Page 1

Installation, Operation

and Maintenance Manual

Standard Industrial AC

Induction Motors

• 180-449 Frames (NEMA)

• 112-280 Frames (IEC)

Page 2

2 Standard Industrial AC Induction Motors

ATTENTION:Onlyqualifiedelectricalpersonnelfamiliar

with the construction and operation of this equipment and

!

the hazards involved should install, adjust, operate, and/or

service this motor. Read and understand this manual in its

entirety before proceeding. Failure to observe this

precautioncouldresult in severe bodily injuryorlossof life.

Table of Contents Receiving and Handling

Acceptance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Storage Conditions - Short Term . . . . . . . . . . . . . . . . . . . . .3

Storage Preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Storage for Extended Periods (greater than 18 months) . . .5

Unpacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Installation

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Lifting Means . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Rotating Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Drain Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Test for General Condition . . . . . . . . . . . . . . . . . . . . . . . . .11

Initial Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Operation

Maintenance and Repair

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Reassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Lubrication of Bearings

Grease Lubricated Bearings . . . . . . . . . . . . . . . . . . . . . . .15

Recommended Lubricant . . . . . . . . . . . . . . . . . . . . . . . . . .16

Lubrication Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Lubrication Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Replacement Bearings

Total Service Programs

Renewal Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Cross Sectional and Parts Identification Drawing

Page 3

Receiving and Handling Acceptance

Thoroughly inspect this equipment before accepting shipment from

the transportation company.If any of the goods called for in the bill of

lading or express receipt are damaged or the quantity is short, do not

accept them until the freight or express agent makes an appropriate

notation on your freight bill or express receipt. If any concealed loss

or damage is discovered later, notify your freight or express agent at

once and request him to make an inspection. We are willing to assist

you in collecting claims for loss or damage in shipment; however, this

willingness on our part does not remove the transportation company's

responsibility in reimbursing you for collection of claims or

replacement of material. Claims for loss or damage in shipment must

not be deducted from the invoice, nor should payment of the invoice

be withheld awaiting adjustment of such claims, as the carrier

guarantees safe delivery.

If considerable damage has been incurred and the situation is urgent,

contact the nearest Allen-Bradley Sales Office for assistance. Please

keep a written record of all such communications.

Standard Industrial AC Induction Motors 3

Storage Conditions - Short Term

Following are requirements for storage:

1. Motors must be kept in their original containers (or with

equivalent protection). In addition, they must be stored in a

warehouse free from extremes in temperature, humidity and

corrosive atmosphere.

2. If unusual vibrations exist at the storage location, the motor

should be protected with isolation pads.

3. All breathers and drains are to be operable while in storage and/or

the moisture drain plugs should be removed. The motors must be

stored so the drain is at the lowest point.

Storage Preparation

Improper storage of electric machines will result in seriously reduced

reliability of that equipment.

For example, the following items can occur to an electric motor that

does not experience regular usage while exposed to normally humid

atmospheric conditions:

• Bearings may rust.

• Rust particles from surrounding surfaces may contaminate the

bearings.

• The electrical insulation may absorb an excessive amount of

moisture leading to the motor winding failing to ground.

Page 4

4 Standard Industrial AC Induction Motors

The following preparations should be followed:

1. Minimize condensation in and around the motor by use of

desiccants or other humidity control methods.

2. Motor space heaters, when specified, must be energized when

there is a possibility that the ambient storage conditions will

reach the dew point. Space heaters are an option.

3. Coat all external machined surfaces with a material to prevent

corrosion. An acceptable product for this purpose is Exxon Rust

Ban #392 (or equivalent).

4. Measure and record the electrical resistance of the winding

insulation witha megger or insulation resistance meter. Minimum

accepted megohm level is the insulation kv rating + 1 megohm.If

levels fall below this value, contact your Allen-Bradley Sales

Office. The recorded data will be needed when the motor is

removed from storage.

5. Some motors have a shipping brace attached to the shaft to

prevent damage during transportation. The shipping brace, if

provided, must be removed and stored for future use. Before the

motor is moved, the brace must be reinstalled to hold the shaft

firmly in place against the bearing.

6. When placing the motor into extended storage (greater than 3

months), the motors with regreasable bearings must be greased

per

Table A. The motor shaft must then be rotated a minimum of

15 times after greasing. Non-regreasable motors with a “Do Not

Lubricate” nameplate should also be rotated 15 times to

redistribute grease within the bearing.

7. Before lubricating the motor, remove the grease drain plug

(opposite the grease fitting) on the bottom of each end bracket.

Replace the plug after greasing.

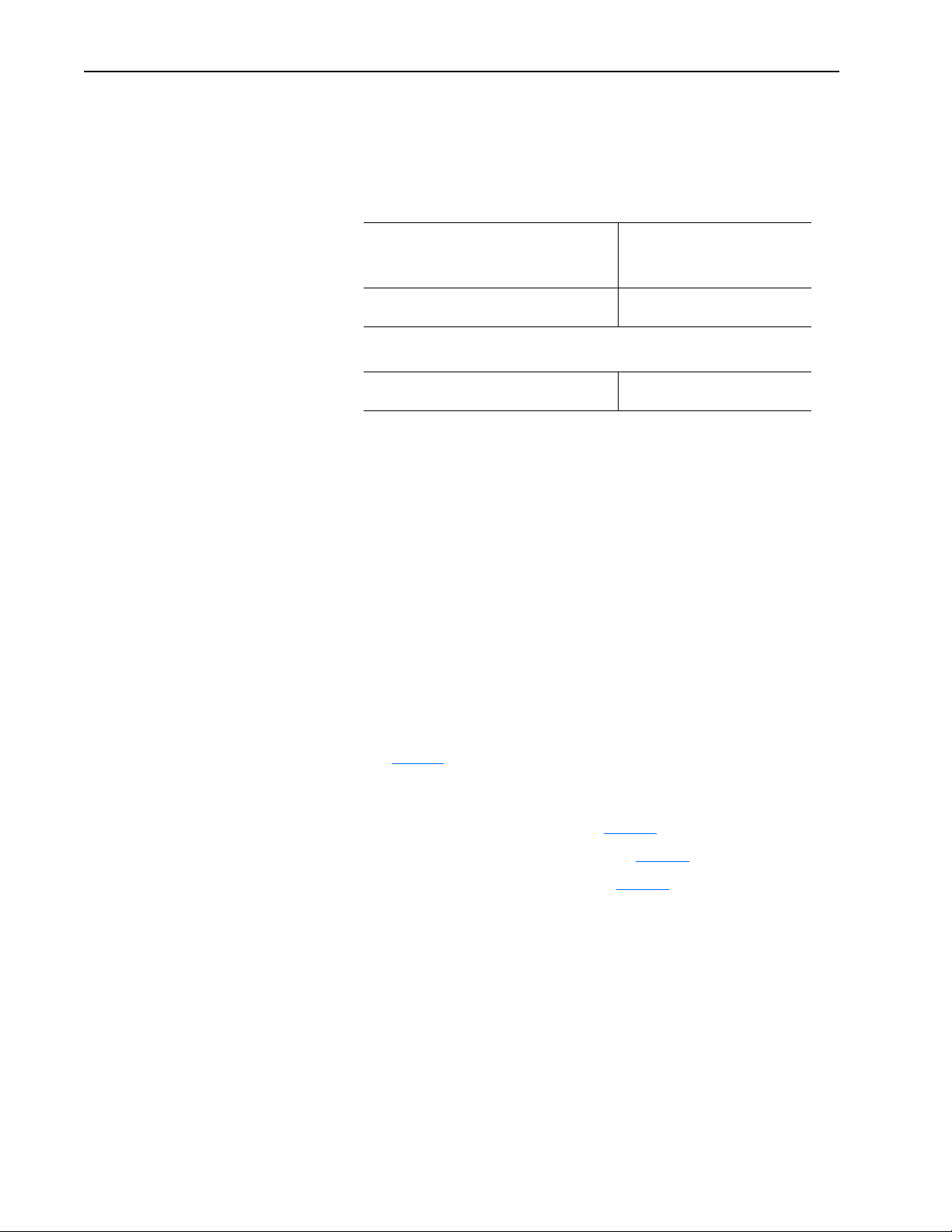

Table A

Lubrication Volume (Storage)

NEMA (IEC) Frame Size Volume in Cubic Inches (cm3)

182-215 (112-132) 0.5 (8)

254-286 (160-180) 1.0 (16)

324-365 (200-225) 1.5 (24)

404-449 (250-280) 2.5 (40)

8. When the motor is placed into extended storage, regreasable

bearings must be greased (see

Table A). Motor shafts are to be

rotated 15 revolutions manually every 3 months and additional

grease added every nine months to each bearing (see

Table A).

Bearings must be greased at the time of removal from storage.

Shafts on non-regreasable motors should be rotated 15

revolutions every 3 months.

9. All breather drains should be fully operable while in storage. The

motors must be stored so the drain is at the lowest point. All

breathers and automatic “T” drains must be operable to allow

breathing at points other than through the bearing fits.

Page 5

Standard Industrial AC Induction Motors 5

10. Space heaters, when specified, are to be connected and operable

while in storage.

11. Windings must be meggered at the time equipment is put in

storage (refer to step 4 on page 4). When the motor is removed

from storage, the insulation resistance must not have dropped

more than 50% from the initial reading. Any drop below this

point necessitates electrical or mechanical drying.

12. When motors are not stored in the original containers, but are

removed and mounted on other pieces of machinery, the

mounting must be such that the drains/breathers and space

heaters are fully operable. In this respect, the drains must be kept

at the lowest point in the motor so that all condensation can

automatically drain out.

Storage for Extended Periods (greater than 18 months)

All of the preceding requirements described in this document apply,

with the following additional requirements.

1. Motor must be crated in a box similar to Export Boxing, but the

“shell” (sides and top of box) will be lag-bolted to the wooden

base (not nailed). This design will allow the box to be opened and

closed many times without destroying the “shell.”

2. The motor will be sealed in an airtight vapor barrier bag with

desiccant inside. This airtight bag will give added protection

during shipment of motor to the permanent storage area.

3. After the first “inspection” (for megger reading, turing the shaft,

etc.) it is recommended that the vapor bag be re-sealed with

masking tape (or similar method). New desiccant should also be

added inside the bag before closing. Once closed, place the shell

over the motor and replace the lap bolts.

4. If a “zipper” type of bag is used (instead of a “heat-sealed” bag),

then close the bag with the zipper (instead of taping).

5. New desiccant must be added inside the bag after each periodic

inspection.

6. Minimize the accumulation of condensed water in and around the

machine.

Unpacking

After unpacking and inspecting, turn the motor shaft by hand to

assure that there are no obstructions to free rotation.

Equipment which has been in storage for some time should be tested

and relubricated (regreasable type) prior to being put into service.

Refer to “Test General Condition” and “Lubrication” for procedure to

be performed after extended storage.

Equipment with roller bearings is shipped with a shaft block. After

removing the shaft block, be sure to replace any bolts that are

required in service and that were used to hold the shaft block in place

during shipment.

Page 6

6 Standard Industrial AC Induction Motors

Installation Inspection

After the motor is unpacked, examine the nameplate data to see that it

agrees with the power circuit to which it is to be connected. The

motor will operate with frequency not more than 5% and voltage not

more than 10% above or below the nameplate data, or combined

variation of voltage and frequency of not more than 10% above or be

low nameplate data. Efficiency, power factor and current may vary

from nameplate data. Performance within these voltage and

frequency variations will not necessarily be in accordance with the

standards established for operation at rated voltage and frequency.

Location

The motor should be installed in a location compatible with the motor

enclosure and specific ambient.

To allow adequate air flow, the following clearances must be

maintained between the motor and any obstruction:

TEFC (IC0141) Enclosures

Fan Cover Air Intake 180-210T Frame 25.4 mm (1.00 in.)

Exhaust Envelope equal to the “P” dimension on the motor dimension sheet

Protected Enclosures

Bracket Intake Same as TEFC

Frame Exhaust Exhaust out the sides-envelope a minimum of the “P” dimension plus

250-449T Frame 101.6 mm (4.00 in.)

IEC 112 - 132 25.0 mm (0.98 in.)

IEC 160 - 280 100.0 mm (3.94)

50.0 mm (1.97 in.). Exhaust out the end-same as intake.

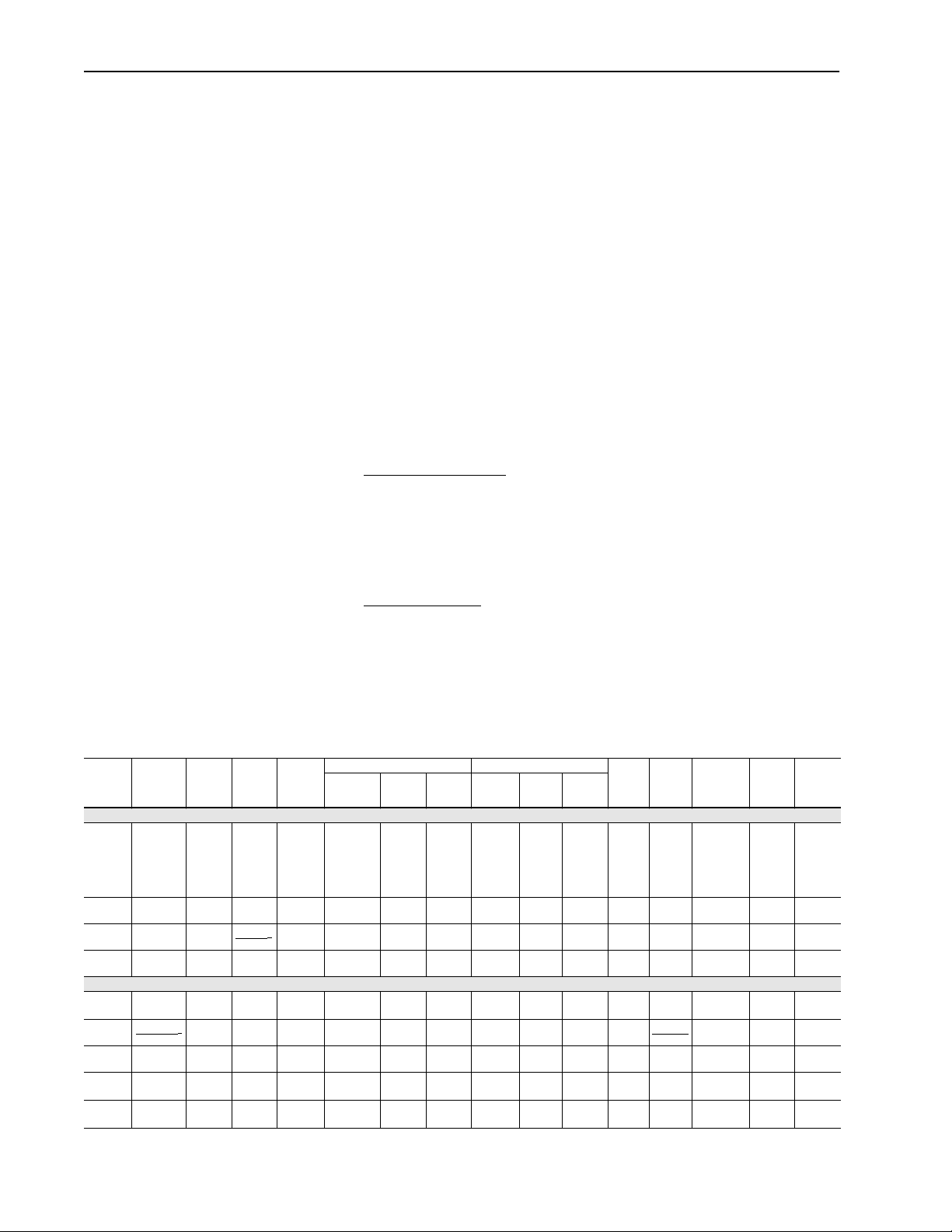

Table B

General Effect of V oltage & Frequency Variation on Induction-motor Characteristics

Starting &

Maximum

Running

Variation

Voltage Variation:

120%

voltage

110%

voltage

Functions

of Voltage

90%

Voltage

Frequency Variation:

105%

frequency

Functionof

frequency

95%

frequency

1% phase

unbalance

2% phase

unbalance

Torque

Increase

44%

Increase

21%

(voltage)

Decrease

19%

Decrease

10%

(frequency)

Increase

11%

Slight

decrease

Slight

decrease

Sync

Speed Slip %

No

change

No

change

2

Constant 1

No

change

Increase5%Practically

1

Frequency (sync

2

Decrease5%Practically

Slight

decrease

Slight

decrease

Decrease

30%

Decrease

17%

(voltage)

Increase

23%

no change

no change

Full Load

Speed

Increase

1.5%

Increase1%Slight

(sync

2

speed slip)

Decrease

1-1/2%

Increase5%Slight

speed slip)

Decrease5%Slight

Slight

decrease2%decrease

Slight

decrease8%decrease

NOTE: This table shows goneral effects, which will vary somewhat for specific ratings.

Efficiency Power Factor/COS

Decrease

6-0%

Decrease

(1-75 HP)

0-3%

Increase

(100-200 HP)

decrease

Decrease

2 points

increase

decrease

Decrease

1/2-2

points

Practically

no change

Practically

no change

Slight

increase

Slight

decrease

7-20

points

Decrease

1-2 points

Increase

1-2 points

Slight

increase

Slight

decrease

Decrease

5-15 points

Decrease

5-10 points

Increase

5 points

Slight

increase

Slight

decrease

5-6%

decrease

7%

decrease

Decrease

10-30

points

Decrease

5 points

Increase

2-3 points

Slight

increase

Slight

decrease

Decrease

15-40

points

Decrease

5-6 points

Increase

4-5 points

Slight

increase

Slight

decrease

Full

Load

Starting

Current

Current

Increase

Increase

12%

20%

Increase

Increase

2-4%

10-12%

voltage (voltage)

Increase

Decrease

11%

10-12%

Slight

Decrease

decrease

5-6%

1

frequency

Slight

Increase

increase

5-6%

1-1/2%

Slight

increase

decrease

3%

Slight

decrease

increase

Temperature

Rise

(full load)

Increase 5-6

degrees C.

(1-75 HP)

Decrease3-4

degrees C.

(100-200 HP)

Increase 3-4

degrees C.

Increase 6-7

degrees C.

Slight

decrease

Increase

slightly

2%

increase

8%

increase

Maximum

Overload

Capacity

Increase

44%

Increase

21%

Decrease

19%

Slight

decrease

Increase

slightly

Magnetic

Noise

(no-loadin

particular)Full-Load 3/4 Load 1/2 Load Full Load 3/4 Load 1/2 Load

Noticeable

increase

Increase

slightly

2

Slight

decrease

Slight

decrease

Increase

slightly

Page 7

Standard Industrial AC Induction Motors 7

Lifting Means

ATTENTION: When lifting means are provided for

handling the motor, it should

!

plus additional equipment such as gears, pumps,

compressors or other driven equipment. Failureto observe

this precaution could result in bodily injury.

In the case of assemblies on a common base, any lifting means

provided on the motor or generator should not be used to lift the

assembly and base. The assembly should be lifted by a sling around

the base or by other lifting means provided on the base. In all cases,

care should be taken to assure lifting in the direction intended in the

design of the lifting means. Precautions should be taken to prevent

hazardous overloads due to deceleration, acceleration or shock forces.

not be used to lift the motor

Mounting

Mount the motor on a foundation sufficiently rigid to prevent

excessive vibration. Rollerbearing and ball-bearing motors may be

mounted with the shaft at any angle. Roller bearing motors are not

suitable for coupled duty applications. After carefully aligning the

motor with the driven unit, bolt securely in place.

When motors, which are normally mounted with the shaft in a

horizontal position, are mounted vertically, it may be necessary to

provide additional guards to prevent foreign objects from falling into

the motor openings and striking rotating parts. Such guards may be

obtained at the time of purchase or from a local service repair center.

Explosion proof motors are shipped from the factory with the conduit

box mounted. If the conduit box is removed or rotated, a minimum of

five (5) full threads of engagement on the motor pipe nipple must be

maintained for explosion proof integrity of the conduit box.

Some motors have standardized frames containing 6 or 8 mounting

holes. 6 hole frames are not suitable for field reversal of mounting

from F-1 to F-2, etc.

use.

Figure 1 indicates the proper mounting holes to

Page 8

8 Standard Industrial AC Induction Motors

Figure 1

Mounting of 6 & 8 Hole Motor Frames

View from above

Not present on "6-hole frame" and not

used on "8-hole frame" (allows F-1 to

F-2 conversion on 8-hole frames)

Drive

Shaft End

Use these holes for short

frame designations 182, 213,

254, 284, 324, 364, 404, 444

(NEMA)

Use these holes for long frame designations 184,

215, 256, 286, 326, 365, 405, 445 (NEMA)

(IEC) 112M, 132M, 160L, 200L, 225M, 250M, 280M

Always use these holes which are closer to

shaft. 112S, 132S, 160M, 180M, 200M,

225S, 250S, 280S (IEC)

Drive

The pulley, sprocket, or gear used in the drive should be located on

the shaft as close to the shaft shoulder as possible. Heat to install.

Driving a unit on the shaft will damage the bearings.

Belt Drive – Align the pulleys so that the belt will run true. Tighten

the belt just enough to prevent slippage, any tighter will cause

premature bearing failure. If possible, the lower side of the belt

should be the driving side.

Chain Drive – Mount the sprocket on the shaft as close to the bracket

as possible. Align the sprockets so that the chain will run true. Avoid

excessive chain tension.

Gear Drive and Direct Connection – Accurate alignment is essential.

Secure the motor and driven unit rigidly to the base.

Rotating Parts

ATTENTION: Rotating parts such as couplings, pulleys,

external fans and unused shaft extensions must be

!

permanentlyguarded against accidentalcontact with hands

or clothing. This is particularly important where the parts

have surface irregularities such as keys, keyways or set

screws. Failure to observe this precaution could result in

personal injury.

Some Satisfactory Methods Of Guarding Are:

• Covering the machine and associated rotating parts with

structural or decorative parts of the driven equipment.

• Providing covers for the rotating parts. Covers should be

sufficiently rigid to maintain adequate guarding in normal

service.

Page 9

Standard Industrial AC Induction Motors 9

ATTENTION:Theuserisresponsibleforconformingwith

the National Electrical code and other applicable local

!

codes. Wiring practices, grounding disconnects and

overcurrentprotectionare ofparticularimportance. Failure

to observe these precautions could resultin personal injury

or loss of life.

Wiring

ATTENTION: The following steps require rotating parts

and/or electrical circuits to be exposed. Stay clear if unit

!

must berunning or disconnect and lockout powersource if

contact must be made.

Connect the motor to the power supply according to the diagram on

the motor nameplate. For most 230/460 volt motors, nine leads are

brought out from the stator windings so that the motor may be

connected for either 230 or 460 volts.

Important: When motors are provided with thermal protection

(typically thermostats), it is important to properly connect

and apply the devices. This will ensure that the motor is

properly protected from being operated if thermal limits

are reached and/or exceeded. The control system must be

configured to reduce the motor load and/or shut down the

motor control system to allowthe motor to cool to a level

within acceptable operating ranges. If the motor is

operated with the thermal protective devices tripped

(indicating an over temperature condition), the motor

insulation could be damaged and complete failure of the

motor insulation is possible. In the event of motor failure

due to an over temperature condition, Rockwell

Automationrequiresthatmotorthermalprotectivedevices

(when supplied) be adequately monitored and

incorporated into the motor control system to maintain

warranty. Failure on the part of the individual installing

this equipment to takethese steps will result inthe factory

warranty being voided.

Grounding

In the USA consult the National Electrical Code, Article 430 for

information on grounding of motors, Article 445 for grounding of

generators, and Article 250 for general information on grounding. In

making the ground connection, the installer should make certain that

there is a solid and permanent metallic connection between the

ground point, the motor or generator terminal housing, and the motor

or generator frame. In other locations consult the appropriate national

or local code applicable.

Page 10

10 Standard Industrial AC Induction Motors

Motors with resilient cushion rings usually must be provided with a

bonding conductor across the resilient member. Some motors are

supplied with the bonding conductor on the concealed side of the

cushion ring to protect the bond from damage. Motors with bonded

cushion rings should usually be grounded at the time of installation in

accordance with the above recommendations for making ground

connections. When motors with bonded cushion rings are used in

multimotor installations employing group fusing or group protection,

the bonding of the cushion ring should be checked to determine that it

is adequate for the rating of the branch circuit overcurrent protective

device being used.

There are applications where grounding the exterior parts of a motor

or generator may result in greater hazard by increasing the possibility

of a person in the area simultaneously contacting ground and some

other nearby live electrical parts of other ungrounded electrical

equipment. In portable equipment it is difficult to be sure that a

positive ground connection is maintained as the equipment is moved,

and providing a grounding conductor may lead to a false sense of

security.

The user must select a motor starter and overcurrent protection

suitable for this motor and its application. Consult motor starter

application data as well as the National Electric Code and/or other

applicable local codes.

ATTENTION: Whencareful consideration of the hazards

involved in a particular application indicate the machine

!

frames should not be grounded or when unusual operating

conditions dictate that a grounded frame cannot be used,

the installer should make sure the machine is permanently

andeffectivelyinsulatedfrom ground. In thoseinstallations

where the machine frame is insulated from ground, it is

recommended that appropriate warning labels or signs be

placed on or in the area of the equipment by the installer.

Failure to observe these precautions could result in severe

bodily injury or loss of life.

Starting

ATTENTION: Before starting the motor, remove all

unused shaft keys and loose rotating parts to prevent them

!

from flying off. Failure to observe this precaution could

result in bodily injury.

ATTENTION: Check direction of motor rotation before

coupling motor to load. Failure to observe this precaution

!

could result in damage to or destruction of the equipment.

Page 11

Standard Industrial AC Induction Motors 11

Before starting the motor, check the following items:

• The rotor should turn freely when disconnected from the load.

• Driven machine should be unloaded when first starting the motor.

The motor should run smoothly with little noise. If the motor fails to

start and produces a decided hum, it may be that the load is too great

for the motor or that it has been connected improperly. Shutdown

immediately and investigate for trouble.

Drain Plugs

If motor is totally enclosed fan-cooled or non-ventilated, it is

recommended that condensation drain plugs, if present, be removed.

These are located in the lower portion of the end-shields. Totally

enclosed fan-cooled “XT” motors are normally equipped with

automatic drains which may be left in place as received.

Rotation

To reverse the direction of rotation, disconnect from power source

and interchange any two of the three line leads for the three-phase

motors.

Test for General Condition

If the motor has been in storage for an extensive period or has been

subjected to adverse moisture conditions, it is best to check the

insulation resistance of the stator winding with a megohmeter.

If the resistance is lower than one megohm the windings should be

dried in one of the two following ways:

1. Bake in an oven at a temperature not exceeding 90 degreesC (200

degrees F) until insulation resistance becomes constant.

2. With rotor locked, apply low voltage and gradually increase

current through windings until temperature (measured with a

thermometer) reaches 90 degrees C (200 degrees F). Do not

exceed this temperature.

Initial Lubrication

Allen-Bradley motors are shipped from the factory with the bearings

properly packed with grease and ready to operate. Where the unit has

been subjected to extended storage (6 months or more) the bearings

should be relubricated (regreasable type) prior to starting.

Page 12

12 Standard Industrial AC Induction Motors

Operation

!

Due to the inherent characteristics of insulating materials, abnormally

high temperatures shorten the operating life of electrical apparatus.

The total temperature, not the temperature rise, should be the measure

of safe operation. The class of insulation determines the maximum

safe operating temperature. Aging of insulation occurs at an

accelerated rate at abnormally high temperatures. A general rule for

gauging the effect of excessive heat is that for each 10 degrees C (50

degrees F) rise in temperature above the maximum limit for the

insulation, the life of the insulation is halved.

Unbalanced voltage or single-phase operation of polyphase machines

may cause excessive heating and ultimate failure. It requires only a

slight unbalance of voltage applied to a polyphase motor to cause

large unbalance currents and resultant overheating.

ATTENTION: Surface temperatures of the motor

enclosure may reach temperatures which can cause

discomfort or injury if contact is made with hot surfaces.

Wheninstalling, protectionmust be providedby theuser to

protectagainst accidental contactwith hot surfaces.Failure

to observe this precaution could result in personal injury.

Periodic checks of phase voltage, frequency and power consumption

of a motor while in operation are recommended. Such checks assure

the correctness of frequency and voltage applied to the motor and

yield an indication of the load offered by the apparatus which the

motor drives.

Comparisons of this data with previous no-load and full-load power

demands will give an indication of the performance of the complete

machine. Any serious deviations should be investigated and

corrected.

Stator problems can usually be traced to one of the following causes:

• Worn bearings

• Operating single-phase

• Moisture

• Poor insulation

• Overloading

• Oil and dirt

Dust and dirt are usually contributing factors. Some forms of dust are

highly conductive and contribute materially to insulation breakdown.

The effect of dust on the motor temperature through restriction of

ventilation is a principal reason for keeping the windings clean.

Squirrel-cage rotors are rugged and in general give little trouble. The

first symptom of a defective rotor is lack of torque. This may cause a

slowing down in speed accompanied by a growling noise or perhaps

failure to start the load. This is caused by an open or high resistance

joint in the rotor bar circuit. Such a condition can generally be

detected by looking for evidence of localized heating.

Page 13

Standard Industrial AC Induction Motors 13

Motors with maximum surface temperatures listed on the nameplates.

ATTENTION: The motor is designed to operate at or

below the maximum surface temperature stated on the

!

nameplate. Failure to operatethe motor properly can cause

this maximum surface temperature to be exceeded. If

applied in a Division 2 or Zone 2 environment, this

excessive temperature may cause ignition of hazardous

materials. Operating the motor under any of the following

conditions can cause the marked temperature to be

exceeded.

• Motor load exceeding service factor value.

• Ambient temperatures above nameplate value.

• Voltages above or below nameplate value.

• Unbalanced voltages.

• Loss of proper ventilation.

• Variable frequency operation.

• Altitude above 1000 meters (3000 feet).

• Severe duty cycles, repeated starts.

• Motor stall.

• Motor reversing.

• Single-phase operation.

Page 14

14 Standard Industrial AC Induction Motors

Maintenance and Repair The fundamental principle of electrical maintenance is keep the

apparatus clean and dry. This requires periodic inspection of the

motor, the frequency depending upon the type of motor and the

service.

ATTENTION: To ensure that the drivenequipment is not

unexpectedlystarted, removeall powerbefore proceeding.

!

Failure to observe this precaution could result in personal

injury or death.

The following should be checked at regular intervals:

• Windings should be dry and free of dust, grease, oil and dirt.

Windings may be cleaned by suction cleaners or by wiping.

Nozzles on suction type cleaners should be nonmetallic. Gummy

deposits of dirt and grease may be removed by using a

commercially available low volatile solvent.

• Terminal connections, assembly screws, bolts and nuts should be

tight. They may loosen if motor is not securely mounted and tend

to vibrate.

• Insulation resistance of motors in service should be checked

periodically at approximately the same temperature and humidity

conditions to determine possible deterioration of the insulation.

When such measurements at regular intervals indicate a wide

variation, the cause should be determined. Motor should be

reconditioned if the motor has been subjected to excessive

moisture by re-winding or re-insulating if necessary. Enclosed

motors require very little attention. Ensure that the external air

chamber of fan-cooled motors does not become clogged with

foreign material which will restrict passage of air.

Disassembly

If it becomes necessary to disassemble the motor, care should be

taken not to damage the stator windings as the insulation may be

injured by improper or rough handling. Precautions to keep bearings

clean should also be exercised. Before removing either end shield:

1. Disconnect motor from power source. Label the leads to assure

proper reconnection.

2. Remove motor from mounting base. Remove fan cover and fan if

present.

3. Mark end brackets relative to position on frame so they can be

easily replaced.

Page 15

Standard Industrial AC Induction Motors 15

Removing Brackets and Rotor

1. Remove bearing cartridge nuts or screws (if used).

2. Remove opposite drive end bracket bolts.

3. Pull bracket.

4. Remove drive end bracket in same manner.

5. Remove rotor.

Removing and Replacing Ball Bearings

Bearings should not be removed unless they are to be replaced. When

removal is necessary, use a bearing puller. A bearing puller may be

rigged by using a metal plate with holes drilled to match the tapped

holes in the inner cap. Use care to keep the pressure equal to prevent

breaking the cap.

To install a bearing, heat the bearing in an oven at 121 degrees C (250

degrees F). This will expand the inner race, allowing it to slip over the

bearing seat. All bearings must be replaced with the identical part. In

many cases special bearings are used which cannot be identified by

markings on the bearing. In all cases, when replacing bearings, use

markings on bearings and motor identification number to obtain

correct replacement bearing. The majority of bearings used now have

a C3 internal fit.

Reassembly

Follow reverse procedure as outlined above. Having marked the

brackets in the original position, replace as marked.

Lubrication of Bearings Motors covered by this Instruction Manual are equipped with several

types of bearings. This description covers regreasable anti-friction

bearings only. Non-regreasable ball bearings require no periodic

maintenance.

Grease Lubricated Bearings

This motor has been properly lubricated at the time of manufacture. It

is not necessary to lubricate at time of installation unless the motor

has been in storage for a period of six months or more.

Lubrication of anti-friction bearings should be done as a part of a

planned maintenance schedule. The Recommended Lubrication

Interval should be used as a guide to establish this schedule.

Cleanliness is important in lubrication. Any grease used to lubricate

anti-friction bearings should be fresh and free from contamination.

Similarly, care should be taken to properly clean the grease inlet area

of the motor to pre vent grease contamination.

Page 16

16 Standard Industrial AC Induction Motors

Recommended Lubricant

For motors operating in ambient temperatures shown below, use the

following lubricants or their equivalent:

Ball Bearing Motors

Operating Temperature:

–25 to 50 degrees C (–15 to 120 degrees F)

Minimum Starting Temperature

–60 degrees C (–76 degrees F)

Roller Bearing Motors

Operating Temperature:

–25 to 50 degrees C (–15 to 120 degrees F)

Lubrication Procedure

Anti-friction bearings may be lubricated with the motor running or

stationary. However, stationary with the motor warm is preferred.

Chevron Oil – SRI No. 2

Exxon – Unirex N2

Shell Oil Co. – Dolium R

Texaco, Inc. – Premium RB

Shell Oil Co. – Aeroshell 7

Chevron Oil – Black Pearl EP No. 2

Texaco, Inc. – Premium RB

1. Locate the grease inlet, clean the area and replace the pipe plug

with a grease fitting (if the motor is not equipped with grease

fittings).

2. If motor is equipped with grease drain plug, remove plug and

loosen any hardened grease that may block drain.

3. Add the recommended volume of the lubricant using a hand

operated grease gun.

4. Run the motor for two hours.

5. Replace the pipe plug in grease drain plug.

6. Grease may not relieve from drain. Use only volume shown in

Table E.

Lubrication Instructions

1. Select Service Condition from Table C.

2. Select Lubrication Frequency from

3. Select Lubrication Volume from

4. Lubricate the motor at the required frequency with the required

lubricant volume in accordance with Lubrication Procedure

above.

Table D.

Table E.

Page 17

Standard Industrial AC Induction Motors 17

ATTENTION:Mixinglubricants is notrecommendeddue

to possible incompatibility. If changing lubricant without

!

motor disassembly is desired, follow lubrication

instructions and repeat lubrication after 100 hours of

service. Care must be taken to look for signs of lubricant

incompatibility, such as extreme “soupiness” visible from

the grease relief area. Failure to observe this precaution

could result in damage to or destruction of the equipment.

Table C

Service Conditions

Standard Conditions: Eight hours per day; normal or light loading, clean, 40 degree C

Severe Conditions: Twenty-four hour per day operation or shock loading, vibration, or in

Extreme Conditions: Heavy shock or vibration, or dust.

Table D

Lubrication Frequency for Ball Bearings

Speed NEMA (IEC) Frame

1800 RPM & slower 182- 215 (112-132) 3 Years 1 Year 6 Months

3600 RPM All 6 Months 3 Months 1 Month

(100 degrees F) maximum ambient.

dirt or dust at 40-50 degrees C (100-120 degrees F) ambient.

Condition

Standard Severe Extreme

254-365 (160-200) 2 Years 6-12 Months 3 Months

404-449 (225-280) 1 Year 6 Months 1-3 Months

Lubrication Frequency for Roller Bearings

For Roller Bearings – divide the above times by 2.

Table E

Recommended Volume

NEMA (IEC) Frame Volume in Cubic Inches (cm

182- 215 (112-132) 0.5 (8)

254-286 (160-180) 1.0 (16)

324-365 (200-225) 1.5 (24)

404-449 (250-280) 2.5 (40)

3

)

Replacement Bearings Your maintenance program will not be complete without including

spare bearings. It must be remembered that the bearing is a wearable

component and therefore must eventually be replaced. To ensure that

you are able to maintain original operation, we recommend the

purchase of spare parts directly from Allen-Bradley.

All bearings are subject to exact specifications and tests necessary to

satisfy performance requirements. In this manner, it is possible to

duplicate your present bearing. Markings on the bearing do not

indicate complete specifications.

Page 18

18 Standard Industrial AC Induction Motors

Total Service Programs Allen-Bradley can provide a wide range of maintenance programs to

help you reduce downtime,improve productivity and increase profits.

Capabilities include:

• Motor Start-up Service

• Motor Electrical and Mechanical Preventive Maintenance

• Vibration Analysis

• Mobile Van Repair Service

• Balancing and Alignment Service

• Maintenance Service

• 24-Hour Technical Support

• Modernization Service

For more information contact your local Allen-Bradley Sales Office.

Renewal Parts

Parts can be obtained from your nearest Allen-Bradley parts

distributor, or directly from the factory. When ordering parts for

which a part number is not available, give complete description of

part and purchase order number, serial number, model number, etc.,

of the equipment on which the part is used.

A detailed parts list, which gives recommendations for spare parts

that should be stocked for your equipment, can also be ordered.

Page 19

Standard Industrial AC Induction Motors 19

Cross Sectional and Parts

Identification Drawing

Find No. Part Description Find No. Part Description Find No. Part Description

1 Frame 9 Frontend Ball Bearing 17 Terminal Box

2 Stator 10 Frontend Inner Cap 18 Fan Clamp

3 Rotor/internal Cooling Fan 11 Wave Washer, Frontend 19 Grease Entry

4 Backend Bracket 12 Fan Cover 20 Condensation Drain

5 Frontend Bracket 13 Outer Cooling Fan 21 Key

6 Shaft 14 Front End Bracket Bolts 22 Slinger

7 Backend Ball Bearing 15 Fan Cover Bolts 23 Backend Cap Bolts

8 Backend Inner Cap 16 Eyebolt 24 Grease Drain

NOTE: Bearings shown are regreasable type. Not all items shown may be present on motor. Not all items on motor may be shown on drawing. Drawing is for general

reference purposes only.

Page 20

Online Documentation

The latest motor information can be obtained from the Allen-Bradley

Drives & Motors home page on the World Wide Web at:

http://www.ab.com/drives/motors

Publication 1329R-UM002A-EN-P Ð August, 2001

Supersedes 1329R-5.1 dated March, 1999 Copyright © 2001 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...