Page 1

Isolated Analog Input Module

Cat. No. 1771-IL Series B

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this control

equipment must satisfy themselves that all necessary steps have been taken

to assure that each application and use meets all performance and safety

requirements, including any applicable laws, regulations, codes

and standards.

The illustrations, charts, sample programs and layout examples shown in

this guide are intended solely for example. Since there are many variables

and requirements associated with any particular installation, Allen-Bradley

does not assume responsibility or liability (to include intellectual property

liability) for actual use based upon the examples shown in this publication.

Allen-Bradley publication SGI–1.1, “Safety Guidelines For The

Application, Installation and Maintenance of Solid State Control”

(available from your local Allen-Bradley office) describes some important

differences between solid-state equipment and electromechanical devices

which should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in whole or

in part, without written permission of Allen–Bradley Company, Inc.

is prohibited.

Throughout this manual we make notes to alert you to possible injury to

people or damage to equipment under specific circumstances.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attention helps you:

Identify a hazard.

Avoid the hazard.

Recognize the consequences.

Important: Identifies information that is especially important for

successful application and understanding of the product.

Important: We recommend you frequently backup your application

programs on appropriate storage medium to avoid possible data loss.

Page 3

Summary of Changes

Summary of Changes

Summary of Changes

This release of this publication contains new and revised information from

the last release.

New Information

This manual covers the series B version of the 1771-IL isolated input

module. The 1771-IL series B module has 16-bit resolution, improved

sample time, and auto-calibration.

Revised Information

Many areas in this manual have been modified. Change bars (as shown to

the right side of this paragraph) are used to indicate new or revised

information. Every chapter in this manual has been revised. Please read

carefully.

S-1

Page 4

Using This Manual

Preface

Purpose of Manual

Audience

Vocabulary

Manual Organization

This manual shows you how to use your Isolated Analog Input module

with an Allen-Bradley programmable controller. It helps you install,

program, calibrate, and troubleshoot your module.

You must be able to program and operate an Allen-Bradley programmable

controller to make efficient use of your input module. In particular, you

must know how to program block transfers.

We assume that you know how to do this in this manual. If you do not,

refer to the appropriate programming and operations manual for your

programmable controller before you attempt to program this module.

In this manual, we refer to:

- the 1771-IL series B analog input module as the “input module,” or

the “1771-IL/B”

- the Programmable Controller as the “controller”

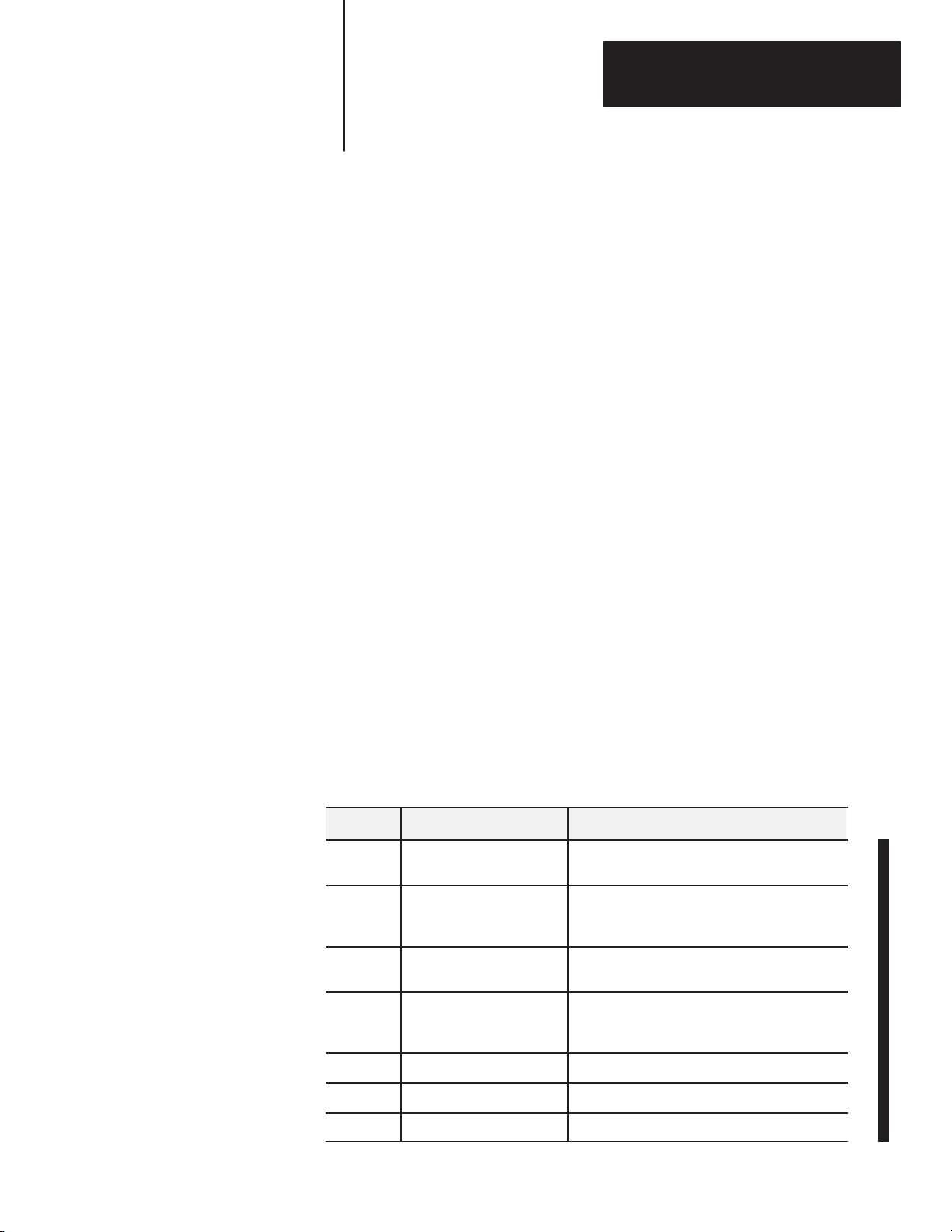

This manual is divided into seven chapters. The following chart shows

each chapter with its corresponding title and a brief overview of the topics

covered in that chapter.

Chapter Title Topics Covered

1 Overview of the input module

2 Installing the module

3

4 Configuring your module

5 Module status and input data Reading data from the module

6 Calibrating your module Information on calibrating your module

7 Troubleshooting Troubleshooting guide for problem diagnosis

Communicating with your

module

Description of the module including general and

hardware features

Module power requirements, keying, chassis

location

Wiring of the field wiring arm

Reading data from your module

Sample programs

Hardware and software configuration

Input range selection

Data format

P-1

Page 5

Preface

mb

ck

Using This Manual

Appendix Title Topics Covered

A Specifications

B Configuration Example

Related Products

Product Compatibility

C Data Formats

D

Block transfer with Mini-PLC-2

and PLC-2/20 processors

Information on BCD, 2s complement binary, signed

magnitude

How to use GET-GET instructions

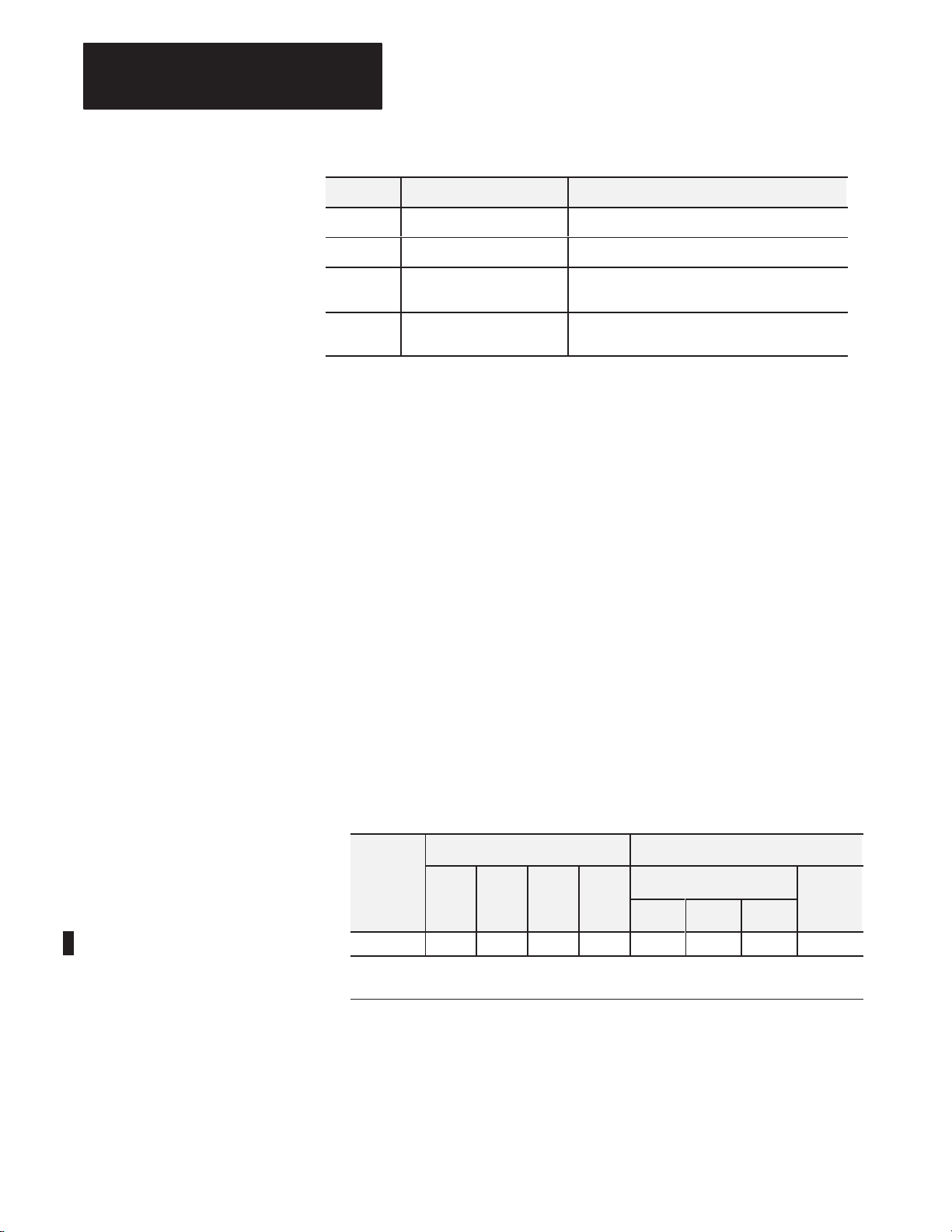

You can install your input module in any system that uses Allen-Bradley

programmable controllers with block transfer capability and the 1771 I/O

structure.

Contact your nearest Allen-Bradley office for more information about your

programmable controllers.

The 1771-IL series B module can be used with any 1771 I/O chassis.

Communication between the analog module and the processor is

bidirectional; the processor block-transfers output data through the output

image table to the module and block-transfers input data from the module

through the input image table. The module also requires an area in the data

table to store the read block and write block. I/O image table use is an

important factor in module placement and addressing selection. The

module’s data table use is listed in Table P.A.

P-2

T

able P

.A

Compatibility

Catalog

Number

1771-IL/B 8 8 15 37 Y Y Y A, B

A

= Compatible with 1771-A1, -A2, -A4

B = Compatible with 1771-A1B, -A2B, -A3B, -A4B

Y = Compatible without restriction.

and Use of Data T

Use of Data Table Compatibility

Input

Bits

Output

Image

Bits

Image

able

Read-

Blocks

Words

WriteBlo

Words

Addressing

1/2-Slot 1-Slot 2-slot

Chassis

Chassis

Series

Page 6

Preface

Using This Manual

You can place your input module in any I/O module slot of the I/O chassis.

You can put two input modules in the same module group. You can put an

input and an output module in the same module group.

Do not put the module in the same module group as a discrete high density

module unless using 1- or 2-slot addressing. Avoid placing output modules

close to ac modules or high voltage dc modules.

Related Publications

For a list of publications with information on Allen-Bradley programmable

controller products, consult our publication index (SD499).

P-3

Page 7

T

able of Contents

Overview of the Input

Module

Installing the Input Module

Chapter 1

Chapter Objectives 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Descriptions 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Features 1-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How Analog Modules Communicate with Programmable Controllers 1-2.

Accuracy 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 1-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2

Chapter Objectives 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Before You Install Your Input Module 2-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Electrostatic Damage 2-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Requirements 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Location in the I/O Chassis 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Keying 2-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Your Input Module 2-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Grounding 2-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Setting the Voltage/Current Selection Jumpers 2-6. . . . . . . . . . . . . . . . . . . .

Module Installation 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Indicator Lights 2-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 2-8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communicating With Your

Module

Configuring Your Module

Chapter 3

Chapter Objectives 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Programming 3-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-2 Programming 3-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-3 Programming 3-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PLC-5 Programming 3-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Module Scan Time 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 3-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4

Chapter Objectives 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring Your Input Module 4-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Range Selection 4-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Block Transfer Write Format 4-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Data Format 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Filtering 4-4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Real Time Sampling 4-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Scaling 4-7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Default Configuration 4-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 4-13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Page 8

T

able of Contents

Module Status and Input

Data

Calibrating Your Module

Troubleshooting

Specifications

Chapter 5

Chapter Objectives 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Reading Data From Your Module 5-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 5-3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 6

Chapter Objective 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tools and Equipment 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Calibrating your Input Module 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

About Auto-calibration 6-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Performing Auto-calibration 6-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter Summary 6-5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 7

Chapter Objective 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostics Reported by the Module 7-1. . . . . . . . . . . . . . . . . . . . . . . . . . .

Status Reported by the Module 7-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix A

Specifications A-1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Example

Data Formats

Block Transfer (Mini–PLC–2

and PLC–2/20 Processors)

Appendix B

Sample Configuration of the Analog Input Module B-1. . . . . . . . . . . . . . . .

Appendix C

4–Digit Binary Coded Decimal (BCD) C-1. . . . . . . . . . . . . . . . . . . . . . . . . .

Signed–magnitude Binary C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Two’s Complement Binary C-2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Appendix D

Multiple GET Instructions–Mini–PLC–2 and PLC–2/20 Processors D-1. . .

Setting the Block Length (Multiple GET Instructions only) D-3. . . . . . . . . .

II

Page 9

Chapter

Overview of the Input Module

1

Chapter

Objectives

Module Descriptions

This chapter gives you information on:

features of the module

how the input module communicates with programmable

controllers

The input module is an intelligent block transfer module that interfaces

analog input signals with any Allen-Bradley programmable controllers that

have block transfer capability. Block transfer programming moves input

data words from the module’s memory to a designated area in the

processor data table in a single scan. It also moves configuration words

from the processor data table to module memory.

The input module is a single-slot module that requires no external power

supply. After scanning the analog inputs, the input data is converted to a

specified data type in a digital format to be transferred to the processor’s

data table on request. The block transfer mode is disabled until this input

scan is complete. Consequently, the minimum interval between block

transfer reads is the same as the total input update time for each analog

input module.

Features

This module senses up to eight analog signals at its inputs and converts

them to a proportional four-digit BCD or 16-bit binary value while

providing channel to channel and channel to ground isolation of +1000V.

You can select from five voltage or three current input ranges. Each input

is software selectable on a per channel basis.

This module’s features include:

Eight software configurable differential inputs

User program selectable input ranges on a per channel basis (see

Table 1.A)

Selectable real-time sampling

Selectable scaling to engineering units

Selectable digital filtering

+1000V input isolation, channel-to-channel, channel-to-ground

Selectable high and low input alarms

1-1

Page 10

Chapter 1

Overview of the Input Module

T

able 1.A

Program

Selectable Input Ranges

Voltage Ranges Current Ranges

1 to 5V dc 4 to 20mA

0 to 5V dc 0 to 20mA

-5 to +5V dc -20 to +20mA

-10 to +10V dc

0 to 10V dc

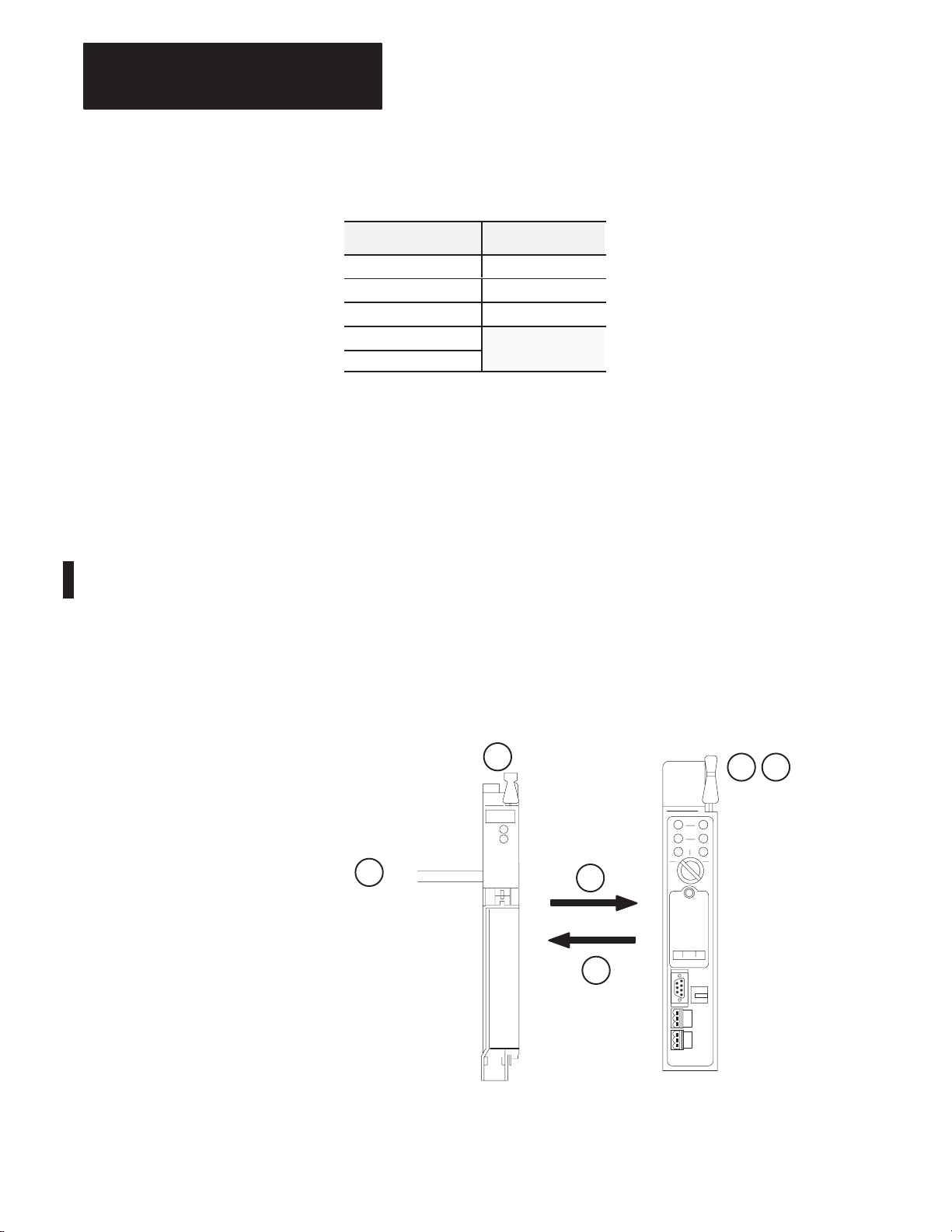

How Analog Modules Communicate with Programmable Controllers

The processor transfers data to the module (block transfer write, BTW) and

from the module (block transfer read, BTR) using BTW and BTR

instructions in your ladder diagram program. These instructions let the

processor obtain input values and status from the module, and let you

establish the module’s mode of operation (Figure 1.1).

1. The processor transfers your configuration data, and alarm values to

the module via a block transfer write instruction.

2. External devices generate analog signals that are transmitted to the

module.

Figure 1.1

Communication

+

2

-

Between Processor and Module

3

I/O Chassis

Backplane

4

56

1-2

Input Module

Cat. No. 1771-IL/B

1

Programmable Controller

11845-I

Page 11

Chapter 1

Overview of the Input Module

3. The module converts analog signals into binary or BCD format, and

stores these values until the processor requests their transfer.

4. When instructed by your ladder program, the processor performs a

read block transfer of the values and stores them in a data table.

5. The processor and module determine that the transfer was made

without error, and that input values are within specified range.

6. Your ladder program can use and/or move the data (if valid) before it

is written over by the transfer of new data in a subsequent transfer.

7. Your ladder program should allow write block transfers to the module

only when enabled by operator intervention or at power-up.

Accuracy

Chapter Summary

The accuracy of your input module is described in Appendix A.

In this chapter you read about the functional aspects of the input module

and how the module communicates with the programmable controller.

1-3

Page 12

Chapter

Installing the Input Module

2

Chapter

Objectives

Before You Install Your Input Module

This chapter gives you information on:

calculating the chassis power requirement

choosing the module’s location in the I/O chassis

configuring your module voltage/current selection jumpers

keying a chassis slot for your module

wiring the input module’s field wiring arm

installing the input module

Before installing your input module in the I/O chassis you should:

You need to: As described under:

Calculate the power requirements of all modules

in each chassis.

Determine where to place the module in the I/O

chassis.

Select the input for each channel.

Key the backplane connector in the I/O chassis. Module Keying, page 2-4.

Make connections to the wiring arm.

Power Requirements, page 2-2.

Module Location in the I/O Chassis, page 2-2.

Setting the Voltage/Current Selection Jumpers,

page 2-2.

Wiring Your Input Module, page 2-5, and

Grounding, page 2-7

Electrostatic Damage

Electrostatic discharge can damage semiconductor devices inside this

module if you touch backplane connector pins. Guard against electrostatic

damage by observing the following precautions:

ATTENTION: Electrostatic discharge can degrade

performance or cause permanent damage. Handle the module as

stated below.

Wear an approved wrist strap grounding device, or touch a grounded

object to rid yourself of electrostatic charge before handling the module.

Handle the module from the front, away from the backplane connector.

Do not touch backplane connector pins.

Keep the module in its static-shield bag when not in use.

2-1

Page 13

Chapter 2

Installing the Input Module

Power Requirements

Module Location in the I/O Chassis

Your module receives its power through the 1771 I/O power supply. The

Isolated Analog input module requires 1.2A at 5V from the power supply.

Add this current to the requirements of all other modules in the I/O chassis

to prevent overloading the chassis backplane and/or backplane

power supply.

Place your module in any I/O module slot of the I/O chassis except for the

extreme left slot. This slot is reserved for programmable controller

processors or adapter modules.

Group your modules to minimize adverse affects from radiated electrical

noise and heat. We recommend the following.

Group analog input and low voltage dc modules away from ac modules

or high voltage dc modules to minimize electrical noise interference.

Do not place this module in the same I/O group with a discrete

high-density I/O module when using 2-slot addressing. This module

uses a byte in both the input and output image tables for block transfer.

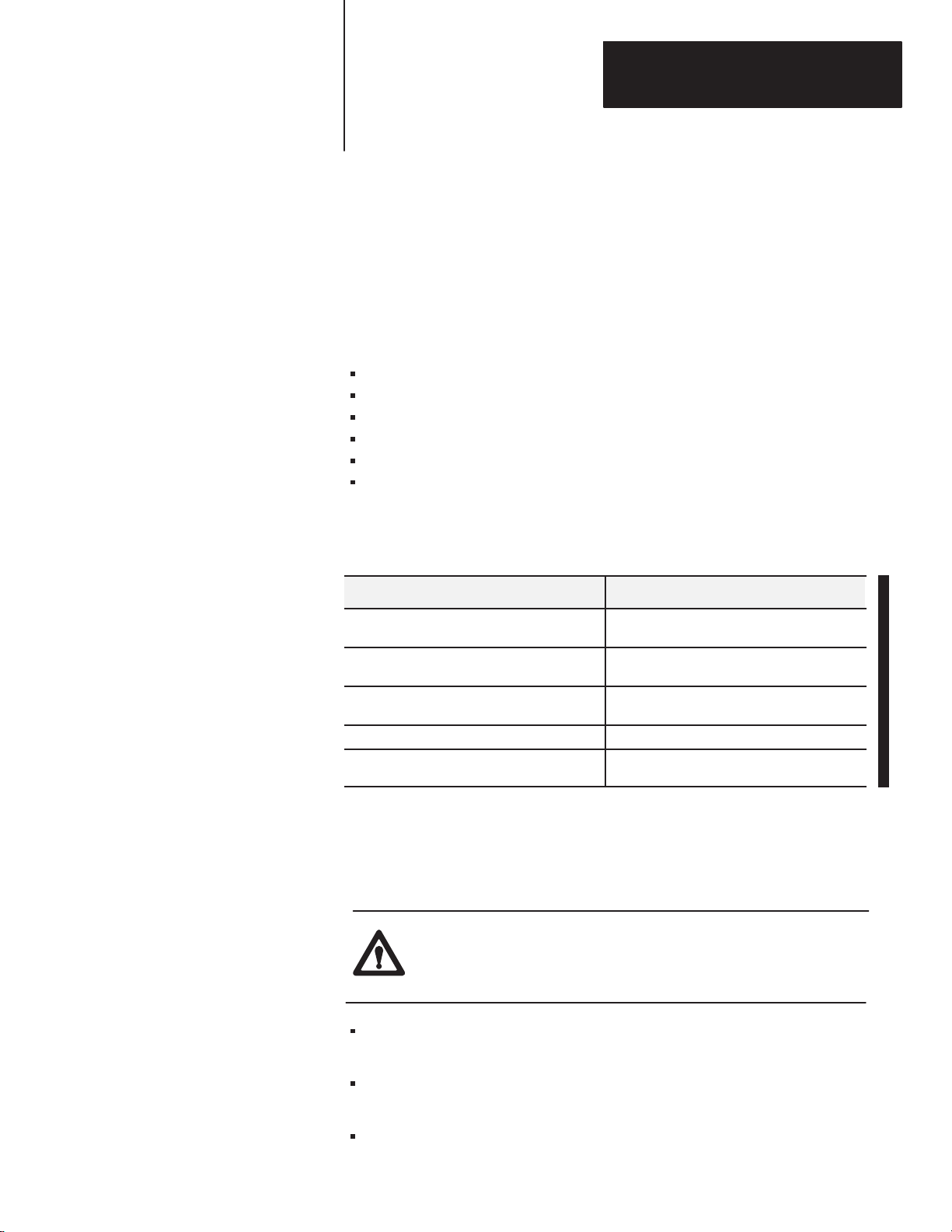

Setting the Voltage/Current Selection Jumpers

After determining the module’s location in the I/O chassis, connect the

wiring arm to the pivot bar at the module’s location.

The Isolated Analog Input Module (1771-IL/B) is shipped with each

channel set for voltage mode. If a milliamp input is desired, you must set a

jumper on the functional analog block (FAB) for that particular channel.

To set the selection jumpers for your desired inputs, proceed as follows:

1. Remove the module’s left hand cover plate (the one without

the labels).

2. Locate the selection plugs (Figure 2.1).

3. Position the jumpers as shown in Figure 2.1 for your

particular module.

4. Reassemble the module after you have finished checking and/or

setting the selection plugs.

2-2

Page 14

Functional Analog Block

Figure 2.1

Configuration

Chapter 2

Installing the Input Module

Jumper Settings for 1771-IL/B Inputs

Voltage/Current

Jumper

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Jumper in

Current position.

Edge View

(enlarged)

Jumper in

Voltage position.

Side V

Channel 6

Channel 7

Channel 8

iew

11847-I

2-3

Page 15

Chapter 2

Installing the Input Module

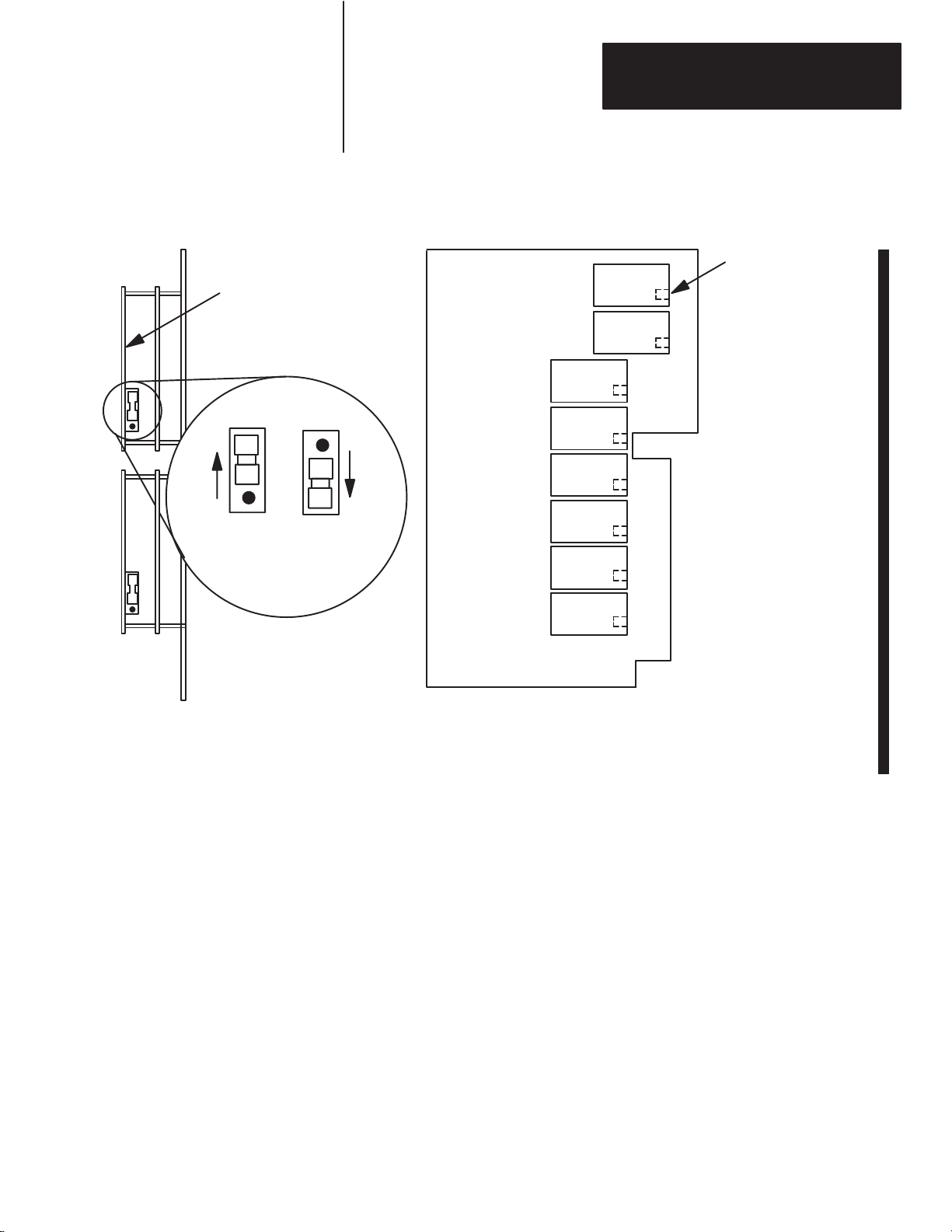

Installing the Analog Module

locking-bar pins

front of chassis

12453-I

To install your module in an I/O chassis:

1. First, turn off power to the I/O chassis:

ATTENTION: Remove power from the 1771 I/O chassis

backplane and disconnect the cable from the module before

removing or installing an I/O module.

Failure to remove power from the backplane could cause injury

or equipment damage due to possible unexpected operation.

Failure to remove power from the backplane could cause

module damage, degradation of performance, or injury.

2. Lift the locking latch holding the module into the chassis. (On chassis

equipped with a chassis locking bar, pull the locking-bar pins to

release the locking bar and swing it up.)

3. Position the keying bands (Figure 2.2) in the backplane connectors to

correspond to the key slots on the module. This prevents you from

inserting the wrong module in this slot. This analog module uses:

between 10 and 12

between 32 and 34

ATTENTION: Observe the following precautions when

inserting or removing keys:

insert or remove keys with your fingers

make sure that key placement is correct

Incorrect keying or the use of a tool can result in damage to

the backplane connector and possible system faults.

You can change the position of these bands if subsequent system

design and rewiring makes insertion of a different type of module

necessary. Use needlenose pliers to insert or remove keying bands.

2-4

Page 16

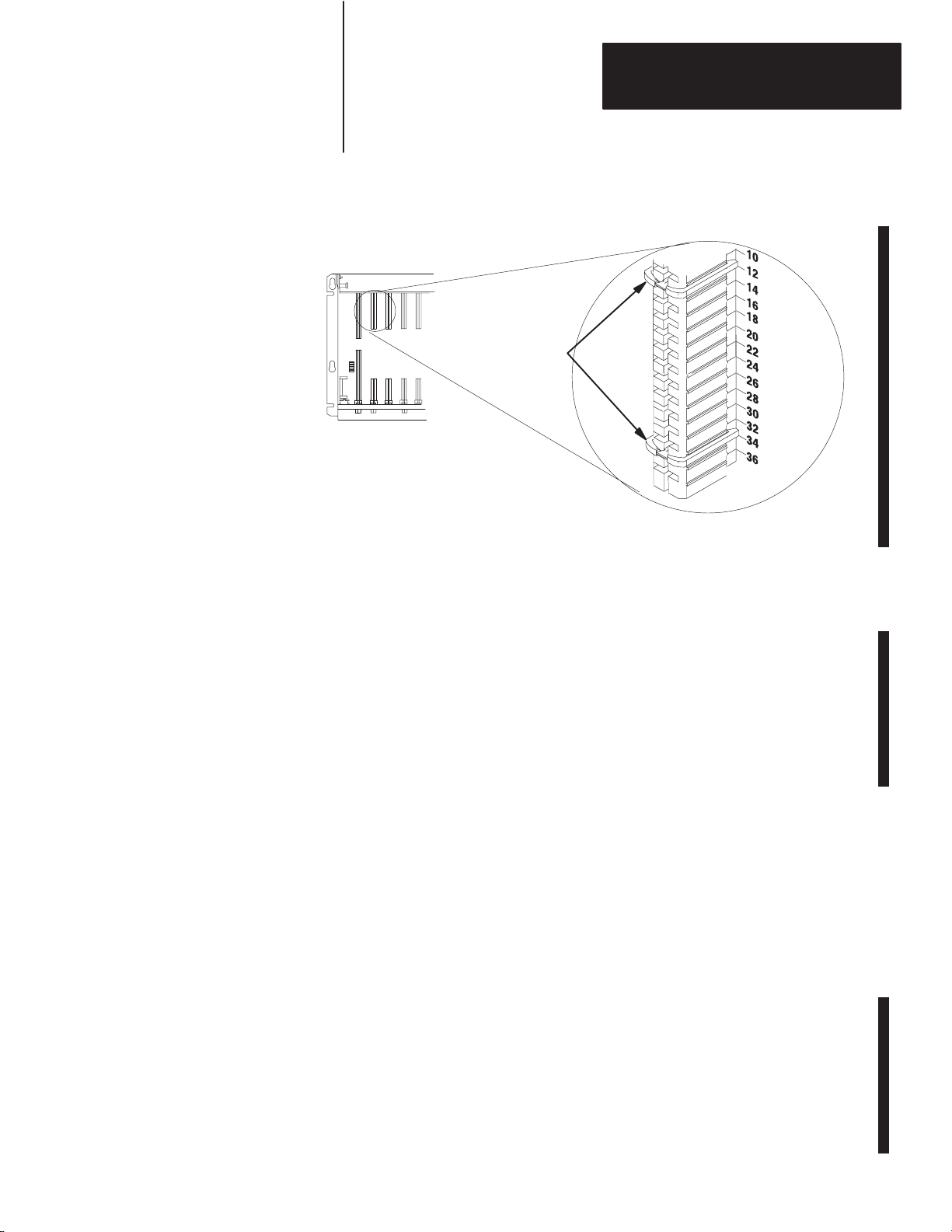

Keying Band Location

Between 10 and 12

Between 32 and 34

Figure 2.2

Keying

Positions

I/O chassis

Keying Bands

ATTENTION: Insert or remove

keying bands with your fingers.

Chapter 2

Installing the Input Module

Connecting Wiring to Your Input Module

Upper Connector

11022-I

4. Place the module in the plastic tracks on the top and bottom of the

slot that guides the module into position.

5. Do not force the module into its backplane connector. Apply firm

even pressure on the module until it is firmly seated in the chassis.

Note: The chassis locking bar will not close if all modules are not

seated properly.

6. Snap the chassis locking bar (or locking latch on earlier chassis) over

the top of the module to secure it. Make sure the locking pins on the

locking bar are fully engaged.

7. Connect the wiring to the module as explained under “Connecting

Wiring” below.

Connect your input devices to the cat. no. 1771-WF wiring arm shipped

with the module. Attach the wiring arm to the pivot bar at the bottom of

the I/O chassis. It pivots upward and connects with the module so you can

install or remove the module without disconnecting the wires.

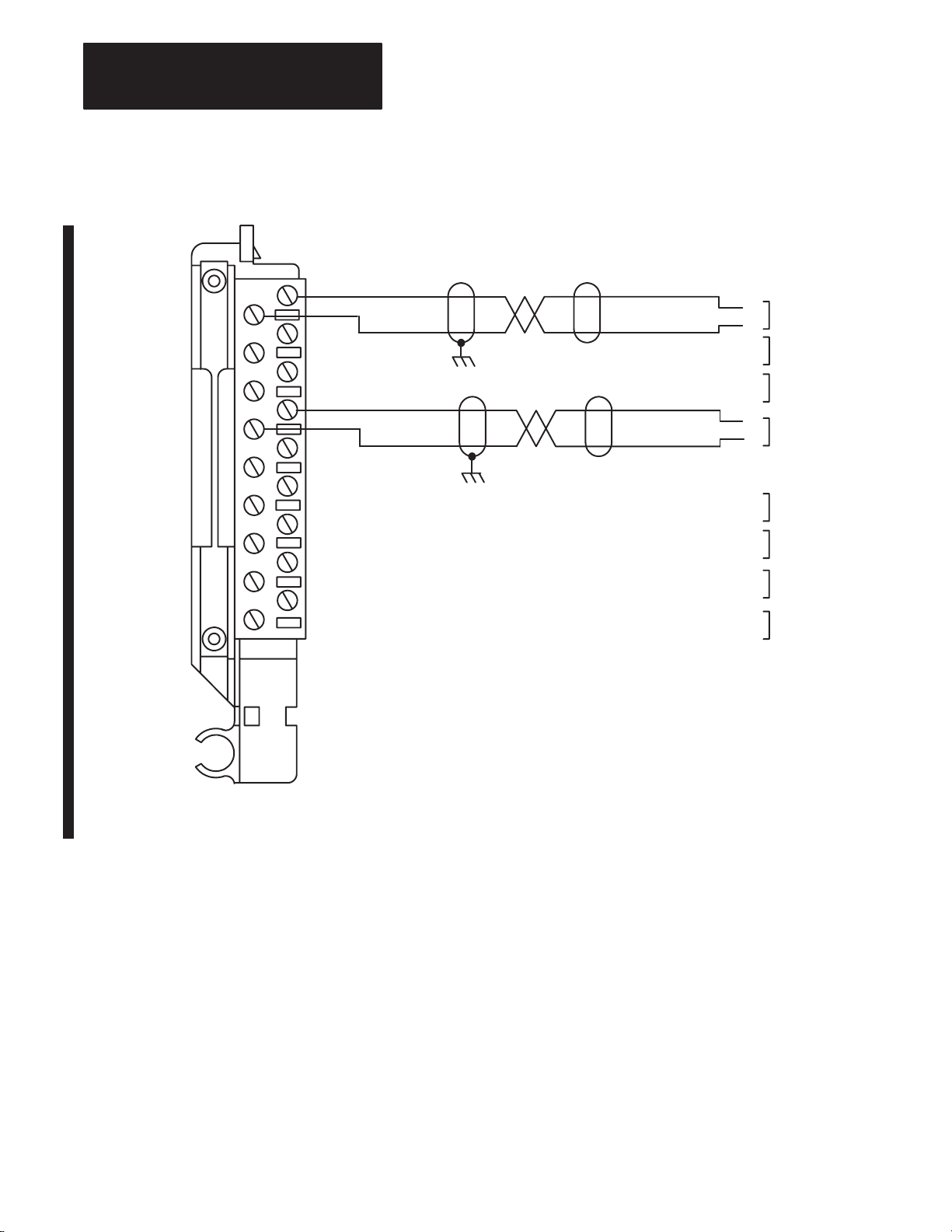

Connect inputs to the 1771-IL/B module as shown in Figure 2.3. This

module is shipped from the factory configured for voltage inputs but can

be configured for any combination of current and voltage inputs. If you

want to change the configuration, refer to “Setting the Voltage/Current

Selection Jumpers” as explained earlier in this chapter.

Important: The module configuration jumpers must be set for either

voltage or current before inserting the module into the I/O chassis.

2-5

Page 17

Chapter 2

Installing the Input Module

Figure 2.3

Wiring

Connections for the Isolated Analog Input Module (1771-IL/B)

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Ground

Ground

+

Analog Source

–

+

Analog Source

–

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Channel 1

Channel 2

Channel 3

Channel 4

Channel 5

Channel 6

Channel 7

Channel 8

NOTE: The 1771-IL/B module does not supply loop power for loop

powered analog sources (transmitters, transducers, etc.).

Loop power must be supplied by the user.

2-6

Field Wiring Arm

Cat. No. 1771-WF

11846-I

Page 18

Chapter 2

Installing the Input Module

Grounding

Remove a length of cable

jacket from the Belden 8761

cable.

Belden

8761 Cable

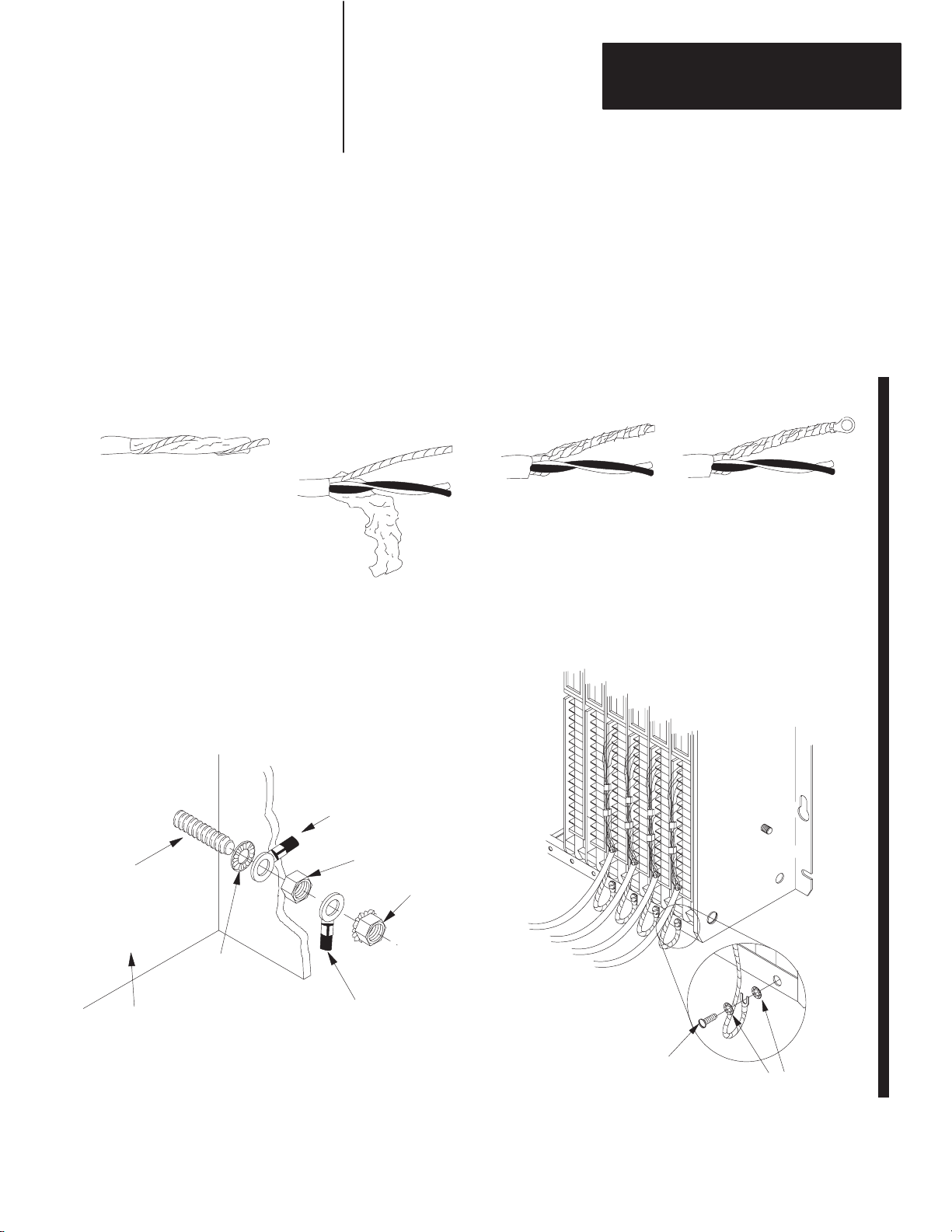

When using shielded cable wire, ground the foil shield and drain wire only

at one end of the cable. We recommend that you wrap the foil shield and

drain wire together and connect them to a chassis mounting bolt

(Figure 2.4). At the opposite end of the cable, tape exposed shield and

drain wire with electrical tape to insulate it from electrical contact.

Figure 2.4

Cable

Grounding

Pull the foil shield and bare

drain wire from the insulated

wires.

Bare

drain

wire

Insulated

wires

Foil

shield

Twist the foil shield and drain

wire together to form a single

strand.

Attach a ground lug.

20104

Chassis Ground Single-point Grounding

When you connect grounding conductors to the I/O chassis

grounding stud, place a star washer under the first lug, then

place a nut with captive lock washer on top of each ground lug.

Ground Lug

Nut

Grounding Stud

Star

Washer

I/O Chassis Side Plate

1

Use

the cup washer if crimp-on lugs are not used.

Ground Lug

Nut and Captive

Washer

1

19480

19923

#10 Thread-forming screw

External-tooth Washers

Refer to Wiring and Grounding Guidelines, publication 1770-4.1, for additional information.

2-7

Page 19

Chapter 2

Installing the Input Module

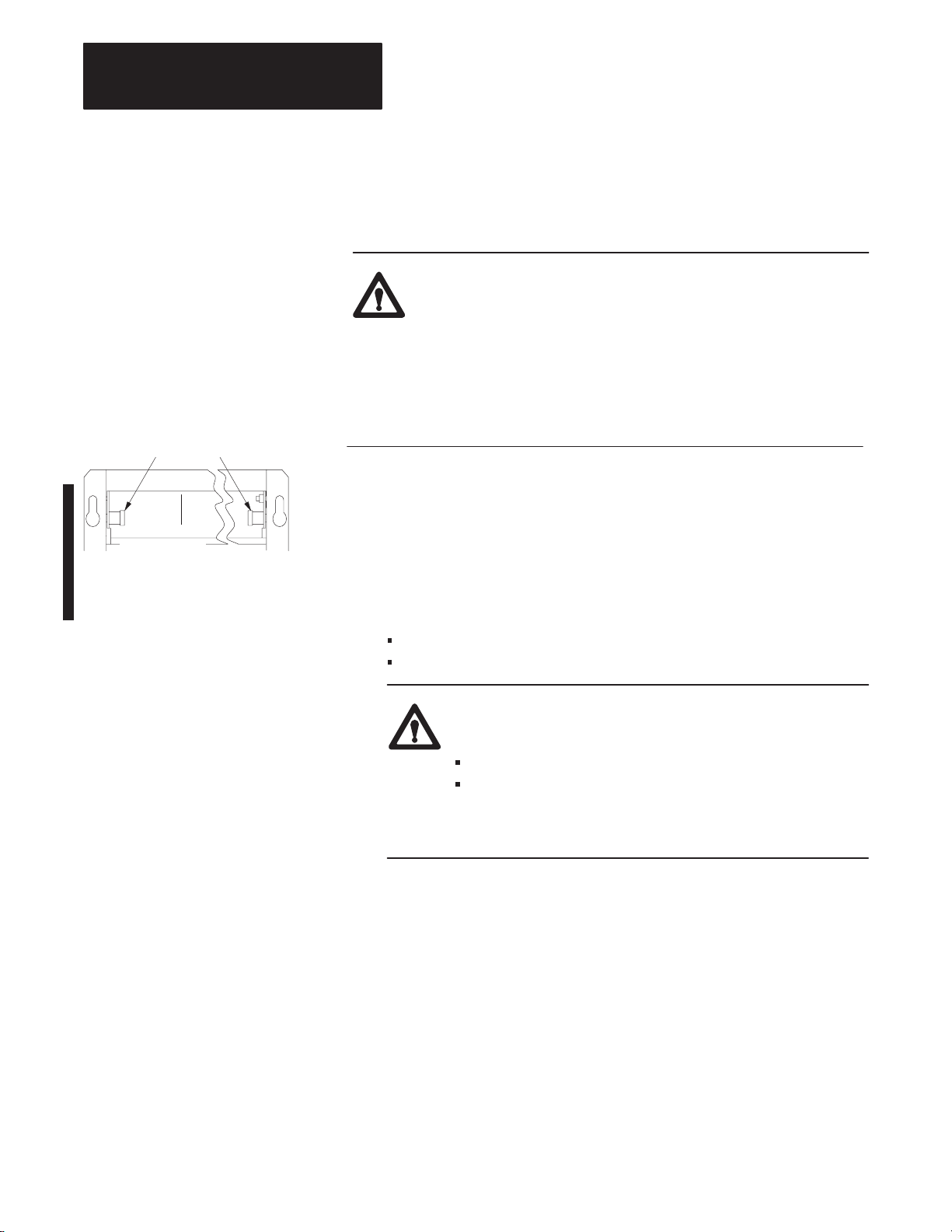

Indicator Lights

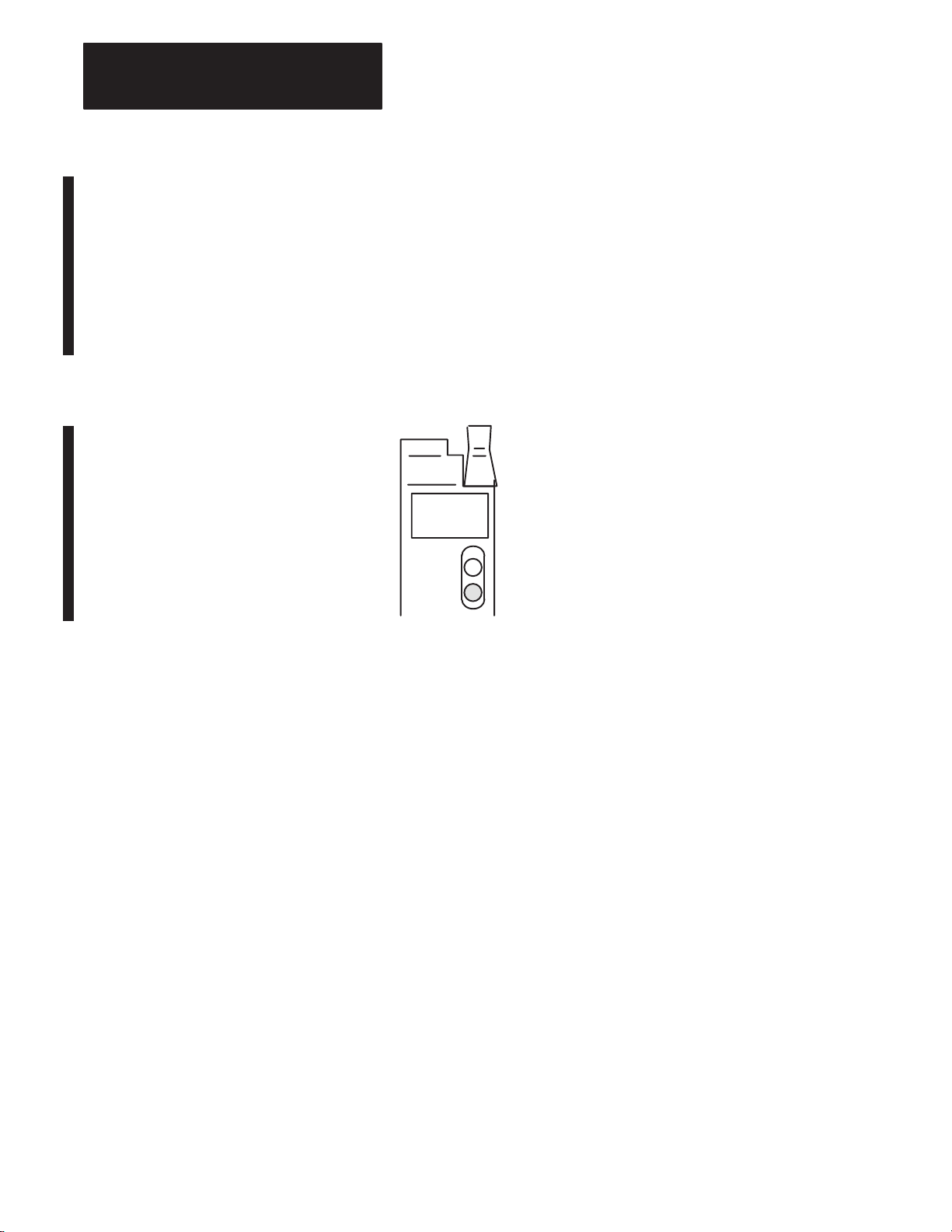

The front panel of the input module contains a green RUN and a red FLT

(fault) indicator (Figure 2.5). At powerup, an initial module self-check

occurs. If there is no fault, the red indicator turns off. The green indicator

will blink until the processor completes a successful write block transfer to

the module. Upon completion of a block transfer write (BTW), the green

RUN indicator will be on and the red FLT indicator will be off. If a fault is

found initially or occurs later, the red FLT indicator lights. Possible module

fault causes and corrective actions are discussed in Chapter 7,

Troubleshooting.

Figure 2.5

Diagnostic

Indicators

ISOLATED

ANALOG INPUT

RUN

FLT

10528-I

Chapter Summary

In this chapter you learned how to install your input module in an existing

programmable controller system and how to wire to the field wiring arm.

2-8

Page 20

Chapter

3

Communicating With Your Module

Chapter

Objectives

Block Transfer Programming

In this chapter, we describe

block transfer programming

quick-start sample programs in the PLC-2, PLC-3 and PLC-5

processors

module scan time issues

Your module communicates with your processor through bidirectional

block transfers. This is the sequential operation of both block transfer read

(BTR) and block transfer write (BTW) instructions.

A configuration BTW is initiated when the analog module is first powered

up, and subsequently only when the programmer wants to enable or disable

features of the module. The configuration BTW sets the bits which enable

the programmable features of the module, such as scaling, alarming, real

time sampling, etc. Block Transfer reads are performed to retrieve

information from the module.

Subsequent BTWs occur only when the programmer wants to write a new

configuration to the module. At all other times the module is basically in a

repetitive block transfer read (BTR) mode.

The following example programs are minimum programs; all rungs and

conditioning must be included in your application program. You can

disable BTRs, or add interlocks to prevent writes if desired. Do not

eliminate any storage bits or interlocks included in the sample programs. If

interlocks are removed, the program may not work properly.

The analog input module will work with a default configuration of

zeroes entered in the configuration block. This results in the default

settings of: 1 to 5V dc or 4 to 20mA (depending on voltage/current

selection jumper), BCD data format, no real time sampling (RTS), no

digital filter, no scaling, and no alarms. Refer to Chapter 4 for more

information. Also, refer to Appendix B for example configuration blocks

and instruction addresses to get started.

Your program should monitor status bits (such as overrange, underrange,

alarms, etc.) and block transfer read activity.

The following example programs illustrate the minimum programming

required for the 1771-IL series B module to powerup and operate.

3-1

Page 21

Chapter 3

Communicating With Your Module

PLC-2 Programming

Program

Rung 1

Block transfer read buffer: the file-to-file

move instruction holds the block transfer

read (BTR) data (file A) until the

processor checks the data integrity. If the

data was successfully transferred, the

processor energizes the BTR done bit,

initiating a data transfer to the buffer (file

R) for use in the program. If the data is

corrupted during the BTR operation, the

BTR done bit is not energized and data

is not transferred to the buffer file. In this

case, the data in the BTR file will be

overwritten by data from the next BTR.

Rungs 2 and 3

These rungs provide for a user-initiated

block transfer write (BTW) after the

module is initialized at power-up.

Pressing the pushbutton locks out BTR

operation and initiates a BTW that

reconfigures the module. Block transfer

writes will continue for as long as the

pushbutton remains closed.

Rungs 4 and 5

These rungs provide a “read-write-read”

sequence to the module at power-up.

They also insure that only one block

transfer (read or write) is enabled during

a particular program scan.

Rungs 6 and 7

These rungs are the conditioning block

transfer rungs. Include all the input

conditioning shown in the example

program.

Action

Block T

1

2

Block T

3

Block T

4

Block T

5

6

7

The PLC-2 program example regulates when each block transfer will be

initiated to eliminate problems caused by limited regulation of

bidirectional block transfers. Both storage bits are needed, (as shown in the

example), to accomplish this task in all PLC-2 systems, local or remote,

with long or short program scans. Therefore, the program as shown is the

minimum required. Note that PLC-2 processors that do not have the block

transfer instruction must use the GET-GET block transfer format which is

outlined in appendix D.

Figure 3.1

PLC-2

Family Sample Program Structure

ransfer Read

Done Bit

Pushbutton [1]

ransfer W

Done Bit

ransfer W

Done Bit

ransfer Read

Done Bit

Power–up

Bit

Storage

Bit B

Power–up

Bit

Storage

Bit A

rite

rite

Storage

Bit A

BTR Done

Bit

Storage

Bit B

FILE TO FILE MOVE

COUNTER

POSITION:

FILE LENGTH:

FILE A:

FILE R:

RA

TE PER SCAN

Pushbutton [1]

Power-up

Bit

BTR

BLOCK XFER READ

DATA ADDR:

MODULE

BLOCK LENGTH:

FILE:

BTW

BLOCK XFER WRITE

DATA ADDR:

MODULE

BLOCK LENGTH:

FILE:

ADDR:

ADDR:

ADDR:

XXXX – XXXX

XXXX – XXXX

RGS

XXXX – XXXX

XXXX – XXXX

XXX

XXX

XXX

XXX

XXX

XX

XXX

RGS

XX

ENABLE

EN

DONE

DN

Storage

Bit A

L

Storage

Bit A

Storage

Bit B

L

Storage

Bit B

U

ENABLE

EN

DONE

DN

ENABLE

EN

X6

DONE

DN

X6

17

15

U

X7

X7

3-2

[1] You can replace the pushbutton with a timer “done” bit to initiate the block transfer

write on a timed basis. You can also use any storage bit in memory

.

Page 22

Chapter 3

Communicating With Your Module

PLC-3 Programming

Program

At power-up, the user program enables a

block transfer read. Then it initiates a block

transfer write to configure the module.

Action

Block transfer instructions with the PLC-3 processor use one binary file in

a data table section for module location and other related data. This is the

block transfer control file. The block transfer data file stores data that you

want transferred to your module (when programming a block transfer

write) or from your module (when programming a block transfer read).

The address of the block transfer data files are stored in the block transfer

control file.

The industrial terminal prompts you to create a control file when a block

transfer instruction is being programmed. The same block transfer

control file is used for both the read and write instructions for your

module. A different block transfer control file is required for every

module.

A sample program segment with block transfer instructions is shown in

Figure 3.2, and described below.

Figure 3.2

PLC-3

Family Sample Program Structure

00

Enable

EN

12

X

Done

DN

15

Error

ER

13

BTR

BLOCK XFER READ

Block Transfer

Read Done Bit

1

RACK:

GROUP:

MODULE:

DATA:

LENGTH:

CNTL:

XXX

X = XXXX

XXXX:XXXX

XXXX:XXXX

Thereafter, the program continuously

performs read and write block transfers.

Block Transfer

Write Done Bit

2

BTW

BLOCK XFER WRITE

RACK:

GROUP:

MODULE:

DATA:

LENGTH:

CNTL:

XXXX:XXXX

XXXX:XXXX

X = XXXX

XXX

00

Enable

EN

02

X

Done

DN

05

Error

ER

03

3-3

Page 23

Chapter 3

Communicating With Your Module

PLC-5 Programming

Program

At power-up, the program enables a block

transfer read (rung 1). Then it examines the

power-up bit in the BTR file and initiates one

block transfer write to configure the module

(rung 2).

Thereafter, the program continuously reads

data from the module (rung 1). A subsequent

BTW operation is enabled by a pushbutton

switch (rung 2). Changing the processor

mode will not initiate a block transfer write.

Action

The PLC-5 program is very similar to the PLC-3 program with the

following exceptions:

1. Block transfer enable bits are used instead of done bits as the

conditions on each rung.

2. Separate block transfer control files are used for the block transfer

instructions.

Figure 3.3

PLC-5

Family Sample Program Structure

BTR Enable

1

2

Bit

Pushbutton

Power–up Bit

BTW Enable Bit

BTR

BLOCK TRANSFER READ

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS: N

BTW

BLOCK TRANSFER WRITE

RACK:

GROUP:

MODULE:

CONTROL:

DATA FILE:

LENGTH:

CONTINUOUS: N

XXX:XX

XXX:XX

00

XXX:XX

XXX:XX

00

EN

X

X

DN

X

ER

EN

X

X

DN

X

ER

3-4

Page 24

Chapter 3

Communicating With Your Module

Module

Scan T

ime

Scan time is defined as the amount of time it takes for the input module to

read the input channels and place new data into the data buffer. Scan time

for your module is shown in Appendix A.

Figure 3.4

Block Transfer T

End of Block

Transfer Write

Block

Transfer

Write

Time

1 2 3 456

ime

Configure

Time

Module available

to perform block transfer

1st

Scan

2nd Scan

3rd Scan

Internal Scan time = 50ms

T = 100ms, 200ms, 300ms, 3.1s.

The following description references the sequence numbers in Figure 3.4.

10529-I

Chapter Summary

Following a block transfer write (1) the module inhibits communication

until after it has loaded the new configuration data (2), scanned the inputs

and/or outputs (3), and filled the data buffer (4). Configuration block

transfers, therefore, should only be performed when the module is being

configured or calibrated.

Any time after the buffer is filled (4), a block transfer read (BTR) request

can be acknowledged.

When operated in the default mode, new data will be available for a BTR

every 50 milliseconds. When operated in real time sample mode

(RTS = T), BTRs will be ignored by the module for “T” milliseconds, at

which time a single BTR will be allowed.

In this chapter, you learned how to program your programmable

controller. You were given sample programs for your PLC-2, PLC-3 and

PLC-5 family processors.

You also read about module scan time.

3-5

Page 25

Configuring Your Module

Chapter

4

Chapter

Objectives

Configuring Your Input Module

In this chapter you will read how to:

configure your module’s hardware

condition your inputs

enter your configuration data.

Because of the many analog devices available and the wide variety of

possible configurations, you must configure your module to conform to the

analog device and specific application that you have chosen. Data is

conditioned through a group of data table words that are transferred to the

module using a block transfer write instruction. Before continuing, make

sure you read “Setting Voltage/Current Selection Jumpers” in

chapter 2.

The software configurable features available with the Isolated Analog

Input Module (1771-IL series B) are:

input range selection

data format

digital filtering

real time sampling

scaling to engineering units

high and low alarms

Configure your module for its intended operation by means of your

programming terminal and block transfer write (BTW) instructions.

Note: Programmable controllers that use 6200 software programming tools

can take advantage of the IOCONFIG utility to configure this module.

IOCONFIG uses menu-based screens for configuration without having to

set individual bits in particular locations. Refer to your 6200 software

literature for details.

Note: Programmable controllers that use process configuration and

operation software (cat. no. 6190-PCO) can take advantage of those

development and runtime tools used for the application of programmable

controllers in process control. The PCO worksheets and the menu-driven

configuration screens and faceplates let you configure, test/debug and

operate the I/O module. Refer to your 6190-PCO software literature for

details.

4-1

Page 26

Chapter 4

Module Configuration

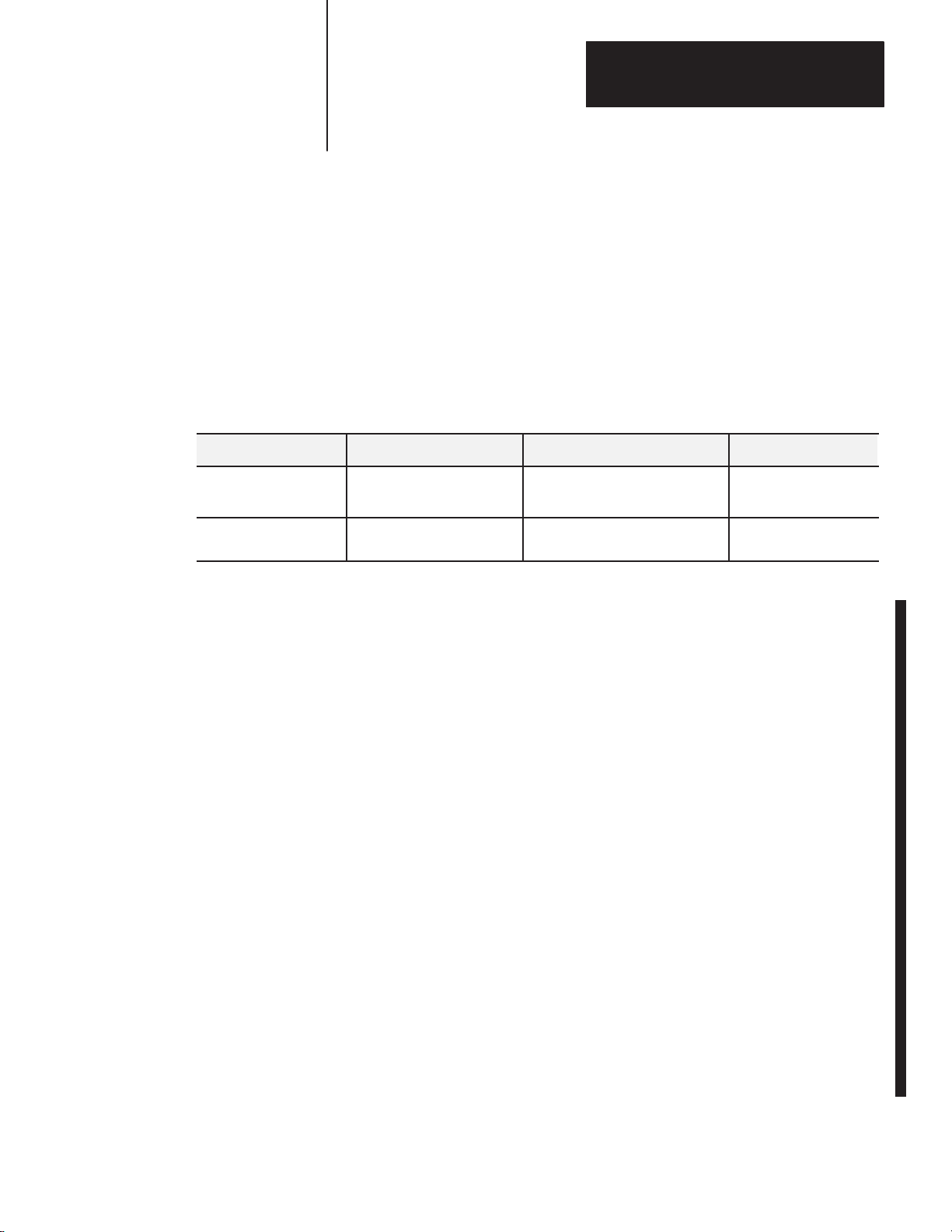

During normal operation, the processor transfers from 1 to 37 words to the

module when you program a BTW instruction to the module’s address.

The BTW file contains configuration words, high and low channel alarm

settings, and calibration values for each channel.

When a block transfer write length of 0 is programmed, the 1771-IL

series B will respond with the Series A default length of 19.

Input Range Selection

Individual inputs are configurable to operate with any one of five voltage

or three current ranges. You can select individual channel ranges using the

designated words of the write block transfer instruction (Table 4.A). Two

bits are allocated for each channel. For example, for channel 1, set bits 00

and 01 as follows:

T

able 4.A

Bit

Settings for V

Bit 01 Bit 00 Voltage or current input

0 0 1 to 5 V DC, 4 to 20 mA

0 1 0 to 5 V DC, 0 to 20 mA

1 0 -5 to +5 V DC, -20 to +20 mA

1 1 -10 to +10 V DC, 0 to 10 V DC

1

Current

input mode selected by configuration plug.

2

Configurable

oltage or Current Inputs

1

1

1

2

using bipolar scaling.

The 1771-IL/B has 16-bit resolution across the +10V range. For

compatibility purposes, the default scaling for all ranges is 12-bits (0-4095

or +4095). This allows the series B module to be directly interchangeable

with the series A module. To use the full 16-bit capability, scaling values

must be changed. Refer to “Scaling” later in this chapter.

4-2

Table 4.B shows the incremented voltage or current assigned to each bit for

the seven different input ranges. For example, if the channel 1 input range

is 0 to +5V and the actual incoming signal is at mid-range (+2.5V) the

value in the module’s data word, if using default scaling, would be 0000

1000 0000 0000 (binary) or 2048 (decimal). The input (default scaling) is

2048/4096, or 1/2 of full scale.

Page 27

Chapter 4

Module Configuration

T

able 4.B

Input Voltage and Current Ranges for the Analog Input Module

Nominal Voltage

or Current Range

+1 to +5V 0000 to +4095 0.98mV 3063 to 15316 0.33mV

0 to 5V 0000 to +4095 1.22 mV 32768 to 15316 0.33mV

-5 to +5V -4095 to +4095 1.22mV -15316 to 15316 0.33mV

-10 to +10V -4095 to +4095 2.44mV -30632 to 30632 0.33mV

0 to +20mA 0000 to +4095 0.0049mA 0 to 15316 0.0013mA

+4 to +20mA 0000 to +4095 0.0039mA 3063 to 15316 0.0013mA

-20 to +20mA -4095 to +4095 0.0049mA -15316 to 15316 0.0013mA

Note: V

oltage and current input ranges are selectable on a per channel basis.

Default Scaling

BCD Output Range

Voltage or

Current Per Bit

Data from

A/D Converter

Voltage or

Current Per Bit

To get the same resolution available from the A/D converter, scale each

channel as shown in Table 4.C.

T

able 4.C

Scaling

Endpoints

Voltage/Current

Range

Minimum

Scaling Endpoint

Maximum

Scaling Endpoint

Block T

ransfer W

rite Format

+1 to 5V 3063 15316

4 to 20mA 3063 15316

0 to 5V 0 15316

0 to 20mA 0 15316

-5 to 5V -15316 15316

-20 to 20mA -15316 15316

-10 to 10V -30632 30632

0 to 10V -30632 30632

You select the format to enter values in the block transfer write table. Bit

08 (10 octal) of BTW word 2 sets the parameters for scaling, high and low

alarms, and the digital filter constant.

Decimal Bit 08

Octal Bit 10

0 BCD (default) BCD

1 Two’s Complement Binary Two’s Complement Binary

BTW Data Format You must enter all values in:

4-3

Page 28

Chapter 4

Module Configuration

Data Format

Digital Filtering

You must also indicate what format will be used to read data from your

module. Typically, BCD is selected with PLC-2 processors, and 2’s

complement binary is selected with PLC-3 and PLC-5 processors. See

Appendix C for details on data format.

T

able 4.D

Selecting

the Data Format

Decimal Bit 10

(Octal Bit 12)

0 0 BCD

0 1 not used

1 0 two’s complement binary

1 1 signed magnitude binary

Decimal Bit 09

(Octal Bit 11)

Data Format

The analog input module has hardware-based high frequency filters on all

channels to reduce the effect of electrical noise on the input signal.

Software digital filtering is meant to reduce the effect of process noise on

the input signal.

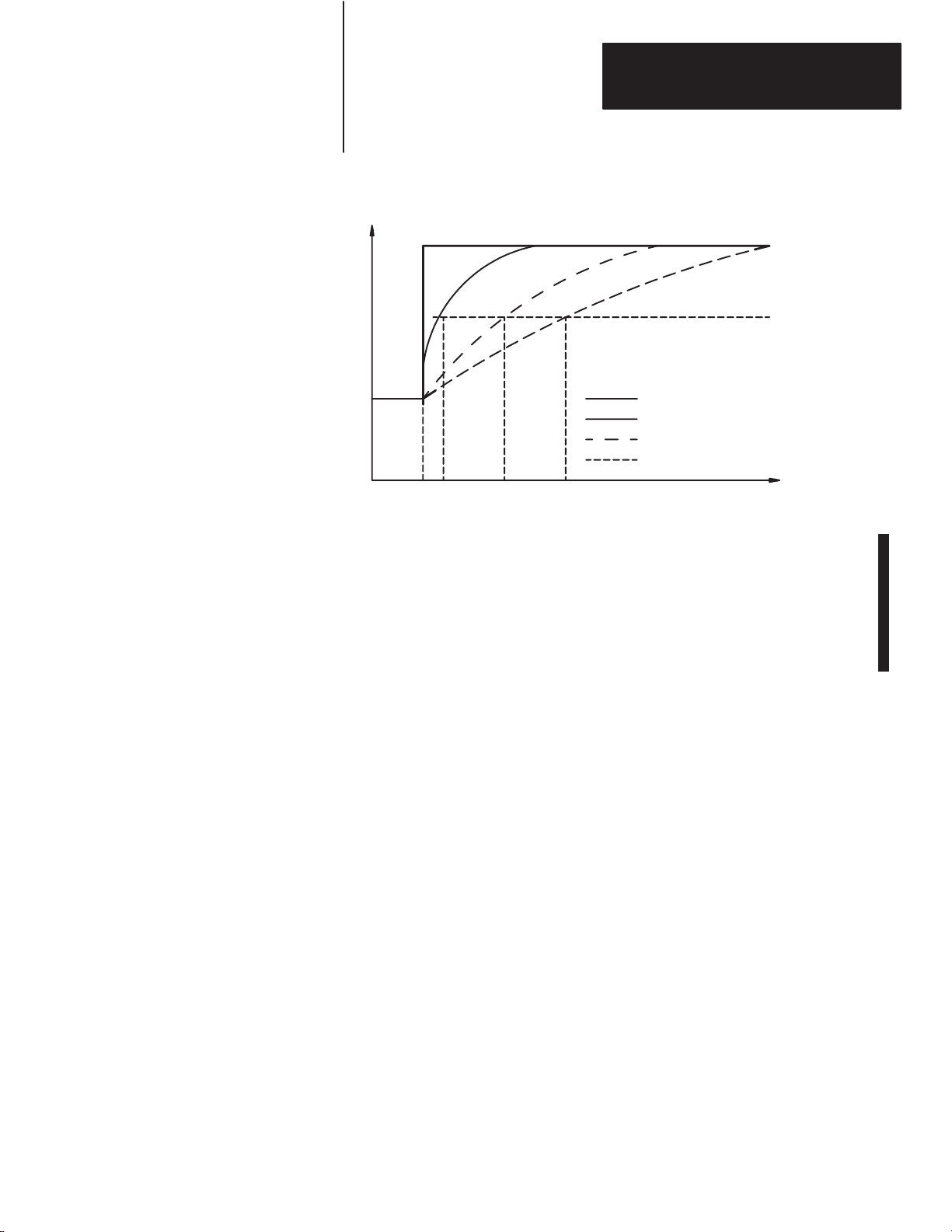

The digital filter equation is a classic first order lag equation (Figure 4.1).

Using a step input change to illustrate the filter response (Figure 4.2), you

can see that when the digital filter constant time elapses, 63.2% of the total

response is reached. Each additional time constant achieves 63.2% of the

remaining response.

4-4

Figure 4.1

Digital

Filter Equation

Yn = Y

Where:

t

(X

- Y

+

n-1

t + TA

Y

n = present output, filtered peak voltage (PV)

Y

n –1 = previous output, filtered PV

t = module channel update time (seconds)

TA = digital filter time constant (seconds)

X

n = present input, unfiltered PV

n

n-1

)

Page 29

Figure 4.2

Digital

Amplitude

Chapter 4

Module Configuration

Filter Lag Equation Illustration

100%

63%

Real Time Sampling

0

0 0.01 0.5 0.99 Time in Seconds

Unfiltered Input

TA = 0.01 sec

TA = 0.5 sec

TA = 0.99 sec

16723

Digital filter time constant values of .00 BCD to .99 BCD (0.00 to 2.55

binary) (.00 = no filter) are set in bits 00 through 07 of word 3 of the block

transfer write instruction. If an invalid digital filter value is entered

(i.e., .1F BCD), the invalid filter value bit in the block transfer read status

area will be set. If an invalid digital filter value is entered, the module will

not perform digital filtering. If you choose to use the digital filtering

feature, the filter time constant value chosen will apply to all input signals.

The real time sampling (RTS) mode of operation provides data gathered at

precisely timed intervals for use by the processor.

Use RTS for time based functions (such as PID and totalization) in the

PLC. RTS allows accurate time based calculations in local or remote I/O

racks. In the RTS mode the module scans and updates its inputs at a user

defined time interval (T) instead of the default interval. The module

ignores block transfer read (BTR) requests for data until the sample time

period elapses. The BTR of a particular data set occurs only once at the

end of the sample period and subsequent requests for transferred data are

ignored by the module until a new data set is available. If a BTR does not

occur before the the end of the next RTS period, a time-out bit is set in the

BTR status area. When set, this bit indicates that at least one data set was

not transferred to the processor. (The actual number of data sets missed is

unknown.) The time-out bit is reset at the completion of the next BTR.

4-5

Page 30

Chapter 4

Module Configuration

Set appropriate bits in the BTW data file to enable the RTS mode. You can

select RTS periods ranging from 50 ms to 3.1 seconds in increments of

100ms for the 1771-IL/B. Refer to Table 4.E below for actual bit settings.

Note that the default mode of operation is implemented by placing all

zeroes in bits 11 through 15 (13 through 17 octal).

T

able 4.E

Examples

of Bit Settings for the Real T

ime Sample Mode

Decimal Bits 15 14 13 12 11

Octal Bits 17 16 15 14 13

0 0 0 0 0 No RTS, Default settings: 50ms

0 0 0 0 1 100ms

0 0 0 1 0 200ms

0 0 0 1 1 300ms

0 0 1 0 0 400ms

0 0 1 0 1 500ms

0 0 1 1 0 600ms

0 0 1 1 1 700ms

0 1 0 0 0 800ms

0 1 0 0 1 900ms

0 1 0 1 0 1.0s

0 1 1 1 1 1.5s

1 0 1 0 0 2.0s

1 1 0 0 1 2.5s

1 1 1 1 0 3.0s

Sample Time Period

4-6

1 1 1 1 1 3.1s

Page 31

Chapter 4

Module Configuration

Scaling

Each channel has two scaling points, low and high. The signal value at

these points is fixed. For example, the high scaling point of a +10V output

channel always corresponds to an input signal equal to +10.000V.

To implement the scaling feature, you insert the minimum and maximum

scaled values in the appropriate configuration words.

The format of the scaling values is determined by the BTW format bit (bit

08, word 2). The range in BCD format is +9999. The range in binary

format is +32767.

For example, assume that at 0mA, the device connected to this input

channel is producing 0 psi, and at 20mA it produces 150 psi, and the

1771-IL/B range selected is 4 to 20mA. Extrapolation indicates that at

4mA, the device is producing 30 psi. By setting the low scale value of the

input to 30 and the high scale value to 150, this input channel will report

data in psi. For better resolution, you can multiply both of the scaling

values by the same multiplier as long as both scale values are in the range

of +9999 BCD or +32767 binary. By setting the low scale to 3000 and the

high scale value to 15000, you would report data in units of 0.01 psi

per count.

Maximum resolution can be obtained by setting the low scale value to

-9999 in BCD and the high scale value to +9999 in BCD (-32767 low and

+32767 high in binary).

For example, if in the 1 to 5V mode, the scaling points are 1 and 5 volts.

If you set the scaling to +32767, the maximum the module will display will

be 32767. If 5.1V is applied, the display will be 32767 and the overrange

bit for that channel will be set.

Note: To achieve the 0 to +10V range you must use bipolar scaling. Select

10V range and scale for + the actual intended range. If you need 0 to

the +

100 gpm, set scaling values at -100 and +100. You will effectively be

creating a 0 to 10V range that is scaled from 0 to 100.

Implementing the Scaling Feature

You implement the scaling feature by:

1. Inserting minimum and maximum scaled values in the appropriate

configuration words

2. If using BCD, and any of the minimum or maximum values are

negative, set the appropriate sign bits in the minimum or maximum

sign bit words.

4-7

Page 32

Chapter 4

95

95

Module Configuration

Scaling Ranges

The maximum range of the scaling values is +9999 BCD or +32767 binary.

These values must be entered in the format selected in word 2, bit 08 (10).

If invalid values are entered into the scaling words, the corresponding

input in the BTR data will be zero and the invalid scaling bit will be set.

T

able 4.F

Default

Scaling V

Input Range Default Scaling Value

-10 to +10V

-5 to +5V

0 to 5V

1 to 5V

alues

-4095 to +40

0 to +40

If scaling and alarms are not selected, the module still requires specific

BTR and BTW file lengths for the number of channels used. Table 4.G

shows the required BTR and BTW file lengths.

T

able 4.G

Block Transfer Read and Write File Lengths (with no scaling or alarms)

Channels Used BTR File Length BTW File Length

1 5 5

2 6 7

3 7 9

4 8 11

5 9 13

6 10 15

7 11 17

8 12 19

Important: Use decimally addressed bit locations for PLC-5 processors.

4-8

Page 33

Chapter 4

Module Configuration

Alarms

Each input channel has alarm functions that provide status indication

through associated status bits in the block transfer read data returned by

the module.

Underrange alarm - This bit is set if the input falls below the minimum

range for that specific input type. This alarm is predefined and cannot be

changed by the user. In current loop inputs, this bit also indicates an

open loop.

Overrange alarm - This bit is set if the input rises above the maximum

range for that specific input type. This alarm is predefined and cannot be

changed by the user. For all voltage inputs, this bit indicates an

open channel.

Range

1 to 5V/4 to 20mA 1V dc or 4mA 5V dc or 20mA

0 to 5V/0 to 20mA Zero 5V dc or 20mA

-5 to 5V/-20 to 20mA -5V dc or -20mA 5V dc or 20mA

-10 to +10V -10V dc +10V dc

User-defined alarms let the user specify a range of “good” input values. If

the input value goes outside of this range, the module will set the low or

high alarm bit for that channel. The alarm values are written to the module

in the same units as the scaling values. Valid alarm values are +9999 BCD

or +32767 binary. If you select “no alarms” you must set both the low

alarm value and the high alarm value to zero. If either the low or high

alarm for a channel is not zero, alarms for that channel are enabled.

Figure 4.3

Alarm

Example

Overrange Limit

User-Defined High Alarm Limit

Input Channel

Underrange Bit is set

when the input signal is

less than:

Overrange Bit is set

when the input signal is

greater than:

alarm inactive

alarm active

User-Defined Low Alarm Limit

Underrange Limit

Time

4-9

Page 34

Chapter 4

1

3

Module Configuration

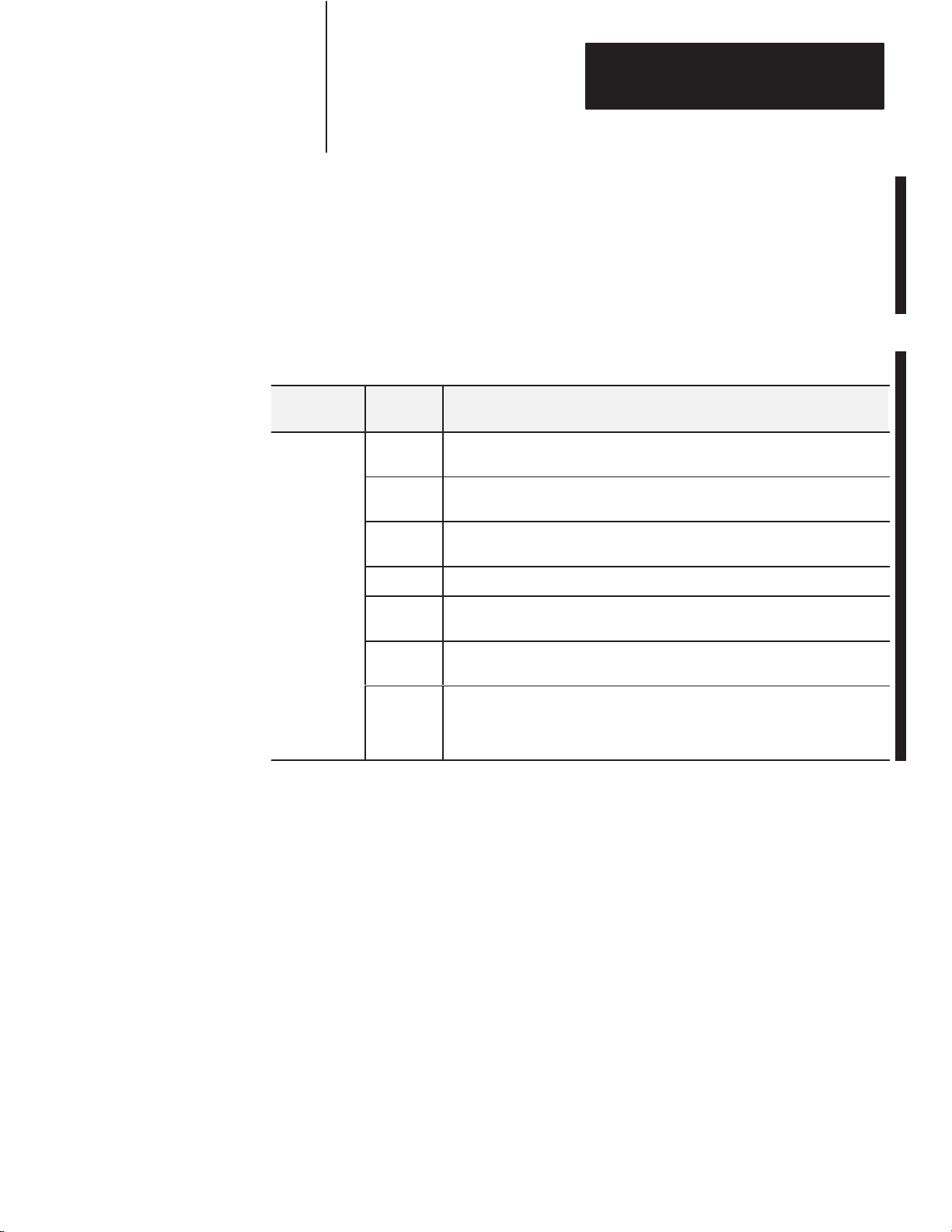

Default Configuration

Decimal Bits 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bits 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Word

If a write block with all zeroes is written to the module, the default

selections will be:

1 to 5V dc or 4 to 20mA (depends on voltage/current selection jumper)

BCD data format

no real time sampling (RTS)

no digital filter

no scaling

no alarms

Note: Input data is set to 0 until an initial block transfer write is received

by the module.

Figure 4.4

Word

Assignments for the Isolated Analog Input Module

(1771-IL series B)Block T

Range Selection Bits for Channels 1 through 8

8 7 6 5 4 3 2 1

ransfer W

rite

2 Real Time Sampling

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Sign bits, maximum scaling values Sign bits, minimum scaling values

4 Channel 1 - minimum scaling

5 Channel 1 - maximum scaling

6 Channel 2 - minimum scaling

7 Channel 2 - maximum scaling

8 Channel 3 - minimum scaling

9 Channel 3 - maximum scaling

10 Channel 4 - minimum scaling

11 Channel 4 - maximum scaling

12 Channel 5 - minimum scaling

13 Channel 5 - maximum scaling

14 Channel 6 - minimum scaling

15 Channel 6 - maximum scaling

Data

Format

BTW

Format

Digital Filter

16 Channel 7 - minimum scaling

4-10

Page 35

Chapter 4

2

37

Module Configuration

17 Channel 7 - maximum scaling

18 Channel 8 - minimum scaling

19 Channel 8 - maximum scaling

00010203040506070809101112131415Decimal Bits

00010203040506071011121314151617Octal Bits

0

8 7 6 5 4 3 2 1 8 7 6 5 4 3 2 1

Sign bits, high alarm values

21 Channel 1 - Low Alarm Value

22 Channel 1 - High Alarm Value

23 Channel 2 - Low Alarm Value

24 Channel 2 - High Alarm Value

25 Channel 3 - Low Alarm Value

26 Channel 3 - High Alarm Value

27 Channel 4 - Low Alarm Value

28 Channel 4 - High Alarm Value

39 Channel 5 - Low Alarm Value

30 Channel 5 - High Alarm Value

31 Channel 6 - Low Alarm Value

32 Channel 6 - High Alarm Value

33 Channel 7 - Low Alarm Value

34 Channel 7 - High Alarm Value

Sign bits, low alarm values

35 Channel 8 - Low Alarm Value

36 Channel 8 - High Alarm Value

8 7 6 5 4 3 2 1 Not Used S G O

Inhibit bits for calibration Calibration bits

4-11

Page 36

Chapter 4

2

3

Module Configuration

Word

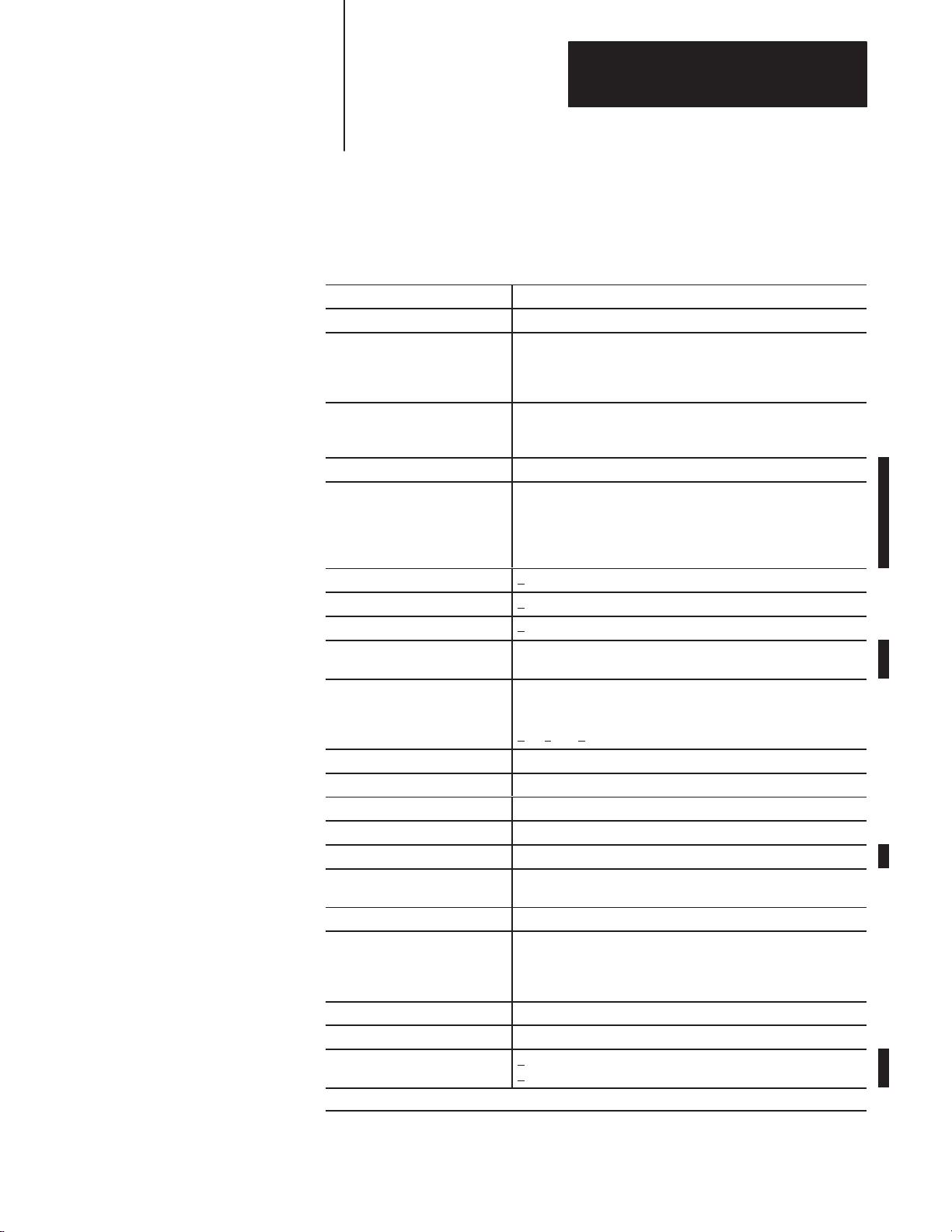

Bit/Word Descriptions for the Isolated Analog Input Module

Configuration Block

Note that decimal bits are shown. Octal bits are shown in parentheses.

Decimal

Bit

(Octal Bit)

Description

Word 1

Word 2

Word

Word

Word 4

Word 5

Bits 00-15

(00-17)

Bits 00-07 Digital filter reduces effect of noise on the input. See “Digital Filtering.”

Bit 08 (10)

Bits 09-10

(11-12)

Bits 11-15

(13-17)

Bits 00-07

Bits 08-15

(10-17)

Bits 00-15

(00-17)

Bits 00-15

(00-17)

Input range selections, grouped 2 bits for each channel, allow selection of any

of 7 input voltage or current ranges. See Table 4.A.

BTW format bit. This bit determines the format for scaling, digital filter

constant, and high and low alarms.

Bit 08 (10) = 0 - Values must be entered in BCD

Bit 08 (10) = 1 - Values must be entered in Two’s Complement Binary

Data format is used to match format of processor. See Table 4.D.

Real time sampling defaults to 50ms if zeroes are entered. See Table 4.E

for other real time sample intervals.

Minimum sign bits, when set, designate minimum scaling values that are

negative in BCD. Default = 0 - positive.

Maximum sign bits, when set, designate maximum scaling values that are

negative in BCD. Default = 0 - positive.

Minimum scaling values for channel 1. Enter in format selected in word 2,

bit 08 (10). Valid entries are between +9999 and -9999 in BCD; -32767 and

+32767 in binary. Default = 0 - no scaling.

Maximum scaling values for channel 1. Enter in format selected in word 2,

bit 08 (10). Valid entries are between +9999 and -9999; -32767 and +32767

in binary. Default = 0 - no scaling.

Words 6-19

Word 20

Word 21

Word 22

Words 23

thru 36

4-12

Bits 00-15

(00-17)

Bits 00-07

Bits 08-15

(10-17)

Bits 00-15

(00-17)

Bits 00-15

(00-17)

Bits 00-15

(00-17)

Minimum and maximum scaling values for channels 2 through 8. Enter in

format selected in word 2, bit 08 (10). Valid entries are between +9999 and

-9999; -32767 and +32767 in binary. Default = 0 - no scaling.

Low alarm sign bits. These bits are only used when BCD format is

chosen in word 2, bit 08 (10). When a bit is set (1), the low alarm value for

that channel is negative. Default is bit reset (0), positive.

High alarm sign bits. These bits are only used when BCD format is

chosen in word 2, bit 08 (10). When a bit is set (1), the high alarm value for

that channel is negative. Default is bit reset (0), positive.

Low alarm value for channel 1. This represents the value at which the low

alarm bit for channel 1 (word 13 of the BTR) will be set.

High alarm value for channel 1. This represents the value at which the high

alarm bit for channel 1 (word 14 of the BTR) will be set.

Low and high alarm values for channels 2 thru 8.

Page 37

Chapter 4

37

Module Configuration

Chapter Summary

Word

Word

Decimal Bit

(Octal Bit)

Offset Calibration bit. When this bit is set (1), offset calibration is to be

Bit 00

Bit 01

Bit 02

Bits 03-07 Not used.

Bits 08-15

(10-17)

performed. When set, no other calibration function bits can be set. Default is

0, no offset calibration.

Gain Calibration bit. When this bit is set (1), gain calibration is to be

performed. When set, no other calibration function bits can be set. Default is

0, no gain calibration.

Save calibration values. When this bit is set (1), new calibration values will

be saved in EEPROM. Default = 0, values not saved.

Inhibit Channel Calibration. When this bit is set (1), that particular channel

will not be calibrated. Default = 0, all channels to be calibrated.

Description

In this chapter you learned how to configure your module’s hardware,

condition your inputs and enter your data.

4-13

Page 38

Chapter

Module Status and Input Data

5

Chapter

Objectives

Reading Data From Your Module

Decimal Bits 15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

Octal Bits 17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Word 1 Not used A HF IA IF RTS IS OR PU Status word

2 Not used 8 7 6 5 4 3 2 1 Underrange bits - Channels 1-8

3 Not used 8 7 6 5 4 3 2 1 Overrange bits - Channels 1-8

4 Not used 8 7 6 5 4 3 2 1 Polarity bits - Channels 1-8

In this chapter you will read about:

reading data from your module

block transfer read data format

Block transfer read programming moves status and data from the input

module to the processor’s data table in one I/O scan (Figure 5.1). The

processor’s user program initiates the request to transfer data from the

input module to the processor.

Figure 5.1

Word

Assignments for the Isolated Analog Input Module

(1771-IL series B) Block Transfer Read

5 Channel 1 Input Channel 1 Input

6 Channel 2 Input Channel 2 Input

7 Channel 3 Input Channel 3 Input

8 Channel 4 Input Channel 4 Input

9 Channel 5 Input Channel 5 Input

10 Channel 6 Input Channel 6 Input

11 Channel 7 Input Channel 7 Input

12 Channel 8 Input Channel 8 Input

13 Not used 8 7 6 5 4 3 2 1 Low Alarm Bits

14 Not used 8 7 6 5 4 3 2 1 High Alarm Bits

15 8 7 6 5 4 3 2 1 CF EF Not used S G O Calibration Status Bits

5-1

Page 39

Chapter 5

2

3

4

Module Status and Input Data

The Isolated Analog Input Module (1771-IL series B) reports the status of

all eight channels to the processor as outlined below.

T

able 5.A

Bit/Word

Read Block Transfer Data

Word

Descriptions for the Isolated Analog Input Modules (1771-IL)

Decimal

Bit

(Octal Bit)

Bit 00

Power up bit (PU) is set after initial power up. It will not reset until the

module receives a valid write block transfer.

Note: Input data is set to zero until the first BTW is received.

Description

Word 1

Word

Bit 01

Bit 02

Bit 03

Bit 04

Bit 05

Bit 06

Bit 07

Bits 08-15

(10-17)

Bits 00-07

Bits 08-15

(10-17)

Out of range bit (OR) is set if one or more channels are either over or

under range.

Invalid scaling bit (IS) is set if the firmware cannot use the scaling

data in the BTW. Acceptable values are between -9999 and +9999 in

BCD, and -32767 to +32767 in binary.

Real time sample (RTS) time out bit is set if the module is using RTS

and a block transfer read has not occurred within the programmed

RTS period.

Invalid Filter bit (IF) is set if the filter parameters are not correct. The

value must be between 00 and 99 (0.00 and 0.99 seconds) in

BCD; or 0 and 255 (0 to 2.55) in binary.

Invalid Alarm bit (IA) is set if any alarm value is unusable, such as

expecting BCD and value is in 2’s complement binary.

Hardware Failure bit (HF) is set if the analog module has an internal

hardware failure (such as fuse blown or open, etc.).

Alarm violation status bit (A) is set if one or more channels are in an

alarm condition.

Not used

Individual underrange bits for each channel. Bit 00 for channel 1, bit

01 for channel 2, etc.

Not used

Bits 00-07

Word

Word 4

Word

Word 5 thru 12 Input data values. Word 5 for channel 1, word 6 for channel 2, etc.

5-2

Bits 08-15

(10-17)

Bits 00-07

Bits 08-15

(10-17)

Individual overrange bits for each channel. Bit 00 for channel 1, bit

01 for channel 2, etc.

Not used

Polarity (sign) bits are set when the input is less than zero in both

BCD and signed magnitude data formats. Bit 00 for channel 1, bit 01

for channel 2, etc.

Not used

Page 40

Chapter 5

13

14

15

Module Status and Input Data

Word

Word 13

Word

Word 14

Word

Word

Decimal Bit

(Octal Bit)

Bits 00-07

(00-07)

Bits 08-15

(10-17)

Bits 00-07

(00-07)

Bits 08-15

(10-17)

Bit 00

Bit 01

Bit 02

Bits 03-05 Not used

Bit 06

Low Alarm bits for channels 1 through 8 respectively. Each bit

represents an alarm indicator for that channel. When the bit is set, the

value of that channel is below the low alarm value.

Not used

High Alarm bits for channels 1 through 8 respectively. Each bit

represents an alarm indicator for that channel. When the bit is set, the

value of that channel is above the high alarm value.

Not used

Offset Calibration Complete (O). When this bit is set, the offset

calibration request was successfully completed.

Gain Calibration Complete (G). When this bit is set, the gain

calibration request was successfully completed.

Save Complete (S). When this bit is set, the “save calibration values

to EEPROM” was successfully completed.

EEPROM Fault (EF). When this bit is set, the calibration values could

not be saved to EEPROM.

Description

Chapter Summary

Calibration Fault (CF). When this bit is set, the module could not

Bit 07

Bits 08-15

(10-17)

perform offset or gain calibration. This bit is set when a save is

requested.

Calibration Inhibited. Each bit represents a channel that was not

calibrated, either due to an error or a user request. If the channel was

requested not to be calibrated, these bits confirm that request.

In this chapter you learned the meaning of the status information that the

input module sends to the processor.

5-3

Page 41

Module Calibration

Chapter

6

Chapter

Objective

Tools and Equipment

Tool or Equipment Description Model/Type Available from:

Precision Voltage Source

Industrial Terminal and

Interconnect Cable

Calibrating your Input Module

In this chapter we tell you how to calibrate your module.

To calibrate your input module you will need the following tools

and equipment:

0-10V, 1µV resolution;

Accuracy of better than 2mV

Programming terminal for A-B

family processors

The analog input module is shipped already calibrated. If it becomes

necessary to recalibrate the module, you must calibrate the module in an I/O

chassis. The module must communicate with the processor and industrial

terminal.

Before calibrating the module, you must enter ladder logic into the processor

memory, so that you can send data to the module (BTW), and the processor can

read data from the module (BTR).

Analogic 3100, Data Precision 8200

or equivalent

Cat. No. 1770-T3 or Cat. No.

1784-T45, -T47, -T50, etc.

Allen-Bradley Company

Highland Heights, OH

About Auto-calibration

Calibration is accomplished using a method called “auto-calibration.”

Auto-calibration calibrates the input by generating offset and gain correction

values and storing them in EEPROM in the module. These values are read out

of EEPROM and placed in RAM memory at initialization of the module.

The auto-calibration routine operates as follows:

- Whenever a block transfer write (BTW) of length 37 is performed to the

module (any time after the module has been powered up), it interrogates

word 37 for a request for auto-calibration.

- The request can be for the following: offset calibration, gain calibration,

save operation (save to EEPROM). Note that only one bit may be set at

one time. To completely calibrate the module, three BTWs must be sent:

one for each offset, gain and save operations.

6-1

Page 42

Chapter 6

Module Calibration

Performing Auto-calibration

Calibration of the module consists of applying 0.00000V across each input

channel for offset calibration, and +10.00000V across each input channel for

gain correction.

ATTENTION: Verify that each channel’s configuration jumper is

set to the voltage mode (refer to “Setting the Voltage/Current

Selection Jumpers” in chapter 2.) Failure to do so can damage

the module.

Offset Calibration

Normally all inputs are calibrated together. To calibrate the offset of an input,

proceed as follows:

1. Verify that each channel has its jumper set for voltage mode. (Refer to

“Setting the Voltage/Current Selection Jumper” in chapter 2. Check the

position of the jumper on each channel.

2. Apply power to the module.

3. Connect shorting links, or apply 0.00000V across each input channel on

the 1771-WF field wiring arm as shown in Figure 6.1.

Figure 6.1

Shorting

T

erminal Identification

Inputs for Offset Calibration

18

Channel 1

17

16

Channel 2

15

14

Channel 3

13

12

Channel 4

11

10

Not used

9

8

Channel 5

7

6

Channel 6

5

4

Channel 7

3

2

Channel 8

1

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

Shorting link.

Repeat for each channel

Short each input,

or apply 0.00000V

across each input channel.

Apply

0.00000V

6-2

Wiring Arm

Cat. No. 1771-WF

10530-I

Page 43

Chapter 6

Module Calibration

4. After the connections stabilize, request the offset calibration by setting bit

00 in block transfer write word 37 and sending a block transfer write

(BTW) to the module. Refer to Table 6.A.

When the BTW is sent, all channels are calibrated to 0.00000V.

T

able 6.A

Write

Block T

ransfer W

ord 28

Decimal Bit

Octal Bit

Word 37

Decimal Bit

Octal Bit

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

Inhibit Calibration Requested Auto-Calibration

8 7 6 5 4 3 2 1 Set these bits to 0

Requested

Save

Values

Requested

Gain Cal.

Requested

Offset Cal.

NOTE: Normally, all channels are calibrated simultaneously (decimal bits

08-15; octal bits 10-17 of word 37 are 0). To disable calibration on any

channel, set the corresponding bit 08 through 15 decimal, or 10 through

17 octal, of word 37.

5. Queue block transfer reads (BTRs) to monitor for offset calibration

complete and any channels which may have not calibrated successfully.

Refer to Table 6.B.

T

able 6.B

Read

Block T

15 14 13 12 11 10 09 08 07 06 05 04 03 02 01 00

17 16 15 14 13 12 11 10 07 06 05 04 03 02 01 00

ransfer W

ord 13

Word 13

Uncalibrated Channels Auto-Calibration Status

Cal.

8 7 6 5 4 3 2 1

Fault

EEPROM

Fault

Not used

6. Reset bit 00 (0) (requested offset calibration).

7. Proceed to Gain Calibration below.

Save to

EEPROM

Complete

Gain Cal.

Complete

Offset

Cal.

Complete

6-3

Page 44

Chapter 6

Module Calibration

Gain Calibration

Calibrating gain requires that you apply +10.00000V across each input channel.

To calibrate the gain of an input, proceed as follows:

NOTE: Normally, all channels are calibrated simultaneously (decimal bits

08015, octal bits 10-17 of word 37 are 0). To disable calibration on any channel,

set (1) the corresponding bit 08-15 decimal (10-17 octal) of word 37.

1. Apply +10.00000V across each input channel as shown in Figure 6.2.

Figure 6.2

Applying

10.00000V for Gain Calibration

T

erminal Identification

18

Channel 1

17

16

Channel 2

15

14

Channel 3

13

12

Channel 4

11

10

Not used

9

8

Channel 5

7

6

Channel 6

5

4

Channel 7

3

2

Channel 8

1

Wiring Arm

Cat. No. 1771-WF

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

+

Apply

10.00000V

-

10531-I

6-4

2. After the connections stabilize, request the gain calibration by setting bit

01 in BTW word 37 and sending a block transfer write (BTW) to the

module. Refer to Table 6.A.

When the BTW is sent, all channels are calibrated to +10.00000V.

3. Queue BTRs to monitor for gain calibration complete and any channels

which may not have calibrated successfully.

Page 45

Chapter 6

Module Calibration

Save Calibration Values

If any ”uncalibrated channel” bits 08-15 (10-17 octal) of word 15 are set, a save

cannot occur. Auto-calibration should be performed again, starting with offset

calibration. If the module has a faulty channel, the remaining functioning

channels can be calibrated by inhibiting calibration on the faulty channel.

The module can be run with the new calibration values, but will lose them on

power down. To save these values, proceed as follows:

1. Request a “save to EEPROM” by setting bit 02 in BTW word 37 and

sending the BTW to the module. Refer to Table 6.A.

2. Queue BTRs to monitor for “save complete”, “EEPROM fault” and

“calibration fault.” An EEPROM fault indicates a nonoperative EEPROM;

a calibration fault indicates at least one channel was not properly offset or

gain calibrated and a save did not occur.

Chapter Summary

In this chapter, you learned how to calibrate your input module.

6-5

Page 46

Troubleshooting

Chapter

7

Chapter

Objective

Diagnostics Reported by the Module

We describe how to troubleshoot your module by observing indicators and by

monitoring status bits reported to the processor.

At powerup, the module momentarily turns on both indicators as a lamp test,

then checks for

correct RAM operation

EPROM operation

EEPROM operation

a valid write block transfer with configuration data

Thereafter, the module lights the green RUN indicator when operating without

fault, or lights the red FAULT indicator when it detects fault conditions. If the