Ricoh SP 210, SP 211, SP 212, SP 213 Service Manual. Parts Catalog

Model OP-P/MF

Field Service Manual

April, 2014

Symbols, Terminology

Conventions

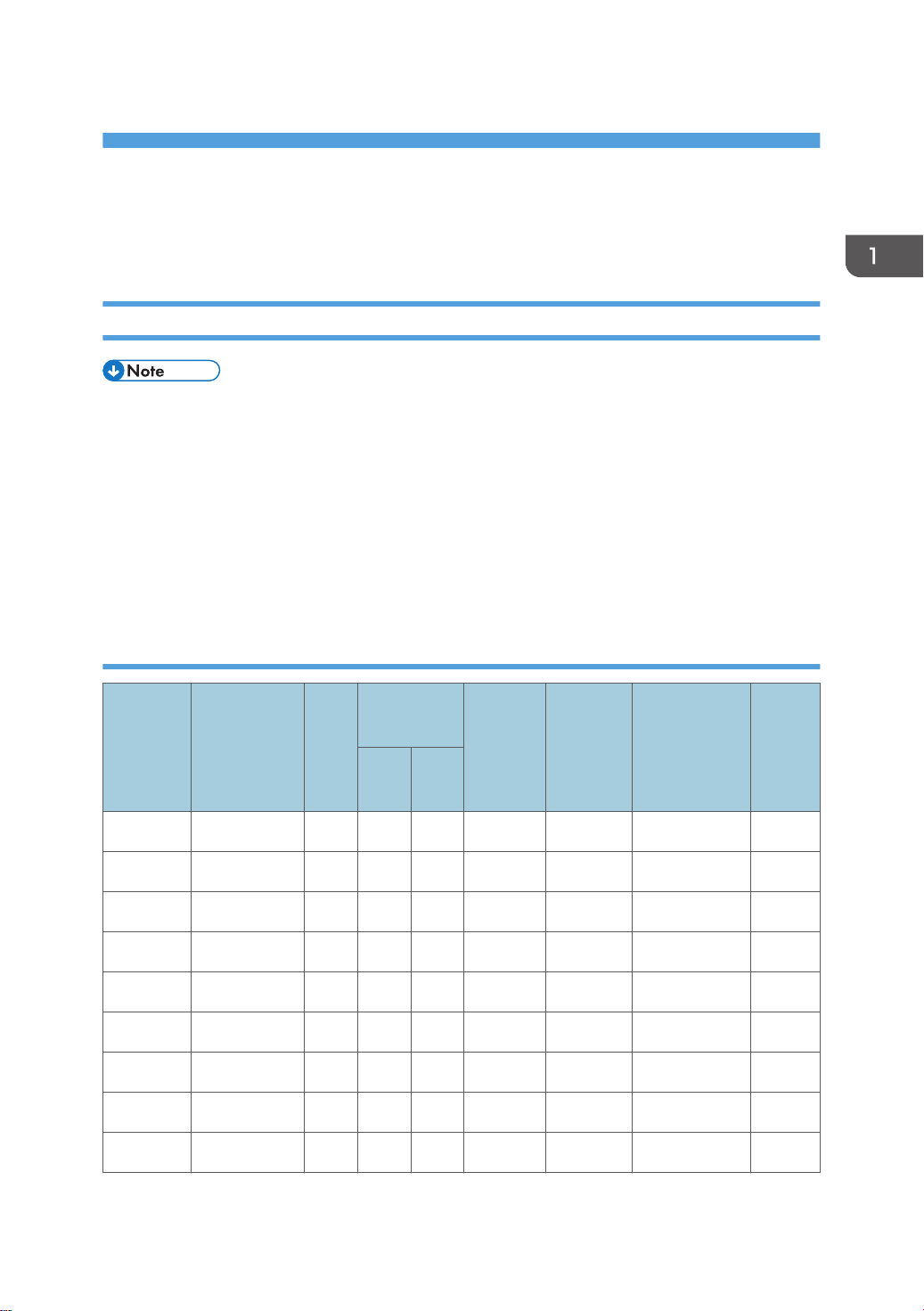

Commonly Used Icons for Replacements and Adjustments

Symbol What it means

Binding screw (shoulder hexagonal head)

Binding screw (round flathead)

Black screw (heavy, fusing unit, TCRU)

Bushing

C-ring

Connector

E-ring

FFC (Flat Film Connector)

FFC (Flat Film Connector)

Gear

Harness clamp

Harness clamp (metal: fusing unit)

Hook (or tab release)

Knob screw (black)

Knob screw (silver)

Pivot screw

Screw (common screw)

Shoulder screw

Spring

1

Symbol What it means

Standoff

Stud screw

Tapping screw (wide threads for plastic)

Timing belt

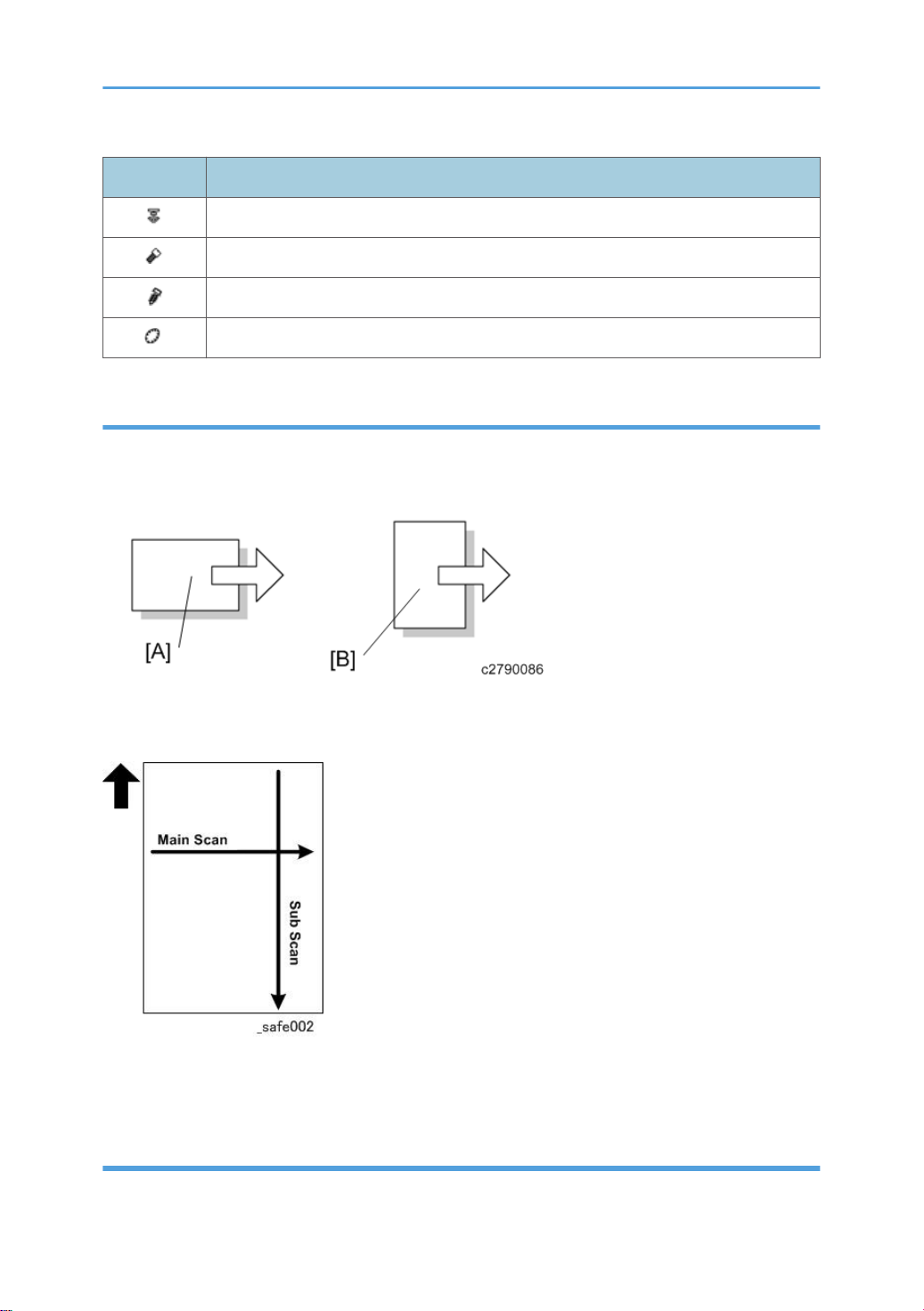

Paper Feed: SEF/LEF

The notations "SEF" and "LEF" describe the direction of paper feed. The arrows indicate the direction of

paper feed.

[A] Short Edge Feed (SEF)

[B] Long Edge Feed (LEF)

In this manual "Main Scan" means "Horizontal" and "Sub Scan" means "Vertical", both relative to the

direction of paper feed.

Smart Organizing Monitor

In this service manual "Smart Organizing Monitor" is often abbreviated as "SOM".

2

• The detailed procedure for entering the service mode of the Smart Organizing Monitor is provided

in the training materials for these machines. The procedure for entering the service mode is not

described in the service manuals.

• Service technicians must know how to enter the service mode before servicing these machines.

Please refer to the training materials.

AIO (All In One) Cartridge

The AIO (print cartridge) in the center of the machine is permanently sealed around these main elements

of the printing mechanisms: 1) OPC drum, 2) charge unit, 3) development unit, 4) drum cleaning unit,

and 5) toner supply unit.

• This print cartridge is called the "AIO" (All-In-One) throughout this service manual.

• When toner runs out, the AIO can be refilled by the service technician or the AIO can be replaced

by the operator. Refilling requires removal of two caps: the square cap to dump the toner and the

round cap for refilling. These two parts are the only service parts for the AIO. There are no other

service parts for the AIO.

• The AIO can be easily removed and replaced by the user. For more details, please refer to the

operating instructions.

Key Presses

Symbol What It Means

[Key]

Select

>

The names of machine operation panel keys and PC keyboard keys are enclosed in

square brackets.

This means to press one of the arrow keys to move the menu selector up/down ( ) or

left/right ( ) to the menu selection you want and then press [OK] on the machine

operation panel.

A right angle bracket means to select a menu item (enclosed in quotation marks) by

pressing the right or left arrow key and then pressing [OK]. For example,

[User Tools] > Select "System Settings" > "Tray Paper Settings"

means, Press the [User Tools], press the right arrow to highlight "System Settings" and

press [OK], and then press [OK] to select "Tray Paper Settings".

3

RoHS Compliance

These machines are fully compliant with Chinese RoHS and contain no restricted materials such as lead,

mercury, cadmium, hexavalent chrome, polybrominated biphenyl, or polybrominated diphenyl ether.

4

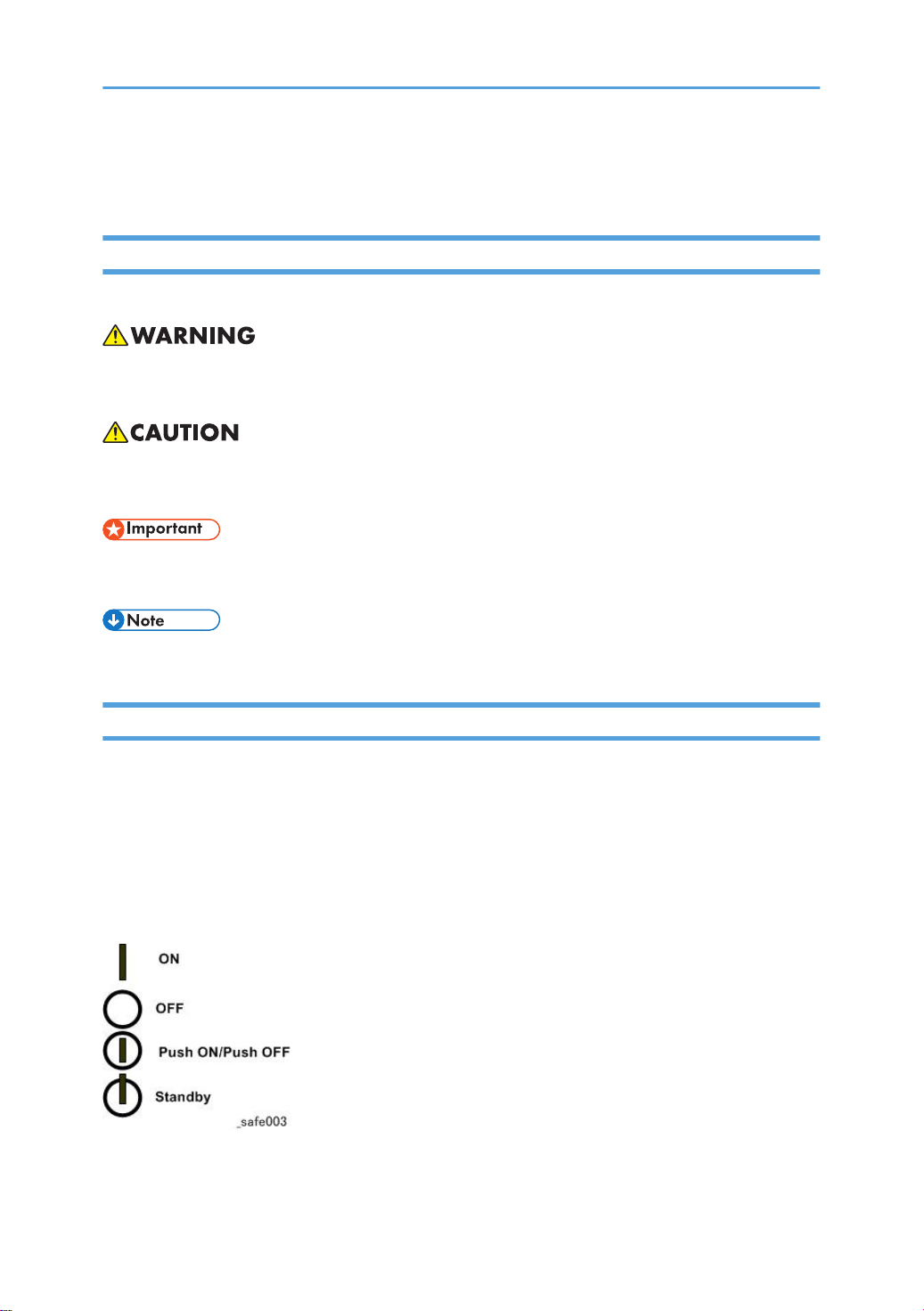

Important Safety Notices

Warnings, Cautions, Notes

In this manual, the following important symbols and notations are used.

• A Warning indicates a potentially hazardous situation. Failure to obey a Warning could result in

death or serious injury.

• A Caution indicates a potentially hazardous situation. Failure to obey a Caution could result in

minor or moderate injury or damage to the machine or other property.

• Obey these guidelines to avoid problems such as misfeeds, damage to originals, loss of valuable

data and to prevent damage to the machine.

• This information provides tips and advice about how to best service the machine.

General Safety Instructions

For your safety, please read this manual carefully before you use this product. Keep this manual handy

for future reference.

Safety Information

Always obey the following safety precautions when using this product.

Safety During Operation

In this manual, the following important symbols and notations are used.

Switches and Symbols

5

Where symbols are used on or near switches on machines for Europe and other areas, the meaning of

each symbol conforms with IEC60417.

Responsibilities of the Customer Engineer

Customer Engineer

Maintenance shall be done only by trained customer engineers who have completed service training for

the machine and all optional devices designed for use with the machine.

Reference Material for Maintenance

• Maintenance shall be done using the special tools and procedures prescribed for maintenance of

the machine described in the reference materials (service manuals, technical bulletins, operating

instructions, and safety guidelines for customer engineers).

• Use only consumable supplies and replacement parts designed for use with the machine.

Before Installation, Maintenance

Shipping and Moving the Machine

• Work carefully when lifting or moving the machine. If the machine is heavy, two or more customer

engineers may be required to prevent injuries (muscle strains, spinal injuries, etc.) or damage to the

machine if it is dropped or tipped over.

• Personnel moving or working around the machine should always wear proper clothing and

footwear. Never wear loose fitting clothing or accessories (neckties, loose sweaters, bracelets,

etc.) or casual footwear (slippers, sandals, etc.) when lifting or moving the machine.

• Always unplug the power cord from the power source before you move the machine. Before you

move the product, arrange the power cord so it will not fall under the machine.

Power

• Always disconnect the power plug before doing any maintenance procedure. After switching off

the machine, power is still supplied to the main machine and other devices. To prevent electrical

shock, switch the machine off, wait for a few seconds, then unplug the machine from the power

source.

6

• Before you do any checks or adjustments after turning the machine off, work carefully to avoid

injury. After removing covers or opening the machine to do checks or adjustments, never touch

electrical components or moving parts (gears, timing belts, etc.).

• After turning the machine on with any cover removed, keep your hands away from electrical

components and moving parts. Never touch the cover of the fusing unit, gears, timing belts, etc.

Installation, Disassembly, and Adjustments

• After installation, maintenance, or adjustment, always check the operation of the machine to make

sure that it is operating normally. This ensures that all shipping materials, protective materials, wires

and tags, metal brackets, etc., removed for installation, have been removed and that no tools

remain inside the machine. This also ensures that all release interlock switches have been restored

to normal operation.

• Never use your fingers to check moving parts causing spurious noise. Never use your fingers to

lubricate moving parts while the machine is operating.

Special Tools

• Use only standard tools approved for machine maintenance.

• For special adjustments, use only the special tools and lubricants described in the service manual.

Using tools incorrectly, or using tools that could damage parts, could damage the machine or

cause injuries.

During Maintenance

General

• Before you begin a maintenance procedure: 1) Switch the machine off, 2) Disconnect the power

plug from the power source, 3) Allow the machine to cool for at least 10 minutes.

• Avoid touching the components inside the machine that are labeled as hot surfaces.

7

Safety Devices

• Never remove any safety device unless it requires replacement. Always replace safety devices

immediately.

• Never do any procedure that defeats the function of any safety device. Modification or removal of

a safety device (fuse, switch, etc.) could lead to a fire and personal injury. Always test the

operation of the machine to ensure that it is operating normally and safely after removal and

replacement of any safety device.

• For replacements use only the correct fuses or circuit breakers rated for use with the machine. Using

replacement devices not designed for use with the machine could lead to a fire and personal

injuries.

Organic Cleaners

• During preventive maintenance, never use any organic cleaners (alcohol, etc.) other than those

described in the service manual.

• Make sure the room is well ventilated before using any organic cleaner. Use organic solvents in

small amounts to avoid breathing the fumes and becoming nauseous.

• Switch the machine off, unplug it, and allow it to cool before doing preventive maintenance. To

avoid fire or explosion, never use an organic cleaner near any part that generates heat.

• Wash your hands thoroughly after cleaning parts with an organic cleaner to prevent contamination

of food, drinks, etc. which could cause illness.

• Clean the floor completely after accidental spillage to prevent slippery surfaces that could cause

accidents leading to hand or leg injuries. Use dry rags to soak up spills.

Power Plug and Power Cord

• Before servicing the machine (especially when responding to a service call), always make sure that

the power plug has been inserted completely into the power source. A partially inserted plug could

lead to heat generation (due to a power surge caused by high resistance) and cause a fire or other

problems.

• Always check the power plug and make sure that it is free of dust and lint. Clean it if necessary. A

dirty plug can generate heat which could cause a fire.

• Inspect the length of the power cord for cuts or other damage. Replace the power cord if

necessary. A frayed or otherwise damaged power cord can cause a short circuit which could lead

to a fire or personal injury from electrical shock.

8

• Check the length of the power cord between the machine and power supply. Make sure the power

cord is not coiled or wrapped around any object such as a table leg. Coiling the power cord can

cause excessive heat to build up and could cause a fire.

• Make sure that the area around the power source is free of obstacles so the power cord can be

removed quickly in case of an emergency.

• Make sure that the power cord is grounded (earthed) at the power source with the ground wire on

the plug.

• Connect the power cord directly into the power source. Never use an extension cord.

• When you disconnect the power plug from the power source, always pull on the plug, not the

cable.

After Installation, Servicing

Disposal of Used Items

• Never incinerate used toner, toner cartridges, or AIO units.

• Toner thrown into a fire can ignite or explode and cause serious injury. At the work site always

carefully wrap used toner and toner cartridges with plastic bags to avoid spillage before disposal

or removal.

• Always dispose of used items (developer, toner, toner cartridges, OPC drums, AIO units, etc.) in

accordance with the local laws and regulations regarding the disposal of such items.

• To protect the environment, never dispose of this product or any kind of waste from consumables at

a household waste collection point. Dispose of these items at one of our dealers or at an

authorized collection site.

• Return used drums to the service center for handling in accordance with company policy regarding

the recycling or disposal of such items.

Points to Confirm with Operators

At the end of installation or a service call, instruct the user about use of the machine. Emphasize the

following points.

• Show operators how to remove jammed paper and troubleshoot other minor problems by

following the procedures described in the operating instructions.

• Point out the parts inside the machine that they should never touch or attempt to remove.

• Confirm that operators know how to store and dispose of consumables.

9

• Make sure that all operators have access to an operating instruction manual for the machine.

• Confirm that operators have read and understand all the safety instructions described in the

operating instructions.

• Demonstrate how to turn off the power and disconnect the power plug (by pulling the plug, not the

cord) if any of the following events occur: 1) something has spilled into the product, 2) service or

repair of the product is necessary, 3) the product cover has been damaged.

• Caution operators about removing paper fasteners around the machine. They should never allow

paper clips, staples, or any other small metallic objects to fall into the machine.

Special Safety Instructions for Toner

Accidental Physical Exposure

• Work carefully when removing paper jams or replacing toner bottles or cartridges to avoid spilling

toner on clothing or the hands.

• If toner is inhaled, immediately gargle with large amounts of cold water and move to a well

ventilated location. If there are signs of irritation or other problems, seek medical attention.

• If toner gets on the skin, wash immediately with soap and cold running water.

• If toner gets into the eyes, flush the eyes with cold running water or eye wash. If there are signs of

irritation or other problems, seek medical attention.

• If toner is swallowed, drink a large amount of cold water to dilute the ingested toner. If there are

signs of any problem, seek medical attention.

• If toner spills on clothing, wash the affected area immediately with soap and cold water. Never use

hot water! Hot water can cause toner to set and permanently stain fabric.

Handling and Storing Toner

• Toner, used toner, and developer are extremely flammable.

• Never store toner, developer, toner cartridges, or toner bottles (including empty toner bottles or

cartridges), or AIO units in a location where they will be exposed to high temperature or an open

flame.

• Do not use a vacuum cleaner to remove spilled toner (including used toner). Vacuumed toner may

cause a fire or explosion due to sparks or electrical contact inside the cleaner. However, it is

possible to use a cleaner designed to be dust explosion-proof. If toner is spilled over the floor,

sweep up spilled toner slowly and clean up any remaining toner with a wet cloth.

10

• Always store toner and developer supplies such as toner and developer packages, cartridges,

bottles (including used toner and empty bottles and cartridges) and AIO units out of the reach of

children.

• Always store fresh toner supplies or empty bottles or cartridges in a cool, dry location that is not

exposed to direct sunlight.

Toner Disposal

• Never attempt to incinerate toner, used toner, or empty toner containers (bottles or cartridges).

Burning toner can explode and scatter, causing serious burns.

• Always wrap used toner and empty toner bottles and cartridges in plastic bags to avoid spillage.

Follow the local laws and regulations regarding the disposal of such items.

• Dispose of used toner and toner cartridges at one of our dealers or at an authorized collection site.

Always dispose of used toner cartridges and toner bottles in accordance with the local laws and

regulations regarding the disposal of such items.

Safety Instructions for the Machine

Prevention of Physical Injury

1. Before disassembling or assembling parts of the machine and peripherals, make sure that the

machine and peripheral power cords are unplugged.

2. The plug should be near the machine and easily accessible.

3. Note that some components of the machine and the paper tray unit are supplied with electrical

voltage even if the main power switch is turned off.

4. If any adjustment or operation check has to be made with exterior covers off or open while the

main switch is turned on, keep hands away from electrified or mechanically driven components.

5. If the [Start] key is pressed before the machine completes the warm-up period (the [Start] key starts

blinking red and green), keep hands away from the mechanical and the electrical components,

because the machine starts making copies as soon as the warm-up period is completed.

6. The inside and the metal parts of the fusing unit become extremely hot while the machine is

operating. Be careful to avoid touching those components with your bare hands.

7. To prevent a fire or explosion, keep the machine away from flammable liquids, gases, and

aerosols.

11

Health Safety Conditions

1. If the machine has ozone filters, never operate the machine without the ozone filters installed.

Always replace the ozone filters with the specified types at the proper intervals.

2. To avoid possible accumulation of ozone in the work area, locate the machine in a large well

ventilated room that has an air turnover rate of more than 30m3/hr/person.

3. Toner and developer are non-toxic, but if you get either of them in your eyes by accident, it may

cause temporary eye discomfort. Try to remove with eye drops or flush with water as first aid. If

unsuccessful, get medical attention.

Observance of Electrical Safety Standards

1. The machine and its peripherals must be installed and maintained by a customer service

representative who has completed the training course on those models.

2. The NVRAM on the system control board has a lithium battery which can explode if replaced

incorrectly. Replace the NVRAM only with an identical one. The manufacturer recommends

replacing the entire NVRAM. Do not recharge or burn this battery. Used NVRAM must be handled

in accordance with local regulations.

Safety and Ecological Notes for Disposal

1. Never incinerate toner bottles or used toner. Toner dust may ignite suddenly when exposed to an

open flame.

2. Dispose of used toner, developer, and organic photoconductors in accordance with local

regulations. (These are non-toxic supplies.)

3. Dispose of replaced parts in accordance with local regulations.

4. When keeping used lithium batteries in order to dispose of them later, do not put more than 100

batteries per sealed box. Storing larger numbers or not sealing them apart may lead to chemical

reactions and heat build-up.

• The danger of explosion exists if a battery of this type is incorrectly replaced.

• Replace only with the same or an equivalent type recommended by the manufacturer. Discard

used batteries in accordance with the manufacturer's instructions.

12

Laser Safety

1. The Center for Devices and Radiological Health (CDRH) prohibits the repair of laser-based optical

units in the field.

2. The optical housing unit can only be repaired in a factory or at a location with the requisite

equipment.

3. The laser subsystem is replaceable in the field by a qualified Customer Engineer.

4. The laser chassis is not repairable in the field.

5. Customer engineers are therefore directed to return all chassis and laser subsystems to the factory

or service depot when replacement of the optical subsystem is required.

• Use of controls, or adjustment, or performance of procedures other than those specified in this

manual may result in hazardous radiation exposure.

• Turn off the main switch before attempting any of the procedures in the Laser Unit section. Laser

beams can seriously damage your eyes.

Trademarks

• Microsoft®, and Windows® are registered trademarks of Microsoft Corporation in the United

States and /or other countries.

• PostScript® is a registered trademark of Adobe Systems, Incorporated.

• PCL® is a registered trademark of Hewlett-Packard Company.

• Ethernet® is a registered trademark of Xerox Corporation.

• PowerPC® is a registered trademark of International Business Machines Corporation.

• Other product names used herein are for identification purposes only and may be trademarks of

their respective companies. We disclaim any and all rights involved with those marks.

13

TABLE OF CONTENTS

Symbols, Terminology........................................................................................................................................1

Conventions....................................................................................................................................................1

Commonly Used Icons for Replacements and Adjustments...............................................................1

Paper Feed: SEF/LEF.............................................................................................................................2

Smart Organizing Monitor...................................................................................................................2

AIO (All In One) Cartridge...................................................................................................................3

Key Presses.............................................................................................................................................3

RoHS Compliance.................................................................................................................................4

Important Safety Notices...................................................................................................................................5

Warnings, Cautions, Notes...........................................................................................................................5

General Safety Instructions............................................................................................................................5

Responsibilities of the Customer Engineer....................................................................................................6

Customer Engineer................................................................................................................................6

Reference Material for Maintenance...................................................................................................6

Before Installation, Maintenance..................................................................................................................6

Shipping and Moving the Machine.....................................................................................................6

Power......................................................................................................................................................6

Installation, Disassembly, and Adjustments.........................................................................................7

Special Tools..........................................................................................................................................7

During Maintenance......................................................................................................................................7

General..................................................................................................................................................7

Safety Devices........................................................................................................................................8

Organic Cleaners..................................................................................................................................8

Power Plug and Power Cord................................................................................................................8

After Installation, Servicing............................................................................................................................9

Disposal of Used Items..........................................................................................................................9

Points to Confirm with Operators.........................................................................................................9

Special Safety Instructions for Toner..........................................................................................................10

Accidental Physical Exposure............................................................................................................10

Handling and Storing Toner...............................................................................................................10

Toner Disposal.....................................................................................................................................11

Safety Instructions for the Machine............................................................................................................11

14

Prevention of Physical Injury...............................................................................................................11

Health Safety Conditions....................................................................................................................12

Observance of Electrical Safety Standards......................................................................................12

Safety and Ecological Notes for Disposal........................................................................................12

Laser Safety..................................................................................................................................................13

Trademarks...................................................................................................................................................13

1. Product Information

Series Comparison...........................................................................................................................................21

OP-P1/MF1.................................................................................................................................................21

OP-P1 SFP............................................................................................................................................21

OP-MF1 3in1......................................................................................................................................22

OP-MF1 4in1......................................................................................................................................23

OP-P2/MF2.................................................................................................................................................24

OP-P2 SFP............................................................................................................................................24

OP-MF2 3in1......................................................................................................................................25

OP-MF2 4in1......................................................................................................................................26

Layout................................................................................................................................................................28

AIO...............................................................................................................................................................28

Paper Path Layout........................................................................................................................................29

Drive Layout..................................................................................................................................................30

Image Writing..............................................................................................................................................31

2. Installation

Installation Requirements.................................................................................................................................33

Installation Procedure..................................................................................................................................33

Environment..................................................................................................................................................33

Power Requirement......................................................................................................................................34

Space Requirements....................................................................................................................................34

Moving the Machine...................................................................................................................................35

3. Preventive Maintenance

PM Parts............................................................................................................................................................37

4. Replacement and Adjustments

Before You Begin.............................................................................................................................................39

Precautions...................................................................................................................................................39

Special Tools................................................................................................................................................39

15

Exterior Covers, Scanner, ADF.......................................................................................................................40

Printer Covers...............................................................................................................................................40

Front Cover..........................................................................................................................................40

Right Cover..........................................................................................................................................40

Left Cover.............................................................................................................................................42

Top Cover............................................................................................................................................43

Rear Cover and Rear Door................................................................................................................44

MF Platen Cover, Flatbed scanner, ADF...................................................................................................45

Platen Cover........................................................................................................................................45

Left Hinge.............................................................................................................................................45

Flatbed Scanner Unit..........................................................................................................................48

MF Inner Cover...................................................................................................................................50

Original Feed Tray..............................................................................................................................50

ADF / Flatbed Unit.............................................................................................................................51

Operation Panels.............................................................................................................................................54

Printer Operation Panel...............................................................................................................................54

OP-MF1 3in1 Operation Panel..................................................................................................................54

OP-MF1 4in1 / OP-MF2 Operation Panel..............................................................................................56

Laser Unit..........................................................................................................................................................58

Removing the Laser Unit..............................................................................................................................58

After Replacing the Laser Unit.....................................................................................................................59

Paper Path.........................................................................................................................................................60

Paper Feed Roller........................................................................................................................................60

Friction Pad...................................................................................................................................................62

Paper Transport Roller.................................................................................................................................63

Image Transfer Roller...................................................................................................................................65

Paper Exit Roller Unit...................................................................................................................................68

Fusing Exit Roller..........................................................................................................................................69

Sensors..............................................................................................................................................................70

Registration Sensor......................................................................................................................................70

Paper End Sensor.........................................................................................................................................71

Bypass Set Sensor........................................................................................................................................71

Paper Exit Sensor.........................................................................................................................................72

16

Main Motor......................................................................................................................................................73

Removing the Main Motor..........................................................................................................................73

Reinstalling the Main Motor........................................................................................................................74

Clutch................................................................................................................................................................75

Paper Feed Clutch........................................................................................................................................75

Switches............................................................................................................................................................76

Front Door Switch........................................................................................................................................76

Interlock Switch............................................................................................................................................77

Fusing Unit.........................................................................................................................................................78

Separating the Fusing Unit..........................................................................................................................78

Pressure Roller..............................................................................................................................................81

Hot Roller, Fusing Lamp...............................................................................................................................82

Thermostat....................................................................................................................................................84

Thermistor ....................................................................................................................................................84

Ground Plate................................................................................................................................................85

Boards...............................................................................................................................................................86

SFP Main Board...........................................................................................................................................86

3in1 MF Main Board..................................................................................................................................86

4in1 MF Main Board..................................................................................................................................87

After Replacing the Main Board.................................................................................................................88

4in1 MF Fax Board.....................................................................................................................................88

4in1 MF Fax Speaker..................................................................................................................................89

PSU................................................................................................................................................................89

H.V.P.P..........................................................................................................................................................91

OP-P1/MF1 Wi-Fi Module........................................................................................................................93

OP-P2/MF2 Wi-Fi PCB..............................................................................................................................94

Scanner Unit.....................................................................................................................................................96

ADF....................................................................................................................................................................97

ADF Friction Pad Ass’y................................................................................................................................97

Refilling the AIO...............................................................................................................................................98

Before You Begin.........................................................................................................................................98

What You Need...........................................................................................................................................98

Refill Procedure............................................................................................................................................99

17

Removing Old Toner...........................................................................................................................99

Filling the AIO with New Toner.......................................................................................................101

4in1 MF: After Refilling.............................................................................................................................103

5. Maintenance Reference

Firmware Update...........................................................................................................................................105

Checking the Machine Firmware Version...............................................................................................108

OP-P1/MF1 Firmware Update Procedure.............................................................................................108

OP-P2/MF2 Firmware Update Procedure.............................................................................................109

Service Tables................................................................................................................................................111

OP-P1/MF1 Service Mode.....................................................................................................................111

Service Mode Screen.......................................................................................................................111

OP-P2/MF2 Service Mode.....................................................................................................................117

Enter the Service Mode from SOM.................................................................................................117

Enter the Service Mode from Operation panel (MF only)............................................................119

Fax Maintenance (4in1 MF only)............................................................................................................123

Fax Service Test Menu (4in1 MF only)...................................................................................................129

Entering the Fax Service Test Menu................................................................................................129

Exiting the Maintenance Mode Menu............................................................................................129

Menu List............................................................................................................................................129

Reports............................................................................................................................................................131

Configuration Page & Maintenance Page (OP-P2/MF2 only)............................................................131

Total Counter.....................................................................................................................................131

Other Reports.............................................................................................................................................131

Test Page....................................................................................................................................................132

To Print the Test Page........................................................................................................................132

Test Pattern Printing (OP-P2/MF2 only)..................................................................................................132

To Print the Test Pattern.....................................................................................................................133

6. Troubleshooting

Service Calls...................................................................................................................................................135

Overview....................................................................................................................................................135

Fusing Related SC Codes.................................................................................................................135

SC Tables...................................................................................................................................................135

SC1xx: Scanning..............................................................................................................................135

18

SC2xx: Scanning..............................................................................................................................136

SC4xx: Image Transfer and Transfer Error.....................................................................................137

SC5xx: Motor, Fusing Error.............................................................................................................137

SC6xx: Communication...................................................................................................................140

SC8xx: Other....................................................................................................................................141

Image Problems.............................................................................................................................................142

Overview....................................................................................................................................................142

Image Quality Problems...........................................................................................................................143

Jam / Paper Feed Problems.....................................................................................................................144

Other Problems..........................................................................................................................................145

7. Energy Saving

Energy Save...................................................................................................................................................147

Energy Save Modes..................................................................................................................................147

Timer Settings....................................................................................................................................147

Recommendations............................................................................................................................147

Paper Save.....................................................................................................................................................149

Effectiveness of Duplex/Combine Functions...........................................................................................149

1. Duplex...........................................................................................................................................149

2. Combine Mode............................................................................................................................149

3. Duplex + Combine.......................................................................................................................149

Total Counter.....................................................................................................................................150

19

20

1. Product Information

Series Comparison

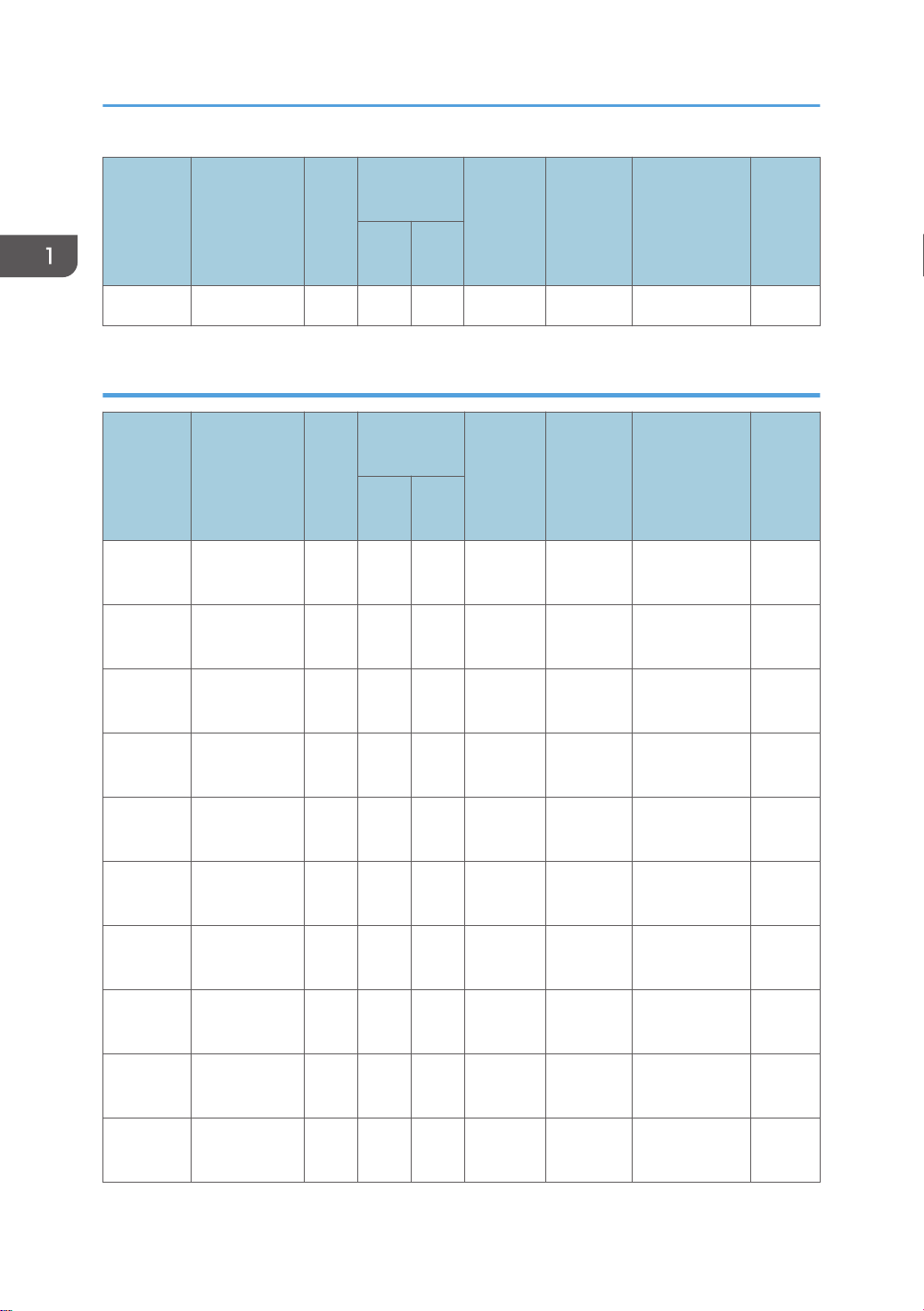

OP-P1/MF1

• Only 4in1 MF (Multi-Function) has Fax function.

• Only 4in1 MF M***-21 (China model) has Handset.

• Only MF with network interface has Scan2USB function

• All MF has Flatbed scanner.

• *1: Can continue print by changing "toner end option",

*2: Cannot print after toner end.

• OP-P1/MF1 only supports GDI printer language.

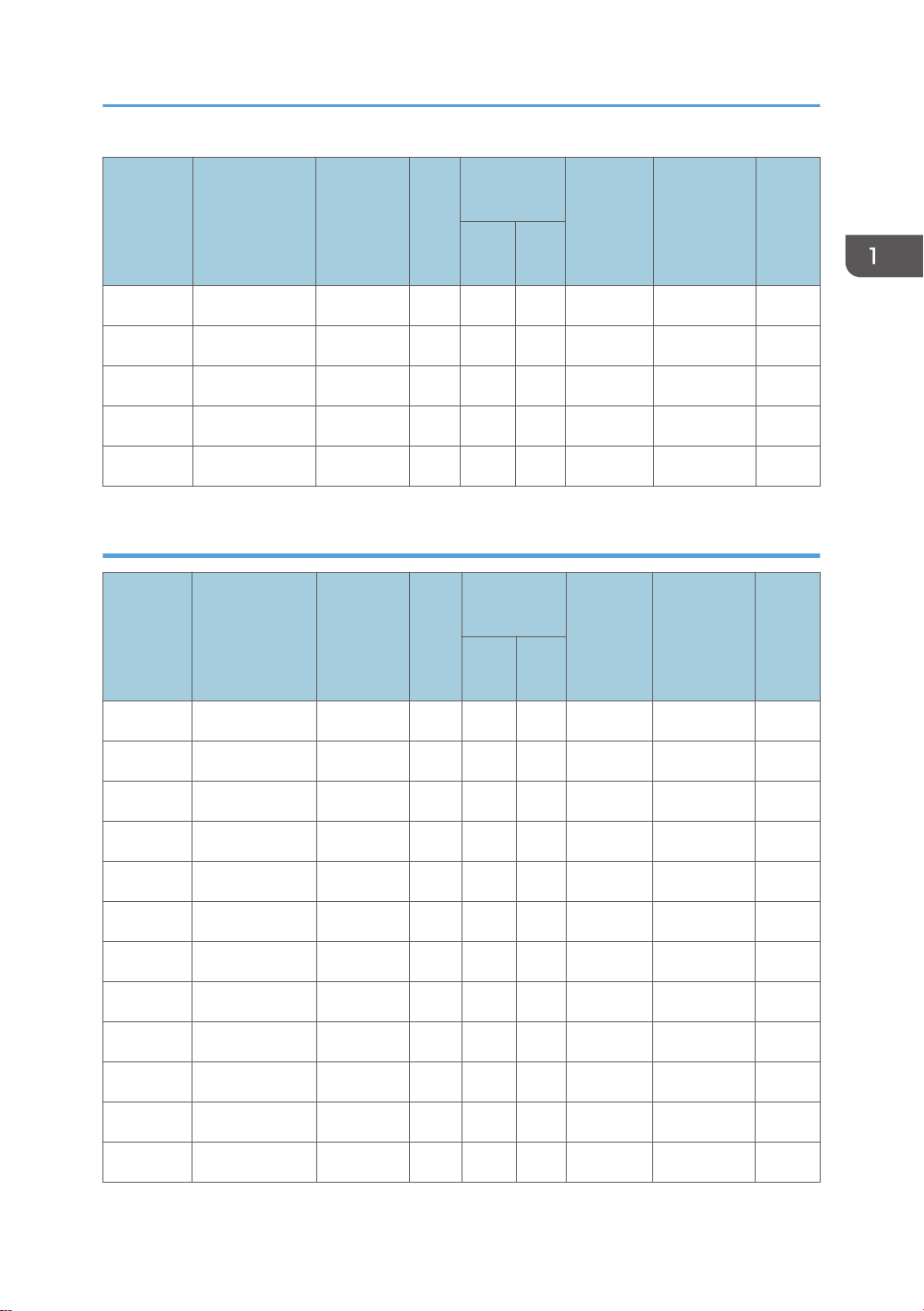

OP-P1 SFP

Network

Machine

Code

M133-21 SP 200 No No No 2 LEDs Yes No 1.0k

M162-27 SP 200 No No No 2 LEDs Yes No 1.0k

M209-21 SP 200 Q No No No 2 LEDs No No 1.0k

M144-21 SP 200N No Yes No 2 LEDs Yes No 1.0k

M163-27 SP 200N No Yes No 2 LEDs Yes No 1.0k

M145-27 SP 201N No Yes No 2 LEDs No Yes *2 0.7k

M145-17 SP 201N No Yes No 2 LEDs No Yes *2 0.7k

M164-27 SP 200Nw No Yes Yes 2 LEDs Yes No 1.0k

M146-27 SP 201Nw No Yes Yes 2 LEDs No Yes *2 0.7k

Product

Name

ADF

Interface

Ether

net

Display Refillable

Wi-

Fi

Genuine AIO

Toner-end

Detection

Starter

AIO

Yield

21

1. Product Information

Network

Machine

Code

Product

Name

ADF

Interface

Ether

net

Display Refillable

Wi-

Fi

Genuine AIO

Toner-end

Detection

M146-17 SP 201Nw No Yes Yes 2 LEDs No Yes *2 0.7k

OP-MF1 3in1

Network

Machine

Code

Product

Name

ADF

Interface

Ether

net

Display Refillable

Wi-

Fi

Genuine AIO

Toner-end

Detection

Starter

AIO

Yield

Starter

AIO

Yield

M134-21 SP 200S No No No

M165-27 SP 200S No No No

M210-21 SP 200S Q No No No

M147-27 SP 203S No No No

M147-17 SP 203S No No No

M142-21 SP 201S No Yes No

M191-21 SP 202S Yes No No

M166-27 SP 202SN Yes Yes No

M148-27 SP 204SN Yes Yes No

2-digit

7-seg

2-digit

7-seg

2-digit

7-seg

2-digit

7-seg

2-digit

7-seg

2-digit

7-seg

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

Yes No 1.0k

Yes No 1.0k

No No 1.0k

No Yes *2 0.7k

No Yes *2 0.7k

Yes No 1.0k

Yes No 1.0k

Yes No 1.0k

No Yes *2 0.7k

22

M148-17 SP 204SN Yes Yes No

2-LINE

LCD

No Yes *2 0.7k

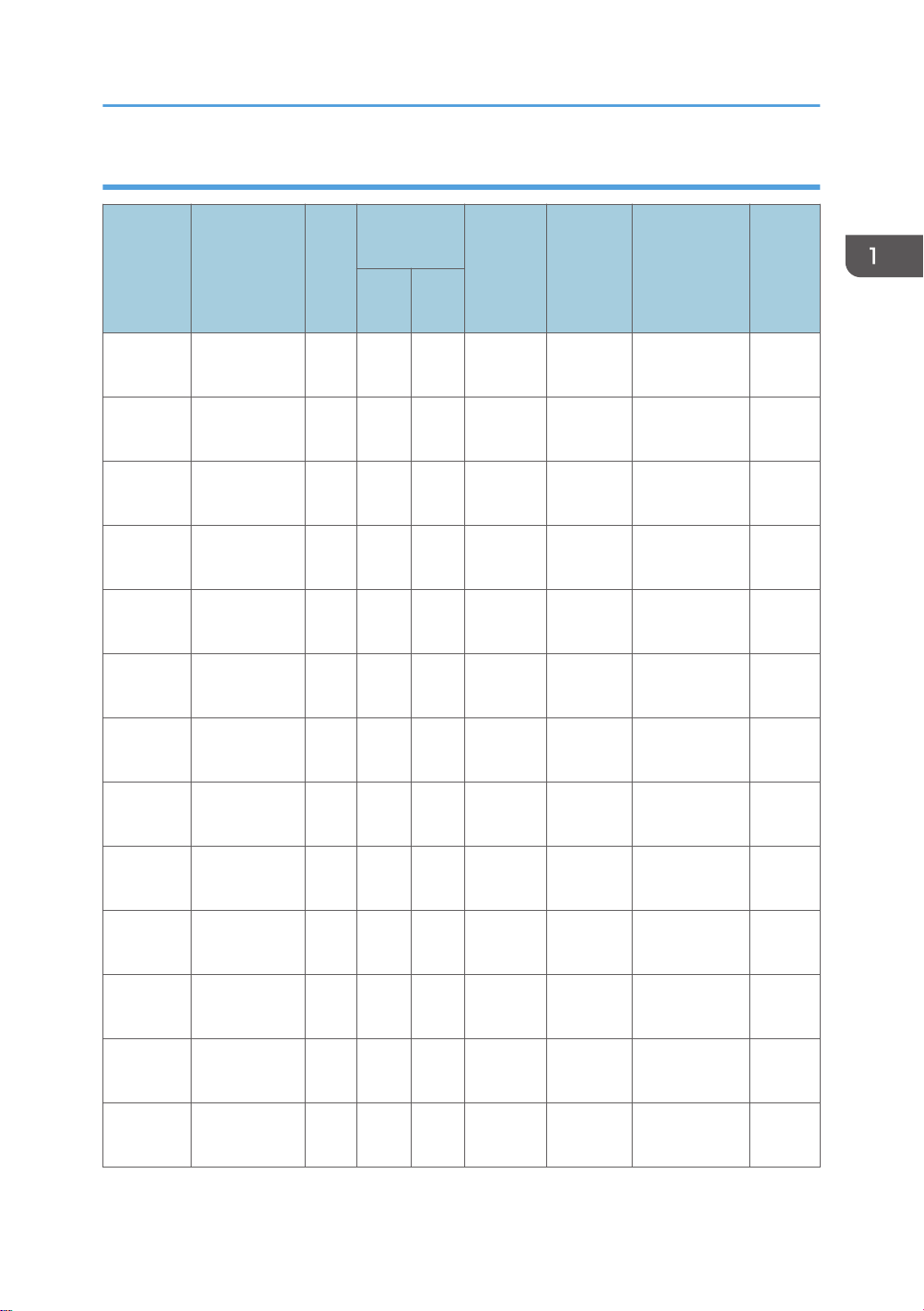

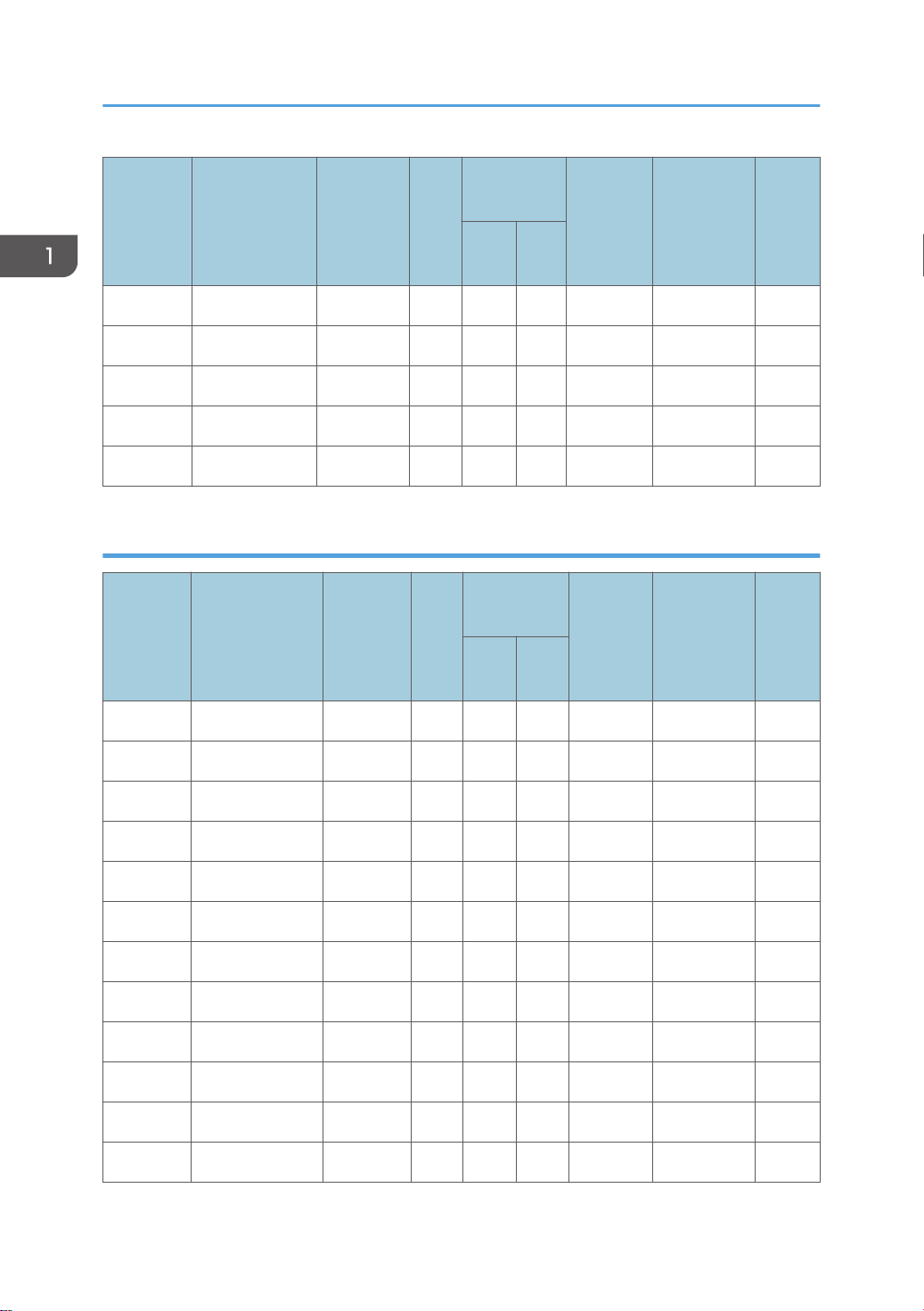

OP-MF1 4in1

Machine

Code

Product

Name

ADF

Network

Interface

Ether

net

Wi-

Fi

Display Refillable

Series Comparison

Genuine AIO

Toner-end

Detection

Starter

AIO

Yield

M141-21 SP 200SF No No No

M212-21 SP 200SF Q No No No

M135-21 SP 201SF Yes No No

M211-21 SP 201SF Q Yes No No

M143-21 SP 202SF Yes Yes No

M167-27 SP 203SF Yes No No

M149-27 SP 204SF Yes No No

M149-17 SP 204SF Yes No No

M168-27 SP 203SFN Yes Yes No

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

Yes Yes *1 1.0k

No Yes *1 1.0k

Yes Yes *1 1.0k

No Yes *1 1.0k

Yes Yes *1 1.0k

Yes Yes *1 1.0k

No Yes *1 0.7k

No Yes *1 0.7k

Yes Yes *1 0.7k

M150-27 SP 204SFN Yes Yes No

M150-17 SP 204SFN Yes Yes No

M169-27 SP 203SFNw Yes Yes Yes

M151-27 SP 204SFNw Yes Yes Yes

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

2-LINE

LCD

No Yes *1 0.7k

No Yes *1 0.7k

Yes Yes *1 1.0k

No Yes *1 0.7k

23

1. Product Information

Machine

Code

Product

Name

ADF

Network

Interface

Ether

net

Wi-

Fi

Display Refillable

Genuine AIO

Toner-end

Detection

Starter

AIO

Yield

M151-17 SP 204SFNw Yes Yes Yes

2-LINE

LCD

No Yes *1 0.7k

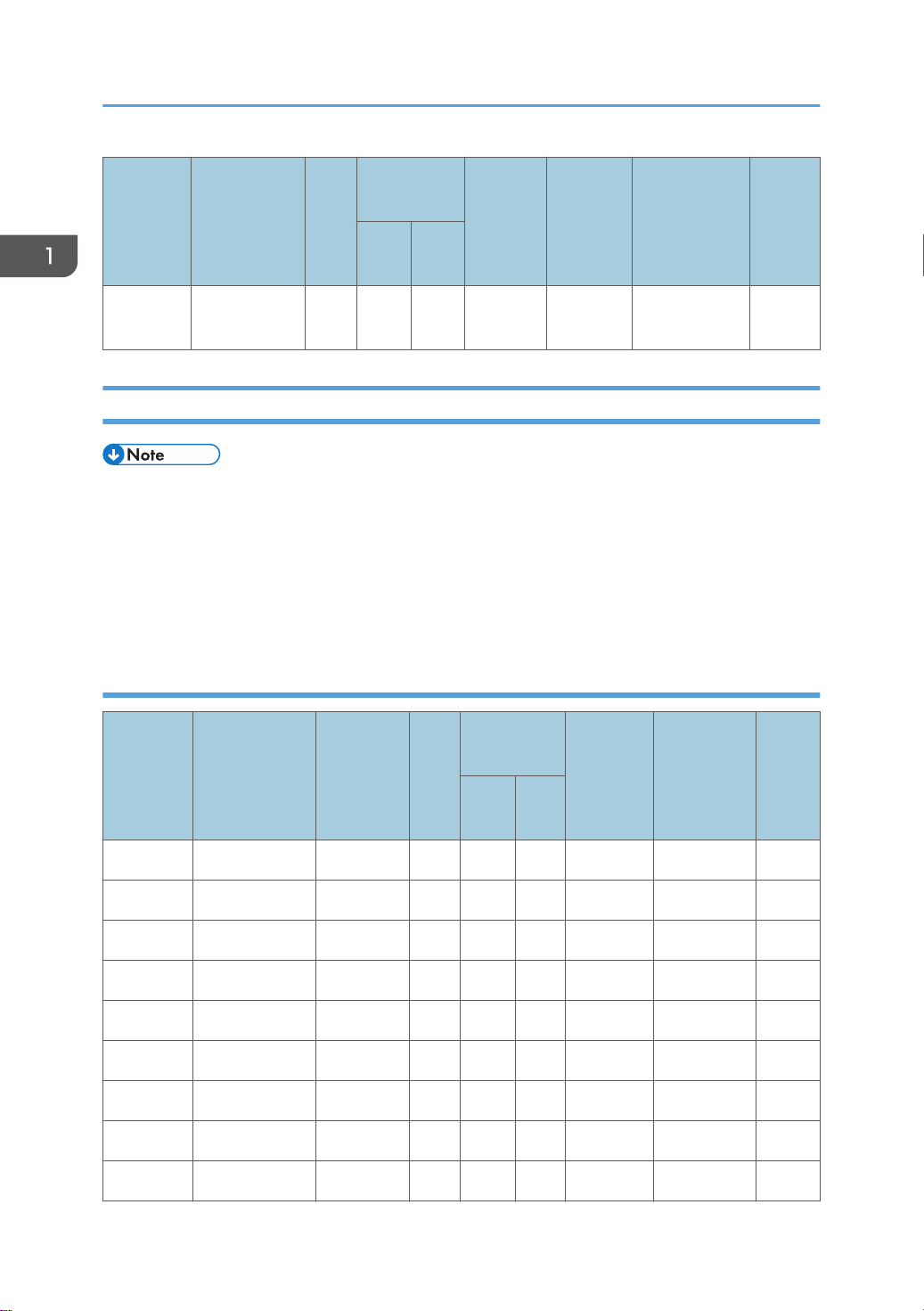

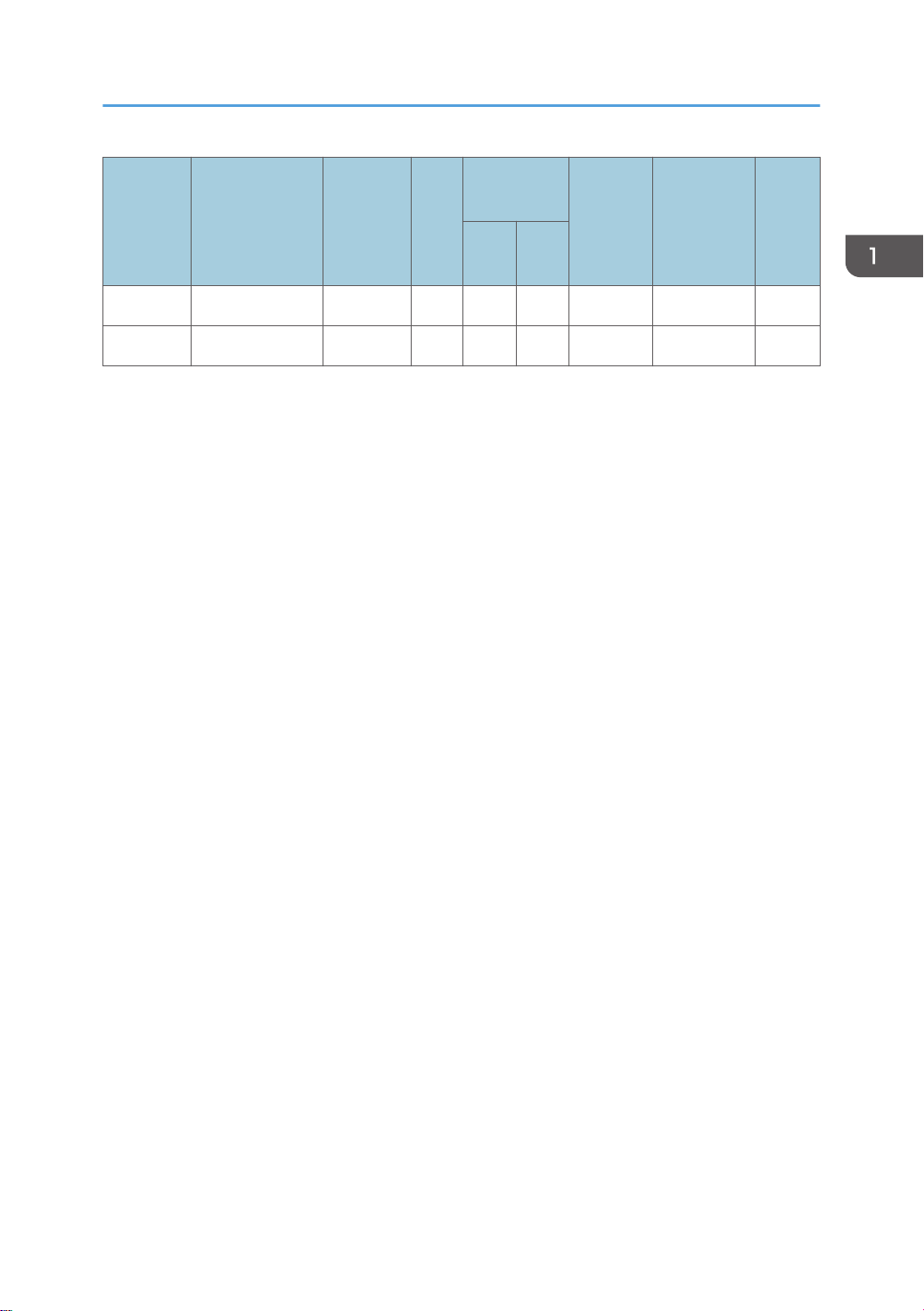

OP-P2/MF2

• All MF has Flatbed scanner, 4-line back light LCD display and Scan2USB function.

• All SFP (Single Function Printer) has 3LEDs display.

• Only 4in1 MF M***-21 (China model) has Handset.

• Only 4in1 MF has Fax function.

• All MF has Flatbed scanner.

OP-P2 SFP

Network

Machine

Code

Product Name

Printer

Language

ADF

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

Starter

AIO

Yield

24

M223-21 SP 210 GDI No No No Yes No 1.0k

M223-29 SP 210 GDI No No No Yes No 1.0k

M223-27 SP 210 GDI No No No Yes No 1.0k

M222-21 SP 210 Q GDI No No No No No 1.0k

M222-27 SP 211 GDI No No No No Yes *2 0.7k

M248-27 SP 212w PCL No No Yes Yes No 1.0k

M245-27 SP 213w PCL No No Yes No Yes *2 0.7k

M214-21 SP 212Nw PCL No Yes Yes Yes No 1.0k

M214-29 SP 212Nw PCL No Yes Yes Yes No 1.0k

Series Comparison

Machine

Code

Product Name

Printer

Language

ADF

Network

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

Starter

M214-27 SP 212Nw PCL No Yes Yes Yes No 1.0k

M214-17 SP 212Nw PCL No Yes Yes Yes No 1.0k

M213-21 SP 212Nw Q PCL No Yes Yes No No 1.0k

M213-27 SP 213Nw PCL No Yes Yes No Yes *2 0.7k

M213-17 SP 213Nw PCL No Yes Yes No Yes *2 0.7k

OP-MF2 3in1

Machine

Code

Product Name

Printer

Language

ADF

Network

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

Starter

AIO

Yield

AIO

Yield

M226-21 SP 210SU GDI No No No Yes No 1.0k

M226-29 SP 210SU GDI No No No Yes No 1.0k

M226-27 SP 210SU GDI No No No Yes No 1.0k

M225-21 SP 210SU Q GDI No No No No No 1.0k

M225-27 SP 211SU GDI No No No No Yes *2 0.7k

M232-21 SP 210S GDI Yes No No Yes No 1.0k

M239-21 SP 210S Q GDI Yes No No No No 1.0k

M239-17 SP 211S GDI Yes No No No Yes *2 0.7k

M249-27 SP 212SUw PCL No No Yes Yes No 1.0k

M246-27 SP 213SUw PCL No No Yes No Yes *2 0.7k

M216-21 SP 212SNw PCL Yes Yes Yes Yes No 1.0k

M216-29 SP 212SNw PCL Yes Yes Yes Yes No 1.0k

25

1. Product Information

Machine

Code

Product Name

Printer

Language

ADF

Network

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

M216-27 SP 212SNw PCL Yes Yes Yes Yes No 1.0k

M216-17 SP 212SNw PCL Yes Yes Yes Yes No 1.0k

M215-21 SP 212SNw Q PCL Yes Yes Yes No No 1.0k

M215-27 SP 213SNw PCL Yes Yes Yes No Yes *2 0.7k

M215-17 SP 213SNw PCL Yes Yes Yes No Yes *2 0.7k

OP-MF2 4in1

Machine

Code

Product Name

Printer

Language

ADF

Network

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

Starter

AIO

Yield

Starter

AIO

Yield

M229-21 SP 210SF GDI Yes No No Yes No 1.0k

M240-21 SP 210SF Q GDI Yes No No No No 1.0k

M235-29 SP 210SF GDI Yes No No Yes No 1.0k

M235-27 SP 210SF GDI Yes No No Yes No 1.0k

M230-27 SP 211SF GDI Yes No No No Yes *1 0.7k

M250-27 SP 212SFw PCL Yes No Yes Yes No 1.0k

M247-27 SP 213SFw PCL Yes No Yes No Yes *1 0.7k

M218-21 SP 212SFNw PCL Yes Yes Yes Yes No 1.0k

M241-21 SP 212SFNw Q PCL Yes Yes Yes No No 1.0k

M237-29 SP 212SFNw PCL Yes Yes Yes Yes No 1.0k

M237-27 SP 212SFNw PCL Yes Yes Yes Yes No 1.0k

M237-17 SP 212SFNw PCL Yes Yes Yes Yes No 1.0k

26

Series Comparison

Machine

Code

Product Name

Printer

Language

ADF

Network

Interface

Ether

net

Refillable

Wi-

Fi

Genuine

AIO Toner-

end

Detection

Starter

AIO

Yield

M217-27 SP 213SFNw PCL Yes Yes Yes No Yes *1 0.7k

M217-17 SP 213SFNw PCL Yes Yes Yes No Yes 0.7k

27

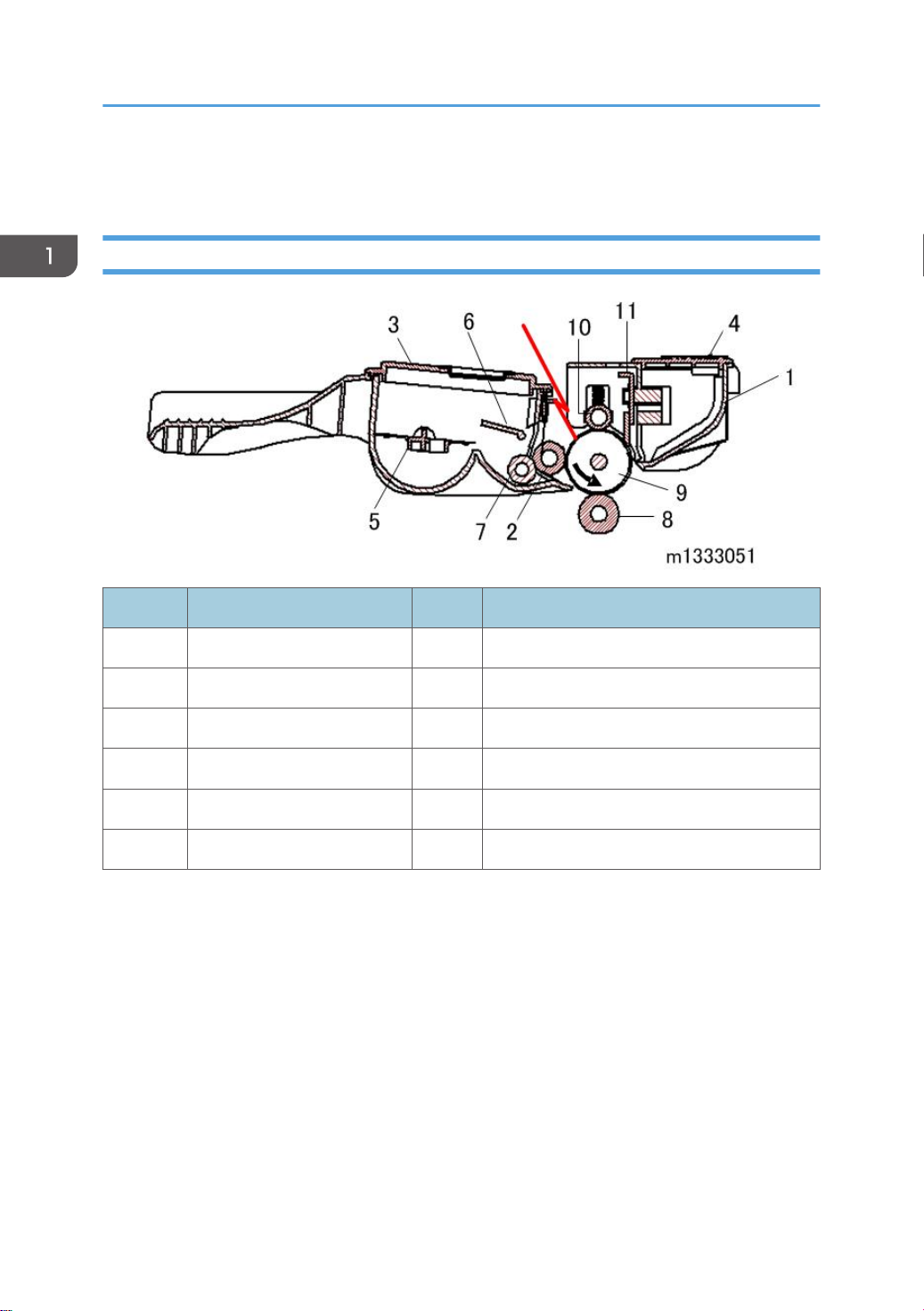

1. Product Information

Layout

AIO

No. Part No. Part

1 Waste Toner Tank 7 Toner Supply Roller

2 Development Roller 8 Image Transfer Roller

3 Toner Hopper 9 Drum

4 ID Chip 10 Charge Roller

5 Agitator 11 Cleaning Blade

6 Agitator Feeler

28

Loading...

Loading...