Model:

QV36DC-A

R

Owner’s Manual

Installation and Operation

CAUTION

DO NOT DISCARD THIS MANUAL

Important operating and

•

maintenance instructions included.

WARNING: If the information in these

instructions is not followed exactly, a fi re

or explosion may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other fl am-

mable vapors and liquids in the vicinity of

this or any other appliance.

• What to do if you smell gas

- Do not try to light any appliance

- Do not touch any electrical switch. Do not

use any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s instructions.

- If you cannot reach your gas supplier, call

the fi re department.

• Installation and service must be performed

by a qualifi ed installer, service agency , or the

gas supplier.

This appliance may be installed as an OEM installation in

manufactured home (USA only) or mobile home and must be

installed in accordance with the manufacturer’s instructions

and the manufactured home construction and safety standard,

Title 24 CFR, Part 3280 or Standard for Installation in Mobile

Homes, CAN/CSA Z240MH.

This appliance is only for use with the type(s) of gas indicated

on the rating plate.

Read, understand and follow

••

these instructions for safe

installation and operation.

DO NOT

DISCARD

Leave this manual with

party responsible for use

and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are hot during

operation AND cool down.

Hot glass will cause burns.

• DO NOT touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in same room as

fi replace.

• Alert children and adults to hazards of high temperatures.

High temperatures may ignite clothing or other fl ammable

materials.

• Keep clothing, furniture, draperies and other fl ammable

materials away.

This appliance has been supplied with an integral barrier

to prevent direct contact with the fi xed glass panel. DO

NOT operate the appliance with the barrier removed.

Contact your dealer or Hearth & Home Technologies if the

barrier is not present or help is needed to properly install one.

In the Commonwealth of Massachusetts installation must be

performed by a licensed plumber or gas fi tter.

See T able of Contents for location of additional Commonwealth

of Massachusetts requirements.

Installation and service of this appliance should be

performed by qualifi ed personnel. Hearth & Home

Technologies suggests NFI certifi ed or factory-trained

professionals, or technicians supervised by an NFI

certifi ed professional.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

1

SAFETY AND WARNING INFORMATION

READ and UNDERSTAND all instructions carefully

!

before starting the installation. FAILURE TO

FOLLOW these installation instructions may result in

a possible fi re hazard and will void the warranty.

Prior to the fi rst fi ring of the fi replace, READ the

!

Using Your Fireplace section of the Owners Guide.

DO NOT USE this appliance if any part has been

!

under water. Immediately CALL a qualifi ed service

technician to inspect the unit and to replace any part

of the control system and any gas control which has

been under water.

THIS UNIT IS NOT FOR USE WITH SOLID FUEL.

!

Installation and repair should be PERFORMED

qualifi ed service person. The appliance and venting

!

system should be INSPECTED before initial use and

at least annually by a professional service person.

More frequent cleaning may be required due to

excessive lint from carpeting, bedding material, etc. It

is IMPERATIVE that the unit’s control compartment,

burners, and circulating air passageways BE KEPT

CLEAN to provide for adequate combustion and

ventilation air.

by a

These units MUST use one of the vent systems

!

described in the Installing the Fireplace section of

the Owner’s Manual. NO OTHER vent systems or

components MAY BE USED.

This gas fi replace and vent assembly MUST be

!

vented directly to the outside and MUST NEVER be

attached to a chimney serving a separate solid fuel

burning appliance. Each gas appliance MUST USE

a separate vent system. Common vent systems are

PROHIBITED.

INSPECT the external vent cap on a regular basis

!

to make sure that no debris is interfering with the air

fl ow.

The glass door assembly MUST be in place and

!

sealed, and the trim door assembly MUST be in

place on the fi replace before the unit can be placed

into safe operation.

DO NOT OPERATE this appliance with the glass

!

door removed, cracked, or broken. Replacement of

the glass door should be performed by a licensed or

qualifi ed service person. DO NOT strike or slam the

glass door.

Always KEEP the appliance clear and free from

!

combustible materials, gasoline, and other fl ammable

vapors and liquids.

NEVER OBSTRUCT the fl ow of combustion and

!

ventilation air. Keep the front of the appliance CLEAR

of all obstacles and materials for servicing and proper

operations.

Due to the high temperature, the appliance should

!

be LOCATED out of traffi c areas and away from

furniture and draperies. Clothing or fl ammable

material SHOULD NOT BE PLACED on or near the

appliance.

Children and adults should be ALERTED to

!

the hazards of high surface temperature and

should STAY AWAY to avoid burns or clothing

ignition. Young children should be CAREFULLY

SUPERVISED when they are in the same room as

the appliance.

The glass door assembly SHALL ONLY be replaced

!

as a complete unit, as supplied by the gas fi replace

manufacturer. NO SUBSTITUTE material may be

used.

DO NOT USE abrasive cleaners on the glass door

!

assembly. DO NOT ATTEMPT to clean the glass

door when it is hot.

Turn off the gas before servicing this appliance. It

is recommended that a qualifi ed service technician

!

perform an appliance check-up at the beginning of

each heating season.

Any safety screen or guard removed for servicing

!

must be replaced before operating this appliance.

DO NOT place furniture or any other combustible

!

household objects within 36 inches of the fi replace

front.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/092

TABLE OF CONTENTS

Safety and Warning Information .................................................2

Service Parts Lists .......................................................................4

Section 1: Approvals and Codes ................................................7

Appliance Certifi cation ....................................................................7

Installation Codes ...........................................................................7

High Altitude Installations ...............................................................7

Electrical Codes..............................................................................7

Requirements for the Commonwealth of Massachusetts ...............8

Section 2: Getting Started ...........................................................9

Introducing the Quadra-Fire Gas Fireplaces ..................................9

Pre-installation Preparation ............................................................9

Section 3: Installing the Fireplace ............................................1 1

Constructing the Fireplace Chase ................................................11

Step 1 Locating the Fireplace ...................................................11

Step 2 Framing the Fireplace ...................................................12

Step 3 Installing the Vent System .............................................14

A. Vent System Approvals ............................................14

B. Installing Vent Components .....................................21

C. Vent Termination ......................................................24

Step 4 Positioning, Leveling, and

Securing the Fireplace ..................................................27

Step 5 The Gas Control System ...............................................27

Step 6 The Gas Supply Line ....................................................28

Step 7 Gas Pressure Requirements .........................................28

Step 8 Wiring the Fireplace ......................................................29

Step 9 Finishing ........................................................................30

Step 10 Installing Trim, Logs, and Ember Material .....................31

Installing the Trim ..........................................................31

Refractory Kit Placement ..............................................31

Positioning the Logs ......................................................32

Shutter Settings ............................................................32

Placing the Ember Material ...........................................32

Glass Specifi cations ......................................................32

Step 11 Before Lighting the Fireplace ........................................32

Step 12 Lighting the Appliance ...................................................33

Step 13 Climate Control .............................................................34

After the Installation .....................................................................34

Section 4: Maintaining and Servicing Your Fireplace. ...........34

Section 5: Troubleshooting. .....................................................35

Limited Lifetime Warranty. ........................................................37

Î

Contact Information .....................................................................39

Î

Î = Contains updated information.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

3

1

Approvals and

Codes

Appliance Certifi cation

The fi replace model discussed in this Owner’s Manual

has been tested to certifi cation standards and listed by the

applicable laboratories.

Certifi cation

MODELS: QV36DC-A

LABORATORY: Underwriters Laboratories, Inc. (UL)

TYPE: Vented Gas Fireplace Heaters

STANDARD: ANSI Z21.88a-2007 • CSA 2.33a-2007

Installation Codes

The fi replace installation must conform to local codes.

Before installing the fi replace, consult the local building

code agency to ensure that you are in compliance with all

applicable codes, including permits and inspections.

In the absence of local codes, the fi replace installation must

conform to the National Fuel Gas Code ANSI Z223.1 (in the

United States) or the CAN/CGA-B149 Installation Codes

(in Canada). The appliance must be electrically grounded

in accordance with local codes or, in the absence of local

codes with the National Electric Code ANSI/NFPA No.

70 (in the United States), or to the CSA C22.1 Canadian

Electric Code (in Canada).

High Altitude Installations

U.L. Listed gas appliances are tested and approved without

requiring changes for elevations from 0 to 2,000 feet in the

U. S. A. and in Canada.

When installing this appliance at an elevation above 2,000

feet, it may be necessary to decrease the input rating by

changing the existing burner orifi ce to a smaller size. Input

rate should be reduced by 4% for each 1000 feet above

a 2000 foot elevation in the U.S.A. or 10% for elevations

between 2000 and 4500 feet in Canada. If the heating

value of the gas has been reduced, these rules do not

apply. To identify the proper orifi ce size, check with the

local gas utility.

If installing this appliance at an elevation above 4,500 feet

(in Canada), check with local authorities.

Electrical Codes

NOTICE: This appliance must be electrically wired and

grounded in accordance with local codes or, in the absence

of local codes, with National Electric Code ANSI/NFPA

70-latest edition or the Canadian Electric Code CSA

C22.1.

This model may be installed in a bedroom or bed-sitting

room in the U.S.A. and Canada.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

• A 110-120 VAC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in compliance

with the applicable electrical codes, when it is installed in

locations such as in bathrooms or near sinks.

7

Note: The following requirements reference various

Massachuset ts and national codes not contained in this

document.

Requirements for the Commonwealth of

Massachusetts

For all side wall horizontally vented gas fueled equipment

installed in every dwelling, building or structure used in

whole or in part for residential purposes, including those

owned or operated by the Commonwealth and where the

side wall exhaust vent termination is less than seven (7)

feet above fi nished grade in the area of the venting, in-

cluding but not limited to decks and porches, the following

requirements shall be satisfi ed:

Installation of Carbon Monoxide Detectors

At the time of installation of the side wall horizontal vented

gas fueled equipment, the installing plumber or gas fi tter

shall observe that a hard wired carbon monoxide detector

with an alarm and battery back-up is installed on the fl oor

level where the gas equipment is to be installed. In addition, the installing plumber or gas fi tter shall observe that

a battery operated or hard wired carbon monoxide detector with an alarm is installed on each additional level of

the dwelling, building or structure served by the side wall

horizontal vented gas fueled equipment. It shall be the

responsibility of the property owner to secure the services

of qualifi ed licensed professionals for the installation of

hard wired carbon monoxide detectors.

In the event that the side wall horizontally vented gas fueled equipment is installed in a crawl space or an attic,

the hard wired carbon monoxide detector with alarm and

battery back-up may be installed on the next adjacent

fl oor level.

In the event that the requirements of this subdivision can

not be met at the time of completion of installation, the

owner shall have a period of thirty (30) days to comply

with the above requirements; provided, however, that during said thirty (30) day period, a battery operated carbon

monoxide detector with an alarm shall be installed.

Inspection

The state or local gas inspector of the side wall horizontally vented gas fueled equipment shall not approve the

installation unless, upon inspection, the inspector observes carbon monoxide detectors and signage installed

in accordance with the provisions of 248 CMR 5.08(2)(a)1

through 4.

Exemptions

The following equipment is exempt from 248 CMR

5.08(2)(a)1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition

of NFPA 54 as adopted by the Board; and

• Product Approved side wall horizontally vented gas fueled equipment installed in a room or structure separate

from the dwelling, building or structure used in whole or

in part for residential purposes.

MANUFACTURER REQUIREMENTS

Gas Equipment Venting System Provided

When the manufacturer of Product Approved side wall

horizontally vented gas equipment provides a venting

system design or venting system components with the

equipment, the instructions provided by the manufacturer

for installation of the equipment and the venting system

shall include:

• Detailed instructions for the installation of the venting

system design or the venting system components; and

• A complete parts list for the venting system design or

venting system.

Gas Equipment Venting System NOT Provided

When the manufacturer of a Product Approved side wall

horizontally vented gas fueled equipment does not provide the parts for venting the fl ue gases, but identifi es

“special venting systems”, the following requirements

shall be satisfi ed by the manufacturer:

Approved Carbon Monoxide Detectors

Each carbon monoxide detector as required in accordance with the above provisions shall comply with NFPA

720 and be ANSI/UL 2034 listed and IAS certifi ed.

Signage

A metal or plastic identifi cation plate shall be permanent-

ly mounted to the exterior of the building at a minimum

height of eight (8) feet above grade directly in line with the

exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment. The sign shall read,

in print size no less than one-half (1/2) in. in size, “GAS

VENT DIRECTLY BELOW. KEEP CLEAR OF ALL OBSTRUCTIONS”.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/098

• The referenced “special venting system” instructions

shall be included with the appliance or equipment installation instructions; and

• The “special venting systems” shall be Product Approved by the Board, and the instructions for that system shall include a parts list and detailed installation

instructions.

A copy of all installation instructions for all Product Approved side wall horizontally vented gas fueled equipment, all venting instructions, all parts lists for venting

instructions, and/or all venting design instructions shall

remain with the appliance or equipment at the completion

of the installation.

See Gas Connection section for additional Commonwealth of Massachusetts requirements.

2

Getting Started

Introducing Quadra-Fire Gas Fireplaces

Quadra-Fire direct vent gas fi replaces are designed to op-

erate with all combustion air siphoned from outside of the

building and all exhaust gases expelled to the outside.

The information contained in this Owner’s Manual, unless

noted otherwise, applies to all models and gas control systems. Gas fi replace diagrams, including the dimensions,

are shown in this section.

Pre-installation Preparation

This gas fi replace and its components are tested and safe

when installed in accordance with this Owner’s Manual.

Report to your dealer any parts damaged in shipment,

particularly the condition of the glass. Do not install any

unit with damaged, incomplete, or substitute parts.

The vent system components and trim doors are shipped

in separate packages. The gas logs may be packaged

separately and must be fi eld installed.

Read all of the instructions before starting the installation. Follow these instructions carefully during the

installation to ensure maximum safety and benefi t. Fail-

ure to follow these instructions will void the owner’s

warranty and may present a fi re hazard.

The Hearth & Home Technologies Warranty will be voided

by, and Hearth & Home Technologies disclaims any

responsibility for, the following actions:

• Installation of any damaged fi replace or vent system

component.

• Modifi cation of the fi replace or direct vent system.

• Installation other than as instructed by Hearth & Home

Technologies.

• Improper positioning of the gas logs or the glass door.

• Installation and/or use of any component part not manufactured and approved by Hearth & Home T echnologies,

not withstanding any independent testing laboratory or

other party approval of such component part or accessory.

ANY SUCH ACTION MAY POSSIBLY CAUSE A FIRE

HAZARD.

When planning a fi replace installation, it’s necessary to

determine:

• Where the unit is to be installed.

• The vent system confi guration to be used.

• Gas supply piping.

• Electrical wiring.

• Framing and fi nishing details.

• Whether optional accessories—devices such as a fan,

wall switch, or remote control—are desired.

If the fi replace is to be installed on carpeting or tile, or on

any combustible material other than wood fl ooring, the

fi replace should be installed on a metal or wood panel that

extends the full width and depth of the fi replace.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

9

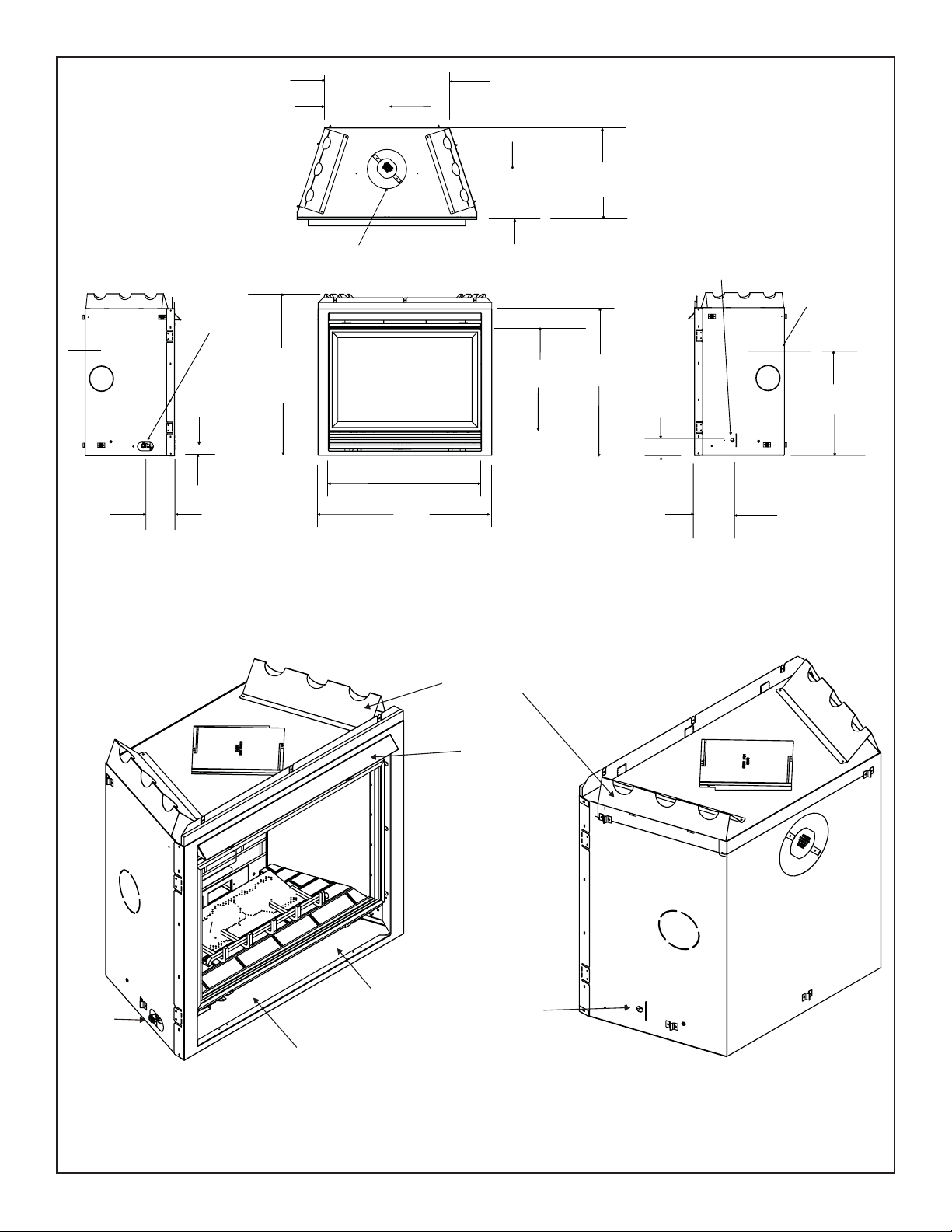

14 1/4

[362mm]

28 1/2 [724mm]

21 1/2 [548mm]

GAS LINE

ACCESS

2 1/8

[55mm]

6 7/8 [174mm]

8 5/8 [219mm]

VENT COLLARS

38

[965mm]

41 1/8

[1044mm]

11 5/8 [297mm]

TOP

STANDOFFS

25 1/4

[642mm]

36 1/8

[916mm]

34 5/8

[879mm]

3 1/2

[90mm]

ELECTRICAL

ACCESS

12 3/4

[323mm]

8 5/8

[219mm]

VENT

COLLARS

26 7/8

[682mm]

GAS

LINE

ACCESS

GAS

CONTROLS

Figure 1. Diagram of the QV36DC-A

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0910

RATING

PLATE AND

LABELS

HOOD

ELECTRICAL

ACCESS

3

Installing the Fireplace

Constructing the Fireplace Chase

A chase is a vertical box-like structure built to enclose the

gas fi replace and/or its vent system. Vertical vents that run

on the outside of a building may be, but are not required

to be, installed inside a chase.

1” MIN. (25mm)

A

B

E

D

CAUTION: TREA TMENT OF FIRESTOP SP ACERS AND

CONSTRUCTION OF THE CHASE MA Y V ARY WITH THE

TYPE OF BUILDING. THESE INSTRUCTIONS ARE NOT

SUBSTITUTES FOR THE REQUIREMENTS OF LOCAL

BUILDING CODES. THEREFORE, YOUR LOCAL BUILDING CODES MUST BE CHECKED TO DETERMINE THE

REQUIREMENTS FOR THESE STEPS.

Factory-built fi replace chases should be constructed in the

manner of all outside walls of the home to prevent cold air

drafting problems. The chase should not break the outside

building envelope in any manner.

This means that the walls, ceiling, base plate and cantilever fl oor of the chase should be insulated. Vapor and air

infi ltration barriers should be installed in the chase as per

regional codes for the rest of the home. Additionally, we

recommend that the inside surfaces be sheetrocked and

taped for maximum air tightness.

To further prevent drafts, the fi restops should be caulked

to seal gaps. Gas line holes and other openings should

be caulked or stuffed with insulation. If the unit is being

installed on a cement slab, we recommend that a layer of

plywood be placed underneath to prevent conducting cold

up into the room.

THE CHASE SHOULD BE CONSTRUCTED SO THAT

ALL CLEARANCES TO THE FIREPLACE ARE MAINTAINED AS SPECIFIED WITHIN THIS INSTALLERS

GUIDE.

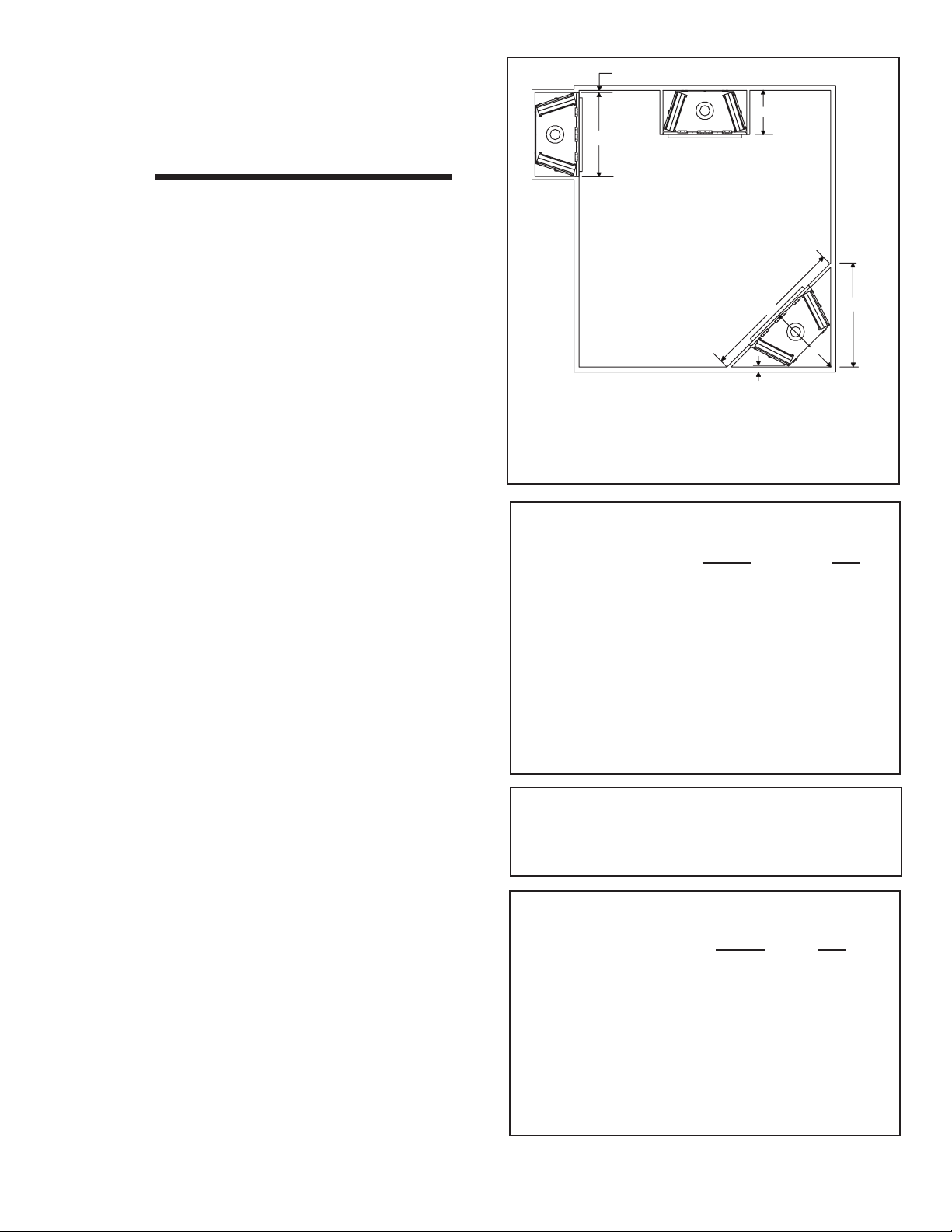

Step 1. Locating the Fireplace

The following diagram shows space and clearance requirements for locating a fi replace within a room.

Clearance Requirements

The top, back, and sides of the fi replace are defi ned by

stand-offs. The minimum clearance to a perpendicular wall

extending past the face of the fi replace is one inch (25 mm).

The back of the fi replace may be recessed 21 1/2 inches

(546 mm) into combustible construction.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

C

1/2” MIN. (13mm)

A B C D E

42” 22” 36” 51” 72”

Figure 2. Fireplace Dimensions, Locations,

and Space Requirements

Minimum Clearances

from the Fireplace to Combustible Materials

Inches mm

Glass Front .........................36 ....................914

Floor ....................................0 ........................ 0

Rear ...................................1/2 ......................13

Sides..................................1/2 ......................13

Surround Sides* ..................0 ........................0

Top ....................................3 1/2 .................... 89

Ceiling** ..............................31 .....................787

* See Figure 3.

** The clearance to the ceiling is measured from the top

of the unit, excluding the standoffs (see Figure 36).

The distance from the unit to combustible construction

is to be measured from the unit outer wrap surface to

the combustible construction, NOT from the screw

heads that secure the unit together.

Minimum Clearances

from the Vent Pipe to Combustible Materials

Inches mm

Vertical Sections. ..............1 ................25

Horizontal Sections

Top ......................................3 .................75

Bottom ................................1 .................25

Sides...................................1 .................25

At Wall Firestops

Top ...................................2 1/2 ............63.7

Bottom .............................. 1/2 ................13

Sides...................................1 .................25

11

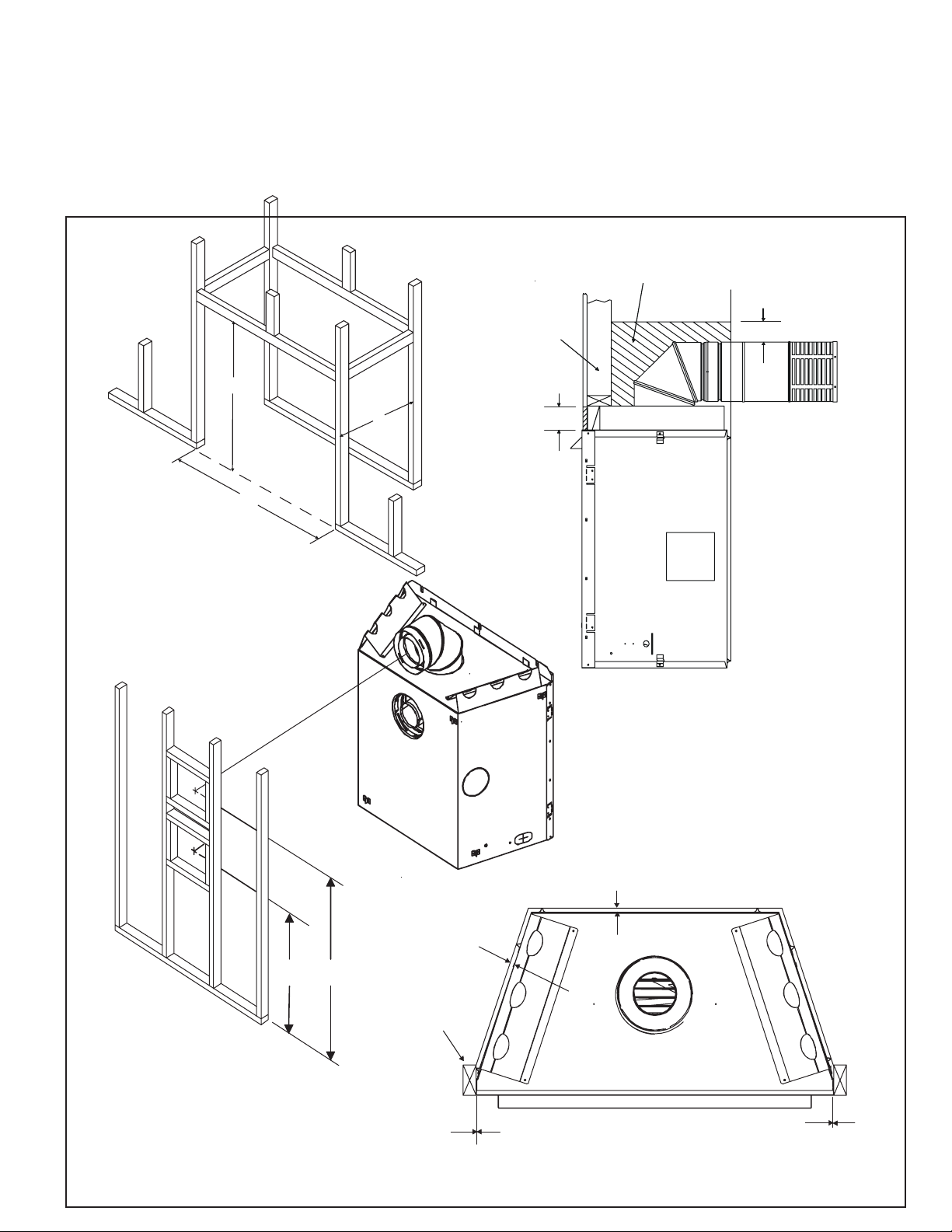

Step 2. Framing the Fireplace

Fireplace framing can be built before or after the fi replace is

set in place. Framing should be positioned to accommodate

wall coverings and fi replace facing material. The diagram

below shows framing reference dimensions.

B

C

A

A. ..............42”*

B. ..........38 1/2”

C. ................22”

D. ..........42 3/4”

E. ..........27 7/8”

CAUTION: MEASURE FIREPLACE DIMENSIONS AND

VERIFY FRAMING METHODS AND WALL COVERING

DETAILS BEFORE FRAMING.

Noncombustible zone is defined

by 3” above the elbow for the

entire width and depth (behind

the front header) of the firebox.

WALL

STUD

31/2”

3

”

Shows

center of 10”x

12” vent framing

holes for top and rear

venting. The center of the

hole is one (1) inch (25.4mm)

above the center of the horizontal

vent pipe.

E D

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0912

1/2” CLEARANCE

FROM BOTH SIDES

OF FIREPLACE

TO COMBUSTIBLE

FRAMING

MEMBER

Framing should be

constructedof2X4

lumber or heavier.

1/2” CLEARANCE FROM BACK OF FIREPLACE TOCOMBUSTIBLE

0” CLEARANCE

0” CLEARANCE TO

FRAMING MEMBER

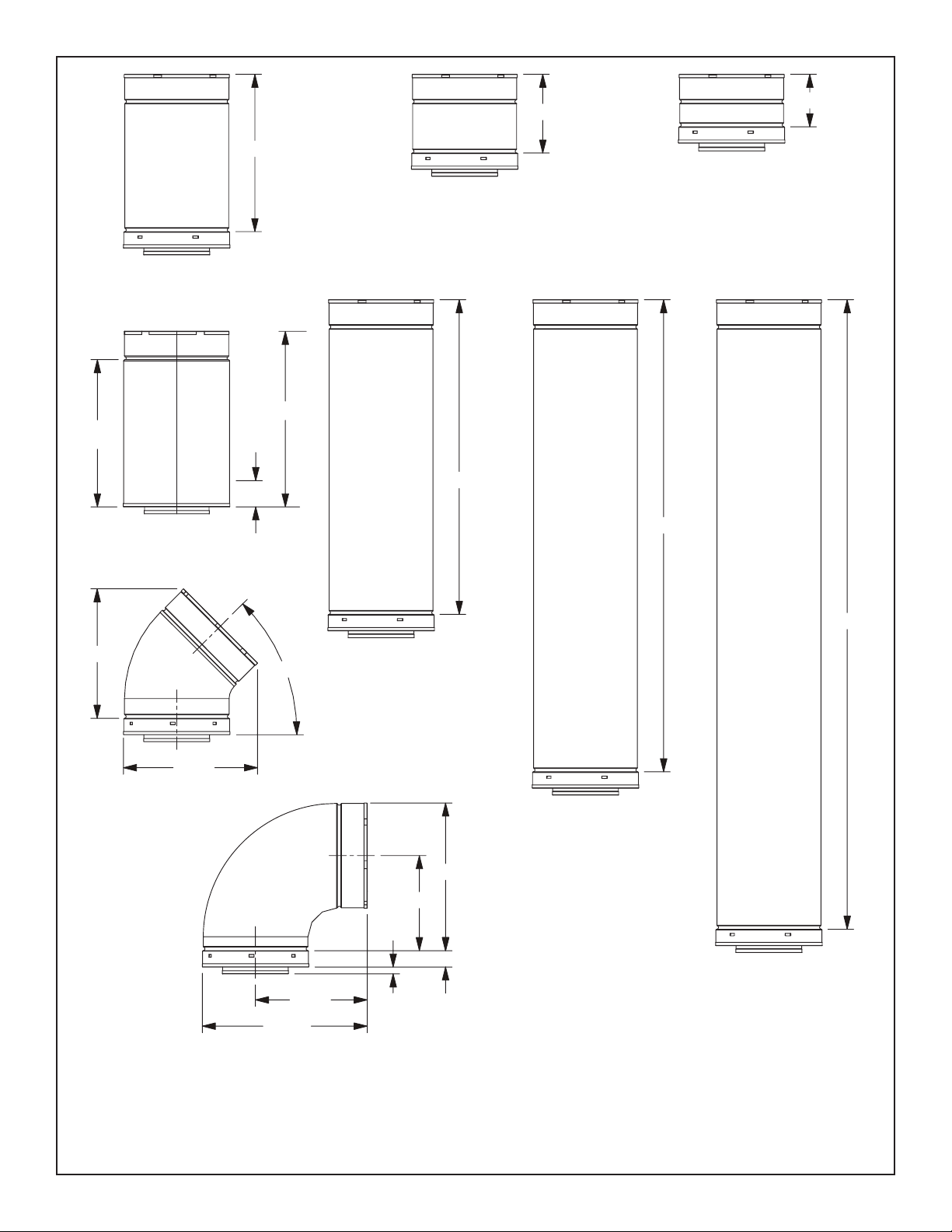

12-3/16

MAX.

DVP12

12

2

MIN.

6

4

DVP4

DVP6

14-1/4

24

9-7/8

DVP12A

10-1/4

DVP45

45.0

DVP24

7-1/4

11-1/4

1-1/4 TYP

36

48

DVP36

DVP48

8-9/16

12-9/16

DVP90ST

1/2 TYP

NOTE: PIPES OVERLAP 1-1/4 INCHES AT EACH JOINT.

Figure 4. DVP-Series Direct Vent Component Specifi cations (5-inch inner pipe / 8-inch outer pipe)

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

13

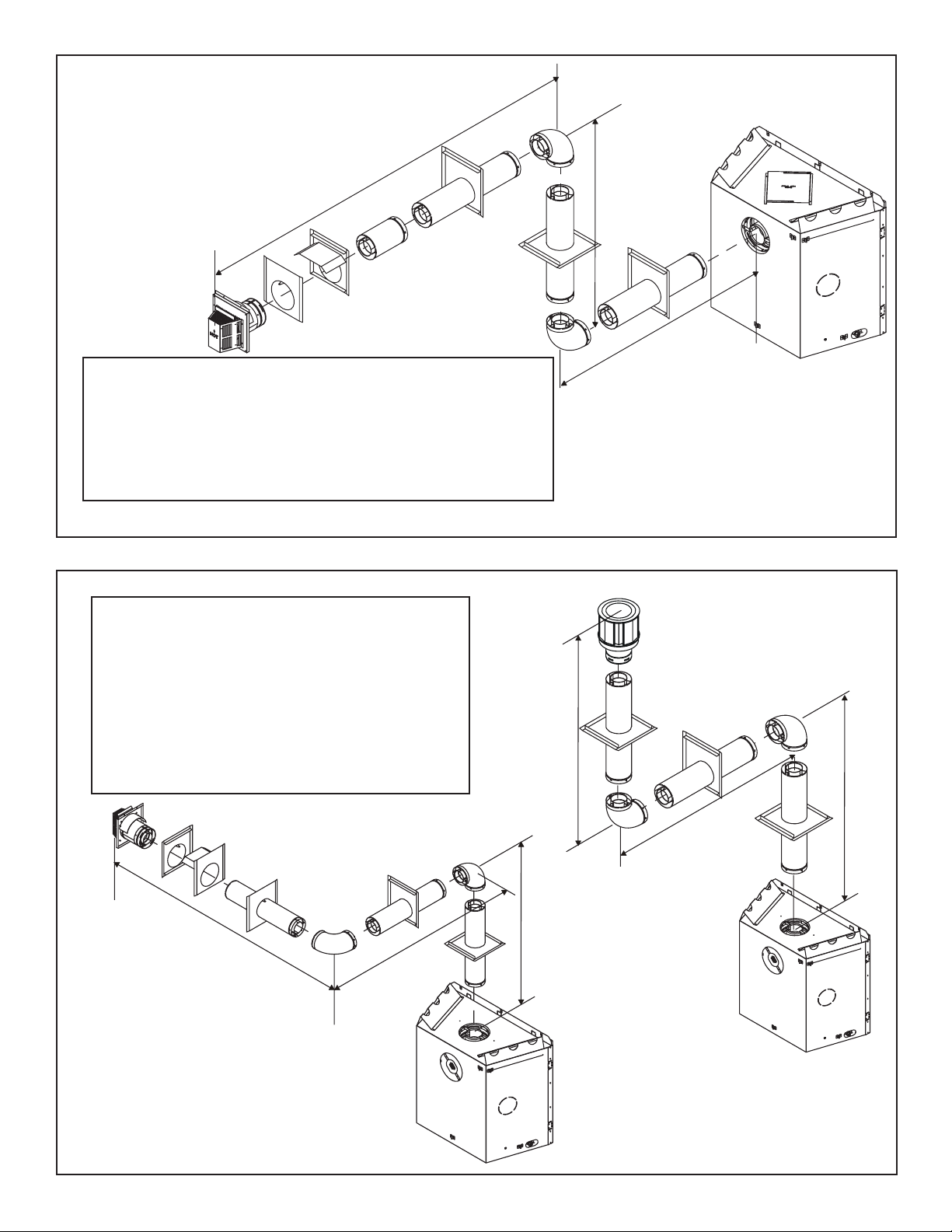

Step 3. Installing the Vent System

Identifying Vent Components

A. Vent System Approvals

This model is approved to use DVP-series direct vent

pipe components and terminations (see Figures 4 and 5).

Approved vent system components are labeled for identifi -

cation. This pipe is tested and listed as an approved component of the fi replace. The pipe is tested to be run inside

an enclosed wall. There is no requirement for inspection

openings at each joint within the wall. There is no required

pitch for horizontal vent runs. NO OTHER VENTING SYS-

TEMS OR COMPONENTS MAY BE USED.

Detailed installation instructions are included with each

vent termination kit and should be used in conjunction with

this Owner’s Manual. The fl ame and ember appearance

may vary based on the type of fuel burned and the venting

confi guration used.

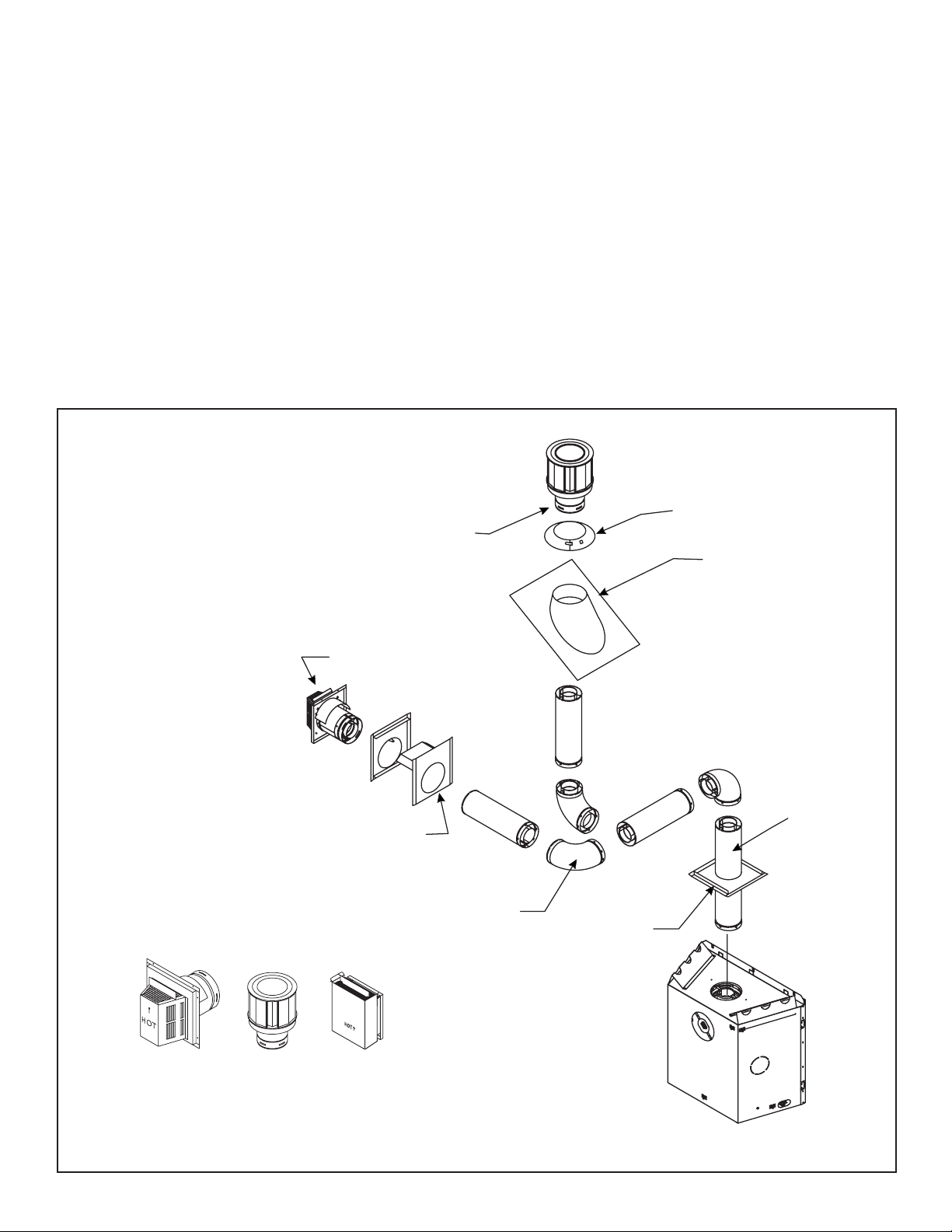

VERTICAL

TERMINATION

The vent systems installed on this gas fi replace may include

one, two, or three 90° elbow assemblies. The relationships

of vertical rise to horizontal run in vent confi gurations using

90° elbows MUST BE strictly adhered to. The rise to run

relationships are shown in the venting drawings and tables.

Refer to the diagrams on the next several pages.

NOTE: Two 45° elbows may be used in place of one 90°

elbow. Rise to run ratios in the vent system must be followed if 45° elbows are used.

This model has vent starting collars on both the top and the

back of the unit. Depending upon the installation, decide

which ONE set of starting collars will be used to attach the

vent system. The starting collar sealing cap must remain

on the starting collar NOT used.

STORM COLLAR

ROOF FLASHING

Terminations Kits

DVP-TRAP SERIES

DVP-TVHW

HORIZONTAL

TERMINATION

WALL FIRESTOP

DVP-TB1

90 DEGREE

ELBOW

(Required to have

a minimum of 3 feet

of vertical in the

vent system)

PIPE LENGTH

CEILING

FIRESTOP

Figure 5. Vent System Components and Termination Kits

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0914

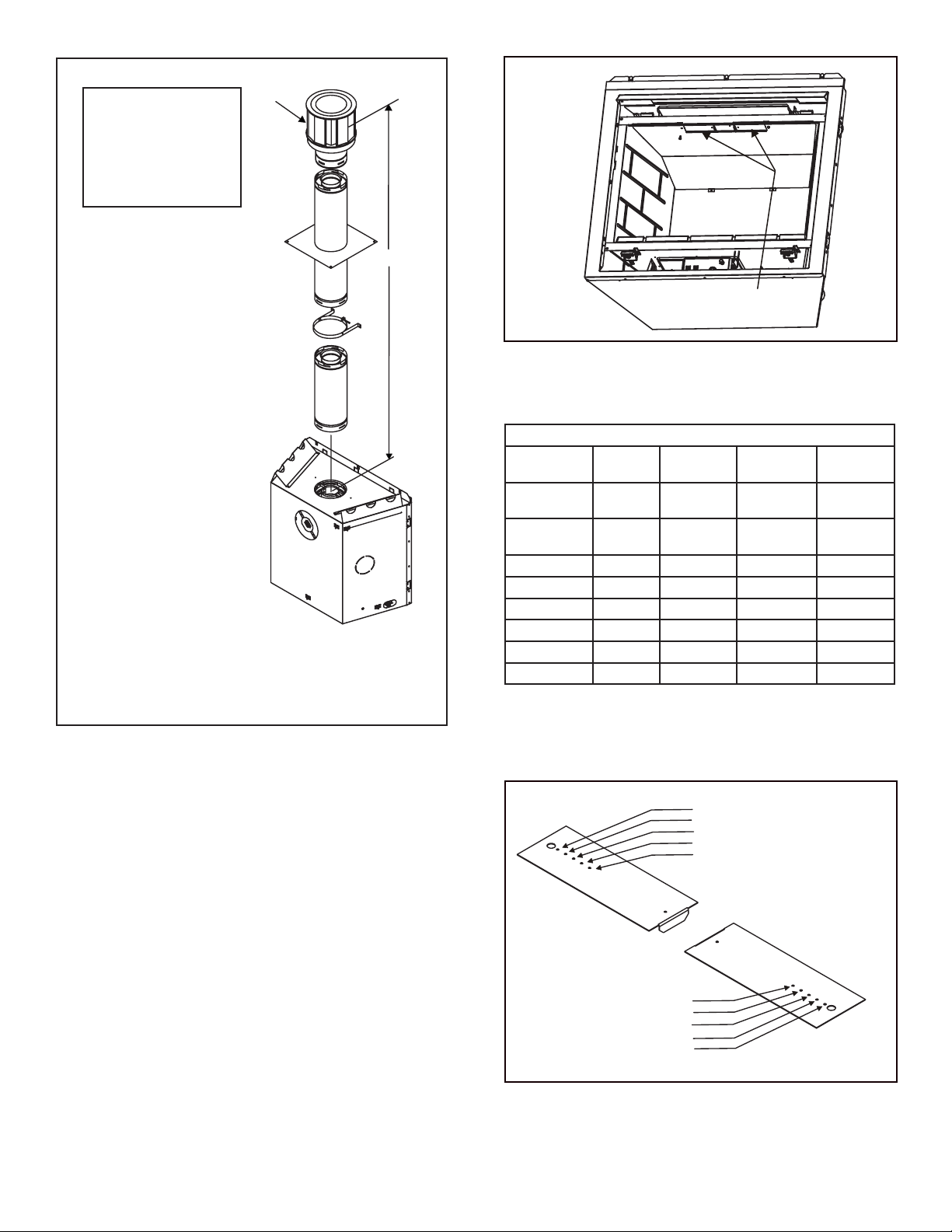

STRAIGHT UP

VERTICAL VENTING

V (FT.)

40’ MAX. (12.4 M)

CAP

NOTE: On vertical venting confi gurations over

20 feet install the fl ue re-

strictor (2027-102). See

fl ue restrictor installation

instructions.

Figure 6.

Straight Up Vertical Venting

V

ADJUSTABLE FLUE

Figure 7.

Vertical Top Vent NGTop Vent LPRear Vent NGRear Vent

4’ 2-2 2-3 No

8’ 3-3 2-3 2-2 No

15’ 3-4 3-4 3-3 2-3

20’ 4-4 3-4 3-4 3-4

25’ 4-4 3-4 3-4 3-4

30’ 4-4 4-4 4-4 3-4

35’ 4-4 4-4 4-4 3-4

40’ 4-5 4-4 4-4 4-4

RESTRICTORS (2)

- CHART -

Restrictor

LP

No

Restrictor

Restrictor

Flue Restrictor Instructions

1. Remove screws with a 1/4 nut driver. Adjust to

desired position per table. See Flue Restricting

chart.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

Adjustable Flue Restrictor (see Figure 8).

5

4

3

2

1

1

2

3

4

Figure 8

5

15

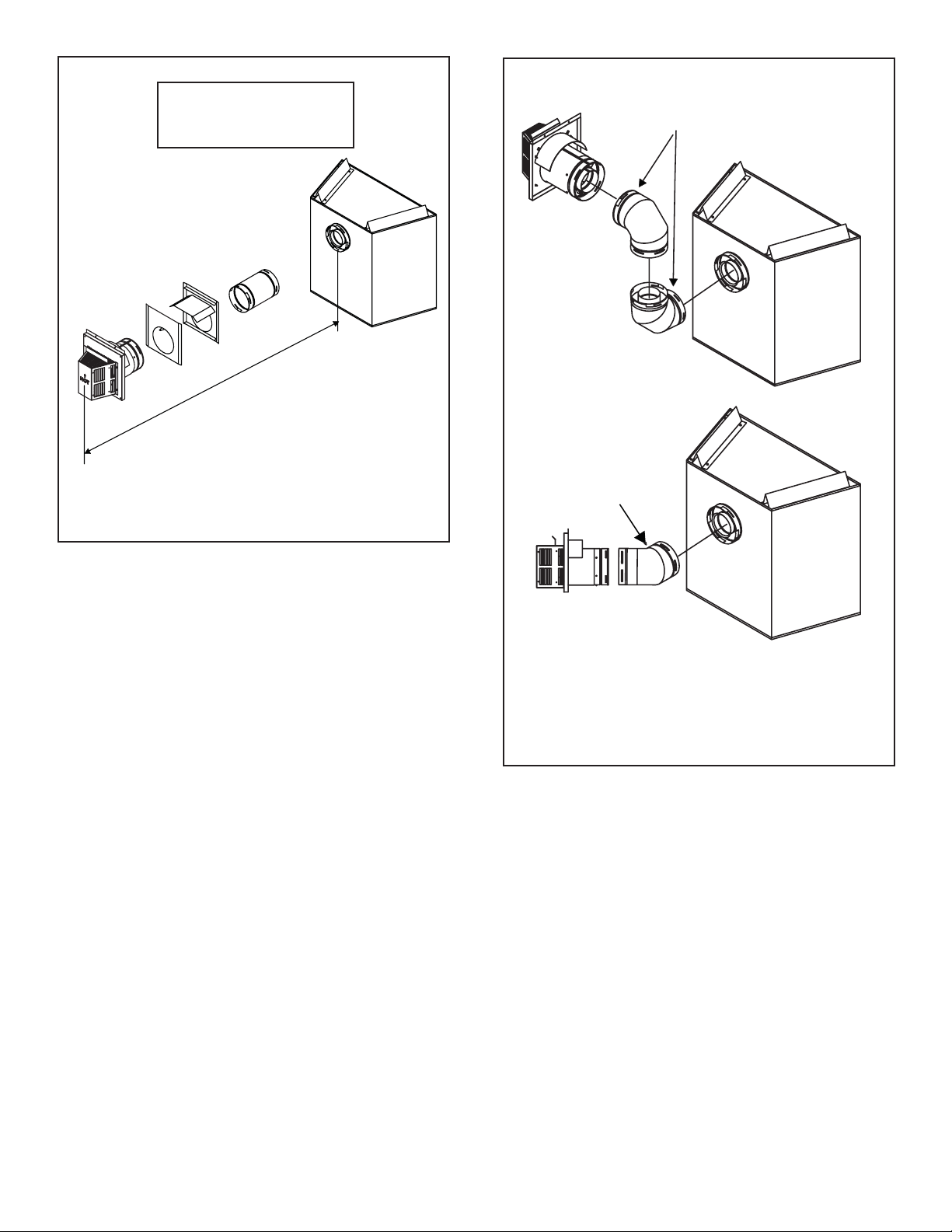

HORIZONTAL VENTING

Kit No. H Max. Run

DVP-TRAP 24” (610 mm)

H

Figure 9. Horizontal Installation

90-DEGREE

ELBOWS

45-DEGREE

ELBOW

NOTE: This model is tested and approved to use

45° elbows in corner installations. However, 90°

elbows will result in better performance.

Figure 10. Corner Installation

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0916

VENTING WITH ONE (1) 90° ELBOW

V H

1’ MIN. (305mm) 2’ MAX. (610mm)

2’ MIN. (610mm) 4’ MAX. (1.22m)

3’ MIN. (914mm) 6’ MAX. (1.86m)

4’ MIN. (1.22m) 8’ MAX. (2.4m)

V+H=40’ MAX. (12.4m) H = 8’ MAX. (2.4m)

NOTE: On vertical venting configurations

where the vertical component is over 10 feet

install the vertical baffl e included in the manual

bag assembly to improve fl ame appearance.

Figure 11. Venting with One 90° Elbow

V

H

VENTING WITH ONE (1) 90° ELBOW

V (FT.) H (FT.)

1’ MIN. (305mm) 5’ MAX. (1.52m)

2’ MIN. (610mm) 10’ MAX. (3.1m)

3’ MIN. (914mm) 15’ MAX. (4.65m)

4’ MIN. (1.22m) 20’ MAX. (6.2m)

V+H= 40’ MAX. (12.4MM) H = 20’ MAX. (6.2m)

H

V

NOTE: If a 90o elbow is

fi rst attached to the unit,

the maximum horizontal

run is 3-feet (914mm).

H

V

NOTE: For corner installations: A 6-inch (152mm)

section of straight pipe may need to be attached to

the fi replace before a 90o elbow, to allow the vent

pipe to clear the top standoffs.

Figure 12. Venting with One 90° Elbow

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

17

VENTING WITH TWO (2)

90° ELBOWS

H

1

V H H + H

1´ MIN. (305 mm) 2´ MAX. (610 mm) 5´ MAX. (1.52m)

2´ MIN. (610 mm) 4´ MAX. (1.22 m) 10´ MAX. (3.1m)

3´ MIN. (914 mm) 6´ MAX. (1.86 m) 15´ MAX. (4.65m)

4´ MIN. (1.22 m) 8´ MAX. (2.48 m) 20´ MAX. (6.2m)

V+H+H1 = 40´ MAX. (12.4 m) H = 8´ MAX. (2.48 m) H+H1 = 20´ MAX. (6.2m)

Figure 13. Venting with Two 90° Elbows

1

V

H

VENTING WITH TWO (2) 90o ELBOWS

V FT. H + H

1’ MIN. (305mm) 5´ MAX. (1.52m)

2’ MIN. (610mm) 10´ MAX. (3.1m)

3’ MIN. (914mm) 15´ MAX. (4.65m) 4’

MIN. (1.22m) 20´ MAX. (6.2m)

V+H+H1= 40’ MAX.(12.4m)

V+V1+H = 40’ MAX.(12.4m)

H

1

H+H1 = 20´ MAX. (6.2m)

(FT.)

1

H

V

1

V

H

V

Figure 14. Venting with Two 90° Elbows

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0918

VENTING WITH THREE (3) 90° ELBOWS

V H H + H

1´MIN. (305mm) 2´MAX. (610mm) 5´MAX. (1.52m)

1

2´MIN. (610mm) 4´MAX. (1.22m) 10´MAX. (3.1m)

3´MIN. (914mm) 6´MAX. (1.86m) 15´MAX. (4.65m)

4´MIN. (1.22m) 8´MAX. (2.48m) 20´MAX. (6.2m)

V1+V+H+H1 = 40´ MAX.(12.4 m) H = 8´MAX.(2.48 m) H+H1 = 20´MAX.(6.2 m)

V

1

V

H

1

H

V H H + H1 + H

2

1´MIN. (305mm) 2´MAX. (610mm) 5´MAX. (1.52m)

2´MIN. (610mm) 4´MAX. (1.22m) 10´MAX. (3.1m)

3´MIN. (914mm) 6´MAX. (1.86m) 15´MAX. (4.65m)

4´MIN. (1.22m) 8´MAX. (2.48m) 20´MAX. (6.2m)

V+H+H1+H2 = 40´ MAX. (12.4 m) H = 8´ MAX. (2.48 m) H+H1+H2 = 20´ MAX. (6.2 m)

V

H

2

H

1

Figure 15. Venting with three 90° elbows

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

H

19

VENTING WITH THREE (3) 90° ELBOWS

H

1

V

1

V

H

V (FT.) H

(FT.)

1’ MIN. (305mm) 5’ MAX. (1.52m)

2’ MIN. (610mm) 10’ MAX. (3.1m)

3’ MIN. (914mm) 15’ MAX. (4.65m)

4’ MIN. (1.22m) 20’ MAX. (6.2m)

NOTE: H + H1 = 20’ MAX. (6.2m)

V + V1 + H + H1= 40’ MAX. (12.4m)

V

1

H

1

V (FT.) H + H1 (FT.)

1’ MIN. (305mm) 5’ MAX. (1.52m)

2’ MIN. (610mm) 10’ MAX. (3.1m)

3’ MIN. (914mm) 15’ MAX. (4.65m)

4’ MIN. (1.22m) 20’ MAX. (6.2m)

H +H

= 20’ MAX. (6.2m)

1

NOTE: V+V

+H +H

1

= 40’ MAX. (12.4m)

1

Figure 16. Venting with three 90° elbows

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0920

H

V

B. Installing Vent Components

After determining which set of starting collars will be used

(top or rear), follow venting instructions accordingly.

Venting Out the Rear Vent

Remove the installed rear seal cap from the rear starting

collars by cutting the strap at each end. (see Figure 17).

Follow the vent confi guration tables accordingly.

Remove the insulation from the REAR fi ve inch fl ue, pull

the heat shield out from outside of the fi rebox.

WARNING: THE T OP HEA T SHIELD (INSIDE THE

!

FIREBOX) MUST REMAIN ATTACHED IF THE

VENT SYSTEM IS ATTACHED TO THE REAR

STARTING COLLARS. SEE FIGURE 17.

Venting Out the Top Vent

Remove the two screws in the top vent collar seal cap and

remove the top vent collar seal cap and the two pieces of

insulation inside the top two starting collars (See Figure

17).

Remove the heat shield from inside the TOP fi ve inch fl ue

from outside of the fi rebox.

You have to take the glass off again for positioning the

logs when the unit is fi nally installed in place and fi nished

around it. Re-install the glass door. Attach vent system to

the top starting collars.

WARNING: YOU MUST LEAVE THE INSULA-

!

TION IN PLACE IN THE SET OF COLLARS

YOU ARE NOT USING.

If your vertical vent component is over 10 feet, you may

want to install the included vertical baffl e to improve fl ame

appearance. Vertical baffl e is located in the bag containing

the instruction manual. Center the vertical baffl e on the fi ve

inch fl ue being used, and with self tapping screws secure

the baffl e to the inside of the fi rebox.

1. Attach the First Vent Component to the

Starting Collars

To attach the fi rst vent component to the starting collars

of the fi replace:

• Make sure that the fi berglass gasket supplied in the

manual bag seals between the fi rst 8 inch (203mm)

vent component and the outer fi replace wrap. Using 2

self-tapping screws from the manual bag secure that

gasket to the outer wrap (see Figure 18).

OUTER

WRAP

FIRST VENT

COMPONENT

FIBERGLASS

GASKET

WARNING: THE REAR VENT COLLAR SEAL

!

CAP MUST REMAIN ATTACHED TO THE

REAR VENT COLLARS IF THE VENT SYSTEM

IS ATTACHED TO THE TOP STARTING COLLARS. SEE FIGURE 18.

WARNING: FAILURE TO REMOVE INSULA-

!

TION IN THE SET OF COLLARS YOU ARE

USING COULD CAUSE A FIRE.

HEAT

SHIELD

DISCARD

and

HEAT SHIELD

Cut the seal cap

strap and remove white

gasket material.

Figure 17.

SEAL

CAP

SEAL

CAP

INSULATION

DISCARD BOTH

PIECES and

HEAT SHIELD

HEAT

SHIELD

CUT

HERE

CUT

HERE

Figure 18. Fiberglass Gasket

DVP PIPE:

1. Attaching the Venting to the Fireplace

Refer to Cinch Pipe and Termination Cap installation

instructions.

2. Assembling Vent Sections

Refer to Cinch Pipe and Termination Cap installation instructions.

WARNING: ENSURE THAT THE FIBERGLASS

!

GASKET SUPPLIED WITH THE FIREPLACE

SEALS BETWEEN THE FIRST VENT COMPONENT

AND THE OUTER FIREPLACE WRAP.

If the installation is for a termination cap attached directly

to the fi replace, skip to the sections, Install Firestops and

Vent Termination.

3. Continue Adding Vent Components

WARNING: INSTALLATION OF THIS FIRE-

!

PLACE REQUIRES THE USE OF A HEAT

SHIELD ABOVE THE FIRST 90

THE VENTING SYSTEM.

0

ELBOW IN

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

21

To Install the Heat Shield:

1. Determine if the heat shield is required. Do so by measuring the vertical distance between the top horizontal

surface of the elbow to any combustible surface above.

If the distance is more than 4 inches, the heat shield is

NOT required. If it is 4 inches or less, the heat shield IS

REQUIRED. Install per the following steps. See Figure

19.

• If the combustible materials are not in place at the time

of install the elbow heat shield may be screwed to the

exhaust pipe (see Figure 21). Cut the tabs as shown and

bend down. Secure the heat shield to the pipe maintaining 3” to 4” between the pipe and shield.

SCREW

Figure 19.

HEAT

SHIELD

COMBUSTIBLE

SURFACE

3” MIN.

(76 mm)

2. Fasten the shield in place using the pilot holes provided

in the part. The shield should be oriented such that the 13

1/8 inch dimension (longest dimension) is running in the

same direction the elbow is pointing. The shield should

be centered directly above the elbow, and positioned so

that it creates a 1/2 inch airspace between the shield

and the combustible surface. See Figure 20.

CORRECT INCORRECT

COMBUSTIBLE SURFACE

DIRECTION

UP

3 in.

(76mm)

Figure 21.

Refer to Cinch Pipe and Termination Cap installation instructions.

• Continue adding vent components, locking each succeeding component into place.

• Ensure that each succeeding vent component is securely

fi tted and locked into the preceding component in the

vent system.

• 90° elbows may be installed and rotated to any point

around the preceding component’s vertical axis. If an

elbow does not end up in a locked position with the

preceding component, attach with a minimum of two (2)

sheet metal screws.

4. Install Support Brackets

Refer to Cinch Pipe and Termination Cap installation instructions.

Figure 20.

HEAT SHIELD

°

ELBOW

90

Figure 22. Adding Venting Components

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0922

5. Install Firestops

For Horizontal Runs - Firestops are REQUIRED on

both sides of a combustible wall through which the vent

passes.

NOTE: Model DVP-TRAP does not need an exterior

fi restop on an exterior combustible wall.

To install fi restops for horizontal runs that pass through

either interior or exterior walls:

• Cut a 10-inch by 12-inch (254mm X 305mm) hole through

the wall.

NOTE: The center of the hole is one (1) inch (25.4mm)

above the center of the horizontal vent pipe.

INTERIOR

WALL SHIELD

10 in.

12 in.

• Position the fi restops on both sides of the hole previously

cut and secure the fi restops with nails or screws.

• The heat shields of the fi restops MUST BE placed to-

wards the top of the hole.

• Continue the vent run through the fi restops.

NOTE: There must be NO INSULATION or other

combustibles inside the framed fi restop opening.

Figure 23. 10” x 12” Hole and Vent Pipe

HEAT SHIELD

INTERIOR

FIRESTOP

Figure 24. Heat Shield, Interior & Exterior Firestops

TRIM HEAT

SHIELD IF TOO

LONG, ADD TO

SHIELD IF TOO

SHORT

EXTERIOR

FIRESTOP

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

23

For Vertical Runs - One ceiling fi restop is REQUIRED at

the hole in each ceiling through which the vent passes.

To install fi restops for vertical runs that pass through

ceilings:

• Position a plumb bob directly over the center of the vertical vent component.

• Mark the ceiling to establish the centerpoint of the

vent.

• Drill a hole or drive a nail through this centerpoint.

• Check the fl oor above for any obstructions, such as wir-

ing or plumbing runs.

• Reposition the fi replace and vent system, if necessary,

to accommodate the ceiling joists and/or obstructions.

• Cut an 10-inch X 10-inch (254mm X 254mm) hole through

the ceiling, using the centerpoint previously marked.

• Frame the hole with framing lumber the same size as

the ceiling joists.

10" (254mm)

CEILING

NEW

FRAMING

MEMBERS

EXISTING CEILING

JOISTS

)mm452("01

CHIMNEY

HOLE

If the area above the ceiling IS an attic, position and secure

the fi restop on top of the previously framed hole.

NOTE: Keep insulation away from the vent pipe at least

1 inch (25mm).

NAILS (4 REQUIRED)

RAFTER

CEILING

CEILING FIRESTOP

Figure 27. Attic Firestop

C. Vent Termination

Refer to Cinch Pipe and Termination Cap installation instructions.

Horizontal Termination

• The termination kit should pass through the wall fi restops

from the exterior of the building and interlock the fl ue

sections.

• Adjust the termination cap to its fi nal exterior position

on the building and interlock the fl ue sections.

Figure 25. 10” x 10” Hole & New Framing Members

If the area above the ceiling is NOT an attic, position

and secure the ceiling fi restop on the ceiling side of the

previously cut and framed hole.

NOTE: There must be NO INSULATION or other

combustibles inside the framed fi restop opening.

JOIST

CEILING

NAILS (4 REQUIRED)

CEILING FIRESTOP

Figure 26. Ceiling Firestop (Ceiling Side)

WARNING: THE TERMINATION CAP MUST BE PO-

!

SITIONED SO THAT THE ARROW IS POINTING UP.

WARNING: VENTING TERMINALS

!

SHALL NOT BE RECESSED INTO A WALL

OR SIDING. VENT TERMINATION CLEARANCES

MUST BE FOLLOWED TO AVOID FIRE DANGER.

SEE VENT TERMINATION MINIMUM CLEARANCES

DIAGRAM ON FOLLOWING PAGE.

Figure 28.

71/4”

(184mm)

Trapezoid Termination Cap

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0924

V

R

M

N

P

Q

(See Note 2)

T

S

Electrical

V

Service

V

S

V

D*

= VENT TERMINAL

V

A = 12 inches.................clearances above grade, veranda,

(See Note 1)

X

= AIR SUPPLY INLET

porch, deck or balcony

B = 12 inches.................clearances to window or door

that may be opened, or to permanently closed window. (Glass)

D* = 18 inches.................vertical clearance to unventilated

soffi t or to ventilated soffi t located

above the terminal

*30 inches ................for vinyl clad soffi ts and below

electrical service

F = 9 inches..................clearance to outside corner

G = 6 inches...................clearance to inside corner

H = 3 ft. (Canada) ..........not to be installed above a gas

meter/regulator assembly within 3

feet (90 cm) horizontally from the

center-line of the regulator

I = 3 ft ...........................clearance to gas service regulator

vent outlet

J = 9 inches (U.S.A.)

12 inches (Canada) clearance to non-mechanical

air supply inlet to building or the

combustion air inlet to any other

appliance

K = 3 ft. (U.S.A.)

6 ft. (Canada) ...........clearance to a mechanical (pow-

ered) air supply inlet

= AREA WHERE TERMINAL IS NOT PERMITTED

L** = 7 ft. ......................... clearance above paved

(See Note 1)

sidewalk or a paved driveway

located on public property

M*** = 18 inches................ cl earance under veranda, porch,

deck, balcony or overhang

42 inches ............... vinyl soffi t and overhang

S = 6 inches................. clearance from sides of electri-

(See Note 5)

cal service

T = 12 inches................ clearance above electrical

(See Note 5)

service

Alcove Applications

N = 6 inches ..................non-vinyl sidewalls

12 inches ................vinyl sidewalls

P = 8 ft.

Q

MIN

1 cap 3 feet 2 x Q

2 caps 6 feet 1 x Q

3 caps 9 feet 2/3 x Q

4 caps 12 feet 1/2 x Q

Q

= # termination caps x 3 R

MIN

= (2 / # termination caps) x Q

MAX

R

MAX

ACTUAL

ACTUAL

ACTUAL

ACTUAL

ACTUAL

** a vent shall not terminate directly above a sidewalk or paved driveway

which is located between two single family dwellings and serves both

dwellings.

*** only permitted if veranda, porch, deck or balcony is fully open on a

minimum of 2 sides beneath the fl oor, or meets Note 2.

Note 1: On private property where termination is less than 7 feet above a

sidewalk, driveway, deck, porch, veranda or balcony, use of a listed cap

shield is suggested.

Note 2: Termination in an alcove space (spaces open only on one side

and with an overhang) are permitted with the dimensions specifi ed for

vinyl or non-vinyl siding and soffi ts. 1. There must be 3 feet minimum

between termination caps. 2. All mechanical air intakes within 10 feet

of a termination cap must be a minimum of 3 feet below the termination

cap. 3. All gravity air intakes within 3 feet of a termination cap must be a

minimum of 1 foot below the termination cap.

Note 3: Local codes or regulations may require different

clearances.

Note 4: Termination caps may be hot. Consider their proximity to

doors or other traffi c areas.

Note 5: Location of the vent termination must not interfere with

access to the electrical service.

WARNING: In the U.S: V ent system termination is NOT permitted in

screened porches. Y ou must follow side wall, overhang and ground

clearances as stated in the instructions.

In Canada: Vent system termination is NOT permitted in screened

porches. Vent system termination is permitted in porch areas with

two or more sides open. You must follow all side walls, overhang

and ground clearances as stated in the instructions.

Heat & Glo assumes no responsibility for the improper performance

of the appliance when the venting system does not meet these

Figure 4.4 Minimum Clearances for Termination

requirements.

CAUTION: IF EXTERIOR WALLS ARE FINISHED WITH VINYL SIDING, IT IS SUGGESTED THAT A VINYL PROTECTOR KIT BE INSTALLED.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

25

For Vertical Terminations - To locate the vent and install

the vent sections:

• Locate and mark the vent centerpoint on the underside

of the roof, and drive a nail through the centerpoint.

• Make the outline of the roof hole around the centerpoint

nail.

• The size of the roof hole framing dimensions depend on

the pitch of the roof. There MUST BE a 1-inch (25.4mm)

clearance from the vertical vent pipe to combustible

materials.

• Mark the roof hole accordingly.

• Cover the opening of the installed vent pipes.

To seal the roof hole, and to divert rain and snow from the

vent system:

• Attach a fl ashing to the roof using nails, and use a non-

hardening mastic around the edges of the fl ashing base

where it meets the roof.

• Attach a storm collar over the fl ashing joint to form a

water-tight seal. Place non-hardening mastic around the

joint, between the storm collar and the vertical pipe.

• Slide the termination cap over the end of the vent pipe

and snap into place.

HORIZONTAL

OVERHANG

• Cut and frame the roof hole.

• Use framing lumber the same size as the roof rafters

and install the frame securely . Flashing anchored to the

frame must withstand heavy winds.

• Continue to install concentric vent sections up through

the roof hole (for inside vent installations) or up past the

roof line until you reach the appropriate distance above

the roof (for outside terminations).

WARNING: MAJOR U.S. BUILDING CODES

!

SPECIFY MINIMUM CHIMNEY AND/OR

VENT HEIGHT ABOVE THE ROOF TOP.

THESE MINIMUM HEIGHTS ARE NECESSARY IN

THE INTEREST OF SAFETY . SEE FIGURE 30 FOR

MINIMUM HEIGHTS, PROVIDED THE TERMINATION CAP IS AT LEAST TWENTY INCHES FROM

A VERTICAL WALL AND 2-FEET BELOW A HORIZONTAL OVERHANG.

NOTE: This also pertains to vertical vent systems

installed on the outside of the building.

2 FT.

MIN.

TERMINATION

CAP

20 INCH MIN.

LOWEST

DISCHARGE

OPENING

X

12

ROOF PITCH

IS X/ 12

H (MIN.) - MINIMUM HEIGHT FROM ROOF

TO LOWEST DISCHARGE OPENING

Roof Pitch H (min.) ft.

fl at to 6/12 1.0

6/12 to 7/12 1.25

over 7/12 to 8/12 1.5

over 8/12 to 9/12 2.0

over 9/12 to 10/12 2.5

over 10/12 to 11/12 3.25

over 11/12 to 12/12 4.0

over 12/12 to 14/12 5.0

over 14/12 to 16/12 6.0

over 16/12 to 18/12 7.0

over 18/12 to 20/12 7.5

over 20/12 to 21/12 8.0

VERTICAL

WALL

Figure 30. Minimum Height from Roof to

Lowest Discharge Opening

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0926

Step 4. Positioning, Leveling, and

Securing the Fireplace

The diagram below shows how to properly position,

level, and secure the fi replace.

ILING TABS

OTH SIDES)

Figure 31. Proper Positioning, Leveling, and

Securing of a Fireplace

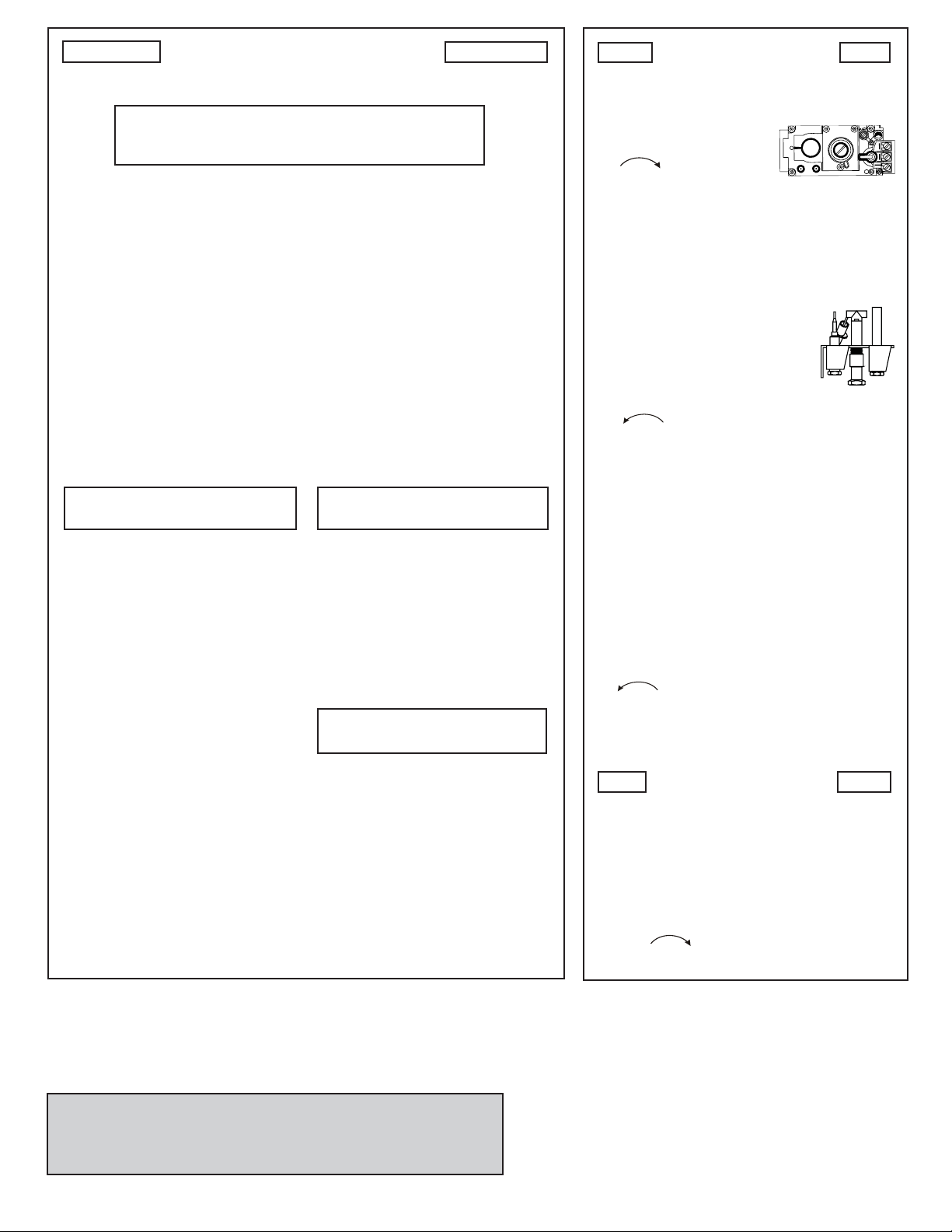

Step 5. The Gas Control System

WARNING: THIS UNIT IS NOT FOR USE

!

WITH SOLID FUEL.

The type of gas control system used with this model is

Standing Pilot Ignition.

Standing Pilot Ignition System

This system includes millivolt control valve, standing pilot,

thermopile/thermocouple fl ame sensor, and piezo ignitor.

WARNING: 110-120 VAC MUST NEVER BE

!

CONNECTED TO A CONTROL VALVE IN A

MILLIVOLT SYSTEM.

STANDING PILOT

• Place the fi replace into position.

• Level the fi replace from side to side and from front to

back.

• Shim the fi replace with non-combustible material, such

as sheet metal, as necessary.

• Secure the fi replace to the framing by nailing or screw-

ing.

Figure 32. Gas Control System

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

27

Step 6. The Gas Supply Line

NOTE: Have the gas supply line installed by a qualifi ed

service technician in accordance with all building codes.

(In the Commonwealth of Massachusetts installation must

be performed by a licensed plumber or gas fi tter).

NOTE: Before the fi rst fi ring of the fi replace, the gas supply

line should be purged of any trapped air.

NOTE: Consult local building codes to properly

size the gas supply line leading to the 1/2 inch

(13 mm) hook-up at the unit.

This gas fireplace is designed to accept a 1/2 inch

(13 mm) gas supply line. To install the gas supply line:

• A listed (and Commonwealth of Massachusetts approved) 1/2 inch (13 mm) tee-handle manual shut-off

valve and a listed fl exible gas connector are connected

to the 1/2 inch (13 mm) inlet of the control valve. NOTE:

If substituting for these components please consult local

codes for compliance.

• Locate the gas line access hole in the outer casing of

the fi replace.

• The gas line may be run from either side of the fi replace

provided the hole in the outer wrap does not exceed 2” in

diameter and it does not penetrate the actual fi rebox.

• Open the fi replace lower grille, insert the gas supply line

through the gas line hole, and connect it to the shut-off

valve.

• When attaching the pipe, support the control so that the

lines are not bent or torn.

• After the gas line installation is complete, all connections

must be tightened and checked for leaks with a commercially available, non-corrosive leak check solution.

Be sure to rinse off all leak check solution following

testing.

USE A WRENCH

CONTROL

VALVE

GAS LINE

ACCESS HOLE

ON SHUT-OFF VALVE

WHEN TIGHTENING

GAS LINE.

MANUAL

SHUT-OFF VALVE

GAS VALVE

CONNECTOR

FLEX

Figure 33. Gas Supply Line

Step 7. Gas Pressure Requirements

Pressure requirements for gas fi replaces are shown

in the table below.

Pressure Natural Gas Propane

Minimum 5.0 inches 11.0 inches

Inlet Pressure w.c. w.c.

Maximum Inlet 14.0 inches 14.0 inches

Gas Pressure w.c. w.c.

Manifold 3.5 inches 10.0 inches

Pressure w.c. w.c.

WARNING: DO NOT USE AN OPEN FLAME

!

TO CHECK FOR GAS LEAKS.

• Insert insulation from the outside of the fi replace and

pack the insulation tightly to totally seal between the

pipe and the outer casing.

• At the gas line access hole the gap between the supply

piping and gas access hole can be plugged with noncombustible insulation to prevent cold air infi ltration.

A connection is provided on the inlet and outlet side of the

gas control for a test gauge connection to measure the

manifold pressure. Use a small phillips screwdriver to crack

open the screw in the center of the tap. Position a rubber

hose over the tap to obtain the pressure reading.

The fi replace and its individual shut-off valve must be

disconnected from the gas supply piping system during any

pressure testing of the system at test pressures in excess

of one-half (1/2) psig (3.5 kPa).

The fi replace must be isolated from the gas supply piping

system by closing its individual shut-off valve during any

pressure testing of the gas supply piping system at test

pressures equal to or less than one-half (1/2) psig (3.5

kPa).

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0928

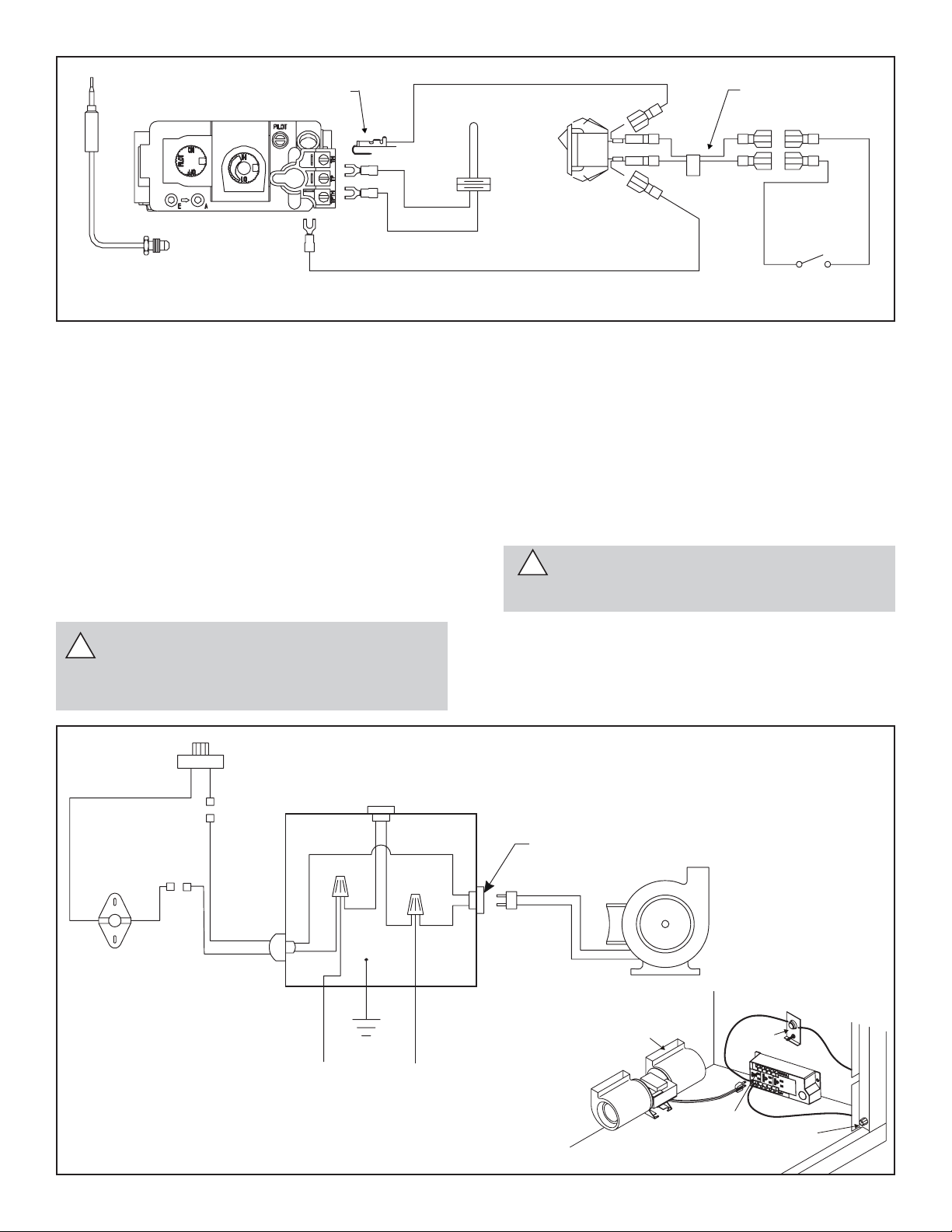

3/16” PIGGYBACK CONNECTOR

BLACK S2

ON

OFF

REMOTE SWITCH

PIGTAIL

WHITE T2

GAS VALVE

THERMOCOUPLE

Figure 34. Standing Pilot Ignition Wiring Diagram

RED T1

THERMOPILE

Step 8. Wiring the Fireplace

NOTE: Electrical wiring must be installed by a licensed

electrician.

CAUTION: DISCONNECT REMOTE CONTROLS IF

ABSENT FOR EXTENDED TIME PERIODS. THIS WILL

PREVENT ACCIDENTAL FIREPLACE OPERATION.

Appliance Requirements

• This appliance DOES NOT require 110-120 VAC to

operate.

• A 110-120 V AC circuit for this product must be protected

with ground-fault circuit-interrupter protection, in compliance with the applicable electrical codes, when it is in-

stalled in locations such as in bathrooms or near sinks.

WARNING: DO NOT CONNECT 110-120

!

VAC TO THE GAS CONTROL VALVE OR

THE APPLIANCE WILL MALFUNCTION

AND THE VALVE WILL BE DESTROYED.

ON/OFF

SWITCH

BLACK S1

OPTIONAL WALL SWITCH,

THERMOSTAT OR REMOTE

Optional Accessories

Optional fan and remote control kits require that 110-120

VAC be wired to the factory installed junction box before

the fi replace is permanently installed.

Wall Switch

Position the wall switch in the desired position on a wall.

Run a maximum of 25 feet (7.8 m) or less length of 18

A.W.G. minimum wire and connect it to the fi replace ON/

OFF switch pigtails

WARNING: DO NOT CONNECT 110-120

!

V AC TO THE W ALL SWITCH OR THE CONTROL VALVE WILL BE DESTROYED.

CAUTION: LABEL ALL WIRES PRIOR TO DISCONNECTION WHEN SERVICING CONTROLS. WIRING ERRORS

CAN CAUSE IMPROPER AND DANGEROUS OPERATION. VERIFY PROPER OPERATION AFTER SERVICING.

BLK

BLK

BLK

TEMPERATURE

SENSOR SWITCH

VARIABLE SPEED CONTROL

BLK

JUNCTION BOX

BLK

BLK

BLK

BLK

110-120 VAC

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

GROUND

GRN

WHT

NOTE: IF ANY OF THE ORIGINAL WIRE

AS SUPPLIED WITH THE APPLIANCE

MUST BE REPLACED, IT MUST BE

REPLACED WITH TYPE 105

BLOWER RECEPTACLE

BLK

WHT

WHT

° C RATED WIRE.

BLOWER

BLOWER

SENSOR

SWITCH

“FAN”

RECEPTACLE

SPEED

CONTROL

29

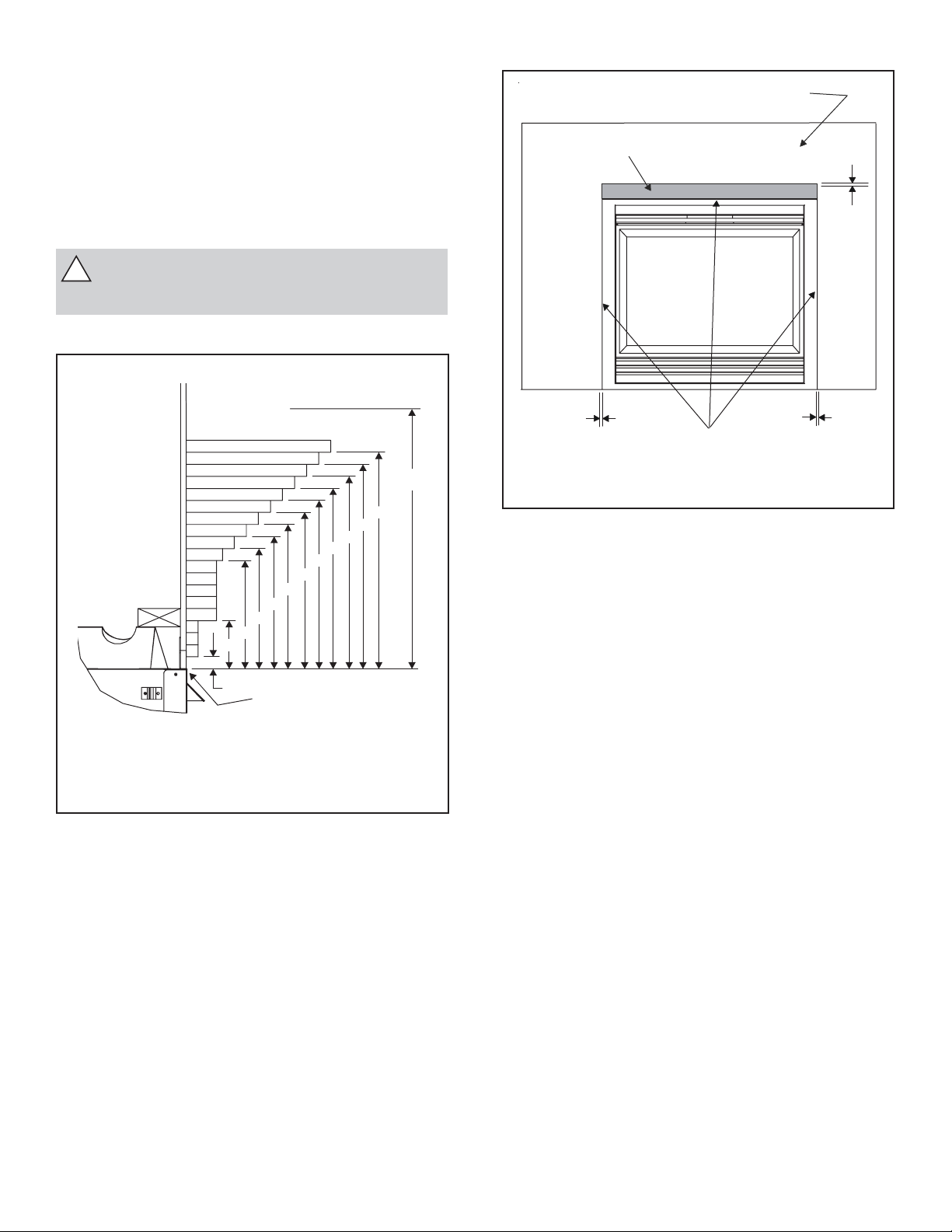

Step 9. Finishing

Figure 36 shows the minimum vertical and corresponding

maximum horizontal dimensions of fi replace mantels or

other combustible projections above the top front edge

of the fi replace. See Figures 2 and 3 for other fi replace

clearances.

Only non-combustible materials may be used to cover the

black fi replace front.

WARNING: WHEN FINISHING THE FIREPLACE,

!

NEVER OBSTRUCT OR MODIFY THE AIR INLET/OUTLET GRILLES IN ANY MANNER.

FINISH WALL MATERIAL MAY BE

COMBUSTIBLE - TOP AND SIDES

NON-COMBUSTIBLE

BOARD

0

12”

11”

10”

9”

8”

7”

6”

5”

4”

3”

13”

12”

2-1/2”

1”

Figure 36.

Minimum Vertical and Maximum Horizontal Dimensions of

Combustibles above Fireplace

11”

10”

9”

4”

1”

TOP FRONT EDGEOF FIREPLACE

14”

15”

16”

17”

TO CEILING

18”

31”

NOTE: There are 3 metal tabs holding the non-combustible

board in place for shipping. These tabs are to be cut off or

bent back before fi nishing around the fi replace front.

0

HIGH TEMPERATURE (300°F/ 149°CMIN.)

TOP &SIDESEAL JOINT

Figure 37. Sealant Material

0

CAUTION: IF JOINTS BETWEEN THE FINISHED WALLS

AND THE FIREPLACE SURROUND (TOP AND SIDES)

ARE SEALED, A 300° F . MINIMUM SEALANT MA TERIAL

MUST BE USED. THESE JOINTS ARE NOT REQUIRED

TO BE SEALED. ONL Y NON-COMBUSTIBLE MA TERIAL

(USING 300° F . MINIMUM ADHESIVE, IF NEEDED) CAN

BE APPLIED AS FACING TO THE FIREPLACE SURROUND (SEE FIGURE 39).

Hearth Extensions

A hearth extension may be desirable for aesthetic reasons.

However, ANSI or CAN/CGA testing standards do not

require hearth extensions for gas fi replace appliances.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0930

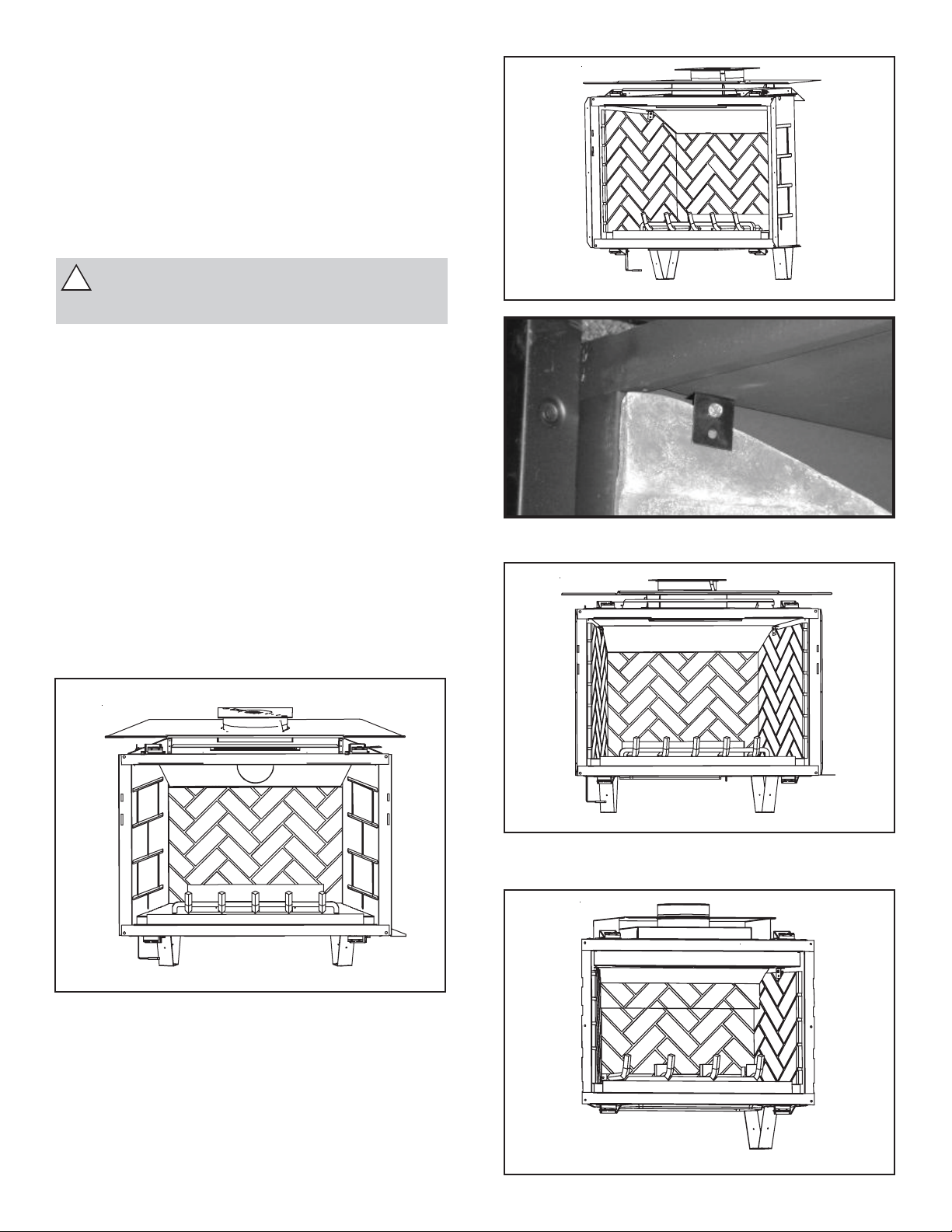

Step 10. Installing Trim, Refractory, Logs,

and Ember Material

Installing the Trim

Combustible materials may be brought up to the specifi ed

clearances on the side and top front edges of the fi replace,

but MUST NEVER overlap onto the front face. The joints

between the fi nished wall and the fi replace top and sides

can only be sealed with a 300° F. (149° C) minimum

sealant.

WARNING: WHEN FINISHING THE FIREPLACE,

!

NEVER OBSTRUCT OR MODIFY THE AIR INLET/OUTLET GRILLES IN ANY MANNER.

Install optional marble and brass trim surround kits as

desired. Marble, brass, brick, tile, or other non-combustible

materials can be used to cover up the gap between the

sheet rock and the fi replace.

Do not obstruct or modify the air inlet/outlet grilles. When

overlapping on both sides, leave enough space so that the

bottom grille can be lowered and the trim door removed.

Figure 39.

Refractory Kit Placement (BRICK-292)

CAUTION: REFRACTORY IS FRAGILE! CAREFULLY

REMOVE THE REFRACTORY FROM THE PACKAGING.

Remove the logs and log grate from the fi replace. Place

the back wall refractory centered against the back of the

fi replace on the back refractory ledge (see Figure 38).

Figure 38.

Figure 40.

Figure 39.

Position the right wall all the way to back wall. Secure in position same as was done for the left wall (see Figure 42).

When positioning the left wall use care in not knocking

the back wall down. Position the left wall all the way back

against the back wall. Using the retaining clip and screw

included, secure the side wall refractory as shown (see

Figures 39 and 40).

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

Figure 42.

31

Positioning the Logs

Refer to the included log instructions.

Shutter Settings

NG LP

Burner Full Open Full Open

Placing the Ember Material

• Release the four glass latches on the glass frame. Re-

move glass door from the unit.

• Glowing Ember material can be placed without remov-

ing logs. Place a single layer of dime size and thickness

pieces on exposed area of burner front and burner

center. Starting in front of two center logs place one

row at a time, completely surrounding all ports in front

of middle logs including those that extend under front

logs. DO NOT press ember material down into ports or

place more than a single layer on burner. Do not place

embers on or near ports behind front logs.

CAUTION: DO NOT COVER BURNER PORTS WITH

EMBER MATERIAL.

• Save the remaining ember materials for use during

fi replace servicing.

• Replace the glass door.

• Pull out and latch the glass clips into the glass frame.

• Install a decorative front.

Step 11. Before Lighting the Fireplace

Before lighting the fi replace, be sure to do the following:

Remove all paperwork from underneath the fi replace.

Check that log retaining rubber bands have been

removed!

Review safety warnings and cautions

• Read the Safety and Warning Information section at

the beginning of this Owner’s Manual.

Double-check for gas leaks

• Before lighting the fi replace, double-check the unit for

possible gas leaks.

Double-check vent terminations and front grilles for

obstructions.

• Before lighting the fi replace, double-check the unit for

possible obstructions that could be blocking the vent

terminations or the front grilles.

Double-check for faulty components

• Any component that is found to be faulty MUST BE

replaced with an approved component. Tampering with

the fi replace components is DANGEROUS and voids all

warranties.

A small amount of air will be in the gas supply lines.

When fi rst lighting the fi replace, it will take a few minutes

for the lines to purge themselves of this air. Once the

purging is complete, the fi replace will light and will operate

normally.

Glass Specifi cations: CERAMIC

Subsequent lightings of the fi replace will not require this

purging of air from the gas supply lines, unless the gas

valve has been turned to the OFF position, in which

case the air would have to be purged.

NOTE: The fi replace should be run 3 to 4 hours on the initial

start-up. Turn it of f and let it cool completely. Remove and

clean the glass. Replace the glass and run the fi replace

for an additional 8 hours. This will help to cure the product

used in the paint and logs.

During this break-in period it is recommended that some

windows in the house be opened for air circulation. This will

help avoid setting off smoke detectors, and help eliminate

any odors associated with the fi replace’s initial burning.

Step 12. Lighting the Appliance

You’ve reviewed all safety warnings, you’ve checked the

appliance for gas leaks, you know the vent system is

unobstructed, and you’ve checked for faulty components.

Now you’re ready to light the appliance.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0932

FOR YOUR SAFETY

READ BEFORE LIGHTING

WARNING: If you do not follow these instructions

exact ly, a fi re or explosion may result causing proper t y

damage, personal injury or loss of life.

A. This appliance has a pilot which

must be lighted by hand. When

lighting the pilot, follow these

instructions exactly.

B. BEFORE LIGHTING, smell all

around the appliance area for gas.

Be sure to smell next to the fl oor

because some gas is heavier than

air and will settle on the fl oor.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch;

do not use any phone in your

building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow

the gas supplier’s instructions.

WARNING:

DO NOT CONNECT 110 VAC TO

THE CONTROL VALVE.

Improper installation, adjustment, alteration, service or maintenance can

cause injury or property damage. Refer to the owner’s information manual

provided with this appliance.

This appliance needs fresh air for

safe operation and must be installed

so there are provisions for adequate

combustion and ventilation air.

If not installed, operated, and maintained in accordance with the manufacturer’s instructions, this product

could expose you to substances in fuel

or fuel combustion which are known to

the State of California to cause cancer, birth defects, or other reproductive harm.

Keep burner and control compartment

clean. See installation and operating

instructions accompanying appliance.

For additional information on operating your

Hearth & Home Technologies fi replace, please refer to www.fi replaces.com.

• If you cannot reach your gas supplier, call the fi re department.

C. Use only your hand to push in or

turn the gas control knob. Never

use tools. If the knob will not push

in or turn by hand, don’t try to

repair it, call a qualifi ed service

technician. Force or attempted

repair may result in a fi re or explo-

sion.

D. Do not use this appliance if any

part has been under water. Immediately call a qualifi ed service

technician to inspect the appliance

and to replace any part of the

control system and any gas control

which has been under water.

CAUTION:

Hot while in operation. Do not touch.

Keep children, clothing, furniture, gasoline and other liquids having fl ammable

vapors away.

Do not operate the appliance with

panel(s) removed, cracked or broken.

Replacement of the panel(s) should be

done by a licensed or qualifi ed service

person.

NOT FOR USE

WITH SOLID FUEL

For use with natural gas and propane.

A conversion kit, as supplied by the

manufacturer, shall be used to convert

this appliance to the alternate fuel.

Also Certifi ed for Installation in a

Bedroom or a Bedsitting Room.

For assistance or additional information, consult a qualifi ed installer, ser-

vice agency or the gas supplier.

LIGHTING

INSTRUCTIONS

1. Turn off all electric power to the appliance.

2. Push in gas control knob

slightly and turn clockwise

NOTE: Knob cannot be turned from “PILOT” to “OFF”

unless knob is pushed in slightly. Do not force.

3. Wait fi ve (5) minutes to clear out any gas.

Then smell for gas, including near the fl oor. If you

smell gas, STOP! Follow “B” in the Safety Information located on the left side of this label. If you don’t

smell gas, go to next step.

4. Find the pilot. The pilot is inside

combustion chamber next to the

main burner.

5. Turn knob on gas control counter clockwise

to “PILOT”.

6. Push in control knob all the way and hold in. Immediately depress red or black piezo button. It may

require several depressions of the red or black

piezo button until PILOT lights. If PILOT light does

not light after 10 seconds, return to step 3. Continue to

hold the control knob in for about one minute after the

pilot is lit. Release knob and it will pop back out. Pilot

should remain lit. If it goes out, repeat steps 3 through 6.

• If knob does not pop up when released, stop and immediately call your service technician or gas supplier.

• If the pilot will not stay lit after several tries, turn

the gas control knob to “OFF” and call your service

technician or gas supplier.

7. Turn gas control knob counterclockwise to

“ON”.

8. To light Burner, fl ip the on/off switch to the “ON”

position, and close access grille.

9. Turn on all electric power to the appliance.

to “OFF”.

TO TURN OFF

GAS TO APPLIANCE

1. Turn off all electric power to the appliance if

service is to be performed.

2. Open control access panel.

3. Move switch to “OFF” position.

4. Push in gas control knob slightly and turn clock-

wise to OFF”. Do not force.

5. Close control access panel.

464-903G

When you light your fi replace, you may notice:

This gas appliance produces heat which does have an associated

odor or smell. If you feel this odor is excessive it may require the

initial 3-4 hour continuous burn on high followed by a second burn

up to 12 hours to fully drive off any odor from paint and lubricants

used in the manufacturing process.

During this break-in period it is recommended that some windows in

the house be opened for air circulation. This will help avoid setting

off smoke detectors, and help eliminate any odors associated with

the fi replace’s initial burning.

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/09

Additionally, for the fi rst few minutes after each lighting,

vapor may condense and fog the glass and fl ames may be

blue. After a few minutes this moisture will disappear and

within 15-30 minutes the fl ames should become yellow.

Noise caused by metal expanding and contracting as it

heats up and cools down, similar to the sound produced

by a furnace or heating duct. This noise does not affect the

operation or longevity of your fi replace.

33

Step 13 Climate Control

This model is equipped with a baffl e which will allow you

to control the usable heat output. The baffl e control lever

is located at the lower left corner of the unit behind the

lower grille.

TOP VENTED: More Heat: Pull handle down and push

back to close the damper. Less Heat: Pull handle forward

and push up to open the damper.

REAR VENTED: More Heat: Pull handle forward and push

up to close the damper. Less Heat: Pull handle down and

push back to open the damper.

4

Maintaining and Servicing Your Fireplace

Fireplace Maintenance

Although the frequency of your fi replace servicing and

maintenance will depend on use and the type of installation,

you should have a qualifi ed service technician perform an

appliance check-up at the beginning of each heating season. See the table below for specifi c guidelines regarding

each fi replace maintenance task.

BAFFLE

CONTROL

LEVER

Figure 43.

After the Installation

LEAVE THIS INSTALLATION MANUAL WITH

!

THE APPLIANCE FOR FUTURE REFERENCE.

Checking Vent System

Frequency: Before initial use and at least annually

thereafter, more frequently if possible.

By: Qualifi ed service technician/Home owner.

Task: Inspect the external vent cap on a regular basis

to ensure that no debris is interfering with the fl ow of air.

Inspect entire vent system for proper function.

IMPORT ANT : TURN OFF THE GAS BEFORE SERVICING

YOUR FIREPLACE.

Replacing old ember material

Frequency: Once annually, during the checkup.

By: Qualifi ed service technician.

Task: Brush away loose ember material near the burner.

Replace old ember material with new dime-size and shape

pieces. New ember material should be placed on top of

the burner. Save the remaining ember material and repeat

this procedure at your next servicing. For more information,

see Placing Ember Material.

Cleaning Burner and Controls

Frequency: Once annually.

By: Qualifi ed service technician.

Task: Brush or vacuum the control compartment, fi replace

logs and burner areas surrounding the logs.

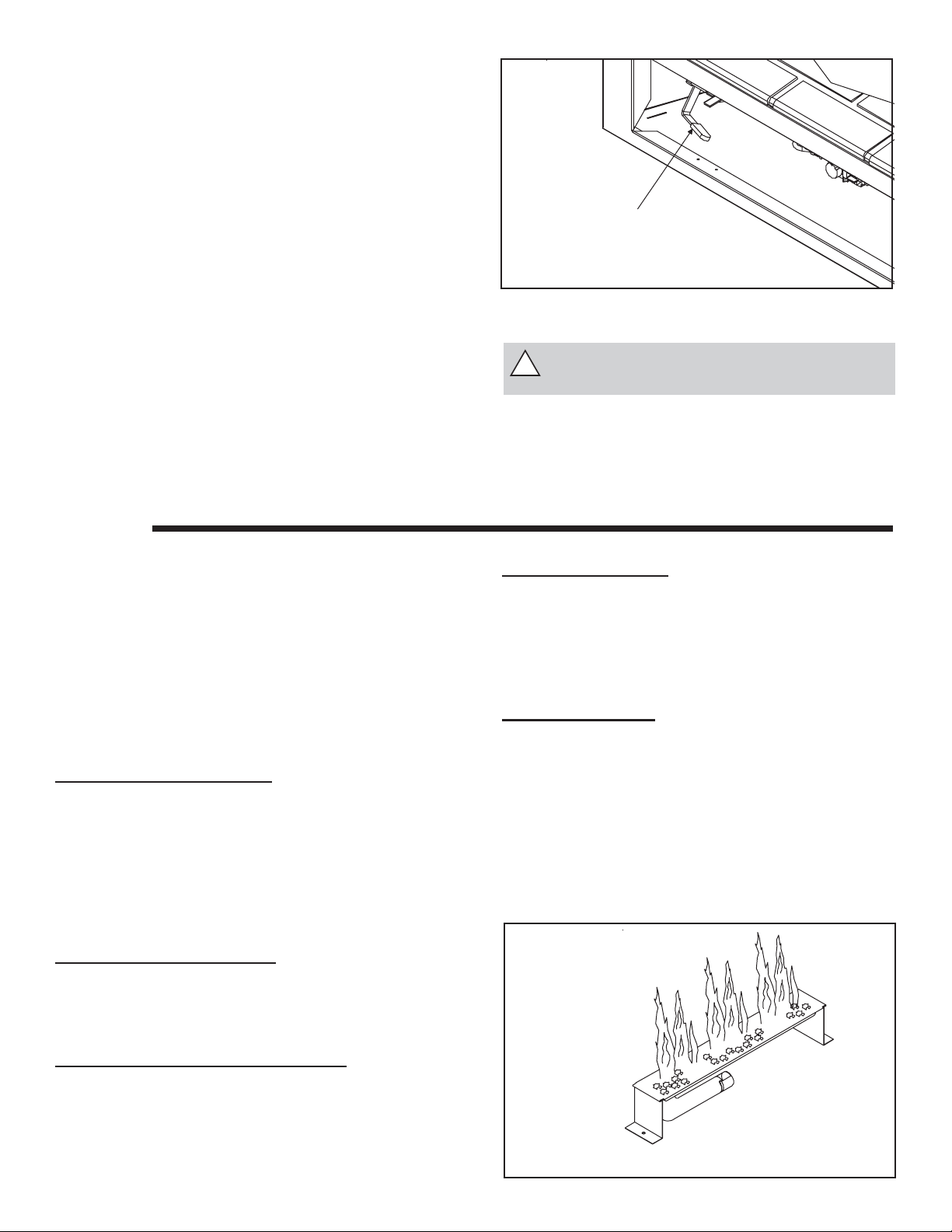

Checking Flame Patterns, Flame Height

Frequency: Periodically.

By: Qualifi ed service technician/Home owner.

Task: Make a visual check of your fireplace’s flame

patterns. Make sure the fl ames are steady - not lifting or

fl oating. See Figure 44. The thermopile/thermocouple tips

should be covered with fl ame (See Figure 32).

Quadra-Fire • QV36DC-A • 2161-900 Rev. C • 6/0934

Cleaning Glass Door

Frequency: After the fi rst 3 to 4 hours of use. As neces-

sary after initial cleaning.

By: Home owner.

Task: Remove and clean glass after the fi rst 3 to 4 hours

of use. After the initial cleaning, clean as necessary, particularly after adding new ember (fl ame colorant) material.

Film deposits on the inside of the glass door should be

cleaned off using a household glass cleaner. NOTE: DO

NOT handle or attempt to clean the door when it is hot

and DO NOT use abrasive cleaners.

MAKESURE THE

FLAMESARE STEADY—

NOTLIFTING OR

FLOATING.

Figure 44. Burner Flame Patterns

Troubleshooting

5

A. Standing Pilot Ignition System

Symptom Possible Causes Corrective Action

With proper installation, operation, and maintenance your gas fi replace will

provide years of trouble-free service. If you do experience a problem, this

troubleshooting guide will assist a qualifi ed service person in the diagnosis

of a problem and the corrective action to be taken. This troubleshooting

guide can only be used by a qualifi ed service technician.

1. After repeated triggering

of the red or black piezo

ignitor button, the spark

ignitor will not light the pilot.

2. The pilot will not stay lit

after carefully following the

lighting instructions.

a. Defective ignitor. Check the spark at the electrode and pilot. If no spark and electrode

wire is properly connected, replace the ignitor.

b. Defective pilot or misaligned

electrode (spark at electrode).