Page 1

Remote I/O Scanner

(Catalog Number 1747-SN)

Installation Instructions

Inside ................................................................................................ page

For More Information ............................................................................... 2

Hazardous Location Considerations ........................................................ 3

Environnements dangereux ..................................................................... 3

Overview .................................................................................................. 4

Hardware Features .................................................................................. 5

Required Tools and Equipment ................................................................ 8

Installation ............................................................................................... 8

RIO Link Wiring ...................................................................................... 10

Specifications ........................................................................................ 12

Publication 1747-IN060D-EN-P - November 2002

Page 2

2 Remote I/O Scanner

For More Information

For Refer to this Document Pub. No.

A more detailed description on how to

install, configure, and operate your Remote

I/O Scanner.

A more detailed description on how to

install and use your modular

SLC 500 system

A reference manual that contains status file

data and instruction set information for SLC

500 processors.

If you would like a manual you can:

• download a free electronic version from the internet:

www.theautomationbooks tore.com

• purchase a printed manual by:

– contacting your local distributor or Rockwell Automation representative

– visiting www.theautomationbookstore.com and placing your order

– calling 1.800.963.9548 (USA/Canada) or

001.330.725.1574 (Outside USA/Canada

Remote I/O Scanner

User Manual

SLC 500 Modular Hardware Style

Installation and Operation Manual

SLC 500 Instruction Set Reference

Manual

1747-6.6

1747-UM011

1747-RM001

Publication 1747-IN060D-EN-P - November 2002

Page 3

Remote I/O Scanner 3

Hazardous Location Considerations

This equipment is suitable for use in Class I, Division 2, Groups A, B, C, D or

non-hazardous locations only. The following WARNING statement applies to use in

hazardous locations.

WARNING

!

EXPLOSION HAZARD

• Substitution of components may impair suitability for Class

I, Division 2.

• Do not replace components or disconnect equipment

unless power has been switched off.

• Do not connect or disconnect components unless power

has been switched off.

• All wiring must comply with N.E.C. article 501-4(b).

Environnements dangereux

Cet équipement est conçu pour être utilisé dans des environnements de Classe I,

Division 2, Groupes A, B, C, D ou non dangereux. La mise en garde suivante

s’applique à une utilisation dans des environnements dangereux.

WARNING

!

DANGER D’EXPLOSION

• La substitution de composants peut rendre cet équipement

impropre à une utilisation en environnement de Classe I,

Division 2.

• Ne pas remplacer de composants ou déconnecter

l'équipement sans s'être assuré que l'alimentation est

coupée.

• Ne pas connecter ou déconnecter des composants sans

s'être assuré que l'alimentation est coupée.

Publication 1747-IN060D-EN-P - November 2002

Page 4

4 Remote I/O Scanner

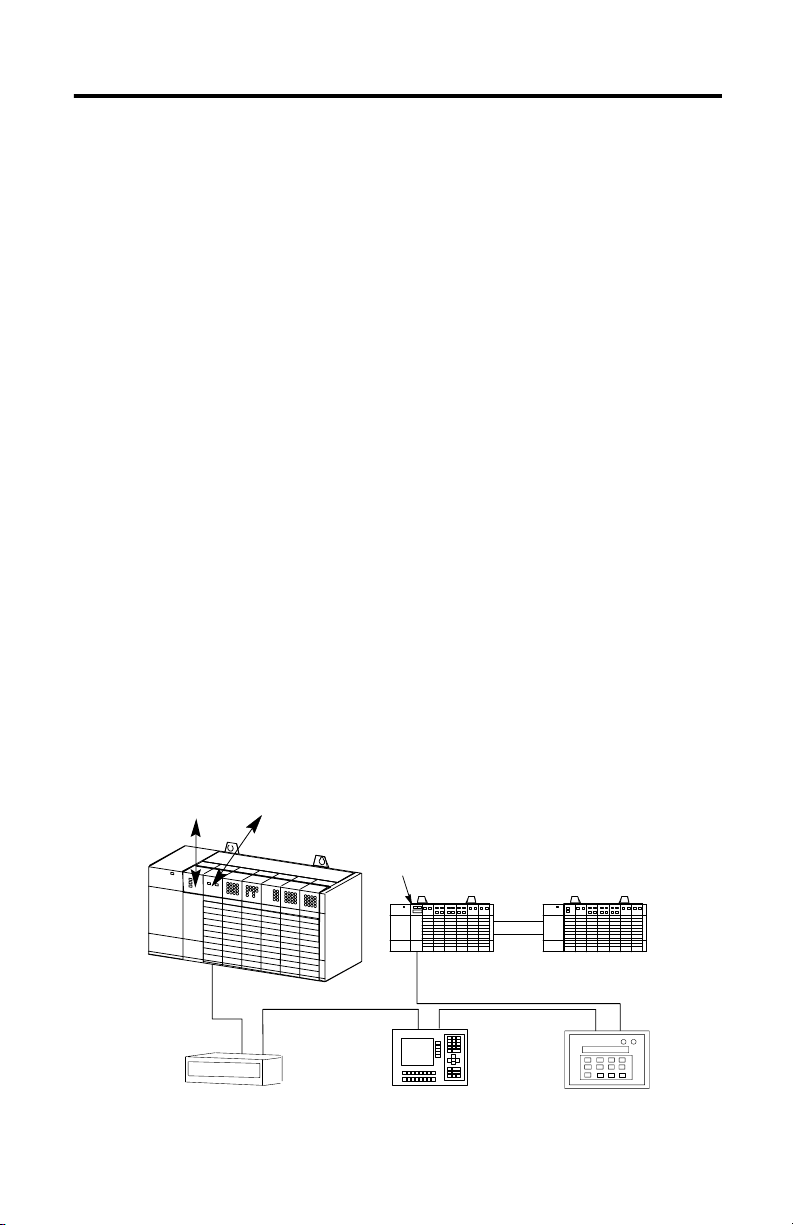

Overview

The Remote I/O (RIO) Scanner, 1747-SN, enables communication between an

SLC™ processor and remotely located 1746 I/O chassis and other RIO-compatible

Allen-Bradley operator interface and control devices. The 1747-SN scanner

communicates with remote devices using the A-B Remote I/O link. The RIO link

consists of a single master (scanner) and multiple slaves (adapters). Communication

between devices occurs over twisted-pair cable with the devices daisy-chained

together. Maximum distance for remote communication is 3,048m (10,000 ft.). The

scanner is compatible with any standard RIO adapter device.

The SLC processor transfers a maximum of 4 logical racks (32 input and 32 output

image words) of discrete remote I/O data into the SLC input and output image files.

You can adjust the size of the scanner image files during configuration of your SLC

system so that the scanner only transfers the discrete I/O data required by your

application program. The 1747-SN Series B or later RIO Scanner can be configured

to transfer up to 64 words of data to a remote device via block transfer. Refer to

publication 1747-6.6, Remote I/O Scanner User Manual, for information on

configuration, programming, and block transfers.

The SLC 500™ processor (SLC 5/02 or higher) supports multiple scanners in its local

I/O chassis. The maximum number is dependent on the following:

• backplane power requirements (power supply dependent)

• SLC 500 processor I/O data table limit (4,096 input and output bits)

• processor memory to support the application (SLC processor dependent)

SLC 5/02 or

later processor

Local SL C Chassis

Dataliner™ Message

Display (Adapter/Slave)

RIO Scanner

(Master of the RIO Link)

PanelView™ Operator Terminal

1747-ASB Module

(Adapter/Slave)

Remote Chassis

(Adapter/Slave)

Remote Expansion Chassis

Redi PANEL™

(Adapter/Slave)

Publication 1747-IN060D-EN-P - November 2002

Page 5

Remote I/O Scanner 5

Hardware Features

The figure below shows the scanner’s features. RIO Link Connector, Status LED,

and DIP Switch information follows.

CAT

SERIAL NO. FAC

SLC 500

Remote I/O Scanner

SER

CLASS I, GROUPS A, B, C, AND D, DIV 2

U

L

LISTED IND. CONT. EQ.

FOR HAZ. LOC. A196

SA

OPERATING

TEMPERATURE

CODE T3C

HOST

FRN

CURRENT REQUIREMENT 600 mA @ 5VDC

PLUG

FRN

MADE IN U.S.A.

B

O

N

1

2

Dip Switch

Cable Tie Slots

SCANNER

COMM FAULT

SW1

O

12

N

12KBAUD

ON

57.6

ON

ON

115.2

OFF

OFF

230.4

ON

OFF

230.4

OFF

CONNECT ONE END OF

CABLE SHIELD TO CHASSIS

MOUNTING BOLT. REFER TO

USERS MANUAL.

Line 1

Shield

Line 2

1747-SN

RIO Link Connector

Status LEDs

RIO Link Connector

This 3-pin male connector connects the scanner to the RIO link. The Allen-Bradley

replacement part number is 1746-RT29.

Publication 1747-IN060D-EN-P - November 2002

Page 6

6 Remote I/O Scanner

Status LEDs

The scanner has two LEDs, FAULT and COMM, which indicate its operating status.

• FAU LT LED - indicates the scanner’s overall status. The red FAULT LED is off

whenever the scanner is configured and operating properly.

• COMM LED - allows you to monitor communication with all configured

devices. This LED is green once the scanner is in the Run mode. It is red if a

hardware fault is detected. The COMM LED status information is valid only

when the FAULT LED is off.

The table below explains the scanner and communication status as indicated by the

FAULT and COMM LEDs.

FAULT LED COMM LED Status Information

Flashing Red Not

Red Not

Off Red Hardware fault detected.

Off Off Scanner is operating properly.

Off Green Scanner is operating properly.

Off Flashing

Off Flashing Red Scanner is operating properly.

applicable

applicable

Green

Scanner configuration error.

No RIO link communication attempted.

Duplicate scanner detected on RIO link.

Major fault on scanner.

No RIO link communication attempted.

Scanner is offline (no RIO link communication attempted).

Scanner is online (active communication established with all devices).

Scanner is operating properly.

At least one configured RIO link device is not communicating.

None of the configured RIO link devices are communicating.

Publication 1747-IN060D-EN-P - November 2002

Page 7

Remote I/O Scanner 7

Baud Rate DIP Switch

The figure below shows the location of the DIP switch and the DIP switch settings

for the supported baud rates.

IMPORTANT

115.2K baud

230.4K baud

230.4K baud

For proper system operation, the baud rate of all devices on the

RIO link must be the same.

O

N

12

57.6K baud

O

N

12

O

N

12

O

N

12

Publication 1747-IN060D-EN-P - November 2002

Page 8

8 Remote I/O Scanner

Required Tools and Equipment

Have the following tools and equipment ready:

• medium blade screwdriver

• termination kit (the package, containing resistors and a ring lug, which was

included with the scanner)

• approximately 38 cm (15 inches) of #20 AWG wire for grounding the drain

shield to the SLC chassis (for Series A retrofits)

• adequate length of RIO communication cable (Belden™ 9463) for your

specific application

Installation

Make sure you have set the DIP switch properly before installing the scanner.

IMPORTANT

Insertion

Before installation, make sure that your modular SLC power

supply has adequate reserve current capacity. The scanner

requires 600 mA at 5V dc.

Module Release

Card G uide

Cable Tie

Publication 1747-IN060D-EN-P - November 2002

Page 9

Remote I/O Scanner 9

1. Disconnect power.

2. Align the full-sized circuit board with the chassis card guides. The first slot

(slot 0) of the first rack is reserved for the SLC 500 processor.

3. Slide the module into the chassis until the top and bottom latches catch.

4. Attach the RIO link cable to the connector on the front of the module,

behind the door. Ground the cable’s shield wire to a chassis mounting

bracket. Refer to the RIO link wiring illustration on page 10.

5. Insert the cable tie in the slots.

6. Route the cable down and away from module, securing it with the cable tie.

7. Cover all unused slots with the Card Slot Filler, Catalog Number 1746-N2.

Removal

1. Disconnect power.

2. Remove all cabling.

3. Press the releases at the top and bottom of the module and slide the module

out of the chassis slot.

4. Cover all unused slots with the Card Slot Filler, Catalog Number 1746-N2.

Publication 1747-IN060D-EN-P - November 2002

Page 10

10 Remote I/O Scanner

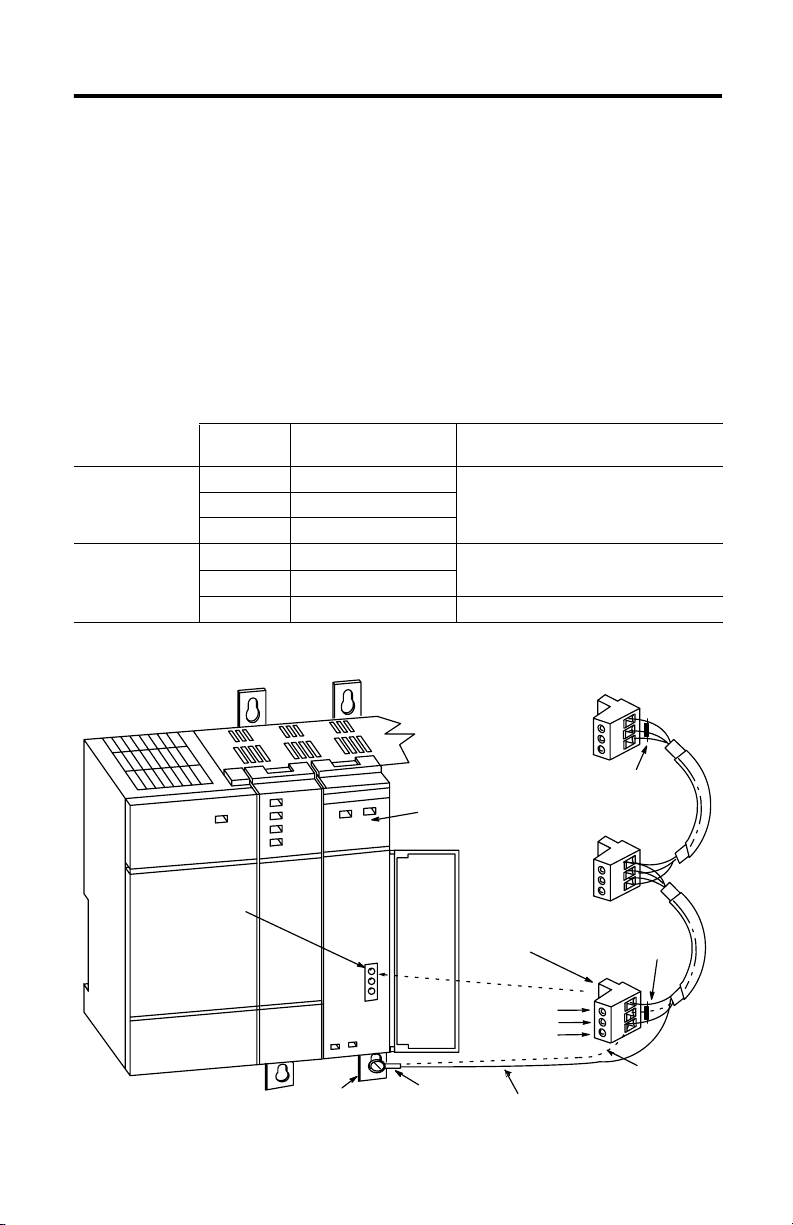

RIO Link Wiring

The scanner is connected to other devices on the RIO link in a daisy-chain (serial)

configuration. There are no restrictions governing the space between each device,

provided the maximum cable distance (Belden 9463) is not exceeded. A 1/2 watt

terminating resistor (included with the module) must be attached across line 1 and

line 2 of the connectors at each end (scanner and last physical device) of the RIO

link. The size of the resistor depends on the baud rate and extended node

capability, as shown in the table below.

Note: To use extended node, all devices on the RIO link must support it. Refer to

each device’s user manual.

Using Extended

Node Capability

Not Using

Extended Node

Capability

Baud Rate Max. Cable Distance

Resistor Size

(Belden 9463)

57.6K baud 3048 m (10,000 ft.) 82Ω 1/2 Watt Gray-Red-Black-Gold

115.2K baud 1524 m (5,000 ft.)

230.4K baud 762 m (2,500 ft.)

57.6K baud 3048 m (10,000 ft.) 150Ω 1/2 Watt Brown-Green-Brown-Gold

115.2K baud 1524 m (5,000 ft.)

230.4K baud 762 m (2,500 ft.) 82Ω 1/2 Watt Gray-Red-Black-Gold

Terminating Resistor Last

Physical Device End

Terminating Resistor

Scanner End

RIO Lin k

Connector

RIO Scanner

Connector

RIO Lin k

Line 1 – Blue

Shield – Shield

Line 2 – Clear

Chassis Mounting

Bracket

Publication 1747-IN060D-EN-P - November 2002

Ring Lug

Shield Drain Wire

(For New Series B Installations)

Shield Drain Wire

(For Series A Retrofits)

Page 11

Remote I/O Scanner 11

For New Installations

To ensure a proper earth ground of the cable shield, follow these steps:

1. While the RIO link connector is plugged into the scanner and lines 1 and 2

are connected, strip the cable back to expose enough shield drain wire to

reach a chassis mounting bracket.

2. Attach the ring terminal lug (supplied) to the end of the shield drain wire.

3. Attach the ring terminal lug to the SLC chassis mounting bracket. Note that

for new installations the middle (shield) terminal is not used when

connecting to the scanner.

IMPORTANT

The RIO cable shield must be grounded at the scanner end only.

For Series A Scanner Retrofits

Refer to the illustration on page 10. To eliminate the need to strip the cable back,

follow these steps:

1. Attach the shield wire and a short piece of #20 AWG wire (dotted line) to the

shield lug of the RIO link connector.

2. Attach the other end of the #20 AWG wire to the ring terminal lug.

3. Attach the ring terminal lug to a chassis mounting bracket.

IMPORTANT

The RIO cable shield must be grounded at the scanner end only.

Ensure that the unshielded portion of the link communication

wire (blue and clear) is as short as possible.

Publication 1747-IN060D-EN-P - November 2002

Page 12

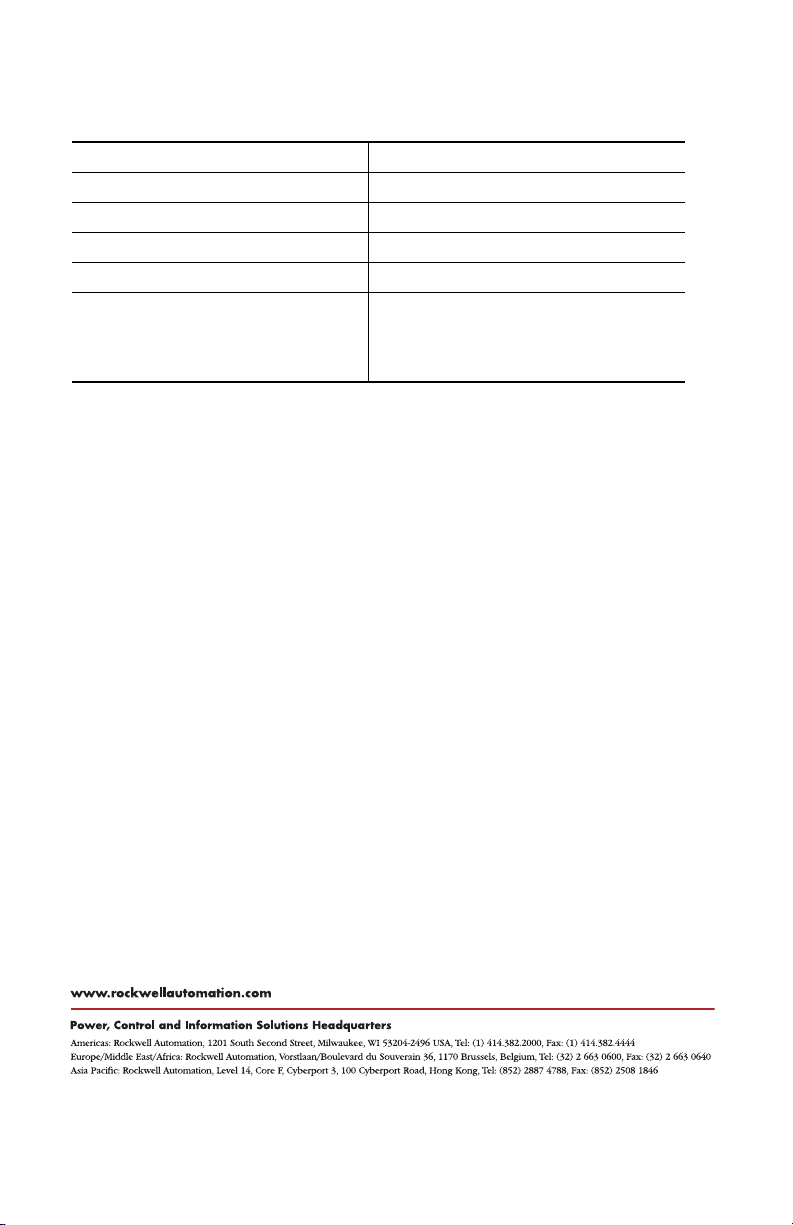

Specifications

Backplane Current Compensation 600 mA at 5V dc

Operating Temperature 0°C to +60°C (+32°F to +140°F)

Storage Temperature -40°C to +85°C (-40°F to +185°F)

Humidity 5 to 95% without condensation

Noise Immunity NEMA Standard ICS 2-230

Agency Certification UL / C-UL listed

Class I, Division 2, Groups A, B, C, D

CE marked for all applicable directives

C-Tick marked for all applicable acts

Rockwell Automation, Allen-Bradley, SLC 500, PanelView, RediPANEL, Dataliner, and TechConnect are trademarks of

Rockwell Automation, Inc.

Trademarks not belonging to Rockwell Automation are property of their respective companies.

Publication 1747-IN060D-EN-P - November 2002 PN 40071-138-01(4)

Supersedes Pub lication 1747-IN060C-EN -P - March 2002 Copyright © 20 07 Rockwell Automati on, Inc. All rights reser ved. Printed in Singapore.

Loading...

Loading...