Page 1

Using RSLogix

Guard PLUS!

Software with

GuardPLC™

Controllers

Bulletin 1753, 1754, 1755

Programming Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

WARNING

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

IMPORTANT

ATTENTION

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

GuardPLC is a trademark of Rockwell Automation.

Modbus is a registered trademark of Schneider Automation, Inc.

DeviceNet is a trademark of Open DeviceNet Vendor Association.

All other trademarks are the property of their respective holders and are hereby acknowledged.

Page 3

Summary of Changes

The information below summarizes the changes to this manual since

the last publication.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

Programming and configuration procedures and examples have been

removed from the GuardPLC Controller Systems User Manual,

publication 1753-UM001 and assembled in this programming manual.

In addition, new and updated information has been provided as

described in the table below.

For Information About See

The hardware, installation, wiring, and communications

information for GuardPLC controllers and distributed I/O

modules

The purpose of this manual page P-1

the GuardPLC Controller

Systems User Manual,

publication 1753-UM001

Related publications pages P-1 and P-2

What to do if communication to a new controller fails page 1-22

Connecting to GuardPLC distributed I/O modules Chapter 2

Understanding the Signal Editor page 3-5

Connecting distributed I/O module signals page 3-10

Connecting analog signals page 3-10

Connecting high-speed counter signals page 3-11

Recovering from a FAILURE_STOP page 4-2

Archiving and restoring projects Chapter 7

Valid data types for variables page 8-4

Programming software versions, compatibility, and firmware

upgrades

Converting projects developed in different software versions page A-5

Creating time-based variables Appendix C

Appendix A

iii Publication 1753-PM001A-EN-P - November 2005

Page 4

iv Summary of Changes

Publication 1753-PM001A-EN-P - November 2005

Page 5

Connect to the GuardPLC

Controller

Table of Contents

Preface

Who Should Use This Manual . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Chapter 1

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Connect to the Controller via RSLogix Guard PLUS! Software 1-1

Connect to a GuardPLC 1200 Controller . . . . . . . . . . . . 1-1

Connect to a GuardPLC 1600 or 1800 Controller . . . . . . 1-2

Connect to a GuardPLC 2000 Controller . . . . . . . . . . . . 1-2

GuardPLC Controller Factory Default Settings . . . . . . . . 1-2

Understand Ethernet Addressing. . . . . . . . . . . . . . . . . . 1-2

Configure the IP Address of Your Programming Terminal 1-3

Go Online with the GuardPLC Controller . . . . . . . . . . . . . . 1-5

Step 1: Open RSLogix Guard PLUS! Software. . . . . . . . . 1-6

Step 2: Create a New Project . . . . . . . . . . . . . . . . . . . . 1-6

Step 3: Configure the Controller Type and SRS . . . . . . . 1-7

Step 4: Get Communication Settings . . . . . . . . . . . . . . . 1-9

Step 5: Change Settings via MAC Address . . . . . . . . . . . 1-10

Step 6: Move the Settings Into Your Offline Project . . . . 1-11

Step 7: Use the Control Panel to Connect to the

GuardPLC Controller . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12

Step 8: Change the Controller to STOP Mode . . . . . . . . 1-14

Step 9: Reset the Controller to the Default Settings . . . . 1-14

Step 10: Ping the Controller . . . . . . . . . . . . . . . . . . . . . 1-15

Step 11: Configure the GuardPLC Controller’s IP

Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-16

Step 12: Recover from a Controller Fault After Using

the Reset Button . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17

Configure the Programming Terminal . . . . . . . . . . . . . . . . 1-19

Specify the Host SRS . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Login Dialog. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-20

Determine the IP Address and SRS of the Controller . . . . . . 1-21

Change the SRS of the Controller . . . . . . . . . . . . . . . . . . . . 1-22

Change the IP Address of the Controller . . . . . . . . . . . . . . 1-23

Chapter 2

Connect to GuardPLC Distributed

I/O Modules

v Publication 1753-PM001A-EN-P - November 2005

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Understand Module Addressing . . . . . . . . . . . . . . . . . . . . . 2-1

Module Default Settings . . . . . . . . . . . . . . . . . . . . . . . . 2-1

SRS (System.Rack.Slot) . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

IP Address. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Add the Module to the Hardware Configuration . . . . . . . . . 2-2

Configure the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Page 6

vi Table of Contents

Create a GuardPLC Project

Set I/O Properties . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Configure the Offline IP Address . . . . . . . . . . . . . . . . . 2-4

Go Online With the Module . . . . . . . . . . . . . . . . . . . . . . . 2-5

Chapter 3

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Start a New Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Configure the Project and Hardware . . . . . . . . . . . . . . . . . 3-2

Configure the Controller Resource . . . . . . . . . . . . . . . . 3-2

Create Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Understand the Signal Editor . . . . . . . . . . . . . . . . . . . . 3-5

Create Signals in the Signal Editor. . . . . . . . . . . . . . . . . 3-6

Connect Signals to I/O Terminals. . . . . . . . . . . . . . . . . . . . 3-6

Connect Digital Input Signals . . . . . . . . . . . . . . . . . . . . 3-7

Connect Output Signals . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Connect Distributed I/O Signals . . . . . . . . . . . . . . . . . . 3-10

Connect Analog Input Signals (GuardPLC 1800

Controllers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Connect High-speed Counter Signals (GuardPLC 1800

Controllers) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-11

Create a Function Block Program. . . . . . . . . . . . . . . . . . . . 3-13

Save, Compile, Test, and Download the Program . . . . . . . . 3-16

Save the Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-16

Compile the Code . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Run an Off-Line Simulation . . . . . . . . . . . . . . . . . . . . . 3-18

Download the Program . . . . . . . . . . . . . . . . . . . . . . . . 3-20

How to Monitor the Routine Online. . . . . . . . . . . . . . . . . . 3-22

Check, Download, Start, and Test

a Routine

Monitor and Force Signals

Publication 1753-PM001A-EN-P - November 2005

Chapter 4

Using This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Check Consistency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Download a Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Troubleshoot the Download Process. . . . . . . . . . . . . . . 4-3

Start a Routine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-4

Test a Routine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

How a Routine Executes . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Controlling a Routine . . . . . . . . . . . . . . . . . . . . . . . . . . 4-6

Chapter 5

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Monitor Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Forcing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Enable Forces . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Start the Force Editor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Specify Force Values and Force Marks . . . . . . . . . . . . . . . . 5-5

Page 7

Access Management

Archive and Restore Projects

Create User-Defined Function

Blocks

Table of Contents vii

Force Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Start Forces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-6

Stop Forces. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Chapter 6

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

How the Controller Uses Access Levels . . . . . . . . . . . . . . . 6-1

Create User Access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Chapter 7

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Archive a Project. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Restore a Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Chapter 8

In This Chapter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Create User-Defined Function Blocks. . . . . . . . . . . . . . . . . 8-1

Declare variables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-4

Define Technical Units and Scaling. . . . . . . . . . . . . . . . 8-6

Define I/O Positions . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

How the Variables Display . . . . . . . . . . . . . . . . . . . . . . 8-8

Move Declared Variables to the User-Defined Function

Block Page . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-9

Generate Function Block Code . . . . . . . . . . . . . . . . . . . . . 8-10

Check for Errors and Warnings. . . . . . . . . . . . . . . . . . . 8-11

Programming Software Versions,

Compatibility, and Firmware

Updates

Appendix A

In This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

RSLogix and RSLogix Guard PLUS! Versions . . . . . . . . . . . . A-1

About RSLogix Guard Software, Version 3.3 . . . . . . . . . A-2

About RSLogix Guard PLUS! . . . . . . . . . . . . . . . . . . . . . A-2

RSLogix Guard PLUS! Software and GuardPLC Firmware

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

RSLogix Guard PLUS! Software and Associated GuardPLC

Firmware Versions . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Firmware and Software Version Compatibility . . . . . . . . A-4

Convert Projects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Upgrade GuardPLC Firmware . . . . . . . . . . . . . . . . . . . . . . A-5

Upgrade CPU Firmware . . . . . . . . . . . . . . . . . . . . . . . . A-6

Upgrade COM Firmware . . . . . . . . . . . . . . . . . . . . . . . A-6

Reset Your SRS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-7

Publication 1753-PM001A-EN-P - November 2005

Page 8

viii Table of Contents

Configure the GuardPLC OPC

Server

Create a Time-based Variable

Appendix B

In This Appendix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Choose an IP Address . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Add the GuardPLC Controller and the OPC Server to the

Project . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Configure the GuardPLC System for OPC Communication. . B-3

Configure the Communication Network . . . . . . . . . . . . B-3

Connect Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Set the System Properties . . . . . . . . . . . . . . . . . . . . . . . B-6

Generate Code for the OPC Server. . . . . . . . . . . . . . . . . . . B-8

Go Online with the Controller . . . . . . . . . . . . . . . . . . . . . . B-8

Use the OPC Server. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Appendix C

Index

Publication 1753-PM001A-EN-P - November 2005

Page 9

Preface

Who Should Use This Manual

Purpose of this Manual

Use this manual if you are responsible for programming, or

troubleshooting control systems that use GuardPLC controllers.

Personnel responsible for installation, programming, operation, and

troubleshooting of safety-related controllers must be familiar with

relevant safety standards for Programmable Electronic Systems (PES).

The manual provides procedural information on programming your

controller system, including information on establishing

communication between your programming terminal and the

GuardPLC controller, creating a GuardPLC project, adding GuardPLC

distributed I/O to your project, and creating user-defined function

blocks.

For information on installing, configuring, operating, and monitoring

the status of your GuardPLC controller system, refer to the GuardPLC

Controller Systems User Manual, publication number 1753-UM001.

This manual does not provide information on SIL 3 or Cat. 4 safety

application requirements. For detailed information on the safety policy

regarding GuardPLC controllers, including information on the

controller’s central functions, input and output channels, operating

system, application program safety and regulations for use, refer to the

GuardPLC Controller Systems Safety Reference Manual, publication

number 1753-RM002.

Related Documentation

1 Publication 1753-PM001A-EN-P - November 2005

The table on the following page lists documents that contain

additional information concerning Rockwell Automation GuardPLC

products.

If you would like a manual, you can:

• download a free electronic version from the internet at

www.rockwellautomation.com/literature.

• purchase a printed manual by contacting your local

Allen-Bradley distributor or Rockwell Automation sales office.

Page 10

2 Preface

For Read this Document Document

Number

In-depth information on the safety concept of GuardPLC

controller systems, including the DeviceNet Safety Scanner for

GuardPLC Controller Systems Safety Reference

Manual

1753-RM002

GuardPLC Controllers.

Information on installing, configuring, operating, and

GuardPLC Controller Systems User Manual 1753-UM001

monitoring the status of your GuardPLC controller system.

Information on installing, configuring, and operating a

DeviceNet Safety Scanner in a GuardPLC application.

Information on operating 1791DS DeviceNet Safety I/O

DeviceNet Safety Scanner for GuardPLC Controllers

1753-UM002

User Manual

DeviceNet Safety I/O User Manual 1791DS-UM001

Modules

Information on using Certified Function Blocks in your GuardPLC

safety application.

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

A description of important differences between solid-state

GuardPLC Certified Function Blocks Safety Reference

1753-RM001

Manual

Industrial Automation Wiring and Grounding

1770-4.1

Guidelines

Application Considerations for Solid-State Controls SGI-1.1

programmable controller products and hard-wired

electromechanical devices

An article on wire sizes and types for grounding electrical

equipment

National Electrical Code - Published by the National Fire Protection

Association of Boston, MA.

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

Publication 1753-PM001A-EN-P - November 2005

Page 11

In This Chapter

Chapter

Connect to the GuardPLC Controller

For information about See page

connecting to the controller via RSLogix Guard PLUS 1-1

going online with the GuardPLC controller 1-5

configuring the programming terminal 1-19

login dialog 1-20

determining the IP address and SRS of the controller 1-21

changing the SRS of the controller 1-22

changing the IP address of the controller 1-23

1

Connect to the Controller via RSLogix Guard PLUS! Software

You connect the controller to the programming terminal via an

Ethernet port on the controller. The programming terminal must have

an Ethernet port or Ethernet communication card.

To directly connect the programming terminal to the controller, use a

cross-over Ethernet cable. The GuardPLC 1600 and 1800 controllers

feature auto-sensing ports so that a cross-over or straight-thru cable

may be used.

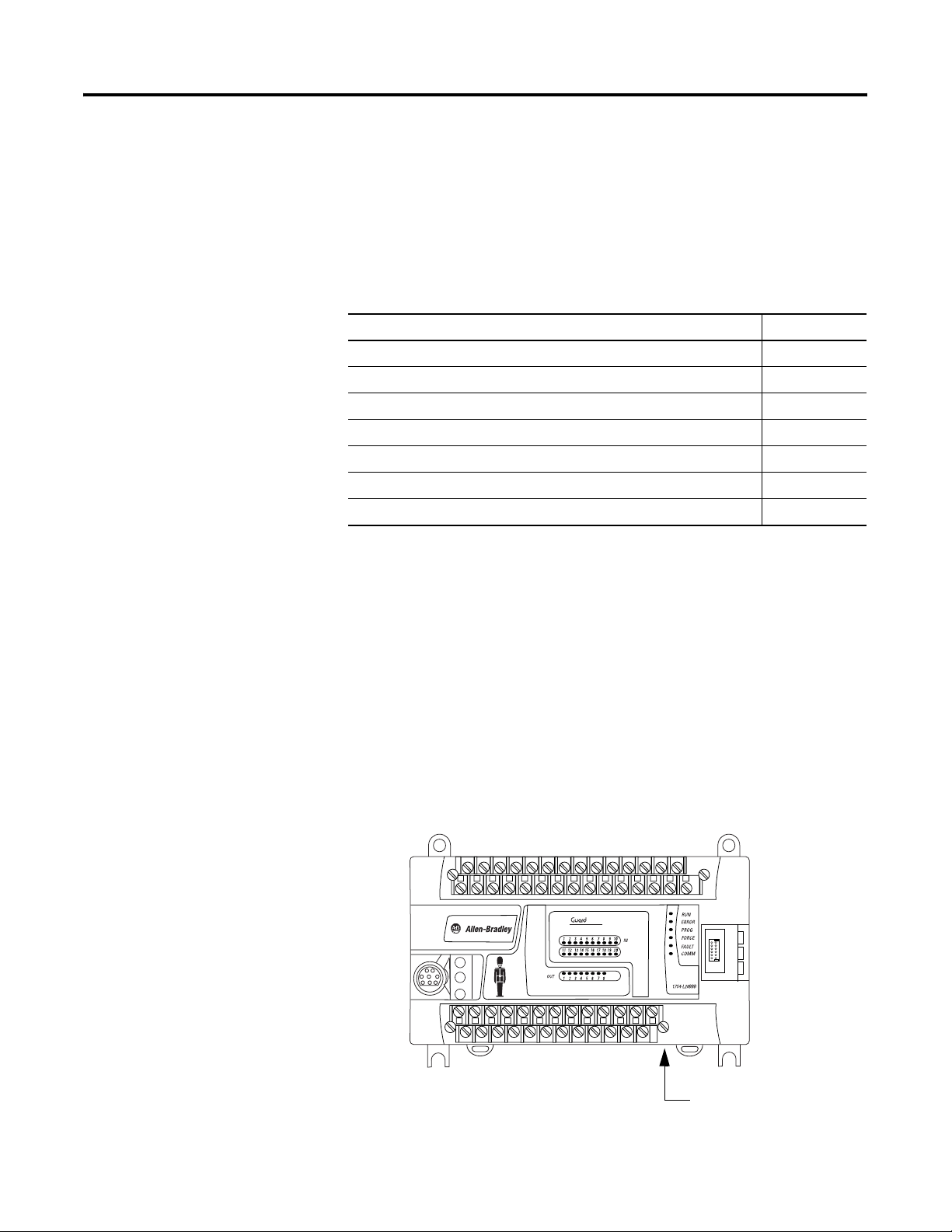

Connect to a GuardPLC 1200 Controller

PLC

1200

Ethernet port

(on the bottom of the controller)

1 Publication 1753-PM001A-EN-P - November 2005

Page 12

1-2 Connect to the GuardPLC Controller

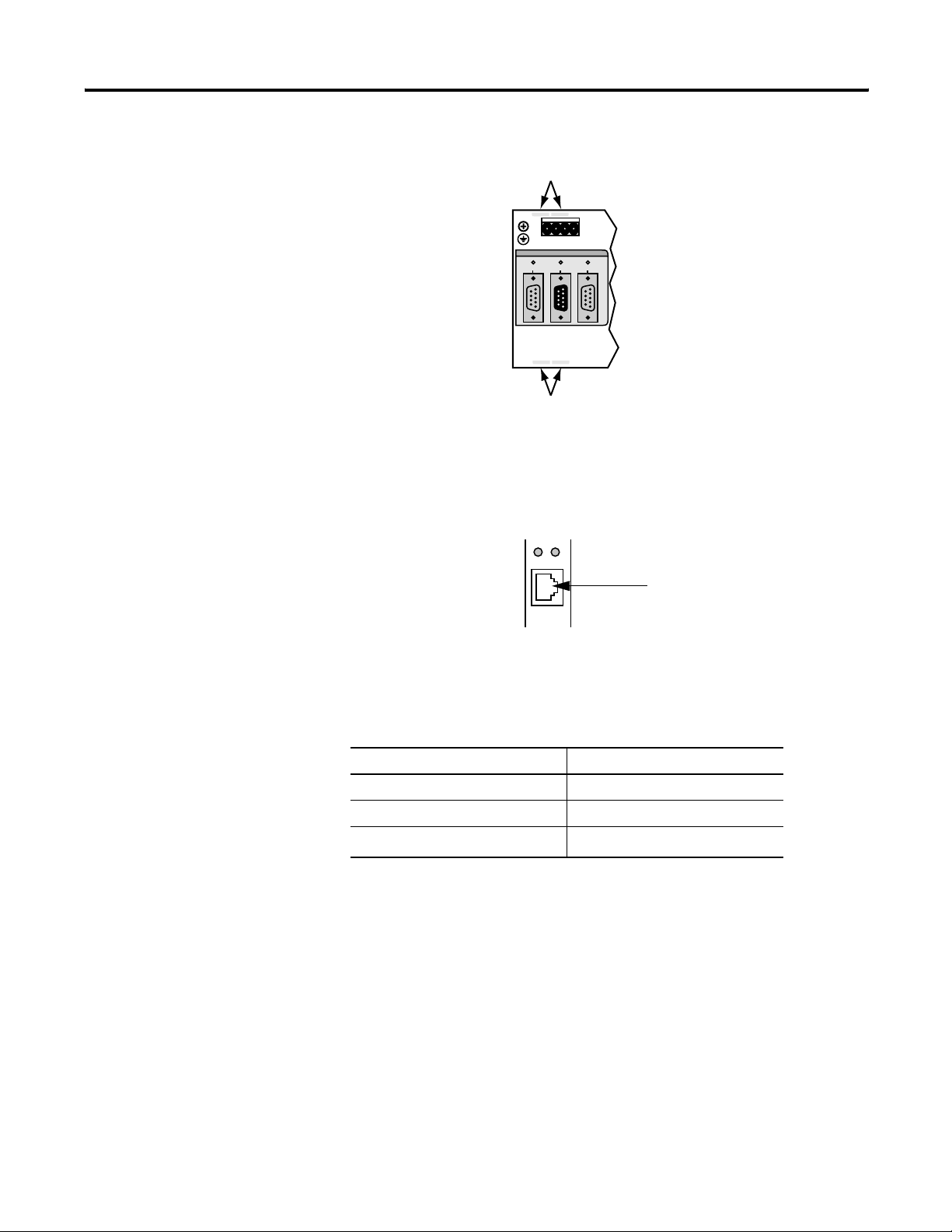

Connect to a GuardPLC 1600 or 1800 Controller

Ethernet Ports 3 and 4

(—)4(—)

3

L-L- L+ L+

24V DC

RS-485

10/100 BaseT

(—)2(—)

1

MODBUS

COMM1

COMM2COMM3

ASCII/HSP

GuardPLC Ethernet

Ethernet Ports 1 and 2

Connect to a GuardPLC 2000 Controller

Tx COL

Ethernet port

10/100 Base T

GuardPLC Controller Factory Default Settings

Parameter Setting

IP Address 192.168.0.99

Subnet Mask 255.255.252.0

(1)

SRS

(1) The SRS code is compiled with the program. It guarantees that the program can only be

downloaded to a GuardPLC controller with a matching SRS stored in non-volatile memory.

60000

Understand Ethernet Addressing

Publication 1753-PM001A-EN-P - November 2005

As with any connection between devices on Ethernet, the IP address

and subnet mask determine if the connection can take place. Every

device on Ethernet has an IP address and subnet mask.

The IP address and subnet mask are made up of four (4) octets

(001.002.003.004) The IP address is made up of the Network ID

Page 13

Connect to the GuardPLC Controller 1-3

(octets 001 and 002) and the Host ID (octets 003 and 004). The

Network ID portion of the IP address is derived from the subnet mask.

When any two devices attempt to talk on Ethernet, a check is made to

see if the Network ID of both the originator and the destination

address match. If they match, then the message is sent on the local

network. If they do not match, then the message is sent to the

Gateway to route the message to the destination. The subnet masks of

all the devices on a local network should be the same.

The example below illustrates how to derive the Network ID based on

the GuardPLC controller’s IP address and subnet mask defaults.

EXAMPLE

Determine the Network ID

Default Settings:

IP Address 192.168.0.99 = 11000000 . 10101000 . 00000000 . 01100011

Subnet Mask 255.255.252.0 = 11111111 . 11111111 . 11111100 . 00000000

Network ID = 11000000 . 10101000 . 000000xx . xxxxxxxx

Set up the programming terminal’s IP address so that it has the same Network ID as

the GuardPLC controller. Octets one and two have to be the same because the

subnet mask octets are 255. The third subnet mask octet is 252, which means that

only the last two bits can be different.

If the factory default settings above are used, the allowable IP addresses for the

programming terminal running RSLogix Guard PLUS! software are:

• 192.168.0.xxx (xxx represents any value between 000-255)

• 192.168.1.xxx

• 192.168.2.xxx

• 192.168.3.xxx

Configure the IP Address of Your Programming Terminal

IMPORTANT

The first time you connect to a controller, you must

use the factory-set IP address of 192.168.0.99 and the

default SRS of 60000. After you establish

communications with the controller (using the steps

on the following pages), you can change the IP

address and SRS to better accommodate your

Ethernet network.

Publication 1753-PM001A-EN-P - November 2005

Page 14

1-4 Connect to the GuardPLC Controller

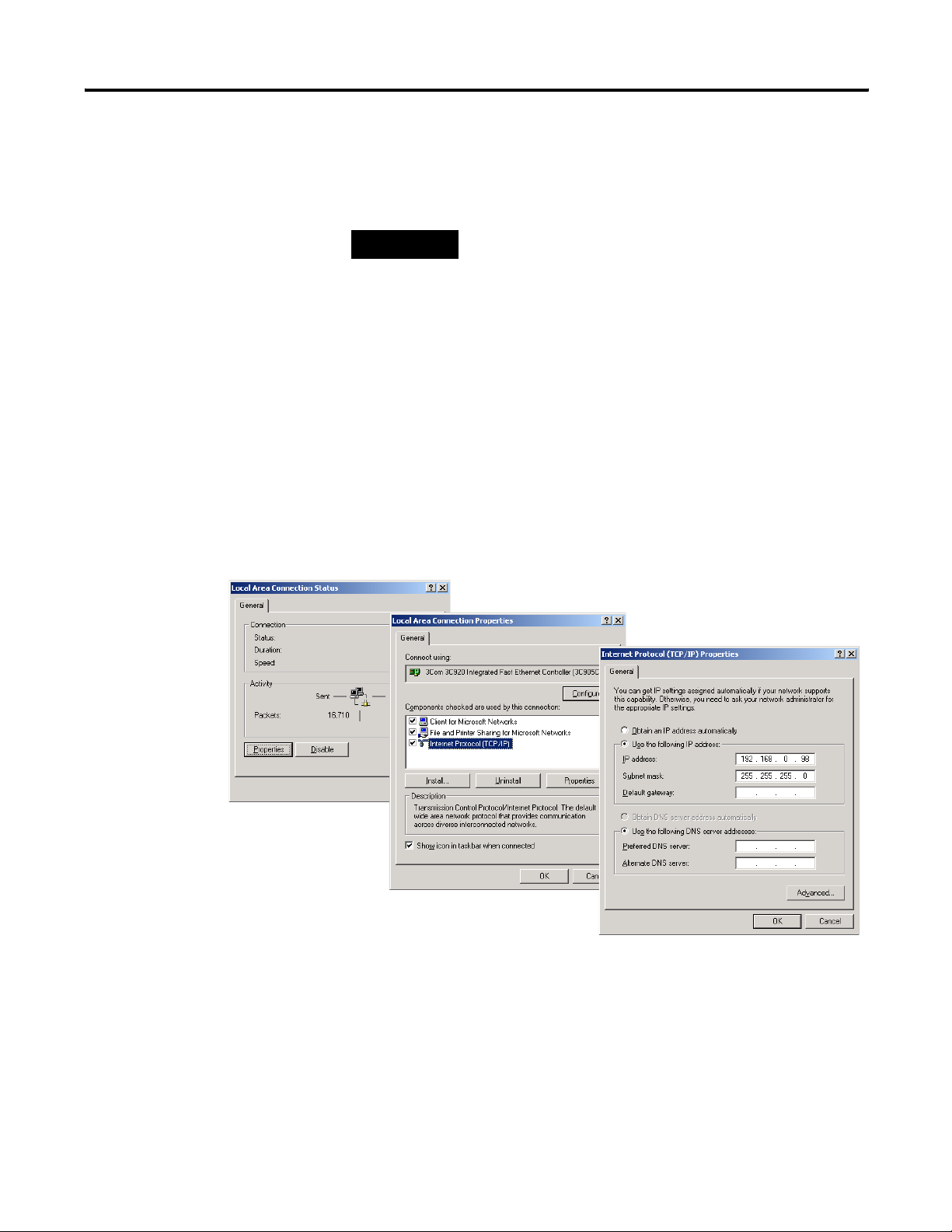

Change the IP address of your programming terminal running RSLogix

Guard PLUS! software so that the GuardPLC controller and

programming terminal can communicate on a local network.

TIP

If you suspect the GuardPLC controller has the

factory-set default IP address of 192.168.0.99 and the

default subnet mask of 255.255.252.0, set your

programming terminal’s IP address to 192.168.0.98

with a subnet of 255.255.252.0 to establish

communications.

To change the IP address:

1. In Windows 2000, choose Start>Setting >Control Panel>Network

and Dial-up Connections.

2. Open Local Area Connections and click Properties. Select TCPIP

and click Properties.

3. Set the General TCP/IP Properties as shown below.

Publication 1753-PM001A-EN-P - November 2005

4. Confirm your settings by clicking OK in both dialog boxes.

Page 15

Connect to the GuardPLC Controller 1-5

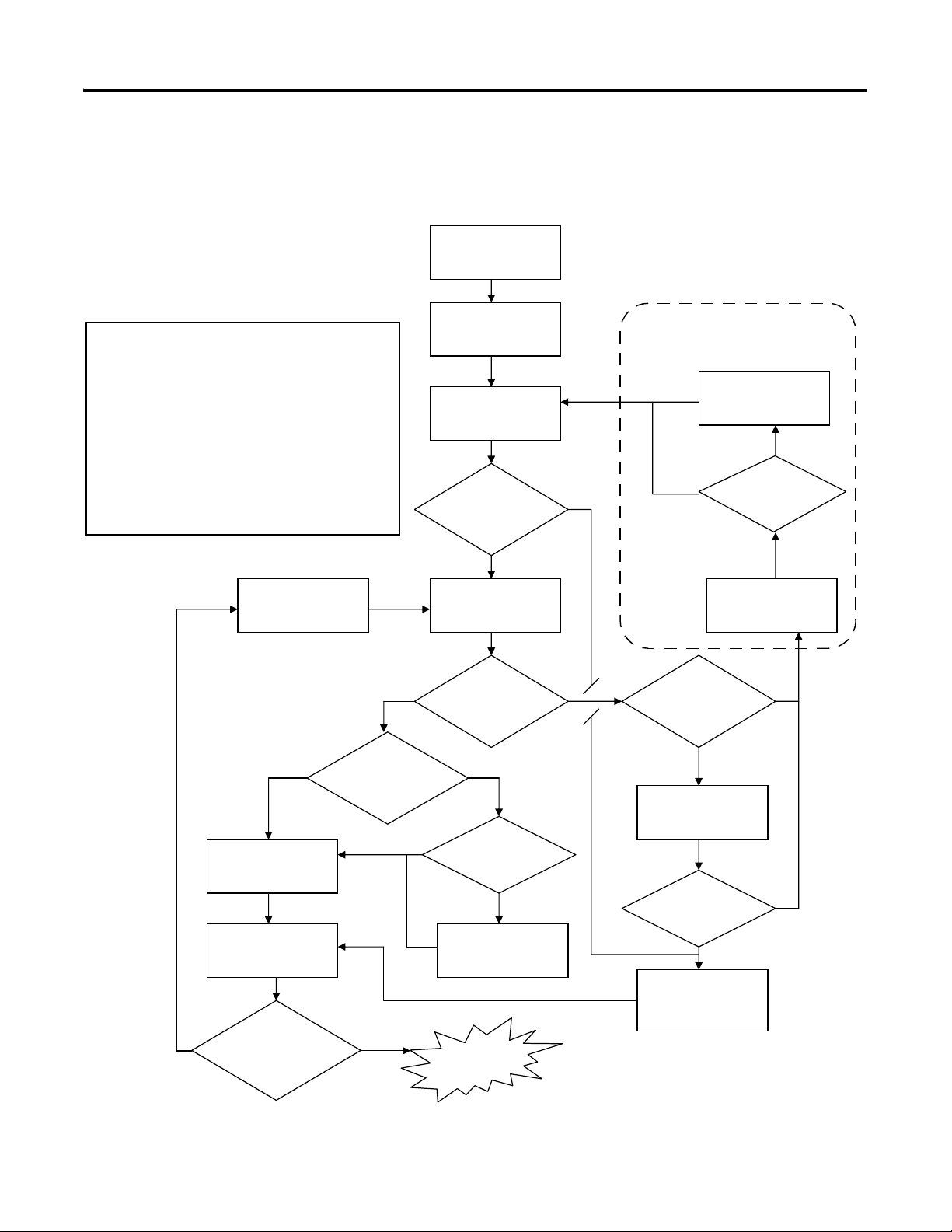

Go Online with the GuardPLC Controller

Notes:

(1) Assume correct SRS was entered in Step 3.

(2) The controller reverts back to its prior settings if it is

not re-configured before the next power cycle.

(3) If the controller was previously running and the SRS

was changed in Step 5, or if the controller is new

(out-of-box), the only way to clear the FAULT is to

download a program with a matching SRS.

Step 8: Change

Controller Mode to

STOP

The following flowchart illustrates the steps required to successfully

go online with the GuardPLC controller.

Step 1: Open RSLogix

Guard PLUS!

Step 2: Create a New

Project

Step 3: Configure the

controller type and SRS

Do you already know

settings?

NO

Step 4: Communication

Settings

YES

Note: This path is not possible for

GuardPLC 1200 and GuardPLC 2000

controllers.

Step 12: Fault Recovery

NO

after Reset.

YES

Is the

FAULT LED

illuminated?

Step 9: Reset Controller

Default Settings

(2)

Step 6: Move Settings

into Offline Project

Step 7: Connect to

Controller Using

Control Panel

NO

Are you online with

the correct settings?

NO

YES

Do you

want to change these

settings in the

controller?

YES

YES

Did

communication

settings read IP/SRS

successfully?

YES

Is the

controller in RUN

mode?

NO

Step 5: Change

Settings via MAC

Address

(3)

DONE

NO

Do you

think you know the

controller settings?

YES

Step 10: Ping the

Controller

Ping successful?

YES

Step 11: Configure

Controller IP

Address

(1)

NO

NO

The steps are described in detail in the following sections.

Publication 1753-PM001A-EN-P - November 2005

Page 16

1-6 Connect to the GuardPLC Controller

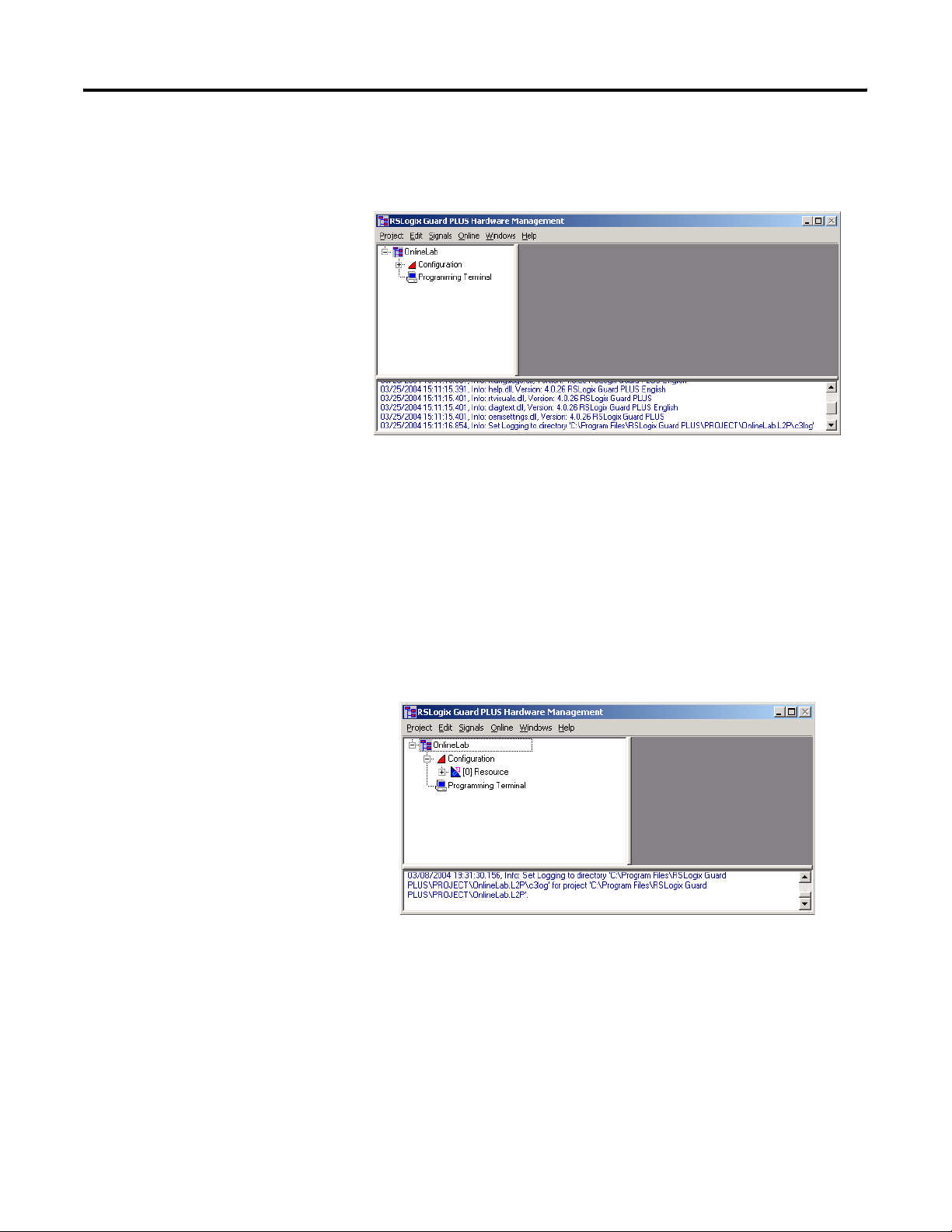

Step 1: Open RSLogix Guard PLUS! Software

Choose Start>Programs>RSLogix Guard PLUS>RSLogixGuardPLUS.

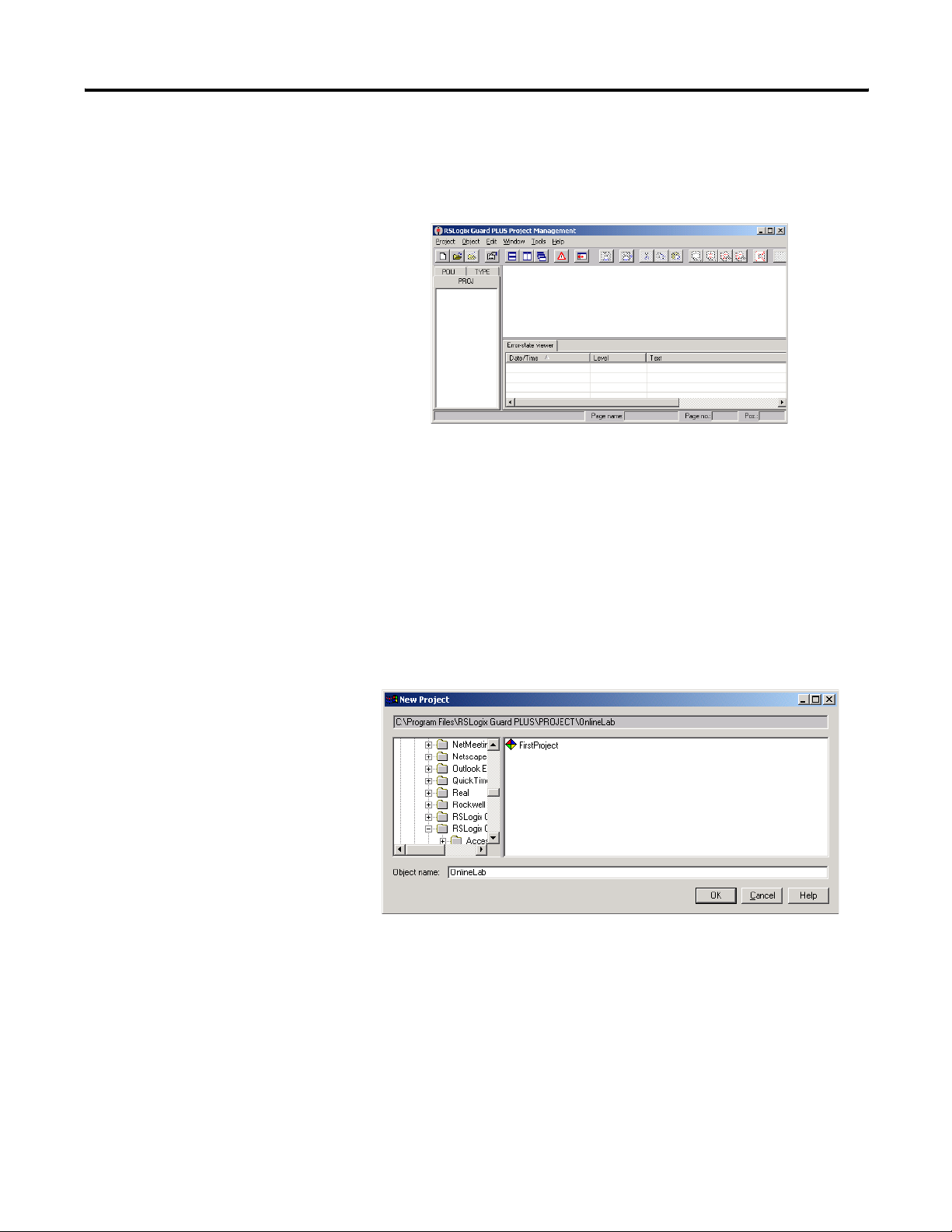

Step 2: Create a New Project

Open an existing project or create a new project that contains a

GuardPLC controller.

1. To create a new project, choose Project>New from the main

menu or click the New icon.

2. Enter the name of the project in the Object Name field.

3. Click OK.

Publication 1753-PM001A-EN-P - November 2005

Page 17

Connect to the GuardPLC Controller 1-7

The RSLogix Guard PLUS! Hardware Management window opens.

Both the Project Management and Hardware Management windows

are normally open when running RSLogix Guard PLUS! software.

Step 3: Configure the Controller Type and SRS

To go online, you must specify the controller type and change the

default SRS. The software defaults to an SRS of zero (0), which is the

only illegal SRS value. To accept the controller type, the SRS must be

changed to a value between 2

(1)

and 65535.

1. Expand the project tree in the Hardware Management window

until [0] Resource is visible.

2. Right-click [0] Resource and choose Properties.

(1) The programming terminal defaults to 1.

Publication 1753-PM001A-EN-P - November 2005

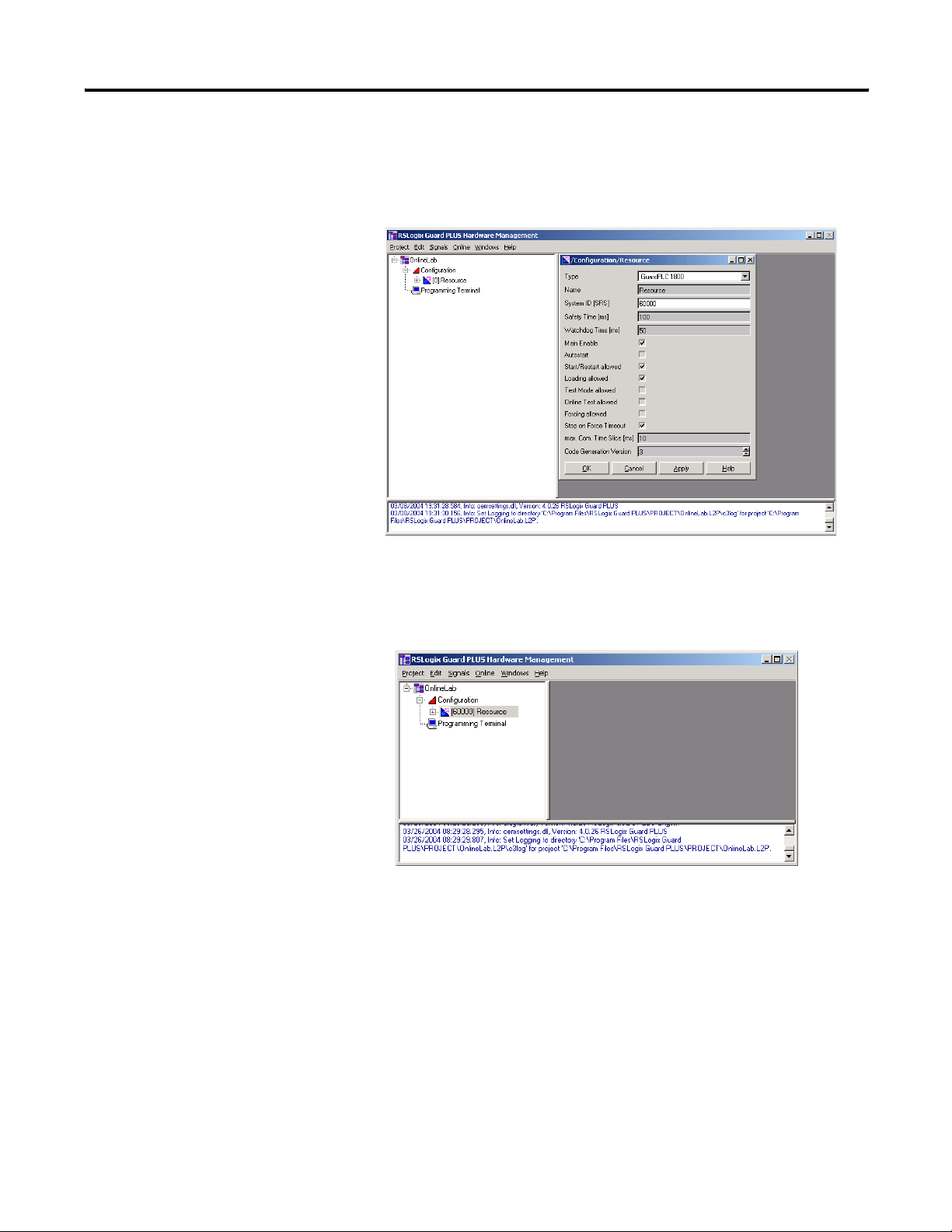

Page 18

1-8 Connect to the GuardPLC Controller

3. Specify the controller type and enter an SRS of 60000.

You must use the default SRS of 60000 the first time you connect

to a GuardPLC controller.

4. Click OK.

The Hardware Management window appears as shown below.

Notice that the SRS has changed to 60000.

Publication 1753-PM001A-EN-P - November 2005

Page 19

Connect to the GuardPLC Controller 1-9

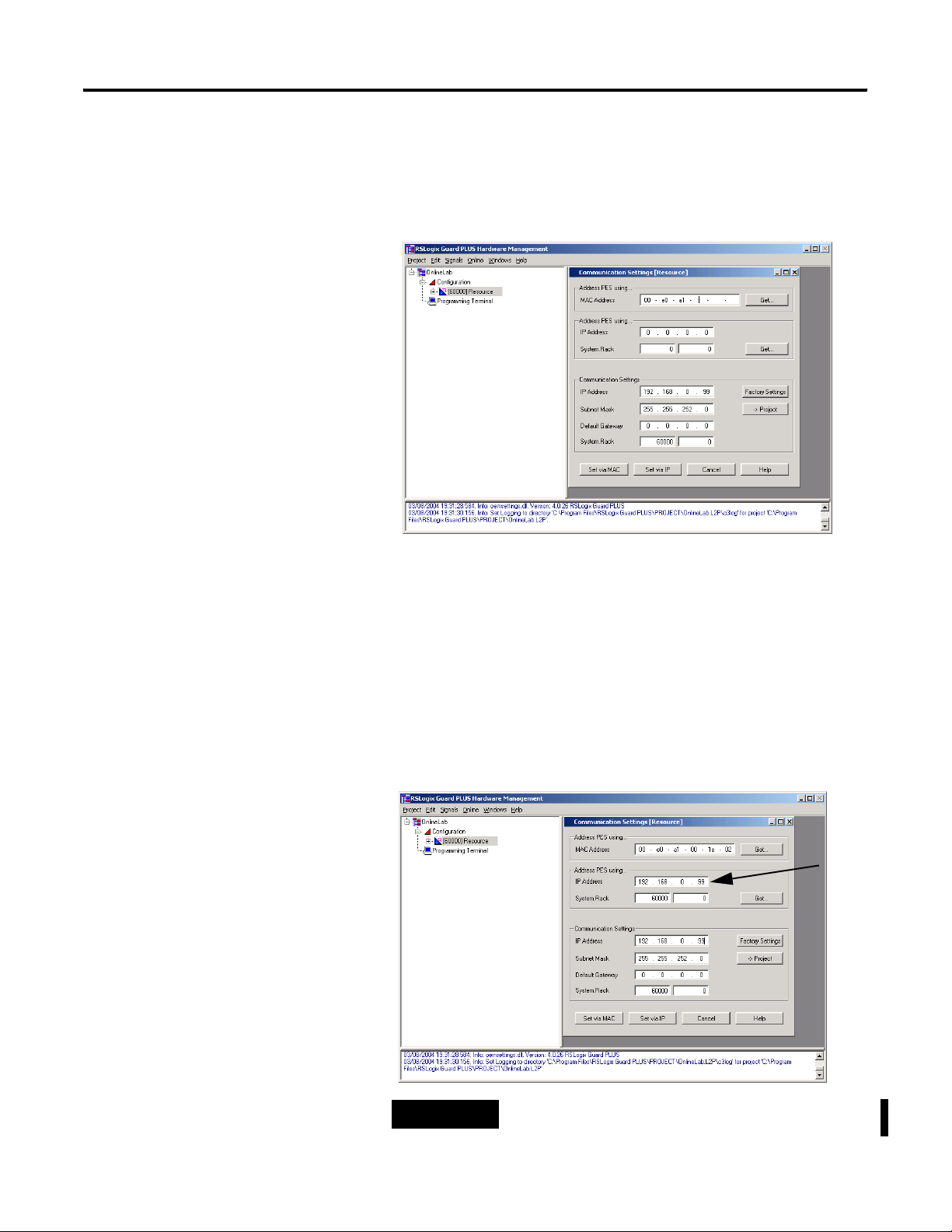

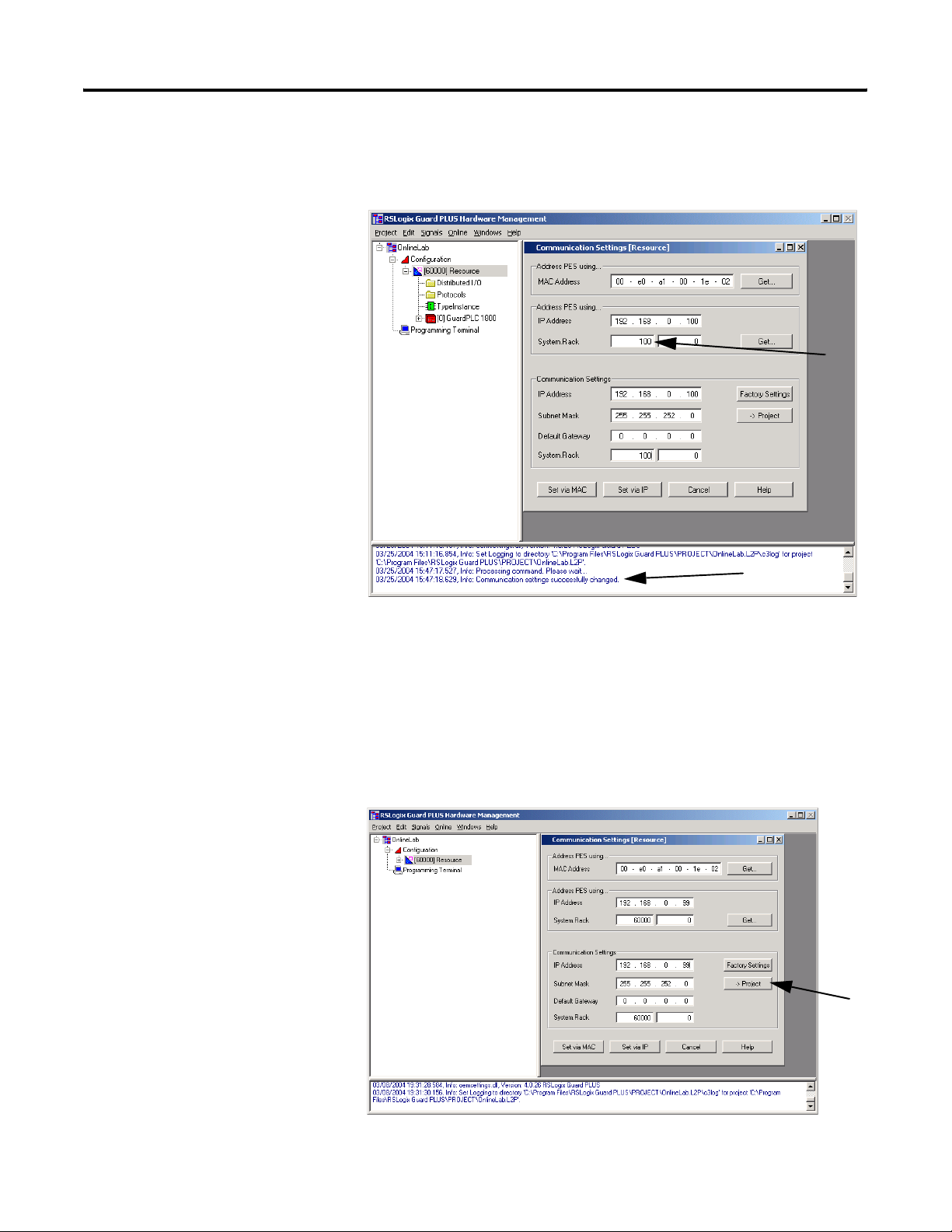

Step 4: Get Communication Settings

1. Choose Online>Communication Settings from the pull-down

menu.

2. Enter the last three elements of the MAC address into the MAC

Address field and click Get.

The MAC address is on the sticker on the side of a GuardPLC

1200 controller, on the label positioned over both lower RJ-45

connections on GuardPLC 1600/1800 controllers and I/O, or on

the front bezel of the AB-CPU module of a GuardPLC 2000

controller.

The IP address and SRS of the GuardPLC controller should

appear in the Address PES using… fields.

TIP

If communication fails, you may need to

disable your fire wall or security settings.

Publication 1753-PM001A-EN-P - November 2005

Page 20

1-10 Connect to the GuardPLC Controller

Step 5: Change Settings via MAC Address

1. Enter desired settings for the IP and SRS in the Communication

Settings fields indicated by the arrows below.

2. Click the Set via MAC button.

3. Enter the default username ‘Administrator’ in the Authentication

window, as shown below.

4. Click OK.

Publication 1753-PM001A-EN-P - November 2005

Page 21

Connect to the GuardPLC Controller 1-11

The IP address and SRS should have changed. A prompt appears at

the bottom of the window and the settings in the middle fields

change.

Step 6: Move the Settings Into Your Offline Project

If you wish to connect using the current GuardPLC controller settings,

move the settings into your offline project.

1. Left-click -> Project.

Publication 1753-PM001A-EN-P - November 2005

Page 22

1-12 Connect to the GuardPLC Controller

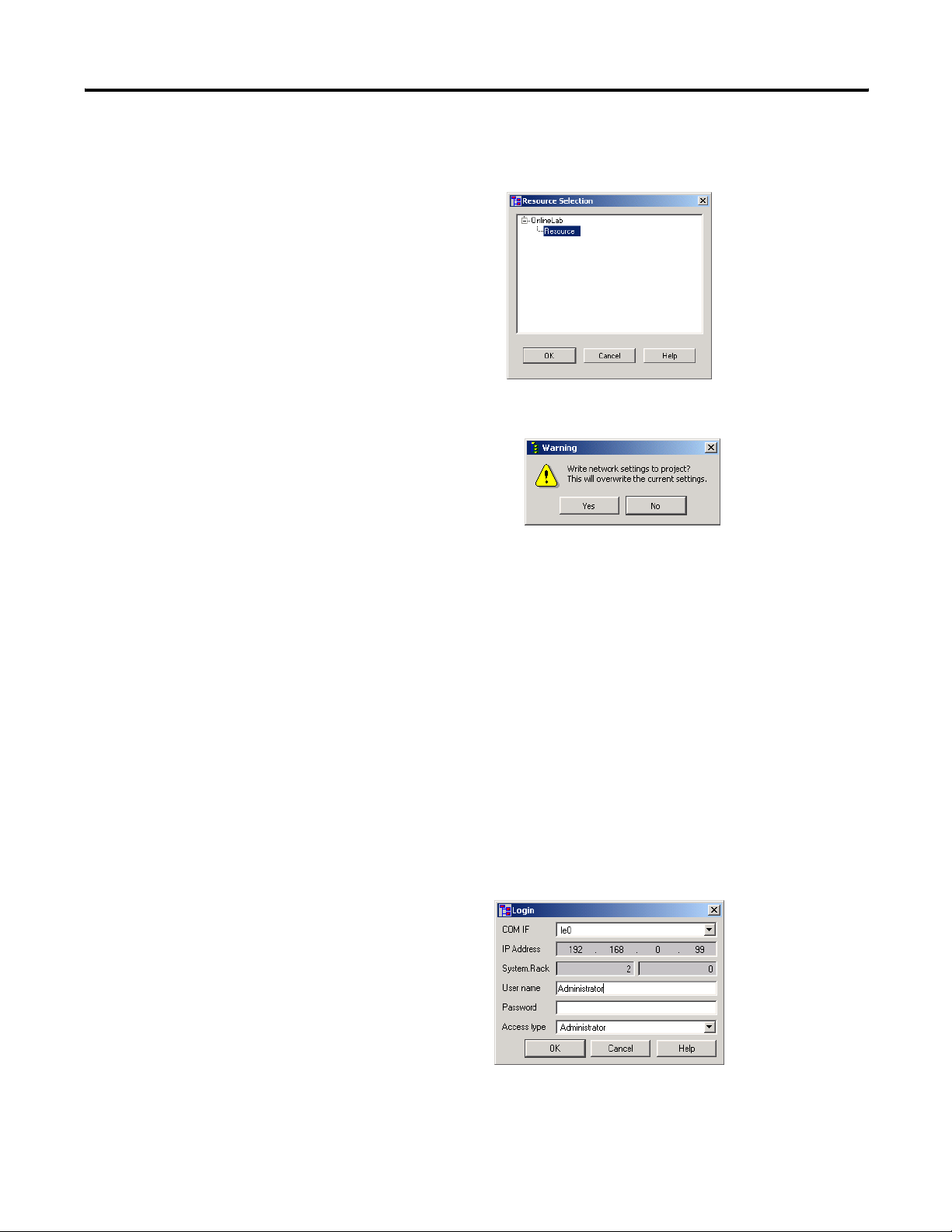

2. Make sure Resource is selected in the Resource Selection

window and click OK.

3. Click Yes.

This moves the IP address and SRS of the GuardPLC controller to your

offline project and overwrites the existing values. These new values

are used in the login screen to connect with the GuardPLC controller.

Step 7: Use the Control Panel to Connect to the GuardPLC

Controller

1. Right-click [60000] Resource.

2. Choose Online>Control Panel.

3. Type [Ctrl]+[A] to fill in the default Username, Password, and

Access Type in the Login Window.

Publication 1753-PM001A-EN-P - November 2005

4. Click OK.

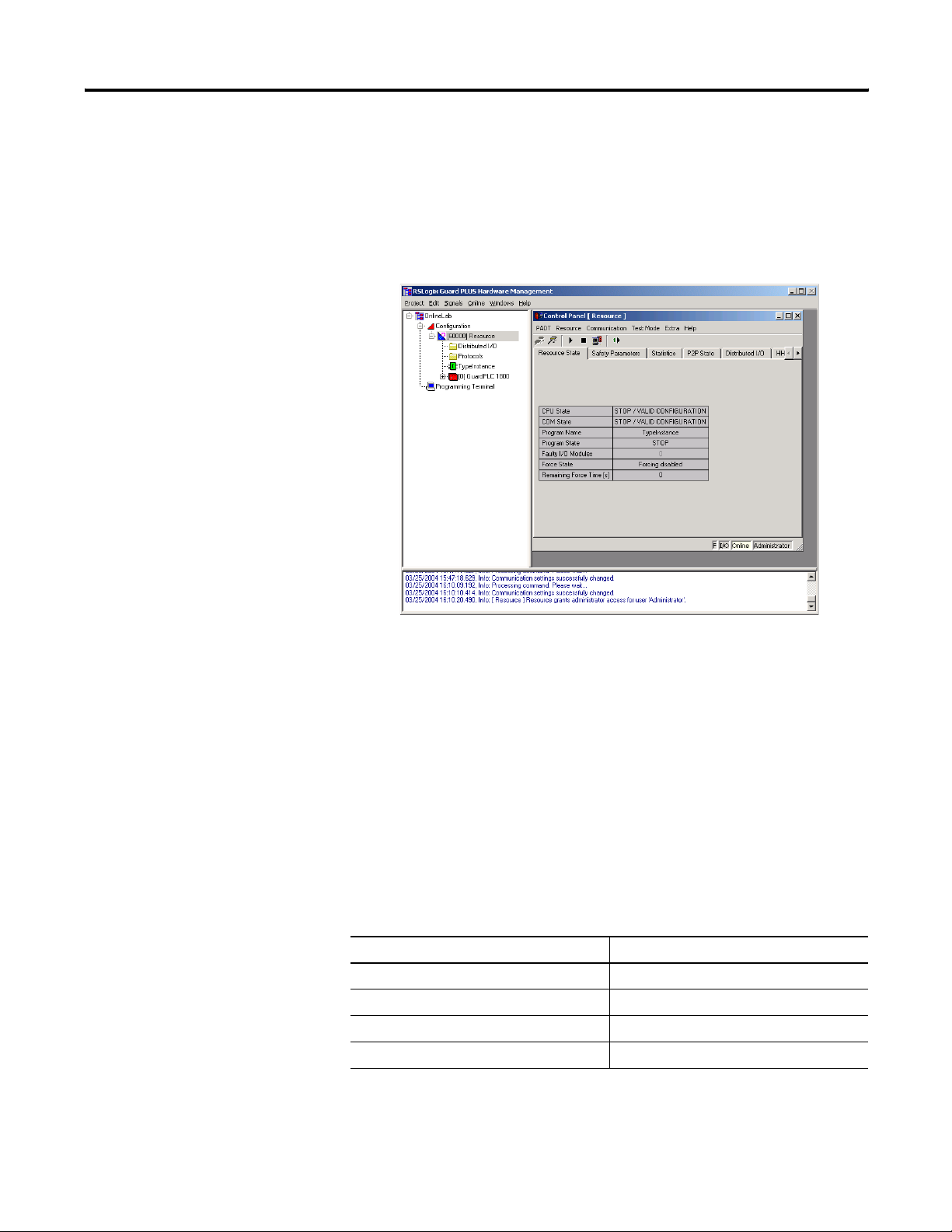

Page 23

Connect to the GuardPLC Controller 1-13

The Control Panel Online indicator will be GREEN if the controller is

in RUN Mode. The Online indicator may also be yellow, white, or red

based on its current state.

TIP

If you are successfully online with the GuardPLC

controller and in RUN mode (Green Online indicator

as shown above), you do not need to continue with

the steps 8 through 12. However, if you are not

online and in RUN mode, consult the flowchart on

page 1-5, and perform the appropriate steps.

Publication 1753-PM001A-EN-P - November 2005

Page 24

1-14 Connect to the GuardPLC Controller

Step 8: Change the Controller to STOP Mode

To change the controller to STOP mode, choose Resource>Stop from

the Control Panel or use the Stop icon.

When in STOP Mode, the Control Panel appears as follows:

Close the Control Panel.

Step 9: Reset the Controller to the Default Settings

In some cases, you may have to reset the GuardPLC controller to its

default IP address and SRS.

GuardPLC 1600 and 1800 controllers have a Reset button that is

accessible via a small hole directly to the right of the Ethernet ports on

top of the controller. The Reset button returns the IP address, SRS and

Password settings to:

Parameter Setting

IP Address 192.168.0.99

SRS 60000

Username Administrator

Password [none]

Publication 1753-PM001A-EN-P - November 2005

Page 25

Connect to the GuardPLC Controller 1-15

To reset the controller:

1. Hold down the Reset button, then power cycle the GuardPLC

controller.

2. Continue to hold down the Reset button until the PROG led

stops flashing.

At the next power cycle, the settings will revert back to the last

configured settings. These could be the settings in place prior to the

Reset operation, if you did not reconfigure them after resetting the

controller.

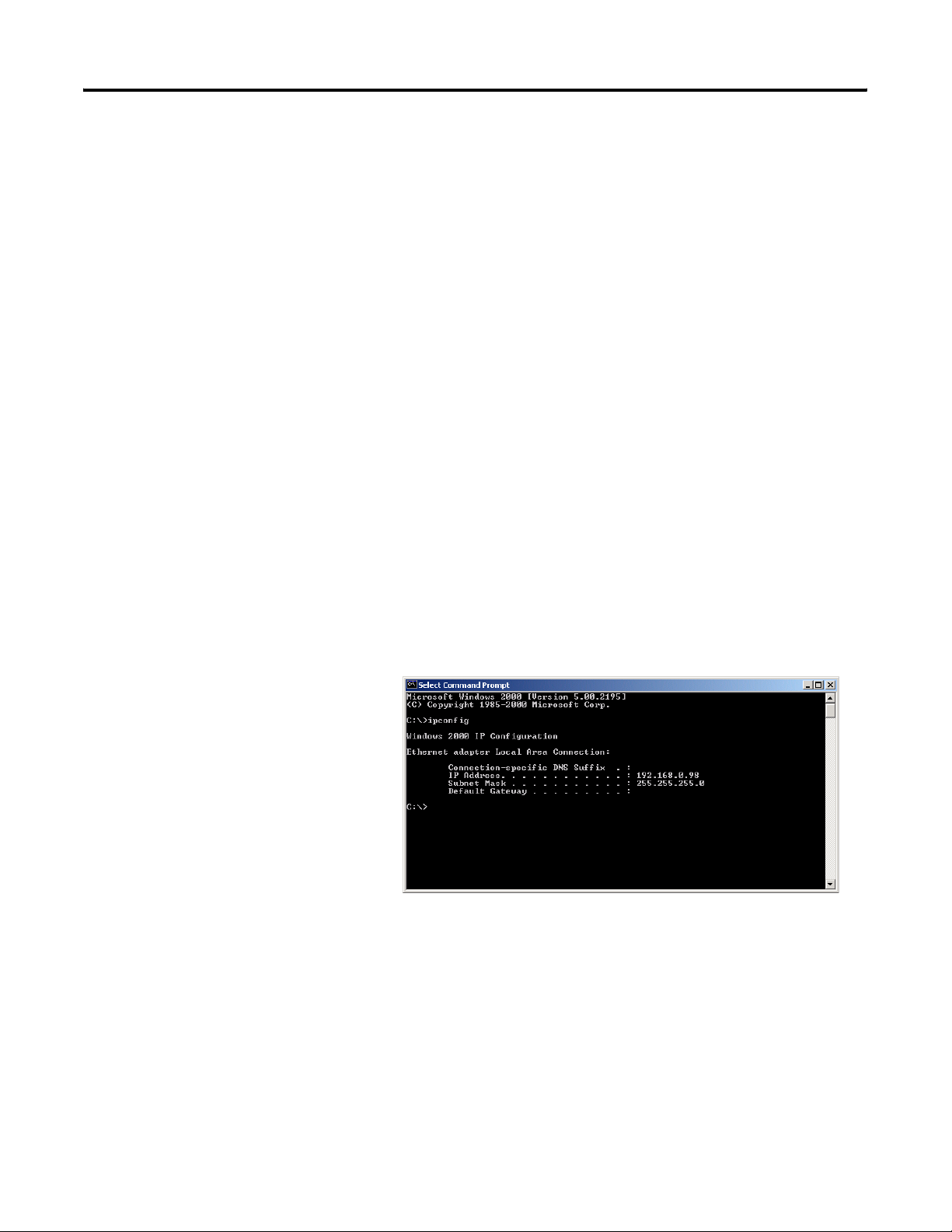

Step 10: Ping the Controller

Use the Start menu to open the RSLogix Guard PLUS! Command

Prompt.

1. Choose Start>Programs>RSLogix Guard PLUS>RSLogix Guard

PLUS Command Prompt.

2. Run IPCONFIG at the DOS Command prompt to verify your

computer’s IP address. It must be on the same local network as

the GuardPLC controller.

Publication 1753-PM001A-EN-P - November 2005

Page 26

1-16 Connect to the GuardPLC Controller

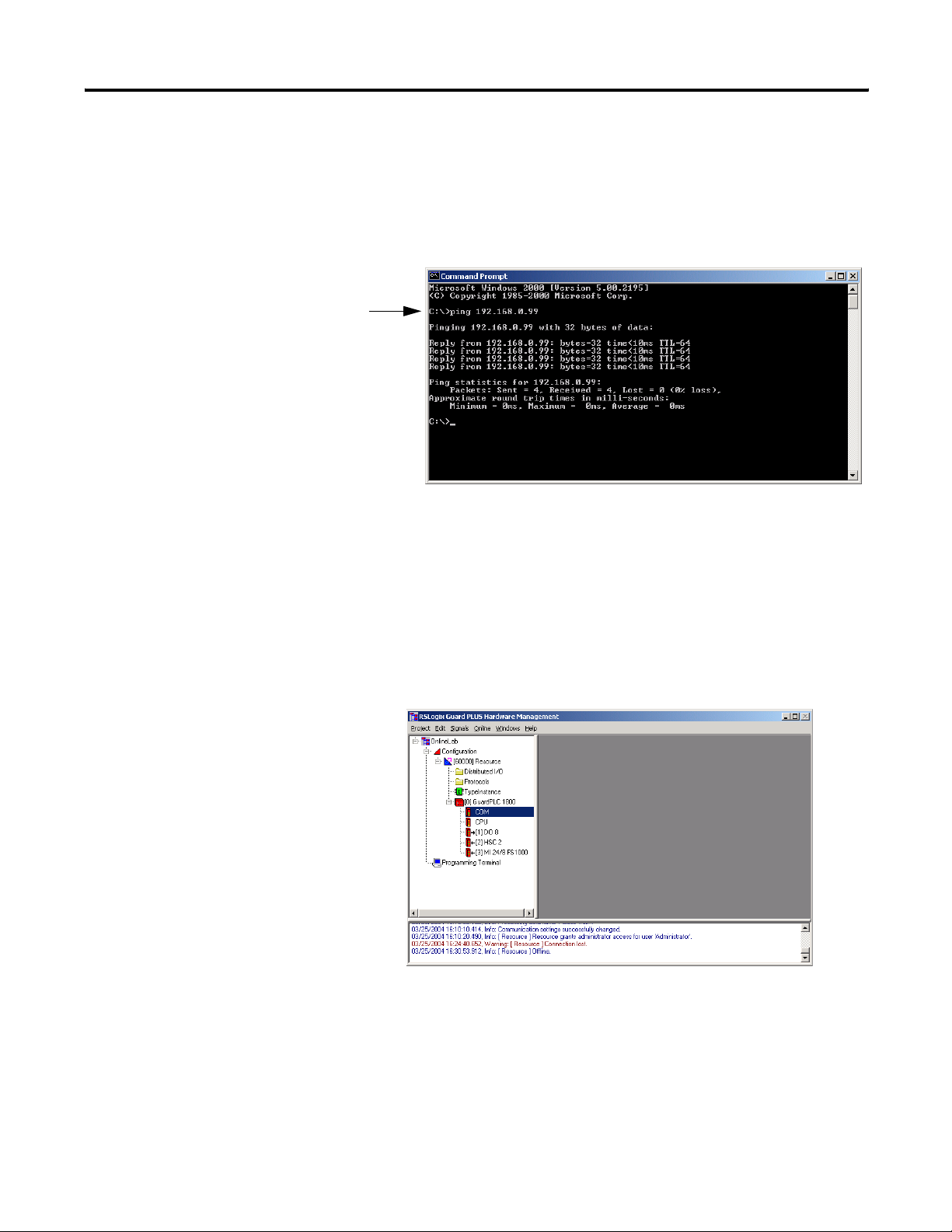

3. Ping the GuardPLC controller using the command shown at the

C:\> below. If the ping is successful, the IP address of the

GuardPLC controller has been verified and the Ethernet link is

operating. If the ping was not successful either the IP address,

subnet mask, or Ethernet link is not correct. The picture below is

the result of a successful ping.

4. Type EXIT at the command prompt to close the Command

Prompt window.

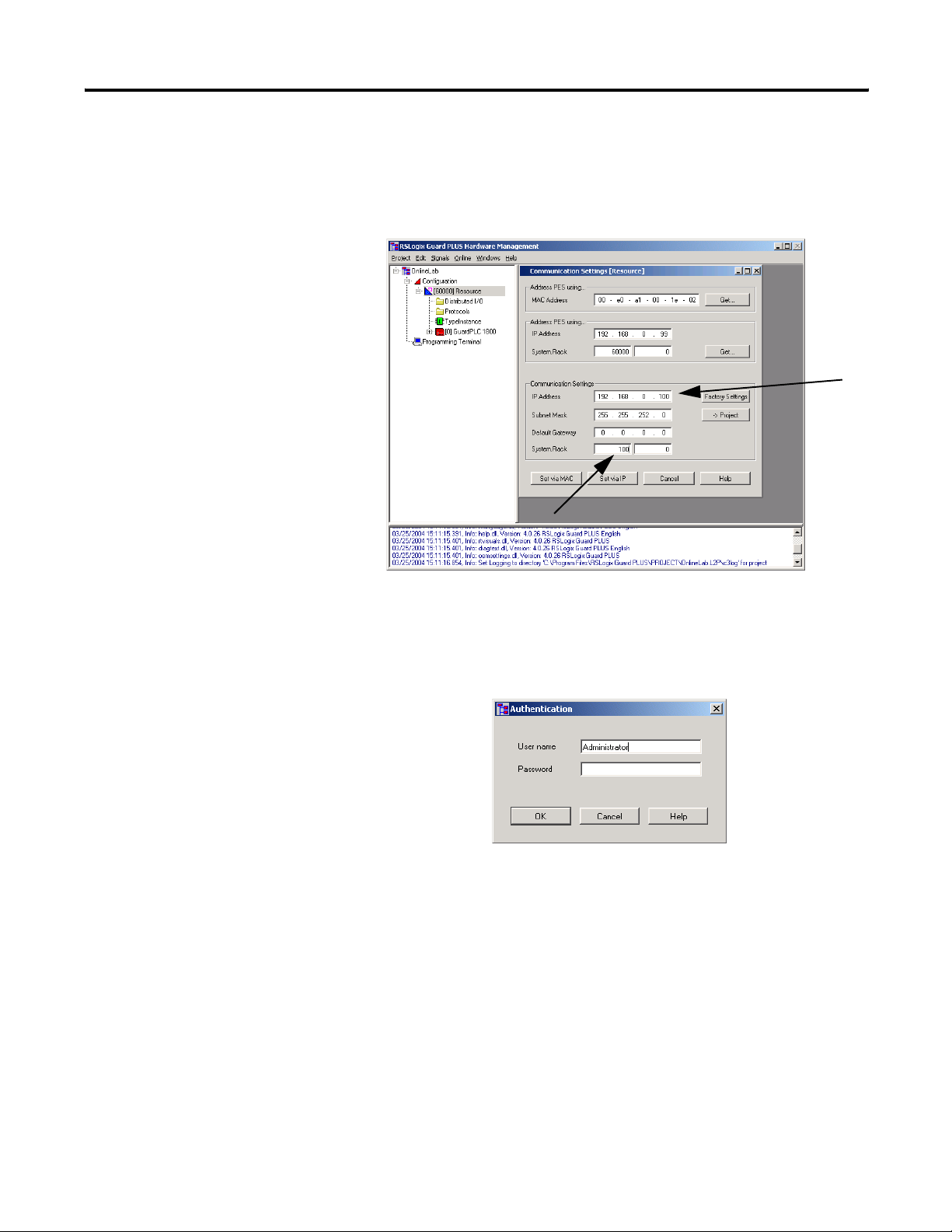

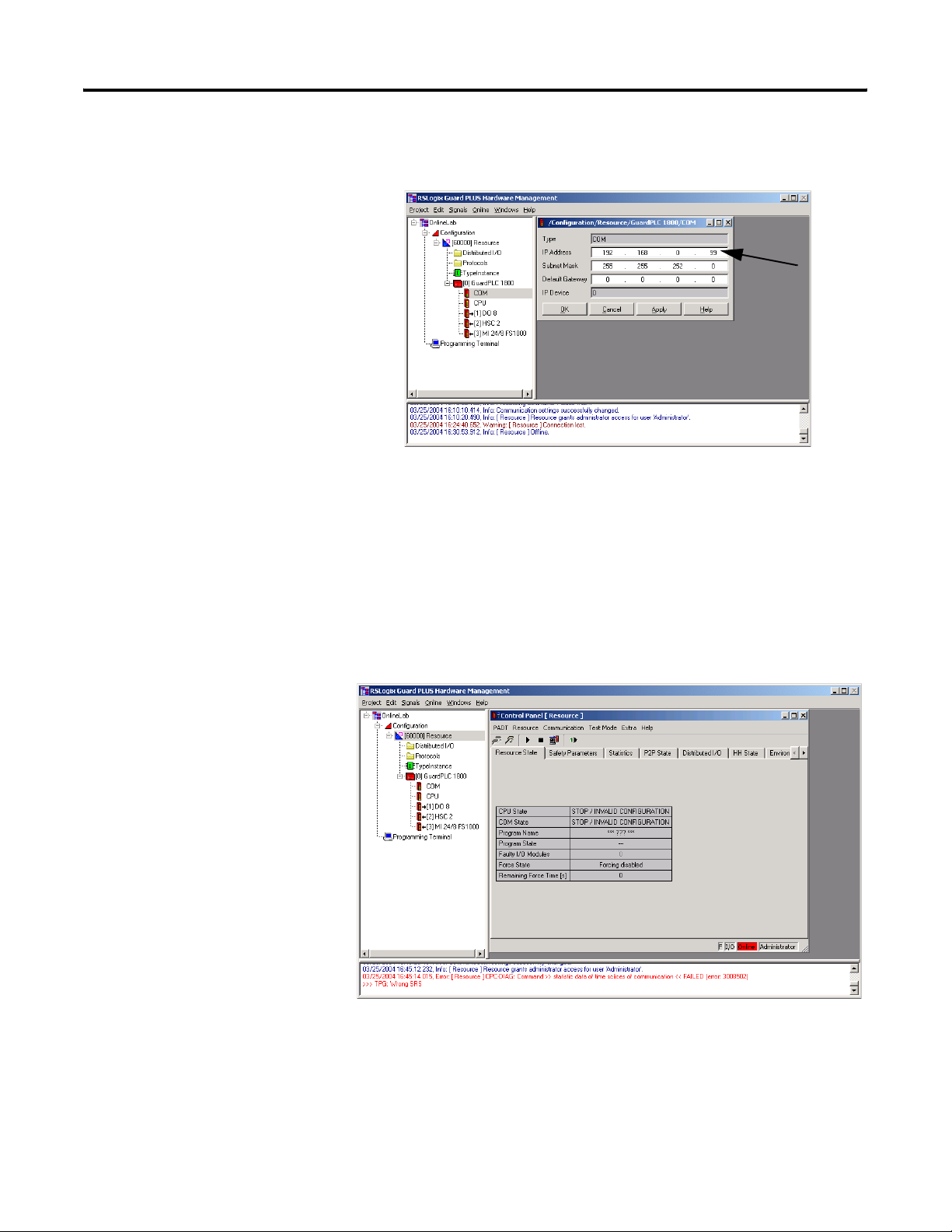

Step 11: Configure the GuardPLC Controller’s IP Address

1. Expand the project tree in the Hardware Management window

until the controller COM icon is visible.

2. Right-click COM and choose Properties.

Publication 1753-PM001A-EN-P - November 2005

Page 27

Connect to the GuardPLC Controller 1-17

3. Edit the IP address to match the GuardPLC controller and click

OK.

Step 12: Recover from a Controller Fault After Using the Reset

Button

After using the Reset button, the Control Panel appears as follows if

the SRS was not originally 60000 prior to the Reset. The Fault LED on

the front of the GuardPLC controller is illuminated, and the CPU State

of the Resource is STOP/INVALID CONFIGURATION.

Publication 1753-PM001A-EN-P - November 2005

Page 28

1-18 Connect to the GuardPLC Controller

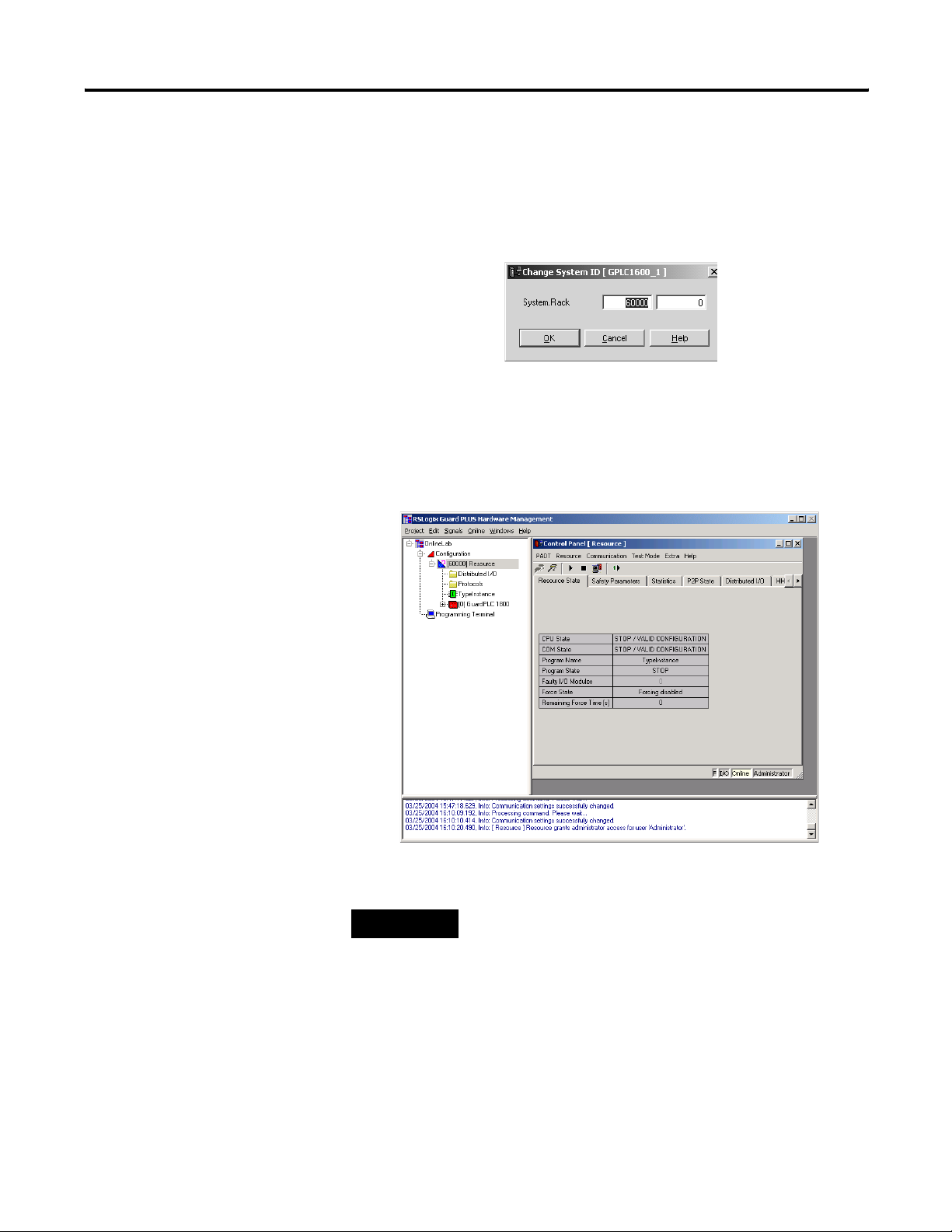

To recover from this fault:

1. Choose Extra>Change System ID from the Control Panel.

2. Verify that 60000 appears in the first window with 0 in the

second, as shown below.

3. Click OK.

The Fault LED should turn off, and the Control Panel should show

that the CPU State has changed to STOP/VALID CONFIGURATION, as

shown below.

Publication 1753-PM001A-EN-P - November 2005

TIP

The Online indicator is white because the GuardPLC

controller is in STOP/VALID mode.

Page 29

Connect to the GuardPLC Controller 1-19

Configure the Programming Terminal

Specify the Host SRS

From the Hardware Management window, you can specify the host

SRS of the programming terminal.

1. Right-click Programming Terminal and choose Properties.

2. Enter the host SRS (1 to 65535) for the programming terminal.

Make sure the host SRS of the programming terminal is not identical to

the system ID (SRS) of any other controllers or programming

terminals.

In a network, as many as five programming terminals can connect to

the same controller at the same time. However, only one

programming terminal can have read/write access.

If another controller logs in with read access, that additional user can

query controller states and parameters (RUN, STOP, controller

switches, etc.) with the Control Panel. The additional user can also

display data values if the programming terminal has the same

configuration as the controller.

If there are multiple programming terminals in one network, each

programming terminal must have a unique host SRS.

Publication 1753-PM001A-EN-P - November 2005

Page 30

1-20 Connect to the GuardPLC Controller

Login Dialog

The Login dialog defines the communication parameters between the

controller and the programming terminal.

Field Description

IP address The IP address of the controller on the Ethernet network.

The factory-set IP address is 192.168.0.99.

SRS SRS stands for System, Rack, Slot. The rack and slot IDs are already preset by the controller, so you only

need to enter the system ID. You can enter any number from 1 to 65,535. However, the number must be

unique from the programming terminal and from any other GuardPLC controllers on the same

Peer-to-Peer Ethernet.

The default (factory-set) SRS is 60000.

Username

(default = Administrator)

Password

(default = <blank>)

Access Type Your access level.

Your username.

The Administrator assigns a username. The username is sensitive to upper and lower case characters. A

username can only contain letters, numbers, and underscore characters.

You can define as many as 10 usernames per GuardPLC controller.

Your password.

An Administrator assigns a password. The password is case sensitive. A password can only contain

letters, numbers, and underscore characters.

Login as one of these options:

Administrator highest privileges

manage usernames and passwords

read data from controller

write routines and data into controller

force tags

stop, start, freeze, and force a routine

download an operating system

change IP address and system ID

reboot the controller

can also login under read/write and read levels

Read/Write read data from controller

write routines and data into controller

force tags

start, stop, freeze, and force a routine

can also login under read level

Read lowest privileges

only read data from controller

As many as five users can login to the same controller at the same time; however, only one of those

users can login as Administrator or Read/Write. The others must login with Read access. If you login

while someone else is logged in with Administrator or Read/Write access, you automatically get Read

access, regardless of the access type you select.

For new controllers, and if the backup battery was removed from a GuardPLC 1200 or 2000 controller,

access is available using the following system defaults:

Username: Administrator

Password <blank>

Access Type Administrator

Publication 1753-PM001A-EN-P - November 2005

Page 31

Connect to the GuardPLC Controller 1-21

Determine the IP Address and SRS of the Controller

The default IP address of a new controller is 192.168.0.99. The default

SRS of a new controller is 60000. To check the current IP address and

SRS of a controller:

1. Choose Online>Communication Settings.

2. In the MAC address field, enter the MAC address of the

controller.

The MAC address is on the sticker on the side of a GuardPLC

1200 controller, on the label positioned over both lower RJ-45

connections on GuardPLC 1600/1800 controllers and I/O, or on

the front bezel of the AB-CPU module of a GuardPLC 2000

controller.

3. Click Get.

The controller responds back with the IP address and the SRS it

is currently using.

Publication 1753-PM001A-EN-P - November 2005

Page 32

1-22 Connect to the GuardPLC Controller

Change the SRS of the

TIP

There are two ways to change the SRS of the controller:

If communication fails:

• check to make sure you entered the address

correctly.

• check that your PC is configured properly.

• anti-virus or firewall programs have blocked

communications.

• the cable is not connected or is not the correct

cable.

– A GuardPLC 1600 or 1800 controller can use

direct or cross-over cable.

– A GuardPLC 1200 or 2000 controller can use a

cross-over cable connected directly from a PC

to the controller or direct cables connected to

a switch or hub.

• your hardware (either the controller or the PC) is

not working.

Controller

From the Control Panel:

1. Choose Change System ID (SRS) from the Extra menu.

2. Enter the SRS.

3. Click OK.

Or follow Step 4: Get Communication Settings on page 1-9 and

Step 5: Change Settings via MAC Address on page 1-10.

Publication 1753-PM001A-EN-P - November 2005

Page 33

Connect to the GuardPLC Controller 1-23

Change the IP Address of the Controller

TIP

After you establish communications with the controller, you can

change the IP address of the controller to match your Ethernet

network. There are two ways to change the IP address of the

controller:

From the Control Panel:

1. Choose Device Settings from the Extra menu.

2. Enter the new IP address.

3. Click OK.

Typically, you change the SRS of the GuardPLC

controller to match that of the controller/routine that

you wish to download to it. Recall that the SRS is

compiled into the executable and ensures that this

.EXE can only be downloaded to a GuardPLC

controller with a matching SRS.

Or follow Step 4: Get Communication Settings on page 1-9 and

Step 5: Change Settings via MAC Address on page 1-10.

TIP

To re-establish communications with the new IP

address and subnet of your GuardPLC controller, you

may need to change the IP and subnet address of

your programming terminal. Use the Network

section of the Windows Control Panel to change the

programming terminal’s IP address and subnet mask.

Publication 1753-PM001A-EN-P - November 2005

Page 34

1-24 Connect to the GuardPLC Controller

Publication 1753-PM001A-EN-P - November 2005

Page 35

In This Chapter

Chapter

2

Connect to GuardPLC Distributed I/O Modules

For this information See page

Understand Module Addressing 2-1

Add the Module to the Hardware Configuration 2-2

Configure the Module 2-3

Go Online With the Module 2-5

This chapter guides you through the process of addressing,

configuring, and connecting to the distributed I/O modules. GuardPLC

distributed I/O modules are ‘owned’ by a GuardPLC controller. This

allows the parent controller to connect signals to the inputs and

outputs of the distributed I/O modules the same way that signals are

connected to the controller’s local I/O.

Understand Module Addressing

Module Default Settings

The out-of-box settings for a GuardPLC distributed I/O module are

shown in the table below.

Parameter Setting

IP Address 192.168.0.99

Subnet Mask 255.255.252.0

(1)

SRS

(1) The SRS code is compiled with the program.

60000.1

SRS (System.Rack.Slot)

The SRS of the parent controller is always xxxxx.0. For example, the

default SRS of a GuardPLC controller is 60000.0. If you change the SRS

to 25, the actual SRS of the controller is 25.0.

1 Publication 1753-PM001A-EN-P - November 2005

Page 36

2-2 Connect to GuardPLC Distributed I/O Modules

Distributed I/O modules inherit the first portion of the SRS from the

parent controller. You configure the second part of the SRS. For

example, the default SRS of distributed I/O modules is 60000.1. If the

module is owned by a controller with an address of 25, then the SRS

of the distributed I/O should be 25.1. If a second module is added to

the controller, its SRS is then 25.2. A third module would be SRS 25.3.

IP Address

Like any Ethernet device, the distributed I/O module requires a

unique IP address.

Add the Module to the Hardware Configuration

To add a distributed I/O module to your GuardPLC project’s hardware

configuration:

1. In the Hardware Management window of RSLogix Guard PLUS!,

right-click the Distributed I/O folder under your controller

Resource.

2. Choose New and the desired I/O module.

Publication 1753-PM001A-EN-P - November 2005

The Specify HH Network dialog appears. Because the controller

and the distributed I/O modules communicate via GuardPLC

Ethernet, you must specify a GuardPLC Ethernet network.

Page 37

Connect to GuardPLC Distributed I/O Modules 2-3

3. Click New….

The Create HH Network dialog appears.

4. Click OK.

The Specify HH Network window reappears showing the

selected network.

Configure the Module

5. Click OK to confirm your selection.

The distributed I/O module now appears in the project tree.

To configure the module, you need to:

• set I/O properties

• configure the offline IP address

Publication 1753-PM001A-EN-P - November 2005

Page 38

2-4 Connect to GuardPLC Distributed I/O Modules

Set I/O Properties

1. In the RSLogix Guard PLUS! Hardware Management window,

right-click the module in the project tree and select Properties.

2. You must change the Rack ID [SRS] to configure the second

portion of the SRS. Change the Rack ID [SRS] value to 1.

3. Click OK.

The offline SRS is now 60000.1. The 60000 comes from the

parent controller, as shown by the arrow in the illustration

above.

Configure the Offline IP Address

1. Expand the module in the project tree.

2. Right-click COM and choose Properties.

Publication 1753-PM001A-EN-P - November 2005

3. Change the IP address to match the module.

4. Click OK.

Page 39

Connect to GuardPLC Distributed I/O Modules 2-5

The offline configuration of the module is complete. The next section

explains how to go online with the module and change the IP address

and SRS to match the offline settings.

Go Online With the Module

Make a point-to-point connection between your programming

terminal and the distributed I/O module. Over this connection,

change the IP address and SRS of the module, following these steps:

1. Right-click the module in the project tree and choose Online >

Communication Settings.

2. Enter the MAC address, which is located on the label positioned

over the RJ-45 connectors.

3. Click Get.

The IP address and SRS of the module appear. If the module is

new, it has the default IP address of 192.168.0.99, the same as

any GuardPLC controller. However, the default SRS is 60000.1.

Publication 1753-PM001A-EN-P - November 2005

Page 40

2-6 Connect to GuardPLC Distributed I/O Modules

4. To change the IP address and SRS settings, enter the new data

into the Communication Settings fields.

5. Click the Set via MAC button.

6. Enter Administrator in the User Name field and click OK.

The new IP address and SRS settings are shown in the Address

PES using … fields.

7. Close the Communication Settings dialog by clicking the Cancel

button.

Publication 1753-PM001A-EN-P - November 2005

Page 41

Create a GuardPLC Project

Chapter

3

In This Chapter

Start a New Project

This chapter guides you through the following basic steps required to

create a project:

• Start a new project.

• Configure the project and hardware.

• Create signals.

• Connect signals to the I/O points.

• Create a Function Block program using the signals.

• Save, compile, test, and download the program to the GuardPLC

controller.

• Monitor the project online.

To start a new GuardPLC project:

1. Start RSLogix Guard PLUS! software.

2. Create a new project using the New icon or by choosing

Project>New.

3. Enter ‘FirstProject’ in the Object Name field as shown below and

click OK.

The Hardware Management window opens. This window is

used to configure the project, controller, I/O, and signals.

1 Publication 1753-PM001A-EN-P - November 2005

Page 42

3-2 Create a GuardPLC Project

4. Return to the Project Management window and expand the

project tree until it matches the example below.

When the project is expanded, you can see that it contains a

Configuration and under the Configuration there is a Resource, which

is the actual GuardPLC controller. Under the Resource is the program

TypeInstance that will run on the GuardPLC controller.

Configure the Project and Hardware

TIP

You can add an additional controller to the project

by right-clicking Configuration and choosing

New > Resource.

Configure the Controller Resource

1. In the Hardware Management window, expand the project tree

so that the Configuration, Resource, and TypeInstance are

visible, as shown below:

Publication 1753-PM001A-EN-P - November 2005

2. Right click [0] Resource and choose Properties.

Page 43

Create a GuardPLC Project 3-3

3. Edit the properties as shown below.

The Resource Type needs to match the type of GuardPLC

controller to which you want to connect. The SRS is a code that

is compiled with the function block routine. The routine can be

downloaded only to a GuardPLC controller with a matching SRS

code stored in its non-volatile memory. For more information on

configuring the controller, refer to the controller configuration

chapter of the GuardPLC Controller Systems User Manual,

publication number 1753-UM001.

TIP

The default SRS of a new controller is 60000.

You must use this SRS to initially establish

communications with the controller. Once you

have established communications, you can

change the SRS.

4. Click Apply to move these values into the project.

5. Check the four (4) unchecked boxes and click OK.

TIP

You can rename the controller using the

Program Management window. Expand the

project tree and the Configuration.

Right-click on Resource and choose

Rename.

Publication 1753-PM001A-EN-P - November 2005

Page 44

3-4 Create a GuardPLC Project

6. Expand the Resource so that the Hardware Management project

tree appears as shown below.

7. Right click COM under the GuardPLC 1800 controller, and

choose Properties.

Create Signals

Publication 1753-PM001A-EN-P - November 2005

8. Enter the IP address of your GuardPLC controller. Neither the

Subnet Mask nor the Default Gateway should require changes.

TIP

T

The GuardPLC controller’s default IP address is

192.168.0.99.

9. Click OK.

Because the example in this chapter uses the GuardPLC 1800

controller, there are predefined I/O listed under the controller in the

project tree. The 1200/1600/1800 are fixed controllers with

pre-configured I/O. If you use a GuardPLC 2000 controller, the I/O

must be configured, since it is a modular controller.

Page 45

Create a GuardPLC Project 3-5

Understand the Signal Editor

The Signal Editor lets you define the signals for your application.

The Name column contains a unique name for the signal. The Name is

required and must be less than 32 characters in length.

The Type column indicates the desired data type for the signal. The

default is Boolean.

Signals are typically stored in RAM memory. However, a checkmark in

the Retain column specifies that the signal be stored in Flash memory,

thus retaining its value following a restart caused by a power cycle or

a STOP to RUN mode transition.

IMPORTANT

Even if a signal is marked as Retain, specific program

code is required to prevent it from being overwritten.

In addition, the Retain feature requires a warmstart,

either by choosing Warmstart from the Resource menu

of the Control Panel or by right-clicking on the Type

Instance of the Resource in the project tree and

choosing Properties. Then, choose Warmstart from the

Autostart Enable pull-down menu.

The Constant column specifies that the value of the signal cannot be

changed in program code. It will always equal the value entered in

the Init Value column.

The Init Value column specifies the initial value of the signal. This

value can be changed by program code if Constant is not checked.

Publication 1753-PM001A-EN-P - November 2005

Page 46

3-6 Create a GuardPLC Project

Create Signals in the Signal Editor

1. To open the Signal Editor, choose Signals > Editor from the

Hardware Management menu bar.

2. Create 3 new signals, START, STOP, and MOTOR:

a. Left-click on New Signal in the Signal Editor. Type START in

the Name field and press the Enter key.

b. Left-click on New Signal again. Type STOP in the Name field

and press the Enter key.

c. Left Click on New Signal again. Type MOTOR in the Name

field and press the Enter key.

Connect Signals to I/O Terminals

Publication 1753-PM001A-EN-P - November 2005

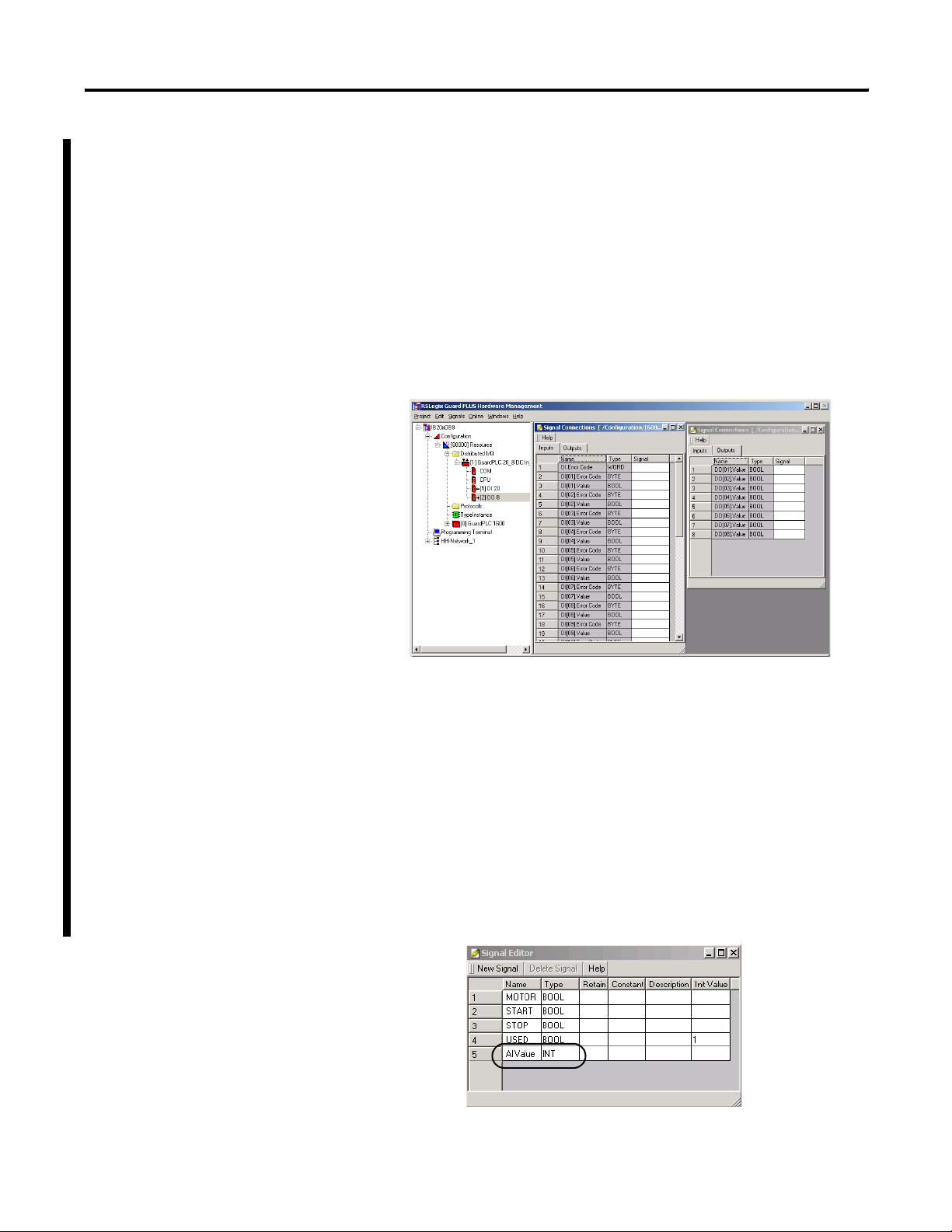

Connect signals to I/O by dragging the signals from the Signal Editor

to the Input or Output tabs of the Connect Signals dialog.

Page 47

Create a GuardPLC Project 3-7

Connect Digital Input Signals

1. Right-click on the controller’s inputs (DI 20 for 1600 or MI 24/8

FS1000 for 1800) or on a Distributed I/O module and choose

Connect Signals.

TIP

Set up your screen so that you can easily drag

signals from the Signal Editor window to the

Signal Connections window. Both the Name

fields in the Signal Editor and the Signal fields

in the Signal Connections window must be

visible, as shown above.

2. Verify that the Inputs tab is selected on the Signal Connections

dialog.

Two signals exist for each input: Value and Error Code. The

GuardPLC 1800 controller adds another signal called Value

Analog.

Error Code is a status signal that can be used for point-level

diagnostics. The Value contains the actual field state of the input:

ON (1) or OFF (0).

Publication 1753-PM001A-EN-P - November 2005

Page 48

3-8 Create a GuardPLC Project

3. Connect the START and STOP signals to inputs by dragging

START and STOP from the Name field in the Signal Editor to the

Signal field in the Signal Connections window.

a. Make sure the cursor is not active in any field in either the

Signal Editor or the Signal Connections dialog.

b. Left-click and hold on the Name field. Drag the signal to the

Signal field in the Signal Connections dialog.

c. Release when over the proper field.

TIP

Signals can only be dragged and dropped onto

Signal fields of the same data type. Dropping a

BOOL signal onto a BYTE field is not

permitted.

When both signals have been connected, the screens should

appear as follows:

Publication 1753-PM001A-EN-P - November 2005

4. If your controller is a GuardPLC 1800, an additional step is

required. The digital inputs on a GuardPLC 1800 controller are

actually analog circuits with a resolution of one (1) bit. Any

voltage greater than 13V dc will be a 1. Any voltage less than

7V dc will be a 0. Since GuardPLC analog circuits require the

user to specify which channels are being used, this is also

required for the 24 digital inputs on the GuardPLC 1800

controller.

a. Add a new signal, called USED, to the Signal Editor.

b. Give this signal an initial value of 1. You will never change

this value in your program, so USED will always be 1.

c. Choose the Outputs tab of MI 24/8 FS1000.

Page 49

Create a GuardPLC Project 3-9

d. Connect USED to the DI channels being used: DI[17].Used,

and DI[18].Used

5. Close the DI Signal Connections window.

Connect Output Signals

1. Right-click the controller’s outputs (DO8) or a Distributed I/O

module and choose Connect Signals.

2. The Signal Connections window defaults to the Inputs tab.

Choose the Outputs tab to view the output fields.

3. Connect the MOTOR signal to the first output, as shown below.

Publication 1753-PM001A-EN-P - November 2005

Page 50

3-10 Create a GuardPLC Project

Connect Distributed I/O Signals

For distributed I/O modules, you connect signals to the distributed

I/O module’s inputs and outputs just as if they were I/O points on a

controller.

1. Expand the distributed I/O module in the Hardware

Management project tree and right-click on DI for inputs or DO

for outputs.

2. Choose the proper tab, Inputs or Outputs, on the Signal

Connections dialog.

3. Drag and drop signals from the Signal Editor onto the Input or

Output tabs to map the signals to the appropriate terminals on

the distributed I/O module.

Connect Analog Input Signals (GuardPLC 1800 Controllers)

1. Right-click the GuardPLC 1800 controller’s inputs (MI 24/8

FS1000) and choose Connect Signals.

2. In the Signal Editor, create signals for the analog values.

Publication 1753-PM001A-EN-P - November 2005

Page 51

Create a GuardPLC Project 3-11

3. Connect these signals to the analog inputs on the Inputs tab of

the Signal Connections dialog.

4. Choose the Outputs tab of the Signal Connections dialog.

5. Connect the USED signal from the Signal Editor to the analog

input channels you are using for your application.

Connect High-speed Counter Signals (GuardPLC 1800 Controllers)

To connect signals to the high-speed counters on the GuardPLC 1800

controller, you must first create signals to configure the high-speed

counters. You will also need to create signals for the counter values.

Then, connect these signals to the counter inputs and outputs.

Create Configuration and Counter Value Signals

1. In the Signal Editor, create true and false signals with constant

values. True signals have a value of 1; false signals have a value

of 0.

Publication 1753-PM001A-EN-P - November 2005

Page 52

3-12 Create a GuardPLC Project

2. Create a Count signal for counter value.

Connect Configuration Signals and Counter Value Signals

1. Right-click the GuardPLC 1800 controller’s high speed counters

(HSC2) and choose Connect Signals to open the Signal

Connections dialog.

2. Choose the Outputs tab.

3. Connect the True and False signals to the counter outputs to

configure the desired counter behavior.

Publication 1753-PM001A-EN-P - November 2005

Page 53

Count Up regardless of Direction

Count Up based on Direction

Create a GuardPLC Project 3-13

Counter[xx] Output Variable Description

5/24V Mode True (1) = 24V

False (0) = 5V

Auto Advance Sense True (1) = Count Up or Down Based on Direction

False (0) = Count Up Regardless of Direction

Direction If Auto Advance Sense is False (0), then count in the

indicated Direction:

• True (1) = Down

• False (0) = Up

Gray Code True (1) = Use Gray Code Mode

False (0) = Use Pulse Mode

Reset True (1) = No Counter Reset

False (0) = Reset Counter

4. Select the Input tab on the Connect Signals dialog.

5. Connect the Count signal you created to the Counter Value

input.

Create a Function Block Program

These signals can now be used in your application program logic.

The following example creates code to start and stop a motor using

the two input signals we created earlier.

TIP

For more information on Function Block

programming, consult the online Help and

Chapter 8, Create User-Defined Function Blocks.

Publication 1753-PM001A-EN-P - November 2005

Page 54

3-14 Create a GuardPLC Project

1. Close the Signal Connections window. Leave the Signal Editor

active, and restore the Project Management window.

2. If necessary, expand the project tree in Project Management

until [I] TypeInstance is visible and double left-click

[I] TypeInstance to open the Function Block Editor program

page.

3. Drag signals from the Signal Editor (in Hardware Management)

to any location on the FB Editor program page.

TIP

To make the Signal Editor and the FB Editor fit

comfortably on your screen, restore both the

Project Management and Hardware

Management windows. Then, choose Tile

Windows Vertically from the Windows task bar

located on the bottom of your screen.

Publication 1753-PM001A-EN-P - November 2005

Whenever a page is edited for the first time, a window appears

asking for a page name. You do not need to name the page.

Click OK to close this dialog box.

Page 55

Create a GuardPLC Project 3-15

4. Minimize the Hardware Management window.

TIP

You can delete the white areas under the

signals, which are used for descriptions, by

clicking the white area and hitting the Delete

key.

5. In the Project Management project tree, expand StandardLibs,

IEC61131-3, and Bistr as shown below.

6. Drag an AND and an OR block onto the routine (Left-click, hold,

drag and release).

Publication 1753-PM001A-EN-P - November 2005

Page 56

3-16 Create a GuardPLC Project

7. Connect the blocks with lines by left-clicking and holding the

very small dots on the edges of the boxes. Drag and release over

the destination dot.

TIP

8. Create a duplicate MOTOR signal by right-clicking MOTOR and

choosing Duplicate. Drag and drop the signal on the page.

9. Invert the STOP signal by right-clicking on the dot and choosing

Invert.

Use the Zoom In tool on the toolbar to

zoom in to see the dots on the edge of the

boxes.

Save, Compile, Test, and Download the Program

Publication 1753-PM001A-EN-P - November 2005

TIP

In addition to standard function blocks, you can

create user-defined function blocks that consist of

standard function block logic, as described in

Chapter 8. You can also purchase

application-specific safety function blocks that have

been certified by TÜV. Go to www.ab.com/guardplc

or contact your local Rockwell Automation

representative for more information.

Save the Program

1. Left-click the Save button to save your program edits.

A window appears, which you can use to document your

changes.

Page 57

2. Click OK

Create a GuardPLC Project 3-17

TIP

The FB editor menu bar displays the number of

edits since the last save. Following a save, it

displays ‘(unchanged)’.

Compile the Code

1. Close the Type Instance Program.

2. Right-click Resource and choose Code Generation.

3. The results of the code generation are shown on the Error State

Viewer.

If the Error State Viewer is not visible, click the red triangle

to make it visible.

If the compile was successful, ‘Error Free code generated’ appears in

the Error-State Viewer.

TIP

If you are using a GuardPLC 1800 controller, you will

see a warning in the Error State Viewer. Go to the

Hardware Management window to view the

warning, which reads ‘USED’ has an initial value, but

no source.’ Disregard this warning, because the

‘USED’ signal has an initial value of 1, but no source

drives its value.

Publication 1753-PM001A-EN-P - November 2005

Page 58

3-18 Create a GuardPLC Project

Run an Off-Line Simulation

To test the code before downloading it to the GuardPLC controller,

run an off-line simulation:

1. Right-click Resource and choose OFF-Line-Simulation.

The OLS tab appears.

2. Double left-click [I] TypeInstance.

The following appears.

Publication 1753-PM001A-EN-P - November 2005

Page 59

Create a GuardPLC Project 3-19

3. Choose points to toggle/view during the simulation. To activate

a point, left-click on a point, drag, release, and left-click again.

4. Start the simulation by left-clicking the blue flag button.

5. Double left-click the yellow field to toggle TRUE/FALSE. Blue

lines represent OFF. Red lines represent ON.

6. When finished testing, stop the simulation by choosing the Stop

icon.

7. Close the Off-line simulation using the Close OLS icon.

TIP

If you do not save your changes, you will

have to re-select the points to simulate.

8. Click the PROJ tab to return to the project tree.

Publication 1753-PM001A-EN-P - November 2005

Page 60

3-20 Create a GuardPLC Project

Download the Program

1. Connect the GuardPLC controller to your PC’s Ethernet port

using a Cat. 5 Ethernet cable.

2. In the Hardware Management window, close the Signal Editor.

3. Right-click [60000] Resource.

4. Choose Online>Control Panel.

5. Enter the default Username (Administrator) with no password

and click OK.

The Control Panel opens.

TIP

You can use the [Ctrl]+[A] shortcut to enter the

default Username and Password.

If you are unable to go online, see Chapter 2 for information on

determining the IP address and SRS of the GuardPLC controller

and for information on the appropriate setting for your PC’s IP

address.

Publication 1753-PM001A-EN-P - November 2005

6. If the GuardPLC controller is in RUN mode, change to STOP

mode. Left-click the Stop icon on the Control Panel.

7. Answer Yes to the warning prompt.

Page 61

Create a GuardPLC Project 3-21

8. Left-click on the Download icon.

9. Answer Yes to the warning prompt.

10. Make sure the download was successful by checking the Status

Field for a ‘Resource Configuration successfully loaded’

message.

11. Put the GuardPLC controller into RUN mode by clicking the

Coldstart button and answering Yes to the warning prompt.

Publication 1753-PM001A-EN-P - November 2005

Page 62

3-22 Create a GuardPLC Project

How to Monitor the Routine Online

To monitor the routine online, you must be online with the controller,

and the controller must be in RUN mode.

1. In the Project Management window, right-click Resource and

choose ON-Line Test.

The Project Manager appears as shown below.

2. Double left-click [I] TypeInstance.

If the lines appear RED (TRUE) and BLUE (FALSE), then the

monitor is active. Test the routine and monitor the function

code.

Publication 1753-PM001A-EN-P - November 2005

Page 63

Create a GuardPLC Project 3-23

3. Close the On-Line Test when finished testing.

4. Click the PROJ tab to return to the project tree.

If the lines are RED/BLACK striped, then the Control Panel is

NOT online with the GuardPLC controller or the controller is not

in RUN mode.

See Chapter 2 for information on going online with the

GuardPLC controller.

TIP

For more information on downloading, see

Chapter 4.

Publication 1753-PM001A-EN-P - November 2005

Page 64

3-24 Create a GuardPLC Project

Publication 1753-PM001A-EN-P - November 2005

Page 65

Using This Chapter

Chapter

Check, Download, Start, and Test a Routine

For information about See page

checking consistency (whether you need to download your routine) 4-1

downloading a routine 4-2

starting a routine 4-4

testing a routine 4-5

how a routine executes 4-6

To download and run a routine, you must:

4

Check Consistency

• Complete your system configuration and your routine logic.

• Save your logic by choosing Object>Save on the Project

Management menu bar.

• Generate code. Make sure all your system configuration is

complete before you generate code.

• Connect the programming terminal (running RSLogix Guard

PLUS! software) to the controller.

• Download the routine to the controller. See page 4-2.

• Start the routine. See page 4-4.

To determine whether or not you need to download your routine, you

can use the Check Consistency feature to verify whether the routine

running in the controller is the same routine you are editing in

RSLogix Guard PLUS! software. Choose Resource>Check Consistency

to compare the two programs. If all the codes match, your offline

routine has been previously downloaded to the controller.

1 Publication 1753-UM001B-EN-P - November 2005

Page 66

4-2 Check, Download, Start, and Test a Routine

Download a Routine

1. Choose Online>Control Panel.

The software automatically asks you to log in.

2. After you successfully log in, the Control Panel opens.

DownloadColdstart

Stop

3. The routine must be stopped before downloading is permitted.

Choose Resource>Stop.

4. Choose Resource>Download to load the routine into the

controller.

IMPORTANT

If your controller is in FAILURE_STOP, it must be

rebooted before you can download a routine. While

online with the controller, choose Reboot Resource

from the Control Panel.

For more information on recovering from a

FAILURE_STOP, refer to the GuardPLC Controller

Systems User Manual, publication number

1753-UM001.

Publication 1753-UM001B-EN-P - November 2005

Page 67

Check, Download, Start, and Test a Routine 4-3

Troubleshoot the Download Process

The SRS of the controller must match the SRS saved in the routine in

order to download the routine. When you specify an SRS for a

controller in a project, that SRS gets saved in the routine when you

generate code.

Check the SRS of the Controller

1. Choose Online>Communication Settings.

2. In the MAC address field, enter the MAC address of the

controller.

The MAC address is on the sticker on the side of a GuardPLC

1200 controller, on the label positioned over both lower RJ-45

connections on GuardPLC 1600/1800 controllers and I/O, or on

the front bezel of the AB-CPU module of a GuardPLC 2000

controller.

3. Click Get.

The controller responds back with the IP address and the SRS it

is currently using.

Now you know the correct SRS to use. Change the SRS and generate

code again. Then the download should work.

Update the SRS in the Controller

In some cases, most likely after a reboot due to a FAILURE_STOP, the

SRS of the controller might be the same as the SRS in the routine, but

the routine still will not download. If this happens, change the SRS to

the same number and click OK, as shown on the following page. This

Publication 1753-UM001B-EN-P - November 2005

Page 68

4-4 Check, Download, Start, and Test a Routine

updates the SRS in the controller and corrects the issue. You should

now be able to download the routine.

TIP

For more information on recovering from

FAILURE_STOP, refer to the GuardPLC Controller

Systems User Manual, publication number

1753-UM001.

1. Choose Extra>Change System ID (SRS).

2. Enter the SRS and click OK.

3. Try the download again.

Start a Routine

After you successfully download a routine, you can start the routine.

From the Control Panel, choose Resource>Coldstart or use the

Coldstart button on the menu bar.

or

Options Description

Warmstart Allows the user routine to be started by the programming terminal

and to continue with the previously saved Retain signals.

You must have Administrator or Read/Write access to initiate a

warmstart.

Coldstart If a routine is in STOP or FREEZE mode, it can be started using this

cold start option. The cold start option re-initializes the routine and

available process values are lost.

Stop Use this option to stop a routine that is in RUN or FREEZE mode.

Publication 1753-UM001B-EN-P - November 2005

Page 69

Check, Download, Start, and Test a Routine 4-5

Test a Routine

Test Option Description

Enter Test Mode (Hot Start) To enter test mode hot, a routine must be loaded and started in the controller.

Enter Test Mode (Warm Start) Halts the execution of the routine with the signals declared as Retain retaining their

Enter Test Mode (Cold Start) A routine must be loaded in the controller to allow you to enter test mode cold.

Test a routine to check for and eliminate errors. You must have

Administrator or Read/Write access to test a routine. Test options are

discussed in the table below.

From the Test Mode menu on the Control Panel, choose the test

option you want

After a security query, the routine is paused (FREEZE) while retaining the current process

data after terminating the cycle. No input signals are processed. The output signals retain

their current state.

values and with all other signals being reset.

After a security query, the routine is initialized, started, and immediately enters FREEZE

mode. No input signals are processed, and all the output signals stay in their basic state.

If the routine was in RUN mode when enter test mode cold was selected, the cycle in

progress is terminated and the process data is re-initialized.

.

Single cycle Single cycle can only be executed when the controller is in the test mode. Use single cycle

to manually trigger the execution of a single cycle of the routine. The routine is executed

exactly once. The input signals are read in, processed, and the resulting output signals are

transferred.

Use the force editor to perform a step-by-step check of the data. See Chapter 5 for

information on forcing.

Continue with Run This option terminates the test mode. The routine mode changes from FREEZE to RUN

without re-initialization. The current process data are retained. (This corresponds to a

routine hot start.)

Publication 1753-UM001B-EN-P - November 2005

Page 70

4-6 Check, Download, Start, and Test a Routine

How a Routine Executes

A controller has only one routine. A routine can be in any one of

these states:

Routine State Description

RUN_RUN The controller is in the RUN mode.

• The routine is executed cyclically by the controller.

• Input data are processed in the routine.

• Output data of the routine are operated.

RUN_FREEZE The controller is in the RUN mode.

• The routine is not executed.

• No input data are processed by the routine.

• No output data of the routine are operated.

IMPORTANT: This mode is not permissible for safety-related

operation!

STOP The controller is in the STOP mode.

• The routine is not (no longer) executed.

• All outputs have been reset.

FAILURE_STOP The controller is in the STOP mode.

• The routine was stopped due to an error.

• All outputs have been reset.

Controlling a Routine

You can control a routine using the actions described below:

Control Action Description

Start the routine from STOP Starting the routine is the same as transferring the controller from the STOP mode into the RUN mode. The

routine is then transferred into the RUN_RUN mode. If Freezing is activated while starting, the routine will

be in the RUN_FREEZE mode. However, freeze operation is only possible if the Freeze Enable software

switch has been enabled. In addition to starting in freeze mode, cold start is also possible.

Starting a routine is only possible when both the controller restart switch and the routine restart switch

are enabled.

Start the routine from RUN The routine is transferred into the RUN_RUN mode if it has not already been operating in this mode.

Starting is also possible in cold start, hot start, and no-freeze modes.

IMPORTANT: This function is not allowed for safety operations of the controller!

Single cycle the routine The routine must be in the RUN_FREEZE mode. Exactly one RUN cycle of the routine is executed, and the

routine is then put back into the RUN_FREEZE mode. The command for the single cycle is the start

command with the attributes hot start and freeze. This does not have any effect on the mode of the

controller. Single cycle is only performed by the controller for the routine if freeze mode is enabled.

IMPORTANT: This function is not allowed for safety operations of the controller!

Restart the routine If the routine is in the FAILURE_STOP mode, it can be restarted via the programming software using a start

command. After the restart, the entire routine is checked again.

Stop the routine Stopping the routine is the same as transferring the controller from RUN mode into STOP mode. The

routine is then transferred from RUN into the STOP mode.

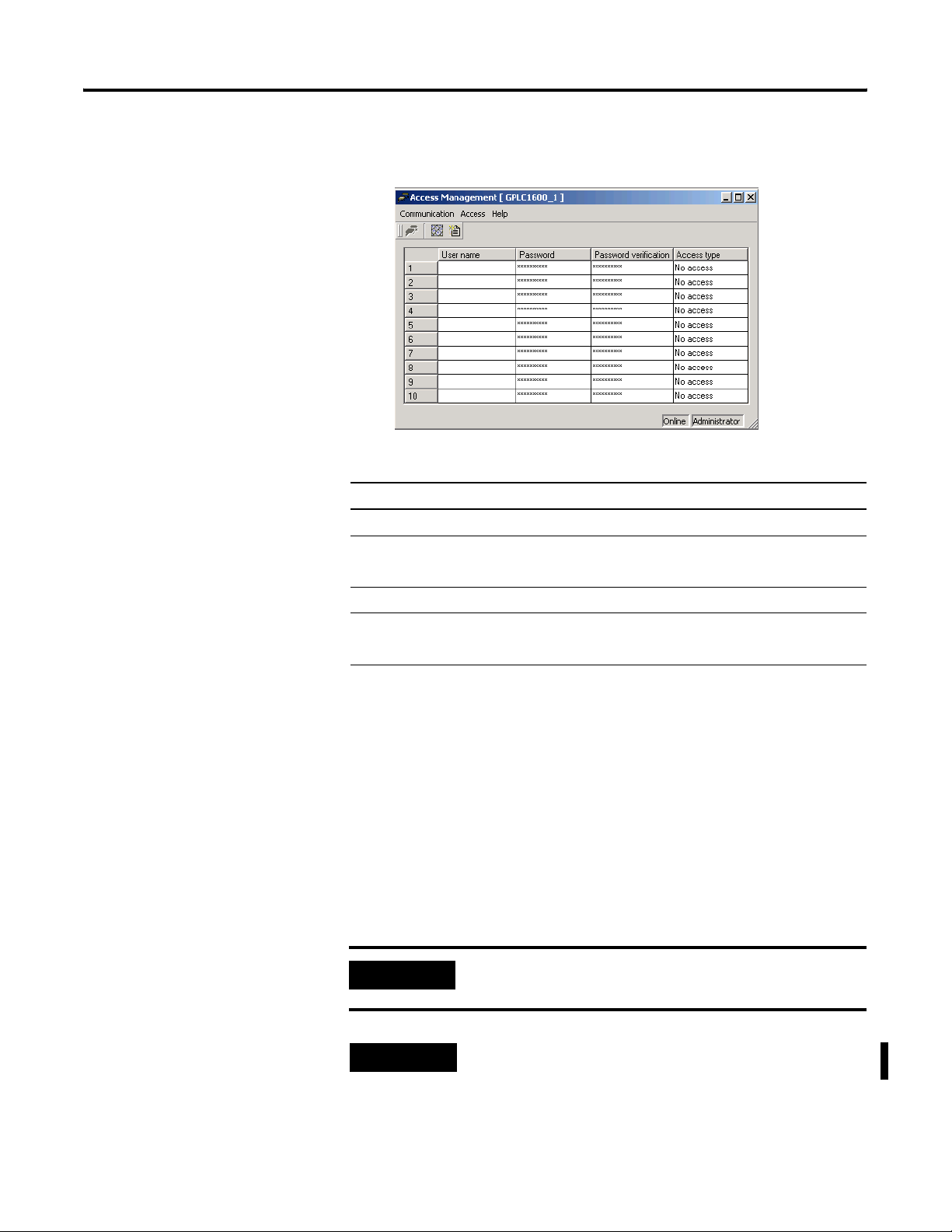

Freeze the routine The routine is transferred from the RUN_RUN mode into the RUN_FREEZE mode. This does not affect the

mode of the controller. Freeze mode must be enabled for the routine.