RIDGID GP90135 User Manual

GP90135

!

WARNING

OPERATOR’S MANUAL

WHEELBARROW

AIR

Read and follow all Safety Rules

before first use of this product.

IN610400AV Printed in U.S.A.

COMPRESSOR

Table of Contents

!

NOTICE

!

CAUTION

!

WARNING

!

DANGER

MANUAL

!

WARNING

!

CAUTION

Safety Instructions

Section Page

Table of Contents

Safety Instructions . . . . . . . . . . . . . . .3

Safety Signal Words . . . . . . . . . . . . .3

Before Using the Air

Compressor . . . . . . . . . . . . . . . . . . . .3

Spraying Precautions . . . . . . . . . . . .5

Breathable Air Warning . . . . . . . . . . .5

Warning Labels . . . . . . . . . . . . . . . . .6

Glossary of Terms . . . . . . . . . . . . . . .7

Unpacking and Checking

Content

Getting to Know Your Air

Compressor

Operating Your Air Compressor . . .10

. . . . . . . . . . . . . . . . . . . . . . . .8

Moisture in Compressed Air . . . . . .10

Lubricaton . . . . . . . . . . . . . . . . . . . .11

Start-up . . . . . . . . . . . . . . . . . . . . . .11

To Start Gasoline Engine . . . . . . . .12

. . . . . . . . . . . . . . . .2

. . . . . . . . . . . . . . . . . . . .8

Section Page

Maintenance

Maintenance Schedule . . . . . . . . . .13

Tank . . . . . . . . . . . . . . . . . . . . . . . . .14

Filter Removal, Inspection, and

Replacement . . . . . . . . . . . . . . . . . .14

Drive Belt . . . . . . . . . . . . . . . . . . . . .15

Storage . . . . . . . . . . . . . . . . . . . . . .15

Troubleshooting . . . . . . . . . . . . . . . .16

Notes . . . . . . . . . . . . . . . . . . . . . . . . .19

Repair Parts . . . . . . . . . . . . . . . . . . .20

Notes . . . . . . . . . . . . . . . . . . . . . . . . .22

Warranty . . . . . . . . . . . . . . . . . . . . . .24

. . . . . . . . . . . . . . . . . . .13

This manual contains information that is

very important to know and understand.

This information is provided for SAFETY

and to PREVENT EQUIPMENT PROBLEMS. To help recognize this information, observe the following symbols.

Safety Signal Words

Danger indicates

an imminently hazardous situation which, if not avoided,

WILL result in death or serious injury.

Warning indicates

a potentially hazardous situation which, if not avoided,

COULD result in death or serious injury.

Caution indicates a

potentially hazardous situation which, if not avoided,

MAY result in minor or moderate injury.

Notice indicates

important information, that if not followed, may cause damage to equipment.

Before Using the Air Compressor

Since the air compressor and other components (pump, spray guns, filters, lubricators, hoses, etc.) used make up a high

pressure pumping system, the following

safety precautions must be observed at

all times:

1. Read all manuals included with this product carefully. Be thoroughly familiar with the controls and

the proper use of the

equipment.

2. Follow all local safety codes as well

as the United States Occupational

Safety and Health Act (OSHA).

3. Only persons well acquainted with

these rules of safe operation should

be allowed to use the compressor.

4. Keep visitors away and NEVER allow

children in the work area.

5. Wear safety glasses and

use hearing protection

when operating the pump

or unit.

6. Do not stand on or use the pump or

unit as a handhold.

7. Before each use, inspect compressed

air system, fuel system and electrical

components for signs of damage,

23

deterioration, weakness or leakage.

Repair or replace defective items

before using.

8. Check all fasteners at frequent intervals for proper tightness.

Never operate

compressor without

a beltguard. Compressors can start automatically without warning. Personal

injury or property damage

could occurfrom contact with

moving parts.

9. Do not wear loose clothing or jewelry

that will get caught in the moving

parts of the unit.

Compressor parts

may be hot even if

the unit is stopped.

Safety Instructions (continued)

!

WARNING

!

DANGER

!

WARNING

!

WARNING

!

WARNING

!

DANGER

!

WARNING

!

DANGER

10. Keep fingers away from a running

compressor; fast moving and hot

parts will cause injury and/or burns.

11. If the equipment should start to

vibrate abnormally, STOP the

engine/motor and check immediately

for the cause. Vibration is generally a

warning of trouble.

NEVER refuel a running or hot engine.

Explosive fuel can cause fires

and severe burns. Avoid overfilling fuel tank.

12. Check fuel level before starting the

engine. Do not fill the gas tank

indoors. Wipe off any spilled gas

before starting the engine.

Gasoline vapor is highly flammable. Refill outdoors or only in

well ventilated areas. Do not

store, spill or use gasoline near

an open flame or heat devices

such as a stove, furnace, or

water heater, which utilize a

pilot light, or any device that

can create a spark. If gasoline

is accidentally spilled, move

unit away from the spill area

and avoid creating any source

of ignition until gasoline vapors

have dissipated.

Motors, electrical

equipment and controls can cause electrical arcs

that will ignite a flammable gas

or vapor. Never operate or

repair in or near a flammable

gas or vapor. Never store flammable liquids or gases in the

vicinity of the compressor.

Carbon monoxide can

cause severe nausea,

fainting or death. Do

not operate unit

inside a closed building or a

poorly ventilated area.

13. To reduce fire hazard, keep

engine/motor exterior free of oil, solvent, or excessive grease.

Never remove or attempt to

adjust safety valve. Keep safety

valve free from paint and other

accumulations.

14. Do not tamper with governor setting

on engine. Overspeeding the unit

severely shortens engine life and may

also be very hazardous.

Never attempt to

repair or modify a

tank! Welding, drilling

or any other modification will

weaken the tank resulting in

damage from rupture or explosion. Always replace worn or

damaged tanks.

15.

Tanks rust from moisture build-up,

which weakens the tank. Make sure to

drain tank daily and inspect periodically for unsafe conditions such as rust

formation and corrosion

4

.

16. Fast moving air will stir up dust and

debris which may be harmful.

Release air slowly when draining

moisture or depressurizing the compressor system.

17.

STOP the engine whenever leaving the

work area, before cleaning, making

repairs or inspections. When cleaning,

repairing or inspecting, make certain all

moving parts have stopped. Disconnect

the spark plug wire and keep the wire

away from the plug to prevent accidental starting.

18. Allow engine to cool before storing.

Spraying Precautions

ed area to prevent health and fire

hazards.

Do not spray flammable materials in

vicinity of open

flame or near ignition sources

including the compressor unit.

19. Do not smoke when spraying paint,

insecticides, or other flammable substances.

20. Use a face mask/respirator when

spraying and spray in a well ventilat-

21. Do not direct paint or other sprayed

material at the compressor. Locate

compressor as far away from the

spraying area as possible to minimize overspray accumulation on the

compressor.

22. When spraying or cleaning with solvents or toxic chemicals, follow the

instructions provided by the chemical manufacturer.

Breathable Air Warning

This compressor/pump is not equipped and should not be used “as

is” to supply breathing quality air. For any application of air for

human consumption, the air compressor/pump will need to be fitted

with suitable in-line safety and alarm equipment. This additional

equipment is necessary to properly filter and purify the air to meet

minimal specifications for Grade D breathing as described in

Compressed Gas Association Commodity Specification G 7.1 - 1966,

OSHA 29 CFR 1910. 134, and/or Canadian Standards Associations

(CSA).

DISCLAIMER OF WARRANTIES

In the event the compressor is used for the purpose of breathing air

application and proper in-line safety and alarm equipment is not

simultaneously used, existing warranties shall be voided, and

Campbell Hausfeld disclaims any liability whatsoever for any loss,

personal injury or damage.

5

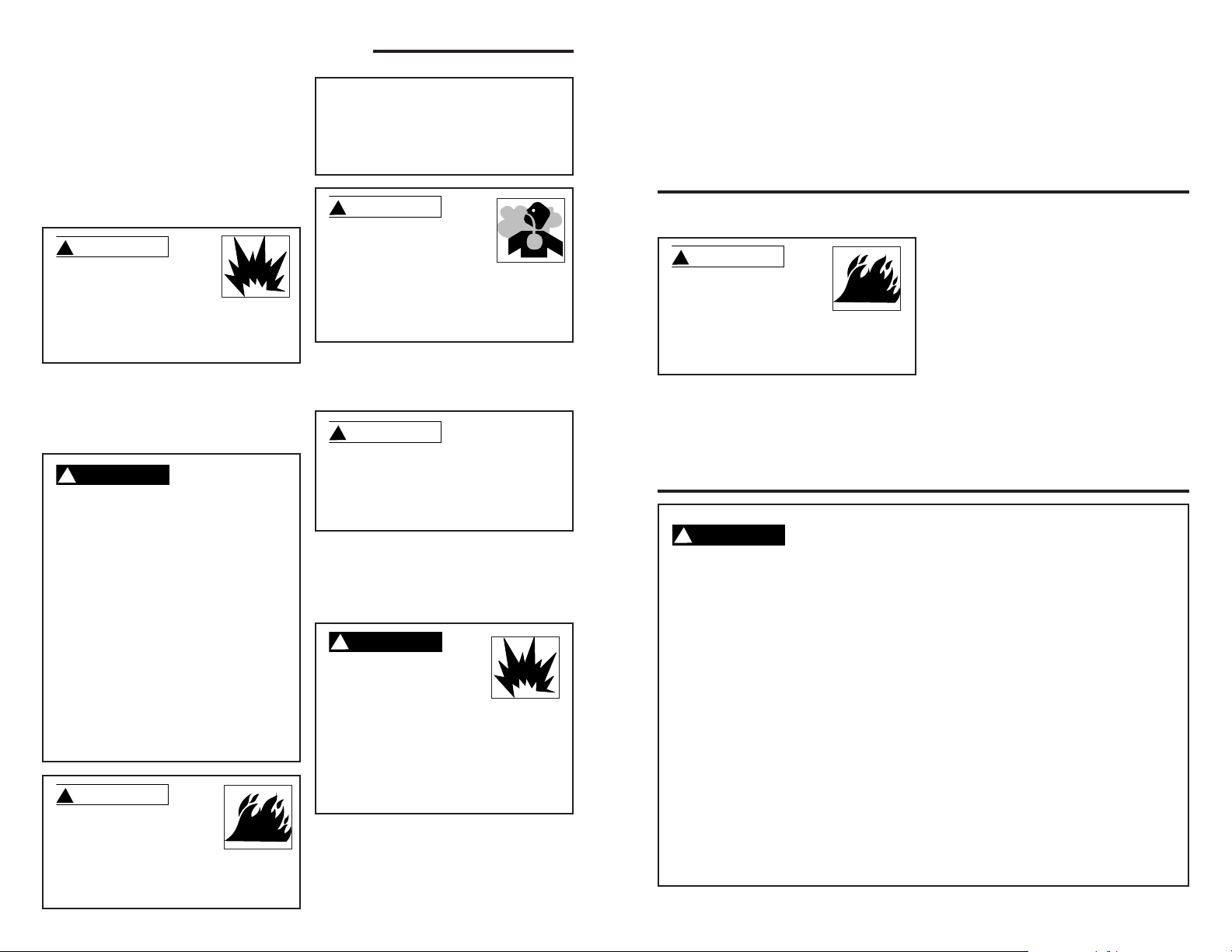

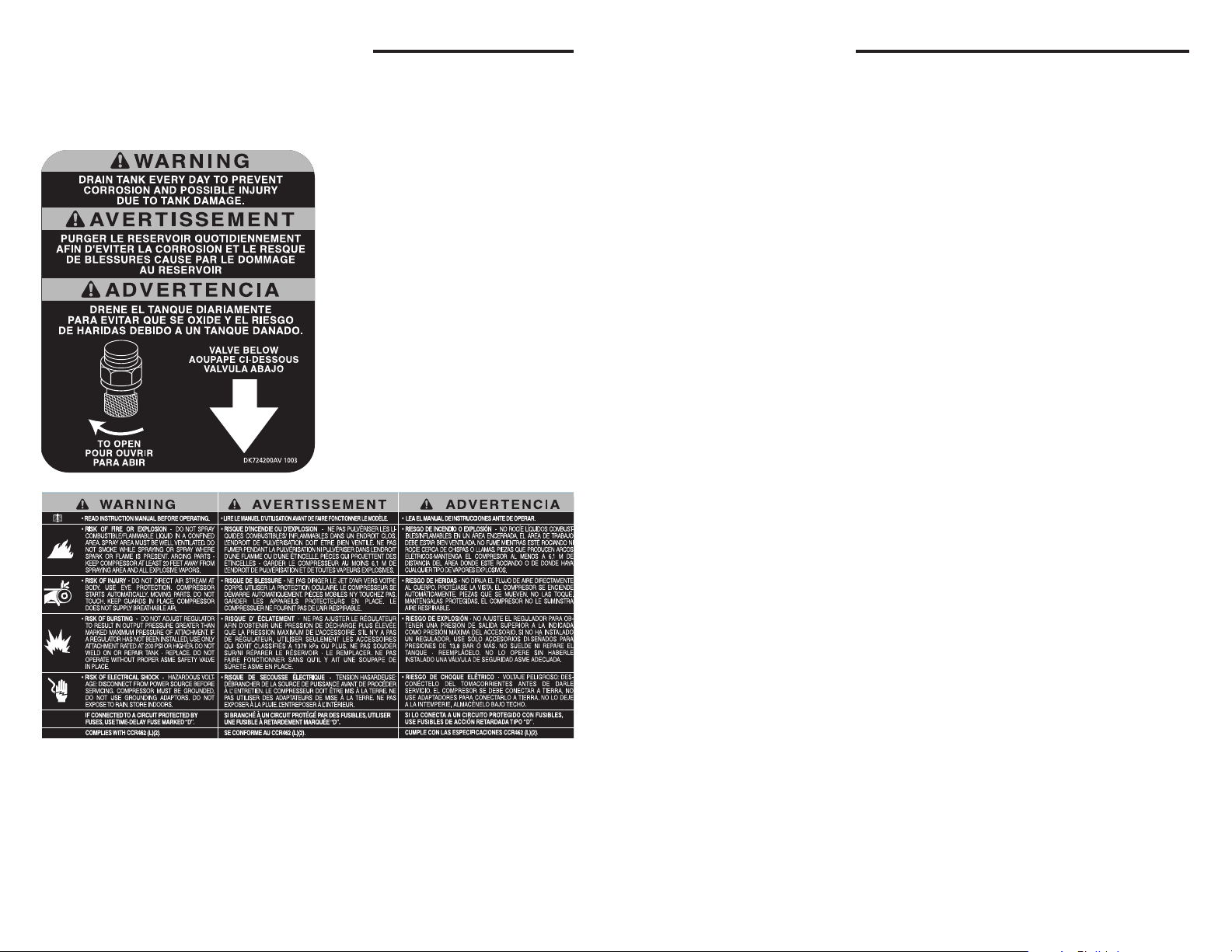

Safety Instructions (continued)

DK724100AV 10003

Glossary of Terms

Warning Labels

Find and read all warning labels found on

the air compressor shown below

ASME Safety Valve

A safety valve that automatically releases

the air if the air receiver (tank) pressure

exceeds the preset maximum.

PSI (Pounds per Square Inch)

Measurement of the pressure exerted by

the force of the air. The actual psi output

is measured by a pressure gauge on the

compressor

SCFM (Standard Cubic Feet per

Minute)

Sometimes called CFM (Cubic Feet per

Minute). Measurement of air volume

delivered by the compressor.

Air Delivery

A combination of psi and SCFM. The air

delivery required by a tool is stated as

(number) SCFM at (number) psi. The

combination of these figures determines

what size unit is needed.

Air Tank Capacity

The volume of air stored in the tank and

available for immediate use. A large tank

allows the intermittent use of an air tool

with an air requirement higher than the

compressor’s rated delivery.

Amps or Amperage

A measure of the electrical force minus

the resistance on an electrical line.

Ridgid air compressors require 15 amps

for operation. Be sure the compressor

will operate on an electrical line with the

proper amps. If other appliances operate

on the same line, they will reduce the

available amps. If the amperage is not

adequate, the result will be blown fuses

or tripped circuits.

Regulator

A control that adjusts the line pressure to

the proper amount needed to operate

spray guns and air tools.

Tank Pressure Gauge

Indicates tank pressure in psi.

Line Pressure Gauge

Displays the current line pressures. It is

regulated by the regulator knob.

Cut-in/Cut-off Pressure

Specific psi at which a compressor starts

and stops while refilling the air tank.

Figure 1

Volts or Voltage

A measurement of the force of an electrical current.

76

Loading...

Loading...