Page 1

Installation Instructions

Lifting Instructions for 1336 PLUS and

FORCE

This publication will guide you through the steps needed to properly

lift and mount the following drives:

• 1336 PLUS – 30-112 kW (40-150 HP)

• 1336 FORCE – 30-112 kW (40-150 HP)

!

“D” Frame Drives

ATTENTION: To guard against possible personal

injury or equipment damage . . .

• Do Not allow any part of the drive or lifting mechanism to make contact with electrically charged conductors or components.

• At no time should a person or their limbs be directly

underneath the items being lifted.

• Do not subject the load to high rates of acceleration

or deceleration.

• Inspect all lifting hardware for proper attachment

before

lifting drive unit.

Required Lifting Components

Vertical Drive Mounting

The following items will be required to properly lift the drive –

mounting method chosen will determine quantities needed.

Item Load Rating Quantity McMaster-Carr P/N

Wire Rope Sling 462.7 kg (1020 lb.) 2 or 4 3550T113

Adjustable Spreader Bar 1134 kg (2500 lb.) 1 3977T11

Anchor Shackle 1361 kg (3000 lb.) 4 or 6 3663T51

“S” Hook 227 kg (500 lb.) 2 or 4 3631T71

Perform the following steps to vertically mount the drive.

1. Determine the center of gravity for the drive. The hoist hook must

be located directly above the center of gravity to assure that the

drive hangs properly. For example, the center of gravity for a

380-480V, 93 kW (125 HP), 1336 PLUS stand-alone open chassis

drive is about 50.8 mm (2 in.) to the left of center.

Page 2

2

Lifting Instructions for 1336 PLUS and FORCE “D” Frame Drives

2. Place two shackles through the spreader bar about 660 mm

(26 in.) apart. Using two wire ropes, hook one end of each rope to

a shackle on the spreader bar. Hook the other end of each rope to

an “S” hook (using a shackle). Perform the appropriate step

below (A or B) for your type of drive.

A. Open Chassis Drive

Insert the “S” hooks into the two top 9.5 mm (0.375 in.) holes

in the drive chassis (A-A). Refer to Figure 1. Proceed to step 3.

B. Drive with NEMA Type 1 Enclosure

Install the two lifting eyebolts (supplied) into the threaded

holes on the top panel of the drive and torque to 9.5 N-m

(7 lb.-ft.). Refer to Figure 1. Insert the “S” hooks into the

eyebolts. Proceed to step 3.

3. Check the hole pattern on the panel to which the drive will be

mounted. Refer to Figure 2 for the correct pattern. Insert, but do

not fully tighten two bolts in the top holes of the panel. Allow

enough room for the drive mounting feet to slide behind the bolt

heads. The bottom bolts will be installed later.

Horizontal Drive Mounting

4. Lift drive into place. Verify that the hardware engages properly

into the keyhole slots.

5. Once the top bolts are properly seated, the bottom bolts can be

installed and tightened. Tighten all bolts to a torque of 13.6 N-m

(120 lb.-in.).

The following procedure will guide you through the steps needed to

horizontally mount an open chassis drive through a cutout into a

gasketed NEMA Type 4 or 12 enclosure.

1. Determine the center of gravity for the drive. The hoist hook must

be located directly above the center of gravity to assure that the

drive hangs properly. For example, the center of gravity for a

380-480V, 93 kW (125 HP), 1336 PLUS stand-alone drive is

through the physical center of drive, 330 mm (13 in.) from the

bottom inside flange and about 50.8 mm (2 in.) to the left of

center.

2. Place two shackles through the spreader bar about 660 mm (26

in.) apart. Using two wire ropes, hook one end of each rope to the

same shackle on the spreader bar. Hook the other end of each

rope to an “S” hook (using a shackle). Repeat for second spreader

bar shackle.

Insert two hooks on each side of the drive, using the 9.5 mm

(0.375 in.) holes specified below (refer to Figure 1).

Important: Use holes A-A & C-C for Common Bus Drives.

Use holes B-B & C-C for Stand-Alone Drives.

Page 3

3. Check the hole pattern on the panel to which the drive will be

mounted. Refer to Figure 3 for the correct pattern.

4. Place the adhesive side of the gasket on the back of the drive.

Line up the holes between the gasket and drive. In this

configuration, the heat sink will be located outside of the

enclosure.

5. Lift drive into place. The screws on the right of the heat sink

should fit through the notches cut into the panel. M5 x 12 mm

screws are required in 18 locations; the tightening torque is 2.9

N-m (26 lb.-in.).

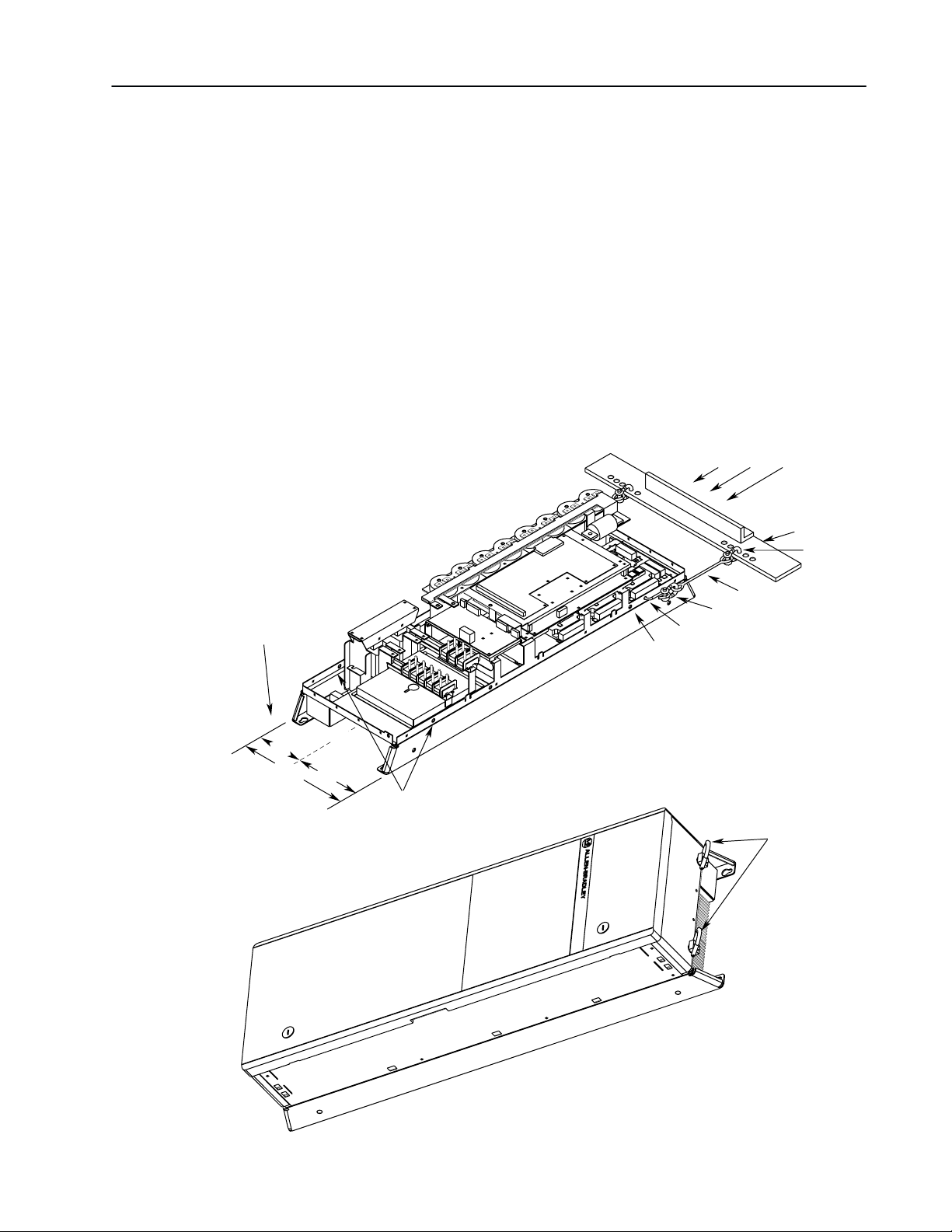

Figure 1

Drive Lifting Locations

Open Chassis Drive

(typical vertical mounting shown)

Hoist Hook MUST be placed

over Drive Center of Gravity

Spreader Bar

Shackle

Center of Gravity is 50.8 mm (2 in.)

to the left of physical center on

a 380-480V AC, 93 kW (125 HP)

stand-alone drive.

140 mm

(5.5 in.)

381.0 mm

(15.0 in.)

cg

241 mm

(9.5 in.)

Wire Rope

Shackle

"S" Hook (Hole A-A)

Hole B-B

Hole C-C

Lifting Eyebolts

NEMA Type 1 Drive

Page 4

Lifting Instructions for 1336 PLUS and FORCE “D” Frame Drives

Figure 3

Mounting Dimensions

325.9 (12.83)

5/16 - 18 or M8 Tapped Hole

4

1216.2 (47.88)

Page 5

5

Lifting Instructions for 1336 PLUS and FORCE “D” Frame Drives

Figure 3

Cutout Dimensions

362.2

1118.6

(44.04)

26.7

(1.05)

356.1

(14.02)

(14.26)

Detail

6.1

(0.24)

4.6 (0.18)

See Detail

9.9 (0.39)

962.7

(37.90)

806.7

(31.76)

650.8

(25.62)

494.5

(19.47)

338.6

(13.33)

1145.3

(45.09)

Cutout as Viewed

from INSIDE Enclosure

1054.4

(41.51)

867.4

(34.15)

773.9

(30.47)

680.5

(26.79)

587.0

(23.11)

182.6

(7.19)

26.7

(1.05)

* Minimum dimension allowed – More space will improve fan effect and heat dissipation.

All Dimensions in Millimeters and (Inches)

M5 Threaded Holes – 16 Required

Back of EnclosureDrive

84.1 (3.31) *

Page 6

1336 FORCE is a trademark of Allen-Bradley Company, Inc.

Allen-Bradley, a Rockwell Automation Business, has been helping its customers improve

productivity and quality for more than 90 years. We design, manufacture and support a broad

range of automation products worldwide. They include logic processors, power and motion

control devices, operator interfaces, sensors and a variety of software. Rockwell is one of the

world’s leading technology companies.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Brazil • Bulgaria • Canada • Chile • China, PRC • Colombia • Costa Rica • Croatia • Cyprus • Czech Republic •

Denmark • Ecuador • Egypt • El Salvador • Finland • France • Germany • Greece • Guatemala • Honduras • Hong Kong • Hungary • Iceland • India • Indonesia •

Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Malaysia • Mexico • Netherlands • New Zealand • Norway • Pakistan • Peru •

Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia–CIS • Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic • Spain •

Sweden • Switzerland • Taiwan • Thailand • Turkey • United Arab Emirates • United Kingdom • United States • Uruguay • Venezuela • Yugoslavia

Allen-Bradley Headquarters, 1201 South Second Street, Milwaukee, WI 53204 USA, Tel: (1) 414 382-2000 Fax: (1) 414 382-4444

Publication 1336-5.20 – November, 1995 PN 74002-134-01(A)

Copyright 1995 Allen-Bradley Company, Inc. Printed in USA

Loading...

Loading...