) are OFF

and the auxiliary output (Y32) is ON.

IMPORTANT Start the GLT logic configuration from 0 to configure 14 and 24 for use with

Starting

Close the gate. Press Reset and Gate Lock Request to lock the gate and turn on

the GLT safety outputs. Press Start to turn the motor ON.

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 33

pulse testing; the PowerFlex® 525 drive can operate with pulse tested inputs to

S1 and S2.

Page 34

Chapter 7 Application Examples

Stopping

Normal production stops are performed by pressing Stop. Access through the

safety gate is initiated by pressing the Gate Unlock Request. The Y32 output of

the GLT safety relay turns OFF, which commands the PowerFlex® drive to

bring the motor to a stop. After the configured time delay (8 seconds) expires,

the GLT safety outputs turn off, and the gate becomes unlocked. After you

leave the cell and close the gate, press Reset to lock the gate and return the

machine to a production state.

The circuit meets the safety requirements up to Category 3, Performance

Leveld in accordance with ISO 13849-1 and SIL CL 2 in accordance with IEC

62061.

34 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 35

Chapter 7 Application Examples

Power

I

n1

In 2

O

u

t

L

o

gic

A2

A1

L12

L11

13

14

23

24

IN1

DI

I

N2

LOGIC

Test O

ut

A

2

A1

B2

3

7

B1

47

48

38

L12

L11

X32

17

27

2

8

18

EMD

17

18

2

7

28

37

3

8

4

7

48

E-stop

K1

K2

M

K1

K2

Reset

U

nlock

2

S11

S21

S12

S22 S32 S42

Y32 S34

TIME

8

RANGE

2

Brown

Blue

Gray

White Black

Brown = +24V DC

White = OSSD 1

Black = OSSD 2

Blue = 24V DC COM

Gray = Lock CMD

L1 L2L3

440G-MZS20*NR*

+24V DC, Class 2, PELV

24V DC COM

Wire to DI and EMD Safety Relay

The 440G-MZ safety switch can be connected to the DI and EMD safety relays.

The DI safety relay monitors the safety outputs of the safety switch and the

EMD enables the gate to be unlocked after a configured delay time expires.

B1 is connected to B2 to allow for retriggering. If you open and close the E-stop

and press Reset before the delay expires, the EMD timer resets.

Upon initial power-up, the safety switch must be cycled for the DI to recognize

the safety switch OSSD signals.

In the example shown in Figure 14

, an E-stop initiates the machine shutdown.

After an eight-second delay, the safety switch is allowed to be unlocked and the

hazards that remain are turned OFF. A selector switch is required to maintain

the gate in an unlock state. The risk assessment must determine adequate time

delay for the machine to achieve a safe state before unlocking the gate.

Figure 14 - DI Safety Relay with EMD Safety Relay and 440G-MZ Safety Switch Schematic

Circuit Status as Shown

The E-stop is released. The gate is open and unlocked. K1 and K2 are OFF. The

DI safety relay is configured for two inputs with monitored manual reset. The

EMD safety relay is configured for 8-second off-delay; Range setting of 2 is 10

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 35

s, Time setting of 8 is 80% of the range. The X32 terminal is ON because the

EMD safety outputs are OFF.

Page 36

Chapter 7 Application Examples

Starting

With the Unlock switch open, close the gate. Press Reset to lock the gate and

turn on the K1…K4 safety contactors.

Stopping

Stopping is initiated by pressing the E-stop. K1 and K2 contactors turn off

immediately. The single wire safety signal from the DI safety relay (L11) to the

EMD safety relay (L12) also turns off immediately, and the EMD starts the offdelay timer. After 8 seconds, X32 goes to 24V. The unlock switch is enabled, and

the gate can be unlocked. While the gate is unlocked, the DI safety relay cannot

turn the safety outputs back ON. After you leave the cell and close the gate,

open the unlock switch to lock the gate, and release the E-stop.

The circuit can meet the safety requirements up to Category 4, Performance

Level e in accordance with ISO 13849-1 and SIL CL 3 in accordance with

IEC62061.

36 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 37

Chapter 7 Application Examples

L1

L2 L3

M

K1

K2

K1

K2

Status

Control

Control

Machine

Control

System

24V DC Com

S32 X3

X2

X4

14S42

13 23

24

S11

S22

X1

A2

DG

440R-DG2R2T

+

440R-ENETR

A

B

C

Status

TIME

0

A1

S12

S21

440S-PFSD

440S-PFSD

440S-PFSD 440S-PFSD

889D-F5NCDM-X 889D-F5NCDM-X

889D-F5NCDM-X889D-F5NCDM-X

440G-MZS20*NR* 440G-MZS20*NR*

440G-MZS20*NR* 440G-MZS20*NR*

+24V DC, Class 2, PELV

Brown

Blue

White

Black

889D-F4NE-X

889D-F4NE-X

Brown

Blue

White

Black

Wire to DG Safety Relay

The 440G-MZ safety switch can be used in GuardLink® applications. The

GuardLink system:

• Is designed to operate with Power to Release switches.

• Uses taps to connect a series of devices to one relay.

• Provides control and status information between the machine control

system and the safety system.

Figure 15

shows four 440G-MZ safety switches that are connected on two

GuardLink circuits from one DG safety relay. The DG safety relay can

accommodate up to 32 devices on each input. The devices can be a mix of many

different safety devices. When guard locking devices are included in the

GuardLink system, the lock/unlock command must come from the machine

control system through the 440R-ENETR module.

See publication 440R-UM015 for further details.

Figure 15 - DG Safety Relay with 440G-MZ Safety Switch Schematic

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 37

Page 38

Chapter 7 Application Examples

05

CR30

4030001020

A1 15 20 21160618A2

071908 10 11

12 13 14

09

17

24V DC Com

Reset

440C-CR30-22BBB

Unlock

Motor Not Running

Lock

Gate control

power supply

Gate control

circuit

4 Gnd

S1

S2

1 Stop

11 +24V DC

PowerFlex

525

2 Start

R5

t081=2

S

R6

Blue (Gnd)

Brown (+24)

440G-MZS20*NR*

Power to Release

No aux

Gray - Lock Cmd

White - OSSD 1

Black - OSSD 2

889D-F5NC-X

Safety Gate

+24V DC, Class 2, PELV

M

L1 L2L3

RT

VUW

Wire to CR30 Safety Relay

The CR30 safety relay is a software configurable safety relay that can easily

interface with the 440G-MZ safety switch. Version 10 and later of the

Connected Components Workbench™ software has a locking function that is

useful for guard locking applications.

Figure 16

shows an example schematic. The CR30 safety relay monitors the

motor running signal from the PowerFlex 525 drive. When the motor is not

running, the safety gate can be unlocked, and the PowerFlex 525 drive goes to a

Safe Torque Off state.

Figure 16 - CR30 Safety Relay with 440G-MZ Safety Switch Schematic

Figure 17 on page 39 shows an example CR30 safety relay configuration that

works with the schematic in Figure 16

38 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

.

Page 39

Chapter 7 Application Examples

The safety switch OSSD outputs drive the Safe Torque Off (STO) signals of the

PowerFlex 525 drive. The STO is enabled after the gate is locked and the Reset

is pressed. The PowerFlex 525 drive STO inputs can tolerate the pulse test that

is generated by the CR30 outputs.

The Lock_Ctrl_1 block controls the unlock command to the safety switch. The

unlock Stop Time delay is set to 5 seconds, and the ULR Latch (Unlock Request)

is set to ON. When an unlock request is made, the command is issued 5

seconds after the motor stops running, and the unlock request is latched ON.

Figure 17 - CR30 Configuration in CCW

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 39

Page 40

Chapter 7 Application Examples

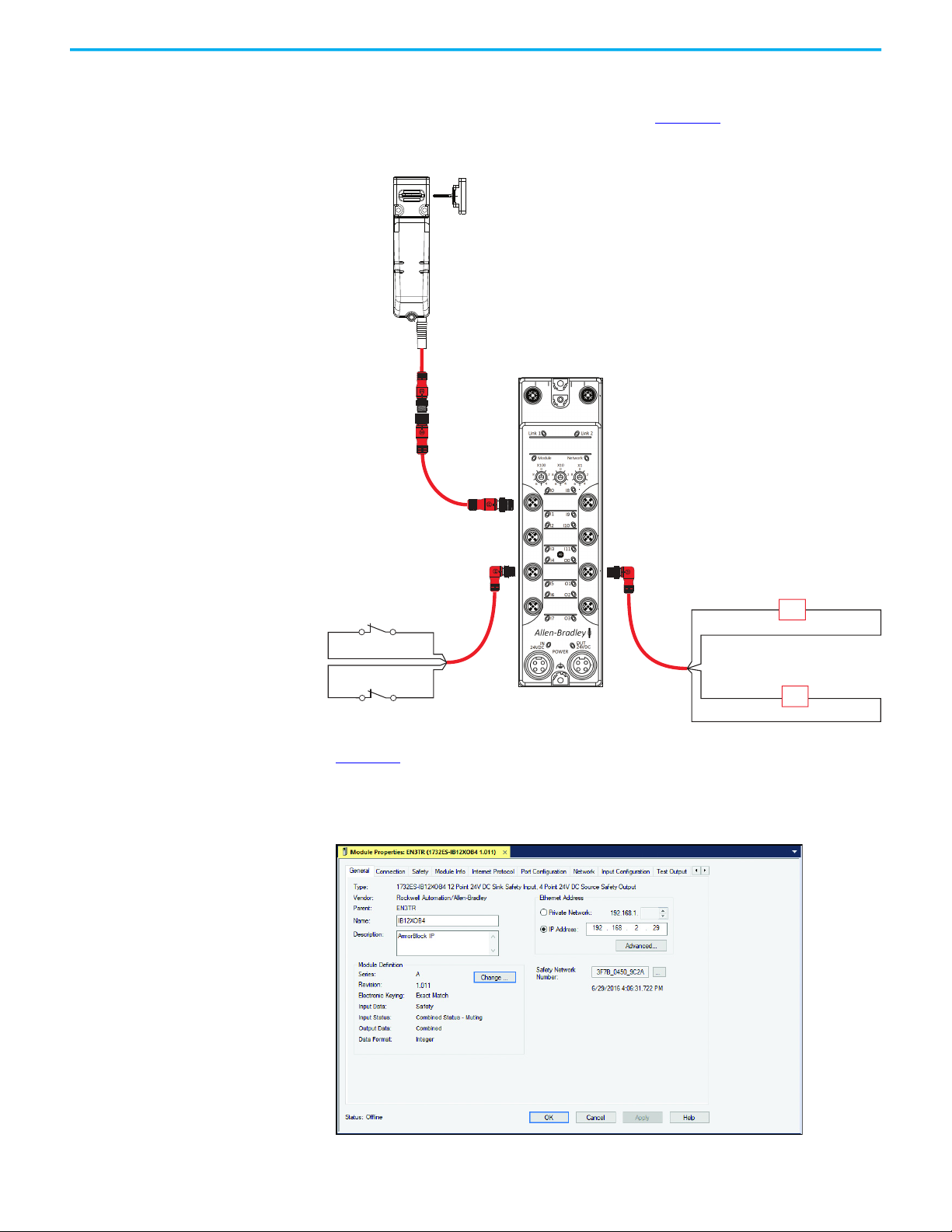

Wire to POINT Guard I/O Module

Figure 18 shows a wiring example of a 440G-MZ Power to Release safety switch

that is connected to a 1734 POINT Guard I/O™ module.

Figure 18 - 1734 Module and 440G-MZ Safety Switch Schematic

440G-MZ

440G-MZS20*NR*

Power to Release

No aux

889D-F5NC-X

Black - OSSD 2

White - OSSD 1

Blue (Gnd)

Gray - Lock Cmd

Brown (+24)

Safety Gate

Ethernet I/P

to GuardLogix®

PLC and HMI

24V DC Com

+24V DC

0

1

263

45

7

I0

I2T0I3

COM COM

K1

1734-IB8S S8BO-4371TNEA-4371

I1

T1M

K2

I4

I6T2I7

COM COM

I5

O0

O2 O3

COM COM

T3M

COM COM COM COM

O4

O1

K1

O5

O6 O7

COM COM

K2

Figure 19 shows the General tab of the 1734-AENTR module properties.

The Input Status can be set to Rack Optimization, Enhanced Rack

Optimization, or Combined Status - Power - Muting as these settings are used

by the Dual Channel Input Stop (DCS) logic block to verify that the 1734-IB8S

switch is operational. The Output Data must be set to Test, as the test outputs

are used to generate test pulses for the output contactors, K1 and K2.

Figure 19 - 1734-AENTR Module Properties - General

40 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 41

Chapter 7 Application Examples

Figure 20 shows the 1734-IB8S General tab. Set the Module Definition with the

following settings:

• Input Data: Safety

•Output: Test

• Input Status: Pt. Status-Power-Muting-Test Output

Figure 20 - 1734-IB8S Module Properties - General

Figure 21 shows the Input Configuration tab of the 1734-IB8S switch module

properties.

In this example, Points 0 and 1 monitor the OSSD outputs of the 440G-MZ

safety switch. The Type is set to Single and the Mode must be set to Safety.

Points 2 and 3 monitor the status of the output contactors, K1 and K2. The Type

should be set to Single. Set Mode to Safety Pulse Test. Safety pulse testing is

used to detect potential faults in the monitoring circuit.

Figure 21 - 1734-IB8S Module Properties - Input Configuration

Rockwell Automation Publication 440G-UM004C-EN-P - January 2021 41

Page 42

Chapter 7 Application Examples

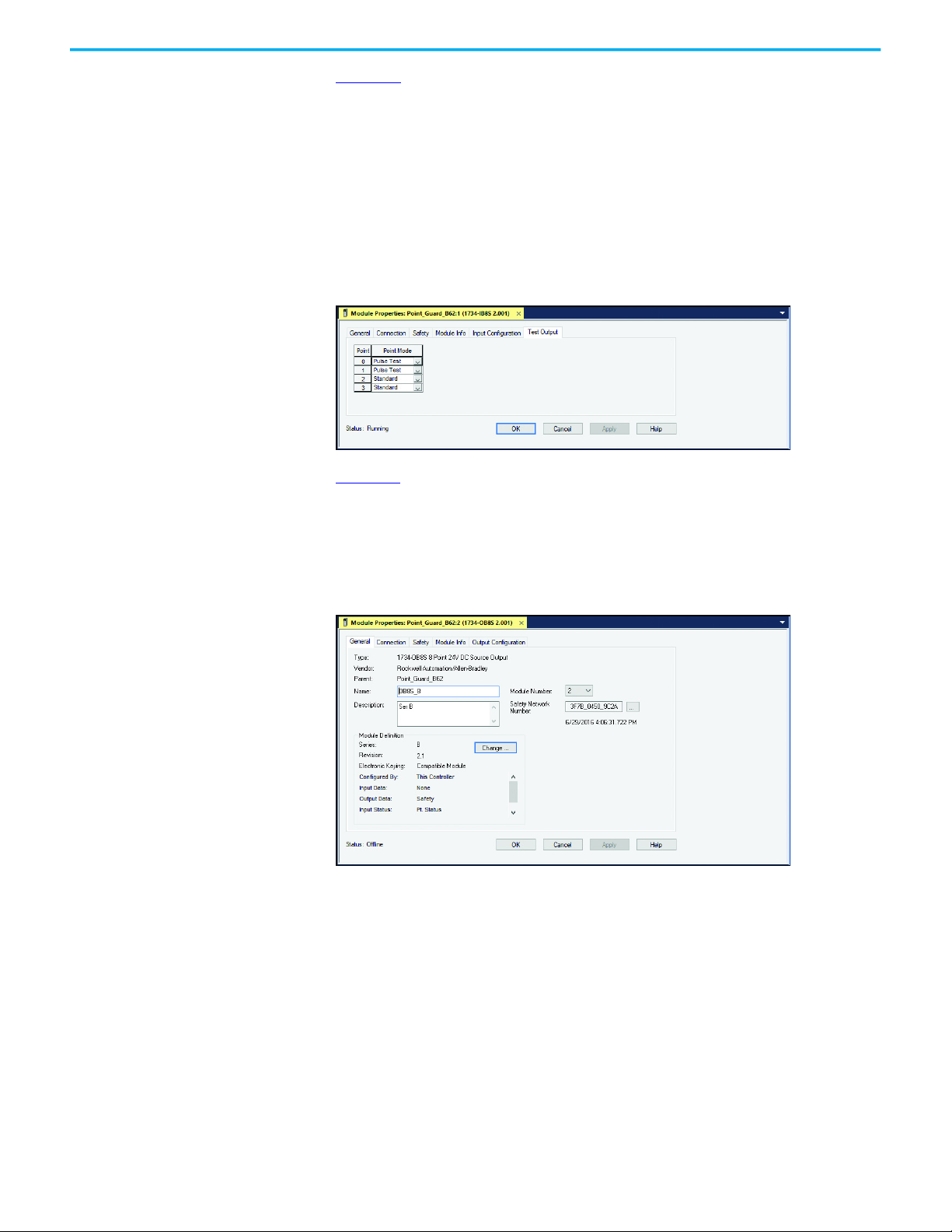

Figure 22 shows the Test Output tab of the 1734-IB8S module properties.

In this example, Points 0 and 1 are set to Pulse Test as these points help check

the integrity of the contactors K1 and K2, to be sure they are off before the logic

program energizes the contactors.

Points 2 and 3 are set to Standard. Point 2 is the LOCK command. Point 3

applies power to the safety switch. By setting it to Standard, you can

programmatically turn these points OFF and ON, in case a nonrecoverable

fault occurs with the switch.

Figure 22 - 1734-IB8S Module Properties - Test Output

Figure 23 shows the General tab of the 1734-OB8S module properties. Set the

Module Definition with the following settings:

• Input Data: None

• Output: Safety

• Input Status: Pt. Status

Figure 23 - 1734-OB8S Module Properties - General

42 Rockwell Automation Publication 440G-UM004C-EN-P - January 2021

Page 43

Chapter 7 Application Examples

Figure 24 shows the Output Configuration tab of the 1734-OB8S switch module

properties.

Points 0 and 1 drive the output contactors K1 and K2. For both points, Type is

set to Dual, and the Mode is set to Safety Pulse Test.

Figure 24 - Module Properties - Output Configuration

Figure 25 on page 44 shows an example program. A Dual Channel Input Stop

function block monitors the 440G-MZ safety switch, and a Configurable

Redundant Output function block controls two contactors. This example can

be used as a starting point for implementation; you must incorporate

additional logic that is based on the risk assessment for the machine.

Rung Description

With the Test Data output setup set as Standard, an HMI input can cycle power ON and OFF to the

0

440G-MZ safety switch to recover from a fault, if necessary. Upon powerup, the N.C. contact

automatically applies power to the 440G-MZ safety switch.

The Dual Channel Input Stop monitors the outputs of the 440G-MZ safety switch. The DCS block is set

1

for automatic start on powerup (cold start) and automatic restart each time the switch is locked.

The output of the DCS in Rung 1 provides a tag that shows the input 440G-MZ input status is OK. This

2

tag is used in Rung 4 to enable the Configurable Output to be reset.

A momentary contact from an HMI input starts a short on delay timer. HMI input must be held long

3

enough for the timer to expire. This timer is intended to help prevent inadvertent reset. The preset

value can be adjusted to suit the application.

When the timer is done, the OSF_Storage_Bit is set. When the HMI_CROUT_Actuate button in Rung 4 is

4

released, the OSF_Storage_Bit goes LO and the OSF_Output_Bit goes HI.

When the OSF_Output_Bit goes HI, the CROUT_Actuate tag is set. The CROUT_Actuate tag is self-sealing

5

because the OSF_Output_Bit is HI only momentarily.