Page 1

Bulletin 1336

Adjustable Frequency AC Drive

User Manual

Page 2

Important User Information

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage or economic loss.

Attentions help you:

• Identify a hazard.

• Avoid the hazard.

• Recognize the consequences.

IMPORTANT: Identifies information that is especially important for

successful application and understanding of the product.

DANGER labels may be located on or inside the drive to alert

people that dangerous voltage may be present.

Page 3

Summary of Changes

Summary of Changes

Summary of Manual Changes This release of the 1336-5.0 User Manual contains some new and updated

information. The new and updated information is summarized in the table

below. For further information, refer to the page numbers provided.

Description of New or Updated Information Page Type

Unit Schematics – Figures 3.1, 3.2, 3.3, 3,4 3-2 – 3-9 Updated

General Installation Requirements Attention 5-1 New

General Wiring Procedures Attention 6-1 New

Page 4

Table of Contents

PreInstallation Care 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving - Once you have received your drive, careful inspection

for shipping damage must be made. Damage to the shipping carton

is usually a good indication that it has received improper handling.

Any and all damage should be immediately reported to the freight

carrier and your nearest AllenBradley Area Sales/Support

Center. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage

Handling - Depending upon the rating and options ordered, the weight

Shipping - The carton and materials that came with your drive have

Electrostatic Discharge - Electrostatic discharge generated by static

Precautions - Complimentary metallic oxide semiconductor devices

- If the drive will not immediately be installed, it should be

stored in a clean, dry area where the ambient temperature is not

less than 405C nor more than +855C. The drive must not be stored

in a corrosive environment nor subject to conditions in excess of the

storage environment parameters stated in Chapter 4

Specifications. 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. T

of your drive can vary

safety precautions and practices must be observed whenever the

drive is being moved from one location to another. 11. . . . . . . . . .

been designed and tested to provide reasonable protection against

damage during transit. Should the drive be shipped to another location,

it is recommended that the original shipping carton and packing

material be used to protect the drive from damage in transit. 11. . .

electricity can damage the 12. . . . . . . . . . . . . . . . . . . . . . . . . . .

on various drive boards. It is recommended that you perform these

procedures to guard against this type of damage when circuit boards

are removed or installed: 12. . . . . . . . . . . . . . . . . . . . . . . . . . . .

o guard against injury to personnel, proper

Overview 31. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring 61. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Important User Information 2. . . . . . . . . . . . . . . . . . . . . . . .

Page 5

Preface

Manual Objective

This manual defines the installation, operation, startup and fault codes for

the Allen-Bradley 1336 Adjustable Frequency AC Drive. It is intended for

use by personnel familiar with the functions of solid-state drive equipment.

Also provided are interconnection drawings for 1336 logic interface

options in Appendix A.

The 1336 User Manual is designed to be read and used like an ordinary

textbook. Read the manual once from the beginning in the order presented

to gain basic knowledge about your drive. Each chapter builds upon

information presented in the previous chapter.

To assure successful installation and operation, the material presented in

each chapter must be thoroughly read and understood before proceeding to

the next chapter. Particular attention should be directed to the Attention and

Important statements contained within. Become familiar with tasks that

must be performed in a sequence for safety and successful completion.

Important: The Handheld Programming Terminal

(Cat. No. 1336-MOD-E1) firmware must be upgraded with Kit SP-148340

(Version 2.01) to be compatible with drive firmware Version 2.01 and 3.01.

The Monitor Display (Cat. No. 1336-MOD-E2) firmware must be

upgraded with Kit SP-148341 (Version 2.01) to be compatible with drive

firmware Version 2.01 and 3.01.

P-1

Page 6

Preface

Manual

Objective (cont.)

Firmware versions are marked at two locations in the drive – on the Main

Control Board and on the Base Driver/Power Supply Board.

For all drive ratings, the microprocessor chip U14 located on the Main

Control Board has the following firmware identification:

• P/N XXXXXXV1.01 –– Firmware Version 1.01.

• P/N XXXXXXV1.10 –– Firmware Version 1.10.

• P/N XXXXXXV1.11 –– Firmware Version 1.11.

• P/N XXXXXXV2.01 –– Firmware Version 2.01.

CAUTION

HAZARDOUS VOLTAGE ON CAPACITORS

WHEN NEON LIGHT IS ON. REMOVE POWER

AND WAIT 60 SECONDS BEFORE SERVICING.

ATTENTION

TENSION DANGEREUSE AU NIVEAU DES

CONDENSATEURS QUAND LES NEONS SONT

ALLUMES. COUPER LE COURANT ET

ATTENDRE 60 SECONDES AVANT DE

COMMENCER L'ENTRETIEN.

VORSICHT

AN DEN KONDENSATOREN BESTEHT

HOCHSPANNUNGSGEFAHR, WENN DS NEON-

LICHT AUFLECUDHTET. STROM UNTER-

BRECHEN UND 60 SEK. WARTEN BEVOR

SERVICEARBEITEN DURCHGEFÜHRT WERDEN.

ATTENZIONE

TENSIONE PERICOLOSA SUI CONDENSATORI

QUANDO LA LUCE AL NEON È ACCESA.

TOGLIERE L'ALIMENTAZIONE ED ASPETTARE 60

¿¬|– [¥

SECONDI PRIMA DI PRESTARE MANUTENZIONE.

†[Ÿ Ÿº |]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º

¬Ÿ[ ¿|]

~|[º ¥‡º Ÿº][ <|>/º ¿Ÿº¿|]

|]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º<|>/º ¥‡º

PRECAUCION

AVOLTAJE PERLIGROSO EN LS CAPACITORES

CUANDO LA LUZ DE NEON ESTÉ ENCENDIO.

ANTES DE DAR SERVICIO.

CORTE LA ENERGIA Y ESPERE 60 DEGUNDOS

GND

GND

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

BULLETIN 1336 ADJUSTABLE FREQUENCY AC DRIVE

Microprocessor Chip U14

Located on Main Control Board

C1

➁

➀

SW1

C2

R

P

Freq

18

17

L3

L2

L1

M3

M2

M1

–DC

+DC

1

8

7

6

5

4

3

2

16

15

14

13

12

11

10

9

Jog

Start

Stop

Enter

R

P

P-2

Page 7

Preface

Manual

Objective (cont.)

For B003-B030 & C003-C030 ratings, microprocessor chip U21 located on

the Base Driver/Power Supply Board has the following firmware

identification:

• P/N XXXXXXV1.01 –– Firmware Version 1.01.

• P/N XXXXXXV1.11 –– Firmware Version 1.11.

• P/N XXXXXXV1.13 –– Firmware Version 1.13.

• P/N XXXXXXV1.14 –– Firmware Version 1.14.

• P/N XXXXXXV3.01 –– Firmware Version 3.01.

CAUTION

HAZARDOUS VOLTAGE ON CAPACITORS

WHEN NEON LIGHT IS ON. REMOVE POWER

AND WAIT 60 SECONDS BEFORE SERVICING.

ATTENTION

TENSION DANGEREUSE AU NIVEAU DES

CONDENSATEURS QUAND LES NEONS SONT

ALLUMES. COUPER LE COURANT ET

ATTENDRE 60 SECONDES AVANT DE

COMMENCER L'ENTRETIEN.

VORSICHT

AN DEN KONDENSATOREN BESTEHT

HOCHSPANNUNGSGEFAHR, WENN DS NEON-

LICHT AUFLECUDHTET. STROM UNTERBRECHEN UND 60 SEK. WARTEN BEVOR

SERVICEARBEITEN DURCHGEFÜHRT WERDEN.

ATTENZIONE

TENSIONE PERICOLOSA SUI CONDENSATORI

QUANDO LA LUCE AL NEON È ACCESA.

TOGLIERE L'ALIMENTAZIONE ED ASPETTARE 60

¿¬|– [¥

SECONDI PRIMA DI PRESTARE MANUTENZIONE.

†[Ÿ Ÿº |]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º

¬Ÿ[ ¿|]

~|[º ¥‡º Ÿº][ <|>/º ¿Ÿº¿|]

|]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º<|>/º ¥‡º

PRECAUCION

AVOLTAJE PERLIGROSO EN LS CAPACITORES

CUANDO LA LUZ DE NEON ESTÉ ENCENDIO.

ANTES DE DAR SERVICIO.

CORTE LA ENERGIA Y ESPERE 60 DEGUNDOS

Microprocessor Chip U21

Located on Base Driver/Power Supply Board

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

BULLETIN 1336 ADJUSTABLE FREQUENCY AC DRIVE

C1

➁

➀

SW1

C2

R

P

Freq

L3

L2

L1

M3

M2

M1

–DC

+DC

GND

GND

1

Jog

Start

Stop

13

12

11

10

9

8

7

6

5

4

3

2

Enter

R

P

18

17

16

15

14

P-3

Page 8

Preface

Manual

Objective (cont.)

For B040-B050 & C040-C050 ratings, microprocessor chip U2 located on

the Base Driver/Power Supply Board has the following firmware

identification:

• P/N XXXXXXV1.11 –– Firmware Version 1.11.

• P/N XXXXXXV1.13 –– Firmware Version 1.13.

• P/N XXXXXXV1.14 –– Firmware Version 1.14.

• P/N XXXXXXV3.01 –– Firmware Version 3.01.

GND

L3

L2

L1

M3

M2

TIGHTENING TORQE 120 INCH POUNDS

M1

USE 75°C COPPER WIRE ONLY WIRE RANGE 2/0 – 6 AWG

–DC

+DC

GND

–

M

+

CAUTION

HAZARDOUS VOLTAGE ON CAPACITORS

WHEN NEON LIGHT IS ON. REMOVE POWER

AND WAIT 60 SECONDS BEFORE SERVICING.

ATTENTION

TENSION DANGEREUSE AU NIVEAU DES

CONDENSATEURS QUAND LES NEONS SONT

ALLUMES. COUPER LE COURANT ET

ATTENDRE 60 SECONDES AVANT DE

COMMENCER L'ENTRETIEN.

VORSICHT

AN DEN KONDENSATOREN BESTEHT

HOCHSPANNUNGSGEFAHR, WENN DS NEON-

LICHT AUFLECUDHTET. STROM UNTER-

BRECHEN UND 60 SEK. WARTEN BEVOR

SERVICEARBEITEN DURCHGEFÜHRT WERDEN.

ATTENZIONE

TENSIONE PERICOLOSA SUI CONDENSATORI

QUANDO LA LUCE AL NEON È ACCESA.

TOGLIERE L'ALIMENTAZIONE ED ASPETTARE 60

¿¬|– [¥

SECONDI PRIMA DI PRESTARE MANUTENZIONE.

†[Ÿ Ÿº |]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º

¬Ÿ[ ¿|]

~|[º ¥‡º Ÿº][ <|>/º ¿Ÿº¿|]

|]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º<|>/º ¥‡º

PRECAUCION

AVOLTAJE PERLIGROSO EN LS CAPACITORES

CUANDO LA LUZ DE NEON ESTÉ ENCENDIO.

ANTES DE DAR SERVICIO.

CORTE LA ENERGIA Y ESPERE 60 DEGUNDOS

BULLETIN 1336 ADJUSTABLE FREQUENCY AC DRIVE

Start

Stop

8

7

6

5

4

3

2

1

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

Microprocessor Chip U2

C1

➁

Located on Base Driver/Power Supply Board

➀

SW1

C2

R

P

Freq

Enter

R

P

Jog

18

17

16

15

14

13

12

11

10

9

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

P-4

Page 9

Preface

Manual Objective (cont.)

For B075-B125 & C075-C125 ratings, microprocessor chip U2 located on

the Base Driver/Power Supply Board has the following firmware

identification:

• P/N XXXXXXV1.11 –– Firmware Version 1.11.

• P/N XXXXXXV1.13 –– Firmware Version 1.13.

• P/N XXXXXXV1.14 –– Firmware Version 1.14.

• P/N XXXXXXV3.01 –– Firmware Version 3.01.

GND

L3

L2

L1

M3

TIGHTENING TORQUE 275 INCH POUNDS

M2

USE 75°C COPPER WIRE ONLY WIRE RANGE 350 MCM –– 6 AWG

M1

– DC

+ DC

–

M

+

–

M

+

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

BULLETIN 1336 ADJUSTABLE FREQUENCY AC DRIVE

C1

➁

➀

SW1

C2

R

P

Freq

Enter

R

P

Jog

Start

Stop

18

17

16

15

14

13

12

11

10

9

8

7

6

5

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

CAUTION

HAZARDOUS VOLTAGE ON CAPACITORS

WHEN NEON LIGHT IS ON. REMOVE POWER

AND WAIT 60 SECONDS BEFORE SERVICING.

ATTENTION

TENSION DANGEREUSE AU NIVEAU DES

CONDENSATEURS QUAND LES NEONS SONT

ALLUMES. COUPER LE COURANT ET

ATTENDRE 60 SECONDES AVANT DE

COMMENCER L'ENTRETIEN.

VORSICHT

AN DEN KONDENSATOREN BESTEHT

HOCHSPANNUNGSGEFAHR, WENN DS NEON-

LICHT AUFLECUDHTET. STROM UNTER-

BRECHEN UND 60 SEK. WARTEN BEVOR

SERVICEARBEITEN DURCHGEFÜHRT WERDEN.

ATTENZIONE

TENSIONE PERICOLOSA SUI CONDENSATORI

QUANDO LA LUCE AL NEON È ACCESA.

TOGLIERE L'ALIMENTAZIONE ED ASPETTARE 60

¿¬|– [¥

SECONDI PRIMA DI PRESTARE MANUTENZIONE.

†[Ÿ Ÿº |]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º

¬Ÿ[ ¿|]

~|[º ¥‡º Ÿº][ <|>/º ¿Ÿº¿|]

|]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º<|>/º ¥‡º

PRECAUCION

AVOLTAJE PERLIGROSO EN LS CAPACITORES

CUANDO LA LUZ DE NEON ESTÉ ENCENDIO.

ANTES DE DAR SERVICIO.

CORTE LA ENERGIA Y ESPERE 60 DEGUNDOS

SERVICING.

–

M

+

4

3

2

1

Microprocessor Chip U2

Located on Base Driver/Power Supply Board

P-5

Page 10

Preface

Manual

Objective (cont.)

For B150-B200 & C150-C200 ratings, microprocessor chip U2 located on

the Base Driver/Power Supply Board has the following firmware

identification:

• P/N XXXXXXV1.11 –– Firmware Version 1.11.

• P/N XXXXXXV1.13 –– Firmware Version 1.13.

• P/N XXXXXXV1.14 –– Firmware Version 1.14.

• P/N XXXXXXV3.01 –– Firmware Version 3.01.

USE 75°C COPPER WIRE ONLY.

WIRE SIZE 2 (3) AWG

GND

TIGHTENING TORQUE 275 INCH POUNDS

L3

L2

L1

USE 75°C COPPER WIRE ONLT.

WIRE RANGE 500 MCM –– 0 AWG

TIGHTENING TORQUE 375 INCH POUNDS

M3

M2

GND

M1

USE 75°C COPPER WIRE ONLT.

– DC

WIRE RANGE 350 MCM –– 6 AWG

TIGHTENING TORQUE 275 INCH POUNDS

+ DC

P-6

CAUTION

HAZARDOUS VOLTAGE ON CAPACITORS

WHEN NEON LIGHT IS ON. REMOVE POWER

AND WAIT 60 SECONDS BEFORE SERVICING.

ATTENTION

TENSION DANGEREUSE AU NIVEAU DES

CONDENSATEURS QUAND LES NEONS SONT

ALLUMES. COUPER LE COURANT ET

ATTENDRE 60 SECONDES AVANT DE

COMMENCER L'ENTRETIEN.

VORSICHT

AN DEN KONDENSATOREN BESTEHT

HOCHSPANNUNGSGEFAHR, WENN DS NEON-

LICHT AUFLECUDHTET. STROM UNTERBRECHEN UND 60 SEK. WARTEN BEVOR

SERVICEARBEITEN DURCHGEFÜHRT WERDEN.

ATTENZIONE

TENSIONE PERICOLOSA SUI CONDENSATORI

QUANDO LA LUCE AL NEON È ACCESA.

TOGLIERE L'ALIMENTAZIONE ED ASPETTARE 60

¿¬|– [¥

SECONDI PRIMA DI PRESTARE MANUTENZIONE.

†[Ÿ Ÿº |]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º

¬Ÿ[ ¿|]

~|[º ¥‡º Ÿº][ <|>/º ¿Ÿº¿|]

|]º] ¬Ÿ[ ¿|] Ÿº][, <|>/º ¥‡º<|>/º ¥‡º

PRECAUCION

AVOLTAJE PERLIGROSO EN LS CAPACITORES

CUANDO LA LUZ DE NEON ESTÉ ENCENDIO.

ANTES DE DAR SERVICIO.

CORTE LA ENERGIA Y ESPERE 60 DEGUNDOS

Microprocessor Chip U2

Located on Base Driver/Power Supply Board

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

3

2

1

BULLETIN 1336 ADJUSTABLE FREQUENCY AC DRIVE

Start

Stop

9

8

7

6

5

4

Jog

CAUTION

HAZARDOUS VOLTAGE ON

CAPACITORS WHEN NEON

LIGHT IS ON. REMOVE POWER

AND WAIT 60 SEC. BEFORE

SERVICING.

11

10

C1

➁

➀

SW1

C2

R

P

Freq

Enter

R

P

18

17

16

15

14

13

12

Page 11

Preface

Manual Objective (cont.)

This manual is meant to guide the user with interface, installation, setup

and troubleshooting of a 1336. The contents are arranged in order from a

general description to troubleshooting and maintenance. To assure

successful installation and operation, the material presented must be

thoroughly read and understood before proceeding. Particular attention

must be directed to the Caution, Warning and Important statements

contained within.

Important Information about this Manual

This manual has been prepared primarily to support this product in a single

application. It is a standard document that is intended to help the user

understand the individual operating characteristics and limitations of this

equipment including hazards associated with installation and setup

procedures. Note the following points:

• This equipment has been designed to meet the requirements of a

component in an integrated system.

• It must be noted that special considerations are to be given to

characteristics of other peripheral solid-state control equipment and the

cumulative impact on safety.

• Manufacturers and engineering groups responsible for specification or

design of electrical control equipment must refer to applicable industry

standards and codes for specific safety guidelines and interface

requirements.

• In the actual factory environment, the user is responsible to assure

compliance with applicable machine and operator safety codes or

regulations which are beyond the scope and purpose of this document.

P-7

Page 12

Preface

General Precautions In addition to the precautions listed throughout this manual, the following

statements which are general to the system must be read and understood.

ATTENTION: Only personnel familiar with the 1336 AC Drive

and associated machinery should plan or implement the

!

installation, start-up and subsequent maintenance of the system.

Failure to comply may result in personal injury and/or equipment

damage.

ATTENTION: This assembly may contain parts and

sub-assemblies that are sensitive to electrostatic discharge. Static

!

control precautions are required when testing, servicing or

repairing this assembly. Component damage may result if you

ignore electrostatic discharge control procedures. If you are not

familiar with static control procedures, reference Allen-Bradley

Publication 8000-4.5.2, Guarding Against Electrostatic Damage or

any other applicable ESD protection handbook.

ATTENTION: An incorrectly applied or installed system can

result in component damage or reduction in product life. Wiring or

!

application errors, such as undersizing the motor, incorrect or

inadequate AC supply, or excessive ambient temperatures may

result in malfunction of the system.

P-8

Page 13

Chapter

1

PreInstallation Care

Before installing and operating your 1336, carefully read this manual and

observe all precautions. The catalog number of your drive as explained in

Chapter 2 — Drive and Option Identification lists the drive rating, type of

enclosure, nominal line voltage, phase and frequency, as well as any

additional options that you may have specified. Specifications for all drives

including standard controls, adjustment range, diagnostics and

environmental qualifications are listed in Chapter 4 — Specifications.

Receiving Once you have received your drive, careful inspection for shipping damage

must be made. Damage to the shipping carton is usually a good indication

that it has received improper handling. Any and all damage should be

immediately reported to the freight carrier and your nearest Allen-Bradley

Area Sales/Support Center.

Carefully unpack the drive, taking care to save the shipping carton and any

packing material should return be necessary. Verify that the items on the

packing list or bill of lading agree with your order.

Storage If the drive will not immediately be installed, it should be stored in a clean,

dry area where the ambient temperature is not less than -40°C nor more

than +85°C. The drive must not be stored in a corrosive environment nor

subject to conditions in excess of the storage environment parameters

stated in Chapter 4 — Specifications.

Handling Depending upon the rating and options ordered, the weight of your drive

can vary. To guard against injury to personnel, proper safety precautions

and practices must be observed whenever the drive is being moved from

one location to another.

Shipping The carton and materials that came with your drive have been designed and

tested to provide reasonable protection against damage during transit.

Should the drive be shipped to another location, it is recommended that the

original shipping carton and packing material be used to protect the drive

from damage in transit.

1-1

Page 14

Chapter 1

Pre-Installation Care

ATTENTION: This assembly contains parts and sub-assemblies

that are sensitive to electrostatic discharge. Static control

!

precautions are required when servicing this assembly. Component

damage may result if you ignore electrostatic discharge control

procedures. If you are not familiar with static control procedures,

reference Allen-Bradley Publication 8000-4.5.2, Guarding Against

Electrostatic Damage, or any other applicable ESD protection

handbook.

Electrostatic Discharge Electrostatic discharge generated by static electricity can damage the

Precautions complimentary metallic oxide semiconductor devices on various drive

boards. It is recommended that you perform these procedures to guard

against this type of damage when circuit boards are removed or installed:

• Wear a wrist type grounding strap that is grounded to the drive chassis.

• Attach the wrist strap before removing the new circuit board from the

conductive packet.

• Remove boards from the drive and immediately insert them into their

conductive packets.

1-2

Page 15

Chapter

2

Drive and Option Identification

The following is an explanation of the catalog numbering system for 1336

Adjustable Frequency AC Drives and options. The catalog number is

coded to identify the drive power rating and can be found on the drive

shipping carton.

1336 Drive Catalog Numbers

Bulletin Number

Drive Ratings A group of four characters coded to indicate input voltage and output

1336 B 015 EAE FA2 L2 S1

Bulletin Drive Enclosure Options Options Options

Number Rating Type

The Allen-Bradley reference number identifying the type or family of

products.

power rating.

The first character indicates the input voltage range of the drive.

Drives with a code “B” are suitable for operating from any one of the

following voltage inputs: 380/415/460V AC, 50/60 Hz, 3-phase.

Drives with a code “C” are suitable for operating only from 500 or 575V

AC, 50/60 Hz, 3-phase voltage input.

Fan Transformer Reconnection for Alternate Drive Input Voltages

Important:

For drives rated C003-C200, reconnection of Fan Transformer T1 is not

necessary.

For drives rated B003-B030, reconnection of Fan Transformer T1 is not

necessary.

For drives rated B040-B200, Fan Transformer T1 must be reconnected for

380 or 415V operation. If Fan Transformer T1 is not connected to match

the incoming voltage, overtemperature fault F08 may occur. Refer to

Chapter 6 for wiring details.

2-1

Page 16

Chapter 2

Drive and Option Identification

The second, third and fourth characters indicate the power rating of the

drive, as shown in Tables 2.1 and 2.2.

Table

2.1 - B003B200 Output Current and kV

Rating Amp kVA Out kVA Out kVA Out

Code Out 380V AC 415V AC 460V AC

B003 6.0 3.9 4.3 4.8

B005 9.6 6.3 6.9 7.6

B007 13.0 8.6 9.3 10.4

B010 17.0 11.2 12.2 13.5

B015 25.0 16.5 18.0 20.0

B020 33.0 22.0 24.0 26.0

B025 41.0 27.0 29.0 33.0

B030 48.0 32.0 35.0 38.0

B040 60.0 39.0 43.0 48.0

B050 75.0 49.0 54.0 60.0

B075 120.0 79.0 86.0 96.0

B100 150.0 99.0 108.0 120.0

B125 180.0 118.0 129.0 143.0

B150 218.0 143.0 157.0 174.0

B200 290.0 191.0 208.0 231.0

A

Table

2.2 - C003C200 Output Current and kV

Rating Amp kVA Out kVA Out kVA Out

Code Out 500V AC 575V AC 600V AC

C003 4.3 3.7 4.3 4.3

C005 6.7 5.8 6.7 6.7

C007 9.9 8.6 9.9 9.9

C010 12.1 10.5 12.1 12.1

C015 19.1 16.5 18.9 18.9

C020 24.0 20.8 23.9 23.9

C025 30.0 26.0 29.9 23.9

C030 35.0 30.3 34.9 34.9

C040 45.0 39.0 44.9 44.9

C050 57.0 49.4 56.8 56.8

C075 85.0 73.6 84.7 84.7

C100 109.0 94.4 108.6 108.6

C125 138.0 119.5 137.4 137.4

C150 158.0 136.8 157.4 157.4

C200 210.0 181.9 209.1 209.1

A

2-2

Page 17

Chapter 2

Drive and Option Identification

Drive Enclosure Type The first character “E” indicates enclosure code.

The second character indicates the type of enclosure as initially shipped

from the factory.

O –– Open style (IP00)

A –– NEMA Type 1 (IP20)

C –– NEMA Type 4 (IP56)

J –– NEMA Type 12 (IP54)

The third character indicates enclosure size by amp rating.

D –– 003, 005, 007 or 010 drive ratings

E –– 015 or 020 drive ratings

F –– 025 or 030 drive ratings

G –– 040 or 050 drive ratings

H –– 075, 100 or 125 drive ratings

J –– 150 or 200 drive ratings

Factory Installed Options All additional characters indicate drive options that were initially installed

at the factory. Each option code is added to the catalog number and

separated by a hyphen.

2-3

Page 18

Chapter

3

Overview

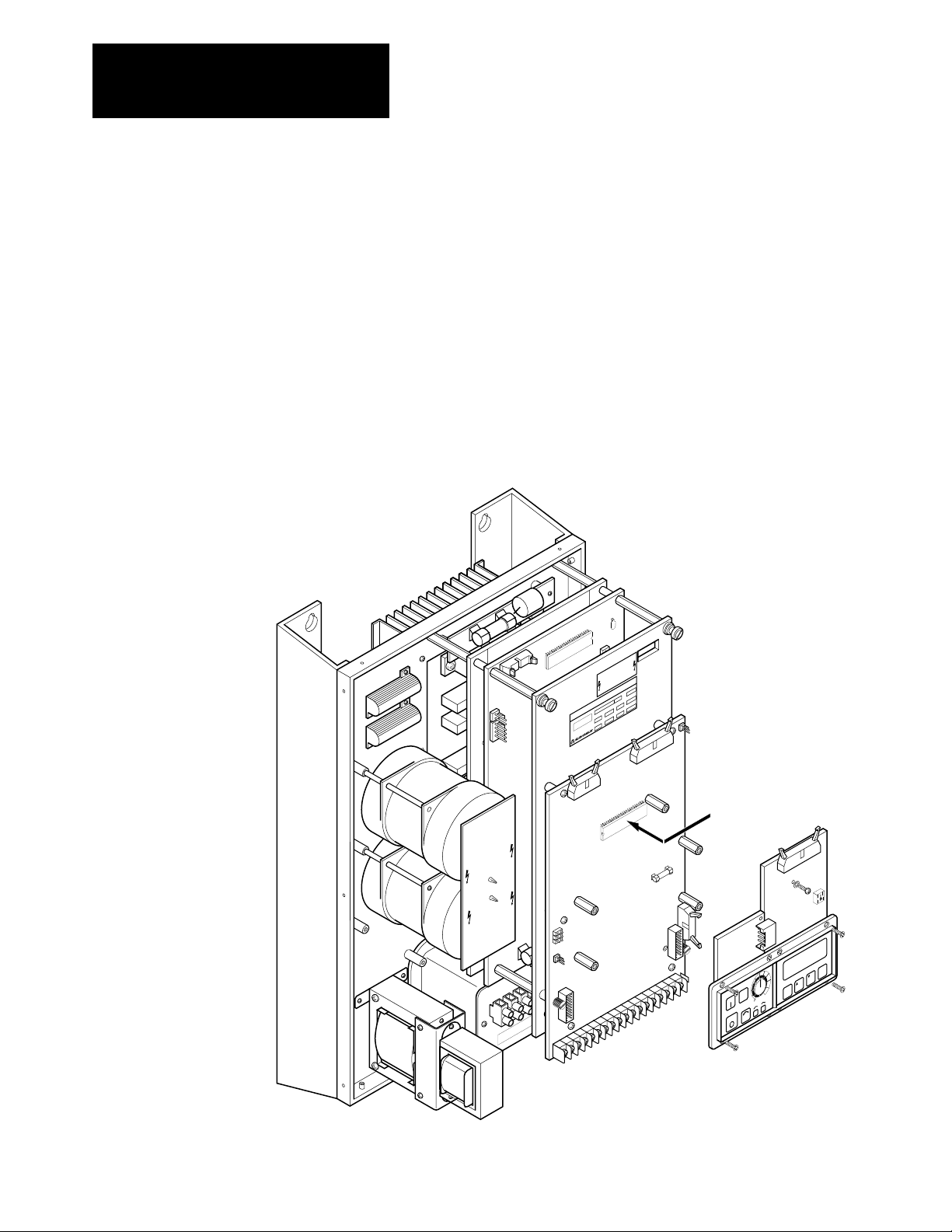

The 1336 is a microprocessor controlled, high performance, adjustable

frequency drive designed to control three phase induction motors on

critical industrial applications. The drive produces a three phase, PWM,

adjustable frequency output to supply an adjustable motor speed. The drive

output voltage is a function of output frequency and is adjustable to match

motor parameters to obtain optimum motor performance.

To help achieve precise and repeatedly accurate control, setup and

operation, the 1336 is digitally programmable. The drive may be

programmed from a Local or Remote Control Panel or through the Serial

Communication Port using optional devices.

Depending upon your configuration, various status and fault conditions are

reported either through the Programming and Display Panel or through the

Serial Communications Port. All fault diagnostics start with both load and

drive self-check diagnostics each time the drive is powered up. While

running, the drive continues to monitor potential fault conditions. To allow

real-time preventive maintenance, parameters such as drive output current

and control conditions can be monitored even while the drive is running.

Should a fault occur, detailed diagnostic codes isolate the problem to

identify the condition, allowing quick, corrective action to be taken to

restore process control.

3-1

Page 19

Chapter 3

Overview

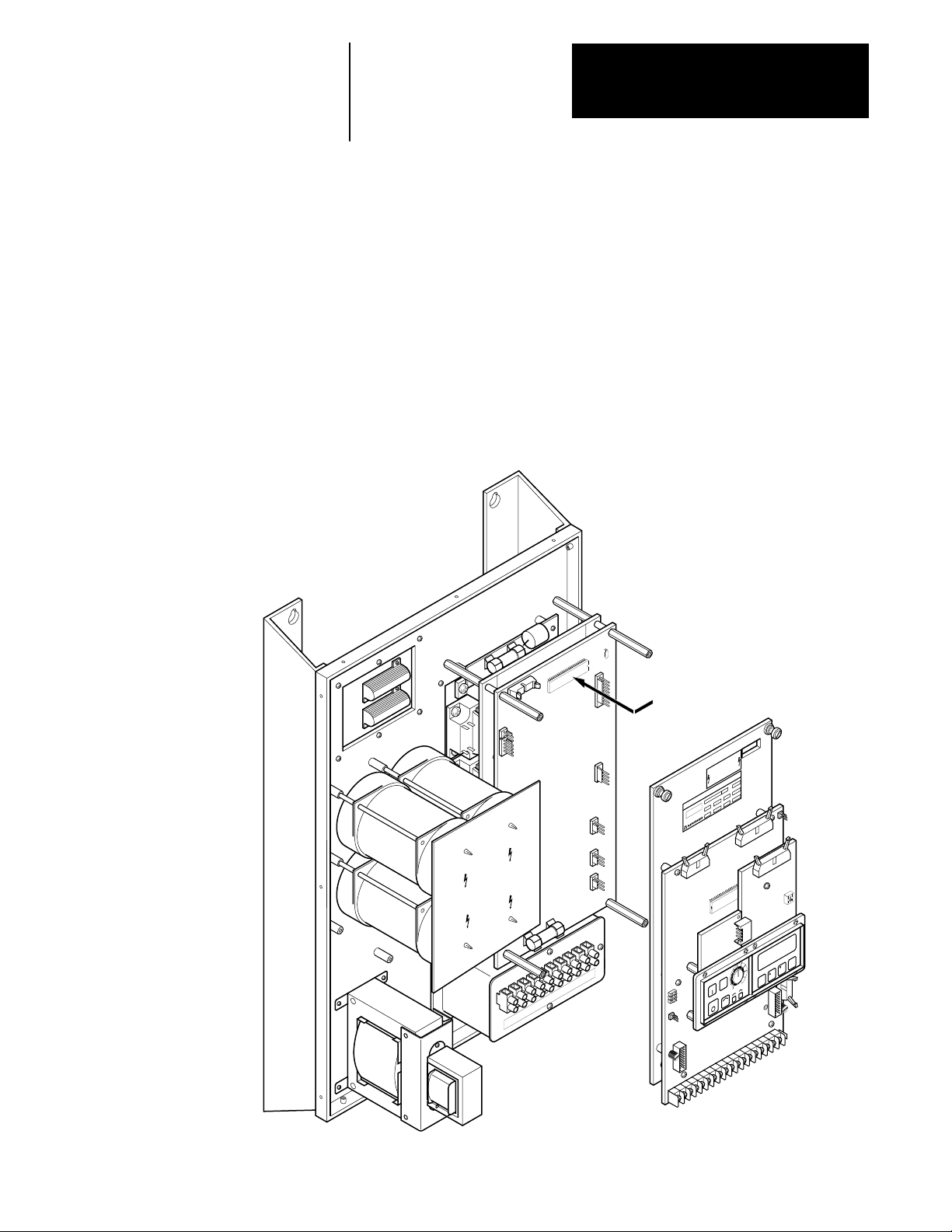

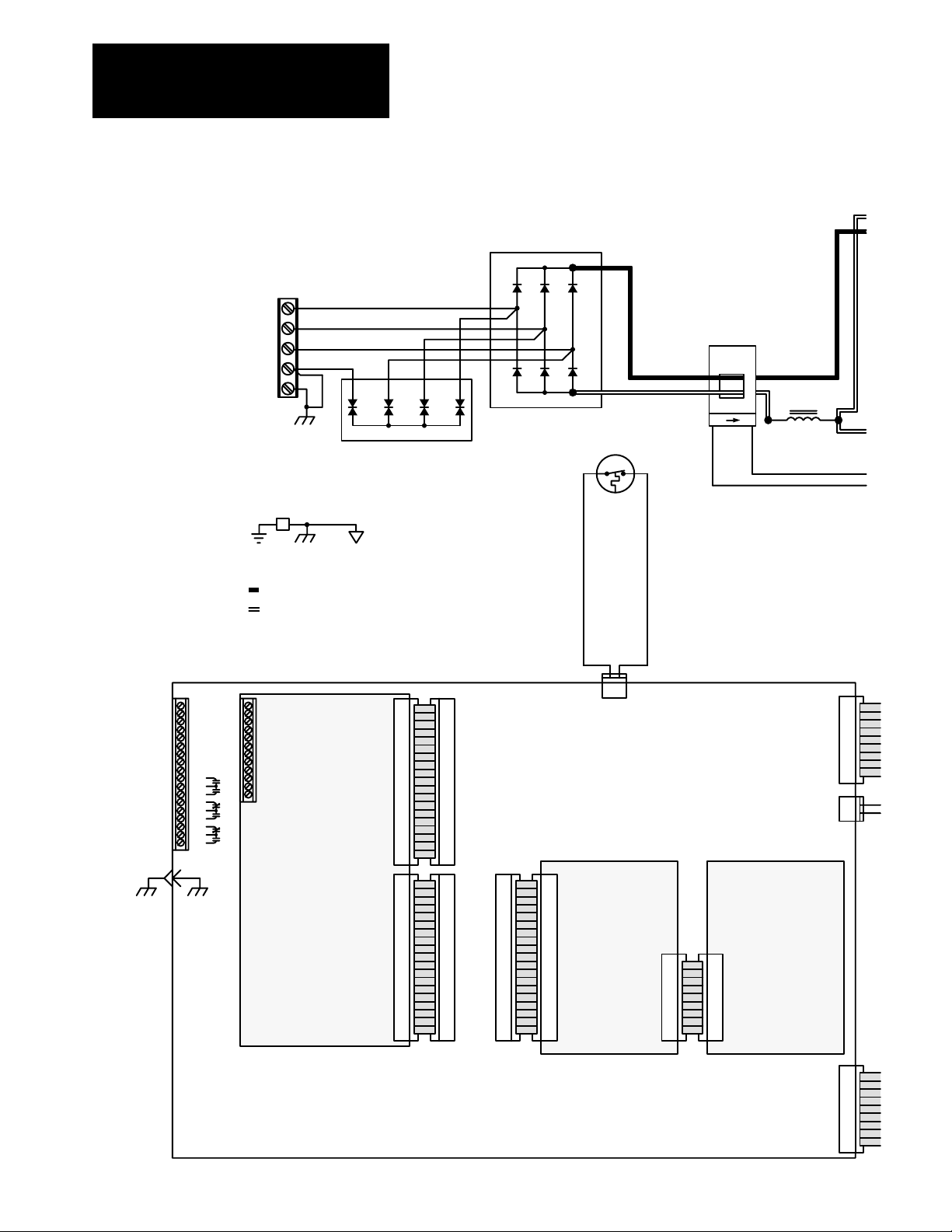

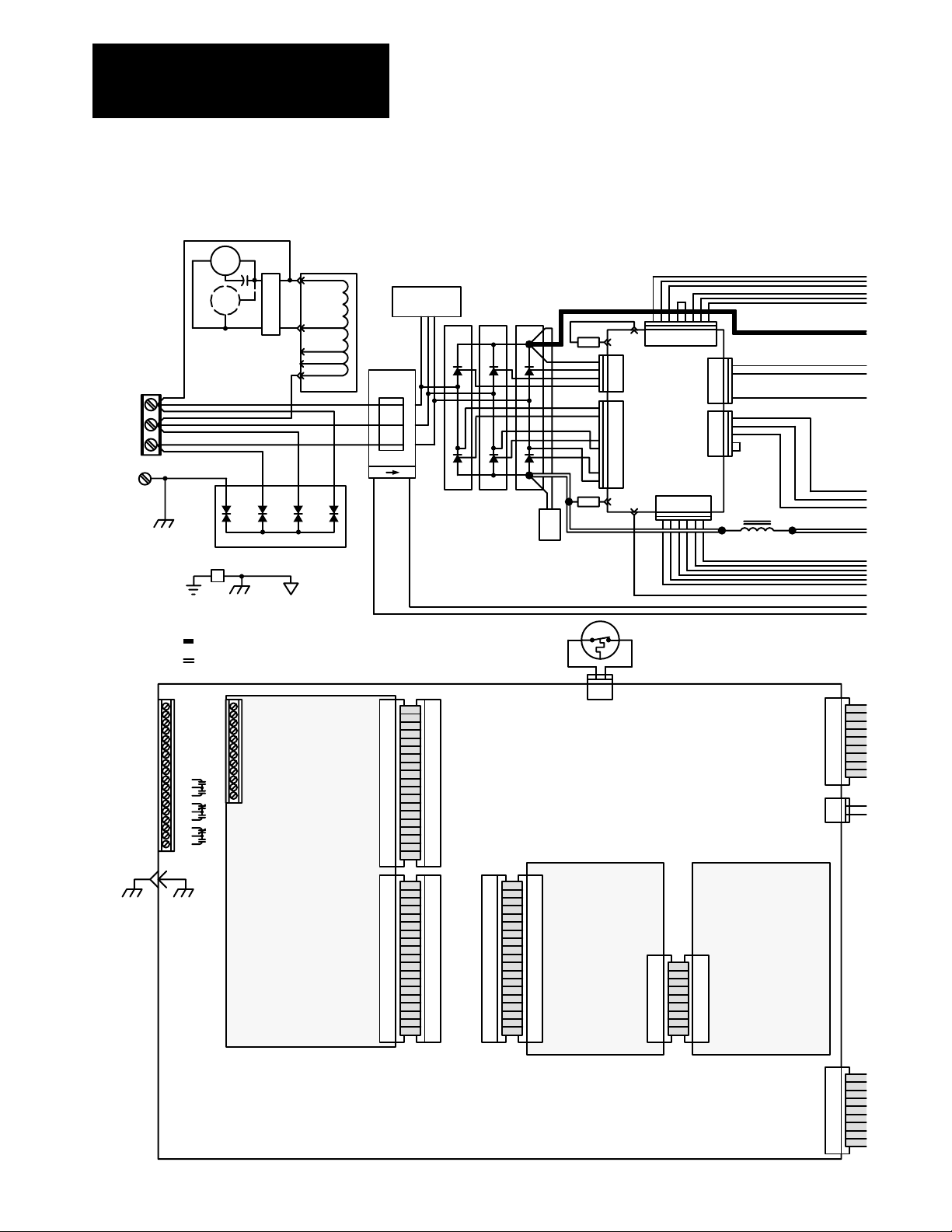

Figure

3.1 - B003B030 & C003C030 Unit Schematic

TB1

L1

L2

L3

GND

GND

GND

4 3 2 1

MOV1

BR1

+

1

2

3

–

ST

12

GND

Sense

(AC)

L1

13

21

EARTH

GROUND

CHASSIS

GROUND

SIGNAL

COMMON

+ BUS

– BUS

1

1

TB2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

E1

19

TB1

20

21

22

23

24

25

26

27

28

29

30

J1

J2

Optional +5V DC TTL

Logic Interface

or

Optional 24V DC Logic

Interface

or

Optional 115V AC Logic

Interface

1

10

11

12

13

14

15

16

17

18

19

1

10

11

12

13

14

15

16

17

18

19

2

3

4

5

6

7

8

9

20

2

3

4

5

6

7

8

9

20

J8

J9 J2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

12

J6

Main Control Board

J1

Programming and

Display Board

(LOCAL DIS)

(MAIN CTL)

J2

1

2

3

4

5

6

7

8

9

10

Optional Logic

J1

1

2

3

4

5

6

7

8

9

10

Control Board

(LOCAL CTL)

J1

1

2

3

4

5

6

7

8

9

10

1

J7

2

3-2

Remote

Serial

Communicatio

Options

For

J4

1

2

3

4

5

6

7

8

ns

9

10

Page 20

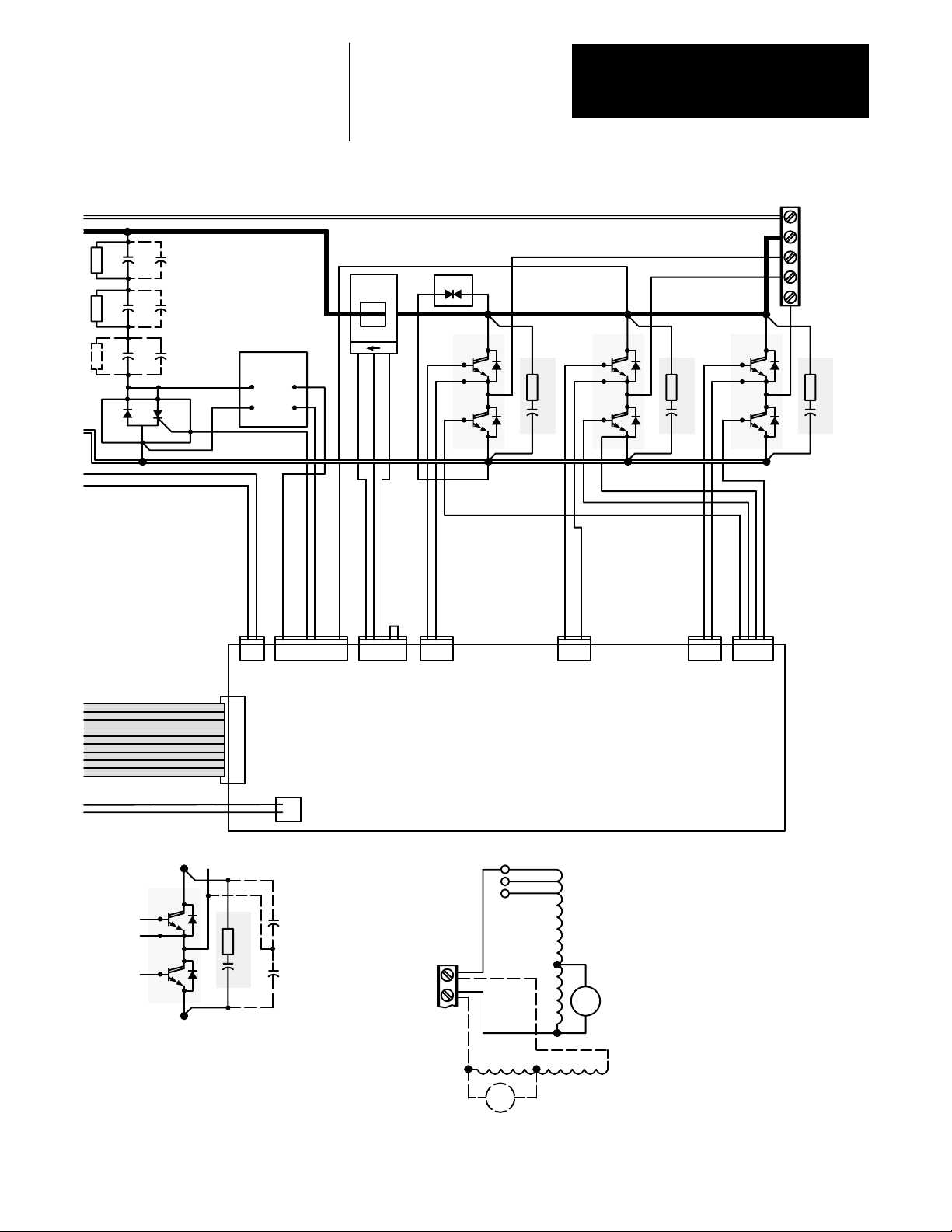

Note:1C2 & 2C2 – B025-B030 & C025-C030 Drives Only

R3 & 3C1 – C003-C030 Drives Only

3C2 – C025-C030 Drives Only

R1 1C1

R2 2C1

R3

M1

1C2

2C2

3C1

3C2

KA

G2

AK

Precharge

M1–K

M1–AK

Board

J7–1

J7–5

Bus

Sense

(AC)

+–

Chapter 3

Overview

MOV2

2

1

Q1

C1 C1 C1

B1

E1

B2

E2

1

SN1

C2

E1

2

Q2

B1

E1

B2

E2

1

SN2

C2

E1

2

Q3

TB1

– DC

+ DC

M1

M2

M3

B1

E1

B2

E2

1

SN3

C2

E1

2

Q1-Q3

B1

E1

B2

21

12345678 12345 123 123 1234123

J8 J7 J6 J5 J4 J3 J2

1

J1

2

3

4

5

6

7

8

9

10

Transformer

1

2

T2

Additional Path Shaping

Snubbers

4C1–6C1 and 4C2–6C2

C1

E2

SN1-3

1

C2

E1

2

C015–C030 Drives Only

4C1, 5C1, 6C1

4C2, 5C2, 6C2

Base Driver/Power Supply Board

(BASEDR/PWRSPLY)

AC

Not Used

Not Used

T1

TB1

L1

L2

Chassis Fan

B010-B030 & C010-C030

Fan

Drives

Xfmr

Fan

Enclosure Fan

B025-B030 & C025-C030

NEMA Type 4 and 12

Enclosures

3-3

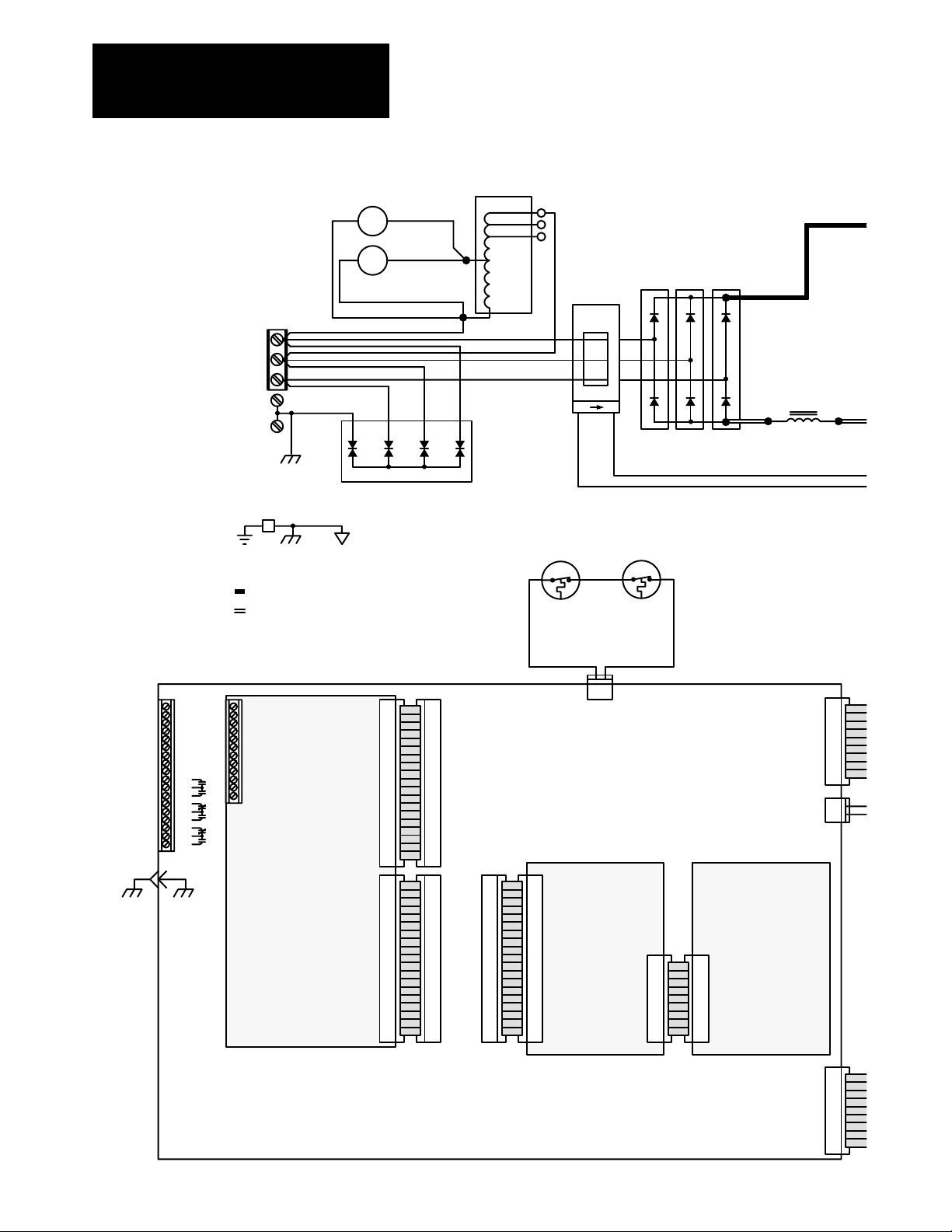

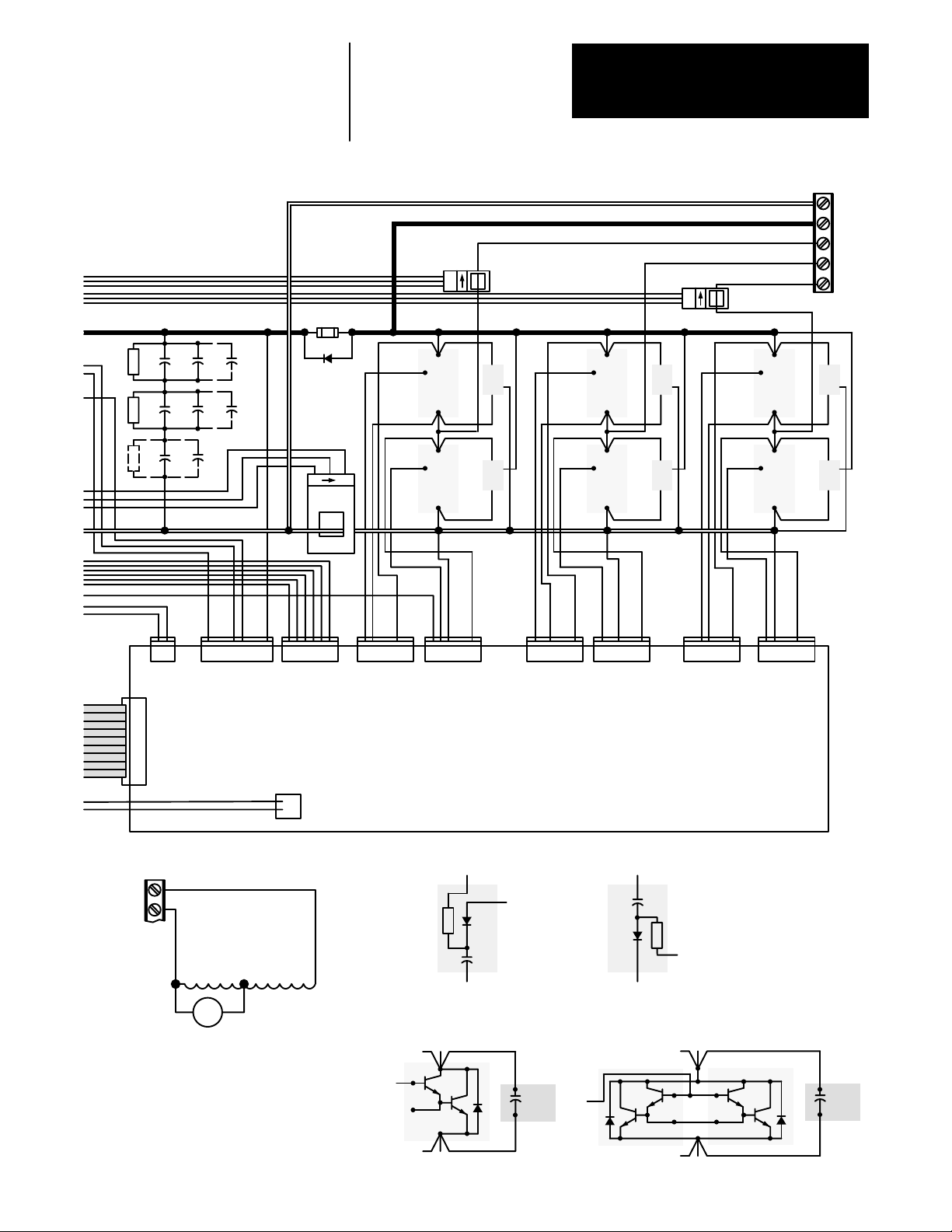

Page 21

Chapter 3

Overview

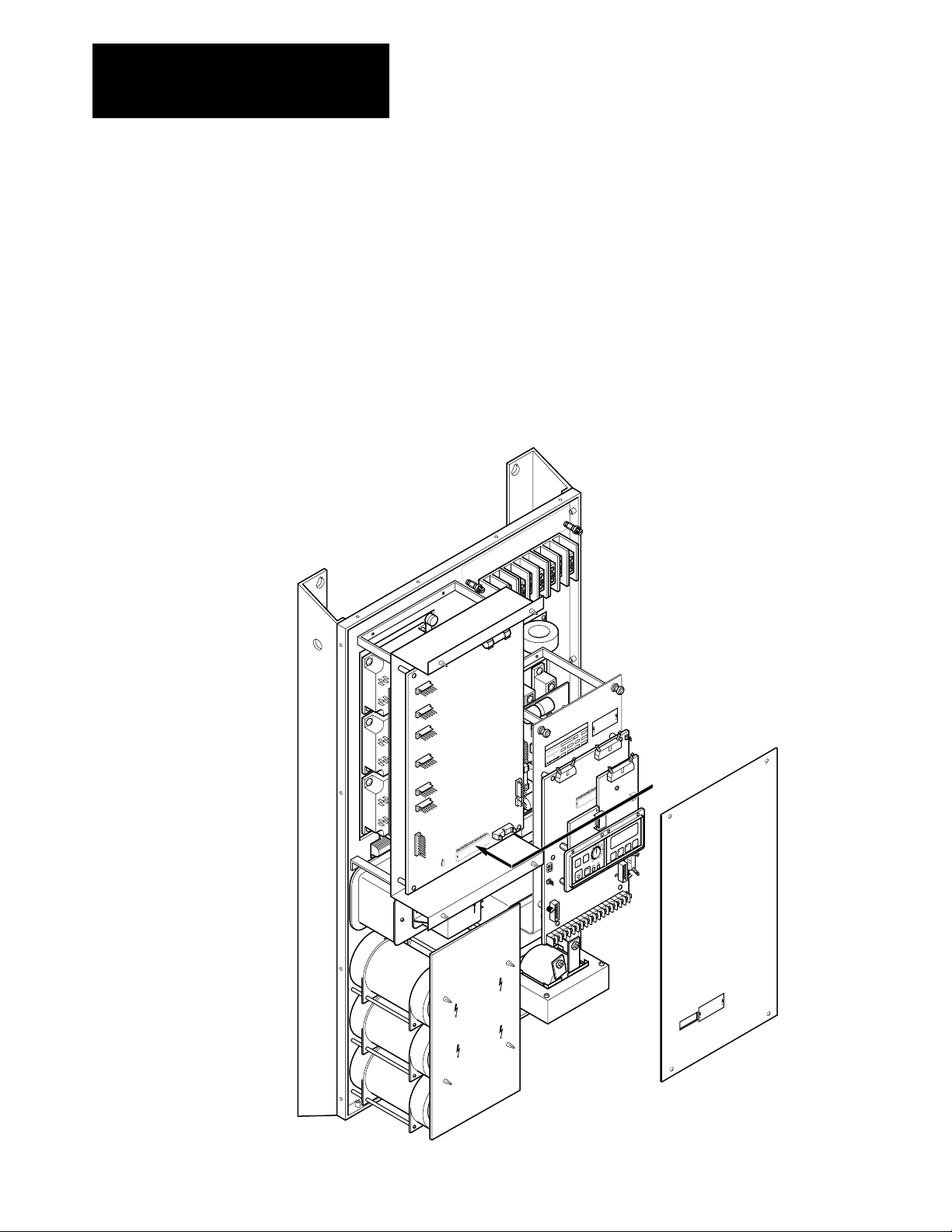

Figure

3.2 - B040B050 & C040C050 Unit Schematic

L1

L2

L3

GND

GND

EARTH

GROUND

GND

+ BUS

– BUS

TB1

CHASSIS

GROUND

1 2 120V AC

Fan 1

1 2 120V AC

Fan 2

MOV1

SIGNAL

COMMON

460V AC

415V AC

380V AC

460/415/380V AC Taps

–

B040-B050 Drives

Only

T1

GND

Sense

+

+

+

1

2

3

(AC)

21

4321

ST1

12

–

BR1 BR2 BR3

ST2

12

–

–

L1

13

1

1

TB2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

E1

19

TB1

20

21

22

23

24

25

26

27

28

29

30

J1

J2

Optional +5V DC TTL

Logic Interface

or

Optional 24V DC Logic

Interface

or

Optional 115V AC Logic

Interface

1

10

11

12

13

14

15

16

17

18

19

1

10

11

12

13

14

15

16

17

18

19

2

3

4

5

6

7

8

9

20

2

3

4

5

6

7

8

9

20

J8

J9 J2

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

15

15

16

16

17

17

18

18

19

19

20

20

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

12

J6

Main Control Board

J1

Programming and

Display Board

(LOCAL DIS)

(MAIN CTL)

J2

1

2

3

4

5

6

7

8

9

10

Optional Logic

Control Board

J1

1

2

3

4

5

6

7

8

9

10

(LOCAL CTL)

Communicatio

For

Remote

Serial

Options

J1

1

2

3

4

5

6

7

8

9

10

1

J7

2

J4

1

2

3

4

5

6

7

8

ns

9

10

3-4

Page 22

Chapter 3

Overview

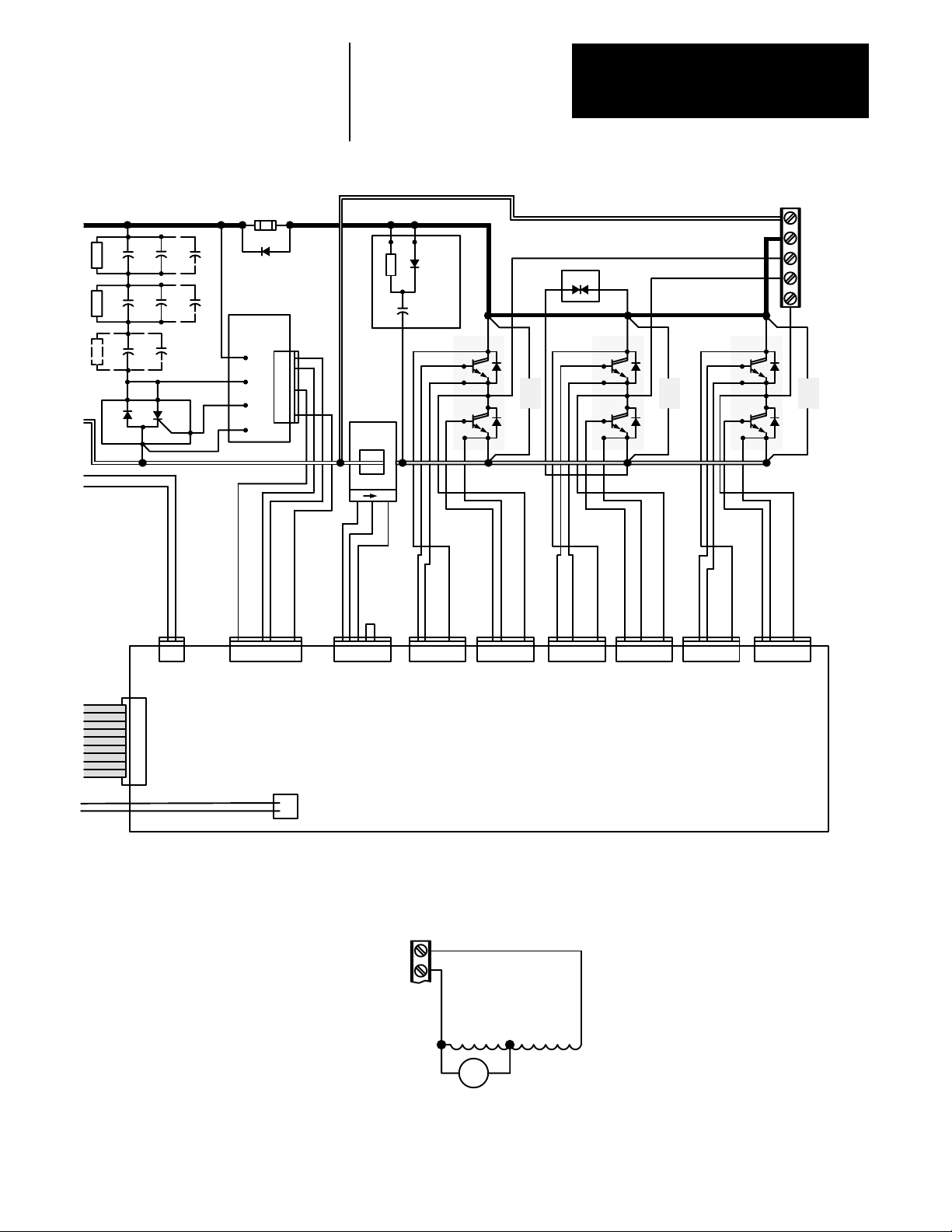

Note:1C3 & 2C3 – B040-B050 Drives Only

R3, 3C1 & 3C2 – C040-C050 Drives Only

1C1 1C2

R1

R2

2C1 2C2

1C3

2C3

R3 3C1 3C2

KA

M1

G2

AK

12

F1

D2

Precharge

J1

B+

M1–K

M1–G1

M1–AK

Board

TB1

– DC

122

1

2

Bus

Snubber

1

Q3

1

2

3

4

5

6

7

8

Bus

Sense

(AC)

+–

C1

B1

C2

E1

B2

SN1

E1

E2

MOV2

2

1

Q2

C1

1

2

B1

E1

B2

E2

1

C2

SN2

E1

2

Q1

C1

B1

E1

B2

E2E2E2

E2

+ DC

M3

M2

M1

1

C2

SN3

E1

2

21

J8 J7

1

J1

2

3

4

5

6

7

8

9

10

12345678

1

2

123456J6123456J5123456

Base Driver/Power Supply Board

(BASEDR/PWRSPLY)

Transformer

T2

TB1

L1

L2

B040-B050 & C040-C050

NEMA Type 4 and 12

J10

Fan

Enclosure Fan

Enclosures

123456J4123456J923456 123456

1

J3

J2

Xfmr

3-5

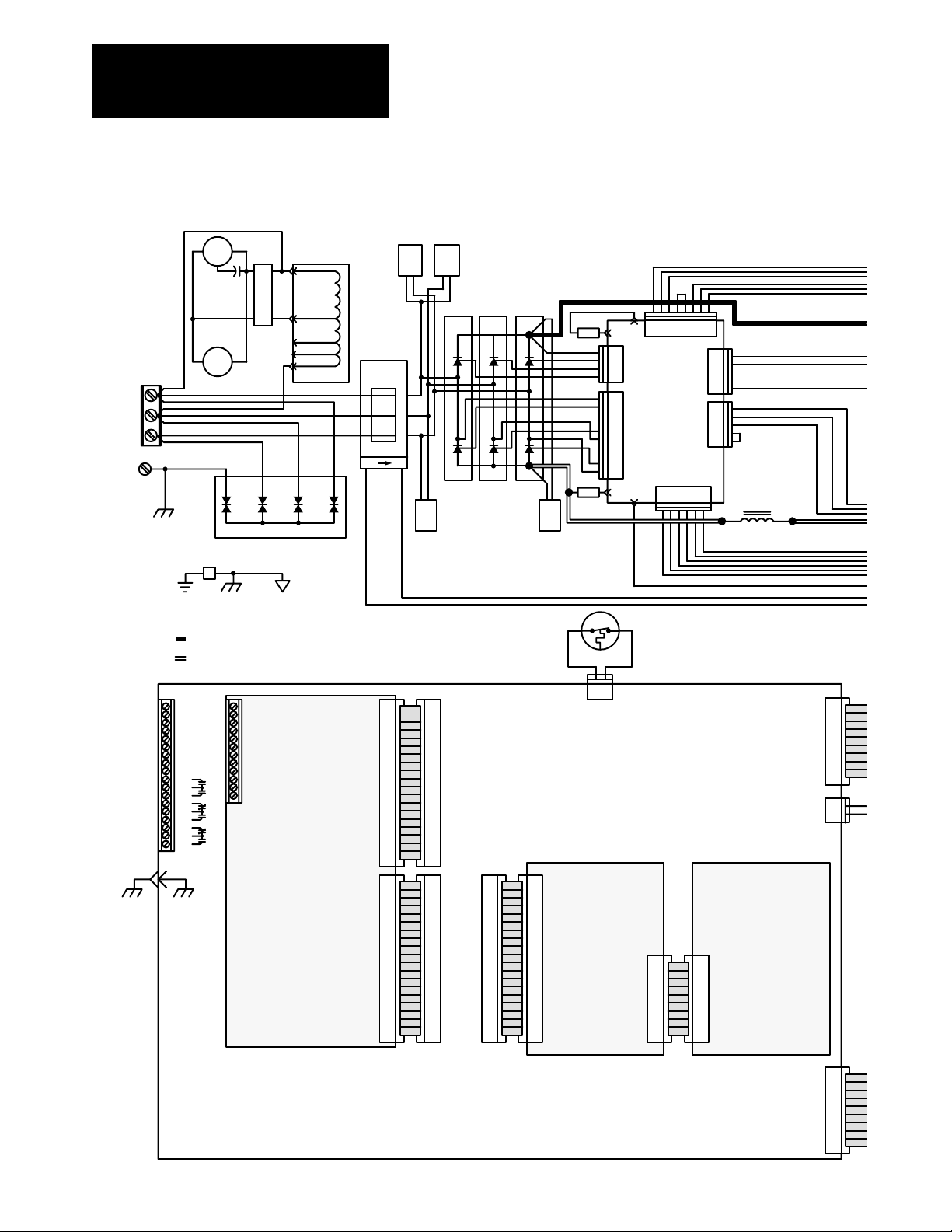

Page 23

Chapter 3

Overview

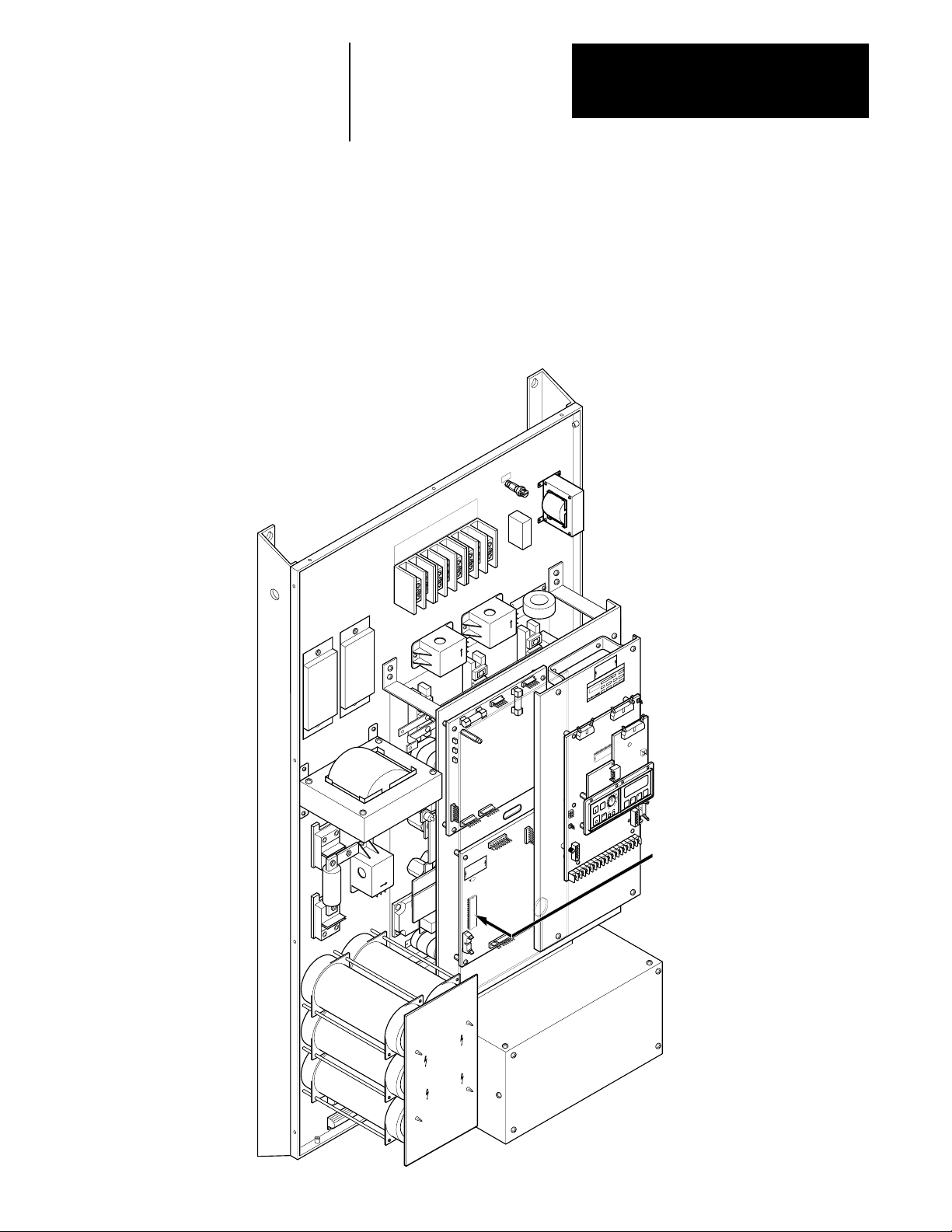

Figure

3.3 - B075B125 & C075B125 Unit Schematic

Note:Aux Fan –

B125 & C125 Drives Only

460/415/380V AC Taps

TB4

1

2

–

B075-B125 Drives

Only

T1

120V AC

380V AC

415V AC

460V AC

GND

Fan

Aux

Fan

TB1

L1

L2

L3

MOV1

GND

Rectifie

r

Snubber

K1K1K1

G1

G1

GND

Sense

(AC)

21

4321

G1

K2

K2

K2

G2

G2

G2

BR1 BR2 BR3

SN7

R5

E2

E1

J8

4

3

2

1

J1

10

9

Precharge

8

Board

7

6

5

4

3

2

J2

1

R4

E3

E4

12345678

5

4

3

2

1

J7

5

4

3

2

1

J6

J5

123456

L1

12

EARTH

GROUND

1

TB2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

E1

CHASSIS

GROUND

SIGNAL

COMMON

+ BUS

– BUS

19

TB3

20

21

22

23

24

25

26

27

28

29

30

Optional +5V DC TTL

Logic Interface

Optional 24V DC Logic

Interface

Optional 115V AC Logic

Interface

ST1

12

12

1

10

11

12

13

14

15

16

17

18

19

1

10

11

12

13

14

15

16

17

18

19

2

3

4

5

6

7

8

9

20

2

3

4

5

6

7

8

9

20

J8

J9 J2

J6

Main Control Board

(MAIN CTL)

1

1

2

2

3

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

Programming and

4

5

Display Board

6

7

(LOCAL DIS)

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

Optional Logic

Control Board

1

2

3

4

5

6

7

8

9

10

(LOCAL CTL)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

or

or

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

J1

2

3

4

5

6

7

8

9

10

J7

1

2

3-6

For

Remote

Serial

Communicatio

Options

J4

1

2

3

4

5

6

7

8

ns

9

10

Page 24

Note:1C3 & 2C3 – B075-B125 Drives

Only

R3, 3C1 & 3C2 – C075-C125 Drives

Only

R1R21C1 1C2

2C1 2C2

1C3

2C3

12

F1

D1

Chapter 3

Overview

TB1

– DC

+ DC

M1

LEM

A

+

–

C

B

X1

E

SN1

C

B

X3

E

SN3

LEM C

+

–

C

B

X5

E

M2

M3

SN5

R3 3C1 3C2

21

J8 J7

J1

1

2

3

4

5

6

7

8

9

10

TB1

L1

L2

12345678

C

+–

BUS

Sense

(AC)

123456J6123456J5123456

B

X2

E

J10

Base Driver/Power Supply Board

(BASEDR/PWRSPLY)

Transformer

1

2

T2

+ BUS

SN2

123456J4123456

Snubber

Diagrams

C (X2, X4, X6)

C

B

X4

E

SN4

123456J3123456

J9

C (+ BUS)

C

B

X6

E

SN6

J2

Fan

Enclosure Fan

B075-B125 & C075-C125

NEMA Type 4 and 12

Enclosures

Xfmr

E (– BUS)

SN2, SN4 & SN6 SN1, SN3 & SN5

X1–6

Output Transistor

Diagrams

C

B

B

B

X

E

B075 & C075

1C4-6C4

B

– BUS

E (X1, X3, X5)

X1–6

C

EE

C

B

B

X

E

C

B

B

X

1C4-6C4

B100-B125 & C100-C125

3-7

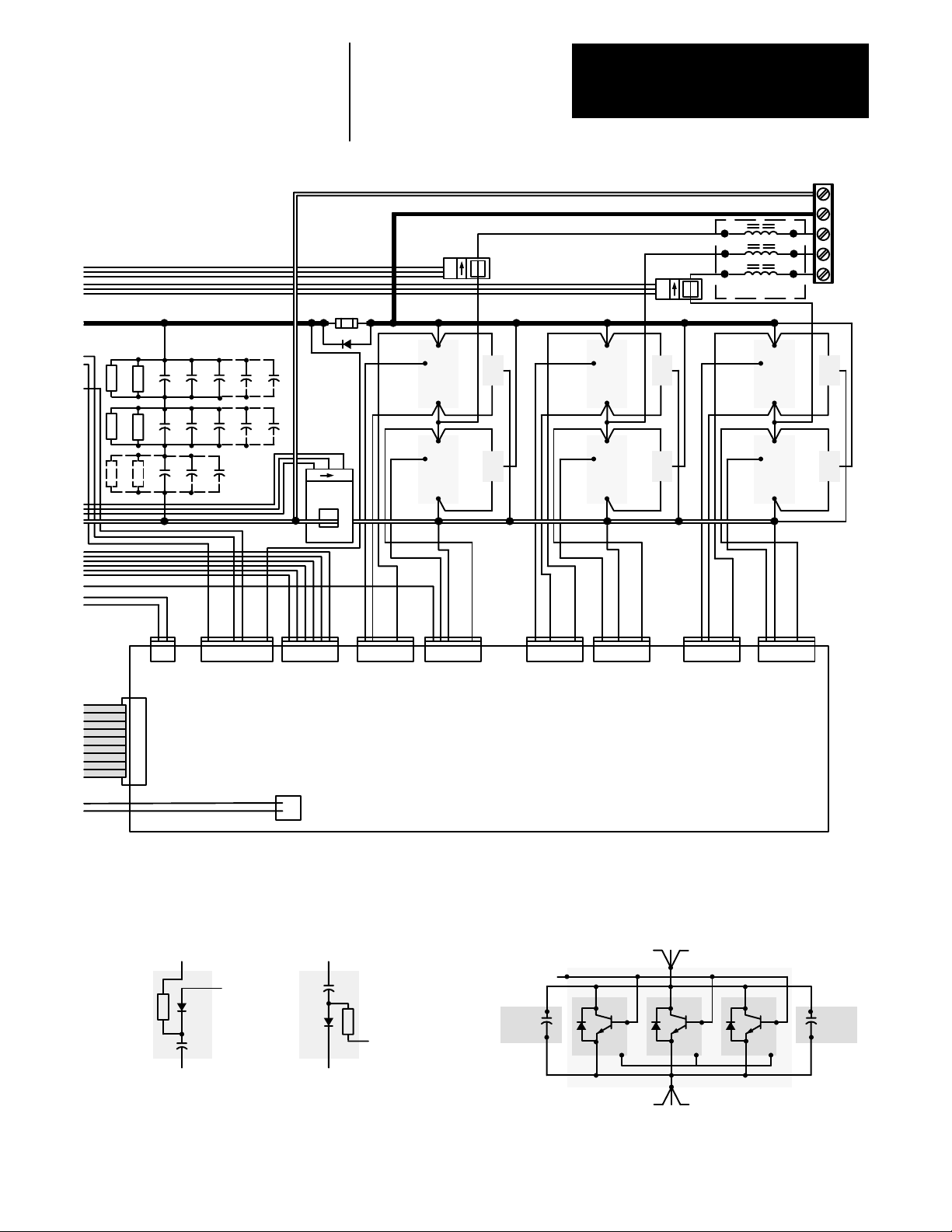

Page 25

Chapter 3

Overview

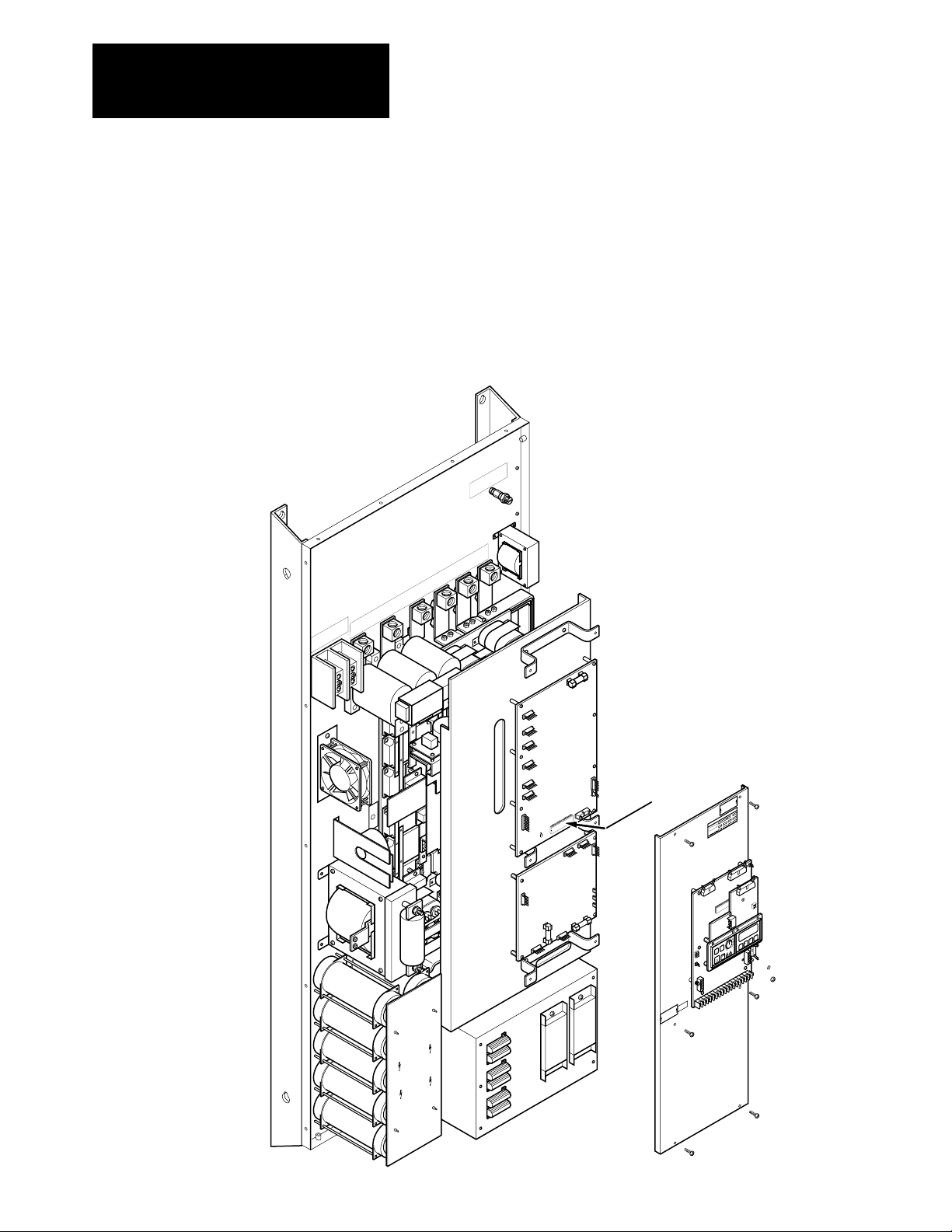

Figure

3.4 - B150B200 & C150C200 Unit Schematic

GND

Fan 1

TB4

1

460/415/380V AC Taps

–

B150-B200 Drives

Only

SN9 SN10

T1

120V AC

TB1

Fan 2

2

380V AC

415V AC

460V AC

GND

Sense

G1

K1K1K1

G1

G1

L1

L2

L3

(AC)

21

4321

K2

G2

BR1 BR2 BR3

K2

K2

G2

G2

SN8

SN7

R7

R8

E2

E1

J8

4

3

2

1

J1

10

9

Precharge

8

Board

7

6

5

4

3

2

J2

1

E3

E4

12345678

5

4

3

2

1

J7

5

4

3

2

1

J6

J5

123456

L1

12

MOV1

GND

EARTH

GROUND

1

TB2

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

E1

+ BUS

– BUS

CHASSIS

GROUND

SIGNAL

COMMON

19

TB3

20

21

22

23

24

25

26

27

28

29

30

Optional +5V DC TTL

Logic Interface

or

Optional 24V DC Logic

Interface

or

Optional 115V AC Logic

Interface

ST1

12

J1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

J8

J9 J2

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

J1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

12

J6

Main Control Board

(MAIN CTL)

Programming and

Display Board

(LOCAL DIS)

J2 J1

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

Optional Logic

Control Board

(LOCAL CTL)

J1

1

2

3

4

5

6

7

8

9

10

J7

1

2

3-8

1

J4

2

3

4

5

6

7

8

9

10

Page 26

R1

R2

R3

Note:1C4, 1C5, 2C4, &

2C5

B150-B200 Drives

Only

R3, R6, 3C1, 3C2 &

3C3

R4

R5

R6

C150-C200 Drives

Only

1C1 1C2 1C3

2C1 2C2 2C3

3C1 3C2 3C3

1C4

2C4

1C5

2C5

F1

12

D1

+–

BUS

Sense

Chapter 3

Overview

TB1

– DC

12

LEM

A

+

–

C

B

X1

E

C

B

X2

E

SN1

SN2

C

B

X3

E

C

B

X4

E

LEM C

+

–

SN3

SN4

12

Optional

2

C

B

X5

E

C

B

X6

E

1

1336-MOD-LR

+ DC

M1

M2

M3

SN5

SN6

J8 J7

1

J1

2

3

4

5

6

7

8

9

10

21

+ BUS

12345678

Snubber

Diagrams

C (X2, X4, X6)

(AC)

123456J6123456J5123456

J10

Base Driver/Power Supply Board

Transformer

1

2

T2

C (+ BUS)

– BUS

123456J4123456

(BASEDR/PWRSPLY)

123456J3123456

J9

J2

Output Transistor Diagram

X1–6

B

C

E

C

C

B

B

X

B

E

B

X

C

B

E

1CX-12CX1CX-12CX

B

X

E (– BUS)

SN2, SN4 & SN6 SN1, SN3 & SN5

E (X1, X3, X5)

E

3-9

Page 27

Chapter 3

Overview

The 1336 is an AC adjustable frequency drive designed for use with a

standard, three-phase induction motor. The standard control is designed as

a constant torque, adjustable speed control with 150% overload capability

and is adaptable through programming to handle a wide variety of

applications.

The 1336 provides an exceptional output voltage and current waveform.

Special considerations however, must be taken when applying an inverter

to an existing motor. At slower speeds, cooling is not as effective due to

reduced fan rotation. Extended operation at full load torque at slow speeds

may damage the motor due to overheating.

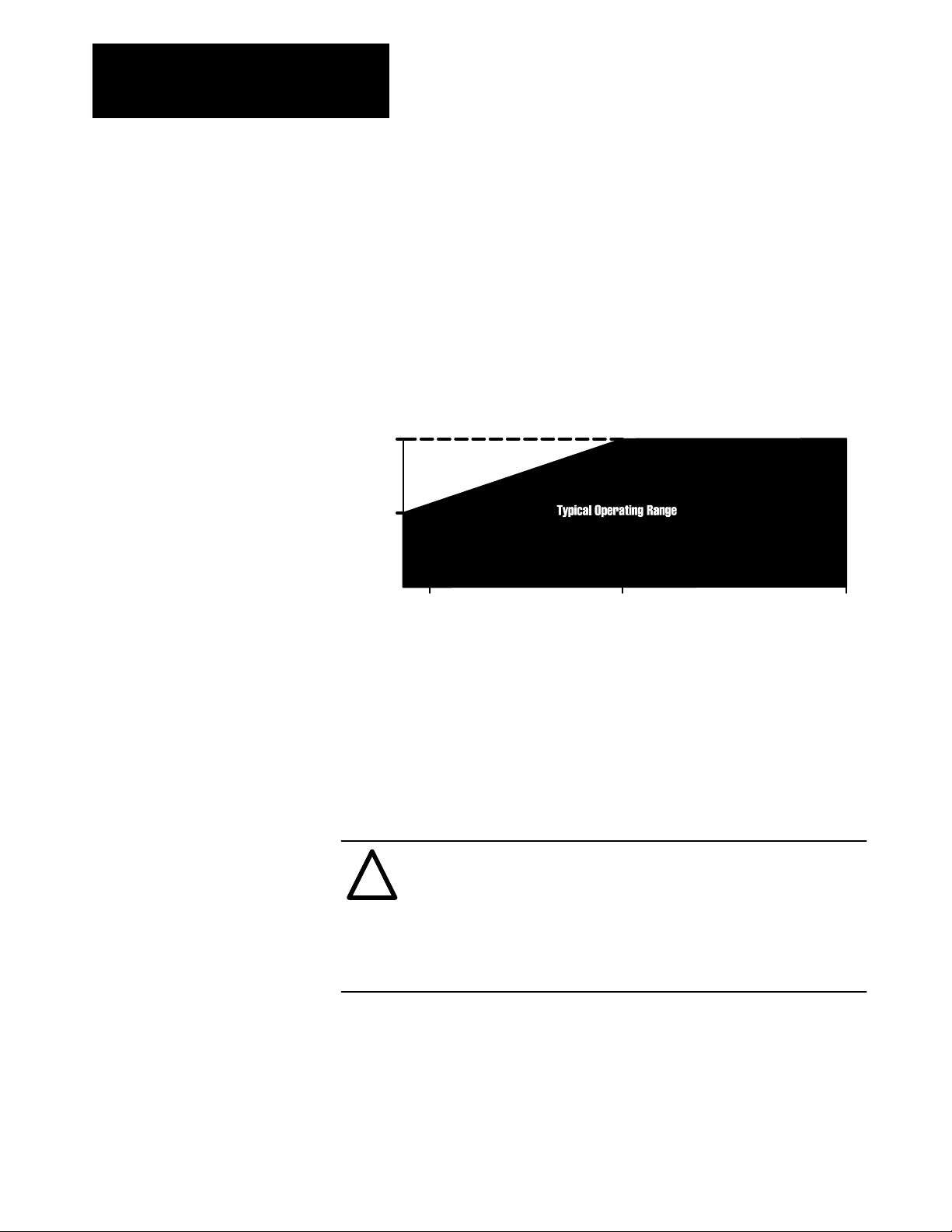

100%

of

Motor

Torque

50%

of

Motor

Torque

303

Frequency (Hz)

60

Shown above is a typical curve plotting torque versus speed. At slow

speeds, if torque requirements continuously exceed levels shown above (10

minutes or longer), a motor rated for the required speed and torque range

must be used. To guard against mechanical problems, it is recommended

that the entire drive train machinery be checked for various limitations due

to the range of the Bulletin 1336.

ATTENTION: Motors may overheat when operated at rated

torque for long periods of time below 50% base speed due to the

!

decreased air flow of armature driven fans.

Motors may require special balancing if operated at more than

125% of base speed. Refer to the motor manufacturer for proper

sizing of the motor for the intended application.

3-10

Page 28

Chapter

4

Specifications

Operating Environment Temperature: Open rating (heat sink), 0 to + 40°C.

Open rating (chassis components), 0 to +50°C.

Enclosed rating (heat sink), 0 to + 40°C.

Enclosed rating (chassis components), 0 to +50°C.

Relative Humidity: 5 to 95% non-condensing –– all ratings.

Altitude: 3,300 feet (1,000 meters) maximum without derating.

Vibration: 0.006 inches (0.152 mm) displacement, 1G peak.

Shock: 15G peak for 11ms duration (±1.0mS).

Storage Environment Temperature: – 40 to +85°C –– all ratings.

Relative Humidity: 5 to 95% non-condensing –– all ratings.

Enclosure Indicated by Catalog Number.

Open (IP00) –– all ratings.

NEMA Type 1 (IP20) –– all ratings.

NEMA Type 4 (IP56), B003-B030 & C003-C030.

NEMA Type 12 (IP54), B003-B200 & C003-C200.

4-1

Page 29

Chapter 4

Specifications

Input Power Conditioning General

Typically the 1336 is suitable for direct connection to a correct voltage,

three phase, AC power line. There are however certain power line

conditions which may introduce the possibility of drive input power

component malfunction. To reduce the possibility of these malfunctions, a

line reactor or isolation type transformer may be required.

The basic rules for determining if a line reactor or isolation type

transformer is required are as follows:

1. If the AC line supplying the drive has power factor correction capacitors

connected, an AC line reactor or isolation type transformer must be

connected between the capacitor bank and the input to the drive.

2. If the AC line frequently experiences transient power interruptions or

significant voltage spikes, an AC line reactor or isolation type

transformer should be used.

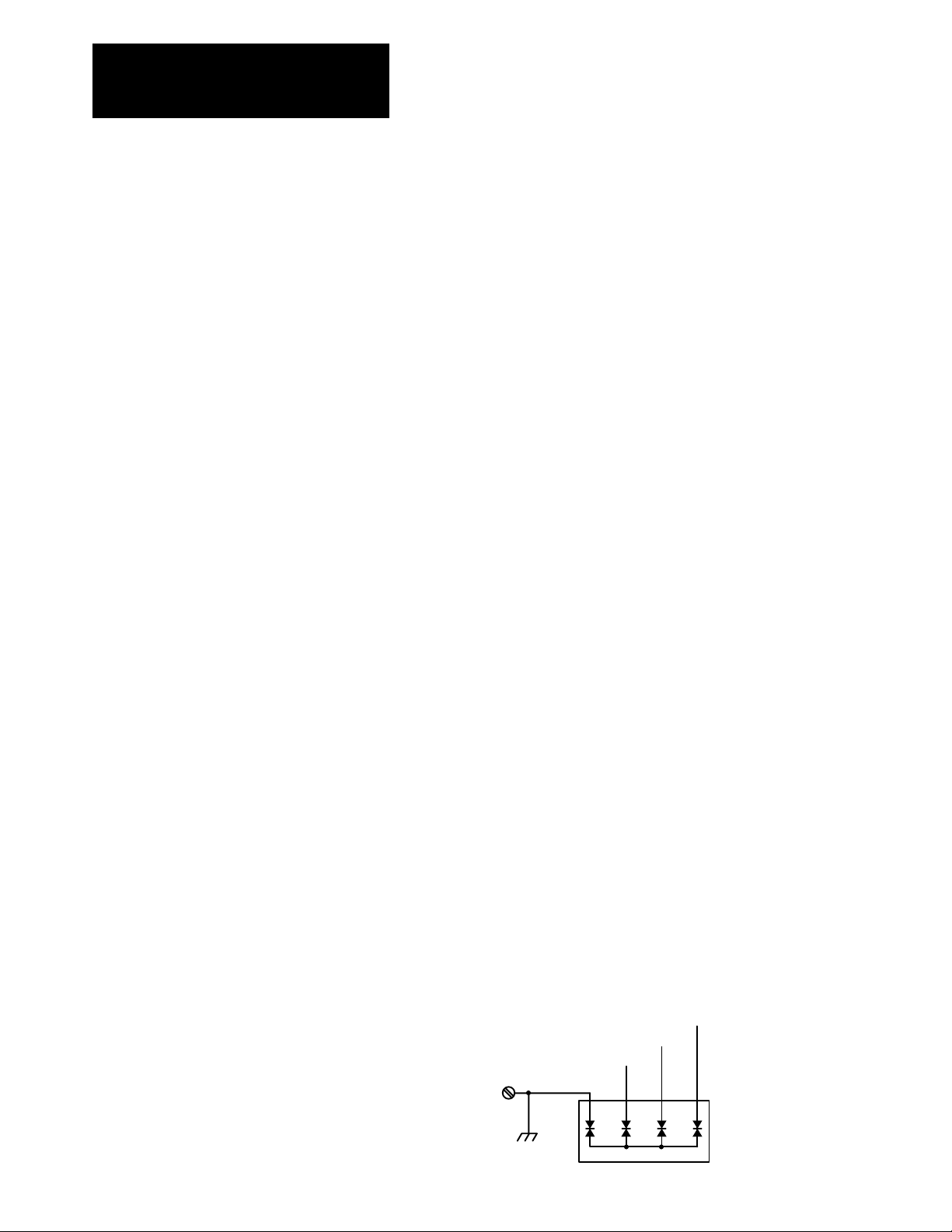

Ungrounded Distribution Systems

All 1336 drives are equipped with an MOV (metal oxide varistor) that

provides voltage surge protection and phase-to-phase plus phase-to-ground

protection which is designed to meet IEEE 587. The MOV circuit is

designed for surge suppression only (transient line protection), not

continuous operation.

With ungrounded distribution systems, the phase-to-ground connection of

the MOV could become a continuous current path to ground. MOV

line-to-line and line-to-ground voltages should not exceed the values listed

below. Exceeding these MOV ratings may cause physical damage to the

MOV.

Line-to-Line MOV Rating

Energy Rating = 320 Joules Turn On Voltage = 850-1000 volts

Line-to-Ground MOV Rating

Energy Rating = 380 Joules Turn On Voltage = 1500 volts

160 Joules

160 Joules

160 Joules

GND

220 Joules

4321

4-2

MOV1

Page 30

Chapter 4

Specifications

B003B200 Input Power Voltage: 380-460V AC ±10%.

Frequency: 48 to 62 Hz.

Phase: 3-phase.

AC Input Overvoltage Trip: 570V AC.

AC Input Undervoltage Trip: 275V AC.

Bus Overvoltage Trip: 810V DC for drive ratings B003-B200.

Bus Undervoltage Trip: 388V DC for Base Driver/Power Supply

Board.

Firmware Versions 1.11-3.01.

456V DC for Base Driver/Power Supply

Board.

Firmware Version 1.01.

Line Transient Protection: Line transients up to 5,000 volts peak, 320

Joules.

Logic Power Ride-Thru: 2 seconds or Longer.

–– subject to the integrity of user supplied

external circuits.

Control Logic Noise: Showering arc transients from 350 to 2,000

Immunity volts peak.

C003C200 Input Power Voltage: 500-575V AC ±10%.

Frequency: 48 to 62 Hz.

Phase: 3-phase.

AC Input Overvoltage Trip: 690V AC.

AC Input Undervoltage Trip: 343V AC.

Bus Overvoltage Trip: 975V DC.

Bus Undervoltage Trip: 485V DC.

Line Transient Protection: Line transients up to 5,000 volts peak, 320

Joules.

Logic Power Ride-Thru: 2 seconds or Longer.

–– subject to the integrity of user supplied

external circuits.

Control Logic Noise: Showering arc transients from 350 to 2,000

Immunity volts peak.

4-3

Page 31

Chapter 4

Specifications

Table

4.1 B003B200 Input Current and kV

Rating kVA In kVA In kVA In Displacement

Amps In Code 380V AC 415V AC 460V AC Angle kW/kVA

5.7 B003 3.8 4.1 4.5 0.95 0.85

9.2 B005 6.1 6.6 7.3 0.95 0.85

13.3 B007 8.8 9.6 10.6 0.95 0.85

17.0 B010 11.2 12.0 14.0 0.95 0.85

25.0 B015 16.0 18.0 20.0 0.95 0.90

34.0 B020 22.0 24.0 27.0 0.95 0.90

42.0 B025 28.0 30.0 33.0 0.95 0.90

49.0 B030 32.0 35.0 39.0 0.95 0.90

61.0 B040 40.0 44.0 49.0 0.95 0.90

76.0 B050 50.0 55.0 61.0 0.95 0.90

122.0 B075 80.0 88.0 97.0 0.95 0.90

153.0 B100 101.0 110.0 122.0 0.95 0.90

184.0 B125 121.0 132.0 147.0 0.95 0.90

222.0 B150 146.0 160.0 177.0 0.95 0.90

296.0 B200 195.0 213.0 236.0 0.95 0.90

A

Input Power

Factor

Table

4.2 C003C200 Input Current and kV

Rating kVA In kVA In kVA In Displacement

Amps In Code 500V AC 575V AC 600V AC Angle kW/kVA

3.2 C003 2.8 3.2 3.2 .95 0.85

5.1 C005 4.4 5.1 5.1 .95 0.85

7.7 C007 6.7 7.7 7.7 .95 0.85

10.2 C010 8.9 10.2 10.2 .95 0.85

15.0 C015 13.0 15.0 15.0 .95 0.90

19.0 C020 17.0 19.0 19.0 .95 0.90

24.0 C025 21.0 24.0 24.0 .95 0.90

29.0 C030 25.0 29.0 29.0 .95 0.90

39.0 C040 33.0 38.0 38.0 .95 0.90

48.0 C050 42.0 48.0 48.0 .95 0.90

73.0 C075 63.0 73.0 73.0 .95 0.90

97.0 C100 84.0 96.0 96.0 .95 0.90

121.0 C125 105.0 121.0 121.0 .95 0.90

146.0 C150 127.0 145.0 145.0 .95 0.90

193.0 C200 167.0 192.0 192.0 .95 0.90

A

Input Power

Factor

4-4

Page 32

Chapter 4

Specifications

Output Power Waveform: Sine coded pulse width modulated waveform.

Voltage: B003-B200

0 to applied input voltage, 380V AC, 415V AC, or 460V

AC (maximum output voltage cannot exceed applied input

voltage).

C003-C200

0 to 575V AC

(maximum output voltage cannot exceed applied input

voltage).

Frequency Range: 0 to 250Hz with programmable minimum and maximum

limits.

Frequency Digital —

Resolution: Preset speeds (serial interface or pulse train input) to

0.005Hz of set frequency within the minimum and

maximum limits.

Analog —

Equal divisions between minimum and maximum limits to

the nearest 0.005 Hz as a function of signal type.

Local speed pot (MOD-FA2 only), 1003 divisions.

Remote speed pot (TB2, Terminals 1, 2 and 3).

514 divisions for Main Control Board Firmware Versions

1.01 and 1.10.

633 divisions for Main Control Board Firmware Versions

1.11-2.01.

0 to 10V DC input (TB2, Terminals 4 and 5), 976

divisions.

4 to 20mA input (TB2, Terminals 4 and 6), 726 divisions.

Frequency Digital Frequency Source: 0.0013% of set frequency,

Regulation: 0 to 40°C ambient temperature range.

Volts-per-Hertz: Fully programmable.

– Minimum 1 to 14.3V/Hz through local programming.

– Wider ranges available through optional programming.

4-5

Page 33

Chapter 4

Specifications

Output Power (cont.) DC Boost: 11 selectable values from 0 to 48V DC peak.

– Adjustable from 0 to 115V DC through optional

programming.

Accel/Decel: Two independently programmable accel times.

Two independently programmable decel times.

Each time may be programmed over a range from

0 to 600 seconds.

Intermittent Programmable MOPC from 50 to 150% of rated output

Overload Capability: current for up to 1 minute maximum.

Inverse Time Designed to meet NEC and UL equivalent requirements.

Overload Capability: Adjustable timing from 50 to 115% of rated drive current

(Main Control Board Firmware Version 1.10 limited to 100%).

Drive 180% of rated output current.

Overcurrent Trip:

Ground Fault: Detects drive output ground fault path by sensing

unbalanced bus or input line currents.

4-6

Page 34

Chapter 4

Specifications

Table

4.3 -- B003B200 Output Current and kV

Drive kVA Out kVA Out kVA Out Dissipation Dissipation Dissipation CFM

Amps Out Rating 380V AC 415V AC 460V AC (BTU/hour) n (BTU/hour) n (BTU/hour) n Required n

6.0 B003 3.9 4.3 4.8 136 239 375 15

9.6 B005 6.3 6.9 7.6 171 307 477 25

13.0 B007 8.6 9.3 10.4 273 512 784 40

17.0 B010 11.2 12.2 13.5 341 682 1023 53

25.0 B015 16.5 18.0 20.0 443 1023 1466 76

33.0 B020 22.0 24.0 26.0 477 1364 1841 95

41.0 B025 27.0 29.0 33.0 614 1705 2319 120

48.0 B030 32.0 35.0 38.0 716 2046 2762 142

60.0 B040 39.0 43.0 48.0 938 2438 3376 175

75.0 B050 49.0 54.0 60.0 1125 2847 3973 205

120.0 B075 79.0 86 .0 96.0 1705 5115 6820 352

150.0 B100 99.0 108.0 120.0 2046 7502 9548 492

180.0 B125 118.0 129.0 143.0 2387 8184 10571 545

218.0 B150 143.0 157.0 174.0 2728 10912 13640 703

290.0 B200 191.0 208.0 231.0 3069 13981 17050 880

A

Internal

Chassis

Component Heatsink

Heat Heat Total Minimum

Table

4.4 -- C003C200 Output Current and kV

Drive kVA Out kVA Out kVA Out Dissipation Dissipation Dissipation CFM

Amps Out Rating 500V AC 575V AC 600V AC (BTU/hour) n (BTU/hour) n (BTU/hour) n Required n

4.3 C003 3.7 4.3 4.3 136 239 375 15

6.7 C005 5.8 6.7 6.7 171 307 477 25

9.9 C007 8.6 9.9 9.9 273 444 717 40

12.1 C010 10.5 12.1 12.1 341 512 853 45

19.0 C015 16.5 18.9 18.9 443 853 1296 60

24.0 C020 20.8 23.9 23.9 477 1023 1500 80

30.0 C025 26.0 29.9 29.9 614 1364 1978 105

35.0 C030 30.3 34.9 34.9 716 1535 2251 115

45.0 C040 39.0 44.8 44.8 938 1876 2814 145

57.0 C050 49.4 56.8 56.8 1125 2217 3342 175

85.0 C075 73.6 84.7 84.7 1705 4433 6138 320

109.0 C100 94.4 108.6 108.6 2046 5797 7843 405

138.0 C125 119.5 137.4 137.4 2387 6820 9207 475

158.0 C150 136.8 157.4 157.4 2728 8525 11253 580

210.0 C200 181.9 209.1 209.1 3069 10571 13640 703

n The above information is provided for reference only. For all ratings the user must verify that the selected enclosure will dissipate the total BTUs

generated within the enclosure without allowing the internal ambient to rise above 50°C. Enclosure mounting and location must allow for the heatsink

to extend outside the enclosure.

•When locating the drive allow a minimum clearance from other components of 4.0 inches (101.6 mm) on the top and bottom, 2.0 inches (50.8 mm) on

either side.

•When mounting the drive, ensure that the heatsink fins are vertical.

With the heatsink exposed to the ambient, the drive will dissipate heat as listed in the Output Current Table above.

A

Internal

Chassis

Component Heatsink

Heat Heat Total Minimum

4-7

Page 35

Chapter 4

Specifications

Required Control Inputs As a minimum requirement for drive operation, the following five control

inputs must be present to operate the drive:

Start

A momentary True input will start the drive. The drive will continue to run

until a stop input is issued or a drive fault occurs. A start input may come

from:

• The optional FA2, RP2 or RP3 control panel start pushbutton.

• A user supplied N.O. contact or start pushbutton connected to the

optional L1, L2, or L3 Logic Interface Board. Refer to Appendix A —

Logic Interface Options and the 1336-MOD-L1, L2, or L3 instruction

manual.

• A user supplied start signal sent to the optional G2 Remote I/O Interface

Board. Refer to the 1336-MOD-G2 instruction manual.

Stop

A momentary False input will stop the drive. A maintained True input will

permit the drive to run or jog. A stop input may come from:

• The optional FA2, RP2 or RP3 control panel stop pushbutton.

• A user supplied maintained contact or stop pushbutton connected to the

optional L1, L2, or L3 Logic Interface Board. Refer to Appendix A —

Logic Interface Options and the 1336-MOD-L1, L2, or L3 instruction

manual.

• A user supplied stop signal sent to the optional G2 Remote I/O Interface

Board. Refer to the 1336-MOD-G2 instruction manual.

• The Main Control Board when Jumper J8 is installed between Pins 11

and 12. Refer to Chapter 6 — Wiring, page 6-16.

Enable

A maintained True input or a maintained closed contact will permit the

drive to start, run, or jog. A momentary False input or an open contact will

disable drive output. An enable input may come from:

• A user supplied maintained contact or switch connected to the optional

L1, L2 or L3 Logic Interface Board. Refer to Appendix A — Logic

Interface Options and the 1336-MOD-L1, L2 or L3 instruction manual.

4-8

• The Main Control Board when Jumper J9 is installed between Pins 7 and

8. Refer to Chapter 6 — Wiring, page 6-16.

Page 36

Required Control Inputs (cont.) Speed Reference

Speed reference sets the drive operating frequency. A speed reference input

may come from:

• A Control Panel speed potentiometer.

• A user supplied 10kΩ remote speed potentiometer connected to terminal

block TB2. Refer to Chapter 6 — Wiring.

• A 4-20mA analog signal connected to terminal block TB2. Refer to

Chapter 6 — Wiring.

• A 0-10V DC analog signal connected to terminal block TB2. Refer to

Chapter 6 — Wiring.

• A pulse train input signal connected to terminal block TB2. Refer to

Chapter 6 — Wiring.

• One of seven preset speed signals connected to the optional L1, L2, or

L3 Logic Interface Board, or the optional G2 Remote I/O Interface

Board. Refer to Appendix A — Logic Interface Options and the

1336-MOD-L1, L2 or L3 instruction manual or the 1336-MOD-G2

instruction manual.

Chapter 4

Specifications

Auxiliary

A maintained True input or a maintained closed contact will permit the

drive to start, run, or jog. A momentary False input or an open contact will

disable drive output and generate Fault F02. An auxiliary input may come

from:

• A user supplied maintained contact or switch connected to the optional

L1, L2 or L3 Logic Interface Board. Refer to Appendix A — Logic

Interface Options and the 1336-MOD-L1, L2, or L3 instruction manual.

• The Main Control Board when Jumper J9 is installed between Pins 9 and

10. Refer to Chapter 6 — Wiring, page 6-16.

4-9

Page 37

Chapter 4

Specifications

Optional Control Inputs Reverse

Reverse changes direction of motor rotation. Reverse inputs may come

from:

• A Control Panel direction pushbutton.

• The optional L1, L2 or L3 Logic Interface Board. Refer to Appendix A

— Logic Interface Options and the 1336-MOD-L1, L2 or L3 instruction

manual.

• The optional G2 Remote I/O Interface Board. Refer to the

1336-MOD-G2 instruction manual.

Jog

Jog jogs the drive at a pre-programmed jog speed. Jog inputs may come

from:

• A Control Panel jog pushbutton.

• The optional L1, L2 or L3 Logic Interface Board. Refer to Appendix A

— Logic Interface Options and the 1336-MOD-L1, L2 or L3 instruction

manual.

• The optional G2 Remote I/O Interface Board. Refer to the

1336-MOD-G2 instruction manual.

Speed Select

Speed select permits switching between two selected speed reference

sources. Speed select inputs may come from:

• The optional L1, L2 or L3 Logic Interface Board. Refer to Appendix A

— Logic Interface Options and the 1336-MOD-L1, L2 or L3 instruction

manual.

• The optional G2 Remote I/O Interface Board. Refer to the

1336-MOD-G2 instruction manual.

2nd Accel/Decel

4-10

2nd accel/decel permits switching between two internally programmed

nd

accel/decel rates. 2

accel/decel inputs may come from:

• The optional L1, L2 or L3 Logic Interface Board. Refer to Appendix A

— Logic Interface Options and the 1336-MOD-L1, L2 or L3 instruction

manual.

• The optional G2 Remote I/O Interface Board. Refer to the

1336-MOD-G2 instruction manual.

Page 38

Chapter 4

Specifications

Load Requirements A balanced 3-phase inductive motor load is typical. Other motor loads may

require application assistance.

Contact Outputs The following contact outputs are available as standard:

Run: 1 N.O. contact, closed when the drive is running.

At Speed: 1 N.O. contact, closed when the drive is at command speed

(within 0.5% of maximum programmed speed), or the

drive reaches the set point reference frequency

programmed by Parameter 77.

Fault: 1 set of Form C contacts that change state on a drive fault

or loss of power.

Drive Alarm: 1 set of Form C contacts that change state to indicate that

the drive is operating outside of rated limits and that a fault

is imminent.

Drive Alarm Conditions are:

• Drive output current is above 150% of rated current.

• Drive output current is above the MOPC limit set by

Parameter 36.

• Bus voltage is above 110% of nominal input

voltage. A continued rise in bus voltage may result

in Parameter 11 Decel Frequency Hold affecting

the decel ramp, or fault F05 Bus Overvoltage.

• Bus voltage is below 85% of nominal input voltage.

• Precharge not complete.

• Parameter 14 Auto Restart is active.

Analog Outputs 0-5V DC output programmable to represent output frequency or percent of

drive load current.

Drive Displays Programming Display frequency and drive control source. May be

and Display toggled to program and display 60 drive parameters

Panels: –– 5-14, 16-50 and 72-86. Should a fault occur while the

drive is running, the panel will display the fault code.

Bus Charged: Internal neon display to indicate bus voltage is greater than

40V DC.

4-11

Page 39

Chapter 4

Specifications

Programmable Parameters The 1336 drive logic uses a set of 90 user parameters to select and control

drive operation. Seventy-one of these parameters are accessible through

any of the Programming and Display Panels. All 90 are accessible through

the Serial Port.

4-12

Page 40

Installation

Chapter

5

General Installation Requirements

ATTENTION: An incorrectly applied or installed system can

result in component damage or reduction in product life. The most

!

common causes are:

• Wiring the AC line to drive output or control terminals.

• Improper bypass or output circuits not approved by

Allen-Bradley.

• Output circuits which do not connect directly to the motor.

• Incorrect or inadequate AC supply.

• Excessive ambient temperature.

Contact Allen-Bradley for assistance with application or wiring.

The 1336 must be installed in an area where the following installation and

environmental guidelines are met.

• Cabinet mounting is upright, leaving room for a minimum clearance of 4

inches (102 mm) on the top and bottom and 2 inches (51 mm) on the

sides for proper ventilation.

• The drive is easily accessible for maintenance and troubleshooting.

• The rated altitude does not exceed 3,300 feet (1,000 meters).

• Vibration will be within the ratings outlined in Chapter 4 –

Specifications.

• The ambient atmosphere contains no volatile or corrosive gas, vapors or

dust.

• The relative humidity does not exceed 95% for all drive ratings.

• The ambient temperature for the drive heatsink is kept within 0 to +40°C

for all open ratings.

• The ambient temperature for the chassis components is kept within 0 to

+50°C.

Important: An input transformer should not be required for normal drive

operation. If the use of an input transformer is desired, only an isolation

type transformer should be used.

Before actual installation, remove all packing material, wedges or braces

from within and around the drive.

5-1

Page 41

Chapter 5

Installation

Dimensions, Weights and Conduit Entry Locations

B003B010 and C003C010

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G H I J K L M N Weight

Open

Chassis

NEMA

Type 1

11.13 18.75 8.76 8.38 18.15 1.38 0.30 6.26 2.50 — — — — — 31.3

(283) (477) (223) (213) (461) (35) (8) (159) (63.5) (14.2)

11.13 18.75 8.76 8.38 18.15 1.38 0.30 6.26 2.50 3.50 4.38 3.44 1.25 1.88 36.3

(283) (477) (223) (213) (461) (35) (8) (159) (63.5) (89) (111) (87) (32) (48) (16.5)

G

I H

E

B

P

R

Start

Stop

Freq

Jog

Enter

P

R

➋

➌

K

➍

J

➊

M

F

D

F

A

(NEMA Type 1 –– Front)

(NEMA Type 1 –– Bottom)

NLN

(NEMA Type 1 –– Side)

C

➊

Mounting Holes –– 0.281" (7.13mm) Diameter

➋

Conduit Entry –– 0.50" (13.0 mm) Diameter

➌

Conduit Entry –– 0.75" (19.0 mm) Diameter and 1.00" (25.4 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

5-2

Page 42

Dimensions, Weights and Conduit Entry Locations

B015B020 and C015C020

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G H I J K L M N Weight

Open

Chassis

NEMA

Type 1

11.13 22.66 8.76 8.38 22.06 1.38 0.30 6.26 2.50 — — — — — 37.1

(283) (576) (223) (213) (560) (35) (8) (159) (63.5) (16.8)

11.13 22.66 8.76 8.38 22.06 1.38 0.30 6.26 2.50 3.50 4.38 3.44 1.25 1.88 43.1

(283) (576) (223) (213) (560) (35) (8) (159) (63.5) (89) (111) (87) (32) (48) (19.5)

Chapter 5

Installation

G

I H

E

Start

Stop

Freq

Jog

Enter

P

R

B

P

R

➋

➌

K

➍

J

➊

F

(NEMA Type 1 –– Front)

➊

Mounting Holes –– 0.281" (7.13mm) Diameter

➋

Conduit Entry –– 0.50" (13.0 mm) Diameter

➌

Conduit Entry –– 0.75" (19.0 mm) Diameter and 1.00" (25.4 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

D

F

A

M

NLN

(NEMA Type 1 –– Bottom)

C

(NEMA Type 1 –– Side)

5-3

Page 43

Chapter 5

Installation

Dimensions, Weights and Conduit Entry Locations

B025B030 and C025C030

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G H I J K L M Weight

Open

Chassis

NEMA

Type 1

14.32 23.59 9.27 11.70 22.41 1.31 0.59 6.64 2.63 — — — — 47.3

(364) (599) (235) (297) (570) (33.3) (15) (159) (67) (21.5)

14.32 23.59 9.27 11.70 22.41 1.31 0.59 6.64 2.63 4.38 4.19 1.88 2.62 54.3

(364) (599) (235) (297) (570) (33.3) (15) (159) (67) (111) (106) (48) (7) (24.6)

G

I

H

E

B

Stop

Enter

P

R

P

R

Freq

Start

Jog

➋

➌

J

➍

➊

F

D

F

A

(NEMA Type 1 –– Front)

➊

Mounting Holes –– 0.312" (7.92mm) Diameter

➋

Conduit Entry –– 0.50" (13.0 mm) Diameter

➌

Conduit Entry –– 1.00" (25.4 mm) Diameter and 1.25" (32.0 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

5-4

K

M

L

(NEMA Type 1 –– Bottom)

M

C

(NEMA Type 1 –– Side)

Page 44

Dimensions, Weights and Conduit Entry Locations

B040B050 and C040C050

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G H I J K L M N O Weight

17.50 34.12 9.38 16.25 32.88 0.63 0.63 6.75 2.63 ——————85.0

Open

Chassis

NEMA

Type 1

(445) (867) (238) (413) (835) (16) (16) (172) (67) (38.3)

17.50 34.12 9.38 16.25 32.88 0.63 0.63 6.75 2.63 9.68 2.06 2.75 2.06 1.50 .63 90.0

(445) (867) (238) (413) (835) (16) (16) (172) (67) (246) (52) (70) (52) (38) (16) (40.5)

Chapter 5

Installation

G

H

I

E

P

R

Start

Stop

Freq

Jog

P

R

B

Enter

➍

J L

K

M

N

➊

F

D

A

(NEMA Type 1 –– Front)

➊

Mounting Holes –– 0.343" (8.71mm) Diameter

➋

Conduit Entry –– 0.50" (13.0 mm) Diameter and 0.75" (19.0 mm) Diameter

➌

Conduit Entry –– 1.00" (25.4 mm) Diameter and 1.50" (38.0 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

F

➋

➌

(NEMA Type 1 –– Top)

O

C

(NEMA Type 1 –– Side)

5-5

Page 45

Chapter 5

Installation

Dimensions, Weights and Conduit Entry Locations

B075B0125 and C075C0125

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G H I J K L M N Weight

Open

Chassis

NEMA

Type 1

25.16 47.94 13.80 23.88 46.82 0.64 0.62 10.55 3.25 — — — — — 200

(639) (1218) (351) (607) (1189) (16) (16) (268) (83) (91)

25.16 47.94 13.80 23.88 46.82 0.64 0.62 10.55 3.25 9.75 2.75 3.00 2.50 2.48 220

(639) (1218) (351) (607) (1189) (16) (16) (268) (83) (248) (70) (76) (64) (63) (100)

G

H

I

E

B

PR

Freq

Start

Jog

Stop

Enter

PR

M

L

J

K

➍

N

➊

F

D

A

(NEMA Type 1 –– Front)

➊

Mounting Holes –– 0.343" (8.71mm) Diameter

➋

Conduit Entry –– 0.875" (22.0 mm) Diameter and 1.125" (29.0 mm) Diameter

➌

Conduit Entry –– 1.375" (35.0 mm) Diameter and 1.968" (50.0 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

F

5-6

➋

➌

(NEMA Type 1 –– Top)

C

(NEMA Type 1 –– Side)

Page 46

Dimensions, Weights and Conduit Entry Locations

B150B200 and C150C200

Open Chassis and NEMA Type 1 Enclosures

Nominal Dimensions and Weights

in Inches (Millimeters) and Pounds (Kilograms)

A B C D E F G1 G2 H I J K L M N Weight

25.16 62.94 17.50 23.92 61.82 0.62 0.62 0.50 11.75 5.75 — — — — — 380

Open

Chassis

NEMA

(639) (1599) (445) (608) (1570) (16) (16) (13) (299) (146) (171)

25.16 62.94 17.50 23.92 61.82 0.62 0.62 0.50 11.75 5.75 4.06 6.75 7.75 3.88 3.12 450

(639) (1599) (445) (608) (1570) (16) (16) (13) (299) (146) (103) (171) (197) (99) (79) (203)

Type 1

Chapter 5

Installation

G

PR

Freq

Start

Jog

Stop

Enter

PR

H

I

E

B

➍

➊

F

D

A

(NEMA Type 1 –– Front)

➊

Mounting Holes –– 0.343" (8.71mm) Diameter

➋

Conduit Entry –– 0.875" (22.0 mm) Diameter and 1.125" (29.0 mm) Diameter

➌

Conduit Entry –– 3.625" (92.0 mm) Diameter and 4.125" (105.0 mm) Diameter

➍

1336-MOD-S1 Serial Port Connector Cover Plate

F

J

K

➋

➌

(NEMA Type 1 –– Top)

M

L

N

C

(NEMA Type 1 –– Side)

5-7

Page 47

Chapter 5

Installation

Dimensions, Weights and Conduit Entry Locations

B003B030 and C003C030

NEMA Type 4 (IP56) Enclosures

B003B200 and C003C200

NEMA Type 12 (IP54) Enclosures

NEMA T

ype 4 (IP56)

Drive Rating A B C Weight Drive Rating A B C Weight Drive Rating A B C Weight

B003-B010 32.00 18.00 12.75 B003-B010 32.00 18.00 12.75 B040-B050 62.00 34.00 14.75

C003-C010 (813) (457) (324)

B015-B030 38.00 22.50 14.56 B015-B030 38.00 22.50 14.56 B075-B125 90.00 34.00 27.75

B015-C030 (965) (572) (370)

n