Page 1

PTQ-PDPMV1

Quantum Platform

PROFIBUS DP Master Network

Interface Module for Quantum

August 12, 2014

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2014 ProSoft Technology, Inc. All rights reserved.

PTQ-PDPMV1 User Manual

August 12, 2014

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Information for ProTalk® Product Users

The statement "power, input and output (I/O) wiring must be in accordance with Class I, Division 2 wiring methods

Article 501-10(b) of the National Electrical Code, NFPA 70 for installations in the U.S., or as specified in section 181J2 of the Canadian Electrical Code for installations within Canada and in accordance with the authority having

jurisdiction".

The following or equivalent warnings shall be included:

A Warning - Explosion Hazard - Substitution of components may Impair Suitability for Class I, Division 2;

B Warning - Explosion Hazard - When in Hazardous Locations, Turn off Power before replacing Wiring Modules,

and

C Warning - Explosion Hazard - Do not Disconnect Equipment unless Power has been switched Off or the Area is

known to be Nonhazardous.

D Caution: The Cell used in this Device may Present a Fire or Chemical Burn Hazard if Mistreated. Do not

Disassemble, Heat above 100°C (212°F) or Incinerate.

WARNING - EXPLOSION HAZARD - DO NOT DISCONNECT EQUIPMENT UNLESS POWER HAS BEEN

SWITCHED OFF OR THE AREA IS KNOWN TO BE NON-HAZARDOUS.

AVERTISSEMENT - RISQUE D'EXPLOSION - AVANT DE DÉCONNECTER L'ÉQUIPEMENT, COUPER LE

COURANT OU S'ASSURER QUE L'EMPLACEMENT EST DÉSIGNÉ NON DANGEREUX.

Warnings

North America Warnings

A Warning - Explosion Hazard - Substitution of components may impair suitability for Class I, Division 2.

B Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or rewiring modules.

Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C Suitable for use in Class I, Division 2 Groups A, B, C and D Hazardous Locations or Non-Hazardous Locations.

ATEX Warnings and Conditions of Safe Usage

Power, Input, and Output (I/O) wiring must be in accordance with the authority having jurisdiction.

A Warning - Explosion Hazard - When in hazardous locations, turn off power before replacing or wiring modules.

B Warning - Explosion Hazard - Do not disconnect equipment unless power has been switched off or the area is

known to be non-hazardous.

C These products are intended to be mounted in an IP54 enclosure. The devices shall provide external means to

prevent the rated voltage being exceeded by transient disturbances of more than 40%. This device must be used

only with ATEX certified backplanes.

D DO NOT OPEN WHEN ENERGIZED.

Warnings

Electrical Ratings

Backplane Current Load: 1100 mA maximum @ 5 Vdc ± 5%

Operating Temperature: 0°C to 60°C (32°F to 140°F)

Storage Temperature: -40°C to 85°C (-40°F to 185°F)

Shock: 30 g operational; 50 g non-operational; Vibration: 5 g from 10 Hz to 150 Hz

Relative Humidity: 5% to 95% (with no condensation)

All phase conductor sizes must be at least 1.3 mm(squared) and all earth ground conductors must be at least

4mm(squared).

Page 4

CE

cULus

Shock & Vibration

CB Safety

GOST-R

RoHS

ATEX

CAUTION: THE CELL USED IN THIS DEVICE MAY PRESENT A FIRE

OR CHEMICAL BURN HAZARD IF MISTREATED. DO NOT

DISASSEMBLE, HEAT ABOVE 100°C (212°F) OR INCINERATE.

Maximum battery load = 200 μA.

Maximum battery charge voltage = 3.4 Vdc.

Maximum battery charge current = 500 μA.

Maximum battery discharge current = 30 μA.

Label Markings

<cULus>

E183151

Class I Div 2

Groups A,B,C,D T6

-30°C <= Ta <= 60°C

<Ex>

II 3 G

EEx nL IIc T6

-20°C <= Ta <= 60°C

Shock & Vibration tested to EN 60068 Standard

Agency Approvals and Certifications

Important Notice:

Page 5

PTQ-PDPMV1 ♦ Quantum Platform Contents

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Information for ProTalk® Product Users .............................................................................................. 3

Warnings ............................................................................................................................................. 3

Warnings ............................................................................................................................................. 3

Important Notice: ................................................................................................................................. 4

Guide to the PTQ-PDPMV1 User Manual 11

1 Start Here 13

1.1 Hardware and Software Requirements ................................................................... 14

1.1.1 Quantum Hardware ................................................................................................. 14

1.1.2 PC and PC Software ............................................................................................... 14

1.2 Deployment Checklist .............................................................................................. 15

1.3 Installing ProSoft Configuration Builder Software ................................................... 16

1.4 Installing the Module ............................................................................................... 17

1.4.1 Installing the ProTalk Module in the Quantum Rack ............................................... 17

1.4.2 Connecting to the ProTalk Configuration/Debug Port ............................................. 18

1.4.3 PTQ-PDPMV1 Configuration / Debug Port Note .................................................... 19

2 Configuring the Module 21

2.1 Configuring the Module with ProSoft Configuration Builder .................................... 22

2.1.1 Setting Up the Project ............................................................................................. 23

2.1.2 Setting Module Parameters ..................................................................................... 25

2.1.3 Updating the Ethernet Settings ............................................................................... 32

2.2 Downloading the Ethernet Configuration to the Module ......................................... 33

2.3 Configuring the PROFIBUS Master ........................................................................ 34

2.3.1 Installing the GSD Files ........................................................................................... 35

2.3.2 Configuring the PROFIBUS Slaves ......................................................................... 36

2.3.3 Exporting the Processor Memory Map .................................................................... 50

2.3.4 Downloading the Project to the Module .................................................................. 53

2.3.5 Backing Up the Project ............................................................................................ 54

2.3.6 File Locations .......................................................................................................... 56

3 Configuring the Processor with Unity Pro 59

3.1 Importing the Functional Module ............................................................................. 60

3.1.1 Updating Checksum Values .................................................................................... 67

3.1.2 Setting Up General Unity Pro Project Settings ....................................................... 69

3.1.3 Configuring the Memory Size for the Processor ..................................................... 71

3.1.4 Building the Project ................................................................................................. 73

3.1.5 Downloading the Project to the Quantum Processor .............................................. 74

3.1.6 Verifying Communication between the Processor and the Module ........................ 75

3.2 Function Blocks Operation Overview ...................................................................... 79

3.3 Derived Function Blocks Overview ......................................................................... 82

ProSoft Technology, Inc. Page 5 of 306

August 12, 2014

Page 6

Contents PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

3.3.1 Using the Derived Function Blocks ......................................................................... 82

3.4 Using Mailbox Function Blocks ............................................................................... 85

3.4.1 Overview ................................................................................................................. 85

3.4.2 Configuration........................................................................................................... 86

3.4.3 Trigger Bytes........................................................................................................... 87

3.4.4 Specific Input Pins .................................................................................................. 88

3.4.5 Specific Output Pins ............................................................................................... 88

3.5 Mailbox Overview ................................................................................................... 91

3.5.1 Acyclic Read Mailbox .............................................................................................. 91

3.5.2 Acyclic Write Mailbox .............................................................................................. 92

3.5.3 Alarm Mailbox ......................................................................................................... 93

3.5.4 GetConfiguration Mailbox ....................................................................................... 94

3.5.5 GetDiagnostics Mailbox .......................................................................................... 95

3.5.6 GetLiveList Mailbox ................................................................................................ 95

3.5.7 SetSlaveAddress Mailbox ....................................................................................... 96

3.5.8 SetOperatingMode Mailbox .................................................................................... 97

3.5.9 SetSlaveMode Mailbox ........................................................................................... 97

3.5.10 StartStopSlaves Mailbox ......................................................................................... 98

3.5.11 Coldboot Mailbox .................................................................................................... 99

4 Configuring the Processor with Concept 2.6 101

4.1 Overview ............................................................................................................... 102

4.2 Before You Begin .................................................................................................. 103

4.3 Information for Concept Version 2.6 Users .......................................................... 104

4.3.1 Installing MDC Configuration Files ....................................................................... 104

4.4 Step 1: Exporting the Files from PCB ................................................................... 106

4.4.1 -.ASC files ............................................................................................................. 107

4.4.2 -.DTY file ............................................................................................................... 108

4.4.3 -.TXT file ............................................................................................................... 108

4.5 Step 2: Converting the Function Blocks ............................................................... 109

4.6 Step 3: Setting up the Concept Project ................................................................ 113

4.7 Step 4: Importing the Variables ............................................................................ 116

4.8 Step 5: Creating the Function Block Instances ..................................................... 119

4.9 Step 6: Downloading the Concept Project ............................................................ 126

4.10 Using the Concept Project .................................................................................... 127

4.10.1 Accessing PROFIBUS Data ................................................................................. 127

4.10.2 Accessing Status Data .......................................................................................... 127

4.10.3 Configuration Validation & SETCRC Function Block............................................ 128

4.11 Using Mailbox Function Blocks ............................................................................. 130

4.11.1 Overview ............................................................................................................... 130

4.11.2 Configuration......................................................................................................... 130

4.11.3 Trigger Register .................................................................................................... 131

4.11.4 Specific Input Pins ................................................................................................ 132

4.11.5 Specific Output Pins ............................................................................................. 132

4.12 Mailbox Overview ................................................................................................. 136

4.12.1 Acyclic Read Mailbox ............................................................................................ 136

4.12.2 Acyclic Write Mailbox ............................................................................................ 137

4.12.3 Alarm Mailbox ....................................................................................................... 138

4.12.4 GetConfiguration Mailbox ..................................................................................... 139

4.12.5 GetDiagnostics Mailbox ........................................................................................ 140

4.12.6 GetLiveList Mailbox .............................................................................................. 140

4.12.7 SetSlaveAddress Mailbox ..................................................................................... 141

Page 6 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 7

PTQ-PDPMV1 ♦ Quantum Platform Contents

PROFIBUS DP Master Network Interface Module for Quantum User Manual

4.12.8 SetOperatingMode Mailbox ................................................................................... 142

4.12.9 SetSlaveMode Mailbox .......................................................................................... 142

4.12.10 Start/Stop Slaves Mailbox ..................................................................................... 143

4.12.11 Coldboot Mailbox ................................................................................................... 143

5 Configuring the Processor with ProWORX 32 147

6 Mailbox Messaging 151

6.1 Mailbox Message Queuing .................................................................................... 152

6.1.1 Queue Timeouts .................................................................................................... 152

6.2 Special Function Mailbox Messaging Commands ................................................ 153

6.2.1 Mailbox Message: Set Slave Mode ....................................................................... 156

6.2.2 Mailbox Message: Get Slave Diagnostics ............................................................. 159

6.2.3 Mailbox Message: Get Slave Configuration .......................................................... 161

6.2.4 Mailbox Message: Set Slave Address ................................................................... 162

6.2.5 Mailbox Message: Get Live List ............................................................................ 165

6.2.6 Mailbox Message: Acyclic Data Read: Class 1 ..................................................... 166

6.2.7 Mailbox Message: Acyclic Data Write: Class 1 ..................................................... 168

6.2.8 Mailbox Message: Alarm Indication ...................................................................... 170

6.2.9 Mailbox Message: Set Operating Mode ................................................................ 172

6.2.10 Mailbox Message: Start Slave ............................................................................... 174

6.2.11 Mailbox Message: Stop Slave ............................................................................... 175

6.3 Receiving Mailbox Message Responses from PTQ Module ................................. 178

6.4 Mailbox Messaging Error Codes ........................................................................... 180

6.4.1 Acyclic Message Status Word ............................................................................... 180

6.4.2 Return Codes ........................................................................................................ 181

6.4.3 Error Codes ........................................................................................................... 182

6.4.4 DP-V1 Error Codes ............................................................................................... 183

7 Hot Standby Support 185

7.1 Hot Standby Overview ........................................................................................... 186

7.1.1 Identical Configurations ......................................................................................... 186

7.1.2 Primary and Standby Controllers .......................................................................... 186

7.1.3 System Components ............................................................................................. 187

7.1.4 Modicon Quantum Hot Standby with Unity and IEC Logic .................................... 188

7.1.5 Understanding System Scan Time in Modicon Quantum Hot Standby with Unity

Systems 188

7.2 Setting Up the Modicon Quantum Hot Standby with Unity System ...................... 191

7.2.1 Overview................................................................................................................ 191

7.2.2 Mapping the Backplane Extensions ...................................................................... 191

7.2.3 PTQ-PDPMV1 Hot Standby Considerations ......................................................... 191

7.2.4 Hot Standby States ............................................................................................... 192

7.2.5 Transition Description ............................................................................................ 193

7.2.6 HSBY State vs. Master Operation Mode ............................................................... 194

7.2.7 Ping Message ........................................................................................................ 194

7.2.8 PTQ Link Message ................................................................................................ 198

7.2.9 Crossed Status Information ................................................................................... 199

7.2.10 Conditions for Switchover...................................................................................... 200

7.3 PTQ-PDPMV1 Operation ...................................................................................... 201

7.3.1 PTQ-PDPMV1 HSBY Diagnostic Data .................................................................. 201

ProSoft Technology, Inc. Page 7 of 306

August 12, 2014

Page 8

Contents PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

7.3.2 Switchover Timeline .............................................................................................. 212

7.3.3 Bus Parameters .................................................................................................... 212

7.3.4 HSBY Master GSD File ........................................................................................ 213

7.3.5 LED Indicators ...................................................................................................... 213

7.3.6 Unsupported Functions ......................................................................................... 214

7.3.7 ProSoft Configuration Builder (PCB) HSBY Option Functionality ........................ 214

7.4 PTQ-PDPMV1 Master Bus Properties for Use of a P&F DP/PA Segment Coupler217

7.4.1 PROFIBUS DP Time Behavior ............................................................................. 217

7.4.2 Commissioning of Communication with the SK1 Segment Coupler ..................... 218

7.4.3 Details for calculating the TWD parameter ........................................................... 221

8 Diagnostics and Troubleshooting 223

8.1 Basic Troubleshooting Steps ................................................................................ 224

8.2 LED Indicators: Front of PTQ Module .................................................................. 225

8.3 Module Status Indicators ...................................................................................... 228

8.4 PROFIBUS Master Indicators ............................................................................... 229

8.5 View the Online Status of the PROFIBUS Network.............................................. 230

8.6 Using ProSoft Configuration Builder (PCB) for Diagnostics ................................. 231

8.6.1 Using the Diagnostic Window in ProSoft Configuration Builder ........................... 231

8.6.2 Navigation ............................................................................................................. 232

8.6.3 Main Menu ............................................................................................................ 233

8.6.4 Input Data View Menu .......................................................................................... 238

8.6.5 Output Data View Menu ........................................................................................ 239

8.7 Standard PROFIBUS Slave Diagnostic Bytes ...................................................... 241

8.7.1 Byte 0 - Station Status 1 Bits ................................................................................ 241

8.7.2 Byte 1 - Station Status 2 Bits ................................................................................ 241

8.7.3 Byte 2 - Station Status 3 Bits ................................................................................ 242

8.7.4 Byte 3 - Master Address ....................................................................................... 242

8.7.5 Byte 4 - Ident Number High .................................................................................. 242

8.7.6 Byte 5 - Ident Number Low ................................................................................... 242

9 Reference 243

9.1 Product Specifications .......................................................................................... 244

9.1.1 Hot Standby Support ............................................................................................ 245

9.1.2 General Specifications .......................................................................................... 245

9.1.3 Hardware Specifications ....................................................................................... 246

9.1.4 Functional Specifications ...................................................................................... 247

9.2 Functional Overview ............................................................................................. 248

9.2.1 About the PROFIBUS Protocol ............................................................................. 248

9.2.2 General Overview ................................................................................................. 248

9.2.3 PROFIBUS DP Architecture ................................................................................. 249

9.2.4 Master/Slave Communication Phases .................................................................. 250

9.2.5 PTQ Input and Output Data Blocks ...................................................................... 251

9.3 PROFIBUS comDTM ............................................................................................ 261

9.3.1 ProSoft Technology Product Availability ............................................................... 261

9.3.2 Introduction to PROFIBUS comDTM .................................................................... 262

9.3.3 System Requirements .......................................................................................... 265

9.3.4 Installation ............................................................................................................. 265

9.3.5 Quick Start ............................................................................................................ 267

9.3.6 Verifying the comDTM Version and comDTM Install Version .............................. 273

9.4 Cable Connections ............................................................................................... 278

Page 8 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 9

PTQ-PDPMV1 ♦ Quantum Platform Contents

PROFIBUS DP Master Network Interface Module for Quantum User Manual

9.4.1 Ethernet Connection .............................................................................................. 278

9.4.2 RS-232 Configuration/Debug Port ........................................................................ 279

9.5 PROFIBUS Master Port ........................................................................................ 280

9.5.1 Constructing a Bus Cable for PROFIBUS DP ....................................................... 280

9.6 Supported PROFIBUS Services ........................................................................... 285

9.7 Quantum to PTQ Communication Protocol ........................................................... 286

9.8 Calculating System Response Time ..................................................................... 288

9.8.1 How to Calculate PROFIBUS Time: TMC4 ........................................................... 288

9.8.2 Calculating System Reaction Time ....................................................................... 289

9.9 Using Multiple PTQ-PDPMV1 Modules with Concept ........................................... 291

9.10 Frequently Asked Questions ................................................................................. 292

9.10.1 How do I configure the module? ........................................................................... 292

9.10.2 Is a .MDC available for configuration of the module? ........................................... 292

9.10.3 Does the module work in a remote rack? .............................................................. 292

9.10.4 Can I use the module in a hot backup system? .................................................... 292

10 Support, Service & Warranty 293

Contacting Technical Support ......................................................................................................... 293

10.1 Return Material Authorization (RMA) Policies and Conditions.............................. 295

10.1.1 Returning Any Product .......................................................................................... 295

10.1.2 Returning Units Under Warranty ........................................................................... 296

10.1.3 Returning Units Out of Warranty ........................................................................... 296

10.2 LIMITED WARRANTY ........................................................................................... 297

10.2.1 What Is Covered By This Warranty ....................................................................... 297

10.2.2 What Is Not Covered By This Warranty ................................................................ 298

10.2.3 Disclaimer Regarding High Risk Activities ............................................................ 298

10.2.4 Intellectual Property Indemnity .............................................................................. 299

10.2.5 Disclaimer of all Other Warranties ........................................................................ 299

10.2.6 Limitation of Remedies ** ...................................................................................... 300

10.2.7 Time Limit for Bringing Suit ................................................................................... 300

10.2.8 No Other Warranties ............................................................................................. 300

10.2.9 Allocation of Risks ................................................................................................. 300

10.2.10 Controlling Law and Severability ........................................................................... 300

Glossary of Terms 301

Index 303

ProSoft Technology, Inc. Page 9 of 306

August 12, 2014

Page 10

Contents PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

Page 10 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 11

PTQ-PDPMV1 ♦ Quantum Platform Guide to the PTQ-PDPMV1 User Manual

Function

Section to Read

Details

Introduction

(Must Do)

Start Here (page 13)

This section introduces the customer to the

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

Diagnostic and

Troubleshooting

Diagnostics and

Troubleshooting

(page 223)

This section describes Diagnostic and

Troubleshooting procedures.

Reference

Product Specifications

Reference (page

243)

Product

Specifications (page

244)

These sections contain general references

associated with this product and its

Specifications..

Support, Service, and

Warranty

Index

Support, Service

and Warranty (page

293)

Index

This section contains Support, Service and

Warranty information.

Index of chapters.

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Guide to the PTQ-PDPMV1 User Manual

ProSoft Technology, Inc. Page 11 of 306

August 12, 2014

Page 12

Guide to the PTQ-PDPMV1 User Manual PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

Page 12 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 13

PTQ-PDPMV1 ♦ Quantum Platform Start Here

In This Chapter

Hardware and Software Requirements ................................................. 14

Deployment Checklist ............................................................................ 15

Installing ProSoft Configuration Builder Software .................................. 16

Installing the Module ............................................................................. 17

PROFIBUS DP Master Network Interface Module for Quantum User Manual

1 Start Here

ProSoft Technology, Inc. Page 13 of 306

August 12, 2014

Page 14

Start Here PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

1.1 Hardware and Software Requirements

1.1.1 Quantum Hardware

This guide assumes that you are familiar with the installation and setup of the

Quantum hardware. The following should be installed, configured, and powered

up before you proceed:

Quantum processor

Quantum rack

Quantum power supply

Quantum Modbus Plus Network Option Module (NOM Module) (optional)

Quantum to PC programming hardware

NOM Ethernet or serial connection to PC

1.1.2 PC and PC Software

ProSoft Technology recommends the following minimum hardware to use the

module:

Windows PC with 80486 based processor (Pentium preferred) with at least

one COM, USB, or Ethernet port

1 megabyte of system memory

Unity™ Pro PLC programming software, version 3.0 or later

or

Concept™ PLC programming software, version 2.6 or later

or

Other Quantum Programming Software

Note: ProTalk module configuration files are compatible with common Quantum programming

applications, including Unity Pro and Concept. For all other programming applications, please

contact technical support.

Page 14 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 15

PTQ-PDPMV1 ♦ Quantum Platform Start Here

PROFIBUS DP Master Network Interface Module for Quantum User Manual

1.2 Deployment Checklist

This is a list of the steps you must complete to install your ProTalk module. We

recommend that you read this section completely before you begin the

installation.

During this procedure, you will install the module in the rack with the processor,

set up a PROFIBUS Master, connect one or more PROFIBUS slave devices, and

then configure the processor with information about the PROFIBUS network. The

example programs you will be configuring are designed to demonstrate that the

module and the processor are correctly configured and communicating with each

other over the backplane. After this initial installation, you may need to perform

additional steps to configure the application for your specific needs.

You must complete these steps in the following order, otherwise the installation

may not be successful.

1 Install the ProSoft Configuration Builder software on your PC

Important: Earlier versions of ProSoft Configuration Builder do not support the Hot Standby

(HSBY) feature on the PTQ-PDPMV1 module. To make full use of the HSBY feature, please

download the latest version of ProSoft Configuration Builder and review the readme files from the

ProSoft Technology website at www.prosoft-technology.com/pcb.

2 Install the ProTalk module in the rack

3 Configure the module

4 Configure the PROFIBUS Master and slaves

5 Export the processor files

6 Configure the processor

7 Verify communication between the processor and the module

ProSoft Technology, Inc. Page 15 of 306

August 12, 2014

Page 16

Start Here PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

1.3 Installing ProSoft Configuration Builder Software

You must install the ProSoft Configuration Builder (PCB) software to configure

the module. You can always get the newest version of ProSoft Configuration

Builder from the ProSoft Technology website.

To install ProSoft Configuration Builder from the ProSoft Technology website

1 Open your web browser and navigate to http://www.prosoft-

technology.com/pcb

2 Click the DOWNLOAD HERE link to download the latest version of ProSoft

Configuration Builder.

3 Choose SAVE or SAVE FILE when prompted.

4 Save the file to your Windows Desktop, so that you can find it easily when

you have finished downloading.

5 When the download is complete, locate and open the file, and then follow the

instructions on your screen to install the program.

If you do not have access to the Internet, you can install ProSoft Configuration

Builder from the ProSoft Solutions Product CD-ROM, included in the package

with your module.

To install ProSoft Configuration Builder from the Product CD-ROM

1 Insert the ProSoft Solutions Product CD-ROM into the CD-ROM drive of your

PC. Wait for the startup screen to appear.

2 On the startup screen, click PRODUCT DOCUMENTATION. This action opens a

Windows Explorer file tree window.

3 Click to open the UTILITIES folder. This folder contains all of the applications

and files you will need to set up and configure your module.

4 Double-click the SETUP CONFIGURATION TOOL folder, double-click the

PCB_*.EXE file and follow the instructions on your screen to install the

software on your PC. The information represented by the "*" character in the

file name is the PCB version number and, therefore, subject to change as

new versions of PCB are released.

Note: Many of the configuration and maintenance procedures use files and other utilities on the

CD-ROM. You may wish to copy the files from the Utilities folder on the CD-ROM to a convenient

location on your hard drive.

Page 16 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 17

PTQ-PDPMV1 ♦ Quantum Platform Start Here

PROFIBUS DP Master Network Interface Module for Quantum User Manual

1.4 Installing the Module

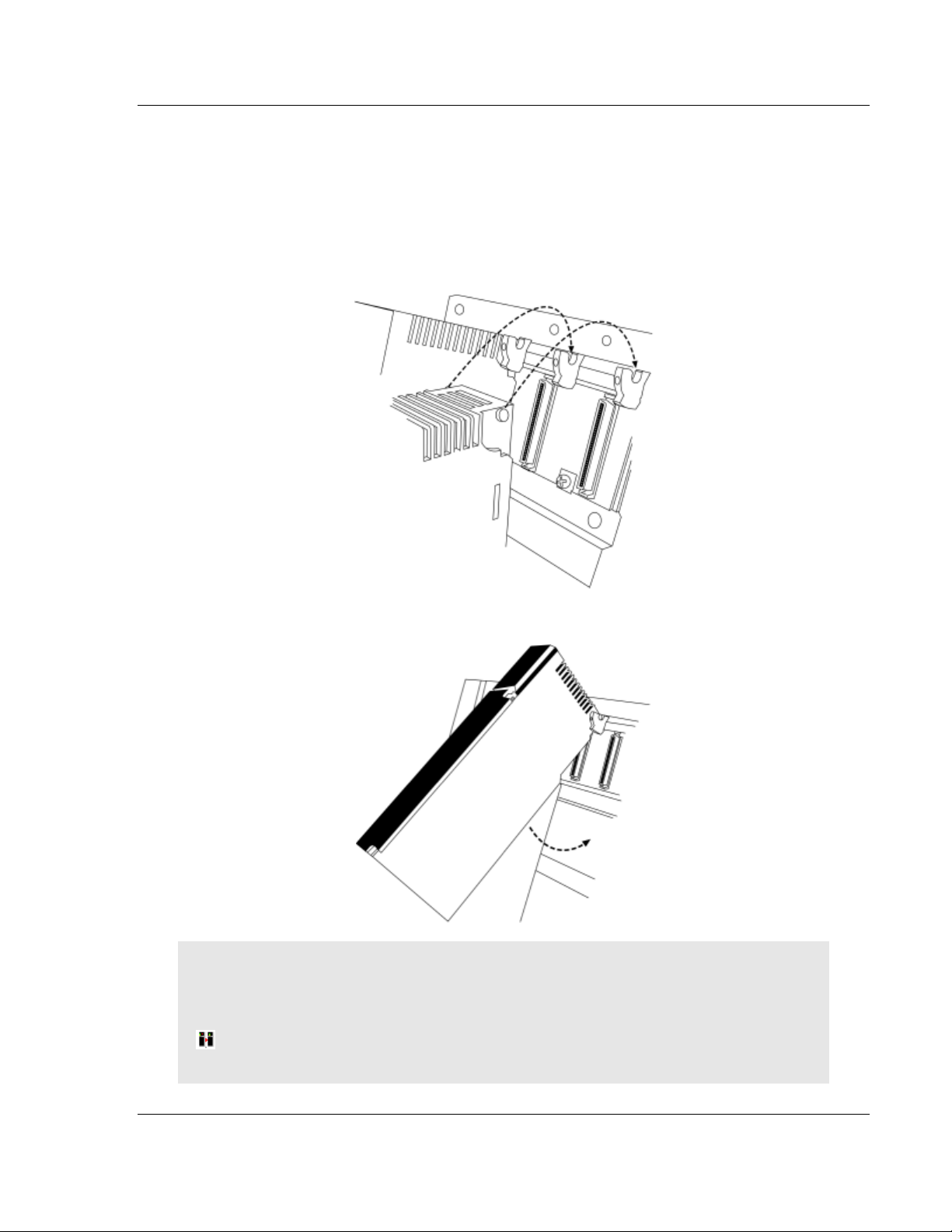

1.4.1 Installing the ProTalk Module in the Quantum Rack

1 Place the module in the Quantum rack. The ProTalk module must be placed

in the same rack as the processor.

2 Tilt the module at a 45 angle and align the pegs at the top of the module with

the slots on the backplane.

3 Push the module into place until it seats firmly in the backplane.

CAUTION: The PTQ module is hot-swappable, meaning that you can install and remove it while

the rack is powered up. You should not assume that this is the case for all types of modules unless

the user manual for the product explicitly states that the module is hot-swappable. Failure to

observe this precaution could result in damage to the module and any equipment connected to it.

HSBY Note: For HSBY setup, repeat the above procedures for the Primary and Standby

modules.

ProSoft Technology, Inc. Page 17 of 306

August 12, 2014

Page 18

Start Here PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

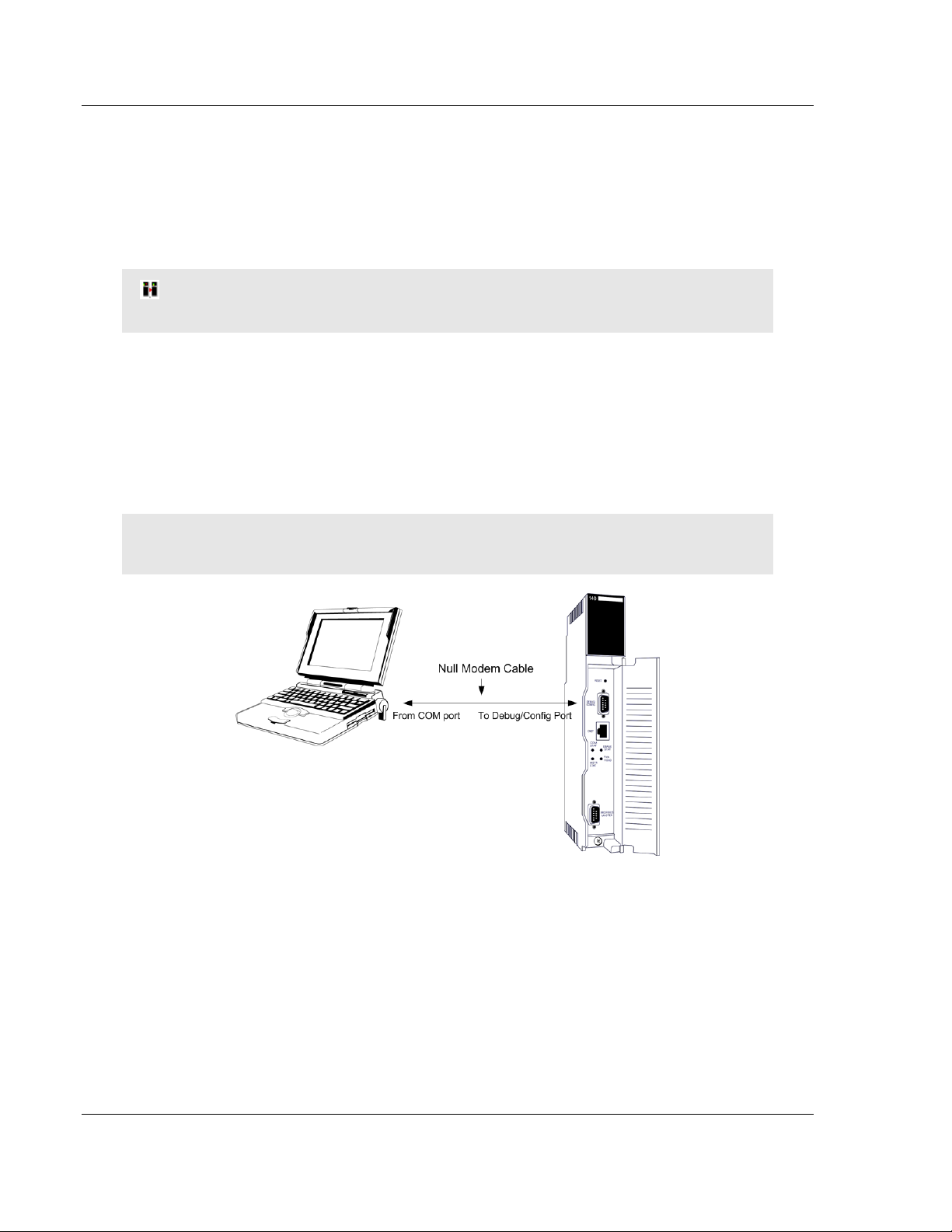

1.4.2 Connecting to the ProTalk Configuration/Debug Port

Note: The module has a serial port as well as an Ethernet port. The first time you connect to the

module to configure it, you can connect to the module’s serial port using the supplied null-modem

cable, because the module’s default Ethernet settings may not match your network.

HSBY Note: For HSBY units the Ethernet connection must be applied. This connection is used

as a backup to ping status messages over the PROFIBUS network. It is also used for DPV1

remote (passive) Master buffer update during switchover.

PC to Ethernet Port Connection

Important: The PTQ-PDPMV1 module is equipped to use an Ethernet connection using the

following defaults:

My_ip: 192.168.0.100

Netmask: 255.255.255.0

Gateway: 192.168.0.1

HSBY Note: For HSBY units the remote (passive) Master module Ethernet connection is

always Primary IP plus 1. For example, Primary IP = 192.168.0.100, Standby module IP =

192.168.0.101. This setting is not configurable: the module's firmware automatically sets the IP

address of the remote (passive) Master.

If you cannot use these defaults for your connection, you must change them

using ProSoft Configuration Builder and then download the new values to the

PTQ-PDPMV1 module, either through a serial cable, or by using a Compact

Flash (CF) writer. If you need to change the Ethernet addresses, use ProSoft

Configuration Builder to change the values in the WATTCP file.

Page 18 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 19

PTQ-PDPMV1 ♦ Quantum Platform Start Here

PROFIBUS DP Master Network Interface Module for Quantum User Manual

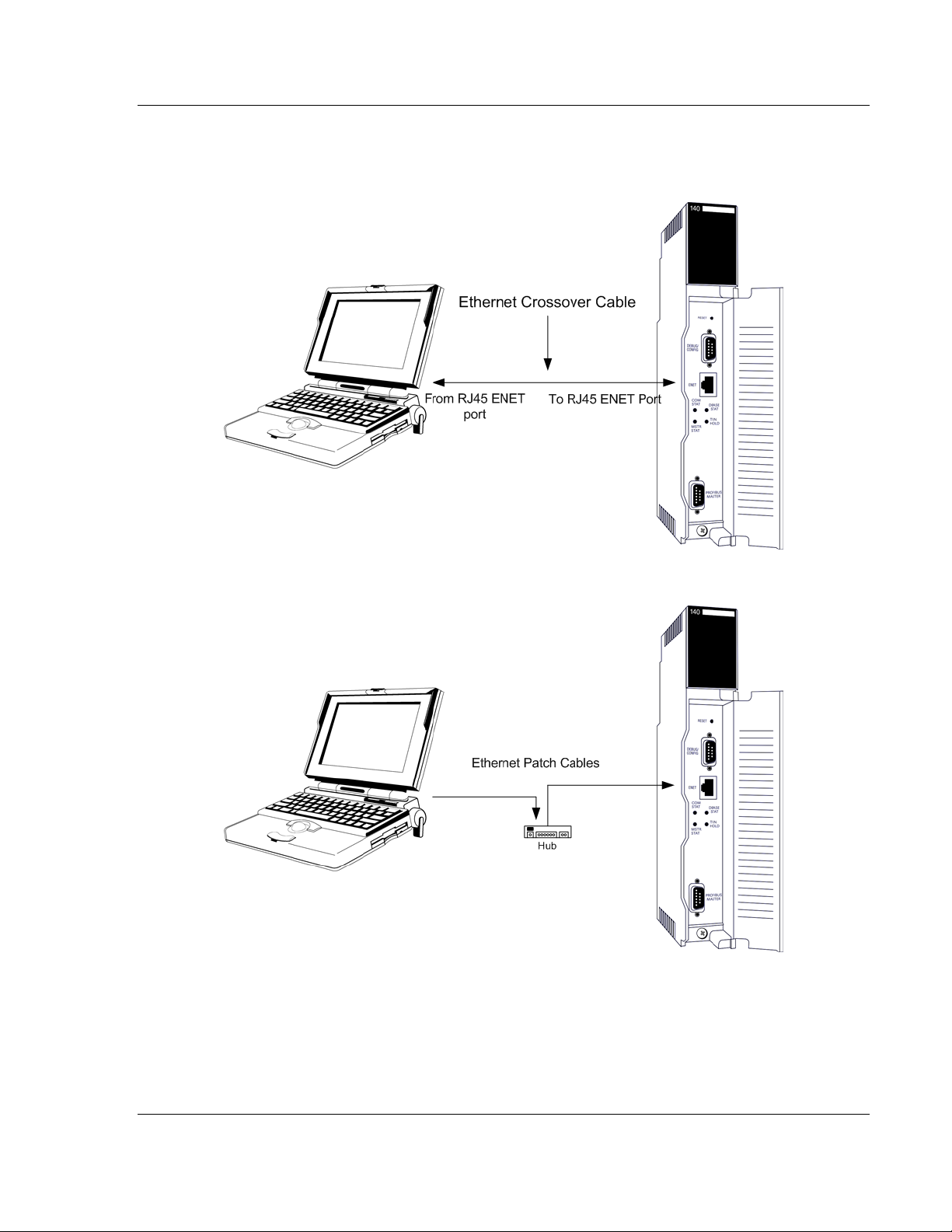

If the default values are valid on your network, and you are using an Ethernet

connection, please connect your computer to the PTQ-PDPMV1 module using

either of the methods described below:

Computer to Ethernet Port Connection via Hub

1.4.3 PTQ-PDPMV1 Configuration / Debug Port Note

After the Ethernet settings are correctly configured, only the Ethernet port should

be used for configuration changes, diagnostics, and PROFIBUS monitoring.

ProSoft Technology, Inc. Page 19 of 306

August 12, 2014

Page 20

Start Here PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

Page 20 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 21

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

In This Chapter

Configuring the Module with ProSoft Configuration Builder ................... 22

Downloading the Ethernet Configuration to the Module ........................ 33

Configuring the PROFIBUS Master ....................................................... 34

PROFIBUS DP Master Network Interface Module for Quantum User Manual

2 Configuring the Module

ProSoft Technology, Inc. Page 21 of 306

August 12, 2014

Page 22

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

2.1 Configuring the Module with ProSoft Configuration Builder

In this step of the setup process, you will use ProSoft Configuration Builder to

configure the parameters that affect the interface between the PTQ module and

the processor (Quantum or Unity). These parameters indicate:

The physical position of the module in the rack.

HSBY Note: For HSBY units, the local (active) and passive modules must be placed in the

same rack location in both racks.

The starting memory address in the processor's State RAM for the module's

input and output data images. For the purpose of this example, we use a

starting address of 1000 for the input image and 3000 for the output image.

To begin, verify that the processor is correctly positioned in the rack, and is

powered up. Connect your PC to the PTQ-PDPMV1 module using the supplied

Null Modem serial cable, as shown in the following illustration.

Note: The serial port should only be used for initial configuration of the Ethernet port through

ProSoft Configuration Builder.

After the Ethernet settings are correctly configured, only the Ethernet port should

be used for configuration changes, diagnostics, and PROFIBUS monitoring.

Page 22 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 23

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

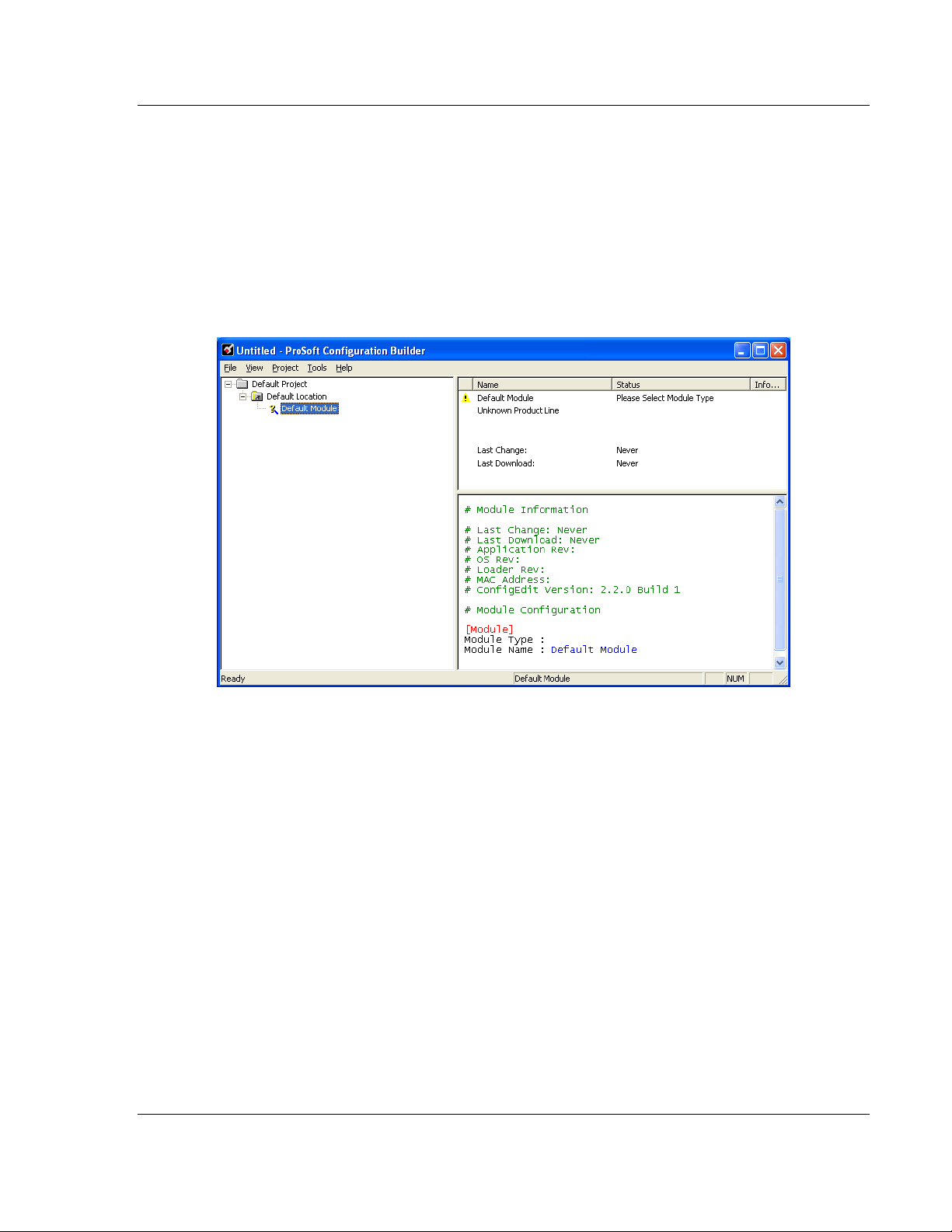

2.1.1 Setting Up the Project

To begin, start ProSoft Configuration Builder. If you have used other Windows

configuration tools before, you will find the screen layout familiar. ProSoft

Configuration Builder’s window consists of a tree view on the left, and an

information pane and configuration pane on the right side of the window.

When you first start ProSoft Configuration Builder, the tree view consists of

folders for Default Project and Default Location, with a Default Module in the

Default Location folder. The illustration below shows the ProSoft Configuration

Builder window with a new project.

Your first task is to add the PTQ-PDPMV1 module to the project.

1 Use the mouse to select DEFAULT MODULE in the tree view, and then click the

right mouse button to open a shortcut menu.

ProSoft Technology, Inc. Page 23 of 306

August 12, 2014

Page 24

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

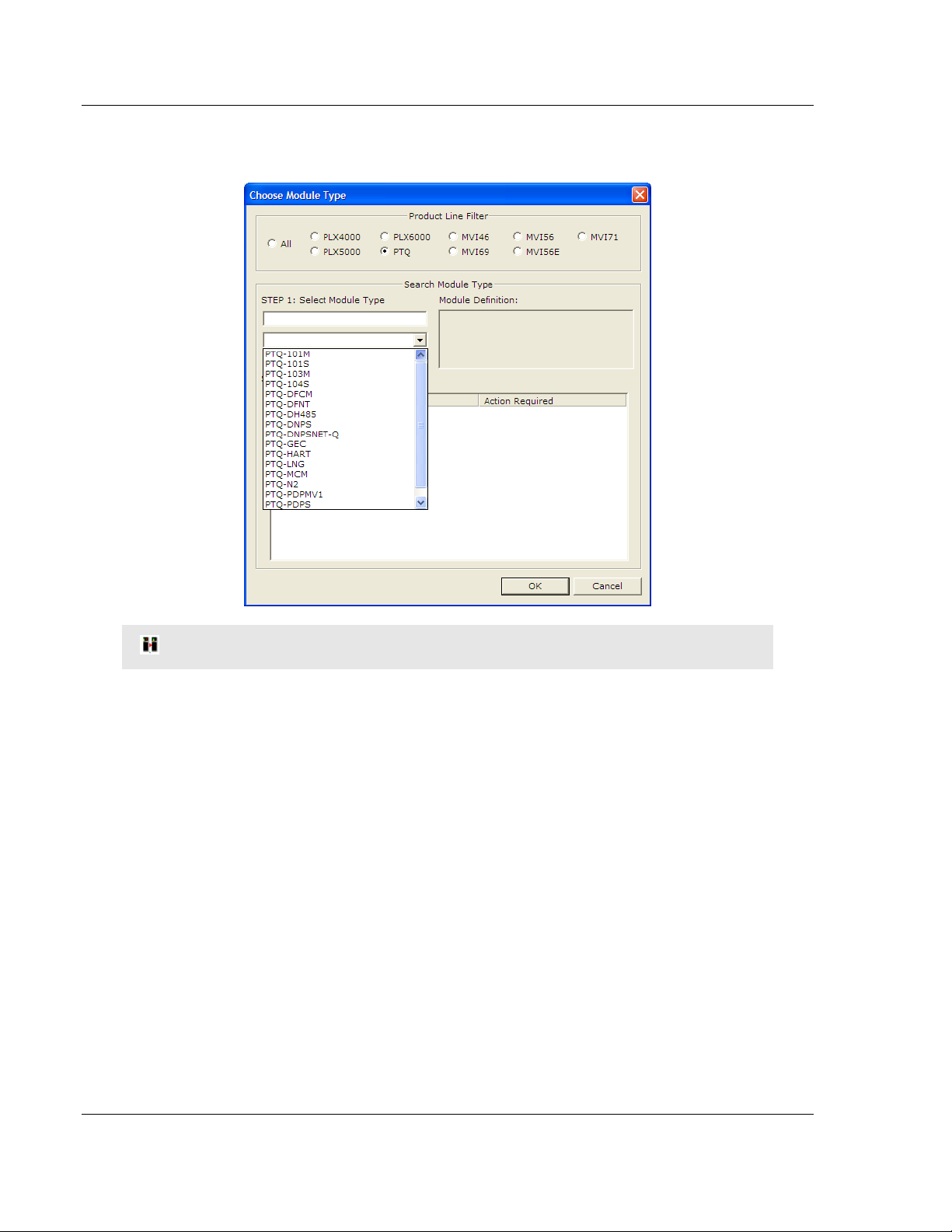

2 On the shortcut menu, select CHOOSE MODULE TYPE. This action opens the

Choose Module Type dialog box.

HSBY Note: For Hot Standby support, select the Enable "Hot Standby" checkbox.

3 In the Product Line Filter area of the dialog box, select PTQ. In the Select

Module Type dropdown list, select PTQ-PDPMV1, and then click OK to save

your settings and return to the ProSoft Configuration Builder window.

The next task is to set the module parameters.

Page 24 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 25

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

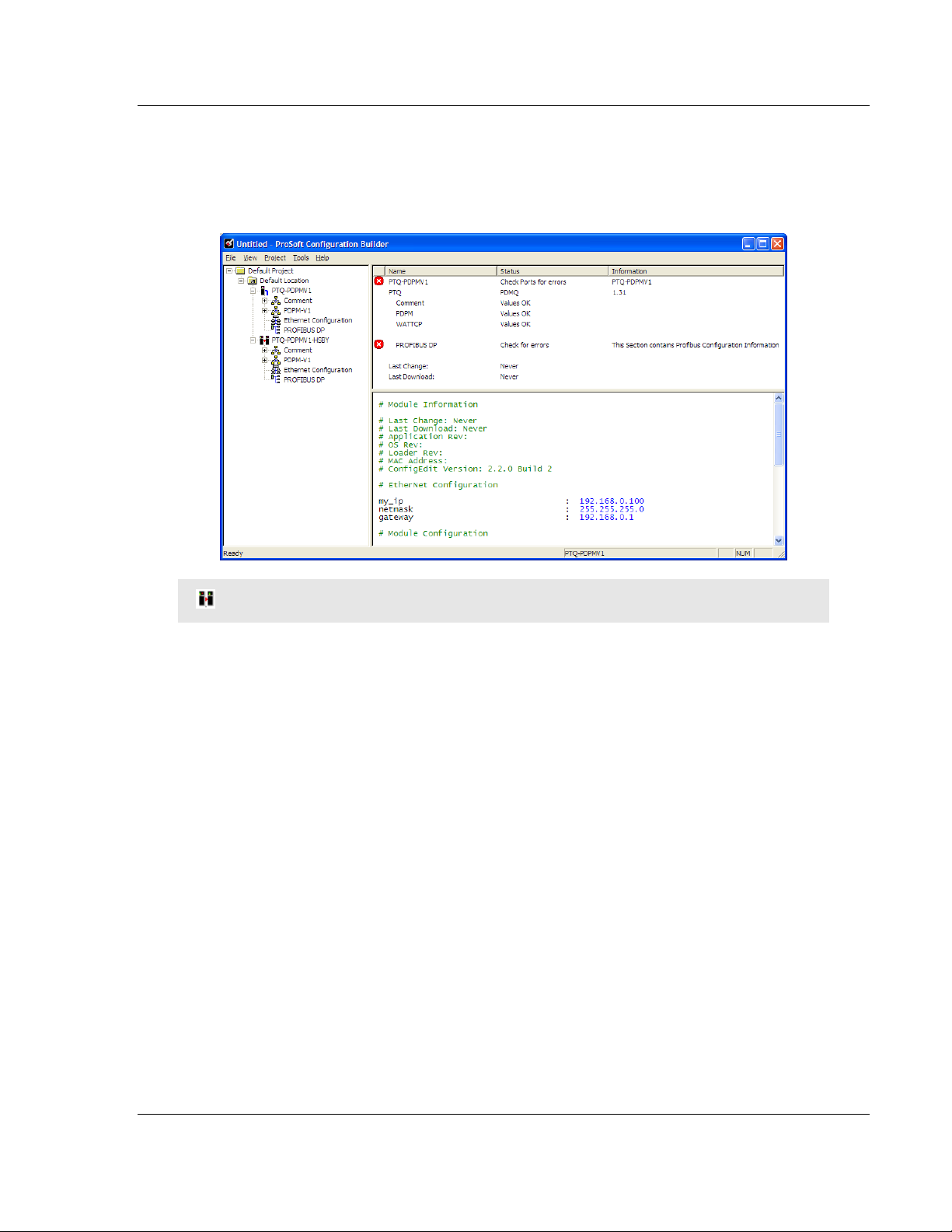

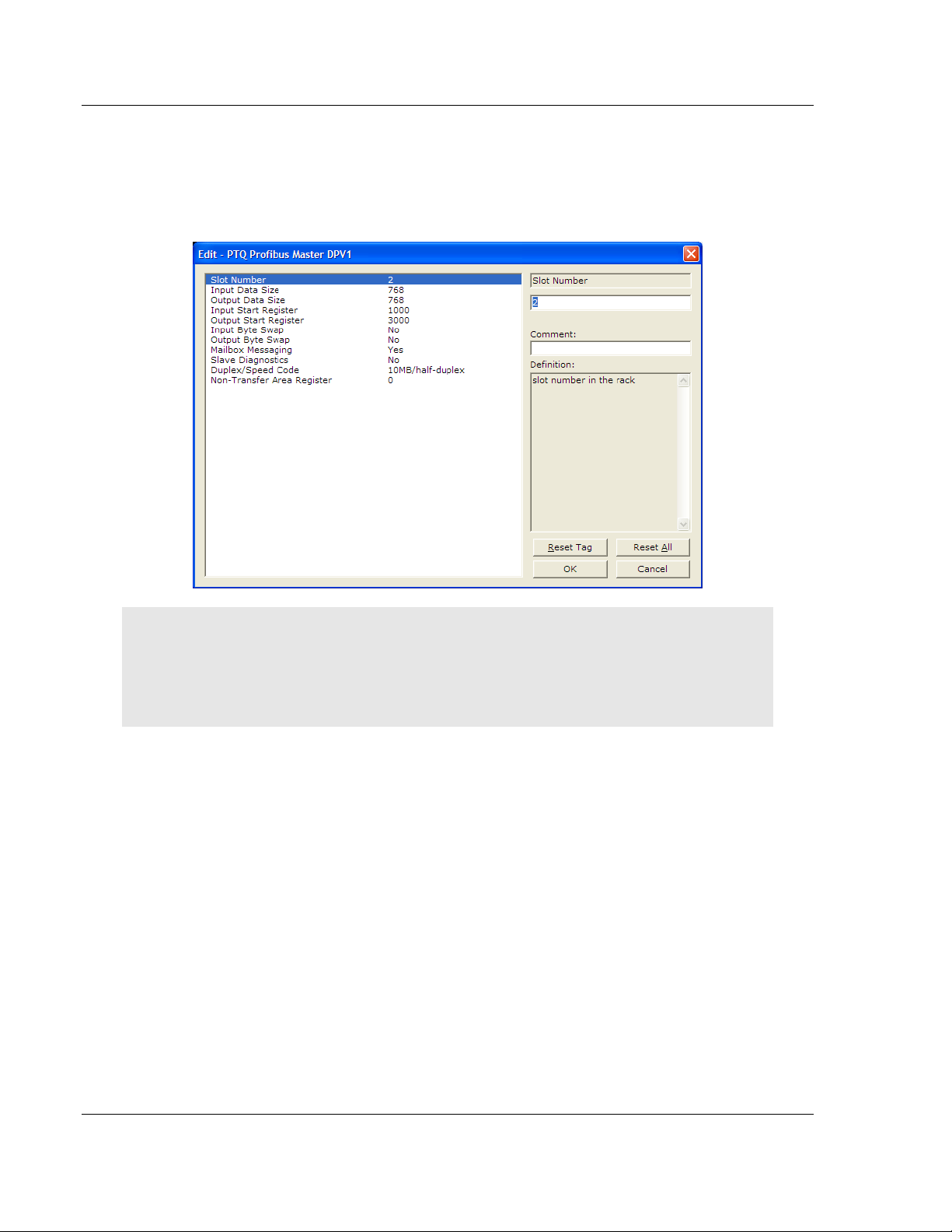

2.1.2 Setting Module Parameters

Notice that the contents of the information pane and the configuration pane

changed when you added the PTQ-PDPMV1 module to the project. The red "X"

icon indicates that the module’s configuration is incomplete.

HSBY Note: For Hot Standby modules, a double module icon will be displayed.

In the following steps, you will provide the missing information to begin

configuring the module.

1 Click the plus sign [+] next to the module to expand the module tree, and

then expand the PDPM-V1 tree.

2 Double-click the PTQ PROFIBUS MASTER DPV1 object. This action opens

the Edit dialog box.

ProSoft Technology, Inc. Page 25 of 306

August 12, 2014

Page 26

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

3 In the Edit dialog box, change the values for the selections in this section of

the configuration to match the values in the following illustration. To change a

value, select the parameter to modify in the left pane, and then type the new

value in the edit field in the right pane. If you are not sure what to enter here,

use the default values.

Note: The values you enter for the purpose of this example configuration are used by the sample

program that you will download to the processor later in this section. You may need to change

these values as you implement your production system. Use the following chapters for your

Quantum or Unity configuration software, or the online help system, for detailed information on

each of the parameters associated with the module.

Page 26 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 27

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Slot Number

The Slot Number is the physical location of the module in the rack. The example

here assumes a basic configuration with a power supply occupying the first slot,

the processor occupying the next two slots, and the PTQ-PDPMV1 module

occupying the fourth slot. In this case the module would be in slot 4.

Note: If the module is not placed in the slot number specified, the module will not operate, and the

CFG ERR light will illuminate. You must specify the actual slot number for the module in the

module configuration file.

Input Data Size

Number of PROFIBUS input point words. Leave this setting at its default value of

768 words.

Output Data Size

Number of PROFIBUS output point words. Leave this setting at its default value

of 768 words.

Start Registers

ProSoft Technology, Inc. Page 27 of 306

August 12, 2014

Page 28

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

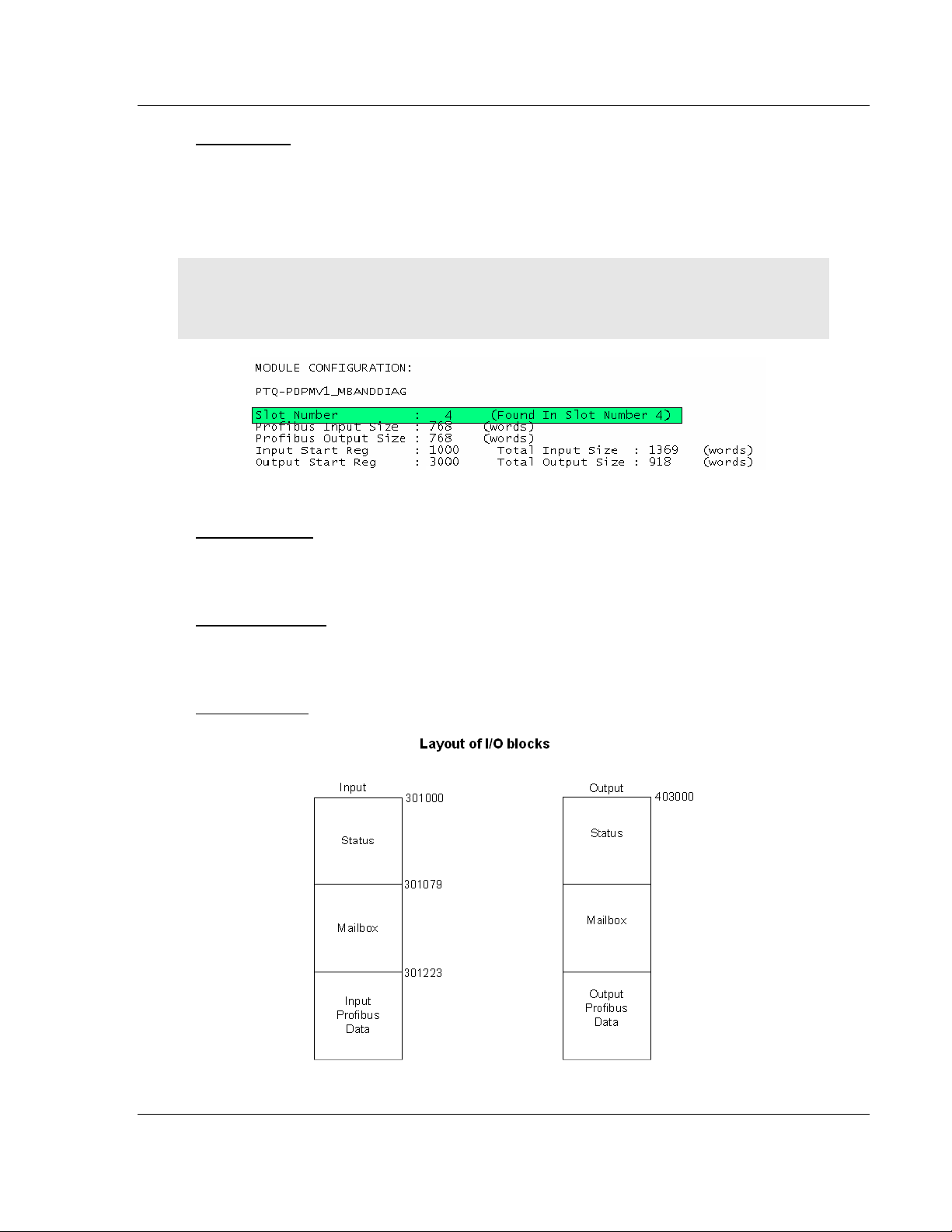

The Input Start Register address refers to the 3x (%IW) location in the

processor’s State RAM and the Output Start Register refers to the 4x (%MW)

location of State RAM. You can view State RAM information in Unity XL Pro.

A common mistake is to assume that because the Input Start Register parameter

starts at address 301000, then the PROFIBUS data associated with the slaves

will also start at the same register. As the diagram above shows, the Input

PROFIBUS Data would start at address 301223 for this example.

Important: The Input and Output Start Register parameters define the start registers for the input

and output blocks that are transferred between the processor and the module. The PROFIBUS I/O

associated to the slaves is part of these blocks. Refer to PTQ Input and Output Data Blocks (page

251) for a description. Each block contains status, PROFIBUS data, and Mailbox/Slave

diagnostics, if chosen.

Input Start Register

The Input Start Register address refers to the 3x (%IW) location in the

processor’s State RAM. You can view State RAM information in Unity XL Pro.

Output Start Register

The Output Start Register refers to the 4x (%MW) location of State RAM. You

can view State RAM information in Unity XL Pro.

Input Byte Swap

Swap bytes in input image (YES or NO). The default value is NO.

This is a user-configured flag to indicate if input data is swapped before being

placed in the input image for the controller. If the parameter is set to 0, no

swapping occurs. If it is not 0, then bytes are swapped.

For more information on byte swapping, please refer to Status Data in the Input

Data Block (page 256).

Output Byte Swap

Swap bytes in output image (YES or NO). The default value is NO.

This is a user-configured flag to indicate if output data is swapped after being

received from the controller. If the parameter is set to 0, no swapping occurs. If it

is not 0, then bytes are swapped.

Mailbox Messaging

Use mailbox messaging over the backplane (Y or N with Y=default).

For this example, leave the setting at its default. For more information on the

effect of this setting, please refer to Mailbox Messaging (page 151).

Page 28 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 29

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

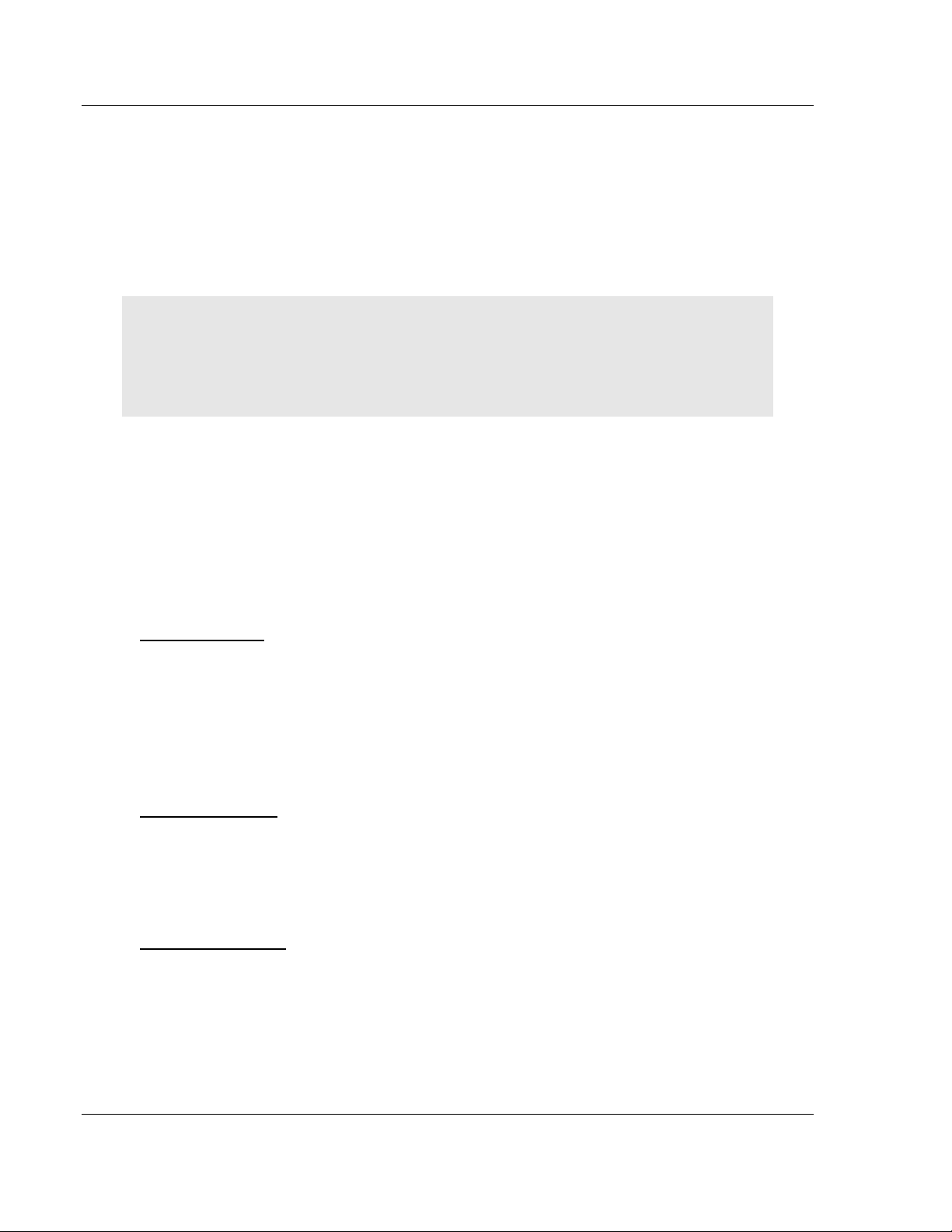

Slave Diagnostics

Get slave diagnostic data (Y/N with N=default).

For this example, leave the setting at its default.

If you change the default value of this setting and the previous one (Mailbox

Messaging) from their default values, the layout of the I/O blocks changes.

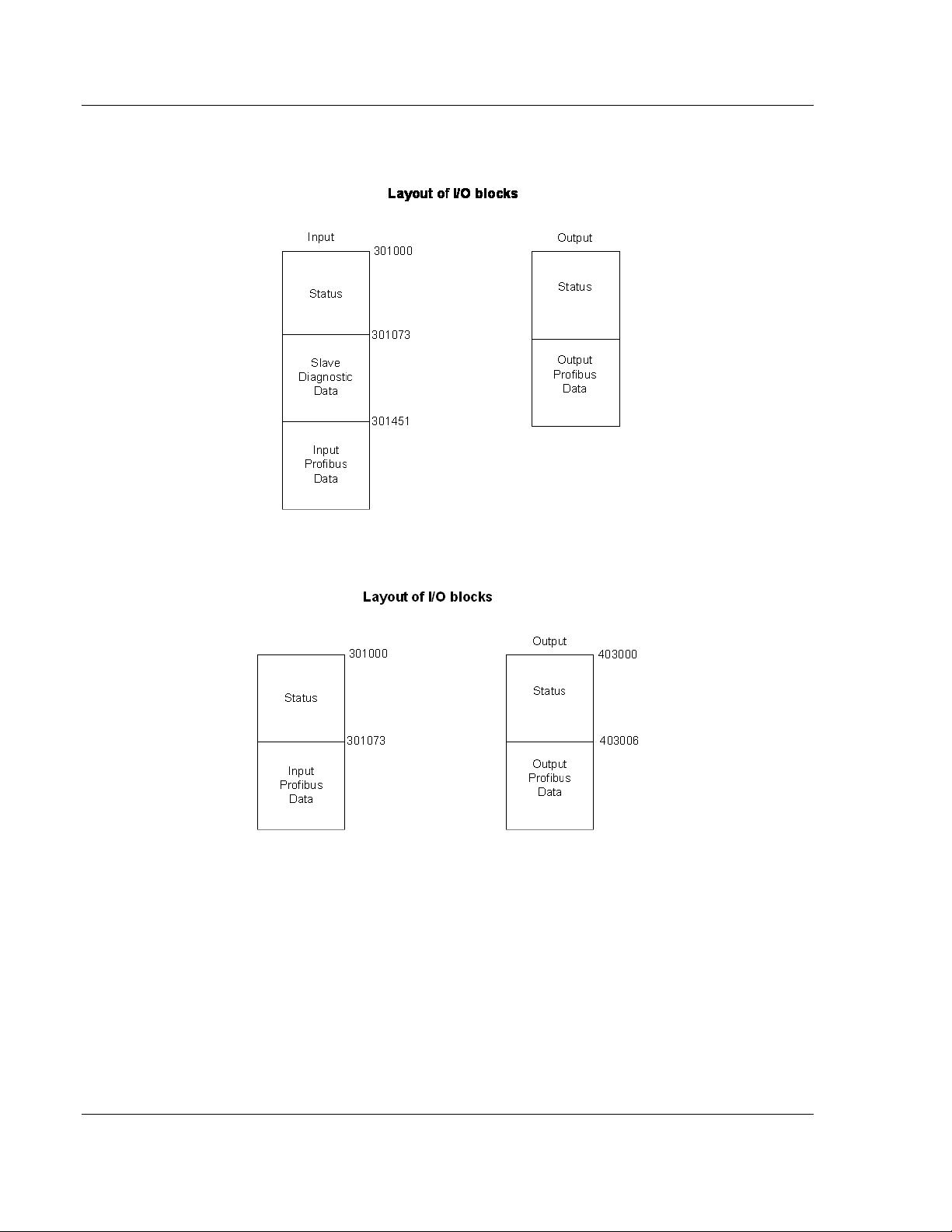

The following diagram shows the layout of the I/O blocks when Mailbox

Messaging is set to YES (the default value), and Get Slave Diagnostic Data is set

to YES.

ProSoft Technology, Inc. Page 29 of 306

August 12, 2014

Page 30

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

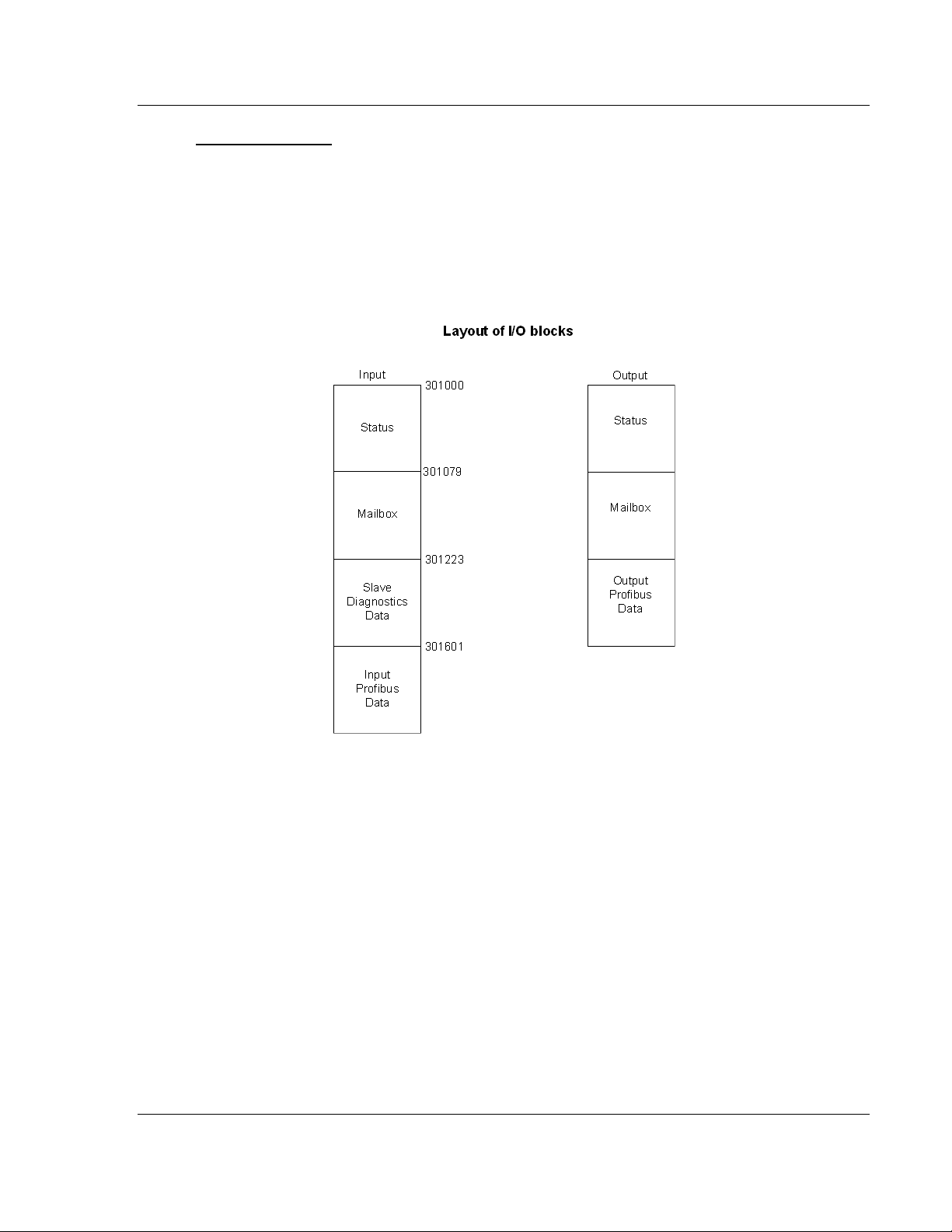

The following diagram shows the layout of the I/O blocks if Mailbox Messaging is

set to NO, and Slave Diagnostics to YES.

The following diagram shows the layout of the I/O blocks if Mailbox Messaging is

set to NO, and Slave Diagnostics to NO.

In ProSoft Configuration Builder, the Show Concept Map and Show Unity Map

commands show the layout of the entire input and output backplane blocks.

Refer to Input and Output Data Block Format (page 251) for detailed information

on the contents of these blocks, and a discussion of how various configuration

options change the layout of these blocks.

Page 30 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 31

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Duplex/Speed Code

0=Auto-negotiate

1=10 MB / half-duplex

2=10 MB / full-duplex

3=100 MB / half-duplex

4=100 MB / full-duplex

This parameter allows you to set the connection speed manually between 10

Mbps full / half-duplex and 100 Mbps full / half-duplex or to auto-negotiate the

baud rate with a hub or switch. The default value is 10 MB / half-duplex.

Non-Transfer Area Register

Note: This configuration option is only available for Hot Standby operation.

If this parameter is set to 0, the PROFIBUS configuration CRC will be derived

from the Output Area.

If this parameter is set to a value GREATER THAN 0, the PROFIBUS configuration

CRC will be derived from the specified Non-Transfer Area register.

You can specify a register outside the Output Area to derive the CRC value for

the PROFIBUS configuration. This parameter allows you to modify the

PROFIBUS DP network configuration without stopping the system.

This data area uses 4 words, and must be located in the 4x memory area. The

module will attempt to read this data asynchronously from the non-transfer data

area. When new values are received, they are placed in the normal area used by

the program. Because this operation is asynchronous to the scan, it may take 2

or more scans for the data to update.

Completing the Example Configuration

When you have finished updating the values, click OK to save your settings and

return to the ProSoft Configuration Builder window.

At this time, you may wish to rename the Default Project and Default Location

folders in the tree view. To rename an object:

1 Select the object, and then click the right mouse button to open a shortcut

menu. From the shortcut menu, choose RENAME.

2 Type the name to assign to the object.

3 Click away from the object to save the new name.

The next task is to update the module's Ethernet settings. This allows you to

connect from your computer to the module using an Ethernet cable rather than a

serial cable.

ProSoft Technology, Inc. Page 31 of 306

August 12, 2014

Page 32

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

2.1.3 Updating the Ethernet Settings

Use this procedure to configure the Ethernet settings for your module. You must

assign an IP address, subnet mask and gateway address. After you complete

this step, you can connect to the module with an Ethernet cable.

1 Determine the network settings for your module, with the help of your network

administrator if necessary. You will need the following information:

o IP address (fixed IP required) _____ . _____ . _____ . _____

o Subnet mask _____ . _____ . _____ . _____

o Gateway address _____ . _____ . _____ . _____

HSBY Note: Hot Standby Primary IP is entered. The Standby IP address will always be the

Primary IP address plus 1.

2 Click [+] to expand the tree for the PTQ-PDPMV1 module.

3 Double-click the ETHERNET CONFIGURATION object. This action opens the Edit

dialog box.

4 Edit the values for my_ip, netmask (subnet mask) and gateway (default

gateway).

5 When you are finished editing, click OK to save your changes and return to

the ProSoft Configuration Builder window.

Page 32 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 33

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

2.2 Downloading the Ethernet Configuration to the Module

In order for your changes to take effect, you must download (copy) the updated

Ethernet configuration from your computer to the module.

1 Connect the serial cable between the module and the computer.

2 Select the ETHERNET CONFIGURATION icon, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose DOWNLOAD.

This action sends the new IP settings to the module, allowing Ethernet

communication between the computer and the module.

HSBY Note: This serial download procedure must be performed for both Master HSBY

modules.

Note: The processor (Quantum or Unity) must be in STOP mode before you download the file to

the module. Use the processor’s softkeys on the display keypad, or the processor’s configuration

program to stop the processor.

The final step is to verify that ProSoft Configuration Builder can communicate

with the module using an Ethernet connection.

1 Plug in an Ethernet cable between the module and an Ethernet hub or router.

HSBY Note: You must leave the Ethernet cable connected to both Hot Standby modules at all

times. The configuration download will not proceed unless both modules are connected.

2 In the tree view in ProSoft Configuration Builder, click once to select the PTQ-

PDPMV1 module.

3 Open the PROJECT MENU, and then choose MODULE, and then choose

DIAGNOSTICS. This action opens the Diagnostics window.

4 Choose Ethernet as the connection type, and then enter the IP address.

Press the [?] key on your keyboard. If the module is communicating

successfully, you will see a menu like this:

ProSoft Technology, Inc. Page 33 of 306

August 12, 2014

Page 34

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

2.3 Configuring the PROFIBUS Master

In this task, you will configure the PROFIBUS Master, and then add PROFIBUS

slaves to the network. When this step is complete, you will download the

configuration information to the PTQ module. You will also export the I/O maps

for the processor.

1 In ProSoft Configuration Builder tree view, click [+] to expand the PTQ-

PDPMV1 tree, and then double-click the PROFIBUS DP icon. This action

opens the PROFIBUS Master Setup dialog box.

2 Click the CONFIGURE PROFIBUS button. This action opens the ProSoft

Configuration Builder for PROFIBUS application.

3 Click [+] to expand the PROFIBUS Master tree.

4 Drag the ProTalk icon into the Bus Configuration window. This is

automatically done by the software for new applications.

For HSBY Units

Page 34 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 35

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

5 Double-click the PROFIBUS MASTER icon in the Bus Configuration window.

This action opens the Master Properties dialog box.

6 On the COMMON tab, name your PROFIBUS drop. The name should match

the module name from step 4 in this procedure.

Note: The PROFIBUS tab contains the address setting and advanced configuration settings for the

Master. The default settings on this tab work best in most applications.

HSBY Note: The correct profile setting for HSBY Master is DP; however, the Hot Standby

check box will be checked. The minimum baud for Hot Standby module to switch over within 300

ms with an average processor scan time of 100ms, is 1500Kbits/second.

7 Click OK to save your changes and return to the Bus Configuration window.

2.3.1 Installing the GSD Files

The GSD configuration files contain information on PROFIBUS slaves that you

can configure as part of your PROFIBUS network. In order for this configuration

information to be available in ProSoft Configuration Builder, you must install the

GSD files.

Tip: GSD configuration files for popular Schneider Electric and ProSoft Technology modules are

included with the installation. If you have other GSD files for your PROFIBUS slaves, copy them

into C:\Documents and Settings\All Users\Application Data\ProSoft\GSD (Windows XP / 2000) or

C:\My Documents\ (Windows 98), and ProSoft Configuration Builder will load them automatically.

ProSoft Technology, Inc. Page 35 of 306

August 12, 2014

Page 36

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

To install GSD files manually

1 In ProSoft Configuration Builder tree view, click [+] to expand the PTQ-

PDPMV1 tree, and then double-click the PROFIBUS DP icon. This action

opens the PROFIBUS Master Setup dialog box.

2 Click the CONFIGURE PROFIBUS button. This action opens the ProSoft

Configuration Builder for PROFIBUS application.

3 Click [+] to expand the PROFIBUS DP tree.

4 Click the right mouse button to open a shortcut menu.

5 On the shortcut menu, choose INSTALL NEW GS* FILE. This action opens a

dialog box that allows you to browse for the location of the GSD configuration

files to install.

6 Choose the file to install, and then click OPEN. If the file already exists in the

configuration file path (see Tip above), you will be prompted to overwrite the

file.

7 You will be prompted to associate the GSD configuration file with a bitmap

image of the slave device. Use the File Open dialog box to browse for the

location of the image file to use.

Note: This procedure does not automatically copy GSD configuration files from their original

location to the GSD file path. In order to load GSD files automatically the next time you start

ProSoft Configuration Builder, copy the files to the configuration file path in the Tip above.

2.3.2 Configuring the PROFIBUS Slaves

There are two essential steps to configuring a slave:

1 Add the slave in ProSoft Configuration Builder (PCB) as a device connected

to the PROFIBUS Master, specifying the slave address and any necessary

input and output configuration. Download the PROFIBUS Master

configuration to the PTQ-PDPMV1 module.

2 Configure the slave (using PCB or the configuration tool supplied by the

manufacturer, for some PROFIBUS slaves). Verify that the slave address

configured in the slave module matches the slave address configured in PCB.

Download the PROFIBUS Slave configuration to the slave module.

Page 36 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 37

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Scanning for Slaves Manually

In this part of the procedure, you will add and configure the PROFIBUS slaves. In

the following steps, you will add and configure a ProLinx PROFIBUS slave

module. The configuration information (.GSD file) for this module is provided on

the PTQ-PDPMV1 Solutions CD-ROM.

1 In ProSoft Configuration Builder for PROFIBUS, click the plus sign [+] to

expand the PROFIBUS DP tree.

2 Navigate to the folder containing the type of slave device to add, and then

click the plus sign [+] to expand the folder.

3 Drag the SLAVE icon into the Bus Configuration window. The slave device

appears in the Bus Configuration window as a network location to the Master.

4 In the tree view, click the plus sign [+] to expand the slave device you added.

This action opens a list of device configuration values. The following

illustration shows the device configuration values for a ProLinx PROFIBUS

slave. The values for other devices may be different, so you should review

the specifications for the product you are installing in order to determine the

correct values to use.

ProSoft Technology, Inc. Page 37 of 306

August 12, 2014

Page 38

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

Input Address configured in PCB (Bytes)

Actual Quantum Input Register Address (Words)

0...1

301223

2...3

301224

4...5

301225

...

...

User Manual PROFIBUS DP Master Network Interface Module for Quantum

5 Drag the input and output parameters to the slot location grid below the Bus

Configuration window. This view displays the configuration data, order

number, and starting input and output addresses.

Important: The starting input and output addresses that you select here are actually byte offsets

within the PROFIBUS Data area inside each Input and Output backplane block.

For example, for the sample configuration for the input block, where the Input Start Register

Parameter = 1000:

The following table shows the actual Quantum address:

Page 38 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 39

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

6 Double click the SLAVE icon to view the Slave properties.

In particular, note the following settings:

o Automatic PROFIBUS Address Assignment:

ProSoft Configuration Builder automatically assigns a PROFIBUS address

to each new slave. The address assignment begins at address 3, and is

incremented by 1 for each new slave added to the network. You can

change the address in the COMMON tab of the Slave Properties dialog

box.

o Automatic Input/Output Address Assignment:

For each new slave added to the PROFIBUS network, ProSoft

Configuration Builder automatically converts the input/output byte

addresses to word input/output addresses for the State RAM in the

processor.

7 Repeat steps 2 through 6 for all slaves you intend to place on the network.

8 When you are finished adding slaves, open the PROJECT menu and choose

EXIT to return to the Master Setup dialog box.

ProSoft Technology, Inc. Page 39 of 306

August 12, 2014

Page 40

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

Using The Autoscan Feature

The concept of Automatic network scanning means that the user can instruct the

Bus Configuration window to automatically gather information about slaves that

are connected to the network. When the scan is completed the user can adopt

the detected slaves to the bus configuration and download to the Master.

This is a quick way to get a network up and running. However, one should be

aware that it is not guaranteed that any particular slave will enter data exchange

since the user parameter data might not match. This is especially obvious if no

associated GSD-file is found during the network scan, this means that no user

parameter data would be sent to the slave.

NETWORK SCAN is selectable from the Online menu as well as from the drop-

down menu for the MASTER icon.

Page 40 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 41

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

When the download is completed, the PROFIBUS Master Configuration window

will initialize the Master to operate as a Class 2 Master only. In this mode it is

possible to initialize the Master even if the database does not contain any slaves.

After successful initialization, the PROFIBUS Master Configuration window will

issue the following mailboxes in order to gather information about the connected

slaves:

1 1. Send FB_APPL_GET_LIVE_LIST in order to detect connected slaves,

2 2. Send FB_APPL_GET_SLAVE_DIAG (external request) to all devices

identified as slaves according to the Live list.

3 3. Send FB_APPL_GET_SLAVE_CONFIG to all devices identified as slaves

according to the Live list.

When the information is collected the PROFIBUS Master Configuration window

will find a matching GSD-file and extract information from it. Refer to the

flowchart below for this sequence:

GSD Selection Algorithm

If two or more matching GSD-files are found, the first one found should be

selected. The other compatible files should be stored so that the user can select

one of them instead. If the user selects another GSD-file, the PROFIBUS Master

Configuration window will run through the Module Selection Algorithm (described

below) again.

ProSoft Technology, Inc. Page 41 of 306

August 12, 2014

Page 42

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

Module Selection Algorithm

The algorithm used to find modules in the GSD based on the Identifier byte(s) is

as follows:

Select the module that matches the largest number of Identifier bytes. If the GSD

contains two or more modules with the exact set of Identifier bytes, use the first

module found.

Example:

If a slave responds with identifier bytes: 0x11, 0x21, 0x31 and that the associated

GSD-file contains five modules: “A” = 0x11, “B” = 0x21, “C” = 0x31, “AB” = 0x11,

0x21 and “BC” = 0x21, 0x31. The PROFIBUS Master Configuration window will

then select modules "AB" and "C".

Note: If no matching module is found in the GSD, The PROFIBUS Master Configuration window

will display the identifier byte(s) instead.

Network scan window

The information extracted from the GSD-file(s) will be displayed in the Network

scan window.

Select

In this column all found slaves will be marked as selected by default, except for

slaves with the special address 126 (refer to the next section that describes the

Address column). Only selected slaves will be added to the PROFIBUS Master

Configuration when the ADOPT SELECTED SLAVES button is clicked.

Address

In this column the node address of the slaves will be displayed. Found slaves

should be listed in ascending order according to their node addresses.

Page 42 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 43

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

Special address 126 -Set Slave address:

If a slave with node address 126 is detected during the network scan, the

PROFIBUS Master Configuration window will display the address in red color. It

will not be possible for the user to adopt the slave to the configuration since it is

not allowed to exchange data with devices having this address. The check box in

the Select column will be grayed out.

To be able to adopt a slave with address 126 the user must first assign a valid

address by clicking the icon next to the node address. By doing so the Set Slave

Address dialog box is started.

Note that the Old slave address is preset to a value of 126 that is not editable (grayed out).

ProSoft Technology, Inc. Page 43 of 306

August 12, 2014

Page 44

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

If the Slave is in the configuration already then it will not affect the addressing.

Example:

After scanning, the network finds these other slaves: 2, 6, 25, and 40

Slaves 2, 6, and 25 are found, but are marked as in the bus configuration (the

mapping of the inputs and outputs will not be affected)

Slaves 40 is new and could be added and the input/output addressing will be

appended to the end as shown on the last screen.

Page 44 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 45

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

The PROFIBUS Master Configuration window will prevent the user from selecting

a New slave address that is already occupied by another device; this includes

detected Master stations as well. If the user selects an occupied address, a

message similar to the one shown here will open.

When an address has been successfully assigned, the PROFIBUS Master

Configuration window will update the Network scan window as shown here. The

node address will be updated to the one that the user selected in the Set Slave

dialog box. The check box in the Select column will be marked allowing the user

to adopt the slave to the configuration.

Slave

In this column the name of the slave as stated in the assigned GSD-file will be

displayed. If no matching GSD-file is found the Ident number will be displayed in

red color in the drop-down list.

Module

This column shows the name of the module(s) as stated in the assigned GSDfile, which matches the Identifier byte(s) derived from the GetCfg mailbox

message. If no GSD-file or no matching module is found the Identifier byte(s) will

be displayed in red color. If the configuration for a slave is constructed of several

modules, the modules will be listed under each other.

ProSoft Technology, Inc. Page 45 of 306

August 12, 2014

Page 46

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

If there is more than one module in the GSD-file that matches the Identifer bytes,

the first matching module will be displayed in blue color in a drop-down list. The

drop-down list will contain all other matching modules so that the user can select

the desired one.

Note: Only modules that have the exact same Identifer bytes as the first matching module will be

displayed in the drop-down list.

GSD-file

This column shows the name of the GSD-file that matches the Ident number

derived from the SlaveDiag mailbox message. If there are more files with the

same Ident number in the device catalog, the first matching GSD-file will be

displayed in blue color in a drop-down list.

This could be the case if the device catalog contains two or more brand labeled

devices, or GSD-files for two or more languages (for example NICEDEV.GSD

and NICEDEV.GSE) exist.

Note: If the user selects another GSD-file, The PROFIBUS Master Configuration window will

update the modules for that slave accordingly.

Page 46 of 306 ProSoft Technology, Inc.

August 12, 2014

Page 47

PTQ-PDPMV1 ♦ Quantum Platform Configuring the Module

PROFIBUS DP Master Network Interface Module for Quantum User Manual

If no GSD-file is found the user will be able to copy the expected GSD to the

device catalog by clicking the icon next to the text No GSD found. This will start

the Install new GS*-file dialog box. When the file is installed, the PROFIBUS

Master Configuration window will verify that the installed file matches the slave

and update the modules for the slave accordingly.

Rescan

Pressing the YES button will trigger a new network scan. Before proceeding with

the scan a message similar to the one below will appear. If a new scan is

accepted, detected slaves found during the previous scan will be lost.

Adopt selected slaves

Pressing this button will cause all selected slaves to be adopted to the

PROFIBUS Master Configuration window. Before carrying on with this action a

message similar to the one below will appear.

ProSoft Technology, Inc. Page 47 of 306

August 12, 2014

Page 48

Configuring the Module PTQ-PDPMV1 ♦ Quantum Platform

User Manual PROFIBUS DP Master Network Interface Module for Quantum

If accepted, the network scan window will close and the PROFIBUS Master

Configuration window will be populated with the slaves that were found during