Page 1

Instructions

1321-M Common Mode Chokes

(Catalog Number 1321-M001, 1321-M009, 1321-M048

1321-M180, 1321-M670)

Where this Option is Used

What this Option Contains

What these Instructions Contain

The 1321-M Common Mode Choke Options can be installed with

1305, 1336 Plus, 1336 Plus

AC drives. When installed at the drive output the common mode

choke helps to guard against interference with other electrical

equipment (programmable controllers, sensors, analog circuits, etc.).

In addition, reducing the PWM carrier frequency reduces the effects

and lowers the risk of common mode noise interference. The table on

page 2 details the common mode chokes available for each drive

rating.

Each 1321-M Common Mode ChokeKitincludestheCommonMode

core and a mounting bracket where applicable. Some models also

contain a terminal block and wiring.

These instructions contain the information you need to properly

install a 1321-M Open Style Common Mode choke. Recommended

mounting and connection procedures are included. Major topics and

page numbers are listed below.

Selection Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

1321-M001 Mounting and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

1321-M009 Mounting and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

1321-M048 Mounting and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

1321-M180 Mounting and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

1321-M670 Mounting and Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Mounting Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

II, 1336 IMPACT

TM

and 1336 FORCE

TM

Page 2

2 1321-M Common Mode Chokes

Selection Table

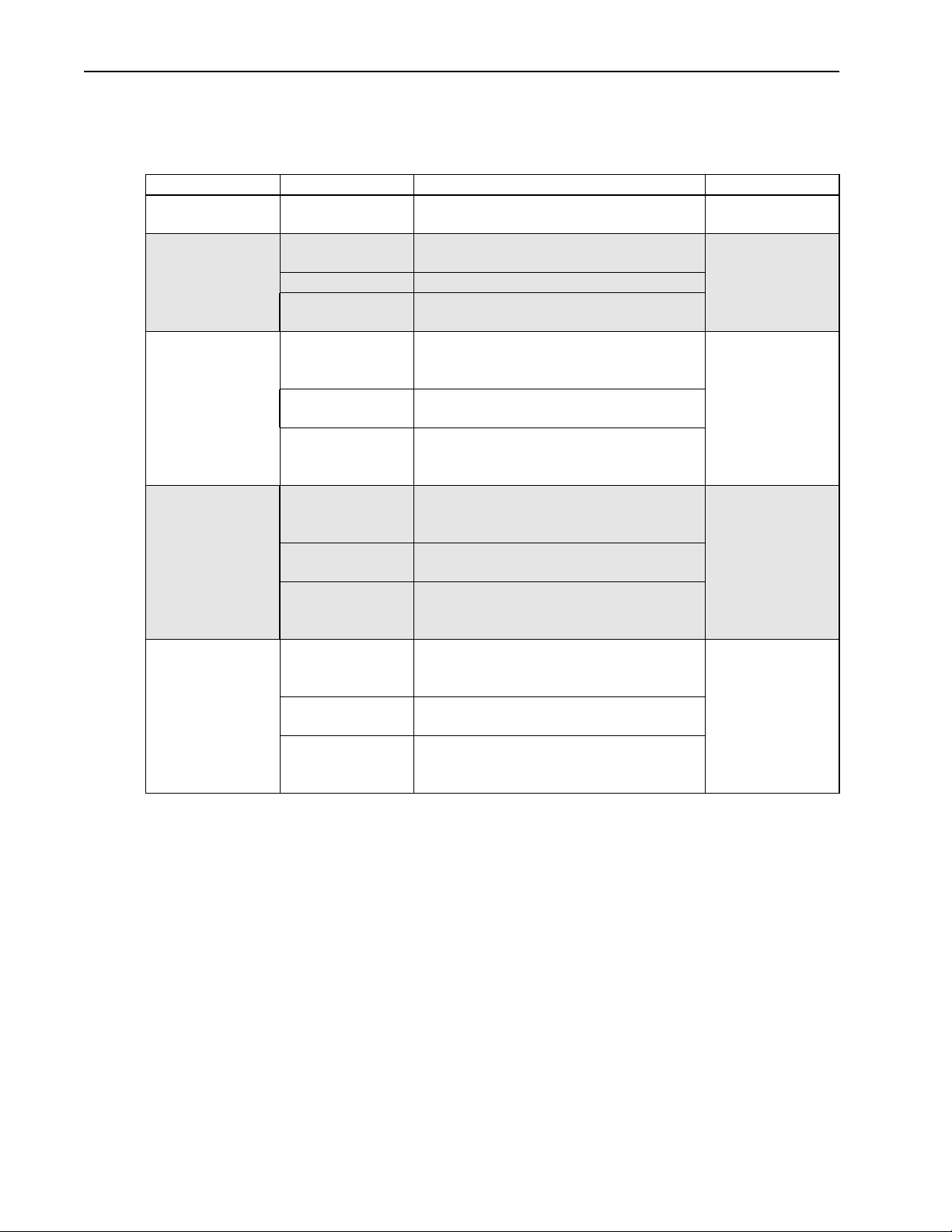

Choke Type Used With: Ratings: Catalog Number

Open Style, 1A All Drives Communication Cables

Open Style, 9A

(with terminal strip)

Open Style, 48A 1336 Plus & Plus II 3-15HP (2.2-11kW) 230V

Open Style, 180A 1336 Plus & Plus II 20-60HP (15-45kW) 230V

Open Style, 670A 1336 Plus & Plus II 75-125HP (56-93kW) 230V

Refer to the following table when selecting an open style 1321-M

type Common Mode Choke for your particular drive.

Analog Signal Cables etc.

1305, 1336 Plus

& Plus II

1336 IMPACT 0.5 - 5HP (0.37-3.7kW) 480V

1336 FORCE 1HP (0.75 kW) 230V

1336 IMPACT 7.5-30HP (5.5-22kW) 480V

1336 FORCE 3-15HP (2.2-11kW) 230V

1336 IMPACT 40-x150HP (30-112kW) 480V

1336 FORCE 20-60HP (15-45kW) 230V

1336 IMPACT 150-600HP (112-448kW) 480V

1336 FORCE 75-125HP (56-93kW) 230V

0.5 - 2HP (0.37-2.2kW) 230V

0.5 - 5HP (0.37-3.7kW) 480V

1-3HP (0.75 -2.2 kW) 480

7.5-30HP (5.5-22kW) 480V

1-40HP (0.75-30kW) 600V

7.5-40HP (5.5-30kW) 600V

3-30HP (2.2-22kW) 480V

1-40HP (0.75-30kW) 600V

40-x150HP (30-112kW) 480V

50-150HP (37-112kW) 600V

50-125HP (37-93kW) 600V

40-x150HP (30-112kW) 480V

50-150HP (37-112kW) 600V

150-600HP (112-448kW) 480V

200-600HP (149-448kW) 600V

200-600HP (149-448kW) 600V

150-600HP (112-448kW) 480V

200-600HP (149-448kW) 600V

1321-M001

1321-M009

1321-M048

1321-M180

1321-M670A

Page 3

1321-M Common Mode Chokes 3

Installation

All choke assemblies should be mounted as close to the bottom of the

drive as possible while leaving sufficient distance between the choke

assembly and the drive unit to provide clearance for cables and leads

to be installed at the drive. All choke assemblies with the exception of

the M001 and M009 are supplied with mounting brackets. Mounting

dimensions for each assembly are provided at the back of this

publication. It is recommended that M001 and M009 assemblies be

tie wrapped to a solid object such as cabinet sheet metal or brackets

when wiring is completed.

M001 Mounting and Wiring

To install the choke assembly, follow these steps:

1. Remove all power connected to the system.

ATTENTION: Electric shock can cause injury or

!

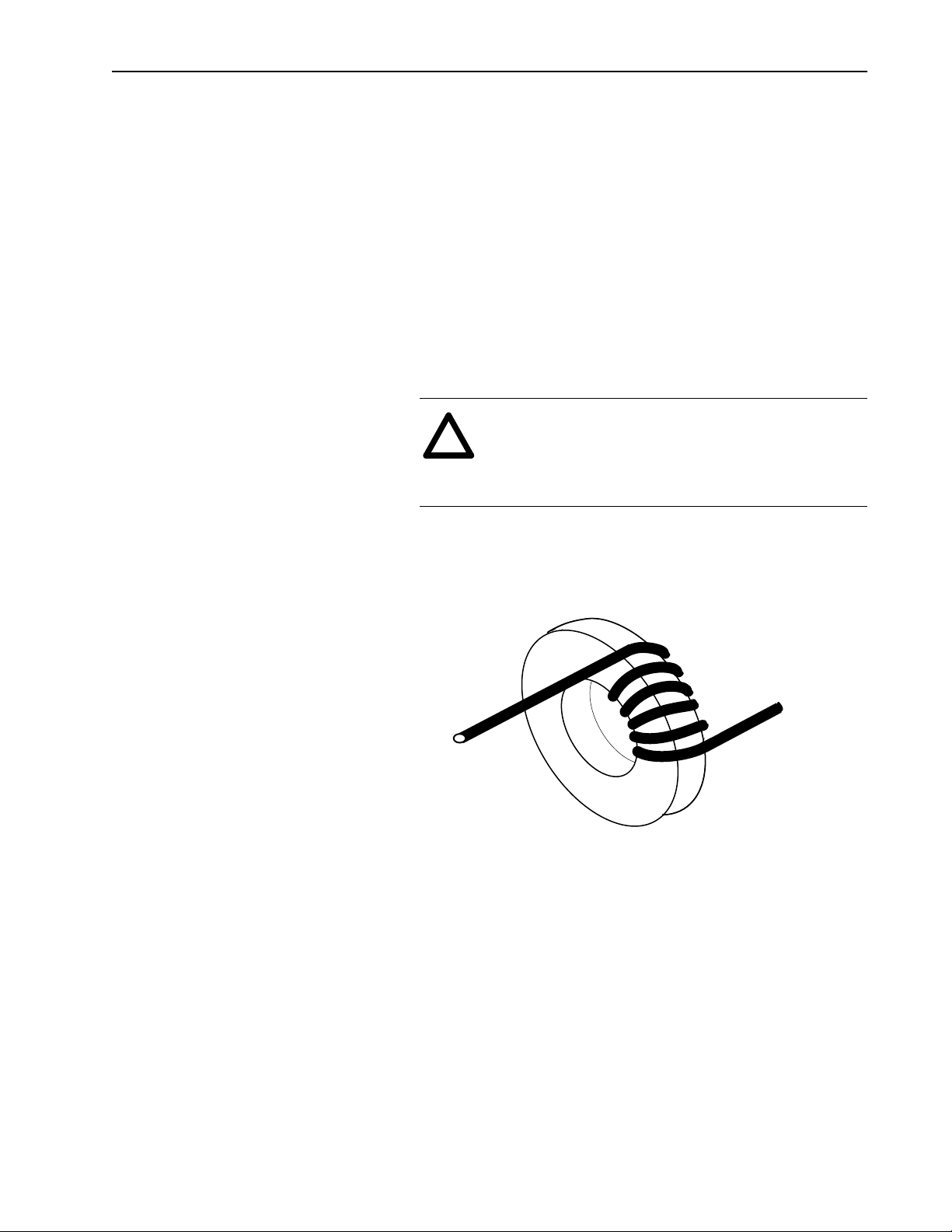

2. Wrap the communication cable thru the choke assembly five

times as shown in the following figure. If the wire gauge is too

large to allow 5 wraps, you may use fewer wraps but this will

diminish the effectiveness of the installation.

death. Remove all power before working with this

product. Verify that the voltage on the bus capacitors

has discharged. The voltage must be zero.

Comm

Cable

From

Communication

Device

To Drive

3. Leave enough cable between the choke assembly and the drive to

allow the communication cable suitable clearance to be

terminated at the drive and for the choke assembly to be mounted

near the bottom of the drive cabinet. When all wiring is

completed, zip tie the choke assembly to the cabinet sheet metal

or another suitable location to provide support for the assembly.

Page 4

4 1321-M Common Mode Chokes

M009 Mounting and Wiring

To install the choke assembly, follow these steps:

1. Remove all power connected to the system.

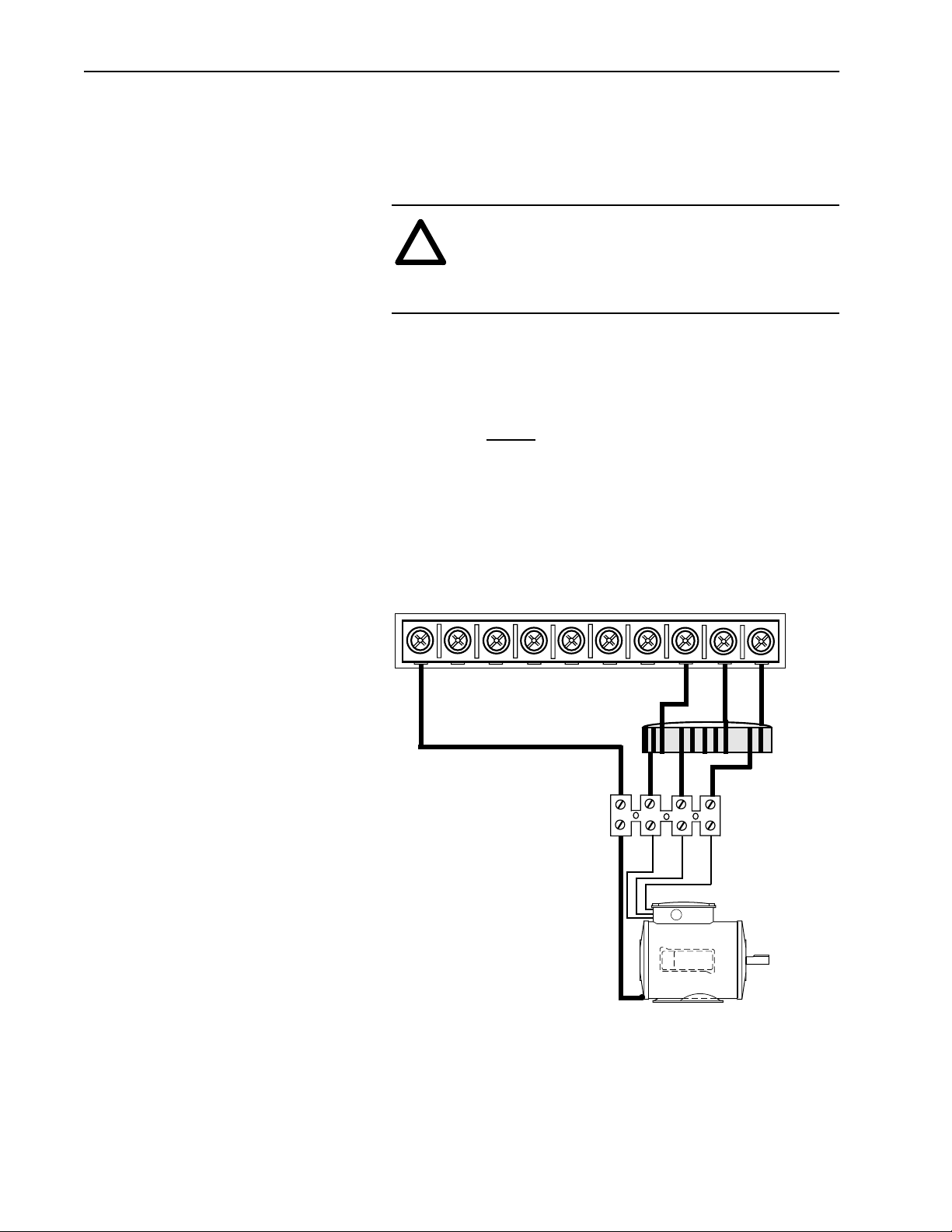

2. A 4 position terminal strip with preinstalled TB leads is included

3. Run motor leads from the terminal strip to the T1/U,T2/V,T3/W

ATTENTION: Electric shock can cause injury or

!

death. Remove all power before working with this

product. Verify that the voltage on the bus capacitors

has discharged. The voltage must be zero.

with M009. Install leads from the terminal strip to TB1 (T3/W),

(T2/V) and (T1/U) of your drive. Make certain to leave at least 2

inches (50 millimeters) clearance between the choke assembly

and the drive terminals. Run the green 12 AWG lead from the

terminal strip

outside the choke assembly to the PE connection on

the drive TB1 as shown in the following figure.

terminals on the motor as shownin the following figure. Run a 12

AWG ground lead from the terminal block to the ground point on

the motor frame.

PE

PE DC+ DC-R(L1) (L2)

Choke Assembly

ST

1321 - M009

PE

GRD

Motor

Frame

Ground

TB1

(L3)

U

T1

UV

(T1)

TB2

TB3

V

T2

W

T3

W

(T2) (T3)

TB-1

TB4

Terminal Strip

(Supplied With

Choke)

4. When all wiring is completed, tie wrap the choke assembly to the

cabinet sheet metal or another suitable location to provide support

for the assembly. If the terminal strip supplied with the choke is to

be panel mounted, an insulation sheet must be used between the

terminal strip and the sheet metal.

Page 5

1321-M Common Mode Chokes 5

M048 Mounting and Wiring

To install the choke assembly, follow these steps:

1. Remove all power connected to the system.

ATTENTION: Electric shock can cause injury or

!

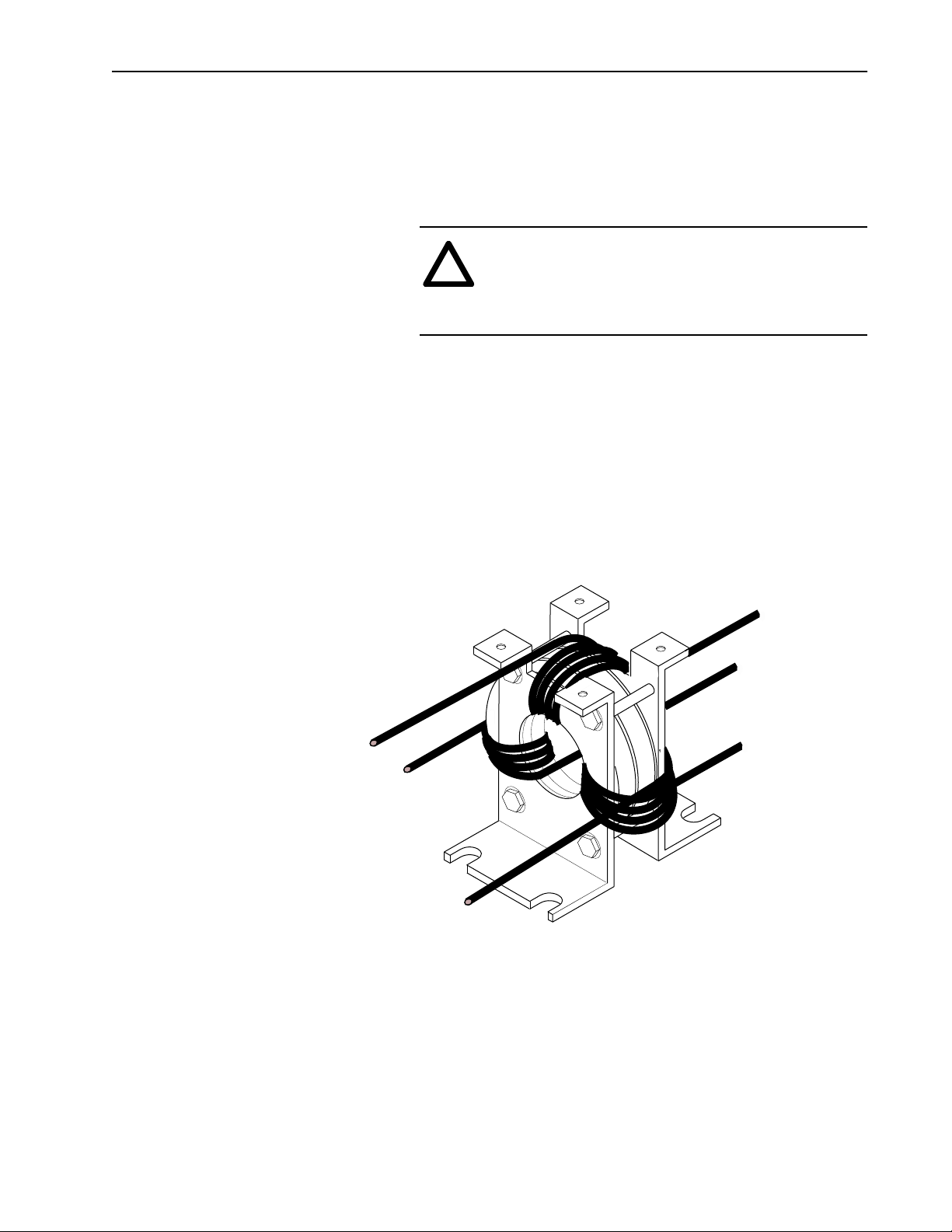

2. Mount the M048 Choke Assembly on a metal surface as near as

possible to the bottom of the drive cabinet using 1/4-20 hardware.

Leave sufficient clearance between the choke assembly and the

drive terminals to allow access to the terminals and provide

proper bend radius for the leads.

3. Terminate the motor leads at the T1/U, T2/V, T3/W connections

on the motor as shown in the following figure. An optional

terminal strip may be used between the choke assembly and the

motor if desired. A properly sized ground conductor from the

motor frame is also required.

death. Remove all power before working with this

product. Verify that the voltage on the bus capacitors

has discharged. The voltage must be zero.

From TB1-V (T2)

From TB1-U (T1)

To Motor V (T2)

To Motor U (T1)

To Motor W (T3)

From TB1-W (T3)

4. Run the leads thru the choke assembly and wrap each lead around

the choke four times as shown in the previous figure before

running the leads to the drive. Each lead should be wrapped in the

same direction starting on the outside of the coil and exiting

inside the coil. If possible, maintain a 120

°

separation of the lead

wraps. Install the motor leads at T1 (U), T2 (V) and T3 (W) at

terminal block TB1 on your drive.

Page 6

6 1321-M Common Mode Chokes

PE

Drive Terminal

Block TB1

PE

DC

DC

+

(L1)

–

1321 - M048

Choke

Assembly

Optional

Terminal

Block

R

S

(L2)T(L3)

U

T1

T2

(T1)

V

U

V

W

(T2)

(T3)

W

T3

Motor Frame

Ground

Motor

Page 7

1321-M Common Mode Chokes 7

M180 Mounting and Wiring

To install the choke assembly, follow these steps

1. Remove all power connected to the system.

ATTENTION: Electric shock can cause injury or

!

2. Mount the M180 Choke Assembly on a metal surface near the

bottom of the drive cabinet using 1/4-20 hardware. Leave

sufficient clearance between the choke assembly and the drive

terminals to allow access to the terminals and provide proper

bend radius for the leads.

3. Terminate the motor leads at the T1/U, T2/V, T3/W connections

on the motor as shown in the figure on the following page. An

optional terminal strip may be used between the choke assembly

and the motor if desired. A properly sized ground conductor from

the motor frame is also required. The ground conductor is routed

around (not through) the choke and connected to the DrivePower

Earth @ TB1-PE.

death. Remove all power before working with this

product. Verify that the voltage on the bus capacitors

has discharged. The voltage must be zero.

From T1 (U)

From T2 (V)

From T3 (W)

To Motor U (T1)

To Motor V (T2)

To Motor W (T3)

4. If possible, wrap each lead once around the core before

terminating at the drive terminals. If the motor lead gauge is too

thick to allow one wrap, run the leads straight thru the choke

assembly to drive terminals TB-1, U (T1), V (T2) and W (T3) as

shown in the following figure. Running the motor leads straight

thru the core, will diminish the effectiveness of the installation.

Page 8

8 1321-M Common Mode Chokes

Drive Terminal

Block TB1

PE

PE

GRD

GRD

Choke

Assembly

1321 - M180

DC

+

R

DC

(L1)

–

Optional

Terminal

S

(L2)

Block

T

(L3)

T1

U

(T1)

U

T2

W

V

(T3)

(T2)

V

W

T3

Motor Frame

Ground

Motor

Page 9

1321-M Common Mode Chokes 9

M670 Mounting and Wiring

To install the choke assembly, follow these steps:

1. Remove all power connected to the system.

ATTENTION: Electric shock can cause injury or

!

2. Mount the M670 Choke Assembly on a metal surface near the

bottom of the drive cabinet using 1/4-20 hardware. Leave

sufficient clearance between the choke assembly and the drive

terminals to allow access to the terminals and provide proper

bend radius for the leads.

3. Terminate the motor leads at the U,V,W connections on the motor

as shown in the figure on the following page. An optional

terminal strip may be used between the choke assembly and the

motor if desired. A properly sized ground conductor from the

motor frame is also required. The ground conductor is routed

around (not through) the choke and connected to the DrivePower

Earth @ TB1-PE.

death. Remove all power before working with this

product. Verify that the voltage on the bus capacitors

has discharged. The voltage must be zero.

From Drive TB1

M1/T1-U

From Drive TB1

M2/T2-V

From Drive TB1

M3/T3-W

To Motor

U (T1)

To Motor

V (T2)

To Motor

W (T3)

Page 10

10 1321-M Common Mode Chokes

4. Run the motor leads straight through the choke assembly and

terminate at TB-1 M1/T1-U, M2/T2-V and M3/T3-W as shown

in the following figure.

–DC+DC PE PE R-L1

TE

Drive Terminal

Block TB1

S-L2 T-L3 U-M1

Choke

Assembly

1321 - M670

Optional

Terminal

Block

U

T1

V-M2 W-M3

V

W

T2

T3

Ground

Motor Frame

Motor

Page 11

1321-M Common Mode Chokes 11

Mounting Dimensions

1321-M001

1321-M001

1321-M009

1321-M009

1.05 (26.67)

Mounting Dimensions for the1321-M001,1321-M009,1321-M048,

1321-M180 and1321-M670 choke assemblies are detailed in the

following schematics:

1.0 (25.4)

SIDE

VIEW

1.0 (25.4)

1.5 (38.1)

.75

(19.05)

I.D.

END

VIEW

1.5 (38.1)

2.15

(54.61)

SIDE

VIEW

.75

(19.05)

I.D.

END

VIEW

Dimensions in inches (mm)

Page 12

12 1321-M Common Mode Chokes

Mount Using

1/4-20 Hardware

1321-M048

1321-M048

2.90 (73.6) O.D.

1.75 (44.4)

SIDE

VIEW

BOTTOM

VIEW

2.8 (71)

1.54 (39)

4.00 (101.6)

3.38

(85.8)

1.53

(38.8)

I.D.

3.94

(100)

END

VIEW

3.94 (100)

Dimensions in inches (mm)

Page 13

END

VIEW

4.00

(101.6)

1321-M160

1321-M180

Mount Using

1/4-20 Hardware

1.53

(38.8)

I.D.

BOTTOM

VIEW

1321-M Common Mode Chokes 13

2.90 (73.6) O.D.

1.75 (44.4)

7.38

6.75

(171.4)

(187.4)

SIDE

VIEW

6.25 (158.7)

4.75 (120.6)

7.38 (187.4)

Page 14

14 1321-M Common Mode Chokes

1321-M670

1321-M670

8.94 (227)

8.38 (212)

BOTTOM

VIEW

Mount Using 1/4-20 Hardware

5.22

(132.5)

2.75

(69.8)

Dimensions in inches (mm)

7.75 (200)

6.13

(155.7)

2.00

(50.8)

2.50

(63.5)

END

VIEW

6.25

(158.4)

SIDE

VIEW

8.94 (227)

Page 15

This Page Intentionally Left Blank

1321-M Common Mode Chokes 15

Page 16

Rockwell Automation helps its customers receive a superior return on their investment by bringing

together leading brands in industrial automation, creating a broad spectrum of easy-to-integrate

products. These are supported by local technical resources available worldwide, a global network

of system solutions providers, and the advanced technology resources of Rockwell.

Worldwide representation.

Argentina • Australia • Austria • Bahrain • Belgium • Bolivia • Brazil • Bulgaria • Canada • Chile • China, People’s Republic of • Colombia • Costa Rica • Croatia • Cyprus

Czech Republic • Denmark • Dominican Republic • Ecuador • Egypt • El Salvador • Finland • France • Germany • Ghana • Greece • Guatemala • Honduras • Hong Kong

Hungary • Iceland • India • Indonesia • Iran • Ireland • Israel • Italy • Jamaica • Japan • Jordan • Korea • Kuwait • Lebanon • Macau • Malaysia • Malta • Mexico

Morocco • The Netherlands • New Zealand • Nigeria • Norway • Oman • Pakistan • Panama • Peru • Philippines • Poland • Portugal • Puerto Rico • Qatar • Romania • Russia

Saudi Arabia • Singapore • Slovakia • Slovenia • South Africa, Republic of • Spain • Sweden • Switzerland • Taiwan • Thailand • Trinidad • Tunisia • Turkey • United Arab Emirates

United Kingdom • United States • Uruguay • Venezuela

Rockwell Automation Headquarters, 1201 South Second Street, Milwaukee, WI 53204-2496 USA, Tel: (1) 414 382-2000, Fax: (1) 414 382-4444

Publication 1321-5.0 – July, 2000 P/N191386(02)

Copyright 1998 Rockwell International Corporation. All rights reserved. Printed in USA.

Loading...

Loading...