Rockwell Automation 1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix, 1769 Compact GuardLogix, 1789 SoftLogix Instruction Manual

...Page 1

Programming Manual

Logix 5000 Controllers Security

1756 ControlLogix, 1756 GuardLogix, 1769 CompactLogix,

1769 Compact GuardLogix, 1789 SoftLogix, 5069

CompactLogix, 5069 Compact GuardLogix, Studio 5000

Logix Emulate

Original Instructions

Page 2

Logix 5000 Controllers Security

personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

temperatures.

for Personal Protective Equipment (PPE).

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to familiarize

themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to

be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be

impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

ARC FLASH HAZARD:

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and

Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

2 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 3

Change

Topic

Updated branding.

Throughout

Summary of changes

This manual includes new and updated information. Use these reference

tables to locate changed information.

Grammatical and editorial style changes are not included in this summary.

Global changes

This table identifies changes that apply to all information about a subject in

the manual and the reason for the change. For example, the addition of new

supported hardware, a software design change, or additional reference

material would result in changes to all of the topics that deal with that subject.

Updated Legal notices. Legal notices on page 8

New or enhanced features

None in this release.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 3

Page 4

Page 5

Summary of changes

Security overview

Configuring source protection

Table of Contents

Preface

in the Logix Designer

application

Studio 5000 environment .......................................................................... 7

Additional resources ................................................................................... 7

Legal notices ................................................................................................ 8

Chapter 1

Introduction ............................................................................................... 11

FactoryTalk Security .................................................................................. 11

Permission sets and Logical Names ................................................... 11

Source Protection ....................................................................................... 12

Chapter 2

Introduction ............................................................................................... 15

Considerations and limitations for License protection and locked

components .......................................................................................... 16

Enable source protection........................................................................... 18

Disable the Configure Source Protection menu option .......................... 18

Protect components with Source Keys ..................................................... 19

About source keys ................................................................................ 20

Source key names ................................................................................ 20

Source key file ....................................................................................... 21

Apply Source Key protection to a component ................................... 22

Specify a Source Key file and location ......................................... 24

View components without a key .................................................. 25

Verify source key protection on a component ............................ 26

Remove access to a protected routine ..................................................... 27

License Source Protection for components ............................................ 27

Protect components with Licenses .................................................... 28

Add Execution Protection to License-protected components ......... 29

Apply License Protection to one or more components .................... 30

Lock a component ................................................................................ 33

Lock all License-Protected content ..................................................... 34

Add an LV instruction to monitor license status ............................... 34

Share License privileges with other users on your network ............. 34

Provide License privileges to other users ..................................... 35

Provide license privileges for remote desktop users ................... 36

Securing a ControlLogix controller with the Logix CPU Security Tool . 39

Accessing a secured controller ................................................................. 42

Removing security from a controller with the CPU Security Tool ......... 43

Removing a password ................................................................................ 45

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 5

Page 6

Table of Contents

Product policies and securable

actions supported by

FactoryTalk Security

Index

Appendix A

Product policies and securable actions ................................................... 48

6 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 7

Resource

Description

publication FTSEC-QS001

security.

website, http://ab.rockwellautomation.com

and other certification details.

Studio 5000 environment

Additional resources

Preface

This manual explains how to configure security for the Logix Designer™

application. It also explains how to set up source protection for your logic and

projects. This manual is one of a set of related manuals that show common

procedures for programming and operating Logix 5000 controllers.

For a complete list of common procedures manuals, refer to the

Logix 5000

Controllers Common Procedures Programming Manual, publication 1756-

PM001.

The term Logix 5000 controller refers to any controller based on the Logix

5000 operating system.

The Studio 5000 Automation Engineering & Design Environment® combines

engineering and design elements into a common environment. The first

element is the Studio 5000 Logix Designer® application. The Logix Designer

application is the rebranding of RSLogix 5000® software and will continue to

be the product to program Logix 5000™ controllers for discrete, process,

batch, motion, safety, and drive-based solutions.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 7

The Studio 5000® environment is the foundation for the future of

Rockwell Automation® engineering design tools and capabilities. The Studio

5000 environment is the one place for design engineers to develop all

elements of their control system.

These documents contain additional information concerning related

products from Rockwell Automation.

Industrial Automation Wiring and Grounding

Guidelines, publication 1770-4.1

FactoryTalk Security System Configuration Guide,

Product Certifications

Provides general guidelines for installing a

Rockwell Automation industrial system.

Provides additional information on FactoryTalk™

Provides declarations of conformity, certificates,

Page 8

Preface

Legal notices

You can view or download publications at

http://www.rockwellautomation.com/literature/

. To order paper copies of

technical documentation, contact your local Allen-Bradley™ distributor or

Rockwell Automation™ sales representative.

Rockwell Automation publishes legal notices, such as privacy policies, license

agreements, trademark disclosures, and other terms and conditions on the

Legal Notices

page of the Rockwell Automation website.

End User License Agreement (EULA)

You can view the Rockwell Automation End User License Agreement (EULA)

by opening the license.rtf file located in your product's install folder on your

hard drive.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\license.rtf.

Open Source Software Licenses

The software included in this product contains copyrighted software that is

licensed under one or more open source licenses.

You can view a full list of all open source software used in this product and

their corresponding licenses by opening the oss_license.txt file located your

product's OPENSOURCE folder on your hard drive. This file is divided into

these sections:

• Components

Includes the name of the open source component, its version number,

and the type of license.

• Copyright Text

Includes the name of the open source component, its version number,

and the copyright declaration.

• Licenses

Includes the name of the license, the list of open source components

citing the license, and the terms of the license.

The default location of this file is:

8 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt.

You may obtain Corresponding Source code for open source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

Page 9

Preface

contacting Rockwell Automation via the Contact form on the Rockwell

Automation website:

http://www.rockwellautomation.com/global/aboutus/contact/contact.page. Please include "Open Source" as part of the request

text.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 9

Page 10

Page 11

Introduction

FactoryTalk Security

Permission sets and

Chapter 1

Security overview

This chapter provides an overview of the security features available in the

Logix Designer application.

The following features are the main security features that protect controller

projects:

• FactoryTalk® Security software, which provides permission-based

control.

• Source Protection, which protects the logic in controller projects.

FactoryTalk® Security integrates a common security model across all

FactoryTalk enabled products. FactoryTalk® Services Platform (FTSP)

includes the FactoryTalk Administration Console that provides the interface

for configuring your system. FactoryTalk Services Platform (FTSP) software is

installed during the installation of the Logix Designer application.

Logical Names

Use FactoryTalk Security to control access to the logic in your projects with

centrally managed, role-based policy enforcement.

For more information about FactoryTalk Security, see the

Security System Configuration Guide, publication FTSEC-QS001.

Permission sets and Logical Names identify a set of actions that are allowed

or denied for one or more user groups or computer groups. You use

permission sets and Logical Names to define user permissions in the

FactoryTalk Administration Console. Use permission sets to apply the same

permissions to multiple controllers or project components. Use a Logical

Name to associate permissions with a specific controller. When you use a

Logical Name, it must match the name of the controller.

When a user opens a project that has been secured with a permission set or a

Logical Name and configured to use only the selected security authority, the

Logix Designer application checks the ID of the FactoryTalk Directory to see if

it matches the ID stored in the project.

• If the ID matches, the Logix Designer application checks the directory

and finds the Logical Name (that matches the controller name), or the

permission set associated with the project, and gets the permissions

for the current user/computer combination.

• If the ID does not match, the project uses the Guest User permissions

defined for that permission set or Logical Name.

FactoryTalk

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 11

Page 12

Chapter 1 Security overview

Source Protection.

versions 30 and 31 of the Logix Designer application.

Source Protection

When a user opens a project that has been secured but has not been

configured to use only the selected security authority, the Logix Designer

application checks the connected FactoryTalk Directory, finds the Logical

Name or the permission set associated with the project, and gets the

permissions for the current user/computer combination. Rockwell

recommends configuring the project to use only the selected security

authority to maintain control over the directory that secures the project.

Permissions for Guest Users

When you configure permission sets and logical names in the FactoryTalk

Administration Console, you can also configure permissions for Guest Users.

The permissions for Guest Users determine the level of access for users who

are not authenticated on the same FactoryTalk directory that the project was

secured with.

Permissions for Guest Users are cached in the project file to which they are

associated. However, the permissions are only stored in the project file for

permission sets that have been applied to objects by a user of the primary

FactoryTalk directory.

Refer to the FactoryTalk online help for more information on permissions for

Guest Users.

Source Protection limits users' ability to view and edit routines and Add-On

Instructions, including equipment phase state routines, without the

associated source key or license. Apply Source Key Protection or License

Source Protection to routines and Add-On Instructions. Apply Execution

Protection to license-protected components to allow execution only on

controllers with a specific execution license.

When protecting a component with License Source Protection, optionally lock

the the component. A locked component does not require the source license to

open the project or execute the locked component, allowing more secure

distribution. A user with the correct license must unlock a component to allow

viewing or editing. Rockwell recommends locking unlocked components in

projects that are distributed from trusted development environments to

unsecured environments to safeguard your intellectual property.

Tip: Routines and Add-On Instructions are currently the only project component types that support

12 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Tip: Execution Protection and component locking is supported only on Compact GuardLogix 5380,

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580 controllers in

License Source Protection and Execution Protection Licenses require the use

of CmSticks and CmCards:

Page 13

device is not required to open a project containing locked components.

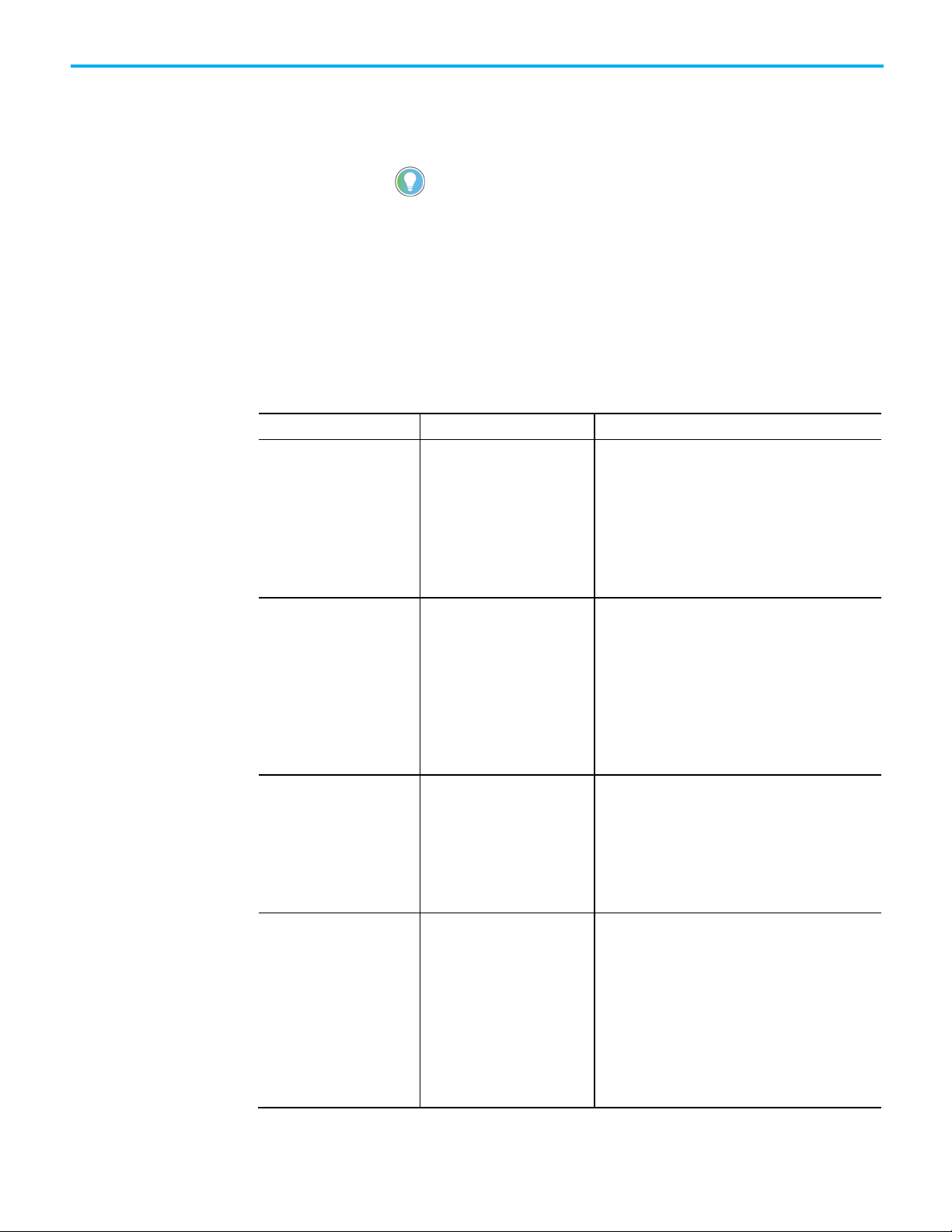

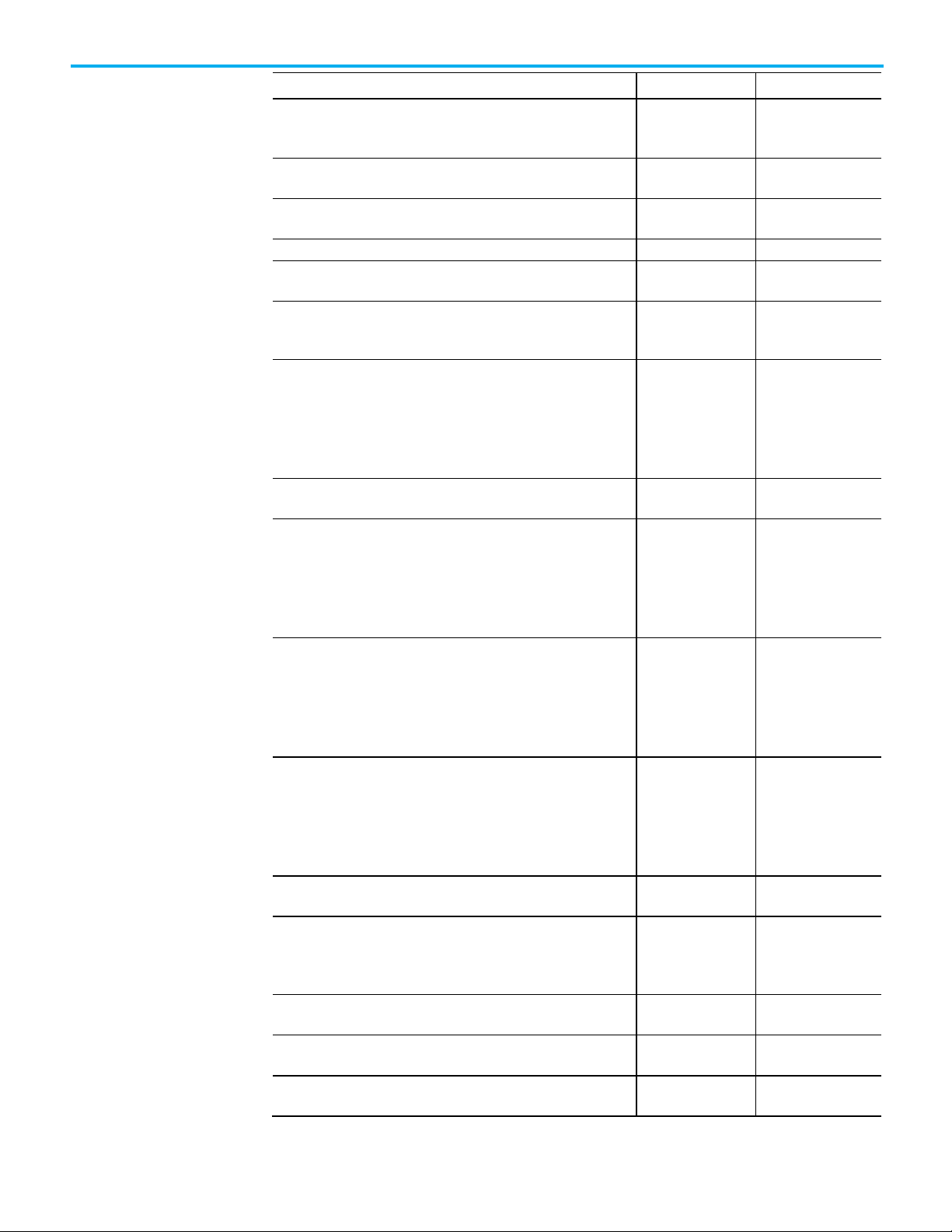

Protection option

Supported controllers

Description

Source Key (Password-based)

All Logix 5000 controllers

Simple legacy protection, not recommended for hardened

from the source code.

Chapter 1 Security overview

• On the computer running the Logix Designer application, a CmStick,

CmCard, or other compatible Wibu device that contains licenses

required for opening a license-protected project and working with

project components.

Tip: On CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, Compact GuardLogix

5380, and GuardLogix 5580 controllers, a CmStick, CmCard, or other compatible Wibu

• On the controller, a CmCard that contains execution licenses required

to run a project that contains components protected with Execution

Protection. If a required execution license is missing, the project does

not download to the controller. If the project has already been

downloaded and the license expires or the CmCard is removed, a

major fault occurs when the controller is switched to Run mode.

The following table describes the types of Source Protection available.

Source Protection

License Source Protection CompactLogix 5370, ControlLogix

5570, Compact GuardLogix 5370,

and GuardLogix 5570 controllers

License Source Protection

(Locked)

CompactLogix 5380,

CompactLogix 5480, ControlLogix

5580, Compact GuardLogix 5380,

and GuardLogix 5580 controllers

intellectual property protection.

• Component source code (logic) is protected with a

password.

• Password must be available to view or edit protected

components.

• Optionally, can be configured to allow logic to be viewed

when password is not available.

Hardened intellectual property protection for sensitive

content:

• Component source code (logic) is protected with a

License on a CmStick installed on the computer running

the Logix Designer application.

• License must be present to open or import the file

containing the protected components.

• Licenses can be configured with different access levels

to allow viewing or editing protected components..

Provides hardened intellectual property protection for

sensitive content and allows easy transfer of projects:

• Component source code (logic) is protected with a

license on a CmStick installed on the computer running

the Logix Designer application.

Executable code is protected and stored separately

•

License Source Protection

(Unlocked)

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 13

CompactLogix 5380,

CompactLogix 5480, ControlLogix

5580, Compact GuardLogix 5380,

and GuardLogix 5580 controllers

Provides protection and access control based on

permissions in the license:

• Users without a dongle can work with unprotected

parts of the project, but users cannot view or edit the

protected content. The dongle is required to work with

the protected content.

• To lock or unlock a component, the source license must

be present on a CmStick plugged into the computer

running the Logix Designer application, and the license

must contain the View permission.

Page 14

Chapter 1 Security overview

Protection option

Supported controllers

Description

License Source Protection +

License Execution Protection

CompactLogix 5380,

CompactLogix 5480, ControlLogix

5580, Compact GuardLogix 5380,

and GuardLogix 5580 controllers

Limits execution of valuable content to only authorized

controllers:

• Provides same protection as License-based Source

Protection.

• Additionally, components can be protected with an

Execution License.

• Protected components can only be downloaded and

executed on a controller that contains a CmCard with

the correct execution license.

14 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 15

Tip: You can optionally allow source-protected components to be available in a read-only

versions 30 and later of the Logix Designer application.

Tip: Execution Protection and component locking is supported only on Compact

GuardLogix 5580 controllers in version 30 of the Logix Designer application.

Introduction

Chapter 2

Configuring source protection in the Logix

Designer application

This chapter describes how to enable and apply source protection for your

Logix Designer components, such as routines and Add-On Instructions. You

can protect project components using Source Key protection or License

protection. You can also apply Execution Protection to source-protected

components to allow execution only on controllers with a specific execution

license.

Source Key protection:

• Protects components using existing source keys.

format on a system that does not have the source key required for access.

License protection:

• Protects components with specific licenses.

Tip: License Source Protection is not supported on Sequential Function Chart routines in

• Execution Protection is an extension of License-Based Source

Protection. You can apply Execution Protection to limit the execution

of routines and Add-On Instructions, including equipment phase state

routines, to controllers that contain a specific execution license.

• When you protect a component with License Source Protection, you

can also lock it. When you lock a component, the routine's logic is

compiled into executable code and encrypted. It is only decrypted by

the controller when it is ready to be executed. As a result, project files

containing locked components can be shared with users without

licenses to work with the locked components. Those users can work

with unprotected parts of the project, upload and download the project

file, and even copy and paste locked components into other project

files. Rockwell recommends locking unlocked components in projects

that are distributed from trusted development environments to

unsecured environments in order to safeguard your intellectual

property.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 15

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and

Page 16

Chapter 2 Configuring source protection in the Logix Designer application

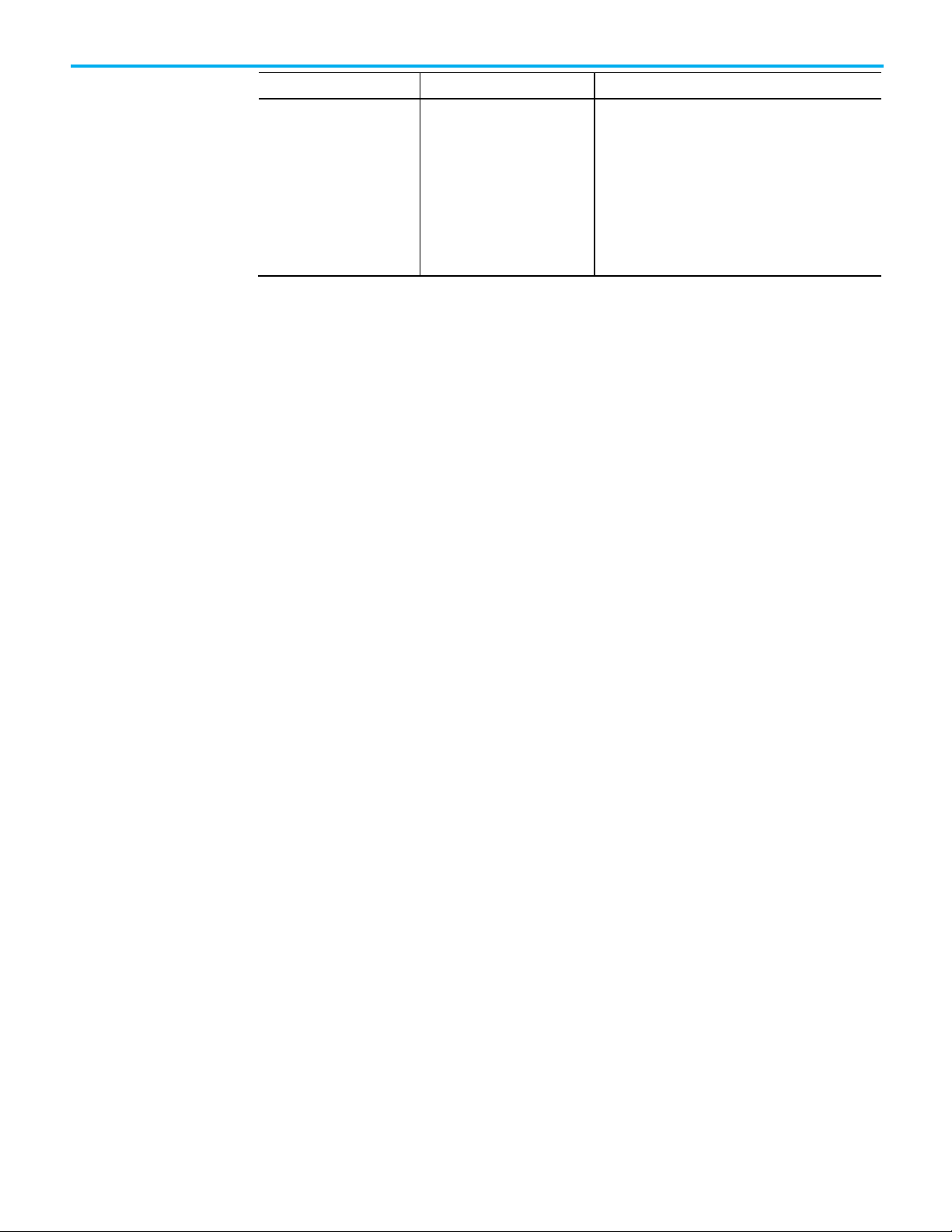

Limitation

Affects routines

Affects AOIs

Cannot resize an array that is referenced by a locked routine.

x

Considerations and

Keep the following considerations and limitations in mind when using

License Source Protection with routines and Add-On Instructions for

limitations for License

protection and

CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, Compact

GuardLogix 5380, and GuardLogix 5580 controllers.

locked components

• Sequential Function Chart routines cannot be protected with License

Source Protection and execution protection.

• Function Block Diagram routines cannot be protected with License

Source Protection and execution protection.

• You cannot overwrite a locked routine with a locked routine of a

different language. If a locked routine needs to be replaced with a

locked routine of a different language, first unlock the routine in the

target file.

• You cannot overwrite a locked routine with an unlocked routine, and

vice versa. To replace a locked routine with an unlocked routine, and

vice versa, first delete the routine to be replaced.

• If you overwrite a locked ladder logic routine that contains label (LBL)

instructions with a locked ladder logic routine that contains similar

labels, other workstations can lose correlation with the project. To

recover correlation, upload the project on the affected workstations.

• The controller SD card holds a maximum of 63 active or expired

licenses, plus the Rockwell activation license for Execution Protection.

If the SD card contains more than 64 licenses, downloads with licenseprotected content fail to the controller. To remove unwanted licenses,

use the removal option on the Wibu administration portal.

• When you lock an Add-On Instruction, the data included in tags is

protected but not to the extent that the logic is protected. If your tags

contain sensitive data, Rockwell recommends putting that data in

literals rather than in tags. Literals are protected at the same level as

the logic in locked routines and Add-On Instructions. In

programmable logic, a literal is a value that is expressed as itself rather

than as a variable's value or the result of an expression.

16 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Cannot change the target of an alias that is referenced by a locked

routine.

Limitations for locked components

After a routine or an Add-On Instruction (AOI) is locked, strict limits apply to

changes made to the routine or to other components the routine references.

This table lists limitations that apply to locked components. An authorized

user can run a locked component. To view or edit a component an authorized

user must unlock the component.

x

Page 17

Limitation

Affects routines

Affects AOIs

allowed.

to a tag of a different type.

element to a target at a different offset from the beginning of the tag.

Cannot change a Produced tag that is used in an IOT instruction to

anything other than a Produced or Module Output tag.

x

Cannot change a Consumed tag to anything other than a Produced,

locked routine.

x

locked routine.

routine.

referenced by a locked routine or AOI.

routine.

Defined Tag that is referenced by a locked routine.

Chapter 2 Configuring source protection in the Logix Designer application

Cannot change a BOOL alias that targets the bit of an integer to target a

x

different bit. However, changing the alias to target a different integer is

Cannot change the target of an alias that is referenced by a locked routine

Cannot change the target of an alias of a member of a UDT or array

x

x

Cannot change an alias referenced by a locked routine to a base tag. x

Cannot change a base tag that is referenced by a locked routine to an

x

alias.

Cannot change an InOut program parameter that is referenced by a locked

x

routine to anything other than an InOut program parameter.

Cannot change a Produced tag to anything other than a Produced,

x

Consumed, Module Input tag or Module Output tag when the Produced tag

is:

• Referenced by a locked routine, and

• Used in a COP, CPS, MAOC or as an InOut argument to an AOI in that

locked routine.

Consumed, Module Input tag, or Module Output tag when the Consumed

tag is:

• Referenced by a locked routine, and

Used in a COP, CPS, MAOC or as an InOut argument to an AOI in that

•

Cannot change a Module Input tag to anything other than a Produced,

Consumed, Module Input tag, or Module Output tag when the Module Input

tag is:

• Referenced by a locked routine, and

Used in a COP, CPS, MAOC or as an InOut argument to an AOI in that

•

Cannot change a Module Output tag to anything other than a Produced,

Consumed, Module Input tag, or Module Output tag when the Module

Output tag is:

• Referenced by a locked routine, and

• Used in a COP, CPS, MAOC or as an InOut argument to an AOI in that

locked routine.

Cannot change a Module Output tag that is used in an IOT instruction to

anything other than a Produced or Module Output tag.

Cannot change a standard tag referenced by a locked routine to a

Produced, Consumed, Module Input, or Module Output tag, if that tag is

used by a COP, CPS, MAOC or used as an AOI InOut argument in that locked

Cannot re-order the members of a User Defined Type of a tag that is

Cannot change the data type of a tag that is referenced by a locked

Cannot update a profile in a way that changes the data type of a Module

x

x

x

x

x x

x

x x

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 17

Page 18

Chapter 2 Configuring source protection in the Logix Designer application

Limitation

Affects routines

Affects AOIs

Cannot reorder, add, change the data type of, or remove parameters in an

x x Cannot convert a project containing locked routines or AOIs to a different

x x Cannot move locked routines or AOIs to a project of a different controller

x

x

currently targeting the same base tag to target different base tags.

referenced by a locked routine.

to a non-Output.

to a local Output.

external Output.

IMPORTANT

Enable source protection

Disable the Configure

Cannot add, remove, or change the data type of a member of a User

Defined Data Type of a tag that is referenced by a locked routine or AOI.

AOI referenced by a locked routine or AOI.

controller family.

family.

Cannot change the target of an AOI output parameter that aliases a local

tag if the AOI is used in a locked AOI.

Cannot change the targets of two aliases referenced by a locked routine

currently targeting different base tags to the same base tag.

Cannot change the targets of two aliases referenced by a locked routine

Cannot change the type of a base tag targeted by an alias that is

Cannot change an external Output that is referenced by a locked routine

Cannot change an external Output that is referenced by a locked routine

Cannot change a local tag that is referenced by a locked routine to an

x x

x

x

x

x

x

x

x

Source Protection

menu option

If Source Protection is unavailable and is not listed in the Tools > Security

menu, enable the Source Protection feature by running the RS5KSrcPtc.exe

tool on the installation CD. The menu item is also enabled when a CmStick

containing a license with protect permissions is inserted into any USB port on

the computer.

Follow these steps to enable Logix Designer source protection.

1. Open the ENU\Tools\Source Protection Tool\Vxx.xx folder on the

Logix Designer installation CD.

2. Run the RS5KSrcPtc.exe file.

You can disable the ability to configure source protection on a workstation by

removing the Configure Source Protection option from the Tools > Security

menu.

Write down the source keys or make a copy of the sk.dat file and store in a secure

location before deleting the sk.dat file.

1. Open the protected project in the Logix Designer application.

2. Click Tools > Security > Configure Source Protection.

3. In the Source Protection Configuration dialog box, click Source Key

Configuration.

4. In the Source Key Configuration dialog box, click Disable Ability To

Configure.

5. In the dialog box that prompts you to confirm the action, click Yes.

18 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 19

permission is connected to the computer.

IMPORTANT

Tip: Password source protection is designed to work with a relatively small number of source keys

opening the Source Protection dialog box.

Protect components

with Source Keys

Chapter 2 Configuring source protection in the Logix Designer application

6. In the dialog box that asks if you want to delete the source key file

(sk.dat), click Yes to remove the source key file from the computer, or

select No to keep the source key file.

Configure Source Protection is removed from the Tools > Security

menu.

Tip: The menu item will not disappear if a CmStick containing a license with the Protect

When Source Key protection is applied to a component, that component is

source-protected. Source keys are user-generated, case-sensitive passwords

that lock Logix Designer components from being viewed or modified by third

parties.

Source Protection can be applied only on a project file that is offline.

Tip: For Add-on Instructions, Source Protection settings cannot be modified if the Add-On

Instruction is sealed. If you wish to source protect and seal an Add-On Instruction, you must apply

the source protection settings before sealing.

in the sk.dat file. When the number of source keys becomes large, there is a corresponding

performance impact when opening source protected projects in the Logix Designer application or

When a component is protected with a Source Key, users without the source

key cannot alter the logic of the component. This affects the following

features:

• Editing - The Language editor does not open, and the edit menus in

the Controller and Logical Organizers are unavailable. The component

icon is also unavailable. If the component is protected with

the Viewable option, users can open the routine editor in read-only

mode.

• Printing - Routines cannot be printed. Add-On instruction can be

printed, but the routines and local tags are not included in the print

out. Routine logic and Add-On Instruction local tags can be printed if

components are protected with the Viewable option.

• Exporting - The protected component is written to the export file in an

encoded format.

• Component Properties - All controls on the dialog boxes of the

components are read-only.

• Search and Replace - Find All is the only available search type

source. Find Next, Replace All, and Replace Next skip the protected

component. When the protected component is skipped, a message

appears on the status bar indicating the source is not available. This

message is also logged to the Search Results tab when performing

a Replace All search. If a component is protected with the Viewable

option, search is permitted but replace is still prevented.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 19

Page 20

Chapter 2 Configuring source protection in the Logix Designer application

IMPORTANT

fail.

About source keys

Source key names

Because users cannot view the logic of a protected routine, the Find All search

results items do not navigate to the found locations. This affects the following:

• Navigation - Users cannot navigate to a protected component.

• Verification - Users cannot navigate to an error in a protected

component.

• Cross Reference - Cross reference information is displayed for items

referenced within a protected component, but users are not allowed to

navigate to the location within the protected component. Doubleclicking to navigate to a protected component beeps and displays a

message on the status bar indicating that users are unable to edit the

component and that the source is not available.

The Go to Location menu item is unavailable.

• Go To - There is no edit item in the Go To dialog box for a protected

component.

• Cut, Copy, Paste - Users can copy, paste, and drag and drop protected

components from the Controller and Logical Organizers.

Use caution when copying and pasting components between different

versions of the Logix Designer application. The application only supports

pasting to the same version or newer version of the application. Pasting to an

earlier version of the application is not supported. When pasting to an earlier

version, the paste action may succeed, but the results may not be as

intended. You cannot paste protected components from later versions of the

application into earlier versions of the application. For example, attempting to

paste from version 19 into version 18 or from version 20 into version 19 will

In version 18 and earlier of RSLogix 5000 software, only IEC-61131 compliant

source keys are recognized. Each source key must begin with a lowercase

character a-z or underscore character ( _ ), and contain only characters

lowercase a-z, 0-9, and an underscore character ( _ ). You can enter uppercase

A-Z characters in RSLogix 5000 software or in the source key file, but the

uppercase characters are converted to lowercase. Source keys are limited to 40

characters in length.

In version 19 and later of the application, source keys are case-sensitive and

may contain any printable ASCII character, excluding the space character.

This includes uppercase A-Z, lowercase a-z, numbers 0-9, and symbols such as

"!@#$%. Source keys are limited to 40 characters in length.

Version 19 and later of the Logix Designer application supports associating

names with source keys. Source key names are descriptive text that help

identify source keys. Where appropriate, the Logix Designer application will

display the source key name in place of the source key itself to provide an

additional layer of security for the source key.

20 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 21

IMPORTANT

IMPORTANT

not already present.

Source key file

Chapter 2 Configuring source protection in the Logix Designer application

Use descriptive names to help identify the purpose of the source. For instance,

a source key used to secure components that field engineers require access

might be named, Field Engineer.

If the same source keys will be used with version 18 and earlier and version 19 and

later of the Logix Designer application, begin each source key with a lowercase

character a-z, or an underscore character ( _ ), and use only characters lowercase az, 0-9 , or an underscore character ( _ ) within the source keys.

If you use source key names in version 19 and later of the application, and your

source keys are IEC61131-3 compliant, your source keys will still work in version 18 and

earlier.

Source keys that are available to the application through an sk.dat file are

unencrypted. We recommend that you write down your source keys or back

up and store the sk.dat file in a secure location. If necessary, the individual

keys can be distributed or provided to the necessary parties.

Source key files are created in an ANSI format in Logix Designer versions 18 and

earlier. In versions 19 and later, the Logix Designer application creates UTF-8

formatted sk.dat files, and modified ANSI sk.dat files are converted to UTF-8 sk.dat

files.

Source keys must not appear on the first line of a UTF-8 formatted sk.dat file. The

first line of UTF-8 formatted sk.dat files is ignored in Logix Designer versions 18 and

earlier. Versions 19 and later insert a header on the first line of the sk.dat file if one is

Follow these steps to assign a name to an existing source key.

1. Click Tools > Security > Configure Source Protection.

2. In the Source Protection Configuration dialog box, click Source Key

Configuration.

3. In the Source Key Configuration dialog box, click View to open the

sk.dat file with a text editor, such as Notepad.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 21

Page 22

Chapter 2 Configuring source protection in the Logix Designer application

preceded with spaces are ignored by the application, and can be used for comments.

IMPORTANT

Apply Source Key

4. Click at the end of an existing, unnamed source key, and press Enter.

Source keys are case sensitive and may use special characters, such as

@#$%(){}[].

5. Press Tab, and type a name for the source key.

Tip: Source keys always begin in the first column of the line in the text editor. A source key

name must be on the line immediately following the source key that it is associated with,

preceded on the line by at least one space. Subsequent lines after the source key that are

6. Save the file. If you used an editor other than Notepad, make sure you

save the file as a text file.

7. Close the Source Key Configuration dialog box and the Source

Protection Configuration dialog box.

8. Click Tools > Security > Configure Source Protection to re-open

the Source Protection Configuration dialog box. The source key name

that you added to the sk.dat file appears as the source key name.

Follow this procedure to apply Source Key protection to a project component.

protection to a component

Source Protection can be applied only on a project file that is offline.

Tip: For Add-on Instructions, Source Protection settings cannot be modified if the Add-On

Instruction is sealed. If you wish to source protect and seal an Add-On Instruction, you must apply

the source protection settings before sealing.

To apply source key protection to a component

1. Open an offline project file in the Logix Designer application.

2. On the menu bar, click Tools > Security > Configure Source

Protection.

3. In the Source Protection Configuration dialog box, select one or more

components that require protection, and click Protect.

By default, the dialog box shows the Protection view in which

components are organized based on the protection applied to them.

When you select the Container view, the components are organized

22 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 23

Chapter 2 Configuring source protection in the Logix Designer application

based on the folder structure in the Controller Organizer and

the Logical Organizer.

4. In the Protect dialog box, on the Protection Type list, click Source Key.

5. In the Source Key to Apply Selected Components list, select the

individual source key for the component.

6. If appropriate, retype the new key in Confirm New Source Key. To

display the source keys in a readable format, select the Show Source

Key check box.

7. If you want to apply a source key name, type the name in Source Key

Name. Do not exceed 40 characters.

8. To allow users to view the logic and local tags on a system that does not

have the source key required for access, select the Allow viewing of

component(s) check box.

9. After you enter the applicable information, click OK.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 23

Page 24

Chapter 2 Configuring source protection in the Logix Designer application

See Enabling source protection on page 18.

Specify a Source Key

10. (optional) In the Source Protection Configuration dialog box,

click Source Key Configuration to open the Source Key Configuration

dialog box and complete details about the source key file location:

• Click Specify to change the path to the source key file location.

• Click View to view the source key file.

• Click Clear to remove the location of the source key file (sk.dat). You

are then given the option to delete the source key file.

• Click Disable Configuration to remove the menu item that invokes

the Source Protection Configuration dialog box. You can then clear

the file location, which is the path listed under Source Key Provider,

or delete the source key file.

file and location

11. Close the Source Protection Configuration dialog box and save the

project file.

Follow these steps to configure a source key file location.

Specify a source key file and location

1. Open an offline project file in the Logix Designer application.

2. On the menu bar, click Tools > Security > Configure Source

Protection.

Tip: This option is not available until you run RS5KSrcPtc.exe

3. In the Logix Designer dialog box, click Yes to specify a file location.

Source protection requires that you specify a source key file location on

your workstation.

4. In the Specify Source Key File Location dialog box, click Browse .

on your workstation.

24 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

5. In the Browse for Folder dialog box, click the folder to store the key

file, and click OK.

Page 25

ocation if one exists on your workstation.

View components

Chapter 2 Configuring source protection in the Logix Designer application

You can save the key file in any accessible folder. In this example the

path to the key file folder is C:\RSLogix 5000\Projects folder.

6. In the Specify Source Key File Location dialog box, click OK.

without a key

The location you selected appears in the Source Protection

Configuration dialog box under Source Key Provider.

If the application does not find a key file in the specified location, the

application prompts you to create a new key file.

Tip: To check for a specific location, on the Source Protection Configuration dialog box,

click Specify. A window appears with the l

7. Click Yes to create a new key file.

Follow these steps to allow source-protected components to be viewed in a

read-only format on a system that does not have the source keys.

To view components without a key

1. On the menu bar, click Tools > Security > Configure Source

Protection.

2. In the Source Protection Configuration dialog box, select one or more

components that require protection and click Protect.

3. Apply a source key to the component.

4. Select the Allow viewing of components check box, and click OK. In

the Source Protection Configuration dialog box, +View appears for

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 25

Page 26

Chapter 2 Configuring source protection in the Logix Designer application

Verify source key

components that are viewable on workstations that do not have the

source key.

5. Click Close.

6. Save the project file and download it to the controller.

Users can open the routine as read-only on a system that does not

contain the source key for the routine, but cannot modify the routine.

Routines or Add-On Instructions that are protected, but are not

configured as viewable, cannot be opened.

protection on a component

Tip: Source-protected content cannot be copied from Logix Designer versions 19 and later

and pasted into earlier software versions. The pasting function is disabled in previous

software versions when source-protected content is placed on the clipboard.

After you apply source key protection to a component, you can verify that the

source key protection is working. To verify a component is protected,

temporarily disable the source key on your workstation.

Follow these steps to verify source key protection by specifying the path to an

empty sk.dat file.

1. On the Source Protection Configuration dialog box, click Specify.

2. On the Specify Source Key File Location dialog box, select a directory

that does not contain an sk.dat file. For example, C:\RSLogix

5000\Projects\Empty.

3. When a message appears asking if you want to create a new file,

click Yes.

4. When the message appears asking if you want to create a new

directory, click Yes. The software points to an empty sk.dat file, which

mimics a user who does not have a source key.

5. Verify that you cannot access the protected component.

6. On the Specify Source Key File Location dialog box, switch back to the

directory that contains your original sk.dat file.

26 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 27

IMPORTANT

License Source Protection

for components

Chapter 2 Configuring source protection in the Logix Designer application

Remove access to a protected routine

You can delete a source key file (sk.dat) from a workstation.

Write down the source keys or make a copy of the sk.dat file and store it in a secure

location before deleting the sk.dat file.

To remove access to a protected routine

1. Open the protected project.

2. Click Tools > Security > Configure Source Protection to open

the Source Protection Configuration dialog box.

3. Click Source Key Configuration.

4. On the Source Key Configuration dialog box, click Clear.

5. When a dialog box asks for confirmation that you want to delete the

source key file, select Yes to remove the source key file from the

workstation.

License Source Protection limits access to projects to only users with the

required license. Users without the required license cannot open the project

or import components protected by the license. A CmStick containing the

corresponding license must be plugged into a USB port on the computer to

open the project containing the component.

License protection uses licenses that you create and administer through a

license portal. Refer to your license portal help for details on using the portal.

Tip: License Source Protection is not supported on the following routine types on Compact

GuardLogix 5380, CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix

5580 controllers:

• Sequential Function Chart routines.

Function Block Diagrams, unless the Function Block Diagram is included in an Add-On Instruction.

When using License Protection on CompactLogix 5380, CompactLogix 5480,

and ControlLogix 5580 controllers, you can also apply Execution Protection

for the component, which allows execution of the component only on a

specific controller family, or only on controllers in a specific controller family

that contain the execution license.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 27

Page 28

Chapter 2 Configuring source protection in the Logix Designer application

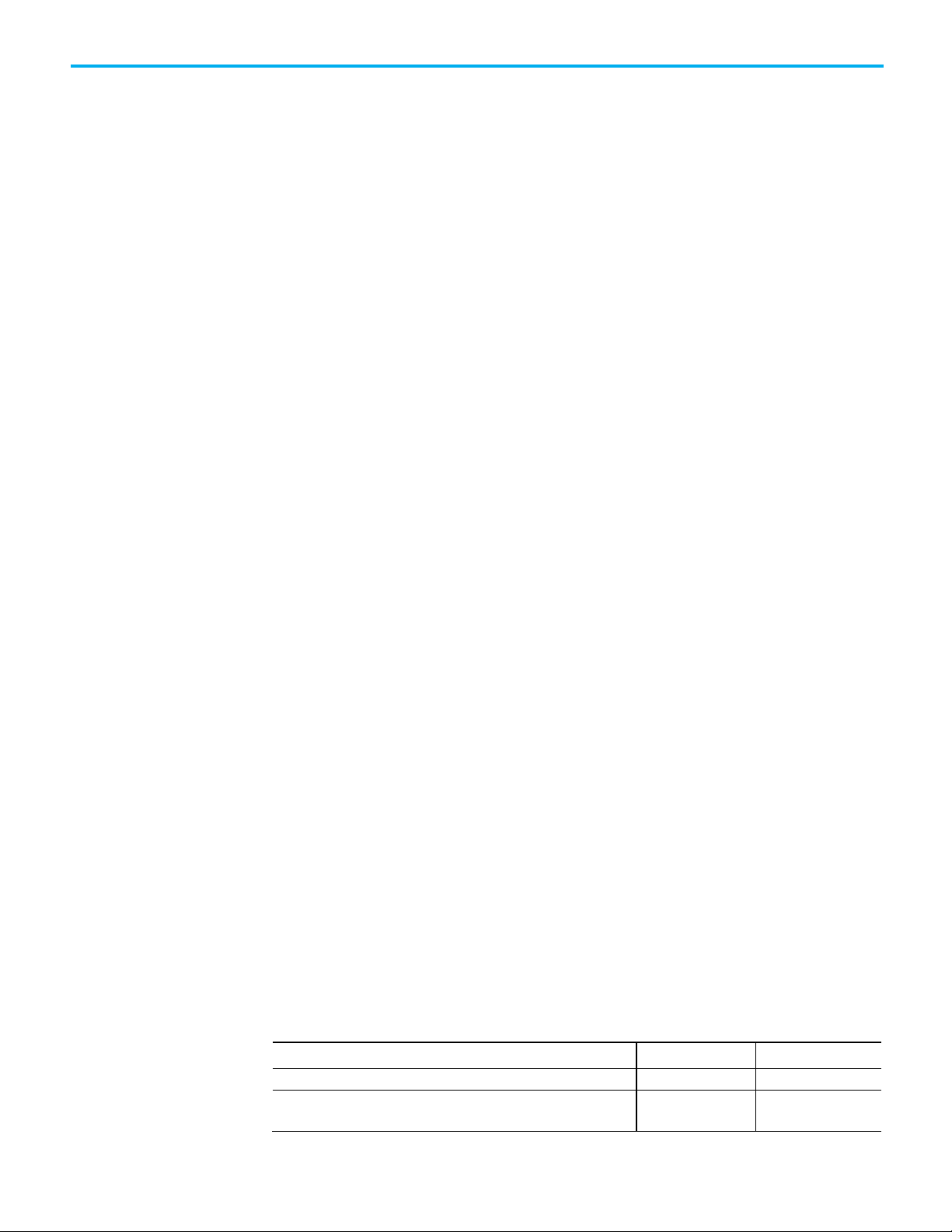

Permission

Description

a License-Protected component when that component has been locked.

Edit

Allows users to edit the routine or Add-On Instruction.

Protected component.

Allows users to copy the logic in the routine or Add

encrypted format.

that component.

Protect components

The following table lists the permissions provided by licenses.

with Licenses

Use This is the minimum permission available for a license. Allows a user to

View Allows users to view routine logic for the component, or local tags for an

open, import, upload, or download the project.

Important: A CmStick containing a license with Use permission must be

present locally on any USB port on the computer. Use permission cannot

be obtained from a network license server. All other license privileges

can be contained on the local CmStick, or provided by a license server

on the network.

On Compact GuardLogix 5380, CompactLogix 5380, CompactLogix

Tip:

5480, ControlLogix 5580, and GuardLogix 5580 controllers, a Use license

is not required to open, import, upload, or download a project containing

Add-On Instruction. It also enables printing, searching, and cross

referencing. Editors and properties dialog boxes for the component are

limited to read-only, and changes are prevented.

Tip: A View license is required to unlock, view, and re-lock a LicenseProtected component.

Tip: A View license is required to unlock, edit, and re-lock a License-

Copy

Export Allows users to export the routine or Add-On Instruction in a non-

Protect Allows users to enable or remove license protection from a component.

Important:

when the Protect permission exists on the license currently protecting

A user can add or remove protection from a component only

-On Instruction.

License Source Protection on a component affects the following features:

• Editing - If the license does not contain the View permission, the

Language editor does not open, the edit menus are unavailable in the

Controller Organizer and the Logical Organizer, and the component

icon is grayed out. With View permission, the editor opens in readonly mode. If the license contains Edit permission, editing is allowed.

• Printing - Routines cannot be printed unless the license contains View

permission. Add-On instructions can be printed, but the routines and

local tags are not printed without View permission.

• Exporting - The protected component is written to the export file in an

encoded format unless the license contains Export permission. To

export in non-encrypted text, the license must contain the Export

permission, and when saving the export file, the user must deselect

the Encode Source Protected Content option. Locked components are

always exported encoded.

•

28 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 29

Tip:

Options dialog box.

Tip:

present.

Important:

from version 20 into version 19 will fail.

Add Execution Protection to

Chapter 2 Configuring source protection in the Logix Designer application

To export protected components in non-encrypted text, you also must uncheck the Always

Encode Protected Content on Export check box on the General tab of the Workstation

• Component Properties - All controls on the dialog boxes of the

components are read-only unless the license contains Edit permission.

• Search and Replace - Find All is the only available search type. Find

Next, Replace All, and Replace Next skip the protected component.

When the protected component is skipped, a message appears on the

status bar indicating the source is not available. This message is also

logged to the search results tab for a Replace All search. Edit and View

permissions control users' ability to search and replace.

When the license does not contain the View permission, users cannot view the

logic of a protected routine, and the Find All search result items do not

navigate to the found locations. This affects the following features:

• Navigation - Users cannot navigate to a protected component.

• Verification - Users cannot navigate to an error in a protected

component.

• Cross Reference - Cross reference information is displayed for items

referenced within a protected component, but users are not allowed to

navigate to the location within the protected component. Doubleclicking to navigate to a protected component displays a message on

the status bar indicating that users are unable to edit the component

and that the source is not available.

Find does not search locked components even when a View license is

License-protected

components

The Go to Location menu item is unavailable.

• Go To - There is no edit item in the Go To dialog box for a protected

component.

• Cut, Copy, Paste - Users can copy, paste, and drag and drop source

protected components from the Controller Organizer or Logical

Organizer. Users cannot copy, paste, or drag and drop logic contained

within the source protected component unless the license contains

Copy permission.

Use caution when copying and pasting components between different versions of

the Logix Designer application. The application only supports pasting to the same

version or newer version of the application. Pasting to an earlier version of the

application is not supported. When pasting to an earlier version, the paste action

may succeed, but the results may not be as intended. You cannot paste protected

components from later versions of the application into earlier versions of the

application. For example, attempting to paste from version 19 into version 18 or

Execution Protection is an extension of License-Based Source Protection. You

can apply Execution Protection to limit the execution of routines and Add-On

Instructions, including equipment phase state routines, to controllers that

contain a specific execution license.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 29

Page 30

Chapter 2 Configuring source protection in the Logix Designer application

Compact GuardLogix 5370, and GuardLogix 5570 controllers.

Apply License Protection to

When you apply Execution Protection to a component, you first apply LicenseBased Source Protection. Therefore, a user applying Execution Protection

must have the same credentials that are required to apply License-Based

Source Protection:

• A CmStick containing a license with Use permission must be present

locally on any USB port on the computer. Use permission cannot be

obtained from a network license server. All other license privileges can

be contained on the local CmStick, or provided by a license server on

the network.

• A license containing the Protect permission, either on a local CmStick

or provided by a license server on the network. When components are

locked, unauthorized users cannot view or edit the component, but

authorized users can run the project without a CmStick.

The following credentials are required to run a component that is protected by

Execution Protection:

• After a component is locked, the controller running the component

must be of the same controller family as the controller on which you

locked the component. For example, when you apply License-Based

Source Protection and Execution Protection to a component on a 5580

controller and lock the component, you can only execute that

component on another 5580 controller. A component that was

protected on a 5580 controller cannot be executed on a 5380 controller.

To execute the component on a controller from a different family, you

must unlock the component and re-lock it on the different family

controller.

• The controller running the component must contain the following

licenses on a CmCard:

one or more components

30 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

• The required Execution license (if any)

• A valid FactoryTalk Activation license for Execution Protection

Follow these steps to apply License Protection to one or more components.

Tip: In this version of the Logix Designer application, License Source Protection does not support

these routine types:

• Safety routines.

• Sequential Function Chart routines.

Function Block Diagrams on Compact GuardLogix 5380, CompactLogix 5380, CompactLogix 5480,

ControlLogix 5580, and GuardLogix 5580 controllers, unless the Function Block Diagram is included

in an Add-On Instruction. However, License-protected Function Block Diagrams are supported are

supported in both routines and Add-On Instructions on CompactLogix 5370, ControlLogix 5570,

Tip: Cannot modify the Source Protection settings if the Add-On Instruction is sealed. To source

protect and seal an Add-On Instruction, apply the source protection settings before sealing.

Page 31

IMPORTANT

corresponding license to open the project or use the component.

Chapter 2 Configuring source protection in the Logix Designer application

On CompactLogix 5380, CompactLogix 5480, ControlLogix 5580, Compact GuardLogix

5380, and GuardLogix 5580 controllers, to open a project when a component is

license-protected but not locked, insert a CmStick containing the corresponding

license into a USB port on the computer. A locked component does not require a

To apply license protection to one or more components

Click Tools > Security > Configure Source Protection to open the Source

Protection Configuration dialog box.

1. Insert the CmStick containing the license that you want to use to

protect the component into the USB port on the computer. Note that

licenses must contain the Protect permission to be used to protect

components. If a license does not contain the Protect permission, it

will not appear in the list of licenses.

2. In the Source Protection Configuration dialog box, select the

component to be protected and click Protect.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 31

Page 32

Chapter 2 Configuring source protection in the Logix Designer application

3. In the Protect dialog box, select the license to apply.

4. On Compact GuardLogix 5380, CompactLogix 5380, CompactLogix

5480, ControlLogix 5580, and GuardLogix 5580 controllers, select the

Execution Protection type:

• Protect with controller key only. This option is selected by default.

With this option selected, the component, when locked, runs only

on a controller in the same family as the one specified for the

project. For example, if you lock a License-Based Protected

component for a project on a 5580 controller, the component can

only be executed on another 5580 controller.

• Protect with controller key and specific license. When you select

this option, the component runs only on a controller in the same

family as the one specified for the project and that contains a

CmCard with the execution license that you select.

If you select Protect with controller key and specific license, select

the execution license from the list of available licenses.

On CompactLogix 5380, CompactLogix 5480, ControlLogix 5580,

Compact GuardLogix 5380, and GuardLogix 5580 controllers, after

components are protected, they can also be locked. Locking a

32 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 33

IMPORTANT

routines and Add-On Instructions.

Tip: When a component is License-Protected, lock and unlock it by selecting it in

once.

Lock a component

Chapter 2 Configuring source protection in the Logix Designer application

component prevents users from viewing or editing the component but

allows authorized users to run it.

5. Click OK to return to the Source Protection Configuration dialog box.

Tip: To save changes to a component that is protected with License-Based Source

Protection, a CmStick containing the required license must be plugged into the computer

running the Logix Designer application.

Make sure you save your edits to the project or lock the protected components before

removing the CmStick containing the required license. If the license is not present, you

could lose your edits to the project.

6. Close the Source Protection Configuration dialog box and save the

project file.

After you apply License Source Protection to a routine or an Add-On

Instruction, you can lock it on Compact GuardLogix 5380, CompactLogix

5380, CompactLogix 5480, ControlLogix 5580, and GuardLogix 5580

controllers.

When locking a component, the routine's logic is compiled into executable

code and encrypted. The code is decrypted by the controller when it is ready

for execution. As a result, sharing project files containing locked components

with users without licenses to use the locked components is possible. Those

users can use unprotected parts of the project, upload and download the

project file, and copy and paste locked components into other project files.

However, if a component is protected using the Protect with controller key

and specific license option, executing the project requires an SD card with the

correct execution license.

Tip: To lock or unlock a component, the source license must be present on a CmStick plugged into

the computer running the Logix Designer application, and the license must contain the View

permission.

When locking a routine or an Add-On Instruction, the data included in tags is

protected, but not to the extent that the logic is protected. If your tags contain

sensitive data, Rockwell recommends putting that data in character string literals

rather than in tags. Literals are protected at the same level as the logic in locked

To lock a component.

1. Apply License Source Protection to the component.

2. In the Source Protection Configuration dialog box, select the

protected component.

3. Click Lock.

4. To unlock the component, select it and click Unlock.

the Controller Organizer, right-clicking, and selecting Lock or Unlock. Use the Security

toolbar to lock and unlock a component or to lock all License-Protected components at

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 33

Page 34

Chapter 2 Configuring source protection in the Logix Designer application

Designer application still locks other components that can be locked without error.

Lock all License-Protected

Add an LV instruction to

content

When a routine or an Add-On Instruction is protected by License Source

Protection, it should be locked if it is shared outside a trust boundary, such as

being emailed over the internet or sent to an end customer. Projects that

contain unlocked components are in a less secure state than locked

components and should not be distributed.

To lock all license-protected components in a project at once, use the Lock All

button on the Security toolbar.

To lock all components in a project:

1. Apply License Source Protection to the components that you need to

protect.

2. On the Security toolbar, click the Lock All button. This button is

disabled when there are no components to be locked.

You can also select, on the main menu, Tools > Security > Lock all

unlocked content.

Tip: If an error prevents a component from locking, an error message appears. The Logix

monitor license status

Share License privileges with other users on your network

To monitor license status and verify the license is not expired or removed,

insert a License Validation (LV) instruction in a Ladder diagram. The LV

instruction checks that a non-expired license associated with a routine or an

Add-On Instruction is present in the controller. Insert additional logic in the

routine to act on the license status.

Adjust network settings to provide additional privileges to users on the

network or to use License Source Protection when using a remote desktop

connection.

When sharing license privileges with users on the network consider:

• Configure the network to allow communication between the devices

that need to share license privileges. Set TCP and UDP ports 22350 to

open on the computer that provides privileges.

• Enable the license to share for network use. Use the License Portal to

configure licenses and optionally enable them for network use.

• The computers that receive permissions from the remote workstation

must install a CmStick that contains the same license with Use

permission. Plug the CmStick into a USB port locally on the

computers.

You can share license privileges with other users and provide license

privileges to users of remote desktop.

34 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 35

IMPORTANT

USB port on your computer.

Provide License privileges

Chapter 2 Configuring source protection in the Logix Designer application

Follow these steps to provide license privileges to users on your network.

to other users

1. To open the CodeMeter Control Center™ application, on the computer

that is going to provide additional privileges, navigate to the

C:\Program Files (x86)\CodeMeter\Runtime\bin folder and run

the CodeMeter.exe file.

Your computer should have a CmStick installed that contains a license with all

the privileges that you want to share. The CmStick should be plugged into a

2. Click WebAdmin to open the CodeMeter WebAdmin window in your

default web browser.

3. Click Configuration > Server, select Run network server, and

click Apply.

4. Click Configuration > Access Control and select Advanced.

5. Under Default action, select Deny and click Apply.

6. Under Access Control Mode, select Basic.

7. Click Add and enter the list of users (user names, IP addresses, user

groups, or subnets) who can access your shared license. Click Apply.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 35

Page 36

Chapter 2 Configuring source protection in the Logix Designer application

IMPORTANT

A CmStick containing a license with

permission must be present locally

permission cannot be obtained from a shared license.

Provide license privileges

8. On the CodeMeter Control Center, navigate to the Process tab to stop

and restart CodeMeter.

9. On the computers that need to receive the shared license privileges,

open the CodeMeter Control Center application.

on any USB port on the computer that receives shared permissions. Use

Use

10. Click WebAdmin to open the CodeMeter WebAdmin window.

11. On the Configuration tab, in the server list, add the name or IP

address of the computer that you configured as a license server.

12. Restart CodeMeter.

Tip: When the Server Search List is blank in the CodeMeter WebAdmin tool, CodeMeter

searches all servers that it finds on your subnet. When a user has a license that is also on a

license server, the user's permissions might be upgraded to match the license on the

server. To prevent accidental granting of privileges and to prevent CodeMeter from

searching unnecessarily, add 127.0.0.1 (the localhost IP address) to the Server Search List.

for remote desktop users

36 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Follow these steps to provide license privileges for remote desktop users on

your network.

Page 37

IMPORTANT

Chapter 2 Configuring source protection in the Logix Designer application

To provide license privileges for remote desktop users

1. On the remote desktop client computer, open the CodeMeter Control

Center application. To open the application, navigate to the

C:\Program Files (x86)\CodeMeter\Runtime\bin folder, and run

the CodeMeter.exe file.

Your computer should have a CmStick installed that contains a license with all

the privileges that you want to use remotely. The CmStick should be plugged

into a USB port on your computer.

2. Click WebAdmin to open the CodeMeter WebAdmin window in your

default web browser.

3. Click Configuration > Server, select Run network server, and

click Apply.

4. Click Configuration > Access Control and select Advanced.

5. Under Default action, select Deny and click Apply.

6. Under Access Control Mode, select Basic.

7. Click Add and enter the list of users (user names, IP addresses, user

groups, or subnets) who can access your shared license. Click Apply.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 37

Page 38

Chapter 2 Configuring source protection in the Logix Designer application

IMPORTANT

A CmStick containing a corresponding license with

permission must be

cannot be obtained from a remote computer.

8. On the CodeMeter Control Center, navigate to the Process tab to stop

and restart CodeMeter.

9. Log onto the remote computer with remote desktop.

10. On the remote computer, open the CodeMeter Control Center

application.

present locally on any USB port on the remote desktop server. Use permission

Use

11. On the Configuration tab, in the server list, add the name or IP

address of the computer that contains the needed permissions.

12. Navigate to the Process tab on the CodeMeter Control Center to stop

and then restart CodeMeter.

Tip: When the Server Search List is blank in the CodeMeter WebAdmin tool, CodeMeter

searches all servers that it finds on your subnet. When a user has a license that is also on a

license server, the user's permissions might be upgraded to match the license on the

server. To prevent accidental granting of privileges and to prevent CodeMeter from

searching unnecessarily, add 127.0.0.1 (the localhost IP address) to the Server Search List.

38 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 39

IMPORTANT

The Logix CPU Security Tool is supported only in Logix Designer application versions

Chapter 2 Configuring source protection in the Logix Designer application

Securing a ControlLogix controller with the Logix CPU Security Tool

You can secure a controller with the Logix CPU Security Tool. The Logix CPU

Security Tool is automatically installed when you install Logix Designer

version 17, 18, or 19. The tool is installed under the Logix Designer menu bar

on the Tools menu.

17, 18, and 19. It is not supported in versions 20 and later.

1. Click the Start button, then click All Programs, then click Rockwell

Software, then click RSLogix 5000, and then click Logix CPU Security

Tool.

2. In the Logix CPU Security dialog box, click the RSWho button to

specify a path to the controller.

Rockwell Automation Publication 1756-PM016O-EN-P - September 2020 39

Page 40

Chapter 2 Configuring source protection in the Logix Designer application

3. Select the controller that you want to secure and click OK.

The Logix CPU Security Tool displays the current status of the

controller. Notice that the controller in the following image is currently

unsecured and there is no password set in the controller.

4. Click Change Password.

5. In the Change Password dialog box, in the New Password box type a

password, and then in the Confirm New Password box, retype the

password. Click OK.

40 Rockwell Automation Publication 1756-PM016O-EN-P - September 2020

Page 41

Chapter 2 Configuring source protection in the Logix Designer application

The Password Status for the controller changes to indicate a Password

exists in the controller, but the controller is not secured yet.

6. Click Secure Controller.

7. In the Secure Controller dialog box, in the Password box, type the

password for the controller and then click Secure.

8. If the controller has nonvolatile memory installed, you can select

the Save to Nonvolatile Memory after controller is secured check box

to save the security state of the controller to nonvolatile memory. Refer