Powermate PW0872400.01 User Manual [en, es, fr]

PW0872400.01

Operator Manual

Manuel de L’opérateur

Manual del operador

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

STOP |

|

|

|

|

|

|

ARRÊT |

|

|

|

|

|

|

ALTO |

|

|

|

DO NOT |

|

STORE! |

|

|

|

|

|

|

|

|

|

NO LO |

|

|

|

|||

|

RETURN TO |

|

|

NE PAS RETOURNER AU MAGASIN! |

DEVUELVA A LA TIENDA! |

||||||||||||||

|

|

CALL US FIRST! |

|

|

|

APPELEZ–NOUS D’ABORD! |

|

|

|

¡PRIMERO LLÁMENOS! |

|

||||||||

|

|

CUSTOMER HOTLINE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

|

|

|

ASSISTANCE TELEPHONIQUE |

|

LÍNEA DIRECTA DE ATENCIÓN |

|

||||||||||||

1-800-445-1805 |

|

|

|

|

A LA CLIENTELE |

|

|

|

|

AL CLIENTE |

|

||||||||

|

|

or 1-308-237-2181 |

|

1-800-445-1805 |

|

1-800-445-1805 |

|

||||||||||||

|

FOR QUESTIONS OR |

|

|

|

ou 1-308-237-2181 |

|

|

|

o 1-308-237-2181 |

|

|||||||||

|

SERVICE INFORMATION |

|

|

POUR L'INFORMATION DE |

|

|

PARA la INFORMACION de |

|

|||||||||||

|

|

|

|

|

|

|

|

QUESTIONS OU SERVICE |

|

|

PREGUNTAS O SERVICIO |

|

|||||||

|

|

|

|

|

|

|

|

|

|||||||||||

|

|

|

|

|

|

|

|

|

|||||||||||

|

IMPORTANT - Please make |

|

|

|

IMPORTANT - Veiller à ce que |

|

|

|

IMPORTANTE - Favor de |

||||||||||

|

certain that everyone who uses |

|

|

toute personne amenée à utiliser cet |

|

|

|

ceciorarse de que toda persona |

|||||||||||

|

the Coleman® Powermate® |

|

|

appareil de Coleman® Powermate® |

|

|

|

que use el Lavador de presión |

|||||||||||

|

Pressure Washer thoroughly |

|

|

lise soigneusement ces instructions |

|

|

|

Coleman® Powermate® lea y |

|||||||||||

|

reads and understands these |

|

|

|

et les comprenne avant de procéder |

|

|

|

entienda todas las instrucciones |

||||||||||

|

|

|

|

à son utilisation. |

|

|

|

||||||||||||

|

instructions prior to operation. |

|

|

|

|

|

|

|

|

antes de la operación. |

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||||||

www.powermate.com |

|

|

|

|

|

|

0063665 02/06 |

||||||||||||

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

.3 |

Starting the Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . . .7 |

CUSTOMER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

CHEMICAL INJECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .7 |

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

CLEANING TECHNIQUES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

Safety Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

3 |

Application of Soap or Degreaser . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

General Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

4 |

Application of Wax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

SAFETY FEATURES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

END OF OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

Thermal Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

Safety Lock Off Latch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

Low Oil Shutdown . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Nozzle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

Spark Arresting Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Water Screen . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

Engine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .8 |

SPRAY NOZZLE SELECTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

5 |

STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .9 |

BEFORE OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Pump Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .9 |

Pre-Start preparation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

Engine Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .9 |

Hose and Gun Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .9 |

Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .10 |

Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

6 |

PERIODIC MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .11 |

OPERATING CONNECTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

ENGINE MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .11 |

High Pressure Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

ENGINE TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .12 |

Water Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

ENGINE SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

. . .12 |

OPERATING INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

CALIFORNIA EMISSION CONTROL WARRANTY . . . . . . . . . . . . |

. .13 |

Start-up Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . |

7 |

PARTS LIST AND PARTS DRAWING . . . . . . . . . . . . . . . . . . . . . . . |

38-42 |

|

|

|

|

TABLE DES MATIÈRES

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 SERVICE CLIENTELE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 Symboles utilisés . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14 Précautions Générales de Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . .15 MESURES DE SÉCURITÉ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Soupape de surpression thermique . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Loquet de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Arrêt suite au bas niveau d’huile . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 Silencieux Pare-étincelles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 SPÉCIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

CHOIX DE BUSE DE PULVÉRISATION . . . . . . . . . . . . . . . . . . . . . . . .16

AVANT TOUTE UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 Préparation précédant la mise en marche . . . . . . . . . . . . . . . . . . . . . .17 Montage du tuyau et du pistolet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 Lubrification du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17 Carburant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

RACCORDEMENTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Tuyau haute pression . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Racordement d’eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Procédure de lancement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18 Mise en marche du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

UTILISATION DE PRODUITS CHIMIQUES . . . . . . . . . . . . . . . . . . . .18

TECHNIQUE DE NETTOYAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Application de Savon ou de Dégraissant . . . . . . . . . . . . . . . . . . . . . . .19 Application de Cire . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 APRES UTILISATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 ENTRETIEN DE L'APPAREIL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Raccords . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Ajutage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Filtre à eau . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 Entretien du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19 RANGEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 Rangement de la pompe . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 Rangement du moteur . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20 DÉPANNAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21 GARANTIE LIMITÉE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22 ENTRETIEN PÉRIODIQUE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 ENTRETIEN DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23 DÉPANNAGE DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24 CARACTERISTIQUES DU MOTEUR . . . . . . . . . . . . . . . . . . . . . . . . . .24

GARANTIE DE CONFORMITÉ AUX RÈGLEMENTS ANTIPOLLUTION DE LA CALIFORNIE . . . . . . . . . . . . . . . . . . . . . . .25 LISTE DES PIÈCES ET SCHEMA DES PIÈCES . . . . . . . . . . . . . .38-42

INDICE

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 SERVICIO PARA LOS CLIENTES . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 Símbolos de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26 Precauciones generales de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . .27

CARACTERÍSTICAS DE SEGURIDAD . . . . . . . . . . . . . . . . . . . . . . . .28 Válvula de descarga de calor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 Dispositivo de seguridad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28 Apagado por bajo nivel de aceite . . . . . . . . . . . . . . . . . . . . . . . . . . .28 Silenciador apagachispas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

ESPECIFICACIONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

SELECCIÓN DE BOQUILLA DE PULVERIZACIÓN . . . . . . . . . . . . .28

ANTES DE LA OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Preparación incial . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Ensamblado de manguera y pistola . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Lubricación del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29 Combustible . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

CONEXIONES DE OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Manguera de alta presión . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Conexion de agua . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 INSTRUCCIONES DE OPERACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . .30 Procedimiento de arranque . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Encendido del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 INYECCION DE QUIMICOS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 TÉCNICAS DE LIMPIEZA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Aplicación de jabón y desgrasador . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Aplicación de cera . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 FIN DE LA APLICACIÓN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

MANTENIMENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Conexiones . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Boquilla . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Rejilla de agua . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31 Mantenimiento del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

ALMACENAMIENTO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 Almacenamiento de la bomba . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 Almacenamiento del motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32 RESOLUCION DE PROBLEMAS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 GARANTIA LIMITADA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34 MANTENIMIENTO PERIÓDICO . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35 MANTENIMIENTO DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

DETECCION DE FALLOS DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . .36

ESPECIFICACIONES DEL MOTOR . . . . . . . . . . . . . . . . . . . . . . . . . . .36

GARANTÍA DEL CONTROL DE EMISIÓN DE CALIFORNIA . . . . 37 LISTA DE PIEZAS Y DIAGRAMA DE PIEZAS . . . . . . . . . . . . . . .38-42

|

|

|

2 |

www.powermate.com |

English

Congratulations on purchasing a Coleman® Powermate® Pressure Washer. Whether you are doing light cleaning at home or are needing power to do the tough jobs, Coleman® Powermate® pressure washers are built to give you the power you need. By following proper break-in procedures, using recommended set-up and operating procedures, and performing preventive maintenance as specified in this manual, your Coleman® Powermate® pressure washer will serve you for years to come.

Most important is the safety of you and those around you. Remember that while the Coleman® Powermate® pressure washer gives you the power you need to complete your job, safety rules should always be followed.

Thank you for selecting our product.

Powermate Corporation

Safety Symbols

The following symbols are used throughout this manual. Follow listed instructions to ensure your safety.

Indicates an imminently hazardous situation which, if not avoided, will result in death or serious injury

Indicates a potentially hazardous situation which, if not avoided, could result in death or serious injury.

CUSTOMER SERVICE

Call our toll free number 1-800-445-1805

8 a.m. to 5 p.m. C.S.T. or www.powermate.com

to obtain warranty service information or order replacement parts or accessories.

Please have the following information available:

1.Model Number.

2.Serial Number.

3.Date and where purchased.

4.Replacement numbers if you are ordering parts.

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

Attention: Warranty Service Department

www.powermate.com

Indicates a potentially hazardous situation exists, which if not avoided, may result in minor or moderate injury or product damage.

NOTE: Indicates operation or maintenance information helpful to improve performance or operation.

|

|

|

www.powermate.com |

3 |

|

|

|

|

English

The following Safety Precautions apply whenever using, storing or servicing Coleman® Powermate® Pressure Washers or their engines to reduce the possibility of personal injury. Overlooking or ignoring these precautions can lead to personal injury or product damage.

•Read this manual carefully. Know your equipment. Consider applications, potential hazards and limitations for your unit.

•Know your equipment. Consider the applications, limitations, and the potential hazards specific to your unit.

•Store the Pressure washer in a well ventilated area with the fuel tank empty. Fuel should not be stored near the pressure washer.

•Never operate under theses conditions:

a.A noticeable change in engine speed.

b.A noticeable loss of pressure.

c.The engine misfires.

d.Smoke or flames are present.

e.Enclosed compartment.

f.Excessive vibration.

g.Rain or inclement weather.

•Water spray must never be directed towards any electric wiring or directly towards the pressure washer.

•Do not allow the hose to come in contact with hot muffler.

•Equipment must be placed on a firm, supporting surface.

•Remove the spark plug or cable from the spark plug to prevent accidental starting, when not in use, or prior to detaching the high pressure hose.

•Keep the pressure washer clean and free of oil, mud and other foreign matter.

•Do not wear loose clothing , jewelry, or anything that may be caught in the engine.

•Never direct spray at people or pets.

•Never allow children to operate pressure washer at any time.

•Use both hands to control the wand.

•Do not touch nozzle or water spray while operating.

•Wear safety goggles while operating.

•Only approved hoses and nozzles should be used.

•The trigger gun must not be jammed in position during operation.

•Never tie knots or kink the high pressure hose.

•All hose connections must be properly sealed.

•Prior to starting the pressure washer in cold weather, be sure ice has not formed in any part of the equipment.

•Use only recommended chemicals.

•Outdoors use only.

•Place the pressure washer away from cleaning site during operation.

•To prevent accidental discharge, the spray gun should be secured by locking trigger when not in use.

•Do not run the pressure washer for more than five minutes without depressing the trigger or damage to the pump may result.

•Check the fuel system periodically for leaks or signs of deterioration such as chafed or spongy hose, loose or missing clamps, or damaged tank or cap. All defects should be corrected before operation.

•Do not touch hot muffler.

•Service, operate and refuel under the following conditions.

a.Good ventilation.

b.Refuel the pressure washer in a well lighted area.

c.Avoid fuel spills and never refuel while the pressure washer is running.

d.Avoid an ignition source when refueling.

e.Use lead free fuel with a minimum of 85 octane.

•Do not smoke near the pressure washer.

•Do not use damaged high-pressure hoses.

|

|

|

4 |

www.powermate.com |

English

SAFETY FEATURES |

|

SPECIFICATIONS |

|

|

|

THERMAL RELIEF VALVE

A thermal relief valve is provided to protect the pump from overheating if the spray gun is closed for an extended length of time or the nozzle becomes plugged. However, it is intended to be used as a backup system and every effort should be made to not permit the pump to heat up.

We recommend turning the pressure washer off if it will not be used for more than five minutes. This saves wear on the unit, reduces fuel consumption and extends the life of the pump by avoiding heat.

SAFETY LOCK OFF LATCH

To prevent accidental discharge of high pressure water, the safety latch on the trigger should be engaged whenever the pressure washer is not in use. (Refer to Operating Instructions.)

LOW-OIL SHUTDOWN

The unit is equipped with a low oil sensor. If the engine oil level becomes lower than required, the pressure washer will automatically shut off. This protects your pressure washer engine from operating without proper lubrication.

If the pressure washer engine shuts off and the oil level is according to specification, check to see if the pressure washer is setting at an angle that forces oil to shift. Place on an even surface to correct this. If the engine fails to start, the oil level may not be sufficient to deactivate low oil level switch. Be sure the sump is completely full of oil.

The pump will overheat and may be damaged, or cause damage if allowed to circulate more that five minutes.

SPARK ARRESTING MUFFLER

YOUR PRODUCT MAY NOT BE EQUIPPED WITH A SPARK ARRESTING MUFFLER. If the product will be used around flammable materials, such as agricultural crops, forests, brush, grass, or other similar items, then an approved spark arrester should be installed and is legally required in the State of California. The California statutes requiring a spark arrester are Sections 13005(b), 4442 and 4443. Spark Arresters are also required on some U.S. Forest Service land and may also be legally required under other statutes and ordinances. An approved spark arrester is available from your Coleman® Powermate® product dealer, or may be ordered from Powermate Corporation, P.O. Box 6001, Kearney, Nebraska 68848. 1-800-445-1805.

Maximum Inlet Pressure . . . . . . . . . . . . . . . . . .Up to 90 PSIG RPM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3600 RPM Temperature of Pumped Fluids . . . . . . . . . . . . . . . .Up to 80°F Inlet Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8” BSP Discharge Ports . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3/8” BSP Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9 lbs. Crankcase oil Capacity . . . . . . . . . . . . . . . . . . . . . . . .4.7 fl. oz. Pump oil . . . . . . . . . . . . . . . . . . . . . . .SAE 30W Nondetergent

Consult the factory for special requirements that must be met if the pump is to operate beyond one or more of the limits specified above.

SPRAY NOZZLE SELECTION

Following is information concerning the four nozzles provided with your pressure washer.

NOTE: The force of the spray on the surface you are cleaning increases as you move closer to the surface.

0° High Pressure (Red): The water stream discharged is very aggressive. Use with extreme caution to prevent damage to the surface being cleaned or injury to persons or animals.

15° High Pressure (Yellow): This is the nozzle used for most cleaning applications. It provides wide coverage and a powerful water stream.

40° High Pressure (White): This nozzle is used for cleaning with a wider coverage over a larger area with a powerful water stream.

65° Low Pressure (Black): Provides low pressure spray and a wide coverage. Used primarily when operating the chemical injector to apply chemicals.

|

|

|

www.powermate.com |

5 |

|

|

|

|

English

BEFORE OPERATION

NOTE: The engine and pump on your Coleman® Powermate® Pressure Washer will often have improved performance after a break-in period of several hours.

PRE-START PREPARATION

Before starting the pressure washer, check for loose or missing parts and for any damage which may have occurred during shipment.

HOSE AND GUN ASSEMBLY

NOTE: Align threaded connections carefully to prevent damaging threads during assembly. Tighten connections securely to prevent leaks during operation.

Attach the hose to the inlet of the trigger gun.

Handle Installation

Install handle and hose hook as shown in Figure 1.

Figure 1

LUBRICATION

DO NOT attempt to start the pressure washer engine without filling the engine crank case with the proper amount and type of oil (See pages 11 and 12 and Figure 2). Your pressure washer engine has been shipped from the factory without oil in the engine crankcase. Operating the unit without oil will ruin the engine.

The pump has been shipped with oil. Before operating the pressure washer check the oil level of the pump to make sure the oil level is to pump manufacturer’s required level.

(See Figure 2). Use oil that is recommended from the pump manufacturer. DO NOT OVERFILL!

If the pump is not equipped with a dipstick or side glass window check oil leaks from the pump. Pump oil is shipped in the pump from factory. Follow pump manufacturer’s maintenance schedule for proper care.

FUEL

Fill the tank with clean, fresh unleaded automotive gasoline. (See Figure 2). Regular grade gasoline may be used provided a high octane rating is obtained (at least 85 pump octane).

Gasoline is very dangerous. Serious injury may result from fire caused by gasoline contacting hot surfaces.

Do not overfill the tank. Keep maximum fuel level 1/2 inch below the bottom of the filler neck. This will allow expansion in hot weather and prevent overflow.

Figure 2

|

|

|

6 |

www.powermate.com |

English

OPERATING CONNECTIONS

HIGH PRESSURE HOSE

Attach the high pressure hose to the fitting located on the pump. (See Figure 2, page 6).

NOTE: DO NOT use a high pressure hose from another manufacturer.

WATER CONNECTION

Before connecting to unit, run water through the garden hose (not supplied) to flush out any foreign matter. Check that the screen is clean and is in the inlet of the pump. Attach garden hose to the pressure washer water inlet. (See Figure 2, page 6).

NOTE: The water supply must provide a minimum of 4 g.p.m. at 20 p.s.i. or the pump will be damaged.

OPERATING INSTRUCTIONS

START-UP PROCEDURE

1.Make sure water supply is connected and turned on.

2.Release gun safety if locked.

3.To allow air to escape from the hose, squeeze trigger on the gun until there is a steady stream of water coming from the nozzle.

4.Remove any dirt or foreign matter from the gun outlet and the male connector of the wand.

5.Insert the nozzle wand into the gun wand and tighten the twistfast fitting securely by hand.

If the wand is not securely locked into place, it could be ejected under high pressure when operating the gun, possibly causing injury or damage.

STARTING THE ENGINE (See Figure 2, page 6)

1.Check oil and fuel level.

2.Adjust choke prime as necessary.

3.Set the engine switch to the “ON” position.

4.Squeeze trigger on pressure washer to release pressure while pulling on the engine starter rope with a fast steady pull. Pressure may otherwise build up making starting the unit difficult.

5.As the engine warms up, readjust the choke.

CHEMICAL INJECTION

This pressure washer is intended for use only with liquid car wash detergents, developed specifically for pressure washer and with mild soaps. We recommend the use of Coleman® Powermate® Pressure Washer Chemicals. Only use chemicals compatible with the aluminum and brass parts of the pressure washer. Powdered soaps may clog the injection system. Always use chemicals according to manufacturer directions. Powermate Corporation assumes no responsibility for any damages caused by chemicals injected through this pressure washer.

1.Attach injection tube assembly to the siphon injector on the pump. (See Figure 2, page 6).

2.Open a container of Coleman® Powermate® Pressure Washer Chemical and place next to the unit near the injection tube.

3.Visually inspect strainer at the end of the injection tube to verify that it is not clogged.

4.Insert the injection tube into the container all the way to the bottom.

5.If chemical injection is adjustable, set injection rate by turning valve clockwise until it is tight. Then turn valve counterclockwise to increase injector rate and clockwise to decrease injector rate.

6.If your pressure washer is equipped with removable nozzles, remove the high-pressure nozzle from the wand and install the black injection nozzle. The solution will automatically be mixed with the water and discharged through the nozzle.

7.If your pressure washer is equipped with an adjustable nozzle, the low pressure nozzle position should be used when operating the chemical injector to apply chemicals. When low pressure is required, grasp and slide the nozzle cover away from the gun.

NOTE: For certain models, if the engine throttle is not in the “fast” position, the injection of the solution may be decreased or stopped.

|

|

|

www.powermate.com |

7 |

|

|

|

|

English

CLEANING TECHNIQUES |

|

MAINTENANCE |

Cleaning Techniques

When cleaning with the pressure washer, many cleaning tasks can be solved with water alone, but for most tasks it is advantageous to use a detergent also. A detergent ensures a quick soaking of the dirt allowing the high pressure water to penetrate and remove the dirt more effectively.

Coleman® Powermate® Pressure Washer Chemicals are specially formulated to be used with your pressure washer.

APPLICATION OF SOAP OR DEGREASER

1.Apply the solution to a DRY work surface.

On a vertical surface, apply horizontally from side to side starting from the bottom to avoid streaking.

NOTE: Wetting the surface first is not recommended, as it dilutes the detergent and reduces its cleaning ability. Avoid working on hot surfaces or in direct sunlight to minimize the chances of the chemical damaging painted surfaces. Damage may occur to painted surface if chemical is allowed to dry on the surface. Hold nozzle far enough away from surface to prevent damage to the surface.

2.Allow chemical to remain on the surface for a short time before rinsing.

3.Rinse with clean water under high pressure. On a vertical surface, first rinse from the bottom up, then rinse from the top down. Hold nozzle 6 to 8 inches from the work surface at a 45° angle using the flat spray as a peeling tool rather than a scrub brush.

APPLICATION OF WAX

1.Immediately after cleaning, apply Coleman® Powermate® Pressure Washer Wax. Place injection tube in container of wax.

2.Apply the wax sparingly in an even layer. Apply to wet surfaces from the bottom up for even distribution and to avoid streaking.

3.Remove the suction tube from the wax bottle and rinse off the surplus wax.

NOTE: IF SURPLUS WAX IS NOT REMOVED, A HAZY FINISH MAY RESULT.

4.Wipe dry to reduce water spotting.

END OF OPERATION

End of Operation

When you have completed use of the chemical injection system, remove tube from container. Continue to run in low pressure position and inject clean water through the tube and injection system by placing end of tube in a container of clean water. Continue to run until it is thoroughly cleaned.

CONNECTIONS

Connections on pressure washer hoses, gun and spray wand should be cleaned regularly and lubricated with the manufacturer’s recommended grease to prevent leakage and damage to the o-rings.

NOZZLE

If the high pressure/low pressure adjustment of the nozzle becomes difficult, please contact Coleman® Powermate® Customer Service Department for proper cleaning and lubrication procedures.

Clogging of the nozzle causes the pump pressure to be too high and cleaning is immediately required.

A nozzle cleaner must only be used when the spray wand is disconnected from the gun or personal injury could result.

1.Separate the wand from the gun.

2.Clear the nozzle with a small rigid piece of wire such as a paper clip.

3.Flush the nozzle backwards with water.

4.Reconnect the wand to the gun.

Restart the pressure washer and depress the trigger on the spray gun. If the nozzle is still plugged or partially plugged, repeat above items 1-4.

If the previous procedure does not clear the nozzle, replace with a new nozzle.

WATER SCREEN

The pressure washer is equipped with a water inlet screen to protect the pump. If the screen is not kept clean, it will restrict the flow of water to the pressure washer and may cause damage to the pump. Do not damage the screen while removing or cleaning screen. Any foreign particles entering the pump may damage the pump. Do not operate pressure washer without the screen in place.

Remove the screen and back flush to remove impurities from screen. Replace immediately.

ENGINE MAINTENANCE

During the winter months, rare atmospheric conditions may develop which will cause an icing condition in the carburetor. If this develops, the engine may run rough, lose power, and may stall. This temporary condition can be overcome by deflecting some of the hot air from the engine over the carburetor area.

NOTE: Refer to pages 11 and 12 for service and maintenance of the engine.

|

|

|

8 |

www.powermate.com |

English

STORAGE |

|

LIMITED WARRANTY |

PUMP STORAGE

If you must store your pressure washer in a location where the temperature is below 32°F, you can minimize the chance of damage to your machine by utilizing the following procedure:

1.Shut off water supply and relieve pressure in the spray gun by depressing the trigger. Disconnect the garden hose from the pressure washer, but leave the high-pressure hose connected.

2.Tip the unit on its side with the inlet connection pointing up.

3.Insert a small funnel (to prevent spilling) into the inlet and pour in approximately 1/4 cup of RV antifreeze.

4.Disconnect spark plug wire.

5.Without connecting garden hose pull the recoil several times to circulate the antifreeze in the pump system. Continue to add antifreeze and pull the recoil until the antifreeze is expelled when the trigger is pulled.

6.Turn the unit upright.

Prior to restarting, thaw out any possible ice from the pressure washer hoses, spray gun and wand.

Another method of reducing risks of freeze damage is to drain your pressure washer as follow:

1.Stop the pressure washer and detach supply hose and high pressure hose. Squeeze the trigger of the discharge gun to drain all water from the wand and hose.

2.Restart the pressure washer and let it run briefly (about 5 seconds) until water no longer discharges from the high pressure outlet.

ENGINE STORAGE

When the pressure washer is not being operated or is being stored more than one month, follow these instructions:

1.Replenish engine oil to upper level.

2.Drain gasoline from fuel tank, fuel line, fuel valve and carburetor.

3.Pour about one teaspoon of engine oil through the spark plug hole, pull the recoil starter several times and replace the plug. Then pull the starter slowly until you feel increased pressure which indicates the piston is on its compression stroke and leave it in that position. This closes both the intake and exhaust valves to prevent the inside of the cylinder from rusting.

4.Cover the pressure washer and store in a clean, dry place that is well ventilated away from open flame or sparks.

NOTE: The use of a fuel additive, such as Coleman® Powermate® Generator Fuel Additive, or an equivalent, will minimize the formulation of fuel gum deposits during storage, Such an additive may be added to the gasoline in the fuel tank of the engine, or to the gasoline in a storage container.

Warranty Coverage: Powermate Corporation (the Company) warrants to the original retail customer in North America that it will repair or replace, free of charge, any parts found by the Company or its authorized service representative to be defective in material or workmanship. This warranty covers the cost of replacement parts and labor for defects in material or workmanship.

Not Covered:

·Transportation charges for sending the product to the Company or its authorized service representative for warranty service, or for shipping repaired or replacement products back to the customer; these charges must be borne by the customer.

·Engine may be covered exclusively by a separate warranty from the engine manufacturer as set forth in the engine Manual (if included).

·Damages caused by abuse or accident, and the effects of corrosion, erosion and normal wear and tear.

·Warranty is void if the customer fails to maintain and operate the product as instructed and recommended by the Company in the owner's manual.

·Warranty applies only if the product is used solely for consumer applications, and does not apply if the product is used for commercial or business applications, or as rental equipment.

·The Company will not pay for repairs or adjustments to the product, or for any costs or labor, performed without the Company's prior authorization.

Warranty Period: One (1) year from the date of purchase. For warranty service, the customer must provide dated proof of purchase and must notify the Company within the warranty period.

For warranty service: Call toll free 800-445-1805, or write to

Powermate Corporation, Product Services, 4970 Airport Road, P. O. Box 6001, Kearney, NE 68848.

EXCLUSIONS AND LIMITATIONS: THE COMPANY MAKES NO OTHER WARRANTY OF ANY KIND, EXPRESS OR IMPLIED. IMPLIED WARRANTIES, INCLUDING WARRANTIES OF MERCHANTABILITY AND OF FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY DISCLAIMED. THE WARRANTY SERVICE DESCRIBED ABOVE IS THE EXCLUSIVE REMEDY UNDER THIS WARRANTY; LIABILITY FOR INCIDENTAL AND CONSEQUENTIAL DAMAGES IS EXCLUDED TO THE EXTENT PERMITTED BY LAW.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state. Some states do not allow a disclaimer of implied warranties, or the exclusion or limitation of incidental and consequential damages, so the above disclaimers and exclusions may not apply to you.

|

|

|

www.powermate.com |

9 |

|

|

|

|

English

PROBLEM |

POSSIBLE CAUSE |

|

CORRECTION |

Engine will not start or stops while |

Low-oil shutdown. |

|

Fill engine with oil. |

operating. |

Engine switch not in the “ON” position. |

|

Turn switch “ON”. |

|

Pressure build up in hose. |

|

Squeeze trigger. |

Engine is overloaded. |

Nozzle partially blocked. |

|

Clean nozzle. |

|

Excessive pressure. |

|

Reduce pressure by using pressure |

|

|

|

adjustment knob |

Water or oil leaking from bottom of pump. |

A small amount of leakage is normal. |

|

If excessive leaking occurs call the |

|

|

|

Customer Service Department. |

Pressure increases when gun is closed. |

Bypass valve not operating properly. |

|

Call the Customer Service Department. |

Engine running but pump not building |

Faucet closed |

|

Open faucet. |

maximum pressure or has irregular |

Unit has been stored in freezing |

|

Thaw out unit completely including hose, |

pressure. |

temperatures. |

|

gun and wand. |

|

Inadequate water supply. |

|

Provide a minimum of 4 gpm at 20 psi. |

|

Water inlet screen clogged. |

|

Clean screen. |

|

Kink in garden hose. |

|

Straighten hose |

|

Wand nozzle worn or damaged. |

|

Replace nozzle, |

|

Air in pump. |

|

Let run with gun open and wand removed |

|

|

|

until steady stream of water is released. |

|

Adjustable pressure knob not set to |

|

Set to maximum position. |

|

maximum position. |

|

|

|

Suction or discharge valves clogged or |

|

Call the Customer Service Department. |

|

worn out. |

|

|

|

By-pass valve not operating effectively. |

|

Call the Customer Service Department. |

No intake of chemicals |

Injection tube not securely inserted into |

|

Push firmly into injector. |

|

unit. |

|

|

|

Tube cracked or split. |

|

Replace tubing. |

|

Wrong nozzle. |

|

Switch to low pressure nozzle. |

|

Injector turned off. |

|

Turn collar counter clockwise. |

|

Injection tube strainer clogged. |

|

Clean strainer. |

|

Nozzle blocked. |

|

Clean nozzle. |

|

Dried chemicals injector. |

|

Dissolve by running warm water trough the |

|

|

|

injection tube. |

Trigger will not move. |

Gun safety lock engaged. |

|

Release safety lock. |

Water in crankcase. |

High humidity. |

|

Change oil more frequently. |

|

Worn seals. |

|

Call the Customer Service Department. |

Noisy operation. |

Worn bearings |

|

Call the Customer Service Department. |

|

Air mixed with water. |

|

Check inlet lines for restrictions and /or |

|

|

|

proper sizing. |

Rough/pulsating operation with pressure |

Worn packing. |

|

Call the Customer Service Department. |

drop. |

Inlet restriction. |

|

Check system for stoppage, air leaks, |

|

|

|

correctly sized inlet plumbing to pump. |

|

Unloader. |

|

Check unloader for proper operation. |

|

Air mixed in water. |

|

Check inlet lines for restrictions and/or |

|

|

|

proper sizing. |

High crankcase temperatures. |

Wrong grade of oil. |

|

Use recommended oil. |

|

Improper amount of oil in crankcase. |

|

Adjust oil level to proper amount. |

|

|

|

|

|

|

|

10 |

www.powermate.com |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

English |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

PERIODIC MAINTENANCE |

|

|

|

|||

|

|

|

|

|

|

|

|

ITEM |

NOTES |

Daily (Before |

Initial |

Every |

Every |

||

operation) |

20 hours |

50 hours |

100 hours |

||||

|

|

||||||

Spark Plug |

Check condition. Adjust gap and |

|

|

ü |

|

|

|

clean. Replace if necessary. |

|

|

|

|

|||

Engine Oil |

Check oil level. |

ü |

|

|

|

|

|

|

Replace. |

|

ü |

|

ü |

||

Air Filter |

Clean, replace if necessary. |

|

|

ü |

|

|

|

Fuel Filter |

Clean fuel filter and fuel tank strainer. |

|

|

|

ü |

||

Replace if necessary. |

|

|

|

||||

Fuel Line |

Check fuel hose for cracks or other |

ü |

|

|

|

|

|

damage. Replace if necessary. |

|

|

|

|

|||

Exhaust |

Check for leakage. Retighten or |

ü |

|

|

|

|

|

System |

replace gasket if necessary. |

|

|

|

|

||

|

Check muffler screen. Clean/replace |

|

|

|

ü |

||

|

if necessary. |

|

|

|

|||

Carburetor |

Check choke operation. |

ü |

|

|

|

|

|

Starting |

Check recoil starter operation. |

ü |

|

|

|

|

|

System |

|

|

|

|

|||

Fittings/ |

Check. Replace if necessary. |

|

|

|

ü |

||

Fasteners |

|

|

|

||||

ENGINE MAINTENANCE

SPARK PLUG

Remove the spark plug and clean the electrodes section with a wire brush or sandpaper. Next, set the gap at .028/.031 inches (0.7-0.8 mm) by adjusting the negative electrode. Replace the spark plug with correct torque: 14 ft-lb (20 N.m)

OIL REPLACEMENT

1.Change oil while engine is warm.

2.Place the generator unit on a level surface.

3.Remove the oil filler cap.

4.Open the oil drain plug and let oil drain completely into a pan placed under the engine.

5.Check gaskets. Replace if required.

6.Reinstall the oil drain plug and refill engine with clean oil.

7.Replace the oil filler cap.

Replace with only the same type of spark plug which was removed. An improper spark plug can cause the engine to overheat, emit smoke, or otherwise perform poorly.

OIL TYPE

Use new good quality oil, SE, SF, or SD grade. The oil to be used depends upon the temperature at which the engine is operated:

Below 32° F (0° C) . . . . . . . . .SAE 10W, 10W-30, or 10W-40 32 to 80° F (0 to 25° C) . . . . . .SAE 20W, 10W-30, or 10W-40 80 to 95° F (25 to 35° C) . . . . .SAE 30W, 10W-30, or 10W-40 Above 95° F (35° C) . . . . . . . . . . . . . . . . . . . . . . . . .SAE 40W

AIR FILTER CLEANING

1.Unscrew the air filter cover.

2.Remove filter element and wash well in solvent.

3.Pour a small amount of oil onto the filter element and gently squeeze out any excess oil.

4.Replace the filter element and air filter cover.

5.Be sure the filter cover seals properly all around.

FUEL VALVE FILTER CLEANING

1.Remove the cup at the bottom of the fuel valve with a small wrench.

2.Remove the fuel valve filter.

3.Clean and wash out the filter and cup and replace.

FUEL STRAINER CLEANING

1.Remove the plastic fuel strainer, located below the fuel tank cap.

2.Wash the strainer in solvent and replace.

|

|

|

www.powermate.com |

11 |

|

|

|

|

English

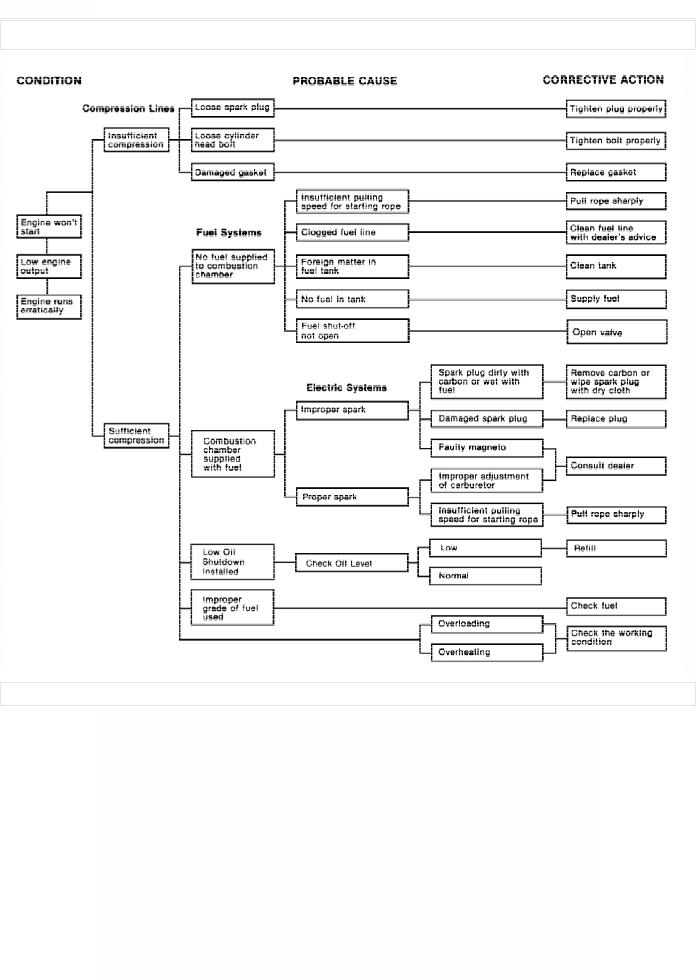

ENGINE TROUBLESHOOTING

ENGINE SPECIFICATIONS

Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-stroke, single cylinder, gasoline, OHV Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171 cc, 10.44 cubic inches Maximum HP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5.5 HP @ 3600 rpm Starting System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Recoil (electronic ignition) Driving System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Direct coupling, tapered crank Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20 oz. Spark Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Champion RN14YC or equivalent Governor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Mechanical (adjustable) Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Forced air cooling Bore x Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . .66.0 X 50.0 mm (2.60 x 1.97 in.) Carburetor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Float Air Cleaner Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Foam element

|

|

|

12 |

www.powermate.com |

English

CALIFORNIA EMISSION CONTROL WARRANTY STATEMENT

YOUR WARRANTY RIGHTS AND OBLIGATIONS

The California Air Resources Board and Powermate Corporation (herein "Powermate") are pleased to explain the evaporative emission control system (EECS) warranty on your 2006 pressure washer. In California, new pressure washers must be designed, built and equipped to meet the State's stringent anti-smog standards. Powermate must warrant the EECS on your pressure washer for the periods of time listed below, provided there has been no abuse, neglect or improper maintenance of your pressure washer.

Your EECS includes parts such as: fuel hoses.

MANUFACTURER'S WARRANTY COVERAGE:

This evaporative emission control system is warranted for two years. The warranty period begins on the date the pressure washer is delivered to an ultimate purchaser.

Powermate warrants to the ultimate purchaser and any subsequent owner that the pressure washer is (i) designed, built and equipped so as to conform with all applicable regulations; and (ii) free from defects in materials and workmanship that cause the failure of a warranted part to be identical in all material respects to that part as described in Powermate's application for certification.

If any evaporative emission-related part on your pressure washer is defective, the part will be repaired or replaced by Powermate.

OWNER'S WARRANTY RESPONSIBILITIES:

As the pressure washer owner, you are responsible for performance of the required maintenance listed in your owner's manual. Powermate recommends that you retain all receipts covering maintenance on your pressure washer, but Powermate cannot deny warranty solely for the lack of receipts. You should, however, be aware that Powermate may deny you warranty coverage if your pressure washer or a part has failed due to abuse, neglect or improper maintenance or unapproved modifications.

You are responsible for presenting your pressure washer to an authorized Powermate warranty service center as soon as the problem exists. The warranty repairs should be completed in a reasonable amount of time, not to exceed 30 days. If you have a question regarding your warranty coverage, you should call Powermate Product Service at 1-800-445-1805.

DETAILS OF YOUR WARRANTY

Subject to certain conditions and exclusions as stated below, the warranty on emission-related parts is as follows:

(1)Any warranted part that is not scheduled for replacement as required maintenance in the written instructions supplied, is warranted for the period stated above. If the part fails during the period of warranty coverage, the part will be repaired or replaced by Powermate according to Subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the remainder of the period.

(2)Any warranted part that is scheduled only for regular inspection in the written instructions supplied, is warranted for the warranty period stated above. Any such part repaired or replaced under warranty will be warranted for the remaining warranty period.

(3)Any warranted part that is scheduled for replacement as required maintenance in the written instructions supplied, is warranted for the period of time before the first scheduled replacement date for that part. If the part fails before the first scheduled replacement date, the part will be repaired or replaced by Powermate according to Subsection (4) below. Any such part repaired or replaced under warranty will be warranted for the remainder of the period prior to the first scheduled replacement date for the part.

(4)Repair or replacement of any warranted part under the warranty provisions herein must be performed at an authorized Powermate warranty service center at no charge to the owner.

(5)The pressure washer owner will not be charged for diagnostic labor that is directly associated with diagnosis of a defective, emission-related warranted part, provided that such diagnostic work is performed at an authorized Powermate warranty service center.

(6)Powermate is liable for damages to other engine or pressure washer components proximately caused by a failure under warranty of any warranted part.

(7)Throughout the pressure washer warranty period stated above, Powermate will maintain a supply of warranted parts sufficient to meet the expected demand for such parts.

(8)Any replacement part may be used in the performance of any warranty maintenance or repairs and must be provided without charge to the owner. Such use will not reduce the warranty obligations of Powermate.

(9)Add-on or modified parts that are not exempted by the Air Resources Board may not be used. The use of any non-exempted add-on or modified parts by the ultimate purchaser will be grounds for disallowing a warranty claims. Powermate will not be liable to warrant failures or warranted parts caused by the use of a non-exempted add-on or modified part.

(10)The repair or replacement of any warranted part otherwise eligible for warranty coverage may be excluded from such warranty coverage if the pressure washer has been abused, neglected or improperly maintained, and such abuse, neglect or improper maintenance was the direct cause of the need for repair or replacement of the part.

WARRANTED PARTS:

The following emission warranty parts list is covered:

Fuel Hose.

|

|

|

www.powermate.com |

13 |

|

|

|

|

Français

Félicitations pour votre achat de nettoyeur haute pression Coleman® Powermate®. Que ce soit pour des travaux de nettoyage ordinaire à la maison ou pour des travaux plus difficiles, les laveuses Coleman® Powermate® ont été conçues pour vous offrir la puissance dont vous avez besoin. Votre laveuse à pression Coleman® Powermate® vous rendra service pendant des années. Pour cela, suivre les procédures de rodage, les procédures de préparation et d'utilisation, et effectuer l'entretien préventif selon les indications de ce document, ainsi que du manuel relatif au moteur, qui l'accompagne.

Le plus important, c'est votre propre sécurité et celle de votre entourage. Ne pas oublier que, si la laveuse à pression Coleman® Powermate® vous offre toute la puissance dont vous avez besoin, il ne faut pas pour autant mettre de côté les règles de sécurité.

Merci d'avoir choisi notre produit.

Powermate Corporation

SERVICE CLIENTELE

Appeler notre numére numéro gratuit 1-800-445-1805

ou www.powermate.com

pour tous renseignements concernant la garantie ou pour commander des pièces de rechange ou des accessoires.

Veuillez être prêt a donner les renseignements suivants:

1.Numéro de modèle

2.Numéro de série.

3.Date et lieu d’achat.

4.Référence des pièces en cas de commande de pièces de rechange.

Powermate Corporation

4970 Airport Road

P.O. Box 6001

Kearney, NE 68848

Attention: Warranty Service Department

www.powermate.com

14

Symboles Utilisés

Les symboles suivants sont utilisés dans ce manuel. Pour votre sécurité, suivre les consignes indiquées.

Indique une situation présentant un danger imminent et qui, en l'absence d'intervention, peut conduire à la mort ou entraîner de graves blessures.

Indique une situation présentant un danger potentiel et qui, en l'absence d'intervention, pourrait conduire à la mort ou entraîner de graves blessures.

Indique une situation présentant un danger potentiel et qui, en l'absence d'intervention, pourrait entraîner des blessures légères ou endommager le produit.

NOTE : indique des renseignements sur l'utilisation ou l'entretien, qui peuvent améliorer les performances ou le fonctionnement.

www.powermate.com

Loading...

Loading...