Page 1

DH485

Communication Interface

(Cat. No. 1770KF3)

User’s Manual

Page 2

Important User Information

Because of the variety of uses for this product and because of the differences between solid

state products and electromechanical products, those responsible for applying and using

this product must satisfy themselves as to the acceptability of each application and use of

this product. For more information, refer to publication SGI-1.1 (Safety Guidelines For

The Application, Installation And Maintenance of Solid State Control).

The illustrations, charts, and layout examples shown in this manual are intended solely

to illustrate the text of this manual. Because of the many variables and requirements

associated with any particular installation, Allen-Bradley Company cannot assume

responsibility or liability for actual use based upon the illustrative uses and applications.

No patent liability is assumed by Allen-Bradley Company with respect to use of

information, circuits, equipment, or software described in this text.

Reproduction of the contents of this manual, in whole or in part, without written permission

of the Allen-Bradley Company is prohibited.

Statement of Compliance

with Federal

Communications

Commission

Statement of Compliance

with Canadian Department

of Communications

Avis de Conformité aux

normes du ministère des

Communications du Canada

Warning and Caution

Symbols

This device complies with Part 15 of the FCC Rules. Operation is subject to the following

two conditions: (1) this device may not cause harmful interference, and (2) this device

must accept any interference received, including interference that may cause undesired

operation.

This digital apparatus does not exceed the Class A limits for radio noise emissions from

digital apparatus set out in the Radio Interference Regulations of the Canadian Department

of Communications. Operation in a residential area may cause unacceptable interference to

radio and TV reception requiring the owner or operator to take whatever steps are

necessary to correct the interference.

Le présent appareil numérique n'émet pas de bruits radioélectriques dépassant les limites

applicables aux appareils numériques de la classe A prescrites dans le Règlement sur

le brouillage radioélectrique édicté par le ministère des Communications du Canada.

L'exploitation faite en milieu résidential peut entraîner le brouillage des réceptions radio et

télé, ce qui obligerait le propriétaire ou l'opérateur à prendre les dispositions nécessaires

pour en éliminer les causes.

Throughout this manual, we make notes to alert you to possible injury to people or damage

to equipment under specific circumstances.

WARNING: Tells readers where people may be harmed if

procedures are not followed properly.

CAUTION:

loss can occur if procedures are not followed properly.

Warnings and Cautions:

identify a possible trouble spot

tell what causes the trouble

give the result of improper action

tell the reader how to avoid trouble

Tells readers where machinery may be damaged or economic

WARNING: No user serviceable parts or adjustments inside module.

Refer servicing to qualified personnel.

1991 Allen-Bradley Company, Inc.

IBM and AT are registered trademarks of the International Business Machine Corporation.

PLC is a registered trademark of Allen-Bradley Company, Inc.

Page 3

Table of Contents

Manual Overview P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Audience P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Related

Related Products P1

Product Overview 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The DH485 Communication Interface 11. . . . . . . . . . . . . . . . . . . . .

The DH485 Network 12

The RS232C/DF1 Data Link 12

Installing the KF3 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Procedures 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Interface Connections 21

DH485 Cabling Considerations 22

RS232C Cabling Considerations 28

Modem Cabling Considerations 212

Voltage

Replacing Fuses 214

Positioning the KF3 215

Publications

Publication Number P1

Product Catalog Number P1

Selection

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

P1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

213. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuring the KF3 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Basic Communication Parameters 35

Advanced Communication Parameters 37

Verifying Your Configuration Parameters 310

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . .

Communicating with the KF3 41. . . . . . . . . . . . . . . . . . . . . . .

DF1

Communication

Communicating with DH485 Master Devices 46

Communicating with DH485 Slave Devices 46

Communicating

with a Modem

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

41. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

49. . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting the KF3 51. . . . . . . . . . . . . . . . . . . . . . . . . .

Interpreting the Front Panel LEDs 51. . . . . . . . . . . . . . . . . . . . . . . .

Interpreting the Numeric Displays 52

. . . . . . . . . . . . . . . . . . . . . . . .

Page 4

Table of Contentsii

Specifications A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

RS232C Interface A1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

DH485 Interface A1

Electrical A1

Physical A2

Environmental A2

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Command Support B1. . . . . . . . . . . . . . . . . . . . . .

Diagnostic Loop B1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Read B2

Diagnostic

Diagnostic Counter Reset B5

Read Link Parameters B6

Set Link Parameters B6

Status

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

B4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Preface

Manual

Overview

Audience

Related Publications

This manual:

describes the features and capabilities of the 1770-KF3

tells you how to install, configure, and operate your 1770-KF3

gives troubleshooting tips on diagnosing problems

defines the specifications of the 1770-KF3

Read this manual if you are installing and configuring a 1770-KF3

Interface Module for use with a DH-485 network.

You should be familiar with:

Allen-Bradley SLC 500 series of programmable controllers

Allen-Bradley DH-485 networks

Publication Publication Number

Data Highway/Data Highway Plus/DH-485 1770-6.5.16

Protocol and Command Set Manual

SLC 500 Advanced Programming Software Manual 1747-801

Related Products

PC/DH-485 Interface Module Installation Data 1784-2.23

Allen-Bradley Standard Driver Software 6001-6.5.5

User’s Manual (6001-F2E)

Bulletin 2755 Bar Code Decoder User’s Manual 2755-816

Product Catalog Number

Advanced Programming Software 1747-PA2E

PC/DH-485 Interface Module 1784-KR

Allen-Bradley Standard Driver Software 6001-F2E

Bar Code Decoder 2755-DM6

SLC 500 RS-485 Link Coupler 1747-AIC

P-1

Page 6

Product Overview

Chapter

1

The DH485 Communication

Interface

The DH-485 Communication Interface module links host computers with

the Allen-Bradley RS-485 Data Highway (DH-485). The module supports

the protocol required to act as a node on the DH-485 network, freeing the

host computer from this task.

Figure 1.1

The

DH485 Communication Interface (1770KF3)

Important: The DH-485 Communication Interface module (cat. no.

1770-KF3) will be referred to as “the KF3” or “the module” throughout the

remainder of this manual.

The host computer communicates with the KF3 over an RS-232C link

using full-duplex or half-duplex DF1 protocol. Through the KF3, the host

computer can communicate with nodes on the DH-485 network.

11

Page 7

Chapter 1

Product Overview

The DH485 Network

The RS232C/DF1 Data Link

The DH-485 communication network allows devices on the plant floor to

share information. Via the network, application programs can:

monitor process and device parameters and status, including fault and

alarm detection

perform data acquisition

perform supervisory control functions

upload/download PLC programs over the network

The DH-485 network offers:

interconnection of up to 32 nodes

multi-master capability

slave devices

token-passing access control

the ability to add or remove nodes without disruption of the network

maximum cable length of 4,000 feet

data rates up to 19,200 baud

The RS-232C/DF1 data link features:

full- or half-duplex DF1 protocol

data rate up to 19,200 baud

cable length up to 50 feet

point-to-point modem connection

Block Check Character (BCC) or Cyclic Redundancy Check (CRC16)

error detection

12

The DF1 Protocol

DF1 is a full- or half-duplex link protocol designed to carry messages

intact over a link. The link protocol delimits messages, detects and signals

errors, retries after errors and controls message flow.

Full-duplex protocol is intended for high performance applications where

maximum throughput is required. Full-duplex protocol only works on a

point-to-point link that allows for two-way simultaneous transmission.

Half-duplex protocol provides a less effective utilization of resources than

full-duplex, but is easier to implement. It can operate on point-to-point or

multi-point applications.

Page 8

Chapter 1

Product Overview

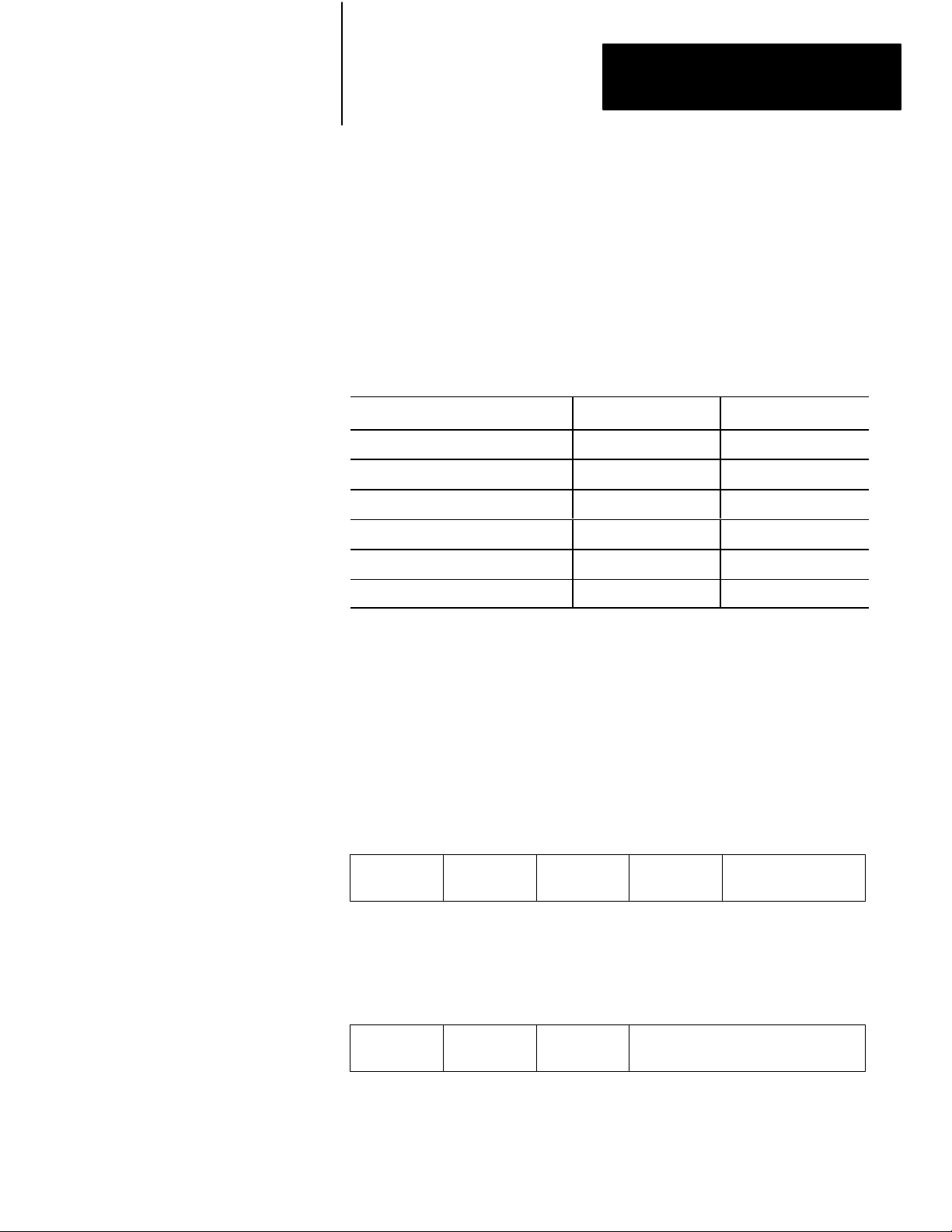

Table 1.A

Protocol

Applications

Protocol PointtoPoint MultiPoint

Fullduplex Yes No

Halfduplex Yes No

A description of these protocols is given in the Data Highway/Data

Highway Plus/DH-485 Protocol and Command Set Manual (publication

1770-6.5.16).

13

Page 9

Installing the KF3

Chapter

2

Installation

Procedures

Interface Connections

To install the KF3, follow these steps:

1. Define your network needs.

2. Construct the necessary cables.

3. Ground and terminate your network correctly.

4. Determine the correct voltage for your application and set the KF3’s

voltage selector. Change power cord if necessary.

5. Check the KF3’s default configuration parameters and change those

which are not suitable for your application.

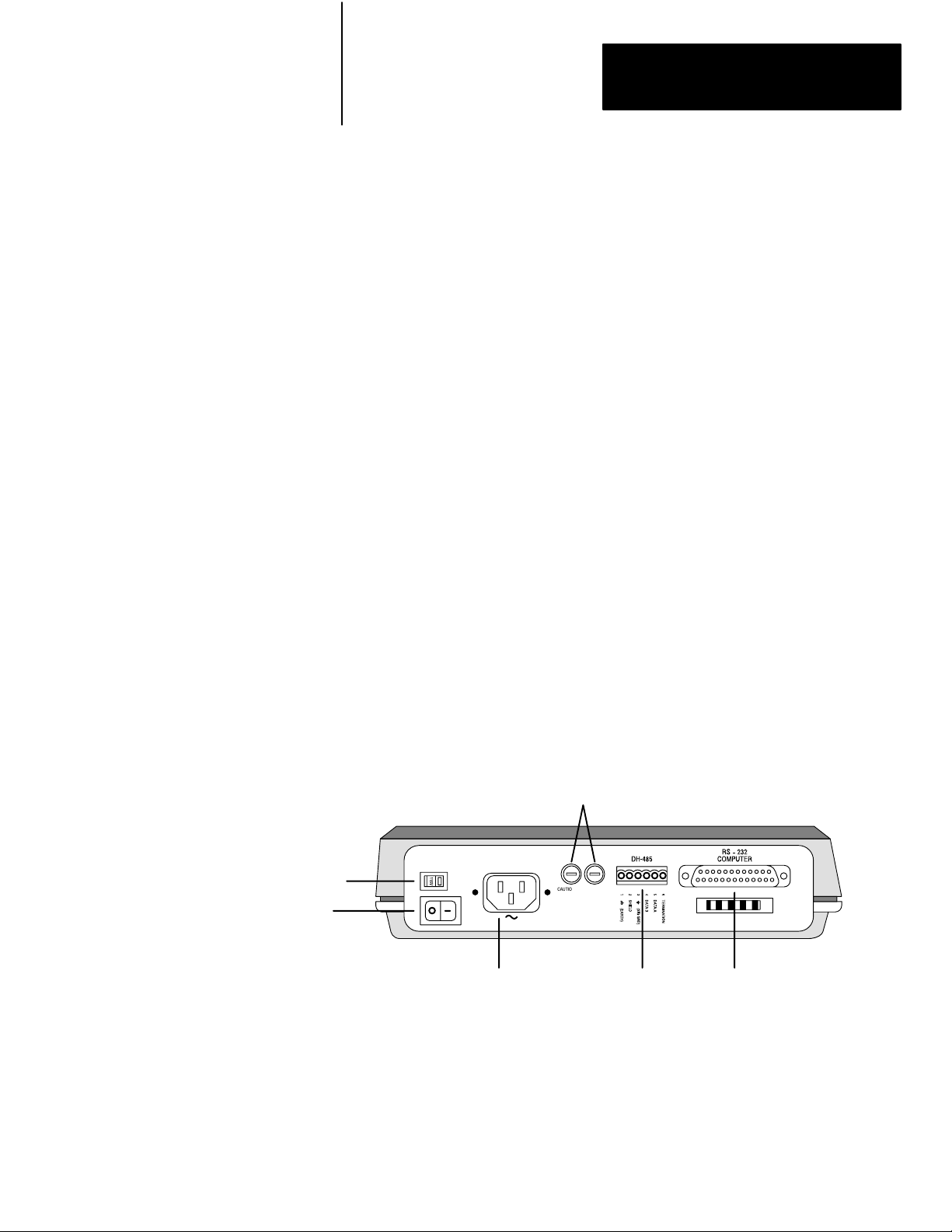

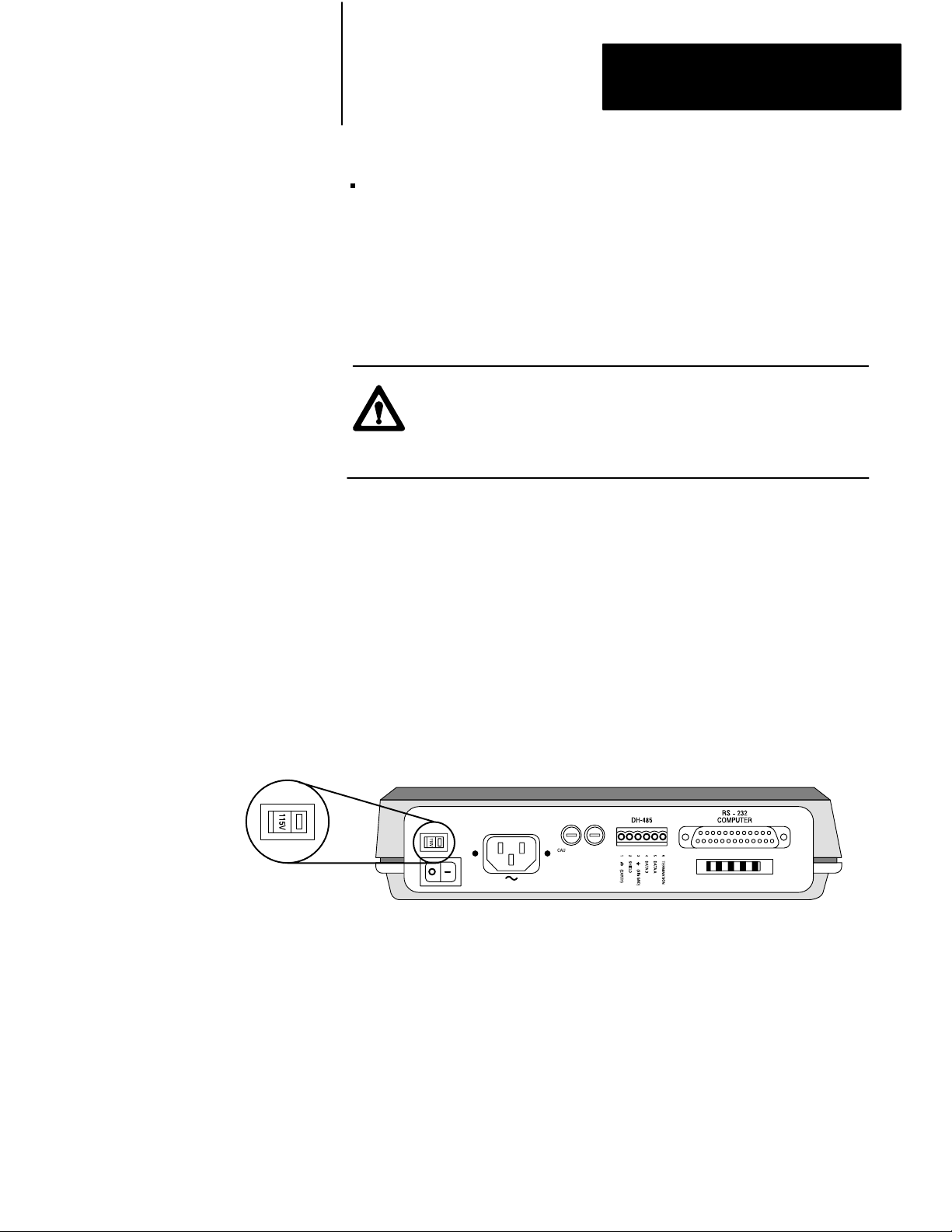

Figure 2.1 shows the back panel of the KF3, including its two

communication connectors. The connector labelled RS-232 Computer

connects to the host computer via an RS-232C cable. The connector

labelled DH-485 connects to the DH-485 network.

Figure 2.1

KF3

Back Panel

115V/230V

Selector

Voltage

Power Switch

AC power connector

(115V/230V)

Fuses

FUSES: 0.1A 250V

TYPE 5mm X 20MM

CAUTION: FOR CONTINUED

PROTECTION AGAINST RISK

OF FIRE REPLACE ONLY

WITH THE SAME TYPE

AND RA

TING OF FUSE.

CAUTION:

DOUBLEFOLD NEUTRAL

FUSES

DH485 connector

links to DH485

network

RS232C connector

links to host computer

via RS232C cable

21

Page 10

Chapter 2

Installing the KF3

DH485 Cabling

Considerations

Depending on your application, you can use the KF3 module to

communicate with a single station via a point-to-point link, or with

multiple DH-485 stations (for example, the SLC 500 family of

programmable controllers), via the DH-485 network.

You must construct the necessary cable or cables for each application. Use

a jacketed and shielded cable with two twisted wire pairs and a drain wire.

One pair provides a balanced signal line; one wire of the other pair serves

as a common signal reference for all nodes on the link. The shield reduces

the effect of electromagnetic noise from the industrial environment.

Belden #9842 cable is recommended.

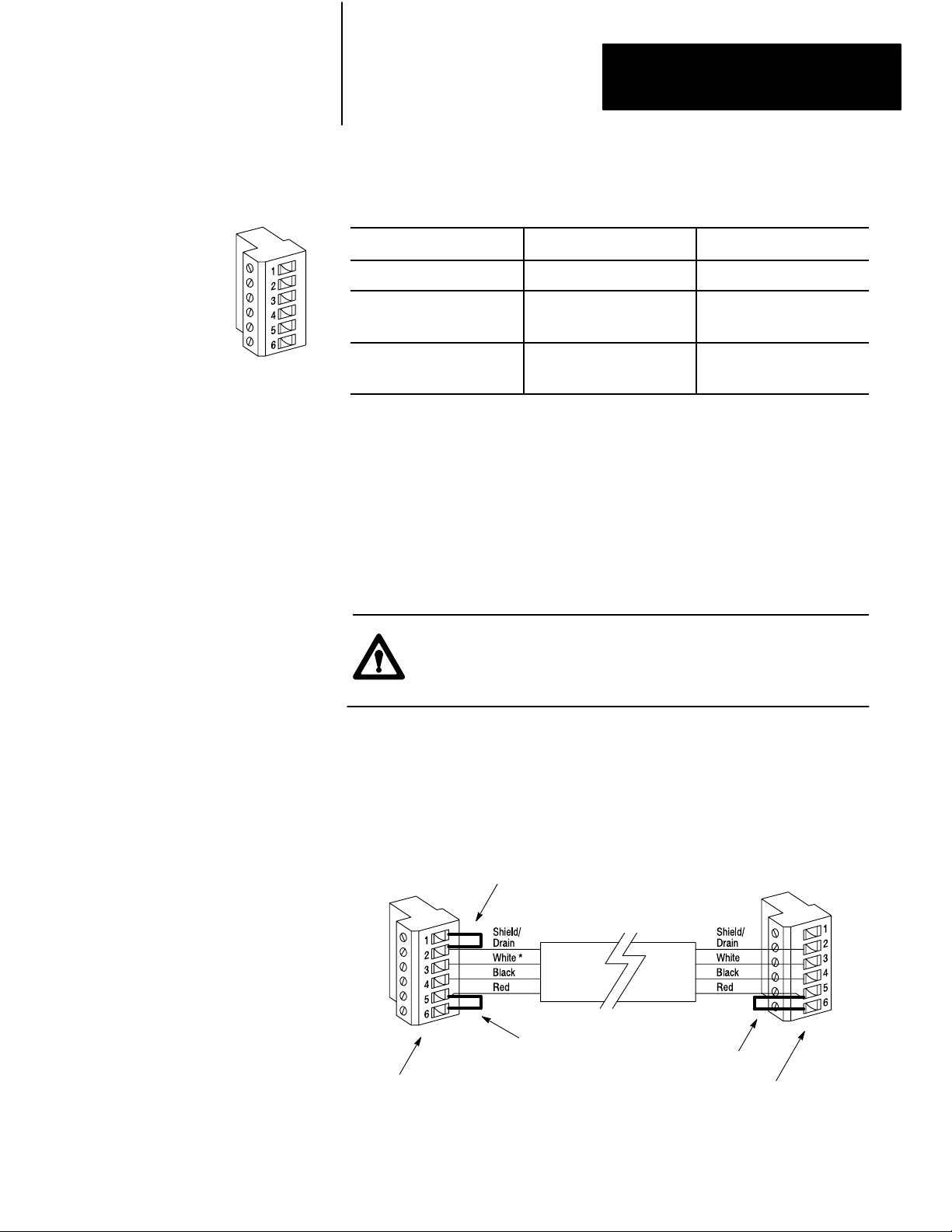

The pinouts for the KF3’s DH-485 connector are shown in Figure 2.2.

Figure 2.2

Pinouts

KF3

FUSES: 0.1A 250V

TYPE 5mm X 20MM

CAUTION: FOR CONTINUED

PROTECTION AGAINST RISK

OF FIRE REPLACE ONLY

WITH THE SAME TYPE

AND RA

TING OF FUSE.

CAUTION:

DOUBLEFOLD NEUTRAL

FUSES

22

Grounding and Terminating the Network

The precise configuration of the cable connectors is determined by their

position on the network.

Connections between intermediate nodes (nodes that are not at either

end of the network) require no jumpers. Table 2.A shows the wire and

terminal connections for a cable linking any two intermediate nodes.

Page 11

Chapter 2

Installing the KF3

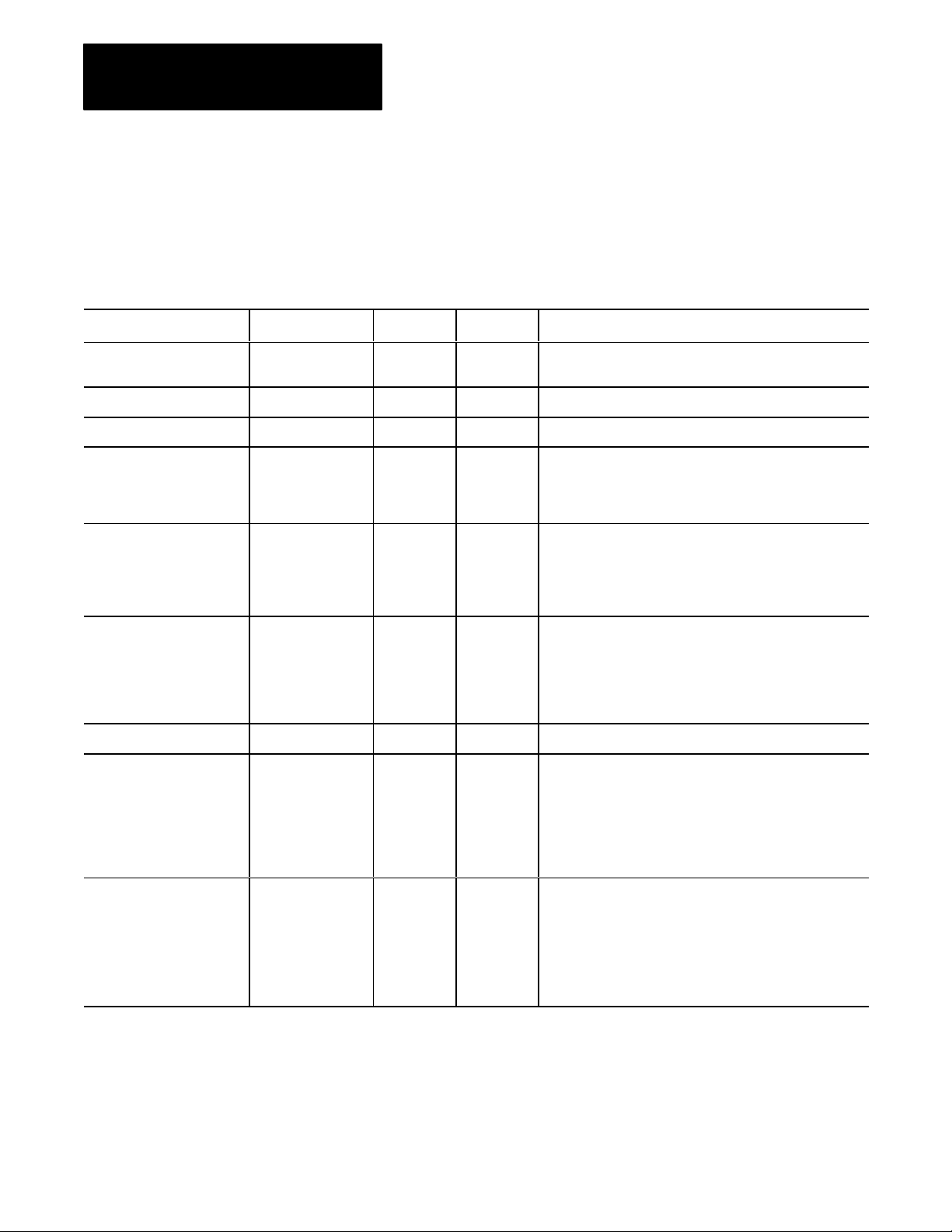

Table 2.A

Wire/Terminal

For this Wire/Pair Connect this Wire To this Terminal

Shield/Drain Nonjacketed Terminal 2 - Shield

Black/White Black Wire

Black/Red Black Wire

Connections for Imtermediate Nodes

White Wire

Red Wire

Cut back - No connection

Terminal 3 (Signal Ground)

Terminal 4 (Data A)

Terminal 5 (Data B)

The nodes at each end of the network must be terminated. Install a jumper

wire between terminals 5 and 6 to enable the impedance built into the

module.

One (not both) of the nodes at the end of the network must have an earth

ground connection for the communication cable shield. For the node

at one end of the network, whether it is the KF3 or some other device,

connect the shield to ground by installing a jumper wire between terminals

1 and 2 of the terminal block.

CAUTION: Be sure no other node on the network has its shield

connected to ground.

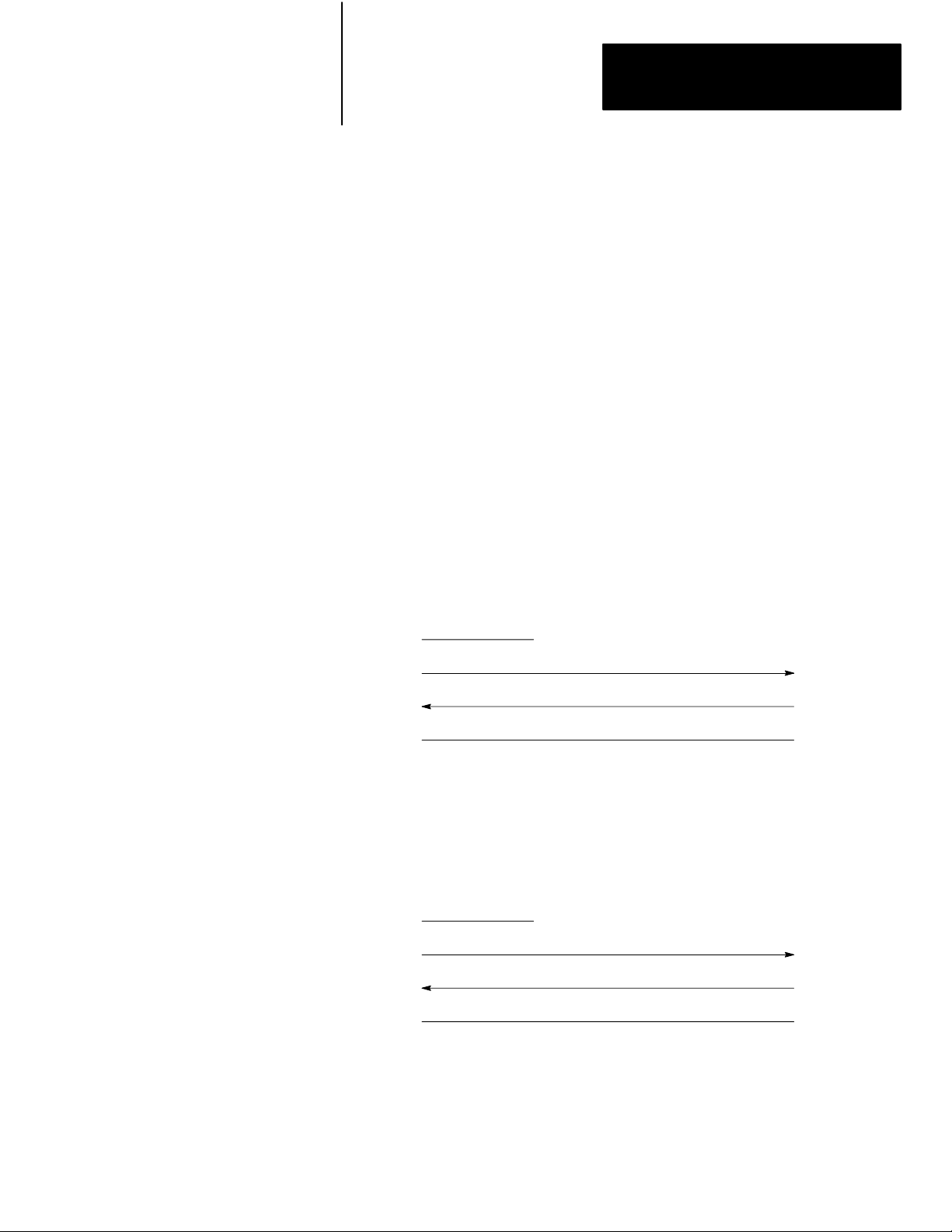

Figure 2.3 illustrates proper jumper connections for end nodes.

Figure 2.3

Connections for End Nodes

Jumper

Jumper

to

ground shield

Jumper to

terminate node

KF3 on one end of the link

* The black wire of the white/black pair should be cut back (no connection).

Jumper to

terminate node

SLC 500 or other device on the other

end of the link

23

Page 12

Chapter 2

Installing the KF3

Host Computer

RS232C

Cable

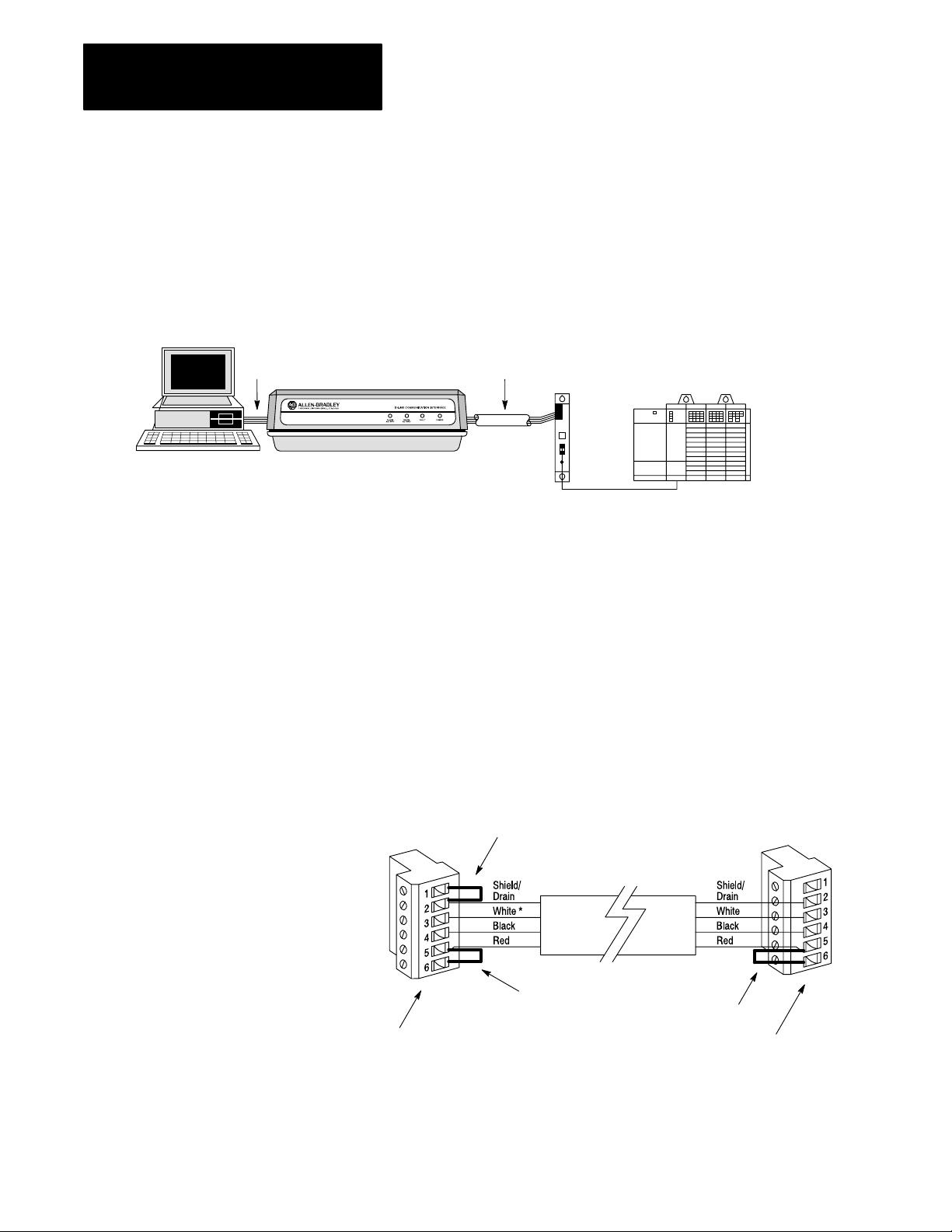

Connecting via a DH485 Link (PointtoPoint Configuration)

Figure 2.4 shows a point-to-point link consisting of a single SLC 500

programmable controller and one host computer station.

Figure 2.4

PointtoPoint DH485 Link

A

DH485

Cable

Belden #9842

Link

KF3

Coupler

1747AIC

1747C1

1 Cable

SLC 500

Controller

This configuration requires a KF3 and one link coupler. The SLC 500

controller is connected to the link coupler with a 1747-C11 cable. The

KF3 is connected directly to the link coupler. In this topology, both the

KF3 and the SLC 500 are end nodes.

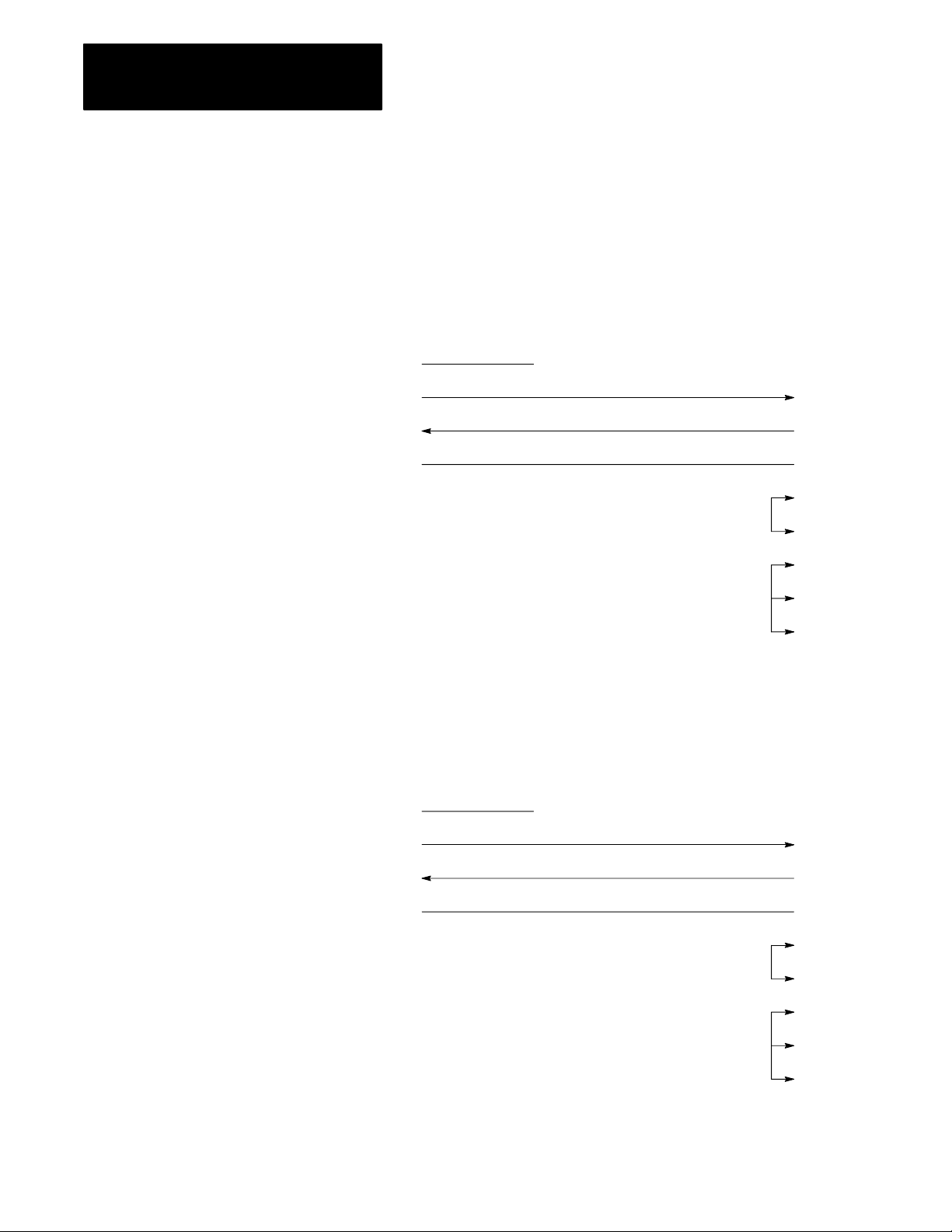

Construct a cable to attach the DH-485 connector on the back of the

KF3 module to the link coupler. Figure 2.5 shows the connection for a

point-to-point DH-485 application. The shield ground could be at either

end, but must be at one end, and one end only.

Figure 2.5

Connection

for KF3 and Single SLC

Jumper

shield connector

KF3 on one end of the link

* The black wire of the white/black pair should be cut back (no connection).

to ground

Jumper to

terminate node

Jumper to

terminate node

SLC 500 or other device at the other end of the link

24

Page 13

Chapter 2

Installing the KF3

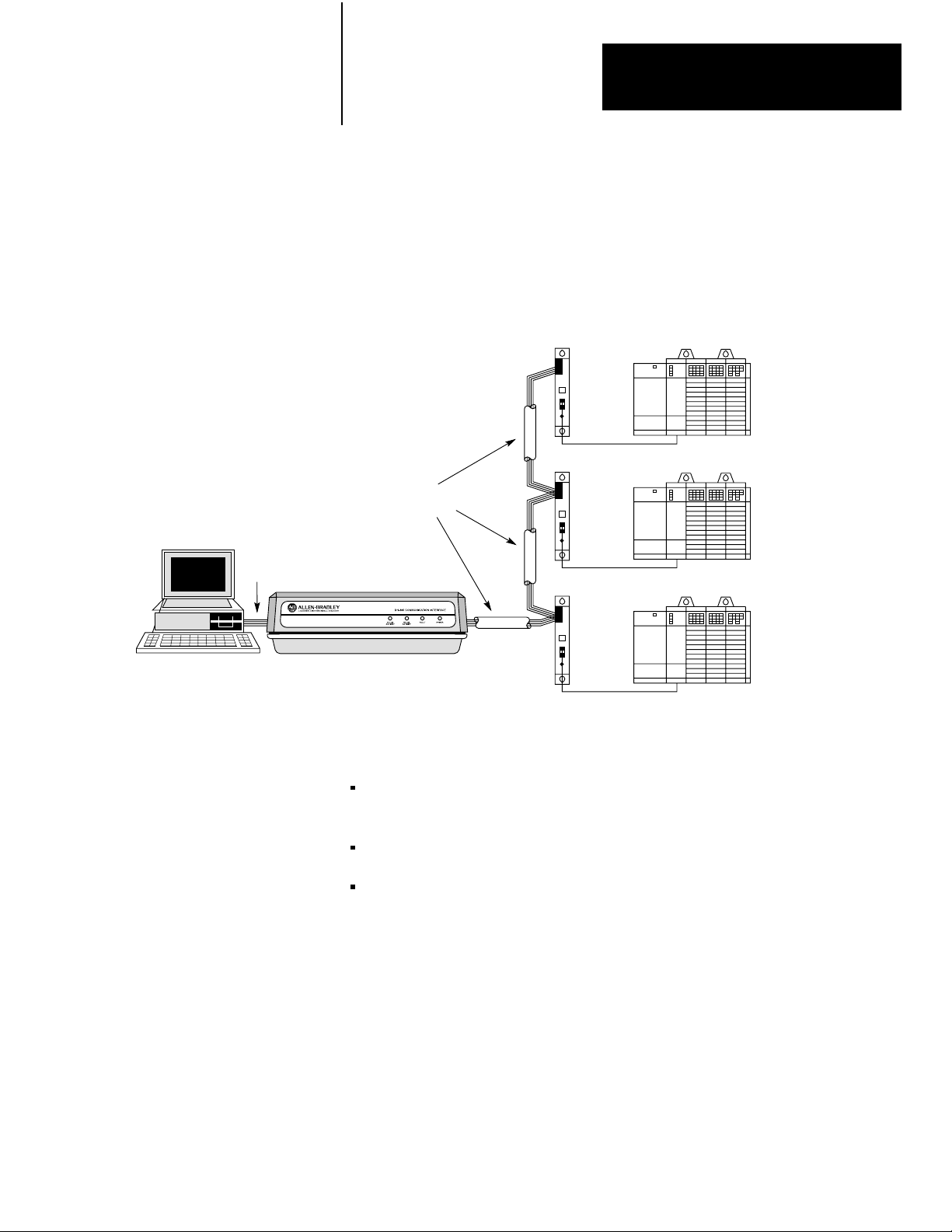

Connecting to a DH485 Network (MultiPoint Configuration)

Figure 2.6 shows a network consisting of three SLC 500 programmable

controllers and one host computer station.

RS232C

Cable

Host Computer

Figure 2.6

Connecting

KF3

to Multiple SLC 500s via the DH485 Network

Link

Coupler

1747AIC

1747C1

DH485

Cable

Belden #9842

Link

Coupler

1747AIC

1747C1

Link

Coupler

1747AIC

1747C1

1 Cable

1 Cable

1 Cable

This configuration requires the KF3 and three link couplers:

SLC 500

Controller

SLC 500

Controller

SLC 500

Controller

one SLC 500 family controller is connected to each of the link couplers

with a 1747-C11 cable

the KF3 is connected to the network at one of the link couplers

the DH-485 cable consists of three segments of cable daisy-chained to

the link couplers and the KF3

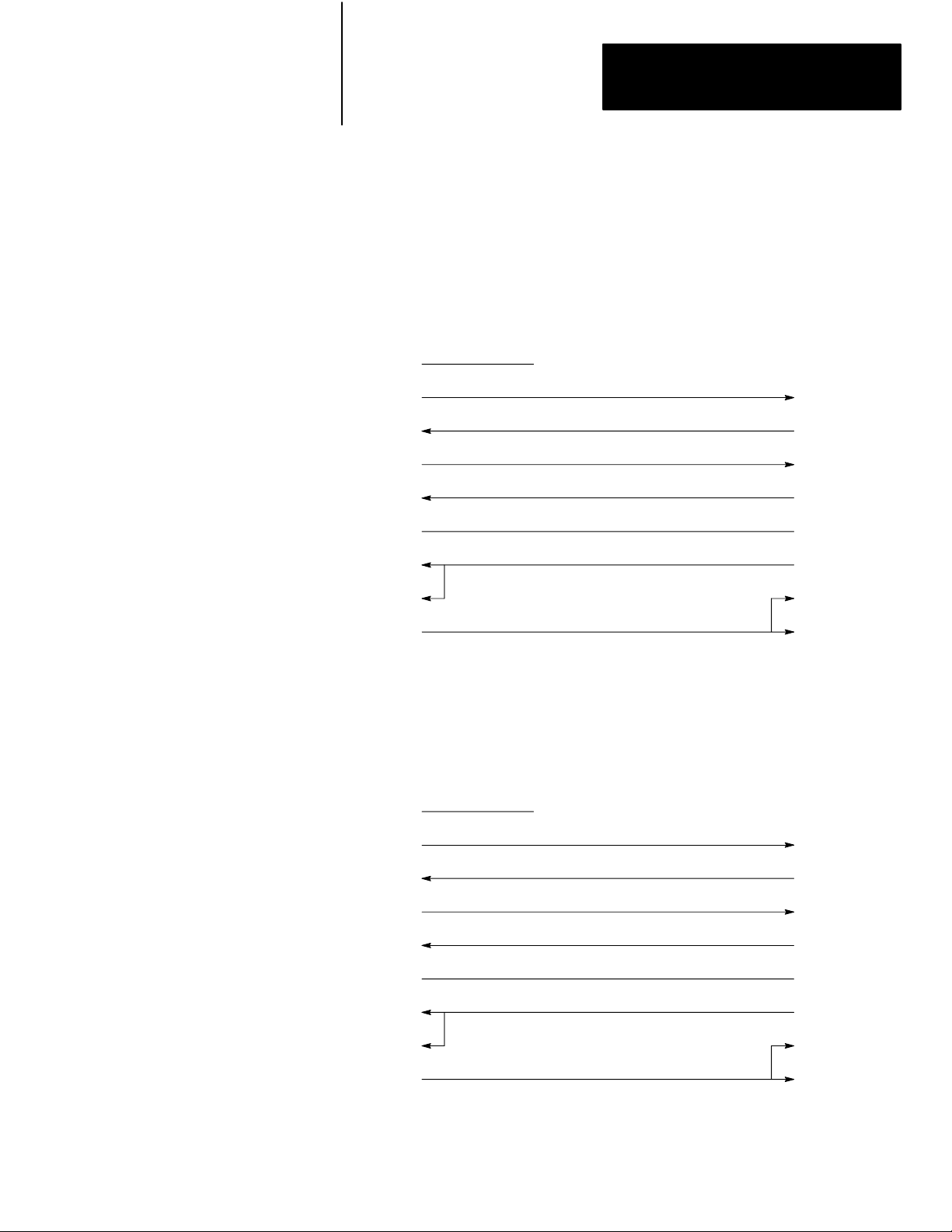

The connection between the first node (the KF3) and the link coupler to the

second node is shown in Figure 2.7.

25

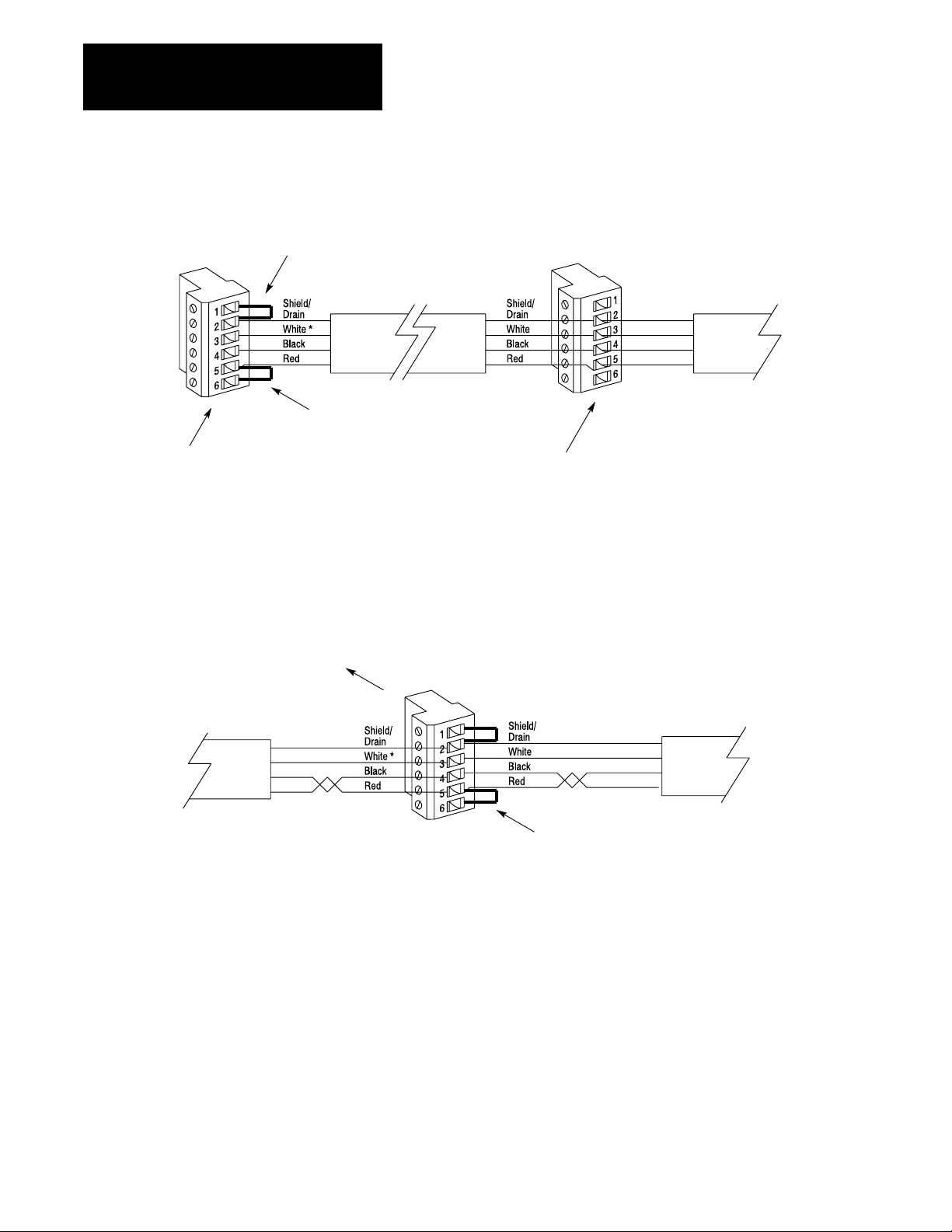

Page 14

Chapter 2

Installing the KF3

Jumper

to ground

shield connector

1770KF3 on one end of the link

Figure 2.7

Connection

Jumper to

terminate node

* The black wire of the white/black pair should be cut back (no connection).

for First Segment of a Multidrop Network

DH485

Cable

Link coupler to first SLC 500

The cable connecting the second and third nodes of the multidrop network

(neither of which is an end station) is shown in Figure 2.8.

Figure 2.8

Connection

Between Two Intermediate Nodes

TO

NEXT

DEVICE

Cable

Belden

#9842

T

o Link Coupler

Red/Black

* The black wire of the white/black pair should be cut back (no connection).

Pair

The connection between the third and fourth (end) node is shown in

Figure 2.9.

Cable

Belden

#9842

FROM

PREVIOUS

DEVICE

26

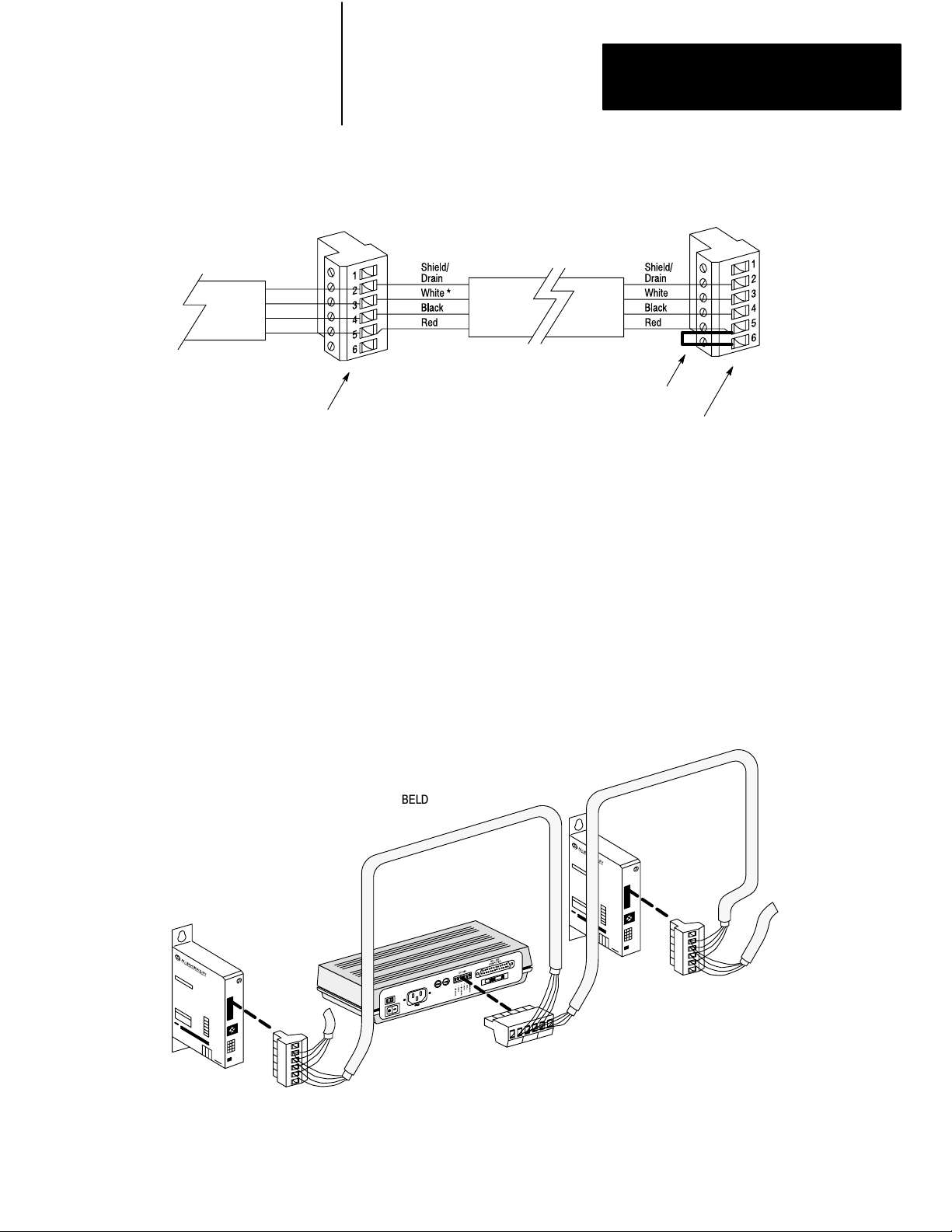

Page 15

Chapter 2

Installing the KF3

DH485

Cable

Figure 2.9

Connection

Third

node

* The black wire of the white/black pair should be cut back (no connection).

for Last Segment of a Multidrop Network

Jumper to

terminate node

Fourth node on the end of the multidrop network

Installing the DH485 Cable

The DH-485 cable consists of a number of daisy-chained segments. The

total length of the combined segments must not exceed 4,000 feet. Cut the

cable segments long enough to route from one node to the next, allowing

sufficient slack to prevent strain on the connectors. Provide strain relief

for the cable after it is plugged in to prevent the cable wires from breaking.

Link

Coupler

1747AIC

Figure 2.10

Connection on a DH485 Link

Cable

BELDEN

#9842

KF3

Connector

(Phoenix

MSTB2.5/6ST

BELDEN

#9842

Link

Coupler

1747AIC

AU)

27

Page 16

Chapter 2

Installing the KF3

RS232C Cabling

Considerations

Cabling for the RS-232C connector of the KF3 will vary depending on

your application. The pinouts for this connector are given in Table 2.B.

Table 2.B

RS232C

Signal Abbreviation Direction Pin No. Meaning

Chassis Ground - - 1 The cable shield must be connected to chassis ground at one

Transmit Data TXD Output 2 RS232C serialized data output from the module.

Receive Data RXD Input 3 RS232C serialized data input to the module.

Request to Send RTS Output 4 A request from the module to the modem to prepare to

Clear to Send CTS Input 5 A signal from the modem to the module that indicates the

Data Set Ready DSR Input 6 A signal from the modem to the module that indicates the

Connector Pinouts

end only.

transmit. With fullduplex protocol, RTS is always asserted.

With halfduplex protocol, it is turned on when the module has

permission to transmit, otherwise it is off.

carrier is stable and the modem is ready to transmit. The

module will not transmit until CTS is on. If CTS is turned off

during transmission, the module will stop transmitting until

CTS is restored.

phone is offhook. It is the modem's answer to DTR. The

module will not transmit or receive unless DSR is on. If

the modem does not control DSR properly, DSR must be

jumpered to a high signal at the module. (It can be jumpered

to DTR.)

Signal Ground GND - 7 Signal ground - a reference point for the data signals.

Data Carrier Detect DCD Input 8 A signal from the modem to the module to indicate that the

carrier from another modem is being sensed on the phone

line. It will not be asserted unless the phone is offhook.

Data will not be received by the KF3 unless DCD is on. With

fullduplex protocol, the module will not transmit unless DCD

is on. If the modem does not control DCD properly, DCD must

be jumpered to DTR at the module.

Data Terminal Ready DTR Output 20 A signal from the module to the modem to connect to the

phone line (i.e., pick up the phone"). The module will assert

DTR all the time except during the phone hangup sequence.

Modems built to North American standards will not respond

to DTR until the phone rings. The KF3 module will not work

correctly with modems which always pick up the phone upon

receiving DTR, whether the phone is ringing or not.

28

Page 17

Chapter 2

Installing the KF3

Use Belden #8723 (or equivalent) cable to construct a cable to connect the

KF3 to a computer.

Important: The length must not exceed 50 feet, and the cable shield must

be connected to chassis ground (using Pin 1) at the KF3 end only.

There are various cabling options depending on whether or not your

application makes use of handshake signals, whether or not you are

connecting to a 9-pin serial port for an IBM AT, and whether or not your

computer uses standard IBM pinouts. Figures 2.11 through 2.16 are for

IBM computers with either 9- or 25-pin connectors. If your computer has

a different pinout, construct a cable using the appropriate signal names for

your computer.

If you are not using handshake signals, use the three wire connections

shown in Figures 2.11 or 2.12.

Figure 2.11

ThreeWire

Connection to IBM Computer (25 pin)

KF3 Computer

1

TXD 2

RXD 3

GND 7

Shield

Figure 2.12

ThreeW

ire Connection to IBM Computer (9 pin)

KF3 Computer

1

TXD 2

RXD 3

Shield

3 RXD

2 TXD

7 GND

2 RXD

3 TXD

GND 7

5 GND

29

Page 18

Chapter 2

Installing the KF3

If your computer requires active DSR and CTS signals, add jumpers to the

computer connections as shown in Figures 2.13 and 2.14.

Figure 2.13

Positions for DSR and CTS Lines (25 pin)

Jumper

KF3 Computer

1

TXD 2

RXD 3

GND 7

Shield

Figure 2.14

Jumper Positions for DSR and CTS Lines (9 pin)

KF3 Computer

1

Shield

3 RXD

2 TXD

7 GND

4 RTS

5 CTS

6 DSR

8 DCD

20 DTR

210

TXD 2

RXD 3

GND 7

2 RXD

3 TXD

5 GND

7 RTS

8 CTS

6 DSR

1 DCD

4 DTR

Page 19

Chapter 2

Installing the KF3

If you are using handshake signals with your computer, use the connection

shown in Figure 2.15 or 2.16.

Figure 2.15

Connection

to IBM Computer with Handshake Signals (25 pin)

KF3 Computer

1

TXD 2

RXD 3

RTS 4

CTS 5

GND 7

DSR 6

DCD 8

DTR 20

Shield

Figure 2.16

Connection to IBM Computer with Handshake Signals (9 pin)

3 RXD

2 TXD

5 CTS

4 RTS

7 GND

20 DTR

6 DSR

8 DCD

KF3 Computer

1

TXD 2

RXD 3

RTS 4

CTS 5

GND 7

DSR 6

DCD 8

DTR 20

Shield

2 RXD

3 TXD

8 CTS

7 RTS

5 GND

4 DTR

6 DSR

1 DCD

211

Page 20

Chapter 2

Installing the KF3

Modem Cabling Considerations

The KF3 is connected to a modem via a direct 25-pin-to-25-pin cable,

which you must construct using Belden #8723 (or equivalent) cable.

Important: The length must not exceed 50 feet, and the cable shield must

be connected to chassis ground (using Pin 1) at the KF3 end only.

Figure 2.17

Connection

between a KF3 and a Modem

KF3 Modem

1

TXD 2

RXD 3

RTS 4

CTS 5

DSR 6

GND 7

Shield

2 RXD

3 TXD

4 RTS

5 CTS

6 DSR

7 GND

DCD 8

DTR 20

8 DCD

20 DTR

The KF3 can be connected to standard asynchronous dial-up modems.

Important: Some modems are designed to respond to the DTR signal by

answering the phone whether it is ringing or not. Since the KF3 asserts

DTR at all times except during the hang-up sequence, the phone would

always appear to be “busy.” Do not use the KF3 with any type of modem

that answers the phone as soon as DTR is asserted.

The types of dial-up network modems that you can use are:

Manual: These are typically acoustically coupled modems. The

connection is established by human operators at both ends, who insert

the handsets into couplers to complete the connection.

DTE Controlled Answer: These unattended modems are directly

connected to the phone lines. The KF3 serves as the data terminal

equipment to control the modem via the DTR, DSR, and DCD signals.

The module incorporates timeouts and tests to properly operate these

types of modems.

212

Page 21

Chapter 2

Installing the KF3

Auto-Answer: These modems have self-contained timeouts and tests,

and can answer and hang up the phone automatically.

The module has no means of controlling an auto-dial modem, but it can be

used in conjunction with a separate auto-dialer.

Voltage

Selection

CAUTION: The KF3 must be set to the correct voltage before

it is powered up. Connecting to 115V power with the switch set

to 230V will result in erratic operation. Connecting to 230V

power with the switch set to 115V can damage the module.

The power select switch is located on the back panel. The switch is set at

the factory for 115V operation.

115V Operation

Ensure the switch is set to “115V” as shown in Figure 2.18. Plug the

power cord supplied with the KF3 into the connector on the back panel,

and plug the other end into any standard 115V AC outlet.

Figure 2.18

Select Switch Set for 115V Operation

Power

Slide

to right for

1

15V operation

FUSES: 0.1A 250V

TYPE 5mm X 20MM

CAUTION: FOR CONTINUED

PROTECTION AGAINST RISK

OF FIRE REPLACE ONLY

WITH THE SAME TYPE

AND RA

TING OF FUSE.

CAUTION:

DOUBLEFOLD NEUTRAL

FUSES

213

Page 22

Chapter 2

Installing the KF3

Slide

to left for

230V operation

230V Operation

Set the power select switch to “230V” as shown in Figure 2.19.

Figure 2.19

Power

Select Switch Set for 230V Operation

FUSES: 0.1A 250V

TYPE 5mm X 20MM

CAUTION: FOR CONTINUED

PROTECTION AGAINST RISK

OF FIRE REPLACE ONLY

WITH THE SAME TYPE

AND RA

TING OF FUSE.

CAUTION:

DOUBLEFOLD NEUTRAL

FUSES

CAUTION: The power cord supplied is approved for 115V

operation only. To guard against electrical shock or fire, you

must replace the cord with one approved for 230V AC by a

recognized agency such as Underwriters Laboratories. To

match the KF3 receptacle, the 230V power cord must be

terminated with a molded female connector (IEC 320/CEE22).

214

Replacing

Fuses

CAUTION: Before replacing fuses, unplug the module’s power

cord.

To replace fuses, insert the fuse into the fuse holder in the cap first. Then

insert the combined assembly into the fuse receptacle and tighten with a

screwdriver.

CAUTION: If you first put the fuse into the receptacle and then

attempt to tighten the cap, damage or breakage may result.

Page 23

Chapter 2

Installing the KF3

Fuse

Holder

Cap Fuse Fuse

Positioning the KF3

Figure 2.20

Replacing

Fuses

Holder Assembly

Fuse

Receptacle

Screwdriver

The KF3 is intended to sit on a flat surface, such as a desk top or shelf.

It has been designed for operation in both control room and plant floor

environments.

Where you place the KF3 is determined largely by the 50-foot RS-232

cable length restrictions, and by access to an AC power outlet.

215

Page 24

Configuring the KF3

Chapter

3

Configuration

You configure the KF3’s communication parameters using the push buttons

and displays located on the bottom of the module. The module saves them

in nonvolatile memory. Factory default settings (shown in Table 3.B)

should be adequate for most industrial usages.

Important: Verify that all parameter settings are correct for your purposes

before connecting the KF3 to your network.

The KF3 has two modes of operation, run mode and configuration

mode. During normal operation, the module functions in run mode.

Communication parameters are changed in configuration mode. The

module continues to communicate while it is in configuration mode.

Changes take effect as soon as they are saved and the module returns to run

mode. In run mode, the configuration displays are turned off.

Important: If your displays show symbols other than those shown in this

chapter, your module is malfunctioning. Contact your A-B representative.

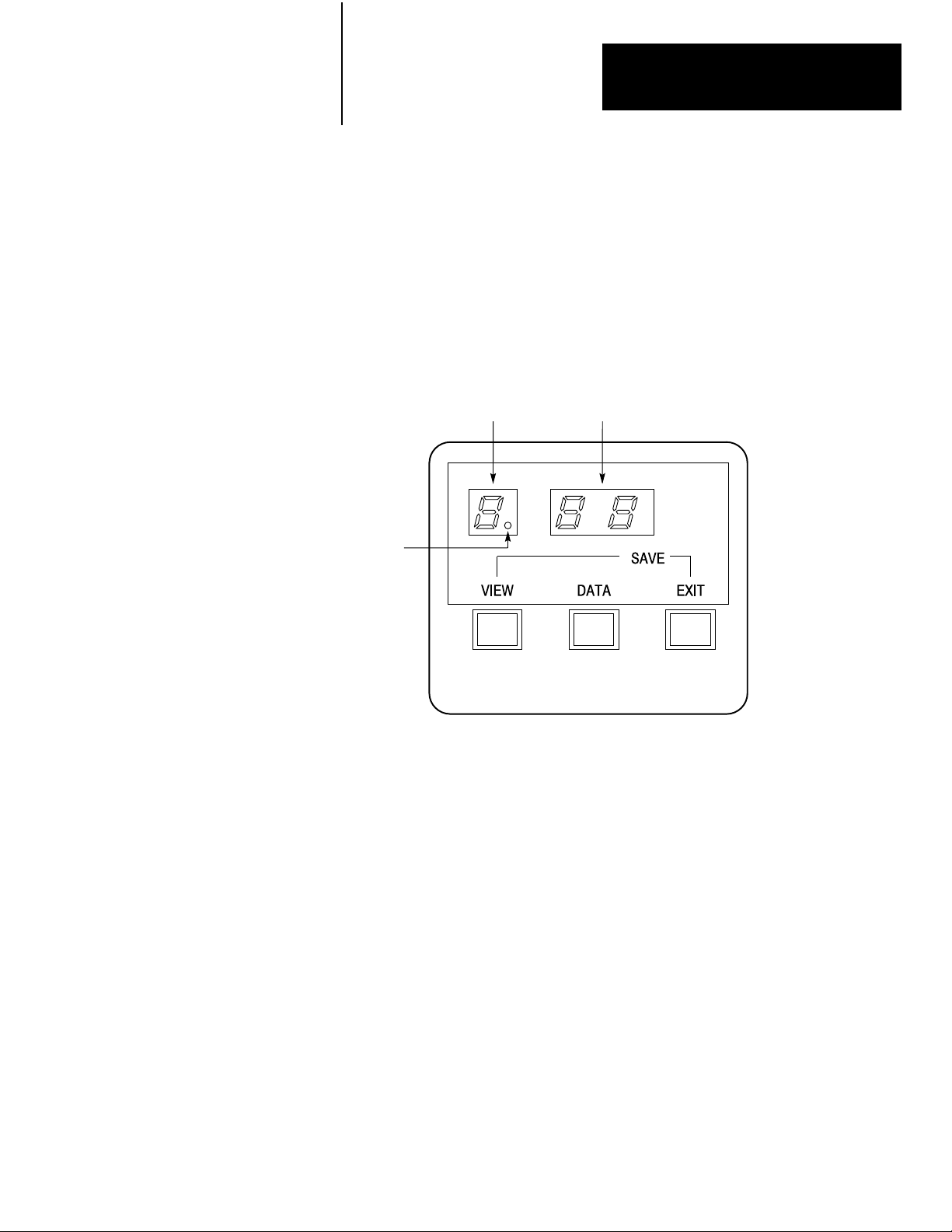

Figure 3.1

Configuration

Communication

Display and Push Buttons

Parameter

Current

Setting

31

Page 25

Chapter 3

Configuring the KF3

Displays

Figure 3.1 shows the configuration displays on the bottom of the module.

The left display (one digit) shows the number of the communication

parameter being configured. The right display (two digits) shows the

current setting for that parameter. Communication parameters are

configured in two menus, a main menu, for basic parameters, and a

submenu, for more advanced parameters.

Push Buttons

Figure 3.1 shows three push buttons labelled View, Data, and Exit. The

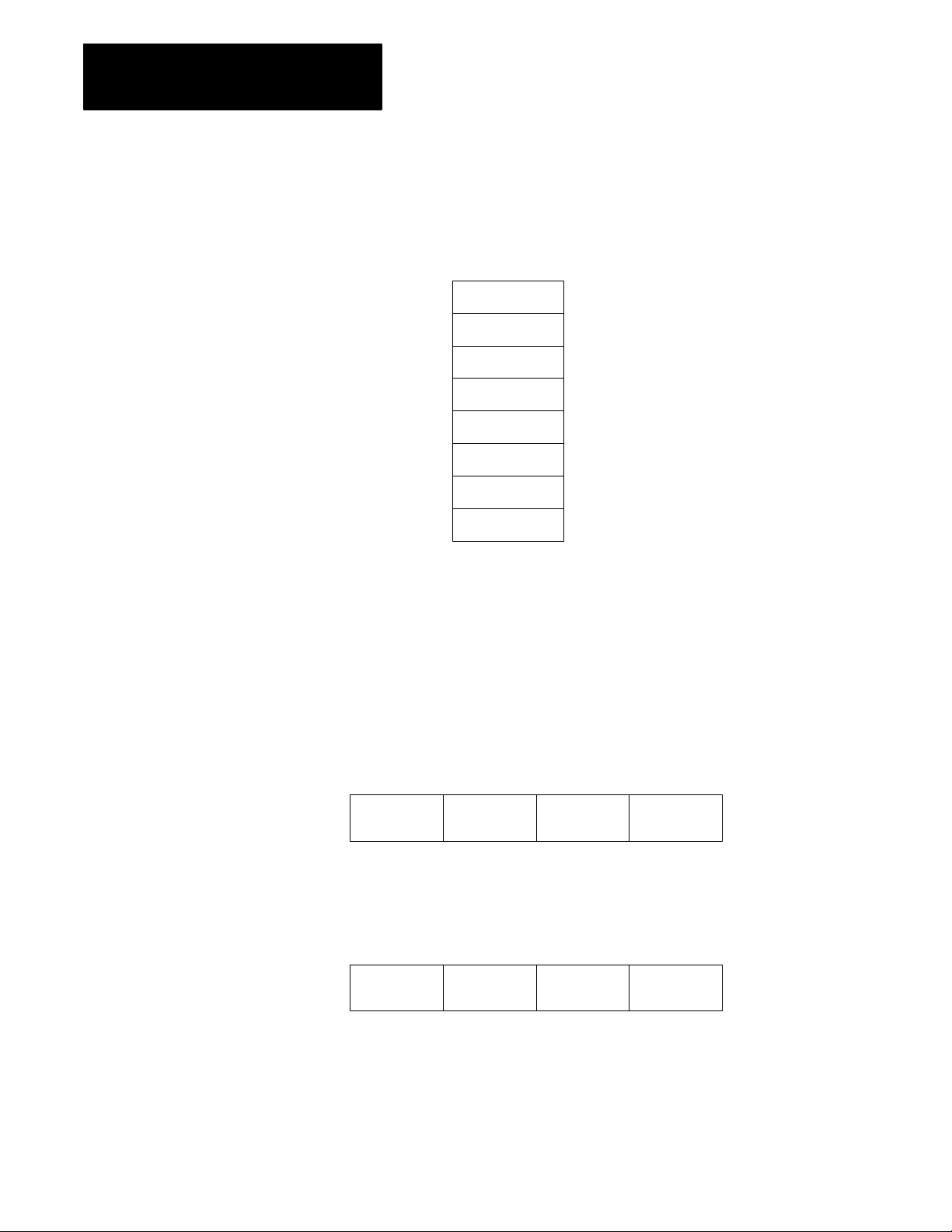

operation of these buttons is described in Table 3.A.

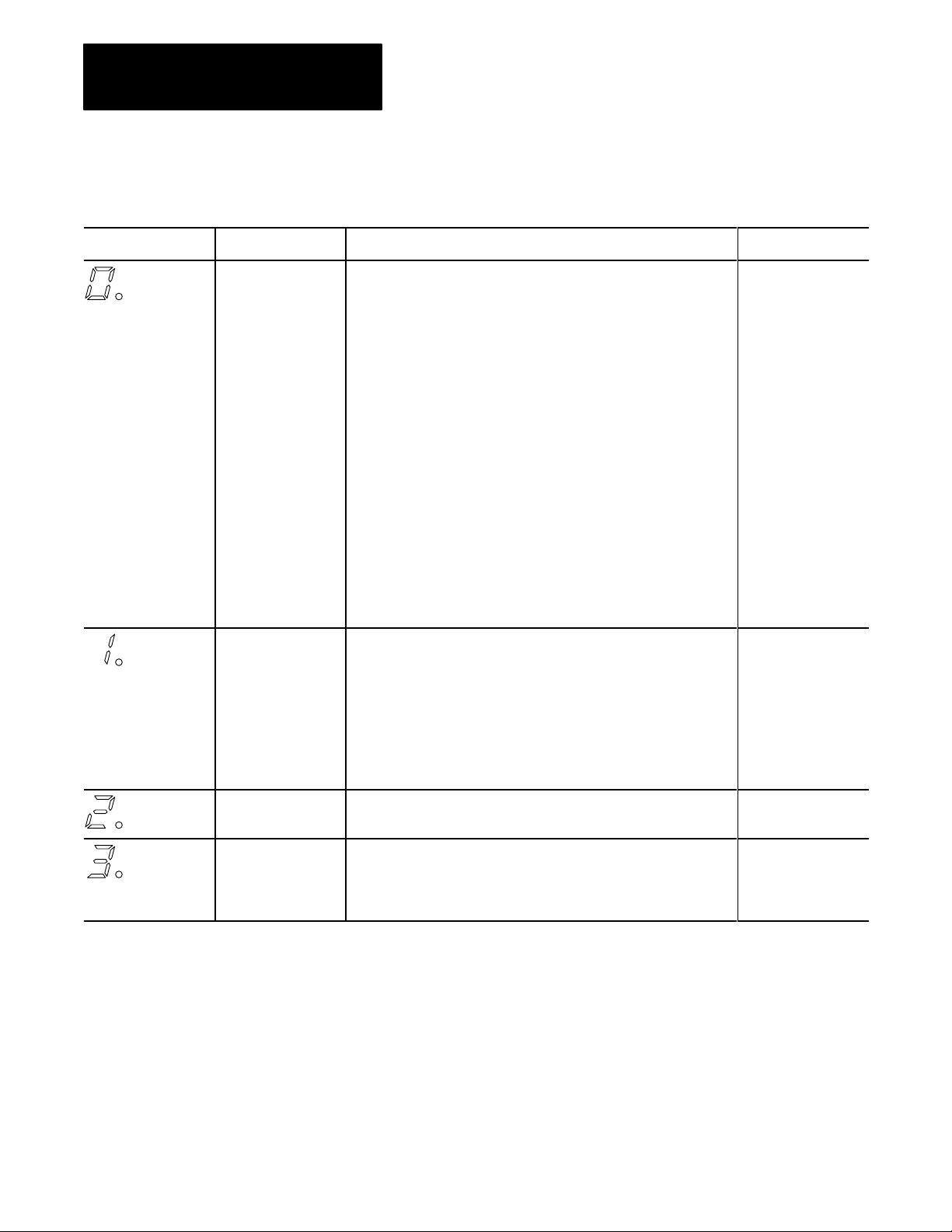

Table 3.A

Button Operation

Push

Pressing this button or

button combination:

View In run mode, takes the module into configuration mode.

Data In configuration mode, cycles through the possible

Exit In configuration mode, from the main menu, returns the module

View + Exit In configuration mode, saves all configuration changes, and

View + Data In configuration mode, resets all communication parameters

Performs this task:

Note: This is the only button that has a function in run mode.

In configuration mode, cycles through the possible

communication parameters (displayed on the left digit).

If you hold the button down for more than 1 second, the

parameter numbers will advance automatically.

communication parameters for the parameter shown on the left.

The data is displayed on the right two digits. If you hold the

button down for more than 1 second, the parameter numbers will

advance automatically.

to run mode without saving any changes. The change in mode

takes effect when the button is released.

From the submenu, returns to the main menu without saving any

changes.

returns the module to run mode from either menu. The module

will begin operating with the new configuration as soon as it

returns to run mode.

to their factory defaults (see Table 3.B). The changes do not

take effect until the configuration is saved, and the module

returns to run modethat is, until View and Exit are pushed

simultaneously.

32

Page 26

Chapter 3

Configuring the KF3

Configuration Steps

Entering Configuration Mode

1. Press the View button to enter configuration mode. The first

parameter number will be displayed on the left, with its current

setting on the right.

The KF3 continues to communicate while in configuration mode.

Changes in configuration do not affect operation until they are saved

and the module returns to run mode.

Configuring

2. Each time you press the View button, the parameter number in the

left display advances, and the parameter’s current setting appears in

the right (data) display.

Press the View button as often as necessary or hold it down until the

desired parameter is reached.

3. Once the desired parameter is displayed, press the Data button to

cycle through the available settings.

4. When you have reached the desired data setting, you can either save

the setting and exit configuration mode, or move on to configure the

next parameter.

To continue configuration, press the View button until the next

parameter you wish to change appears in the display. Use the Data

button to modify its setting.

Save and Exit

5. To save the new data and exit configuration mode, press the View

and Exit buttons simultaneously. The parameters you have changed

will be saved in nonvolatile memory. If the save is successful, each

display will show three dashes (see Figure 3.2) for a period of

two seconds. When the module returns to run mode, the new

configuration takes effect immediately, and the displays turn off.

If you press View and Exit simultaneously while in either menu, all

parameters in both menus will be saved and the module will return to

run mode.

33

Page 27

Chapter 3

Configuring the KF3

Figure 3.2

Successful

Save Display

If the save is not successful, your KF3 is malfunctioning. The left

display will show hardware fault number 6 (see Table 5.B) and the

front panel fault indicator will light. If this happens, contact your

A-B representative.

Exit Without Saving

6. Pressing only the Exit button while in the main menu takes the

module out of configuration mode and into run mode without saving

any changes. The previous settings will remain in effect.

Pressing only the Exit button while in the submenu takes the module

back to the main menu without saving any changes.

Important: If the module is left inactive (i.e., with no buttons pressed) in

configuration mode for 3 minutes, it will return to run mode. Any changes

will be lost. If the KF3 is turned off while in configuration mode, any

changes will be lost.

Setting Factory Defaults

Pressing the View and Data buttons simultaneously when in configuration

mode will reset all parameters to their factory defaults. When this button

combination is pressed, the module displays the first parameter and its

factory default. Like any other changes, the factory default parameters are

not saved until the View and Exit buttons are pressed simultaneously. If

only the Exit button is pressed, the module will return to run mode without

resetting to factory defaults.

34

Page 28

Chapter 3

Configuring the KF3

Basic Communication Parameters

For normal operation, the basic communication parameters must be

configured. For special communication needs, configure the advanced

communication parameters, which permit more flexibility in tuning the

operation of the module.

Important: The KF3 is shipped from the factory with the DH-485 Node

Address set to 00. If there is to be more than one KF3 on the network,

or if a station with this address already exists, you will have to change

this parameter setting. The default settings for the other parameters are

intended to cover most situations, and need only be changed if they do not

meet your requirements.

The basic communication parameters are divided into two groups: those

that control the link with the DH-485 network, and those that control the

RS-232C link with the computer. The parameter number is shown in the

left display, the current setting in the two right displays.

Table 3.B describes each basic communication parameter and its valid

settings. The numbers in parentheses are the factory default values as they

appear in the display.

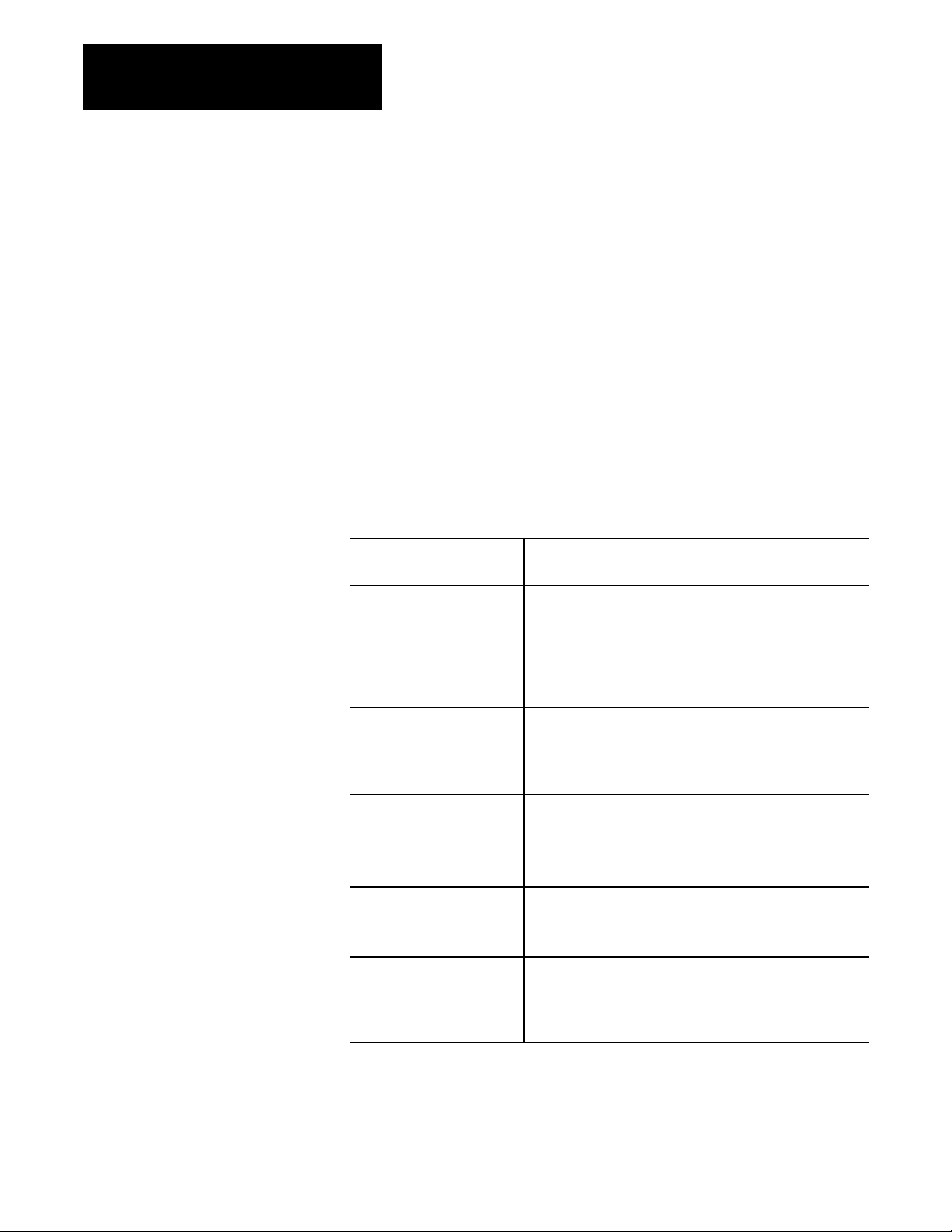

Table 3.B

Configuration Parameters

Basic

Parameter Number Parameter Description Factory Default

DH485 Parameters

DH485 Node Address The address of this node on the DH485 network. Valid station addresses

are 0031. Every station on the DH485 network must be given a unique

station address. If the KF3 detects another station with the same address,

the front panel Fault LED will flash. You should then change this station's

address to an unused one.

For optimum network performance, set your stations to consecutive

addresses, starting at 0. For example, if you have 4 stations, their

addresses should be 0, 1, 2, and 3. This minimizes the solicitation of the

new stations that is required.

DH485 Baud Rate Sets the baud rate (the speed in bits/second at which data is transferred)

of the DH485 link. Possible rates are 300 (03), 1200 (12), 2400 (24),

4800 (48), 9600 (96), 19200 (19).

Important: All stations on DH485 must be set to the same baud rate.

Diagnostic Command

Execution

Determines whether diagnostic commands are executed directly by the

KF3 (01) or whether they are passed through to the host computer (00).

(00).

9600 baud (96).

They are executed by

the KF3 (01).

35

Page 29

Chapter 3

Configuring the KF3

Table 3.B

Configuration Parameters (continued)

Basic

Parameter Number Parameter Description Factory Default

RS232C Parameters

RS232C Baud Rate Baud rate of the RS232C link between the host computer and the KF3.

The host computer and KF3 must be set to the same baud rate.

Possible rates are 300 (03), 600 (06), 1200 (12), 2400 (24), 4800 (48),

9600 (96), 19200 (19).

RS232C Parity Parity of the characters on the RS232C link. Parity can be None (00) or

Even (01). The host computer and KF3 must have the parity set to the

same value.

DF1 Device Category Sets the communication protocol to be used on the RS232C link.

Choices are DF1 fullduplex (00), DF1 halfduplex slave, local mode (01),

or DF1 halfduplex slave, remote mode (02). See Chapter 4,

Communicating with the KF3, for details.

Error Detection Two forms of error detection are available on the DF1 link: BCC Block

Check Code (00) or CRC16 Cyclic Redundancy Check (01).

The application program running on the host computer must use the same

error detection as the KF3. Refer to your application user's manual for

information on the type of error detection it is using, and set the KF3 to the

same value.

Flow Control Determines whether modem handshake lines are used for flow control:

disabled (00) or enabled (01).

Flow control is normally enabled when communicating with a modem.

Duplicate Message

Detection

Determines whether duplicate message detection is disabled (00) or

enabled (01).

When duplicate message detection is enabled, the KF3 will acknowledge

(and discard) duplicate messages.

9600 baud (96).

None (00).

Fullduplex (00).

BCC (00).

Disabled (00).

Enabled (01).

Other Parameters

36

Submenu Parameters Lets you into the submenu to set the advanced communication

parameters; the data display will show two dashes.

See the section on Advanced Communication Parameters for more

information.

Series and Revision Displays the series and revision level of the module. The first digit shows

the series (AJ), the second the revision (AJ). For example, Series A,

Revision B is displayed as AB." You cannot set this value.

N/A

N/A

Page 30

Chapter 3

Configuring the KF3

Advanced Communication Parameters

The advanced communication parameters are located in the Submenu.

When parameter 9, the Submenu entry parameter, is shown on the left

display, the Data display on the right will show dashes. Press the Data

button to enter the Submenu and display the submenu parameter numbers.

The number on the left will change from 9 to 0, and its decimal point will

light up, remaining lit as long as you are in the Submenu.

Figure 3.3

Submenu

Submenu

Indicator

Indicator

Communication

Parameter

Current

Setting

Important: Changing the default setting of these parameters can disrupt

operation of the network.

Once in the submenu, you change parameters and select parameters in

the same manner as in the main menu, using the View and Data buttons.

When the last submenu parameter is reached, press View to go back to the

first submenu parameter.

Press the Exit button alone to return to the main menu without saving

submenu changes. Press Exit and View simultaneously to save all changes

in both menus and return the module to run mode.

Table 3.C describes each advanced (submenu) communication parameter

and its valid settings. The numbers in parentheses are the factory default

values as they appear in the display.

37

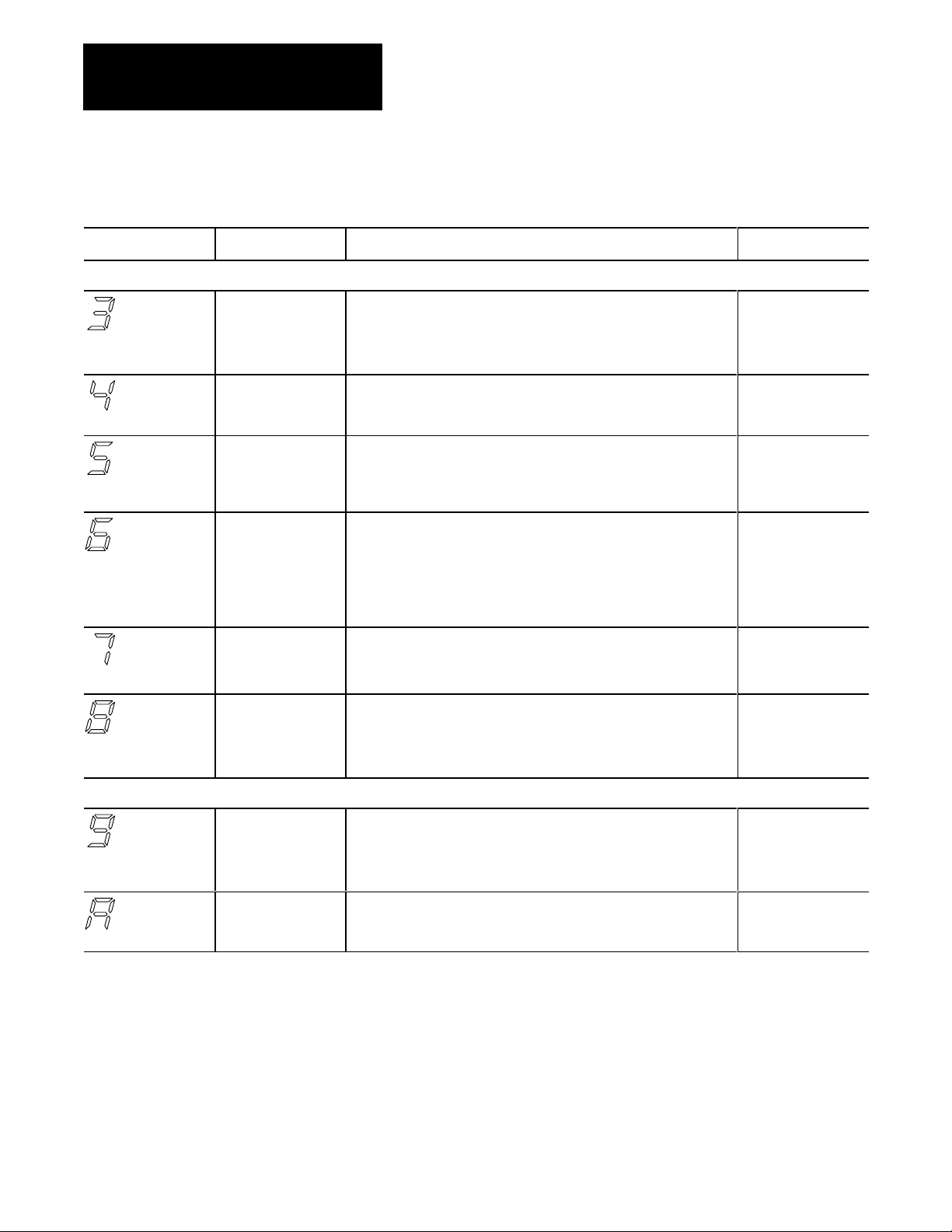

Page 31

Chapter 3

Configuring the KF3

Table 3.C

Submenu

Parameter Number Parameter Description Factory Default

Maximum Token

Holder

The node address of the highestnumbered master station on the Address

DH485 link. The valid range for Maximum Token Holder is 0131.

If all stations have consecutive addresses, this parameter should be set

to the address of the highestnumbered master station on the link. For

example: if there are 5 stations, addressed 0 to 4, this parameter should

be set to 04.

This improves the token rotation time (the time it takes for the token to

go once around the network) by limiting the station solicitation that is

required, but only when all stations have consecutive addresses

starting at zero. If gaps exist in the station addresses, setting this

parameter to the highest station address will have no effect on link

performance.

Note that setting this parameter to the highest station address will not

allow new stations above that address onto the network. Their addresses

would be above the maximum token holder address, and therefore they

would never be solicited to join. Stations with addresses higher than the

maximum token holder address value are not solicited to join the network,

but are removed from the network. If you want to add new stations, you

must reset this parameter to a higher value.

The KF3 will not allow you to set this value to less than its current station

address.

Configuration Parameters

(31).

Token Hold Factor The number of message that this station is allowed to send on the DH485

link while it has the token. The valid range is 0110.

Consider carefully before changing this parameter. Setting all stations to

a value of 01 gives all stations on the network equal access to the link,

and does not allow any one station to affect the performance of other

stations. Increasing this value for one station allows that station to hold

the token longer if it has more than one message to send. This improves

the performance of that station, but at the expense of the other stations on

the network.

Number of Retries The number of allowable retries on the RS232C link. Valid numbers are

00 (no retries per attempt) to 10 (10 retries per attempt).

DF1 ACK Timeout The time to wait for an ACK to be received from the host computer. The

timeout is from 0.1 to 5 seconds in 0.1 second increments. To calculate

the timeout, multiply the number in the display by 0.1 seconds.

For example: A setting of 14 means 14 x 0.1 = 1.4 seconds.

(01).

2 retries per attempt

(02).

1 second (10).

38

Page 32

Chapter 3

Configuring the KF3

Table 3.C

Submenu

Parameter Number Parameter Description Factory Default

CTS to Transmit Delay The delay between the CTS signal and the start of transmission by the

KF3 (halfduplex only). The delay is from 0 seconds to 0.99 seconds,

in 10 ms (0.01 second) increments. To calculate the delay, multiply the

number in the display by 0.01 seconds.

For example: A setting of 48 means 48 x 0.01 = 0.48 seconds.

This parameter is only required when communicating with the type of

radio modem that requires a delay after exerting the Clear To Send (CTS)

signal. Refer to your modem manual for information on this point.

This parameter only takes effect when the module is in HalfDuplex DF1

(local or remote) mode and handshaking is enabled. See Chapter 4,

Communicating with the KF3, for more details of local and remote modes.

End of Message to

RTS Off

The delay between the end of a message and the KF3 setting RTS

inactive (halfduplex only). The delay is from 0 seconds to 0.99 seconds,

in 10 ms (0.01 second) increments. To calculate the delay, multiply the

number in the display by 0.01 seconds.

For example: A setting of 50 means 50 x 0.01 = 0.50 seconds.

This parameter is only required when communicating with modems

that require a delay between sending the last character and raising

the Request To Send (RTS) signal. Refer to your modem manual for

information.

This parameter only takes effect when the module is in HalfDuplex DF1

(local or remote) mode, and handshaking is enabled.

Configuration Parameters

No delay (00).

No delay (00).

HalfDuplex Master

Station Address

Group Number Used in halfduplex remote mode to provide a means of addressing more

The station address of the halfduplex master device. This value is in

octal and can range from 0077 inclusive.

This parameter only takes effect when the module is in halfduplex remote

mode. See Chapter 4

remote mode.

than 32 DH485 stations from the halfduplex link. The group number can

be 0007 inclusive.

Station addresses for DH485 nodes on a multidrop link combine the

group number and the DH485 node address. This parameter only takes

effect when the module is in halfduplex remote mode. See Chapter 4,

Communicating with the KF3, for more details.

,

Communicating with the KF3, for more details of

(10 octal).

(00).

39

Page 33

Chapter 3

Configuring the KF3

Verifying Your Configuration Parameters

Before connecting the KF3 to your network, cycle through the parameter

settings. If you have properly defined your network needs, you know what

parameter settings your network requires. Compare the parameters you

need for your network to the settings in the module. If you have made

no changes to the default settings, the values shown in parentheses in the

Factory Default column of the Tables 3.B and 3.C should appear in the

displays.

When you connect the module to your network and turn it on, the displays

will cycle through the numbers 1-3 and then turn off. If your DH-485

parameters are correctly configured, the DH-485 Activity LED on the front

of the module will light up. If the Fault LED lights up instead, check your

station address, as stated in Parameter Number 0, Table 3.B. If no lights

come on, check your DH-485 Baud Rate setting (Table 3.B, Parameter

Number 1).

Once you initiate active communication on the DF1 link, the RS-232

Activity LED will light up. If this fails to happen, check your RS-232C

parameters (Table 3.B, Parameters 3-8).

If your displays show symbols other than those shown in this chapter, your

module is malfunctioning. Contact your A-B representative.

For more information on troubleshooting, see Chapter 5, Troubleshooting

the KF3.

310

Page 34

Chapter

4

Communicating with the KF3

Read this chapter if you are configuring a half-duplex network or if you

plan to write a communication driver. A thorough understanding of DF1

protocol, PLC command sets and the use of slave devices on the DH-485

communication network is required.

DF1 Communication

The KF3 supports full-duplex DF1 protocol and half-duplex DF1 slave

protocol on its RS-232C connection to a host computer. The details

of these protocols can be found in the Data Highway/Data Highway

Plus/DH-485 Protocol and Command Set Manual.

Full-duplex DF1 protocol is provided for applications where high

performance peer-to-peer communication is needed.

The KF3 provides two modes of addressing in half-duplex: local and

remote modes. You select one of these by configuring Submenu option 5 –

DF1 Device Category (see Table 3.C).

Local mode is provided for compatibility with earlier DF1 products,

such as the 1770-KF2. Some users may prefer local mode for use in

applications where the RS-232C link is not multidrop, since it simplifies

the polling algorithm.

Remote mode should be used with a half-duplex master, such as the

1771-KGM, or when SLC 500 communication is added to existing

half-duplex networks. Because the KF3 is transparent to the master

device, existing drivers can be used without rewriting.

FullDuplex DF1 Protocol

In full-duplex mode, the KF3 detects embedded responses. The module

will not send embedded responses until it receives one from the host.

The KF3 makes the assumption that if a host computer sends embedded

responses, it can also receive them.

In full-duplex mode, the destination address in a packet sent from the host

computer to the KF3 is the address of the DH-485 network node for which

the packet is intended. The source address in packets received by the host

computer from the KF3 is the node address of the sender.

41

Page 35

Chapter 4

Communicating with the KF3

HalfDuplex DF1 Protocol Local Mode

Local mode requires an intelligent master device, capable of specifying

both a station address and a destination address. Because the KF3 acts as

a slave on a DF1 half-duplex network, the half-duplex master’s access to

the DH-485 nodes is indirect: i.e., the destination address and the station

address are generally different.

In local mode, the polling algorithm used by the half-duplex master is

simplified so that the master only needs to poll the single KF3. The KF3

will respond to messages from the half-duplex master only if the station

address contained in these messages is the node address of the KF3. The

KF3 then forwards the packet to the appropriate DH-485 node, as defined

by the destination address. Responses from remote nodes on the DH-485

network will contain a destination address equal to that of the KF3, and

not that of the half-duplex master device. The KF3 will respond to poll

packets from the half-duplex master by returning whatever data has been

forwarded to it by the remote nodes under its jurisdiction.

Host

Computer

(Master)

RS232C

Cable

Figure 4.1

Mode Addressing

Local

Link Couplers

SLC 500

Controller

SLC 500

Controller

SLC 500

Controller

KF3

Node

02

Node01Node

03

DH485

Network

Node

00

In Figure 4.1, the half-duplex master running on the computer only polls

the KF3 at station address 01. Messages from the half-duplex master to

the SLC 500s are sent using a master message containing both the station

address of the KF3 (01) and the destination address of the SLC 500 (03, for

example). Responses from the SLC500s to the half-duplex master contain

the destination address of the KF3 (01), which then returns all responses to

the half-duplex master station upon being polled.

42

Page 36

Chapter 4

Communicating with the KF3

HalfDuplex DF1 Protocol Remote Mode

The valid range of slave addresses on a half-duplex network is 000-376

octal – a total of 255 stations. The valid range of addresses on a DH-485

network is 00-31 decimal. In order to make these two systems compatible,

two special submenu configuration options have been included in the KF3

(see Table 3.C).

The first, submenu option 6, must be set to the address of the half-duplex

master. This value is limited by the KF3 to a range of 00 to 77 octal (out

of a possible range of 000-376 octal). The default address is 10 octal.

The second configuration option, submenu option 7, must be set to the

group number. Group numbers range form 00 to 07, with each group

consisting of up to 32 DH-485 nodes. The KF3 uses group numbers to

create unique half-duplex DF1 addresses for each node on the DH-485

network.

In remote mode, the KF3 appears transparent to the half-duplex master, so

that remote SLC 500s can be polled directly as individual slaves on the

half-duplex network. The KF3 responds to the half-duplex master if the

station address specified corresponds to the node address of any master

(token-passing) station on the DH-485 network.

Messages from remote nodes on the DH-485 network (such as the SLC

500s) use the destination address of the KF3. To maintain its transparency

to the half-duplex master, the KF3 overwrites this destination address with

the value configured in submenu option 6. The message received by

the half-duplex master will contain a source address equal to the station

address specified in the poll packet and a destination address equal to the

address of the half-duplex master device.

Table 4.A provides the address conversion using the group number.

Remember that half-duplex DF1 (group) addresses are in octal and

DH-485 node addresses are in decimal.

43

Page 37

Chapter 4

Address

Communicating with the KF3

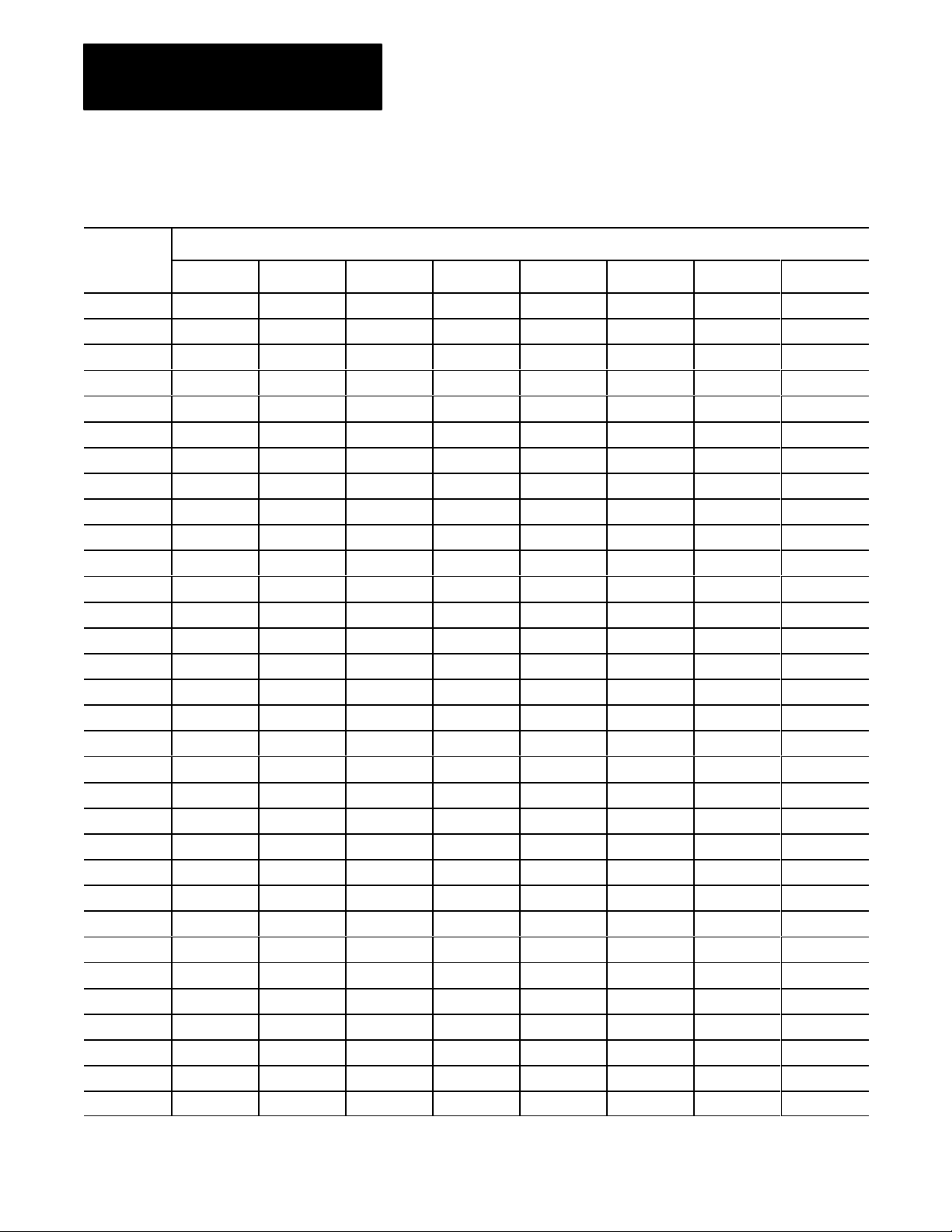

Table 4.A

HalfDuplex

DH485 Node

Address

(Decimal)

00 000 040 100 140 200 240 300 340

01 001 041 101 141 201 241 301 341

02 002 042 102 142 202 242 302 342

03 003 043 103 143 203 243 303 343

04 004 044 104 144 204 244 304 344

05 005 045 105 145 205 245 305 345

06 006 046 106 146 206 246 306 346

07 007 047 107 147 207 247 307 347

08 010 050 110 150 210 250 310 350

09 011 051 111 151 211 251 311 351

10 012 052 112 152 212 252 312 352

11 013 053 11 3 153 213 253 313 353

12 014 054 114 154 214 254 314 354

13 015 055 115 155 215 255 315 355

14 016 056 116 156 216 256 316 356

15 017 057 117 157 217 257 317 357

16 020 060 120 160 220 260 320 360

17 021 061 121 161 221 261 321 361

18 022 062 122 162 222 262 322 362

19 023 063 123 163 223 263 323 363

20 024 064 124 164 224 264 324 364

21 025 065 125 165 225 265 325 365

22 026 066 126 166 226 266 326 366

23 027 067 127 167 227 267 327 367

24 030 070 130 170 230 270 330 370

25 031 071 131 171 231 271 331 371

26 032 072 132 172 232 272 332 372

27 033 073 133 173 233 273 333 373

28 034 074 134 174 234 274 334 374

29 035 075 135 175 235 275 335 375

30 036 076 136 176 236 276 336 376

31 037 077 137 177 237 277 337 Illegal

Group 00

Group 01 Group 02 Group 03 Group 04 Group 05 Group 06 Group 07

Remote Address Conversion T

HalfDuplex DF1 Address (Octal)

able

44

Page 38

Chapter 4

Communicating with the KF3

Example: Remote Mode Addressing on a Multidrop Network

This example uses the 1771-KGM as the half-duplex master in a multidrop

configuration. Each of the KF3s is set to half-duplex remote mode, and

has the half-duplex Master Address set to the address of the 1771-KGM

(010).

Figure 4.2

Mode Addressing

Remote

PLC2/

1771KGM

010

Key:

GROUP 00

KF3

001

(01)

SLC 500

005

(05)

DH485

SLC 500

002

(02)

SLC 500

011

(09)

XXX = Address on RS232 Multidrop (octal)

(XX) = Address on local DH485 network (decimal)

DH485

Modem

ModemModem

Multidrop Network

GROUP 01

KF3

040

(00)

SLC 500

041

(01)

SLC 500

042

(02)

DH485

Modem

GROUP 02

KF3

101

(01)

SLC

500

100

(00)

SLC 500

102

(02)

SLC 500

103

(03)

SLC 500

104

(04)

45

Page 39

Chapter 4

Communicating with the KF3

The group number is used by the KF3 to create a unique half-duplex DF1

address for each node on the DH-485 networks. The nodes’ addresses

would be as follows:

Communicating with

DH485 Master Devices

Table 4.B

Multidrop

Group Number Device Address on DH485 Address on DF1

00 1770KF3

01 1770KF3

02 SLC 500

Addresses

SLC 500

SLC 500

SLC 500

SLC 500

SLC 500

1770KF3

SLC 500

SLC 500

SLC 500

01

02

05

09

00

01

02

00

01

02

03

04

HalfDuplex

001

002

005

011

040

041

042

100

101

102

103

104

The KF3 operates as a token-passing master on the DH-485 network. It

can communicate with other DH-485 master stations (such as the SLC 500

series of programmable controllers) and with DH-485 slave devices.

Communicating with

DH485 Slave Devices

46

The KF3 communicates with other master stations using the Allen-Bradley

programmable controller command set. A detailed description of this

command set is found in the Data Highway/Data Highway Plus/DH-485

Protocol and Command Set Manual.

The DH-485 network also supports slave (nontoken-passing) devices.

The KF3 communicates with slaves using a special PLC command (CMD)

byte.

Application programs communicate with slaves via SRD (Send and

Receive Data) messages on DH-485. The SRD message is a link layer

service provided on DH-485. The Programmable Controller Command Set

has been extended to provide SRD messages by setting the PCCC CMD

byte to 09.

The following section on packet formats is advanced information, not

required for common applications.

Page 40

Chapter 4

Communicating with the KF3

Slave Packet Formats

To invoke DH-485 link layer services, a special PCCC CMD byte is used

to support the addition of link-specific information to the packet. Setting

the CMD byte = 09 indicates that the packet contains extended link

information.

When the CMD byte = 09, the packet contains a “Link Type” field (one

byte), a “Link Status” field (one byte), and information specific to the

link-type command being sent.

Figure 4.3 shows the SRD request packet format.

Figure 4.3

SRD Request Packet Format

The

DLE STX DST SRC CMD09LINK

TYPE

Link Type (LTYP)

This one-byte field defines the Link Type as follows:

1 – SRD Link Request

2-255 – Reserved for future expansion

Link STS (LSTS)

This one-byte field indicates the Link Status of the SRD request. It is used

on replies to SRD requests only. When sending an SRD command, this

field should be set to zero.

00 Success. The message was successfully sent to the destination

device. Note that some slaves will return data with the success

code (ACK with Data).

01 NAK, No Memory at Destination (SRD reply). This link error

is returned when the KF3 receives a NAK, No Memory message

from the destination station in response to an SRD request.

LSTS LINK PACKET

INFORMATION

DATA... DLE ETX BCC/CRC

02 NAK, Undeliverable Message (SRD reply). This link error

is returned if the 1770-KF3 was unable to send the SRD to the

destination station (as may occur when the destination does not

exist on the network).

47

Page 41

Chapter 4

Communicating with the KF3

03 NAK, Bad LSAP (SRD reply). This link error is returned when

the KF3 receives a NAK, Bad LSAP message from the destination

station in response to an SRD request. This indicates that the

LSAP you are trying to send the SRD request to is invalid for that

destination device.

04 NAK, Unimplemented Function (SRD reply). This link error is

returned when the KF3 receives a NAK, Unimplemented Function

message from the destination station in response to an SRD

request. The most likely cause is invalid data being sent to the

destination device.

05 Invalid or Unsupported Link Type. This link error is returned

if the link type specified does not exist, or the destination of the

message is the KF3 and it does not know how to interpret it. The

KF3 currently recognizes only 01 as a valid link type. Any other

value for the link type will produce this link error.

Link Packet Information

This field contains information specific to the link request. In the case of

an SRD request, this field will contain the Destination Link Service Access

Point (DLSAP) of the SRD.

Command Format, SRD Request

The format of an SRD request command is shown in Figure 4.4:

the CMD byte must be set to 09H

the Link Type byte must be set to 01

the Link Status byte must be set to 00

the Link Packet Information must contain the DLSAP for the slave

station

The format of the data is completely dependent on how the destination

device was implemented. Refer to the destination device’s user manual for

this information.

48

Figure 4.4

Command

DLE STX DST SRC CMD09LINK TYPE

Packet Format for an SRD Request

01

LSTS

00

DATA... DLE ETX BCC/CRCDLSAP

Page 42

Chapter 4

Communicating with the KF3

Reply Format, SRD Request

The format of a reply to an SRD request is shown in Figure 4.5:

the CMD byte will have the reply bit set

the link type will be set to SRD Request

the link status will indicate success or failure

the LSAP of the slave device (SLSAP) will be included

if the request was successful, the data will be included. Note that

some devices may not return data. The format of data is completely

dependent on how the destination device was implemented. Refer to the

destination device’s user manual for this information.

DLE STX DST SRC CMD49LINK TYPE

Communicating with a

Modem

Figure 4.5

Reply Packet Format

SRD

01

LSTS DATA... DLE ETX BCC/CRCSLSAP

The handshaking option must be enabled for the KF3 to properly control a

modem.

The KF3 module continually asserts DTR when it is waiting for a call.

Under this condition, the modem will answer a call and assert DSR as

soon as it detects ringing. The KF3 does not monitor the ring indicator in

the RS-232C interface. Once it detects DSR, the module starts a timer

(approximately 10 seconds) and waits for the DCD signal. When the

module detects DCD, communication can start.

If the KF3 does not detect DCD within the 10-second timeout, the

module turns DTR off. This causes the modem to hang up and break the

connection. When the hang-up is complete, the modem turns off DSR.

This causes the module to reassert the DTR line and wait for another call.

This feature protects access to the phone if someone calling a wrong

number reaches this node.

After detecting DCD, the KF3 continues to monitor the DCD line. If DCD

goes off, the module restarts the 10-second timeout. If DCD is not restored

within the timeout, the module initiates the hang-up sequence. This feature

allows the remote node to redial in the event that the connection is lost

through a fault in the phone network.

49

Page 43

Chapter 4

Communicating with the KF3

This handshaking is necessary to guarantee access to the phone line. If the

handshaking protocol is defeated by improper selection of modem options

or by jumpers at the connectors, the modem may still answer a call. But

if the connection is lost, the modem will not hang up. It will then be

impossible for the remote node to reestablish the connection because it will

get a busy signal.

410

Page 44

Troubleshooting the KF3

Chapter

5

Interpreting the Front Panel LEDs

There are four LEDs on the front panel of the KF3. These indicators

can help you in diagnosing problems with the module’s installation and

operation.

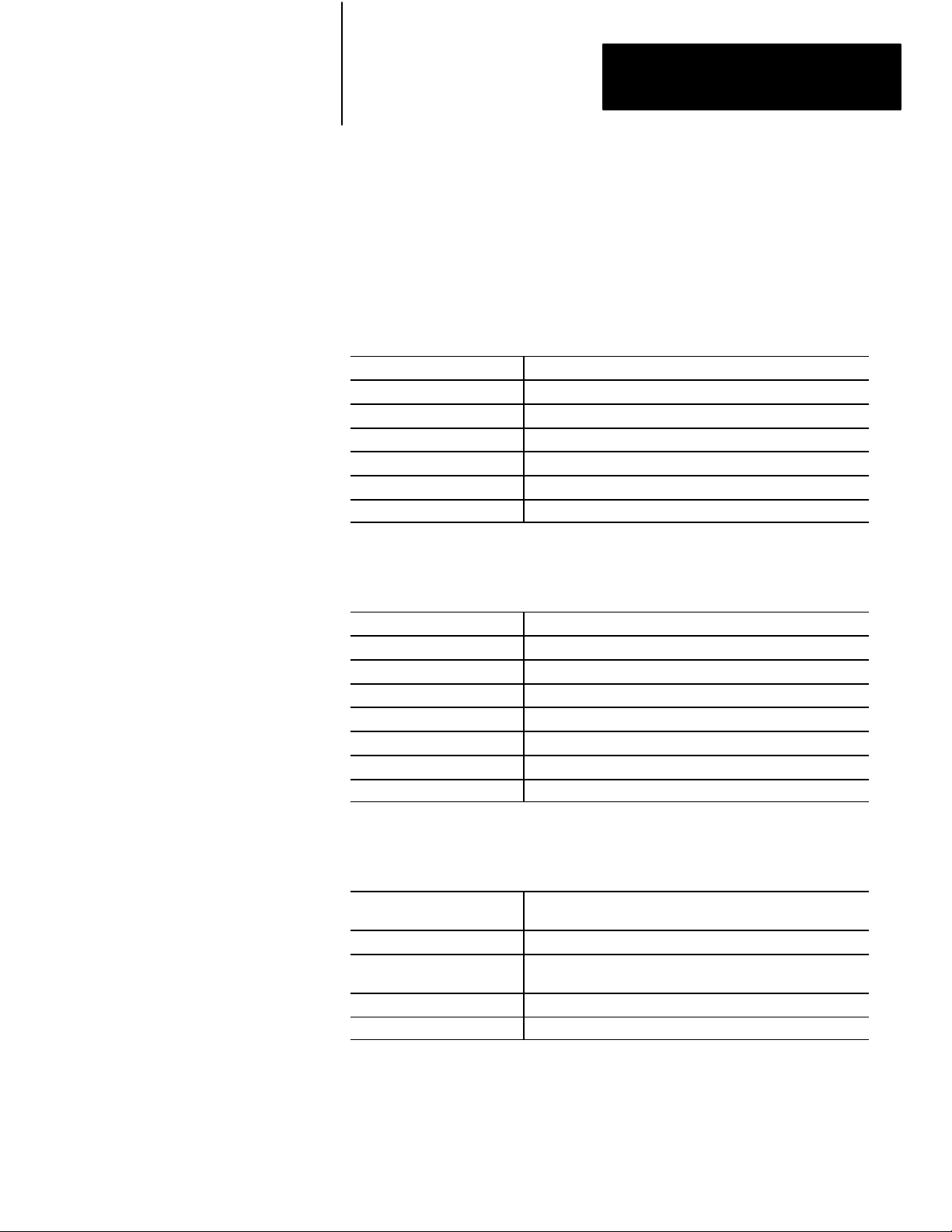

Table 5.A

LED Indicators

LED Indicator

Power This indicator is lit (green) when the module is plugged in and turned on.

Fault This indicator goes on solid red if a hardware fault is detected on power

RS232C Activity This indicator flickers green when data is received by the module from

DH485 Activity Shows activity on the DH485 network. It turns on (green) while the KF3

Description

up, or during operation. If this occurs, the type of fault is displayed on the

left numeric display on the bottom of the module. Refer to the section on

Interpreting the Numeric Displays" on page 52 for information on fault

codes.

This indicator will flash red at 1second intervals when a station with

the same address as this node is detected. To correct the fault, go into

configuration mode and change the address of one of the stations to an

unused one.

the host computer. The more activity on the RS232C link, the faster this

indicator will flash. At times of high activity, the indicator may flash so

rapidly that it appears to be solid green.

has the token, and turns off when another station on the network has

the token. It will flash slower as more stations are added to the network,

since this node will have the token less frequently. It will also slow down

if other nodes on the network are transmitting large data packets.

51

Page 45

Chapter 5

Troubleshooting the KF3

Interpreting the Numeric Displays

The numeric displays are used to indicate hardware fault conditions.

When the front panel fault indicator is lit, the left display will show a

number indicating the type of hardware fault. Table 5.B gives a

description of the faults.

Table 5.B

Hardware

This number: Indicates this fault:

Faults

Processor Fault. A hardware fault was detected in the processor. This is

a major fault requiring the module to be returned for servicing.

EPROM fault. The checksum stored in the EPROM does not match

the actual checksum for the EPROM. This indicates bad cells in the

EPROM. This is a major fault requiring the module to be returned for

servicing.

RAM Fault. The static RAM cannot be reliably written to. This is a major

fault requiring the module to be returned for servicing.

Stuck Button Detected. One or more of the push buttons are stuck on.

This could be caused by a mechanical problem with the buttons, or by

some object pressing on the push buttons. If the cause is mechanical,

the module should be returned for servicing. Otherwise, remove the

pressure from the push buttons. This should clear the fault condition.

The KF3 will continue to communicate when this fault is detected, but

configuration will not be possible.

EPROM Write Fault. The Flash EPROM could not be burned correctly

during download of new firmware. This is a major fault requiring the

module to be returned for servicing.

EEPROM Major Fault. The KF3 was unable to write the new

configuration to the EEPROM. This is a major fault requiring the module

to be returned for servicing.

EEPROM Minor Fault. On power up, the KF3 detected invalid

configuration data in the EEPROM. The KF3 was able to recover by

writing the factory default configuration to the EEPROM. You must power

the module off and back on, and then reconfigure it. This is not a major

fault, but if the problem persists, the module should be returned for

servicing.

Power Failure. The power supply voltage is below the minimum rating for

the KF3.

52

If your displays show meaningless symbols at startup, or if any values

other than the above are displayed, your module is malfunctioning.

Contact your A-B representative.

When you connect the module to your network and turn it on, the displays

will cycle through the numbers 1-3 and then turn off. If your DH-485

parameters are correctly configured, the DH-485 Activity LED on the front

of the module will light up. If the Fault LED lights up instead, check your

station address, as stated in Parameter Number 0, Table 3.B. If no lights

come on, check your DH-485 Baud Rate setting (Table 3.B, Parameter 1).

Page 46

Chapter 5

Troubleshooting the KF3

Once you initiate active communication on the DF1 link, the RS-232

Activity LED will light up. If this fails to happen, check your RS-232C

parameters (Table 3.B, Parameters 3-8).

If you are unable to save new configurations successfully, the left display

will display hardware fault 6, and the Fault LED on the front will light

up. This indicates a malfunction in the module. Contact your A-B

representative.

53

Page 47

RS232C Interface

Appendix

A

Specifications

Start bits 1

Data bits 8

Parity None, Even

Stop bits 1

Baud rates 300, 600, 1200, 2400, 4800, 9600, 19200

Connector DB25P (male)

Output RS232C

DH485 Interface

Electrical

Start bits 1

Data bits 8

Parity Even

Stop bits 1

Baud rates 300, 1200, 2400, 4800, 9600, 19200

KF3 connector 6pin, Phoenix MSTBA1.5/6GAU

Cable connector 6pin, Phoenix MSTB2.5/6STAU

Output RS485

AC input voltage 85132 VAC (RMS)

170264 VAC (RMS)

AC input frequency 4763 Hz

Fuse UL 198G and CSA C22.2, No. 59 rated,

5 mm x 20 mm, 0.1 Amp, 250V, fastacting

Connector IEC 320 power inlet

Power consumption 5 watts maximum

A1

Page 48

Appendix A

Specifications

Physical

Environmental

Dimensions 9.5" (24.1 cm) wide x 7.1" (18.0 cm) long x 2.4" (6.1 cm) high

Weight 2 lbs. (.9 kg) approx.

Operating temperature

Storage temperature

Operating humidity 5% to 95% (noncondensing)

Safety requirements UL 1950

Electromagnetic interference FCC Part 15, Subpart J, Class A

0°C to 60°C (32°F to 165°F)

40°C to 85°C (40°F to 210°F)

DOC R.I.R. SEP. 1988

A2

Page 49

Appendix

B

Diagnostic Command Support

The KF3 will interpret and respond to the following diagnostic commands:

Table B.A

Diagnostic Commands

KF3

Description Command Byte Function Code (hex)

Diagnostic Loop 06 00

Diagnostic Read Counters 06 01

Diagnostic Status 06 03

Diagnostic Loop

Reset Diagnostic Counters 06 07

Read Link Parameters 06 09

Set Link Parameters 06 0A

You can use this command to check the integrity of the transmissions over

the communication link. The command message transmits up to 243 bytes

of data to a node interface module. The receiving module should reply to

this command by transmitting the same data back to the originating node.

Figure B.1

Diagnostic

CMD

06

Figure B.2

Diagnostic

Loop Command Format

1

byte

Loop Reply Format

1 byte

STS TNS FNC

2 bytes

1 byte

00

243 bytes max

DATA

CMD

46

1

byte

1 byte

STS TNS DATA

2 bytes

243 bytes max

B1

Page 50

Appendix B

Diagnostic Command Support

Diagnostic Read

This command reads the diagnostic counters from the KF3. The format of

these counters is given below. Note that the address and size fields can

have any value (but they must be included).

Figure B.3

Diagnostic

CMD

06

Figure B.4

Diagnostic

CMD

46

Read Command Format

byte

1

1 byte

STS TNS FNC

Read Reply Format

1

byte

1 byte

STS TNS DATA

2 bytes

2 bytes

1 byte

01

2 bytes

ADDR

0000

1 byte

SIZE

00

52 bytes

B2

Page 51

Appendix B

Diagnostic Command Support

Table B.B contains the diagnostic read reply values for the KF3:

Table B.B

Diagnostic

Byte Description

0 Total DH485 packets received, low byte

1 Total DH485 packets received, high byte

2 Total DH485 packets transmitted, low byte

3 Total DH485 packets transmitted, high byte

4 Number of DH485 retries

5 Number of DH485 packets where the retry limit was exceeded

6 Number of DH485 NAK, No Memory sent

7 Number of DH485 NAK, No Memory received

8 Number of DH485 bad messages received

9 Number of DH485 line errors

10 Total RS232C packets received, low byte

11 Total RS232C packets received, high byte

12 Total RS232C packets transmitted, low byte

13 Total RS232C packets transmitted, high byte

14 Number of RS232C retries

15 Number of RS232C packets where the retry limit was exceeded

16 Number of RS232C NAKs sent

17 Number of RS232C NAKs received

18 Number of RS232C bad messages received

19 Number of RS232C line errors

2051 DH485 Active Node Table*

Read Reply V

alues