Page 1

Allen-Bradley

ULTRA

200 Series

User

Digital Servo

Drives

Manual

Page 2

Important User

!

Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, chart s, sample programs and la yout examples shown

in this guide are intended solely for purposes of example. Since there

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intell ectual proper ty liabili ty) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Allen-Bradley office), describes some

important differences between solid-state equipment and

electromechanical devices that should be taken into consideration

when applying products such as those described in this publication.

Reproduction of the cont ents of t his copyrigh ted public ation, in whole

or in part, without written permission of Allen-Bradley Company,

Inc., is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations. For example:

Intro

ATTENTION: This symbol identifies inf ormation about

practices or circumst ances tha t can lead t o personal injury

or death, property damage or economic loss.

Attention statements help you to:

● identify a hazard

● avoid the hazard

● recognize the consequences

Note: This symbol iden tifies in formation that is critical for succes sful

application and understanding of the product.

Mathcad is a registered tradem ark of MathSoft, Inc.

Microsoft, MS-DOS and Window s ar e trademarks of Microsoft Corporation.

UL and cUL are registered trademarks of Underwriters Laboratories.

Page 3

Table of Contents

IntroTable of Contents

Table of Contents Intro-1

List of Figures Intro-7

List of Tables Intro-11

Preface Intro-15

About This Manual .........................Intro-16

Additional Instructions and Manuals ...............Intro-17

Host Commands and ULTRA Master .............Intro-17

TouchPad .............................Intro-18

Symbols and Conventions .....................Intro-19

Typographical and Wording Conventions ...........Intro-19

Graphical Symbols and Warning Classifications .......Intro-20

Pictorial Index ............................Intro-21

Chapter 1

Chapter 2

Safety

Installing and Using the ULTRA 200 Series .............1-1

Potential Hazards...........................1-1

Safety Guidelines ............................1-3

Selecting Other System Components

ULTRA 200 Series Overview .....................2-1

Drive Power Ratings .........................2-1

Interface Cables............................2-2

ULTRA 200 Series Features ......................2-2

Stand-alone Design..........................2-2

High Performance Microcontroller Technology .........2-2

IPM Technology ...........................2-2

Analog and Digital Interfaces ....................2-2

Encoder Control ...........................2-2

Encoder Output ............................2-3

Digital I/O ...............................2-3

Analog I/O...............................2-3

AC Input Power............................2-3

Personality Module..........................2-3

Multiple Protection Circuits.....................2-4

ULTRA Master Softw are ......................2-4

Publication 1398-5.0 – October 1998

Page 4

Intro-2 Table of Contents

Communications............................2-4

Autotuning ...............................2-5

Agency Approvals...........................2-5

Options .................................2-5

Motors ...................................2-6

European Union Requirements .....................2-7

Chapter 3

Chapter 4

Chapter 5

ULTRA Master Installation

Hardware and Software Requirements .................3-1

Installing ULTRA Master ........................3-2

Starting a nd Quitting ULTRA Master .................3-3

Version Level .............................3-3

The ULTRA Master Start-Up Screen ................3-3

The readme File ............................3-4

Firmware Files .............................3-4

Unpacking, Inspecting and Storing

Unpacking the Drive ...........................4-1

Inspection Procedure...........................4-1

Testing the Unit..............................4-2

Hardware Setup ............................4-3

Drive Checkout Test .........................4-4

Storing the Unit..............................4-7

Installation

Mechanical Installation Requirements .................5-1

Interface Connections ..........................5-5

Wiring .................................5-6

Electromagnetic Compatibility ...................5-6

Qualified AC Line Filters.......................5-6

Allen-Bradley AC Line Filters....................5-7

Chapter 6

Publication 1398-5.0 – October 1998

Interfaces

J1 – Controller ..............................6-1

Digital I/O Power ...........................6-3

Digital Inputs..............................6-4

Digital Outputs.............................6-9

Analog Inputs ............................6-14

Analog Outputs ...........................6-16

Motor Encoder Output Signals ..................6-17

Auxiliary Encoder Inputs .....................6-19

Interface C able Examples .....................6-21

J1 Terminal Strip/Breakout Board.................6-26

J2 – Encoder ..............................6-27

Page 5

Table of Contents Intro-3

J2 Terminal Strip/Breakout Board ................ 6-30

J3 – Auxiliary Port ..........................6-31

J4 and J5 – Serial Port ........................ 6-34

Serial Communications Overview ................ 6-36

RS-232 Connections ........................ 6-38

Four Wire RS-485 Connections.................. 6-40

A1, A2, and COM – Analog Outputs ................ 6-44

Interface Connections ......................... 6-45

Chapter 7

Chapter 8

Power Connections

TB1 – DC Bus and AC Power .....................7-1

Motor Power Cabling ........................7-3

Motor Over load Protection .....................7-5

Emergency Stop Wiring .......................7-6

DC Bus.................................7-6

AC Power Cabling ..........................7-7

Auxiliary Power .......................... 7-10

TB2 – Shunt Regulator ........................ 7-11

External Shunt Connection .................... 7-14

Application and Configuration Examples

Analog Control..............................8-1

Hardware Setup............................8-1

Connection Diagram .........................8-2

Configuration .............................8-3

Tuning ................................8-4

Operation ...............................8-5

Preset Controller .............................8-6

Hardware Setup............................8-6

Connection Diagram .........................8-8

Configuration .............................8-8

Tuning ............................... 8-10

Operation .............................. 8-11

Position Follower (Master Encode r) ................. 8-12

Hardware Setup........................... 8-12

Connection Diagram ....................... 8-13

Configuration ............................ 8-13

Tuning ................................ 8-15

Operation .............................. 8-16

Position Follower (Step/Direction) ................. 8-17

Hardware Setup........................... 8-17

Connection Diagram ........................ 8-18

Configuration ............................ 8-18

Tuning ................................ 8-20

Publication 1398-5.0 – October 1998

Page 6

Intro-4 Table of Contents

Operation...............................8-21

Position Follower (Step Up/Step Down) ...............8-22

Hardware Setup ...........................8-22

Connection Diagram ........................8-23

Configuration ............................8-23

Tuning ................................8-25

Operation...............................8-26

Incremental Indexing .........................8-27

Hardware Setup ...........................8-28

Connection Diagram ........................8-29

Configuration ............................8-29

Tuning ................................8-31

Operation...............................8-32

Registration Indexing .........................8-33

Hardware Setup ...........................8-34

Connection Diagram ........................8-35

Configuration ............................8-35

Tuning ................................8-37

Operation...............................8-38

Absolute Indexing ...........................8-39

Hardware Setup ...........................8-39

Connection Diagram ........................8-40

Configuration ............................8-41

Tuning ................................8-43

Operation...............................8-44

Modifying User Units .........................8-45

Changing the Display Units Settings ...............8-45

Chapter 9

Chapter 10

Publication 1398-5.0 – October 1998

Tuning

Tuning Guidelines ............................9-1

General Tuning Rules .........................9-1

High Inertia Loads...........................9-1

Mechanical Resonance ........................9-2

Backlash ................................9-3

Auto Tune Mode .............................9-4

Auto Tuning ..............................9-4

Manual Tune Mode............................9-6

Gains ..................................9-6

Filters ..................................9-7

Manual Tuning.............................9-8

Velocity Loop Tuning Examples .................9-10

Status Display

Operating Messages ..........................10-1

Page 7

Table of Contents Intro-5

Error Messages............................. 10-2

Run-Time Error Codes....................... 10-2

Power-Up Error Codes....................... 10-3

Chapter 11

Appendix A

Maintenance and Troubleshooting

Maintenance .............................. 11-1

Periodic Maintenance ....................... 11-1

Fuse Replacement ......................... 11-1

EEPROM Personality Module .................. 11-2

Firmware Upgrading ......................... 11-5

Firmware Upgrade Procedure using ULTRA Master...... 11-5

Troubleshooting ............................ 11-6

Error Codes ............................. 11-6

RS-232 Communication Test ...................11-11

Testing Digital Outputs ......................11-12

Testing Digital Inputs .......................11-14

Testing Analog Outputs ......................11-14

Testing Positive and Negative Current Limits..........11-15

Testing Encoder Inputs.......................11-17

Options and Accessories

ULTRA 200 Series Drives .......................A-1

Fuses ...................................A-2

Options and Accessories ........................A-2

Publications................................A-3

Interface Cables .............................A-3

Serial Inte rface Cables .........................A-3

Encoder Feedback Cables........................A-4

Motor Power Cables...........................A-5

Connector Kits ..............................A-6

Mating Connectors............................A-6

Appendix B

Appendix C

Cable Diagrams, Schematics and Examples

Interface Cables .............................B-3

Serial Inte rface Cables ........................B-11

Encoder Feedback Cables.......................B-14

Motor Power Cables .........................B-21

Cabling Examples ...........................B-26

Allen-Bradley 9/Series CNC Family Connections.........B-30

TouchPad Instructions

Installation and Operation........................C-1

TouchPad Commands ..........................C-3

Supplemental Instructions .......................C-6

Publication 1398-5.0 – October 1998

Page 8

Intro-6 Table of Contents

Motor Selection ............................C-6

Displays ................................C-6

Motor Table...............................C-10

TouchPad Options ...........................C-12

TouchPad Lists .............................C-13

Appendix D

Appendix E

Creating Custom Motor Files

Drive and Motor File Config uration with U LTRA Ma ster .... D-2

Motor Parameter Set ........................ D-2

General Parameters ......................... D-5

Feedback Parameters ........................ D-8

Electrical Parameters ........................D-10

Rating Parameters ..........................D-11

Example of Custom Motor File Creation ..............D-14

Manufacturer’s Data.........................D-14

Parameter Conversions .......................D-15

Custom Motor File .........................D-16

Troubleshooting Custom Motor Files ................D-16

Electromagnetic Compatibility Guidelines

for Machine Design

Filtering ..................................E-2

AC Line Filter Selection .......................E-3

Grounding .................................E-5

Shielding and Segregation........................E-6

Appendix F

Appendix G

Publication 1398-5.0 – October 1998

Dynamic Braking Resistor Selection

Dynamic Braking Equations.......................F-1

Sample Calculations..........................F-3

Specifications

Power .................................. G-5

Power Dissipation ........................... G-7

Index Index-1

Page 9

List of Figures

IntroList of Figures

Product Parts Explained .....................Intro-21

Chapter 1

Chapter 2 Selecting Other System Components

Chapter 3 ULTRA Master Installation

Chapter 4 Unpacking, Inspecting and Storing

Chapter 5

Chapter 6

Safety

Connection Diagram

...........................4-4

Installation

1398-DDM Mounting Dimensions (sheet 1 of 2)

MDF AC Line Filter Mounting Diagrams

MIF Single Phase AC Line Filter Mounting Diagram

Power Wiring Diagrams

(sheet 1 of 3)

..............5-8

................5-11

Interfaces

Digital Input Circuit

Drive Input Connected to a Switch/Relay Contact

Drive Input Connected to an Opto-Isolator

Drive Input Connected to an Active High Sourcing Transistor

Drive Input Connected to Active Low Output using

a Switch/Relay

Drive Input Connected to Active Low Output using

an Opto-Isolator

Drive Input Connected to Sourcing Output

READY and BRAKE Circuits

Digital Output Circuit

Drive Output Connected to an Opto-Isolator

Drive Output Connected to an LED Indicator

Drive Output Connected to a Resistive Load

Drive Output Connected to a Switch/Relay

Drive Output Connected to Active Low Input using

a Switch/Relay ...........................6-13

Drive Output Connected to Active Low Input using

an Opto-Isolator ..........................6-13

Drive Output Connected to Active High (Sinking) Input .....6-13

Positive and Negative Current Limit Circuits ...........6-14

Analog COMMAND Input Circuit .................6-15

ANALOG 1 and ANALOG 2 Output Circuits ...........6-16

Output Encoder Interface Circuit ..................6-17

Auxiliary Encoder Input Types ...................6-19

Auxiliary Encoder Input Circuit ...................6-19

...........................6-4

..............6-7

............................6-7

...........................6-8

.............6-8

......................6-9

.........................6-10

............6-11

............6-12

............6-12

...........5-3

.......5-10

.........6-7

..6-7

...........6-12

Publication 1398-5.0 – October 1998

Page 10

Intro-8 List of Figures

External Encoder Interface via TTL Differential Line Drivers

Complementary Encoder Interface via 7406 Line Drivers

with Pull-up Resistors

Complementary Encoder Interface via Standard TTL Logic

Single-Ended Encoder Interface via Open Collector

Transistor without Pull-up (not recommended)

Single-Ended Encoder Interface via Standard TTL Signals

(not recommended)

Single-Ended Encoder Interface via Open Collector Transistor

with 5 VDC to 12 VDC Pull-up (not recommended)

Single-Ended Encoder Interface via Open Collector

Transistor with 24 VDC Pull-up (not recommended)

External Step/Direction Interface via TTL Differential

Line Drivers

External Step/Direction Interface via Single-Ended

TTL Line Drivers (not recommended)

External CW/CCW (Step Up/Step Down) Interface via TTL

Differential Line Drivers

External CW/CCW (Step Up/Step Down) Interface via

Single-Ended Line Drivers (not recommended)

Motor Encoder Interface Circuit

Hall Effect Sensor Circuit

ULTRA 200 Series Motor Encoder Connections

RS-232/485 Interface Circuit

Sixteen Position Rotary Addressing Switch

RS-232 Connection Diagrams

RS-485/RS-422 Communication Comparison

Four Wire RS-485 Daisy Chain Connection Diagram

RS-232 to RS-485 Multi-Drop Connection Diagram

ANALOG 1 and ANALOG 2 Output Circuits

1398-DDM Interface Connection Diagram

.............................6-25

........................6-21

....6-22

.........6-22

.........................6-23

......6-23

......6-24

..............6-25

......................6-25

.........6-26

...................6-28

.......................6-28

...........6-30

.....................6-34

.............6-36

.....................6-38

...........6-40

........6-42

.........6-43

...........6-44

..............6-45

...6-21

Chapter 7

Chapter 8

Publication 1398-5.0 – October 1998

Power Connections

Motor Power EMC Shield Connection

Pigtail Ground

Emergency Stop Contactor Wiring

External Shunt Wiring Examples

External Shunt Mounting Diagram ..................7-14

............................. 7-4

................ 7-3

.................. 7-7

...................7-13

Application and Configuration Examples

Analog Controller Connection Diagram ............... 8-2

Preset Controller Connection Diagram ................ 8-8

Master Encoder Connection Diagram ................8-13

Step/Direction Controller Connection Diagram ..........8-18

Step Up/Step Down Controller Connection Diagram .......8-23

Incremental Indexing Examples ...................8-27

Incremental Indexing Connection Diagram .............8-29

Registration Indexing Examples ...................8-33

Page 11

List of Figures Intro-9

Registration Indexing Connection Diagram

Absolute Indexing Examples

Absolute Indexing Connection Diagram

PC Display Units – Default Dialog

Chapter 9

Chapter 10

Chapter 11 Maintenance and Troubleshooting

Appendix A

Appendix B Cable Diagrams, Schematics and Examples

Tuning

Velocity Loop Structure

Torque Current Conditioning Structure

Signal Nomenclature

Underdamped Signal

Overdamped Signal

Critically Damped Signal (Ideal Tuning)

..........................9-11

Status Display

Fuse and Jumper Locations

Options and Accessories

J1 to J3 Interface Cable (P/N 9101-1367) ................B-3

J1 to No Connector Interface Cable (P/N 9101-1370) . . . . . . . . B-4

J3 to J3 Interface Cable (P/N 9101-1463) ................B-5

J3 to No Connector Interface Cable (P/N 9101-1368) . . . . . . . . B-6

J1 to 50-pin Terminal Block Kit Diagram

(P/N 9101-1391 and 9101-1560) ....... ...........B-7

J1 to 50-pin D-Connector Cable (P/N 9101-1369) . . . . . . . . . . B-8

J2 to 25-pin Terminal Block Kit Diagram (P/N 9101-1392) . . . . .B-9

J2 to 25-pin D-Connector Cable (P/N 9101-1371) . . . . . . . . . B-10

J5 to 9-pin D-Shell Interface Diagram (P/N 9101-1372) . . . . . . B-11

J5 to J5 Serial Interface Cable (P/N 9101-1374) . . . . . . . . . . . B-12

J5 to No Connector Serial Interface Cable (P/N 9101-1379) . . . . B-13

F- or H-Series Motors to No Connector Encoder Cable

(P/N 9101-1365) ..........................B-14

J2 to F- or H-Series Encoder Cable (P/N 9101-1366) . . . . . . . . B-15

J2 to Y-Series Encoder Cable (P/N 9101-1375) . . . . . . . . . . . B-16

No Connector to Y-Series Encoder Cable (P/N 9101-1373) . . . . B-17

J2 to No Connector Encoder Cable (P/N 9101-1380) . . . . . . . . B-18

J2 to N-Series Encoder Cable (P/N 9101-1468) . . . . . . . . . . . B-19

No Connector to N-Series Encoder Cable (P/N 9101-1469) . . . . B-20

2000 or 3000 F- or H-Series Power Cable (P/N 9101-1381) . . . . B-21

4000 F- or H-Series Power Cable (P/N 9101-1382) . . . . . . . . . B-22

6100 or 6200 F- or H-Series Power Cable (P/N 9101-1383) . . . . B-22

6300 H-Series Power Cable (P/N 9101-1399) ............B-23

8000 H-Series Power Cable (P/N 9101-1384) ............B-23

Y-Series Power Cable (P/N 9101-1385) ...............B-24

.....................8-39

..................8-45

.........................9-3

.........................9-10

.........................9-11

.....................11-4

............8-35

..............8-40

................9-3

..............9-12

Publication 1398-5.0 – October 1998

Page 12

Intro-10 List of Figures

N-Series Power Cable (P/N 9101-1467) ...............B-25

F or H-Series Motors to ULTRA 200 Series Drive . . . . . . . .B-26

F- or H-Series Motors to ULTRA 200 Series Drive

using P2 Terminal Strip .......................B-27

Y-Series Motors to ULTRA 200 Series Drive . . . . . . . . . . . . .B-28

Y-Series Motors to ULTRA 200 Series Drive

usingP2TerminalStrip ........... ............B-29

Appendix C

Appendix D

Appendix E

Appendix F

TouchPad Instructions

TouchPad Connection and Pinouts ... ...............C-2

TouchPad Version Number Display .................C-2

TouchPad Command Tree

(sheet 1 of 2) ...............C-4

Creating Custom Motor Files

Allen-Bradley Motor Naming Convention .............D-3

Required Back-EMF and Hall Signal Phasing

for Clockwise Rotation .......................D-4

Phasing of the Encoder Signals for Clockwise Rotation . . . . . . D-4

Index Offsets ..............................D-8

Hall Offsets ...............................D-9

Motor Thermal Protection Software Method . . . . . . . . . . . D-13

Back-EMF and Hall Signals, Clockwise Rotation . . . . . . . . . D-14

Electromagnetic Compatibility Guidelines

for Machine Design

EMI Source-Victim Model ......................E-2

Single Point Ground Types ......................E-5

Dynamic Braking Resistor Selection

Appendix G Specifications

Publication 1398-5.0 – October 1998

Page 13

IntroList of Tables

Chapter 1 Safety

Chapter 2 Selecting Other System Components

Chapter 3 ULTRA Master Installation

Chapter 4 Unpacking, Inspecting and Storing

Chapter 5 Installation

Qualified AC Line Filters

MDF AC Line Filter Dimensions

MIF AC Line Filter Dimensions

........................5-7

....................5-9

....................5-10

List of Tables

Chapter 6

Interfaces

24 Volt Power Supply Specifications

5 Volt Power Supply Spe c ifications

General and Dedicated Inputs

INPUT1, INPUT2, INPUT3, INPUT4

and FAULT RESET Functions

Digital Input Specifications

.......................6-6

READY Output Specifications

BRAKE Output Specifications

.....................6-10

General and Dedicated Outputs

OUTPUT1, OUTPUT2, OUTPUT3 and OUTPUT4 Functions

Transistor Output Specifications

Analog Inputs +I LIMIT and -I LIMIT

Positive and Negative Current Limit Imput Specification

Analog Command Input

........................6-15

Analog Command Input Specifications

Analog Outputs: ANALOG 1 and ANALOG 2

Analog Output Specifications

Motor Encoder Output Signal

.....................6-17

.....................6-18

Motor Encoder Output Specifications ................6-18

Auxiliary Encoder/Step and Diection/CW & CCW

(Step Up & Down) Signals .....................6-20

Quadrature Interface Specifications .................6-20

Step/Direction and CW/CCW (Step Up/Step Down)

Interface Specifications .......................6-24

J2- Motor Encoder Connector Pin-Outs ...............6-28

J3 – Auxiliary Connector Pin-Outs ..................6-32

J4 and J5 – Serial Port Connector Pin-Outs .............6-35

Drive Addressing ...........................6-36

Analog outputs ANALOG 1 and ANALOG 2 ...........6-44

..................6-3

..................6-4

.....................6-5

....................6-5

.....................6-9

...................6-10

...6-10

...................6-11

................6-14

.....6-14

...............6-15

...........6-16

Publication 1398-5.0 – October 1998

Page 14

Intro-12 List of Tables

Chapter 7 Power Connections

TB1 – Motor Power Terminals

Motor Power Contact and Wire Sizing Recommendations

TB1 – DC Bus Terminals

TB1 – AC Power Terminals

AC Input Power Sizing Requirements

Auxiliary Power Terminals

Auxiliary Power Sizing Requirements

TB2 – Shunt Regulator Terminals

Internal Shunt Power Ratings for Drive Models

Maximum External Shunt Power Ratings for Drive Models

Minimum Ratings for Customer Supplied External

Shunt Resistor

............................7-13

..................... 7-3

.....7-5

........................ 7-7

....................... 7-8

................ 7-9

.......................7-10

................7-10

...................7-12

..........7-12

....7-12

Chapter 8

Chapter 9

Chapter 10

Chapter 11

Appendix A

Appendix B Cable Diagrams, Schematics and Examples

Application and Configuration Examples

Preset Binary Inputs

.......................... 8-6

Tuning

Velocity Loop Gains

Position Loop Gains

.......................... 9-6

.......................... 9-7

Status Display

Run-Time Error Codes

Power-Up Error Codes

.........................10-2

.........................10-4

Maintenance and Troubleshooting

Troubleshooting Guide

........................11-6

Options and Accessories

9/260 or 9/290 to Breakout Board

9/260 or 9/290 to J1 Connector

9/230 to Breakout Board

9/230 to J1 Connector

........................B-30

..........................B-31

...................B-30

....................B-30

Appendix C

Publication 1398-5.0 – October 1998

TouchPad Instructions

TouchPad Fault/Error/Warning Displays .............C-9

TouchPad Motor Table Identification by Motor Series .......C-10

TouchPad Motor Table Identification by Motor ID .........C-11

Option Selections for the TouchPad .................C-12

Drive Communications Parameter List for the TouchPad .....C-13

Baud Rate Parameter List for TouchPad ...............C-13

Encoder Output Parameter List for TouchPad ...........C-13

IO Mode Parameter List for TouchPad ................C-13

Index Pointer Parameter List for TouchPad .............C-14

Index Termination Parameter List for TouchPad ..........C-14

Page 15

List of Tables Intro-13

Home Type Parameter List for TouchPad

Homing Auto-Start Parameter List for TouchPad

Reverse Enable for Homing

Digital Input Parameter List for TouchPad

Digital Output Parameter List for TouchPad

Analog Output Parameter List for TouchPad

Drive Status List for TouchPad

Input Flags Parameter List for TouchPad

Output Flags Parameter List for TouchPad

Appendix D

Appendix E Electromagnetic Compatibility Guidelines

Creating Custom Motor Files

......................C-15

....................C-16

..............C-14

.........C-14

.............C-15

............C-15

...........C-16

..............C-17

.............C-17

for Machine Design

Appendix F

Appendix G

AC Line Filter Installation

Dynamic Braking Resistor Selection

Dynamic Braking Resistor Parameters

Specifications

ULTRA 200 Series Power Ratings

........................E-4

................F-1

...................G-5

Publication 1398-5.0 – October 1998

Page 16

Intro-14 List of Tables

Publication 1398-5.0 – October 1998

Page 17

Preface

IntroPreface

This manual provides a step-by-step approach to building a servo

system using a ULTRA 200 Series drive. The manual is divided into

chapters that cover specif ic pha ses of t he sy stem des ign proc ess ; from

ordering comp onents that will complement the performance of t he

ULTRA 200 Series drive, to recei ving, installing and ver ifying the

drive’s functionality.

Chapters and appendices in the manual include:

● Safety

● Selecting O ther System Components

● ULTRA Master Installation

● Unpacking, Inspecting and Storing

● Installation

● Interfaces

● Power Connections

● Application and Configuratio n Examp les

● Tuning

● Status Display

● Maintenance and Troubleshooting

● Options and Accessories

● Cable Diagrams, Schematics and Examples

● TouchPad Instructions

● Creating Custom Motor Files

● Electromag netic Compatibility Guidelines for Machine Design

● Dynamic Braking Resistor Selection

● Specifications

The intent of the manual is to assemble a high-performance servo

system in a methodical manner. By making correct decisions and

taking appropriat e actions a servo syst em that performs “as de signed”

can be assured.

Publication 1398-5.0 – October 1998

Page 18

Intro-16 Preface

About This Manual This manual provides instructions on how to setup and connect the

ULTRA 200 Series drive to a controlling device and a motor. A

ULTRA 200 Series drive may operate in one of several different

functional modes. The hardware connections necessary to run the

drive are explained and basic software instructions are provided for

common set up procedures. For detailed explanation of software

instructions, refer to the comprehensive on-line instructions available

in the ULTRA Master software.

This manual explains how to install your ULTRA 200 Series drive

using ULTRA Master software with a personal computer. If you are

using a T o uchPad device, abbreviated command titles are displ aye d

but the setup steps remain the same.

This manual is organized into chapters and appendixes. The topics

covered in each chapter and section are briefly described.

Typographical conventions, warning and cautions specific to the

drive, and complementary manuals are also described.

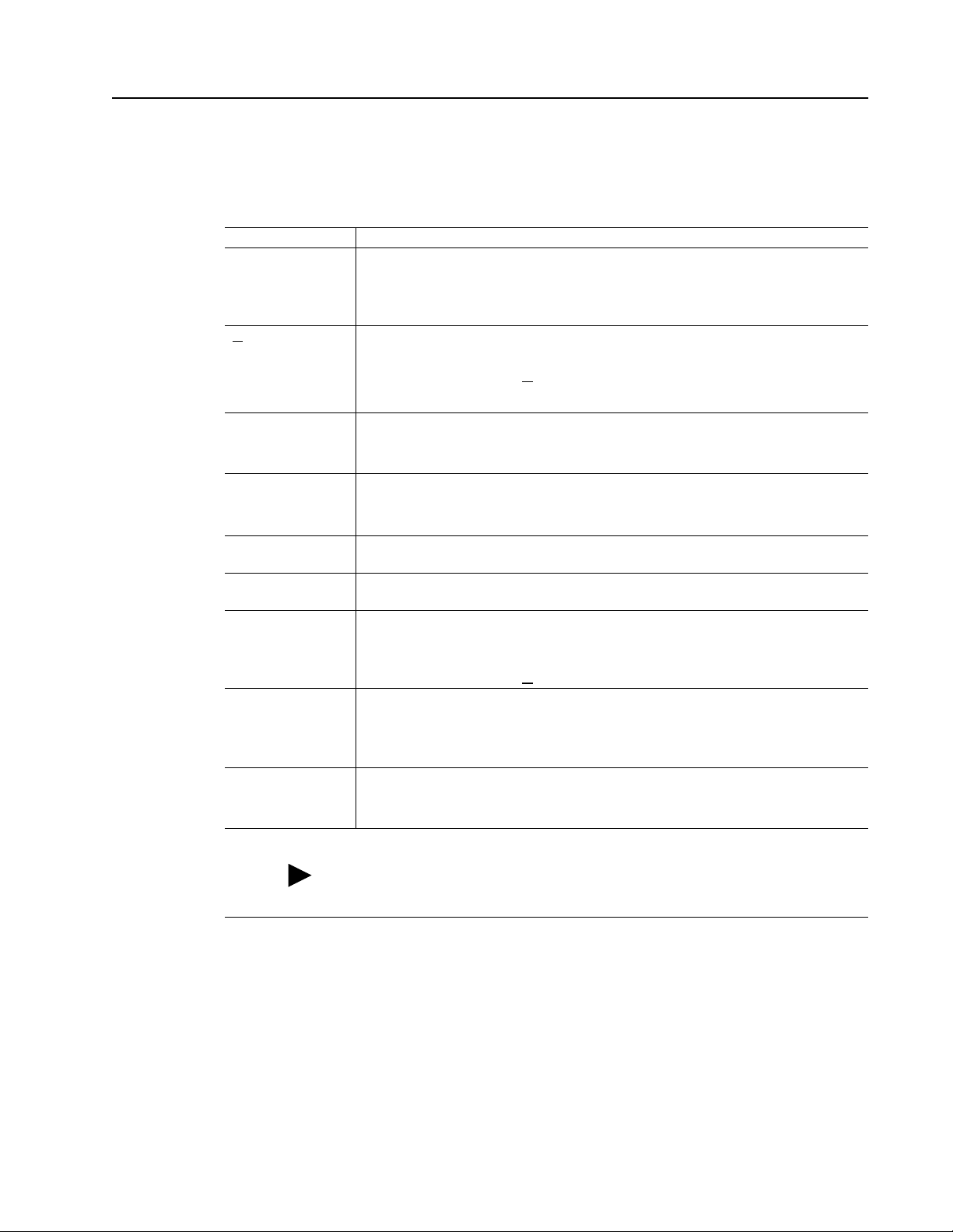

Title Description

Safety Lists general safety requirements that must be followed when installing

or servicing the drive.

Selecting Other System

Components

ULTRA Master Installation Explains how to install, access and exit ULTRA Master.

Unpacking, Inspecting and

Storing

Installation Instructs you on how to physically install your ULTRA 200 Series drive.

Interfaces Provides comprehensive information about the signals available on

Reviews the major features of the ULTRA 200 Series drives and identifies motors and signal types that are compatible.

Lists what should be included with your ULTRA 200 Series drive and

instructs you on how to perform a basic functional test before installi ng

or storing the drive.

each connector. Each signal or set of signals is identified by:

• Power requirements for driving the signal.

• Functions performed by the signal.

• Specifications, including ON and OFF states.

• Schematic depictions of the circuit design for each signal type.

The signals are grouped under the following connectors.

• J1 – Controller

Diagrams show cable connections needed for common interfaces.

• J2 – Encoder

Details information ab out the enco der sign als, Hal l Eff ect switche s and

thermostat connections available through this connector.

• J3– Auxiliary Port

Provides a secon d con troller conne ction that du plica tes th e first 26 pins

on J1, the Controller connector

• J4 and J5 – Serial Port

Diagrams and instructions detail how to connect one or more drives

using RS-232 communications in a single or daisy-chain connection, or

to connect several drives using Multi-Drop RS-485.

• A1, A2, and COM – Analog Outputs

Describes the connections that allow monitoring of the analog command signals with external equipment.

Publication 1398-5.0 – October 1998

Page 19

Preface Intro-17

Title Description

Power Connections Provides information on making motor power, DC bus and AC Power

connections.

Application and Conf iguration

Examples

Tuning Provides instructions on how to tune a drive and motor combination

Status Display Discusses the operator indicators available on the front panel. Operat-

Maintenance and Troubleshooting

Options and Accessories Lists the optional equipment available for the ULTRA 200 Series drives.

Cable Diagrams, Schemat-

ics and Examples

T ou chPad Instructions Describes how to progra m a ULTRA 200 Series dri ve using the o ptional

Creating Custom Motor Files Describes how to create a custom motor file for use with an ULTRA 200

Electromagnetic Compatibility Guidelines for Machine

Design

Dynamic Braking Resistor

Selection

Specifications Details the design and operational specifications for the ULTRA 200

Describes the hardware and software set up necessary to install the

drive as one of the following types:

• Analog Control in velocity or torque mode

• Preset Controller in velocity or torque mode

• Position Follower (Master Encoder) in velocity mode

• Position Follower (Step/Direction) in velocity mode

• Position Follower (Step Up/Step Down) in velocity mode

• Incremental Indexing

• Registration Indexing

• Absolute Indexing

• Modifying User Units

using the autotuning or manual tuning features in ULTRA Master.

ing or Error Messages are explained.

Describes the minimal maintenance necessary with the ULTRA 200

Series drives and provides a comprehensive troubleshooting chart of

potential problems and their solutions.

Provides schematics and cabling examples.

TouchPad device. Tables reference the various motor types that are

programmed to work with the ULTRA 200 Series d rive. A TouchPad

Command Tree card for the current firmware version is bound into the

manual.

Series drive.

Describes commo n ele ct r ic al no is e pro blems and suggests me thods to

ensure ElectroMagnetic Compatibility.

Provides equations to assist in sizing resistors for dynamic braking.

Series drives in a tabular format.

Additional Instructions and Manuals

Host Commands and ULTRA Master

All ULTRA 200 Series drives are setup through serial Host

Commands. The drives may be configured directly through the Host

Command language or indirectly through the ULTRA Master

software. ULTRA Master is a graphical user interface that provides a

visual method of accessing the Host Command language through the

Microsoft Windows Operating System.

Publication 1398-5.0 – October 1998

Page 20

Intro-18 Preface

All documentation for both the Host Commands and ULTRA Master

is on-line. Host Command information is available through a

comprehensive on-line r eference manua l. ULTRA Master inf ormation

is available through Help menus. The on-line documents provide indepth explanations of the Host Command language as well as the

menus, windows and dialog boxes that make ULTRA Master a

convenient method for programming ULTRA 200 Series drives.

● To access the Host Command Reference

Click on the Host Command Reference icon in the

ULTRA Master program group.

● To access ULTRA Master Help

Open ULTRA Master by clicking on the ULTRA Master icon in

the ULTRA Master group, and

Press the F1 key.

TouchPad

The optional TouchPad may be used to monitor and configure the

UL TRA 200 Series drive. The TouchPad command structure is similar

to the structure of ULTRA Master, but operates through an

abbreviated keypad interface. The card TouchPad Instructions is

provided with the TouchPad. It describes the installation and

operational instructions in a pocket-sized directory. The TouchPad

Command Tree Car d and additional instructions for the TouchPad are

included in the section titled, “TouchPad Instructions” which begins

on page C-1. The TouchPad Command Tree Card is a graphical

presentation of both the operational instructions and the command

structure for the ULTRA 200 Series drives. You may find it

convenient to refer to th e card when using the TouchPad with a drive.

Publication 1398-5.0 – October 1998

Page 21

Symbols and Conventions Ty pographical and Wording Conventions

This manual uses the following typographical and wording

conventions:

Example Description

»

Drive Set Up Text shown in this font and underlined indicates a Hot Key (keystroke combina-

ULTRA Master Text shown in this font is information to enter in a window or dialog box. For

win Text in lower case bold is information to enter at a keyboard. For example,

ALT+F4

ALT, F, N Keys that should be pressed in sequence are shown with a comma (,) between

Choose The wording indicates tha t an icon or a comm and is to be sele cted from a win dow

Select The wording indicates that options are to be defined or selected from a list. For

Typ e The wording indicate s that comm ands are to be entered int o a comman d box. For

a

Text preceded by right guillemet explains how to access the particular function in

the preceding paragraph. For example,

To Start ULTRA Master in Windows

» Choose the icon ULTRA Master.

tion) to quickly access a command. For example,

Choose Drive Set Up.

indicates typing ALT+D followed by ENTER accesses this command.

example,

Choose the icon ULTRA Master.

To start Windows from the DOS prompt, type win and then

press ENTER.

Keys that should be pressed simultaneously are shown with a plus sign (+)

between the key names. This example closes the active window.

the key names. This example opens the File menu and then opens a new file.

or a command box . F or example, the ins truc tio n f or accessing the com ma nd ic on

Drive Set Up states:

Choose Drive Set Up.

example, the instruction for accessing or entering information states:

Select Drive Type and Motor Model from the respective list

box.

example, the instruction for loading ULTRA Master states:

Type a:setup and then press ENTER.

Tips provide hints or shortcuts that are useful to know. For example,

Preface Intro-19

Note: UL TRA Master always displays the Help menu – Quick Start – when

it is first accesse d. T o disable thi s automatic di splay, choose the menu item

Show Quick Start from the Help menu.

a. Microsoft® Windows™ reserves certain multiple keystroke combinations to a ct ivate Windows comman ds.

Publication 1398-5.0 – October 1998

Page 22

Intro-20 Preface

!

Graphical Symbols and Warning Classifications

This manual uses the following graphical symbols and warning

classifications. The use of a symbol and signal word is based on an

estimation of the likeli hood of exp osure to the ha zardou s situat ion and

what could happen as a result of exposure to the hazard.

Example Description

Protective conductor terminal (Earth ground)

Chassis terminal (not a protective ground)

Symbol plus ATTENTION: These notices provide information

intended to prevent potential personal injury and equipment

damage.

Publication 1398-5.0 – October 1998

Page 23

Preface Intro-21

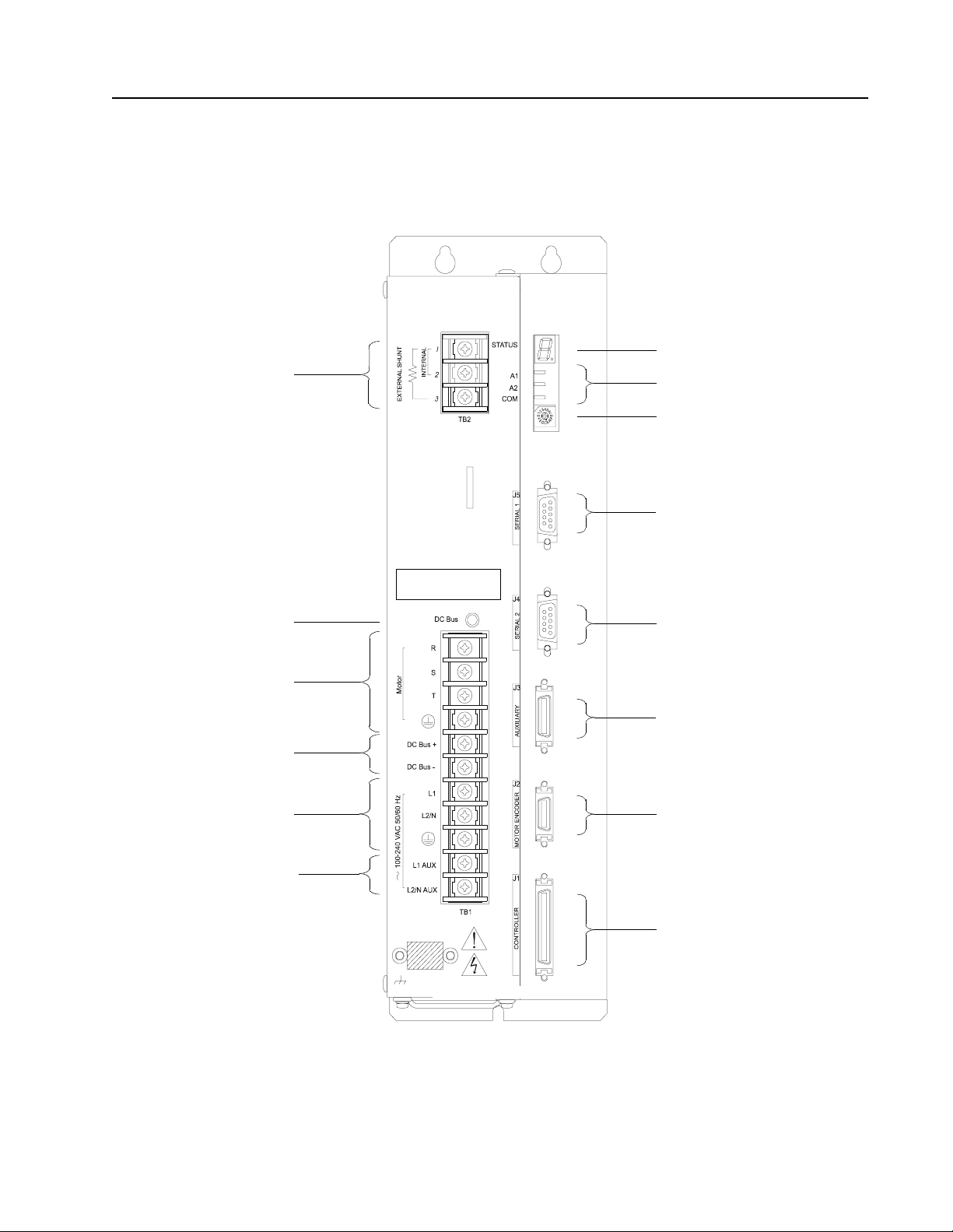

Pictorial Index Shown here are face views of the product, with pointers to where

individual parts are discussed.

Product Parts Explained (sheet 1 of 3)

Intro

page 10-1, 11-6

page 7-11

page 7-6

page 7-3

page 7-6

page 7-7

WARNING:

HIGH VOLTAGE

MAY EXIST FOR UP TO FIVE MI NUTES

AFTER REMOVING POWER.

page 6-44

page 6-36

page 6-34

page 6-34

page 6-31

page 6-27

page 7-10

page 6-1

Models:

1398-DDM-010 and 1398-DDM-010X,

1398-DDM-020 and 1398- DDM -02 0X,

1398-DDM-030 and 1398-DDM-030X

Publication 1398-5.0 – October 1998

Page 24

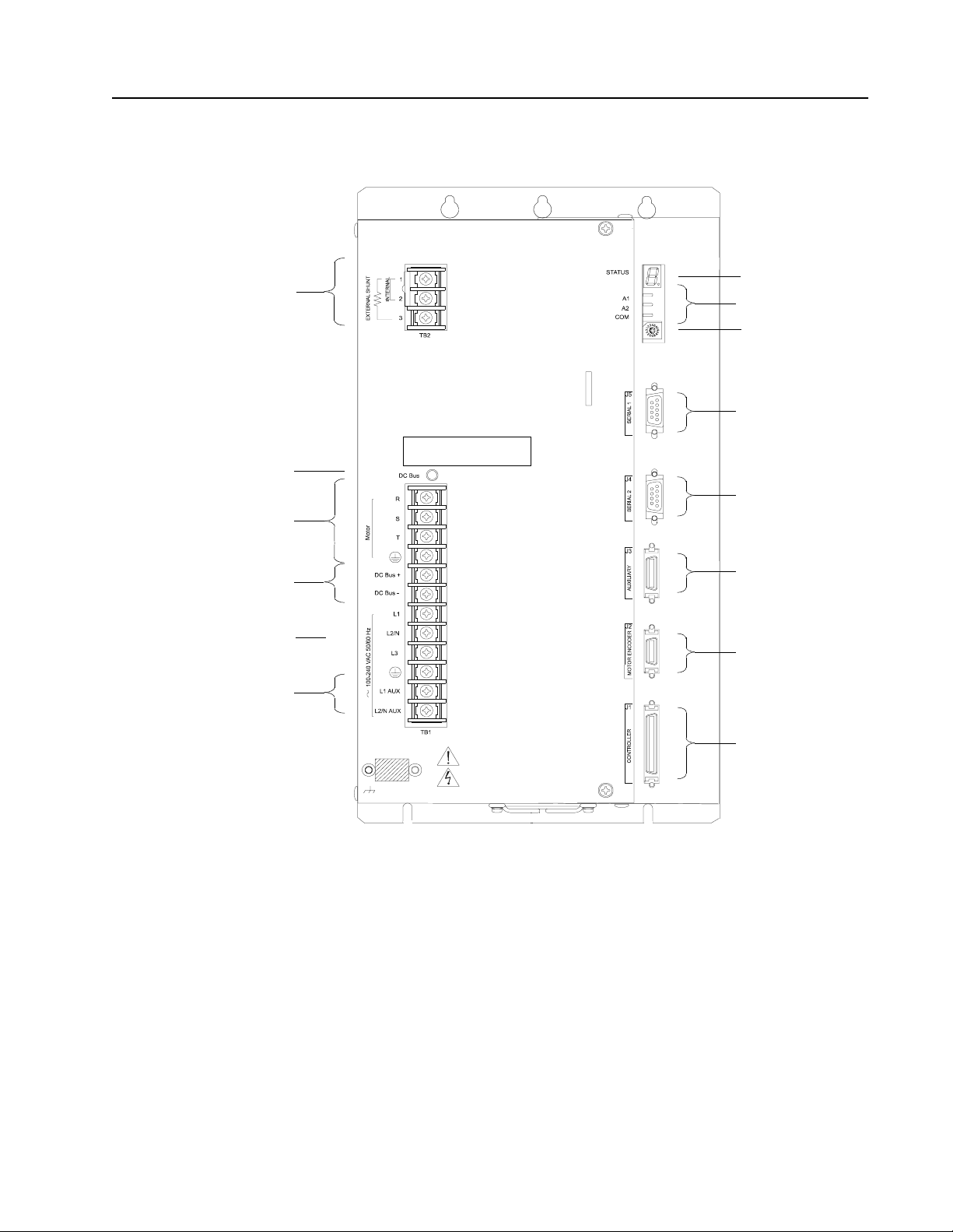

Intro-22 Preface

Intro

page 7-11

page 7-6

page 7-3

Product Parts Explained (sheet 2 of 3)

WARNING:

HIGH VOLTAGE

MAY EXIST FOR UP TO EIGHT MINUTES

AFTER REMOVING POWER.

page 10-1, 11-6

page 6-44

page 6-36

page 6-34

page 6-34

page 7-6

page 7-7

page 7-10

page 6-31

page 6-27

page 6-1

Models:

1398-DDM-075 and 1398-DDM-075X

Publication 1398-5.0 – October 1998

Page 25

Intro

page 7-11

page 7-6

page 7-3

Product Parts Explained (sheet 3 of 3)

WARNING:

HIGH VOLTAGE

MAY EXIST FOR UP TO EIGHT MINUTES

AFTER REMOVING POWER.

Preface Intro-23

page 10-1, 11-6

page 6-44

page 6-36

page 6-34

page 6-34

page 7-6

page 7-7

page 7-10

page 6-31

page 6-27

page 6-1

Models:

1398-DDM-150 and 1398-DDM-150X

Publication 1398-5.0 – October 1998

Page 26

Intro-24 Preface

Publication 1398-5.0 – October 1998

Page 27

Chapter 1

Safety Chapter 1

Installing and Using the

ULTRA 200 Series

Read the complete manual before attempting to instal l or operate the

ULTRA 200 Series drive. By reading the manual you will become

familiar with practices and procedures that allow you to operate the

ULTRA 200 Series drive safely and effectively.

Potential Hazards

The equipment described in this manual is intended for use in

industrial drive systems. This equipment can endanger life through

rotating machinery and high voltages, therefore it is essential that

guards for both electrical and mechanical parts are not removed. The

main hazards which can be encountered in the use of this equipment

are:

● Electric shock hazards

● Electric fire hazards

● Mechanical hazards

● Stored energy hazards

These hazards must be controlled by suitable machine design, using

the safety guidelines which follow. There are no chemical or ionizing

radiation hazards.

Voltage Potentials

Intro

ATTENTION: DC bus capacitors may retain hazar dous

!

Voltage potentials for the internal drive cir cuitry vary fr om 325 Volts

above to 325 Volts below earth ground for a 240 Volt input. Voltages

can exceed 450 VDC or 240 VAC within the ULTRA 200 Series. All

circuits, including the connections on the front panel, should be

considered “hot” when main or auxiliary power is connected and for

the time specified in the warning on the front of the drive after power

is removed.

voltages for several minutes after input power has been

removed, but will normally discharge in several seconds.

Measure the DC bus voltage to verify it has rea ched a safe

level each time power is removed before working on the

drive; or wait for the t ime i ndi cat ed in the warning on the

front of the drive. Failure t o observe this precau tion could

result in severe bodily injury or loss of life.

Publication 1398-5.0 – October 1998

Page 28

1-2 Safety

Your Responsibilities

As the user or person installing this drive, you are responsible for

determining the suita bilit y of the pro duct for the intende d applic ation.

Rockwell Automation is neither responsible nor liable for indirect or

consequential damage resulting from the inappropriate use of this

product.

A qualified person is someone who is familiar with all safety notes

and established safety practices, with the installation, operation and

maintenance of this equipment and the hazards involved. For more

detailed d efinitions , refer to IEC 364.

It is recommended t hat anyone who oper ates or main tains e lectr ical or

mechanical equipment shoul d have a basic kn owledge of Firs t Aid. As

a minimum, they should know where the First Aid equipment is kept

and the identity of the official First Aiders.

Publication 1398-5.0 – October 1998

Page 29

Safety 1-3

Safety Guidelines Electrical shock and fire hazards are avoided by using normal

installation pr oce dur es for electrical p ower equipment in an industr ial

environment. Installation must be undertaken by suitably qualified

personnel. Note that this amplifier must be installed in an industrial

cabinet such that access is restricted to suitable qualified personnel.

Mechanical hazards are associated with potentially uncontrolled

movement of the motor shaft. If this imposes a risk in the machine,

then appropriate precautions must be made to electrically disconnect

the motor from the drive when perso nnel have access to moving parts

of the machine. Note also that the motor must be securely mounted at

all times.

Stored energy hazards are both electrical and mechanical.

● Electrical hazard s can be avoided by dis connecti ng the driv e from

its power source and measur ing the DC bus vol tage to verif y it has

reached a safe level or by waiting for the time indicated in the

warning on the front of the drive prior to removing the protective

covers or touching any connections.

● Mechanical hazard s requi re a ri sk a nalysi s on the ef f ects of stor ed

mechanical energy when the machine is running at speed, as well

as the potential for the conversion of electrical energy stored in

the drive being convert ed to mechanical energy. Electrical energy

may be stored in drive for the time indicated in the warning on the

front of the drive.

The following points should be observed for the safety of personnel.

These safety notes do not represent a complete list of the steps

necessary to ensure safe operation of the equipment. Contact your

nearest Allen-Bradley representative for additi onal informat ion.

● Only qualified personnel familiar with the equipment are

permitted to install, operate and maintain the device.

● System documentation must be available and observed at all

times.

● All non-qualified personnel are kept at a safe distance from the

equipment.

● The system must be i nstalled in accorda nce with local re gul at ion s.

● The equipment is intended for permanent connection to a main

power input. It is not intended for use with a portabl e power input.

● Do not power up the unit without the covers in place and the

protective conductor connected.

● Do not operate the unit wit hout connecting the motor conduct or to

the appropriate terminal on the drive.

● Always remove power before making or removing any

connection on the unit.

Publication 1398-5.0 – October 1998

Page 30

1-4 Safety

● Before removing the cover of the unit, shut off the main and

auxiliary power and measure the DC bus voltage to verify it has

reached a safe level or wait for the time indicated in the warning

on the front of the drive.

● Do not make any connections to the internal circuitry.

Connections on the front panel are the only points where users

should make connections.

● Be careful of the DC bus and shunt terminals. High voltage is

present when power is applied to the ULTRA 200 Series.

● Never connect the DC- terminal to earth ground, the drive

requires a floating DC bus.

● Do not use the ENABLE input as a safety shutdown. Always

remove power to the ULTRA 200 Series before maintaining or

repairing the unit.

● When operating a 1398-DDM-075 or 1398-DDM-075X with a

single phase power input, the current limits must be set correctly.

● Motors without thermal prot ection dev ices re quire a valid thermal

time constant. Otherwise the motor overload protection will not

function properly.

Publication 1398-5.0 – October 1998

Page 31

Selecting Other System Components Chapter 2

The Allen-Bradley ULTRA 200 Series drives are part of a family of

digital drives that use microcontrollers to manage the current,

velocity , an d position. All s ystem and appli cation parame ters are set i n

software, which ensures repeatability of all functions and prevents

element drift.

This chapter reviews the ULTRA 200 Series and associated motors,

command sources and interfaces. Selection of complementary servo

components allows you to efficiently connect other devices to your

ULTRA 200 Series drive. Pertinent information about each is

provided to assist you in planning your servo system.

ULTRA 200 Series Overview Drive Power Ratings

Several power levels of ULTRA 200 Series drives are available. All

models have integral power supplies and shunt regulators and are

functionally equivale nt. They diff er only in output power and physic al

size:

Chapter 2

● 1398-DDM-010 and 1398-DDM-010X with continuous output

power of 1000 Watts using a single phase power source

● 1398-DDM-020 and 1398-DDM-020X with continuous output

power of 2000 Watts using a single phase power source

● 1398-DDM-030 and 1398-DDM-030X with continuous output

power of 3000 Watts using a single phase power source

● 1398-DDM-075 and 1398-DDM-075X with continuous output

power of 3000 Watts using a single phase power source

● 1398-DDM-075 and 1398-DDM-075X with continuous output

power of 7500 Watts using a three phase power source

● 1398-DDM-150 and 1398-DDM-150X with continuous output

power of 15000 watts using a three phase power source.

The ULTRA 200 Series drives, when combined with Allen-Bradley

brushless servomotors, provide continuous torque ranging from

0.34 Nm to 50.8 Nm (3 to 450 lb-in) and peak torque ranging from

1.02 Nm to 125 Nm (9 lb-in to 1100 lb-in).

Publication 1398-5.0 – October 1998

Page 32

2-2 Selecting Other System Components

Interface Cables

Standard Allen-Bradley mot or power and enco der fe edback c ables, a s

well as communications cables, are a vailabl e to complet e your motion

control system and provide reliable, trouble free start-up. Refer to

“Options and Accessories” on page A-1 for optional equipment. Use

of these cables is required for compliance to the European

Electromagnetic Compatibility (EMC) Directive and to protect your

warranty rights.

ULTRA 200 Series Features Stand-alone Design

A single unit fully encloses all electronics, including both the power

supply and a built-in shunt regulator. An external transformer is not

required on the main power line. All connectors and indicators are

accessible and clearly marked on the front panel.

High Performance Microcontroller Technology

Dual microco ntrollers pe rform all digital current, velocity and

position loop calculations as well as the motor commutation

calculation.

IPM Technology

IPM (Intelligent Power Module) technology in the output stage

provides a high frequency, digital PWM (Pulse Width Modulation)

sine wave that controls the current loop, including overcurrent, short

circuit and overtemperature protection.

Analog and Digital Interfaces

All ULTRA 200 Series drives allow the user to select one of the

following analog or digital command interfaces:

● ±10 Volt analog interface – position, velocity or torque control

● Presets (from one to eight binary inputs) – torque or velocity

control

● Quadrature encoder digital interface – electronic gearing position

follower

● Step/Direc tion digital in terface – position con trol

● CW/CCW (step up/step down) interface – position control

● Indexing (available o nly on 1398-DDM-010X, 1398-DDM-0 20X,

1398-DDM-030X, 1398-DDM-075X and 1398-DDM-150X.

Encoder Control

Publication 1398-5.0 – October 1998

A single, motor mounted encoder provides complete commutation

information and velocity feedback.

Page 33

Selecting Other System Components 2-3

Encoder Output

A selectable output allows the encoder resolution to be specified for

maximum performance without adding circuitry. Outputs are

differential line drivers capable of dividing the motor encoder signal,

PPR (pulses per revolution), by a factor of 1, 2, 4 or 8.

Digital I/O

Digital I/O channels allow the user to program the drive to fit the

specific application. Selections include:

● Five selectable, 24 Volt, current sinking, optically isolated, active

high inputs.

● One dedicated, control (ENABLE), current sinking, optically

isolated, active high input.

● Four selectable, 24 Volt, current sourcing, optically isolated,

active high outputs.

● Two dedicated (BRAKE and DRIVE READY), normally open

relay outputs.

Analog I/O

Two analog inputs are dedicated to current limits and two analog

outputs can be customized to fit the application:

● T w o d edi cat ed 10 bit, 0 – 10 Volt, analog inputs (+I LIMIT a nd - I

LIMIT)

● Two selectable, ±10 Volt analog outputs, one 12-bit and one 8-bit

(ANALOG1 and ANALOG2).

AC Input Power

ULTRA 200 Series drives are powered directly from a main 100-240

VAC line:

● 1398-DDM-010, 1398-DDM-010X, 1398-DDM-020,

1398-DDM-020X, 1398-DDM-030 and 1398-DDM-030X r equire

single-phase main power

● 1398-DDM-075 and 1398-DDM-075X requ ire either s ingle phase

or three-phase main power.

● 1398-DDM-150 and 1398-DDM-150X require three-phase main

power.

Personality Module

EEPROM (electrically erasable programmable read-only memory)

stores both motor and application specific settings and parameters for

the drive in a removable personality module. This module simplifies

installation, set up, maintenance and reduces spares requirements.

Publication 1398-5.0 – October 1998

Page 34

2-4 Selecting Other System Components

Multiple Protection Circuits

Device and circuit protection, and diagnostic information is provided

by:

● Seven segment drive status display

● Overtemperature, short circuit and overcurrent protection for the

power output

2

● I

T (power-time) protection

● Bus Overvoltage

● Bus Undervoltage

● Overspeed

● Fault diagnostics

● Fused power supply outputs

● Three watchdog timers provide fail-safe operation

ULTRA Master Software

A Windows based software interface provides start-up selections.

Tasks are organized for efficient set up, control and maintenance.

Context sensitive, on-line help provides immediate assistance.

● Set up is simp lified by a series of logically arranged set up

screens.

● Files can be stored and printed for on-line or off-line

modification, and on-site or off-site back-up.

● Diagnostic and set up tools make system integration easy.

● Critical information is available with complete on -line help.

● User defined velocity, acceleration, position and torque

parameters.

● Tuning and diagnosis is aided with an on-screen dual channel

digital oscilloscope.

● On-screen meters and software tools provid e rapid debugging and

measurement.

Communications

One serial port, with two connectors, allows from 1 to 32 drives to be

connected in parallel using four-wire RS-485 communications. The

serial interface allows the user to program a drive using any PC or

host computer that permits RS-232 or four-wire RS-485

communications.

Publication 1398-5.0 – October 1998

Page 35

Selecting Other System Components 2-5

Autotuning

Digital auto tuning allows easy setup. All adjustments are made in

software, which immediately sets the servo system compensation

parameters. This eliminates the time-consuming adjustments required

by potentiometers.

Agency Approvals

● UL listed

● cUL listed

● CE marked.

Options

● Power and feedback cables are potted and molded with 360

degree shielding.

● AC line filters.

● Breakout boards for I/ O control and encoder i nterface.

● TouchPad – a compact and highly portable input and display

device.

Publication 1398-5.0 – October 1998

Page 36

2-6 Selecting Other System Components

Motors The ULTRA 200 Series is com patible with many motors, both

Allen-Bradley motors and motors from other manufacturers. Drive

and motor parameters for all compatible Allen-Bradley motors are

programmed into each ULTRA 200 Series drive at the factory.

Allen-Bradley motors t hat are compa tible wi th the ULTRA 200 Series

of drives include all:

● F-Series

● H-Series

● N-Series

● Y-Series

ULTRA Master software speed s dr ive and motor set up by p red ef ine d

parameters for each drive and motor combination.

Refer to the Torque/Speed curves in the Allen-Bradley standard

product catalog and handbook (Publication 1398-2.0) or contact your

local Allen-Bradley distributor for motor sizing a nd compatibility

assistance.

Custom motors or motors no t ma nufactured by Allen-Bradl ey ma y be

used with the ULTRA 200 Series. Appendix D, “Creating Custom

Motor Files” explains how to configure the drive to control a custom

motor.

Publication 1398-5.0 – October 1998

Page 37

Selecting Other System Components 2-7

European Union Requirements

ULTRA 200 Series drives conform to the following European Union

Directives:

● Machinery Directive (89/392/EEC, Article 4.2 and Annex II,

sub B)

● Low Voltage Directive (72/23/EEC, 93/68/EEC)

● Electromagnetic Compatibility Directive (89/336/EEC, 92/31/

EEC, 93/68/EEC). Compliance with the EEC Directives is

contingent on:

– Installation of AC line filters between the power source and the

drive, and

– Use of Allen-Bradley cabl es to co nnec t mot or s. See “European

Union EMC Directives” on page 5-6; Appendix A, “Options and

Accessories” lists the mentioned equipment and Allen-Bradley

part number.

Allen-Bradley motors available for use with ULTRA 200 Series

drives include all:

● F-Series motors

● H-Series motors

● Y-Series motors

● N-Series motors

Publication 1398-5.0 – October 1998

Page 38

2-8 Selecting Other System Components

Publication 1398-5.0 – October 1998

Page 39

Chapter 3

ULTRA Master Installation Chapter 3

Installati on of ULTRA Master on a PC is covered in this chapter,

which:

● Lists the minimum PC hardware and software necessary to run

ULTRA Master.

● Provides step-by-step instructions on how to load ULTRA Master.

● Shows you how to start and quit ULTRA Master and introduces

the Drive Window,

the main command window for ULTRA Master.

● Instructs you on how to access on-line help.

Instructions for using the features available in ULTRA Master are

detailed in on-line he lp. To access the Help menu, depress the

F1 key.

Hardware and Software Requirements

The minimum personal computer (PC) requirements to run the

software are:

● A DOS computer with a 286 microprocessor

● A hard disk, with 2.0 MB of free disk space

● 3½ inch, 1.44MB floppy disk drive

● 2 MB of RAM

● A Video Graphics Array (VGA) monitor

● Microsoft Windows version 3.1

● A mouse is recommended.

Windows must be installed on your PC. If Windows is not already

installed, refe r to the appropriate Microsoft m anual to in stall W indo ws

on your computer.

Publication 1398-5.0 – October 1998

Page 40

3-2 ULTRA Master Installation

Installing ULTRA Master To install ULTRA Master software on a hard drive:

1. Make a backup copy of the ULTRA Master disk in one of the fol-

lowing ways:

• Copy the ULTRA Master disk using the disk menu in the

Windows File Manager.

• If your computer has only one floppy disk drive, type from

the DOS command line prompt

ENTER. The software will prompt you when to i nsert th e

press

SOURCE (ULTRA Master) disk and when to insert the TARGET (blank) disk.

diskcopy a: b: and then

2. If Windows is not running, type

win at the DOS prompt (C:>).

If Windows is already running, close any open applications.

3. Insert the ULTRA Master disk into a 1.44MB floppy disk drive,

typically drive A:, and close the drive door.

4. Choose

5. Type

Run, from the File menu in Windows Program Manager.

a:setup and then press ENTER. A message box will appe ar

saying that the setup is initializing. The message box may be

present for up to 40 seconds, depending on the speed of the PC.

6. A dialog box requires you to confirm whether or not

ULTRA Master should be installe d on the hard dr ive (C: dr ive) of

the PC.

• To install ULTRA Master, choose

ontinue, or press ENTER,

C

and continue with the next step.

• To stop th e in st allation, choose

xit. You are returned to Win-

E

dows.

7. Setup then asks where you would like to install ULTRA Master.

• To accept the path that Setup proposes in the

(c:\ultramst\...), choose C

ontinue,

Path: box

Publication 1398-5.0 – October 1998

• To choose another directo ry, type a new path in the Path: box ,

and then choose C

ontinue. You will not have the opportunity

to confirm your entry so type carefully.

• To return to the initial Setup window, choose B

• To stop the installation, choose E

xit. You will return to Win-

ack.

dows.

• To obtain on-line help with the installation, Choose H

elp.

8. A status bar will keep you informed of the installation progress.

When Setup is complete, choose

OK or press ENTER to return to

Windows.

Page 41

ULTRA Master Installation 3-3

Starting and Quitting

ULTRA Master

Version Level

The release level and date for ULTRA Master may be displayed by

selecting

bout ULTRA Master from the Help menu. This

A

information also appears in the initial ULTRA Master screen. The

About ULTRA Master window includes additional data about system

resources typically displayed in Windows Help.

The ULTRA Master Start-Up Screen

When ULTRA Master star ts for the first time, its defau lt instruction s

are:

● Display the Help menu - Quick Start.

● Present the Drive Selec t window. The Drive Select window offers

Drive 0, which is the default drive ad dress as si gned at th e facto ry.

The default ULTRA Master Start-up screen is shown below. The

comments point out many of the Windows controls that are available

in ULTRA Master.

4XLFN6WDUW

Pop-up menus accesses

PC-based commands

Tool bar buttons provide

quick access to common

commands and windo ws

Buttons perform typical Windows func tions such as

sizing or scrolling, opening or closing windows.

Note: ULTRA Master displays the Help menu – Quick Start –when

it is first acce ssed. To disable this automatic display, deselect the menu

item

Show Quick Start from the Help menu.

Setup automatically creates the ULTRA Master program group and

then returns you to Windows. The ULTRA Master program group

provides access to the ULTRA Master application icon,

Online Help e xplains tasks

and commands

Hypertext links to specific

items in online Help

Status bar reveals current

menu selection and statu s

information

Publication 1398-5.0 – October 1998

Page 42

3-4 ULTRA Master Installation

From the C:> Prompt

1. Type

win c:\ultramst\ultramst.exe.

The ULTRA Master start-up screen will open.

Note: This step assumes that ULTRA Master was loaded into the

c:\ultramst directory during setup.

From Windows

1. Choose the ULTRA Master program group from the Program

Manager in Windows.

Note: If the UL TRA Master window is not active, hold down ALT and

press TAB (ALT+TAB) un ti l the ULTRA Master title bar and icon are

highlighted, or select UL TRA Master from the list in t he W

indow menu.

2. Choose the ULTRA Master icon from the ULTRA Master pro-

gram group.

The ULTRA Master start-up screen will open.

The readme File

A file, titled README, may be included in the ULTRA Master

directory. This file contains installation instructions, change notes

from previous revisions, and information that became available after

this manual was printed. After you install ULTRA Master you can

access this file by choosing the Read Me icon in the ULTRA Master

window or by using Microsoft Write or an equivalent application

program to view the file

readme.wri in the directory path where

ULTRA Master is installed.

Firmware Files

Firmware files are supplied in the Miscellaneous directory on the

ULTRA Master diskette.

The current revision level of drive firmware, excluding the TouchPad

firmware, is displayed in the Drive Information window of

ULTRA Master. The current revision level of TouchPad firmware is

displayed as part of the TouchPad initialization when a TouchPad is

connected to the drive.

Publication 1398-5.0 – October 1998

The types of files and their functions are:

● Firmware – Ma in Operating firmware for th e drive

● Boot Block – Drive Initialization firmware for the drive

Page 43

Chapter 4

Unpacking, Inspecting and Sto ringChapter 4

This chapter describes four steps which should ensure that the drive

functions correctly. The steps include:

● Unpacking the ULTRA 200 Series drive

● Inspecting the drive for shipping damage

● Testing the basic functionality of the drive

● Guidelines for storing the drive.

Unpacking the Drive 1. Remove the ULTRA 200 Series drive from the shipping carton

and remove all pack ing mat erial s fr om the u nit. Th e mater ials and

carton may be retained for storage or shipment of the drive.

2. Check all items against the packing list. A label located on the

side of the unit identifies:

• model number

• s erial number

• manufacturing date code.

Inspection Proced ure T o protect your investment and ensure your rights unde r warranty, we

recommend the following steps be performed upon receipt of the unit:

● Inspect the unit for any physical damage that may have been

sustained during shipment.

● Perform the drive checkout test to verify the functionality of the

unit.

If you find damage, eit her concea led or obv ious, cont act your b uyer to

make a claim with the shipper. If degraded performance is detected

when testing the unit, contact your distributor or Allen-Bradley to

obtain a Return Material Authorization (RMA). Do this as soon as

possible after receipt of the unit.

Publication 1398-5.0 – October 1998

Page 44

4-2 Unpacking, Inspecting and Storing

!

Testing the Unit Drives are burned-in and individually tested before they leave the

factory. However, damage may occur during shipping. Perform the

procedures below to ensure the ULTRA 200 Series drive is

operational and undamaged.

Abbreviated directi ons for connecting the dr ive to a moto r and a PC

are provided.

The test requires:

● Approximately 20 minutes to complete

● A motor with appropriate power and encoder cables

● A PC with the ULTRA Master software package installed

● An RS-232 communications cable

● A single phase or three phase 100-240 VAC, 50/60 Hz power

source. Standard wall outlet pow er is suitable for verification

testing of ULTRA 200 Series drives, except the 1398-DDM-150

or 1398-DDM-150X, which require three phase power.

● A test cable constr ucted from two normally open swi tches, sever al

2

pieces of 1.5 mm

Connectors are listed in “Mating Connectors” on page A-6.

Appendix A, “Options and Accessories” lists the cables.

(16 AWG) wire and a mating connector.

During the test, power is removed several times. Measure the DC bus

voltage at TB1 to verify the bus capacitors are fully discharged, or

wait for the time indicated in the warning on the front of the drive.

The bus capacitors must be fully discharged for the subsequent steps

to be valid.

If problems are encountered during this procedure, refer to “Fuse and

Jumper Locations” on page 11- 4, re view other appropriate se cti ons in

this manual, or call your local Allen-Bradley distributor.

Intro

ATTENTION: Perform the initial power-up with the

motor shaft disconnected from a load and the shaft key

removed. Improper wiring or undisc overed shi pping da mage could result in undes ired motor motion. Be prepared to

remove power if excessive motion occurs.

Publication 1398-5.0 – October 1998

Page 45

Unpacking, Inspecting and Storing 4-3

Hardware Setup

Make the connections described below and shown in Figure 4.1.

1. Connect an RS-232 cable between the serial port on the PC and

the J4 connector on the ULTRA 200 Series.

• An Allen-Bradley cable connects the 9-pin serial port of the

ULTRA 200 Series to a 9-pin D-shell connector on a serial

port of the PC. Allen-Bradley cables are available in various

lengths for connecting between J4 or J5 and a computer.

Appendix A, “Options and Accessories” lists the cables.

• A three wire cable is shown in the figure below, solely for

illustrative purposes.

2. Connect a Motor/Feedback cable fr om the moto r t o the J 2 conn ec-

tor on the drive.

3. Connect a jumper wire with a toggle switch between J1-20

(ENABLE) and J1-26 (+24VDC). This provides manual control

for enabling or disabling the drive. Figure 4.1 shows the jumper,

including its normally open toggle switch.

4. Connect a power cable between the external 100/ 240 VAC, 50/60

Hz power source:

Intro

ATTENTION: When operating the model 1398-DDM-

!

075 or 1398-DDM-075X with single- phase power the current limits must be set correctly.

• A 1398-DDM-010, 1398-DDM-010X, 1398-DDM-020,

1398-DDM-020X, 1398-DDM-030, 1398-DDM-030X,

1398-DDM-075 or 1398-DDM-075X connects to the L1, L2/

N and (Gnd) connections on TB-1 when using a single

phase power source.

• A 1398-DDM-075, 1398-DDM-075X, 1398-DDM-150 or

1398-DDM-150X connects to the L1, L2, L3 and (Gnd)

connections on TB-1 when using a three pha se power sourc e.

Publication 1398-5.0 – October 1998

Page 46

4-4 Unpacking, Inspecting and Storing

!

Figure 4.1 Connection Diagram

Intro

DRIVE

Close to ENABLE drive

Close to RESET faults

XMT

RCV

COM

J4

2 RCV

3 XMT

5 COM

J1

26 +24V

20 ENABLE

21 FAULT RESET

J2

Motor

Encoder

TB1

Phase R 1

Phase S 2

Phase T 3

Motor Gnd 4

TB1

L1 7

L2/N 8

Gnd 9/10

TB1

L1 7

L2/N 8

L3 9

Gnd 10

100-240 VAC

50/60 Hz

Single Phase

Power Source

Gnd = Pin 9 for DDM-010, DDM-020, DDM-030

Gnd = Pin 10 for DDM-075 using single phase

or

100-240 VAC

50/60 Hz

Three Phase

Power Source

Publication 1398-5.0 – October 1998

Drive Checkout Test

This test seq uentially ve rifies that:

● Drive power wiring is correct and start-up logic is functio ning

● The drive and motor are correctly wired

● Drive serial communications are operational

Intro

A TTENTION: Be prepared to disable the drive or r emove

input power if excessive motor motion occurs while performing the following steps.

Before beginning “Initial Power-up”, please check the following:

● All wiring and mounting to verify correct installation

● Input voltages to ensure they do not exceed specifications for the

drive or motor.

Page 47

Unpacking, Inspecting and Storing 4-5

Initial Power-up

1. Verify the AC power is withi n specificati ons.

2. Switch the AC Power to ON and verify:

• green DC BUS LED is ON

• d isplay is not flashing.

3. Switch the power OFF and wait until the DC Bus Voltage is below

30 Volts, to prevent electrical shock.

4. Connect the motor windings to:

• R (TB1-1)for the Phase R winding

• S (TB1-2) for the Phase S winding

• T (TB1-3) for the Phase T winding

• (TB1-4) for the Ground connection.

5. Switch AC Power ON again and verify:

• green DC BUS LED is ON

• d isplay is not flashing.

6. Switch the power OFF and wait until the DC Bus Voltage is below

30 Volts, to prevent electrical shock.

Communications Verification

7. Start ULTRA Master on the PC.

8. Close any windows that are open in ULTRA Master.

9. Select

C Set Up from the Communications menu in

P

ULTRA Master.

10. Verify the communication port settings match those of the drive,

then select

• Baud Rate:

OK. Factory default drive settings are:

9600

• Data Bits: 8

•Parity: None

• Stop Bits: 1

• Serial Port: COM1

Assignment of communications ports on PCs varies between

manufacturers. The COM port setting for the drive and PC must

match. Refer to “Troubleshooting” on page 11-6 if

communication problems are encountered.

Publication 1398-5.0 – October 1998

Page 48