Page 1

ControlLogix

DH-485

Communication

Module

1756-DH485

User Manual

Page 2

Important User Information

SHOCK HAZARD

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application, Installation and

Maintenance of Solid State Controls (publication SGI-1.1 available from your local

Rockwell Automation sales office or online at

http://literature.rockwellautomation.com

) describes some important differences

between solid state equipment and hard-wired electromechanical devices. Because of

this difference, and also because of the wide variety of uses for solid state equipment,

all persons responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or

consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes.

Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of

information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written

permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety

considerations.

WARNING

Identifies information about practices or circumstances that can cause

an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful application and

understanding of the product.

Identifies information about practices or circumstances that can lead

to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize

the consequence

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that dangerous voltage may be present.

BURN HAZARD

Labels may be located on or inside the equipment, for example, a drive

or motor, to alert people that surfaces may be dangerous

temperatures.

The first line of trademarks is an example; the brand or product name changes according to publication but the rest of the line should remain the

same. The second line should be used exactly as listed below in any case where it applies.

Allen-Bradley, ControlLogix, and RSLinx are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Page 3

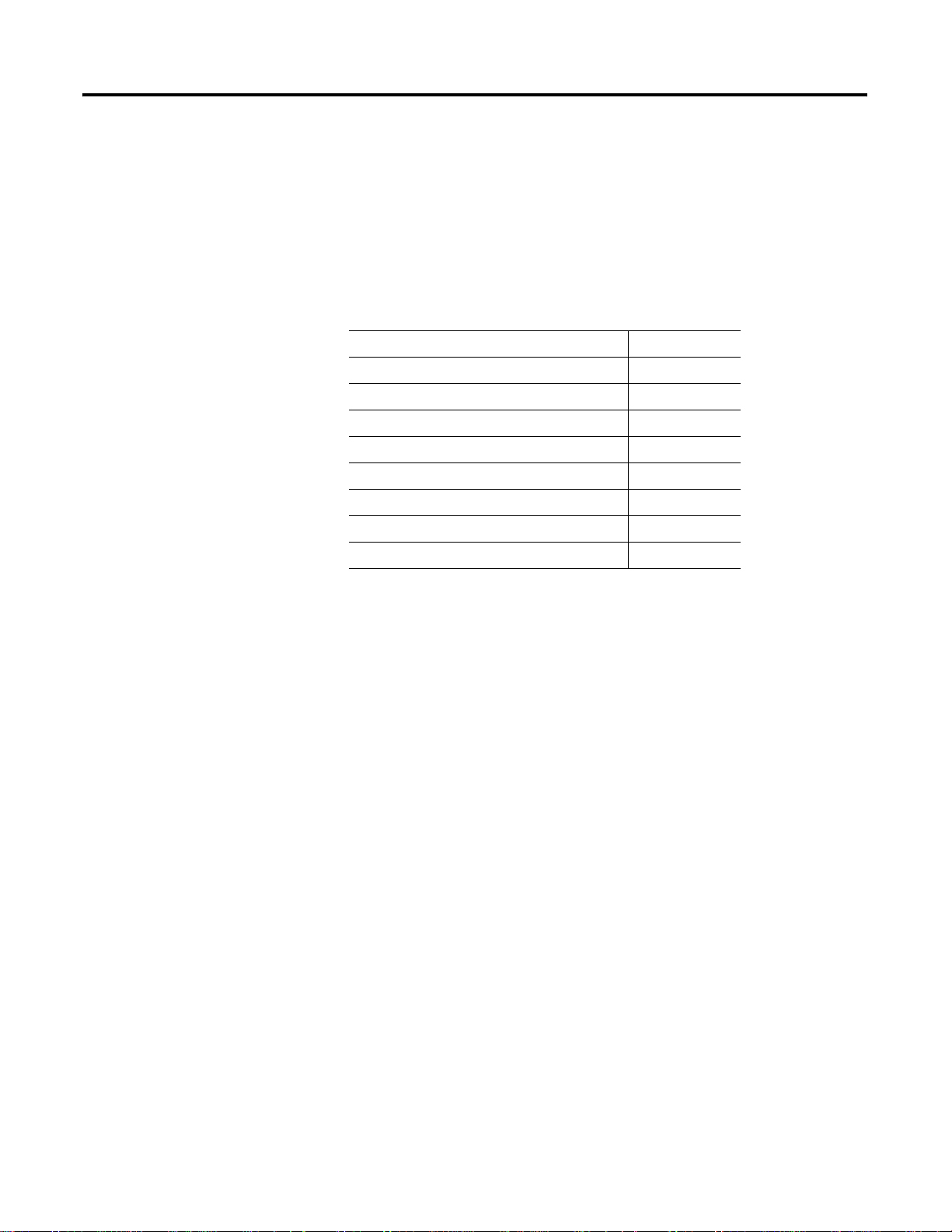

Table of Contents

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Preface

1756-DH485 Module Overview

Overview of the DH-485 Network

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-i

Who Should Use This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . Preface-i

Other Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Preface-i

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

What the Module Does . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Module Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Module Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Removal and Insertion Under Power . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Typical Applications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

Remote Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Remote Upload and Download . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Routing Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

DH-485 and CIP Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-8

Alphanumeric Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DH-485 Network Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

DH-485 Network Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

DH-485 Token Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

DH-485 Network Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Devices that Use the DH-485 Network . . . . . . . . . . . . . . . . . . . . . . . 2-3

1747-AIC Isolated Link Coupler for DH-485 . . . . . . . . . . . . . . . . . . 2-4

1761-NET-AIC Advanced Interface Converter Product Overview . 2-6

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Device Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-6

Node Address Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Misconception about the 1761-NET-AIC Converter . . . . . . . . . . . . 2-7

1747-UIC USB to DH-485 Interface Converter . . . . . . . . . . . . . . . . 2-7

Example System Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Configure the SLC 5/03, SLC 5/04, and SLC 5/05 Controller

Channel 0 for DH-485. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Important Planning Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Hardware Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-10

Software Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Additional Resources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

i Publication 1756-UM532A-EN-P - May 2006

Page 4

Table of Contents ii

Use Data Highway 485 Network

Use RSLinx Software to Create a

Routing Table

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

What Is Data Highway 485? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Link Design . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Two Methods of Communication Over a DH-485 Network . . . . . . 3-2

Use DH-485 Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Local DH-485 Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Limitations of Local DH-485 Messaging . . . . . . . . . . . . . . . . . . . 3-5

Remote DH-485 Messaging . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Configuration Information in DH-485 Messaging. . . . . . . . . . . . . . 3-11

Application Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Example DH-485 Network Routing Configuration. . . . . . . . . . . . . 3-13

Use the Common Industrial Protocol (CIP) Messaging. . . . . . . . . . 3-14

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Choose the Correct Software. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Use RSLinx Software to Create a Routing Table . . . . . . . . . . . . . . . . 4-2

What Is a Routing Table? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

ControlLogix Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Create the Routing Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-3

Set the Controller Slot . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Communicate from an SLC 5/03

Controller to a Logix Controller

over a DH-485 Network

Chapter 5

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Use the Controller Slot to Route the Local Message . . . . . . . . . . . . . 5-3

Create a Local Message in RSLogix 500 . . . . . . . . . . . . . . . . . . . . . . . 5-4

Configure the Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Create a Logic Map for the Local Message in

RSLogix 5000 Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Publication 1756-UM532A-EN-P - May 2006

Page 5

Communicate Between SLC

Controllers over DH+ and DH485

Networks

Communicate Between a PLC-5

Controller and a Remote SLC 5/03

Controller over Multiple DH-485

Networks

Table of Contents iii

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

SLC 5/04 Controller Sends a Remote Message . . . . . . . . . . . . . . . . . 6-2

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Create the Routing Table in RSLinx Software . . . . . . . . . . . . . . . 6-3

Configure the SLC 5/03 Controller Channel 1 Link ID . . . . . . . 6-4

Configure the SLC 5/04 Channel 1 Link ID . . . . . . . . . . . . . . . . 6-5

Create a Message in RSLogix 500 . . . . . . . . . . . . . . . . . . . . . . . . . 6-6

Configure the Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

SLC 5/03 Controller Sends a Remote Message . . . . . . . . . . . . . . . . . 6-8

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-8

Create the Routing Table in RSLinx Software . . . . . . . . . . . . . . . 6-9

Create a Remote Message in RSLogix 500 . . . . . . . . . . . . . . . . . 6-10

Configure the Message . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-11

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Create the Routing Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Configure the PLC-5 DH+ Channel 1A Link ID . . . . . . . . . . . . 7-4

Create a Message in RSLogix 5 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Configure the Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Communicate from an SLC 5/05

Controller to an SLC 5/03

Controller over an EtherNet/IP

Network

Communicate to a SLC 5/03

Controller on a DH-485 Network

Chapter 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Create a Message in RSLogix 500 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

Configure the Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Review the Multihop Feature in RSLogix 500 . . . . . . . . . . . . . . . . . . 8-5

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Create a Message in RSLogix 5000 . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-3

Configure the Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Publication 1756-UM532A-EN-P - May 2006

Page 6

Table of Contents iv

Communicate from a Logix

Controller to an SLC 5/03

Controller over EtherNet/IP and

DH-485 Networks

Specifications

Troubleshoot the 1756-DH485

Module

Index

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

Hardware Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-2

Create a Remote 1756-ENBT Message in RSLogix 5000 . . . . . . . . 10-3

Configure the Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-4

Appendix A

Appendix B

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Check Power Supply and Module Status . . . . . . . . . . . . . . . . . . . . . . B-1

Interpret the LED Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Interpret the Alphanumeric Indicators . . . . . . . . . . . . . . . . . . . . . . . . B-3

Interpret the OK

Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Routing Errors in DH-485 Messaging . . . . . . . . . . . . . . . . . . . . . . . . B-4

Routing Errors in Local DH-485 Messaging . . . . . . . . . . . . . . . . B-4

Routing Errors in Remote DH-485 Messaging . . . . . . . . . . . . . . B-5

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . . . Backcover

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . Backcover

New Product Satisfaction Return . . . . . . . . . . . . . . . . . . . Backcover

Publication 1756-UM532A-EN-P - May 2006

Page 7

Preface

Purpose of This Manual

Who Should Use This Manual

Other Resources

This manual describes how to understand, configure, and troubleshoot your

ControlLogix Data Highway 485 communication interface module.

This manual also provides step-by-step procedures on how to use the

1756-DH485 module to send DH-485 messages between ControlLogix, PLC,

and SLC controllers in DH-485 applications.

Use this manual if you program applications that use 1756-DH485 modules.

We assume you have a good understanding of the Data Highway 485 protocol.

This user manual contains a brief description of the Data Highway 485

network in Chapter 2, Overview of the DH-485 Network.

Refer to the manuals listed in the table Devices that Use the DH-485 Network

on page 2-3.

i Publication 1756-UM532A-EN-P - May 2006

Page 8

Preface ii

Notes:

Publication 1756-UM532A-EN-P - May 2006

Page 9

1756-DH485 Module Overview

Chapter

1

Introduction

What the Module Does

This chapter describes the 1756-DH485 module, and what you must know and

do before you begin to use it.

For See

What the Module Does 1-1

Module Requirements 1-1

Module Features 1-2

Prevent Electrostatic Discharge 1-3

Removal and Insertion Under Power 1-4

Typical Applications 1-5

Remote Messaging 1-7

Routing Limitations 1-8

The 1756-DH485 module supports the following types of communication:

• Data Highway 485 (DH-485) Messaging

• Connectivity to two separate DH-485 networks in one module

• Common Industrial Protocol (CIP) Messaging

Module Requirements

1 Publication 1756-UM532A-EN-P - May 2006

The following are required for using the 1756-DH485 communication

module:

• RSLinx Software, version 2.41 or later

• Node address within the range of 0-31

• AIC+ link coupler (1761-NET-AIC) communications adapter

• Compatible with SLC 5/03 controllers or later

Page 10

1-2 1756-DH485 Module Overview

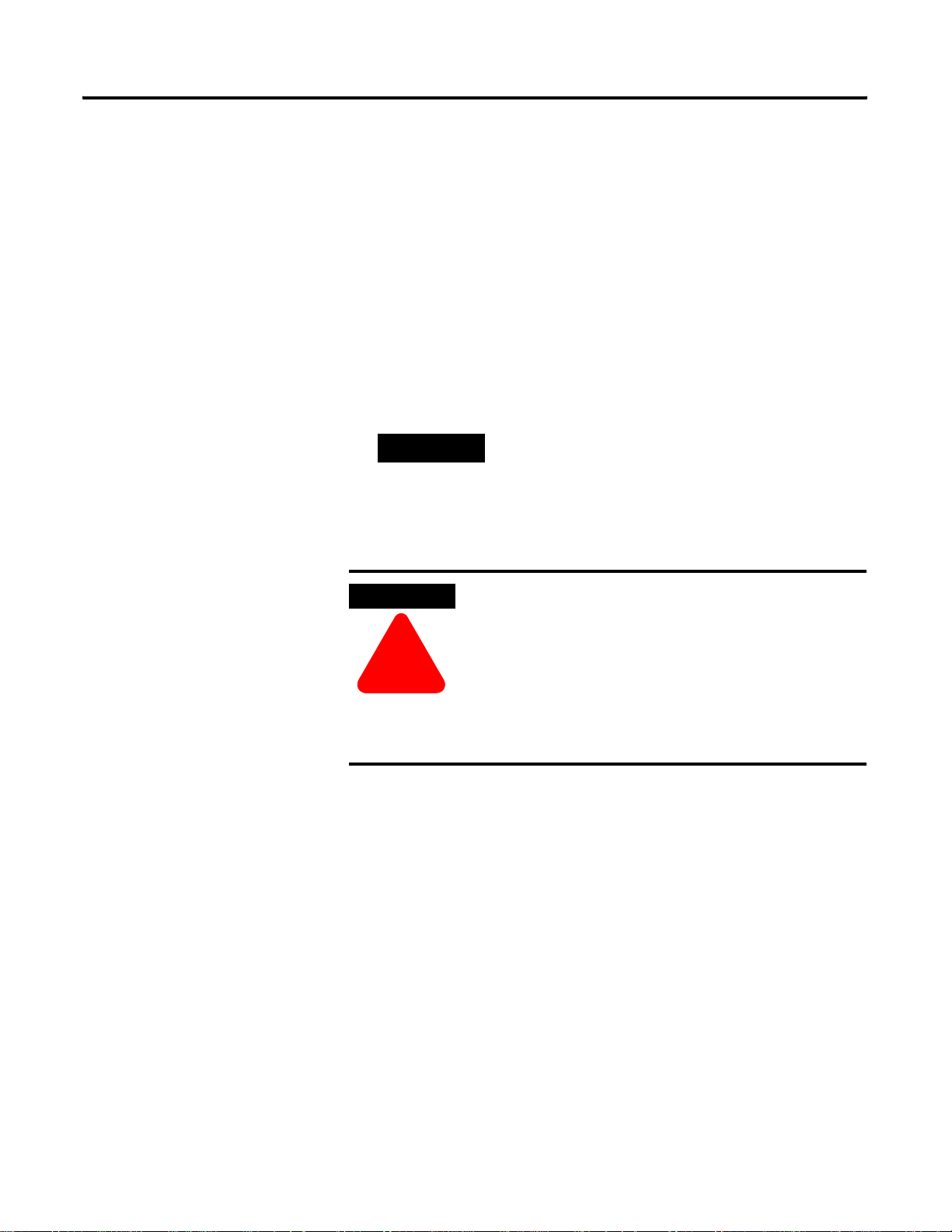

WARNING

Module Features

The 1756-DH-485 module offers the following features:

• Sends messages between devices on DH-485 networks and devices on

other networks such as ControlNet, EtherNet/IP, or other DH-485

networks

• Bridges support to other NetLinx networks via the CLX gateway

• Configure channels and ports using RSLinx Classic software, version

2.43 or later

• Accesses other networks by using a routing table editor that lets

DH-485 devices use the 1756-DH485 module and ControlLogix chassis

• Supports all benefits and attributes of a ControlLogix communication

module

• Supports firmware upgrades

TIP

• Removal and insertion under power (RIUP), can be removed and

inserted under power without disrupting power to other modules in the

chassis

Download firmware upgrades via the backplane. Do

not use DH485 network for downloads.

When you insert or remove the module while backplane

power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

!

• 4-character display

• Default Controller Slot feature for local messaging

• Serial Port Configuration

• No limit on number of modules per chassis, up to the number of

available slots and the capabilities of the power supply

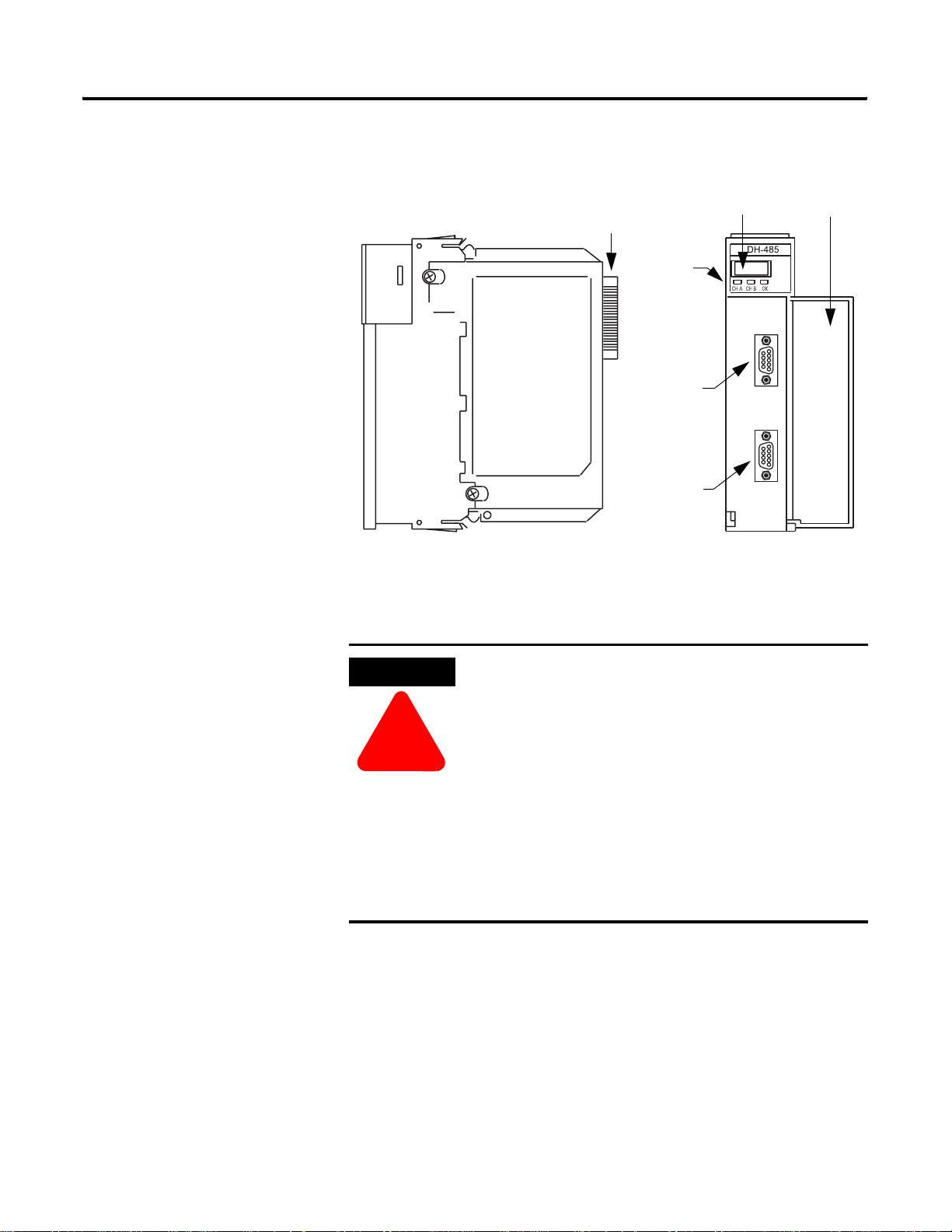

This figure shows the external features of the 1756-DH485 module.

before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical

resistance that can affect module operation.

Publication 1756-UM532A-EN-P - May 2006

Page 11

External Features of the 1756-DH485 Module

1756-DH485 Module Overview 1-3

Prevent Electrostatic

Backplane

Connector

Channel

and

Module

Status

Indicators

Channel A

Connector

Channel B

Connector

Alphanumeric

Status Indicator

The DH-485 module is sensitive to electrostatic discharge.

Door

Label

43842

Discharge

ATTENTION

!

This equipment is sensitive to electrostatic discharge, which

can cause internal damage and affect normal operation.

Follow these guidelines when you handle this equipment:

• Touch a grounded object to discharge potential static.

• Wear an approved grounding wriststrap.

• Do not touch connectors or pins on component

boards.

• Do not touch circuit components inside the equipment.

• Use a static-safe workstation, if available.

• Store the equipment in appropriate static-safe

packaging when not in use,.

Publication 1756-UM532A-EN-P - May 2006

Page 12

1-4 1756-DH485 Module Overview

WARNING

Removal and Insertion Under Power

You can install or remove the module while chassis power is applied if you

observe the following precautions.

When you insert or remove the module while backplane

power is on, an electrical arc can occur. This could cause an

explosion in hazardous location installations.

Be sure that power is removed or the area is nonhazardous

!

before proceeding. Repeated electrical arcing causes

excessive wear to contacts on both the module and its

mating connector. Worn contacts may create electrical

resistance that can affect module operation.

Publication 1756-UM532A-EN-P - May 2006

Page 13

1756-DH485 Module Overview 1-5

Typical Applications

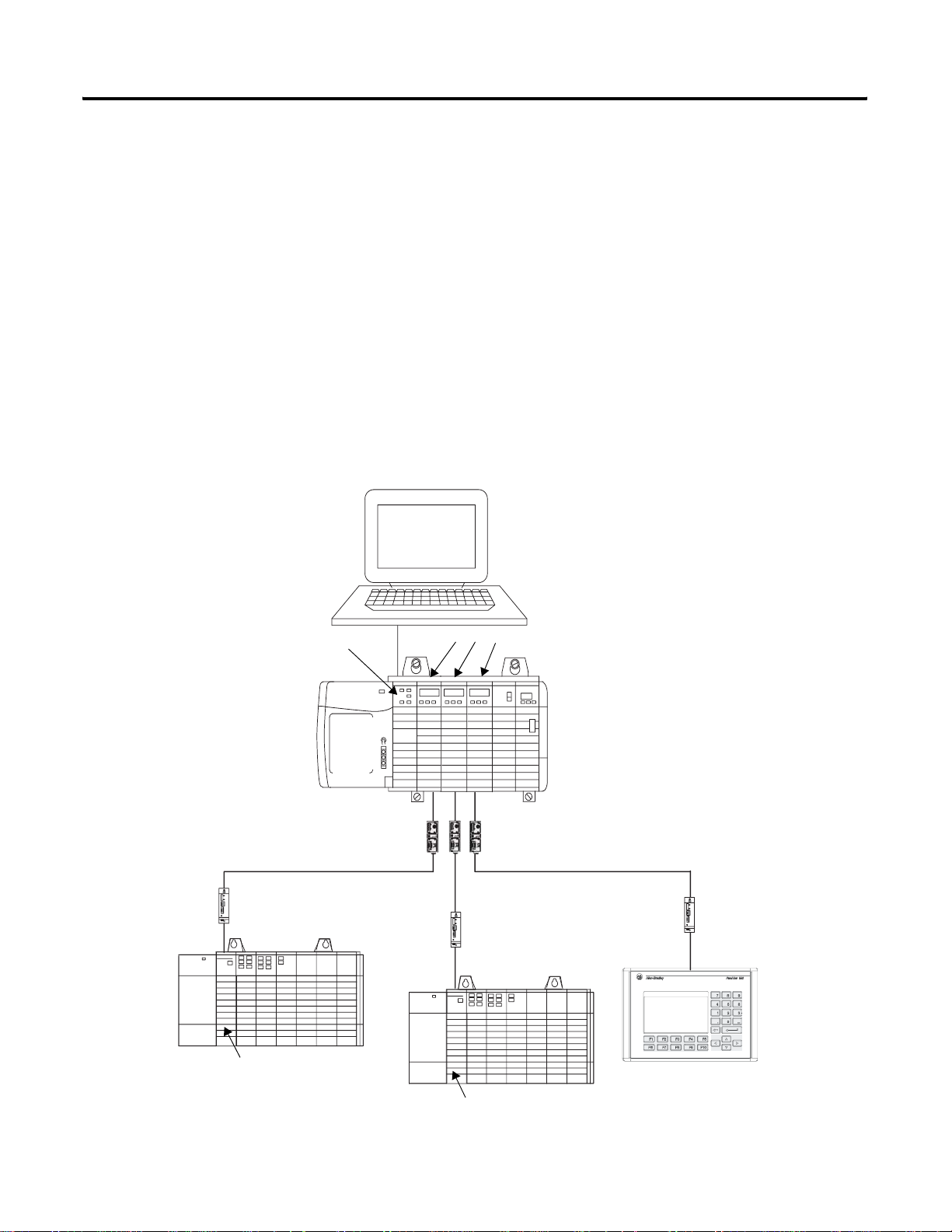

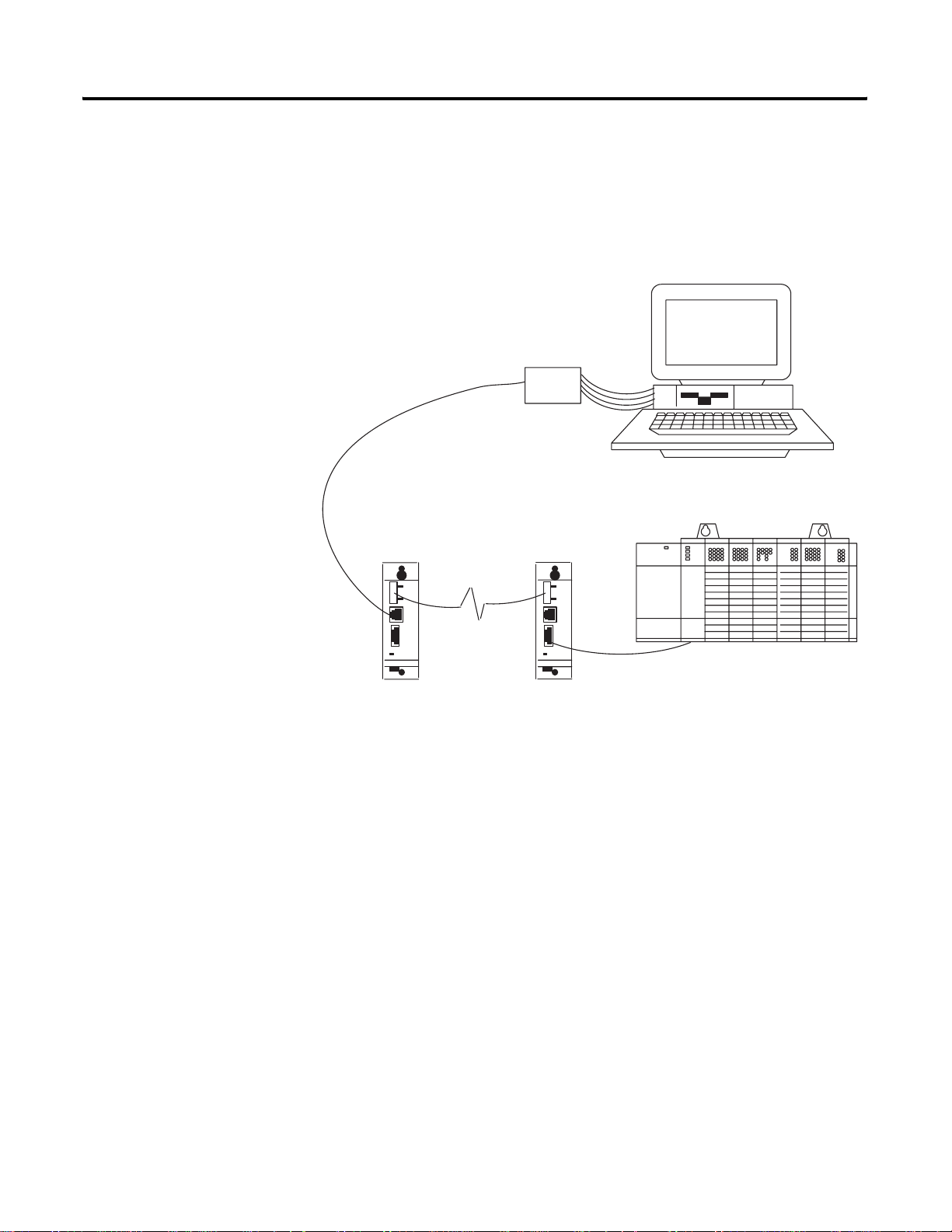

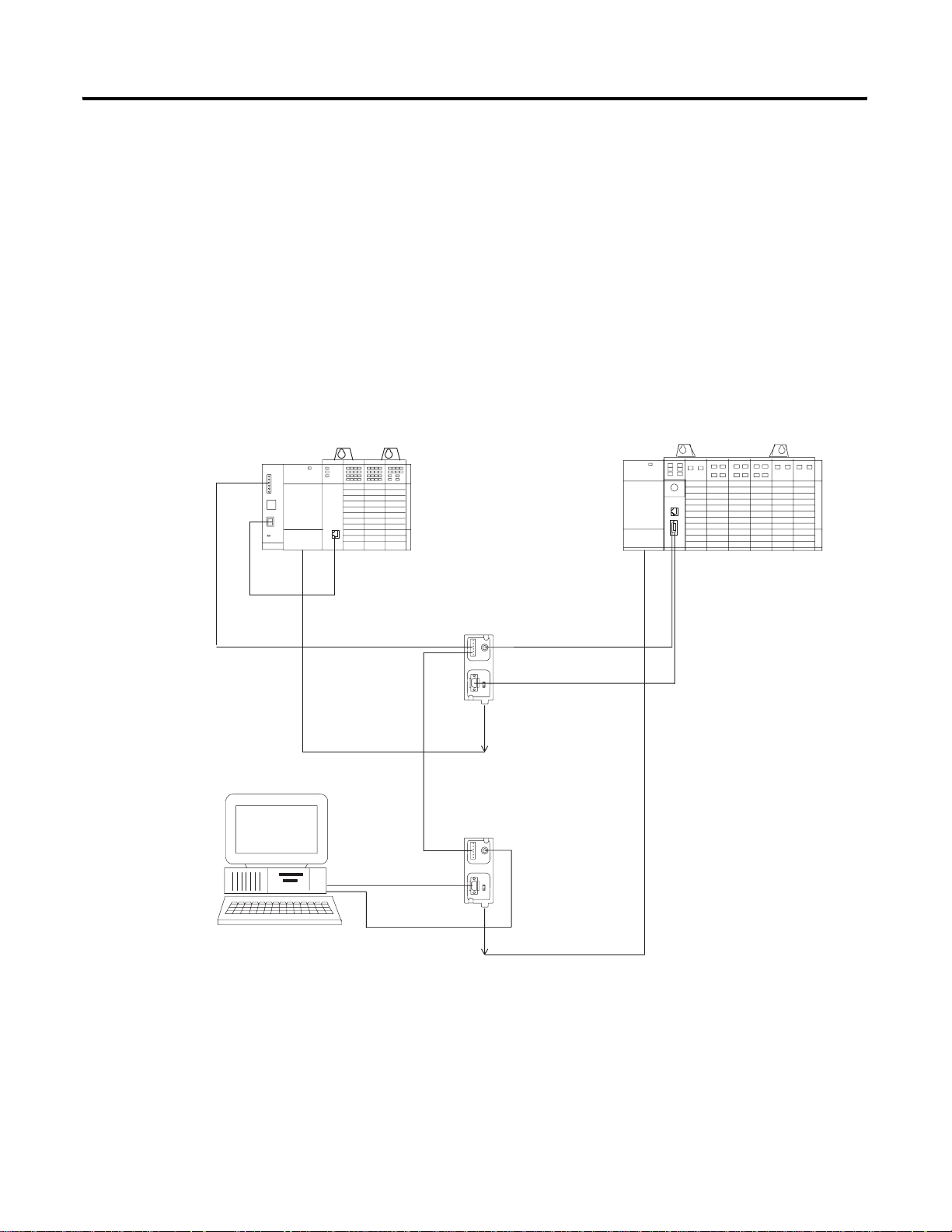

The first example is a typical gateway application connecting multiple networks

together.

In this example you can:

• upload and download SLC 500 and Panelview display programs.

• seamlessly communicate between SLC controllers.

• connect multiple DH-485 networks together for inter-network

communications, for example, messages between SLC 5/03 controllers.

• provide connection to other NetLinx networks, such as EtherNet/IP, to

allow a single-point access, for example: upload and download to an

SLC controller, MicroLogix controller, and Panelview display.

Connection of Multiple Networks

Computer with RSlogix 500

and RSLogix 5000 Software

1756-ENBT

AIC Link Coupler

SLC 5/03 Controller

1756-DH485

AIC+ Link Couplers

AIC Link Coupler

SLC 5/03 Controller

PanelView

AIC Link Coupler

44137

Publication 1756-UM532A-EN-P - May 2006

Page 14

1-6 1756-DH485 Module Overview

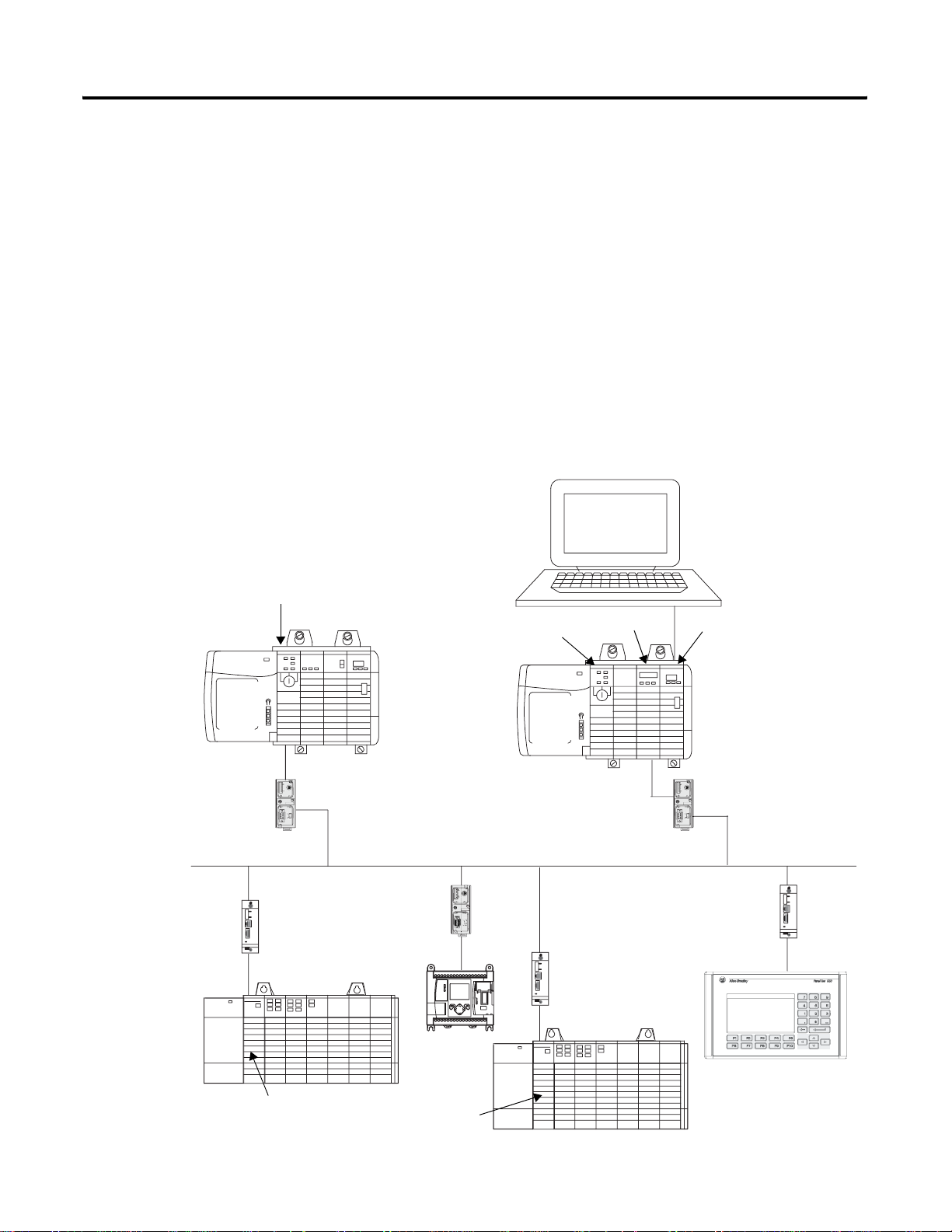

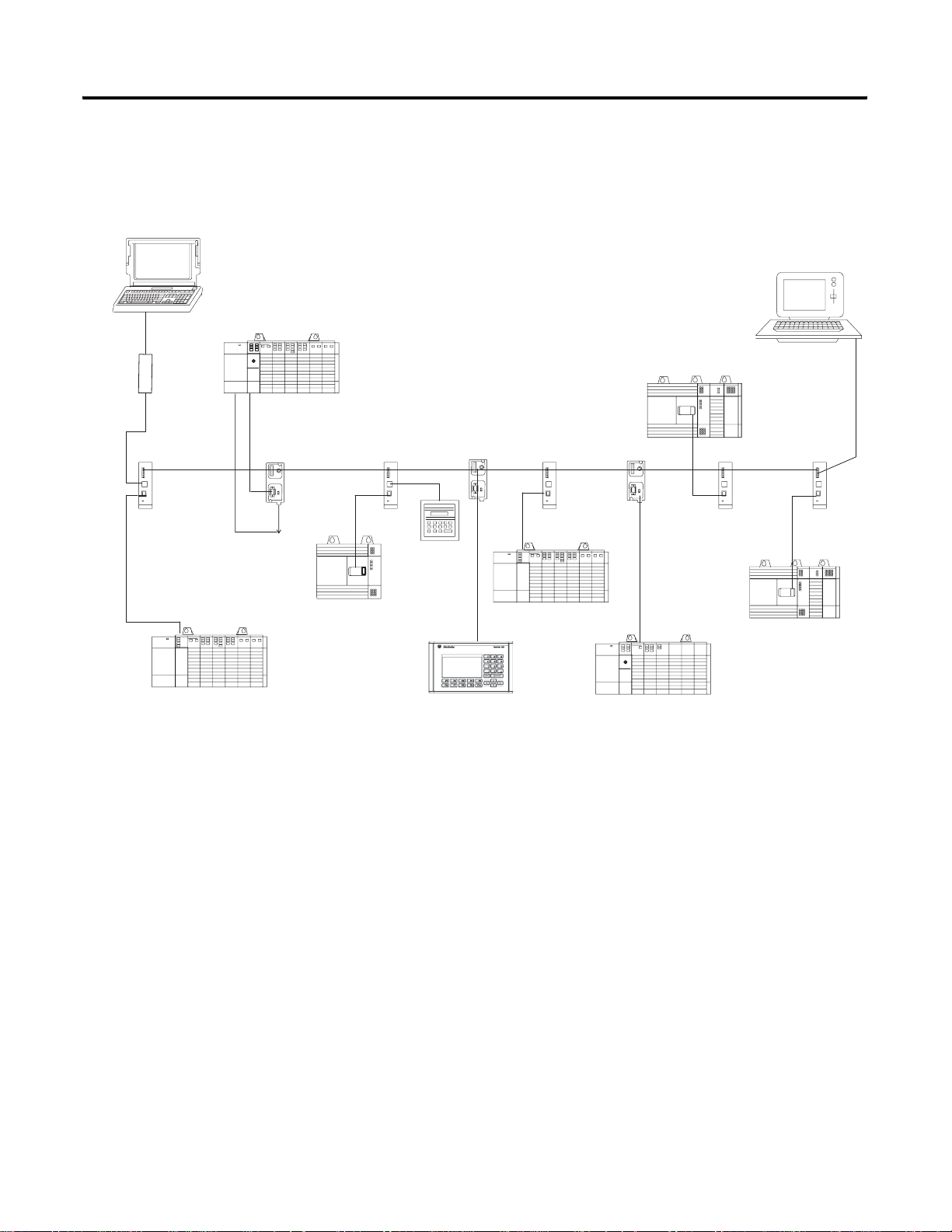

The second example shows how you can connect or migrate a legacy system to

a new installation with RSLogix software.

• Connect multiple DH-485 networks together for inter-network

communications.

• Message between SLC 5/03 controllers.

• Provide connection to other NetLinx networks.

• Access through a single point and download to an SLC controller,

MicroLogix controller, and Panelview display.

• Allow communications between legacy and ControlLogix systems for

high integration of control systems (except for fixed SLC controllers).

• Phase SLC systems into ControlLogix architecture by using a migration

tool.

Connect or Migrate a Legacy System to a New Installation

Computer with RSlogix 500

and RSLogix 5000 Software

ControlLogix Controller

AIC+ Link Coupler

AIC Link Coupler

AIC+

MicroLogix

ControlLogix Controller

DH485 Network

AIC Link Coupler

1756-DH485

1756-ENBT Module

AIC+ Link Coupler

AIC Link Coupler

SLC 5/03 Controller

Publication 1756-UM532A-EN-P - May 2006

SLC 5/03 Controller

PanelView Display

44136

Page 15

1756-DH485 Module Overview 1-7

Remote Messaging

The configuration of remote messaging is similar to data highway remote I/O

(DHRIO). It is achieved through routing table functions and module

configuration. The multi-hop functionality is available in RSLogix 5 and 500

(version 6.3 or later)

Remote Upload and Download

You can bridge EtherNet/IP and ControlNet networks to a DH-485 network

using the 1756-DH485 module

You can upload and download:

• all MicroLogix and SLC 500 controllers on DH-485 from NetLinx

network by using RSLinx Classic software.

• PanelView Standard terminals on DH-485 from NetLinx network by

using RSLinx Classic.

Logix controllers message via a NetLinx network through a ControlLogix

gateway to the DH-485 network to all MicroLogix and SLC 5/03 (and above)

controllers on DH-485 network. RSLinx Classic software on the DH-485

network can browse through the ControlLogix gateway to any device on a

NetLinx network.

IMPORTANT

Logix controllers on a NetLinx network will not be able to

initiate messages through the ControlLogix gateway to the

DH-485 network to fixed SLC 500, SLC 5/01, or SLC

5/02 controllers on a DH-485 network.

Publication 1756-UM532A-EN-P - May 2006

Page 16

1-8 1756-DH485 Module Overview

Routing Limitations

Data Collection and

Recipe Management

The 1756-DH485 module can route a message through up to four

communications networks and three chassis. This limit applies only to the

routing of a message and not to the total number of networks or chassis in a

system.

DH-485 and CIP Messaging

The 1756-DH485 module lets devices, such as ControlLogix, PLC, and SLC

controllers exchange information. With the 1756-DH485 module, you may

exchange information between the ControlLogix, PLC, or SLC controllers on

different networks. Communication between SLC controllers on different

networks is accomplished using remote messaging.

Communication Between SLC Controllers on Differen t Networks

RSView

Programming Terminal

EtherNet/IP Network

DH-485

SLC 5/03

PanelView

ControlLogix

Chassis

MicroLogix

SLC 5/03

DH-485

ControlLogix

Chassis

PanelView

44056

Publication 1756-UM532A-EN-P - May 2006

Page 17

1756-DH485 Module Overview 1-9

Alphanumeric Indicators

When you apply power to the module, the alphanumeric display begins to

cycle through the following sequence.

1. All LEDs flash on then off -CHA, CHB OK

2. OK displays red then changes to green.

3. INIT displays.

4. Firmware Revision flashes on scrolling display: DH-485

5. Channel A and the network used for channel A.

6. Channel A node address.

7. Channel A status.

8. Channel B and the network used for channel.

9. Channel B node address.

10. Channel B status.

This sequence runs continuously during normal module operation.

EXAMPLE

For example, if your module uses the following:

• Channel A for DH-485 with node address 14

• Channel B is not connected

and the channels are operating properly, you see the

following sequence:

A DH, A#14, A OK, B DH, B#00, ONLY NODE

Refer to Appendix B, Troubleshoot the 1756-DH485 Module and publication

1756-IN587, the ControlLogix DH-485 Communications Module Installation

Instructions, for more information about LEDs and status indicators.

Publication 1756-UM532A-EN-P - May 2006

Page 18

1-10 1756-DH485 Module Overview

Notes:

Publication 1756-UM532A-EN-P - May 2006

Page 19

Overview of the DH-485 Network

Chapter

2

Introduction

The information in this chapter will help you plan, install, and operate devices

on a DH-485 network. This chapter also contains information that describes

the DH-485 network functions, network architecture, and performance

characteristics.

For See

DH-485 Network Description 2-1

DH-485 Network Protocol 2-2

DH-485 Token Rotation 2-2

DH-485 Network Initialization 2-2

Devices that Use the DH-485 Network 2-3

1747-AIC Isolated Link Coupler for DH-485 2-4

1761-NET- AIC Advanced Interface Converter Product Overview 2-6

Operating Modes 2-6

Device Compatibility 2-6

1747-UIC USB to DH-485 Interface Converter 2-7

Example System Configuration 2-8

Important Planning Considerations 2-10

Additional Resources 2-13

DH-485 Network Description

1 Publication 1756-UM532A-EN-P - May 2006

The DH-485 network passes information between devices on the plant floor.

The network monitors process parameters, device parameters, device status,

process status, and application programs to support data acquisition, data

monitoring, program upload/download, and supervisory control.

The DH-485 network offers:

• interconnection of 32 devices.

• multi-master capability.

• token passing access control.

• the ability to add or remove nodes without disrupting the network.

(1)

• maximum network length of 1219 m (4000 ft)

(1) The network can be extended to 2,438 meters (8,000 feet) by connecting two AIC+ Advanced Interface

Converters (1761-NET-AIC). Refer to the AIC+ Advanced Interface Converter User Manual, publication number

1761-6.4.

.

Page 20

2-2 Overview of the DH-485 Network

T

The protocol used to control message transfers on the DH-485 network

supports two classes of devices: initiators and responders. All initiators on the

network get a chance to initiate message transfers. To determine which

initiator has the right to transmit, a token passing algorithm is used.

DH-485 Network Protocol

DH-485 Token Rotation

A node holding the token is able to transmit a configurable number of

message packets (plus two retries) onto the network before having to pass the

token on to the next node. This configuration parameter is called the Token

Hold Factor and has a minimum value of one and a maximum value of four.

Once a node holding the token has sent any messages that it has to send, up to

its Token Hold Factor maximum allowed, it attempts to pass the token to its

successor by sending a token-pass packet.

If no network activity occurs, the initiator sends the token-pass packet again.

After two retries (a total of three tries) the initiator will attempt to find a new

successor.

IMPORTAN

The allowable range of the node address of an initiator is 0 to 31. The

allowable address range for all responders is 1 to 31. There must be at least one

initiator on the network.

The maximum address that the initiator will search for

before wrapping to zero is the value in the configurable

parameter maximum node address. The default value for

this parameter is 31 for all initiators and responders.

DH-485 Network Initialization

Publication 1756-UM532A-EN-P - May 2006

Network initialization begins when a period of inactivity exceeding the time of

a link dead timeout is detected by an initiator on the network. When the time

for a link dead timeout is exceeded, usually the initiator with the lowest address

claims the token. When an initiator has the token it will begin to build the

network. The network requires at least one initiator to initialize it.

Building a network begins when the initiator that claimed the token tries to

pass the token to the successor node. If the attempt to pass the token fails, or

if the initiator has no established successor (for example, when it powers up), it

begins a linear search for a successor starting with the node above it in the

addressing.

When the initiator finds another active initiator, it passes the token to that

node, which repeats the process until the token is passed all the way around

the network to the first node. At this point, the network is in a state of normal

operation.

Page 21

Overview of the DH-485 Network 2-3

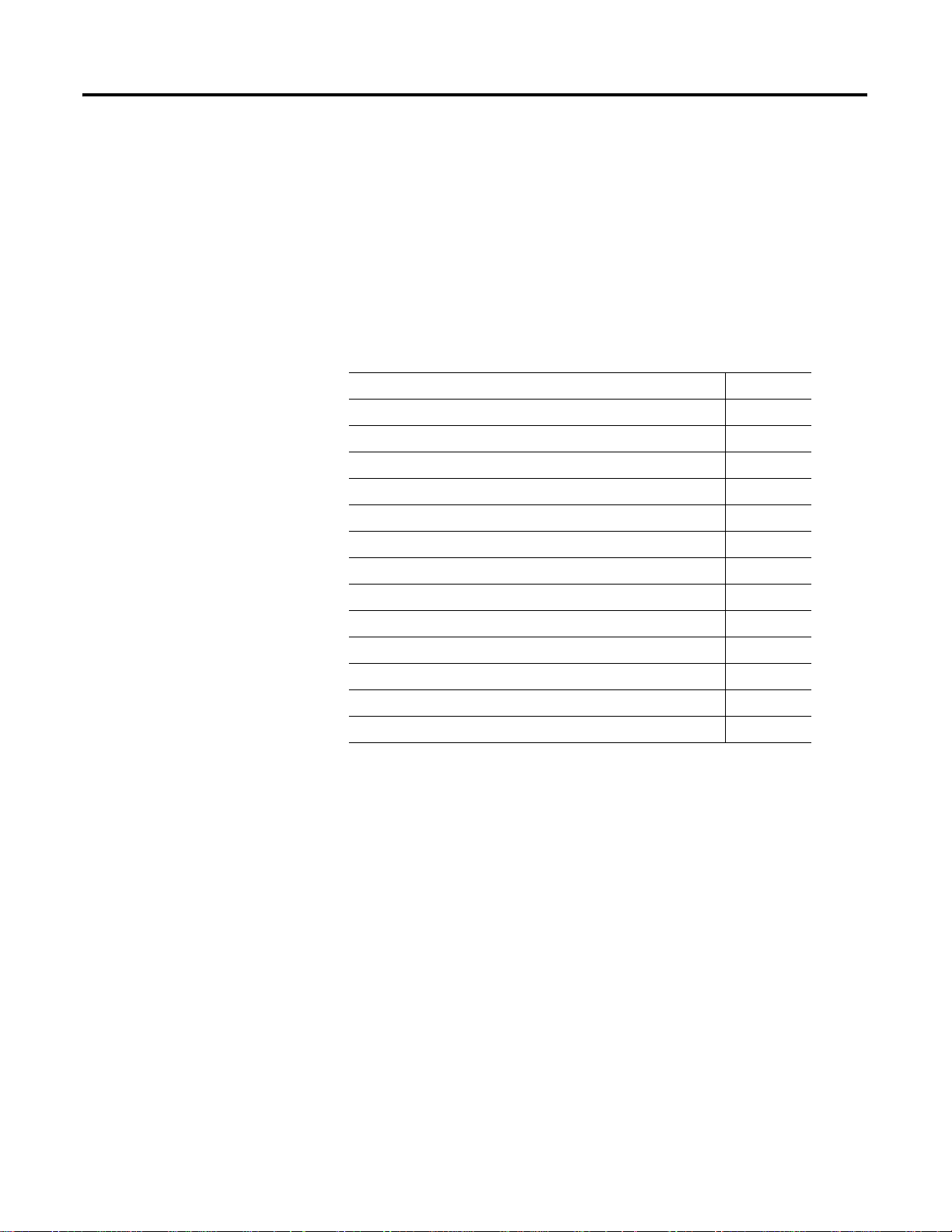

Devices that Use the

Presently, the following SLC 500 devices support the DH-485 network:

DH-485 Network

Devices that Use the DH-485 Network

Catalog Number Description Installation

Requirement

1756-DH485 ControlLogix DH485

Communication

Module

1747-Lxxx SLC 500

Programmable

Controllers

1747-KE DH-485/DF1

Interface Module

1747-UIC USB to DH-485

Interface Converter

1747-AIC Isolated Link Coupler Standalone Provided connection to SLC 500 family devices to the

ControlLogix

Chassis

SLC Chassis Programmable controllers. 1747-UM011

SLC Chassis Provides a non-isolated DH-485 interface for

Standalone Provides connection to personal computer’ s USB port

Function Publication

Bridge DH485 messages in ControlLogix. 1756-UM532

SLC 500 devices to host computers over RS-232

using full- or DF1 half-duplex protocol. Enables

remote programming to an SLC 500 controller or the

DH-485 network through modems. Ideal for low cost

RTU/SCADA applications.

and features an RS-232 and an RS-485 port for

connection to SLC 500 controllers.

DH-485 network. The coupler provides a 6-position

removable terminal block for connection to the

DH-485 communication cable.

1747-IN006

1747-IN063

1747-UM011

1761-NET-AIC Advanced Interface

Converter

1770-KF3

1785-KA5 DH+/DH-485

1785-KA5P Standalone

1784-KTX, 1784-KTXD PC DH-485 Interface

1784-PCMK PCMCIA Interface

1761-L

1762-L

1763-L

1764-L

1756-L

1769-L

1794-L

(1)

DH-485/DF1

Interface Module

Gateway

Card

Card

MicroLogix

Programmable

Controllers

Logix Programmable

Controllers

Standalone Provides a communication link between various

Standalone, or

desktop

(1771) PLC

Chassis

ISA Bus Provides DH-485 or DH+ connection. 1784-6.5.22

PCMCIA slot in

computer

Standalone Programmable Controllers 1761-UM003

1756 Chassis or

DIN Rail

1761-UM004

networks devices.

Provides an isolated DH-485 interface for SLC 500

devices to host computers over RS-232 using full- or

DF1 half-duplex protocol. Enables remote

programming to an SLC 500 controller or the DH-485

network through modems.

Provides communication between stations on the

PLC-5 (DH+) and SLC 500 (DH-485) networks. Lets

communication and data transfer from PLC to SLC

500 on DH-485 network. Also enables software

programming or data acquisition across DH+ to

DH-485.

Provides DH-485 or DH+ connection. 1784-6.5.19

Programmable Controllers 1756-UM001

1770-6.5.18

1785-6.5.5

1785-1.21

1762-UM001

1763-UM001

1764-UM001

1769-UM011

1794-UM001

Publication 1756-UM532A-EN-P - May 2006

Page 22

2-4 Overview of the DH-485 Network

Devices that Use the DH-485 Network

Catalog Number Description Installation

Requirement

2707-L8P1

2707-L8P2

2707-L40P1

2707-L40P2

2707-V40P1

2707-V40P2

2707-V40P2N

2707-M232P3

2707-M485P3

2711-K5A2,

2711-B5A2,

2711-K5A5,

2711-B5A5,

2711-K5A1,

2711-B5A1,

2711-K9A2,

2711-T9A2,

2711-K9A5,

2711-T9A5,

2711-K9A1, and

2711-T9A1

(1)

,

(1)

,

(1)

,

(1)

,

(1)

,

(1)

,

(1)

(1)

(1)

,

, and

DTAM Plus and

DTAM Micro

Operator

Interfaces

PanelView 550 and

PanelView 900

Operator Terminals

(1)

Panel Mount Provides electronic operator interface for SLC 500

Panel Mount Provides electronic operator interface for SLC 500

Function Publication

2707-800,

controllers.

controllers.

2707-803

2711-UM014DF

1784-PKTX,

1784-PKTXD

(1) This product is no longer available for order.

PC DH-485 Interface

Card

1747-AIC Isolated Link Coupler for DH-485

PCI Bus Provides DH-485 or DH+ connection 1784-6.5.27

Use the isolated link coupler (1747-AIC) to connect SLC 500 family devices to

the DH-485 network (as shown on page 2-5). The coupler provides a

6-position removable terminal block for connection to the DH-485

communication cable.

To establish network connections for:

• SLC 500 controllers (SLC 5/03 and below), use a 304.8 mm (12 in.)

cable, supplied with the link coupler (catalog number 1747-C11).

If you need to connect a peripheral device that is between 1.8 m (6 ft) and 6.1

m (20 ft) away, use the 1747-C20 cable.

To protect connected devices, the coupler provides 1500V dc isolation

between the communications cable and the attached SLC 500 controller and

peripheral devices.

Publication 1756-UM532A-EN-P - May 2006

Page 23

Overview of the DH-485 Network 2-5

You can also use the isolated link coupler to provide connectivity between

devices for distances greater than 1.8 m (6 ft) up to a maximum of 1219 m

(4000 ft). Below is an example of a remote connection between a computer

running your programming software and an SLC 500 controller.

Remote Connection Between a Computer Running Programming Software and an

SLC 500 Controller

RSLogix 500

Software

1747-UIC

UIC

1747-C13

1747-AIC

+24V dc

1747-AIC

>1.8m (6 ft)

1747-C11

Publication 1756-UM532A-EN-P - May 2006

Page 24

2-6 Overview of the DH-485 Network

1761-NET-AIC Advanced Interface Converter Product Overview

Operating Modes

The AIC+ advanced interface converter provides a communication link

between various networks devices. Ports 1, 2, and 3 are used for making the

communication connections. The AIC+ is compatible with a variety of SLC

and MicroLogix controllers and the 1756-DH485 communications module.

The MicroLogix controllers provide power to the AIC+ via port 2’s cable.

However, if a controller is not connected to port 2, a 24V dc power supply

connected to the converter’s external power terminals is required. The DC

power source selector switch needs to be set for your particular configuration.

The baud rate selector switch is used to match the baud rate filter of the AIC+

to the network baud rate. This switch does not change the network baud rate

and is normally left in the AUTO position. In high noise environments, the

baud rate selector switch should be taken out of the AUTO mode and set to

the same baud rate as the network.

The AIC+ can be used in the following modes for DH-485:

• point-to-point RS-232 isolator

• RS-232 to RS-485 isolator

Communication is established using hardware handshaking or auto transmit

signals.

Device Compatibility

The AIC+ can be used to interconnect the following devices:

• SLC 500, 5/01, 5/02, and 5/03 controllers (channel 1)

• SLC 5/03, 5/04, and 5/05 controllers (channel 0)

• MicroLogix controllers

• Logix Controllers

• Operator interface devices

• PC serial ports (or any 9-pin DTE serial port)

• Logix controller serial port (DH485 mode)

• 1756-DH485 module

TIP

The 1761-HHP-B30 Hand-Held Programmer is not

connectable to the AIC+ advanced interface converter.

Publication 1756-UM532A-EN-P - May 2006

Page 25

Node Address Identification

Overview of the DH-485 Network 2-7

Misconception about the 1761-NET-AIC Converter

There is no node

address associated

with the network port

(Port 3).

1 Node Address

Port

(The node address

is configured in the

device connected to

Port 1.)

Port 2 Node Address

(The node address is

configured

connected to Port 2.)

Use this write-on area

to mark the node address

of each connection.

in the device

The function of the 1761-NET-AIC converter is to accomplish two tasks. The

first is to convert RS232 electrical signals to RS485 electrical signals and RS485

electrical signals to RS232 electrical signals.

The second function is to provide electrical isolation between all three

communication ports. This protects against ground loops and voltage

differences between devices connected to the 1761-NET-AIC converter.

1747-UIC USB to DH-485 Interface Converter

A common misconception is that the 1761-NET-AIC device converts

protocol, this is not true, it passes the protocol but converts the electrical

signals. An example device that would convert protocol and electrical signal is

the 1747-KE module.

Refer to the Isolation Interface Converter (AIC+) User Manual, publication

1761-UM004 for complete information.

The 1747-UIC lets you connect DH-485 devices directly to a computer’s USB

port. It features an RS-232 port for connection to SLC 5/03 and higher

controllers, MicroLogix, PanelView 300 and higher terminals,

1761-NET-AIC+, and Logix controllers, as well as an RS-485 port for

connection to SLC 5/03 and lower controllers, PanelView 300 and higher

terminals, and 1747-AIC. The converter can communicate with devices on the

DH-485 network at 19.2K baud.

Publication 1756-UM532A-EN-P - May 2006

Page 26

2-8 Overview of the DH-485 Network

Example System Configuration

Personal Computer

SLC 5/03, 5/04, or 5/05

1747-UIC

Interface

Converter

1747-AIC

Isolated

Link

Coupler

Modular Controller

1761-NET-AIC

Advanced Interface

Converter

SLC 500 20-Point

Fixed Controller

Below is an example of a DH-485 network.

Example DH-485 Network System Configuration

DH-485 Network

max. length 1219 m (4,000 ft)

1747-AIC

Data Table

Access

Module

SLC 5/01 Modular Controller

1747-AIC

SLC 500 20-Point Fixed

Controller with 2-Slot

Expansion Chassis

1747-AIC

1761-NET-AIC

SLC 500 Fixed Controller

Personal Computer

1747-AIC

SLC 5/02 Modular Controller

PanelView

ControlLogix Controller and 1756-DH485

Communications Module

44138

Publication 1756-UM532A-EN-P - May 2006

Page 27

Overview of the DH-485 Network 2-9

Configure the SLC 5/03, SLC 5/04, and SLC 5/05 Controller Channel 0 for DH-485

The RS-232 port (channel 0) of the SLC 5/03, SLC 5/04, and SLC 5/05

controllers can be configured for DH-485 protocol. You can connect channel

0 of the SLC 5/03, SLC 5/04, and SLC 5/05 controllers to a DH-485 network

using the 1747-CP3 cable and a 1761-NET-AIC Advanced Interface

Converter (AIC+). In this case, the AIC+ must be powered with 24V dc. The

1746-P1, -P2, -P4, -P5, and -P6 power supplies provide 24V dc user power

that may be used to power the AIC+

Configure an SLC Controller for DH-485.

DH-485

1747-AIC

Personal Computer

APS

SLC 5/01

1747-C11

DH-485

SLC 5/03, 5/04, or 5/05

24V dc Power

Supply

1761-NET-AIC

1761-CBL-PM02 or

1747-CP3

RS-232

24V dc User Power

Connection

1761-NET-AIC

1747-CP3 or

1761-CBL-PM02

24V dc User Power Connection

Publication 1756-UM532A-EN-P - May 2006

Page 28

2-10 Overview of the DH-485 Network

Important Planning Considerations

Carefully plan your network configuration before installing any hardware.

Listed below are some of the factors that can affect system performance:

• Amount of electrical noise, temperature, and humidity in the network

environment

• Number of devices on the network

• Connection and grounding quality in installation

• Amount of communication traffic on the network

• Type of process being controlled

• Network configuration

The major hardware and software issues you need to resolve before installing a

network are discussed in the following sections.

Hardware Considerations

You need to decide the length of the communication cable, where you will

route it, and how to protect it from the environment where it will be installed.

Before you install the communication cable, you need to know how many

devices are to be connected during installation and how many devices will be

added in the future. The following sections will help you understand and plan

the network.

Number of Devices and Length of Communication Cable

You must install a link coupler communications adapter (1747-AIC or

1761-NET-AIC) for each node on the network. If you plan to add nodes later,

provide additional link couplers during the initial installation to avoid recabling

after the network is in operation.

The maximum length of the communication cable is 1219 m (4000 ft). This is

the total cable distance from the first node to the last node on the network.

Publication 1756-UM532A-EN-P - May 2006

Page 29

Overview of the DH-485 Network 2-11

Plan Cable Routes

Follow these guidelines to help protect the communication cable from

electrical interference:

• Keep the communication cable at least 1.52 m (5 ft) from any electric

motors, transformers, rectifiers, generators, arc welders, induction

furnaces, or sources of microwave radiation.

• If you must run the cable across power feed lines, run the cable at right

angles to the lines.

• If you do not run the cable through a contiguous metallic wireway or

conduit, keep the communication cable at least 0.15 m (6 in.) from ac

power lines of less than 20A, 0.30 m (1 ft) from lines greater than 20A,

but only up to 100k VA, and 0.60 m (2 ft) from lines of 100k VA or

more.

• If you run the cable through a contiguous metallic wireway or conduit,

keep the communication cable at least 0.08 m (3 in.) from ac power lines

of less than 20A, 0.15 m (6 in.) from lines greater than 20A, but only up

to 100k VA, and 0.30 m (1 ft) from lines of 100k VA or more.

Running the communication cable through conduit provides extra

protection from physical damage and electrical interference. If you route

the cable through conduit, follow these additional recommendations:

– Use ferromagnetic conduit near critical sources of electrical

interference. You can use aluminum conduit in non-critical areas.

– Use plastic connectors to couple between aluminum and

ferromagnetic conduit. Make an electrical connection around the

plastic connector (use pipe clamps and the heavy gauge wire or wire

braid) to hold both sections at the same potential.

– Ground the entire length of conduit by attaching it to the building

earth ground.

– Do not let the conduit touch the plug on the cable.

– Arrange the cables loosely within the conduit. The conduit should

contain only serial communication cables.

– Install the conduit so that it meets all applicable codes and

environmental specifications.

For more information on planning cable routes, see Industrial Automation

Wiring and Grounding Guidelines, Publication Number 1770-4.1.

Publication 1756-UM532A-EN-P - May 2006

Page 30

2-12 Overview of the DH-485 Network

Software Considerations

Software considerations include the configuration of the network and the

parameters that can be set to the specific requirements of the network. The

following are major configuration factors that have a significant effect on

network performance:

• Number of nodes on the network

• Addresses of those nodes

• Baud rate

• Maximum node address selection

• SLC 5/03, SLC 5/04, and SLC 5/05 controllers only: token hold factor

• Maximum number of communicating devices

The following sections explain network considerations and describe ways to

select parameters for optimum network performance (speed).

Number of Nodes

The number of nodes on the network directly affects the data transfer time

between nodes. Unnecessary nodes (such as a second programming terminal

that is not being used) slow the data transfer rate. The maximum number of

nodes on the network is 32.

Set Node Addresses

The best network performance occurs when node addresses start at 0 and are

assigned in sequential order. Controllers cannot be node 0. Also, initiators such

as personal computers should be assigned the lowest numbered addresses to

minimize the time required to initialize the network.

Set Controller Baud Rate

The best network performance occurs at the highest baud rate. All devices

must be at the same baud rate.

Publication 1756-UM532A-EN-P - May 2006

Page 31

Overview of the DH-485 Network 2-13

T

Maximum Node Address Setting

The maximum node address parameter should be set as low as possible. This

minimizes the amount of time used in soliciting successors when initializing

the network. If all nodes are addressed in sequence from 0, and the maximum

node address is equal to the address of the highest addressed node, the token

rotation will improve by the amount of time required to transmit a solicit

successor packet plus the slot timeout value.

You cannot add any nodes to the network without affecting the response time.

On the other hand, since the time required to hold an open station address is

greater than the time required to pass a token, it can be useful to leave a

temporary device (such as a personal computer) connected if there is only one

such device. A solicit successor packet requires the same transmission time as

the token pass, but there is an added slot timeout period.

See your programming software user manual for the procedures to set node

addresses, controller baud rate, and maximum node addresses.

Additional Resources

IMPORTAN

The SLC 500 Series A (only) controllers set the maximum

node address to 31 when power is cycled increasing

initialization and response time of the network.

Maximum Number of Communicating Devices

SLC 500 fixed and SLC 5/01 controllers can be selected by two initiators

maximum at the same time. Using more than two initiators to select the same

SLC 500 fixed and SLC 5/01 controllers at the same time can cause

communication timeouts.

Refer to the manuals listed in the table Devices that Use the DH-485 Network

on page 2-3.

Publication 1756-UM532A-EN-P - May 2006

Page 32

2-14 Overview of the DH-485 Network

Notes:

Publication 1756-UM532A-EN-P - May 2006

Page 33

Use Data Highway 485 Network

Chapter

3

Introduction

What Is Data Highway 485?

This chapter describes the basics of the Data Highway 485 system and the

operation of a DH-485 network.

For See

What Is Data Highway 485? 3-1

Two Methods of Communication Over a DH-485 Network 3-2

Use DH-485 Messaging 3-3

Configuration Information in DH-485 Messaging 3-11

Application Timeout 3-12

Example DH-485 Network Routing Configuration 3-13

Use the Common Industrial Protocol (CIP) Messaging 3-14

On the most basic level, Data Highway 485 is a wire or cable and a protocol

that connects computers and peripheral devices so that they can communicate.

The wire used for a network is called the network medium.

A DH-485 link transfers data between ControlLogix controllers, SLC

controllers, and other devices that use the DH-485 network. These devices are

called stations. You can connect a maximum of 32 stations to a single DH-485

link.

1 Publication 1756-UM532A-EN-P - May 2006

Page 34

3-2 Use Data Highway 485 Network

Link Design

When you design your DH-485 link, you should use good design practices,

including laying out the link before installation. We also recommend you

consider the following when designing your DH-485 link:

• All performance requirements

• Maintenance

• Possible future changes to the link

Use a Belden 9842 or a Belden 3106A cable to connect your module to

DH-485. Only connect a DH-485 network using a daisy-chain configuration.

If you need to know how to install a DH-485 network, refer to publication

1747-UM011, SLC 500 Modular Hardware Style User Manual.

Two Methods of Communication Over a DH-485 Network

The 1756-DH485 module acts as a bridge for two methods of communication.

These methods are:

• DH-485 Messaging

• Common Industrial Protocol (CIP) Messaging

The table Types of Communication on the 1756-DH485 Module lists the

devices that support each communication method.

Types of Communication on the 1756-DH485 Module

Type of Communication Devices and Software Support

DH-485 messaging SLC-500 -5/05, 5/04, 5/03, 5/02, 5/01, MicroLogix

Logix controllers

RSLinx and RSLogix 500 software

Common Industrial Protocol

(CIP) messaging

Logix controllers

RSLogix 5000 and RSLinx software

Publication 1756-UM532A-EN-P - May 2006

Page 35

Use Data Highway 485 Network 3-3

Use DH-485 Messaging

DH-485 Messaging offers the following benefits:

• You can send messages between devices on the same link.

• You can send messages between devices on different links.

DH-485 messaging is divided into two types:

• Local DH-485 Messaging - See page 3-3

• Remote DH-485 Messaging - See page 3-5

Before you can design a control system to meet your application needs, be

aware of the difference between Local DH-485 Messaging and Remote

DH-485 Messaging.

Local DH-485 Messaging

Devices use local DH-485 messaging to communicate between devices on the

same physical link. A device that uses local DH-485 messaging must:

• generate local DH-485 packets.

• support local DH-485 protocol.

• send and receive messages.

TIP

SLC 5/01 controller receives and replies, but does not

initiate.

Publication 1756-UM532A-EN-P - May 2006

Page 36

3-4 Use Data Highway 485 Network

This figure shows an SLC controller sending a local message to Channel A on

the 1756-DH485 module. Because the controller slot for Channel A is

configured to 0, the message is forwarded to the ControlLogix controller in

slot 0.

SLC Controller Sending a Local Message to Channel A on the 1756-DH485 Module

ControlLogix Chassis

AIC+ Link Coupler

1756-DH485 Module

Channel A

AIC Link Coupler

44052

SLC 5/03 Controller

Because a local DH-485 message has only enough address information to get

the message to a target node on the same DH-485 network, the 1756-DH485

module that receives this message cannot identify where to send the message.

The 1756-DH485 module uses the Controller Slot configuration parameter in

RSLinx software to send the message to the local controller.

Publication 1756-UM532A-EN-P - May 2006

Local DH-485 messaging does not require a populated routing table. Local

DH-485 messaging does require a default or applied controller slot for each

channel configured for a DH-485 network.

IMPORTANT

Local DH-485 Messaging can target only one ControlLogix

controller per DH-485 channel. The ControlLogix

controller must reside in the same chassis as the

1756-DH485 module receiving the message.

Refer to Remote DH-485 Messaging on page 3-5 for more

information.

Page 37

Use Data Highway 485 Network 3-5

Limitations of Local DH-485 Messaging

When using Local DH-485 Messaging, you must remember:

• the DH-485 message contains only a node ID for a node on the

DH-485 network.

• a local DH-485 message sent to the node ID of a port on the

1756-DH485 module is forwarded to a single user-configured controller

slot.

• messages on one DH-485 network cannot be routed to other networks.

Logix controllers message via a NetLinx network through a ControlLogix

gateway to DH-485 network to all MicroLogix and SLC 5/03 (and above)

controllers on DH-485 network. RSLinx Classic on DH-485 network can

browse through ControlLogix gateway to any device on NetLinx network.

IMPORTANT

Logix controllers on NetLinx network will not be able to

message through ControlLogix gateway to DH-485

network to fixed SLC 500, SLC 5/01, or SLC 5/02

controllers on DH-485 network.

Remote DH-485 Messaging

Devices use remote DH-485 messaging to communicate between devices on

physically separate networks. A device that uses remote DH-485 messaging

must be able to:

• generate Remote Data Highway 485 network packets.

• support Remote Data Highway 485 network protocol.

• send and receive messages.

Remote DH-485 messaging should be used when:

• The message originating device or the message target device is one of

the supported devices.

Refer to table Types of Communication on the 1756-DH485 Module

on page 3-2.

• There is a DH-485 network link in the message’s path from originator to

target.

• The originating and the target devices are on separate networks

communicating through a ControlLogix gateway.

Publication 1756-UM532A-EN-P - May 2006

Page 38

3-6 Use Data Highway 485 Network

TERMTT

AAA

A

B

B

This figure shows an example of remote DH-485 messaging between SLC/03

(or later) controller A and SLC 5/03 (or later) controller B. In this example, the

following information must be included in the remote DH-485 message

routing message instruction:

• Local DH-485 node = 020

• Destination link ID = 2

• Remote DH-485 node = 030

Remote DH-485 Messaging Between

SLC 5/03 Controller A and SLC 5/03 Controller B

1756-DH485 Module

ControlLogix Chassis

Link ID 1

Channel A - Node: 020

AIC+

Channel B - Node: 025

AIC+

AIC

Link ID 2

AIC

SLC 5/03 Controller A

SLC 5/03 Controller B

Node: 030

44053

Link IDs

To use remote DH-485 messaging, each network that is an originating network

or target network must have a unique link ID. The 1756-DH485 module

requires these link IDs to be decimal values between 1-199. Each DH-485

channel on a 1756-DH485 module must have its own unique link ID.

Publication 1756-UM532A-EN-P - May 2006

Page 39

Use Data Highway 485 Network 3-7

The message originates on the source network. The destination network is the

message’s target network. This applies to all source and destination networks,

including DH-485, ControlNet, EtherNet/IP, and a ControlLogix chassis

backplane.

IMPORTANT

For remote DH-485 messaging, the ControlLogix chassis

backplane should be considered a separate, independent

network. Therefore, a system of 1 DH-485 network and

one ControlLogix chassis is a two-link system.

The ControlLogix chassis backplane is required to be a

separate, independent link for DH-485 messaging if there

is more than one message target ControlLogix controller in

a ControlLogix chassis.

Routing Tables in Remote DH-485 Messaging

The 1756-DH485 module contains a routing table that you define for your

application. The routing table contains information used to steer Remote

DH-485 Messages through the system to remote nodes located on separate

networks. By using the routing table, the 1756-DH485 module lets existing

devices, such as an SLC controller, to use DH-485 Remote Addressing for

messaging.

You must use RSLinx software to configure your routing table. Refer to Use

RSLinx Software to Create a Routing Table on page 4-2, for more information.

Publication 1756-UM532A-EN-P - May 2006

Page 40

3-8 Use Data Highway 485 Network

Programming Message Block Instructions in a Controller for Remote DH-485

Messaging

Before programming your message block instructions in your controller, you

must:

• determine which links will send and receive remote DH-485 messaging.

• draw a network to make sure you meet the design requirements for

remote DH-485 messaging.

If you are using remote DH-485 messaging, you must also:

• assign link numbers.

The numbers must be a decimal value between 1-199. ControlLogix

chassis backplane may also be assigned link IDs.

• assign DH-485 node numbers.

• use RSLinx software to load routing tables into each 1756-DH485

module.

When using remote DH-485 messaging, you must include the following in the

message instruction:

• Destination link ID - A user-defined number representing a network in

your system.

• Remote node or slot - The node or slot on the remote network with

which you want to communicate.

If the message originates on a DH-485 network, you must also include a local

DH-485 node. The node on your local DH-485 network is capable of routing

the message. If the message originates on EtherNet/IP, ControlNet, or

ControlLogix, you must also include a CIP path to the first 1756-DH485

module.

Publication 1756-UM532A-EN-P - May 2006

Page 41

Use Data Highway 485 Network 3-9

The following table lists what the controllers are capable of on DH-485.

Controllers and the Types of Messaging Capable on a DH-485 Network

Controller

Messaging

Respond to

Local DH-485

Initiate Local

DH-485

Respond to

Remote

DH-485

MicroLogix 1000 Yes Yes Yes No

MicroLogix 1100 Yes Yes Yes Yes

MicroLogix 1200 Yes Yes Yes Yes

MicroLogix 1500 Yes Yes Yes Yes

SLC 500 fixed Yes No No No

SLC 5/01 Yes No No No

SLC 5/02 Yes Yes No No

SLC 5/03 Yes Yes Yes Yes

SLC 5/04 Yes Yes Yes Yes

SLC 5/05 Yes Yes Yes Yes

Logix Yes Yes

(1)

Yes for CIP remote messaging only.

No

(1)

Initiate

Remote

DH-485

Yes

Publication 1756-UM532A-EN-P - May 2006

Page 42

3-10 Use Data Highway 485 Network

Limitations of Remote DH-485 Messaging

Remote DH-485 messages are encapsulated in CIP messages and sent on CIP

connections when they are sent across ControlNet, EtherNet/IP, and the

ControlLogix chassis backplane. Although this is transparent to the user, there

are resource limits associated with CIP on the 1756-DH485 module.

The 1756-DH485 module supports up to 32 CIP connections. These

connections are made when devices want to send a DH-485 message out of a

1756-DH485 module’s DH-485 channel. The 1756-DH485 module makes

these connections when it receives DH-485 message traffic. The 1756-DH485

module recovers connections if they are not being used.

Because of the various paths involved, the 1756-DH485 module responds to

‘out of connections’ in one of the following ways:

• The 1756-DH485 module may generate a Routing Error on DH-485 for

DH-485 message requests if there are no connections available.

• The Message Originator may generate an application timeout if a remote

1756-DH485 module has no connections available for a DH-485

Message response.

For more information on application timeouts, refer to Application

Timeout on page 3-12.

• The Message Originator may receive an ‘out of connections’ error if the

path from the originator to the 1756-DH485 module is a ControlLogix

chassis, a ControlNet network, or an EtherNet/IP network.

Publication 1756-UM532A-EN-P - May 2006

Page 43

Use Data Highway 485 Network 3-11

Configuration Information in DH-485 Messaging

When you are doing DH-485 messaging, you must first set up the

1756-DH485 module configuration. The following configuration information

is stored in the non-volatile (NVS) memory on your 1756-DH485 module

when you configure the module using RSLinx software.

• Any routing table that may be needed to send DH-485 messages

through the module. - This information must be applied to the module’s

configuration separately from other information. Use RSLinx to apply

the routing table.

For more information about routing tables, see the section Use RSLinx

Software to Create a Routing Table in Chapter 4.

• Controller slot assignment for each DH-485 channel.

Refer to Set the Controller Slot on page 4-8 for more information on

local messaging.

• The node number of the module.

IMPORTANT

If you restore defaults with RSLinx software, the slot

number will remain the 1756-DH485 module’s non-volatile

memory, but the routing table and the controller slot for

both DH-485 channels will be reset.

Publication 1756-UM532A-EN-P - May 2006

Page 44

3-12 Use Data Highway 485 Network

Application Timeout

DH-485 Link 1

When an error occurs while sending a message to a remote link, it appears to

the sending station as an application timeout because error messages are not

routed back. When an error occurs during routing, it may be dropped.

For example, if an SLC 5/03 controller sends a message to another SLC 5/03

controller, and the second SLC 5/03 controller’s buffers are full, three

things happen:

• The SLC 5/03 controller refuses the message because the buffers are

full.

• The originator detects an application timeout when no reply is received.

• The originator increments its error count.

The SLC 5/03 controller can retry to send the message later. This figure

shows an example of an application timeout.

Example of an Application Timeout

1756-DH485 Module

ControlLogix Chassis

DH485

1756-DH485 Module

DH485

AIC+

AIC

SLC 5/03 controller detects an

application timeout and

increments an error bit.

Routed messages sent

over the backplane.

AIC+

AIC

DH-485

Link 2

SLC 5/03 controller

buffers are full.

44068

SLC 5/03 Controller

Publication 1756-UM532A-EN-P - May 2006

Page 45

Use Data Highway 485 Network 3-13

Example DH-485 Network Routing Configuration

1756-DH485 Module

Channel A Node 15

Channel B Node 16

ControlLogix Controller

Slot 0

ControlLogix Chassis

AIC

SLC 5/03 Controller

Node 30

Link ID 6

The Example of DH-485 Routing Configuration figure below shows an

example DH-485 routing configuration. All node numbers on DH-485 are

given in decimal. Node numbers on ControlNet and slot numbers in

ControlLogix chassis are given in decimal. Links IDs for all networks are given

in decimal.

IMPORTANT

Some devices in this figure have the same node number

because they are on different networks. Devices on the

same network must have unique node numbers. You must

assign the node numbers.

Example of DH-485 Routing Configuration

1756-DH485 Module

Channel A Node 30

Channel B Node 31

ControlLogix Controller

Slot 5

DH485

DH485

AIC+

DH-485

Link ID 4

DH-485

Link ID 1

AIC

SLC 5/03 Controller

Node 20

DH-485

Link ID 2

AIC+

AIC

PanelView

Node 21

AIC+

DH-485

Link ID 5

AIC

AIC

SLC 5/03

Controller

Node 20

SLC 5/03

Controller

Node 20

44054

Publication 1756-UM532A-EN-P - May 2006

Page 46

3-14 Use Data Highway 485 Network

Use the Common Industrial Protocol (CIP) Messaging

Common Industrial Protocol (CIP) is the communication mechanism on

ControlLogix chassis, ControlNet, and EtherNet/IP networks with the

Encapsulation Protocol (EPIC) protocol.

Like DH-485 messaging, CIP supports communication between devices on

the same link and physically separate links. However, CIP messaging uses a

different method to route messages than DH-485 messaging.

CIP uses a relative path concept for routing messaging. Because the message

itself, or the connection the message is sent on, contains all the information

required to route the message, CIP messages do not require any routing table

or link IDs.

Devices such as ControlLogix devices, devices that use the ControlNet

network, and devices that use CIP protocol support this new type of

communication.

IMPORTANT

Your 1756-DH485 module supports bridging CIP

messaging over a DH-485 link. However, your

1756-DH485 module does not support bridging CIP I/O

data from a ControlLogix controller to an 1756-I/O

module.

Publication 1756-UM532A-EN-P - May 2006

Page 47

Chapter

4

Use RSLinx Software to Create a Routing Table

Introduction

Choose the Correct Software

This chapter describes how to configure your 1756-DH485 module in

DH-485 applications. For more information on the configuration software,

refer to the online help in each.

For See

Choose the Correct Software 4-1

Use RSLinx Software to Create a Routing

Table

Create the Routing Table 4-3

The programming software you need is dependent on what products you are

using with the 1756-DH485 module. The table below explains what software is

needed for your application.

Software Needed for 1756-DH485 Applications

If you are using this product with the

1756-DH485 module to read/write data

in a DH-485 application

SLC Controllers RSLinx, version 2.43 or later

4-2

You must use this software

RSLogix 500, version 6.3 or later

ControlLogix Controllers RSLinx, version 2.43 or later

RSLogix 5000

1 Publication 1756-UM532A-EN-P - May 2006

Page 48

4-2 Use RSLinx Software to Create a Routing Table

Use RSLinx Software to Create a Routing Table

DH-485 protocols do not use the Common Industrial Protocol (CIP), the

communication protocol used in the ControlLogix architecture. The

1756-DH485 module is the transition point from the DH-485 network to

ControlLogix. In this capacity, the 1756-DH485 module serves as the DH-485

message source and requires a full message route, or path, to deliver the

message. A routing table, using link IDs and node addresses, provides the full

path.

What Is a Routing Table?

Before you can create a routing table for your 1756-DH485 module, you must

assign link IDs to all networks (including ENET and CNET) that route

information through the module. Link IDs are numbers from 1 to 199.

DH-485 module addressing provides the link IDs and node addresses. The

routing table translates link IDs and node address information into path, or

routing, information. Thus, the routing table specifies a 'map' to other links in

the system. Routing tables are set up at each node to build accurate

connections.

ControlLogix Routing

The ControlLogix routing protocols use CIP, a message-based protocol that

implements a relative path to send a message from the source device in a

system to the destination device. In this way, the source device in a networks

system contains the path information that steers the message along the proper

route to reach its destination. Since the source device holds this information,

other devices along the path simply pass this information; they do not need to

store it. ControlLogix routing has two significant benefits:

• You do not need to configure routing tables in the bridging module,

greatly simplifying maintenance and module replacement.

• You maintain full control over the route taken by each message, enabling

you to select alternative paths for the same end device.

Publication 1756-UM532A-EN-P - May 2006

Page 49

Use RSLinx Software to Create a Routing Table 4-3

Create the Routing Table

A.Expand the configuration

tree until the module

appears.

B.Right-click on the

1756-DH485 module.

C.Select Module

Configuration.

To create a routing table for your application, follow these steps:

1. Start RSLinx.

2. Browse the network.

3. Right-click on the 1756-DH485 module.

4. Use the left-side navigation bar to see your DH-485 application, as

shown in the example below.

Publication 1756-UM532A-EN-P - May 2006

Page 50

4-4 Use RSLinx Software to Create a Routing Table

5. Select the DH-485 Routing Table tab.

You must build the routing table based on the 1756-DH485 modules in

the ControlLogix chassis. Each link ID (for example: chassis backplane,

channels A and B of any 1756-DH485 module in the chassis) is initially

undefined.

Publication 1756-UM532A-EN-P - May 2006

Page 51

A. Right-click on the

1756-DH485 module.

B. Click Edit Module.

C.Assign Link IDs and click OK.

Use RSLinx Software to Create a Routing Table 4-5

6. You must assign link IDs, as shown below.

IMPORTANT

Keep track of your Link ID assignments. You need the

Link ID values when you send messages via RSLogix 500

and RSLogix 5000 software.

Publication 1756-UM532A-EN-P - May 2006

Page 52

4-6 Use RSLinx Software to Create a Routing Table

The 1756-DH485 routing table displays with the link IDs defined.

Publication 1756-UM532A-EN-P - May 2006

Page 53

A.Right-click on the

Backplane.

B.Click Edit Module.

C.Assign Link IDs and click OK.

Use RSLinx Software to Create a Routing Table 4-7

7. Assign a Link ID for the chassis backplane.

8. Click OK

The software prompts you to download routing table changes.

9. Click Yes.

This completes the routing table creation process.

Publication 1756-UM532A-EN-P - May 2006

Page 54

4-8 Use RSLinx Software to Create a Routing Table

Set the Controller Slot

Setting the controller slot location creates a simple way for the SLC controllers

to exchange data with the ControlLogix controller as long as the SLC

controller is on the same DH-485 network as the module. The SLC controller

can use local messaging to send data to a ControlLogix controller with this

feature. No routing table is required.

A. Change the

controller slot, if

needed.

B.Click OK.

IMPORTANT

This is not the slot location of the 1756-DH485 module, it

is the slot location of the ControlLogix controller where

you want to send the local message.

The controller slot is the physical location of a ControlLogix controller in a

DH-485 application. The default setting is slot 0. If necessary, use the Channel

Configuration tabs to change the controller slot number.

Publication 1756-UM532A-EN-P - May 2006

For more information about using the DH-485 network, refer to Chapter 3,

Use Data Highway 485 Network.

Page 55

Chapter

5

Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Network

Introduction

This chapter describes how to set up the communications initiated by an SLC

5/03 controller through a 1756-DH485 module to a 1756-Lx controller.

For See

Hardware Configuration 5-2

Use the Controller Slot to Route the Local Message 5-3

Create a Local Message in RSLogix 500 5-4

Configure the Message 5-5

Create a Logic Map for the Local Message in

RSLogix 5000 Software

IMPORTANT

The examples use SLC 5/03 modules to send DH-485

messages. In each case, the use of these devices is strictly

for example purposes and not an indication of restrictions

on the 1756-DH485 module.

5-6

1 Publication 1756-UM532A-EN-P - May 2006

Page 56

5-2 Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Network

TERMTET

AAA

A

BBB

COMCC

Hardware Configuration

In this hardware configuration, the communications are initiated by an SLC

5/03 controller. The message is sent to a 1756-DH485 module and the

1756-Lx controller is located in slot 11.

Communications Between an SLC 5/03 Controller and a 1756-DH485 Module

1756--L1 Controller

DH+/RIO

DH485 network

communicating

through link

couplers.

1756-DH485

DH485

AIC+

SLC 5/03 Controller

44070

AIC

Publication 1756-UM532A-EN-P - May 2006

Page 57

Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Net work 5-3

Use the Controller Slot to Route the Local Message

Enter the slot number of the

controller.

When a local DH485 message is received, the message will automatically be

routed to the controller based on the configured slot number. In this case, the

1756-Lx controller is in slot 11. A routing table is not needed.

Publication 1756-UM532A-EN-P - May 2006

Page 58

5-4 Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Network

Create a Local Message in RSLogix 500

This is an example of a local message being initiated by the SLC 5/03

controller.

Publication 1756-UM532A-EN-P - May 2006

Page 59

Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Net work 5-5

Configure the Message

This is the Setup dialog for the example message.

Publication 1756-UM532A-EN-P - May 2006

Page 60

5-6 Communicate from an SLC 5/03 Controller to a Logix Controller over a DH-485 Network

Create a Logic Map for the Local Message in RSLogix 5000 Software

You must logically map the SLC data address to the ControlLogix tag. To get

to the Logix Map in RSLogix 5000 software go to: Logic > Map PLC/SLC

Messages.

This is the logic map needed for the example message.

Publication 1756-UM532A-EN-P - May 2006

Page 61

Chapter

6

Communicate Between SLC Controllers over DH+ and DH485 Networks