Page 1

Installation, Operation

and Maintenance Manual

AC Induction Motors

• Frames L180 - L440

• Specifically designed for use with Adjustable

Frequency AC Drives

Page 2

2 AC Induction Motors

General Description The motors described in this publication are high performance motors

specifically designed for use with adjustable frequency drives. The

basic design includes Class H insulation, 1.0 service factor, 40 degree

C ambient, continuous duty. Standard enclosures are totally enclosed

blower cooled, totally enclosed fan-cooled, non-ventilated and dripproof force ventilated. Modifications and accessories are available.

Important: These motors are equipped with metric hardware.

ATTENTION:Only qualified electrical personnelfamiliar

!

with the construction and operation of this equipment and

the hazards involved should install, adjust, operate, and/or

service this motor. Read and understand this manual in its

entirety before proceeding. Failure to observe this

precaution could result in personal injury or loss of life.

Table of Contents General Description

Receiving and Handling . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Drain Plugs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Conduit Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Stub Shaft Installation Procedure . . . . . . . . . . . . . . . . . . . . 6

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Encoder Connection Diagrams . . . . . . . . . . . . . . . . . . . . . 10

Motor Application Data

Maximum Safe Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Minimum V-Belt Sheave Diameters . . . . . . . . . . . . . . . . . .12

Shaft Extension and Method of Drive . . . . . . . . . . . . . . . . 12

Shaft Loads - Axial and Radial . . . . . . . . . . . . . . . . . . . . . 13

Operation

Motor Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Balance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Maintenance

Lubrication - Frames L180 - L400 . . . . . . . . . . . . . . . . . . . 17

Repacking Bearings or Greasing New Bearings . . . . . . . . 18

Disassembly and Reassembly Instructions

Axial Float . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Anti-Friction Bearing Assemblies . . . . . . . . . . . . . . . . . . . .19

Bearing Replacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Bracket Re-Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Stub Shaft Removal Procedure . . . . . . . . . . . . . . . . . . . . . 20

Replacement Bearings/Spare Parts . . . . . . . . . . . . . . . . . 21

Parts Identification Drawing . . . . . . . . . . . . . . . . . . . . . . . . 22

Total Service Programs . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Page 3

Receiving and Handling Acceptance

Thoroughly inspect this equipment before accepting shipment from

the transportation company. If any of the goods called for in the bill of

lading or express receipt are damaged or the quantity is short, do not

accept them until the freight or express agent makes an appropriate

notation on your freight bill or express receipt. If any concealed loss

or damage is discovered later, notify your freight or express agent at

once and request him to make an inspection. We are willing to assist

you in collecting claims for loss or damage in shipment; however, this

willingness on our part does not remove the transportation company's

responsibility in reimbursing you for collection of claims or

replacement of material. Claims for loss or damage in shipment must

not be deducted from the invoice, nor should payment of the invoice

be withheld awaiting adjustment of such claims, as the carrier

guarantees safe delivery.

If considerable damage has been incurred and the situation is urgent,

contact the nearest Allen-Bradley Sales Office for assistance. Please

keep a written record of all such communications.

AC Induction Motors 3

Handling

ATTENTION: Eyebolt(s) or lifting lug(s) are intended for

!

!

In all cases, care should be taken to assure lifting in the direction

intended in the design of the lifting means. Lift using all lugs

provided. Likewise, precautions should be taken to prevent hazardous

overloads due to deceleration, acceleration or shock forces.

Angle of lift with rope or chain must be greater than 45 degrees from

horizontal.

For unusual conditions, such as side-wall and ceiling mounting of

horizontal motors or installation of vertical motors shipped in a

horizontal position, special precautions must be taken. It is

recommended that an experienced rigger be employed.

lifting the motor only with the standard accessories such as

tachometer, brakes, etc., mounted by Allen-Bradley. The

lifting means on the motor must not be used to lift the unit

plus additional equipment. Failure to observe this

precaution could result in personal injury.

ATTENTION: Eyebolts may unscrew during lifting.

Verify that eyebolts are tight and secure from turning, or lift

the unit on a sling or platform. Failure to observe this

precaution could result in personal injury.

Page 4

4 AC Induction Motors

Storage

Motors must be stored in a clean, dry area protected from extremes of

temperature, moisture, shock and vibration. Storage temperatures of

10 to 49 degrees C (50 to 120 degrees F) with a maximum relative

humidity of 60% must be observed. In addition, motors subjected to

extended storage must be handled and treated per the requirements

specified in publication “Motors-5.0.” This publication is available

from your Allen-Bradley Sales Office or online at:

http://www.controlmatched.com.

All drains to be fully operable while in storage, and/or the drain plugs

removed. The motors must be stored so that the drain is at the lowest

point. All breathers and automatic “T” drains must be operable to

allow breathing at points other than through the bearing fits.

Installation Allen-Bradley AC motors are designed and built in accordance with

Safety Standard for Construction and Guide for Selection,

Installation and Use Of Electric Motors And Generators published by

the National Electrical Manufacturers Association (NEMA),

publication MG-2-1983 (ANSI C51.5). It is recommended that this

publication be referred to whenever you select or install any AC

motor.

The application of motors and other electrical equipment in

hazardous locations is restricted by the National Electric Code. Users

must observe these regulations and consult with local code inspection

and enforcement agencies to insure compliance.

Location

Locate the machine where the ambient temperature is not over 40

degrees C (104 degrees F) and where clean air has free access to

ventilating intake and outlet openings. Except for machines with a

suitable protective enclosure, the location should be clean and dry.

Important: The cooling system on standard totally enclosed, blower

cooled motors requires clean air tobe forced through ducts

which are integral to the stator frame. It is important that

these air passages be kept clean and that sufficient

clearance be provided on the blower motor air inlets and

stator duct outlets for unrestricted flow of air.

For Drip-Proof Force Ventilated Enclosures, sufficient clearance must

be provided on all inlet and outlet openings to provide for unrestricted

flow of air. Separately ventilated motors with exhaust to ambient

(pipe-in only) must have at least 152.4 mm (6 in.) of clearance

between the opening and adjacent walls or floor.

Important: Motors located in a damp, moist environment must have

space heaters to protect against condensation when motor

is not operating.

Page 5

AC Induction Motors 5

Drain Plugs

If motor is totally enclosed, it is recommended that condensation

drain plugs be removed. These are located in the lower portion of the

end-shields (not included on L180 frames). Totally enclosed “XT”

motors are equipped with automatic drains which should be left in

place as received.

Power Supply

This is an adjustable speed motor designed for operation with

adjustable frequency drives.

Verify that the motor nameplate data corresponds to the drive output

rating and follow the Drive User Manual for motor installation and

connection.

Conduit Box

The standard conduit box location for totally enclosed motors is top

mounted for F1-F2 versatility without motor disassembly. For dripproof force ventilated, F1 is standard. Conduit box can be rotated in

90 degree increments for lead outlet at front, back or sides. On L180

frame motors the conduit box is mounted on the top for all enclosure

types.

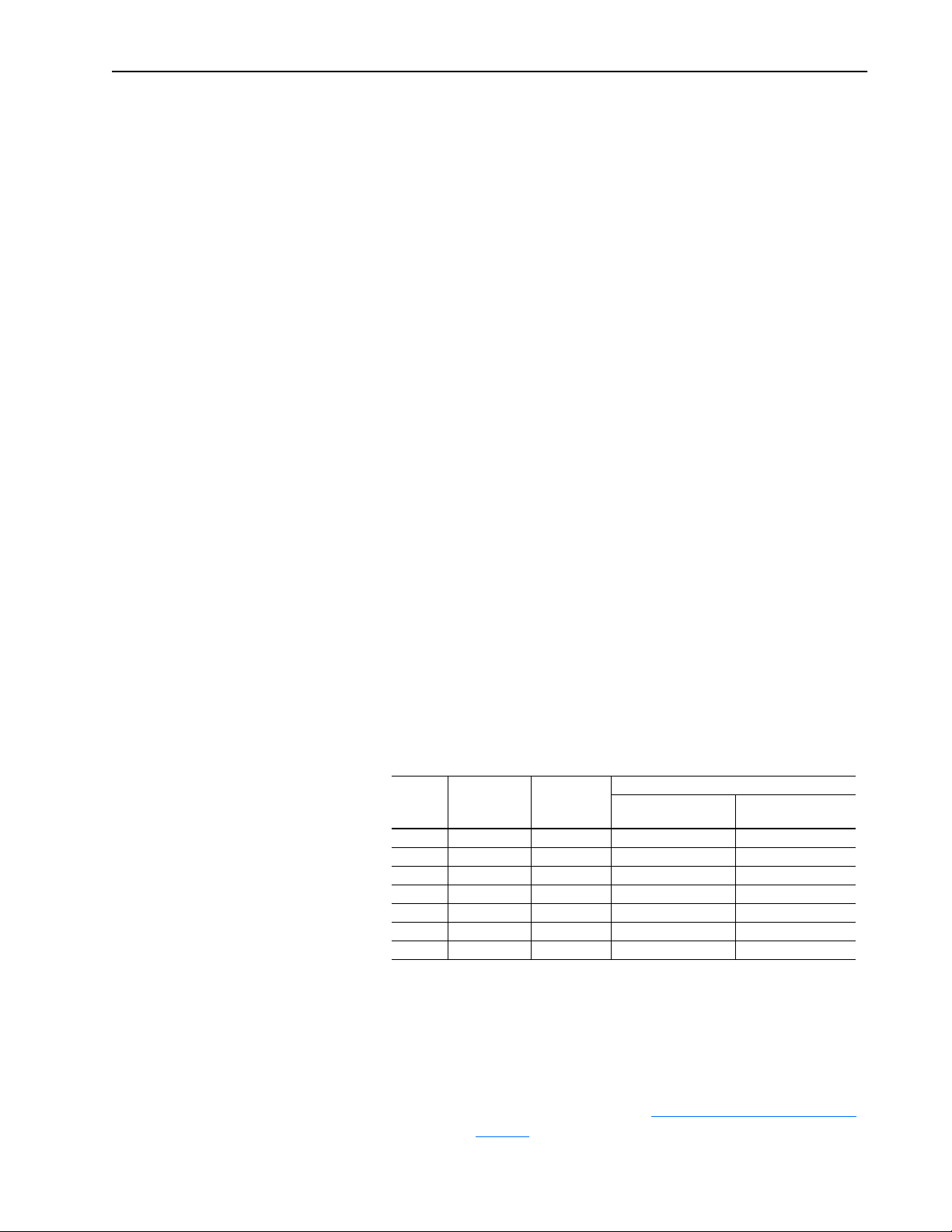

Mounting

Motors must be mounted on a rigid, solid base or foundation. Poor

base construction may cause resonances in the motor/base assembly

which can result in bearing failure and other motor damage. All hold

down bolts must be the correct grade for the type of mounting and

must be torqued to their recommended value.

Table A

Recommended Torque

Recommended Torque

Frame

L180 11.2 (0.44) 3/8-16 45-50 (33-37) 64-72 (47-53)

L210 11.2 (0.44) 3/8-16 45-50 (33-37) 64-72 (47-53)

L250 14.2 (0.56) 1/2-13 113-126 (83-93) 159-179 (117-132)

L280 14.2 (0.56) 1/2-13 113-126 (83-93) 159-179 (117-132)

L320 17.5 (0.69) 5/8-11 210-239 (155-176) 271-338 (200-249)

L360 20.6 (0.81) 3/4-10 372-420 (274-310) 527-597 (389-440)

L400 26.9 (1.06) 7/8-9 588-659 (434-486) 835-934 (616-689)

Hole Diameter

mm (in.)

Belted Drive

Motor slide bases or rails, when used, must be securely anchored to

the foundation with the proper bolts.

Bolt Size and

Thread

SAE 5

N-m (lb.-ft.)

SAE 8

N-m (lb.-ft.)

Important: The motor shaft and load shaft must be parallel and the

sheaves aligned. Refer to

“Motor Application Data” on

page 11.

Page 6

6 AC Induction Motors

Coupled Drive

Motors will operate successfully mounted on the floor, wall or

ceiling, and with the shaft at any angle from horizontal to vertical.

Special mountings, duty or thrust demands may, however, require a

different bearing system.

ATTENTION: Motor C-face is intended for mounting

!

auxiliary equipment such as pumps and gears. When

mounted horizontally, C-face motors should be supported

by the feet and not by the C-face. Installations requiring

horizontally mounted motor frames L280C and L440 must

be supported by the feet as well as C-face or D-flange.

Failure to observe these precautions can result in damaged

equipment and/or personal injury.

Stub Shaft Installation Procedure

Screw-in Stub Shaft

1. Turn off and lockout power to the motor.

2. Remove in-line blower motor and cover assembly by removing

the hex head cap screws on the cover (if enclosure is TEAOBlower cooled).

Important: An extended blower cover is required whena feedback

device is installed. Contact Allen-Bradley for

assistance with an in-line blower.

3. Check the motor shaft center hole for chips, dirt, or other residue

and clean as required.

4. Obtain the stub shaft to be screwed into the motor shaft.

®

5. Apply an even coat of Loctite

stub shaft thread. Place stub shaft in motor shaft threaded hole

and hand tighten.

6. Using a spanner wrench on the motor shaft drive end (or alternate

means of locking motor shaft), torque the stub shaft to 27 N-m

(20 lb.-ft.).

7. Using a dial indicator with 0.0005 inch graduations, indicate the

stub shaft to within 0.002 inch T.I.R. When Inland tachometers

are used, the tachometer stub shafts must indicate to within 0.001

in. T.I.R.

Number 271 (or equivalent) to the

8. Mount feedback device per manufacturer's instructions.

Page 7

AC Induction Motors 7

Connections

ATTENTION: The user isresponsible forconforming with

!

!

Bypass Mode

If the motor is to be used in bypass mode, the user must select a motor

starter and overcurrent protection suitable for this motor and its

application. Consult motor starter application data as well as the

National Electric Code and/or other applicable local codes. Contact

Allen-Bradley to determine suitability of motor for specific

applications in bypass mode.

the National Electrical Code and all other applicable local

codes. Wiring practices, grounding, disconnects and

overcurrent protection are of particular importance. Failure

to observe these precautions could result in severe bodily

injury or loss of life.

ATTENTION: This equipment is at line voltage when AC

power is connected. Disconnect andlockout all ungrounded

conductors of the power line. Failure to observe these

precautions could result in personal injury and/or loss of

life.

Power Wiring

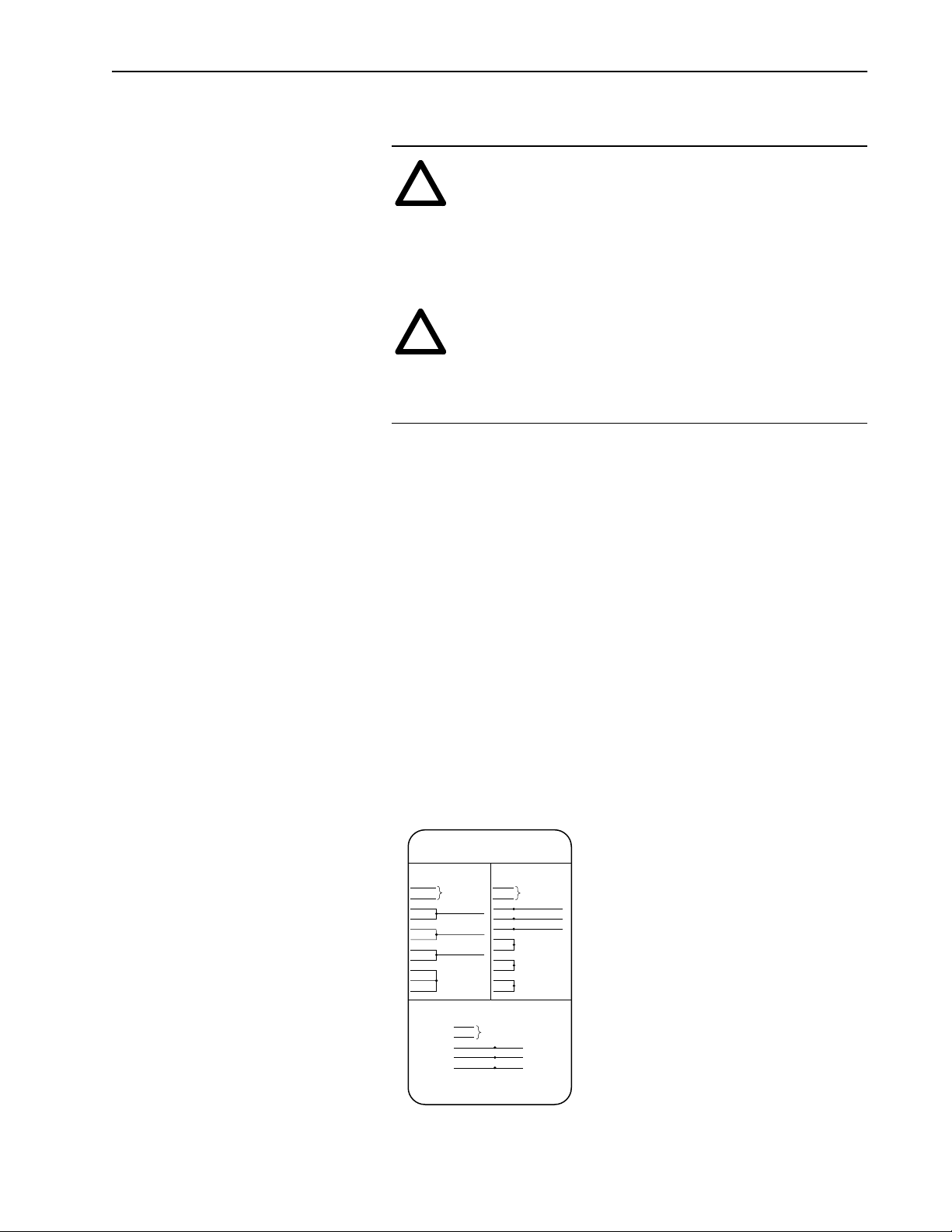

Single Voltage Motors – On Single voltage, three lead motors,

connect leads marked U/T1, V/T2, W/T3, to the appropriate drive

output terminals. Refer to the Drive User Manual for further

information.

Dual Voltage Motors – Be sure the motor leads are connected

properly for the desired “Low” or “High” voltage connection per the

motor connection diagram (see below). Refer to the Drive User

Manual for proper drive output connections.

3 PHASE-DUAL VOLTAGE

LOW VOLTAGE

P1

P2

U/T1

T7

V/T2

T8

W/T3

T9

T4

T5

T6

THERMOSTAT

LEADS

3 PHASE-SINGLE VOLTAGE

P1

P2

U/T1

V/T2

W/T3

P1

P2

U/T1

L1

V/T2

W/T3

L2

T4

T7

L3

T5

T8

T6

T9

THERMOSTAT

LEADS

HIGH VOLTAGE

THERMOSTAT

LEADS

L1

L2

L3

L1

L2

L3

Page 8

8 AC Induction Motors

Direction of Rotation

These motors are capable of bi-directional shaft rotation. When

voltages in an A-B-C phase sequence are applied to leads U/T1, V/

T2, W/T3, clockwise shaft rotation facing the opposite drive end will

result. If shaft rotation is incorrect, change the direction of rotation as

follows:

ATTENTION: The drive may apply hazardous voltages to

!

1. Turn off and lockout all power to the motor. Verify that the

2. Reverse any two of the three motor power leads.

the motor leads after drive power has been removed. Verify

that the drive is incapable of delivering hazardous voltages

and that the voltage at the motor leads is zero before

proceeding. Failure to observe this precaution could result

in personal injury and/or death.

voltage at the motor leads is zero.

Thermostat Leads (Thermal Protector)

As a standard feature, these motors have three (3) normally closed

thermostats (one per phase) connected in series with leads P1 & P2

and terminated in the main conduit box.

To protect against motor overheating, thermostats must be connected

to the appropriate drive circuit (function loss). Failure to connect the

thermostats will void the motor warranty. Follow the Drive User

Manual for correct thermostat lead connections.

Blower Motor

Motors which are blower cooled incorporate an independently

powered three-phase AC blower motor to assure continuous cooling

air flow regardless of motor speed.

ATTENTION: The blower motor is typically wired to the

!

AC input of the drive and will be energized even when the

drive is not running. Remove and lockout the main power

supply before touching blower components. Failure to

observe this precaution could result in personal injury and/

or death.

Blower motor fuse protection kits are required for blower motor

overload protection.

The specific blower motor will vary depending on frame size and

enclosure. Follow the connection diagram supplied with the blower

motor, which in general will be one of the following:

Page 9

AC Induction Motors 9

(Delta) (Star)

T6 T4 T5

T1 T2 T3

L1 L2 L3

Low Volts Line High Volts

T6 T4 T5

T1 T2 T3

L1 L2 L3

or

(Delta) (Star)

W2

U2 V2

U1 V1 W1

L1 L2 L3

Low Volts Line High Volts

U1 = Black

U2 = Green

W2 U2 V2

U1 V1 W1

L1 L2 L3

V1 = Blue

V2 = White

or Connection Diagram shown on page 7.

Procedure:

1. Connect for low or high voltage as shown.

2. Check that the direction of air flow is in agreement with the

“direction of air flow” arrows mounted on the motor. If

directional flow is incorrect, interchange power leads to T1 & T2

or U1 & V1.

Grounding

W1 = Brown

W2 = Yellow

ATTENTION: Connect an appropriate equipment

!

grounding conductor to the drive ground terminal, motor

frame, transformer enclosure (if used), drive electrical

enclosure and an appropriate grounding electrode. Failure

to observe these precautions could result in personal injury

and/or death.

The user is responsible for assuring that the grounding method is in

accordance with the National Electric Code and the applicable local

codes. The ground connection should be a solid and permanent

metallic connection between the ground point, the motor terminal

housing and the motor frame. A ground lead is provided inside the

terminal box.

Due to the need to carry higher frequency ground currents (from

switch voltage waveforms) the ground connection/path must be low

impedance/low resistance. Such ground currents exist during normal

operation on inverter power.

Drive

L180-L320 frame motors are supplied with a shaft suitable for a belt

or coupled drive.

Belt loads should be checked against maximum allowable radial loads

“Shaft Loads - Axial and Radial” on page 13. Contact Allen-

under

Bradley to determine L440 frame belt load requirements.

Frames L360S and L400S are suitable for coupled duty only, larger

shafts are supplied for belted duty.

Page 10

10 AC Induction Motors

ATTENTION: Incorrect motor rotation may cause

!

personal injury or damage the equipment. Check direction

of motor rotation before coupling motor to load.

ATTENTION: Ensure that allguards are properlyinstalled

!

before proceeding. Exercise extreme care to avoid

contacting rotating parts. Failure to observe these

precautions could result in personal injury.

Proper alignment is a key step for long life of bearings, shafts and

belts, and minimum downtime. Misalignment can cause excessive

vibration and damaging forces on shaft and bearings. For direct

coupled drives, flexible couplings facilitate alignment. For belt drives,

the sheave must be placed as close as possible to the motor bracket.

Shipping Blocks

Motors supplied with roller bearings at the drive end are shipped with

wooden blocking to prevent axial movement of the shaft during

shipment. Remove the blocking and bolts securing it and discard.

Make sure motor shafts turn freely. If motor is to be reshipped,

blocking of bearing is required.

Encoder Connection Diagrams

Dynapar H20 – 10 pin M/S Connector

360

°

° ±45°

90

Output A

Output B

Index

Output waveform

CCW Rotation of Shaft

Electrical

360° ±180

°

Lakeshore – Epic Connector or Plain Cable

The following table is a universal wiring guide for the latching Epic

connector or plain cable. Wires that are not used should be left not

connected (never connect to power or common). For optimum EMI

noise immunity, connect the encoder shield (pin 10 or braid) to the

cable shield. The encoder shield is internally isolated from the

encoder frame. The cable shield should still be connected to ground at

the receiving end. This encoder has a line driver output. A pull-up

resistor is not required.

Output Terminations

Signal Pin

Output A A

Output B B

Output Z C

Vcc D

Common F

Case G

No Connection E

Output A (NOT) H

Output B (NOT) I

Output Z (NOT) J

Page 11

Epic Connector or Plain Cable Connections

Pin Signal Color Pin Signal Color

1 Common Black 6 5-15V Red

2 B Green 7 B (NOT) Yellow

3 A Blue 8 A (NOT) Gray

4 Z Violet 9 Z (NOT) Orange

5 No Connection – 10 Shield Braid

Motor Application Data Maximum Safe Speed

ATTENTION: The machinery builder and/or user are

!

The speeds given in Table B are the maximum mechanically safe

operating speeds for frames with standard construction. These speeds

must not be exceeded under any condition. Motor control must hold

the maximum speed under any load condition including no-load

within the maximum safe speed. Drive systems whose design

characteristics inherently prevent the AC motor from exceeding the

motor maximum safe operating speed must prevent the motor from

exceeding the maximum safe speed if a single component failure

should occur.

responsible for assuring that all drive train mechanisms, the

driven machine, and process material are capable of safe

operation at the maximum speed at which the machine will

operate. Failure to observe these precautions could result in

personal injury.

AC Induction Motors 11

Table B

Maximum Safe Speed

Frame Diameter Maximum Safe Speed

L180 7200 RPM

L210 5000 RPM

L250 5000 RPM

L280 5000 RPM

L320 4000 RPM

L360 3750 RPM

L400 3750 RPM

L440 2700 RPM

With special construction maximum safe speed may differ from the

above values. In all cases, the maximum safe speed is indicated on the

motor nameplate.

Important: Normal operating speeds must be limited to those listed in

order to meet nameplate rating and assure validity of

warranty.

Page 12

12 AC Induction Motors

Minimum V-Belt Sheave Diameters

Application of Pulleys, Sheaves, Sprockets and Gears on Motor Shafts

To avoid excessive bearing loads and shaft stresses, belts should not

be tightened more than necessary to transmit the rated torque. The

pre-tensioning of the V-belt drive should be based on the total

tightening force required to transmit the horsepower divided by the

number of belts. This procedure avoids the excessive load caused by

tightening individual belts to a prescribed level recommended by belt

manufacturers.

Mounting

In general, the closer pulleys, sheaves, sprockets or gears are mounted

to the bearing on the motor shaft, the less will be the load on the

bearing. This will give greater assurance of trouble-free service.

The center point of the belt, or system of V-belts, must not be beyond

the end of the motor shaft.

The inner edge of the sheave or pulley rim should not be closer to the

bearing than the shoulder on the shaft but should be as close to this

point as possible.

The outer edge of a chain sprocket or gear must not extend beyond

the end of the standard motor shaft.

Shaft Extension and Method of Drive

Frames L180-L250 are supplied with a shaft and bearing system

suitable for either coupled or belted drives. Belt loads should be

checked against maximum allowable radial loads under

- Axial and Radial” on page 13. Frames L280-L320 may be supplied

with roller bearings for belt duty applications. Frames L360-L440 are

supplied with larger shafts and roller bearings when belted drives are

specified.

Preferred V-Belt Drives

(Sheave Centerline is Toward Motor from End of Shaft)

where:

V

d = Minimum pitch diameter of V-belt sheave in inches or

x

d

millimeters.

hp = Rated horsepower at base speed.

kw = Rated kilowatts at base speed.

x = Axial distance of the sheave centerline from the end of

the shaft in inches or millimeters. The distance is

measured from the end of the shaft (x is negative if

centerline is beyond the end of the shaft and positive if

toward the motor.) The formula should not be used for

negative values of x greater than one half of the V

dimension of the shaft extension.

“Shaft Loads

Page 13

AC Induction Motors 13

Table C

Constants for Calculating the Minimum Sheave Diameters for V-Belt Drives

Frame Units

L210 inches 3.50 A 40.6 30.0 19.77 14.63

millimeters 88.9 C 1384 1022 674 499

L250 inches 4.00 A 23.33 18.25 12.67 9.47

millimeters 101.6 C 795 622 432 323

L280 inches 4.50 A 20.28 16.17 11.2 8.32

millimeters 114.3 C 691 551 382 284

L320 inches 5.00 A 18.47 14.25 9.97 –

millimeters 127.0 C 630 486 340 –

UL360 inches 6.25 A 10.42 8.08 5.89 –

millimeters 158.8 C 355 275 201 –

UL400 inches 8.00 A 8.9 6.9 4.8 –

millimeters 203.2 C 303 235 163 –

“V”

Dimension Constant

B 7.26 5.43 3.56 2.09

D 9.73 7.28 4.77 2.80

B 3.58 2.3 1.17 0.57

D 4.80 3.08 1.57 0.76

B 2.94 1.75 0.84 0.43

D 3.94 2.35 1.13 0.58

B 2.00 1.24 0.59 –

D 2.68 1.66 0.79 –

B 0.46 0.25 0.13 –

D 0.62 0.34 0.17 –

B 0.30 0.23 0.16 –

D 0.40 0.31 0.21 –

Base RPM

850 1150 1750 2500

Shaft Loads - Axial and Radial

These motors are suitable for limited shaft loads as shown in Tables D

and

E. Recommended maximum thrust loads depend on the mounting

position, either horizontal or vertical. For recommendations for loads

in excess of those shown, contact Allen-Bradley.

Table D

Axial Thrust Capacity - No Radial Load

Horizontal Mounting Vertical Mounting

Frame Units

L180 pounds 430 500 600 675 430 ±60 500 ±60 600 ±60 675 ±62

kilograms 195 227 272 306 198 ±27 227 ±27 272 ±27 306 ±27

L210 pounds 477 551 662 742 498 ±61 564 ±61 676 ±61 756 ±61

kilograms 217 251 301 338 227 ±28 257 ±28 308 ±28 344 ±28

L250 pounds 509 600 722 828 541 ±86 629 ±86 755 ±86 865 ±86

kilograms 231 272 327 376 245 ±39 285 ±39 342 ±39 392 ±39

L280 pounds 590 700 850 975 644 ±122 754 ±122 905 ±122 1038 ±122

kilograms 268 318 386 442 292 ±56 342 ±56 411 ±56 471 ±56

L320 pounds 705 835 1020 1170 770 ±175 905 ±175 1095 ±175 1250 ±175

kilograms 320 379 463 531 349 ±80 411 ±80 497 ±80 567 ±80

L360 pounds 875 1075 1350 1525 830 ±293 1020 ±293 1300 ±293 1475 ±293

kilograms 397 488 612 692 376 ±133 463 ±133 590 ±133 669 ±133

L400 pounds 1350 1630 2000 2250 1470 ±352 1820 ±352 2210 ±352 2475 ±352

kilograms 612 740 908 1021 667 ±160 826 ±160 1003 ±160 1123 ±160

L440 pounds 1300 1550 1800 2050 1365 ±1085 1600 ±1085 1865 ±1085 2080 ±1085

1

Thrust capacity for vertical mounting includes a constant whose value is plus or minus depending on the direction of the thrust load. The constant is plus for thrust loads

acting upward against the force of gravity and minus for loads acting downward with gravity.

kilograms 590 703 816 930 619 ±492 726 ±492 846 ±492 943 ±492

2500 RPM 1750 RPM 1150 RPM 850 RPM 2500 RPM 1750 RPM 1150 RPM 850 RPM

Page 14

14 AC Induction Motors

ATTENTION: The use of these radial load capacities

!

requires the accurate calculation of the radial load for the

application. Radial loads for gears, sprockets, and flywheel

are usually accurately determined but the radial loads due

to V-belt drives are subject to miscalculations because they

do not include all of the pre-tension load (belt tightening).

The calculations of the radial load for a V-belt drive must

include the pre-tension for transmitting the horsepower,

pre-tension for centrifugal force on the belts, pre-tension

for high start torques, rapid acceleration or deceleration,

pre-tension for driveswith short arc-of-contact between the

V-belt and sheave, and low coefficient of friction between

belt and sheave caused by moisture, oil or dust. Failure to

observe these precautions could result in damage to or

destruction of the equipment.

Table E

Radial Load Capacity - No Axial Load

Radial Load Capacities at the End of the Shaft in kg (lbs.)

Frame

L180 202 (445) 202 (445) 202 (445) 202 (445)

L210 397 (875) 397 (875) 397 (875) 397 (875)

L250 623 (1375) 692 (1525) 692 (1525) 692 (1525)

L280 703 (1550) 796 (1755) 796 (1755) 796 (1755)

L320 764 (1685) 816 (1800) 816 (1800) 816 (1800)

UL360

UL400

1

Data for motors with roller bearings at the drive end (back end). Motors with ball bearings at the drive

end are for coupled duty only.

2

Contact Allen-Bradley to determine L440 frame belt load requirements.

2500 RPM 1750 RPM 1150 RPM 850 RPM

1

1157 (2550) 1304 (2875) 1497 (3300) 1501 (3310)

1

1644 (3625) 1855 (4090) 2132 (4700) 2354 (5190)

2

Operation Motor Start-Up

ATTENTION: Before initial start-up observe the

!

following precautions.

• Remove all unused shaft keys and loose rotating parts

• When the motor is supplied as part of drive system,

Failure to observe these precautions could result in

personal injury or death.

to prevent them from flying off. Replace covers and

protective devices.

refer to the Drive User Manual for operating

instructions. Tachometer feedback must be properly

connected for closed loop operation. Reverse

polarities or broken connections can cause dangerous

overspeeds.

Page 15

AC Induction Motors 15

In addition to observing the above precaution, all precautions

(Attentions) mentioned previously in this document should be

observed.

• Stop and remove power from the motor per the Drive User

Manual directions.

• Verify that the DC bus voltage is zero per the Drive User Manual.

• The interior of the motor should be clean and dry.

• Connections must be tight.

• The driven machine should be unloaded, if possible.

Important: Machines designed for cooling by a separate source of

forced ventilation must not be operated without the air

supply. Be sure blower is running in proper direction.

While operating the motor, observe the performance. It should run

smoothly with little noise. The bearings should not overheat and

should reach a leveling off temperature. Any undue noise,

overheating, or erratic performance should be investigated and

necessary corrective action taken immediately to prevent serious

damage. Before attempting any repairs, please contact your AllenBradley Sales Office.

All motors are lubricated before shipment and will operate for a long

period before regreasing is required. The period will vary depending

on environmental and service conditions. Refer to

“Maintenance” on

page 16.

ATTENTION: Surface temperature of the motorenclosure

!

may reach temperatures which can cause discomfort or

injury to personnel coming into contact with hot surfaces.

The user must apply appropriate guards and/or shields to

protect against accidental contact with motor surface.

Failure to observe this precaution may result in personal

injury.

Balance

Motors are dynamically balanced to commercial limits unless ordered

differently. Balance is done with a full length 1/2 height shaft key. A

full shaft key is shipped with the motor. Sheave or coupling should be

balanced with a 1/2 height shaft key.

Standard Dynamic Balance Limits

Highest Rated Speed

(RPM)

3,000 - 4,000 0.0010

1,500 - 2,999 0.0015

1,000 - 1,499 0.0020

Up to 999 0.0025

Maximum Amplitude

(Inches)

Page 16

16 AC Induction Motors

Maintenance

ATTENTION: Internal parts of this motor may be at line

!

potential even when it is not rotating. Before performing

any maintenance which could result in contacting any

internal part, besure to disconnectall power from the motor.

Failure to observe this precaution could result in severe

personal injury or death.

Amount of grease to be added to motors is shown in Table F. See

Table H for relubrication interval. Use Chevron SRI-2 or equivalent

grease unless motor nameplate specifies special grease.

Table F

Coupled/Belted or Tandem Duty Grease Amounts

Volume Weight

Frame

L180 - L280 1.0 16 0.5 14

L320 - L400 2.0 32 1.0 28

L440 3.0 48 1.5 42

Cubic Inches Cubic Centimeters Ounces Grams

Using the table below, determine service condition on the basis of the

most severe operating parameter (i.e. temperature, bearing load,

atmosphere, or operating hours per day).

Table G

Service Condition

Service

Condition Ambient Temperature Bearing Load Atmosphere

Standard –18 to 40 degrees C

Severe –30 to 50 degrees C

Extreme

1

Motors must be specially designed for operation in ambient outside the range of –25 to 40 degrees C

(–13 to 104 degrees F). Special grease is required.

2

"EXTREME" service conditions are rare in actual practice. Corresponding lubrication cycles should

therefore beapplied with caution.In addition, itis advisable tocheck with Allen-Bradleyfor related special

instructions.

(0 to 104 degrees F)

(–22 to 122 degrees F)

2

–54 to 65 degrees C

(–65 to 149 degrees F)

Steady Clean 8

Medium Shock, Vibration

1

(less than 0.2 in/sec.)

Heavy Shock, Vibration

1

(more than 0.44 in/sec)

Medium Dirt,

Abrasives,

Corrosion

Heavy Dirt,

Abrasives,

Corrosion

Operating

Hours/Day

8 to 24

8 to 24

Page 17

AC Induction Motors 17

Table H

Relubrication Periods - Frames L180 - L440

Relubrication Interval (Months)

Maximum Normal

Operating Speed (RPM)

3450 and higher All 9 4 1

2400 - 3449 L180 - L250 24 9 3

1700 - 2399 L180 - L320 36 12 3

800 - 1699 L180 - L320 36 24 8

500 - 799 L180 - L320 48 36 12

499 and lower L180 - L440 48 36 12

1

Maximum speed occupying more than 30% of operating time.

2

For Tandem drives increase frequency of lubrication by multiplying values by 0.8.

1

Frame

L280 - L440 9 3 1

L360 - L440 18 6 2

UL360 - UL440 9 3 1

L360 - L440 36 12 3

UL360 - UL440 9 6 1

L360 - L440 36 24 8

UL360 - UL440 18 12 4

UL360 - UL440 24 18 6

Standard

Service

Severe

Service

Extreme

Service

Lubrication - Frames L180 - L440

These motors are designed to route new grease directly into the

bearing. The relubrication periods shown in

guide for varying service conditions, speeds, bearing types and

operating hours.

Important: Certain special motors may have a lubrication instruction

plate permanently attached. These specific lubricating

instruction must be followed.

Lubrication Procedure

ATTENTION: If relubrication is done while motor is

!

running, stay clear of rotating parts. Failure to observe this

precaution could result in personal injury.

1. Relubrication with the shaft stationary and a warm motor is

recommended. If lubrication must be done with the motor

running, stay clear of rotating parts and electrical circuits.

2. Locate the grease inlet at the top of the bearing hub, clean the

area and replace the 1/8 inch pipe plug with a grease fitting (if the

motor is not equipped with a grease fitting).

Table H are offered as a

3. Remove grease drain plug located opposite the grease inlet.

4. Using a manual grease gun, pump in the recommended grease in

the amount shown in

Table F. This amount of grease will provide

an ample supply of lubricant between lubrication periods as

determined from

Table H for the service condition listed in Table

G.

Page 18

18 AC Induction Motors

Use Chevron SRI-2 grease or equivalent unless motor nameplate

specifies special grease. Use only clean, fresh grease from clean

containers and handle carefully to keep it clean.

In general, mixing of greases is not recommended. If an

incompatible grease is used, the lube system must be repacked

completely with the new grease.

5. Wipe away any excess grease at the grease drain or relief and

replace drain plugs.

Repacking Bearings or Greasing New Bearings

When existing bearings have been completely cleaned of old grease

or when bearings are replaced, use this procedure for packing the

bearing.

1. Apply one bead of grease around the inboard side of the bearing,

between bearing and inner cap. Assure that grease adheres to

balls or rollers.

2. Apply one bead of grease around outboard side of bearing,

making sure grease adheres to balls or rollers.

3. Completely fill grease inlet and outlet passage holes with grease.

4. Fill outboard bearing cavity 60% to 90% full of grease.

5. If possible, rotate shaft of assembled machine at least three

revolutions by hand to distribute grease within bearings before

starting motor.

Bearings

Bearing housing designs provide protection to windings and interior

of machine by minimum grease leakage. They also provide good

protection against external contamination.

Various types of anti-friction bearings are used in the wide range of

frames as needed to meet specific load, speed and service

requirements.

Most commonly used bearings are:

• Single row, open ball bearings for coupled and belted duty for

frames L180 - L320.

• Single row, open ball bearings for coupled duty for frames L360

and L400.

• Cylindrical roller bearings at drive end for belted duty on frames

UL360 and UL400.

Page 19

AC Induction Motors 19

Frequent bearing checks are recommended. If temperatures become

excessive, investigate immediately for the cause. Total bearing

temperatures should not exceed 121 degrees C (250 degrees F).

Causes for high bearing temperature are:

• Contaminated grease.

• Insufficient grease or excessive amount.

• Incorrect grease.

• Excessive load or thrust due to misalignment or motor overload.

• Loose bearings.

• Bearing failure.

• Excessive ambient temperature.

Replacement bearings should be ordered from Rockwell Automation

in order to obtain the same carefully selected bearing as the original.

Bearings should never be exposed by disassembly of the motor unless

absolutely necessary for inspection or replacement of the bearing or

maintenance in other parts of the machine. Protect good bearings

from dirt and contamination at all times. Most bearing failures are

caused by dirt.

Disassembly and Reassembly Instructions

The open ball bearings for motor frames L180 - L320 are the same

regardless of whether application is coupled or belted. Belted duty for

frames UL360 and UL440 requires the use of roller bearings.

Coupled duty uses ball bearings.

Axial Float

Motors have a wave spring washer between the drive end bracket and

bearing. The opposite drive end bearing is positioned axially by a

float restricting inner cap. Axial float (including bearing internal

clearance) should be within the limits listed below. The L440 frame

spring is located on the opposite drive end.

Axial Float

Frame Maximum Minimum

L180 - L440 1.29 mm (0.051 in.) 0.33 mm (0.013 in.)

Anti-Friction Bearing Assemblies

The bearings are positioned and secured in a machined cavity in the

end brackets. Open type ball bearings are used for direct coupled and

belt drive applications for frames L180 - L320 (employ ball bearings

at both ends) and are protected by inner caps at both ends.

Frames UL360, UL400 and UL440 employ a cylindrical roller

bearing on the drive end for belt drives, and a ball bearing for coupled

service.

Page 20

20 AC Induction Motors

Bearing Replacement

Remove bearing by means of bearing puller. Clean bearing housing

and bearing seat prior to assembly of bearing. Place new bearing in a

bake oven for 1/2 hour at 121 degrees C (250 degrees F). Place

bearing onto shaft and push home to bearing shoulder. Hold it in

place for a minimum of 30 seconds.

After bearing has cooled down for about 1 minute, add 1/2 cu. in. of

fresh grease into back of bearing. Once motor is assembled, grease

bearings per instructions found herein.

Bracket Re-Assembly

To obtain proper planity between the integral mounting feet on the

front and back end brackets of L210-L440 frame motors, a smooth

level surface should be used to align the brackets when they are

assembled to the frame. Check for proper shaft alignment after

reinstalling the motor.

Stub Shaft Removal Procedure Drive-in Stub Shaft

1. Turn off and lockout power to the motor.

2. Remove in-line blower motor and cover assembly by removing

the hex head cap screws on cover (if enclosure is TEAO-Blower

cooled).

3. After removal of blower assembly, obtain the stub shaft puller

backplate and assemble over the stub shaft against the end of the

motor shaft.

4. Obtain the stub shaft puller plate (available from Rockwell

Automation) and assemble over the stub shaft, and up against the

puller backplate.

Important: Note 7/16 inch set screws must be backed out enough

to clear the stub shaft O.D. 1/2inch jack screws should

be backed out to allow puller plate to fit up flush against

the backplate.

5. Screw the 7/16 inch set screws in on each side of the puller plate

until they contact the stub shaft. Keep the stub shaft reasonably

centered between the jack screws. Tighten screws securely.

6. Using a 3/8 inch allen wrench, turn the jack screws, in equal

amounts, in a clockwise manner to remove the stub shaft. If the

set screws slip, retighten and repeat process.

7. Replace blower motor and cover assembly (if TEAO - blower

cooled) with the correct extended blower cover, using the hex

head cap screws previously removed.

Page 21

AC Induction Motors 21

Screw-in Stub Shaft

1. Turn off and lockout power to the motor.

2. Remove in-line blower motor and cover assembly by removing

the hex head cap screws on cover (if enclosure is TEAO-Blower

cooled).

3. After removal of blower assembly, motor shaft will need to be

locked from turning. The use of a spanner wrench on motor drive

shaft or alternate means can be used. Place an open-end wrench

on stub shaft flats and turn counter clockwise (right-hand

threads).

4. Replace blower motor and cover assembly (if TEAO - blower

cooled) with the correct extended blower cover, using the hex

head cap screws previously removed.

Replacement Bearings/Spare Parts

Your maintenance program will not be complete without including

spare bearings. It must be remembered that the bearing is a wearable

component and therefore must eventually be replaced. To ensure that

you are able to maintain original operation, we recommend the

purchase of spare parts directly from Rockwell Automation.

All bearings are subject to exact specifications and tests necessary to

satisfy performance requirements. In this manner, it is possible to

duplicate your present bearing. Markings on the bearing do not

indicate complete specifications.

A detailed parts list, which gives Allen-Bradley recommendations for

spare parts that should be stocked for your equipment, can be ordered

from your Allen-Bradley Sales Office. Be sure to include complete

nameplate data - serial number, model number, rating, etc. - for your

equipment when ordering the spare parts list.

Page 22

22 AC Induction Motors

Parts Identification Drawing Totally Enclosed Blower Cooled

Item No. Part Description Item No. Part Description

1 Frame/stator 13 Grill, Blower

2 Rotor 14 Eyebolt

3 Bracket, B.E. 15 Conduit Box, Main Motor

4 Bracket, F.E. 16 Grease Fitting, B.E.

5 Shaft 17 Grease Fitting, F.E.

6 Ball Bearing, B.E. 18 Key, Shaft Extension

7 Inner Cap, B.E. 19 Feedback Device (When Supplied)

8 Ball Bearing, F.E. 20 Connector, Feedback Device

9 Inner Cap, F.E. 21 Coupling, Feedback Device

10 Wave Washer, B.E. 22 Mounting Adapter, Feedback Device

11 Blower Motor 23 Blower Motor Conduit Box

12 Cover, Blower

Total Service Programs Allen-Bradley can provide a wide range of maintenance programs to

help you reduce downtime, improve productivity and increase profits.

Capabilities include:

• Motor Start-up Service

• Motor Electrical and Mechanical Preventive Maintenance

• Vibration Analysis

• Mobile Van Repair Service

• Balancing and Alignment Service

• Maintenance Service

• 24-Hour Technical Support

• Modernization Service

For more information contact your local Allen-Bradley Sales Office.

Page 23

Notes

AC Induction Motors 23

Page 24

Online Documentation

The latest motor information can be obtained from the Allen-Bradley

Drives & Motors home page on the World Wide Web at:

http://www.controlmatched.com

Publication 1329L-UM001A-EN-P – July, 2001

Supersedes 1329L-5.0 dated March, 2000 Copyright © 2001 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...