Page 1

Remote I/O Scanner

1747-SN

User Manual

Page 2

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls (Publication SGI-1.1

available from your local Rockwell Automation sales office or online at

http://www.ab.com/manuals/gi) describes some important differences

between solid state equipment and hard-wired electromechanical devices.

Because of this difference, and also because of the wide variety of uses for

solid state equipment, all persons responsible for applying this equipment

must satisfy themselves that each intended application of this equipment is

acceptable.

In no event will Rockwell Automation, Inc. be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for illustrative

purposes. Because of the many variables and requirements associated with

any particular installation, Rockwell Automation, Inc. cannot assume

responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to

use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of Rockwell Automation, Inc. is prohibited.

Throughout this manual, when necessary we use notes to make you aware of

safety considerations.

WARNING

IMPORTANT

ATTENTION

SHOCK HAZARD

BURN HAZARD

Identifies information about practices or circumstances

that can cause an explosion in a hazardous environment,

which may lead to personal injury or death, property

damage, or economic loss.

Identifies information that is critical for successful

application and understanding of the product.

Identifies information about practices or circumstances

that can lead to personal injury or death, property

damage, or economic loss. Attentions help you:

• identify a hazard

• avoid a hazard

• recognize the consequence

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that dangerous voltage may

be present.

Labels may be located on or inside the equipment (e.g.,

drive or motor) to alert people that surfaces may be

dangerous temperatures.

Page 3

Summary of Changes

The information below summarizes the changes to this manual since

the last printing. Updates to the manual include using RSLogix 500

instead of APS software.

To help you find new and updated information in this release of the

manual, we have included change bars as shown to the right of this

paragraph.

The table below lists the sections that document new features and

additional or updated information on existing features.

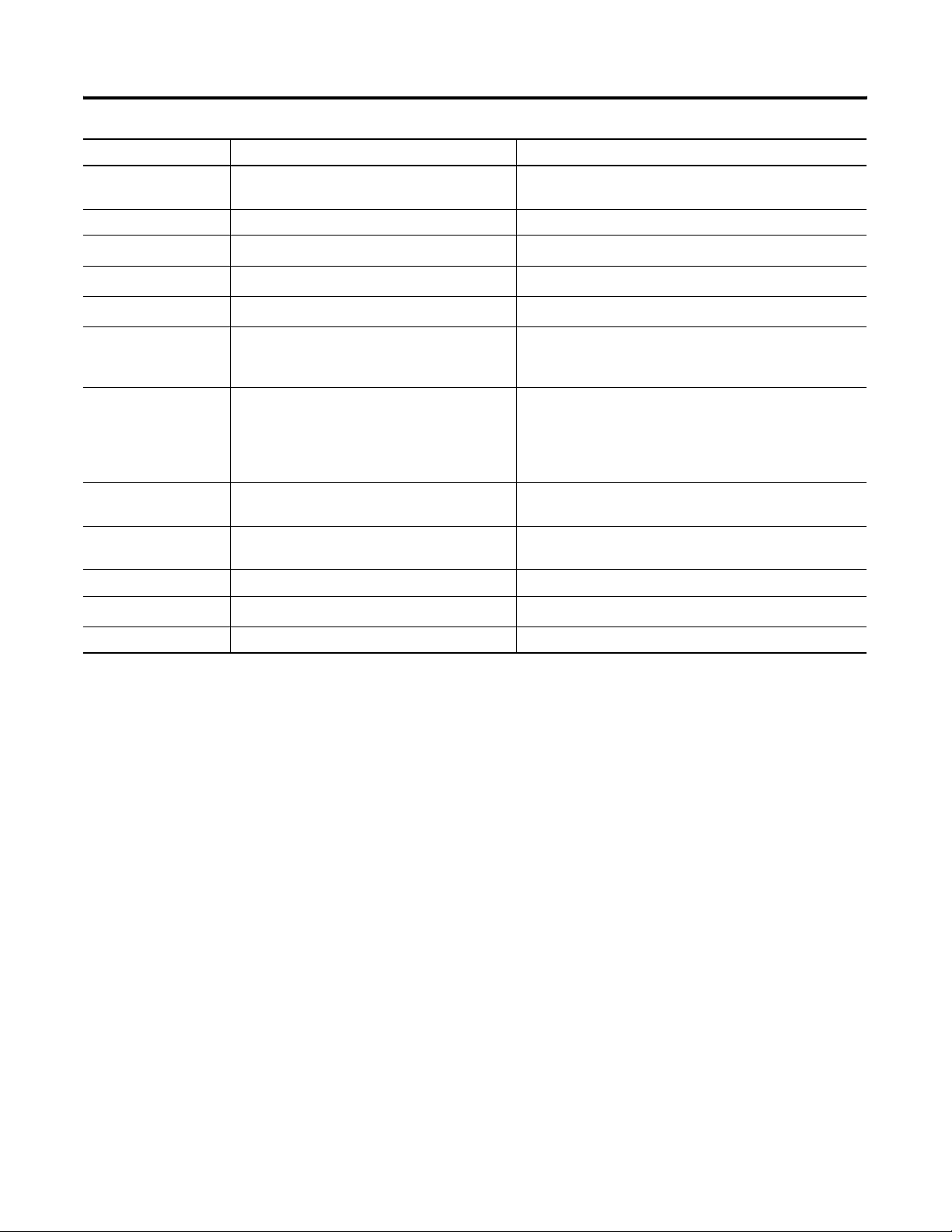

For this information: See

configuring RIO using G Files page 4-4

using block transfer instruction (BTR and

BTW)

removed Chapter 7 application examples can be found in

configuring G files using RSLogix 500 page B-9

block transfer examples for earlier

processors

page 5-5

Chapter 4 and Chapter 5

Appendix D

1 Publication 1747-UM013B-EN-P - January 2005

Page 4

Summary of Changes 2

Publication 1747-UM013B-EN-P - January 2005

Page 5

Important User Information . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Table of Contents Chapter 1

Overview

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Scanner I/O Image Division . . . . . . . . . . . . . . . . . . . . . 1-3

How the Scanner Scans Remote I/O . . . . . . . . . . . . . . . . . 1-4

SLC and Scanner Asynchronous Operation . . . . . . . . . . 1-4

How the Scanner Interacts with Adapters . . . . . . . . . . . . . . 1-5

Scanner I/O Image Concepts . . . . . . . . . . . . . . . . . . . . . . . 1-6

Example Scanner I/O Image. . . . . . . . . . . . . . . . . . . . . 1-7

Transferring Data with RIO Discrete and Block Transfers 1-9

Physical and Logical RIO Link Specifications . . . . . . . . . 1-9

Extended Node Capability . . . . . . . . . . . . . . . . . . . . . . 1-9

Complementary I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10

Complementary I/O: Placing Modules with 2-Slot Addressing

1-12

Complementary I/O: Placing Modules with 1-Slot Addressing

1-13

Complementary I/O: Placing Modules with 1/2-Slot

Addressing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14

Summary for Placing Modules Used In Complementary I/O.

1-15

Complementary I/O Application Considerations . . . . . . 1-17

Complementary 1771 I/O Module Details . . . . . . . . . . . 1-17

Hardware Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

Baud Rate DIP Switch . . . . . . . . . . . . . . . . . . . . . . . . . 1-18

LEDs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

RIO Link Connector . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Compatible Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-19

Table of Contents

Chapter 2

Quick Start for Experienced Users

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . 2-1

Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Chapter 3

Installation and Wiring

1 Publication 1747-UM013B-EN-P - January 2005

Compliance to European Union Directives . . . . . . . . . . . . . 3-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Baud Rate Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Scanner Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Insertion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

RIO Link Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

New Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

For Series A Scanner Retrofits . . . . . . . . . . . . . . . . . . . . 3-7

Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Scanner Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

At Power Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

In Run Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Page 6

Table of Contents 2

Scanner Configuration and

Programming

When Changing From Run Mode . . . . . . . . . . . . . . . . . 3-8

Status LEDs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Chapter 4

Understanding Remote Input and Output Image Files. . . . . 4-1

RIO Configuration Using G Files . . . . . . . . . . . . . . . . . . . . 4-4

Rules for Configuring the Scanner. . . . . . . . . . . . . . . . . 4-7

Considerations When Configuring Remote I/O . . . . . . . . . . 4-12

G File Considerations. . . . . . . . . . . . . . . . . . . . . . . . . . 4-12

Crossing Logical Rack Boundaries . . . . . . . . . . . . . . . . 4-13

Understanding M Files. . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

M Files Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

M0 Control File Description . . . . . . . . . . . . . . . . . . . . . 4-16

M0 File - RIO Device Inhibit Control. . . . . . . . . . . . . . . 4-17

M0 File - RIO Device Reset Control. . . . . . . . . . . . . . . . 4-18

M0 File - Remote Output Reset Control. . . . . . . . . . . . . 4-19

Device Reset and Remote Output Reset Considerations. . . . 4-21

M1 Status File Description . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

General Communication Status - Enable Device Fault Bit. . .

4-23

General Communication Status - Communication Attempted

Bit. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-23

RIO Baud Rate Status . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Logical Device Starting Address Status . . . . . . . . . . . . . 4-24

Logical Device Image Size Status . . . . . . . . . . . . . . . . . 4-25

Active Device Status. . . . . . . . . . . . . . . . . . . . . . . . . . . 4-26

Logical Device Fault Status . . . . . . . . . . . . . . . . . . . . . . 4-27

RIO Status Example . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-28

RIO Communication Retry Counter (M1:e.16 -47) . . . . . . . . 4-30

Understanding Slot Addressing . . . . . . . . . . . . . . . . . . . . . 4-32

SLC/Scanner Configuration . . . . . . . . . . . . . . . . . . . . . . . . 4-33

RIO Block Transfer

Troubleshooting

Publication 1747-UM013B-EN-P - January 2005

Chapter 5

RIO Block Transfer Theory of Operation . . . . . . . . . . . . . . 5-1

What Is RIO Block Transfer? . . . . . . . . . . . . . . . . . . . . 5-1

Using Block Transfer Instructions (BTR and BTW) . . . . . . . 5-5

RIO Block Transfer General Functional Overview . . . . . 5-5

Parameters for BTR and BTW. . . . . . . . . . . . . . . . . . . . 5-6

Control Status Bits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Instruction Operation. . . . . . . . . . . . . . . . . . . . . . . . . . 5-11

Programming Examples . . . . . . . . . . . . . . . . . . . . . . . . 5-12

Comparison to the PLC-5 BTR and BTW . . . . . . . . . . . . 5-16

Chapter 6

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Page 7

Specifications

M0 - M1 Files and G Files

Table of Contents 3

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Retry Counters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Block Transfers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Appendix A

Scanner Operating Specifications . . . . . . . . . . . . . . . . . . . . A-1

Network Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Throughput Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

RIO Network Throughput Components. . . . . . . . . . . . . A-2

Calculating Throughput. . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Discrete I/O Throughput without Block Transfers (Tdm-nbt)

Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Discrete I/O Throughput with Block Transfers (Tdm-bt)

Present . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Block Transfer Throughput . . . . . . . . . . . . . . . . . . . . A-10

RIO Scanner Output Delay Time (TSNo) Tables . . . . . A-13

Appendix B

M0 - M1 Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Addressing M0-M1 Files . . . . . . . . . . . . . . . . . . . . . . . . B-2

Restrictions on Using M0-M1 Data File Addresses . . . . . B-2

Monitoring Bit Addresses . . . . . . . . . . . . . . . . . . . . . . . B-2

Transferring Data Between Processor Files and M0 or M1 Files

B-4

Access Time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Minimizing the Scan Time . . . . . . . . . . . . . . . . . . . . . . B-7

Capturing M0-M1 File Data. . . . . . . . . . . . . . . . . . . . . . B-8

Specialty I/O Modules with Retentive Memory . . . . . . . B-8

G Files . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

Configuring G Files using RSLogix 500 . . . . . . . . . . . . . B-9

After all devices have been properly mapped, click OK and

the G file is automatically configured. This procedure

eliminates the bit by bit process needed to configure the G

file with other programming tools. . . . . . . . . . . . . . . . B-13

Editing G File Data . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

RIO Configuration Worksheet

Block Transfer Examples for

Earlier Processors

Appendix C

Directions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-1

Appendix D

BTR and BTW Control Logic Examples . . . . . . . . . . . . . . . D-1

Block Transfer Read Control Logic Example . . . . . . . . . D-1

Block Transfer Write Control Logic Example . . . . . . . . D-4

Directional Continuous Block Transfer Example . . . . . . D-6

Directional Repeating Block Transfer Example . . . . . . . D-9

Publication 1747-UM013B-EN-P - January 2005

Page 8

Table of Contents 4

Glossary

Index

Directional Non-Continuous Block Transfer Example . D-12

Bidirectional Continuous Block Transfer Example . . . . D-16

Bidirectional Alternating Block Transfer . . . . . . . . . . . D-21

Bidirectional Alternating Repeating Block Transfer . . . D-27

Rockwell Automation Support . . . . . . . . . . . . . . . . . . . . . . 1-7

Installation Assistance . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

New Product Satisfaction Return. . . . . . . . . . . . . . . . . . 1-7

Publication 1747-UM013B-EN-P - January 2005

Page 9

Overview

This chapter contains the following information:

• system overview

• how the scanner interacts with the SLC processor

• how the scanner interacts with adapter modules

• scanner I/O image concepts

• extended node capability

• complementary I/O

• scanner features

• compatible network devices

Chapter

1

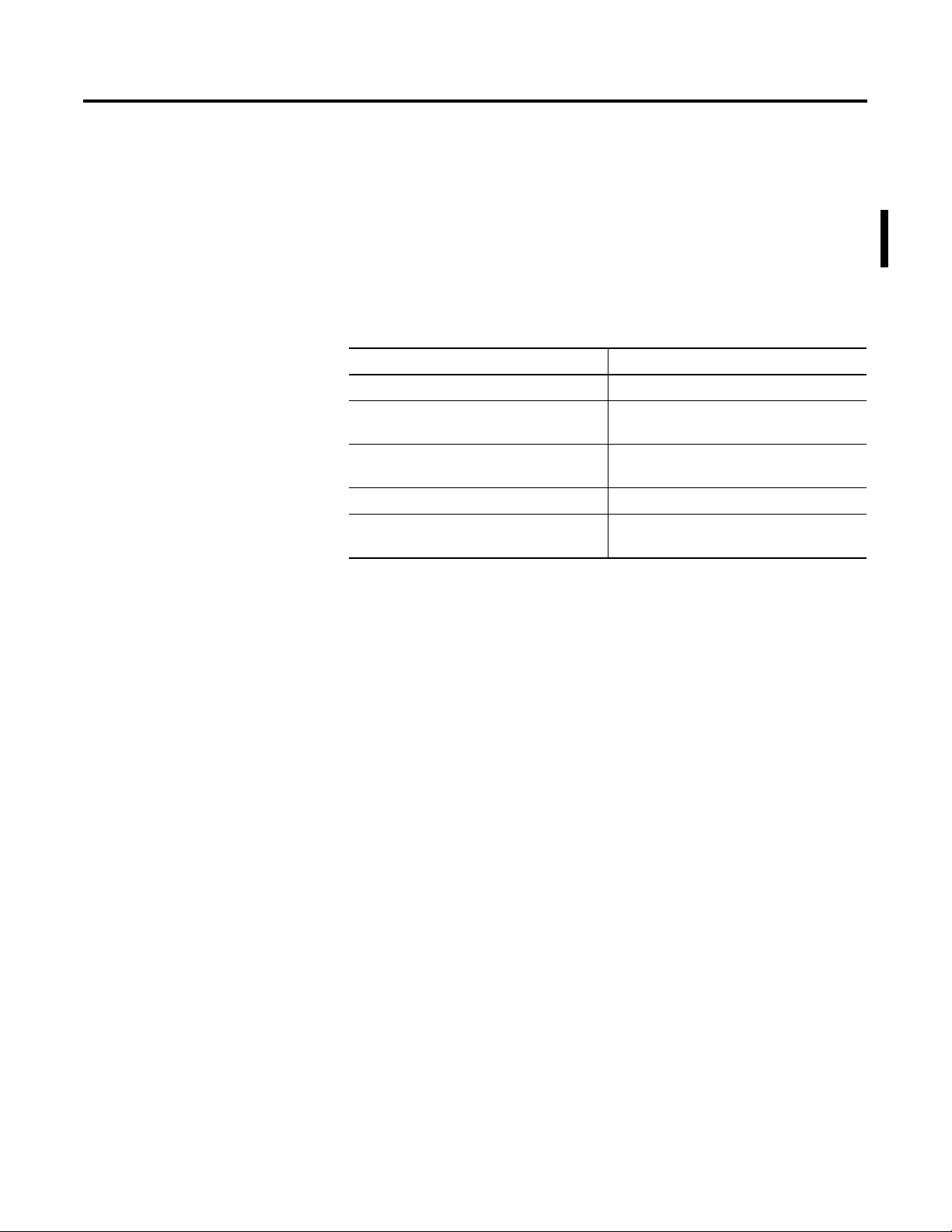

System Overview

The Remote I/O (RIO) Scanner, Catalog Number 1747-SN, is the

remote I/O scanner for the SLC 500. It enables communication

between an SLC processor (SLC 5/02 or later) and remotely located

(3,048 meters [10,000 feet] maximum) 1746 I/O chassis and other RIO

compatible Allen-Bradley operator interface and control devices. The

1747-SN Scanner communicates with remotely located devices using

the Allen-Bradley Remote I/O link. The RIO link consists of a single

master (scanner) and multiple slaves (adapters). Communication

between devices occurs over twisted pair cable with the devices

daisy-chained together. The scanner can reside in any slot of the local

SLC chassis except for slot 0.

The Remote I/O (RIO) Scanner, Catalog Number 1747-SN, is the

remote I/O scanner for the SLC 500. It enables communication

between an SLC processor (SLC 5/02 or later) and remotely located

(3,048 meters [10,000 feet] maximum) 1746 I/O chassis and other RIO

compatible Allen-Bradley operator interface and control devices. The

1747-SN Scanner communicates with remotely located devices using

the Allen-Bradley Remote I/O link. The RIO link consists of a single

master (scanner) and multiple slaves (adapters). Communication

between devices occurs over twisted pair cable with the devices

daisy-chained together. The scanner can reside in any slot of the local

SLC chassis except for slot 0.

1 Publication 1747-UM013B-EN-P - January 2005

Page 10

1-2 Overview

SLC 5/02

or Later

Processor

Local SLC Chassis

Dataliner Message Display

(Adapter/Slave)

RIO Scanner

(Master of the

RIO Link)

The scanner transfers input and

output data between itself and all

configured network devices over

twisted pair cable. Note that the

end-to-end length of the cable can be

a maximum of 3,048 meters (10,000

feet).

PanelView Operator Terminal

(Adapter/Slave)

The scanner can be configured for and transfer a maximum of 4

logical racks of discrete data on the RIO link. The scanner provides

discrete I/O and block (Series B or later) transfers. Configurations

allowed are any combination of quarter, half, three-quarter, or full

logical rack devices.

1747-ASB Module

(Adapter/Slave)

Remote Chassis

Remote Expansion Chassis

RediPANEL

(Adapter/Slave)

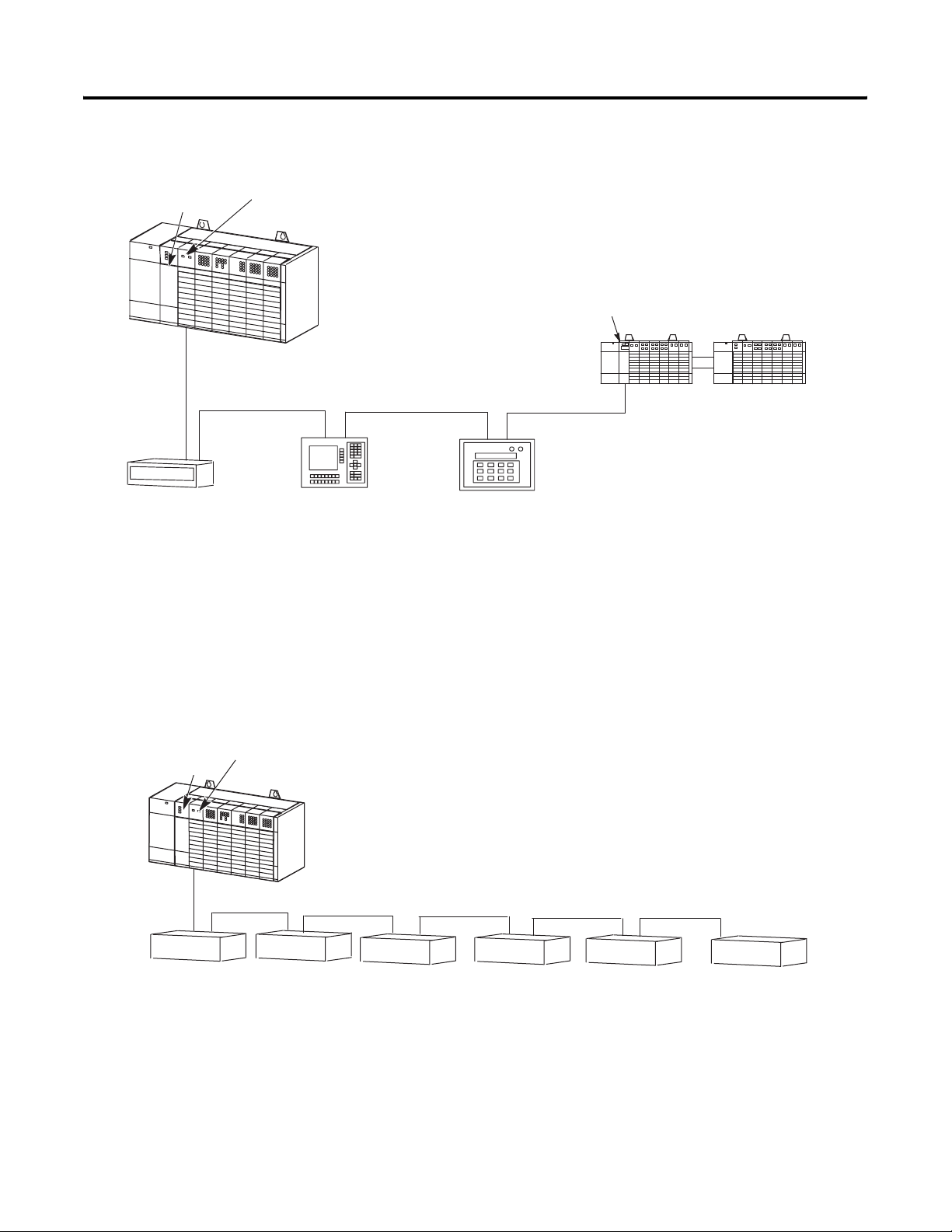

SLC 5/02

or Later

Processor

Adapter 1

Half Logical

Rack

Device

Publication 1747-UM013B-EN-P - January 2005

RIO

Scanner

Adapter 2

Quarter Logical

Rack

Device

The scanner transfers discrete input and output data

between itself, remote adapters, and the SLC processor..

Remote adapters consist of 1746 chassis and other

Allen-Bradley operator interface and control devices.

Adapter 3 Adapter 4

Half

Logical Rack

Device

Three-Quarter

Logical Rack

Device

Adapter 5

Full

Logical Rack

Device

Adapter 6

Full

Logical Rack

Device

The SLC processor transfers the scanner’s 4 logical racks (32 input

image and 32 output image words) of discrete remote I/O image data

into the SLC input and output image files. You can adjust the size of

the scanner input and output image file during configuration of your

SLC system so that the scanner only transfers the discrete I/O data

Page 11

Overview 1-3

your application program requires. Configuration is done through the

confiGuration file (G file). Refer to Chapter 4, Configuration and

Programming, for more information.

IMPORTANT

The SLC 500 processor (SLC 5/02 or later) supports

multiple scanners in its local I/O chassis. The

maximum number is dependent on the following:

• backplane power requirements (power supply

dependent)

• SLC 500 processor I/O data table limit (4,096 I/O)

• processor memory to support the application

(SLC 500 processor dependent)

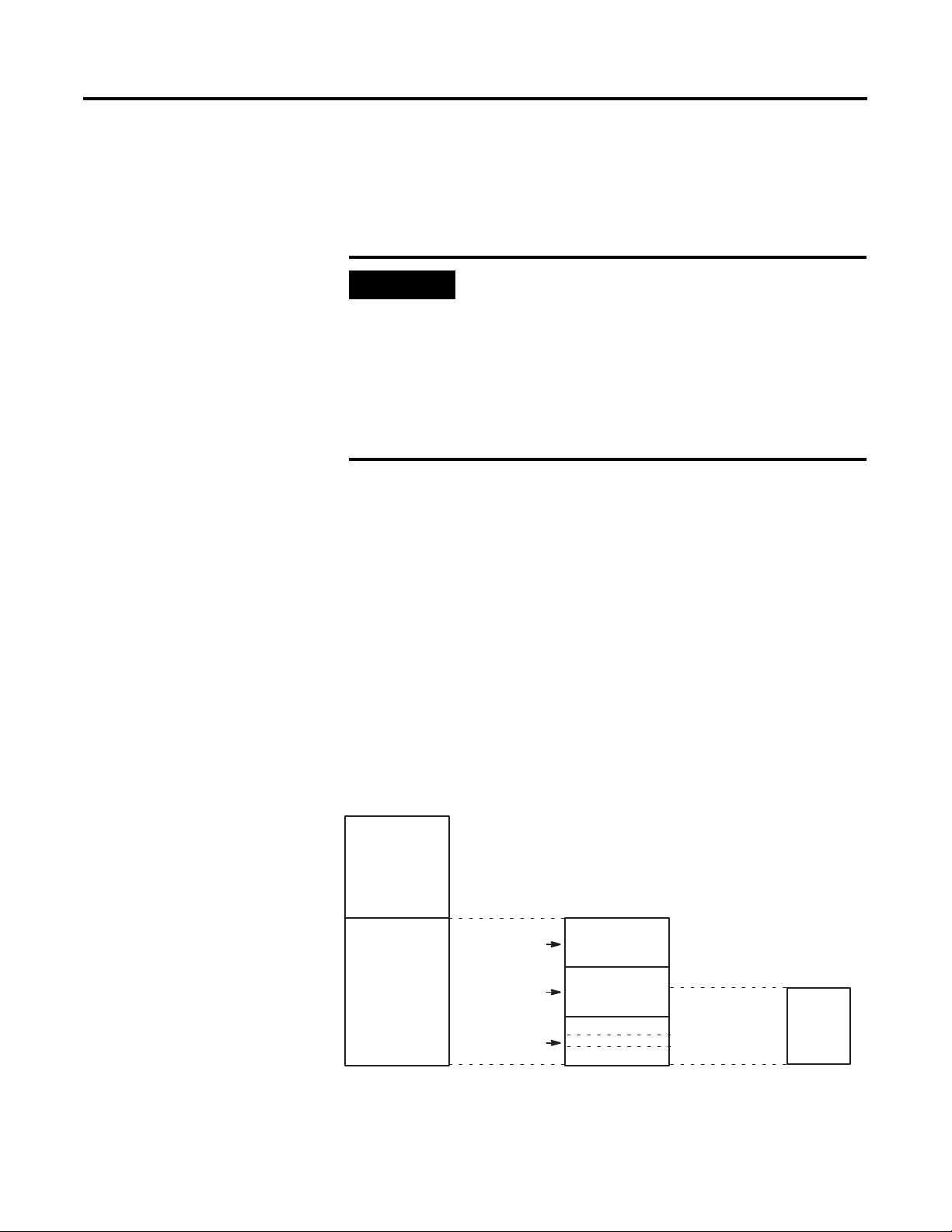

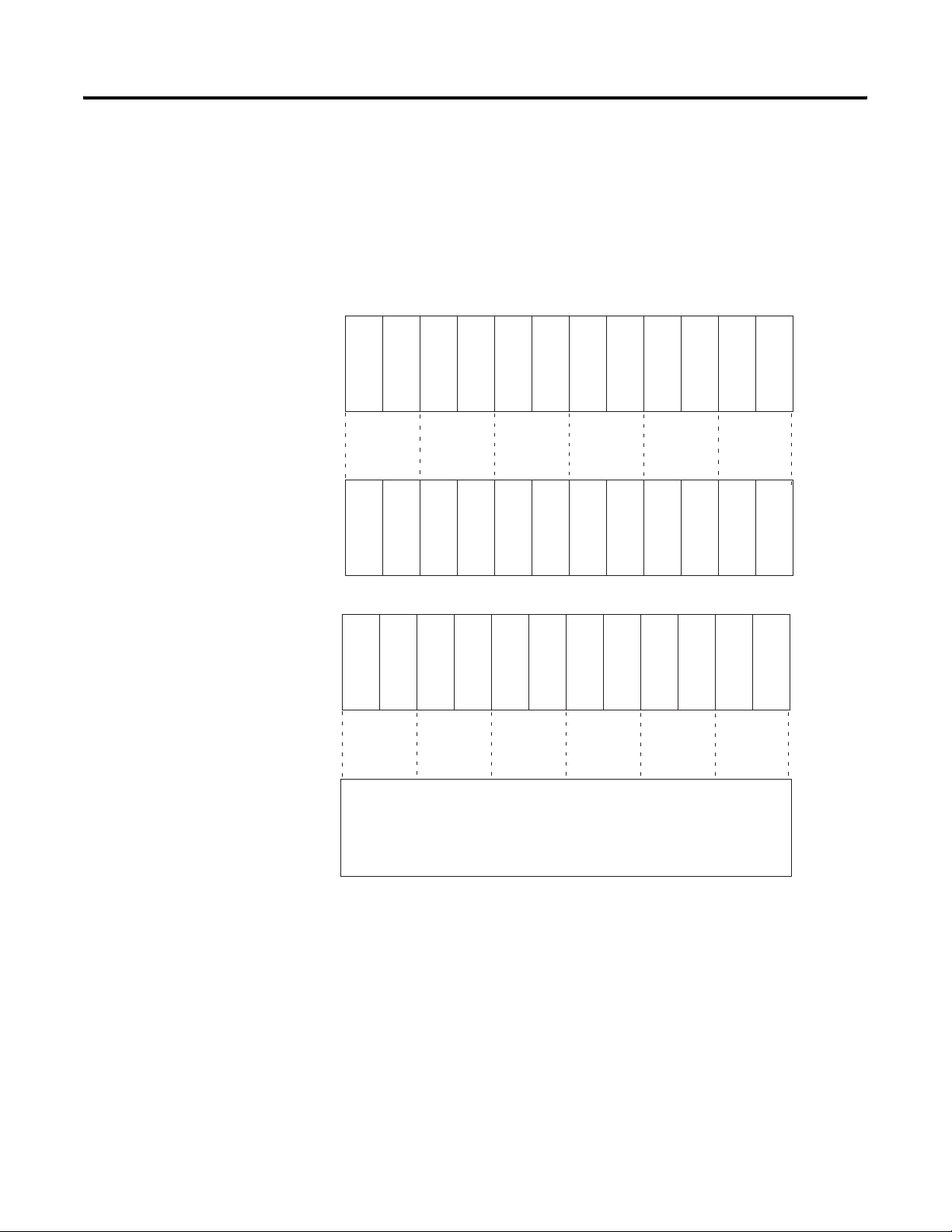

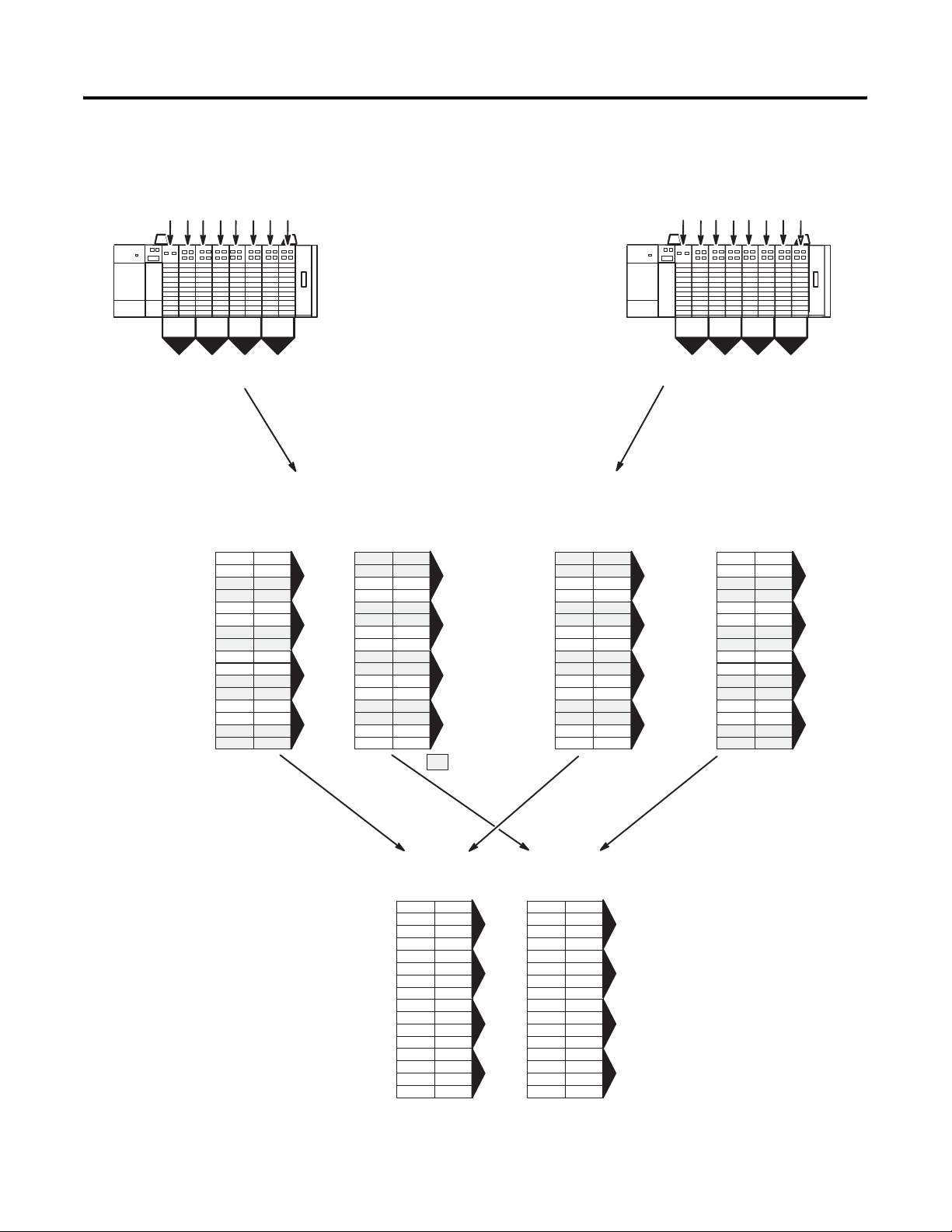

Scanner I/O Image Division

The scanner allows each adapter to use a fixed amount (user defined)

of the scanner’s input and output image. Part of the SLC processor’s

image is used by local I/O, the other portion is used by the scanner

for remote I/O.

The scanner remote I/O image is divided into logical racks and further

divided into logical groups. A full logical rack consists of eight input

and eight output image words. A logical group consists of one input

and one output word in a logical rack. Each logical group is assigned

a number from 0 to 7.

Local I/O

Logical Rack 0

Remote I/O

(Scanner Image)

Processor I/O Image Scanner I/O Image Adapter

Logical Rack 1

Logical Group 0

Logical Rack 2

Logical Group 7

Image

Publication 1747-UM013B-EN-P - January 2005

Page 12

1-4 Overview

The scanner image contains the image of each adapter on the RIO

link. The adapter is assigned a portion of the scanner image, which is

referred to as the adapter image.

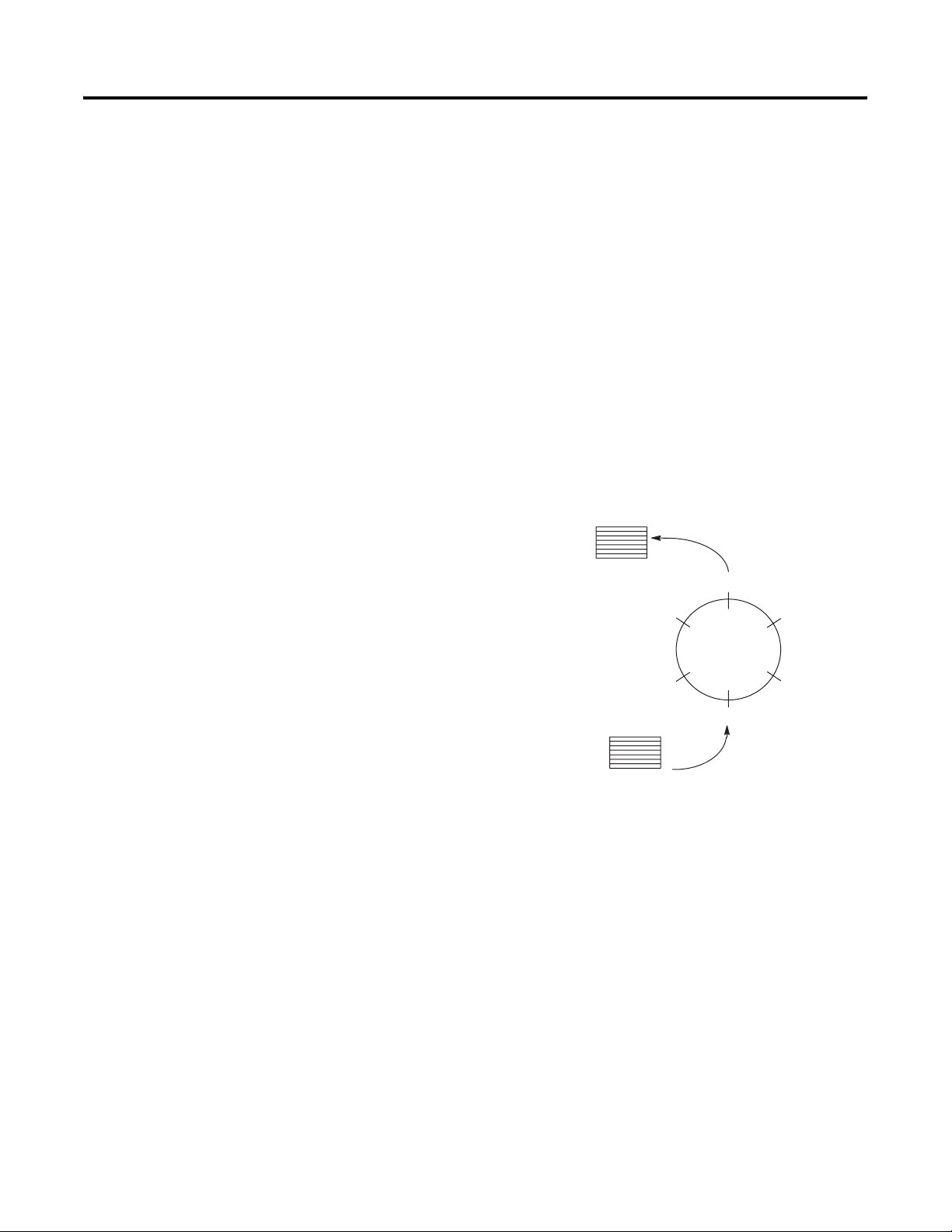

How the Scanner Scans Remote I/O

The scanner communicates with each logical device in a sequential

fashion. First, the scanner initiates communication with a device by

sending output data to the device. The device then responds by

sending its input data back to the scanner, as illustrated below. You

refer to this exchange as a discrete I/O transfer. After the scanner

completes its discrete I/O transfer with the last configured network

device, it begins another discrete I/O transfer with the first device.

It is important to understand that the scanner transfers RIO data on a

logical device basis not on an adapter basis. A logical device is a full

logical rack or portion of a logical rack assigned to an adapter.

RIO Scanner Scan

The scanner updates its

input image file each time

it scans a logical device.

Scanner

Input

Image File

Input

Device 3

Output

Device 3

Output

Device 2

Input

Device 1

Output

Device 1

Input

Device 2

Publication 1747-UM013B-EN-P - January 2005

Scanner Output

Image File

SLC and Scanner Asynchronous Operation

The SLC processor scan and RIO scanner scan are independent

(asynchronous) of each other. The SLC processor reads the scanner

input image file during its input scan and writes the output image file

to the scanner during its output scan. The RIO scanner continues

reading inputs and writing outputs to the scanner I/O image file,

independent of the SLC processor scan cycle.

Depending on your SLC processor, RIO link configuration, and

application program size, the scanner may complete multiple scans

before the SLC processor reads the scanner’s input image file. The RIO

scanner updates its I/O files on a per logical rack basis.

Page 13

The figure below illustrates the asynchronous operation of the SLC

t

processor and RIO scanner.

SLC Processor Scan Cycle RIO Scanner Scan Cycle

Overview 1-5

The SLC processor reads the

scanner input image file into the

SLC input image file, processes

it, and creates an SLC output

image file. The SLC processor

ransfers its output file to the

scanner..

Important: The outputs of the RIO are updated after the end of the first SLC processor scan.

Program

SLC Processor

How the Scanner Interacts with Adapters

Input

Image

Device 1

Input

Image

Device 2

Output

Image

Device 1

The scanner updates its

input image file each time

it scans a logical device.

The scanner may scan all

of its configured logical

devices several times

before the SLC processor

reads the scanner's input

image file.

SLC Input

Image File

SLC Output

Image File

Scanner

Input

Image File

Input

Image

Device 3

Output

Image

Device 2

Scanner Output

Image File

Output

Image

Device 3

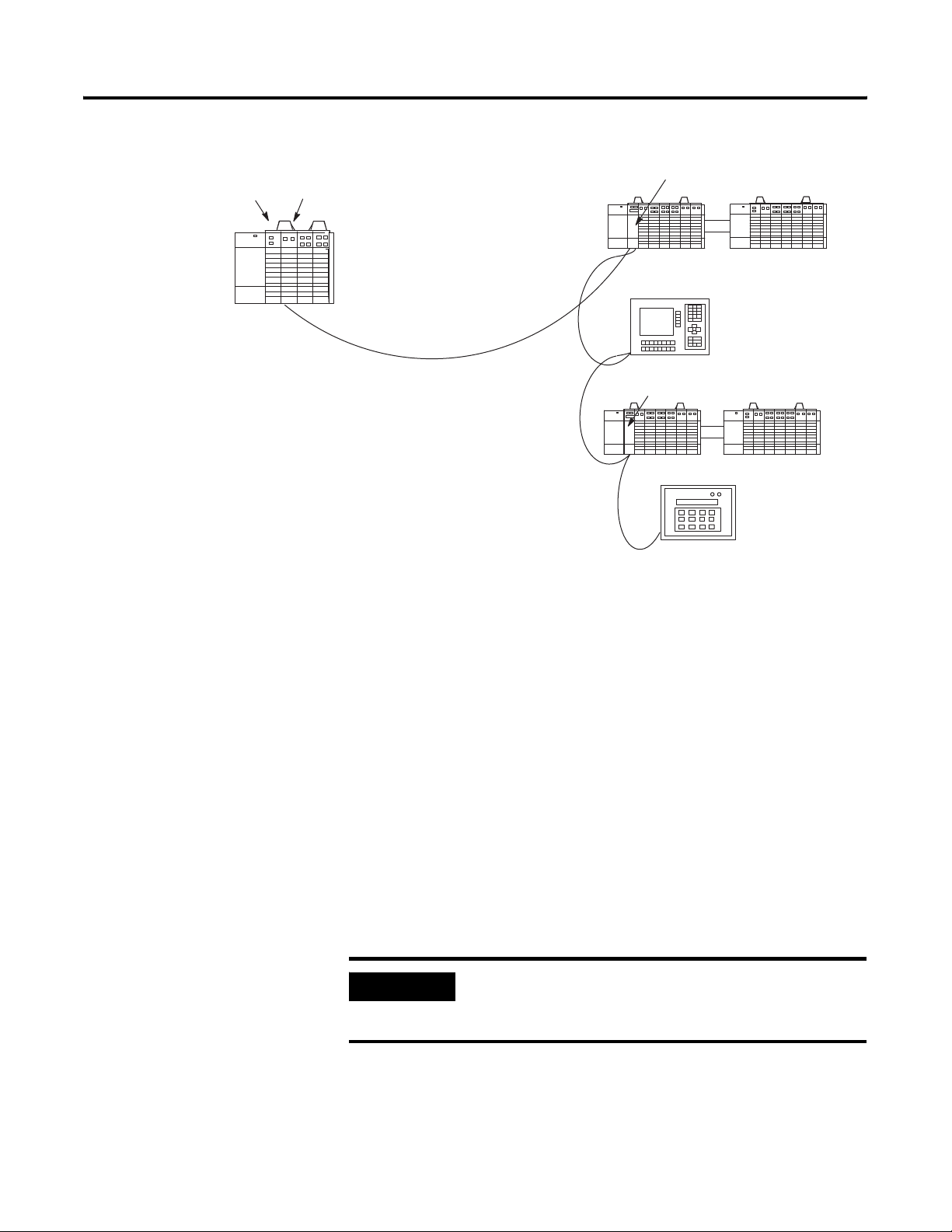

The scanner’s function is to continuously scan the adapters on the RIO

link in a consecutive manner. This scan consists of one or more RIO

discrete transfers to each adapter on the RIO link.

RIO discrete transfers consist of the scanner sending output image

data and communication commands to the adapter that instruct the

adapter on how to control its output. (These include run, adapter

reset, and reset decide commands.) The adapter responds by sending

input data to the scanner. The scanner performs as many RIO discrete

transfers as necessary to update the entire adapter image. If RIO

discrete transfers do not occur, data is not exchanged between the

scanner and adapter. RIO discrete transfers are asynchronous to the

processor scan.

Publication 1747-UM013B-EN-P - January 2005

Page 14

1-6 Overview

SLC Local Chassis

Processor

Scanner

RIO Discrete

Transfers

with Adapter 1

RIO Discrete

Transfers

with Adapter 2

RIO Discrete

Transfers

with Adapter 3

RIO Discrete

Transfers

with Adapter 4

PanelView Operator

Terminal

RediPANEL

Scanner I/O Image Concepts

The scanner’s I/O image consists of RIO logical racks and I/O groups.

A full RIO logical rack consists of eight input image and eight output

image words. (A word consists of 16 bits of data.) Each word within

an RIO logical rack is assigned an I/O group number from 0 to 7.

You assign devices on the RIO link a portion of the scanner’s image.

Devices can occupy a quarter logical rack (2 input and output words),

half logical rack (4 I/O words), three-quarter logical rack (6 I/O

words), or full logical rack. You may configure devices to start at any

even I/O group number within an RIO logical rack. More than one

physical device’s (adapter) I/O information can reside in a single

logical rack. Also, by crossing logical rack boundaries, a device can

consist of more than one logical rack.

IMPORTANT

The following illustration shows only the input

image configuration of the scanner’s I/O image. The

output image configuration is the same.

Publication 1747-UM013B-EN-P - January 2005

Page 15

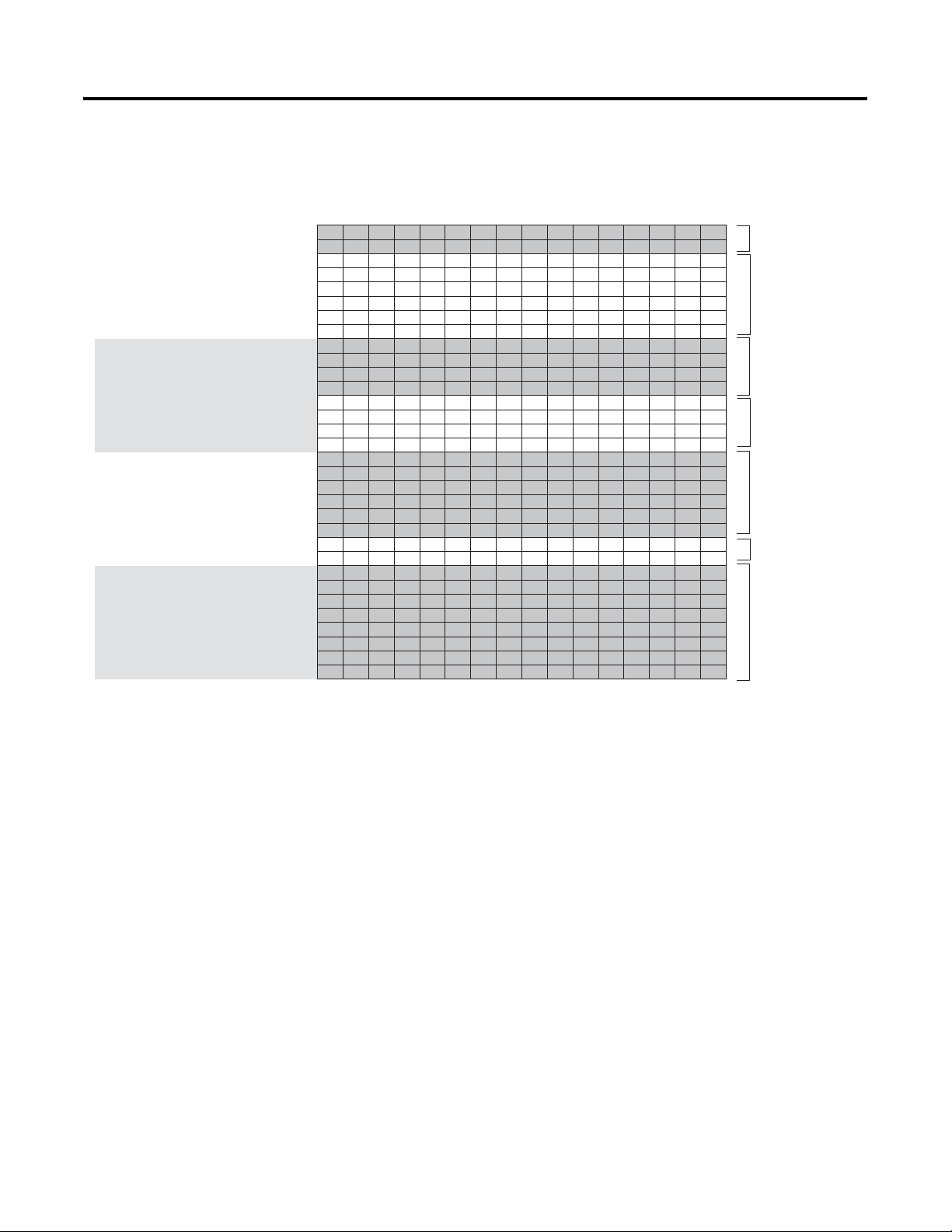

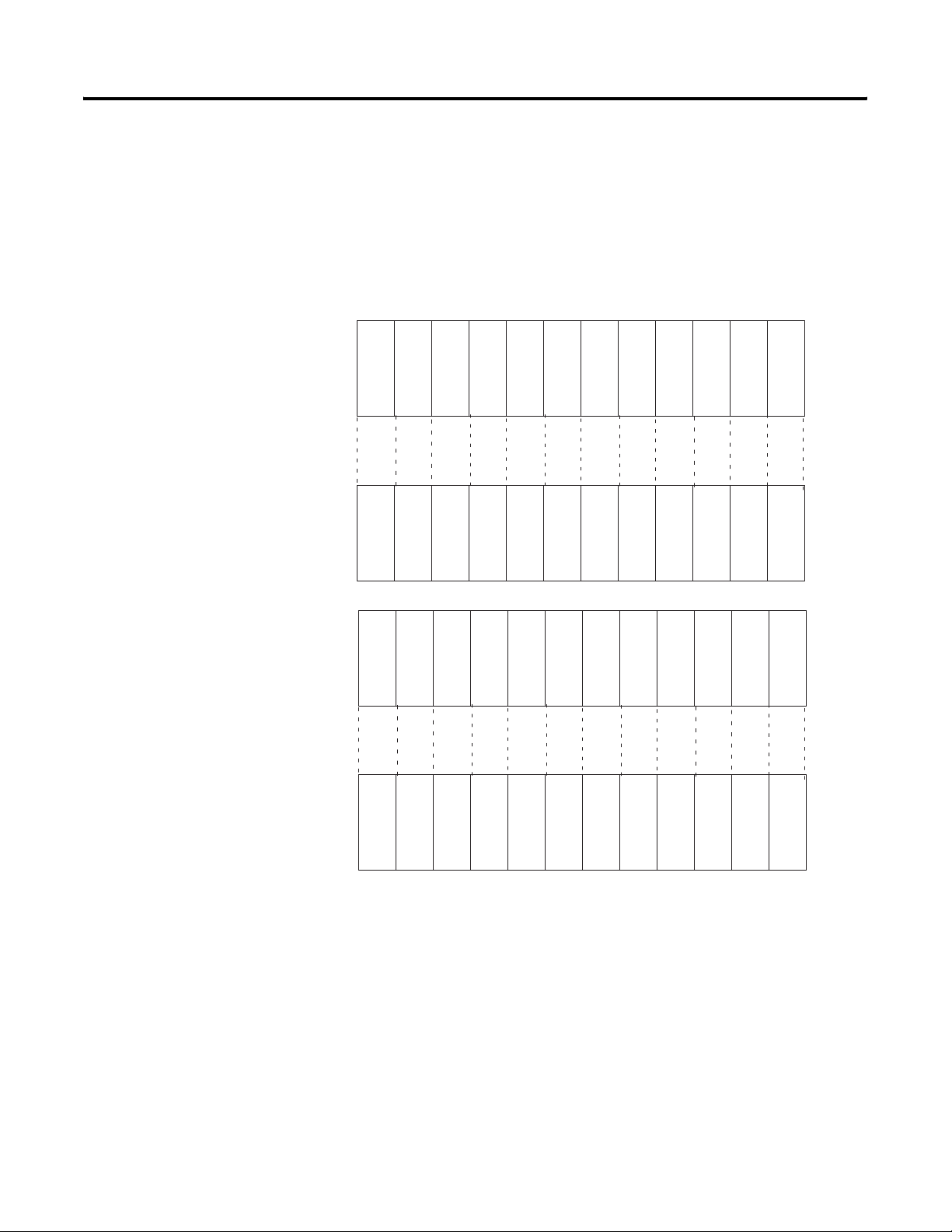

Input Image Half of a Scanner's I/O Image

Overview 1-7

RIO

Logical

Rack 0

RIO

Logical

Rack 1

RIO

Logical

Rack 2

RIO

Logical

Rack 3

Bit Number (decimal)

Rack 0 Group 0

Rack 0 Group 1

Rack 0 Group 2

Rack 0 Group 3

Rack 0 Group 4

Rack 0 Group 5

Rack 0 Group 6

Rack 0 Group 7

Rack 1 Group 0

Rack 1 Group 1

Rack 1 Group 2

Rack 1 Group 3

Rack 1 Group 4

Rack 1 Group 5

Rack 1 Group 6

Rack 1 Group 7

Rack 2 Group 0

Rack 2 Group 1

Rack 2 Group 2

Rack 2 Group 3

Rack 2 Group 4

Rack 2 Group 5

Rack 2 Group 6

Rack 2 Group 7

Rack 3 Group 0

Rack 3 Group 1

Rack 3 Group 2

Rack 3 Group 3

Rack 3 Group 4

Rack 3 Group 5

Rack 3 Group 6

Rack 3 Group 7

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 11

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

Word 24

Word 25

Word 26

Word 27

Word 28

Word 29

Word 30

Word 31

Bit Number (octal)

0123456789101112131415

Quarter Logical

Rack

Not Used In This

Example

Half Logical

Rack

Not Used In This

Example

Three-Quarter

Logical Rack

Not Used In This

Example

Full

Logical

Rack

0

1828384858687

8108118128138148158168178

8

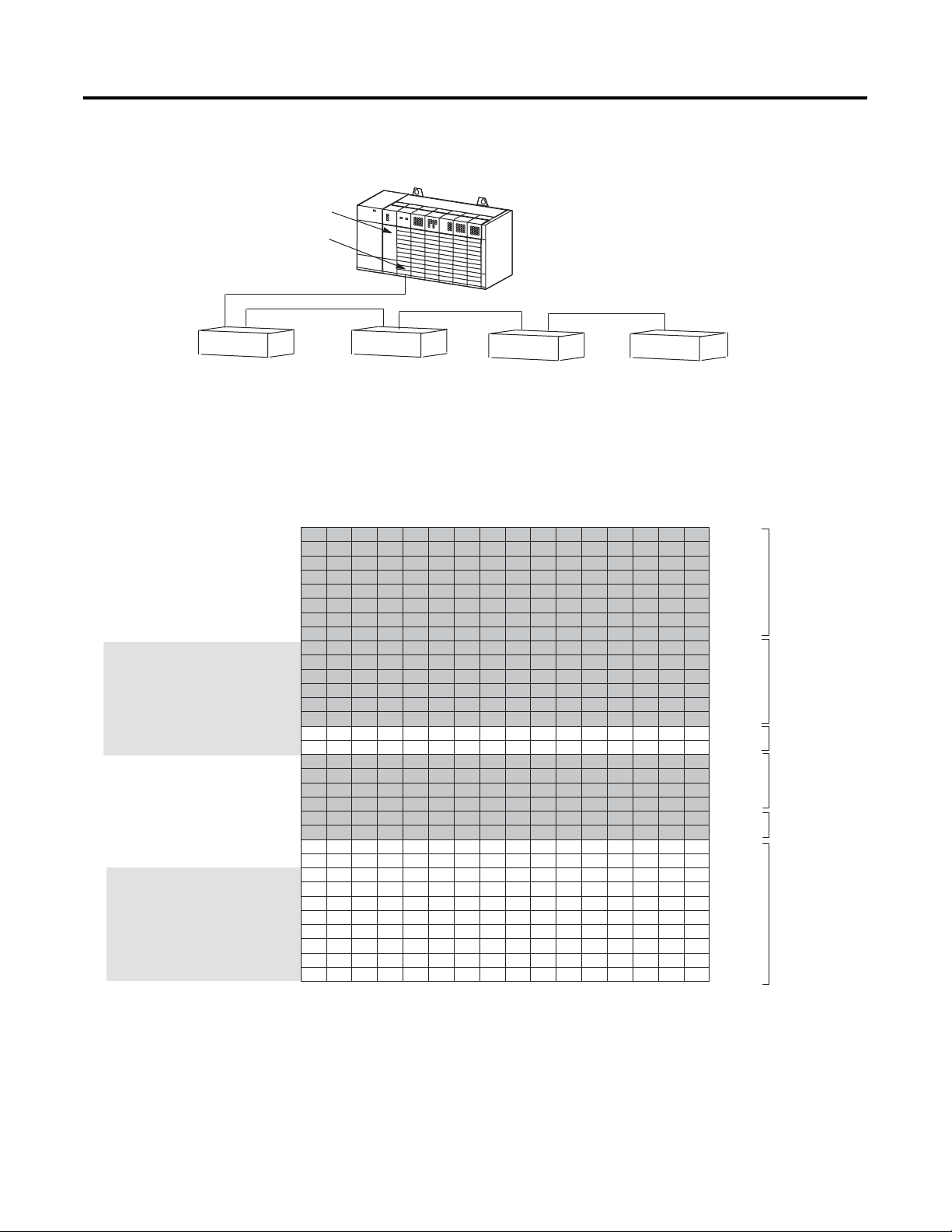

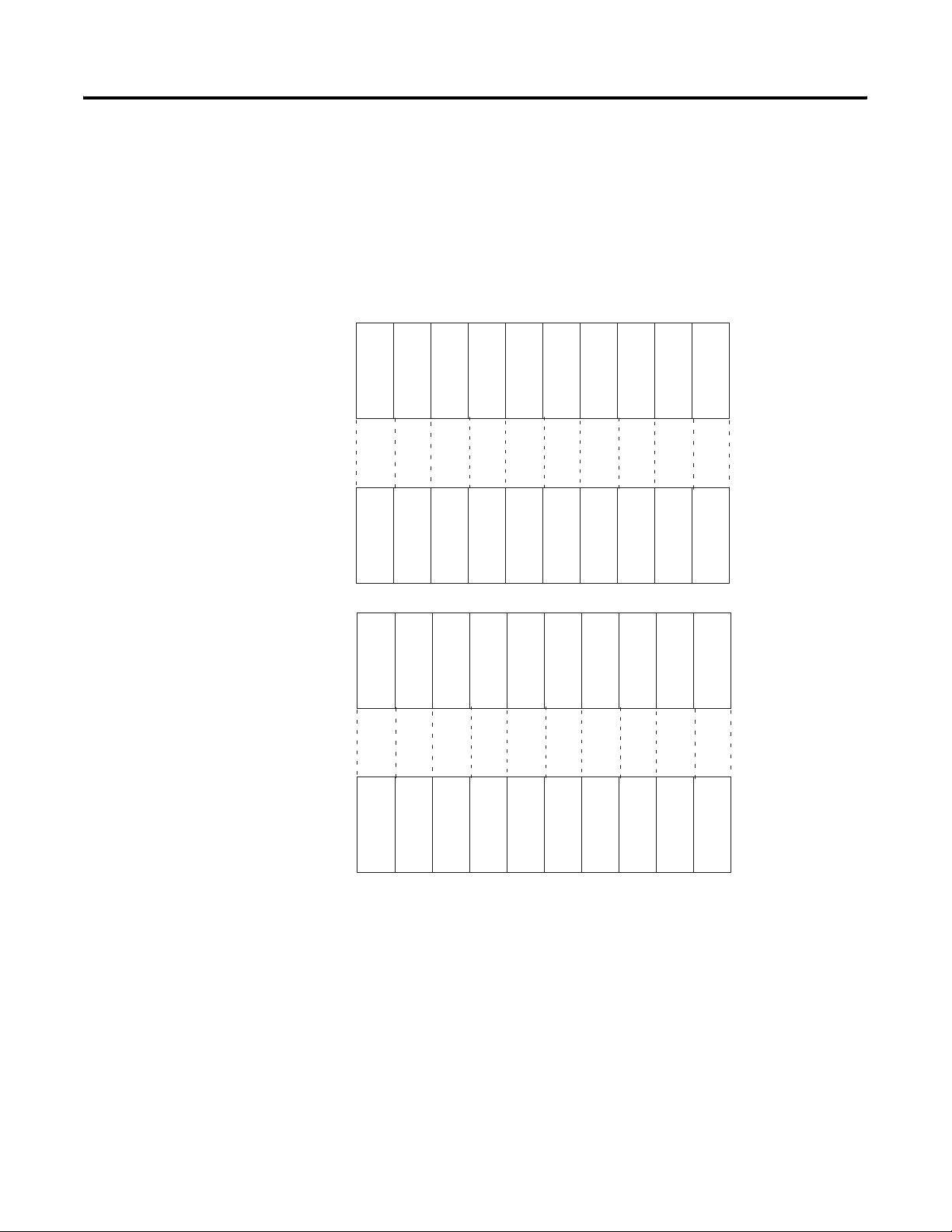

Example Scanner I/O Image

The illustrations below show a scanner’s input image of 4 RIO link

devices.

Publication 1747-UM013B-EN-P - January 2005

Page 16

1-8 Overview

SLC 5/02

or Later

Processor

RIO

Scanner

RIO

Logical

Rack 0

RIO

Logical

Rack 1

RIO

Logical

Rack 2

RIO

Logical

Rack 3

Device 1

Full Logical Rack

Device

Begins at Logical

Rack 0, Group 0.

Important: The illustration below shows only the scanner's input image. The output image looks the same.

Bit Number

Rack 0 Group 0

Rack 0 Group 1

Rack 0 Group 2

Rack 0 Group 3

Rack 0 Group 4

Rack 0 Group 5

Rack 0 Group 6

Rack 0 Group 7

Rack 1 Group 0

Rack 1 Group 1

Rack 1 Group 2

Rack 1 Group 3

Rack 1 Group 4

Rack 1 Group 5

Rack 1 Group 6

Rack 1 Group 7

Rack 2 Group 0

Rack 2 Group 1

Rack 2 Group 2

Rack 2 Group 3

Rack 2 Group 4

Rack 2 Group 5

Rack 2 Group 6

Rack 2 Group 7

Rack 3 Group 0

Rack 3 Group 1

Rack 3 Group 2

Rack 3 Group 3

Rack 3 Group 4

Rack 3 Group 5

Rack 3 Group 6

Rack 3 Group 7

Bit Number (octal)

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 11

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

Word 24

Word 25

Word 26

Word 27

Word 28

Word 29

Word 30

Word 31

Device 2

Three-Quarter Logical

Rack Device

Begins at Logical

Rack 1, Group 0.

Device 3 Device 4

Half Logical Rack

Device

Begins at Logical

Rack 2, Group 0.

8108118128138148158168178

e = slot number of the SLC chassis containing the scanner

Quarter Logical Rack

Device

Begins at Logical

Rack 2, Group 4.

Input File

0123456789101112131415

Address

I:e.0

I:e.1

I:e.2

I:e.3

I:e.4

I:e.5

I:e.6

I:e.7

I:e.8

I:e.9

I:e.10

I:e.11

I:e.12

I:e.13

I:e.14

I:e.15

I:e.16

I:e.17

I:e.18

I:e.19

I:e.20

I:e.21

I:e.22

I:e.23

I:e.24

I:e.25

I:e.26

I:e.27

I:e.28

I:e.29

I:e.30

I:e.31

0

1828384858687

8

Device 1

Device 2

Not Used

Device 3

Device 4

Not Used

Publication 1747-UM013B-EN-P - January 2005

Page 17

Overview 1-9

Transferring Data with RIO Discrete and Block Transfers

Input and output image data and command information are quickly

exchanged between a scanner and adapter using RIO discrete

transfers. RIO discrete transfers are the simplest and fastest way a

scanner and adapter communicate with each other. RIO discrete

transfers, which are transparent to the user, consist of the scanner

sending the output image data to the adapter, and the adapter

transmitting input data to the scanner. Each RIO discrete transfer also

contains scanner commands for the adapter.

Through your control program, you command the SLC processor to

initiate RIO block transfers, which directs the scanner to exchange

large amounts of data to/from an adapter. Block Transfers (BTs) use

the basic RIO discrete transfer mechanism of the RIO link. However,

the actual transfer of data occurs asynchronous to the discrete

transfers. It is possible for several discrete transfers to occur before the

scanner processes a block transfer. Refer to Chapter 5, RIO Block

Transfer for more details.

Physical and Logical RIO Link Specifications

The maximum number of adapters with which your scanner can

communicate is determined by the scanner’s and adapter’s physical

and logical specifications, as described below:

• Physical Specifications are the maximum number of adapters

that can be connected to the scanner. For more information, see

Extended Node Capability below.

• Logical Specifications for the scanner are the maximum number

of logical racks the scanner can address, how the logical racks

can be assigned, and whether the scanner can perform BTs.

Extended Node Capability

Extended node functionality allows you to connect up to 32 physical

devices on an RIO link. You must use 82 Ohm RIO link resistors in an

extended node configuration. You can only use extended node if all

RIO link devices have extended node capability. (Refer to the

Compatible Devices table at the end of this chapter, or to the

specifications of your device.) The 1747-SN Series B Scanner has

extended node capability. However, the smallest logical rack division

is 1/4 logical rack and the scanner image size is 4 logical racks.

Therefore, the scanner is limited to 16 devices unless complementary

Publication 1747-UM013B-EN-P - January 2005

Page 18

1-10 Overview

I/O is used. Refer to the following section for more information on

complementary I/O.

Complementary I/O

Complementary I/O is very useful when portions of your input and

output images are unused because it allows the images of two

adapters to overlap each other in the scanner’s I/O image. To use

complementary I/O, the I/O image from one adapter must be the

mirror (complement) of the other. This means that there must be an

input module in the primary chassis and an output module in the

same slot of the complementary chassis. This enables total use of the

scanner’s 32 input and 32 output word image for I/O addressing of up

to 1024 discrete points.

ATTENTION

Because the primary and complementary chassis

images overlap, input and specialty combination I/O

modules must never share the same image location.

Inputs received by the scanner may be incorrect and

RIO block transfers will not be serviced properly.

If an output module shares its output image with

another output module, both output modules receive

the same output information.

If you want to use complementary I/O, two adapters that support this

function are required (e.g., 1747-ASB modules). One adapter is

configured (via its DIP switches) as a primary chassis, the other as a

complementary chassis. If a primary chassis exists, it is scanned first.

Primary and complementary chassis cannot have the same logical rack

number. The logical rack numbers must be assigned to the primary

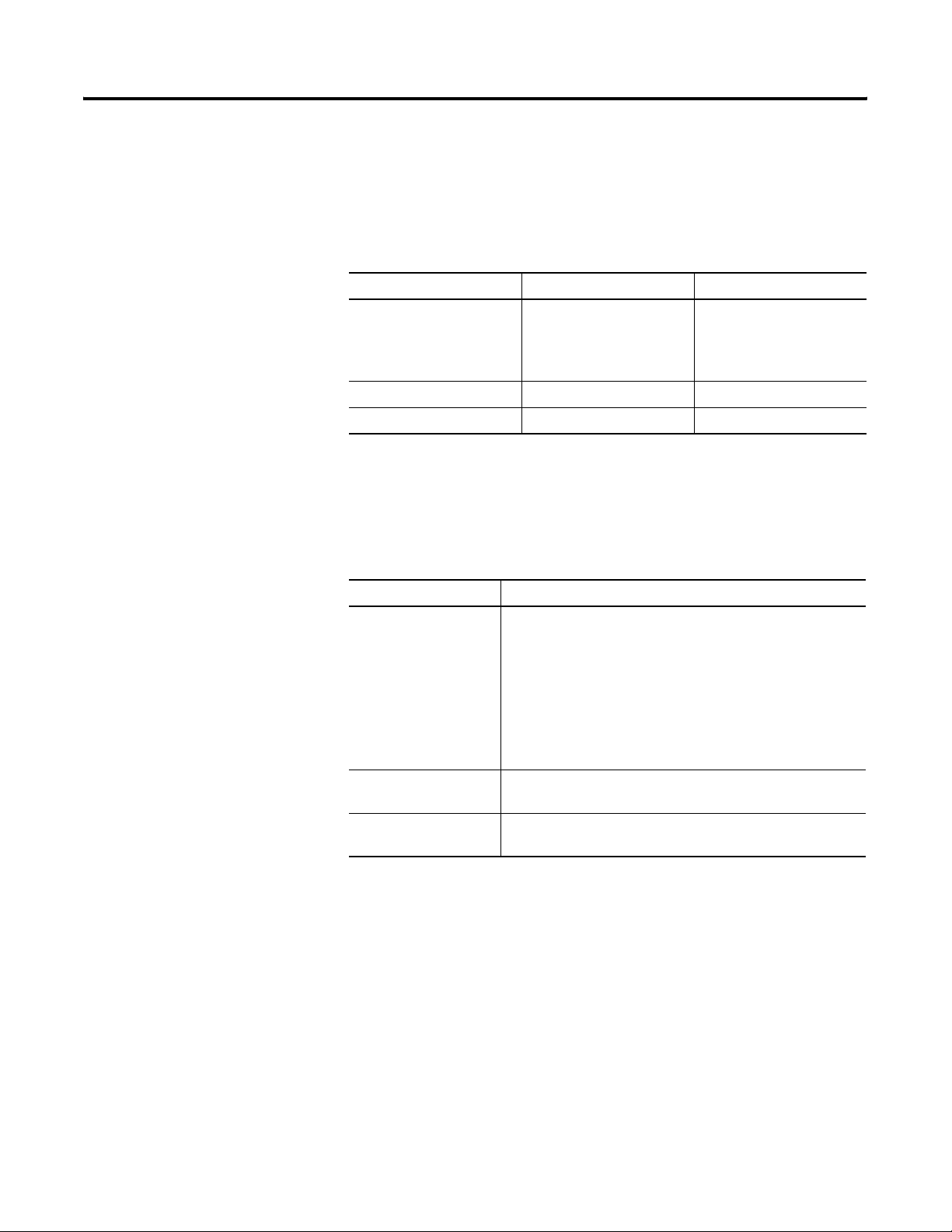

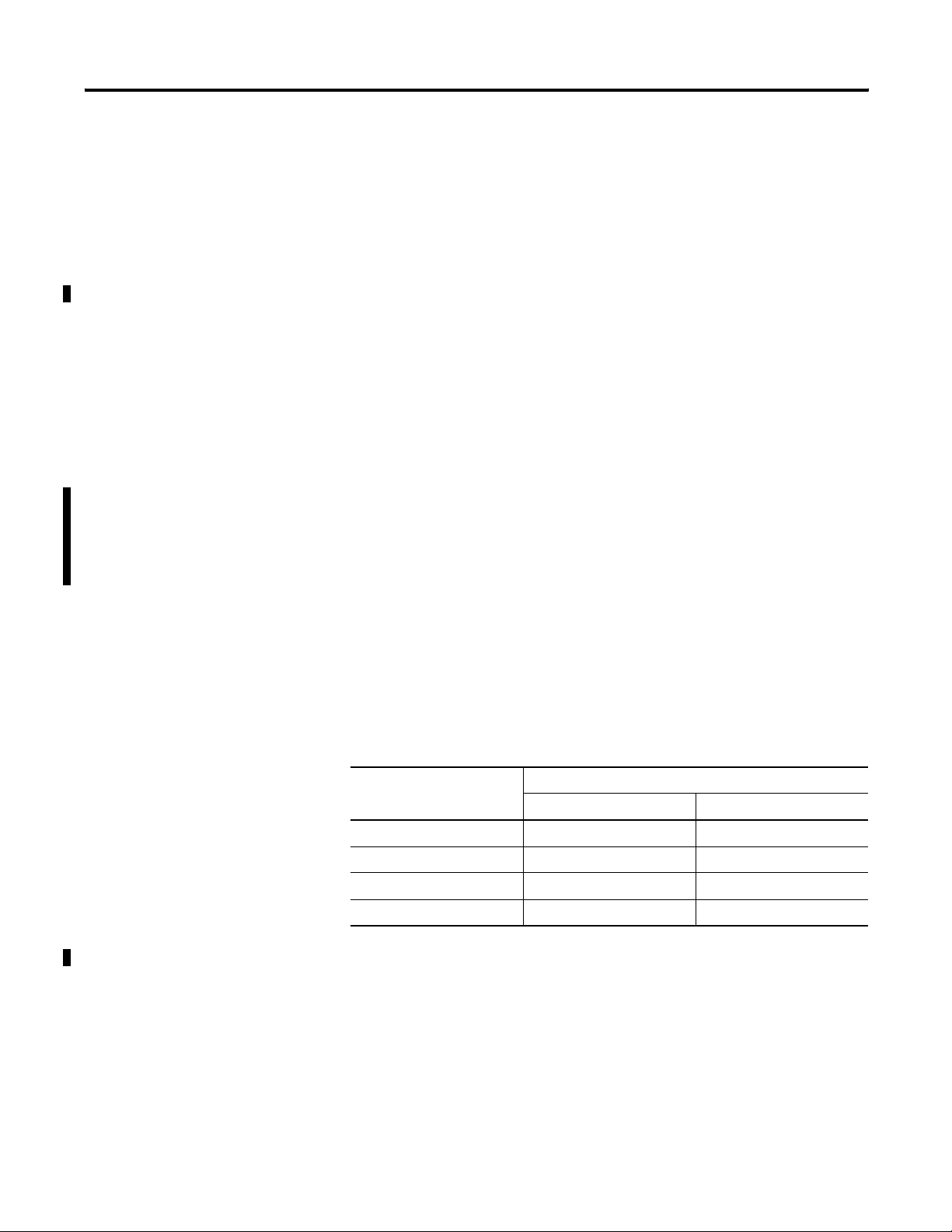

and complementary racks as shown below:

Primary Chassis Logical

Rack Number

Complementary Chassis Logical Rack Number

Decimal Octal

Publication 1747-UM013B-EN-P - January 2005

0810

1911

21012

31113

Page 19

Overview 1-11

ATTENTION

If the logical rack numbers are not properly

assigned, unpredictable operation of both ASB

modules results. No ASB module errors occur. Refer

to your ASB module user manual for specific

information on setting the address of the

complementary chassis. (For example, in the

1771-ASB manual the addresses for the

complementary chassis are referred to as

complementary chassis 0-3.)

Guidelines for Configuring Complementary I/O

When you configure your remote system for complementary I/O,

follow these guidelines:

• You can place an output module in the primary chassis opposite

another output module in the complementary chassis; they use

the same bits in the output image table. However, we do not

recommend this placement of modules for redundant I/O.

• You cannot use complementary I/O with a chassis that uses

32-point I/O modules and 1-slot addressing or 16-point I/O

modules with 2-slot addressing.

• Do not place an input module in the primary chassis opposite

an input module in the complementary chassis; they will use the

same bits in the input image table.

Publication 1747-UM013B-EN-P - January 2005

Page 20

1-12 Overview

Example 1

Complementary I/O: Placing Modules with 2-Slot Addressing

The following figures illustrate a possible module placement to

configure complementary I/O using 2-slot addressing.

Example 2

I

8

012345

O

8

I

16

012345

I

8

O

8

O

16

O

8

I

8I 8

I

16

O

8

O

16

I

16

E

M

P

T

Y

I

16

O

16O 8O 8

11

E

M

O

P

8O 8

T

Y

O

16

12

I

16

1

O

16

BT

E

M

P

T

Y

I

16

O

8

I

8

O

8

O

16

O

BT

8

E

E

M

M

P

P

T

T

Y

I

16

Y

2

O

16

2

2

Publication 1747-UM013B-EN-P - January 2005

Outputs in the complementary chassis would use the same bits in the

output image table as the outputs in the primary chassis. You cannot

place inputs in the complementary chassis.

1 = Output modules use the same output image table bits. This is not recommended.

2 = Must be empty if corresponding primary slot is a block transfer module.

Important: With 2-slot addressing, if an input module resides in either slot associated with a

logical group of the primary chassis, an input module cannot reside in that logical group' s

complementary chassis.

Page 21

Example 1

Overview 1-13

Complementary I/O: Placing Modules with 1-Slot Addressing

The figure below illustrates a possible module placement to configure

complementary I/O using 1-slot addressing.

Example 2

I

I

16

01234 5

O

16O 16I 16I 16

I

16

01234 5

O

16

16O16

I

I

16

16I 16I 16I 16I 16I 16I 16I 16I 16

O

16

I

16

O

16

I

16

O

BT I

16

1

67 0 1 2 3

O

16

1

67 0 1 2 3

16O 16O 16

E

M

P

O

T

16

Y

2

I

16

I

16

I

16O 16

I

16

O

16O 16

I = Input Module (8- or 16-point) O = Output Module (8- or 16-point)

BT = Block Transfer Module

1 = Output modules use the same output image table bits. This is not recommended.

2 = Must be empty if corresponding primary slot is block transfer..

O

16O 16O 16O 16O 16O 16O 16O 16O 16O 16

Publication 1747-UM013B-EN-P - January 2005

Page 22

1-14 Overview

Example 1

Complementary I/O: Placing Modules with 1/2-Slot Addressing

The figure below illustrates a possible module placement to configure

complementary I/O using 1-slot addressing.

IIOOO O BT I

I

1

O

Example 2

01 23 45 67 01 23

OOII IOO1I

I I

01 23 45 67 01 23 45 67 01 23

OO

IIIIIIII

OOO OOO OO

45 67 01 23

E

M

P

T

Y

2

O

Publication 1747-UM013B-EN-P - January 2005

I = Input Module (8-, 16-, or 32-point) O = Output Module (8-, 16-, or 32-point)

BT = Block Transfer Module

1 = Output modules use the same output image table bits. This is not recommended.

2 = Must be empty if corresponding primary slot is block transfer.

Page 23

Overview 1-15

Summary for Placing Modules Used In Complementary I/O

Discrete Modules

Addressing Method Types of Modules used Placement

2-slot 8-point Install input modules

opposite output modules,

and output modules

opposite input modules.

1-slot 8-point, 16-point

1/2-slot 8-point, 16-point, 32-point

(1) If an input module resides in either slot associated with a logical group of the primary chassis, an input module

cannot reside in that logical group’s complementary chassis.

Block Transfer Modules

(1)

Addressing Method Placement

2-slot The right slot of the primary I/O group can be another block

transfer module, or an 8-point input or output module.

The left slot of the complementary I/O group must be empty.

In the right slot of the complementary I/O group, you can place

an 8-point output module; this slot must be empty if the

corresponding slot in the primary I/O group is a block transfer

module.

1-slot Leave the corresponding I/O group in the complementary

chassis empty.

1/2-slot Leave the corresponding I/O group in the complementary

chassis empty.

The following example illustrates how I/O modules requiring two

words of the input or output image can leave unused image space.

Publication 1747-UM013B-EN-P - January 2005

Page 24

1-16 Overview

OOOO

IIII

012 3 45 678

Slot Slot

Slot Pair

1234

I = Input Module

O

= Output Module

Primary Chassis

Primary Chassis Configured As:

Logical Rack Number 0

Logical Group Number 0

Image Size (logical groups) 16

Addressing Mode 1/2-slot

Primary/Complementary Primary

Primary Chassis I/O Image Complementary Chassis I/O Image

Input Image

from Primary Chassis

701017

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

07815

1

2

3

4

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

Octal

Decimal

Slot Pair

Output Image

from Primary Chassis

701017

Decimal

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

07815

1

2

3

4

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

Input Image

Octal

Slot Pair Slot Pair Slot Pair

from Complementary Chassis

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

= unused image space

OOOO

IIII

012 3 45 678

Slot Pair

1234

Complementary Chassis

Complementary Chassis Configured As:

Logical Rack Number 8 (decimal)

Logical Group Number 0

Image Size (logical groups) 16

Addressing Mode 1/2-slot

Primary/Complementary Complementary

701017

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

Decimal

07815

1

2

3

4

from Complementary Chassis

Octal

Output Image

701017

Slot 1

Slot 1

Slot 1

Slot 1

Slot 2

Slot 2

Slot 2

Slot 2

Slot 3

Slot 3

Slot 3

Slot 3

Slot 4

Slot 4

Slot 4

Slot 4

Slot 5

Slot 5

Slot 5

Slot 5

Slot 6

Slot 6

Slot 6

Slot 6

Slot 7

Slot 7

Slot 7

Slot 7

Slot 8

Slot 8

Slot 8

Slot 8

Octal

Decimal

07815

1

2

3

4

Scanner's I/O Image

Both images are overlapped in the

scanner. The overlapped image

appears where the primary chassis

image is configured to reside.

In this case, the primary chassis

image is configured as starting

logical rack 0 and starting logical

group 0.

Publication 1747-UM013B-EN-P - January 2005

Logical

Rack 0

Logical

Rack 1

Group 0

Group 1

Group 2

Group 3

Group 4

Group 5

Group 6

Group 7

Group 0

Group 1

Group 2

Group 3

Group 4

Group 5

Group 6

Group 7

Input Image Output Image

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

701017

Octal

Decimal

07815

Slot 1

Slot 1

1

Slot 2

Slot 2

Slot 3

Slot 3

2

Slot 4

Slot 4

Slot Pair Slot Pair

Slot 5

Slot 5

3

Slot 6

Slot 6

Slot 7

Slot 7

4

Slot 8

Slot 8

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

701017

Slot 1

Slot 1

Slot 2

Slot 2

Slot 3

Slot 3

Slot 4

Slot 4

Slot 5

Slot 5

Slot 6

Slot 6

Slot 7

Slot 7

Slot 8

Slot 8

Octal

Decimal

07815

1

2

3

4

Page 25

Logical

g

a

g

t

e

Rack 0

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Overview 1-17

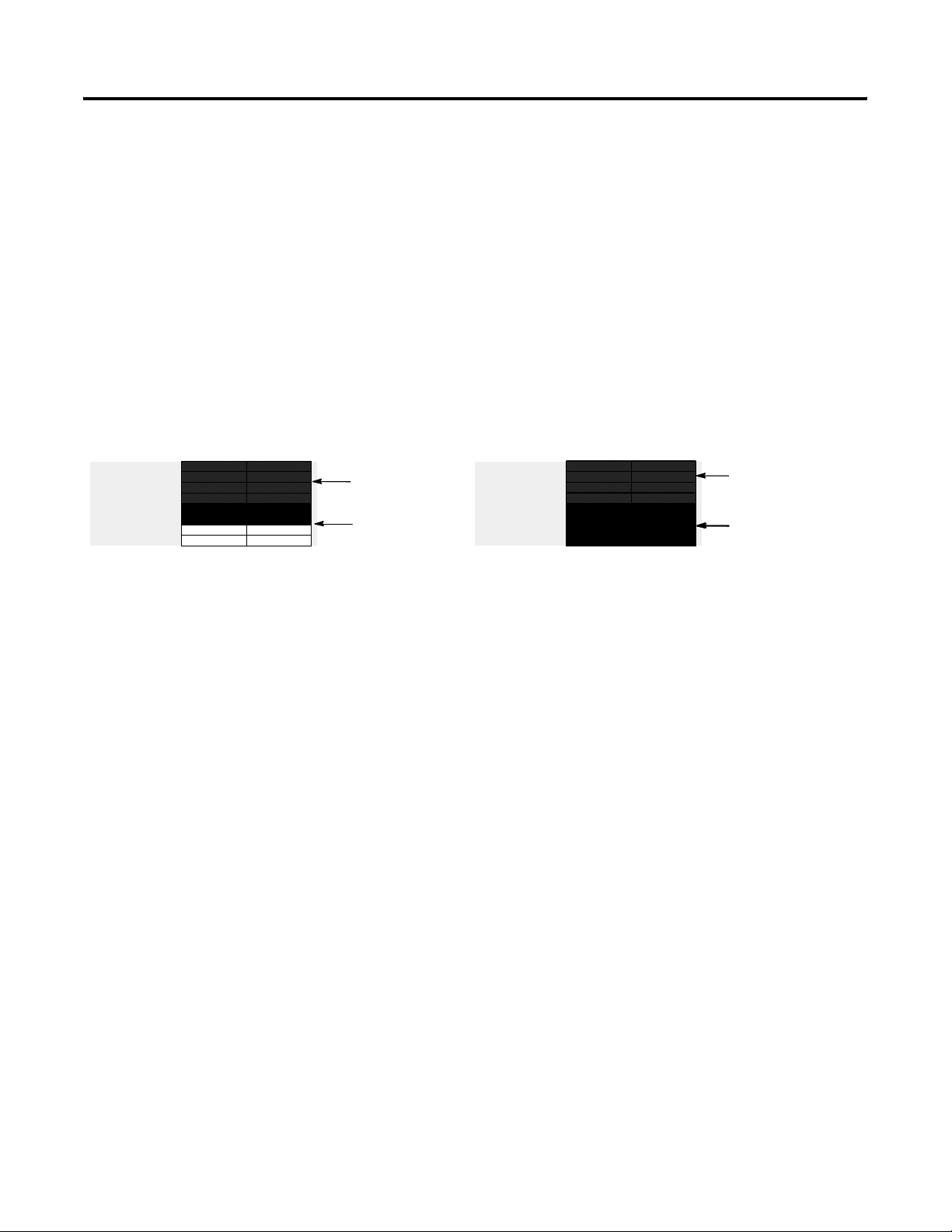

Complementary I/O Application Considerations

If you configure a complementary device to use more I/O image

space than an associated primary device, then block transfers can only

be performed to locations in the complementary device that have

associated I/O image space in the primary device. For example, if a

primary device is 1/2 logical rack and a complementary device is a full

logical rack, block transfers can be performed only in the first 1/2

logical rack of the complementary device. Attempting block transfers

in the last half of the complementary device will result in a BT error

(error - 11 - device not configured).

1/2 logical rack

1/2 logical rack

configured and

usable

1/2 logical rack not

configured

Logical

Rack 8

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

1/2 logical rack

ured and us

confi

configured and usable

1/2 logical rack

1/2 logical rack

confi

ured, but no

usable for BT sinc

configured, but not

Words 4-7 are not

usable for BT since

configured for the

Words 4 to 7 are not

primary device.

configured for the

primary device.

Complementary 1771 I/O Module Details

Use the following modules in either primary or complementary I/O

chassis opposite any type of module:

• Communication Adapter Module (1771-KA2)

• Communication Controller Module (1771-KE)

• PLC-2 Family/RS-232-C Interface Module (1771-KG)

• Fiber Optics Converter Module (1771-AF)

• DH/DH+ Communication Adapter Module (1785-KA)

• DH+/RS-232C Communications Interface Module (1785-KE)

Use the following modules in either primary or complementary I/O

chassis opposite any type of module. However, these modules do not

work as stand-alone modules; each one has an associated master

module. Use care when placing the master modules in the I/O chassis:

• Analog Input Expander Module (1771-E1, -E2, -E3)

• Analog Output Expander Module (1771-E4)

• Servo (Encoder Feedback) Expander Module (1771-ES)

• Pulse Output Expander Module (1771-OJ)

Publication 1747-UM013B-EN-P - January 2005

Page 26

1-18 Overview

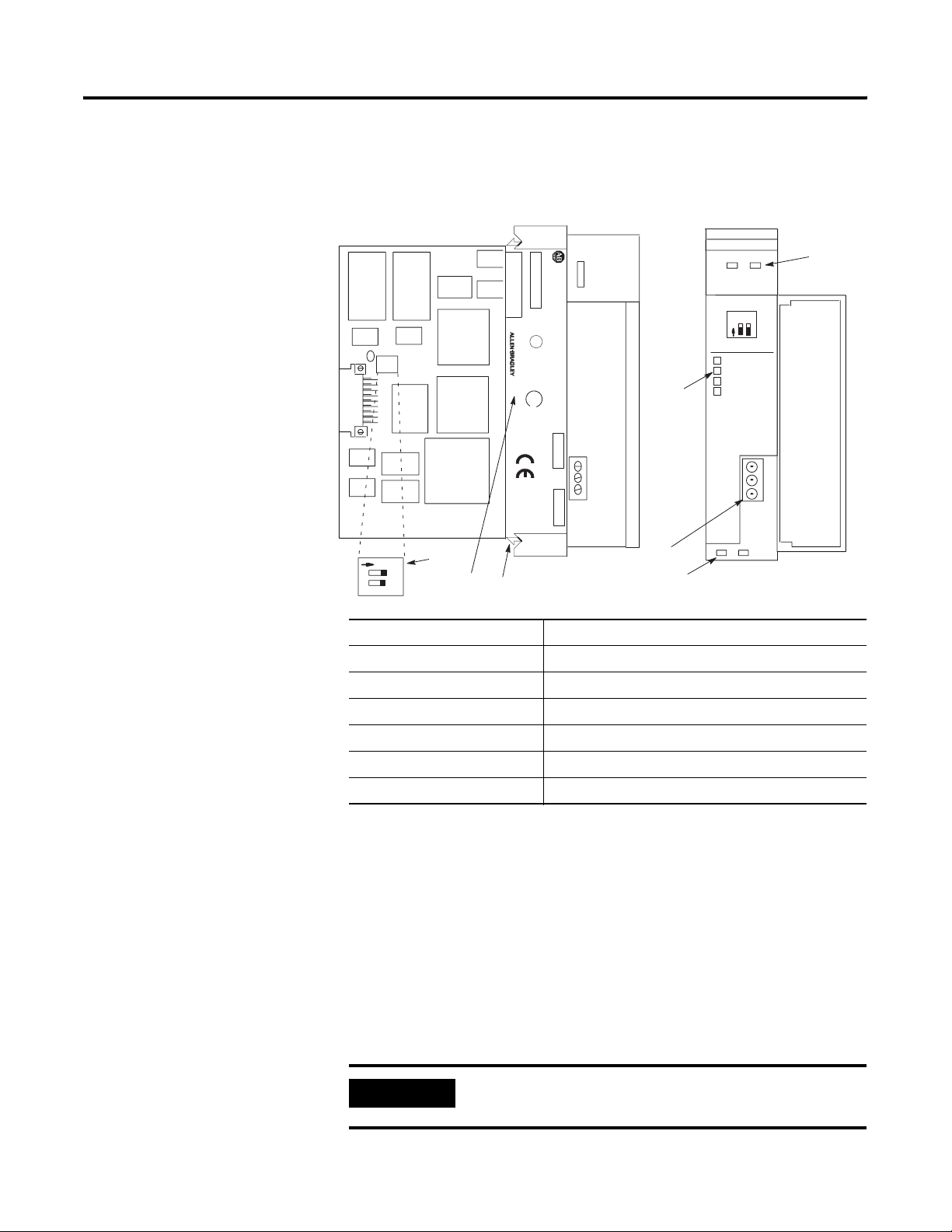

Hardware Features

Below are the scanner’s features. You can find LED information in

Chapter 6, Troubleshooting.

2

SCANNER

COMM FAULT

SW1

O

12

N

/

1 2 KBAUD

ON

ONON57.6

OFF

115.2

OFF

ON

230.4

OFF OFF

230.4

CONNECT ONE END OF

CABLE SHIELD TO CHASSIS

MOUNTING BOLT. REFER T O

USER'S MANUAL.

LINE 1

SHIELD

LINE 2

1747±SN

1

CAT

SERIAL NO.

Remote I/O Scanner

SLC 500

SER

FAC

)

CLASS I, GROUPS A, B, C AND D, DIV.2

U

L

FOR HAZ. LOC. A196

LISTED IND. CONT. EQ.

SA

)

OPERATING

TEMPERATURE

CODE T3C

HOST

FRN.:

CURRENT REQUIREMENT: 600 mA @5VDC

FRN.:

PLUG

MAKE IN U.S.A.

B

N

O

12

7

6

5

3

4

1. Status Led Displays normal communication and fault status

2. Front Label Allows user to record configured baud rate

3. RIO Link Connector Allows for connections to RIO link devices

4. Cable Tie Slots Secures communication wiring from module

5. Self-Locking Tabs Secures module in chassis slot

6. Side Label (Nameplate) Provides module information

7. Baud Rate DIP Switch Allows user to set baud rate

Baud Rate DIP Switch

The Baud Rate DIP switch selects the RIO link baud rate. The baud

rates are:

• 57.6 Kbaud

• 115.2 Kbaud

• 230.4 Kbaud

Publication 1747-UM013B-EN-P - January 2005

IMPORTANT

For proper system operation, the baud rate of all

devices on the RIO link must be the same.

Page 27

Overview 1-19

LEDs

Two LEDs allow you to monitor scanner and communication status.

FAULT LED - allows you to monitor scanner status. This LED is red.

The FAULT LED’s normal state is off; therefore, it is off whenever the

scanner is operating properly.

COMM LED - allows you to monitor communication with all

configured devices. This LED is green and its normal state is on once

the processor has entered Run mode. The LED is red if there is a

communication problem. The COMM LED status information is valid

only when the FAULT LED is off.

RIO Link Connector

This 3-pin male connector connects the scanner to the RIO link. The

Allen-Bradley repair part number is 1746-RT29.

Compatible Devices

Catalog Number Device Comments

1785-LT/x

1785-LT2

1785-LT3

1785-L30x

1785-L40x

1785-L60x

1771-ASC Remote I/O Adapter Module -

1771-ASB

1771-AM1

1771-AM2

1784-F30D

1771-RIO Remote I/O Interface Module -

(1) (2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(1)(2)

(3) (4)

(1)

(1)

(1)

PLC- 5/15 (in adapter mode) -

PLC- 5/25 (in adapter mode) -

PLC- 5/12 (in adapter mode) -

PLC- 5/30 (in adapter mode) -

PLC- 5/40 (in adapter mode) -

PLC- 5/60 (in adapter mode) -

Remote I/O Adapter Module -

1-Slot I/O Chassis W/Integral Power Supply and

Adapter

2-Slot I/O Chassis W/Integral Power Supply and

Adapter

Plant Floor Terminal Remote I/O Expansion

Module

-

-

-

Publication 1747-UM013B-EN-P - January 2005

Page 28

1-20 Overview

Catalog Number Device Comments

1771-JAB

(1)

Single Point I/O Adapter Module Single Point I/O

-

Adapter Module

1771-DCM Direct Communication Module -

1778-ASB

1747-DCM

2706-xxxx

2705-xxx

(1)

(1)

(1)(5)

(1)

Remote I/O Adapter Module -

Direct Communication Module -

DL40 Dataliner -

RediPANEL Requires half logical rack configuration if you want to use

stored messages.Requires half logical rack configuration if

you want to use stored messages.

2711-xx

(1)

PanelView Terminal You can address PanelView Terminals as up to four full

logical racks of discrete I/O. You can also assign partial

logical racks.You can address PanelView Terminals as up to

four full logical racks of discrete I/O. You can also assign

partial logical racks.

1336-G2

(1)

Remote I/O Adapter for 1336 AC Industrial

-

Drives

1395-NA

(1)

Remote I/O Adapter for 1395 DC Industrial

-

Drives

1791-xxx Block I/O Products The adapter is built into the block.

1747-ASB

(1)

SLC 500 Remote I/O Adapter Module -

1794-ASB Flex I/O 24VDC Remote I/O Adapter -

(1) Extended node capability

(2) In adapter mode

(3) Series A, B, and C

(4) Extended node capability for Series B and C

(5) Must be Catalog Number 2706-ExxxxxB1

Publication 1747-UM013B-EN-P - January 2005

Page 29

Chapter

2

Quick Start for Experienced Users

This chapter helps you to get started using the RIO Scanner. We base

the procedures here on the assumption that you have a basic

understanding of SLC 500 products.

You must:

• understand electronic process control

• be able to interpret the ladder logic instructions for generating

the electronic signals that control your application

Because it is a start-up guide for experienced users, this chapter does

not contain detailed explanations about the procedures listed. It does,

however, reference other chapters in this book where you can get

more detailed information. It also references other documentation that

may be helpful if you are unfamiliar with programming techniques or

system installation requirements.

Required Tools and Equipment

If you have any questions, or are unfamiliar with the terms used or

concepts presented in the procedural steps, always read the

referenced chapters and other recommended documentation before

trying to apply the information.

This chapter:

• tells you what tools and equipment you need

• lists preliminary considerations

• describes when to address, configure and program the module

• explains how to install and wire the module

• discusses system power-up procedures

Have the following tools and equipment ready:

• medium blade screwdriver

• programming equipment

• termination kit (package of resistors and ring lug included with

the scanner)

• approximately 15 inches of #20 AWG for grounding the drain

shield to the SLC chassis (for Series A retrofits)

• an adequate length of RIO communication cable (Belden 9463)

for your specific application

1 Publication 1747-UM013B-EN-P - January 2005

Page 30

2-2 Quick Start for Experienced Users

Procedures

1. Check the contents of the shipping box.

Unpack the module making sure that the contents include:

• RIO Scanner (Catalog Number 1747 SN)

• termination kit

If the contents are incomplete, call your local Allen-Bradley

representative for assistance.

2. Ensure you chassis supports placement of the 1747-SN module.

Review the power requirements of your system to see that your

chassis supports placement of the scanner module. The scanner

consumes 600 mA @ 5VDC.

For modular style systems, calculate the total load on the system

power supply using the procedure described in the SLC 500

Modular Hardware Style User Manual, Publication 1747-UM011.

See Chapter 3, Installation and Wiring and Appendix A

Specifications in this manual.

3. Configure the module using the DIP switches.

Set the DIP switches (located on the printed circuit board) to the

desired baud rate. Note that all RIO devices must be configured

for the same baud rate.

Baud Rate DIP Switch Position

Switch 1 Switch 2

57.6K baud on on

115.2K baud on off

230.4K baud off on

230.4K baud off off

See Chapter 3, Installation and Wiring.

4. Insert the 1747-SN module into the chassis.

Publication 1747-UM013B-EN-P - January 2005

Page 31

Quick Start for Experienced Users 2-3

ATTENTION

Never install, remove, or wire modules with

power applied to the chassis or devices wired

to the module.

Make sure system power is off; then insert the scanner module

into your 1746 chassis. In this example procedure, local slot 1 is

selected.

See Chapter 3, Installation and Wiring.

Make sure system power is off; then insert the scanner module into your 1746 chassis.

In this example procedure, local slot 1 is selected.

Top and Bottom

Module Release(s)

Card

Guide

5. Connect all RIO link devices.

Ensure that you:

• Daisy chain each RIO link device.

• Ground the shield drain wire to the nearest chassis mounting

bolt.

• Connect the appropriate termination resistors on each end of the

link.

6. Configure the system.

Set up your system I/O configuration for the particular slot in

which you installed the scanner (slot 1 in this example). If your

module is not listed in your software version, select Other and

enter the scanner input module ID code (13608) at the prompt

on the I/O configuration display.

See Chapter 4, Configuration and Programming.

Publication 1747-UM013B-EN-P - January 2005

Page 32

2-4 Quick Start for Experienced Users

7. Enter the number of scanned words.

Enter the number of Scanned Input and Output Words using the

Specialty I/O and Advanced Setup menus. The default value is

32 I/O words. You can specify less than 32 and reduce the

processor scan time by transferring only the part of the input

and output image that your application requires. It is important

that you do not set either of these values to 0. If you do, the

scanner will not work correctly.

See Chapter 4, Configuration and Programming.

8. Set the M0 - M1 and G file sizes.

Using the Specialty I/O Configuration menu, set the M1 and M0

file sizes to 32 words (48 words if using complementary I/O).

(32 words is the minimum required for operation.) If you do not

set the M1 and M0 file sizes to at least 32 words, the

programming device will not allow you to access the M files in

the SLC control program.

Set the G file size to 3 (5 if using complementary I/O) using the

Specialty I/O Configuration menu. Do the programming

necessary to configure the M0 and M1 Block Transfer Buffers. If

you are using the block transfer (BT) function, you should set

the M1 and M0 file sizes to 3,300. Ensure that you refer to

chapter 5 before completing this selection.

Write the remainder of the SLC control program that specifies

how your scanner will transfer data to/from the SLC processor

and RIO devices.

Refer to Chapter 4, Configuration and Programming and

Chapter 5, RIO Block Transfer.

9. Go through the system start-up procedure.

a. Apply power.

b. Download your program to the SLC.

c. Place the SLC in Run mode.

The scanner’s FAULT LED is off and the COMM LED is green, as

shown below. (This is the valid LED pattern when in Run mode

or after a Run mode to Program mode transition.)

Publication 1747-UM013B-EN-P - January 2005

See Chapter 3, Installation and Wiring.

Page 33

SCANNER

COMM

FAULT

Quick Start for Experienced Users 2-5

FAULT LED is off.

COMM LED is green.

Publication 1747-UM013B-EN-P - January 2005

Page 34

2-6 Quick Start for Experienced Users

Publication 1747-UM013B-EN-P - January 2005

Page 35

Installation and Wiring

This chapter contains the information necessary to:

• select the baud rate

• insert the scanner into the SLC chassis

• wire the RIO link

• power up the scanner

Chapter

3

Compliance to European Union Directives

If this product has the CE mark, it is approved for installation within

the European Union and EEA regions. It has been designed and tested

to meet the following directives.

EMC Directive

This product is tested to meet Council Directive 89/336/EEC

Electromagnetic Compatibility (EMC) and the following standards, in

whole or in part, documented in a technical construction file:

• EN 50081-2

EMC - Generic Emission Standard, Part 2 - Industrial

Environment

• EN 50082-2

EMC - Generic Immunity Standard, Part 2 - Industrial

Environment

This product is intended for use in an industrial environment.

1 Publication 1747-UM013B-EN-P - January 2005

Page 36

3-2 Installation and Wiring

Baud Rate Selection

Below are supported baud rates and switch positions:

Baud Rate DIP Switch Position

Switch 1 Switch 2

57.6K baud on on

115.2K baud on off

230.4K baud off on

230.4K baud off off

The figure below shows the location of the DIP switches on the

scanner. Also, the DIP switch settings are shown for each baud rate.

IMPORTANT

For proper RIO link system operation, all devices

must be configured for the same baud rate.

Scanner Installation

Baud Rate

DIP Switch

N

O

12

57.6K baud 115.2K baud

N

O

12

230.4K baud 230.4K baud

N

O

12

N

O

12

Installation procedures for this module are the same as for any other

discrete I/O or specialty module. Refer to the illustration on page 2-4

to identify chassis and module components listed in the procedures

below.

Publication 1747-UM013B-EN-P - January 2005

Page 37

Installation and Wiring 3-3

ATTENTION

IMPORTANT

IMPORTANT

Insertion

Disconnect system power before attempting to

install, remove, or wire the scanner.

Make sure you have set the DIP switches properly

before installing the scanner.

Before installation, ensure that your modular SLC

power supply has adequate reserve current capacity.

The scanner requires 600 mA @ 5V dc.

1. Disconnect power.

2. Align the full-sized circuit board with the chassis card guides.

The first slot (slot 0) of the first rack is reserved for the SLC 500

processor.

3. Slide the module into the chassis until the top and bottom

latches catch.

4. Attach the RIO link cable to the connector on the front of the

module, behind the door. Ground the cable’s shield wire to a

chassis mounting bracket. See the RIO link wiring illustration on

page 2-4.

5. Insert the cable tie in the slots.

6. Route the cable down and away from module, securing it with

the cable tie.

7. Cover all unused slots with the Card Slot Filler, Catalog Number

1746-N2.

Publication 1747-UM013B-EN-P - January 2005

Page 38

3-4 Installation and Wiring

Module Release

Card Guide

Cable Tie

Removal

1. Disconnect power.

2. Remove all cabling.

3. Press the releases at the top and bottom of the module and slide

the module out of the chassis slot.

4. Cover all unused slots with the Card Slot Filler, Catalog Number

1746-N2.

Publication 1747-UM013B-EN-P - January 2005

Page 39

Installation and Wiring 3-5

RIO Link Wiring

The scanner is connected to other devices on the RIO link in a daisy

chain (serial) configuration. There are no restrictions governing the

space between each device, provided the maximum cable distance

(Belden 9463) is not exceeded.

A 1/2 watt terminating resistor (included with the module) must be

attached across line 1 and line 2 of the connectors at each end

(scanner and last physical device) of the RIO link. The value of the

resistor depends on the baud rate and extended node capability, as

shown in the table that follows.

IMPORTANT

To use extended node, all devices on the RIO link

must support it. Refer to each device’s user manual.

Using Extended

Node Capability

Baud Rate Maximum Cable

Distance (Belden 9463)

57.6K baud 3048 meters (10,000 feet) 82 ohm 1/2 Watt

115.2K baud 1524 meters (5000 feet)

230.4K baud 762 meters (2500 feet)

Resistor Size

Brown - Green Brown - Gold

Not Using Extended

Node Capability

57.6K baud 3048 meters (10,000 feet) 150 ohm 1/2 Watt

115.2K baud 1524 meters (5000 feet)

230.4K baud 762 meters (2500 feet) 82 ohm 1/2 Watt Gray

Brown - Green Brown - Gold

- Red - Black - Gold

Publication 1747-UM013B-EN-P - January 2005

Page 40

3-6 Installation and Wiring

RIO Link

Connector

LINE 1 _______

SHIELD _____

LINE 2 _______

RIO Scanner

RIO Link

Connector

Terminating

Resistor Last Physical

Device End

Terminating

Resistor

Scanner End

Line 1 ± Blue

Shield ± Shield

Line 2 ± Clear

Chassis

Mounting

Bracket

Ring Lug

Shield Drain Wire

For New Installations

Using Series B

Scanners

Shield Drain Wire

For Series A

Scanner

Retrofits

New Installations

To ensure a proper earth ground of the cable shield, follow these

steps:

1. While the RIO link connector is plugged into the scanner and

lines 1 and 2 are connected, strip the cable back to expose

enough shield drain wire to reach a chassis mounting bracket.

2. Attach the ring terminal lug (supplied) to the end of the shield

drain wire.

Publication 1747-UM013B-EN-P - January 2005

3. Attach the ring terminal lug to the SLC chassis mounting bracket.

Note that for new installations the middle (shield) terminal is not

used when connecting to the scanner.

Page 41

Installation and Wiring 3-7

IMPORTANT

The RIO cable shield must be grounded at the

scanner end only.

For Series A Scanner Retrofits

To eliminate the need to strip the cable back, follow these steps:

1. Attach the shield wire and a short piece of #20 AWG wire

(dotted line) to the shield lug of the RIO Link Connector.

2. Attach the other end of the #20 AWG wire to the ring terminal

lug.

3. Attach the ring terminal lug to a chassis mounting bracket.

IMPORTANT

The RIO cable shield must be grounded at the

scanner end only. Ensure that the unshielded portion

of the link communication wire (blue and clear) is as

short as possible.

Start Up

The following steps will assist you in the start up of your RIO system.

1. Apply power to your SLC processor. If you powered down with

the SLC processor in Program, Test, or Fault mode, you will have

to place your processor in Run mode.

When power is applied to your scanner it requires about three

seconds to complete its power up diagnostics. During this time,

the FAULT and COMM LEDs cycle on and off. After the

diagnostics are complete and the SLC processor is in the Run

mode, the scanner’s LEDs are in the following states:

• The FAULT LED is off.

• The COMM LED is green.

IMPORTANT

The above states are true only if the scanner is

configured properly and all RIO link devices

are communicating.

Publication 1747-UM013B-EN-P - January 2005

Page 42

3-8 Installation and Wiring

2. Make sure you have configured your SLC processor and

downloaded an application program. (Refer to chapter 4.)

3. Make sure power is applied to all devices on the RIO link.

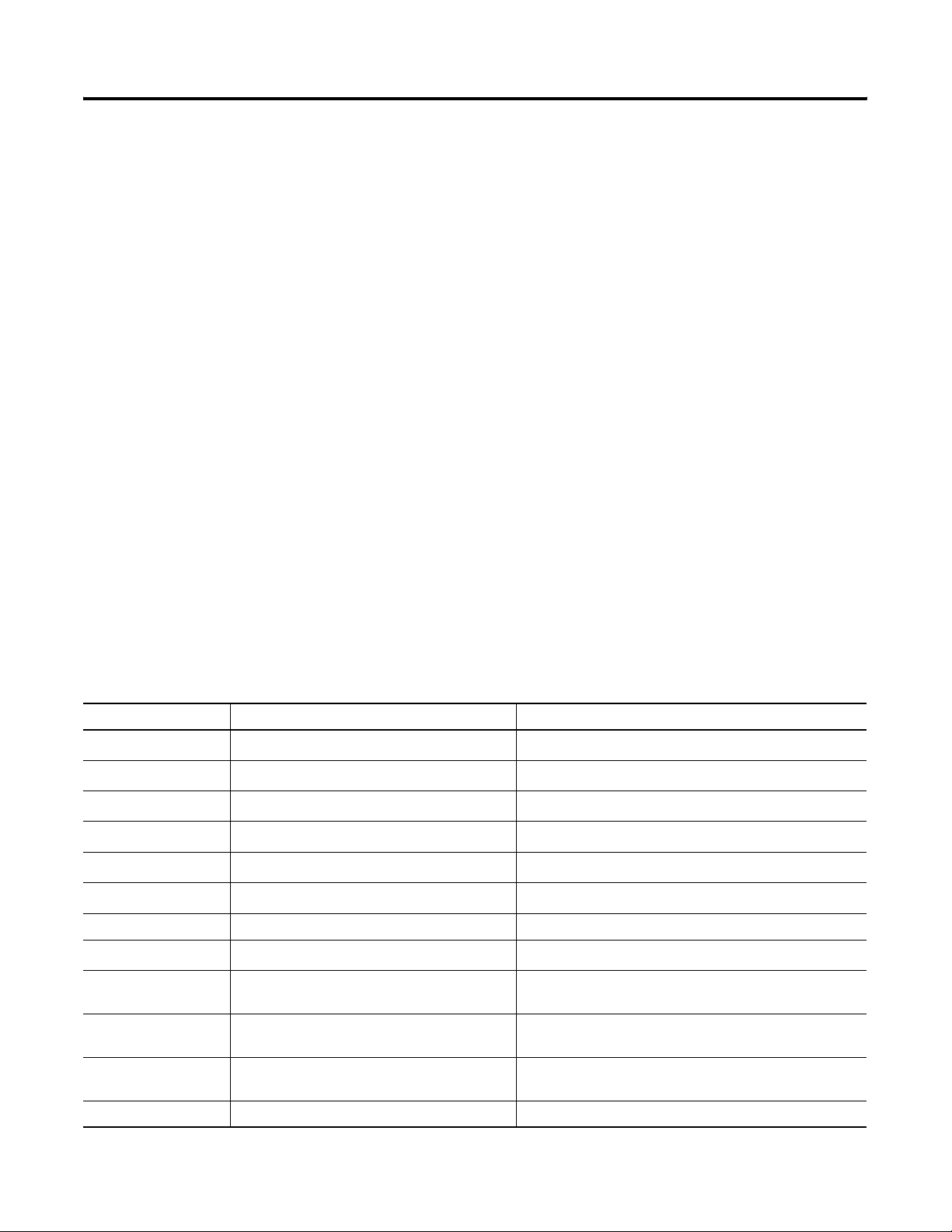

Scanner Operation

Below is a description of the scanner’s operation at power up, run

mode, and when changing from run mode to program or test mode.

At Power Up

At power up, the scanner’s communication LED (green LED) is off

until the SLC is changed to Run or Test mode.

In Run Mode

During normal scanner operation (SLC in Run mode), the scanner’s

LEDs illuminate as shown below:

SCANNER

COMM

FAULT

Publication 1747-UM013B-EN-P - January 2005

FAULT LED is off.

COMM LED is green.

When Changing From Run Mode

When the SLC processor is changed from Run mode, to Program or

Test mode the following occurs:

• scanner’s COMM LED remains green.

• the scanner continues to read its input devices and send output

data to its RIO adapters.

• the scanner instructs adapters to either clear all outputs or hold

them in their last state (depending on their configuration). Refer

to the user manual included with each RIO device for specific

information relating to the Hold Last State setting.

Page 43

Installation and Wiring 3-9

Status LEDs

IMPORTANT

If you are using Block Transfer (BT)

functionality, BTs may not function on adapters

in Hold Last State settings. Refer to each device’s

user manual for information on BTs and Hold

Last State settings.

The scanner has two LEDs that indicate its operating status, FAULT

and COMM. The FAULT LED indicates the scanner’s overall status. The

COMM LED indicates the RIO link communication status.

The FAULT LED is off whenever the scanner is configured and

operating properly. The COMM LED state is valid only when the

FAULT LED is off.

The table below provides the scanner and communication status as

indicated by the FAULT and COMM LEDs.

FAULT LED COMM LED Status Information

Flashing Red Not Applicable Scanner configuration error

No RIO link communication attempted

Duplicate scanner detected on RIO link

Red Not Applicable Major fault on scanner

No RIO link communication attempted

Off Red Hardware fault detected

Off Off Scanner is operating properly

Scanner is offline (no RIO link communication

attempted)

Off Green Scanner is operating properly

Scanner is online (active communication established

with all devices)

Off Flashing Green Scanner is operation properly

At least one configured RIO link device is not

communicating

Off Flashing Red Scanner is operating properly

None of the configured RIO link devices are

communicating

Publication 1747-UM013B-EN-P - January 2005

Page 44

3-10 Installation and Wiring

Publication 1747-UM013B-EN-P - January 2005

Page 45

Chapter

Scanner Configuration and Programming

This chapter contains information necessary to:

• understand remote I/O image files

• understand RIO configuration using G files

• control and view RIO devices using the M0 and M1 files

• understand slot addressing

• quickly configure the RIO Scanner

4

Understanding Remote Input and Output Image Files

The SLC system allows you to assign up to 32 words of input and

output image data to a scanner. This allows your scanner to access a

maximum of 4 full logical racks (512 input and output points) of data

from remote devices.

1 Publication 1747-UM013B-EN-P - January 2005

Page 46

4-2 Scanner Configuration and Programming

SN Series B Scanner

(RIO Master)

Bit Number Decimal

Logical

Rack 0

Logical

Rack 1

Logical

Rack 2

Logical

Rack 3

Word 10

Word 1 1

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

Word 24

Word 25

Word 26

Word 27

Word 28

Word 29

Word 30

Word 31

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Output Image

Scanner Input and Output Images

0717 10Bit Number Octal

07815

The scanner

accommodates

up to 32 words

of output for

remote devices.

Bit Number Decimal

Logical

Rack 0

Logical

Rack 1

Logical

Rack 2

Logical

Rack 3

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 1 1

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

Word 24

Word 25

Word 26

Word 27

Word 28

Word 29

Word 30

Word 31

Input Image

Note that some RIO devices (e.g.,

1771) use octal bit numbers.

0717 10Bit Number Octal

07815

The scanner

accommodates

up to 32 words

of input from

remote devices.

Publication 1747-UM013B-EN-P - January 2005

The illustration below shows how logical racks, logical groups, and

words are allocated within the I/O image files. Note that this

illustration describes the input image file. The scanner’s output image

file is the same, except that its addressing scheme starts with O:e.0

and ends with 0:e.31.

Page 47

Logical

Rack 0

Logical

Rack 1

Logical

Rack 2

Logical

Rack 3

Bit Number (decimal)

Logical Rack 0 Group 0

Logical Rack 0 Group 1

Logical Rack 0 Group 2

Logical Rack 0 Group 3

Logical Rack 0 Group 4

Logical Rack 0 Group 5

Logical Rack 0 Group 6

Logical Rack 0 Group 7

Logical Rack 1 Group 0

Logical Rack 1 Group 1

Logical Rack 1 Group 2

Logical Rack 1 Group 3

Logical Rack 1 Group 4

Logical Rack 1 Group 5

Logical Rack 1 Group 6

Logical Rack 1 Group 7

Logical Rack 2 Group 0

Logical Rack 2 Group 1

Logical Rack 2 Group 2

Logical Rack 2 Group 3

Logical Rack 2 Group 4

Logical Rack 2 Group 5

Logical Rack 2 Group 6

Logical Rack 2 Group 7

Logical Rack 3 Group 0

Logical Rack 3 Group 1

Logical Rack 3 Group 2

Logical Rack 3 Group 3

Logical Rack 3 Group 4

Logical Rack 3 Group 5

Logical Rack 3 Group 6

Logical Rack 3 Group 7

Word 0

Word 1

Word 2

Word 3

Word 4

Word 5

Word 6

Word 7

Word 8

Word 9

Word 10

Word 11

Word 12

Word 13

Word 14

Word 15

Word 16

Word 17

Word 18

Word 19

Word 20

Word 21

Word 22

Word 23

Word 2

Word 25

Word 26

Word 27

Word 28

Word 29

Word 30

Word 31

Bit Number (octal)

Scanner Configuration and Programming 4-3

e = slot number of the SLC chassis containing the scanner

0123456789101112131415

SLC Input

File Address

I:e.0

I:e.1

I:e.2

I:e.3

I:e.4

I:e.5

I:e.6

I:e.7

I:e.8

I:e.9

I:e.10

I:e.11

I:e.12

I:e.13

I:e.14

I:e.15

I:e.16

I:e.17

I:e.18

I:e.19

I:e.20

I:e.21

I:e.22

I:e.23

4

17

8

11

8128138148158168

5

86878108

1

8283848

I:e.24

I:e.25

I:e.26

I:e.27

I:e.28

I:e.29

I:e.30

I:e.31

0

8

The 1747-SN Scanner’s I/O image structure is described below:

• The I/O image file consists of four logical racks (numbered

0,1,2, and 3) of input image and four logical racks of output

image.

• Each logical rack consists of eight logical groups

(numbered 0, 1, 2, 3, 4, 5, 6, and 7).

• Each logical group consists of two words (an input word and an

output word).

• Each word consists of two bytes (a high and a low byte). Low

byte is bits 0 to 7 and high byte is bits 8 to 15.

• Each byte consists of 8 bits with each bit having the ability to

control one discrete I/O point.

Publication 1747-UM013B-EN-P - January 2005

Page 48

4-4 Scanner Configuration and Programming

RIO Configuration Using G Files

When you program your SLC system you use the G file to configure

the scanner’s I/O image file. Your scanner’s G file configuration is

based on the devices that you have on the RIO link. G file

configuration consists of setting logical device starting addresses and

the logical device image size of each physical device/adapter with

which the scanner communicates.

Publication 1747-UM013B-EN-P - January 2005

For RSLogix 500 version 5.50 and later, configure the 1747-BSN M0/M1

size for 5548 words so that this non-generic G file configuration

screen appears after you click on the configure G file button. For

RSLogix 500 versions prior to 5.50, configure the 1747-BSN M0/M1

size for 5547 words in order for this non-generic G file configuration

screen to appear after you click on the configure G file button.

Neither your application program nor your programming device can

access or alter the G file while online with the processor. To change

the G file you must go offline into the program file, make any

necessary changes, and download the program containing the altered

Page 49

Scanner Configuration and Programming 4-5

configuration. The G file consists of five words which are described

below.

Word 0 - contains scanner information for the SLC processor. Your