Page 1

Installation Instructions

17

ControlNet Scanner Card

Catalog Number 1784-KTCS

To the Installer

This document describes how to install and use the 1784-KTCS ControlNet

scanner card.

Topic Page

Introducing the KTCS Card

Understanding the Application Software 3

Compliance to European Union Directives 3

Configuring the Card Hardware 5

Selecting the Base Memory Address Location 6

Selecting the Base I/O Space Address Location 9

Setting the Jumpers 14

Installing the Card 15

Installing IOLinx Software 16

Running the Installation Check Wizard 19

Connecting the Card 21

Connecting Another Device to ControlNet Through the NAP 23

Connecting the Card Directly to the ControlNet Network 26

Interpreting the Status Indicators 26

Removing IOLinx Software 28

CSA Hazardous Location Approval 29

Specifications 31

Publication 1784-5.35 – April 1999

2

Page 2

2 ControlNet Scanner Card

If you are connecting the card directly to a ControlNet network, you also need to

read:

• ControlNet Tap Installation Instructions, publication 1786-5.7

• ControlNet Cable Planning and Installation Manual, publication 1786-6.2.1

Important

Because

for the application and use of this control equipment must satisfy themselves that all necessary

steps have been taken to assure that each application and use meets all performance and

safety requirements, including any applicable laws, regulations, codes and standards.

The illustrations, charts, sample programs and layout examples shown in this guide are intended

solely for purposes of example. Since there are many variables and requirements associated with

any particular installation, Allen-Bradley does not assume responsibility or liability (to include

intellectual property liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the Application, Installation, and Maintenance

of Solid State Control

dif

ferences between solid-state equipment and electromechanical devices that should be taken into

consideration when applying products such as those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or in part, without written

permission of Allen-Bradley Company, Inc., is prohibited.

Throughout this document we use notes to make you aware of safety considerations:

!

Attention statements help you to:

Important:

of the product.

User Information

of the variety of uses for the products described in this publication, those responsible

(available from your local Allen-Bradley of

ATTENTION:

personal injury or death, property damage or economic loss.

S

identify a hazard

S

avoid the hazard

S

recognize the consequences

Identifies information that is critical for successful application and understanding

Identifies information about practices or circumstances that can lead to

fice), describes some important

Introducing the 1784-KTCS Communication Interface Card

The KTCS Communication Interface card lets a 16-bit ISA- or 32-bit EISAcompatible computer communicate directly with other ControlNet products.

Publication

1784-5.35 – April 1999

Page 3

ControlNet Scanner Card 3

Understanding the Application Software

The Allen-Bradley standard application programming interfaces (APIs) are

INTERCHANGE, WINtelligent LINX, IOLinx, and RSLinxsoftware from

Rockwell Software, Inc. Contact your local Rockwell Automation sales

representative or distributor for further information.

Compliance to European Union Directives

If this product bears the

European Union and EEA regions. It has been designed and tested to meet the

following directives.

marking, it is approved for installation within the

EMC Directive

This product is tested to meet Council Directive 89/336/EEC Electromagnetic

Compatibility (EMC) and the following standards, in whole or in part,

documented in a technical construction file:

• EN 50081-2EMC - Generic Emission Standard, Part 2 - Industrial Environment

• EN 50082-2EMC - Generic Immunity Standard, Part 2 - Industrial Environment

This product is intended for use in an industrial environment.

Low Voltage Directive

This product is tested to meet Council Directive 73/23/EEC Low Voltage, by

applying the safety requirements of EN 61131-2 Programmable Controllers,

Part 2 - Equipment Requirements and Tests.

For specific information required by EN 61

the following Allen-Bradley publications:

131-2, see the appropriate sections in

• Industrial Automation Wiring and Grounding Guidelines for Noise Immunity,

publication 1770-4.1

• Automation Systems Catalog, publication B111

Publication

1784-5.35 – April 1999

Page 4

4 ControlNet Scanner Card

ATTENTION:

limits for radio noise emissions from digital apparatus set out in the

Radio Interference Regulations of the Canadian Department of

Communications.

Le présent appareil numérique n’émet pas de bruits radioélectriques

dépassant les limites applicables aux appareils numériques de la class A

prescrites dans le Règlement sur le brouillage radioélectrique édicté par

le ministère des Communications du Canada.

This digital apparatus does not exceed the Class A

Handling the Card

ATTENTION:

sensitive to electrostatic dischar

whenever you are handling the card. Handling a card without any ESD

protection can cause internal circuit damage that may not be apparent

during installation or initial use.

T

ake these precautions to guard against ESD damage:

The card uses CMOS technology

ge (ESD). ESD may be present

, which is highly

• Before handling the card, be sure to touch a grounded object such as a PC’s

metal chassis to dischar

ge any built-up static charge.

• Avoid touching the backplane connector or interface connector pins located

on the card.

• If the card is not in use, store it in the anti-static clamshell that the card was

shipped in.

Important: Remember

grounded object.

You are now ready to configure your card.

Publication

1784-5.35 – April 1999

, a computer with ac power disconnected is

not

a

Page 5

Configuring the Card Hardware

ControlNet Scanner Card 5

Before you install the card, you must set the card’

•

ROM I/O expansion area of the host processor’s system

s physical addresses for the:

memory—enables the card and the host computer to exchange data through

the dual-port interface. This is the base memory address.

•

host processor

commands from the host computer

Y

ou can have as many as four KTCS cards in one computer as long as each card

has dif

ferent base memory and base I/O space addresses.

T

o configure these addresses, you set switches on the card. The card comes

’s I/O map—enables the card’

. This is the

s I/O devices to receive

base I/O space addr

ess.

factory-set with these default addresses:

Address Type Address Setting (hex)

base memory D000:0000

base I/O space memory 220

Important: When

deciding which addresses to use, remember that each card

in your computer must have a unique

base memory address and a

unique base I/O space memory address. If another card in the host

computer is using one or both of the factory-set addresses, you

must change a card’

s switch settings to an available address.

If you are: go to:

changing addresses on the card

using the factory-set addresses “Installing the Card” on page 15

“Selecting the Base Memory Address

Location” on page 6

Publication

1784-5.35 – April 1999

Page 6

6 ControlNet Scanner Card

Selecting the Base Memory Address Location

The host computer and the card exchange data via a dual-port interface. The

dual-port interface is 16 Kbytes long; it begins at the specified base memory

address location.

The card comes set to memory address D000:0000. You may find that this

selected memory address has been allocated to other interface cards or expansion

memory cards you have installed in your computer system. If this occurs,

change the switch settings to an available memory address.

T

o select a new base memory address:

1. Pick an available address from the ROM I/O adapters area of the host

computer’s memory.

Be sure to choose a block that is 16 Kbytes long.

2.

Us W

orksheet A to select a new memory address for the card.

3.

Use W

orksheet B to determine the proper switch settings.

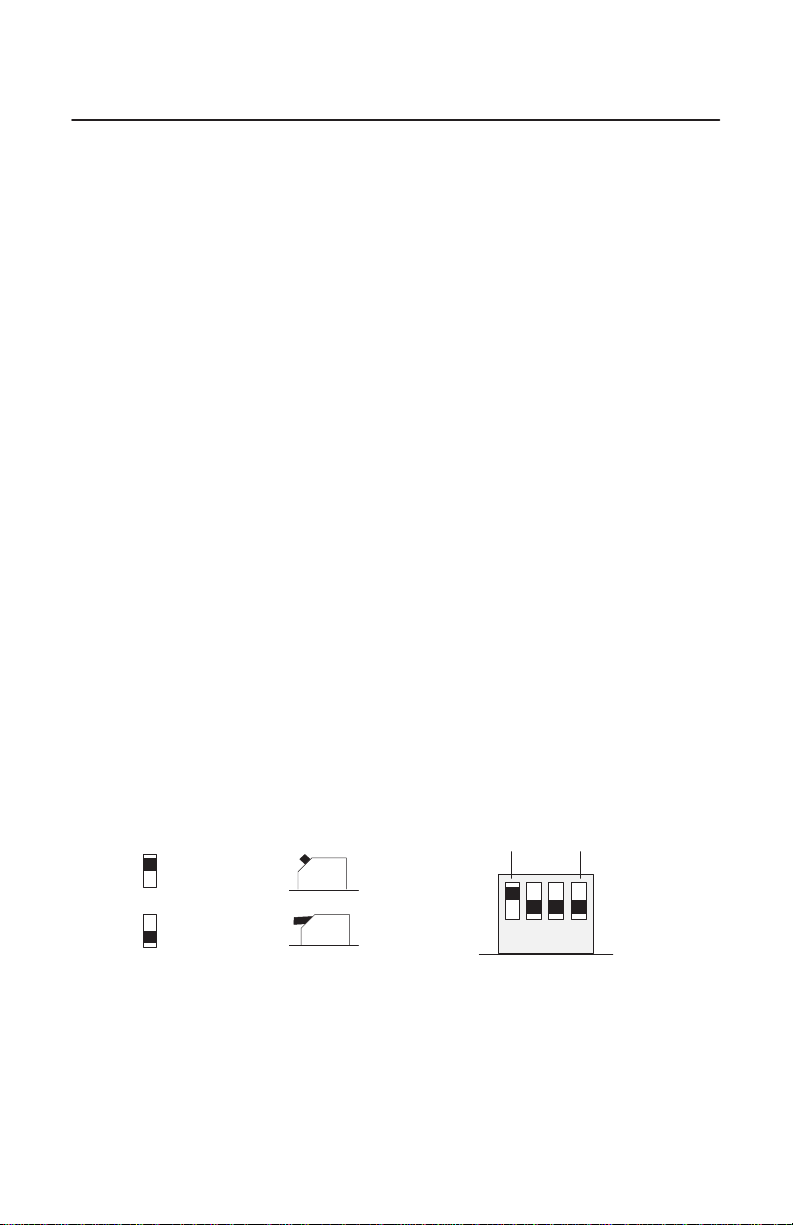

Follow this guide to properly set your switches.

Front View

up (1)

12 123 4

down (0)

MSBLSB

up (1)

down (0)

Side ViewFront View

S2 S1

4. Fill in Worksheet C after you have determined your switch settings.

5. Follow the instructions that begin on page 11.

Publication

1784-5.35 – April 1999

Page 7

W

(area available for

orksheet

Base

A

memory allocation worksheet

ControlNet Scanner Card 7

Base Memory Address

(hex)

0000:0000–7000:FFFF

8000:0000–9000:FFFF

A000:0000– V

A400:0000–

A800:0000–

AC00:0000–

B000:0000–

B400:0000–

B800:0000–

BC00:0000–

C000:0000–

C400:0000–

C800:0000–

CC00:0000–

D000:0000–

Host Computer Assignments Your System

512K Read/Write Memory on

System Board

128K Read/W

Expansion in I/O Channel

ideo Buf

Expansion Card Area

memory addresses)

Factory Default

rite Memory

fer

KTCS

D400:0000–

D800:0000–

DC00:0000–

E000:0000–F000:FFFF

128K ROM Reserved on System

Board

Publication

1784-5.35 – April 1999

Page 8

8 ControlNet Scanner Card

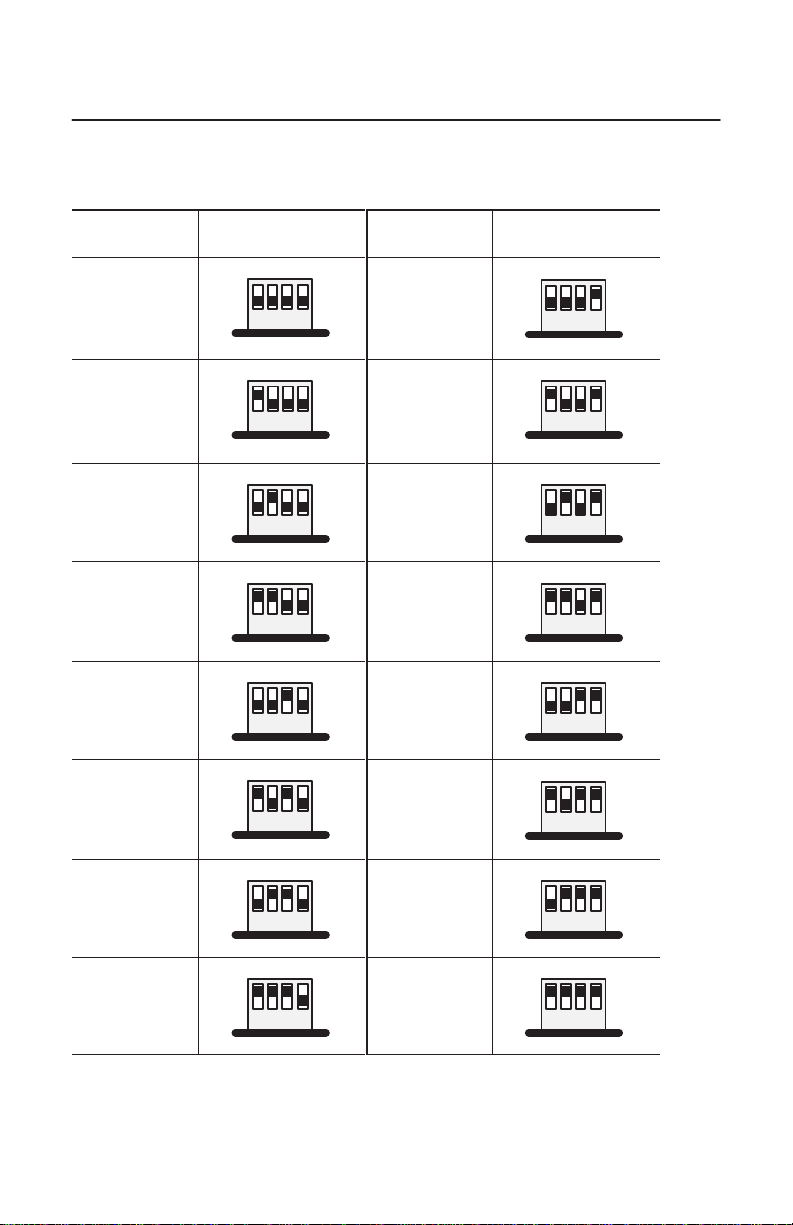

W

orksheet B

KTCS

switch settings

Base Memory Addr

(hex)

C000:0000

C400:0000

C800:0000 up (1)

CC00:0000

W

orksheet C

Your

base memory address

Switch Settings

12 1234

down (0)

12 1234

down (0)

12 1234

down (0)

12 1234

down (0)

up (1)

up (1)

up (1)

Base Memory Addr

(hex)

D000:0000

factory

set default

address &

recommended setting

D400:0000

D800:0000

DC00:0000 up (1)

Switch Settings

up (1)

12 1234

down (0)

up (1)

12 1234

down (0)

up (1)

12 1234

down (0)

12 1234

down (0)

Record the base memory address for the KTCS card:

Card:

Slot number:

Using default address:

yes no

If no, new memory address:

Publication

1784-5.35 – April 1999

up (1)

S2 S1

12 1234

down (0)

Page 9

ControlNet Scanner Card 9

Selecting the Base I/O Space Address Location

The

host addresses I/O devices on the card by using their I/O space addresses.

The host addresses individual devices through registers that have addresses

based on the I/O space base address. The registers are 2 bytes (1 word) long.

The card comes set to base I/O space address 220. Y

ou may find that this

selected address has been allocated to other interface cards or expansion memory

cards you have installed in your computer system. If this occurs, change the

switch settings to an open address.

Important: When selecting configuration settings, check for conflicts with

other interface cards and system memory. If there is a conflict, the

system will not operate properly.

T

o select a new base I/O space address:

1. Pick an available address from the I/O map area of the host computer’s

memory.

Be sure to choose a block that is 2 bytes long.

Important: Each card requires 2 bytes of I/O space.

2.

Use W

orksheet D to select a new base I/O space address for the card

(i.e., to determine the switch settings for the new address).

Follow this guide to properly set your switches:

Side ViewFront View

up (1)

Front View

up (1)

MSBLSB

down (0)

1234

down (0)

S3

3. Fill in Worksheet E after you have determined your switch settings.

4. Follow the instructions that begin on page 11.

Publication

1784-5.35 – April 1999

Page 10

10 ControlNet Scanner Card

W

orksheet D

KTCS

switch settings

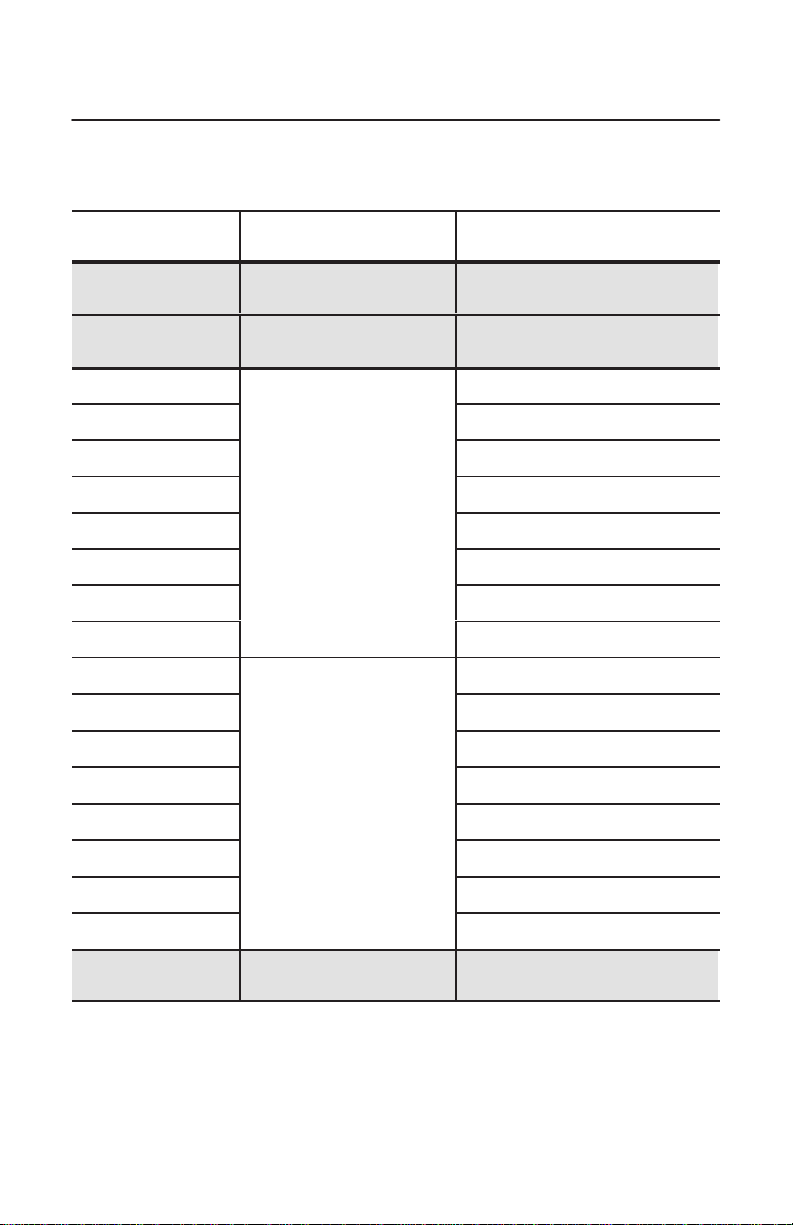

Base

I/O Address

(hex)

200

Switch Settings

up (1)

Base I/O

(hex)

Address

300

Switch Settings

up (1)

potential device

conflict: game port

220

factory-set

default

address &

recommended setting

240

260

280

2A0

2C0

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

potential device

conflict:

prototype cards

320

potential device

conflict: HDD

340

360

380

potential device

conflict: SDLC

3A0

potential device

conflict: SDLC

3C0

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

1234

down (0)

up (1)

potential device

conflict: EGA

2E0

potential device

conflict: GPIB

Publication

1784-5.35 – April 1999

1234

down (0)

up (1)

1234

down (0)

potential device

conflict: EGA

3E0

1234

down (0)

up (1)

1234

down (0)

Page 11

W

orksheet E

Your

base I/O space address

Record the base I/O space address for the KTCS card:

Card:

Slot number:

Using default address:

If no, new I/O space address:

yes no

Setting the Card’s Switches

ControlNet Scanner Card 11

up (1)

S3

1234

down (0)

ATTENTION:

When setting the switches, be sure to avoid touching

other components on the card.

1. Follow the card handling instructions on page 4.

2. Remove the card from the anti-static clamshell.

Important: When selecting configuration settings, check for conflicts with

other interface cards and system memory. If there is a conflict,

the host computer will not operate properly.

You must find a way to disable caching and shadow memory for at least the 16K

of memory space occupied by each card. This can usually be accomplished

through your CMOS setup program and/or memory manager

, and must be done

before running applications with the KTCS cards.

Publication

1784-5.35 – April 1999

Page 12

12 ControlNet Scanner Card

3. If you are using the card’s default memory addr

If you are setting a new base memory address

, set the switches to the up or

down position to reflect the selected address from W

Front of Switches

D000:0000

Factory-set

(recommended setting)

address

up (1)

S2 S1

12 123 4

down (0)

ess setting

orksheet C.

up (1)

down (0)

, go to step 4.

20629–M

Side ViewFront View

Publication

1784-5.35 – April 1999

Page 13

ControlNet Scanner Card 13

4. If you are using the card’s default base I/O space addr

next section, Installing the Card.

If you are setting a

new base I/O space addr

ess

, set the switches to the up or

down position to reflect the selected address from Worksheet E.

Front of Switches

220h

Factory-set

(recommended setting)

address

up (1)

up (1)

S3

1234

down (0)

down (0)

ess setting

, go to the

20629–M

Side ViewFront View

Publication

1784-5.35 – April 1999

Page 14

14 ControlNet Scanner Card

Setting the Jumpers

Important: When you receive your card, the jumpers are in the default

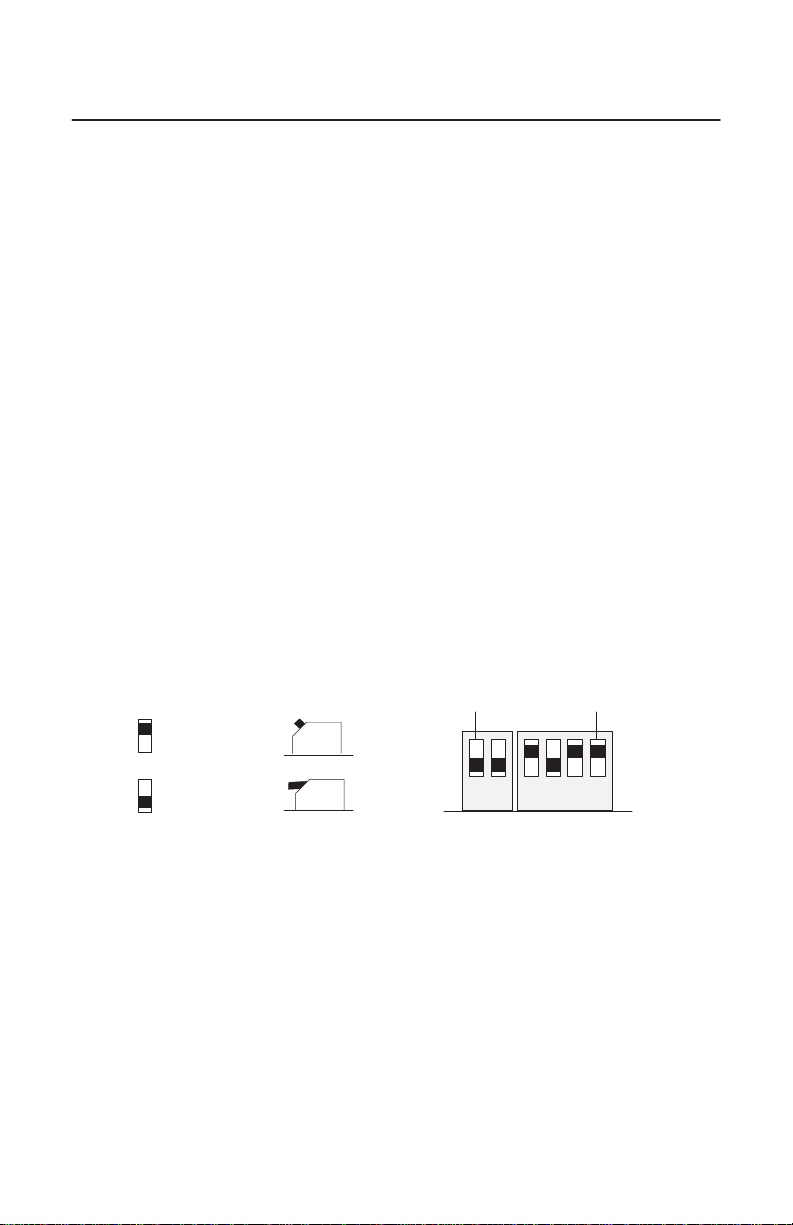

Figure 1

KTCS

jumpers

positions, as shown in Figure 1. Do

See Figure 2 for an explanation of these jumpers.

E2

E1

not

alter these positions.

Figure 2

Jumper Explanations

E2

E1

E2

E1

Publication

Use these jumper positions for:

– normal card operation

– field flash upgrade of the card’s main code

Use these jumper positions for field flash upgrade of the

card’s boot code.

IMPORTANT: All other E1 and E2 jumper combinations are illegal.

Unknown card operation will result.

1784-5.35 – April 1999

E3

20628-M

Page 15

ControlNet Scanner Card 15

Installing the Card

Important: Before you install the card, make sure you know how to configure

the computer’

manager, and shadowing of memory, and that you know how to

install hardware in your computer. Consult your computer’s

documentation for specific information.

To install the card, you need to:

•

access the computer’s expansion slots

You need a Phillips-head or a flat-head screwdriver, depending on your

system.

s options, e.g., disabling cache memory

, memory

• insert the card into the computer

Accessing the Computer’s Expansion Slots

To

install the card, you must access the computer’s expansion slots. Follow

these general steps, or refer to your computer’s user guide for more explicit

instructions.

1. Power down the host computer by turning off the power switch.

2. Remove the computer’

3. Select a vacant 16- or 32-bit expansion slot.

Important: The card will function only in a 16- or 32-bit ISA/EISA

expansion slot.

4.

Remove the slot’

(rear bracket) of the computer.

s cover

.

s expansion cover by loosening the screw on the back

Publication

1784-5.35 – April 1999

Page 16

16 ControlNet Scanner Card

Inserting the Card

To insert the card inside the computer:

1. Follow the card handling instructions on page 4.

2.

Make sure you have correctly set all of the switches on the card.

3. Insert the card into the edge connector and tighten the expansion slot screw.

4. Turn on the computer to make sure it powers up correctly.

If the computer: then:

powers up

does not power up correctly you probably have a memory or I/O conflict

go to step 5

You should

• change switch settings and cycle power, or

• remove all other cards and try again

If you are still unsuccessful, contact your local

Rockwell Automation sales representative or

distributor, or Rockwell Automation Technical

Support at (440) 646-6800.

5. Replace the CPU cover (when computer powers up correctly).

Installing IOLinx Software

Important: IOLinx software requires Microsoft Windows NT 4.0 or later.

Follow these steps to install the IOLinx software.

1.

Insert the CD in the CD-ROM drive.

Important: We strongly recommend that you exit all Windows

programs before running this Setup program.

Publication

1784-5.35 – April 1999

Page 17

ControlNet Scanner Card 17

Note: The CD-ROM will carry the Windows Autorun. Once inserted into

the CD-ROM drive, if you have Autorun configured, the IOLinx software

installation will automatically start at the first setup screen.

If Autorun is not configured, go to step 2.

2. From the Start menu, choose Run.

Y

ou see:

3. T

ype

d:\setup (if it doesn’t appear automatically), where d

is your CD-ROM

drive letter.

4.

Click OK.

Y

ou see the progress bar

, followed by the welcome screen.

5. Select from this decision table.

If you want to click on

continue with this Setup Next

cancel Setup (because you have not

exited other Windows programs)

You see “Enter name, company, and product

serial number.”

Cancel

Close those programs then run Setup again.

Publication

1784-5.35 – April 1999

Page 18

18 ControlNet Scanner Card

6. Enter your name, company, and product serial number.

label

serial number on label

7. Click Next.

Y

ou see the “Choose Destination Location” screen.

8. Select from this decision table.

If you want to click on

install IOLinx in this directory:

C:\Program

install IOLinx in a different directory Browse and select the directory

exit Setup (not install IOLinx) Cancel

You

Publication

Files\Rockwell Automation\IOLinx\ControlNet

see the W

1784-5.35 – April 1999

elcome screen.

Next

The IOLinx installation program

launches the ControlNet Scanner

Configuration Tool (SCT) installation.

Page 19

ControlNet Scanner Card 19

9. Choose

10.

a destination location.

Y

ou see the Setup progress bar

, followed by the “Setup Complete” screen.

Check the checkboxes on the “Setup Complete” screen to choose to view the

Read Me file and/or to launch the IOLinx configuration tool.

The IOLinx configuration applet may be launched at a later time from the

Control Panel (Start➝Settings➝Control Panel).

Important: The configuration applet must be run before IOLinx is

started for the first time.

11. Click Finish to complete Setup.

Running the 1784-KTCS Installation Check Wizard

The installation check wizard is copied to your computer when the IOLinx

software is installed, and appears in your menu (Program Files➝Rockwell

Automation➝IOLinx for ControlNet➝

To make sure you have installed the card properly, run the installation check

wizard. Follow these steps:

1. Launch the 1784-KTCS Installation Wizard.

Check W

izard).

Y

ou see the W

elcome screen. The wizard guides you through a series of

steps to be certain that your 1784-KTCS card is installed correctly.

2.

Click Next to continue.

The wizard prepares to copy the necessary files to your system directory.

3.

Click Next to continue.

The wizard copies the files to your system directory and brings up the Select

I/O Address window.

Publication

1784-5.35 – April 1999

Page 20

20 ControlNet Scanner Card

4. Select

the I/O Base Address for this card.

Refer to Worksheet E on page 11. You

recorded your I/O base address there.

Important:

Make sure that the card is

not

connected to a ControlNet network.

5.

Click Next to continue.

The wizard prepares to locate the card at the I/O address you defined. If you

have installed multiple cards, the check wizard can be run for each card by

entering a different I/O address each time.

6.

Click Next to continue.

The wizard attempts to locate your 1784-KTCS card at the specified I/O

address.

When the wizard locates your card, it displays

Card has been found, and:

DualPort address where the card was found

Bootcode version

serial number

main code version

7.

Click Next to continue.

The wizard attempts to put the KTCS card in the online state.

Important:

Make sure that the KTCS card is

not

connected to a

ControlNet network.

Click Next to continue.

8.

Y

ou see the message:

9.

Click Next to continue.

Y

ou see the message:

Publication

1784-5.35 – April 1999

Going Online.

Online State Reached.

Page 21

10. Click Next to continue.

ControlNet Scanner Card 21

The wizard prepares to reset the card, and reports

LEDs should be alternating green and red. Congratulations, the check wizard

has verified proper configuration of your 1784-KTCS card in your computer.

If the wizard fails, check the I/O base address on the card against the I/O base

address you entered into the wizard. If the check wizard fails and the card I/O

address and wizard address are identical, call Rockwell Automation T

Support at 440-646-6800 for assistance.

Card has been r

eset.

echnical

Connecting the Card

After you have installed the card, you can connect it:

• to a device already connected to the ControlNet network via the 1786-CP

network access port cable (page 23)

Important: This is only a temporary connection. As a permanent

connection, the KTCS card should connect via a

ControlNet tap.

• directly to a ControlNet network via a ControlNet tap (page 26)

Figure 3 shows the card connector.

Publication

1784-5.35 – April 1999

Page 22

22 ControlNet Scanner Card

Figure 3

KTCS

card connector

Diagnostic status

indicators

Redundant media

BNC connectors

A

B

Network Access Port (NAP)

RJ-45 connector for connecting programming

terminals to devices on a ControlNet network

Channel A

BNC connectors for connecting directly to a

ControlNet network

Channel B

1784KTCS

TIP: The light icon is channel A;

the dark icon is channel B.

ATTENTION: Do not use the card to connect to more than one

network at a time. Attempting to connect to a second network will

cause your communication system to operate erratically.

See page 26 for information about status indicators. Indicators diagnose only

redundant media BNC connections.

Important: If you are using a non-redundant cabling system, all ControlNet

devices must be on the same channel, channel

A.

Publication

1784-5.35 – April 1999

Page 23

ControlNet Scanner Card 23

Connecting Another Device to ControlNet

Through the Network Access Port

By using the card’

s RJ-45 connector (known as the network access port or

NAP), you can connect another device, e.g., programming interface such as a

1784-PCC card, to a ControlNet network, without a tap, through a

programmable controller, I/O adapter, or another KTCS card.

The 1786-CP cable (Figure 4) connects a host computer

, such as one with a

1784-KTCS card, to another ControlNet device (Figure 5). The 1786-CP cable

has two RJ-45 8-pin connectors.

Figure 4

1786-CP

cable

RJ-45 8-pin connectors

1786-CP cable

ATTENTION:

Use the

1786-CP

cable when connecting a

programming terminal to the network through the network access port

(NAP); using another cable could result in possible network failures or

product damage.

W

e designed the network access port as only a temporary connection.

For permanent connections, a ControlNet tap, e.g., 1786-TYPR,

-TYPS, should be used.

Publication

1784-5.35 – April 1999

Page 24

24 ControlNet Scanner Card

T

able

A shows the wiring for the cable.

T

able

A

Wiring

for 1786-CP connector cable

Connector 1

Wire Number Signal Mnemonic Signal Name

1 ISO-GND Isolated Ground

2 N.C. No Connection

3 PTTX-H Transmit Data High

4 PTTX-L Transmit Data Low

5 PTRX-L Receive Data Low

6 PTRX-H Receive Data High

7 N.C. No Connection

8 ISO-GND Isolated Ground

Connector 2

Wire Number Signal Mnemonic Signal Name

Publication

1 ISO-GND Isolated Ground

2 N.C. No Connection

3 PTRX-H Receive Data High

4 PTRX-L Receive Data Low

5 PTTX-L Transmit Data Low

6 PTTX-H Transmit Data High

7 N.C. No Connection

8 ISO-GND Isolated Ground

1784-5.35 – April 1999

Page 25

ControlNet Scanner Card 25

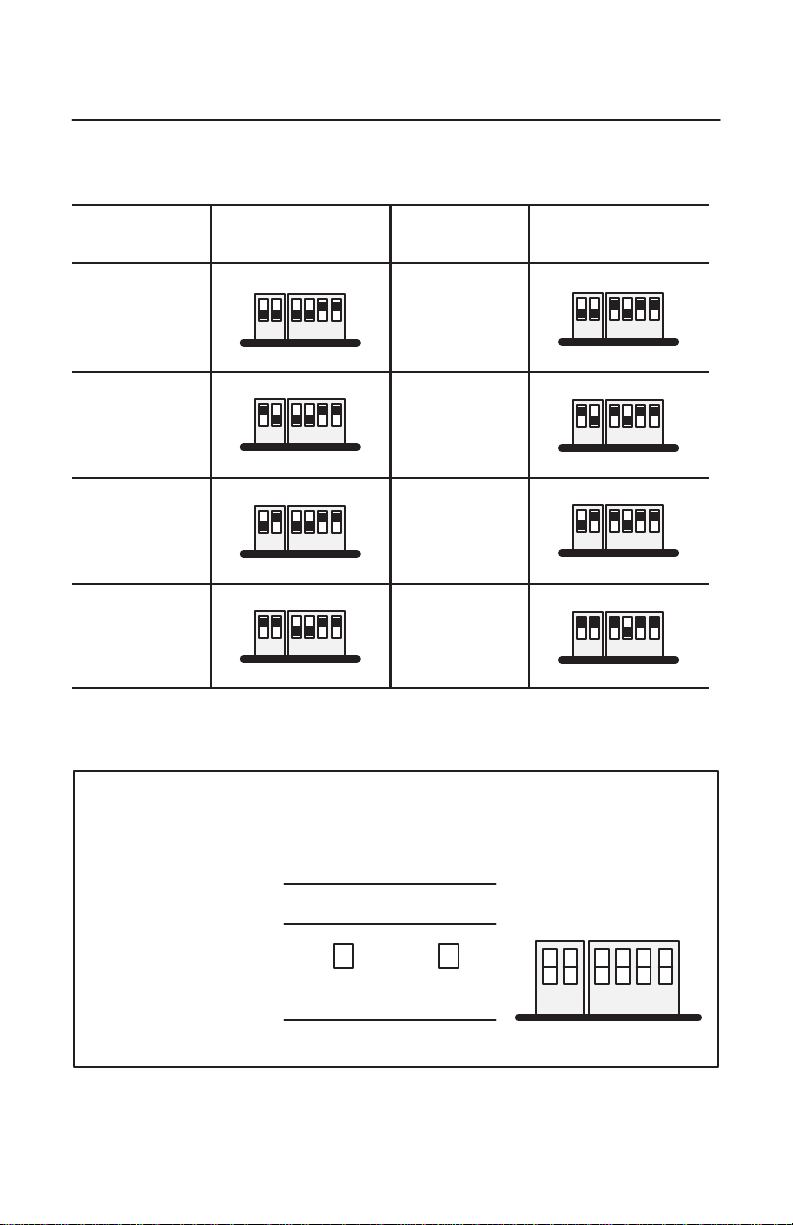

Figure 5

Host

computer connected to ControlNet device via 1786-CP cable

1784–PCC

communication

interface card

1786–CP cable

1784–KTCS

scanner card

Laptop computer

ATTENTION: If you connect the product to a cable system that does

not support or is not using redundant media, connect the tap dropline to

the BNC connector labeled channel A. Channel B is left open.

If the cable system is redundant, connect the product such that all

devices on the network use the same cable for the same channel.

That is, all channel A connectors connect to one cable; all channel B

connectors connect to the other.

Tap

Desktop

computer

Tap

1794–ACN15

Tap

Tap

30433–M

Publication

1784-5.35 – April 1999

Page 26

26 ControlNet Scanner Card

Connecting the Card Directly to the ControlNet Network

To connect the card directly to a ControlNet network as shown in Figure 6,

follow the instructions in these publications:

• ControlNet Tap Installation Instructions, publication 1786-5.7

• ControlNet Cable Planning and Installation Manual, publication 1786-6.2.1

Figure 6

1784-KTCS

card connected directly to a ControlNet network

desktop

host

computer

ControlNet network

1784-KTCS

1786-TPR, -TPS, -TPYR, or -TPYS tap

Channel A

Channel B

Interpreting the Status Indicators on the KTCS

The status indicators on the card give you information about the card and the

network when you’re connected via the BNC connectors. T

states and explains what each state means to you and the action you should take,

if any, to correct that state.

able B outlines the

Publication

1784-5.35 – April 1999

Page 27

T

la ing gr no

able B

ControlNet

ControlNet Scanner Card 27

status interpretation

• steady – indicator

• alternating – the

both indicators

• flashing – the

independent

A B

and

off

steady red

alternating red/green

alternating red/of

A B

or

off

steady green

flashing green/of

flashing red/of

flashing red/green

➀ The

configuration keeper node is the node responsible for distributing ControlNet configuration data to all nodes on the

network.

is on continuously in the defined state.

two indicators alternate between the two defined states at the same time (applies to

viewed together

indicator alternates between the two defined states (applies to each indicator

of the other). If both indicators are flashing, they must flash together

f

f

f

). The two indicators are always in opposite states, out of phase.

, in phase.

Cause: Action:

no power none or power up

faulted unit

self-test none

incorrect node configuration

Cause: Action:

channel disabled

normal operation

temporary errors

node is not configured to go on line

media fault

no other nodes present on network add other nodes to the network

incorrect network configuration

cycle power or reset unit

If fault persists, contact your Rockwell

Automation representative or distributor

check network address and other

ControlNet configuration parameters

program network for redundant media,

if required

none

none; unit will self-correct

make sure the configuration keeper node

is present and working

check media for broken cables, loose

connectors, missing terminators, etc.

cycle power or reset unit

If fault persists, contact your Rockwell

Automation representative or distributor

➀

viewed

.

.

Important: The LEDs do not apply to the network access port (NAP)

connection.

Publication

1784-5.35 – April 1999

Page 28

28 ControlNet Scanner Card

Removing IOLinx Software

Use the Start menu or the Add/Remove control panel applet to uninstall the

IOLinx software.

Important: Uninstall will not succeed if the IOLinx folder is active on the

desktop.

Y

ou see:

1. Select from this decision table.

If you want to press

remove the IOLinx software Yes

You see the progress bar, which indicates the

percentage of files removed from your machine.

retain the IOLinx files on your machine No

2. Press

OK.

When removal is complete, you see a confirmation message.

3.

Press OK.

4. Restart your machine.

Publication

1784-5.35 – April 1999

Page 29

ControlNet Scanner Card 29

rature code rating

!

area is known to be non-hazardous.

!

CSA Hazardous Location Approval

CSA certifies products for general use as well as for use in hazardous locations. Actual CSA

certification is indicated by the product label as shown below, and not by statements in any

user documentation.

Example of the CSA certification product label

To comply with CSA certification for use in hazardous locations, the following information

becomes a part of the product literature for this CSA-certified industrial control product.

• This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D, or non-hazardous

locations only.

• The products having the appropriate CSA markings (that is, Class I Division 2, Groups A, B,

C, D), are certified for use in other equipment where the suitability of combination (that is,

application or use) is determined by the CSA or the local inspection office having jurisdiction.

Important: Due to the modular nature of a programmable control system, the product with the

highest temperature rating determines the overall temperature code rating of a programmable

control system in a Class I, Division 2 location. The temperature code rating is marked on the

product label as shown.

Tempe

The following warnings apply to products having CSA certification for use in hazardous locations.

I

I

Look for temperature code

rating here

CSA

logo is a registered trademark of the Canadian Standards Association.

WARNING: Explosion hazard —

• Substitution of components may impair suitability for Class I, Division 2.

• Do not replace components unless power has been switched off or the area

is known to be non-hazardous.

• Do not disconnect equipment unless power has been switched off or the

area is known to be non-hazardous.

• Do not disconnect connectors unless power has been switched off or the

area is known to be non-hazardous. Secure any user-supplied connectors

that mate to external circuits on this equipment by using screws, sliding

latches, threaded connectors, or other means such that any connection

can withstand a 15 Newton (3.4 lb.) separating force applied for a minimum

of one minute.

• Batteries must be changed only in an area known to be non-hazardous.

Publication

1784-5.35 – April 1999

Page 30

30 ControlNet Scanner Card

A certifie les produits d’utilisation générale aussi bien que ceux qui s’utilisent dans d

aux du code de températur

averti

ants s’appliquent aux produits ayant la certification CSA pour leur

Approbation

La CS

emplacements dangereux. La certification CSA en vigueur est indiquée par l’étiquette du

produit et non par des affirmations dans la documentation à l’usage des utilisateurs.

Exemple d’étiquette de certification d’un produit par la CSA

Pour satisfaire à la certification de la CSA dans des endroits dangereux, les informations

suivantes font partie intégrante de la documentation ce produit industriel de contrôle certifié par

la CSA.

• Cet équipement convient à l’utilisation dans des emplacements de Classe 1, Division 2,

Groupes A, B, C, D, ou ne convient qu’à l’utilisation dans des endroits non dangereux.

• Les produits portant le marquage approprié de la CSA (c’est à dire, Classe 1, Division 2,

Groupes A, B, C, D) sont certifiés à l’utilisation pour d’autres équipements où la convenance

de combinaison (application ou utilisation) est déterminée par la CSA ou le bureau local

d’inspection qualifié.

Important: Par suite de la nature modulaire du système de contrôle programmable, le produit

ayant le taux le plus élevé de température détermine le taux d’ensemble du code de

température du système de contrôle d’un programmable dans un emplacement de Classe 1,

Division 2. Le taux du code de température est indiqué sur l’étiquette du produit.

T

Les

utilisation dans des emplacements dangereux.

Le

d’utilisation dans des emplacements dangereux par la CSA

e

ssements suiv

AVERTISSEMENT: Risque d’explosion —

• La substitution de composants peut rendre ce matériel inacceptable pour

lesemplacements de Classe I, Division 2.

• Couper le courant ou s’assurer quel’emplacement est désigné non

!

sigle CSA est la marque déposée de l’Association des Standards pour le Canada.

dangereux avant de remplacer lescomposants.

• Avant de débrancher l’équipement, couper le courant ou s’assurer que

l’emplacement est désigné non dangereux.

• Avant de débrancher les connecteurs, couper le courant ou s’assurer que

l’emplacement est reconnu non dangereux. Attacher tous connecteurs

fournis par l’utilisateur et reliés aux circuits externes de cet appareil à l ’aide

de vis, loquets coulissants, connecteurs filetés ou autres moyens permettant

aux connexions de résister à une force de séparation de 15 Newtons

(3,4 lb. - 1,5 kg) appliquée pendant au moins une minute.

• Afin d’eviter tout risque d’explosion, s’assurer que l’emplacement est designe

non dangereux avant de changer la batterie.

I

Le taux du code de

température est indiqué ici

I

es

Publication

1784-5.35 – April 1999

Page 31

ControlNet Scanner Card 31

Specifications

The operating parameters describe the environment within the KTCS slot.

Refer to the documentation for your computer for environmental requirements.

The card should not exceed those specifications.

General

Characteristic Value

Power

Requirements

Conductor Category 2

Environmental

Slot Temperature 0 to 50° C (32 to 122° F) –40 to 85° C (–40 to 185° F)

Humidity 5 to 95% without condensation 5 to 95% without condensation

Vibration 10 to 150 Hz, constant .012 in

Shock 30G peak/11 ms 50G peak/11 ms

Agency Certification

(when product or packaging is marked)

Specifications

5V dc, 640mA Maximum

1

Specifications

Operating Nonoperating

not applicable

displacement

10 to 150 Hz, constant 2.0G

acceleration

Class 1, Division 2

Groups A, B, C, D

marked for all applicable directives

1

Refer

to the Industrial Automation Wiring and Grounding Guidelines for Noise Immunity

publication 1770-4.1

Publication

,

1784-5.35 – April 1999

Page 32

DH+, FLEX I/O, IOLinx, PanelView, and PLC-5/40C

are trademarks of Rockwell Automation.

ControlNet is a trademark of ControlNet International.

WINtelligent LINX and WINtelligent LINX Gateway

are trademarks of Rockwell Software Inc.

Ethernet is a registered trademark of Digital Equipment Corporation,

Intel, and Xerox Corporation.

Windows NT is a trademark of Microsoft Corporation.

Worldwide representation.

Argentina •

Colombia • Costa Rica • Croatia • Cyprus • Czech Republic • Denmark • Ecuador • Egypt • El Salvador

Finland •

Indonesia •

Mexico •

Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore

Africa, Republic • Spain • Sweden

United Kingdom • United States • Uruguay • V

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA

Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication

Supersedes

Australia • Austria • Bahrain • Belgium

• Brazil •

Bulgaria • Canada • Chile • China, PRC

France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India

Ireland • Israel • Italy • Jamaica •

Netherlands

• New

Zealand • Norway

• Switzerland • T

1784-5.35 – April 1999

1784-5.35 – January 1999

PN 955138-02B

Japan • Jordan • Korea • Kuwait • Lebanon

• Pakistan •

Peru

• Philippines •

Poland • Portugal

• Slovakia • Slovenia •

aiwan

enezuela • Y

E

ugoslavia

1999 Rockwell International Corporation. All rights reserved. Printed in USA.

• Thailand • T

urkey • United Arab Emirates

• Malaysia •

South

•

•

•

•

•

Loading...

Loading...