Page 1

Allen-Bradley

PLC-5 Backup

Communication

User

Module

(1785-BCM, 1785-BEM)

product

icon

Manual

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences

between solid state products and electromechanical products, those responsible

for applying and using this product must satisfy themselves as to the

acceptability of each application and use of this product. For more information,

refer to publication SGI-1.1 (Safety Guidelines For The Application,

Installation and Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended

solely to illustrate the text of this manual. Because of the many variables and

requirements associated with any particular installation, Allen-Bradley

Company cannot assume responsibility or liability for actual use based upon the

illustrative uses and applications.

No patent liability is assumed by Allen-Bradley Company with respect to use of

information, circuits, equipment or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen-Bradley Company is prohibited.

Throughout this manual we make notes to alert you to possible injury to people

or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

- Identify a hazard

- Avoid the hazard

- recognize the consequences

Important: Identifies information that is critical for successful application and

understanding of the product.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains new updated information.

To help you find updated information in this release of the manual, we

have included change bars as shown to the left of this paragraph.

Page 4

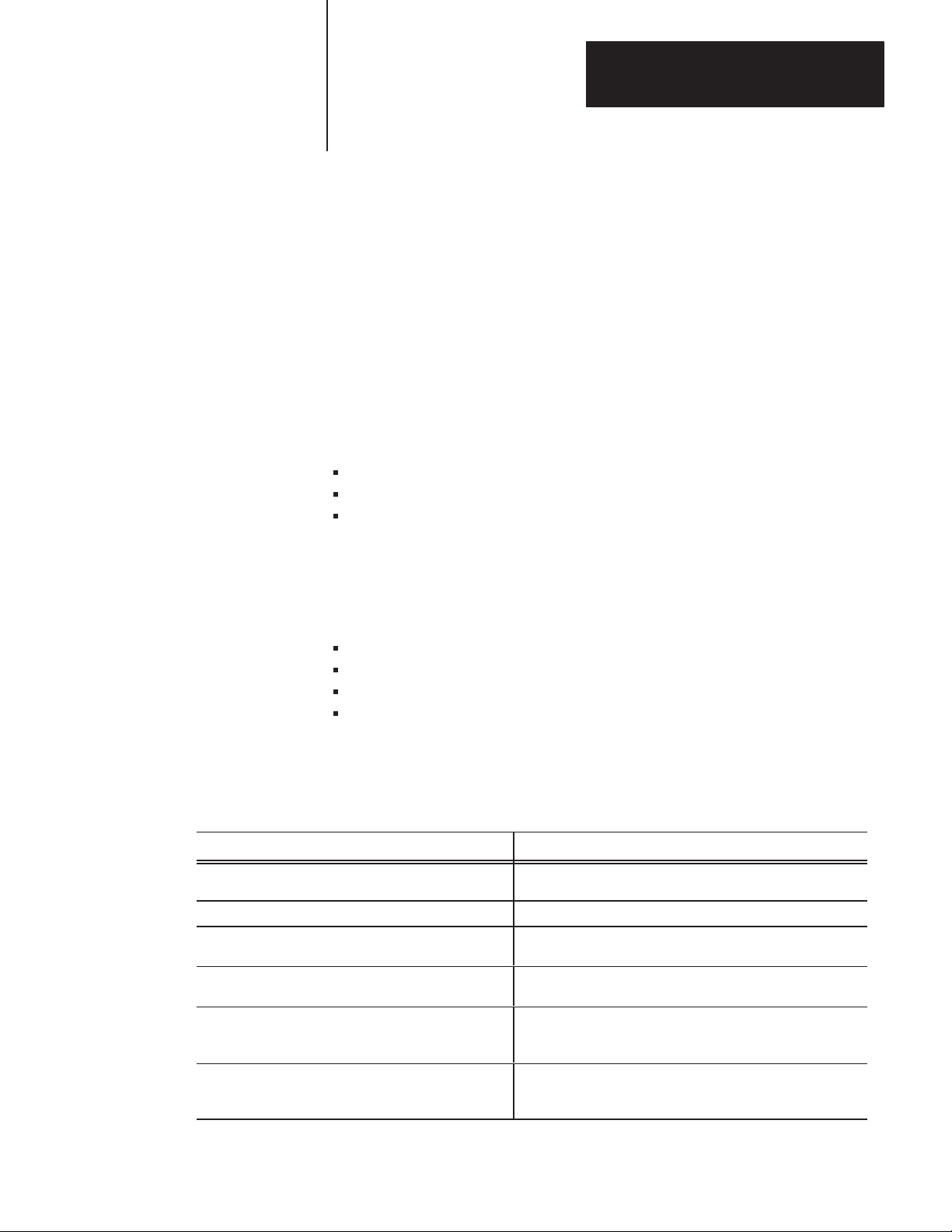

Using This Manual

Preface

Manual Objectives

Audience

This manual shows you how to use 1785-BCM series B backup communication

modules with a PLC-5 programmable controller (PLC-5/15 series B, -5/20,

-5/25, -5/30, -5/40, and -5/60 processors). These modules enable high-speed

communication transfer between two PLC-5 processors and provide system

backup should the processor or other equipment in the system fail.

In this manual we describe:

backup system concepts

procedures for installing and operating your modules

various programming techniques

Before you read this manual or attempt to use 1785-BCM modules, you should

be familiar with PLC-5 programmable controllers. In addition, you need to be

familiar with:

6200 Series Software

remote I/O system

Data Highway Plus network

block-transfer instructions

What this Manual Contains

an overview of backup concepts; description of backup

system that uses 1785-BCM module.

a description of 1785-BCM module hardware. 2 – Understanding the 1785-BCM Module Hardware Components

procedures for installing the1785-BCM module; procedures

for connecting the backup system.

description of 1785-BEM backup expansion module and

procedures for installing

an overview of how the 1785-BCM module and the backup

system operate; procedures for starting, powering-up,

disconnecting, and restarting a repaired system.

considerations for timing, divergence, I/O forces, Data

Highway Plus switching, Remote I/O switching, special

sections of the data table, and data integrity.

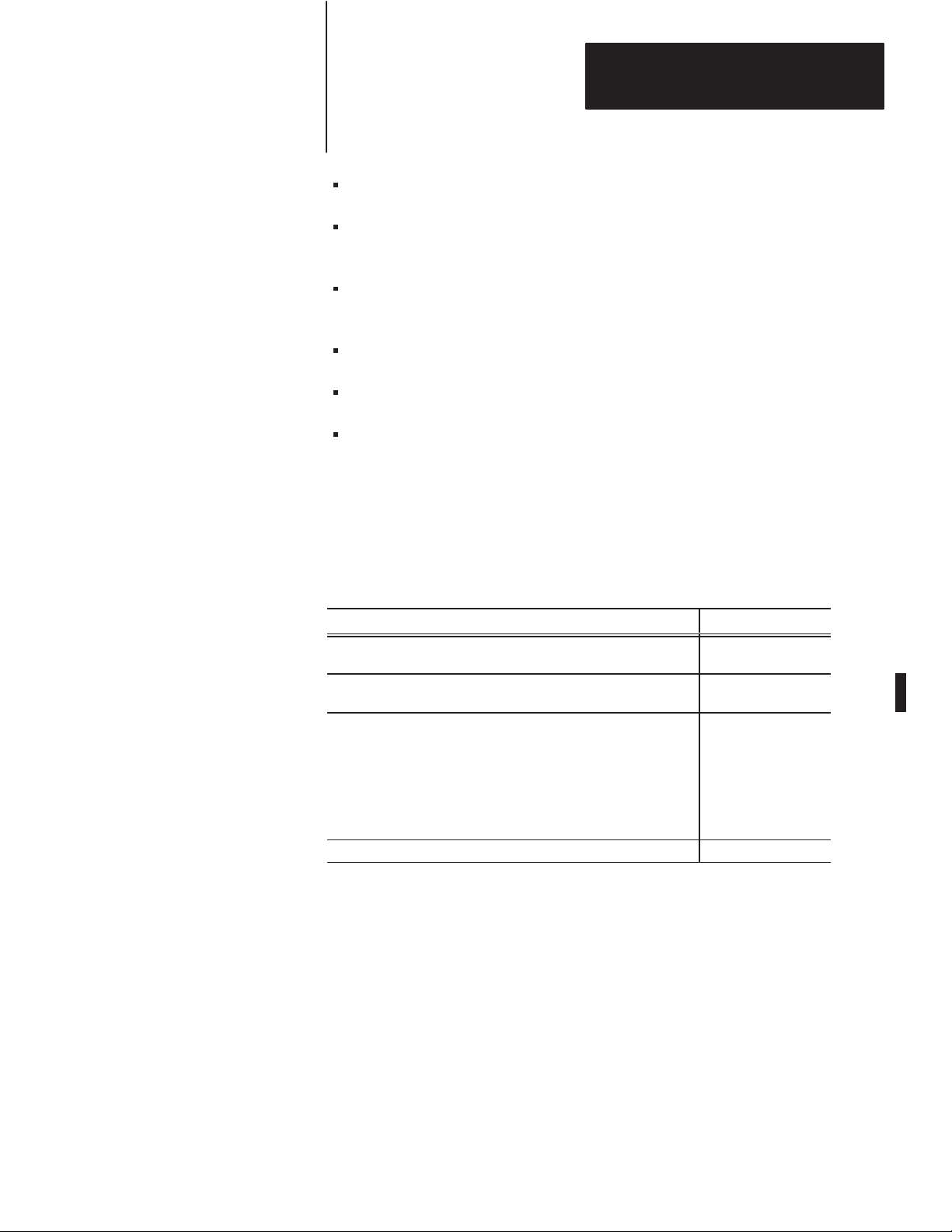

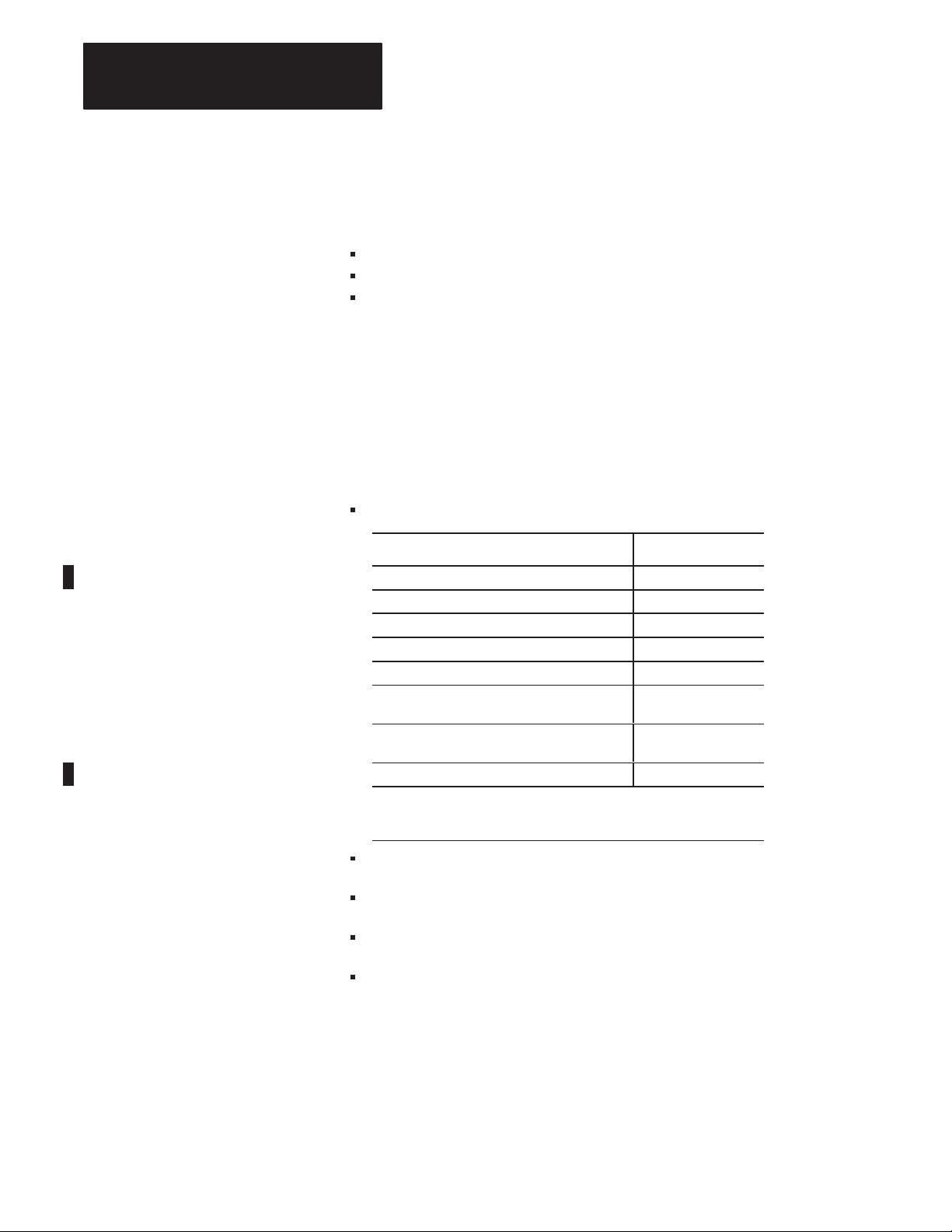

The following table lists each chapter of this manual and describes the contents

of each.

If you want to read about: Refer to chapter:

1 – Backup Concepts for the PLC-5 System

3 – Installing Your 1785-BCM Series B Backup System

4 – Installing Your 1785-BEM Module

5 – Operating Your PLC-5 Backup System

6 – Switchover Considerations

i

Page 5

Preface

If you want to read about: Refer to chapter:

PLC-5

two methods you can use to program your backup system;

considerations for using instructions that can cause

problems in your backup system.

1785-BCM module faults (as indicated by the module’s

status indicators and bits of the system status word) and

procedures for correcting faults.

specifications for the 1785-BCM module. 9 – Specifications

sample Programs for method 1 (transferring one block of

data at a time) and method 2 ( transferring multiple blocks

of data at a time); data table transfer times for both

programming methods.

answers to common PLC-5 backup system questions;

delay times between the primary and the secondary

processor for both programming methods and formulas for

determining delay times.

describes differences between a 1785-BCM series A

backup module and a 1785-BCM series B backup module

Processor Reference

7 – Programming Techniques

8 – Diagnosing Faults

Appendix A – Sample Programs

Appendix B – Reference Information

Appendix C – Using a Series A 1785-BCM Module

In this manual, the term PLC-5 processor refers to the following processors:

PLC-5/11

PLC-5/15

PLC-5/20

PLC-5/25

PLC-5/30

PLC-5/40

PLC-5/60

PLC-5/80

Terms and Conventions

ii

Contact your Allen-Bradley Sales Office or your Allen-Bradley distributor for

additional PLC-5 processors that can be configured with the 1785-BCM

modules.

Some terms used in this manual may be unfamiliar to you. We list these terms

with a brief definition of each.

HSSL is the 1785-BCM module’s High-Speed Serial Link. It is a dedicated

communication link between the primary and secondary 1785-BCM modules

and is used to pass I/O, status, and data table information.

Primary System is the PLC-5 processor that controls the I/O and the other

equipment associated with that processor.

Secondary System is the PLC-5 processor that is ready to assume control of

the I/O and the equipment associated with that processor.

Backup System is the primary and secondary systems.

Page 6

Preface

Switchover is the transfer of I/O control from the primary processor to the

secondary processor.

Bumpless switchover is the transfer of I/O control from the primary

processor to the secondary processor where the operation of the process

being controlled is not affected.

Asynchronous processing is processing where the ladder program scan and

the block-transfer scan operate independently of each other within the same

scan time.

BTW is block-transfer write; transfer of up to 64 words from the processor to

the block-transfer module.

BTR is block transfer read; transfer of up to 64 words from the block transfer

module to the processor.

Smart Switch Interface is a remote I/O interface in the 1785-BCM module

that responds to secondary scanner poll commands with actual input values

from the remote I/O link, making the scanner think it is talking with

remote I/O.

Related Publications

For more information about components used with the 1785-BCM module in a

PLC-5 backup system, refer to the following publications:

Publication Title Publication Number

Enhanced and Ethernet PLC-5 Programmable Controllers

User Manual

Classic 1785 PLC-5 Family Programmable Controllers Hardware

Installation Manual

PLC-5 Programming Software Documentation Set 6200-N8.001

PLC-5 Programming Software: Installing and

Configuring the Software

PLC-5 Programming Software: Programming 6200-6.4.7

PLC-5 Programming Software: Instruction Set Reference

PLC-5 Programming Software: I/O Configuration Software

Remote I/O Adapter Module (cat. no. 1771-ASB) Installation Data 1771-2.162

1785-6.5.12

1785-6.6.1

6200-6.4.6

6200-6.4.11

6200-6.4.12

iii

Page 7

Table of Contents

Backup Concepts for the

PLC-5 System

Understanding the

1785-BCM Hardware

Components

Installing Your PLC-5

Backup System

Chapter 1

Chapter Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Why Use a Backup System? 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Applying 1785-BCM Backup Communication Modules to

the PLC-5 Programmable Controller 1-2. . . . . . . . . . . . . . . . . . . . . .

What to do Next 1-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Indicators 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Arm 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Links 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Customer Relay 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Switch Assemblies 2-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Backplane Interface 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What to Do Next 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Backup System Installation Overview 3-1. . . . . . . . . . . . . . .

Determining Power Supply Requirements 3-3. . . . . . . . . . . . . . . . .

Setting the I/O Chassis Switches 3-4. . . . . . . . . . . . . . . . . . . . . . . . .

Terminating the Data Highway Plus and Remote I/O Links 3-4. . . .

Installing the 1785-BCM Module 3-5. . . . . . . . . . . . . . . . . . . . . . . .

Connecting Your PLC-5 Backup System 3-9. . . . . . . . . . . . . . . . . .

What to Do Next 3-19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Your 1785-BEM

Module

Chapter 4

Chapter Objectives 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Backup Expansion Module 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Components 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Determining Power Supply Requirements 4-6. . . . . . . . . . . . . . . . .

Installing the 1785-BEM Module 4-7. . . . . . . . . . . . . . . . . . . . . . . .

Connecting Your 1785-BEM Module 4-13. . . . . . . . . . . . . . . . . . . . .

What to Do Next 4-21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Page 8

Table of Contents

Operating Your PLC-5

Backup System

Switchover Considerations

Chapter 5

Chapter Objectives 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How the 1785-BCM Module Operates 5-1. . . . . . . . . . . . . . . . . . . .

How the Backup System Operates 5-13. . . . . . . . . . . . . . . . . . . . . . .

Starting the Backup System 5-17. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Powering Up the Backup System 5-18. . . . . . . . . . . . . . . . . . . . . . . .

Disconnecting/Repairing a Faulted Backup System 5-18. . . . . . . . . .

Restarting a Repaired Backup System 5-19. . . . . . . . . . . . . . . . . . . .

Switching the Processor’s Operating Mode 5-19. . . . . . . . . . . . . . . .

Editing or Programming On-line 5-20. . . . . . . . . . . . . . . . . . . . . . . . .

What to Do Next 5-20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Chapter Objectives 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Requirements 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Divergence 6-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Forcing I/O 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Highway Plus Switching 6-4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote I/O Switching 6-6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Table Considerations 6-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Integrity 6-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

What to Do Next 6-12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Techniques

Diagnosing Faults

Specifications

Chapter 7

Chapter Objectives 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Getting Started 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Methods to Transfer Data Table Values 7-3. . . . . . . .

Accounting for Instructions That Could Cause Problems

During Switchover 7-9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Summary of Programming Considerations 7-13. . . . . . . . . . . . . . . . .

Chapter 8

Chapter Objectives 8-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnosing Faults with the Status Indicators 8-1. . . . . . . . . . . . . . .

Diagnosing Faults with Bits of the System Status Word 8-4. . . . . . .

Chapter 9

Specifications 9-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

II

Page 9

Table of Contents

Sample Programs

Reference Information

Using a Series A 1785-BCM

Module

Appendix A

Appendix

Method 1 Sample – Transferring Data One Block at a Time A-1. . . . . . . .

Method 2 Sample – Transferring Data Multiple Blocks at a Time A-13. . . .

Objectives

Appendix B

Appendix

Answers to PLC-5 Backup Configuration Questions

Determining Data Table Transfer Time B-5. . . . . . . . . . . . . . . . . . . . . . . .

Objectives

Appendix C

Appendix

1785-BCM Series A Backup Module Characteristics

Objectives

A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B-1. . . . . . . . . . . . . .

C-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

C-1. . . . . . . . . . . . . .

III

Page 10

Chapter

1

Backup Concepts for the PLC-5 System

Chapter Objectives

Why Use a Backup System?

This chapter describes concepts for using a backup system with your

programmable controller. In addition, this chapter provides an overview of

a PLC-5 processor backup system that uses 1785-BCM backup

communication modules and a system that also uses 1785-BEM backup

expansion modules.

The objective of any redundant system (backup system) is to improve the

amount of up-time of a machine or process by ensuring consistent

availability of that machine, and by reducing costs associated with

equipment failure. By using this backup system, you can guard your

application against shutdowns caused by the programmable controller.

ATTENTION: Backup does not protect you from faults caused

by programming errors or system timeouts because such an

error or timeout will also occur in the secondary processor.

The backup option is used where you must transfer the control of the

process to a secondary system, without thereby interrupting the

machine/process operation.

To guard against system shutdown, a backup system must provide:

equipment with exceptional reliability

automatic fault isolation

minimal disturbance of the process when switching from the primary to

the secondary system

1-1

Page 11

Chapter 1

Backup Concepts for the PLC-5 System

Applying 1785-BCM Backup Communication Modules to the PLC-5 Programmable Controller

A PLC-5 system configured with 1785-BCM modules provides high speed

backup communication and switchover of the Data Highway Plus and

remote I/O links. In this section we:

show a typical PLC-5 backup configuration

explain how the backup system works

describe the role of the 1785-BCM module (including 1785-BEM

module)

A Typical PLC-5 Backup Configuration

You must use BCM series B, revision C or later if you are using PLC-5/20,

-5/30, -5/40, or -5/60 processors.

A PLC-5 backup system contains two of each of the following hardware

components:

PLC-5 processor module

Processor:

PLC-5/11 series A, revision B or later 1785-L11B

PLC-5/15 series B, any revision 1785-LT series B

PLC-5/20 series A, revision B or later 1785-L20B

PLC-5/25 any revision 1785-LT2

PLC-5/30 series A, revision C or later 1785-L30B

PLC-5/40 series A, revision F or later

PLC-5/60 series A, revision F or later

PLC-5/80 series C, revision A or later 1785-L80B

*

Contact your Allen-Bradley Sales Office or your Allen-Bradley distributor

for additional PLC-5 processors that can be configured with the

1785-BCM modules.

*

or series B, revision C or later

or series B, revision C or later

Catalog Number:

1785-L40B

1785-L60B

1-2

1785-BCM module

1785-BEM module (when applicable)

power supply

local chassis

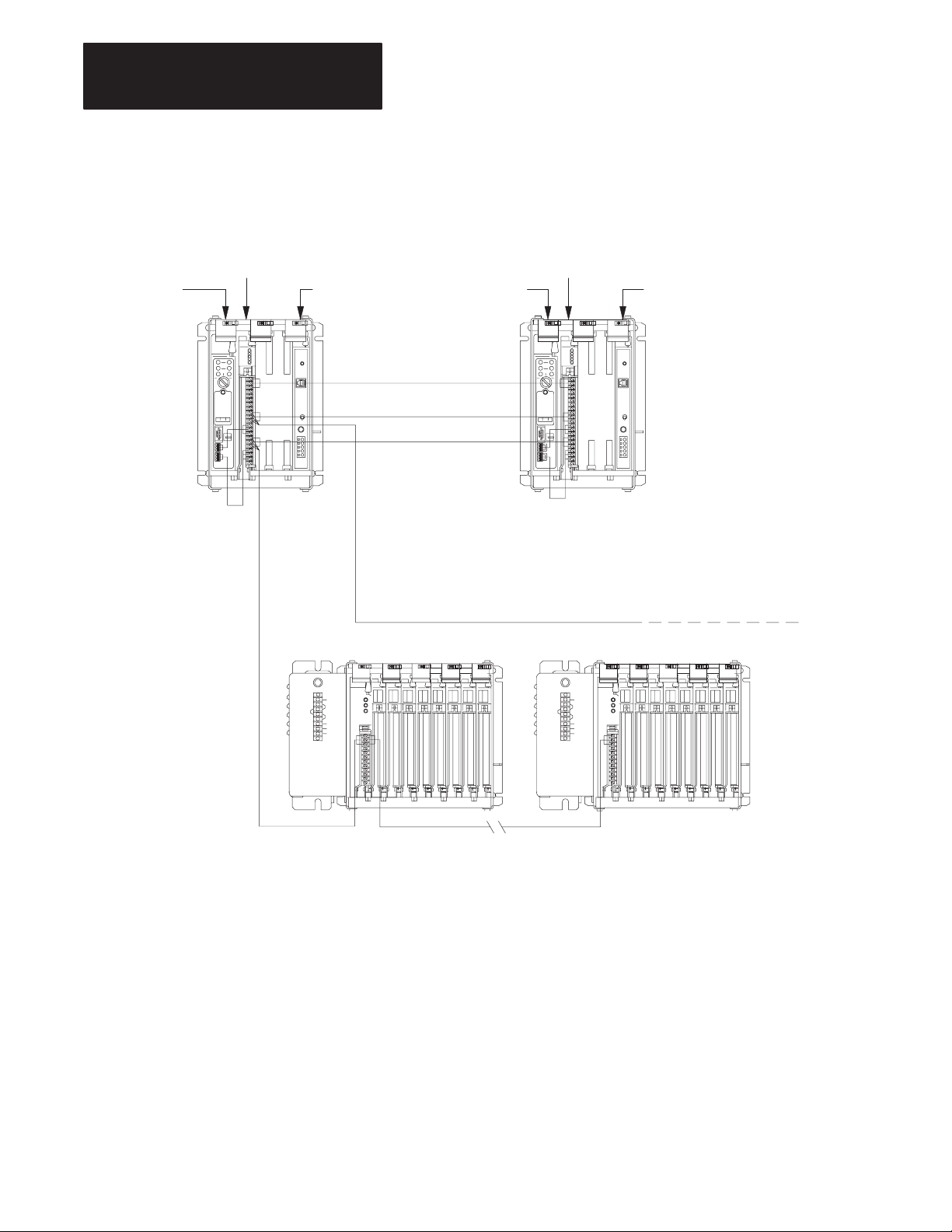

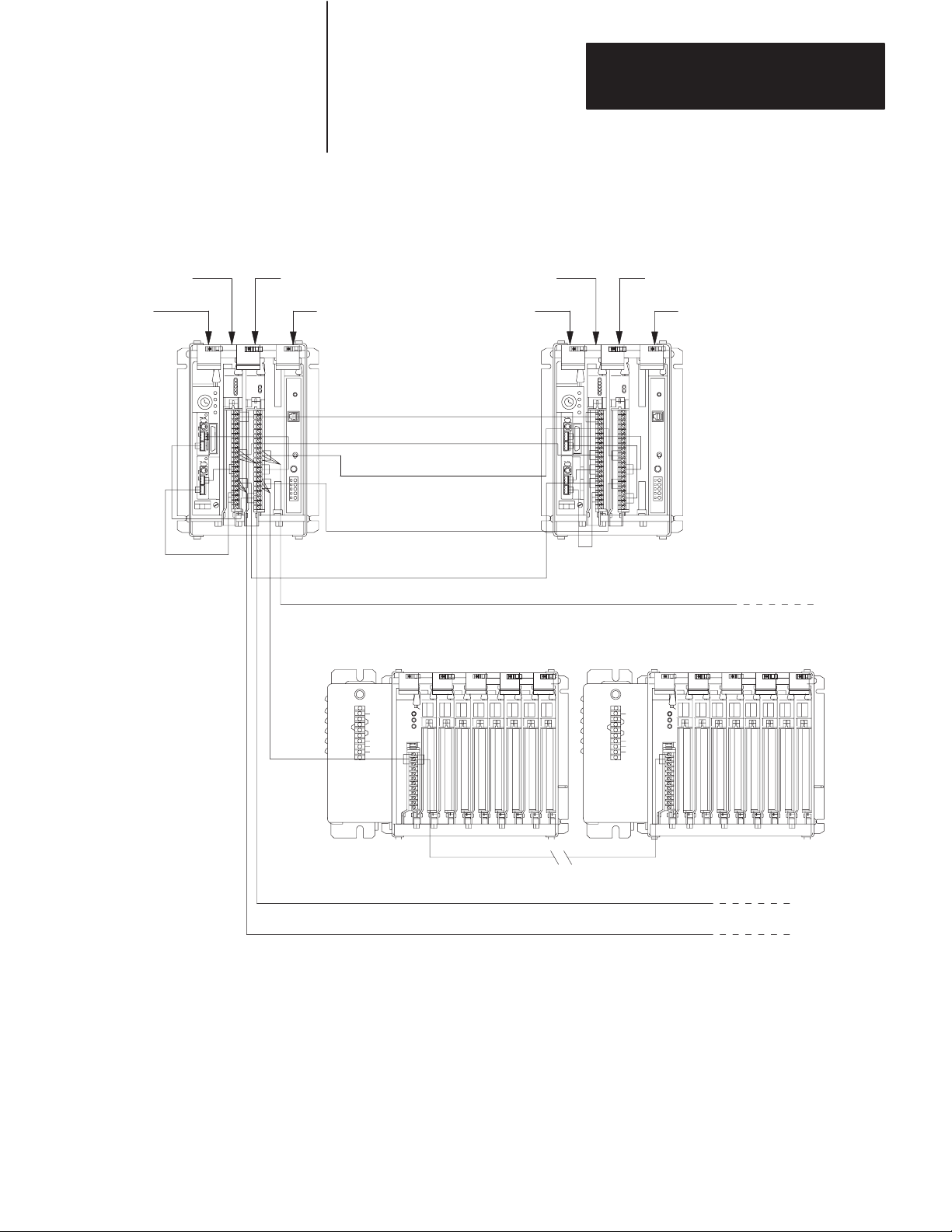

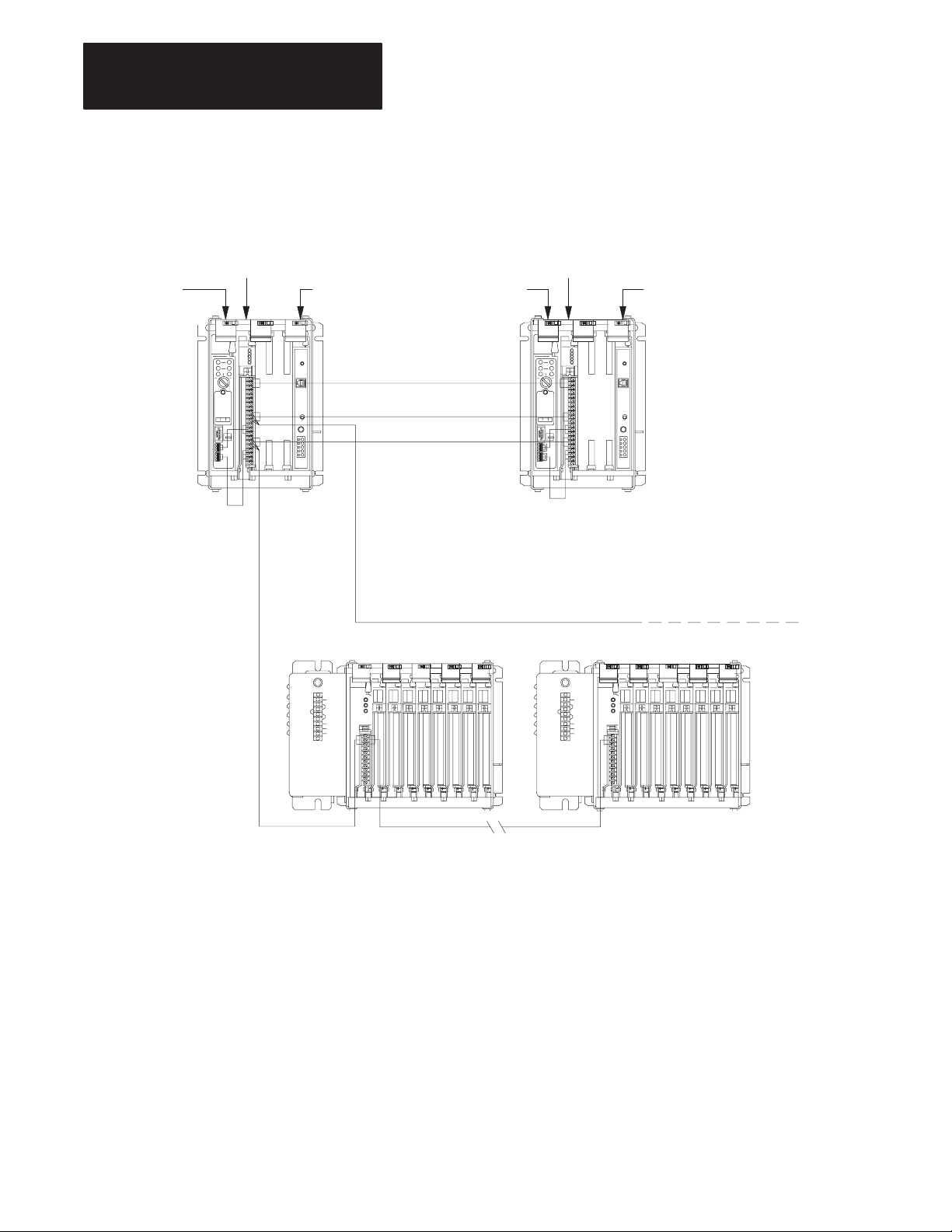

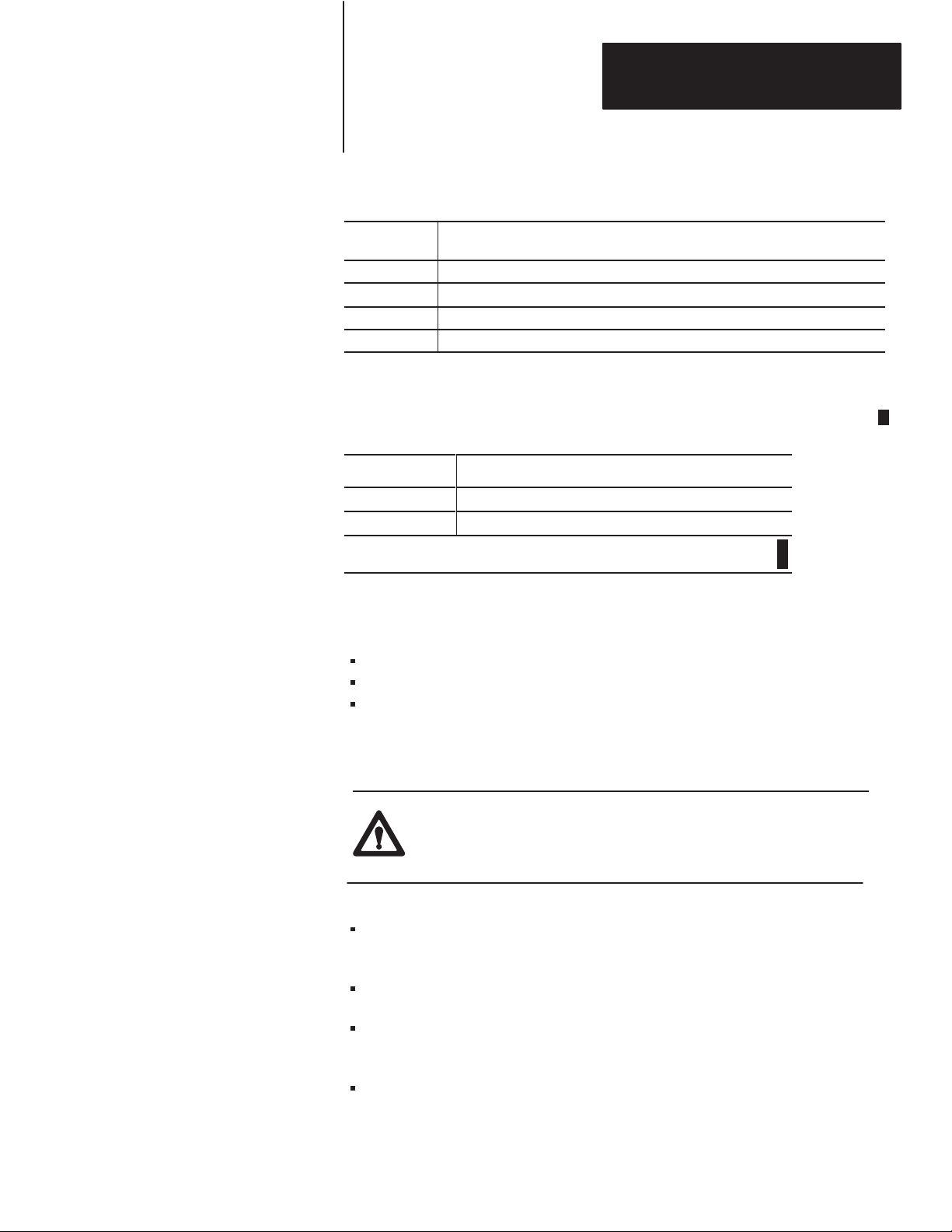

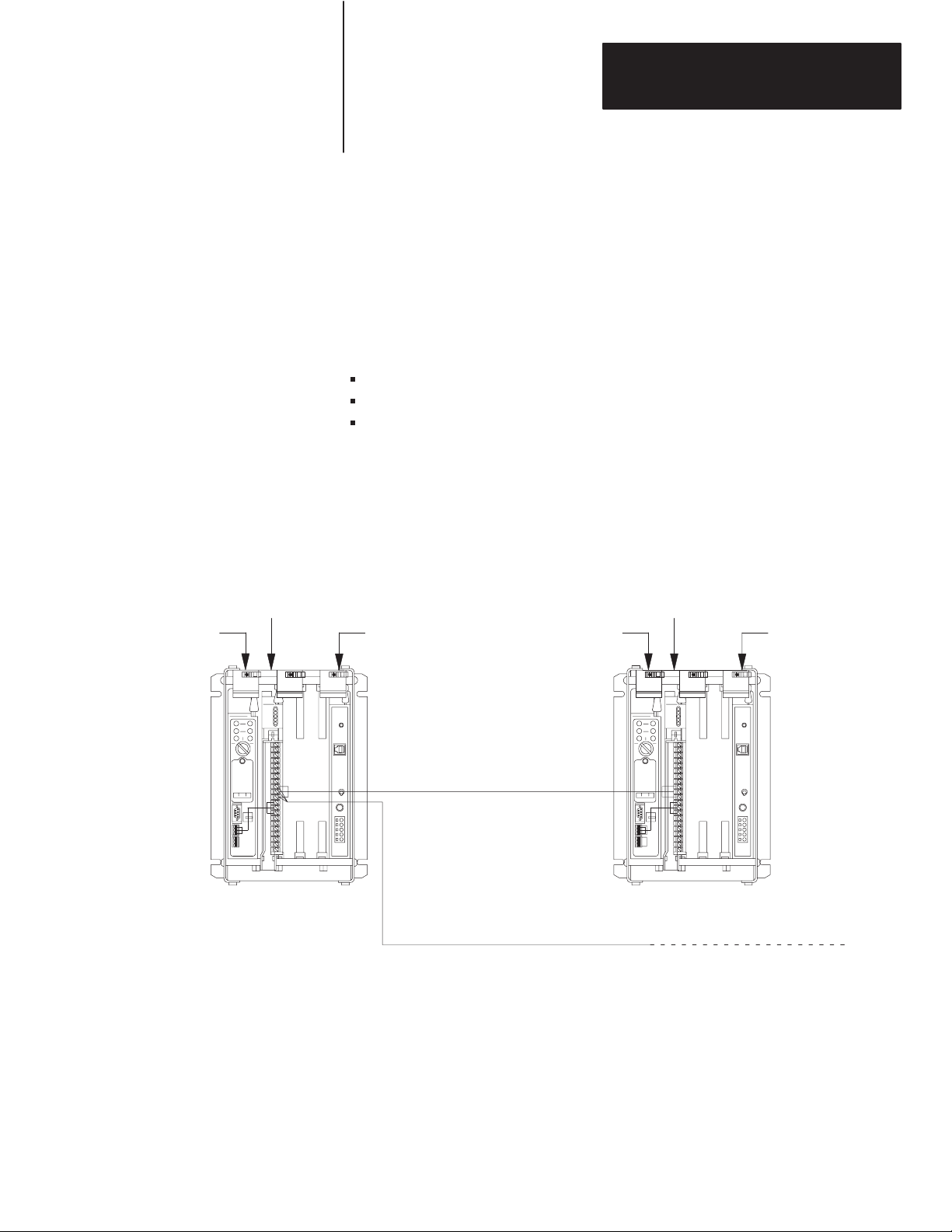

Figure 1.1 shows a typical PLC-5 backup configuration using PLC-5/15

processors and 1785-BCM modules. Figure 1.2 shows a typical PLC-5

backup configuration using PLC-5/40 or PLC-5/60 processors, 1785-BCM

modules, and 1785-BEM modules.

Page 12

Chapter 1

Backup Concepts for the PLC-5 System

Figure 1.1

PLC-5

Backup System Configuration Using 1785-BCM Module Only

Local I/O ChassisLocal I/O Chassis

1785 –BCM Module

PLC-5 processor PLC-5 processor

Remote I/O

1771 –P4S

Power Supply

HSSL

Data Highway Plus

Remote I/O

Do not put modules for controlling your

process in local I/O chassis.

Remote I/O Chassis Remote I/O Chassis

1785 –BCM Module

1771 –P4S

Power Supply

To

Data Highway Plus

Network

1-4

Remote I/O

Applications that use more than two ports (PLC-5/40, or PLC-5/60 processors)

may require a 1785-BEM module (not shown).

17990

Page 13

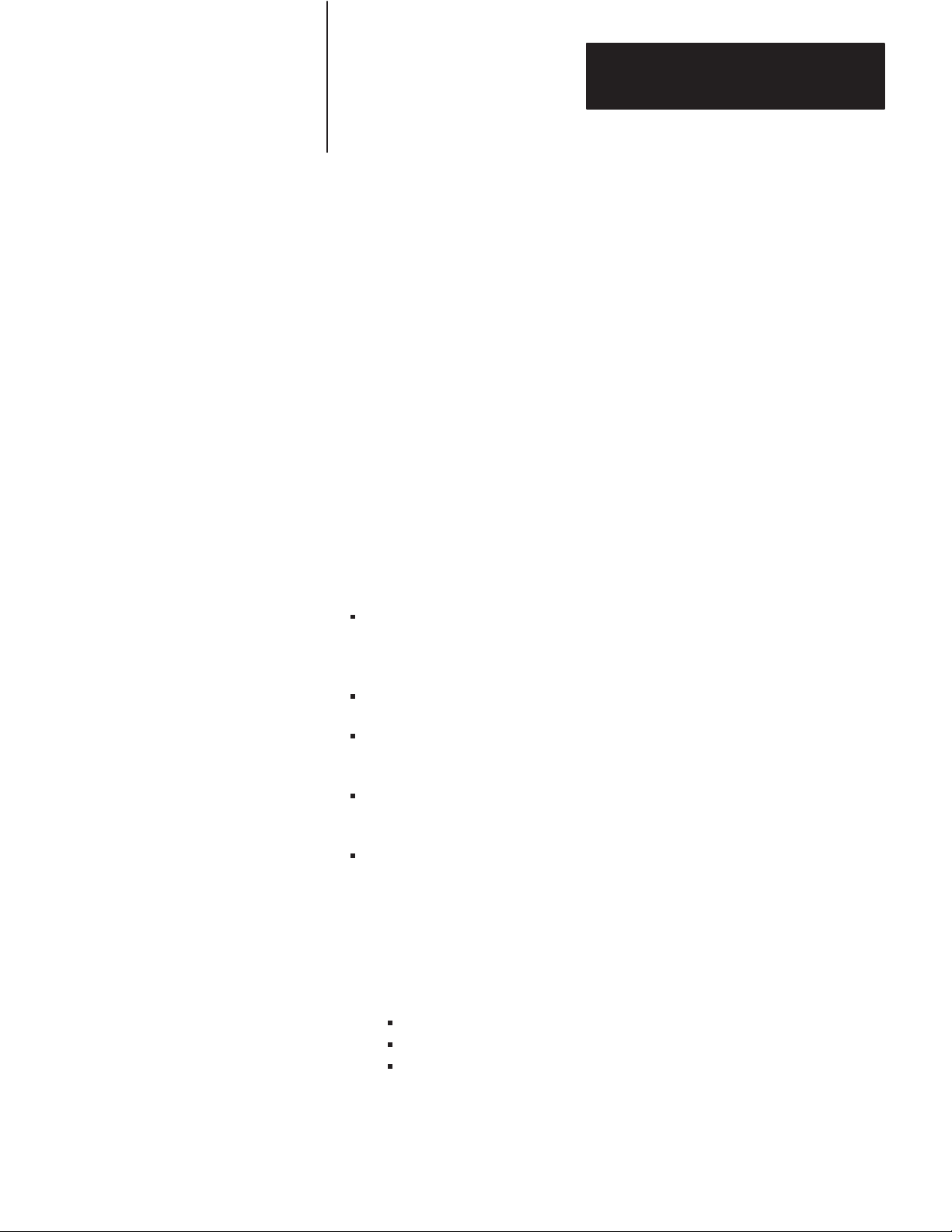

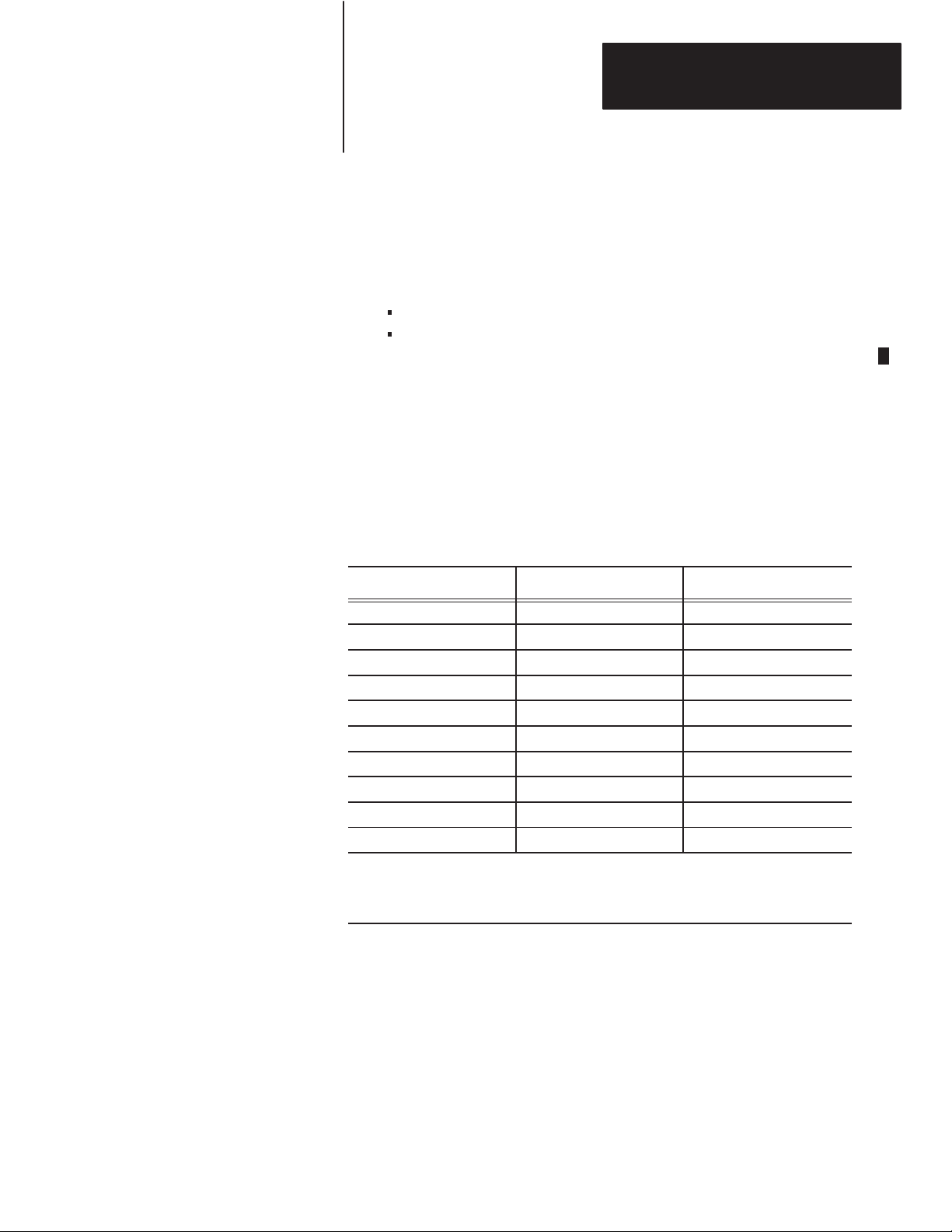

Figure 1.2

PLC-5

Backup System Configuration Using 1785-BCM

and 1785-BEM Modules

Local I/O ChassisLocal I/O Chassis

Chapter 1

Backup Concepts for the PLC-5 System

1785 –BCM Module

PLC –5/60

or –5/40

1785 –BEM Module

1771 –P4S

Power Supply

BCM DH+ or RIO

Remote

I/O

(BEM

Module)

1785 –BCM Module

PLC –5/60

or –5/40

HSSL

BCM DH+ or RIO

BEM DH+ or RIO

BEM RIO

Remote I/O Chassis No. 1

1785 –BEM Module

1771 –P4S

Power Supply

Do not put modules

for controlling your

process in local I/O

chassis.

DH+ or RIO (BEM Module)

Remote I/O Chassis No. n

DH+ or RIO (BCM Module)

DH+ or RIO (BCM Module)

HSSL connects between the two 1785-BCM modules only.

19088

1-5

Page 14

Chapter 1

Backup Concepts for the PLC-5 System

How the PLC-5 Backup System Works

In the PLC-5 backup configuration, one system (consisting of one PLC-5

processor, 1785-BCM module, power supply, and chassis) controls the

operation of the remote I/O. This system is referred to as the primary

system. The other system is ready to take control of the remote I/O in the

event of a fault in the primary system. This is referred to as the

secondary system. The PLC-5 backup system does not back up local I/O;

therefore, do not install I/O in the local chassis.

Data Transfer

During normal operation, the primary system sends remote input and data

table data to the secondary system so that in the event of a switchover, the

secondary system (which becomes the new primary system) has the same

data.

Remote I/O data is automatically transferred over the High-Speed Serial

Link (see Figure 1.1). This transfer is independent of the application

program.

Data table values are transferred from the primary to the secondary system

with block transfer instructions that you include in your ladder program.

You do not have to transfer data table values if not necessary for your

application. Figure 1.3 shows how data table data is transferred from the

primary to the secondary system.

Figure 1.3

Transfer

Primary

PLC-5

of Data T

BTW

able Data From the Primary to Secondary System

Primary

1785-BCM

Data is sent

over the

HSSL

Secondary

1785-BCM

BTR

Secondary

PLC-5

11050I

For detailed information about data transfer from the primary to the

secondary system, refer to Chapter 5, “Operating Your PLC-5 Backup

System.”

1-6

Page 15

Chapter 1

Backup Concepts for the PLC-5 System

Switchover

Should a fault occur in the primary processor, control switches to the

secondary system in less than 50 ms (maximum). When a switchover

occurs, the outputs in the remote I/O maintain their last state until they

come under the control of the secondary processor.

However, keep in mind that the program scans of the two processors are

not synchronized. This means that the secondary processor may be

scanning all, none, or only part of the program (at your discretion). This

manual explains the switchover process, and provides guidelines for

developing programs for your PLC-5 backup system. (For more

information about switchover, refer to Chapter 6, “Switchover

Considerations.”)

Role of the 1785-BCM Series B Module

As an integral part of the backup system, the 1785-BCM modules enable

high speed communication between the two PLC-5 processors, and permit

the secondary processor to assume control of the process. In addition, the

1785-BCM module provides:

high speed transfer of the data table values from the primary to the

secondary system, to ensure that the secondary system’s data table is a

copy of the primary system’s

a buffer of 4K words for data table values

exchange of information on the status of the primary and secondary

systems

automatic transfer to the secondary system of the remote input and

block transfer read values (analog values, etc.)

transfer of control from the primary processor to the secondary

processor when one of the following conditions occur:

- power failure

- processor fault

- 1785-BCM module fault

- change in the primary processor’s mode from:

RUN to PROGRAM (manual switchover)

REM RUN to REM PROG

REM RUN to REM TEST

1-7

Page 16

Chapter 1

Backup Concepts for the PLC-5 System

transfer of control from the primary processor to the secondary when

one of the following conditions is detected by the secondary processor:

- communication timeout in the High Speed Serial Link (HSSL)

between the two 1785-BCM modules and primary system is not

updating the remote I/O

- transfer of control command from the primary 1785-BCM module

substitution of equipment without interruption of the process; that is, the

faulted system can be repaired while the other system is controlling the

process

connections for remote I/O and Data Highway Plus network (the

1785-BCM module routes the remote I/O network and the Data

Highway Plus network to the active processor)

isolation of the systems, in order to guarantee that a fault in one system

does not affect the other

What to do Next

diagnostics information

remote programming capability for secondary processor

capability of switching up to four configurable communication channels

when using the 1785-BEM backup expansion module

Backup Expansion

The 1785-BCM module has two channels. The PLC-5/40 and PLC-5/60

processors have four communication channels. You can provide the backup

of the other two processor channels by adding the 1785-BEM backup

expansion module. For more information about the 1785-BEM backup

expansion module, refer to Chapter 4.

Compatibility

The 1785-BCM series B backup module is compatible with the 1785-BCM

series A backup module when you properly configure switch assembly

SW1 and switch assembly SW2 of the series B module.

This chapter provided an overview of backup concepts and the PLC-5

backup system. Read chapter 2 to understand the 1785-BCM module

hardware components.

1-8

Page 17

Chapter

Understanding the 1785-BCM

Hardware Components

2

Chapter Objectives

Status Indicators

This chapter describes the major components that make up the 1785-BCM

module. These components include:

status indicators

1771-WG wiring arm

1785-BCM communication links

- high-speed serial link (HSSL)

- Data Highway Plus link (DH+)

- remote I/O link (RIO)

customer relay (contact)

switch assemblies

backplane interface

Refer to Chapter 4 for information about the 1785-BEM backup expansion

module.

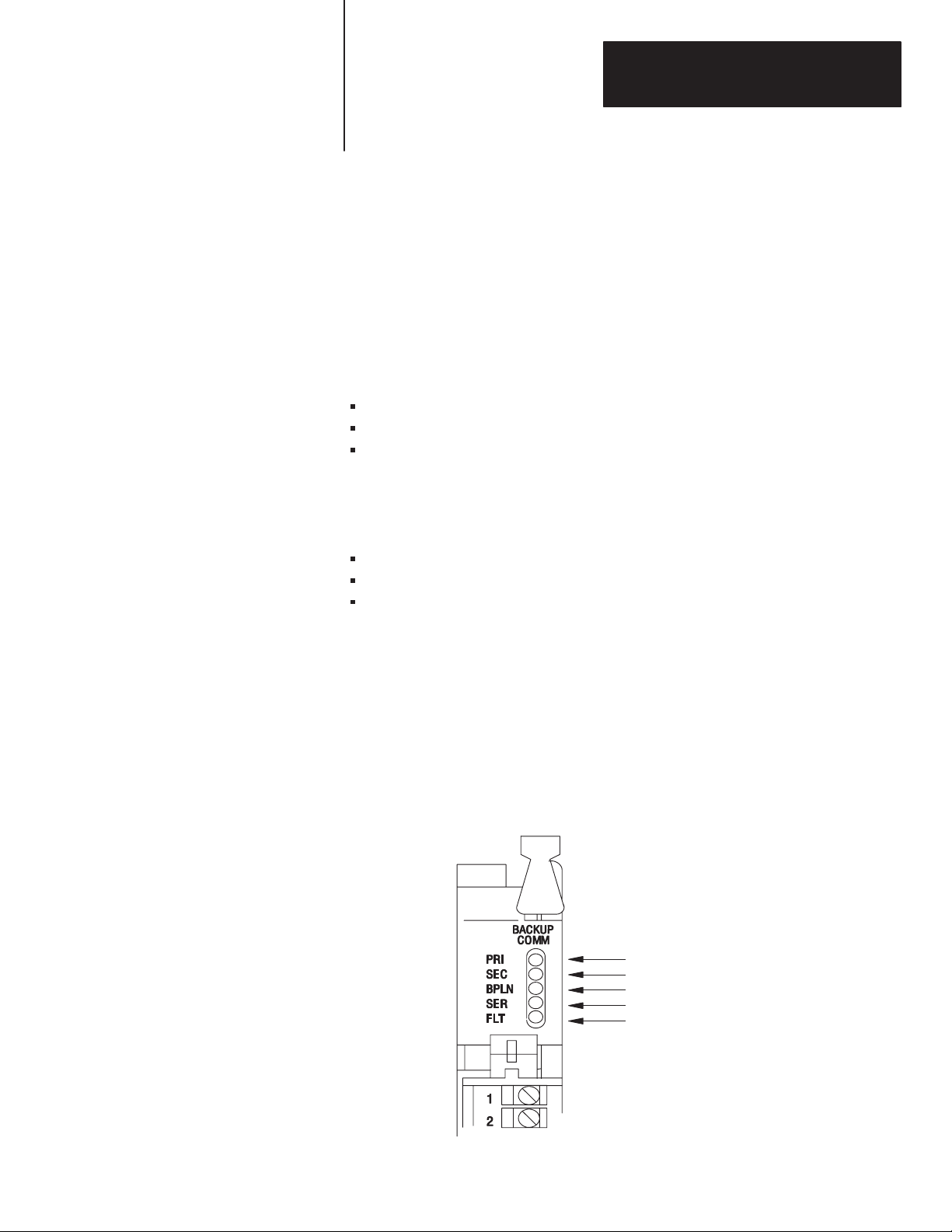

The 1785-BCM module has five status indicators on the front panel of the

module (Figure 2.1). The indicators show both normal operation and error

conditions of your PLC-5 backup system.

Figure 2.1

1785-BCM

Module Status Indicators

Primary

Secondary

Backplane

Serial Communication Link (HSSL)

Fault

17978

2-1

Page 18

Chapter 2

Understanding the 1785-BCM

Hardware Components

All indicators light at power up or when a hardware fault occurs in the

1785-BCM module. With the exception of the FLT indicator, all of the

1785-BCM module’s indicators are related to individual bits of the system

status word. For more information on the system status word, refer to

Chapter 5, “Operating Your PLC-5 Backup System.”

For information about locating faults using the status indicators, refer to

Chapter 8, “Diagnosing Faults”.

Wiring Arm

Communication Links

You make connections to your communication links with the 1771-WG

wiring arm, which is shipped with the module.

Your wiring arm attaches to the pivot bar on the bottom of the I/O chassis.

It pivots upward and connects with the module so you can install or

remove the module without disconnecting the wires.

The 1785-BCM module has ports for three communication links for

connection with the Remote I/O, Data Highway Plus network, and the

other 1785-BCM module (Figure 2.2). In addition, the module has a relay

for customer connection.

As shown in Figure 2.2, there are two user-configurable ports (Channels

1A and 1B) that support remote I/O or Data Highway Plus modes.

Table 2.A lists the communication ports and describes how the system uses

each one.

2-2

Page 19

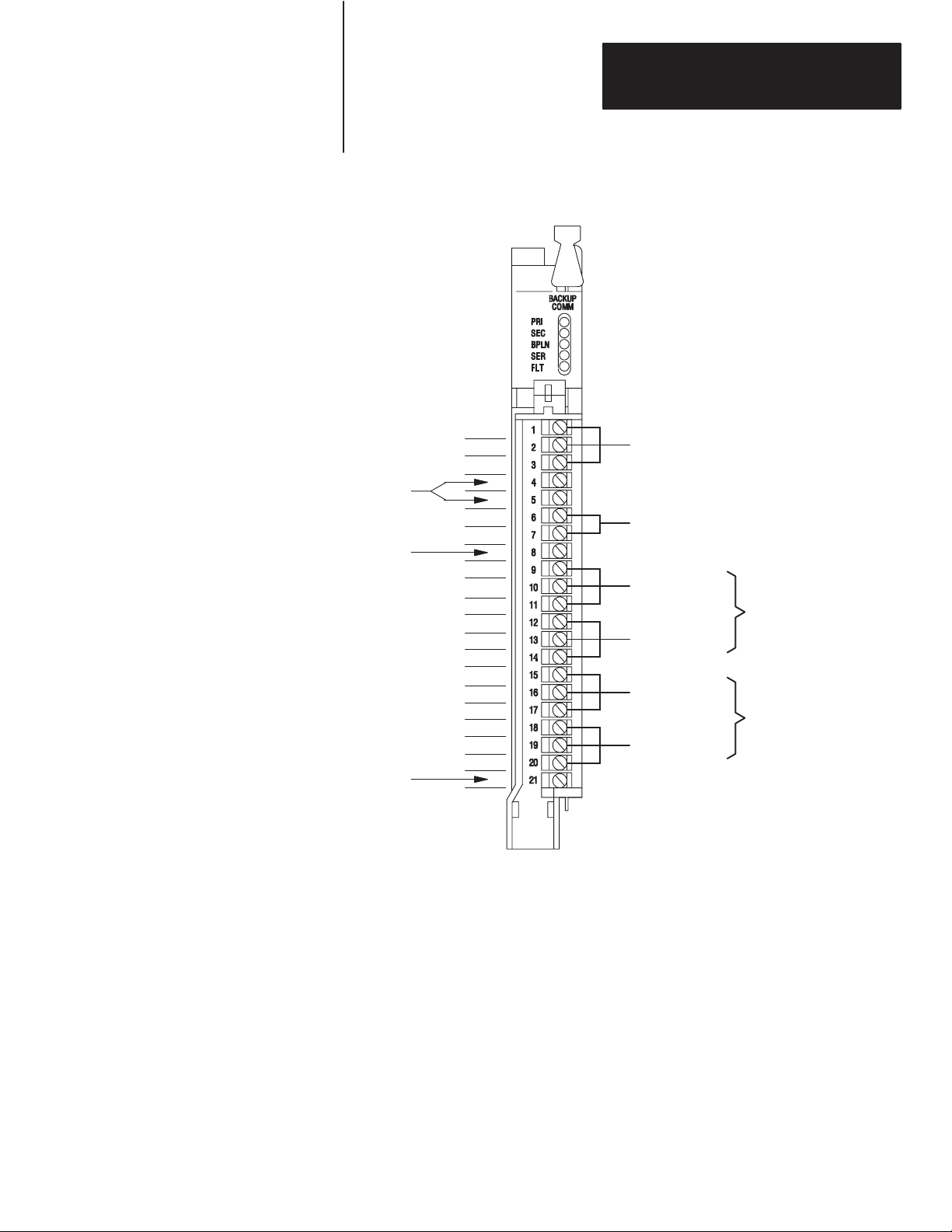

Figure 2.2

1785-BCM

Not Used

Module Communication Links

1

Sh

2

Chapter 2

Understanding the 1785-BCM

Hardware Components

High Speed Serial Link

1

Not Used

Not Used

1

Terminals 9, 10, and 11 are connected between the 1785–BCM modules in the backup

system; in addition terminals 9, 10, and 11 of one of the 1785 BCM modules are connected to

the DH+ network or to the remote I/O link.

2

Terminals 15, 16, and 17 are connected between the 1785–BCM modules in the backup

system; in addition terminals 15, 16, and 17 of one of the 1785 BCM modules are connected

to the DH+ network or to the remote I/O link.

2

1

Sh

2

1

Sh

2

1

Sh

2

1

Sh

2

Customer Relay

1

To Link

(RIO/DH+)

From Controller

2

To Link

(RIO/DH+)

From Controller

Channel 1A

(Remote I/O or

Data Highway Plus)

Channel 1B

(Remote I/O or

Data Highway Plus)

19082

2-3

Page 20

Chapter 2

Understanding the 1785-BCM

Hardware Components

T

able 2.A

Communication

Communication Port: This link is used to:

High Speed Serial Link (HSSL) permit two-way alternating communication (half-duplex)

Channel 1A connect the primary PLC-5 processor to the Data Highway

Channel 1B connect the primary PLC-5 processor to the Data Highway

Ports

between the two 1785-BCM modules of the backup system

at a distance of up to 15 feet.

Plus network or to the remote I/O link; the secondary

processor is isolated from this link.

Plus network or to the remote I/O link; the secondary

processor is isolated from this link.

Channels 1A and 1B have a default communication mode which can be

changed by resetting switches, if necessary. Table 2.B describes the default

communication mode for each of the two channels.

T

able 2.B

Default

Communication Modes

Channel Default Communication Mode

1A Data Highway Plus

1B Remote I/O – Scanner mode at 57.6 kbaud

With the exception of the HSSL, all of the connections in the 1785-BCM

module have an internal relay whose contacts are closed when the

controller is primary and open when the processor is secondary. Figure 2.3

shows these relays for processor A and processor B of a PLC-5 backup

system.

2-4

Page 21

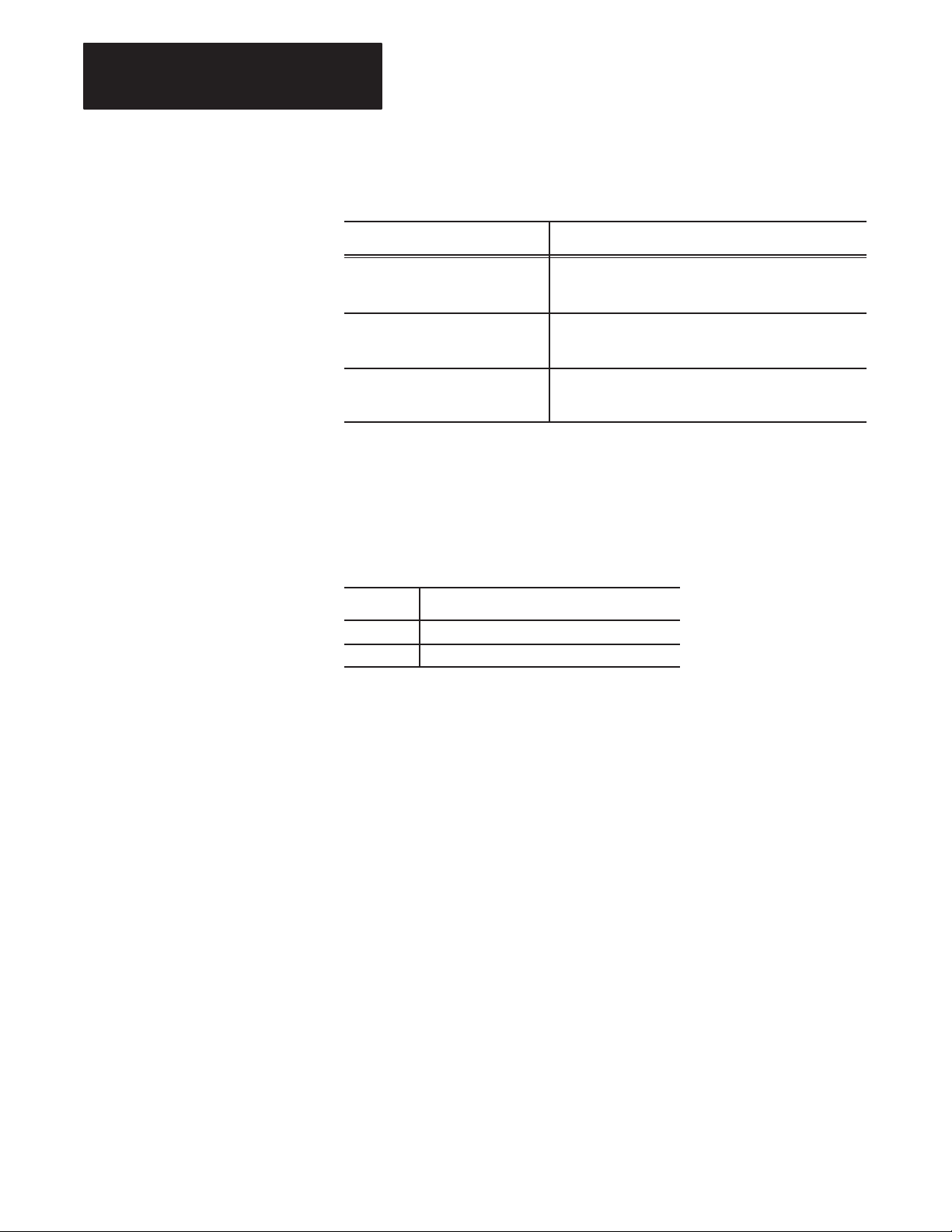

Figure 2.3

Relays

for Processor A and Processor B

Chapter 2

Understanding the 1785-BCM

Hardware Components

Processor A (primary)

PLC-5

Customer Relay

Processor A (secondary)

PLC-5

Customer

Relay

Processor B (secondary)

1785-BCM 1785-BCM

HSSL

DH+

Remote I/O

Processor B (primary)

1785-BCM 1785-BCM

HSSL

DH+

Remote

I/O

PLC-5

PLC-5

11051I

Customer Relay

Important: When using a 1785-BCM module with a PLC-5/40, PLC-5/60,

or PLC-5/80 processor, you can add a 1785-BEM backup expansion

module to provide backup for all processor communication channels. The

channels of the 1785-BEM module, like the 1785-BCM module, can be

configured for Data Highway Plus or remote I/O. For more information on

the 1785-BEM backup expansion module, refer to Chapter 4.

The customer relay connection on the 1785-BCM module is used to switch

external devices. Relay contacts are rated at .25A @ 24V dc resistive.

Loads with inductive characteristics will require additional suppression

devices.

2-5

Page 22

Chapter 2

Understanding the 1785-BCM

Hardware Components

Switch

Assemblies

There are two switch assemblies located at the top and at the bottom of the

1785-BCM module. Refer to Figure 2.4 for locations of the switch

assemblies. Refer to Table 2.C for a description of the function of the

1785-BCM module switch assemblies.

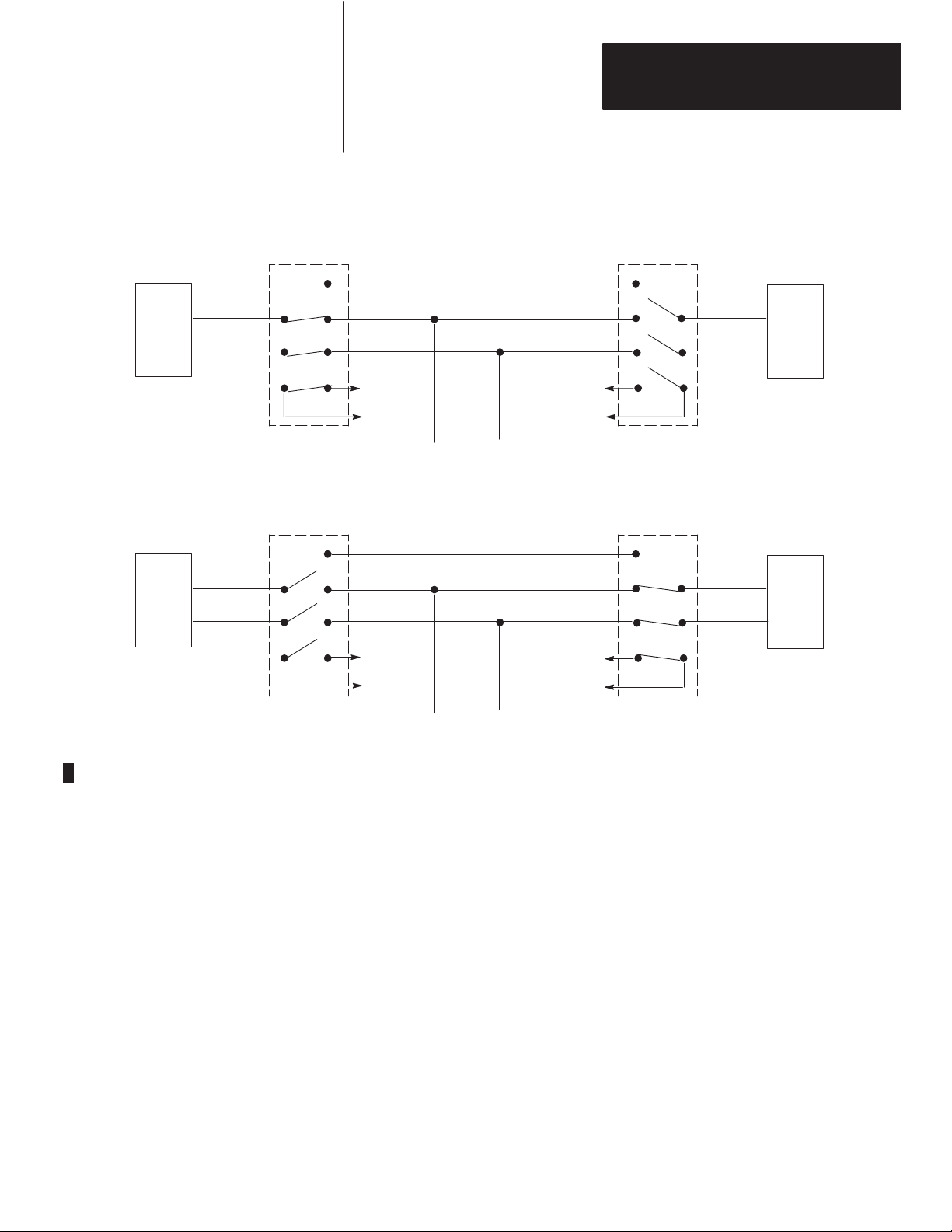

Figure 2.4

1785-BCM

Module Switch Assemblies

Switch Assembly SW1

Top View

Switch Assembly SW2

Bottom View

19084

T

able 2.C

1785-BCM Module Switch Assembly Functions

Use this switch assembly: To:

SW1 • establish communication between the 1785-BCM

series B module and a 1785-BCM series A module.

• establish the fast data transfer mode from the

secondary module to the secondary processor.

SW2 • specify if Channels 1A and 1B are going to establish

communication with Data Highway Plus network or

with the remote I/O link. With the remote I/O link,

determine the baud rate as well as the mode of

operation of the processor (scanner or adapter).

To set the switches described above, refer to Chapter 5, “Operating Your

PLC-5 Backup System.”

2-6

Page 23

Chapter 2

Understanding the 1785-BCM

Hardware Components

I/O Backplane Interface

What to Do Next

Through its connection with the I/O chassis backplane, the 1785-BCM

module can execute block transfer read (BTR) and block transfer write

(BTW) instructions from a PLC-5 processor. With the inherent

block-transfer queuing capabilities of the PLC-5 processor, multiple

block-transfer instructions per program scan can be executed to the same

1785-BCM module.

This chapter described the hardware components of the 1785-BCM

module. Now that you are familiar with the module and some of the

backup concepts for the PLC-5 backup system as described in chapter 1,

you are ready to install the backup system. Chapters 3 and 4 describes

installation procedures for the PLC-5 backup system (1785-BCM and

1785-BEM modules, respectively).

2-7

Page 24

Chapter

3

Installing Your PLC-5 Backup System

Chapter Objectives

PLC-5 Backup System Installation Overview

This chapter provides an overview of an installed PLC-5 backup system

and describes procedures for installing your PLC-5 backup system

(1785-BCM series B module only). These procedures are:

determining power supply requirements

setting the I/O chassis switches

setting the module switches

installing the 1785-BCM module

connecting the PLC-5 backup system

When installing a backup system for a PLC-5/40, PLC-5/60, or PLC-5/80

processor, you may choose to use a 1785-BEM backup expansion module

to provide backup for the two additional channels of the processor. Refer

to Chapter 4 for installation procedures for the 1785-BEM backup

expansion module.

Figure 3.1 shows a typical configuration of a PLC-5 backup system. In

this system, communication between the controllers is accomplished

through the two 1785-BCM modules. All of the cable connections

between the primary and backup system require a 1770-CD (Belden 9463)

cable.

Important: Do not install I/O modules for controlling your process in

the local chassis. Only the I/O modules residing in the remote chassis will

be backed up. Local chassis are necessary for housing the processor,

1785-BCM backup communication module, 1785-BEM backup expansion

module, and power supply for the backup system. Local I/O is not

backed up.

When a coprocessor is in the same chassis (standalone mode) or directly

connected to a PLC-5 processor (direct-connect mode), place the

1785-BCM and 1785-BEM modules in any other available I/O module

group in that chassis

Important: Do not place the 1785-BCM module in the same module

group (as defined by 2-slot addressing) as the coprocessor. The

1785-BCM module can reside in an adjacent slot, but not in the same

module group (under the same chassis locking tab).

3-1

Page 25

Chapter 3

Installing Your PLC-5 Backup System

Figure 3.1

PLC-5

Backup System Configuration

Local I/O ChassisLocal I/O Chassis

1785 –BCM Module

PLC-5 processor PLC-5 processor

Remote I/O

1771 –P4S

Power Supply

HSSL

Data Highway Plus

Remote I/O

Do not put modules for controlling your

process in local I/O chassis.

Remote I/O Chassis Remote I/O Chassis

1785 –BCM Module

1771 –P4S

Power Supply

To

Data Highway Plus

Network

3-2

Remote I/O

Some applications that use more than two ports (PLC-5/40, PLC-5/60, or PLC-5/80

processors) may require a 1785-BEM module (not shown).

17990

Page 26

Chapter 3

Installing Your PLC-5 Backup System

Determining Power Supply Requirements

The logic circuit of the 1785-BCM module is driven by a power supply

through the backplane of the I/O chassis. Determine the power supply

requirements for your PLC-5 backup system:

1. Add these values to determine output current needed from the power

supply.

1.0A at 5V for a 1785-BCM module and

2.5A for the PLC-5/15 or PLC-5/25 processor or

3.3A for PLC-5/11, -5/20, -5/30, -5/40, -5/60, or -5/80 processor

2. Refer to Table 3.A to choose the power supply that provides

sufficient power for all modules in your backup system.

Important: Refer to Chapter 4 to select your power supply when you add

a 1785-BEM module in your backup system.

T

able 3.A

Power

Supplies for a PLC-5 Backup System

Power Supply Output Current (in amps) Power Supply Location

1771-P4 8 slot

1771-P4R

1771-P4S 8 slot

1771-P4S1 8 slot

1771-P6S 8 slot

1771-P6S1 8 slot

1771-P6R 8 slot

1771-PS7 16 external

1

A P4R redundant power supply can prevent system switchover due to power supply failures

or incoming power failures.

2

You cannot use an external power supply and a power supply module to power the same

chassis; they are not compatible.

1

1771-P5 8 slot

1771-P7 16 external

8 slot

2

2

3. Use separate power sources for the primary and secondary

processors. Connect the power supplies through different power

sources to take precautions against interruptions and incoming power

failures.

3-3

Page 27

Chapter 3

Installing Your PLC-5 Backup System

Setting the I/O Chassis Switches

The I/O chassis switch assembly is located on the left side of the chassis

backplane. Table 3.B lists the settings we recommend for the local chassis

of your PLC-5 backup system. (Local refers to the chassis with the PLC-5

processor and the 1785-BCM module.) You can set remote system

switches for your specific application. For more information about setting

your I/O chassis backplane switches refer to the Enhanced and Ethernet

PLC-5 Programmable Controllers User Manual (publication 1785-6.5.12).

Important: The addressing mode and local chassis size you select can

affect the number of remote racks available. Refer to the Enhanced and

Ethernet PLC-5 Programmable Controllers User Manual (publication

1785-6.5.12) for the maximum number of remote racks that can be

addressed by the PLC-5 processor(s) in your system.

T

able 3.B

Recommended

Set switch(es) To this position:

2 and 3 both OFF – these switches are not used

4 and 5 4 – ON configure for 1/2-slot addressing*

6 and 7 as required for your application

Important:

switches 4 and 5 for 1/2-slot addressing or 1-slot addressing. If not configured as 1/2- or 1-slot addressing, a PLC-5

processor fault will occur

I/O Chassis Switch Settings for Local Chassis

1 OFF – to turn off outputs in the chassis when a fault is detected.

5 – OFF configure for 1/2-slot addressing*

8 as required for your application

*

The

1785-BCM module appears to the PLC-5 processor as a 32-point input module. Y

. If you are installing a 1785-BEM module, you must select 1/2-slot addressing.

ou must configure

Terminating the Data Highway Plus and Remote I/O Links

3-4

If your processor is an end device on the Data Highway Plus or remote I/O

link, a terminator must be connected to the processor. In the PLC-5

backup system, you should set each PLC-5 processor in the backup system

as if the other PLC-5 processor does not exist and no 1785-BCM modules

are present. Terminate both links (DH+ and remote I/O):

for a PLC-5/15 or PLC-5/25 processor using switch assembly SW3 on

the PLC-5 processor. See Table 3.C.

for a PLC-5/11, -5/20, -5/30, -5/40, -5/60, or -5/80 processor by

installing an external resistor on the PLC-5 processor. See Table 3.D.

Page 28

T

able 3.C

Terminate

Chapter 3

Installing Your PLC-5 Backup System

PLC-5/15 or -5/25 Backup System DH+ and Remote I/O Links

Installing the 1785-BCM Module

Set SW3

switch

1 ON – indicating that the PLC-5 processor is on the end of the remote I/O link

1 OFF – indicated that PLC-5 processor is not on the end of the remote I/O link

2 ON – indicating that PLC-5 processor is on the end of the DH+ link

2 OFF – indicating that PLC-5 processor is not on the end of the DH+ link

T

able 3.D

Terminate

and Remote I/O Links

For this kbaud: Install this terminating resistor:

57.6 or 115.2

1

230.4

1

Refer to the Enhanced and Ethernet PLC-5 Programmable Controllers User

Manual to install the terminating resistor.

To this position:

PLC-5/1

1

1, -5/20, -5/30, -5/40, -5/60, or -5/80 Backup System DH+

150 ohm, 1/2 watt resistor

82 ohm

To install the 1785-BCM module, you:

key the I/O chassis

set the switches of the module

insert the module into the chassis

Electrostatic Discharge Damage

ATTENTION: Under some conditions, electrostatic discharge

can degrade performance or damage the module. Observe the

following precautions to guard against electrostatic damage.

Wear an approved grounded wrist strap or touch a grounded object to

discharge potential before handling the module.

Do not touch the backplane connector or connector pins.

If

you configure or replace internal components, do not touch other circuit

components

When not in use, keep the module in a static-shielded bag.

inside the module. If available, use a static-free work station.

3-5

Page 29

Chapter 3

Installing Your PLC-5 Backup System

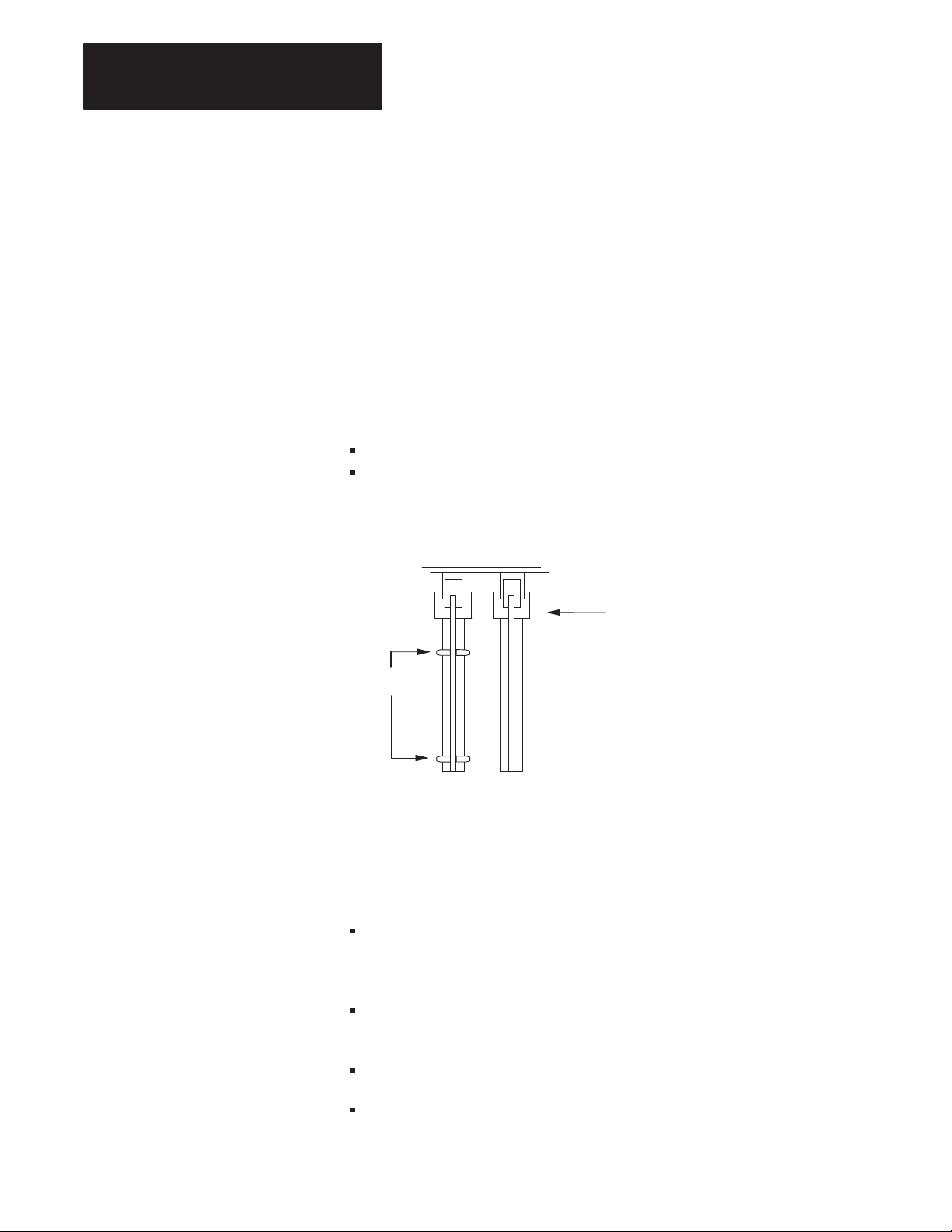

Keying Your I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, to key the

chassis slot to accept only the 1785-BCM module.

The module circuit board is slotted in two places on the rear edge. The

position of the keying bands on the backplane connector must correspond

to these slots to allow insertion of the module. You can key any connector

in an I/O chassis to receive this module except for the left-most connector

reserved for the processor modules.

Place keying bands between the following numbers labeled on the

backplane connector (Figure 3.2):

Between 8 and 10

Between 34 and 36

Figure 3.2

Keying

Positions

Backplane Connectors

11052I

Keying bands

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

Setting the 1785-BCM Series B Switch Assemblies

The switch assembly SW1, located at the top of the 1785-BCM module,

has four switches as shown in Figure 3.3. Refer to Table 3.E for

instructions on setting the four switches. The functions of the four switches

are:

Switch 1 indicates to the 1785-BCM series B module whether the other

1785-BCM module is a series A or a series B module. If it is a series A

module, functions of switches 2 through 4 will not apply.

3-6

Switch 2 selects the Fast Data-Transfer mode from the secondary

module to the secondary processor (1785-BCM series B module only).

Switch 3 is not used.

Switch 4 is not used.

Page 30

Chapter 3

Installing Your PLC-5 Backup System

The 1785-BCM series B module switch assembly SW1 is preset at the

factory to operate:

with another 1785-BCM series B module

in the Fast Data-Transfer mode. Fast data-transfer mode means that

when the secondary module receives a data block, it immediately

enables it to be read by the secondary processor.

Figure 3.3

1785-BCM

Series B Switch Assembly SW1

Switch Assembly SW1

Toggle pushed

toward top

OFF (open).

Top View

T

able 3.E

Setting 1785-BCM Series B SW1 Switches

When: Set this switch: To this position:

the other 1785-BCM module is a series A 1

1

1

2

ON (closed)

OFF (opened)

OFF (opened)

OFF (opened)

OFF (opened)

ON (closed)

ON (closed)

OFF (opened)

ON (closed)

Toggle pushed

toward bottom

ON (closed).

19085

OFF (opened)

the other 1785-BCM module is a series B 1 OFF (opened)

you want fast data transfer 2

you want the secondary BCM module to enable

BTRs to the secondary PLC-5 processor only

when all blocks of a multi-block segment have

been received

2

2

2

ON (closed)

OFF (opened)

3-7

Page 31

Chapter 3

Installing Your PLC-5 Backup System

When: To this position:Set this switch:

switch 3 is always unused 3 OFF (opened)

switch 4 is always unused 4 OFF (opened)

1

To be compatible with 1785-BCM series A modules, you must set these switches as

shown. If you use this module with a series A module and do not set switch assembly

SW2 as shown, the LEDs on the series B module will flash.

2

This switch applies when both modules are 1785-BCM series B modules only.

The switch assembly SW2, located at the bottom of the 1785-BCM

series B module, has six switches. The function of the six switches is to

establish the configuration of Channels 1A and 1B of the module. Refer to

Figure 3.4 for the location of SW2.

Figure 3.4

1785-BCM

Series B Switch Assembly SW2

Switch Assembly SW2

Toggle pushed

toward top

OFF (open).

Toggle pushed

toward bottom

Bottom View

ON (closed).

Switches 1, 2, and 3 determine the configuration of Channel 1A. Switches

4, 5, and 6 determine the configuration of Channel 1B. These channels can

be configured for Data Highway Plus or Remote I/O mode, either with the

PLC-5 processor operating in adapter mode or in scanner mode.

The 1785-BCM series B module is shipped with Channel 1A configured

for Data Highway Plus and Channel 1B configured for Remote I/O ( to be

used with a processor in scanner mode set at 57.6 kbaud).

Refer to Table 3.F to configure Channels 1A and 1B using switch assembly

SW2 switches.

19086

3-8

Page 32

T

able 3.F

Configuring

Chapter 3

Installing Your PLC-5 Backup System

1785-BCM Series B Channels 1A and 1B using SW2

Configure Channel 1A switches

Configure Channel 1B switches

for:

Data Highway Plus network at 57.6 kbaud (refer to Chapter 5, section

“Secondary Processor Remote Programming”)

Remote I/O – adapter mode using 57.6 kbaud ON ON OFF

Remote I/O – adapter mode using 115.2 kbaud ON OFF ON

Remote I/O – adapter mode using 230.4 kbaud ON OFF OFF

Relay switching or unused Channel

Remote I/O – scanner mode with 57.6 kbaud OFF ON OFF

Remote I/O – scanner mode with 115.2 kbaud OFF OFF ON

Remote I/O – scanner mode with 230.4 kbaud OFF OFF OFF

1

Switches 1, 2, and 3 determine configuration for Channel 1A.

2

Switches 4, 5, and 6 determine configuration for Channel 1B.

3

Does not function as a smart switch but as a relay with contacts either opened or closed. Also, set

the switches in this configuration if you are not going to use this channel.

3

1

2

1

4

ON ON ON

OFF ON ON

2

5

3

6

Important: The positions of the switches are read at the module power-up.

If the position of the switches is changed after module power-up, the

1785-BCM module does not recognize the new position.

Inserting the 1785-BCM Module into the I/O Chassis

To insert the 1785-BCM module in your I/O chassis, perform the following

steps. We recommend that you insert your 1785-BCM module into the

left-most slot of the first I/O module group in the I/O chassis.

ATTENTION: Remove power from the 1771 I/O chassis

backplane and wiring arm before removing or installing an I/O

module.

Failure to remove power from the backplane or wiring arm

could cause module damage, degradation of performance, or

injury.

Failure

or equipment damage due to possible unexpected operation.

to remove power from the backplane

could cause injury

3-9

Page 33

Chapter 3

Installing Your PLC-5 Backup System

1. Turn off power to the I/O chassis.

2. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

3. Do not force the module into its backplane connector. Apply firm,

even pressure on the module to seat it properly.

4. Snap the chassis latch over the top of the module to secure its

position.

5. Connect the wiring arm to the module.

6. Make wiring connections to the wiring arm as indicated in the next

sections.

Connecting Your PLC-5 Backup System

To connect your PLC-5 backup system, you:

connect the 1785-BCM modules

make remote I/O connections

make Data Highway Plus network connections

You make the connections to the 1785-BCM module’s wiring arm

(cat. no. 1771-WG). Figure 3.5 shows an overview of the connections.

Important: Note that the connections described in the following

paragraphs refer to the 1785-BCM module default configuration, that is

Channel 1A is configured for Data Highway Plus and Channel 1B is

configured for Remote I/O scanner mode.

3-10

Page 34

Figure 3.5

assis B

1785-BCM

Chapter 3

Installing Your PLC-5 Backup System

Module Connections

Ch 1A

1

SH

2

RIO/DH+

Ch 1B

DH+/RIO

Clear

Shield

Blue

Clear

Shield

Blue

Clear

Shield

Blue

Blue

Shield

Clear

Chassis A

1

2

3

9

10

11

12

13

14

15

16

17

Blue

Shield

Clear

Clear

Shield

Blue

Blue

Shield

Clear

HSSL

Ch 1A

1

SH

2

Ch 1B

Clear

Shield

Blue

Blue

Shield

Clear

Clear

Shield

Blue

Clear

Shield

Blue

Blue

Shield

Clear

Ch

10

12

14

11

13

15

16

1

2

3

17

9

Clear

Shield

Blue

*

Replace this with a

terminator if this node is

at the end of this

physical link.

Blue

Shield

Clear

*

*

1

SH

2

PLC-5/40

Blue

Shield

Clear

Blue

Shield

Clear

18

19

20

1785-BCM

Series B

1

SH

2

PLC-5/40

Blue

Shield

Clear

Blue

Shield

Clear

18

19

20

1785-BCM

Series B

3-11

Page 35

Chapter 3

Installing Your PLC-5 Backup System

Local I/O Chassis Local I/O Chassis

Connecting the 1785-BCM Modules

Connect the High Speed Serial Link (HSSL) to establish communication

between the 1785-BCM modules of the primary system and the secondary

system. The cable for these connections can be a maximum of 15 feet. To

do this, connect a 1770-CD or Belden 9463 cable to terminals 1, 2, and 3

on the wiring arm of each 1785-BCM module as shown in Figure 3.6.

Figure 3.6

1785-BCM

Module Connections for High-Speed Serial Link

1785-BCM module

PLC-5 processor PLC-5 processor

1771-P4S

power supply

High Speed Serial Link (HSSL)

1770-CD Cable or Belden 9463

(15 feet maximum)

Blue

Shield

Clear

1785-BCM module

1771-P4S

power supply

Blue

Shield

Clear

Connections show default configuration with Channel 1A as Data Highway Plus

and Channel 1B as Remote I/O Scanner.

ATTENTION: The 1785-BCM series B module communicates

with the 1785-BCM series A module only if switch 1 of the

SW1 switch assembly is set to ON and if SW2 switch assembly

is properly configured.

3-12

17980

Page 36

Chapter 3

Installing Your PLC-5 Backup System

Making Remote I/O Connections

Figure 3.7 shows Channel 1B configured to establish communication with

the remote I/O scanner mode (default configuration). The connections you

must make for your PLC-5 backup system are between the:

PLC-5 and the 1785-BCM module

two 1785-BCM modules

1785-BCM module and Remote I/O Adapter module

Steps to make these connections follow the figure.

Figure 3.7

Remote

I/O Connections

Local I/O ChassisLocal I/O Chassis

1785 –BCM Module

PLC-5 processor PLC-5 processor

Remote

I/O

Remote

I/O

1771 –P4S

Power Supply

Remote I/O

Remote I/O Chassis No. 1 Remote I/O Chassis No. n

1785 –BCM Module

1771 –P4S

Power Supply

Remote

I/O

Connections show default configuration with Channel 1A as Data Highway Plus and

Channel 1B as Remote I/O Scanner.

HSSL was previously connected but is not shown for clarity.

Make all connections with 1770-CD cable.

17981

3-13

Page 37

Chapter 3

Local I/

assis Local I/

assis

Installing Your PLC-5 Backup System

1. Connect one end of a 1770-CD cable to the REM I/O connector on

one of the PLC-5 programmable controllers as shown in Figure 3.8.

Figure 3.8

Remote

I/O Connections Added Between PLC-5 and 1785-BCM Module

PLC-5 processor

O Ch

1785-BCM module

1771-P4S

power supply

Remote I/O

PLC-5 processor

O Ch

1785-BCM module

1771-P4S

power supply

Remote I/O

Blue

Shield

Clear

Blue

Shield

Clear

HSSL was previously connected but is not shown for clarity.

Connections show default configuration with Channel 1A as Data Highway Plus and Channel 1B as Remote I/O scanner.

2. Connect the other end of the 1770-CD cable to terminals 18, 19, and

20 on the wiring arm of the 1785-BCM module in the same chassis as

shown in Figure 3.8.

3-14

17982

Page 38

Chapter 3

Local I/

assis

Local I/

assis

Installing Your PLC-5 Backup System

3. Perform steps 1 and 2 for the other PLC-5 programmable controller

and 1785-BCM module.

4. Connect a 1770-CD cable to terminals 15, 16, and 17 on each of the

1785-BCM wiring arms as shown in Figure 3.9.

Figure 3.9

Remote

I/O Connections Added Between 1785-BCM Modules

O Ch

1785-BCM Moddule

PLC-5 processor PLC-5 processor

Blue

Shield

1771-P4S

power supply

O Ch

1785-BCM Moddule

1771-P4S

power supply

Blue

Clear

HSSL was previously connected but is not shown for clarity.

Connections show default configuration with Channel 1A as Data Highway Plus and Channel 1B as Remote I/O scanner.

5. Connect one end of a 1770-CD cable to terminals 15, 16, and 17 on

the wiring arm of one of the 1785-BCM modules as shown in

Figure 3.10.

Shield

Clear

17983

3-15

Page 39

Chapter 3

Installing Your PLC-5 Backup System

Figure 3.10

Remote

I/O Connections Added Between 1785-BCM Module

and Remote I/O Adapter Module

Local I/O ChassisLocal I/O Chassis

1785-BCM Module

PLC-5 processor PLC-5 processor

1771-ASB Remote

Adapter Module

15

16

17

1771-P4S

power supply

Blue

Shield

Clear

Remote I/O Chassis No. 1

1785-BCM Module

1771-P4S

power supply

1771-ASB Remote

Adapter Module

Remote I/O Chassis No. n

3-16

Blue

Shield

Clear

HSSL was previously connected but is not shown for clarity.

1

2

3

Connections show default configuration with Channel 1A as Data

Highway Plus and Channel 1B as Remote I/O Scanner.

Note that the remote I/O link from the adapters connect to either

1785-BCM module; the remote I/O link does not connect directly to

the processor.

17984

Page 40

Chapter 3

Local I/

assisLocal I/

assis

Installing Your PLC-5 Backup System

6. Connect the other end of the 1770-CD cable to terminals 1, 2, and 3

r

on the wiring arm of the Re

mote I/O Adaptor module as shown in

Figure 3.10.

Making Data Highway Plus Connections

Figure 3.11 shows Channel 1A configured to establish communication

with Data Highway Plus network (default configuration). The connections

you must make for your PLC-5 backup system are between the:

PLC-5 and the 1785-BCM module

two 1785-BCM modules

1785-BCM module and Data Highway Plus network

Steps to make these connections follow the figure.

Figure 3.1

Data

OCh

1785-BCM Module

PLC-5 processor PLC-5 processor

HSSL and Remote I/O link were previously connected but are not

shown for clarity.

1

Highway Plus Connections

1771-P4S

Power Supply

Data Highway Plus

Data Highway Plus Network

OCh

1785-BCM Module

1771-P4S

Power Supply

Connections show default configuration with Channel 1A as Data

Highway Plus and Channel 1B as Remote I/O Scanner.

Make all connections with 1770-CD cable.

17986

3-17

Page 41

Chapter 3

Local I/

assisLocal I/

assis

Installing Your PLC-5 Backup System

1. Connect one end of a 1770-CD cable to the PEER COMM INTFC

connector on one of the PLC-5 programmable controllers, as shown

in Figure 3.12.

Figure 3.12

Data

Highway Plus Connections Added Between PLC-5

and 1785-BCM Module

OCh

1785-BCM Module

PLC-5 processor PLC-5 processor

Data Highway Plus

1771-P4S

Power Supply

Data Highway Plus

OCh

1785-BCM Module

1771-P4S

Power Supply

3-18

Clear

Shield

Blue

Clear

Shield

Blue

HSSL and Remote I/O link were previously connected but are

not shown for clarity.

Connections show default configuration with Channel 1A as Data Highway Plus and

Channel 1B as Remote I/O Scanner.

17985

Page 42

Chapter 3

Installing Your PLC-5 Backup System

2. Connect the other end of the 1770-CD cable to terminals 12, 13, and

14 on the wiring arm of the 1785-BCM module in the same chassis as

shown in Figure 3.12.

3. Perform steps 1 and 2 for the other PLC-5 programmable controller

and 1785-BCM module.

4. Connect a 1770-CD cable to terminals 9, 10, and 11 on the wiring

arm of each 1785-BCM module as shown in Figure 3.13.

Figure 3.13

Data

Highway Plus Connections Added Between 1785-BCM Modules

Local I/O Ch assisLocal I/O Cha ssis

1785-BCM Module

PLC-5 processor PLC-5 processor

9

1771-P4S

Power Supply

Data Highway Plus

Clear

9

1785-BCM Module

1771-P4S

Power Supply

Clear

10

11

Shield

Blue

HSSL and Remote I/O link were previously connected but are

not shown for clarity.

Connections show default configuration with Channel 1A as Data

Highway Plus and Channel 1B as Remote I/O Scanner.

10

11

Shield

Blue

17987

3-19

Page 43

Chapter 3

Local I/

assisLocal I/

assis

Installing Your PLC-5 Backup System

5. Connect the 1770-CD cable from the Data Highway Plus network to

9, 10, and 11 on the wiring arm of one of the 1785-BCM modules as

shown in Figure 3.14.

Figure 3.14

Data

Highway Plus Connections Added Between 1785-BCM Module and

Data Highway Plus Network

OCh

1785-BCM Module

PLC-5 processor PLC-5 processor

9

10

11

1771-P4S

Power Supply

Clear

S h ield

Blue

Data Highway Plus

Data Highway Plus Network

HSSL and Remote I/O link were previously connected but are

not shown for clarity.

Connections show default configuration with Channel 1A as Data

Highway Plus and Channel 1B as Remote I/O Scanner.

OCh

1785-BCM Module

1771-P4S

Power Supply

What to Do Next

3-20

Note that the Data Highway Plus connects to either 1785-BCM

module; it does not connect directly to the processor.

Now that you’ve installed your PLC-5 backup system and made

connections, you are ready to start up your system. Before doing so,

double check all connections against the procedures described in this

chapter. If your backup systems requires the use of a 1785-BEM module,

refer to Chapter 4 for a description of the module and installation

procedures. Chapter 5 describes the operation of the 1785-BCM module

and the backup system and shows procedures for starting up and operating

your system.

Page 44

Chapter

4

Installing Your 1785-BEM Module

Chapter Objectives

Backup Expansion Module

Hardware Components

This chapter:

describes the 1785-BEM backup expansion module

identifies major components of the 1785-BEM module

provides an overview of an installed PLC-5/40, -5/60, or -5/80

backup system

provides procedures for determining power supply requirements

provides procedures for installing your 1785-BEM modules

provides procedures for connecting the 1785-BEM modules in the

PLC-5 backup system

The 1785-BEM is the backup expansion module for the 1785-BCM

series B module. It has the capability of switching two additional

configurable communication channels when you are using a 1785-BCM

series B module with a PLC-5/40, -5/60, or PLC-5/80 processor.

The major components of a 1785-BEM module are:

status indicators

1771-WG wiring arm

1785-BEM communication links

- Data Highway Plus (DH+)

- remote I/O (RIO)

customer relay (contact)

switch assembly

I/O backplane interface

4-1

Page 45

Chapter 4

Installing Your 1785-BEM Module

Status Indicators

The 1785-BEM module has two status indicators on the front panel of the

module (Figure 4.1).

Figure 4.1

1785-BEM

Module Status Indicators

BACKUP

EXPANSION

Run

Fault

19087

RUN (green) indicator is on to show normal operation of the 1785-BEM

module.

FLT (red) indicator is on when a hardware fault is detected in the

1785-BEM module.

Note that these indicators light at power up or when a hardware fault

occurs in the 1785-BEM module.

ATTENTION: If the RUN indicator is blinking on the

secondary 1785-BEM module, it means that there is a switch

setting error. Note that switches of switch assembly SW2 must

be in the same position in both 1785-BEM modules. (If the

blinking RUN indicator goes unnoticed, it could prevent a

switchover.)

4-2

Page 46

Chapter 4

Installing Your 1785-BEM Module

Wiring Arm

You make connections to your communication links with the 1771-WG

wiring arm, which is shipped with the module.

Your wiring arm attaches to the pivot bar on the bottom of the I/O chassis.

It pivots upward and connects with the module so that you can install or

remove the module without disconnecting the wires.

Communication Links

The 1785-BEM module has ports for two communication links that

connect with remote I/O and Data Highway Plus network (Figure 4.2).

In addition, the module has a relay for customer connection.

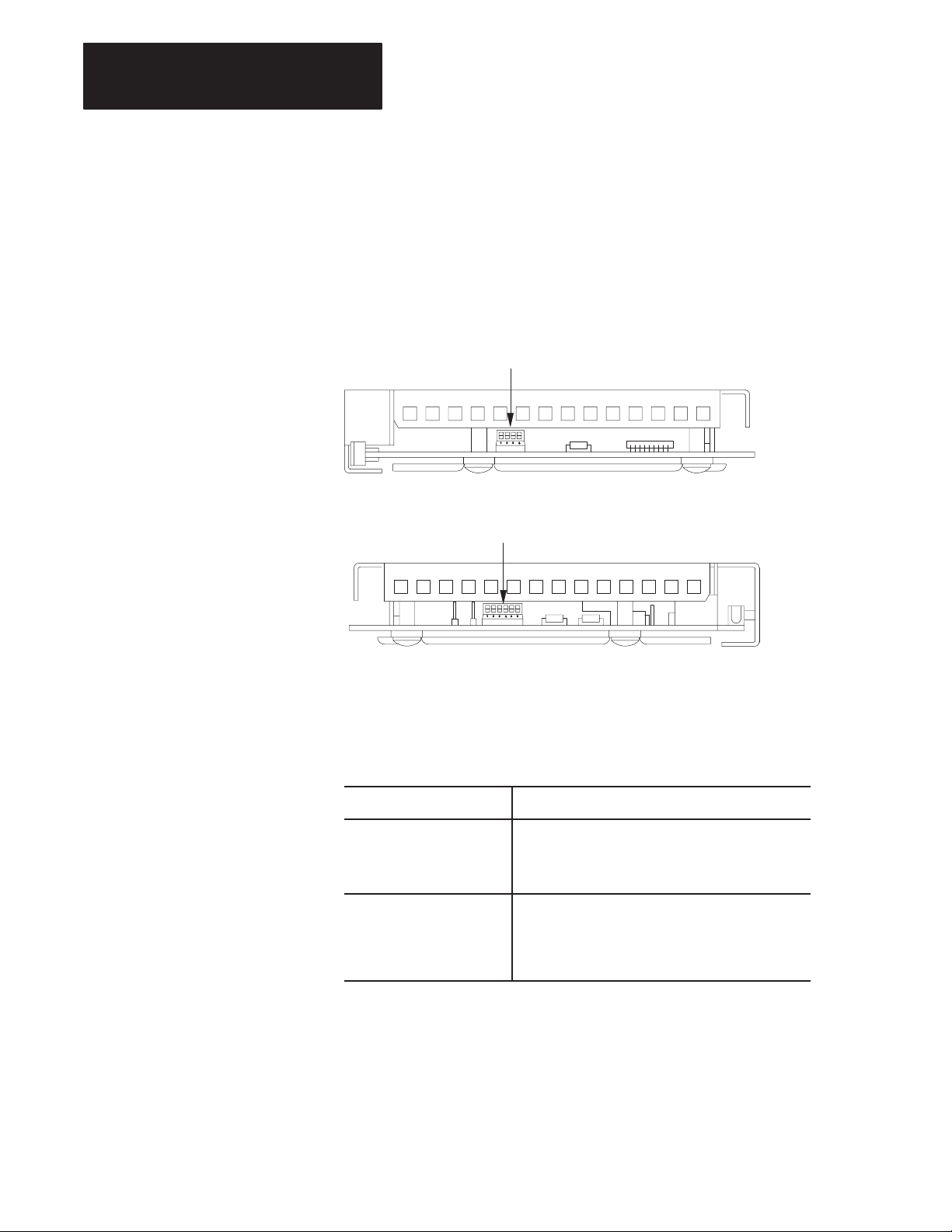

Figure 4.2

1785-BEM

Module Communication Links

Not Used

Customer Relay

Not Used

1

To Link

(RIO/DH+)

From Controller

2

To Link

(RIO/DH+)

From Controller

Not Used

1

Terminals 9, 10, and 11 are connected between the 1785 –BEM modules in the backup system; in addition terminals 9,

10, and 11 of one of the 1785 –BEM modules are connected to the DH+ network or to the Remote I/O link.

2

Terminal 15, 16, and 17 are connected between the 1785 –BEM modules in the backup system; in addition, terminals

15, 16 and 17 of one of the 1785 –BEM modules are connected to the DH+ network or to the Remote I/O link.

2

Channel A

(Remote I/O or

Data Highway Plus)

2

Channel B

(Remote I/O or

Data Highway Plus)

19083

4-3

Page 47

Chapter 4

Installing Your 1785-BEM Module

As shown in Figure 4.2, there are two user-configurable ports (Channels

2A and 2B) that support remote I/O or Data Highway Plus modes.

Table 4.A lists the communication ports and describes how the system uses

each port.

T

able 4.A

Communication

Communication Port This link is used to:

Channel 2A connect the primary PLC-5/40, -5/60, or PLC-5/80 processor to the Data

Channel 2B connect the primary PLC-5/40, -5/60, or PLC-5/80 processor to the Data

Ports

Highway Plus network or to the Remote I/O link; the secondary PLC-5/40

or PLC-5/60 processor is isolated from this link.

Highway Plus network or to the Remote I/O link; the secondary PLC-5/40

or PLC-5/60 processor is isolated from this link.

The 1785-BEM module is shipped with Channel 2A configured for Data

Highway Plus mode and Channel 2B configured for Remote I/O scanner

mode at 57.6 kbaud (default configuration).

Important: Note that I/O, status, and data table communication between

the primary and secondary backup systems is accomplished over the

HSSL, which is connected between the primary and secondary 1785-BCM

modules only. Each 1785-BEM module communicates with the 1785-BCM

series B module, in its same rack, via a secondary backplane bus. Remote

I/O or Data Highway Plus is connected between the primary and secondary

1785-BEM modules through Channels 2A and 2B.

Channels 2A or 2B have an internal relay whose contacts are closed when

the controller is primary and are open when the processor is secondary.

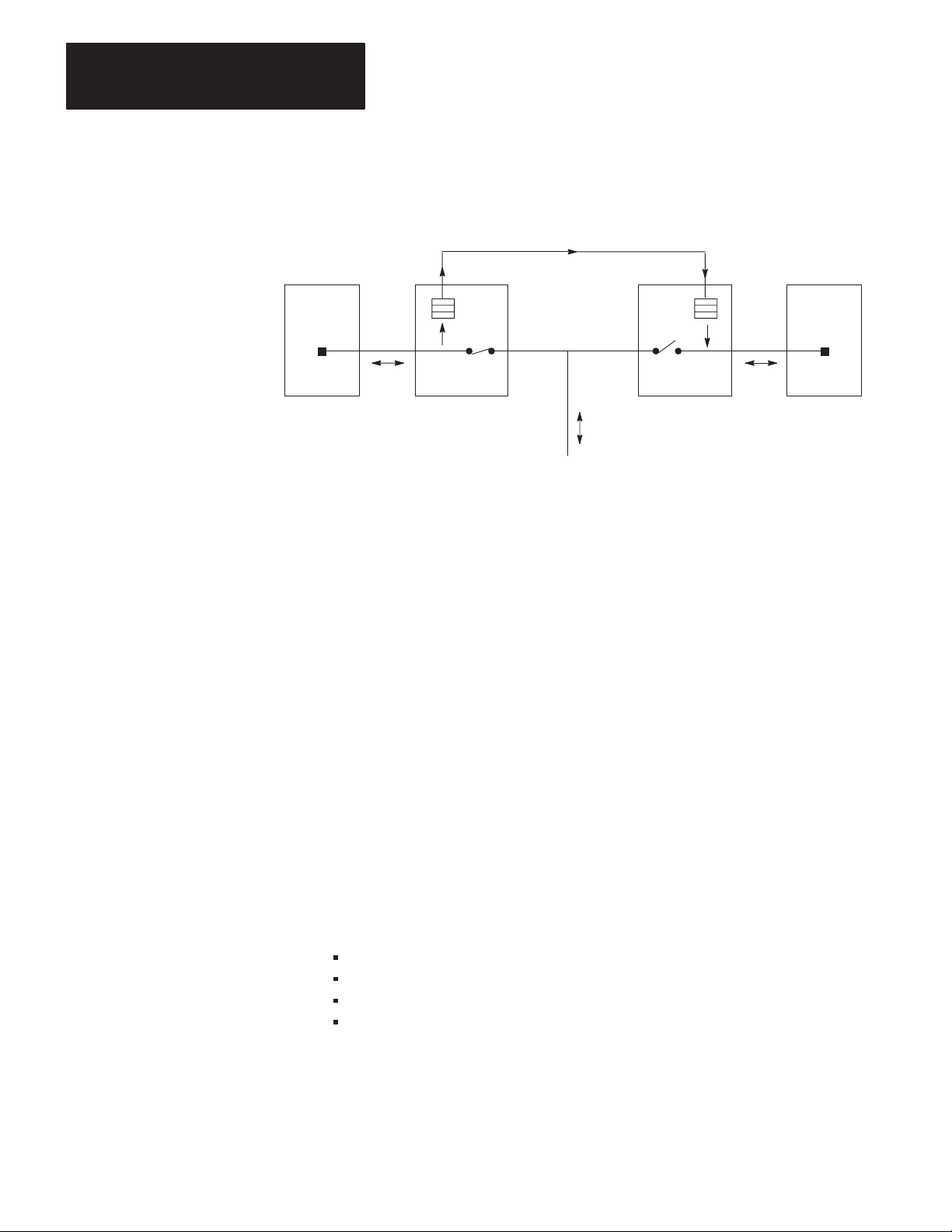

Figure 4.3 shows these relays for processor A and processor B of a PLC-5

backup system.

4-4

Page 48

Figure 4.3

Relays

for Processor A and Processor B

Chapter 4

Installing Your 1785-BEM Module

Processor A (primary)

1785-BCM

PLC-5

2A

2B

1A

1B

Processor A (secondary)

1785-BCM

PLC-5

2A

2B

1A

1B

Processor B (secondary)

1785-BEM 1785-BEM

DH+/RIO

DH+/RIO

Processor B (primary)

1785-BEM 1785-BEM

1785-BCM

PLC-5

2A

2B

1A

1B

1785-BCM

PLC-5

2A

2B

1A

1B

DH+/RIO

DH+/RIO

11679I

Customer Relay

The customer relay connection on the 1785-BEM module is used to switch

external devices. Relay contacts are rated at .25A at 24V DC resistive.

Loads with inductive characteristics will require additional suppression

devices.

4-5

Page 49

Chapter 4

Installing Your 1785-BEM Module

Switch Assembly

The 1785-BEM module has a switch assembly which specifies if Channels

2A and 2B are going to establish communication with Data Highway Plus

network or with the remote I/O link. When the module establishes

communication with the remote I/O link, the switch also determines the

baud rate and the mode of operation of the processor (scanner or adapter).

To set these switches, refer to the section on “Setting the Switch

Assembly.”

I/O Backplane Interface

The 1785-BEM module communicates with the 1785-BCM module

through its connection with the I/O chassis backplane.

Determining Power Supply Requirements

The logic circuit of the 1785-BEM module is driven by the power supply

through the backplane of the I/O chassis. Use the following guidelines to

determine the power supply requirements for your PLC-5 backup system.

1. Add these values to determine output current needed from the power

supply for all the modules in that chassis.

0.6A at 5V for the 1785-BEM module and

1.0A at 5V for the 1785-BCM module and

3.3A for the PLC-5/40 or PLC-5/60 processor

2. Refer to table 3.A, Power Supplies for a PLC-5 Backup System, to

select your power supply.

3. Use separate power sources for the primary and secondary

processors. Connect the power supplies through different power

sources to take precautions against interruptions and incoming power

failures.

4-6

Page 50

Chapter 4

Installing Your 1785-BEM Module

Installing

Module

the 1785-BEM

The installation procedures for the 1785-BEM backup expansion module

are:

determining power supply requirements

setting the 1785-BEM module switches

keying the I/O chassis

inserting the module into the chassis

ATTENTION: In the backup system, switch 1 of the local I/O

chassis should be in OFF position in order to allow the

switchover when a fault is detected. In remote chassis, this

switch should be positioned at the user’s discretion.

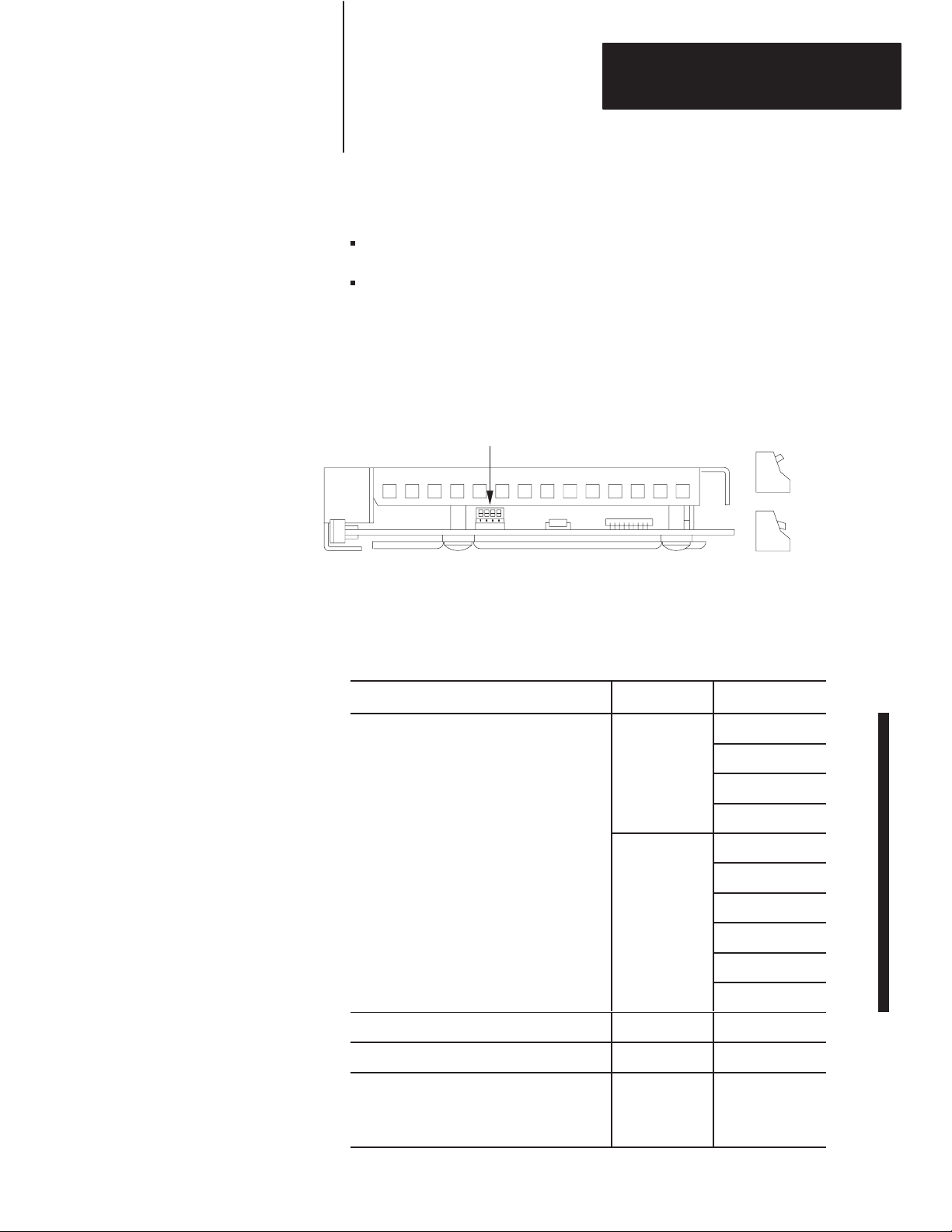

Figure 4.4 shows a typical configuration of a PLC-5 backup system using

the 1785-BEM module. In this system, all of the cable connections

between the primary and backup system require a 1770-CD cable.

Important: Do not install I/O modules for controlling your process in

the local chassis. Only the I/O modules residing in the remote chassis will

be backed up. Local chassis are necessary for housing the processor,

1785-BEM module, 1785-BCM module, and power supply for the backup

system.

4-7

Page 51

Chapter 4

Installing Your 1785-BEM Module

Figure 4.4

PLC-5

Backup System Configuration (using a 1785-BEM module)

1785-BCM module 1785-BEM module1785-BCM module 1785-BEM module

PLC-5/40 or -5/60 PLC-5/40 or -5/60

1771-P4S

Power Supply

Local I/O ChassisLocal I/O Chassis

1771-P4S

Power Supply

Remote

I/O

(BEM

module)

HSSL

BCM DH+ or RIO

BEM DH+ or RIO

BEM RIO

BCM DH+ or RIO

Remote I/O Chassis No. 1

Do not put modules

for controlling your

process in local I/O

chassis.

DH+ or RIO (BEM module)

Remote I/O Chassis No. n

4-8

HSSL connects between the two 1785-BCM modules only.

DH+ or RIO (BCM module)

DH+ or RIO (BCM module)

19088

Page 52

Chapter 4

Installing Your 1785-BEM Module

Electrostatic Discharge Damage

ATTENTION: Under some conditions, electrostatic discharge

can degrade performance or damage the module. Observe the

following precautions to guard against electrostatic damage.

Wear an approved grounded wrist strap or touch a grounded object to

discharge potential before handling the module.

Do not touch the backplane connector or connector pins.

If you configure or replace internal components, do not touch other

circuit components inside the module. If available, use a static-free

work station.

When not in use, keep the module in a static-shielded bag.

Keying the I/O Chassis

Use the plastic keying bands, shipped with each I/O chassis, to key the

chassis slot to accept only the 1785-BEM module.

The module circuit board is slotted in two places on the rear edge. The

position of the keying bands on the backplane connector must correspond

to these slots to allow insertion of the module. You can key any connector

in an I/O chassis to receive this module except for the left-most connector

which is reserved for processor modules. Place keying bands between the

following numbers that are labeled on the backplane connector

(Figure 4.5).

Figure 4.5

Keying

Positions

2

4

6

8

10

12

14

Keying bands

16

18

20

22

24

26

28

30

32

34

36

11680I

4-9

Page 53

Chapter 4

Installing Your 1785-BEM Module

Setting the 1785-BEM Module Switch Assembly

Switch assembly SW2, located at the bottom of the 1785-BEM module,

has six switches. The function of the six switches is to establish the

configuration of Channels 2A and 2B of the module. Figure 4.6 shows the

location of SW2.

Figure 4.6

Switch

Assembly SW2

Switch Assembly SW2

Toggle pushed

toward top

OFF (open).

Toggle pushed

toward bottom

Bottom View

ON (closed).

Switches 1, 2, and 3 determine the configuration of Channel 2A. Switches

4, 5, and 6 determine the configuration of Channel 2B.

These channels can be configured for Data Highway Plus (DH+) or for

Remote I/O (RIO) mode with the PLC-5 processor operating either in

adapter mode or in scanner mode.

The 1785-BEM module is shipped with Channel 2A configured for Data

Highway Plus (DH+) and Channel 2B configured for Remote I/O (RIO)

with the processor in scanner mode at 57.6 kbaud.

Refer to Table 4.B to configure Channels 2A and 2B using switch

assembly SW2 switches.

19086

4-10

Page 54

T

able 4.B

Configuring

Chapter 4

Installing Your 1785-BEM Module

Channels 2A and 2B

Configure Channel 2A switches

Configure Channel 2B switches

for:

Data Highway Plus network ON ON ON

Remote I/O – adapter mode using 57.6 kbaud ON ON OFF

Remote I/O – adapter mode using 115.2 kbaud ON OFF ON

Remote I/O – adapter mode using 230.4 kbaud ON OFF OFF

Relay switching or unused Channel

Remote I/O – scanner mode with 57.6 kbaud OFF ON OFF

Remote I/O – scanner mode with 115.2 kbaud OFF OFF ON

Remote I/O – scanner mode with 230.4 kbaud OFF OFF OFF

1

Switches 1, 2, and 3 determine configuration for Channel 2A.

2

Switches 4, 5, and 6 determine configuration for Channel 2B.

3

Does not function as a smart switch but as a relay with contacts either opened or closed. Also, set

the switches in this configuration if you are not going to use this channel.

3

1

2

1

4

OFF ON ON

2

5

3

6

Important: The positions of the switches are read at module power-up. If

the position of the switches is changed after module power-up, the

1785-BEM module will not recognize the new position.

Inserting the 1785-BEM Module into the I/O Chassis

To insert the 1785-BEM module in your I/O chassis, perform the following

steps. We recommend that you insert you 1785-BEM module into the

right-most slot of the first I/O module group in the I/O chassis. The

1785-BEM module must be in the same module group (as defined by

2-slot addressing) with the 1785-BCM module.

ATTENTION: Remove power from the 1771 I/O chassis

backplane and wiring arm before removing or installing an I/O

module.

- Failure to remove power from the backplane or wiring arm could

cause module damage, degradation of performance, or injury.

- Failure to remove power from the backplane could cause injury or