Page 1

Bulletin 1329I

Integrated

Drive/Motor

(Series B)

1.0 - 5.0 HP

FRN 3.xx

User Manual

Page 2

•

•

•

Important User Information

Solid state equipment has operational characteristics differing from those of

electromechanical equipment. “ Safety Guidelines for the Application,

Installation and Maintenance of Solid State Controls ” (Publication SGI-1.1)

describes some important differences between solid state equipment and

hard-wired electromechanical devices. Because of this difference, and also

because of the wide variety of uses for solid state equipment, all persons

responsible for applying this equipment must satisfy themselves that each

intended application of this equipment is acceptable.

In no event will the Allen-Bradley Company be responsible or liable for

indirect or consequential damages resulting from the use or application of

this equipment.

The examples and diagrams in this manual are included solely for

illustrative purposes. Because of the many variables and requirements

associated with any particular installation, the Allen-Bradley Company

cannot assume responsibility or liability for actual use based on the

examples and diagrams.

No patent liability is assumed by Allen-Bradley Company with respect to

use of information, circuits, equipment, or software described in this

manual.

Reproduction of the contents of this manual, in whole or in part, without

written permission of the Allen-Bradley Company is prohibited.

Throughout this manual we use notes to make you aware of safety

considerations.

ATTENTION: Identifies information about practices or

circumstances that can lead to personal injury or death, property

damage, or economic loss.

Attentions help you:

identify a hazard

avoid the hazard

recognize the consequences

Important: Identifies information that is especially important for successful

application and understanding of the product.

Shock Hazard labels may be located on or inside the drive to

alert people that dangerous voltage may be present.

DeviceNet is a trademark of the Open DeviceNet Vendor Association.

Page 3

Series B Summary of Changes

• Additional Start Mode Selection Feature

Local operator units can now be controlled from either the operator controls or the

terminal block.

• Terminal Block Stop Input

The terminal block stop input and local operator stop key are now acti v e for all start

mode selections.

• Zero Speed Operation

The minimum speed has been reduced from 90 RPM (3 Hz) to zero.

• Storage Temperature Range Extended

The storage temperature rating has been extended from 70°C to 85°C.

• CE Mark

The unit now conforms to the EMC and LVD directives for CE. An optional line

filter is required.

• CE Line Filter Option

Single and three phase line filters are now available. This option can be mounted

internally or is packaged for external mounting.

• DeviceNet Communication Option

A DeviceNet communication option is now available, which is installed inside the

unit. Refer to the Bulletin 1329I DeviceNet Option User Manual for more

information.

• Drive Parameters Added

The unit now has drive display parameters and drive program parameters. These

parameters can be viewed or changed through a DeviceNet connection. Refer to the

Bulletin 1329I DeviceNet Option User Manual for more information.

Series B Application/Installation Considerations

Keep the following in mind if you are replacing a Bulletin 1329I Series A with a Series

B unit.

Minimum Speed

• The minimum speed has been reduced from 90 RPM (3 Hz) to 0 RPM (0 Hz).

Terminal Block Stop Input

• Terminal block stop input must be present for local operator control units.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 4

Series B Summary of Changes

End of Section

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 5

Installation Checklist

Chapter 1 Step 1 - Identify Your Unit

1.1 1329I Standard Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.1 Standard Unit Display Description . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

1.1.2 Standard Unit Reverse LED Description . . . . . . . . . . . . . . . . . . . . 1-2

1.2 1329I Local Operator Control Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

1.2.1 Local Operator Control Unit Key Descriptions . . . . . . . . . . . . . . . . 1-4

1.2.2 Local Operating Control Unit Display Description . . . . . . . . . . . . . 1-4

1.2.3 Local Operating Control Unit Reverse LED Description . . . . . . . . 1-4

1.2.4 Operating the Unit Using the Local Operator Controls . . . . . . . . . . 1-5

Chapter 2 Step 2 - Plan the Installation

2.1 Wire Routing Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

2.2 Handling and Lifting Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3 CE Conformity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

2.3.1 Essential Requirements for a Conforming EMC Installation . . . . . 2-4

2.3.2 Low Voltage Directive 73/23/EEC Compliance . . . . . . . . . . . . . . . 2-5

Table of Contents

Chapter 3 Step 3 - Mount the Unit

3.1 Mounting Guidelines for Face-Mounted Motors . . . . . . . . . . . . . . . . . . . . . 3-1

3.2 Mounting Dimensions for NEMA Frames . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

Chapter 4 Step 4 -Install External

Power Components

4.1 Installing an AC Input Disconnect . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.2 Installing Branch Circuit Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

4.3 Installing Input Isolation Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Chapter 5 Step 5 -Wire AC Power to the Unit and Ground the Unit

5.1 Grounding the Unit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Chapter 6 Step 6 - Install a Hardwired Stop

Chapter 7 Step 7 -Wire the Control Signal Terminal Block

7.1 Wiring Function Loss . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.2 Wiring the Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

7.3 Wiring the Relay Control Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.4 Wiring RPM or Percent Load Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.5 Wiring the Speed Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-6

7.5.1 Wiring the Preset Speed Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

7.5.2 Wiring the Speed Reference Signal Potentiometer . . . . . . . . . . . . 7-8

7.5.3 Wiring an External Speed Reference . . . . . . . . . . . . . . . . . . . . . . . 7-8

7.6 Wiring Start / Stop Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

7.7 Wiring Forward / Reverse Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

7.8 Wiring Reset Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Chapter 8 Step 8 -Verify the Setup and Adjust Switches if Required

8.1 Adjusting the Maximum Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

8.2 Adjusting the Acceleration / Deceleration Time . . . . . . . . . . . . . . . . . . . . . 8-3

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 6

ii

8.3 Modifying the Setup Using the Setup DIP Switch . . . . . . . . . . . . . . . . . . . . 8-5

8.3.1 Run On Power Up (Position 1) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-5

8.3.2 Speed Reference Select (Position 2) . . . . . . . . . . . . . . . . . . . . . . . 8-6

8.3.3 Relay Control Output - Running or Faulted (Position 3) . . . . . . . . .8-6

8.3.4 Auto Restart (Position 4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-7

8.3.5 Torque Curve (Position 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-8

8.3.6 Stop Type (Position 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-8

8.3.7 Reverse Disable (Position 7) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

8.3.8 Minimum Speed Select (Position 8) . . . . . . . . . . . . . . . . . . . . . . . . 8-9

8.3.9 Start Mode Select (Position 9) . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-10

8.3.10 Parameter Mode for DeviceNet Option (Position 10) . . . . . . . . . . .8-10

Chapter 9 Step 9 - Check the Installation

9.1 Checking the Installation with the Power Off . . . . . . . . . . . . . . . . . . . . . . . .9-1

9.2 Checking the Direction of Motor Rotation . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.3 Attaching the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-2

9.3.1 Rotating the Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-3

9.4 Checking the Speed Reference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-4

Chapter 10 Step 10 - Set the Operating Speed

Chapter 11 Diagnostics and Troubleshooting

11.1 Fault Codes and Corrective Actions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-2

11.2 Troubleshooting Tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-5

11.3 Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-7

Chapter 12 Maintenance Guidelines

12.1 General Unit Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

12.2 Motor Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12-1

Appendix A Technical Specifications

Unit Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Operating Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Operating Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Mechanical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-3

Drive Protection/Fault Detection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-5

I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Analog inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Analog output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Logic inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

Relay output (1 form A N.O. contact) Isolated . . . . . . . . . . . . . . . . . . . . . . .A-6

Approvals and Standards Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-6

Appendix B Product Features

Appendix C 1329I System Diagram

Appendix D Installation Record

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 7

❑

❑

❑

❑

❑

❑

❑

❑

❑

❑

Checklist

Installation Checklist

This manual describes how to install, troubleshoot, and maintain the 1329I unit. Use

the following checklist to guide you through the installation process.

Read Manual

Installation Procedure

Step 1 Identify your unit 1.0

Understand how the standard unit

operates

Understand how the local operator control

unit operates

Step 2 Plan the installation 2.0

Step 3 Mount the unit 3.0

Step 4 Install external components

AC input disconnect

Branch circuit protection

Input isolation transformers

Step 5 Wire AC power to the unit and ground the unit 5.0

Step 6 Install a hardwired stop 6.0

Step 7 Wire the control signal terminal strip 7.0

Step 8 Verify the setup and adjust it if required 8.0

Step 9 Check the installation

Perform power-off checks

Verify the direction of motor rotation

Attach the cover

Check the speed reference

Step 10 Set the operating speed 10.0

Section(s)

1.1

1.2

4.0

4.1

4.2

4.3

9.0

9.1

9.2

9.3

9.4

If problems occur during unit operation, refer to Chapter 11 for troubleshooting

guidelines.

Getting Assistance from Allen-Bradley

If you have any questions or problems with the products described in this instruction

manual, contact your local Allen-Bradley distributor.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 8

Checklist-2

Installation Checklist

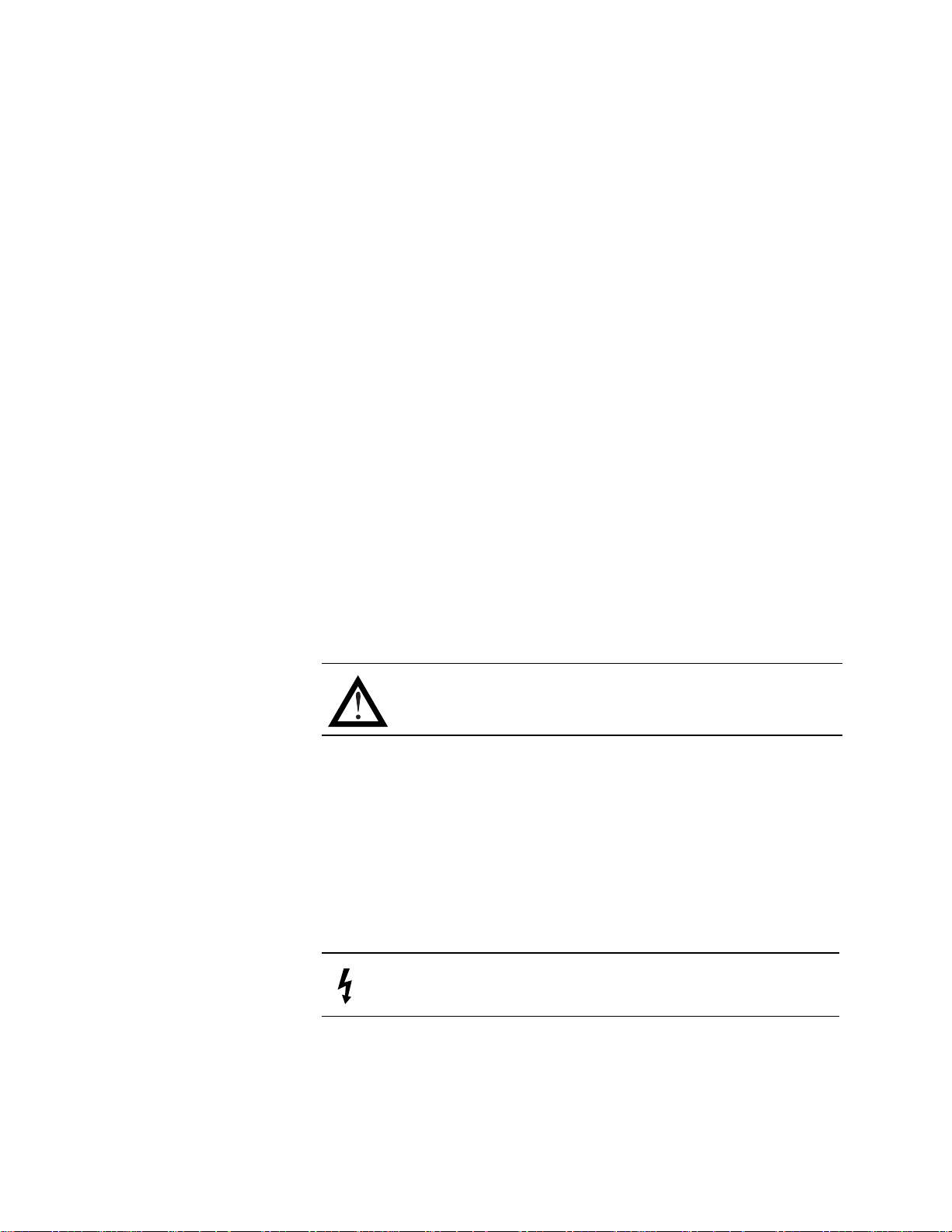

Installation Overview

➌

0 = 1 Second Accel/5 Sec Decel

1 = 5 Seconds (Default)

2 = 10 Seconds

3 = 15 Seconds

0 = 1500 RPM (50 Hz)

1 = 1800 RPM (60 Hz) Default

2 = 2100 RPM (70 Hz)

3 = 2400 RPM (80 Hz)

Selectors and Connectors

Max Speed Switch (SW2) Accel/Decel Switch (SW1)

4 = 20 Seconds

5 = 30 Seconds

6 = 60 Seconds

7 = 90 Seconds

AC Input Power Connections

4 = 2700 RPM (90 Hz)

5 = 3000 RPM (100 Hz)

6 = 3300 RPM (110 Hz)

7 = 3600 RPM (120 Hz)

DC+

DC Bus (Do Not Wire)

DC-

DBR (Do Not Wire)

DBR

10 V olt Reference ➊

0 – 10V DC Speed Reference Input

4 – 20 mA Speed Reference Input

Common

1 2 3 4 5 6 7 8 9 1011121314151617181920

AC Inputs

T/L3

S/L2

R/L1

Ground / Protective Earth

PE

0 – 10 V olt Output

Common

-+

24 Volt DC ➋

Speed Preset 2

Speed Preset 1

RPM/Percent Load Display

Function Loss ➋

Speed Preset 0

= N.O. Momentary Contact

Reset

Start

Forward/Reverse

24 Volt DC

RPM

% Load

= N.C. Momentary Contact

Stop ➌24 V olt DC Common

= Maintained Contact - Closed

= Maintained Contact - Open

N.O. Rela y

Connect to external device.

Relay Common

➌ The jumper between terminals 13 and 17 must be removed when

wiring the Stop input. See Section 7.6 for more information.

Control Signal T erminal Bloc k

13 16 17

Enabled

T erminal Block

Faulted

Enabled

Constant

Ramp-to-Rest

Disabled

From T erminal Block

From T erminal Block

From EEPROM Memory

OFF ON

0 Hz

Variable

Setup DIP Switch (SW3)

Disabled

Operator Controls

Run On Power Up

Speed Reference ➊

Running

Relay Control Output

Disabled

Auto Restart

Coast-to-Rest

T orque Curve

Stop

Enabled

Reverse

Minimum Speed

From Setup Switches

From Operator Controls

Start Mode ➊

Parameter Mode ➋

1329I-5.5 Integrated Drive/Motor — January, 2000

= Default Setting (OFF Position)

➊ Switches 2 and 9 apply to local operator control units only.

10 V olt Reference ➊

0 – 10V DC Speed Reference Input

4 – 20 mA Speed Reference Input

Common

0 – 10 V olt Output

Common

Speed Preset 2

Speed Preset 1

24 Volt DC ➋

1 2 3 4 5 6 7 8 9 1011121314151617181920

Speed Preset 0

Function Loss ➋

Forward/Reverse

24 Volt DC ➌RPM/Percent Load Display

Standard Unit Local Operator Control Unit

5K Ω

+10V DC

➋ Switch 10 applies to the De viceNet Communication option only.

-+

Fwd

RPM

Reset

Rev

% Load

Start

Maintained 2-Wire Start.

Stop ➌24 V olt DC Common

N.O. Rela y

Relay Common

Momentary 3-Wire Start.

Connect to external device.

wiring the Function Loss input. See Section 7.1 for more information.

➋ The jumper between terminals 7 and 11 must be removed when

be connected. See Section 7.5.3 of the User Manual for more inf ormation.

➊ An external 0 to 10 volt or 4 to 20 mA speed reference source can

Page 9

Chapter

1

Step 1 - Identify Your Unit

The 1329I integrated drive/motor is an AC drive integrally mounted with an inverter

duty motor. Each unit consists of a Drive Section and a Motor Section.

The Drive Section is a single- or three-phase input, three-phase output in verter providing

open loop V/Hz re gulation. It houses the PC boards and the blower . The Motor Section

is a four-pole, three-phase induction motor.

The unit’s default setup suits a wide range of applications. Two rotary switches and a

10-position slide switch on the Control board are used to adjust the setup, if required.

1329I units are identified by catalog number. This number appears on the shipping label

and on the unit’s nameplate. Table 1.1 shows the format of this number and what it

indicates.

Table 1.1

Catalog Number Format

1329I – B M 001 18 BC A – A

Speed

Range

B 20:1

Voltage

Rating

J 115V

K 200-230V 1L 200-230V 3M 380-460V

∅

∅

Horsepower

Rating

001 1

002 2

003 3

005 5

Base

Speed

18 1800 RPM

Enclosure

Design

BC Totally Enclosed

Blower Cooled

Motor

Frame Size

(All with C-Face

and Foot Mount)

A 56 Frame

B 140 Frame

C 180 Frame

Display

Options

A Local Control

B Display Only

Standard units, described in Section 1.1, provide remote operator control.

Local operator control units, described in Section 1.2, provide local control.

Table 1.2

Option Kits

Drive Input Rating CE Filter Option Kit DeviceNet Communication

Option Kit

115V, 230V

Internal Mount NEMA 12 Enclosed

1329I-NLF1 1329I-JLF1

Internal Mount

Single Phase

1329I-DN1

230V, 460V

1329I-NLF3 1329I-JLF3

Three Phase

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 10

1-2

Step 1 - Identify Your Unit

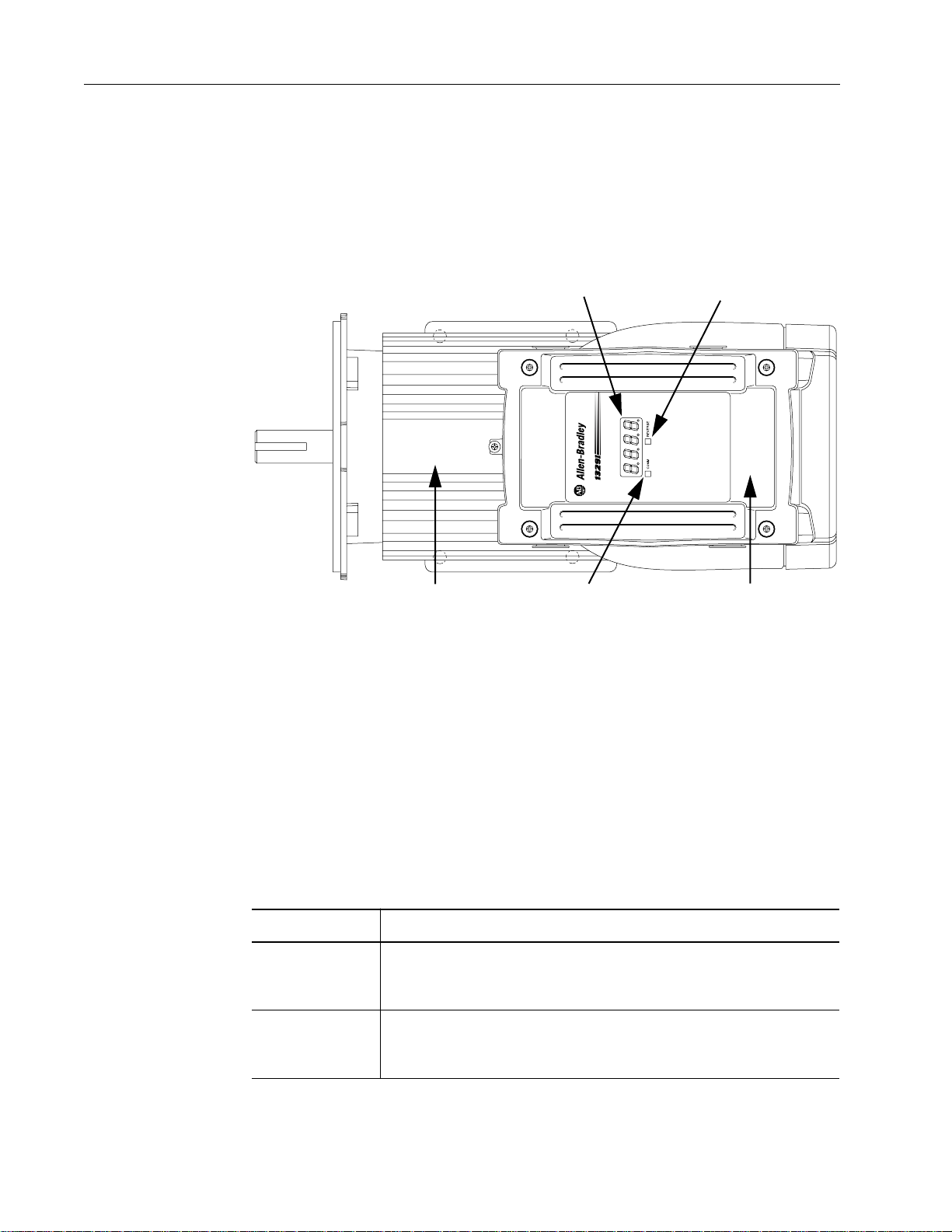

1.1 1329I Standard Unit

The standard unit, shown in Figure 1.1, provides a local display for speed or percent

load, and diagnostic information. A control signal terminal block in the Drive Section

connects to a user-supplied remote operator control station.

Figure 1.1

1329I Standard Unit

Display

➊

Refer to the

Motor Section

Bulletin 1329I DeviceNet Option User Manual

Communication LED ➊

1.1.1 Standard Unit Display Description

The four-character, seven-segment display shows the drive output speed in RPM or

percent load, and displays active fault codes. Speed in RPM is the default display. To

display percent load, see Section 7.4.

Reverse LED

Drive Section

for a description of the Communication LED .

If a fault occurs, the unit displays the corresponding fault code. Refer to Chapter 11 for

more information about fault codes and corrective actions.

1.1.2 Standard Unit Reverse LED Description

The REVERSE LED indicates the requested direction of motor rotation:

LED Status Definition

OFF The requested direction of motor rotation is forward.

(The 1329I unit is shipped with the forward direction defined as CCW shaft

rotation as viewed from the motor shaft end.)

ON The requested direction of motor rotation is reverse.

(The 1329I unit is shipped with the reverse direction defined as CW shaft

rotation as viewed from the motor shaft end.)

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 11

Step 1 - Identify Your Unit

If the motor is turning and you request a change to motor direction, the LED turns on

or off immediately ev en though it may tak e some time for the motor to decelerate and

begin turning in the opposite direction.

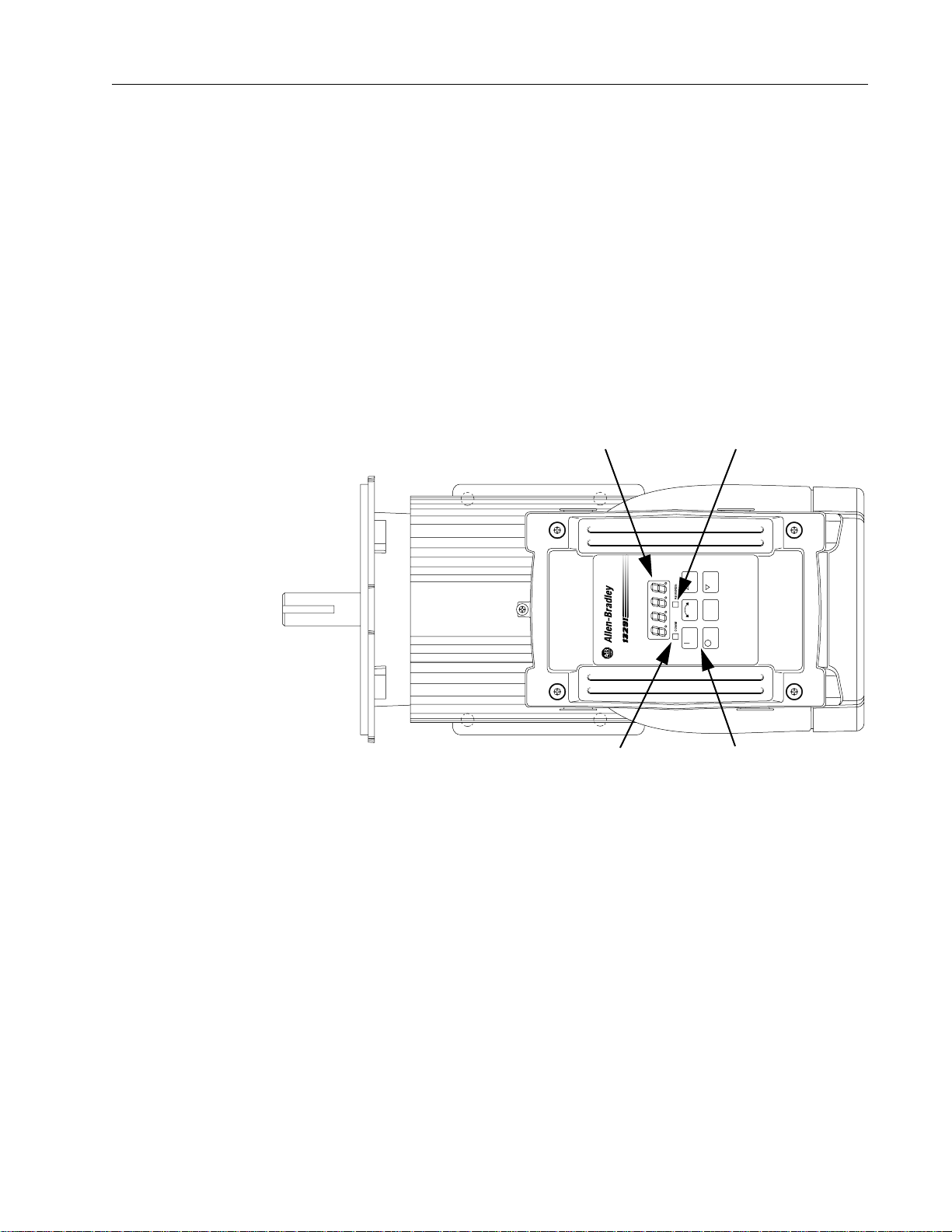

1.2 1329I Local Operator Control Unit

The local operator control unit (see Figure 1.2) provides local start, stop, forward,

reverse, reset, and speed control functions. The controls replace the Start, Stop, Reset,

and Forward / Reverse input signals at the terminal block.

The local operator control unit receives its speed reference from the keypad (default)

or the analog input terminals (user option). Refer to Section 8.3.2 for more information.

Figure 1.2

1329I Local Operator Control Unit

1-3

Display

Communication LED

Reverse LED

RESET

Local Operator

Controls

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 12

1-4

Step 1 - Identify Your Unit

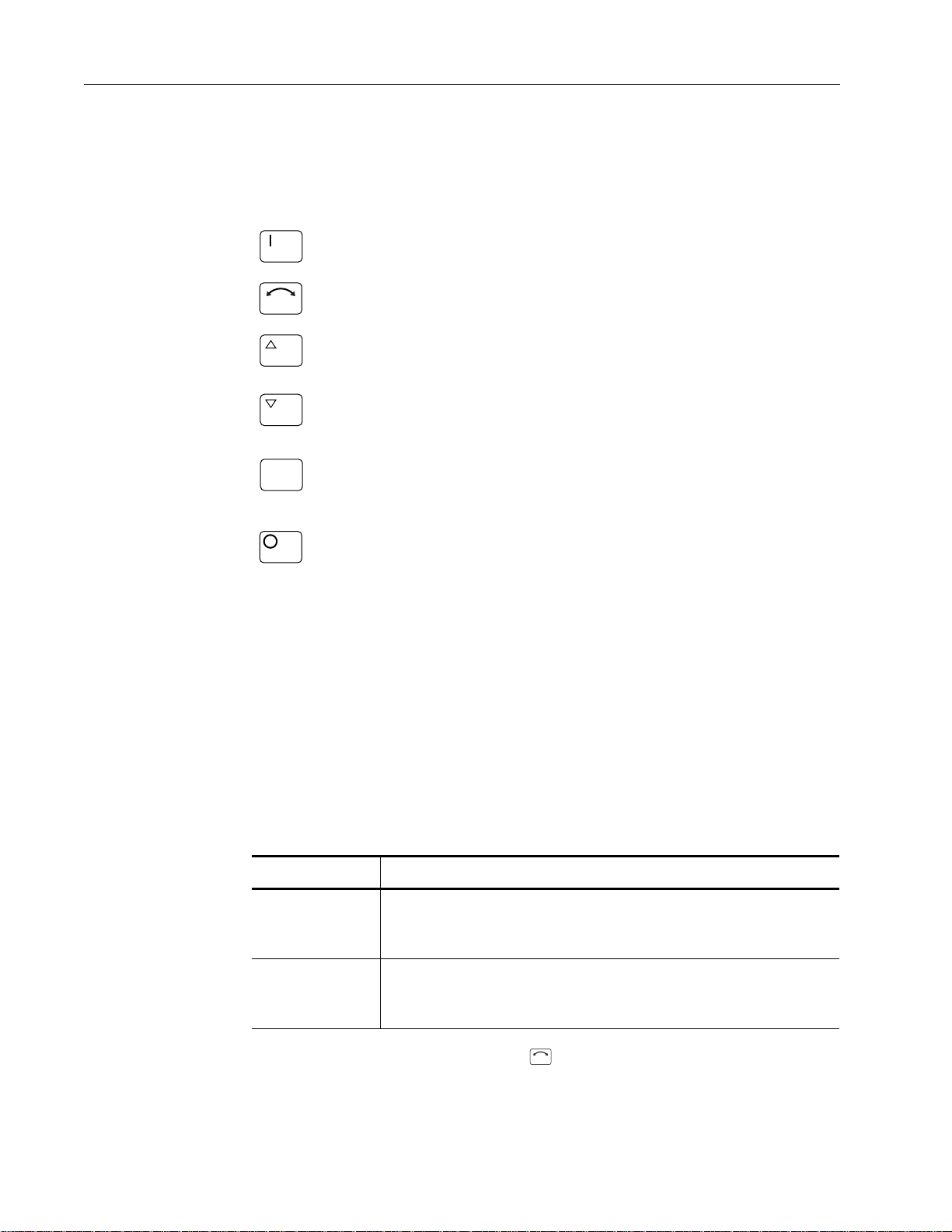

1.2.1 Local Operator Control Unit Key Descriptions

Figure 1.3 shows each key’s function.

Figure 1.3

Local Operator Control Key Functions

The START key applies power to the Motor Section.

The FORWARD/REVERSE key toggles the direction of motor rotation.

Press the UP ARROW key once to display the current speed reference. Hold this

key down to increase the speed reference value. The longer the key is pressed,

the faster the reference value increases.

Press the DOWN ARROW key once to display the current speed reference. Hold

this key down to decrease the speed reference value. The longer the key is

pressed, the faster the reference value decreases.

RESET

The RESET key resets any active faults or aborts an Auto Restart sequence.

See Section 8.3.4 for important information regarding the Auto Restart mode of

operation.

The STOP key interrupts Drive Section output to the Motor Section.

1.2.2 Local Operating Control Unit Display Description

The four-character, se ven-segment display sho ws output speed in RPM or percent load,

the current speed reference, and active fault codes. Speed in RPM is the default display.

To display percent load, see Section 7.4.

If a fault occurs, the unit displays the corresponding fault code. Refer to Chapter 11 for

more information about fault codes and corrective actions.

1.2.3 Local Operating Control Unit Reverse LED Description

The REVERSE LED indicates the requested direction of motor rotation:

LED Status Definition

OFF

The requested direction of motor rotation is forward.

(The 1329I unit is shipped with the forward direction defined as CCW

shaft rotation as viewed from the motor shaft end.)

ON

The requested direction of motor rotation is reverse.

(The 1329I unit is shipped with the reverse direction defined as CW shaft

rotation as viewed from the motor shaft end.)

Note that if the motor is turning and the key is pressed, the LED turns on or off

immediately even though it may take some time for the motor to decelerate and be gin

turning in the opposite direction.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 13

Step 1 - Identify Your Unit

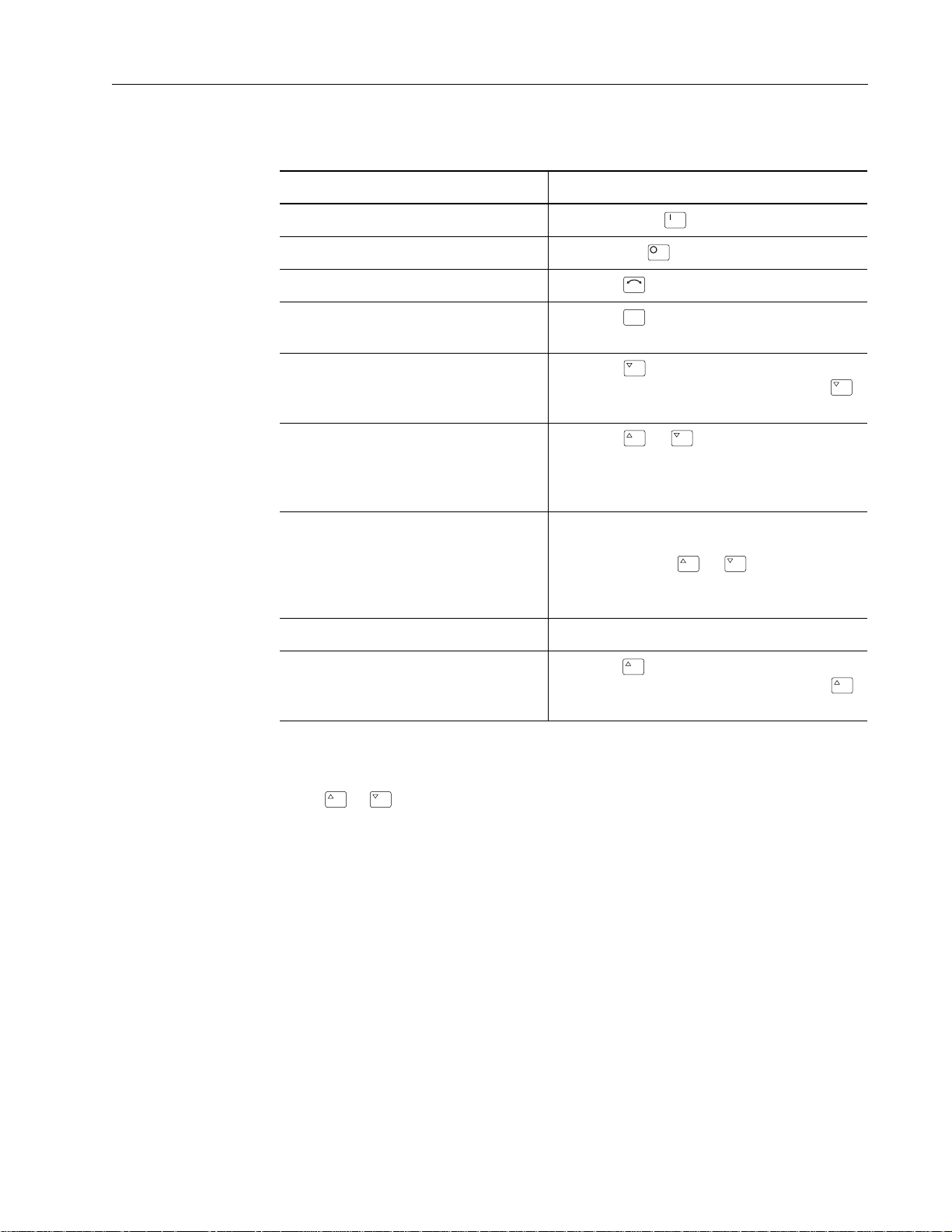

1.2.4 Operating the Unit Using the Local Operator Controls

Desired Action User Steps

1-5

Start the unit.

➊

Stop the unit. Press the red

Change the direction of motor rotation.

Clear faults or abort Auto Restart

Press the green

➊

Press the

Press the

key.

RESET

key.

key.

key.

sequence.

Decrease the speed reference.

➋

Press the

displayed is the desired v alue. The longer the

key until the speed reference

key is held down, the faster the value decreases.

Display the current speed reference.

Press the

or

key once.

➋

The display returns to indicating speed in RPM or

percent load after three to five seconds. Holding

down either key will change the speed ref erence .

Display the speed in RPM No action required; speed in RPM is the default

display based on status of terminal 12 (see

Section 7.4). If the

or

keys are not

pressed for several seconds, the display returns

to indicating actual motor speed in RPM.

Display percent load Close contact on terminal 12 (see Section 7.4)

Increase the speed reference.

➋

Press the

displayed is the desired v alue. The longer the

key until the speed reference

key is held down, the faster the value increases.

➊

These functions are only active when in local operator start mode (see Section 8.3.9).

➋

If the unit is using a terminal block or preset speed reference (see Section 8.3.2), pressing

the

or

key will have no effect on unit operation.

Important: If the local operator controls are disconnected from or connected to the

unit after power up, the unit will stop due to a non-resettable fault. Refer

to Chapter 11 for information about faults.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 14

1-6 Step 1 - Identify Your Unit

End of Chapter

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 15

Step 2 - Plan the Installation

ATTENTION: Only qualified electrical personnel, familiar with the

construction and operation of this equipment and the hazards involved,

should install, adjust, operate, and/or service this equipment. Read and

understand this instruction manual in its entirety before proceeding.

Failure to observe this precaution could result in sev ere bodily injury or

loss of life.

ATTENTION: This equipment is at line voltage when AC power is

connected. Disconnect and lockout all ungrounded conductors of the AC

power line before working on the unit. Failure to observe these

precautions could result in severe bodily injury or loss of life.

ATTENTION: The user is responsible for conforming with all applicable

local, national, and international codes. Failure to observe this precaution

could result in personal injury and/or damage to, or destruction of, the

equipment.

Chapter

2

It is the user’s responsibility to ensure that this equipment is installed properly according

to this manual and in conformance with all applicable codes. Consult your local

inspecting agency for information about any local, national, or international codes that

may apply.

Review all installation and wiring instructions thoroughly before proceeding.

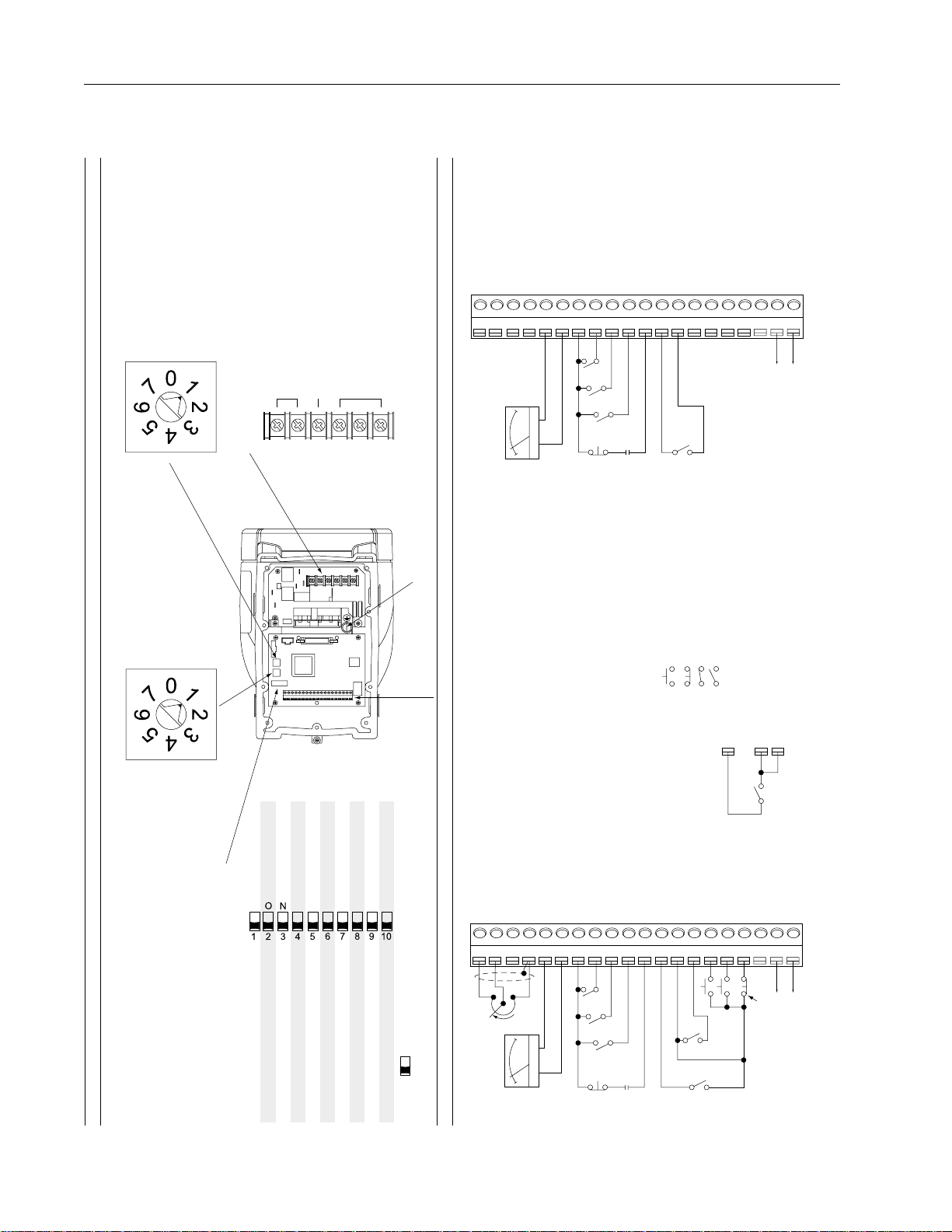

Throughout the installation procedures, use Figure 2.1 to locate wiring termination

points and setup switches.

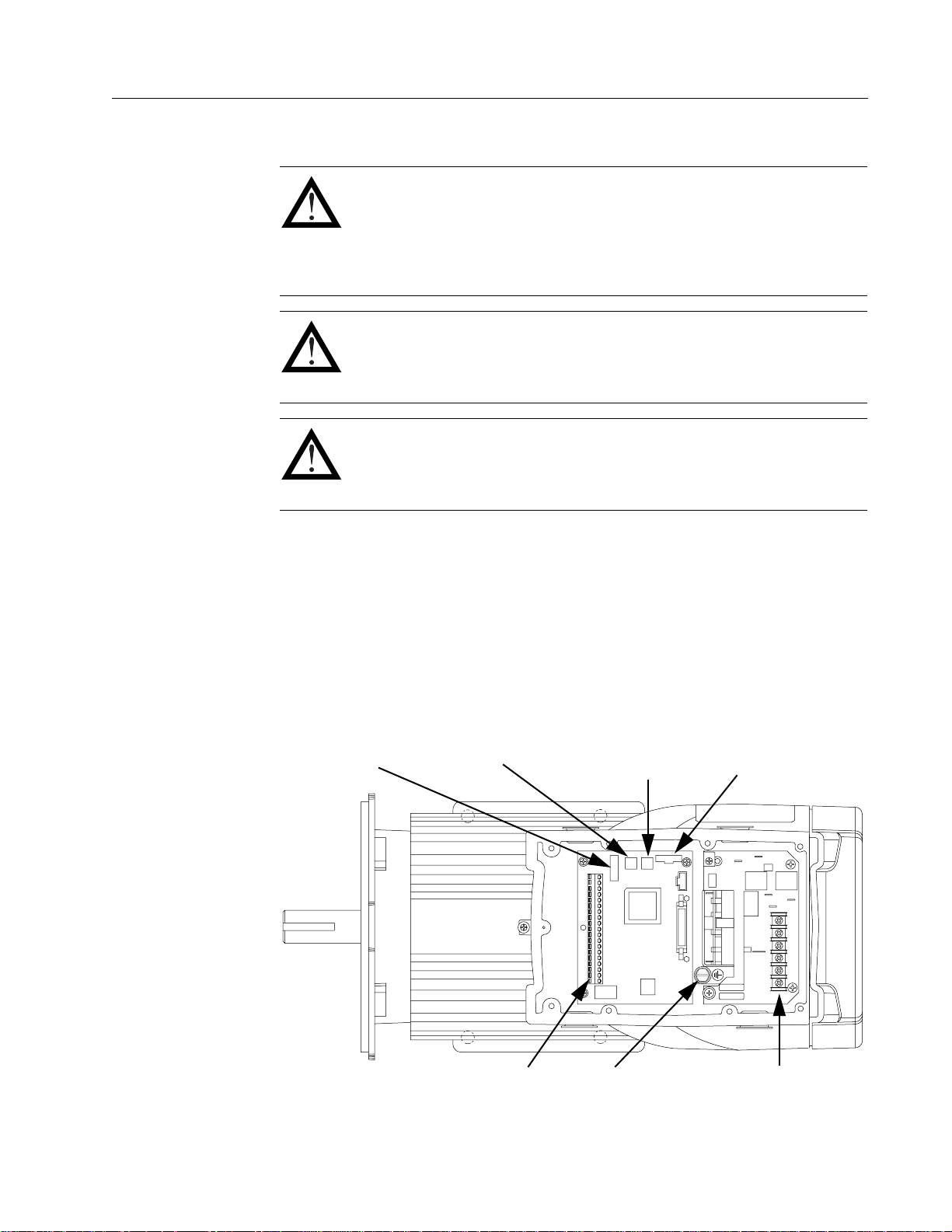

Figure 2.1

Component Location

Setup DIP

Switches

Max Speed

Switch

Accel/Decel

Switch

PE

Display Board

Connector

DC+

DCDBR

T/L3

S/L2

R/L1

Control Signal

Terminal Block

Ground/

Protective Earth

1329I-5.5 Integrated Drive/Motor — January, 2000

AC Input P o wer

Terminal Block

Page 16

2-2 Step 2 - Plan the Installation

Planning the installation is necessary to ensure you have acceptable en vironmental and

operating conditions for the unit. Read and follow the requirements giv en below before

proceeding with the installation:

• Locate the unit where it will have unrestricted clearance as shown in Figure 2.2.

• Locate the unit where it will be kept clean (away from oil, coolants, or airborne

contaminants). The 1329I unit has an IP54/NEMA Type 12 rating. An IP rating

designates the enclosure’s level of protection. The first number in the rating (5)

indicates that the 1329I unit is dust-resistant. The second number (4) indicates that

the unit is splashproof.

• Mount the unit on a flat surface.

• Verify that the ambient temperature will remain between 0

104

˚F).

˚C to 40˚C (32˚F to

• Verify that the relative humidity will be between 5 percent and 95 percent,

non-condensing.

• For installations above 1000 meters (3300 feet), refer to Appendix A for derating

guidelines.

• Verify that there will be adequate clearance for opening the cover. See Figure 2.2.

• Verify that there will be adequate clearance for blower intake. See Figure 2.2.

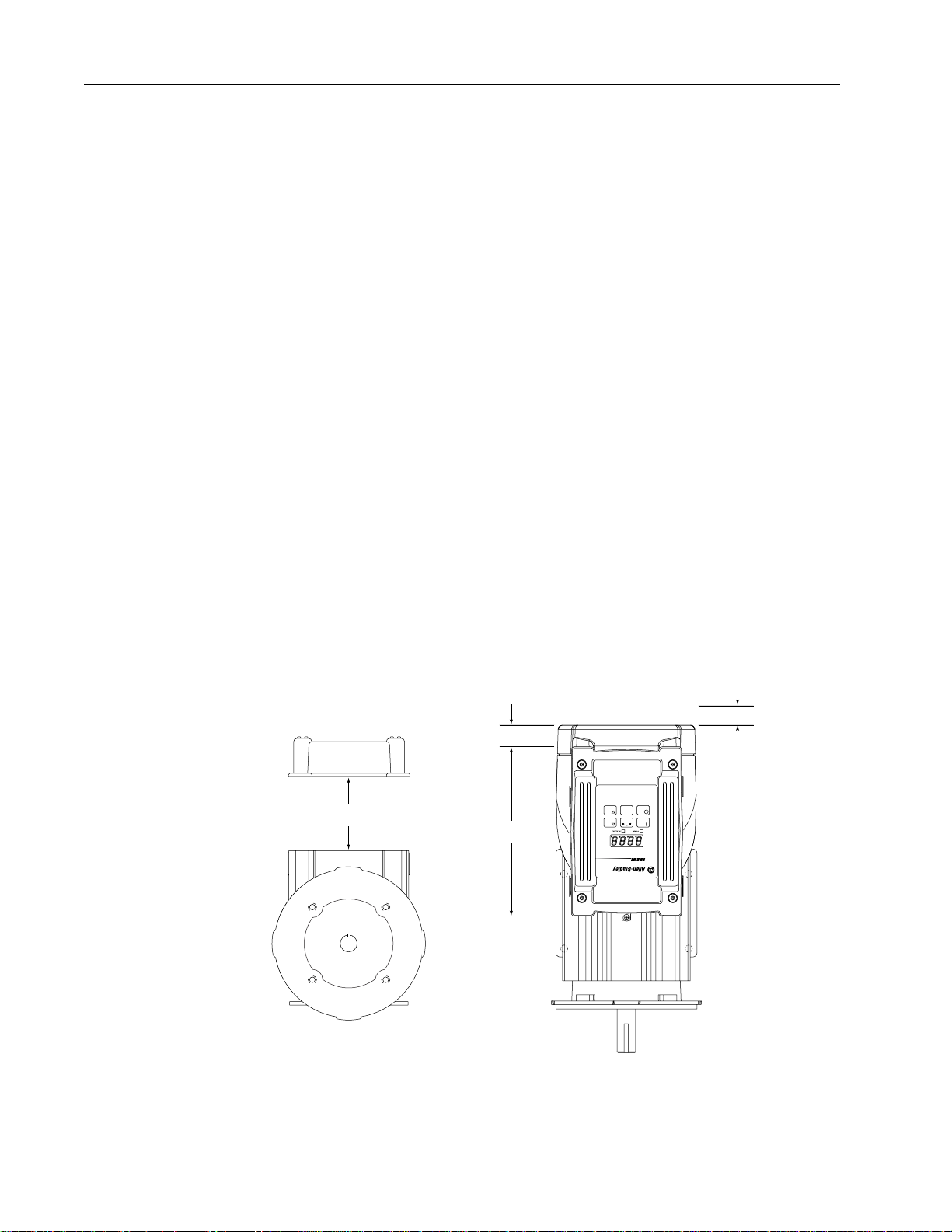

Figure 2.2

Access Clearances

Blower Intake

Cover Clearance

Clearance

1 in

1.3 in

3 in

RESET

10.25 in

Front View

1329I-5.5 Integrated Drive/Motor — January, 2000

Top View

Page 17

2.1 Wire Routing Guidelines

The 1329I unit is shipped from the factory with plastic conduit plugs installed. These

plugs must be removed. Before wiring, replace these plugs with appropriate 3/4-inch

NPT connectors having a similar enclosure rating. After wiring, seal unused routing

holes using permanent, user-supplied 3/4-inch NPT plugs. Seal all threaded

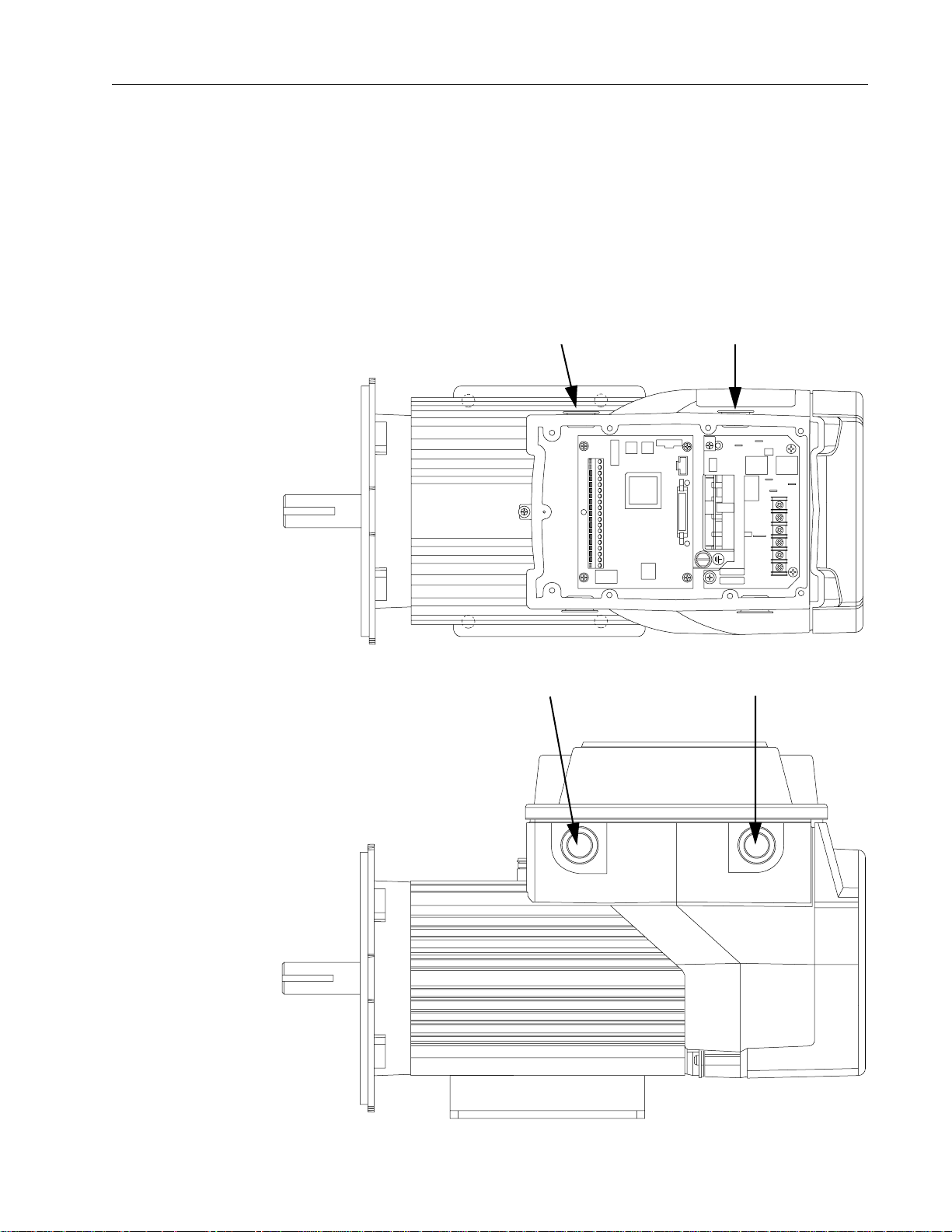

connections. Route the power and control wiring as shown in Figure 2.3.

Figure 2.3

Wire Entry Locations

Step 2 - Plan the Installation 2-3

Control Signal Wiring

Control Signal Wiring

AC Input Power Wiring

DC+

DC-

PE

DBR

T/L3

S/L2

R/L1

AC Input Power Wiring

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 18

2-4 Step 2 - Plan the Installation

2.2 Handling and Lifting Guidelines

Follow these handling and lifting guidelines:

• In the case of assemblies on a common base, carefully lift the assembly by a sling

around the base or by other lifting means on the base.

• When designing the lifting means, take care to assure lifting in the intended

direction.

• Do not lift the unit by the plastic blower cover.

• Do not use any lifting means under the Drive Section.

• Do not lift attached equipment by lifting the motor.

• Do not use the 1329I unit as a step.

2.3 CE Conformity

This drive is a component intended for implementation in machines or systems for the

industrial environment. It is CE marked for conformity to the Low Voltage (LV)

Directive 73/23/EEC when installed as described. It also has been tested to meet the

Council Directive 89/336 Electromagnetic Compatibility (EMC). The standards used

for this testing are, LV: EN50178, EN60204-1, EMC: EN61800-3, EN50081-1,

EN50082-2.

Important: The conformity of the drive and filter to any standard does not guarantee

that the entire installation will conform. Many other factors can influence

the total installation and only direct measurements can verify total

conformity . It is therefore the responsibility of the machine manufacturer,

to ensure, that the conformity is met.

A copy of the Declaration of Conformity (DOC) is available from your local Rockwell

Automation Sales Office.

2.3.1 Essential Requirements for a Conforming EMC Installation

The following three items are required for CE Conformance:

1. A CE filter option (see Chapter 1) must be installed to reduce conducted

emissions.

2. Grounding of equipment and cable shields must be solid, with low impedance

connections.

3. All control and signal wiring must use shielded cable or be in grounded metal

conduit.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 19

Step 2 - Plan the Installation 2-5

2.3.2 Low Voltage Directive 73/23/EEC Compliance

This product complies with Low Voltage Directive 72/23/EEC when conforming with

the following installation requirements:

• Review ATTENTION statements throughout this manual prior to installing the

product.

• The product is intended to be installed with a fixed connection to the earth. The use

of residual-current-operated protective de vices (RCDs) or ground fault indicators is

not recommended. If unavoidable, the Bulletin 1329I is compatible with type B

RCDs only.

• The product should be installed in an appropriate or suitable enclosure.

Important: The conformity of this drive and filter to any standard does not guarantee

that the entire installation will conform. Many factors can influence the

total installation and only direct measurements can verify total

conformity.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 20

2-6 Step 2 - Plan the Installation

End of Chapter

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 21

Chapter

Step 3 - Mount the Unit

Mount the unit on a foundation sufficiently rigid to guard against excessive vibration.

The unit may be mounted at any orientation. After carefully aligning the 1329I unit with

the driven machinery, bolt securely in place.

When the unit is mounted vertically, it may be necessary to use additional guards to

prevent foreign objects from falling into the motor fan openings and striking rotating

parts.

Mounting dimensions are provided on the following pages of this chapter.

3.1 Mounting Guidelines for Face-Mounted Motors

Use the following guidelines when mounting 56C and 140C face-mounted motors:

• Before mounting a C-face motor to the mating flange, be sure both surfaces and all

mounting holes are smooth and free of debris.

• When mounting into a quill-type reducer, make sure the input and output shafts are

coated with an anti-seize compound suitable for the application.

3

• When mounting through a flexible coupling, make sure that there is adequate

clearance between the driven equipment shaft, the coupling interface, and the motor

shaft. Insufficient clearance may result in binding of the shafting and premature

bearing failure.

• Always slide the motor tenon into the mating flange to its full depth before

tightening the mounting bolts. Do not allow the motor to hang by the shaft

extension while assembling it to the driven equipment (for example, a quill input

gear case) as this may bend or crease the shaft and damage any seals that are

present.

• Make sure to use the proper mounting bolts. For 56C and 140C motors, these

should be 9.5 mm (0.375 in, 16 threads per inch) and sized for length such that

engagement into the motor flange does not exceed 14.3 mm (0.563 in).

For example, a gearcase with a 9.5 mm (0.38 in) flange thickness requires a bolt

that is 9.5 mm (0.38 in) + 14.3 mm (0.56 in). That is, 23.8 mm (0.94 in) should be

the maximum bolt length. Since 23.8 mm (0.94 in) is not a standard bolt length, a

22.2 mm (0.88 in) bolt or a 25.4 mm (1.0 in) bolt with a lock washer can be used.

Important: Using a bolt that is too long may cause damage to the motor resulting in

premature failure and/or a loose assembly.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 22

3-2 Step 3 - Mount the Unit

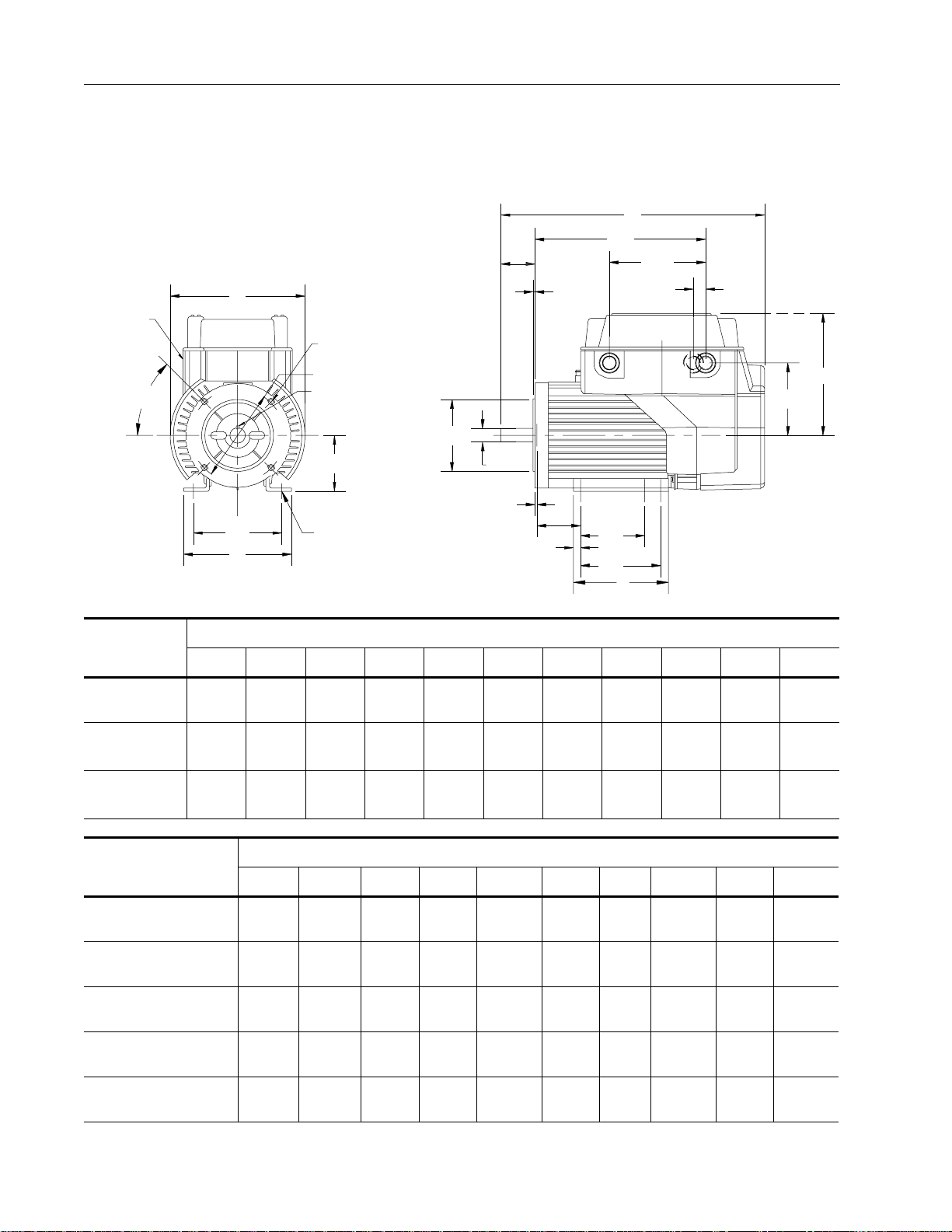

3.2 Mounting Dimensions for NEMA Frames

Figure 3.1

NEMA Frame Mounting Dimensions

P

3/4 Conduit

Both Sides

BF

AH

BB

C

BV

*

6.00

**

.75

AJ

45

°

2E

A

Face Runout and Eccentricity .004 Max. T.I.R.

Shaft Runout .002 Max. T.I.R.

S - Key Width/Height

ES - Key Length

AK

D

H - Diameter Through

* Denotes Control Wiring Ports

** Denotes Input Power Port Opposite Side

U

BC

BA

EV

2F 1

2F 2

Frame Size Dimensions in millimeters (inches)

A2EH DBFAJAKUAHSES

56C

143TC

145TC

182TC

184TC

170

(6.71)

170

(6.71)

216

(8.50)

140

(5.50)

140

(5.50)

191

(7.50)

8.6

(0.34)89(3.50)

8.6

(0.34)89(3.50)

8.6

(0.34)

114

(4.50)

16-3/8 149

(5.88)

16-3/8 149

(5.88)

13-1/2 184

(7.25)

114

(4.50)

114

(4.50)

216

(8.50)

B

15.9

(0.625)52(2.06)

22.3

(0.875)54(2.12)

28.6

(1.125)67(2.62)

8.01

4.50

4.8

(.19 SQ)32(1.25)

4.8

(.19 SQ)32(1.25)

6.4

(.25 SQ)38(1.50)

Frame Size Dimensions in millimeters (inches)

BC BB BA B 2F 1 2F 2 EV C P BV

56C

4.8

(0.19)

143TC

3.0

(0.12)

145TC

3.0

(0.12)

182TC

3.0

(0.12)

184TC

3.0

(0.12)

1329I-5.5 Integrated Drive/Motor — January, 2000

3.0

(0.12)70(2.75)

3.0

(0.12)70(2.75)

3.0

(0.12)70(2.75)

6.4

(0.25)89(3.50)

6.4

(0.25)89(3.50)

165

(6.50)76(3.00)

165

(6.50)

165

(6.50)

165

(6.50)

165

(6.50)

102

(4.00)

102

(4.00)

114

(4.50)

114

(4.50)

127

(5.00)12(0.47)

127

(5.00)12(0.47)

127

(5.00)12(0.47)

140

(5.50)13(0.50)

140

(5.50)13(0.50)

404

(15.90)

418

(16.46)

405

(15.96)

476

(18.75)

502

(19.75)

213

(8.38)

213

(8.38)

213

(8.38)

224

(8.80)

224

(8.80)

258

(10.14)

258

(10.14)

270

(10.64)

315

(12.39)

340

(13.39)

Page 23

Step 4 - Install External

Power Components

Install external power components using the guidelines in the following sections.

4.1 Installing an AC Input Disconnect

ATTENTION: Local codes and la ws require that an input disconnect be

provided in the incoming power lines. Failure to observ e this precaution

could result in severe bodily injury or loss of life.

An A C input disconnect must be provided in the incoming AC power lines in accordance

with local codes and laws.

4.2 Installing Branch Circuit Protection

ATTENTION: Local codes and laws require that AC branch circuit

protection be provided to protect input power wiring. The input fuse

ratings listed in Table 4.1 are applicable for one 1329I unit per branch

circuit. No other load can be applied to that fused branch circuit. Failure

to observe this precaution could result in severe bodily injury or loss of

life.

Chapter

4

Install the required, user-supplied branch circuit protection fuses according to Local

codes and laws. Refer to Table 4.1 for recommended fuse ratings.

Table 4.1

Required AC Branch Circuit Protection

NEC Amps Input

Input Voltage Unit HP Input Current Fuse Rating

460 VAC 1 HP 2.3 A 3.5 A

460 VAC 2 HP 3.7 A 6.0 A

460 VAC 3 HP 5.7 A 9.0 A

460 VAC 5 HP 9.0 A 15.0 A

230 VAC 1 HP 4.5 A 7.0 A

230 VAC 2 HP 7.6 A 12.0 A

230 VAC (1-Phase) 1 HP 5.8 A 9.0 A

230 VAC (1-Phase) 2 HP 14.0 A 20.0 A

115 VAC 1 HP 14.0 A 20.0 A

➊

➊

Recommended fuse type: UL Class J or CC, 600V, time delay.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 24

4-2 Step 4 - Install External Power Components

4.3 Installing Input Isolation Transformers

ATTENTION: Distribution system capacity above the maximum

recommended system KVA (100 KVA for 460 VAC three-phase, 5%

impedance) requires using an isolation transformer, a line reactor , or other

means of adding similar impedance. Failure to observe this precaution

could result in damage to, or destruction of, the equipment.

Depending upon the requirements of the application, the 1329I unit may require input

isolation transformers to help eliminate the following:

• Damaging AC line voltage transients from reaching the 1329I unit.

• Line noise from the 1329I unit being fed back to the incoming power source.

An isolation transformer or line reactors of 3% drive input impedance should be used

between the distribution source and the 1329I unit in situations such as the following:

• The power distribution system feeding the 1329I unit contains power factor

correction capacitors.

• The power distribution system feeding the 1329I unit connects with heavy

industrial equipment that causes instantaneous line distribution shorts such as arc

welders, line-commutated thyristor converters, or line-started AC induction motors

greater than 50 HP (37 KVA).

• The distribution transformer is rated more than 100 KVA for 460 VAC with less

than 5% impedance.

• The distribution system is prone to frequent power outages or transient power

interruptions or significant voltage spikes.

Refer to Table 4.2 for the appropriate line reactor for your unit.

Table 4.2

Input Line Reactors

1329I Unit Input Line Reactor

HP Input Voltage Inductance Rated Amps Part No.

1 460V, 3-Phase 6.5 mH 4.0 1321-3RA4-B

2 460V, 3-Phase 3.0 mH 8.0 1321-3RA8-B

3 460V, 3-Phase 2.5 mH 12.0 1321-3RA12-B

5 460V, 3-Phase 1.5 mH 18.0 1321-3RA18-B

1 230V, 3-Phase 1.5 mH 8.0 1321-3RA8-A

2 230V, 3-Phase 0.8 mH 18.0 1321-3RA18-A

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 25

Chapter

5

Step 5 - Wire AC Power to the Unit

and Ground the Unit

ATTENTION: If the distribution system capacity exceeds the unit’s

maximum symmetrical fault short-circuit current of 10,000 amps,

additional impedance should be added to the AC line supplying the unit

to limit available current in the event of a fault. Failure to observe this

precaution could result in severe bodily injury or loss of life.

ATTENTION: The dri ve is intended to be commanded by control input

signals that will start and stop the motor. A device that routinely

disconnects then reapplies input power to the drive for the purpose of

starting and stopping the motor should not be used. If it is necessary to

use this method for starting and stopping, or if frequent cycling of power

is unavoidable, make sure that it does not occur more than once a minute.

Observe the following guidelines when wiring AC power:

• The terminal block accepts up to 3.31 mm

• The recommended tightening torque is 1.3 newton-meters (12 in-lb).

• Verify that the input power to the unit corresponds to the unit v oltage and frequency

and that the input supply is of sufficient capacity to support the input current

requirements. Refer to Appendix A, Technical Specifications.

• Size the AC line conductors for the unit rating and in accordance with all applicable

local, national, and international codes.

Use the following procedure to wire AC power to the unit. Grounding instructions are

provided in Section 5.1.

Remove the cover by loosening the four cover screws. Note that the keypad/display

ribbon cable is designed to disconnect from the main unit when the cover is removed

as shown in Figure 5.1.

Figure 5.1

Removing the Cover

Four Cover Screws

2

(12 AWG) wire.

Keypad/Display Board

Ribbon Cable Connector

(Side View of Cover)

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 26

5-2 Step 5 - Wire AC Power to the Unit and Ground the Unit

• Connect the incoming three phase AC line to terminals R, S, and T, as shown in

Figure 5.2.

• Connect the incoming single phase AC line to any two of the terminals R, S, and T,

as shown in Figure 5.2.

Figure 5.2

Grounding the Unit

AC Input Terminal

PE

PE

Ground/Protective Earth

5.1 Grounding the Unit

ATTENTION: The user is responsible for conforming with all local,

national, and international codes applicable to the grounding of this

equipment. Failure to observe this precaution could result in sev ere bodily

injury or loss of life.

DC+

DC-

DBR

T/L3

S/L2

R/L1

DC+

DC-

DBR

T/L3

S/L2

R/L1

DC Bus

(Do not wire.)

Not Used

AC Inputs

Connect the ground wire brought in with the incoming A C power to the unit’ s grounding

screw ➊ (see Figure 5.2). This grounding conductor must run unbroken from the unit

to earth ground.

➊

Recommended tightening torque is 2.6 N-m (32 lb.-in.).

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 27

Chapter

6

Step 6 - Install a Hardwired Stop

ATTENTION: The user must provide an external, hardwired stop circuit

outside of the 1329I unit circuitry. This circuit must disable the system

in case of improper operation. Uncontrolled machine operation may result

if this procedure is not followed. Failure to observe this precaution could

result in bodily injury.

Depending upon the requirements of the application, the 1329I unit can be set up to

provide either a coast-to-rest (default) or a ramp-to-rest (user option) operational stop.

The unit’s Function Loss input provides an additional coast-to-rest operational stop.

In addition to the operational stop, the user must provide a hardwired stop external to

the unit. The hardwired stop circuit must contain only hardwired electromechanical

components. Operation of the hardwired stop must not depend on electronic logic

(hardware or software) or on the communication of commands over an electronic

network or link.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 28

6-2 Step 6 - Install a Hardwired Stop

End of Chapter

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 29

Chapter

7

Step 7 - Wire the Control Signal

Terminal Block

The following sections describe how to wire the control signal terminal block shown

in Figure 7.1.

Refer to either Figure 7.2 (standard units) or Figure 7.3 (local operator control units)

before you begin wiring. These figures show typical wiring connections and the sections

in this chapter where the signals are described in detail.

Note the following when wiring the terminal block:

• The terminal block is isolated from the input power.

• Route the control wires separately from the power wires.

• The terminal block accepts 0.326 mm

wire.

• The maximum lead length is 300 meters (1000 ft).

• The maximum tightening torque is 0.8 Nm (7 in-lb).

2

(22 AWG) through 3.31 mm2 (12 AWG)

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 30

7-2 Step 7 - Wire the Control Signal Terminal Block

Figure 7.1

Control Signal Terminal Block

1 2 3 4 5 6 7 8 9 1011121314151617181920

Table 7.1

Terminal Functions

Terminal Number Terminal Function

1 10 Volt Reference

2 0 – 10 Volt Speed Reference Input

3 4 – 20 mA Speed Reference Input

4 Common

5 0 – 10 Volt Output

6 Common

7 24 Volt DC

8 Speed Preset 2

9 Speed Preset 1

10 Speed Preset 0

11 Function Loss

12 RPM/Percent Load Display

13 24 Volt DC

14 Forward/Rev erse

15 Reset

16 Start

17 Stop

18 24 Volt DC Common

19 N.O. Relay

20 Relay Common

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 31

Step 7 - Wire the Control Signal Terminal Block 7-3

Figure 7.2

Typical Control Signal Connections for Standard Units

% Load

-+

RPM

+10V DC

Fwd

Rev

5K Ω

1 2 3 4 5 6 7 8 9 1011121314151617181920

10 Volt Reference

0 – 10V DC Speed Reference Input

4 – 20 mA Speed Reference Input

Common

0 – 10 Volt Output

Common

24 V olt DC

Speed Preset 2

Speed Preset 1

Speed Preset 0

Function Loss

RPM/Percent Load Displa y

24 V olt DC ➌

Forward/Re verse

Reset

Start

Stop ➌

24 Volt DC Common

N.O. Rela y

Relay Common

➊

➋

➋

Table 7.2

User Wiring for Standard Units

Signal Refer to Section

Function Loss 7.1

Analog Output 7.2

Relay Control Output 7.3

RPM/Percent Load Display 7.4

Speed Reference (select one)

Preset Speed 7.5.1

Speed Potentiometer 7.5.2

External Speed Reference (0 – 10V DC or 4 – 20 mA) 7.5.3

Start 7.6

Stop 7.6

Forward/Reverse 7.7

Reset 7.8

➊

An external 0 to 10 volt DC or 4 to 20 mA speed reference source can be connected. See Section 7.5.3

for more information.

➋

The jumper between terminals 7 and 11 must be removed when wiring the Function Loss input. See

Section 7.1 for more information.

➋

The jumper between terminals 13 and 17 must be removed when wiring the Stop input. See Section

7.6 for more information.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 32

7-4 Step 7 - Wire the Control Signal Terminal Block

Figure 7.3

Typical Control Signal Connections for Local Operator Control Units

% Load

-+

RPM

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

10 V olt Reference ➊

0 – 10V DC Speed Reference Input

4 – 20 mA Speed Reference Input

Common

0 – 10 Volt Output

Common

24 V olt DC ➋

Speed Preset 2

Speed Preset 1

Speed Preset 0

Function Loss ➋

RPM/Percent Load Displa y

24 V olt DC ➌

Forward/Re verse

Reset

Start

Stop ➌

24 Volt DC Common

N.O. Rela y

Relay Common

Table 7.3

User Wiring for Local Operator Control Units

Signal Refer to Section

Function Loss 7.1

Analog Output 7.2

Relay Control Output 7.3

RPM/Percent Load Display 7.4

Speed Reference (select one)

Preset Speed 7.5.1

Speed Potentiometer 7.5.2

External Speed Reference (0 – 10V DC or 4 – 20 mA) 7.5.3

➊

An external 0 to 10 volt DC or 4 to 20 mA speed reference source can be connected. See Section 7.5.3

for more information.

➋

The jumper between terminals 7 and 11 must be removed when wiring the Function Loss input. See

Section 7.1 for more information.

➌

The jumper between terminals 13 and 17 must be removed when wiring the Stop input. See Section

7.6 for more information.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 33

Step 7 - Wire the Control Signal Terminal Block 7-5

7.1 Wiring Function Loss

For the unit to run, you must maintain a signal at the Function Loss input (the connection

between control terminals 7 and 11). If the Function Loss signal is not present, the unit

turns off the power devices and coasts to rest. To restart the unit, you must restore the

Function Loss signal, clear any faults, and reassert the Start command.

The unit ships from the factory with a jumper between terminals 7 and 11 which provides

the Function Loss signal. The Function Loss input should be wired in series with the

drive’ s external interlocks as shown in Figure 7.4. In this case, remov e the jumper before

making the connections.

Function Loss provides an operational stop. It does not fulfill the requirements of a

hardwired stop. Refer to Chapter 6 for information regarding hardwired stop

requirements.

Figure 7.4

Function Loss Control Wiring

User-supplied

Function Loss

Pushbutton

User-supplied

Safety Interlocks

7891011

7.2 Wiring the Analog Output

The analog output provides a 0 to 10 VDC signal to a user-supplied metering device.

This output indicates speed (default) or percent load (user option), based on the status

of input terminal 12.

If you select speed indication, 0 to 10 V = 0 to the maximum speed as defined by the

maximum speed rotary switch. (Refer to Chapter 8 for a description of the rotary switch.)

If you select percent load indication, 0 to 10 V = 0 to 200percent load.

Wire to the analog output as shown in Figure 7.5.

Figure 7.5

Analog Output Wiring

24 V olt DC

Function Loss

-+

4567

0 – 10 Volt Output

Common

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 34

7-6 Step 7 - Wire the Control Signal Terminal Block

7.3 Wiring the Relay Control Output

A single form A relay on the terminal block can be used to indicate the unit is running

(default) or has faulted (user option) based on the setup DIP switch setting. Refer to the

setup DIP switch description in Chapter 8.

Figure 7.6

Relay Control Output Wiring

Connect to external device

such as PLC input.

7.4 Wiring RPM or Percent Load Display

The RPM or Percent Load Display input (control terminal 12) selects the type of

information displayed by the analog output and the built-in display, speed in RPM or

percent load. W ire a switch between control terminals 12 and 13 as shown in Figure 7.7.

17 18 19 20

N.O. Rela y

Relay Common

Figure 7.7

RPM or Percent Load Display Wiring

11 12 13 14

RPM

% Load

RPM or Percent Load Displa y

24V DC

7.5 Wiring the Speed Reference

The standard 1329I unit provides two motor speed reference options:

• Seven preset speeds

• An external 0 to 10 VDC or 4 to 20 mA speed reference source

The 1329I unit with local provides three motor speed reference options:

• The local operator controls (using the keys)

• Seven preset speeds (the keys are not used)

• An external 0 to 10 VDC or 4 to 20 mA speed reference source (the keys

are not used)

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 35

Step 7 - Wire the Control Signal Terminal Block 7-7

Select the option that is the most suitable for your application. The following sections

provide wiring information for each option except the local operator controls. Refer to

Section 1.2 for information on the local operator controls.

7.5.1 Wiring the Preset Speed Inputs

Control terminals 8, 9, and 10 select seven preset speeds as shown in Table 7.4. Note

that if you select a preset speed that is greater than the maximum speed setting (based

on the rotary switch setting), the unit uses the maximum speed setting value.

Important: DIP switch position 8 defines whether terminals 8, 9, and 10 are used as

presets (default) or to define the unit’s minimum speed (user option).

Refer to Section 8.3.8 for information about using terminals 8, 9, and 10

to select minimum speed.

Table 7.4

Fixed Preset Speed Selections

Selected Speed Reference

Terminal 8

Status

Open Open Open Analog speed reference Local operator control

Open Open Closed Preset 1 - 300 RPM (10 Hz)

Open Closed Open Preset 2 - 600 RPM (20 Hz)

Open Closed Closed Preset 3 - 900 RPM (30 Hz)

Closed Open Open Preset 4 - 1200 RPM (40 Hz)

Closed Open Closed Preset 5 - 1500 RPM (50 Hz)

Closed Closed Open Preset 6 - 1800 RPM (60 Hz)

Closed Closed Closed Preset 7 - 2100 RPM (70 Hz)

Terminal 9

Status

Terminal 10

Status

Standard Unit Local Operator

Control Unit

To use the preset speeds to set the speed reference, wire to terminals 8, 9, and 10 as

shown in Figure 7.8.

Figure 7.8

Preset Speed Input Wiring

687 9 10 11

24 V olt DC

Speed Preset 2

Speed Preset 1

Speed Preset 0

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 36

7-8 Step 7 - Wire the Control Signal Terminal Block

7.5.2 Wiring the Speed Reference Signal Potentiometer

Control terminal 1 provides a 10 VDC reference for use with the user-supplied 5 kΩ

potentiometer. Perform the follo wing procedure to wire the potentiometer as the speed

reference (refer to Figure 7.9):

1. Mount the speed reference potentiometer at an appropriate operator-accessible

location, less than 300 meters (1000 feet) from the 1329I unit.

2. Connect one end of the potentiometer to control terminal 1 (10V reference) and

the other end to control terminal 4 (signal common).

3. Connect the potentiometer’s wiper to control terminal 2 (speed reference input).

Figure 7.9

Speed Reference Potentiometer Wiring

Shield

+10V DC

12345

10 V olt Reference

0 – 10 Volt Speed Reference Input

5K Ω

(Drive end only)

Common

7.5.3 Wiring an External Speed Reference (0 to 10 VDC or 4 to 20 mA)

The terminal block provides both 0 to 10 VDC and 4 to 20 mA inputs. Use only one of

these inputs for the external speed reference. The other input must remain unconnected.

0 to 10 VDC External Speed Reference

To use an external 0 to 10 VDC signal to set the speed reference, connect the signal

leads as shown in Figure 7.10. 0 to 10 VDC = minimum speed to maximum speed.

Figure 7.10

0 to 10 VDC External Speed Reference Wiring

Shield

+

–

12345

0 – 10 Volt Speed Reference Input

Common

1329I-5.5 Integrated Drive/Motor — January, 2000

(Drive end only)

Page 37

Step 7 - Wire the Control Signal Terminal Block 7-9

4 to 20 mA External Speed Reference

T o use an external 4 to 20 mA signal to set the speed reference, connect the signal leads

as shown in Figure 7.11. 4 to 20 mA = minimum speed to maximum speed.

Figure 7.11

4 to 20 mA External Speed Reference Wiring

12345

Shield

4 – 20 mA Speed Reference Input

Common

(Drive end only)

7.6 Wiring Start / Stop Control

Important: The terminal block start function is only active when in terminal block

start mode.

The system looks for an open-to-closed transition at the Start input before starting the

unit unless you have the Run on Power Up switch (setup DIP switch 1, see Section

8.3.1) set to ON. If you use a maintained start device and power to the unit is lost, you

must open and reclose the start device before the unit will start again. Both the Stop and

the Function Loss input signals must be present and there must be no active faults for

the unit to start.

In order for the unit to run, you must maintain a signal at the Stop input. If the signal

is interrupted, the unit coasts to rest (default) or ramps to rest (user option). To restart

the unit, you must restore the signal and reassert the Start input.

Figure 7.12 illustrates wiring for a maintained 2-wire and for a momentary 3-wire

Start / Stop control

Figure 7.12

Start / Stop Control Wiring

12 13 14 15 16 17 18

24 V olt DC ➊

Start

Stop ➊ ➋

12 13 14 15 16 17 18

24 V olt DC ➊

Start

Stop ➊ ➋

Maintained 2-Wire Momentary 3-Wire

➊

The jumper between terminals 13 and 17 must be removed when wiring the Stop input.

➋

Refer to Chapter 8 to select a stop method via SW3 Selector Switch.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 38

7-10 Step 7 - Wire the Control Signal Terminal Block

7.7 Wiring Forward / Reverse Control

Important: The terminal block forward/reverse functions are only active when in

terminal block start mode.

The Forward / Rev erse input (the connection between terminals 13 and 14) defines the

requested direction of motor rotation. If the input is open, the requested direction is

forward. Switching the Forward / Reverse input causes the motor to ramp to rest and

then accelerate in the opposite direction. Note that the 1329I unit is shipped with the

forward direction defined as CCW shaft rotation as viewed from the motor shaft end.

Figure 7.13 shows the Forward / Re verse control wiring for the 1329I unit. If you disable

(lock out) reverse using the setup DIP switch, do not wire to this input because the dri ve

ignores any transition on this input. Refer to the setup DIP switch description in

Chapter 8

Figure 7.13

Forward / Reverse Control Wiring

12 13 14 15

Rev

Fwd

7.8 Wiring Reset Control

An open-to-closed transition at the Reset input (control terminal 15) clears a fault once

the appropriate corrective action has been taken. After clearing the fault, you must

reassert the Start command in order to restart the unit.

Wire a normally-open (N.O.) push-button between control terminals 15 and 13 as sho wn

in Figure 7.14. Refer to Chapter 11, Diagnostics and Troubleshooting, for more

information on faults.

Figure 7.14

Reset Control Wiring

24 V olts DC

Forward/Re verse

12 13 14 15 16

24 V olt DC

1329I-5.5 Integrated Drive/Motor — January, 2000

Reset

Page 39

Chapter

8

Step 8 - V erify the Setup and Adjust

Switches if Required

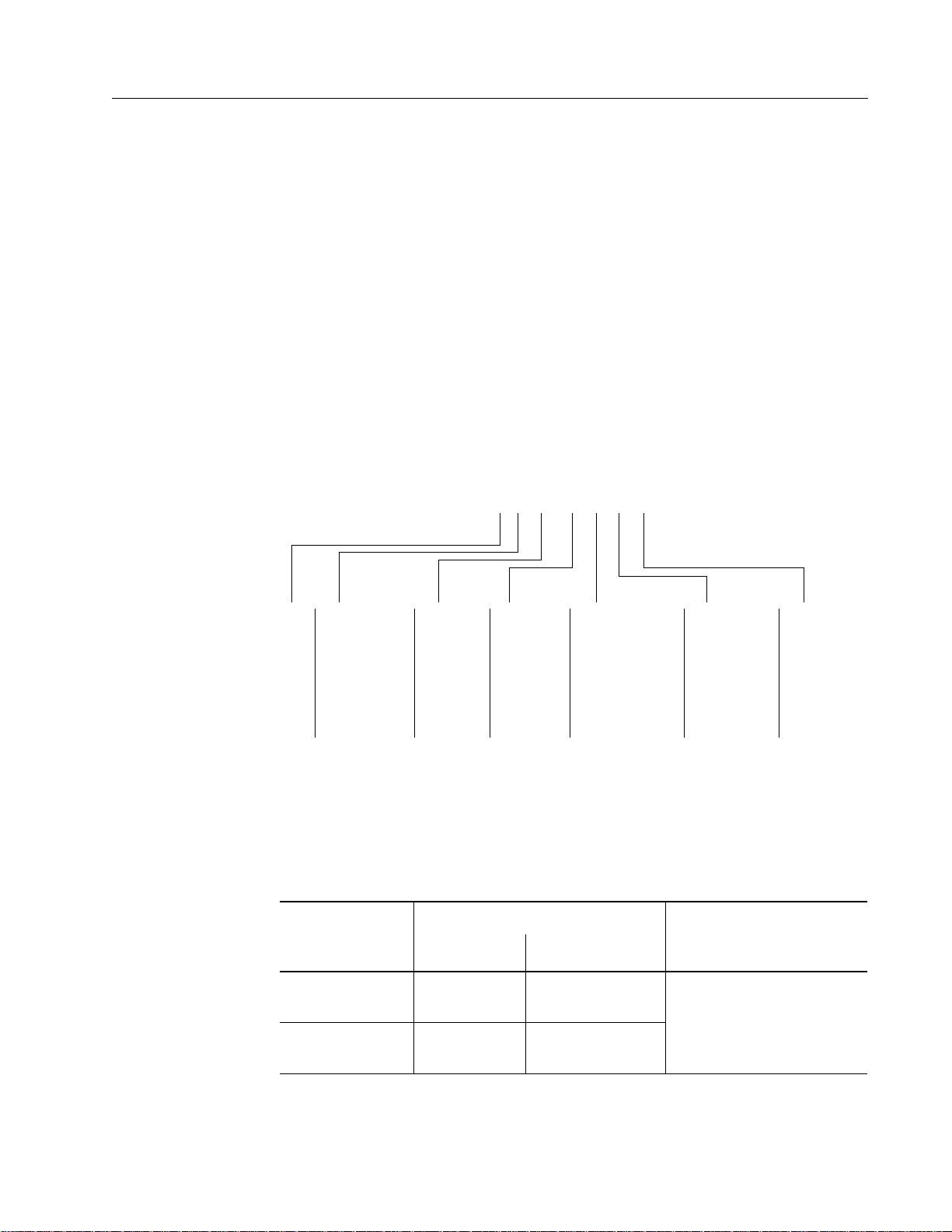

The 1329I unit is set up using two rotary switches and a 10-position DIP switch mounted

on the printed circuit board as shown in Figure 8.1. Figure 8.1 shows the setting

selections and the factory defaults. Normally, no adjustments will be needed to the

factory settings.

If your application requires adjustment to these settings, refer to the following sections

in this chapter. If no adjustment is needed, go to Chapter 9 to complete the installation

procedure.

ATTENTION: Only qualified personnel familiar with the construction

and operation of this equipment and the hazards involv ed should install,

adjust, operate, and/or service this equipment. Read and understand this

instruction manual in its entirety before proceeding. Failure to observe

this precaution could result in severe bodily injury or loss of life.

ATTENTION: All adjustments to these components should be made

with power removed. Failure to observe this precaution could result in

severe bodily injury or loss of life.

ATTENTION: After disconnecting input power wait five minutes and

check with a voltmeter to assure that DC bus capacitors are discharged.

The voltmeter should read zero volts. Failure to observe this precaution

could result in severe bodily injury or loss of life.

ATTENTION: The cov er scre ws must be securely tightened in order to

properly ground the cover . V erify that all four cover scre ws are tight before

applying power to the unit. Failure to observe this precaution could result

in severe bodily injury or loss of life.

Review all setup instructions thoroughly before making any adjustments or applying

power to the unit.

After changing the setup, go to Chapter 9 to complete the installation.

Before making any adjustments to the unit, be sure to take the following precautions:

1. Turn off, lockout, and tag AC input power to the unit.

2. Wait five minutes. Then remove the cover and use a voltmeter to verify that the

DC bus capacitors are discharged. The voltmeter should read zero volts. Refer to

Figure 5.2 for the DC bus test points.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 40

8-2 Step 8 - Verify the Setup and Adjust Switches if Required

Figure 8.1

Rotary Switches and Setup DIP Switch Locations

Setup DIP Switch

(SW3)

Max Speed Switch

(SW2)

Accel/Decel Switch

(SW1)

OFF ON

PE

8.1 Adjusting the Maximum Speed

DC+

DCDBR

T/L3

S/L2

R/L1

ATTENTION: The user is responsible for ensuring that driven

machinery and all drive-train mechanisms are capable of safe operation

at maximum speed. Failure to observe this precaution could result in

severe bodily injury or loss of life.

The maximum speed rotary switch limits the speed reference to the unit. Regardless of

what speed reference is supplied, the unit will not command a speed greater than value

selected by this rotary switch.

Figure 8.2

Maximum Speed Rotary Switch Settings

0 = 1500 RPM (50 Hz)

1 = 1800 RPM (60 Hz) Default

2 = 2100 RPM (70 Hz)

3 = 2400 RPM (80 Hz)

4 = 2700 RPM (90 Hz)

5 = 3000 RPM (100 Hz)

6 = 3300 RPM (110 Hz)

7 = 3600 RPM (120 Hz)

Range: 1500 RPM (50 Hz) to 3600 RPM (120 Hz)

Default: 1800 RPM (60 Hz)

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 41

Step 8 - Verify the Setup and Adjust Switches if Required 8-3

To set the maximum speed:

1. To increase the maximum speed, turn the maximum speed rotary switch to a higher

position number.

-orTo decrease the maximum speed, turn the maximum speed rotary switch to a lower

position number.

2. Connect the display board ribbon cable and replace the cover. Verify that all four

cover screws are in place and tightened.

3. Apply AC input power.

4. Set the operator’s speed reference signal to maximum.

Standard units: Use the speed potentiometer or other user-supplied external speed

reference device.

Local operator control units: Use the key to increase the speed reference and the

key to decrease the speed reference.

5. Use a hand held tachometer to monitor motor speed.

6. Repeat the adjustment procedure until the desired maximum speed is obtained.

Note that changes to the maximum speed setting are recognized only while the

drive is stopped.

Important: If speed is erratic or not as expected, verify that only one of the speed reference

inputs (0 to 10 VDC or 4 to 20 mA) has been wired.

8.2 Adjusting the Acceleration / Deceleration Time

The acceleration / deceleration time is the amount of time it takes the motor to ramp

from stop to the maximum speed setting of the unit. This is also the amount of time it

takes the motor to ramp from the maximum speed setting to stop. For all settings except

Setting 0, Acceleration time is equal to Deceleration time.

Figure 8.3

Acceleration/Deceleration Rotary Switch

0 = 1 Second Accel/5 Sec Decel

1 = 5 Seconds (Default)

2 = 10 Seconds

3 = 15 Seconds

4 = 20 Seconds

5 = 30 Seconds

6 = 60 Seconds

7 = 90 Seconds

Range: 1, 5, 10, 15, 20, 30, 60, 90 seconds

Default: 5 seconds

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 42

8-4 Step 8 - Verify the Setup and Adjust Switches if Required

Note that if the operator speed reference setting is less than the maximum speed value,

the acceleration / deceleration ramp time is proportionately less than the acceleration /

deceleration setting.

Example

1800 RPM

900 RPM

Assume:

Max Speed = 1800 RPM

Operating Speed = 900 RPM

Accel/Decel Time Setting = 30 Seconds

Use this formula:

Operating Speed

Max Speed

x Accel/Decel Time Setting = Time to Operating Speed

SPEED

TIME

15 Sec 30 Sec

900

x 30 = 15

1800

It will take 15 seconds to ramp from stop to 900 RPM.

To adjust the acceleration / deceleration time:

1. To increase the acceleration / deceleration time, turn the accel / decel rotary switch to a

higher position number.

-or-

To decrease the acceleration / deceleration time, turn the accel / decel rotary switch to a

lower position number .

2. Connect the display board ribbon cable and replace the cover. Verify that all four

cover screws are in place and tightened.

3. Apply AC input power.

4. Set the desired operating speed.

5. Standard units: Use the speed potentiometer or other user-supplied external

speed reference device.

6. Local operator control units: Use the key to increase the speed reference

and the key to decrease the speed reference.

7. Repeat the adjustment procedure until the desired acceleration / deceleration time

is obtained. Note that changes to the acceleration / deceleration time are recognized only while the drive is stopped.

Important: If speed is erratic or not as expected, verify that only one of the speed

reference inputs (0 to 10 VDC or 4 to mA) has been wired.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 43

Step 8 - Verify the Setup and Adjust Switches if Required 8-5

8.3 Modifying the Setup Using the Setup DIP Switch

The switches in the 10-position setup DIP switch define the characteristics of the 1329I

unit as shown in Figure 8.4. The switches are preset at the factory to suit a wide range

of applications and normally do not need to be changed. The following sections describe

how to modify the setup to suit your specific application, if required.

Important: Changes to the DIP switch settings are recognized only while the drive is

stopped.

Figure 8.4

Setup DIP Switch Selections

OFF (Factory Default) ONOFF ON

Run On Pow er Up

Speed Reference ➊

Relay Control Output

Auto Restart

T orque Curve

Stop

Reverse

Minimum Speed

Start Mode ➊

Parameter Mode ➋

Disabled

From Operator Controls

Running

Disabled

Variable

Coast-to-Rest

Enabled

0 Hz

From Operator Controls

From Setup Switches

Enabled

From Terminal Block

Faulted

Enabled

Constant

Ramp-to-Rest

Disabled (Rev erse Lockout)

From Terminal Block

From Terminal Block

From EEPROM Memory

➊

Switches 2 and 9 apply to local operator control units only.

➋

Switch 10 applies to the DeviceNet Communication option only.

8.3.1 Run On Power Up (Position 1)

Enabling this feature causes output power to be applied to the Motor Section

automatically at drive power up.

ATTENTION: When this feature is enabled, the drive may start at any

moment. This feature may only be used as outlined in NFPA79, Under

Voltage Protection for specialized applications. Equipment damage

and/or personal injury or loss of life may result if this feature is used in

an inappropriate application.

Important: If AC power is lost, the drive will restart if the unit is wired for 2-wire

control.

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 44

8-6 Step 8 - Verify the Setup and Adjust Switches if Required

The switch at position 1 enables or disables the run on power up function. When this

function is enabled, output power is applied to the Motor Section automatically at power

up if all run on power up permissive conditions are met. These conditions are:

• No faults are active.

• The terminal strip function loss input is closed.

• In terminal block start mode: In addition to the start permissive conditions listed

above, the terminal strip Start and Stop inputs must be closed.

• In operator control start mode: The unit will simulate a start signal edge; you do

not have to press the green key.

Settings (Position 1):

OFF position (Default) = Run On Power Up Disabled

ON position = Run On Power Up Enabled

8.3.2 Speed Reference Select (Position 2)

Important: This applies only to local operator control units.

The switch at position 2 is used to select whether the unit gets its speed reference from

the operator controls or from the analog input terminals. If this switch is set to the OFF

position, the speed reference will come from the operator controls. If this switch is set

to the ON position, the speed reference will come from the analog input terminals, and

the and keys are not functional.

Settings (Position 2):

OFF position (Default) = Speed Reference from Operator Controls

ON position = Speed Reference from Analog Input Terminals

8.3.3 Relay Control Output - Running or Faulted (Position 3)

The switch at position 3 specifies the type of status indication provided by the normally

open (N.O.) relay control output (control terminals 19 and 20). See Section 7.3 for a

description of control terminals 19 and 20. The relay can be used to indicate that the

unit is running (power is applied to the Motor Section) or has faulted (an active drive

fault exists).

Relay Control

Switch 3 Position State of Unit

OFF (Unit running indication selected)

ON (Unit faulted indication selected)

Running Closed

Stopped Open

No Faults Closed

Active Fault Open

Output Status

Settings (Position 3):

OFF position = Unit Running Indication (Default)

ON position = Unit Faulted Indication

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 45

Step 8 - Verify the Setup and Adjust Switches if Required 8-7

8.3.4 Auto Restart (Position 4)

ATTENTION: When this feature is enabled, the Drive Section will

restart automatically after an auto-restartable fault occurs (see T able 8.1).

This feature may only be used as outlined in NFPA79, Under Voltage

Protection for specialized applications. Equipment damage and/or

personal injury or loss of life may result if this feature is used in an

inappropriate application. An auto-restart can be canceled by pressing the

RESET

key or remote Reset device.

The switch at position 4 enables or disables the auto-restart function. If the auto-restart

function is enabled, the unit shuts down as usual upon the detection of a fault, waits five

seconds, and attempts to start automatically. If the fault reoccurs, the Drive Section

again waits five seconds before trying to start, up to a maximum of four attempts within

a five minute period. If the Drive Section f ails all these attempts, it remains in the faulted

state and displays the fault it is attempting to clear.

Auto Restart Countdown

As a precaution, the drive will visually count do wn for 5 seconds prior to an auto restart

attempt. The following character groups are displayed in sequence to indicate that the

countdown is in progress.

... ... ... ...

Table 8.1

Auto-Restartable Faults

Fault Code Description

Overcurrent

Overload

High bus voltage

Low bus voltage

Overtemperature

Settings (Position 4):

OFF position (Default) = Auto-Restart Disabled

ON position = Auto-Restart Enabled

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 46

8-8 Step 8 - Verify the Setup and Adjust Switches if Required

8.3.5 Torque Curve (Position 5)

The switch at position 5 selects either a variable torque curve or a constant torque curve.

The variable torque selection provides a squared V/Hz curve and 110% electronic

thermal overload and 110% current limit for one minute. The constant torque selection

provides a linear V/Hz curv e and 150% electronic thermal ov erload and 150% current

limit for one minute.

Figure 8.5

Torque Curve

Output

Voltage

Settings (Position 5):

OFF position (Default) = Variable Torque Curve

ON position = Constant Torque Curve

8.3.6 Stop Type (Position 6)

The switch at position 6 selects how the motor will stop when the Stop input is asserted

(or the red key is pressed). A coast-to-rest stop turns off the transistor po wer device

drivers. A ramp-to-rest stop continues to switch the transistor power de vice drivers until

the output frequency equals 0 Hz (decelerating the motor at a rate based on the accel /

decel switch setting), and then turns off the power device drivers.

Settings (Position 6):

CT

Hz

VT

Base

Frequency

OFF position = Coast-to-Rest (Default)

ON position = Ramp-to-Rest

1329I-5.5 Integrated Drive/Motor — January, 2000

Page 47

Step 8 - Verify the Setup and Adjust Switches if Required 8-9

8.3.7 Reverse Disable (Position 7)

The switch at position 7 enables or disables reverse rotation of the motor . It is factory-set

to enable a forward-to-reverse change of motor direction. If this switch is in the ON

position, the reverse direction is disabled (locked out). In other words, the motor can

run in the forward direction only.

Settings (Position 7):

OFF position = Reverse Enabled (Forward/reverse change allowed; default)

ON position = Reverse Disabled (Reverse direction prohibited)

8.3.8 Minimum Speed Select (Position 8)