Page 1

ProSoft i-View

Mobile Process Monitoring and Control

Application

Version 2.0.2

September 29, 2011

USER MANUAL

Page 2

Your Feedback Please

We always want you to feel that you made the right decision to use our products. If you have suggestions, comments,

compliments or complaints about our products, documentation, or support, please write or call us.

How to Contact Us

ProSoft Technology

5201 Truxtun Ave., 3rd Floor

Bakersfield, CA 93309

+1 (661) 716-5100

+1 (661) 716-5101 (Fax)

www.prosoft-technology.com

support@prosoft-technology.com

Copyright © 2011 ProSoft Technology, Inc., all rights reserved.

ProSoft i-View User Manual

September 29, 2011

ProSoft Technology ®, ProLinx ®, inRAx ®, ProTalk ®, and RadioLinx ® are Registered Trademarks of ProSoft

Technology, Inc. All other brand or product names are or may be trademarks of, and are used to identify products

and services of, their respective owners.

ProSoft Technology® Product Documentation

In an effort to conserve paper, ProSoft Technology no longer includes printed manuals with our product shipments.

User Manuals, Datasheets, Sample Ladder Files, and Configuration Files are provided on the enclosed CD-ROM in

Adobe® Acrobat Reader file format (.PDFs). These product documentation files may also be freely downloaded from

our web site: www.prosoft-technology.com

Page 3

Quick Start

What is ProSoft i-View?

ProSoft i-View is a native iPhone® and iPod touch® application for real-time monitoring of industrial PLCbased systems and processes.

In can be applied to building automation, industrial process control, mini-hydro power plants, water plants,

and applications where reliable, instant access to real-time remote data is essential.

Page 4

Main Features

o

Local or remote access, and any number of concurrent PLCs

o

Very fast, independent of project size, immediate connection and display

o

Integer, floating-point, and boolean values

o

Advanced String and Arrays Support

o

Direct file import from Excel

o

Configurable accounts with access levels

o

Alarms, trend graphs

o

Lookup texts, expressions

o

Direct connection to PLCs and RTUs without servers

o

TCP/IP-based security

How to Use ProSoft i-View in Five Simple Steps

1 Create an Excel sheet that specifies parameters for the variables to be controlled.

See Data Source Files (page 15).

2 Export or save into a CSV file.

3 Import the file created in Step 2 into ProSoft i-View. See File Import (page 63).

4 Set the PLC IP address in ProSoft i-View if you did not do so in Step 1.

See Network Settings (page 75).

5 Monitor process variable states and values from anywhere with mobile or WiFi access.

Page 5

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Contents

Version 2.0.2 User Manual

Contents

Your Feedback Please ........................................................................................................................ 2

How to Contact Us .............................................................................................................................. 2

ProSoft Technology® Product Documentation .................................................................................... 2

Quick Start 3

What is ProSoft i-View? ...................................................................................................................... 3

Main Features ..................................................................................................................................... 4

How to Use ProSoft i-View in Five Simple Steps ................................................................................ 4

1 General Aspects 7

1.1

Supported Protocols .................................................................................................. 8

2 User Interface Elements 9

2.1

2.2

2.3

2.4

2.1.1

2.1.2

2.1.3

2.1.4

2.1.5

Tabbed Interface ..................................................................................................... 10

Settings.................................................................................................................... 10

File Server ............................................................................................................... 10

Files ......................................................................................................................... 10

Connections ............................................................................................................ 10

Home ....................................................................................................................... 10

Variables in ProSoft i-View ...................................................................................... 10

Home Tab Bar and Navigation Bar ......................................................................... 12

Bottom Panel ........................................................................................................... 13

3 Data Source Files 15

3.1

3.1.1

3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7

3.1.8

3.1.9

3.1.10

3.1.11

3.1.12

3.1.13

3.2

3.2.1

3.2.2

3.3

ProSoft Technology, Inc. Page 5 of 106

September 29, 2011

Data Sources Created in Excel ............................................................................... 15

Specification of Variable Names (Column A) .......................................................... 16

Variable Types (Column B) ..................................................................................... 18

Variable Addresses (Column C) .............................................................................. 20

Attributes (Column D) .............................................................................................. 24

Attribute Scope and Type ........................................................................................ 25

Tag Attributes .......................................................................................................... 25

Global Attributes ...................................................................................................... 33

Pages, Sections, Rows and Data Sources ............................................................. 36

Lookup Tables ......................................................................................................... 37

Alarms ..................................................................................................................... 39

Comments in Data Sources .................................................................................... 40

Specification of Communication Protocol................................................................ 40

Expressions ............................................................................................................. 46

Rockwell RSLogix 5000 as a Data Source Generator ............................................ 60

Building a Project in RSLogix 5000 ......................................................................... 60

Exporting Controller Tags from RSLogix 5000........................................................ 60

Editing Source Files in a Text Editor ....................................................................... 61

Page 6

Contents ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

4 File Import into ProSoft i-View 63

4.1

4.2

4.3

Source Files Supported by ProSoft i-View ............................................................. 65

Other Files Supported by ProSoft i-View ................................................................ 66

Custom Company Logo .......................................................................................... 67

5 Connections 69

6 User Accounts 71

6.1

6.2

Restrictions for Non-Administrator Users ............................................................... 72

Managing Accounts ................................................................................................ 73

7 Network Settings for Local Access 75

7.1

7.2

PLC Settings for Local Access ............................................................................... 76

ProSoft i-View Settings for Local PLC Access ....................................................... 77

8 Network Settings for Remote Access 79

9 Security 81

9.1

9.2

9.3

9.1.1

9.2.1

Validation Codes ..................................................................................................... 81

Custom Validation Tag ........................................................................................... 83

Background Task Processing ................................................................................. 84

Keep Connected ..................................................................................................... 84

Performance ........................................................................................................... 86

10 Pre-installed Examples 89

10.1

10.2

10.3

10.4

10.5

10.6

10.7

10.8

10.9

10.10

10.11

10.12

10.13

10.14

10.14.1

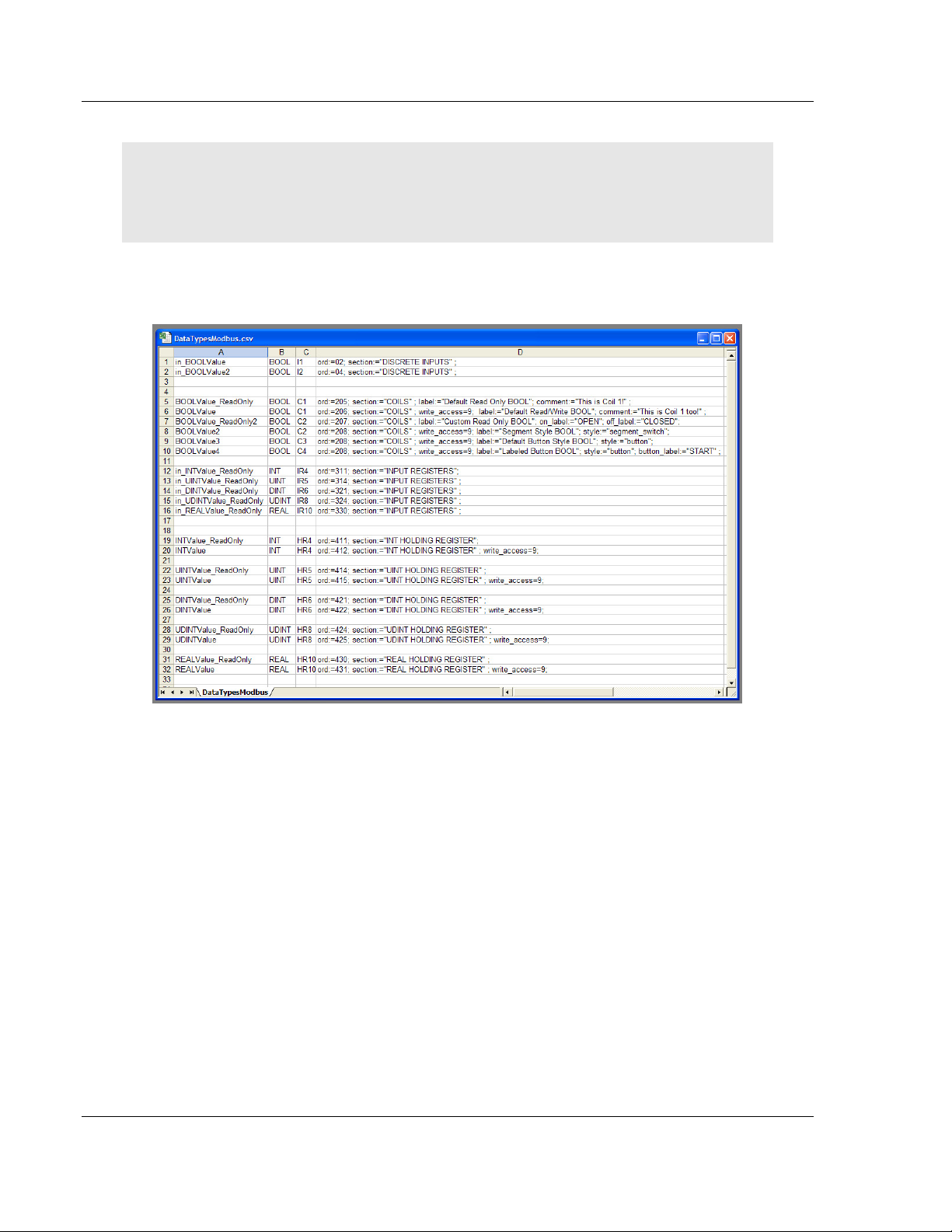

DataTypesModbus.csv ........................................................................................... 91

DataTypesModbusWSource.csv ............................................................................ 92

EIP_TAG_Examples.csv ........................................................................................ 93

EIP_PCCC_Examples.csv ...................................................................................... 94

PagesExampleModbus.csv .................................................................................... 95

PagesExampleEIP.csv ........................................................................................... 96

StylesExampleModb.csv ......................................................................................... 97

StylesExampleEIP_PCCC.csv ................................................................................ 98

AlarmsModbus.csv ................................................................................................. 99

AlarmsEIP_PCCC.csv .......................................................................................... 100

ColorfulControlsModbus.csv ................................................................................. 101

ColorfulControlsEIP_PCCC.csv ............................................................................ 102

Formula-ONE.csv ................................................................................................. 103

Document Revision History .................................................................................. 104

Version 2.0.0. ........................................................................................................ 104

Index 105

Page 6 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 7

ProSoft i-View ♦ Mobile Process Monitoring and Control Application General Aspects

Version 2.0.2 User Manual

1 General Aspects

In This Chapter

Supported Protocols ................................................................................ 8

ProSoft i-View is presented in a tabbed interface. Every tab has its own role within the

application and allows for different functions. With ProSoft i-View you can monitor data

coming from various PLCs.

Generally, you will use the S

deployment stages.

The H

OME

tab shows real-time values of process variables in PLCs, and is the one you

will use for normal monitoring. ProSoft i-View automatically goes to this tab on launch.

ProSoft i-View uses the concept of Data Sources (see Data Sources (page 15)) and

Connections (see Connections (page 69)) to do its job. Data Sources contain the variable

definitions and Connections represent links with PLCs. A Source is always associated

with a Connection, but a single Connection can belong to several Sources.

ProSoft i-View also supports user accounts with access levels that can limit the ability to

perform certain operations

ETTINGS

, F

ILE SERVER

, F

ILES

, and C

ONNECTIONS

tabs during

ProSoft Technology, Inc. Page 7 of 106

September 29, 2011

Page 8

General Aspects ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

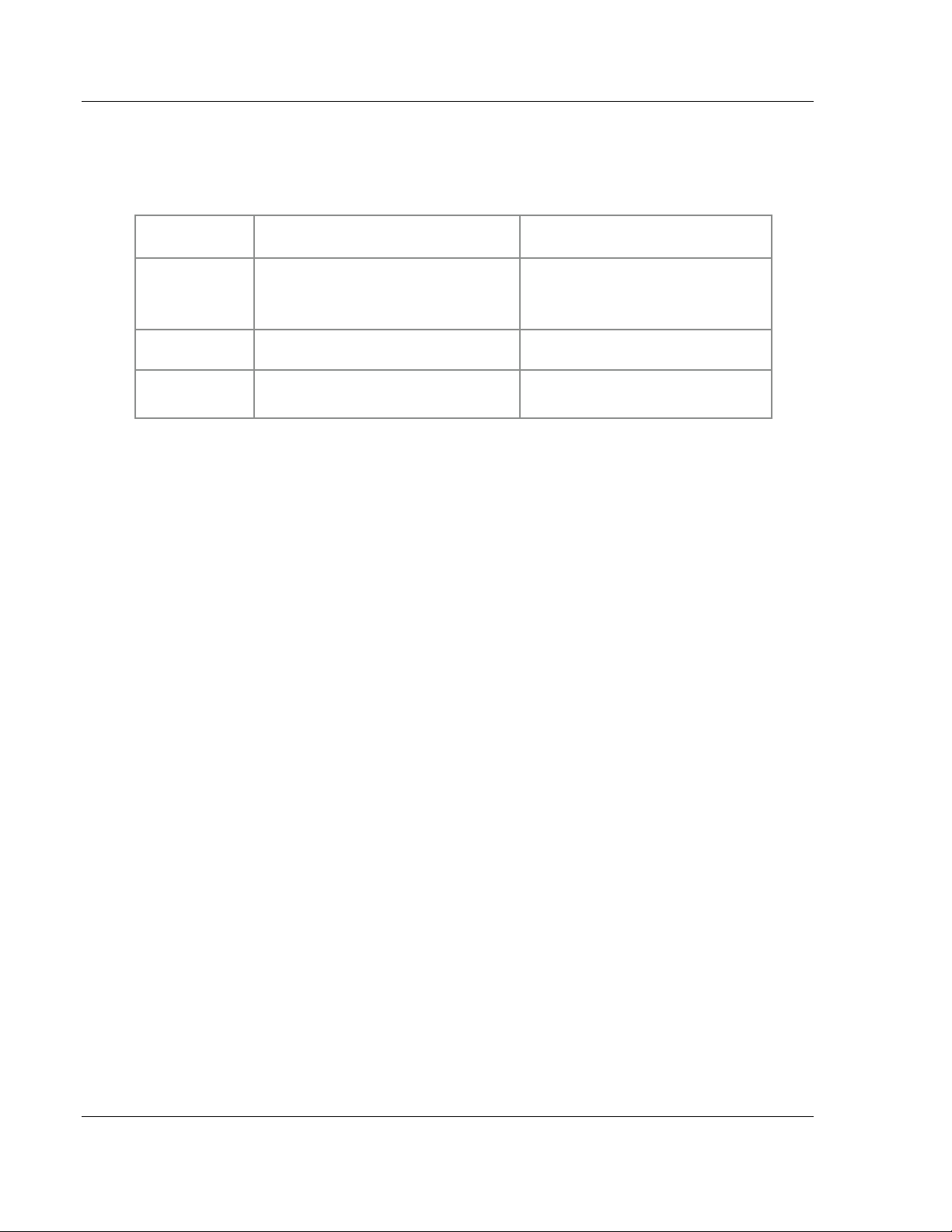

1.1 Supported Protocols

ProSoft i-View gets variable values from industrial PLCs by polling them using TCP/IP

industrial protocols. The following protocols are supported.

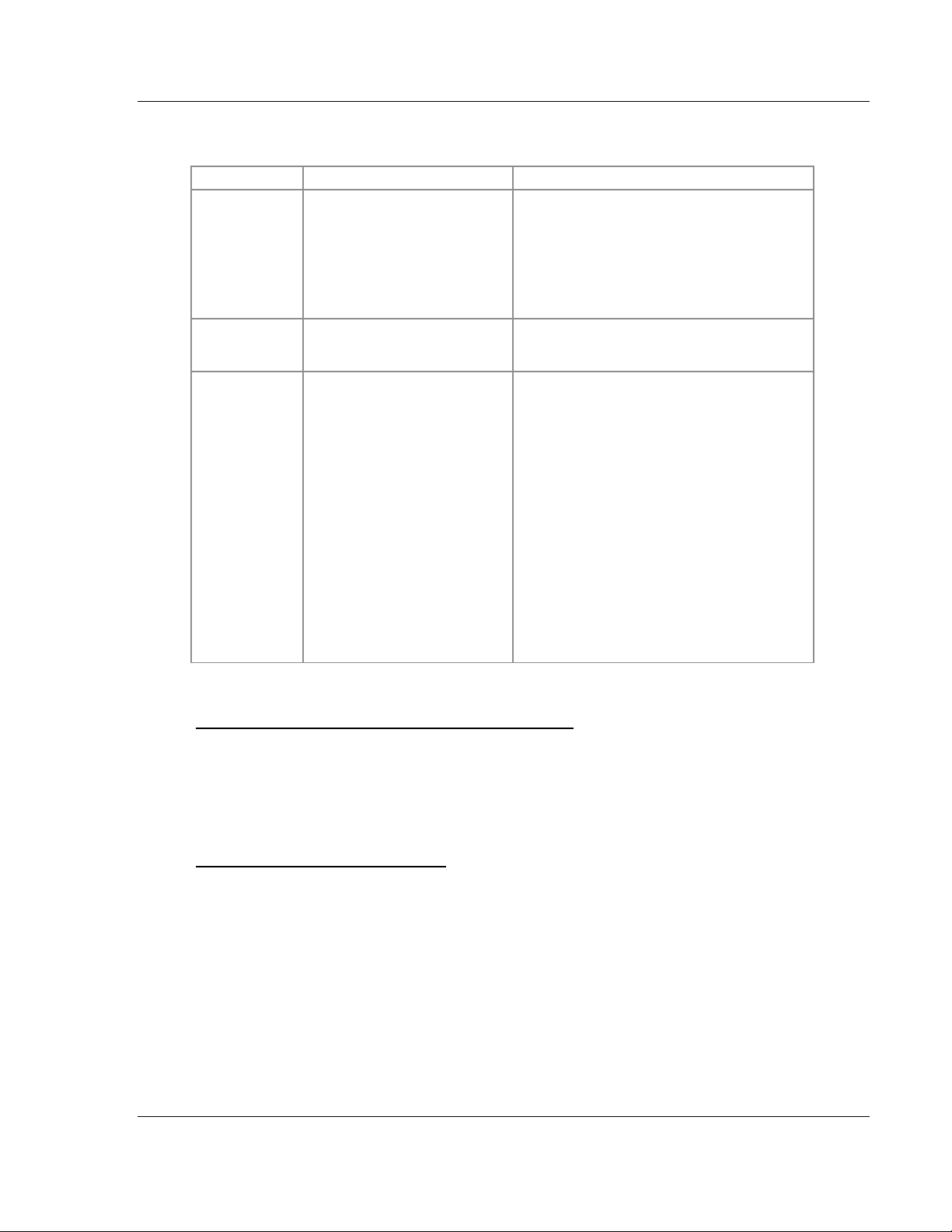

PROTOCOL

NAME

Modbus TCP Schneider® Electric, Automation Direct®,

EIP/Native Allen Bradley® ControlLogix® and

EIP/PCCC Allen Bradley SLC™ 500 and

SUPPORTED PLCs or Brands

(Not exhaustive)

Phoenix Contact®, Wago®...

CompactLogix™

MicroLogix™ controllers

REMARKS

For communication with PLCs and

RTUs using the Modbus TCP/IP

specification

Native CIP® communications using

EtherNet/IP™ Explicit Messaging

PCCC commands (DF1) encapsulated

in EtherNet/IP.

Page 8 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 9

ProSoft i-View ♦ Mobile Process Monitoring and Control Application User Interface Elements

Version 2.0.2 User Manual

2 User Interface Elements

In This Chapter

Tabbed Interface ................................................................................... 10

Variables in ProSoft i-View .................................................................... 10

Home Tab Bar and Navigation Bar ........................................................ 12

Bottom Panel ......................................................................................... 13

This section provides an overview of the main aspects of the ProSoft i-View user

interface. It is not an exhaustive explanation. Most interface elements will be described

as needed in later sections.

ProSoft Technology, Inc. Page 9 of 106

September 29, 2011

Page 10

User Interface Elements ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

2.1 Tabbed Interface

ProSoft i-View uses the typical iPhone® tabbed interface to organize several aspects of

the application. On each tab, a navigation interface is usually presented. Not all tabs are

available to all user accounts and not all the options in a tab are accessible to all users.

Five tabs are available.

2.1.1 Settings

Available to all users, but with restricted options for non-Administrator users. From this

tab, Administrator users can create accounts, log in to a particular account, set several

user interface behaviors, and specify default communication settings.

Non-Administrator users have all options disabled except the log in feature.

2.1.2 File Server

Only available to the Administrator user. Allows for managing, uploading, and

downloading files into ProSoft i-View through an embedded Web Server.

2.1.3 Files

Only available to the Administrator user. Presents a list of source files containing tag

definitions, and allows for placing a selection of the relevant ones for an application.

2.1.4 Connections

Available to all users, but with restricted options for non-Administrator users. Presents a

series of entries, called connections, that represent actual links to PLCs. Within each

connection, you can check the communication status and set validation codes. Relevant

communication settings and parsing information is presented for source files related to

each connection. You can also switch monitoring ON or OFF from this section.

Non-Administrator users are allowed only to switch monitoring ON or OFF from this tab.

Connections are hidden for these users.

2.1.5 Home

This is the main view and the place where actual tags and tag values are presented. It is

available to all users, but access levels on tags are applied depending on the current

source files configuration, so what each user views may vary. Trend graphs and alarms

are also displayed in this tab.

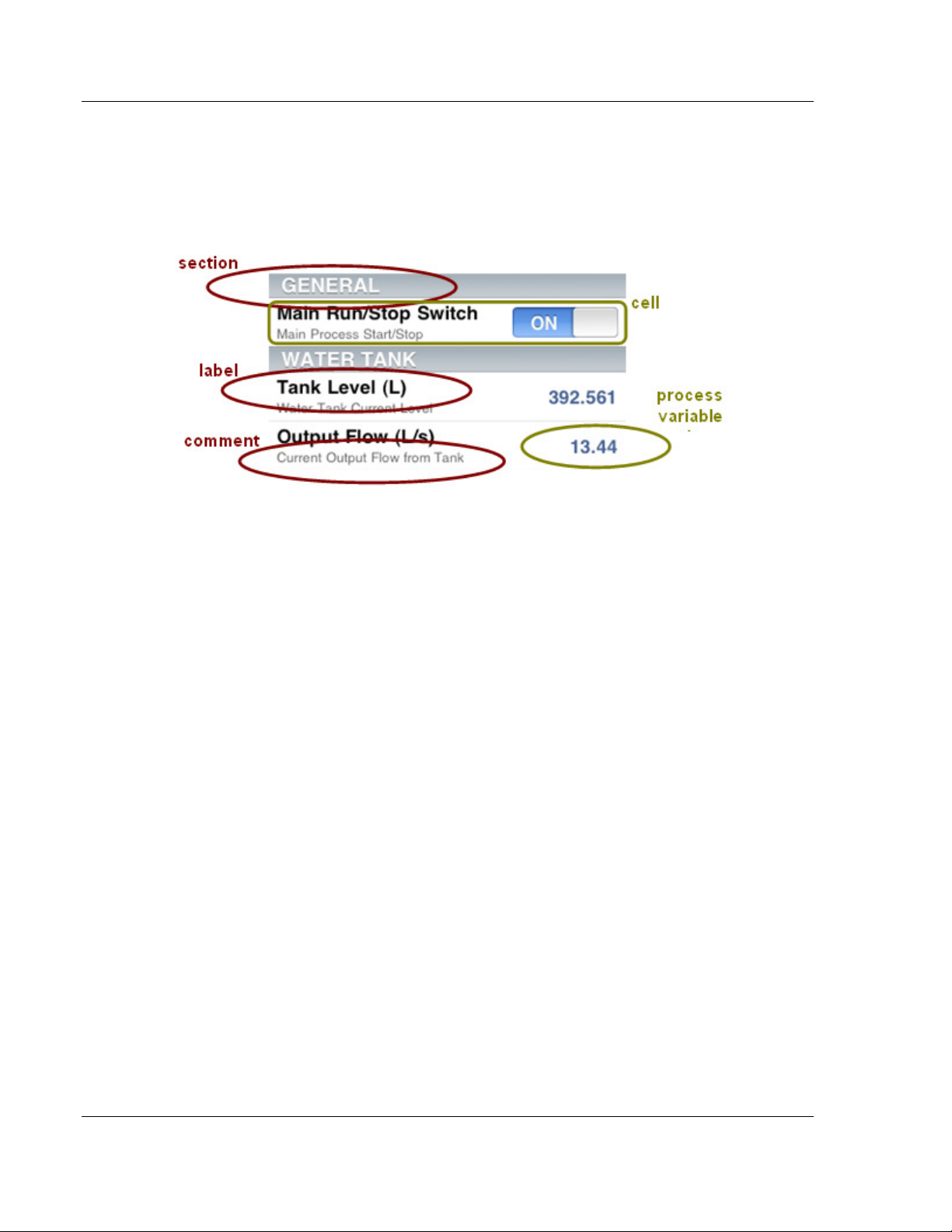

2.2 Variables in ProSoft i-View

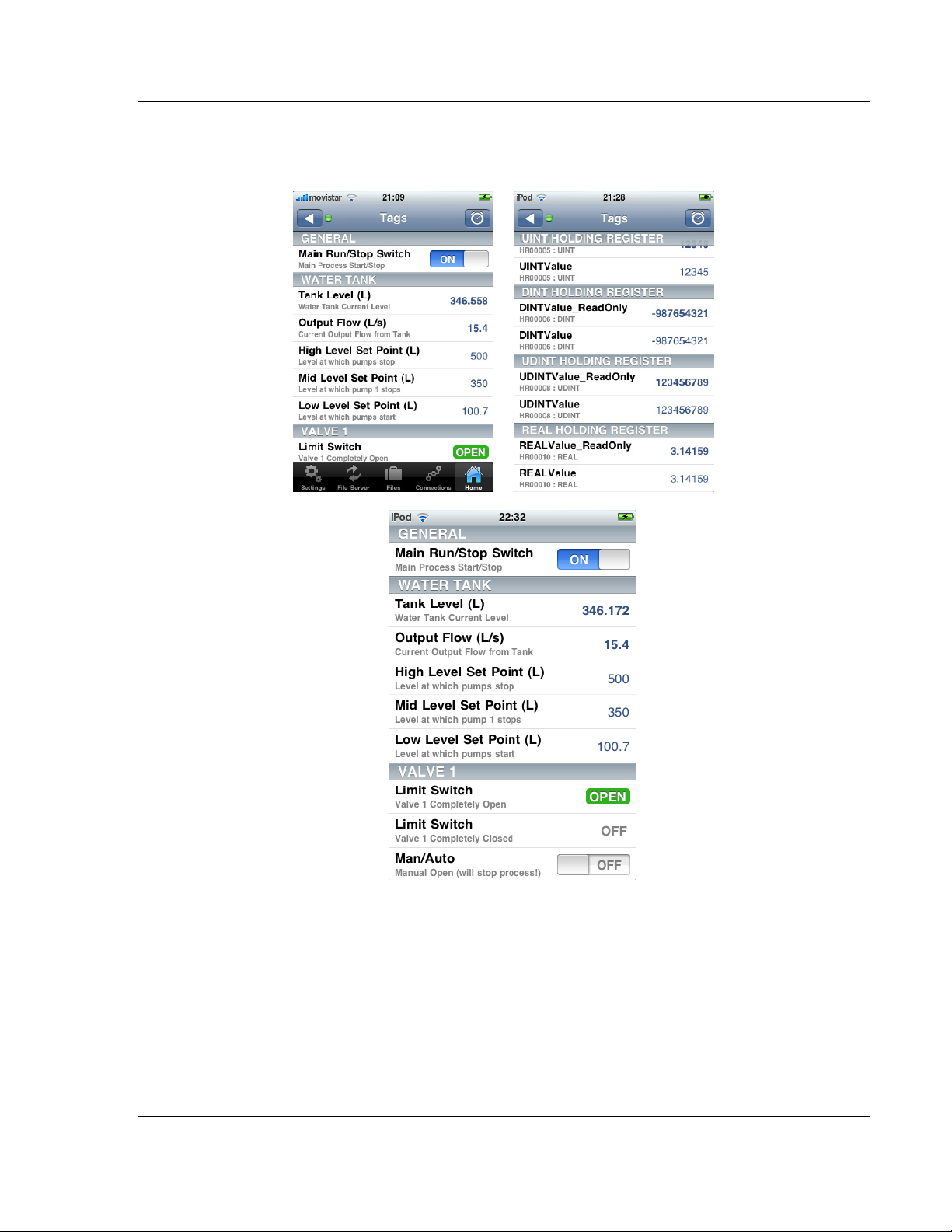

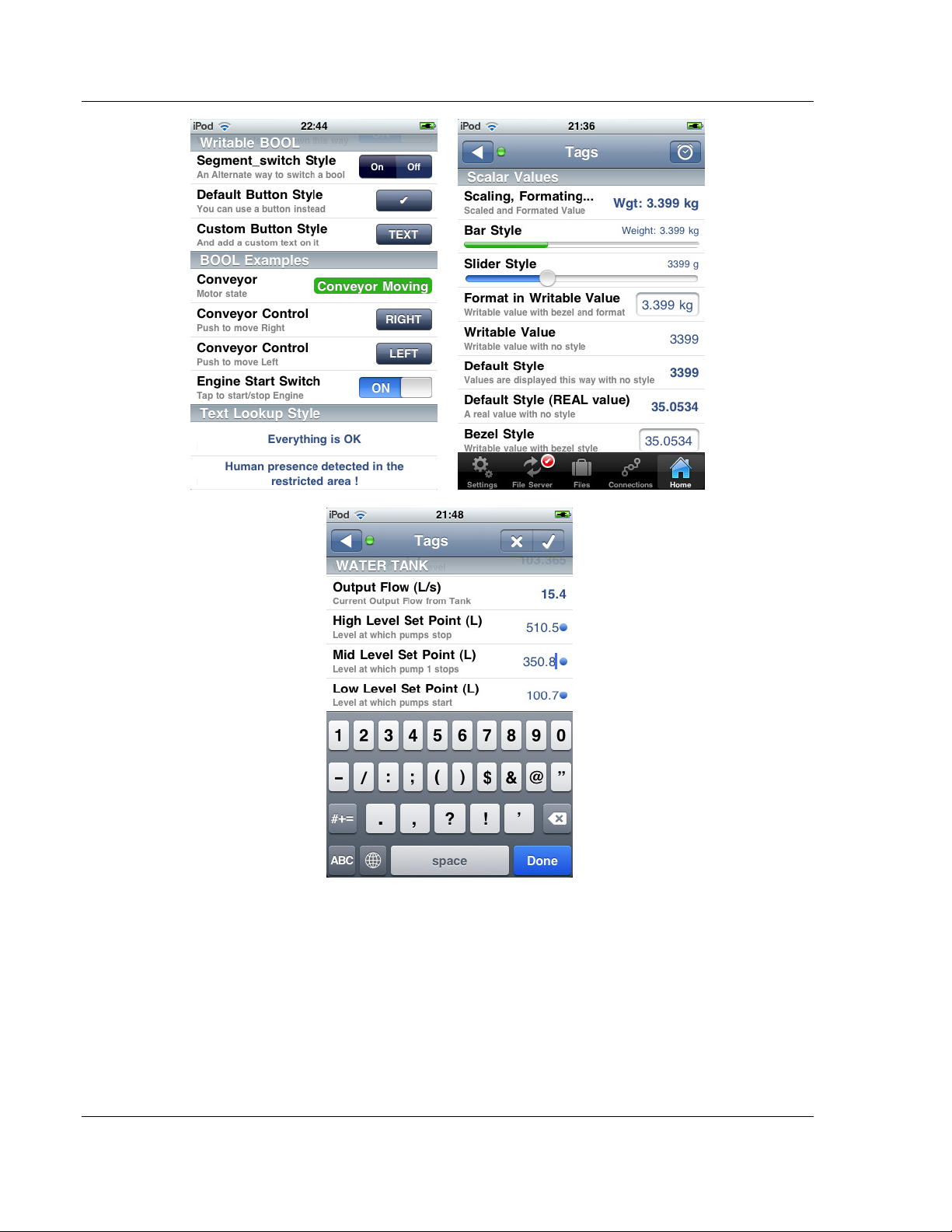

Process variables or tag values coming from PLCs are organized in ProSoft i-View as a

list with sections in a way similar to the iPhone Contacts Application. The specific display

may vary depending on variable type, style, and other characteristics.

Page 10 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 11

ProSoft i-View ♦ Mobile Process Monitoring and Control Application User Interface Elements

Version 2.0.2 User Manual

On the left side of each row, the list shows relevant information for identifying variables,

such as their name, or their particular role in the monitored process. Real-time values of

variables or suitable controls for interacting with them are shown on the right side.

The following examples demonstrate several ways of displaying elements on the Home

view list.

ProSoft Technology, Inc. Page 11 of 106

September 29, 2011

Page 12

User Interface Elements ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

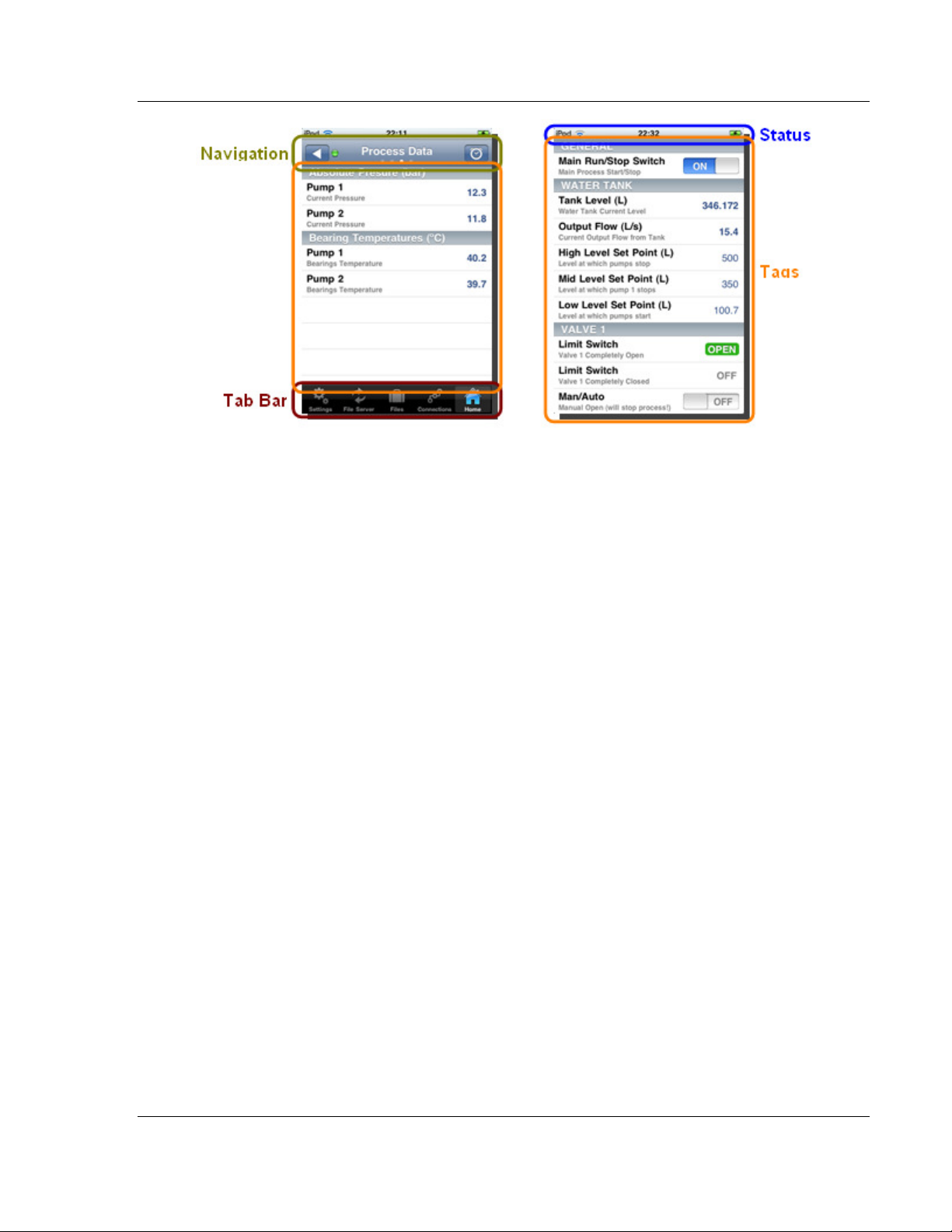

2.3 Home Tab Bar and Navigation Bar

The Home tab is where tags are displayed and where users can interact with their PLC

variables. Like most iPhone productivity applications, the interface consists of a

navigation bar on top, and a tab bar at the bottom of the screen. The standard iPhone

status bar is always visible in ProSoft i-View.

Page 12 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 13

ProSoft i-View ♦ Mobile Process Monitoring and Control Application User Interface Elements

Version 2.0.2 User Manual

Tab Bar and Navigation Bar Hidden Tab Bar and Navigation Bar

To optimize the available space on the Home tab view, users can choose to hide the tab

bar as well as the navigation bar as shown in the above screenshots.

You can perform the following interactions on these basic interface elements.

To hide or show the tab bar on the Home view, use the H

IDE BOTTOM BAR

option on

the Settings tab.

To scroll to the top of the Tags table, tap on the status bar at the top of the iPhone

screen.

To hide or show the navigation bar on the Home view, use a scroll down motion while

on top of the Tags table.

To switch from one page to another, use a scroll left or scroll right motion on the page

title.

To hide or show the page control on the navigation bar, use the P

AGE DETENTS

option

on the Settings tab.

To navigate to the list of pages, tap on the navigation bar's left button.

To see alarms or trend graphs, tap on the navigation bar's right button.

2.4 Bottom Panel

Tapping on the navigation bar's right button in Home view will cause the bottom panel to

appear.

The various user interface elements in it allow you to view and acknowledge alarms, as

well as to create any number of trend graphs with any number of plots in them.

ProSoft Technology, Inc. Page 13 of 106

September 29, 2011

Page 14

User Interface Elements ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

Just scroll the panel left and right to move to various pages on it. The page control on the

bottom also provides a way to switch between bottom panel pages

Page 14 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 15

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

3 Data Source Files

In This Chapter

Data Sources Created in Excel ............................................................. 15

Rockwell RSLogix 5000 as a Data Source Generator ........................... 60

Editing Source Files in a Text Editor ..................................................... 61

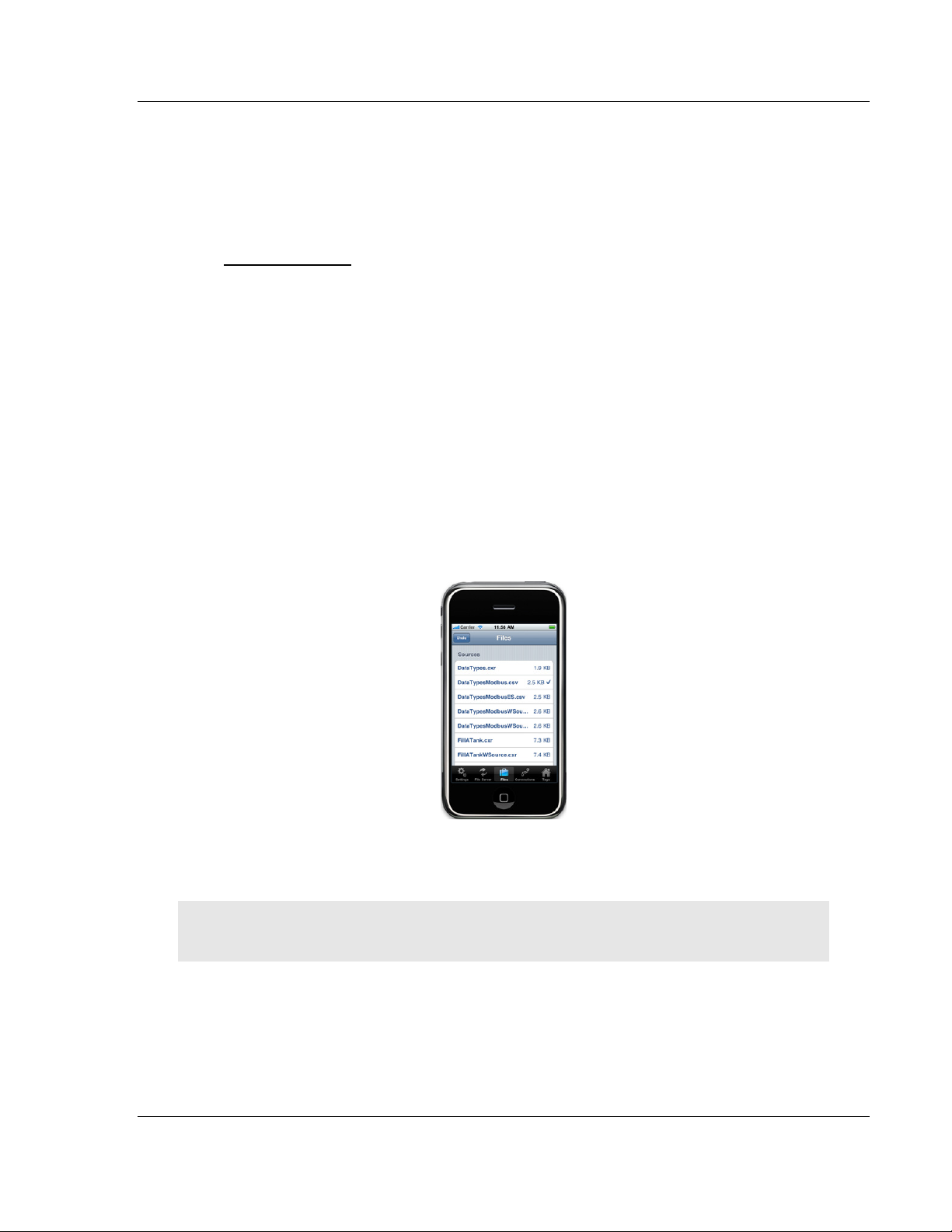

Source files contain information that ProSoft i-View needs for visualizing PLC process

variables as required by users.

ProSoft i-View accepts csv files created in Excel or Open Office. For some PLC brands, it

also supports files directly created from PLC vendors' development tools, such as Allen

Bradley RSLogix.

Source files imported into ProSoft i-View are shown in the Files tab under the Sources

section. One or more sources can be selected and variables from all of them will be

displayed depending on current user access level.

Each source refers to a single PLC, but several sources can refer to the same PLC. All

sources that point to the same PLC are automatically joined into a single connection.

Note: Be sure you have at least one selected source or ProSoft i-View will not

display any variables.

3.1 Data Sources Created in Excel

You can use Excel or Open Office to compose a data source file for ProSoft i-View. The

file must be exported or saved in CSV format.

ProSoft Technology, Inc. Page 15 of 106

September 29, 2011

Page 16

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

Note: CSV file format is not identical for all language localizations due to different

use of delimiters. ProSoft i-View accepts any csv files in any of the supported

languages, but unfortunately this is not the case for MS Excel. Consequently,

Excel may not correctly open the provided examples in the wrong language.

An Excel spreadsheet with variable specifications has four (4) columns, and one row per

variable.

ProSoft i-View looks for the following information in each column.

Column A : variable name

Column B : data type

Column C : variable address

Column D : tag or global attributes including display and communication attributes

3.1.1 Specification of Variable Names (Column A)

Tag names are entered in column A, they must begin with a letter and should not contain

spaces or special characters. For Register or Memory Area based protocols, tag names

are only informative or for documentation purposes. Variables can hold numeric values,

strings or arrays.

For EIP/Native, variable names are symbolic names that are actually sent to remote

devices for communications. In this case, any valid reference to a scalar type (see

Variable Types (page 18)), including members of structures or array elements, is allowed.

Page 16 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 17

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

EIP/Native protocol (AB Logix controllers) Legacy Note

Prior to ProSoft i-View version 1.5, EIP/Native tag names used to be specified in Column

A. However, with the incorporation of expressions and in order to favor a general syntax

for all protocols, this has been deprecated. From ProSoft i-View version 1.5, it is

obligatory to adhere to the General Rule if you want to use tags in expressions. In this

case you must specify EIP/Native as communication protocol and you have to set the

actual PLC tag name in Column C instead of column A. The name that you enter in

Column A can be used then in expressions. If you are not going to use expressions you

can still enter a EIP/Native PLC tag name in Column A and write "TAG" in column C as in

pre 1.5 versions. Although this is still allowed and existing source files will continue to

work, it is recommended for integrators to switch to the new syntax for new projects and

to start a transition plan for existing ones.

For example, myStructData[2,3].intMember may refer to an integer value referenced by

the intMember member of element (2,3) of an array of structures. Look at the

EIP_TAG_Examples.csv template for more examples of how to specify tag names for

Allen Bradley Logix controllers.

As a general rule, any Tag name path that refers to a scalar value (BOOL, SINT, INT,

DINT, REAL) in a Logix Controller will be accessed by ProSoft i-View.

Note that ProSoft i-View performs a Validation Code security check before any other

attempt to access any tags is made; therefore, it is mandatory to have a tag named

SMValidationCode of type INT in your PLC. For more information, see Validation Codes

(page 81).

Tag Scope

Tags can be defined to have a local or global scope

Local tags are identified as per the general specification of variable names, that

is beginning with a letter. Global tags are identified by placing a $ sign before

their actual name.

Examples:

local_var

$global_var

Local tags have a scope limited to the data source file they are in. When a local

name is found in an expression its definition is looked for only in the same file the

expression appears, therefore you can use the same names and expressions in

several source files without conflicts.

Global tags have an application wide scope so you can only have single

instances of them across all selected source files. The advantage of using them

is that you can access to their values from anywhere in your project even if the

project is made of several source files.

ProSoft Technology, Inc. Page 17 of 106

September 29, 2011

Page 18

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

3.1.2 Variable Types (Column B)

Data types determine in part how variables will be displayed. Non-boolean scalar types

can be represented in various ways such as by a number, a slider control, or a progress

bar. Boolean values can also be displayed in several formats depending on attributes.

Arrays of values can also be stored in variables and transferred from/to PLCs. By

properly using array expressions you can retrieve individual values as desired.

To indicate that a variable holds an array you append [n] to its data type. In such

case, ‘n’ indicates the total number of elements that the array will hold.

Page 18 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 19

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

The following types are supported.

DATA TYPE REMARKS

BOOL[n] Value that can adopt one of two states

SINT[n] 8-bit signed integer value (-128 ... +127)

INT[n] 16-bit signed integer value (-32768 ... +32767)

UINT[n] 16-bit unsigned integer value (0 ... 65535)

UINT_BCD[n] 4-digit BCD value stored in a 16-bit register using 4 bits per digit (0 ... 9999)

DINT[n] 32-bit signed integer value (-2147483648 ... +2147483647)

UDINT[n] 32-bit unsigned integer value (0 ... 4294967295)

UDINT_BCD[n] 8-digit BCD value stored in two 16-bit registers using 4 bits per digit (0 ...

99999999)

REAL[n] 32-bit floating-point value (IEEE 754) (approx -1e38 ... +1e38)

CHANNEL[n] Same as UINT

WORD[n] Same as UINT

DWORD[n] Same as UDINT

STRING[n] Type containing a characters string. Actual representation depends on

protocol, for example Allen Bradley controllers can hold up to 82 character

bytes. Strings on controllers are interpreted by default as per the WINDOWSLATIN1 encoding, but other encodings are possible if a Explicitly Encoding or

a UTF-16 file is given. The STRING type should be used with the appropriate

string memory area or string tag type in the controller when available.

On protocols with no explicitly support for strings ProSoft i-View uses a

generic string representation consisting on a leading word (16 bit register)

containing the length of the string followed by a 82 byte long string buffer.

Note that STRING[n] does not indicate a string containing n characters but an

array holding n strings with the default capacity. Particularly do not confuse

with CHAR[n]

CHAR[n] Similar to STRING except that it does not insert a leading length word. It can

be used on protocols with no specific support for strings such as Modbus. In

this case 'n' indicates the string buffer length, i.e. the number of character

bytes that should be allocated in the PLC for the string, starting from the

address specified in column C.

Note that CHAR[20] would mean an array of 20 character bytes, however in all

cases it will be treated as a single string with a capacity of 20 bytes.

Keep in mind that if you use a string encoding other that the default, you must

expect the string to hold less than n characters. This is because on some

encodings a single character may require multiple bytes to be represented.

LOOKUP This is a special-purpose type used to create a text entry on a table, which is

referred to by tags having the Lookup style attribute. Rows with the Lookup

data type in column B will not cause any read or write operations to PLCs. For

more information, see Lookup Tables (page 37).

When specifying the tag type, you can optionally define an array size for it as shown above in

italics.When you do so, the related variable will hold an array of values of the relevant type instead

of a single value. See Memory Arrays for more information.

Size definition is obligatory for CHAR types.

ProSoft Technology, Inc. Page 19 of 106

September 29, 2011

Page 20

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

3.1.3 Variable Addresses (Column C)

A variable address represents a memory location or a register in a PLC to which a

variable refers. Addresses are specified in different ways depending on which

communications protocol they belong to. Therefore, each protocol has its own set of valid

addresses. Addresses belonging to different protocols cannot be mixed in a particular

source file. Use a separate source file for each PLC and communication protocol. The

relevant communication protocol for a source file is uniquely determined by the kind of

variable addresses included in it.

The particular protocol to use can be specified by means of a comment on the

first line as described in Specification of Communication Protocol. This comment

may look something like this:

# %protocol eip/native

For protocols based on registers or memory locations, Variable Addresses are specified

by a prefix referring to the appropriate memory area followed by a numeric value

indicating the position in that area.Allen Bradley's Ethernet/IP for Logix Controllers is

based on symbolic names. Write PLC Tag symbolic names in Column C

Page 20 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 21

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

The following memory areas and prefixes are supported.

PROTOCOL AREA PREFIX REMARKS

Modbus TCP/IP I: Input Discrete (read only)

C: Coil

IR: Input Register (read only)

HR: Holding Register

EIP/Native

(Allen Bradley)

EIP/PCCC

(Allen Bradley)

TAG (deprecated, do not use) Actual symbolic tag name is given in column

O0: Outputs

I1: Inputs

S2: Status

B3: Binary

T4: Timer

C5: Counter

R6: Control

Nn: Integer

Fn: Floating Point

STn: String

To access Coil number 10, specify C10. To

access Holding register 1, specify HR1.

Individual bits in HRs can be accessed for

reading or writing using a dot notation. For

example, HR1.3 would refer to bit 3 in HR1.

A. See Variable Names (page 16). However,

"TAG" must still be specified in column C.

Tags are specified by file type, file number and

offset in the regular way. Individual bits in

words can be accessed using the usual slash

notation.

Examples:

B3:5 would access word 5 on file 3 of type B

N7:0 would access value at position 0 in N7

file

N7:0/3 would access bit 3 in N7:0

Accessing Data Types Longer Than One Register

For data types requiring more than one register or memory location, the lower address in

their range must be specified. For example, a variable of type DINT addressed by HR100

will use HR100 and HR101 because 2 Modbus registers (16 bits) are required to

accommodate the complete variable (32 bits). Integrators must be aware of this to avoid

overlapping tag values. This applies to all protocols except EIP/Native.

Accessing a Register as a BOOL

It is possible to specify a BOOL type for a register or memory location even if it is

not meant to hold a BOOL. For example, you specify on a row that HR1 is a

writable BOOL. In this case, ProSoft i-View will use a switch control for that row,

and will write a value of one (1) or zero (0) to the register depending on user

interaction on the switch. This applies to all protocols except EIP/Native.

EIP/Native does not allow a non BOOL PLC Tag to be treated as BOOL due to

the strict type checking that this protocol encourages. You can use the ‘bool’

style instead to force the same effect.

ProSoft Technology, Inc. Page 21 of 106

September 29, 2011

Page 22

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

Accessing Individual Bits in a Register

Individual bits in registers can be accessed by using the BOOL type and by

specifying a bit address using dot (.) or slash (/) notation, depending on protocol

(see table above). ProSoft i-View will use the appropriate protocol command to

avoid overwriting bits on the register. Note that this feature does not apply to

EIP/Native. On EIP/Native you can still use the dot notation to access individual

bits on variables, but due to strict type checking.you must set the correct variable

type on column B. In order to force ProSoft i-view to display such values as bools

you can use the 'bool' style.

Note on EIP/Native Communication Protocol

EIP/Native communications do not rely on particular memory locations or

positions, but on symbolic names. With this protocol, the user is relieved of the

responsibility of assigning memory addresses or registers, as well as the need to

take tag sizes into account for storage. Additionally, EIP/Native tags hold data

information such as type and size, which ProSoft i-View uses to check against

type mismatches on PLC returned values. As a result, it is not possible to store

values that differ in type or size from the values uniquely defined in the PLC. Any

attempt to do so will result in a ‘type mismatch’ error for the offending tag. For

EIP/Native symbolic names any valid reference to an existing scalar or array

type tag including structure members or array elements is allowed.

For example “myStructData[2,3].intMember” may refer to an integer value

referenced by the intMember member of element (2,3) of an array of structures.

Look at ‘EIP_TAG_Examples.csv’ template for more examples of how to specify

tag names for Allen Bradley Logix controllers. As a general rule, any Tag name

path referring to an existing scalar value (BOOL, SINT, INT, DINT, REAL,

STRING) or array of such elements in a Logix Controller can be accessed by

ProSoft i-View.

To access arrays as a whole you need to define an array size next to the type, as

discussed on the previous and following sections.

You can also access program tags by using the following syntax

Program:<program_name>.<tag_name>

Note that ‘Program’ is literal. <program_name> and <tag_name> identify just

what they suggest.

Note also that ProSoft i-View performs a Validation Code security check before

any other attempt to access other tags is made, therefore, it is mandatory to

have a tag named “SMValidationCode” of type INT in your PLC for

communications to work.

Page 22 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 23

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

Internal Tags

Internal tags are stored and managed inside the ProSoft i-View app. Internal

tags mostly behave as actual PLC tags except that they are not linked to an

actual PLC address. Thus, internal tags do not require an active TCP connection

to display a value. In combination with expressions, internal tags are a powerful

feature that allows for presenting calculated values to the user or holding

intermediate values for subsequent use.

Internal tags support most of the available attributes except the ones specifically

targeted at PLC tags such as the 'scale' attribute.

To specify that a Tag is internal use the word 'INTERNAL' instead of a PLC

address or Symbolic Tag

Protocol AREA

PREFIX or

TAG

All INTERNAL

LOCAL

(deprecated)

REMARKS

Indicates that this tag does not have a link to an actual PLC tag.

Instead, it exists only in the app. Internal tags can be used to

store and represent intermediate values, or expression results.

Just as regular PLC tags, internal tags can have Local or Global scope. To

identify an Internal tag to have a Global scope just prefix it with a $ sign.

ProSoft Technology, Inc. Page 23 of 106

September 29, 2011

Page 24

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

3.1.4 Attributes (Column D)

Process variables in ProSoft i-View are represented in ‘cells.'

You can configure the behavior and display of the monitored variables by setting the

appropriate attributes. For example, some of the available attributes are "section," "label"

and "comment."

An attribute description in column D of a source file follows this general pattern:

attribute := value;

For example, a boolean process variable like the one represented in the first cell on the

figure above could have the following attribute description:

ord := 1 ; section := "GENERAL" ; label := "Main Run/Stop Switch" ;

comment := "Main Process Start/Stop" ; access := 3 ; write_access

:= 5;

The way the cell is actually displayed in the figure implies that the current user has an

access level of 5 or above, because a selectable switch is provided as the process

variable value instead of static text. See User Accounts (page 71).

Page 24 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 25

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

3.1.5 Attribute Scope and Type

Attributes by Scope

Most attributes apply to a single tag. They are referred to as tag attributes. Others have

a global scope within a source file, and we refer to them as global attributes. In the

following sections, all attributes are discussed individually.

Attributes by Type

Attributes can hold a numeric value, a text , a special text or list of values depending

on their meaning or purpose.

Numeric values are expressed as decimal numbers with optional decimal point and

decimal digits if applicable to the attribute.

Several special values are provided for convenience.

true : equals 1.0

false : equals 0.0

-inf : represents a very large negative number

+inf : represents a very large positive number

Numeric values are expressed directly after the equal sign without quotation marks,

including the convenience values. Examples:

write_access := 3 ;

word_swap := true ;

Text usually represent text labels or fields in the application interface. They are only

required to be enclosed in quotation marks if they contain spaces or the semicolon

character. However, to maintain readability, it is advisable to always use quotation

marks.

label := "Main Run/Stop Switch" ;

suffix := " %" ;

Attributes requiring a special text only accept specific, pre-defined text strings. Valid

texts vary depending on the particular attribute.

style := "bezel" ;

format := "4.2" ;

Value Lists are used in cases where a single numeric value is not enough to provide

the information required by the attribute. The general format is a list of numbers

separated by colons and enclosed between ‘{‘ and ‘}’ characters.

scale := { 0, 360, 0, 100 } ;

bounds := { 0, 100 } ;

color_bounds := { -inf, 50 } ;

3.1.6 Tag Attributes

A tag attribute is applied to a tag at the same row and exclusively affects that tag. All

attributes are optional, and the specified attributes can be in any order.

ProSoft Technology, Inc. Page 25 of 106

September 29, 2011

Page 26

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

The following attributes are supported.

TAG ATTRIBUTE

Page text Text indicating which page the variable belongs to.

Section text Text indicating which section the variable belongs to.

Label text Main text in the cell representing a variable. If not

Comment text Secondary text in the cell representing a variable. If

Style special text Text attribute allowing for additional ways to represent

TYPE DESCRIPTION

Text values must be enclosed in quotation marks. For

example, page:="FIRST PAGE";

Text values must be enclosed in quotation marks. For

example, section:="SECTION ONE";

specified, the variable name in column A will be used

instead.

not specified, a text comprising the variable address

and its type will be displayed instead.

the value of a variable.

"switch" - The default style for writable booleans. It

displays a boolean variable using a "switch" control.

The variable will change its state on each touch. Will

be ignored if the variable is not writable.

"segment_switch" - Displays an alternative to the

"switch" style for writable booleans

"button" - Presents a push button for writing of

boolean values. Contrary to the "switch" style, the

related process variable does not change

permanently but goes to 1 (true) on button press and

goes to 0 (false) on button release.

"bezel" - Draws a bezel line around a text field for

highlighting writable numeric values. Note that it is

only applicable to writable tags

"slider" - Presents a writable tag as a slider control.

Min and Max values are given with the Bounds

attribute.

"bar" - Presents a read-only tag as a bar. Min and

Max values are given with the Bounds attribute.

"lookup" - Displays text from a lookup table instead of

the actual tag value. The tag value is used to

determine which entry in the table is shown. Note that

this attribute will only affect read-only tags.

"alarm" - Tags with this style are not shown in the

main tag table. Instead they are treated as alarm

conditions. They may be combined with the Bounds

attribute. See Alarms (page 39).

Ord number Numeric value determining the order in which pages,

sections and tags are displayed. For more

information, see Pages, Sections, Rows and Data

Sources (page 36).

Access number Indicates the minimum access level a user needs in

order to view a variable. By default, access:=9; is set.

Page 26 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 27

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

TAG ATTRIBUTE

Write_access number Indicates the minimum access level an user needs in

On_label Expression(string) String expression displayed for a read-only boolean

Off_label Expression(string) String expression for a read-only boolean variable

Button_label Expression(string) String expression In combination with the "button"

Scale array A four-element array in the form {x1,x2,y1,y2} where

Bounds array A two-element array in the form {min,max} where min

TYPE DESCRIPTION

order to trigger changes (write) to a process variable

value. Omitting this attribute forbids any change to the

associated variable.

variable when its value is 1 (true).

when its value is 0 (false).

style, it defines the text for the button.

x1, x2 represent a pair of numeric values in raw units

as present in the PLC and y1, y2 represent the same

values in engineering units as will be displayed on

ProSoft i-View. By setting this tag attribute, you can

convert (scale) raw values to engineering values on

the display by applying a linear transformation. This

attribute can be specified for any read-only or writable

tag. Example: scale:={0,100,0,1};

and max are numeric values used to indicate a range

expressed in engineering units. This attribute can

have several meanings depending on other attributes,

particularly the Style and the Write_access attributes.

On writable tags, it determines and limits the available

range of values that users will be able to enter.

On read/only tags, its meaning depends on the

particular style of the tag. It is currently supported by

the "bar", "slider", and "alarm" styles.

Example: bounds:={-100,100};

Format special text Text in the form "m.n" where m represents the

minimum number of characters to be displayed. If the

value to be displayed is shorter than this number, the

result is padded with blank spaces (or zeros if the

number starts with zero). The value is not truncated

even if the result is larger. n represents the number of

digits to be displayed after the decimal point.

Example: format:="07.2"; will display the REAL

value 12.345 as 0012.34

Prefix text Text to be prepended just before the variable value.

Example: prefix:="$";

Suffix text Text to be appended to the variable value. Example:

suffix:=" %";

ProSoft Technology, Inc. Page 27 of 106

September 29, 2011

Page 28

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

TAG ATTRIBUTE

Color special text Indicates a color to apply to a variable value or

Color Expression

Tint_color special text Indicates an alternate color to apply. The

Color_bounds Value list A two-element array in the form {low,high} where low

TYPE DESCRIPTION

control. Colors can be specified by name as listed in

http://www.w3schools.com/css/css_colornames.asp.

Colors can also be given by RGB value in

hexadecimal format. The Color_bounds attribute

determines when the color will be applied. Supported

values also include "TextDefault", "BarDefault" and

"DefaultGreen," which are the colors used by default

on texts, bars and boolean tags.

Examples: color := "red"; color := "olive" ; color

:=#FF3300;

Numeric

Numeric Expression. The color attribute used in this

way expects a 32 bit integer value containing the

RGB color coordinates in the three lower significance

bytes, with the B value in the least significant byte.

The method SM.color can be used for convenience to

generate a color from its RGB coordinates or name.

Color_bounds and Tint_color_bounds attributes

determine color application ranges. Refer to the Color

attribute for valid color values.

Example: tint_color := "red";

and high are numeric values determining the range of

values for the tag where the color will NOT be

applied, also known as an exclusion range.

Examples:

color_bounds := {-inf,50};. This will exclude tag

values below 50 from displaying in the color set in the

Color attribute. Therefore, tag values will be displayed

in the specified color when they are above 50.

color_bounds := {-50,50};. Tag values from -50 to

50 will be excluded from displaying in the color set in

the Color attribute. Therefore tag values will be

displayed in the specified color only when they are

below -50 or above +50, effectively enabling coloring

for edge conditions.

For boolean tags the color_bounds attribute has a

predetermined value that will always make the tag

appear in the color color for the On state.

Page 28 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 29

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

TAG ATTRIBUTE

Tint_color_bounds Value list A two-element array in the form {low,high} where low

blink Expression

TYPE DESCRIPTION

and high are numeric values determining the range of

values for the tag where the tint color will NOT apply,

also known as an exclusion range. Refer to the

Color_bounds attribute for more information.

When both Tint_color_bounds and Color_bounds

attributes are specified, Color_bounds takes

preference over Tint_color_bounds. However,

Tint_color_bounds still has the chance to act in the

range that has been excluded by Color_bounds,

allowing for further color customization based on tag

value.

Combined examples:

color_bounds := {-inf,50}; tint_color_bounds := {inf,0}; Will display all values above 50 in the Color

color; positive values up to 50 will be displayed in the

Tint_color color.

color_bounds := {-50,50}; tint_color_bounds := {20,20}; Will display all values below -50 and above 50

in the Color color. Values from -20 to 20 will be

excluded from the Tint_color color, so the tint color

will show for values from -50 to -20 and from +20 to

+50.

For boolean tags color_bounds and tint_color_bounds

have predetermined values. You can simply use

tint_color to display a color for both Off and On states,

while color will supersede the color for the On state.

booleean

Numeric Expression. Will cause any non writable tag

to blink on the interface when the value assigned to

the attribute is not zero (true)

blink_bounds Value list A two elements array in the form {low,high} where low

and high are numeric values determining the range of

tag values where blinking will NOT be applied. If

specified on a read only tag, the tag will visually blink

with a period of 1 second for the values not in the

specified range.

Example (to set a tag to blink always) :

blink_bounds:={-inf,-inf};

Example (to set a tag to blink when its value goes

below -10 or above +10) :

blink_bounds:={-10,10};

Example (to set a boolean tag to blink for the On

state) :

blink_bounds:={0,0};

plot_color special text Determines the color to be used in trend graphs when

plotting this tag. If omitted a sequential color is

chosen automatically.

ProSoft Technology, Inc. Page 29 of 106

September 29, 2011

Page 30

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

value expression Specifies a value to write on the related tag based on the result of

an expression (see Expressions)

Note that the 'value' attribute has a slightly different behavior for

Internal tags than for regular PLC tags:

For PLC tags the result of the expression is first written to the PLC

already converted to the relevant type and appropriately limited and

descaled according to the 'bounds' and 'scale' attributes. On

reading, the tag value is scaled back to the engineering unit. As a

consequence a tag may end having a slightly different value after

that. For example a Tag of type INT having scale={0,10,0,1}; will

become 1.2 when assigning 1.234 to it through a 'value' change. Of

course, the value in the PLC will become 12.due to the scaling and

type conversion.

On PLC writes involving STRINGS implicit conversions will also be

performed if possible. For example, the STRING "2.3" will be

converted to the number 2.3 upon writing a REAL tag. Similarly, the

number 2.3 will result to the sequence of characters "2.3" when

writing to a STRING tag.

For INTERNAL tags no type or scale conversion is performed on the

result of the 'value' expressions. Internal tags are just given the

result of the expression as it evaluates. Thus, the 'scale' and

'bounds' attributes will have no effect. Even the tag type is ignored to

the effects of the assignment and the variable may hold a

completely different type.

The following considerations also apply:

INTERNAL tags containing tag references in its 'value' expression

can not be user writable and will ignore an eventual 'write_access'

attribute (NOTE: this restriction was removed after version

1.5).Despite the preceding consideration, INTERNAL tags will

preserve the meaning of the 'write_access' attribute if their 'value'

expression represents a constant value, in such case the expression

will provide the initial value for the tag.

Writable INTERNAL tags will simulate a write-read round on a virtual

PLC taking into account tag type, 'scale' and 'bounds' attributes with

the same effects as a real write-read round as described above.

hidden expression

(boolean)

style special

text

Numeric expression. Will make the row hidden when the result of

the expression is non zero. Hiding all rows in a Section will remove

the entire section including the section title. Hiding all rows/sections

on a page will remove that page from the interface.

Hiding/showing interface elements is fully animated and dynamic on

evaluation of the 'hidden' expression. Dynamic hiding is useful to

switch among several rows that selectively meet an arbitrary

condition, or to force display parts of the interface depending on

user or PLC triggered conditions.

Attribute containing one of the texts below determining ways to

represent or display the value of a variable.

Page 30 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 31

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

"switch" It is the default style for writable booleans. It

displays a boolean variable using a “Switch”

control. The variable will change its state on

each touch. Will be ignored if the variable is

not writable.

"segment_switch" Displays an alternative to the “switch” style

for writable booleans.

"button" Presents a Push Button for writing of boolean

values. Contrary to the “switch” style, the

related process variable does not change

permanently but it goes to 1 (true) on button

press and goes to 0 (false) on button release.

"bezel" Draws a bezel line around a text field for

highlighting writable numeric values. Note

that it is only applicable to writable tags.

“bool” Presents the tag as a boolean even if it is not

of type BOOL, limiting the possible values to

0 or 1. It also activates related attributes such

as on_label and off_label and brings the

special meanings of some attributes for bool

types.

"slider"

"bar"

"lookup"

"picker" It is like the "lookup" style except that it will

Presents a tag as a slider control or a bar

depending on whether it is writable. Min and

Max values are given with the bounds

attribute. Both are identical and can be used

indistinctly.

Displays a text from a lookup table instead of

the actual tag value. The tag value is used to

determine which entry in the table is shown.

This attribute will work both on read only tags

and writable tags. On writable tags the

bounds attribute is used to determine which

range on the lookup table will be made

available to the user for selection. See

Lookup Table.

draw a bezel around the displayed lookup

text when used on writable tags.

ProSoft Technology, Inc. Page 31 of 106

September 29, 2011

Page 32

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

"alarm" Tags with this style are referred to as Alarm

Tags and they are not shown on the main

table but on the Alarms Panel. They can be

combined with the bounds attribute. See

Alarms.

“barcode” Activates the barcode reader for this tag. The

tag must be writable (usually of type

STRING). After reading a barcode with the

device camera, the tag will be updated with

the scanned code.

Tag attributes specific to Modbus devices:

MODBUS TAG

ATTRIBUTE

Slave_id number This attribute identifies the associated tag as belonging to a

TYPE MEANING

particular Modbus device. Specifically, Modbus serial devices

with the specified ID that are connected through a TCP

gateway will be accessed. The default value is 1.

Note that the Slave_id attribute for Modbus is a tag attribute, so it applies only to

the register it is next to. This is in contrast to the Controller_slot attribute, which

is global and applies to a source file.

Page 32 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 33

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

3.1.7 Global Attributes

Global attributes are modifiers that apply to all tags or have a meaning in the context of

the whole source file. Global attributes can be placed anywhere in column D of source

files. So they can be specified next to any variable and they will still have a global scope.

Note: If a particular global attribute is included more than once in a source file,

only its first occurrence will take effect.

Communication settings are global and therefore need to be specified only once in a

source file.

COMMUNICATION

ATTRIBUTES

Local_ip text Source address in text format for local access (LAN).

Local_port number TCP port used for local connections (LAN) to this source.

Remote_host text Source address or host name for remote connections.

TYPE DESCRIPTION

Example: "192.168.1.40"

If it is not specified, ProSoft i-View will use the standard

port for the protocol of the current source file. (For

example, 502 for Modbus. Note that this can differ from

the default port specified in the ProSoft i-View Settings

tab.)

Example: "remote.remotehost.com"

Remote_port number TCP port used for remote connections to this source

(WAN-Internet). If it is not specified ProSoft i-View will use

the standard port for the protocol of the current source file.

Ssl number

(boolean)

Validation_tag Special text Allows for using a custom validation tag on protocols

If no attribute from this group is specified, ProSoft i-View will dynamically use values from the

application Settings tab view.

Specifies whether TLS/SSL encryption is required for a

remote connection. Nonzero numeric values are

considered true. Default value is ‘false’.

supporting it.

For EIP/PCCC use validation_tag = "Nx:y"; only N files

can be used and the code is stored as an INT (default is

N98:0).

For FINS/TCP use validation_tag = "Dx"; only DM area

can be used and the code is stored as a WORD (default is

D19998).

For EIP/NATIVE the validation tag name is always

SMValidationTag, it can not be changed.

For MODBUS/TCP no validation tag is available.

The Modbus specification does not define exactly how the data is stored in registers or

the order in which bytes or words are sent. The following global attributes help to deal

with this. Swapped words/bytes options for Modbus are global.

ProSoft Technology, Inc. Page 33 of 106

September 29, 2011

Page 34

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

MODBUS GLOBAL

ATTRIBUTES

rtu_mode number

Word_swap number

Byte_swap number

The combined effect swap attributes is as follows:

Assuming a default of 'ABCD' for a byte order where 'A' is the Most Significant Byte (MSB) and 'D'

is the Least Significant Byte (LSB), you can combine Word_swap and Byte_swap with the

following results:

1- word_swap:=false; byte_swap:=false; will give 'ABCD' for 32-bit values and 'AB' for 16-bit

values.

2- word_swap:=false; byte_swap:=true; will give 'BADC' for 32-bit values and 'BA' for 16-bit

values.

3- word_swap:=true; byte_swap:=false; will give 'CDAB' for 32-bit values and 'AB' for 16-bit

values.

4- word_swap:=true; byte_swap:=true; will give 'DCBA'. for 32-bit values and 'BA' for 16-bit

values.

Note: These attributes are only meant for Modbus communications and are ignored for the rest of

the supported protocols.

TYPE DESCRIPTION

ProSoft i-View will use "Modbus/RTU over TCP" instead

(boolean)

(boolean)

(boolean)

of "Modbus/TCP". This will allow for accessing serial

modbus/RTU devices behind an Ethernet-to-serial

gateway not supporting MBAP. Use the 'slave_id' attibute

on tags to route commands to the right modbus slave

node.

Swaps words for 32-bit data (such as DINT or REAL)

before sending to or upon receiving from a Modbus

device. Nonzero values are 'true.' Default value is ‘false.’

Swaps bytes for 16-bit or 32-bit data before sending to or

upon receiving from a Modbus device. Nonzero values

are ‘true.’ Default value is ‘false.’

Page 34 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 35

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

Allen Bradley ControlLogix controllers can be plugged into any slot on the

backplane.Ethernet/IP messages can be sent "connected" or "unconnected". The

following attributes can be used to determine these characteristics. These are global

attributes.

EIP/NATIVE GLOBAL

ATTRIBUTES

controller_slot number Identifies the slot where the Logix controller is located.

connected_mode number

ProSoft i-View currently supports two EIP mechanisms to send commands to AB PLCs:

(1) For a Micrologix or SLC it will send PCCC commands (DF1) embedded in EIP using a direct

path.

(2) For a ControlLogix/CompactLogix it will send native CIP commands using a Backpane, Slot-

Number path. The Backpane defaults to 1 and the Slot number is given in controller_slot.

ProSoft i-View uses CIP Explicit Messages to retrieve and send data from/to Ethernet/IP enabled

PLCs. Explicit messages can be sent "unconnected" or "connected". "Connected" messages

require a Connection ID which is first asked to the PLC before sending other messages, while

"unconnected" messages identify the specific path to the destination in the same message.

Connected messaging is generally considered to be more reliable than unconnected because it

reserves buffer space for the message, and is therefore less likely to be blocked by other

message traffic. However, if the TCP link between the message originator and the receiver is

weak or prone to fail, unconnected messaging may be a better choice. Wireless spots or carrier

networks can easily drop due to lack of coverage or weak signal, in these cases connected

messaging communications may take longer to reestablish after a fault, resulting in less overall

reliability and more user perceived delays than unconnected messaging. ProSoft i-View uses

unconnected messaging by default, but you can set it to use connected messaging for a source

file by setting the connected_mode attribute to true.

Note that since the Controller_slot attribute is a global one, it applies to the whole source file. This

is in contrast to the Slave_id attribute for Modbus, which only applies to the tag next to it. Also,

note that since different protocols cannot be mixed in the same source file, the two attributes are

incompatible between them, and the non-relevant one will be ignored.

TYPE DESCRIPTION

Default value is 0.

When true, ProSoft i-View will use "connected

(boolean)

messaging" instead of the default "unconnected

messaging" for retrieving data from Ethernet/IP enabled

PLCs. Look below for a discussion on what possible

effects you might expect. Default value is ‘false’.

ProSoft Technology, Inc. Page 35 of 106

September 29, 2011

Page 36

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

3.1.8 Pages, Sections, Rows and Data Sources

Page, Section and Ord Attributes

The ProSoft i-View interface for the iPhone and iPod Touch consists of a set of cells or

rows representing PLC variable values, which in turn are arranged in pages containing

section headers for groups or rows.

Variables are optionally assigned a page and section through the Page and Section

attributes. All variables having exactly the same Page name will belong and be added to

a page with such name. Similarly, the Section name attribute is used to put all variables

belonging to the same section under a heading with that name.

A single attribute, the Ord attribute, is used to force pages, sections and rows to be

placed in specific locations.

Pages and sections are arranged according to their first appearance in the source files

based on global order of all variables. This is used to force sections and pages to appear

in the desired place. Variables without an order number will be considered to fall below or

after ordered variables, but they will maintain their relative positions in the source file.

How It Works

First, rows from all selected data source files are sorted from low to high using their Ord

attribute. As stated above, variables with no Ord attribute are moved to the end of the list,

always keeping their original relative order.

As sorting is performed, the variables' Ord numbers are used to determine their page and

section position order.

Pages are arranged in position orders determined by the smaller Ord number of all

variables belonging to each page. In other words, a particular page will be shown in the

order given by the Ord number of the first variable belonging to that page.

Within each page, sections are then arranged according to the smaller (or first) Ord

number of all variables belonging to that section and page.

Finally, variables are placed within their page and section according to their Ord number.

Page 36 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 37

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

Example

The following Page / Section / Ord attributes in a series of tags from two sources will be

arranged as shown below.

3.1.9 Lookup Tables

The Lookup table feature allows a tag to pick up a text string from a previously entered

list based on current tag value, and display this text instead of the tag value.

To have a tag display a lookup text instead of the usual value, use the Style attribute with

"lookup" as value.

style := "lookup" ;

If you would like to show the lookup text alone as shown in the StylesExampleModb

example, you might consider setting the tag label to an empty text.

label := "" ;

The actual table is given in additional rows in the CSV file by using special tags of type

LOOKUP (set in column B) and by specifying the related indexes in column C. The text or

the comment attribute value on column D is the Lookup Text.

ProSoft Technology, Inc. Page 37 of 106

September 29, 2011

Page 38

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

As an example, this is what you could do to create a two-entry table with indexes 1 and 2.

Column A Column B Column C Column D

entry1 LOOKUP 1 This is the lookup table at index 1

entry2 LOOKUP 2 This is the second entry in the table so it will display if

a lookup tag value is 2

Lookup numbers do not need to be ordered or contiguous. They can be any number that

fits in 16 bits (0 to 65535).

Multiple User Lookup Tables

You can specify an access level for entries in column D. In this case, you must set the

lookup text in the Comment attribute. This allows for having different texts depending on

user level. For example, consider the following:

Column A Column B Column C Column D

entry1_boss LOOKUP 1 access:=9; comment:= "Only I will see this

message. I’m the boss!";

entry1_worker LOOKUP 1 access:=3; comment:= "I can see this with my

user level of 3 or more";

Multiple Range Lookup Tables

Lookup styled tags use the engineering unit as the index to the table. Therefore you can

use the scale attribute to make a lookup styled tag access to determinate portions or

ranges of the table.

For example, the setting: scale:={0,10,100,110}; will forward any raw value coming from

the PLC in the range from 0 to 10 to table text entries from 100 to 110.

You can use this feature to effectively have several virtual tables simultaneously in use.

The StylesExampleModb example shows how this concept works.

The global lookup table is available to expressions with the SM.lookup

method.

Page 38 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 39

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

3.1.10 Alarms

An alarm tag is a special kind of tag that is not displayed in the main tags table. An alarm

tag is characterized by its Style attribute being set to "alarm." Alarm conditions can be

specified with the Style attribute in combination with the Bounds attribute attached to the

tag.

Alarms are tracked and listed on a separate table as shown in the screenshot below.

When an alarm condition is triggered, the tag Label attribute is used to display the text on

the left, which may refer to an alarm group, and the Comment attribute contains the alarm

message displayed on the right.

Alarms will remain on the list as long as they remain active or have not been

acknowledged. Their current state will be shown by small icons next to the alarm text.

Bright Red Alarm Clock icon means active and not acknowledged

Dark Red icon means active and acknowledged

Gray Clock icon means inactive and not acknowledged

For scalar type variables such as INT or REAL, the bounds attribute determines the

exclusion range of the alarm condition. In other words, an alarm styled tag will be

considered active if its current value is NOT in the specified range. For example consider

the following:

style:="alarm"; bounds:={0,100};

The tag holding these attributes will be treated as an alarm, which will become active

when its value is below 0 or above 100.

To support simple min or max condition alarms, the special numeric values "-inf" and "inf"

can be used. For more information, refer to Attribute Scope and Kind (page 25). For

example,

style:="alarm"; bounds:={-inf,100};

ProSoft Technology, Inc. Page 39 of 106

September 29, 2011

Page 40

Data Source Files ProSoft i-View ♦ Mobile Process Monitoring and Control Application

User Manual Version 2.0.2

will trigger the alarm only when the value on the tag is above 100.

The default value for the Bounds attribute on alarm tags is bounds:={0, 0};. Therefore,

any non-zero value in a tag will trigger an alarm. This is especially relevant for BOOL tag

alarms, because by default they will become active when the tag goes to 1 (true) and

inactive otherwise, just as you would expect.

Example

The following rows in a source file represent the settings for the alarm tags that

generated the first and fourth rows on this page:

Alarm1 INT HR1 label:="Group 1"; comment:="Weight Value went above 6

kg"; style:=alarm; bounds:={-inf,6};

Alarm4 BOOL C1 label:="Group 2"; comment:="Someone Manipulated the

Switch!"; style=alarm;

Performance Considerations

Unlike regular tags, alarm tags are continuously polled from PLCs even if they are not

shown on the screen. Also, ProSoft i-View may continue polling them while running in the

background. So it is recommended that special care be taken when deciding what tags

will be reserved for alarms. Particularly, it is highly recommended to group alarms in tags

as contiguously as possible, and to use boolean alarms instead of scalar value alarms as

much as possible. Arrays of BOOL are the best choice, if supported by the protocol.

Observing this recommendation will lead to shorter communication patterns and less

network overhead than if no special care was taken, ultimately improving the end user

experience.

3.1.11 Comments in Data Sources

You can comment Rows on Source Files for documental purposes or while you

are testing your project. To do so just start the row with the '#' character.

Examples:

# These are the lookup table entries for the style selection texts we are using

# This alarm checks for a value being too high on the statistics page

3.1.12 Specification of Communication Protocol

Starting with version 1.5 you can explicitly set the communication protocol on

source files, instead of having ProSoft i-View determining it by the kind of

addresses used in Column C as before. This feature has been provided to grant

future compatibility with a larger number of communication protocols, where

some addressing naming conventions could conflict or overlap existing ones.

To tell the actual communication protocol on a source file you must insert the

following comment as the first line.

Page 40 of 106 ProSoft Technology, Inc.

September 29, 2011

Page 41

ProSoft i-View ♦ Mobile Process Monitoring and Control Application Data Source Files

Version 2.0.2 User Manual

# %protocol <protocol_string>

As <protocol_string> you can use one of the following;

eip/native

eip/pccc

modbus/tcp

fins/tcp

For example to communicate to an Allen Bradley ControlLogix you would have the following as the

first line on your source file:

# %protocol eip/native

NOTE: Protocol Specification in this way will be made obligatory in the future, so

it is recommended for integrators and advanced users to use the new syntax for

new projects and to set a plan to edit their source files to conform with it.

3.1.13 International Languages Support and String Encodings

The ProSoft i-View iOS app includes localizations for English and Spanish for its

user interface interface. However, International Characters and Strings in any

language are fully supported. Integrators can therefore chose to present their

project interface in any language.

To represent strings the concept of String Encodings is used. String Encodings

are international conventions that determine how characters representing

particular languages are stored into files and device memory.

ProSoft Technology, Inc. Page 41 of 106

September 29, 2011