Page 1

Guardmaster DG Safety Relay

and GuardLink System

Catalog Numbers 440R-DG2R2T (DG Safety Relay); 440S-SF8D,

440S-SLF8D, 440S-SF5D, 440S-MF5D, 440S-MF8D,

440S-MLF8D, 440S-PF5D, 440S-PF5D4 (Taps);

898D-418U-DM2 (Terminator); 440S-GLTAPBRKx (Bracket);

440R-ENETR (EtherNet/IP Network Interface)

User Manual

Original Instructions

Page 2

Guardmaster DG Safety Relay and GuardLink System User Manual

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WA RN I NG : Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property

damage, or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous

voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may

reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to

potential Arc Flash. Arc Flash will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL

Regulatory requirements for safe work practices and for Personal Protective Equipment (PPE).

2 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 3

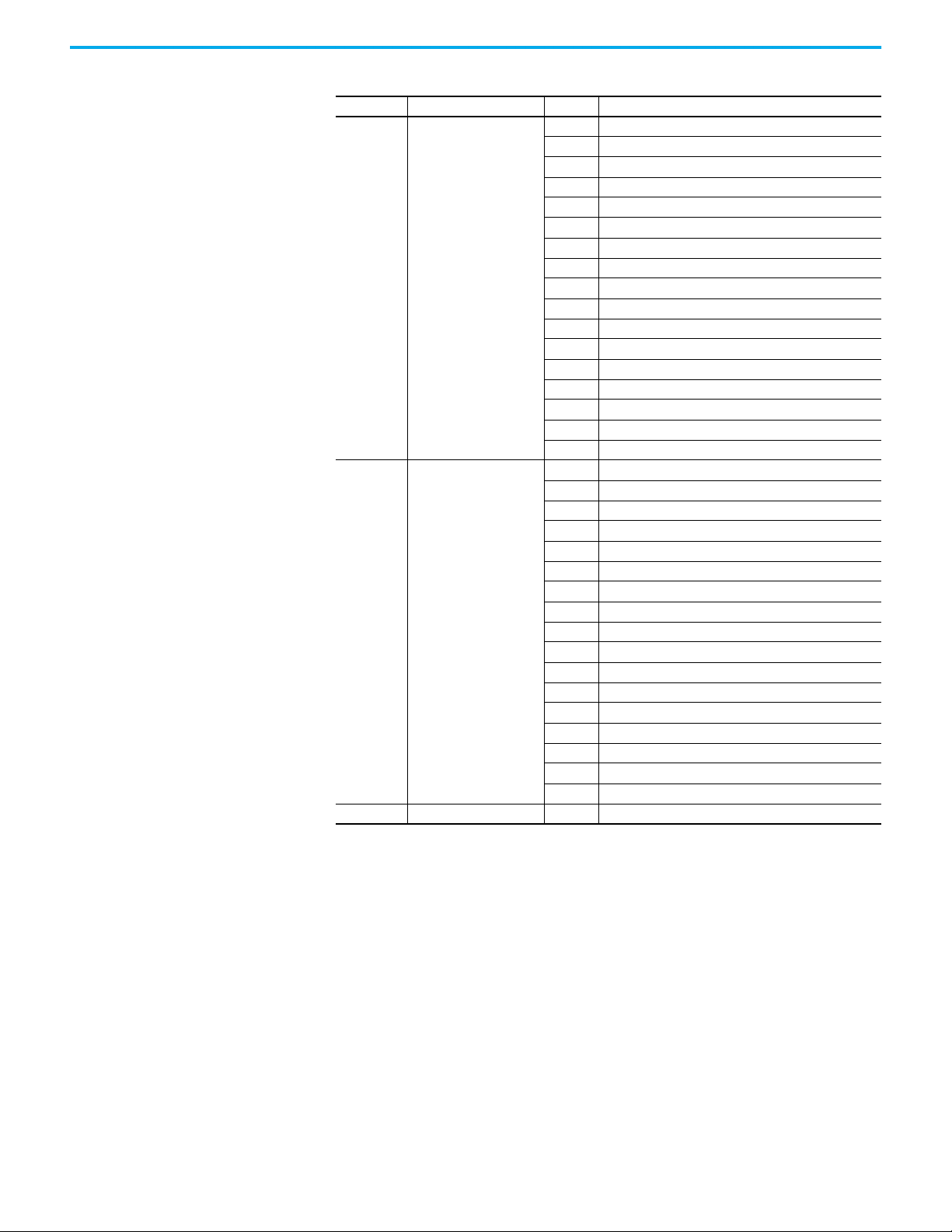

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Download Firmware, AOP, EDS, and Other Files . . . . . . . . . . . . . . . . . . . . 7

Summary of Changes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Definitions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1

Overview What Is a GuardLink System? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Taps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

DG Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Safety Device Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Single Wire Safety (SWS) Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Output Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

GuardLink Principle of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GuardLink State . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

GuardLink Transition from Safe State to Operational State . . . . . . 17

GuardLink Transition from Operational State to Safe State . . . . . . 17

GuardLink Fault Reset Command . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

OSSD Tap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

EMSS Tap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Passive Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Passive Power Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Guard Locking with GuardLink Systems . . . . . . . . . . . . . . . . . . . . . . . 19

Guard Locking Application Example. . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 2

GuardLink System Design Design Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

System Current Calculation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Voltage Drop Consideration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Tap Cabling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Terminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Tap Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 3

Page 4

Chapter 3

Installation Mounting Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

DIN Rail Mounting and Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Spacing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Terminal Block Removal and Replacement . . . . . . . . . . . . . . . . . . . . . . . . 33

Terminal Block Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Terminal Block Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Tap Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Enclosure Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

DG Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Taps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Prevent Excessive Heat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

DG Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Taps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Chapter 4

Power, Ground, and Wire Wiring Requirements and Recommendation . . . . . . . . . . . . . . . . . . . . . . 37

DG Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Wire Size . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Terminal Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Terminal Assignment and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Tap Pin Assignment and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Power Supply Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

DG Safety Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Taps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Multiple Power Supplies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

DG Safety Relay Input Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

GuardLink Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Devices with OSSD Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Voltage-free Contacts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Single Wire Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

SWS Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Safety Output Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

13/14 and 23/24 Safety Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Surge Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

4 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 5

Chapter 5

Configuration Config/Set Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Run Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Sel./Save Push Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Run Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuration Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Reset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Configuration Steps. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

Delay Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Verification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Buttons on the Front of DG Safety Relay . . . . . . . . . . . . . . . . . . . . . . . 53

AOP in the Studio 5000 Environment. . . . . . . . . . . . . . . . . . . . . . . . . . 54

Chapter 6

Status Indicators DG Safety Relay Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Tap Status Indicators. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Chapter 7

Pulse Testing Functions Pulse Testing for Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

EMSS Tap Pulse Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Chapter 8

Opto-link Communications Optical Bus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Arrangement with 440R?ENETR Interface . . . . . . . . . . . . . . . . . . . . . . . . 60

Chapter 9

Safety Function Calculations GuardLink System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

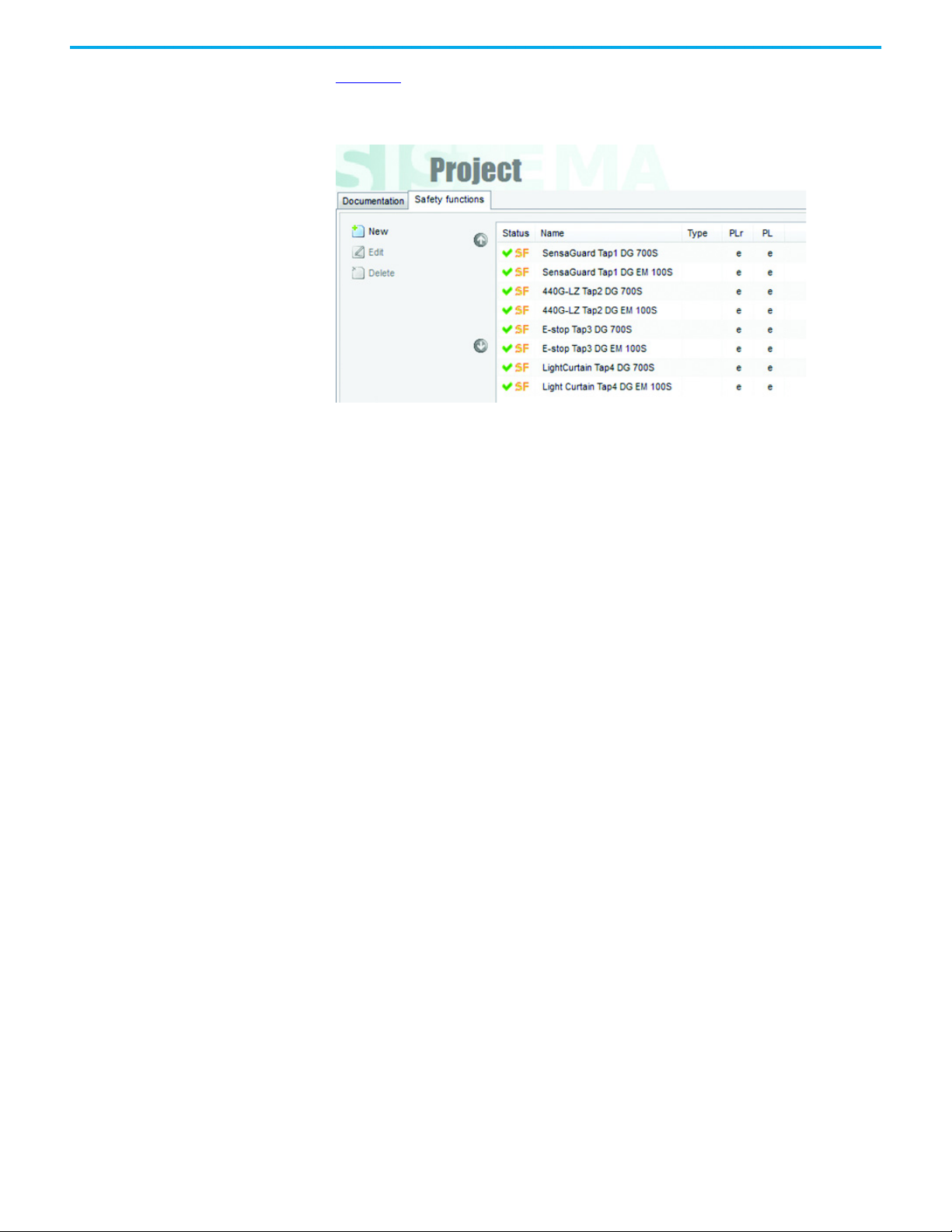

SISTEMA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Appendix A

Specifications DG Safety Relay. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Tap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 5

Page 6

Appendix B

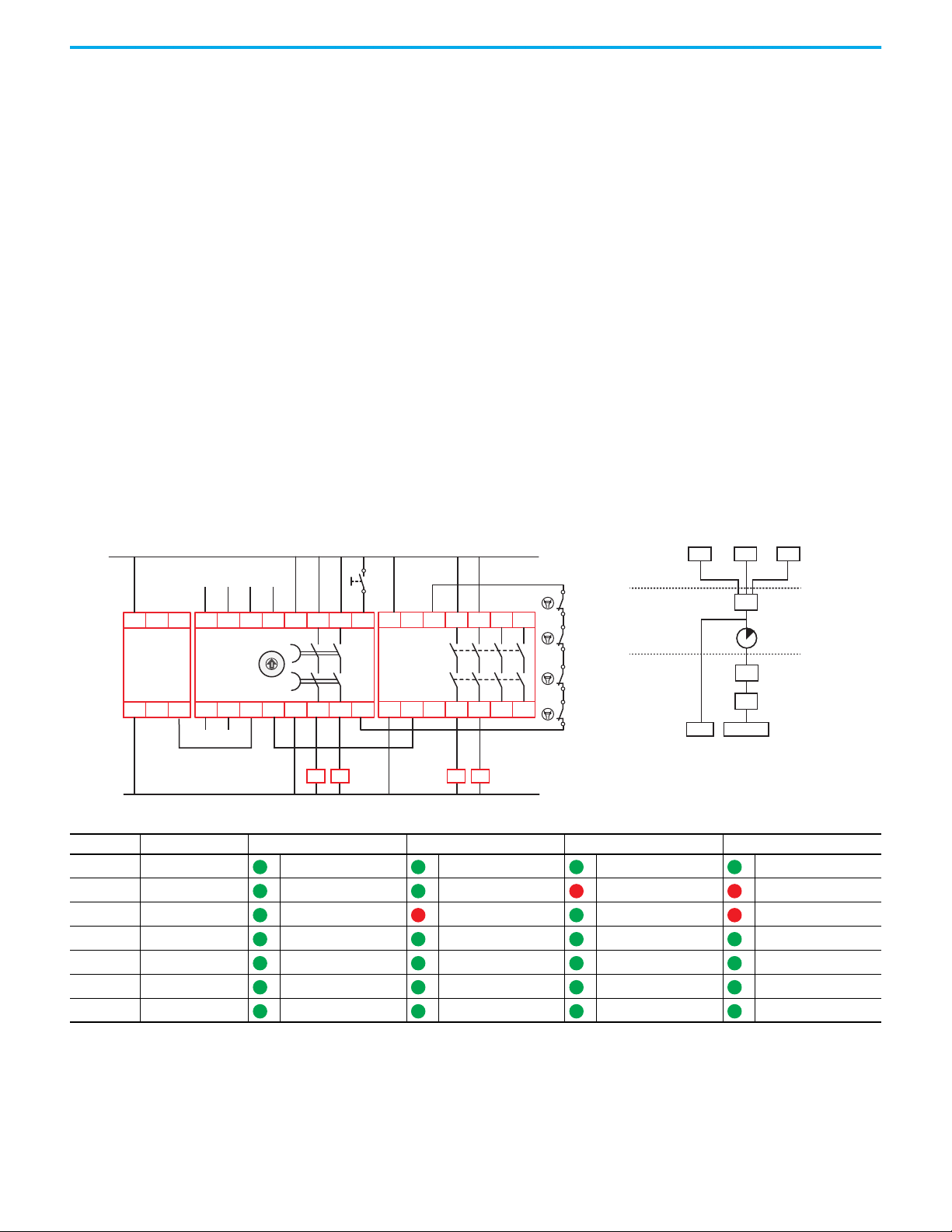

Configuration Examples Configuration 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

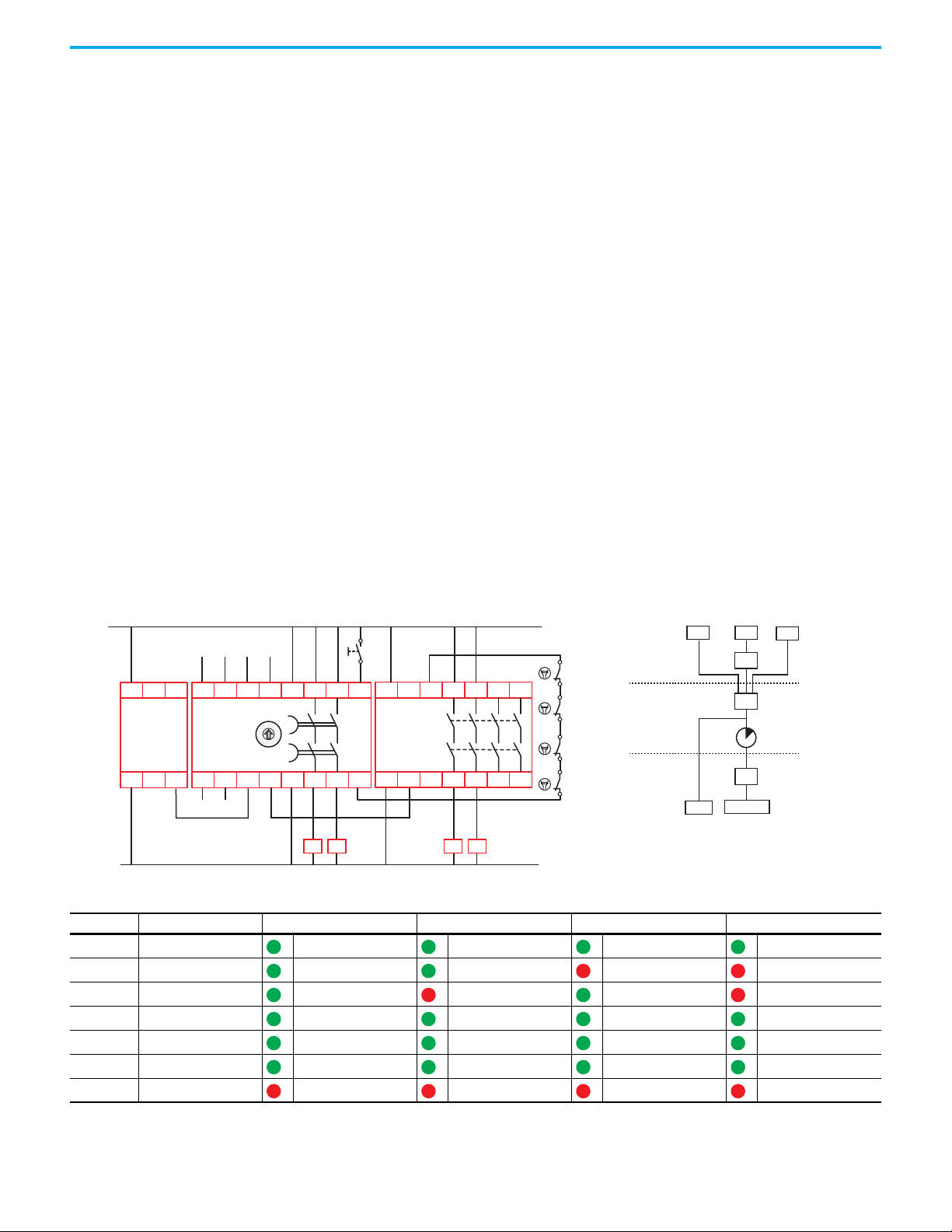

Configuration 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Configuration 3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

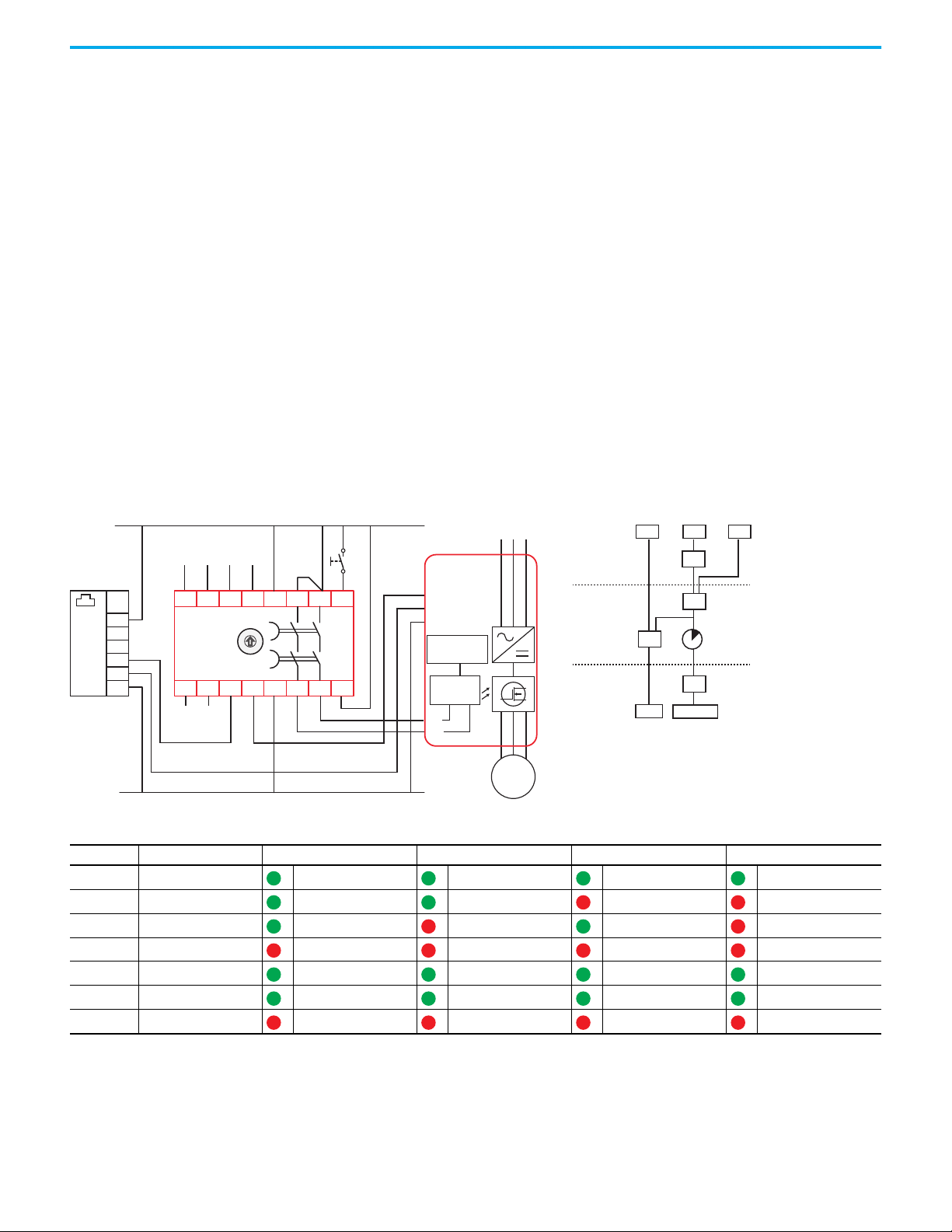

Configuration 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

Configuration 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

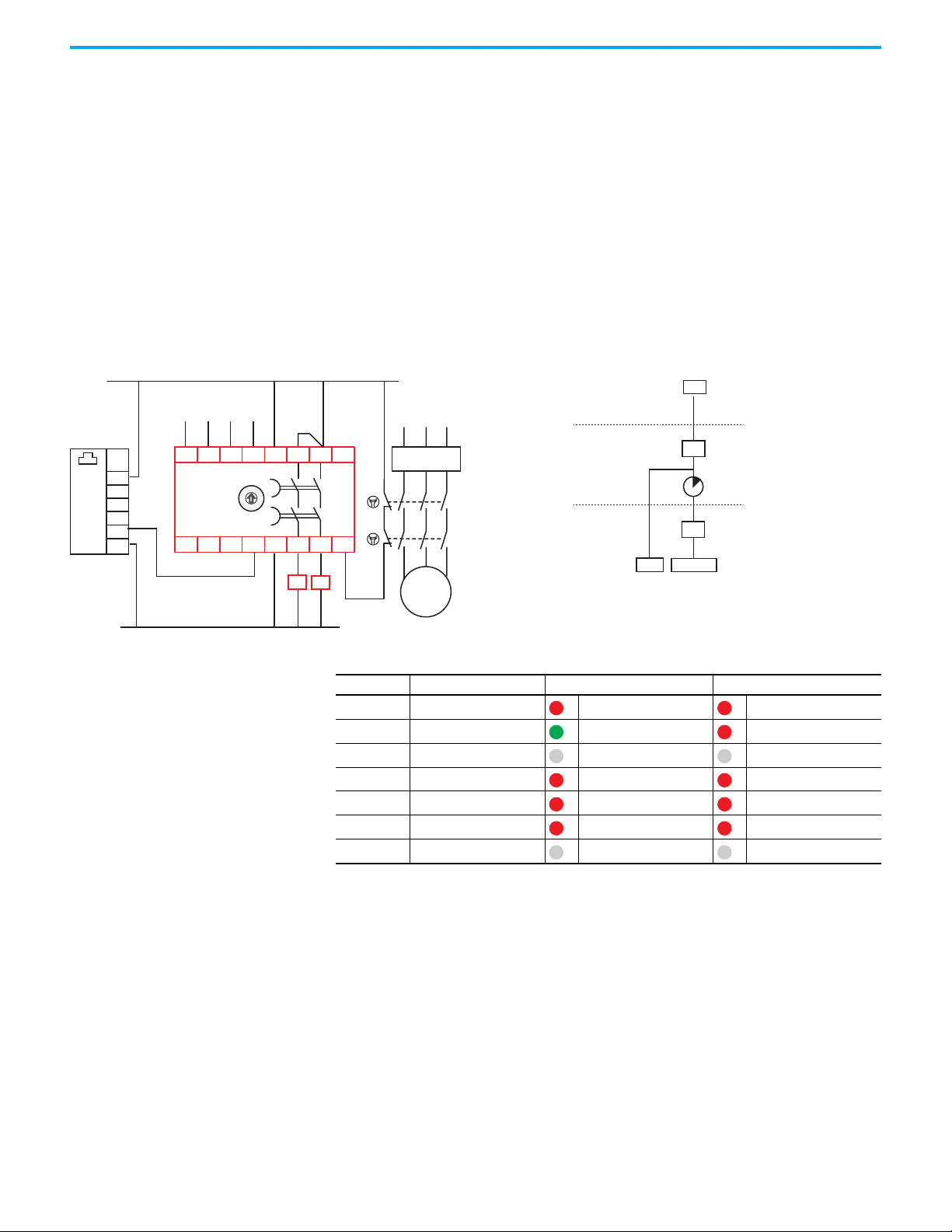

Configuration 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Configuration 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 76

Configuration 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Configuration 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Configuration 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Configuration 11 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Configuration 12 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Configuration 13 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Configuration 14 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Configuration 15 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 84

Configuration 16 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Configuration 17 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Configuration 18 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87

Configuration 19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Configuration 20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Appendix C

Regulatory Approvals Agency Certifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Compliance to European Union Directives . . . . . . . . . . . . . . . . . . . . . . . . 91

Machine Safety Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

DG Safety Relay Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

SIL Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Performance Level/Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Tap Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

SIL Rating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Performance Level/Category. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Declaration of Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 94

Appendix D

DG Safety Relay Indicator Fault

Codes

Determine a Fault. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Clear a Fault . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .99

6 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 7

Preface

This user manual is a reference guide for the GuardLink® safety system, plugin modules, and accessories. It describes the procedures that you use to install,

wire, and troubleshoot your relay. This manual explains how to install and wire

your relay and gives you an overview of the GuardLink safety system

Who Should Use This Manual

Download Firmware, AOP, EDS, and Other Files

Summary of Changes

Use this manual if you are responsible for the design, installation,

programming, or troubleshooting of control systems that use the GuardLink

safety system.

You must have a basic understanding of electrical circuitry and familiarity

with safety-related control systems. If you do not, obtain the proper training

before using this product.

Download firmware, associated files (such as AOP, EDS, and DTM), and access

product release notes from the Product Compatibility and Download Center at

rok.auto/pcdc

This publication contains the following new or updated information. This list

includes substantive updates only and is not intended to reflect all changes.

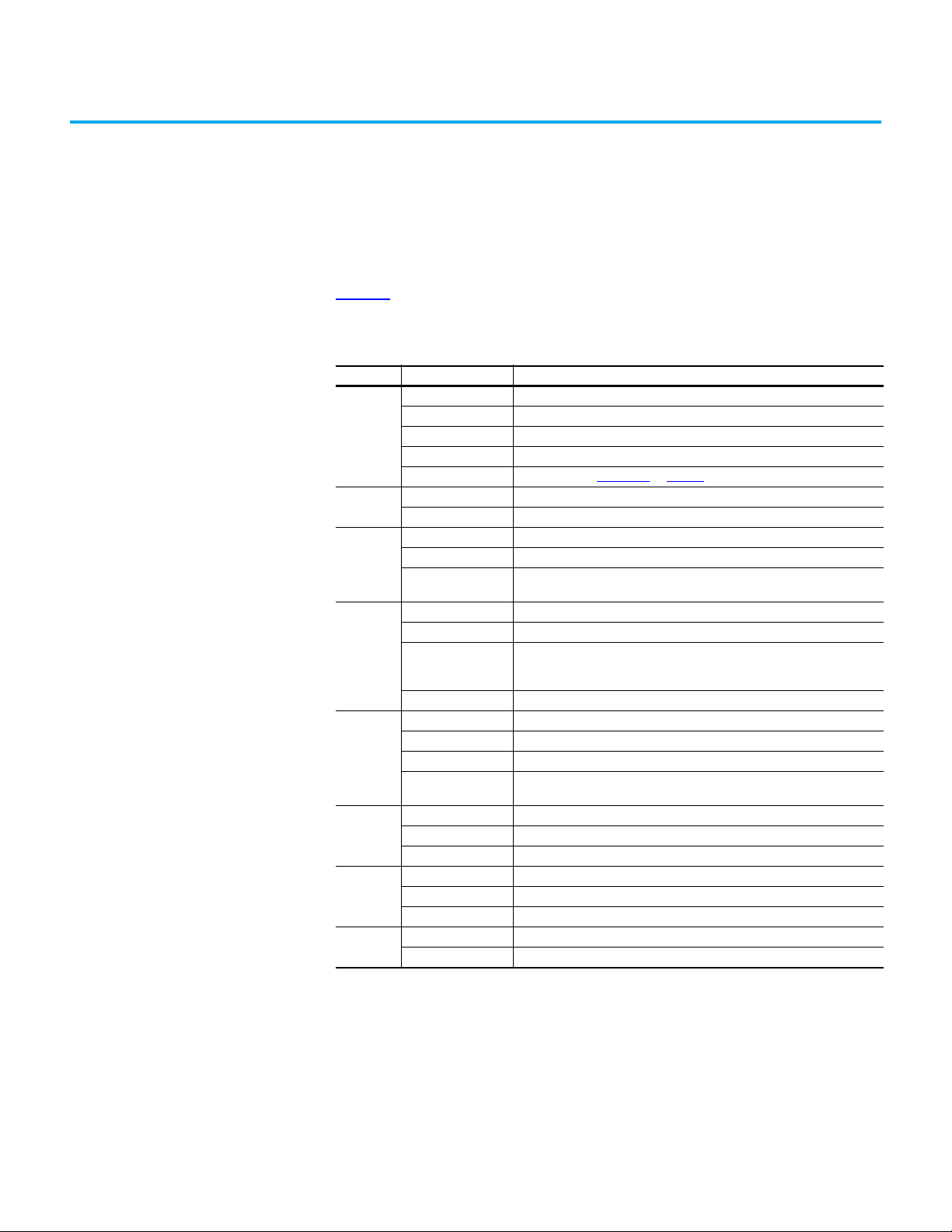

Top ic Page

Updated Catalog Number List.

Updated Guard Locking with GuardLink Systems section. 19

Updated Figure 7

Updated figure headings for Figure 21

Updated Table 19…Table 24 66…68

.

Front - User

Manual

.28

…Figure 27.39…41

Definitions

Publication AG-7.1 contains a glossary of terms and abbreviations that are used

by Rockwell Automation to describe industrial automation systems. The

following is a list of specific terms and abbreviations that are used in this

manual.

• Electrical Mechanical Safety Switch (EMSS) - A type of tap that

interfaces with safety devices that have redundant voltage-free

contacts. The tap generates pulse tests to detect short circuits to the DC

power supply, short circuits to the DC common, and shorts circuits

between the two contacts.

• GuardLink Control, Lock, and Unlock (CLU) Signal - This signal is

either static or dynamic. When static, this signal is LO when the system

is operational and HI when a demand is placed on the safety system.

The signal is dynamic when an unlock command is issued to guard

locking devices.

• GuardLink Operational State - All taps on the GuardLink circuit

indicate that their associated safety device is ready for the machine to

operate.

• GuardLink Safe State - One or more of the taps on the GuardLink

circuit indicate that their associated safety device is not ready for the

machine to operate.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 7

Page 8

• GuardLink Safety Signal - A known dynamic safety signal in

operational mode and a two-way communication signal that the DG

safety relay initiates to determine the status of the taps in the safe state.

• HI - The ON state of the output of a logic block or the state of an input

to a logic block or a voltage level to be above the turn-on threshold.

• LO - Logic state of being OFF or a voltage level to be below the turn-off

threshold.

• N/C - No connection

• N.C. (Normally Closed) - A voltage-free electrical contact whose normal

state (that is, no pressure or electrical potential applied) is in the closed

position.

• N.O. (Normally Open) - A voltage-free electrical contact whose normal

state (that is, no pressure or electrical potential applied) is in the open

position.

• Output Signal Switching Device (OSSD)- Generally a pair of solid-state

signals that are pulled up to the DC source supply. The signals are

pulse-tested for short circuits to the DC power supply, short circuits to

the DC common and shorts circuits between the two signals.

• Reaction Time - The time between the true states of one input to the

ON state of the output.

• Recovery Time - The time that is required for the input to be in the LO

state before returning to the HI state.

• Response Time - The time between the trigger of one input to the OFF

state of the output.

• Safety Function - The complete process from sensing the action (for

example, open a safety gate) to executing the final output device (for

example, turning off a pair of contactors).

• Single Wire Safety (SWS) - A unique unidirectional safety-rated signal

that is sent over one wire to indicate a safety status and command the

initiation of a safety function. The SWS can be used in Category 4,

Performance Level e, per ISO 13849-1 and safety integrity level (SIL) 3,

per IEC 62061 and IEC 61508.

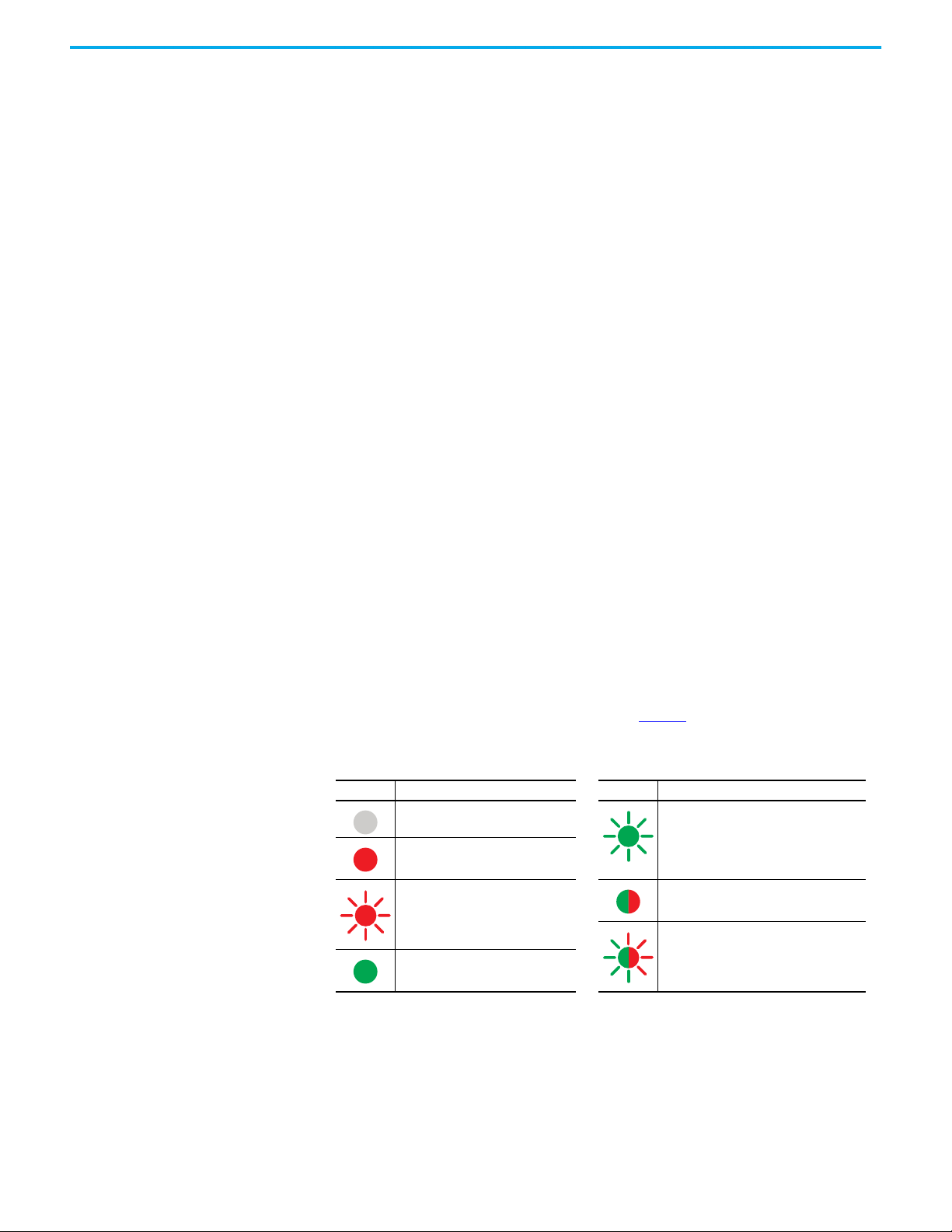

• Status Indicators - The status indicators on the front face of the DG

safety relay and the taps are bicolor. Table 1

shows how the status

indicators are used in this publication.

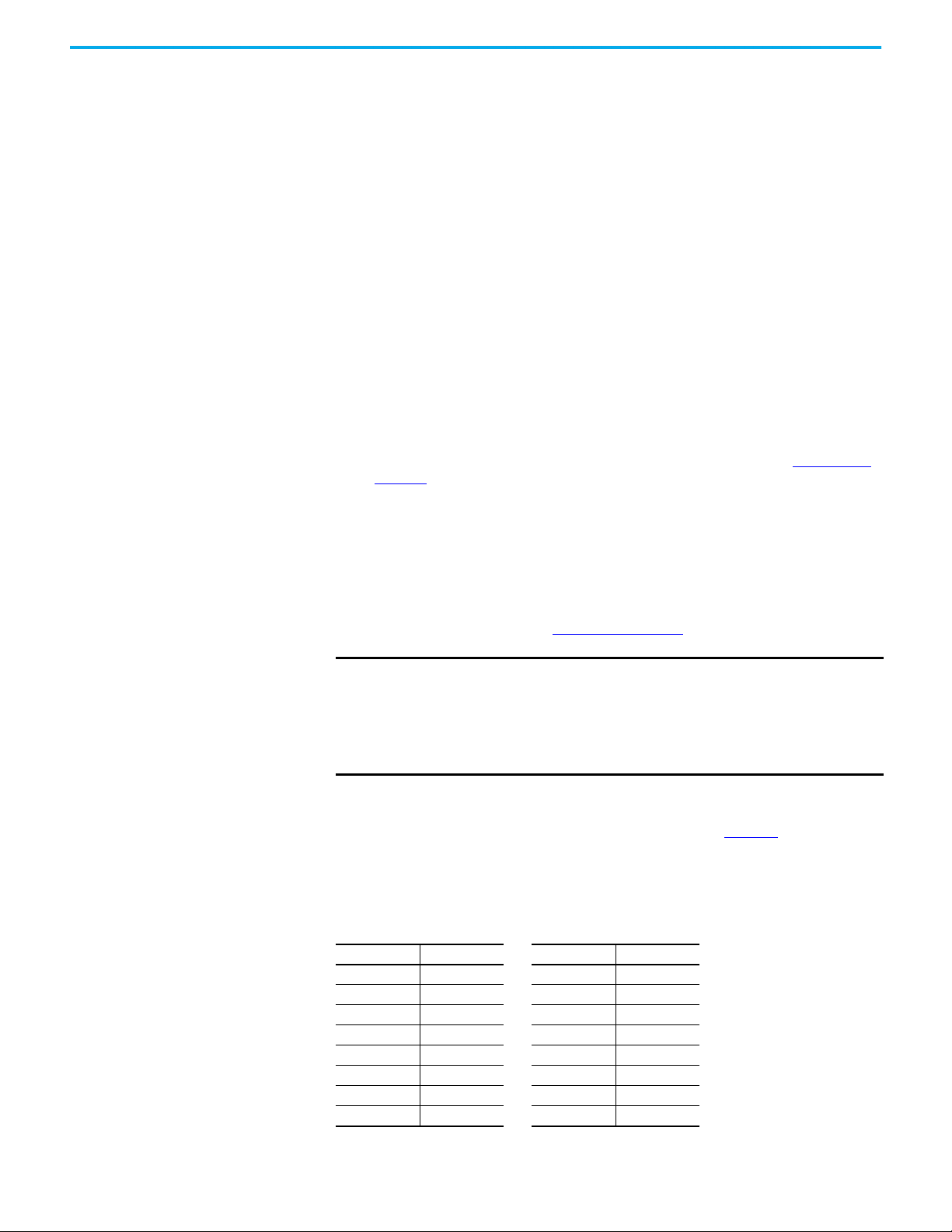

Table 1 - Status Indicator State

Symbol Description Symbol Description

Green indicator is OFF

Red indicator is OFF

Green indicator is OFF

Red indicator is ON

Green indicator is OFF

Red indicator flashes with certain

frequency

Green indicator is ON

Red indicator is OFF

• Tap - A connection in a GuardLink circuit that associates a safety device

to the GuardLink circuit.

• Voltage-free Contacts - Electrical contacts that have no voltage that is

applied to them. These contacts are typically N.O. or N.C. contacts that

change state due to a mechanical (for example, someone pressing a

push button) or electromechanical (for example, solenoid operated)

stimulus.

8 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Green indicator flashes with certain frequenc y

Red indicator is OFF

Green indicator is ON

Red indicator is ON

Green indicator flashes with certain frequenc y

Red indicator flashes with certain frequency

Page 9

Additional Resources

These documents contain additional information concerning related products

from Rockwell Automation.

Resource Description

NEMA Standard 250 and IEC 60529

Guardmaster EtherNet/IP Network Interface User

Manual, publication 440R-UM009

Industrial Automation Glossary, publication AG-7.1

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

Product Certifications website,

rok.auto/certifications.

You can view or download publications at rok.auto/literature

Provides explanations of the degrees of protection that is

provided by different types of enclosure.

A detailed description of module functionality, configuration,

installation procedure, and information on how to use the

Guardmaster® EtherNet/IP™ Network Interface (catalog

number 440R-ENETR).

A glossary of industrial automation terms and abbreviations.

Provides general guidelines for installing a Rockwell

Automation industrial system.

Provides declarations of conformity, certificates, and other

certification details.

.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 9

Page 10

Notes:

10 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 11

Overview

Chapter 1

What Is a GuardLink System?

A GuardLink® system is a collection of components to simplify a series

connection of safety devices while achieving the highest industrial safety

rating. The system has these important features:

• Simplifies the connection of series connected safety devices.

• Facilitates the scalability of the safety series connections.

• Provides diagnostic information about each device in the system without

having to run a separate status wire back to the machine control system.

• Allows the simultaneous or individual lock and unlock of guard locking

interlocks in the series connected system. No need for an additional wire

from the machine control system to lock and unlock the safety gate.

• Helps ease communication to the machine control system over

EtherNet/IP™. Communication includes sending non-safety commands

to devices and receiving status information back from the safety devices.

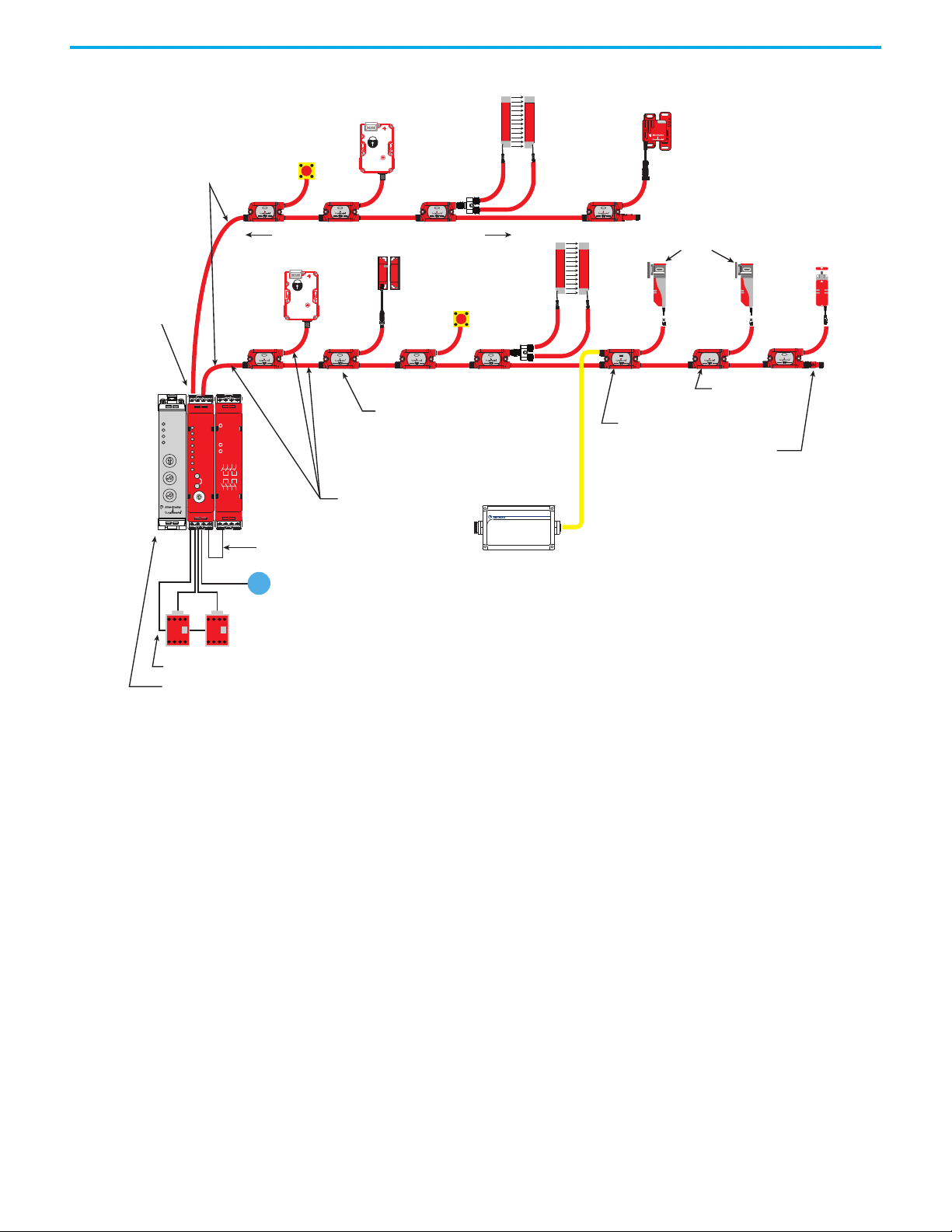

Figure 1 on page 12

GuardLink tap has M12 quick disconnect terminations to facilitate wiring with

cordsets and patchcords. The DG safety relay can accommodate one or two

GuardLink circuits or a combination of GuardLink and individual safety

devices.

Each GuardLink circuit can accommodate up to 32 taps. The DG safety relay

operates and monitors two safety contactors and has a monitored manual

reset.

shows the basic components of a typical application. The

A typical GuardLink system consists of the following:

• One DG (dual GuardLink) Guardmaster® safety relay (GSR)

• One tap for each safety device

• One terminator for each GuardLink circuit

• Patchcords and cordsets

• An optional Ethernet interface

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 11

Page 12

Chapter 1 Overview

R

INPUTPWR

INPUT

1607-XT

INPUT

INPUT INPUT INPUT INPUT

INPUTINPUT INPUT

INPUT

NS

LNK2

LNK1

MS

4

3

2

1

0

5

6

7

8

9

A2A1

LNK2

LNK1

IP: 192. 168. 1. ABC

4

3

2

1

0

5

6

7

8

9

4

3

2

1

0

5

6

7

8

9

A

B

C

33 34 43 44

A1 A2 S11 S12

PWR/Fault

Logic IN

OUT

L12 L11 X32

13 14 23 24

EM

13 14 23 24

33 34 43 44

S12 S22 S32 S42

A1 A2 S11 S21

X1 X2 X3 X4

13 14 23 24

OUT

IN 1

IN X

Reset

FB

Cong/Set

Sel./Save

DG

Reset

Time

OUT X

IN 2

PWR/Fault

0

.

2

.

4

.

6

.

8

.

1

0

.

1

2

.

1

4

.

Each DG safety relay can accommodate

up to two GuardLink circuits, each

containing up to 32 devices.

Standard Safety Devices

GuardLink

Enabled

Devices

One Terminator for

each GuardLink Circuit

Passive Power Tap

for Extra Power

Single Wire Safety for Expansion

Output Monitoring

One Optional Ethernet Module (Required for Guard Locking)

Upstream

Downstream

Cordsets and Patchcords

On-Machine™

Power Supply

One DG

Safety Relay

Passive Tap for

GuardLink Enabled

Devices

Figure 1 - Typical GuardLink System

Taps Taps create nodes in the GuardLink circuit. A safety device is connected to

each tap. The following types of taps are available:

• GuardLink enabled taps that interface with devices having voltage-free

safety contacts

• GuardLink enabled taps that interface with devices that have OSSD

signals

• Passive taps that interface with devices that are GuardLink enabled

• Passive power taps that interface with devices that are GuardLink

enabled and add power to the link

GuardLink enabled taps are available in an 8-pin and 5-pin device connection

version. Passive style taps are only available in a 5-pin device connection

version.

The taps are intended to be mounted on the machine, near the location of the

device it monitors. The different types and versions can be connected in any

order and can be mixed.

12 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 13

Chapter 1 Overview

DG Safety Relay The DG safety relay is the host of the GuardLink system. By using a sequence of

push buttons on the front face, the DG safety relay can be configured for many

types of safety applications. The DG safety relay can do the following:

• Monitor up to two GuardLink circuits, two safety devices or a

combination

• Use Single Wire Safety (SWS) input and output for expansion

• Execute Stop Categories 0 or 1 (immediate and delayed outputs)

• Monitor the status of output safety devices, like contactors

• Be configured for automatic or monitored manual reset

• Be configured to initiate a lock function for guard locking with a

GuardLink circuit

• Be configured to initiate an unlock function for guard locking with a

GuardLink circuit

Safety Device Inputs

The DG safety device inputs can be configured in one of the following

arrangements:

• One GuardLink circuit

•Two GuardLink circuits

• One GuardLink circuit and one safety device

•Two safety devices

• One safety device

The DG safety relay applies AND logic to all used inputs. Unused inputs are

ignored.

Single Wire Safety (SWS) Input

The DG safety relay then applies AND logic to the SWS input if configured for

use. The single wire safety input is ignored if not included in the

configuration.

Output Monitoring

The DG safety relay monitors the status of external safety output devices. After

all safety inputs are satisfied, the DG safety relay checks the monitoring input

terminal. If 24V is present, the DG safety relay proceeds to execute the reset

function.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 13

Page 14

Chapter 1 Overview

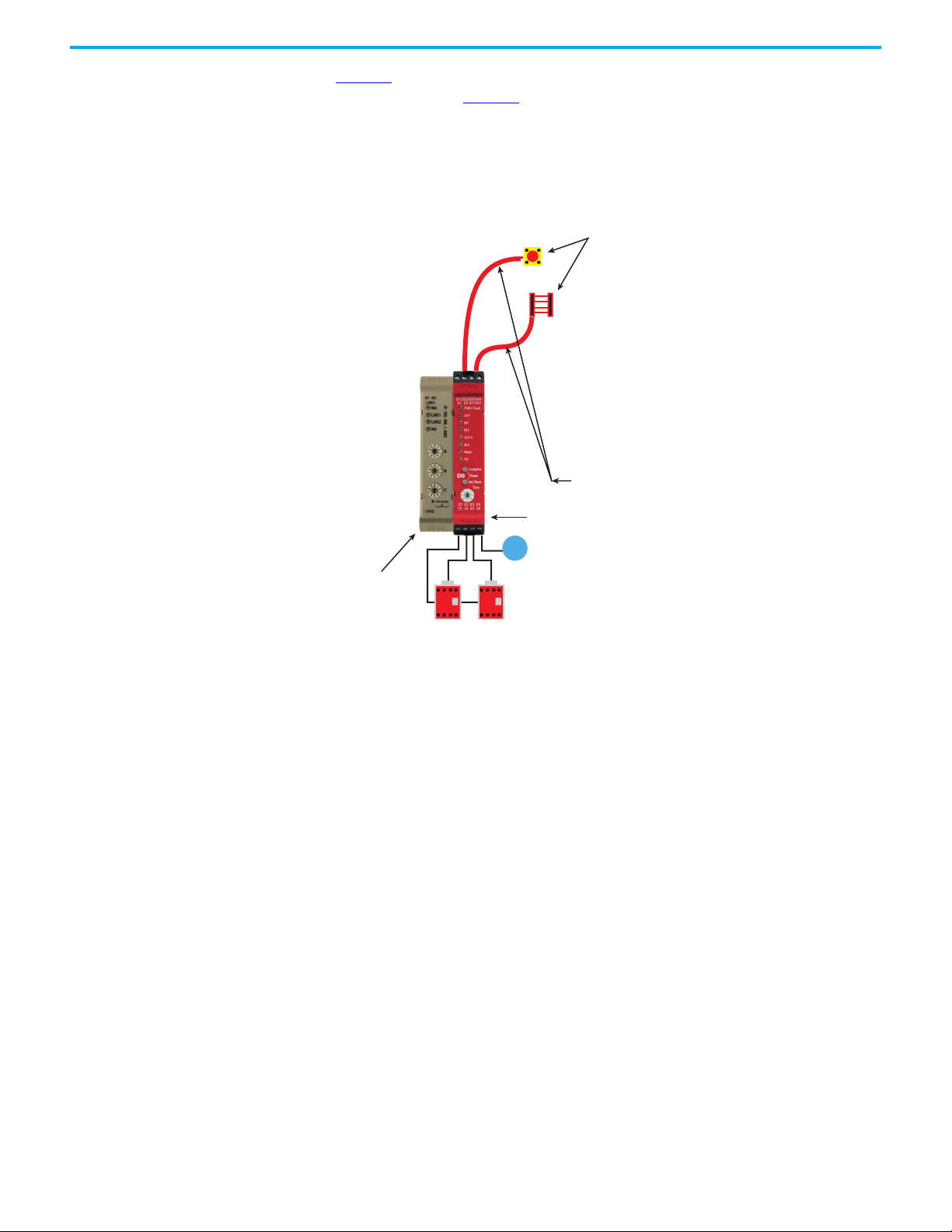

R

GuardLink circuit - one tap for each safety device

Safety device (E-stop, mechanical interlock, light curtain,

scanner, OSSD interlocks)

DG safety relay

EtherNet/IP

interface

Output

monitoring

Monitored

Manual

Reset

Reset

The DG safety relay reset function can be applied one of three ways:

• Automatic reset (no connection needed)

• Monitored manual reset by a momentary push button that is connected

to an input terminal

• With an Ethernet interface, the machine control system can initiate the

reset function.

The DG safety relay allows both an input terminal and the machine control

system to perform the monitored manual reset function. The reset signal must

transition from LO to HI and back to LO within a window of 0.25…3 seconds.

The reset occurs on the trailing edge. When using a programmable logic

controller (PLC) to generate the reset signal, use a narrower window

(0.26…2.99 s) for more reliable reset action.

ATTENTION: The reset function must not be used to start or restart the

machine.

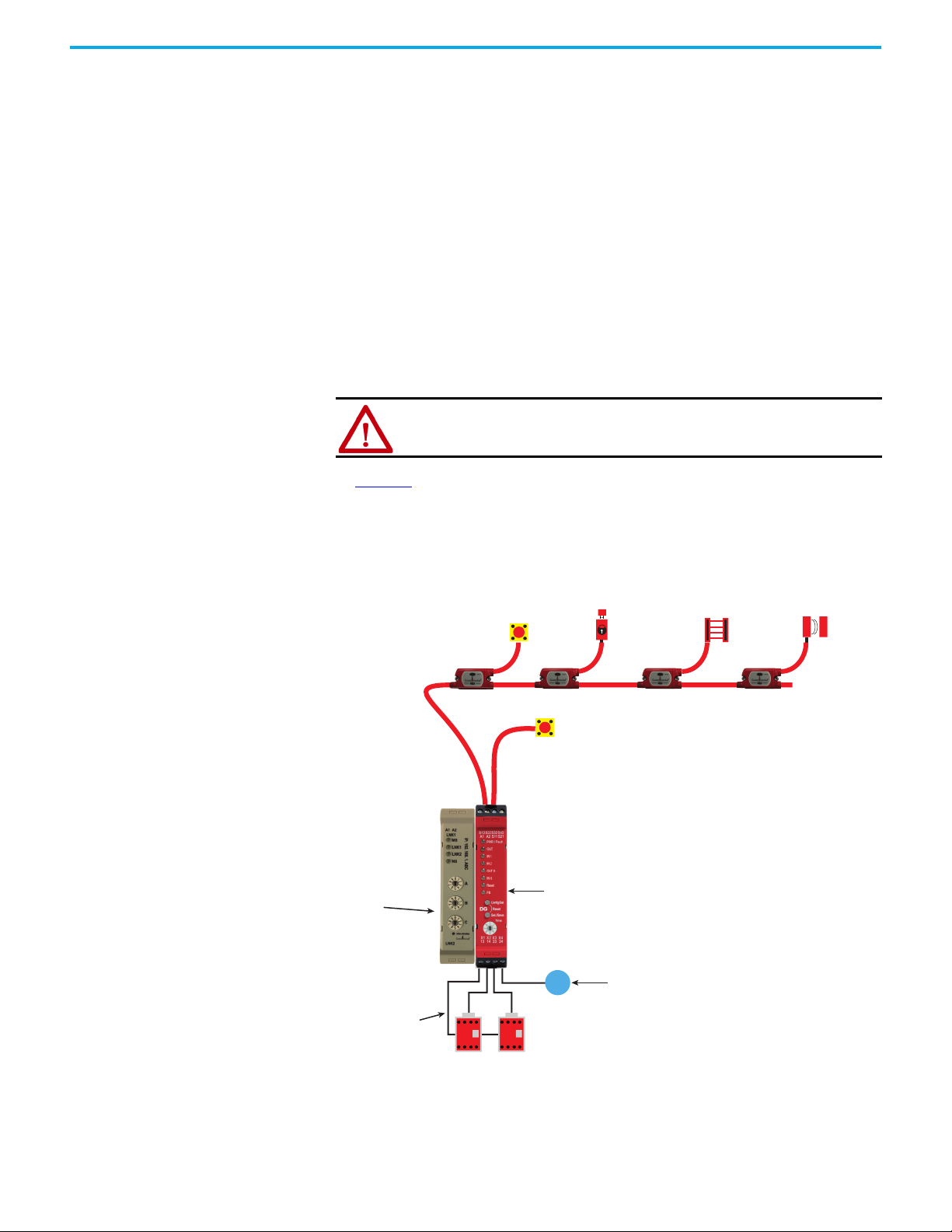

In Figure 2

device input. The EtherNet/IP interface reports status information to the

machine control system. The DG safety relay monitors the status of the two

output contactors and uses monitored manual reset to energize the

contactors.

Figure 2 - One GuardLink Circuit and One Safety Device

, the DG safety relay has one GuardLink circuit and one safety

R

14 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 15

Chapter 1 Overview

RR

DG safety relay

Two safety devices (E-stops, mechanical interlocks,

light curtains, scanners, OSSD interlocks)

Cordsets or

patchcords

Optional

EtherNet/IP

interface

Figure 3 shows an example of a DG safety relay operating as the equivalent of a

DI safety relay. In Figure 3

, the DG safety relay is configured to accept two

input devices, control and monitor two contactors with a manual reset input.

The 440R-ENETR interface reports the status to the machine control system.

The machine control system can also initiate a reset command.

Figure 3 - Two Safety Devices

GuardLink Principle of Operation

The GuardLink circuit is a continuous chain of safety devices that are

connected in series with only four wires. Two wires provide power and ground

to the taps and devices.

The third wire (GuardLink safety signal) performs the diagnostics on the taps

and the devices that are connected to each tap while in the safe state. It also

carries the dynamic safety signal while in an operational state.

The fourth wire (CLU) provides the lock/unlock commands to guard locking

devices on the circuit.

GuardLink State

The GuardLink chain can be in one of four states:

• Initialization

•Safe

•Operational

•Fault

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 15

Page 16

Chapter 1 Overview

Initialization State

The initialization state starts when power is applied to the GuardLink circuit

and ends when the GuardLink circuit enters the safe state. If no errors exist,

the GuardLink circuit transitions to the safe state; the initialization state

cannot transition to the operational state.

During initialization, the DG safety relay establishes and verifies the validity of

the circuit by checking the following items:

• All devices set their node number

• Not more than 32 devices exist

• The firmware of the taps is compatible with the DG safety relay

firmware.

• The DG safety relay detects node type and position automatically. When

a 440R-ENETR interface is used, it acquires the node types and positions

from the DG safety relay. The 440R-ENETR interface validates the correct

type and position against the setup that is provided by the Studio 5000®

Add-On-Profile (AOP). If validation is not successful, the 440R-ENETR

interface reports an error.

• Validates a terminator is attached to the GuardLink circuit.

Safe State

The GuardLink safety signal commands the DG safety relay to a safe state,

which turns all safety outputs OFF. The GuardLink safety signal monitors the

circuit for changes of state from the taps.

The CLU signal is HI (if guard locking devices are not used) or sending a

dynamic unlock signal (if guard locking devices are used). The taps indicate

this state by a steady red Link indicator.

Operational State

The GuardLink operational state is described as the GuardLink safety signal

that generates a specific dynamic signal to the DG safety relay and the CLU

signal being LO. The state of the DG safety relay safety outputs can be OFF or

ON. The state depends on the configuration, other safety device inputs, the

feedback monitoring input, and the reset input.

Fault State

The DG safety relay and the taps have two fault states: recoverable and

nonrecoverable. When a fault occurs, the taps and DG safety relay are in a safe

state. Diagnostic information is provided by the indicators. The DG safety

relay also sends diagnostic information to the EtherNet/IP interface.

Recoverable faults can be cleared by cycling the faulted input devices.

Nonrecoverable faults require the power to the cycled and can also require

troubleshooting and correction of the fault. When an EtherNet/IP interface is

used, the machine control system can issue a fault reset (equivalent to a power

cycle).

16 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 17

Chapter 1 Overview

GuardLink Transition from Safe State to Operational State

When the GuardLink signal is in the safe state, the DG safety relay holds the

CLU signal in the high or dynamic unlocking state. The DG safety relay puts all

taps in the safe state. For the GuardLink signal to return to the operational

state, the DG safety relay must know that all taps are ready to go to the

operational state. If the taps are ready to go, the CLU signal is set to LO.

Now that the CLU is set to LO, the last tap generates the safety signal. Each

successive upstream device verifies that the previous device is in a safe state,

confirms that its own device is in a safe state, and sends an inverted safe state

signal to the next device.

When the DG safety relay receives the safety signal, the GuardLink circuit is in

an operational state, and the DG safety relay continues with the evaluation of

the other inputs, output monitoring, and reset inputs.

GuardLink Transition from Operational State to Safe State

Once an input device has a demand on its safety function, the tap stops

sending the safety signal. When the DG safety relay no longer detects the

safety signal, the CLU signal is set to HI to make all taps enter the safe state.

GuardLink Fault Reset Command

Devices with OSSD outputs can sometimes go to a fault state that requires

power cycling. The Ethernet interface can be used to send a fault reset signal

from the machine control system to individual devices. This reset signal cycles

the power to the device connected to the specified tap.

OSSD Tap

The OSSD tap is designed to specifically interface with safety products that

generate OSSD outputs. The OSSD tap does not perform testing on the OSSD

signals as the input device must perform the test.

The OSSD tap is looking to see if the outputs of the connected device are

energized or de-energized. If the outputs are de-energized, then the tap goes

to a safe state, and the input indicator is red. If the outputs of the device are

energized, then the tap shows a solid or flashing green input indicator.

If the OSSD tap inputs are not the same state for three or more seconds, then

the tap enters a recoverable fault state. Both inputs must go to LO and then

back to HI to recover.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 17

Page 18

Chapter 1 Overview

EMSS Tap

The EMSS tap is designed to interface with two voltage-free contacts. The tap

applies 24V to one side of the contact on both channels and looks for the 24V on

the monitoring input. These contacts are pulse tested by the tap, see Pulse

Testing Functions on page 57 for pulse details.

The tap is looking to see if both contacts are closed or open. When the contacts

open, the tap goes to a safe state, and the input indicator is red. When the

contacts close, the tap goes to an operational state, which turns the input

indicator either solid or flashing green.

The EMSS tap has a 10 second simultaneity window. If one contact opens, the

second contact must open within 10 seconds. Similarly, if one contact closes,

the second contact must close within 10 seconds. If the simultaneity window

requirement is not met, the tap goes to a recoverable fault state. To recover,

both contacts must be cycled open and then closed again within 10 seconds.

Passive Tap

The passive tap is designed to interface with safety rated devices that have

built-in GuardLink technology. The passive tap simply passes the GuardLink

signals to and from the device. The passive tap does not operate with safety

devices that have OSSD or EMSS outputs.

Passive Power Tap

The passive power tap has two significant features:

• The passive power tap acts as a passive tap by passing the GuardLink

signals directly to devices with built-in GuardLink technology, and

• The passive power tap allows additional power to be introduced into the

GuardLink circuit to compensate for voltage drops resulting from long

cable lengths and numerous devices in the circuit.

18 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 19

Chapter 1 Overview

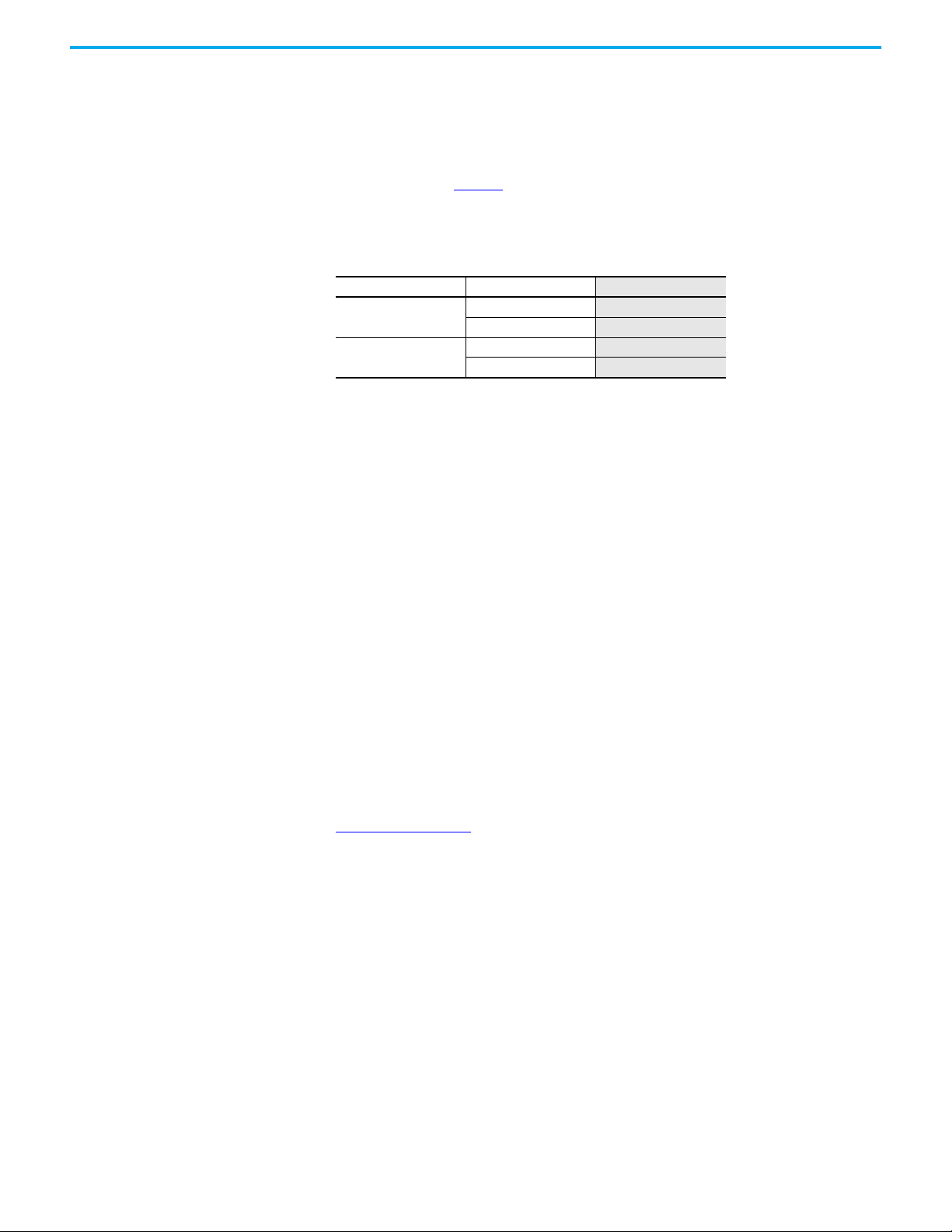

Guard Locking with GuardLink Systems

Both Power to Release and Power to Lock guard locking devices can be

connected to GuardLink taps. Power to Release switches must be connected to

Power to Release taps, and Power to Lock switches must be connected to Power

to Lock taps (see Table 2

440R-ENETR interface must be used. The lock and unlock commands can only

be issued to the guard locking devices through the 440R-ENETR interface.

Table 2 - Guard Locking Taps

Locking Operation Switch Outputs Tap

Power to Release

Power to Lock

When a GuardLink circuit has both Power to Release and Power to Lock

devices, a lock command that is sent to all devices causes both PTR and PTL

devices to a locked state. An unlock command sent to all devices causes both

PTR and PTL devices to an unlocked state.

). When guard locking devices are connected, a

EMSS contacts 440S-MF8D

OSSD

EMSS contacts

OSSD 440S-SLF8D

440S-SF8D

440S-MLF8D

When an unlock request is issued, the DG safety relay turns off OUT X

(terminal X2) immediately and starts the off-delay timer. When the off-delay

timer expires, the DG safety relay issues an unlock command to the GuardLink

circuit and turns off its safety outputs (terminals 13/14 and 23/24).

When multiple guard locking devices are installed on a GuardLink system, the

DG safety relay inserts a short delay between commands to each successive

device to minimize the momentary inrush current to the solenoids. The device

closest to the DG safety relay receives the command first. The device furthest

away from the DG safety relay receives the command last.

The delay between commands is between 135…300 ms. When a few guard

locking devices are used, the delay is 135 ms. As more guard locking devices are

included in the circuit, the delay increases. When 32 guard locking devices are

used, the delay can be up to 300 ms between each device.

Figure 4 on page 20

shows an example timing diagram. The delay switch is set

to position 5 (1 second delay). The first guard unlocking command starts at

1000 ms. The second unlock signal occurs at 1135 ms. The third unlock signal

occurs at 1270 ms. If 32 guard locking devices are installed, the last one receives

the unlock command at 10,600 ms.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 19

Page 20

Chapter 1 Overview

1270 1405 1540 10,600113510000

1

2

3

4

5

32

Unlock Commands to

Guard Locking Devices

Time [ms]

Unlock Request

OUT X (X2)

OUT (13/14, 23/24)

Figure 4 - Unlock Command Timing Diagram

Guard Locking Application Example

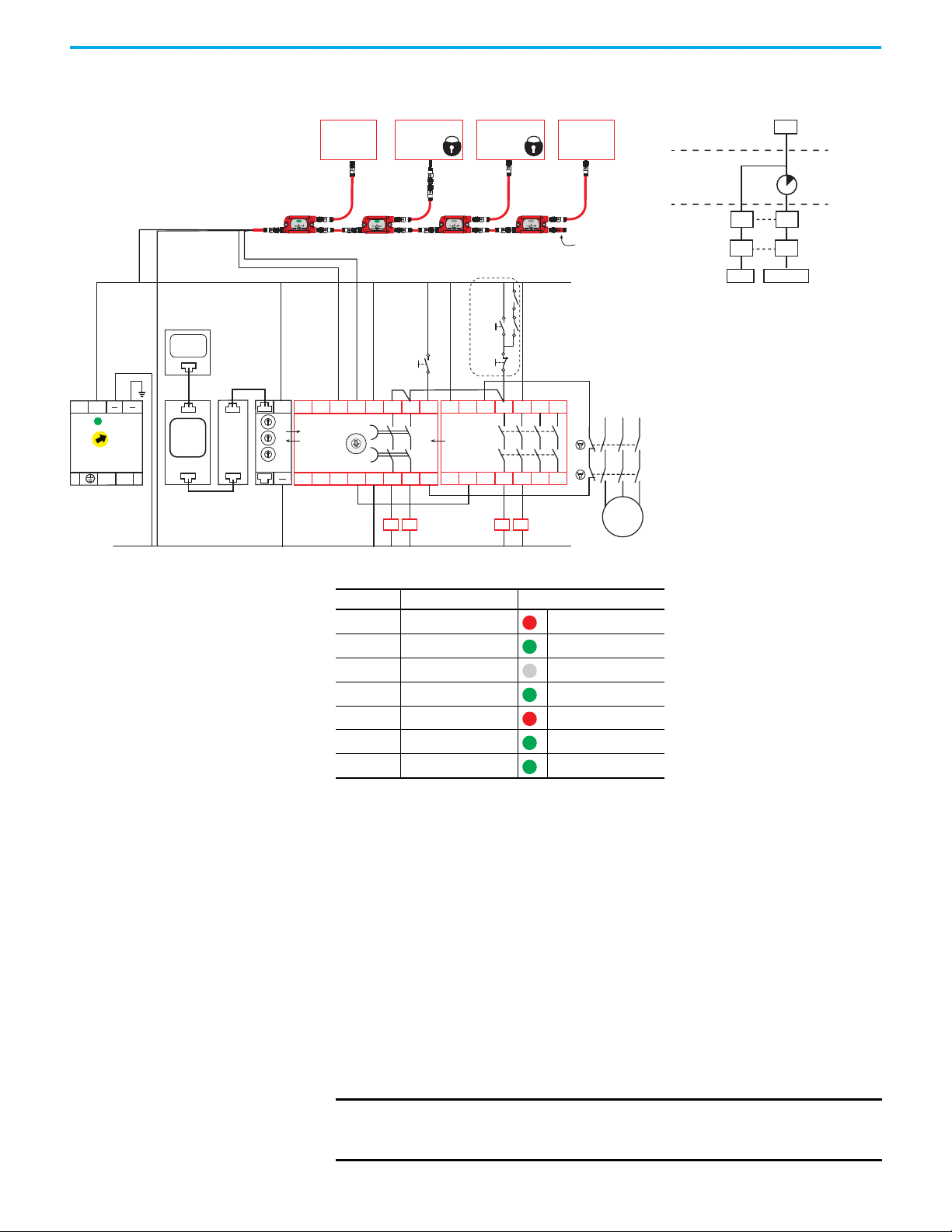

Figure 5 on page 21 shows a typical guard locking application example. The DG

safety relay has four taps on the GuardLink circuit:

• First tap — SensaGuard™ integrated-latch interlock switch

• Second tap — 440G-LZ guard locking interlock switch

• Third tap — TLS –ZR guard locking switch

• Fourth tap — SensaGuard flat pack interlock switch

The TIME switch on the DG safety relay is set to position 9, which provides a

5 second delay to allow the motor to coast to a full stop.

The SensaGuard switches allow immediate access to the machine. Additional

risk reduction measures must be provided to help prevent access to the

hazards during the timing period.

Because guard locking is used, a 440R-ENETR interface must be included in

the application. An HMI and PLC initiate the unlock and lock control

commands. The PLC sends the command to the 440R-ENETR interface. Over

the optical bus, the 440R-ENETR interface instructs the DG safety relay to

generate the unlock and lock commands through the GuardLink circuit. The

DG and EM safety relays report status information over the optical bus back to

the PLC through the 440R-ENETR interface.

20 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 21

Figure 5 - Guard Locking Application Example Schematic and Logic

A1

L12

X32

L11 34

13 23 33 43

4414 24A2

EM

440R-EM4R2

0

.

2

.

4

.

6

.

8

.

1

0

.

1

2

.

1

4

.

9

INPUT

+24V DC

Ethernet

Host PC

Ethernet

24V DC Com

Reset

Stop

Start

Feedback

100S

Contactors

Immediate

Acting

Loads

A1

S32 14S42

13 23

24

S11 S12S21 S22

X2

X3

X4

X1

A2

DG

440R-DG2R2T

OUT X

SWS

PLCHMI

L1

L2 L3

M

K1

K2

+

440R-ENETR

A

B

C

TIME

440N-Z21SS3PH

SensaGuard

Interlock

898D-418U-DM2

Terminator

440N-Z21SS2JN9

SensaGuard

Interlock

INPUT INPUT

440G-LZS21SPRH

Guard Locking

Safety Switch

INPUT

440S-SF8D 440S-SF8D

440S-SF8D

440G-TZS21UPRH

Guard Locking

Safety Switch

L

++

N

1606-XLP95E

2428V

DC ok

K2

K1

440S-SF5D

K1 K2

Status Status

Control

Schematic Logic

SMF Level

LOGIC Level

SOF Level

Chapter 1 Overview

IN 1

RR

FBFB

OUT X OUT 14/24

Table 3 - Guard Locking Application Example Configuration

Indicator Function Configuration ID: 0x6A

OUT Safety Functions IN1

IN 1 Input Type GuardLink

IN 2 Input Type Not used

OUT X Output Type SWS

IN X Input Mode SWS Disabled

Reset Reset Type Monitored Manual

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 21

FB Reset Assignment SOF

• Circuit Status

The gates that the SensaGuard interlock switches monitor are closed.

The guard locking switches are closed and locked. The DG and EM safety

relays are OFF and ready for reset.

•Starting

Press the Reset button to energize the DG and EM safety relays. Their

output contacts close. Press the Start button to start the motor via

contactors K1 and K2 and energize the two immediate acting loads.

controlled system to start or restart the hazards after the safety system

is reset.

•Stopping

Press the Stop button to turn off the motor and immediate acting loads.

The immediate acting loads and contactors K1 and K2 de-energize

immediately, and the motor coasts to a stop. This action does not unlock

the guard locking switches.

IMPORTANT The Start/Stop circuit can be replaced by an equivalent machine

Page 22

Chapter 1 Overview

• SensaGuard Switches

Opening either SensaGuard interlock turns off the DG and EM safety

relays. The EM safety relay turns off K1 and K2 immediately, and the

motor coasts to a stop. With the Time switch on the DG safety relay set to

9, the 13/14 and 23/24 outputs on the DG safety relay turn off after

5 seconds. This action does not unlock the guard locking switches.

• Unlock the Guard Locking Switches

Use the HMI to unlock the guard locking switches. The EM safety relay

turns off K1 and K2 immediately, and the motor coasts to a stop. After

5 seconds, both the 13/14 and 23/24 outputs of the DG safety relay turn off

the immediate acting loads and the guard locking switches are unlocked.

IMPORTANT The outputs of the DG safety relay (13/14 and 23/24) turn off and the

unlock command occurs after the time delay expires. The immediate

acting loads must remove the hazards that they control quickly before

you can open the gate and reach the hazard.

•Restart

Close the safety gates. If the gates were unlocked, use the HMI to initiate

a lock command. Both gates are locked and the GuardLink circuit is

satisfied. Press the Reset button. Press the Start button to energize the

immediate acting loads and turn on the motor.

22 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 23

Chapter 2

GuardLink System Design

Design Considerations The design of a GuardLink® circuit requires knowledge of the power

requirements of the input devices and the length of the link cables. A voltage

drop occurs across each tap. The cumulative voltage drop determines the

number of taps that can be included in the circuit.

The GuardLink system makes it easy to monitor multiple devices over long

distances when multiple access points to the hazardous area are required.

The DG safety relay monitors the GuardLink system. The GuardLink system

can provide diagnostic information on each access point back to the machine

control system.

The GuardLink system must be designed considering these factors:

• Voltage available at each node

• Current flowing through each node

• Cable lengths

•Wire size

• Power requirements for each tap

• Safety device power requirements

The GuardLink system is designed to operate on a 24V DC system. The

maximum continuous current on the link circuit must not exceed 4 A; the taps

and link cables are rated for 4 A continuous.

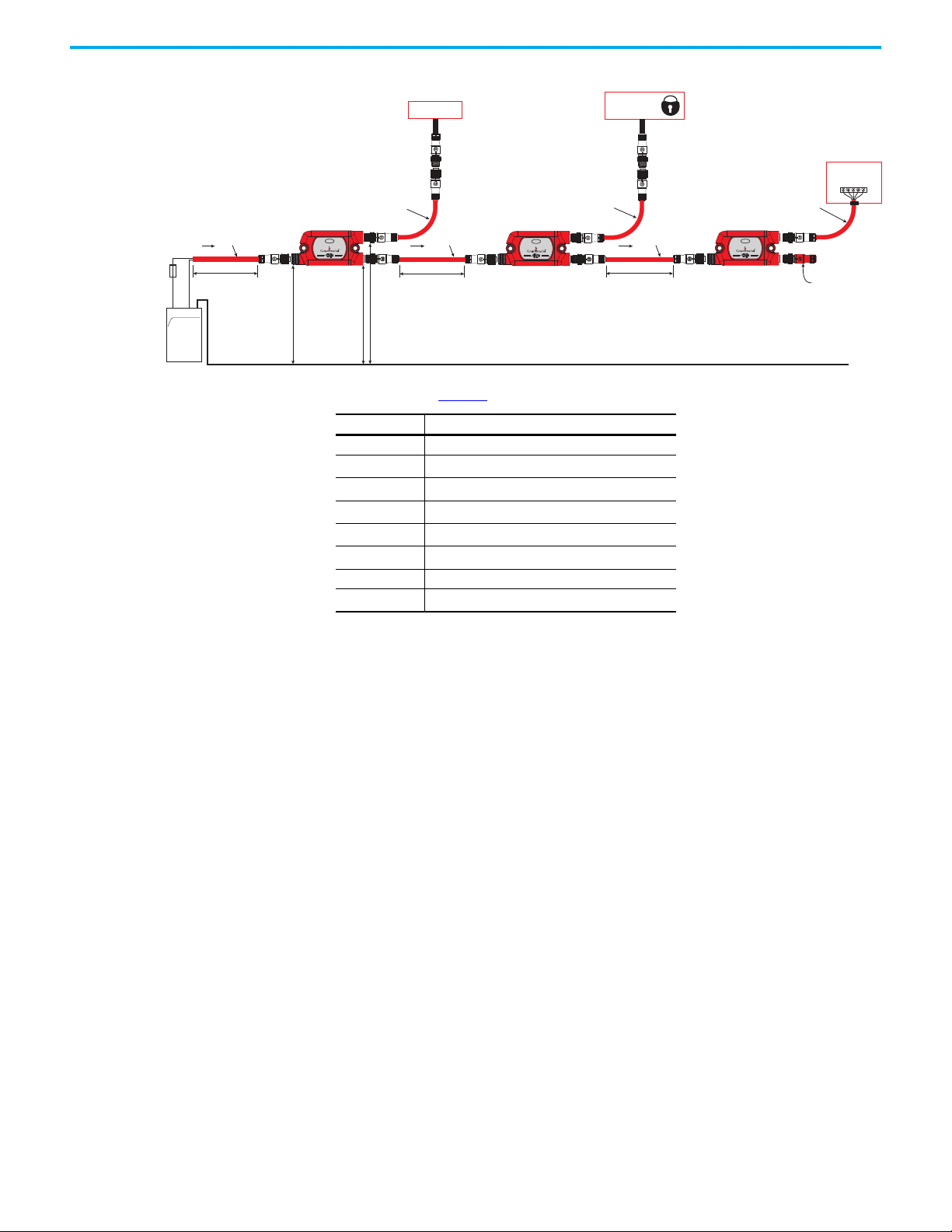

Figure 6 on page 24

and safety signals are sourced to connection J1. J2 is connected to downstream

taps. J3 of each tap is connected to a safety device.

identifies three tap connections: T1, T2, and T3. The voltage

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 23

Page 24

Chapter 2 GuardLink System Design

R

1

I

+ + - Vs=24V

Power

Supply

1

Link Cable

L

1

Fuse

4 A

SLO-BLO™

Figure 6 - Tap Connections

Safety Device 2

Device Cable

J3

J2

D2

Safety Device 3

D3

Device Cable

J3

J2

T3

Terminator

I

3

Link Cable

L

R

3

3

J1

Safety Device 1

D1

Device Cable

J3

INPUT INPUT

J1

V

J1

J2

T1

VJ2V

J3

I

2

Link Cable

L

2

R

2

INPUT

J1

T2

Table 4 - Key for Figure 6

Item Description

D1, D2, D3 Safety devices

, I2, I

I

1

I

, IT2, I

T1

I

, ID2, I

D1

L

, L2, L

1

R

, R2, R

1

T1, T2, T3 Taps

VJ1, VJ2, V

Current in the link cable (A)

3

Current required by a tap (A)

T3

Current required by a safety device (A)

1D3

Length of link cable (m)

3

Resistance of wire (Ω)

3

Voltage at tap connector (V)

J3

System Current Calculation The GuardLink circuit current must be calculated to determine whether a

significant voltage drop occurs to a safety device.

The total system current, I

plus the current required by the device that is connected to the first tap plus

the current required by the downstream circuit. The total system current must

not exceed 4 A, continuous.

I

= IT1 + ID1 + I2

1

The current in each segment of the GuardLink circuit is calculated in a similar

fashion.

I

= IT2 +ID2 + I

2

I3 = IT3 + I

D3

The total system current, I1, is therefore the sum of the device currents plus the

sum of the tap currents.

I

= ∑ IT + ∑ I

1

D

, is the sum of the current required by the first tap

1

3

24 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 25

Chapter 2 GuardLink System Design

Voltage Drop Consideration With the potential of using up to 32 taps and long cable lengths between taps,

the voltage available to the safety devices at connector J3 must be calculated.

The voltage available to the safety device has two components:

• The voltage drop due to the wire resistance of the cables

• The voltage drop within the tap

The resistance of the recommended 18 AWG cordsets and patchcords is

(0.02095 ohms/m (0.00664 ohms/ft). The wire resistance of the cordset from

the power supply to tap 1 (R

R

= 0.02095 * L

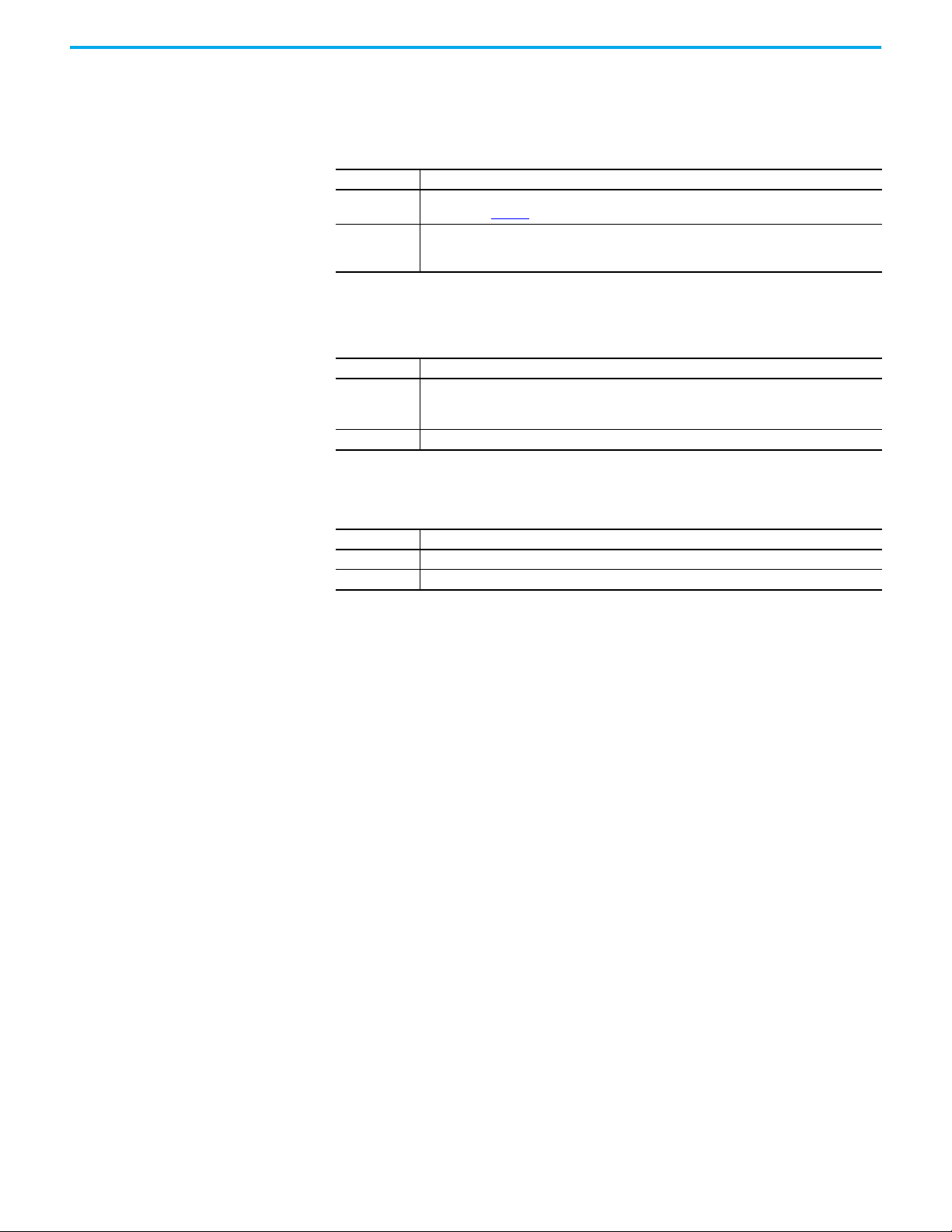

1

1

The wire resistance must be considered for both the power and ground;

therefore the voltage drop is multiplied by two. The voltage at connector J1 of

tap T1 (V

) is:

J1

V

= 2 * I1 * R

J1

1

) is:

1

The tap has a small voltage from connector J1 to J2. The typical voltage at

connector J2 (V

V

= VJ1 - (2 * 0.028V)

J2

) drop through the tap from J1 to J2 is:

J2

The voltage available at connector J3 is dependent on the device that is

connected to J3. The typical voltage drop from J1 to J3 is 0.4V when the device

uses 50 mA.

V

= VJ1 - 0.4V (typical)

J3

IMPORTANT

The voltage drop from J1 to J3 can be as high as 1.2V with a maximum

load of 500 mA at the highest rated ambient temperature.

The TLS-ZR guard locking switch voltage drop is 0.29V when locked and

0.31V when unlocked.

The taps consume 25 mA when OFF. The EMSS taps consume an additional

15 mA (7.5 mA per channel) when the contacts are closed. The OSSD taps

consume an additional 6 mA (3 mA per channel), when the outputs are ON.

A spreadsheet can be used to calculate the voltage available to the safety device.

Table 5 on page 26

shows the voltage available to the safety device of a number

of different devices. Assuming that the power supply voltage is set to 24V, and

the cable is the recommended 18 AWG, the voltage available to the safety

devices is shown in the right-hand column.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 25

Page 26

Chapter 2 GuardLink System Design

When guard locking devices are used in the circuit, the taps and wiring

components are subjected to momentary surges in current. With the

sequential operation of the lock/unlock command, the momentary surges

should not adversely affect the performance of the GuardLink circuit.

The operating voltage specification of the tap is 20.4…26.4V. In the example

that is shown in Table 5

, the voltage at J1 of tap 6 has fallen below the lowest

supply voltage specification of 20.4V DC. This system is not feasible, and

remedial action must be taken (see Table 6

).

IMPORTANT

Table 5 assumes the following:

•Supply voltage = 24V

• Link cable wire gauge = 18 AWG

• Link wire resistance = 0.02095 ohms/m

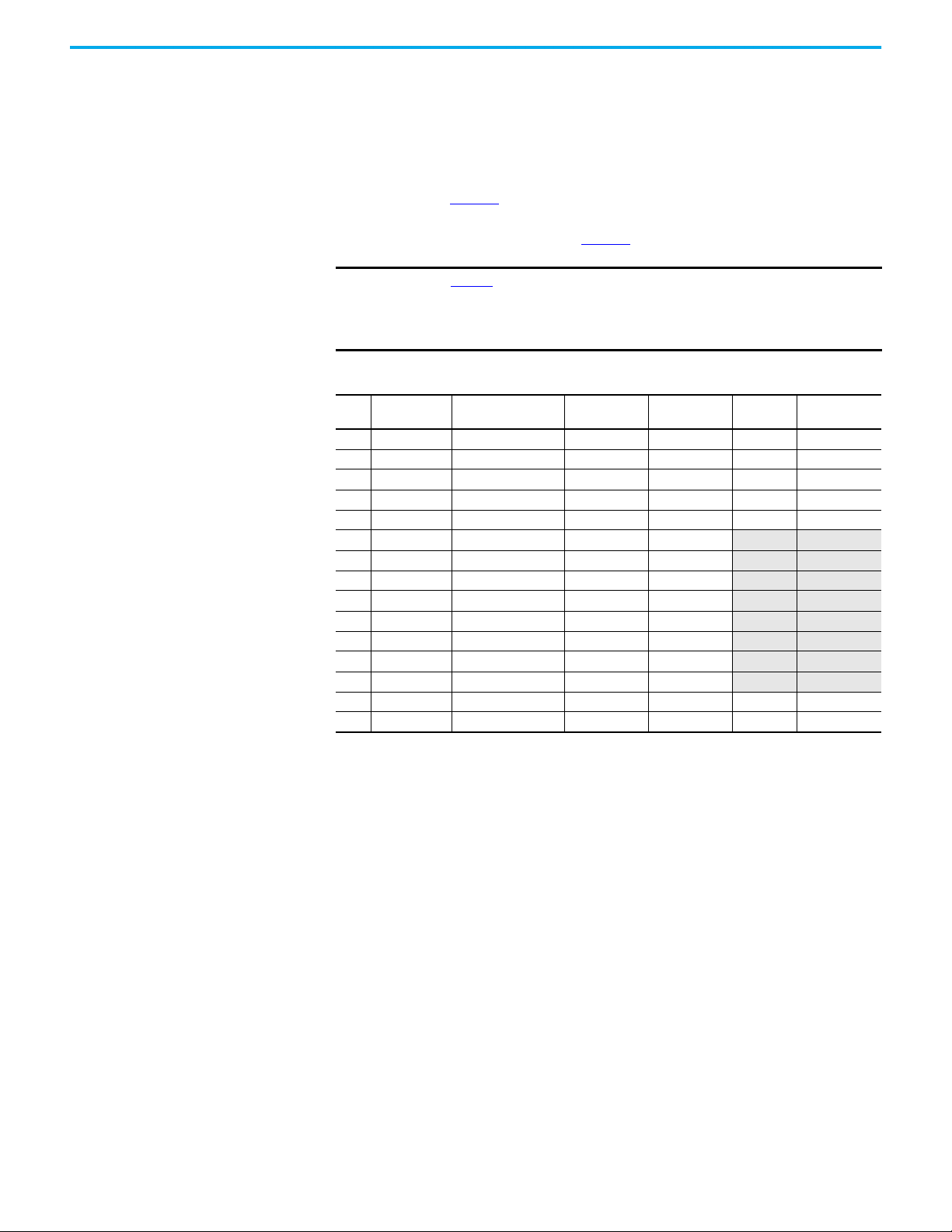

Table 5 - Voltage Calculation at 24V Supply

Cable Length

Tap

[m (ft)]

1 15 (49.2) SensaGuard™ Ser A 81 1105 23.24 22.84

2 15 (49.2) SensaGuard Ser A 81 1024 22.54 22.14

3 15 (49.2) Lite Lock 440G-LZ 135 943 21.90 21.50

4 15 (49.2) 800F E-stop 40 808 21.34 20.94

5 15 (49.2) Lifeline™ 4 40 768 20.82 20.42

6 15 (49.2) LifeLine 5 81 728

7 15 (49.2) TLSZR-GD2 PLe 135 647

8 15 (49.2) TLSZR-GD2 PLe 135 512

9 15 (49.2) Lite Lock 440G-LZ 135 377 19.27 18.87

10 15 (49.2) SensaGuard Ser A 81 242

11 15 (49.2) SensaGuard Ser A 81 161

12 15 (49.2) Mechanical Switch 40 80 18.94 18.54

13 15 (49.2) Mechanical Switch 40 40

14 0 (0) — 0 0 — —

15 0 (0) — 0 0 — —

Safety Device

Tap + Device

Current (mA)

Total Current

(mA)

J1 Voltage

(V)

20.32 19.92

19.88 19.48

19.53 19.13

19.10 18.70

18.99 18.59

18.91 18.51

Typical (V)

J3 Voltage

26 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 27

Chapter 2 GuardLink System Design

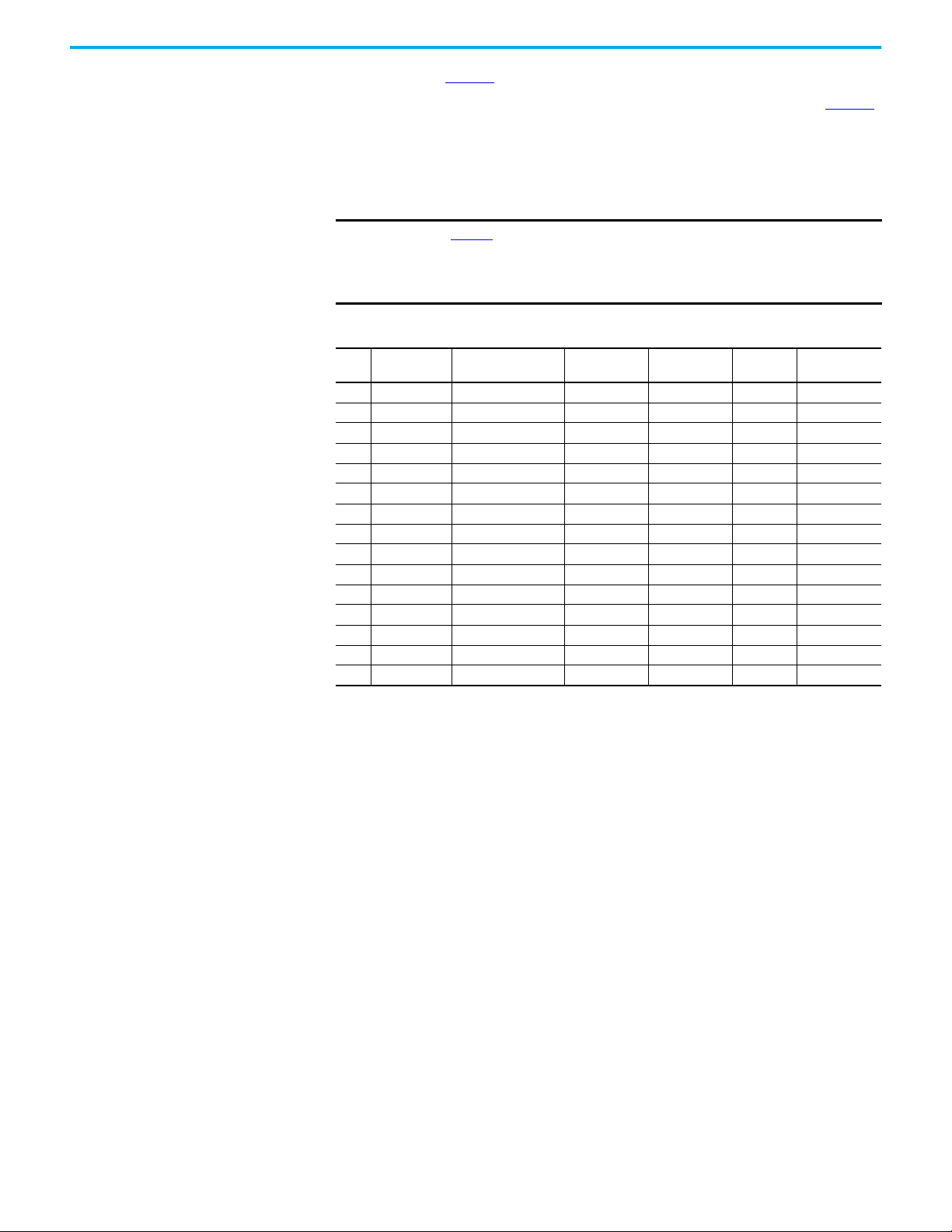

The example in Table 5, can be corrected in one of two ways:

• The supply voltage can be increased from 24V to 26V as shown in Table 6

Now, all 13 taps meet the minimum voltage specification of 20.4V at

connector J1.

• Where voltage drops below 20.4V DC on the link, a passive power tap

(440S-PF5D4) can be added to bring voltage on the link back to within

necessary specification.

.

IMPORTANT

Table 6 assumes the following:

•Supply voltage = 26V

• Link cable wire gauge = 18 AWG

• Link wire resistance = 0.02095 ohms/m

Table 6 - Voltage Calculation at 26V Supply

Cable Length

Tap

[m (ft)]

1 15 (49.2) SensaGuard Ser A 81 1105 25.24 25.84

2 15 (49.2) SensaGuard Ser A 81 1024 24.54 24.14

3 15 (49.2) Lite Lock 440G-LZ 135 943 23.90 23.50

4 15 (49.2) 800F E-stop 40 808 23.34 23.94

5 15 (49.2) LifeLine 4 40 768 22.82 22.42

6 15 (49.2) LifeLine 5 81 728 22.32 21.92

7 15 (49.2) TLSZR-GD2 PLe 135 647 21.88 21.48

8 15 (49.2) TLSZR-GD2 PLe 135 512 21.53 21.13

9 15 (49.2) Lite Lock 440G-LZ 135 377 21.27 20.87

10 15 (49.2) SensaGuard Ser A 81 242 21.10 20.70

11 15 (49.2) SensaGuard Ser A 81 161 20.99 20.59

12 15 (49.2) Mechanical Switch 40 80 20.90 20.54

13 15 (49.2) Mechanical Switch 40 40 20.91 20.51

14 0 (0) — 0 0 — —

15 0 (0) — 0 0 — —

Safety Device

Tap + Device

Current (mA)

Total Current

(mA)

J1 Voltage

(V)

J3 Voltage

Typical (V)

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 27

Page 28

Chapter 2 GuardLink System Design

889D-F5NCDM-x

5wire Patchcord or

889D-F8NBDM-x

8wire Patchcord

10 m (32.8 ft) length, max

889D-F4NE-x

4-wire Cordset

30 m (98.4 ft) length, max

889D-F4NEDM-x

4wire Patchcord

5 m (16.4 ft) length, max

889D-418U-DM2

Ter min at or

Standard Safety

Device

Standard

Safety Device

DG

Safety

Relay

White

Black Brown Blue

24V

Power

Supply

GuardLink Enabled

Safety Device

889D-M5NC-x

5wire Cordset or

889D-M8NB-x

8wire Cordset

10 m (32.8 ft) length, max

889D-F5NCDM-x

5wire Patchcord

10 m (32.8 ft) length, max

889D-F4NEDM-x

4wire Patchcord

25 m (82 ft) length, max

30 m (98.4 ft) length, max

between GuardLink enabled taps

GuardLink Enabled Tap Passive Tap GuardLink Enabled Tap

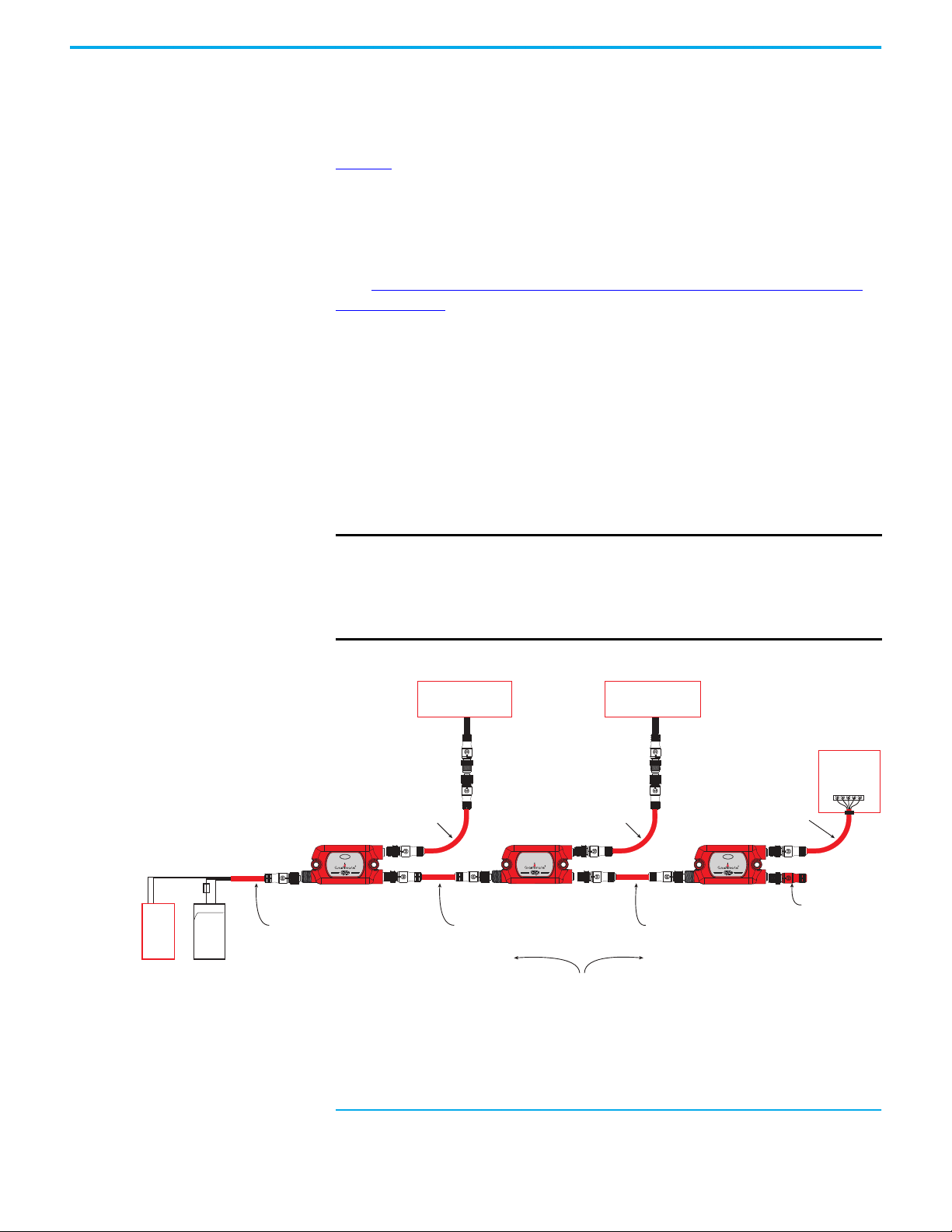

Tap Cabling The GuardLink system was designed with the intent to minimize wiring by

using quick-disconnect patchcords, while also allowing some manual wiring to

terminals, when pinout incompatibilities exist.

Figure 7

shows the recommended cable options for the various stages of a

GuardLink system (to show the cable options only two taps are required, a full

system has 32 taps). These cables are red-colored, PVC, unshielded, with epoxycoated hardware. Although any color jacket can be used, the red color is

preferred to indicate a safety circuit.

Visit ab.rockwellautomation.com/Connection-Devices/DC-Micro-Cordsets-

and-Patchcords for other options, like right-angle connectors, stainless steel

couplings, and shielded cables.

To maintain the safety integrity of the GuardLink signal, the wiring distance

between GuardLink enabled taps is limited to 30 m (98.4 ft) and requires

18 AWG (0.82 mm) wire. If the distance between devices is greater than

30 m (98.4 ft), then a GuardLink enabled tap must be inserted at least every

30 m (98.4 ft). A field-attachable quick-disconnect can be wired as a shorting

plug for the device connection. The wiring distance between taps and the

safety device is limited to 10 m (32.8 ft), and requires at least 24 AWG (0.2 mm)

wire size.

IMPORTANT

The max distance between GuardLink enabled taps is 30 m (98.4 ft).

A passive tap with a shorting plug in the device input port does not

count as a GuardLink enabled tap.

To maintain integrity of the GuardLink safety signal, a GuardLink

enabled tap must be replicated at least every 30 m (98.4 ft).

+ + - -

Figure 7 - Recommended Cable Options

(a)

INPUT INPUT

INPUT

28 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

(a) Replace the x with 0M3 (0.3 m [0.984 ft]), 0M6 (0.6 m [1.968 ft]), 1 (1 m [3.28 ft]), 2 (2 m

[6.56 ft]), 5 (5 m [16.4 ft]), 10 (10 m [32.8 ft]), 15 (15 m [9.2 ft]), 20 (20 m [65.6 ft]), or 30 (30 m

[98.4 ft]) for standard cable lengths.

Page 29

Chapter 2 GuardLink System Design

Ter mi nat or The terminator (Figure 8), must be installed on the J2 connector of the last tap

to complete the link connection. The terminator contains internal electrical

components specifically for a GuardLink system; other terminators cannot be

used as substitutes.

To help troubleshoot a GuardLink system, reduce the number of taps in the

GuardLink circuit by relocating the terminator. After relocation, cycle power to the

DG safety relay to allow the DG safety relay to relearn how many taps are

connected. If the 440R-ENETR interface is used, then it must also be power cycled,

and its AOP must be updated.

Figure 8 - Terminator — Catalog Number 898D-418U-DM2

Tap Replacement A GuardLink tap can be replaced with the same type of tap while the link is

powered. When the connections are remade; the GuardLink circuit recovers

automatically.

When a GuardLink tap is replaced with another type of tap, removed from the

circuit, or added to the circuit; cycle power to the DG safety relay to allow the

DG safety relay to relearn how many and what types of taps are connected. If

the 440R-ENETR interface is used, then it must also be power cycled, and its

AOP must be updated.

Response Time The GuardLink circuit has a fast response time. When a safety device opens,

the tap responds within 5 ms. The GuardLink safety signal then travels

upstream to the DG safety relay, which takes an additional 35 µs through each

upstream tap.

Figure 9 on page 30

In this example, a SensaGuard™ rectangular flat pack interlock, which is

connected to Tap 4, opens.

shows an example GuardLink safety circuit with six taps.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 29

Page 30

Chapter 2 GuardLink System Design

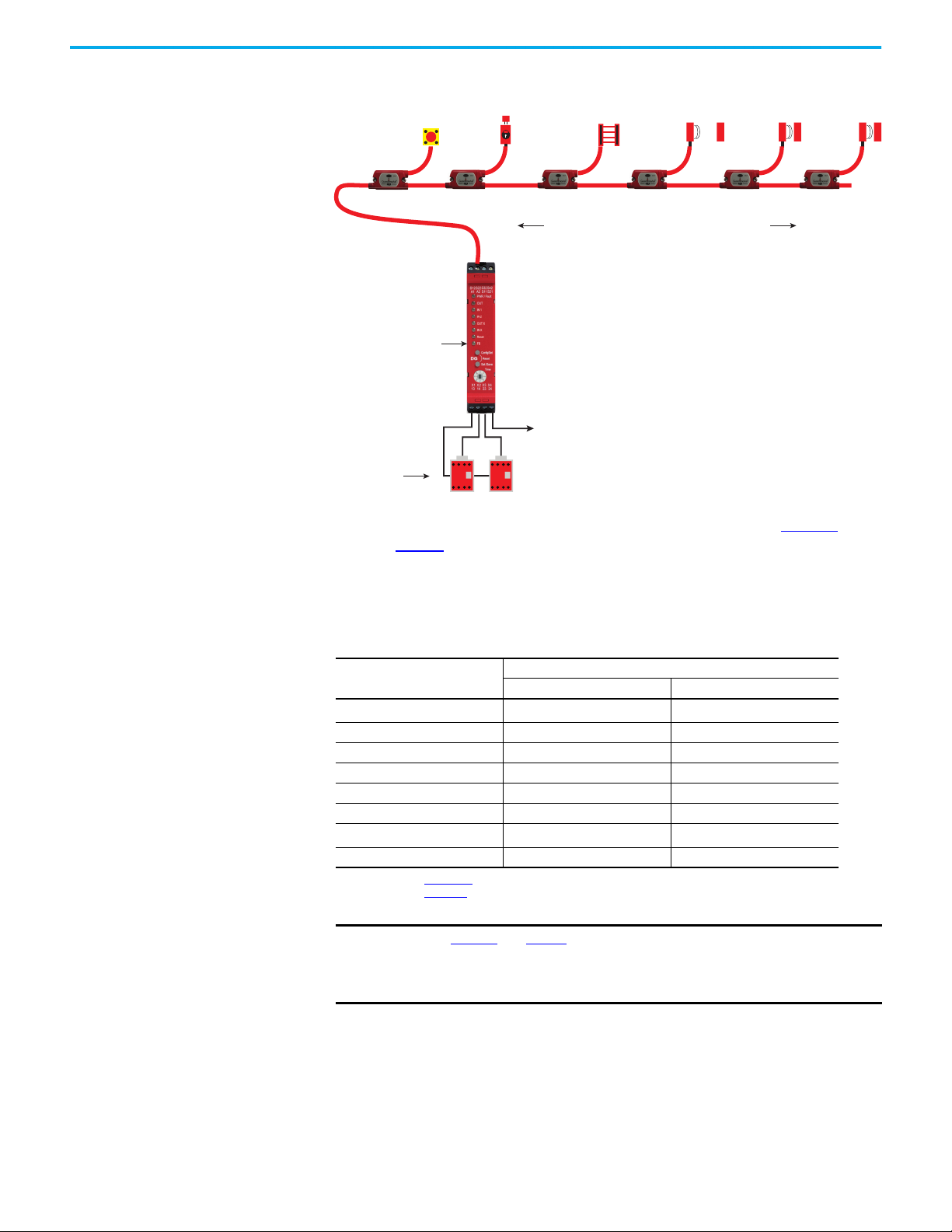

Tap 1 Tap 2 Tap 3 Tap 4 Tap 5 Tap 6

Upstream Downstream

SensaGuard

Opens

DG Safety Relay

Single Wire Safety Out

100S-C09EJ

Safety

Contactors

Figure 9 - Response Time Example Calculation

The safety system response time for the system that is shown in Figure 9 is

listed in Table 7

. The time from when the SensaGuard interlock opens to the

time when the 100S contactors drop out is 169.105 ms. The time from when the

SensaGuard interlock opens to the time when the SWS signal turns OFF is

114.105 ms.

Table 7 - Example Response Time Calculation

Component

SensaGuard

DG Safety Relay 60.0 55.0

100S Contactor

(1) See publication 440N-IN018.

(2) See publication 100-TD013.

IMPORTANT

(1)

Tap 4 5.0 5.0

Tap 3 0.035 0.035

Tap 2 0.035 0.035

Tap 1 0.035 0.035

(2)

Total 169.105 114.105

Figure 9 and Table 7 show only a portion of a complete safety system.

Additional time (for example, for motor stopping time and the response

DG Output 13/14, 23/24 DG Output SWS (X2)

Response Time [ms]

54.0 54.0

50.0 0.0

time of additional components that are connected to the SWS signal)

must be considered.

30 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 31

Installation

113.6 (4.47)

119.14

(4.69)

22.5

(0.88)

S12 S22 S32 S42

A1 A2 S11 S21

X1 X2 X3 X4

13 14 23 24

OUT

IN 1

IN X

Reset

FB

Cong/Set

Sel./Save

DG

Reset

Time

OUT X

IN 2

PWR/Fault

0

.

2

.

4

.

6

.

8

.

1

0

.

1

2

.

1

4

.

57 (2.24)

79.64 (3.14)

17

(0.67)

38.5 (1.51)

19.25 (0.76)

14

(0.55)

9 (0.35)

2X Ø5.4 (0.21) for M5 screws

(Ø9.8 (0.38) max screw head)

M12 X 1 thread

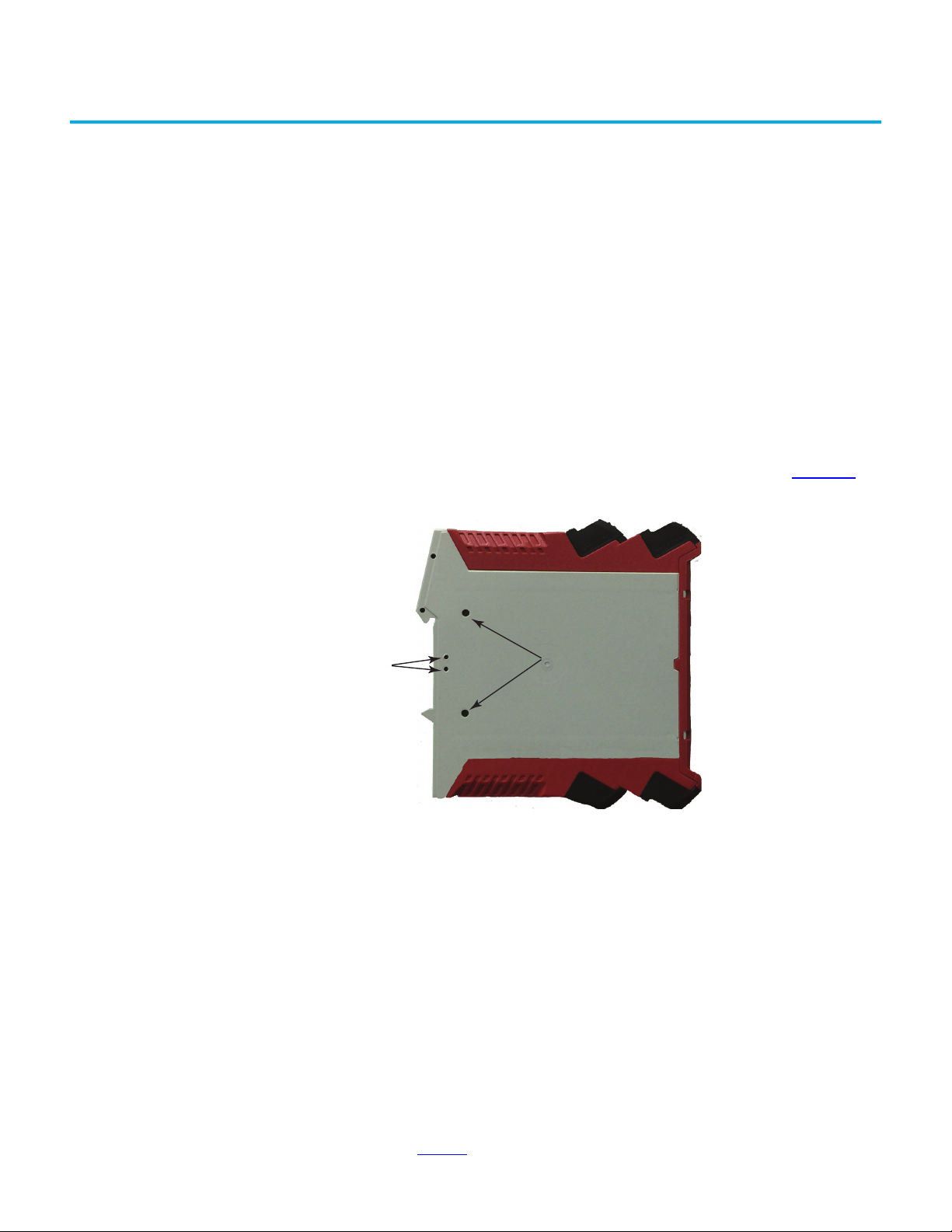

The DG safety relay uses the same housing as GSR modules. The module

dimensions are shown in Figure 10

Mounting Dimensions Figure 10 - DG Safety Relay Dimensions [mm (in.)]

, while Figure 11 shows the tap dimensions.

Chapter 3

Figure 11 - Tap Dimensions [mm (in.)]

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 31

Page 32

Chapter 3 Installation

DIN Rail Latch

DIN Rail

DIN Rail Mounting and Removal

The DG safety relay easily mounts onto 35 mm (1.4 in.) DIN rails:

35 x 7.5 x 1 mm (1.4 x 0.3 x 0.04 in.) (EN 50022 - 35x7.5).

1. Hold the top at an angle (Figure 12

).

2. Slide down until the housing catches the rail.

3. Swing the bottom down and give a little push until the latch clips onto

the rail.

Figure 12 - DIN Rail Mounting

2

1

3

Removal

To remove the DG safety relay, use a screwdriver to pry the DIN rail latch

downwards until it is in the unlatched position. Then, swing the module up.

Spacing

The DG safety relay can be mounted next to other GSR safety relays. When the

GSR Ethernet interface is used, the GSR module must be mounted within 10

mm (0.39 in.) of the module next to it to maintain effective communications.

Maintain 50 mm (2 in.) of space above, below, and in front of the relay for

adequate ventilation.

32 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 33

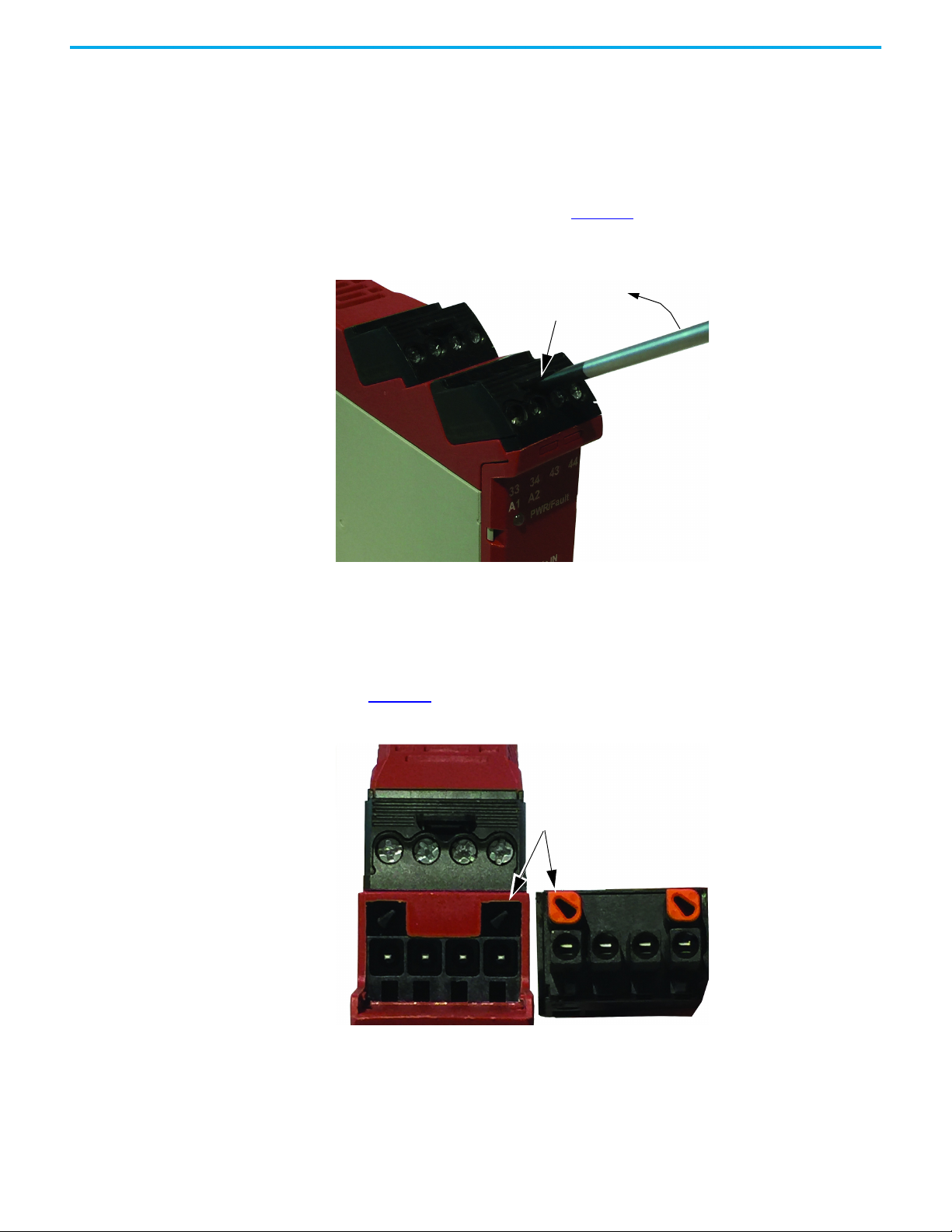

Chapter 3 Installation

1. Insert

2. Pry Up

Orange inserts

match keys

Terminal Block Removal and Replacement

Terminal blocks can be removed and replaced following these instructions.

Terminal Block Removal

DG safety relays have removable terminal blocks. Use a screwdriver as a lever

to remove the blocks. As shown in Figure 13

and pry up.

Figure 13 - DG Terminal Removal

, insert the screwdriver into the slot

Terminal Block Replacement

The terminal blocks are keyed to help prevent a block from being inserted into

an incorrect location. The orange-colored insert provides the orientation of the

key (Figure 14

Figure 14 - Orange-colored Keyway

).

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 33

Page 34

Chapter 3 Installation

M5 Screws

40 mm

(1.6 in.)

Quick Release Clip

Recessed Mounting Holes (x6)

6 x Ø5.4 (0.21) for M5 screws

(Ø11 (0.43) max screw head)

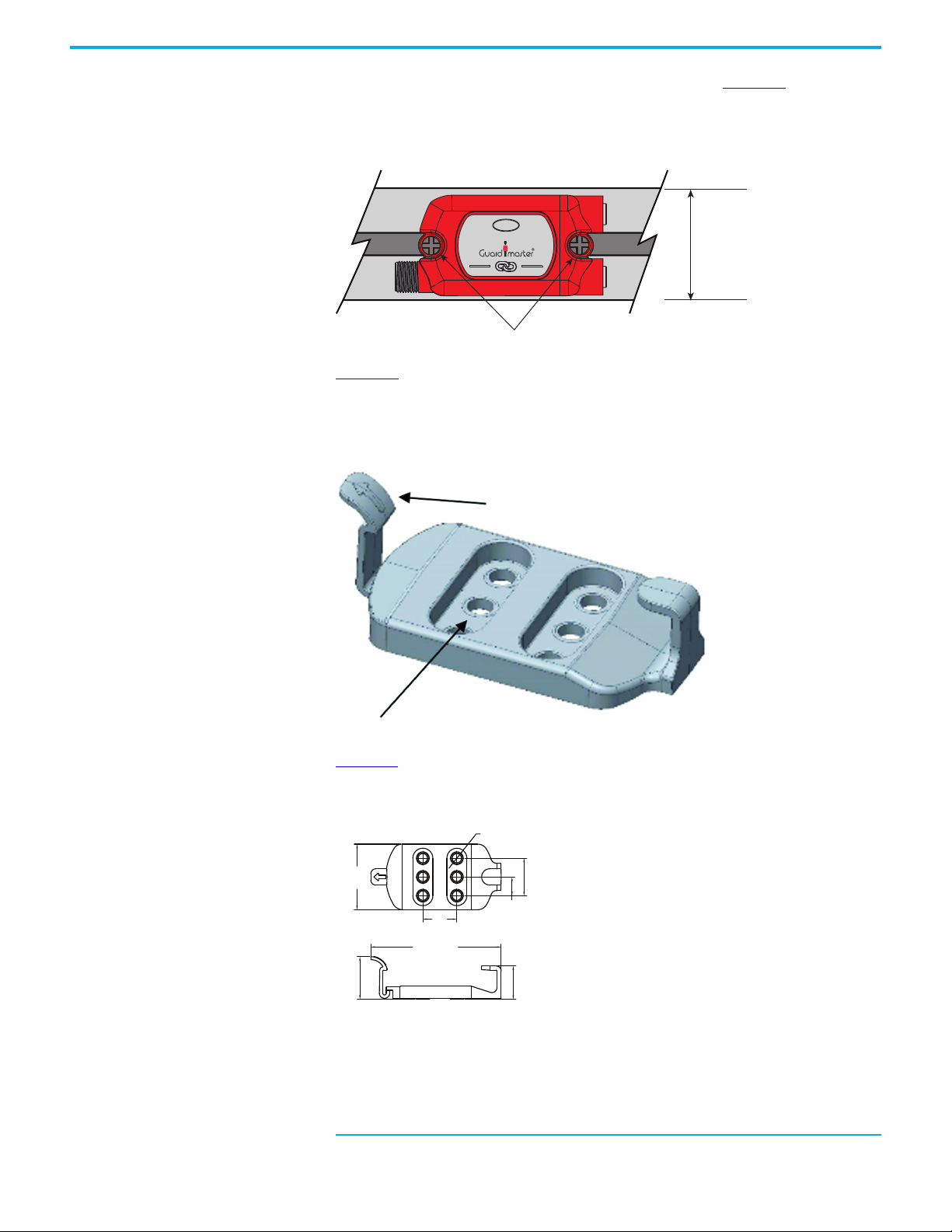

Tap Installation The tap can be installed directly with two M5 screws. In Figure 15, the 38.5 mm

(1.5 in.) wide tap fits neatly on a standard 40 mm (1.6 in.) aluminum extrusion

construction profile.

Figure 15 - Mounting Directly on 40 mm (1.6 in.) Profile

INPUT

Figure 16 shows an optional quick mounting bracket, catalog number

(a)

440S-GLTAPBRKx

snaps into place and can be easily removed to install patchcords and cordsets.

Figure 16 - Quick-release Mounting Bracket

, is available to facilitate installation and removal. The tap

Figure 17 shows the dimensions of the quick-release mounting bracket.

Figure 17 - Mounting Bracket Dimensions

38.5

(1.51)

20

(0.79)

76.6 (3.01)

25

(0.98)

(a) Replace the x with 1 to order one bracket and replace with a 5 for a package of five brackets.

34 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

22

(0.87)

11

(0.43)

19.6

(0.77)

Page 35

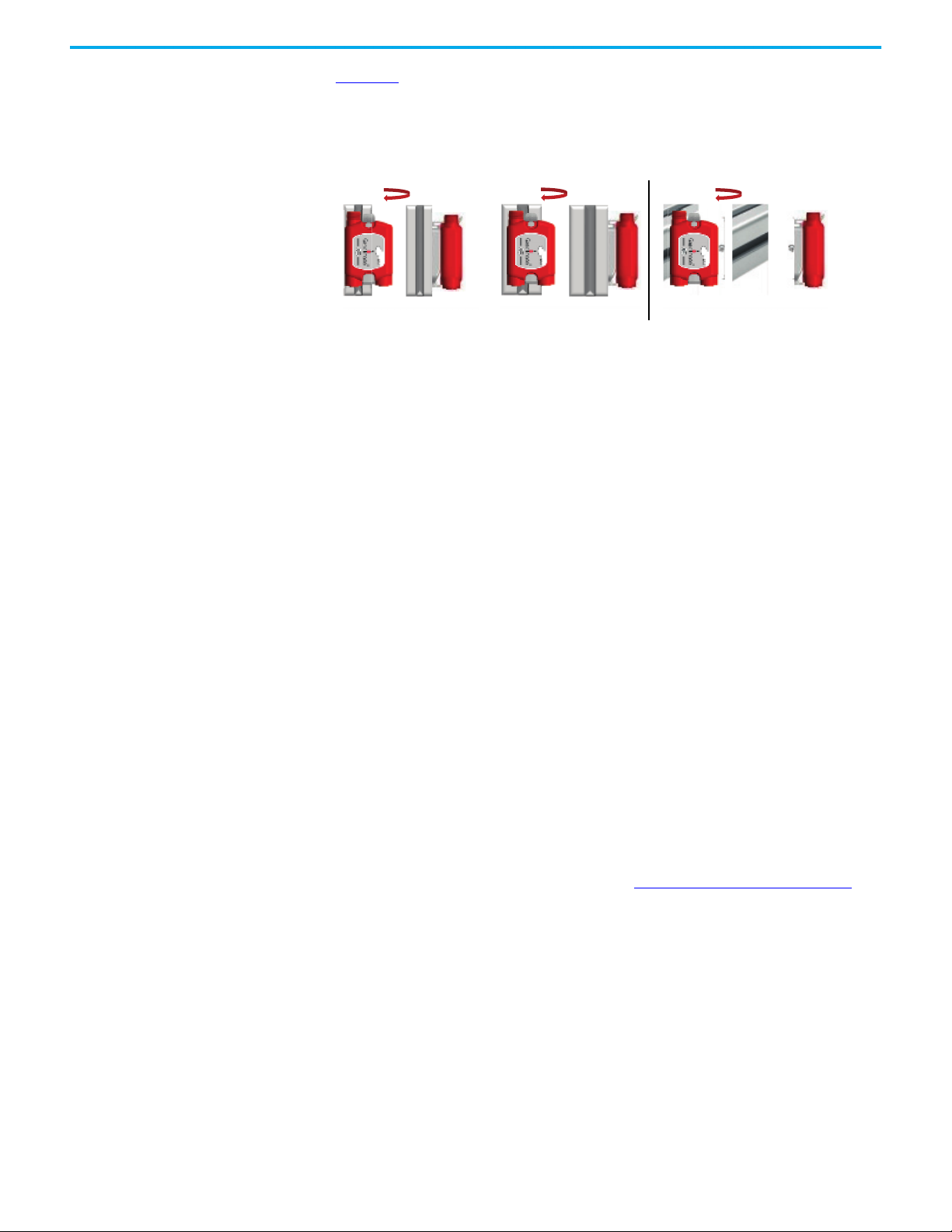

Chapter 3 Installation

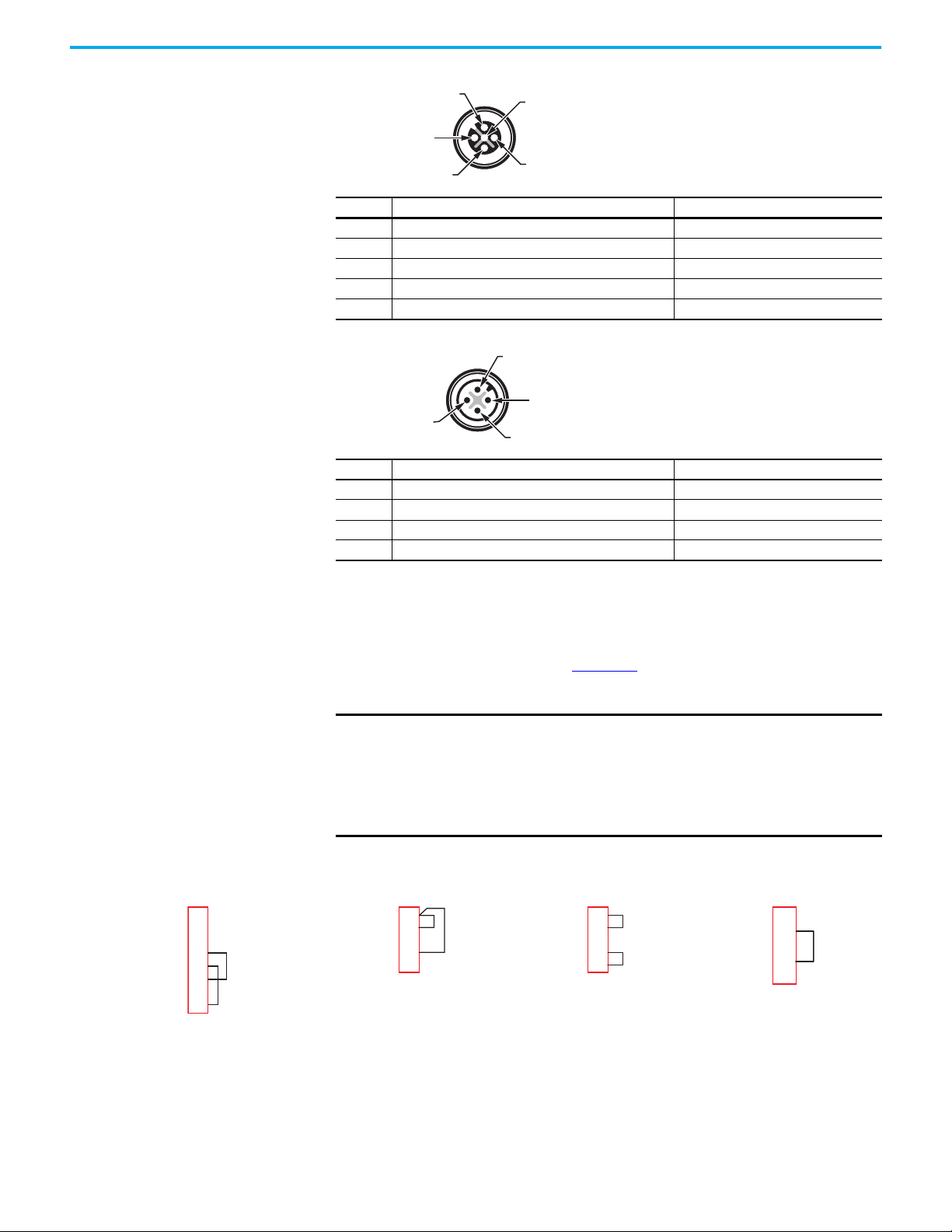

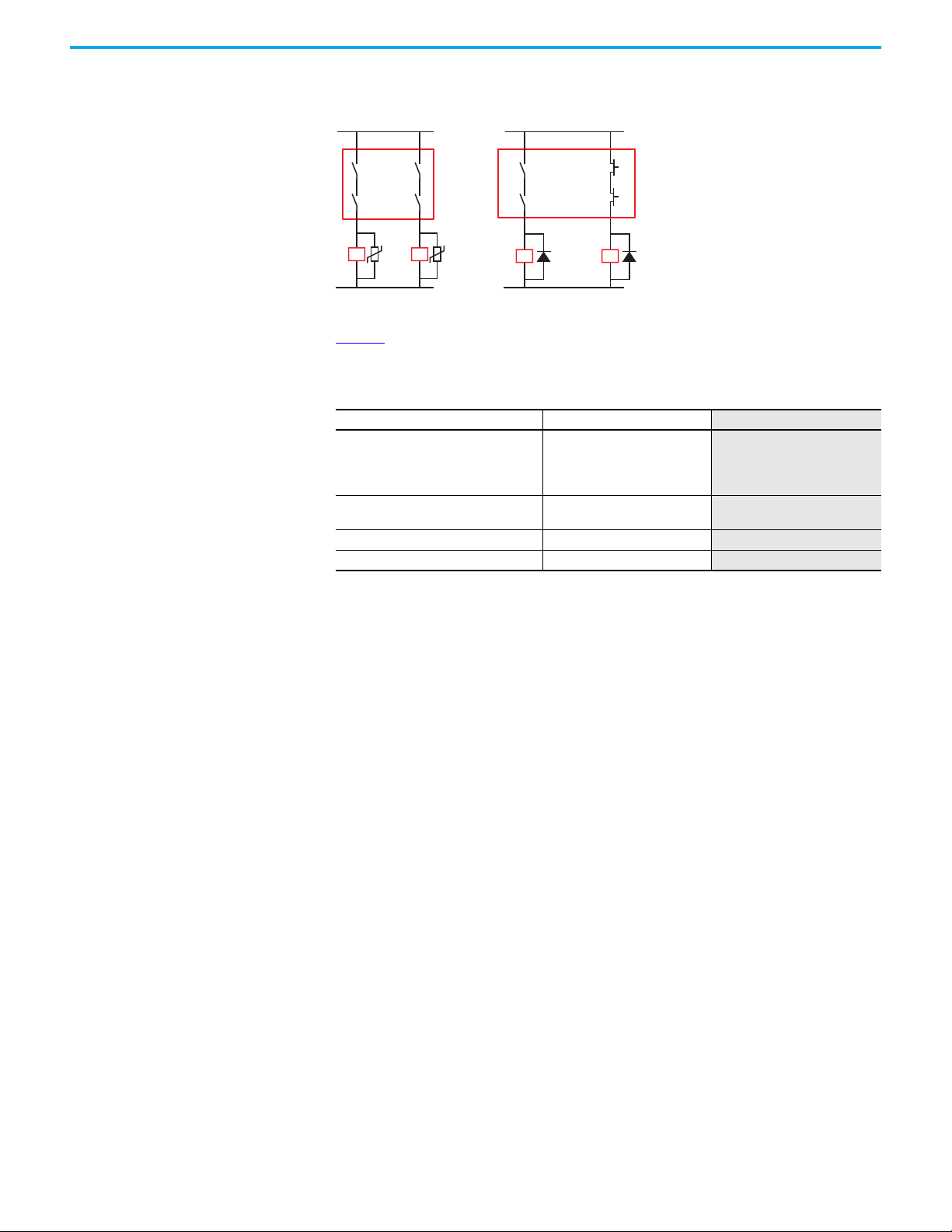

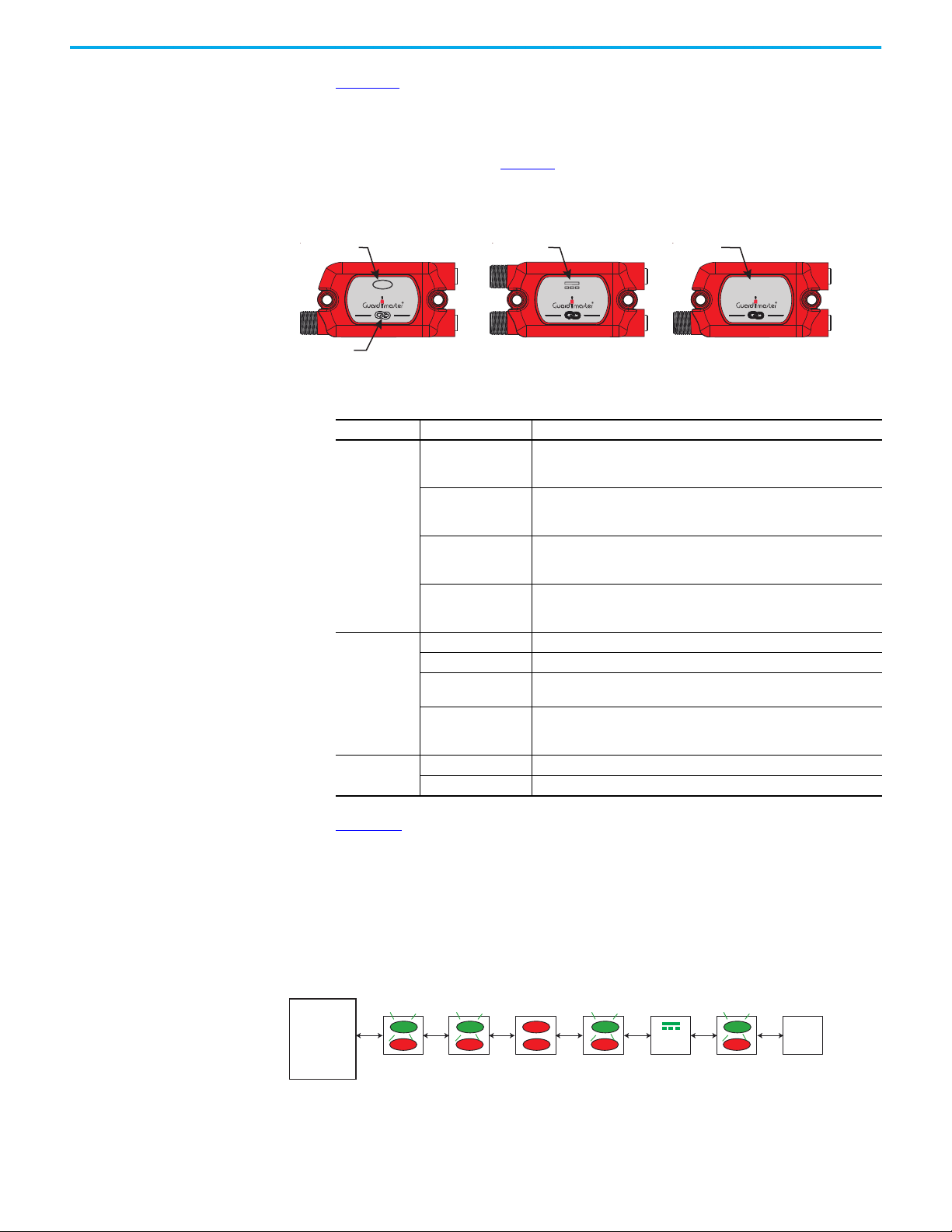

20 mm Profile 30 mm Profile 45 mm Profile

In-line with Profile

Across Profile

Figure 18 shows some of the mounting options with the quick release bracket.

The bracket can be mounted on various sizes of profile and can mount in-line

or across the profile.

Figure 18 - Mounting Options with Quick-release Bracket

Enclosure Considerations Consider the following when choosing your DG safety relay and tap enclosure.

DG Safety Relay

The DG safety relay is intended for use in a Pollution Degree 2 industrial

environment, in overvoltage Category II applications (as defined in

IEC 60664-1), at altitudes up to 2000 m (6562 ft) without derating. This

equipment is considered Group 1, Class A industrial equipment according to

IEC/CISPR 11. Without appropriate precautions, there can be difficulties with

electromagnetic compatibility in residential and other environments due to

conducted and radiated disturbances.

The DG safety relay is supplied as open-type equipment. It must be mounted

within an enclosure that is suitably designed for those specific environmental

conditions that are present and appropriately designed to help prevent

personal injury that results from accessibility to live parts. The enclosure must

have suitable flame-retardant properties to help prevent or minimize the

spread of flame that complies with a flame spread rating of 5VA, V2, V1, V0 (or

equivalent) if non-metallic. The interior of the enclosure must be accessible

only by the use of a tool. Subsequent sections of this publication may contain

additional information regarding specific enclosure type ratings that are

required to comply with certain product safety certifications.

Other helpful publications can be found in Additional Resources on page 9

.

Taps

Taps are intended to be mounted on the machine and are rated for

Pollution Degree 3.

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 35

Page 36

Chapter 3 Installation

Prevent Excessive Heat Consider the following to help prevent excessive heat for your DG safety relay

and tap.

DG Safety Relay

For most applications, normal convective cooling keeps the DG safety relay

within the specified operating range. Verify that the specified temperature

range is maintained. Proper spacing of components within an enclosure is

usually sufficient for heat dissipation.

In some applications, other equipment inside or outside the enclosure produce

a substantial amount of heat. In this case, place blower fans inside the

enclosure to help with air circulation and to reduce hot spots near the

controller.

Additional cooling provisions can be necessary when high ambient

temperatures are encountered. Do not bring in unfiltered outside air. Place the

controller in an enclosure to help protect it from a corrosive atmosphere.

Harmful contaminants or dirt can cause improper operation or damage to

components. In extreme cases, you may need to use air conditioning to help

protect against heat buildup within the enclosure.

Taps

The taps have no spacing requirements.

36 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 37

Wiring Requirements and Recommendation

Chapter 4

Power, Ground, and Wire

WA RN I NG : Before you install and wire any device, disconnect power to the

system.

WA RN I NG : Calculate the maximum possible current in each power and common

wire. Observe all electrical codes that dictate the maximum current allowable for

each wire size. Current above the maximum rating can cause wiring to overheat,

which can cause damage.

• Allow for at least 50 mm (2 in.) between I/O wire ducts or terminal strips

and the relay.

• Route incoming power to the relay by a path separate from the device

wiring. Where paths must cross, their intersection must be

perpendicular.

• Do not run signal or communications wiring and power wiring in the

same conduit. Route wires with different signal characteristics by

separate paths.

• Separate wiring by signal type. Bundle wiring with similar electrical

characteristics together.

• Separate input wiring from output wiring.

• Label wiring to all devices in the system. Use tape, shrink-tubing, or

other more dependable means to label wire. Use colored insulation as

well to identify wiring by signal characteristics. For example, use blue for

DC wiring and red for AC wiring.

DG Safety Relay Wire Size

Each terminal can accommodate copper wire with size from 0.2…2.5 mm

(24…14 AWG). Use copper that can withstand 60/75 °C (140/167 °F).

Terminal Torque

Torque terminals to 0.4 N•m (4 lb•in).

Rockwell Automation Publication 440R-UM015F-EN-P - December 2020 37

Page 38

Chapter 4 Power, Ground, and Wire

}X2

}X1

}X3

}X4

X1

X2

X3 X4

S12 S22 S32 S42

A1 A2 S11 S21

X1 X2 X3 X4

13 14 23 24

OUT

IN 1

IN X

Reset

FB

Cong/Set

Sel./Save

DG

Reset

Time

OUT X

IN 2

PWR/Fault

0

.

2

.

4

.

6

.

8

.

1

0

.

1

2

.

1

4

.

Terminal Assignment and Function

The relays have four terminals: two on the top and two on the bottom. As

shown in Figure 19

further back. The X1 and X3 terminals apply to the terminals closest to the

front.

Figure 19 - DG Terminal Identification

, the X2 and X4 terminal markings apply to the terminals

Some of the terminals can be configured for multiple functions. Table 8 lists

the functions available for each terminal.

Table 8 - Terminal Assignments and Functions

Terminal Function

A1 +24V Supply (+10%, -15%)

A2 0V Common

S11 Pulse Test Output

S21 Pulse Test Output

S12 GuardLink® Safety or Safety N.C.

S22 GuardLink CLU or Safety N.C.

S32 GuardLink Safety or Safety N.C.

S42 GuardLink CLU or Safety N.C.

X1 SWS In or OSSD In

X2 SWS Out or OSSD Out

X3 Standard Input (Feedback)

X4 Standard Input (Reset)

13

14

23

24

Redundant Positive-Guided Relay Output 1

Redundant Positive Guided Relay Output 2

38 Rockwell Automation Publication 440R-UM015F-EN-P - December 2020

Page 39

Chapter 4 Power, Ground, and Wire

GuardLink Enabled and Passive

J1 Link In J1 Link In

J4 Power In

J2 Link Out

J3 Device

Passive Power

J2 Link Out

J3 Device

J1 Link In (Male) J2 Link Out (Female)

2: GuardLink Safety 2: GuardLink Safety

1: +24V DC 1: +24V DC

4: GuardLink CLU 4: GuardLink CLU

3: 0V DC 3: 0V DC

2: +24V DC

1: Aux

7: 0V

6: Safety OSSD B

3: Lock/Unlock Command

8: Safety OSSD A+

4: Safety OSSD B+

5: Safety OSSD A

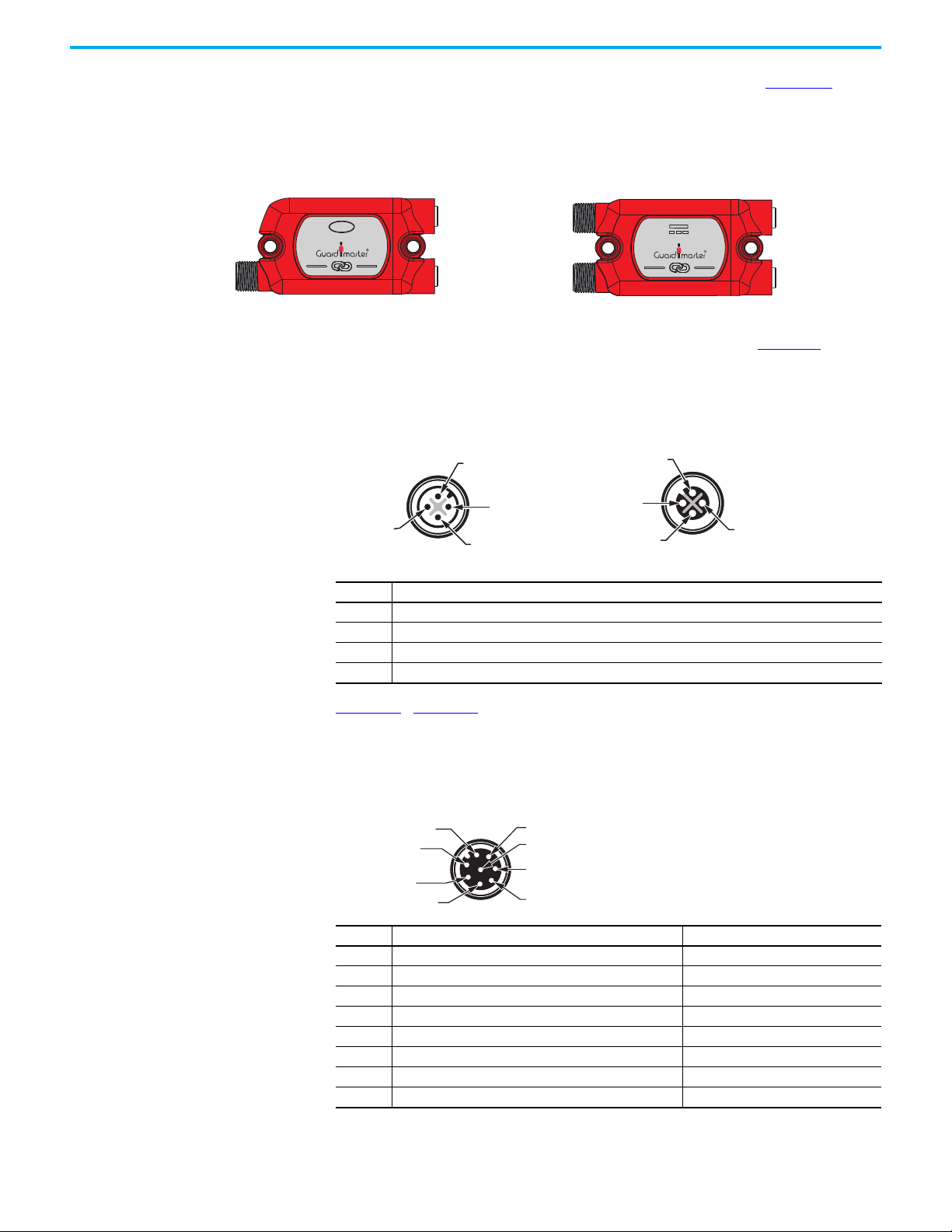

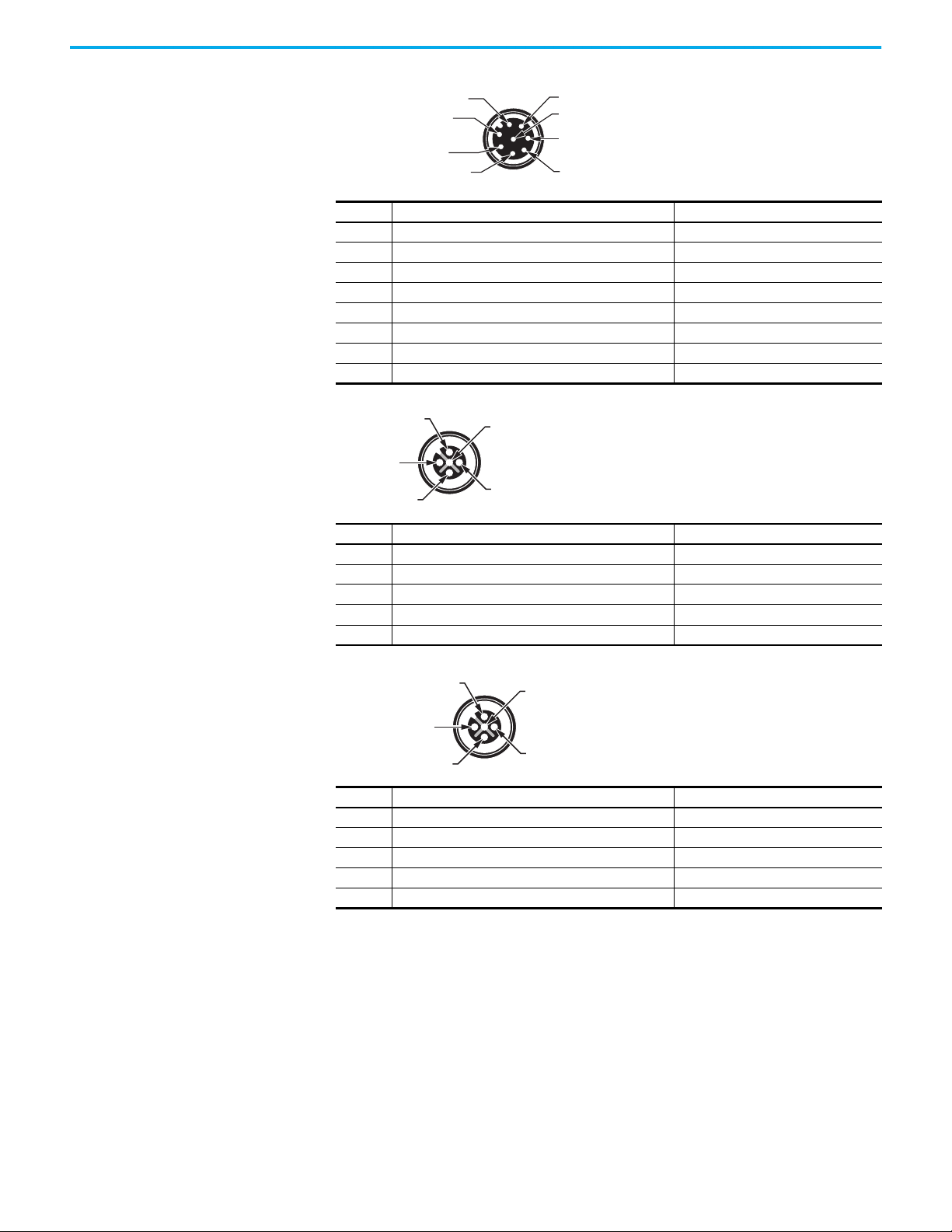

Tap Pin Assignment and Function

The taps have three or four M12 quick disconnect connectors (Figure 20). The

system is designed to use premanufactured patchcords to facilitate

installation, modification, and troubleshooting. The link connectors are 4-pin.

The device connectors are either 5-pin or 8-pin.

Figure 20 - Tap Connection Identification

INPUT

INPUTPWR

The link connections carry the power and command signals. Figure 21 shows