REMKO PGM Series, PGM 30 E, PGM E Series, PGM 30, PGM 60 E Operating And Installation Instructions

...

Operating and

installation instruction

REMKO PGM (E) series

Propane gas heating systems

PGM 30 (E), PGM 60 (E)

This product is not suitable as a main heater.

Edition GB - Q04 Read the instructions prior to performing any task!

Contents

Safety notes 4

Unit description 5

Installation instructions 6

Gas connection 7-9

Commissioning 9-10

Shutdown 11

Care and maintenance 11-12

Troubleshooting 13

Intended use 14

Customer service and guarantee

Environmental protection and recycling 14

Exploded view of PGM 30

Spare parts list for PGM 30 17

Exploded view of PGM 60 18

Replacement parts list for PGM 60 19

Maintenance protocol 20

Technical data

Electrical wiring diagram 22

21

14

16

Carefully read this operating manual prior to commissioning/using

the unit!

This operating manual is a translation of the German original.

These instructions are an integral part of the unit and must always be

kept in the vicinity of the installation location or on the unit itself.

Subject to modifications; no liability accepted for errors or misprints!

3

REMKO PGM (E) series

Safety notes

Always observe the respective local building code and fire prevention guidelines as well as the guidelines of

the accident prevention and insurance associations when using the units.

The units have been subjected

to extensive material, functional

and quality inspections prior to

delivery. However, dangers can

arise from the units if they are

used improperly or not as intended

by untrained personnel!

Please observe the following

information:

■

The units may only be operated

by persons that have been

instructed in their operation

■

The power plug must be pulled

out of the mains socket before

maintenance and repair work

■

The units must be installed such

that they are stable on a noncombustible surface

■

It is necessary to ensure

that no flammable objects

or materials can be drawn in

■

This unit can be used by

children above the age of

8, as well as by people with

impaired physical, sensory or

mental capabilities or a lack

ofexperience and knowledge

if they are supervised or have

received instruction in the safe

operation of the unit, and if

they understand the associated

potential hazards. Children must

never play with the unit.

■

Cleaning and user maintenance

must not be carried out by

unsupervised children.

■

The units must be installed and

operated in such a way that

personnel are not endangered

by exhaust gases and radiant

heat and no fires may occur

■

Portable liquid gas tanks must

be installed such that they are

stable and upright

■

Liquid gas tanks must never

be used whilst lying horizontal

during unit operation

■

All unit electrical cables must be

protected against damage, e.g.

by animals

■

The units must then only

be operated in areas where

the units can be supplied with

an adequate amount of air

for combustion

■

The units must only be installed

in well-ventilated spaces and

away from flammable materials.

Personnel must not remain

in the installation area

Appropriate prohibition

signs should be put up

at the entrances!

■

A safety zone of 1.5 m must

be maintained around the units,

incl. to non-combustible items

■

A minimum distance of 3 m

must be maintained from the

unit outlet

■

The unit outlet must not be

restricted or fitted with hoses

or pipes

■

Never insert foreign objects

in the unit

■

The air intake grille must always

be kept free of dirt and loose

objects

■

The units must not be exposed

to direct jets of water

e.g. pressure washers, etc.

CAUTION

The units must not be used

for heating living spaces

in residential buildings.

!

CAUTION

If there is a gas leak,

immediately close the shut-off

valve to the gas supply system,

switch off the gas heater,

unplug the power plug, open

windows/doors for ventilation

and seek the cause of the gas

leak in order to neutralise this.

Do not use the unit again

before the gas leak has been

eliminated!

4

Unit description

The units are mobile fan-assisted

air heaters (WLE) directly fired

with liquid gas, without a heat

exchanger.

The units operate without an

exhaust gas connection and

are designed exclusively for

commercial use.

The units are equipped with

integrated power regulation

for the stepless control of

the heating capacity, quiet and

low-maintenance axial fans,

robust gas burners with thermal

monitoring, electric solenoid valve,

piezo ignition and mains cable with

earthed safety plug.

The units are intended exclusively

for manual operation and cannot

be thermostatically controlled.

The units conform to

the fundamental health and safety

requirements of the appropriate

EU stipulations and are simple

to operate.

The units are EC type-tested,

DVGW-registered and approved

for EU countries.

The units may be used among

other things for the following:

■

Drying newly completed

buildings

■

Spot heating of outdoor

workplaces

■

Spot heating workplaces

in open, non-flammable

manufacturing facilities and

halls

■

Temporarily heating enclosed

spaces with a sufficient fresh air

supply

■

De-icing machines, vehicles and

non-combustible warehoused

goods

■

Maintaining the temperature

of frost-sensitive parts

Operating sequence

After switching on the units,

the supply air fan is put into

operation and the electric solenoid

valve is opened.

However, the gas supply to

the burner remains closed at this

point.

Only after actuating the pressure

pin of the safety pilot is the gas

supply to the gas burner enabled.

The liquid gas is now transported

through the gas nozzle under

pressure into the mixing tube.

Here, the liquid gas is enriched

with a quantity of oxygen

determined based on the

respective burner output.

The gas/air mixture produced in

this way is ignited at the burner

head by an electric ignition spark.

The ignition spark is generated

through the manual actuation of

the piezo igniter.

The heating of the thermocouple

activates the thermal monitoring

of the flame in operation.

The pressure pin of the safety pilot

must now be released.

In the event of any irregularities

or if the flame is extinguished,

the gas supply is interrupted.

A safety temperature limiter (STB)

interrupts with an overheating

of the gas supply and interlocks

all unit functions.

Regulation of the min/max heating

capacity can be implemented on a

stepless basis during unit operation

on the integrated “power

regulation”.

NOTE

For optimum operation

the units should not be

operated above an ambient

temperature of 25 °C.

Monitoring the units

It is possible to safely monitor all

functions with the safety devices

of the units.

In the event of irregularities or if

the flame is extinguished, the units

are switched off and interlocked.

Safety temperature limiter (STB)

The units are equipped with a

safety temperature limiter (STB),

which interrupts the gas supply

in case of overheating and

electrically interlocks the unit.

A manual reset of the STB can only

be implemented after the units

have cooled down.

CAUTION

If the safety temperature

limiter has been triggered,

the cause of the malfunction

must be identified and rectified

before a reset is performed.

The STB is reset by actuating

the reset key 2.

1. Unscrew the protective cap 1.

2

1

2. Push in the pressure pin 2.

3. Screw the protective cap 1 back

on again.

CAUTION

Safety devices must not

be bypassed or disabled.

5

REMKO PGM (E) series

Installation instructions

■

The safety regulations

of the accident prevention

and insurance associations,

the respective regional building

regulations and the combustion

appliances regulations apply

to operation of the units.

For example, for Germany:

Combustion plant order (FeuVo)

■

for the individual federal states

Accident prevention regulations

■

DGUV Regulation 79 “Use of

liquid gas”

Workplace directives ASR 5

■

Workplace regulations §§ 5

■

and 14

Outdoor installation

■

The operation of the units

must not present a hazard

or unreasonable loading

■

The unit operator must

ensure that it is not possible

for unauthorised persons

to manipulate either the unit

or the power supply

■

To prevent damage due

to inclement weather, units

installed outdoors must be

adequately protected

Installation in enclosed, wellventilated rooms

■

The units are designed without

an exhaust gas connection

according to type, and can

only be used in enclosed rooms

on a conditional basis

■

Reliable extraction of

the combustion gases must be

guaranteed in all cases in order

to exclude impermissible

contamination of the room

air with hazardous substances

The fresh air supply required

for trouble-free combustion

must be ensured. It is practical

to have the fresh air supply

provided by windows and

doors or through appropriately

dimensioned openings

in the outside wall

■

The units must not operate

continuously whilst unattended

The units may only be operated

in rooms if:

■

a sufficient quantity of air

is supplied to the units for

the combustion

■

these are well ventilated and

aerated

the proportion of substances

■

harmful to health in

the breathing air is at a harmless

level

There is good natural ventilation

and aeration if:

1.

the room volume in m3 is at

least 30 times the nominal

heating capacity kW of all of

the units operating in the space,

and if the natural change of air

is guaranteed by windows and

doors or

constantly open ventilation

2.

openings are present for

incoming and exhaust air in

the vicinity of the ceiling and

floor, whose size in m2 is at least

0.003 times the nominal heating

capacity in kW of all of the units

operating in the space.

!

CAUTION

For use in public buildings,

national regulations must

be observed.

CAUTION

The units must only be

installed in well ventilated

spaces and not in living areas

or similar recreational areas.

6

Gas connection

The gas connection / unit

operation must take place

exclusively on the basis of

the accident prevention regulation

DGUV 79 “

as well as the respective local

construction and fire prevention

regulations.

The fuel supply must be installed

in accordance with DIN 4755 for

oil-fired warm air heaters, DVGW

Code of Practice G 600 for gasfired warm air heaters and TRF for

liquid gas.

The units are operated with liquid

gas in accordance with DIN 51622.

They require a constant

connection pressure of 1.5 bar.

It is prohibited to exceed or

undershoot the connection

pressure.

CAUTION

A constant unit connection

pressure of 1.5 bar (1500

mbar) must be guaranteed,

also in continuous operation.

■

When using longer hose lines,

consider the respective pressure

loss

■

Only use components that have

been tested and are suitable for

the respective purpose, such

as gas hose, pressure controller

and hose breakage protection

or leak gas protection

Use of liquid gas”

unit

,

CAUTION

Before all work on the gas

supply and when replacing

gas cylinders, all shut-off

valves must be closed and no

ignition sources are permitted

in the immediate vicinity.

■

The use of longer hose lines

is permissible if:

- special operational reasons exist

- appropriate additional safety

measures are observed and

the hose lengths are kept

as short as possible

■

Hose lines must be

fundamentally protected

against chemical, thermal and

mechanical damage

■

In particular, torsional stress

must be avoided

■

The units may only be operated

out of the gas phase

■

The units must be serviced

by qualified persons only

■

Only original spare parts may

be used for repairs

■

Unit parts that are prone to

wear and ageing (e.g. gas

hoses) must be replaced at

regular intervals

■

Gas connection nipple on

the unit - G1/4 LH - KN

■

All common gas cylinder sizes

are permitted for the gas

supply. However, a gas

cylinder with at least 11 kg

filling weight is recommended.

For longer operation and

nominal heat outputs above

50 kW, it is recommended that

the gas be drawn from several

gas cylinders in parallel. (Multicylinder accessories set)

NOTE

This does not apply

if the correct condition

is confirmed by an expert.

CAUTION

The units must not be used

below ground level

in basements, without suitable

gas monitoring equipment.

NOTE

It is prohibited to exceed

or undershoot the required

connection pressure.

, e.g.

■

If possible, the length of the gas

hose should not exceed 2 m

■

Only pressure controllers with

a fixed outlet pressure setting

are permitted. The units may

only be operated out of the gas

phase

■

When selecting the hose, make

sure that the pressure class is

sufficient

7

REMKO PGM (E) series

Connecting the gas supply

1. Connect pressure

controller

to the gas

cylinder or gas

supply system.

Observe left-handed thread!

2. Open cylinder

valve(s) or shutoff valve of the

supply line.

With simultaneous discharge

from multiple gas cylinders, all

valves must be opened.

3. Push the unlock

button on

the hose breakage

protection after

opening

the valve(s).

This process is also necessary

after every cylinder change.

4. Check all gas connections for

leak-tightness using suitable

media.

for example with:

Soap solution or

leak detection

spray.

Assembly note

During the assembly or

disassembly of the gas hose, it is

necessary to counter-hold

by the gas connection nipple

with an open-end wrench size 17,

whilst observing the left-handed

thread.

This process also applies

to the pressure controller, hose

breakage protection and all further

gas components.

Tighten gas hose:

Turn the union nut anticlockwise

counter-hold

Loosen gas hose:

Turn the union nut clockwise

counter-hold

the unit

Icing up of gas cylinders

With insufficiently dimensioned

gas supply systems, there is a risk

of the pressurised gas cylinder

icing up.

Due to the reduction of the gas

pressure, it is no longer possible

to guarantee the correct gas

supply to the unit.

Crystalline frost formation on

the gas cylinder(s) must not

be defrosted with naked flames,

glowing objects, radiators, etc.

In order to avoid the gas

cylinder(s) icing up, it is necessary

to configure the gas supply

in accordance with the unit

connection value, the time

in operation and the ambient

temperature of the supply tank.

Attachment multi-cylinder set (accessory)

NOTE

Because these are ball

nipple screw connections

in accordance with DIN 4815,

part 2, only appropriate,

fitting hoses may be used.

NOTE

Only hoses for liquid gas in

accordance with DIN EN 16436-1,

pressure class 30 may be used

for construction site operations.

8

In order to ensure a regular gas take-off insofar as possible,

all cylinder valves must be open.

The cylinder battery can be expanded with ease,

through the use of additional sets.

Legend:

1 = Gas hose to the unit

2 = Hose breakage protection

3 = Gas pressure controller

4 = HP hose 0.4 m

5 = T-connection

6 = Cylinder valve

6

5

6

4

6

4

1

2

3

5

s

s

s

s

s

s

Commissioning

Tank gas systems

When connecting the units to tank

gas systems, ensure sufficient pipe

dimensions depending on the pipe

length.

A sufficient gas supply to the

consumer system can be ensured

through the use of an evaporator.

In order to guarantee the faultless

unit function, it is advisable to

install a permanently set pressure

controller with 1.5 bar outlet

pressure and corresponding gas

throughput (see unit name plate),

as well as a shut-off device tailored

and approved for the respective

pre-pressure.

In order to avoid malfunctions

of the unit’s control and safety

equipment due to harmful

substances such as rust and dust

from the gas supply line or tank(s),

it has proven to be essential to

install gas filters before the control

and safety equipment of the units

(see DIN EN 676 and TRF 88

section 5).

The units should be checked for

visible defects on the operating

Connecting the units

to the electrical power supply

and safety devices as well as

proper installation and correct

electrical and gas connections

before commissioning.

1. Move the operating

switch to the "0"

(off) position.

A person, who has been

adequately trained in the handling

of the units and the use of liquid

gas per DGUV 79, must be tasked

with operation and monitoring

of the units.

2. Connect the unit's power

plug to a properly

installed and fused

mains socket.

Connect 230 V/50

Hz.

CAUTION

In the event of defects that

endanger the operational

safety of the units, operation

of the units must be

discontinued immediately and

NOTE

The electrical connection for

the units must be made at a

separate feed point with a residual

current device in accordance with

VDE 0100, Section 55.

the supervisor informed!

Before the unit start, ensure that the gas supply cylinders are correctly

secured and are not positioned directly in the heat radiated by the units.

The pressurised gas tanks must be positioned to the side / rear

of the unit.

NOTE

Installation work on the tank

gas systems and the supply

lines may only be performed

by qualified specialist

personnel.

CAUTION

Before all work on the gas

supply and when replacing

gas cylinders, all shut-off

valves must be closed and no

ignition sources are permitted

in the immediate vicinity.

CAUTION

The tanks must never

be heated or de-iced through

the unit hot air flow.

There is a risk of explosion!

CAUTION

Pressurised gas tanks must

not lie horizontal when used

during unit operation.

Gas outlet in the liquid phase.

9

REMKO PGM (E) series

Heating mode

1. Move the operating

switch to the "I" position.

The supply air fan starts

up.

CAUTION

Before executing the

ignition process, check to

ensure the correct function

of the supply air fan.

2. Push in the pressure

pin 2 of

the safety pilot

and hold down.

2

3. With pressure

pin 2 depressed,

after approx. 2 to 3

sec.actuate

the piezo igniter 3.

If necessary, actuate

the piezo igniter multiple times.

4. After a flame appears, depress

the pressure pin 2 for a further

approx. 10-15 sec. until

the thermal flame monitoring

is activated.

5. If the flame goes out when

the pressure pin 2 is released,

repeat the ignition process.

Observe a waiting time of

approx. 1 minute.

3

Setting and controlling

the heating capacity

The desired or required heating

capacity can be steplessly set

on the “power regulation”.

Turning to the left:

higher heating capacity

Turning to the right:

lower heating capacity

The heating capacity can also be

steplessly changed during unit

operation.

Safety distances

■

For safe operation, a 1 m safety

distance must be maintained

around the unit

■

A minimum distance of 3 m

must be maintained from

the unit outlet

CAUTION

It is essential to observe

the necessary safe distances

from flammable and fire

hazardous materials.

Ventilate

In this operating mode, the supply

air fan runs permanently.

The units can be used for air

recirculation or ventilation

purposes.

1. Close the shut off valve(s)

of the gas supply system and

allow the gas flame to burn out.

2. Move the operating

switch to the "II"

(Ventilate) position.

No heating operation is possible

in this operating mode.

NOTE

Overpressure and underpressure

in the installation area

should be avoided as this will

inevitably lead to combustionrelated faults.

With a repeat ignition process,

hold the pressure pin for a little

longer if necessary.

CAUTION

The units must not be used

below ground level

in basements, without suitable

gas monitoring equipment.

10

, e.g.

■

Flooring and ceilings must be

fire retardant

CAUTION

In case of a gas leak, halt unit

operation immediately.

All gas shut-off valves must

be closed and the units

disconnected from the power

supply.

CAUTION

It must be ensured that supply

air can be freely sucked in and

that heated air can be blown

out without obstruction.

The unit intake and outlet

must not be restricted or fitted

with hoses or pipes.

Shutdown

Care and maintenance

1. Close the shut off valve(s)

of the gas supply system and

allow the gas flame to burn out.

2. Move the operating

switch to the "0"

(off) position.

3. If the units are

inactive for longer

periods, disconnect

them from the mains

power supply.

NOTE

Regular care and maintenance,

at the latest after every

heating period, is the basic

requirement for a long service

life and malfunction-free

operation of the units.

In accordance with the operating

conditions, the units must be

checked as and when required,

but at least every two years, by

a specialist to ensure that they

are in a condition that is safe

to use.

The results of this test must be

recorded in a test certificate.

The test certificate must be stored

until the next test and presented

for inspection by authorised

persons on request.

■

Check the inlet and outlet grille

for contamination on a regular

basis

■

Check hoses and seals for

damage on a regular basis

■

Replace damaged hoses, seals,

etc. immediately

■

Clean the gas burner, gas

nozzle and the combustion air

openings regularly

■

Check ignition and ionisation

electrodes regularly and adjust

and clean if necessary

CAUTION

Before undertaking any work

on the unit, the gas supply

must be shut off and the power

plug must be removed from

the mains socket.

■

Keep the units free of dust and

other deposits

■

Only clean the units with a dry

or moistened cloth

■

Never use direct jets of water.

such as high-pressure cleaners

etc.

■

Never use abrasive or solvent-

based cleaners

■

Use only suitable cleaners, even

for heavy contamination

NOTE

Replace defective or damaged

parts immediately and

exclusively with original spare

parts.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualified

technicians.

CAUTION

An electrical safety check must

be carried out in accordance

with VDE 0701 after any work

on the units.

11

REMKO PGM (E) series

Disassembling and cleaning

the gas burner

1. Switch off the gas supply

to the unit and remove the

power plug from the mains

socket.

2. Remove the protective outlet

grille, exterior cladding and

inspection cover.

3. Undo the clamping screw 6

of the nozzle holder.

4. Remove the ignition cable from

the ignition electrode 4.

5. Detach the capillary tube 3

of the thermocouple from the

safety pilot.

6. Loosen the clamping screw 5

on the electrode bracket and

carefully draw out the ignition

electrode.

7. Carefully pull the thermocouple

with capillary tube down and

out.

Be aware of the extremely

sensitive capillary tube here!

10. Carefully clean the gas burner

with a suitable brush and

possibly compressed air.

11. Clean the gas nozzle

if necessary.

Do not use any sharp-edged

objects!

12. Carefully remove deposits

or soiling in the unit base.

13. After all cleaning work on

the gas burner, carefully refit

all parts in reverse order.

14. After using the gas nozzle,

tighten the clamping screw 6

again.

15. Adjust the ignition

electrode and thermocouple

in accordance with the sketch

and tighten the clamping

screw 5 of the electrode

bracket.

16. Carefully refit all parts

of the unit in reverse order.

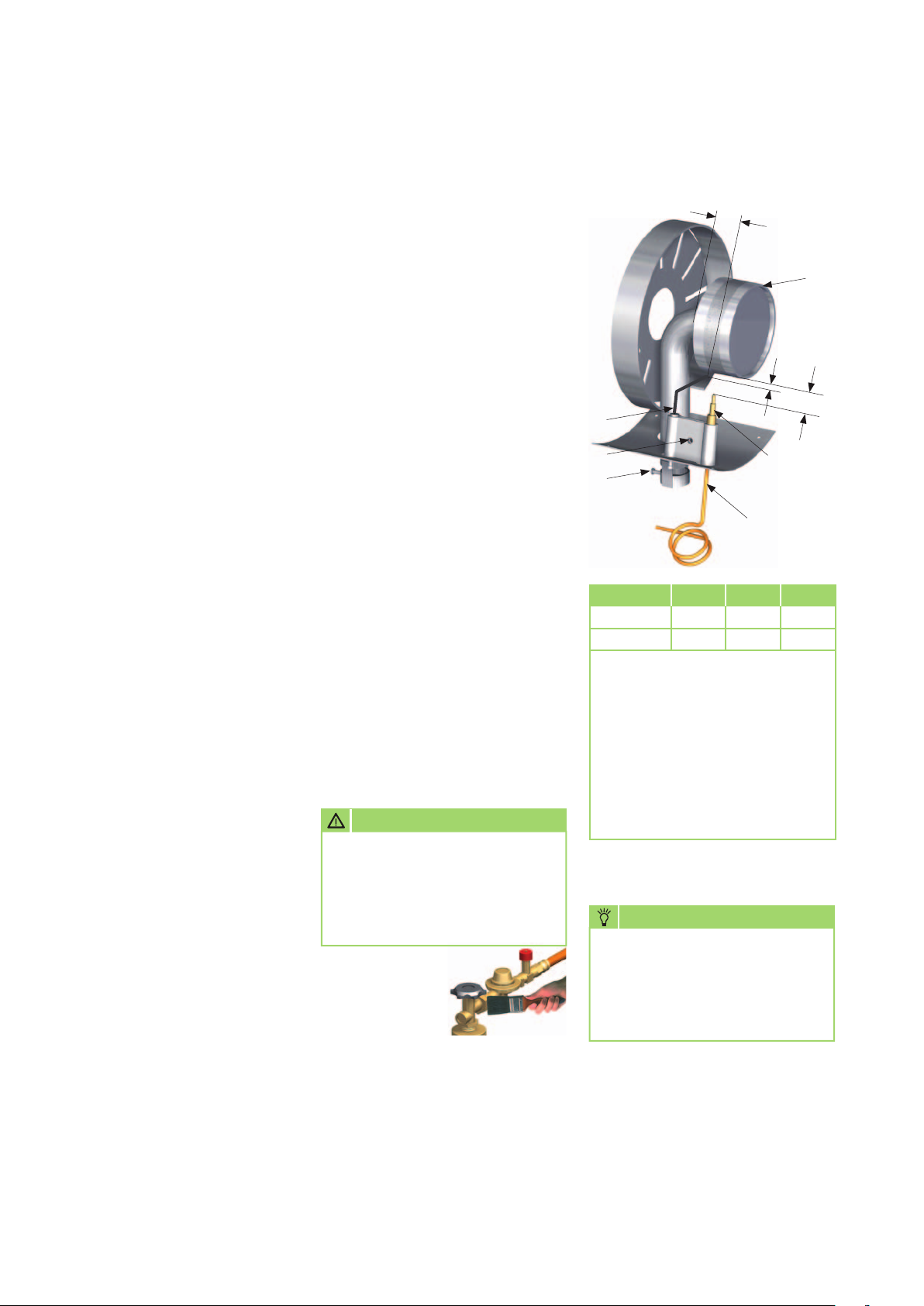

CAUTION

Gas burner

B

A

4

5

6

Unit type A B C

PGM 30

PGM 60

All dimensions in mm

Legend:

1 = Gas burner

2 = Thermocouple

3 = Capillary tube

(fixed component of the thermocouple)

4 = Ignition electrode

5 = Clamping screw (electrodes)

6 = Clamping screw (gas nozzle)

approx. 3 approx. 15 approx. 20

approx. 3 approx. 15 approx. 35

2

3

1

C

8. Carefully remove any adhered

deposits from the ignition

electrode and thermocouple.

9. Detach the fastening screws

of the gas burner and remove

the complete gas burner from

the unit.

12

A functional inspection of

the entire unit including leak

testing of all gas-conveying

connections must be

conducted

for example with:

Soap solution or

leak detection

spray.

NOTE

A strongly yellowy flame

indicates an inadequate

fresh air supply or dirt inside

the unit.

Troubleshooting

Malfunctions: Cause:

The unit does not start.

The unit switches off during operation.

The fan runs, but the gas supply is blocked

or no flame appears.

The flame extinguishes after the pressure pin of the safety pilot

is released.

The gas supply is interrupted,

or the flame is extinguished.

The unit consumes too much fuel.

The unit cannot be switched off.

The heating capacity drops in permanent operating mode.

1 – 2 – 3 – 4 – 7

2 – 4 – 7 – 12 – 13

4 – 5 – 8 – 9 – 12

8 – 10 – 11

4 – 6 – 7 –10 – 11 – 12 – 13

12 – 15

3 – 14

13

Cause: Remedial measures:

1. The unit is not connected to the electricity supply.

2. The fan motor is overloaded or the supply air fan runs irregularly

or is blocked.

3. The operating switch is defective.

4. No gas pressure.

Connect the plug with an appropriate socket (230V/50Hz).

Replace the plug if it is defective.

Check the motor, fan blade and drive clutch.

Replace the operating switch.

Check whether the gas supply to the unit is present.

Check the contents of the gas cylinders.

Check the gas hose for damage.

Disengage or replace the hose breakage protection.

5. No ignition sparks are generated.

6. The protective intake grille of the supply air fan is contaminated.

7. The temperature limiter triggers a switch-off.

8. The safety pilot does not open the gas supply

or keep it open.

9. The piezo igniter is defective.

10. The thermocouple or temperature limiter are defective.

11. Loose or dirty connection between the safety pilot and

thermocouple.

12. The pressure controller is defective or an incorrect pressure controller

is fitted, or the hose breakage protection (Sbs) has locked.

13. The gas cylinder(s) is (are) iced up due to an excessively high gas

take-off and low temperatures.

14. The solenoid valve does not close - Close the gas supply.

15. Leaky gas line.

Set the ignition electrode in accordance with specifications.

Check the ignition cable.

Check the porcelain insulation of the electrode.

Clean the protective intake grille.

Check the protective intake and outlet grilles (clean if necessary).

Check whether the fresh air supply is sufficient.

Replace the safety pilot.

Replace the piezo igniter.

Check the thermocouple or temperature limiter and replace

if necessary

Check the connection and clean if necessary.

Fit an original pressure controller.

Disengage or replace the hose breakage protection.

Replace the gas cylinder(s) and connect 2-3 cylinders with the multicylinder set, EDP no. 1014050.

Allow the flame to burn out.

Set the operating switch to the "0" position and remove the power

plug from the mains socket.

Replace the solenoid valve.

Use foaming media to search for the leak and remedy this.

13

REMKO PGM (E) series

Intended use Customer service and

guarantee

The units are designed

exclusively for heating and

ventilation purposes in industrial

or commercial use (not for living

space heating in private use)

on the basis of their structural

design and equipment.

According to DIN EN 1596,

the device definition is “warm air

heaters not intended for domestic

use without heat exchangers with

forced convection”.

The units must only be operated

by appropriately instructed

personnel.

With non-observance

of the manufacturer's

specifications, the respective

local legal requirements or after

arbitrary alterations to the units,

the manufacturer shall not be

liable for resulting damages.

As a prerequisite for any

guarantee claims to be

considered, it is essential

that the ordering party or their

representative complete and return

the "certificate of guarantee"

to REMKO GmbH & Co. KG at the

time when the units are purchased

and commissioned.

The units were tested

at the factory

several times to verify their correct

function.

However, if malfunctions should

arise that cannot be remedied by

the operator with the assistance

of the troubleshooting section,

please contact your specialist

dealer or contractual partner.

Environmental protection and recycling

Disposing of packaging

When disposing of packaging

material, please consider

our environment.

Our units are carefully packed

and delivered in sturdy transport

packaging made from cardboard

and polystyrene.

The packaging materials are

environmentally-friendly and can

be recycled.

By recycling packaging materials,

you make a valuable contribution

to the reduction of waste and

conservation of raw materials.

Therefore, only dispose of

packaging material at appropriate

collection points.

Disposal of the old unit

NOTE

Operation other than the types

listed in this operating manual

is prohibited.

With non-observance, any

manufacturer liability or guarantee claims are voided.

!

CAUTION

Copyright

The redistribution, even

in part, or the use of this

documentation for purposes

other than intended is

prohibited without the written

authorisation of

REMKO GmbH

& Co. KG

.

NOTE

Adjustment and maintenance

work may only be carried out

by authorised and qualified

technicians.

The manufacturing process for

the units is subject to continuous

quality control.

Only high-grade materials are

processed, the majority of which

are recyclable.

You also contribute

to environmental protection

by ensuring that your old

equipment is only disposed

of in an environment friendly

manner.

Therefore, only bring the old

unit to an authorised recycling

business or to an appropriate

collection point.

14

15

REMKO PGM (E) series

Exploded view of PGM 30 (E)

31

29

32

33 34

28

1

2

27

26

25

24

30

23

15

19

17

21

12

20

14

19

18

15

9

14

12

16

13

10

35

37

36

11

10

9

7

8

6

3

4

5

6

16

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

Spare parts list

No. Description EDP no.

1 Transport handle 1101142

2 Exterior cladding PGM 30 1101405

2a Exterior cladding PGM 30 E 1101477

3 Combustion chamber 1121186

4 Completion panel, front 1101479

5 Protective outlet grille 1101383

6 Safety temperature limiter 1101197

7 Inspection cover 1101385

8 Terminal block 6x 1101366

9 Thermocouple 1101164

10 Ignition cable 1101283

11 Ignition electrode 1101180

12 OT elbow union 1101316

13 Gas nozzle 1101159

14 Gas supply pipe Z/D 1101452

15 Gas supply pipe M/R 1101441

16 Piezo igniter 1101364

17 Gas control 1101411

18 Screw connection M10x1 1101409

19 Gas supply pipe R/Z 1101451

20 IT elbow union 1101468

21 Safety pilot 1101169

23 GE-screw connection 1101396

24 Solenoid valve 1101376

25 Gas connection nipple 1101134

26 Adjusting knob, cpl. 1101192

27 Operating switch 1101188

28 Strain relief 1101267

29 Mains cable with plug 1101320

30 Completion panel, rear 1101480

31 Fan motor 1108049

32 Drive clutch B 6 Ø 1108455

33 Fan blade 1101392

34 Clutch plate 1101375

35 Gas burner 1101417

36 Grommet 1101304

37 Retaining clip 1101395

xx Pressure controller with hose breakage protection 1101470

xx 2 linear m. Gas hose 1101419

xx 2 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1101174

xx 5 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1108410

xx 10 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1108411

xx Multi-cylinder set (2-3 cylinders) 1014050

xx T-connection for multi-cylinder set 1101177

xx Nylon seal for T-connection 1101178

xx HP hose 0.4 m for multi-cylinder set 1101179

xx = not illustrated

When ordering replacement parts, please always state the EDP no. and unit number (see name plate)!

17

REMKO PGM (E) series

Exploded view of PGM 60 (E)

36

37

38

39

41

34

1

2

3

28

16 22

11

35

21

20

27

33

17

24

23

32

15

14

13

31

29

26

19

8

18

12

30

22

16

4

7

8

24

9

10 12

11

40

5

6

18

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

Spare parts list

No. Description EDP no.

1 Transport handle 1101142

2 Exterior cladding PGM 60 1101420

2a Exterior cladding PGM 60 E 1101461

3 Insulation 1101421

4 Combustion chamber 1101422

5 Gas burner 1101423

6 Protective outlet grille 1101424

7 Gas nozzle 1101426

8 Gas supply pipe Z/D 1101458

9 OT elbow union 1101316

10 Ignition electrode 1101280

11 Ignition cable 1101283

12 Thermocouple 1101164

13 Support, front 1101427

14 Unit base 1101428

15 Inspection cover 1101469

16 Gas supply pipe R/Z 1101459

17 IT elbow union 1101468

18 Safety pilot 1101169

19 GE-screw connection 1101359

20 Gas control 1101412

21 Screw connection M10x1 1101409

22 Gas supply pipe M/R 1101441

23 Support, rear 1101249

24 Safety temperature limiter 1101197

26 GE-screw connection 1101396

27 Solenoid valve 1101376

28 Piezo igniter 1101364

29 Gas connection nipple 1101134

30 Adjusting knob, cpl. 1101192

31 Strain relief 1101267

32 Operating switch 1101188

33 Terminal block, 6x 1101366

34 Grommet 1101304

35 Mains cable with plug 1101320

36 Protective intake grille 1101432

37 Fan motor 1101254

38 Drive clutch B 8 ø 1101255

39 Fan blade 1101150

40 Retaining clip 1101395

41 Clutch plate 1101375

xx Pressure controller with hose breakage protection 1101470

xx 2 linear m. Gas hose 1101419

xx 2 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1101174

xx 5 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1108410

xx 10 linear m. HP gas hose (version for construction site operation per DIN 4815 part 1, pressure class 30) 1108411

xx Multi-cylinder set (2-3 cylinders) 1014050

xx T-connection for multi-cylinder set 1101177

xx Nylon seal for T-connection 1101178

xx HP hose 0.4 m for multi-cylinder set 1101179

xx = not illustrated

When ordering replacement parts, please always state the EDP no. and unit number (see name plate)!

19

REMKO PGM (E) series

Maintenance protocol

Unit type: .................................. Unit number: ...................................

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Unit cleaned - outside -

Unit cleaned - inside -

Fan blade cleaned

Combustion chamber cleaned

Gas burner cleaned

Ignition electrode adjusted

Gas hose checked for damage

Gas-transporting parts checked for leak-tightness

Safety equipment checked

Safety devices checked

Unit checked for damage

All fastening screws checked

Electrical safety check

Test run

✍

Comments: ..........................................................................................................................................................

.............................................................................................................................................................................

.............................................................................................................................................................................

1. Date: ..............

..............................

Signature

6. Date: ..............

..............................

Signature

11. Date: ............

..............................

Signature

16. Date: ............

..............................

Signature

2. Date: ..............

..............................

Signature

7. Date: ..............

..............................

Signature

12. Date: ............

..............................

Signature

17. Date: ............

..............................

Signature

3. Date: ..............

..............................

Signature

8. Date: ..............

..............................

Signature

13. Date: ............

..............................

Signature

18. Date: ............

..............................

Signature

4. Date: ..............

..............................

Signature

9. Date: ..............

..............................

Signature

14. Date: ............

..............................

Signature

19. Date: ............

..............................

Signature

5. Date: ..............

..............................

Signature

10. Date: ............

..............................

Signature

15. Date: ............

..............................

Signature

20. Date: ............

..............................

Signature

20

Unit to be maintained only by authorised specialists in accordance with the statutory regulations.

Technical data

Series PGM 30 (E) PGM 60 (E)

Nominal heat load max

. kW 26.00 55,00

Nominal heat capacity P

Minimum heat capacity P

nom

min

Air volume flow m

kW 26.00 55,00

kW 10.00 25,00

3

/h 725 1310

Fuel Liquid gas

Fuel/gas type Cat I

3P

Energy efficiency ratio A A

Unit connection pressure bar 1.5 1,5

Unit connection value kg/h 0.78 - 2.0 1,95 - 4,27

Auxiliary power consumption

at nominal heating capacity el

at minimum heating capacity el

in Standw-By mode el

Pilot flame power requirement P

Thermal efficiency at nominal

heating capacity

Thermal efficiency at minimum

heating capacity

η

th,nom

η

th,min

max

min

SB

pilot

kW 0.070 0.100

kW 0.070 0.100

kW 0.000 0.000

kW N/A N/A

% 100.0 100,0

% 100.0 100,0

Type of room temperature control

two or more manually adjustable stages,

no room temperature control

Power supply V/Ph/Hz 230/1~/50 230/1~/50

Rated current consumption A 0.6 0,95

Electrical protection

provided by the customer)

(

A 10 10

Enclosure class IP 11 11

Sound pressure level L

pA

1m

dB(A) 56 - 69 62 - 72

1)

Dimensions: Length mm 450 650

Width mm 260 320

Height mm 410 510

Weight kg 12 20

Product ID number CE-0085AP0240

1)

Noise measurement in acc. with DIN 45635 - 01 - KL 3 in heating mode

We reserve the right to modify the dimensions and design as part of the ongoing technical development process.

21

REMKO PGM (E) series

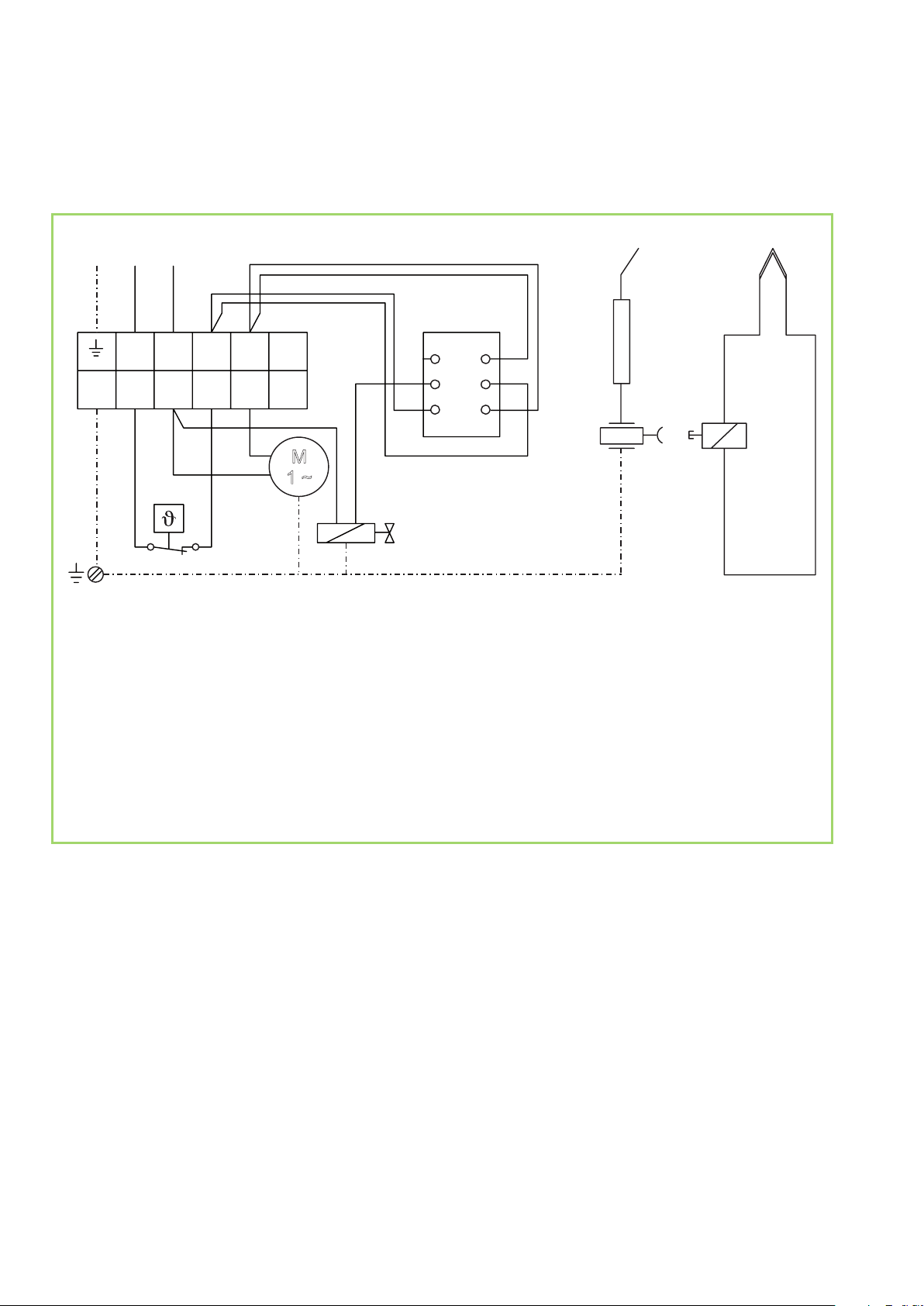

Electrical wiring diagram

PE L1 N

S

L1 N

5 4

STB

3

2 1

KL

3

2 16

A3

A2

A1

M

1 ~

B6

B5

B4

TE

Z

TMV

PZ

C

1

Legend:

KL

= Terminal block

M = Fan motor

MV = Solenoid valve

PZ = Piezo igniter

MV

S = Operating switch

STB = Safety temperature limiter

TE = Thermocouple

TMV = Safety pilot (thermo-electric gas valve)

Z = Ignition electrode

22

23

REMKO QUALITY WITH SYSTEMS

Air-Conditioning | Heating | New Energies

Telephone +49 (0) 5232 606-0

Telefax +49 (0) 5232 606-260

E-mail info@remko.de

URL www.remko.de

REMKO GmbH & Co. KG

Klima- und Wärmetechnik

Im Seelenkamp 12

32791 Lage

Hotline within Germany

+49 (0) 5232 6 06-0

Hotline International

+49 (0) 5232 606-130

We reserve the right to make technical changes, and provide no guarantee as to the accuracy of this data!

Loading...

Loading...