Page 1

GuardPLC Controller Systems

Bulletin

User Manual

1753, 1754, 1755

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of electromechanical equipment. Safety Guidelines

for the Application, Installation and Maintenance of Solid State Controls (publication SGI-1.1

Automation sales office or online at http://www.rockwellautomation.com/literature/

between solid state equipment and hard-wired electromechanical devices. Because of this difference, and also because of the

wide variety of uses for solid state equipment, all persons responsible for applying this equipment must satisfy themselves that

each intended application of this equipment is acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use

or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and

requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or liability for

actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software

described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is

prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

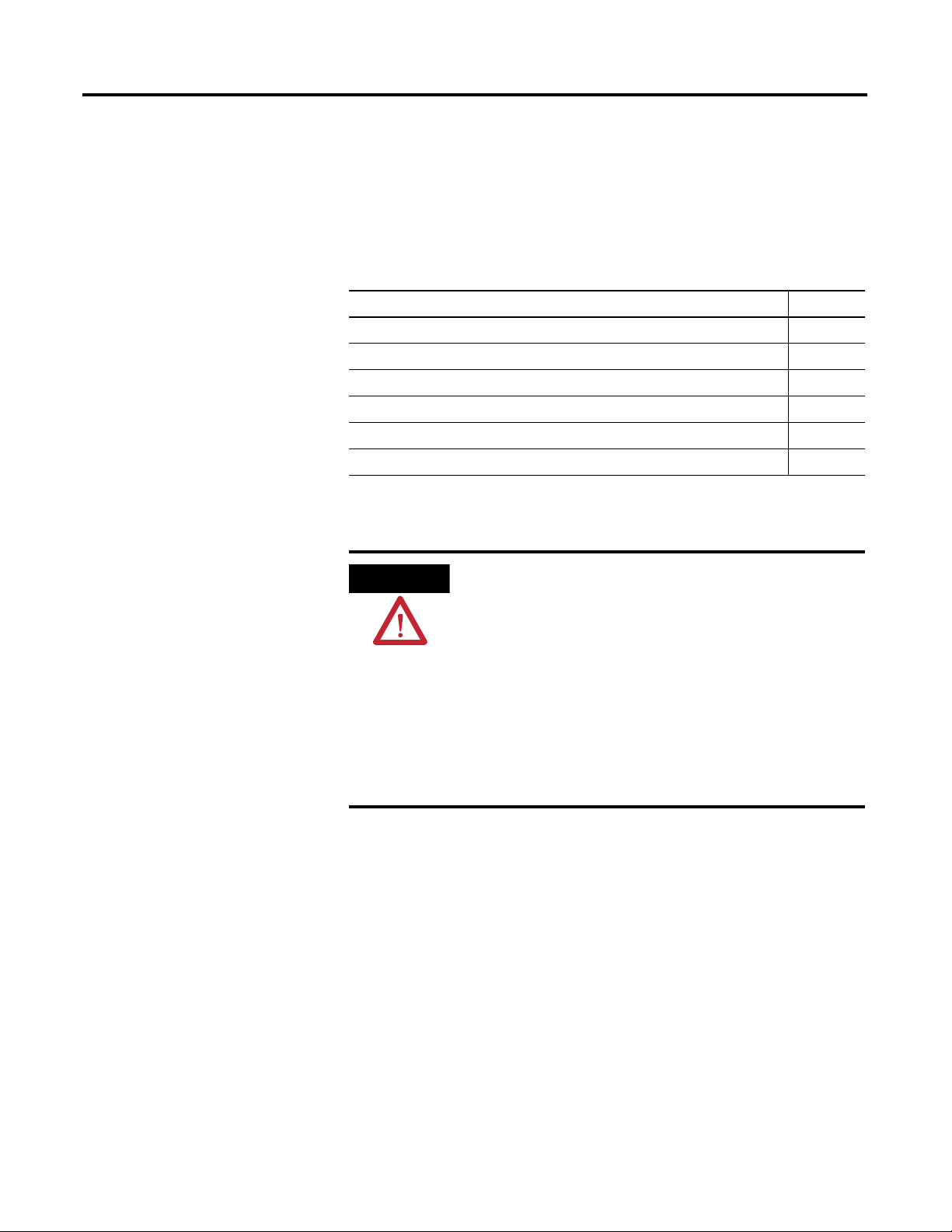

WARNING

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property damage, or economic loss.

available from your local Rockwell

) describes some important differences

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Allen-Bradley, Rockwell Automation, GuardPLC, GuardPLC 1200, GuardPLC 1600, GuardPLC 1800, GuardPLC 2000, RSLogix Guard PLUS!, RSNetWorx, RSNetWorx for EtherNet/IP, RSLinx, RSLogix,

RSLogix 5, RSLogix 5000, PLC-5, ControlLogix, FlexLogix, CompactLogix, SLC 500, PanelView, PanelView Plus, VersaView, FLEX I/O, POINT I/O, PanelBuilder 32, Rockwell Software, and

TechConnect are trademarks of Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Identifies information that is critical for successful application and understanding of the product.

Identifies information about practices or circumstances that can lead to personal injury or death, property damage,

or economic loss. Attentions help you identify a hazard, avoid a hazard, and recognize the consequence

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may

be present.

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach

dangerous temperatures.

Page 3

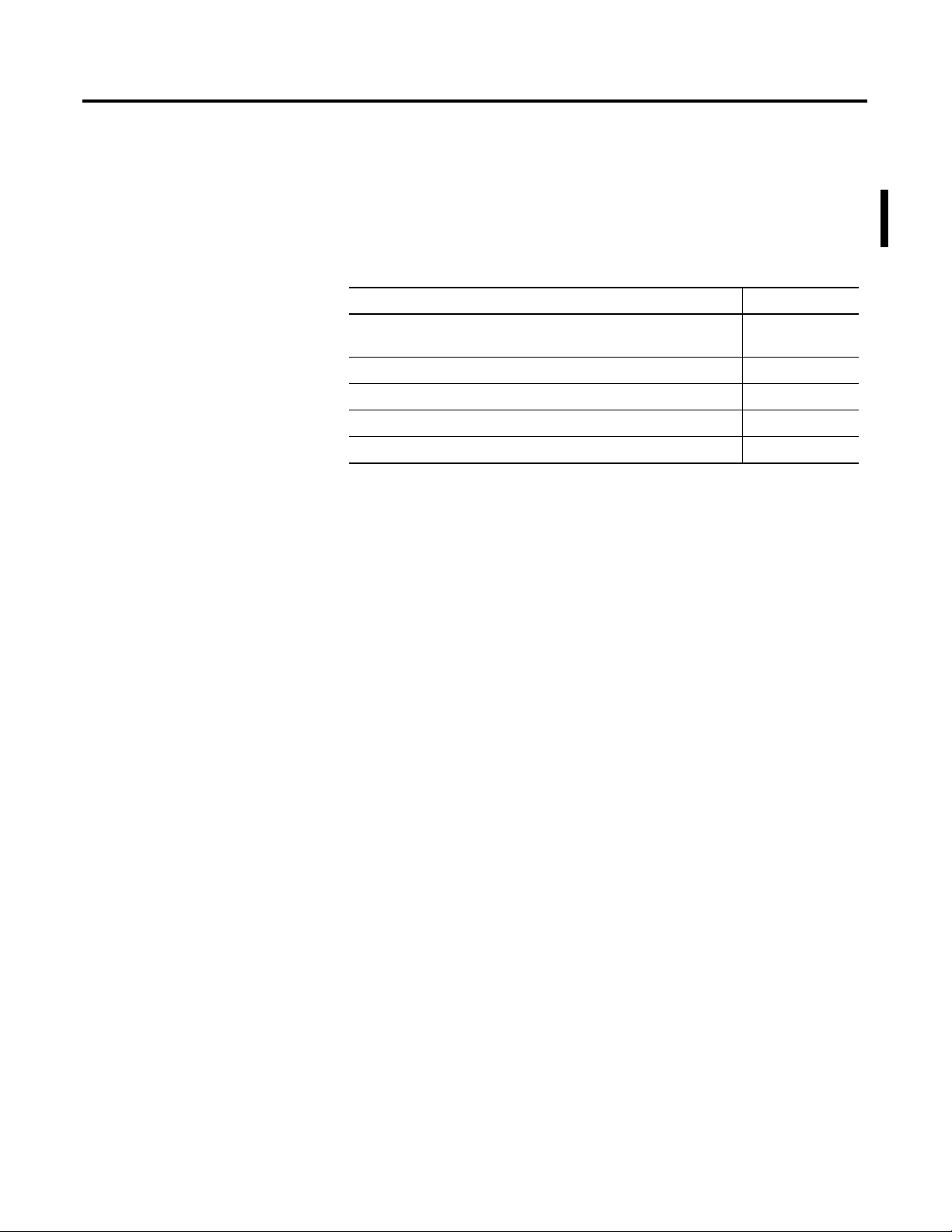

Summary of Changes

The information below summarizes the changes to this manual since

the last publication.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

For Information About See

Configuring Communication Between the Controller and a

PanelView PLUS Terminal

Updated GuardPLC 1800 specifications 286

Added service life specifications for 1753-OW8 module 294

Updated information on battery replacement Appendix D

Various updates to style and format throughout

205

3Publication 1753-UM001C-EN-P - March 2010 3

Page 4

Summary of Changes

Notes:

4 Publication 1753-UM001C-EN-P - March 2010

Page 5

Overview of Safety Controllers

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . . 17

Purpose of This Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Additional Resources. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Chapter 1

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Safety Concept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Response to Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Safe States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

GuardPLC System Hardware . . . . . . . . . . . . . . . . . . . . . . . . 21

GuardPLC 1200 System . . . . . . . . . . . . . . . . . . . . . . . . . 21

GuardPLC 1600 and GuardPLC 1800 System . . . . . . . . . . 22

GuardPLC Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . 23

GuardPLC 2000 System . . . . . . . . . . . . . . . . . . . . . . . . . 25

Communication Capabilities . . . . . . . . . . . . . . . . . . . . . . . . 27

GuardPLC Ethernet Network. . . . . . . . . . . . . . . . . . . . . . 27

EtherNet/IP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

ASCII. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

High-speed Safety Protocol . . . . . . . . . . . . . . . . . . . . . . 29

Modbus RTU Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

PROFIBUS DP Slave. . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

OPC Server . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Installation

Chapter 2

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

General Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Mount the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . 32

GuardPLC 1600 and GuardPLC 1800 Controllers,

and Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

GuardPLC 2000 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . 34

GuardPLC 2000 Controller, I/O, and Power Supply . . . . . 36

Communication Connections . . . . . . . . . . . . . . . . . . . . . . . . 38

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . 38

GuardPLC 1600 and GuardPLC 1800 Controllers . . . . . . . 39

GuardPLC Distributed I/O Modules . . . . . . . . . . . . . . . . 41

GuardPLC 2000 Controller . . . . . . . . . . . . . . . . . . . . . . . 42

Reset Pushbutton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

5Publication 1753-UM001C-EN-P - March 2010 5

Page 6

Table of Contents

General Wiring Considerations

Wire GuardPLC 1600, GuardPLC

1800, and GuardPLC 1200

Controllers

Chapter 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Prevent Electrostatic Discharge . . . . . . . . . . . . . . . . . . . . . . 45

Power Supply Considerations . . . . . . . . . . . . . . . . . . . . . . . 45

Ground the Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Considerations for Grounding All Controllers . . . . . . . . . 46

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . 46

GuardPLC 1600 and GuardPLC 1800 Controllers and

Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

GuardPLC 2000 Chassis . . . . . . . . . . . . . . . . . . . . . . . . . 47

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Shield-contact Plate Connections . . . . . . . . . . . . . . . . . . . . . 48

Detailed Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . 48

Chapter 4

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . 49

GuardPLC 1600 and GuardPLC 1800 Controllers . . . . . . . 49

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . 50

Safety-related Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . 50

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . 51

Safety-related Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . 51

High-speed Counters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Wire the GuardPLC 1600 Controller . . . . . . . . . . . . . . . . . . . 53

Safety-related Digital Input Terminals . . . . . . . . . . . . . . . 53

Safety-related Digital Output Terminals. . . . . . . . . . . . . . 54

Wire the GuardPLC 1800 Controller . . . . . . . . . . . . . . . . . . . 54

Safety-related Digital Input Terminals . . . . . . . . . . . . . . . 55

Safety-related Digital Output Terminals. . . . . . . . . . . . . . 56

Safety-related Analog Input Terminals. . . . . . . . . . . . . . . 56

Safety-related High-speed Counter Terminals . . . . . . . . . 58

Wire the GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . 58

Lower Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Upper Terminal Block . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Chapter 5

Wire the GuardPLC 2000 Controller

and I/O

6 Publication 1753-UM001C-EN-P - March 2010

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Safety-related Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . 61

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . 62

Safety-Related Analog Inputs (1755-IF8) . . . . . . . . . . . . . . . . 62

High-speed Counter Module (1755-HSC) . . . . . . . . . . . . . . . 63

Safety-related Analog Output Module (1755-OF8). . . . . . . . . 64

Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Wire the 1755-IB24XOB16 Digital I/O Module . . . . . . . . . . . 65

Wire the 1755-IF8 Analog Input Module. . . . . . . . . . . . . . . . 66

Page 7

Wire 1753-IB16, 1753-OB16, and

1753-IB20XOB8 Modules

Table of Contents

Wire the 1755-OF8 Analog Output Module. . . . . . . . . . . . . . 66

Wire the 1755-HSC Counter Modules . . . . . . . . . . . . . . . . . . 68

Chapter 6

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Safety-related Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . 69

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . 70

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . 70

Wire the 1753-IB16 Input Module . . . . . . . . . . . . . . . . . . . . 71

Safety-related Digital Inputs . . . . . . . . . . . . . . . . . . . . . . 71

Pulse Test Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Wire the 1753-OB16 Output Module . . . . . . . . . . . . . . . . . . 73

Operating Voltage Considerations. . . . . . . . . . . . . . . . . . 73

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . 73

Wire the 1753-IB20XOB8 Combination Module . . . . . . . . . . 75

Safety-related Digital Inputs . . . . . . . . . . . . . . . . . . . . . . 75

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . 76

Wire and Configure the

1753-IB8XOB8 Module

Wire and Configure the

1753-IB16XOB8 Module

Chapter 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Safety-related Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . 77

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 78

Surge on Digital Inputs . . . . . . . . . . . . . . . . . . . . . . . . . 78

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . 78

Signals for Output Configuration . . . . . . . . . . . . . . . . . . 79

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Pulse Test Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

Chapter 8

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83

Safety-related Digital Inputs. . . . . . . . . . . . . . . . . . . . . . . . . 83

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 85

Safety-related Digital Outputs . . . . . . . . . . . . . . . . . . . . . . . 86

Configuration. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 86

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 90

Monitor for Line Short Line Break . . . . . . . . . . . . . . . . . . . . 91

Line Monitoring for Lamp and Inductive Loads . . . . . . . . 91

Line Monitoring with Reduced Voltage for Resistive,

Capacitive Loads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Required Signals for Line Monitoring . . . . . . . . . . . . . . . 93

Pulse Test Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 93

Publication 1753-UM001C-EN-P - March 2010 7

Page 8

Table of Contents

Wire the 1753-IF8XOF4 Analog I/O

Module

Wire the 1753-OW8 Relay Output

Module

Pulse Testing

Chapter 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Safety-related Analog Inputs . . . . . . . . . . . . . . . . . . . . . . . . 95

Voltage Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Current Measurement. . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Standard Analog Outputs. . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . 98

Chapter 10

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Safety-related Relay Outputs . . . . . . . . . . . . . . . . . . . . . . . . 99

Terminal Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Example: Connecting Actuators to the Outputs . . . . . . . 100

Voltage Supply Considerations. . . . . . . . . . . . . . . . . . . . . . 100

Chapter 11

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

Response to OS Configurable Faults. . . . . . . . . . . . . . . . . . 102

Wire for OS Configurable Line Control. . . . . . . . . . . . . . . . 103

GuardPLC 1600 Controller and 1753-IB20XOB8

Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

1753-IB16, 1753-IB8XOB8, and 1753-IB16XOB8

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

Input Configuration for Pulse Testing. . . . . . . . . . . . . . . . . 105

Chapter 12

High-Speed Counters

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Counter/Decoder Modes . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Counter Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Decoder Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 108

Understand Counter Module Configuration . . . . . . . . . . . . 109

Counter Mode/Manual Direction. . . . . . . . . . . . . . . . . . 109

Counter Mode/Direction and Reset . . . . . . . . . . . . . . . . 110

Decoder Mode/Gray Codes . . . . . . . . . . . . . . . . . . . . . 111

Chapter 13

Controller Configuration and

Modes of Operation

8 Publication 1753-UM001C-EN-P - March 2010

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Controller Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Recover From a Failure_Stop . . . . . . . . . . . . . . . . . . . . 116

Controller Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Routine Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Load a Configuration and Routine (in Stop Mode only). . . . 121

Test Mode of the Routine . . . . . . . . . . . . . . . . . . . . . . . . . 122

Page 9

Use the Control Panel to Monitor

Status

Diagnostics

Table of Contents

Chapter 14

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Resource State Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Safety Parameters Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Statistics Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

P2P (Peer-to-Peer) State Tab . . . . . . . . . . . . . . . . . . . . . . . 127

Distributed I/O Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

HH (High-level High-speed) State Tab . . . . . . . . . . . . . . . . 128

Environment Data Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

OS Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

HSP Protocol Tab . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

EIP Protocol Tab. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Use the Multi Control Panel. . . . . . . . . . . . . . . . . . . . . . . . 132

Control Panel Resource Menu . . . . . . . . . . . . . . . . . . . . . . 135

Control Panel Extra Menu . . . . . . . . . . . . . . . . . . . . . . . . . 136

Chapter 15

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 139

View Controller Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . 139

Choose Online or Offline Diagnostics . . . . . . . . . . . . . . 141

Filtering Diagnostic Data . . . . . . . . . . . . . . . . . . . . . . . 141

GuardPLC 1200 Controller Status Indicators . . . . . . . . . . . . 142

GuardPLC 1600 and GuardPLC 1800 Controllers and GuardPLC

Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

System Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . 143

Communication Status Indicators . . . . . . . . . . . . . . . . . 144

GuardPLC 2000 Controller Status Indicators . . . . . . . . . . . . 145

Controller Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Routine Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . 146

Ethernet Communication Indicators . . . . . . . . . . . . . . . 146

Serial Communication Indicators. . . . . . . . . . . . . . . . . . 147

1755-IB24XOB16 Module Status Indicators . . . . . . . . . . . . . 147

Power Supply and Module Status . . . . . . . . . . . . . . . . . 147

I/O Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

1755-IF8 Analog Input Module Status Indicators . . . . . . . . . 148

1755-OF8 Analog Output Module Status Indicators . . . . . . . 149

1755-HSC Combination High-speed Counter and Output Module

Status Indicators . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Power Supply and Module Status . . . . . . . . . . . . . . . . . 150

I/O Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 150

Chapter 16

Peer-to-peer Communication

Overview

Publication 1753-UM001C-EN-P - March 2010 9

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Peer-to-peer Communication Basics. . . . . . . . . . . . . . . . . . 151

Networking Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . 152

Page 10

Table of Contents

Network Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . 153

HH Protocol Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . 153

Token Group ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Protocol Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 154

Link Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Response Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Token Cycle Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Token Alive Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Primary Timeout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Secondary Interval . . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Link Mode (Extern) . . . . . . . . . . . . . . . . . . . . . . . . . . . 156

Response Time (Extern) . . . . . . . . . . . . . . . . . . . . . . . . 156

Peer-to-peer Protocol Parameters. . . . . . . . . . . . . . . . . . . . 157

Message Response Time (ReponseTime). . . . . . . . . . . . 157

Receive Timeout (ReceiveTMO) . . . . . . . . . . . . . . . . . . 158

Resend Timeout (ResendTMO) . . . . . . . . . . . . . . . . . . . 159

Acknowledge Timeout (AckTMO) . . . . . . . . . . . . . . . . 159

Queue Length (QueueLen). . . . . . . . . . . . . . . . . . . . . . 159

Production Rate (ProdRate) . . . . . . . . . . . . . . . . . . . . . 160

Watchdog Time (WDZ) . . . . . . . . . . . . . . . . . . . . . . . . 160

Worst-case Reaction Time (TR). . . . . . . . . . . . . . . . . . . 160

HH Network Profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Profile I: Fast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Profile II: Medium . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

The None Profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 167

Peer-to-Peer Network Profiles . . . . . . . . . . . . . . . . . . . . . . 168

Peer-to-Peer Profile I: Fast & Cleanroom . . . . . . . . . . . . 169

Peer-to-Peer Profile II: Fast & Noisy . . . . . . . . . . . . . . . 170

Peer-to-Peer Profile III: Medium & Cleanroom. . . . . . . . 171

Peer-to-Peer Profile IV: Medium & Noisy . . . . . . . . . . . 172

Peer-to-Peer Profile V: Slow & Cleanroom. . . . . . . . . . . 173

Peer-to-Peer Profile IV: Slow & Noisy . . . . . . . . . . . . . . 174

Chapter 17

Configure Peer-to-Peer

Communication

10 Publication 1753-UM001C-EN-P - March 2010

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Considerations for Using Peer-to-peer . . . . . . . . . . . . . . . . 175

Set Peer-to-Peer Controller Properties . . . . . . . . . . . . . . . . 176

Create a Peer-to-peer Network. . . . . . . . . . . . . . . . . . . . . . 178

Create Token Group(s) . . . . . . . . . . . . . . . . . . . . . . . . 178

Add Controllers to Token Group(s) . . . . . . . . . . . . . . . 179

Configure Token Group(s) . . . . . . . . . . . . . . . . . . . . . . 179

Design the Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180

Create Peer-to-peer Signals. . . . . . . . . . . . . . . . . . . . . . 180

Use Peer-to-peer System Signals . . . . . . . . . . . . . . . . . . 181

Design the Logic for all Controllers. . . . . . . . . . . . . . . . 182

Page 11

Table of Contents

Configure Peer-to-peer Communication . . . . . . . . . . . . . . . 184

Define Controller Connections . . . . . . . . . . . . . . . . . . . 184

Assign HH-Network . . . . . . . . . . . . . . . . . . . . . . . . . . . 185

Choose a Peer-to-peer Profile. . . . . . . . . . . . . . . . . . . . 186

Define Peer-to-peer Parameters . . . . . . . . . . . . . . . . . . 186

Define The Signals to Exchange Between Each

Controller Connection . . . . . . . . . . . . . . . . . . . . . . . . . 187

Compile and Download . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Compile Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Start Download . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Network Optimizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 190

Check Routine Timing . . . . . . . . . . . . . . . . . . . . . . . . . 191

Reconfigure Watchdog Time . . . . . . . . . . . . . . . . . . . . 192

Check HH Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 193

Check Peer-to-peer Status. . . . . . . . . . . . . . . . . . . . . . . 194

Reconfigure ResponseTime . . . . . . . . . . . . . . . . . . . . . 195

Reconfigure Receive Timeout . . . . . . . . . . . . . . . . . . . . 197

Introduction to EtherNet/IP

Communication

Chapter 18

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 199

EtherNet/IP Communication Overview. . . . . . . . . . . . . . . . 199

GuardPLC Controller as an Adapter . . . . . . . . . . . . . . . 199

GuardPLC Controller as a Scanner . . . . . . . . . . . . . . . . 201

Data Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 202

Software Required to Configure EtherNet/IP

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 203

Add EtherNet/IP Protocol to the Resource . . . . . . . . . . . . . 203

View the Controller IP Settings . . . . . . . . . . . . . . . . . . . . . 204

Configuring Communication Between the Controller and a

PanelView PLUS Terminal . . . . . . . . . . . . . . . . . . . . . . . . . 205

Set Up FactoryTalk View Studio Machine Edition

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 206

Add Ethernet/IP Protocol to Your Project . . . . . . . . . . . 208

Read Integers from the Controller and Display Them

on the PanelView Plus Terminal . . . . . . . . . . . . . . . . . . 209

Read BOOLs from the GuardPLC Controller and Display

Them on the PanelView Plus Terminal . . . . . . . . . . . . . 210

Writing Integers to the GuardPLC Controller from the

PanelView Plus Terminal . . . . . . . . . . . . . . . . . . . . . . . 212

Writing BOOLs to the GuardPLC Controller from the

PanelView Plus Terminal . . . . . . . . . . . . . . . . . . . . . . . 213

Publication 1753-UM001C-EN-P - March 2010 11

Page 12

Table of Contents

Use GuardPLC Controller as an

Adapter

Chapter 19

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 215

Configure the GuardPLC Controller as an Adapter . . . . . . . 215

Configure the Adapter Input Assembly . . . . . . . . . . . . . 215

Configure the Adapter Output Assembly . . . . . . . . . . . . 216

Connect Signals to the Adapter Assemblies . . . . . . . . . . 217

Open a Class 1 Connection from a Logix Controller to the

GuardPLC Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Configure the Logix Controller in RSLogix 5000

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 219

Configure the Type of Connection . . . . . . . . . . . . . . . . 220

Download and Go Online . . . . . . . . . . . . . . . . . . . . . . 225

Monitor Connection Status . . . . . . . . . . . . . . . . . . . . . . 226

Use the Force Editor to Test the Connection . . . . . . . . . 227

Remove or Inhibit a Connection . . . . . . . . . . . . . . . . . . 228

Open a Class 3 Connection from a Logix Controller . . . . . . 228

Configure the GuardPLC Controller Assemblies . . . . . . . 228

Create a Project for the Logix Controller . . . . . . . . . . . . 229

Create Tags to Read and Write Assembly Data . . . . . . . 229

Create Ladder Logic . . . . . . . . . . . . . . . . . . . . . . . . . . . 230

Download and Go to Run . . . . . . . . . . . . . . . . . . . . . . 233

Verify the Data Exchange. . . . . . . . . . . . . . . . . . . . . . . 233

Use a GuardPLC Controller as an Unconnected Adapter . . . 235

Use Unconnected PCCC Messaging from a PLC-5 or

SLC 5/05 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 235

Configure an EtherNet/IP Driver. . . . . . . . . . . . . . . . . . 237

Create an EtherNet/IP Project in RSLogix Programming

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 237

Add a Message Instruction to Your Application Program

Logic. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 239

Use Unconnected CIP Messaging from a PanelView

Standard Terminal. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 243

Create an EtherNet/IP Application . . . . . . . . . . . . . . . . 244

Configure the PanelView Terminal for EtherNet/IP

Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 245

Configure a Write Operation . . . . . . . . . . . . . . . . . . . . 246

Configure a Read Operation . . . . . . . . . . . . . . . . . . . . . 247

Chapter 20

Use the GuardPLC Controller as a

Scanner

12 Publication 1753-UM001C-EN-P - March 2010

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Prepare the GuardPLC Controller for Class 1 Scanner

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 249

Connect the Scanner Signals. . . . . . . . . . . . . . . . . . . . . 250

Disable Scanner Function on the Controller . . . . . . . . . 251

Configure the EtherNet/IP Driver . . . . . . . . . . . . . . . . . . . . 252

Page 13

Communicate with ASCII Devices

Table of Contents

Configure Connections in RSNetWorx for EtherNet/IP

Software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 254

Open a Connection to a Logix Controller . . . . . . . . . . . . . . 260

Create a Producing Data Tag . . . . . . . . . . . . . . . . . . . . 260

Configure Connections from the GuardPLC Controller

to the Logix Controller . . . . . . . . . . . . . . . . . . . . . . . . . 261

Save the Connection Configuration in the GuardPLC

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 262

Remove the Connection Configuration. . . . . . . . . . . . . . . . 263

Chapter 21

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 265

Connect the Controller to an ASCII Device. . . . . . . . . . . . . 265

Connect to a GuardPLC 1200 Controller . . . . . . . . . . . . 265

Connect to a GuardPLC 1600 or 1800 Controller . . . . . . 266

Connect to a GuardPLC 2000 Controller . . . . . . . . . . . . 267

Configure the ASCII Serial Port . . . . . . . . . . . . . . . . . . . . . 268

Connect Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 269

ASCII Protocol . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270

ASCII Master - Request. . . . . . . . . . . . . . . . . . . . . . . . . 270

ASCII Slave - Controller Response. . . . . . . . . . . . . . . . . 271

Data Type Formats. . . . . . . . . . . . . . . . . . . . . . . . . . . . 273

Communicate with Modbus and

Profibus Devices

Specifications

Chapter 22

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 275

Modbus RTU Slave Protocol . . . . . . . . . . . . . . . . . . . . . . . 275

Connect the Controller to a Modbus Device . . . . . . . . . 276

Configure the Modbus Serial Port . . . . . . . . . . . . . . . . . 276

Connect Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 277

Profibus DP Slave Protocol . . . . . . . . . . . . . . . . . . . . . . . . 279

Connect the Controller to a Profibus DP Device . . . . . . 279

Configure the Profibus DP Serial Port . . . . . . . . . . . . . . 280

Connect Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 280

Configure the Profibus Master . . . . . . . . . . . . . . . . . . . 282

Appendix A

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 283

GuardPLC 1600 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 284

GuardPLC 1800 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 286

Distributed I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 288

1753-IB16 Input Module. . . . . . . . . . . . . . . . . . . . . . . . 288

1753 Combination I/O Modules . . . . . . . . . . . . . . . . . . 290

1753-IF8XOF4 Analog Combination Module . . . . . . . . . 292

1753-OW8 Relay Output Module . . . . . . . . . . . . . . . . . 294

1753-OB16 Output Module. . . . . . . . . . . . . . . . . . . . . . 296

Publication 1753-UM001C-EN-P - March 2010 13

Page 14

Table of Contents

System Signal Variables

GuardPLC 2000 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 297

GuardPLC 2000 Distributed I/O Modules . . . . . . . . . . . . . . 298

1755-IB24XOB16 Digital I/O Module . . . . . . . . . . . . . . 298

1755-IF8 Analog Input Module . . . . . . . . . . . . . . . . . . . 299

1755-OF8 Analog Output Module . . . . . . . . . . . . . . . . . 300

1755-HSC High Speed Counter Module. . . . . . . . . . . . . 302

GuardPLC 2000 Power Supply . . . . . . . . . . . . . . . . . . . . . . 303

Appendix B

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 305

Programming Controller Data . . . . . . . . . . . . . . . . . . . . . . 305

I/O Variables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 307

Digital I/O Module Variables (AB-DIO) for

GuardPLC 1200 and 2000 Controllers . . . . . . . . . . . . . . 307

Analog Input Module Variables (AB-AI) for

GuardPLC 2000 Controller . . . . . . . . . . . . . . . . . . . . . . 309

Analog Output Module Variables (AB-AO) for

GuardPLC 2000 Controller . . . . . . . . . . . . . . . . . . . . . . 311

High-Speed Counter Variables For GuardPLC 1200 and

2000 Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 312

Module Variables for GuardPLC 1600 and 1800

Controllers and Distributed I/O . . . . . . . . . . . . . . . . . . 315

Digital Input Module Variables for GuardPLC 1600

Controllers and Distributed I/O . . . . . . . . . . . . . . . . . . 316

Digital Output Module Variables for

GuardPLC 1600/1800 Controllers, 1753-IB20XOB8

Modules, and 1753-OB16 Modules . . . . . . . . . . . . . . . . 318

Digital Output Parameters for 1753-IB8XOB8

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 319

Digital Output Parameters for 1753-IB16XOB8

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 320

Digital Relay Output Parameters for 1753-OW8

Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 322

Analog Input Signals for 1753-IF8XOF4 Modules . . . . . . 323

Analog Output Signals for 1753-IF8XOF4 Modules . . . . 325

Counter Module Variables for GuardPLC 1800

Controllers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 326

Digital (Analog) Input Variables for the GuardPLC 1800

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 328

14 Publication 1753-UM001C-EN-P - March 2010

Page 15

Wiring Examples

Replacing the Back-up Battery

Table of Contents

Appendix C

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 331

GuardPLC 1600 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 332

GuardPLC 1800 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 333

1753-IB16 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 334

1753-OB16 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 335

1753-IB20XOB8 Module . . . . . . . . . . . . . . . . . . . . . . . . . . 336

1753-IB8XOB8 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . 337

1753-IB16XOB8 Modules. . . . . . . . . . . . . . . . . . . . . . . . . . 338

1753-OW8 Modules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 339

1753-IF8XOF4 Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 340

GuardPLC 1200 Controller . . . . . . . . . . . . . . . . . . . . . . . . . 341

1755-IB24XO16 Digital Input/Output Modules . . . . . . . . . . 342

1755-IF8 Analog Input Modules . . . . . . . . . . . . . . . . . . . . . 343

1755-OF8 Analog Output Modules . . . . . . . . . . . . . . . . . . . 343

1755-HSC High Speed Counter Module . . . . . . . . . . . . . . . 344

Appendix D

Preventing Electrostatic Discharge . . . . . . . . . . . . . . . . . . . 345

GuardPLC 1200 Controllers . . . . . . . . . . . . . . . . . . . . . . . . 346

GuardPLC 2000 Power Supply . . . . . . . . . . . . . . . . . . . . . . 347

Battery Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 347

Index

Publication 1753-UM001C-EN-P - March 2010 15

Page 16

Table of Contents

16 Publication 1753-UM001C-EN-P - March 2010

Page 17

Preface

Who Should Use This Manual

Purpose of This Manual

Use this manual if you are responsible for designing, installing,

programming, or troubleshooting control systems that use GuardPLC

controllers.

Personnel responsible for installation, programming, operation, and

troubleshooting of safety-related controllers must be familiar with

relevant safety standards for programmable electronic systems (PES).

The manual only briefly describes the safety concept of the GuardPLC

family of controllers. Its purpose is to provide information on

installing and operating your controller system.

For detailed information on the safety policy regarding GuardPLC

controllers, including information on the controller’s central functions,

input and output channels, operating system, application program

safety and regulations for use, refer to the GuardPLC Controller

Systems Safety Reference Manual, publication 1753-RM002

For procedural information on programming and configuring

GuardPLC Controller Systems with RSLogix Guard PLUS! programming

software, refer to Using RSLogix Guard PLUS! Software with GuardPLC

Controllers, publication 1753-PM001

.

.

Additional Resources

The table on the following page lists documents that contain

additional information concerning Rockwell Automation GuardPLC

products.

You can view or download publications at

http://www.rockwellautomation.com/literature

of technical documentation, contact your local Rockwell Automation

distributor or sales representative.

. To order paper copies

17Publication 1753-UM001C-EN-P - March 2010 17

Page 18

Preface Preface

Resource Description

Using RSLogix Guard PLUS! Software with GuardPLC

Controllers Programming Manual, publication 1753-PM001

GuardPLC Controller Systems Safety Reference Manual,

publication 1753-RM002

DeviceNet Safety Scanner for GuardPLC Controllers User

Manual, publication 1753-UM002

DeviceNet Safety I/O User Manual, publication

1791DS-UM001

GuardPLC Certified Function Blocks Safety Reference Manual,

publication 1753-RM001

EtherNet/IP Performance and Application Guide, publication

ENET-AP001

Industrial Automation Wiring and Grounding Guidelines,

publication 1770-4.1

Application Considerations for Solid-State Controls,

publication SGI-1.1

National Electrical Code - Published by the National Fire

Protection Association of Boston, MA.

Provides procedural information for programming GuardPLC Controller

Systems Using RSLogix Guard PLUS! Programming Software

Contains in-depth information on the safety concept of GuardPLC

controller systems, including the DeviceNet Safety Scanner for GuardPLC

Controller.

Provides information on installing, configuring, and operating a DeviceNet

Safety Scanner in a GuardPLC application

Provides information on operating 1791DS DeviceNet Safety I/O Modules

Provides information on using Certified Function Blocks in your GuardPLC

safety application

Information on EtherNet/IP protocol

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state programmable

controller products and hard-wired electromechanical devices

An article on wire sizes and types for grounding electrical equipment

18 Publication 1753-UM001C-EN-P - March 2010

Page 19

Introduction

Chapter

Overview of Safety Controllers

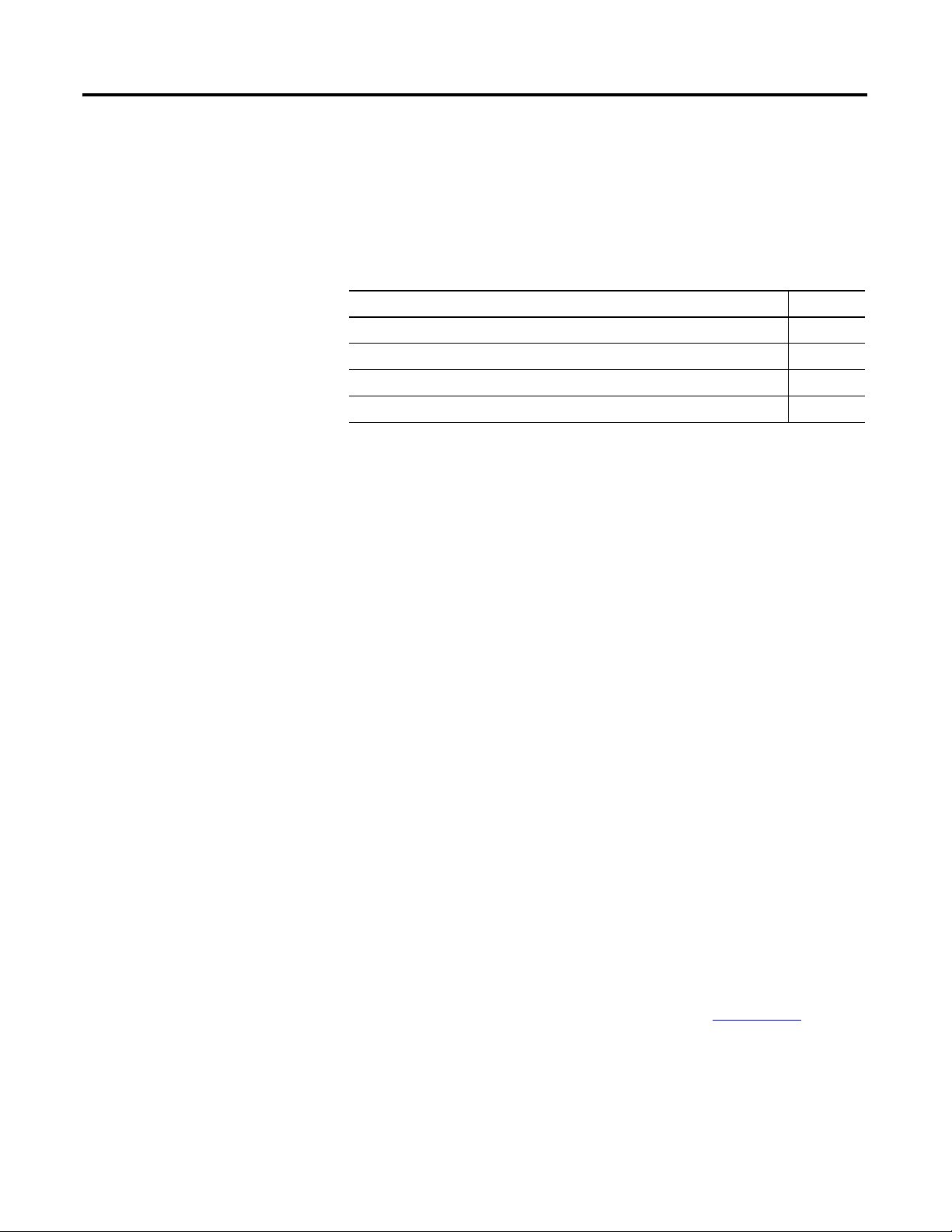

Topic Page

Safety Concept 19

Safe States 21

GuardPLC System Hardware 21

Communication Capabilities 27

1

Safety Concept

GuardPLC controllers feature a fail-safe CPU according to IEC 61508

(SIL 3) and ISO 13849-1 (PLe/Cat. 4). Faults that cause loss of safety

function are detected within the safety time you specify. Faults that

cause loss of safety function only in combination with another fault,

are detected at least within the multiple error occurrence time (24

hours).

This results in these requirements for the safety concept:

• You specify the safety time and the watchdog time. The multiple

error occurrence time is preset to 24 hours.

• Even upon the detection of an error, the controller continues to

react in a safety-related way.

• Faulty input signals (for example, incorrectly transmitted input

values) do not affect the safe function of the controller. Faulted

input signals have a 0 value.

• An error in a non-safety-related module does not affect the

safety of the controller.

• The failure of the controller has no effect on the safety of other

safety-related modules.

For more information on the safety concept, refer to the GuardPLC

Controllers Safety Reference Manual, publication

19Publication 1753-UM001C-EN-P - March 2010 19

1753-RM002.

Page 20

Chapter 1 Overview of Safety Controllers

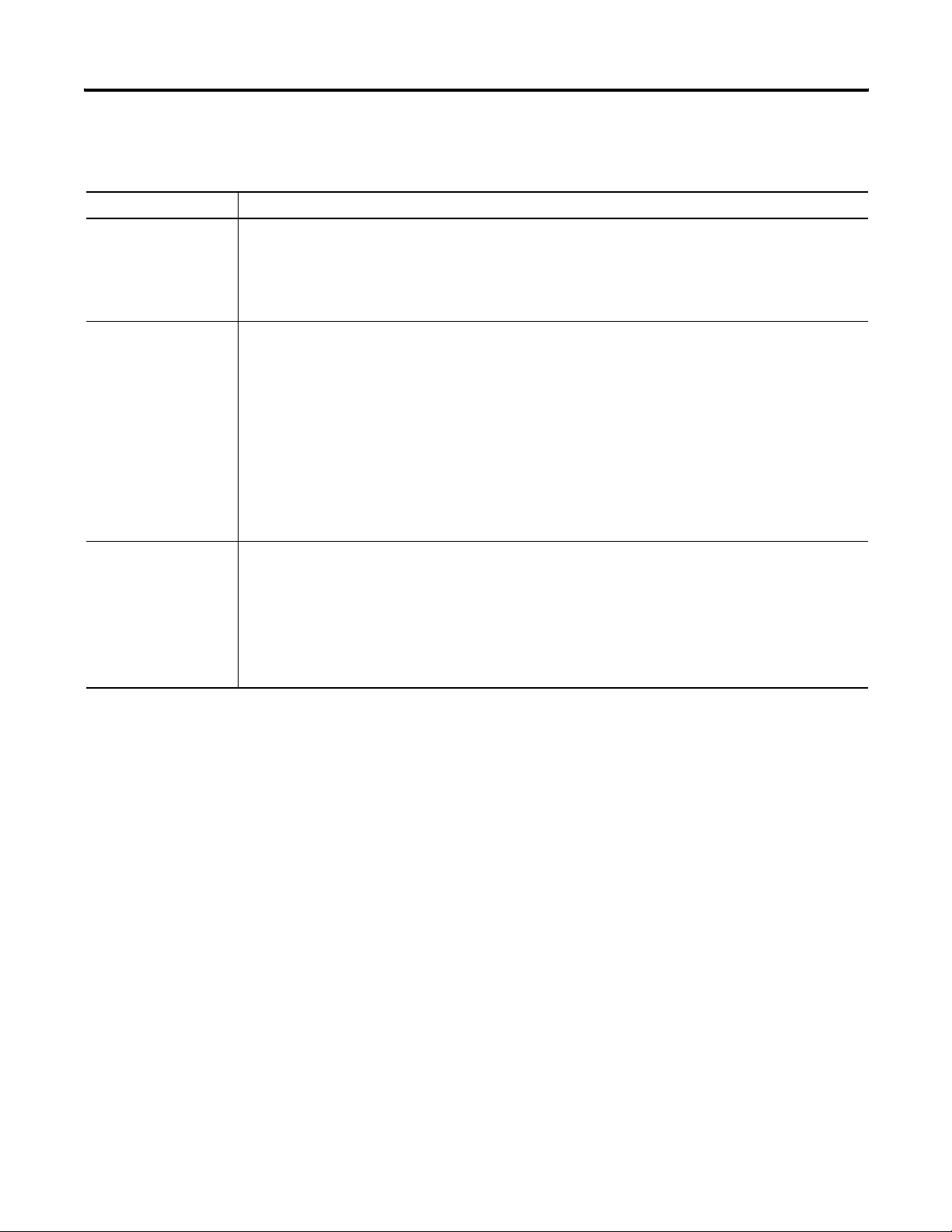

Response to Faults

Type of I/O Error Controller Behavior

Permanent If an error occurs at an I/O point, only this I/O point is considered faulty and not the entire module.

In case of faulty input points, ‘0’ is assumed to be the safe value. Faulty output channels are de-energized. If it

is not possible to de-energize a single point, the entire module is considered to be faulty, the entire module is

de-energized, and the corresponding error status is set. The controller reports the error to the user program. If

the entire module cannot be de-energized, the controller goes to Failure_Stop.

Transient A transient error is an error that occurs in an I/O module and then disappears by itself. If a transient error

occurs, the module performs a self test. If the test is successful, the status of the I/O module is set to ‘good’

and the module’s normal function continues.

In the process, the GuardPLC controller performs a statistical evaluation of the frequency of errors. The I/O

module is permanently set to ‘faulty’ if the pre-set error frequency is exceeded. In this case, the module does

not resume its normal function after the error has disappeared. To resume normal function, you must cycle

power or change the controller to Stop and then Run.

If an error persists for a period of time exceeding that of the multiple error occurrence time (24 hours), the I/O

module is permanently set to ‘faulty’ and does not continue normal function after the disappearance of the

error. The I/O module can only resume normal function after you cycle power or Stop/Start the controller.

For faulty modules, the controller uses safe values (0, LOW).

Controller Upon the detection of an error, the controller goes to Failure_Stop and all output channels are set to the safe

state (value = 0).

In some cases in which a Failure_Stop occurs, a power cycle will not enable normal operation. A manual reset

from Stop to Run, using RSLogix Guard PLUS! software, is required. Cat. 4 faults typically require manual

resets.

An error in the user program is not considered an error of the controller.

The controller also monitors the timing and consistency of the:

• hardware self-tests and software self-tests of the controller.

• cycle of the user program.

• processing of the I/O signals including I/O tests.

• run cycle of the controller.

• transition from Run to Stop.

20 Publication 1753-UM001C-EN-P - March 2010

Page 21

Overview of Safety Controllers Chapter 1

Safe States

GuardPLC System Hardware

Inputs

The safe state of an input is indicated by a 0 signal being passed to

the user program logic. When a fault occurs, the inputs are switched

off (0).

Outputs

An output is in the safe state when it is de-energized. In the event of a

fault, all outputs are switched off. This includes faults in Ethernet

communication.

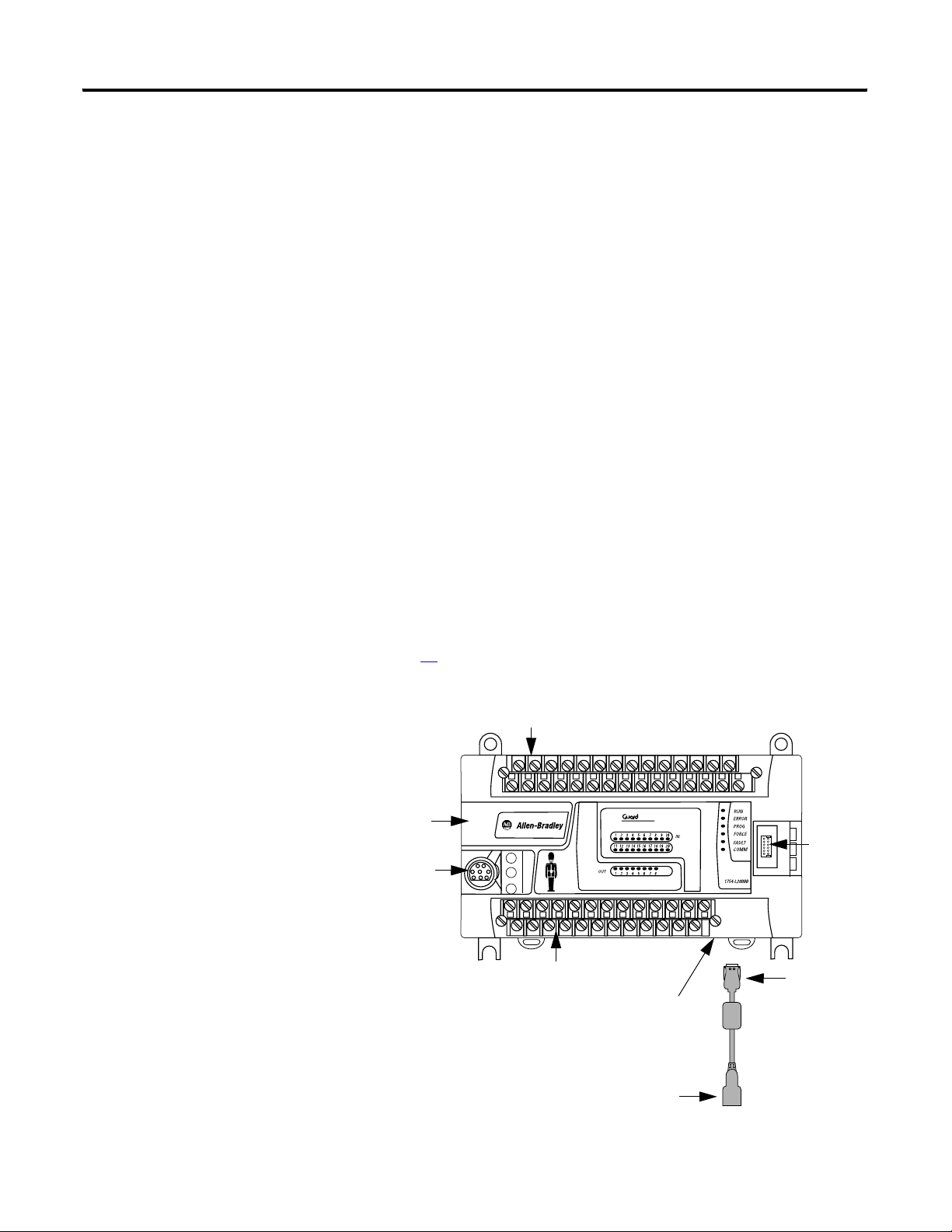

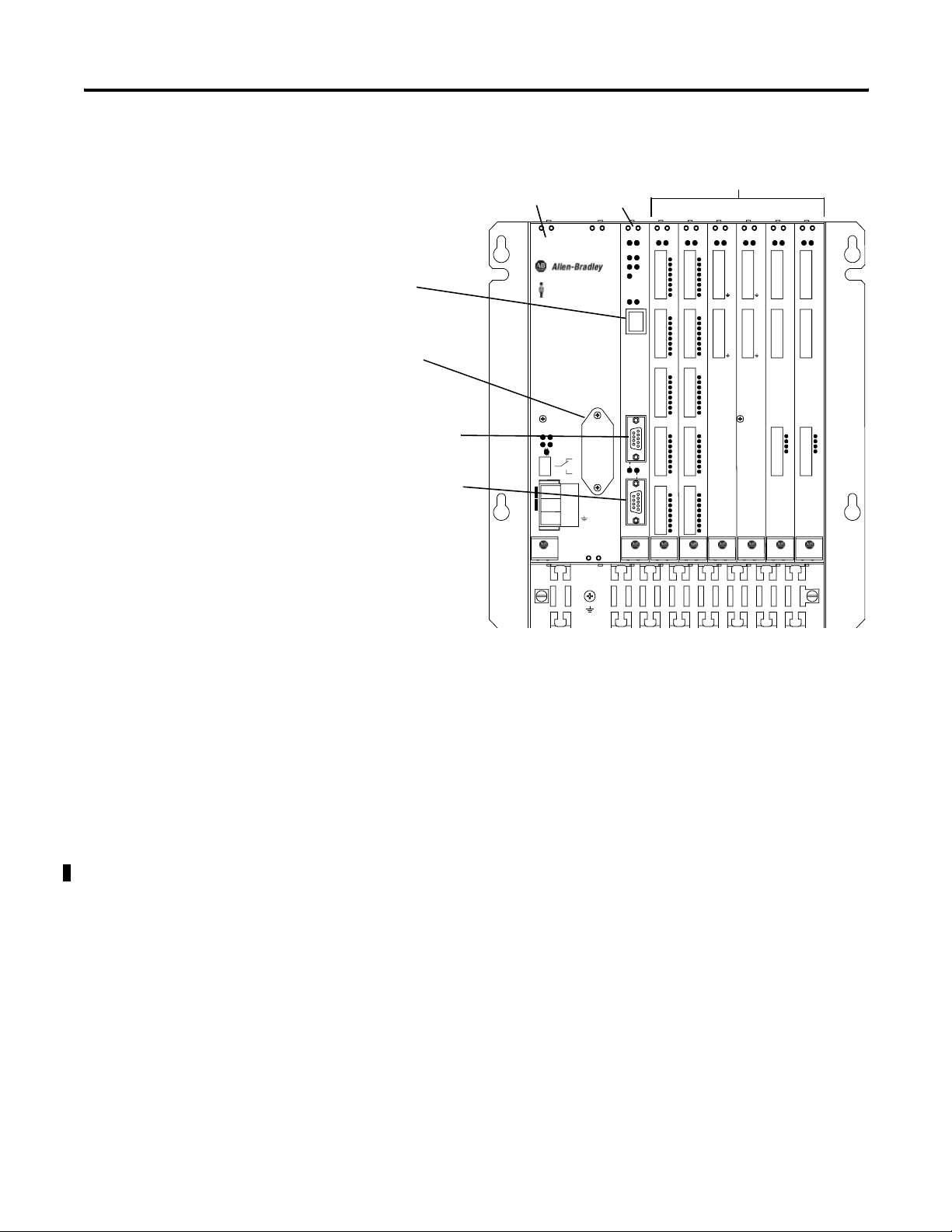

GuardPLC 1200 System

The GuardPLC 1200 controller is a compact system consisting of a

CPU, watchdog, and on-board digital I/O. The GuardPLC 1200

controller features 20 digital inputs, 8 digital outputs, and 2

high-speed counters. An RS-232 serial port supports ASCII

communication and an Ethernet port provides safety-related

communication. A user-supplied 24V DC power supply is required.

See page

45 for power supply connections.

GuardPLC 1200 Controller

Upper Terminal Block

Back-up Battery

Compartment

ASCII Serial Port

Lower Terminal Block

PLC

1200

Ethernet Port

(on Bottom of Controller)

RJ-45 Port

Port for

Factory

Use Only

Ethernet Dongle

Required

Publication 1753-UM001C-EN-P - March 2010 21

Page 22

Chapter 1 Overview of Safety Controllers

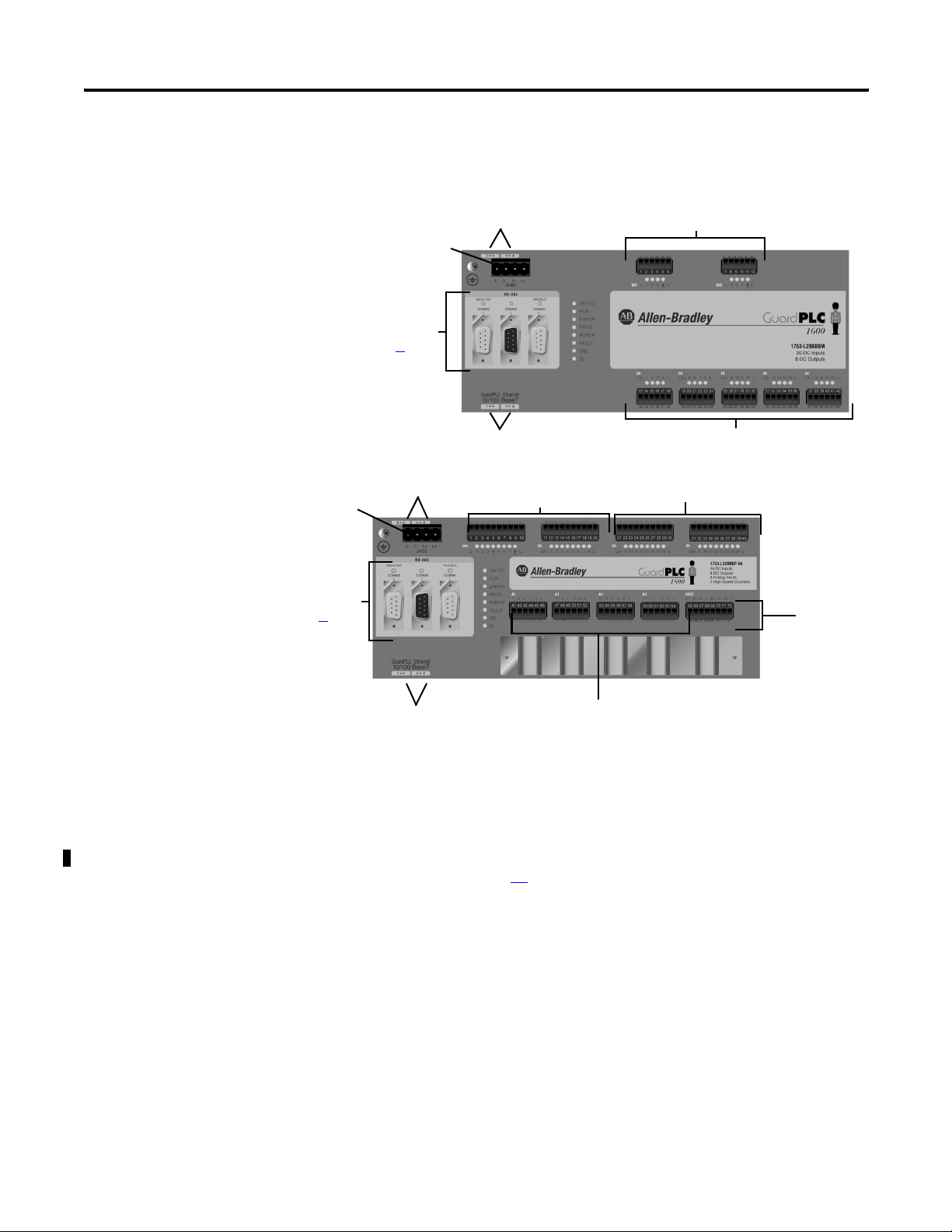

GuardPLC 1600 and GuardPLC 1800 System

GuardPLC 1600 Controller

RJ-45 Ethernet Ports

Voltage Supply

Connection

RS-485 Serial Ports

(See Page 23)

(on Top of Controller)

Digital Outputs

RJ-45 Ethernet Ports

Voltage Supply

Connection

RS-485 Serial Ports

(See Page 23)

RJ-45 Ethernet Ports (on Bottom of Controller)

RJ-45 Ethernet Ports (on Bottom of Controller)

Digital Inputs

GuardPLC 1800 Controller

(on Top of Controller)

Digital Outputs

Analog Inputs

Digital Inputs

High Speed

Counter

The GuardPLC 1600 system features 20 digital inputs and 8 digital

outputs with the addition of optional distributed Safety I/O. The

GuardPLC 1800 system features 24 digital inputs, 8 digital outputs, 8

safety-related analog inputs, and 2 high-speed counters, as well as

optional distributed Safety I/O. The status of inputs and outputs is

indicated via status indicators. A user-supplied 24V DC power supply

is required. See page

45 for information on power supply

requirements.

Each controller features four 10/100BaseT, RJ-45 connectors to

provide safety-related communication via the GuardPLC Ethernet

network to distributed I/O and other GuardPLC controllers, OLE for

(1)

Process Control (OPC) servers

, and with RSLogix Guard PLUS!

programming software. The four connectors and the controller are

connected via an internal Ethernet switch.

(1)

The OPC server is not suitable for safety-related communication.

22 Publication 1753-UM001C-EN-P - March 2010

Page 23

Overview of Safety Controllers Chapter 1

Three ports are located on the front of the controller, providing these

non-safety-related communication options.

Serial Port

Designation

COMM1

(RS-485)

COMM2 not used

COMM3

(RS-485)

Function

Modbus RTU Slave (1753-L28BBBM or 1753-L32BBBM-8A)

Profibus-DP-Slave (1753-L28BBBP or 1753-L32BBBP-8A) Read/Write

GuardPLC ASCII Protocol (Read-only)/High-Speed Safety Protocol (HSP)

The COMM3 (RS-485) also supports High-Speed Safety Protocol (HSP)

for high-integrity communication with the 1753-DNSI DeviceNet

Safety Scanner.

Refer to the DeviceNet Safety Scanner for GuardPLC Controllers User

Manual, publication 1753-UM002

, for more information.

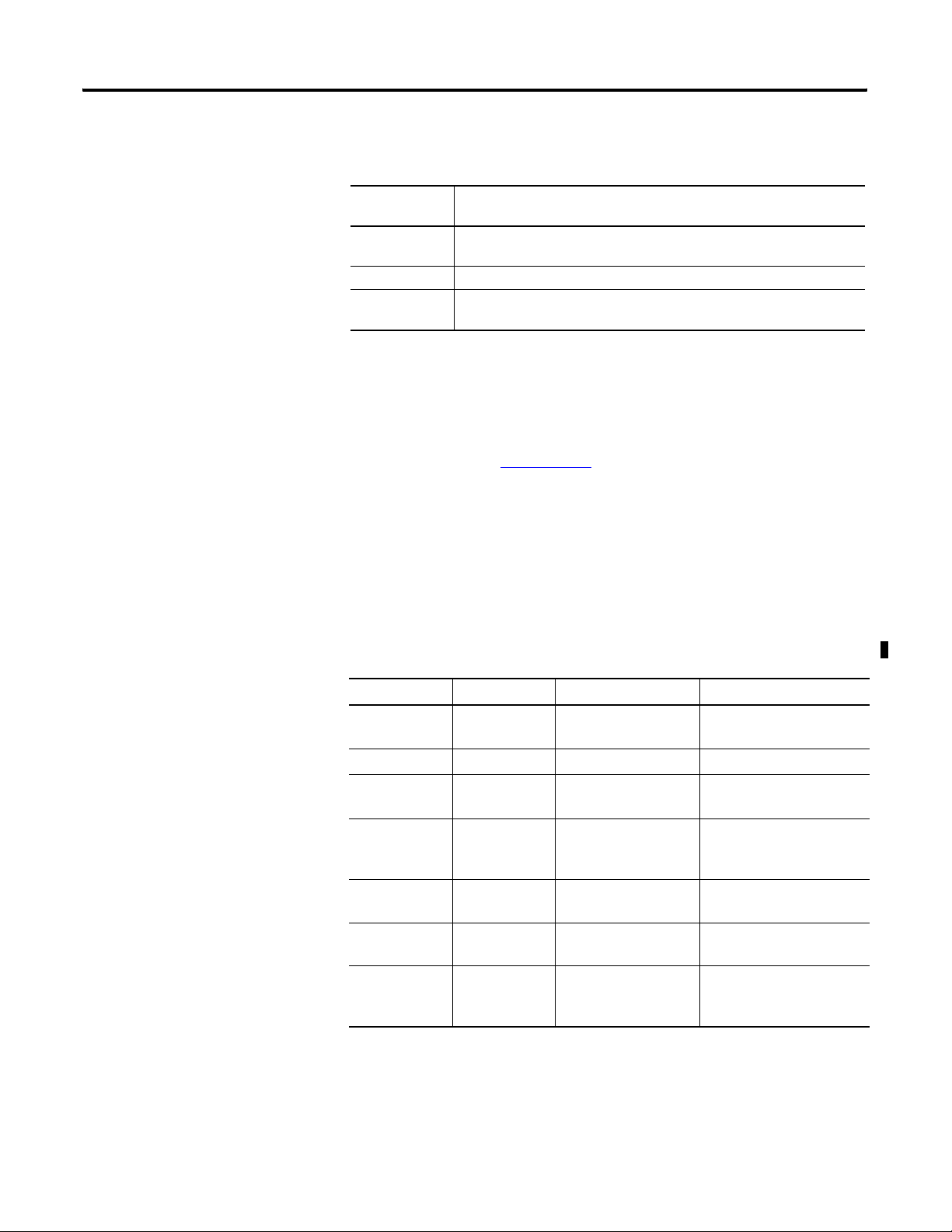

GuardPLC Distributed I/O

The following modules are available for use with the GuardPLC 1600

controllers, GuardPLC 1800 controllers, and series C GuardPLC 1200

controllers, and with series C GuardPLC 2000 CPUs. Module status is

indicated via status indicators.

Cat. No. Description Inputs Outputs

1753-IB16 Input Module 16 digital (not isolated)

4 pulse test sources

1753-OB16 Output Module NA 16 digital (not isolated)

1753-IB20XOB8 Input/Output

Module

1753-IB8XOB8 Input/Output

Module

1753-IB16XOB8 Input/Output

Module

1753-OW8 Relay Output

Module

1753-IF8XOF4 Analog

Input/Output

Module

20 digital (not isolated) 8 digital (not isolated)

8 digital (not isolated)

2 pulse test sources

16 digital (not isolated)

2 pulse test sources

NA 8 relay

8 analog 4 standard analog

NA

8 positive-switching digital

2 negative-switching digital

(not isolated)

8 two-pole digital

(not isolated)

Publication 1753-UM001C-EN-P - March 2010 23

Page 24

Chapter 1 Overview of Safety Controllers

1753-IB16 Module

Voltage Supply Connection

123456

123456

1LS+ LS+ LS+L-D1234

LS+ 13 L-14 15 16

19 20 21 22 23 24

19 20 21 22 23 24

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

L-L- L+ L+

24V DC

BL

Digital Inputs

Ethernet Ports

(on Bottom of Module)

Voltage Supply Connection

GuardPLC 1753 Digital I/O Modules

Digital Inputs

789101112

789101112

5L-

678

D1

16 DC Inputs

4 Pulse Test Sources

Pulse Test Sources

13 14 15 16 17 18

13 14 15 16 17 18

9L-

10 11 12

D1

1753-IB16

PO PULSE TEST

L- 1 L-234

25 26 27 28 29 30

25 26 27 28 29 30

Digital Outputs

1753-IB20XOB8 Module

Voltage Supply

(on Bottom of Module)

Connection

L-L- L+ L+

24V DC

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

Ethernet Ports

1753-OB16 Module

Digital

Outputs

123456

123456

1L- L-DO 2 3 4

9L- L-DO 10 11 12

13 14 15 16 17 18

13 14 15 16 17 18

Voltage Supply

Connection

L-L- L+ L+

24V DC

Digital Outputs

Digital

Outputs

789101112

789101112

5L- L-DO 6 7 8

16 DC Outputs

13L- L-DO 14 15 16

19 20 21 22 23 24

19 20 21 22 23 24

1753-OB16

GuardPLC Ethernet

10/100 BaseT

Ethernet Ports

Voltage Supply

Connection

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

1753-IB8XOB8 Module

Pulse Test Sources

123456

L-L- L+ L+

24 V DC

ERROR

PROG

FORCE

FAULT

24V DC

RUN

OSL

BL

PO PULSE TEST

LS+DI1L-234

19 20 21 22 23 24

1LS+ L-S+

Ethernet Ports (on Bottom of Module)

L-L- L+ L+

24V DC

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

(—)2(—)

1

(on Bottom of Module)

Digital Outputs

789101112 131415161718

248-

1L-2 3 4+ L-

DO-

DO (2A)

Digital Inputs

123456

123456

1L- L-DO 2 3 4

1LS+ LS+ LS+ LS+ LS+L-D1234

13 14 15 16 17 18

5L-678+

DO (2A)

1753-IB8XOB8

8 DC Inputs

8 DC Outputs

LS+DI5L-678

25 26 27 28 29 30

789101112

789101112

(2A)

D1

5L-

678

19 20 21 22 23 24

19 20 21 22 23 2413 14 15 16 23 24

7L- L-DO 8 9 10

D1

9L-

25 26 27 28 29 30

25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

Voltage Supply

Connection

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

Ethernet Ports (on Bottom of Module)

10 11 12

(2A)

L-L- L+ L+

24V DC

1753-IB20OXB8

13 L-D114 15 16

31 32 33 34 35 36

1753-IB16XOB8 Module

123456 87

S+

DO +-

1

2

3

4

5

6

7

8

LS+ LS+ 1 2 3 4 L-L-

33 34 35 36 37 38 39 40 41 42

20 DC Inputs

8 DC Outputs

17 L-D118 19 20

37 38 39 40 41 42

Pulse Test Sources

11112222

S+ S+ S+ S- S- S- S-

Digital Outputs

91011121314 1615

1- 1+ 2- 2+ 3- 3+ 4+4- 5- 5+ 6- 6+ 7- 7+ 8+8DO DO

17 18 19 20 21 22 2423 25 26 27 28 29 30 3231

1753-IB16 OXB8

LS+ LS+ 5 6 7 8 L-L- LS+ LS+ 9 10 11 12 L-L- LS+LS+ 13 14 15 16 L-L-

43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72

Digital Inputs

PO PULSE TEST

16 DC Inputs

8 DC Outputs

24 Publication 1753-UM001C-EN-P - March 2010

Page 25

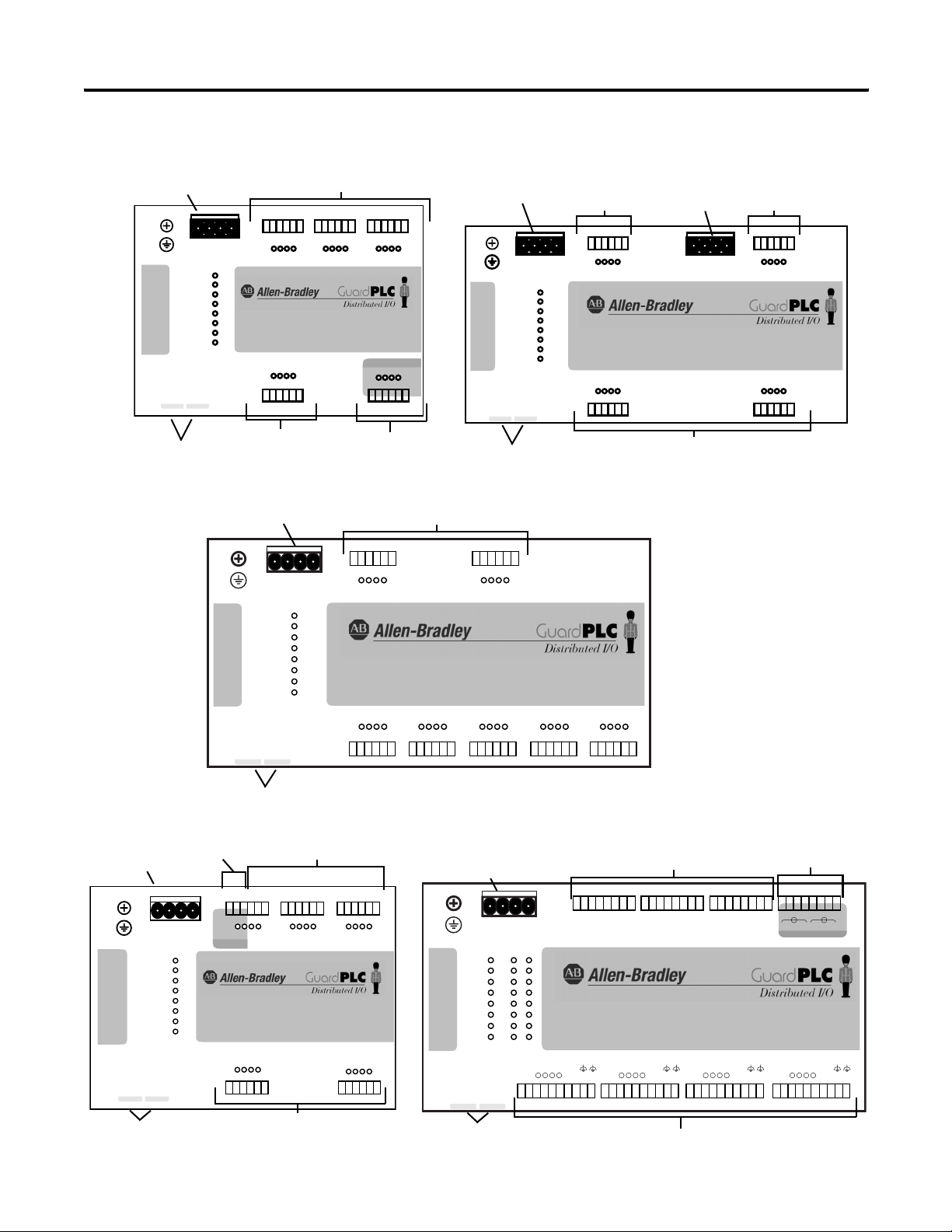

Voltage Supply

Connection

L-L- L+ L+

24V DC

1753-OW8 Module

Relay Outputs

1 2

DO 1

3 4

DO 2

5 6

DO 3

DO5 DO6 DO7 DO8

9 10 11 12 13 14 15 16

1753 Relay Output and Analog I/O Modules

Voltage Supply

Connection

7 8

DO 4

1753-OW8

8 Digital Outputs

L-L- L+ L+

24V DC

GuardPLC Ethernet

10/100 BaseT

<—>2<—>

1

24 V DC

RUN

ERROR

PROG

FORCE

AI

FAULT

T1 I1 L- T2 I2 L-AIT3 I3 L- T4 I4 L-AIT5 I5 L- T6 I6 L-AIT7 I7 L- T8 I8 L-

OSL

BL

1 2 34 5 6 7 8 9101112 13 1415161718 192021222324

Overview of Safety Controllers Chapter 1

1753-IF8XOF4 Module

Safety Analog Inputs

1753-IF8XOF4

8 Analog Inputs

4 Analog Outputs

AO

O1 O2 O3 O4

+-+-+-+-

25 26 27 28 29 30 31 32

STD ANALOG OUTPUTS

Ethernet Ports (on Bottom of Module)

Relay Outputs

Ethernet Ports (on Bottom of Module)

Standard Analog Outputs

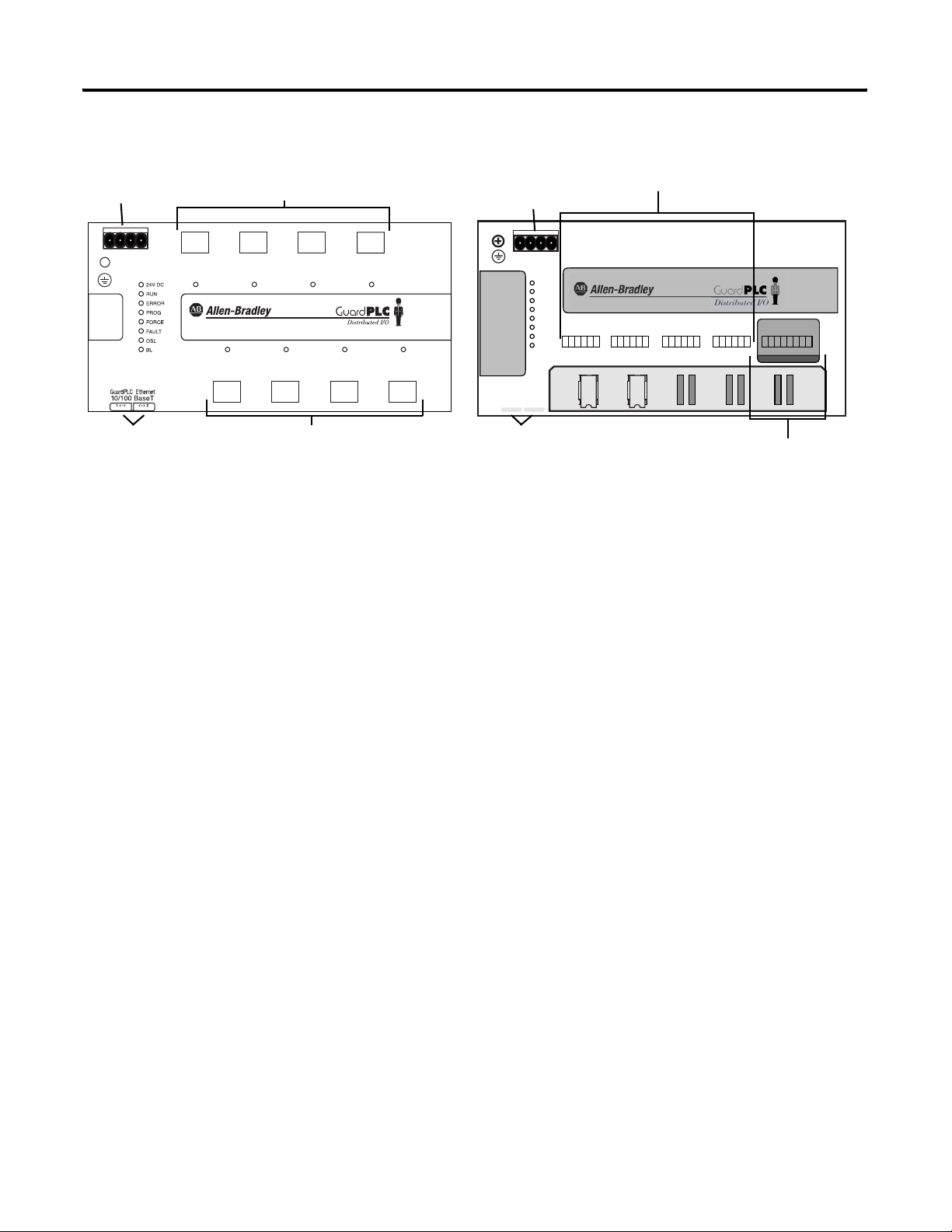

GuardPLC 2000 System

The GuardPLC 2000 controller is a modular system consisting of a

controller (1755-L1), which provides central CPU and communication

functions, and a separate power supply and I/O residing in a

GuardPLC 1755-A6 chassis. A maximum of six I/O modules may be

used in a single system.

The GuardPLC 2000 controller has one active RS-232 serial port for

non-safety related communication. It also features an Ethernet port for

configuration and safety-related communication. The lower DB9 port

supports RS-232 ASCII (read-only) communication; the upper port is

inactive.

Publication 1753-UM001C-EN-P - March 2010 25

Page 26

Chapter 1 Overview of Safety Controllers

GuardPLC 2000 Controller, Power Supply, and I/O Modules

GuardPLC 2000 Power Supply

Ethernet Port

Back-up Battery

Compartment

RS-232 Serial Port

(Inactive)

RS-232 Serial Port

(Active)

GuardPLC 2000

1755-

PB720

GuardPLC 2000

24V

FAULT

3,3V

5V

RESTA RT

1

2

3

FAULT

L+

DC 24V

L-

PS

GuardPLC 2000 I/O Modules

Controller

1755-

1755-

L1

IB24XOB16

RUN ERR RUN RUN RUN ERR RUN ERRERR

RUN ERR

1

LS+

2

I1

3

I2

4

I3

5

I4

6

I5

7

I6

8

I7

9

I8

Tx COL

10

LS+

11

I9

12

I10

13

I11

14

I12

10/100BaseT

15

I13

16

I14

17

I15

18

I16

LS+

19

I17

20

I18

21

I19

22

I20

23

I21

24

I22

25

I23

26

I24

27

28

L-

29

O1

30

O2

31

O3

32

O4

33

O5

34

O6

FB1

35

O7

36

O8

FB2

37

L-

38

O9

39

O10

40

O11

41

O12

42

O13

43

O14

44

O15

45

O16

CPU DIO AI AO CO

DIO

3V DC

LITH-BATT.

RUN STOP

PROG FAULT

FORCE

1755-

1755-

1755-

1755-

IB24XOB16

IF8

OF8

ERR

1

1

LS+

1

2

2

I1

2

3

3

I2

3

4

4

I3

4

5

5

I4

5

6

6

I5

6

7

7

I6

7

8

8

I7

8

9

9

I8

9

10

LS+

10

11

I9

11

12

I10

12

13

I11

13

14

I12

14

15

I13

15

16

I14

16

17

I15

17

18

I16

18

LS+

19

I17

20

I18

21

I19

22

I20

23

I21

24

I22

25

I23

26

I24

27

L-

28

O1

29

O2

30

O3

31

O4

32

O5

33

O6

34

O7

35

O8

36

L-

37

O9

38

O10

39

O11

40

O12

41

O13

42

O14

43

O15

44

O16

45

O1+

1

I1+

1

2

O1-

2

I-

O2+

3

I2+

3

O2-

4

I-

4

O3+

5

I3+

5

O3-

6

I-

6

O4+

7

I4+

7

O4-

8

I-

8

9

9

I5+/1-

O5+

10

10

I-

O5-

11

11

O6+

I6+/2-

12

12

I-

O6-

13

13

I7+/3-

O7+

14

14

I-

O7-

15

15

I8+/4-

O8+

16

16

I-

O8-

17

17

18

18

1755-

HSC

HSC

RUN ERR

C-

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

C-

1

A1

2

A1

B1

B1

3

Z1

Z1

4

C1

C1

5

C-

C-

6

C-

C-

7

C-

C-

8

C-

C-

9

C-

C-

10

A2

A2

11

B2

B2

12

Z2

Z2

13

C2

C2

14

C-

C-

15

C-

C-

16

C-

C-

17

C-

C-

18

L-

L-

19

1

1

20

2

2

21

3

3

22

4

4

23

L-

L-

24

L-

L-

25

L-

L-

26

L-

L-

27

CO

GuardPLC 2000 Power Supply

The 1755-PB720 power supply module provides two voltages

(3.3V DC and 5V DC) for the GuardPLC 2000 controller. They are

electrically isolated from the supply voltage, 24V DC.

1755-IB24XOB16 I/O Module

The 1755-IB24XOB16 digital input/output module provides 24 digital

inputs and 16 digital outputs. The status of each I/O signal is

displayed with a status indicator located on the right side of the front

plate connectors. Inputs and outputs are electrically isolated from the

supply voltage, 24V DC.

1755-IF8 Analog Input Module

The 1755-IF8 analog input module has eight inputs. These inputs can

be used as either eight single-ended inputs or four differential analog

inputs that are electrically isolated from the logic side of the GuardPLC

module. The measured input value can be either voltage or current. If

you use the input module for current, you need a shunt resistor. The

measured value is digitally transferred to the processor system as a

value between 0 and 2000.

26 Publication 1753-UM001C-EN-P - March 2010

Page 27

Overview of Safety Controllers Chapter 1

1755-OF8 Analog Output Module

The 1755-OF8 analog output module provides eight outputs,

galvanically isolated in groups of 2 (that is, 2 outputs per power

supply). They are electrically isolated from the processor system. Each

analog output can operate as a current source or a voltage source.

1755-HSC High Speed Counter Module

The 1755-HSC counter module provides two counters and four digital

outputs. They are electrically isolated from the processor system. The

status of the four output signals is displayed with status indicators

located at the right side of the front plate output connector.

Communication Capabilities

GuardPLC Ethernet Network

The GuardPLC Ethernet network provides safe communication via

Ethernet protocol for distributed I/O and peer-to-peer communication

for all GuardPLC controllers. It also provides non-safety-related

communication with the OPC server. Programming and configuration

of controllers is accomplished via the GuardPLC Ethernet network.

Various GuardPLC systems can be networked together on the

GuardPLC Ethernet network, using star or daisy-chain configurations.

A programming device running RSLogix Guard PLUS! software can

also be connected wherever required.

IMPORTANT

Make sure that a network loop is not generated. Data packets

must only be able to reach a node via a single path.

Publication 1753-UM001C-EN-P - March 2010 27

Page 28

Chapter 1 Overview of Safety Controllers

Star Configuration

To Programming Terminal

(—)4(—)

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

3

L-L- L+ L+

24V DC

RS-485

ASCII

COMM3

COMM2 COMM1

GuardPLC Ethernet

10/100 BaseT

(—)4(—)

3

123456

789101112

123456

1314 15 16 17 18

1L- L-DO 2 3 4

1LS+ LS+ LS+ LS+ LS+L-D1234

(2A)

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

789101112

7L- L-DO 8 9 10

5L-D1678

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

(2A)

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

L-L- L+ L+

24V DC

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

DIO

123456

1234

56

1L-

L-DO 2

34

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

(2A)

5L-D1678

1LS+- LS+ LS+ LS+ LS+L-D1234

13 14 15 16 17 18

19 20 21 22 23 24

19 20 21 22 23 241314 15 16 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

MODBUS

GuardPLC Ethernet Networking Example

123456

789101112

123456

1L- L-DO 2 3 4

(2A)

1LS+ LS+ LS+ LS+ LS+L-D1234

1314 15 16 17 18

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

DIO

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

789101112

789101112

7L- L-DO 8 9 10

(2A)

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

789101112

7L- L-DO 8 9 10

5L-D1678

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

(2A)

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

789101112

78910

25 26 27 28 29 30

24 V DC

L-L- L+ L+

24V DC

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

1112

5L- L-DO 6

7 8

(2A)

Controller

1753-L28BBBM

20 DC Inputs

8 DC Outputs

9L-D1101112

13 L-D1141516

17 L-D1181920

31 32 33 34 35 36

37 38 39 40 41 42

123456

789101112

123456

1314 15 16 17 18

1L- L-DO 2 3 4

1LS+ LS+ LS+ LS+ LS+L-D1234

(2A)

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

789101112

7L- L-DO 8 9 10

5L-D1678

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

(2A)

L-L- L+ L+

24V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

DIO

123456

123456

L-L- L+ L+

24V DC

1L- L-DO 2 3 4

(2A)

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

1LS+ LS+ LS+ LS+ LS+L-D1234

5L-D1678

1314 15 16 17 18

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

DIO

Daisy-chain (Line) Configuration

To Programming Terminal

(—)4(—)

3

ASCII

COMM3

GuardPLC Ethernet

10/100 BaseT

L-L- L+ L+

24V DC

RS-485

COMM2 COMM1

(—)4(—)

3

123456

1234

56

1L-

L-DO 2

34

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

(2A)

1LS+- LS+ LS+ LS+ LS+L-D1234

5L-D1678

13 14 15 16 17 18

19 20 21 22 23 24

19 20 21 22 23 241314 15 16 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42

MODBUS

Controller

123456

123456

L-L- L+ L+

24V DC

1L- L-DO 2 3 4

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

1LS+ LS+ LS+ LS+ LS+L-D1234

1314 15 16 17 18

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

123456

789101112

78910

25 26 27 28 29 30

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

L-L- L+ L+

24V DC

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

1112

5L- L-DO 6

7 8

(2A)

1753-L28BBBM

20 DC Inputs

8 DC Outputs

9L-D1101112

13 L-D1141516

17 L-D1181920

31 32 33 34 35 36

37 38 39 40 41 42

123456

1314 15 16 17 18

1L- L-DO 2 3 4

1LS+ LS+ LS+ LS+ LS+L-D1234

(2A)

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

789101112

789101112

5L-D1678

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

DIO

DIO DIO

(2A)

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

789101112

789101112

7L- L-DO 8 9 10

5L-D1678

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

(2A)

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

GuardPLC Ethernet

10/100 BaseT

(—)2(—)

1

123456

123456

L-L- L+ L+

24V DC

1L- L-DO 2 3 4

(2A)

24 V DC

RUN

ERROR

PROG

FORCE

FAULT

OSL

BL

1LS+ LS+ LS+ LS+ LS+L-D1234

1314 15 16 17 18

7L- L-DO 8 9 10

(2A)

9L-D1101112

5L-D1678

1920 21 22 23 24

1920 21 22 23 241314 15 16 23 24

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3132 33 34 35 36

3738 39 40 41 42

789101112

789101112

7L- L-DO 8 9 10

(2A)

9L-D1101112

2526 27 28 29 30

2526 27 28 29 30 3132 33 34 35 36 37 38 39 40 41 42

3132 33 34 35 36

1753-IB20OXB8

20 DC Inputs

8 DC Outputs

13 L-D1141516

17 L-D1181920

3738 39 40 41 42

EtherNet/IP

GuardPLC 1600 and GuardPLC 1800 controllers support EtherNet/IP

communication. Able to run EtherNet/IP communication at the same

time as safety-rated GuardPLC Ethernet network, the GuardPLC

controller uses the EtherNet/IP network to communicate status about

the safety control system to other standard devices such as PLCs

(ControlLogix, FlexLogix, CompactLogix, SLC 500, or PLC-5

controllers), HMIs (PanelView, PanelView Plus, and VersaView

terminals) and others. The GuardPLC controller can even control

standard I/O, like FLEX I/O and POINT I/O modules, on an

EtherNet/IP network.

ASCII

This read-only, non-safety-related protocol can be used to extract

diagnostic and status information from the GuardPLC controllers.

ASCII protocol is available over the RS-232 port on the GuardPLC 1200

and GuardPLC 2000 controllers and via the RS-485 Comm 3 port on

GuardPLC 1600 and GuardPLC 1800 controllers.

See Chapter 21 for details on communication with ASCII devices.

28 Publication 1753-UM001C-EN-P - March 2010

Page 29

Overview of Safety Controllers Chapter 1

High-speed Safety Protocol

GuardPLC 1600 and 1800 controllers support High-speed Safety

Protocol (HSP), which allows them to connect to the DeviceNet safety

network via the 1753-DNSI DeviceNet Safety Scanner.

Refer to the DeviceNet Safety Scanner for GuardPLC Controllers User

Manual, publication

1753-UM002, for more information.

Modbus RTU Slave

Modbus is a standard industrial non-safety-related serial protocol in

which the Modbus master can communicate with a maximum of 255

slave devices. The Modbus master initiates and controls all

communication on the network.

Modbus RTU Slave protocol is available via the RS-485 Comm 1 port

on GuardPLC 1600 and GuardPLC 1800 controllers with catalog

numbers ending in ‘M’.

Modbus RTU Slave protocol allows both the reading and writing of

data.

For more information on the Modbus RTU Slave protocol, see the

Modbus Protocol Specifications, available from

www.modbus.org/specs.

PROFIBUS DP Slave

PROFIBUS DP protocol is a non-safety-related serial protocol,

designed for high-speed data transmission between automation

systems and distributed peripherals.

PROFIBUS DP slave protocol is available via the RS-485 Comm 1 port

on GuardPLC 1600 and GuardPLC 1800 controllers with catalog

numbers ending in ‘P’.

PROFIBUS DP Slave protocol allows both the reading and writing of

data.

Publication 1753-UM001C-EN-P - March 2010 29

Page 30

Chapter 1 Overview of Safety Controllers

OPC Server

The GuardPLC 1600, GuardPLC 1800, series C GuardPLC 1200, and

series C GuardPLC 2000 controllers are OPC clients. An OPC server,

catalog number 1753-OPC, is available from Rockwell Automation and

lets personal computer applications read and write data to and from

the GuardPLC controller (non-safety-related communication only).

30 Publication 1753-UM001C-EN-P - March 2010

Page 31

Introduction

Chapter

Installation

Topic Page

General Safety 31

Mount the Equipment 32

Communication Connections 38

Reset Pushbutton 43

2

General Safety

Open style devices must be provided with environmental and safety

protection by proper mounting in enclosures designed for specific

application conditions. See NEMA Standards 250 and IEC 60529, as

applicable, for explanations of the degrees of protection provided by

different types of enclosure.

ATTENTION

Consider the following before installing your GuardPLC

1200/1600/1800 controller or distributed I/O.

These products are grounded through the DIN rail. Use

zinc-plated yellow-chromate steel DIN rails to assure proper

grounding. The use of other DIN rail materials (for example,

aluminum and plastic) that can corrode, oxidize, or are poor

conductors, can result in improper or intermittent grounding.

31Publication 1753-UM001C-EN-P - March 2010 31

Page 32

Chapter 2 Installation

M

ount the Equipment

GuardPLC 1200 Controller

The GuardPLC 1200 controller can be either snapped onto a DIN rail

or mounted to a back panel by using bolts. DIN rail mounting is the

easiest way to attach the controller and should be used wherever

possible.

IMPORTANT

DIN Rail

1. Hook the two top latches, on the back of the GuardPLC 1200

controller, over the top of the DIN rail.

For cooling reasons:

• the GuardPLC 1200 controller must be mounted horizontally

with the Ethernet socket facing down.

• a location where air flows freely or use an additional cooling

fan.

• the minimum clearance around the

GuardPLC 1200 controller must be at least 100 mm (3.94 in.).

• do not mount the GuardPLC 1200 controller over a heating

device.

2. If the lower latches are extended (see figure below), push them

up until they lock into place. If the lower latches are not

extended, press the GuardPLC 1200 controller into the DIN rail

until they lock into place.

PLC

1200

Lower Latch (Not Extended)

TIP

Lower Latch (Extended)

If you need to remove the controller from the DIN rail, use a

screwdriver to pull down the lower latches, then lift the

controller toward you.

32 Publication 1753-UM001C-EN-P - March 2010

Page 33

Back Panel

Installation Chapter 2

ATTENTION

Do not bend the controller. Bending the controller will damage

it.

Use the four brackets on the GuardPLC 1200 controller to mount it

onto a back panel.

Top Brackets

Use the following to mount the

controller.

PLC

1200

Bottom Brackets

Top Brackets Bottom Brackets

M4 screws (2) M5 screws (2)

lock washer lock washer

washers washers

nut nut

If the mounting brackets are not flat before the nuts are tightened, use

additional washers as shims, so the controller does not bend when

you tighten the nuts.

GuardPLC 1600 and GuardPLC 1800 Controllers,

and Distributed I/O

IMPORTANT

Publication 1753-UM001C-EN-P - March 2010 33

For effective cooling:

• mount the device horizontally.

• provide a gap of at least 100 mm (3.94 in.) above and below the device and at

least 20 mm (0.79 in.) horizontally between devices.

• the wire duct can run in the 100 mm (3.94 in.) of free space above and below

the controller if it is no deeper than 40 mm (1.58 in.). If the depth is greater

than 40 mm (1.58 in.), the devices must be placed on stand-offs that match the

depth of the duct. If stand-offs are not used, you must provide a gap of at least

80 mm (3.15 in.) between the device and the duct.

• select a location where air flows freely or use an additional fan.

• do not mount the controller or I/O module over a heating device.