Page 1

Allen-Bradley

1394 Digital AC

Multi-Axis

Motion Control

System

(Catalog No. 1394-50)

User

Manual

Page 2

Important User Information

Because of the variety of uses for the products described in this

publication, those res ponsible for the application and use of this control

equipment must sati sfy themselves that all nec essary steps have been

taken to ass ure that each applica tion and use meets al l performance and

safety requiremen ts, inclu ding any a pplicable l aws, re gulations, c odes

and standards.

The illustrations, c harts, sample progr ams and layout ex amples shown

in this guide ar e inte nded so lely f or pur poses of exa mple . Since ther e

are many variables and requirements associated with any particular

installation, Allen-Bradley does not assume responsibility or liability

(to include intellec tual property liabil ity) for actual use based upon the

examples shown in this publication.

Allen-Bradley publication SGI-1.1, Safety Guidelines for the

Application, Installation, and Maintenance of Solid-State Control

(ava ilable from your local Allen-Bradley off ice), describes some

important differences between solid-state equipment and

electromechanical de vices that should be taken into consid eration when

applying products such as those described in thi s publication.

Reproduction of the content s of this copyri ghted publication, in whole

or in part, without writte n permission of Allen-Bradley Compa ny , Inc.,

is prohibited.

Throughout this manua l we use notes to make you aware of safet y

considerations:

ATTENTIO N: Identifies information about practices

or circumstances that can lead to personal injury or

!

Attention statements help you to:

• identify a hazard

• avoid the hazard

• recognize the consequences

Important: Identifies information that is critical for successful

GML, IMC, Flex I/O, PanelView, Data Highway Plus, SCANport, SLC, SLC 5/03, SLC 5/04, and SLC 5/05 are t rademarks of

Allen-Bradley Company, Inc.

PLC is a registered trademark of Allen-Bradley Company, Inc.

death, property damage or economic loss.

application and understanding of the product.

Page 3

Table of Contents

Preface

Overview

Who Should Use this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Purpose of this Manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-1

Contents of this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-2

Related Documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

Conventions Used in this Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

Module Series Designator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-3

1394 Product Receiving and Storage Responsibility . . . . . . . . . . . . . . . . .P-4

Allen-Bradley Support. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Local Product Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Technical Product Assistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .P-4

Chapter 1

The 1394 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Series Note . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-2

1394 System Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

GMC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-3

CNC Interface System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5

SERCOS System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6

Analog Servo System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-7

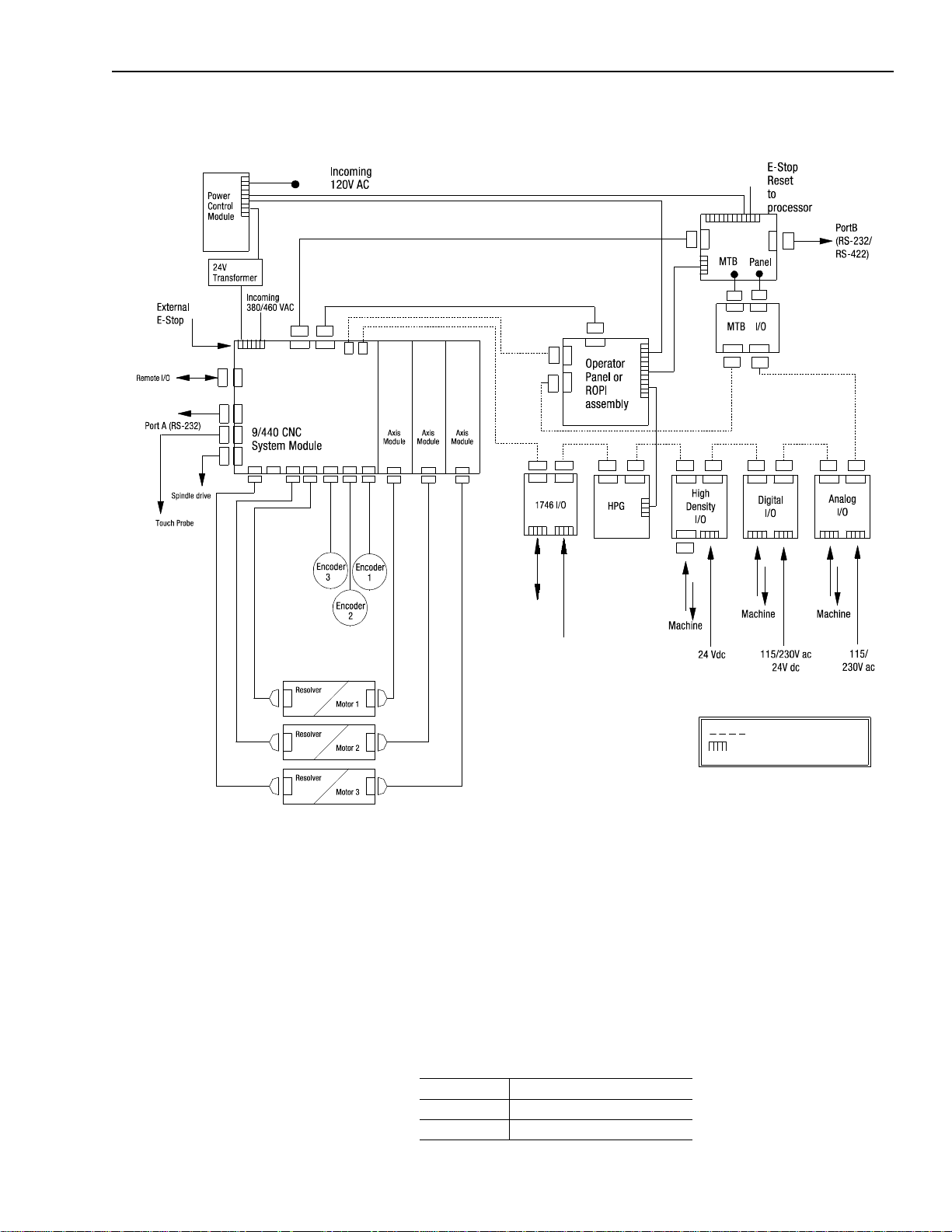

9/440 CNC System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 -8

What is a 1394 System?. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-9

System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-10

Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-11

External Shunt Module (used with 22 kW System) . . . . . . . . . . . . . . .1-11

1326AB Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1326AS Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-12

1326AH Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13

Drive Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

DC Link Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-14

Standard Features of the 1394 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-15

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Integration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16

Installing Your 1394

(applies to all systems)

Chapter 2

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Complying With European Union Directives. . . . . . . . . . . . . . . . . . . . . . . .2-1

EMC Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-1

Low Voltage Directive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -2

Before Mounting Your System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Storing Your 1394 Before Installation . . . . . . . . . . . . . . . . . . . . . . . . . .2-2

Unpacking Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

System Mounting Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-3

Determining Your System Mounting Hole Layout . . . . . . . . . . . . . . . . .2-4

Mounting Your 1394 Through the Back of the Cabinet . . . . . . . . . . . . .2-6

Bonding Your System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Bonding Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2-6

Bonding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 -8

Publication 1394-5.0 — May 2000

Page 4

ii Table of Contents

Wiring System, Axis, and Shunt

Modules, and Motors

(for all systems)

Mounting Your 1394 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-8

Mounting Your 1394-DCLM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-11

Mounting the External Shunt Resistor for 5 and 10 kW System Modules 2-11

Mounting External Shunt Modules for 22 kW System Modules. . . . . . . . 2-11

Shunt Module Mounting Orientation . . . . . . . . . . . . . . . . . . . . . . . . . . 2-12

Shunt Module Mounted Outside the Cabinet . . . . . . . . . . . . . . . . . . . 2-13

Shunt Module Mounted Inside the Cabinet . . . . . . . . . . . . . . . . . . . . . 2-14

Mounting the Shunt Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-15

Mounting Considerations for GMC and GMC Turbo Systems . . . . . . . . . 2-16

Mounting GMC and GMC Turbo Systems Next to Flex I/O . . . . . . . . . 2-16

Chapter 3

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Finding Additional Wiring Information for 1394 Systems . . . . . . . . . . . . . . 3-1

Understanding Basic Wiring Requirements. . . . . . . . . . . . . . . . . . . . . . . . 3-2

Routing High and Low Voltage Cables . . . . . . . . . . . . . . . . . . . . . . . . . 3-3

System Module Wire Sizes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

EMI/RFI Shielding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

EMI/RFI Bonding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Input Power Conditioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Determining Your Type of Input Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Grounded Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-6

Ungrounded Power Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

Setting the Ground Jumper in a 5 or 10 kW System Module for

Ungrounded Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 3-8

Setting the Ground Jumper in a 22 kW System Module for

Ungrounded Power Configurations . . . . . . . . . . . . . . . . . . . . . . . . . 3-9

Grounding Your 1394 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Grounding your System to the Subpanel . . . . . . . . . . . . . . . . . . . . . . 3-12

Grounding Multiple Subpanels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Wiring System Module Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-13

Terminal Block Locations for 5 and 10 kW System Module

(Series A and B) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-14

Connector Locations for 5 and 10 kW System Module (Series C) . . . 3-15

Terminal Block Locations for a 22 kW System Module . . . . . . . . . . . . 3-16

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Connecting Power Wiring for 5 and 10 kW (Series A and B)

and 22 kW System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Connecting Power Wiring for 5 and 10 kW System Modules

(Series C) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Connecting Motor Power to Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . 3-19

Connecting Thermal and Brake Leads to Axis Modules . . . . . . . . . . . 3-20

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-20

Wiring Motor Power, Thermals and Brakes . . . . . . . . . . . . . . . . . . . . . 3-21

Connecting Feedback to System Modules. . . . . . . . . . . . . . . . . . . . . . . . 3-24

Connecting Your Motor Cables to Motors. . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Connecting Your External Shunt Resistor . . . . . . . . . . . . . . . . . . . . . . . . 3-26

Connecting Your External Shunt Resistor (Series A and B) . . . . . . . . 3-27

Connecting Your External Shunt Resistor (Series C) . . . . . . . . . . . . . 3-28

Publication 1394-5.0 — May 2000

Page 5

Wiring 1394 GMC and GMC Turbo

Systems

Table of Contents iii

Connecting Your Shunt Module (required for 22 kW system) . . . . . . . . . 3-28

Required Tools and Equipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-28

Wiring the Shunt Module Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-29

Wiring Shunt Module Fan Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-33

Chapter 4

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Finding Additional Wiring Information for 1394 Systems. . . . . . . . . . . . . . 4-1

Understanding GMC and GMC Turbo Wiring and Connections . . . . . . . . 4-1

Understanding Input Wiring Board Layout. . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Using the Terminal Operating Tool to Insert Wires . . . . . . . . . . . . . . . . 4-4

Input Wiring Board Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 4-5

Connecting Your Communication Cables . . . . . . . . . . . . . . . . . . . . . . . . . 4-7

Encoder Feedback Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-10

Serial Communications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-11

Data Highway Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-13

AxisLink . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-14

GMC Turbo System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-15

Remote I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

Flex I/O . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-16

SLC Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-17

Connecting a GMC and GMC Turbo to a 1394-DIM . . . . . . . . . . . . . . . . 4-19

1394-DIM System Example . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-19

1394-DIM with 1398-DDM-

1394-DIM Configurations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-21

Configuration Examples . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-22

1394-System Module Input Power Wiring When

Not Using Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Understanding DIM Signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

DROK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-24

Drive Enable Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Analog Output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25

Wiring and Configuring an External Drive to the 1394-DIM. . . . . . . . . . . 4-26

Connecting the Remote Drive to the DIM Connector . . . . . . . . . . . . . 4-26

Connecting the Position Feedback Encoder to the Feedback Input . . 4-29

Connecting the DIM Ground Wire to the 1394 System Ground . . . . . 4-30

Installing the Resolver Feedback Input Plug . . . . . . . . . . . . . . . . . . . 4-30

xxx

System Example . . . . . . . . . . . . . . . . 4-20

Wiring Your 1394 Analog Servo System

Chapter 5

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

Finding Additional Wiring Information for 1394 Systems. . . . . . . . . . . . . . 5-1

Understanding Analog Servo Wiring and Connections . . . . . . . . . . . . . . . 5-1

Input Wiring Board Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-2

Using the Terminal Operating Tool to Insert Wires . . . . . . . . . . . . . . . . 5-2

Input Wiring Board Signal Descriptions . . . . . . . . . . . . . . . . . . . . . . . . 5-4

Connecting AQB and SCANport Cables . . . . . . . . . . . . . . . . . . . . . . . . . . 5-5

Analog Servo Encoder (A Quad B) Wiring . . . . . . . . . . . . . . . . . . . . . . 5-5

SCANport Adapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-7

Publication 1394-5.0 — May 2000

Page 6

iv Table of Contents

Commissioning 1394 GMC and GMC

Turbo Systems

Commissioning Your 1394 Analog

Servo System

Chapter 6

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

General Startup Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

Applying Power to the System. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-2

Setting Up Your System Using GML Commander . . . . . . . . . . . . . . . . . . . 6-3

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-3

Preparing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-4

Setting Up Your System Using GML 3.x.x . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Preparing the System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-5

Chapter 7

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

General Startup Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

Setting Up Your 1394 Analog Servo System . . . . . . . . . . . . . . . . . . . . . . . 7-2

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Exiting Before You’re Finished . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Continuing From Where You Left Off . . . . . . . . . . . . . . . . . . . . . . . . 7-2

Removing and Re-Applying Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-3

Setting Up at the System Level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

Setting Up Analog Test Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Defining Your Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-5

Defining a Reference Source for Your Axes . . . . . . . . . . . . . . . . . . . . . 7-6

Defining Analog Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-7

Defining Analog Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Defining Digital Velocity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Defining Digital Torque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Defining Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-10

Auto Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Before You Perform an Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Performing the Auto Tune . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11

Configuring Your 1394 Analog Servo

System

Troubleshooting

Publication 1394-5.0 — May 2000

Chapter 8

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

Where to Look fo r Other Programming Information. . . . . . . . . . . . . . . . . . 8-1

Conventions Used in this Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-2

Understanding Analog Servo System Parameters. . . . . . . . . . . . . . . . . . . 8-3

1394 Analog Servo Software Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . 8-28

Chapter 9

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

Understanding How to Detect a Problem. . . . . . . . . . . . . . . . . . . . . . . . . . 9-2

Understanding System and Axis Module LEDs . . . . . . . . . . . . . . . . . . . . . 9-2

Understanding System Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Finding GMC Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Viewing Instantaneous Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-5

Viewing Continuous Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-6

Finding Analog Servo System Faults . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Page 7

Table of Contents v

Finding 9/440 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-7

Finding CNC Interface Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-8

Understanding GMC Turbo and GMC Controller Faults. . . . . . . . . . . . . . . 9-9

Understanding Analog Servo System Module Faults . . . . . . . . . . . . . . . 9-10

Understanding Analog Servo System Axis Faults . . . . . . . . . . . . . . . 9-12

Troubleshooting General System Problems. . . . . . . . . . . . . . . . . . . . . . . 9-13

Replacing System and Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-16

Removing an Axis Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-17

Installing a Replacement Axis Module . . . . . . . . . . . . . . . . . . . . . . . . 9-18

Removing a System Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-19

Installing a Replacement System Module . . . . . . . . . . . . . . . . . . . . . 9-20

Replacing System Modules of the Same Series . . . . . . . . . . . . . . 9-22

Replacing System Modules of a Different Series . . . . . . . . . . . . . . 9-22

Completing Connections and Downloading Parameters . . . . . . . . 9-22

Checking fo r a Blown Fuse in the 1394-DCLM . . . . . . . . . . . . . . . . . . . . 9-23

Replacing the 1394 Shunt Module Fuse . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Replacing the 1394-SR10A Fuse . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-25

Replacing the 1394-SR9A, -SR9AF, -SR36A, and -SR36AF Fuse . . 9-26

Replacing the AM50 and AM75 Axis Module Fan. . . . . . . . . . . . . . . . . . 9-28

Removing the Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-28

Installing the New Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-31

Specifications

Appendix A

Chapter Objectives . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

Certification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1

System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-2

Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

Contact Ratings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-3

DC Link Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Drive Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

Filters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-4

User-Supplied Contactor (M1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

User-Supplied Line Input Fusing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-5

User-Supplied 24V Logic Input Power . . . . . . . . . . . . . . . . . . . . . . . . . A-5

Input Transformer for 24V Control Power . . . . . . . . . . . . . . . . . . . . . . . A-6

User-Supplied 5V Auxiliary Encoder Power Supply . . . . . . . . . . . . . . . A-6

Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-6

External Shunt Resistor Kit for 5 and 10 kW Systems . . . . . . . . . . . . . A-8

1394 Shunt Module for the 22 kW System . . . . . . . . . . . . . . . . . . . . . . A-8

Environmental Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-9

Power Dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-10

DC Link Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Drive Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Internal Shunt Resistor for the 5 and 10 kW System (standard) . . . . A-11

Communication Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Encoder Input Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-11

Publication 1394-5.0 — May 2000

Page 8

vi Table of Contents

Interconnect and CE Diagrams

Dedicated Discrete I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . A-12

Serial I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-12

DH-485 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

Flex I/O Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-13

GMC System Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-14

Remote I/O Adapter Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . .A-15

AxisLink Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-16

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-17

1394 System Module Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . A-17

Axis Module Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-18

Filter Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-20

External Shunt Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-22

Motor Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-25

Servo Motor Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-32

1326AB Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-32

1326AS Performance Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-33

Appendix B

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1

GMC, Analog Servo, and CNC Interface Interconnect Diagrams. . . . . . . . B-2

1394 GMC Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-3

1394 Analog Servo Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . B-9

1394 CNC Interconnections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-12

Thermal Interconnect Diagrams. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-14

1394 GMC Systems (1394x-SJTxx-C and -T) . . . . . . . . . . . . . . . . . . B-15

1394 GMC Systems (1394C-SJTxx-L) . . . . . . . . . . . . . . . . . . . . . . . . B-19

1394 Analog Servo Systems (1394x-SJTxx-A) . . . . . . . . . . . . . . . . . B-21

Cable Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-23

1326 Cable Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-23

1394 Cable Pin-outs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-26

Grounding for 1394 CE Requirements . . . . . . . . . . . . . . . . . . . . . . . .B-30

Using the Human Interface Module

(HIM)

Publication 1394-5.0 — May 2000

Appendix C

Chapter Objectives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

The Human Interface Module (HIM). . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1

Understanding HIM Keys . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-2

Understanding HIM Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-4

Understanding HIM Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Display Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Program Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Link Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Startup Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

EEProm Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-5

Search Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Control Status Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Password . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Linking Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-6

Using Copy Cat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-7

Copying a System’s Information . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-8

Page 9

Catalog Numbers

Table of Contents vii

Pasting a System’s Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-9

Auto Tuning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-10

Getting an Overview of HIM Programming . . . . . . . . . . . . . . . . . . . . . C-11

Removing the HIM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . C-14

Removing the HIM from the HIM Cradle . . . . . . . . . . . . . . . . . . . . . . C-14

Disconnecting the HIM from the System Module . . . . . . . . . . . . . . . . C-14

Setting Up the HIM fo r Hand-Held Use . . . . . . . . . . . . . . . . . . . . . . . C-15

Placing the HIM in the HIM Cradle . . . . . . . . . . . . . . . . . . . . . . . . . . . C-16

Appendix D

Understanding Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

Determining Catalog Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-1

System Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

1394 System Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-2

9/440 System Module (Resolver based systems) . . . . . . . . . . . . . . . . D-2

CNC Serial Drive System Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-3

9/440 High Resolution/Absolute CNC System Module . . . . . . . . . . . . D-3

Axis Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

External Shunt Modules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-4

Shunt Resistor Kit for 5 and 10 kW System Modules . . . . . . . . . . . . . . D-4

Shunt Modules for 22 kW System Modules . . . . . . . . . . . . . . . . . . . . . D-4

System Module Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Control Interface Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Single Axis Flying Lead Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

Two-Axis Prewired Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-5

1326AB Servo Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-6

1326 Shaft Oil Seal Kit for 1326AB Motors . . . . . . . . . . . . . . . . . . . . . D-6

Motor Junction Box Kit for 1326AB Motors . . . . . . . . . . . . . . . . . . . . . . D-7

Feedback Mounting Adapter Kit for 1326AB Motors . . . . . . . . . . . . . . D-7

1326AS Servo Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-8

1326 Shaft Oil Seal Kit for 1326AS Motors . . . . . . . . . . . . . . . . . . . . . D-8

Motor Junction Box Kit for 1326AS Motors . . . . . . . . . . . . . . . . . . . . . . D-9

Feedback Mounting Adapter Kit for 1326AS Motors . . . . . . . . . . . . . . D-9

1326AH Servo Motors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-10

Power and Feedback Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Motor Power Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-11

Motor Feedback Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-12

Encoder Feedback Cables for 1326AB Motors . . . . . . . . . . . . . . . . . D-12

Miscellaneous Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D-13

Publication 1394-5.0 — May 2000

Page 10

viii Table of Contents

Publication 1394-5.0 — May 2000

Page 11

Preface

Read this preface to familiarize yourself with the rest of the manual. This

preface co vers the following topics:

• Who should use this manual

• The purpose of this manual

• Contents of this manual

• Related documentati on

• Conventions used in this manual

• 1394 product receiving and storage responsibility

• Allen-Bradley support

Who Should Use this Manual

Purpose of this Manual

Use this manual if you are respons ible for designing, inst al ling,

programming, or troubles hooting the Allen-Bradley 1394 fa mily of

products.

If you do not have a basic understanding of the 1394, contact your local

Allen-Bradley re presenta tiv e for inf ormation on a va ilable traini ng courses

before using this product.

This manual is a user guide for the 1394. It gives you an overview of the

1394 family and describes the procedures you use t o install, set up, us e ,

and troubleshoot the 1394.

Publication 1394-5.0 — May 2000

Page 12

P-2 Preface

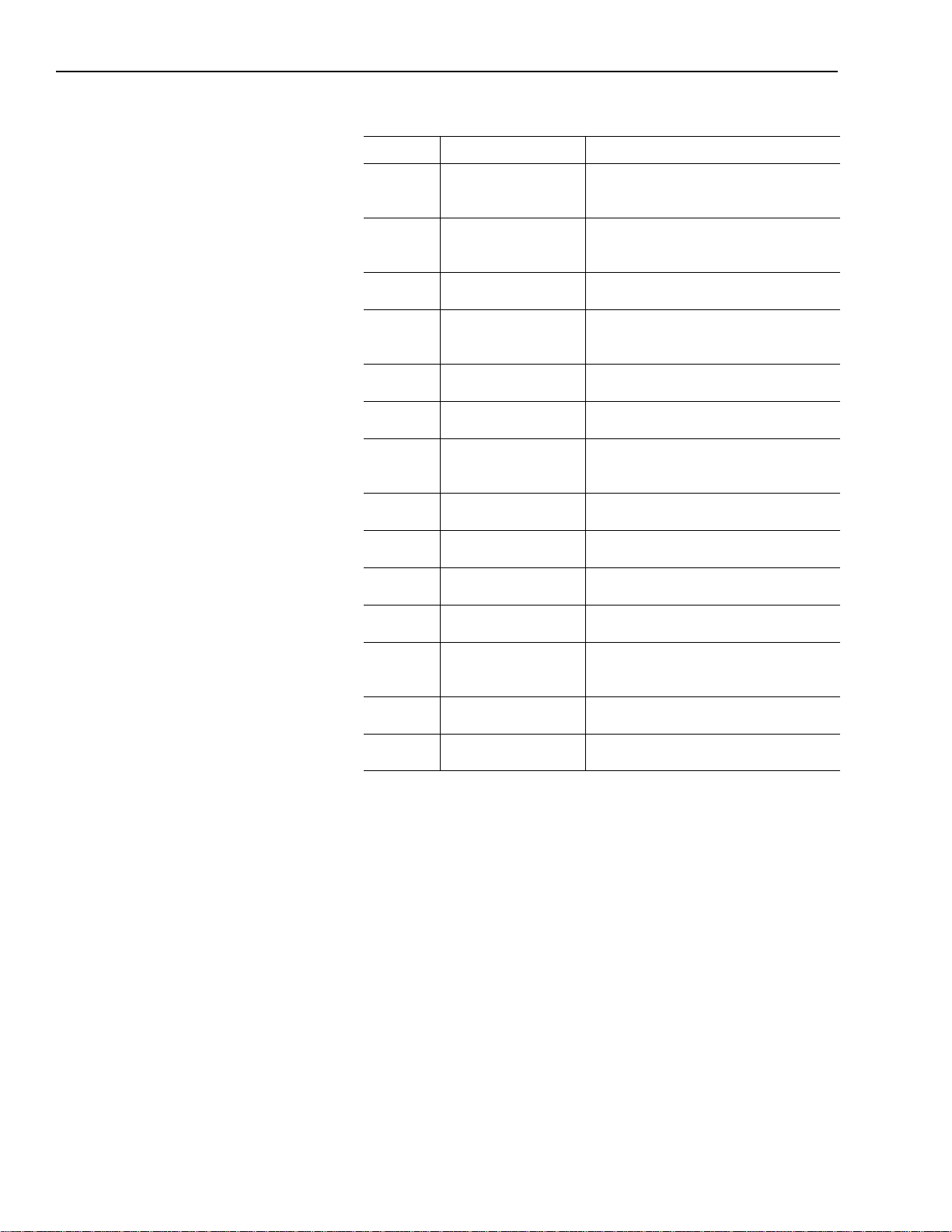

Contents of this Manual

Chapter Title Contents

Preface Describes the purpose, background, and scope

of this manual. Also specifies the audience for

whom this manual is intended.

1

Overview Explains and illustrates the theory behind the

1394’s operation. Covers hardware and software

features.

2

3

4

5

6

7

8

9

Appendix A

Appendix B

Appendix C

Appendix D

Installing Your 1394

(applies to all systems)

Wiring System, Axis, and

Shunt Modules, and

Motors (for all systems)

Wiring 1394 GMC and

GMC Turbo Systems

Wiring Your 1394 Analog

Servo System

Commissioning 1394

GMC and GMC Turbo

Systems

Commissioning Your 1394

Analog Servo System

Configuring Your 1394

Analog Servo System

Troubleshooting Explains how to interpret and correct problems

Specifications Provides physical, electrical, environmental, and

Interconnect and CE

Diagrams

Using the Human Interface

Module (HIM)

Catalog Numbers Provides catalog number descriptions of 1394

Provides mounting information for your 1394

system.

Provides information on how to connect your

1394 system components together.

Provides information on how to wire your 1394

GMC and GMC Turbo System Mod ules.

Provides information on how to wire your 1394

Analog Servo System Module.

Provides information about parameters used to

configure your 1394 GMC and GMC Turbo.

Provides information about parameters used to

configure your 1394 Analog Servo Module.

Provides supplemental information on using

communication tools.

with your 1394 system.

functional specifications for the 1394.

Provides diagrams showing the interconnections

for the available 1394 configurations and

installation requirements to meet CE directives.

Provides information that will help you to use the

HIM.

and related products.

Publication 1394-5.0 — May 2000

Page 13

Preface P-3

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

Related Documentation

The following doc u ments contain additional information conce rning

related All en-Bradley produc ts. To obtain a copy, contact your local

Allen-Bradley office or distributor.

For: Read This Document: Document Number:

A description and specifications for the 1394 family 1394 Digital, AC, Multi-Axis Motion Control

System Product Data

A description and specifications for the 1326A Torque Plus

Motors used with the 1394

A description and specifications for the 1326A Rare Earth

Motors used with the 1394

Product information regarding cables used with the 1326AB and

1326AB 460V, Torque Plus Series, AC Servo

Motors Product Data

1326AS Series 460V, Low Inertia, Brushless

Servo Motors Product Data

1326 Cables for 460V AC Servo Motors 1326A-2.11

1326AS motors

A user guide for GML

programming to be used with the 1394

GML Commander Reference Manual GMLC-5.2

GMC System.

An overview of the Flex I/O

products Flex I/O Product Profile 1794-1.14

Specifications for the Flex I/O products Flex I/O Product Data 1794-2.1

An overview of the PanelView

550/600 product PanelView 550/600 Product Profile 2711-1.13

An overview of the 9/Series products 9/Series CNC Product Profile 8520-1.3

A manual that provides you information on RIO communications Installation Guidelines for the Twinaxial Cable 92-D1770-BCO

A manual that assists you with integrating and maintaining the

9/Series Integration and Maintenance Manual 8520-6.2

9/Series to be used with the 1394 CNC Interface System

An article on wire sizes and types for grounding electrical

National Electrical Code Published by the National Fire

equipment

A glossary of industrial automation terms and abbreviations Allen-Bradley Industrial Automation Glossary AG-7.1

1394-2.0

1326A-2.9

1326A-2.10

Protection Association of Boston, MA.

Conventions Used in this Manual

Module Series Designator

The following conventions are used throughout this manual:

• Bulleted lists su ch as this one pro vide in formation, not procedural

steps.

• Numbered lists provide sequential steps or hierarchical

information.

• Words that you type or select appear in bold.

• When we refer you to another location, the section or chapter

name appears in italics .

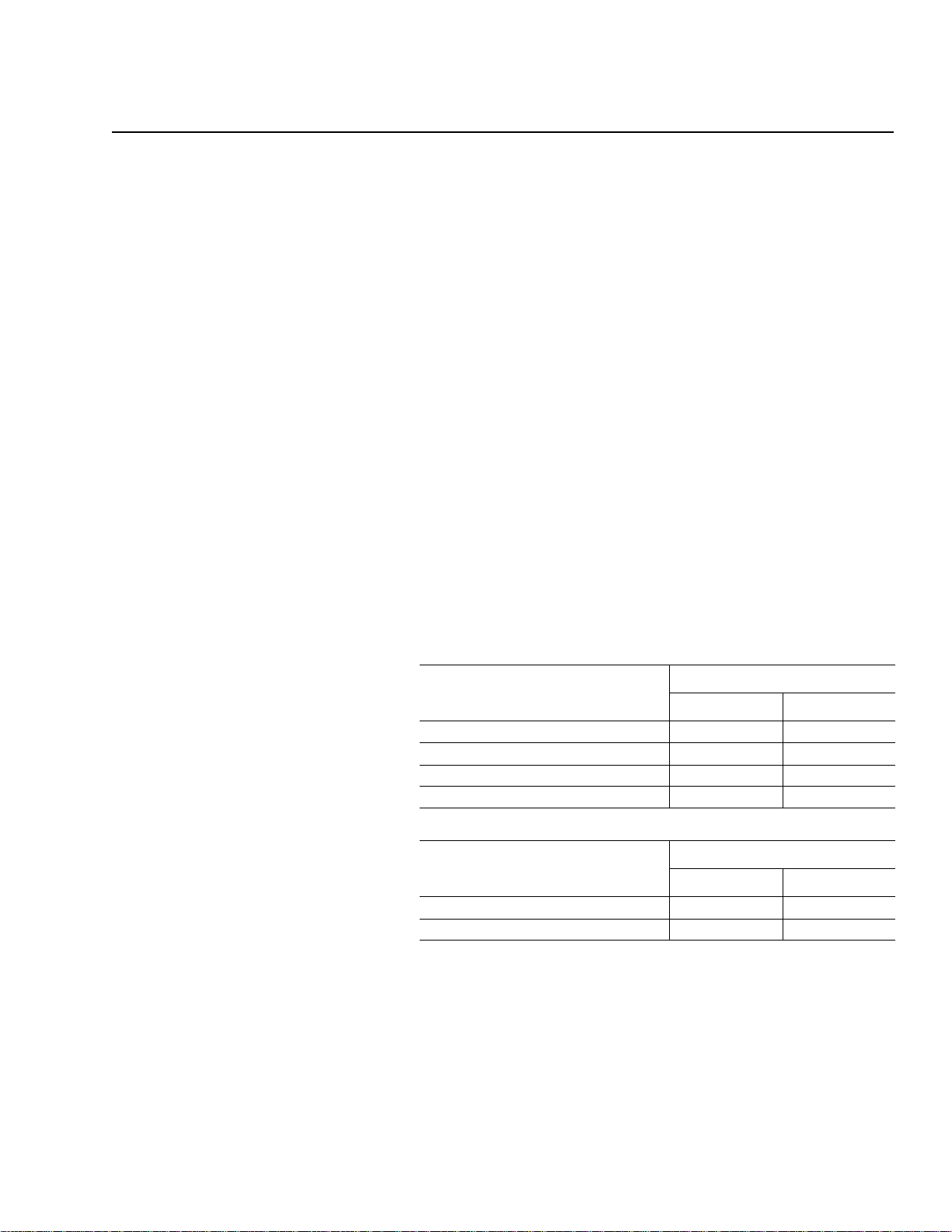

To determine the series designator, check the seri es f ie ld on the Alle nBradley label attached to your system, axis, and shunt modules. The

series designator is located as shown in the example below.

Figure P.1

Allen-Bradley Label

ALLEN-BRADLEY

BULLETIN 1394 300W SHUNT MODULE

CAT.

INPUT DC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

PART

R

SER.

INPUT AC

Series Field

Shunt Module Example

1394 Digital Servo Controller

300W Shunt Module

ALLEN-BRADLEY

R

BULLETIN 1394 300W SHUNT MODULE

CAT. PART SER.

INPUT DC INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

Publication 1394-5.0 — May 2000

Page 14

P-4 Preface

1394 Product Receiving and Storage Responsibility

Allen-Bradley Support

You, the customer, are responsible for thoroughly inspecting the

equipment before accept ing the shipment from the freight company.

Check the item(s) you receive against your purchase order. If any

items are obviously damaged, it is your responsibility to refuse

delivery until the freight agent has noted the damage on the freight

bill. Should you discover any concealed damage during unpacking,

you are responsible for not ifying the freig ht agent. Lea ve the shipping

container intact and request that the freight agent make a visual

inspection of the equipment.

Leave the pro duct in its shi pping contai ner prior to installat ion. If you

are not going to use the equipment for a period of time, store it:

• in a clean, dry location

• within an ambient temperature range of 0 to 65° C (32 to 149° F)

• within a relative humidity range of 5% to 95%, non-condensing

• in an area where it cannot be exposed to a corrosive atmosphere

• in a non-construction area

Allen-Bradley offers support services worldwide, with over 75 Sales/

Support Offices, 512 authorized Distributors and 260 authorized

Systems Integrators located throughout the United States alone, plus

Allen-Bradley representatives in every major country in the world.

Local Product Support

Contact your local All en-Bradley representat ive for:

• sales and order support

• product technical traini ng

• warranty support

• support service agreements

Technical Product Assistance

If you need to contact Allen-Bradley for technical assistance, please

review the information in the Troubleshooting chapter first. Then call

your local Allen-Bradley representative. For the quickest possible

response, please have the catalog numbers of your products available

when you call.

Publication 1394-5.0 — May 2000

Page 15

Overview

Chapter

1

The 1394 System

The 1394 is a modular, multi-axis motion control and drive system

family. Its unique design allows the 1394 to be used as an integrated

motion controller and drive sys te m (GMC) with Turbo or standard

IMC S Class Compact functionality, an integrated 9/440 CNC

system, a 9/Series CNC digital interface drive system, a SERCOS

servo drive system, or an analog serv o drive system.

All 1394 systems pro vide direct line conne ction (transformerless) for

360 and 480V three-phase input power, efficient IGBT power

conv e rsi on, and slide-and-lock, module-to -module connection

systems. Each system module can be configured with up to four axis

modules, with each axis module interfacing to a motor. The 1394

provides significant panel space and interconnect savings.

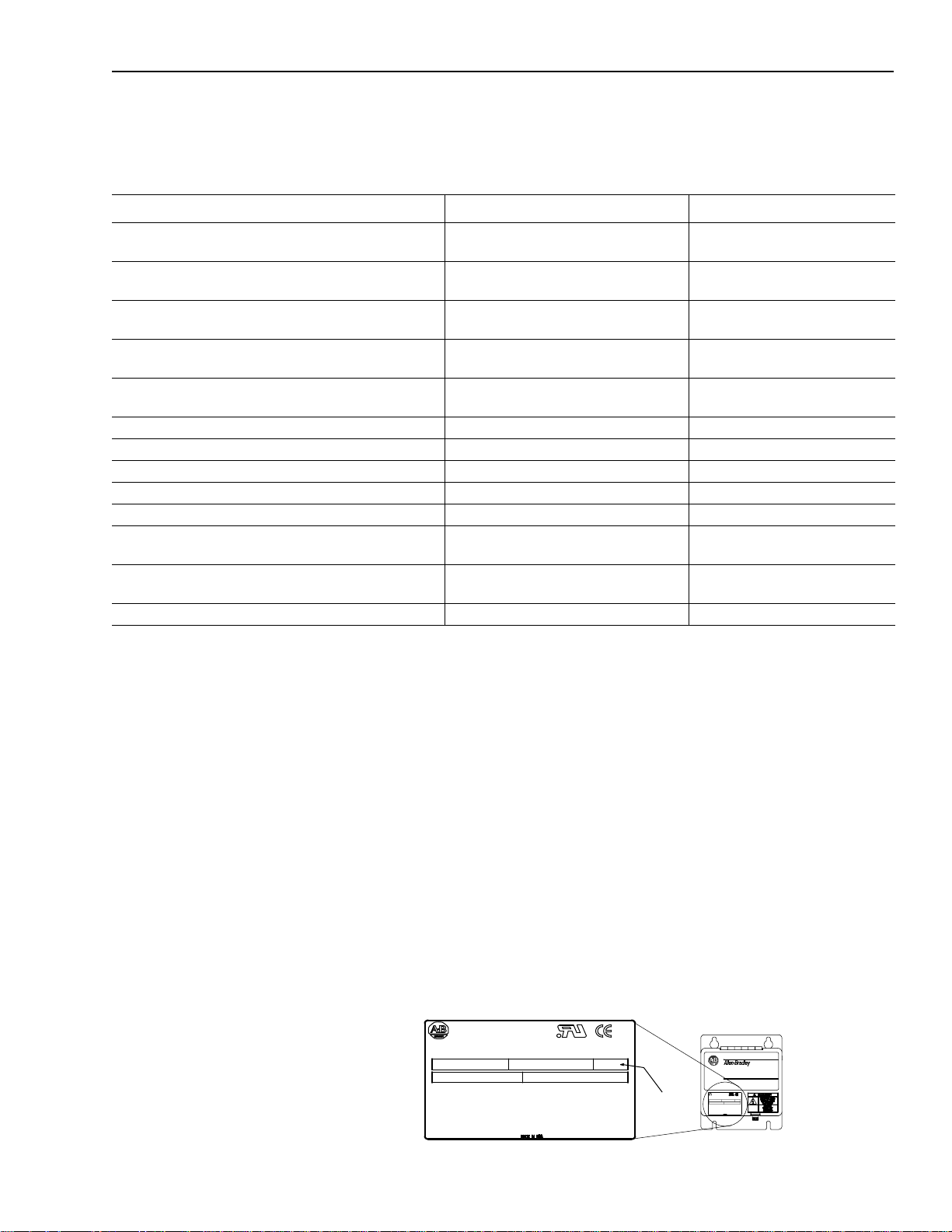

Series Note

Series C system modules (catalog numbers 1394C-SJTxx-x) and axis

modules (catalog numbers 1394C-AMxx and -AMxx-IH) include

features not available on Series A and B modules (catalog numbers

1394-SJTxx-x and 1394-AMxx).

System Module Features:

Connector (plug-in) input power ter mi nati on

Cable Clamp (strain relief, shield bond)

EMI filter (24V input power, registration)

Smart Power (Soft Start, power monitor)

Feature Availability

Series C Series A and B

Yes No

Yes No

Yes No

Yes 22 kW systems only

Axis Module Features:

Cable Clamp (strain relief, shield bond)

EMI filter (motor brake and thermal circuit)

Series C system modules are interchangeable with Ser ies A and B.

Likewise, Series A, B, and C axis modules are interchangeable with

each other.

Series C is recommended for all ne w app li cat ions. See the tables

above for feature availabil ity. For help in dete rmining the se ries of

your module(s), refer to the section Module Series Designator in the

Preface.

Feature Availability

Series C Series A and B

Yes No

Yes No

Publication 1394-5.0 — May 2000

Page 16

1-2 Overview

Safety Precautions

The following general precautions apply to the 1394:

ATTENTIO N: Only those familiar with the 1394

Digital, AC, Multi-Axis Motion Co ntrol System and

!

!

associated machinery should plan or implement the

installation, startup, and subsequent maintenance of

the system. Failure to comply can result in personal

injury and/or equipment damage.

ATTENTIO N: This product contains stored energy

devices. To avoid haza rd of e lectr ical shock, w ait five

minutes after r emoving po wer or verify that all vol tage

on the capacitors has been discharged before

attempting to service, repair, or remove this unit. You

should only attempt the procedures in this manual if

you are qualif ied to do so and fa miliar with solid-stat e

control equipment and the safety procedures in

publication NFPA 70E.

ATTENTIO N: The system integrator is responsible

for local safety and electrical codes.

ATTENTIO N: An incorrec tly applied or installe d

drive can res ul t in compone nt damage or a reduc ti on

in product life. Wiring or applicatio n errors, such as

undersizing the motor, incorrect or inadequate AC

supply, or excessive ambient temperatu res can result

in malfunction of the drive.

ATTENTIO N: This drive contains ESD

(Electrostatic Discharge) sensitive parts and

assemblies. Static control p recau tions are required

when installing, testing, servicing, or repairing this

assembly. Component damage can result if ESD

control procedures are not followed. If you are not

familiar with static control procedures, refer to AllenBradley publication 8000-4.5.2, Guarding Against

Electrostatic Damage or any other applicable ESD

Protection Handbook.

Publication 1394-5.0 — May 2000

Page 17

Overview 1-3

AEC

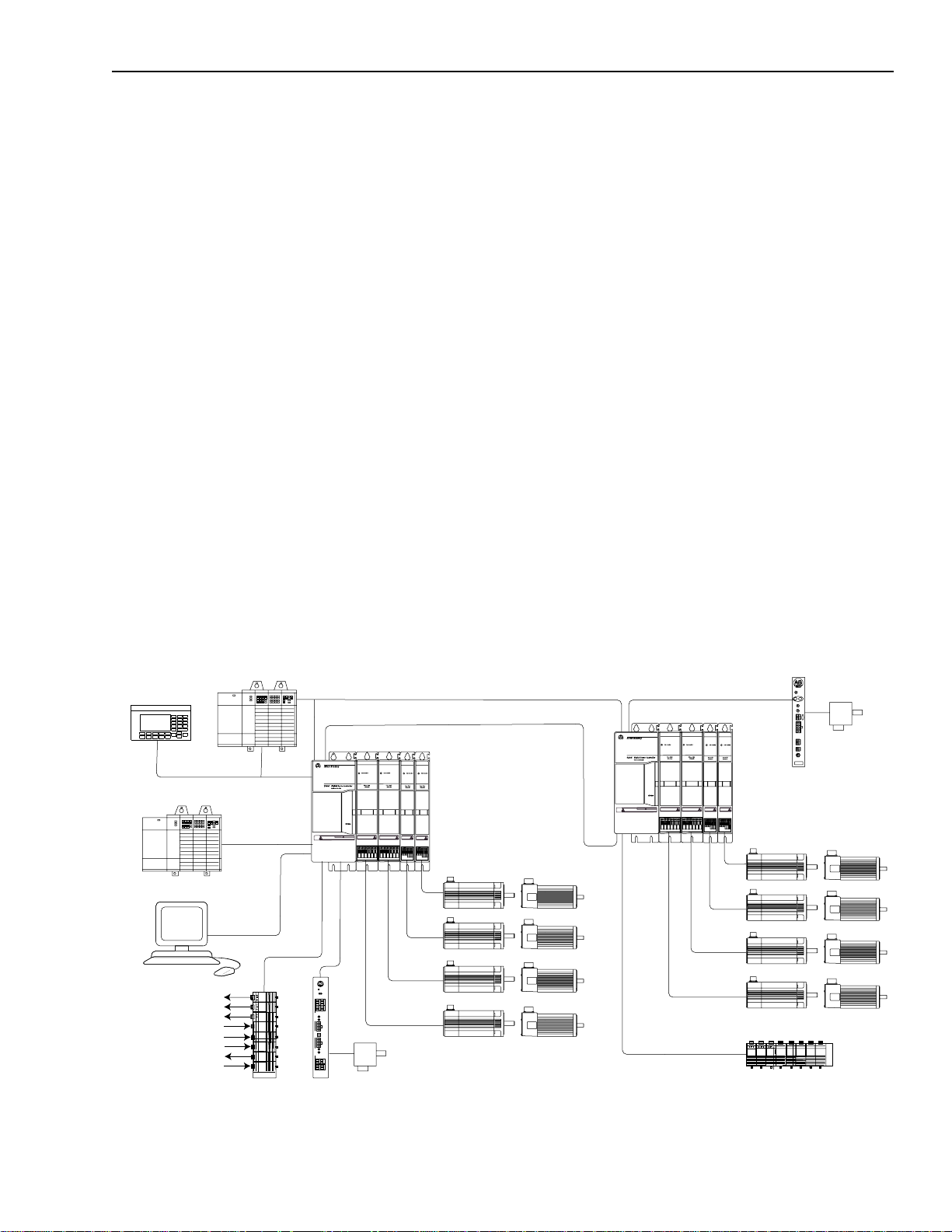

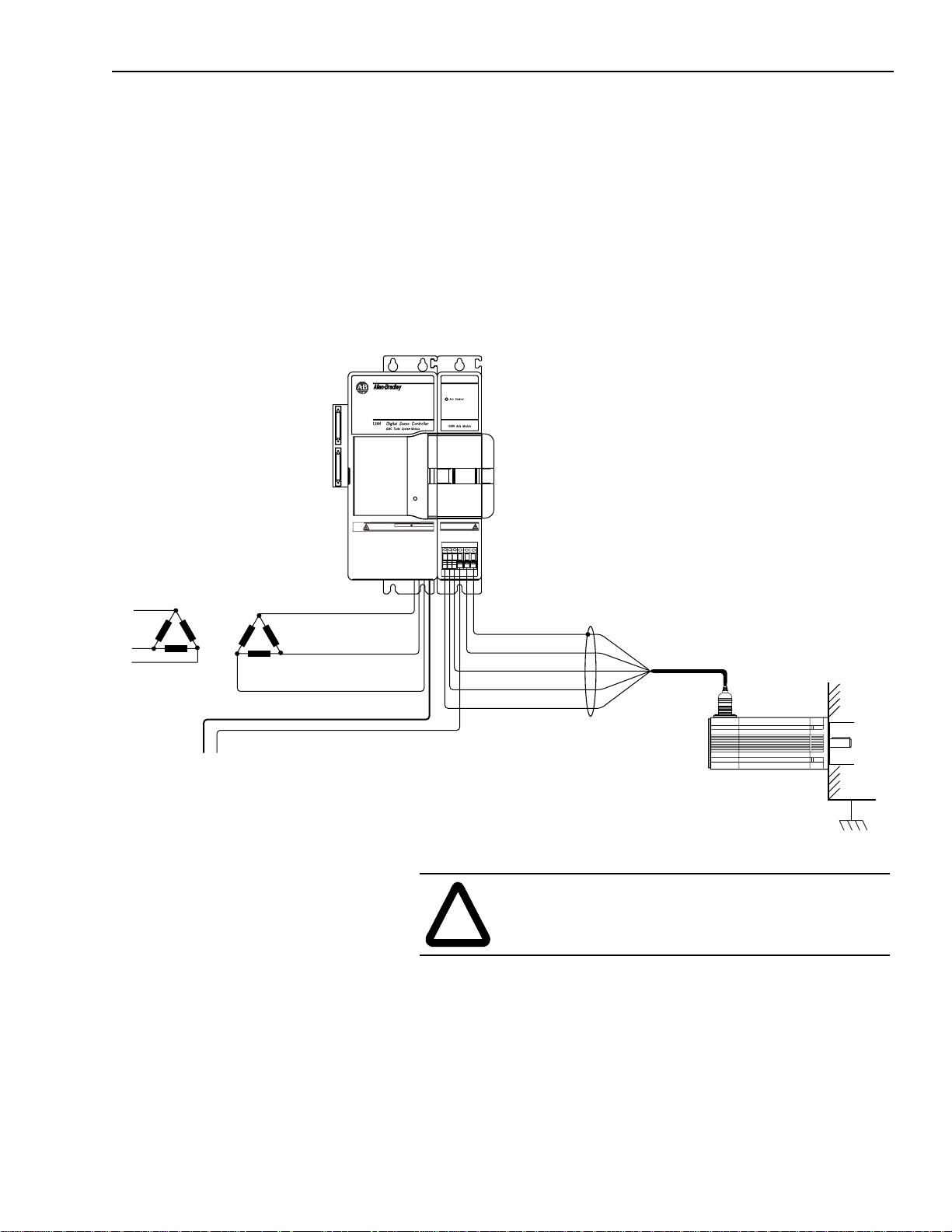

1394 System Overview

GMC System

The 1394 GMC System provides all the functionality of the IMC S

Class Compact Motion Controller and power conversion within the

1394 system module. Allen-Bradley offers two versions of the 1394

GMC system module (Standard GMC and GMC Turbo). Both

systems are completely programmed and commissioned using

GML (Graphical Motion Control Language), offer Allen-Bradley

DH485, RS-232, and RS-422 as standard communications, and have

Remote I/O and AxisLink available as communication options.

The 1394x-SJTxx-C (Standard GMC) system supports four axis

modules and provides four channels of auxiliary encoder input. The

1394C-SJTxx-L (Standard GMC) provides the same functionality of

the 1394x-SJTxx-C, but supports only one axis module and provides

two channels of auxiliary encoder input.

In addition, the 1394x-SJTxx-T (GMC Turbo) provides more GML

application program memory and executes the programs faster. The

1394x-SJTxx-T offers 64K of memory with a 32-bit processor while

the 1394x-SJTxx-C offers 32K of program memory with a 16-bit

processor. The 1394x-SJTxx-T also inc lud es a dire ct , high speed link

to the SLC 5/ 03, 5/04, or 5/05 that simplifies the programming

required to transfer data between the 1394x-SJTxx-T and the SLC.

PanelView 550

TM

SLC 5/03, 5/04, or 5/05

1746-C7 or -C9

GML

RS-232/-422

Discrete Outputs

Discrete Inputs

Analog Outputs

Analog Inputs

SLC 500

DH-485

1

Flex I/O

1

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

SSIControl

2

7

1

6

4

8

3

7

2

6

1

5

0

A

is

x

A

B

ConfigurationConfiguration

2

1

Encoder EncoderPower

A

1

is

B

x

Switches Switches

A

4

8

3

7

2

6

1

5

5

10

4

9

3

8

2

7

SSI Control

1

6

AB

AEC

4100-AEC

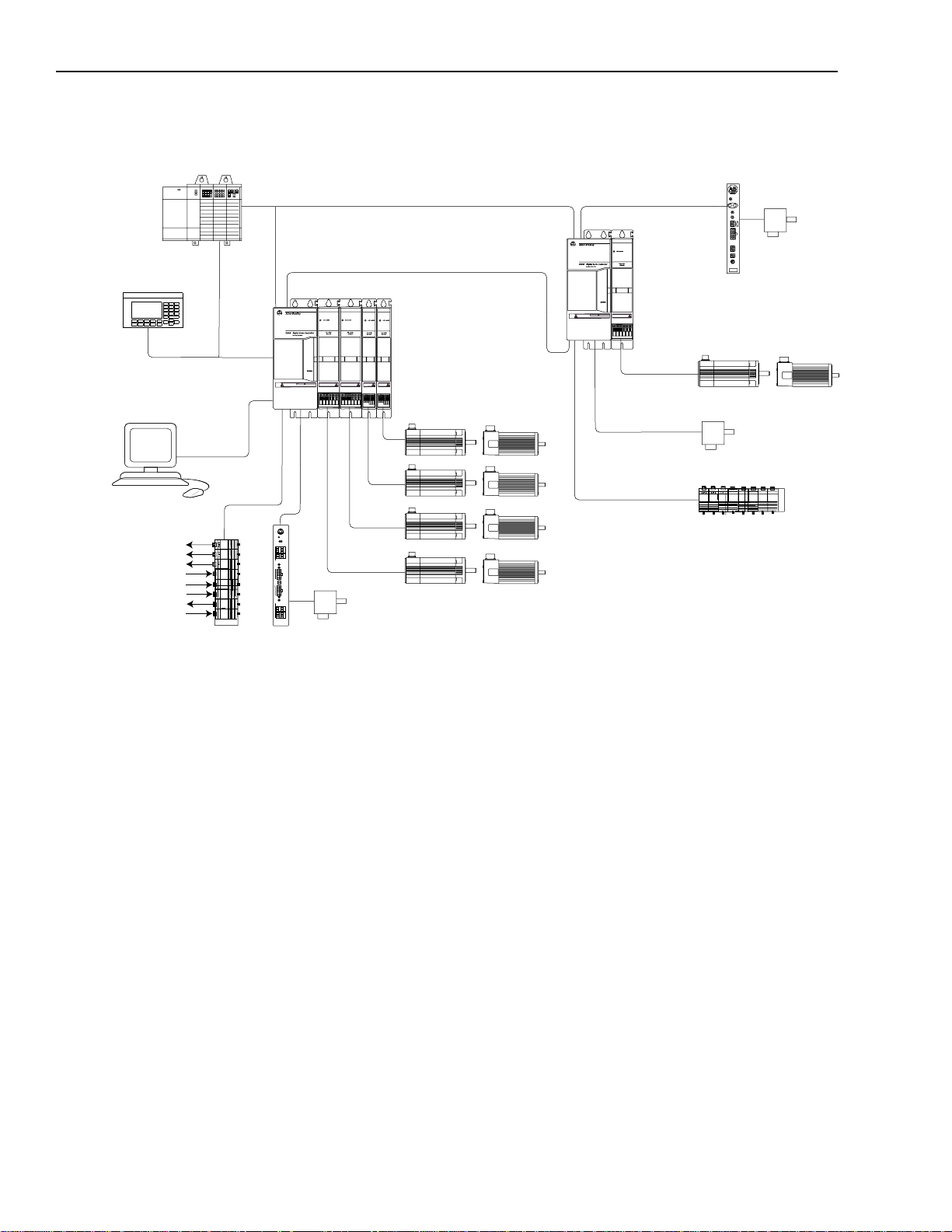

Figure 1.1

Two GMC Turbo Systems (1394

RIO

AxisLink

1394x-SJTxx-T

DANGER

1326AB and 1326AS Motors

842A

Encoder

1

This interface is only available with the 1394

x

-SJTxx-T)

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

x

-SJTxx-T system module.

AxisLink

ALEC

845H

Encoder

x

-SJTxx-T

1394

1326AB and 1326AS Motors

Flex I/O

Publication 1394-5.0 — May 2000

Page 18

1-4 Overview

AEC

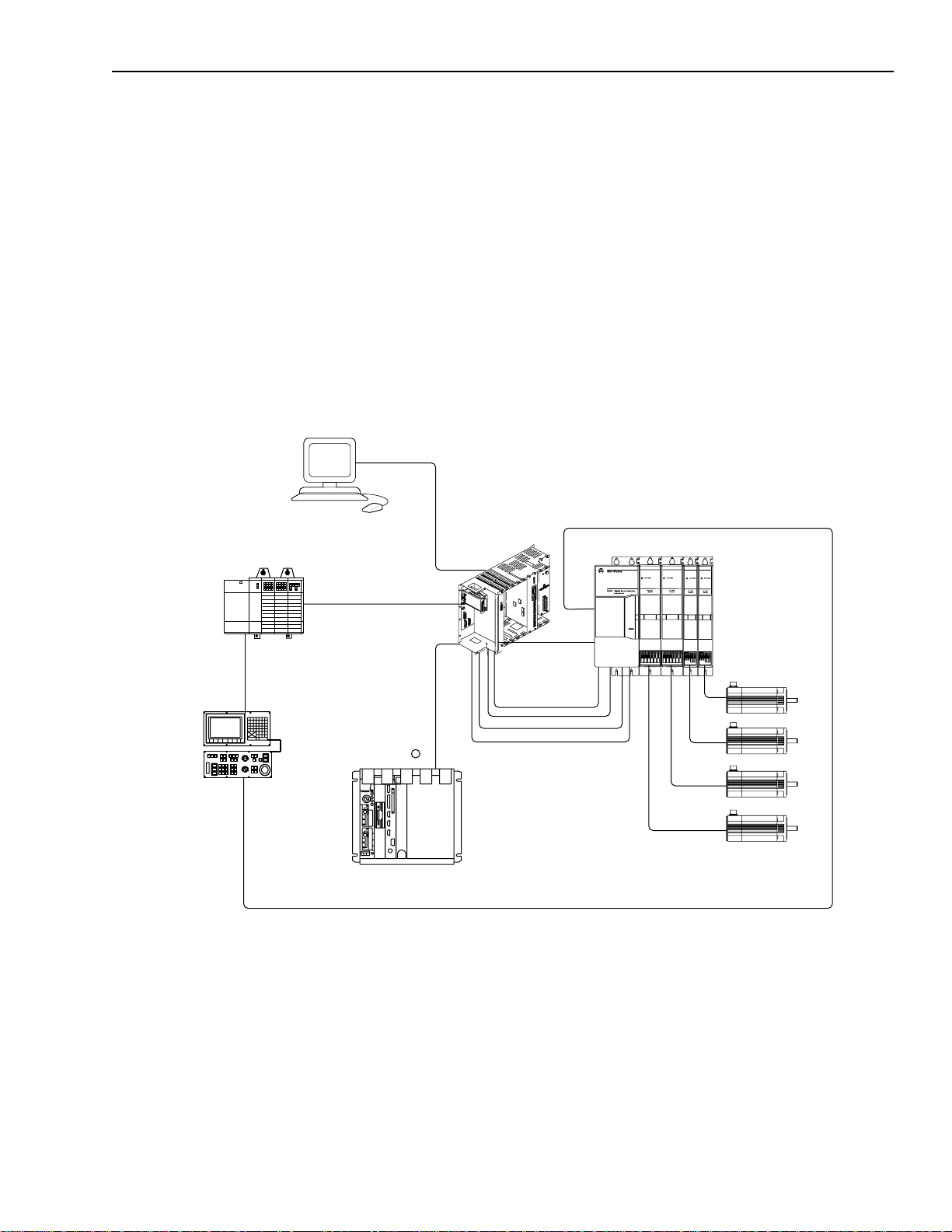

Figure 1.2

Two Standard GMC Systems (1394

x

-SJTxx-C and 1394C-SJT-xx-L)

SLC 500

PanelView 550

DH-485

GML

Discrete Outputs

Discrete Inputs

Analog Outputs

Analog Inputs

RS-232/-422

Flex I/O

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

Reset

Axis 0 Axis 1

AB

5

10

4

9

3

8

SSIControl

2

7

1

6

4

8

3

7

2

6

1

5

0

A

is

x

A

B

ConfigurationConfiguration

2

1

Encoder EncoderPower

A

1

is

B

x

Switches Switches

A

4

8

3

7

2

6

1

5

5

10

4

9

3

8

2

7

SSI Control

1

6

AB

AEC

4100-AEC

ALEC

RIO

AxisLink

845H

Encoder

AxisLink

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

1394C-SJT

DANGER

xx

-L

1326AB or 1326AS Motor

1394

x

-SJTxx-C

DANGER

1326AB and 1326AS Motors

845H Encoder

Flex I/O

842A

Encoder

Publication 1394-5.0 — May 2000

Page 19

ODS Software

Overview 1-5

CNC Interface System

The 1394 9/Series CNC Interf ace system (1394-SJTxx-E) provides a

digital servo system to be used with the 9/260 and 9/290 CNC. This

system provides all power electronics and uses a cost-saving digital

interface app roach. Servo control for this system is handled by th e 9/

Series CNC. A fiber optic I/O ring is provided to the 1394 and the

system is completely interfaced with and programmed using ODS

(Off-Line Development System) and the CNC operator panel. AllenBradley Remote I/O, MMS/Ethernet (9/260 and 9/290 only), and

Data Highway Plus (9/260 and 9/290 only) communications are

avai lable options with the 9/Series CNC interface system.

Figure 1.3

CNC Interface System

1746 I/O

Fiber Optic Ring

Operator Panel

MTB Panel

Fiber Optic Ring

RIO

R

PLC

9/230, 9/260, or

9/290 CNC

1394

Fiber Optic Ring

1326AB Motors

Fiber Optic Ring

Publication 1394-5.0 — May 2000

Page 20

1-6 Overview

1756-M

xx

SE Interface

SERCOS System

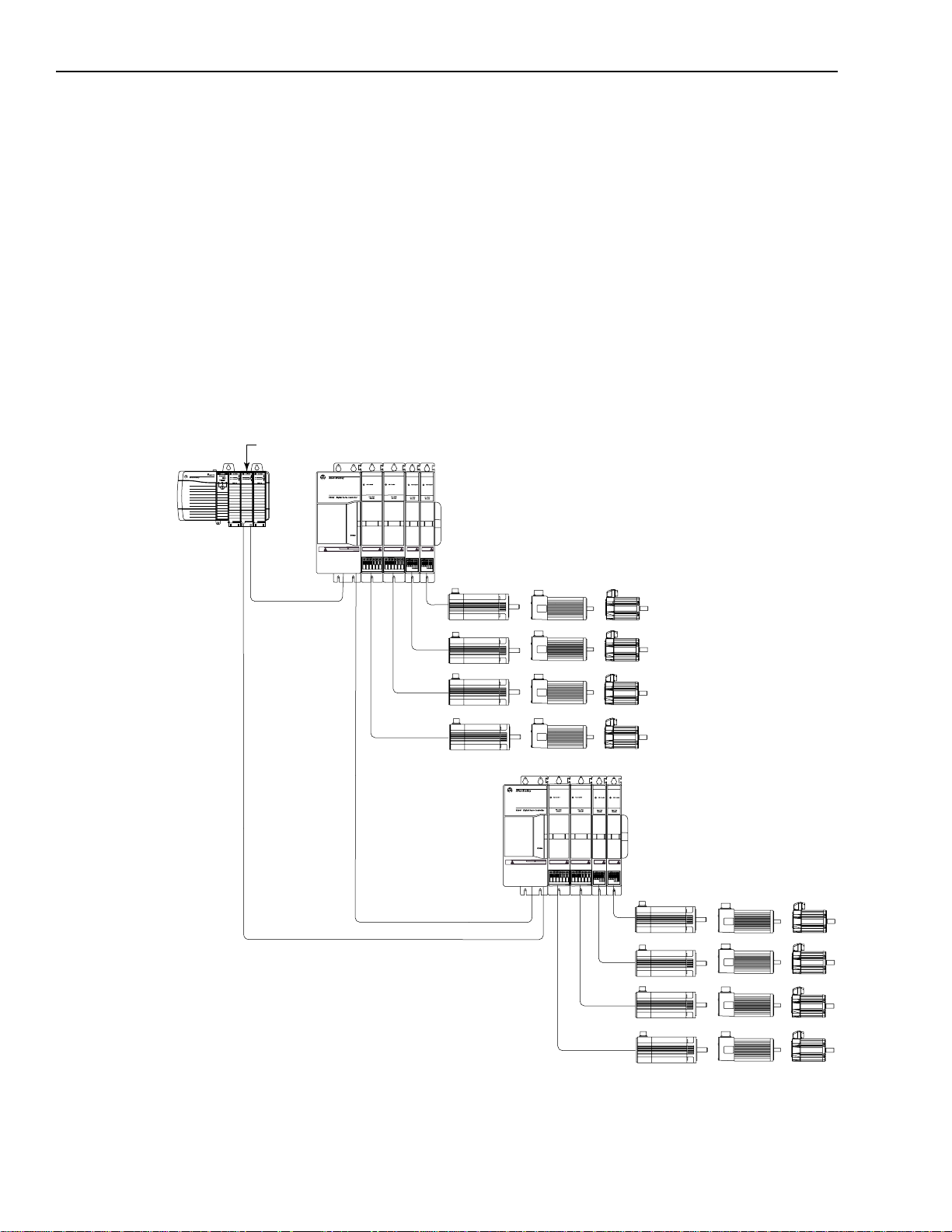

The 1394 SERCOS system module (1394C-SJTxx-D) provides a

digital servo drive sy st em with a fiber-opti c di gi tal network interf ace.

It can be used as a velocity or torque control system and is quickly

commissioned with the Allen-Bradley SERCOS Interface Module

(Bulletin 1756 with 1756-MxxSE), which provides access to auto

tuning and start-up prompti ng. The 13 94 als o pro vide s a SCANp ort

interface as a standard feature.

For specific installation and wiring information refer to the 1394

SERCOS Multi-Axis Motion Control System User Manual

(publication 1394 -5.20).

Figure 1.4

SERCOS System

ControlLogix Chassis

SERCOS

SERCOS

SERCOS System Module

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

1394 SERCOS System

DANGER

1326AB, 1326AS, and MP Series Motors

SERCOS System Module

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

DANGER

1394 SERCOS System

1326AB, 1326AS, and MP Series Motors

SERCOS

Publication 1394-5.0 — May 2000

Page 21

SLC 500

Overview 1-7

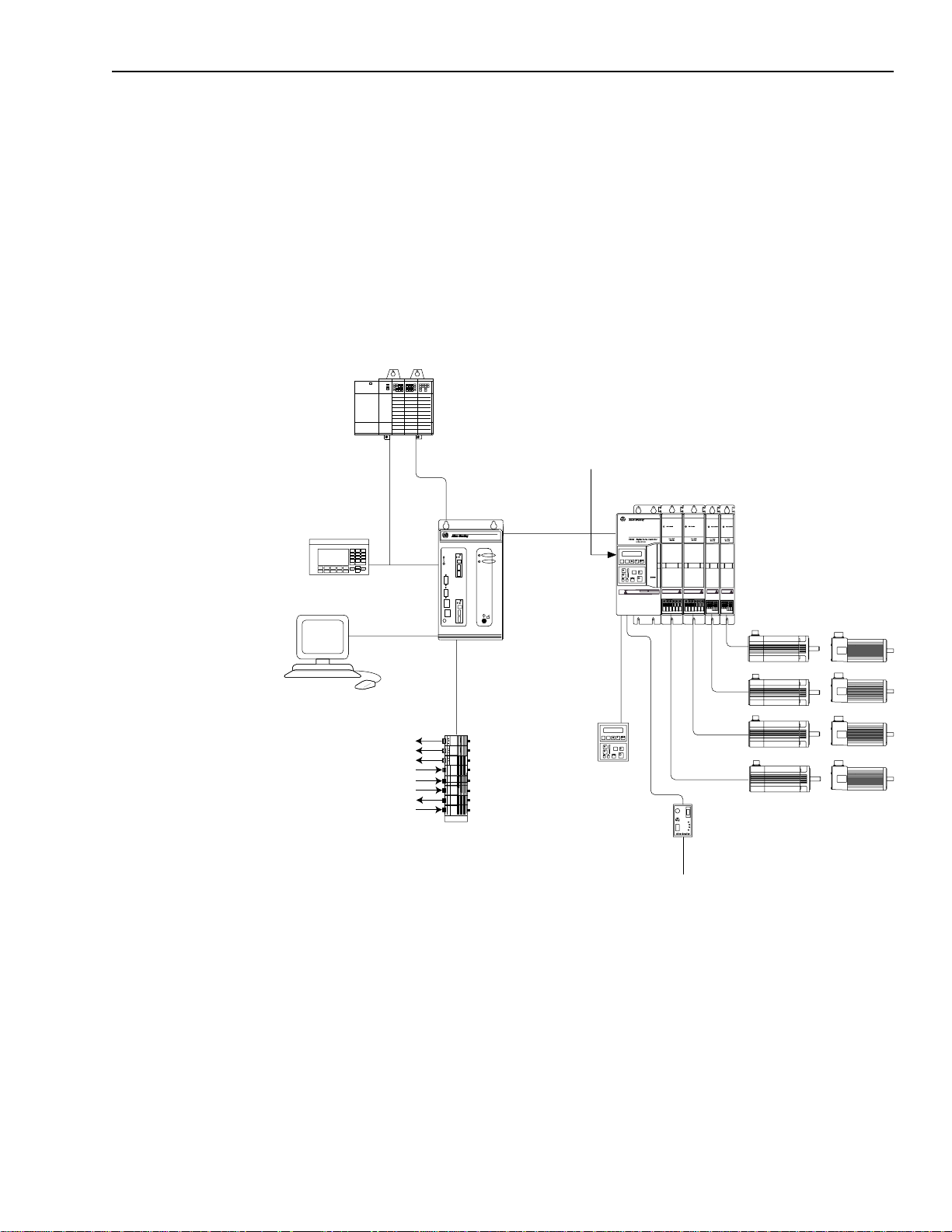

Analog Servo System

The 1394 Analog Servo system (1394x-SJTxx-A) provides a digital

servo drive system with a traditional ±10V DC analog interface. It can

be used as a velocity or torque control system and is quickly

commissioned with the Allen-Bradley universal Bulletin 1201 HIM

(Human Interface Module), which provides access to auto tuning and

start-up prompting. The 13 94 also pro vides a SCANport interfa ce as a

standard feature.

Figure 1.5

Analog Servo System

Bulletin 1201 HIM

RIO

(purchased separately)

PanelView 550

GML

RS-232/-422

Discrete Outputs

Discrete Inputs

Analog Outputs

Analog Inputs

DH-485

Flex I/O

IMC S Class

Compact, Control

Logix (or other

customer supplied

motion controller)

SCANport

Optional Bulletin 1201

HIM or other remote

SCANport interface

Optional Bulletin 1203

Communication Module

1394

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

1326AB and 1326AS Motors

To RIO, Serial, DeviceNET,

SLC, etc.

Publication 1394-5.0 — May 2000

Page 22

1-8 Overview

9/440 CNC System

The 9/440 CNC system module gives you all the power and

programming capabilities of a 9/Series CNC, integrated into the

compact packaging of the 1394 System Module. The 9/440 CNC

System Module provides ter m inating points for:

•Resolvers

• Encoder feedback (for optional position feedback or spindle

control)

• Two serial ports (for communicating with the 9/Series ODS or

other peripherals such as printers or tape readers)

• E-STOP string and status

• Spindle outputs

• 9/Series fiber optic ring connection

• Touch probe interface

• Remote I/O connection

There are three versions of the 9/440 CNC System:

Number of

Resolver

Catalog

Version:

1 Axis 9/440 8520-1S

3 Axis 9/440 8520-3S

4 Axis 9/440 8520-4Sx4

1

You can connect a total of three feedback devices. If you use three resolvers, the encoder port (J11) is

not available. If you use the encoder feedback port (J11), the third resolver feedback (J3) is disabled.

2

You can connect a total of six feedback devices. If you use four resolvers, the last encoder port (J11) is

not available. If you use all three encoder feedback ports, the third resolver feedback (J3) is disabled.

Number:

Axis

modules:

x

1 1 2 0

x

3

feedback

ports:

1

3

2

4

Analog

outputs:

2

2

Encoder

feedback

ports:

1

1

2

3

For more in fo rmation on the 9 / 440, refer to th e 9/Series Integration

and Maintenance Manual (publication 8520-6.2).

Publication 1394-5.0 — May 2000

Page 23

Figure 1.6

9/440 System

Overview 1-9

What is a 1394 System?

Optical signal cable

Terminal type connection

The 1394 system consists of the follo wing components (catalog number

appears in parenthesis ):

• One System Module (1394x-SJTxx-x)

• One to four Axis Modules (1394x-AMxx-xx)

• One to four servo m oto rs (1326Ax-Bxxxx)

• One to four power and feedback cables

Also available are the DC Link Mod ule (1394-DCL M ) and Drive

Interface Module (1394-DIM).

The: Is used:

1394-DCLM In addition to the axis module(s)

1394-DIM In place of an axis module.

Publication 1394-5.0 — May 2000

Page 24

1-10 Overview

ANGER

RISK OF ELECTRICAL SHOCK.

HIGH

VOL

AGE MA

EXIST UP

TO FIVE MINUTES

AFTER REMOVING POWER.

Axis modules are connected to system modules using slide-and-lock,

module-to-module conn ections. For information on mot ors and cables,

refer to the 1326AB 460V , T orque Plus Series, A C Servo Motors Pro duct

Data (publication 1326A-2.9), 1326AS Series 460V, Low Inertia,

Brushless Servo Motor s Product Data (publication 1326A-2.10), and

1326 Cables for 460V AC Servo Motors Product Data (publication

1326A-2.11).

In addition to the equi pment sho wn abov e, you will nee d to supply the

following:

• Three phase input contactor

• Three phase input fusing

• 24V AC or DC logic power for system module and contactor

enable (Analog Servo only)/DRIVEOK power (all modul es)

Refer to Appendix A for inform ation on these top ics.

Note: An externa l shunt resistor kit (1394-SR10A) is a va ilable for 5

and 10 kW systems with regenerative loads that exceed the

capacity of the inter nal 2 00W shunt res istor pro vi ded. Most 5

and 10 kW systems will not r equire a shunt res istor kit. All 22

kW 1394 based products require an external shunt module

(1394-SR9Ax or 1394-SR36Ax). This includes b oth 1394 and

8520 catalog items.

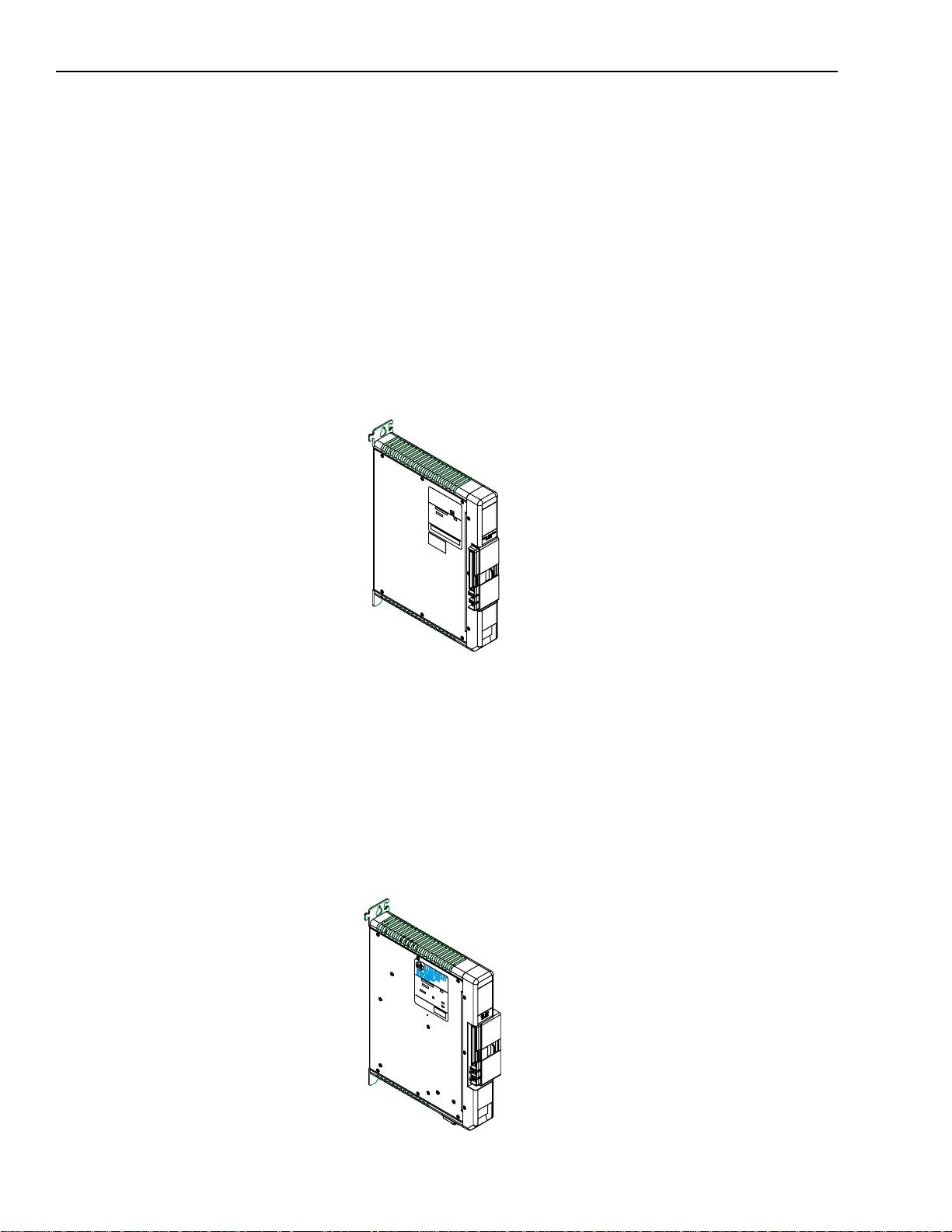

System Modules

System modules, av ail able with r atings of 5, 10 and 22 kW (at 460V),

house the system control PCB and convert 360 to 480VAC, threephase, 50/60 Hz input power to a 530 - 680VDC link voltage. The 5

and 10 kW system modules have an internal shunt resistor with a

200W continuous rating and a peak rating of 40,000W. The 22 kW

system module requires an external shunt module.

Figure 1.7

1394 System module

R

E

G

N

DA

Y

A

M

E

G

TA

L

O

V

H

G

I

H

.

K

C

O

H

S

L

A

C

I

R

T

C

E

L

.

E

R

E

F

O

W

O

K

P

S

I

G

R

N

I

V

O

M

E

R

R

E

T

F

A

S

E

T

U

N

I

M

E

V

I

F

O

T

P

U

T

S

I

X

E

Publication 1394-5.0 — May 2000

Page 25

Overview 1-11

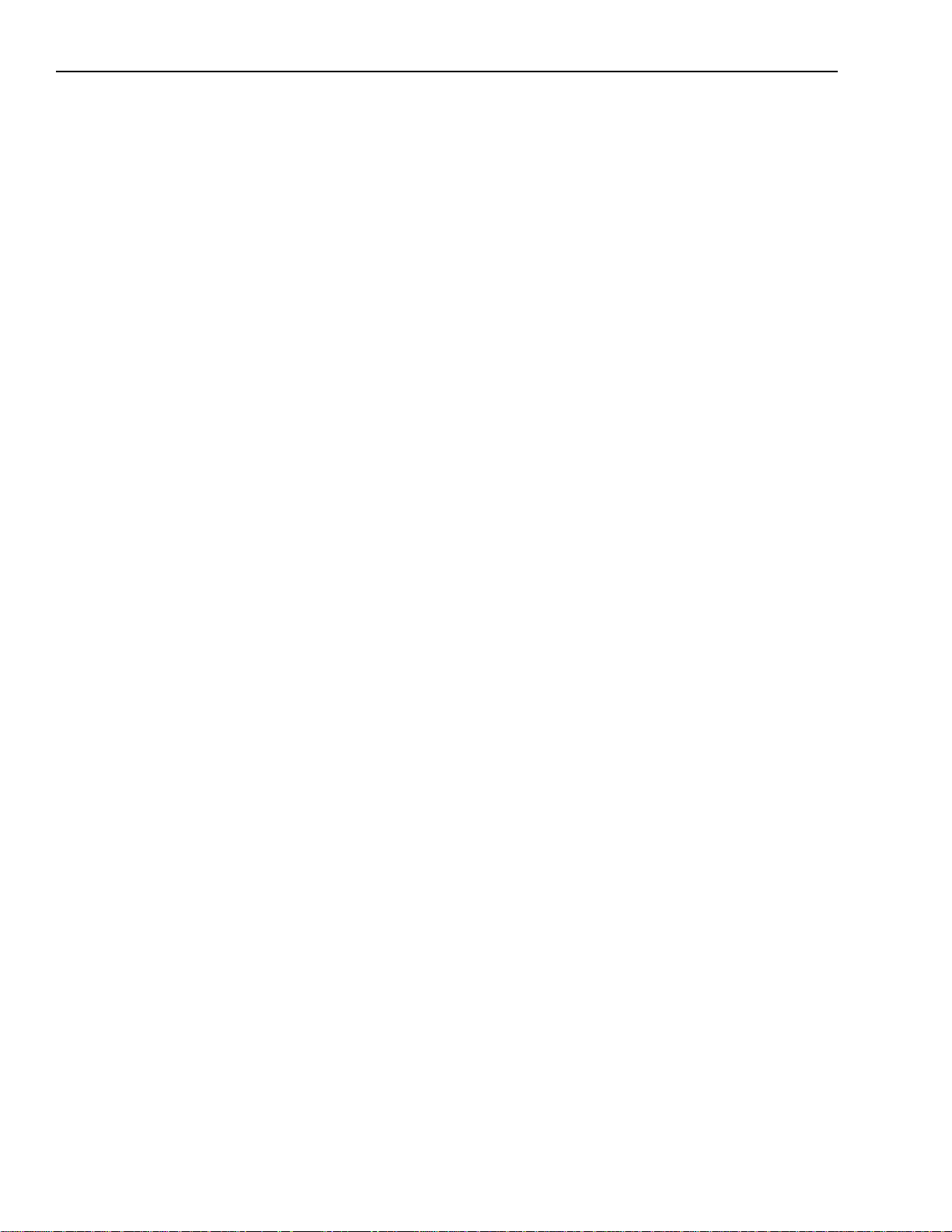

Axis Modules

Axis modules, with continu ous out put cur rents (RMS) of 3.0 , 4.5, 7 .5

23.3 and 35.0A, con vert the DC power suppl ied by the sys tem module

to a variable AC voltage. You will require one axis module for every

1326Ax-Bxxxx servo motor you plan to run using the 1394. Choose

each axis module based on t he current requirements of the servo motor .

Figure 1.8

1394 Axis Module

External Shunt Module (used with 22 kW System)

Shunt modules with (rms) po we r output of 300, 900, 1800 and

3600W continuous, 160,000W peak are available for use with the

smart power 22 kW s ystem module. T he shunt module dissipates

excess regenerative power from the Bulletin 1394 system. You must

use one shunt module with each 22 kW smart power system module.

Available in two sizes, each package contains an integral fuse and

terminal block. The 3600 W p ackage is a vailable with a 115 /230V AC

cooling fan. Choose your shunt module based on the shunt

requirements of the 1326Ax-Bxxxx servo motors you plan to run

using the 1394.

Note: 5 and 10 kW system modules can use an optional 1400W shun t

module kit to dissipate excess regenerative energy

(unpackaged components).

Figure 1.9

1394 External Shunt Module

Publication 1394-5.0 — May 2000

Page 26

1-12 Overview

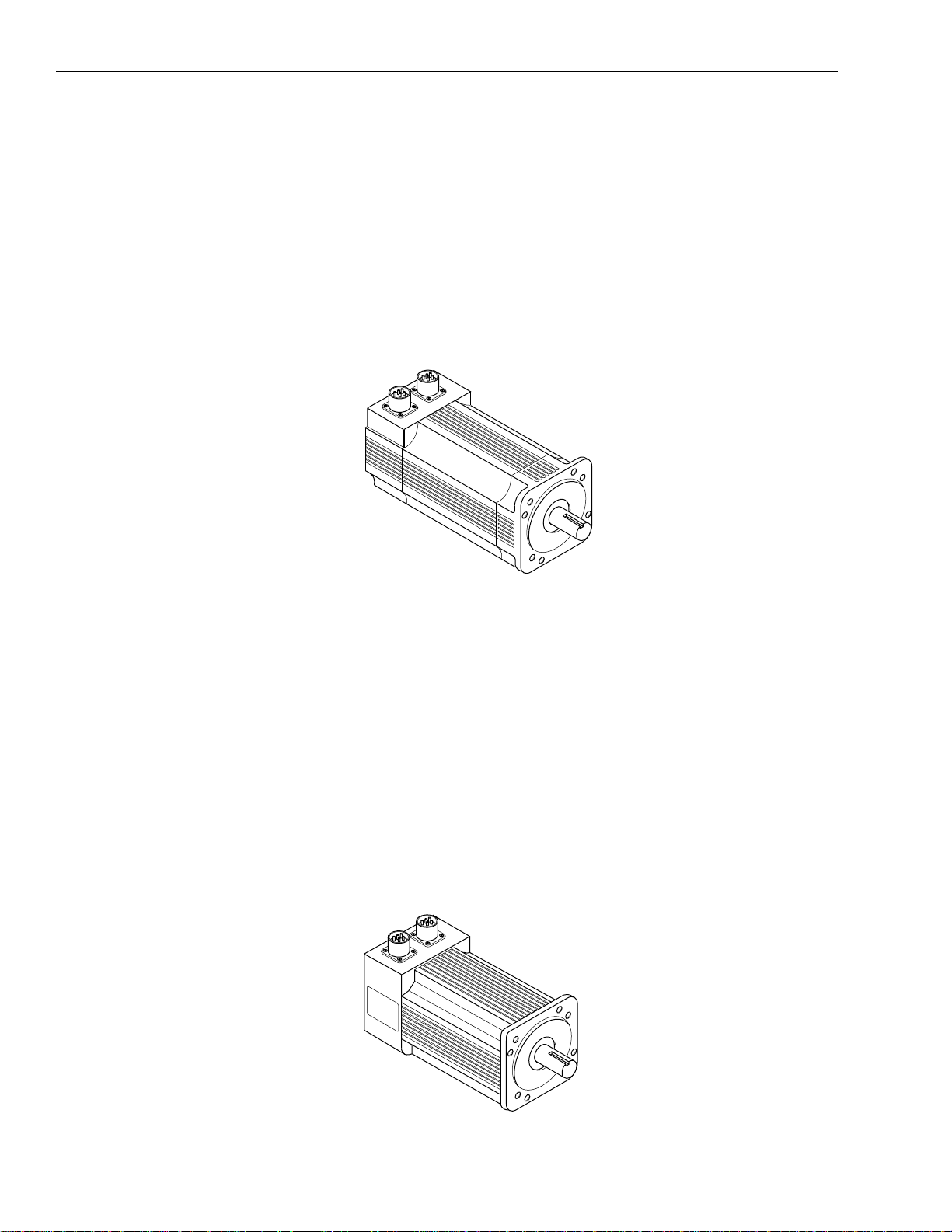

1326AB Motors

This family of high-p erfor mance, medi um inert ia, fe rrit e, thre e-phas e

servo motors feature a specially designed housing that reduces motor

length. They are a vailab le with continuous t orque ratings of 2.3 to 53 .0

N-m (20.7 to 469.0 lb-in.). Refer to the 1326AB 460V, Torque Plus

Series, AC Servo Motors Prod uct Data (publication 1326A-2.9) for

more information on features and options. IP65 protection rating is

standard when used with the shaf t oil seal kit. IP67 pr otection r ating is

avai lable (specify -L in the ca talog number, refer to Appendix D).

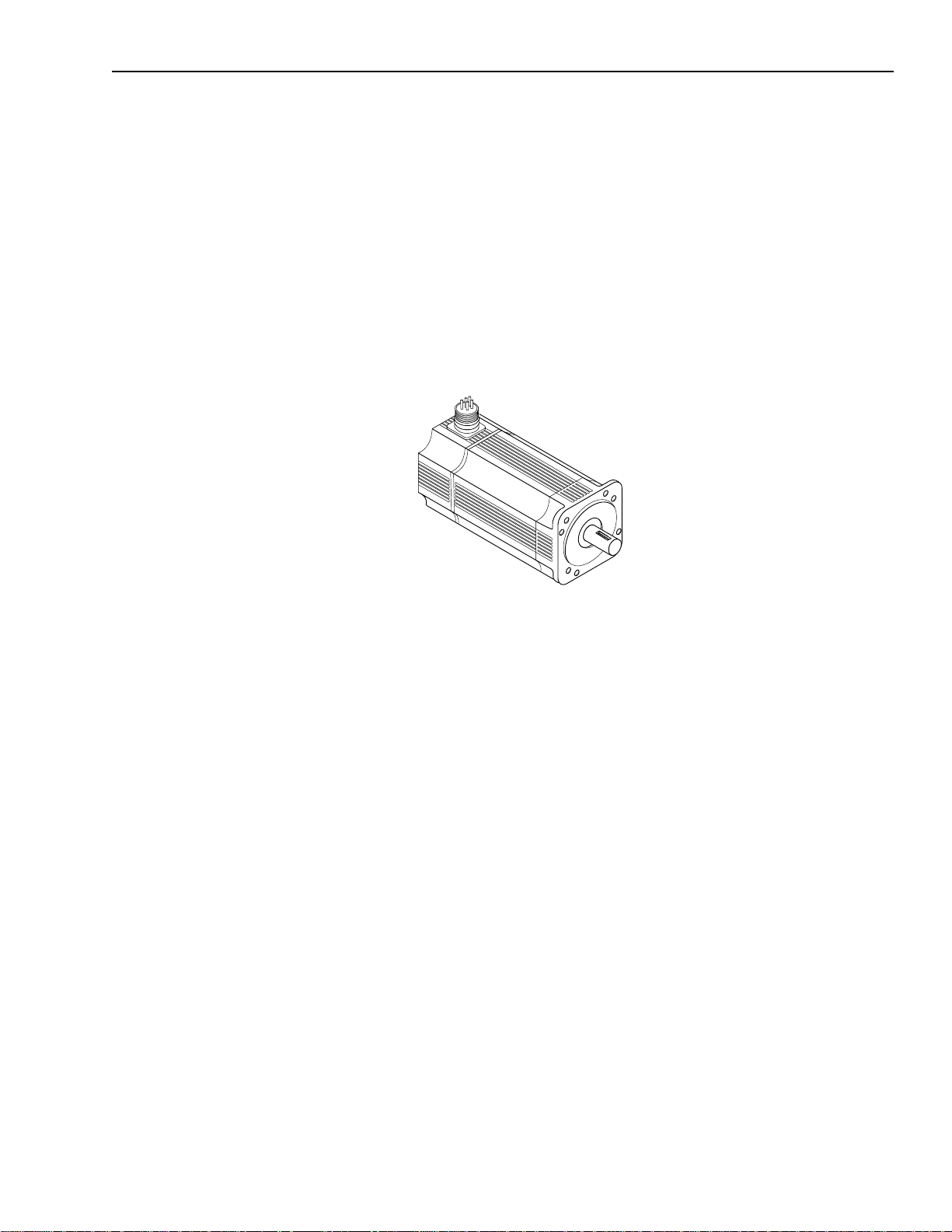

Figure 1.10

1326AB Motor

1326AS Motors

This family of high-performance servo motors feature neodymiumiron-boro n pe rm anent magne t rotors that provide low inertias, hi gh

accelerations and high peak torques. They are available with

continuous torque ratings of 0.49 to 49.3 N-m (4.33 to 436 lb-in.).

Refer to the 1326AS Series 460V, Low Inertia, Brushless Servo

Motors Product Data (public ati on 1326A-2. 10) fo r more infor mat ion

on features and options. IP65 pr otection rating is standard when used

with the shaft oil seal.

Important: 1326AS-Bxxxx motors cannot be used with the 9/Series

and 9/440 controllers.

Figure 1.11

1326AS Motor

Publication 1394-5.0 — May 2000

Page 27

Overview 1-13

1326AH Motors

This family of hazardous duty motors are UL recognized AC

brushless servo motors. Construction of the motor is a totally

enclosed non-ventilated (TENV) square frame design utilizing a

permanent magnet rotor and a fixed stator winding. Rare earth

magnets, long life ball bearings, and brushless construction also

assures maximum performance. The y are available wit h conti nuou s

torque ratings of 2.97 to 16.9 N-m (26.3 to 149.8 lb-in.). Refer to the

1326AH Hazardous Duty Motors Product Data (publication

1326AH-TD001B-US-P) for more information.

Figure 1.12

1326AH Motor

Publication 1394-5.0 — May 2000

Page 28

1-14 Overview

Drive Inter face Module

The 1394-DIM (Drive Interface Module) provides four channels of

analog output, four drive enable outputs, and four drive fault inputs.

The 1394-DIM allows the 139 4x-SJTxx-C, -T, or -L system module to

be used to cont rol any external driv e with a ±10V velocity torque

reference command and quadrature encoder output. Each 1394-DIM

can support up to four drives . However , the maximum number of axe s

(1394-DIM controlled dri ves pl us 139 4x-AMxx axis modules) cannot

exceed four per 1394x-SJTxx-C or -T system module and one per

1394C-SJTxx-L system module. The 1394-DIM is not compatible

with the 1394x-SJTxx-A syste m module.

Figure 1.13

Drive Interface Module

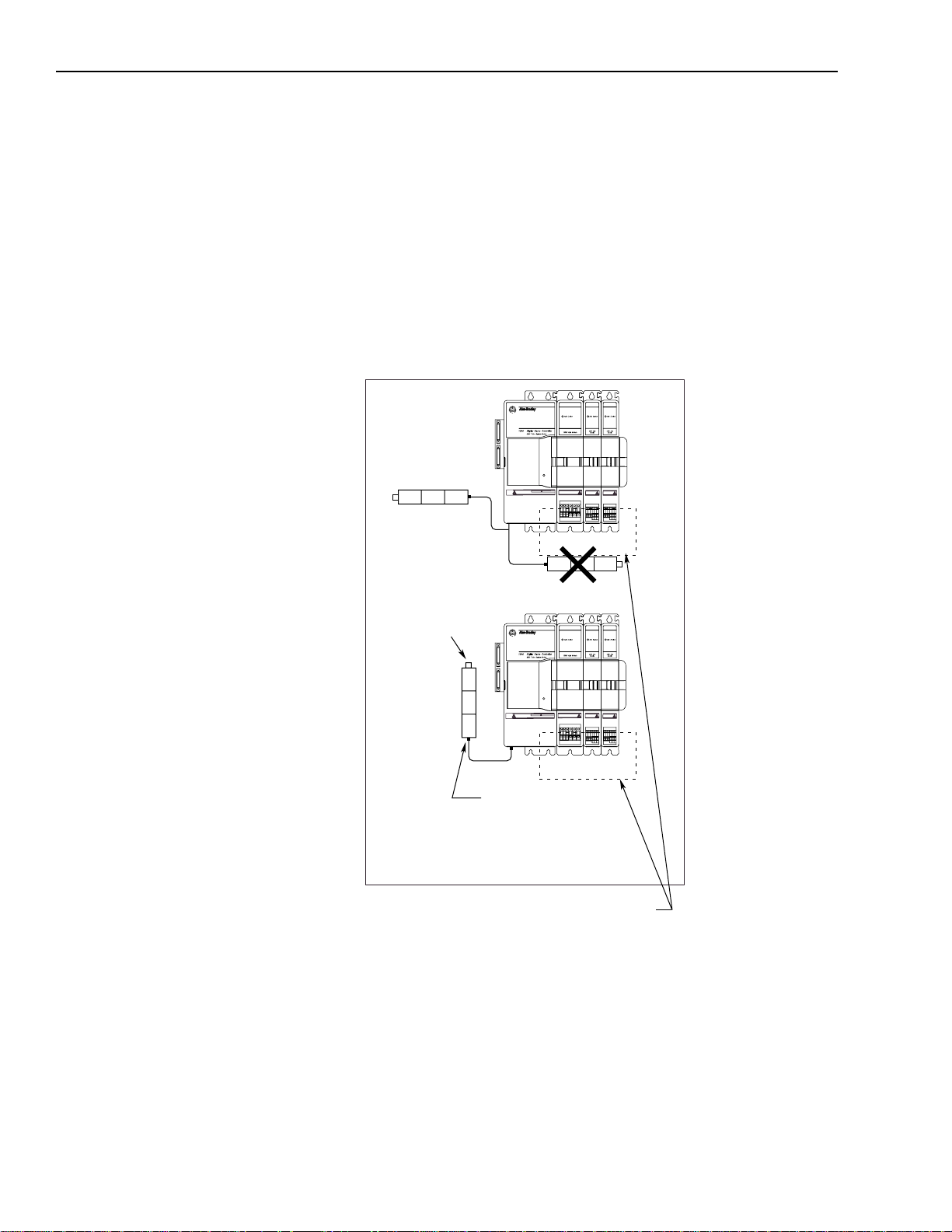

DC Link Module

The 1394-DCLM (DC Link Module) provides additional load

leveling and energy storage (capacitance) for 1394 systems. This

allows additi ona l re gene rative ener gy to b e stor ed duri ng the mac hine

cycle, increasing system capacity, lowering cycle time, and avoiding

resistive heat loss. The module can be used alone or two modules can

be used to interconnect two 1394 systems using the DC Link cable.

Figure 1.14

DC Link Module

Publication 1394-5.0 — May 2000

Page 29

Overview 1-15

Standard Features of the 1394

The 1394 provides the following standard features:

• UL Listed a n d CUL Certified

•CE Marked

Control

• Supports Standard GMC (1394x-SJTxx-C and -L) and GMC

Turbo , CNC Interface, SERCOS, and Analog Servo

configurations with a standard array of hardware.

• Digitally-adjus ted veloc ity and current loop compensati on, which

accommodates a wide range of system inertias.

• Two configurable analog test outputs that can be li nked t o crit ical

system parameters for troubleshooting (GMC and Analog Servo

system modules).

• All systems provide digital fault and diagnostic utilities

(including a current monitor, thermal overload detection, and a

feedback signal monitor).

• Status LEDs for system and axis modules.

• Status LEDs for motion board, Axislink, and RIO (GMC system

only).

• Highly-integrated surface mount circuitry.

• Encoder signal output (A QUAD B) for encoder emulation

(Analog Servo system modules only).

• DSP assisted processing.

• Smart Power contro l, a v ail able on al l 22 kW system modul es and

5 and 10 kW system modules (Series C or later), allows poweruse monitoring for process optimization.

• Smart Power system mod ules, available on all 22 kW system

modules and 5 and 10 kW system modules (Series C or later),

include active Soft Start inrush current limiting for DC link

charging.

• Electrical Noise Protection included on GMC, GMC Turbo,

SERCOS, and Analog Servo system modules (Series C or later)

and axis modules (Series C or later).

• Improved grounding terminations on GMC, GMC Turbo,

SERCOS, and Analog Servo system modules (Series C or later)

and axis modules (Series C or later).

Note: To determine the series of your module, refer to Figure P.1 in

the Preface.

Publication 1394-5.0 — May 2000

Page 30

1-16 Overview

Power

• IGBT technology for efficient, quiet operation.

• Transie nt (MOV) voltage, phase loss, and ground fault protected

input.

• An integral 200W shunt resistor is available (5 and 10 kW only).

An external 1400W shunt kit is available (5 and 10 kW only).

Other external shunt kits and modules from 300 to 3600W

continuous.

• Current ratings of 3.0, 4.5, and 7.5A continuous, a t 50°C (122°F)

(inside cabinet) and 23.3 and 35A continuous, at 40°C (104°F)

(with heat sinks out the back) with up to 300% motor ratings for

high duty-cycle oper at ion producing continuous to rque ranges of

0.7 to 53.0 N-m (6 to 469 lb-in.).

• 324-528V AC, three-phase, 50/60 Hz direct line operation.

• No isolation transformer or inductors are required (360/480VAC

Hz direct line operation) for most applications.

• Advanced protective features, such as software-based current

foldback, which provides overload tolerant operation and soft

current limiting.

Integration

• Hinged system module front cover for easy access to control and

power wiring.

• System and axis modules that can be quickly removed and easily

interchanged for troubleshooting and diagnostics.

• Standard widths of 50 mm (1394x-AM03, -04, and -07) and 75

mm (1394x-AM50-xx and -AM75-xx) ax is modules are available.

• Mass termination plugs and reliable, contact-type, terminal

blocks are used for easy install ation and service.

• Plug interconnects for auxiliary, encoder input (GMC), encoder

output and motor resolver input (all).

• Slide-and-lock, module-to-module connection, which eliminates

bus bars and wiring harnesses.

• Advanced communicat ions and I/O capabi lities help inte grate the

1394 to standard plant floor networks.

Publication 1394-5.0 — May 2000

Page 31

Installing Your 1394

(applies to all systems)

Chapter

2

Chapter Objectives

This chapter covers the following to pi cs:

• Complying with European Union directives

• Before mounting your system

• Unpacking your modules

• System mounting requirements

• Bonding your system

• Mounting your 1394 system

• Mounting your 1394-DCLM

• Mounting the external shunt resistor for 5 and 10 kW system

modules

• Mounting external shunt modules for 22 kW system modules

• Mounting considerations for GMC and GMC Turbo systems

ATTENTIO N: The following information is a

guideline for proper installation. The National

!

Electrical Code and any other governing regional or

local codes overrule this informa tion. The AllenBradley Compan y cannot assume responsibility fo r the

compliance or the noncompliance with any code,

national, local or otherwis e, for the proper inst allation

of this system or associate d equipment. If you ignore

codes during installation, hazard of personal injury

and/or equipment damage exists.

Complying With European Union Directives

If this product is ins ta ll ed wi thin the European Union or EEC r e gions

and has the CE mark, the following regulations apply.

EMC Directive

This unit is tested to meet Counc il Directive 89/336 Electromagnetic

Compatibility (EMC) using a technical construction file and the

following standards, in whole or in part:

• EN 5008x-2 EMC - Emission Standard, Part 2 - Indust rial

Environment

• EN 5008x-2 EMC - Immunity Standard, Part 2 - Industrial

Environment

Publication 1394-5.0 — May 2000

Page 32

2-2 Installing Your 1394 (applies to al l systems)

The product described in this manu al is intended for use in an

industrial environment.

To meet CE requirements, the following additions are required:

• You must run three-phase in put wiring in a conduit that is

• You must install a power line filter (Allen-Bradley catalog

• You must terminate the shields of t he moto r po we r cable s and the

Low Voltage Directive

These units are tested to meet Council Dir ect ive 73/23/EEC Low

Voltage Directive. The EN 60204-1 Safety of Machinery-Electrical

Equipment of Machines, Part 1-Specificati on for General

Requirements standard applies in whole or in part.

grounded to the enclosure.

number SP-74102-006-01, SP-7 4102 -006 -02, SP-74102-006-03

or equivalent based on system current) between the three-phase

input line and the system module input.

motor feedback cables to the enc los ure at the point of entry.

Before Mounting Your System

Refer to Appendix B for interconnect information.

Before you mount your 1394 system make sure you understand the

following:

• how to store your 1 39 4 before insta llation

• how to unpack the system and axis modules

• the minimum mounting requirements

• how to determine your mounting hole layout

Storing Your 1394 Before Installation

The 1394 System module and Axis modules should remain in their

shipping containers prior to installation. If the equipment is not to be

used for a period of time, store it as follows:

• Store the equipment in a clean, dry locati on that is not ex posed to

a corrosive atmosphere.

• Do not store equipment in a construction area.

• Store within an ambient temperature range of 0 to 65° C (32 to

149° F).

Publication 1394-5.0 — May 2000

• Store with in a relative humidity rang e of 5 to 95%,

noncondensing.

Page 33

Installing Your 1394 (app lies to all systems) 2-3

Unpacking Modules

Each 1394 System module ships with the following:

• One system module

• One system terminator

• One terminal operat ing tool (part number 1394-194)

• One user manual (publication 1394-5.0)

• One appl ic ation program loc k key (G MC and GMC Turbo only)

• Mating power conne ctors (5 and 10 kW Series C only)

• Cable shie ld grounding c lamps (5, 10, and 22 kW Series C only)

Note: To determine the series of your module, refer to Figure P.1 in

the Preface.

Each 1394 Axis Module ships with the following:

• One 1394 Axis module

• TB1 and TB2 connectors

• One 1394 Axis module information sheet (publication 1394 -5.5)

Remove all packing material, wedges, and braces from within and

around the components. After unpacking, check the item(s)

nameplate catalog number against the purchase order. Refer to

Appendix D for more information on catalog numbers.

System Mounting Requirements

There are several things that you need to take into account when

preparing to mount the 1394:

• The ambient te mperature of the l oc ation in which y o u will install

the 1394 must not exceed 50° C (122° F).

• You must install the panel on a flat, rigid, vertical sur face that

won’t be subje cted to shock, vib ration, mois ture, oil mist , dust, or

corrosive vapors.

• You have to mount the system vertically.

• You need to maintain minimum clearances (see Figur e 2.1) for

proper airflow , easy module access, and proper cable bend radius.

Refer to Appendix A for mounting dimensions, po wer d issipation , and

envir onmental specificat ions for the 1394.

Publication 1394-5.0 — May 2000

Page 34

2-4 Installing Your 1394 (applies to al l systems)

Figure 2.1

Minimum System and Axis Module Mounting Requirements

Allow 50.8 mm (2.00 in.) clearance

for airflow and installation.

ATTENTIO N: This driv e contains ESD (Electrostatic

Discharge) sensitive parts and assemblies. You are

!

required to follow static control precautions when you

install, test, service, or repair this assembly. If you do

not follow ESD contro l procedures, components can be

damaged. If you are not f amiliar with static control

procedures, refer to Allen-Bradley publication 8000-

4.5.2, Guarding Against Electrostatic Damage or any

other applicable ESD Protection Handbook.

Status

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

Allow 10.0 mm (0.4 in.) side clearance.

Allow 25.4 mm (1.00 in.) clearance

at cover tab for opening and closing.

(See ATTENTION: statement below)

Wire entry area for cable ground clamps and

Allow additional clearance below the system module to provide the recommended cable bend radius.

Refer to

1326 Cables for 460V AC Servo Motors

Status

DANGER

RISK OF ELECTRICAL SHOCK. HIGH VOLTAGE MAY

EXIST UP TO FIVE MINUTES AFTER REMOVING POWER.

signal, power, and motor connections.

(publication 1326A-2.11) for more information.

Allow 10.0 mm (0.4 in.) side clearance.

Allow 76.2 mm (3.00 in.) clearance

ATTENTIO N: If you are mounting a 1394x-SJTxx-

T system module, and using the SLC Interface, you

!

will need an additional 101.6 mm (4 in.) of cl ear ance

to the left of the system module to allow for connecting

the SLC interface cable (1746-C7 or -C9).

Determining Your System Mounting Hole Layout

for depth of terminator.

Publication 1394-5.0 — May 2000

To prepare your subpanel for mounting:

1. Before you mount your 1394 System, use the illustration and

table on the next page to identify your axis module combination.

Page 35

Installing Your 1394 (app lies to all systems) 2-5

Figure 2.2

1394 Mounting Hole Layout

Axis Module

Combination

Dimensions are in millimeters and (inches)

50

(1.97)

0

(0.00)

System module

mounting holes

System

62.5

(2.46)

50

(1.97)

B

AAA

C

D

E

100

(3.94)

125

(4.92)

137.5

(5.41)

(5.91)

C

B

D

E

150

175

(6.89)

(7.87)

B

200

212.5

(8.37)

(8.86)

D

A

E

C

225

B

250

(9.84)

275

(10.83)

C

outline

385

(15.16)

33.5 TYP

(1.32)

Heat sink

cutout for the

AM50/75

module

only

67 TYP

(2.64)

Heat sink

cutout for the

AM50/75

module

only

Heat sink

cutout for the

AM50/75

module

only

8 TYP

(0.32)

Type of Axis Module Number of Axes Cutout Needed?

287.5

(11.32)

DE

Heat sink

cutout for the

AM50/75

module

only

19.5

(0.768)

348

(13.70)

M6 tapped hole or

1/4-20 UNC - 2B

1394x-AM50, or -AM75, and

A

1394C-AM50-IH, or -AM75-IH

0no

1394x-AM03, AM04, or AM07 up to 4 no

1394x-AM50, or -A M75, and

B

1394C-AM50-IH, or -AM75-IH

1 yes (1394x-AM50 or -AM7 5)

no (1394C-AM50-IH or -AM75-IH)

1394x-AM03, AM04, or AM07 up to 3 no

1394x-AM50, or -A M75, and

C

1394C-AM50-IH, or -AM75-IH