Page 1

Installation, Operation

and Maintenance Manual

DC Motors

• Frames DC180ATZ, C180ATZ and

DC210ATZ

Page 2

2 DC Motors

General Description

The products described in this publication are designed specifically for use

on rectified power. The basic design includes Class F Insulation, 1.0 Service

Factor, 40 degree C (104 degree F) ambient, continuous duty, with

drip-proof guarded and force-ventilated enclosure, with horsepower speed

ratings, overload and voltage in accordance with NEMA Standards. A wide

variety of modifications, enclosures and accessories is available.

ATTENTION: Only qualified electrical personnel familiar with

the construction and operation of this equipment and the hazards

!

involved should install, adjust, operate, and/or service this motor.

Read and understand this manual in its entirety before

proceeding. Failure to observe this precaution could result in

personal injury or loss of life.

Table of Contents

General Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiving and Handling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Motor Application Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly & Reassembly Instructions. . . . . . . . . . . . . . . . . . . . .

12

15

21

2

2

3

8

Acceptance

Thoroughly inspect this equipment before accepting shipment from the

transportation company. If any of the goods called for in the bill of lading or

express receipt are damaged or the quantity is short, do not accept them

until the freight or express agent makes an appropriate notation on your

freight bill or express receipt. If any concealed loss or damage is discovered

later, notify your freight or express agent at once and request him to make

an inspection. We are willing to assist you in collecting claims for loss or

damage in shipment; however, this willingness on our part does not remove

the transportation company's responsibility in reimbursing you for

collection of claims or replacement of material. Claims for loss or damage

in shipment must not be deducted from the invoice, nor should payment of

the invoice be withheld awaiting adjustment of such claims, as the carrier

guarantees safe delivery.

If considerable damage has been incurred and the situation is urgent,

contact the nearest Allen-Bradley Sales Office for assistance. Please keep a

written record of all such communications.

Page 3

DC Motors 3

Handling

ATTENTION: Eyebolt(s) or lifting lug(s) are intended for

lifting the motor only with the standard accessories such as

!

tachometer, brakes, etc., mounted by Allen-Bradley. The lifting

means on the motor must not be used to lift the unit plus

additional equipment. The lifting means on the motor cannot be

used to lift assemblies or equipment mounted on a common base.

Failure to observe this precaution could result in personal injury.

In all cases, care should be taken to assure lifting in the direction intended

in the design of the lifting means. Lift using all lugs provided. Likewise,

precautions should be taken to prevent hazardous overloads due to

deceleration, acceleration or shock forces.

Angle of lift with rope or chain must be greater than 45 degrees from

horizontal.

For unusual conditions, such as side-wall and ceiling mounting of

horizontal motors or installation of vertical motors shipped in a horizontal

position, special precautions must be taken. It is recommended that an

experienced rigger be employed.

Installation

Storage

Motors must be stored in a clean, dry area protected from extremes of

temperature, moisture, shock and vibration. Storage temperatures of 10 to

49 degrees C (50 to 120 degrees F) with a maximum relative humidity of

60% must be observed. In addition, motors subjected to extended storage

must be handled and treated per the requirements specified in publication

“Motors-5.0.” This publication is available from your Allen-Bradley Sales

Office or online at: http://www.controlmatched.com.

DC motors have characteristics which can cause serious or fatal injury

unless they are selected, installed, maintained and operated by qualified

personnel familiar with special requirements of DC machines.

Allen-Bradley DC motors are designed and built in accordance with Safety

Standard for Construction and Guide for Selection, Installation and Use Of

Electric Motors And Generators published by the National Electrical

Manufacturers Association (NEMA), publication MG-2-1983 (ANSI

C51.5). It is recommended that this publication be referred to whenever you

select or install any motor.

The application of motors and other electrical equipment in hazardous

locations is restricted by the National Electric Code. Users must observe

these regulations and consult with local code inspection and enforcement

agencies to insure compliance.

Page 4

4 DC Motors

Location

Locate the machine where the ambient temperature is not over 40 degrees C

(104 degrees F) and where clean air has free access to ventilating intake and

outlet openings. Except for machines with a suitable protective enclosure,

the location should be clean and dry.

Important: Sufficient clearance must be provided on all inlet and outlet

openings to provide for unrestricted flow of air. Separately

ventilated motors with exhaust to ambient (pipe-in only) must

have at least 152.4 mm (6 in.) of clearance between the opening

and adjacent walls or floor.

Air Supply

Cooling air through a self-ventilated or forced-ventilated motor must be

clean and have relative humidity between 30 and 100% with no free water

in the air. Use of damp, cool outside air with high humidity and free water

may cause the motor to flash over. Use of excessively dry air may cause

excessive brush and commutator wear. Cooling air temperature must not

exceed the maximum ambient temperature indicated on the motor

nameplate (standard 40 degrees C/104 degrees F). Cooling air temperature

must not be lower than 0 degrees C (to provide base speed and regulation

within NEMA limits). Use of outside air below 0 degrees C may cause

excessive brush and commutator wear due to the low humidity. Cooling air

absolute humidity must be at least 2 grains per cu. ft.

Important: Motors located in damp, moist environment must have space

heater or fields energized at 50% voltage to protect against

condensation when motor is not operating.

Separately ventilated motors must have the following volume of air to

adequately cool the motor unless the motor nameplate specifies a different

value.

Frame

DC180ATZ,

C180ATZ and

DC210ATZ

Base Speed

RPM

2500 152 2.0

1750 and lower 105 0.95

Air Volume

CFM

Static Pressure

Inches of Water

Power Supply

Check the motor nameplate to be sure the voltage and type of power rating

is the same as that of the power source.

A code stamped on the nameplate identifies the type of power supply that

must be used to supply armature power to the motor in order to obtain the

rated nameplate output. Since the code letter has been selected in alphabetic

order of increasing magnitude of ripple current, a motor may be operated on

a power supply having a letter designation prior in the alphabet to the letter

stamped on the nameplate, with no loss in nameplate rating.

Page 5

DC Motors 5

For example, a motor designed for a D type of power supply may be used

on a C power supply having the same voltage rating. The types of power

supplies are defined as follows.

Description Code

DC generator, battery or twelve pulse/cycle, 6 phase, full control A

Six pulse cycle, 3 phase, full control 230 or 460 volt, 60 Hz input to rectifier C

Three pulse/cycle, 3 phase, semi-bridge, half control 230 or 460 volt, 60 Hz input to rectifier D

Three pulse/cycle, 3 phase, half-wave (single way) 460 volt, 60 Hz input to rectifier E

Two pulse/cycle, 1 phase full wave (bridge circuit with 2 controlled rectifiers and

K

2-uncontrolled rectifiers with free wheeling rectifier) 230 volt, 60 Hz input

1

When the armature power supply cannot be designated by a single letter code (A. K etc.) the power supply shall

be identified by the following code stamped on the motor nameplate: “M/N F-V-H-L.”

where M = Total pulses per cycle

N = Total controlled pulses per cycle

F = Free wheeling (if used)

V = Nominal line-to-line a-c voltage to rectifier

H = Line frequency-Hz

L = Value of series inductance (in millihenries) to be added externally to the motor armature circuit.

Examples:

A. "6/3 F-380-50-12" defines a power supply having 6 total pulses per cycle, 3 controlled pulses per cycle

(S-3), with free wheeling, 380 volts. 50 Hz AC input to bridge, and a 12 millihenry choke to be added

externally to the motor armature circuit.

B. "3/3 480" defines a power supply having three total pulses per cycle, three control pulses per cycle. 480

volts line-to-line input to the rectifier. 60 Hz power supply and no external inductance required in the

armature circuit. Note that since the power source is 60 Hz and no series inductance is required. both

quantities may be omitted from the code. If one of the quantities is indicated, both must be included to

avoid confusion.

Conduit Box

1

Conduit boxes can be rotated in 90 degree increments for lead outlet at top,

sides or bottom.

Conduit box locations can be changed from F1 to F2 or F2 to F1 by rotating

the commutator end bracket 180 degrees and reconnecting the leads. The

conduit box location cannot be changed on DC180ATZ & DC210ATZ

frames.

Connections

Important: If motor has parallel leads, all lugs with the same marking: For

example, A1, A1, must be connected together.

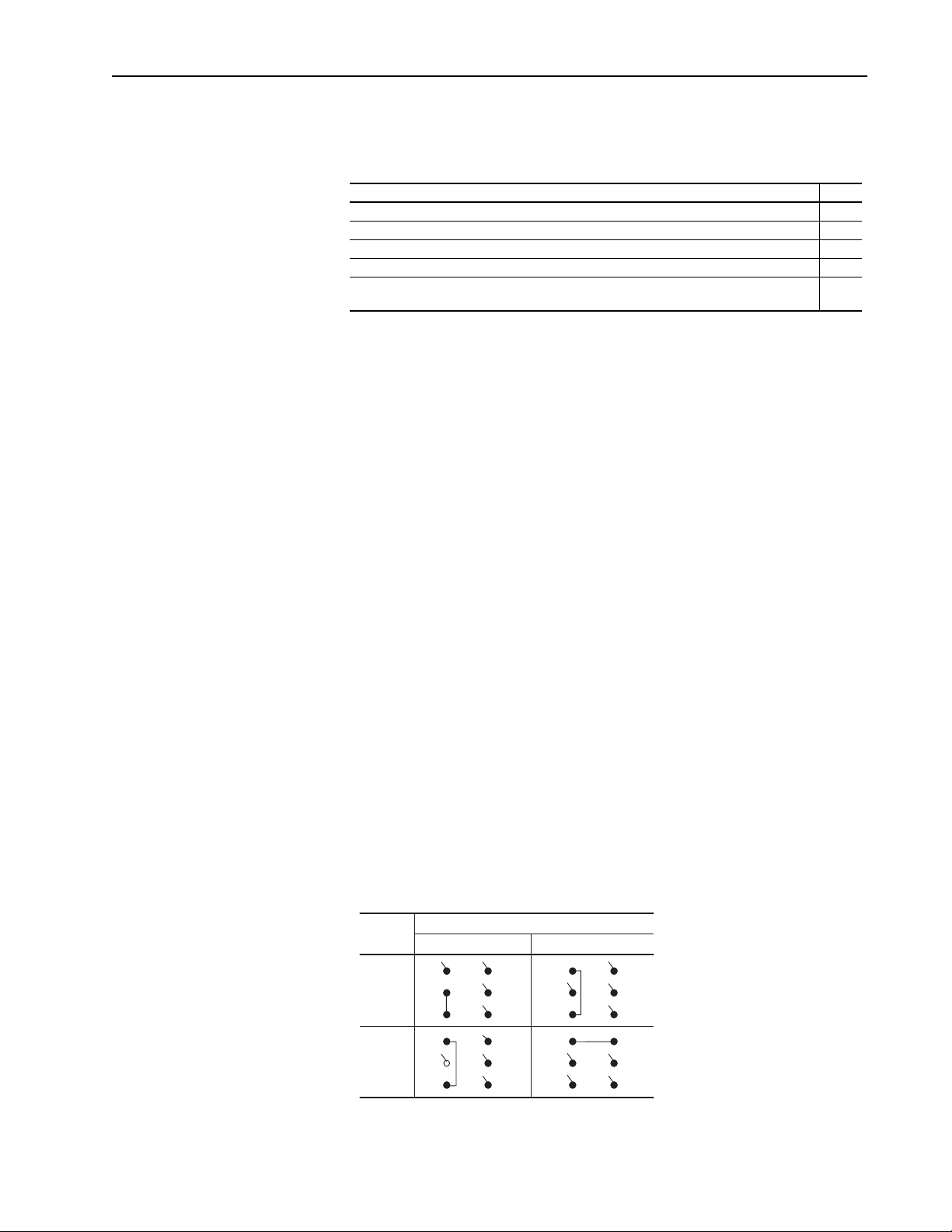

Figure 1 Basic DC Motor and Generator Connections

Rotation Facing Commutator End

Type

Motor

Generator

+A1

A2

S1

A1

+A2

S1

CCW

–S2

+F1

–F2

–S2

–F1

+F2

A1

+A2

S1

A1

+A2

–S1

CW

–S2

+F1

–F2

S2

+F1

–F2

If machine has no series field, disregard S1 and S2 above. For machines

with special windings, refer to motor or generator and controller diagrams.

Page 6

6 DC Motors

Thermostat (Thermal Protector)

Important: When motors are provided with thermal protection (typically

thermostats), it is important to properly connect and apply the

devices. This will ensure that the motor is properly protected

from being operated if thermal limits are reached and/or

exceeded. The control system must be configured to reduce the

motor load and/or shut down the motor control system to allow

the motor to cool to a level within acceptable operating ranges.

If the motor is operated with the thermal protective devices

tripped (indicating an over temperature condition), the motor

insulation could be damaged and complete failure of the motor

insulation is possible. In the event of motor failure due to an

over temperature condition, Rockwell Automation requires that

motor thermal protective devices (when supplied) be

adequately monitored and incorporated into the motor control

system to maintain warranty. Failure on the part of the

individual installing this equipment to take these steps will

result in the factory warranty being voided.

Important: Motors may have one or more thermostats (leads marked P1,

P2, etc.) designed to trip before the frame reaches the

maximum allowable temperature for specific class and group.

The normally closed contacts of the thermostat must be

connected in that motor control circuit so that power to the

motor armature and field is removed immediately when the

thermostat trips. An explosion-proof tachometer mounted on

the motor will also have an internal thermostat which must be

connected to stop the drive within 30 seconds upon tripping.

Failure to connect the thermostat leads will void the motor

warranty. the rating of the thermostat contact is:

Maximum Voltage 250V, 60 Hz

Rated Current 6.3 amps

Maximum Breaking Current 20 amps

Important: Motors with an overspeed switch must have the overspeed

switch terminals properly connected in the control circuit to

remove armature power when the switch reaches the set speed.

Grounding

The user is responsible for assuring that the grounding method is in

accordance with the National Electric Code and the applicable local codes.

The ground connection should be a solid and permanent metallic

connection between the ground point, the motor terminal housing and the

motor frame. On two pole units, DC180ATZ, C180ATZ & DC210ATZ, the

ground connection is a tapped hole in the end bracket adjacent to the

conduit box.

Page 7

DC Motors 7

Mounting

Motors must be mounted on a rigid, solid base or foundation. Poor base

construction may cause resonances in the motor/base assembly which can

result in bearing failure and other motor damage. All hold down bolts must

be the correct grade for the type of mounting and must be torqued to their

recommended value.

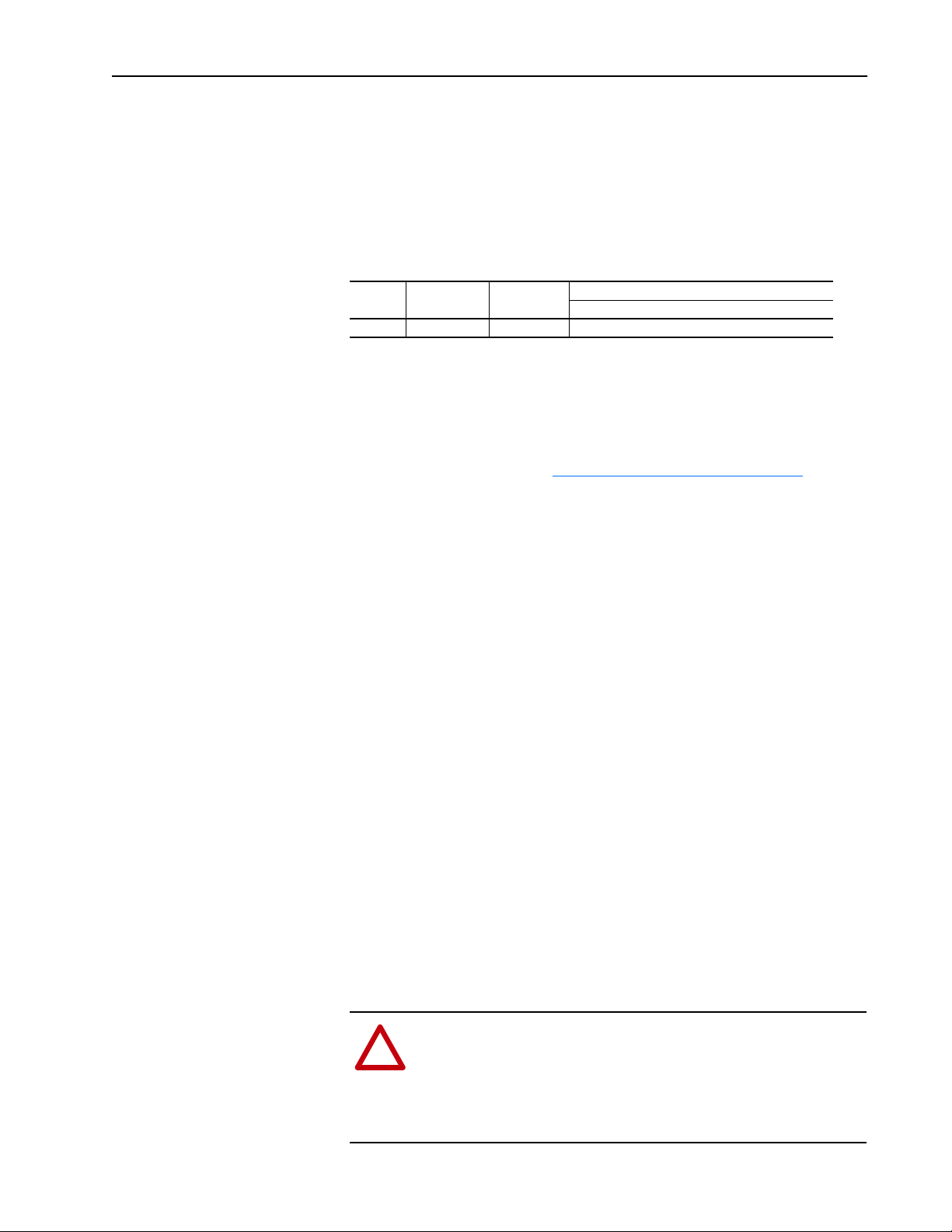

Table A Recommended Torque

Frame

C180ATZ 11.2 (0.44) 3/8-16 1.81 (16)

Hole Diameter

mm (in.)

Bolt Size and

Thread

SAE Grade I Dry Components-Not Lubricated

N-m (lb.-ft.)

Belted Drive

Motor slide bases or rails, when used, must be securely anchored to the

foundation with the proper bolts.

Important: The motor shaft and load shaft must be parallel and the sheaves

aligned. Refer to

“Motor Application Data” on page 8.

Coupled Drives

Important: Flexible couplings must be used between the motor shaft and

the load shaft. Motor shaft and load shaft must be aligned to

values recommended for the specific coupling before coupling

is connected.

Important: Motors will operate successfully mounted on the floor, wall or

ceiling, and with the shaft at any angle from horizontal to

vertical. Special mountings, duty or thrust demands may,

however, require a different bearing system. Drive-end bracket

and/or outer caps can be rotated either 90 or 180 degrees to

conveniently locate grease fittings, or air outlet openings.

Handhole covers can be interchanged as necessary.

Important: Vertical mount drip covers are required to provide protection to

vertically mounted Drip-Proof motors. Stock motors and other

motors designed for horizontal mounting can be adapted for

vertical mounting by ordering vertical mount drip covers.

Self-ventilated frames cannot be mounted vertical shaft up and

retain the drip-proof feature due to louvers on the drive end

bracket.

Motor C-Face is intended for mounting auxiliary equipment such as pumps,

gears, etc. When mounted horizontally, these motors should be supported

by the feet and not by the C-Face. Installations requiring a horizontally

mounted motor without feet should use a D-Flange.

ATTENTION: Surface temperature of the motor enclosure may

reach temperatures which can cause discomfort or injury to

!

personnel coming into contact with hot surfaces. The user must

apply appropriate guards and/or shields to protect against

accidental contact with motor surface. Failure to observe this

precaution may result in personal injury.

Page 8

8 DC Motors

Direction of Rotation

Unless otherwise ordered, brush rigging is assembled for NEMA standard

direction of rotation, counterclockwise for motors and clockwise for

generators facing the commutator end. These motors will operate in either

direction of rotation, without changing the angle of the brush holders for

normal field weakened speed ranges. Extended field weakened speed range

motors should have the direction of rotation specified.

Drive

DC180ATZ, C180ATZ & DC210ATZ frame motors are supplied with a

shaft suitable for a belt or coupled drive.

Proper alignment is a key step for long life of bearings, shafts and belts, and

minimum downtime. Misalignment can cause excessive vibration and

damaging forces on shaft and bearings. For direct coupled drives, flexible

couplings facilitate alignment. For belt drives, the driving and driven

tension must be adjusted as required for proper operation. The belt sheaves

should be placed as close as possible to the motor bracket.

Motor Application Data

ATTENTION: To guard against personal injury and/or machine

damage caused by incorrect motor rotation, verify direction of

!

motor rotation before coupling motor to load.

ATTENTION: Ensure that all guards are properly installed, to

guard against personal injury caused by contact with rotating

!

parts,

Shipping Blocks

Motors supplied with roller bearings at the drive end are shipped with

wooden blocking to prevent axial movement of the shaft during shipment.

Remove the blocking and bolts securing it and discard. Make sure motor

shafts turn freely. If motor is to be reshipped, blocking of bearing is

required.

Maximum Safe Speed

ATTENTION: The machinery builder and/or user are

responsible for assuring that all drive train mechanisms, the

!

driven machine, and process material are capable of safe

operation at the maximum speed at which the machine will

operate. Failure to observe these precautions could result in

personal injury.

Page 9

DC Motors 9

The speeds given in Table B are the maximum mechanically safe operating

speeds for frames with standard construction. These speeds must not be

exceeded under any condition. Motor control must hold the maximum

speed under any load condition including no-load within the maximum safe

speed. Drive systems whose design characteristics inherently prevent the

DC motor from exceeding the motor maximum safe operating speed must

prevent the motor from exceeding the maximum safe speed if a single

component failure should occur.

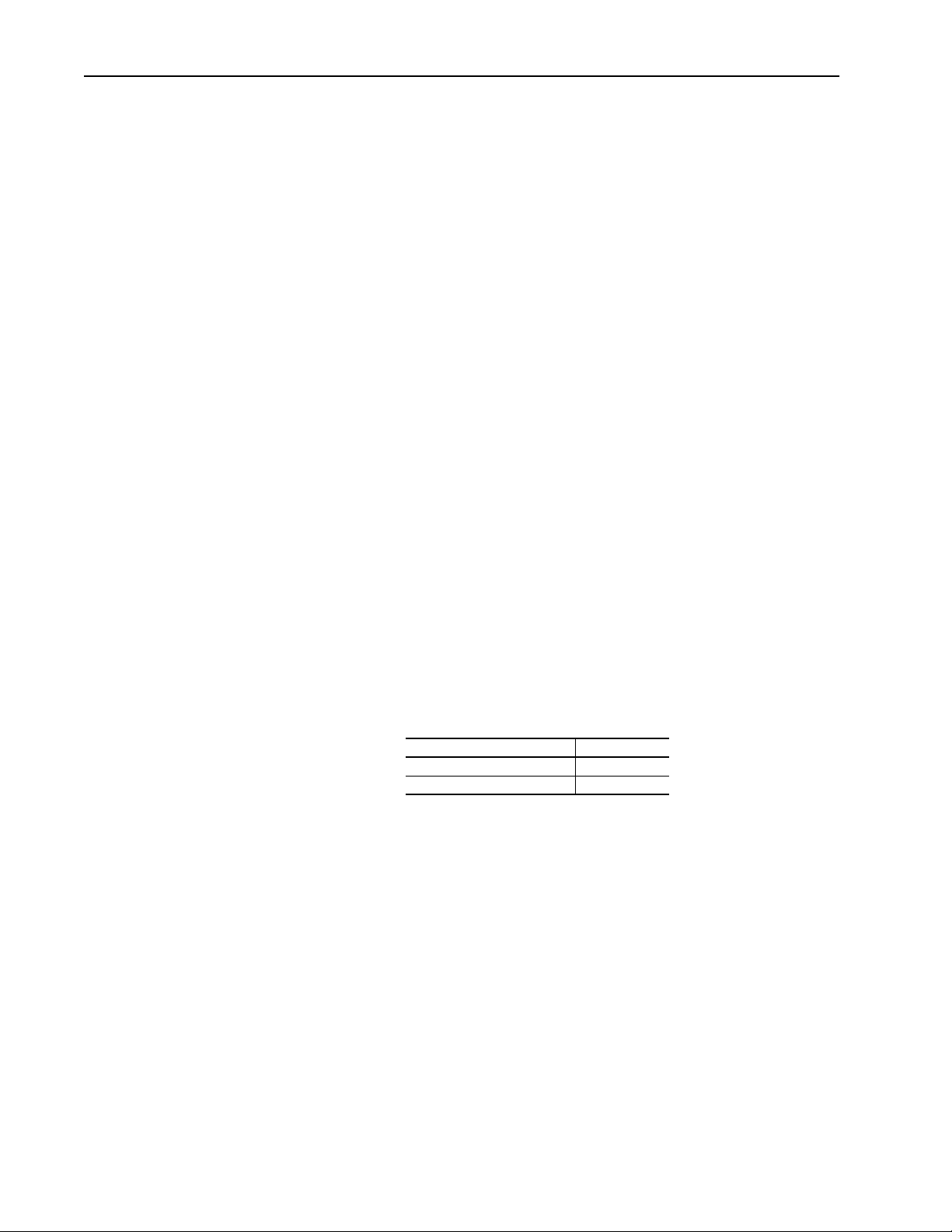

Table B Maximum Safe Speed

Frame Diameter Maximum Safe Speed

DC180ATZ 4500 RPM

C180ATZ 5000 RPM

DC210ATZ 4500 RPM

With special construction, maximum safe speed may differ from the above

values. In all cases, maximum safe speed is indicated on the motor

nameplate.

Important: Normal operating speeds must be limited to those listed in

order to meet nameplate rating and assure validity of warranty.

Application of Pulleys, Sheaves, Sprockets and Gears On Motor Shafts

To avoid excessive bearing loads and shaft stresses, belts should not be

tightened more than necessary to transmit the rated torque. The

pre-tensioning of the V-belt drive should be based on the total tightening

force required to transmit the horsepower divided by the number of belts.

This procedure avoids the excessive load caused by tightening individual

belts to a prescribed level recommended by belt manufacturers.

Mounting

In general, the closer pulleys, sheaves, sprockets or gears are mounted to the

bearing on the motor shaft, the less will be the load on the bearing. This will

give greater assurance of trouble-free service.

The center point of the belt, or system of V-belts, must not be beyond the

end of the motor shaft.

The inner edge of the sheave or pulley rim should not be closer to the

bearing than the shoulder on the shaft but should be as close to this point as

possible.

The outer edge of a chain sprocket or gear must not extend beyond the end

of the standard motor shaft.

Page 10

10 DC Motors

Shaft Extension and Method Of Drive

V-belts should be within the limits of NEMA Standard MG1-14.67.a.

Frames DC180ATZ, C180ATZ, DC210ATZ are supplied with the same size

shaft for either coupled or belted drives.

Table C Multipliers for Drives other than V-belt

Drive Multiplier

Flat Belt (See Note 1) 1.33

Timing Belt (See Note 2) 0.9

Chain Sprocket 0.7

Spur Gear 0.75

Helical Gear 0.85

1

The abovemultiplier is intendedfor use withconventional single-ply flat,belts. When otherthan single-ply flatbelts

are used, the use of a larger multiplier is recommended.

2

It is often necessary to install belts with a snug fit. However, tension should be no more than necessary to avoid

belt slap or tooth jumping.

Shaft Loads – Axial and Radial

DC motors are suitable for limited shaft load as shown in Tables D and E.

Recommended maximum thrust loads depend on the mounting position,

either horizontal or vertical. For load recommendations in excess of those

shown, contact your local Sales Office.

ATTENTION: The use of these radial load capacities requires

the accurate calculation of the radial load for the application.

!

Radial loads for gears, sprockets, and flywheel are usually

accurately determined but the radial loads due to V-belt drives are

subject to miscalculations because they do not include all of the

pre-tension load (belt tightening). The calculations of the radial

load for a V-belt drive must include the pre-tension for

transmitting the horsepower, pre-tension for centrifugal force on

the belts, pre-tension for high start torques, rapid acceleration or

deceleration, pre-tension for drives with short arc-of-contact

between the V-belt and sheave, and low coefficient of friction

between belt and sheave caused by moisture, oil or dust. Failure

to observe these precautions could result in damage to or

destruction of the equipment.

Table D Axial Thrust Capacity

Horizontal Mounting Vertical Mounting

Frame Units

DC180ATZ &

DC210ATZ

C180ATZ lbs. 295 345 417 477 370

2500 RPM 1750 1150 850 2500 1750 1150 850 RPM

lbs. 176 207 251 286 190

kg 80 94 114 130 86

kg 134 156 189 216 139

1

± 45 217 ± 45 265 ± 45 295 ± 45

± 20 99 ± 20 120 ± 20 134 ± 20

± 45 357 ± 45 430 ± 45 492 ± 50

± 20 162 ± 20 195 ± 20 223 ± 20

1

Thrust capacity for vertical mounting includes a constant whose value is plus or minus depending on the

direction of the thrust load. The constant is plus for thrust loads acting upward against the force of gravity and

minus for loads acting downward with gravity.

Page 11

DC Motors 11

Table E Radial Load Capacity

Capacity at End of Shaft in kg (lbs.)

Frame

DC210ATZ &

DC180ATZ

C180ATZ 226.8 (500) 256.3 (565) 283.5 (625) 283.5 (625)

1

Data for motors with roller bearings at the drive end (back end). Motors with ball bearings at the drive end are

for coupled duty only.

2500 RPM 1750 RPM 1150 RPM 850 RPM

140.6 (310) 156.5 (345) 179.2 (395) 200.0 (440)

1

Deriving Motor Constants

Various motor constants are required to set control functions for stabilized

operation of motor and controls. The following information will make it

possible to derive approximate motor constants from the nameplate data.

Required Nameplate Data

• Frame

• HP

• RPM

• Volts (Va)

• Amps (Ia)

From

Table F, the following factors are available, based on frame size.

• Ra´

• La´

• WK

2

•τe´

This will provide approximate results with a ±25% margin of error.

The following data can be derived:

La = La´ x (Va/rpm)2 Arm. Circ. Ind. (millihenries)

Ra = Ra´ x (Va/rpm)

2

Arm. Circ. Resistance

τe = τe´

τe´ = La/Ra x 103Elec.Time Constant

J (SEC) = WK2 x (rpm)2/1.62 x (10)6 x hp where WK2 is in terms of lb-ft

J (SEC) = WK2 x (rpm)2/0.0922 x (10)6 x kw where WK2 is in terms of kg-m

R = Ia x Ra/(Va – IaRa)

Table F Resistance & Inductance Factors

2

WK

Frame

C1811ATZ 0.683 0.029 56.6 616 0.011

C1812ATZ 0.787 0.033 40.5 500 0.012

2

Ra La τelb.-ft.2kg.-m.

2

2

Page 12

12 DC Motors

Operation

Balance

Motors are dynamically balanced to commercial limits unless ordered

differently. Balance is done with a full length 1/2 height shaft key. A full

shaft key is shipped with the motor. Sheave or coupling should be balanced

with a 1/2 height shaft key.

Table G Standard Dynamic Balance Limits

Highest Rated Speed

(RPM)

3,000 - 4,000 0.0010

1,500 - 2,999 0.0015

1,000 - 1,499 0.0020

Up to 999 0.0025

Maximum Amplitude

(Inches)

Series Wound Motors

Important: Series wound motors must be solidly connected to the driven

machine and never operated without load to avoid possible

destructive high speeds.

Motor Start-up

ATTENTION: To guard against personal injury and/or machine

damage, observe the following precautions before initial start-up:

!

• Remove all unused shaft keys and loose rotating parts to

prevent them from flying off. Replace covers and protective

devices.

• Verify that all separately excited fields are excited at their rated

voltage and that relative polarities of all fields are correct. See

“Checking Relative Polarity of DC Motor Fields” on page 14.

• When the motor is supplied as part of drive system, refer to the

Drive User Manual for operating instructions. Tachometer

feedback must be properly connected for closed loop

operation. Reverse polarities or broken connections can cause

dangerous overspeeds.

Maximum safe mechanical operating speeds are shown in

Table B on page 9. Motor control circuitry must prevent motor

speeds from exceeding the stated values.

Page 13

DC Motors 13

In addition to observing the above precaution, all precautions (Attentions)

mentioned in this document should be observed. The following items must

be checked before starting and during operation.

• The armature should rotate freely and be clear of any obstructions.

• The brushes should move easily in their holders and should make

proper contact on the commutator.

• The interior of the motor should be clean and dry.

• Connections must be tight.

• The driven machine should be unloaded, if possible.

When starting, small sparks may appear on the commutator due to particles

of dirt. Other than this. there should be little, if any, sparking at the brushes.

Important: Machines designed for cooling by a separate source of forced

ventilation must not be operated without the air supply. Be sure

blower is running in proper direction.

While operating the motor, observe the performance. It should run smoothly

with little noise. The bearings should not overheat and should reach a

leveling off temperature. Any undue noise, overheating, sparking or erratic

performance should be investigated and necessary corrective action taken

immediately to prevent serious damage. Before attempting any repairs,

please contact your Allen-Bradley Sales Office.

All motors are lubricated before shipment and will operate for a long period

before regreasing is required. The period will vary depending on

environmental and service conditions. Refer to

ATTENTION: Surface temperature of the motor enclosure may

reach temperatures which can cause discomfort or injury to

!

personnel coming into contact with hot surfaces. The user must

apply appropriate guards and/or shields to protect against

accidental contact. Failure to observe this precaution may result

in personal injury.

“Maintenance” on page 15.

Page 14

14 DC Motors

DC Motor Field Heating

ATTENTION: To guard against motor damage caused by

inadequate ventilation, assure that motors designed for forced

!

ventilation as standard have cooling air when fields are excited at

rated voltage. Installations having the air supply interrupted when

the motor is not operating must have field disconnected or field

voltage reduced to 67%, rated by means of field economizing

resistor and relay. The motor insulation life can be significantly

reduced if the above precaution is not followed.

Standard continuous duty DPG, TEFC and TENV stabilized shunt wound

DC motors have continuous duty fields capable of continuous excitation at

standstill (armature circuit not energized) under normal industrial

conditions.

Important: Motors designed for forced ventilation or with a dual-cooled

heat exchanger as standard must have cooling air when fields

are excited at rated voltage. Installations having the air supply

interrupted when the motor is not operating must have field

disconnected or field voltage reduced to 50% rated by means of

field economizing resistor and relay.

Standard continuous duty self-ventilated motors are suitable for rated load

at rated speed operation at field voltages up to 110% of rated value.

However, insulation life will be reduced if operated below 60% of base

speed for prolonged periods.

Checking Relative Polarity of DC Motor Fields

Motor speed is unstable if speed increases due to an increase in load

current. As a result of instability, motor speed may hunt or overspeed. These

are unsatisfactory, possibly dangerous, drive conditions.

One of the possible causes of unstable performance of shunt wound DC

motors is incorrect series field polarity relative to the shunt field due to

improper connection. Relative polarity of the shunt and series fields can be

checked as follows:

1. Connect a low scale (3 volt) DC voltmeter across the shunt field

terminals (F1, F2) with F1 connected to the positive (+) terminal of the

meter. At least one of the shunt field leads must be disconnected from

the controller.

2. Use two flashlight batteries as a source of low voltage (3 volts). Hold or

connect the negative, to contact the S-2 series field terminal. Hold one

end of a wire conductor to the positive (+) center terminal so that the

other end of the wire can be used to make and break contact with the S-I

series field terminal.

3. Watch the deflection of the voltmeter needle when contact is made with

S-I and when contact is broken.

Page 15

DC Motors 15

4. When contact is made, the needle will first deflect in either the up scale

or down scale direction and then return to zero. Deflection will be in the

opposite direction when contact is broken.

5. Relative polarities of the shunt and series fields are correct

(ampere-turns are cumulative) if the voltmeter needle deflects up scale

when contact is made and down scale when contact is broken.

6. Relative polarities of the shunt and series fields are incorrect

(ampere-turns are differential) if the voltmeter needle deflects down

scale when contact is made and up scale when contact is broken. The

motor connections must be changed so that relative polarity is correct.

Relative polarity can be incorrect because of an error in the connections to

the control or because the series fields leads are improperly marked. In any

case, the motor connections must be changed so that relative polarity is

correct.

If only one series field terminal is available at the controller, use it and the

available armature terminal for the test. For example, use S-2 and A-l, if S-1

and A-2 arc connected together at the motor and not brought to the

controller.

Maintenance

ATTENTION: Internal parts of this motor may be at line

potential even when it is not rotating. Before performing any

!

maintenance which could result in contacting any internal part, be

sure to disconnect all power from the motor. Failure to observe

this precaution could result in severe personal injury or death.

Inspections

Regular inspection at intervals dependent upon service conditions is the best

insurance against costly maintenance and breakdown. Experience is the best

guide. Record inspection results and maintenance action required or

performed.

Cleanliness

Keep the interior parts of machines clean and dry. Remove dust, dirt,

corrosion, grease, oil and moisture. If used, ventilating air filters must be

kept clean or replaced to assure full volume of cooling air.

Lubrication - Frames DC180ATZ & DC210ATZ

DC180ATZ frame has oversize grease reservoirs to provide lifetime

operation in normal industrial applications. Where severe duty conditions

require regreasing, the following procedures should be followed:

Page 16

16 DC Motors

Drive End Bearing

Bearing fits in machined cavity in bracket with inner cap. To regrease

bearing, remove bracket (four nuts hold bracket to frame) and inner cap

(two bolts). Clean old grease from bearing and cavity and repack with

Chevron SRI-2 or equivalent grease.

Commutator End Bearing

Bearing has single shield and single seal with seal on side facing

commutator. To regrease bearing, snap out brushes and remove bracket

(four nuts hold bracket to frame). Clean old grease from around bearing and

cavity and repack around bearing and Chevron SRI-2 or equivalent grease.

Amount of grease to be added to motors is shown in

Table H. See Table J

for relubrication interval. Use Chevron SRI-2 or equivalent grease unless

motor nameplate specifies special grease.

Recommended Lubricant

For motors operating in ambient temperatures shown below, use the

following lubricants or their equivalent:

Ball Bearing Motors

Operating Temperature:

–25 to 50 degrees C (–15 to 120 degrees F)

Minimum Starting Temperature

–60 degrees C (–76 degrees F)

Table H Coupled/Belted or Tandem Duty Grease Amounts

Volume Weight

Frame

C180ATZ 1.0 16 0.5 14

Cubic Inches Cubic Centimeters Ounces Grams

Using the table below, determine service condition on the basis of the most

severe operating parameter (i.e. temperature, bearing load, atmosphere, or

operating hours per day).

Chevron Oil – SRI No. 2

Exxon – Unirex N2

Shell Oil Co. – Dolium R

Texaco, Inc. – Premium RB

Shell Oil Co. – Aeroshell 7

Table I Service Condition

Service

Condition Ambient Temperature Bearing Load Atmosphere

Standard –18 to 40 degrees C

Severe –30 to 50 degrees C

Extreme

1

2

(0 to 104 degrees F)

(–22 to 122 degrees F)

2

–54 to 65 degrees C

(–65 to 149 degrees F)

Motors must be specially designed for operation in ambient outside the range of –30 to 40 degrees C

(–22 to 104 degrees F). Special grease is required.

“Extreme” service conditions are rare in actual practice. Corresponding lubrication cycles should therefore be

applied with caution. It is also advisable to check with Allen-Bradley for related special instructions.

Steady Clean 8

Medium Shock, Vibration

1

(less than 0.2 in/sec.)

Heavy Shock, Vibration

1

(more than 0.44 in/sec)

Medium Dirt,

Abrasives, Corrosion

Heavy Dirt,

Abrasives, Corrosion

Operating

Hours/Day

8 to 24

8 to 24

Page 17

DC Motors 17

Table J Relubrication Periods – Frames C180ATZ

Relubrication Interval (Months)

Maximum Normal

Operating Speed (RPM)

3450 and higher C180ATZ 9 4 1

2400 - 3449 C180ATZ 24 9 3

1700 - 2399 C180ATZ 36 12 3

800 - 1699 C180ATZ 36 24 8

500 - 799 C180ATZ 48 36 12

499 and lower C180ATZ 48 36 12

1

Maximum speed occupying more than 30% of operating time.

2

For Tandem drives increase frequency of lubrication by multiplying values by 0.8.

1

Frame

Standard

Service

Severe

Service

2

Extreme

Service

Lubrication – Frames C180ATZ

These motors are designed to route new grease directly into the bearing.

The relubrication periods shown in

service conditions, speeds, bearing types and operating hours.

Important: Certain special motors may have a lubrication instruction plate

permanently attached. These specific lubricating instruction

must be followed.

Table J are offered as a guide for varying

Lubrication Procedure

ATTENTION: To guard against personal injury or death from

rotating parts or electrical shock, relubrication should only be

!

performed while the motor is stationary and disconnected from

the power source.

1. Relubrication with the shaft stationary and a warm motor is

recommended.

2. Locate the grease inlet at the top of the bearing hub, clean the area and

replace the 1/8 inch pipe plug with a grease fitting (if the motor is not

equipped with a grease fitting).

3. When provided, remove grease drain plug located opposite the grease

inlet. The following motors do not have a grease drain plug, but have a

grease relief around the grease inlet pipe:

– Frames C180ATZ on commutator end (opposite drive end).

– All C-Face and D-Flange frames on drive end.

4. Using a manual grease gun, pump in the recommended grease in the

amount shown in

Table H. This amount of grease will provide an ample

supply of lubricant between lubrication periods as determined from

Table J for the service condition listed in Table I. An excessive amount

of grease will damage the motor.

Use Chevron SRI-2 grease or equivalent unless motor nameplate

specifies special grease. Use only clean, fresh grease from clean

containers and handle carefully to keep it clean.

Page 18

18 DC Motors

In general, mixing of greases is not recommended. If an incompatible

grease is used, the lube system must be repacked completely with the

new grease.

5. Wipe away any excess grease at the grease drain or relief and replace

drain plugs.

Repacking Bearings or Greasing New Bearings

When existing bearings have been completely cleaned of old grease or

when bearings are replaced, use this procedure for packing the bearing.

1. Apply one bead of grease all around inboard side of bearing between

bearing and inner cap, making sure that grease adheres to balls or rollers.

2. Apply one bead of grease all around outboard side of bearing, making

sure grease adheres to balls or rollers.

3. Completely fill grease inlet and outlet passage holes with grease.

4. Fill outboard bearing cavity 60% to 90% full of grease.

5. If possible, rotate shaft of assembled machine at least three revolutions

by hand to distribute grease within bearings before starting motor.

Bearings

These motors are designed to provide a mounting for anti-friction bearings

to give:

• Maximum protection to windings and interior of machine by preventing

grease leakage from bearing housing.

• Maximum protection to bearings against excess lubricant, insufficient

lubricant, dirt and moisture.

Various types of anti-friction bearings are used in the wide range of frames

as needed to meet specific load, speed and service requirements.

Most commonly used bearings are:

• Single row, open ball bearings for coupled and belted duty for frames

C180ATZ. Frames DC180ATZ and DC210ATZ have a single-shielded

bearing on the commutator end.

Frequent bearing checks are recommended. If temperatures become

excessive, investigate immediately for the cause. Total bearing temperatures

should not exceed 90 degrees C (194 degrees F). Causes for high bearing

temperature are:

• Contaminated grease.

• Insufficient grease or excessive amount.

• Incorrect grease.

• Excessive load or thrust due to misalignment or motor overload.

• Loose bearings.

• Bearing failure.

• Excessive ambient temperature.

Page 19

DC Motors 19

Replacement bearings should be ordered from Allen-Bradley in order to

obtain the same carefully selected bearing as the original. Bearings should

never be exposed by disassembly of the motor unless absolutely necessary

for inspection or replacement of the bearing or maintenance in other parts of

the machine. Protect good bearings from dirt and contamination at all times.

Most bearing failures are caused by dirt.

The open ball bearings for motor frames C180ATZ are the same regardless

of whether application is coupled or belted.

Brushes

Brush pressure is correctly established at the factory and maintained at the

correct value throughout the life of the brush by means of a constant

pressure design. Brushes and brush-holders should be clean so that the

brushes are free to move in the holders. Replace brushes with new brushes

of the same grade before wear permits the rivet or tamped pigtail to score

the commutator. It is best to change out complete set.

Fit the face of new brushes to the contour of the commutator with sandpaper

only, no emery abrasive. Keep brush lead (pigtail) connections tight.

Replacement brushes should have sleeved pigtails.

ATTENTION: To guard against personal injury or death, ensure

that all power to the motor has been removed and the motor shaft

!

is stationary. Brushes must not be touched or replaced while

motor is energized or rotating.

Commutator

A commutator in good condition is clean and smooth with a medium polish

and a light brown color. Keep clean by occasionally wiping with a canvas

pad. Use no lubricant or emery abrasive. If a commutator becomes rough, it

needs to be resurfaced. Roughness can be easily detected with the machine

running by resting a pencil-like rod of insulating material (dry wood) on

one of the brushes. In mild cases, a commutator dressing stone can be used.

Very rough or out of round commutators require turning in a lathe. In every

case, maintain concentricity and remove the minimum material required for

proper cleanup. Undercut the mica approximately l/16” and polish. Adjust

brush holders for approximately 1/8” clearance to commutator.

The finished diameter and the minimum diameter of the commutator for the

various frames sizes are as follows:

New Diameter Minimum Diameter

Frame

DC180ATZ &

DC210ATZ

C180ATZ 4.12 104.8 3.66 93.0

Inches Millimeters Inches Millimeters

3.01 76.5 2.62 66.5

The commutator should be replaced if the final diameter would have to be

turned down to a value less than minimum limits.

Page 20

20 DC Motors

Commutation

Intermittent sparking due to overloads or slight visible sparking does not

necessarily indicate poor commutation. Poor commutation exists when

there is excessive sparking requiring abnormal maintenance. Every case of

excessive sparking should be investigated to determine the cause and

correct it. The chart in

problems. DC motors and generators are brushed for full load current. If

unit or units are consistently operated at less than 1/2” rated load a

condition known as threading will result.

Table K Commutation Problem Quick Check

Symptom Identified By Possible Cause

1. Excessive sparking at motor

or generator commutator.

2. High commutator bars

produce a rough commutator.

3. Low commutator bars

produce rough commutator.

4. Streaking or threading of

commutator surface.

5. Bar etching or burning. Rough commutator with associated sparking and eventual

6. Bar marking at pole-pitching

spacing.

7. Bar marking at slot-pitch

spacing.

8. Rapid commutator or brush

wear.

Sparking 1. Dirty or corroded commutator due to dirt,

Generally associated with sparking and noisy operation of

the brushes on the commutator.

Generally associated with sparking and noisy operation of

the brushes on the commutator.

Rough commutator with associated sparking. Fine lines in

brush track.

flashover.

1. Two bars marking 180 degrees C (356 degrees F)

apart on 4-pole machine at start.

2. Three bars marking 120 degrees C (248 degrees F)

apart on 6-pole machine at start.

3. As pitch bar marking progresses, it will eventually

show at all bars on the machine.

4. Associated sparking and eventual flashover.

Sparking and marking of one or more bars at equal

spacing around commutator according to bar-per-slot ratio

with eventual flashover.

Bright commutator surface. 1. Abrasive material under brush.

Table K may help in analyzing commutation

ambient contaminants, oil or oil mist, etc.

2. Brushes incorrectly seated.

3. High or feather-edged mica.

4. Faulty machine adjustment.

5. Interpoles failed or improperly adjusted.

6. Loss of brush spring tension.

7. Brushes sticking in brush holder.

8. Unit overload.

9. Defective commutator or armature.

10. Unequal spacing of holders around commutator.

1. Loose commutator.

1. Loose commutator.

2. High mica.

3. Open or high resistance connection at

commutator.

1. Low average current density in brushes due to

light machine loading.

2. Contaminated atmosphere.

3. Oil on commutator or oil mist in air.

4. Humidity too low.

5. Lack of film forming properties in brush.

6. Brush too abrasive.

1. High mica.

2. Operation of machine with brushes off neutral.

3. Commutator dirty.

4. Incorrect spring tension.

5. Machine overload or rapid load change such as

plugging.

1. Shorted commutator bars or coils.

2. Open armature or field circuit.

3. Unequal air gap.

4. Cyclic disturbance either electrical or

mechanical.

1. Unequal compensation of armature coils. The

energy unbalance is reflected into the last coil in

the slot to undergo commutation, and will result

in a spark at the brush.

2. Too abrasive a brush.

3. Low average brush current density due to light

machine loading.

4. Contaminated atmosphere.

5. Humidity too low.

6. Incorrect brush tension.

Page 21

DC Motors 21

Windings

For long life, keep windings clean and dry. Dirt or dust can be removed by

wiping them with a clean cloth, by blowing with clean, dry, low pressure air

or by vacuum cleaner. Oil or grease can be removed with a cloth moistened

with mineral solvent. Be sure not to get any solvent on the commutator and

observe all product warnings.

Filters – Cleaning

When supplied, filters on motors must be kept clean to assure proper air

flow and cooling of the motor. The following procedure should be used to

clean these filters:

1. For light accumulations of dust, use compressed air to clean.

2. For moderate accumulations, water may be used.

3. For heavy accumulations of dirt and grease, clean the filter using water

and detergent.

Disassembly & Reassembly Instructions

4. Always completely dry filter after cleaning with water.

5. After heavy cleaning, spray with a very light coat of protective oil to

protect against possible loss of plating.

Important: Do Not use flammable solvents to clean filters.

Important: Standard washable filters may not be suitable for motors

operating in atmospheres with heavy concentrations of oil mist.

Oil mist may be drawn into the motor and cause damage to the

commutator and windings. Contact Allen-Bradley for motors

operating in heavy oil mist atmospheres.

Brakes

Motor mounted brake, when supplied, must be adjusted and maintained in

accordance with the instructions for the specific brake. Refer to separate

instructions supplied with the motor

The motor design incorporates many new techniques which are described in

this section. It is recommended that these differences be understood

thoroughly before any disassembly work is done to avoid possible damage

or harm to either machine and/or maintenance personnel.

Page 22

22 DC Motors

Air Gap And Shimming

(Frame C180ATZ)

Main Pole

Steel or brass shims, when used, are placed between pole and frame. If for

any reason the shims are removed they must be replaced under the same

poles. Main pole bolts are steel SAE Grade 5 (120,000 psi).

Axial Float

Frames C180ATZ have wavy spring washers between B.E. bracket and

bearing. Axial float should be within the limits listed on the chart below.

Axial Float

Frame Maximum Minimum

All 1.22 mm (0.048 in.) 0.20 mm (0.08 in.)

Anti-friction Bearing Assemblies

The bearings are positioned and secured by various means depending on

size and application requirements. Open type ball bearings are used for

direct coupled and belt drive applications. Below are standard construction

details for the various frames.

DC180ATZ & DC210ATAZ

Drive end bearing fits in a machined cavity in the bracket with inner cap.

Commutator end bearing has single seal on side facing commutator.

C180ATZ

Bearings fit in a machined cavity in the end brackets. Inner caps are used.

Bearing Replacement

Remove bearing by means of bearing puller. Clean bearing housing and

bearing seat prior to assembly of bearing. Place new bearing in a bake oven

for one hour at 121 degrees C (250 degrees F). Place bearing onto shaft and

push home to bearing shoulder. Hold it in place for a minimum of 30

seconds.

After bearing has cooled down for about 1 minute, add 1/2 cu. in. of fresh

grease into back of bearing. When the motor has been assembled, grease per

instructions found on

page 15.

Page 23

DC Motors 23

Brush Rigging and Brush Holders

The brush holders in all motors are often constant pressure design and do

not require nor are capable of adjustment over the life of the brushes.

DC180ATZ & DC210ATZ

Conduit box is attached to the commutator end top hand hole cover and

cannot be located on the side.

C180ATZ

Conduit box is located on the commutator end bracket.

Parts Identification C180AT, DC180ATZ & DC210ATZ

Number Description Number Description

1 Grease Plug (C180 only) FE 12 Inner Coil

2 Grease Plug (C180 only) BE 13 Armature Core

3 Ball Bearing FE 14 Frame

4 Ball Bearing BE 15 Armature Coil

5 Rocker 16 Inner Fan

6 Bracket FE 17 Key

7 Bracket BE 18 Shaft

8 Brush 19 Conduit Box

9 Brush Holder 20 Bearing Cap BE

10 Commutator 21 Bearing Cap (C180 only)

(Cap not shown)

11 Field Coil

FE

Page 24

Online Documentation

The latest motor information can be obtained from the Allen-Bradley

Drives & Motors home page on the World Wide Web at:

http://www.controlmatched.com

Publication 1325L-UM001B-EN-P – August, 2001

Supersedes 1325L-UM001A-EN-P dated May, 2001 Copyright © 2001 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...