Page 1

1785 PLC-5 Programmable Controllers

Quick Reference

Addressing Instruction SetHardware Components Switch Settings Troubleshooting

Front Panels ........................ 1-1

Processor Comparison......... 1-6

1771 I/O Chassis ...............1-10

Power Supplies.................. 1-11

Keyswitch..........................1-13

Processor Status File ......... 1-14

I/O Status File .................... 1-30

Data Table Files ...................2-1

Program Files ......................2-4

I/O Image Addressing...........2-5

Logical Addressing...............2-6

Indexed Addressing..............2-7

Indirect Addressing ..............2-7

I/O Addressing Modes ..........2-8

I/O Placement ......................2-8

Concept Summary................2-9

Status Bits........................... 3-1

Relay................................... 3-2

Timer .................................. 3-5

Counter ............................... 3-7

Compare ............................. 3-9

Compute ........................... 3-12

Logical .............................. 3-22

Conversion ........................ 3-24

Bit Modify and Move.......... 3-26

File.................................... 3-28

Diagnostic ......................... 3-30

Shift Register..................... 3-32

Sequencer......................... 3-35

Program Control ................ 3-36

Processor Control and

Message ........................... 3-41

Block and ControlNet

Transfer ............................ 3-43

ASCII ................................. 3-47

Chassis Backplane............... 4-1

Chassis Configuration ..........4-3

Complementary I/O .............. 4-4

Enhanced and

Ethernet PLC-5 ....................4-7

ControlNetwork Address ....4-11

Classic PLC-5 ....................4-12

Ethernet Jumper ................ 4-21

Enhanced and Ethernet PLC-5

General .........................5-1

Communication.............5-3

PLC-5/40L and PLC-5/60L

Communication ....................5-5

Ethernet

Status and Transmit .............5-7

ControlNet

Status Indicators ..................5-8

Classic PLC-5

General ..............................5-12

Adapter Mode .............5-14

Scanner Mode.............5-15

Remote I/O .........................5-17

Extended Local I/O .............5-25

Flex I/O ControlNet .............5-28

1771 I/O ControlNet............5-29

ControlNet I/O Status..........5-30

ControlNet Errors................5-35

Fault Codes ........................5-45

Page 2

Using this Manual

This Quick Reference provides information frequently needed for using and maintaining your Allen-Bradley

PLC-5 processor.

It is intended for reference purposes only, and not as the sole source of information.

For more specific information on any topic in this Quick Reference, see:

• Enhanced and Ethernet PLC-5 Family Programmable Controllers User Manual, publication 1785-6.5.12

• Classic PLC-5 User Manual, publication 1785-6.2.1

• ControlNet PLC-5 Programmable Controllers Phase 1.5 User Manual, publication 1785-6.5.22

Important User Information

Because of the variety of uses for the products described in this publication, those responsible for the application

and use of this control equipment must satisfy themselves that all necessary steps have been taken to assure that

each application and use meets all performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended solely for

purposes of example. Since there are many variables and requirements associated with any particular installation,

Allen-Bradley does not assume responsibility or liability (to include intellectual property liability) for actual use

based upon the examples shown in this publication.

Page 3

The Safety Guidelines for the Application, Installation, and Maintenance of Solid State Control, publication

SGI-1.1 (available from your local Allen-Bradley office), describes some important differences between

solid-state equipment and electromechanical devices which should be taken into consideration when applying

products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or in part, without written permission of

Allen-Bradley Company, Inc. is prohibited.

Summary of Changes

In this release of the PLC-5 Quick Reference, we have altered the way we reference software documentation.

Rather than show specific screens and key sequences which may vary according to the software package you

are using, we refer you instead to the programming software documentation that accompanies your particular

software package. Of course, we still provide the essential reference information you need to quickly accomplish

your tasks, but if you have specific questions about software procedures, you should refer to your programming

software documentation set.

To help you find new information, we included change bars as shown to the left of this paragraph.

Page 4

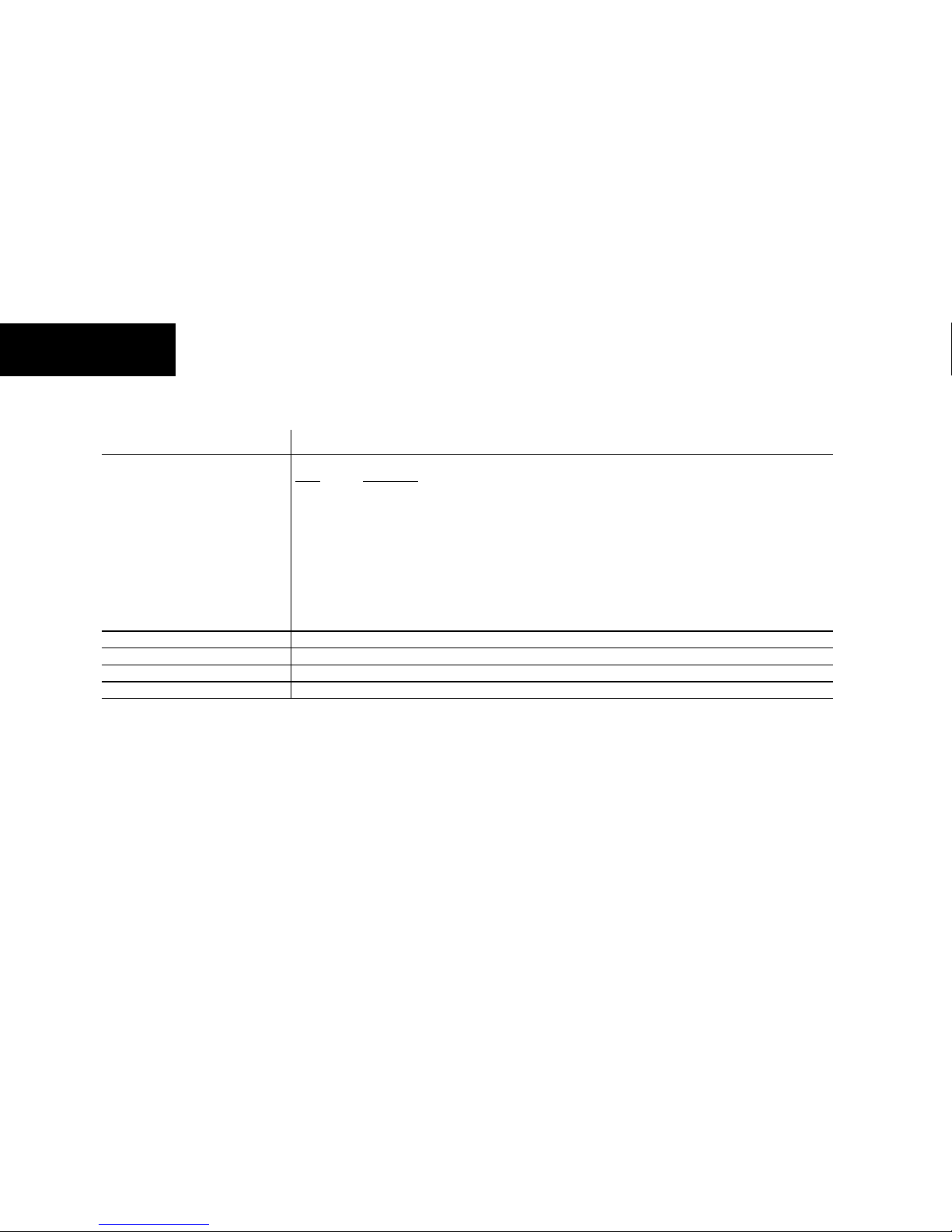

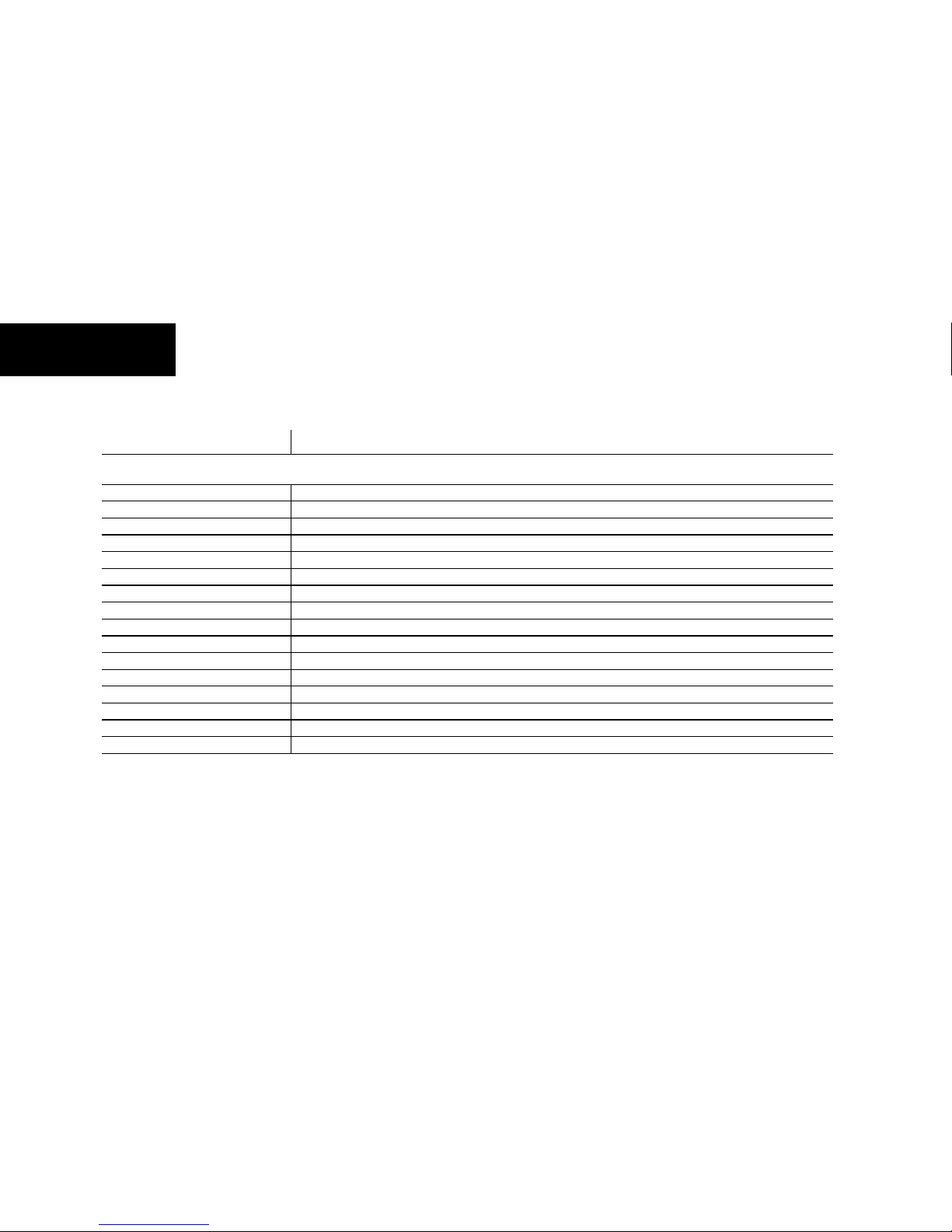

Conventions

The table below describes the naming conventions used in this manual:

☞ You see this symbol in the lower right-hand corner of the page when information is continued on the next page.

© 1999 Rockwell Automation

PLC, PLC-2, PLC-3, PLC-5, PLC-5/10, PLC-5/11, PLC-5/12, PLC-5/15, PLC-5/20, PLC-5/25, PLC-5/30, PLC-5/40, PLC-5/40L, PLC-5/60, PLC-5/60L, PLC-5/80, PLC-5/20E, PLC-5/40E, PLC-5/80E, PLC-5/250,

PLC-5/20C, PLC-5/40C, PLC-5/80C, Ethernet, and DH+ are trademarks of Rockwell Automation.

This name: Represents these processors:

Enhanced

PLC-5/11™PLC-5/40

™

PLC-5/20™PLC-5/60

™

PLC-5/30™PLC5/80

™

PLC-5/40L™PLC-5/60L

™

Ethernet

PLC-5/20E™PLC-5/40E

™

PLC5/80E

™

ControlNet

Phase 1.5

PLC-5/20C15™ 5/40C15

™

5/80C15

™

Classic

PLC-5/10™PLC-5/15

™

PLC-5/12™PLC-5/25

™

Page 5

Hardware Components

Front Panel 1-1

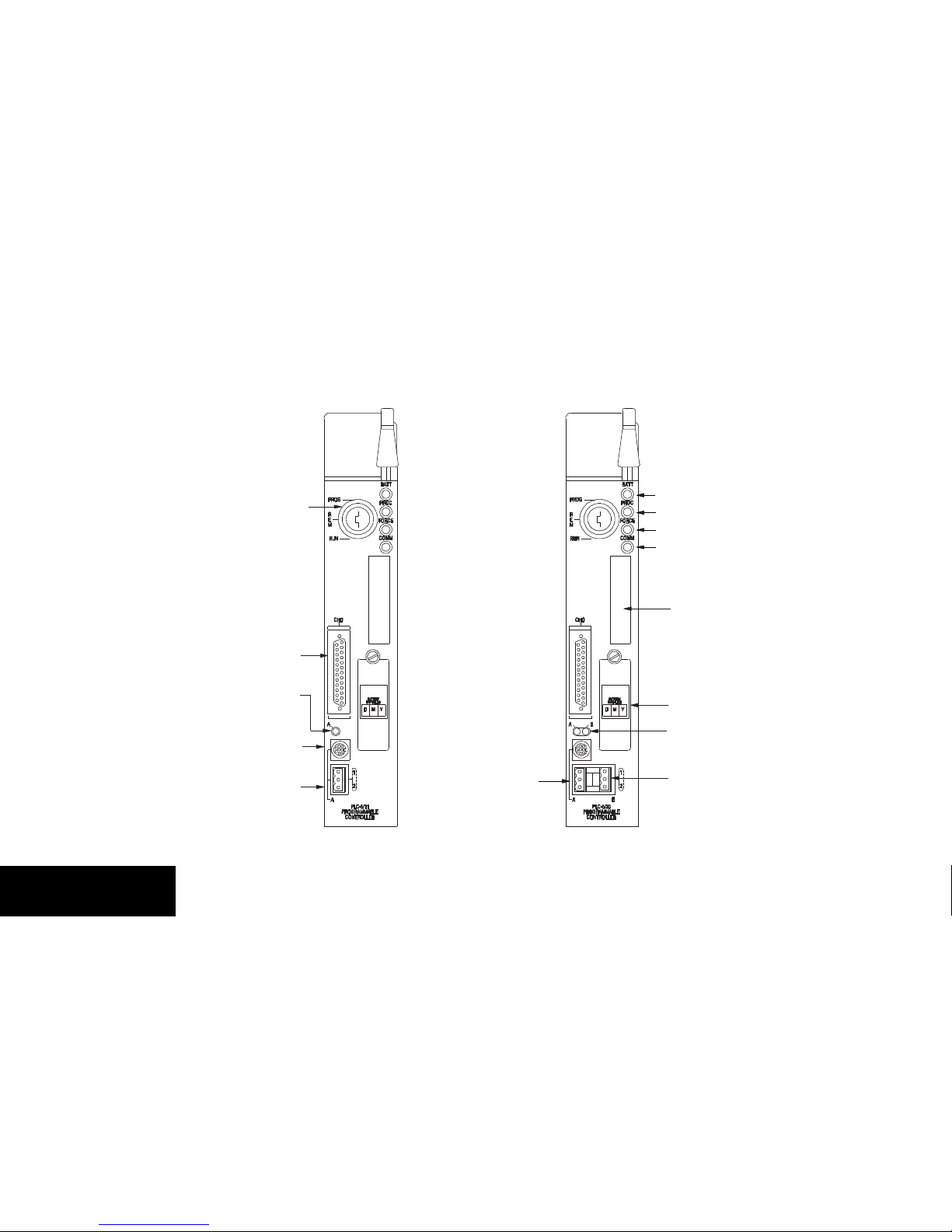

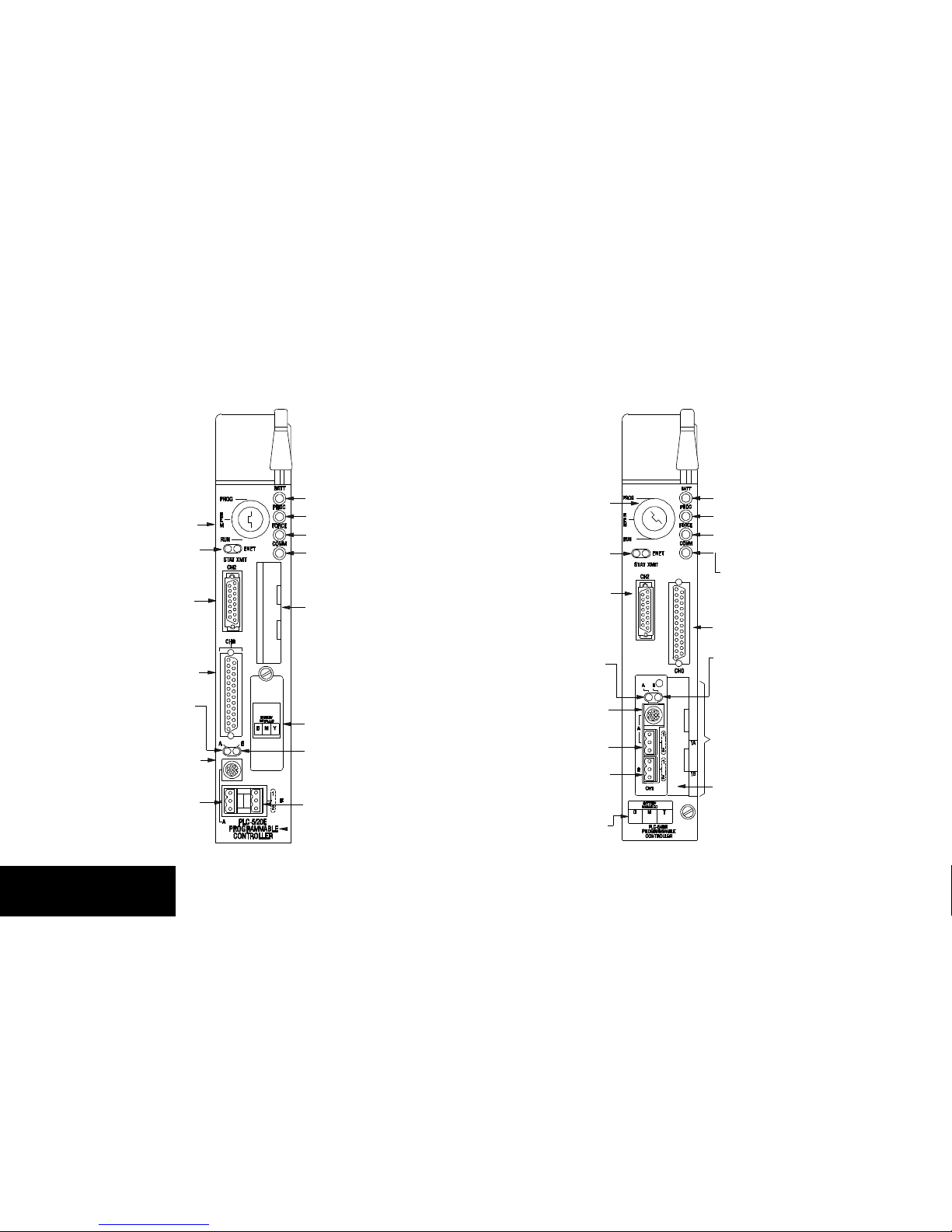

Front Panel – Enhanced

PLC-5 Processors

Channel 1A

fixed DH+ port

Keyswitch

Channel 0 - on-board

serial port

Channel 1A status

indicator (green/red)

Connect programming terminal

here when channel 1A is configured

for DH+ communications

Channel 1A communication port

Install memory

module here

Battery holder

Channel 1B status

indicator (green/red)

Channel 1B

communication port

PLC-5/11 Processor PLC-5/20 Processor

Battery (red)

Processor RUN/FAULT (green/red)

Force (amber)

Channel 0 communication

status (green)

Indicators:

Page 6

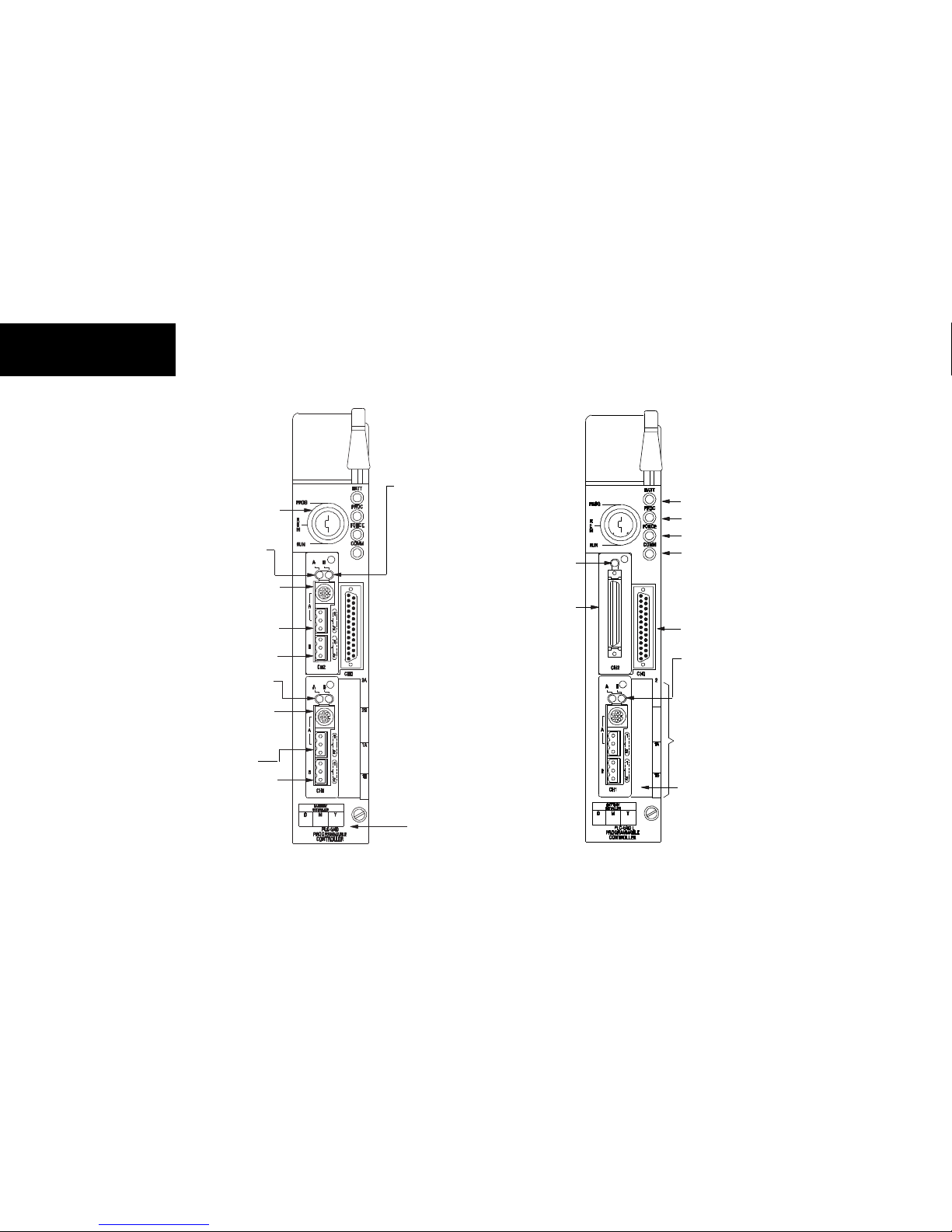

Hardware Components

Front Panel 1-2

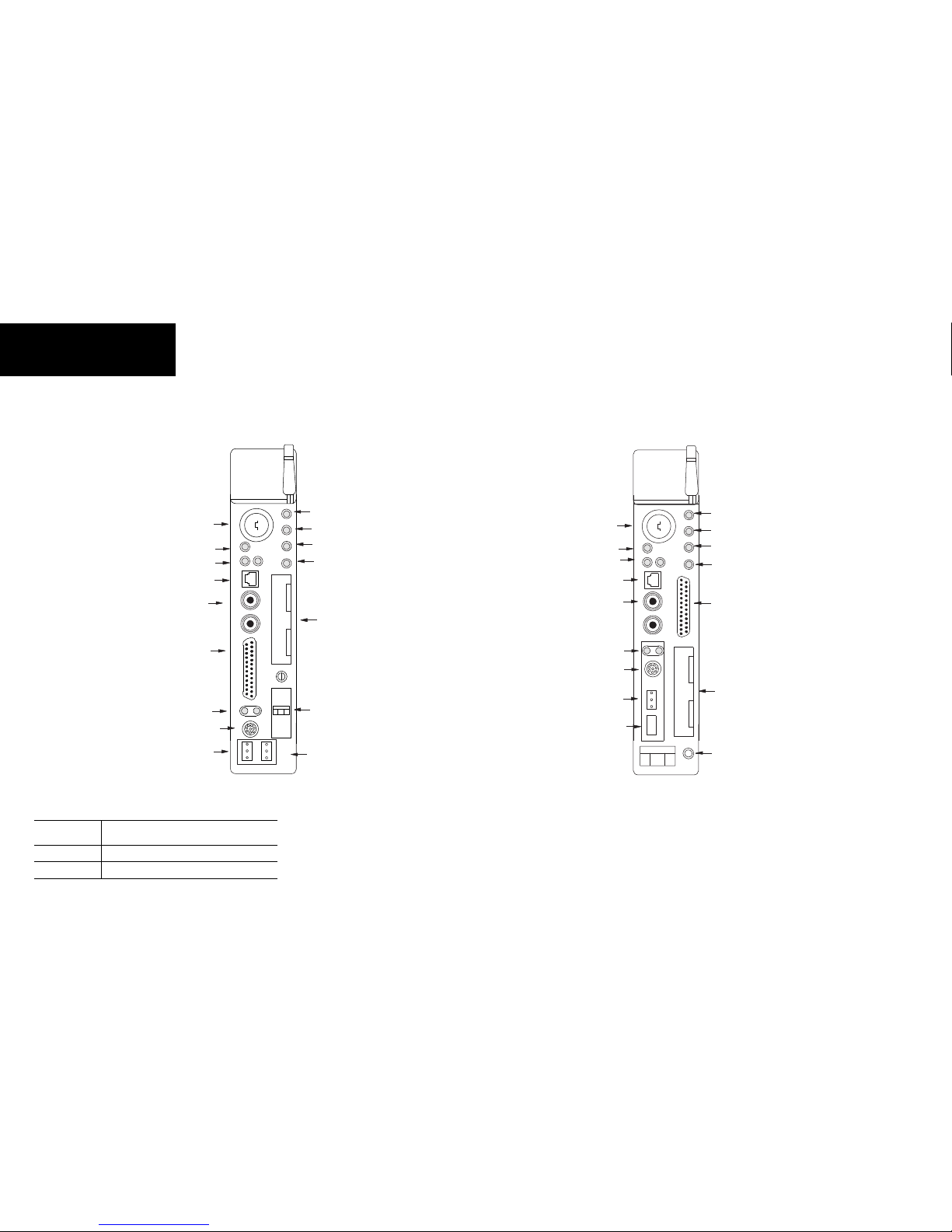

PLC-5/30, -5/40, -5/60,

-5/80 Processor

PLC-5/40L, -5/60L Processor

Keyswitch

Battery holder

Channel 2A status

indicator (green/red)

Connect programming terminal here

when channel 2A is configured for

DH+ communications

Channel 2A communication port

Channel 2B communication port

Channel 1A status

indicator (green/red)

Channel 1A communication port

Channel 1B communication port

Channel 2 status

indicator (green/red)

Channel 2

extended-local I/O

communication port

Channel 2B

status indicator

(green/red)

Install memory

module here

Channel 1B

status indicator

(green/red)

Channel 0 - on-board

serial port

The PLC-5/30 processor has 2 communication ports and 1 serial port

Battery (red)

Processor RUN/FAULT (green/red)

Force (amber)

Communication ACTIVE/FAULT

status (green/red)

Indicators:

Labels to write information

about the channel

communication mode,

station addresses, etc.

Connect programming terminal here

when channel 1A is configured for

DH+ communications

Page 7

Hardware Components

Front Panel 1-3

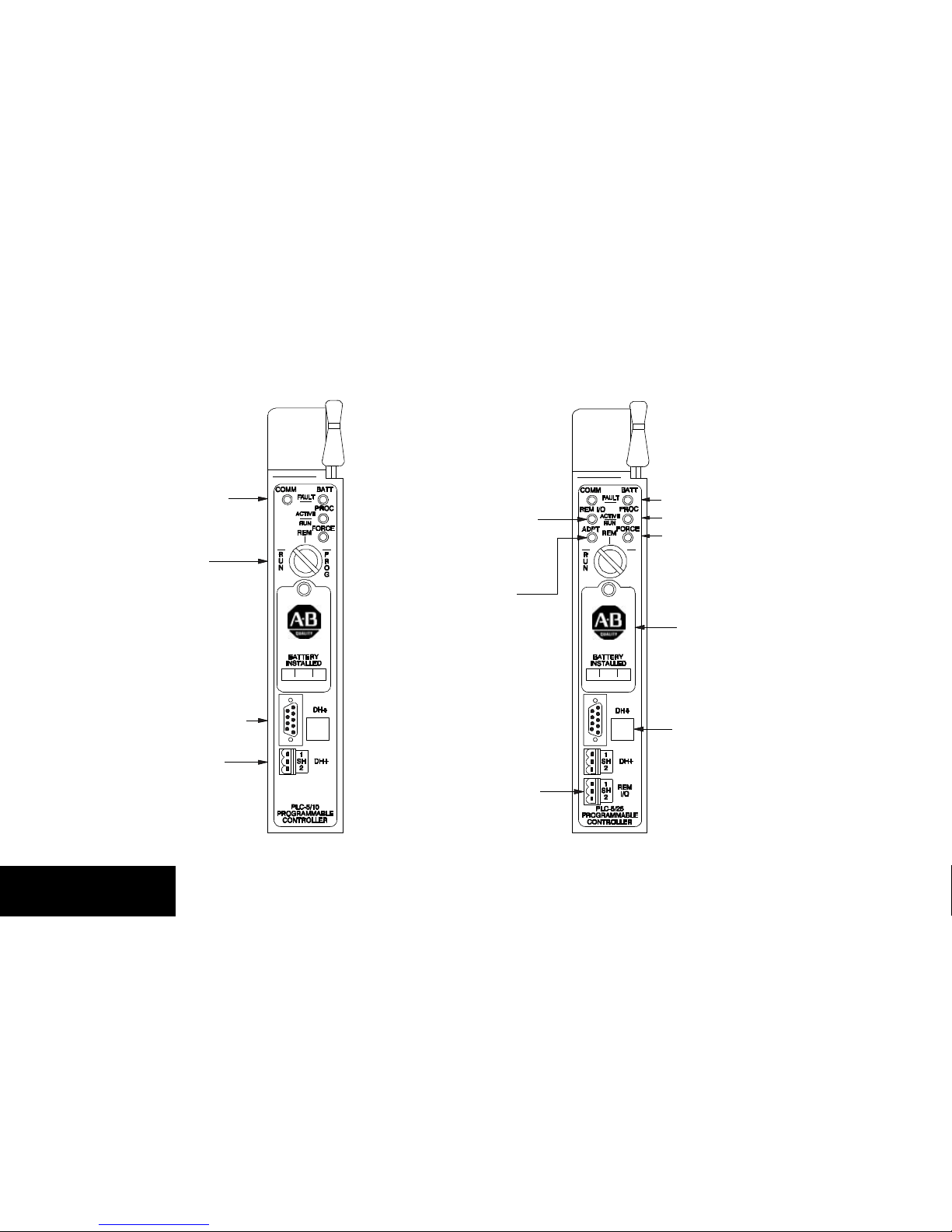

Front Panel – Ethernet

PLC-5 Processors

PLC-5/20E Processor

Keyswitch

Channel 0 - on-board

serial port

Channel 1A status

indicator (green/red)

Connect programming

terminal here

Channel 1A

Battery (red)

Processor RUN/FAULT (green/red)

Force (amber)

Channel 0 communication

status (green)

Install memory

module here

Battery holder

Channel 1B status

indicator (green/red)

Channel 1B

Channel 2 Ethernet

status indicators

Channel 2

Indicators:

Battery (red)

Force (amber)

Communication

ACTIVE/FAULT (green/red)

Channel 0 - on-board

serial port

Labels to write information

about the channel

communication mode,

station addresses, etc.

Keyswitch

Channel 1A

Channel 1B

Battery holder

Channel 2

Indicators:

PLC-5/40E, -5/80E Processor

Channel 1A status

indicator (green/red)

Connect programming

terminal here

Channel 2 Ethernet

status indicators

Processor RUN/FAULT

(green/red)

Install memory

module here

Channel 1B status

indicator (green/red)

Page 8

Hardware Components

Front Panel 1-4

Channel 2 Status Indicators

PLC-5/20C15 Processor

Keyswitch

I/O Status Indicator

Network Access Port

Channel 2

Channel 0

Channel 1 Status Indicators

DH+ Programming Terminal

Connection to Channel 1A

Channel 1A

Battery

Processor RUN/FAULT

Force

Channel 0 Communication

ACTIVE/FAULT

Memory Module Space

Battery Holder

Channel 1B

Keyswitch

I/O Status Indicator

Channel 2 Status Indicators

Network Access Port

Channel 2

Channel 1 Status Indicators

DH+ Programming Terminal

Connection to Channel 1A

Channel 1A

Channel 1B

Battery

Processor RUN/FAULT

Force

Channel 0 Communication

ACTIVE/FAULT

Channel 0 - on-board serial port

Memory Module Space

Battery Holder

PLC-5/40C15, -5/80C15 Processor

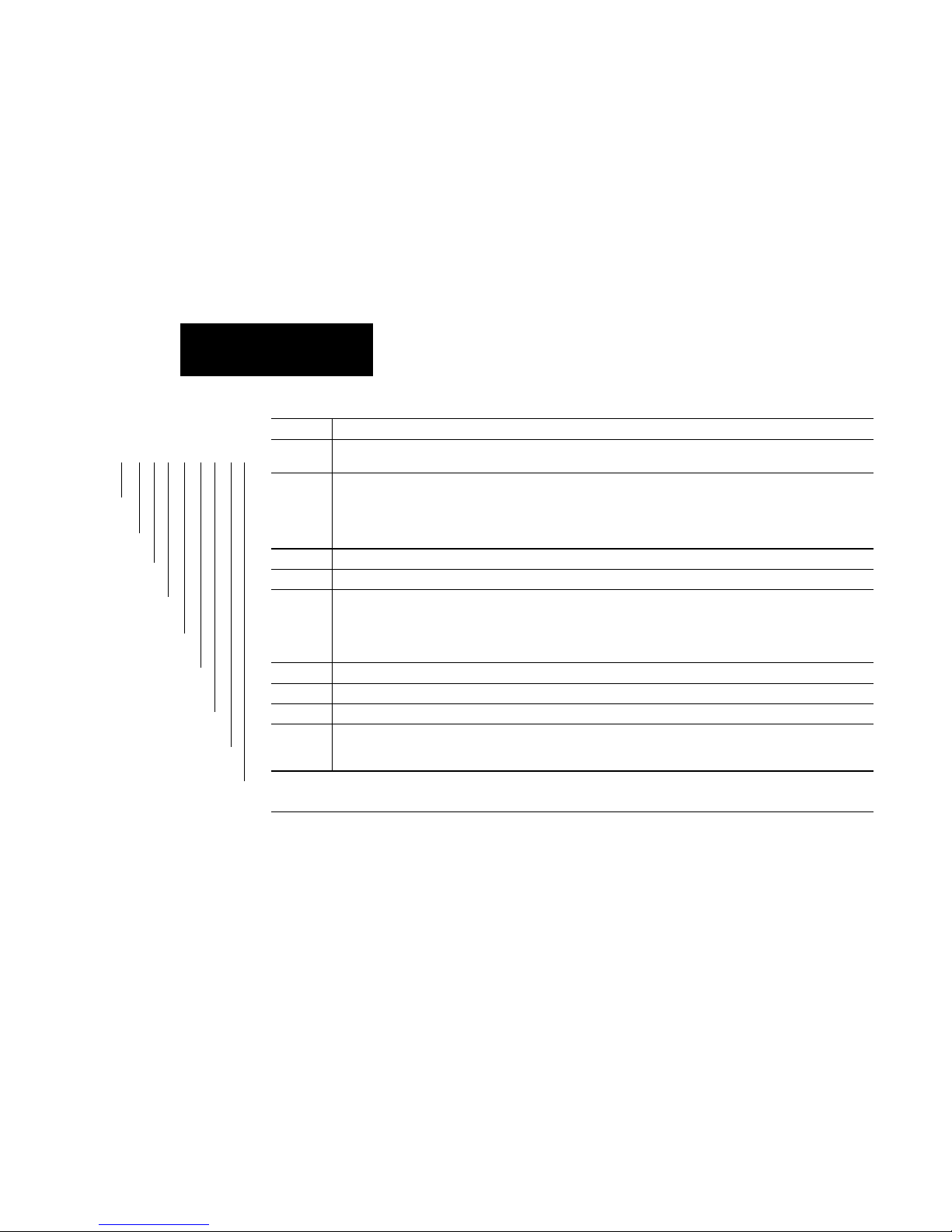

Front Panel – ControlNet PLC-5 Processors

ControlNet PLC-5 Processors

Phase Catalog Number

1.0/1.25 1785L20C, -L40C, -L80C

1.5 1785L20C15, -L40C15, -L80C15

Page 9

Hardware Components

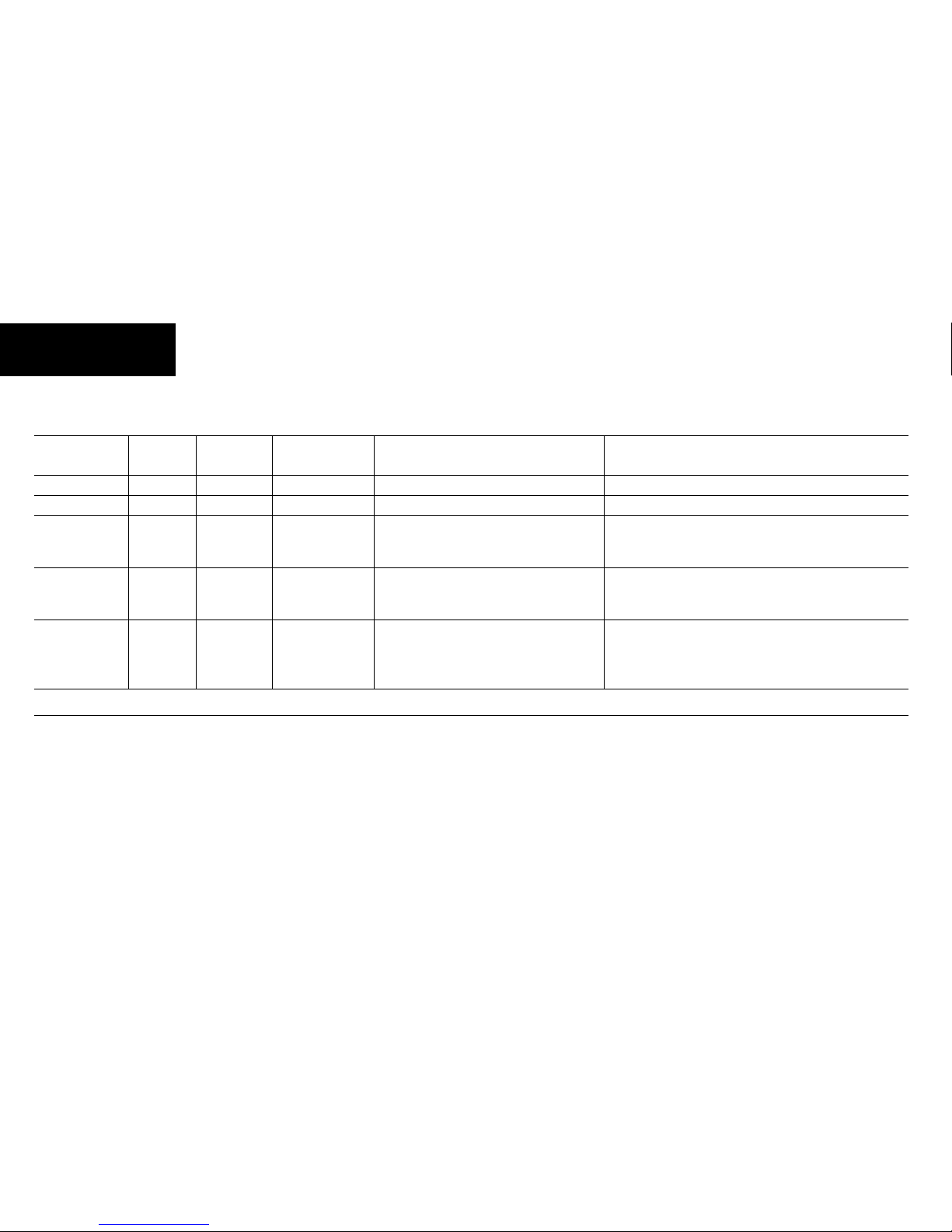

Front Panel 1-5

Hardware Components

REM I/O indicator

ACTIVE/FAULT

(green/red)

P

R

O

G

PLC-5/10 Processor PLC-5/12, -5/15, -5/25 Processor

Keyswitch

DH+ communication

indicator ACTIVE/FAULT

(green/red)

Connect programming

terminal here

Connect DH+

link here

Adapter indicator

(green)

Connect remote

I/O link here

Battery holder

Write the DH+

network station

number on this label

12373

Battery (red)

Processor RUN/FAULT (green/red)

Force (amber)

Indicators:

Front Panel – Classic

PLC-5 Processors

Page 10

Hardware Components

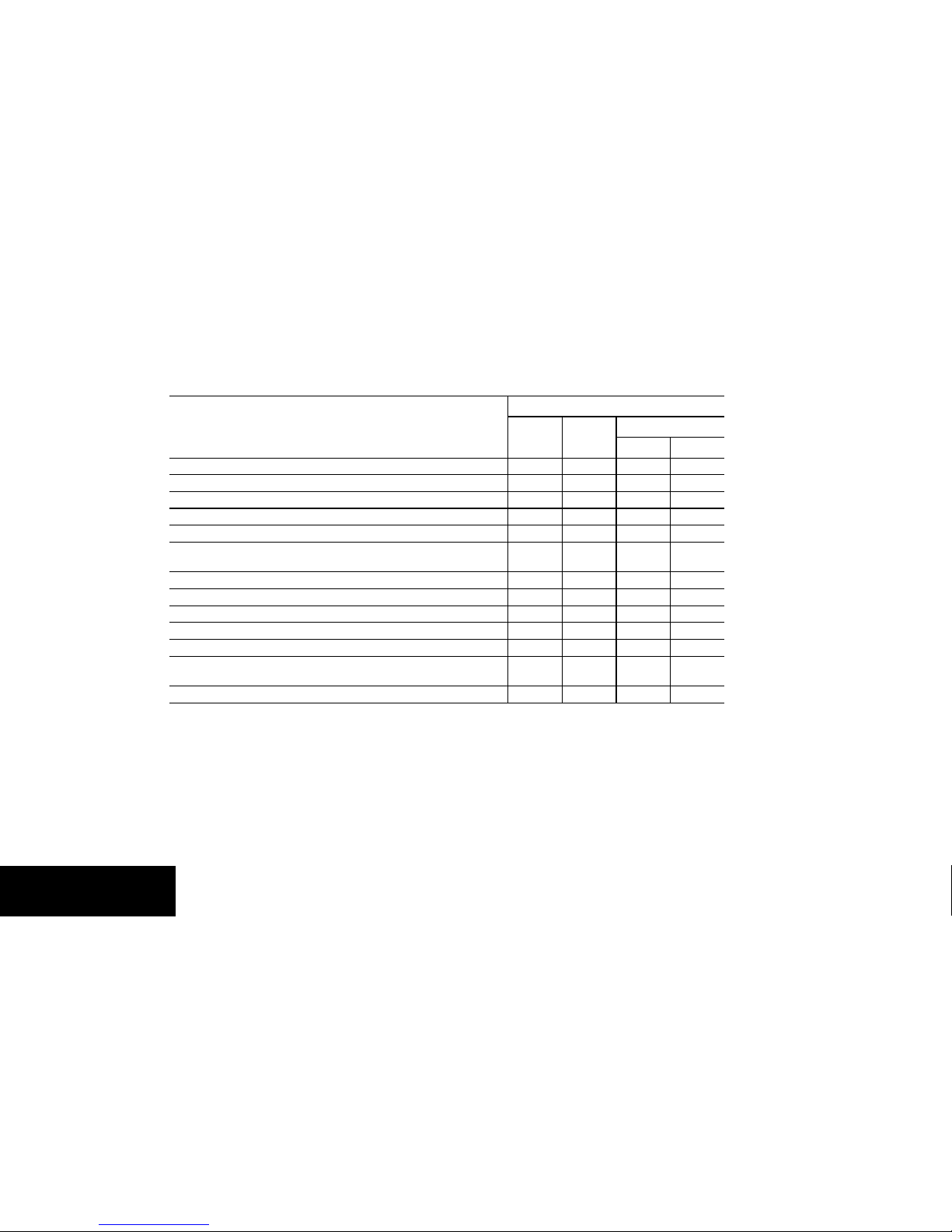

Processor Comparison 1-6

Comparison Chart for

PLC-5 Family Processors

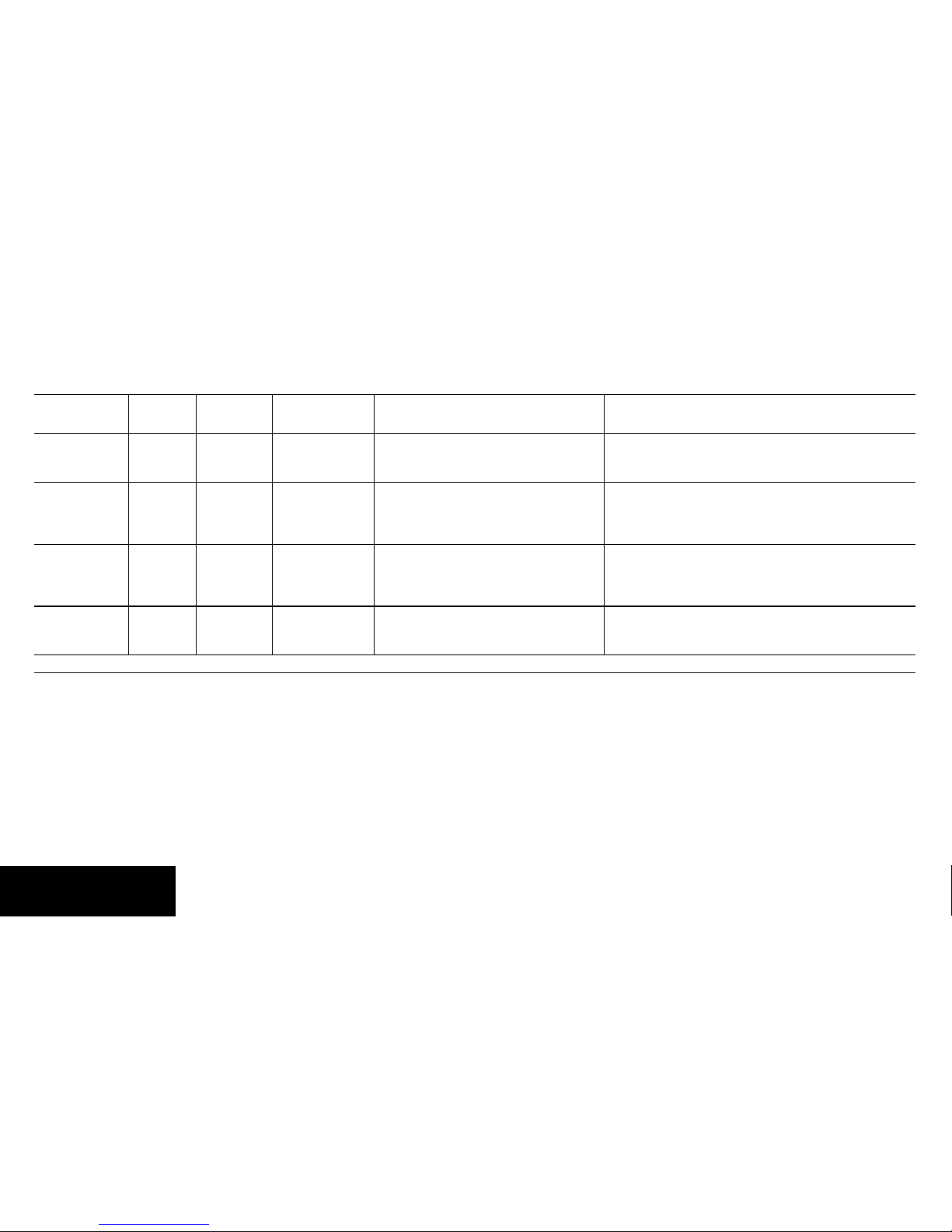

Processor Memory

(Words)

Local

Chassis

Remote Chassis

(I/O Racks)

I/O Capacity Communication

PLC-5/10 6K 1 resident none

128 (8-pt) 1, 256 (16-pt) 1, 512 (32-pt)

1

DH+ link

PLC-5/12 6K 1 resident none

128 (8-pt) 1, 256 (16-pt) 1, 512 (32-pt)

1

adapter, DH+ link

PLC-5/15 6K

(expands to

14K)

1 resident 12

(3 I/O racks)

• 512

1

• 512 inputs and 512 outputs using 16- or

32-pt modules

2

adapter/remote I/O scanner, DH+ link

PLC-5/25 13K

(expands to

21K)

1 resident 28

(7 I/O racks)

• 1024

1

• 1024 inputs and 1024 outputs using 16or 32-pt modules

2

adapter/remote I/O scanner, DH+ link

PLC-5/11 8K 1 resident 4

(1 I/O rack)

rack must be

addressed as rack

3

• 256 (8-pt), 384 (16-pt), or 512 (16-pt)

1

• 512(16-pt) or 768 (32-pt)

2

• 1 channel (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

1 Any mix of I/O

2 Maximum I/O possible using 16-pt modules with 2-slot addressing or 32-pt modules with 1-slot addressing. Modules must alternate input/output in the chassis slots.

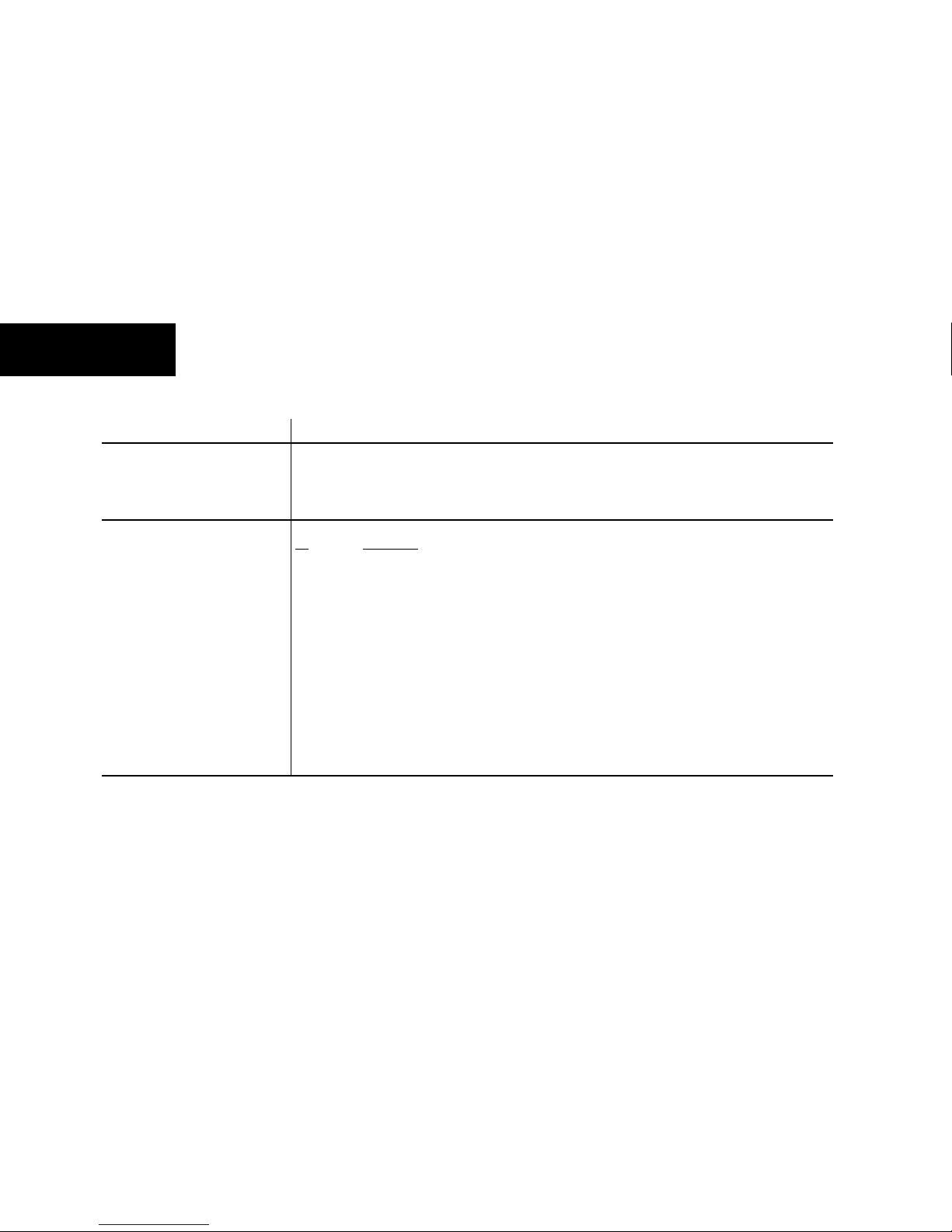

Page 11

Hardware Components

Processor Comparison 1-7

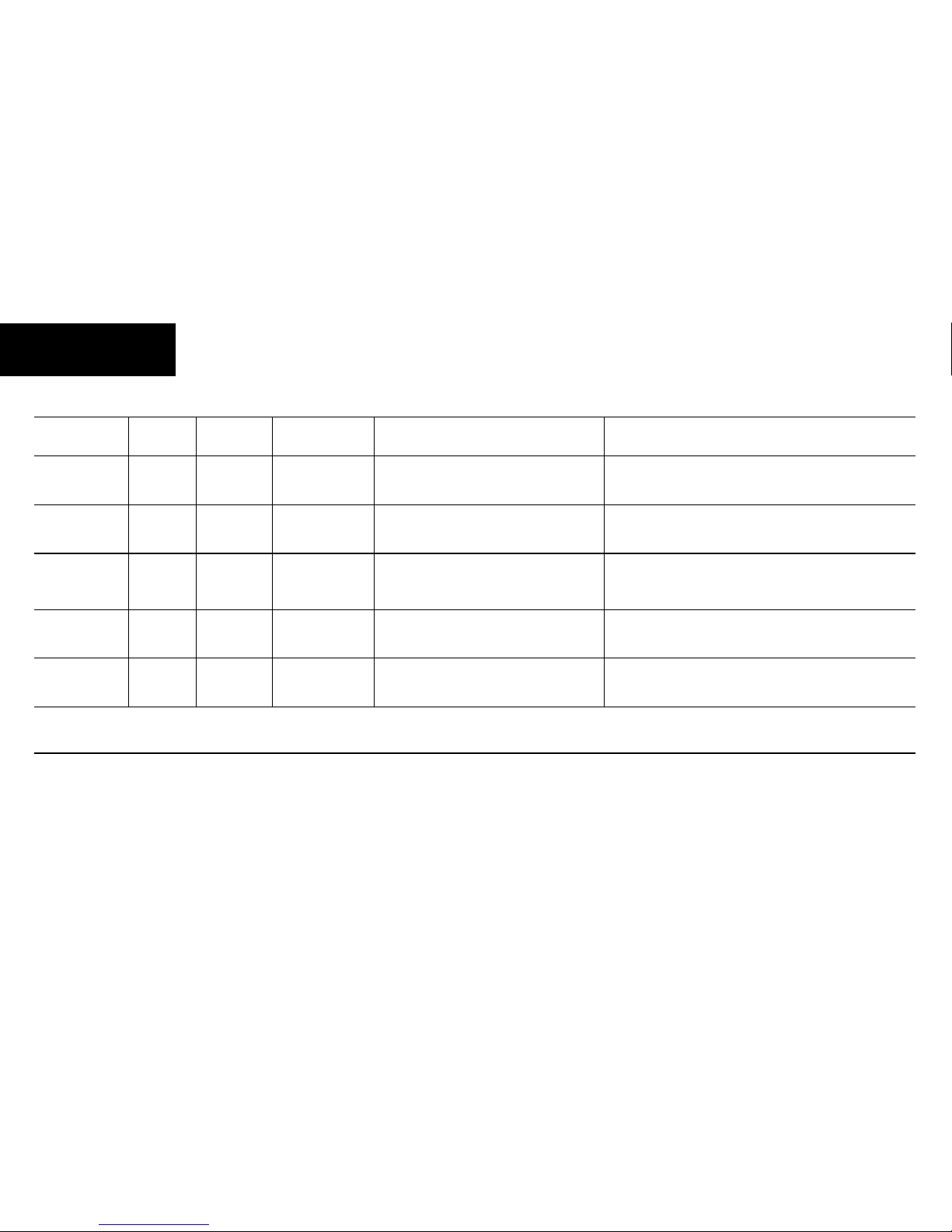

PLC-5 comparison chart continued...

Processor Memory

(Words)

Local

Chassis

Remote Chassis

(I/O Racks)

I/O Capacity Communication

PLC-5/20 16K 1 resident 12

(3 I/O racks)

• 512

1

• 512 inputs and 512 outputs using 16- or

32-pt modules

• 1 channel (remote I/O scanner, adapter, DH+ link)

• 1 channel DH+ link

• 1 RS-232, RS-422, RS-423 serial port

PLC-5/20E 16K 1 resident 12

(3 I/O racks)

• 512

1

• 512 inputs and 512 outputs using 16- or

32-pt modules

• 1 channel (remote I/O scanner, adapter, DH+ link)

• 1 channel DH+ link

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel Ethernet

PLC-5/20C15 16K 1 resident 12 (3 I/O racks)

• 512

1

• 512 inputs and 512 outputs using 16- or

32-pt modules

• 1 channel (remote I/O scanner, adapter, DH+ link)

• 1 channel DH+ link

• 1 RS-232, RS-422, RS-423 serial port

• ControlNet

PLC-5/30 32K 1 resident 28

(7 I/O racks)

• 1024

1

• 1024 inputs and 1024 outputs using16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

1

Any mix of I/O

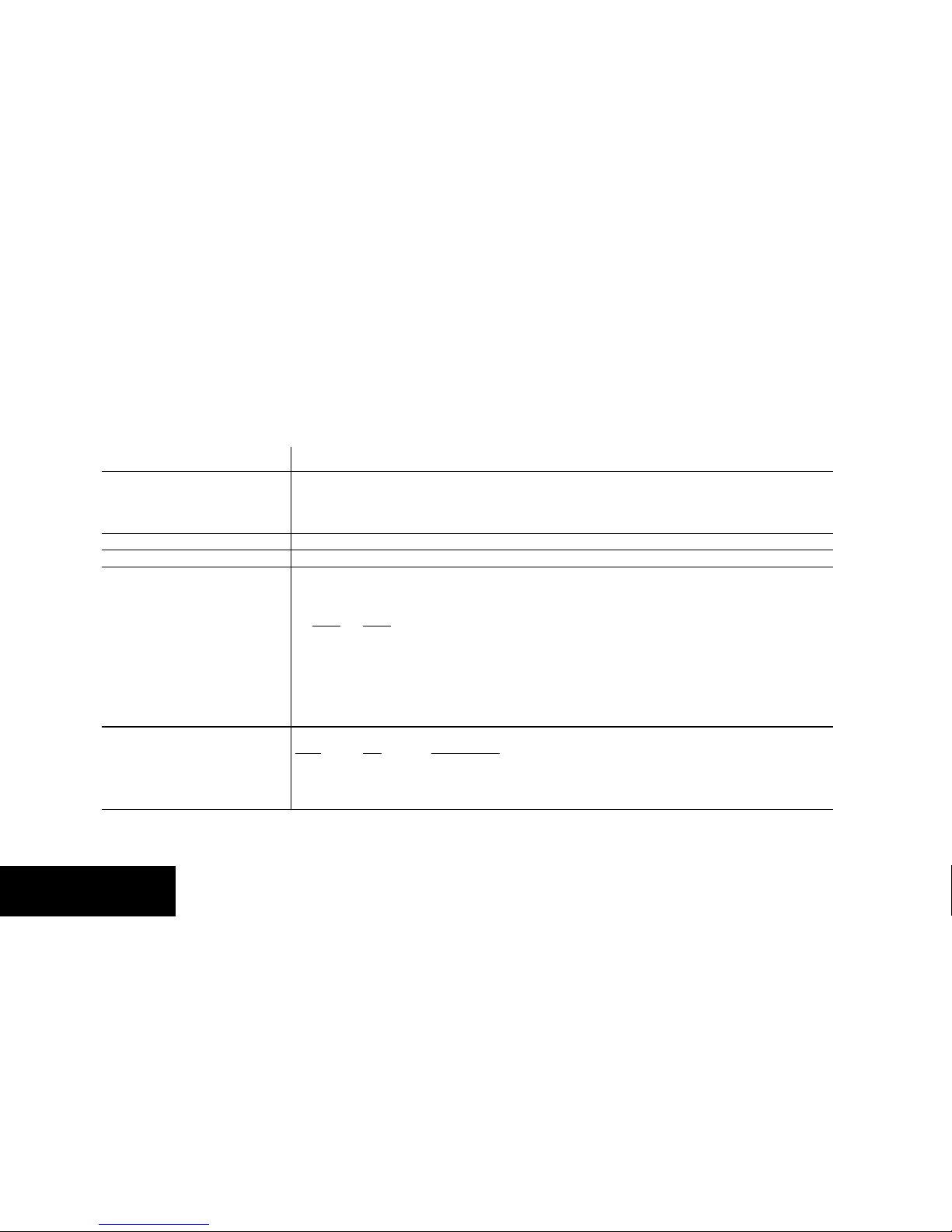

Page 12

Hardware Components

Processor Comparison 1-8

PLC-5 comparison chart continued...

Processor Memory

(Words)

Local

Chassis

Remote Chassis

(I/O Racks)

I/O Capacity Communication

PLC-5/40

48K

3

1 resident

60

2

(15 I/O racks)

• 2048

1

• 2048 inputs and 2048 outputs using 16or 32-pt modules

• 4 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

PLC-5/40L

48K

3

1 resident up

to 16

extended

60

2

(15 I/O racks)

• 2048

1

• 2048 inputs and 2048 outputs using 16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel extended local I/O scanner

PLC-5/40E

48K

3

1 resident

(16 rack

addressing

capability)

60

(15 I/O racks)

• 2048

1

• 2048 inputs and 2048 outputs using 16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel Ethernet

PLC-5/40C15

48K

3

1 resident 60

15 I/O racks

• 2048

1

• 2048 inputs and 2048 outputs using 16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel ControlNet

PLC-5/60

3

64K 1 resident

92

2

(23 I/O racks)

• 3072

1

• 3072 inputs and 3072 outputs using 16or 32-pt modules

• 4 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

1

Any mix of I/O

2

Maximum of 32 physical devices/channel

3

Maximum of 57K words per program file and 32K words per data table file

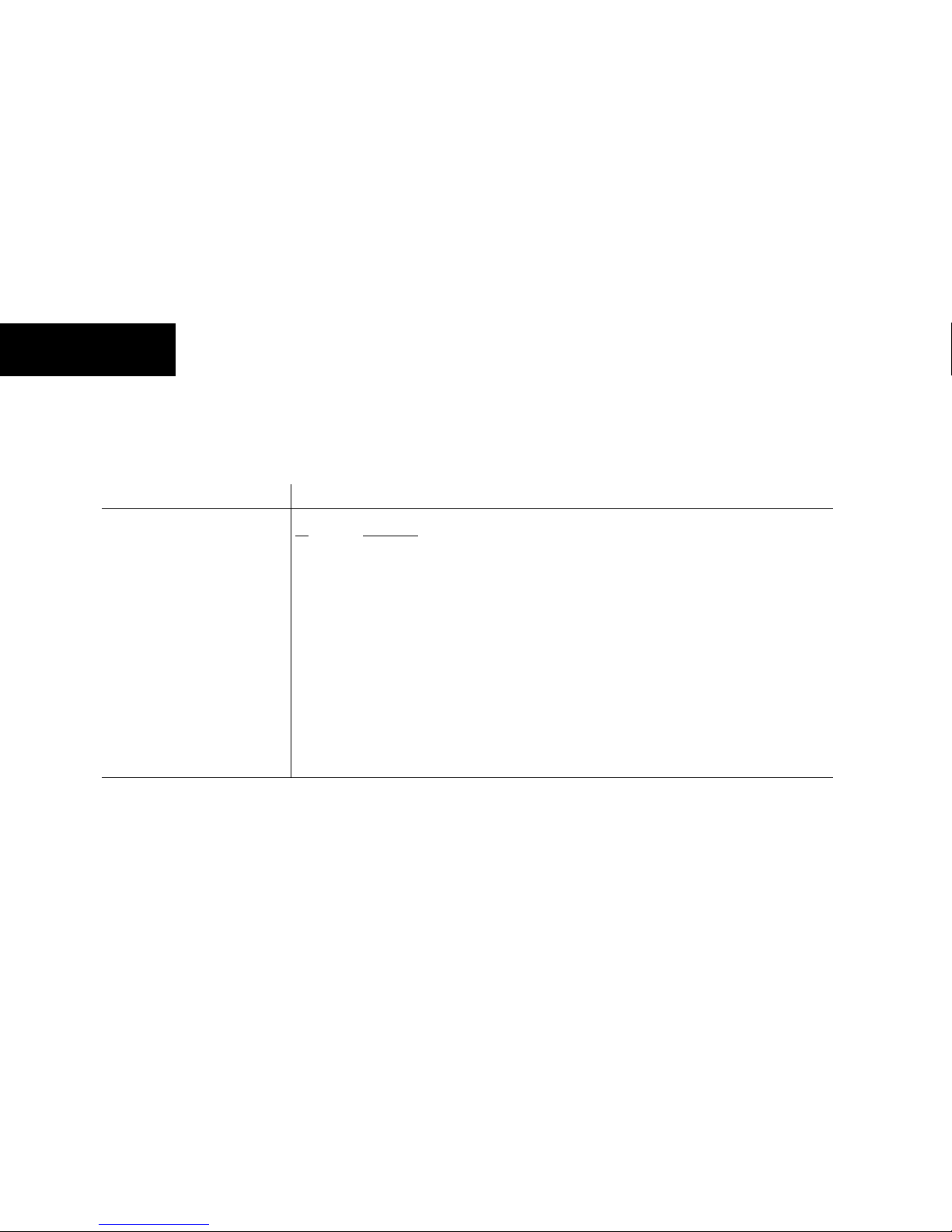

Page 13

Hardware Components

Processor Comparison 1-9

PLC-5 comparison chart continued...

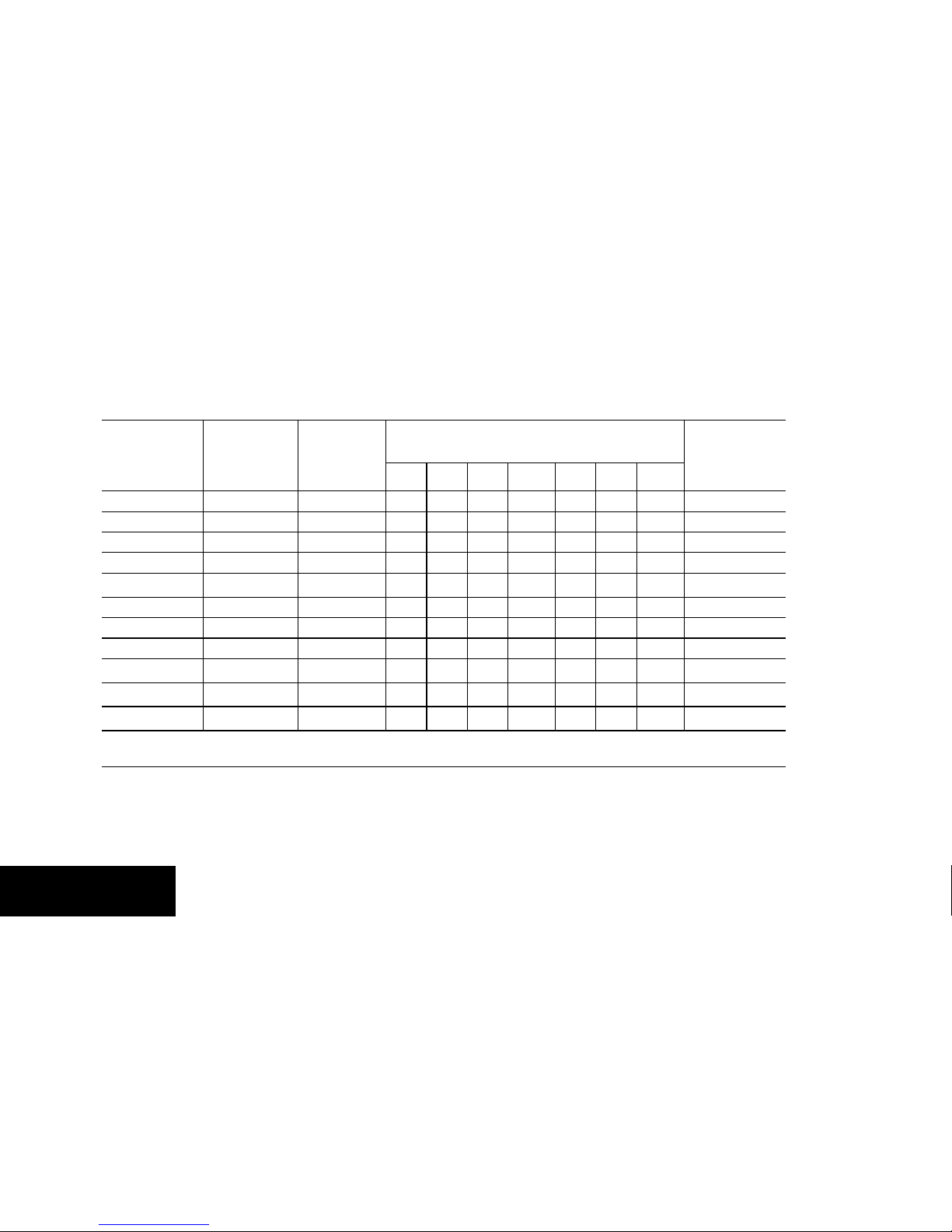

PLC-5 ControlNet Processors - Maximum I/O Map Entries

Processor Memory

(Words)

Local

Chassis

Remote Chassis

(I/O Racks)

I/O Capacity Communication

PLC-5/60L

3

64K 1 resident up

to 16

extended

64

2

(23 I/O racks)

• 3072

1

• 3072 inputs and 3072 outputs using16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel extended local I/O scanner

PLC-5/80

3.4

100K 1 resident

92

2

(23 I/O racks)

• 3072

1

• 3072 inputs and 3072 outputs using 16or 32-pt modules

• 4 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

PLC-5/80E

3,4

100K 1 resident

92

2

(23 I/O racks)

• 3072

1

• 3072 inputs and 3072 outputs using 16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel Ethernet

PLC-5/80C15

3.4

100K 1 resident

92

2

(23 I/O racks)

• 3072

1

• 3072 inputs and 3072 outputs using 16or 32-pt modules

• 2 channels (remote I/O scanner, adapter, DH+ link)

• 1 RS-232, RS-422, RS-423 serial port

• 1 channel ControlNet

1

Any mix of I/O

2

Maximum of 32 physical devices/channel

3

Maximum of 57K words per program file and 32K words per data table file

4

Maximum of 64K words total data table space

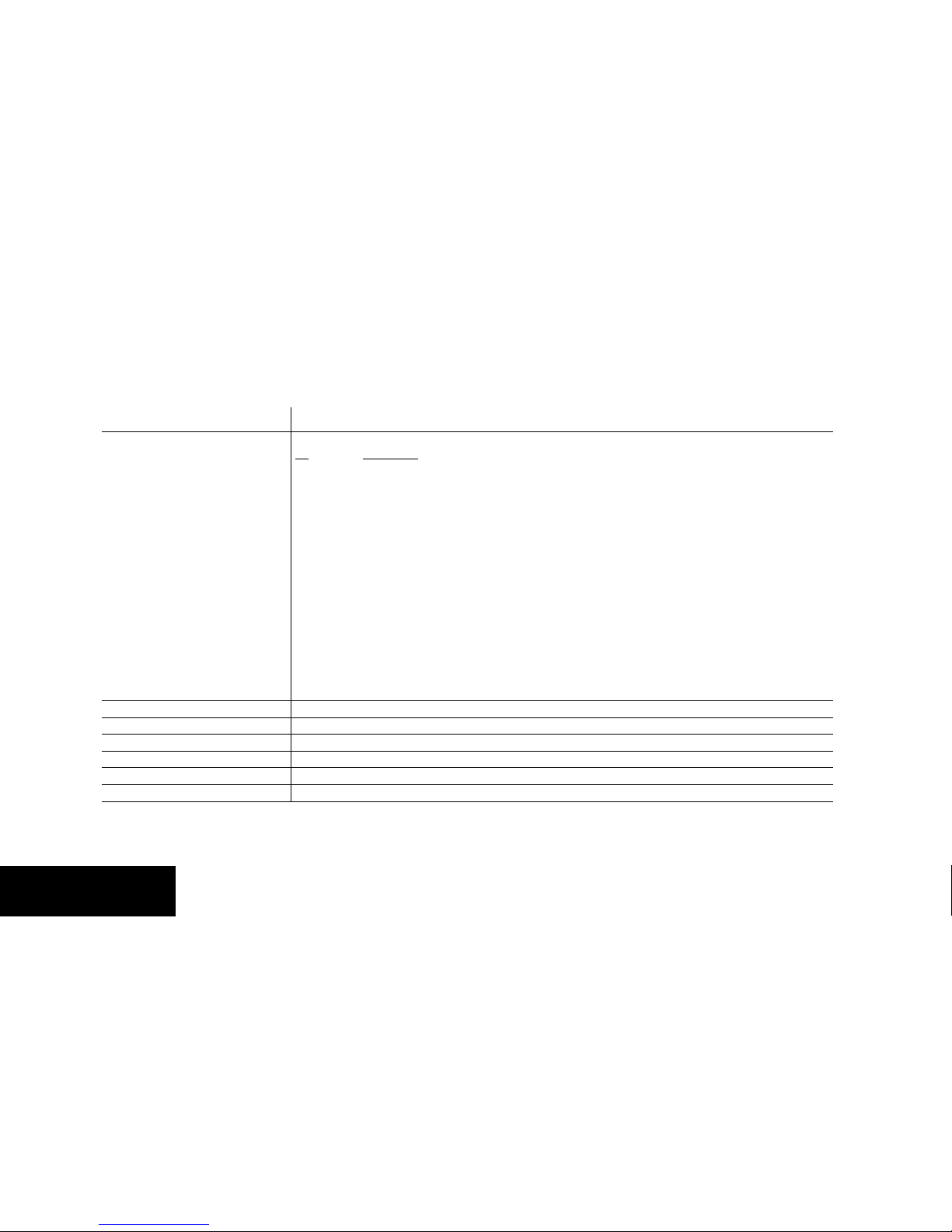

Phase 1.0/1.25 Phase 1.5

Processor Number of

Mappings:

Number of

DIF

Files:

Number of

DIF

Words:

Number of

DOF

Files:

Number of

DOF

Words:

Processor Number of

Mappings:

Number of

DIF

Files:

Number of

DIF

Words:

Number of

DOF

Files:

Number of

DOF

Words:

PLC-5/20C 64 1 1000 1 1000 PLC-5/20C 64 2 2000 2 2000

PLC-5/40C 64 1 1000 1 1000 PLC-5/40C 96 3 3000 3 3000

PLC-5/80C 64 1 1000 1 1000 PLC-5/80C 128 4 4000 4 4000

Page 14

Hardware Components

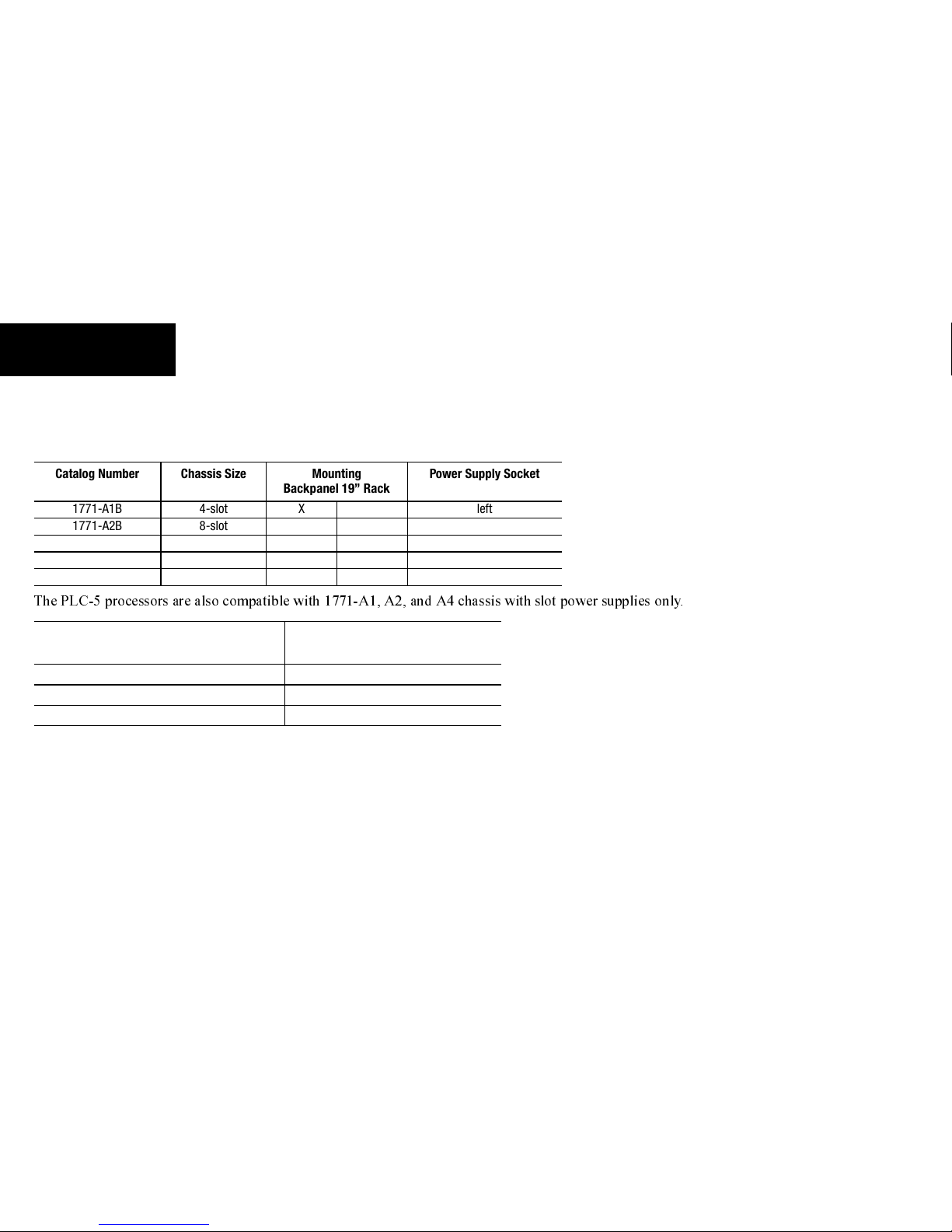

1771 I/O Chassis 1-10

1771 I/O Chassis for PLC-5 Family

Processors

7KH3/&SURFHVVRUVDUHDOVRFRPSDWLEOHZLWK$$DQG$FKDVVLVZLWKVORWSRZHUVXSSOLHVRQO\

Catalog Number Chassis Size Mounting

Backpanel 19” Rack

Power Supply Socket

1771-A1B 4-slot X left

1771-A2B 8-slot X left

1771-A3B 12-slot X X top

1771-A3B1 12-slot X left

1771-A4B 16-slot X left

When using these processors with the

1771-A1, A2, and A4 chassis:

Only this mode of addressing is

supported:

Classic PLC-5 processors 2-slot and 1-slot in the local rack

Enhanced and Ethernet PLC-5 processors 2-slot addressing

ControlNet PLC-5 processors 2-slot addressing

Page 15

Hardware Components

Power Supply Modules 1-11

Power Supply Modules in a Chassis

(containing a PLC-5 processor)

Output

Current

Output Current (in amps) when Parallel with: Power Supply

Power Supply Input Power (in Amps) P3 P4 P4S P4S1 P5 P6S P6S1 Location

1771-P3 120V ac 3 6 11 11 slot

1771-P4 120V ac 8 11 16 16 slot

1771-P4S 120V ac 8 11 16 16 slot

1771-P4S1 100V ac 8 16 slot

1771-P4R 120V ac

8, 16, 24

2

slot

1771-P5 24V dc 8 16 slot

1771-P6S 220V ac 8 16 slot

1771-P6S1 200V ac 8 16 slot

1771-P6R 220V ac

8, 16, 24

2

slot

1771-P7 120/220V ac 16

external

1

1771-PS7 120/220V ac 16

external

1

1

You cannot use an external power supply and a power supply module to power the same chassis; they are not compatible.

2

See publication 1771-2.166 for more information.

Page 16

Hardware Components

Power Supplies 1-12

Power Supplies in a Remote Chassis (1771-ASB)

or an Extended Local I/O Chassis (1771-ALX)

Output Current Output Current (in amps) when Parallel with: Power Supply

Power Supply Input Power (in Amps) P3 P4 P4S P4S1 P5 P6S P6S1 Location

1771-P3 120V ac 3 6 11 11 slot

1771-P4 120V ac 8 11 16 16 slot

1771-P4S 120V ac 8 11 16 16 slot

1771-P4S1 100V ac 8 16 slot

1771-P4R 120V ac 8, 16, 24

2

slot

1771-P5 24V dc 8 16 slot

1771-P6S 220V ac 8 16 slot

1771-P6S1 200V ac 8 16 slot

1771-P6R 220V ac 8, 16, 24

2

slot

1771-P1 120/220V ac 6.5 external

1

1771-P2 120/220V ac 6.5 external

1

1771-P7 120/220V ac 16 external

1

1771-PS7 120/220V ac 16 external

1

1777-P2 120/220V ac 9 external

1

1777-P4 24V dc 9 external

1

1

You cannot use an external power supply and a power supply module to power the same chassis; they are not compatible.

2

See publication 1771-2.166 for more information.

Page 17

Hardware Components

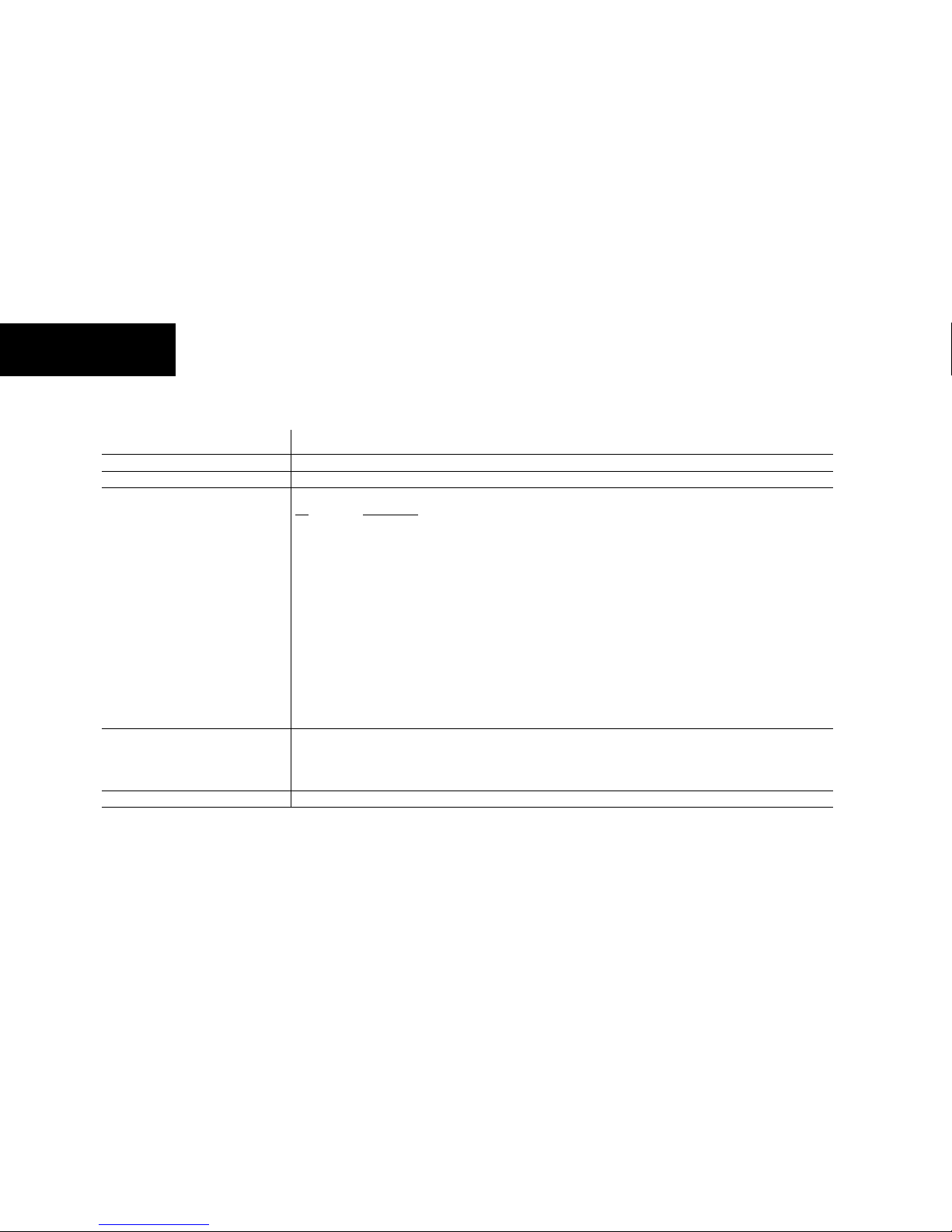

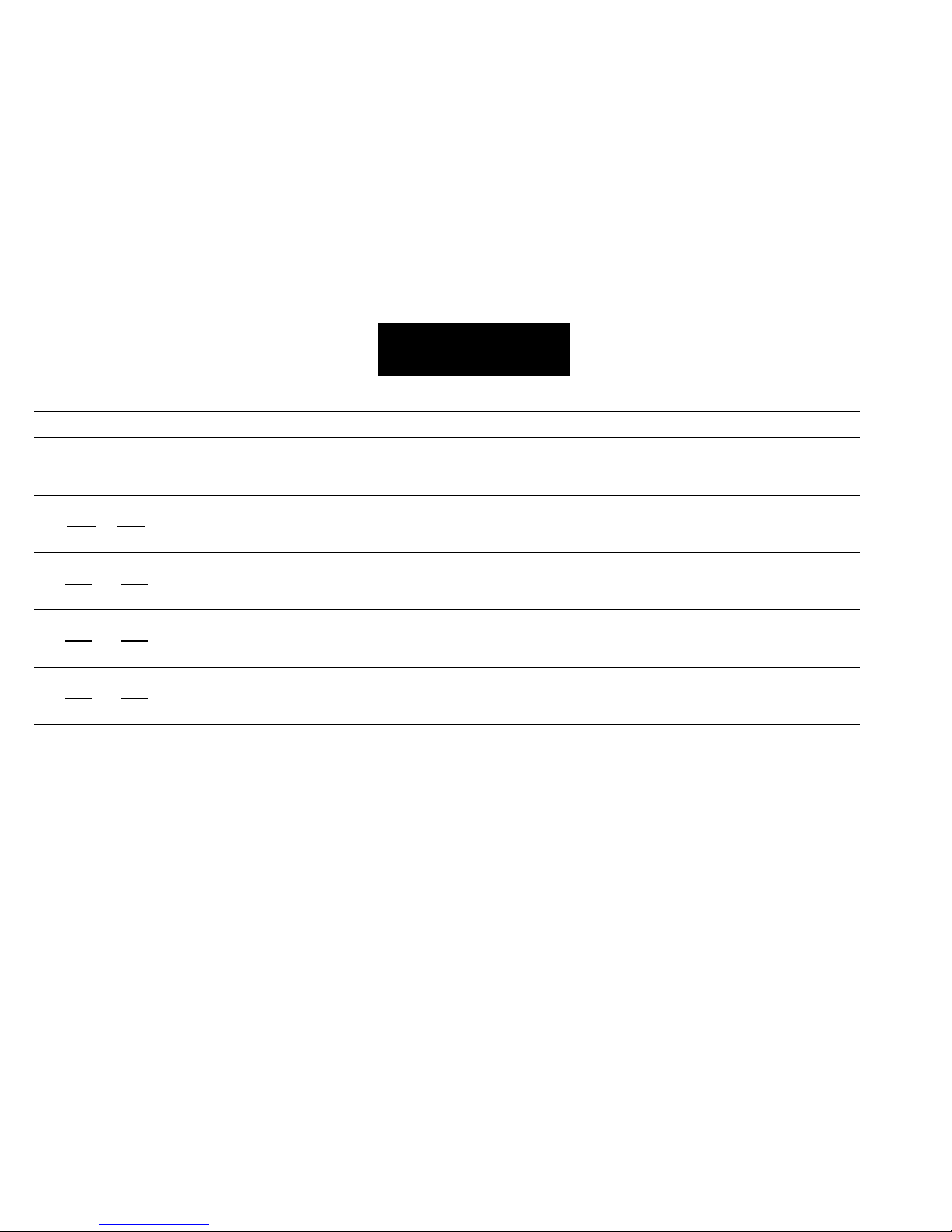

Keyswitch 1-13

Front Panel Keyswitch

Keyswitch Position

Operation RUN PROG REM

RUN PROG

Execute programs (with outputs enabled) X X

Execute programs (with outputs disabled)

Save program to disk X X X X

Restore programs X X X

Create or delete: ladder files, SFC files, data table files X X

Edit online: ladder files and SFC files

(program files already exist)

X X X

Force live outputs X X

Prohibit processor from scanning program X X

Change operating mode using a programming device X X

Download to/from EEPROM X X

Automatically configure remote I/O X X

Edit data table values

(data table files already exist)

X X X X

Establish ControlNet connections and exchange data X X X X

Page 18

Hardware Components

Processor Status File 1-14

Processor Status File

This word of the status file: Stores:

S:0 Arithmetic flags

• bit 0 = carry

• bit 1 = overflow

• bit 2 = zero

• bit 3 = sign

S:1 Processor status and flags

Bit

Description

0 RAM checksum is invalid at power-up

1 processor in RUN mode

2 processor in TEST mode

3 processor in PROG mode

4 processor burning EEPROM

5 processor in download mode

6 processor has test edits enabled

7 mode select switch in REMOTE position

8 forces enabled

9 forces present

10 processor successfully burned EEPROM

11 performing online programming

12 not defined

13 user program checksum calculated

14 last scan of ladder or SFC step

15 processor running first program scan or the first scan of the next step

in an SFC

Page 19

Hardware Components

Processor Status File 1-15

processor status file continued

This word of the status file: Stores:

S:7 Global status bits:

• S:7/0-7 - - rack fault bits for racks 0-7

• S:7/8-15 - - rack queue-full bits for racks 0-7

See also S:27, S:32, S:33, S:34, and S:35

S:8 Last program scan (in ms)

S:9 Maximum program scan (in ms)

S:2 Switch setting information

• bits 0 - 6 DH+ station number

• bit 11-12 are set based on the I/O chassis backplane switches

• bit 12

bit 11 = I/O chassis addressing

0 0 illegal

1 01/2-slot

0 11-slot

1 12-slot

• bit 13: 1 = load from EEPROM

• bit 14: 1 = RAM backup not configured

• bit 15: 1 = memory unprotected

S:3 to S:6 Active Node table for channel 1A

Word Bits DH+ Station #

3 0-15 00-17

4 0-15 20-37

5 0-15 40-57

6 0-15 60-77

Page 20

Hardware Components

Processor Status File 1-16

processor status file continued...

This word of the status file: Stores:

S:10 Minor fault (word 1)

Bit Description

0 battery is low (replace in 1-2 days)

1 DH+ active node table has changed

2 STI delay too short, interrupt program overlap

3 EEPROM memory transfer at power-up

4 edits prevent SFC continuing; data table size changed

during program mode; reset automatically in run mode

5 invalid I/O status file

6 not defined

7 no more command blocks exist

8 not enough memory on the memory module to upload the program from the processor

9 no MCP is configured to run

10 MCP not allowed

11 PII word number not in local rack

12 PII overlap

13 no command blocks exist to get PII

14 arithmetic overflow

15 SFC action overlap

See also S:17

Page 21

Hardware Components

Processor Status File 1-17

processor status file continued...

This word of the status file: Stores:

S:11 Major fault

Bit Description

0 corrupted program file (codes 10-19)

1 corrupted address in ladder file (codes 20-29)

2 programming error (codes 30-49)

3 SFC fault (codes 71-79)

4 error while assembling program (code 70); duplicate LBLs found

5 start-up protection fault; processor sets this bit when powering up in run mode if bit S:26/1 is

set

6 peripheral device fault

7 jumped to fault routine (codes 0-9)

8 watchdog faulted

9 system configured wrong (codes 80-89)

10 recoverable hardware error

11 MCP does not exist or is not ladder or SFC file

12 PII does not exist or is not ladder

13 STI does not exist or is not ladder

14 fault routine does not exist or is not ladder

15 fault occurred in a non-ladder file

Page 22

Hardware Components

Processor Status File 1-18

processor status file continued...

This word of the status file: Stores:

S:12 Fault codes

Code Description

0-9 user-defined

10 failed data table check

11 bad user program checksum

12 bad integer operand type

13 bad mixed mode operand type

14 not enough operands for instruction

15 too many operands for instruction

16 bad instruction found

17 no expression end in a CPT math expression

18 missing end of edit zone

19 download aborted

20 indirect address out of range (high)

21 indirect address out of range (low)

22 attempt to access undefined file

23 file number less than 0 or greater than number of defined files; or,

indirect reference to file 0, 1, 2; or bad file number24

indirect reference to wrong file type

25 reserved

26 reserved

27 reserved

28 reserved

29 reserved

30 subroutine jump nesting level exceeded

Page 23

Hardware Components

Processor Status File 1-19

processor status file continued...

This word of the status file: Stores:

S:12 continued... Fault codes

Code Description

31 too few subroutine parameters

32 jump to non-ladder file

33 CAR routine not 68000 code

34 bad timer parameters entered

35 bad PID delta time entered

36 PID setpoint out of range

37 invalid I/O specified in an immediate I/O instruction

38 invalid use of return instruction

39 FOR loop missing NXT

40 control file too small

41 NXT instruction with no FOR

42 jump target does not exist or JMP missing LBL

43 file is not an SFC

44 error using SFR

45 invalid channel number entered

46 IDI or IDO instruction length operand too long (> 64 words)

46-69 reserved

Page 24

Hardware Components

Processor Status File 1-20

processor status file continued...

This word of the status file: Stores:

S:12 continued... Fault codes

Code Description

70 duplicate labels

71 SFC subchart is already executing

72 tried to stop an SFC that is not running

73 maximum number of SFC subcharts exceeded

74 SFC file error

75 SFC contains too many active steps

76 SFC step loops back to itself

77 SFC references a step, transition, subchart, or SC file that is

missing, empty or too small

78 SFC could not continue after power loss

79 error in downloading an SFC to a processor that cannot run

SFCs or this specific PLC processor does not support this

Enhanced SFC

80 I/O configuration error

81 illegal setting of I/O chassis backplane switch

82 illegal cartridge type

83 user watchdog fault

84 error in user-configured adapter mode block transfers

85 bad cartridge

86 cartridge incompatible with host

87 rack addressing overlap (includes any adapter channel)

Page 25

Hardware Components

Processor Status File 1-21

processor status file continued...

This word of the status file: Stores:

S:12 continued... Fault codes

Code Description

88 scanner channels are overloading the remote I/O buffer; too much data for the

processor to process

90 Sidecar module extensive memory test failed

91 Sidecar module undefined message type

92 Sidecar module requesting undefined pool

93 Sidecar module illegal maximum pool size

94 Sidecar module illegal ASCII message

95 Sidecar module reported fault, which may be the result of a bad

program that corrupts memory or of a hardware failure

96 Sidecar module not physically connected to the PLC-5 processor

97 Sidecar module requested a pool size that is too small for PCCC command (occurs at power-up)

98 Sidecar module first/last 16 bytes RAM test failed

99 Sidecar module-to-processor data transfer faulted

100 Processor-to-sidecar module data transfer failed

101 Sidecar module end of scan data transfer failed

102 The file number specified for raw data transfer through the sidecar

module is an illegal value

103 The element number specified for raw data transfer through the

sidecar module is an illegal value

104 The size of the raw data transfer requested through the sidecar module is an illegal size

105 The offset into the raw data transfer segment of the sidecar module is an illegal value

Page 26

Hardware Components

Processor Status File 1-22

processor status file continued...

This word of the status file: Stores:

S:12 continued... Fault codes

Code Description

106 Sidecar module transfer protection violation; for PLC-5/26, -5/46,

and -5/86 processors only

200 ControlNet scheduled output data missed

201 ControlNet input data missed

202 Not used

203 Reserved

204 ControlNet configuration is too complex

205 ControlNet configuration exceeds bandwidth

206 Reserved

207 Reserved

208 Too many pending ControlNet I/O connections

S:13 Program file where fault occurred

S:14 Rung number where fault occurred

S:15 VME status file

S:16 I/O Status File

Page 27

Hardware Components

Processor Status File 1-23

processor status file continued...

This word of the status file: Stores:

S:17 Minor fault (word 2)

Bit Description

0 BT queue full to remote I/O

1 queue full – channel 1A; maximum remote block transfers used

2 queue full – channel 1B; maximum remote block transfers used

3 queue full – channel 2A; maximum remote block transfers used

4 queue full – channel 2B; maximum remote block transfers used

5 no modem on serial port

6 remote I/O rack in local rack table; or, remote I/O rack is greater than the image size

7 firmware revision for channel pairs 1A/1B or 2A/2B does not

match processor firmware revision

8 ASCII instruction error

9 duplicate node address

10 DF1 master poll list error

11 protected processor data table element violation

12 protected processor file violation

13 using all 32 ControlNet MSGs

14 using all 32 ControlNet 1771 READ and/or 1771 WRITE CIOs

15 using all 8 ControlNet Flex I/O CIOs

See also S:10.

S:18 Processor clock year

S:19 Processor clock month

S:20 Processor clock day

S:21 Processor clock hour

S:22 Processor clock minute

S:23 Processor clock second

Page 28

Hardware Components

Processor Status File 1-24

processor status file continued...

This word of the status file: Stores:

S:24 Indexed addressing offset

S:25 Reserved

S:261. User control bits

Bit

Description

0 Restart/continuous SFC: when reset, processor restarts at first step in SFC.

When set, processor continues with active step after power loss or change to RUN

1 Start-up protection after power loss: when reset, no protection.

When set, processor sets major fault bit S:11/5 when powering up in run mode

2 Define the address of the local rack: when reset, local rack

address is 0. When set, local rack address is 1

3 Set complementary I/O: when reset, complementary I/O is not

enabled. When set, complementary I/O is enabled

4 Local block transfer compatibility bit: when reset, normal

operation. When set, eliminates frequent checksum errors to

certain BT modules

5 PLC-3 scanner compatibility bit: when set (1), adapter channel

response delayed by 1 ms; when reset (0), operate in

normal response time

6 Data table-modification inhibit bit. When set (1), user cannot edit

the data table while processor is in run mode

S:27 Rack control bits:

• S:27/0-7 - - I/O rack inhibit bits for racks 0-7

• S:27/8-15 - - I/O rack reset bits for racks 0-7

See also S:7, S:32, S:33, S:34, and S:35.

S:28 Program watchdog setpoint

Page 29

Hardware Components

Processor Status File 1-25

processor status file continued...

This word of the status file: Stores:

S:29 Fault routine file

S:30 STI setpoint

S:31 STI file number

S:32 Global status bits:

• S:32/0-7 - - rack fault bits for racks 10-17 (octal)

• S:32/8-15 - - rack queue-full bits for racks 10-17

See also S:7, S:27, S:33, S:34, and S:35.

S:33 Rack control bits:

• S:33/0-7 - - I/O rack inhibit bits for racks 10-17 (octal)

• S:33/8-15 - - I/O rack reset bits for racks 10-17

See also S:7, S:27, S:32, S:34, and S:35.

S:34 Global status bits:

• S:34/0-7 - - rack fault bits for racks 20-27 (octal)

• S:34/8-15 - - rack queue-full bits for racks 20-27

See also S:7, S:27, S:32, S:33, and S:35.

S:35 Rack control bits:

• S:35/0-7 - - I/O rack inhibit bits for racks 20-27 (octal)

• S:35/8-15 - - I/O rack reset bits for racks 20-27

See also S:7, S:27, S:32, S:33, and S:34.

S:36 Reserved

S:37 Reserved

Page 30

Hardware Components

Processor Status File 1-26

processor status file continued...

This word of the status file: Stores:

Classic PLC-5 processors use only 37 words for the status file. Therefore, the following descriptions apply only to

Enhanced, Ethernet, and ControlNet processors.

S:38 - S:45 Reserved

S:46 PII program file number

S:47 PII module group

S:48 PII bit mask

S:49 PII compare value

S:50 PII down count

S:51 PII changed bit

S:52 PII events since last interrupt

S:53 STI scan time (in ms)

S:54 STI maximum scan time (in ms)

S:55 PII last scan time (in ms)

S:56 PII maximum scan time (in ms)

S:57 User program checksum

S:58 Reserved

S:59 Extended-local I/O channel discrete transfer scan (in ms)

S:48 PII bit mask

Page 31

Hardware Components

Processor Status File 1-27

processor status file continued...

This word of the status file: Stores:

S:60 Extended-local I/O channel discrete maximum scan (in ms)

S:61 Extended-local I/O channel block-transfer scan (in ms)

S:62 Extended-I/O channel maximum block-transfer scan (in ms)

S:63 Protected processor data table protection file number

S:64 The number of remote block transfer command blocks being used by channel pair 1A/1B.

S:65 The number of remote block transfer command blocks being used by channel 2A/2B or by channel 2 (ControlNet)

S:66 Reserved

S:72* ControlNet node of this processor

S:73* ControlNet PLC-2 compatibility file

S:74* Time in msec between itemations of ControlNet subsystem diagnostics

S:75* Maximum of S:74

S:76 Number of slots in processor-resident local chassis

S:77 Communication time slice for communication housekeeping functions (in ms)

S:78 MCP I/O update disable bits

Bit 0 for MCP A

Bit 1 for MCP B, etc.

* Applies only to ControlNet phase 1.5 PLC-5 processors.

Page 32

Hardware Components

Processor Status File 1-28

processor status file continued...

This word of the status file: Stores:

S:79 MCP inhibit bits

Bit 0 for MCP A

Bit 1 for MCP B

etc.

S:80-S:127 MCP file number

MCP scan time (in ms)

MCP max scan time (in ms)

The above sequence applies to each MCP; therefore, each MCP has 3 status words.

For example, word 80: file number for MCP A

word 81: scan time for MCP A

word 82: maximum scan time for MCP A

word 83: file number for MCP B

word 84: scan time for MCP B

etc.

Page 33

Hardware Components

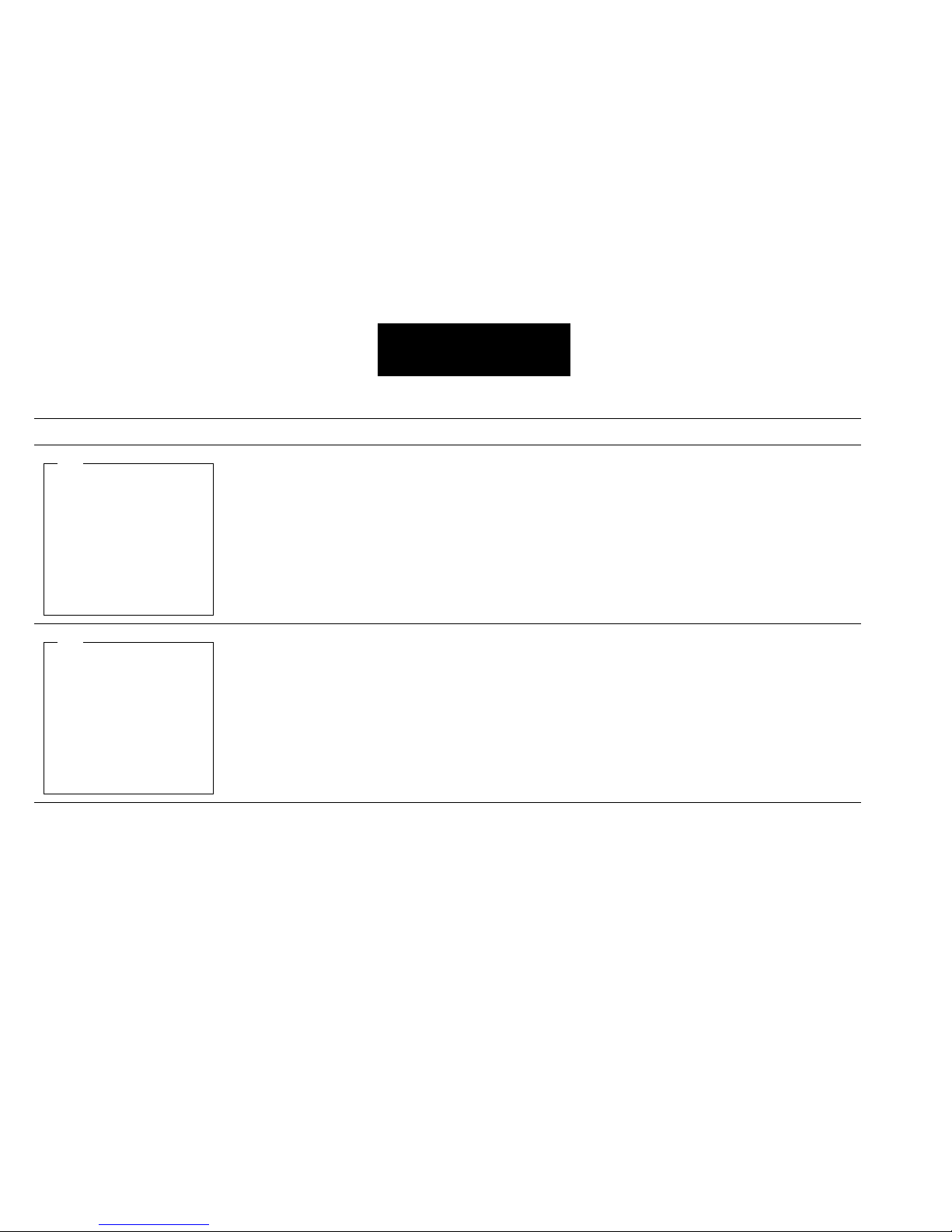

I/O Status File 1-29

I/O Status File Format

(N:15 is defined in word S:16 of the processor status file.)

Defined I/O status file

N15:0

N15:1

N15:14

N15:15

rack 0

rack 7 (maximum for PLC-5/25, -5/30 processors)

Word in integer file

N15:30

N15:31

rack 17 (maximum for PLC-5/40, -5/40L, -5/40E, -5/40C processors)

N15:46

N15:47

rack 27 (maximum for PLC-5/60, -5/60L, -5/80, -5/80E, -5/80C processors)

rack 3 (maximum for PLC-5/11, -5/15, -5/20, -5/20E, and -5/20C) processors

Page 34

Hardware Components

I/O Status File 1-30

Word 1 in the I/O Status File

This bit: Corresponds to:

Fault bits 00 first 1/4 rack starting I/O group 0

01 second 1/4 rack starting I/O group 2

02 third 1/4 rack starting I/O group 4

03 fourth1/4 rack starting I/O group 6

Present bits 08 first 1/4 rack starting I/O group 0

09 second 1/4 rack starting I/O group 2

10 third 1/4 rack starting I/O group 4

11 fourth1/4 rack starting I/O group 6

00010203040506070809101112131415

Not Used

Not Used

Fault Bits

Present Bits

N15:14

Page 35

Hardware Components

I/O Status File 1-31

Word 2 in the I/O Status File

This bit: Corresponds to:

Inhibit bits 00 first 1/4 rack starting I/O group 0

01 second 1/4 rack starting I/O group 2

02 third 1/4 rack starting I/O group 4

03 fourth1/4 rack starting I/O group 6

Reset bits 08 first 1/4 rack starting I/O group 0

09 second 1/4 rack starting I/O group 2

10 third 1/4 rack starting I/O group 4

11 fourth1/4 rack starting I/O group 6

ATTENTION: When you use a ladder program or the software to inhibit and reset an I/O rack, you must set or

clear the reset and inhibit bits that correspond to each quarter rack in a given chassis. Failure to set all the appropriate

bits could cause unpredictable operation due to scanning only part of the I/O chassis.

00010203040506070809101112131415

Not Used

Not Used

Inhibit Bits

Reset Bits

N15:15

Page 36

Page 37

Addressing

Data Table Files 2-1

Addressing Data Table Files

(Enhanced, Ethernet, and ControlNet Processors) Series E and Later –

File Type

File-Type

Identifier

File

Number

Maximum Size of File

16-bit words and structures

c

Memory Used in

Overhead for each

File

(in 16-bit words)

Memory Used

(in 16-bit words) per

Word, Character, or

Structure

PLC-5/11, -5/20 PLC-5/30 PLC-5/40 PLC-5/60, -5/80

Output image O 0 32 64 128 192 6 1/word

Input image I 1 32 64 128 192 6 1/word

Status S 2 128 128 128 128 6 1/word

Bit (binary) B

3

a

D7KLVLVWKHGHIDXOWILOHQXPEHUDQGW\SH)RUWKLVILOHW\SH\RXFDQDVVLJQDQ\ILOHQXPEHUIURPWKURXJK

2000 words 6 1/word

Timer T

4

a

6000 words/2000 structures 6 3/structure

Counter C

5

a

6000 words/2000 structures 6 3/structure

Control R

6

a

6000 words/2000 structures 6 3/structure

Integer N

7

a

2000 words 6 1/word

Floating-point F

8

a

4000 words/2000 structures 6 2/structure

ASCII A 3-999 2000 words 6 1/2 per character

BCD D 3-999 2000words 6 1/word

Block-transfer BT 3-999 12000 words/2000 structures 6 6/structure

CIO CT 3-999 12000 words/2000 structures 6 6/structure

Message MG 3-999

32760 words/585 structures

b

E7KHPD[LPXPVL]HRIDGDWDWDEOHILOHLV.ZRUGV7KHPD[LPXPVL]HRIWKHHQWLUHGDWDWDEOHLV.ZRUGV

F&RQWURO1HW3/&VGRQRWVXSSRUWHOHPHQWVILOH7KHPD[LPXPVL]HRIDGDWDWDEOHILOHLV.ZRUGV7KHPD[LPXPVL]HRIWKHHQWLUHGDWDWDEOHLV.ZRUGV

G&RQWURO1HW3/&VRQO\

6 56/structure

PID PD 3-999

32718 words/399 structures

b

6 82/structure

SFC status SC 3-999 6000 words/2000 structures 6 3/structure

ASCII string ST 3-999

32760 words/780 structures

b

6 42/structure

Unused -- 9-999 6 6 0

Page 38

Addressing

Data Table Files 2-2

File Type

File-Type

Identifier

File

Number

Maximum Size of File

16-bit words and structures

Memory Used in

Overhead for each File

(in 16-bit words)

Memory Used

(in 16-bit words) per Word,

Character, or Structure

PLC-5/11, -5/20 PLC-5/30 PLC-5/40 PLC-5/60, -5/80

Output image O 0 32 64 128 192 6 1/word

Input image I 1 32 64 128 192 6 1/word

Status S 2 128 128 128 128 6 1/word

Bit (binary) B

3

a

1000 words 6 1/word

Timer T

4

1

3000 words/1000 structures 6 3/structure

Counter C

5

1

3000 words/1000 structures 6 3/structure

Control R

6

1

3000 words/1000 structures 6 3/structure

Integer N

7

1

1000 words 6 1/word

Floating-point F

8

1

2000 words/1000 structures 6 2/structure

ASCII A 3-999 1000 words 6 1/2 per character

BCD D 3-999 1000words 6 1/word

Block-transfer BT 3-999 6000 words/1000 structures 6 6/structure

Message MG 3-999

32760 words/585 structures

b

6 56/structure

PID PD 3-999

32718 words/399 structures

2

6 82/structure

SFC status SC 3-999 3000 words/1000 structures 6 3/structure

ASCII string ST 3-999

32760 words/780 structures

2

6 42/structure

Unused -- 9-999 6 6 0

D7KLVLVWKHGHIDXOWILOHQXPEHUDQGW\SH)RUWKLVILOHW\SH\RXFDQDVVLJQDQ\ILOHQXPEHUIURPWKURXJK

E7KHPD[LPXPVL]HRIDGDWDWDEOHILOHLV.ZRUGV7KHPD[LPXPVL]HRIWKHHQWLUHGDWDWDEOHLV.ZRUGV

F&RQWURO1HW3/&VGRQRWVXSSRUWHOHPHQWVILOH

Page 39

Addressing

Data Table Files 2-3

Data Table Files - Classic Processors

File Description

Number

(Default

File)

Maximum Size of File

(16-bit words and

structures)

Memory Used

PLC-5/10,

-5/12, -5/15

PLC-5/25

Output Image O 0 32 64 2/file + 1/word

Input Image I 1 32 64 2/file + 1/word

Status S 2 32 32 2/file + 1/word

Bit (binary) B 3-999 (3) 1000 words 2/file + 1/word

Timer T 3-999 (4) 3000 words/1000 structures 2/file + 3/structure

Counter C 3-999 (5) 3000 words/1000 structures 2/file + 3/structure

Control R 3-999 (6) 3000 words/1000 structures 2/file + 3/structure

Integer N 3-999 (7) 1000 words 2/file + 1/word

Floating Point F 3-999 (8) 1000 words 2/file + 2/structure

ASCII A 3 - 999 1000 words 2/file + 1/2 per

character

BCD D 3 - 999 1000 words 2/file + 1/word

Extra Storage 3 - 999

PLC-5 Memory

Data Table

program

Page 40

Addressing

Program Files 2-4

Program Files

Program File Number Program File Number

Description Classic

PLC-5 Processors

Enhanced, Ethernet, and ControlNet

PLC-5 Processors

System 0 0

Sequential Function 1

1 - 1999

2

Ladder 2 - 999

2 - 1999

2

Structured Text

1

2 - 1999

2

Assigned as needed:

Subroutines

Fault Routines

Selectable Timed Interrupts

Processor Input Interrupts

1

SFC Step/Transition

SFC Actions

1

3 - 999 2 - 1999

1

Enhanced, Ethernet, and ControlNet PLC-5 processors only.

2

Enhanced, Ethernet, and ControlNet PLC-5 processors can have up to 16 main control programs (in any combination of SFC,

ladder, and structured text).

PLC-5 Memory

Data Table

program

Page 41

Addressing

I/O Images/Symbolic 2-5

I/O Image Addressing

a:bbc/dd

a I/O data type identifier

I - input device

O - output device

bb I/O rack number

00 - 03 (octal) PLC-5/10, -5/11, -5/12, -5/15, -5/20, -5/20E, -5/20C15

00 - 07 (octal) PLC-5/25, -5/30

00 - 17 (octal) PLC-5/40, -5/40L, -5/40E, -5/40C15

00 - 27 (octal) PLC-5/60, -5/60L, -5/80, -5/80E, -5/80C15

c I/O group number 0 - 7 (octal)

dd terminal (bit) number 00 - 17 (octal)

Examples: I:001/07 input device, rack 00, group 1, terminal (bit) 7

O:074/10 output device, rack 07, group 4, terminal (bit) 10

Page 42

Addressing

Logical 2-6

Logical Addressing

Where: Is the:

# File address identifier. Omit for bit, word, and structure addresses (also indicates indexed addressing, see next

page)

X

File type: B - binary N - integer T - timer MG - message 1 CT - ControlNet Transfer

2

C - counter O - output A - ASCII PD - PID

1

ST - ASCII string

1

F - floating point R - control D - BCD SC - SFC status

1

I - input S - status BT - block transfer

1

F File number: 0 - output 1 - input 2 - status 3 - 999 any other type

: Colon delimiter separates file and structure/word numbers

e Structure/word number: 0 - 277

octal for input/output files

0 - 31 decimal for the status file (Classic PLC-5 processors)

up to: 0 - 127 decimal for the status file

0 - 999 for all the file types except MG, PD, and ST files

. Period delimiter is used only with structure-member mnemonics in counter, timer and control files

s Structure-member mnemonic is used only with timer, counter, control, BT, MG, PD, SC, and ST files

/ Bit delimiter separates bit number

b Bit number: 00 - 07 or 10 - 17 for input/output files

00 - 15 for all other files

00 - 15,999 for binary files when using direct bit address

1

Enhanced, Ethernet, and ControlNet PLC-5 processors only.

2

ControlNet only.

bit number

bit delimiter

structure-member

delimiter

structure/word number

delimiter

file number

file type

file address

mnemonic

identifier

# X F: 3. s / b

Page 43

Addressing

Indexed/Indirect 2-7

Indexed Addressing

Indexed addressing offsets an address by the number of elements you select. You store the offset value in an offset word in word 24 of the status

file S:24. The processor starts operation at the base address plus the offset. You can manipulate the offset word in your ladder logic.

The indexed address symbol is the # character. Place the # character immediately before the file-type identifier in a logical a ddress.

Important: File instructions manipulate the offset value stored at S:24. Make sure that you monitor or load the offset value you want prior to

using an indexed address. Unpredictable machine operation could occur.

Indirect Addressing

• You can indirectly address the following: file number; element number; bit number

• Substitute address must be of type: N, T, C, R, B, I, O, S.

• Enter the address in brackets [ ]

Examples: Indirect Address Variable

N[N7:0] file number

N7:[C5:7.ACC] element number

B3:/[I:017] bit number

Page 44

Addressing

Module Placement 2-8

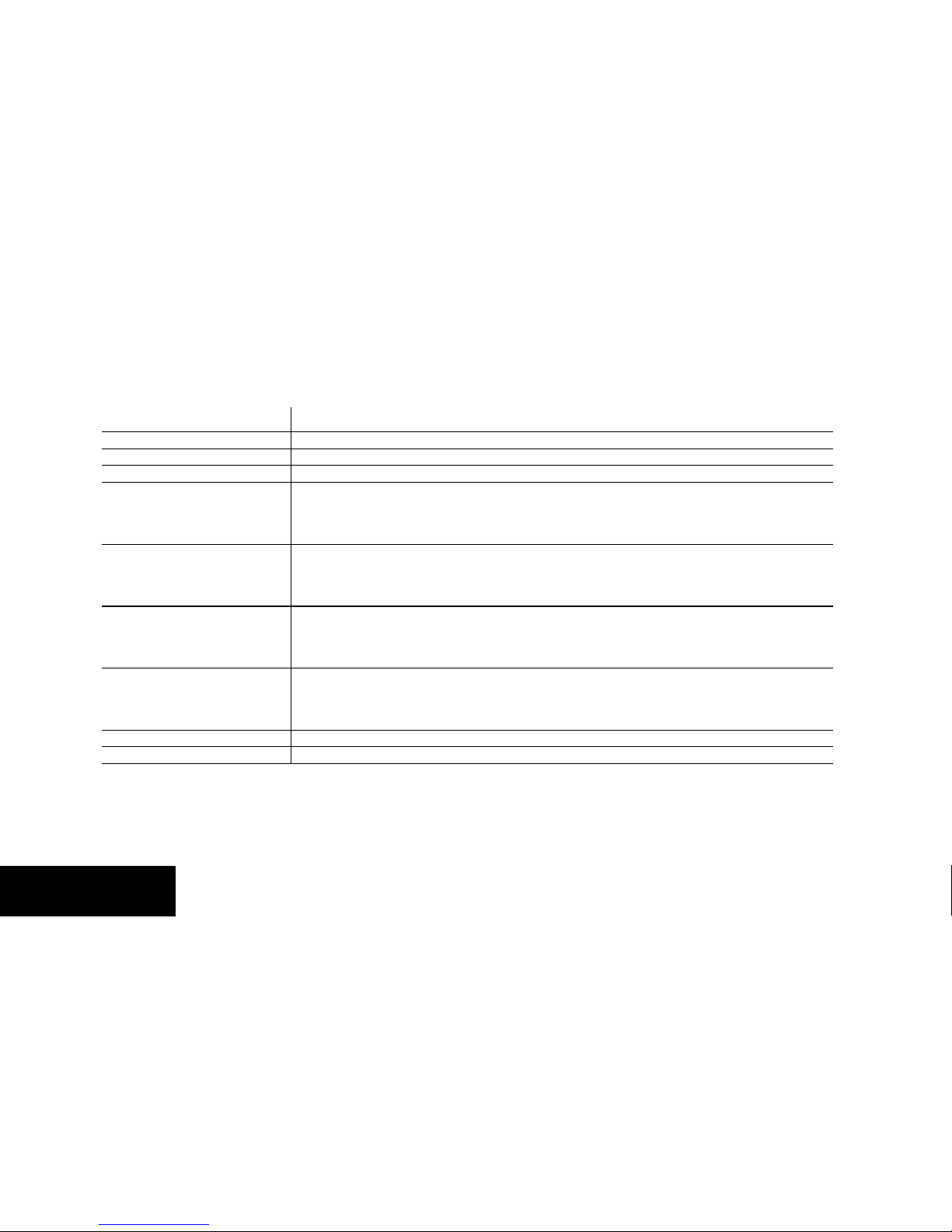

I/O Addressing Modes

Discrete I/O Module Placement for Addressing Modes

Addressing Concept Summary

2-slot addressing 1-slot addressing 1/2-slot addressing

• two I/O module slots = 1 group

• each physical 2-slot I/O group corresponds to one

word (16 bits) in the input image table and one

word (16 bits) in the output image table

• one I/O module slot = 1 group

• each physical slot in the chassis corresponds to

one word (16 bits) in the input image table and one

word (16 bits) in the output image table

• one half of an I/O module slot = 1 group

• each physical slot in the chassis corresponds to

two words (32 bits) in the input image table and

two words (32 bits) in the output image table

I/O 2-slot addressing 1-slot addressing 1/2-slot addressing

8-pt

modules

no restriction on module placement no restriction on module placement, but does

not make best use of I/O image and available

I/O addresses

no restriction on module placement, but does

not make best use of I/O image and available

I/O addresses

16-pt

modules

must use 1 input and 1 output module per even/odd

slot pair

no restriction on module placement no restriction on module placement, but does

not make best use of I/O image and available

I/O addresses

32-pt

modules

not allowed must use 1 input and 1 output module per

even/odd slot pair

no restriction on module placement

If you are using this chassis size: 2-slot addressing 1-slot addressing 1/2-slot addressing

4-slot 1/4 rack 1/2 rack 1 rack

8-slot 1/2 rack 1 rack 2 racks

12-slot 3/4 rack 1 1/2 racks 3 racks

16-slot 1 rack 2 racks 4 racks

Page 45

Instruction Set

Status Bits 3-1

Instruction Set

Instruction Set – Status Bits

Category Mnemonic

Word 0

Word 1 Word 2

15 14 13 12 11 10 09 08

TIMER (T4:

n

)

2

TON TOF RTO EN TT DN .PRE .ACC

COUNTER (C5:

n

)

2

CTU CTD CU CD DN OV UN .PRE .ACC

FILE (R6:

n

)

2

FAL EN DN ER .LEN .POS

FSC

EN DN ER IN FD .LEN .POS

FFL FFU

EN EU DN EM .LEN .POS

LFL

1

LFU

1

EN EU DN EM .LEN .POS

BSL BSR

EN DN ER UL .LEN .POS

FBC DDT

EN DN ER IN FD .LEN .POS

SQI SQO SQL EN

DN ER .LEN .POS

ASCII (R6:

n

)

2

ARL 1AWT 1AWA 1EN EU DN EM ER UL .LEN .POS

AHL

1

EN DN EM ER FD

ACB 1ABL

1

EN EU DN EM ER FD

COMPUTE (R6:n)

2

AVE 1SRT 1STD 1EN DN ER .LEN .POS

1

Enhanced, Ethernet, and ControlNet PLC-5 processors only

2

n

= starting structure number 0-999

Status Bits:

.EN – enable

.TT – timing

.DN – done

.OV – overflow

.UN – underflow

.EU – unload

enable

.FD – found

.UL – unload

.ER – error

.EM – empty

.CD – count down

enable

.CU – count up

enable

.IN – inhibit

.EU – queue

Page 46

Instruction Set

Relay 3-2

Relay Instructions

Instruction Description

Examine On

XIC

Examine data table bit I:012/07, which corresponds to terminal 7 of an input module in I/O

rack 1, I/O group 2. If this data table bit is set (1), the instruction is true.

Examine Off

XIO

Examine data table bit I:012/07, which corresponds to terminal 7 of an input module in I/O

rack 1, I/O group 2. If this data table bit is reset (0), the instruction is true.

Output Energize

OTE

If the input instructions preceding this output instruction on the same rung go true, set (1) bit

O:013/01, which corresponds to terminal 1 of an output module in I/O rack 1, I/O group 3.

Output Latch

OTL

If the input conditions preceding this output instruction on the same rung go true, set (1) bit

O:013/01, which corresponds to terminal 1 of an output module in I/O rack 1, I/O group 3. This

data table bit remains set until an OTU instruction resets the bit.

Output Unlatch

OTU

If the input conditions preceding this output instruction on the same rung go true, reset (0) bit

O:013/01, which corresponds to terminal 1 of an output module in I/O rack 1, I/O group 3. This

is necessary to reset a bit that has been latched on.

I:012

] [

07

I:012

] / [

07

O:013

()

01

O:013

(L)

01

O:013

(U)

01

Page 47

Instruction Set

Relay 3-3

relay instructions continued...

Instruction Description

Immediate Input

IIN

This instruction updates a word of input–image bits before the next normal input-image update.

For a local chassis, program scan is interrupted while the inputs of the addressed I/O group are

scanned; for a remote or ControlNet chassis, program scan is interrupted only to update the

input image with the latest states as found in the remote I/O or ControlNet buffer.

Immediate Output

IOT

This instruction updates a word of output–image bits before the next normal output-image

update. For a local chassis, program scan is interrupted while the outputs of the addressed I/O

group are scanned; for a remote or ControlNet chassis, program scan is interrupted only to

update the remote I/O or ControlNet buffer with the latest states as found in the output image.

01

(IIN)

01

(IOT)

Page 48

Instruction Set

Relay 3-4

relay instructions continued...

Instruction Description

Immediate Data

Input

IDI

for ControlNet

processors only

If the input conditions are true, an immediate data input is initiated that updates the destination

file from the private ControlNet buffers before the next normal input-image update. The Data file

offset (232) is where the data is stored. The Length (10) identifies the number of words in the

transfer – it can be an immediate value ranging from 1 to 64 or a logical address that specifies

the number of words to be transferred. The Destination (N11:232) is the destination of the

words to be transferred. The Destination should be the matching data-table address in the Data

Input File (DIF) except when you use the instruction to ensure data-block integrity in the case of

Selectable Timed Interrupts (STIs).

Immediate Data

Output

IDO

for ControlNet

processors only

If the input conditions are true, an immediate data output is initiated that updates the private

ControlNet output buffers from the source file before the next normal output-image update. The

Data file offset (175) is the offset into the buffer where the data is stored. The Length (24)

identifies the number of words in the transfer-it can be an immediate value ranging from 1 to 64

or a logical address that specifies the number of words to be transferred. The Source (N12:175)

is the source of the words to be transferred. The Source should be the matching data-table

address in the Data Output File (DOF) except when you use the instruction to ensure data-block

integrity in the case of Selectable Timed Interrupts (STIs).

IMMEDIATE DATA INPUT

Data file offset 232

Length 10

Destination N11:232

IDI

IMMEDIATE DATA OUTPUT

Data file offset 175

Length 24

Source N12:175

IDO

Page 49

Instruction Set

Timer 3-5

Timer Instructions

Instruction Description

Timer On Delay

TON

Status Bits:

EN – Enable

TT – Timer Timing

DN – Done

If the input conditions go true, timer T4:1 starts incrementing in 1-second intervals. When

the accumulated value is greater than or equal to the preset value (15), the timer stops

and sets the timer done bit.

Timer Off Delay

TOF

Status Bits:

EN – Enable

TT – Timer Timing

DN – Done

If the input conditions are false, timer T4:1 starts incrementing in 10 ms intervals as long as the

rung remains false. When the accumulated value is greater than or equal to the preset value

(180), the timer stops and resets the timer done bit.

TIMER ON DELAY

Timer T4:1

Time Base 1.0

Preset 15

Accum 0

TON

Rung

ConditionEN15TT14DN13

ACC

Value

TON

Status

False 0000 Reset

True 1 1 0 increase Timing

True 1 0 1 >=preset Done

TIMER OFF DELAY

Timer T4:1

Time Base .01

Preset 180

Accum 0

TOF

Rung

ConditionEN15TT14DN13

ACC

Value

TOF

Status

True 1010 Reset

False 0 1 1 increase Timing

False 0 0 0 >=preset Done

Page 50

Instruction Set

Timer 3-6

timer instructions continued...

Instruction Description

Retentive Timer On

RTO

Status Bits:

EN - Enable

TT - Timer Timing

DN - Done

If the input conditions go true, timer T4:10 starts incrementing in 1-second intervals as long as

the rung remains true. When the rung goes false, the timer stops. If the rung goes true again,

the timer continues. When the accumulated value is greater than or equal to the preset (10), the

timer stops and sets the timer done bit.

Timer Reset

RES

If the input conditions go true, timer T4:1 is reset. This instruction resets timers

and counters, as well as control blocks. This is necessary to reset the RTO

accumulated value.

RETENTIVE TIMER ON

Timer T4:10

Time Base 1.0

Preset 10

Accum 0

RTO

Rung

ConditionEN15TT14DN13

ACC

Value

RTO

Status

False 0000 Reset

True 1 1 0 increase Timing

False 0 0 0 maintains Disabled

True 1 0 1 >=preset Done

T4:1

(RES)

Page 51

Instruction Set

Counter 3-7

Counter Instructions

Instruction Description

Count Up

CTU

Status Bits:

CU-Count Up

CD-Count Down

DN-Count Done

OV-Overflow

UN-Underflow

If the input conditions go true, counter C5:1 starts counting, incrementing by 1 every time the

rung goes from false-to-true. When the accumulated value is greater than or equal to the preset

value (10), the counter sets the counter done bit.

COUNT UP

Counter C5:1

Preset 10

Accum 0

CTU

Rung

Condition

CU15DN13OV12ACC

Value

CTU

Status

False 0000 Reset

Toggle True 1 0 0 incr by 1 Counting

True 1 1 0 >=preset Done

True 1 1 1 >32767 Overflow

Page 52

Instruction Set

Counter 3-8

counter instructions continued...

Instruction Description

Count Down

CTD

Status Bits:

CU-Count Up

CD-Count Down

DN-Count Done

OV-Overflow

UN-Underflow

If the input conditions go true, counter C5:1 starts counting, decrementing by 1 every time the

rung goes from false-to-true. When the accumulated value is less than or equal to the preset

value (10), the counter resets the counter done bit.

Counter Reset

RES

If the input conditions go true, counter C5:1 is reset. This instruction resets timers and counters,

as well as control blocks.

COUNT DOWN

Counter C5:1

Preset 10

Accum 35

CTD

Rung

Condition

CD14DN13UN11ACC

Value

CTD

Status

False 0000 Reset

False 0 1 0 >=preset Preload

Toggle True 1 1 0 decr by 1 Counting

True 1 0 0 <preset Done

True 1 0 1 <-32768 Underflow

C5:1

(RES)

Page 53

Instruction Set

Compare 3-9

Compare Instructions

Instruction Description

Compare

CMP

If the expression is true, this input instruction is true. The CMP instruction can perform these

operations: equal (=), less than (<), less than or equal (<=), greater than (>), greater than or

equal (>=), not equal (<>). Complex expressions (up to 80 characters) are valid with Enhanced

and ControlNet PLC–5 processors only.

Limit Test

LIM

If the Test value (N7:15) is >= the Low Limit (N7:10) and <= the High Limit (N7:20), this

instruction is true.

COMPARE

Expression

N7:5 = N7:10

CMP

LIMIT TEST (CIRC)

Low limit N7:10

3

Test N7: 1 5

4

High limit N7:20

22

LIM

Low Limit Test High Limit LIM

0010T

–5510T

51110F

1000T

10 5 –5 F

10 11 5 T

Page 54

Instruction Set

Compare 3-10

compare instructions continued...

Instruction Description

Mask Compare Equal

MEQ

The processor takes the value in the Source (D9:5) and passes that value through the Mask

(D9:6). Then the processor compares the result to the Compare value (D9:10). If the result and

this comparison values are equal, the instruction is true.

MASKED EQUAL

Source D9:5

0000

Mask D9:6

0000

Compare D9:10

0000

MEQ

Source Mask Compare MEQ

0008 0008 0009 F

0008 0001 0001 F

0087 000F 0007 T

0087 00F0 0007 F

Page 55

Instruction Set

Compare 3-11

compare instructions continued...

Instruction Description

Equal to

EQU

If the value in Source A (N7:5) is = to the value in Source B (N7:10), this instruction is true.

Greater than or Equal GEQ If the value in Source A (N7:5) is > or = to the value in Source B (N7:10), this instruction is true.

Greater than

GRT

If the value in Source A (N7:5) is > the value in Source B (N7:10), this instruction is true.

Less than or Equal

LEQ

If the value in Source A (N7:5) is < or = to the value in Source B (N7:10), this instruction is true.

Less than

LES

If the value in Source A (N7:5) is < the value in Source B (N7:10), this instruction is true.

Not Equal

NEQ

If the value in Source A (N7:5) is not equal to the value in Source B (N7:10), this instruction is true.

xxxxxxxxxxxxx

Source A N7:5

3

Source B N7:10

1

xxx

Source A Source B EQU GEQ GRT LEQ LES NEQ

10 10 T T F T F F

5 6 FFFTTT

21 20 F T T F F T

–30 –31 FTTFFT

–15 –14 FFFTTT

Page 56

Instruction Set

Compute 3-12

Compute Instructions

Instruction Description

Compute

CPT

If the input conditions go true, evaluate the Expression N7:4 – (N7:6 * N7:10) and store the

result in the Destination (N7:3). The CPT instruction can perform these operations: add (+),

subtract (–), multiply (*), divide (|), convert from BCD (FRD), convert to BCD (TOD), square root

(SQR), logical and (AND), logical or (OR), logical not (NOT), exclusive or (XOR), negate (–), clear

(0), and move. In addition, Enhanced PLC-5 processors can do: X to the power of Y (**), radians

(RAD), degrees (DEG), log (LOG), natural log (LN), sine (SIN), cosine (COS), tangent (TAN), inverse

sine (ASN), inverse cosine (ACS), inverse tangent (ATN). Complex expressions (up to 80

characters) are valid with Enhanced and ControlNet PLC-5 processors only.

Arc Cosine

ACS

(Enhanced, Ethernet, and

ControlNet PLC-5

processors only)

When the input conditions are true, take the arc cosine of the Source (F8:19) and store the

result in the Destination (F8:20). The Source must be greater than or equal to –1 and less than

or equal to 1.

COMPUTE

Dest N7:3

3

Expression

N7:4 – (N7:6 * N7:10)

CPT

ARCCOSINE

Source F8:19

0.7853982

Destination F8:20

0.6674572

ACS

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

Salways resets

Page 57

Instruction Set

Compute 3-13

compute instructions continued...

Instruction Description

Addition

ADD

When the input conditions are true, add the value in Source A (N7:3) to the value in Source B

(N7:4) and store the result in the Destination (N7:12).

Arc Sine

ASN

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the arc sine of the Source (F8:17) and store the result

in the Destination (F8:18). The Source is interpreted as radians and must be greater than or

equal to -1 and less than or equal to 1.

ADD

Source A N7:3

3

Source B N7:4

1

Dest N7:12

4

ADD

Status Bit Description

C sets if carry is generated; otherwise resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

ARCSINE

Source F8:17

0.7853982

Destination F8:18

0.9033391

ASN

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

Salways resets

Page 58

Instruction Set

Compute 3-14

compute instructions continued...

Instruction Description

Arc Tangent

ATN

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the arc tangent of the Source (F8:21) and store the

result in the Destination (F8:22). The Source is interpreted as radians.

Average

AVE

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

Status Bits:

EN-Enable

DN-Done Bit

ER-Error Bit

When the input conditions go from false-to-true, add N7:1, N7:2, N7:3, and N7:4. Divide the

sum by 4 and store the result in N7:0.

ARCTANGENT

Source F8:21

0.7853982

Destination F8:22

0.6657737

ATN

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

AVERAGE FILE

File #N7:1

Dest N7:0

Control R6:0

Length 4

Position 0

AVE

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 59

Instruction Set

Compute 3-15

compute instructions continued...

Instruction Description

Clear

CLR

When the input conditions are true, clear BCD file 9, word 34 (set to zero).

Cosine

COS

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the cosine of the Source (F8:13) and store the result in

the Destination (F8:14). The Source is interpreted as radians.

CLR

Dest D9:34

0000

CLR

Status Bit Description

Calways reset

Valways reset

Zalways set

Salways reset

COSINE

Source F8:13

0.7853982

Destination F8:14

0.7071068

COS

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 60

Instruction Set

Compute 3-16

compute instructions continued...

Instruction Description

Division

DIV

When the input conditions are true, divide the value in Source A (N7:3) by the value in Source B

(N7:4) and store the result in the Destination (N7:12).

Natural Log

LN

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the natural log of the Source (N7:0) and store the result

in the Destination (F8:20). The Source must be positive (greater than 0).

DIVIDE

Source A N7:3

3

Source B N7:4

1

Dest N7:12

3

DIV

Status Bit Description

Calways resets

V sets if division by zero or overflow; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

NATURAL LOG

Source N7:0

5

Destination F8:20

1.609438

LN

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 61

Instruction Set

Compute 3-17

compute instructions continued...

Instruction Description

Log to the Base 10

LOG

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the log base 10 of the Source (N7:2) and store

the result in the Destination (F8:3). The Source must be positive (greater than 0).

Multiply

MUL

When the input conditions are true, multiply the value in Source A (N7:3) by the value in

Source B (N7:4) store the result in the Destination (N7:12).

LOG BASE 10

Source N7:2

5

Destination F8:3

0.6989700

LOG

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

MULTIPLY

Source A N7:3

3

Source B N7:4

1

Dest N7:12

3

MUL

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 62

Instruction Set

Compute 3-18

compute instructions continued...

Instruction Description

Negate

NEG

When the input conditions are true, take the opposite sign of the Source (N7:3) and store the

result in the Destination (N7:12). This instruction turns positive values into negative values and

negative values into positive values.

Sine

SIN

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the sine of the Source (F8:11) and store the result in

the Destination (F8:12). The Source is interpreted as radians.

NEGATE

Source N7:3

3

Destination N7:12

–3

NEG

Status Bit Description

C sets if the operation generates a carry; otherwise resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

SINE

Source F8:11

0.7853982

Destination F8:12

0.7071068

SIN

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 63

Instruction Set

Compute 3-19

compute instructions continued...

Instruction Description

Square Root

SQR

When the input conditions are true, take the square root of the Source (N7:3) and store the

result in the Destination (N7:12).

Sort

SRT

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

Status Bits:

EN - Enable

DN - Done Bit

ER - Error Bit

When the input conditions go from false-to-true, the elements in N7:1, N7:2, N7:3.and N7:4 are

sorted into ascending order.

SQUARE ROOT

Source N7:3

25

Destination N7:12

5

SQR

Status Bit Description

Calways resets

V sets if overflow occurs during floating point to integer

conversion; otherwise resets

Z sets if the result is zero; otherwise resets

Salways resets

SORT

File #N7:1

Control R6:0

Length 4

Position 0

SRT

Page 64

Instruction Set

Compute 3-20

compute instructions continued...

Instruction Description

Standard Deviation

STD

(Enhanced, Ethernet, and

ControlNet PLC-5 processors

only)

Status Bits:

EN - Enable

DN - Done Bit

ER - Error Bit

When the input conditions go from false-to-true, the elements in N7:1, N7:2, N7:3 and N7:4 are

used to calculate the standard deviation of the values and store the result in the Destination

(N7:0). The result is stored in N7:0.

Subtract

SUB

When the input conditions are true, subtract the value in Source B (N7:4) from the value in

Source A (N7:3) and store the result in the Destination (N7:12).

STANDARD DEVIATION

File #N7:1

Dest N7:0

Control R6:0

Length 4

Position 0

STD

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

SUBTRACT

Source A N7:3

3

Source B N7:4

1

Dest N7:12

2

SUB

Status Bit Description

C sets if borrow is generated; otherwise resets

V sets if underflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 65

Instruction Set

Compute 3-21

compute instructions continued...

Instruction Description

Tangent

TAN

(Enhanced, Ethernet and

ControlNet PLC-5 processors

only)

When the input conditions are true, take the tangent of the Source (F8:15) and store the result in the

Destination (F8:16). The Source must be greater than or equal to –102943.7 and less than or equal to

102943.7. The Source is interpreted as radians.

TANGEN T

Source F8:15

0.7853982

Destination F8:16

1.0000000

TAN

Status Bit Description

Calways resets

V sets if overflow is generated; otherwise resets

Z sets if the result is zero; otherwise resets

S sets if the result is negative; otherwise resets

Page 66

Instruction Set

Logical 3-22

Logical Instructions

Instruction Description

AND When the input conditions are true, the processor evaluates an AND operation (bit-by-bit)

between Source A (D9:3) and Source B (D9:4) and stores the result in the Destination (D9:5).

The truth table for an AND operation is:

Source A Source B Result

000

100

010

111

NOT Operation When the input conditions are true, the processor performs a NOT (takes the opposite of)

operation (bit-by-bit) on the Source (D9:3) and stores the result in the Destination (D9:5). The

truth table for a NOT operation is:

Source Destination

01

10

BITWISE AND

Source A D9:3

3F37

Source B D9:4

00FF

Dest D9:5

0037

AND

NOT

Source A D9:3

00FF

Destination D9:5

FF00

NOT

Status Bit Description

Calways resets

Valways resets

Z sets if the result is zero; otherwise resets

S sets if the most significant bit (bit 15 for decimal or bit 17 for octal) is set (1); otherwise resets

Page 67

Instruction Set

Logical 3-23

logical instructions continued...

Instruction Description

OR When the input conditions are true, the processor evaluates an OR operation (bit-by-bit)

between Source A (D9:3) and Source B (D9:4) and stores the result in the Destination (D9:5).

The truth table for an OR operation is: