Page 1

MiniPLC2/02, 2/16, 2/17 Processor

(cat. no. 1772LZ, LZP, LX, LXP,

LW, LWP)

User Manual

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences

between solid state products and electromechanical products, those responsible

for applying and using this product must satisfy themselves as to the

acceptability of each application and use of this product. For more information,

refer to publication SGI-1.1 (Safety Guidelines For The Application, Installation

and Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended

solely to illustrate the text of this manual. Because of the many variables and

requirements associated with any particular installation, Allen-Bradley Company

cannot assume responsibility or liability for actual use based upon the illustrative

uses and applications.

No patent liability is assumed by Allen-Bradley Company with respect to use of

information, circuits, equipment or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written

permission of the Allen-Bradley Company is prohibited.

Throughout this manual we make notes to alert you to possible injury to people

or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

- Identify a hazard

- Avoid the hazard

- recognize the consequences

Important: Identifies information that is critical for successful application and

understanding of the product.

Page 3

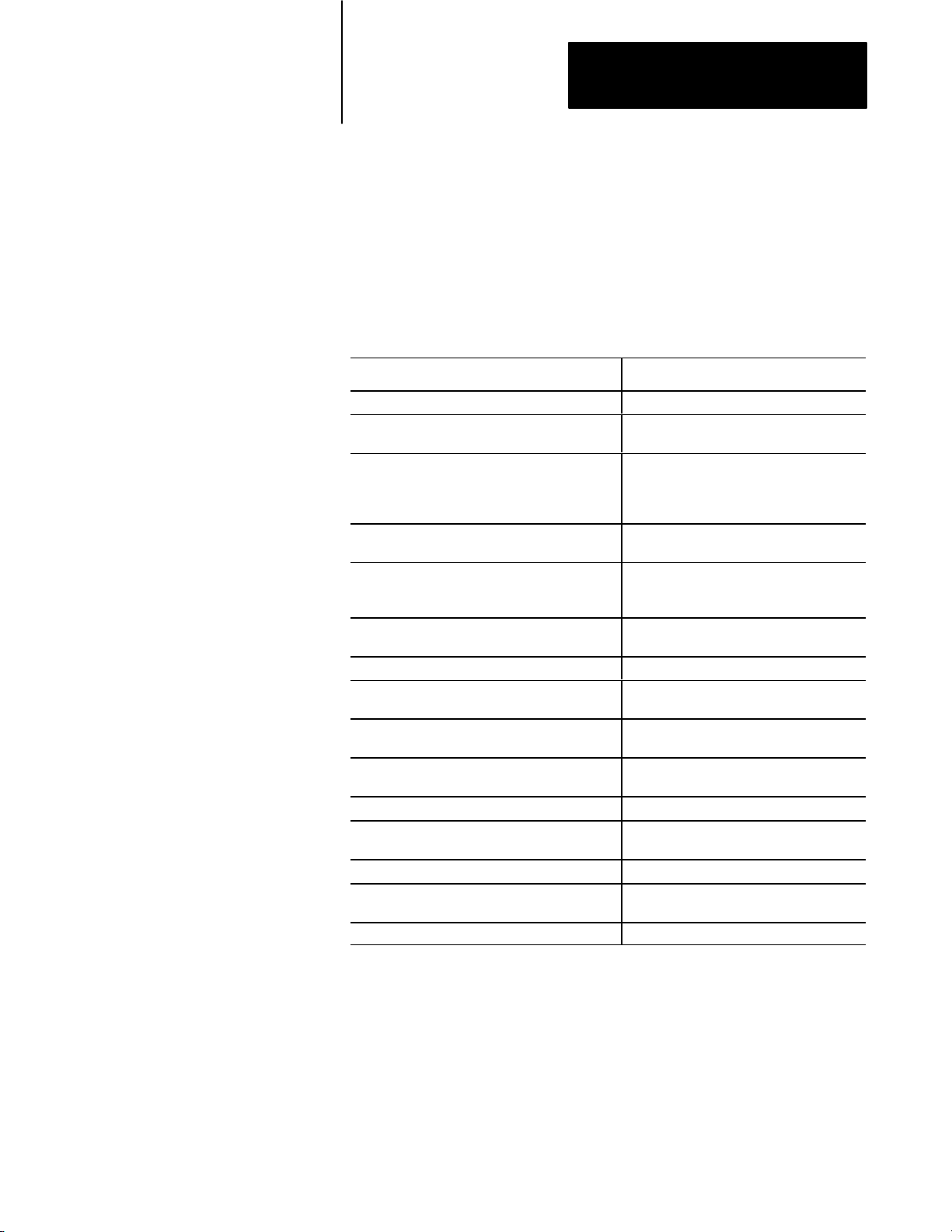

Summary of Changes

Summary of Changes

Summary of Changes

This release of the publication contains updated information:

For this updated information: See:

revised conventions chapter 1

clarified ATTENTION statement about using

1770XZ batteries

revised illustrations showing the new chassis

(1771A1B, A2B, A3B, A3B1, and A4B)

minor corrections to the structure for

2slot addressing

added information about adding Branch Start and

Branch End instructions while programming

on line

corrected last counter address information for

counter instructions

minor corrections to Limit Test examples chapter 12

added more information about output alarms and

output limits

minor correction to FIFO ladder diagram examples chapter 15

added warning about using Jump instructions;

corrections to programming examples

corrections to programming examples chapter 18

added warning about using selectable timed

interrupt routines

minor revisions to programming examples chapter 25

clarified the Important statement about

illegal opcodes

new format all chapters and appendices

chapter 3

chapter 3

chapter 4

chapter 5

chapter 10

chapter 7

appendix E

chapter 9

chapter 11

chapter 16

appendix E

chapter 17

chapter 22

chapter 26

To help you find new information in this publication, we have included

change bars as shows to the left of this paragraph.

i

Page 4

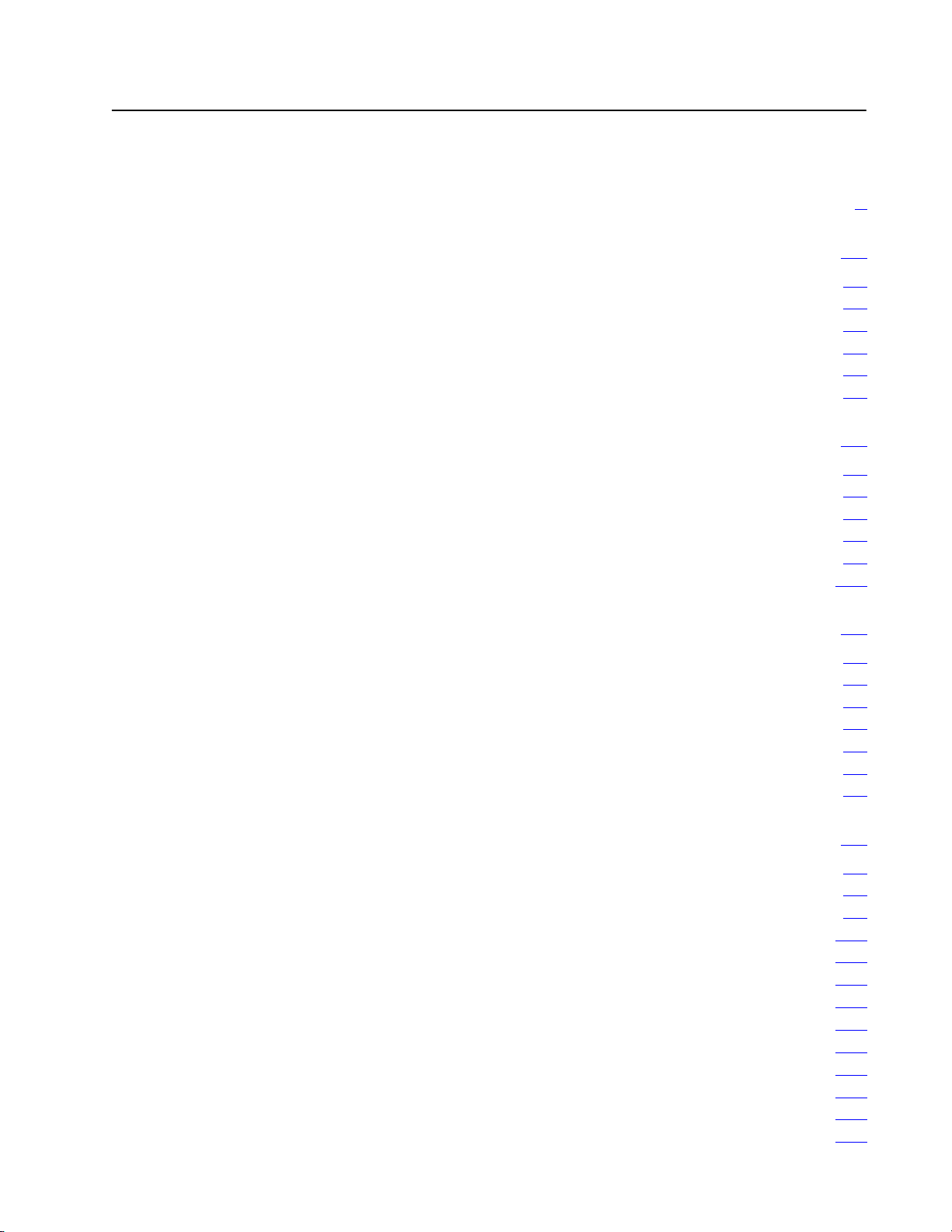

Table of Contents

Summary of Changes

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Using This Manual 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Differences 11

What's this User Manual Contains 12

Vocabulary 12

Conventions 13

Related

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Publications

11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fundamentals of a Programmable Controller 21. . . . . . . . . . .

Chapter

Traditional Controls 21

Programmable Systems 22

The Four Major Sections 22

Control Sequence 29

Scan Sequence 210

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Features 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

i

Chapter

Major Features 31

Processor Features 31

Series Changes 32

Special Features 33

Processors 33

Optional

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment

31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

37. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Your Programmable Controller 41. . . . . . . . . . . . . .

Chapter

Related Hardware 41

Planning Your Processor System 42

How

Step 1 - Mounting the Backpanel 414

Step 2 - Mounting and Grounding Components on the Backpanel 415

Step

Step 4 - Installing Keying Bands and Field Wiring Arms 424

Step

Step 6 - Backup Battery 428

Step

Step 8 - Installing the Processor 431

Step 9 - Installing the Power Supply 431

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

to Install Y

3 - Setting the Switches within the Switch Group Assembly

5 - Installing I/O Modules

7 - Installing the EEPROM Memory Module

our Processor 413. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

.

422. .

426. . . . . . . . . . . . . . . . . . . . . . . . . .

429. . . . . . . . . . . . .

Page 5

Table of Contentsii

Step 10 - Connecting to the Field Wiring Arms 432. . . . . . . . . . . . . . .

Step 11 - Connecting Power to the Processor or Power Supply 437

Step 12 - Connecting the Industrial Terminal 442

Master Control Relay 443

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . .

Starting Your Processor 51. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Verify Your System's Addresses 51

Status Indicators for I/O Modules 53

Addressing Your Hardware 54

Before You Supply AC Power 518

Testing Output Devices 518

Testing Input Devices 520

Objectives

51. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintaining and Troubleshooting Your Processor 61. . . . . . .

Chapter

General 61

Preventive Maintenance 61

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Organization 71. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Introduction 71

Memory Areas 72

Adjusting the Data Table 77

Expanding the Data Table Between 48 and 128 Words 77

Expanding the Data Table Between 130 and 256 Words 79

User Program 711

Message Storage 711

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

71. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . .

Scan Theory 81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Scan Function 81

Average Scan Time 83

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

81. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RelayLike Instructions 91. . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Programming Logic 91

Bit

Examine On and Examine Off 94

Bit

Output Energize 95

Output

Branching Instructions 98

Objectives

Examining

Controlling

Latch/Unlatch

91. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

93. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

95. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

96. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 6

Table of Contents iii

Branch

Start/End

Nesting 911

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

99. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Control Instructions 101. . . . . . . . . . . . . . . . . . . . . .

Chapter

Introduction 101

Output Override Instructions 101

Immediate

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

I/O Update Instructions

101. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

105. . . . . . . . . . . . . . . . . . . . . . . .

Timers and Counters 111. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Introduction 111

Timer Instructions 112

Timer On Delay 112

Timer

Retentive Timer On 114

Retentive Timer Reset 115

Counter Instructions 117

Up Counter 117

Down Counter 118

Counter Reset 119

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Of

f Delay

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

111. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Manipulation and Comparison Instructions 121. . . . . . . .

Chapter

Get 121

Put 122

Compare Instructions 123

Equal To 123

Less Than 124

Limit Test 125

Operations Involving Transfer and Comparison Instructions 128

Equal To or Less Than 128

Greater Than 129

Equal To or Greater Than 1210

Get Byte 1211

Get

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Byte/Put

121. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ThreeDigit Math Instructions 131. . . . . . . . . . . . . . . . . . . . . .

Chapter

ThreeDigit

Entering a ThreeDigit Math Instruction 133

Objectives

Math

131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

131. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

Page 7

Table of Contentsiv

EAF Math Instructions 141. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Two Operand EAFs 141

Addition and Subtraction 146

Multiplication and Division 148

Y

One Operand EAFs 1410

Exponential and Square Root 1414

10

Reciprocal 1418

BCD to Binary 1419

Binary

EAF

Chapter

One Operand EAFs 151

Log to Base 10 or Log to Base e 155

Sine and Cosine 156

FIFO Load and FIFO Unload 157

Objectives

to the X

to the X

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

to BCD

Logarithmic, T

Objectives

141. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

149. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

1417. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1420. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

rigonometric, and FIFO Instructions 151. . .

151. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

EAF Process Control Instructions 161. . . . . . . . . . . . . . . . . . .

Chapter

PID Control 161

Loop Considerations 165

Programming 165

Entry and Display of a Selectable Timed Interrupt

Software

Cascading Loops 1621

DeScaling

Averaging and Standard Deviation Functions 1634

Difference Between ThreeDigit and SixDigit Functions 1634

Wall Clock/Calendar 1645

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

(STI) Controlled PID Function 1614

Manual Control Station

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inputs

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . .

161. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1620. . . . . . . . . . . . . . . . . . . . . . . . .

1623. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Jump Instructions and Subroutine Programming 171. . . . . . . .

Chapter

Jump 171

Jump to Subroutine 172

Label 172

Return 173

Entering Jump Instructions 173

Subroutine Area Instruction 173

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

171. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 8

Table of Contents v

Block Transfer 181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Basic Operation 181

Block Transfer Format 184

Block Transfer Read 188

Block Transfer Write 1811

BiDirectional Block Transfer 1812

Multiple

Buffering

Two

Support Rungs 1823

Objectives

Reads of Dif

Data

Get Method

181. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

ferent Block Lengths 1816. . . . . . . . . . . . . . . . . . .

1817. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1820. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Transfer File Instructions 191. . . . . . . . . . . . . . . . . . . . . .

Chapter

FiletoFile Move Instruction 192

WordtoFile Move Instruction 1913

FiletoWord Move Instruction 1914

Data Monitor Display 1916

Adjusting the Data Table Size 1918

Objectives

191. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Bit Shift Registers 201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Bit

Bit

Examine

Examine

Set

Reset

Objectives

Shift Left

Shift Right

Of

On Bit Shift

Bit Shift

Bit Shift

f Bit Shift

201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

201. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

205. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

207. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

209. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2011. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2013. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Sequencers 211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Comparison

Mask 212

Programming

Sequencer Instructions 213

Sequencer

Sequencer

Sequencer Load 2120

Objectives

with File Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Limitations

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input

Output

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

211. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

211. . . . . . . . . . . . . . . . . . . . . . . .

213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

215. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2113. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 9

Table of Contentsvi

Selectable Timed Interrupt 221. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Introduction 221

Selectable Timed Interrupt 223

Operational Overview 224

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

221. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Report Generation 231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Report Generation Commands 232

Entering a Message 238

Graphic Programming 2316

Program

Chapter

Editing a Program 241

Online Data Change 246

Search Functions 247

Clearing Memory 2411

Special Programming Aids 2413

Online Programming 2415

Data

Objectives

Editing

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initialization Key

231. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

241. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2416. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Programming Techniques 251. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

OneShot Programming 251

Restart 253

Cascading Timers 254

Temperature Conversions 255

Program Control 259

Objectives

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

251. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Program Troubleshooting 261. . . . . . . . . . . . . . . . . . . . . . . . .

Chapter

Run Time Errors 261

Bit

Contact Histogram 263

Force Functions 265

Temporary End Instruction 267

Testing Your Program 269

ERR Message for an Illegal Opcode 2610

Objective

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monitor/Manipulation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

261. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

263. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . .

Page 10

Table of Contents vii

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Processor Comparison Chart B1. . . . . . . . . . . . . . . . . . . . . .

Number Systems C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Objectives C1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Decimal Numbering System C1

Octal Numbering System C2

Binary Numbering System C3

Hexadecimal Numbering System C5

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

Glossary D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction D1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Quick Reference E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

List of References E1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Data Table E2

Block Transfer Instructions E4

Clearing Memory E6

Counter Instructions E7

Data Monitor Functions E8

Data Transfer File Instructions E9

EAF Function Numbers E10

Editing Functions E11

Execution Times and Words Per Instruction E12

FIFO Load and FIFO Unload E16

Graphic Programming E17

Help E19

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Layout E20

Memory Structure E21

PID Control Block E24

PROC Indicator E28

Report Generation E29

Search E30

Sequencer Instructions E31

Switch Group Assembly Settings E32

Timer Instructions E34

Diagnostic Word 027 E35

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 11

Using This Manual

Chapter

1

Chapter Objectives

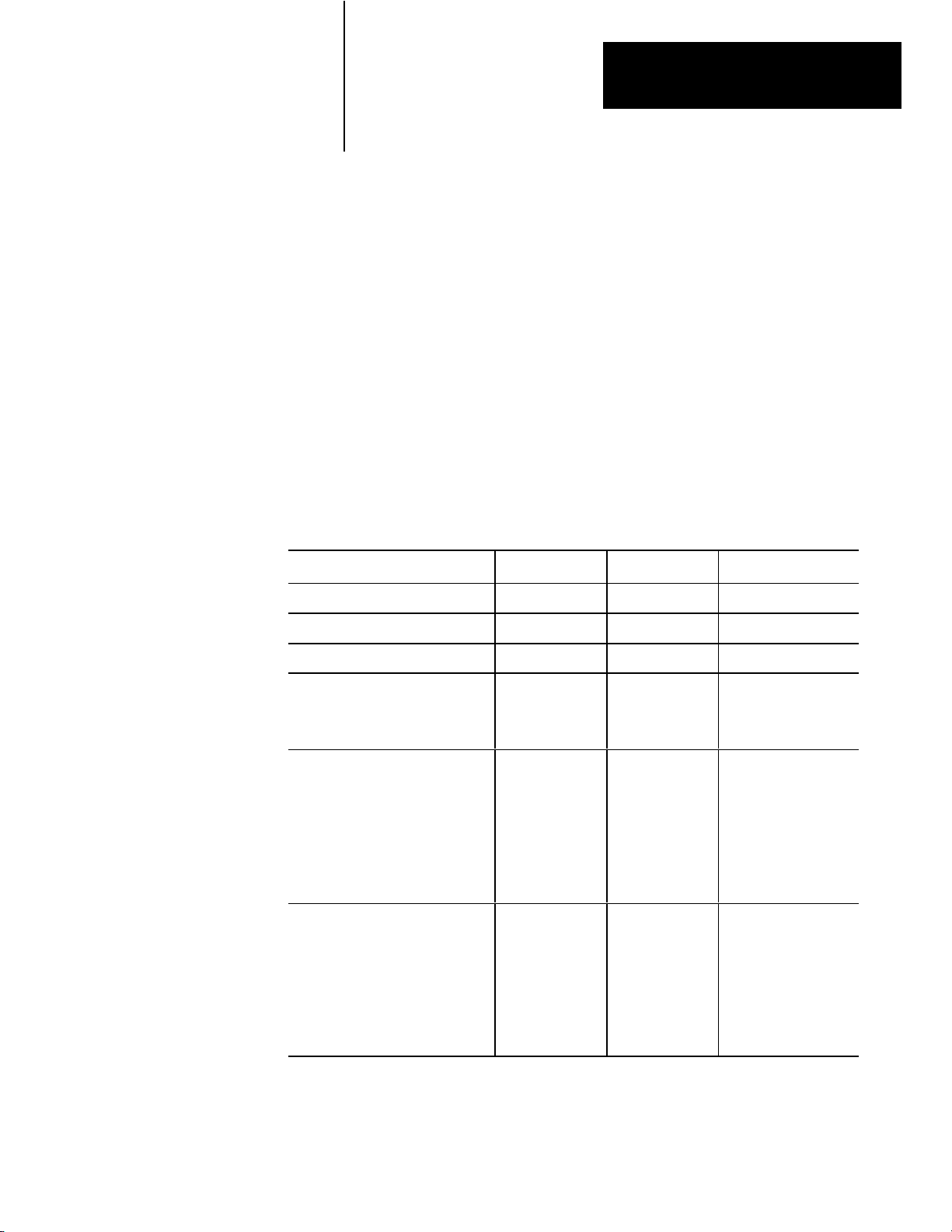

Differences

Read this chapter before you use your processor.

Important: This manual is for the series D Mini-PLC-2/02,

Mini-PLC-2/16 and Mini-PLC-2/17 processors. See the Series Changes on

page 3-2 for the differences with other processor series.

This manual describes the Mini-PLC-2/02, Mini-PLC-2/16 and

Mini-PLC-2/17 processors. Unless stated otherwise, assume the features

or instructions are common to all the processors.

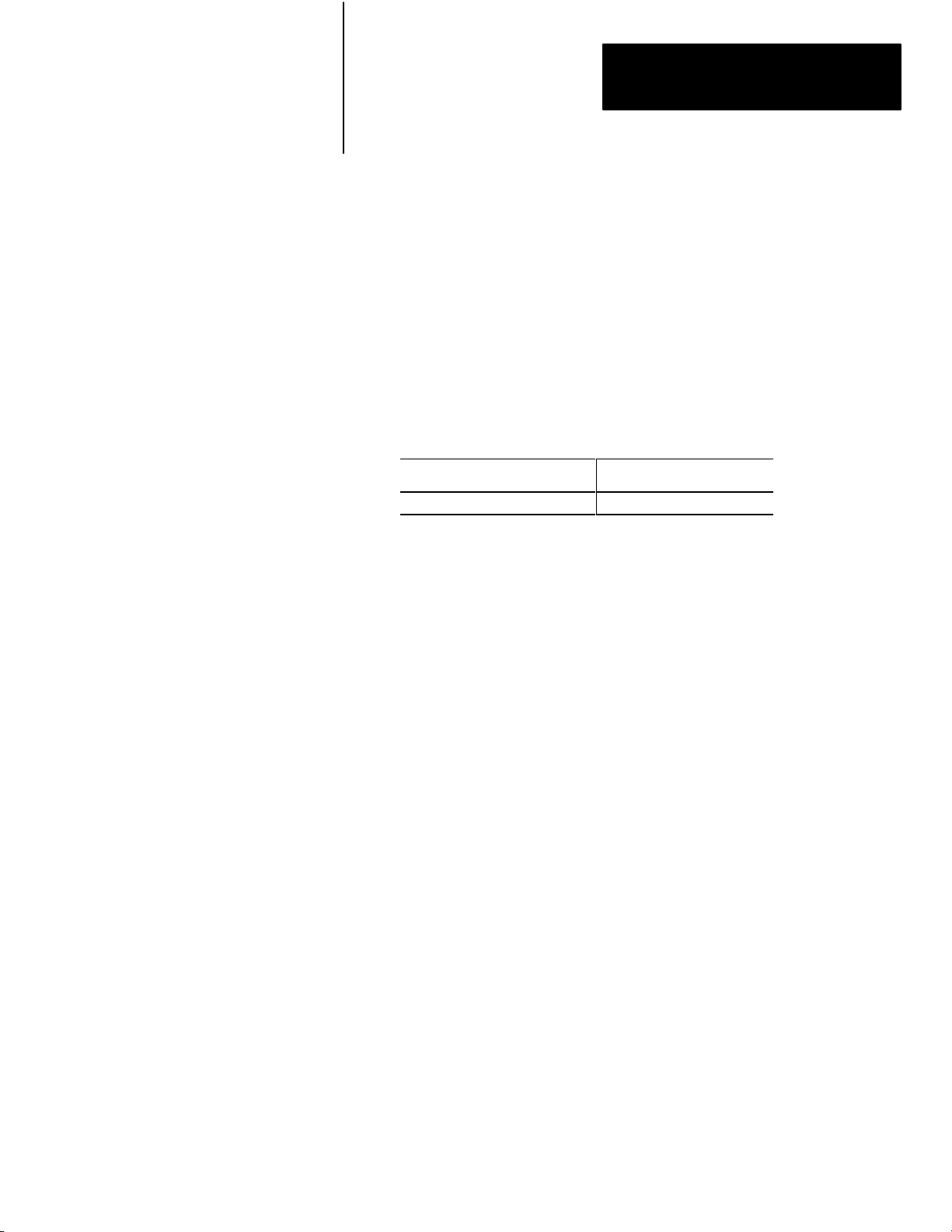

Feature MiniPLC2/02 MiniPLC2/16 MiniPLC2/17

Size of memory (words) 2K 4K 7.75K

Size of EEPROM backup (words) 4K 4K 8K

Data table expansion (words) 1920 3968 7808

EAF instructions (up to 12 digits) Add

Subtract

Multiply

Divide

EAF instructions Square Root

BCD to Binary

Binary to BCD

FIFO Load

FIFO Unload

Log

10

Sin X

Cos X

x

10

Add

Subtract

Multiply

Divide

Square Root

BCD to Binary

Binary to BCD

FIFO Load

FIFO Unload

Log

10

Sin X

Cos X

x

10

Add

Subtract

Multiply

Divide

Square Root

BCD to Binary

Binary to BCD

FIFO Load

FIFO Unload

Log

10

Sin X

Cos X

x

10

Additional EAF instructions none none Log

y+/

e+/

Reciprocal of x

Averaging

Standard

Deviation

PID

Wall Clock/Calendar

e

x

x

1-1

Page 12

Chapter 1

Using This Manual

What's this User

Manual Contains

This manual is divided into eight sections (Table 1.A):

Table 1.A

Sections of the MiniPLC2/02, MiniPLC2/16, and MiniPLC2/17

Processor User Manual

Information Sections What's Covered In Chapters

Overview how to use this manual; fundamentals of

Hardware the processor's hardware features; how to assemble,

Basic instruction set how to use basic instructions common to all PLC2

Advanced instruction set how to use advanced instructions unique to some

Programming procedures and

troubleshooting

Specifications, comparison chart,

number systems, and glossary

12

programmable controllers

3

install, start, maintain, and troubleshoot the processor

413

family processors

1422

the processors

how to use special programming techniques and follow

a troubleshooting guide so you can minimize production

down time

specifications; PLC2 family comparison chart;

explanation of number systems; and list of processor

terms used in this manual

2326

Appendices AD

Vocabulary

Quick reference selected tables in this manual Appendix E

This manual is procedure oriented. It tells you how to program and

operate your Mini-PLC-2/02, Mini-PLC-2/16, and Mini-PLC-2/17

processor. If you need to learn more about these processors, contact your

local Allen-Bradley representative or distributor.

To make this manual easier to read and understand, we refer to the:

We Refer to the: As the:

MiniPLC2/02, MiniPLC2/16, and

MiniPLC2/17 Processors

Electrically Erasable Programmable

Read Only Memory

Programmable Read Only Memory PROM

Execute Auxiliary Function EAF

Complementary Metal Oxide

Semiconductor Random Access Memory

Industrial Terminal (cat. no. 1770T3) 1770T3 terminal

processors

EEPROM

CMOS RAM

1-2

A glossary at the back of this manual clarifies technical terms.

Page 13

Chapter 1

Using This Manual

Conventions

A word equals 16 bits; a byte equals 8 bits (1/2 of a word).

Words in [ ] denote a key name or symbol. Words in < > denote

information that you must provide - for example, an address value.

All word addresses are displayed in the octal numbering system.

Therefore, references to base 8 are not displayed.

Word values are displayed in:

decimal (0-9) for timers, counters, and mathematics

010

00

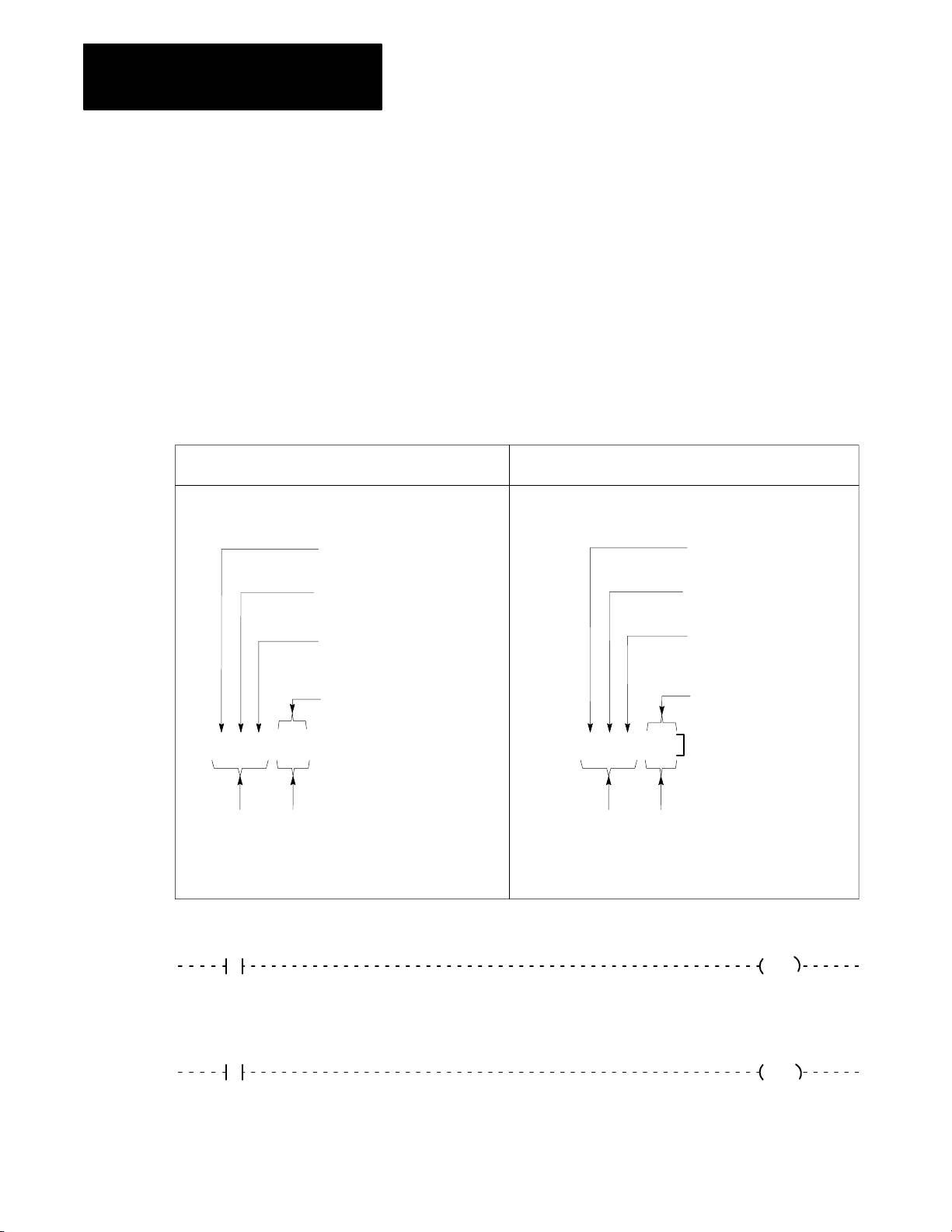

Decimal

hexadecimal values (0-9, A-F) for Get and Put instructions

010

010

011 012

GG

00

00

030

CTU

PR 555

AC 123

030

00FFF 123

Hexadecimal

Important: Numbers 0-9 are displayed the same in decimal and

hexadecimal.

octal byte values for examine on and output energize instructions

0101 030

B

237

Octal

Keystroke directions are divided into two columns:

tells you what key or keys to press

tells you the processor’s action

00

1-3

Page 14

Chapter 1

Using This Manual

Figure 1.1 shows the keystrokes to produce a display.

DISPLAY

0

Figure 1.1

Illustration

Showing Keystroke Conventions

Start by positioning your cursor on the words SEQUENCER INPUT.

Use the arrow keys to move the cursor.

The word display appears in the lower left hand corner of the screen.

BINARY DATA MONITOR

SEQUENCER OUTPUT

COUNTER ADDR: 200

OUTPUT ADDR: 110

DATA:

MASK ADDR: 070

DATA:

STEP WORD 1

001

00000000 00000000

002

00000000 00000000

003

00000000 00000000

004

00000000 00000000

005

00000000 00000000

006

00000000 00000000

00000000 00000000

00000000 00000000

STEP: 001 SEQUENCER LENGTH: 006

FILE: 400- 413

201

00000000 00000000

071

00000000 00000000

WORD 2

00000000

00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000

00000000 00000000

A: 00000000 00000000

DAT

Related Publications

1-4

The publication index, publication SD 499, lists all available publications

to further inform you about products related to the Mini-PLC-2/02,

Mini-PLC-2/16, and Mini-PLC-2/17 processors. Consult your local

Allen-Bradley distributor or sales engineer for information regarding this

publication or any needed information.

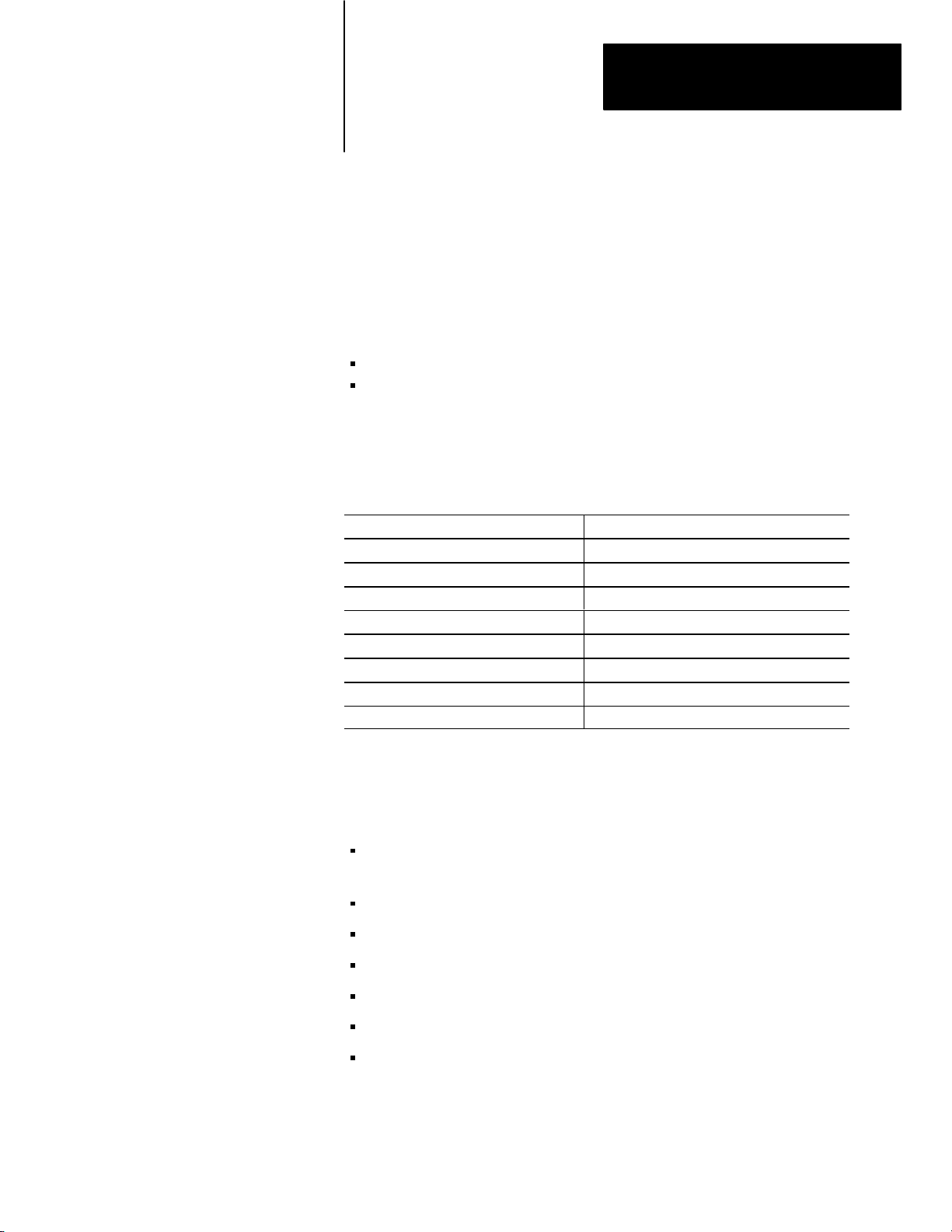

Page 15

Chapter

2

Fundamentals of a Programmable Controller

Chapter Objectives

Traditional Controls

In this chapter, you review general fundamentals common to our

programmable controllers. This chapter:

describes what a programmable controller does

describe the functions of a programmable controller

describes the four major sections of a programmable controller

gives an example of a simple program

You are probably familiar with the traditional methods of machine control.

Relays

Machine

Sensing

Devices

Sensing devices located on the machine detect changes in the machine’s

condition. For instance, a part arriving at a work station contacts and

closes a limit switch, the sensing device. As a result, an electrical circuit is

completed and a signal is sent to the control panel.

Control Panel

Output

Devices

11591

At the control panel, the electrical signal enters a bank of relays or other

devices, such as solid state modules. Circuits within the control panel open

or close causing additional electrical signals to be sent to output devices at

the machine. For example, a relay energized by the limit switch closed by

the arriving part may complete another circuit energizing the output

device, a clamp, which secures the part at the work station.

2-1

Page 16

Chapter 2

Fundamentals of a

Programmable Controller

Programmable Systems

Systems run by programmable controllers operate in much the same way.

Programmable controllers can perform many of the functions of traditional

controls. Input sensing devices report machine conditions; output devices

respond to commands.

Programmable

Controller

Conditons

Machine

Sensing

Devices

Control Panel

Action

Command

Output

Devices

Wiring between the machine and the controller provides electrical paths

from the sensing devices to the controller and from the controller to the

output devices.

However, instead of wiring relays together to produce a desired response,

you simply tell your programmable controller how you want it to respond.

11592

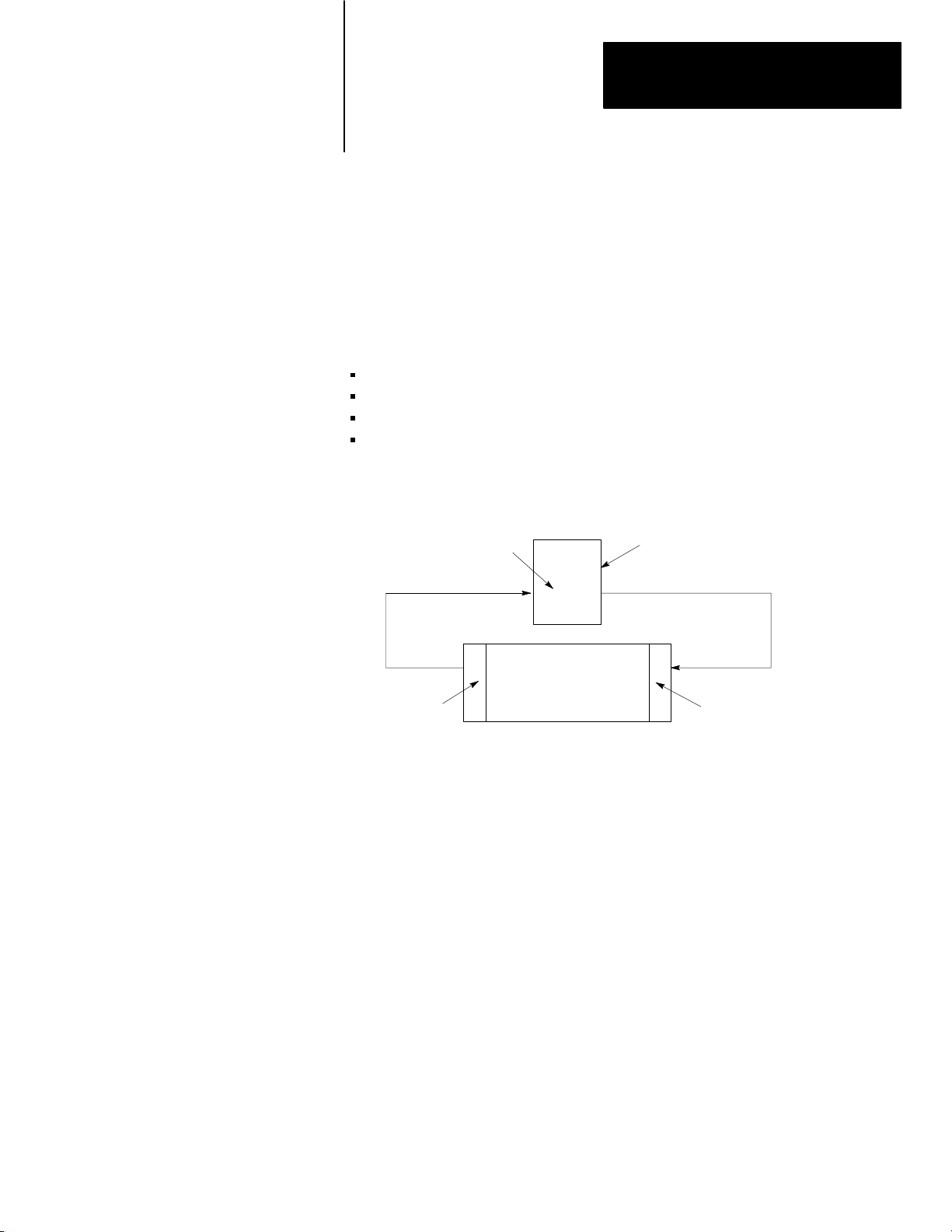

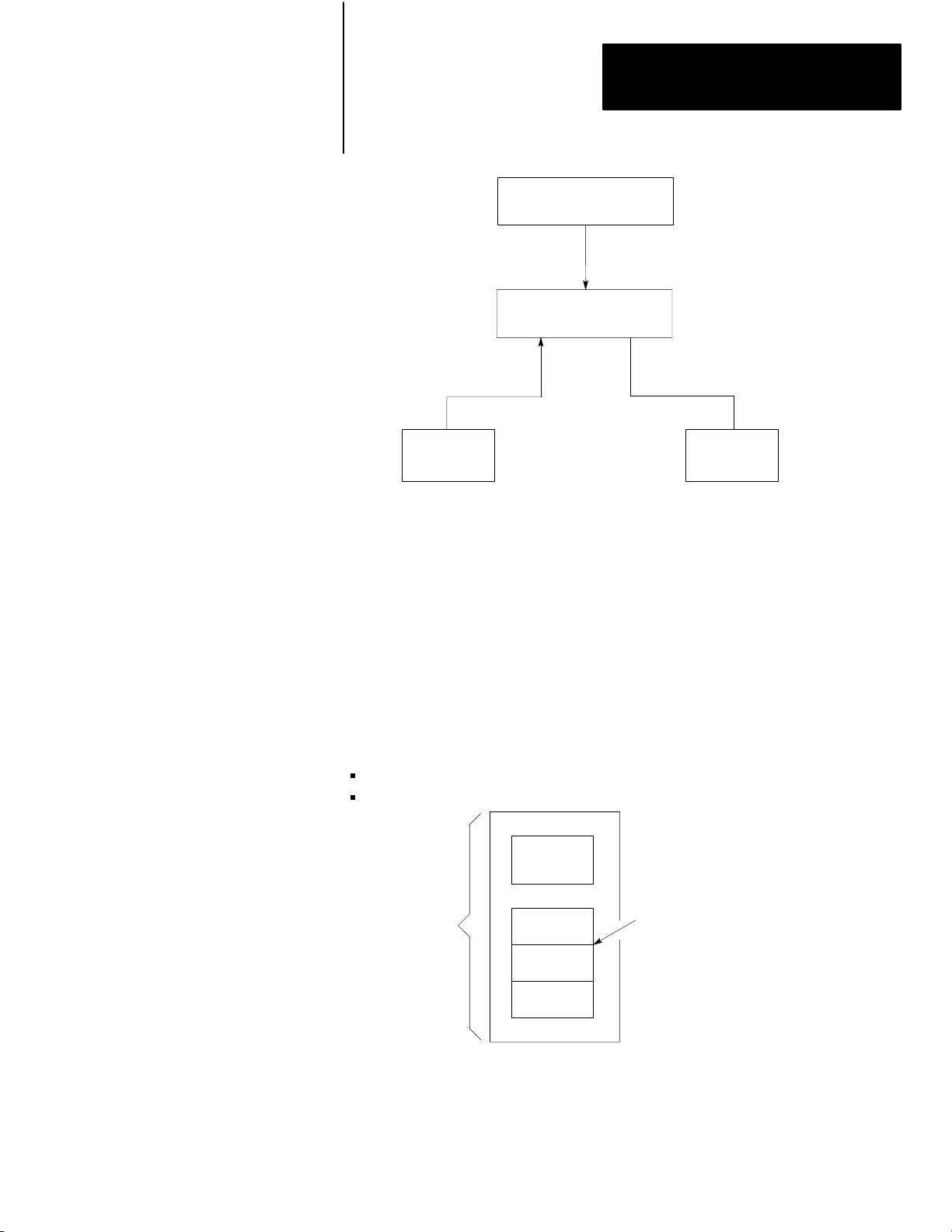

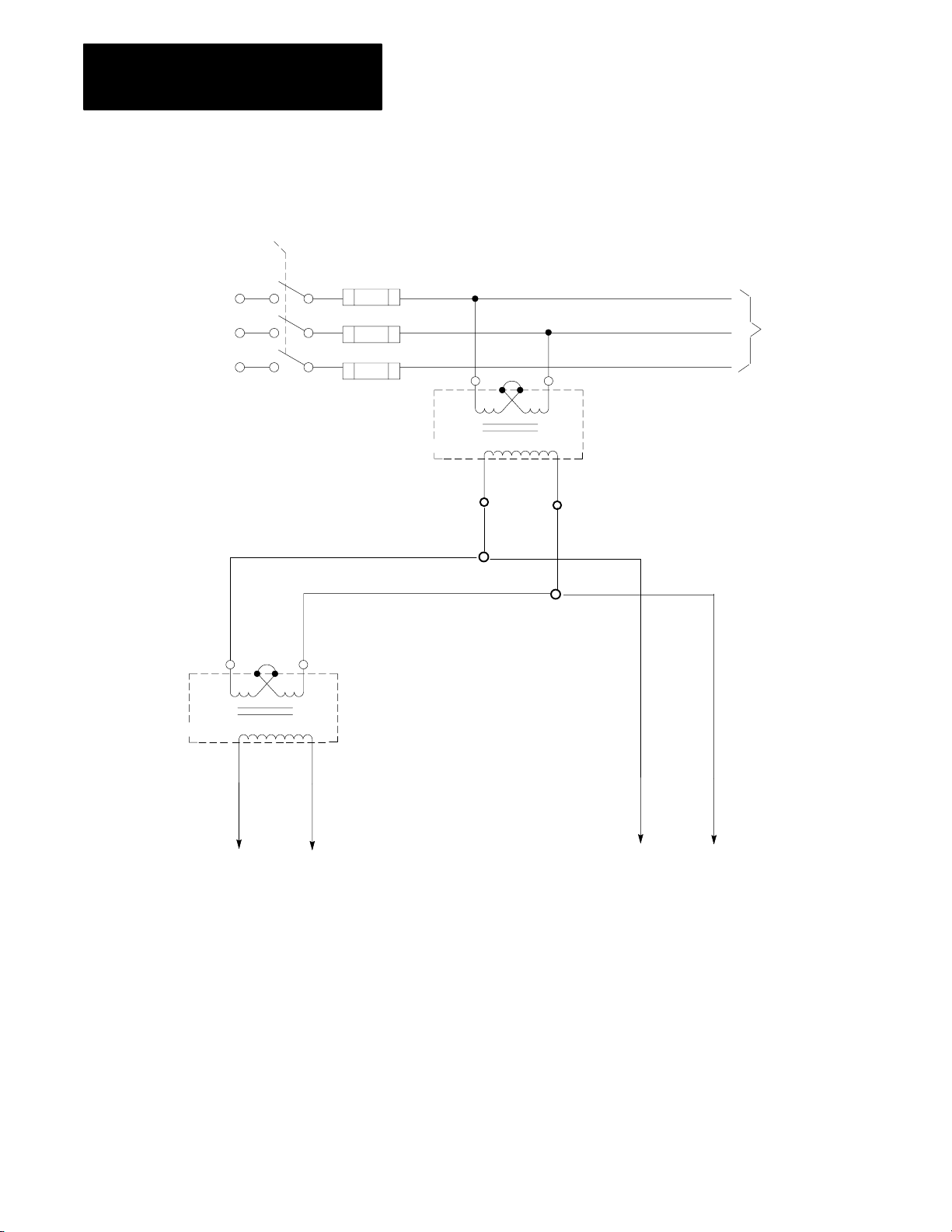

The Four Major Sections

A program tells your programmable controller what you want it to do. A

program is nothing more than a set of instructions you give the

programmable controller telling it how to react to certain conditions within

the machine.

A typical programmable controller system usually consists of four

major sections:

processor

input modules

output modules

power supply

2-2

Page 17

Chapter 2

Fundamentals of a

Programmable Controller

Power Supply

Processor

(Decision Making)

Information

Input Output

Limit, Proximity, Pressure,

•

Temperature Switches

•

Push Buttons

•

Logic

•

BCD

•

Analog

Action

Solenoids•

•

Motor Starters

•

Indicators

•

Alarms

•

Logic

•

BCD

•

Analog

Processor

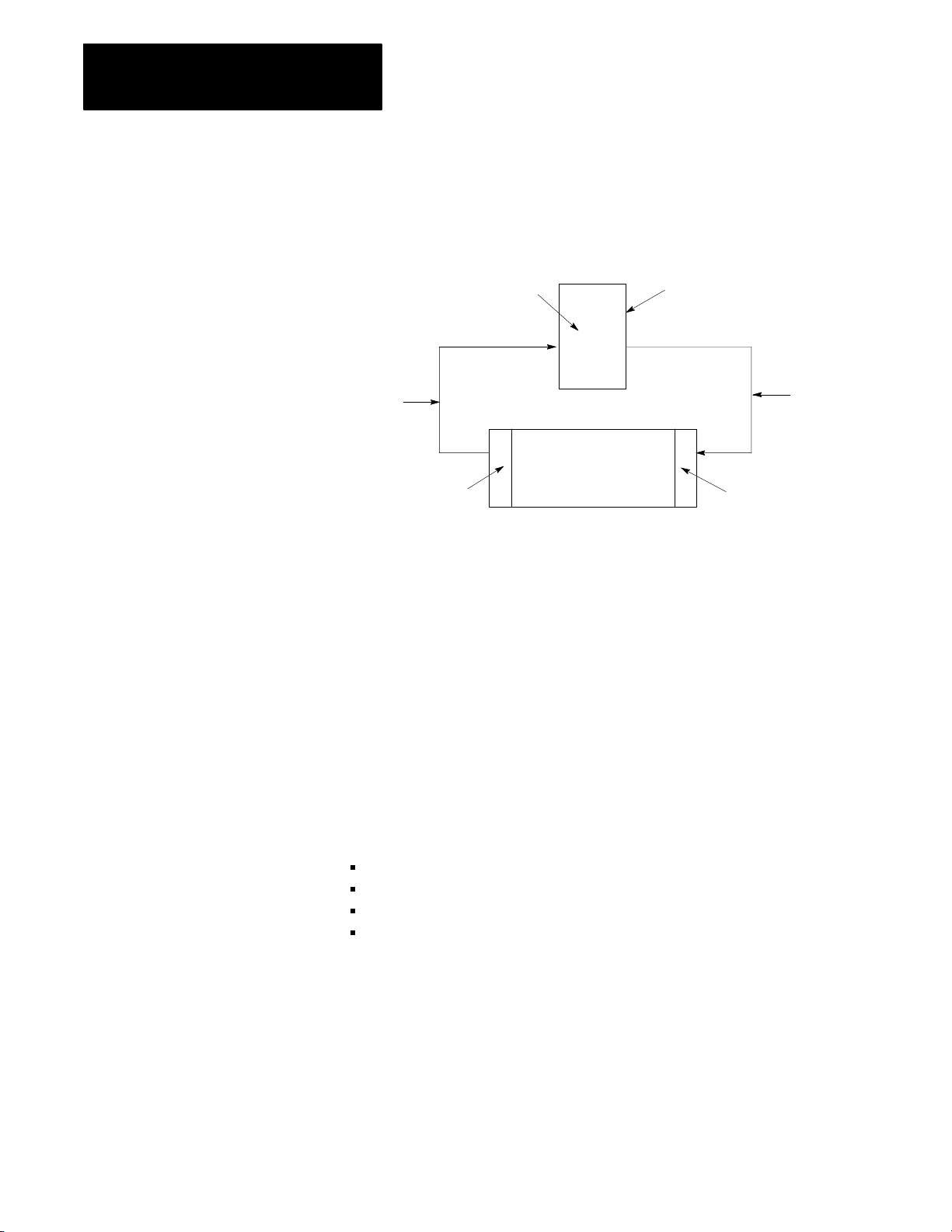

The first section of a programmable controller is the processor. The

processor might be called the “brains” of the programmable controller. It

is divided into halves:

central processing unit

memory

CPU

Processor

Section

Data

Table

Program

Storage

Message

Storage

Memory

Central Processing Unit

The Central Processor Unit (CPU) makes decisions about what the

processor does according to the program you write.

2-3

Page 18

Chapter 2

Fundamentals of a

Programmable Controller

Memory

Memory serves three functions:

stores information in the data table that the CPU may need

stores sets of instructions called a program

stores messages

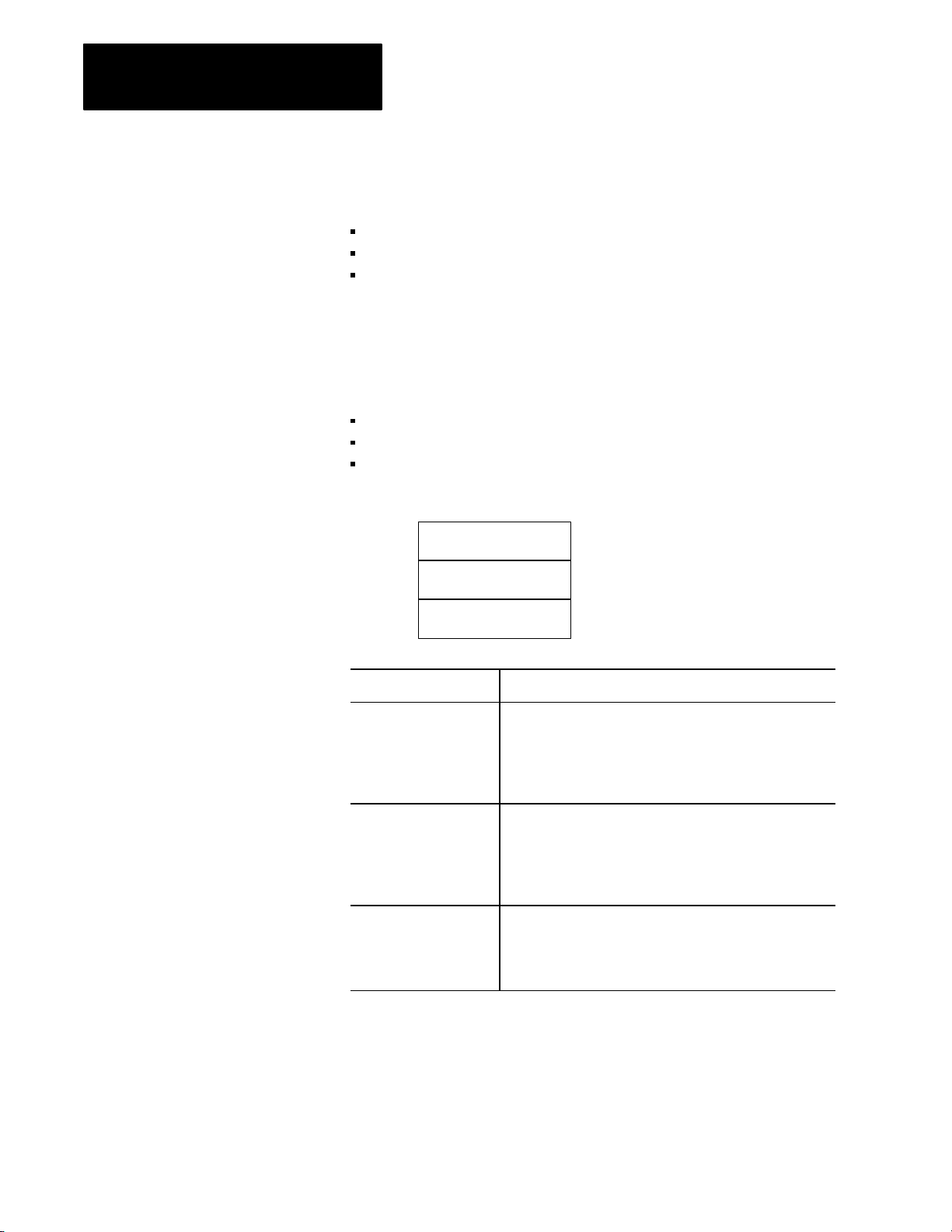

Data Table

The area of memory where data is controlled and used, is called the data

table. The data table is divided into several smaller sections according to

the type of information to be remembered. These smaller sections are

called:

output image table

input image table

timer/counter storage

Data Table

Output Image Table

Input Image Table

Timer/Counter

Storage

This memory area:

output image tables The output image table controls the on or off status of the

input image tables The input image table duplicates the on or off status of the

timer/counter storage Timer and Counter instructions are output instructions. They

Serves this purpose:

output devices wired to the output module's terminals. If an

output image table bit is ON (1), its corresponding output

device is ON (energized). If a bit is OFF (0), its corresponding

output device is OFF (deenergized). Output image table bits

are controlled by the user's program.

input devices. If an input device is ON (closed), its

corresponding input image table bit is ON (1). If an input

image table bit is OFF (open), its corresponding input image

table bit is OFF (0). Input image table bits are monitored by the

user's program.

provide many of the capabilities available with timing relays

and solidstate timing and counting devices. Usually

conditioned by examine instructions, they keep track of timed

intervals or counted events according to the logic of the rung.

2-4

Page 19

Chapter 2

Fundamentals of a

Programmable Controller

I/O Image Tables

The input image table reflects the status of the input terminals. The output

image table reflects the status of bits controlled by the program.

Each image table is divided into a number of smaller units called bits. A

bit is the smallest unit of memory. A bit is a tiny electronic circuit that the

processor can turn on or off. Bits in the image table are associated with a

particular I/O terminal in the input or output section.

When the processor detects a voltage at an input terminal, it records that

information by turning the corresponding bit on. Likewise, when the

processor detects no voltage at an input terminal, it records that

information by turning the corresponding bit off. If, while executing your

program, the CPU decides that a particular output terminal should be

turned on or off, it records that decision by turning the corresponding bit

on or off. In other words, each bit in the I/O image tables corresponds to

the on or off status of an I/O terminal.

When people who work with personal computers talk about turning a bit

on, they use the term “set.” For example - “The processor sets the bit”

means “turns it on.” On the other hand, we use the term “reset” when we

talk about turning the bit off - for example, “The processor reset the bit.”

Picture memory as a page that has been divided into many blocks. Each

block represents one bit. Since each bit is either on or off, we could show

the state of each bit by writing “on” or “off” in each block. However, there

is an easier way. We can agree that the numeral one (1) means on and that

the numeral zero (0) means off. We can show the status of each bit by

writing 1 or 0 into the appropriate block. For example, you might hear

expressions like, “The CPU responded by writing a one into the bit when

the limit switch closed.” Of course, the processor didn’t really write a one

into memory: it simply set the bit by turning it on.

When the I/O device is: The bit status is said to be:

on

on

off

1

set

off

0

reset

If you heard the expression, “The processor wrote a zero into that bit

location.” What actually happened? If you said the processor merely reset

the bit by turning it off, you’re right.

2-5

Page 20

Chapter 2

Fundamentals of a

Programmable Controller

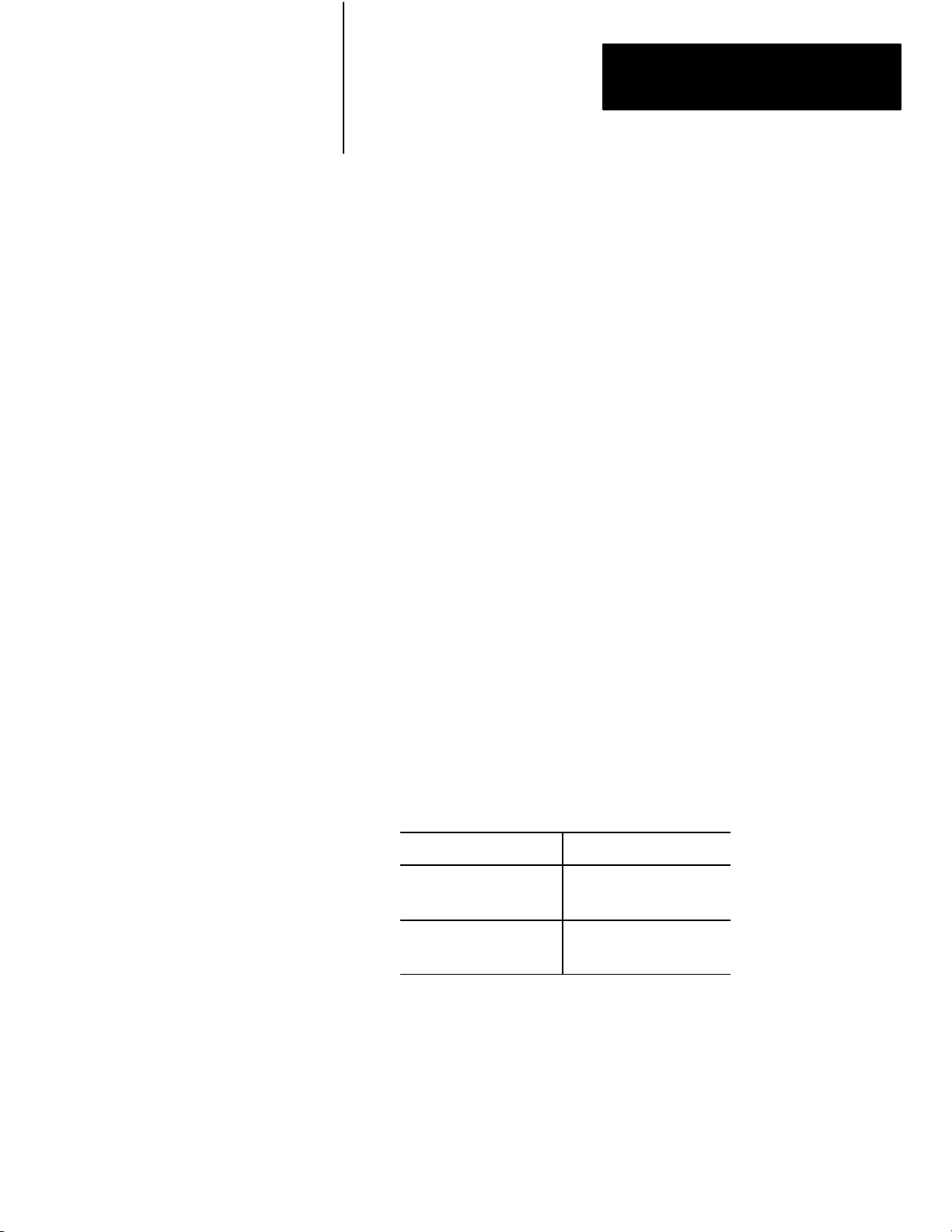

Program Storage

Program storage takes up the largest portion of memory. This is where the

user’s program is stored. Each program is made up of a set of statements.

Each statement does two things:

It describes an action to be taken. For instance, it might say, “Energize

motor starter number one.”

It describes the conditions that must exist in order for the action to

take place.

Statement

Statement

Statement

Statement

Statement

Statement

Program

Program Storage Area

of Memory

ActionConditions

Program

Statement

For example, you may want this action to take place: “Whenever a certain

limit switch closes.” So your condition could be: “If limit switch number

two is closed,...” The action would be: “energize motor starter number

one.” Therefore, when limit switch number two at the machine closes, the

programmable controller energizes the motor starter. If limit switch

number two does not close, the programmable controller does not energize

the motor starter. Thus, when limit switch number two opens, the

programmable controller de-energizes the motor starter because that action

is implied in the statement.

A program is made up of a number of similar statements. Typically, there

is one statement for each output device on the machine. Each statement

lists the conditions that must be met and then, states the action to be taken.

Each condition is represented by a specific instruction; therefore, each

action is represented by a specific instruction. These instructions tell the

processor to do something with the information stored in the data

table.Some instructions tell the processor to read what’s written in the

image table. When the processor is instructed to read from an image table,

it examines a specific bit to see if a certain I/O device is on or off.

2-6

Other instructions tell the processor to write information into the image

table. When the processor is instructed to write into the output image

table, it writes a one or a zero into a specific bit. The corresponding output

device will turn on or off as a result.

Page 21

Chapter 2

Fundamentals of a

Programmable Controller

Message Storage

The third area of memory, message storage, begins after the end statement

in the user’s program. Two alphanumeric characters can be stored in a

word. Messages are entered into memory from either a 1770-T3 terminal

or a peripheral device.

Messages are displayed on a 1770-T3 terminal or a peripheral device each

time a message is required. The messages are activated through program

control by programming specific instructions in the ladder

diagram program.

Input Modules

The input modules of a programmable controller have four functions:

termination

indication

conditioning

isolation

Termination

The input provides terminals for the field wiring coming from the sensing

devices on the machine.

Indication

The input of most modules also provides a visual indication of the state of

each input terminal with LED indicators. The indicator is on when there is

a voltage applied to it terminal. The indicator is off when there is no

voltage applied to its terminal. Since the indicator reveals the status of its

terminal, it’s usually called an input status indicator.

Input indicators are only associated with terminals used for wiring sensing

devices to the input section. The terminal that’s used to provide a ground

for the sensing circuits has no indicator.

Conditioning

Another function of input modules is signal conditioning. Voltage levels

used at the machine are usually not compatible with the voltage levels used

within the programmable controller. The input modules receives the

electrical signal from the machine and converts it to a voltage level

compatible with the programmable controller’s circuitry.

Isolation

The input isolates the machine circuitry from the programmable

controller’s circuitry. Isolation helps protect the programmable controller’s

circuitry from unwanted and dangerous voltage levels that may occur

occasionally at the machine or in the plant’s wiring system.

2-7

Page 22

Chapter 2

Fundamentals of a

Programmable Controller

Output Modules

The output modules of a programmable controller have four functions:

termination

indication

conditioning

isolation

Termination

The output provides terminals for the field wiring going to the output

devices on the machine.

Indication

The output of most modules provides a visual indication of the selected

state of each output device with LED indicators. The output status

indicator is on when the output device is energized. A common term

applied to either input status indicators or output status indicators is I/O

status indicators. I/O stands for either input or output.

In older modules, when power is present at the output terminals, the status

indicators are ON. In high density modules, power may not be present at

the output terminals for the status indicator to be ON.

Conditioning

The output conditions the programmable controller’s signals for the

machine. That is, it converts the low-level dc voltages of the

programmable controller to the type of electrical power used by the output

devices at the machine.

Isolation

The output isolates the circuitry of the programmable controller from

unwanted and dangerous voltages that occasionally occur at the machine

or the plant’s wiring system. Some situations require additional

external protection.

Power

Supply

The power supply provides low-level dc voltage for the electronic circuitry

of the processor, its input and output modules. It converts line voltages to

the lower logic voltages required by the processor and its input and

output modules.

2-8

Page 23

Chapter 2

Fundamentals of a

Programmable Controller

Control Sequence

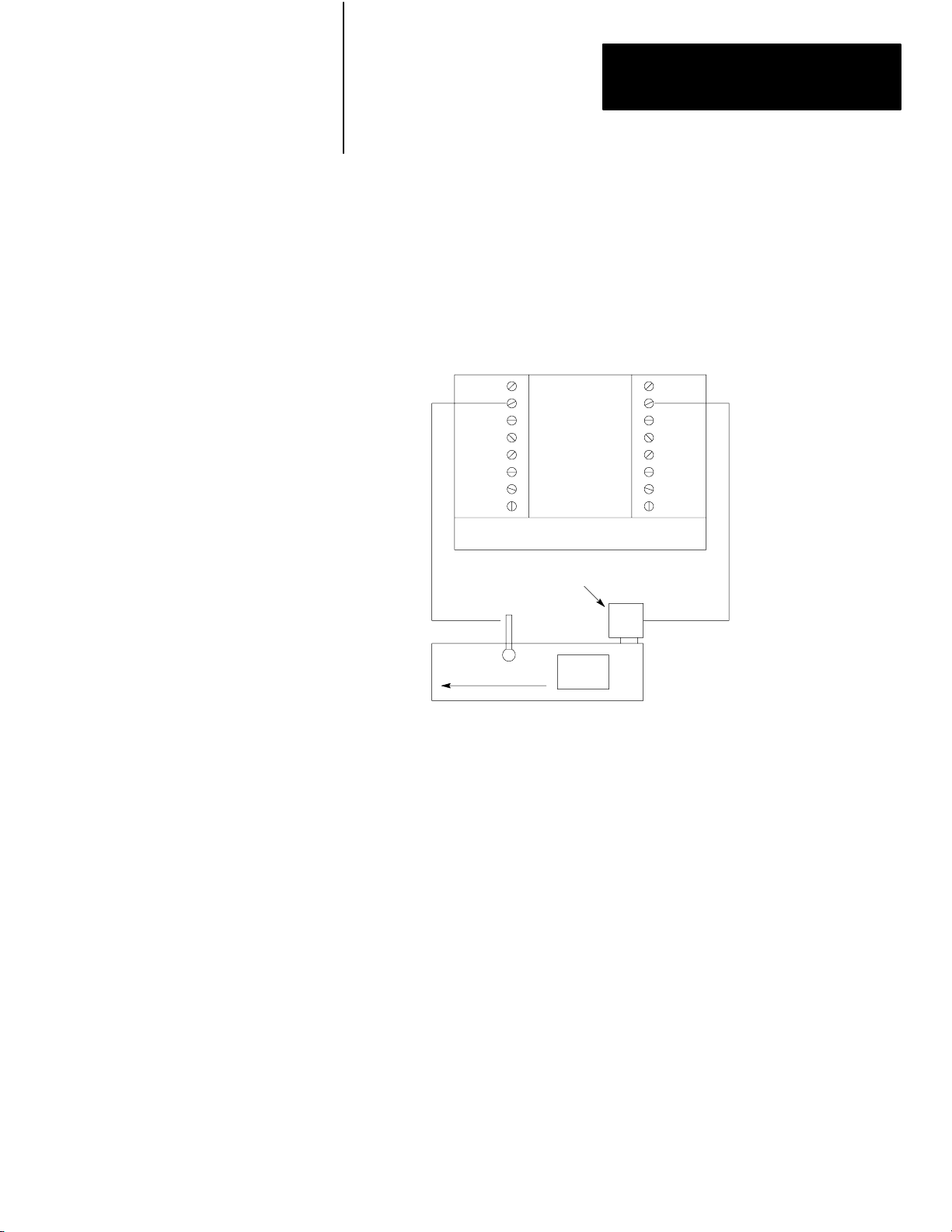

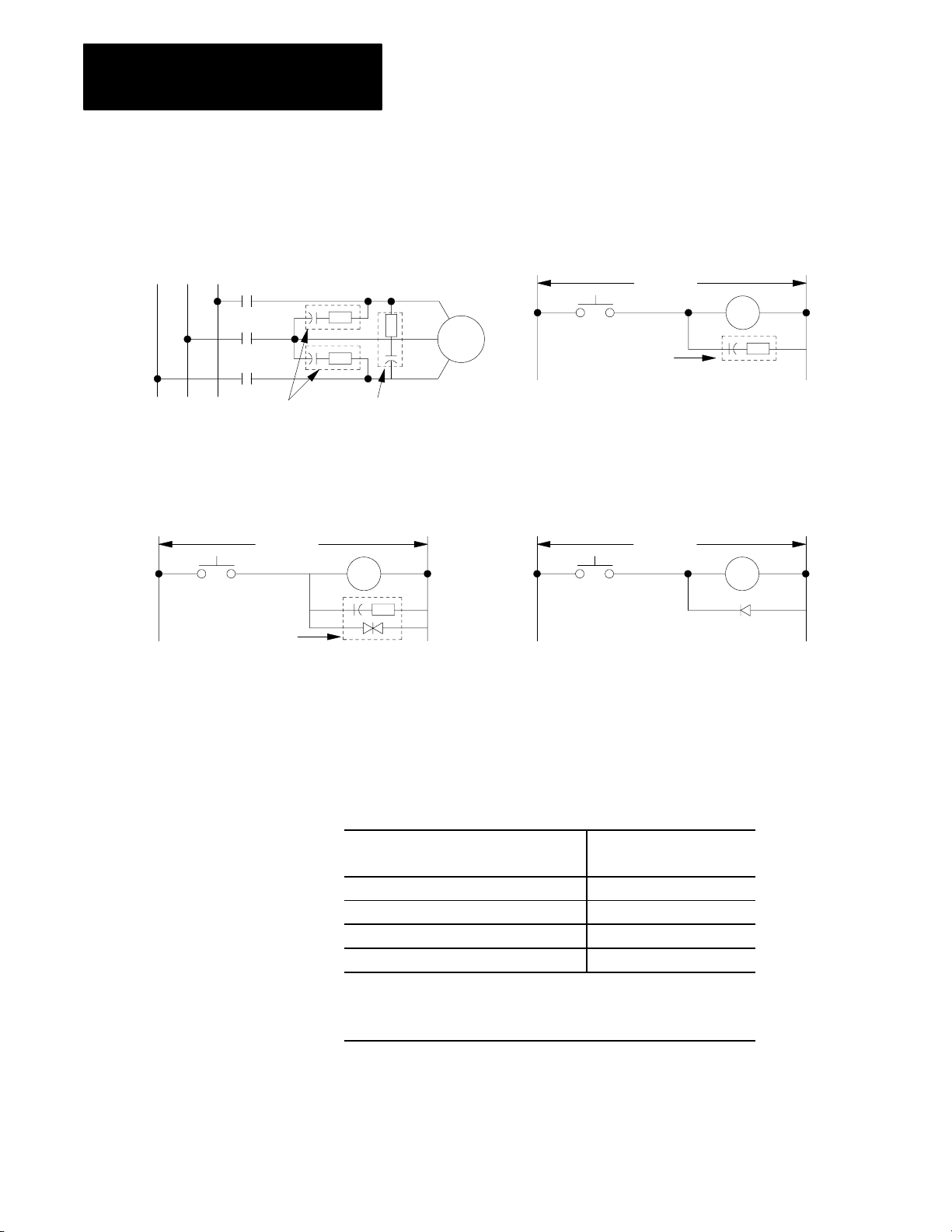

Let’s look at a simple example to see the sequence of events that take place

in controlling a machine with a programmable controller (Figure 2.1).

Suppose you are making a part. The motor driven conveyor carries a unit

to the work area. The limit switch detects wen the part arrives at the work

area. when that happens, we want the conveyor to stop so you can work on

the part.

Figure 2.1

Simplified Example of a Machine with a Programmable Controller

A

Controller

Input Output

Conveyor

Motor

Limit

Switch

Conveyor

Unit

11594

Notice how the limit switch and motor are wired to the programmable

controller. The limit switch, wired to terminal 02, is normally-closed. The

arriving part will open the switch. Therefore, the program statement

controlling the conveyor motor must read: “If there is voltage at input

terminal 02 (limit switch), then energize output terminal 02 (conveyer

motor).” The conveyor motor is wired to output terminal 02.

Important: Figure 2.1 is for demonstration purposes only. We do not

show the associated wiring, a motor starter, or an emergency stop button.

Since the limit switch is wired normally-closed, the conveyor motor runs

until the arriving part opens the switch. At that time, the condition for

energizing the motor is not longer met. Therefore, the motor is

de-energized.

When the condition is met, we say it is true. When the condition is not

met, we say it is false. There may be more than one condition which must

be met before an action is executed. When all the conditions are met, the

action is executed and we say the statement is true. When one or more of

the conditions are false, the action is not executed and we say the statement

is false.

2-9

Page 24

Chapter 2

Fundamentals of a

Programmable Controller

Scan Sequence

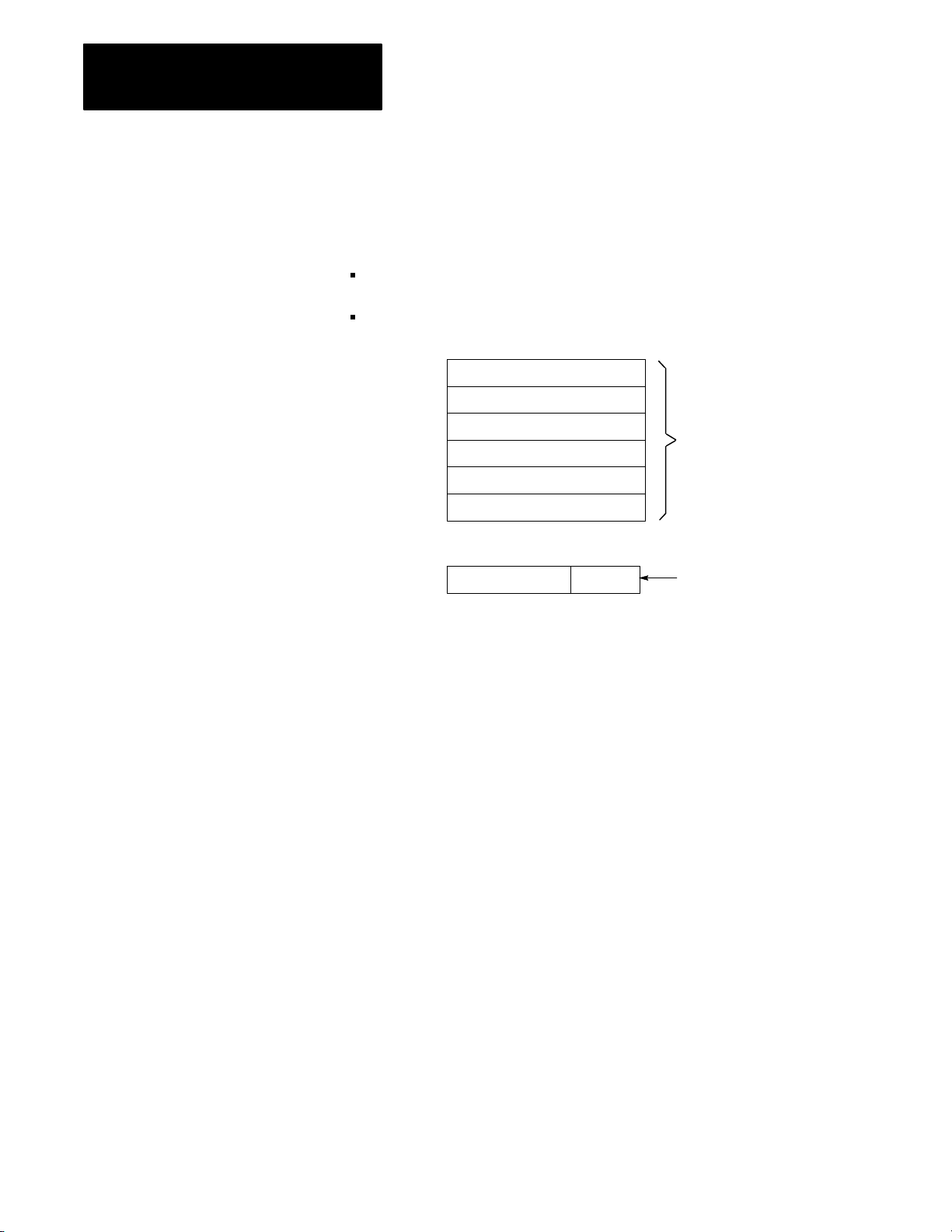

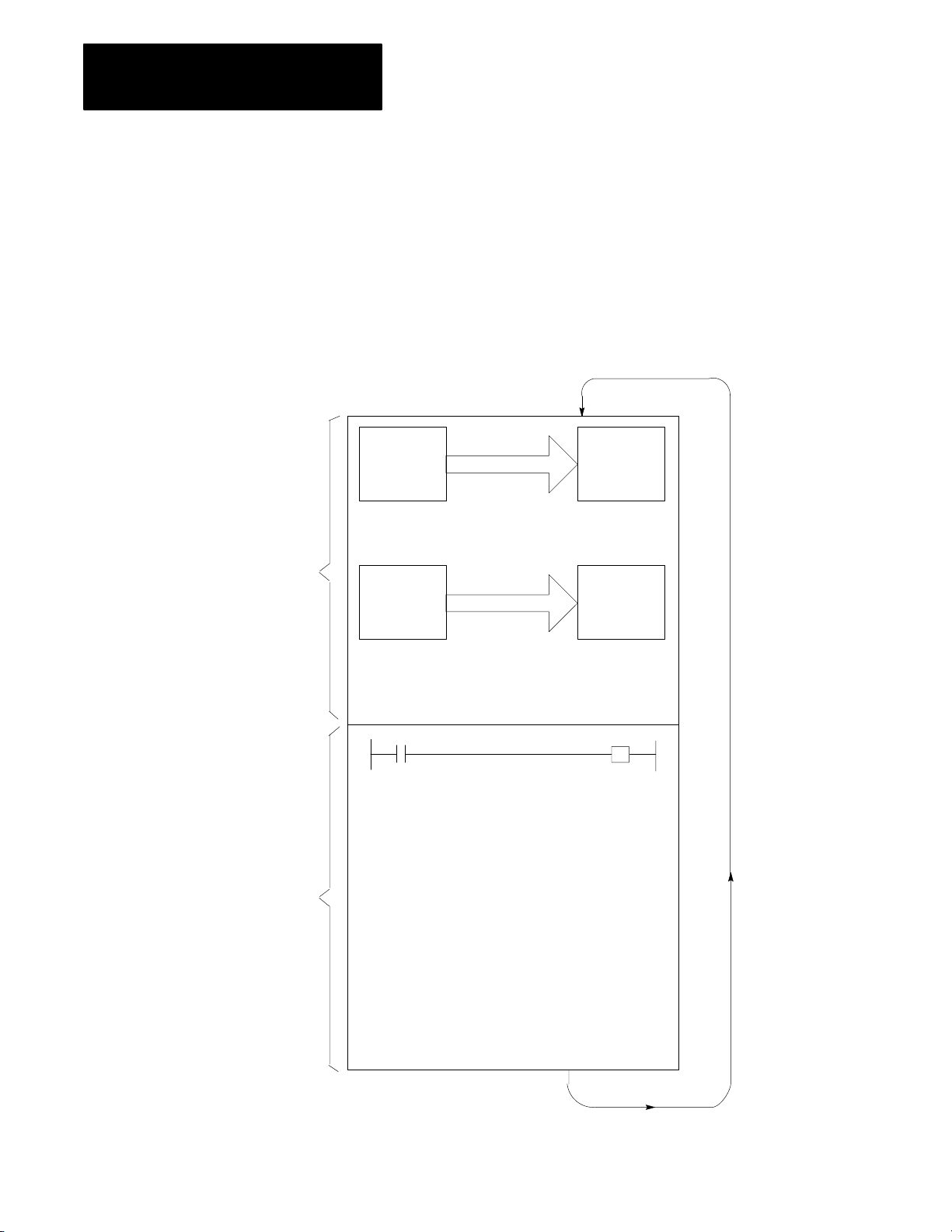

I/O

Scan

On power up, the processor begins the scan sequence (Figure 2.2) with a

program pre-scan. This pre-scan is completed as if the entire program lies

within an active MCR zone. Next the processor completes the I/O scan.

During the I/O scan, data from input modules is transferred to the input

image table. Data from output image table is transferred to the

output modules.

Figure 2.2

Sequence

Scan

Output

Image

Table

Copy output image table status

into output terminal circuits.

Input

Terminals

Output

Terminals

Input

Image

Table

Program

Scan

Copy input terminal status into

input image table.

Program Statement

Execute each program rung in

sequence, writing into bits in the

data table, including the output

image table.

11597

2-10

Page 25

Chapter 2

Fundamentals of a

Programmable Controller

Next, the processor scans the program. It does this statement by statement.

Each statement is scanned in this way:

1. For each input instruction, the processor checks, or “reads,” the

image table to see if the condition has been met.

2. If the set of conditions has been met, the CPU writes a 1 into the bit

location in the output image table corresponding to the output

terminal to be energized. On the other hand, if the set of conditions

has not been met, the processor writes a 0 into the bit location,

indicating that the output terminal should not be energized.

Here is a simple explanation of the program. If input 02 is on, then turn on

output 02. If input 02 is off, then turn off output 02. The program could

be written this way:

If (condition) Then (action)

Input bit 02 is on Turn output bit 02 on

In this example, the processor reads a 1 at input bit location 02 and knows

that the condition has been met. The processor then carries out the action

instruction by writing a 1 into output bit location 02.

If there were more statements in the program, the processor would

continue in this same manner scanning each statement and executing each

instruction until it reached the end of the program. Statement by

statement, the processor would write a 0 or a 1 into an output bit as

directed by the program. Then, the processor would read specific image

table bits to see if the proper set of conditions were met. After reading and

executing all program statements, the processor scans the output image

table and energizes or de-energizes output terminals. The processor then

goes to the input modules to update the input image table.

Now the entire process is repeated. In fact, it’s repeated over and over

again, many times a minute. Each time, the processor sets or resets output

bits. Next, the processor senses the status of the input terminals. Finally,

the processor scans the program and orders each output terminal on or off

according to the state of its corresponding bit in the output image table.

When forcing is attempted, the processor’s I/O scan slows down to do the

forcing (see chapter 19). When forcing is terminated, the processor

automatically switches back to the faster I/O scan mode.

When this example begins, the processor is energizing output terminal 02

because output bit 02 is on.

When the part is conveyed to the work station, it turns the limit switch off.

When the limit switch is off, there is no voltage at input terminal 02. The

processor scans the input image table, senses no voltage, and responds by

writing a zero into bit 02 in the input image table.

2-11

Page 26

Chapter 2

Fundamentals of a

Programmable Controller

The processor scans the program. Our program states that if (conditions)

input bit 02 is on, turn on output 02. If input bit 02 is off then output bit 02

is off. Since the alter condition is not true, the processor turns off output

bit 02.

When the processor next scans the output image table, it sees the zero in

output bit 02 and responds by de-energizing output terminal 02. The

action causes the conveyor to stop.

2-12

Page 27

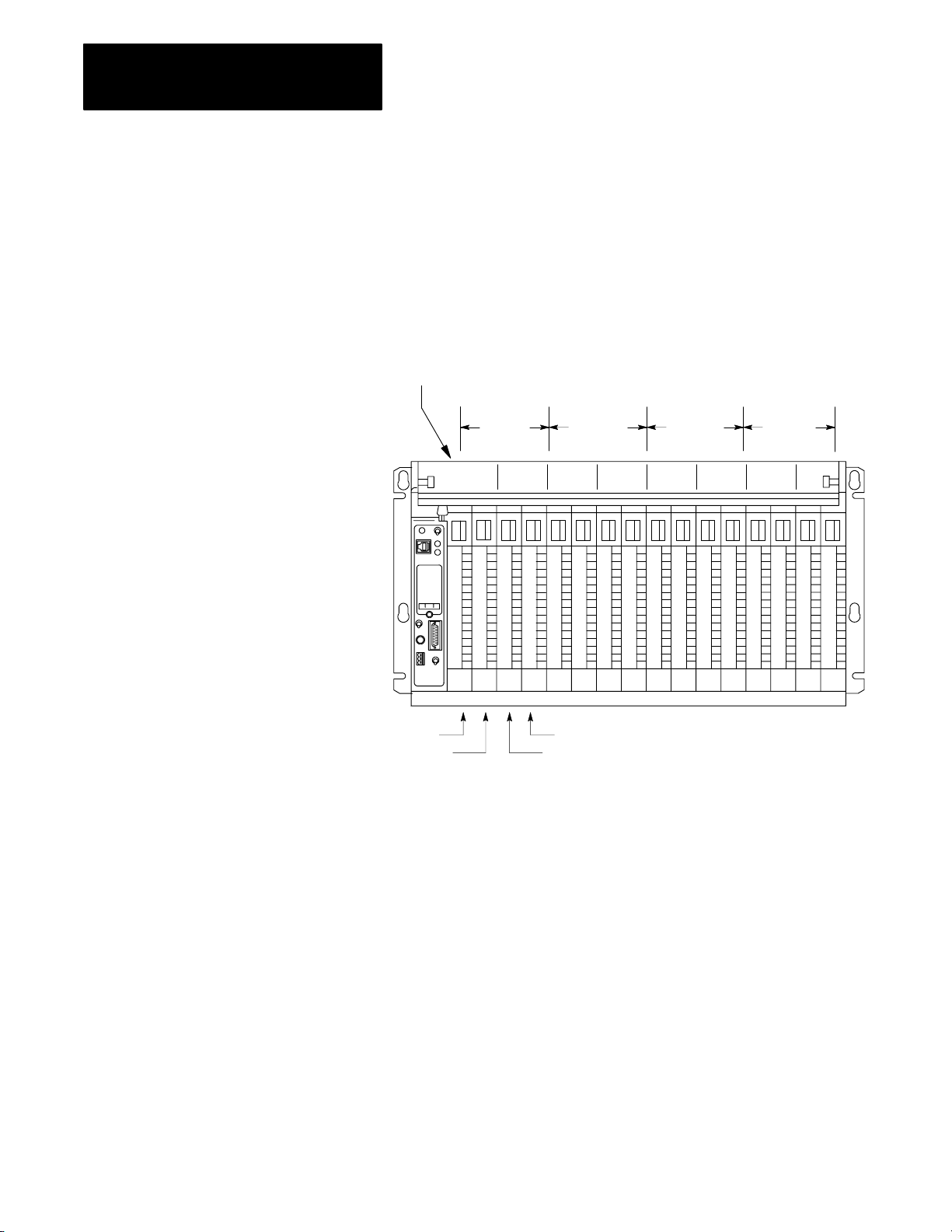

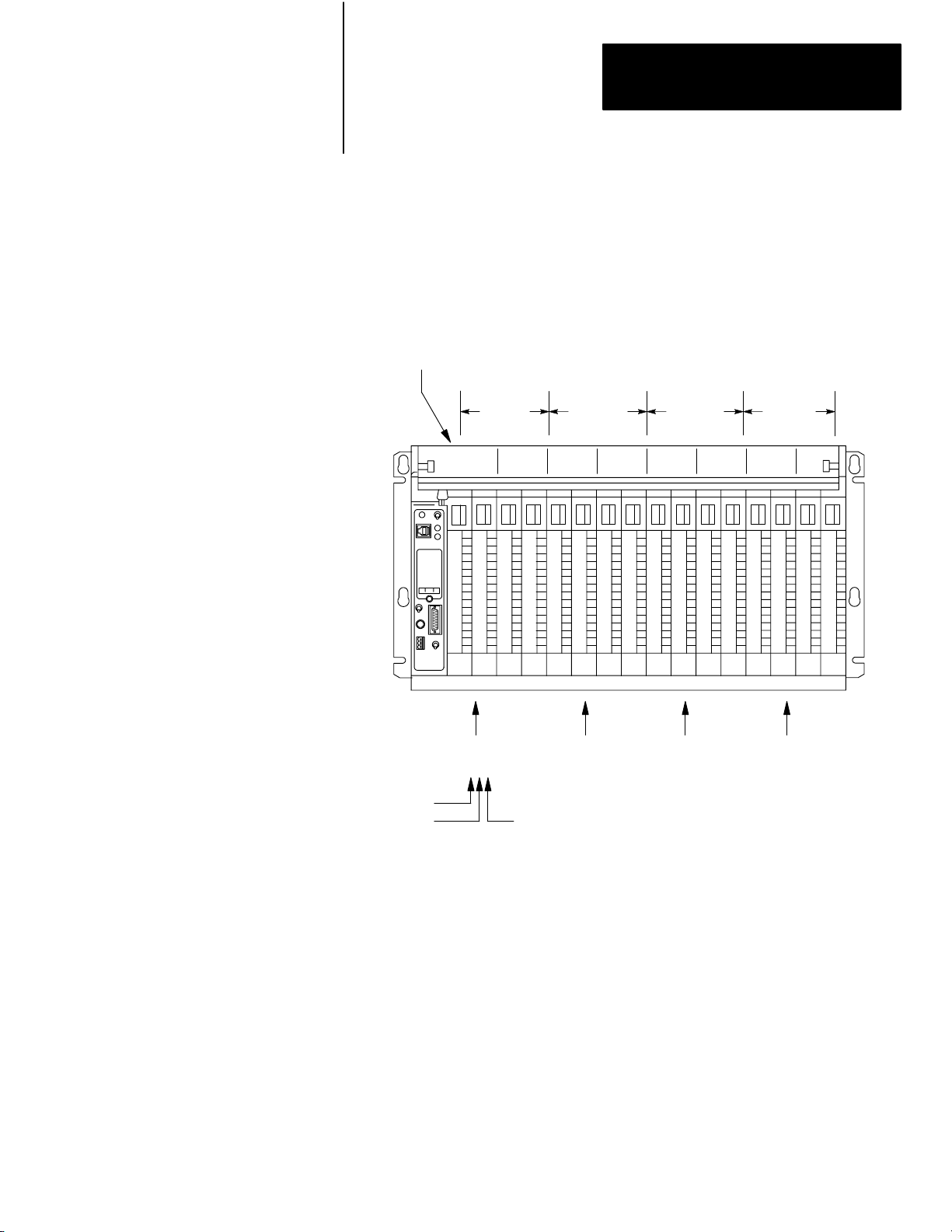

Hardware Features

Chapter

3

Chapter Objectives

Major Features

Processor Features

This chapter is a summary of the Mini-PLC-2/02, -2/16, and -2/17

processors. In this chapter, you will read about:

major features

processor features

series changes

special features

optional equipment

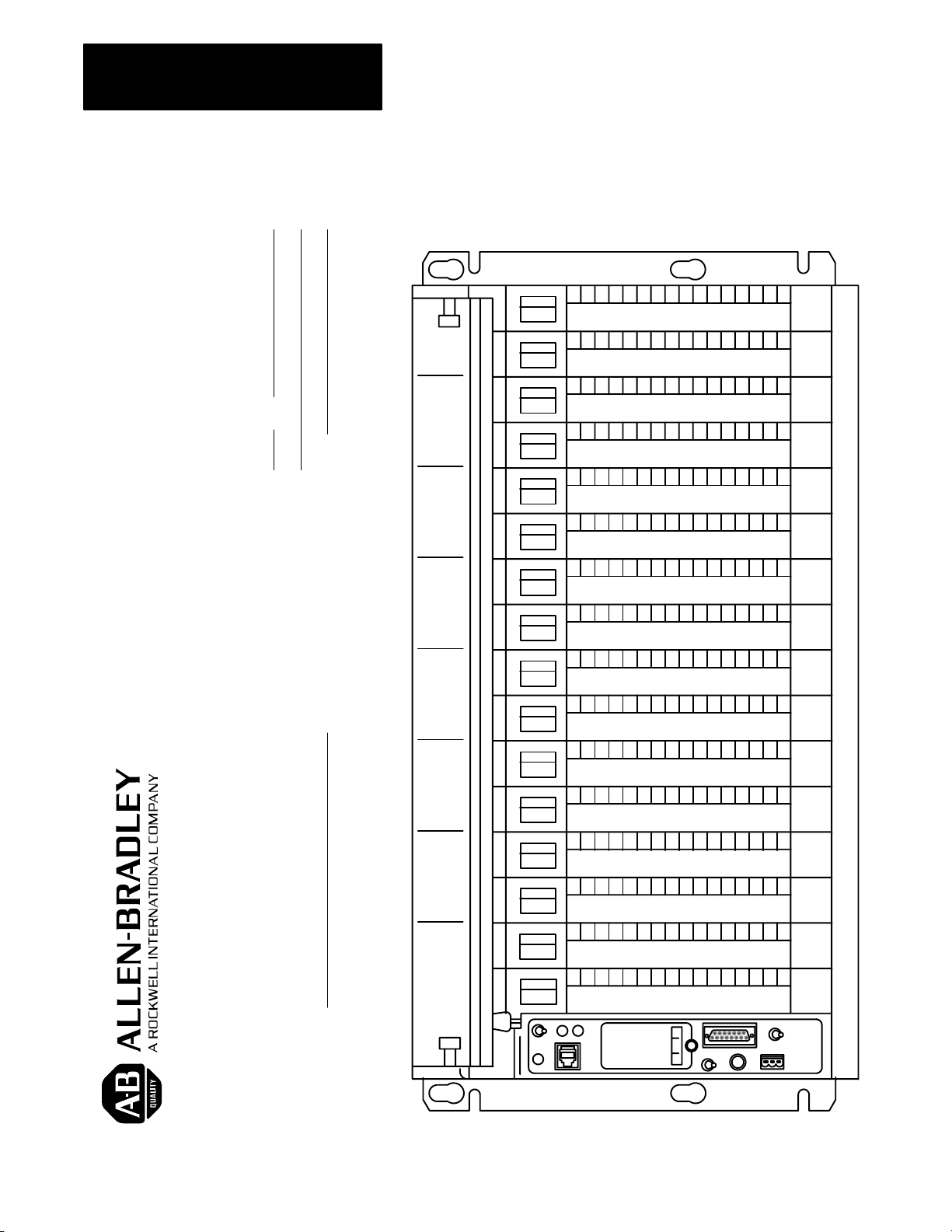

A complete processor system consists of the following major components:

a processor

I/O chassis

power supply

as many as 16 I/O modules

industrial terminal (cat. no. 1770-T3)

This manual incorporates the features and instructions of three processors:

Mini-PLC-2/02, -2/16, and -2/17. Unless stated otherwise, assume that the

features or instructions are common to all processors.

1

memory and data table

memory protection above word address 177

self-contained 120/220V AC power supply in cat. nos. 1772-LWP and

1772-LXP; cat. no. 1772-LZP supplies an additional 4A to the

backplane for I/O

mode select key switch

diagnostic indicators

I/O capacity: 128 for Mini-PLC-2/02

256 for Mini-PLC-2/16

512 for Mini-PLC-2/17

1/2-, 1-, or 2-slot addressing

1 Series C of the T3 terminal gives you the additional features required to take full advantage of all of the

processor functions described.

See Industrial Terminal section of this chapter.

8

3-1

Page 28

Chapter 3

Hardware Features

basic instruction set:

-relay-like instructions

-up to 488 timers and counters in the processors

-program control instructions

-data manipulation and comparison

-three-digit math (add, subtract, multiply, and divide)

advanced instruction set:

-jump instructions and subroutine programming

-block transfer instructions

-data-transfer file instructions

-sequencer instructions

-bit shift register instructions (bit shifts)

-EAF functions: 6-digit add, subtract, multiply and divide, square root,

Binary/BCD conversions, FIFO Load and Unload, log10, sine,

cosine, 10x

Series Changes

-The Mini-PLC-2/17 can perform these additional EAF functions:

loge, y+/- x and e+/- x, reciprocal of x, averaging, standard deviation,

PID, clock and calendar

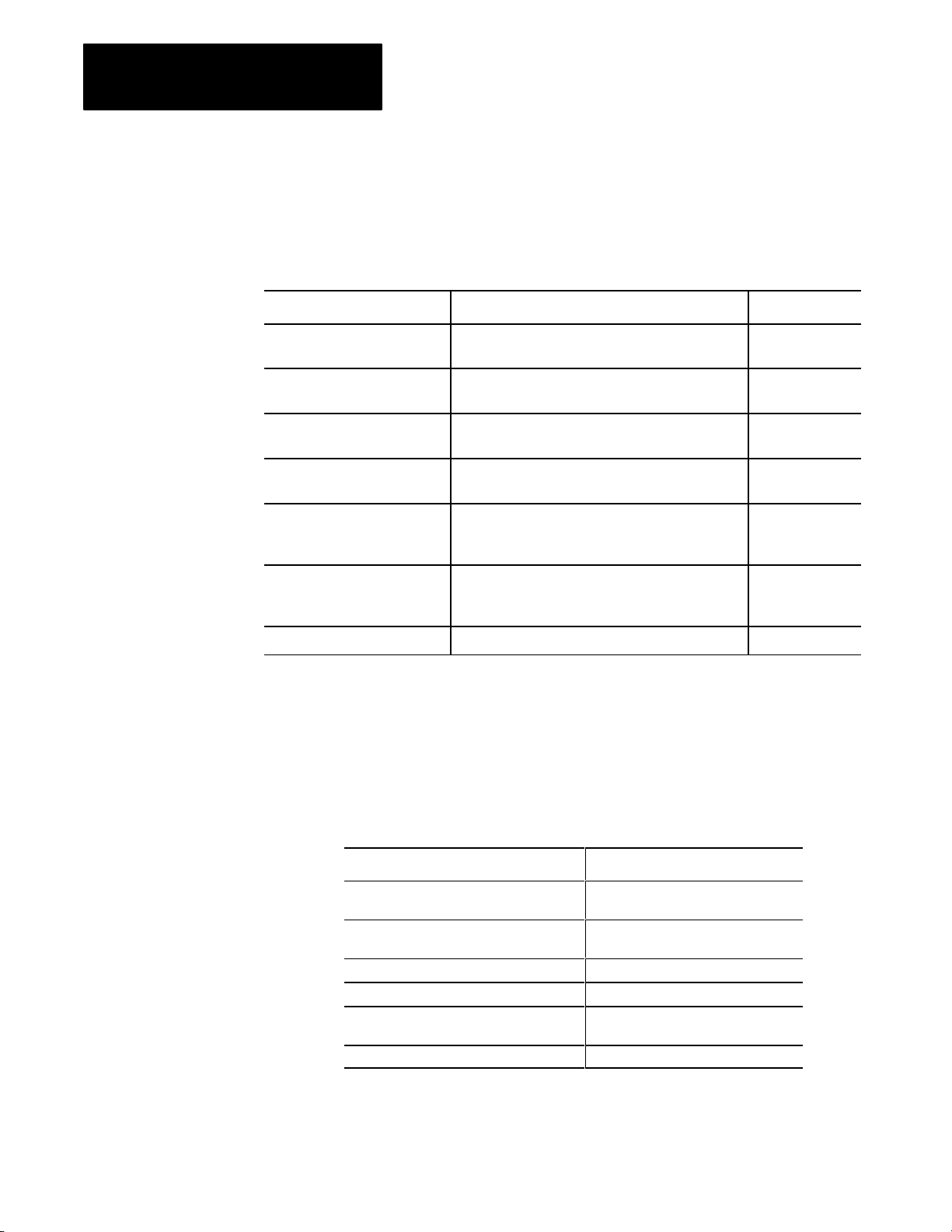

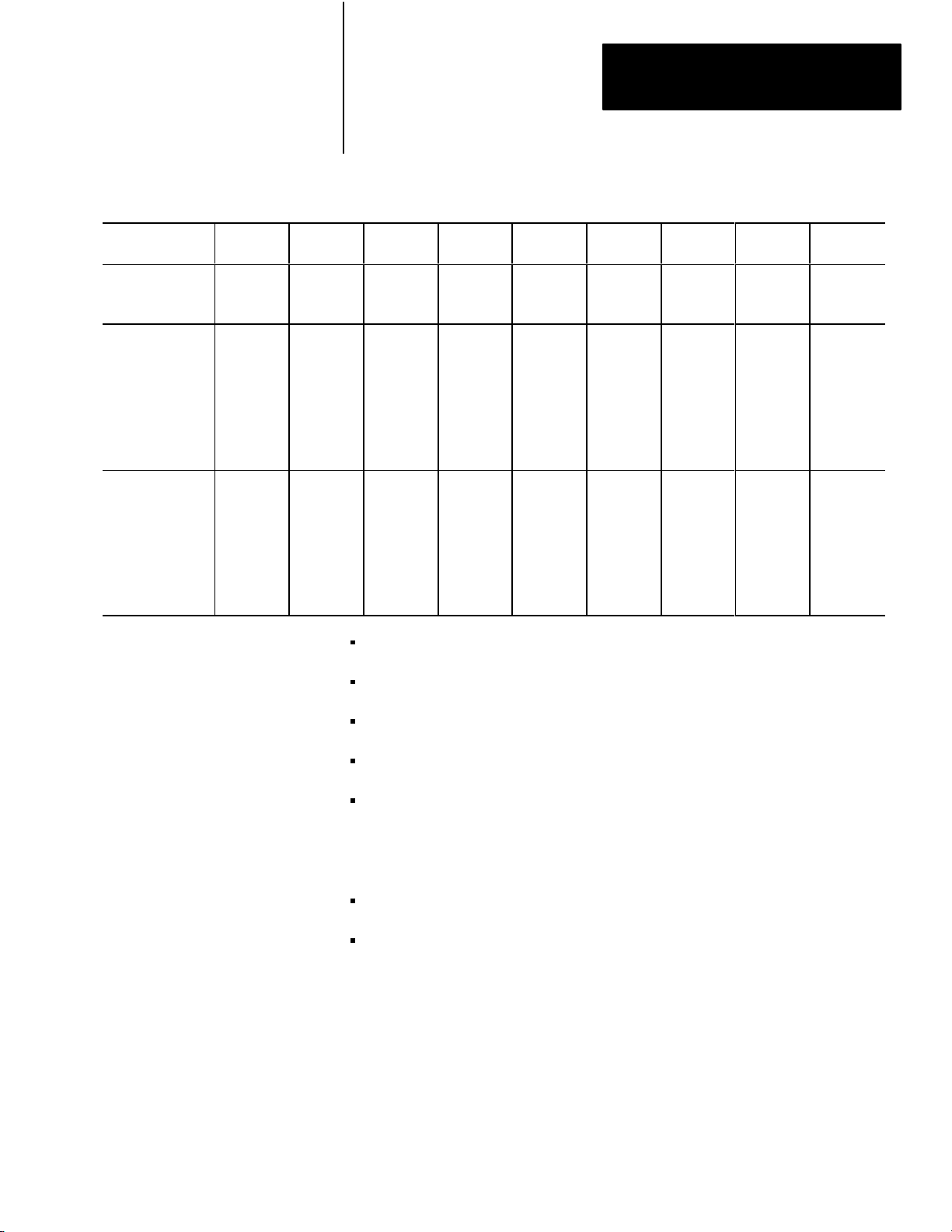

The additional features of the various series of the processors are outlined

in Table 3.A.

Important: The processor features described in the previous section apply

to all series except where noted in Table 3.A.

3-2

Page 29

Chapter 3

Hardware Features

MiniPLC2/02

Series A

Series D

MiniPLC2/16

Series A

Series B

Rev A or B

Series B

Rev C or later

Series C

Series D

MiniPLC2/17

Series A

Series B

Rev A or B

Series B

Rev C or later

Series C

Series D

AA

Batt

X X

X X

12.5msec/

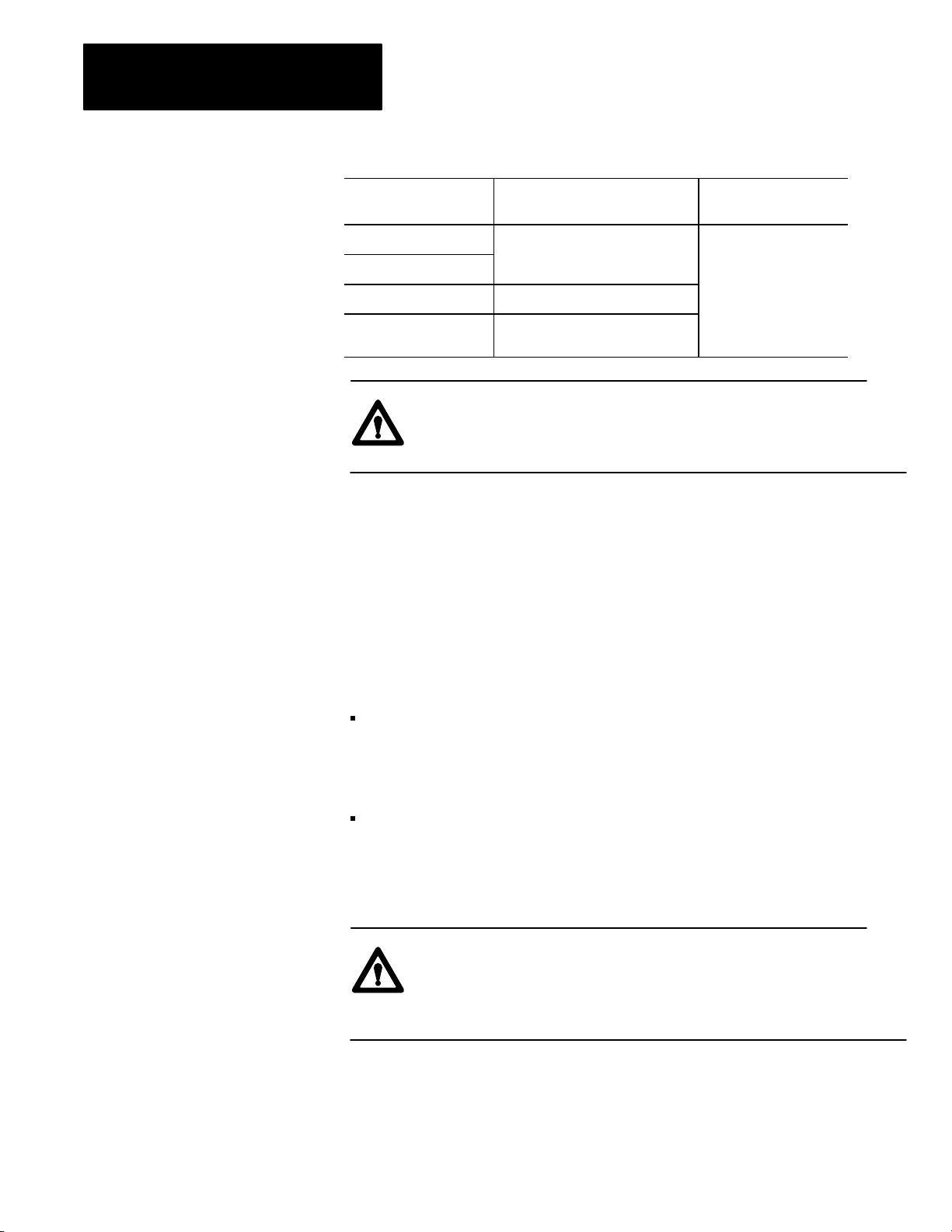

Table 3.A

Additional

K Scan

X X

X

X

X

X

X

X

Features of MiniPLC2 Processors

1/2AA

Batt

X

X

X

X

X

X

X

X

X

Key

Switch

X

X

X

X

X

X

X

X

X

X

Last

State

X

X

X

X

X

X

1/2Slot

Addr

X

X

X

X

X

X

X

X

X

Bit

Shift

X

X

X

X

X

X

X

X

X

7.5msec/

K Scan

X

X

Memory

1K

2K

3K

3K

3K

3K

4K

6K

6K

6K

6K

7.75K

Special Features

Processors

on-line data change

on-line programming

selectable timed interrupt enables recurring subroutine

self-contained lithium battery for memory

full I/O forcing when using 2-slot addressing — I/O forcing only on

rack 1 addresses when using 1-slot or 1/2-slot addressing and a series B

1770-T3 terminal, or earlier. The series C 1770-T3 terminal allows full

I/O forcing when using 2-slot, 1-slot or1/2-slot addressing.

data highway interface

report generation

The front panels of the processors are nearly identical. The only visual

difference between them is the catalog number across the bottom of the

processor (Mini-PLC-2/02, Mini-PLC-2/16, or Mini-PLC-2/17).

3-3

Page 30

Chapter 3

Hardware Features

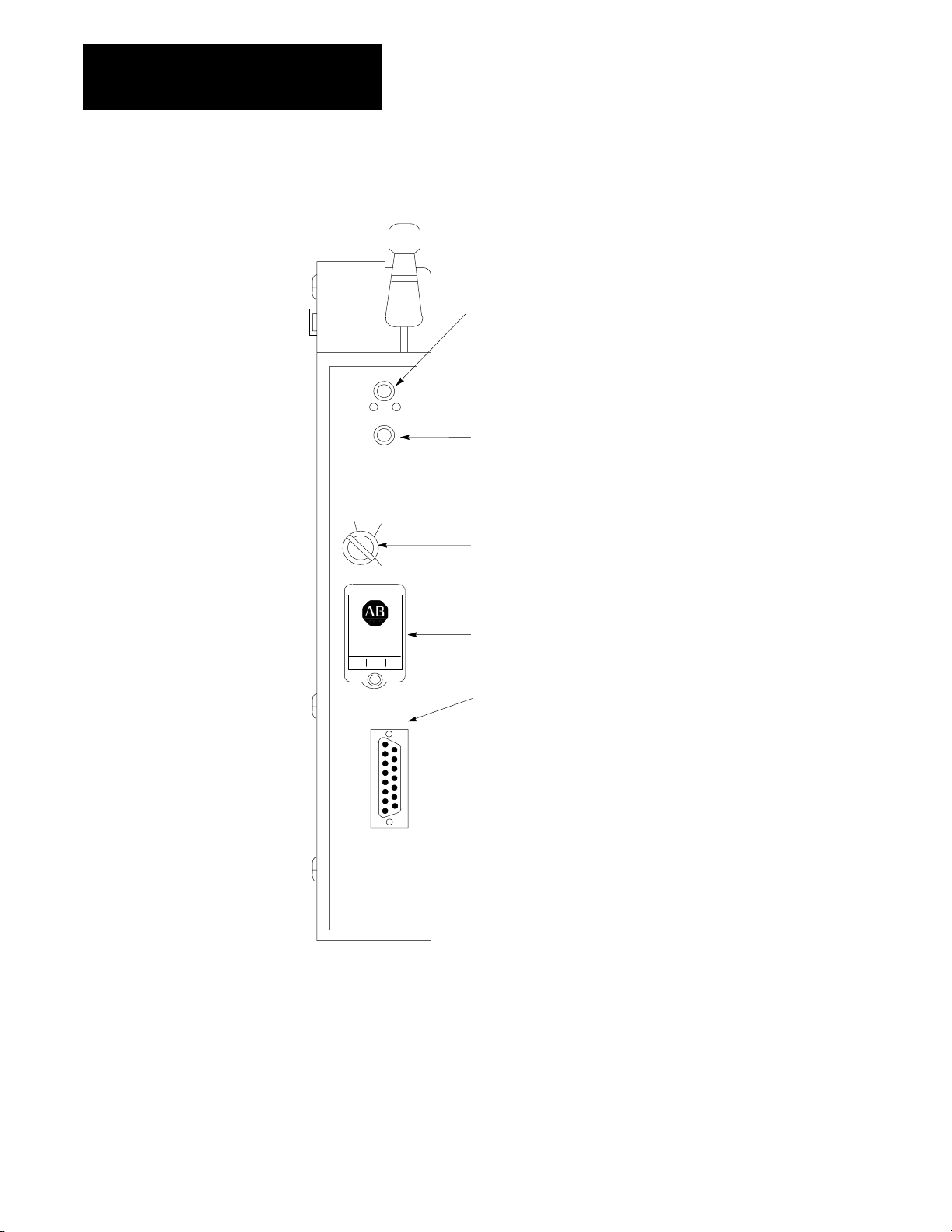

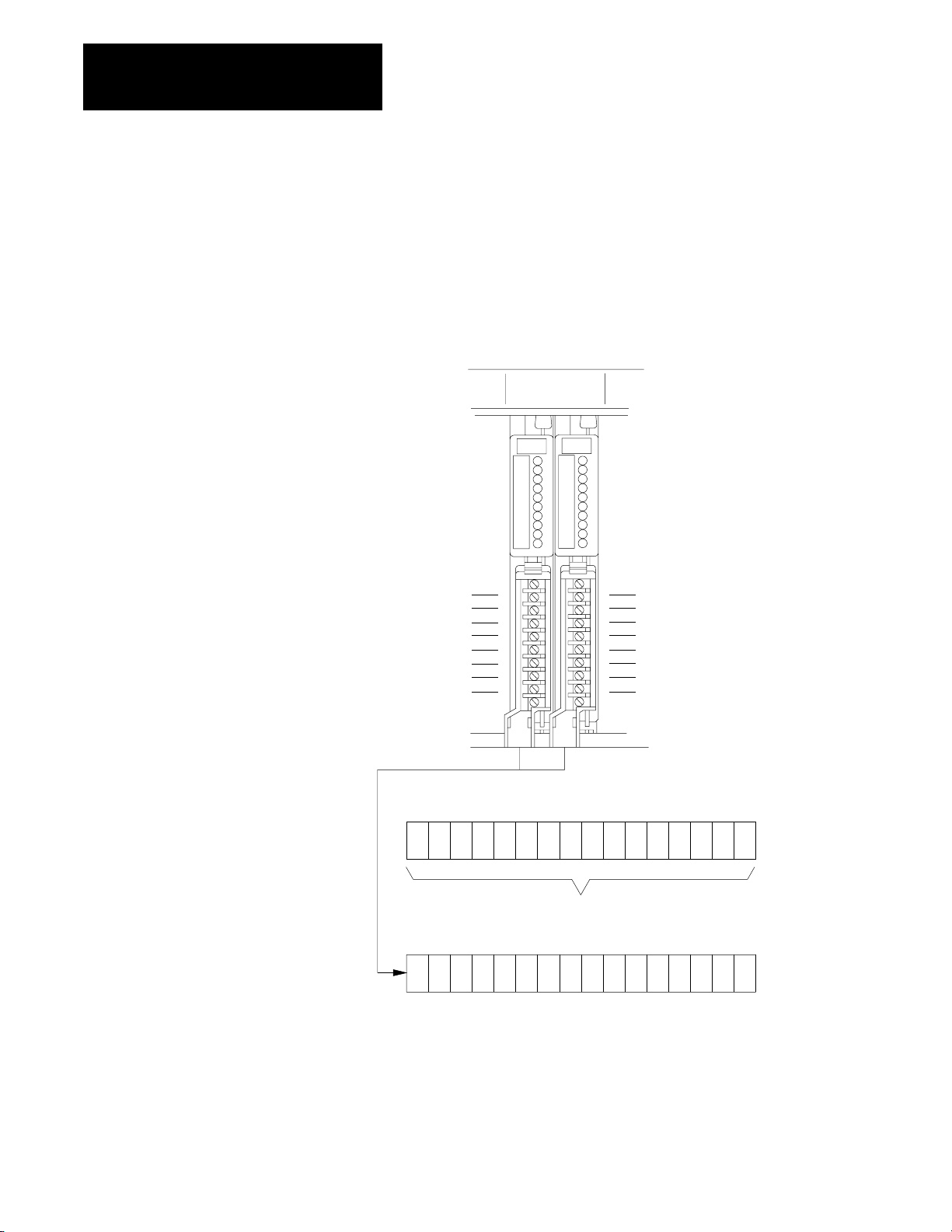

Figure 3.1

Without

PROC

F

A

U

L

T

BATT

RUN

R/P

MEM

STORE

a Power Supply

PROC indicator lights green for normal operation

and red for a processor fault. Off indicates that

you are in Program Mode or a possible runtime

error. You reset this LED by cycling power.

R

U

N

BATT (Red) lights when battery should be replaced.

Key Switch selects one of four positions:

PROG: Program

R/P: Run/Program

RUN: Run

MEM STORE: Transfer program to MEM STORE backup EEPROM

BATTERY

INSTALLED

INTFC

MINI-PLC-2/17

Battery backup helps protect stored memory.

Interface Port allows you to connect information sources such as

a 1770T3 terminal, handheld terminal. Data Highway

or

Report Generation module.

10294-I

3-4

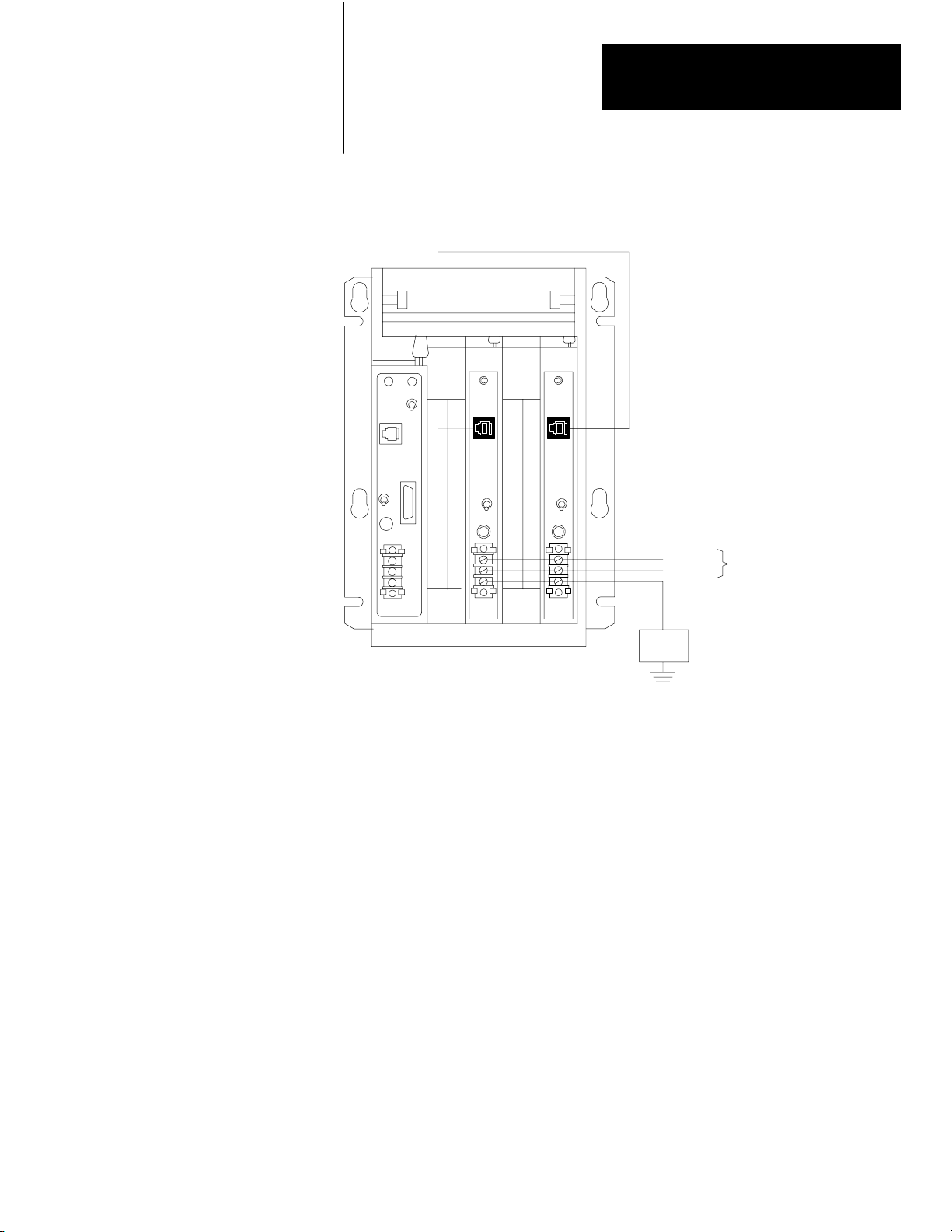

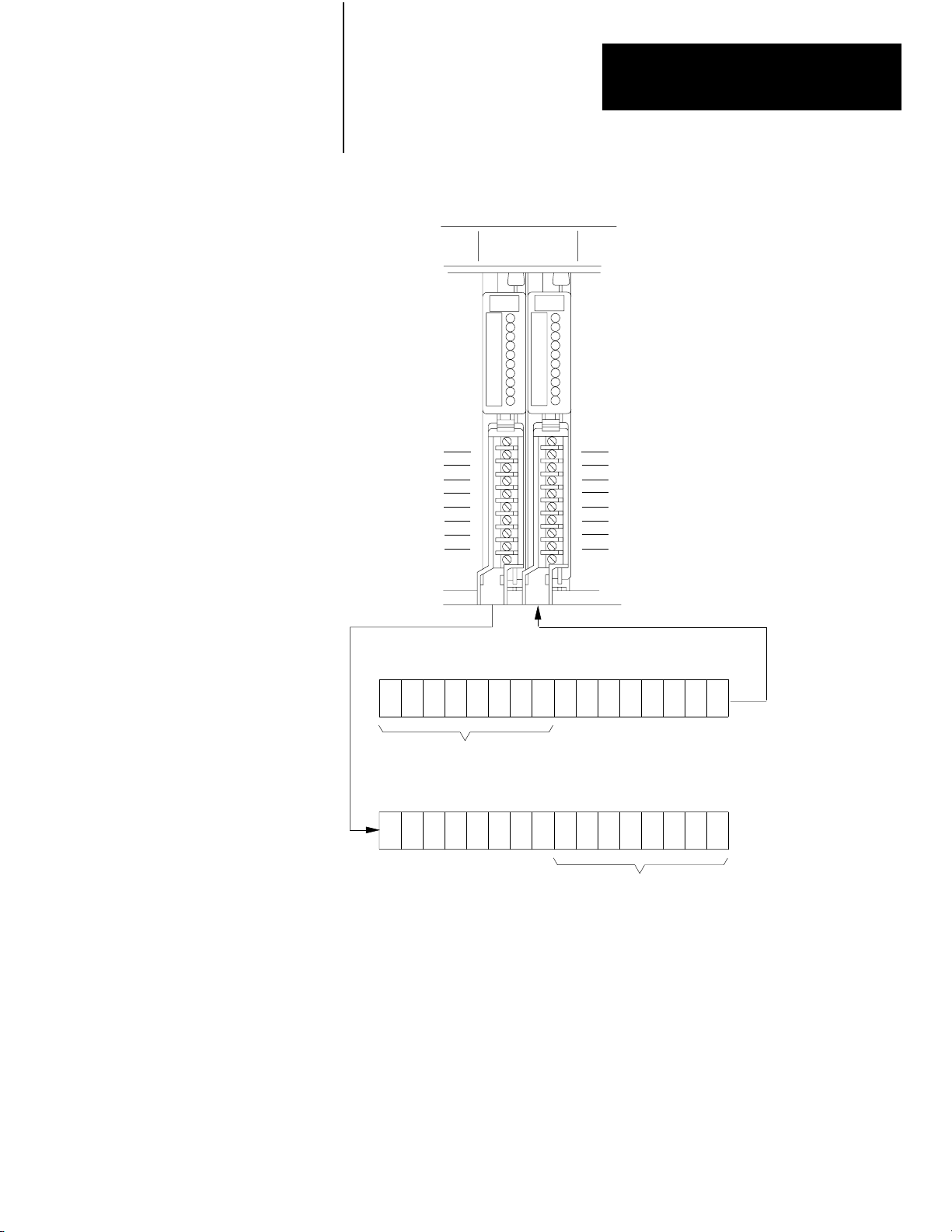

Page 31

Green LED lights for normal

power supply operation.

Port allows you to parallel the processor

power supply with another power supply

in the I/O chassis.

Figure 3.2

a Power Supply

With

P/S

ACTIVE

P

/

S

P

R

L

RUN

PROC

F

A

U

L

T

BATT

R/P

MEM

STORE

Chapter 3

Hardware Features

PROC indicator lights green for normal operation and

red for a processor fault. Off indicates that you are in

Program Mode or a possible runtime error. You

reset this LED by cycling power.

R

U

N

BATT (Red) lights when battery should be replaced.

Key Switch selects one of four positions:

PROG: Program

R/P: Run/Program

P

RUN: Run

R

O

MEM STORE: Transfer program to MEM STORE backup EEPROM

G

Toggle switch controls the

processor power supply.

Fuse holder for a 1A, 250V,

slowblow power supply fuse.

120/220VAC terminals:

L1 - Line

L2/N - Line (220V)/Neutral (120V)

GND - Ground Bus

Battery backup helps protect stored memory.

BATTERY

INSTALLED

POWER

INTFC

ON

OFF

1A 250V

SLOW BLOW

120/220

V.A.C.

L1

L2/N

GND

MINI-PLC-2/17

W/POWER SUPPLY

Mode

Select Key Switch

Interface Port allows you to connect

information sources such as a 1770T3

terminal, handheld terminal. Data Highway

or Report Generation module.

Line Voltage Selector Switch (located in rear)

10295–I

You can place the processor in any one of three modes of operation or

program the EEPROM with the key switch located on the front of

the processor.

3-5

Page 32

Chapter 3

Hardware Features

PROG – You can enter and edit your program from the 1770-T3 industrial

terminal. User program and I/O are not scanned when the switch is in this

position and outputs are disabled. You cannot change to another mode of

operation with the 1770-T3 terminal when the switch is in this position.

R/P – When your key switch is in this position, the processor can be

programmed for any one of three modes of operation.

Run/Program – Change your key switch from PROG through R/P to

RUN and back to R/P or, using the 1770-T3 terminal, press the key

sequence SEARCH 590. In this mode, your program is continuously

scanned and executed. You can:

- make on-line changes to the data table

- force instructions

- make on-line programming changes

- select remote mode of operation

Remote Program – Change your key switch from PROG to RP or, using

a 1770-T3 terminal, press the key sequence SEARCH 592. In

this mode:

- you can enter and edit a program.

- the processor stops scanning and executing its stored program and

waits for commands from the programmer.

Remote Test – Use this mode to test your program.

Using a 1770-T3 terminal, press the key sequence SEARCH 591.

1. program is executed

2. inputs are scanned

3. outputs are disabled

RUN – The processor scans and executes your program. You cannot

change to another mode of operation with the 1770-T3 terminal when the

switch is in this position nor can you alter the program or change any data.

MEM STORE – The processor will load your program to be backed up by

EEPROM when you switch to this position, then to PROG, then back to

the MEM STORE position within one second.

3-6

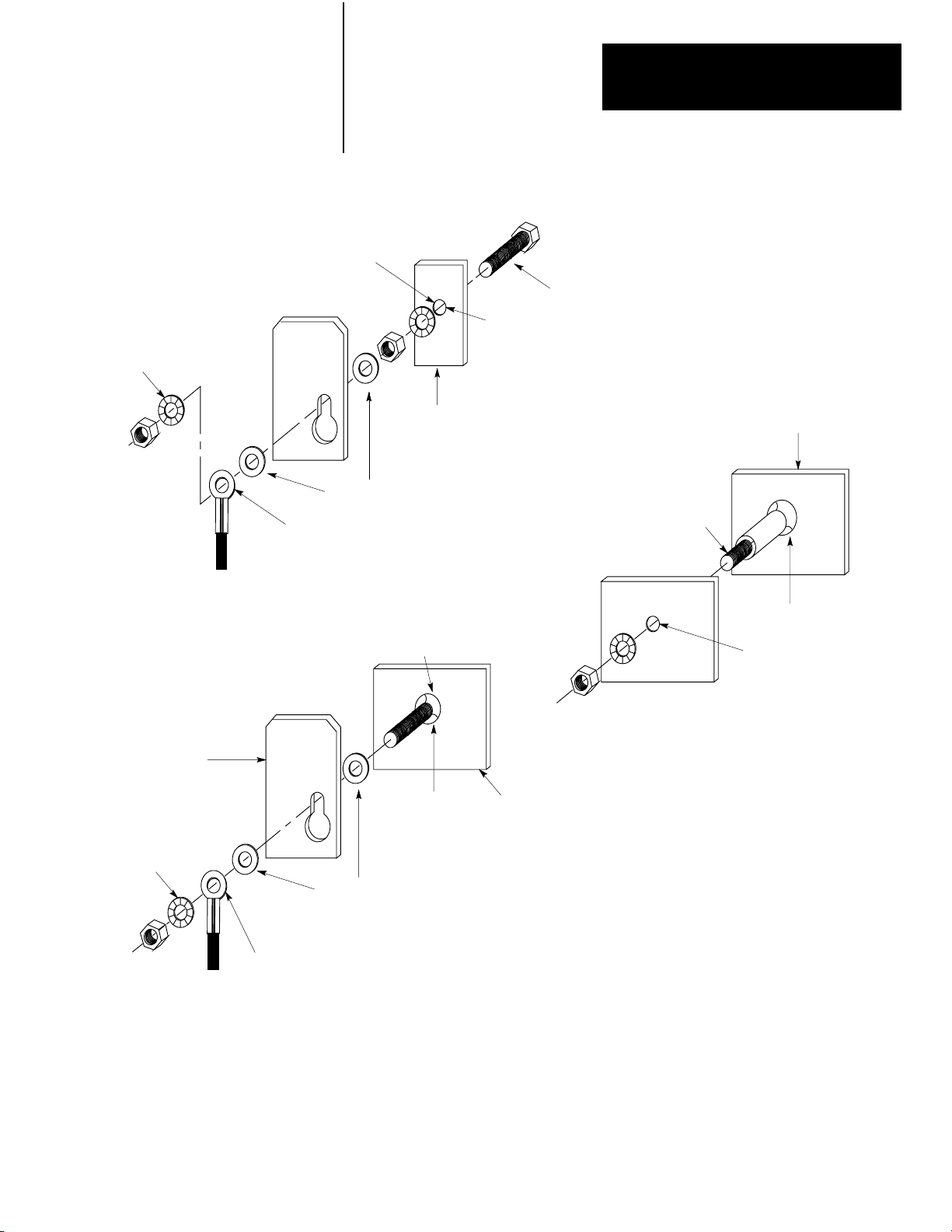

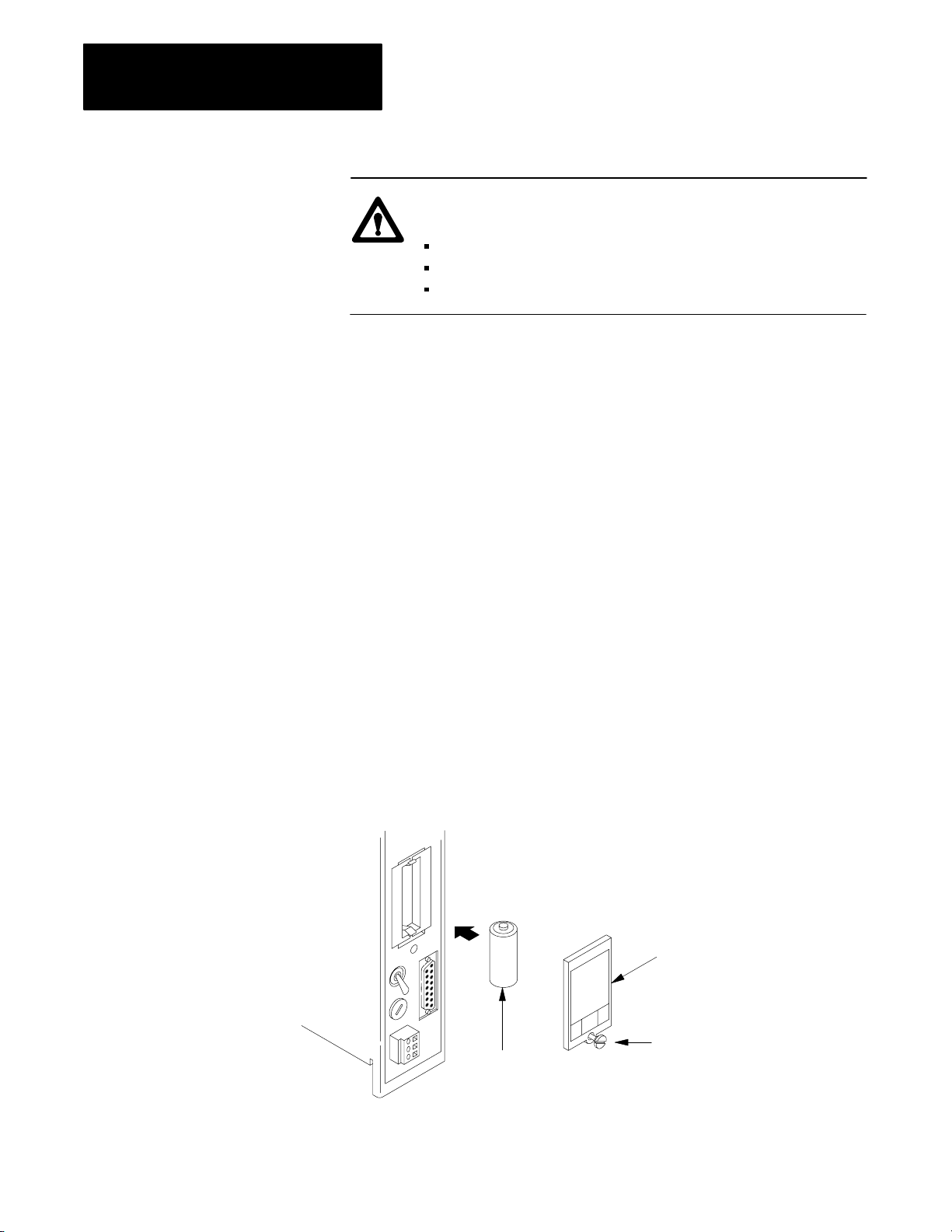

Battery

Backup

Memory contents may be lost when the processor loses power. A battery

in the processor guards against loss of data. The battery holder accepts a

AA lithium battery (cat. no. 1770-XZ).

Page 33

Chapter 3

Hardware Features

ATTENTION: Use only an Allen-Bradley authorized 1770-XZ

3.6V “1/2AA” size (Tadiran TL 2150 Type 1/2AA/s lithium

thionyl chloride battery with pressure contacts. Using an

unauthorized battery could result in sub-standard performance

of your processor.

See chapter 4 for details about battery installation and disposal.

INTFC (socket)

The 15 pin socket, labeled INTFC, provides communication between the

processor and the programming terminal (1770-T3 or 1784-T50), the

1770-RG report generation module, the 1770-T11 hand held terminal, the

1772-KG interface module or 1771-KA communications interface module.

Optional Equipment

Processor Module and: Through: Catalog Number:

Industrial Terminal (cat. no. 1770T3) PLC2 Program Panel

Interconnect Cable

Industrial Terminal (cat. no. 1784T50) PLC2 Program Panel

Interconnect Cable

Data Highway Communication Modules Data Highway/Processor Cables 1771CN, CO, or CR

PLC2 Family Report Generation Module

(cat. no. 1770RG)

PLC2 Program Panel

Interconnect Cable

1772TC

1772TC or 1784CP2

1772TC

(with external ground wire only)

The 1784-T50 also requires PLC-2 6200 programming software (cat. nos.

6201-PLC2, 6203-PLC2, 6211-PLC2, or 6213-PLC2).

Industrial

T

erminal

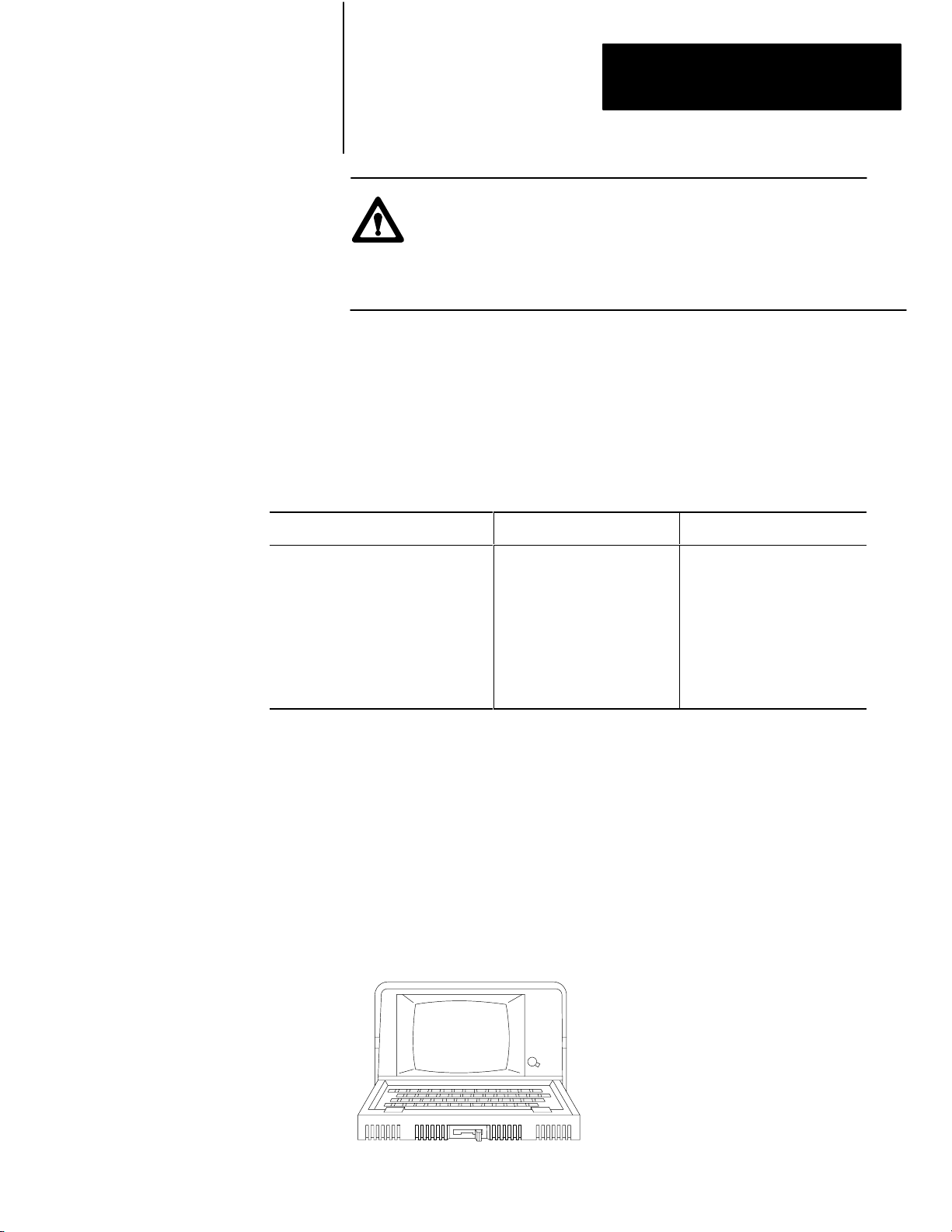

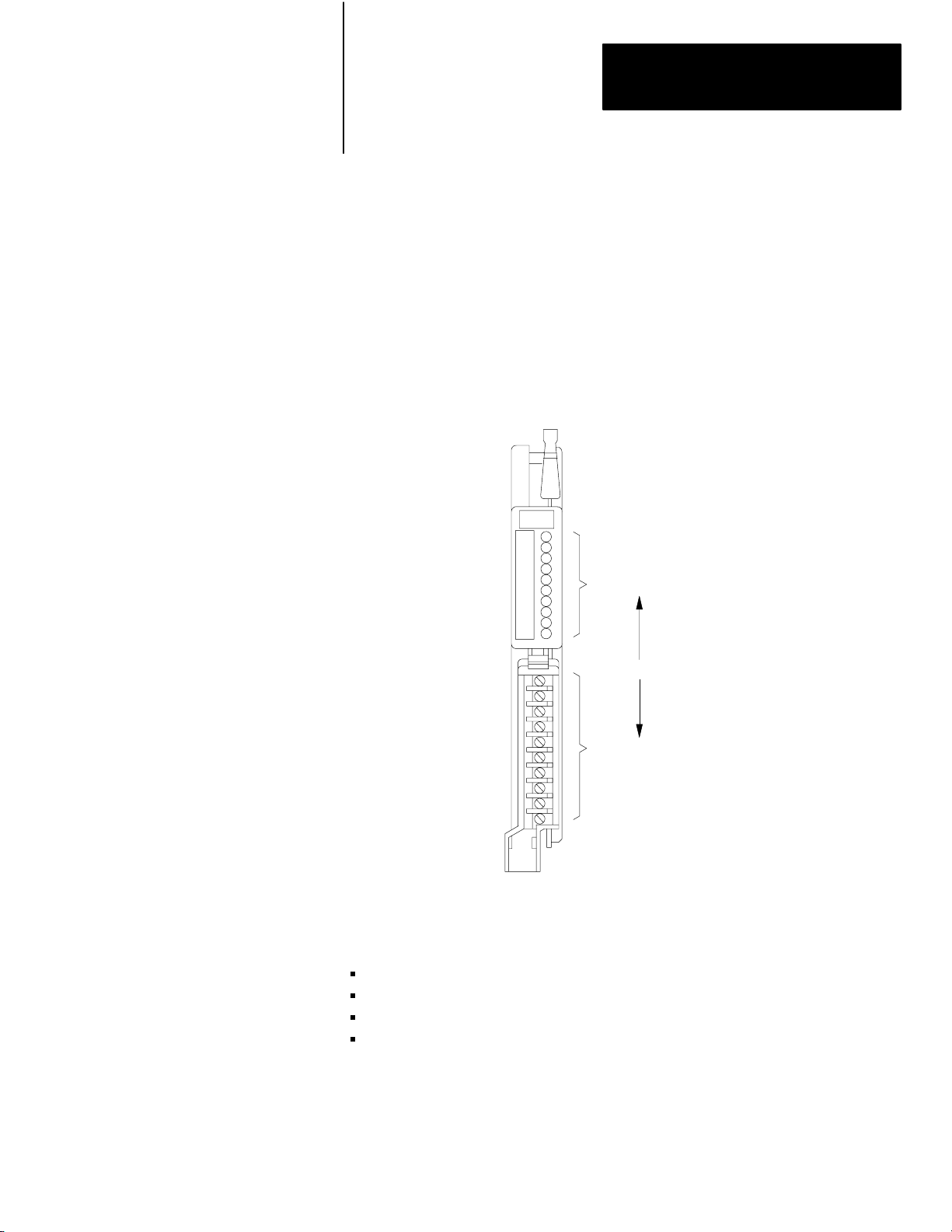

Use a 1770-T3 terminal (Figure 3.3) to program your processor. With this

1770-T3 terminal you can enter, edit, test, and troubleshoot your program.

Figure 3.3

Industrial T

An

erminal System

10697I

3-7

Page 34

Chapter 3

Hardware Features

We recommend that you use a series C, revision C or later 1770-T3

terminal; earlier versions do not provide full functionality. You can use

a 1770-T1 or 1770-T2 industrial terminal to program the processors;

however, only instructions supported by these terminals can

be programmed.

ATTENTION: Programs entered using a 1770-T3 Industrial

Terminal must not be edited with either a 1770-T1 or a 1770-T2

industrial terminal. Such editing could result in unexpected

operation with possible damage to equipment and injury

to personnel.

When using 1-slot or 1/2-slot addressing, use a series C 1770-T3 terminal

to obtain full compatibility with the processor. With this series terminal,

you can perform the following operations in rack 1, 2, 3 or 4.

immediate I/O

block transfer

full forcing

Installing

the 1770T3 T

erminal

Before you start to program your processor make sure all of your

peripheral equipment is installed properly. Follow these basic instructions

to connect the 1770-T3 terminal to the processor (Figure 3.4).

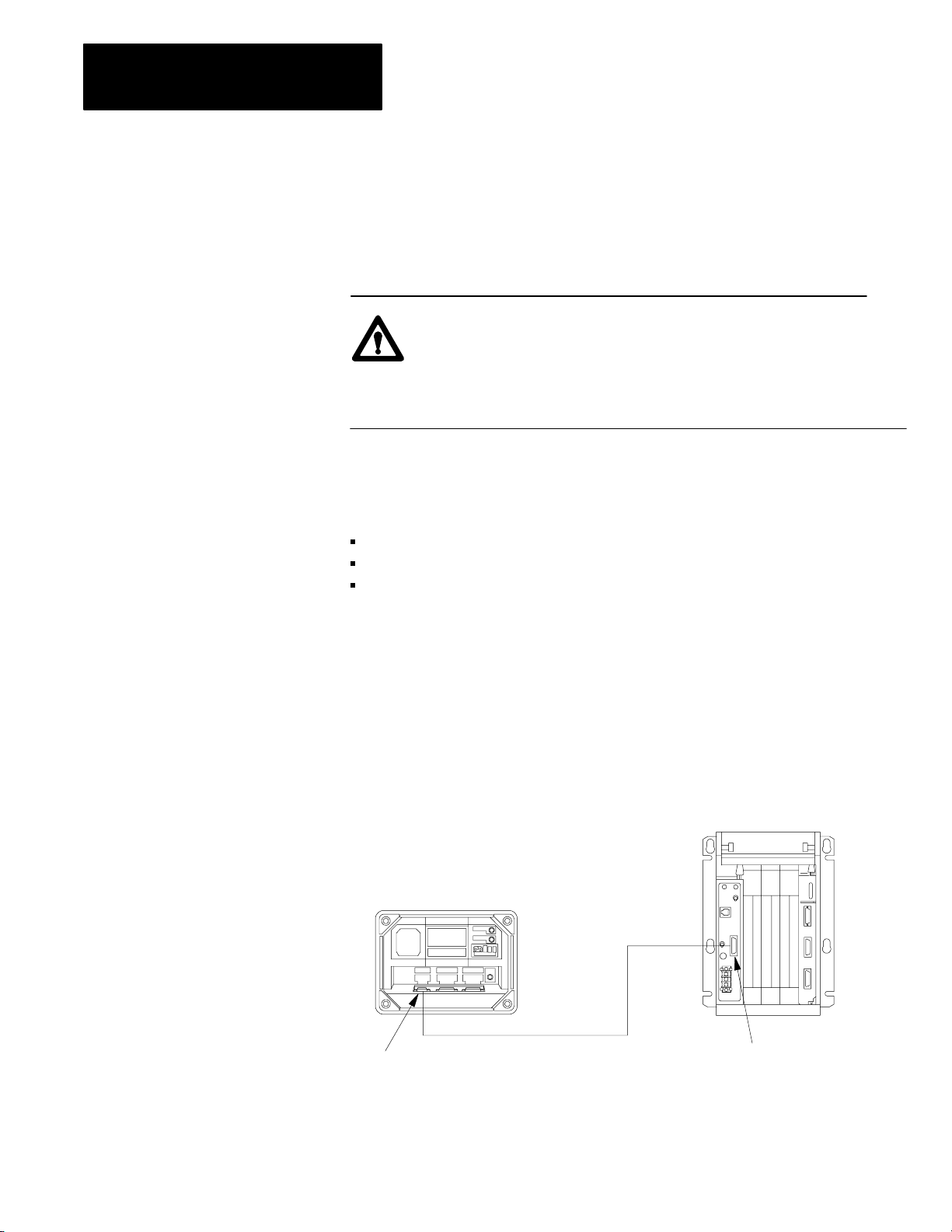

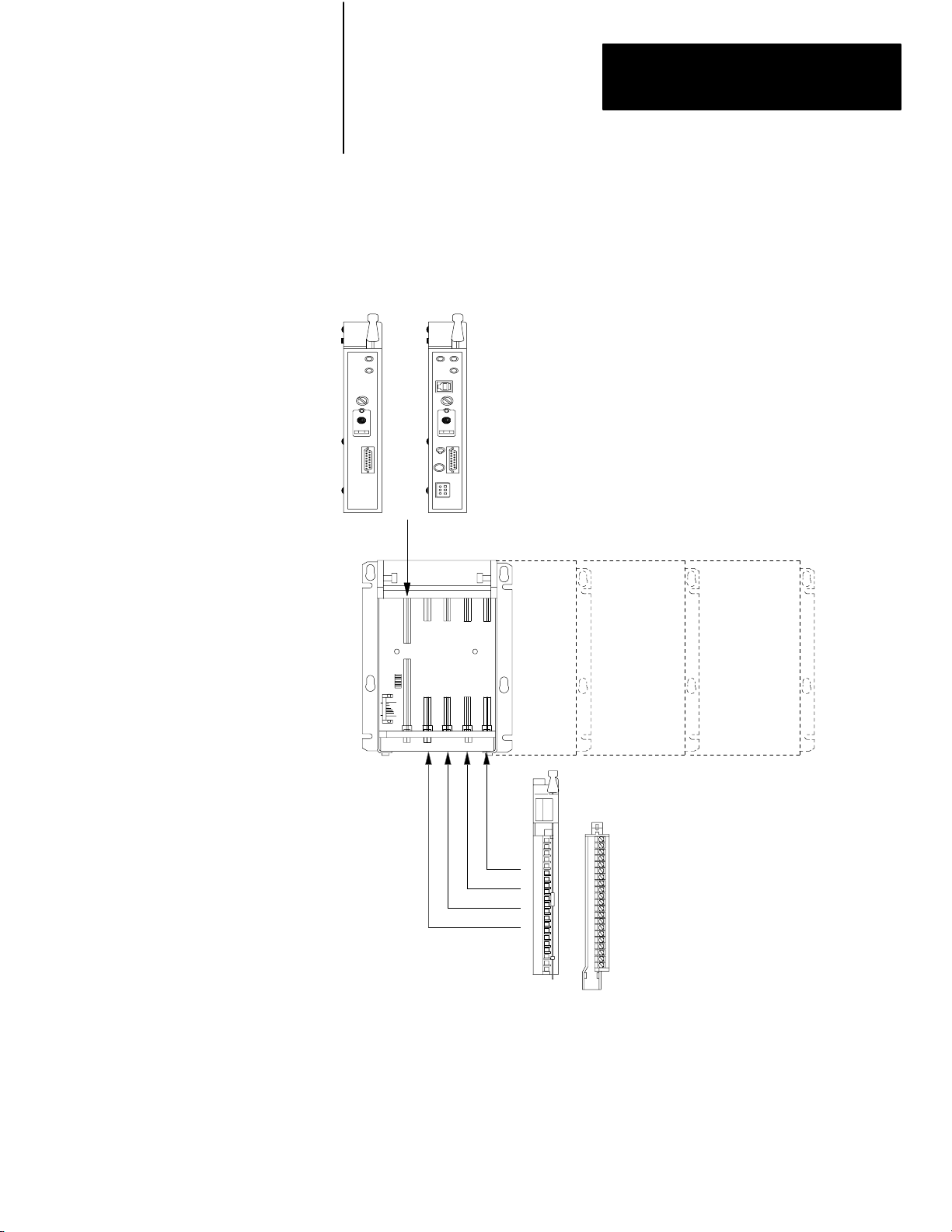

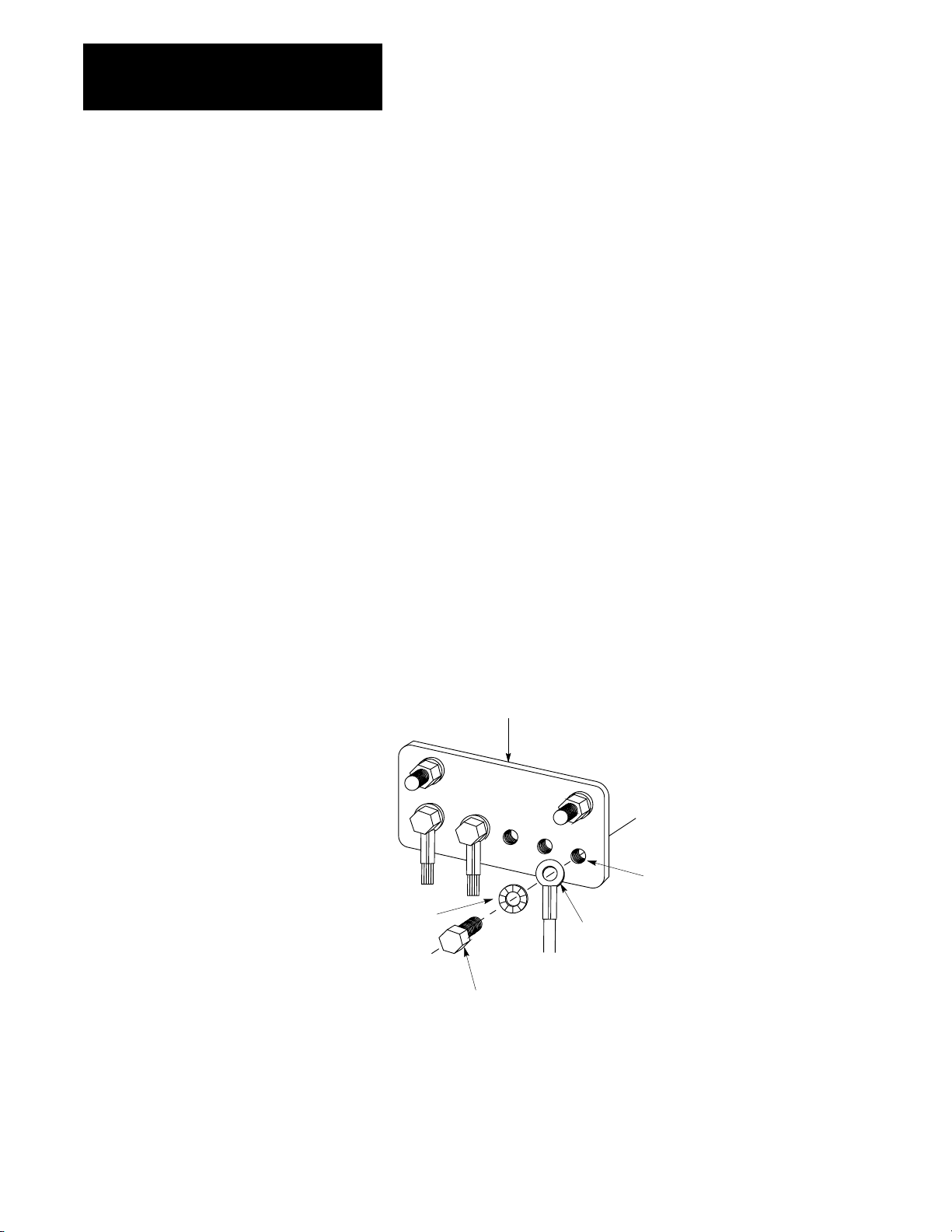

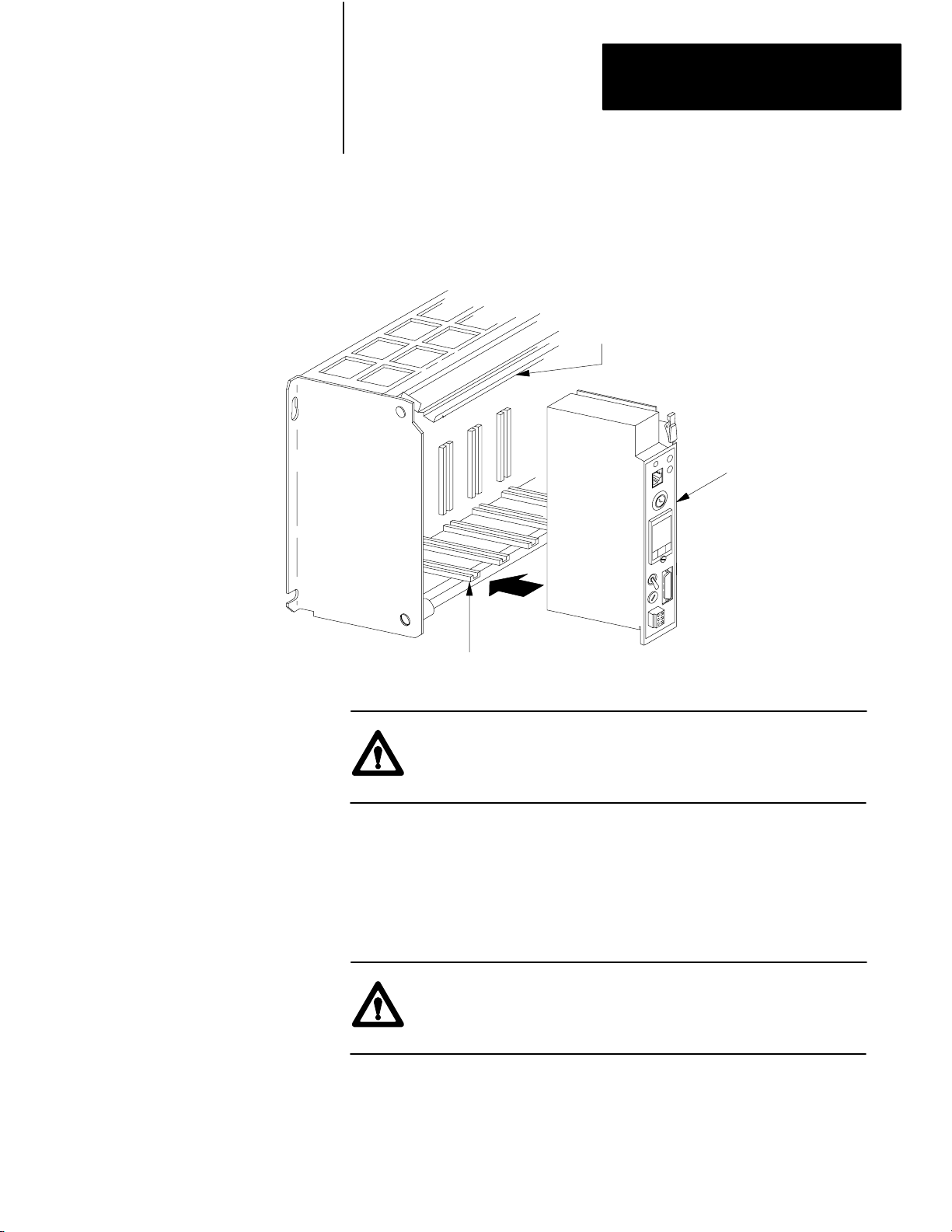

Figure 3.4

Connections Between an Industrial T

The

Industrial Terminal

(rear view)

erminal and a Processor

MiniPLC2/02, 2/16, 2/17

3-8

Channel A

PLC2 Family

Program Panel

Interconnect Cable

Interface

10249

Page 35

MODE

SELECT

DATA

INIT

EXPAND

ADDR

SBR

T.END

Chapter 3

Hardware Features

1. Connect one end of the PLC-2 Program Panel Interconnect Cable

(cat. no. 1772-TC) to CHANNEL A at the rear of the

industrial terminal.

2. Connect the other end of the cable to the socket labeled INTFC at the

front of the processor.

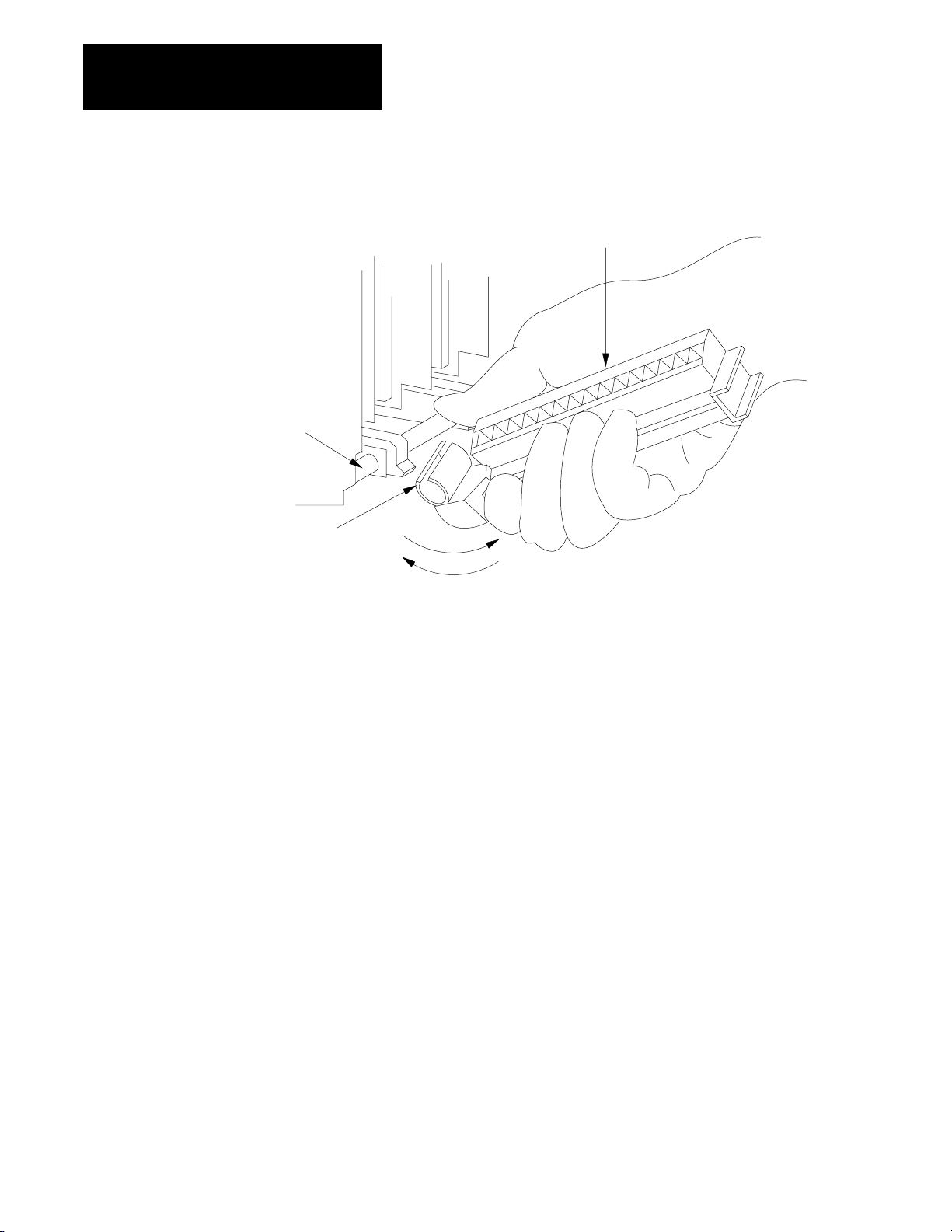

3. Place the PLC-2 Family Keytop Overlay (cat. no. 1770-KFA)

(Figure 3.5) onto the keyboard.

Figure 3.5

PLC2 Family Keytop Overlay

A

-(RET)-

-(JSR)-

LBL

-(JMP)-

EAF

CONVERT FILE SEQ

-(SCT)-

SHIFT

REG

BLOCK

X-FER

RECORD

HELP

SHIFT

RUNG SEARCH

DISPLAY INSERT REMOVE

CLEAR

MEMORY

CANCEL

COMMAND

-[ G ]-

÷ )-

-(

-( X )-

-( – )-

-[ I ]-

-(CTU)- -(TON)-

-[ = ]-

-( + )-

-[ L

]-

-(CTD)- -(TOF)-

-[ < ]-

-[ B ]-

-(PUT)- -(IOT)- -(ZCL)- -(RTR)-

-( L

)-

-( U )-

-(CTR)- -(RTO)- -(MCR)-

-( )-

A

7

B

8

D

4

C

9

E

5

F

6

123

FORCE

ON

0

FORCE

OFF

4. Plug the ac power cord of the terminal into the ac power source.

5. If using a 1772-LWP, -LXP, or -LZP processor, plug the power cord

into the ac power source.

6. Turn the power switch on the front of the industrial terminal to the

ON position.

7. Turn the power switch of the 1772-LWP, -LXP, -LZP processor to the

ON position.

3-9

Page 36

Chapter 3

Hardware Features

8. After a short while the following display appears.

DIAGNOSTICS PASSED

MODE SELECTION

MODULE 1770-FD C SERIES B/H

FOR USE WITH

INSERT

KEYTOP OVERLAY:

1770-KBA

1770-KCB

1770-KAA

THE FOLLOWING

PROCESSORS:

MODE:

10 = PLC

1

1 = PLC-2

KEYBOARD

PLC

MINI-PLC-2,PLC-2

PLC-2/02

PLC-2/05,PLC-2/15

PLC-2/16,PLC-2/17

PLC-2/20(PL1)

PLC-2/20(LP2)

PLC-2/3012 = ALPHANUMERIC

SELECT DESIRED MODE?

9. Select the PLC-2 mode by pressing [1] [1] on the 1771-T3 terminal.

Industrial

T

erminal Keyboard

The detachable keyboard houses PROMs, a sealed touchpad, and a

keytop overlay.

There are three keytop overlays:

PLC-2 family processor –– for use with any PLC-2 family processor.

PLC processor –– for use with any PLC family processor.

Alphanumeric –– for alphanumeric characters and graphic

characters generation.

Key Symbols –– There are no numbered keys greater than 9. To display

numbers greater than 9 press the individual keys. For example:

To display: 10 234

Press individually: [1][0] [2][3][4]

3-10

Page 37

Chapter 3

Hardware Features

Some keys have two symbols occupying one key (Figure 3.5). To display

the top section of each key, press your shift key before the desired symbol.

For example:

To display: 7 A

Press individually: 7 [Shift] A

Data Monitor Functions –– You can display on a CRT and print directly to

a data terminal – binary, hexadecimal, and ASCII data monitor functions

with the keystrokes in Table 21.B.

Data Cartridge Recorder

The data cartridge recorder is a portable recorder that loads programs into

and records the memories of the programmable controllers. Be sure switch

no. 8 of the backplane switch group is OFF (disable memory protect) to

load a program from a cartridge. See the Data Cartridge Recorder User

Manual, publication 1770-6.5.4, for details.

ATTENTION: You must ensure that the addressing mode

stored on the data cartridge and the current addressing mode

selected for the rack are the same prior to uploading a data

cartridge. Failure to do so would result in unpredictable

machine operation. The series C, revision C 1770-T3 terminal

prompts you in choosing the proper addressing mode.

Report Generation Module

The report generation module (cat. no. 1770-RG) provides bi-directional

communication for report generation between the processor and an EIA

RS-232-C peripheral device. The module allows you to store, delete, edit,

report, and display messages in the processor memory.

Power

Supply Modules

The following table lists the power supplies we recommend. If you are

going to parallel a power supply and a 1772-LWP, -LXP, or -LZP

processor, use either a 1771-P3 or 1771-P4 power supply.

3-11

Page 38

Chapter 3

Hardware Features

This Power Supply:

1771P3

1771P4

1771P5 an external 24V dc power source

1771P7 an external 120V or 220V ac

Receives Power from: And Supplies this Power

to the Chassis:

an external 120V ac power source +5V dc

power source

ATTENTION: Do not parallel a 1771-P5 power supply and a

1772-LWP, -LXP, or -LZP processor because of power-up and

power-down timing differences.

Paralleling Cable

Use the 1771-CT paralleling cable to connect the 1771-P3 and 1771-P4

power supplies in parallel with the 1772-LZP, -LXP, or -LWP processor.

EEPROM

The 1785-MJ EEPROM provides 8K backup; the 1772-MJ EEPROM

provides 4K backup. Both EEPROMs are non-volatile and are physically

interchangeable.

You can use the 1772-MJ with the PLC-2/02 and -2/16 processors. You

can also use it with a PLC-2/17 processor if your program END

statement address is not greater than 4095 and you have no stored

messages.

If your PLC-2/17 processor END statement is greater than 4095, then,

you must use the 1785-MJ for backup memory.

Important: You can use the 1785-MJ with the PLC-2/02 or -2/16

processors but you won’t use its full capacity.

ATTENTION: You must ensure that the addressing mode

stored on the EEPROM and the current addressing mode for the

selected rack are the same prior to uploading the EEPROM.

Failure to do so may result in unpredictable machine operation.

3-12

Page 39

Chapter 3

Hardware Features

Transferring a Program into the EEPROM (Burning the EEPROM)

1. Put the processor in the remote program or program mode

of operation.

2. Place the keyswitch into the MEM STORE position, then to PROG,

and then back to MEM STORE within one second until the green

PROC RUN indicator turns ON. This indicator turns OFF after a few

seconds. If the PROC RUN indicator does not turn green (or if it

turns red), the program was not stored.

Important: Be careful not to touch any of the keys on the industrial

terminal keyboard at any time during the EEPROM burn. If any key is

pressed during the burn, the terminal will exhibit temporary

communications problems and must be re-initialized to the PLC-2

programming mode. Press [1] [1] to re-initialize the terminal after the

EEPROM burn is complete.

Important: Do not leave the keyswitch in the MEM STORE position

after the burn is complete. The terminal will display program mode, but

ladder programming operations will be extremely slow.

Transferring a Program into the Processor from EEPROM

1. Turn off power to the processor.

2. Set switch 6 of the switch assembly group on the I/O chassis

backplane to the OFF position. This allows the processor to

unconditionally load its memory with EEPROM contents on

power up.

3. Turn on power to the processor.

Program transfer and execution begin immediately.

See the EEPROM Memory Module Product Data, publication 1772-2.22

for details. See Table 4.D for further information about setting switch 6.

3-13

Page 40

Chapter

4

Installing Your Programmable Controller

Chapter Objectives

Related Hardware

This chapter discusses the location and methods of installing your

processor. When you have finished, you should be able to:

determine where to locate your processor system

install your processor system

Table 4.A lists the hardware needed to install your processor system.

Table 4.A

Hardware for Y

The quantity of the hardware you need depends on your application.

Consult your local Allen-Bradley sales engineer or distributor for more

information concerning these items.

our Processor System

AllenBradley Hardware Catalog Number

I/O chassis 1771A1B, A2B, A3B, A3B1, A4B

I/O modules 1771 product line

Industrial terminal 1770T3 series C

Power supplies 1771P3, P4, P5, P7