Page 1

Installation Instructions

1326AB Absolute Encoder Feedback

Mounting Adapter Kit

(Catalog No. 1326AB-MOD-Mx2)

Introduction

What This Kit Contains

This publication will guide you through the installation of Bulletin

842A-31-xx absolute encoders to 1326AB servo motors.

Use the information in the following table to verify that you have

received the correct kit for your motor

This adapter kit:

1326AB-MOD-M42 1326AB-B4

1326AB-MOD-M52 1326AB-B5

1326AB-MOD-M72 1326AB-B7

Couples 842A encoders to

this servo motor:

xxxx

xxxx

xxxx

.

Verify that your mounting adapter kit contains the items listed in the

following table. If you r kit does not contai n t he correct items, cont act

your Allen-Bradley sales representative.

Quantity: Description:

1 Encoder adapter

1 Coupling

1 Gasket, endbell

2 Inspection plug

1

3-6

3 Encoder screws

1 7/64 Allen wrench

1 Coupling instruction sheet

1

Number of adapter screws vary with size of motor.

Adapter screws

Page 2

2

1326AB Absolute Encoder Feedback Mounting Adapter Kit

Installing the Encoder Feedback Mounting Adapter Kit

Important: This adapter is designed to accept Allen-Bradley 842A

encoders only.

ATTENTION: To avoid a shock hazard, ensure that

all power to the moto r is remo ved befor e inst alli ng th e

!

To install the encoder feedback mounting adapter kit:

1. Remove the back plate and gasket from the end of the motor

(discard the old gasket). Refer to Figure 3 for an overview of the

installation.

2. Thoroughly clean the shafts, coupling bores, and mounting faces

to remove oil or any other substance that may be present.

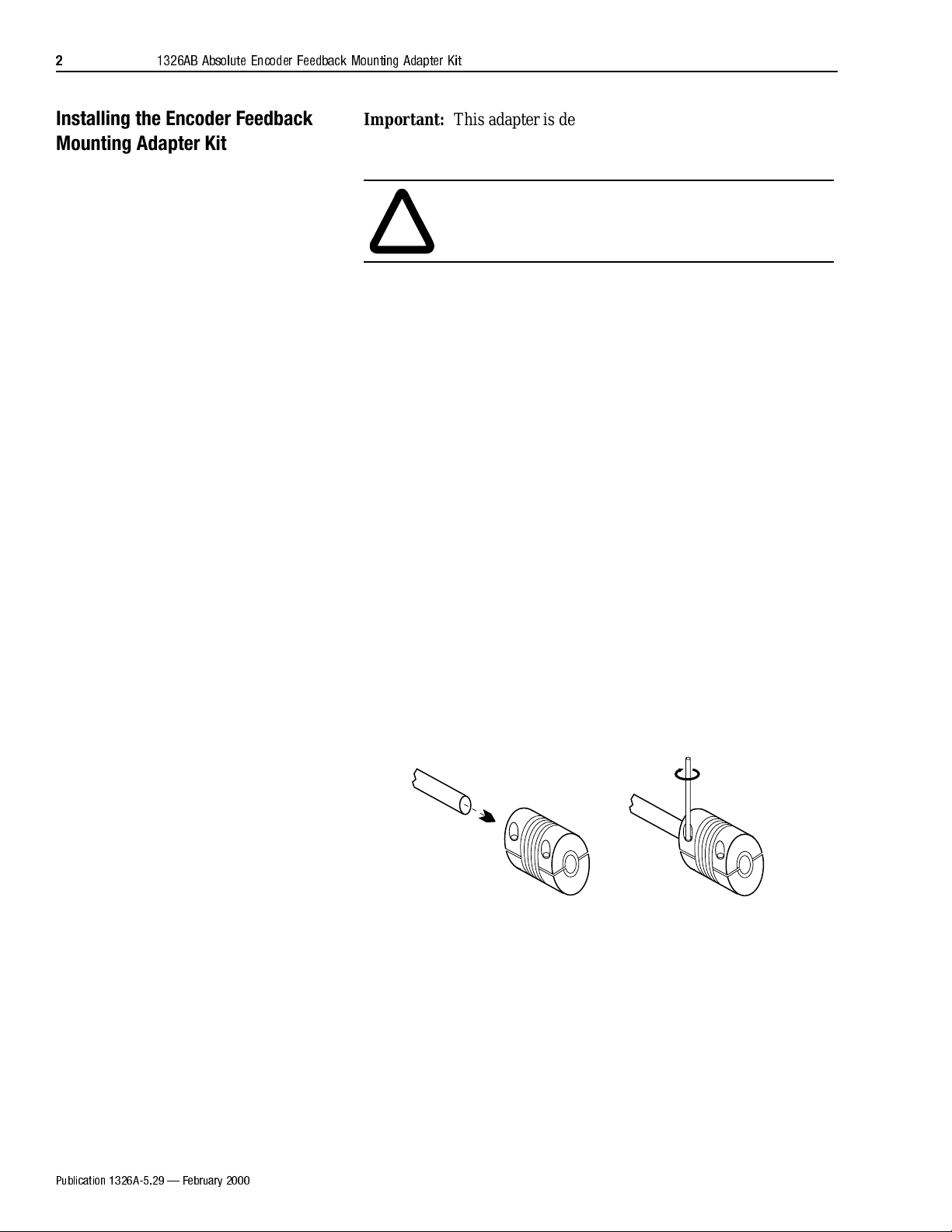

3. Using the allen wrench supplied in the kit, attach the flexible

coupling to the stub shaft of the motor (refer to Figure 1 below).

When tightening, use no more than 1.8-2.0 N-m (16-18 lb-in.) of

torque. The shaft must be visible through the spacings in the

coupling.

adapter.

Important: The flexible coupling contains an insulating sleeve

on one end. The sleeve guards against motor

generated heat migrating to the encoder. The

coupling end with the insulating sleeve must be

positioned towards the encoder.

Figure 1

Attaching the Coupling to Motor Shaft

Motor Shaft

Coupling

Important: The coupling is a fle xib le t ype t hat must b e ins tall ed

in a relaxed state (not compressed or stretched).

Installation in the compressed state will limit the

ability of the coupling to flex adequately.

Installation in a stretched condition might exceed

the couplings yield point when flexed. Either

condition will shorten the life of the coupling.

Publication 1326A-5.29 February 2000

4. Attach the en coder to the adapter using the screws supplied.

Tighten the scre ws usi ng no more than 2. 3-2.8 N- m (20- 25 lb -in.)

of torque.

Page 3

1326AB Absolute Encoder Feedback Mounting Adapter Kit

3

5. Apply the new endbell gasket on the adap te r, position the ada pter

assembly onto the back of the mot or, and insert the encoder shaft

into the coupling.

6. Attach the ad apter to the mo tor using the screws supplied.

Tighten the screws usi ng no more than 2.3-2. 8 N-m ( 20-25 lb-i n.)

of torque.

7. Remove the in spection plugs on the side of the adapter to gain

access to the coupling.

8. Rotate the co upling in relation to the unfastened sha ft, allowing

the coupling to seek a normal resting position.

Figure 2

Bringing the Coupling to its Normal Resting Position

Motor Shaft

Coupling

Encoder Shaft

9. Tighten the coupli ng onto t he encoder s haft. When tightening, use

no more than 1.8-2 .0 N-m (16- 18 lb-i n.) of t orque. The shaft must

be visible through the spacings in the coupling.

10. Replace the inspection plugs.

Important: Ensure that the coupling is not compressed or

stretched after it has reached its normal resting

position.

11. Check for proper operation.

Publication 1326A-5.29 February 2000

Page 4

Figure 3

Encoder screws (3)

Encoder Feedback Mounting Adapter Overview

(remove and discard)

Gasket

Access to Coupling

Coupling

1326AB Motor

1

Number of screws will vary with size of motor.

Adapter screws

1

Adapter

(side view)

83.3 mm (3.28 in.) Maximum for All Motors

Adapter

(rear view)

842A

Encoder

Publication 1326A-5.29 — February 2000 191629

2000 Rockwell International. All rights reserved. Printed in USA

Loading...

Loading...