Page 1

Installation Instructions

1204 Reflected Wave Reduction Device

with Common Mode Choke

(Catalog Number 1204-RWC-17-A)

This publication will guide you through installation (including mounting,

wiring and grounding procedures) of the 1204 Reflected Wave Reduction

Device with Common Mode Choke (1204-RWC).

Contents

Where this Option is Used

Where this Option is Used . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Catalog Number Explanation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Nameplate Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Determining the Maximum Cable Length for your System . . . . . . . . . . . .4

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

The 1204 Reflected Wave Reduction Device with Common Mode Choke

(RWC) is designed to be used with Allen-Bradley 1336 family of AC drives

with compatible current ratings. Call factory for advice on using the

1204-RWC with drives other than the 1336 family of AC drive. When

installed near the drive, the device can reduce potentially destructive

reflected wave spikes that can occur with long motor leads and reduces the

effect of Common Mode noise.

Catalog Number

Explanation

1204 – RWC – 17

First Position Second Position Third Position Fourth Position

Type Current Rating Mounting Config.

Description Letter Description Code Rating Letter Mounting

Bulletin

Number

(1)

Consult factory for 240V applications.

(2)

Chassis is rated IP20 (NEMA Type 1) for Book Style mounting.

RWC Reflected Wave

Reduction Device

IP20 (NEMA Type 1)

17 17.5 Amps at

(1)

– A

A Book Style

380-480V,

12 Amps at

575-600V

(2)

Page 2

2 1204 Reflected Wave Reduction Device with Common Mode Choke

Specifications

Input Power 380-600VAC, Three-Phase

Drive Carrier Frequency 2 kHz Recommended (used for most applications)

Important: 6kHz Absolute Maximum – Refer to Chart below and page 4 for application

restrictions.

Ambient Temperature 0-50 Degrees C (32-122 Degrees F)

Humidity 5-95% Non-Condensing

Atmosphere Atmosphere should not contain hazardous (volatile) dust, vapor, gas or liquid.

IP20 (NEMA Type 1) = Book Style Mount

IP00 (Open Chassis) = Horizontal Mount

Current Rating 17.5 Amperes at 480 Volts (12.0 Amperes at 600 Volts)

Vibration 1.0 G Operational

Agency Certification

D

9

6

E

6

T

X

S

I

L

I

N

Q

D

E

C

T

N

O

Altitude Derating Above 1000 meters (3300 feet) derate at 6% of RWC rated amperes per 1000 meters (3300

feet) elevation to 4000 meters (13200 feet) maximum.

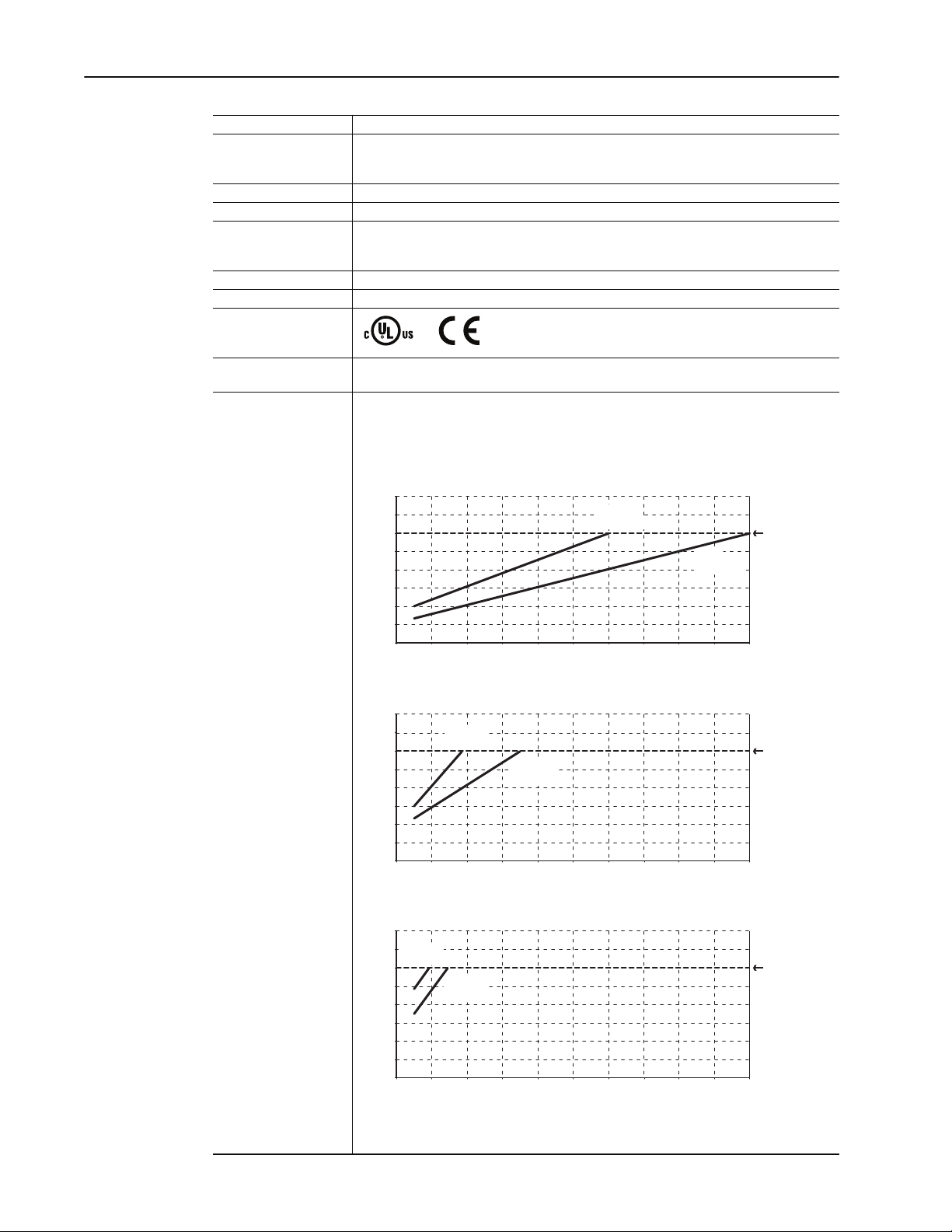

Heat Dissipation Use the cable length and drive carrier frequency to find the approximate RWC losses for your

system. Vertical movement inside the loss band will be dependent on exact cable type and

motor load.

Total Watts Loss

240

210

180

150

120

90

60

Total RWC Losses (Watts)

30

0

0 61.0

(200)

121.9

(400)

240

210

180

4 kHz

600V +10%

150

120

90

60

Total RWC Losses (Watts)

30

0

0 61.0

240

210

180

150

120

6 kHz

600V +10%

121.9

(200)

(400)

6 kHz

600V +10%

6 kHz

480V +10%

90

60

Total RWC Losses (Watts)

30

0

0 61.0

(1)

Do not run unit above Rated Power.

(200)

121.9

(400)

2 kHz Carrier Frequency

182.9

243.8

(800)

304.8

(1000)

(600)

Cable Length – meters (feet)

4 kHz Carrier Frequency

4 kHz

480V +10%

182.9

243.8

(800)

304.8

(1000)

(600)

Cable Length – meters (feet)

6 kHz Carrier Frequency

182.9

243.8

(600)

304.8

(800)

(1000)

Cable Length – meters (feet)

2 kHz

600V +10%

365.8

396.2

(1200)

(1300)

365.8

396.2

(1200)

(1300)

365.8

396.2

(1200)

(1300)

426.7

(1400)

426.7

(1400)

426.7

(1400)

2 kHz

480V +10%

457.2

487.7

(1500)

(1600)

457.2

487.7

(1500)

(1600)

457.2

487.7

(1500)

(1600)

Rated Power

Rated Power

Rated Power

(1)

(1)

(1)

Page 3

1204 Reflected Wave Reduction Device with Common Mode Choke 3

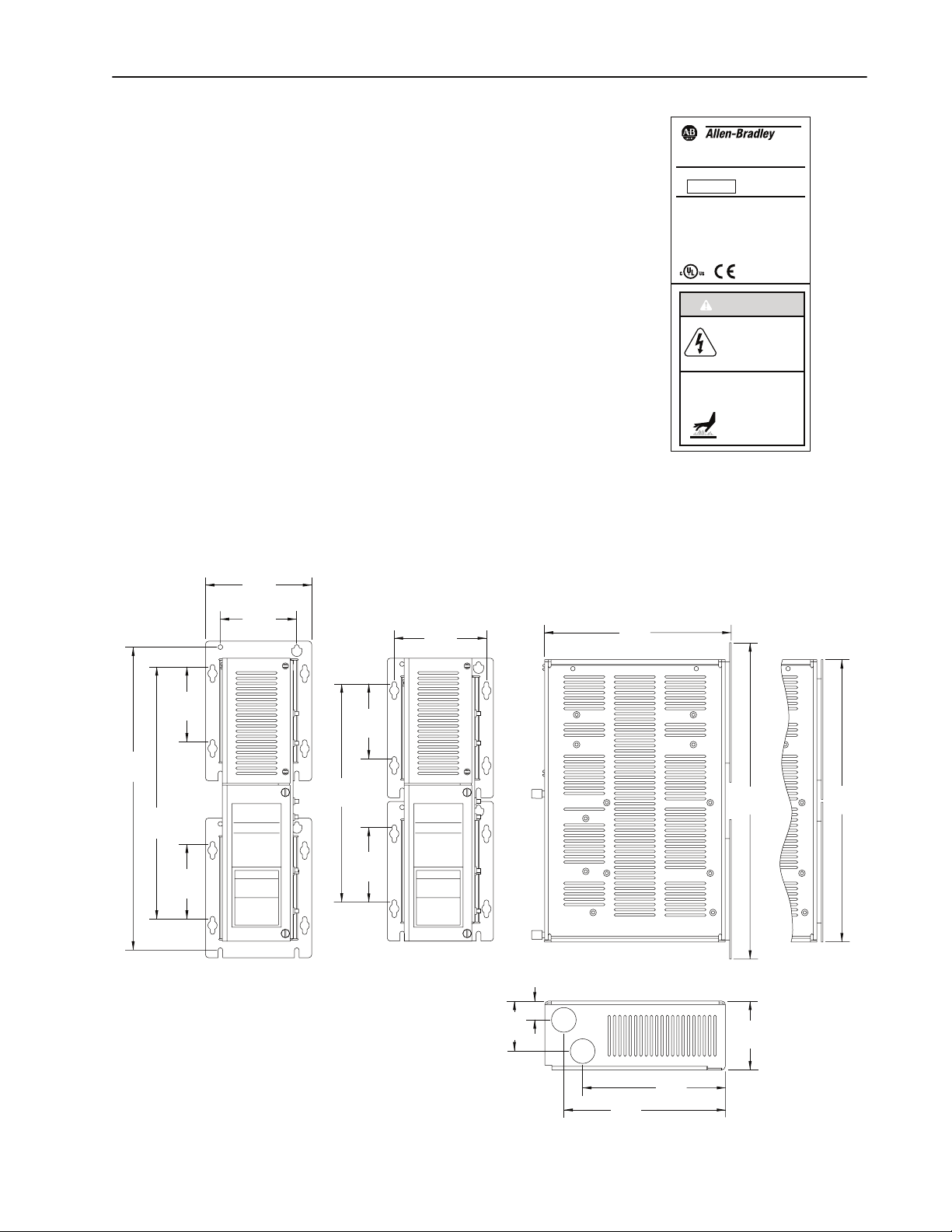

Nameplate Information

Dimensions

The nameplate is located on the front of

the unit. In addition, a manufacturing

date is stamped on the bottom of the unit.

Dimensions are in millimeters and (inches).

Shipping weight = 4.1 kg (9.0 lb)

Reflected Wave

Reduction Device

CAT 1204-RWC-17-A SER A

Maximum Rating

VOLTS

AMPS

480V 3 ∅

600V 3 ∅

Refer to manual for maximum cable

length and drive carrier frequency.

9

D

6

E

6

T

X

S

I

L

I

N

Q

D

E

T

C

N

O

WATTS

17.5A

12A

Assembled in Mexico

180W

180W

DANGER

DISCONNECT AND

LOCKOUT ALL POWER

SOURCES BEFORE

SERVICING

SURFACES

MAY BE HOT

ALLOW TO COOL

BEFORE SERVICING

327.4

(12.89)

272.0

(10.71)

81.0

(3.19)

81.0

(3.19)

114.8

(4.52)

82.6

(3.25)

234.0

(9.21)

81.0

(3.19)

81.0

(3.19)

99.6

(3.92)

54.1

(2.13)

20.3

(0.80)

201.7

(7.94)

341.9

(13.46)

74.4

(2.93)

304.8

(12.00)

174.5

(6.87)

154.2

(6.07)

Page 4

4 1204 Reflected Wave Reduction Device with Common Mode Choke

Determining the Maximum Cable

Length for your System

Volts at

Motor

1000 Type A 2 kHz 488 (1600) 488 (1600) 488 (1600) 425 (1400)

1200 Type B 2 kHz 488 (1600) 488 (1600) 488 (1600) 488 (1600)

1600 1329 R/L 2 kHz 488 (1600) 488 (1600) 488 (1600) 488 (1600)

Volts at

Motor

1000 Type A 2 kHz 488 (1600) 305 (1000) 182 (600) 60 (200)

1200 Type B 2 kHz 488 (1600) 488 (1600) 488 (1600) 488 (1600)

1600 1329 R/L 2 kHz 488 (1600) 488 (1600) 488 (1600) 488 (1600)

The following tables will help you determine the maximum cable length for

your system.

1336 Plus/Plus II/Impact/1336T 3.7-7.5 kW (5-10 HP) and 3.7-7.5 kW (5-10 HP) Motors

Table A: 380-400V Drives

Drive

Motor

Insulation

Carrier

(1)

Frequency

4 kHz 244 (800) 244 (800) 244 (800) 244 (800)

6 kHz 76 (250) 76 (250) 76 (250) 76 (250)

4 kHz 244 (800) 244 (800) 244 (800) 244 (800)

6 kHz 76 (250) 76 (250) 76 (250) 76 (250)

4 kHz 244 (800) 244 (800) 244 (800) 244 (800)

6 kHz 76 (250) 76 (250) 76 (250) 76 (250)

Table B: 480V Drives

Drive

Motor

Insulation

Carrier

(1)

Frequency

4 kHz 244 (800) 244 (800) 182 (600) 60 (200)

6 kHz 76 (250) 75 (250) 76 (250) 45 (150)

4 kHz 244 (800) 244 (800) 244 (800) 244 (800)

6 kHz 76 (250) 76 (250) 76 (250) 76 (250)

4 kHz 244 (800) 244 (800) 244 (800) 244 (800)

6 kHz 76 (250) 76 (250) 76 (250) 76 (250)

Maximum Cable Length in meters (feet)

Shielded

Nominal Line

Voltage

Maximum Cable Length in meters (feet)

Shielded

Nominal Line

Voltage

(2)

High Line

(3)

Voltage

(2)

High Line

(3)

Voltage

Unshielded

Nominal Line

Voltage

Unshielded

Nominal Line

Voltage

High Line

Voltage

High Line

Voltage

(3)

(3)

1204-RWC

Maximum

Cable

Length

488 (1600)

244 (800)

75 (250)

1204-RWC

Maximum

Cable

Length

488 (1600)

244 (800)

75 (250)

(4)

(4)

Table C: 600V Drives

Maximum Cable Length in meters (feet)

Shielded

Volts at

Motor

Motor

Insulation

Drive

Carrier

(1)

Frequency

Nominal Line

Voltage

1000 Type A 2 kHz 90 (300)

4 kHz 90 (300)

6 kHz 60 (200)

1200 Type B 2 kHz 365 (1200) 305 (1000) 182 (600) 60 (200)

4 kHz 120 (400) 120 (400) 120 (400) 60 (200)

6 kHz 60 (200) 60 (200) 60 (200) 60 (200)

(5)

1600

1329 R/L 2 kHz 365 (1200) 365 (1200) 365 (1200) 365 (1200)

4 kHz 120 (400) 120 (400) 120 (400) 120 (400)

6 kHz 60 (200) 60 (200) 60 (200) 60 (200)

(1)

Type A = No phase paper or misplaced phase paper, lower quality insulation systems, corona inception voltages between 850 and 1000 volts.

Type B = Properly placed phase paper, medium quality insulation systems, corona inception voltages between 1000 and 1200 volts.

1329 R/L = “Control Matched” motors for use with Allen-Bradley drives, premium grade insulation system, typical corona inception voltage is 1600 volts.

(2)

Includes wire run in conduit.

(3)

High line condition is defined at rated input system voltage +10% with a fully rated motor condition.

(4)

Maximum cable length is restricted by power dissipation within the 1204-RWC package at 40°C (104°F) ambient under rated load.

(5)

When used on 600V systems, 1329 R/L motors have a corona inception voltage rating of approximately 1850V.

(6)

Not recommended with 1204-RWC.

Call factory for advice on using the 1204-RWC with drives other than the 1336 family of AC drive.

(2)

High Line

Voltage

(6) (6) (6)

(6) (6) (6)

(6) (6) (6)

(3)

Nominal Line

Voltage

Unshielded

High Line

Voltage

(3)

1204-RWC

Maximum

Cable

(4)

Length

365 (1200)

120 (400)

60 (200)

Page 5

1204 Reflected Wave Reduction Device with Common Mode Choke 5

Installation

The following steps will guide you through mounting the Reflected Wave

Reduction Device.

ATTENTION: To avoid a shock hazard, ensure that all power

to the drive has been removed before proceeding. In addition,

!

wait 3 minutes for the DC bus to discharge.

ATTENTION: Enclosure surfaces may be hot and can cause

sever burns. Install in a location that minimizes accidental

!

contact.

Mounting

1. Assure that all power has been removed from the drive.

2. Attach the mounting brackets to the back of the chassis using the eight

screws provided. The brackets can be positioned either flush or extended

as shown below.

3.6 N-m

32 lb.-in.

Brackets Extended Brackets Flush

Page 6

6 1204 Reflected Wave Reduction Device with Common Mode Choke

3. Mount the device on a vertical metal surface and oriented so the wiring

knockouts are on the bottom – the device must be mounted within 3.0

meters (10 feet) of the drive.

Important: To assure proper heat dissipation, minimum clearances must be

maintained as shown below.

76.2 mm

(3.0 in.)

25.4 mm

(1.0 in.)

Drive

25.4 mm

(1.0 in.)

76.2 mm

(3.0 in.)

38.1 mm

(1.5 in.)

Page 7

Wiring

k

e

3.1 m (10 ft.) - Maximum Length

() g

1204 Reflected Wave Reduction Device with Common Mode Choke 7

4. Wire the device as indicated below. The maximum and minimum wire

size accepted by the RWC terminal block is 4.0 and 0.75 mm

2

(10 and

18 AWG). Use copper wire only with a minimum temperature rating of

75 degrees C. Maximum torque is 1.81 N-m (16 lb.-in.).

AC Driv

from Drive Terminal U

from Drive Terminal V

from Drive Terminal W

from Drive Ground

Motor Ground

Motor Phase U

Motor Phase V

Motor Phase W

RWC Terminal Bloc

U

V

W

PE

PE

U1

V1

W1

Page 8

8 1204 Reflected Wave Reduction Device with Common Mode Choke

)

)

g

(L3)

D

e

)

(T2)

)

D

Grounding

5. Follow the recommended grounding practices provided in your drive

User Manual. The following diagram shows an example of system

grounding practices.

ATTENTION: National Codes and standards (NEC, VDE, BSI,

etc.) and local codes outline provisions for safely installing

!

electrical equipment. Installation must comply with

specifications regarding wire types, conductor sizes, branch

circuit protection and disconnect devices. Failure to do so may

result in personal injury and/or equipment damage.

Conduit/4-Wire Cable

R(L1

S(L2

T

PE/GR

U(T1

V

W(T3

PE/GR

Motor Frame

Ground Rod/Grid

or Buildin

Structure Steel

Driv

RWC

Ground per

Local Codes

Drive Programming

6. The recommended drive carrier frequency for optimal RWC

performance is 2 kHz. The maximum carrier frequency allowed is

6 kHz. If the drive default is higher than this maximum, the drive must

be reprogrammed. Refer also to the Maximum Cable Length tables on

page 4 for further information.

7. Carefully check that motor rotation is in the desired direction.

Publication 1204-IN001A-EN-P — February 2002 P/N 195686

Copyright ® 2002 Rockwell Automation. All rights reserved. Printed in USA.

Loading...

Loading...