Page 1

PanelViewt1200 Operator Terminals

(Catalog Numbers 2711-KA1, KC1, TA1, TC1, TA4, TC4)

User Manual

Page 2

Important User Information

Solid-state equipment has operational characteristics differing from those

of electromechanical equipment. “Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls” (Publication

SGI–1.1) describes some important differences between solid-state

equipment and hard-wired electromechanical devices. Because of this

difference, and also because of the wide variety of uses for solid-state

equipment, all persons responsible for applying this equipment must satisfy

themselves that each intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

Attention Identifies information about practices or circumstances

that can lead to personal injury or death, property damage, or

economic loss.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

Important Identifies information that is especially important for successful

application and understanding of the product.

PanelBuilder, PanelView, Data Highway Plus, DH+, SLC and SLC 500 are trademarks, and PLC, PLC-2, and PLC-3 are registered

trademarks of Allen-Bradley Company, Inc.

Intel is a trademark of Intel Corp.

IBM, PC, AT, XT, PS/2 and PC DOS are registered trademarks of International Business Machines Corporation

Epson is a registered trademark of Seiko Epson Corporation

Microsoft Windows is a trademark, and Microsoft, MS, and MS-DOS are registered trademarks of Microsoft Corporation

Page 3

Table of Contents

Preface P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Manual Overview P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Intended Audience P1

Glossary

Related

AfterSales Support P4

of T

Publications

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erms P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

The PanelView 1200 T

Wide Range of Applications 13

PanelView 1200 Features 13

Cost

Rugged,

Panel or 19" Rack Mounting 13

12" Monochrome or Color Display 14

Direct Connection to any AllenBradley PLC Remote I/O Link 14

Direct or Data Highway Plus and Remote I/O Downloading 14

Factory Installed Battery Provides Extended Backup 14

UserDefinable Keys 15

Custom Keypad Legend Inserts 15

Touch Screen Terminal for Simplicity and Space Saving 15

Message

Builtin Clock 16

Audio and Visual Feedback 16

Alarm Relay 16

RS232 Port 16

PanelView 1200 Terminal Diagnostics 17

Options and Accessories 17

Upload/Download Cable 17

Optional Remote Keyswitch & RS232 Port Assembly 17

Optional EEPROM or EPROM for Backup or Additional

Application Memory 17

Functional Variations Among Terminal Types 18

Keypad Terminals 18

Function Keys 19

Numeric Keypad 19

Special Keys 110

Touch Screen Terminals 110

Objects, Windows, and PLC Control Options 111

Objects

Objects for the Keypad Terminal 115

Objects for the Touch Screen Terminal 116

to PanelV

Optimized for OEM Applications

High Quality Design

and Alarm Handling Utilities

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common to All PanelV

iew 1200 Operator Terminals 11. . . . . .

erminal Family

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iew 1200 Terminals 113. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

11. . . . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . .

13. . . . . . . . . . . . . . . . . . . . . . . . .

. . .

. . . .

. . . . . . . .

. . . . . .

15. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

. . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Information and Alarm Windows 116. . . . . . . . . . . . . . . . . . . . . . . . .

Summary

Applicable Programmable Controllers and Connections 117

of PLC Controlled Options

117. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

PLC5/11, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60 and 5/250 Processors 118

PLC5/10 Processor 118. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC3 and PLC3/10 Processors 118

PLC2 Family Processors via 1771SN or 1772SD2 118

SLC5/02 via 1747SN 119

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1771SN I/O Subscanner Module 119

6008SI

IBM PC I/O Scanner

6008SV VME I/O Scanner 119

6008SQ DEC QBUS I/O Scanner 119

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

119. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

PanelView 1200 Terminal Functions 21. . . . . . . . . . . . . . . . . .

Contrast, Brightness and the Mode Select Keyswitch 21. . . . . . . . . .

Fault

Conditions

Major

Faults

Minor

Faults

PowerUp Functions 23

Checksum and Read/Write Memory Tests 23

Battery Failure Test 24

Communication Test 25

Watchdog Test 25

Starting Up the Terminal in Configuration Mode 25

The Configuration Mode Menu 26

Upload/Download 26

Serial Port 27

Rack Assignments 28

Access Codes 29

Audio Response 210

Alarm Relay 210

Preset Operations 210

Time and Date 212

Screen Saver 212

Screen

Alignment

Stuck

Button/Cell T

False Depression Test (Touch Screen Only) 214

User EPROM/EEPROM PowerUp Test 215

PassThrough Download Options 217

Unit Tests 221

Run Mode Functions 223

Online Diagnostic Testing 224

PLC

Communication T

Invalid Screen Request 224

Application Data Checksum 224

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imeout 214. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

imeout 224. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Table of Contents iii

Battery Failure 224. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PanelView 1200 T

Print Priorities 225

Page

Formatting

NonPrintable Characters 226

Printer Errors 226

erminal Printing

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

224. . . . . . . . . . . . . . . . . . . . . . . .

225. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Your PanelV

The PanelView 1200 Terminal 32. . . . . . . . . . . . . . . . . . . . . . . . . . .

The RS232 Port 32

The Alarm Relay Connector 33

The

Remote I/O Connector

The AC Power Connector 34

Installing a User PROM 35

PanelView 1200 Terminal Dimensions 39

Installation Notes 311

PanelView 1200 T

Keypad Terminals (2711KA1, 2711KC1) 312

Touch Screen Terminals (2711TA1, TC1) 313

Touch Screen Terminals (2711TA4, TC4) 314

Optional Clip or Stud Rack Mount Kits 315

Remote Keyswitch Assembly Dimensions 316

Upload/Download Cable 316

iew 1200 Terminal 31. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

erminal Cutouts

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

34. . . . . . . . . . . . . . . . . . . . . . . . . . .

311. . . . . . . . . . . . . . . . . . . . . . . .

Verifying the PanelView 1200 Terminal Operation 41. . . . . . .

Testing the PanelView 1200 Terminal 41. . . . . . . . . . . . . . . . . . . . . .

Downloading

Matching

Downloading

Running

Connecting the PLC Controller 43

Testing

Testing the Whole System 44

the Application File

Communications Settings

the Application

the Application File

Retentive Objects

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . .

42. . . . . . . . . . . . . . . . . . . . . . . . . .

43. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

44. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining Your PanelV

Cleaning 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Changing the Filter on Color Units 52

Screen Saver 52

Degauss 52

Strong

Magnetic Fields

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

iew 1200 Terminal 51. . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

53. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contentsiv

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Design Certifications, Standards and Compliances A1. . . . . . . . . . . .

Design Standards Complied With A1

Terminal Weights A2

Keypad Terminals A2

Front Panel Design A2

Touch Screen Terminals A2

CRT Display A3

Color

Unit Display Attributes

Monochrome

PLC

Remote I/O Communications

Serial Communications Port A5

AC Power A5

Fuses A6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Character

User Memory A6

Alarm Relay A6

Batteries A7

Time and Date Clock A7

Temperature,

Heat Generation A8

Shock and Vibration A9

Set

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ambient Operating Temperature Limits A8

Storage Temperature Limits A8

Humidity A8

Maximum

Monochrome Terminals A8

Color Terminals A8

Shock

Amplitudes

Vibration

Vibration Amplitudes for NonOperating Units A9

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Unit Display Attributes

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Humidity

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Altitude

Amplitudes for Operating Units

, and High Altitude

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

A3. . . . . . . . . . . . . . . . . . . . . . . . . .

A4. . . . . . . . . . . . . . . . . . . .

A4. . . . . . . . . . . . . . . . . . . . . . . .

A6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

A8. . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

A8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

A9. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

Troubleshooting B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Verifying

PanelView 1200 Major Fault Error Messages B1

PanelView 1200 Minor Fault Error Messages B2

PLC Communication Problems B3

PassThrough Upload/Download Problems B4

PanelBuilder Problems B7

Configuration Settings

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

PLC Controllers Required for PassThrough B5

Common Error Messages for Manual Address

Source Configuration B6

Common PassThrough Error Codes B6

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

B1. . . . . . . . . . . . . . . . . . . . . . . . . .

Page 7

Preface

Preface

Manual Overview

Intended Audience

This manual describes the features and specifications of PanelView1200

terminals. PanelView 1200 terminals are available as keypad or touch

screen terminals, with color or monochrome display.

Note The term “PanelView 1200” is the new name for PanelView

terminals. It refers to all 12-inch CRT PanelView terminals, from Series A

upwards.

The manual provides information and examples for:

installing and maintaining a PanelView 1200 terminal

operating a PanelView 1200 terminal

connecting a PanelView 1200 terminal to an Allen-Bradley

Programmable Logic Controller (PLCr)

troubleshooting a PanelView 1200 terminal

This manual is written to help you install and maintain PanelView 1200

terminals.

Glossary of Terms

The following terms are used throughout this manual.

Application File: A PanelView 1200 terminal application file contains a

series of screens and configurations which, when interpreted and executed

by PanelView 1200, replace the functions of a control panel of buttons,

switches and indicators. The screens are created on a development

computer running PanelBuilder Development Software or

PanelBuilder 1200 Configuration Software for Windows, and then saved

in an application file on the development computer’s disk. The application

file is then downloaded to a PanelView 1200 terminal where it stays in

battery-backed RAM.

Battery-Backed RAM: Application files are stored in the PanelView 1200

terminal’s random access memory (RAM). The RAM is backed by an

internal battery so that the application file and the status of the retentive

objects are maintained even when AC power is switched off.

P-1

Page 8

Preface

Hex Files: Application files which have been converted into Intel Hex

format for transfer to user PROMs.

Object: An object is an individual component of a PanelView 1200 screen.

Each object takes the function of a button, switch or indicator on a control

panel. The objects can be dynamic—they can change color or value and

can display information. Each object is defined by the developer of the

PanelView 1200 screen. Examples of objects include Push Buttons,

Selectors, Bar Graphs, Numeric Displays, etc.

PanelBuilder Software: The program runs on the development computer

to develop application files for PanelView 1200 terminals. There are two

types of PanelBuilder software: PanelBuilder 1200 Configuration

Software for Windows and PanelBuilder Development Software for DOS.

PanelView 1200 Terminal: A type of Allen-Bradley terminal with a touch

screen or rugged keypad, designed for easy operator interaction with a

PLC system over the Remote I/O link.

Retentive: An object is described as retentive when it “retains” its PLC

value in the PanelView 1200 terminal after a screen change, an operator’s

object action, and even after the terminal’s power cycle. For example,

when a maintained push button is pressed, the corresponding PLC input is

set to 1 and will not change until the button is pressed a second time.

Retentive objects always display their current states or values.

Screen: A display containing objects (such as push buttons or bar graphs)

which can monitor and control a PLC system. Screens are created with

either type of the PanelBuilder software.

SRAM: Static Random Access Memory. A type of memory that can

maintain its contents through the use of a battery. It does not require

continuous refreshing to maintain its contents.

System Memory: The read-only memory that contains the operating

firmware for the PanelView 1200 terminal.

Upload/Download: Downloading is the process of transferring an

application file from a development computer running either type of the

PanelBuilder software, to a PanelView 1200 terminal. Uploading is the

process of transferring an application file from the terminal back to the

development computer.

P-2

User PROM: The read-only memory chip that can be used to contain a

back-up copy of an application file, or to increase the memory available for

the application file from 64K to 128K. The chip can be either an EPROM

or an EEPROM.

Page 9

Preface

There are two types of user PROM chips that can be used in PanelView

1200 terminal: EPROMs and EEPROMs. EPROMs are Electrically

Programmable Read Only Memory chips. EEPROMs are Electrically

Erasable Programmable Read Only Memory chips.

The user PROMs store application files in memory that is protected from

power failure and failure of the internal battery. A PROM burner is

required to copy application files into a user EPROM.

If your system includes a user EEPROM, application files downloaded

through the Upload/Download cable will be stored in both battery-backed

RAM and in the EEPROM. No PROM burner is required.

Window: An area on the screen containing information. These windows

are triggered by the PLC controller and overlay any screen that is

displayed.

Related Publications

The following related publications provide additional information on

programmable controllers and I/O scanners.

Publication Pub. No.

1772SD/SD2 Remote I/O Scanner/Distribution Panel

1775S4A I/O Scanner-Programmer Interface Module User's Manual 17756.5.1

1775S5, 1775SR5 I/O ScannerCommunication Adapter Module User's

Manual

5150RS PI Startup and Integration Manual 50006.5.1

6008SI IBMt PCt I/O Scanner User's Manual

6008SV VME I/O Scanner User's Manual 60086.5.2

6008SQ QBus I/O Scanner Utility Software User's Manual 60086.4.1

1771SN Sub I/O Scanner Module Data Sheet 17712.91

1747SN RIO Scanner User's Manual 1747NM005

Publication Pub. No.

1772LP2 PLC2/20 Programming and Operations Manual

1772LP3 PLC2/30 Controller Programming and Operations Manual 17726.8.3

PLC3 Family Controller Programming Reference Manual 17756.4.1

PLC5 Family Programmable Controllers Hardware Installation Manual 17856.6.1

PLC5 Programming Software 62006.4.7

5250LP1, LP2 PLC5/250 Programming Manual 50006.4.8

SLCt 500 Family of Programmable Controllers Advanced Programming

Software User's Manual

17722.18

17756.5.5

60086.5.3

17726.8.1

1747NM002

P-3

Page 10

Preface

To identify the manuals referring to these programmable controllers,

consult the Publications Index, Publication SD499, available from

Allen-Bradley.

AfterSales Support

If you need help with your PanelView 1200 terminal, contact:

Allen-Bradley

Global Technical Support

6680 Beta Drive

Mayfield Village, Ohio 44143

Inside USA and Canada: 1-800-289-2279

Outside USA and Canada, contact your local Allen-Bradley office or call

USA (216) 646-6800.

Your terminal’s catalog number, series, revision letter and firmware

revision are shown on the label on the back of the terminal. Please have

this information ready when you call for technical support.

Please register your PanelView 1200 terminal by mailing the registration

card to the address above, or by FAXing the card to (216) 646-6770.

P-4

Page 11

Chapter

БББББ

БББББ

БББББ

БББББ

БББББ

Á

Á

БББББ

Á

1

Introduction to PanelView 1200 Operator

Terminals

This chapter provides an overview of the PanelView 1200 terminals. It

describes:

the types and features of PanelView 1200 terminals

the available options and accessories

the supported Allen-Bradley programmable controllers and remote I/O

scanners

The PanelView 1200 Terminal Family

PanelView 1200 terminals provide a fast, easy, flexible and low cost

operator interface for a PLC system. They are ideal replacements for

traditional control panels.

PanelView 1200 terminals are pre-assembled and ready to install in a

control panel cut-out or 19” rack. They connect directly to any

Allen-Bradley remote I/O link.

An Allen-Bradley, IBM or compatible computer (the development

computer) is used to create PanelView 1200 terminal screens and

functions. See the PanelBuilder Development Software User Manual for

information on PanelBuilder Development Software for DOS. See the

PanelBuilder 1200 Configuration Software for Windows User Manual for

more information on PanelBuilder 1200 Configuration Software for

Windows.

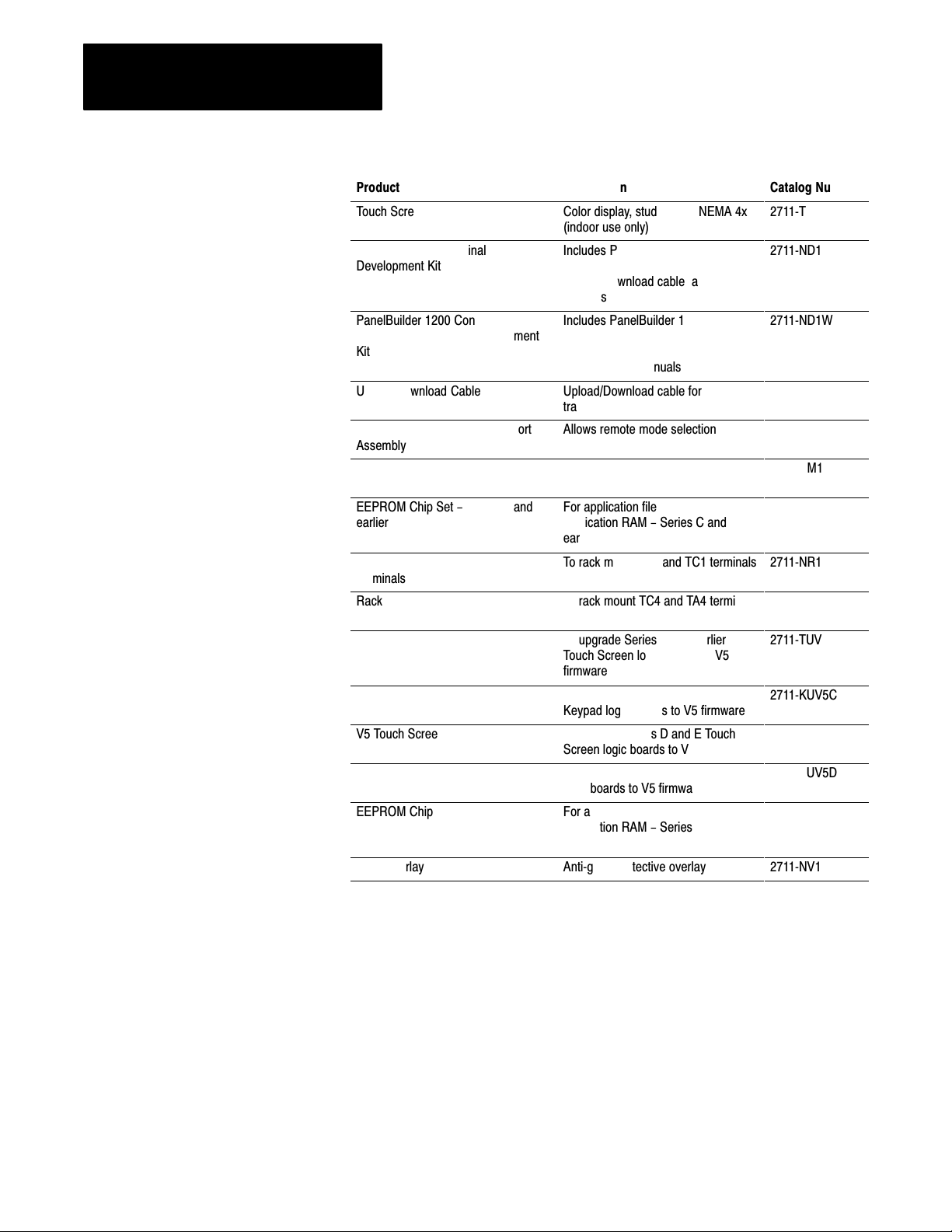

The PanelView 1200 terminal family includes the following products and

corresponding catalog numbers:

Table 1.A

PanelView

Product

Keypad Terminal

Keypad Terminal

Touch Screen Terminal

Touch Screen Terminal

Touch Screen Terminal

ББББББББ

1200 Products and Catalog Numbers

Description

Amber display

Color display

Amber display, clip mount, NEMA 12

Color display, clip mount, NEMA 12

Amber display, stud mount, NEMA 4X

ББББББББ

(indoor use only)

Catalog Number

2711KA1

2711KC1

2711TA1

2711TC1

2711TA4

ÁÁÁÁ

1-1

Page 12

Chapter 1

БББББ

Á

Á

БББББ

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

Á

БББББ

Á

Á

Á

Á

БББББ

Á

Á

Á

БББББ

Á

БББББ

Á

Á

Á

Á

БББББ

Á

Á

БББББ

Á

Á

БББББ

Á

Á

Á

БББББ

Á

Á

Á

БББББ

Á

БББББ

Á

Á

БББББ

Á

Á

Á

БББББ

Á

БББББ

Introduction to PanelView 1200 Operator

Terminals

Product

Touch Screen Terminal

ББББББББ

PanelView 1200 Terminal

ББББББББ

Development Kit

ББББББББ

ББББББББ

PanelBuilder 1200 Configuration

ББББББББ

Software for Windows Development

Kit

ББББББББ

Upload/Download Cable

ББББББББ

Remote Keyswitch & RS-232 Port

Assembly

ББББББББ

EPROM Chip Set

EEPROM Chip Set - Series C and

ББББББББ

earlier

ББББББББ

Rack Mount Kit for Touch Screen

Terminals

Rack Mount Kit for Touch Screen

Terminals

ББББББББ

V5 Touch Screen Firmware Upgrade

Kit

ББББББББ

V5 Keypad Firmware Upgrade Kit

ББББББББ

V5 Touch Screen Firmware Upgrade

Kit

V5 Keypad Firmware Upgrade Kit

ББББББББ

EEPROM Chip

ББББББББ

Lens Overlay

Description

Color display, stud mount, NEMA 4x

(indoor use only)

ББББББББ

Includes PanelBuilder Development

ББББББББ

Software (for DOS),

Upload/Download cable and

ББББББББ

manuals

ББББББББ

Includes PanelBuilder 1200

ББББББББ

Configuration Software for Windows,

PanelView 1200 Transfer Utility

ББББББББ

Software, and manuals

Upload/Download cable for

ББББББББ

transferring applications serially

Allows remote mode selection and

serial port access

ББББББББ

For application file backup - Series

C and earlier logic boards

For application file backup or extra

ББББББББ

application RAM - Series C and

earlier logic boards

ББББББББ

To rack mount TA1 and TC1 terminals

To rack mount TC4 and TA4 terminals

ББББББББ

To upgrade Series C and earlier

Touch Screen logic boards to V5

ББББББББ

firmware

To upgrade Series C and earlier

Keypad logic boards to V5 firmware

ББББББББ

To upgrade Series D and E Touch

Screen logic boards to V5 firmware

To upgrade Series D and E Keypad

ББББББББ

logic boards to V5 firmware

For application file backup and extra

application RAM - Series D and E

ББББББББ

logic boards

Antiglare protective overlay

Catalog Number

2711TC4

ÁÁÁÁ

2711ND1

ÁÁÁÁ

ÁÁÁÁ

ÁÁÁÁ

2711ND1W

ÁÁÁÁ

ÁÁÁÁ

2711NC1

ÁÁÁÁ

2711NC2

ÁÁÁÁ

2711NM1

2711NM2

ÁÁÁÁ

ÁÁÁÁ

2711NR1

2711NR2

ÁÁÁÁ

2711TUV5C

ÁÁÁÁ

2711KUV5C

ÁÁÁÁ

2711TUV5D

2711KUV5D

ÁÁÁÁ

2711NM3

ÁÁÁÁ

2711NV1

1-2

Page 13

Chapter 1

БББББББ

БББББББ

БББББББ

БББББББ

БББББББ

БББББББ

БББББББ

Introduction to PanelView 1200 Operator

Terminals

PanelView 1200 Features

Table 1.B

1200 T

PanelView

Replacement Part

Spare Mode Select Keys

Series D and E Logic Board

Touch Screen Mounting Hardware

for NEMA 12 mounting

БББББББББ

Touch Screen - Series C or earlier

БББББББББ

erminal Replacement Parts and Numbers

Part Number Catalog Number

4671541401

4671544801

4671541601

ББББББ

4671546001

ББББББ

БББББ

БББББ

Touch Screen - Series D and E 2711-NT1

Keyswitch Assembly

БББББББББ

Blank Keypad Legend Inserts

БББББББББ

Remote I/O Connector

БББББББББ

4671541801

ББББББ

4671541901

ББББББ

2211204603

ББББББ

БББББ

БББББ

БББББ

Keypad Faceplate - Series D and E 2711-NK1

Wide Range of Applications

PanelView 1200 terminals provide many pre-configured functions

allowing for a wide range of applications across many industries. This

enables you to standardize on PanelView 1200 terminals, thereby

simplifying service stock and reducing the cost and time required to train

your personnel on many different products.

Cost Optimized for OEM Applications

Since PanelBuilder software resides outside the PanelView 1200 terminal,

the terminal is not burdened with this overhead.

Rugged, High Quality Design

PanelView 1200 terminals are designed to strict Allen-Bradley

specifications, with high grade components and rugged construction for

long trouble-free operation in harsh industrial environments.

Panel or 19" Rack Mounting

All PanelView 1200 terminals can be panel or 19” rack-mounted. Keypad

and stud-mounted touch screen terminals are rated NEMA 4X (Indoor use

only). Clip-mounted touch screen terminals are rated NEMA 12.

1-3

Page 14

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

12" Monochrome or Color Display

All PanelView 1200 terminals have a 12” display in monochrome (amber)

or color. Color terminals can display 8 colors at a time from a choice of 16.

Direct Connection to any AllenBradley PLC Remote I/O Link

You can integrate a PanelView 1200 terminal quickly and easily into any

PLC system capable of supporting the Allen-Bradley 1771 Remote I/O

Link.

A PanelView 1200 terminal appears as one or more PLC I/O racks on an

Allen-Bradley PLC Remote I/O link; it can be configured as up to 8

different racks—or fractional racks—with any valid PLC rack numbers.

Communications between the PLC controller and the PanelView 1200

terminal are provided through the discrete I/O image table area, and up to 5

block transfers (up to 32 words per block). Block transfers allow you to

transfer more information at a time than does discrete I/O. The

PanelView 1200 terminals can also communicate to the SLC-5/02

controller through the use of the 1747-SN module.

Direct or Data Highway Plus and Remote I/O Downloading

Application files can be downloaded from the development computer to

the terminal via the Upload/Download cable (an RS-232 connection), or

via a Data Highway Plus, using the PLC-5 Pass-Through feature.

By using the Data Highway Plus for downloading, you can download to

several terminals from a single development computer without having to

go from terminal to terminal, connecting the Upload/Download cable for

each one.

Factory Installed Battery Provides Extended Backup

The built-in battery maintains power to the terminal’s memory so the

application file is not lost when the terminal is switched off. PanelView

1200 terminals come equipped with a RAM memory chip that requires

minimal power from the lithium battery. Also, the battery is not burdened

when AC power is applied to the terminal. This provides exceptional life

for the battery, which is expected to last for the life of the terminal.

1-4

Page 15

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

UserDefinable Keys

The keypad terminal has 21 user-definable keys on its front panel. Each

one can perform a variety of operations—from turning on PLC input bits

to changing screens. PanelView 1200 terminals are extremely flexible:

each key can be assigned a different function for each screen.

Custom Keypad Legend Inserts

The function keys on keypad terminals are pre-labeled at the factory, but

you can create key labels to suit your application. The included Legend Kit

provides blank card material that can be written on with most types of

markers or paste-on labels. Replacing the labels on the terminals is a quick

and easy task.

Touch Screen Terminal for Simplicity and Space Saving

A touch-sensitive surface overlays the monitor on the touch screen

terminal. Selections are made by touching the display directly. Since a

keypad is not required, these terminals require less panel space.

Message and Alarm Handling Utilities

A PanelView 1200 terminal application can be set up with stored messages

that can be triggered by the PLC controller. There are three kinds of

message displays:

Local Message Displays can appear in any free location on a specific

screen (875 messages maximum)

Information Windows can pop up regardless of the screen currently

displayed (496 messages maximum)

Alarm Windows can pop up regardless of the screen currently displayed

(496 messages maximum)

For each type of message displayed—local, information or alarm—there is

a message list. Using PanelBuilder software, you can add or edit messages.

Messages are numbered and listed in numerical order in the message list.

See your PanelBuilder 1200 Configuration Software for Windows User

Manual for more information on PanelBuilder 1200 Configuration

Software for Windows. See your PanelBuilder Development Software User

Manual for more information on PanelBuilder Development Software for

DOS.

1-5

Page 16

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Builtin Clock

The battery-backed clock runs even when the terminal is powered down.

PanelView 1200 can display the current time and date and can send it to

the PLC controller. The clock may also be set by the PLC controller.

Audio and Visual Feedback

A PanelView 1200 terminal can be configured to:

activate a beeper each time a function button or touch cell is pressed

light up a screen button (if it has a border) when its function key or

allow the PLC controller to activate the beeper at the terminal

touch cell is pressed.

allow Alarm Messages to activate the beeper at the terminal

Alarm Relay

You can attach a horn or a warning light to the PanelView 1200 terminal’s

alarm relay. Relay connections are made via the terminal block labeled

“Alarm Contacts” at the rear of the terminal. Specific alarm messages, or a

PLC program, can then trigger the relay.

Attention The Alarm Relay must be used only as a warning

system, not for control purposes.

RS232 Port

All PanelView 1200 terminals include one RS-232 port for printing on-line

alarm messages, uploading and downloading application files, and printing

screens.

1-6

Page 17

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

PanelView 1200 Terminal Diagnostics

When a PanelView 1200 terminal starts up, it performs a number of fault

detection tests. The PanelView 1200 terminal also performs continuous

tests for fault conditions when it is communicating online with the PLC

controller. In the event of a fault, a message appears, pinpointing the exact

nature of the fault.

An operator can also initiate diagnostic tests from the terminal.

For a description of the diagnostic tests, and the various fault conditions,

refer to Chapter 2, PanelView 1200 Terminal Functions, in this manual.

Options and Accessories

Optional hardware is available that you may find convenient to use with

either type of the PanelBuilder software and the PanelView 1200 terminal.

For catalog numbers see tables 1.A and 1.B.

Upload/Download Cable

The Upload/Download cable connects the development computer’s RS-232

Port to the PanelView 1200 terminal’s RS-232 Port. You use it to transfer

applications serially between the development computer and the

PanelView 1200 terminal If you have a number of terminals, you may want

to order more than one Upload/Download cable.

Optional Remote Keyswitch & RS232 Port Assembly

On the back of all PanelView 1200 terminals is a Mode Select Keyswitch

and RS-232 Port. The Remote Keyswitch and RS-232 Port Assembly

allows you to mount the port and keyswitch to the front of your control

panel while maintaining a NEMA 4X seal. This is convenient if you don’t

have easy access to the rear of the PanelView 1200 terminal. See Chapter

3, Installing Your PanelView 1200 Terminal, for details on mounting and

dimensions.

Optional EEPROM or EPROM for Backup or Additional Application

Memory

Earlier PanelView 1200 terminals contained two sockets for optional

EPROM or EEPROM chips. Series D and E PanelView 1200 terminals

have one socket for an optional EPROM/EEPROM, called the user PROM.

1-7

Page 18

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

an EPROM can be used for application file back-up. The application file

an EEPROM can be used for application file back-up or for extra

Functional Variations Among Terminal Types

is programmed into the EPROM with a PROM burner. Once

programmed, it cannot be erased or overwritten.

application memory

when the EEPROM is used for application back-up, the downloaded

application file is automatically copied to the EEPROM during the

download operation

an EEPROM can also be used to increase the memory available for

application file storage from 64K to 128K. If the EEPROM is used in

this way, it cannot be used as back-up for the application file.

Keypad Terminals

The terminals are configured almost identically with these exceptions:

buttons are set up differently on keypad terminals and touch screen

terminals

certain screen objects are specific to keypad terminals, others to touch

screen terminals. For more information on objects see your

PanelBuilder 1200 Configuration Software for Windows User Manual,

or your PanelBuilder Development Software User Manual.

foreground and background colors can be assigned only for color

PanelView 1200 terminals. Inverse video and intensity settings are

assigned for monochrome terminals

The keypad terminal has:

21 user-definable function keys

a keypad for entering numeric values

up, down, left and right arrow keys

1-8

Home, Enter, Select, Cancel, Raise, Lower and Backspace keys

The user-definable function keys on keypad terminals are pre-labeled at the

factory, but you can create key labels (legends) to suit your application.

The replacement key legends slide in from the rear of the faceplate. The

included Legend Kit provides blank card material that can be written on

with most types of markers or paste-on labels.

Page 19

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

You can also configure the terminal to beep when a key is pressed.

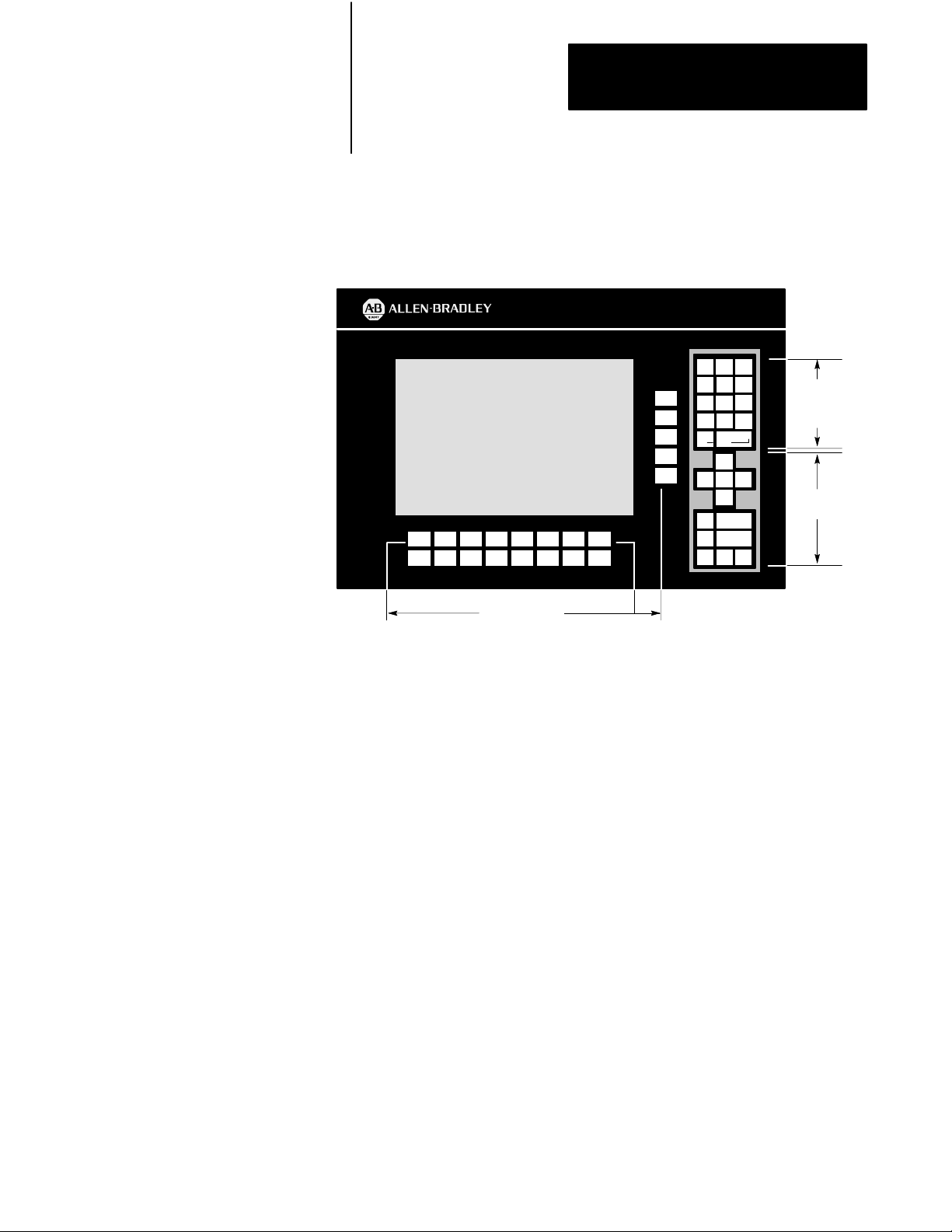

Figure 1.1

T

Keypad

erminal

F1

F9

F10

PanelView

7 8 9

4 5 6

F17

1 2 3

F18

F19

F20

F21

F8

F7

F6

F5

F4

F3

F2

F16

F15

F14

F13

F12

F11

Raise

Lower

A

•

HOME

0 -

AA

Y

B

SELECT

CANCEL

"

Special Keys

Numeric

Keypad

Function Keys

21000

Function Keys

When creating screens, you can assign any of the 21 function keys to

objects so that they can perform a wide variety of functions, ranging from

turning on PLC input bits to changing screens. Keys can have different

functions for each screen created.

Numeric Keypad

The keypad terminal has a numeric input keypad that includes number

keys, Enter, Backspace, – (negative), and . (decimal) keys. When you

need to make a numeric entry, you call up a pop-up Numeric Entry

Scratchpad that displays the numbers as you type.

The Numeric Entry Scratchpad is displayed on the screen any time the

operator is required to enter numeric data and send it to a PLC controller.

1-9

Page 20

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Special Keys

There are a series of special keys on the keypad terminal:

the arrow keys are used with the Set Bit and Numeric Cursor Points and

Home, Select work with the Set Bit and Numeric Input Cursor Points

Cancel is designed to be used with all numeric keypads, Numeric Input

Raise and Lower are used with Numeric Input Cursor Points only.

The three blank keys at the bottom right are reserved for future

development, and are not configurable.

the ASCII Input object

and Set Bit Cursor Points.

Touch Screen Terminals

For more details, see your PanelBuilder Development Software User

Manual, or your PanelBuilder 1200 Configuration Software for Windows

User Manual.

Touch screen terminals are simple to use: an operator presses a selection

directly on the screen to carry out the desired task.

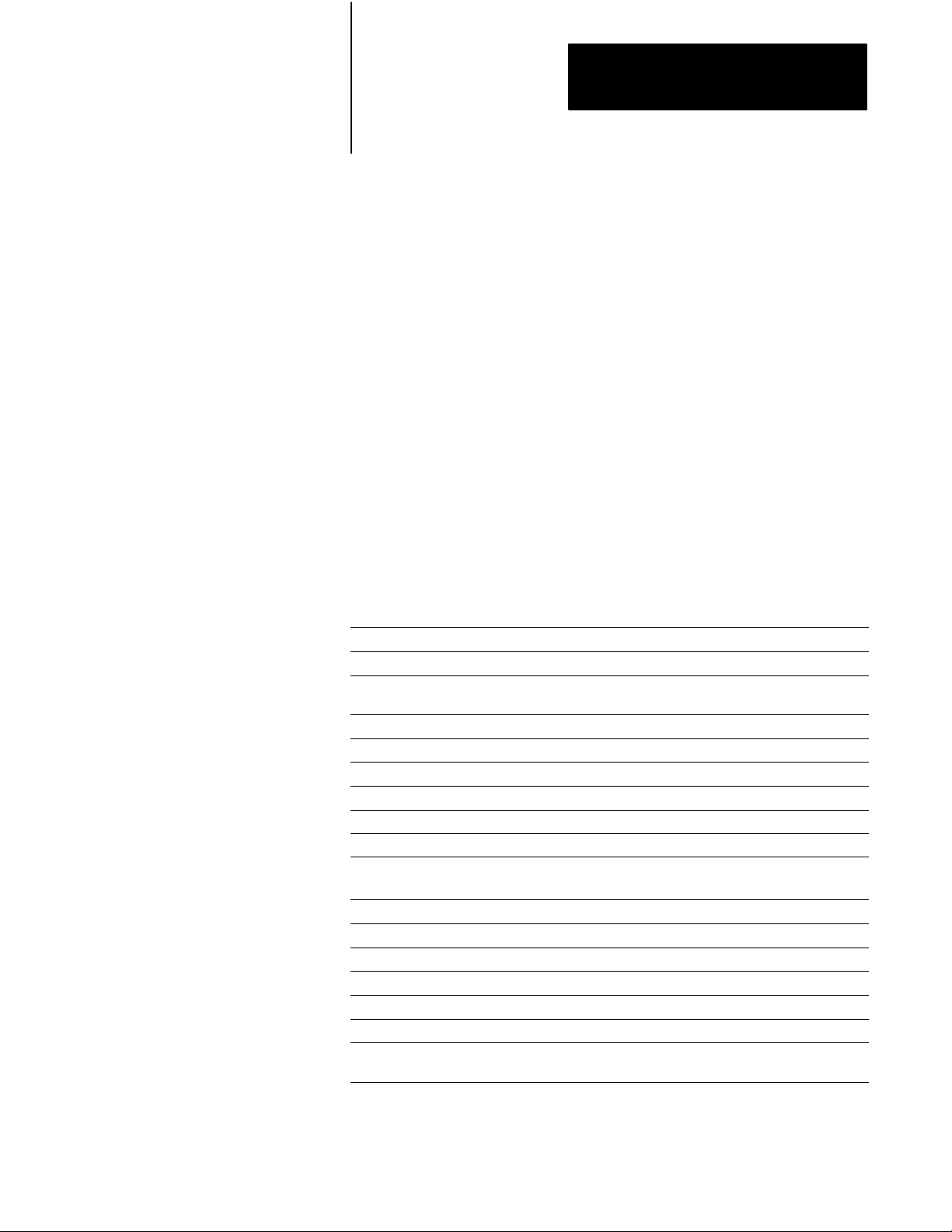

Figure 1.2

Touch

Screen T

erminal

1-10

PanelView

21003

Page 21

16 characters fit in one touch cell

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

The touch screen terminal contains 120 touch cells. Each touch cell is 2

characters high by 8 characters wide. You can configure the terminal to

beep when a touch cell is pressed.

20002

Touch cells are grouped to create different types and sizes of buttons. The

following figure illustrates a single touch cell ON button with double

height and double width characters, and a solid border. You can activate

input functions by touching the appropriate object on the touch screen.

Button

Border

Objects, Windows, and PLC Control Options

20216

The objects, windows and PLC control options are listed in three groups:

those used on both keypad and touch screen terminals, those used for

keypad terminals only, and those used for touch screen terminals only.

You will note that the objects are identified as either dynamic or static.

Dynamic objects interact with the PLC controller; static objects do not.

For complete details on all objects, windows and options that can be

controlled from the PLC controller, refer to your PanelBuilder

Development Software User Manual, or your PanelBuilder 1200

Configuration Software for Windows User Manual.

The following table lists the objects, and indicates which terminal types

they are suited for. It also shows whether the object is dynamic or static.

1-11

Page 22

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Table 1.C

Objects

for PanelV

iew 1200 T

erminals

Object Type Keypad or Touch

Momentary Push Button (Normally Open)

Momentary Push Button (Normally Closed) Dynamic Both

Latched Input Push Button Dynamic Both

Maintained Push Button Dynamic Both

Interlocked Push Button Dynamic Both

Control List Selector with Enter Dynamic Both

Control List Selector without Enter Dynamic Both

Set Bit Cursor Point Dynamic Keypad

Goto Screen Button Static Both

Return to Previous Screen Button Static Both

Screen List Selector Static Both

Screen KeypadEnable Button Static Keypad

Keypad Screen Selector Static Touch Screen

Multistate Indicator Dynamic Both

List Indicator Dynamic Both

Set Value Button Dynamic Both

Increment Value Button Dynamic Both

Decrement Value Button Dynamic Both

Numeric Data Display Dynamic Both

Numeric KeypadEnable Button Dynamic Keypad

Numeric Input Cursor Point Dynamic Keypad

Numeric Keypad (small and large) Dynamic Touch Screen

ISA Symbol Dynamic Both

Bar Graphs (vertical or horizontal) Dynamic Both

Time Display Dynamic Both

Date Display Dynamic Both

ASCII Input Dynamic Both

Scrolling List Object Dynamic Both

Screen Print Button Static Both

Local Message Display Dynamic Both

ASCII Display Dynamic Both

Text Static Both

Line, Line Arrows, Line Connect Characters Static Both

Box Static Both

Arc Static Both

Circle Static Both

Dynamic Both

Screen terminal

1-12

Page 23

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Objects Common to All PanelView 1200 Terminals

The following objects can be displayed on both the keypad terminal and

the touch screen terminal:

Momentary Push Button (Normally Open) turns on (sets to 1) a PLC

input control bit, as long as the button is held.

Momentary Push Button (Normally Closed) resets a PLC input

control bit that is normally set to 1. This bit stays off as long as the

button is pressed.

Latched Input Push Button turns on a PLC input control bit and holds

the bit on until the PanelView 1200 terminal sees a PLC output bit

(handshake bit) turn on.

Maintained Push Button turns on a specific PLC input control bit until

the button is pressed a second time.

Interlocked Push Buttons are several push buttons functioning as a

group. When you press one of the buttons, it cancels the other buttons

and makes the selection. The PLC controller is informed—via a

common PLC input address—which button in the group is the currently

selected option.

Control List Selector with Enter contains a vertical list of operator

choices. An operator can use the object’s Up Cursor and Down Cursor

buttons to move an arrow through the available selections. The selection

is sent to the PLC controller only when the Enter button is pressed.

Control List Selector without Enter contains a vertical list of choices.

The operator uses the object’s Up Cursor and Down Cursor buttons to

move through the available selections. The current selection is

automatically sent to the PLC controller via the object’s PLC input

control address.

“Goto Screen” Button allows the operator to switch to an assigned

screen.

“Return To Previous Screen” Button switches back to the previous

screen.

Screen List Selector allows an operator to choose a screen from a list.

Multistate Indicator is a display area with up to sixteen different

display states, each with a unique combination of text, colors and

attributes. The value in the PLC address determines which state is

displayed.

1-13

Page 24

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

List Indicator displays a list of PLC states and highlights the current

Set Value Button transfers a pre-defined value to the PLC controller via

Increment Value Button increases the value stored at a PLC input

Decrement Value Button decreases the value stored at a PLC input

state. The value of the PLC address determines the item that will be

highlighted in the list.

the assigned PLC input address.

address each time the button is pushed. If the button is held down, the

PLC controller input value continues to increase to a pre-assigned upper

limit.

address each time the button is pushed. If the button is held down, the

PLC controller value continues to decrease to a pre-assigned bottom

limit.

Numeric Data Display displays the current value of an assigned PLC

controller address (binary, BCD, or integer). Scaling (Y=Mx+b) and

other options can be used to display the number in appropriate units.

ISA Symbols (32 in total) allow you to assign display attributes to four

possible states for each symbol object. The symbols have two sizes:

large and small.

Bar Graphs can be used to monitor changing conditions, such as

temperature or fluid levels. Each graph can be up to 80 characters wide

and 24 characters high.

Time Display can be located anywhere on the screen.

Date Display can be located anywhere on the screen.

ASCII Input allows the PanelView 1200 terminal operator to send

ASCII strings of up to 64 characters to the assigned PLC input address.

Scrolling List object is an extended and enhanced control list

selector/list indicator that is not limited by the number of lines on the

screen. The Scrolling List can consist of any combination of local

message display, multistate indicator, and numeric display lists with up

to 999 items in each list. The Scrolling List object reduces PLC ladder

logic and addressing typically needed to display and edit large amounts

of data.

1-14

This object can be used to control and monitor sequential operations in

both auto and manual modes or to provide operators with a selection

list.

Page 25

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Screen Print Button allows an operator to print any screen currently

displayed on the PanelView 1200 terminal.

Local Message Display can be defined as a rectangular area of any size,

and placed in any location on the PanelView 1200 terminal screen. A

PLC control address is assigned to the object, allowing the PLC

controller to trigger any one of up to 875 messages to appear in this

area.

ASCII Display is used to display a character string, sent from the PLC

controller, directly on the PanelView 1200 terminal. The display is

updated whenever the string changes.

Text is used for screen titles, to provide instructions, or for any text that

is not bound to an object.

Lines (Horizontal, vertical and diagonal) are used to illustrate, and to

separate sections of screens.

Objects for the Keypad Terminal

Line Arrows are used to illustrate.

Line Connect Characters are used to connect lines and lines and

objects.

Boxes are graphic objects like lines, which can surround other objects or

simply illustrate.

Arcs are used to illustrate quarter, semi, and three quarter circles, as

well as circles. They can also be used to connect line objects to form

rounded corners.

Circles are composed of four arcs. They are used to illustrate.

The following objects can be displayed only on a keypad terminal:

Numeric Input Cursor Point consists of a numeric display and a

cursor character. This object can be used to enter numbers into an array

of numeric fields similar to an array of thumb-wheel switches on a

control panel. This object has an associated PLC input address in which

the value is communicated to the PLC controller.

Numeric Keypad-Enable Button pops up the Numeric Entry

Scratchpad in which the operator can enter a number. The number is

then stored in the specified PLC input address.

Screen Keypad-Enable Button pops up the Numeric Entry Scratchpad

in which the operator can enter a screen number. The screen with that

number is displayed.

1-15

Page 26

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Set Bit Cursor Point consists of a bit and a cursor character. This

object is used to “point” to a screen character. Several set bit cursor

points can be in the same screen. Each one can have a different

(user-defined) pointer; only the current pointer is visible and blinking.

The current cursor point’s input bit is always on, so the PLC controller

always “knows” the current selection.

Both the set bit and numeric input cursor points can be used on the same

screen.

Objects for the Touch Screen Terminal

Information and Alarm Windows

The following objects can be displayed only on a touch screen terminal:

Keypad Screen Selector allows an operator to display a screen by

entering the screen number. The selector is available in large and small

sizes.

Numeric Keypad is used to send a value to the PLC controller. A PLC

input address is assigned to each Numeric Keypad; the value that the

operator enters is stored at this address. The keypad is available in large

and small sizes.

The Information and Alarm Windows can pop up on the screen at any time

to display important information:

Information Window displays a message when triggered by the PLC

controller. The window remains until the operator presses the Clear

button, or until the PLC controller clears it. There can be as many as

496 different messages for the Information Window.

Alarm Window is similar to the Information Window but with many

additional features. Each message can be configured to sound the audio

indicator (beeper), trip the alarm relay or print a message on a printer.

1-16

Alarms are time and date stamped and listed in the order they occur. The

operator can acknowledge the alarm, clear the display, silence the alarm,

view the Alarm History Screen, or view the Alarm Status Screen. There

can be as many as 496 different messages for the Alarm Window.

Page 27

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

Summary of PLC Controlled Options

The following options can be controlled by the PLC controller:

PLC Controlled Audio allows the PLC controller to control the

PanelView 1200 terminal’s audio beeper. A PLC bit address is assigned.

When the PLC controller sets this bit, the terminal’s beeper is activated.

This does not interfere with the Alarm Window’s use of the beeper.

PLC Controlled Alarm Relay allows the PLC controller to control the

PanelView 1200 terminal’s alarm relay. A PLC bit address is assigned,

and when the PLC controller sets this bit, the terminal’s alarm relay is

energized. This does not interfere with the Alarm Window’s use of the

relay.

PLC Controlled Alarm Quantity/Accum Time Reset allows the PLC

controller to reset the alarm count and the accumulated time-in-alarm

total. These totals are shown in the Alarm Status screen.

PLC Controlled Screen Number allows the PLC controller to control

which screen is displayed. When the PLC controller puts a screen

number in an assigned address, the PanelView 1200 terminal displays

the screen. This PLC controlled screen change always has precedence

over operator-controlled screen changes, and operator-generated screen

changes are allowed only if the PLC address contains 0.

Applicable Programmable Controllers and Connections

PLC Controlled Screen Print allows the PLC controller to trigger a

printout of the screen displayed on the PanelView 1200 terminal.

PLC Controlled Time and Date allows the PanelView 1200 terminal

to read the time and date from the PLC controller and set its internal

clock.

PLC Controlled Clear Window clears the alarm window, the alarm

beeper and the alarm relay when a 0 to 1 transition is detected in the

assigned PLC address bit.

PLC Controlled Silence Alarms silences the beeper and deactivates

the alarm relay when a 0 to 1 transition is detected on this bit.

PanelView 1200 terminals can be connected to any Allen-Bradley 1771

Remote I/O Link. Applicable host controllers include almost all

Allen-Bradley Programmable Logic Controllers as well as certain IBM

computers, VME Controllers, and the DEC Q-Bus interface.

Newly released Allen-Bradley programmable controllers that are not yet

listed will support PanelView 1200 terminals, as long as they support the

1771 remote I/O.

1-17

Page 28

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

The PanelView 1200 terminal appears as one or more I/O rack(s) to a PLC

controller. It has the same configurability—and more—as a standard I/O

rack. Refer to your applicable Allen-Bradley Programmable Controller and

Remote I/O Scanner user’s manuals for various connection and remote I/O

configuration limitations.

PLC5/11, 5/15, 5/20, 5/25, 5/30, 5/40, 5/60 and 5/250 Processors

You can connect one or more PanelView 1200 terminals directly to a

PLC-5 Remote I/O Port (in Scanner Mode) along with other I/O racks. If

the PLC-5 Remote I/O Port is used in the adapter mode, one or more

PanelView 1200 terminals can be connected to that PLC-5 along with other

I/O racks via a 1771-SN I/O Subscanner Module.

All Series C Rev A and later terminals can communicate at 230.4K baud

with any PLC-5 capable of supporting that baud rate.

If you are using a PLC-5/15 with partial rack addressing and block

transfers, you must use PLC-5/15 series B, revision J or later.

PLC5/10 Processor

One or more PanelView 1200 terminals can be connected to this processor

along with other I/O racks via the 1771-SN I/O Subscanner Module.

PLC3 and PLC3/10 Processors

One or more PanelView 1200 terminals can be connected directly to a

PLC-3 or PLC-3/10 remote I/O Scanner along with other I/O racks.

If you are using a 1775-S4A Remote Scanner/Distribution panel, you must

use Series B or higher.

PLC2 Family Processors via 1771SN or 1772SD2

This includes the PLC-2/05, 2/15, 2/30, etc. One or more PanelView 1200

terminals can be connected to these processors along with other I/O racks

via the 1771-SN I/O Subscanner Module.

1-18

If you are using a 1772-SD2 Scanner/Distribution panel, you must use

revision 3 or later.

Page 29

Chapter 1

Introduction to PanelView 1200 Operator

Terminals

SLC5/02 via 1747SN

One or more PanelView 1200 terminals can be connected to the 1747-SN

I/O Subscanner Module (SLC–5/02 RIO connection) for the SLC–5/02

processor. Each module provides an additional remote I/O link for the host

programmable controller. The rack range of the 1747-SN is 0 to 3.

Important No block transfers are possible with the SLC-5/02 and 1747-SN

Series A module.

1771SN I/O Subscanner Module

One or more 1771-SN I/O Subscanner Modules can be installed in any

standard Allen-Bradley 1771 I/O rack. Each module provides an additional

remote I/O link for the host programmable controller. One or more

PanelView 1200 terminals can be connected to any of the previously

mentioned processors along with other I/O racks via a 1771-SN I/O

Subscanner Module. Refer to the 1771-SN Sub I/O Scanner Module Data

Sheet for specific details.

6008SI IBM PC I/O Scanner

This module can be installed in an IBM PCr or compatible computer to

provide the computer with an Allen-Bradley 1771 Remote I/O Link. You

can then connect Allen-Bradley Remote I/O racks and devices such as the

PanelView 1200 terminal to this computer.

6008SV VME I/O Scanner

This module can be installed in a VME backplane, providing the VME

controller with an Allen-Bradley 1771 Remote I/O Link. Allen-Bradley

Remote I/O racks and devices such as the PanelView 1200 terminal can

then be connected to this VME controller.

6008SQ DEC QBUS I/O Scanner

This module can be installed into a DEC Q-Bus controller to provide it

with an Allen-Bradley 1771 Remote I/O Link. Allen-Bradley Remote I/O

racks and devices such as the PanelView 1200 terminal can then be

connected to this controller.

1-19

Page 30

Chapter

2

PanelView 1200 Terminal Functions

This chapter describes how to use the PanelView 1200 terminal’s two

operating modes and discusses the power-up and on-line tests that the

terminal performs.

The PanelView 1200 terminal has two modes of operation: Configure

mode and Run mode. Configure mode allows you to set up the terminal,

and Run mode executes the application file. The PanelView 1200 terminal

communicates with your PLC controller only when it’s in Run mode, so set

it to this mode to monitor and control your PLC application.

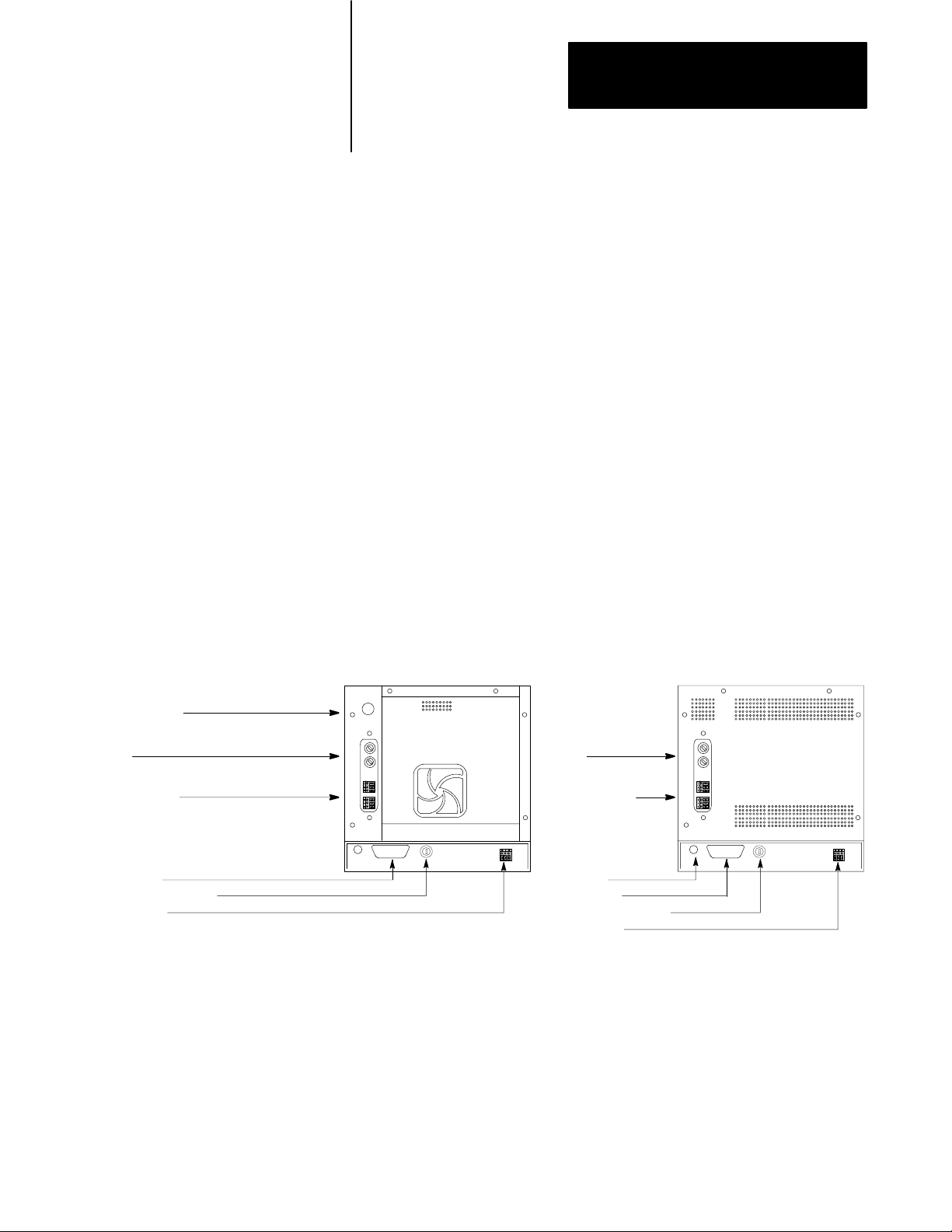

Contrast, Brightness and the Mode Select Keyswitch

Contrast Control

Fuses

Terminal Blocks

RS232 Port

Mode Select Keyswitch

PLC interface

The following illustration shows the rear panel of a PanelView 1200

terminal. Note the location of the Mode Select Keyswitch, the brightness

control, (Monochrome terminals), and the contrast control (Color

terminals).

Figure 1.1

PanelView

1200 T

erminal Rear Panels

Fuses

Terminal Blocks

........

......

Brightness

RS232 Port

Mode Select Keyswitch

PLC interface

Color Back Panel Monochrome Back Panel

........

......

20153

The Brightness and the Contrast Controls adjust the terminal display

intensity. The Mode Select Keyswitch switches between Configuration and

Run modes.

2-1

Page 31

Chapter 2

PanelView 1200 Terminal Functions

With the optional Remote Keyswitch Assembly, you can access the Mode

Select Keyswitch and RS-232 port from the front of the rack where the

PanelView 1200 terminal is mounted.

For more information on the Remote Keyswitch Assembly, see the

instruction sheet supplied with that option.

Fault Conditions

There are two types of faults: major faults and minor faults.

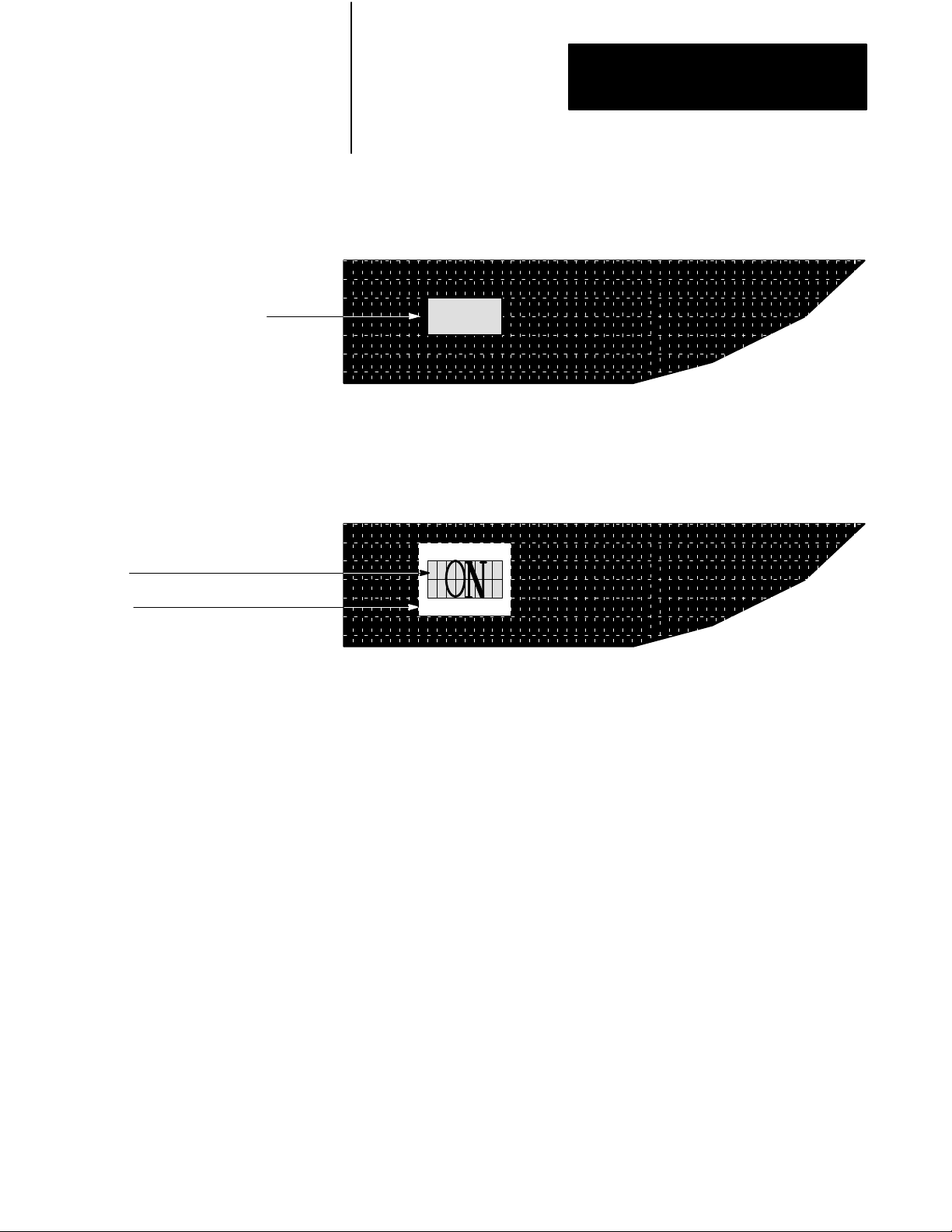

Major Faults

If the PanelView 1200 terminal detects a major fault, it enters Major Fault

mode, and displays a message in the Major Fault Window, like this:

20201

While in Major Fault mode, the PanelView 1200 terminal cannot control or

monitor PLC controller functions. The operator must correct the problem

and restart the terminal, or switch modes.

In Run mode, the faults logged to the Major Fault Window cannot be

cleared. If the terminal is set to Configuration mode, the Major Faults

detected on power-up will be logged to the Minor Fault Window and can

be cleared from there.

2-2

While the PanelView 1200 terminal is in Major Fault mode, it appears as a

faulted rack to the host PLC controller. You can design your PLC program

to monitor the rack fault bits that correspond to the PanelView 1200

terminal’s rack assignments, and to respond whenever these bits indicate

that the terminal isn’t operating or communicating properly. See your PLC

controller and I/O scanner user’s documentation for details on how to use

the rack fault bits.

Minor Faults

If the PanelView 1200 terminal detects any minor faults, it disables normal

input entry and displays a message in the Minor Fault Window, like this:

Page 32

Chapter 2

PanelView 1200 Terminal Functions

Clear

20318

The operator must press the Clear button to resume normal operation. The

Clear button temporarily overrides the function that was previously

assigned to the associated function key or touch cells. Minor faults do not

affect PLC communications.

PowerUp Functions

When you power up the PanelView 1200 terminal, it performs a number of

tests for major or minor faults to determine if any problems will affect its

operation. If a major fault is detected, the system will enter Fault mode.

Once all the tests are successfully completed, the PanelView 1200 terminal

will go into Configuration or Run mode, depending on the Mode Select

Keyswitch setting.

Important If an application file is in battery-backed RAM and a user

memory PROM containing a different application file has been installed,

the application file in RAM will be overwritten with the application file in

user PROM at power up.

Checksum and Read/Write Memory Tests

At powerup, the Checksum tests verify the firmware memory, the

application file stored in the battery-backed RAM, and the user PROM.

There is also a read-write memory test which verifies the battery-backed

RAM.

if the firmware memory fails, it is a major fault

if the application file fails, it is a major fault

if the user PROM fails, it is a minor fault

if the battery-backed RAM fails, it is a major fault.

2-3

Page 33

Chapter 2

PanelView 1200 Terminal Functions

Important If the optional user EPROM or EEPROM is corrupted or not

installed, the terminal will display this fault message each time it is

powered up:

Clear

You can safely clear this message and continue. You can also disable this

message altogether, through the Configuration Mode Menu item User

EPROM/EEPROM

Power-up Test

, explained later in this chapter.

20200

If the battery fails and terminal power

is lost:

And no user PROM is installed

And the user EPROM/EEPROM contains

a backup application file

In the case of a corrupted application file, download the file again. If the

problem persists, your PanelView 1200 terminal requires servicing; contact

your Allen-Bradley representative.

Battery Failure Test

The battery should last the life of the PanelView 1200 terminal. However,

the battery is constantly monitored when the PanelView 1200 terminal is in

Run mode because the battery-backed RAM is so important to PanelView

1200 terminal operation.

If the battery should fail, a Minor Fault message will appear to inform the

operator. As long as the terminal’s power is not turned off, there is no

problem. If power is lost and restored to the terminal, the results depend on

whether there is a user PROM installed.

The following table lists the results of terminal power loss after battery

failure.

This happens: Fault level: What to do when terminal power is

The application file in batterybacked

RAM is lost.

The application file will be reloaded into

RAM from the user EPROM/EEPROM,

but any retained values will be lost.

MAJOR FAULT: For temporary use of the terminal,

MINOR FAULT: Press CLEAR to clear the message and

returned:

download the file again and do not cycle

power. Call your AB representative to

replace the board.

proceed. Call your AB representative to

replace the board the battery is on.

2-4

Page 34

Chapter 2

PanelView 1200 Terminal Functions

Communication Test

The PLC Communication test verifies that the communication card is

installed and functioning. If the test fails, the following message is

displayed in the status window at the top of the screen:

PLC communication lost

20314

Starting Up the Terminal in Configuration Mode

When this occurs, the status window will continue to flash on and off until

the problem with the PLC controller is corrected.

Watchdog Test

The Watchdog test verifies that the watchdog circuit is able to reset the

terminal. If the PanelView 1200 terminal fails this test, it is a major fault,

and the terminal will require servicing by Allen-Bradley.

To start up your PanelView 1200 terminal in Configuration mode, set the

Mode Select Keyswitch to Configure and connect the power.

You’ll want to start up in Configuration mode until you’ve configured the

terminal and downloaded your application file. When in Configuration

mode, your PanelView 1200 terminal will appear as a faulted rack to your

PLC controller.

All major faults detected in Configuration mode will be displayed in the

Minor Terminal Fault Window and can be cleared by pressing the fault

window’s Clear button.

2-5

Page 35

Chapter 2

PanelView 1200 Terminal Functions

The Configuration Mode Menu

Internal Version Number

Date Identification

Software Version

With the Mode Select Keyswitch set to Configure mode, the terminal

displays the Configuration Mode Menu.

CONFIGURATION MODE MENU

Upload / Download

Serial Port

Rack Assignments

Access Codes

Audio Response

Alarm Relay

Preset Operations

Time and Date

Screen Saver

Screen Alignment

Stuck Button Timeout

User EPROM/EEPROM Power-up Test

"

Pass-Through Download Options

Unit Tests

Firmware Rev 05.00.00 06/21/93 (050900) 06/21/93 05:36:59 AM

Application File Name: DEMO 10801 Bytes Used, 52175 Bytes Free

Important The Configuration Mode Menu for a touch screen terminal also

contains a False Depression Test which is discussed later in this chapter.

Up

Cursor

Down

Cursor

Enter

23593

Upload/Download

There are two methods of uploading and downloading application files:

using the Upload/Download cable connected to the computer and the

terminal’s RS-232 port

via a Data Highway Plus using the PLC-5’s Pass-Through feature

Uploading and Downloading instructions for application files are provided

in the PanelBuilder Development Software User Manual, the PanelBuilder

1200 Configuration Software for Windows User Manual, and the

PanelView 1200 Transfer Utility User Manual.

If you are using an older version of PanelView 1200 firmware, see your

PanelBuilder software user manual for details on version compatibility.

2-6

Page 36

Chapter 2

PanelView 1200 Terminal Functions

Important Downloading via the Pass-Through feature requires

configuration in PanelBuilder software or “Manual” configuration in the

terminal’s Pass-Through Download Options menu, so that the network

information and the PanelView 1200 terminal’s location on the network is

correct. Refer to the instructions in your PanelView 1200 Transfer Utility

User Manual, the PanelBuilder Development Software User Manual or see

the Pass-Through Download Options section later in this chapter.

Serial Port

Use this menu item to set the serial communication port for downloading

or uploading application files, or for printing alarm messages or screens.

1 Choose Serial Port from the PanelView 1200 terminal’s Configuration

Mode menu by cursoring to Serial Port and pressing ENTER.

2 Press the Choose List button. The list of parameters in the window on

the left will toggle between these headings:

Upload/Download to configure the port for uploading or

downloading your application file

Printer to configure the port for printing alarm messages or screens

on a serial printer.

The default settings for Upload/Download and Printer can be displayed

in the Serial Port screen as follows:

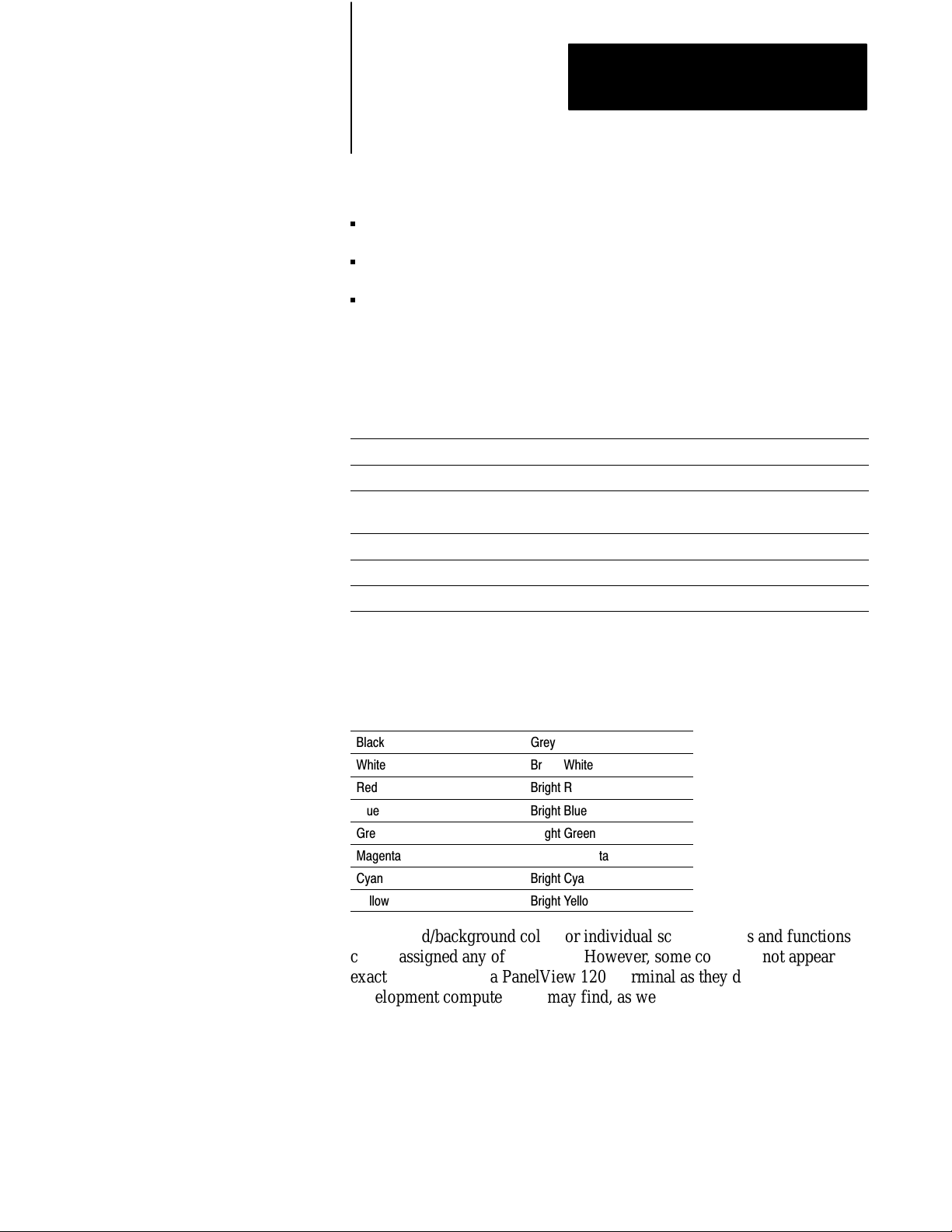

Port Parameters Upload/Download Printer

Baud Rate

Parity None None

Data Bits 8 8

Stop Bits 1 1

Handshake Type Hardware Software

AutoLine Feed Off (not configurable) On

AutoForm Feed Off (not configurable) On

9600 9600

3 Using the Change Data button, set the desired baud rate, number of

bits, parity, etc.

4 When the desired values have been configured, press the Save & Exit

button to save them permanently to RAM.

2-7

Page 37

Chapter 2

PanelView 1200 Terminal Functions

Important The Auto Line Feed and Auto Form Feed parameters are not

used for uploading/downloading, and cannot be changed. Although you

can choose 7 or 8 for the “Data Bits” option, always use 8 (the default), or

you won’t be able to transfer. The 7 data bits option applies only to printer

settings.

You should not have to change the default settings for Upload/Download;

the PanelBuilder software expects these settings. If you do change the

settings, be sure you set the PanelBuilder development computer’s serial

port to match. See instructions for configuring the computer’s serial port in

your PanelBuilder software user manual, along with instructions for

uploading and downloading.

For printer settings, refer to your printer’s manual.

Rack Assignments

Choose Rack Assignments to view the rack assignments and block transfer

file definitions of the current application file. These settings can be

changed only in the development computer using PanelBuilder software.

Important You must first download an application file for this function to

work.

The Rack Assignments screen shows the rack assignments, the PLC type,

and the baud rate. A button allows you to view the block transfer file

definitions. The following illustration shows the Rack Assignments screen

for a touch screen terminal.

RACK ASSIGNMENTS

PLC Type: PLC-5/15 integral

Baud Rate: 57.6K

Rack

Number

1

2

*

*

*

*

*

*

Starting

Module Group

0

0

*

*

*

*

*

*

Rack

Size

1/2

Full

*

*

*

*

*

*

Last

Chassis

Yes

Yes

*

*

*

*

*

*

Block

Transfers

Exit

2-8

20203

Page 38

Chapter 2

PanelView 1200 Terminal Functions

Access Codes

Choose Access Codes to assign up to eight security code settings. Once

security codes are set, an operator will have to sign on using the

appropriate code, in order to view screens that have assigned security.