Page 1

AllenBradley

1772 Mini

PLC2/05

Processor

(Cat. No. 1772-LS,

LSP)

Programming

and

Operations

Manual

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences

between solid state products and electromechanical products, those responsible

for applying and using this product must satisfy themselves as to the

acceptability of each application and use of this product. For more information,

refer to publication SGI-1.1 (Safety Guidelines For The Application,

Installation and Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended

solely to illustrate the text of this manual. Because of the many variables and

requirements associated with any particular installation, Allen-Bradley

Company cannot assume responsibility or liability for actual use based upon the

illustrative uses and applications.

No patent liability is assumed by Allen-Bradley Company with respect to use of

information, circuits, equipment or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen-Bradley Company is prohibited.

Throughout this manual we make notes to alert you to possible injury to people

or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

- Identify a hazard

- Avoid the hazard

- recognize the consequences

Important: Identifies information that is critical for successful application and

understanding of the product.

Page 3

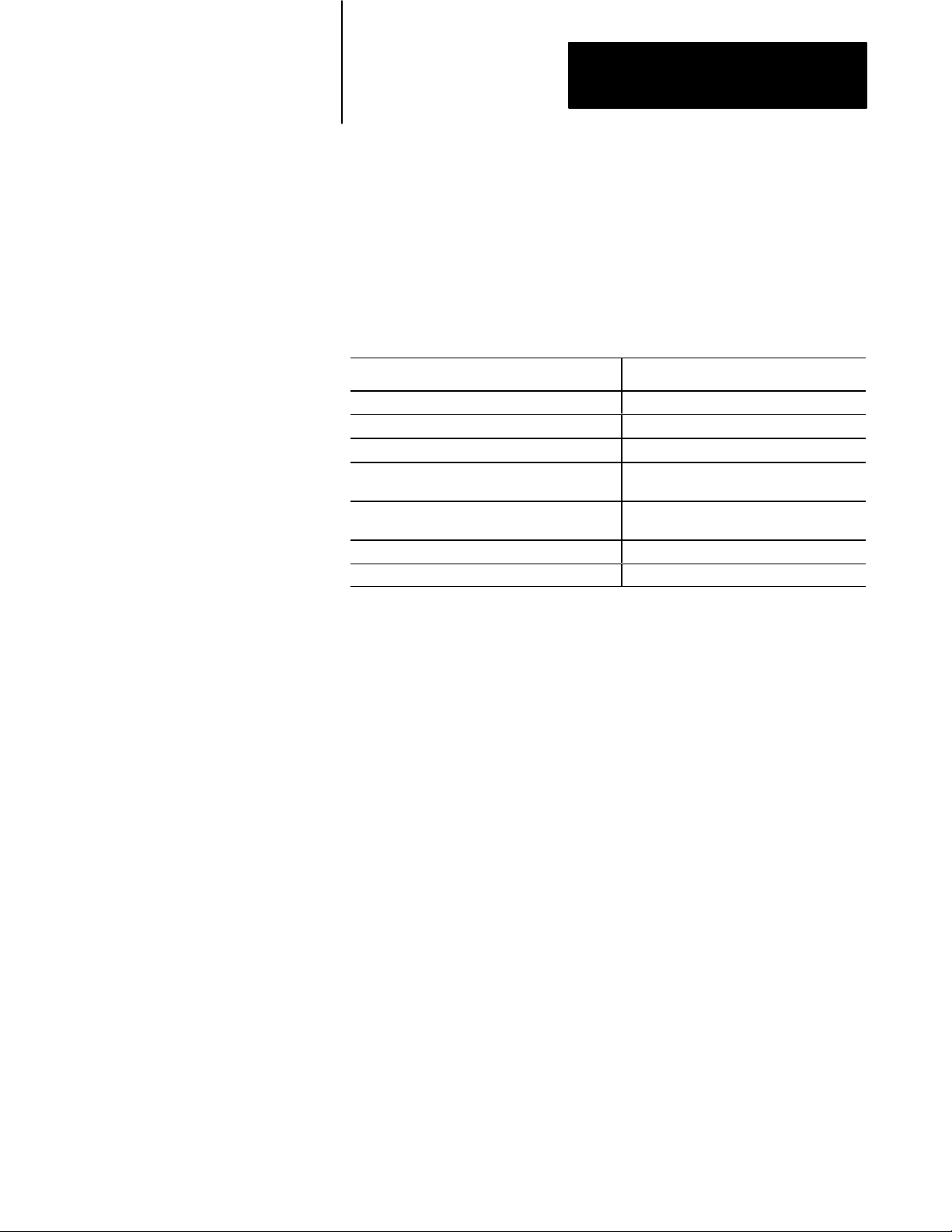

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains updated information:

For this updated information: See:

revised conventions chapter 1

clarification to switch settings for 1772LSP chapter 3

description of keys on keytop overlay (1770KCB) chapter 3

corrections to the discussion about

automatic restart

corrections to the discussion about

program control

addition of ZCL to glossary appendix B

new format all chapters and appendices

chapter 18

chapter 18

To help you find new information in this publication, we have included

change bars as shows to the left of this paragraph.

i

Page 4

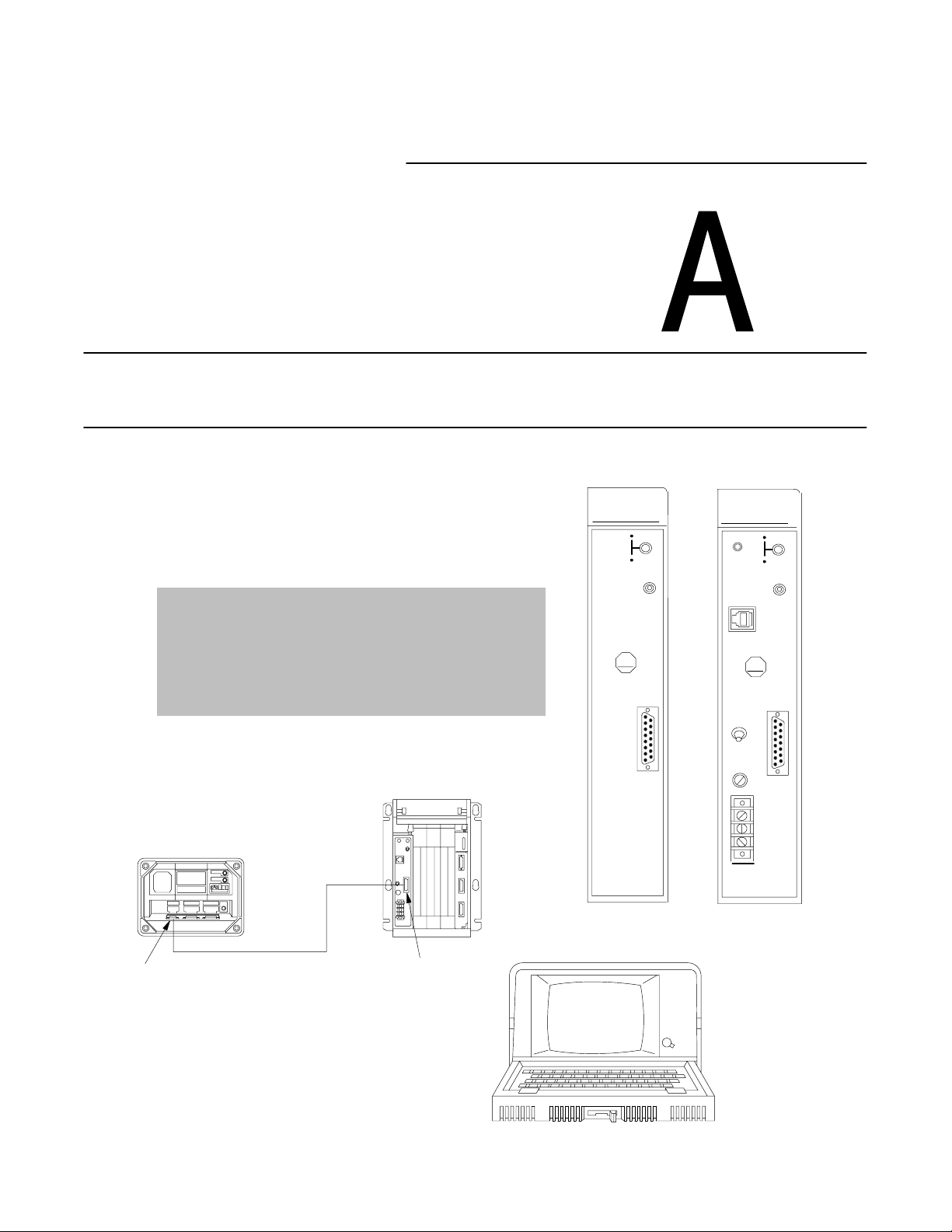

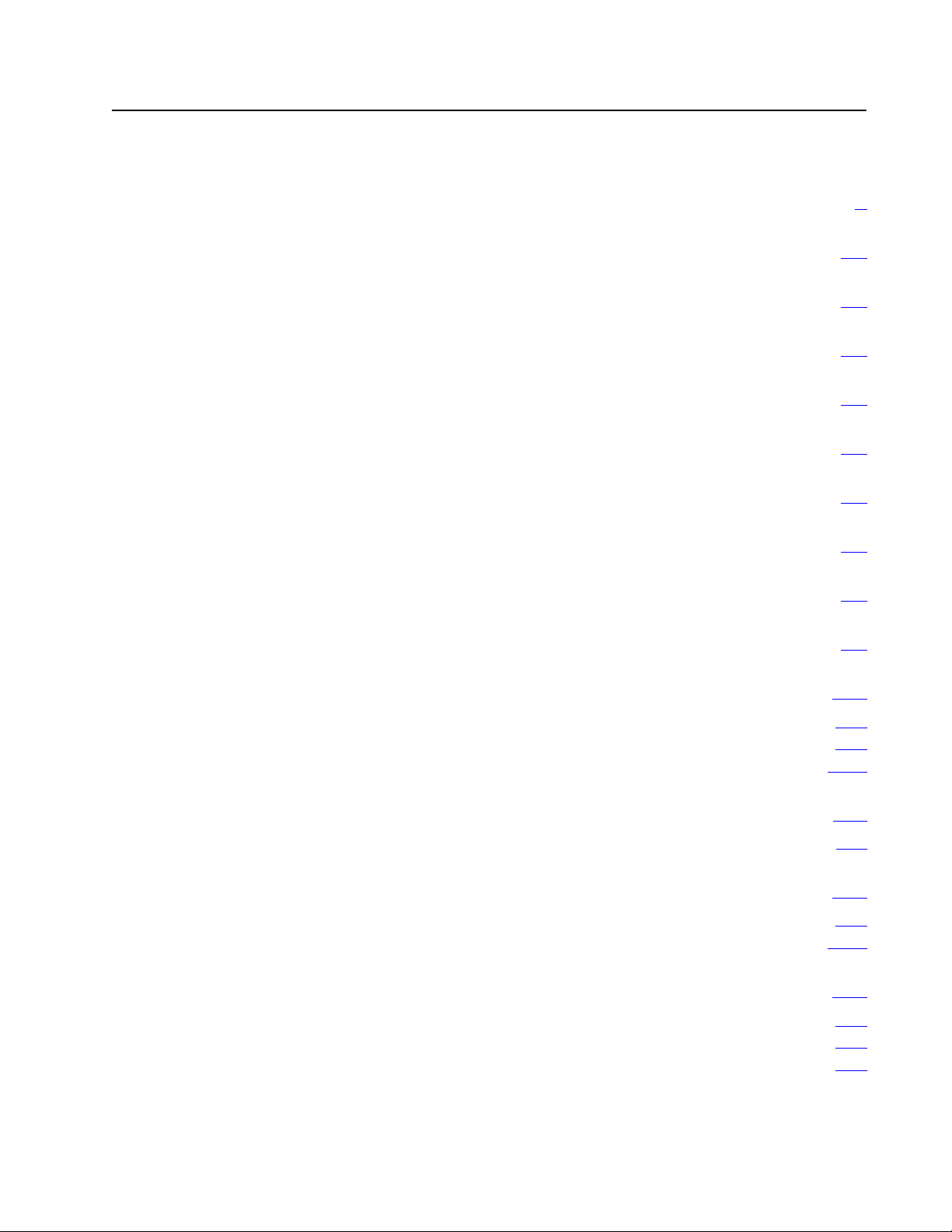

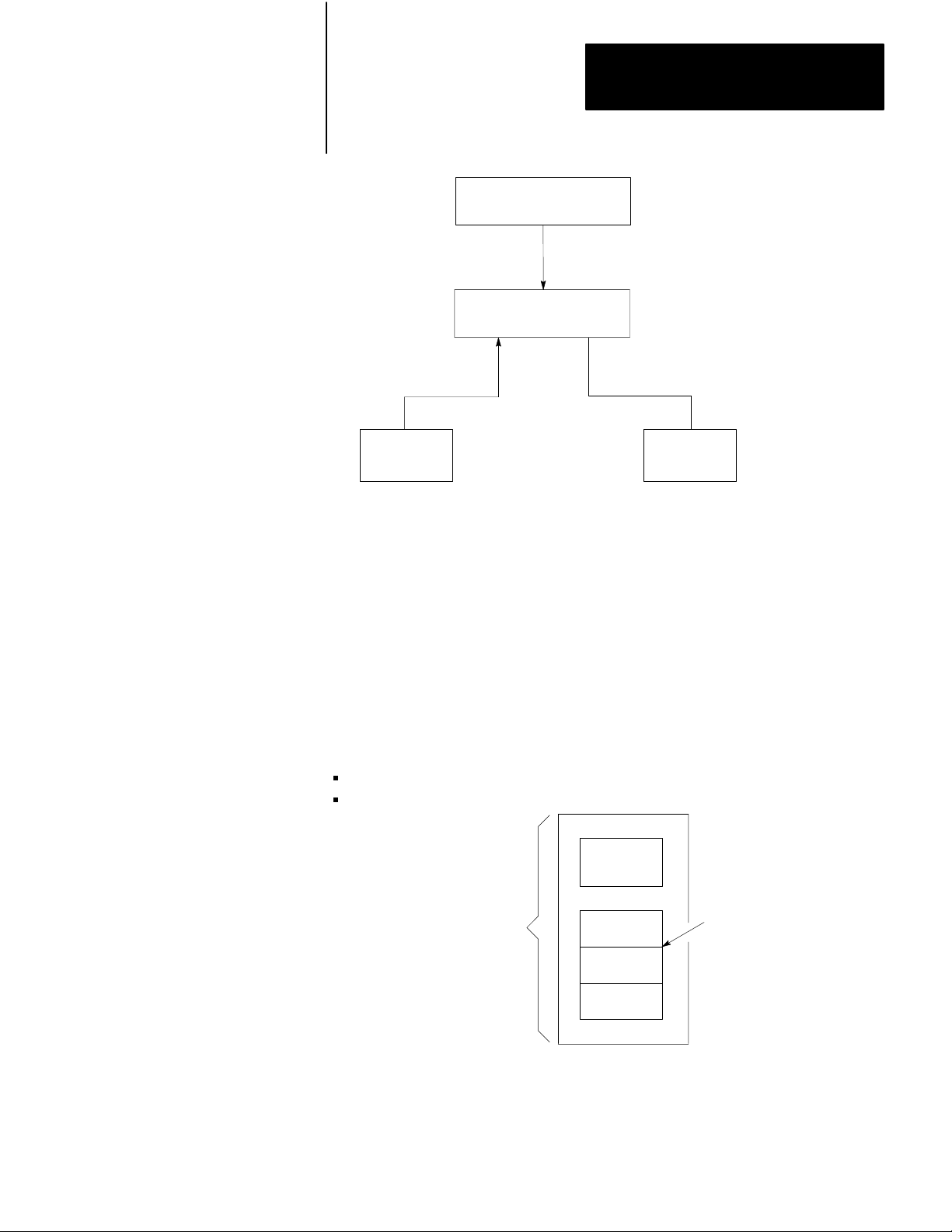

Part

Hardware Overview

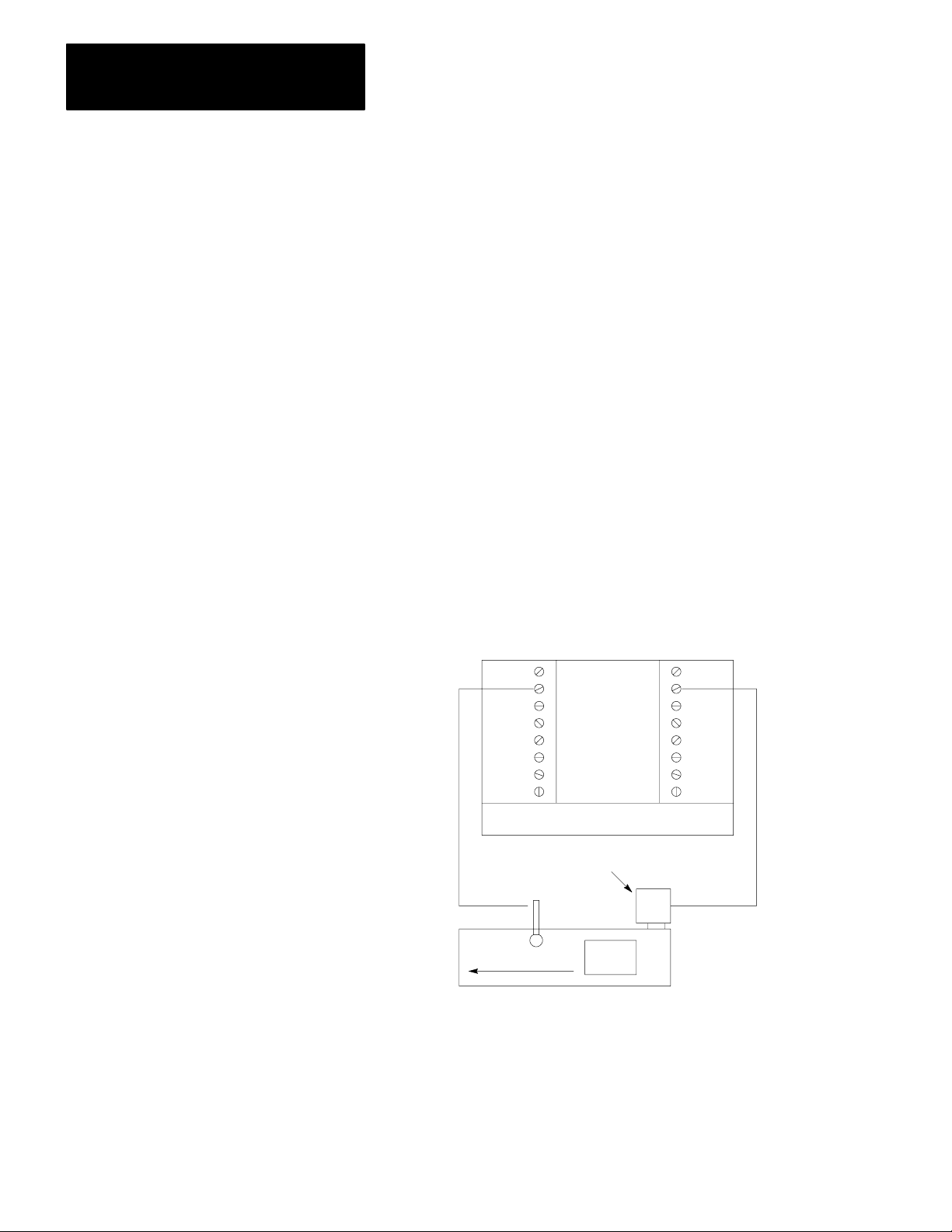

Industrial Terminal

(rear view)

Channel A

PLC2 Family

1 Before You Begin

2 An Introduction to Programmable Controllers

3 Hardware

MiniPLC2/05

Program Panel

Interconnect Cable

Interface

RUN

P

R

O

C

FAULT

ON

MEMORY

STORE

ON

AB

INTFC

MINI PLC2/05

W/O Power Supply

P

R

O

P/S

C

ACTIVE

MEMORY

STORE

P/S

PARALLEL

AB

POWER

ON

OFF

I.0A 125V

SLOW BLOW

120V

GND

MINI PLC2/05

W Power Supply

AC

RUN

FAULT

ON

ON

INTFC

L1

N

Page 5

4 Memory Organization

5 Scan Theory

6 Relay-type Instructions

7 Program Control Instructions

8 Timers and Counters

9 Data Manipulation Instructions

10 Math Instructions

11 Data Transfer File Instructions

12 Sequencers

13 Jump

Instructions and

Subroutines

14 Block Transfer

15 Selectable Timed Interrupt

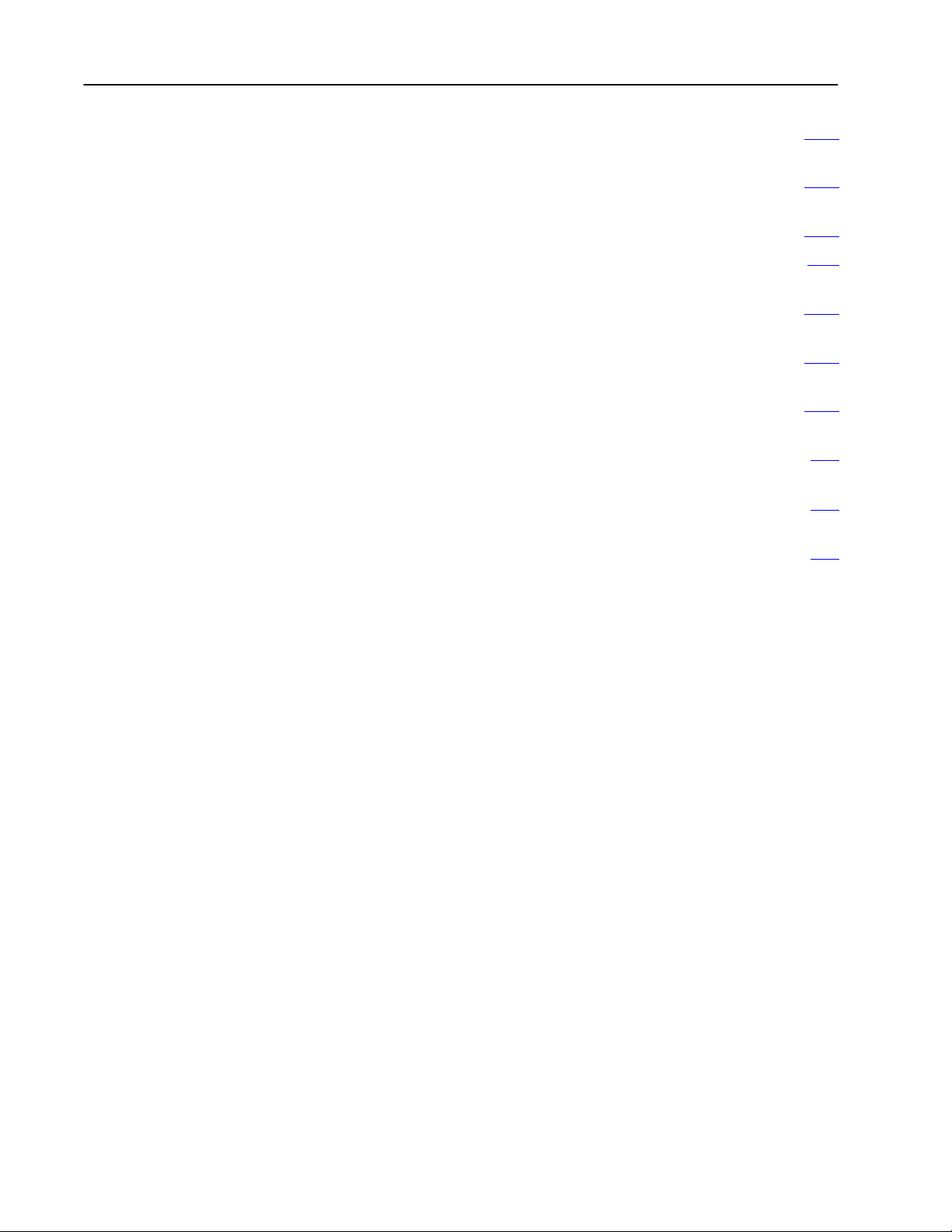

Part

Memory / Instruction Set

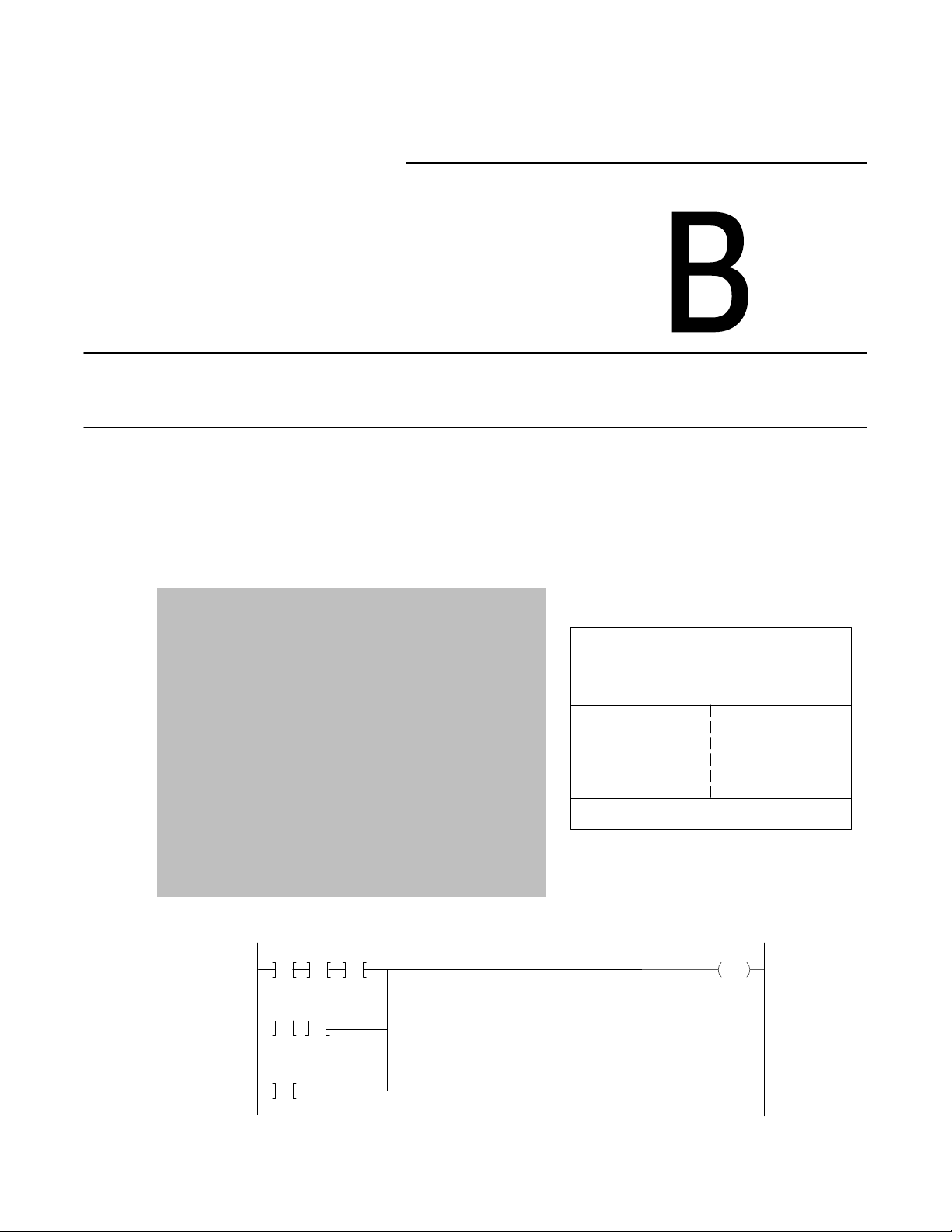

Data Table

Main Program

User Program

Subroutine

Message Storage Area

110

110 110

00

10

11

110

110

12

11

110

13

010

00

Page 6

16 Program Editing

Part

Program Editing

( )

( P )

FOR

USE WITH PLC2 F

1982 ALLENBRADLEY 97534302

AMILY CAT

. NO. 1770 KCB

Page 7

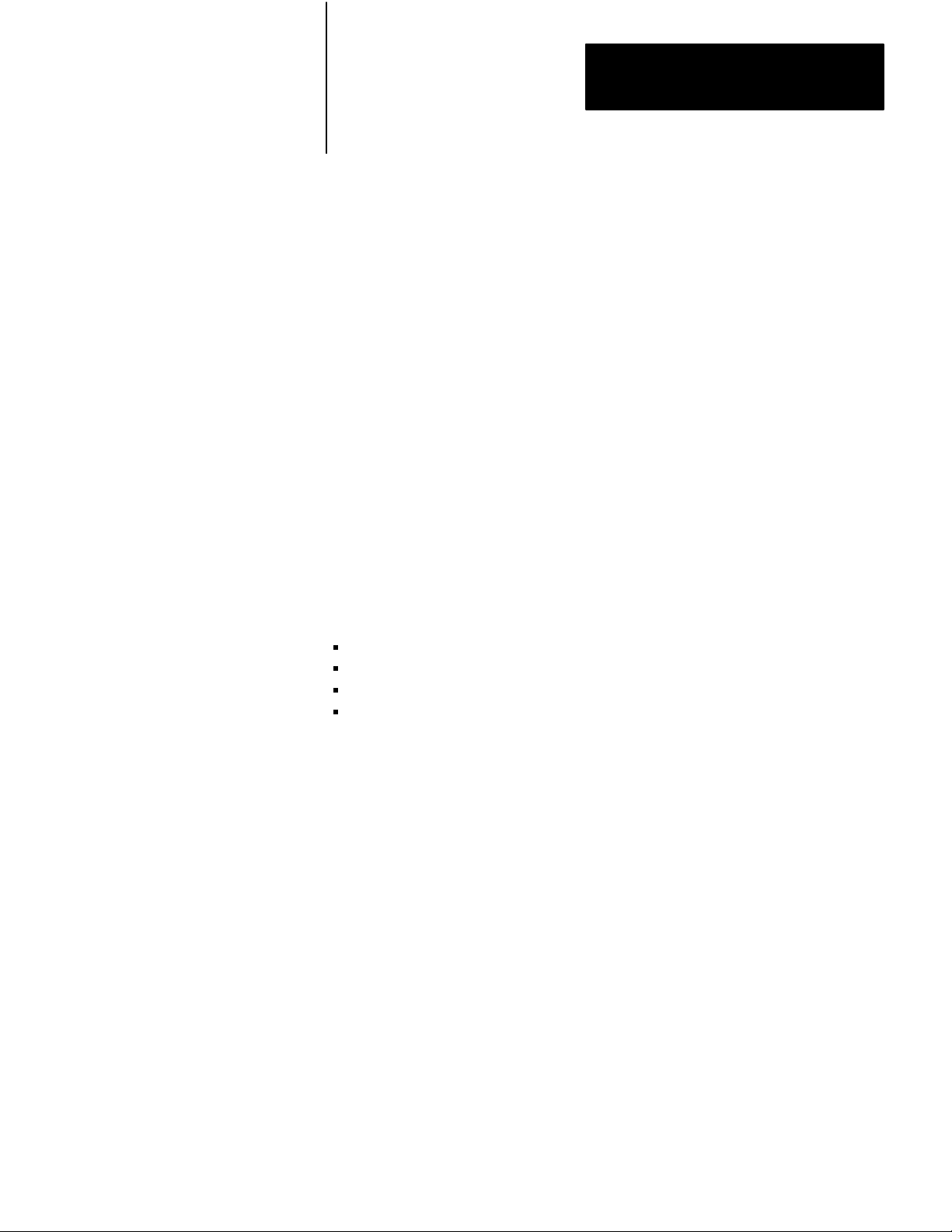

Part

Report Generation /

Application Programming Techniques

17 Report Generation

18 Programming Techniques

MS.0

198 MESSAGES SELECTED

MESSAGE CONTROL WORDS ( ENTER 5 DIGIT WORD ADDRESS)

ADDRESS 00200 – 00227

MESSAGE MESSAGE MESSAGE MESSAGE MESSAGE MESSAGE

CONTROL NUMBERS CONTROL NUMBERS CONTROL NUMBERS

WORDS WORDS WORDS

027 1–6

00200 010–017 00210 1010–1017 00220 2010–2017

00201 110–117 00211 1110–1117 00210 2110–2117

00202 210–217 00212 1210–1217

00203 310–317 00213 1310–1317

00204 410–417 00214 1410–1417

00205 510–517 00215 1510–1517

00206 610–617 00216 1610–1617

Page 8

19 Program Troubleshooting

Part

Program Troubleshooting

hr.mn.sec.

OFF or ON 00:00'00.00

ON 00:00:00.00OFF 00:00:00.00ON 00:00:00.00

On Time

WORD ADDRESS: 0030

BIT NO.: 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

STATUS : 1 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0

FORCE :

Off Time

On Time

Page 9

Part

Appendices

A Number Systems

B Glossary

C Quick Reference

Index

Key Sequences:

[SEARCH]

[Instruction key]

(Address)

[SEARCH]

[5][3]

[

←] or [→]

[1] or [0]

This appendix contains defines terms and abbreviations that because of their

complexity or recent introduction are not widely understood. These terms are:

AC Input Module

An I/O module that converts various AC signals originating at user devices to the

appropriate logic level signal for use within the processor.

AC Output Module

An I/O module that converts the logic level signal of the processor to a usable

output signal to control a user AC device.

[SEARCH]

[5][3]

[Address]

[

↑]or[↓]

357

8

3 x 82 = 192

1

= 40

5 x 8

0

= 7

7 x 8

192

40

7

239

10

23910 = 357

8

Page 10

Table of Contents

Summary of Changes

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Begin 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

An Introduction to Programmable Controllers 21. . . . . . . . . .

Hardware 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Organization 41. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scan Theory 51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Relaytype Instructions 61. . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Control Instructions 71. . . . . . . . . . . . . . . . . . . . . .

Timers and Counters 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Manipulation Instructions 91. . . . . . . . . . . . . . . . . . . . .

i

Math Instructions 101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ThreeDigit

Expanded

Chapter Summary 1021

Math

Math

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

104. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfer File Instructions 111. . . . . . . . . . . . . . . . . . . . . .

Types

of File Instructions

111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequencers 121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Comparison

Chapter Summary 1222

with File Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

121. . . . . . . . . . . . . . . . . . . . . . . .

Jump Instructions and Subroutines 131. . . . . . . . . . . . . . . . . .

Label Instruction 133. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Subroutine Area Instruction 134

Chapter Summary 137

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 11

Table of Contentsii

Block Transfer 141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Selectable Timed Interrupt 151. . . . . . . . . . . . . . . . . . . . . . . . .

Program

Rules

Editing

for Editing Instructions

Report Generation 171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Techniques 181. . . . . . . . . . . . . . . . . . . . . . . . .

Program Troubleshooting 191. . . . . . . . . . . . . . . . . . . . . . . . .

Number Systems A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Glossary B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Reference C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

161. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 12

Chapter

1

Before You Begin

Important: Read this chapter before you use the Mini-PLC-2/05 Processor (cat.

no. 1772-LS,-LSP). It tells you how to use this manual.

Purpose

To the Reader

The Mini-PLC-2/05 processor is functionally similar to the Mini-PLC-2/15

processor. The Mini-PLC-2/05 processor has some additional features:

selectable timed interrupt

memory protect switch

fast I/O scan

user selectable PROM/RAM backup

3K memory

expanded mathematics

However, this processor does not have a mode select switch.

This manual is divided into six parts (Table 1.A).

Table 1.A

of the MiniPLC2/05 Processor Programming and Operations Manual

Parts

Part Title What's Covered

A Hardware Overview basic theory concerning the hardware features available when using

this processor

B Memory/Instruction Set describes the memory and informs you about the techniques you can

use when programming this processor

C Program Editing how to edit your program once it has been entered into the memory

D Report Generation/Application

Program Techniques

E Program Troubleshooting acts as a guide so you can minimize production down time

F Appendices contains tables and reference information useful when programming

how to do report generation and use special program techniques

your processor

This manual is procedure oriented. It tells you how to program and operate your

Mini-PLC 2/05 Processor. If you need to learn more about the Mini-PLC-2/05

Processor, contact your local Allen-Bradley representative or distributor.

11

Page 13

Chapter 1

Before You Begin

Vocabulary

Conventions

To make this manual easier to read and understand, we refer to the:

We Refer to the: As the:

MiniPLC2/05 Processor processor

Electrically Erasable Programmable

Read Only Memory

Execute Auxiliary Function EAF

Complementary Metal Oxide

Semiconductor Random Access Memory

Industrial Terminal (cat. no. 1770T3) 1770T3 terminal

EEPROM

CMOS RAM

A glossary at the back of this manual clarifies technical terms.

A word equals 16 bits; a byte equals 8 bits (1/2 a word).

Words in [ ] denote the key name or symbol. Words in < > denote information

that you must provide - for example, an address value.

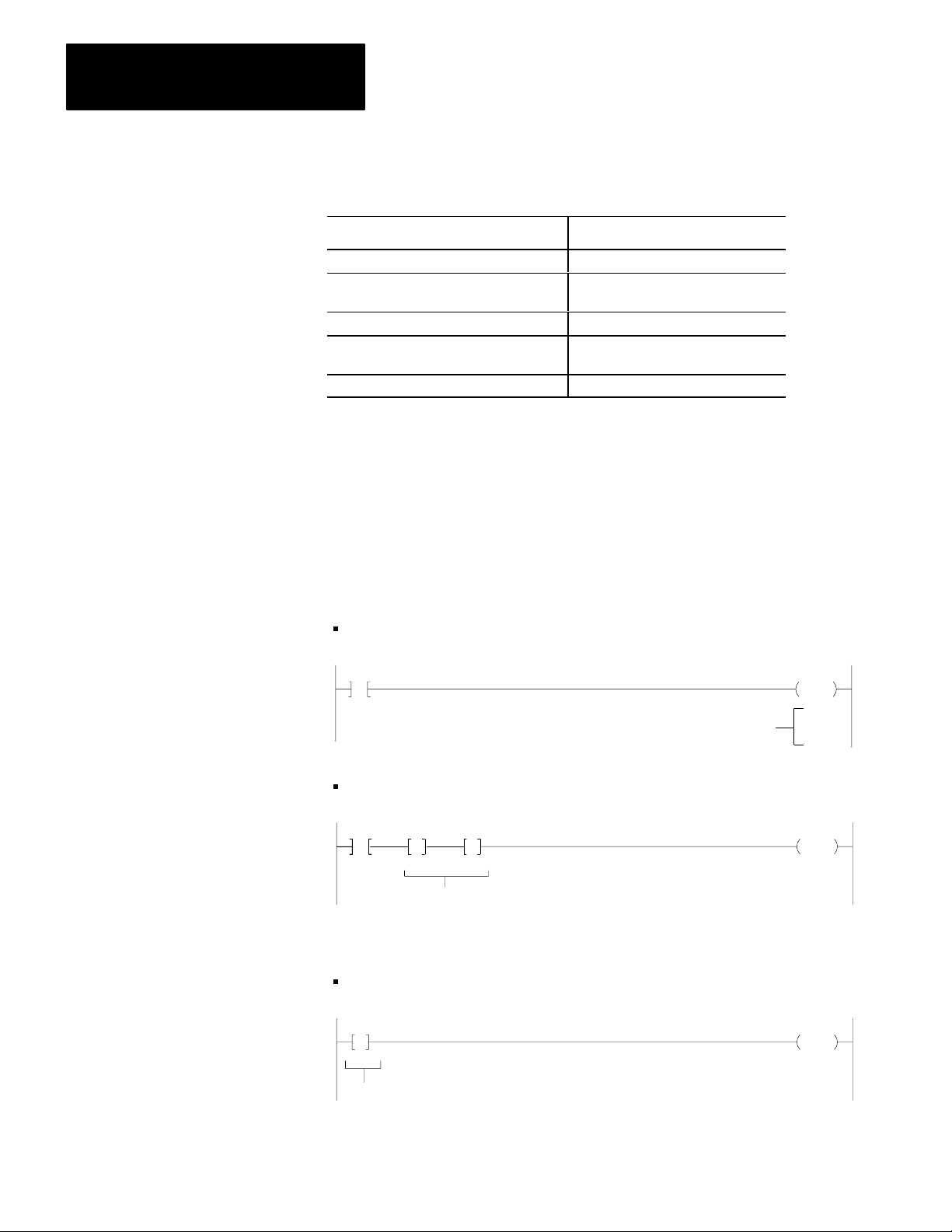

Word values are displayed in:

decimal (0-9) for timers, counters, and mathematics

010

00

Decimal

030

CTU

PR 555

AC 123

hexadecimal values (0-9, A-F) for gets and puts

010

010

011 012

GG

00

00

Hexadecimal

030

00FFF 123

Important: Numbers 0-9 are displayed the same in decimal and hexadecimal.

octal for byte values

0101 030

B

237

Octal

00

12

Page 14

Chapter 1

Before You Begin

Keystroke directions are divided into two columns:

tells you what key or keys to press

Related Publications

tells you the processor’s action.

The publication index, publication SD 499, lists all available publications to

further inform you about products related to the Mini-PLC-2/05 processor.

Consult your local Allen-Bradley distributor or sales engineer for information

regarding this publication or any needed information.

13

Page 15

Chapter

2

An Introduction to Programmable Controllers

Chapter Objectives

Traditional Controls

In this chapter, you review general fundamentals common to our programmable

controllers. This chapter:

describes what a programmable controller does

describe the four major sections of a programmable controller

describes how the four major sections of a programmable controller interact

gives an example of a simple program

You are probably familiar with the traditional methods of machine control.

Relays

Machine

Sensing

Devices

Sensing devices located on the machine detect changes in the machine’s

condition. For instance, a part arriving at a work station contacts and closes a

limit switch, the sensing device. As a result, an electrical circuit is completed

and a signal is sent to the control panel.

Control Panel

Output

Devices

11591

At the control panel, the electrical signal enters a bank of relays or other

devices, such as solid state modules. Circuits within the control panel open or

close causing additional electrical signals to be sent to output devices at the

machine. For example, a relay energized by the limit switch closed by the

arriving part may complete another circuit energizing the output device, a

clamp, which secures the part at the work station.

21

Page 16

Chapter 2

An Introduction to

Programmable Controllers

Programmable Controls

Programmable controllers can perform many of the functions of traditional

controls. Sensing devices report to the processors. The output devices at the

machine operate the same as they would with traditional controls.

Programmable

Controller

Conditons

Machine

Sensing

Devices

Control Panel

Output

Devices

Action

Command

11592

The field wiring between the machine and the control panel provides electrical

paths from the sensing devices to the control panel, and from the control panel

to the output devices.

However, inside the control panel you’ll find a programmable controller rather

than relays or discrete solid state devices. Instead of wiring those devices and

relays together to produce a desired response, you simply tell your

programmable controller by means of a program how you want it to respond to

the same conditions.

The Four Major Sections

22

Programming is telling your programmable controller what you want it to do.

A program is nothing more than a set of instructions you give the programmable

controller telling it how to react to different conditions within the machine.

Let’s take a closer look at a typical programmable controller. It usually consists

of four major sections:

processor

input

output

power supply

Page 17

Power Supply

Processor

(Decision Making)

Chapter 2

An Introduction to

Programmable Controllers

Information

Input Output

Limit, Proximity, Pressure,

•

Temperature Switches

•

Push Buttons

•

Logic

•

BCD

•

Analog

Action

Solenoids•

•

Motor Starters

•

Indicators

•

Alarms

•

Logic

•

BCD

•

Analog

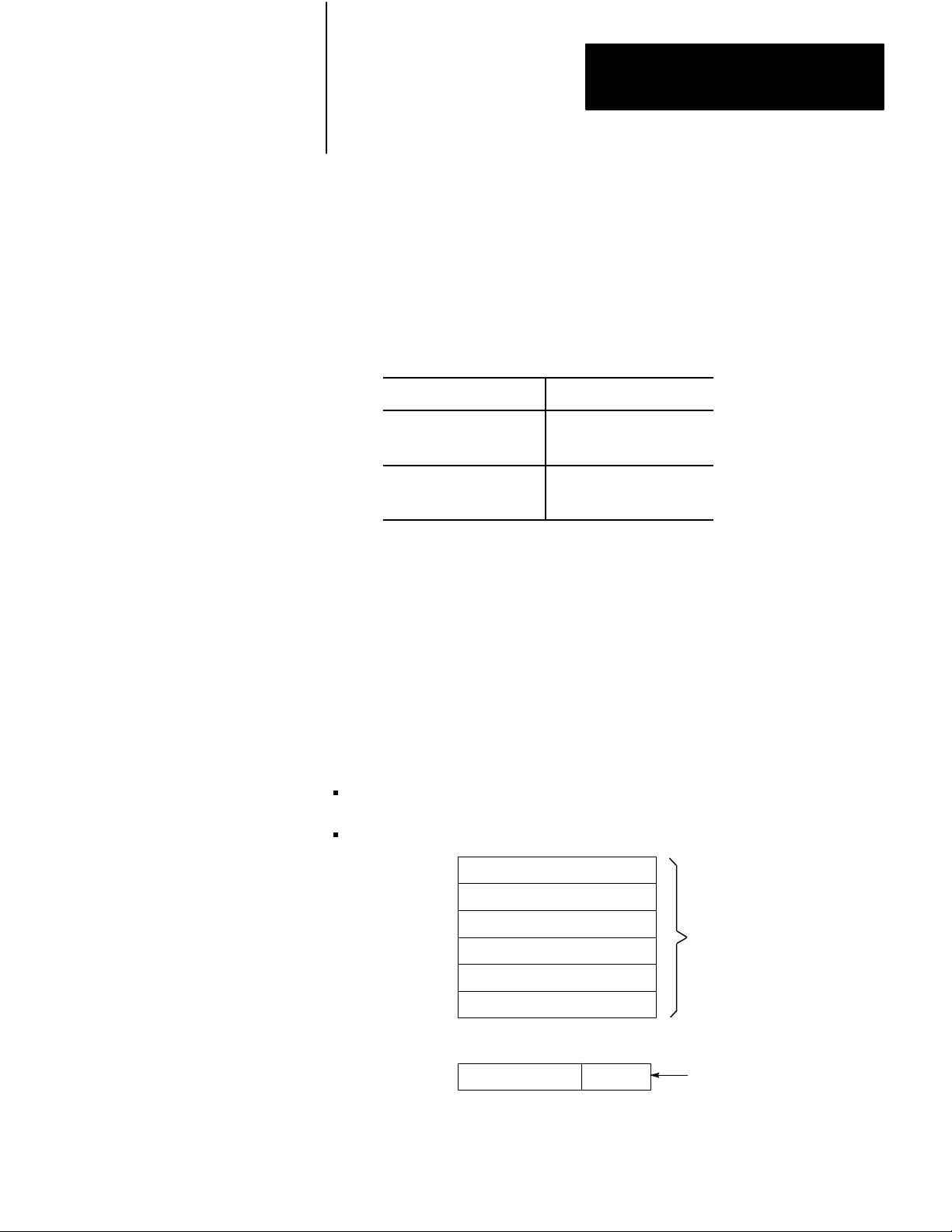

Processor

The first section of a programmable controller is the processor. The processor

might be called the “brains” of the programmable controller. It is divided

into halves:

central processing unit

memory

CPU

Processor

Section

Data

Table

Program

Storage

Message

Storage

Memory

Central Processing Unit

The central processor unit (CPU) makes decisions about what the

processor does.

23

Page 18

Chapter 2

An Introduction to

Programmable Controllers

Memory

Memory serves three functions:

stores information in the data table that the CPU may need

stores sets of instructions called a program

stores messages

Data Table

The area of memory where data is controlled and used, is called the data table.

The data table is divided into several smaller sections according to the type of

information to be remembered. These smaller sections are called:

output image table

input image table

timer/counter storage

Data Table

Output Image Table

Input Image Table

Timer/Counter

Storage

At this time, we will only discuss the input and output image tables and

program storage.

I/O Image Tables

The input image table reflects the status of the input terminals. The output

image table reflects the status of bits controlled by the program.

Each image table is divided into a number of smaller units called bits. A bit is

the smallest unit of memory. A bit is a tiny electronic circuit that the processor

can turn on or off. Bits in the image table are associated with a particular

I/O terminal in the input or output section.

When the processor detects a voltage at an input terminal, it records that

information by turning the corresponding bit on. Likewise, when the processor

detects no voltage at an input terminal, it records that information by turning the

corresponding bit off. If, while executing your program, the CPU decides that a

particular output terminal should be turned on or off, it records that decision by

turning the corresponding bit on or off. In other words, each bit in the

I/O image tables corresponds to the on or off status of an I/O terminal.

24

When people who work with personal computers talk about turning a bit on,

they use the term “set.” For example - “The processor sets the bit” means

“turns it on.” On the other hand, we use the term “reset” when we talk about

turning the bit off - for example, “The processor reset the bit.”

Page 19

Chapter 2

An Introduction to

Programmable Controllers

Picture memory as a page that has been divided into many blocks. Each block

represents one bit. Since each bit is either on or off, we could show the state of

each bit by writing “on” or “off” in each block. However, there is an easier

way. We can agree that the numeral one (1) means on and that the numeral zero

(0) means off. We can show the status of each bit by writing 1 or 0 into the

appropriate block. For example, you might hear expressions like, “The CPU

responded by writing a one into the bit when the limit switch closed.” Of

course, the processor didn’t really write a one into memory: it simply set the bit

by turning it on.

When the I/O device is: The bit status is said to be:

on

on

off

1

set

off

0

reset

If you heard the expression, “The processor wrote a zero into that bit location.”

What actually happened? If you said the processor merely reset the bit by

turning it off, you’re right.

Program Storage

The other major area of memory, program storage, takes up the largest portion

of memory. You’ll recall that this is where your instructions to the

programmable controller are stored. You’ll also recall that this set of

instructions is called a program.

Program Language

A program is made up of set of statements. Each statement does two things:

It describes an action to be taken. For instance, it might say, “Energize motor

starter number one.”

It describes the conditions that must exist in order for the action to take place.

Statement

Statement

Statement

Statement

Statement

Program

Statement

Program Storage Area

of Memory

ActionConditions

Program

Statement

25

Page 20

Chapter 2

An Introduction to

Programmable Controllers

For example, you may want this action to take place: ”Whenever a certain limit

switch closes.” So your condition could be: “If limit switch number two is

closed,...” The action would be: “energize motor starter number one.” The entire

statement is then: “If limit switch number two is closed, then energize motor

starter number one.” Therefore, when limit switch number two at the machine

closes, the programmable controller energizes the motor starter. If limit switch

number two does not close, the programmable controller does not energize the

motor starter. Thus, when limit switch number two opens, the programmable

controller de-energizes the motor starter because that action is implied in

the statement.

A program is made up of a number of similar statements. Typically, there is one

statement for each output device on the machine. Each statement lists the

conditions that must be met and then, states the action to be taken.

Instructions

Each condition is represented by a specific instruction; therefore, each action is

represented by a specific instruction. These instructions tell the processor to do

something with the information stored in the data table.

Some instructions tell the processor to read what’s written in the image table.

When the processor is instructed to read from an image table, it examines a

specific bit to see if a certain I/O device is on or off.

Other instructions tell the processor to write information into the image table.

When the processor is instructed to write into the output image table, it writes a

one or a zero into a specific bit. The corresponding output device will turn on or

off as a result.

Input

The second section is the input, which serves four very important functions:

termination

indication

conditioning

isolation

Termination

The input provides terminals for the field wiring coming from the sensing

devices on the machine.

Indication

The input of most modules also provides a visual indication of the state of each

input terminal with indicators. The indicator is on when there is a voltage

applied to it terminal. It is off when there is no voltage applied to its terminal.

Since the indicator reveals the status of its terminal, it’s usually called an input

status indicator.

26

Page 21

Chapter 2

An Introduction to

Programmable Controllers

You should also notice another important characteristic of input indicators. They

are only associated with terminals used for wiring sensing devices to the input

section. The terminal that’s used to provide a ground for the sensing circuits

has no indicator.

Conditioning

Another function of the input is signal conditioning. The electrical power used

at the machine is usually not compatible with the signal power used within the

programmable controller. Therefore, the input section receives the electrical

signal from the machine and converts it to a voltage compatible with the

programmable controller’s circuitry.

Isolation

The input isolates the machine circuitry from the programmable controller’s

circuitry. Isolation helps protect the programmable controller’s circuitry from

unwanted and dangerous voltage levels that may occur occasionally at the

machine or in the plant’s wiring system.

Output

The third section is the output, which serves functions similar to those of the

input image table:

termination

indication

conditioning

isolation

Termination

The output provides terminals for the field wiring going to the output devices on

the machine.

Indication

The output of most modules provides a visual indication of the selected state of

each output device with indicators.

The output status indicator is on when the output device is energized. A

common term applied to either input status indicators or output status indicators

is I/O status indicators. I/O stands for either input or output.

In addition, the output section of modules with fuses has blown fuse indicators.

When one of the fuses in the group opens, the blown fuse indicator lights.

Conditioning

The output conditions the programmable controller’s signals for the machine.

That is, it converts the low-level dc voltages of the programmable controller to

the type of electrical power used by the output devices at the machine.

27

Page 22

Chapter 2

An Introduction to

Programmable Controllers

Isolation

The output isolates the more sensitive electronic circuitry of the programmable

controller from unwanted and dangerous voltages that occasionally occur at the

machine or the plant’s wiring system. Some situations require additional

external protection.

Power Supply

The fourth section is the power supply. It provides a low level dc voltage

source for the electronic circuitry of the processor. It converts the higher level

line voltages to low level logic voltages required by the processor’s

electronic circuitry.

Control Sequence

Let’s look at a simple example to see the sequence of events that take place in

controlling a machine with a programmable controller (Figure 2.1). Suppose

you are making a part. The motor driven conveyor carries a unit to the work

area. The limit switch detects wen the part arrives at the work area. When that

happens, we want the conveyor to stop so you can work on the part.

Figure 2.1

Simplified Example of a Machine with a Programmable Controller

A

Controller

Input Output

Conveyor

Motor

Limit

Switch

28

Conveyor

Unit

11594

Notice how the limit switch and motor are wired to the programmable

controller. The limit switch, wired to terminal 02, is normally-closed. The

arriving part will open the switch. Therefore, the program statement controlling

the conveyor motor must read: “If there is voltage at input terminal 02 (limit

switch), then energize output terminal 02 (conveyer motor).” The conveyor

motor is wired to output terminal 02.

Page 23

Chapter 2

An Introduction to

Programmable Controllers

Important: Figure 2.1 is for demonstration purposes only. We do not show the

associated wiring, a motor starter, or an emergency stop button.

Since the limit switch is wired normally-closed, the conveyor motor will run

until the arriving part opens the switch. At that time, the condition for

energizing the motor is not longer met. Therefore, the motor is de-energized.

When the condition is met, we say it is true. When the condition is not met, we

say it is false. There may be more than one condition which must be met before

an action is executed. When all the conditions are met, the action is executed

and we say the statement is true. When one or more of the conditions are false,

the action is not executed and we say the statement is false.

Scan Sequence

On power up, the processor begins the scan sequence (Figure 2.2) with the

I/O scan. During the I/O scan, data from input modules is transferred to the

input image table. Data from output image table is transferred to the

output modules.

29

Page 24

Chapter 2

An Introduction to

Programmable Controllers

Figure 2.2

Sequence

Scan

I/O

Scan

Program

Scan

Output

Image

Table

Copy output image table status

into output terminal circuits.

Input

Terminals

Copy input terminal status into

input image table.

Program Statement

Output

Terminals

Input

Image

Table

210

Execute each program rung in

sequence, writing into bits in the

data table, including the output

image table.

11597

Page 25

Chapter 2

An Introduction to

Programmable Controllers

Next, the processor scans the program. It does this statement by statement.

Each statement is scanned in this way:

1. For each condition, the processor checks, or “reads,” the image table to see

if the condition has been met.

2. If the set of conditions has been met, the CPU writes a one into the bit

location in the output image table corresponding to the output terminal to

be energized. On the other hand, if the set of conditions has not been met,

the processor writes a zero into the bit location, indicating that the output

terminal should not be energized.

Here is a simple explanation of the program. If input 02 is on, then turn on

output 02. If input 02 is off, then turn off output 02. The program could be

written this way:

If (condition) Then (action)

Input bit 02 is on Turn output bit 02 on

In this example, the processor reads a 1 at input bit location 02 and knows that

the condition has been met. The processor then carries out the action

instruction by writing a 1 into output bit location 02.

If there were more statements in the program, the processor would continue in

this same manner scanning each statement and executing each instruction until

it reached the end of the program. Statement by statement, the processor would

write a 0 or a 1 into an output bit as directed by the program. Then, the

processor would read specific image table bits to see if the proper set of

conditions were met. After reading and executing all program statements, the

processor scans the output image table and energizes or de-energizes output

terminals. The processor then goes to the input modules to update the input

image table.

Now the entire process is repeated. In fact, it’s repeated over and over again,

many times a minute. Each time, the processor sets or resets output bits. Next,

the processor senses the status of the input terminals. Finally, the processor

scans the program and orders each output terminal on or off according to the

state of its corresponding bit in the output image table.

When forcing is attempted, the processor’s I/O scan slows down to do the

forcing (see chapter 19). When forcing is terminated, the processor

automatically switches back to the faster I/O scan mode.

When this example begins, the processor is energizing output terminal 02

because output bit 02 is on.

When the part is conveyed to the work station, it turns the limit switch off.

When the limit switch is off, there is no voltage at input terminal 02. The

processor scans the input image table, senses no voltage, and responds by

writing a zero into bit 02 in the input image table.

211

Page 26

Chapter 2

An Introduction to

Programmable Controllers

The processor scans the program. Our program states that if (conditions) input

bit 02 is on, turn on output 02. If input bit 02 is off then output bit 02 is off.

Since the alter condition is not true, the processor turns off output bit 02.

When the processor next scans the output image table, it sees the zero in output

bit 02 and responds by de-energizing output terminal 02. The action causes the

conveyor to stop.

Chapter Summary

We reviewed fundamentals common to A-B processors. The next chapter

summarizes hardware features of the Mini-PLC-2/05 processors.

212

Page 27

Hardware

Chapter

3

Chapter Objectives

Major Features

General Features

This chapter is a summary of the Mini-PLC-2/05 Processor Assembly and

Installation Manual, publication 1772-6.6.6. In this chapter, you will

read about:

major features

general features

hardware features

optional features

A complete processor system consists of the following major components:

Mini-PLC-2/05 processor

I/O chassis

power supply

I/O modules (up to 16 modules)

industrial terminal (cat. no. 1770-T3)

The processor has the following features:

3K CMOS RAM memory

488 timers

up to 2944 word capacity data table (23 blocks)

ladder diagram and functional block instruction set

four function arithmetic capabilities

remote mode selection

on-line programming

block transfer capability

70 message storage (with the 1770-T3 terminal only)

198 message storage with the PLC-2 Family Report Generation Module

(catalog number 1770-RG)

data highway compatibility

selectable timed interrupts

expanded math capability

3-1

Page 28

Chapter 3

Hardware

Hardware Features

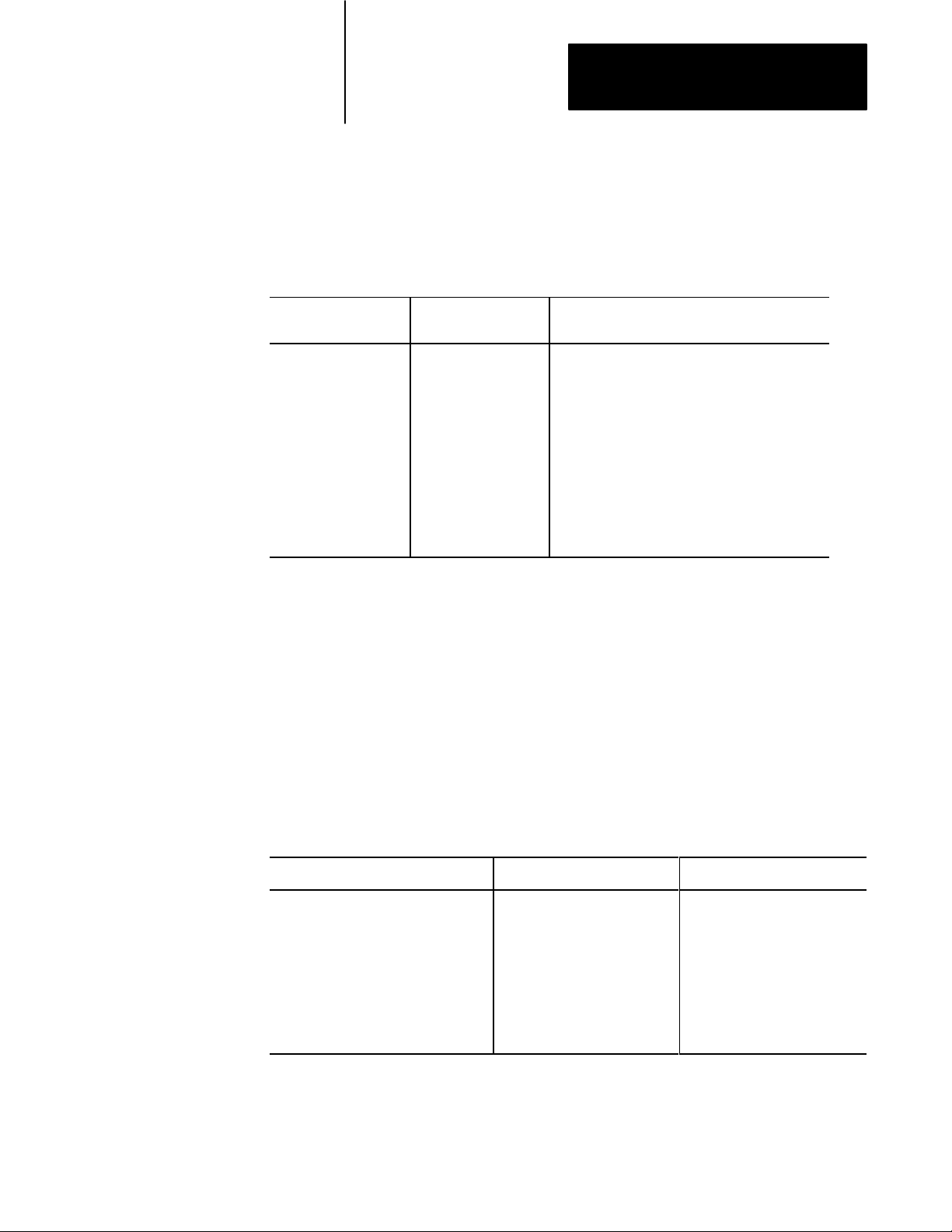

MiniPLC2/05 Processor (cat. no. 1772LS)

The Mini-PLC-2/05 Processor (cat. no. 1772-LS) comes equipped with the

following hardware features (Figure 3.1):

Figure 3.1

MiniPLC2/05

Processor (cat. no. 1772LS)

RUN

P

R

O

C

FAULT

ON

MEMORY

STORE

ON

AB

INTFC

3-2

MINI PLC2/05

W/O Power Supply

10663I

Page 29

Chapter 3

Hardware

Processor

Status Indicator

PROC RUN/FAULT: This red/green LED keeps you informed of the

processor’s operating conditions.

Table 3.A

Indication

Status

Status

Indicator

PROC RUN/FAULT Green

P/S ACTIVE Green

If the

color is

Blinking Green

Red

Off

Off

MEMORY STORE (Switch)

Purpose: Enables you to backup or copy the program into the optional

EEPROM Memory Module.

Then the Indication represents

The processor module is in the run mode and will

begin operation.

The EEPROM memory module (if present) is being

programmed.

There is a fault. Recycle power to reset the

processor module.

Either program mode of operation, run time error,

memory error or a program error.

AC and DC is all right.

There has been a power supply fault, overcurrent

condition, improper input voltage or the module has

been turned off.

Hardware: An optional EEPROM Memory Module (cat. no. 1772-MJ) can

be installed in the module.

INTFC

(Interface socket)

Purpose: The 15 pin socket, labeled INTFC, provides communication

between the processor and the programming terminal (1770-T3 or

1784-T50), the 1770-RG report generation module, the 1770-T11 hand

held terminal, the 1772-KG interface module or 1771-KA communications

interface module.

Processor Module and: Through: Catalog Number:

Industrial Terminal (cat. no. 1770T3) PLC2 Program Panel

Interconnect Cable

Industrial Terminal (cat. no. 1784T50) PLC2 Program Panel

Interconnect Cable

Data Highway Communication Modules Data Highway/Processor Cables 1771CN, CO, or CR

PLC2 Family Report Generation Module

(cat. no. 1770RG)

PLC2 Program Panel

Interconnect Cable

1772TC

1772TC or 1784CP2

1772TC

(with external ground wire only)

The 1784-T50 also requires PLC-2 6200 programming software (cat. nos.

6201-PLC2, 6203-PLC2, 6211-PLC2, or 6213-PLC2).

Function: Provides interface to the above devices.

3-3

Page 30

Chapter 3

Hardware

MiniPLC2/05 Processor (cat. no. 1772LSP)

The Mini-PLC-2/05 Processor (cat. no. 1772-LSP) contains all the

hardware features of the LS processor and in addition contains the

following (Figure 3.2):

Figure 3.2

MiniPLC2/05

RUN

P

R

O

P/S

C

FAULT

ACTIVE

MEMORY

STORE

P/S

PARALLEL

AB

INTFC

POWER

ON

OFF

I.0A 125V

SLOW BLOW

120V

AC

L1

N

GND

MINI PLC2/05

W Power Supply

Processor with Power Supply (cat. no. 1772LSP)

ON

ON

10717I

3-4

Processor

Status Indicator

P/S ACTIVE: This green LED keeps you informed of the power supply

section’s operating conditions (table 3.A).

P/S PARALLEL (socket)

Purpose: Enables paralleling connections between these two sockets on

two power supply modules.

POWER (switch)

Purpose: This is on/off toggle switch lets you provide power to

your processor.

If the switch is: Then you are:

On Supplying power to your processor module.

Off Not supplying power to your processor module.

Page 31

Chapter 3

Hardware

Fuse

Purpose: Guards against overcurrent conditions on the input line.

Sizes: 1.0 amp fuse for 120V AC operations

Terminal Strip

Purpose: To provide wire connections for the processor.

Hardware: Terminals L1, N and GND label the AC input connections.

Switch

Assembly on the I/O Chassis

Purpose: Determines processor response to memory protect and

power-up sequence.

Location: Left side of the I/O chassis backplane.

Settings:

If Then

Switch 8 is on Memory protection is on. Memory above 2008 cannot be changed by

the programmer.

Switch 8 is off Memory protection is disabled. memory can be changed by the

programmer. Memory can be changed when the processor module is

in the program mode.

Switch 6 is off Contents of the EEPROM is always transferred to the CMOS RAM at

powerup.

Switch 6 is on

and

Switch 7 is off

Switch 6 is on

and

Switch 7 is on

The settings for Switch 1- Switch 5 do not matter.

Memory transfer does not occur and the module gives a fault

indication.

If the CMOS RAM passes its checksum on powerup, the contents of

the EEPROM transfer to the CMOS RAM.

Important: Series A/Revision A of the 1770-T3 industrial terminal is not

compatible with memory protect feature.

ATTENTION: Use a ball point pen to set each switch. Do not

use a lead pencil because the tip can break off and jam

the switch.

3-5

Page 32

Chapter 3

Hardware

Optional Features

Battery

Backup

Purpose: Provides battery backup power for the processor’s memory.

Hardware: Size AA, 3.6V Lithium Battery, 1.785 amp hr, 0 to 70

o

C

Function: In order for you to retain processor memory after loss of power,

the processor contains an AA size lithium battery. A removeable holder

located at the rear of the processor module houses your battery. This

battery supports stored memory for up to two years. We recommend

documenting the start-up date of your processor. Put the date on the label

at the side of the processor.

Industrial

T

erminal

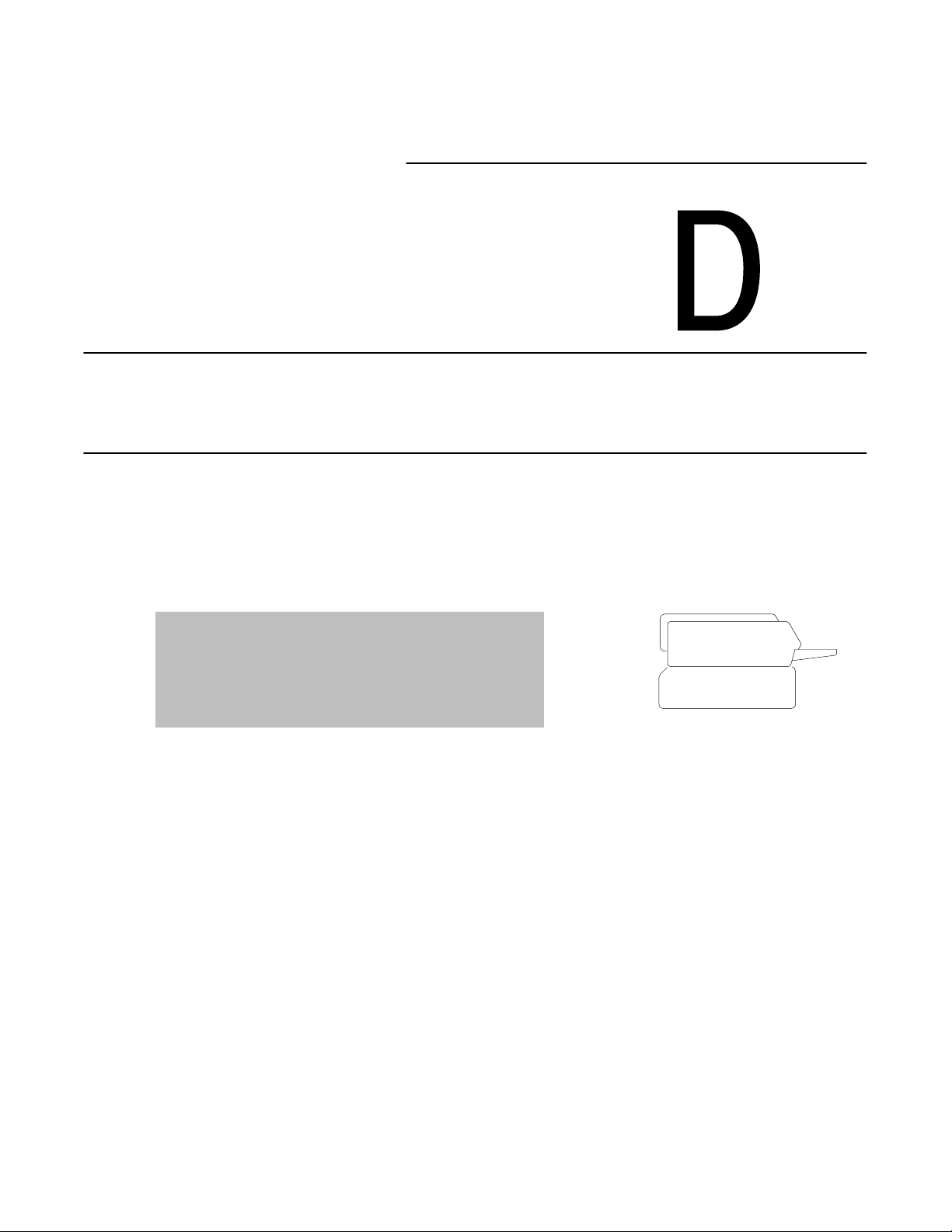

Purpose: You need the Industrial Terminal System (cat. no. 1770-T3) or an

Industrial Terminal (cat. no. 1784-T50) with 6200 programming software

(6201-, 6203-, 6211-, 6213-PLC2) to program the processor and access the

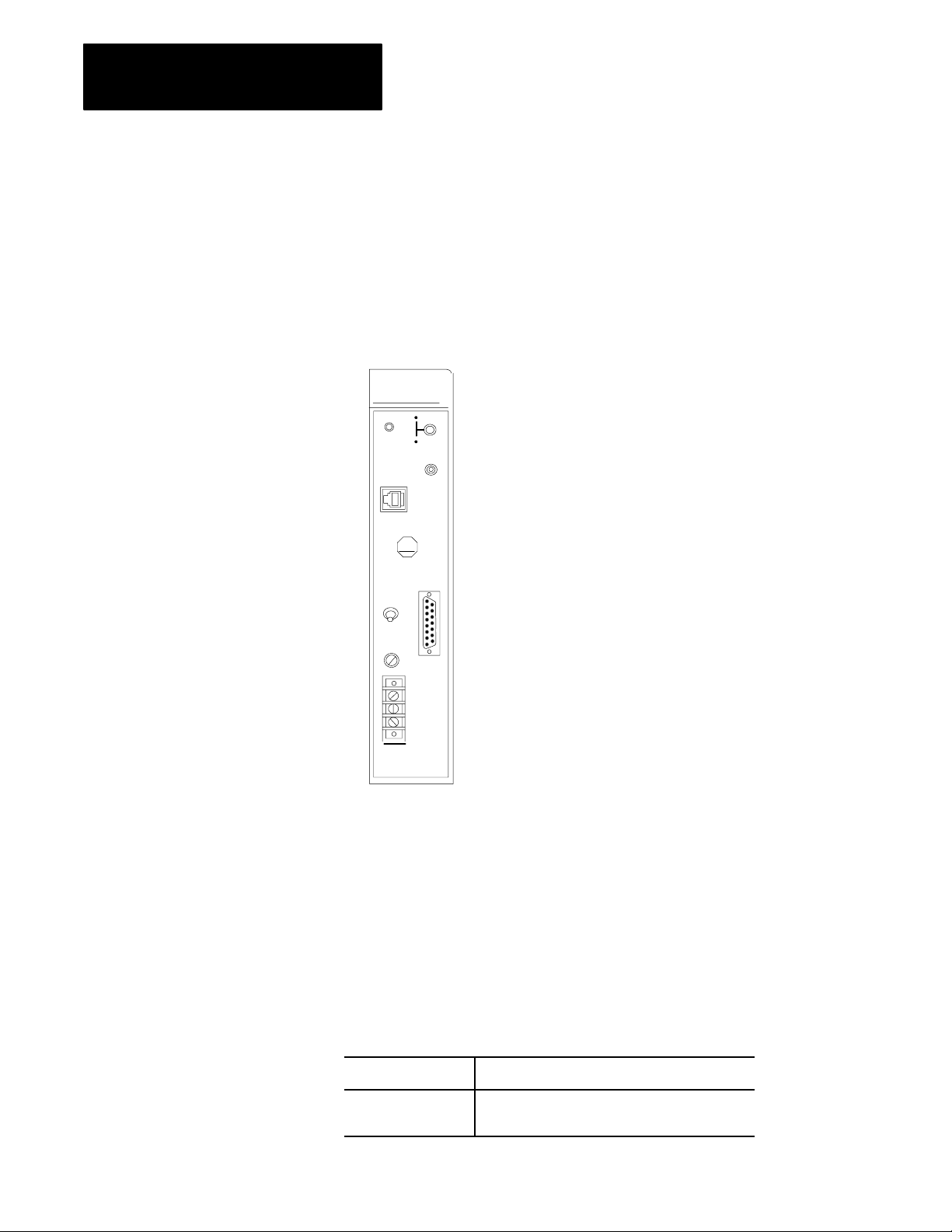

processor modes of operation (Figure 3.3).

Figure 3.3

Industrial

T

erminal System

3-6

10697I

Function: With your industrial terminal you can:

enter

edit

test

troubleshoot

your program.

Page 33

Chapter 3

Hardware

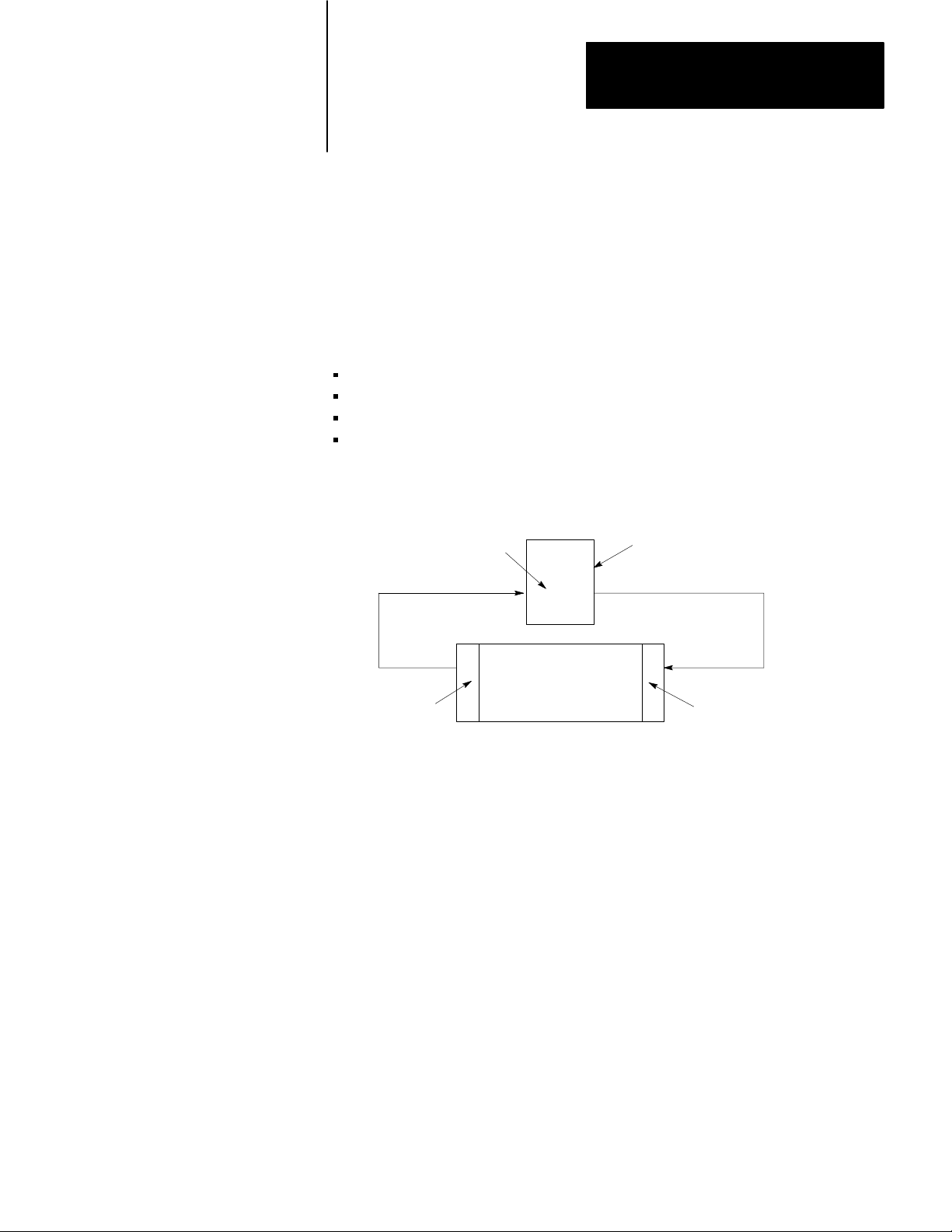

Installation

Before you start to program your processor make sure all of your

peripheral equipment is installed properly. Follow these basic instructions

to install the industrial terminal to the processor. Refer to Figure 3.4 when

following these instructions.

Figure 3.4

T

Industrial

Industrial Terminal

(rear view)

Channel A

PLC2 Family

erminal Installation

Program Panel

Interconnect Cable

MiniPLC2/05

Interface

1. Plug the ac power cord of the industrial terminal to the incoming

ac power source.

2. Connect one end of the PLC-2 Program Panel Interconnect Cable

(cat. no. 1772-TC) to CHANNEL A at the rear of the

industrial terminal.

10249

3. Connect the other end of the cable to the socket labeled INTFC at the

front of the processor.

3-7

Page 34

Chapter 3

Hardware

MODE

SELECT

DATA

INIT

EXPAND

ADDR

SBR

T.END

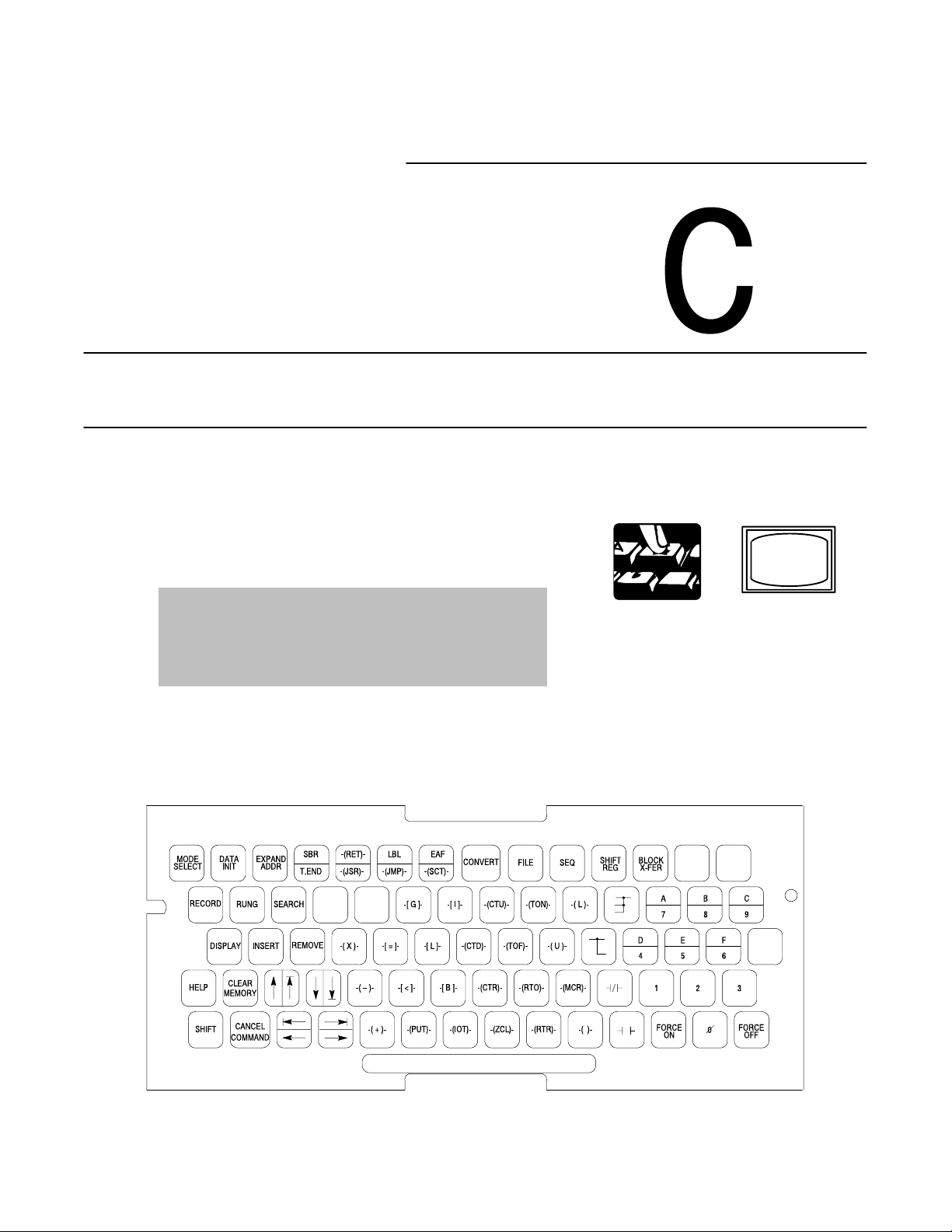

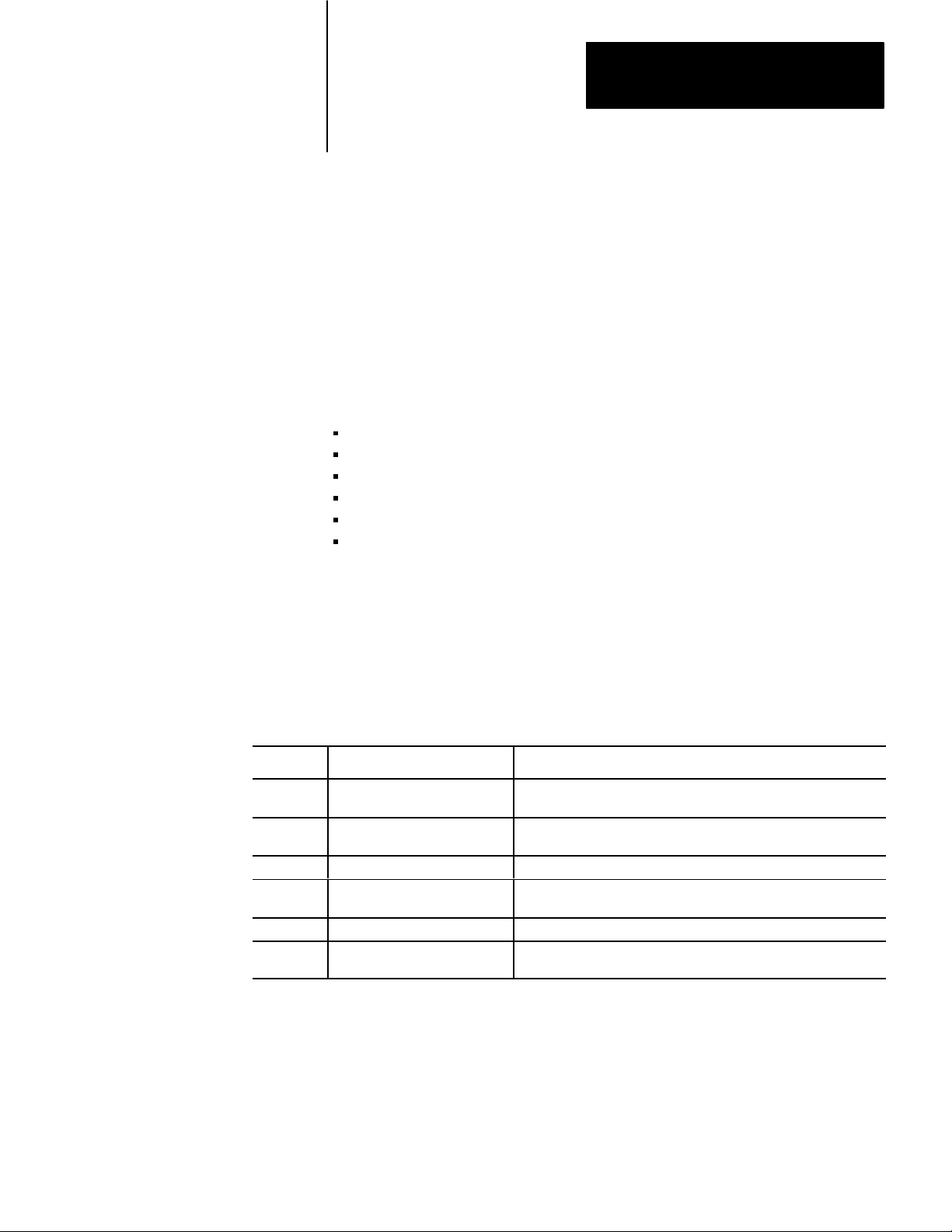

4. Place the PLC-2 Family Keytop Overlay (cat. no. 1770-KCB)

(Figure 3.5) onto the keyboard.

Figure 3.5

Family Keytop Overlay

PLC2

(RET)

(JSR)

LBL

(JMP)

EAF

(SCT)

CONVERT

FILE SEQ

SHIFT

REG

BLOCK

XFER

RECORD

DISPLAY INSERT

HELP

MEMORY

SHIFT

RUNG SEARCH

CLEAR

CANCEL

COMMAND

REMOVE

( )

( P )

( X ) [ = ] [ L ] (CTD) (TOF) ( U )

( - ) [ < ] [ B ] (CTR) (RTO) (MCR)

[ G ] [ I ] (CTU) (TON) ( L )

( + ) (PUT) (IOT) (ZCL) (RTR) ( )

FOR

USE WITH PLC2 F

AMILY CAT

. NO. 1770 KCB

A

7

D

4

123

FORCE

ON

1982 ALLENBRADLEY 97534302

Table 3.B

Definitions

This key: Does this: This key: Does this: This key: Does this:

top row of keys

MODE

SELECT

select terminal mode

DATA

INIT

of Keys

enter data into a file

EXPAND

ADDR

enter expanded address

B

8

E

5

C

9

F

6

FORCE

0

OFF

10291–I

3-8

SBR

T.END

EAF

(SCT)

SEQ

SHIFT

routine

enter temporary

– enter sub

SHIFT – enter

EAF, expanded

not applicable

math

to MiniPLC-2/05

enter sequencer

-

(RET)

(JSR)

CONVERT

SHIFT

REG

SHIFT – enter

return

enter jump to sub-

not applicable to

MiniPLC2/05

not applicable to

MiniPLC2/05

LBL

(JMP)

FILE

BLOCK

XFER

SHIFT – enter

label

enter

jump to jump

enter file instruction

enter block transfer

Page 35

second row of keys

enter new data

RECORD

RUNG

specify rung

Chapter 3

Hardware

specify search

SEARCH

( )

(CTU)

C

9

third row of keys

DISPLAY

( X )

(CTD)

enter 3digit divide

enter up counter

enter branch end

SHIFT – enter C

enter 9

display specified data

enter 3digit multiply

enter down counter

enter branch start

[ G ]

(TON)

A

7

INSERT

[ = ]

(TOF)

D

4

enter get

enter timer ondelay

SHIFT – enter A

enter 7

insert the next specified

item

enter equal

enter timer offdelay

SHIFT – enter D

enter 4

[ I ]

( L )

B

8

REMOVE

[ L ]

( U )

E

5

enter immediate input

enter output latch

SHIFT – enter B

enter 8

remove the next specified

item

enter limit test

enter output unlatch

SHIFT – enter E

enter 5

F

6

fourth row of keys

HELP

[ B ]

(MCR)

2

SHIFT – enter F

enter 6

display help directory

SHIFT

– move cur

sor down

CLEAR

MEMORY

-

( - )

clear processor memory

enter 3digit subtract

move cursor

down

enter get byte

(CTR)

enter master control reset enter examine off

enter a 2

3

enter counter reset

enter a 3

[ < ]

(RTO)

1

SHIFT

sor up

move cursor up

– move cur

enter less than

enter retentive timer

ondelay

enter a 1

-

3-9

Page 36

Chapter 3

Hardware

fifth row of keys

SHIFT

(IOT)

access function on top

half of keys that support

two functions

SHIFT

– move cur

sor right

move cursor

right

enter immediate output

CANCEL

COMMAND

-

( + )

(ZCL)

end current function

without saving

enter 3digit add

enter zone control

last state

(PUT)

(RTR)

SHIFT – move cur

sor left

move

cursor left

enter put

enter retentive timer reset

-

( )

enter output energize enter examine on

enter a 0

0

FORCE

OFF

specify force off

FORCE

ON

specify force off

5. Turn the power switch on the front of the industrial terminal to the

ON position.

6. After a short while the following display will appear.

DIAGNOSTICS PASSED

MODE SELECTION

KEYBOARD MODULE 1770-FDC SERIES B/E

FOR USE WITH

THE FOLLOWING

PROCESSORS:

PLC

MINI-PLC-2, PLC-2

MINI-PLC-2/15

PLC-2/20 (LP1)

PLC-2/20 (LP2)

PLC-2/30

10 = PLC

= PLC-211

12 = ALPHANUMERIC

INSERT

KEYTOP OVERLAY:MODE:

1770-KBA

1770-KCB

1770-KAA

3-10

SELECT DESIRED MODE?

11595

Select your desired processor mode by pressing 11 on the

1770-T3 terminal.

7. After initialization has been completed, select the processor mode of

operation using the keystrokes below:

Page 37

Chapter 3

Hardware

Run/Program [SEARCH] 590

Remote test [SEARCH] 591

Remote Program [SEARCH] 592

ATTENTION: Use only Allen-Bradley authorized

programming devices to program Allen-Bradley programmable

controllers. Using unauthorized programming devices may

result in unexpected operation, possibly causing equipment

damage and/or injury to personnel.

Important: When power is re-applied following a power failure and if

switch 6 is on, the processor returns to the last programmed mode

of operation.

If you are not familiar with each mode of operation, here is the way we

define each term:

Run/Program - This is the normal mode of operation where the

program controls your outputs. you can edit your program and make

on-lien data changes when you are in this operational mode.

Remote Test - The program is executed, the inputs are scanned, the

outputs are disabled. The selectable timed interrupts are executed.

Remote Program - The processor stops scanning and executing its

stored program and waits for commands from the programmer. If you

have an optional EEPROM memory module, you must be in the remote

program mode when duplicating RAM memory contents to the

EEPROM memory module. Refer to Memory Module Product Data

(publication 1771-936) for operational details on memory transfer.

Industrial

T

erminal Keyboard

Function: The detachable keyboard houses PROM memory, a sealed

touchpad, and a keytop overlay.

There are three keytop overlays:

PLC-2 Family - for use with any PLC-2 family processor.

PLC - for use with any PLC family processor.

Alphanumeric - for alphanumeric characters and graphic

characters generation.

Key Symbols - There are no numbered keys greater than 9. To display

numbers which are greater than 9 press the individual keys. For example:

3-11

Page 38

Chapter 3

Hardware

To display: 1011

Press individually: 1011

Some keys have two symbols occupying one key (Figure 3.5). To display

the top section of each key use your shift key before the desired symbol.

For example:

Press 7: To display 7

Press[SHIFT] A: To display A

Data Monitor Functions - You can display on a CRT and print directly to a

data terminal - binary, hexadecimal, and ASCII data monitor functions by

performing the keystrokes in table 16.B.

Chapter Summary

Paralleling

Cable

Purpose: using the 1772-CT parallel cable, you can parallel with 1772-P3,

1771-P4 power supply for start up.

EEPROM Memory Module

Purpose: Provides you with a 3K non-volatile backup.

Hardware: EEPROM Memory Module (cat. 1772-MJ)

Function: After you’ve entered the application program into the processor

module’s CMOS RAM memory, the program can be copied into

the EEPROM.

So far, we’ve briefly described the hardware associated with your

Mini-PLC-2/05 processors. The next chapter explains memory and how the

processor stores and manipulates data. Read the next chapter carefully. It

is a fundamental concept that you must master before continuing.

3-12

Page 39

Memory Organization

Chapter

4

Chapter Objectives

Introduction

In this chapter, you will read about:

hardware and its relationship to your program

memory and its components

This chapter provides detailed concepts of the memory’s organization and its

structure. Understanding these concepts aids you in programming your

processor.

Before we explain memory organization and its structure, read the

following definitions:

Bit - the smallest unit of information that memory is capable of retaining

Byte - a group of 8 consecutive bits (00-07

Word - a group of 16 consecutive bits (00-17

Hardware and Your Program

Figure 4.1 and the following chart represents how the hardware of your

processor relates to the input and output image tables. Understanding the two

figures help you understand programming.

or 10-1708)

08

)

08

41

Page 40

Chapter 4

Memory Organization

Figure 4.1

Address Equals Memory Bits

Word

Concept Example

Hardware Terminology Hardware Terminology

Input (1) or Output (0)

Rack No. (Always 1)

Module Group No.

(0-7)

Terminal No.

(00-07, 10-17)

X X/XXX

Word

Address

I/O terminal bit

module group word

module slot byte

one rack eight words

if the terminal has voltage (on state) a specific bit is on, which is a 1 in memory

if the terminal has no voltage (off state) a specific bit is off, which is a 0 in memory

Bit

Address

Data Table Terminology

Hardware vs Your Program

0 0/121

Word

Address

Data Table Terminology

Output: 0

Rack No.: 1

Module Group No.: 0

Terminal No.: 12

Bit

Address

10248

42

To calculate the input and output image tables’ areas and how these values

compare with the hardware of your processor.

Remember: 1 rack = 8 words

You can only have one rack in this system.

Therefore: 8 words/rack x 16 bits - 128 I/O

Conclusion: The combined amount of usable bits in the input image

table and/or the output image table is 128 I/O.

Page 41

Chapter 4

Memory Organization

Memory Areas

Memory is divided into three major sections: data table, user program and a

message storage area. The areas store input status, output status, your program

instructions and messages.

We describe these areas in detail so you can gain programming flexibility using

your processor.

Data Table

The first part of memory is the data table (Figure 4.2). The processors are

factory configured for 128 words. Figure 4.3 shows memory structure with a

factory configured data table. The specific concepts throughout this publication

refer to a factory configured data table.

Figure 4.2

Memory

Structure

Data Table

Main Program

Subroutine

Message Storage Area

User Program

10151I

43

Page 42

Chapter 4

Memory Organization

Figure 4.3

Table Organization, Factory Configured

Data

Total

Decimal

Words

8

16

24

64

72

Decimal

Words

Per

Area

8

8

8

40

8

Processor Work Area

No. 1

Output

Image Table

Bit/Word Storage

Reserved

2

Timer/Counter

Accumulated Values (AC)

(or Bit/Word Storage)

Processor Work Area

No. 2

Input

Image Table

Word

Address

000

007

010

017

020

1

026

027

030

3

077

100

Bit

Address

00

17

00

17

00

17

00

17

00

FactoryConfigured

Data

Table

6

Maximum

Size of

Data Table

17

107

00

110

80

88

8

Bit/Word Storage

4

8

Timer/Counter

Preset Values (PR)

128

40

(or Bit/Word Storage)

Expanded Data Table

2944

2816

3072 128

May not be used for accumulated values.

1

Not available for bit/word storage. Bits in this word are used by the processor.

2

3

Unused timer/counter memory words can reduce data table size and increase user program area.

4

May not be used for preset values.

Do not use word 127 for block transfer data storage.

5

and/or User Program

User Program

Can be decreased to 48 words.6

44

17

117

00

120

5

17

127

00

130

17

177

00

200

5577 17

End of Memory

10148I

Page 43

Chapter 4

Memory Organization

The data table area is a major part of memory. It is divided into six sections

which includes the input and output image tables. (These two areas were

described in chapter 2). The processor controls and utilizes words stored in the

data table. The input devices coupled with the control logic from your program

determines the status of the output devices. Input devices are limit switches,

pushbutton switches, pressure switches, etc. Output devices are solenoids,

motor starters, alarms, etc. Transfer of input data from input devices and the

transfer of output data to output devices occur during I/O scan. If the status of

the output instruction changes in the program then the on or off status of the

output devices update during the I/O scan to reflect the change.

To use the data table, you must understand the following:

The processor initially reserves the first 128 words in the memory for the

data table.

You can decrease the data table size to 48 words in two word increments.

You can increase the data table size to 256 words in two word increments.

Then you can increase the data table size in blocks of 128 words.

When the data table is set to 256 words, you can program up to 104

timer/counter instructions.

You can change the data size from 48 words to 2,944 words using the

1770-T3 terminal.

Data Table Expansion

Using the 1770-T3 industrial terminal, you can adjust the data table size to be

anywhere from 48 words to 2944 words. Expanding the data table provides

additional timers/counters and space for files (see chapter 8 for timers/counters

and chapter 10 for file information), but it also proportionally reduces the

program storage and memory areas.

Expansion is in increments of two words until a table of 256 is reached and then

in increments of 128 words.

Important: When using the data table expansion capability, allow sufficient

room for both data table and user program.

45

Page 44

Chapter 4

Memory Organization

SEARCH

50

To expand your data table do this:

The

word SEARCH appears in the lower left hand corner of

the screen.

DAT

A TABLE CONFIGURA

TION

NUMBER OF 128WORD D.T

NUMBER OF INPUT/OUTPUT RACKS

NUMBER OF T/C (if applicable)

DAT

A T

ABLE SIZE

. BLOCKS

01

2

40

128

The following chart helps you adjust the data table size for your processor:

Enter Data Table Size

01 128

02 256

03 384

04 512

05 640

06 768

07 896

08 1024

09 1152

10 1280

11 1408

12 1536

13 1664

14 1792

15 1920

16 2048

17 2176

18 2304

19 2432

20 2560

21 2688

22 2816

23 2944

46

After you adjust the data table, press [CANCEL COMMAND].

Important: Other industrial terminal commands are summarized in

appendix C.

Page 45

Chapter 4

Memory Organization

Data Table Areas

The following areas make up the data table. They are:

processor work area no. 1

output image table

bit/word storage (020-027)

timer/counter accumulated values and internal storage

processor work area no. 2

input image table

bit/word storage (120-127)

timer/counter preset values and internal storage

Chapter 1 describes the input and output image tables. The following sections

describe the remaining areas.

Processor Work Areas

Purpose: The processor uses these 16 words for its internal control functions.

Description: There are two processor work areas. They are located at addresses

000-007 and 100-107. You cannot access these data table words. Their word

addresses are not available for addressing.

Important: The term address is defined in chapter 6. Remember, all addresses

are in octal values.

Accumulated Values and Internal Storage

Purpose: Stores accumulated values of timer or counter instructions. This area

also stores data by words and/or bits from your program instructions

(addresses 030-077).

Description: Each timer or counter instruction uses two words of data table.

one word is stored in the accumulated value area, the other is the preset value

area. When the accumulated value equals the preset value (AC=PR), a status bit

is set and can be examined to turn on or off an output device.

Preset Values and Internal Storage

Purpose: Stores preset values (PR) of timer or counter instructions. This area

also stores data by words and/or bits from your program (addresses 130-177).

Description: The preset value is the number of timed intervals or events to be

counted. The preset value is 100 octal words above the accumulated word.

Therefore, a timer/counter having an address of 030 automatically has its preset

value stored at address 130.

47

Page 46

Chapter 4

Memory Organization

User Program

The second major part of memory is the user program (Figure 4.2). It is divided

into two areas:

main ladder diagram program

subroutine area

The user program area begins at the end of the data table.

Main Program

Purpose: The program is a group of ladder diagram and functional block

instruction used to control an application.

Description: A program is a list of instructions that guides the processor. These

instructions can examine or change the status of bits in the memory of the

processor. The status of these bits determines the operation of output devices.

The program specifies the things you want done in your application and the

conditions that must be met before those things are done. For example, if you

want a solenoid energized when a limit switch is closed, you would specify:

Condition: If limit switch is closed

Action: Energize solenoid

Programming logic differs from relay logic in an important way. Programming

logic is only concerned with whether or not conditions have been met. These

conditions may be open or closed input or output devices. We must have a

continuous or unbroken path of true logic conditions for an action to be taken.

The number of conditions is not important. There can be none, one, or many

conditions preceding an output action.

When the path of conditions is continuous, we say that the rung is true. When

the path of conditions is not continuous, we say the rung is false.

Subroutine Area

Purpose: Used to jump to a defined ladder diagram area. This allows you to

perform ladder diagram subroutines.

Description: The subroutine area is between the main program and the message

store areas. This area acts as the end of program statement for the main

program. It allows storage of small programs that are to be accessed

periodically. Subroutine areas are not scanned unless you program the

processor to jump to this area.

48

A maximum of eight subroutines can be programmed in the subroutine area.

Each subroutine begins with a label instruction and (when you want to exit to

your main program) ends with a return instruction.

Page 47

Chapter 4

Memory Organization

Message Storage Area

The third major part of memory is the message storage area (Figure 4.2). You

can print out messages in hard copy form. You can store up to 70 messages

using the 1770-T3 industrial terminal, or 198 messages using the 1770- T3

terminal with the 1770-RG module.

Message storage follows the end statement of your program and is limited by

the number of unused words remaining in memory. Each word stores two

message characters. A character is any alpha or numerical figure (this includes

blank spaces).

Messages are written to display current data table information such as the

number of parts rejected in a production run for a particular time period. you

can write your program to display messages when a pushbutton switch

is activated.

Chapter Summary

Address 027 controls messages 1-6. You designate control words which control

your messages in groups of 8. Your control word must be arranged in

consecutive order.

Report generation (see chapter 17) is a function of your message control words.

Reserve bit addresses 02710 thru 02717 for this automatic report generation

function to determine status of this function. These bit addresses should not be

used for any other functions if you want to achieve maximum flexibility within

your program.

We described detailed concepts of memory organization and its structure. The

next chapter explains how the processor scans the program.

49

Page 48

Scan Theory

Chapter

5

Chapter Objectives

Scan Function

In this chapter you will read about:

scan function

scan time

The processor controls the status of output devices or instructions in accordance

with program logic. Every instruction in your program requires execution time.

These times vary greatly depending upon the instruction, the amount of data to

be operated on, and whether the instruction is true or false.

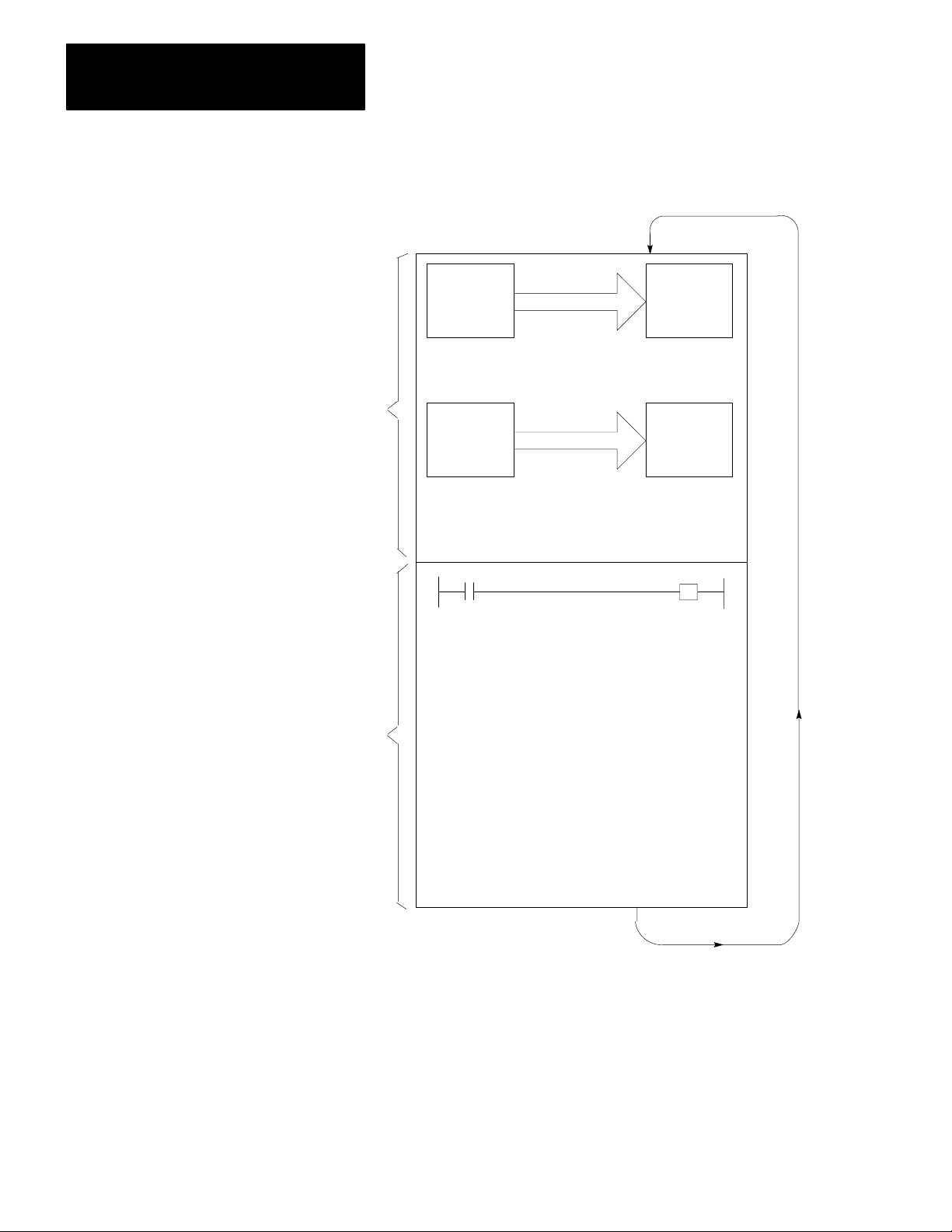

As a review from chapter 1, there are two types of scans (Figure 5.1):

I/O scan (775µs without forcing: 1 ms with forcing)

Program scan (15ms/K of user memory)

51

Page 49

Chapter 5

Scan Theory

Figure 5.1

Sequence

Scan

I/O

Scan

Program

Scan

Output

Image

Table

Input

Terminals

Output

Terminals

Copy output image table status

into output terminal circuits.

Input

Image

Table

Copy input terminal status into

input image table

Program Statement

52

Execute each program rung in

sequence, writing into bits in the

data table, including the output

image table.

11597

Page 50

Chapter 5

Scan Theory

On power-up, the processor begins the scan sequence with the I/O scan. Data

from output image table is written to the output modules. Data from the input

modules is read into the input image table.

Next, the processor scans the program statement by statement:

1. For each condition, the processor checks, or “reads,” the image table to see

if the condition has been met.

2. If the set of conditions has been met, the processor writes a one into the bit

location in the output image table corresponding to the output terminal to

be energized. On the other hand, if the set of conditions has not been met,

the processor writes a zero into that bit location, indicating that the output

terminal should not be energized.

Important: When your processor is in the remote test mode, all outputs are

held off. When your processor is in the run/program mode, all outputs are

controlled by the user program.

Average Scan Time

Average scan time is the average amount of time it takes the processor to

monitor and update input and outputs, and to execute instructions in the

program. The scan is performed serially; first the I/O image table is updated,

(other parts of the data table are not scanned), then the user program is scanned.

There are two ways to measure average scan time:

Append the rungs in Figure 5.2 to your program.

Figure 5.2

Average

031

14

031

14

031

14

031

14

Scan T

ime

Store

032

1

GG

000

010

Rung 1

Rung 2

Rung 3

Rung 4

Rung 5

Rung 6

031

CTU

PR 999

AC 000

031

CTU

PR 999

AC 000

032

RTO

0.1

PR 999

AC 000

Store

Store

23

000 .

:

000

032

RTR

PR 999

AC 000

032

RTR

PR 999

AC 000

:

53

Page 51

Chapter 5

Scan Theory

Add the execution values for each instruction by using Table 5.A. The sum of

these values added to the I/O scan time is the average scan time.

Table 5.A

Approximate

Instruction Name Symbol

Examine on, Examine off

Output energize

Output latch (L) 17 13

Output unlatch (U) 17 13

Get [G] 28

Put (PUT) 26 14

Equal (=) 23 11

Less than (<) 25 13

Get byte |B| 16

Limit test |L| 24 11

Counter reset (CTR) 20 14

Retentive timer reset (RTR) 20 14

Timer ondelay (TON) 75 47

Retentive timer ondelay (RTO) 78 48

Timer offdelay (TOF) 82 60

Up counter (CTU) 70 55

Down counter (CTD) 75 60

3 Digit Math

Add (+) 48 15

Subtract () 80 19

Multiply (x)(x) 615 60

Divide

Add to any of the above when its

address is 4008 or greater

Expanded Math

Add EAF 01 400500 40

Subtract EAF 02 400500 40

Multiply EAF 03 8002250 40

Divide EAF 04 5003250 40

Square root EAF 05 1850 40

BCD to binary EAF 13 500 40

Binary to BCD EAF 14 500 40

Master control reset (MCR) 16 16

Zone control last state

Branch start 16 16

Branch end 18 18

End, temporary end T.END 27 27

Subroutine area SBR 27 27

Immediate input update

Immediate output update (IOT) 70(with forcing on 80) 17

1

Execution T

ime Per Scan (in average microseconds)

Instruction

True

| |,| / |

( )

( ÷ )( ÷ )

(ZCL) 22(no skip) 20+(13 per word skipped)

[ I ]

45 (with forcing on 55)

14 11

16 16

875 60

27 27

Instruction

False

54

Page 52

Chapter 5

Scan Theory

Instruction Name

Label LBL 34

Return (RET) 30 15

Jump to subroutine (JSR) 100 15

Jump (JMP) 55 15

Block transfer read BLOCK

XFER 1

Block transfer write BLOCK

XFER 0

Sequencer load SEQ 2 390(80/extra word) 105

Sequencer input SEQ 1 420(90/extra word) 55

Sequencer output SEQ 0 470(90/extra word) 110

Filetoword move FILE 12 250 45

Wordtofile move FILE 11 250 45

Filetofile move FILE 10440 (+10/word

transferred)

1

When a rung that contains a ZCL instruction is false, the execution time of each instruction between the start fence and

end fence is 17 microseconds per word.

Instruction

TrueSymbol

80 75

80 75

200

Instruction

False

Here is an explanation of the rungs in Figure 5.2:

Rung 1 - The count increments its accumulated value each time this rung

is true.

Chapter Summary

Rung 2 - This rung enables the counter to increment on the next scan. If we did

not have this rung, the counter would always be true and it would not

increment. Remember: Counters increment only on false to true transitions.

Rung 3 - The timer times in tenths of seconds when we are counting. This

value is displayed on the industrial terminal screen.

Rung 4 - The average scan time is displayed beneath store 2 and store 3

in milliseconds.

Important: Refer to three digit math in chapter 10.

Rung 5 - The counter overflow bit is re-setting the timer.

Rung 6 - The counter overflow bit is resetting the counter.

We described scan sequence and a method to measure average scan time. The

next chapter explains some of the instructions you use in a program.

55

Page 53

Relaytype Instructions

Chapter

6

Chapter Objectives

Programming Logic

This chapter describes:

relay-type instructions

how to define conditions before an action takes place

A program is a list of instructions that the processor executes. These

instructions can examine or change the status of bits in the data table of the

processor. The status of these bits can determine the operation of

other instructions.

The program you specifies the order of things you want done in your

application and the conditions that must be met before those things are done.

For example, if you want a solenoid energized when a limit switch is closed,

you specify:

Condition: if limit switch is closed

Action: energize solenoid

Programming logic differs from relay logic in an important way. Programming

logic is only concerned with whether or not conditions have been met. These

conditions may be open or closed input or output devices. We must have a

continuous or unbroken path or true logic conditions for an action to be taken.

The number of conditions is not important. There can be none, one, or many

conditions preceding an output action.

Perhaps an example might make this clearer:

True

C1

True

False

Here, a series of conditions (C2, C2, C3) must be true before action A

is performed.

True

C2

True

C3

A

61

Page 54

Chapter 6

Relay-type Instructions

C1 = Input switch 1. When the switch is on, this condition is true. This switch

turns on a conveyer belt.

C2 = Input sensor 1. When the sensor is off, this condition is true. This sensor

detects if the temperature in the factory is below 40

o

C.

C3 = Input sensor 2. When the sensor is on, this condition is true. This sensor

detects the presence of a part of the conveyer belt.

A = The part will be drilled. = The path of conditions is continuous, that is, all

conditions are true.

When C1, C2, and C3 are true, then a continuous path is made to a particular

action. In this case, the continuous path causes the part to be drilled. When the

path of conditions is continuous, we say that the rung is true. When the path of

conditions is not continuous, we say the rung is false.

True

C1

True

False

False

C2

True

C3

A

Here the path of conditions is not continuous because condition 2 is false.

Therefore, the action A is not performed. We say the rung is false.

62

Set vs. Reset

As a review, if the device goes on, then we say the corresponding bit in data

table is set to a 1. If the device goes off, we say the corresponding bit in data

table is reset to a 0. (From this point on, set means the on-condition or 1. Reset

means the off-condition or 0.)

If the device is: Then a bit in memory is

on set

off reset

Addresses

The processor scans the status of inputs and controls output devices. It does not

go to the input or output terminals to see if outputs are on or off. Rather, it

checks the status of the input and output devices by scanning corresponding bits

in the input and output image area of the data table. The processor uses

addresses to refer to words and bits in the data table.

Page 55

Chapter 6

Relay-type Instructions

Each input and output bit has a five-digit address. Reading from left to right:

the first number denotes the type of I/O module:

- 0 output

- 1 input

the second number denotes an I/O chassis and it always is a 1.

the third number denotes a module group. This number will range from 0-7.

the fourth and fifth numbers denote a terminal designation:

- 00-07 left slot of the module group

- 10-17 right slot of the module group

Important: Remember a Mini-PLC-2/05 processor can use only one rack.

Important: For addressing purposes, I/O modules in a given I/O rack are

organized into “module groups.” A module group is a pair of adjacent I/O

modules. Thus, the module group number of an individual I/O module depends

only on the I/O slot the module occupies. It is important to note that the first

module group in any I/O chassis is always module group 0.

Programming Instructions

You can use seven programming instructions to write a program. These

instructions are divided into three categories: bit examining, bit controlling, and

branch instructions.

Bit Examining

Examine On and Examine Off

Purpose: The Examine On -] [- and Examine Off -]/[- instructions tell the

processor to examine a bit at a specified data table location

112

04

Bit Examining

Examine On

112

05

Bit Examining

Examine Off

Determines the bit condition. The bit condition becomes:

012

13

012

14

True - Examine On detects a bit in the data table that is set.

True - Examine Off detects a bit in the data table that is reset.

False - Examine On detects a bit in the data table that is reset.

False - Examine Off detects a bit in the data table that is set.

63

Page 56

Chapter 6

Relay-type Instructions

Keystrokes: Enter an Examine On or Examine Off instruction by performing

the following steps.

1. Press either -] [- or -]/[- as required.

2. Enter <address>.

Removing the Examine On or Examine Off Instruction

You remove an Examine On or a Examine Off instruction by performing the

following steps.

1. Position the cursor over the Examine On or Examine Off instruction you

want to remove.

2. Press [REMOVE] -] [- or -]/[-.

Editing a Partially Completed or a Completed Rung

You edit an Examine On or Examine Off by performing the following steps.

If you are editing a completed rung, proceed to step 1. If you are editing a

partially completed rung, enter the next instruction and proceed to step 1.

1. Position the cursor over the Examine On or Examine Off instruction you

want to edit.

2. Press either -] [- or -]/[- or any other appropriate instruction type key.

3. Enter <address>.

Bit Controlling

Output Energize

Purpose: This Output Energize instruction tells the processor to set or reset a

specified data table bit.

112

06

Controls a specific bit based on the rung condition. When its rung

conditions are:

012

15

Bit Controlling