Page 1

Allen-Bradley

PanelBuilder Software

User

(Cat. No 2711-ND3)

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Allen-Bradley does not assume responsibility

or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Allen-Bradley

Company, Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

death, property damage or economic loss.

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

application and understanding of the product.

PanelBuilder, FontTool, PanelView 550, PanelView 600, PanelView 900, PanelView 1400, SLC, SLC 500, SLC 5/01, SLC

5/02, SLC 5/03, SLC 5/04, MicroLogix, Data Highway Plus are trademarks of Allen-Bradley Company, Inc.

PLC and PLC-5 are registered trademarks of Allen-Bradley Company, Inc.

RSLinx and INTERCHANGE are trademarks of Rockwell Software Inc.

Microsoft, Windows, and MS-DOS are registered trademarks, and Windows NT is a trademark of Microsoft Corporation.

Page 3

Preface

Intended Audience P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software Package P–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contents of Manual P–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Conventions P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related Publications P–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Technical Support Services P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Software/Firmware Upgrades P–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of PanelBuilder

Installation

Planning an Application

Chapter 1

Chapter Objectives 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is PanelBuilder? 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is an Application? 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Project? 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Features 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Typical Application Screens 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Objects 1–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Requirements 2–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing PanelBuilder 2–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RSLinx Lite Software 2–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

INTERCHANGE Device Configuration Utility 2–10. . . . . . . . . . . . . . . . .

INTERCHANGE Notes 2–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Design Checklist 3–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applications and Projects 3–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Steps for Creating an Application 3–3. . . . . . . . . . . . . . . . . . . . . . . . .

Safety Considerations 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen Worksheets 3–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Linking Screen Objects to Controller Data 3–6. . . . . . . . . . . . . . . . . . .

Controller Data Files 3–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Types 3–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Formats 3–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Review Addressing 3–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Tags 3–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Requirements/Tips 3–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Page 4

Table of Contentsii

Communications Overview

PanelBuilder Basics

Chapter 4

Chapter Objectives 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Terminal Ports 4–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH-485 Communications 4–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH+ Communications 4–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DF1 Communications 4–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH-485/DH+/DF1 Communication Considerations 4–5. . . . . . . . . . . . .

Remote I/O Communications 4–6. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Discrete I/O 4–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfers 4–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 5

Chapter Objectives 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Windows Environment 5–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Windows 5–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menus 5–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tool Bar 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Bar 5–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format Bar 5–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Toolboxes 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Display 5–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Color Palette 5–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dialog Boxes 5–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spreadsheet Editors 5–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Defaults 5–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Help 5–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Working with Applications and Screens

Chapter 6

Chapter Objectives 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 6–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting PanelBuilder 6–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

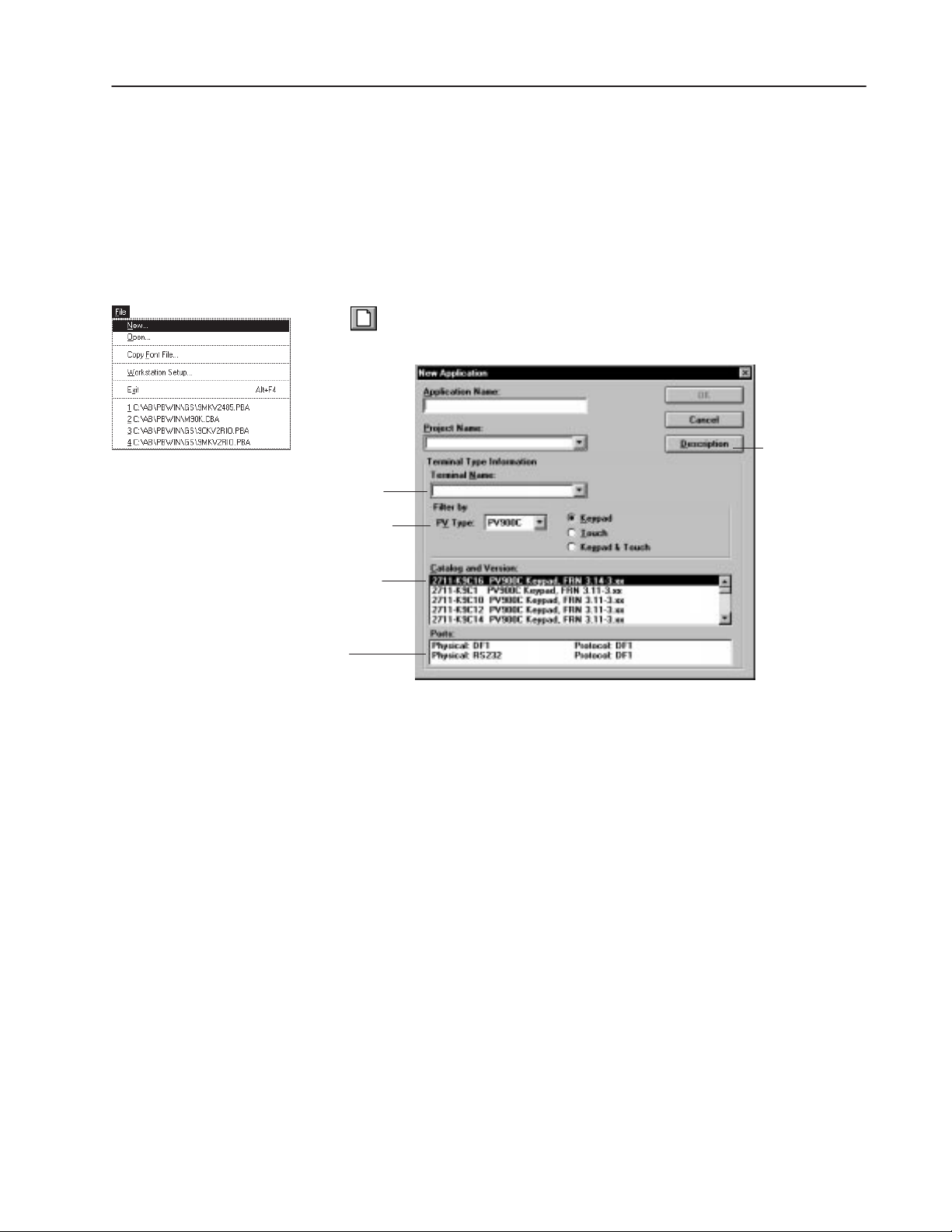

Creating a New Application 6–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening an Existing Application 6–5. . . . . . . . . . . . . . . . . . . . . . . . . .

Renaming and Describing an Application 6–8. . . . . . . . . . . . . . . . . . . .

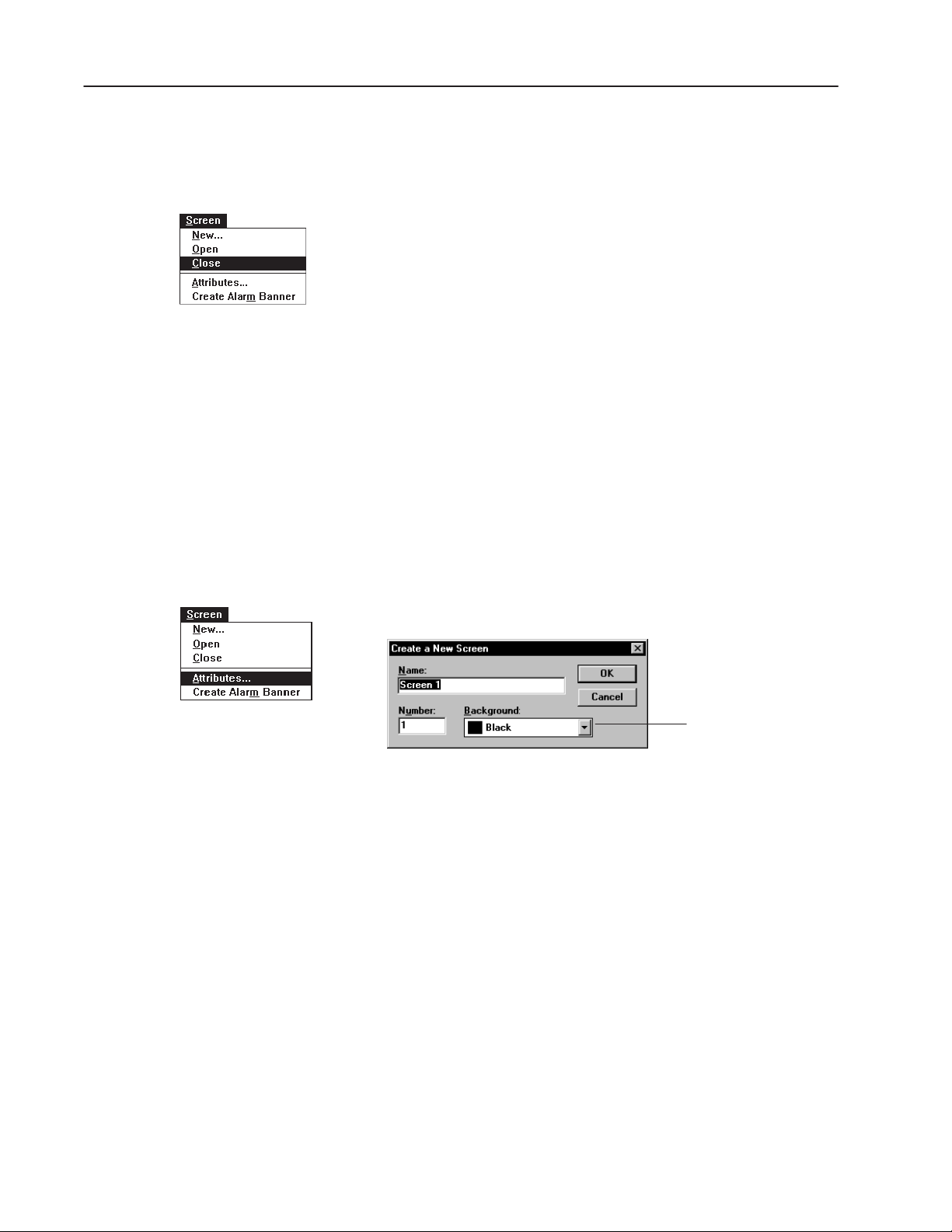

Opening a New Screen 6–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening an Existing Screen 6–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening Multiple Screens 6–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing Screens 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Screen Attributes 6–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting Screens 6–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Screens within an Application 6–15. . . . . . . . . . . . . . . . . . . . .

Copying Screens to Another Application 6–16. . . . . . . . . . . . . . . . . . . .

Moving Screens to Another Application 6–17. . . . . . . . . . . . . . . . . . . . .

Saving an Application 6–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Closing an Application 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exiting PanelBuilder 6–21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 5

Table of Contents iii

Working with Objects

Chapter 7

Chapter Objectives 7–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessing Objects 7–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Draw Pointer 7–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Objects in Display Area 7–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning Objects 7–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Objects on Function Keys 7–7. . . . . . . . . . . . . . . . . . . . . . . .

Selecting Objects 7–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sizing Objects 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving Objects 7–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grouping and Ungrouping Objects 7–10. . . . . . . . . . . . . . . . . . . . . . . .

Stacking Objects 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zooming In and Out 7–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Object Inner Text 7–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Formatting Objects 7–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Default Colors for Objects 7–13. . . . . . . . . . . . . . . . . . . . . . . . .

Editing Object Attributes 7–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring States of Multistate or List Objects 7–15. . . . . . . . . . . . . . . .

Entering a Description for an Object 7–18. . . . . . . . . . . . . . . . . . . . . . .

Hiding an Object 7–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying/Cutting and Pasting Objects 7–20. . . . . . . . . . . . . . . . . . . . . . .

Deleting Objects 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reversing an Operation 7–22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Push Buttons

Creating Control List Selectors

Chapter 8

Chapter Objectives 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 8–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Push Button Types 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact Types 8–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Push Button Text and Graphics 8–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Push Buttons 8–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Push Button 8–4. . . . . . . . . . . . . . . . . . . . . . . .

Configuring Push Button States 8–8. . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 9

Chapter Objectives 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 9–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Standard Control Lists 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piloted Control Lists 9–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Control List Options 9–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Control List Selector 9–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Control List Selector 9–6. . . . . . . . . . . . . . . . . .

Configuring States for a Control List Selector 9–10. . . . . . . . . . . . . . . . .

Creating List Keys 9–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 6

Table of Contentsiv

Creating Data Entry Controls

Chapter 10

Chapter Objectives 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 10–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Entry Controls 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Enable Button 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entry Cursor Point 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scratchpad 10–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Entry Examples 10–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Entry Scaling 10–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Numeric Entry Object 10–7. . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Numeric Entry Object 10–7. . . . . . . . . . . . . . .

ASCII Entry Controls 10–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Keypad Enable Button 10–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entry Cursor Point 10–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ASCII Scratchpad – Keypad or Keypad/Touch Screen Terminals 10–13.

ASCII Scratchpad – 550 Touch Screen Terminals 10–14. . . . . . . . . . . .

ASCII Scratchpad – 900/1000/1400 Touch Screen Terminals 10–15. . . .

Scratchpad in other Languages 10–16. . . . . . . . . . . . . . . . . . . . . . . . .

Creating an ASCII Entry Object 10–16. . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of an ASCII Entry Object 10–17. . . . . . . . . . . . . . . .

Creating Screen Selectors

Creating Bar Graphs, Indicators and Numeric Displays

Chapter 11

Chapter Objectives 11–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 1 1–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Goto Screen Button 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Goto Config Screen Button 1 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Return Screen Button 1 1–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Screen List Selector 11–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Screen Buttons 11–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of Screen Buttons 1 1–4. . . . . . . . . . . . . . . . . . . . . . .

Creating a Screen List Selector 1 1–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Screen List Selector 1 1–6. . . . . . . . . . . . . . . . . .

Configuring Entries in a Screen List Selector 11–7. . . . . . . . . . . . . . . . .

Creating List Keys 11–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC/SLC Controlled Screen Changes 1 1–9. . . . . . . . . . . . . . . . . . . . . .

Chapter 12

Chapter Objectives 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 12–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling Data 12–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error States 12–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bar Graphs 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Bar Graphs 12–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Bar Graph 12–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Bar Graph 12–5. . . . . . . . . . . . . . . . . . . . . . .

Creating a Bar Graph Scale 12–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 7

Table of Contents v

Creating Tick-Mark Labels 12–8. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Numeric Data Displays 12–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Numeric Data Displays 12–9. . . . . . . . . . . . . . . . . . . . . . . .

Creating a Numeric Data Display 12–10. . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Numeric Data Display 12–10. . . . . . . . . . . . . . .

Multistate Indicators 12–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Multistate Indicators 12–12. . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering an Indicator State 12–13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Multistate Indicator 12–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Multistate Indicator 12–14. . . . . . . . . . . . . . . . .

Configuring States for a Multistate Indicator 12–16. . . . . . . . . . . . . . . .

List Indicators 12–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of List Indicators 12–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering a List Entry 12–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a List Indicator 12–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a List indicator 12–20. . . . . . . . . . . . . . . . . . . . .

Configuring Entries of a List indicator 12–22. . . . . . . . . . . . . . . . . . . . .

Creating Message Displays

Using Global Objects

Creating Alarms

Chapter 13

Chapter Objectives 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 13–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Messages 13–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Triggering Messages 13–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error State 13–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating a Message Display 13–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Properties of a Message Display 13–6. . . . . . . . . . . . . . . . . . . .

Configuring Messages 13–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating an Object to Print Messages 13–10. . . . . . . . . . . . . . . . . . . . .

Chapter 14

Chapter Objectives 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is a Global Object? 14–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining a Global Object 14–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using a Global Object 14–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving and Resizing a Global Object 14–6. . . . . . . . . . . . . . . . . . . . . .

Chapter 15

Chapter Objectives 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Overview of Alarms 15–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating the Alarm Banner 15–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating an Alarm List 15–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Global Parameters for Alarms 15–12. . . . . . . . . . . . . . . . . . .

Defining Alarm Triggers 15–14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Alarms 15–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Optional Trigger Tags 15–22. . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Remote Tags used by Controller 15–26. . . . . . . . . . . . . . . . . . .

Alarm Examples 15–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 8

Table of Contentsvi

Adding Graphics

Formatting Objects and Text

Chapter 16

Chapter Objectives 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 16–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graphic Objects 16–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Graphic Tools 16–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing a Line 16–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing Connected Lines 16–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Drawing Shapes 16–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Freeform Drawings 16–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding ISA Symbols 16–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding Background Text 16–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing/Exporting Bitmap Graphics 16–10. . . . . . . . . . . . . . . . . . . . . . .

Using Background Graphics 16–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 17

Chapter Objectives 17–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Format Options 17–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Appearance of Objects 17–3. . . . . . . . . . . . . . . . . . . . . .

Changing Object Shape 17–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Line T ype 17–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing Fill Pattern 17–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Blink Option 17–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Foreground/Background Colors 17–8. . . . . . . . . . . . . . . . . . .

Reversing Foreground/Background Colors 17–9. . . . . . . . . . . . . . . . .

Working with Inner Text 17–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Inner Text 17–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting Time or Date 17–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting a Numeric Variable 17–14. . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting an ASCII Variable 17–16. . . . . . . . . . . . . . . . . . . . . . . . . . .

Working with Inner Graphics 17–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adding Inner Graphic 17–20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Foreground/Background Colors 17–21. . . . . . . . . . . . . . . . . . .

Reversing Foreground/Background Colors 17–22. . . . . . . . . . . . . . . . .

Removing an Inner Graphic 17–23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Graphics 17–23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Appearance of Text 17–24. . . . . . . . . . . . . . . . . . . . . . . . .

Sizing Text 17–25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aligning Text 17–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Underlining Text 17–27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Blink Option 17–28. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Foreground/Background Colors 17–29. . . . . . . . . . . . . . . . . . .

Reversing Foreground/Background Colors 17–30. . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 9

Table of Contents vii

Using the Text Editor

Working with Tags

Chapter 18

Chapter Objectives 18–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Text Editor 18–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Entering New Text 18–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Editing Text 18–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting V ariables in Text 18–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sorting Text 18–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filtering Text 18–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Text 18–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Deleting Unused Text 18–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Renumbering Text 18–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving Text 18–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Text into Objects 18–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 19

Chapter Objectives 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using the Tag Editor 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table View 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Form View 19–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening the Tag Editor 19–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Navigating through the Tag Editor 19–3. . . . . . . . . . . . . . . . . . . . . . .

Validating Tag Addresses 19–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Tags 19–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Tags 19–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Tags 19–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inserting and Deleting Tags 19–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying Tags 19–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duplicating Tags 19–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Finding Tags 19–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sorting Tags 19–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Tags 19–12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using Tools 19–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tag Import/Export Utility 19–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Importing Tags 19–16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Handling Data Collisions 19–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exporting Tags 19–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Examining the Results of an Import/Export 19–19. . . . . . . . . . . . . . . . .

Interpreting Error Messages 19–20. . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 10

Table of Contentsviii

Terminal and Communication Setup

Managing Projects

Chapter 20

Chapter Objectives 20–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminal Setup Overview 20–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining DH-485 Communications 20–3. . . . . . . . . . . . . . . . . . . . . . . . .

Defining DH+ Communications 20–5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining DF1 Communications 20–7. . . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Remote I/O Communications 20–9. . . . . . . . . . . . . . . . . . . . . .

Defining Block Transfers 20–11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the Printer Port 20–13. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Terminal Type 20–15. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Power-Up Options 20–17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Time/Date Format 20–19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting Advanced Terminal Options 20–21. . . . . . . . . . . . . . . . . . . . . . . .

Setting a Display Maintenance Schedule 20–23. . . . . . . . . . . . . . . . . . . .

Defining PLC/SLC Control Tags 20–24. . . . . . . . . . . . . . . . . . . . . . . . . .

Defining Status Tags 20–26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 21

Chapter Objectives 21–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Projects 21–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Projects 21–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Managing Devices in Projects 21–4. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Copying a Project to Another Computer 21–6. . . . . . . . . . . . . . . . . . . . .

Restoring a Project 21–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Moving an Application to Another Computer 21–7. . . . . . . . . . . . . . . . . .

Replacing Duplicate Tags and Devices in a Project 21–8. . . . . . . . . . . . .

Adding Unknown Tags or Devices to a Project 21–9. . . . . . . . . . . . . . . .

Setting Preferences for Replacing or Adding Tags and Devices 21–10. . . .

Restoring a Project Created with a Restricted PanelBuilder Release 21–11.

Multilingual Support

Publication 2711-6.0

Chapter 22

Chapter Objectives 22–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What Y ou Will Learn? 22–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

System Requirements 22–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Terminology 22–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What is FontTool? 22–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Method Editor 22–4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using FontTool 22–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating Font Files 22–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Viewing Sample Text 22–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Opening Font Files 22–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Saving Font Files 22–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Files 22–10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating an Application Using a Font File 22–11. . . . . . . . . . . . . . . . . . . .

Troubleshooting 22–15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Translating Application Text in Excel 22–16. . . . . . . . . . . . . . . . . . . . . . .

Page 11

Table of Contents ix

Validating and Transferring Applications

Chapter 23

Chapter Objectives 23–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Helpful Hints 23–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V alidating Applications 23–2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Correcting Validation Errors 23–3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Printing Validation Messages 23–4. . . . . . . . . . . . . . . . . . . . . . . . . .

Sending V alidation Messages to File 23–5. . . . . . . . . . . . . . . . . . . . .

Transfer Options 23–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView Terminal 23–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Card 23–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DOS File 23–7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transfer Utilities 23–8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelBuilder Application Menu 23–8. . . . . . . . . . . . . . . . . . . . . . . . .

Application File Transfer Utility 23–8. . . . . . . . . . . . . . . . . . . . . . . . .

PanelView DOS File Transfer Utility 23–8. . . . . . . . . . . . . . . . . . . . . .

Internal DF1 Driver 23–9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading Directly to a Terminal 23–10. . . . . . . . . . . . . . . . . . . . . . . .

Downloading on a Local DH+ Link 23–12. . . . . . . . . . . . . . . . . . . . . . . . .

Downloading to a Terminal Using Pass-Through 23–13. . . . . . . . . . . . . . .

Remote I/O Pass-Through Setup 23–14. . . . . . . . . . . . . . . . . . . . . . .

DH-485 Pass-Through Setup 23–15. . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading to a DOS Memory Card 23–16. . . . . . . . . . . . . . . . . . . . . .

Downloading to a DOS File 23–18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Uploading Directly from a Terminal 23–19. . . . . . . . . . . . . . . . . . . . . . . .

Uploading on a Local DH+ Link 23–21. . . . . . . . . . . . . . . . . . . . . . . . . . .

Uploading from a Terminal Using Pass-Through 23–22. . . . . . . . . . . . . . .

Using the Application File Transfer Utility 23–23. . . . . . . . . . . . . . . . . . . .

Verifying an Application 23–24. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Downloading to a PanelView Terminal 23–25. . . . . . . . . . . . . . . . . . . .

Uploading from a PanelView Terminal 23–27. . . . . . . . . . . . . . . . . . . .

Decreasing Size of Application for Downloads 23–28. . . . . . . . . . . . . . . .

Exceeding RAM Memory in Terminal 23–28. . . . . . . . . . . . . . . . . . . . . . .

Creating Reports

Chapter 24

Chapter Objectives 24–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Types of Reports 24–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Connecting a Printer 24–1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Creating and Printing a Report 24–2. . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Report Setup 24–3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting up a Printer 24–5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sending the Report to a File 24–6. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publication 2711-6.0

Page 12

Table of Contentsx

Appendix A – Command Summary

Appendix B – Tool Summary

Appendix C – PanelBuilder Worksheets

Appendix D – Software Error and Warning Messages

Appendix E – Validation Messages

Appendix F – Troubleshooting

Appendix G – Internal Read Only Tags

Appendix H – Using Extended ASCII Characters

Glossary

Index

Publication 2711-6.0

Page 13

Preface

Preface

This manual is a reference guide for the PanelBuilder

Configuration Software. It describes features and procedures used to

create control panel applications for the family of PanelView

Operator Terminals.

Because this is a reference manual it covers all the features of the

software. You may not use or need to use all the features, so use the

manual as needed.

If you’re just getting started, you might want to read the Getting

Started Manual first. It takes you through all the steps of creating a

sample application including how to download and run the

application in the terminal.

Intended Audience

Software Package

This manual is for the individual responsible for designing control

panel applications that will run in a PanelView terminal.

The PanelBuilder Configuration Software runs in Microsoft

Windows . You should know how to use a mouse, choose

commands, and work with windows and dialog boxes.

You should also have a basic understanding of:

• PLC and SLC logic controllers, especially the controller’s

program and data files.

• communication network on which application will run.

The PanelBuilder Configuration Software package includes:

1

• 3

inch installation disks to install

/2

– PanelBuilder Software

– INTERCHANGE or RSLinx Lite Software

– AB Utilities Software

• PanelBuilder Configuration Software user manual

• PanelView Operator Terminal user manual

• Getting Started manual

• PanelView File Transfer Utility manual

Publication 2711-6.0

Page 14

PrefaceP–2

Contents of Manual

This manual is organized as follows:

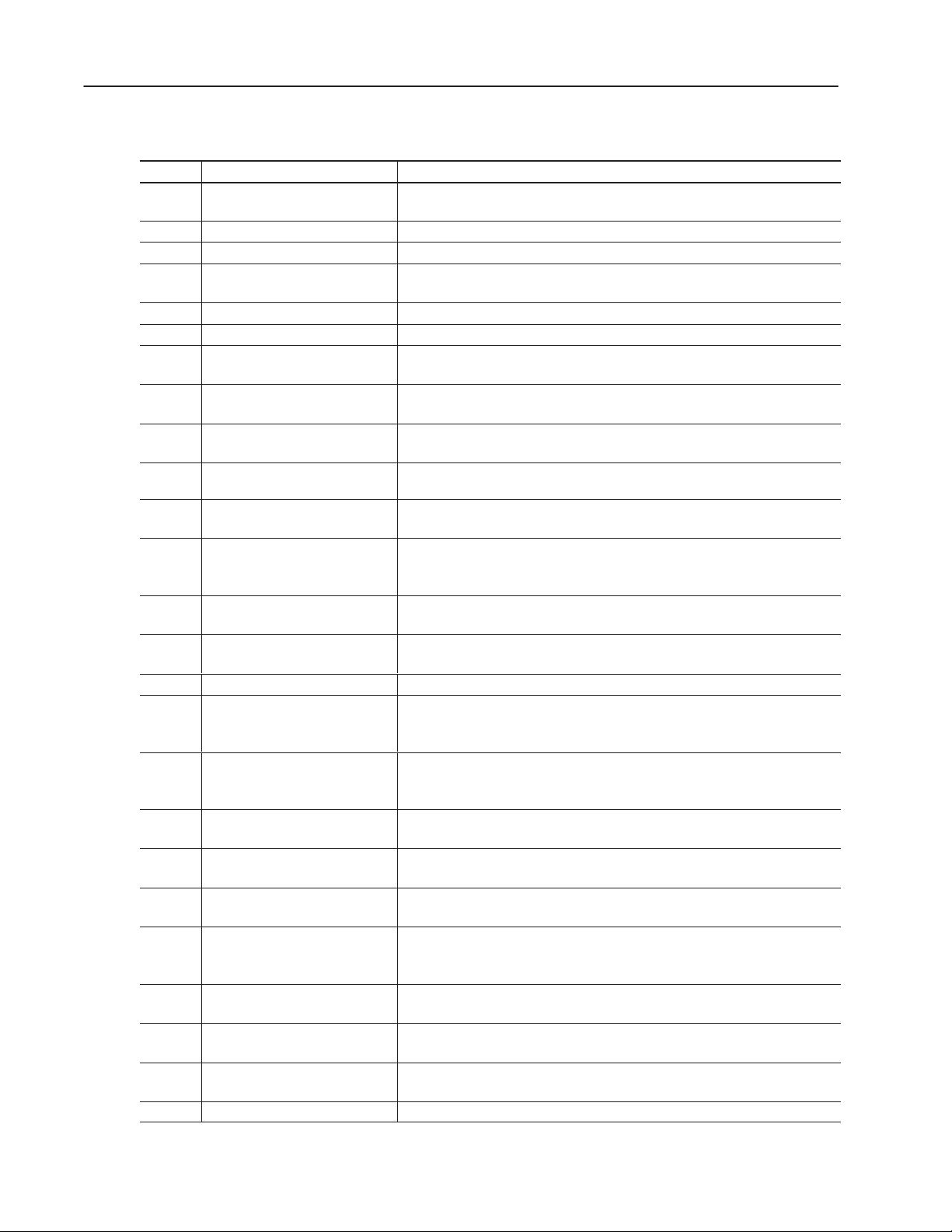

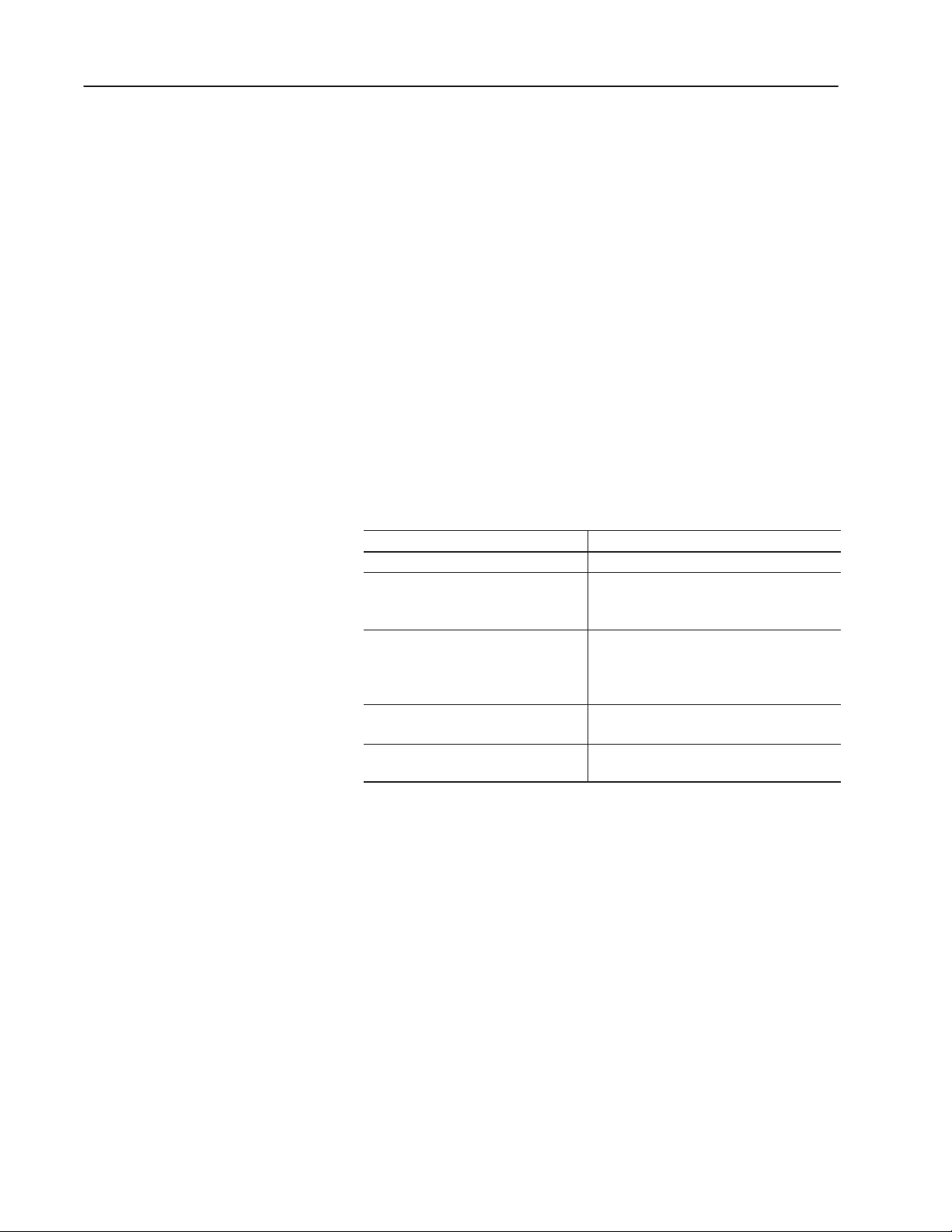

Chapter Title Description

Preface Describes the purpose and contents of the manual, the intended audience and

conventions used.

1 Overview of PanelBuilder Describes PanelBuilder and product features.

2 Installation Tells how to install PanelBuilder on a personal computer.

3 Planning an Application Gives guidelines for planning an application. Also describes worksheets for

application planning.

4 Communications Overview Gives an overview of DH-485, DH+, and Remote I/O communications.

5 PanelBuilder Basics Covers some basics on using PanelBuilder.

6 Working with

Application Files and Screens

7 Working with Objects Describes how to access, create and edit objects. Also describes basic operations

8 Creating Push Buttons Shows how to create and configure momentary, maintained, latched and multistate

9 Creating Control

List Selectors

10 Creating

Data Entry Controls

11 Creating Screen Selectors Shows how to create screen selectors for navigating between screens in an

12 Creating Bar Graphs,

Indicators and Numeric Displays

13 Creating Message Displays Shows how to create message displays and print only message devices which

14 Using Global Objects Tells how to flag an object for global use and access global objects.

15 Creating Alarms Describes alarm components (Alarm Banner display, Alarm buttons, Alarm List,

16 Adding Graphics Shows how to add lines, shapes, ISA symbols and background text to screens.

17 Formatting Objects and Text Shows how to use formatting options to change the visual appearance of objects

18 Using the Text Editor Describes how to use the application Text Editor to create, edit, sort, filter and print

19 Working with Tags Shows how to use the tag editor to enter/edit

20 Terminal and Communication

Setup

21 Managing Projects Tells how to link a project to an application and how to copy, rename, delete

22 Multi-Lingual Support Shows how to use the FontTool utility to create and use font files (in specific

23 Validating and

Transferring Applications

24 Creating Reports Tells how to create and print application reports.

Shows how to open, close and save application files and screens. Also tells how to

exit PanelBuilder.

such as how to select, size, move, group and zoom objects.

push button controls.

Shows how to create and configure standard and piloted control lists.

Shows how to create objects that open a scratchpad for numeric or ASCII data

entry.

application. Screen selectors include goto/goto config screen/return screen buttons

and a screen list.

Shows how to create and configure multistate indicators, list indicators, bar graphs

and numeric data displays.

present status information or instructions to the operator.

global alarm parameters, alarm and trigger definitions) and how to use those

components to trigger alarm conditions.

Also shows how to import bitmap graphics from other programs such as

Paintbrush.

and text, including how to add inner text/graphics to objects.

application text, as well as how to reuse text.

tag information, print tags, and import/export tags.

Tells how to set operating and runtime communication parameters for the

PanelView terminal and how to convert applications from one terminal type to

another.

projects or devices in projects.

languages) for PanelBuilder applications.

Describes how to validate and transfer a PanelBuilder application between a

personal computer and a PanelView terminal, PCMCIA memory card or disk file.

Publication 2711-6.0

Page 15

Conventions

Preface P–3

The following conventions are used throughout this manual:

• PanelBuilder refers to the PanelBuilder Configuration Software.

• PanelView or terminal refers to any one of the PanelView

terminals unless specifically stated.

• Windows refers to Windows 95, Windows NT, or Windows 3.1 or

higher.

• Keys on the keyboard appear in small capital letters. For

example, the Ctrl key appears as

ALT, and so on.

CTRL in the text, the Alt key as

• When keys are to be pressed in combination, you’ll see them

connected by a +. For example,

key while you press F4.

ALT+F4 means hold down the ALT

• Procedures begin with bold text followed by a semicolon.

To open an application file:

• A solid right cursor in the left margin indicates a tip or hint.

Anchor point is the handle opposite the handle you choose. The

anchor point doesn’t move when sizing objects.

Related Publications

The following table lists publications related to the PanelBuilder

Configuration Software and the PanelView Operator Terminals.

Publication Title Publication No.

PanelView Terminal User Manual 2711-6.1

PanelBuilder Getting Started Manual 2711-6.2

DeviceNet Communications for PanelView Terminals 2711-6.0.4

ControlNet Communications for PanelView Terminals 2711-6.10

PanelView File Transfer Utility 2711-805

For information relating to your logic controller, INTERCHANGE

or RSLinx Lite Software, or Microsoft Windows, refer to the

appropriate documentation.

Publication 2711-6.0

Page 16

PrefaceP–4

echnical Support Services

T

If you have any questions about PanelBuilder, please consult the

manuals or the online help first. If you can’t find the answer, contact

Rockwell Automation International Support:

Rockwell International

Technical Support

6680 Beta Drive

Mayfield Village, Ohio 44143

Or call 1–440–646–7800 or fax 1–440–646–7801 for technical

support between 8

Please have the serial number of your software ready when you call.

You can find this number in three places:

AM and 5 PM (EST), Monday to Friday.

• on the registration card you received with the software

• on the screen that appears when you start the PanelBuilder

• in the main Help menu, when you choose About

Documents answering frequently asked questions are available from

the Allen-Bradley:

• AutoFax service at 1–440-646-5436

This service provides an index of available documents and will

automatically fax a document 24 hours a day, 7 days a week.

• website www.ab.com on the Technical Support/FAQ menu

Software/Firmware Upgrades

As new features and enhancements become available, you may want

to upgrade your PanelBuilder software and PanelView firmware.

To automatically receive free software upgrades, complete and send

in your software registration card to Rockwell Software. You can

also receive software upgrades by contacting:

• local Allen-Bradley sales office

• Rockwell Software at 1–440-646-7700 or fax 1–440–646–7701

• access the website www.software.rockwell.com. Under Support,

select Software Updates and search for PanelBuilder or

2711ND3.

To receive firmware upgrades:

• contact Rockwell Software at 1–440-646-7700

• access the Allen-Bradley website www.ab.com and download the

upgrade by selecting Rockwell Automation Technical Support

and then file download.

Publication 2711-6.0

Page 17

Overview of PanelBuilder

Chapter Objectives

What is PanelBuilder?

What is an Application?

This chapter contains the following sections:

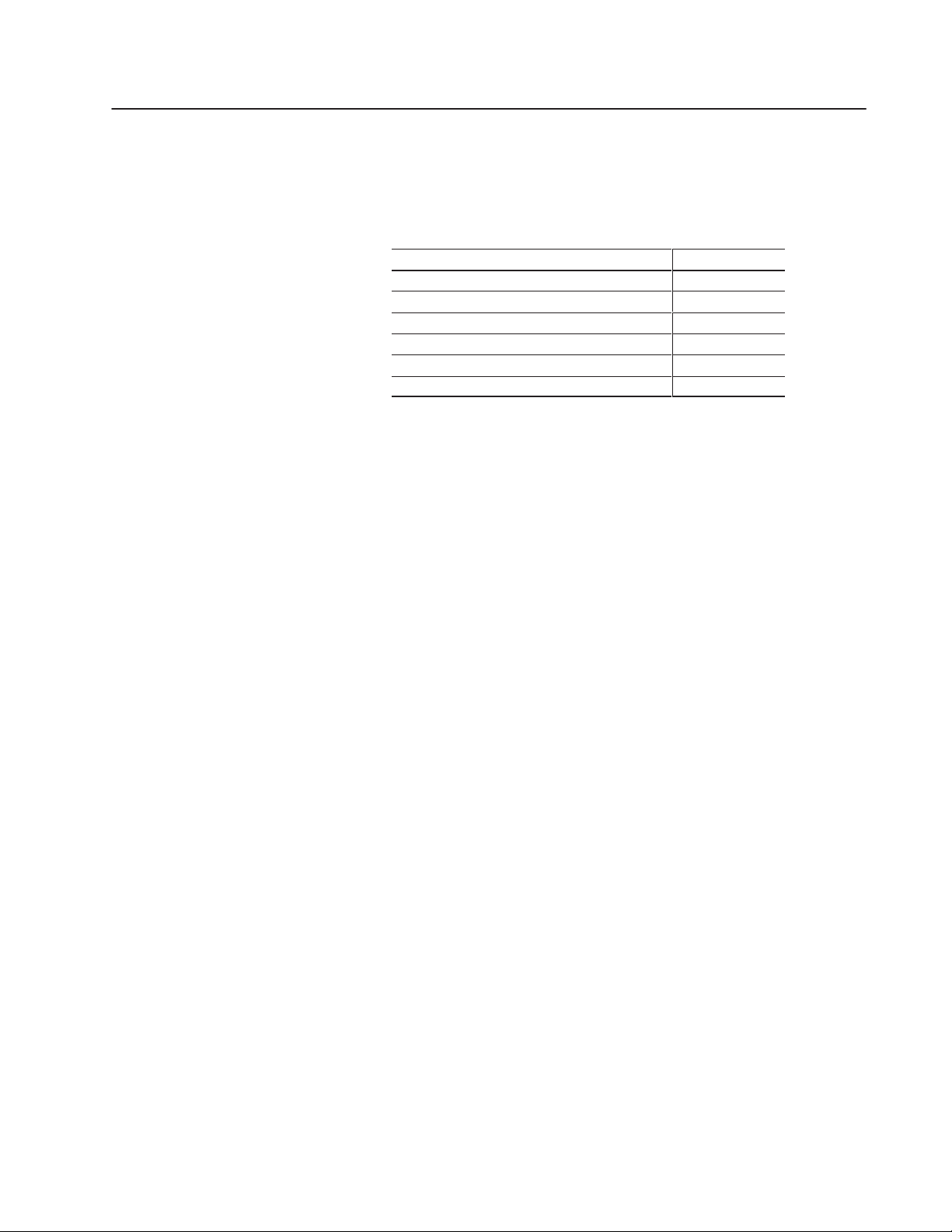

Section Page

What is PanelBuilder? 1–1

What is an Application? 1–1

What is a Project? 1–1

PanelBuilder Features 1–2

Typical Application Screens 1–5

Screen Objects 1–6

PanelBuilder is a Microsoft Windows based package that lets you

design control panel applications for PanelView terminals. To

simplify application design, the software uses menus, dialog boxes

and tools which are standard in Windows.

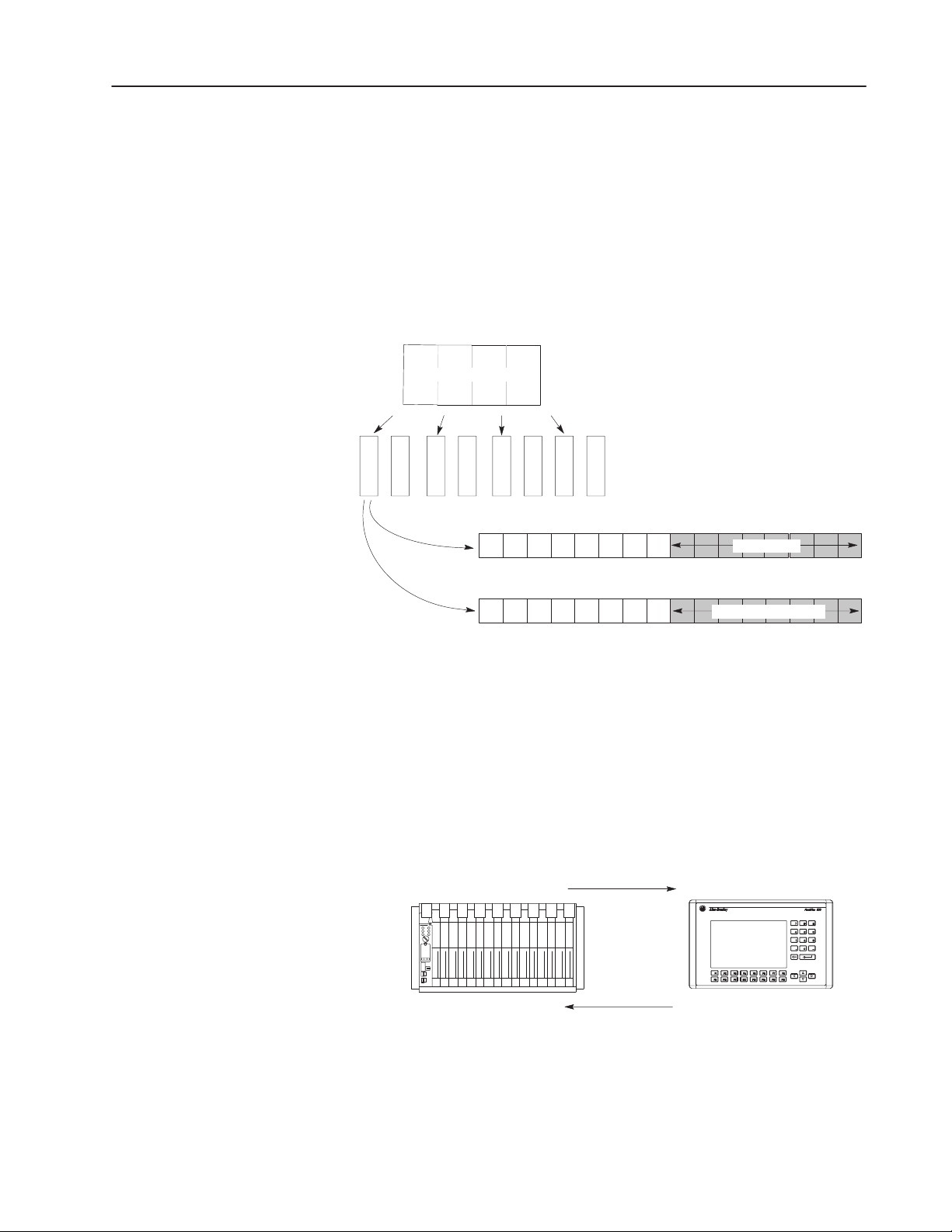

A PanelBuilder application is a logical arrangement of screens

containing objects such as push buttons, indicators, control lists, bar

graphs and alarms. When the application is downloaded to a

terminal, the operator interacts with these objects by pressing

function keys or touching the terminal screen.

What is a Project?

Applications are transferred between your computer and a

PanelView terminal using a serial connection, memory card or

Pass-Through.

PanelBuilder applications communicate with logic controllers on a

variety of networks including: DH-485, DH+, DF1, Remote I/O,

DeviceNet and ControlNet.

The ports on the PanelView terminal determine the communication

protocol used.

Each PanelBuilder application (.PBA file) is associated with a

project. The project identifies:

• controller addresses, called tags, that PanelBuilder objects write

to or read from. (Tags defined in the Tag Editor.)

• runtime communication parameters for the PanelView terminal

and controller (Devices defined in Terminal Setup.)

Different applications can use the same project tags if the

applications use the same communication protocol.

Publication 2711-6.0

Page 18

1–2 Overview of PanelBuilder

PanelBuilder Features

This section gives an overview of PanelBuilder features.

Tool or Menu Operation

PanelBuilder runs under Microsoft Windows. Tools, keystrokes or

menu commands are used to perform most functions. Use any or all,

whichever you find most convenient.

Spreadsheet Editors

Spreadsheets are used to simplify many editing operations, for

example to:

• edit states of multistate or list objects

• edit application text

• edit alarms and alarm triggers

Many formatting options for text and objects can be configured

directly from cells in the spreadsheet.

T ool Bar

✓

Status Bar

✓

T oolbox

✓

✓

ISA Symbols

✓ Color Palette

✓ Keypad

ST 0

Selectable Preferences

Set features of the workspace window to those you prefer or like to

use often. Options like the tool bar and toolboxes can be toggled on

or off depending on their usage. PanelBuilder uses the last settings

when a new application is created or when you start a new session.

Help and Status Bar Information

Status bar and help options provide immediate online assistance.

Predefined Objects and Drawings

To simplify application development, PanelBuilder provides a set of

predefined objects (such as push buttons, bar graphs, ISA symbols).

Additional graphics are available to create your own drawings or to

enhance screens. You can also import bitmap graphics (monochrome

or color) created with other programs. A variety of format options

are available to change the appearance of objects and text.

Global Objects

Publication 2711-6.0

A global object references an object that appears multiple times in an

application. Any non-graphic object can be designated as a global

object. You can access a global object from any screen. When

modifying a global object, PanelBuilder automatically updates all

links to it. The PanelView terminal stores one copy of a global

object regardless of the number of links to it.

Page 19

1–3Overview of PanelBuilder

Tag Editor

The Tag Editor is used to enter, update, print, import/export

application tags. Each tag has attributes defining how an object

interacts with a controller address. Enter all tags at once using the

table view or one tag at a time using the tag form dialog.

Color Palette

A fixed color palette is available for creating color or grayscale

applications. For color terminals, the palette supports 16 standard

EGA colors. For grayscale terminals, the palette supports 4 colors.

Use the palette to apply colors to the foreground and background of

objects, text and graphics. Color and grayscale applications support

both monochrome and color bitmaps.

Foreground and background colors are accessed from the Format

menu, the color palette, or the State tab of multistate/list objects.

Alarms

The Alarm System includes:

• Alarm Banner display that pops up over the current screen to

notify the operator when an alarm occurs.

• Alarm Buttons to allow the operator to act on an alarm.

• Alarm List displays information on the last 100 alarms including

whether they have been acknowledged.

• Alarm List buttons to print or clear alarms in an alarm list.

• Alarm Setup dialog that provides a set of tabs to configure

alarms, triggers and global alarm parameters.

Reports

Create customized reports for an application including:

• application description

• object attributes

• application text

• terminal settings

• tags

• alarm definitions

• screen images and alarm banner display

Print reports to a file or a graphic printer supported by Microsoft

Windows.

Publication 2711-6.0

Page 20

1–4 Overview of PanelBuilder

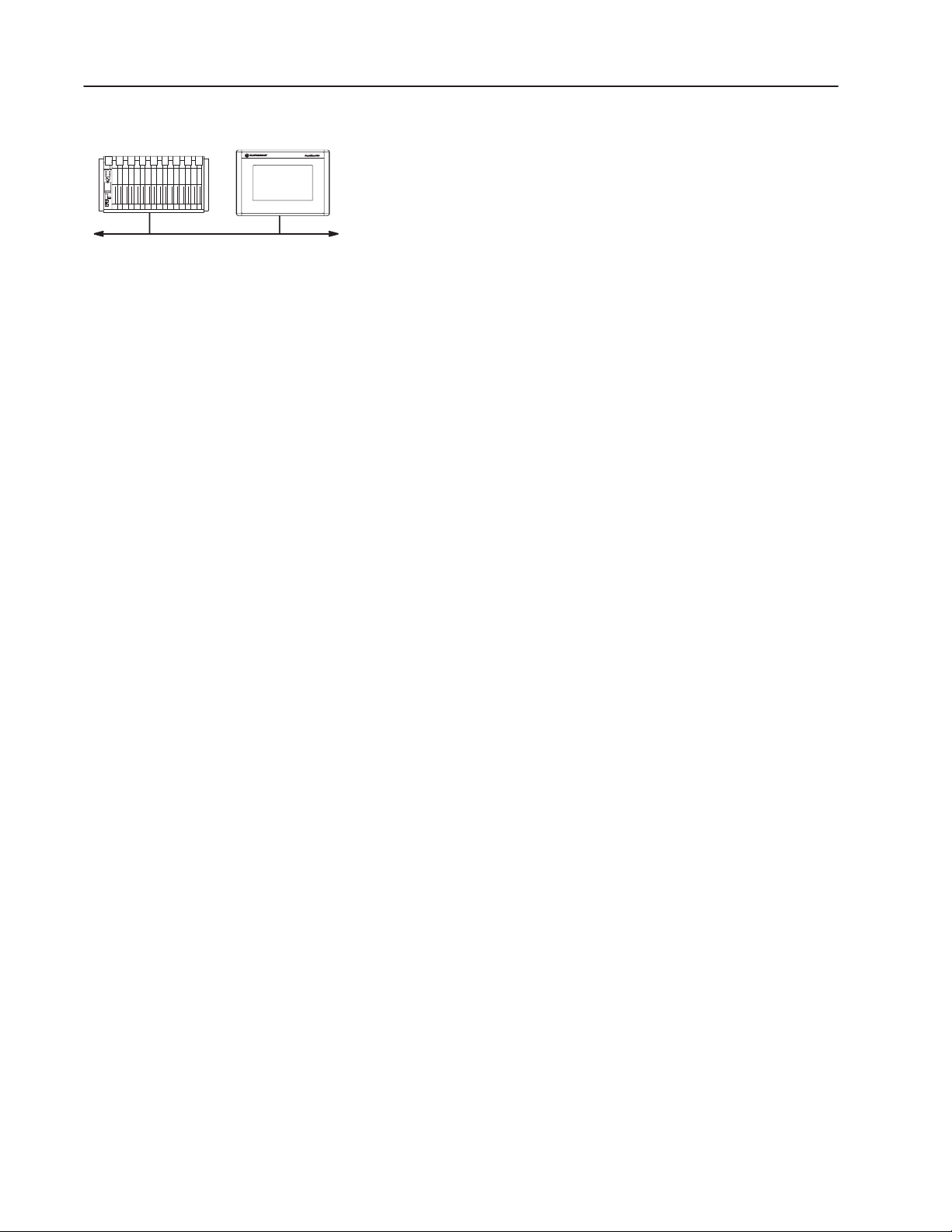

PLC Controller

PanelView Terminal

Terminal and Communication Setup

Operating and runtime communication parameters for the PanelView

terminal and logic controller are accessed from the Terminal Setup

dialog, including:

• RS-232 printer port setup

• power-up defaults

• time/date display format

• font file selection (for a specific language)

• PLC/SLC controlled options (screen and time/date changes)

• auto repeat settings for terminal keys/touch cells, display settings,

language setting for terminal messages, and handshake timeout

Application Validation

Use the validation feature to check an application for correct

operation. An application is validated automatically when it is

downloaded to a terminal. You can also validate an application at

any time using a menu command. Warnings or errors detected

during validation can be viewed or printed to a printer or file.

Application Upload / Download Capabilities

Transfer applications between the computer running PanelBuilder

and a PanelView terminal using a:

• serial connection

• Pass-Through from a computer on the DH+ network

• memory card

• DOS file

Computers with a DataBook TMB-240 or TMB-250 card drive can

transfer applications to/from Allen-Bradley’s flash memory cards

(Catalog No. 2711-NM11, -NM12, -NM13, -NM14).

Computers with a PCMCIA/ATA card drive can transfer applications

to/from Allen-Bradley’s ATA memory cards (Catalog No.

2711-NM22, -NM24, -NM26). Laptops are compatible with the

ATA memory cards, supporting Windows 95 Plug and Play devices.

Publication 2711-6.0

Page 21

1–5Overview of PanelBuilder

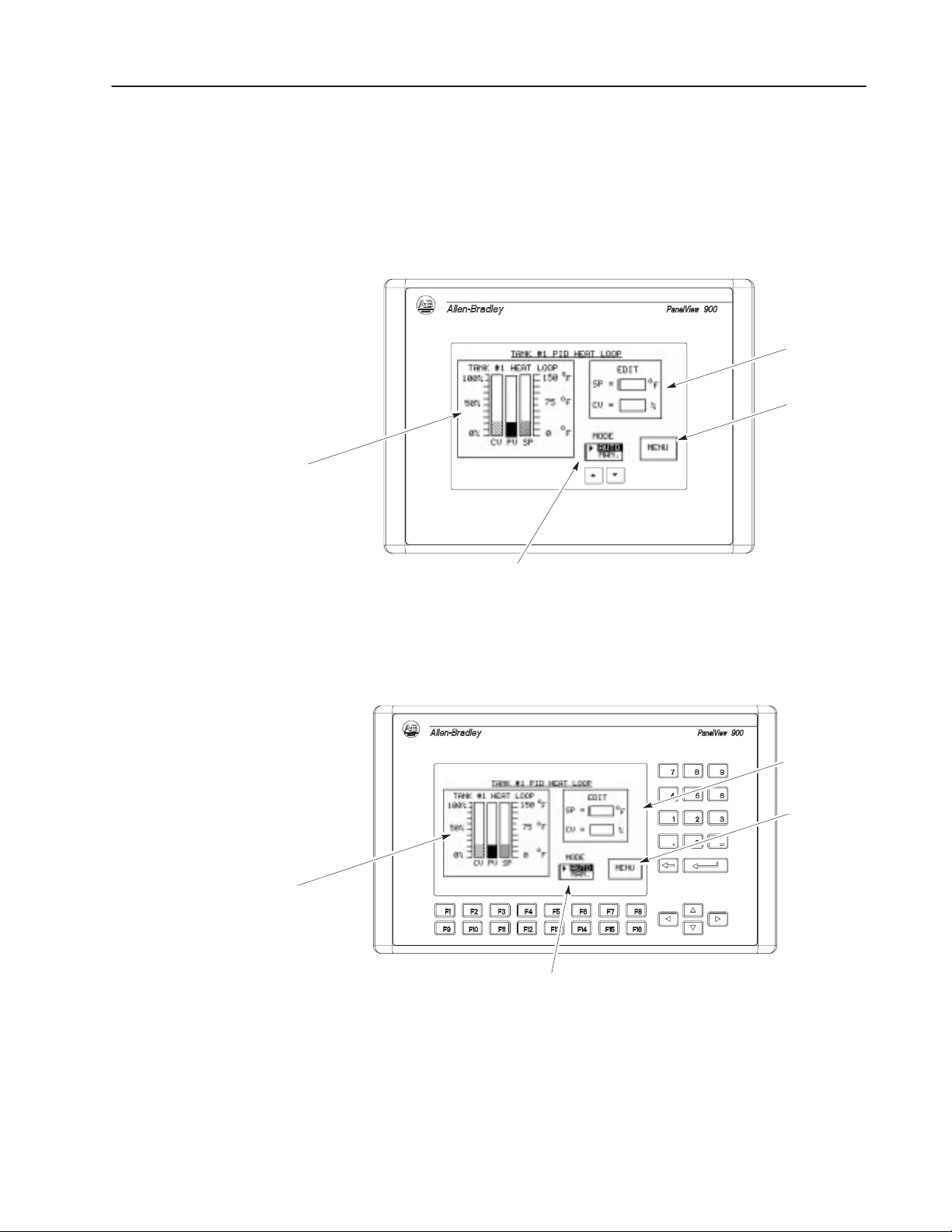

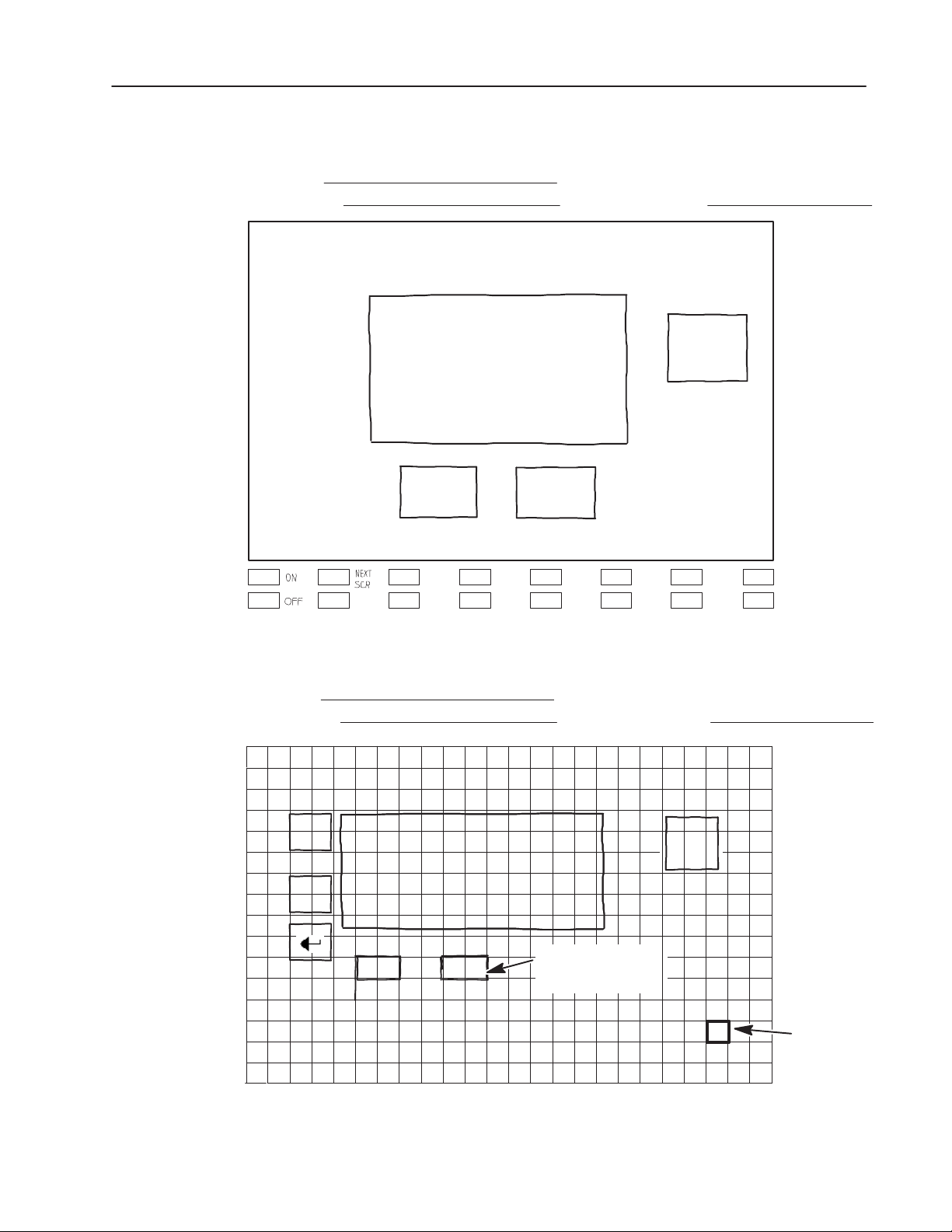

pical Application Screens

Ty

Bar Graphs

Application screens can contain a variety of control, display or

graphic objects. The following screens show examples of:

• Control list selector

• Numeric entry cursor points

• Bar graphs

• Goto screen button

Numeric Entry

Cursor Points

Goto

Screen Button

Control List Selector

Bar Graphs

On touch screen terminals, the operator activates input functions by

touching a screen object. For example, to view the main menu

screen, the operator touches the MENU button.

Numeric Entry

Cursor Points

F6

Control List Selector

F6

F7

F8

Goto

Screen Button

On keypad terminals, the operator activates input functions by

pressing the function key assigned to the object. For example, to

view the main menu screen, the operator presses the F8 or MENU

function key. To activate the cursor point objects, the operator

presses the function keys labeled F6 or F7 (SP or CV).

Publication 2711-6.0

Page 22

1–6 Overview of PanelBuilder

Control List Selectors

or when the Enter key is pressed. Pressing Enter is an option selected

umeric Data Entr

umeric Data Entr

CII Data Entr

CII Data Entr

ata Displays

creen electors

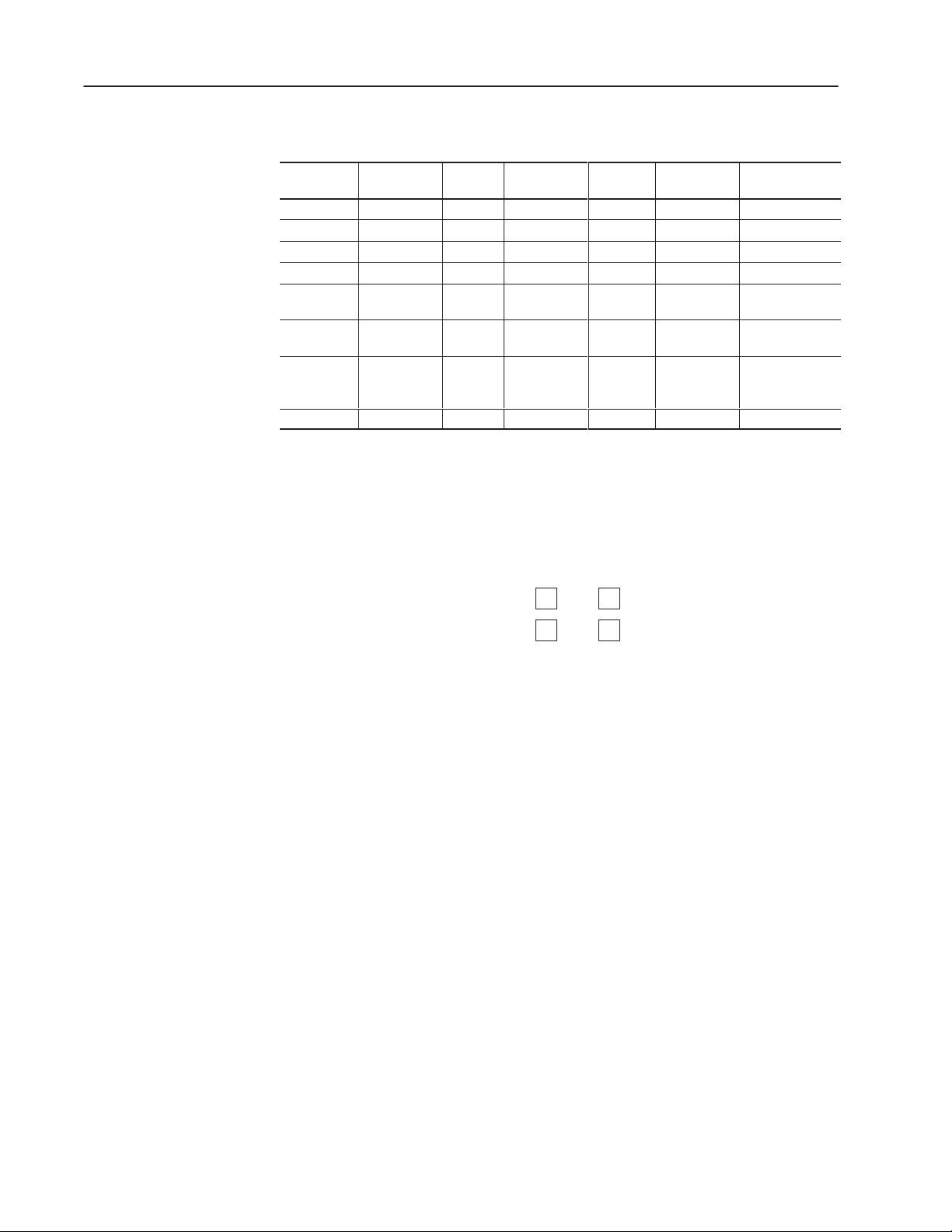

Screen Objects

Screen Objects Description Type

Push Button Controls

N

N

AS

AS

Indicators and

Data Displays

D

Variables

Screen Selectors

y

y

y

y

The table below lists objects you can place on a screen. An object is

either dynamic or static.

• Dynamic objects interact with a controller address.

• Static objects do not interact with a controller address.

Momentary Push Button Changes state when pressed and returns to original state when released. Dynamic

Maintained Push Button Changes state when pressed and remains in this state when released.

Press and release again to return push button to its original state.

Latched Push Button

Multistate Push Button Supports 2 - 16 states. Changes state each time button is pressed. After

Standard Control List➀

Piloted Control List➀

Cursor Point Displays current value at controller address in a data box. When

Keypad Enable Button

Cursor Point Displays current string at controller address in a data box. When

Keypad Enable Button

Multistate Indicator Displays one of up to 2,000 unique states. The value at a controller

List Indicator Highlights a state in a scrolling list supporting up to 255 states. The value

Bar Graph

Numeric Data Display Shows current value at a controller address (binary, BCD, integer, float).

Message Display Presents status information or instructions to operator. The controller

Print Only Message Object Similar to a message display but messages print out on the connected

Time Inserts a time variable within a text string. Static

Date Inserts a date variable within a text string. Static

ASCII Variable

Numeric Variable

Goto Screen Button Moves to a specific application screen. Static

Goto Config Screen Button Displays the PanelView terminal’s Configuration Mode menu. Static

Return Screen Button

Screen List Selector➀

Changes state when pressed and remains in state until unlatched by

controller.

the last state, the button returns to its initial state and repeats cycle.

Allows operator to select a control option from a scrolling list of up to 255

options. The terminal’s up and down arrow keys are used to move

through the list. The selected option is sent to the controller immediately

during application configuration.

Restricts control list access to the controller, operator or both. A piloted

control list allows the controller to select a state from the list.

selected, the scratchpad opens allowing you to change the value using

the keypad.

When pressed, opens the scratchpad and activates the terminal keypad

or touch screen keypad for numeric data entry.

selected, the scratchpad opens allowing you to change the character

string using the keypad.

When pressed, opens the scratchpad and activates the terminal keypad

or touch screen keypad for ASCII data entry.

address determines which state to display.

at a controller address determines which state to highlight.

Monitors changing conditions such as temperature, pressure or fluid

levels. Create bar graphs with or without scales.

Use scaling (y=mx+b) to display value in appropriate units.

triggers messages from a predefined list of up to 2,000 messages.

printer when triggered rather than display on the terminal screen.

Inserts an ASCII variable within a text string.

Inserts a numeric variable within a text string.

Returns to previous screen. Static

Displays a screen selected from a list of screens. The terminal’s up and

down arrow keys are used to move through the list.

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Dynamic

Static

Publication 2711-6.0

Page 23

List Keys➀

ist e s

raphics

Alarms

Graphics

Screen Objects TypeDescription

Move Up Moves cursor up one item in a control list or screen list selector. Static

Move Down Moves cursor down one item in a control list or screen list selector. Static

Home Moves cursor to the first item in a control list or screen list selector. Static

End Moves cursor to the last item in a control list or screen list selector. Static

Page Up

Moves cursor up one page in a scrolling control list or screen list. Static

Page Down Moves cursor down one page in a scrolling control list or screen list. Static

Backspace Returns cursor to currently highlighted selection in a control or screen list. Static

Enter Displays screen selected from a screen list selector or confirms a control

list selection and sends that selection to the controller.

Acknowledge Button Acknowledges the alarm displayed in the Alarm Banner and removes the

Alarm Banner from the terminal display.

Clear Button Clears the Alarm Banner from the terminal display without acknowledging

the alarm.

Print Button Prints the current message displayed in the Alarm Banner. Static

Acknowledge All Button

Acknowledges all alarms (current and pending) and removes the Alarm

Banner from the terminal display.

Alarm List ➀

Displays a list of triggered alarms. The operator can acknowledge alarms

in the list, clear the list or print the list

Print Alarm List Button Prints all alarms in the Alarm List. Static

Clear Alarm List Button Clears the Alarm List. Also clears the Alarm Banner even though the

alarm condition may still exist.

Line/Connected Line Creates a line or connected lines. Static

Rectangle Creates a rectangle or square. Static

Circle/Ellipse Creates a circle or ellipse. Static

Freeform Creates a freehand drawing. Static

Scale

Creates scale with tick marks for bar graph or other purpose. Static

Background Text Creates screen titles or background text not linked to object. Static

ISA Symbols Select one of 32 predefined drawings such as a valve to place in an

object or on the screen.

Imported Graphics Imports/exports bitmaps created with other programs. Static

1–7Overview of PanelBuilder

Static

Dynamic

Static

Dynamic

Dynamic

Static

Static

➀ PanelView 900, 1000 and 1400 Touch Screen terminals require list keys to move the cursor through a control list, screen list selector, or alarm

list. The list keys are also supported on the keypad versions of these terminals.

Publication 2711-6.0

Page 24

1 Publication XXXX-X.X.X - Month Year

Page 25

Installation

Chapter Objectives

System Requirements

This chapter contains the following sections:

Section Page

System Requirements 2–1

Installing PanelBuilder Software 2–2

RSLinx Lite Software 2–7

INTERCHANGE Device Configuration Utility 2–10

INTERCHANGE Notes 2–16

The minimum hardware and software requirements for installing and

running PanelBuilder are:

• personal computer using a 386 or higher processor

• MS-DOS operating system version 5.0 or later

• Windows 3.1 or later (Windows for Workgroups version 3.11 or

later), Windows 95, or Windows NT 4.0.

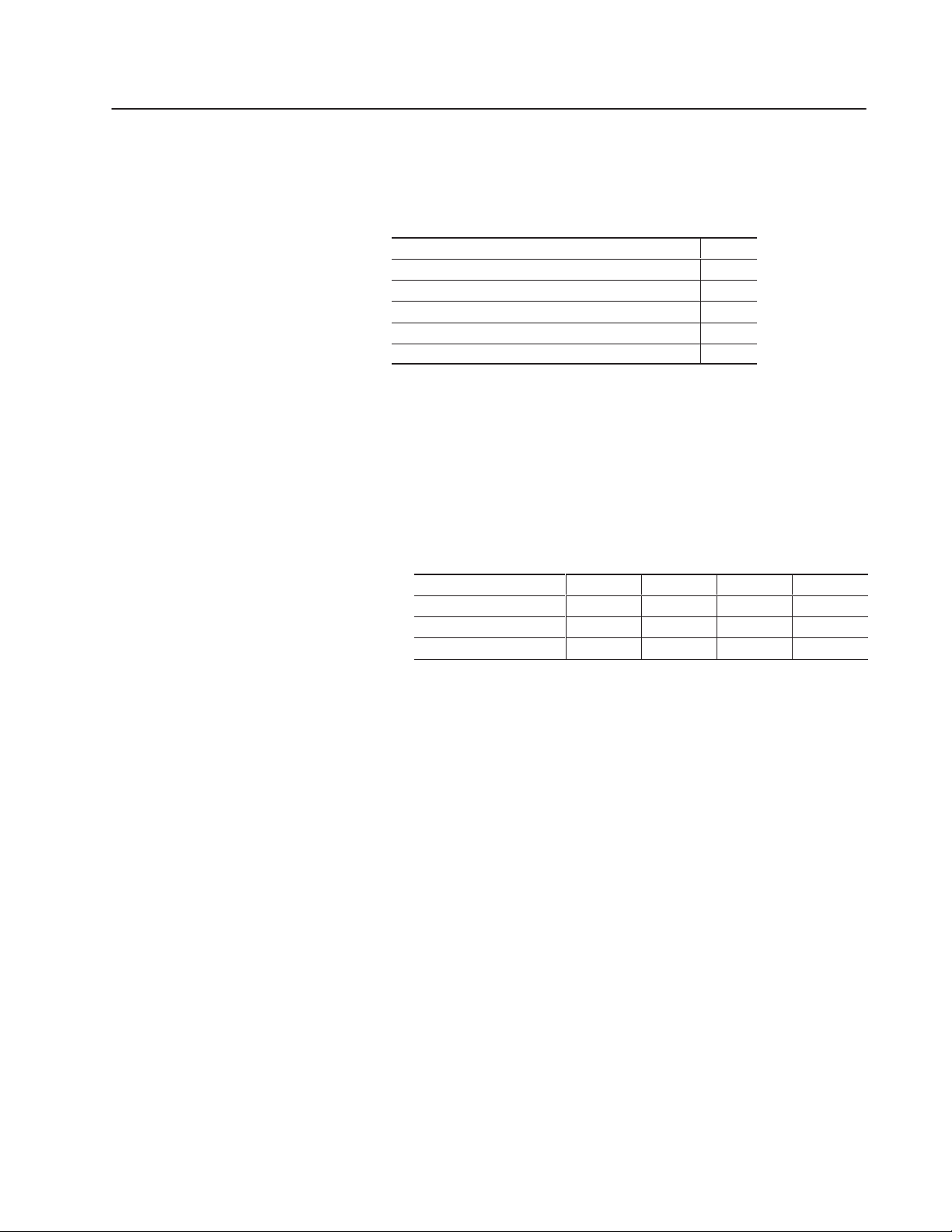

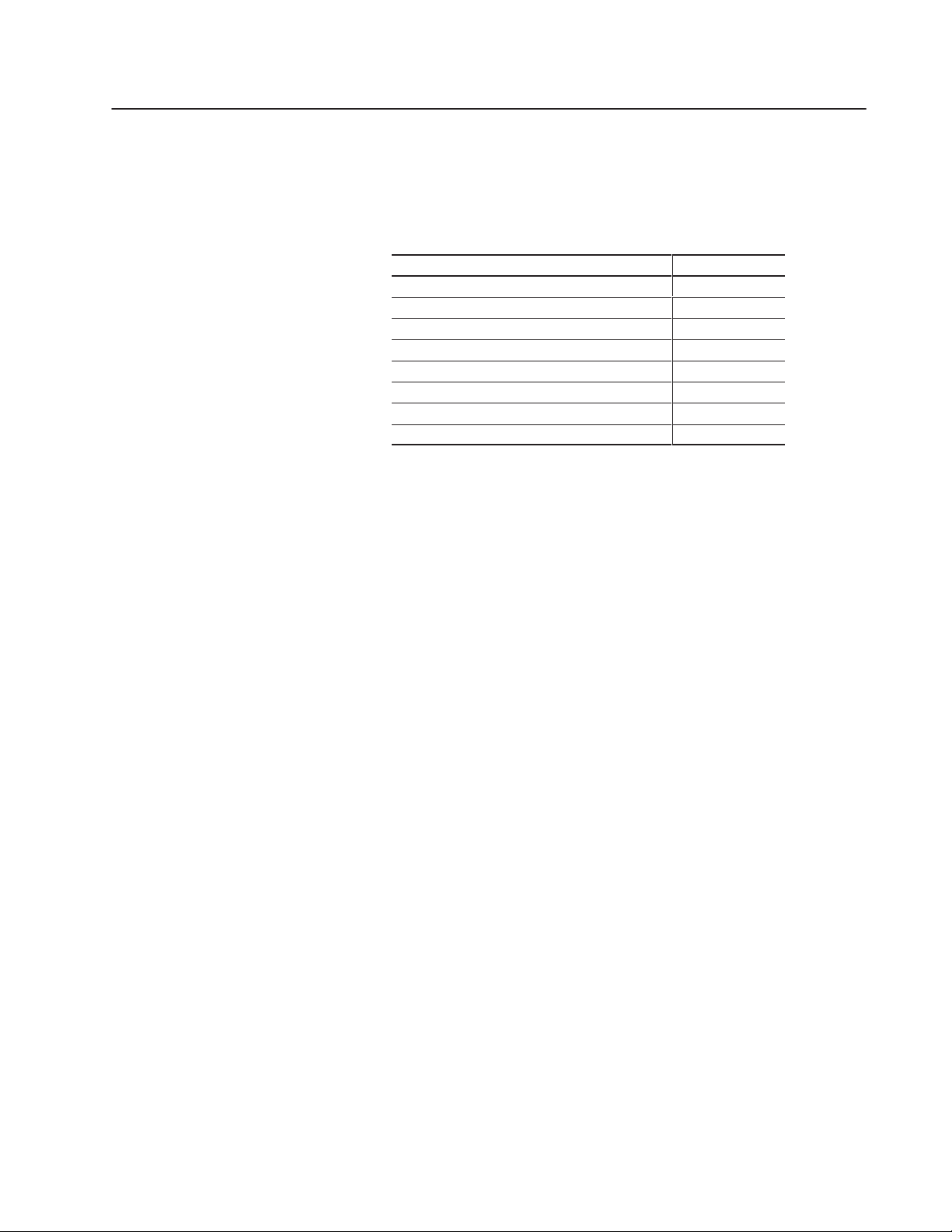

The RAM requirements for each operating system are as follows:

Software 3.X 95 NT 4.0 NT 4.0/486

PanelBuilder 8 MB 16MB 32 MB 32 MB

External Font Support 8 MB 8 MB 16 MB 32 MB

RSLinx Lite ➀

➀ RSLinx Lite only runs in Windows 95 or Windows NT 4.0.

Note: To determine the RAM required to run PanelBuilder with

other components use the maximum specified. For example, to

run PanelBuilder and RSLinx in NT 4.0, 32 MB is required.

N/A 16 MB 16 MB 32 MB

• 500K free conventional memory

• at least 40 MB available hard disk space

• VGA or other high-resolution display supported by Windows

• Mouse or other Windows pointing device

• One of the following for downloading or uploading applications:

– Personal Computer Interface Converter (Catalog No.

1747-PIC) and cable (Catalog No. 1747-C10,-C11,-C20) for

transferring applications between a computer and a DH-485

PanelView terminal.

– Cable (Catalog No. 2711-NC13, -NC14, 2706-NC13) for

transferring applications directly between a computer and the

RS-232/DF1 port of a PanelView terminal.

– ATA card drive or DataBook TMB240/TMB250 (Windows

3.x or 95 only) card drive for transferring applications to/from

a memory card.

– Appropriate communications card and cables if transferring

applications using Pass-Through over a DH+ network.

Publication 2711-6.0

Page 26

2–2 Installation

Optional Equipment

• Graphic printer that’s supported by Windows

• Power Supply (Catalog No. 1747-NP1) for desktop transfers

between a personal computer and a DH-485 PanelView terminal.

Provides power to Personal Computer Interface Converter when

terminal isn’t connected to controller.

Installing PanelBuilder

The PanelBuilder installation installs:

• PanelBuilder Software

• AB Utilities Software

• INTERCHANGE or RSLinx Lite Software

INTERCHANGE or RSLinx Lite Software

To download applications to a PanelView terminal, the appropriate

communication driver must be configured on your system. You can

configure a driver using:

• RSLinx Lite Software (Windows 95 or Windows NT 4.0) or

• INTERCHANGE Software (Windows 95 or Windows 3.x)

INTERCHANGE is a common set of real mode

communication drivers that can be shared by different Windows

programs. INTERCHANGE may already be installed on your

computer. The APS and 6200 Programming Software use

INTERCHANGE in DOS or Windows.

To check the version of INTERCHANGE running on your computer,

type DTLVER at the DOS prompt.

DOS TSR

Publication 2711-6.0

RSLinx Lite provides a set of communication drivers that can be

shared by Windows programs. To check the version of RSLinx on

your computer, select About RSLinx from the Help menu.

Installation Notes

Before installing PanelBuilder on a computer running Windows

•

95, check the C:\Windows\System folder for these files:

– VDF1.386

– V485.386

If these files exist, delete them.

• Check that your computer has sufficient system resources and

memory available.

• Close all Windows applications before installing PanelBuilder.

Press

ALT+TAB to check for open applications.

Page 27

2–3Installation

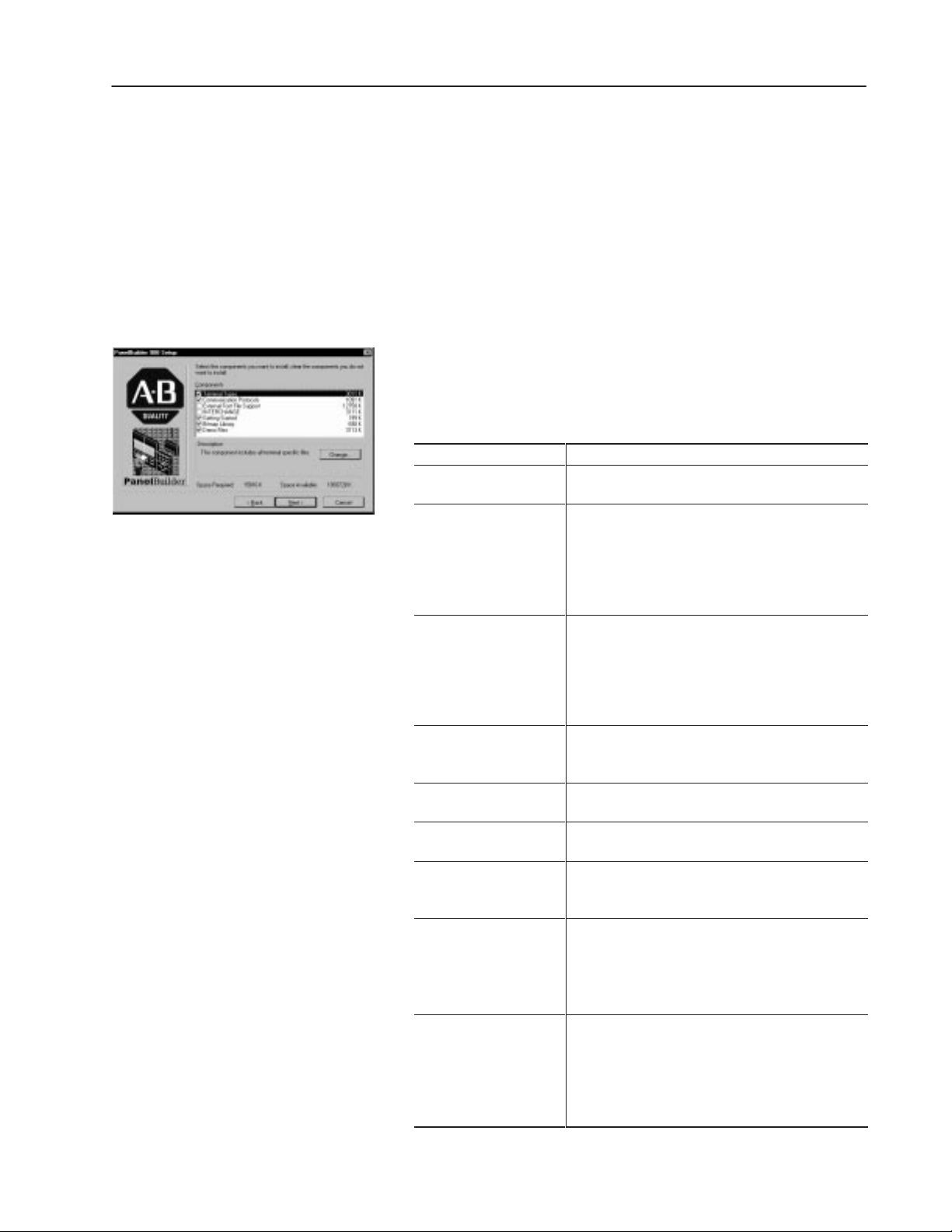

Installation Setup

The setup options available when installing the PanelBuilder are:

• Typical Setup – installs all components listed under the custom

setup except External Font File Support and either

INTERCHANGE or RSLinx communication software.

Note that on Windows 95/NT systems, RSLinx is the default

communication software installed.

• Compact Setup – installs all communication protocols, all

terminal types, and the PanelBuilder Software.

• Custom Setup – installs only specific components that you select

and the PanelBuilder Software. Enable/disable options by

selecting/deselecting check boxes. The custom setup lists the disk

space used by each component with available disk space.

Custom Components Description

PanelBuilder Main

Terminal Types

Communication Protocols

External Font File Support

Getting Started

Bitmap Library

Demo Files

INTERCHANGE

RSLinx

Installs all the files necessary to run PanelBuilder. The

target folder for installing files is C:\AB.

Load all or specific terminal types. You must select at

least one terminal type.

To select all terminal types, click the Terminal Types

check box.

To access the list of terminals, click the Terminal Types

check box and then the Change button.

Loads all or specific communication protocols. You

must select at least one protocol.

To select all communication protocols, click the

Communication Protocols check box.

To access the list of protocols, click the Communication

Protocols check box and then the Change button.

Loads the FontTool utility which is used to create font

files for PanelBuilder applications. Font files are created

in \AB\PBWIN\FONT.

Installs sample applications referenced in the Getting

Started manual. Files are copied to \AB\PBWIN\GS.

Installs .BMP files used by the Import/Export Graphics

function in \AB\PBWIN\PBLIB.

Installs demo application files for the PanelView

terminals. Demo files are copied to

\AB\PBWIN\DEMOS.

Loads INTERCHANGE software which allows you to

configure communication drivers for transferring

applications. Files are copied to C:\RSI.

INTERCHANGE is the default selection in Windows 3.x.

You can load INTERCHANGE or RSLinx, not both.

Loads RSLinx software which allows you to configure

communication drivers for transferring applications.

Files are copied to Program Files\Rockwell Software.

RSLinx is the default selection in Windows 95/NT.

You can load RSLinx or INTERCHANGE, not both (in

Windows 95).

Publication 2711-6.0

Page 28

2–4 Installation

Installation Procedure

If the installation procedure detects the same version of

PanelBuilder, AB Utilities, INTERCHANGE or RSLinx Lite

software, you are given the option of reinstalling these components.

If the installation detects a newer version of software than what you

are installing, you are given the option of downgrading.

If you try to install RSLinx in Windows 95, and INTERCHANGE is

installed, you are warned of the conflict. The same is true if you try

to install INTERCHANGE and RSLinx is already installed.

To install PanelBuilder in Windows 95 or Windows NT:

1. Insert PanelBuilder disk 1 in Drive A: or Drive B:.

2. Click the Start button, click Settings and then click the Control

Panel.

3. Double-click the Add/Remove Programs icon.

4. On the Install/Uninstall tab, click the Install button.

5. Follow the install instructions on the screen.

To install PanelBuilder in Windows 3.x:

1. Insert PanelBuilder disk 1 in Drive A: or Drive B:.

2. In Program Manager, choose Run from the File menu (

ALT+F, R).

3. Type the location you’re installing from plus the word setup.

For example, type a:setup

4. Click OK and follow the install instructions on the screen.

PanelBuilder setup with INTERCHANGE

To successfully transfer applications using INTERCHANGE drivers,

you must install PanelBuilder with

INTERCHANGE. You cannot

install PanelBuilder and INTERCHANGE as separate components.

1. Enter and verify registration information. The serial number is on

your registration card.

2. Select setup option. Typical or Custom will install PanelBuilder

with INTERCHANGE.

Publication 2711-6.0

3. Select destination folder for files.

• Default for PanelBuilder and AB Utility files is C:\AB.

• Default for INTERCHANGE files is C:\RSI.

Page 29

2–5Installation

4. Installation files are copied to the appropriate folders.

5. Specify whether you want to update your AUTOEXEC.BAT file.

The CALL ABICRUN.BAT statement must be correctly placed.

The file may contain multiple configurations which require

updating. Below is a sample AUTOEXEC.BAT file.

SET ABIC_CONFIG=C:\RSI\IC\BIN

.

.

PATH= C:\DOS;C:\WINDOWS

SET PATH= C:\AB\BIN;%PATH%;C:\RSI\IC\BIN

.

.

SHARE.EXE (Windows 3.x only)

.

.

➀

CALL ABICRUN.BAT

WIN

➀

CALL statement ensures that the remaining lines of AUTOEXEC.BAT execute (used only with

DOS version 5.0 or later). The CALL statement (CALL ABICRUN.BAT) must be the last driver

(TSR) loaded before running Windows (WIN).

6. In Windows 95, select the PanelBuilder folder for storing

program icons.

In Windows 3.x, program icons are stored in the PanelBuilder

group under Program Manager.

7. The INTERCHANGE Device Configuration utility opens.

Optionally, select and configure the communication driver that

your computer will use to transfer PanelView applications.

8. Review the release note that appears at the end of the installation.

9. When the installation is complete, you must exit Windows and

reboot your computer.

When the setup utility finishes:

• In Windows 95, PanelBuilder programs and INTERCHANGE

appear on the Start menu under Programs

PanelBuilder.

• In Windows 3.x, PanelBuilder programs and INTERCHANGE

appear as icons in the PanelBuilder group.

Publication 2711-6.0

Page 30

2–6 Installation

PanelBuilder Setup with RSLinx

1. PanelBuilder setup utility

• Enter and verify registration information. The serial number

is on your registration card.

• Select setup option. Typical or Custom will install

PanelBuilder with RSLinx.

• Select destination folder for installing PanelBuilder files and

the AB Utilities software. The default is C:\AB.

• PanelBuilder files are copied to the appropriate folders.

• Select the PanelBuilder folder (\Windows\Start

Menu\Programs) for storing program icons.

When the setup utility finishes, PanelBuilder programs will

appear on the Start menu under Programs

PanelBuilder.

2. RSLinx setup utility

• Select destination folder for RSLinx files. The default is

C:\Program Files\Rockwell Software\RSLinx\.

• Select the Rockwell Software folder (\Windows\Start

Menu\Programs\) for storing program icons.

• RSLinx files are copied to appropriate folders.

When the setup utility finishes, RSLinx programs will appear on

the Start menu under Programs

Rockwell Software.

PanelBuilder Programs

In Windows 95, PanelBuilder programs are accessed using the Start

button. In Windows 3.1 program icons are accessed from the

PanelBuilder group icon.

PanelBuilder includes the following components:

• Application File Transfer Utility – transfers converted

applications (.PVA files) between a computer and PanelView

terminal within Windows, but outside of PanelBuilder.

• Font Tool (optional) – creates font files for specific languages

which can be accessed within PanelBuilder.

• PanelBuilder – creates applications for PanelView terminals.

• PanelBuilder Release Notes – displays the most updated

information, including problems and workarounds for the

PanelBuilder software.

• PBUninstall – uninstalls PanelBuilder from your system.

If INTERCHANGE was installed, the INTERCHANGE Device

Config. Utility and release notes will also appear.

Publication 2711-6.0

Page 31

2–7Installation

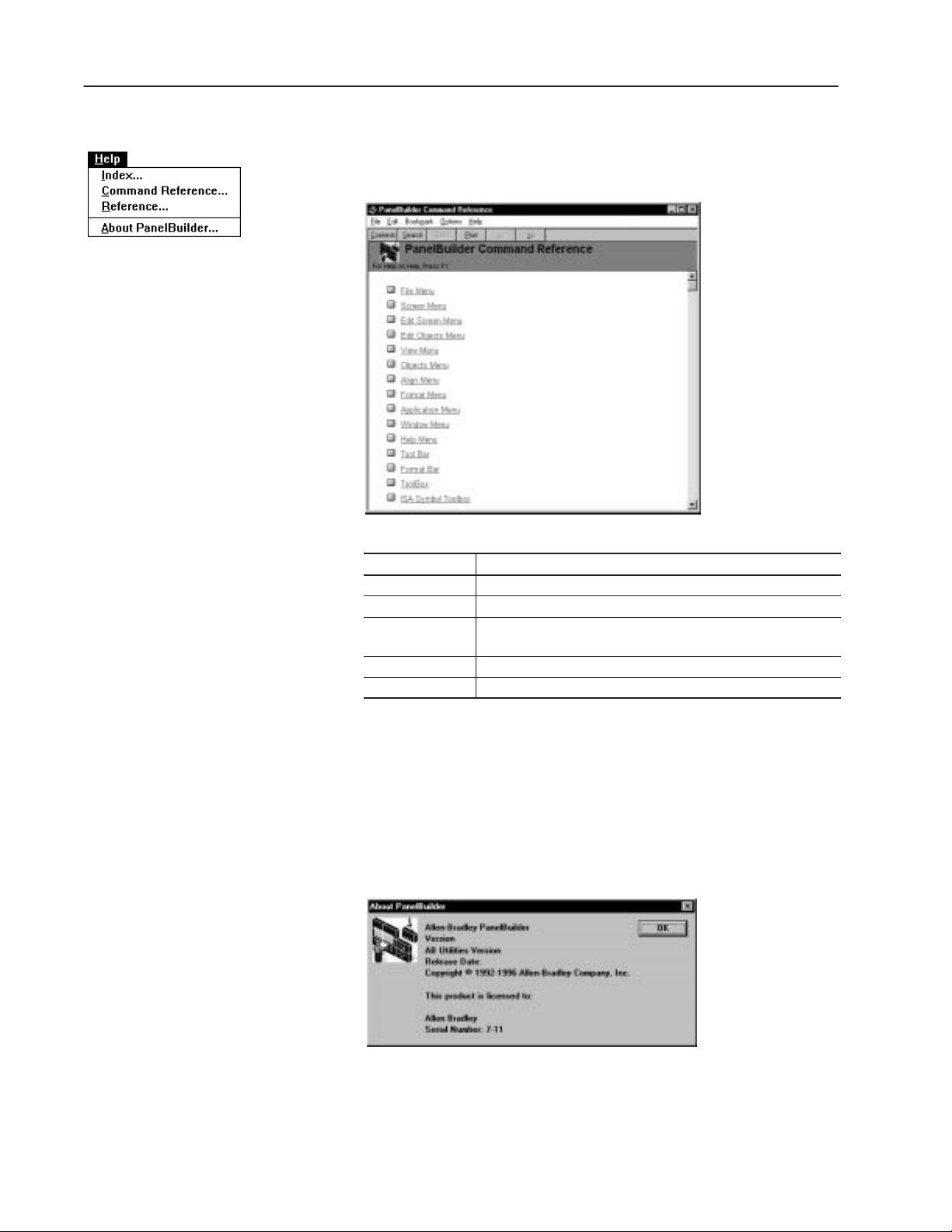

RSLinx Lite Software

→

PanelBuilder’s File Menu

In Windows 95 or Windows NT, use the RSLinx Lite software to

configure communication drivers that your computer requires to

transfer PanelBuilder applications.

To transfer applications using a serial connection (Internal DF1

driver), memory card or DOS file (using the PanelView File Transfer

Utility for DH-485 terminals), RSLinx is not required.

To access RSLinx Lite:

• In Windows 95 or Windows NT, click the Start button, click

Programs, click Rockwell Software, click the RSLinx submenu

and select RSLinx.

• Or choose the Workstation Setup command from the File menu of

the PanelBuilder software.

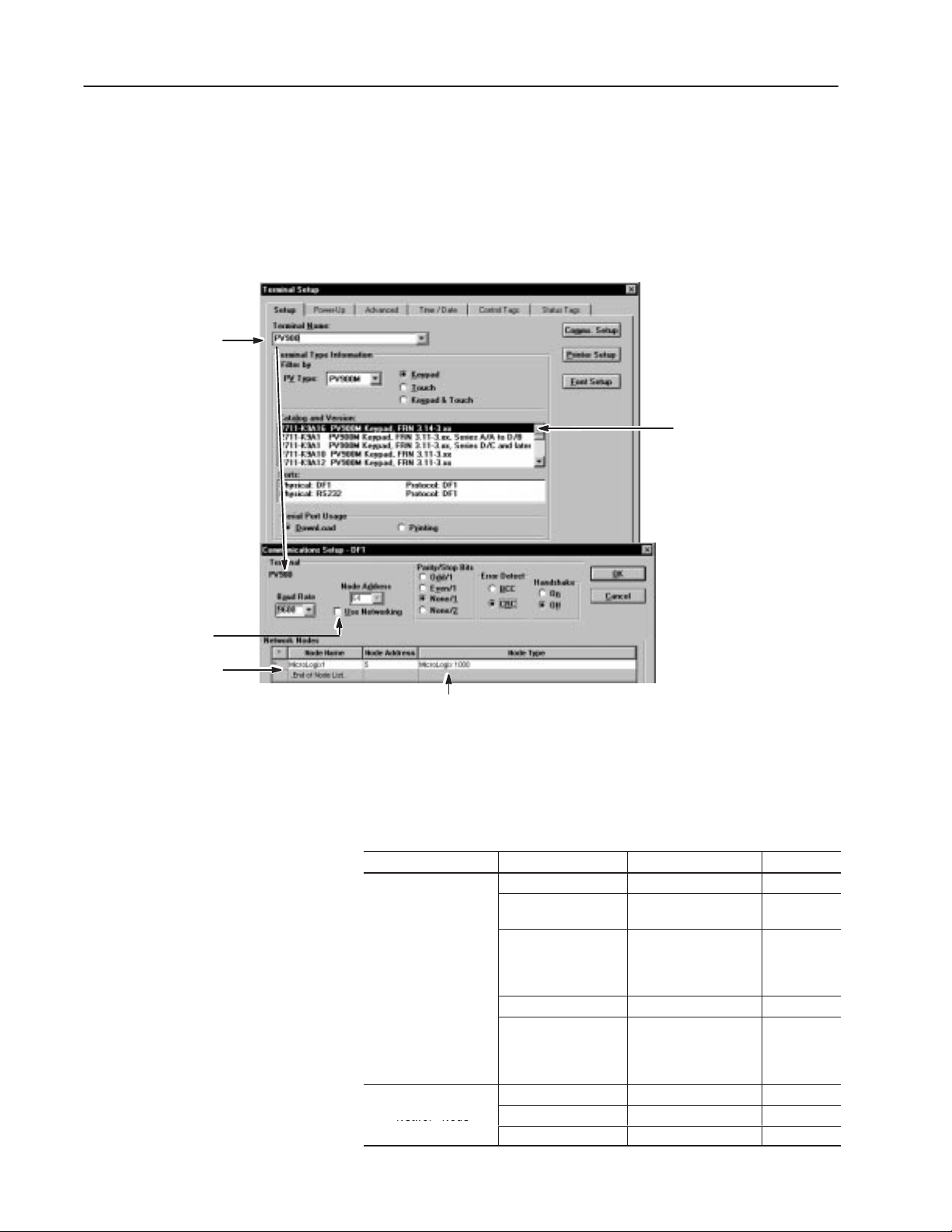

Configuring RSLinx Communication Drivers

The following procedures show how to configure a DF1 or 1747-PIC

driver for transferring PanelBuilder applications. For details on how

to configure other RSLinx drivers, refer to RSLinx documentation.

To configure a DF1 or 1747-PIC (DH-485) driver:

1. From the Communications menu, click Configure Drivers.

For Direct Transfers Select: For These Terminals: To Transfer Applications:

RS–232 DF1 Devices➀

1747-PIC Device

➀ Driver is not required. PanelBuilder has an Internal DF1.

DF1, Remote I/O, DH+,

DeviceNet, ControlNet

RS-232 (DH-485) between a computer and the RS-232 port of an RS-232 PanelView terminal.

DH-485

between the RS-232/DF1 port of a Remote I/O PanelView terminal and a computer

using DF1 (RS232) communications.

between a computer on the DH-485 network and the DH-485 port of a DH-485

PanelView terminal using a 1747-PIC interface converter.

Publication 2711-6.0

Page 32

2–8 Installation

2. From the Available Drivers List, click the desired driver by

double-clicking it or by clicking it and then clicking Add New.

The configuration dialog for the selected driver opens.

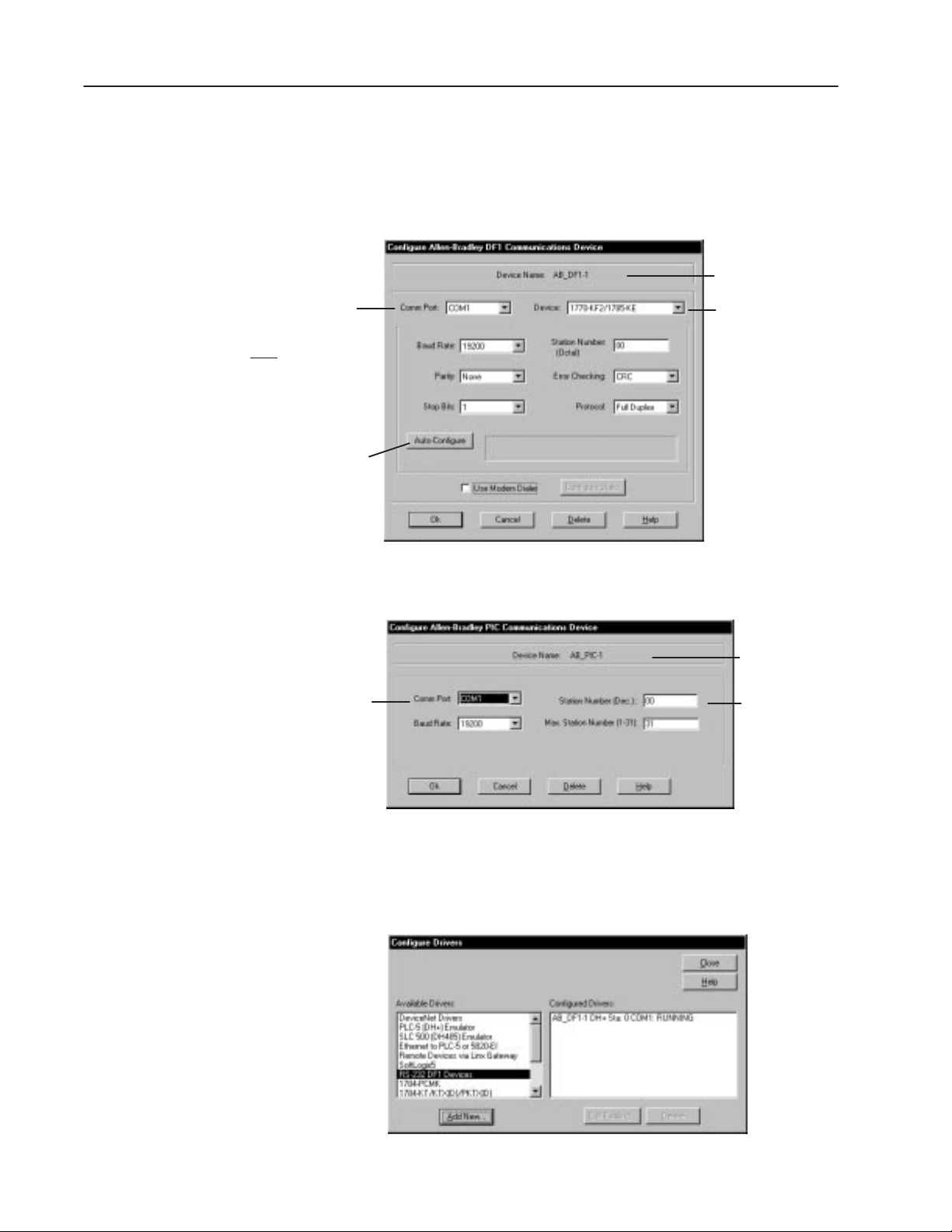

DF1 Driver

Default name

given to driver

Serial COM port on computer

DF1 parameters for a PanelView

terminal must

Baud: 19200

Parity: None

Error Detect: CRC

Stop Bits: 1

Protocol: Full Duplex

Automatically detects the settings of the

DF1 driver on the serial COM port (when

connected to a PanelView terminal).

Serial COM port on computer

be set to:

Device Type of

DF1 driver on computer

1747-PIC Driver

Default name

assigned to driver

Station address

of computer is

typically 0.

Publication 2711-6.0

3. Edit the driver parameters and click OK.

The driver appears in the Configured Drivers list. Click Close to

exit the Configure Devices dialog.

Page 33

Maps the configured

DF1 driver to 1KT:0.

2–9Installation

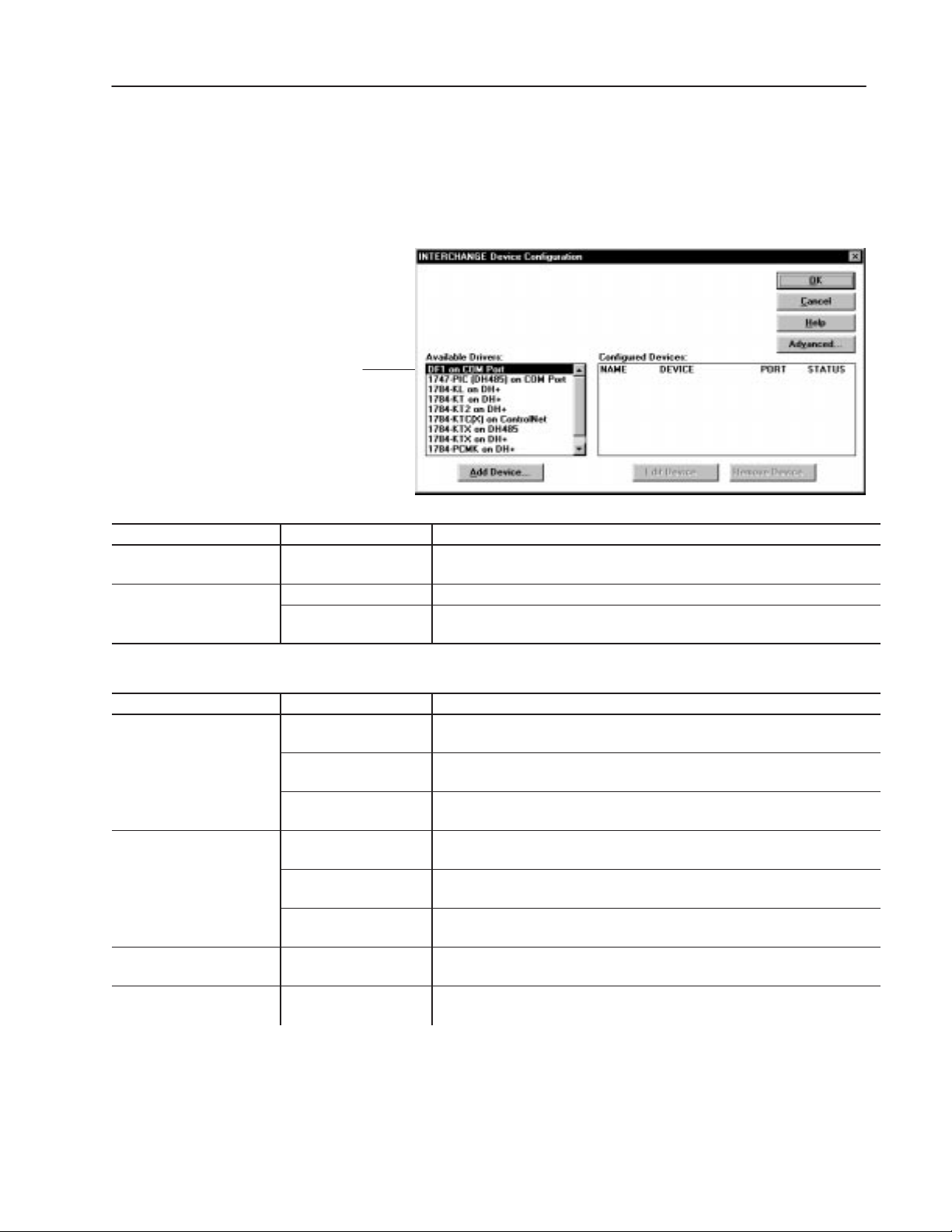

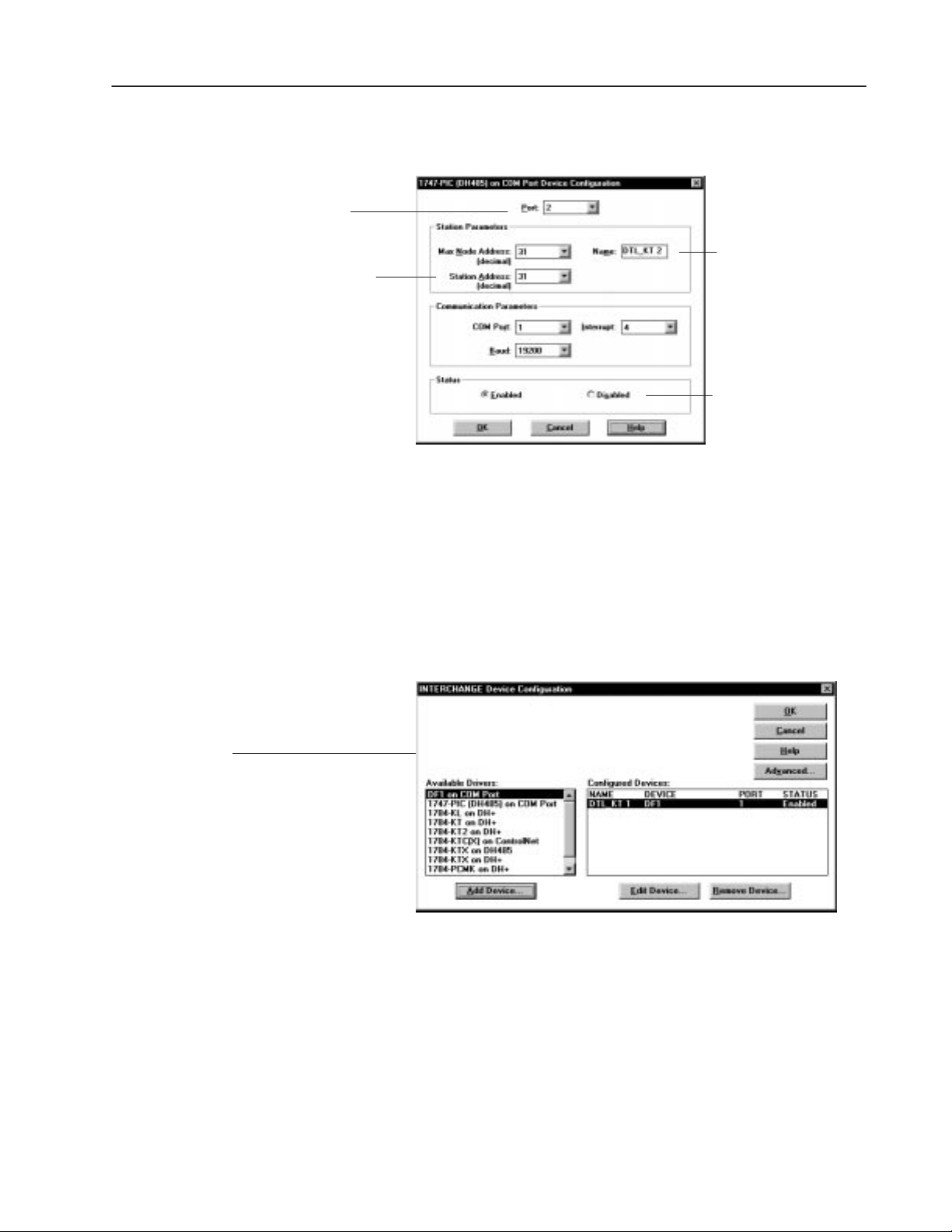

To assign a communication driver to a port:

After configuring a driver, you must map the driver to one of driver

ports.