Page 1

InstallationInstructionsIN

Snubber Board Kit

(Catalog Number 1336-SN-SP18A)

Bulletin 1336T, 1336E, 1336S, and 1336F Common Bus

ACDrives

Drive Ratings R060 – R125, W075 – W125 and R150 – R250, W150 – W250

Table of Contents Where This Kit is Used. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

What This Kit Contains. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

How to Use These Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

Safety Precautions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-3

Electrostatic Discharge Precautions. . . . . . . . . . . . . . . . . . . . . . . I-4

Torque Sequence. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-4

Ratings R060 – R125 and W075 – W125 . . . . . . . . . . . . . . . . . . . . I-6

Product Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-6

Drive and Option Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

1336 FORCE Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-7

1336 IMPACT Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-8

1336 PLUS Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-9

1336 PLUS II Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-10

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-11

SCR Module Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-11

1336 FORCE Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-12

1336 IMPACT Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-14

1336 PLUS Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-16

1336 PLUS II Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-18

All 1336 FORCE, IMPACT, PLUS, and PLUS II Drives. . . . . . I-20

Snubber Board Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-22

SCR Module Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-24

SCR Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-26

Ratings R150 – R250 and W150 – W250 . . . . . . . . . . . . . . . . . . . I-28

Product Identification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-28

Drive and Option Identification. . . . . . . . . . . . . . . . . . . . . . . . . . I-29

1336 FORCE Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-29

1336 IMPACT Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-30

1336 PLUS Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-31

1336 PLUS II Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-32

1336-5.39 – August, 1999

Page 2

I-2

Torque Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-33

SCR Module Access. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-33

1336 FORCE Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-34

1336 IMPACT Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-38

1336 PLUS Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-42

1336 PLUS II Drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-46

All 1336 FORCE, IMPACT, PLUS, and PLUS II Drives. . . . . . I-50

Snubber Board Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-52

SCR Module Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-54

SCR Module Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-56

1336-5.39 – August, 1999

Page 3

Where This Kit is Used You can use this kit to install a snubber board on the SCR module in

your drive.

What This Kit Contains This kit contains a snubber board assembly and these instructions.

SCR module testing and replacement information is included in these

instructions.

How to Use These Instructions To install a snubber board on your drive:

1. Determine the rating of the drive, refer to “Ratings R060 – R125

and W075 – W125” on page I-6 or “Ratings R150 – R250 a nd

W150 – W250” on page I-28.

2. Access the SCR module, refer to “SCR Module Access” on

page I-11 or I-33, depending on the drive rating.

3. Install the snubber board, refer to “Snubber Board Installation”

on page I-22 or I-52, depending on the drive rating.

If your drive is not working correctly, refer to “SCR Module Test” on

page I-24 or I-54, depending on the drive rating.

I-3

Safety Precautions

ATTENTION: Some printed circuit boards and drive

components may contain hazardous voltage levels.

!

!

Remove and lock out power before you disconnect or

reconnectwires,and beforeyouremoveor replacefuses

and circuit boards. Verify bus voltage by measuring the

voltagebetween+DCand-DConTerminal Block TB1.

Do not attempt to service the drive until the bus voltage

has discharged to zero volts.

ATTENTION: Potentially fatal voltages may result

from improper usage of oscilloscope and other test

equipment. The oscilloscope chassis may be at a

potentially fatal voltage if not properly grounded. If an

oscilloscopeisusedtomeasurehighvoltagewaveforms,

use only a dual channel oscilloscope in the differential

mode with X 100 probes. It is recommended that the

oscilloscopebe usedintheA minus BQuasi-differential

mode with the oscilloscope chassis correctly grounded

to an earth ground.

1336-5.39 – August, 1999

Page 4

I-4

Electrostatic Discharge Precautions

ATTENTION: This assembly contains parts and subassemblies that are sensitive to electrostatic discharge.

!

Electrostatic discharge generated by static electricity can damage the

complimentary metallic oxide semiconductor devices on various

driveboards. It is recommended that you perform these procedures to

guard against this type of damage when circuit boards are removed or

installed:

Static control precautions are required when servicing

this assembly. Component damage may result if you

ignoreelectrostaticdischargecontrol procedures.Ifyou

arenotfamiliar with staticcontrolprocedures, reference

Allen-Bradley Publication 8000-4.5.2, Guarding

Against Electrostatic Damage, or any other applicable

ESD protection handbook.

• Wear a wrist-type grounding strap that is grounded to the drive

chassis.

• Attach the wrist strap before removing the newcircuit board from

the conductive packet.

• Remove boards from the drive and immediately insert them into

their conductive packets.

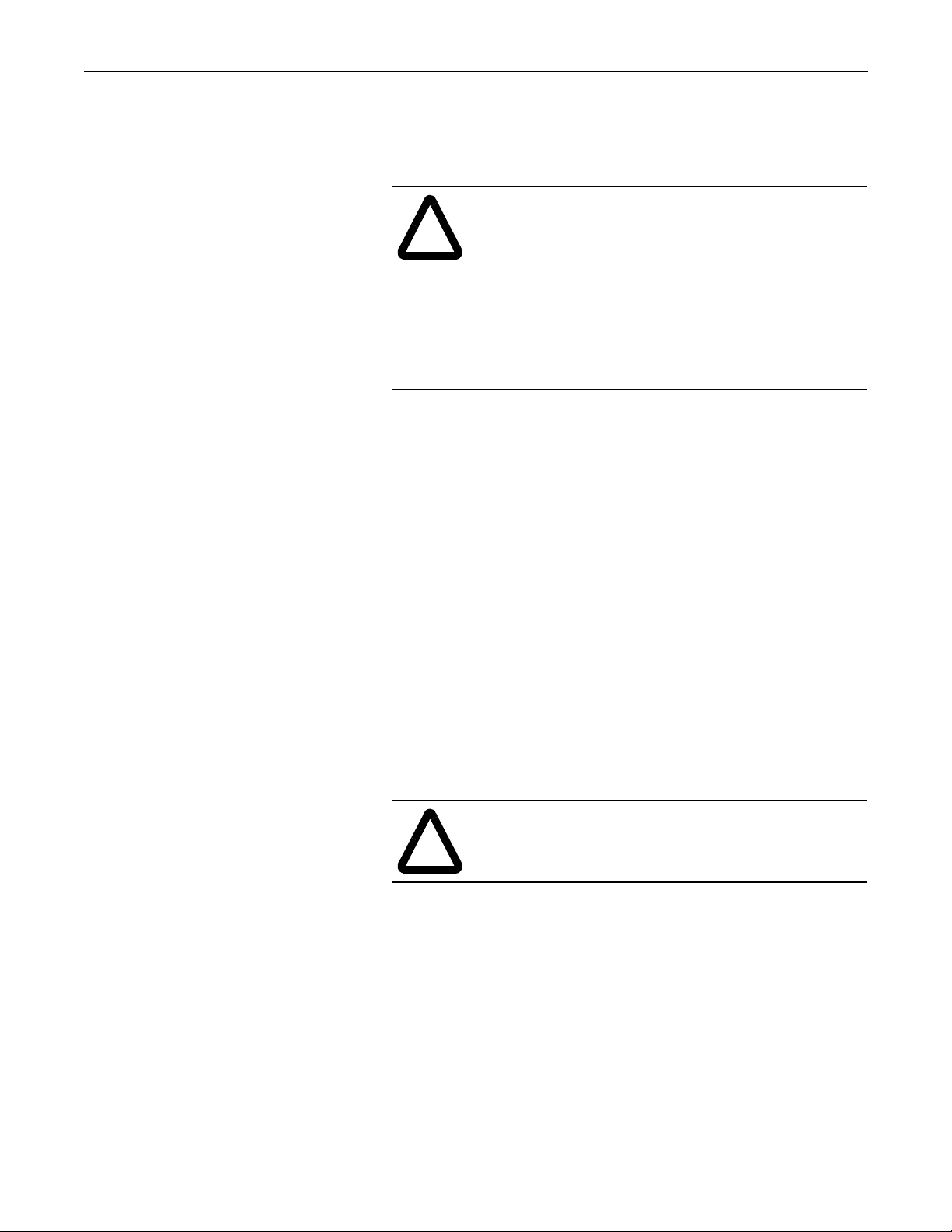

Torque Sequence When mounting components to a drive’s heat sink,

component-fastener torque sequences and tolerances are crucial to

component-to-heat sink heat dissipation.

ATTENTION: Component can be damaged if

temporary tightening procedure is not performed to

!

The following illustratestemporary and final tightening sequences for

components fastened to a heat sink using two, four, and six screws.

Temporary torque is 1/4 (25%) of final torque. The numeric

illustration labels are for your assistance. Drive components do not

carry these labels.

specification.

1336-5.39 – August, 1999

Page 5

Figure I-1

Tw o-Point Mounting

12

T w o-Point Mounting

12

Temporary Tighten

I-5

21

Final Tighten

AB0906

Figure I-2

Four-Point Mounting

1

4

Four-Point Mo un tin g

12 34

Temporary Tighten

43 21

Final Tighten

3

2

AB0903

Figure I-3

Six-Point Mounting

654

2 5 3 6 1 4

Temporary Tighten to 0.5 N-m (4 l b-in.)

123

2 5 3 6 1 4

Final Tighten to 3 N-m (26 lb-in.)

Six-Point Mounting

Important: Do not exceed 0.5 Newton-meters (4 lb-in.) or initial

torque of all six screws.

1336-5.39 – August, 1999

AB0902

Page 6

I-6

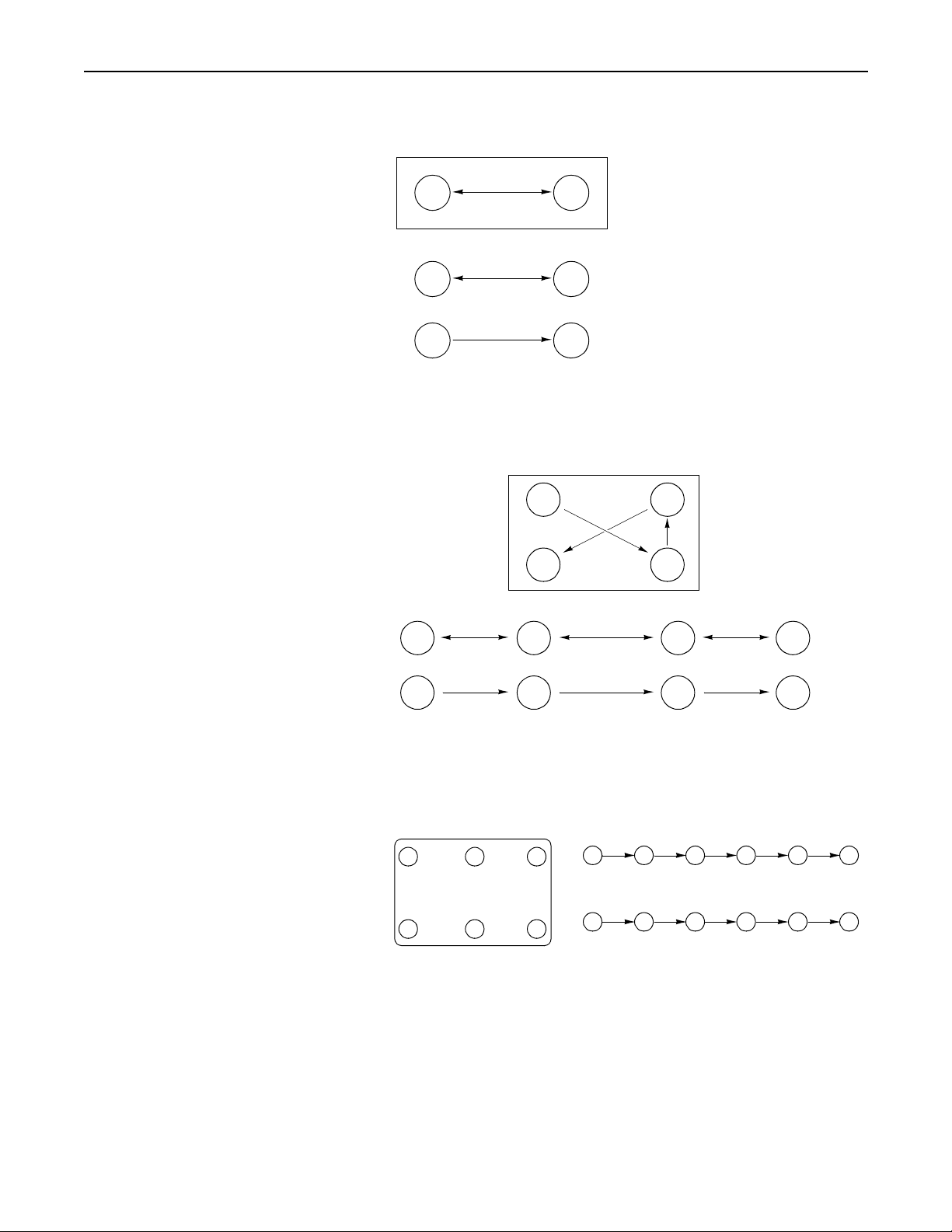

Ratings R060 – R125 and W075 – W125

Product Identification Drive Nameplate Location

The drive nameplate is located on the face of the Control Board/

Adapter Mounting Plate. The drive nameplate contains the drive’s

catalog number and other important drive information. Reference the

catalog number to determinethe rating of your drive, when callingfor

technical assistance, and when ordering replacement parts.

Figure I-4

Drive Name plate Location

Nameplate located on tab of Contr ol

Board/Ada pter Mounting Plate.

AB0901

1336-5.39 – August, 1999

Page 7

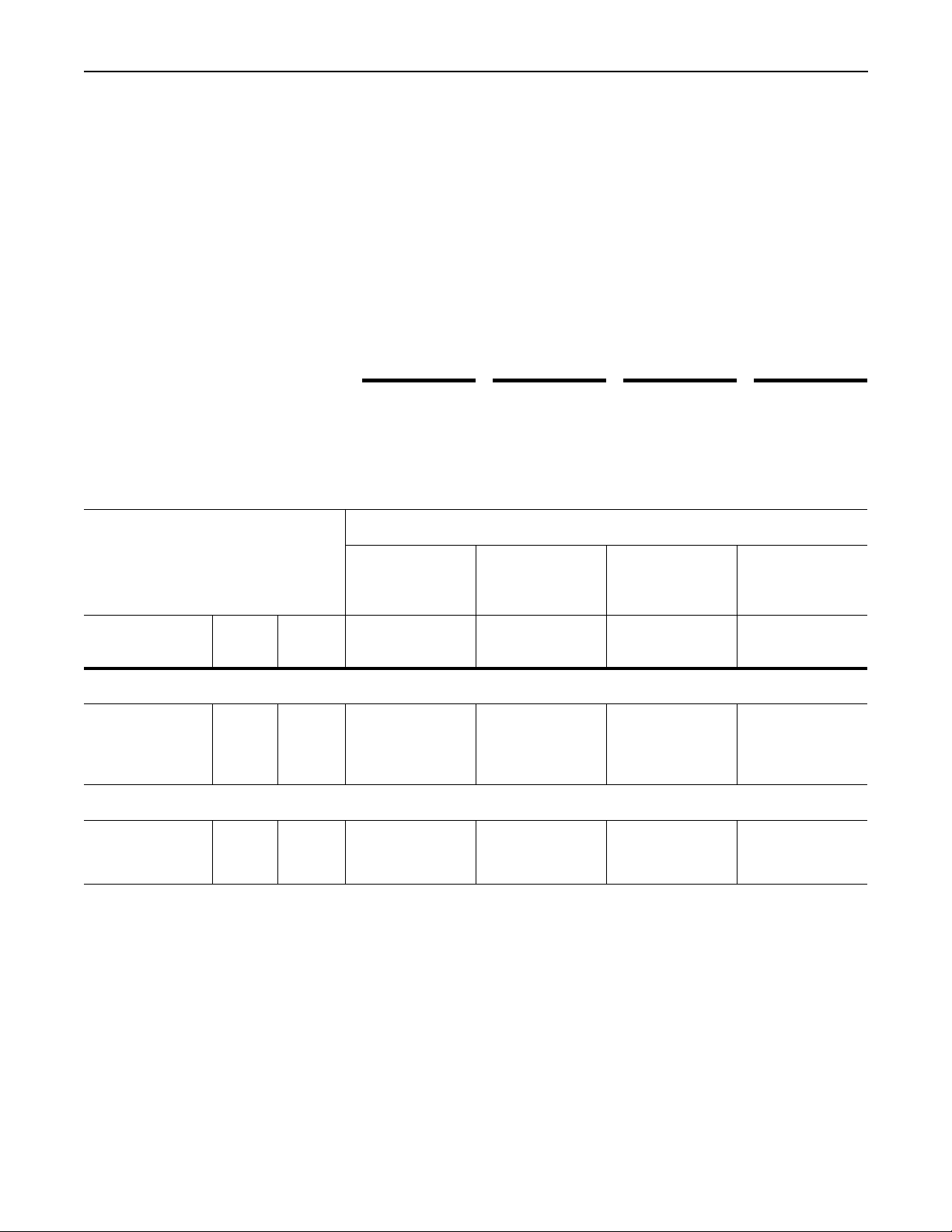

Drive and Option Identification 1336 FORCE Drives

The following is an explanation of the catalog numbering system for

1336 FORCE Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– Use Number

1336T

for Specific

Constant

Torque Drive

I-7

– GT2EN – L6

Drive Rating

Frame

Designation

D 96.9

D85.8

Output

Amps

120.3

149.2

180.4

109.1

138.6

Nominal

60

75

100

125

75

100

125

HP

RATING-

BULLETIN NO.

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R060-AN

R075-AN

R100-AN

R125-AN

675 – 800V DC Input

W075-AN

W100-AN

W125-AN

ENCLOSURE

(MUST BE

SPECIFIED)

Enclosures

NEMA Type 1

IP20

General Purpose

R060-AA

R075-AA

R100-AA

R125-AA

W075-AA

W100-AA

W125-AA

ADAPTER

OPTION

(MUST BE

SPECIFIED)

NEMA Type 4

IP56

Resist Water, Dust

Not available

Not available

Not available

Not available

Not available

Not available

Not available

OPTIONS AS

REQUIRED

(OPTIONAL)

NEMA Type 12

IP54

Industrial Use

Not available

Not available

Not available

Not available

Not available

Not available

Not available

1336-5.39 – August, 1999

Page 8

I-8

1336E

– Use Number for

Specific Constant

Torque Drive

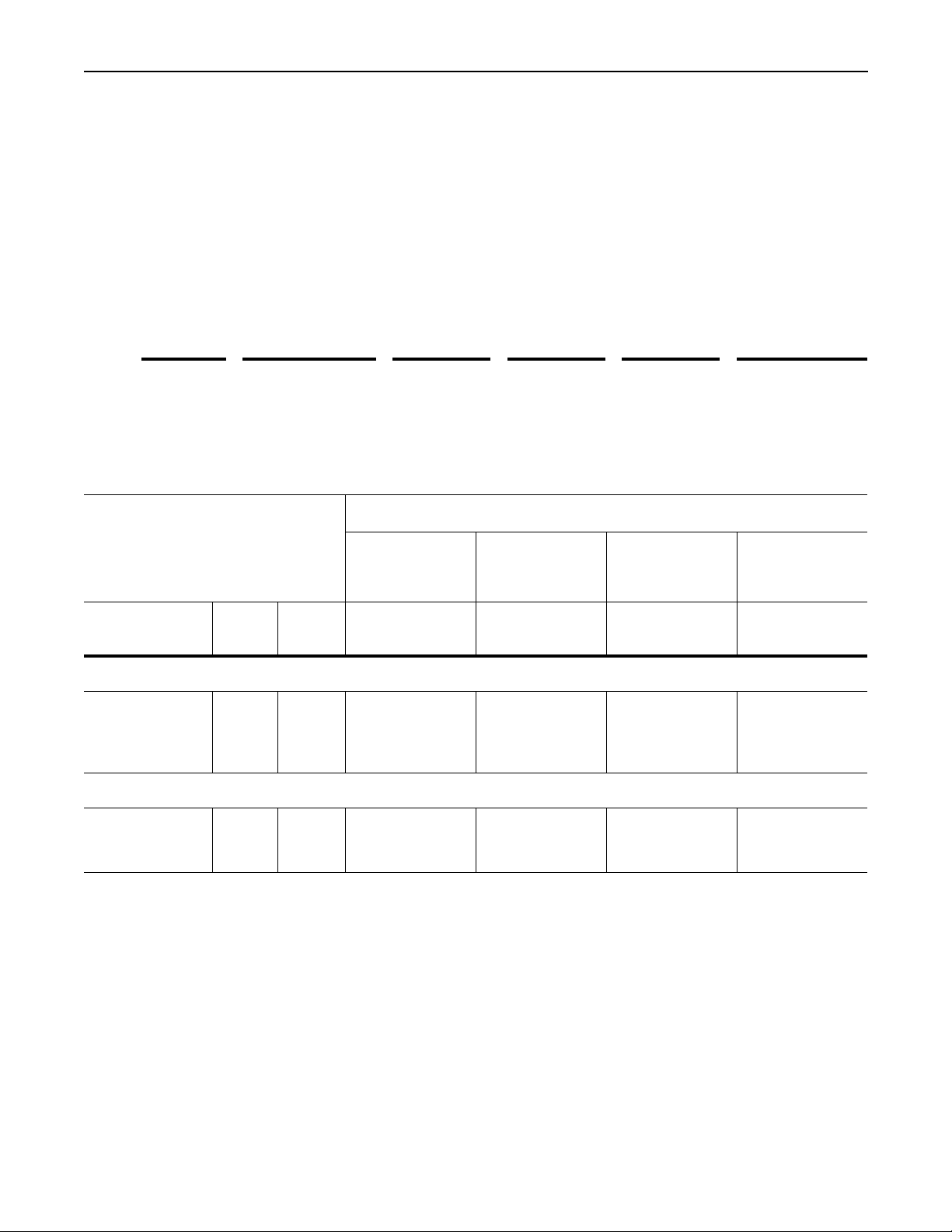

1336 IMPACT Drives

The following is an explanation of the catalog numbering system for

1336 IMPACT Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate

Catalog Number Explanation

– EN – L6 – HA1 – GM1

RATING-

BULLETIN

NO.

Drive Rating

Frame

Designation

D 96.9

D85.8

Output

Amps

120.3

149.2

180.4

109.1

138.6

ENCLOSURE

(MUST BE

SPECIFIED)

Nominal

60

75

100

125

75

100

125

HP

LANGUAGE

MODULE

(MUST BE

SPECIFIED)

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R060-AN

R075-AN

R100-AN

R125-AN

675 – 800V DC Input

W075-AN

W100-AN

W125-AN

R060-AA, -AE

R075-AA, -AE

R100-AA, -AE

R125-AA, -AE

W075-AA

W100-AA

W125-AA

L-Option

(OPTIONAL)

Enclosures

NEMA Type 1

IP20

General Purpose

HUMAN

INTERFACE

(OPTIONAL)

NEMA Type 4

IP56

Resist Water, Dust

Not available

Not available

Not available

Not available

Not available

Not available

Not available

COMMUNICATION

CARD

(OPTIONAL)

NEMA Type 12

IP54

Industrial Use

R060C-AJ

R075C-AJ

R100C-AJ

R125C-AJ

Not available

Not available

Not available

1336-5.39 – August, 1999

Page 9

1336S

BULLETIN

NO.

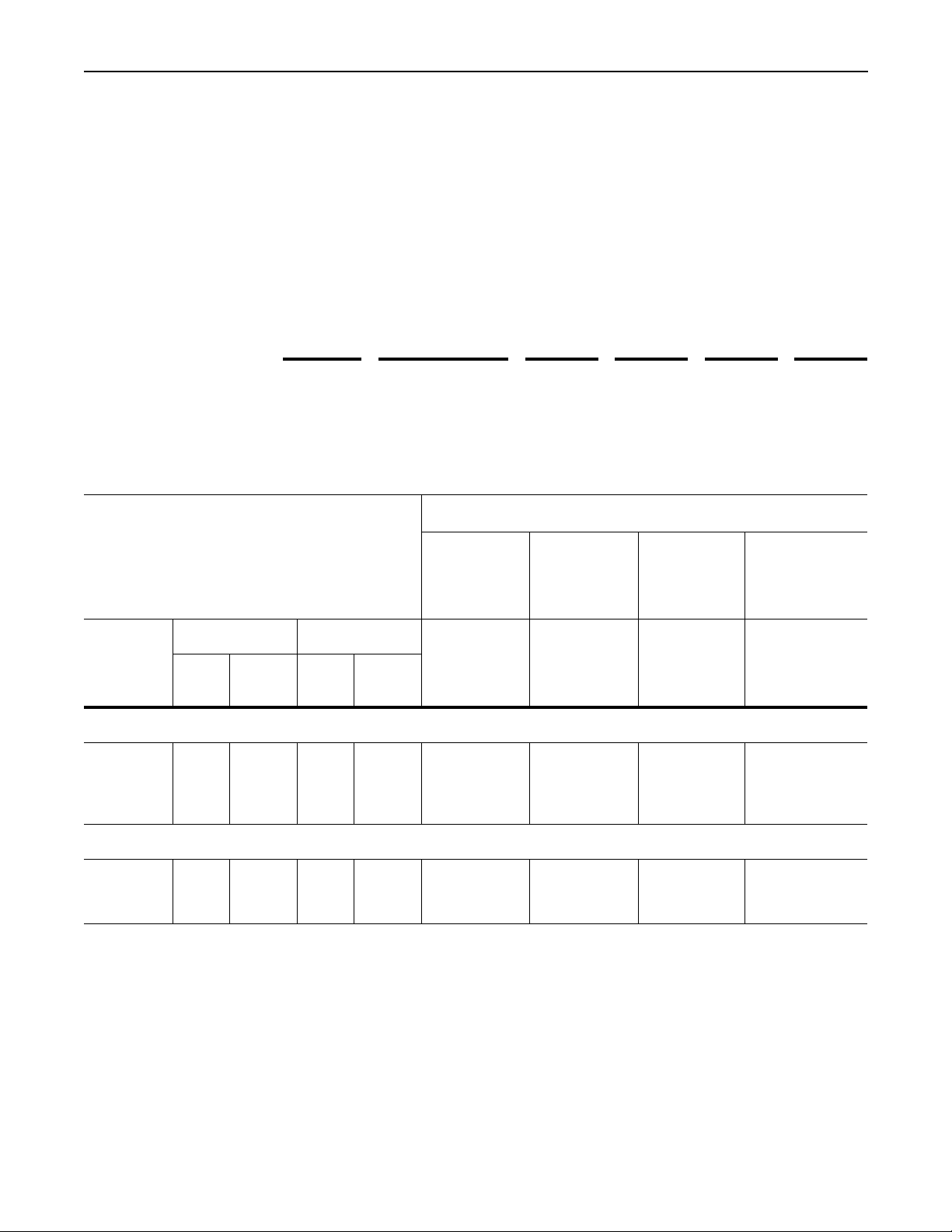

1336 PLUS Drives

The following is an explanation of the catalog numbering system for

1336 PLUS Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– Use Number for

Specific Constant

Torque Drive

RATING-

ENCLOSURE

(MUST BE

SPECIFIED)

– BM – GM1 – HA1C . . .

OPTIONS AS REQUIRED

I-9

Constant Torque Variable Torque

Frame

Designation

D 85.0

D85.0

Output

Amps

106.0

138.0

173.0

109.0

138.0

Drive Rating

NominalHPOutput

60

75

100

125

75

100

125

Amps

96.0

120.0

150.0

180.0

85.0

109.0

138.0

Nominal

HP

75

100

125

150

75

100

125

Enclosures

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R060-AN

R075-AN

R100-AN

R125-AN

675 – 800V DC Input

W075-AN

W100-AN

W125-AN

NEMA Type 1

IP20

General

Purpose

R060-AA

R075-AA

R100-AA

R125-AA

W075-AA

W100-AA

W125-AA

NEMA Type 4

IP56

Resist Water,

Dust

Not available

Not available

Not available

Not available

Not available

Not available

Not available

NEMA Type 12

IP54

Industrial Use

Not available

Not available

Not available

Not available

Not available

Not available

Not available

1336-5.39 – August, 1999

Page 10

I-10

1336F

– Use Number for

Specific Constant

Torque Drive

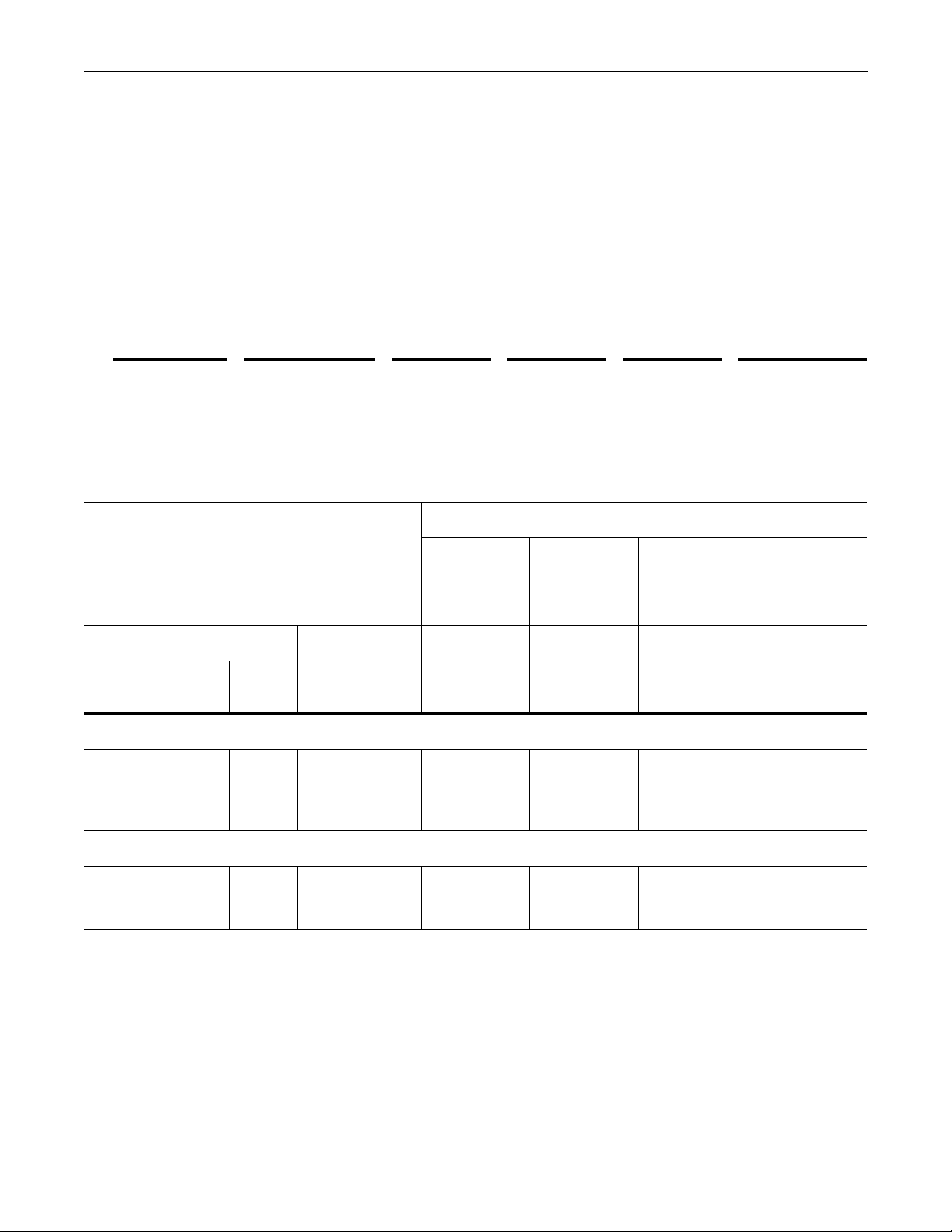

1336 PLUS II Drives

The following is an explanation of the catalog numbering system for

1336 PLUS II Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– EN – LA6 – HAS1 – GMS1

BULLETIN NO.

Constant Torque Variable Torque

Frame

Designation

D 85.0

Output

Amps

106.0

138.0

173.0

RATING-

ENCLOSURE

(MUST BE

SPECIFIED)

Drive Rating

NominalHPOutput

60

75

100

125

Amps

96.0

120.0

150.0

180.0

Nominal

HP

75

100

125

150

LANGUAGE

(MUST BE

SPECIFIED)

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R060-AN

R075-AN

R100-AN

R125-AN

CONTROL

INTERFACE

(OPTIONAL)

NEMA Type 1

IP20

General

Purpose

R060-AA

R075-AA

R100-AA

R125-AA

HUMAN

INTERFACE

(OPTIONAL)

Enclosures

NEMA Type 4

Resist Water,

Not available

Not available

Not available

Not available

IP56

Dust

COMMUNICATION

CARD

(OPTIONAL)

NEMA Type 12

IP54

Industrial Use

Not available

Not available

Not available

Not available

D85.0

109.0

138.0

1336-5.39 – August, 1999

75

100

125

85.0

109.0

138.0

75

100

125

675 – 800V DC Input

W075-AN

W100-AN

W125-AN

W075-AA

W100-AA

W125-AA

Not available

Not available

Not available

Not available

Not available

Not available

Page 11

Torque Specifications The following table lists fastener locations by component,

application,and torque specifications.Refer to “TorqueSequence”on

page I-4 for fastening two-point, four-point, and six-point

components to the heat sink.

I-11

Component Fastener Application Fastener Used

SCR Module Module to Heat Sink M6 x 16 mm Screw 52 5.9

Snubber Board Board to SCR M4 x 8 mm Screw 12 – 16 1.4 – 1.8

Gate Driver Board Mounting Plate Plate to Chassis M5 x 10 mm Screw 23 – 36 2.6 – 4.1

Control Boar d Mounting Plate Plate to Gate Driver Board Mounting Plate M6 Nut 23 – 36 2.6 – 4.1

Control Board Mounting Plate Plate to Gate Driver Board Mounting Plate M4 x 8 mm Screw 12 – 16 1.4 – 1.8

Enclosure Bottom, Top, and Side Panels Enclosure Sheet Metal M5 x 10 mm Screw 23 – 36 2.6 – 4.1

TB1 Wires Wires to TB1 M8 Nut 52 5.9

Converter Bus Bar Wires Wires to Converter Bus Bar M6 x 12 mm Screw 50 – 72 5.6 – 8.1

Ground Wire TE (G ate Driver Board) Wire to TB1 Terminal TE Compression 6 – 8 0.7 – 0.9

TB20 Wires, PLC Comm Adapter Board Wires to TB20 Captive Screw – –

TB21 Wires, PLC Comm Adapter Board W ires to TB21 on Main Control Board Captive Screw – –

TB5 Wires, Stan dard Adapter Board Wires to TB5 on Main Control Board Captive Screw 12 – 16 1.4 – 1.8

TB6 Wires, Stan dard Adapter Board Wires to TB6 on Main Control Board Captive Screw 12 – 16 1.4 – 1.8

TB7 Wires, Stan dard Adapter Board Wires to TB7 on Main Control Board Captive Screw 12 – 16 1.4 – 1.8

TB3 Wires, Standard Adapter o r

L-Option Board

Wires to TB3 on Control Interface Board or

L-Option Board

Captive Screw 8 – 10 0.9 – 1.1

Torque

in.-lb

Torque

N-m

Enclosure Door Ground Wire Wire to Enclosure Door M6 Nut 23 – 36 2.6 – 4.1

SCR Module Access

ATTENTION: Disconnect and lock out power from

the drive before disassembling the drive. Failure to

!

Important: Before you removeconnections and wires from the drive

components, mark the connections and wires to correspond with their

component connections and terminals to prevent incorrect wiring

during assembly.

disconnect power may result in death or serious injury.

Verify bus voltage by measuring the voltage between

+DC and -DC on Ter minal Block TB1. Do not attempt

to service the driveuntil the bus voltage has discharged

to zero volts.

ATTENTION: Wear a wrist-type grounding strap

when servicing drives. Failure to protect drive

components against ESD may damage drive

components. Refer to “Electrostatic Discharge

Precautions”onpageI-4.

1336-5.39 – August, 1999

Page 12

I-12

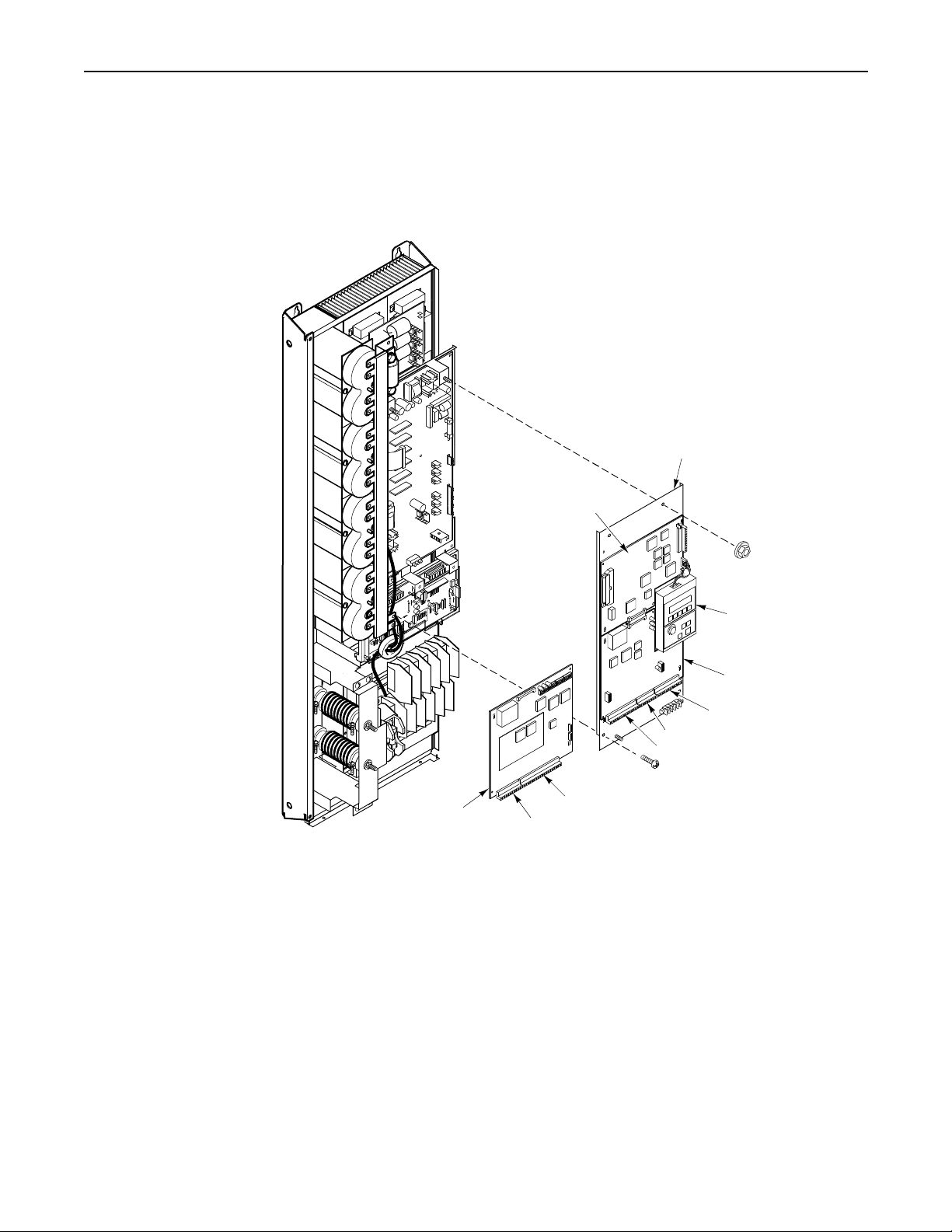

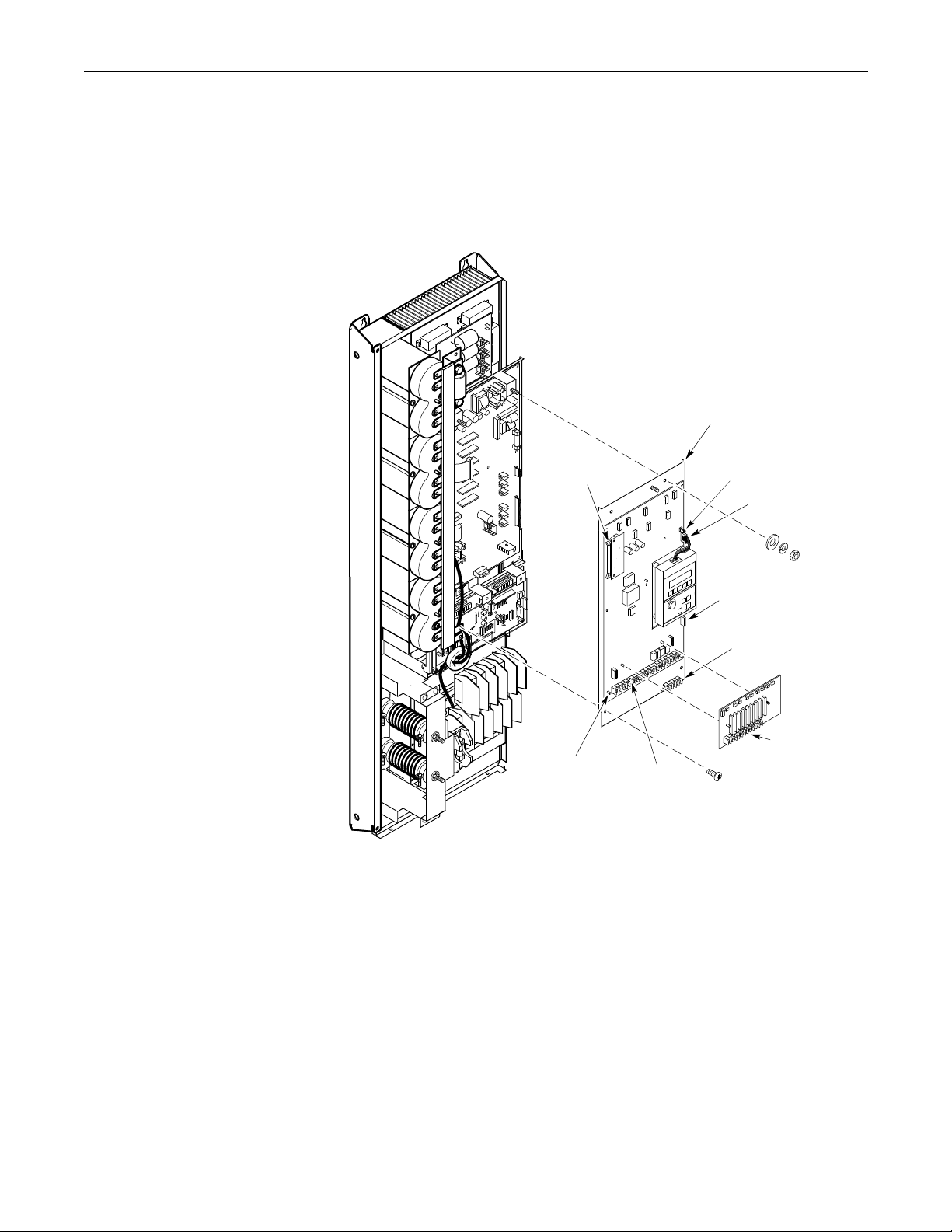

1336 FORCE Drives

Remove the Control Board/Adapter Mounting Plate

Figure I-5

Control Board/Adapter Mounting Plate.

Control Board

Mounting Plate

Main Control

Board

PLC Comm

Adapter Board

HIM (Standard Adapter

Board only)

Standard

Adapter Board

TB7

TB6

TB5

TB21

TB20

AB0899

1336-5.39 – August, 1999

Page 13

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage at:

– TB20andTB21ondrivesusingaPLCCommAdapterBoard

– TB5, TB6, and TB7 on drives using a Standard Adapter

Board

5. Remove the wires and c onnectors from the Standard or PLC Comm Adapter Board.

6. Remove the nuts at the top of the Control Board/Adapter Mounting Plate.

I-13

7. Remove the two screws at the bottom of the Control Board/ Adapter Mounting Plate.

8. Lift the Control Board/Adapter Mounting Plate out of the drive

9. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-20.

1336-5.39 – August, 1999

Page 14

I-14

1336 IMPACT Drives

Remove the Main Control Board Mounting Plate

Figure I-6

Main Control Board Mounting Plate

Main Control Board

Mounting Plate

Connector J5

TB10

Connector J1

Main Control

Board

Connector J7

TB11

Mounting Plate

Screw

Terminal

Block TE

AB0947

1336-5.39 – August, 1999

Page 15

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage at:

– TB10

– TB11

– L-Option Board (if used)

5. Remove the ground wire from the Enclosure door.

6. Disconnect the following from the Main Control Board:

– J1 connector

I-15

– J5 ribbon cable connector

– J7 connector

– Ground wires from terminal block TE

– Chassis ground wire at the top-right corner of the

Main Control Board Mounting Plate

7. Remove the nuts at the top of the Main Control Board Mounting Plate.

8. Remove the two screws at the bottom of the Main Control Board Mounting Plate.

9. Lift the Main Control Board Mounting Plate out of the drive.

10. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-20.

1336-5.39 – August, 1999

Page 16

I-16

1336 PLUS Drives

Remove the Main Control Board Mounting Plate

Figure I-7

Main Control Board Mounting Plate

Main Control Board

Mounting Plate

Connector J2

Ground Wire

Stake-on

Connector J10

Connector J1

Connector J6

Connector J8

Terminal

Block TE

Terminal

Block TB3

Terminal

Block TB2

AB0946

1336-5.39 – August, 1999

Page 17

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage at:

– TB2

– TB3

5. Disconnect the following from the Main Control Board:

– J2 ribbon cable connector

– J1 connector

– Ground wire at terminal block TE

I-17

– J10 ground wire at the stake-on connector

– J6 connector

– J8 connector

– All wires from the terminals on TB2 and TB3

6. Remove the nuts at the top of the Main Control Board Mounting Plate.

7. Remove the two screws at the bottom of the Main Control Board Mounting Plate.

8. Lift the Main Control Board Mounting Plate out of the drive.

9. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-20.

1336-5.39 – August, 1999

Page 18

I-18

1336 PLUS II Drives

Remove the Main Control Board Mounting Plate

Figure I-8

Main Control Board Mounting Plate

Main Control Boa rd

Mounting Plate

Comm

Connector

Plug

Connector J2

Ground Wire

Stake-on

Connector J10

Connector J5

Comm Connector

Terminal

Block TE

Terminal

Block TB2

AB0965

1336-5.39 – August, 1999

Page 19

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage.

5. Disconnect the following from the Main Control Board:

– J2 ribbon cable connector

– J10 ground wire at the stake-on connector

– J5 connector

– Comm connector

– All wires from the terminals on TB2 and TE

I-19

6. Remove the nuts at the top of the Main Control Board Mounting Plate.

7. Remove the two screws at the bottom of the Main Control Board Mounting Plate.

8. Lift the Main Control Board Mounting Plate out of the drive.

9. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-20.

1336-5.39 – August, 1999

Page 20

I-20

All 1336 FORCE, IMPACT, PLUS, and PLUS II Drives

Remove the Gate Driver Board and Precharge Board Mounting Plates

Figure I-9

Gate Driver Board and Prech arge Board Mo unting Plates

Mounting Pl ate and Gat e

Driver Board

J3

Mounting Plate

and Precharge

Board

J2

Precharge

Guard

J1

J6

J2

J13

J7

J8

TB7

TB6

J10

AB0900

1336-5.39 – August, 1999

Page 21

1. Remove Gate Driver Board connections:

– TB7groundwire

– J2 Ground Sense CT connector

– J13 connector

– J7 Power Module connector

– J8 Power Module connector

– J10 Bus Capacitor Bank connector

– J6 connector

– TB6 Fan connector, if applicable

– J9 Precharge Board connector

ATTENTION: Whenremovingtheentirewireharness

connectingGateDriverBoardconnectorJ9toPrecharge

!

Board connector J3, align the wires on the harness

terminals with the pins on the board connectors.

Incorrect harness connection may result in faulty drive

operation and may damage the equipment.

I-21

2. Removethe screws fastening the bottom of the Gate DriverBoard Mounting Plate to the drive.

3. Slide the plate toward the top of the drive to disengage the

mounting plate tabs from the slots on the chassis.

4. Lift the plate out of the drive.

5. Remove the guard from the Precharge Board.

6. Disconnect the following from the Precharge Board:

– J2 connector

– J3 connector

7. Remove the screws fastening the top of the Precharge Board Mounting Plate to the chassis.

8. Lift the Precharge Board Mounting Plate out of the enclosure.

1336-5.39 – August, 1999

Page 22

I-22

Snubber Board Installation Figure I-10

Snubber Board Installation

SCR

Bus Bar

Snubber

Board

Preform

AB0912

1336-5.39 – August, 1999

Page 23

I-23

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-11.

2. Remove the three nuts and wires from the SCR Module.

3. Position the bus bar over the SCR Module as shown in

Figure I-10.

4. Replace the bolts and wires to fasten the bus bar to the SCR Module.

5. Remove the black screw covers from the Bus Bar.

6. Place the preform between the Snubber Board and the Bus Bar

and attach the Snubber Board to the Bus Bar with the nuts

provided.

7. Attach the Snubber Board connecting wire to the SCR Module as

shown in Figure I-10. Finger-tighten the nuts, alternating

between the two, 1/4 turn at a time. Refer to “Torque Sequence”

on page I-4. Refer to “Torque Specifications” on page I-11 for

final tightening.

Assemble the drive in reverse order of removal.

ATTENTION: Replace all guards before applying

power to the drive.Failureto replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 24

I-24

SCR Module Test Important: There are two styles of connectors for the SCR Module.

Both styles are shown in Figure I-11.

Figure I-11

SCR Module Test

G

SCR A

K

Spade

Lugs

3

2, K

AB0897B

SCR B

12 3

K

G

1

K

Spade

Lugs

G

3

2, K

1

DiodeSCR

1336-5.39 – August, 1999

Page 25

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-11.

2. Set your meter to test diodes.

3. The following table shows meter connections and ideal meter

readings for those connections. Refer to Figure I-11 for meter

connection locations.

Nominal Meter Reading

Meter (+) Lead Meter (-) Lead

Volts Ohms

I-25

Diode

SCR

131 – 3 MΩ open 3 1 0.3 – 0.4V 0 – 200KΩ 1 2 open 0.2 – 0.6 MΩ 2 1 open 0.2 – 0.6 MΩ 2G0.0055 – 20 Ω G20.0055 – 20 Ω

4. Replace the SCR Module if any meter readings are not as shown.

Refer to “SCR Module Replacement” on page I-26.

5. If the SCR Module shorted, check the IGBT Modules for

damage.

Important: Refer to your Service or Troubleshooting Manual for

IGBT Module test information.

Assemble the drive in reverse order of removal. Refer to “Torque

Sequence” on page I-4. Refer to “Torque Specifications” on page I-11

for final tightening.

ATTENTION: Replace all guards before applying

power to the drive.Failureto replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 26

I-26

SCR Module Replacement Figure I-12

SCR Module

Preform

SCR

1336-5.39 – August, 1999

AB0915

Page 27

I-27

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-11.

2. Remove all cable connections from the SCR Module.

3. Remove the screws fastening the SCR Module to the drive.

4. Clean all surfaces between the SCR Module and t he heat sink

using a soft, clean cloth.

5. Replace the Preform between the SCR Module and the heat sink.

6. Install the SCR Module in reverse order of removal. Refer to

“Torque Sequence” on page I-4. Refer to “Torque Specifications”

on page I-11 for final tightening.

Assemble the drive in reverse order of removal.

ATTENTION: Replace all guards before applying

power to the drive.Failureto replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 28

I-28

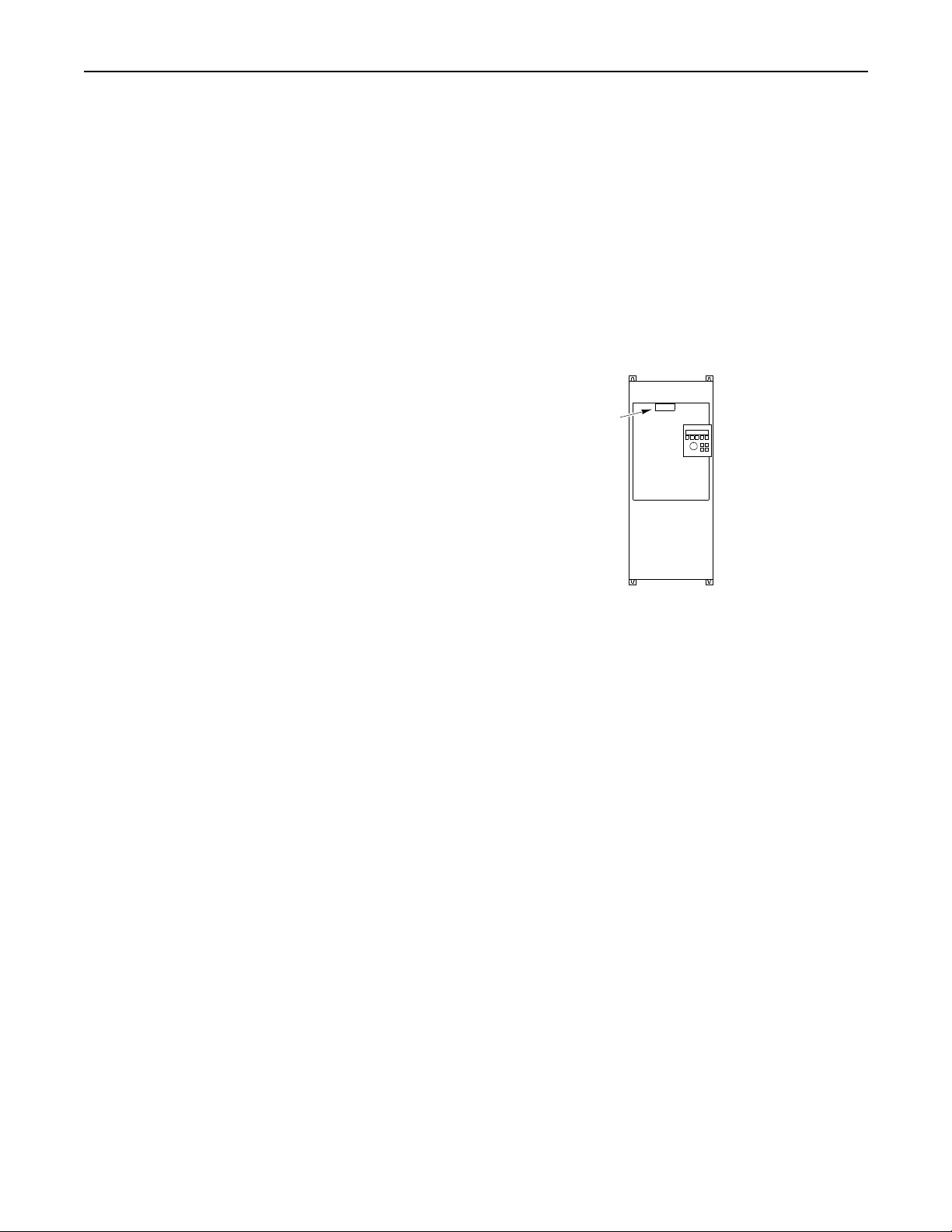

Ratings R150 – R250 and W150 – W250

Product Identification Drive Nameplate Location

The drive nameplate is located on the face of the Control Board/

Adapter Mounting Plate. The drive nameplate contains the drive’s

catalog number and other important drive information. Reference the

catalog number to determinethe rating of your drive, when callingfor

technical assistance, and when ordering replacement parts.

Figure I-13

Drive Name plate Location

Nameplate located on top edge of

Control Board/Adapter Mo un tin g

Plate.

AB0905

1336-5.39 – August, 1999

Page 29

Drive and Option Identification 1336 FORCE Drives

The following is an explanation of the catalog numbering system for

1336 FORCE Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– Use Number for

1336T

Specific Constant

or Variable Torque

Drive

I-29

– GT2EN – L6

Drive Rating

Constant Torque

Frame

Designation

E240.0

Output

Amps

291.4

327.4

Nominal

HP

150

200

250

RATING-ENCLOSURE

BULLETIN NO.

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R150-AN

R200-AN

R250-AN

675 – 800V DC Input

(MUST BE

SPECIFIED)

Enclosures

NEMA Type 1

IP20

General Purpose

R150-AA

R200-AA

R250-AA

LANGUAGE

MODULE

(MUST BE

SPECIFIED)

NEMA Type 4

IP56

Resist Water, Dust

Not available

Not available

Not available

CONTROL

INTERFACE

(OPTIONAL)

NEMA Type 12

IP54

Industrial Use

R150C-AJ

R200C-AJ

R250C-AJ

E159.7

228.6

284.0

150

200

250

W150-AN

W200-AN

W250-AN

W150-AA

W200-AA

W250-AA

Not available

Not available

Not available

W150C-AJ

W200C-AJ

W250C-AJ

1336-5.39 – August, 1999

Page 30

I-30

1336E

– Use Number

for Specific

Constant or

Variable T orque

Drive

1336 IMPACT Drives

The following is an explanation of the catalog numbering system for

1336 IMPACT Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– EN – L6 – HA1 – GM1

RATING-

BULLETIN NO.

Drive Rating

Frame

Designation

E240.0

ENCLOSURE

(MUST BE

SPECIFIED)

Constant Torque

Output

Amps

291.4

327.4

Nominal

HP

150

200

250

LANGUAGE

MODULE

(MUST BE

SPECIFIED)

Open

IP00

No Enclosure

Code Code Code Code

513 – 620V DC Input

R150-AN

R200-AN

R250-AN

675 – 800V DC Input

L-OPTION

(OPTIONAL)

Enclosures

NEMA Type 1

IP20

General Purpose

R150-AA, -AE

R200-AA, -AE

R250-AA, -AE

HUMAN

INTERFACE

(OPTIONAL)

NEMA Type 4

IP56

Resist Water, Dust

Not available

Not available

Not available

COMMUNICATION

CARD

(OPTIONAL)

NEMA Type 12

IP54

Industrial Use

R150C-AJ

R200C-AJ

R250C-AJ

E159.7

1336-5.39 – August, 1999

252.6

283.6

150

200

250

W150-AN

W200-AN

W250-AN

W150-AA

W200-AA

W250-AA

Not available

Not available

Not available

W150C-AJ

W200C-AJ

W250C-AJ

Page 31

1336S

1336 PLUS Drives

The following is an explanation of the catalog numbering system for

1336 PLUS Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– Use Number for

Specific Constant or

Variable Torque

Drive

I-31

– BM – GM1 – HA1C . . .

BULLETIN NO.

Constant Torque Varia ble Torque

Frame

Designation

E199.0

E158.0

Output

Amps

263.0

325.0

252.0

284.0

Drive Rating

Nominal HPOutput

150

200

250

150

200

250

RATING-ENCLOSURE

(MUST BE SPECIFIED)

.

Nominal

Amps

240.0

292.0

325.0

158.0

252.0

284.0

HP

513 – 620V DC Input

200

250

250

675 – 800V DC Input

150

200

250

OPTIONS AS REQUIRED

Enclosures

Open

IP00

No Enclosure

Code Code Code Code

R150-AN

R200-AN

R250-AN

W150-AN

W200-AN

W250-AN

NEMA Type 1

IP20

General

Purpose

R150-AA

R200-AA

R250-AA

W150-AA

W200-AA

W250-AA

NEMA Type 4

IP56

Resist Water,

Dust

Not available

Not available

Not available

Not available

Not available

Not available

NEMA Type 12

IP54

Industria l Use

R150-AJ

R200-AJ

R250-AJ

W150-AJ

W200-AJ

W250-AJ

1336-5.39 – August, 1999

Page 32

I-32

1336F

– Use Number

for Specific

Constant or

Variable Torque

Drive

1336 PLUS II Drives

The following is an explanation of the catalog numbering system for

1336 PLUS II Common Bus AC Drives and options. The catalog

number is coded to identify the drive power rating and can be found

on the drive shipping carton and nameplate.

Catalog Number Explanation

– EN – LA6 – HAS1 – GMS1

BULLETIN NO.

Constant Torque Varia ble Torque

Frame

Designation

E199.0

E158.0

Output

Amps

263.0

325.0

252.0

284.0

RATING-

ENCLOSURE

(MUST BE

SPECIFIED)

Drive Rating

Nominal HPOutput

150

200

250

150

200

250

Amps

240.0

292.0

325.0

158.0

252.0

284.0

LANGUAGE

(MUST BE

SPECIFIED)

Nominal

HP

513 – 620V DC Input

200

250

250

150

200

250

R150-AN

R200-AN

R250-AN

675 – 800V DC Input

W150-AN

W200-AN

W250-AN

CONTROL

INTERFACE

(OPTIONAL)

Open

IP00

No Enclosure

Code Code Code Code

NEMA Type 1

IP20

General

Purpose

R150-AA

R200-AA

R250-AA

W150-AA

W200-AA

W250-AA

HUMAN

INTERFACE

(OPTIONAL)

Enclosures

NEMA Type 4

Resist Water,

Not available

Not available

Not available

Not available

Not available

Not available

COMMUNICATION

(OPTIONAL)

IP56

Dust

R150-AJ

R200-AJ

R250-AJ

W150-AJ

W200-AJ

W250-AJ

CARD

NEMA Type 12

IP54

Industria l Use

1336-5.39 – August, 1999

Page 33

Torque Specifications The following table lists fastener locations by component,

application,and torque specifications.Refer to “Torque Sequence” on

page I-4 for fastening two-point, four-point, and six-point

components to the heat sink.

I-33

Component Fastener Application

Snubber Board Board to SCR Module 50 6

SCR Module Module to heat sink 50 6

Wires (PE) Wires to Ground Stud 80 9

Wires Wires to TB1 80 9

Wire (TE) Wire to TB1 50 6

Wires Wires to TB3 8 – 10 0.9 – 1.13

Main Control, Gate Driver, Precharge

Board Mounting Pla t es

High Voltage Guard Guard to chassis 26 3

Plates to chassis 26 3

Torque

lb-in.

Torque

N-m

SCR Module Access

ATTENTION: Disconnect and lock out power from

the drive before disassembling the drive. Failure to

!

disconnect power may result in death or serious injury.

Verify bus voltage by measuring the voltage between

+DC and -DC on Ter minal Block TB1. Do not attempt

to service the driveuntil the bus voltage has discharged

to zero volts.

ATTENTION: Wear a wrist-type grounding strap

when servicing drives. Failure to protect drive

!

components against ESD may damage drive

components. Refer to “Electrostatic Discharge

Precautions” on page I-4.

Important: Before you removeconnections and wires from the drive

components, mark the connections and wires to correspond with their

component connections and terminals to prevent incorrect wiring

during assembly.

1336-5.39 – August, 1999

Page 34

I-34

1336 FORCE Drives

Remove the High Voltage Guard

Figure I-14

High Voltage Guard

High Voltage Guard

AB0907

1336-5.39 – August, 1999

Page 35

I-35

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage at:

– TB20andTB21ondrivesusingaPLCCommAdapterBoard

– TB5, TB6, and TB7 on drives using a Standard Adapter

Board

5. Remove the screws fastening the High Voltage Guard to the

standoffs.

6. Lift the guard upward to disengage the tabs on the right side from

the bus bar supports.

7. Pull the guard away from the drive.

1336-5.39 – August, 1999

Page 36

I-36

Remove the Control Board/Adapter Mounting Plate

Figure I-15

Control Board/Adapter Mounting Plate

PLC Comm

Adapter Board

Mounting Plate

Main Control

Board

TB10

J7

J1

J5

J7

TB21

TB20

HIM (Standard Adapter

Board only)

Standard

Adapter

Board

J1

TB7

TB6

TB5

AB0908

1336-5.39 – August, 1999

Page 37

I-37

1. Remove the wires and c onnectors from the Standard or PLC

Comm Adapter Board.

2. Remove the wires and connectors from the Main Control Board.

3. Slide the LEM harness out of the clip located at the top-left of the

Control Board/Adapter Mounting Plate.

4. Remove the two screws fastening the bottom of the Control

Board/Adapter Mounting Plate to the standoffs.

5. Remove the nuts fastening the top of the Control Board/Adapter

Mounting Plate to the Gate Driver Board Mounting Plate.

6. Lift the Control Board/Adapter Mounting Plate out of the drive.

7. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-50.

1336-5.39 – August, 1999

Page 38

I-38

1336 IMPACT Drives

Remove the High Voltage Guard

Figure I-16

High Voltage Guard

High Voltage Guard

AB0951

1336-5.39 – August, 1999

Page 39

I-39

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage at:

– TB10

– TB11

– L-Option Board (if used)

5. Remove the screws fastening the High Voltage Guard to the

standoffs.

6. Lift the guard upward to disengage the tabs on the right side from

the bus bar supports.

7. Pull the guard away from the drive.

1336-5.39 – August, 1999

Page 40

I-40

Remove the Main Control Board Mounting Plate

Figure I-17

Main Control Board Mounting Plate

Main Control

Board

Connector

J5

Terminal

Block TE

Mounting Plate

Slide-Mount

Stand-Off

Connector

J1

Connector

J7

Mounting

Screw

AB0949

1336-5.39 – August, 1999

Page 41

I-41

1. Disconnect the following from the Main Control Board:

– J1 connector

– J5 ribbon cable connector

– J7 connector

– Ground wires from terminal block TE

– Chassis ground wire at the top-right corner of the Main

Control Board Mounting Plate

2. Slide the LEM harness out of the clip located at the top-left of the

Main Control Board Mounting Plate.

3. Remove the two screws fastening the bottom of the Main Control

Board M ounting Plate to the standoffs.

4. Remove the nuts fastening the top of the Main Control Board

Mounting Plate to the Gate Driver Board Mounting Plate.

5. Lift the Main Control Board Mounting Plate out of the drive.

6. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-50.

1336-5.39 – August, 1999

Page 42

I-42

1336 PLUS Drives

Remove the High Voltage Guard

Figure I-18

High Voltage Guard

High Voltage Guard

1336-5.39 – August, 1999

AB0950

Page 43

I-43

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage.

5. Remove the screws fastening the High Voltage Guard to the

standoffs.

6. Lift the guard upward to disengage the tabs on the right side from

the bus bar supports.

7. Pull the guard away from the drive.

1336-5.39 – August, 1999

Page 44

I-44

Remove the Main Control Board Mounting Plate

Figure I-19

Main Control Board Mounting Plate

Connector

J2

Ground

Stud

Terminal

Block TE

Mounting

Plate

Main Control

Board

Connector J1

Connector J6

8-Pin HIM Connector

Connector J8

Terminal Block

TB2

Terminal Block

TB3

AB0948

1336-5.39 – August, 1999

Page 45

I-45

1. Disconnect the following from the Main Control Board:

– J1 connector

– J2 ribbon cable connector

– J8 connector

– 8-pin connector from the HIM M ounting Plate on the Main

Control Board

– Ground wires from terminal block TE

– Chassis ground wire at the top-right corner of the Main

Control Board Mounting Plate

2. Slide the LEM harness out of the clip located at the top-left of the

Main Control Board Mounting Plate.

3. Remove the two screws fastening the bottom of the Main Control

Board M ounting Plate to the standoffs.

4. Remove the nuts fastening the top of the Main Control Board

Mounting Plate to the Gate Driver Board Mounting Plate.

5. Lift the Main Control Board Mounting Plate out of the drive.

6. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-50.

1336-5.39 – August, 1999

Page 46

I-46

1336 PLUS II Drives

Remove the High Voltage Guard

Figure I-20

High Voltage Guard

High Voltage Guard

1336-5.39 – August, 1999

AB0966

Page 47

I-47

1. Remove power from the drive.

2. Open the Enclosure door.

Drive s hown with door open, sides removed.

3. Check for zero volts at TB1 terminals +DC and -DC.

4. Check for the absence of control voltage.

5. Remove the screws fastening the High Voltage Guard to the

standoffs.

6. Lift the guard upward to disengage the tabs on the right side from

the bus bar supports.

7. Pull the guard away from the drive.

1336-5.39 – August, 1999

Page 48

I-48

Remove the Main Control Board Mounting Plate

Figure I-21

Main Control Board Mounting Plate

Main Control Board Mounting Pl ate

Connector J2

Comm Connector

Plug

Ground Wire

Stake-on

Connector J10

Connector J5

Comm Connector

Terminal

Block TB2

Terminal

Block TE

AB0967

1336-5.39 – August, 1999

Page 49

I-49

1. Disconnect the following from the Main Control Board:

– J2 ribbon cable connector

– Comm connector

– J10 ground wire at the stake on connector

– J5 connector

– All wires from the terminals on TB2 and TE

2. Slide the LEM harness out of the clip located at the top-left of the

Main Control Board Mounting Plate.

3. Remove the two screws fastening the bottom of the Main Control

Board M ounting Plate to the standoffs.

4. Remove the nuts fastening the top of the Main Control Board

Mounting Plate to the Gate Driver Board Mounting Plate.

5. Lift the Main Control Board Mounting Plate out of the drive.

6. Continue with “Gate Driver Board and Precharge Board

Mounting Plates” on page I-50.

1336-5.39 – August, 1999

Page 50

I-50

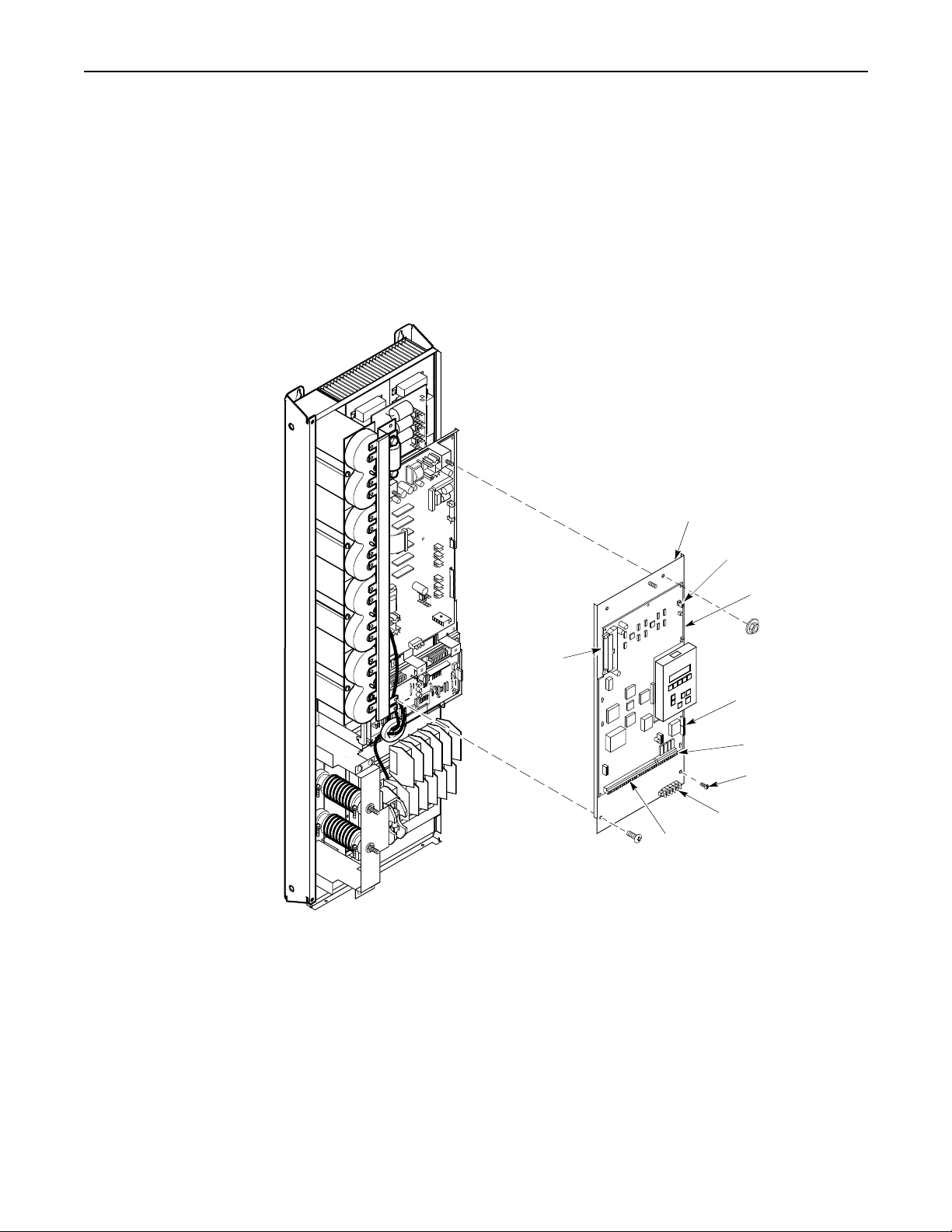

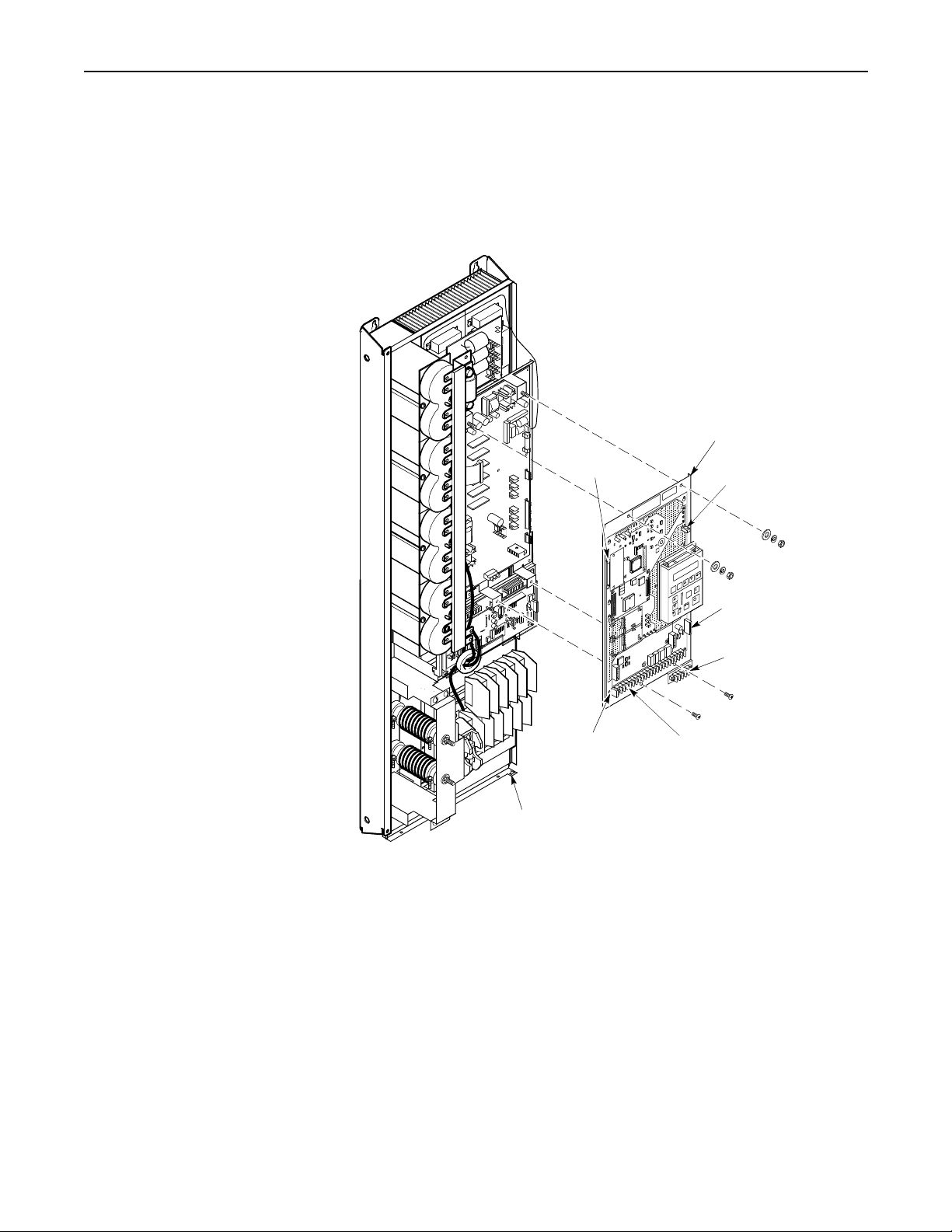

All 1336 FORCE, IMPACT, PLUS, and PLUS II Drives

Remove the Gate Driver Board and Precharge Board Mounting Plates

Figure I-22

Gate Driver Board and Prech arge Board Mo unting Plates

J8

J3

Ground

Stud

Mounting

Plate

J2

J6

Ground Stud

J2

J10

Mounting

Plate

J13

J7

J8

J9

AB0909

1336-5.39 – August, 1999

Page 51

1. Remove Gate Driver Board connections:

– J2 connector

– J6 connector

– J7 connector

– J8 connector

– J9 connector

– J10 connector

– TB6 High Voltage Aux. Input (if equipped)

– Ground wire from the top of the Gate DriverBoard Mounting

Plate

– J13 connector

ATTENTION: Whenremovingtheentirewireharness

connectingGateDriverBoardconnectorJ9toPrecharge

!

Board connector J3, align the wires on the harness

terminals with the pins on the board connectors.

Incorrect harness connection may result in faulty drive

operation and may damage the equipment.

I-51

2. Removethe screws fastening the bottom of the Gate DriverBoard

Mounting Plate to the chassis.

3. Slide the plate toward the top of the drive to disengage the

mounting plate tabs from the slots on the chassis.

4. Life the plate out of the drive.

5. Disconnect the following from the Precharge Board:

– J2 connector

– J3 connector

– Ground wire from the stud at the bottom left of the mounting

plate

6. Remove the screws fastening the top of the Precharge Board

Mounting Plate to the chassis.

7. Slide the Precharge Board Mounting Plate toward the bottom of

the drive to disengage the tabs from the slots in the chassis.

8. Lift the Precharge Board Mounting Plate out of the enclosure.

1336-5.39 – August, 1999

Page 52

I-52

Snubber Board Installation Figure I-23

Snubber Board Installation

Snubber Board

SCR

Bus Bar

Preform

AB0911

1336-5.39 – August, 1999

Page 53

I-53

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-33.

2. Remove the three nuts and wires from the SCR Module.

3. Position the bus bar over the SCR Module as shown in

Figure I-23.

4. Replace the bolts and wires to fasten the bus bar to the SCR

Module.

5. Remove the black screw covers from the Bus Bar.

6. Place the preform between the Snubber Board and the Bus Bar

and attach the Snubber Board to the Bus Bar with the nuts

provided.

7. Attach the Snubber Board connecting wire to the SCR Module as

shown in Figure I-23. Finger-tighten the nuts, alternating

between the two nuts, 1/4 turn at a time. Refer to “Torque

Sequence” on page I-4. Refer to “Torque Specifications” on

page I-33 for final tightening.

Assemble the drive in reverse order of removal.

ATTENTION: Replace all guards before applying

power to the drive.Failure to replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 54

I-54

SCR Module Test Important: There are two styles of connectors for the SCR Module.

Both styles are shown in Figure I-24.

Figure I-24

SCR Module Test

G

SCR A

K

Spade

Lugs

3

2, K

AB0898

SCR B

12 3

K

G

1

K

Spade

Lugs

G

3

2, K

1

DiodeSCR

1336-5.39 – August, 1999

Page 55

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-33.

2. Set your meter to test diodes.

3. The following table shows meter connections and ideal meter

readings for those connections. Refer to Figure I-24 for meter

connection locations.

Nominal Meter Reading

Meter (+) Lead Meter (-) Lead

Volts Ohms

I-55

Diode

SCR

131 – 3 MΩ open 3 1 0.3 – 0.4V 0 – 200KΩ 1 2 open 0.2 – 0.6 MΩ 2 1 open 0.2 – 0.6 MΩ 2G0.0055 – 20 Ω G20.0055 – 20 Ω

4. Replace the SCR Module if any meter readings are not as shown.

Refer to “SCR Module Replacement” on page I-56.

5. If the SCR Module shorted, check the IGBT Modules for

damage.

Important: Refer to your Service or Troubleshooting Manual for

IGBT Module test information.

Assemble the drive in reverse order of removal. Refer to “Torque

Sequence” on page I-4. Refer to “Torque Specifications” on page I-33

for final tightening.

ATTENTION: Replace all guards before applying

power to the drive.Failureto replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 56

I-56

SCR Module Replacement Figure I-25

SCR Module

Preform

SCR

AB0910

1336-5.39 – August, 1999

Page 57

I-57

1. Access the SCR Module. Refer to “SCR Module Access” on

page I-33.

2. Remove the screws fastening the Positive and Negative Converter

Bars to the DC Bus Inductor.

3. Remove the TB1 Input Bus Bars and the Precharge Board Wiring

Harnesses from the SCR Module.

4. Remove the screws fastening the SCR Module to the heat sink.

5. Clean all surfaces between the SCR Module and t he heat sink

using a soft, clean cloth.

6. Replace the Preform between the SCR Module and the heat sink.

7. Install the SCR Module in reverse order of removal. Refer to

“Torque Sequence” on page I-4. Refer to “Torque Specifications”

on page I-33 for final tightening.

Assemble the drive in reverse order of removal.

ATTENTION: Replace all guards before applying

power to the drive.Failureto replace guards may result

!

in death or serious injury.

1336-5.39 – August, 1999

Page 58

Notes:

I-58

Publication 1336-5.39 – August, 1999

Copyright 1999 Rockwell International Corporation. All rights reserved. Printed in USA

191601 (01)

Loading...

Loading...