Page 1

Allen-Bradley

Bulletin 1203

Remote I/O

Communications

Module

Cat. Nos. 1203-GD1,

1203-GK1, or 1336-GM1

Firmware 1.xx – 4.xx

User Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those responsible for the application and use of this

control equipment must satisfy themselves that all necessary steps

have been taken to assure that each application and use meets all

performance and safety requirements, including any applicable laws,

regulations, codes and standards.

The illustrations, charts, sample programs and layout examples

shown in this guide are intended solely for purposes of example.

Since there are many variables and requirements associated with any

particular installation, Rockwell Automation does not assume

responsibility or liability (to include intellectual property liability) for

actual use based upon the examples shown in this publication.

Rockwell Automation publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(available from your local Rockwell Automation office or online at

www.ab.com/manuals/gi), describes some important differences

between solid-state equipment and electromechanical devices that

should be taken into consideration when applying products such as

those described in this publication.

Reproduction of the contents of this copyrighted publication, in

whole or in part, without written permission of Rockwell

Automation, is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations:

ATTENTION: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• Identify a hazard.

• Avoid the hazard.

• Recognize the consequences.

Important: Identifies information that is critical for successful

application and understanding of the product.

death, property damage or economic loss.

Page 3

Summary of Changes

The information below summarizes the changes made to this manual

since the last release.

Updated Information

Updates and Additions

This manual incorporates the information found in the following two

manuals:

• Bulletin 1203 Remote I/O Communication Module Getting

Started Manual, Publication 1203-5.1.

• Bulletin 1203 Remote I/O Communications Module Reference

Manual, Publication 1203-5.0.

It also contains new information.

The information below summarizes the changes to this manual since

its last release:

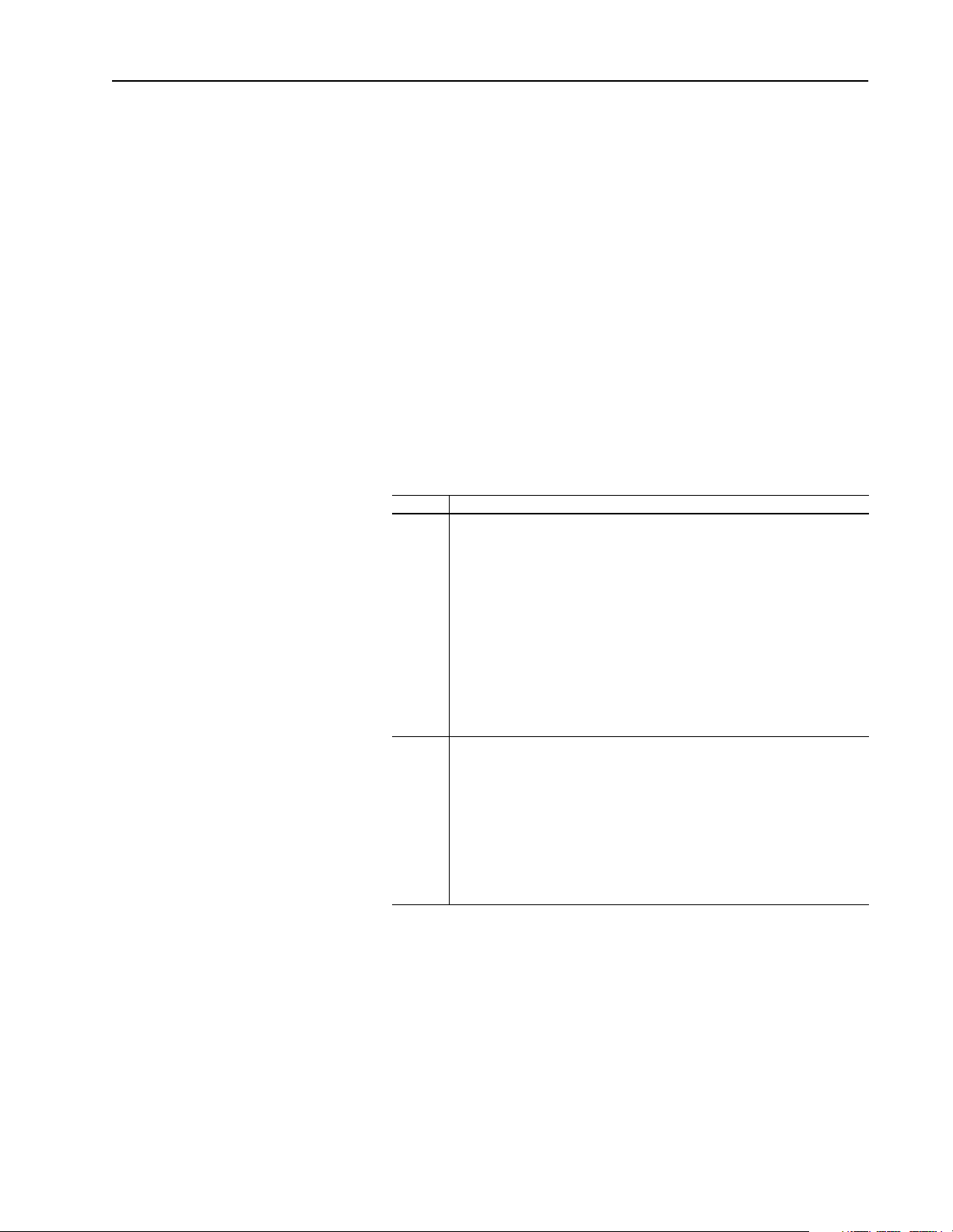

Page Description

2-5 Important statement added:

Injury or equipment damage can result from loss of PLC or Controller Logic

Commands (Stop, Start, etc.) when all these conditions are true:

- module firmware 3.04 or lower.

- 230.4k baud rate.

- block transfer is enabled (DIP switch SW3-1 is ON).

- block transfers to the module are used (in the ladder program or by DriveTools/

DriveTools32 using a Remote I/O pass thru connection).

Do not use the 230.4k baud rate if you are using a module with 3.04 or earlier

firmware and your program uses block transfers. Use the 57.6k or 115.2k baud

rate instead.

2-6 Attention statement added:

Due to an anomaly in firmware release 4.01, Remote I/O modules that are used

only for block transfer messages require the following configuration: switches for

block transfer and reference/feedback should both be enabled (SW 3.1 and SW

3.3 are ON. SW 3.2 and SW 3.4 through 3.8 are OFF).

This configuration prevents a fault on power up. It does not affect rack I/O

allocation or the ladder logic program because it still fits within 1/4 rack I/O space.

The drive will, however, generate a serial fault if the communications module is

disconnected or loses power.

Page 4

2

End of Summary of Changes

Page 5

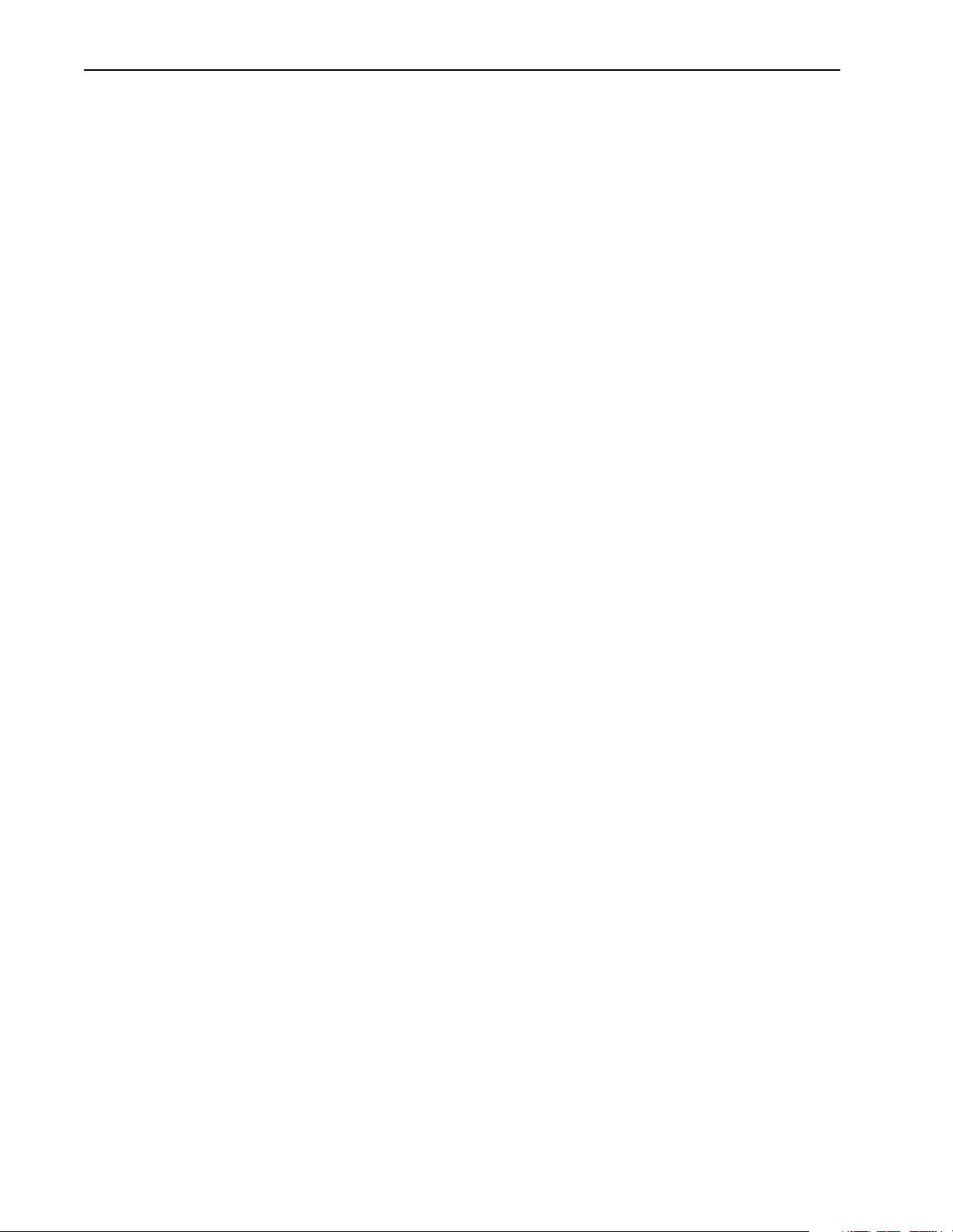

Using This Manual

Overview

Configuring the Module

Table of Contents

Preface

Preface Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Audience for This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Purpose of This Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Firmware Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-1

Terms and Abbreviations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-2

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-3

Rockwell Automation Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . P-4

Chapter 1

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Description of the Remote I/O Communications Modules . . . . . . . . . . . . 1-1

Features of the Communications Module . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Required Tools and Equipment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Overview of Setting Up the Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Chapter 2

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Safety Precautions and Important Information . . . . . . . . . . . . . . . . . . . . . 2-1

Locating the DIP Switches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Factory-Default Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Quick Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Configuring the module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Setting Switches on SW3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-5

Setting Switches on SW2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Setting Switches on SW1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Installing the Module

Creating Ladder Logic

Programs

Chapter 3

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Selecting a Termination Resistor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Installing a 1203-GD1 or 1203-GK1 Module. . . . . . . . . . . . . . . . . . . . . . . 3-3

Installing a 1336-GM1 Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Understanding the I/O Image Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Control Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Datalinks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Settings for the Ladder Logic Program Examples. . . . . . . . . . . . . . . . . . . 4-5

Example PLC Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-8

Example SLC Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Example Logix5550 Ladder Logic Program . . . . . . . . . . . . . . . . . . . . . . 4-12

Page 6

ii Table of Contents

Using Block Transfer Messages

Troubleshooting

Chapter 5

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Understanding Block Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Understanding the Block Transfer Status Word . . . . . . . . . . . . . . . . . . . . . 5-2

Understanding Data Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Example PLC Block Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-3

Example SLC Block Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Example Logix5550 Block Transfers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Notes Regarding Block Transfer Programming . . . . . . . . . . . . . . . . . . . . . 5-8

Chapter 6

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

LEDs on the Remote I/O Communications Module . . . . . . . . . . . . . . . . . . 6-1

FAULT LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

SCANport STS LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Health LED. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Rem I/O ACT LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Rem I/O STS LED . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Specifications

Supported Block Transfer

Messages

Appendix A

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

1336-GM1 Board Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

1203-GD1 Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

1203-GK1 Module Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Appendix B

Appendix Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Supported Block Transfer Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-1

Block Transfer Data Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-2

Parameter Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-3

Parameter Value Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-4

Parameter Read Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-5

Product ID Number Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-8

Scattered Parameter Value Read. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-10

Scattered Parameter Value Write. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-12

Continuous Parameter Value Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-14

Save/Recall/Initialize . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-16

Fault Command Write . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-17

Fault Queue Entry Read Full . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-18

Fault Queue Size Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-20

Trip Fault Queue Number Read . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-21

Block Transfer Quick Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B-22

Page 7

Using This Manual

Preface

Preface Objectives

Audience for This Manual

Read this preface to familiarize yourself with the rest of the manual.

In this preface, you will read about the following:

• Intended audience for this manual.

• Purpose of this manual.

• Firmware supported by this manual.

• Terms and abbreviations.

• Safety precautions.

• Rockwell Automation support.

Use this manual if you are responsible for setting up and using a

Remote I/O communications module (Bulletin numbers 1203-GD1,

1203-GK1, or 1336-GM1). You must have previous experience with

and a basic understanding of communications terminology,

configuration procedures, required equipment, and safety precautions.

To use this Remote I/O communications module efficiently, you must

be able to program and operate programmable controllers as well as

have a basic understanding of the parameter settings and functions of

the SCANport™ product with which you are communicating.

Purpose of This Manual

Firmware Support

This manual is an installation and user guide for the Remote I/O

communications module. The 1203 Remote I/O communications

modules are available for products that include SCANport.

This manual provides the following information:

• An overview of the Remote I/O communications module.

• Procedures that you need to install, configure, and troubleshoot

the Remote I/O communications module.

• Example ladder logic programs for controlling a product and

using block transfer messages.

Important:

This manual supports firmware versions 1.xx to 4.xx (the “xx”

designator may vary). Features that work with specific firmware

versions will be identified.

You should read this manual in its entirety before

configuring, installing, operating, or troubleshooting the

Remote I/O communications module.

Page 8

P–2 Using This Manual

Contents of this Manual

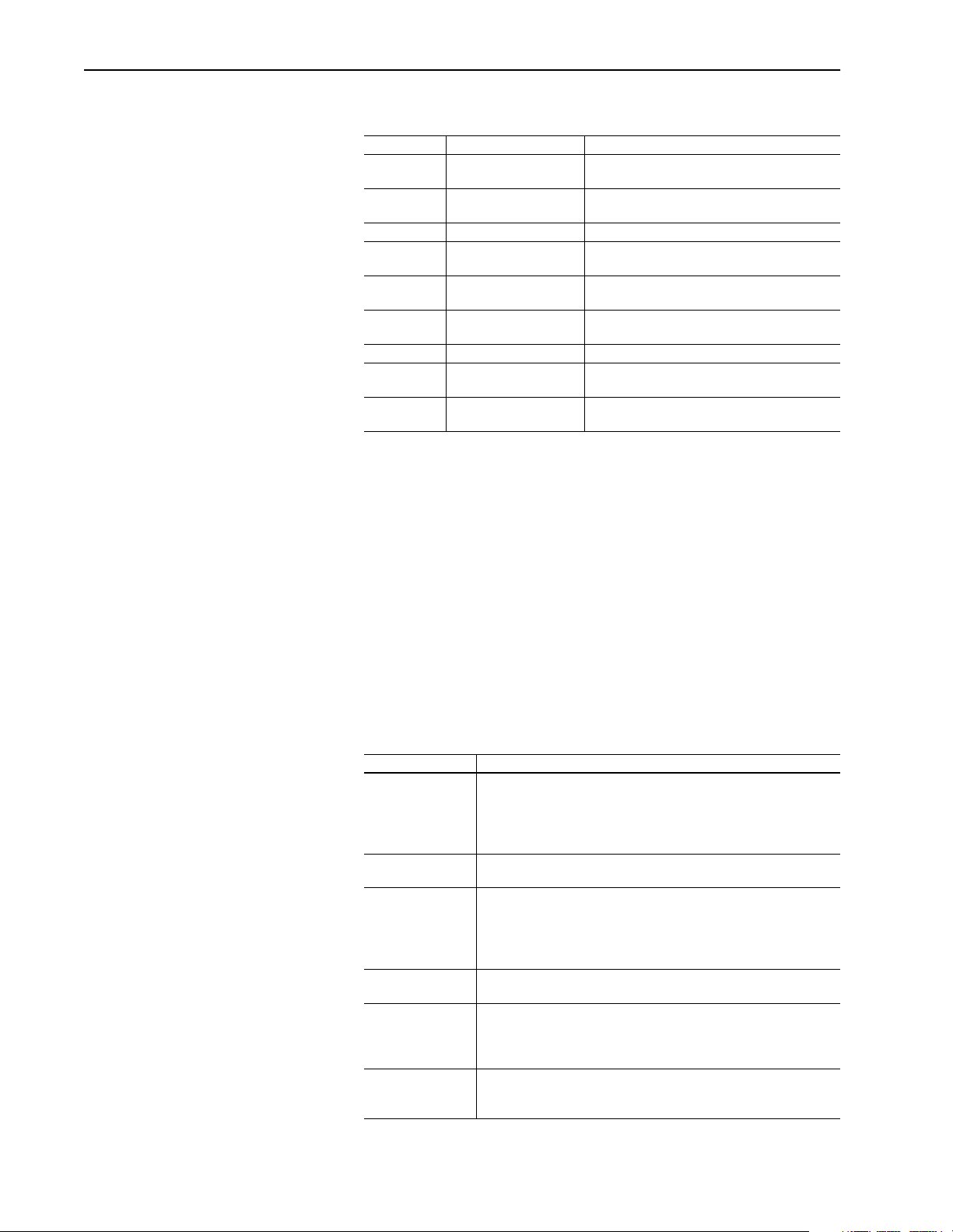

Chapter Title Contents

Preface Using This Manual Descriptions of the audience, purpose, back-

ground, and scope of this manual.

1 Overview Features of the Remote I/O communications

module.

2 Configuring the Module Procedures for setting DIP switches.

3 Installing the Module Procedures for mounting, connecting cables, and

connecting power.

4 Creating Ladder Logic

Programs

5 Using Block Transfer

Messages

6 Troubleshooting Information about troubleshooting the module.

A Specifications Environmental, electrical, and communication

B Supported Block Transfer

Messages

Information about addressing, information transfer, and sample programs.

Information about messaging and sample programs.

specifications.

Information about block transfer messages.

Related Documentation

You can obtain documentation about Allen-Bradley products,

including PLC controllers, SLC controllers, Logix5550 controllers,

and drives, from your local Rockwell Automation office or

distributor. You can also access documents online at

http://www.ab.com/manuals

Terms and Abbreviations

Application notes are available at

http://www.ab.com/drives/stddrives/faxback/faxback.htm

The following terms are specific to this product. For a complete

listing of automation terminology, refer to the Rockwell Automation

Industrial Automation Glossary, Publication Number AG-7.1.

Terms Definition

Controller A solid-state control system that has a user-programmable memory for

storage of instructions to implement specific functions such

as I/O control, logic, timing, counting, report generation, communication, arithmetic, and data file manipulation. A controller is also called a

“programmable logic controller” or “processor.”

Remote I/O I/O connected to a processor across a serial link. With a serial link,

Remote I/O

Communications

Module

SCANport A standard peripheral communications interface for various

SCANport

Peripheral

SCANport

Product

remote I/O can be located long distances from the processor.

This module connects a SCANpor t product to a Remote I/O link. There

are three types of Remote I/O communications modules: 1203-GD1

module, 1203-GK1 module, and 1336-GM1 board. The Remote I/O

module is also referred to as “adapter,” “module,” and communications

module.”

Allen-Bradley drives and power products.

A device that provides an interface between SCANport and a commu-

nications system such as Remote I/O. It is often referred to as an

adapter or communications module. For example, the Remote I/O

module is a SCANport peripheral.

A device that uses the SCANport communications interface to communicate with one or more peripheral devices. For example, a motor drive

such as a 1336 PLUS is a SCANport product.

Page 9

Safety Precautions

Using This Manual P–3

ATTENTION: Only personnel familiar with SCANport

!

!

!

devices and associated machinery should plan or implement

the installation, start-up, configuration, and subsequent

maintenance of the Remote I/O communications module.

Failure to comply may result in personal injury and/or

equipment damage.

ATTENTION: The 1336-GM1 board contains Electrostatic Discharge (ESD) sensitive parts and assemblies. Static

control precautions are required when handling this assembly. Component damage may result if ESD control procedures are not followed. If you are not familiar with static

control procedures, refer to Allen-Bradley Publication

8000-4.5.2, Guarding Against Electrostatic Damage or any

other applicable ESD protection handbook.

ATTENTION: Injury or equipment damage can result

from loss of PLC or Controller Logic Commands (Stop,

Start, etc.) when all these conditions are true:

• module firmware 3.04 or lower.

• 230.4k baud rate.

• block transfer is enabled (DIP switch SW3-1 is ON).

• block transfers to the module are used (in the ladder

program or by DriveTools/DriveTools32 using a

Remote I/O pass thru connection).

Do not use the 230.4k baud rate if you are using a module

with 3.04 or earlier firmware and your program uses block

transfers. Use the 57.6k or 115.2k baud rate instead.

ATTENTION: Hazard of equipment damage exists. If

!

!

block transfer messages are programmed to frequently

write parameter data, the EEPROM (Non-Volatile Storage)

will quickly exceed its life cycle and cause the product to

malfunction. Do not create a program that frequently uses

block transfer messages to write parameter data to a

product. Datalinks do not write to the EEPROM and should

be used for frequently changed parameters.

ATTENTION: Hazard of equipment damage exits.

Firmware version 3.04 has the following anomaly: If DIP

Switch 2-5 is OFF (No Fault), the product remains in its last

state after a communications loss occurs no matter how DIP

Switch 2-4 is set. If you must use zero data, contact

Rockwell Automation Technical Support.

Page 10

P–4 Using This Manual

Rockwell Automation Support

Rockwell Automation offers support services worldwide, with more

than 75 sales/support offices, more than 500 authorized distributors,

and more than 250 authorized systems integrators located throughout

the United States alone. In addition, Rockwell Automation

representatives are in every major country in the world.

Local Product Support

Contact your local Rockwell Automation representative for:

• Sales and order support.

• Product technical training.

• Warranty support.

• Support service agreements.

Technical Product Support

If you need to contact Rockwell Automation for technical assistance,

please call your local Rockwell Automation representative.

Page 11

Overview

Chapter

1

Chapter Objectives

Description of the Remote I/O

Communications Modules

Chapter 1 provides an overview of the Remote I/O communications

module (1203-GD1 module, 1203-GK1 module, and 1336-GM1

board). In this chapter, you will read about the following:

• Function of the module.

• Features of the module.

• Compatible SCANport products and programmable controllers.

• Parts and hardware of the module.

• Steps for setting up the module.

• Required tools and equipment.

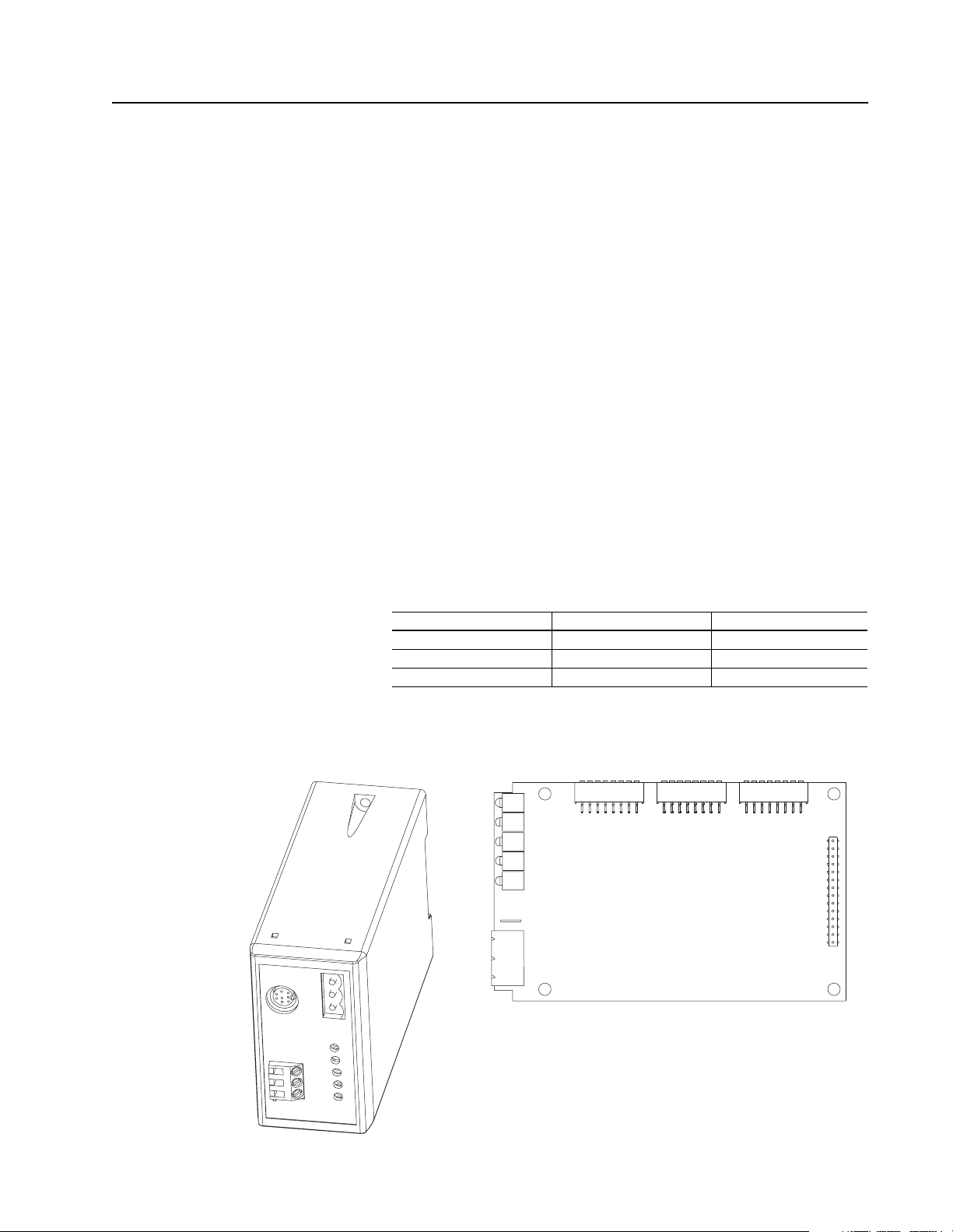

The Remote I/O communications module is an optional interface

designed to provide a direct, digital link between an Allen-Bradley

programmable controller and any one Allen-Bradley SCANport

product. A module is required for each product that you want to

connect to Remote I/O. There are three types of Remote I/O

communications modules:

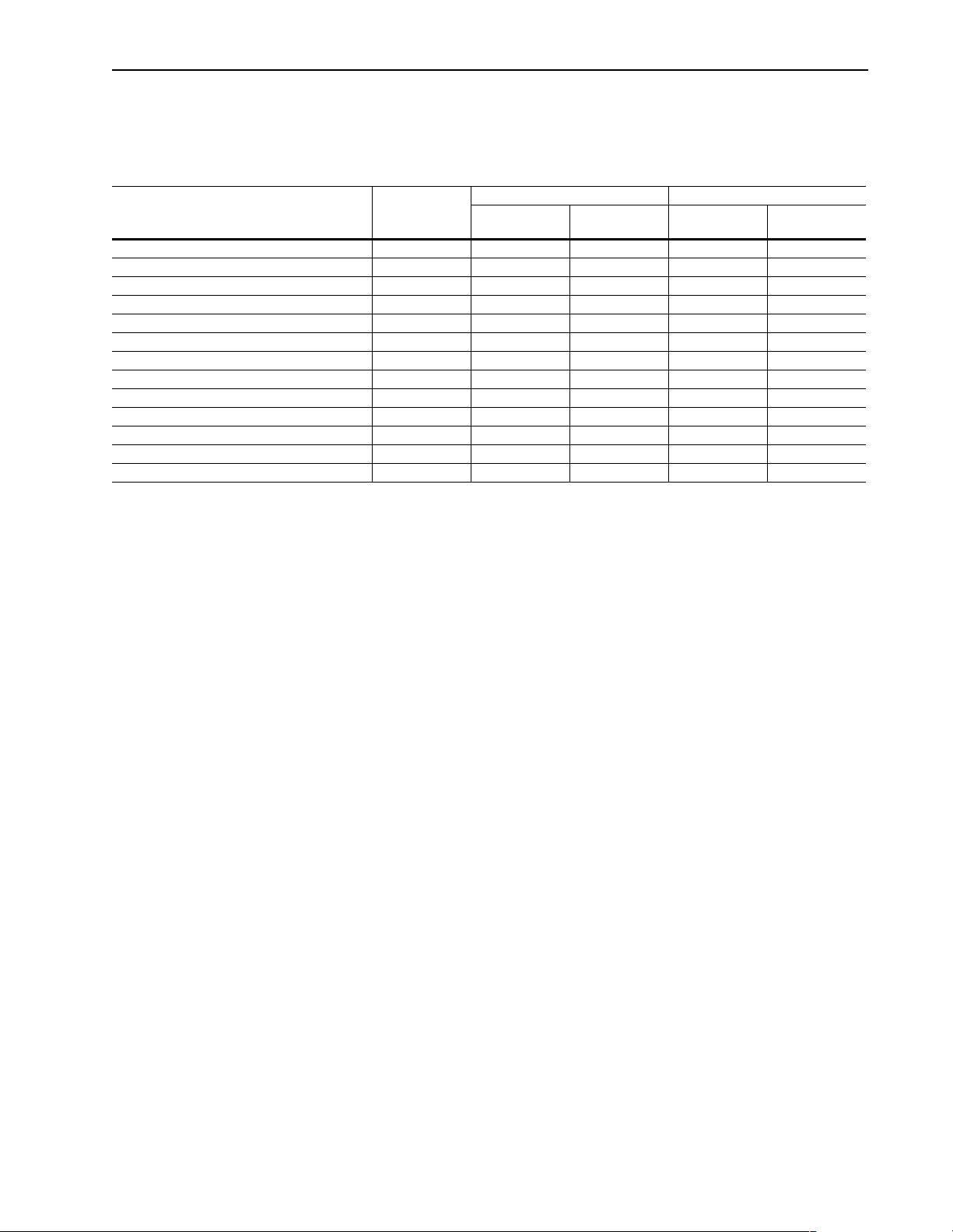

Catalog Number Enclosure Required Power Supply

1203-GD1 NEMA Type 1 85 – 264V AC

1203-GK1 NEMA Type 1 24V DC +/- 10%

1336-GM1 Open Drive Supplied

1203-GD1 Module

and

1203-GK1 Module

Figure 1.1 Module and Board

1336-GM1 Board

Page 12

1–2 Overview

The 1203-GD1 and 1203-GK1 modules mount on a DIN rail. They

connect to a SCANport product using a SCANport cable and to the

Remote I/O link using a Remote I/O cable. The 1336-GM1 board

mounts directly onto selected SCANport products. It connects to a

SCANport product using an internal SCANport connector and to the

Remote I/O link using a Remote I/O cable.

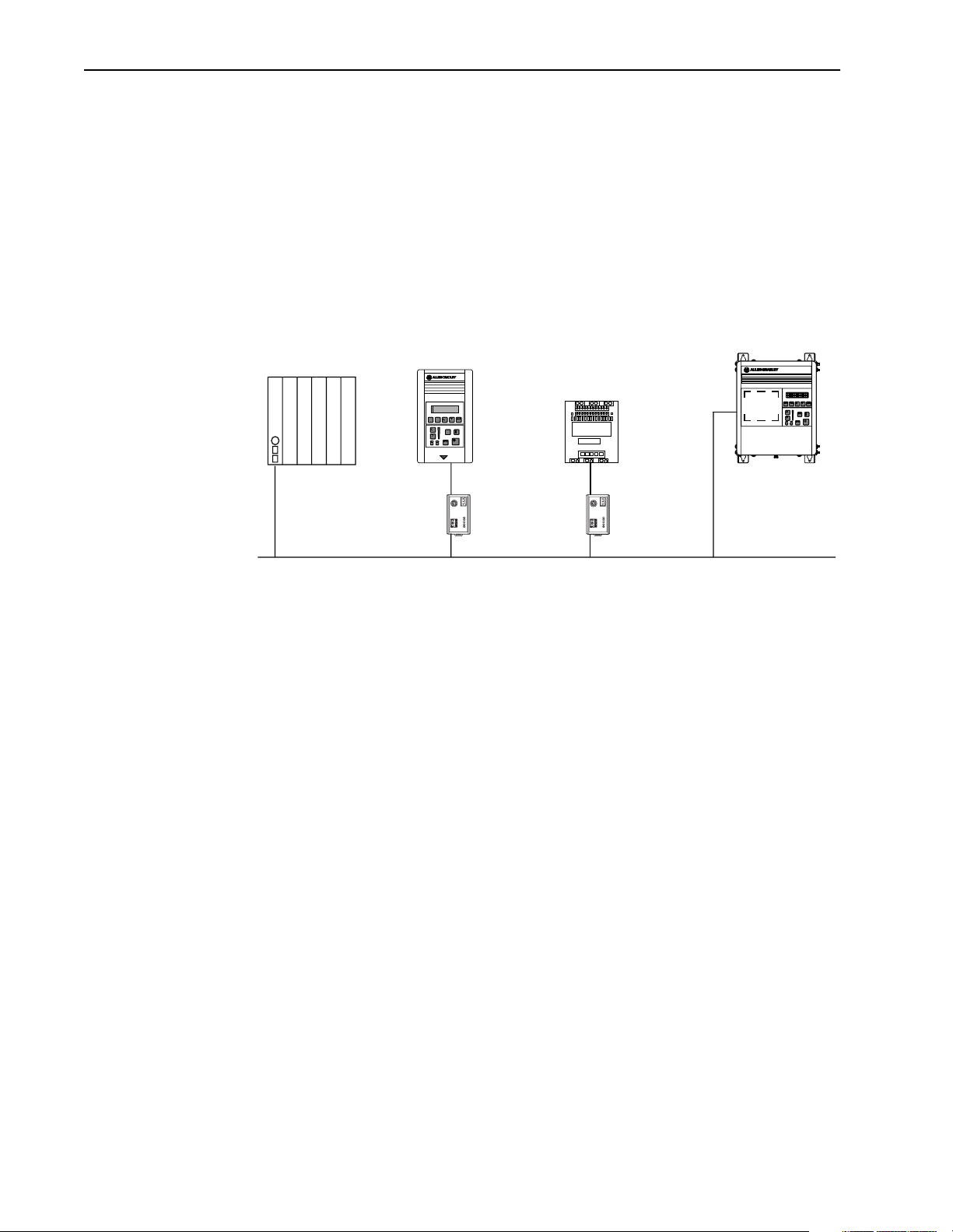

Figure 1.2 shows how the modules connect SCANport products to the

Remote I/O link.

Figure 1.2 Remote I/O Link with Remote I/O Communications Modules

Features of the

Communications Module

PLC-5 1305 Drive SMC

1203-GD1

Remote I/O Link

The 1203-GD1 module, 1203-GK1 module, and 1336-GM1 board let

you connect SCANport products to Remote I/O links and devices.

These modules feature the following:

• DIP switches let you configure how the Remote I/O module

operates before connecting it to the link.

• User-configurable fault action DIP switches let you customize the

module actions when communication errors occur.

• LEDs report link, module, and SCANport product health.

• Datalinks are supported in the module. Datalinks are a SCANport

mechanism for transferring information between a controller and

SCANport device. Each enabled datalink uses two words in the

I/O image table unless it is truncated.

PLUS Drive

1336-

GM1

1203-GK1

Page 13

Overview 1–3

Compatibility

SCANport Products

Remote I/O modules are compatible with many SCANport products,

including the following:

Number of

Peripherals

Product

1305 AC MICRO Drive

1336 IMPACT™ Drive 6

1336 PLUS AC Drive 6

1336 PLUS II Drive 6

1336 FORCE™ Drive 6

1336 REGEN Line Regeneration Package 2 0 2

1336 SPIDER Drive 6

1394 AC Mult-Axis Motion Control System508YesNo

SMC Dialog Plus™ 102

SMP-3 Smart Motor Protector 2 0 2

1397 Digital DC Drive 508YesNo

1557 Medium Voltage Drive 508YesNo

2364F Regenerative DC Bus Supply Unit 608YesNo

The Remote I/O modules are compatible with 1305 drives using firmware release 2.xx or greater.

➀

Lower horsepower products may not support a sixth peripheral. To connect multiple peripherals to a SCANport product, a port expander may be required. Refer to

➁

the product user manual to verify that it supports a sixth peripheral.

Many SCANport products support 10 words of I/O (Command/Logic, Speed Reference, and four datalinks). Remote I/O, however, supports only 8 words of I/O.

➂

Drive must be B-frame or larger. If it is a 1336 FORCE drive, it must use a standard adapter board.

➃

Datalinks are not supported by this product.

➄

➀

Supported

508YesNo

➁

➁

➁

➁

➁

I/O Words Module Use

1203-GD1 or

Minimum Maximum

08YesYes

08YesYes

08YesYes

08YesYes

08YesYes

➂

1203-GK1 1336-GM1

➃

➃

➃

➄

➄

➄

Ye s N o

Ye s N o

Ye s N o

If you intend to use datalinks to communicate with and control your

SCANport product, verify that your SCANport product supports

datalinks before enabling them in the module.

Controllers

This Remote I/O communications module is compatible with many

programmable controllers, including the following:

• Logix5550

• PLC-2/30

• PLC-3

• PLC Classic Family, including the PLC-5/10 (only with 1771-SN

in Discrete Mode), PLC-5/15

• PLC Enhanced family, including the PLC-5/20

PLC-5/40

PLC-5/60L

• PLC-5/250

• PLC scanner modules and subscanners

• SLC 500

®

with SD2 (module version 1.02 or later)

®

™

, PLC-5/25™ family

™

, PLC-5/40L™, PLC-5/60™,

™

family, PLC-5/80

™

™

with 1747-SN scanner

™

™

, PLC-5/30,

Page 14

1–4 Overview

Hardware Description

The hardware included with the module depends on the module that

you have.

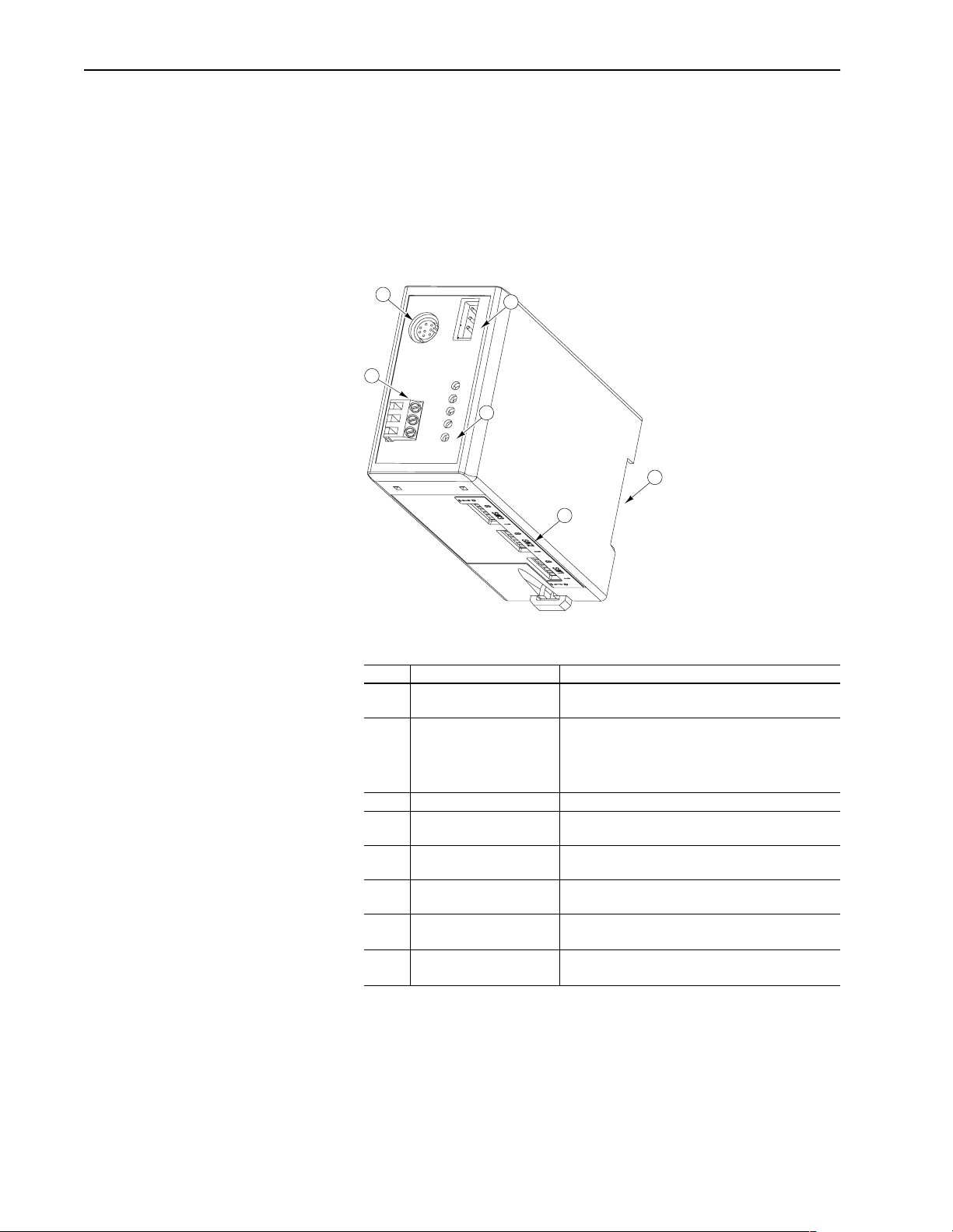

1203-GD1 and 1203-GK1 Modules

The 1203-GD1 module and 1203-GK1 module share the same parts.

Figure 1.3 illustrates these parts.

Figure 1.3 Parts of the 1203-GD1 and 1203-GK1 Module

1

2

3

4

6

5

# Part Description

1 SCANport Connection Standard SCANport 8-pin mini-DIN connector for the

SCANport cable.

2 Power Supply Connections Connections for the power supply. Multiple connec-

tions allow daisy-chaining.

The 1203-GD1 module uses 85 – 264V AC.

The 1203-GK1 module uses 24V DC.

3 Remote I/O Connection Standard 3-pin Remote I/O connector.

4 LEDs Status indicators for the module, SCANport connec-

tion, and Remote I/O connection. Refer to Chapter 6.

5 DIP Switches Switches used to configure the module. Refer to

6 DIN Rail Mount Mount for securely attaching and electrically ground-

Not

Remote I/O connector One 3-pin connector for connecting the Remote I/O

Shown

Not

Termination Resistors Two termination resistors for terminating the I/O link at

Shown

Chapter 2.

ing the module to a DIN rail.

cable to the module.

its physical ends. Refer to Chapter 3.

Page 15

Overview 1–5

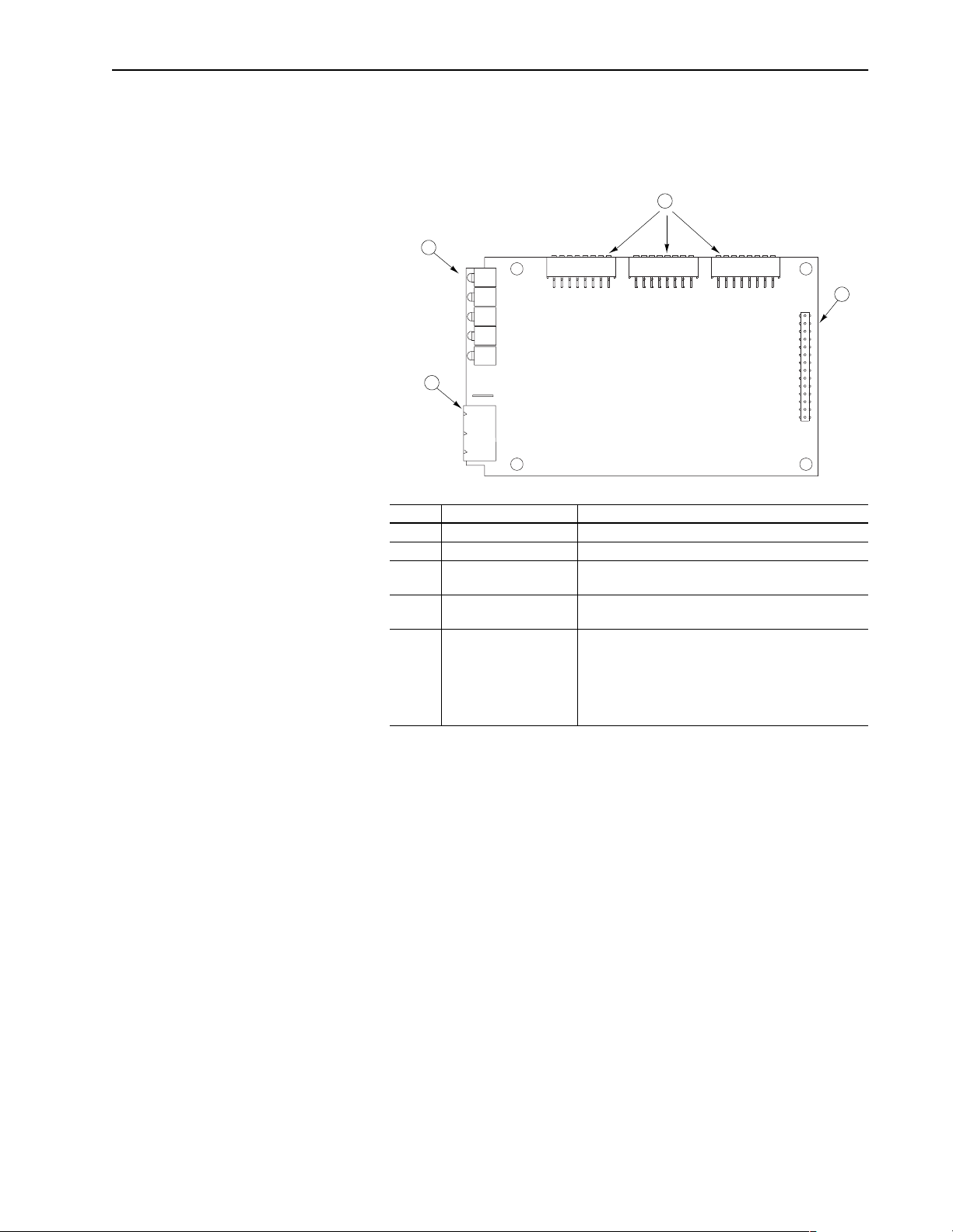

1336-GM1 Board Hardware

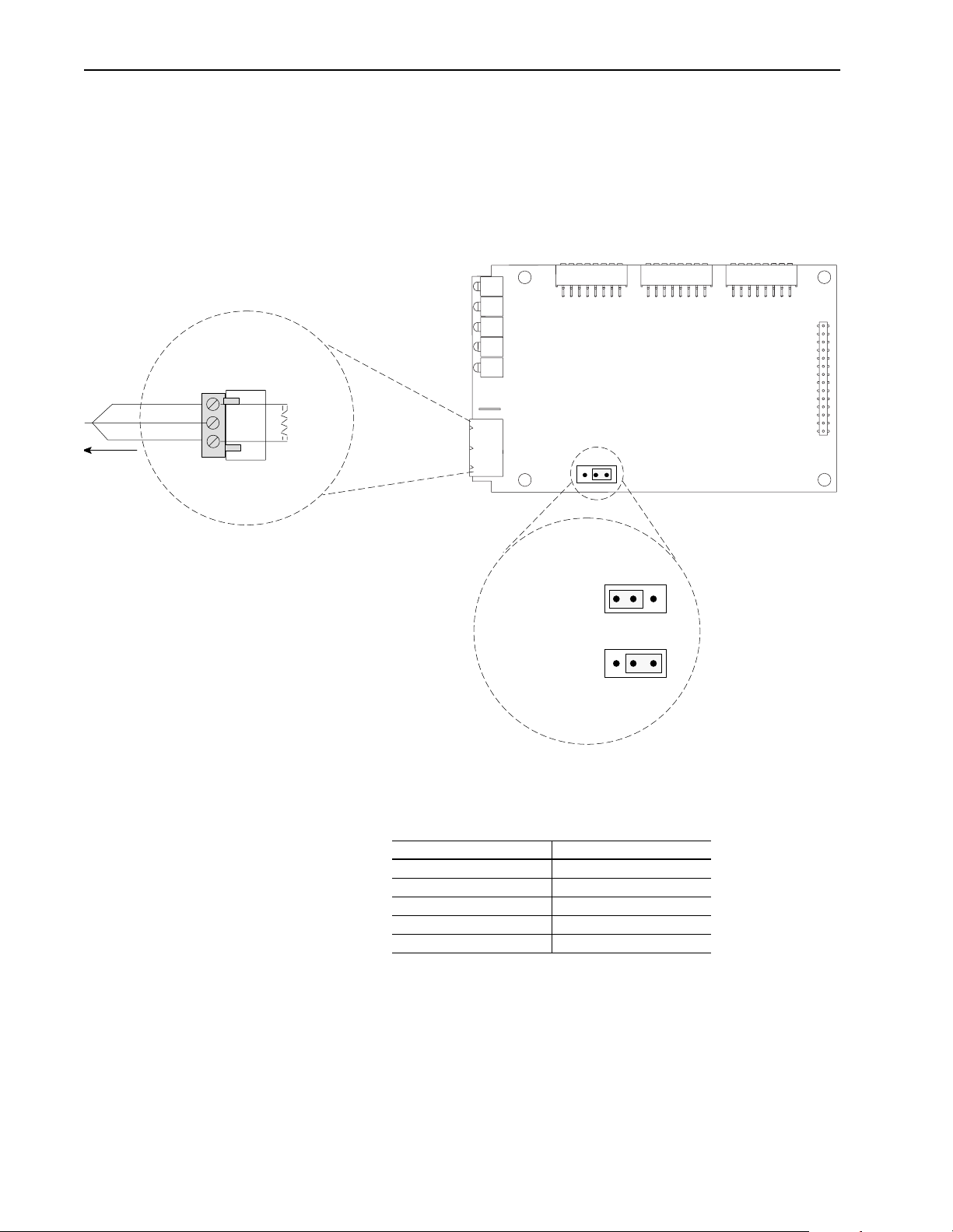

Figure 1.4 illustrates the main parts of a 1336-GM1 board.

Figure 1.4 Parts of the 1336-GM1 Board

4

3

2

1

# Part Description

1 SCANport Connection Internal 14-pin female SCANport connector.

2 Remote I/O Connection Standard 3-pin Remote I/O connector.

3 LEDs Status indicators for the module, SCANport connection,

4 DIP Switches Switches used to configure the module. Refer to

Not

Kit Materials for mounting the board to the SCANport prod-

Shown

and Remote I/O connection. Refer to Chapter 6.

Chapter 2.

uct. These material include one grounding wrist strap,

four Phillips mounting screws, four stand-off nylon headers, one 3-pin Remote I/O connector, one snap-in comm

housing with mounting instructions, and termination

resistors.

Page 16

1–6 Overview

Required Tools and Equipment

The tools and equipment required, depend on if you are using a

1203-GD1 module, 1203-GK1 module, or 1336-GM1 board.

1203-GD1 or 1203-GK1 Module

To install and configure a 1203-GD1 module or 1203-GK1 module,

you need the following:

• Remote I/O communications module (1203-GD1 or 1203-GK1).

• 35 x 7.5 mm DIN rail.

• Termination resistor(s).

• Power source.

• 1/8" flathead screwdriver.

• Appropriate cables for SCANport and Remote I/O connections.

Refer to Chapter 3.

• Software such as RSLogix5, RSLogix500, or RSLogix5000 for

programming the controller.

1336-GM1 Board

To install and configure a 1336-GM1 board, you need the following:

• Remote I/O communications board (1336-GM1).

• A kit that includes one grounding wrist strap, four Phillips

mounting screws, four stand-off nylon headers, one 3-pin

connector, and one snap-in comm housing with mounting

instructions (supplied with board).

• #1 Phillips screwdriver.

• Appropriate cable for the Remote I/O connection. Refer to

Chapter 3.

• Software such as RSLogix5, RSLogix500, or RSLogix5000 for

programming the controller.

Overview of Setting Up the

Module

To set up the Remote I/O communications module, you must perform

the following tasks:

1. Read the safety precautions in this manual.

2. Configure the module using the DIP switches. Refer to Chapter 2.

3. Install the module or mount the board. Refer to Chapter 3.

4. Create a ladder logic program to control the SCANport product

(Chapter 4) or send messages to it (Chapter 5).

Page 17

Configuring the Module

Chapter

2

Chapter Objectives

Safety Precautions and

Important Information

Chapter 2 provides instructions and information for configuring the

Remote I/O communications module (1203-GD1, 1203-GK1, or

1336-GM1). In this chapter, you will read about the following:

• Factory-default settings.

• Recording the I/O image table.

• Configuring the module.

Important:

Please observe the following safety precautions:

!

!

The communications module is not compatible with

complementary I/O configurations because it uses both

output and input image words for proper product control.

ATTENTION: Hazard of equipment damage exists. When

you make changes to the switch settings, use a blunt, pointed

instrument. Do not use a pencil or pen.

ATTENTION: Hazard of injury or equipment damage

exists. Failure to check connections and switch settings for

compatibility with your application could result in

unintended or undesirable operation. Verify the

configuration is correct for your application.

!

Important:

ATTENTION: Hazard of injury or equipment damage

exists. Unintended or incorrect machine motion can result

from the initial configuration. When a system is configured

for the first time, the motor must be disconnected from the

machine or process during initial system testing.

Due to an anomaly in firmware release 4.01, Remote I/O

modules that are used only for block transfer messages

require the following configuration: switches for block

transfer and reference/feedback should both be enabled

(SW 3.1 and SW 3.3 are ON. SW 3.2 and SW 3.4 through

3.8 are OFF).

This configuration prevents a fault on power up. It does not

affect rack I/O allocation or the ladder logic program

because it still fits within 1/4 rack I/O space. The drive will,

however, generate a serial fault if the communications

module is disconnected or loses power.

Page 18

2–2 Configuring the Module

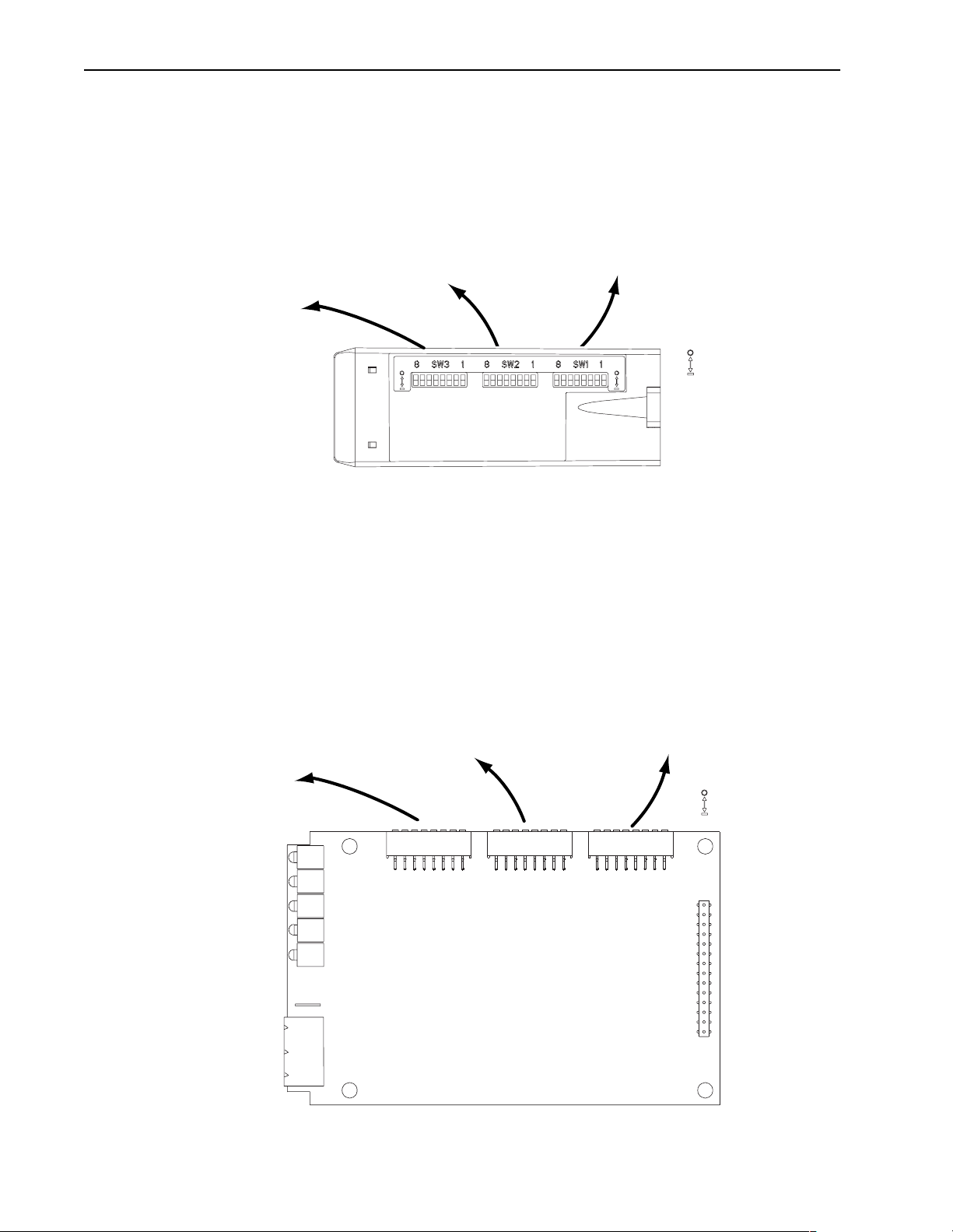

Locating the DIP Switches

SW3.1 = Block Transfer

SW3.2 = Logic Command/Status

SW3.3 = Reference/Feedback

SW3.4 = Datalink A Settings

SW3.5 = Datalink B Settings

SW3.6 = Datalink C Settings

SW3.7 – Datalink D Settings

SW3.8 = Truncate Last Datalink

Figure 2.1 Switches on the 1203-GD1 and 1203-GK1 Modules

SW2.1 – SW2.2 = Starting Module Group

SW2.3 = Last Rack Setting

SW2.4 = Hold Last State/Zero Data

SW2.5 = Communications Loss

SW2.6 = Reset/Program/Test

SW2.7 – SW2.8 = RIO Baud Rate

Bottom View

SW1.1 – SW1.2 = Not Used

SW1.3 – SW1.8 = Rack Address

= Open = Off = 0

= Closed = On = 1

SW3.1 = Block Transfer

SW3.2 = Logic Command/Status

SW3.3 = Reference/Feedback

SW3.4 = Datalink A Settings

SW3.5 = Datalink B Settings

SW3.6 = Datalink C Settings

SW3.7 – Datalink D Settings

SW3.8 = Truncate Last Datalink

Figure 2.2 Switches on the 1336-GM1 Board

SW2.1 – SW2.2 = Starting Module Group

SW2.3 = Last Rack Setting

SW2.4 = Hold Last State/Zero Data

SW2.5 = Communications Loss

SW2.6 = Reset/Program/Test

SW2.7 – SW2.8 = RIO Baud Rate

8

8

1

SW1.1 – SW1.2 = Not Used

SW1.3 – SW1.8 = Rack Address

8

1

1

= Open = Off = 0

= Closed = On = 1

Front View

Page 19

Configuring the Module 2–3

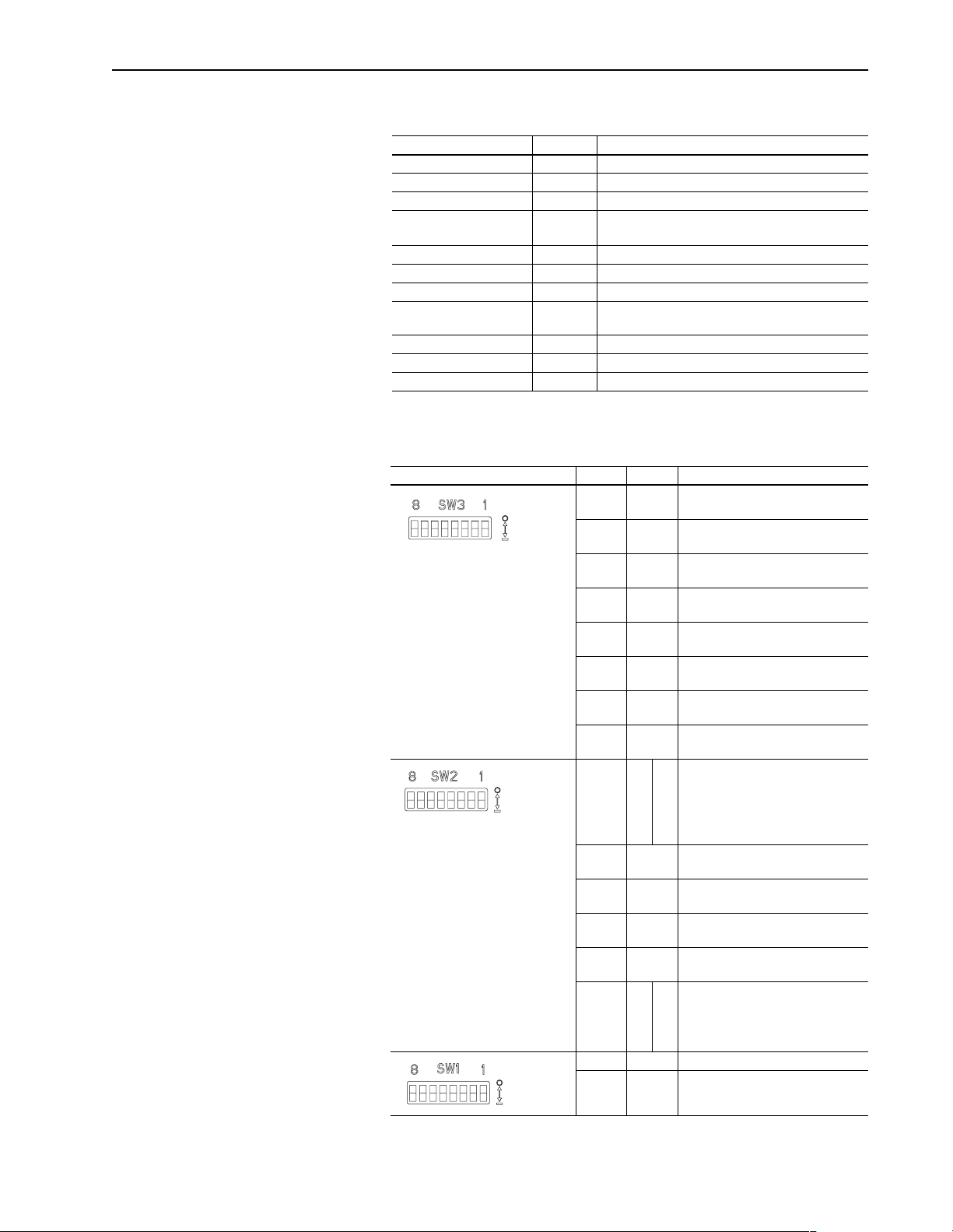

Factory-Default Settings

Quick Configuration

The module is shipped with the following settings:

Feature Switch(es) Default Setting

Block Transfer 3.1 Enabled

Logic Command/Status 3.2 Enabled

Reference/Feedback 3.3 Enabled

Datalinks 3.4 – 3.7 Datalinks A and B are Enabled

Datalinks C and D are Disabled

Truncate Last Datalink 3.8 Disabled

Starting Group 2.1 – 2.2 0

Last Rack 2.3 Not Last Rack

Fault Action 2.4 – 2.6 Fault on communications loss

Baud Rate 2.7 – 2.8 57.6K

Not Used 1.1 – 1.2 Not Used

Rack Address 1.3 – 1.8 2

Hold last state on reset/program/test

For detailed switch information, refer to pages 2–4 through 2–13.

Switch Setting Description

3.1 01Disable block transfer

Off = 0

On = 1

Off = 0

On = 1

Off = 0

On = 1

3.2 01Disable Logic Command/Status

3.3 01Disable Reference/Feedback

3.4 01Disable Datalink A (A1 and A2)

3.5 01Disable Datalink B (B1 and B2)

3.6 01Disable Datalink C (C1 and C2)

3.7 01Disable Datalink D (D1 and D2)

3.8 01Disable truncate last datalink

2.1 – 2.2 2.2

1

0

1

0

2.3 01Not last rack

2.4 01Hold last state

2.5 01No fault. Use action of switch 2.4

2.6 01No fault. Use action of switch 2.4

2.7 – 2.8 2.8

0

0

1

1.1 – 1.2 Not Used

1.3 – 1.8 Varies See “Setting the Rack Address” on

Enable block transfer

Enable Logic Command/Status

Enable Reference/Feedback

Enable Datalink A (A1 and A2)

Enable Datalink B (B1 and B2)

Enable Datalink C (C1 and C2)

Enable Datalink D (D1 and D2)

Enable truncate last datalink

2.1

1

Starting group 0

1

Starting group 2

0

Starting group 4

0

Starting group 6

Last rack with this address

Zero data

Fault drive on communications loss

Fault drive on Reset/Program/Test

2.7

0

57.6 kbps

1

115.2 kbps

0

230.4 kbps

page 2-13

Page 20

2–4 Configuring the Module

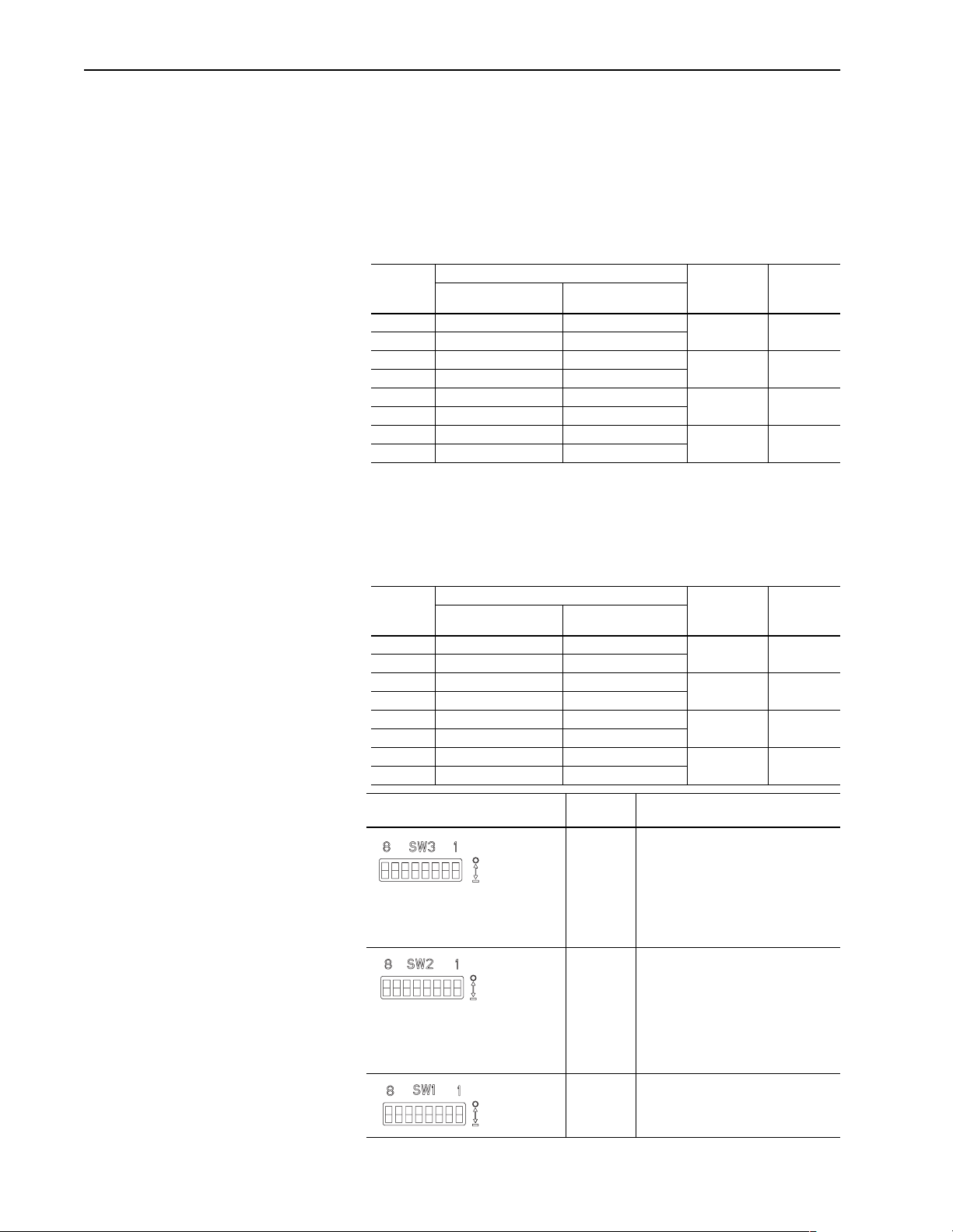

Configuring the module

As you configure your module, you should complete the I/O image

table. First, size the I/O using switch SW3. Next, set the rack address

using switch SW1. Finally, select the starting group, last rack setting,

fault action, and baud rate using switch SW2. For more information

on the I/O image table, refer to the example below and Chapter 4.

I/O Image Table

Remote

I/O

Address

Reserved For: Minimum

Required

Rack Size

1/4 Rack 0, 2, 4, or 6

1/2 Rack 0, 2, or 4

3/4 Rack 0 or 2

Full Rack 0 only

Starting

GroupOutput Image Input Image

Example I/O Image Table

In this example, we use the factory-default settings. We use rack 2,

and record it as our address. Because we are using a full rack, we use

starting group 0, so block transfer starts at word 0.

Remote

I/O

Address

020 Block Transfer Block Transfer 1/4 Rack 0, 2, 4, or 6

021 Logic Command Logic Status

022 Reference Feedback 1/2 Rack 0, 2, or 4

023 Datalink A Datalink A

024 Datalink A Datalink A 3/4 Rack 0 or 2

025 Datalink B Datalink B

026 Datalink B Datalink B Full Rack 0 only

027

Reserved For: Minimum

Required

Rack Size

Starting

GroupOutput Image Input Image

Switch

Off = 0

On = 1

Off = 0

On = 1

Off = 0

On = 1

Settings

8 ---> 1 Description

00011111 Block transfer is enabled.

Logic command/status is enabled.

Reference/feedback is enabled.

Datalink A is enabled.

Datalink B is enabled.

Truncate last datalink is disabled.

00011011 Starting group is 0.

This is not the last rack.

Drive will fault when communications

are disrupted, and it will hold last state

when the controller is placed in

program/reset/test.

Remote I/O baud rate is 57.6K.

10111100 Rack address is 2.

Page 21

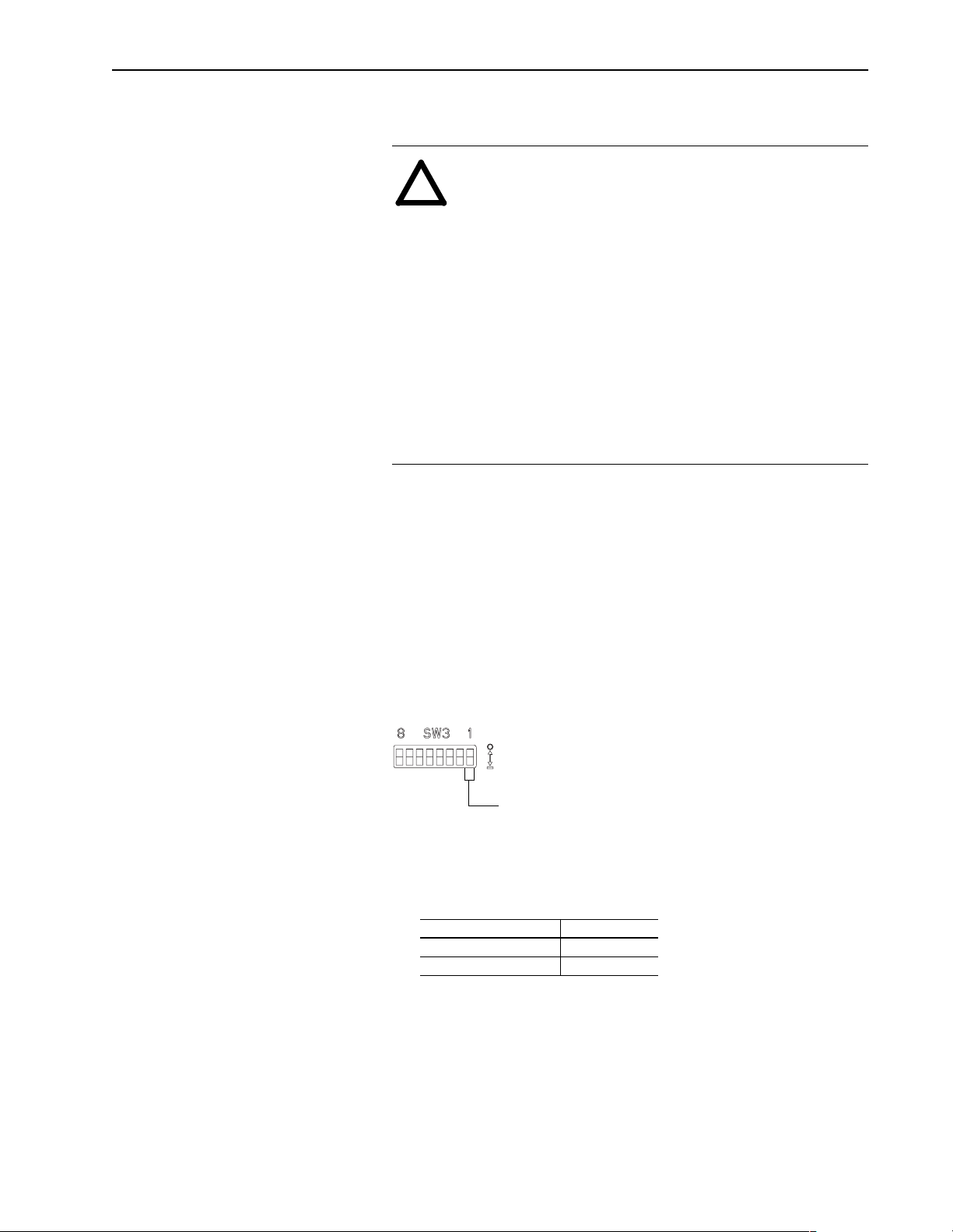

Setting Switches on SW3

ATTENTION: Injury or equipment damage can result

!

from loss of PLC or Controller Logic Commands (Stop,

Start, etc.) when all these conditions are true:

• module firmware 3.04 or lower.

• 230.4k baud rate.

• block transfer is enabled (DIP switch SW3-1 is ON).

• block transfers to the module are used (in the ladder

program or by DriveTools/DriveTools32 using a

Remote I/O pass thru connection).

Do not use the 230.4k baud rate if you are using a module

with 3.04 or earlier firmware and your program uses block

transfers. Use the 57.6k or 115.2k baud rate instead.

Setting Block Transfer

Configuring the Module 2–5

SW 3.1 enables or disables block transfer. Enable block transfer if

you are using messages (refer to Chapter 5) in your ladder logic

program or if you are using DriveTools32 software.

Important:

You cannot use both messages and DriveTools32 software

at the same time.

Block transfer uses the first module group (word) in the rack and

group.

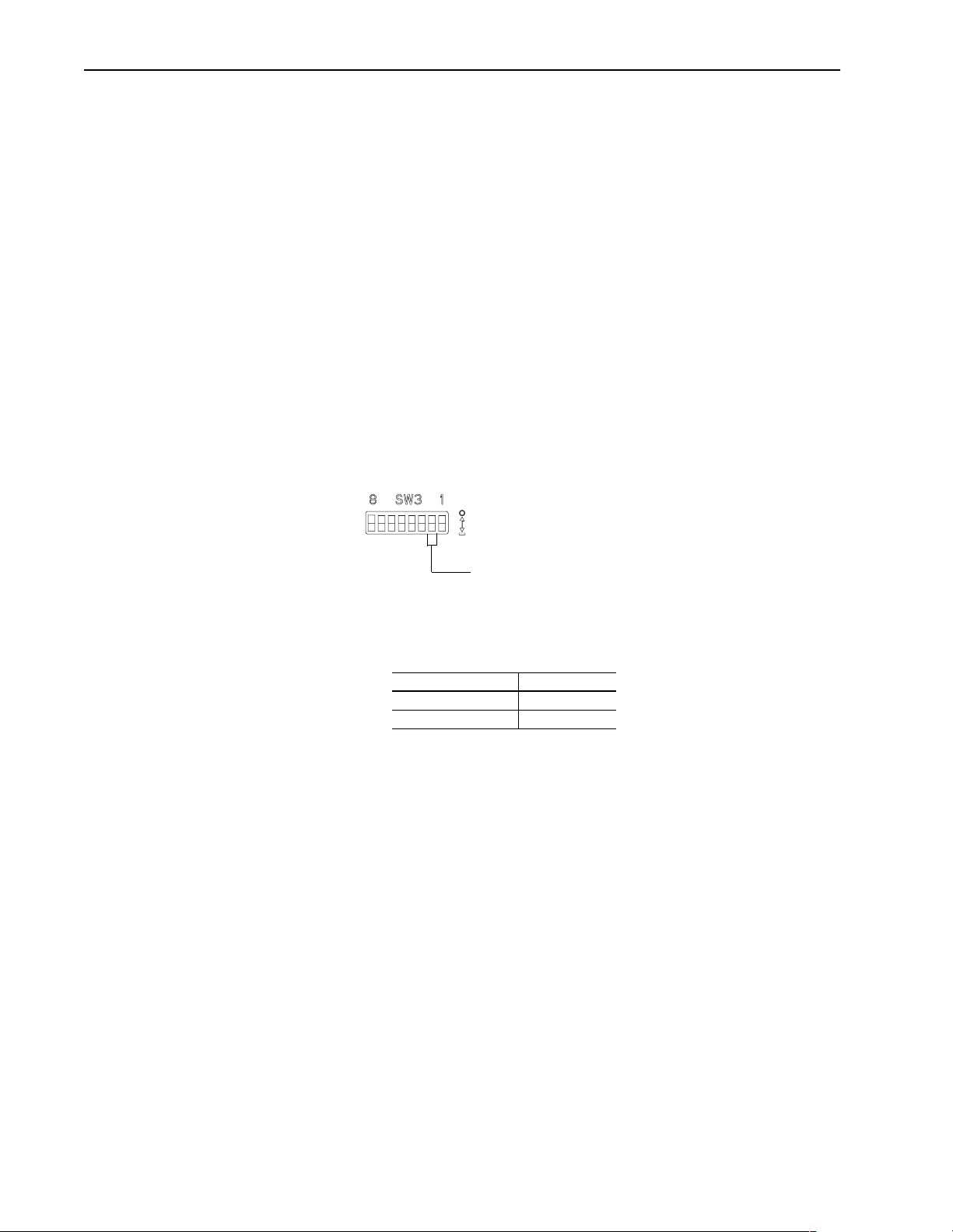

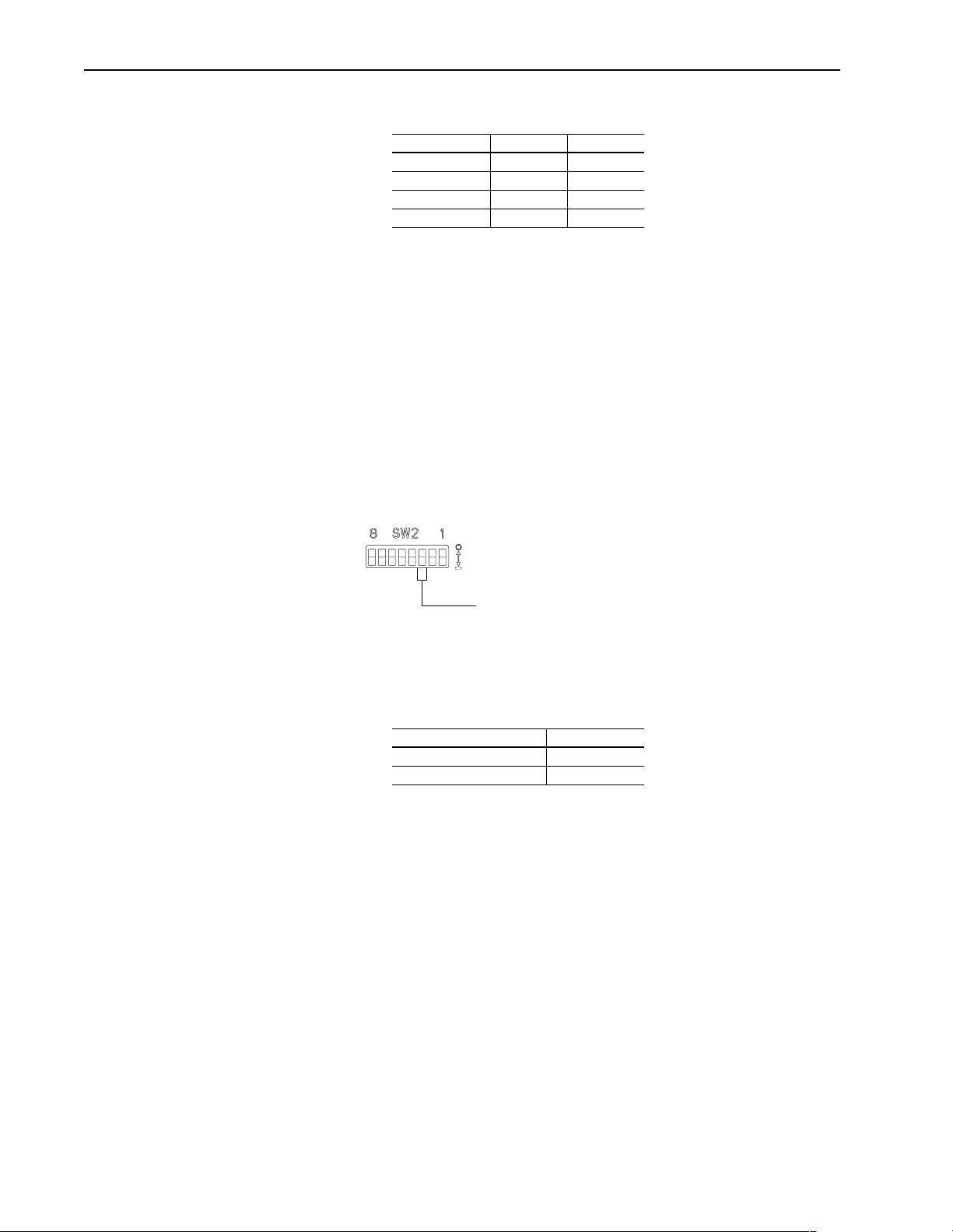

Figure 2.3 Block Transfer Switch

Off = 0

On = 1

Use SW 3.1 for setting the

block transfer

To edit the block transfer setting, you need to:

1. Refer to the following table to determine the setting for SW 3.1:

Block Transfer SW 3.1

Disabled 0

Enabled 1

2. Slide the switch to its appropriate position.

3. If Block Transfer is enabled, record “Block Transfer” in the first

module group (word) of your I/O image table on page 2–4.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Page 22

2–6 Configuring the Module

Important:

Due to an anomaly in firmware release 4.01, Remote I/O

modules that are used only for block transfer messages

require the following configuration: switches for block

transfer and reference/feedback should both be enabled

(SW 3.1 and SW 3.3 are ON. SW 3.2 and SW 3.4 through

3.8 are OFF).

This configuration prevents a fault on power up. It does

not affect rack I/O allocation or the ladder logic program

because it still fits within 1/4 rack I/O space. The drive will,

however, generate a serial fault if the communications

module is disconnected or loses power.

Setting Logic Command and Status

SW 3.2 enables or disables the word used for logic command and

status (e.g., start, stop, direction). Logic command/status uses one

word in the rack and group.

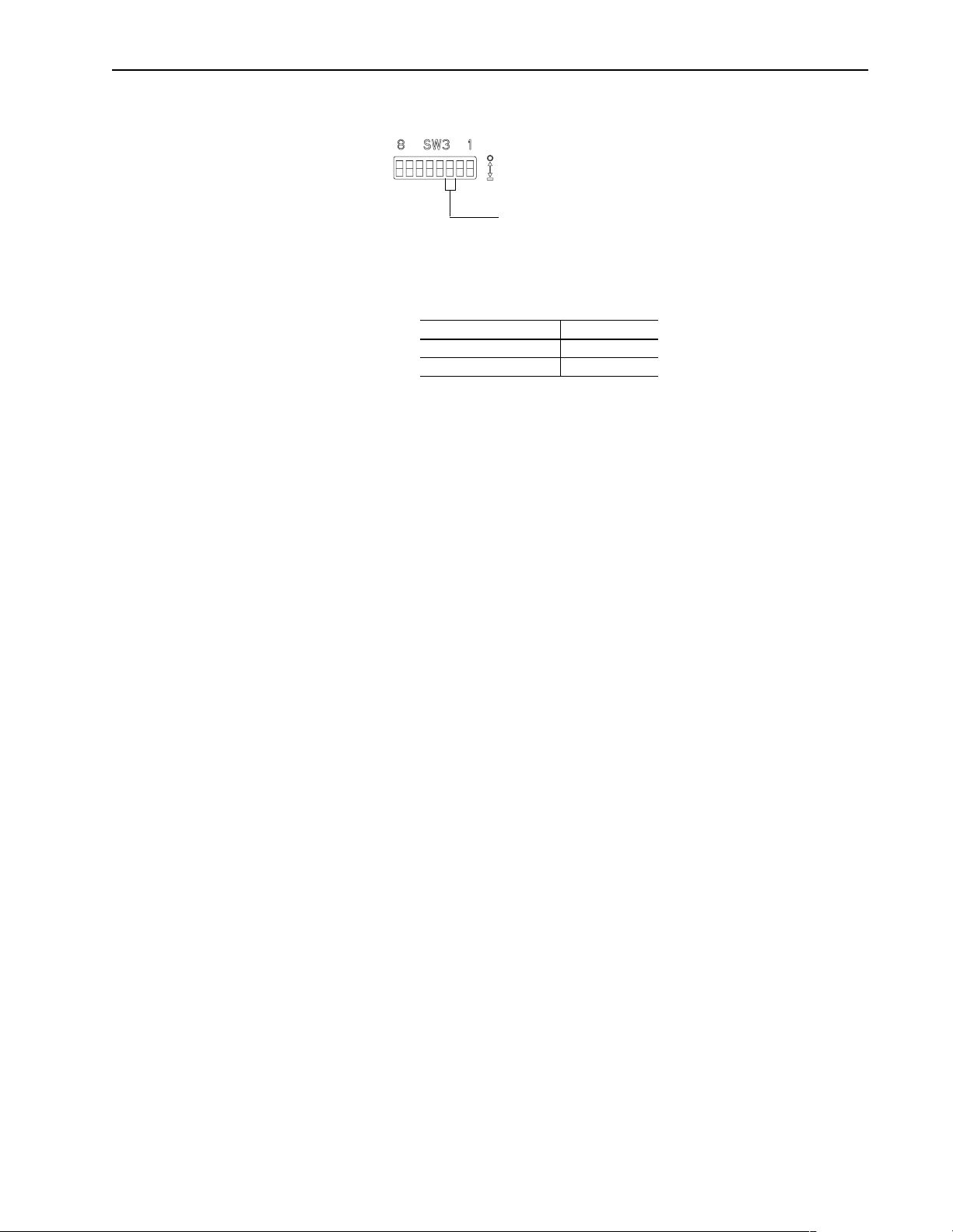

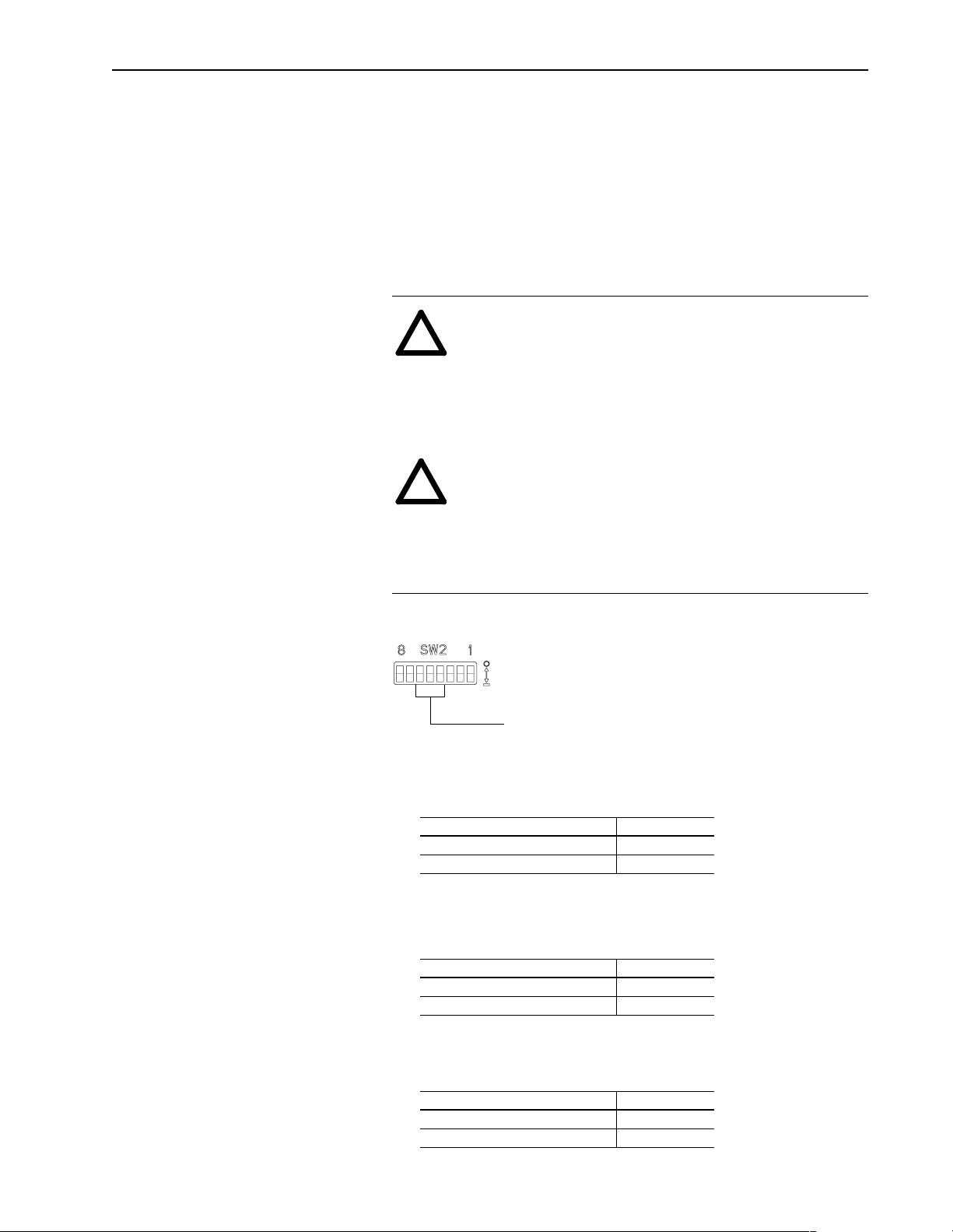

Figure 2.4 Logic Command/Status Switches

Off = 0

On = 1

Use SW 3.2 for setting logic/

status word.

To edit the command/status setting, you need to:

1. Refer to the following table to determine the setting for SW 3.2:

Command I/O SW 3.2

Disabled 0

Enabled 1

2. Slide the switch to its appropriate position.

3. If Logic Command/Status is enabled, record “Logic Cmd” in the

first available module group (word) of the output column and

“Logic Sts” in the first available module group (word) of the

input column of your I/O image table on page 2–4.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Setting the Reference and Feedback

SW 3.3 enables or disables the word used for reference and feedback

(e.g., speed reference, torque reference). Reference/feedback uses one

word in the rack and group.

Page 23

Configuring the Module 2–7

Figure 2.5 Reference/Feedback Switch

Off = 0

On = 1

Use SW 3.3 for setting the

command I/O

To edit the reference/feedback setting, you need to:

1. Refer to the following table to determine the setting for SW 3.3:

Reference/Feedback SW 3.3

Disabled 0

Enabled 1

2. Slide the switch to its appropriate position.

3. If Reference/Feedback is enabled, record “Reference” in the first

available module group (word) of the output column and

“Feedback” in the first available module group (word) of the

input column of your I/O image table on page 2–4.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Page 24

2–8 Configuring the Module

Setting Datalinks

SW 3.7 through SW 3.4 enable or disable datalinks. A datalink is a

type of pointer used by some SCANport products to transfer data to

and from a controller. You can use datalinks to change or monitor the

value of parameters without using block transfer messages. Each

datalink consists of two 16-bit words of input and two 16-bit words of

output. You can enable up to four datalinks (eight words in and out).

Refer to Chapter 4 for detailed datalink information and examples.

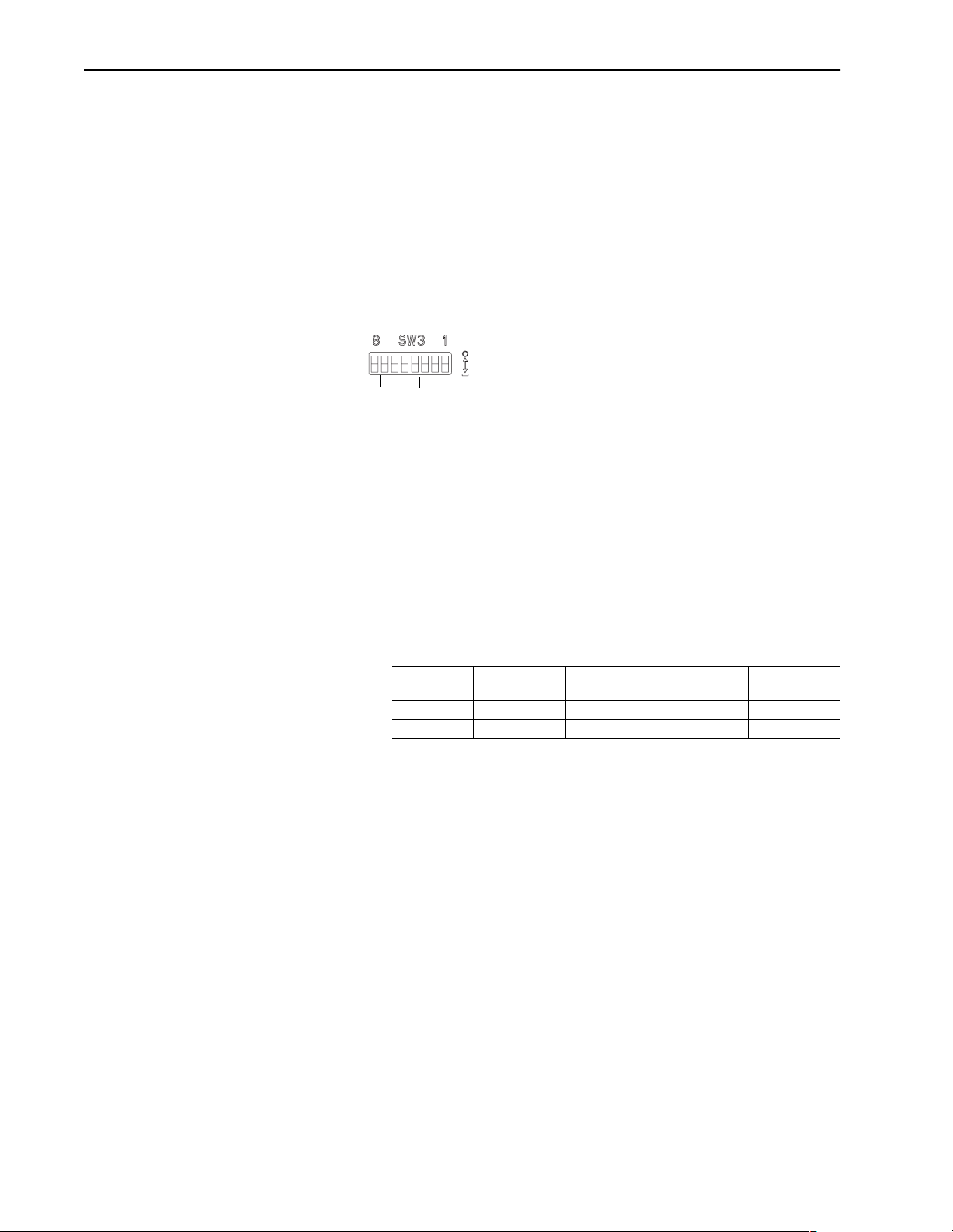

Figure 2.6 Datalink Switches

Off = 0

On = 1

Use SW 3.7 through SW 3.4 for

setting the datalinks.

Important:

Ensure that datalinks are supported and enabled in the

SCANport product before you enable them in the Remote

I/O module. You do not have to use datalinks. If you do

use them, remember that a datalink in a drive can be used

by only one communications module. Datalinks do not

write to the EEPROM.

To edit the datalinks, you need to:

1. Refer to the following table to determine the settings for SW 3.7

through SW 3.4:

Datalink D

Function

Disable0000

Enable1111

SW 3.7

Datalink C

SW 3.6

Datalink B

SW 3.5

Datalink A

SW 3.4

2. Slide the switches to their appropriate positions.

3. For each enabled datalink, record “Datalink [A, B, C, or D]” in

the first two available module groups (words) of the output and

input columns of your I/O image table on page 2–4.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Setting the Truncate Last Datalink Feature

SW 3.8 enables or disables the truncate last datalink feature. All

datalinks are two words. If this feature is enabled, the second word of

the last datalink is deleted. For example, if datalinks A and B are

enabled and this feature is enabled, Data In B2 and Data Out B2 are

truncated. This feature can save rack space by maintaining an even

number of words in your rack.

Important:

This feature is available only on modules with firmware

1.02 or later.

Page 25

Configuring the Module 2–9

Figure 2.7 Truncate Last Datalink Switch

Off = 0

On = 1

Use SW 3.8 for truncating the

last datalink.

To set the truncate last datalink feature, you need to:

1. Refer to the following table to determine the setting for SW 3.8:

Duplicate Message Detection SW 3.8

Disable 0

Enable 1

2. Slide the switch to its appropriate position.

3. If the switch is enabled, cross out the second module group

(word) of the last datalink in your I/O image table on page 2–4.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Setting Switches on SW2

Setting the Starting Group

SW 2.2 and SW 2.1 set the starting group. A starting group is the

word in a rack at which the group starts. The starting group depends

on the rack size. To determine the starting group, you must set the

switches on SW3 and calculate the rack size. A full rack is 8 words.

For example, if we enabled the switches for Logic Command/Status,

Reference/Feedback, and datalink A, we use 4 words in the rack, so

we need a 1/2 rack. Using the table below as a guide, we could set the

starting group for word 0, 2, or 4 for our example.

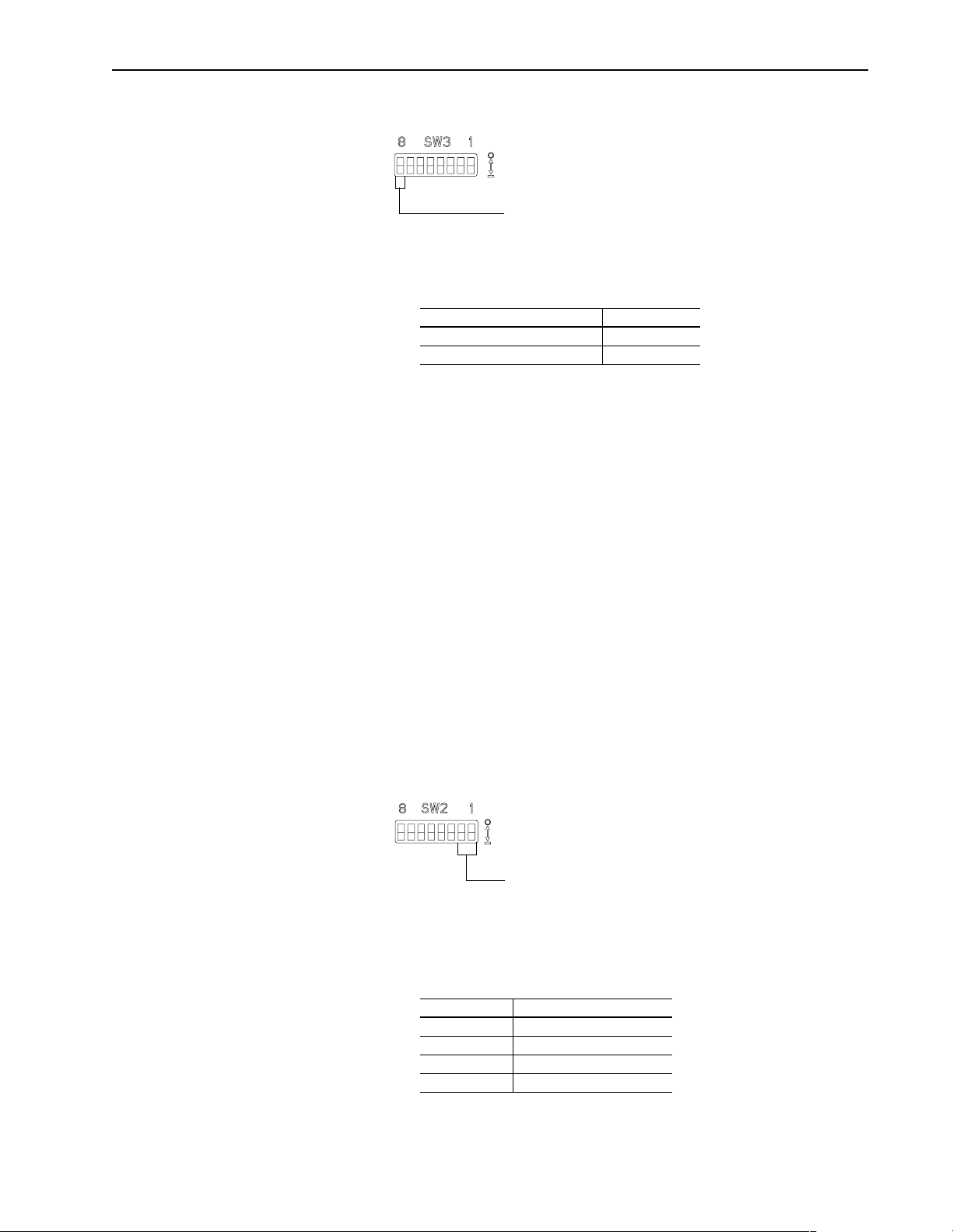

Figure 2.8 Starting Group Switches

Off = 0

On = 1

Use SW 2.2 and SW 2.1

for setting the starting group.

To edit the starting group, you need to:

1. Refer to the following table to determine starting groups that you

can use:

Rack Size Starting Group

1/4 0, 2, 4, or 6

1/2 0, 2, or 4

3/4 0 or 2

Full 0

Page 26

2–10 Configuring the Module

2. Refer to the following table to set SW 2.2 and SW 2.1:

Starting Group SW 2.2 SW 2.1

011

201

410

600

3. Slide the switches to their appropriate positions.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Setting the Last Rack Switch

SW 2.3 lets you notify a controller that the connected product is the

last device with this rack address. You must set this switch if a

product is the last device with this rack address and you are using a

PLC-2 controller. It is recommended that you set this switch when

you are using other controllers.

Figure 2.9 Last Rack Switch

Off = 0

On = 1

Use SW2.3 for setting the

last rack.

To edit the last rack settings, you need to:

1. Refer to the following table to determine the switch setting for

SW 2.3:

Setting SW2.3

Not Last Rack 0

Last Rack 1

2. Slide the switch to its appropriate position.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Page 27

Configuring the Module 2–11

Setting the Fault Action

SW 2.6 through SW 2.4 let you configure how a Remote I/O module

and connected product act when Remote I/O communications fail

(e.g., disconnected cable) or the controller is switched to program or

test mode. You can use fault, hold last state, or zero data. If you select

hold last state, a product continues in its present state after a

communications disruption. If you select zero data, the data output to

the product is zeroed. Zero data does not command a stop.

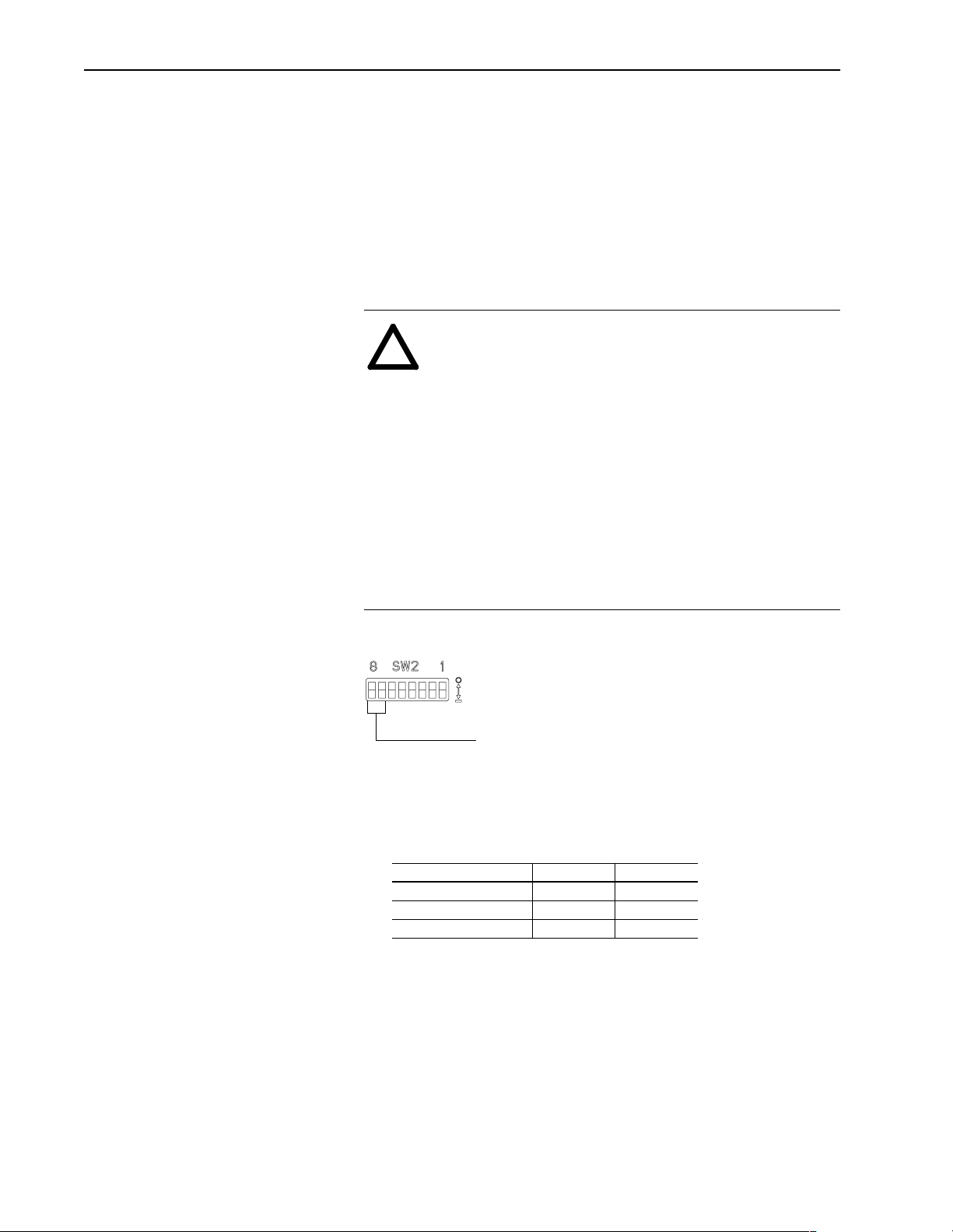

ATTENTION: Risk of bodily injury or equipment damage

!

!

exists. These switches allow the user to change the default

configuration that would fault the drive if communication

is lost. Precautions should be taken to ensure that settings

for these switches do not create a hazard of bodily injury or

equipment damage.

ATTENTION: Hazard of equipment damage exits.

Firmware version 3.04 has the following anomaly: If DIP

Switch 2.5 is OFF (No Fault), the product remains in its last

state after a communications loss occurs no matter how DIP

Switch 2.4 is set. If you must use zero data, contact

Rockwell Automation Technical Support.

Figure 2.10 Fault Action Configuration Switches

Off = 0

On = 1

Use SW 2.6 through SW 2.4

for setting the fault action.

To change the fault action, you need to:

1. Refer to the following table to determine the setting for SW 2.6:

Fault on Reset/Program/Test SW 2.6

No Fault 0

Fault Product 1

Important:

Switch SW 2.6 is active only on modules with

firmware 2.xx and later

2. Refer to the following table to determine the setting for SW 2.5:

Fault on Communications Loss SW 2.5

No Fault 0

Fault Product 1

3. If you set SW 2.6 or SW 2.5 to 0 (No Fault), set SW 2.4 to select

an action when a condition that normally causes a drive fault

occurs:

Function SW 2.4

Hold last state 0

Zero data 1

Page 28

2–12 Configuring the Module

4. Slide the switches to their appropriate positions.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Setting the Remote I/O Baud Rate

SW 2.8 and SW 2.7 set the baud rate at which the Remote I/O module

communicates.

ATTENTION: Injury or equipment damage can result

!

from loss of PLC or Controller Logic Commands (Stop,

Start, etc.) when all these conditions are true:

• module firmware 3.04 or lower.

• 230.4k baud rate.

• block transfer is enabled (DIP switch SW3.1 ON).

• block transfers to the module are used (in the ladder

program or by DriveTools/DriveTools32 using a

Remote I/O pass thru connection).

Do not use the 230.4k baud rate if your module firmware

is 3.04 or earlier and if your program uses block transfers.

Use the 57.6k or 115.2k baud rate instead.

Figure 2.11 Remote I/O Baud Rate Switches

Off = 0

On = 1

Use SW 2.8 and SW 2.7 for setting

the baud rate.

To change the baud rate, you need to:

1. Refer to the following table to determine settings for SW2.8 and

SW2.7:

Baud Rate Switch 2.8 SW2.7

57.6 K 0 0

115.2 K 0 1

230.4 K 1 0

2. Slide the switches to their appropriate positions.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Page 29

Configuring the Module 2–13

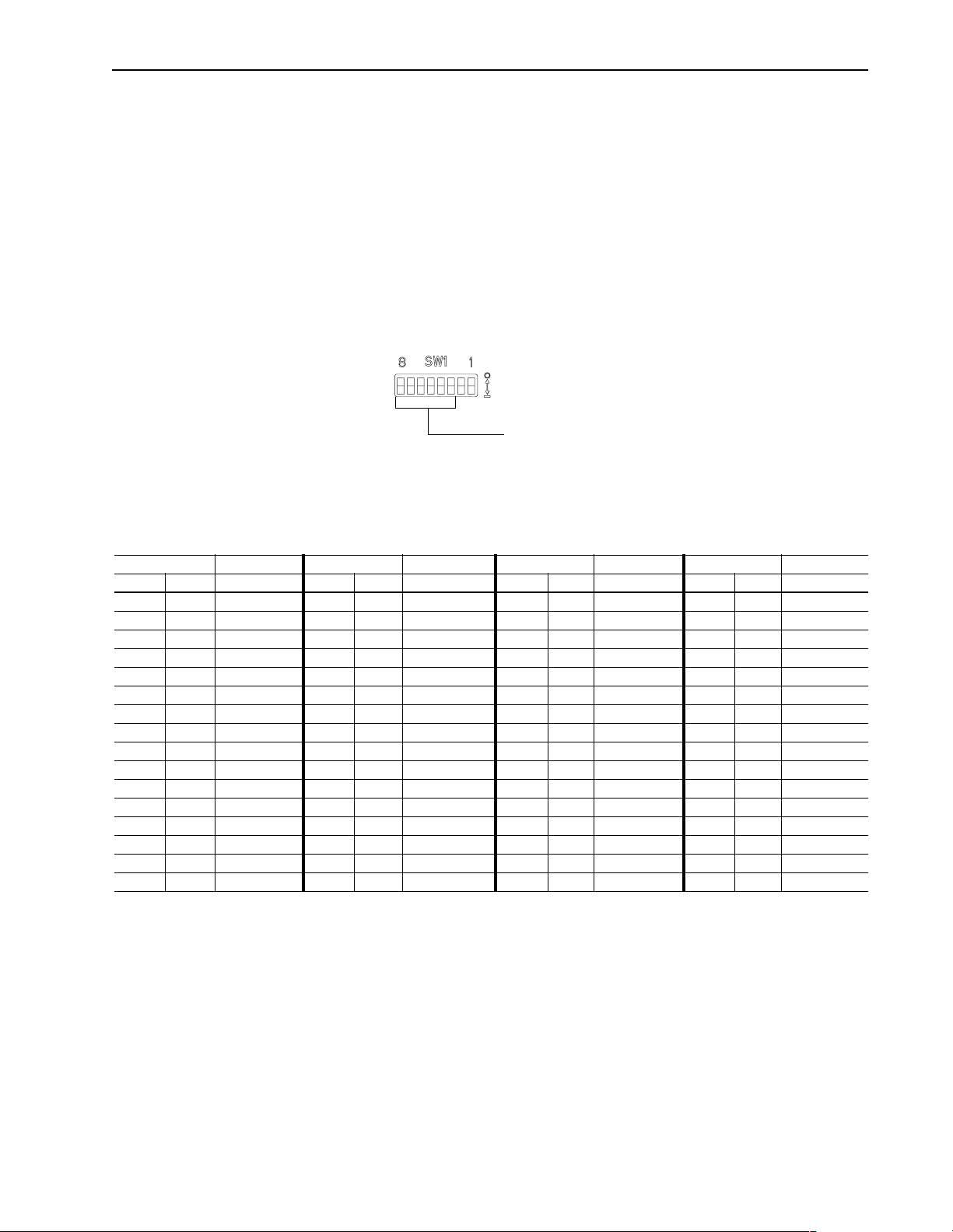

Setting Switches on SW1

Setting the Rack Address

DIP switches 8 through 3 on SW 1 set the rack address for the

Remote I/O module. Each Remote I/O device must have a rack

address that the controller can recognize. Each rack contains 8 words.

Important:

When using a PLC-2 family processor, add 1 to the rack

number set on the Remote I/O module DIP switches to

your PLC code. The PLC-2 cannot have a Remote I/O rack

numbered zero, so add a value of one to the rack number

value when writing your PLC code.

Figure 2.12 Rack Address Switches

Off = 0

On = 1

Use DIP switches 8 through 3 on SW1

for setting the module address.

To edit the rack address, you need to:

1. Refer to the following table to determine the settings for SW1.8

through SW1.3:

Address Switch Setting Address Switch Setting Address Switch Setting Address Switch Setting

Decimal Octal 8 <---- 3 Decimal Octal 8 <---- 3 Decimal Octal 8 <---- 3 Decimal Octal 8 <---- 3

0 0 111111 16 20 111101 32 40 111110 48 60 111100

1 1 011111 17 21 011101 33 41 011110 49 61 011100

2 2 101111 18 22 101101 34 42 101110 50 62 101100

3 3 001111 19 23 001101 35 43 001110 51 63 001100

4 4 110111 20 24 110101 36 44 110110 52 64 110100

5 5 010111 21 25 010101 37 45 010110 53 65 010100

6 6 100111 22 26 100101 38 46 100110 54 66 100100

7 7 000111 23 27 000101 39 47 000110 55 67 000100

8 10 111011 24 30 111001 40 50 111010 56 70 111000

9 11 011011 25 31 011001 41 51 011010 57 71 011000

10 12 101011 26 32 101001 42 52 101010 58 72 101000

11 13 001011 27 33 001001 43 53 001010 59 73 001000

12 14 110011 28 34 110001 44 54 110010 60 74 110000

13 15 010011 29 35 010001 45 55 010010 61 75 010000

14 16 100011 30 36 100001 46 56 100010 62 76 100000

15 17 000011 31 37 000001 47 57 000010 63 77 000000

Important:

Not all controllers support all of these node addresses.

Refer to the documentation for your controller. The

maximum number of devices on a Remote I/O link is 32.

2. Slide the switches to their appropriate positions.

Settings take effect when a module or board first receives power.

When you change a setting, you must remove and then reapply power

for the new setting to take effect.

Page 30

2–14 Configuring the Module

Page 31

Installing the Module

Chapter

3

Chapter Objectives

Selecting Cables

Chapter 3 provides the information that you need to install the

module (1203-GD1 module, 1203-GK1 module, or 1336-GM1

board). In this chapter, you will read about the following:

• Selecting cables.

• Selecting a termination resistor.

• Installing a 1203-GD1 or 1203-GK1 module.

• Installing a 1336-GM1 board.

Refer to the following table to determine the required cables:

If Installing: Required Cables

1203-GD1, 1203-GK1 SCANport and Remote I/O

1336-GM1 Remote I/O

SCANport Cables

When selecting the SCANport cable to connect a module to the

SCANport product, you need to:

• Use an Allen-Bradley SCANport cable. Refer to the table below:

Male to Male Connection Male to Female Connection

Length Catalog Number Length Catalog Number

1/3 m 1202-C03 1/3 m 1202-H03

1 m 1202-C10 1 m 1202-H10

3 m 1202-C30 3 m 1202-H30

9 m 1202-C90 9 m 1202-H90

➀

Cables with male to female connections are generally used as extension cables.

➀

• Use 10 meters (33 feet) or less of cable between the SCANport

product and all peripherals.

• Keep SCANport cables away from high power cables to guard

against introducing noise into your system.

Important:

SCANport cables lock into a connection. To remove a

SCANport cable, you must push it in and then pull it out.

Page 32

3–2 Installing the Module

Remote I/O Cables

Remote I/O communications modules are connected to Remote I/O

links with twinaxial cable used for Remote I/O and Data Highway

Plus (DH+) communications. When selecting a cable, remember the

following:

• Only 1770-CD Belden #9463 is tested and approved for RIO and

DH+ installations. Using other cables is at your own risk.

• The total cable length depends on the baud rate that you are

using. Refer to the following table:

Baud Rate Maximum Length

57.6 K 3,048 m (10,000 ft)

115.2 K 1524 m (5,000 ft)

230.4 K 762 m (2,500 ft)

• All three of the following conductors must be connected at each

node.

Color Description

Blue 1

Shield SH

Clear 2

Selecting a Termination

Resistor

• Do not use a star topology. Only two cables may be connected at

any wiring point. You can use a series topology and daisy-chain

two wires at a point.

You must terminate both ends of a Remote I/O link to ensure proper

operation. This termination is required only at the ends of the

physical cable. Each Remote I/O link should have exactly two

termination resistors.

If the device that you connect is an end device on the Remote I/O

link, it must be terminated. Refer to the following table to select a

resistor.

Important:

You must use an 82 ohm external termination resistor if

the link is operating at 230.4 kbps.

Device Description

Programmable Controller Refer to its manual.

1336-GM1

(Using Jumpers)

1203-GD1, 1203-GK1, or

1336-GM1

(Using an external termi-

nation resistor)

Set J2 in position 1-2 for termination and 2-3 for no termination.

Refer to Figure 3.8. The jumper enables a 150 ohm resistor

Connect a resistor between terminals 1 and 2 on the Remote I/O

connector. Refer to Figure 3.4.

Use an 82 ohm termination resistor unless a device requires a

150 ohm termination resistor

➀

.

➀

.

➀

The following scanners require 150 ohm termination resistors on the RIO link: 1771-SN, 1772-SD,

1772-SD2, 1775-SR, 1775-S4A, 1775-S4B, 6008-SQH1, and 6008-SQH.

The following adapters require a 150 ohm termination resistors on the RIO link: 1771-AS, 1772-ASB

(Series A), 1771-DCM.

The following devices require a 150 ohm termination resistors on the RIO link: 1771-AF.

Page 33

Installing the Module 3–3

Installing a 1203-GD1 or

1203-GK1 Module

Required Tools and Equipment

To install your module, you need the following tools and equipment:

• Remote I/O communications module (1203-GD1 or 1203-GK1).

• 35 x 7.5 mm DIN rail.

• Appropriate cables for SCANport and Remote I/O connections.

Refer to the “Selecting Cables” section in this chapter.

• Termination resistor (if necessary). Refer to the “Selecting a

Termination Resistor” section in this chapter.

• 115 V/230 V AC or 24 V DC power supply.

Installing the 1203-GD1 or 1203-GK1 Module

1. Remove power from the Remote I/O link.

2. Hook the top lip of the module DIN rail mount onto the top of the

DIN rail and then rotate the module onto the DIN rail. It snaps

into a locked position.

Figure 3.1 Mounting a Module onto the DIN Rail

Page 34

3–4 Installing the Module

3. Connect a SCANport cable (1202-Cxx) to a module and product.

Important:

For the location of the SCANport connector on your

product, refer to its user manual. If you are using a port

expander, refer to its documentation.

Figure 3.2 Connecting the SCANport Cable

SCANport Product

.

Module

Blue

Shield

Clear

4. Connect a Remote I/O cable to the module and link or controller.

Figure 3.3 Connecting the Remote I/O Cable

PLC Controller

.

1

SH

2

Module

.

.

Clear

Shield

Blue

SH

2

1

Page 35

Installing the Module 3–5

5. If the module is the last device on the Remote I/O link, connect

the termination resistor. If the Remote I/O link uses 230Kbps,

you must use an 82 ohm termination resistor.

Figure 3.4 Connecting the Termination Resistor

6. Connect the power supply to the module.

Figure 3.5 Connecting the Power Supply

1203-GD1 Module

To

Another Remote I/O

Link Device

Clear

Shield

Blue

2

Sh

1

1203-GK1 Module

I50 Ohm

or

82 Ohm

1 watt

+/-10%

Hi 115V/230V AC

Low 115V/230V AC

GND

L

N

G

24V DC

Supply

+

-

GND

7. Apply power to the Remote I/O link. The module is now

installed. Its LEDs are as follows:

LED Status

Fault Red (Blinking)

SCANport STS Green or amber

Health Green or amber

➀ ➁

➁

Rem I/O ACT Off

Rem I/O STS Off

➀

This LED is off if the module use firmware 2.xx or lower.

➁

Early versions of the module use amber LEDs.

You are now ready to create a ladder logic program.

Important:

If your LEDs are different, refer to Chapter 6.

+

G

Page 36

3–6 Installing the Module

Installing a 1336-GM1 Board

Required Tools and Equipment

To install your 1336-GM1 board, you need the following tools and

equipment:

• Remote I/O communications board (1336-GM1).

• A kit that includes one grounding wrist strap, four Phillips

mounting screws, four stand-off nylon headers, and one snap-in

comm housing with mounting instructions (supplied with board).

• #1 Phillips screwdriver.

• Appropriate cable for the Remote I/O connection. Refer to the

“Selecting Cables” section in this chapter.

Installing the 1336-GM1 Communications Board

The following instructions explain how to physically install a Remote

I/O communications board.

ATTENTION: The 1336-GM1 communications board

!

contains ESD (Electrostatic Discharge) sensitive parts.

Static control precautions are required when installing, testing, or servicing this board. Device malfunction may occur

if you do not follow ESD control procedures. If you are not

familiar with static control procedures, refer to Rockwell

Automation Publication 8000-4.5.2, Guarding Against

Electrostatic Damage, or other applicable ESD protection

handbook.

ATTENTION: Remove all power from the SCANport

!

Important:

1. Remove power from the SCANport product, and verify that it is

2. Remove power from the Remote I/O link.

3. Put on the grounding wrist strap.

product before installing the 1336-GM1 board. Failure to

disconnect power may result in death or serious injury. Verify all power is removed before installing the 1336-GM1

board.

If you are attaching the communications board to a 1336

PLUS II, refer to the one-page insert included with the kit

for mounting instructions.

not holding power.

Page 37

Installing the Module 3–7

4. Screw the four stand-off nylon headers into the appropriate

spaces on the drive main control board.

Figure 3.6 Mounting the Open Style Communications Board

5. Insert the SCANport connector into the 14-pin SCANport header

on the control board. The DIP switches should be facing you.

6. Screw the board securely into place, being careful not to

overtighten the four screws.

7. Connect the Remote I/O cable.

Figure 3.7 Connecting the Remote I/O Cable

PLC Controller

.

.

Blue

Shield

Clear

Blue

Shield

Clear

SH

1

2

J4

1

SH

2

.

SCANport Product

.

1336-GM1

Board

Page 38

3–8 Installing the Module

8. If the module is the last device on the Remote I/O link, either user

the internal termination resistor (J2) or an external termination

resistor. If the Remote I/O link uses 230Kbps, you must use an

external 82 ohm termination resistor.

Blue

Shield

Clear

To

Another

Remote I/O

Link Device

External Termination

1

Sh

2

I50 Ohm

or

82 Ohm

1 watt

+/-10%

Important:

Use only one type of termination (internal or external),

Figure 3.8 Using a Termination Resistor

123

J2

Not Last Device,

(Factory Default)

Last Device on link,

Termination

Resistor Inserted

Enables 150 ohm

Termination Resistor

123

123

Internal Termination

9. Reapply power to the SCANport product.

10. Apply power to the Remote I/O link. The module is now

installed. Its LEDs are as follows:

LED Status

Fault Red (Blinking)

SCANport STS Green or amber

Health Green or amber

➀ ➁

➁

Rem I/O ACT Off

Rem I/O STS Off

➀

This LED is off if the module use firmware 2.xx or lower.

➁ Early versions of the module use amber LEDs.

You are now ready to create a ladder logic program.

Important:

If your LEDs are different, refer to Chapter 6.

Page 39

Chapter

Creating Ladder Logic Programs

4

Chapter Objectives

Chapter 4 provides information about ladder logic programs for

products connected to a Remote I/O communications module. In this

chapter, you will read about the following:

• I/O image table.

• Control Features.

• Datalinks.

• Example ladder logic programs for PLC, SLC, and Logix5550

controllers.

ATTENTION: When you configure a system for the first

!

!

time, you should disconnect the motor from the machine or

the process during the initial testing.

ATTENTION: The configurations and program examples

shown in this manual are intended solely for purposes of

example. Since there are many variables and requirements

associated with any particular installation, Rockwell Automation does not assume responsibility or liability (to include intellectual property liability) for actual use based

upon the examples shown in this publication.

Understanding the I/O Image

Tab le

The Remote I/O communications module allows a SCANport product

to look and act like a Remote I/O chassis when connected to a

programmable controller. Data contained in the input/output image

table is transferred between the programmable controller by the

Remote I/O scanner, the same as with any Remote I/O chassis. You

control the location of data transferred by setting the rack address and

starting group. You control the amount of data by setting the DIP

switches on SW3.

Important:

Important:

The communications module does not scale the data that

is transferred. Consequently, all scaling of the data must

be done in the controller. Refer to the user manual for your

SCANport product for details on device units.

The Remote I/O to SCANport conversion is asynchronous.

Data sent to the adapter for transfer to the drive must be

maintained until the drive has received data.

Page 40

4–2 Creating Ladder Logic Programs

DIP switches on SW3 determine how the data contained in the

programmable controller I/O image table is used in the drive. Figure

4.1 shows an I/O image table.

Figure 4.1 I/O Image Table

Remote I/O SCANport

8 words maximum

8 words maximum

Controller

Image

Output Image

O:010

O:011

O:012

O:013

O:014

O:015

O:016

O:017

Input Image

I:010

I:011

I:012

I:013

I:014

I:015

I:016

I:017

1

Optionally enabled using DIP switches on the module. Refer to Chapter 2.

Remote I/O

Communications

Module

Block Transfer

Logic Command

Reference

Datalink A1

Datalink A2

Datalink B1

Datalink B2

Datalink C1

Datalink C2

Datalink D1

Datalink D2

Block Transfer

Logic Status

Feedback

Datalink A1

Datalink A2

Datalink B1

Datalink B2

Datalink C1

Datalink C2

Datalink D1

Datalink D2

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

SCANport Product

Message Handler

Logic Command

Reference

Data In A1

Data In A2

Data In B1

Data In B2

Data In C1

Data In C2

Data In D1

Data In D2

Message Handler

Logic Status

Feedback

Data Out A1

Data Out A2

Data Out B1

Data Out B2

Data Out C1

Data Out C2

Data Out D1

Data Out D2

Control Features

Datalinks

SW 3.1 through SW 3.3 select the basic control features: Block

Transfer, Logic Command/Status, and Reference/Feedback. When

enabled, each of these features adds one word to the input I/O image

table and one word to the output I/O image table.

SW 3.4 through SW 3.8 enable or disable the datalinks.

Description

A datalink is a type of pointer used by some SCANport products to

transfer data to and from the controller. Datalinks allow a parameter

value to be changed without using a block transfer message. When

enabled, each datalink consumes two 16-bit words in both the input

and output image table of the controller. When SW3.8 is ON, the last

datalink is truncated so that it uses only one word in the input and

output image table.

Page 41

Creating Ladder Logic Programs 4–3

Products That Support Datalinks

To use datalinks, your SCANport product must support them. Refer

to your product user manual.

Using Datalinks

The following are the rules for using datalinks:

• Normally, each enabled datalink reserves two words in both the

input and output image tables of the controller. This increases

your I/O image size. The starting module group on the module

must be set to support the size of the I/O image table. Truncation

can be used to minimize the required rack size used by the

Remote I/O module. Refer to Chapter 2.

• Each set of datalink parameters in a SCANport product can be

used by only one communications module. If more than one

module is connected to a single SCANport product, they must not

attempt to use the same datalink.

• Parameter settings in the SCANport product determine the data

passed through the datalink mechanism. Refer to the user manual

for your SCANport product for more information.

• When you use a datalink to change a value, the value is not

written to the EEPROM. The value is stored in volatile memory

and lost when the drive loses power.

• The 1336 FORCE and 1336 IMPACT drives use datalinks in a

special way. Refer to their user manuals for information.

Example Application 1

The simplest application of datalinks is to set a parameter number

into a Data In parameter. The controller output image table word

connected to this datalink will then control the value of the parameter

set into the Data In parameter.

For example, to change the value of parameter 27 in a 1336 PLUS

drive, you need to:

1. In the 1336 PLUS drive, set parameter 111 (Data In A1) to 27.

2. On the communications module, slide SW 3.4 to ON. See Figure

2.6.

3. If your communications module is configured like Figure 4.1,

word 3 (fourth word) in the output image will be the value that

parameter 27 uses. This value is stored in volatile memory and

lost when the drive loses power.

Page 42

4–4 Creating Ladder Logic Programs

Example Application 2

Another application for datalinks is to set a parameter into a Data Out

parameter. The controller input image table word connected to this

datalink will then receive the value of the parameter programmed into

the Data Out parameter.

For example, to monitor the value of parameter 27 in a 1336 PLUS

drive, you need to:

1. In the 1336 PLUS drive, set parameter 119 (Data Out A1) to 27.

2. On the module, slide SW 3.4 to ON. See Figure 2.6.

3. If your communications module is configured like Figure 4.1,

Example Application 3

A third application for datalinks is to change multiple parameters

with only two datalinks enabled. During each scan, this application

changes a parameter and then verifies that it has been changed.

word 3 (fourth word) in the input image would receive the value

of parameter 27.

For example, to change parameters 27, 28, and 29 in a 1336 PLUS

drive, you need to:

1. In the 1336 PLUS drive, set the following parameters:

Parameter: Setting

111 (Data In A1) 112

119 (Data Out A1) 112

113 (Data In B1) 120

2. On the module, slide SW 3.4 and SW 3.5 to ON to enable

datalinks A and B (See Figure 2.6). Slide the other DIP switches

on SW3 to OFF.

A parameter number must be moved or copied into word 0 (first

word) and word 2 (third word) of the output image for each scan.

The new parameter value must be moved or copied into word 1

(second word) of the output image. In our example, we move the

following data into the input image table:

Scan Word 0 and 2 Word 1 Description

1 27 123 Parameter 27 will be set to 123.

2 28 456 Parameter 28 will be set to 456.

3 29 789 Parameter 29 will be set to 789.

A successful scan yields the following results in word 0 and 1 in

the input image table:

Scan Word 0 Word 1 Description

1 27 123 Parameter 27 has been set to 123.

2 28 456 Parameter 28 has been set to 456.

3 29 789 Parameter 29 has been set to 789.

Logic can be developed for the controller that uses the values in

word 0 (first word) and word 1 (second word) of the input image

to verify that the change was completed successfully.

Page 43

Creating Ladder Logic Programs 4–5

Figure 4.2 illustrates the first scan in Example Application 3.

Figure 4.2 Example Scan using Datalinks

Remote I/O SCANport

Controller

Image

Output Image

O:010 = 27

O:011 = 123

O:012 = 27

O:013

O:014

O:015

O:016

O:017

I:010 = 27

I:011 = 123

I:012

I:013

I:014

I:015

I:016

I:017

1

In this example scan, the parameter being changed is P27-[Preset Freq 1]. Its new value will be 123.

1

1

Input Image

Remote I/O

Communications

Module

Block Transfer

Logic Command

Reference

Datalink A1

Datalink A2

Datalink B1

Datalink B2

Datalink C1

Datalink C2

Datalink D1

Datalink D2

Block Transfer

Logic Status

Feedback

Datalink A1

Datalink A2

Datalink B1

Datalink B2

Datalink C1

Datalink C2

Datalink D1

Datalink D2

1336 PLUS Drive

Message Handler

Logic Command

Reference

P111 (Data In A1) = Sends "27" to P112

P112 (Data In A2) = Sends "123" to P27

P113 (Data In B1) = Sends "27" to P120

P114 (Data In B2)

P115 (Data In C1)

P116 (Data In C2)

P117 (Data In D1)

P118 (Data In D2)

Message Handler

Logic Status

Feedback

P119 (Data Out A1) = Gets "27" from P112

P120 (Data Out A2) = Gets "123" from P27

P121 (Data Out B1)

P122 (Data Out B2)

P123 (Data Out C1)

P124 (Data Out C2)

P125 (Data Out D1)

P126 (Data Out D2)

Settings for the Ladder Logic

Program Examples

The example ladder logic programs in this manual use the following

settings.

Remote I/O Communications Module Settings

The Remote I/O module used for examples in this manual is

connected to a 1336 PLUS drive. It is configured for the following:

• Rack Address = 2

• Rack Size = 1/2 Rack

• Starting Group = 0

DIP switches on SW3 are set as follows:

Settings

Switch

Off = 0

On = 1

8 ---> 1 Description

00001110 Logic command/status, reference/

feedback, and datalink A are enabled. All

other features are disabled.

Page 44

4–6 Creating Ladder Logic Programs

SCANport Product Settings

Logic Command bits

In our example, we are using a 1336 PLUS drive. The Logic

Command bits for it are:

Logic Command Bits

Function Description1514131211109876543210

XStop

X Start 1=Start, 0=No Operation

X Jog 1=Jog, 0=No Operation

X Clear Faults 1=Clear, 0=No Operation

X X Direction 00=No Operation, 01=Forward,

X Local 1=Local, 0=Multiplexed

X MOP Increment 1=Increment MOP, 0=No Operation

X X Accel Rate Select 00=No Operation, 01=Rate 1, 10=Rate 2

X X Decel Rate Select 00=No Operation, 01=Rate 1, 10=Rate 2

X X X Reference

X MOP Decrement 1=Decrement MOP, 0=No Operation

➀

Asserting a 1 will stop the product.

➀

Selection

1=Stop, 0=No Operation

10=Reverse

000=No Operation

001=External Reference 1 (Par 5)

010=External Reference 2 (Par 6)

011=Preset 3

100=Preset 4

101=Preset 5

110=Preset 6

111=Preset 7

The 1305 drives, 1336 PLUS II drives, and 1336 Spider drives use the

same Logic Command and Logic Status data. For other drives, refer

to their user manuals.

Page 45

Creating Ladder Logic Programs 4–7

Logic Status Bits

The Logic Status bits for the 1336 PLUS drive that we use in our

example are as follows:

Logic Status Bits

Function Description1514131211109876543210

X Enabled 1=Enabled, 0=Not Enabled

X Running 1=Running, 0=Not Running

X Command

Direction

X Rotating Direction 1=Forward, 0=Reverse

X Acceleration 1=Accelerating, 0=Not

X Deceleration 1=Decelerating, 0=Not

X Warning 1=Warning Present, 0=Not

X Fault 1=Faulted, 0=Not Faulted

X At Speed 1=At Speed, 0=Not At Speed

X X X Local 000=Terminal I/O has Local

X X X X Reference Source 0000=External Reference 1

1=Forward, 0=Reverse