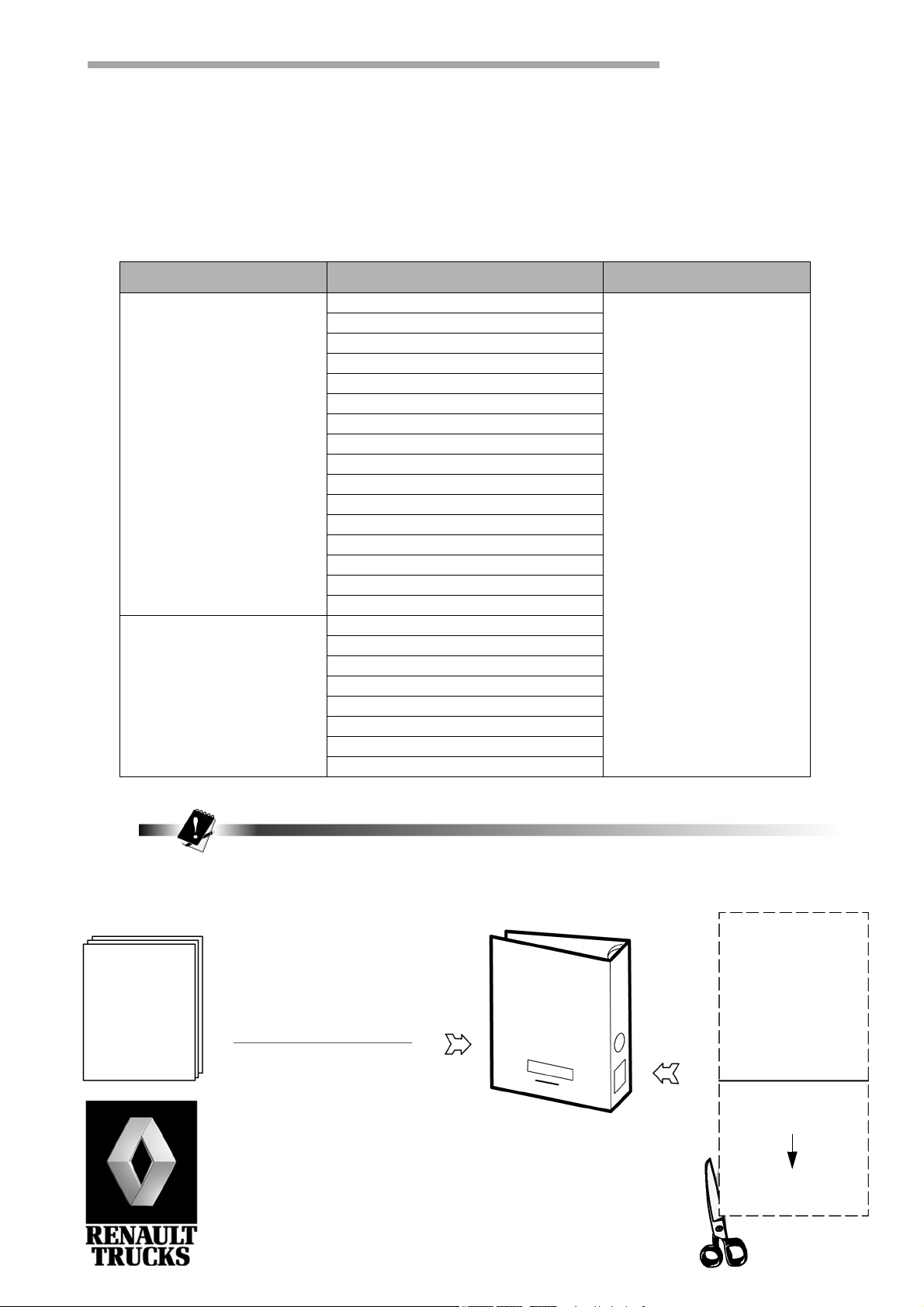

RENAULT V.I.

20 660 - GB -

ENGINE - DCI 11

RANGE FAMILY VARIANT

KERAX

PREMIUM

02/2004

33AA P 8X4

33BB P 8X4

33CC P 8X4

33DD P 8X4

33GG P 6X4

33HH P 6X4

33JJ P 6X4

33KK T 6X4

33LL T 6X4

33MM P 6X6

33NN T 6X6

33PP P 4X2

33QQ T 4X2

33RR P 4X4

33SS T 4X4

22AA P 4X2

22CC T 4X2

22EE P 6X2/4

22HA P 6X2/4

22JJ T 6X2 PUSHER

22QQ P 6X2

22RR T 6X2

33II P 6X4

12094

22C T 4X2

The above information may change in the course of time. Only the "Consult" section of the workshop manuals

repertory in standard N° 10320 serves as reference.

20 660

20.6

20.6 . . . .

20.6 . . . .

50 21 014 139

20 660

CONTENTS

Generalities. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .A-1 →→→→ 5

Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .B-1 →→→→ 3

— General features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B1 -2 → 7

— Tightening torques . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B2-1 → 7

— Dimensions and tolerances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . B3 -1 → 10

Tools / Consumables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .C-1 →→→→ 13

Stripping and mounting on stand. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .D-1 →→→→ 8

— Stand 1000 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D1-2 → 4

— Belt tensioner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D2-1 → 2

— Compressor (air conditioner) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D3-1 → 1

— Alternator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D4 -1 → 1

— Fan control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D5-1 → 1

— Damper. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D6-1 → 2

— Starter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D7-1 → 1

— Engine brackets . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . D8-1 → 1

1

Cylinder head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .E -1 →→→→ 3

— Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E1-2 → 5

— Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E2-1 → 7

— Disassembly/inspection/assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . E3 -1 → 6

Valve timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . F-1 →→→→ 14

Reciprocating gear. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .G-1 →→→→ 13

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .H-1 →→→→ 2

— Oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H1 -2 → 2

— Centrifugal oil filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . H2-1 → 2

Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I-1 →→→→ 3

— Heat exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I1 -2 → 3

— Ventilation control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I2-1 → 3

— Water pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . I3 -1 → 4

Injection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J-1 →→→→ 2

— Generalities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J1-2 → 17

— Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . J2-1 → 30

© RENAULT V.I. 02 /2004 - Imprimé en France - le 03/2004

50 21 014 139

2

Diagnostics aid (setting B43) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .K-1 →→→→ 17

Diagnostics aid (setting +J01). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . L -1 →→→→ 23

Diagnostics aid (setting +J01) variant 14102. . . . . . . . . . . . . . . . . . . . . . M-1 →→→→ 23

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .N-1 →→→→ 4

Jake brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .O-1 →→→→ 7

20 660

RENAULT V.I. 02/2004

20 660

A-1

GENERALITIES

RENAULT V.I. 02/2004

A-2

20 660

Warnings

In this document, safety instructions are symbolized as follows:

DANGER! NON-OBSERVANCE OF THE PROCEDURE DESCRIBED OR LACK OF CARE OR ATTENTION, RISK CAUSING

SERIOUS INJURY OR EVEN DEATH.

WARNING! Any different or inappropriate working method risks causing damage to the product.

NOTE! Draws attention to particular or important points of the method.

Comply without fail with the regulations in force relative to the recovery and treatment of used parts and

waste.

RENAULT V.I. 02/2004

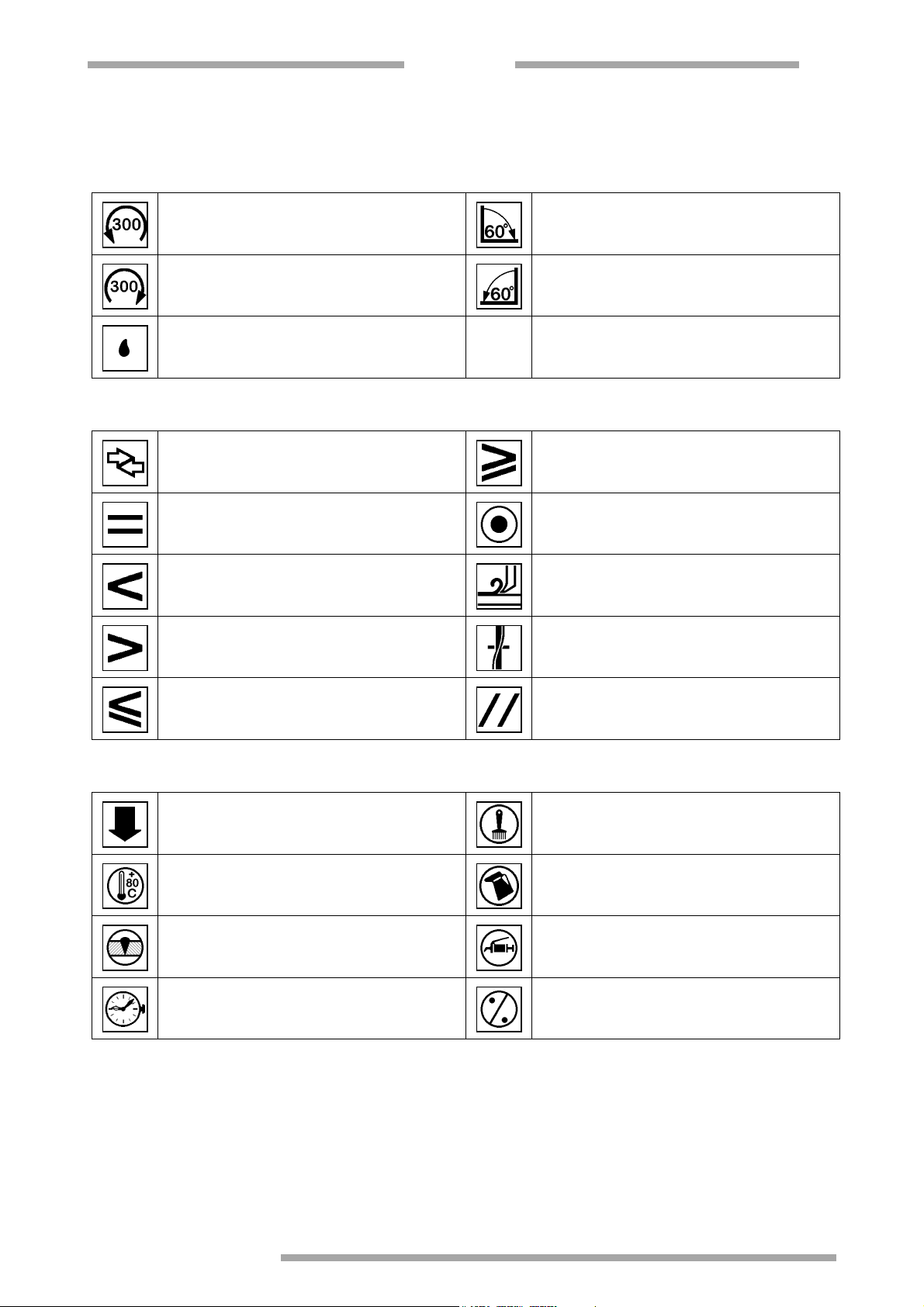

Conventional symbols

Fitting

Tighten to torque (Nm) (left-hand thread) Tighten by indicated value

Tighten to torque (Nm) (right-hand thread) Loosen by indicated value

Tightening torque with lubricated threaded

hardware

Dimensioning

Tightening ... Greater than or equal to ...

20 660

A-3

Repair

Equal to Wear limit

... Less than ... Machining limit or dimension

... Greater than ... Maximum out-of-true

... Less than or equal to ... Maximum parallelism error

Force to be exerted in the direction shown

(hammer - press)

Heat or cool: Temperature in degrees

Celsius (e.g. + 80 °C)

Weld bead Grease or oil (see "Consumables" table)

Smear or coat (see "Consumables" table)

Fill to level (see "Technical Data" and

"Consumables" table)

Repair time - Heating time Mark - Assemble according to marking

RENAULT V.I. 02/2004

A-4

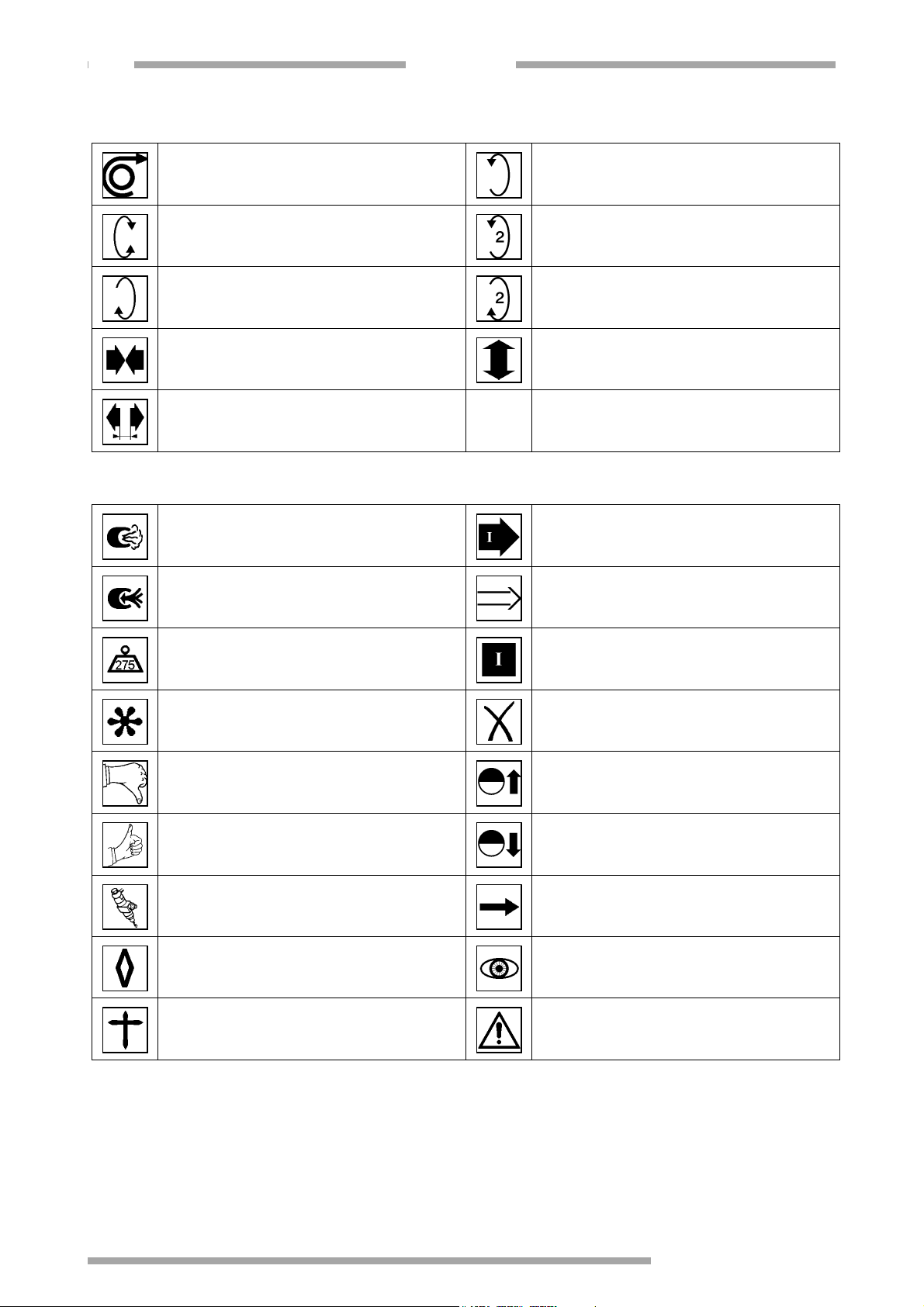

Adjustment

20 660

Rotating friction torque Turn anti-clockwise

Turn in alternate directions

Turn clockwise

Place in contact Move in the direction shown

Dimension to be assured (mm)

Various information

Exhaust - Outlet Operation with a sequence

Intake - Inlet Involves

Weight in kg (example: 275 kg)

Turn anti-clockwise

(the figure shows the number of turns)

Turn clockwise

(the figure shows the number of turns)

Return to numbered operation Connected with numbered operation

Depending on versions or options Withdraw - Delete

Wrong

Correct

Injection ... to ...

Repair dimension Inspect - Check condition of part

Part to be replaced Danger for persons, vehicle or equipment

Direction of disassembly

(the arrow shows the direction)

Direction of assembly

(the arrow shows the direction)

RENAULT V.I. 02/2004

20 660

A-5

General instructions

Practical advice

Prior to any work:

– Clean the major unit and its surrounds (See Driving Servicing Handbook, "Vehicle washing").

– Ensure the batteries are disconnected.

– Mark the pipes and wiring harnesses, if necessary.

– Protect all ports to prevent the ingress of foreign matter.

– Before disconnecting an air pipe, drop the circuit pressure.

– If liquid is splashed onto the bodywork, clean quickly with a cleaning product recommended by

RENAULT TRUCKS.

Preparation prior to assembly:

Carefully clean and check all the parts.

Do not unpack a new bearing until you are ready to install it. Do not clean off the protective grease on new

bearings.

Old seals and lock-plates must be discarded and new ones fitted.

Never force fit parts with copper or brass punches or drifts. Always use a specially adapted driver to prevent

ingress of metal particles into the casings and bearings. Always oil parts prior to force fitting.

Always apply grease on the inside of seal ring lips.

Shrink fitted parts are to be heated with a hot air blower or in an oven. etc. Flame heating is strictly forbidden.

When using a torque multiplier, calibrate the torque wrench/multiplier unit at the required torque loading.

Fastening, locking, sealing and adhesive products:

Prior to assembly, carefully clean the product application surfaces of the parts. Old product residue is to be

removed. Threaded portions are to be brushed, tapped and, if necessary, cleaned with a suitable product.

Using the product:

Always adapt the recommended product while observing the utilization conditions appearing on the pack:

– Surface finish,

– Working temperature,

– Reaction, drying, etc. time,

– Shelf life.

Observe the assembly method so as to guarantee the quality of the repair.

RENAULT V.I. 02/2004

A-6

20 660

RENAULT V.I. 02/2004

20 660

B1-1

TECHNICAL DATA

RENAULT V.I. 02/2004

B1-2

20 660

General features

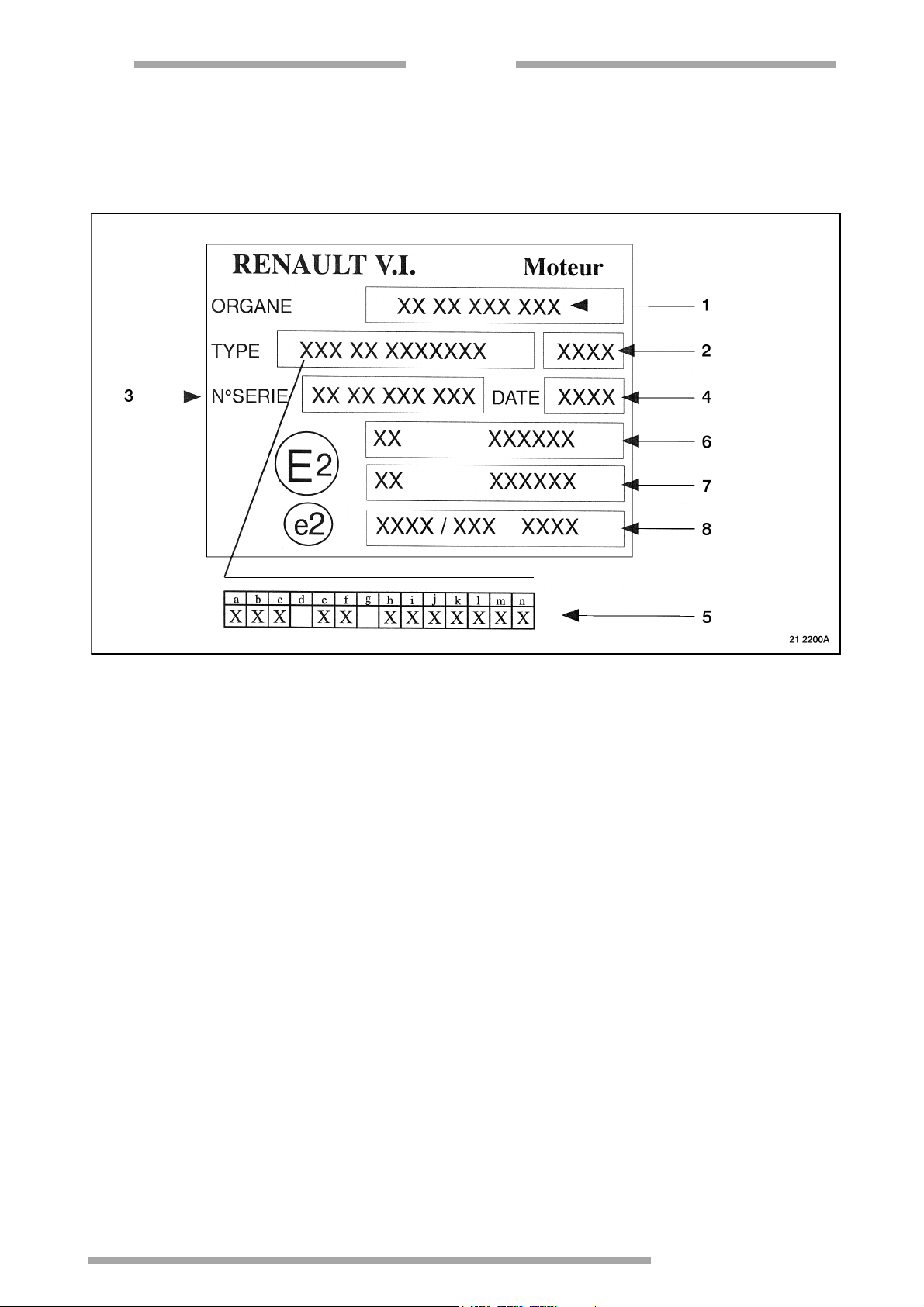

Identification plate 14102 (original engine)*

– 1: Spare Parts Reference N°

– 2: Family N°

– 3: Manufacturing N°

– 4: Manufacturing Date

– 5: Engine type (see symbolization)

– 6: Power rating

– 7: Smoke

– 8: Emissions

RENAULT V.I. 02/2004

a D Diesel

b C Common Rail

c I Injection

d

20 660

B1-3

e

f

g

h

i

j +

k J

l

m

11

B

01

Capacity:

11: 11 litres

6: 6 litres

4: 4 litres

+: Multi-mode (several power ratings available)

Blank space: Single-mode (one single power rating available)

Month of application of pollutant emissions regulation:

A: January

B: February

C: March

......

L: December

Year of application of pollutant emissions regulation:

00: 2000

01: 2001

02: 2002

......

Post-combustion equipment (particulate filter):

n

Blank space or 0: without

1: with

RENAULT V.I. 02/2004

B1-4

20 660

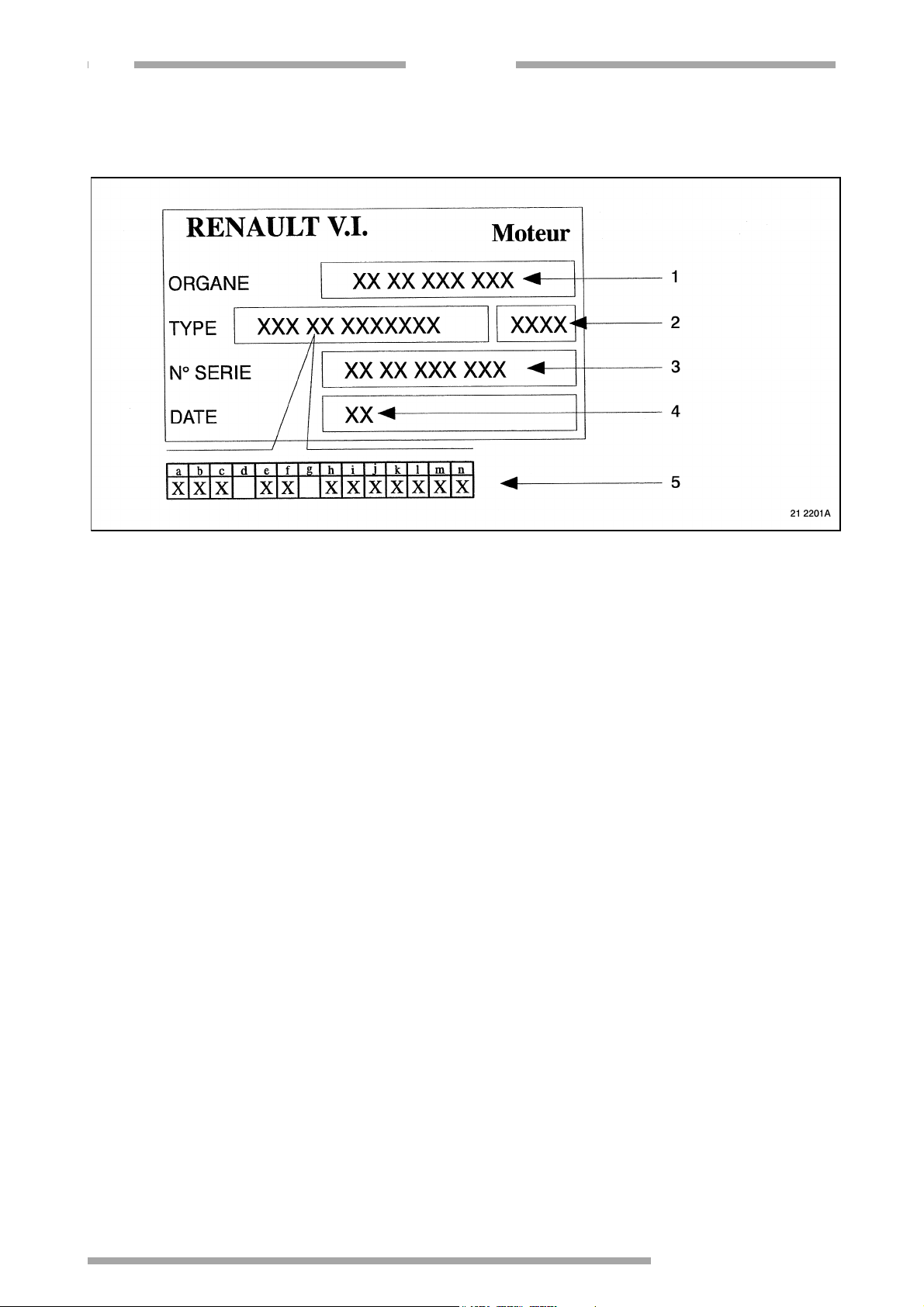

Identification plate (original engine)*

– 1: Spare Parts Reference N°

– 2: Family N°

– 3: Manufacturing N°

– 4: Manufacturing Date

– 5: Engine type (see symbolization)

Service exchange engine

To identify service exchange engines: see Spare Parts department technical comments.

RENAULT V.I. 02/2004

Symbolization

a D Diesel

b C Common Rail

c I Injection

d

20 660

B1-5

e

f

g

h

i

j +

k J

l

m

11

B

01

Capacity:

11: 11 litres

6: 6 litres

4: 4 litres

+: Multi-mode (several power ratings available)

Blank space: Single-mode (one single power rating available)

Month of application of pollutant emissions regulation:

A: January

B: February

C: March

......

L: December

Year of application of pollutant emissions regulation:

00: 2000

01: 2001

02: 2002

......

Post-combustion equipment (particulate filter):

n

Blank space or 0: without

1: with

RENAULT V.I. 02/2004

B1-6

20 660

Technical data

Power setting index B43 / B+J01 / C+J01 / E+J01 / F+J01 / G+J01 / H+J01 / I+J01

Cubic capacity 11 l

Compression ratio 17/1

Firing order 1.5.3.6.2.4

n°1 cylinder: flywheel end

Engine rotation clockwise

Fuel: diesel fuel

Supercharged: by turbocharger with intercooler

Cooling:

Circulating coolant activated by thermostat-regulated pump.

Beginning of opening: 83 °C

End of opening: 90 °C

Min. full opening dimension: 9.4 mm

Arctic cold cooling pack:

Circulating coolant activated by thermostat-regulated pump.

Beginning of opening: 88 °C

End of opening: 98 °C

Min. full opening dimension: 9.4 mm

RENAULT V.I. 02/2004

Lubrication

Oil pressure (dCi 11 B43)

20 660

B1-7

Engine speed

in rpm

1000 85 2.9

2100 4.8

Oil pressure (dCi 11 J+01)

Filter head Block rail

Engine speed in

rpm

1000 85 2.7 85 2.5

2000 4.7 4.3

Lubrication: forced by gear pump

Oil: specifications and operating temperatures (see Driving & Servicing handbook).

Oil capacity: (see Driving & Servicing handbook).

Temperature

in °C

Temperature

in °C

Pressure

in bar

Block rail

Pressure

in bar

Temperature

in °C

Pressure

in bar

RENAULT V.I. 02/2004

B1-8

20 660

RENAULT V.I. 02/2004

20 660

B2-1

Tightening torques

Definitions

There are several types of tightening:

– Tightening to torque (in Nm)

– Tightening to angle (in °)

– Tightening to torque-angle (en Nm + °)

Torques given in Nm are nominal torques (average value calculated on the basis of the minimum torque and the

maximum torque).

The tightening precision class defines the tolerance of this torque in percent as a function of the nominal torque

applied.

Tightening precision classes:

– Class I: Special threaded hardware (tolerances ± 10% of the final torque).

– Class II: Reserved for precise tightening (tolerance ± 10% of the nominal torque).

– Class III: Reserved for normal standard tightening (tolerance ± 20% of the nominal torque).

For standard threaded hardware indicated in the table below, use tightening class III.

For other torques, see the following page(s).

"FIH" type (Nylstop) locknuts must be replaced whenever removed. "DRH" type (oval) locknuts can be

re-used. If locknuts (DRH, FIH or other) are re-used, make absolutely certain that the screw-thread of the bolt

protrudes least two threads above the top edge of the nut.

RENAULT V.I. 02/2004

B2-2

20 660

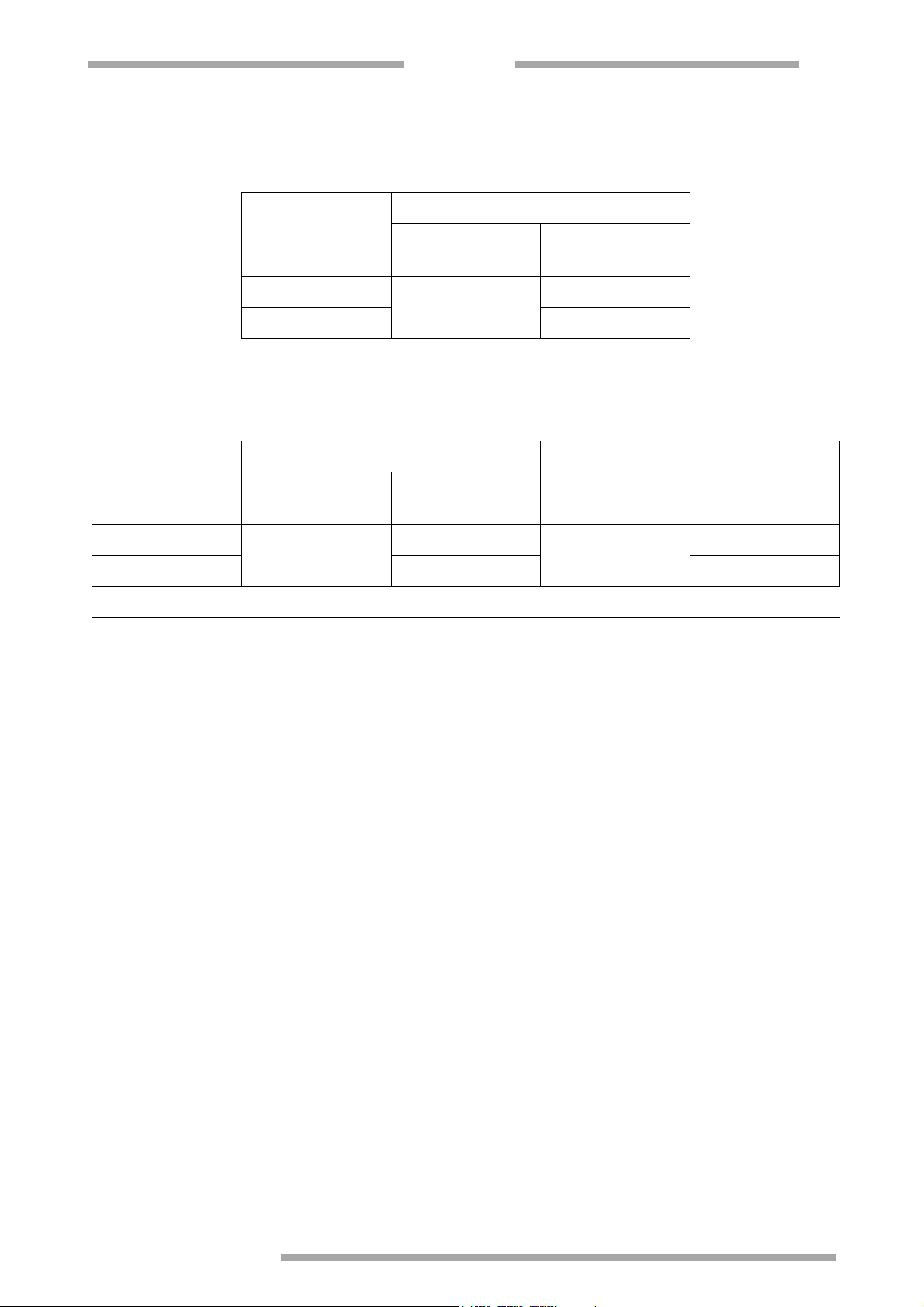

Standard nut and bolt tightening torques table

The tightening torque values given in the table are based on standard 01.50.4002 and apply to new nuts and bolts

fitted dry and re-used nuts and bolts with oil applied to the screw-threads. If any nuts and bolts are replaced, it is

absolutely essential to use nuts and bolts recommended by the RENAULT TRUCKS Spare Parts Department

(coefficient of friction in compliance with standard 01.50.4002).

Tightening torque values in Nm for conventional "metric system" threaded hardware based

on standard 01.50.4002 (H: normal and HE: with flange)

Quality class III

dia. and pitch of nuts and bolts

Quality class 8.8 Quality class 10.9

6 x 1.00

7 x 1.00

8 x 1.00

8 x 1.25

10 x 1.00

10 x 1.25

10 x 1.50

12 x 1.25

12 x 1.50

12 x 1.75

14 x 1.50

14 x 2.00

16 x 1.50

16 x 2.00

18 x 1.50

18 x 2.50

20 x 1.50

20 x 2.50

22 x 1.50

22 x 2.50

24 x 2.00

24 x 3.00

7.5 ± 1.5

15 ± 3

20 ± 4

20 ± 4

40 ± 8

40 ± 8

40 ± 8

70 ± 14

65 ± 13

60 ±12

105 ± 21

100 ± 20

160 ± 32

150 ± 30

240 ± 48

210 ± 42

330 ± 66

300 ± 60

450 ± 90

410 ± 82

560 ± 112

510 ± 102

11 ± 2.2

20 ± 4

30 ± 6

27 ± 5.4

60 ± 12

60 ± 12

50 ± 10

100 ± 20

95 ± 19

90 ± 18

155 ± 31

145 ± 29

220 ± 44

220 ± 44

340 ± 68

310 ± 62

480 ± 96

435 ± 87

650 ± 130

595 ± 119

820 ± 164

750 ± 150

Standard tightening torques table for union bolts with Cu gaskets and BS rings

Nominal tightening torque values for union bolts with CU gaskets and self-centring BS rings

Nominal dia. Tightening torque Nominal dia. Tightening torque

8

10

12

14

10 ± 2

20 ± 4

27 ± 5.4

32 ± 6.4

16

18

22

24

RENAULT V.I. 02/2004

40 ± 8

50 ± 10

80 ± 16

80 ± 16

20 660

Cylinder head

Cylinder head securing bolt (see page E-2-1)

Rocker shaft securing bolt (see page E-2-4)

Cylinder head cover bolt (see page E-2-5)

Inlet manifold securing bolt(see page E-2-6)

Exhaust manifold securing bolt (see page E-2-6)

Valve yoke adjusting nut 35 ± 7 Nm

Rocker arm adjusting nut 40 ± 8 Nm

Preheat plug(s) 41 ± 8 Nm

Heat insulating screen(s) setscrew M8 = 20 ± 4 / M10 = 60 ± 12 Nm

Reciprocating gear

B2-3

Crankshaft bearing cap securing bolt (see page G-7)

Flywheel securing bolt (see page G-13)

Connecting rod cap securing nut (see page G-10)

Block stiffener securing bolt 30 ± 6 Nm

Flywheel housing setscrew M14 = 150 ± 30 / M8 = 20 ± 4 Nm

Timing

Damper hub setscrew (see page F-11)

Oil sump securing bolt (see page F-13) 20 ± 4 Nm

Oil sump securing nut (see page F-13) 20 ± 4 Nm

Oil sump securing stud (see page F-13) 20 ± 4 Nm

Fan bracket securing stud 20 ± 4 Nm

Camshaft stop securing bolt (FRENETANCH 242) 20 ± 4 Nm

Tappet retaining pin setscrew 20 ± 4 Nm

Idler gear hub securing bolt 100 ± 20 Nm

Pulley to hub securing bolt 67 ± 7 Nm

Damper to hub securing bolt 120 ± 12 Nm

Alternator bracket securing stud 20 ± 4 Nm

Alternator bracket securing nut 60 ± 12 Nm

Alternator bracket securing bolt cl 8.8 = 20 ± 4 Nm

Alternator bracket securing bolt cl 10.9 = 30 ± 4 Nm

RENAULT V.I. 02/2004

B2-4

Air conditioning compressor bracket securing bolt 60 ± 12 Nm

Air compressor pinion securing nut 550 cm3 (variant 33118) 137.5 ± 27.5 Nm

Air compressor pinion securing nut 442 cm3 (variant 33124) 270 ± 20 Nm

Hydraulic pump pinion securing nut 60 ± 12 Nm

Hydraulic pump securing stud 30 ± 6 Nm

Oil pump securing bolt 20 ± 4 Nm

High pressure pump securing nut 195 ± 20 Nm

High pressure pump securing stud (FRENETANCH 242) 20 ± 4 Nm

20 660

High pressure pump securing nut (tighten in diametrically opposed

sequence, then retighten first nut only)

Breather impeller setscrew 11 ± 1 Nm

Air conditioner and alternator tensioner setscrew 40 ± 8 Nm

60 ± 12 Nm

Lubrication

Oil sump securing nut (see page F-13) 20 ± 4 Nm

Oil sump securing stud (see page F-13) 20 ± 4 Nm

Oil nozzle setscrew 20 ± 4 Nm

Oil pump securing bolt 20 ± 4 Nm

Oil aspiration tube setscrew 20 ± 4 Nm

Oil pump delivery pipe to block stiffener setscrew 20 ± 4 Nm

Oil sump drain plug 70 ± 14 Nm

Heat exchanger oil drain plug 40 ± 5 Nm

Centrifugal filter cover securing nut 30 ± 3 Nm

Centrifugal filter bracket/cover securing stud (FRENETANCH 242) 30 ± 3 Nm

Oil level sender 50 ± 10 Nm

Jake brake

Mechanism to rocker shaft securing bolt (see page O-3) 60 ± 6 Nm + 120 ± 6°

Mechanism to cylinder head securing bolt 65 ± 7 Nm

Solenoid valve to mechanism 7 ± 0.7 Nm

Slave piston adjusting nut 40 ± 4 Nm

RENAULT V.I. 02/2004

20 660

Turbocharger

Turbocharger to exhaust manifold securing bolt 60 ± 12 Nm

Exhaust brake to turbocharger securing nut (GRAISSE GRIPCOTT NF)

20 ± 4 Nm

Exhaust brake to turbocharger securing stud (GRAISSE GRIPCOTT NF)

10 ± 2 Nm

Lube tube union nut 24 ± 4.8 Nm

Cooling

Water pump securing bolt 20 ± 4 Nm

Fan bracket securing stud 20 ± 4 Nm

Fan bracket securing nut 60 ± 12 Nm

B2-5

Fan pulley securing bolt 150 ± 30 Nm

Fan drive belt tensioner securing bolt (FRENETANCH 242) 40 ± 8 Nm

Heat exchanger tube coolant drain plug 40 ± 5 Nm

Air compressor

Air compressor pinion securing nut 550 cm3 (variant 33118) 137.5 ± 27.5 Nm

Air compressor pinion securing nut 442 cm3 (variant 33124) 270 ± 20 Nm

Air compressor securing stud 550 cm3 (variant 33118)(FRENETANCH 242) 30 ± 6 Nm

Air compressor securing stud 442 cm3 (variant 33124)(FRENETANCH 242) 30 ± 6 Nm

Air compressor securing nut 550 cm3 (variant 33118) 40 ± 8 Nm

Air compressor securing nut 442 cm3 (variant 33124) 60 ± 8 Nm

Air compressor securing bolt 550 cm3 (variant 33118)(FRENETANCH 242) 20 ± 4 Nm

Air compressor securing bolt 442 cm3 (variant 33118)(FRENETANCH 242) 60 ± 12 Nm

Coolant pipe union nut 25 ± 5 Nm

RENAULT V.I. 02/2004

B2-6

20 660

Sensors

Coolant temperature sensor 18 ± 5 Nm

Speed sensor 7.5 ± 1.5 Nm

Oil pressure sensor (FRENETANCH 242) 18 ± 5 Nm

Oil temperature sensor 18 ± 5 Nm

Oil level sender 50 ± 10 Nm

Common rail pressure sensor 60 ± 5 Nm

Pressure and boost air sensor setscrew 6.5 ± 1.5 Nm

Fuel-Injection

High pressure pipe gallery union nut (see page J-2-6)

Cylinder head fuel delivery pipe nut (see page J-2-10)

Injector nozzle-holder flange setscrew (see page J-2-11)

High pressure pump securing nut 195 ± 20 Nm

High pressure pump securing stud (FRENETANCH 242)

(+ Loctite Frenétanch) 20 ± 4 Nm

High pressure pump securing nut (tighten in diametrically opposed

sequence, then retighten first nut only)

Booster pump securing bolts

(tighten in diametrically opposed sequence)

High pressure pump speed sensor setscrew 8 ± 1 Nm

Scavenge valve 30 + 10 Nm

Scavenge valve plug 15 + 5 Nm

Pressure and boost air sensor setscrew 6.5 ± 1.5 Nm

Flow limiter 85 ± 5 Nm

Pressure limiter to common rail 45 ± 5 Nm

Common rail pressure sensor 35 ± 5 Nm

60 ± 12 Nm

8 ± 1 Nm

ECU cooler piping setscrew 8 ± 1.5 Nm

Injector supply wire securing nut 1 ± 0.25 Nm

Accelerator pedal sensor setscrew 10 ± 2 Nm

Pressure sensor to rail union 45 ± 5 Nm

Fuel leak-off return pipe to pressure limiter union 30 ± 3 Nm

Fuel leak-off return union setscrew 12 ± 2.4 Nm

Low pressure polyamide pipes securing clamp nut 15 ± 3 Nm

High pressure pump oil filler plug 35 ± 5 Nm

RENAULT V.I. 02/2004

20 660

Polyamide pipe union nut 28 ± 2 Nm

Wiring harness to engine block attaching clamp screw 30 ± 6 Nm

Fuel low pressure and leak-off return pipes securing nut on clips 3.5 ± 0.7 Nm

B2-7

RENAULT V.I. 02/2004

B2-8

20 660

RENAULT V.I. 02/2004

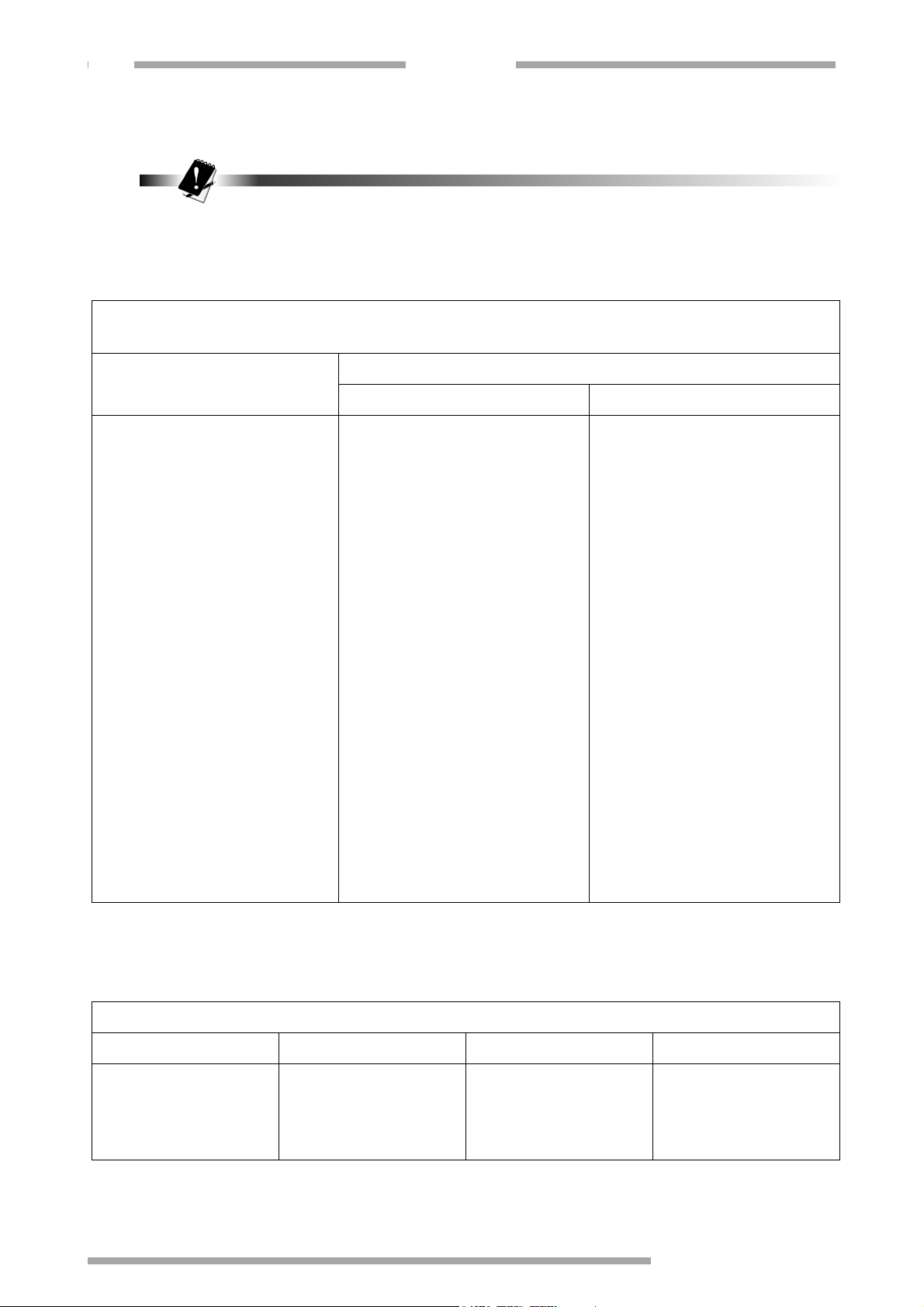

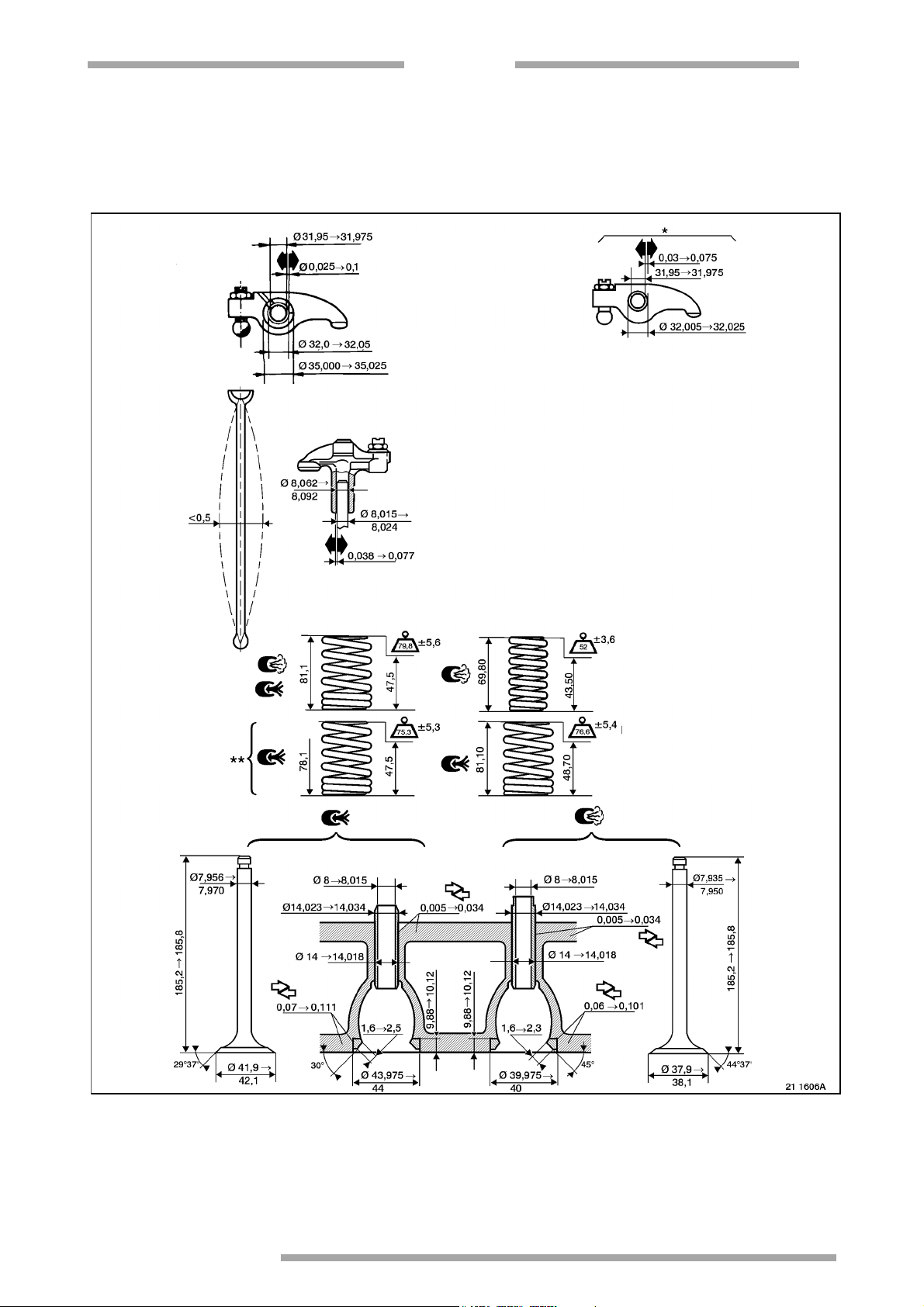

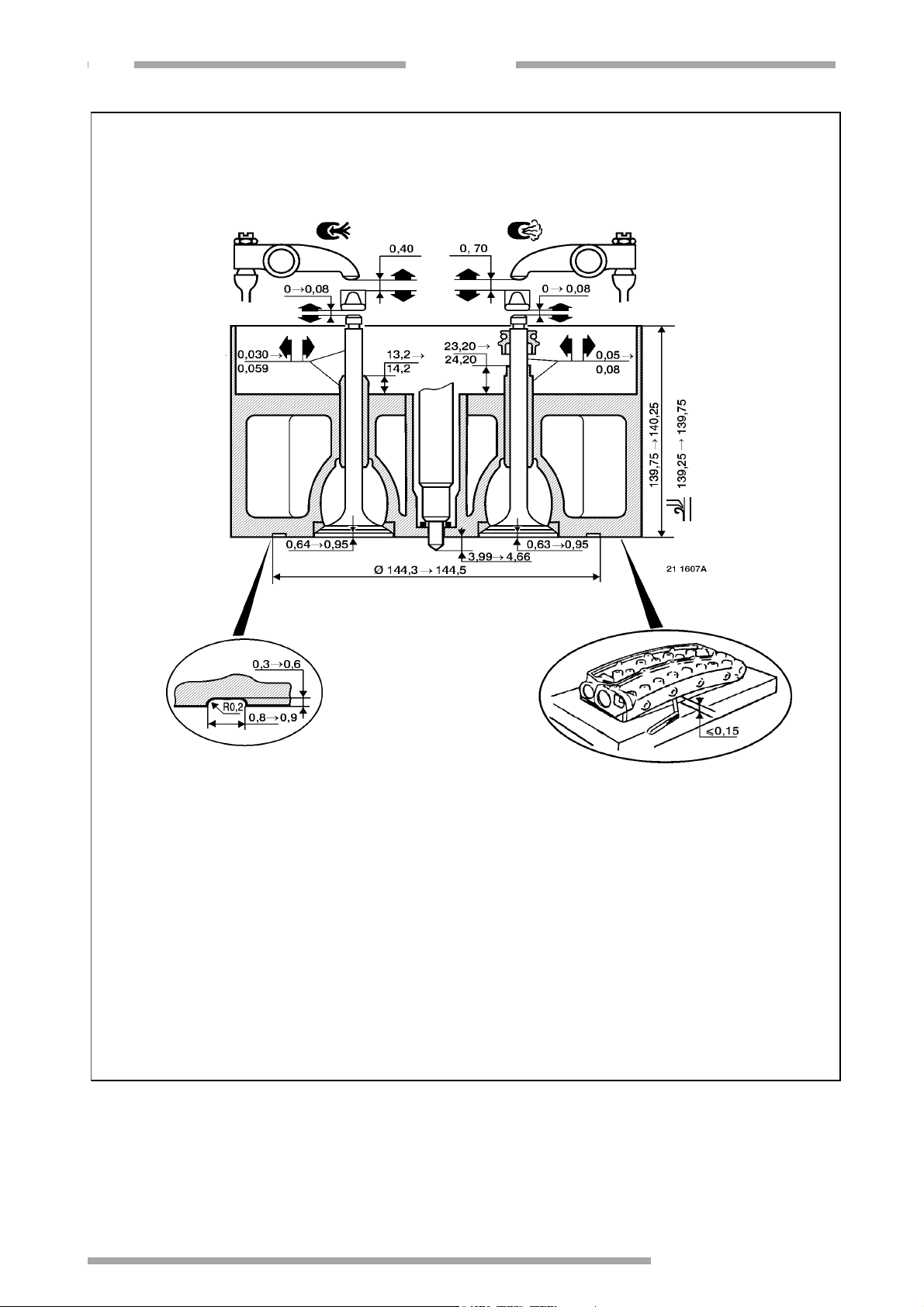

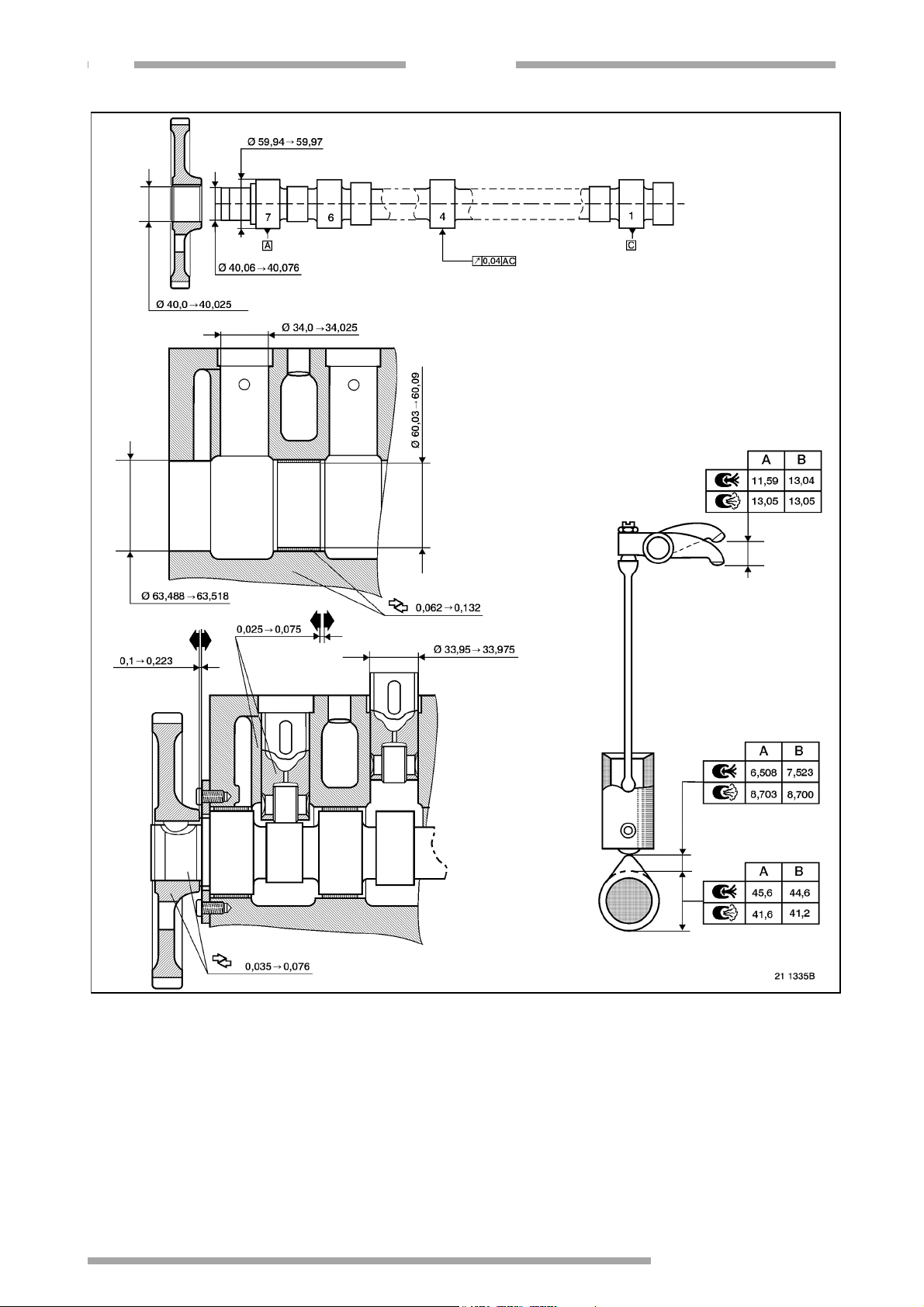

Dimensions and tolerances

Cylinder head

20 660

B3-1

* Only for: dCi 11 B43

** With Jake brake

RENAULT V.I. 02/2004

B3-2

20 660

RENAULT V.I. 02/2004

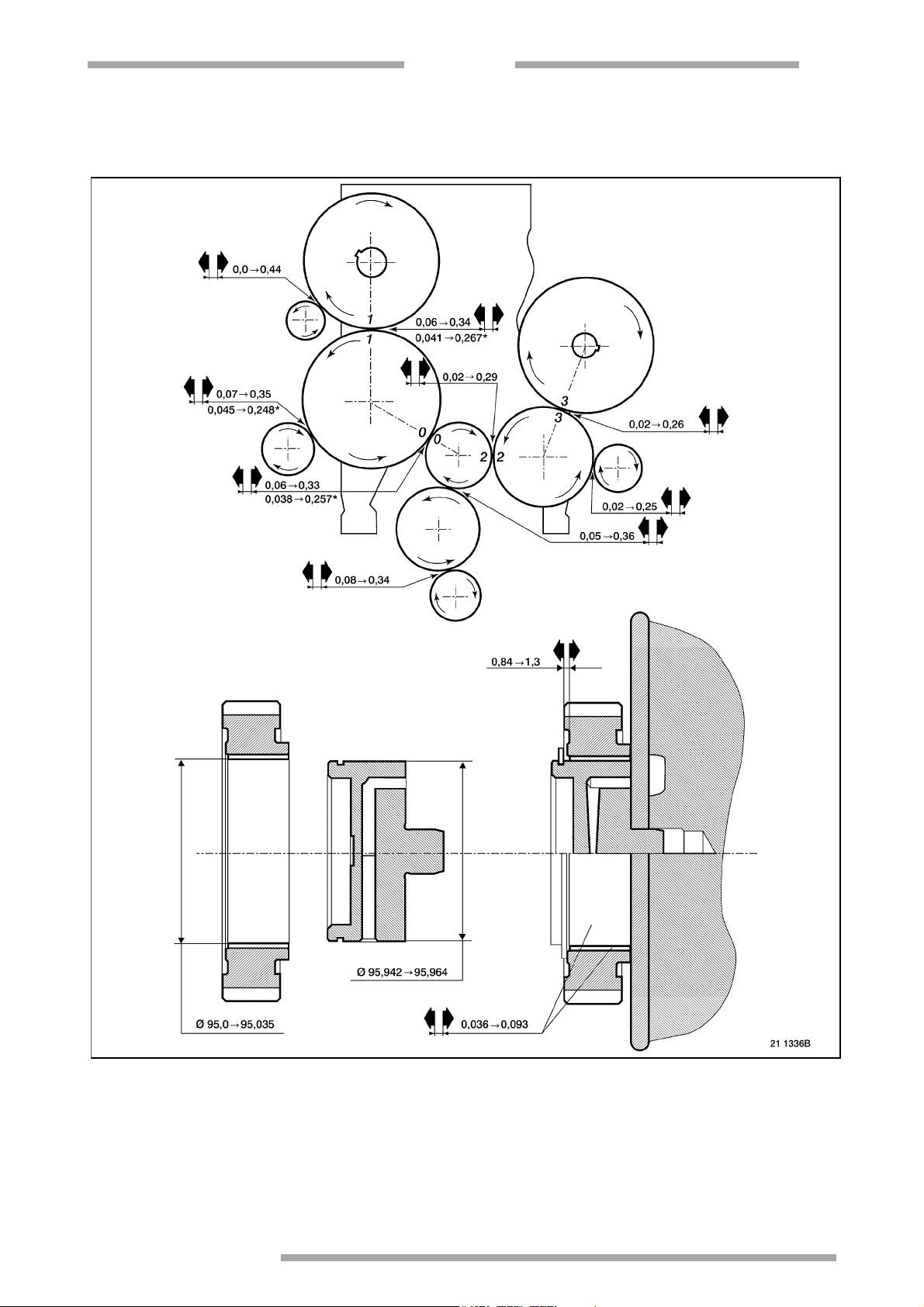

Timing

20 660

B3-3

Clearance value with reduced play camshaft idler pinion N° 5010 550 239.

RENAULT V.I. 02/2004

B3-4

20 660

Engine with power setting A: dCi 11 B43.

Engine with power setting B: dCi 11 + J01.

RENAULT V.I. 02/2004

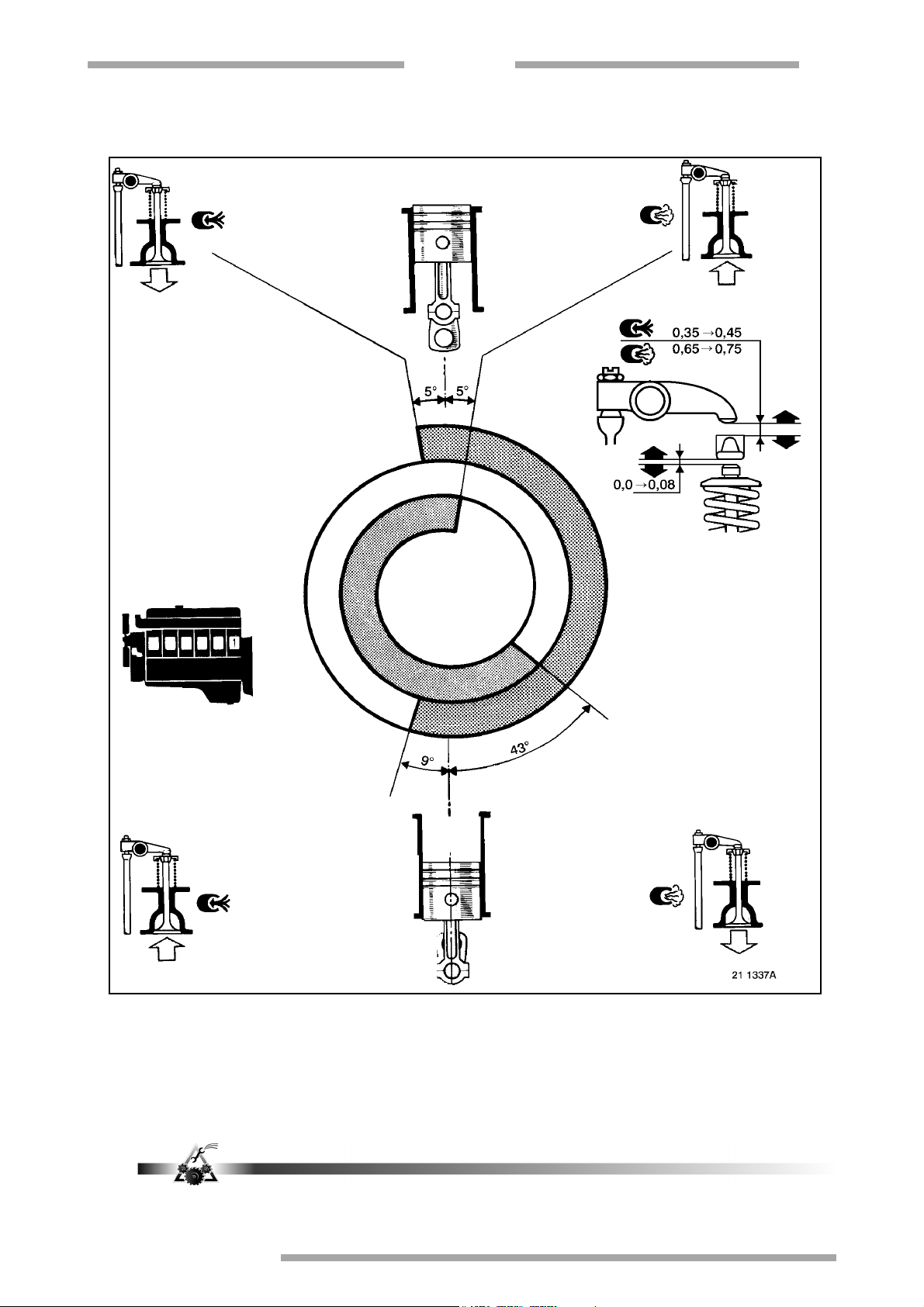

Quick timing check (dCi 11 B43):

20 660

B3-5

– Position the piston of N° 1 cylinder at end of exhaust/beginning of intake TDC (in the direction of rotation).

– Scribe a mark on the crankshaft pulley.

– Adjust the valve clearances to zero (without compressing the control springs)

– Crank the engine through one revolution while lining up the marks on the crankshaft pulley so as to arrive

at "compression TDC".

– Check the valve clearances, which should be:

•Inlet: 0.80 →→→→ 1.10 mm.

• Exhaust: 1.28 →→→→ 1.58 mm.

Repeat this check twice so as to provide more accuracy when adjusting the rocker arm clearance

to zero.

RENAULT V.I. 02/2004

Loading...

Loading...