Page 1

PS69-DPS

CompactLogix or MicroLogix

Platform

Profibus DP Slave Communication

Module

May 9, 2014

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2014 ProSoft Technology, Inc., All rights reserved.

PS69-DPS User Manual

May 9, 2014

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed DVD, and are

available at no charge from our web site: www.prosoft-technology.com

Printed documentation is available for purchase. Contact ProSoft Technology for pricing and availability.

North America: +1.661.716.5100

Asia Pacific: +603.7724.2080

Europe, Middle East, Africa: +33 (0) 5.3436.87.20

Latin America: +1.281.298.9109

Throughout this manual, you will see references to other product names such as:

RIF 1769-DPM

SYCON.net

These product names (RIF 1769, SYCON.net) are legacy versions, and are mentioned for backward compatibility

with existing implementations. These products are now supported and maintained by ProSoft Technology.

The ProSoft and legacy versions of these products may not be interchangeable.

Page 3

PS69-DPS ♦ CompactLogix or MicroLogix Platform Contents

Profibus DP Slave Communication Module User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Guide to the PS69-DPS User Manual 7

1 Start Here 9

1.1 Software Requirements ........................................................................................... 10

1.2 Hardware Requirements ......................................................................................... 10

1.3 Reference Systems ................................................................................................. 10

1.4 Programmable Controller Functionality ................................................................... 11

1.5 Package Contents ................................................................................................... 12

1.6 Installing the Module in the Rack ............................................................................ 13

1.7 Connecting Your PC to the Processor .................................................................... 16

1.8 PS69-DPS Sample Add-On Instruction Import Procedure ...................................... 17

1.8.1 Create a new RSLogix5000 project ........................................................................ 17

1.8.2 Create the Module ................................................................................................... 18

1.8.3 Import the Ladder Rung .......................................................................................... 20

1.8.4 Adding Multiple Modules (Optional) ........................................................................ 25

1.9 Downloading the Sample Program to the Processor .............................................. 32

1.9.1 Configuring the RSLinx Driver for the PC COM Port .............................................. 33

1.10 Adapter (PROFIBUS-DP-Slave) ............................................................................. 35

2 Configuration and Start-Up 37

2.1 RSLogix 5000 .......................................................................................................... 38

2.1.1 Module Selection ..................................................................................................... 38

2.1.2 Module Properties 1 ................................................................................................ 40

2.1.3 Module Properties 2 ................................................................................................ 41

2.2 RSLogix 500 ............................................................................................................ 42

2.2.1 Module Selection ..................................................................................................... 42

2.2.2 Expansion General Configuration ........................................................................... 43

2.2.3 Generic Extra Data Config ...................................................................................... 44

2.3 Slave Configuration ................................................................................................. 45

2.3.1 General .................................................................................................................... 45

2.3.2 GSD File .................................................................................................................. 45

2.3.3 Configuration by Master .......................................................................................... 45

2.3.4 Configuration by Controller Application ................................................................... 46

2.3.5 Explanation of settable configuration values ........................................................... 47

3 RSLogix Example Program 49

3.1 CompactLogix I/O Example..................................................................................... 50

3.2 CompactLogix Messaging Example ........................................................................ 52

ProSoft Technology, Inc. Page 3 of 108

May 9, 2014

Page 4

Contents PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

4 Diagnostics and Troubleshooting 55

4.1 Hardware Diagnostics (LED) .................................................................................. 56

4.1.1 CompactLogix ......................................................................................................... 56

4.1.2 MicroLogix 1500...................................................................................................... 56

4.1.3 PS69 LEDs ............................................................................................................. 57

4.2 Troubleshooting ...................................................................................................... 58

4.2.1 CompactLogix I/O LED ........................................................................................... 58

4.2.2 MicroLogix Fault LED ............................................................................................. 58

4.2.3 SYS and COM Status LEDs ................................................................................... 58

4.2.4 Error Sources and Reasons ................................................................................... 58

4.2.5 Cable ....................................................................................................................... 60

5 Reference 61

5.1 Specifications .......................................................................................................... 62

5.1.1 General Specifications ............................................................................................ 62

5.1.2 Hardware Specifications ......................................................................................... 63

5.1.3 Functional Specifications ........................................................................................ 64

5.1.4 PROFIBUS Interface .............................................................................................. 65

5.2 RSLogix5000 User Defined Data Types ................................................................. 66

5.2.1 Input: DPS_INPUT_ARRAY ................................................................................... 66

5.2.2 Input: DPS_DEV_STATUS_REGISTER ................................................................ 66

5.2.3 Input: DPS_FW_REVISION .................................................................................... 66

5.2.4 Input: DPS_STATUS_FIELD .................................................................................. 67

5.2.5 Output: DPS_OUTPUT_ARRAY ............................................................................ 67

5.2.6 Output: DPS_DEV_COMMAND_REGISTER ......................................................... 67

5.2.7 APP_CONSTANT_PATTERN ................................................................................ 68

5.2.8 APP_DPV1_PROG_CONTROL ............................................................................. 68

5.2.9 APP_DPV1_STAT_COUNTER .............................................................................. 68

5.2.10 DPS_DIAGNOSTIC_CONFIRM ............................................................................. 69

5.2.11 DPS_DIAGNOSTIC_REQUEST ............................................................................. 69

5.2.12 DPS_DPV1C1_ALARM_CONFIRM ....................................................................... 70

5.2.13 DPS_DPV1C1_ALARM_REQUEST ...................................................................... 70

5.2.14 DPS_DPV1C1_RW_INDICATION.......................................................................... 71

5.2.15 DPS_DPV1C1_RW_RESP_CONFIRM .................................................................. 71

5.2.16 DPS_DPV1C1_RW_RESP_REQUEST ................................................................. 72

5.3 PROFIBUS Functionality ........................................................................................ 73

5.3.1 DPV0 Services ........................................................................................................ 73

5.3.2 DPV1 Services ........................................................................................................ 74

5.3.3 Start/Stop Communication ...................................................................................... 74

5.4 Communication ....................................................................................................... 75

5.4.1 IO Communication and IO Memory Map ................................................................ 75

5.4.2 CIP Messaging........................................................................................................ 84

5.5 Constructing a Bus Cable for PROFIBUS DP ........................................................ 99

6 Support, Service & Warranty 103

Contacting Technical Support ........................................................................................................ 103

6.1 Warranty Information ............................................................................................ 105

Index 107

Page 4 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 5

PS69-DPS ♦ CompactLogix or MicroLogix Platform Contents

Profibus DP Slave Communication Module User Manual

ProSoft Technology, Inc. Page 5 of 108

May 9, 2014

Page 6

Contents PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

Page 6 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 7

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

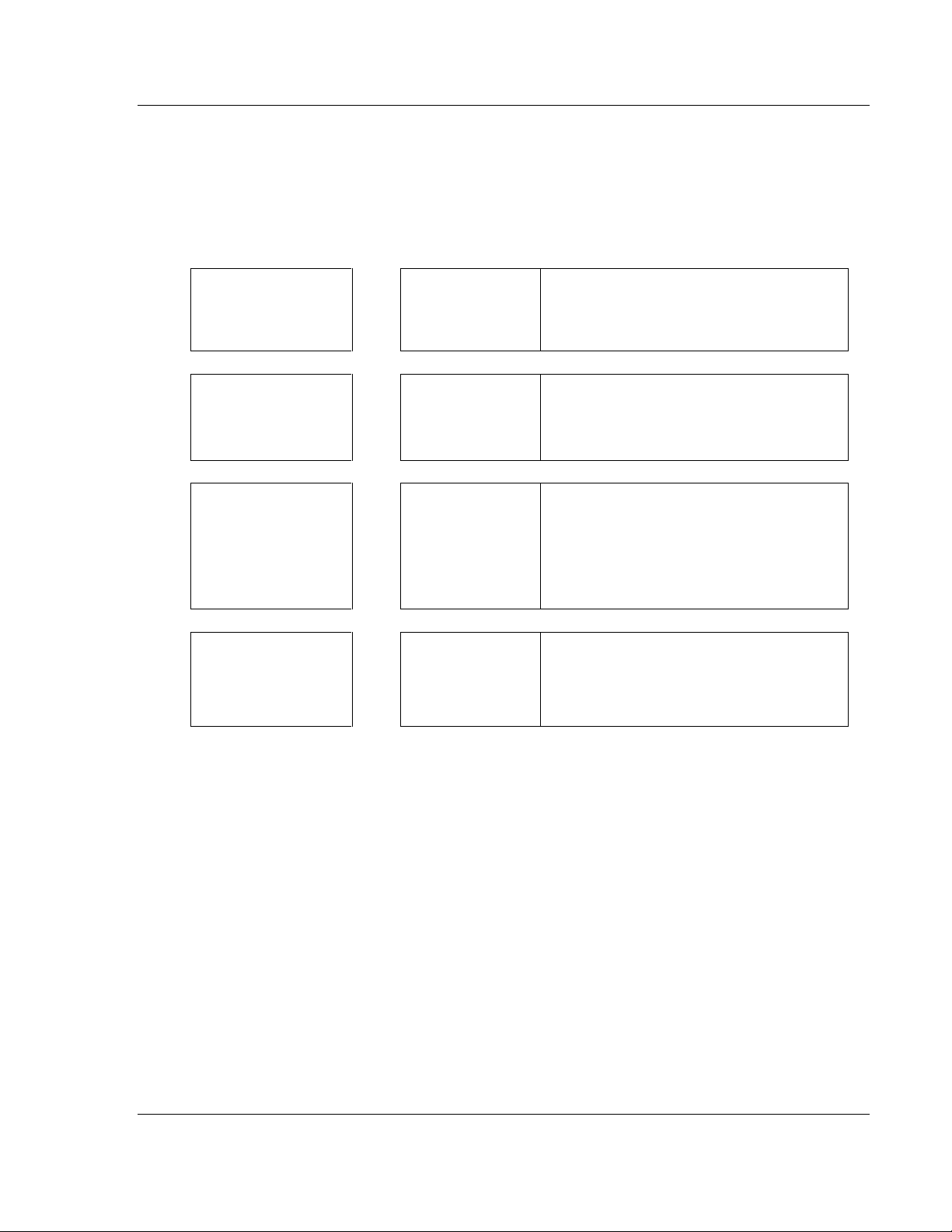

Function

Section to Read

Details

Introduction

(Must Do)

Start Here (page 9)

This section introduces the customer to the

module. Included are: package contents,

system requirements, hardware installation, and

basic configuration.

Diagnostic and

Troubleshooting

Diagnostics and

Troubleshooting

(page 55)

This section describes Diagnostic and

Troubleshooting procedures.

Reference

Product Specifications

Functional Overview

Reference (page 61)

Product

Specifications (page

62)

Functional Overview

These sections contain general references

associated with this product, Specifications, and

the Functional Overview.

Support, Service, and

Warranty

Index

Support, Service

and Warranty (page

103)

Index

This section contains Support, Service and

Warranty information.

Index of chapters.

Profibus DP Slave Communication Module User Manual

Guide to the PS69-DPS User Manual

ProSoft Technology, Inc. Page 7 of 108

May 9, 2014

Page 8

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

Page 8 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 9

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

In This Chapter

Software Requirements ......................................................................... 10

Hardware Requirements........................................................................ 10

Reference Systems ............................................................................... 10

Programmable Controller Functionality ................................................. 11

Package Contents ................................................................................. 12

Installing the Module in the Rack ........................................................... 13

Connecting Your PC to the Processor ................................................... 16

PS69-DPS Sample Add-On Instruction Import Procedure .................... 17

Downloading the Sample Program to the Processor ............................. 32

Adapter (PROFIBUS-DP-Slave) ............................................................ 35

Profibus DP Slave Communication Module User Manual

1 Start Here

To get the most benefit from this User Manual, you should have the following

skills:

Rockwell Automation® RSLogix™ software: launch the program, configure

ladder logic, and transfer the ladder logic to the processor

Microsoft Windows: install and launch programs, execute menu commands,

navigate dialog boxes, and enter data

Hardware installation and wiring: install the module, and safely connect

PROFIBUS DP and CompactLogix or MicroLogix devices to a power source

and to the PS69-DPS module’s application port(s)

The PS69-DPS module expands the functionality of Rockwell Automation’s

CompactLogix or MicroLogix to include PROFIBUS DP V0/V1. The PS69-DPS is

a more cost-effective option offering more features than the PS69-PDPS, and

supports both I/O control and messaging. Explicit ladder logic CIP message

blocks provide slave status diagnostic data and acyclic messaging.

The PS69-DPS interface appears to the CompactLogix or MicroLogix controller

as a standard I/O module allowing it to be configured via RSLogix5000, or

configuration can be transferred from the Master to the PS69-DPS. For third

ProSoft Technology, Inc. Page 9 of 108

May 9, 2014

party configuration a GSD file is supplied. The slave interface possesses a

diagnostic interface and has rotary switches for setting of the bus address.

Complete program examples for simple and quick start-up are available.

Each module is equipped with LEDs to display communication and device status.

Page 10

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

PS69-DPS

CompactLogix 1769-L20

CompactLogix 1769-L32E

Firmware V10.2

Firmware V13.18

Firmware V13.28

PS69-DPS

MicroLogix 1500 (Processor 1764-LRP/A Rev2.0)

Firmware V10.2

Firmware: OS 1510; Series C ; Revision 9.0

User Manual Profibus DP Slave Communication Module

1.1 Software Requirements

Follows are the software requirements for using the PS69-DPS module within a

CompactLogix system. You must have the following software installed on your

computer unless otherwise noted:

CompactLogix System

RSLogix 5000, V13.00 or higher

MicroLogix 1500 System

RSLogix 500, V6.30 or higher

1.2 Hardware Requirements

The following minimum hardware is required to use the PS69-DPS PROFIBUS

module.

CompactLogix System

Personal Computer

1769: Programmable Controller

1769: Power Supply

1769: Right or Left handed Termination End Cap

Serial Cable for interface to the 1769-Programmable Controller.

MicroLogix 1500 System

Personal Computer

1764: MicroLogix 1500 Programmable Controller

1769: Right handed Termination End Cap

Serial Cable for interface to the 1764-Programmable Controller.

1.3 Reference Systems

The firmware of the communication module PS69-DPS was developed and

tested with following CompactLogix / MicroLogix Controller types and firmware

revisions.

CompactLogix System

MicroLogix 1500 System

Page 10 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 11

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

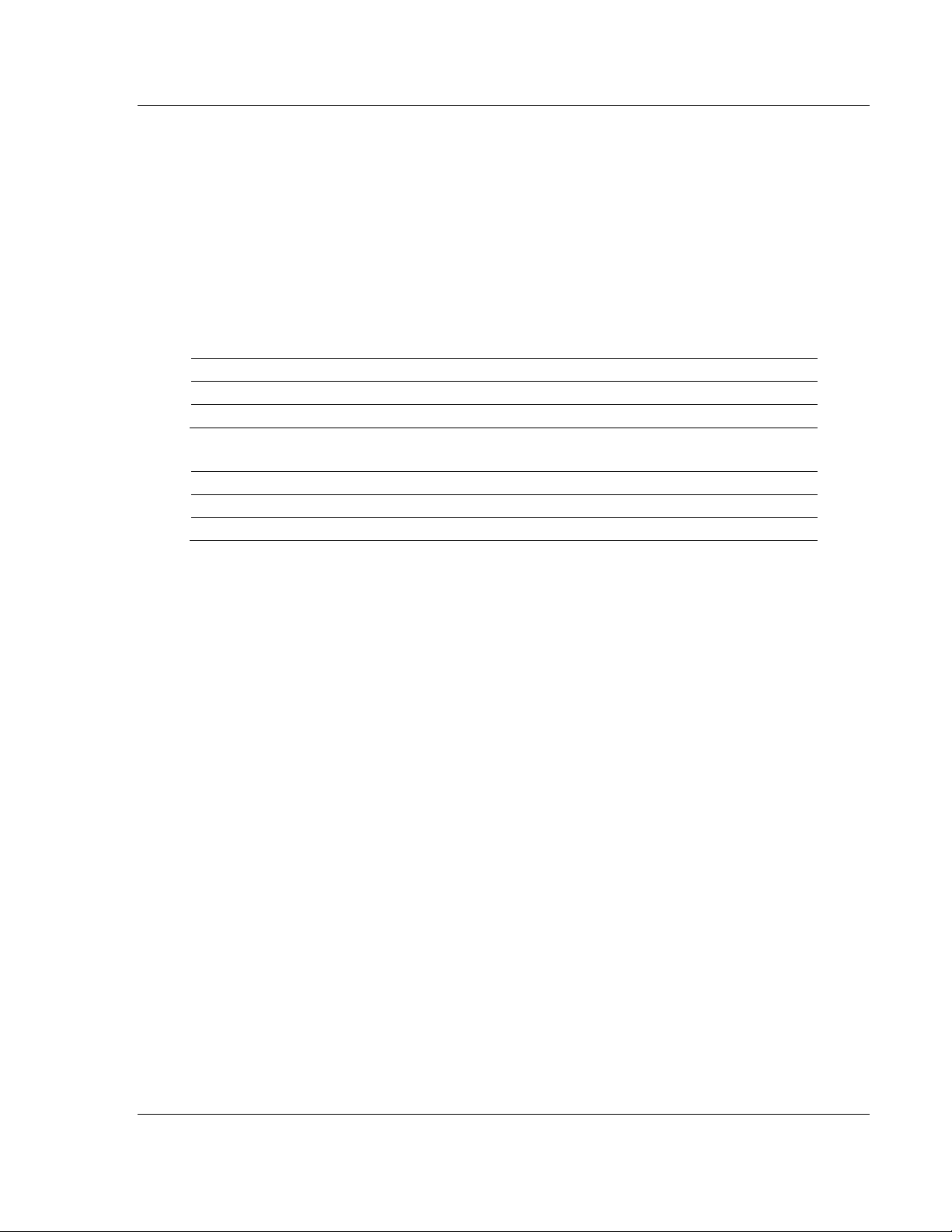

Processor/ Features

1769-L20

1769 -L30

1769 -L31

1769 -L32E

1769- L35E

I/O

yes

yes

yes

yes

yes

CIP Messaging

no

no

yes

yes

Yes

Processor/ Features

1764 -LRP

1764 -LSP

I/O

yes

yes

CIP Messaging

no

no

Profibus DP Slave Communication Module User Manual

1.4 Programmable Controller Functionality

PROFIBUS-DP supports acyclic services through messages. These PROFIBUSDP services are supported by the RSLogix5000 programming tool using CIP

messages. Not all of the 1769 Programmable Controllers support CIP

messaging. If your Controller does not support messaging, these services are not

available.

The basic PROFIBUS-DP acyclic services Global Control or Slave Diag request

are also executable in addition to the CIP method by using the I/O area. Follows

is a matrix of 1769 Programmable Controllers and the functionality that they

support.

CompactLogix System

MicroLogix 1500 System

yes = functionality supported

no = functionality not supported

ProSoft Technology, Inc. Page 11 of 108

May 9, 2014

Page 12

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

Qty.

Part Name

Part Number

Part Description

1

PS69-DPS Module

PS69-DPS

Profibus DP Slave Communication Module

1

ProSoft Solutions

DVD

DVD-001

Contains sample programs, utilities and

documentation for the PS69-DPS module.

User Manual Profibus DP Slave Communication Module

1.5 Package Contents

The following components are included with your PS69-DPS module, and are all

required for installation and configuration.

Important: Before beginning the installation, please verify that all of the following items are

present.

If any of these components are missing, please contact ProSoft Technology

Support for replacement parts.

Page 12 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 13

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

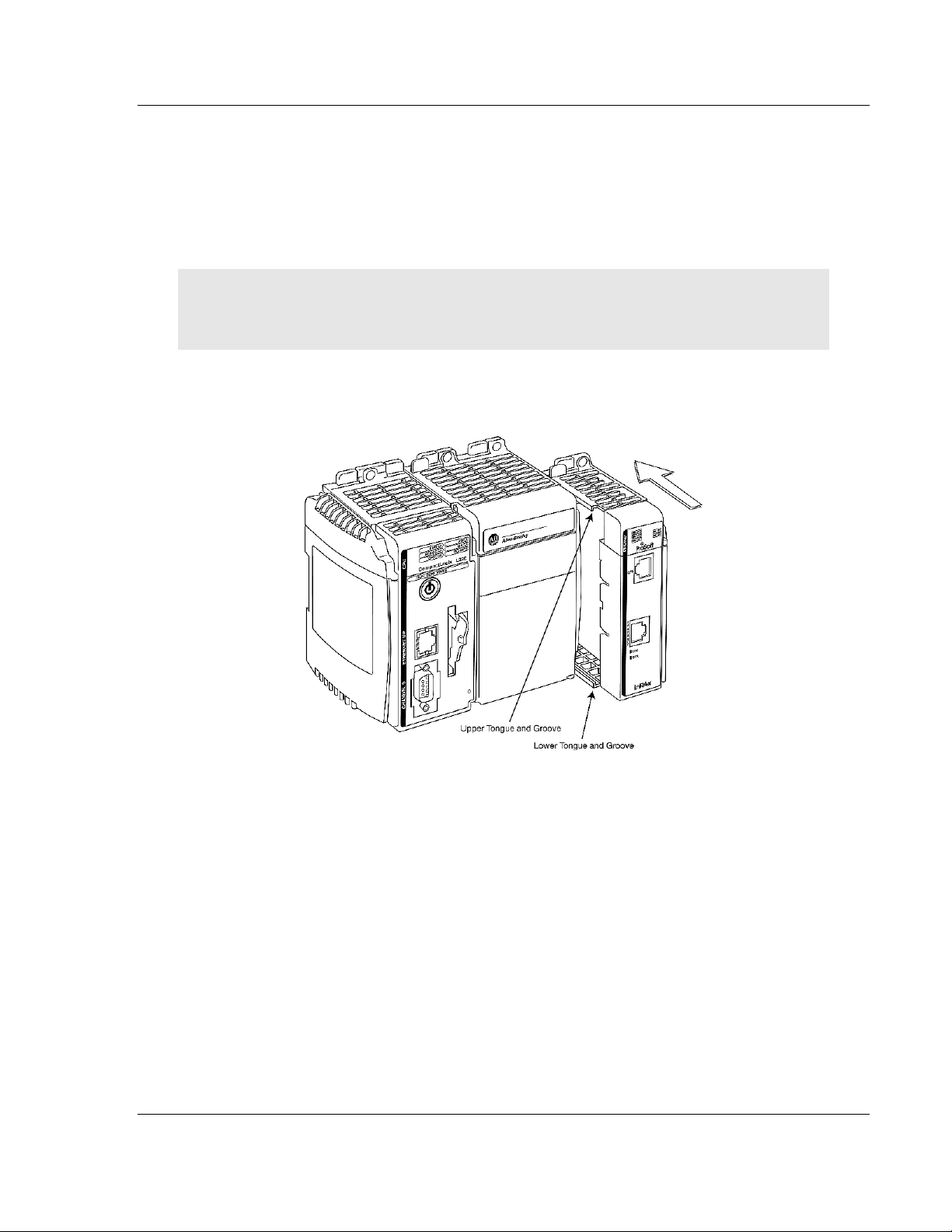

1.6 Installing the Module in the Rack

This section describes how to install the module into a CompactLogix or

MicroLogix rack.

Before you attempt to install the module, make sure that the bus lever of the

adjacent module is in the unlocked (fully right) position.

Warning: This module is not hot-swappable! Always remove power from the rack before

inserting or removing this module, or damage may result to the module, the processor, or other

connected devices.

1 Align the module using the upper and lower tongue-and-groove slots with the

adjacent module and slide forward in the direction of the arrow.

2 Move the module back along the tongue-and-groove slots until the bus

connectors on the PS69 module and the adjacent module line up with each

other.

ProSoft Technology, Inc. Page 13 of 108

May 9, 2014

Page 14

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

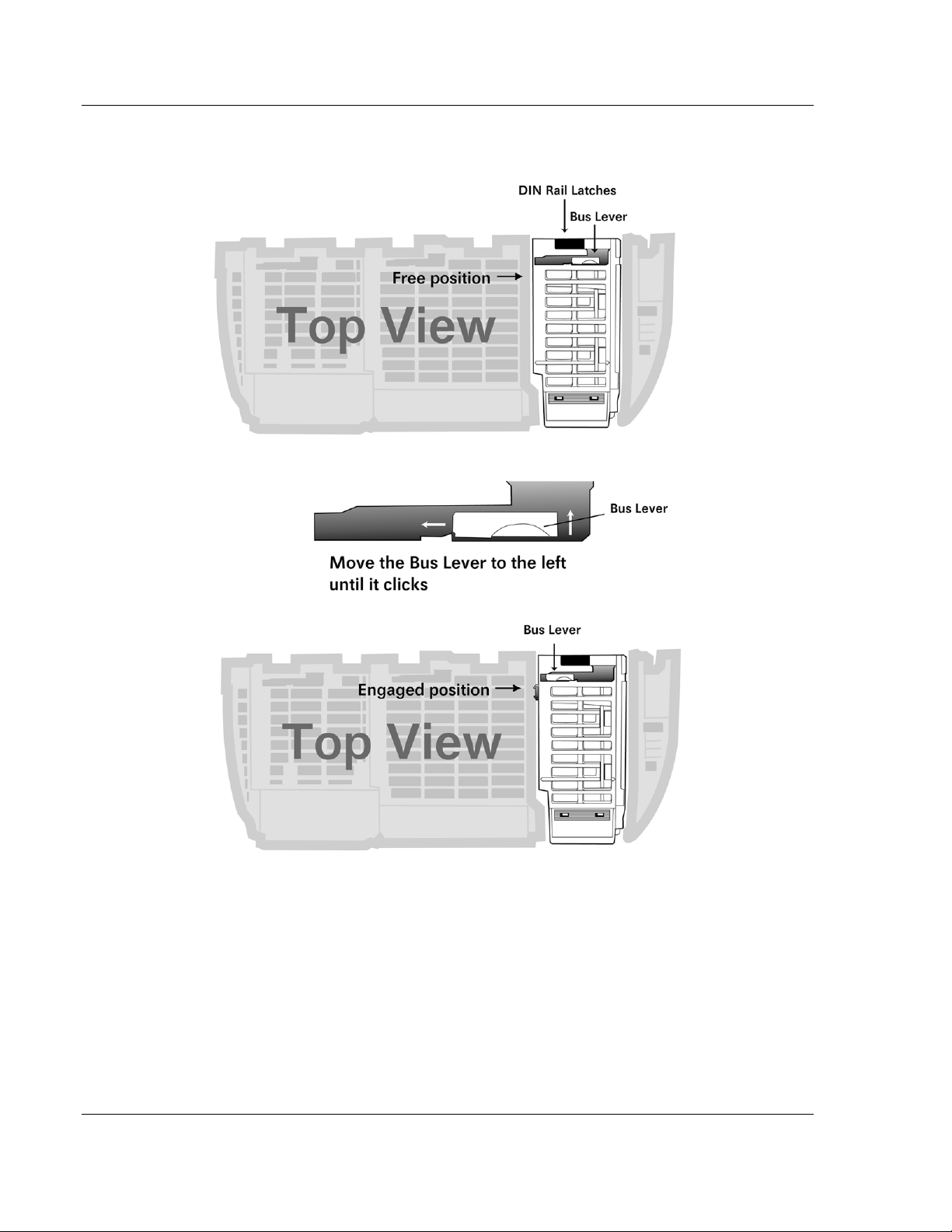

3 Push the module’s bus lever back slightly to clear the positioning tab and

move it firmly to the left until it clicks. Ensure that it is locked firmly in place.

4 Close all DIN-rail latches.

Page 14 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 15

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

5 Press the DIN-rail mounting area of the controller against the DIN-rail. The

latches will momentarily open and lock into place.

ProSoft Technology, Inc. Page 15 of 108

May 9, 2014

Page 16

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

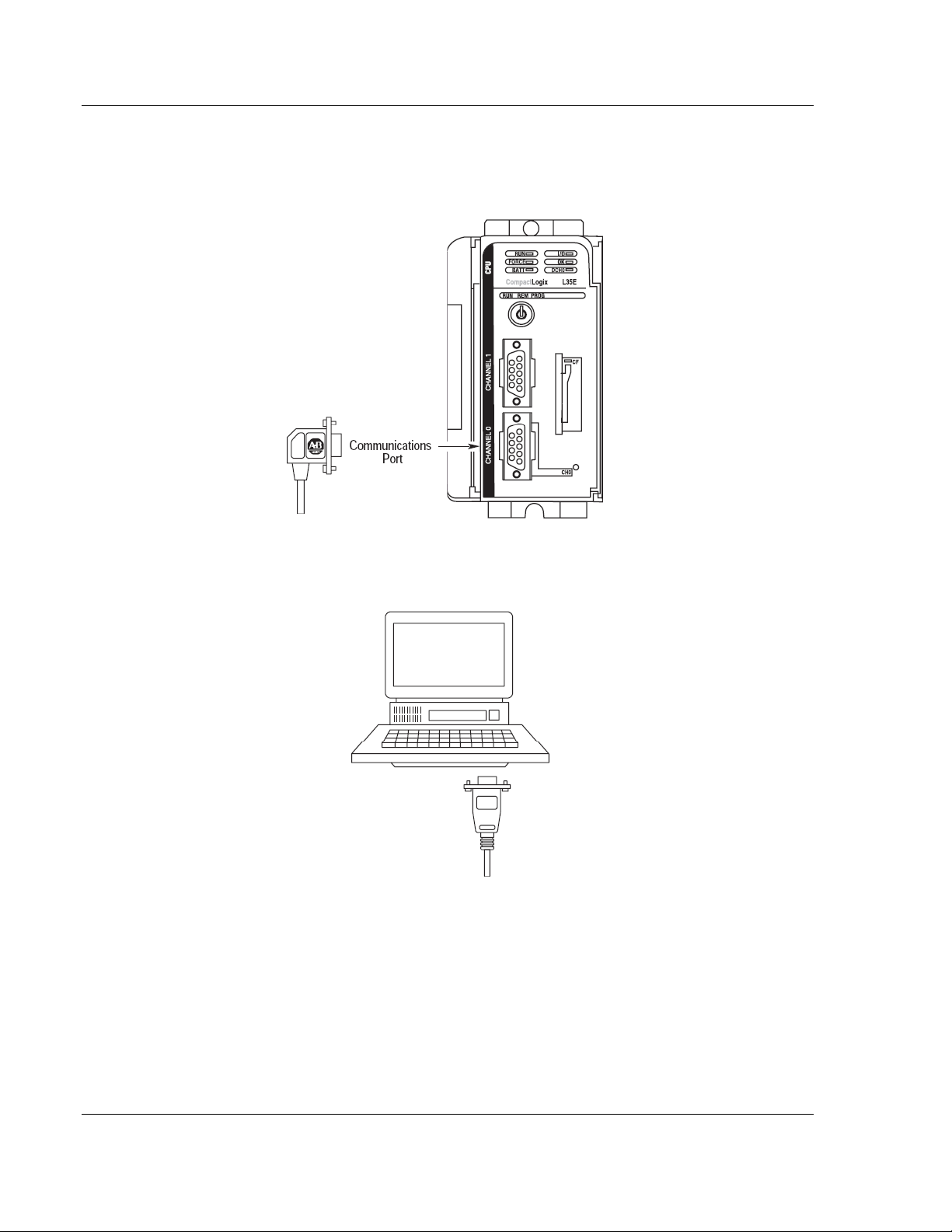

1.7 Connecting Your PC to the Processor

1 Connect the right-angle connector end of the cable to your controller at the

communications port.

2 Connect the straight connector end of the cable to the serial port on your

computer.

Page 16 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 17

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

File Name

Description

AOIPS69DPS_<Version #>.L5X

L5X file contains the Add-On instruction, the user defined data

types, data objects and ladder logic required to set up the

PS69-DPS module

Profibus DP Slave Communication Module User Manual

1.8 PS69-DPS Sample Add-On Instruction Import Procedure

Note: this section only applies if you are using RSLogix 5000 version 16 or higher.

The following file is required before you start this procedure. Copy the file from

the ProSoft Solutions DVD, or download it from www.prosoft-technology.com.

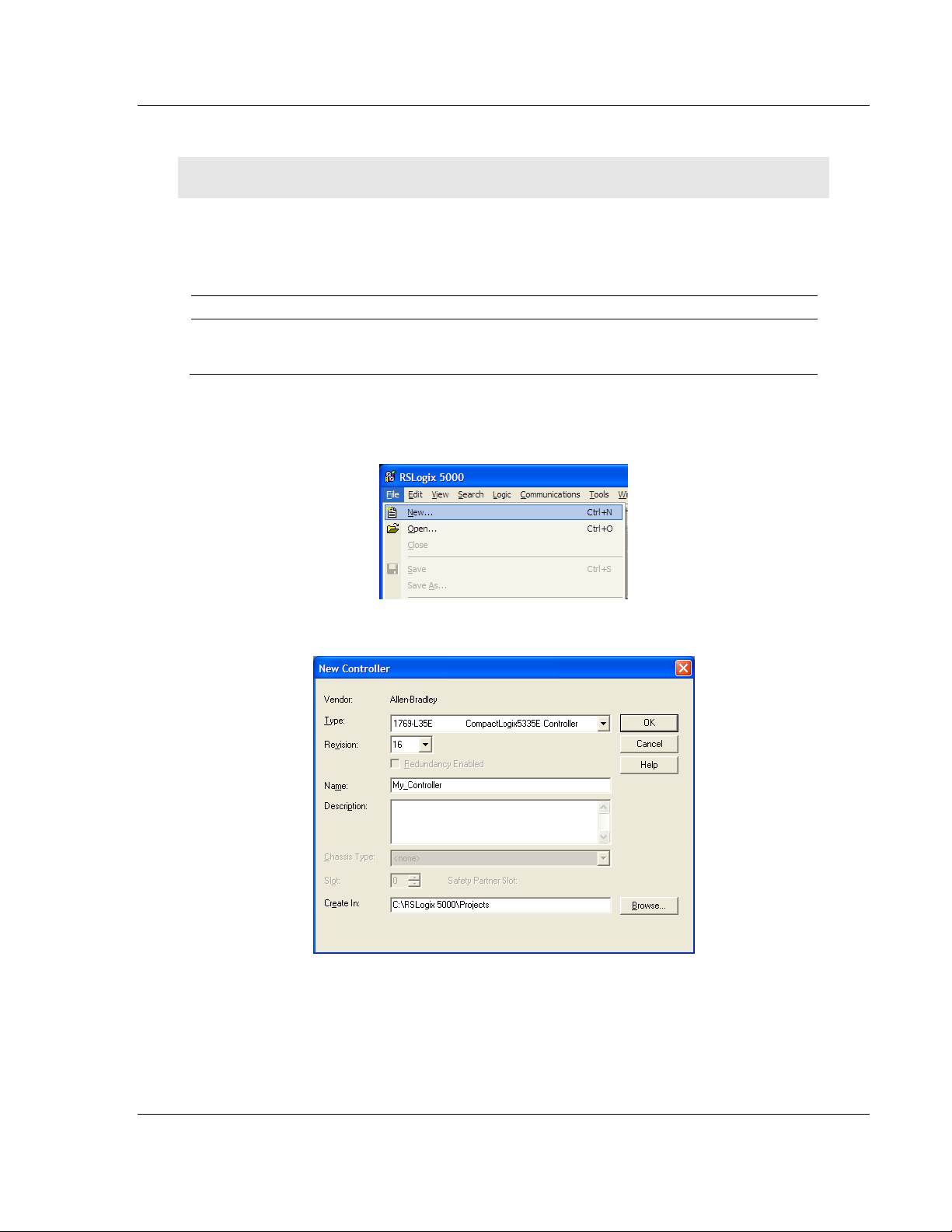

1.8.1 Create a new RSLogix5000 project

1 Open the FILE menu, and then choose NEW…

2 Select REVISION 16

ProSoft Technology, Inc. Page 17 of 108

May 9, 2014

Page 18

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

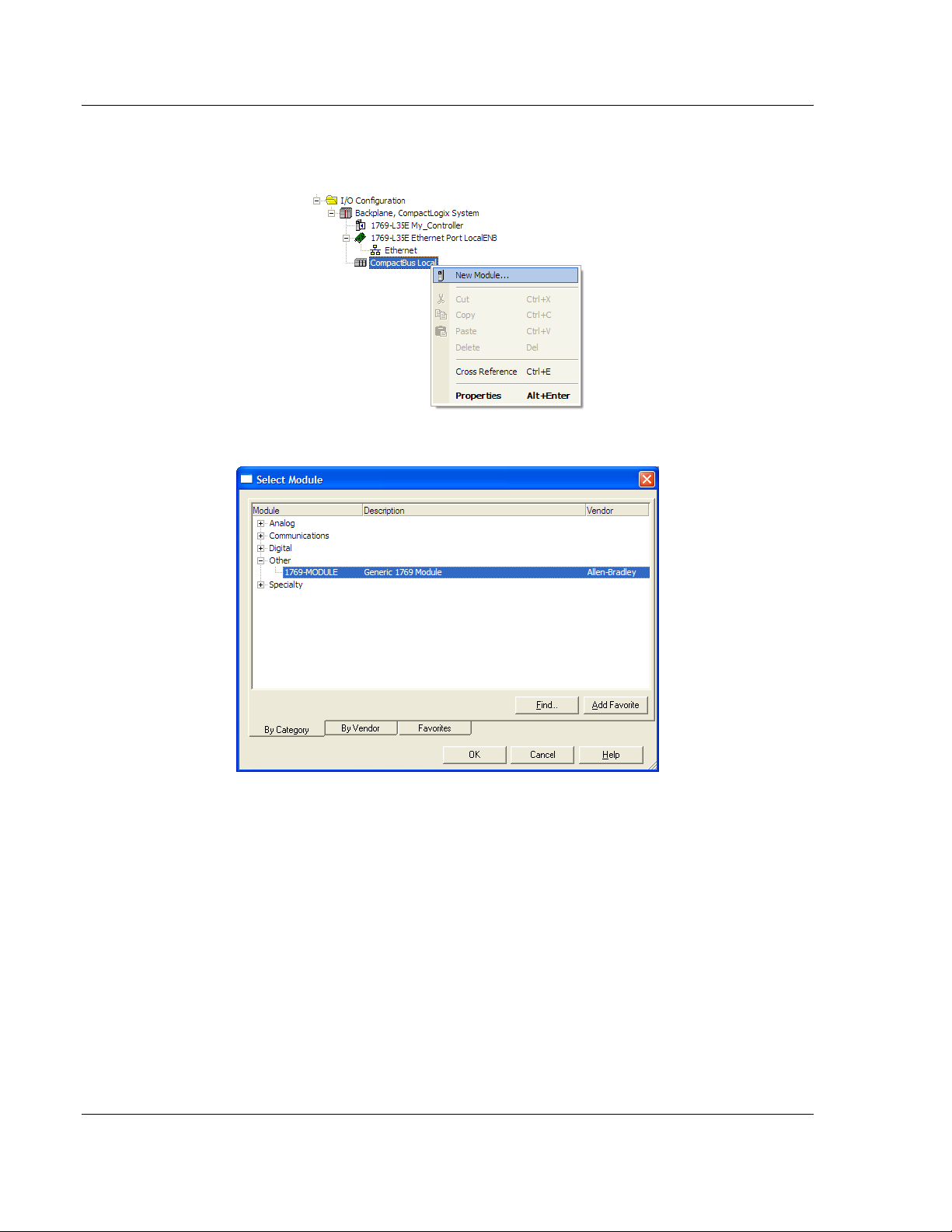

1.8.2 Create the Module

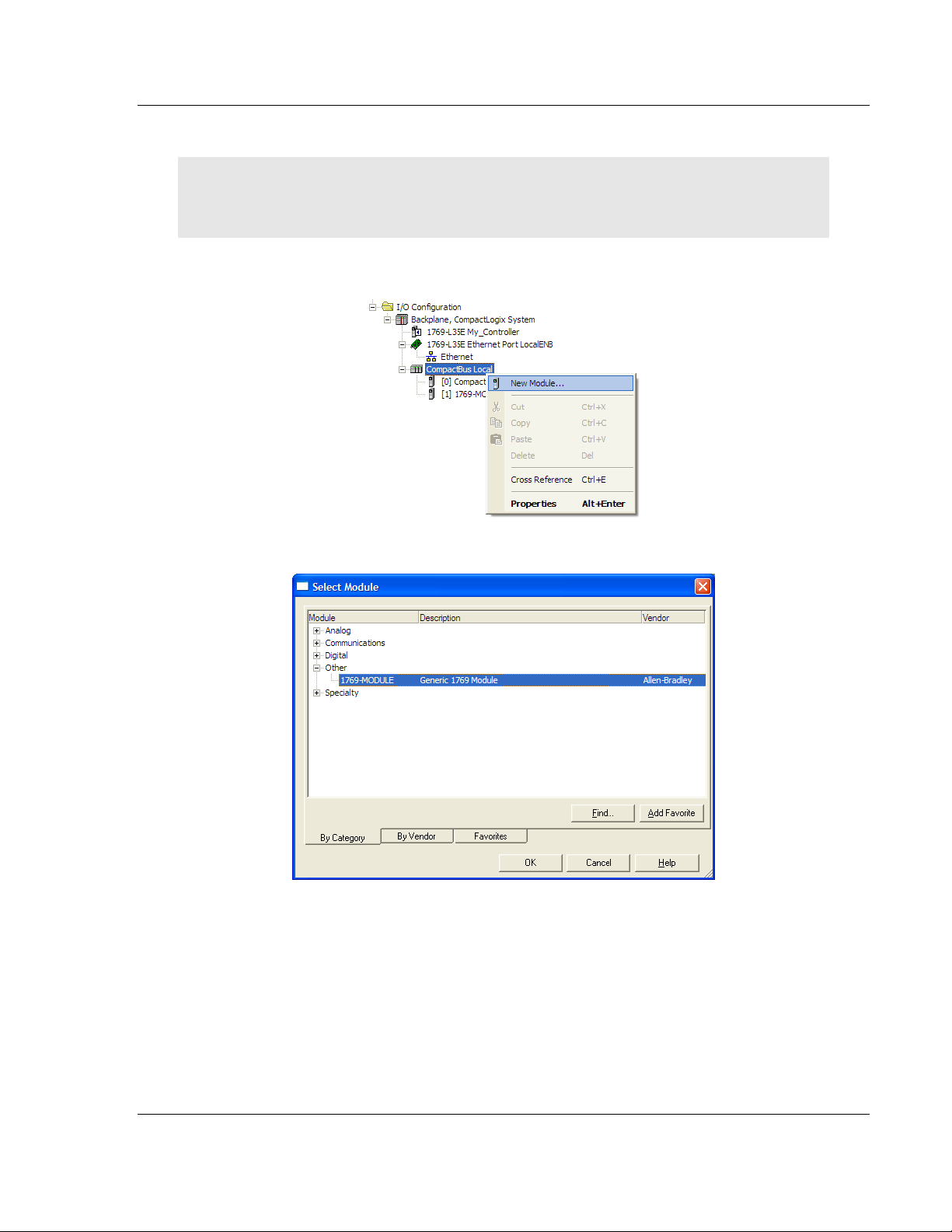

1 Right-click I/O Configuration and choose New Module…

2 Select 1769-MODULE

Page 18 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 19

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Parameter

Value

Name

Enter a module identification string. Example: PS69DPS

Description

Enter a description for the module. Example: Profibus DP

Slave Communication Module.

Comm Format

Select Data-INT

Slot

Enter the slot number in the rack where the PS69-DPS

module will be installed.

Input Assembly Instance

101

Input Size

190

Output Assembly Instance

100

Output Size

124

Configuration Assembly Instance

102

Configuration Size

32

Profibus DP Slave Communication Module User Manual

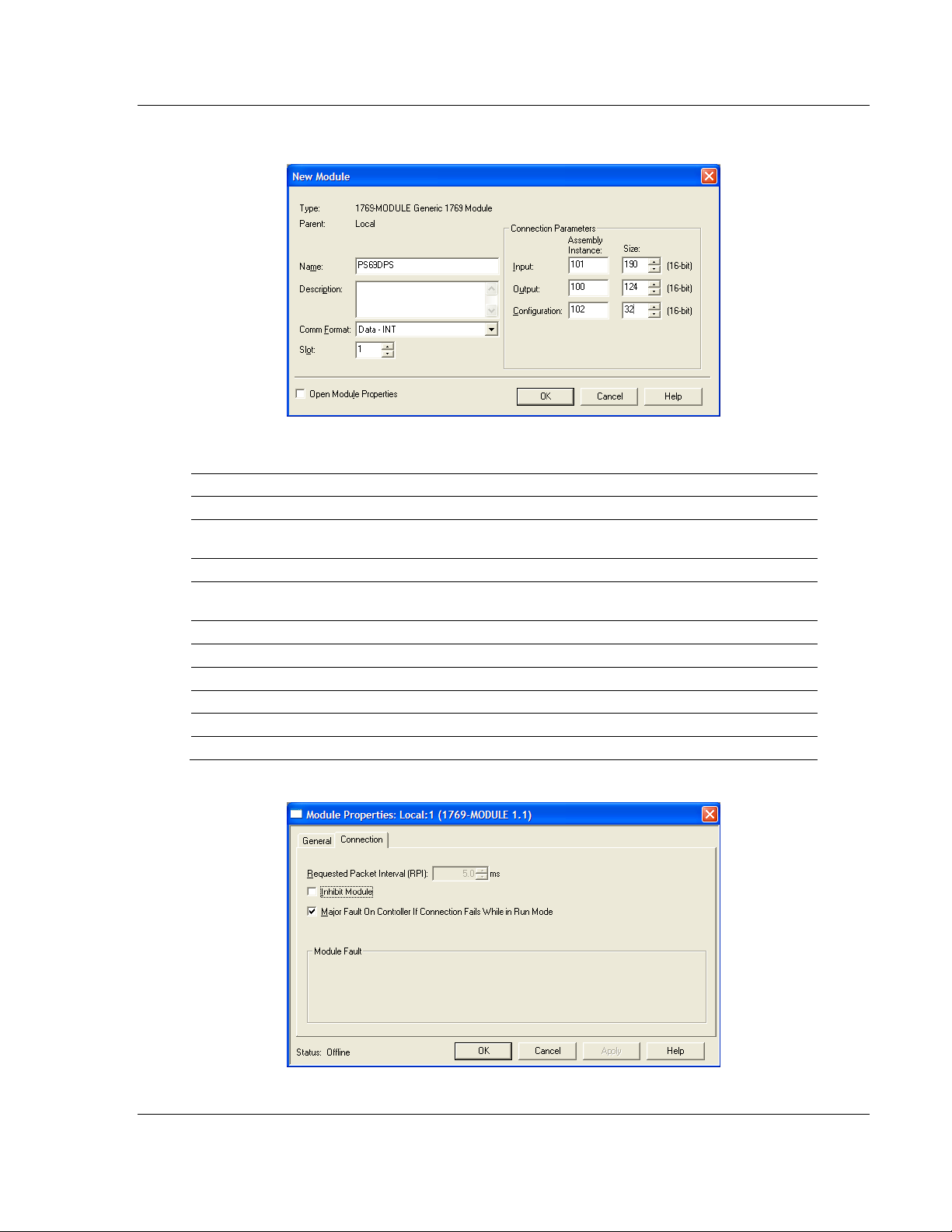

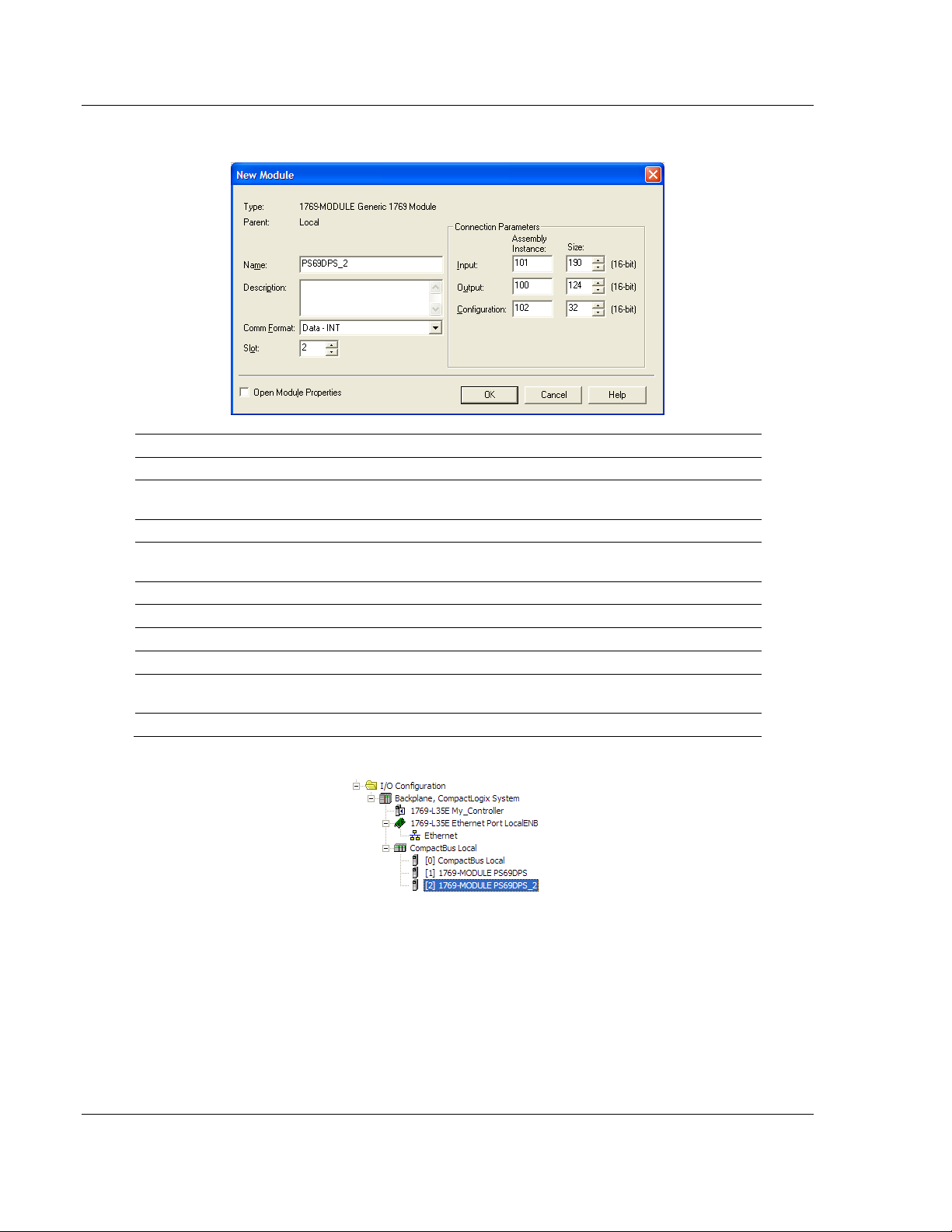

3 Set the Module Properties values as follows:

4 On the Connection tab, check or un-check, as desired the Major fault option.

ProSoft Technology, Inc. Page 19 of 108

May 9, 2014

Page 20

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

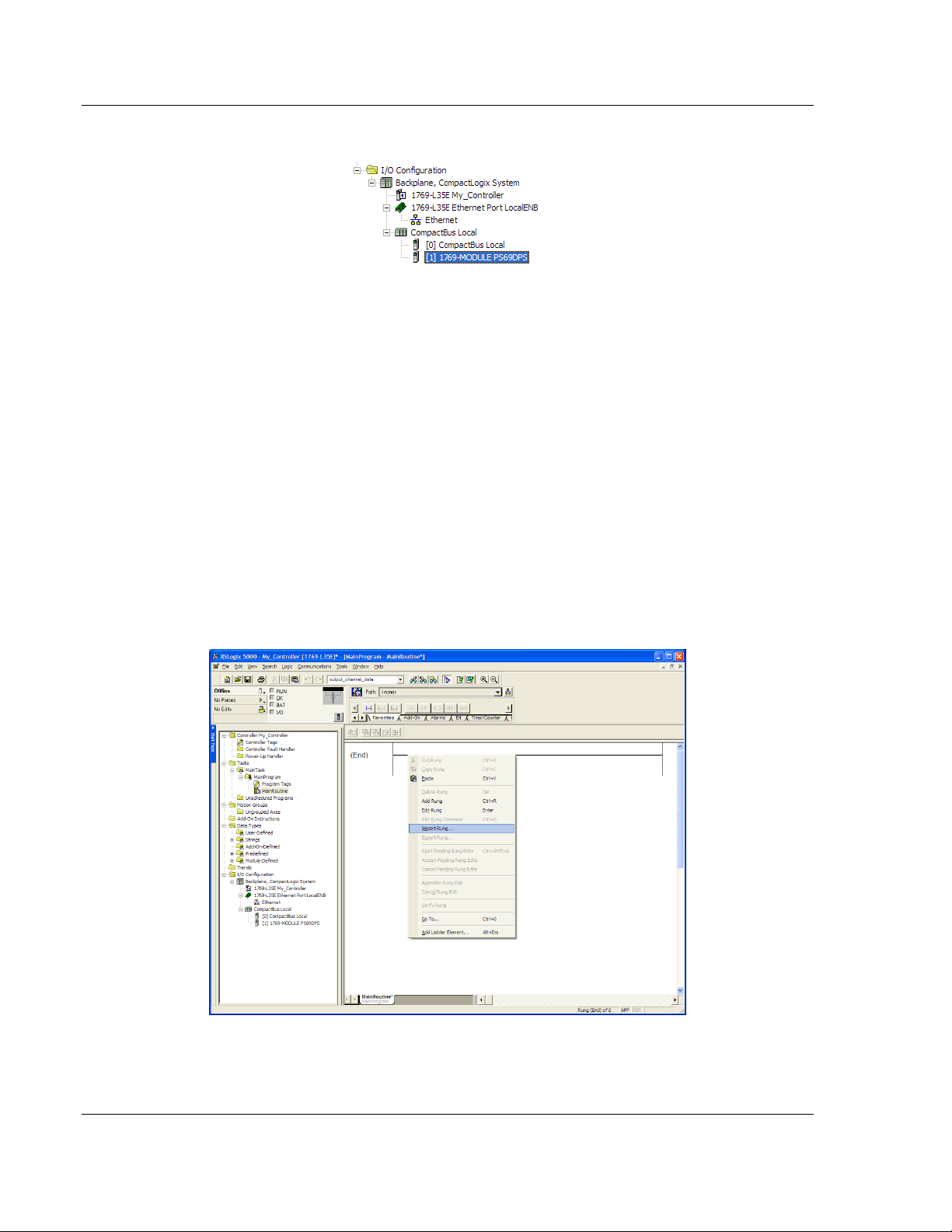

Now the PS69-DPS module will be visible at the I/O Configuration section

1.8.3 Import the Ladder Rung

1 Open your application in RSLogix 5000.

2 To create a new routine, expand the TASKS folder, and then expand the MAIN

TASK folder.

3 On the MAIN PROGRAM folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose NEW ROUTINE.

4 In the NEW ROUTINE dialog box, enter the name and description of your

routine, and then click OK. In this example we are demonstrating the

importing of the ladder rung using the default MainRoutine. In the case where

you create a routine by an other name for placing the Add-On instruction,

then in your original routine where your other ladder logic is located you need

to add a rung with a jump instruction to the new routine holding the Add-On

instruction.

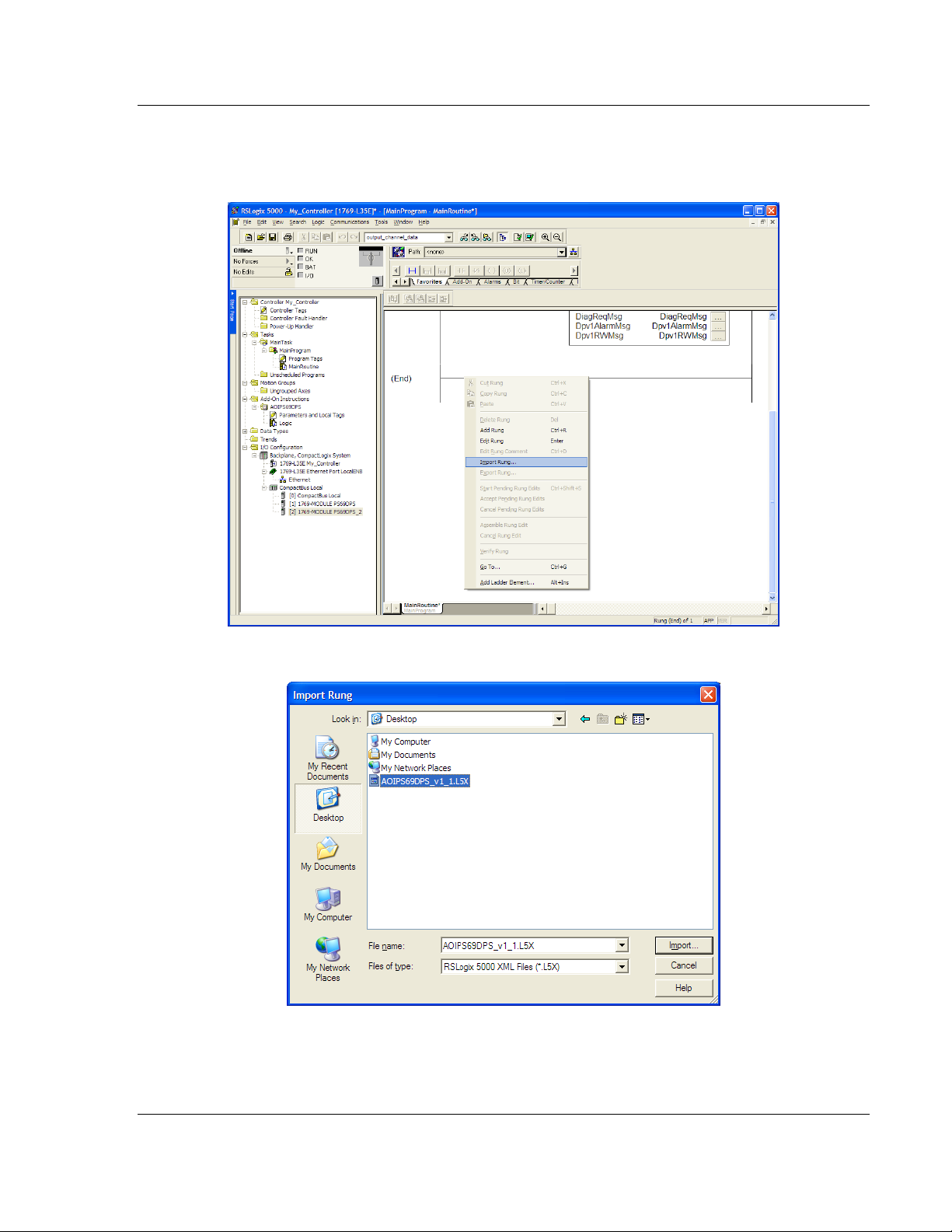

5 Select an empty rung in the new routine, and then click the right mouse

button to open a shortcut menu. On the shortcut menu, choose "IMPORT

RUNG…".

Page 20 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 21

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

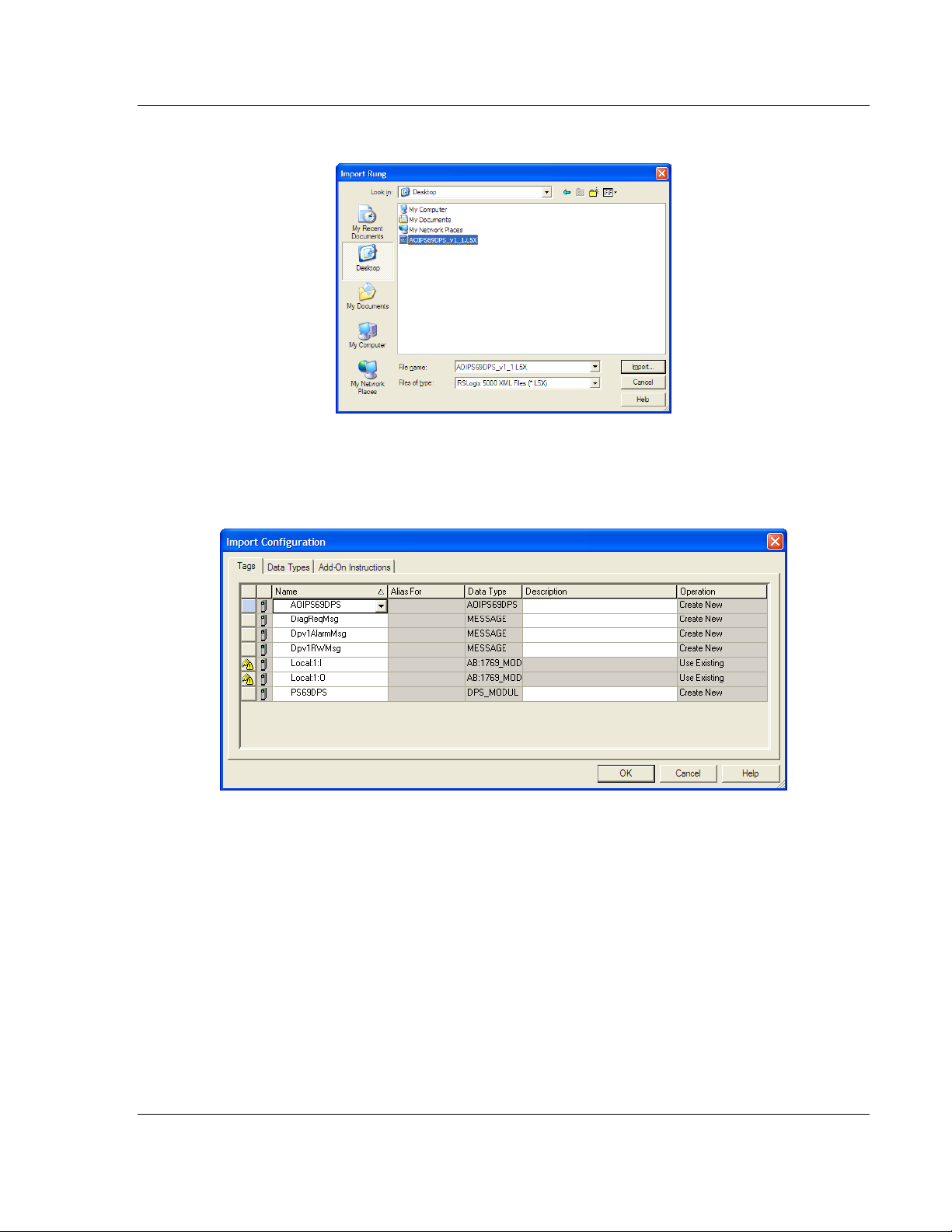

6 Select the AOIPS69DPS_<Version #>.L5X file

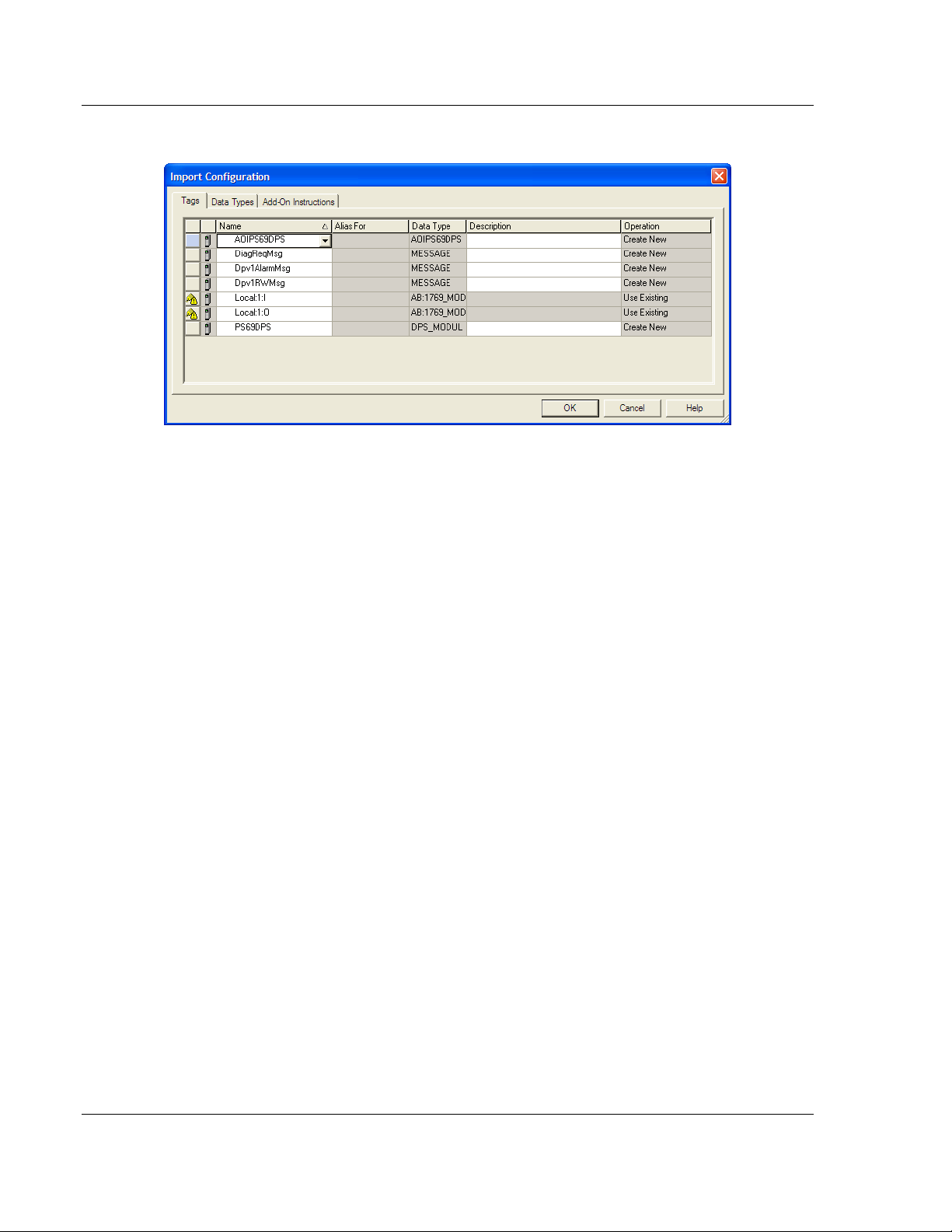

7 The following window will be displayed showing the controller tags to be

created during the import procedure: If desired, the description, "PS69-DPS

Interface AOI" may be typed into the description field for

AOIPS69DPS_<Version #>.L5X file.

ProSoft Technology, Inc. Page 21 of 108

May 9, 2014

Page 22

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

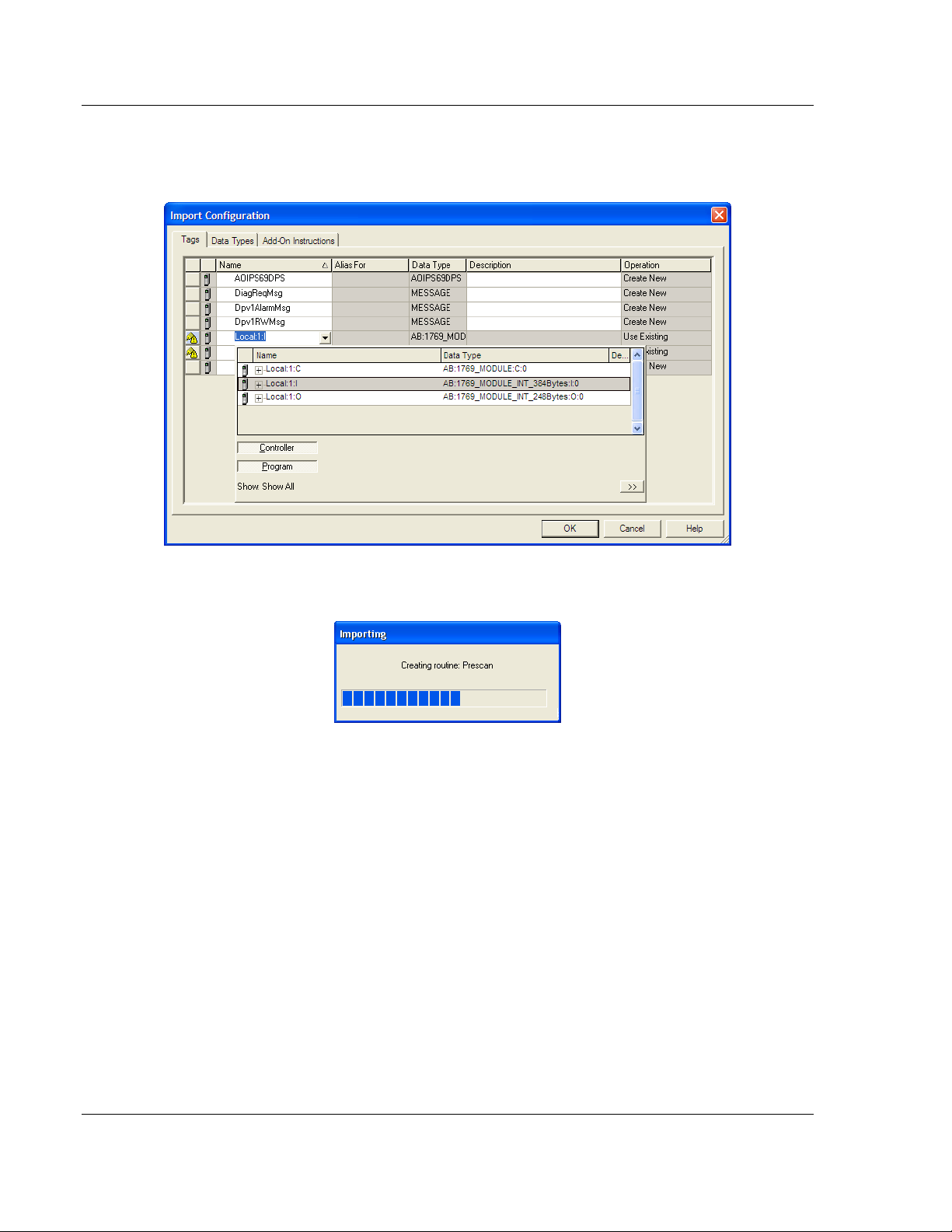

8 If you are using the module in a different slot (or remote rack) select the

correct connection input and output variables associated to the module. If

your module is located in slot 1 of the local rack this step is not required.

Click OK to confirm the import. RSLogix will indicate that the import is under

progress:

Page 22 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 23

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

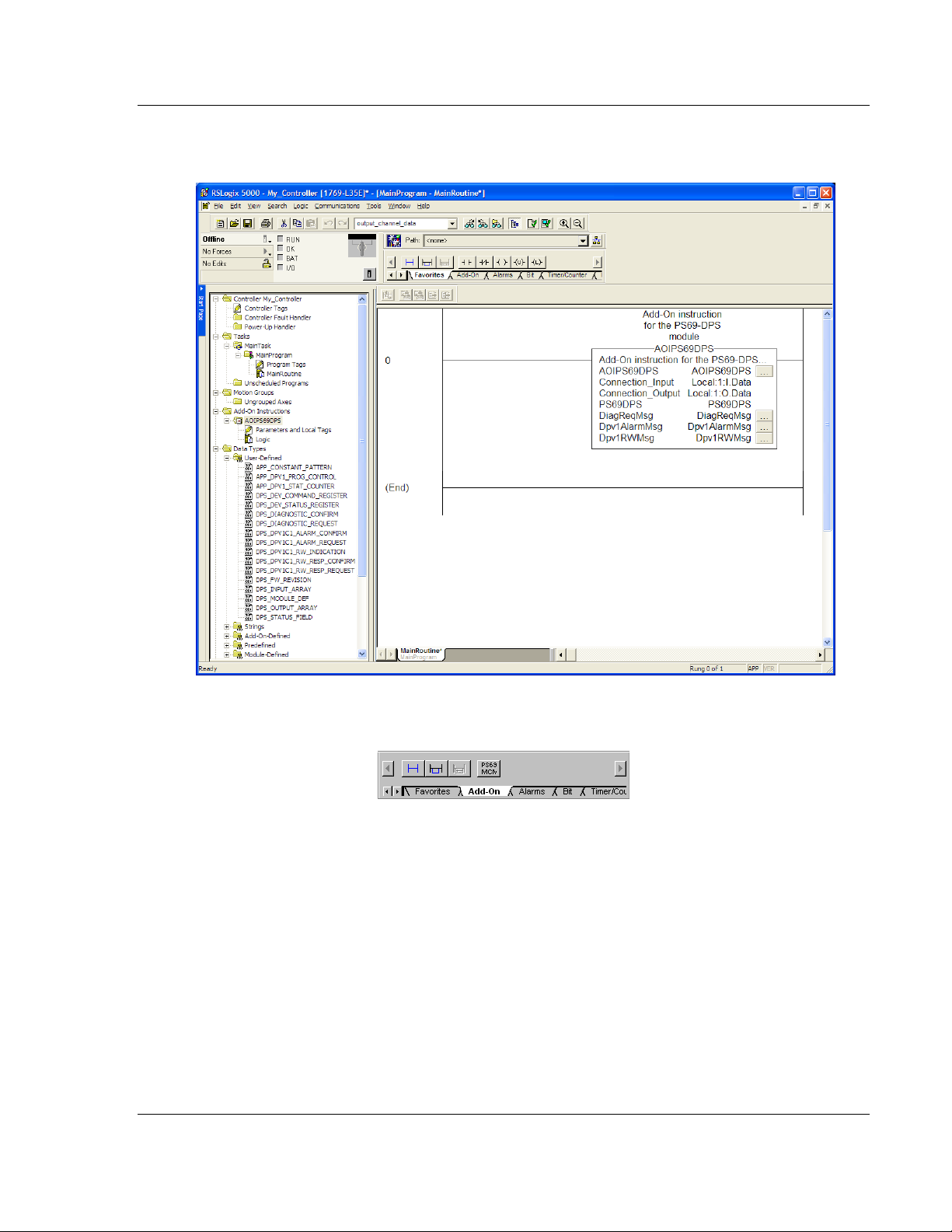

When the import is completed, the new rung with the Add-On instruction will

be visible as shown in the following illustration.

The procedure has also imported new user defined data types, data objects

and the Add-On instruction to be used at your project.

9 In the Add-On Instruction, click the [...] button next to each MSG tag to open

the MESSAGE CONFIGURATION TAG.

ProSoft Technology, Inc. Page 23 of 108

May 9, 2014

Page 24

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

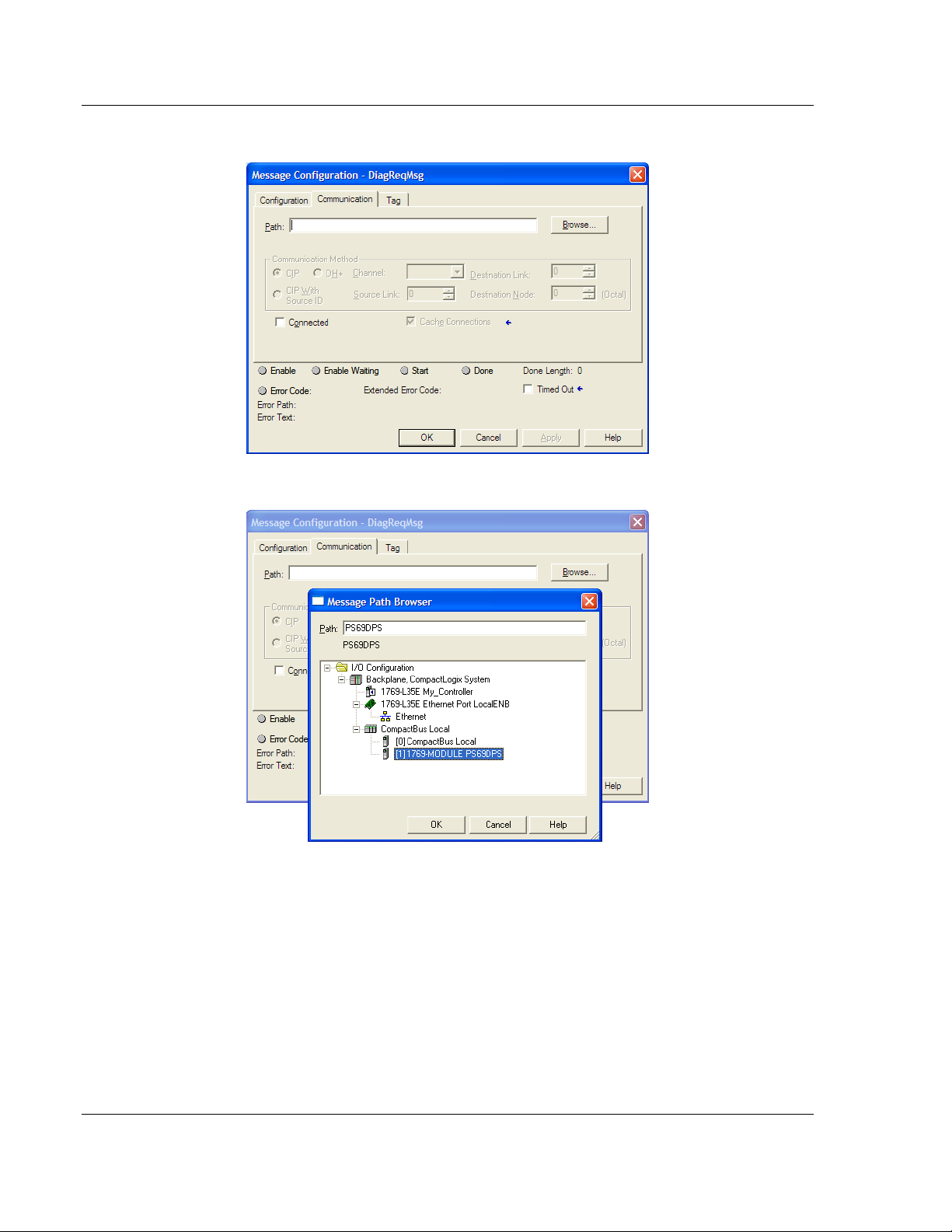

10 Click the COMMUNICATION tab and click the BROWSE button as follows.

11 Select the module to configure the message path.

12 Repeat steps 9 through 11 to configure the message path for Dpv1AlarmMsg

and DPv1RWMsg.

Page 24 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 25

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

1.8.4 Adding Multiple Modules (Optional)

Important: If your application requires more than one PS69-DPS module into the same project,

follow the steps below and make certain that both modules are assigned identical Block Transfer

Sizes.

1 In the I/O CONFIGURATION folder, click the right mouse button to open a

shortcut menu, and then choose NEW MODULE.

2 Select 1756-MODULE

ProSoft Technology, Inc. Page 25 of 108

May 9, 2014

Page 26

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

Parameter

Value

Name

Enter a module identification string. Example: PS69DPS_2

Description

Enter a description for the module. Example: Profibus DP Slave

Communication Module

Comm Format

Select Data-INT

Slot

Enter the slot number in the rack where the PS69-DPS module will

be installed.

Input Assembly Instance

101

Input Size

190

Output Assembly Instance

100

Output Size

124

Configuration Assembly

Instance

102

Configuration Size

32

User Manual Profibus DP Slave Communication Module

3 Fill the module properties as follows:

4 Click OK to confirm. The new module is now visible:

5 Expand the TASKS folder, and then expand the MAINTASK folder.

6 On the MAINPROGRAM folder, click the right mouse button to open a shortcut

menu. On the shortcut menu, choose NEW ROUTINE. As an alternative to

creating a separate New Routine, you could skip to Step 8 and import the

AOI for the second module into the same routine you created for the first

module.

7 In the NEW ROUTINE dialog box, enter the name and description of your

routine, and then click OK.

Page 26 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 27

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

8 Select an empty rung in the new routine or an existing routine, and then click

the right mouse button to open a shortcut menu. On the shortcut menu,

choose IMPORT RUNG…

9 Select the AOIPS69DPS5X file

ProSoft Technology, Inc. Page 27 of 108

May 9, 2014

Page 28

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

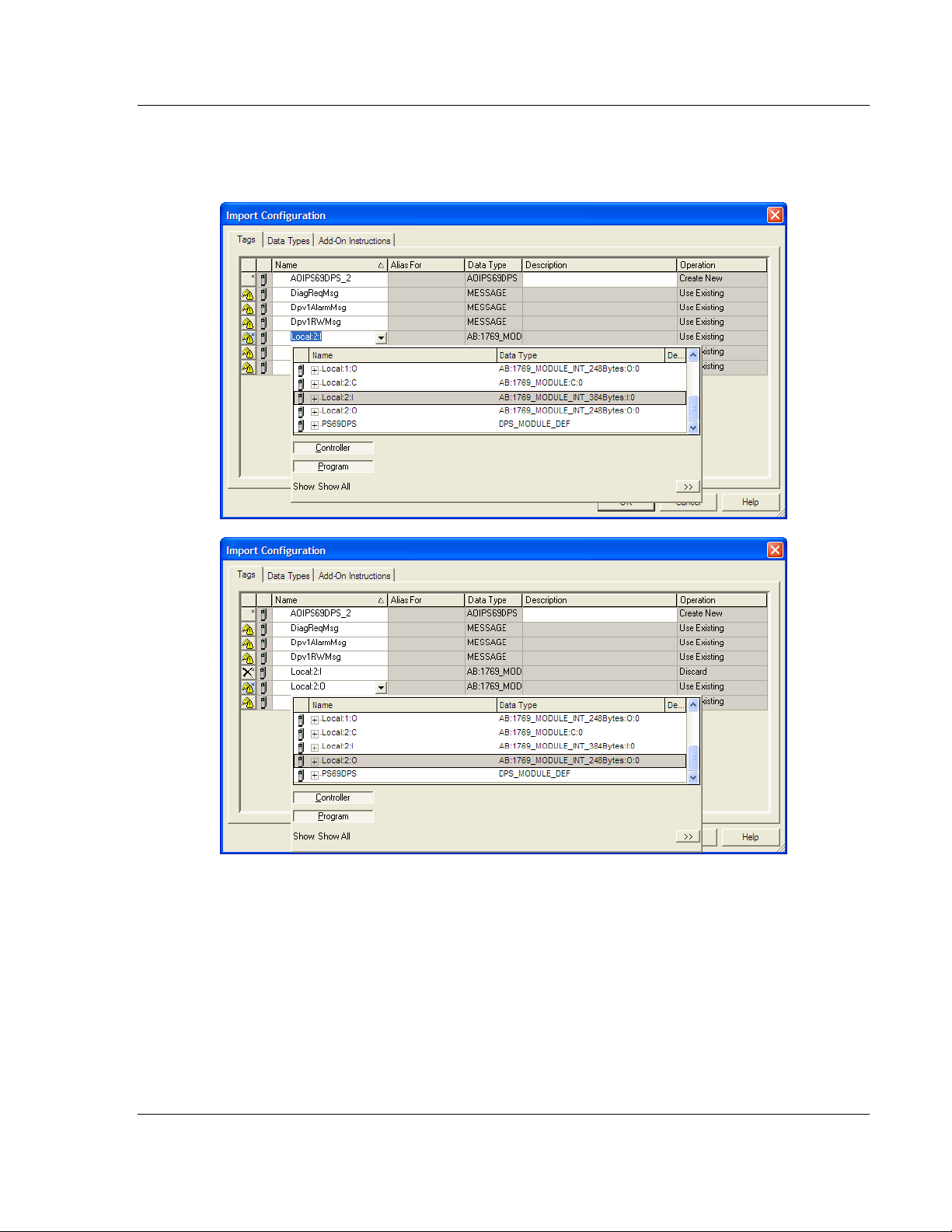

10 The following window will be displayed showing the tags to be imported:

Page 28 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 29

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

11 Associate the I/O connection variables to the correct module. The default

values are Local:1:I and Local:1:O. These require re-assignment to the new

module's location.

ProSoft Technology, Inc. Page 29 of 108

May 9, 2014

Page 30

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

12 Change the default tags PS69DPS and AOIPS69DPS to avoid conflict with

existing tags. This example procedure will append the string "_2" as follows:

13 You will be prompted to confirm your change. Click OK to continue.

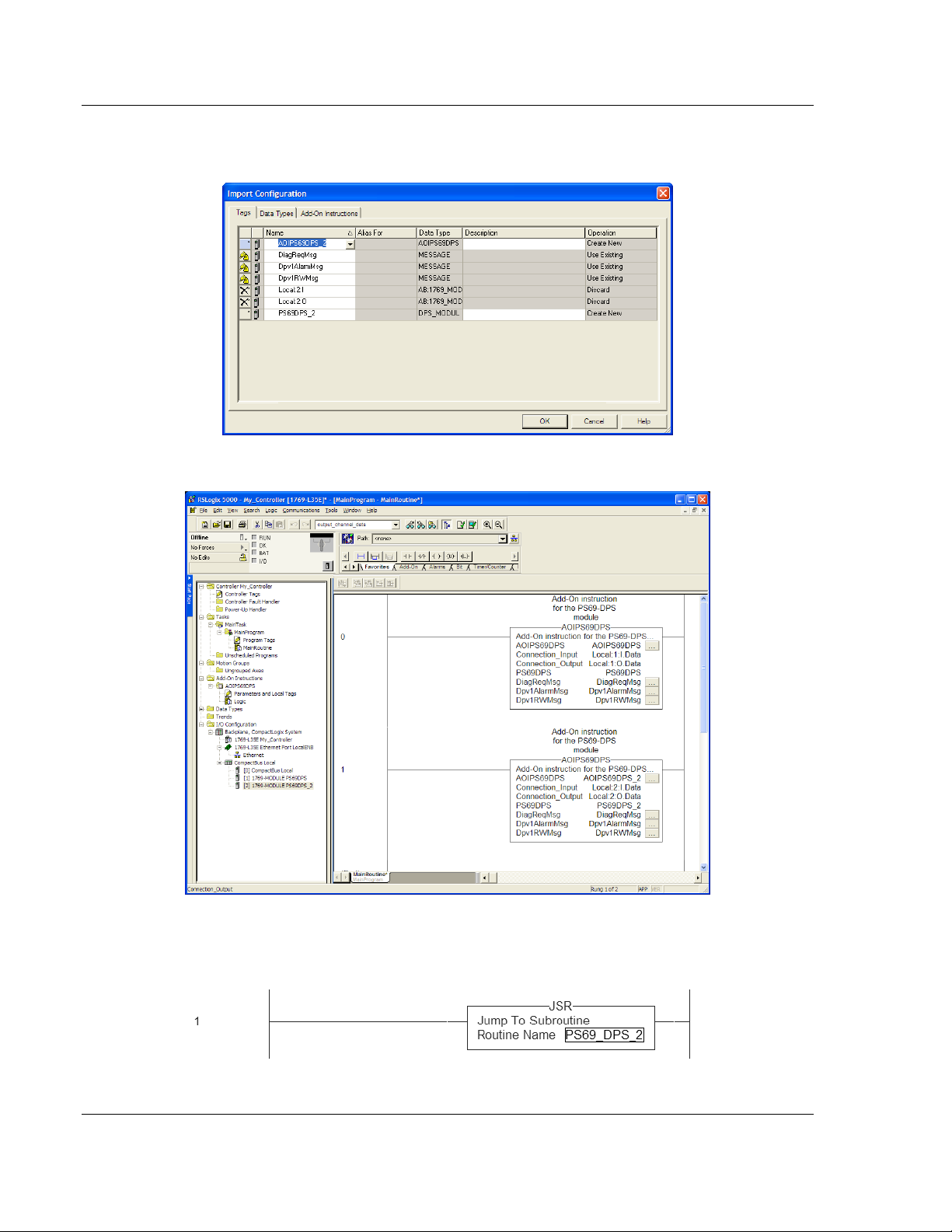

If the second module's logic was created in a new routine, enter a rung in the

Main routine with a JSR instruction to the new routine to enable the PLC logic

to communicate with both modules.

Page 30 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 31

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

14 In the Add-On Instruction, click the [...] button next to each MSG tag to open

the MESSAGE CONFIGURATION TAG.

15 Click the COMMUNICATION tab and click the BROWSE button as follows.

16 Select the module to configure the message path.

17 Repeat steps 14 through 16 to configure the message path for

Dpv1AlarmMsg and DPv1RWMsg.

The setup procedure is now complete. Save the project and download the

application to your CompactLogix processor.

ProSoft Technology, Inc. Page 31 of 108

May 9, 2014

Page 32

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

1.9 Downloading the Sample Program to the Processor

Note: The key switch on the front of the CompactLogix processor must be in the REM or PROG

position.

1 If you are not already online to the processor, open the COMMUNICATIONS

menu, and then choose DOWNLOAD. RSLogix will establish communication

with the processor.

2 When communication is established, RSLogix will open a confirmation dialog

box. Click the DOWNLOAD button to transfer the sample program to the

processor.

3 RSLogix will compile the program and transfer it to the processor. This

process may take a few minutes.

4 When the download is complete, RSLogix will open another confirmation

dialog box. Click OK to switch the processor from PROGRAM mode to RUN

mode.

Note: If you receive an error message during these steps, refer to your RSLogix documentation to

interpret and correct the error.

Page 32 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 33

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

1.9.1 Configuring the RSLinx Driver for the PC COM Port

If RSLogix is unable to establish communication with the processor, follow these

steps.

1 Open RSLinx.

2 Open the COMMUNICATIONS menu, and choose CONFIGURE DRIVERS.

This action opens the Configure Drivers dialog box.

Note: If the list of configured drivers is blank, you must first choose and configure a driver from the

Available Driver Types list. The recommended driver type to choose for serial communication with

the processor is RS-232 DF1 Devices.

3 Click to select the driver, and then click CONFIGURE. This action opens the

Configure RS-232 DF1 Devices dialog box.

ProSoft Technology, Inc. Page 33 of 108

May 9, 2014

Page 34

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

4 Click the AUTO-CONFIGURE button. RSLinx will attempt to configure your

serial port to work with the selected driver.

5 When you see the message Auto Configuration Successful, click the OK

button to dismiss the dialog box.

Note: If the auto-configuration procedure fails, verify that the cables are connected correctly

between the processor and the serial port on your computer, and then try again. If you are still

unable to auto-configure the port, refer to your RSLinx documentation for further troubleshooting

steps.

Page 34 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 35

PS69-DPS ♦ CompactLogix or MicroLogix Platform Start Here

Profibus DP Slave Communication Module User Manual

1.10 Adapter (PROFIBUS-DP-Slave)

ProSoft Technology, Inc. Page 35 of 108

May 9, 2014

Page 36

Start Here PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

Page 36 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 37

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

In This Chapter

RSLogix 5000 ........................................................................................ 38

RSLogix 500 .......................................................................................... 42

Slave Configuration ............................................................................... 45

Profibus DP Slave Communication Module User Manual

2 Configuration and Start-Up

The following sections will describe the individual steps for configuration and

start-up of the PS69-DPS module. Install the PROFIBUS Slave module into a

free slot in the CompactLogix or MicroLogix controller. Information regarding

installation of communication modules in CompactLogix or MicroLogix systems

can be found in the section Installation and Wiring or in the Rockwell installation

manual for the appropriate controller system. The slave module must be within 6

modules of the I/O bank's power supply.

Configuration and parameterization of the module is carried out in three steps

Configuration of the module in a CompactLogix or MicroLogix project of the

RSLogix5000 or RSLogix 500 programming tool.

Determine configuration method to be used by the Slave module during

startup.

Creating the data objects and the ladder diagram in RSLogix5000

ProSoft Technology, Inc. Page 37 of 108

May 9, 2014

Page 38

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

2.1 RSLogix 5000

This section contains instructions for configuring the PS69-DPS module in a

CompactLogix system using RSLogix5000.

Note: The simplest way to startup the module in RSLogix5000 project is to use the

"PS69_DPS_L32E.ACD" example project. In this example project, the slot number in the

configuration dialog of the module may have to be changed to match the users system.

2.1.1 Module Selection

Create a new project in RSLogix5000 using a CompactLogix controller.

In the Controller Organization window, select CompactBus Local, and then click

the right mouse button to open a shortcut menu. On the shortcut menu, choose

New Module.

Page 38 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 39

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

Profibus DP Slave Communication Module User Manual

This action opens the following dialog box.

Select "1769-MODULE Generic 1769 module", and then click then OK.

ProSoft Technology, Inc. Page 39 of 108

May 9, 2014

Page 40

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

Connection Parameter

Assembly Instance

Size (in Words)

Input

101

68 + X ... 190

Output

100

2 + Y... 124

Configuration

102

32

User Manual Profibus DP Slave Communication Module

2.1.2 Module Properties 1

The communications parameters for the module should be set as shown in the

dialog below.

Select a name and enter a short description for the module. Select the slot

number in which the module is installed in the controller. Select Data - INT as the

Comm_Format. Set the connection parameters as they are shown in the dialog.

X = Number of words configured for slave modules (PROFIBUS output data);

output size can be in the range between 68 and 190 words

Y = Number of words configured for slave modules (PROFIBUS input data); input

size can be in the range between 2 and 124 words

Input Size: The input size must be at least 68 Words (136 Bytes). It must be

large enough to accommodate the status information required by the module,

which is 68 Words (136 Bytes) plus the number of PROFIBUS output data.

The user can increase the size of this area using the size of each Output

module connected. The PROFIBUS Output area starts with Word 68 (Byte

136).

Output Size: The output size must be at least 2 Words (4 Bytes). It must be

large enough to accommodate the command information required by the

module, which is 2 Words (4 bytes), plus the number of PROFIBUS input

data. The user can increase the size of this area using the size of each Input

module connected. The PROFIBUS Input data image starts with byte 4.

Configuration Size: The size for the configuration array must be always 32

Words.

Note: If the parameters do not correspond to the template values, then the controller cannot

establish communication with the module.

Select Next >> for the next configuration dialog.

Page 40 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 41

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

Profibus DP Slave Communication Module User Manual

2.1.3 Module Properties 2

The Requested Packet Interval RPI is shown in the following dialog box. Within

this time interval, the I/O data between module and controller are exchanged.

It is not possible to change the RPI in this dialog separately for each module. The

RPI can be changed in the properties dialog of the "CompactBus Local" for all I/O

modules. Values in 1.0 ms steps are possible. The PROFIBUS PS69-DPS

module supports all possible RPI values.

End the configuration of the module with Finish>>.

ProSoft Technology, Inc. Page 41 of 108

May 9, 2014

Page 42

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

2.2 RSLogix 500

Contained in the sections below are the instructions for configuring the PS69DPS module in a MicroLogix system using RSLogix500.

2.2.1 Module Selection

Create a new project in RSLogix500 using a MicroLogix1500 controller. Then the

first step is to select the module and add it to your project. In the Controller

Organization window, expand the Controller folder, and then select IO

Configuration. Click the right muse button to open a shortcut window, and then

choose Open.

This action opens the following dialog box.

In the I/O Configuration dialog box, select the slot number in the left pane. In the

right pane, select and double-click Other - Requires I/O Card Type ID.

Page 42 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 43

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

Expansion General Configuration

Value

Vendor

283

Product Type

12

Product Code

4

Series/Major Rev/Minor Rev

A

Input Words

(68 + X ) ... 190

Output Words

(2 + Y ) ... 124

Extra Data Length

32

Profibus DP Slave Communication Module User Manual

2.2.2 Expansion General Configuration

Fill in the values on the Expansion General Configuration tab as shown in the

following illustration.

X = Number of Words configured for slave modules (PROFIBUS output data).

The output size can range from 68 to 190 words.

Y = Number of Words configured for slave modules (PROFIBUS input data). The

input size can range from 2 to 124 words.

Vendor Name / Product Type / Product Code for the PS69-DPS module are

283,12,4.

Input Size: This value must be large enough to accommodate 68 words (136

bytes) of status information required by the module, plus the number of words

of PROFIBUS output data. You can increase the size of this area using the

size of each Output module connected. The PROFIBUS Output data image

starts with Word 68 (Byte 136).

Output Size: This value must large enough to accommodate 2 Words (4

Bytes) of command information required by the module, which is 2 Words (4

bytes), plus the number of words of PROFIBUS input data. You can increase

the size of this area using the size of each Input module connected. The

PROFIBUS Input data image starts with byte 4.

Configuration Size: The size for the configuration array must be always 32

Words.

Note: If the parameters do not correspond to the template values, then the controller cannot

establish communication with the module.

ProSoft Technology, Inc. Page 43 of 108

May 9, 2014

Page 44

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

2.2.3 Generic Extra Data Config

If you select the "Generic Extra Data Config" Tab you can enter a configuration

for the module manually. For the first project it is not necessary to enter any

configuration data here. If you don't enter any configuration data the slave will

receive its configuration data from the Profibus master. For more information

about the slave configuration see the following section "Slave Configuration"

The meaning of each word of the configuration array can be found in section

"Configuration by Controller Application".

Click OK to end the I/O configuration of the module.

Page 44 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 45

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

Profibus DP Slave Communication Module User Manual

2.3 Slave Configuration

2.3.1 General

The following section will detail the basics of configuring the PS69-DPS module.

The PROFIBUS-DP Slave module does not require a configuration tool. There

are two ways to configure the Slave module. These two methods are described

in the following sections.

2.3.2 GSD File

A GSD file is kind of an electronic datasheet for a particular Slave device. The

GSD-File for the PS69-DPS slave named "PSFT097A.gsd" is located on the

DVD supplied with the module. You have to provide this file to the configuration

tool for the network master. Refer to the Master’s user manual of how to import

GSD files.

2.3.3 Configuration by Master

The "Configuration by Master" is the easiest way to configure the Slave. The

projects on the DVD contain examples which show the use of this method.

During the network startup phase, the PROFIBUS Master sends the expected

slave configuration over the network to compare it with the real configuration of

the Slaves connected to the bus. The slave PS69-DPS automatically takes over

the configuration which is sent by the master during its comparison of the

configuration. This method is activated by default, since the parameter "Force

User Config" in the configuration area is set to 0. The only setting required by the

user is setting the Address rotary switches on the front of the module to the

required network address.

Note: This is the easiest way to configure the Slave. But be aware that the master can send a new

configuration to the slave at any time. This can cause inconsistency, if the new configuration does

not match to the controller application. For more safety use the method "Configuration by Controller

Application". With this method the slave module does not start any communication as long as the

slave configuration and the master configuration don't match to each other.

ProSoft Technology, Inc. Page 45 of 108

May 9, 2014

Page 46

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

Word Offset

Configuration word

Data type

Low/High Byte

Description

Valid values

0

Local: 1:C.Data[0]

INT

LOW Byte

Busaddress

0 ... 125

HIGH Byte

Force User

Configuration

0 =

ForceMasterConfig

1 = ForceUserConfig

1

Local: 1:C.Data[1]

INT Reserved

2

Local: 1:C.Data[2]

INT Watchdog Time

0 … FFFFh

3

Local: 1:C.Data[3]

INT Number of valid config

bytes

(starting with

Local:1:C.Data[8])

2 ... 48

4

Local: 1:C.Data[4]

INT Reserved

5

Local: 1:C.Data[5]

INT Reserved

6

Local: 1:C.Data[6]

INT Reserved

7

Local: 1:C.Data[7]

INT Reserved

8

Local: 1:C.Data[8]

INT

LOW Byte

Module 1 Type

see table "Module

Types"

HIGH Byte

Module 1 Length

see table "Module

Types"

9

Local: 1:C.Data[9]

INT

LOW Byte

Module 2 Type

see table "Module

Types"

HIGH Byte

Module 2 Length

see table "Module

Types"

...

...

...

...

31

Local: 1:C.Data[31]

INT

LOW Byte

Module 24 Type

see table "Module

Types"

HIGH Byte

Module 24 Length

see table "Module

Types"

User Manual Profibus DP Slave Communication Module

2.3.4 Configuration by Controller Application

The second option to configure the Slave module is to let the controller

application decide on the configuration. To do so the parameter "Force User

Config" in the configuration array has to be set to 1. By setting this parameter

and initialization of the other values the controller program can configure the

slave. With this method the slave module will not start any network

communication as long as the master and slave configuration don't match to

each other. The following table shows the outline of the mapping of the

configuration data image.

Page 46 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 47

PS69-DPS ♦ CompactLogix or MicroLogix Platform Configuration and Start-Up

Address Switches

Configuration Address Parameter

Active Bus Address

Description

1 .. 99

XX

1 .. 99

Address switches are valid

0

0 .. 125

0 .. 125

Configuration parameter is valid

0

> 125

XX

Invalid (will cause an initialization

error)

Profibus DP Slave Communication Module User Manual

2.3.5 Explanation of settable configuration values

Busaddress

The valid PROFIBUS address range is from 0 to 125. The module has two

rotating address switches to set the network address from 0 to 99.

With the rotating switches, however, you are not able to select bus addresses

above 99. If you choose 0 on the address switches, then the module will take the

address parameter from the configuration data array. Now you are able to set up

bus addresses above 99.

XX - Don't Care

Force User Configuration

If the parameter ForceUserConfiguration is set to 1, the slave will not start its

network communication until the master and slave configurations match

each other. If this value is set to 0, the slave accepts any valid configuration sent

from the master.

Watchdog Timeout

The Slave module supervises its I/O exchange with the controller with a timeout.

If the controller does not update the output data within this time, the Slave stops

the cyclic data exchange to the master and goes into a safe state.

If the parameter ForceUserConfiguration is set to 0 then the module calculates

automatically a timeout value by the RPI (Requested Packet Interval). The

calculated watchdog results to 2 x the RPI (+/- 5ms). The smallest watchdog

value is 15 ms. The module will round the watchdog to a multiples of 5 ms.

WATCHDOG_TIME (ms) = MAX ( 2 * RPI ; 15 ) (+/-5ms)

If the parameter "ForceUserConfiguration" is set to 1 the module will take the

watchdog value from the configuration array. Make sure that the watchdog is not

smaller than the RPI. The module will also round the watchdog to the next

multiple of 5ms.

Number of Valid Configuration Bytes

This parameter holds the number of valid configuration bytes that define

PROFIBUS Input/Output modules.

ProSoft Technology, Inc. Page 47 of 108

May 9, 2014

Page 48

Configuration and Start-Up PS69-DPS ♦ CompactLogix or MicroLogix Platform

Parameter

Data type

Valid values

Description

Module Type

SINT

0 = IN Byte

1 = IN Word

2 = OUT Byte

3 = OUT Word

4 = IN Byte con

5 = IN Word con

6 = OUT Byte

con

7 = OUT Word

con

8 = Blank space

Input Byte without consistence

Input Word without consistence

Output Byte without consistence

Output Word without consistence

Input Byte with consistence

Input Word with consistence

Output Byte with consistence

Output Word with consistence

Blank space

ModuleLength

SINT

0

1

2

3

4

5

6

7

8

9

1 Byte/Word

2 Byte/Word

3 Byte/Word

4 Byte/Word

8 Byte/Word

12 Byte/Word

16 Byte/Word

20 Byte/Word

32 Byte/Word

64 Byte/Word

User Manual Profibus DP Slave Communication Module

Module n Type / Module n Length

The PS69-DPS PROFIBUS-DP Slave offers a flexible, modular composition of its

I/O data. This means that parts of the input and output image can be viewed as

single modules. The master can put the different modules from the PROFIBUSDP Slave to different locations in its I/O area. The individual configured modules

are mapped linearly in the I/O area of the Slave module. It is possible to

configure up to 24 I/O modules. A module is defined by a Module Type and its

Module Length:

Note: Please notice the definition of Input/Output modules and do not confuse them with the input

and output area of the module in the controller memory map. PROFIBUS gives a clear definition of

Inputs/Outputs. Inputs and Outputs modules are always defined from viewpoint of the PROFIBUS

master. If you configure an Output module you will see this in the input area of the communication

module, because the input area of the controller memory map is the output area from point of view

of a PROFIBUS master. The same applies to an Input module. If you define an Input module it is

mapped in the output area of the controller memory map, because the output area is the input area

from viewpoint of a PROFIBUS master.

The projects on the DVD can also be used as an example for a module

configuration by the controller application. You only have to set the parameter

"ForceUserConfiguration" from 0 to 1 in the configuration array. In chapter

"RSLOGIX SAMPLE PROGRAM" later in this manual explains the predefined

configuration parameter of the sample project.

Page 48 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 49

PS69-DPS ♦ CompactLogix or MicroLogix Platform RSLogix Example Program

In This Chapter

CompactLogix I/O Example ................................................................... 50

CompactLogix Messaging Example ...................................................... 52

Sample Project

Controller Type

RSL Version

Description

AOIPS69DPS.L5X

1769-L32E

5000 V16

CompactLogix Add-On Instruction

PS69_DPS_L32E_V13.ACD

1769-L32E

5000 V13

Basic CompactLogix I/O example

PS69_DPS_messaging_L32E_v13.ACD

1769-L32E

5000 V13

Basic CompactLogix messaging example

PS69_DPS_ML15.rss

MicroLogix 1500

500 V6.2

Basic MicroLogix I/O example

Profibus DP Slave Communication Module User Manual

3 RSLogix Example Program

The ProSoft Solutions DVD contains example Ladder Logic programs. These

examples should be used as templates for starting your project. An explanation

of each project is in the following sections. If you are using another type of

CompactLogix Controller, change the ControllerType in RSLogix and then store it

to your individual project. If you setup up a new controller project you can use the

Copy and Paste functionality of RSLogix to transfer the user defined data types

or ladder logic needed with the module PS69-DPS from the template projects to

your own application

ProSoft Technology, Inc. Page 49 of 108

May 9, 2014

Page 50

RSLogix Example Program PS69-DPS ♦ CompactLogix or MicroLogix Platform

Configuration

word

Data

type

Low/High

Byte

Description

Configured

values

Explanation

0

INT

LOW Byte

Busaddress

2

This address will be active if the

rotary switches of the module are

adjusted to "00"

HIGH Byte

Force User

Configuration

0

0 = ForceMasterConfig

The module will take over the

configuration from the master.

1

INT Reserved

2

INT Watchdog Timeout

C8h (200dec)

Watchdog 200 ms

3

INT Number of valid config

bytes

(starting with

Local:1:C.Data[8])

8

8 Bytes of the module definition

array are valid

4

INT Reserved

5

INT Reserved

6

INT Reserved

7

INT Reserved

8

INT

LOW Byte

Module 1 Type

4

Module 1 Type:

Input Byte with consistency

HIGH Byte

Module 1 Length

3

Module 1 Length: 4 (byte)

User Manual Profibus DP Slave Communication Module

3.1 CompactLogix I/O Example

This ladder logic program is a basic example for the setup of the PROFIBUS-DP

Slave communications module "PS69-DPS" in RSLogix5000. This example can

be used to start a project when using a CPU 1769-L32E. Basic PROFIBUS I/O

data exchange is shown. Details on the Subroutines created and the User

Defined Data Types are as follows.

MainRoutine: The MainRoutine calls all of the following routines. This routine

also contains a simple I/O transfer function block.

DPS_Update_Ext_Data: The DPS_Update_Ext_Data routine serves as an

example of how the user can map each of the different extended status

information provided in the ExtStatusInfo array. This routine evaluates the

content of the ExtStaSelect value and copies the information into the

appropriate user defined data type.

SR_Copy_Input: The SR_Copy_Input routine on every scan updates the

DpsInputArray structure with the Input Data of the module.

SR_Copy_Output: The SR_Copy_Output routine on every scan updates the

DpsOutputArray structure with the Output Data of the module.

Numerous user defined data types have been created to make it easier to

address different elements of the Input and Output array of the module. The two

main structures are DpsInputArray and DpsOutputArray. Their definitions and the

structures included in each are shown in the following tables.

The I/O example program can also be used as an example for the two methods

of configuration "Configuration by Master" (ForceMasterConfig) and

"Configuration by Controller Application" (ForceUserConfig). The configuration

array of the sample project is pre-initialized with following values:

Page 50 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 51

PS69-DPS ♦ CompactLogix or MicroLogix Platform RSLogix Example Program

Configuration

word

Data

type

Low/High

Byte

Description

Configured

values

Explanation

9

INT

LOW Byte

Module 2 Type

5

Module 2 Type:

Input Word with consistency

HIGH Byte

Module 2 Length

1

Module 2 Length: 2 (word)

10

INT

LOW Byte

Module 3 Type

6

Module 3 Type:

Output Byte with consistency

HIGH Byte

Module 3 Length

3

Module 3 Length: 4 (byte)

11

INT

LOW Byte

Module 4 Type

7

Module 4 Type:

Output Word with consistency

HIGH Byte

Module 4 Length

1

Module 4 Length: 2 (word)

...

...

...

...

31

INT

LOW Byte

Module 24 Type

0

HIGH Byte

Module 24 Length

0

Profibus DP Slave Communication Module User Manual

The parameter "ForceUserConfiguration" is initialized with 0. If you want to

activate the pre-defined modules set this parameter to 1. When this parameter is

active the master configuration has to match exactly with this configuration

otherwise the slave will not start the communication with the master.

The parameter busaddress is independent from the parameter

"ForceUserConfiguration". This parameter will be active, if the rotary address

switches of the module are set to "00".

ProSoft Technology, Inc. Page 51 of 108

May 9, 2014

Page 52

RSLogix Example Program PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

3.2 CompactLogix Messaging Example

This ladder logic program is a CIP messaging example for the setup of the

PROFIBUS-DP Slave communications module "PS69-DPS" in RSLogix5000.

This example can be used to start a project when using a CPU 1769-L32, which

supports CIP messaging. Basic PROFIBUS I/O data exchange and all

messaging function examples are shown. Details on the Subroutines created and

the User Defined Data Types are as follows.

MainRoutine: The MainRoutine calls all of the following routines based on

conditions such as doing a diagnostic request or to check the progress of

each individual DPV1 function issued by the Master. This routine also

contains a simple I/O transfer function block.

Diagnostic_Req: This subroutine Diagnostic_Req assembles a Diagnostic

Request message which will be sent to the Master. A CIP Generic Message

is used to send this message.

Diagnostic_Req_Progress: This subroutine Diagnostic_Req_Progress

checks the status of the diagnostics request message sent to the Master.

When the Diagnostic request is done it will increment a status counter to

check how many requests have been send successfully and how many failed.

DPV1C1_Alarm_Req: This subroutine DPV1C1_Alarm_Req assembles a

DPV1 Alarm message which will be sent to the Master. A CIP Generic

Messages is used to send this message.

DPV1C1_Alarm_Req_Progress: This subroutine

DPV1C1_Alarm_Req_Progress checks the status of the Alarm request

message sent to the Master. When the Alarm request is done it will increment

a status counter to record how many requests have been send successfully

and how many have been failed.

DPV1C1_Progress: This subroutine DPV1C1_Progress checks the

inprogress bit of each service and sends the appropriate response. CIP

Generic Messages are used to send the response message from the Slave to

the Master.

DPV1C1_Read_Resp: This subroutine DPV1C1_Read_Resp assembles the

DPV1 Read response message. A CIP Generic Message is used to send this

message. This routine will return immediately if there is still a DPV1 Read

Response in progress.

DPV1C1_Read_Resp_Progress: This subroutine

DPV1C1_Read_Resp_Progress checks the status of the DPV1 Read

Response sent to the Master. When the Read response request is done it will

increment a status counter to record how many response requests have been

sent successfully and how many failed.

DPV1C1_Write_Resp: This subroutine "DPV1C1_Write_Resp" assembles

the DPV1 Write response message. A CIP Generic Message is used to send

this message. This routine will return immediately if there is still a DPV1 Write

Response in progress.

Page 52 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 53

PS69-DPS ♦ CompactLogix or MicroLogix Platform RSLogix Example Program

Profibus DP Slave Communication Module User Manual

DPV1C1_Write_Resp_Progress: This subroutine

DPV1C1_Write_Resp_Progress checks the status of the DPV1 Write

Response message sent to the Master. When the Write response request is

done it will increment a status counter to check how many response requests

have been sent successfully and how many failed. If the Write Response

message was successful the first Rung will copy the Write data to a local

buffer which can be transferred with a CIP response message.

SR_Copy_Input: The SR_Copy_Input routine on every scan updates the

DpsInputArray structure with the Input Data of the module.

SR_Copy_Output: The SR_Copy_Output routine on every scan updates the

DpsOutputArray structure with the Output Data of the module.

SR_Main_Init: Initializes several variables used by different routines.

Numerous user defined data types have been created to make it easier to

address different elements of the Input and Output array of the module. The two

main structures are DpsInputArray and DpsOutputArray.

ProSoft Technology, Inc. Page 53 of 108

May 9, 2014

Page 54

RSLogix Example Program PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

Page 54 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 55

PS69-DPS ♦ CompactLogix or MicroLogix Platform Diagnostics and Troubleshooting

In This Chapter

Hardware Diagnostics (LED) ................................................................. 56

Troubleshooting ..................................................................................... 58

Profibus DP Slave Communication Module User Manual

4 Diagnostics and Troubleshooting

This section describes the possible diagnostics and troubleshooting procedures

for the PS69-DPS Slave module.

ProSoft Technology, Inc. Page 55 of 108

May 9, 2014

Page 56

Diagnostics and Troubleshooting PS69-DPS ♦ CompactLogix or MicroLogix Platform

Indicator

Color/Status

Description

RUN

Off

No task(s) running; controller in Program mode

Green

One or more tasks are running; controller is in the Run mode

FORCE

Off

No forces enabled

Amber

Forces enabled

Amber Flashing

One or more input or output addresses have been forced to an On or Off state,

but the forces have not been enabled.

OK

Off

No power applied

Green

Controller OK

Red flashing

Recoverable controller fault

Red

Non-recoverable controller fault:

Cycle power. The OK LED should change to flashing red.

If LED remains solid red, replace the controller.

I/O

Off

No activity; no I/O or communications configured

Green

Communicating to all devices

Green flashing

One or more devices not responding

Red flashing

Not communicating to any devices

controller faulted

User Manual Profibus DP Slave Communication Module

4.1 Hardware Diagnostics (LED)

The following section contains the LED diagnostic indications and their meaning

for both the CPU in use and the PS69-DPS module.

4.1.1 CompactLogix

The following table shows the possible LED indications of the CompactLogix

CPU module.

4.1.2 MicroLogix 1500

To identify problems via possible LED indications of a MicroLogix1500 controller

refer to the MicroLogix1500 User Manuals chapter "Troubleshooting Your

System". Here you will find a detailed description of fault indications and possible

reasons.

Page 56 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 57

PS69-DPS ♦ CompactLogix or MicroLogix Platform Diagnostics and Troubleshooting

LED

Color

State

Description

SYS

Yellow

Flashing cyclic at

1Hz

Device is in boot loader mode and is waiting for firmware

download.

Yellow

Flashing cyclic at

5Hz

Firmware download is in progress.

Yellow

Flashing irregular (*)

Hardware or runtime error detected.

Green

Static On

Slave in cyclic data exchange with DP Master.

Green

Flashing cyclic at

5Hz

Slave has no cyclic data exchange with DP Master.

Green

Flashing irregular (*)

Power Up: Configuration missing or faulty, device needs

commissioning.

Runtime: Host Watchdog timeout

Off

Off

Device has no power supply or hardware defect or PLC holds

the module in reset.

COM

Green

On

Slave has received parameter data/configuration data from

the DP Master and has reached the state of data exchange.

Red

On

unused

Off

Off

Slave has not reached the state data exchange.

(*) 3 times fast at 5 Hz, 8 times between 0,5Hz and 1Hz

Profibus DP Slave Communication Module User Manual

4.1.3 PS69 LEDs

The LEDs as shown on the front panel will be used to indicate status information

of the PS69-DPS Slave module. Each LED has a specific function during Run

time, configuration download, and error indications. The following table shows

the reaction of each during these states for the Slave.

ProSoft Technology, Inc. Page 57 of 108

May 9, 2014

Page 58

Diagnostics and Troubleshooting PS69-DPS ♦ CompactLogix or MicroLogix Platform

Behavior

Significance

Typical Reason

Help

CompactLogix

I/O LED is flashing Green

No communication with the

PS69 module (or other

modules)

Modules slot number in

RSLogix program does not

match with the physical slot

of the module

Configured Input / Output /

Configuration array size is

wrong

Check modules slot number

in RSLogix project

Compare configured Input /

Output size with required

values

User Manual Profibus DP Slave Communication Module

4.2 Troubleshooting

Troubleshooting of the system is done by examining the LEDs on the front panel

of the CPU and the LEDs on the front of the module. The following sections

contain some troubleshooting ideas.

4.2.1 CompactLogix I/O LED

Communication between the module and controller is displayed via the I/O LED

of the Controller. The proper communication state is reached, if the I/O LED of

the CompactLogix Controller is static Green. If this LED is flashing or off, no

communication has been established between controller and the Slave Module.

4.2.2 MicroLogix Fault LED

When the Fault LED of the MicroLogix Controller is off, the module is not in a

fault state.

If there is a problem with the expansion module, the Fault LED will be flashing

red. To diagnose the error, go online with your RSLogix500 project and open up

the processor status dialog box. Click the Error tab to view the fault reason.

4.2.3 SYS and COM Status LEDs

This PS69-DPS module has two bicolor status LEDs. They inform the user about

the communication state of the module.

The SYS-LED shows the common system status of the card. It may flash

yellow or green.

The COM-LED displays the status of the PROFIBUS communication. It can

be solid green or off.

If the SYS-LED is solid Green and the COM-LED solid green, the card is in cyclic

data exchange with the Master and the communication is running with outfault.

4.2.4 Error Sources and Reasons

This section describes typical problems, error sources and questions that come

up while commissioning the PROFIBUS-DP Slave module PS69-DPS. The

following table summarizes the typical error sources and gives a hint of possible

reasons for the problem.

Page 58 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 59

PS69-DPS ♦ CompactLogix or MicroLogix Platform Diagnostics and Troubleshooting

Behavior

Significance

Typical Reason

Help

MicroLogix

Fault LED is flashing Red

No communication with the

PS69 module (or other

modules)

Modules slot number in

RSLogix program does not

match with the physical slot

of the module

Configured Vendor ID /

Module ID / Input / Output /

Configuration array size is

wrong

Check modules slot number

in RSLogix project

Compare configured Input /

Output size / Vendor ID

/Module ID with required

values

PS69-DPS

COM LED is off SYS LED

Flashing irregular green

Configuration missing or

faulty

No configuration or faulty

stored

Check initialization values of

the configuration array

Check the value "LastError"

in SlaveStatusField to

determine the error reason

Watchdog expired

Watchdog value in

configuration is smaller then

RPI (Requested

PackedIntervall)

Increase Watchdog value in

configuration array

Module has to be reset

PS69-DPS

COM LED is off and SYS

LED flashing cyclic fast

green

Application is not ready

PLC is not in RUN Mode.

PLC application has set the

NRDY bit.

PLC has no I/O

communication with the

module

Bring PLC into RUN Mode.

Check that the PLC

application has deleted the

NRDY bit.

Check PLC’s I/O LED

Master and Slave

Configuration mismatch

The configuration of the

master which wants to

communicate with the

module don't match to the

configuration of the slave

module

Use the ExtStaInfo in

SlaveStatusField to compare

what the expected

configuration is from the

master and the modules

configuration

Network problem

No physical network

connection

No master present who

wants to communicate

Check if the slave module is

properly connected to the

PROFIBUS Network

Check if bus activity can be

detected in "IrqCounter" in

SlaveStatusField

Check if a master is present

who wants to communicate

to the module and check if

the slave address is correct

Master output data can not

be found in RSLogix

program

Input array mismatch

Configured input size in

RSLogix too small

Check if the configured input

size in RSLogix covers the

mandatory size of 136 byte

status data plus the size of

the outputs configured.

Inputs are not transferred to

Master although PROFIBUS

is running

Output array mismatch

Configured output size in

RSLogix too small

Check if the configured

output size in RSLogix

covers the mandatory size of

4 byte status data plus the

configured PROFIBUS input

data

Profibus DP Slave Communication Module User Manual

ProSoft Technology, Inc. Page 59 of 108

May 9, 2014

Page 60

Diagnostics and Troubleshooting PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

4.2.5 Cable

Check that the cable is wired correctly (page 99).

Check to confirm that the bus termination resistors are switched on at the

beginning and the end of the cable and switched off at all other connectors in

between.

Page 60 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 61

PS69-DPS ♦ CompactLogix or MicroLogix Platform Reference

In This Chapter

Specifications ........................................................................................ 62

RSLogix5000 User Defined Data Types ................................................ 66

PROFIBUS Functionality ....................................................................... 73

Communication ..................................................................................... 75

Constructing a Bus Cable for PROFIBUS DP ....................................... 99

Profibus DP Slave Communication Module User Manual

5 Reference

ProSoft Technology, Inc. Page 61 of 108

May 9, 2014

Page 62

Reference PS69-DPS ♦ CompactLogix or MicroLogix Platform

User Manual Profibus DP Slave Communication Module

5.1 Specifications

The PS69-DPS module expands the functionality of Rockwell Automation’s

CompactLogix or MicroLogix to include PROFIBUS DP V0/V1. The PS69-DPS is

a more cost-effective option offering more features than the PS69-PDPS, and

supports both I/O control and messaging. Explicit ladder logic CIP message

blocks provide slave status diagnostic data and acyclic messaging.

The PS69-DPS interface appears to the CompactLogix or MicroLogix controller

as a standard I/O module allowing it to be configured via RSLogix5000, or

configuration can be transferred from the Master to the PS69-DPS. For third

party configuration a GSD file is supplied. The slave interface possesses a

diagnostic interface and has rotary switches for setting of the bus address.

Complete program examples for simple and quick start-up are available.

Each module is equipped with LEDs to display communication and device status.

5.1.1 General Specifications

Single Slot - 1769 backplane compatible

The module is recognized as an Input/Output module and has access to

processor memory for data transfer between processor and module

Ladder Logic is used for data transfer between module and processor.

Sample ladder file included.

Configuration data obtained from configuration text file downloaded to

module. Sample configuration file included.

Supports all CompactLogix processors: L20/L30/L31/L32/L35 and L43 (L43

supported with RSLogix 5000 v16)

Also supports MicroLogix 1500 LRP

Page 62 of 108 ProSoft Technology, Inc.

May 9, 2014

Page 63